Corrosion inhibition bactericide for normal-pressure shale gas field

A technology of fungicides and corrosion inhibitors, applied in the field of slow-release fungicides for atmospheric shale gas fields, can solve the problems of fungicides polluting the environment, inability to completely kill microorganisms, and poor compatibility, and achieve the goal of delaying corrosion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

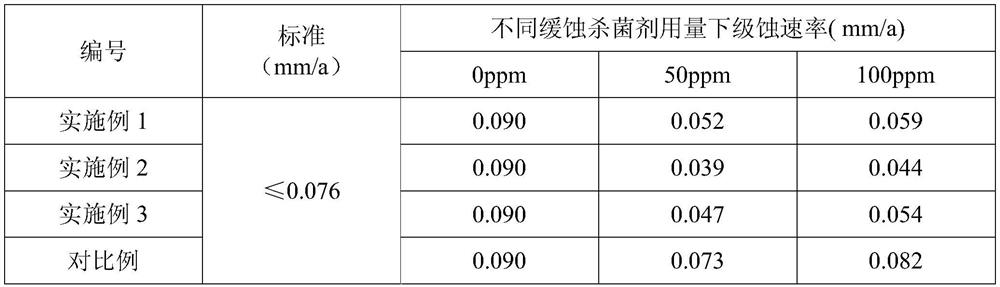

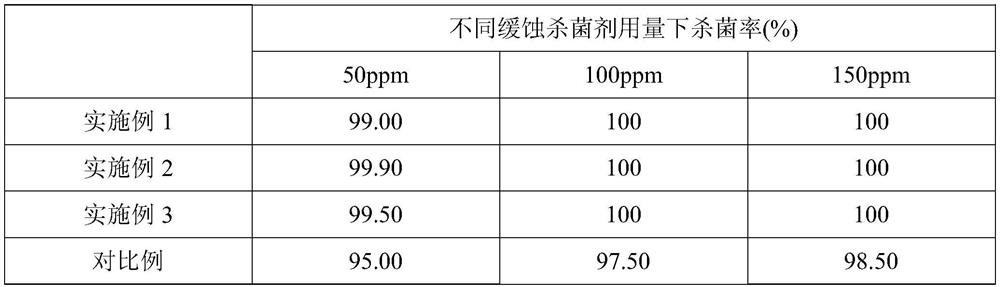

Examples

Embodiment 1

[0019] A corrosion inhibitor and bactericide for normal pressure shale gas fields, comprising the following components in parts by weight:

[0020] Component A: 12 parts of didecyl dimethyl ammonium chloride, 7 parts of sodium dihydrogen phosphate, 1.0 parts of sodium dodecylsulfonate, 80 parts of water I;

[0021] Component B: 5.4 parts of sodium chlorite, 1 part of sodium chloride, and 93.6 parts of water II.

[0022] The preparation steps are as follows:

[0023] (1) Add 12 parts of didecyldimethylammonium chloride, 7 parts of sodium dihydrogen phosphate and 1.0 part of sodium dodecylsulfonate into 80 parts of water I, stir and dissolve at room temperature, and store at room temperature;

[0024] (2) Add 5.4 parts of sodium chlorite and 1 part of sodium chloride to 93.6 parts of water II, stir and dissolve at room temperature, and store at 5-10°C.

[0025] Mix component A and component B at a weight ratio of 1:1 before use.

Embodiment 2

[0027] A corrosion inhibitor and bactericide for normal pressure shale gas fields, comprising the following components in parts by weight:

[0028] Component A: 13 parts of dodecyl dimethyl benzyl ammonium chloride, 7 parts of sodium dihydrogen phosphate, 1.0 parts of sodium dodecylsulfonate, 79 parts of water I;

[0029] Component B: 5.4 parts of sodium chlorite, 1 part of sodium chloride, and 93.6 parts of water II.

[0030] The preparation steps are as follows:

[0031] (1) Add 13 parts of dodecyldimethylbenzyl ammonium chloride, 7 parts of sodium dihydrogen phosphate and 1.0 part of sodium dodecylsulfonate to 79 parts of water I, stir and dissolve at room temperature, and save;

[0032] (2) Add 5.4 parts of sodium chlorite and 1 part of sodium chloride to 93.6 parts of water II, stir and dissolve at room temperature, and store at 5-10°C.

[0033] Mix component A and component B at a weight ratio of 1:1.2 before use.

Embodiment 3

[0035] A corrosion inhibitor and bactericide for normal pressure shale gas fields, comprising the following components in parts by weight:

[0036] Component A: 15 parts of dodecyl dimethyl benzyl ammonium chloride, 9 parts of sodium dihydrogen phosphate, 2 parts of sodium dodecylsulfonate, 74 parts of water I;

[0037] Component B: 6.8 parts of sodium chlorite, 2 parts of sodium chloride, and 91.2 parts of water II.

[0038] The preparation steps are as follows:

[0039] (1) Add 12 parts of dodecyldimethylbenzyl ammonium chloride, 7 parts of sodium dihydrogen phosphate and 1.0 part of sodium dodecylsulfonate to 80 parts of water I, stir and dissolve at room temperature, and then save;

[0040] (2) Add 5.5 parts of sodium chlorite and 1.5 parts of sodium chloride to 93 parts of water II, stir and dissolve at room temperature, and store at 5-10°C.

[0041] Mix component A and component B at a weight ratio of 1:1.2 before use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com