Patents

Literature

32 results about "Pressure shale" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pressure shale is shale that has been exposed to high pressures that causes it to fracture, usually into large concave pieces. In mud logging, watching for this type of shale is one method of monitoring for the possibility of drilling into high pressures that might cause a blowout.

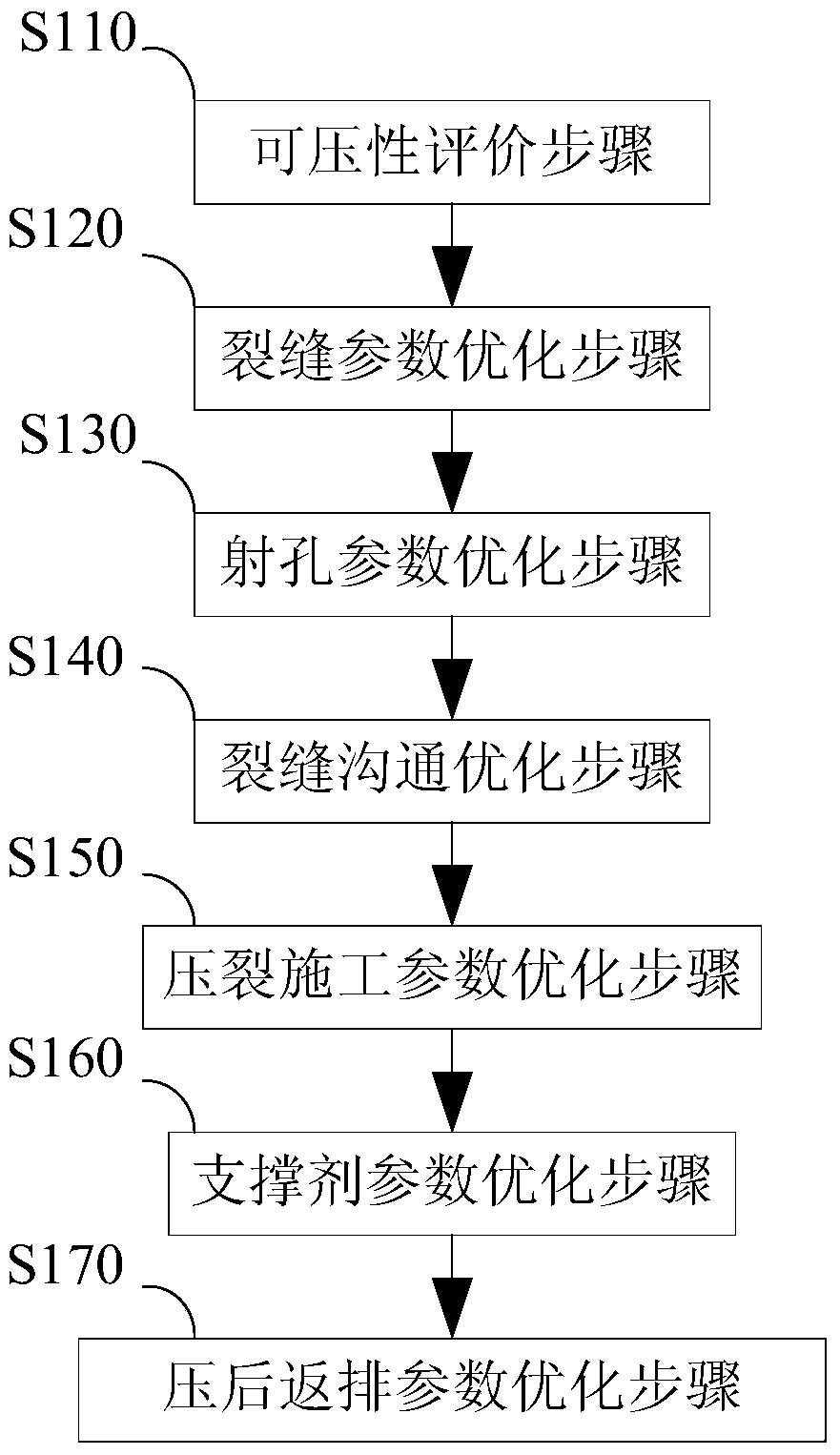

Normal-pressure shale gas horizontal well volume fracturing method

ActiveCN107545088AIncrease the volume of the transformationExpand the scope ofData processing applicationsFluid removalEconomic benefitsCompressibility

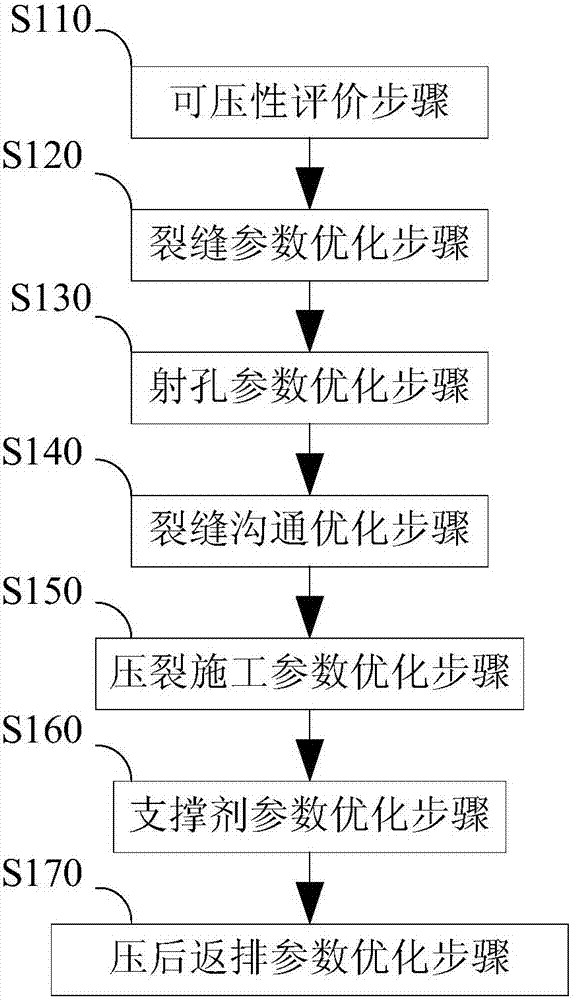

The invention discloses a normal-pressure shale gas horizontal well volume fracturing method, which comprises the following steps that: compressibility evaluation; crack parameter optimization; perforation parameter optimization; crack communication optimization; fracturing construction parameter optimization; propping agent parameter optimization; and after-pressure flowback parameter optimization. By use of the method, the development technical level and the economic benefit of a shale gas reservoir can be improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

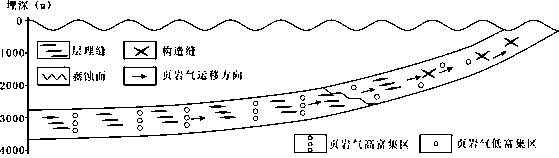

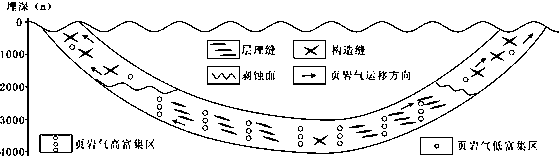

Normal-pressure shale gas enrichment and high production target optimization method based on three-factor gas control

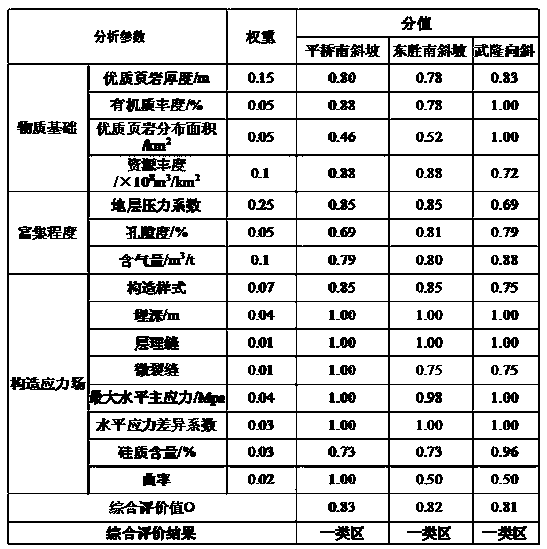

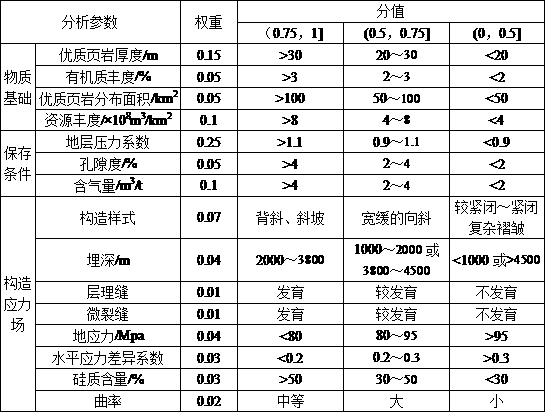

The invention discloses a normal-pressure shale gas enrichment and high production target optimization method based on three-factor gas control. The normal-pressure shale gas enrichment and high production target optimization method comprises the following steps that (1) on the basis of single well dissection of a normal-pressure shale gas well and analysis of target enrichment and high production laws, the three main control factors affecting normal-pressure shale gas enrichment and high production are determined; (2) by taking the normal-pressure shale gas enrichment and high production main control factors as a main line, parameters highly related with the main control factors are optimized as analysis parameters; (3) different weights are given to the analysis parameters, and a normal-pressure shale gas enrichment and high production target optimization parameter list is established; and (4) an analysis target is subjected to quantitative classification analysis according to a target comprehensive evaluation value, and thus optimization of an exploitable area and well position deployment are guided. The normal-pressure shale gas enrichment and high production target optimization method has the beneficial effects that normal-pressure shale gas exploration of the Wufeng formation and the Long maxi formation in a southeast Chongqing district is guided effectively, and the exploration success rate is increased.

Owner:CHINA PETROLEUM & CHEM CORP +1

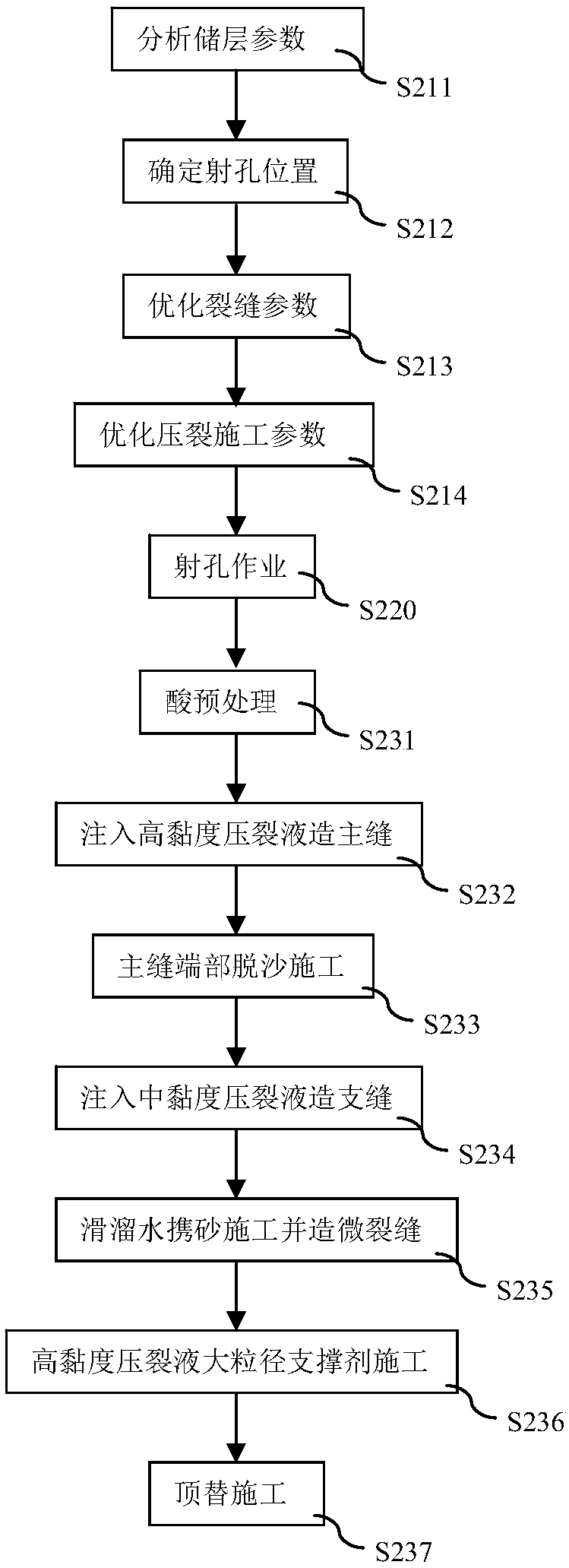

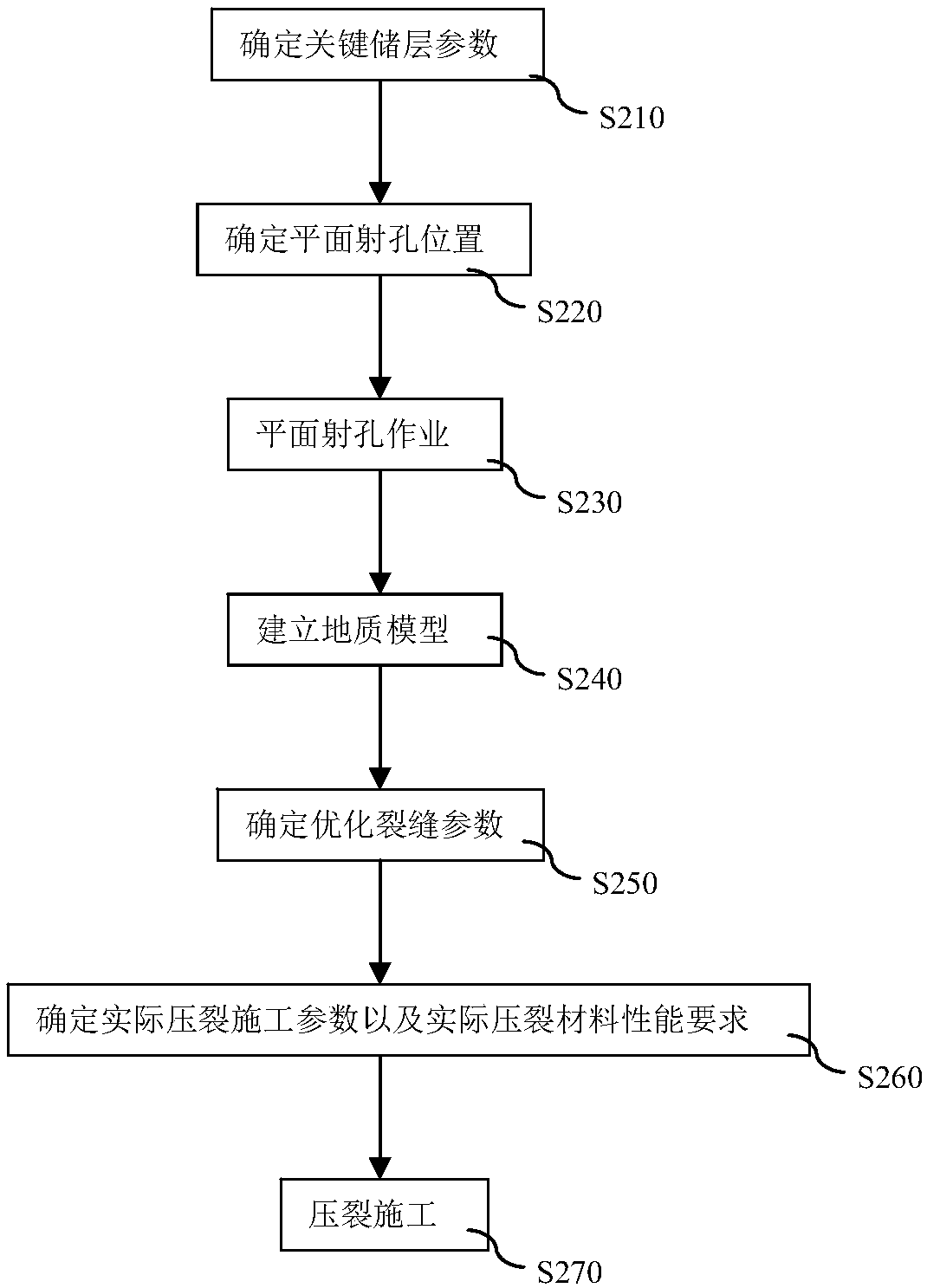

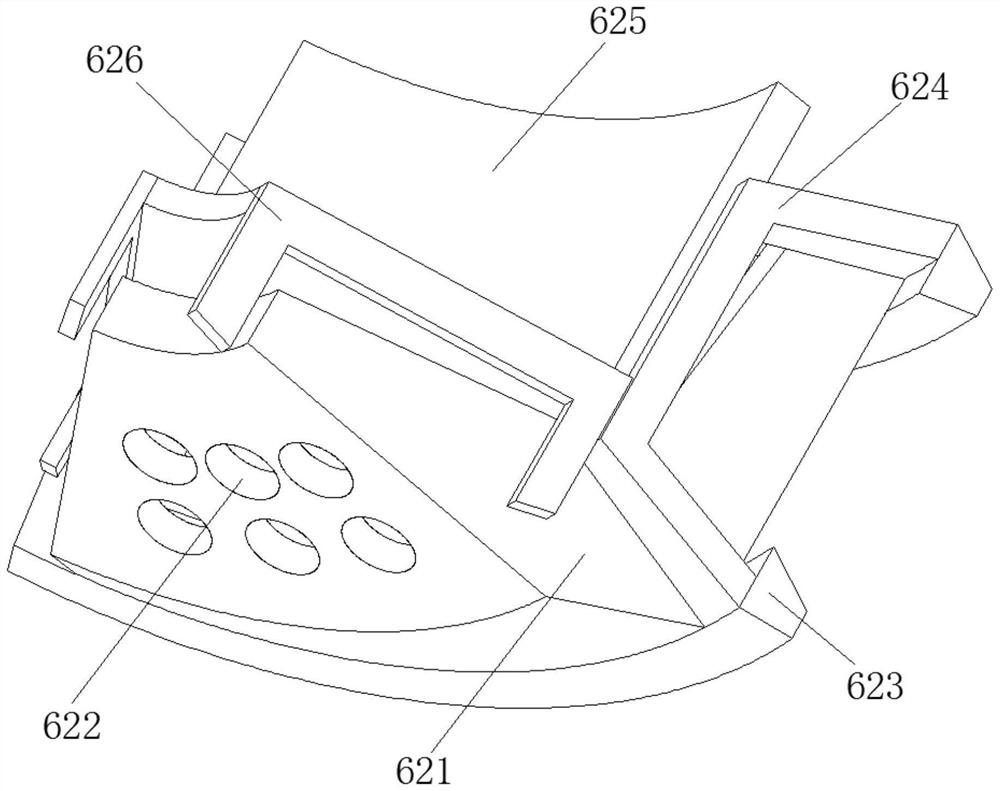

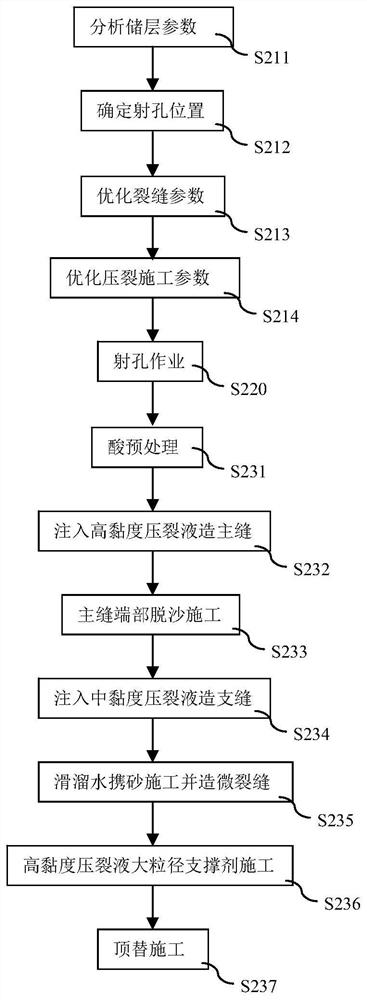

Ordinary-pressure shale gas screen pipe completion hydraulic injection volume fracturing method

ActiveCN108952655ARaise the level of developmentReduce development costsFluid removalAbrasive blastingInjection volume

The invention discloses an ordinary-pressure shale gas screen pipe completion hydraulic injection volume fracturing method. The ordinary-pressure shale gas screen pipe completion hydraulic injection volume fracturing method comprises the steps that (1) evaluation of key parameters of a shale before fracturing is performed; (2) the hydraulic injection position is determined; (3) fracture parametersare optimized; (4) fracturing construction parameters are optimized; (5) sandblasting perforation fracturing operation is performed through large diameter coiled tubing or 3<1 / 2>in conventional tubing; (6) acid pretreatment operation is performed; (7) low-viscosity slickwater fracturing fracture-forming construction is performed, and low-viscosity slickwater with the viscosity of 1mPa.s-2mPa.s isadopted for communicating and extending more small micro-scale fracture systems; (8) low-viscosity slickwater 70 mesh-140 mesh proppant injection construction is performed; (9) high-viscosity glue solution sand fracturing construction is performed; and (10) displacing operation is performed. The ordinary-pressure shale gas screen pipe completion hydraulic injection volume fracturing method can ensure that multi-cluster volume fracturing construction is performed on an ordinary-pressure shale gas horizontal well, can greatly increase the transforming volume of an ordinary-pressure shale gas fracturing fracture, and improves the development level of ordinary-pressure shale gas. The development of the ordinary-pressure shale gas becomes cost-effective.

Owner:CHINA PETROLEUM & CHEM CORP +1

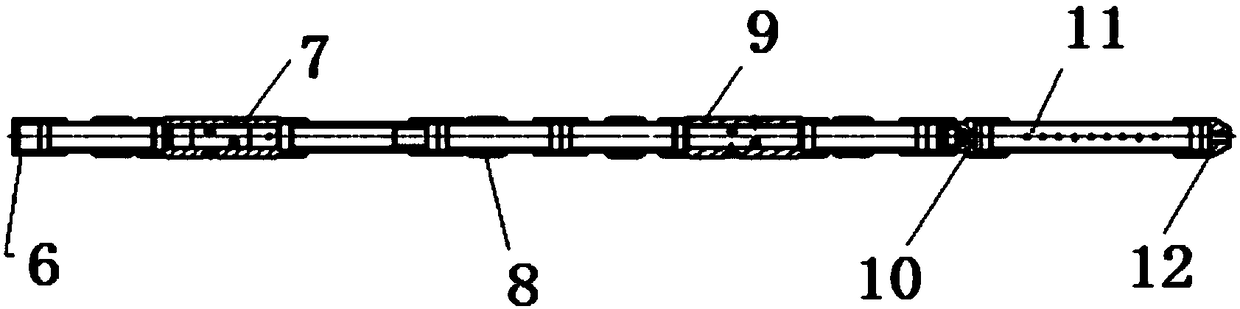

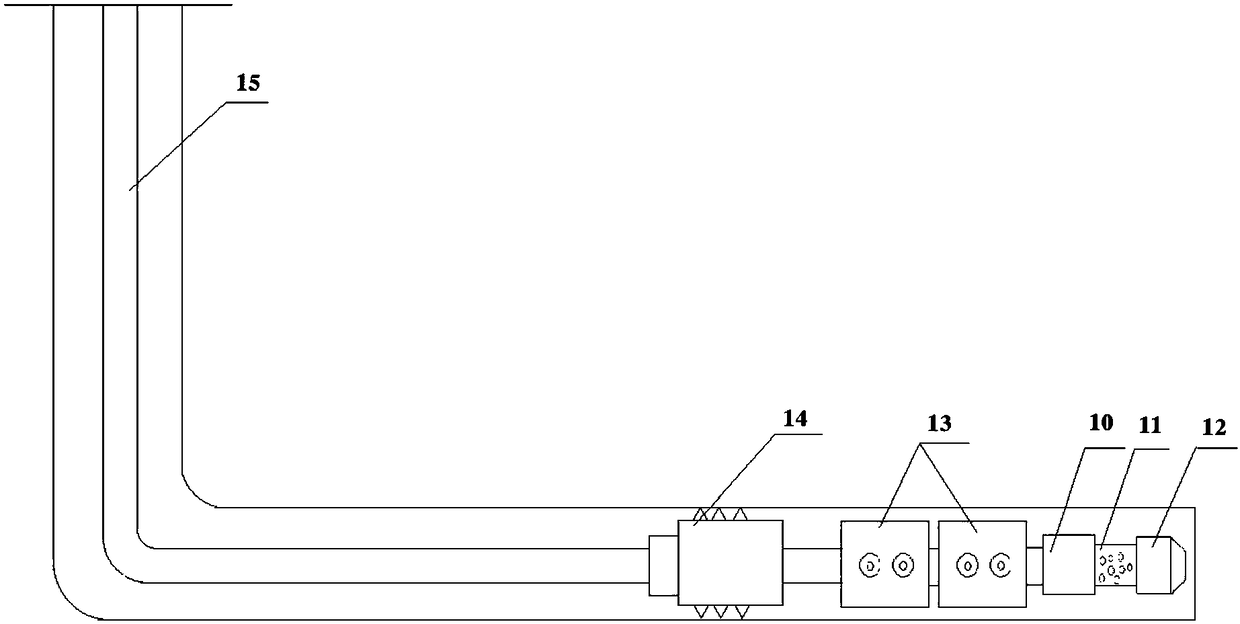

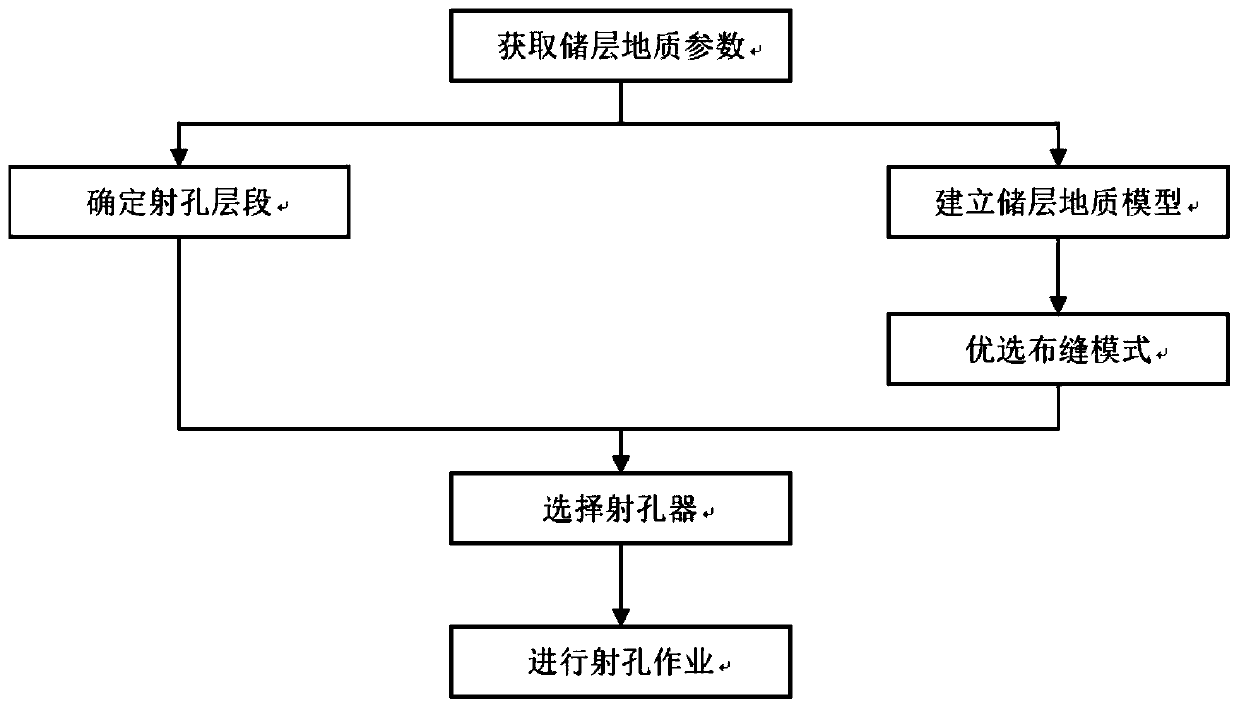

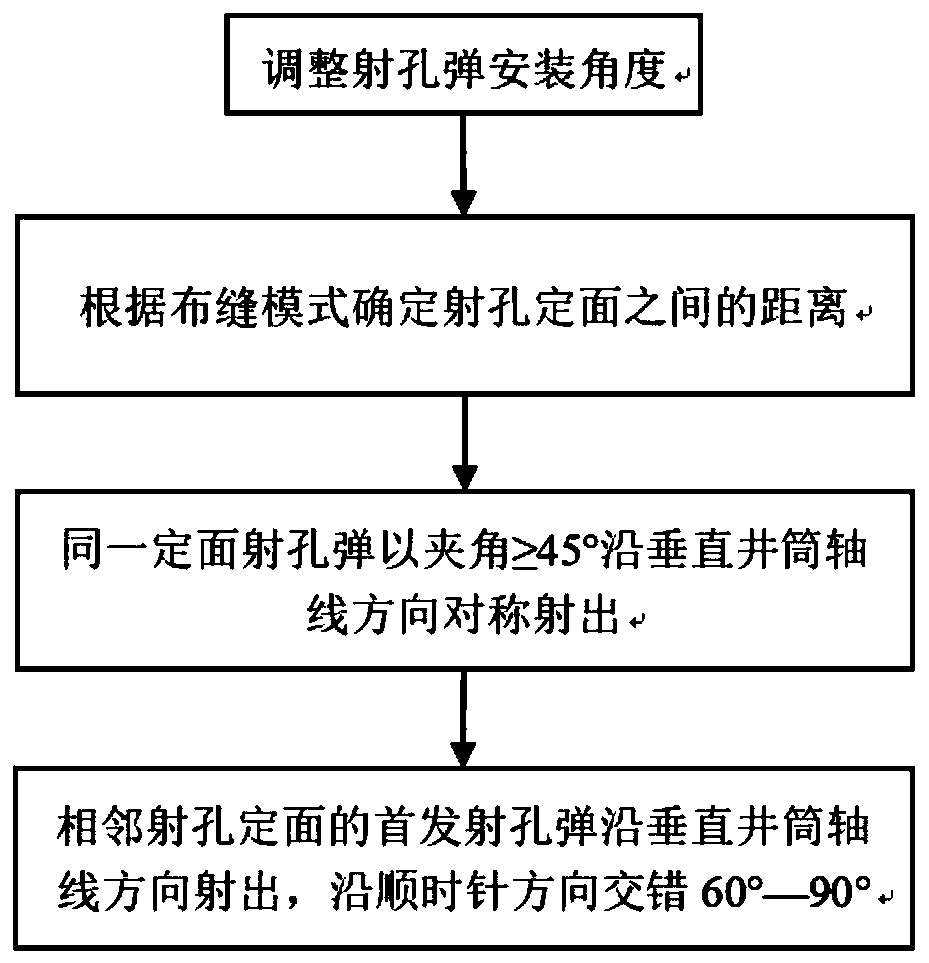

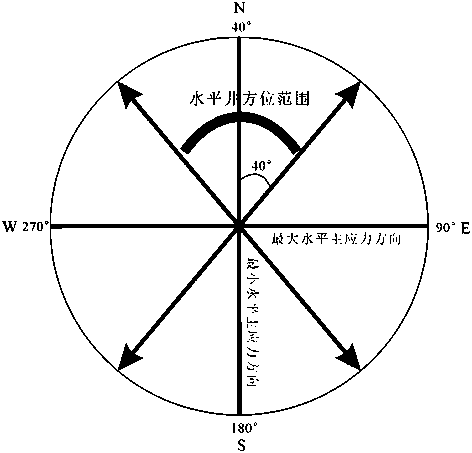

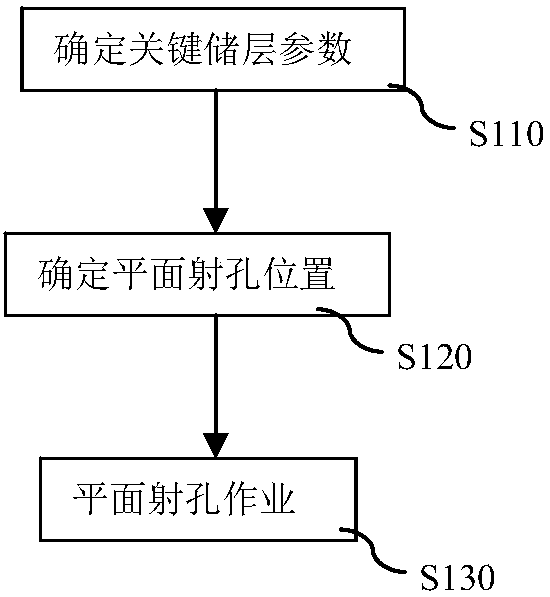

Perforation construction method for volume fracturing of normal-pressure shale reservoir horizontal well

The invention discloses a perforation construction method for volume fracturing of a normal-pressure shale reservoir horizontal well. The perforation construction method comprises the following stepsthat on the basis of fixed-plane perforation, the mounting angles of perforating bullets are adjusted, multiple perforating bullets on the same fixed plane of two wings of a horizontal shaft are symmetrically ejected in the direction perpendicular to the axis of the shaft, and the first perforating bullets on the adjacent fixed planes are distributed in the clockwise direction. According to the perforation construction method, the extension and the expansion of a fracturing crack are controlled favorably, the crack close to the shaft is promoted to form a fracture network, the flow conductivity of the crack is enhanced, a reservoir communicates with the shaft, and the volume fracturing effect of the shale reservoir can be effectively improved.

Owner:CHINA UNIV OF MINING & TECH

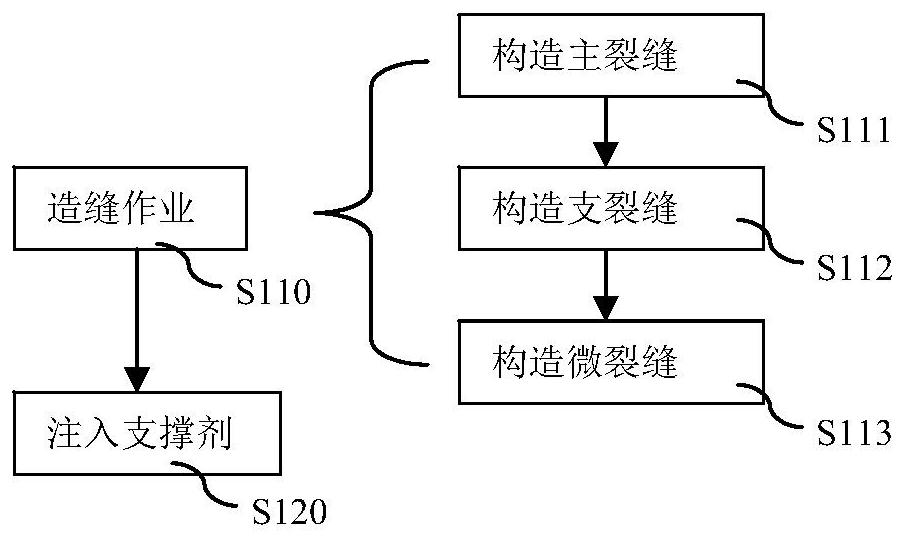

Fracturing method for atmospheric pressure shale gas horizontal well

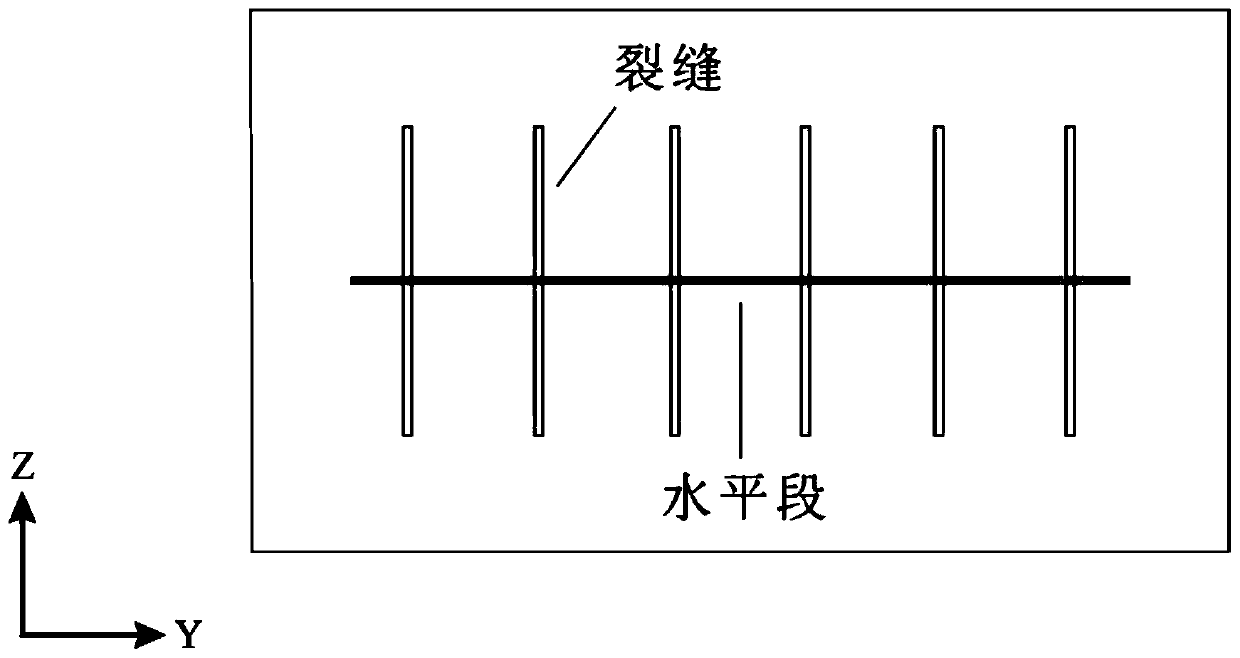

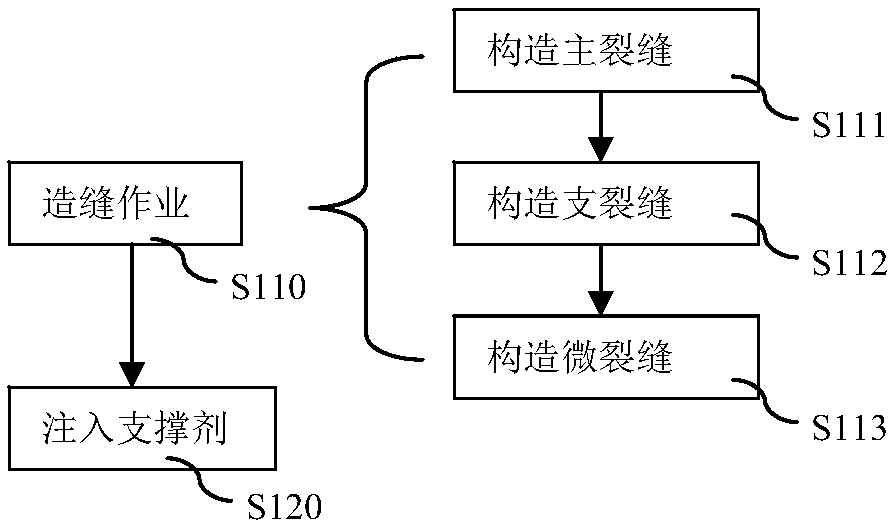

The invention discloses a fracturing method for an atmospheric pressure shale gas horizontal well. The method comprises: constructing a tree-shaped crack system comprising a main crack, branch cracksand micro cracks, wherein the main crack, the branch cracks and the micro cracks are sequentially constructed on the basis of fracturing fluid with different property characteristics, the branch cracks communicate with the main crack, and the micro cracks communicate with the branch cracks; and injecting a propping agent into the tree-shaped crack system. According to the method, the tree-shaped crack system for normal-pressure shale gas fracturing exploitation can be constructed, the crack complexity and the transformation size are improved, and economic and effective development of the normal-pressure shale gas horizontal well is ensured.

Owner:CHINA PETROLEUM & CHEM CORP +1

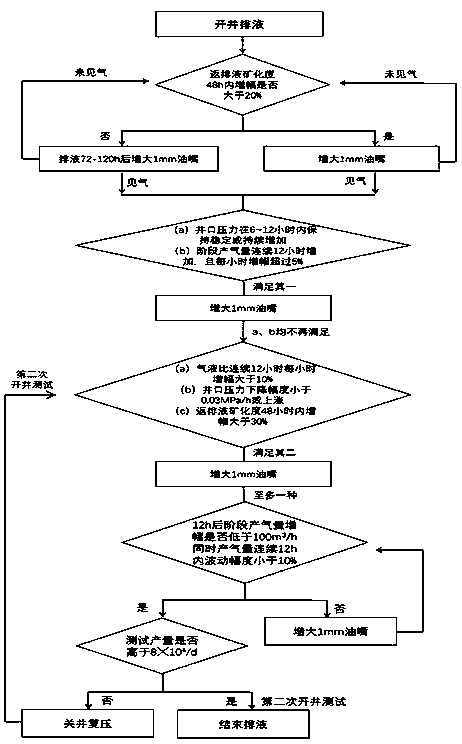

Method for adjusting oil nozzle through liquid drainage test after fracturing of normal-pressure shale gas horizontal well

ActiveCN111396003ARealize quantization operationReduce drain test operation timeFluid removalHorizontal wellsWell test

The invention discloses a method for adjusting an oil nozzle through liquid drainage test after fracturing of a normal-pressure shale gas horizontal well, and relates to the technical field of oil-gaswell liquid drainage test operation in the field of oil-gas field exploration and development. The method is characterized in that the whole liquid drainage test stage after fracturing of the normal-pressure shale gas horizontal well is divided into four stages of pure liquid phase flow, initial stage of gas breakthrough, gas increase and liquid drop and gas-liquid stabilization, four key indexesof wellhead pressure, flowback liquid mineralization degree, stage gas production rate and gas-liquid ratio are determined, and the adjustment time of the oil nozzle is determined by analyzing one ofthe key indexes of the four stages or the combination of the multiple key indexes of the four stages. According to the method, the key flowback parameters after fracturing of the normal-pressure shale gas horizontal well are judged, so that the adjustment time of the oil nozzle is judged, the complete oil nozzle adjustment method is established, the maximum yield of the normal-pressure shale gassingle-well test is achieved, and meanwhile, the overall test operation time is controlled.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Fracturing method of normal-pressure shale gas reservoir

ActiveCN108952668ARaise the complexity indexImprove fracturing effectFluid removalGeomorphologyFracturing fluid

The invention provides a fracturing method of a normal-pressure shale gas reservoir. The fracturing method comprises the following steps that firstly, reservoir evaluation parameters are obtained; secondly, fracturing construction parameters are determined, specifically, the viscosity, the displacement and the using amount of fracturing liquid and the particle size and the using amount of proppingagents are determined; and thirdly, fracturing construction is conducted, specifically, the reservoir is subjected to segment-by-segment fracturing construction through a spiral-slug-type mixed particle size sand-adding mode. According to the fracturing method of the normal-pressure shale gas reservoir, the complexity index of cracks of the normal-pressure shale gas reservoir can be effectively increased, and the fracturing transformation effect of the normal-pressure shale reservoir is improved accordingly.

Owner:CHINA PETROLEUM & CHEM CORP +1

High-density oil-based drilling fluid and preparation method thereof

InactiveCN111057527AGood emulsificationStrong demulsification voltageDrilling compositionPolyamideDioxyethylene Ether

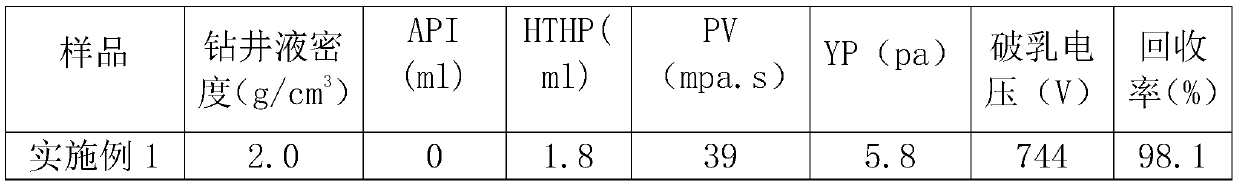

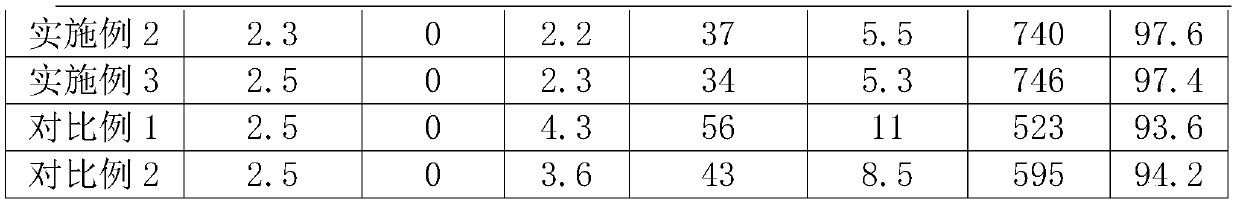

The invention relates to the field of high-density oil-based drilling fluid, in particular to a high-density oil-based drilling fluid suitable for a high-pressure shale gas stratum and a preparation method thereof. The high-density oil-based drilling fluid is prepared from the following raw materials in parts by weight: 80-90 parts of base oil, 2-4 parts of a main emulsifier, 0.5-3 parts of an auxiliary emulsifier, 1-2 parts of organic bentonite, 2-3 parts of an alkalinity regulator, 3-5 parts of a filtrate reducer, 10-20 parts of a calcium chloride water solution with a mass fraction of 25-35%, and a weighting agent, wherein the main emulsifier is composed of higher fatty acid ester diethylene triamine, maleic polyamide and polyoxyethylene ether, and the auxiliary emulsifier is sodium dodecyl benzene sulfonate. The oil-based drilling system taking the diesel oil or white oil as the continuous phase has a good emulsifying effect, a high demulsification voltage, low water loss under a high pressure at a high temperature, a strong inhibition performance, and good fluidity under a high solid content.

Owner:中石化石油工程技术服务有限公司 +1

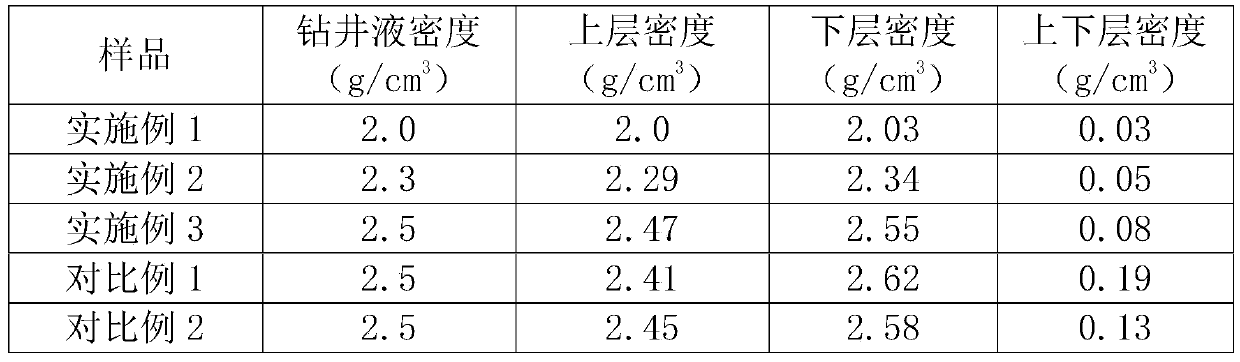

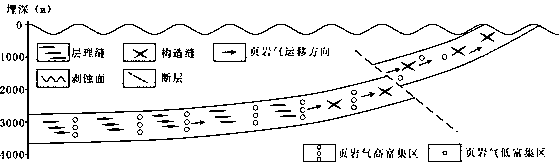

Basin edge complex tectonic zone normal-pressure shale gas horizontal well integrated design method

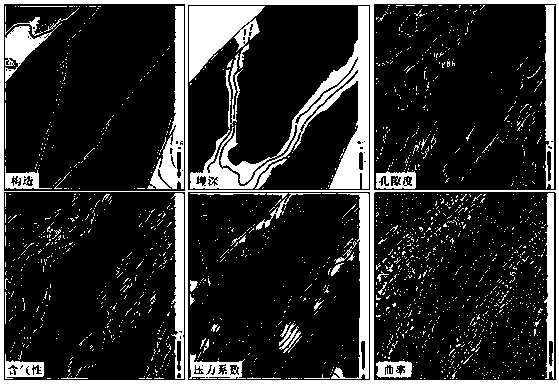

InactiveCN110295882AHigh Efficiency DrillingEnsure drilling safetyFluid removalPorosityGeomorphology

The invention relates to a basin edge complex tectonic zone normal-pressure shale gas horizontal well integrated design method. In the design process, for the characteristics that such as the Southeast Chongqing basin edge transition zone is strong in tectonic deformation, and the geological condition is complex, through superposition evaluation of a structural figure, a burial depth figure, a porosity figure, a gas content figure, a pressure coefficient figure and a curvature figure, geology and engineering optimal dessert areas are optimized, well sites are deployed, the seismic attribute isused for predicting stratum seam hole development situation, interval intvl losing is avoided, the well drilling aging is improved, and through target window and horizontal well orientation optimization and curvature prediction, the reservoir stratum fracturing effect is improved, the reservoir stratum capacity is sufficiently released, the single well economic benefits are improved, the technical support is provided for efficient exploration and development of the basin edge transition zone shale gas, operation is high, and the application prospect is wide.

Owner:CHINA PETROLEUM & CHEM CORP +1

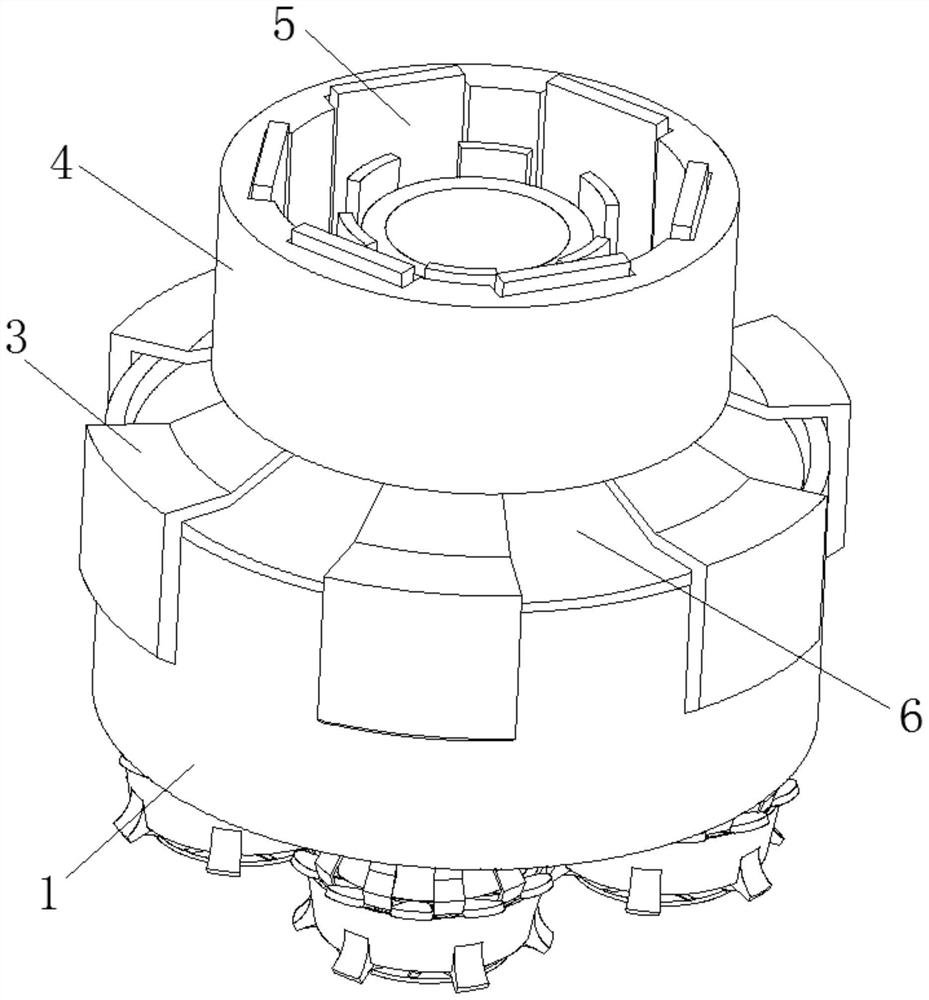

Construction method for atmospheric pressure shale gas volume fracturing

PendingCN109751018AIncrease the volume of the transformationImprove efficiencyFluid removalEconomic benefitsUnconventional oil

The invention discloses a construction method for atmospheric pressure shale gas volume fracturing, comprising the following steps: conducting directional perforating to form two rows of holes in theupper wing and the lower wing of a horizontal well shaft along the direction of the horizontal well shaft on the basis of plane perforation, and forming an orthogonal state with the plane perforation.According to the method disclosed by the invention, the reservoir transformation volume can be greatly increased, so that the problems that the post-fracturing effect cannot reach the expectation andthe stable yield cannot reach the economic exploitation value in the normal-pressure shale gas fracturing technology are solved. By the adoption of the method, the production potential of the reservoir is fully excavated, comprehensive popularization of the volume fracturing technology is facilitated, and great significance is achieved for improving the development technology level and economic benefits of an unconventional oil and gas reservoir.

Owner:CHINA PETROLEUM & CHEM CORP +1

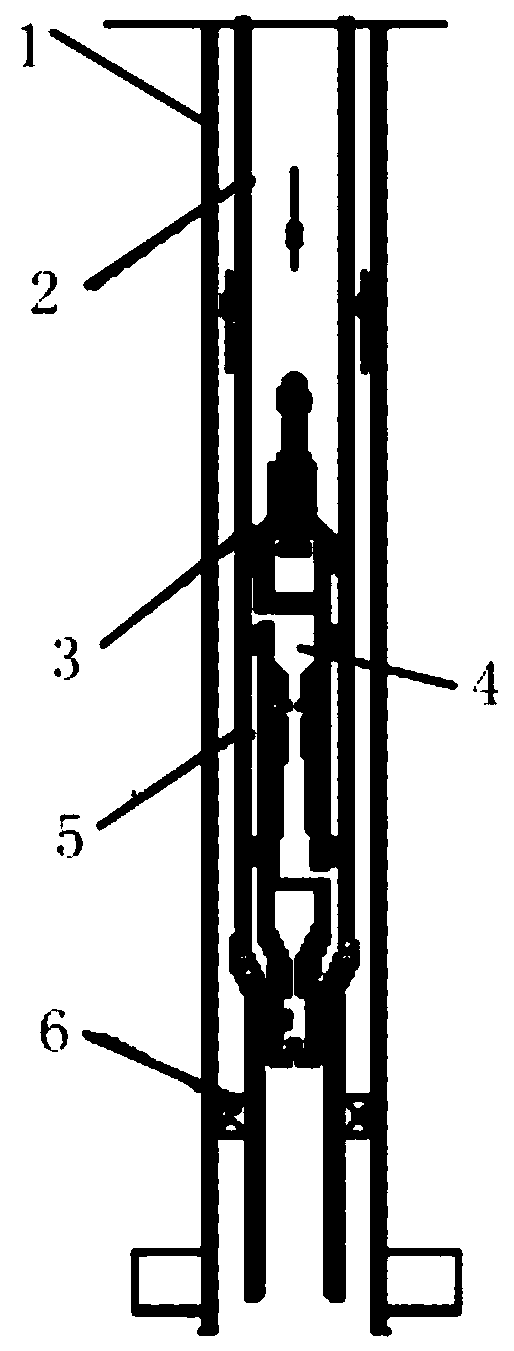

Single-tube jet pump liquor drainage technology method for normal-pressure shale gas well

InactiveCN108868698ALarge amount of liquidDrain fastFluid removalPulp and paper industryPressure shale

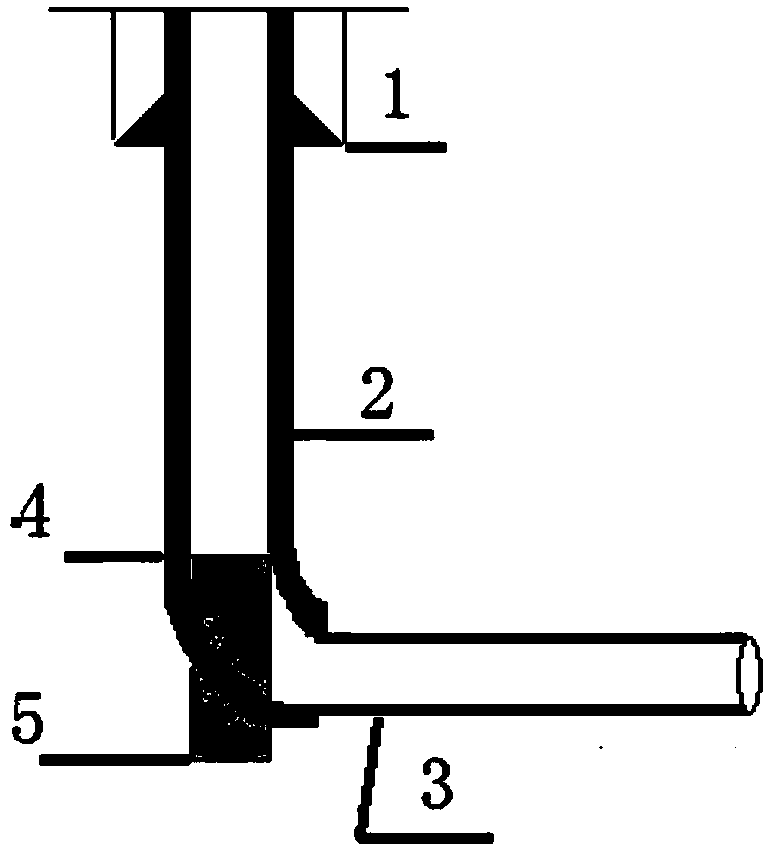

The invention discloses a single-tube jet pump liquor drainage technology method for a normal-pressure shale gas well. In the method, firstly, a packer assembly and a jet pump cylinder are lowered into the well through an oil tube; then a jet pump core is put into the oil tube and pushed into the jet pump cylinder through well flushing, direct-cycle well flushing production is performed, and a single-tube jet pump liquor drainage device is formed. With the oil tube being a power liquor injecting tube, an annulus is formed between the oil tube and a production casing to be used as a mixed liquor discharging tube; in this way, rapid liquor drainage is realized for the normal-pressure shale gas well.

Owner:中国石油化工股份有限公司华东油气分公司采油气工程服务中心

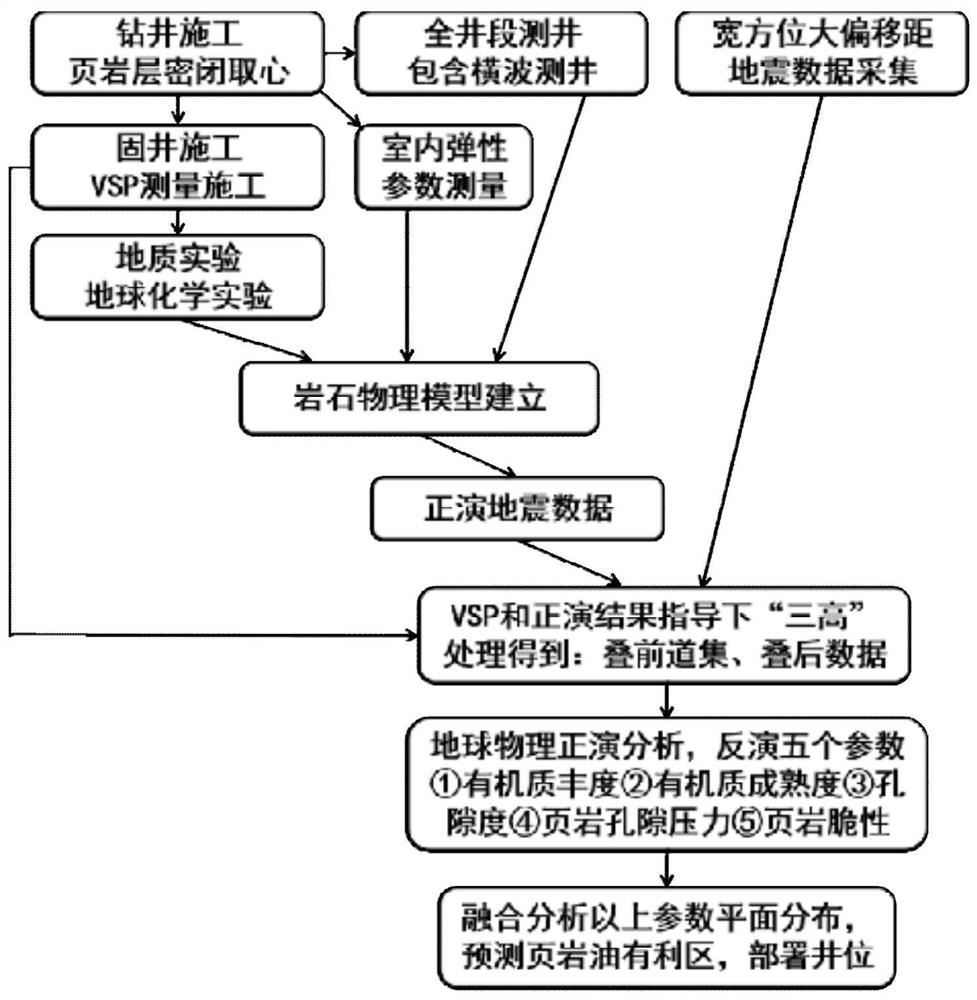

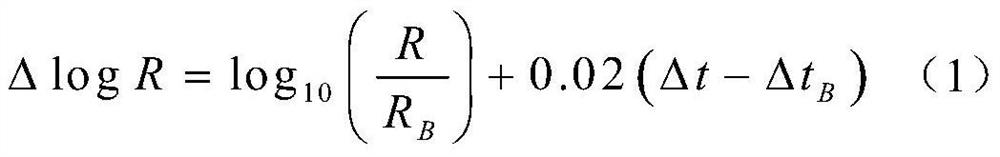

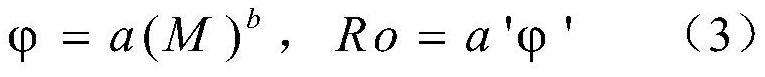

Geophysical prediction method for unconventional oil and gas favorable area

PendingCN112363226AImprove guidanceHigh Guided High FidelitySeismic signal processingSeismology for water-loggingPorosityExperimental laboratory

The invention provides a geophysical prediction method for an unconventional oil and gas favorable area, which is used for solving the problems of multiplicity and uncertainty of an existing shale oilexploration favorable area prediction result dominated by geological research. The method comprises the steps of (1) drilling and coring, and logging in the whole well section; (2) carrying out indoor geological test and geochemical measurement; (3) carrying out acoustic laboratory measurement; (4) establishing a rock physical model and collecting VSP; (5) processing 'three highs' seismic data under the guidance and constraint of VSP and forward modeling results; (6) performing geophysical forward modeling, and performing inversion prediction on five parameters including TOC, Ro, shale porosity, pore pressure and shale brittleness; and (7) comprehensively analyzing and comparing to determine a shale oil exploration favorable area. The method is mainly based on geophysical means, can predict five indexes of the shale oil exploration favorable area in a targeted manner, has the progress from qualitative to quantitative, and has a reference significance for unconventional oil and gas (shale oil) exploration and related scientific research.

Owner:DAQING OILFIELD CO LTD +1

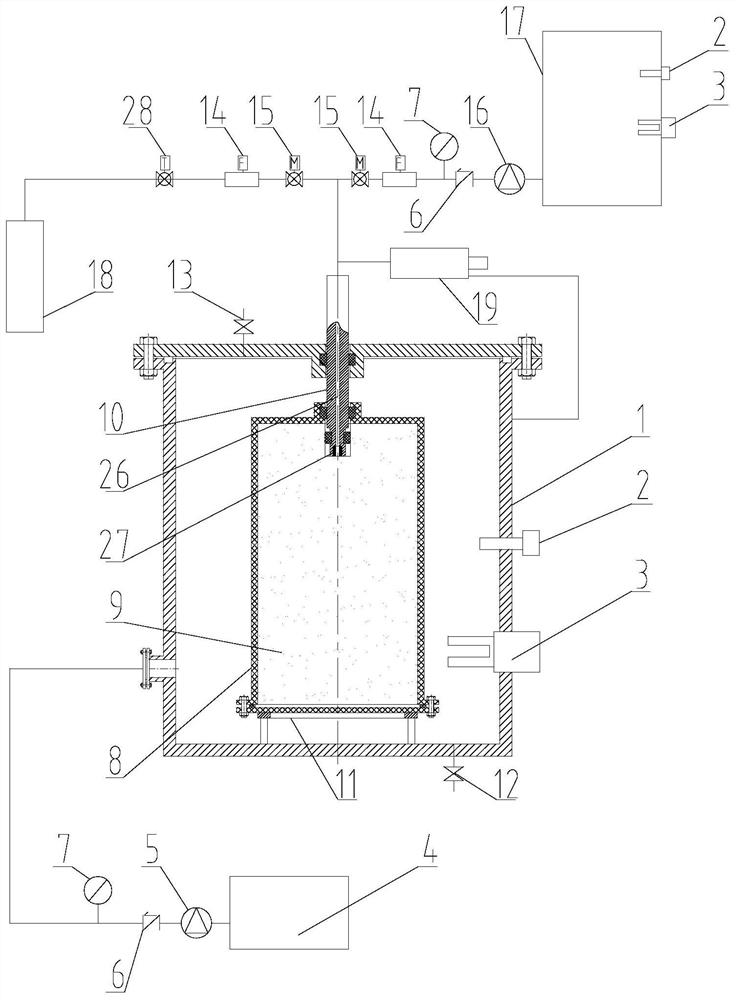

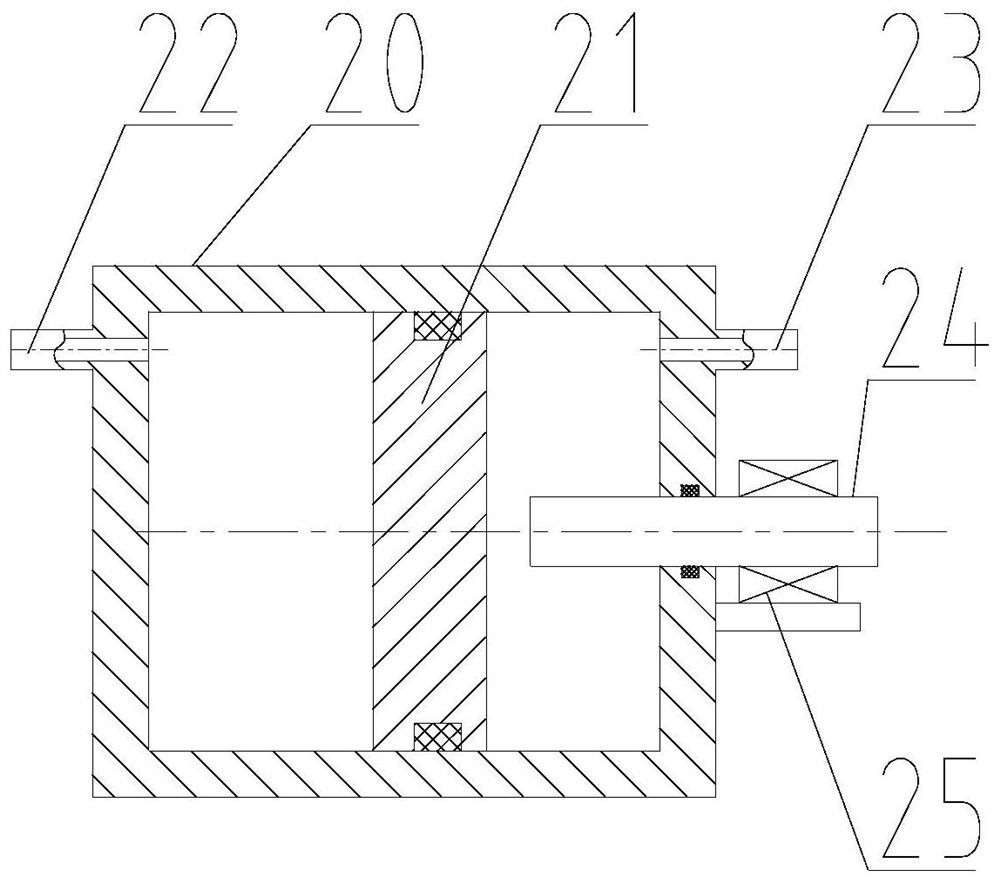

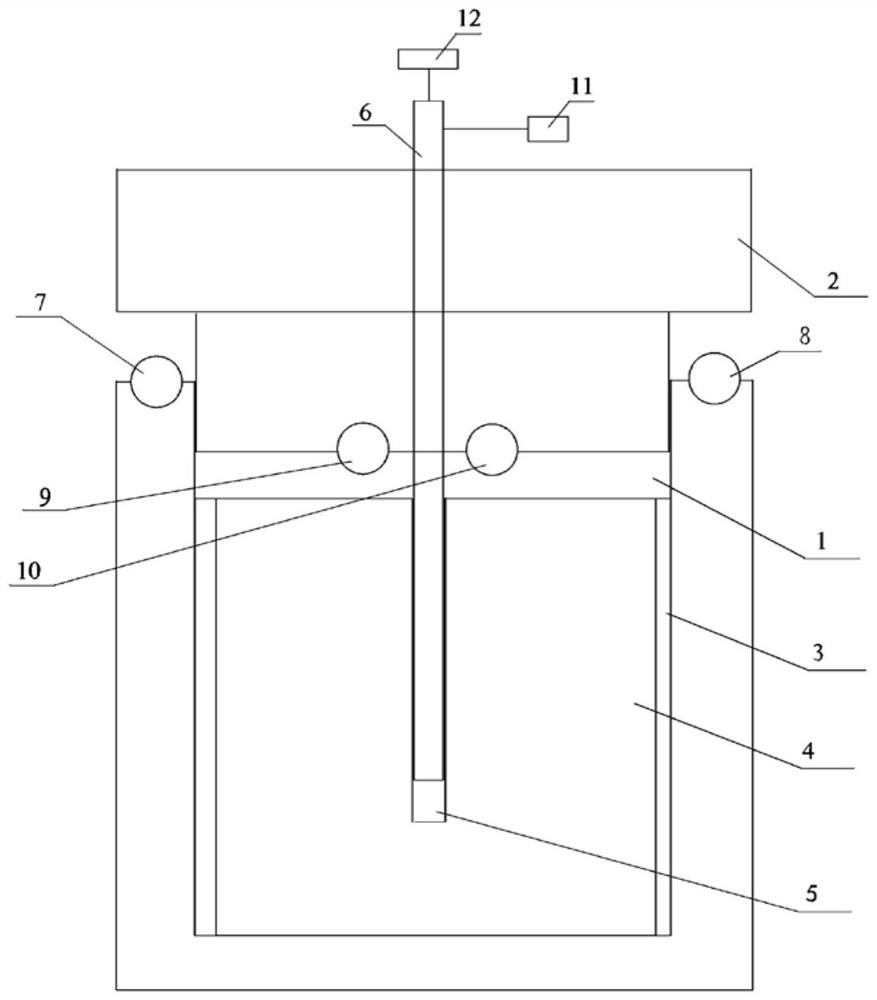

High-temperature and high-pressure shale oil reservoir imbibition evaluation device

ActiveCN112177608ASaturation is not affectedSaturation effectSurveyFluid removalRock coreFracturing fluid

The invention discloses a high-temperature and high-pressure shale oil reservoir imbibition evaluation device and relates to the technical field of compact oilfield oil extraction evaluation. A compression sleeve is arranged at the bottom of a pressure tank, a rock core is arranged in the compression sleeve, a fracturing pipe is inserted into a counter bore of the rock core above the rock core, the fracturing pipe extends upwards to penetrate through the compression sleeve and is connected with the compression sleeve in a sealed mode, and the fracturing pipe penetrates through a flange cover of the pressure tank and is connected with the flange cover in a sealed mode. The high-temperature and high-pressure shale oil reservoir imbibition evaluation device has the following beneficial effects: the compression sleeve is arranged to separate the rock core from the outer part, an oil reservoir in the rock core does not leak, the external pressure and temperature can act on the rock core, the rock core can be kept balanced under pressure through a pressure balancer, the oil-water distribution in gaps of the compact oil reservoir rock core does not change, the processes of fracturing fluid injection into the stratum, soaking and imbibition replacement oil extraction are simulated, important influences are generated on fracturing fluid component optimization, soaking time determinationand imbibition mechanism research, and effective experimental equipment is provided for a rock core imbibition experiment in a high-temperature and high-pressure environment.

Owner:大庆亿莱检验检测技术服务有限公司

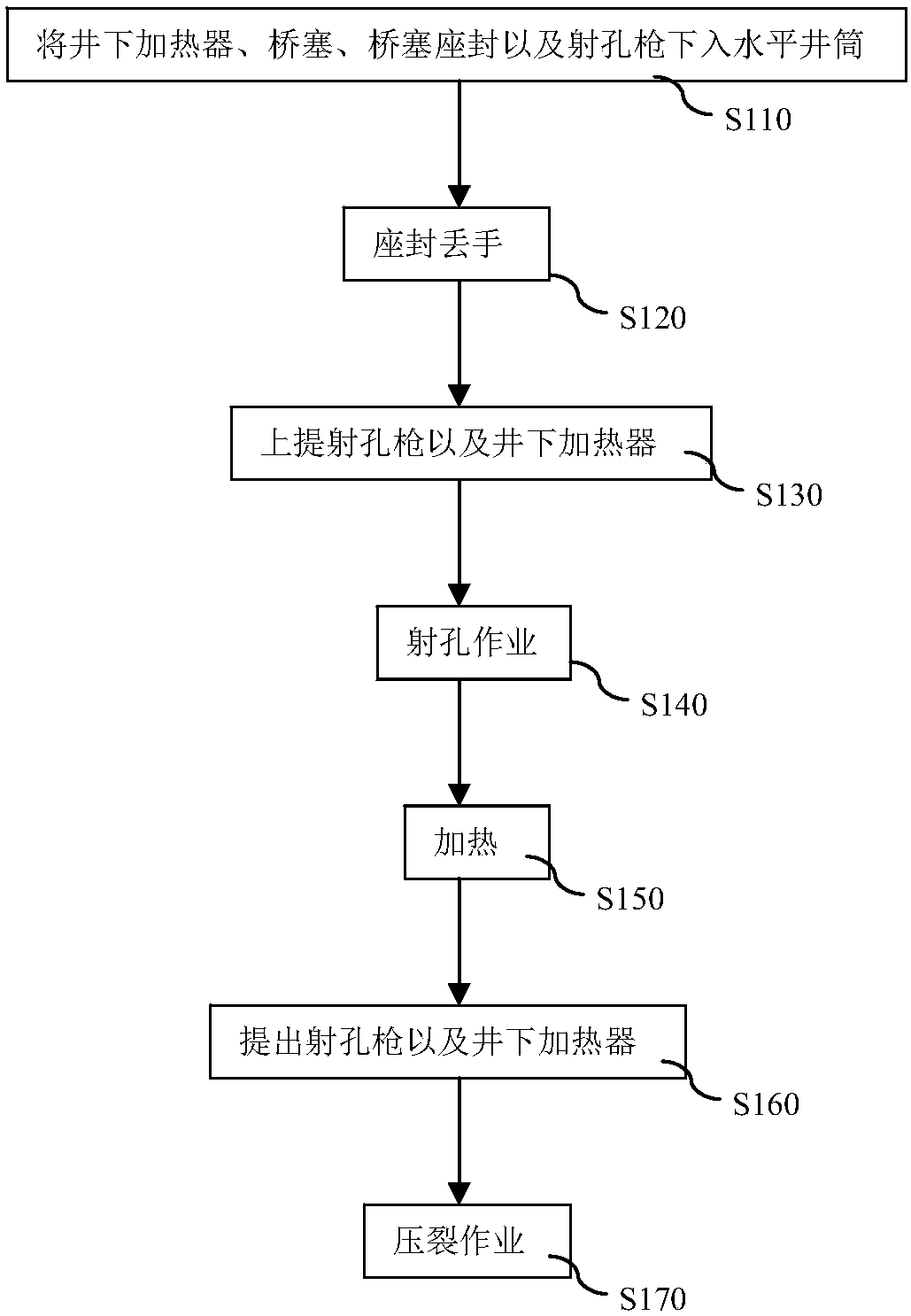

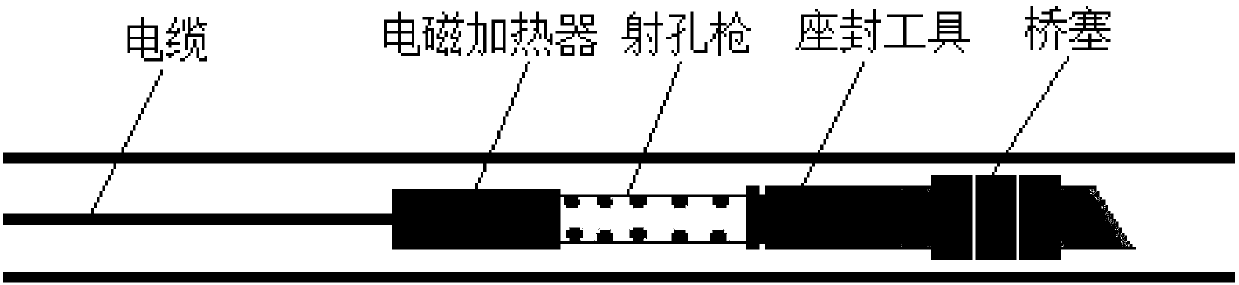

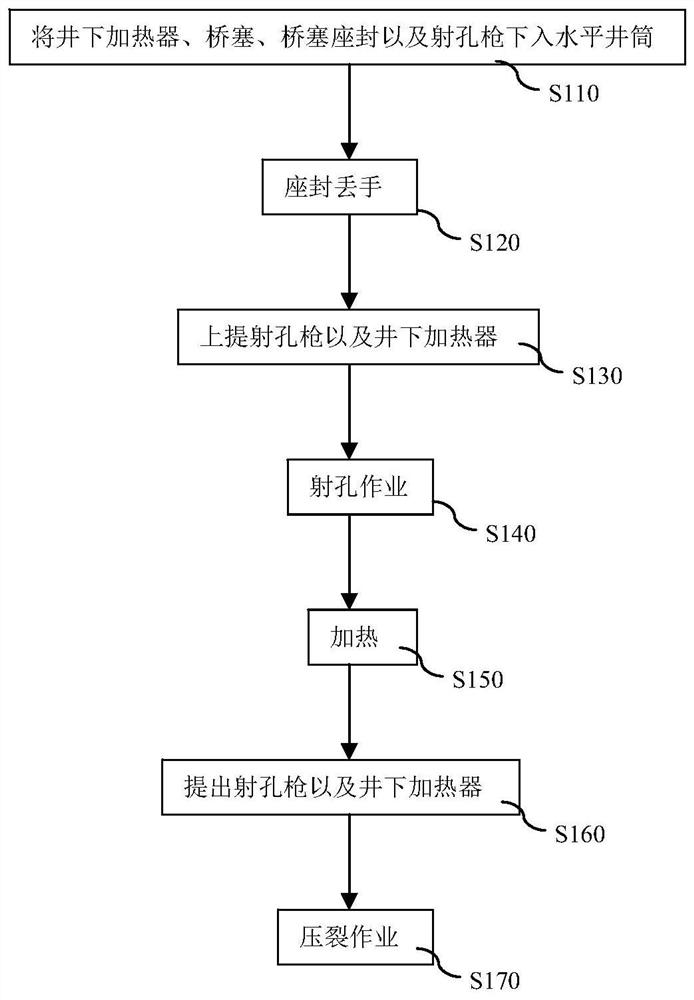

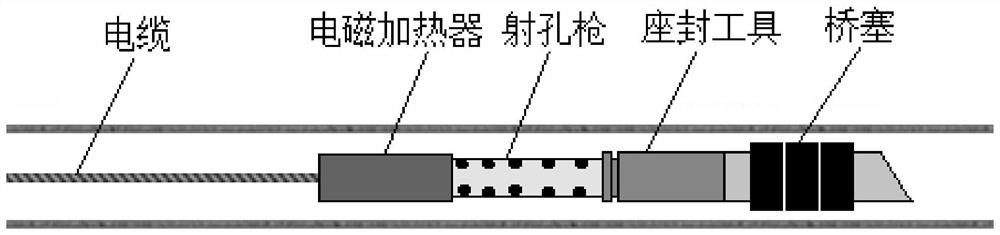

Method and construction process for improving complexity of fracturing mining crack system

ActiveCN109751026AIncreased complexityImprove long-term effective diversion capacityFluid removalMaterial PerforationWellbore

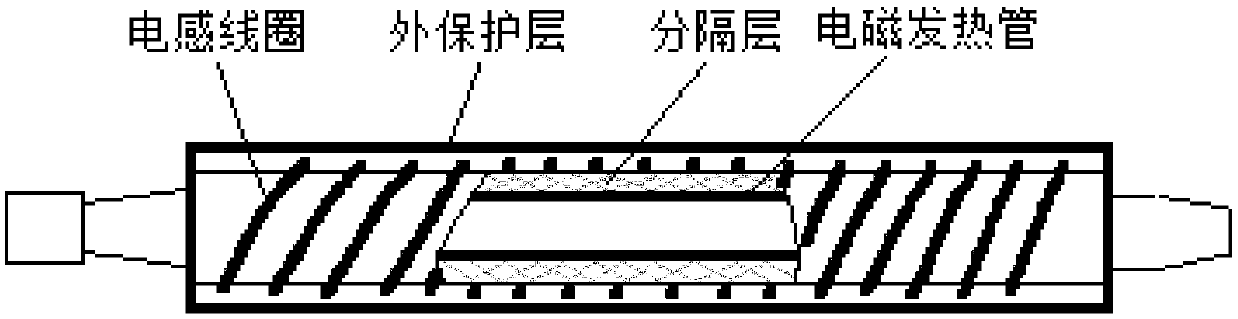

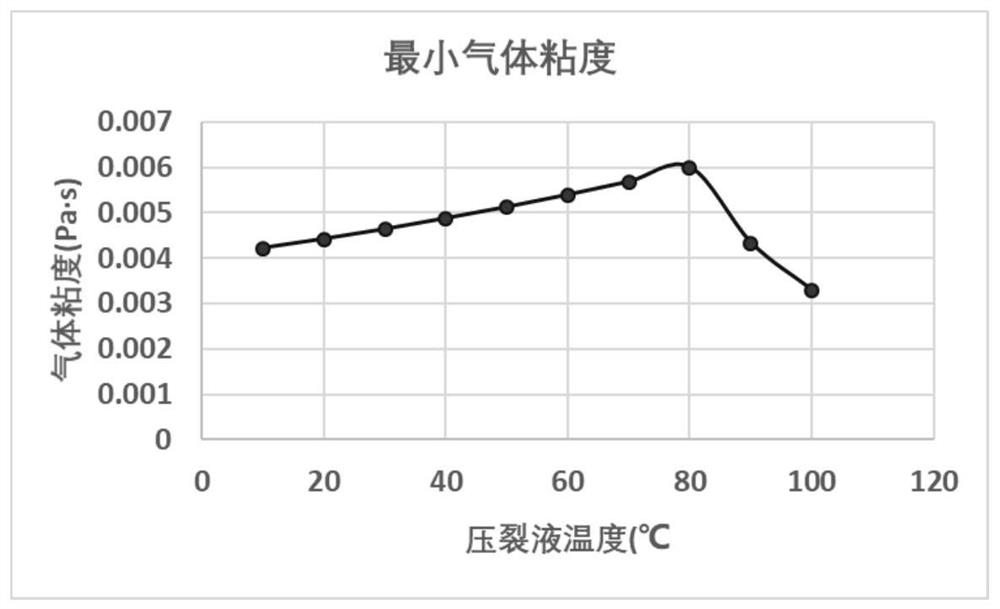

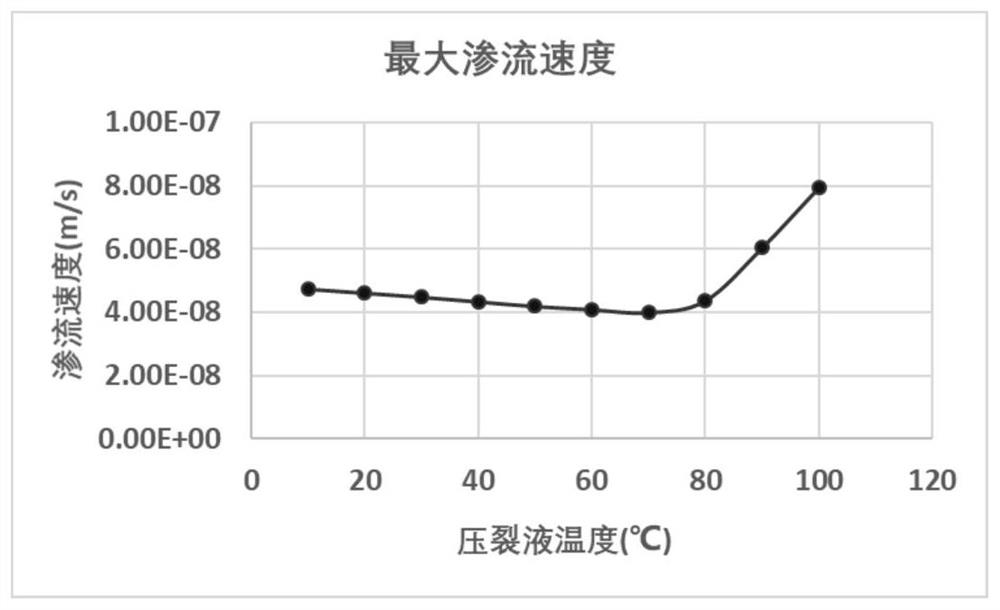

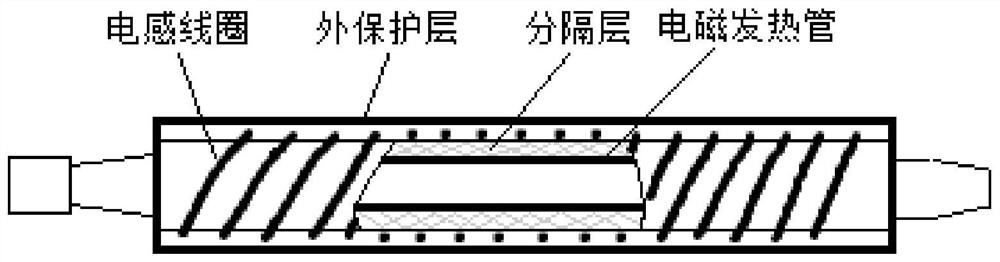

The invention discloses a method for improving the complexity of a fracturing exploitation crack system, a fracturing operation method and an underground heating device. The method for improving the complexity of the fracturing exploitation crack system comprises the steps that in the fracturing operation process, slick water in a horizontal shaft is heated after perforation is completed so as toincrease the complexity of cracks. According to the method disclosed by the invention, the complexity of the fracturing exploitation fracture system can be effectively improved, so that the long-termeffective flow conductivity of the normal-pressure shale gas reservoir fracture is improved, the effective period of a yield increase measure is prolonged, and the economic development benefit is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Reservoir transformation method and application of normal-pressure shale gas horizontal well

The invention discloses a yield increasing method and application of a normal-pressure shale gas well. The yield increasing method comprises the steps that a shaft is subjected to acid treatment, and specifically, the shaft is pretreated through single-section acid liquor; prepad glue liquid joint making is conducted, glue liquid is injected to serve as fracturing fluid, the glue liquid displacement is increased in a stepped mode, and it is guaranteed that joints are effectively opened; pump injection of proppant-carrying hot slickwater is conducted for energy-enhancing joint expansion, the hot slickwater carrying a proppant is injected in a segmented mode, regular fluctuation of a construction pressure curve is controlled, and the purposes of improving reservoir energy, accelerating glue breaking and expanding the joints are achieved. According to the method, the shale energy value increased by fracturing can be quantified, so that the problems that the fracturing result cannot be quantified, the original reservoir temperature is reduced by the fracturing fluid, the reservoir energy of the normal-pressure shale gas reservoir is low, so that self-spraying production cannot be achieved, the natural gas in organic matter pores is slowly released, glue breaking is not thorough, the reservoir damage is easily caused and the like are solved. The method is high in operability, and the normal-temperature and normal-pressure shale gas fracturing effect is obviously improved and quantitatively evaluated.

Owner:刘常青

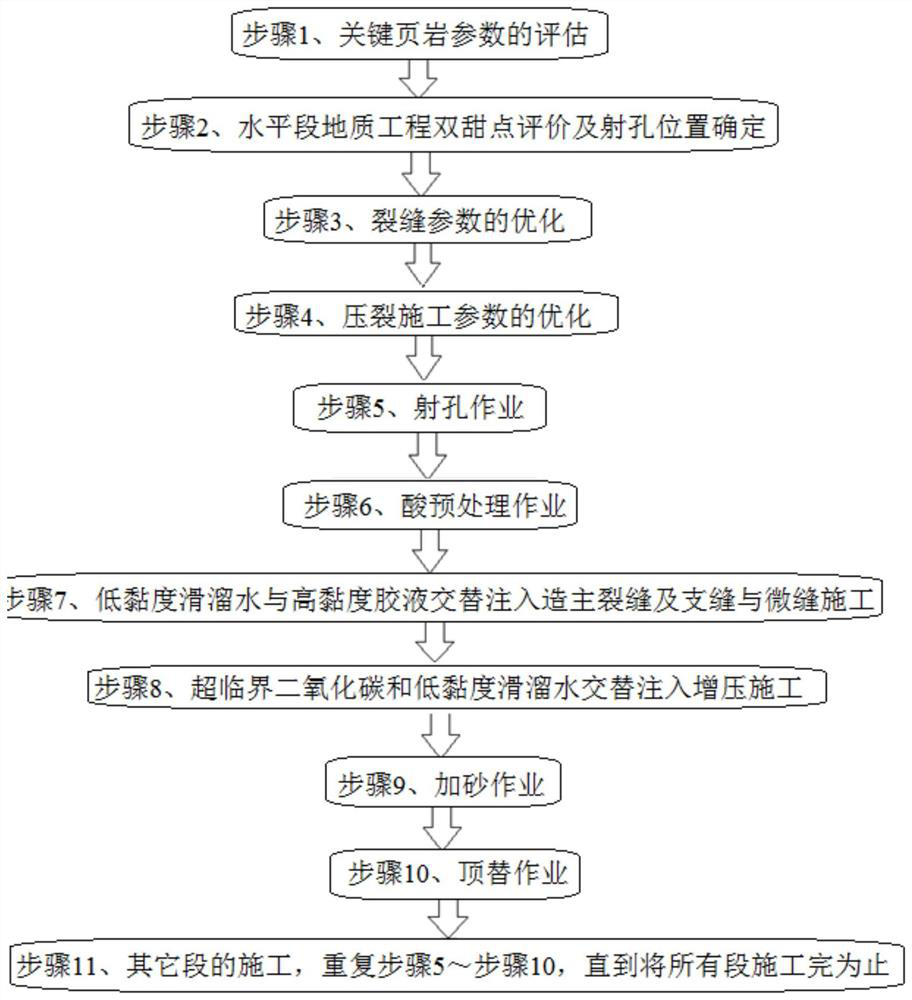

High-tectonic-stress normal-pressure shale gas volume fracturing method

ActiveCN111911128AGood effectImprove the effect of economic developmentFluid removalTectonic stressPre treatment

The invention discloses a high-tectonic-stress normal-pressure shale gas volume fracturing method. The method comprises the following steps of 1) evaluating shale key reservoir parameters; 2) performing geological engineering double-sweet-spot evaluation and perforation position determination; 3) optimizing a crack parameter system; 4) optimizing fracturing construction parameters; 5) performing cluster perforation operation; 6) performing acid pretreatment operation; 7) performing high-viscosity glue solution high-displacement splitting vertical main crack construction; 8) performing low-viscosity slickwater variable displacement communication and extension of a branch seam system and a horizontal bedding seam system; 9) performing small-particle-size long-section plugging or continuous sand adding construction; 10) performing sand adding construction on a first high-viscosity glue solution slug; 11) performing small-particle-size medium-sand-liquid-ratio medium-displacement construction of slickwater; 12) performing sand adding construction on a second high-viscosity glue solution slug; 13) performing small-particle-size high-sand-liquid-ratio high-discharge-capacity constructionof slickwater; and 14) performing high-viscosity glue solution high-displacement sand-carrying filling vertical main crack construction. The post-fracturing transformation volume of a normal-pressureshale gas well can be increased, so that the economic development effect of the normal-pressure shale gas well is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for establishing accumulation model of atmospheric pressure shale gas reservoir in complicated basin marginal tectonic zone

InactiveCN110259440AGeological measurementsBorehole/well accessoriesTectonic zoneAtmospheric sciences

The invention discloses a method for establishing an accumulation model of anatmospheric pressure shale gas reservoir in a complicated basin marginal tectonic zone. Based on the analysis of the basic geological characteristics,the enrichment law research and the exploration and development practice of the atmospheric shale gas, theaccumulation model of the atmospheric pressure shale gas reservoir in the complicated basin marginal tectonic zonewith "sedimentation phase supplying hydrocarbon and controlling storage, constructing movement to control and ensure enrichment and loss retention for accumulation" is established; understanding of further deepening the atmospheric pressure shale gas reservoirin thecomplicated basin marginal tectonic zone is realized,and theoretical support isprovided for the exploration of the atmospheric pressure shale gas reservoir; and after exploration and practice verification, breakthroughs in atmospheric pressure shale gas exploration are achieved, the method is of great significance for the increase and storage of the atmospheric pressure shale gas in southern China.

Owner:CHINA PETROLEUM & CHEM CORP +1

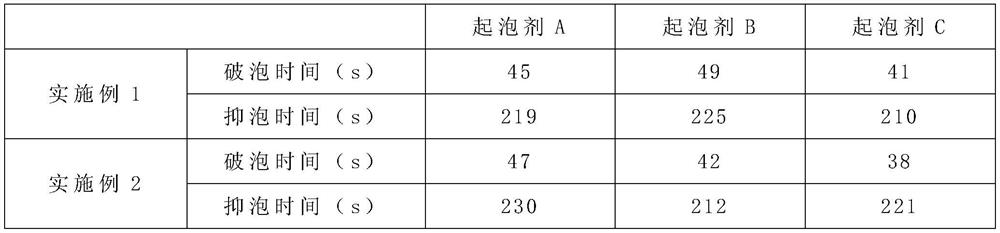

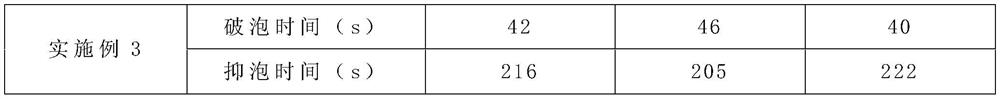

Foam scrubbing defoaming agent for developing normal-pressure shale gas and preparation method of foam scrubbing defoaming agent

InactiveCN113350834AGood anti-foam performanceImprove versatilityFoam dispersion/preventionAlcoholOil viscosity

The invention provides a foam scrubbing defoaming agent for developing normal-pressure shale gas and a preparation method of the foam scrubbing defoaming agent. The defoaming agent comprises silicone oil I, silicone oil II, silicone oil III, an emulsifier, n-propyl alcohol, ascorbic acid and water. The viscosity of the silicone oil I is 5-10 cps; the viscosity of the silicone oil II is 400 to 600 cp s; and the content of the silicone oil III is 5000-6000 cp s. The preparation process comprises the following steps: adding the silicone oil I, the silicone oil II and the silicone oil III into a stirring tank, and then adding the emulsifier into the stirring tank to obtain a mixed solution I; adding ascorbic acid into water, stirring until the ascorbic acid is dissolved, and then adding n-propyl alcohol to obtain a mixed solution II; heating the mixed solution I to 50 DEG C, and then adding the mixed solution II into the mixed solution I to obtain the defoaming agent. In the foam scrubbing defoaming agent, three kinds of silicone oil with different viscosities are selected as active substances of the defoaming agent, so that the universality of the defoaming agent can be effectively improved, and the foam breaking time of the defoaming agent is effectively shortened. The preparation method is simple, easy in process control and suitable for popularization and application.

Owner:CHINA PETROLEUM & CHEM CORP +2

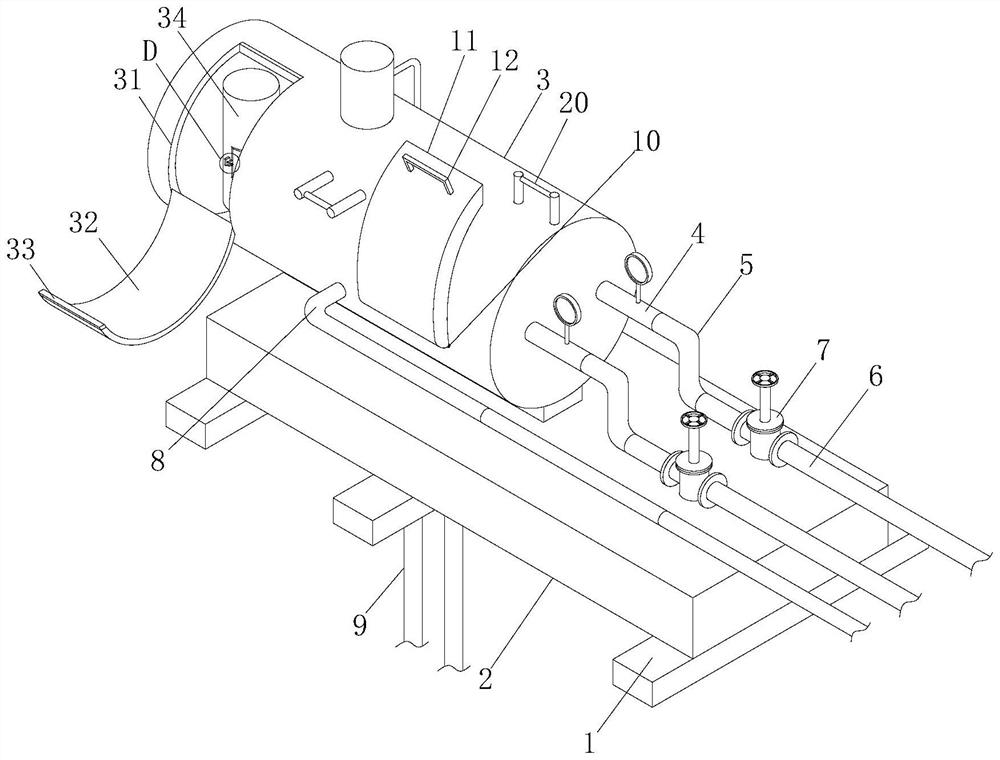

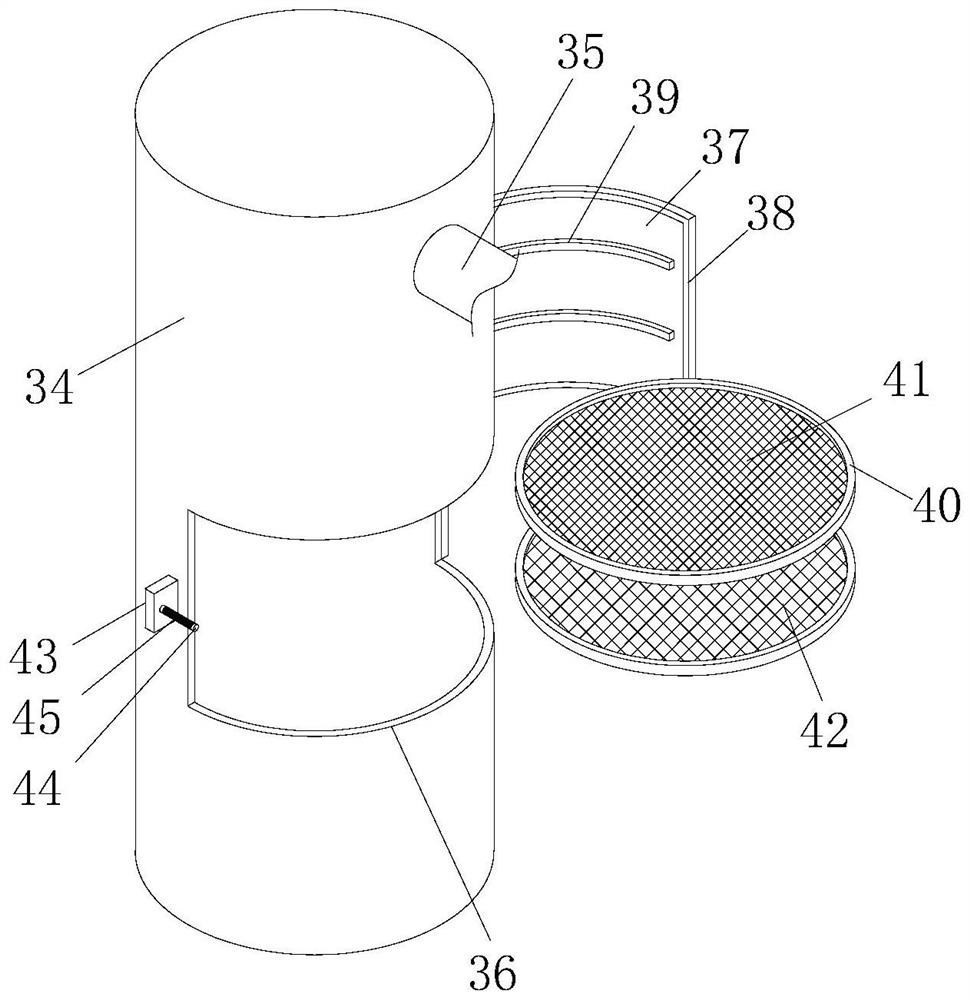

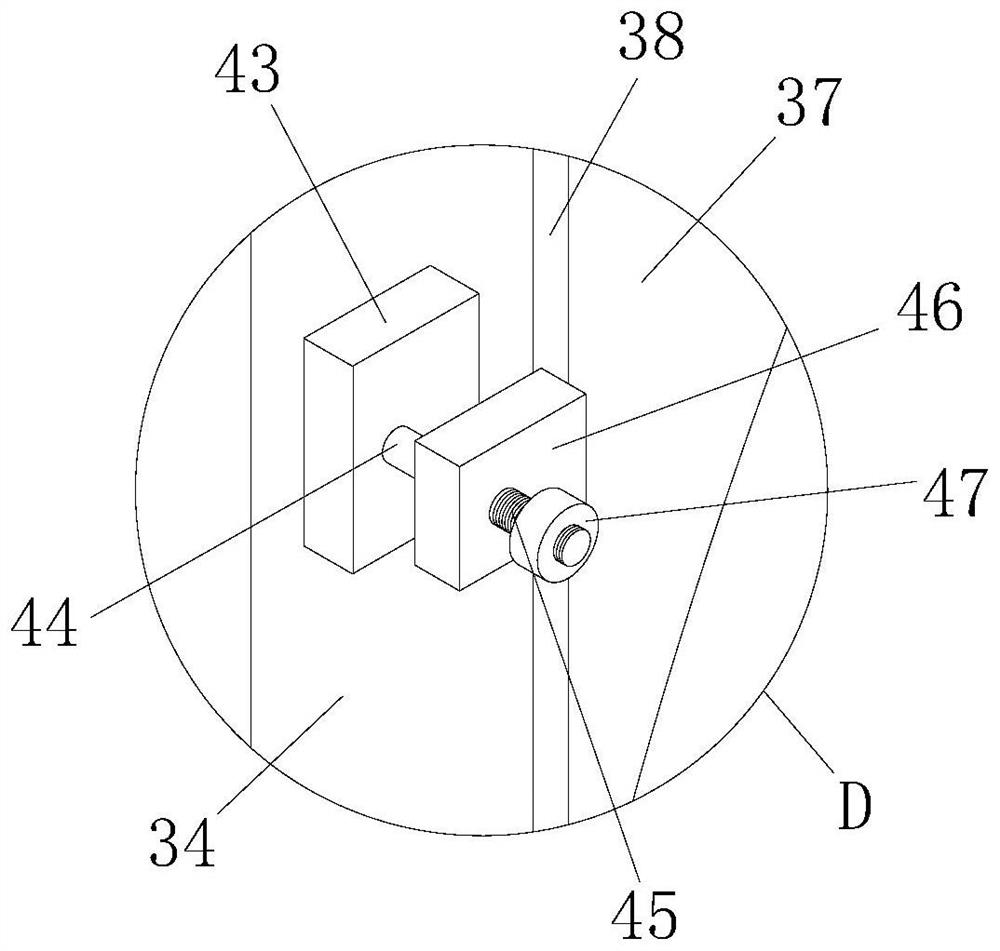

Integrated normal-pressure shale gas drainage gas recovery and on-site treatment device

ActiveCN114293967AHigh separation precisionEasy to clogDrilling rodsFluid removalThermodynamicsPetroleum oil

The invention relates to the technical field of petroleum and natural gas extraction devices, and discloses an integrated normal-pressure shale gas drainage gas recovery and on-site treatment device which comprises a plurality of bottom supporting mechanisms arranged at equal intervals and a bearing mechanism fixedly installed on the tops of the bottom supporting mechanisms. A gas-water separation device in the collection tank can perform primary gas-water separation on natural gas collected in a rock stratum, a first filtering mechanism and a second filtering mechanism in the gas-water separation device can be matched with an external filtering mechanism to filter and convey the gas, and firstly, a sealing bin door can be opened from the collection tank; according to the gas-water separation device, the filter mechanism in the gas-water separation device directly moves to the outside of the gas-water separation device along with the control door at the same time, the filter mechanism is replaced after being detached, and then the control door is closed, sealed and fixed with the inside of the gas-water separation device again, so that the cleanliness of the filter mechanism is ensured, and the service life of the gas-water separation device is prolonged. The filterability of fuel gas is improved, and the purity of shale gas is improved.

Owner:SICHUAN KEYUAN TESTING CENT OF ENG TECH CO LTD

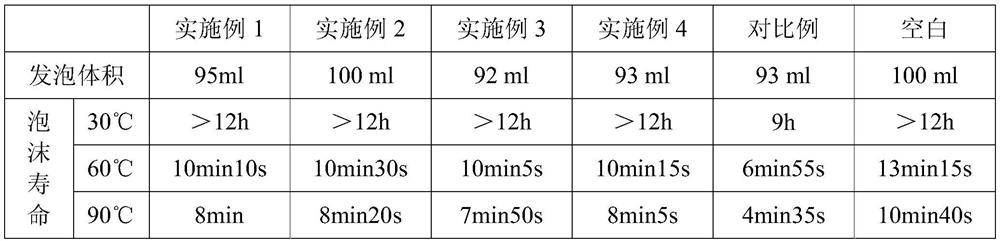

Foam drainage foaming agent for normal-pressure shale gas development and preparation method thereof

The invention relates to a foam drainage foaming agent for normal-pressure shale gas development and a preparation method thereof, and belongs to the technical field of oil and gas development. The foam drainage foaming agent for normal-pressure shale gas development comprises the following components in parts by weight: 4-10 parts of sodium dodecyl sulfate, 1-4 parts of sodium dodecyl benzene sulfonate, 1-3 parts of alkylphenol polyoxyethylene, 2-6 parts of polyvinyl alcohol, 4-5 parts of Tween 80, 1-2 parts of EDTA (Ethylene Diamine Tetraacetic Acid), 5-8 parts of triethanolamine, 5-10 parts of ammonium salt and the balance of water. By optimizing the components of the foam drainage foaming agent, the components cooperate with one another, so that the liquid carrying capacity and foam stabilizing performance of the foaming agent are enhanced, and meanwhile, the temperature resistance of the foaming agent is synergistically enhanced.

Owner:CHINA PETROLEUM & CHEM CORP +2

Efficient filtering type shale gas exploitation device

InactiveCN114876418AAvoid structural damageImprove filtering effectFluid removalThermodynamicsEngineering

The invention discloses an efficient filtering type shale gas mining device which comprises a mining shell, an outer anti-extrusion plate is fixedly connected to the top of the mining shell, a collecting pipe shell is fixedly connected to the upper surface of the outer anti-extrusion plate, an inner expansion plate is fixedly connected to the inner wall of the collecting pipe shell, and a collecting device is fixedly connected to the interior of the mining shell. The collecting device comprises an upper sealing collecting pipe, the outer surface of the upper sealing collecting pipe is arranged in the exploiting shell in a sleeved mode, and an exploiting unit is fixedly connected to the bottom of the inner surface of the exploiting shell. According to the efficient filtering type shale gas exploitation device, by arranging the top sleeve cover, when the device is impacted by high-pressure shale gas at the bottom, the action spring can achieve a proper blocking effect by limiting the bottom of the force bearing elastic rod, and the situation that the impact force of the flow velocity of the shale gas is too large, and consequently the internal device structure is damaged is prevented.

Owner:张启仁

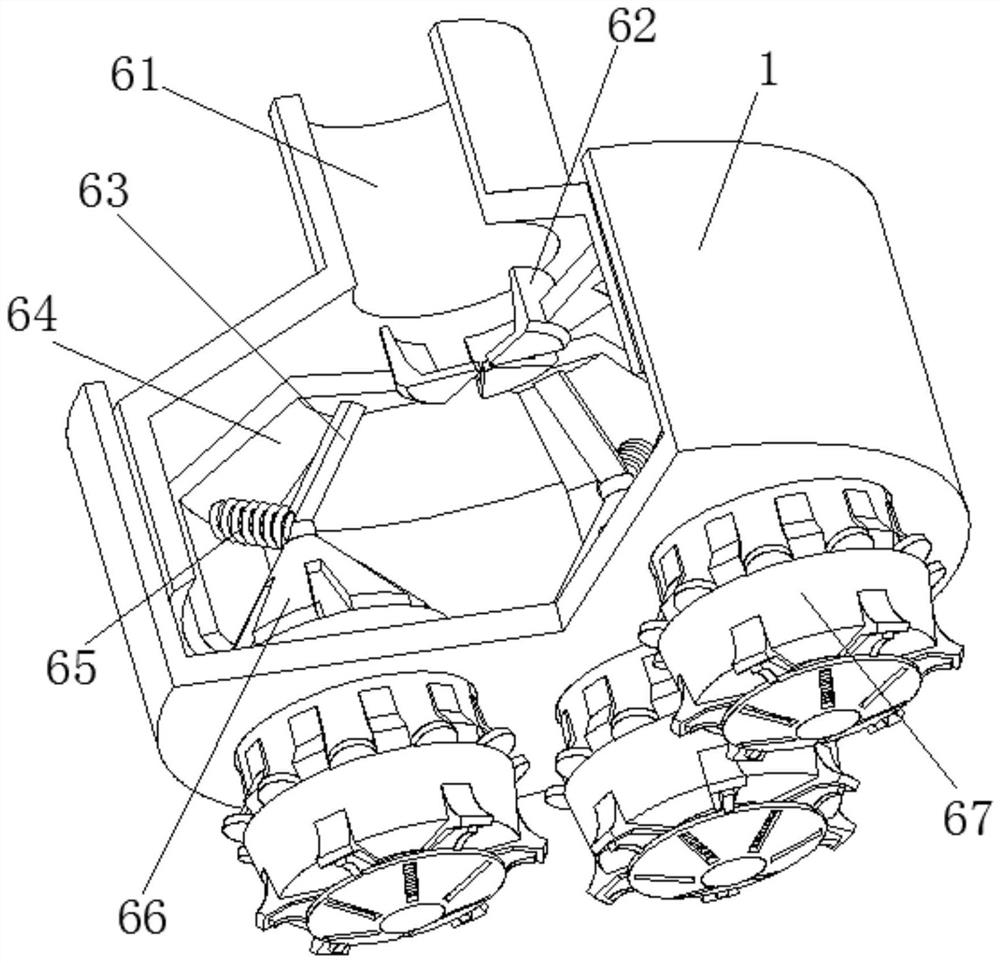

Method for achieving volume fracturing through pre-pressurization of normal-pressure shale gas and application

ActiveCN113685164AEffective guidance for fracturing constructionReasonable designFluid removalBulk chemical productionPre treatmentShale gas

The invention discloses a method for achieving volume fracturing through pre-pressurization of normal-pressure shale gas. According to the method, multi-cluster jet holes in a section are comprehensively adopted to increase the induction pressure, supercritical carbon dioxide and low-viscosity slickwater are injected to increase the formation pressure, a variable-viscosity variable-displacement injection process is adopted to promote complication of main fractures and branch fractures, the type of pretreatment acid is reasonably selected, and the normal-pressure shale gas reservoir is effectively transformed and the transformation volume is increased in cooperation with the process technologies such as the liquid injection amount and injection process parameter optimization. The normal-pressure shale gas fracturing transformation effect is greatly improved, the optimization result can effectively guide fracturing construction, the transformation volume is greatly increased, the construction effect is obviously improved, and therefore the maximum economic benefits are obtained.

Owner:CHINA PETROLEUM & CHEM CORP +1

A fracturing method for normal pressure shale gas horizontal wells

ActiveCN109751027BEfficient developmentIncreased complexityFluid removalThermodynamicsHorizontal wells

The invention discloses a fracturing method for an atmospheric pressure shale gas horizontal well. The method comprises: constructing a tree-shaped crack system comprising a main crack, branch cracksand micro cracks, wherein the main crack, the branch cracks and the micro cracks are sequentially constructed on the basis of fracturing fluid with different property characteristics, the branch cracks communicate with the main crack, and the micro cracks communicate with the branch cracks; and injecting a propping agent into the tree-shaped crack system. According to the method, the tree-shaped crack system for normal-pressure shale gas fracturing exploitation can be constructed, the crack complexity and the transformation size are improved, and economic and effective development of the normal-pressure shale gas horizontal well is ensured.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of fracturing method of normal pressure shale gas reservoir

ActiveCN108952668BRaise the complexity indexImprove fracturing effectFluid removalFracturing fluidReservoir evaluation

The invention provides a fracturing method of a normal-pressure shale gas reservoir. The fracturing method comprises the following steps that firstly, reservoir evaluation parameters are obtained; secondly, fracturing construction parameters are determined, specifically, the viscosity, the displacement and the using amount of fracturing liquid and the particle size and the using amount of proppingagents are determined; and thirdly, fracturing construction is conducted, specifically, the reservoir is subjected to segment-by-segment fracturing construction through a spiral-slug-type mixed particle size sand-adding mode. According to the fracturing method of the normal-pressure shale gas reservoir, the complexity index of cracks of the normal-pressure shale gas reservoir can be effectively increased, and the fracturing transformation effect of the normal-pressure shale reservoir is improved accordingly.

Owner:CHINA PETROLEUM & CHEM CORP +1

A method and construction technology for increasing the complexity of the fracture system in fracturing production

ActiveCN109751026BIncreased complexityImprove long-term effective diversion capacityFluid removalThermodynamicsShale gas

The invention discloses a method for increasing the complexity of the fracturing and exploitation fracture system, a fracturing operation method and an underground heating device. Water to increase the complexity level of cracks. The method according to the invention can effectively increase the complexity of the fracture system in fracturing and fracturing, thereby improving the long-term effective conductivity of the fractures in normal pressure shale gas reservoirs, so as to increase the effective period of stimulation measures and improve economic development benefits.

Owner:CHINA PETROLEUM & CHEM CORP +1

An experimental analysis method for the study of compressibility of shale samples

ActiveCN108535112BMaterial strength using tensile/compressive forcesStatistical analysisScanning electron microscope

An experimental analysis method for studying the compressibility of a shale sample, comprising the following steps: processing the shale sample into a cylindrical plunger, and drilling a hole axially along the axis of the plunger; The plunger sample is placed in the sleeve; the outer edge of the sleeve with the built-in shale plunger sample is coated with silicone grease and put into the autoclave; the fluid is pumped into the autoclave, and the autoclave is heated at the same time and detected by the pressure sensor Pumping pressure; after the shale sample is broken, adjust the temperature of the autoclave until the fluid solidifies, and keep it for a time t1; cut and grind the formed fractured specimen into thin slices, and analyze and observe the fracture morphology characteristics. The present invention simulates the fracturing of shale fluid and maintains the original state after fracturing. With the help of technical means such as microscope, scanning electron microscope and energy spectrum analysis, the shape, direction, quantity and mechanism of fracturing of fluid fracturing are analyzed. Conduct observation and statistical analysis to provide theoretical guidance for shale sample frackability evaluation and fracturing practice.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of acid slick water composite fracturing method for shale gas horizontal well

ActiveCN109209332BIncrease the effective transformation volumeIncreased complexityFluid removalHorizontal wellsReservoir evaluation

The invention discloses an acid slick water composite fracturing method for a shale gas horizontal well. Including: (1) reservoir evaluation before fracturing; (2) perforation scheme optimization; (3) acidic slick water injection; (4) addition of 70-140 mesh proppant; (5) injection of iso-viscosity conventional slick water; (6) Injection of high-viscosity conventional glue; (7) Injection of 40-70 mesh and 30-50 mesh proppants. The method of the present invention improves the complexity of the fracturing fractures of deep normal pressure shale gas, and the filling rate of fracture systems of different scales, thereby increasing the effective volume of deep normal pressure shale gas stimulation, and improving the effect of increasing production and stabilizing production after fracturing .

Owner:CHINA PETROLEUM & CHEM CORP +1

A volume fracturing method for horizontal shale gas wells at normal pressure

ActiveCN107545088BIncrease the volume of the transformationIncrease in sizeData processing applicationsFluid removalThermodynamicsHorizontal wells

Owner:CHINA PETROLEUM & CHEM CORP +1

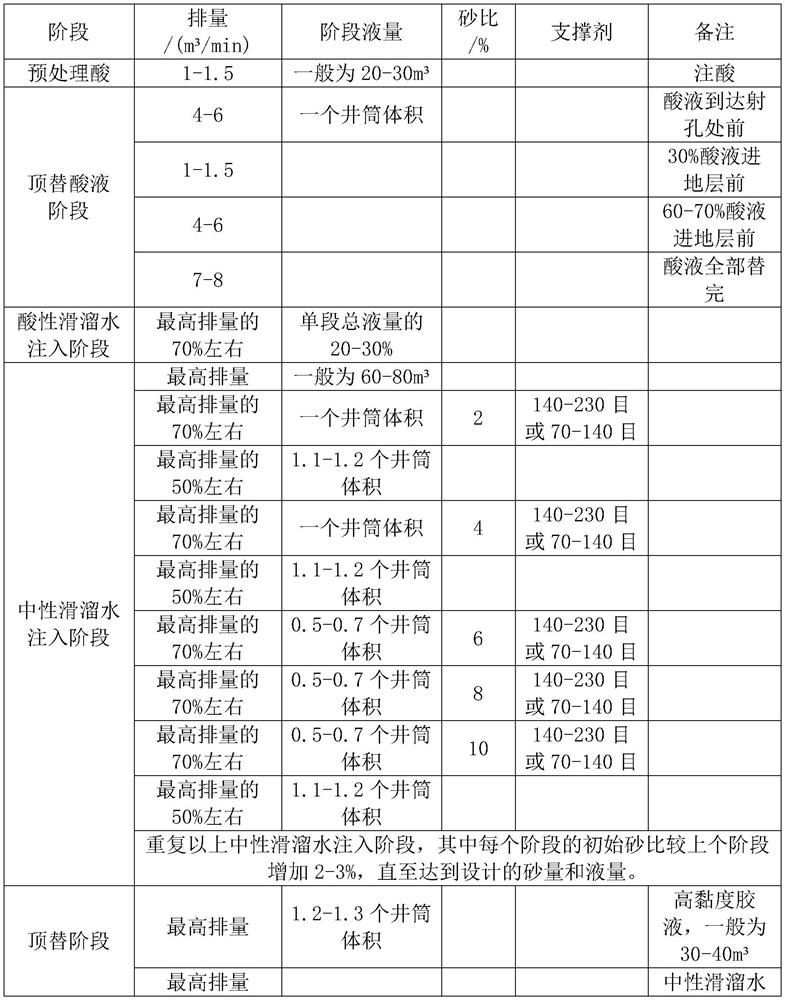

A high frequency variable displacement volumetric fracturing method for atmospheric shale gas reservoirs

ActiveCN109751037BIncreased crack complexityImprove development potentialFluid removalPre treatmentShale gas

The invention discloses a high-frequency variable displacement volume fracturing method for normal-pressure shale gas reservoirs. Including: (1) Evaluation of key shale reservoir parameters (2) Optimization of fracture parameters (3) Determination of geological engineering sweet spot and cluster perforation location (4) Optimization of fracturing construction parameters (5) Cluster perforation operation ( 6) Acid pretreatment (7) Acidic slick water injection into main fractures (8) Neutral slick water high displacement injection construction (9) Medium displacement injection construction of 140-230 mesh or 70-140 mesh proppant (10 ) Low displacement injection of spacer fluid for construction (11) Repeat steps 8) to 10) until the total fluid volume and proppant amount of the current section are used up; (12) Replacement operation. The invention adopts the acid slick water system and the neutral slick water high-frequency variable displacement process. Improve the post-pressure production effect of atmospheric shale gas wells, and better realize the goal of economically and effectively developing atmospheric shale.

Owner:CHINA PETROLEUM & CHEM CORP +1

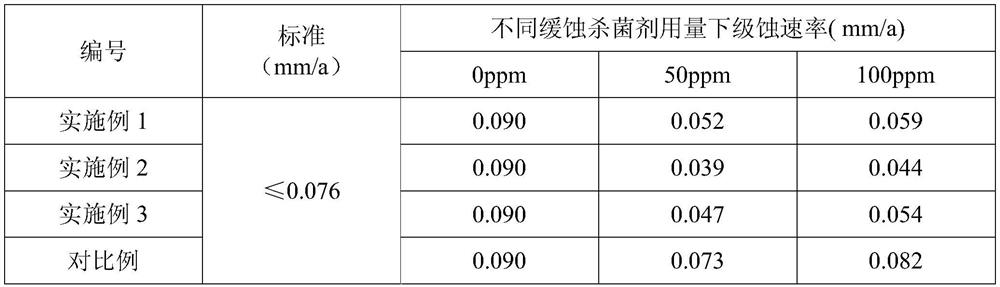

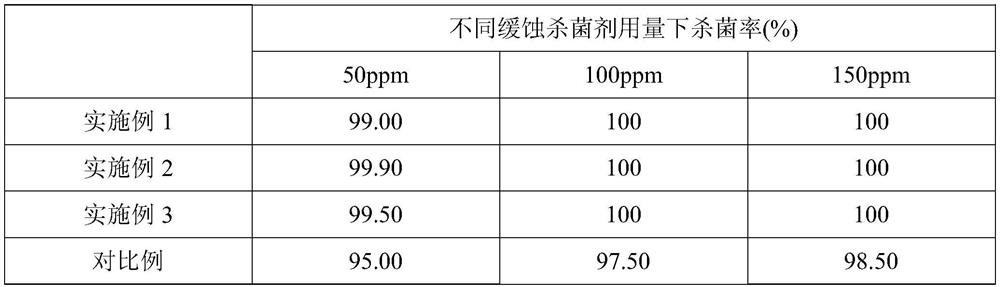

Corrosion inhibition bactericide for normal-pressure shale gas field

InactiveCN113337263AReduce corrosionEffective destructionBiocideDisinfectantsActive agentSurface-active agents

The invention relates to a corrosion inhibition bactericide for a normal-pressure shale gas field, and belongs to the technical field of oil and gas development. The corrosion inhibition bactericide for the normal-pressure shale gas field is composed of a component A and a component B. The component A comprises the following components in parts by weight: 10-15 parts of a corrosion inhibitor, 6-9 parts of sodium dihydrogen phosphate, 1-2 parts of a surfactant and 74-83 parts of water I; and the component B is prepared from the following components in parts by weight: 4.5 to 6.8 parts of sodium chlorite, 1 to 2 parts of sodium chloride and 94.5 to 91.2 parts of water II. The bactericide disclosed by the invention not only can play a role in corrosion inhibition, but also can effectively kill microorganisms in a production system, so that the bactericide has two effects.

Owner:CHINA PETROLEUM & CHEM CORP +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com