Patents

Literature

743results about How to "Effective destruction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

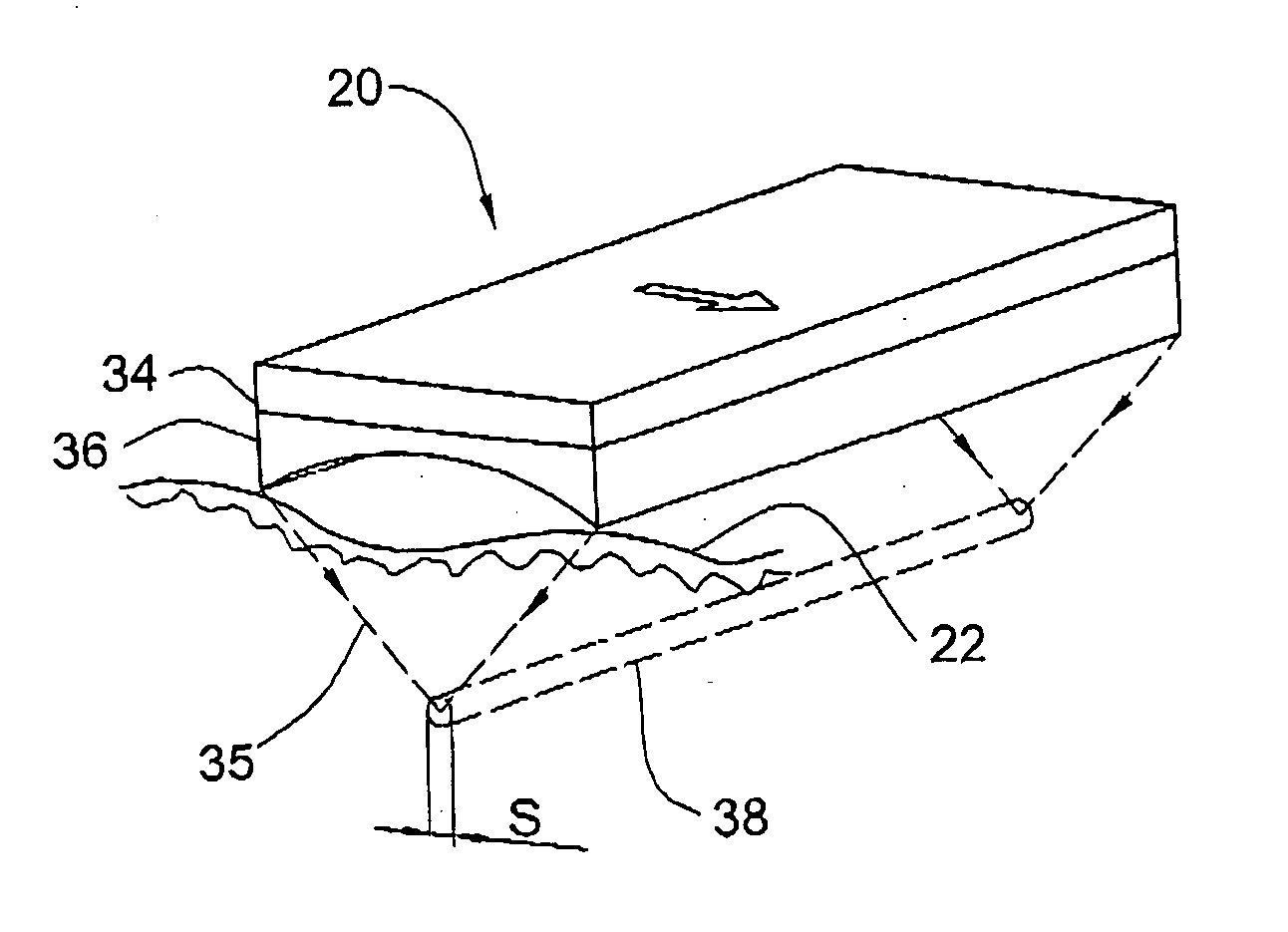

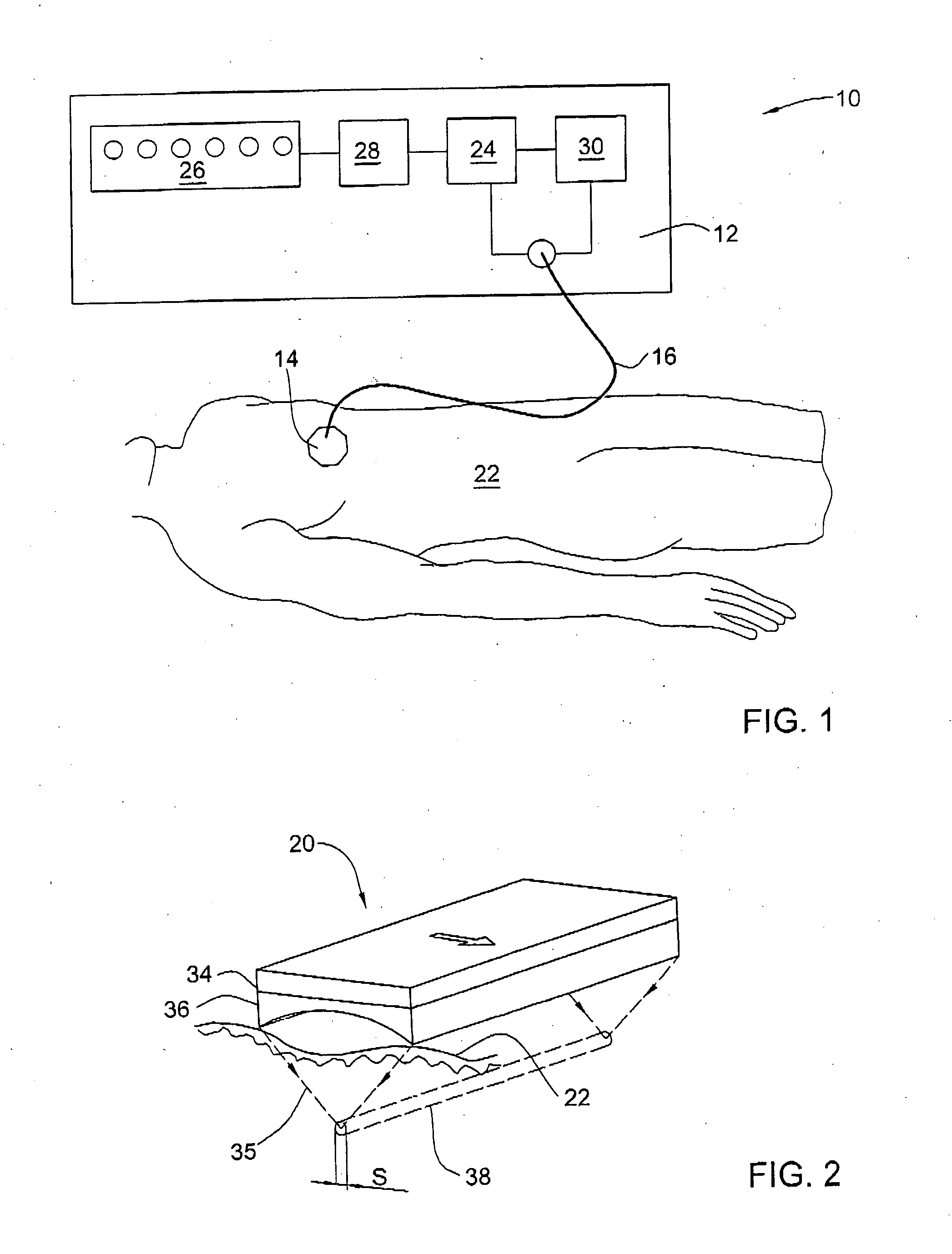

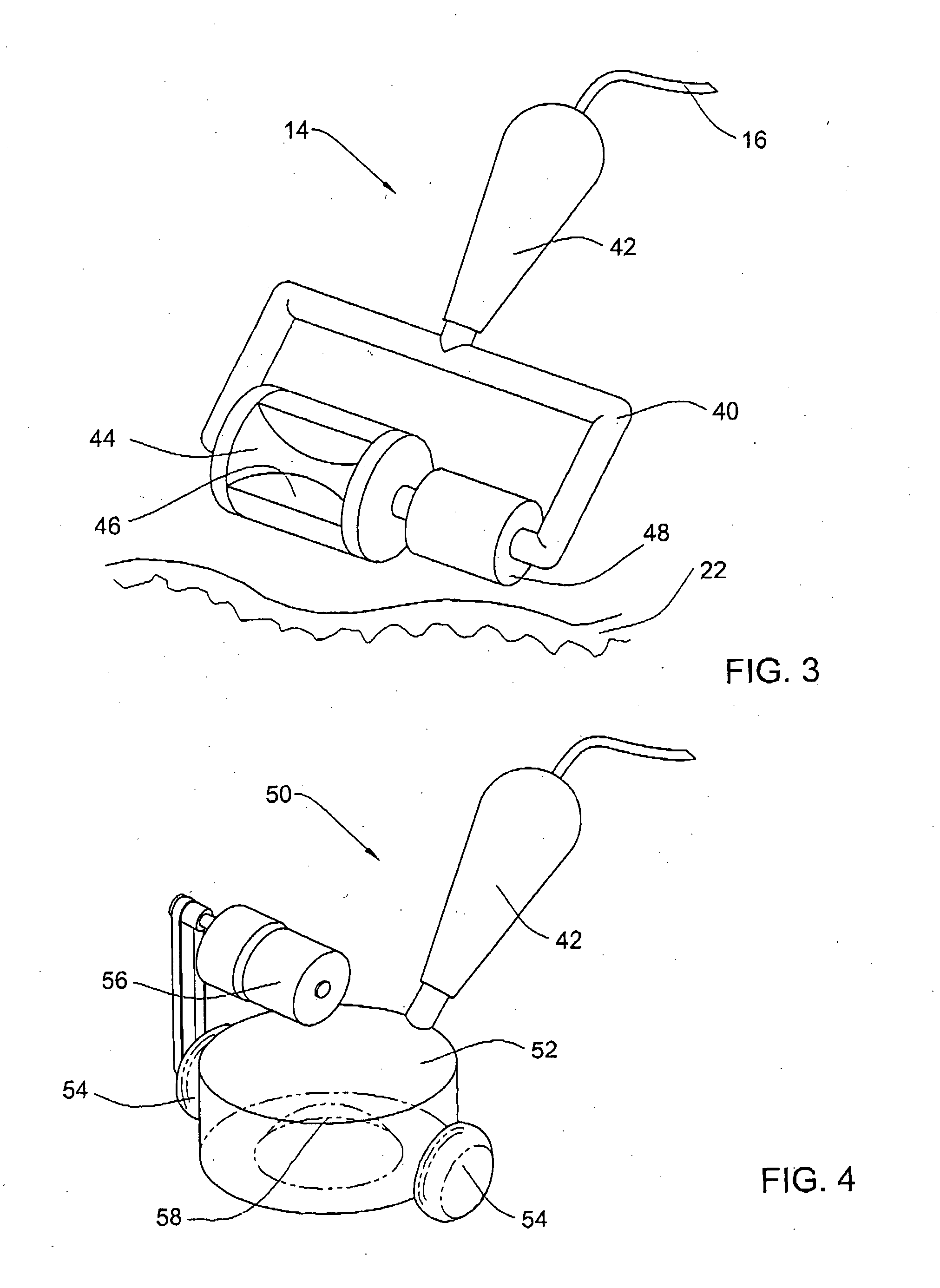

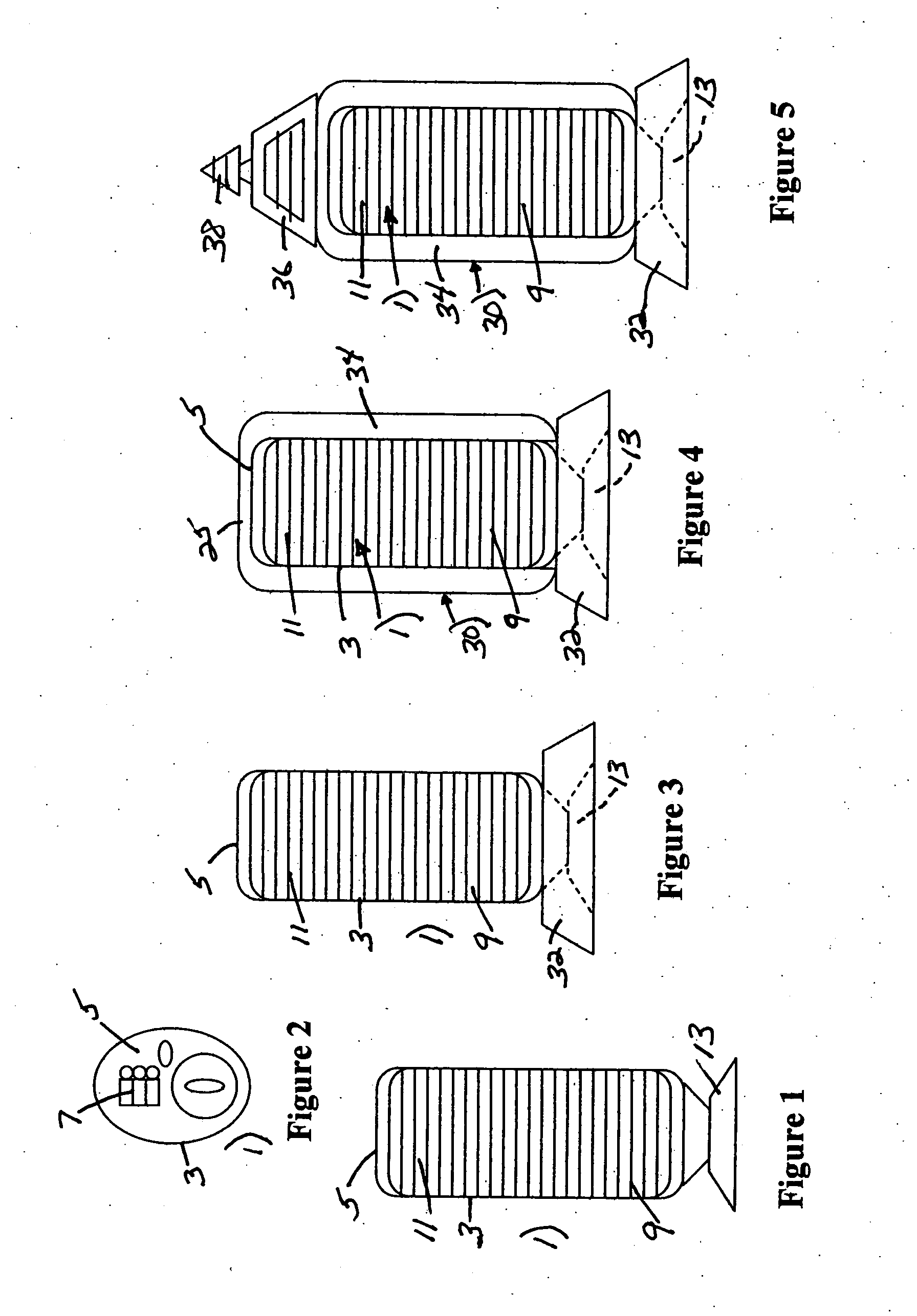

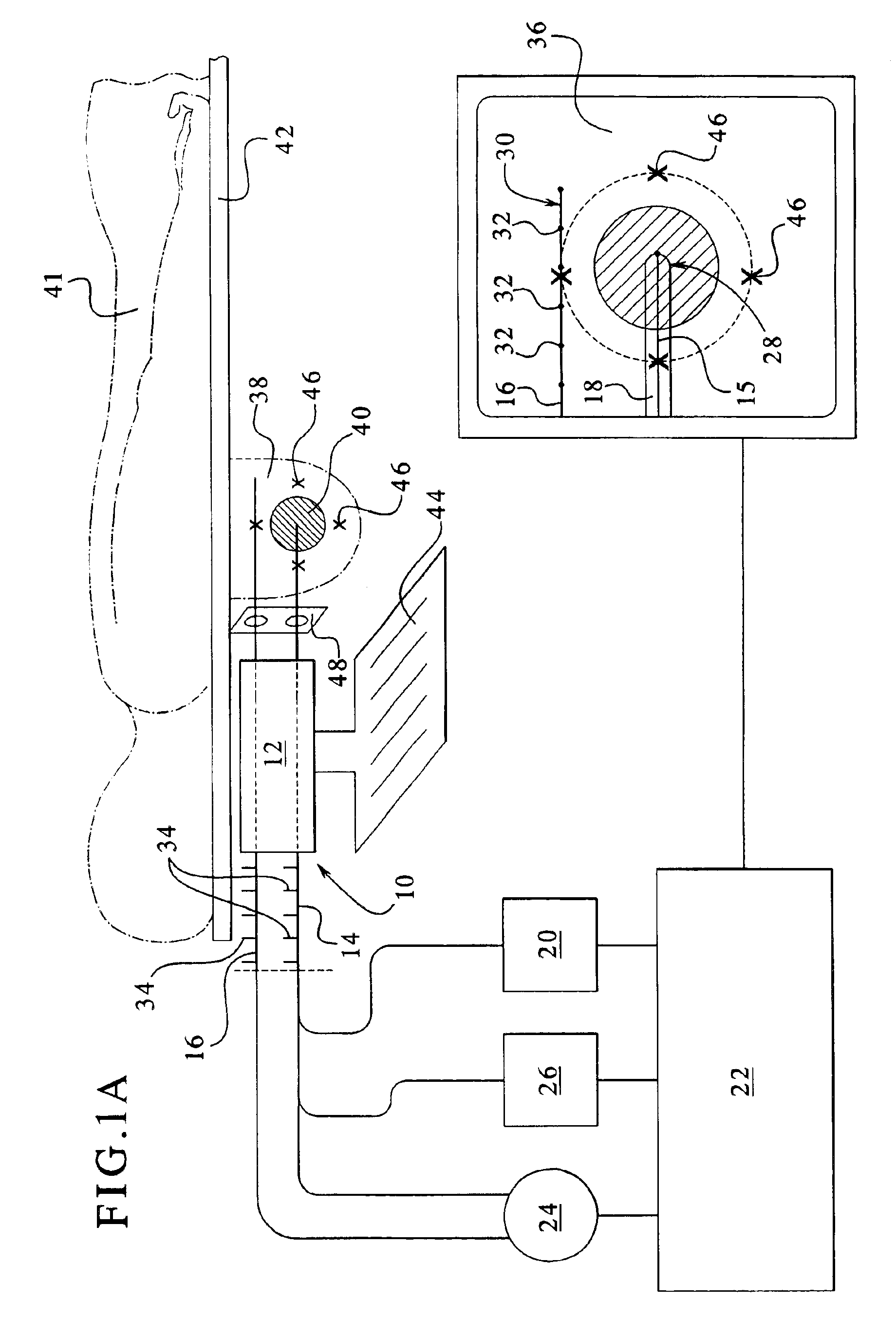

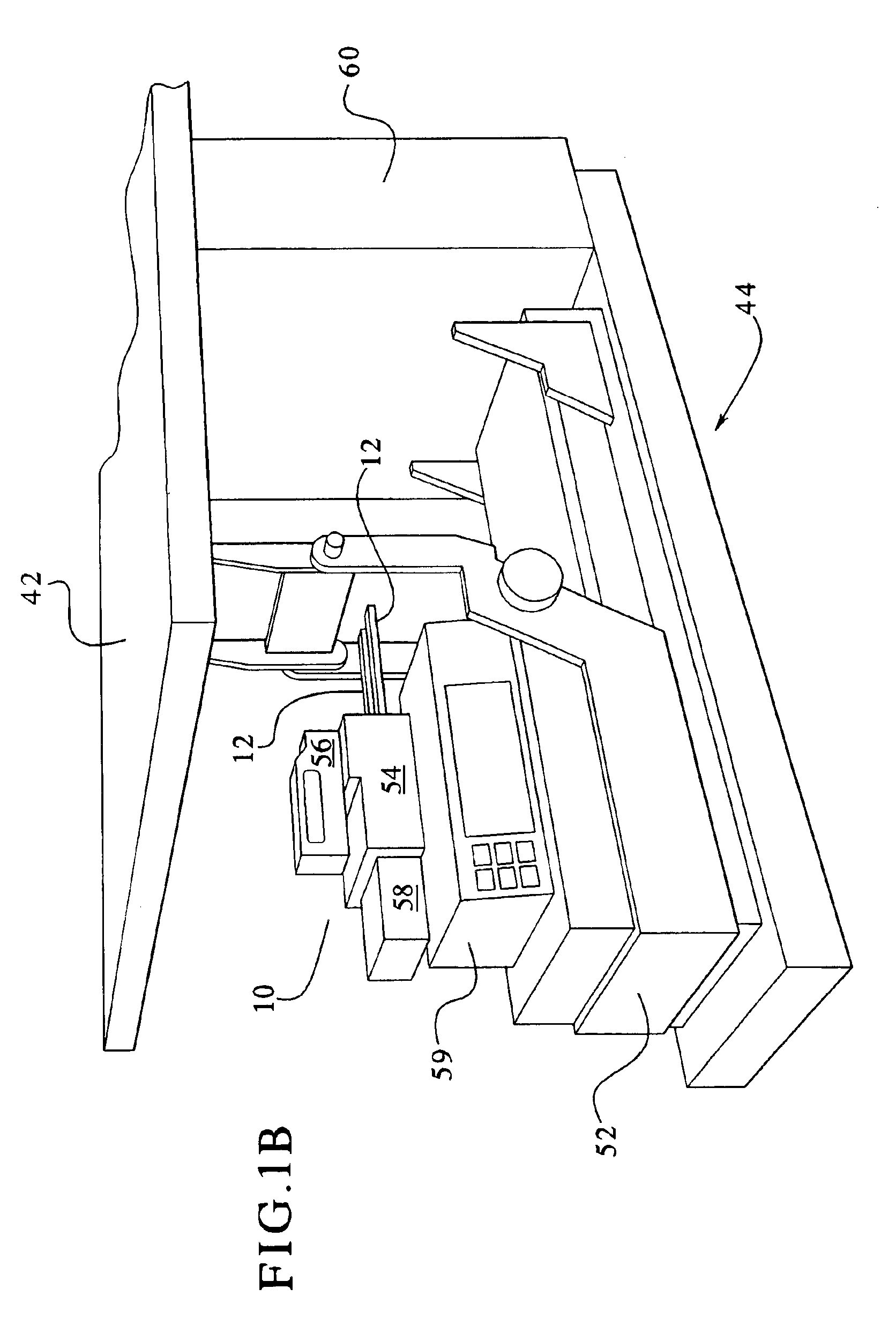

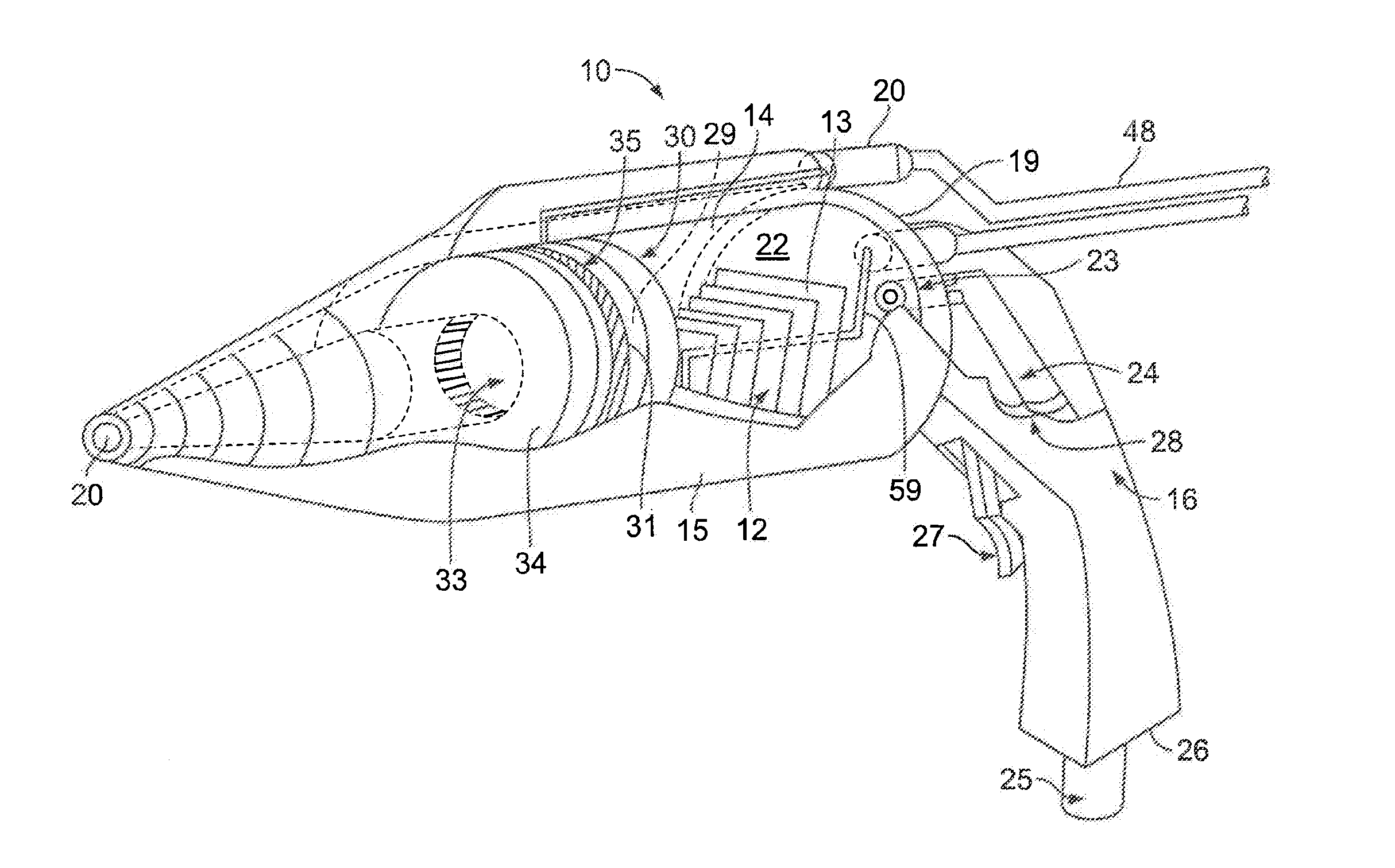

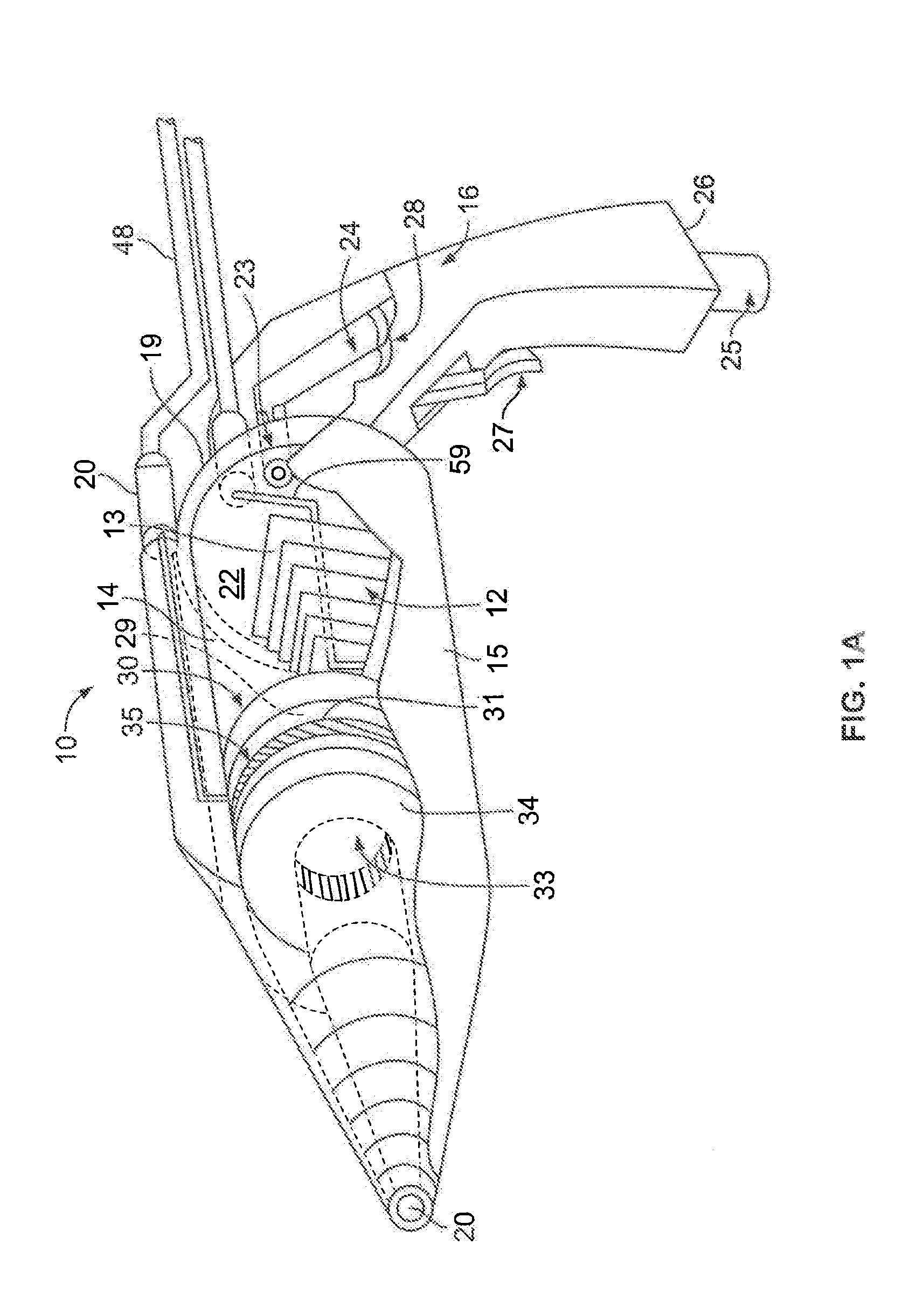

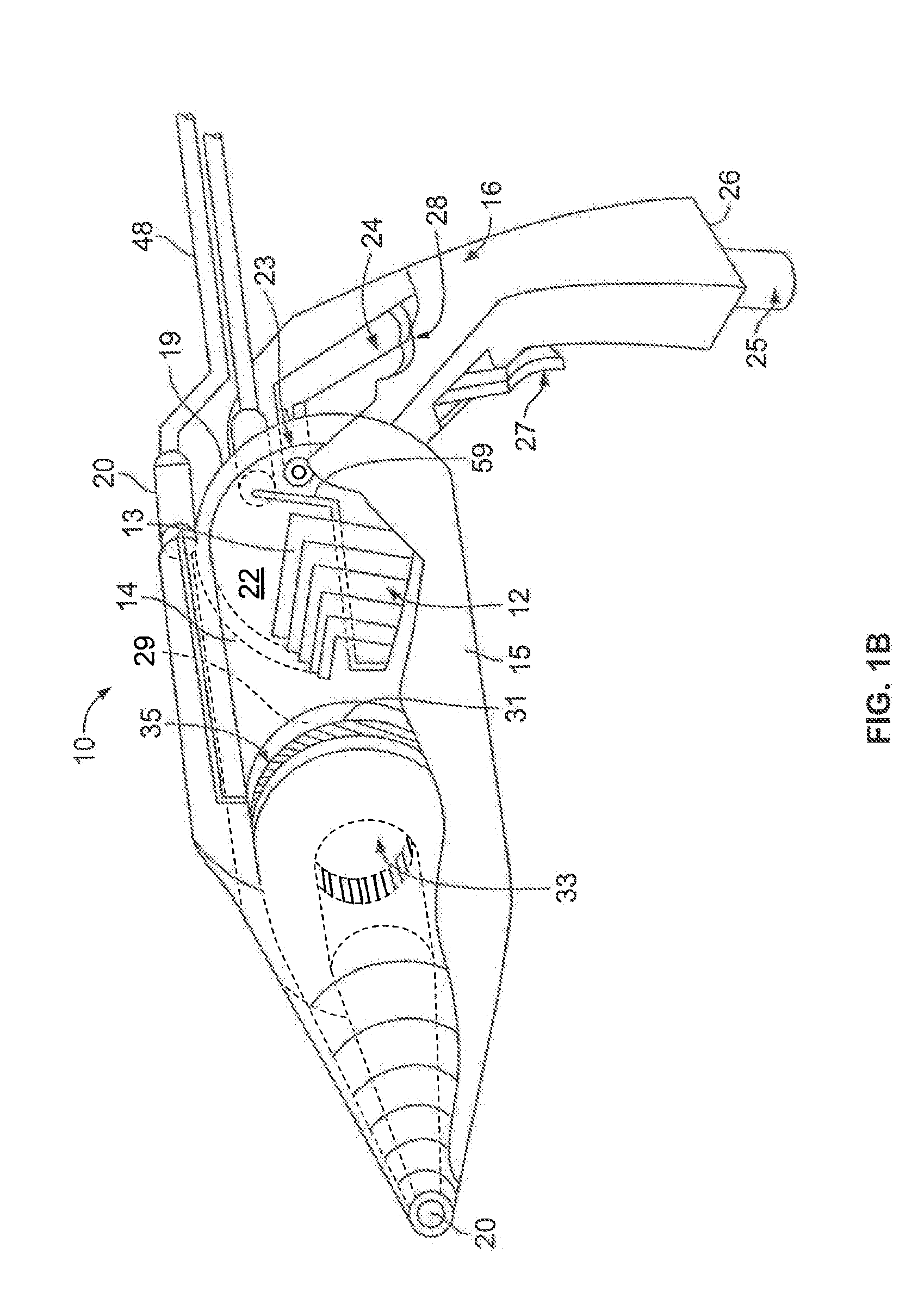

Method and device for sub-dermal tissue treatment

InactiveUS20050055018A1Avoid heat damageAvoid tissue damageUltrasound therapySurgical instruments for heatingCavitationHand held

System and method for non-invasive lysis of sub-dermal tissue by means of focused ultrasonic energy, the system comprising: a source of ultrasonic energy adapted to operate in continuous wave mode and to focus ultrasonic energy in a focal zone within the sub-dermal tissue, the ultrasonic energy being adapted to induce tissue cavitation in the focal zone; means for continuous displacement of the source over the skin surface; and means for determining a safe speed for the displacement, the safe speed allowing to avoid thermal tissue damage. The source of ultrasonic energy is accommodated in a hand-held applicator including a wheeled traction system powered by an electric drive.

Owner:SYNERON MEDICAL LTD

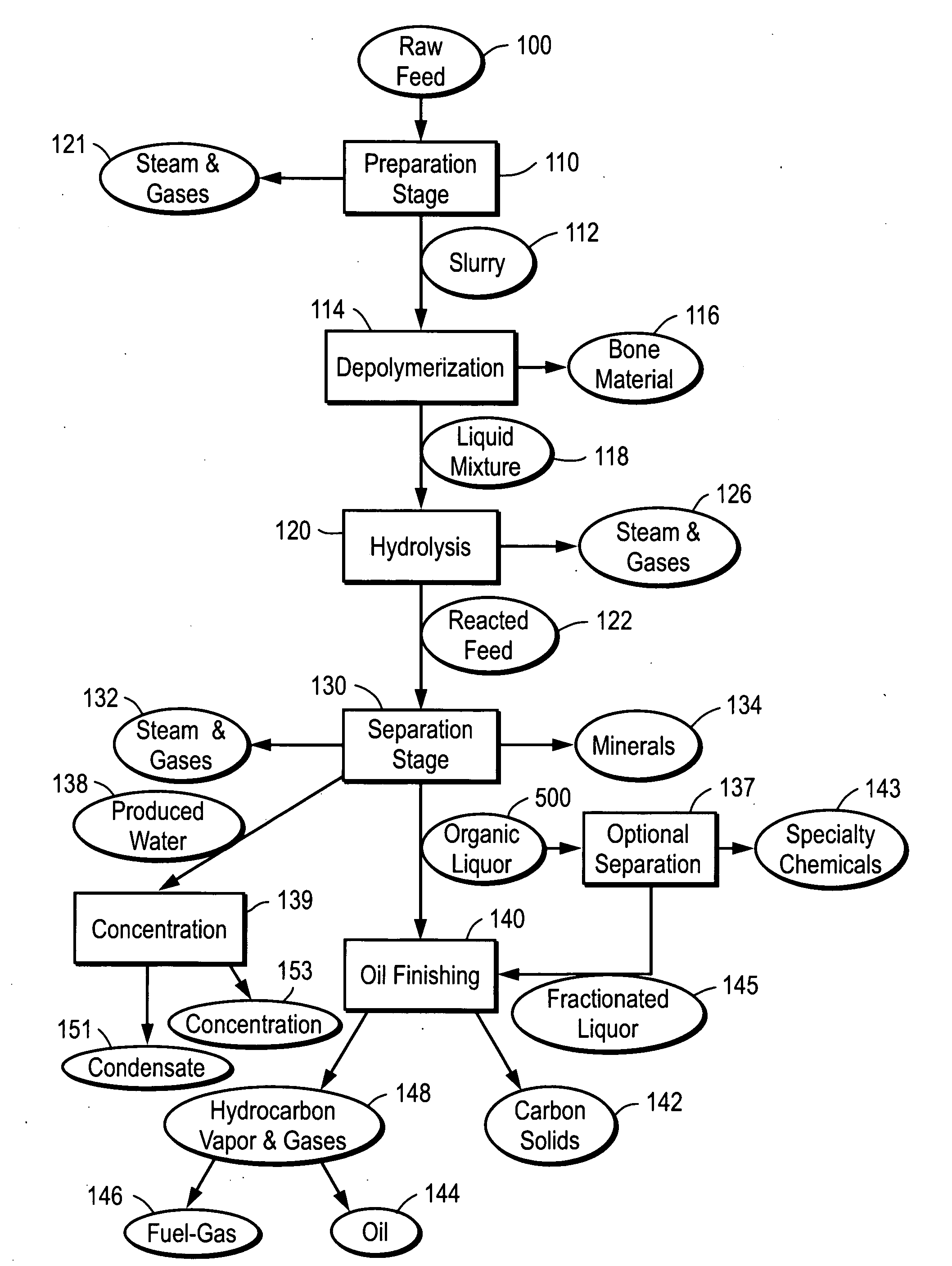

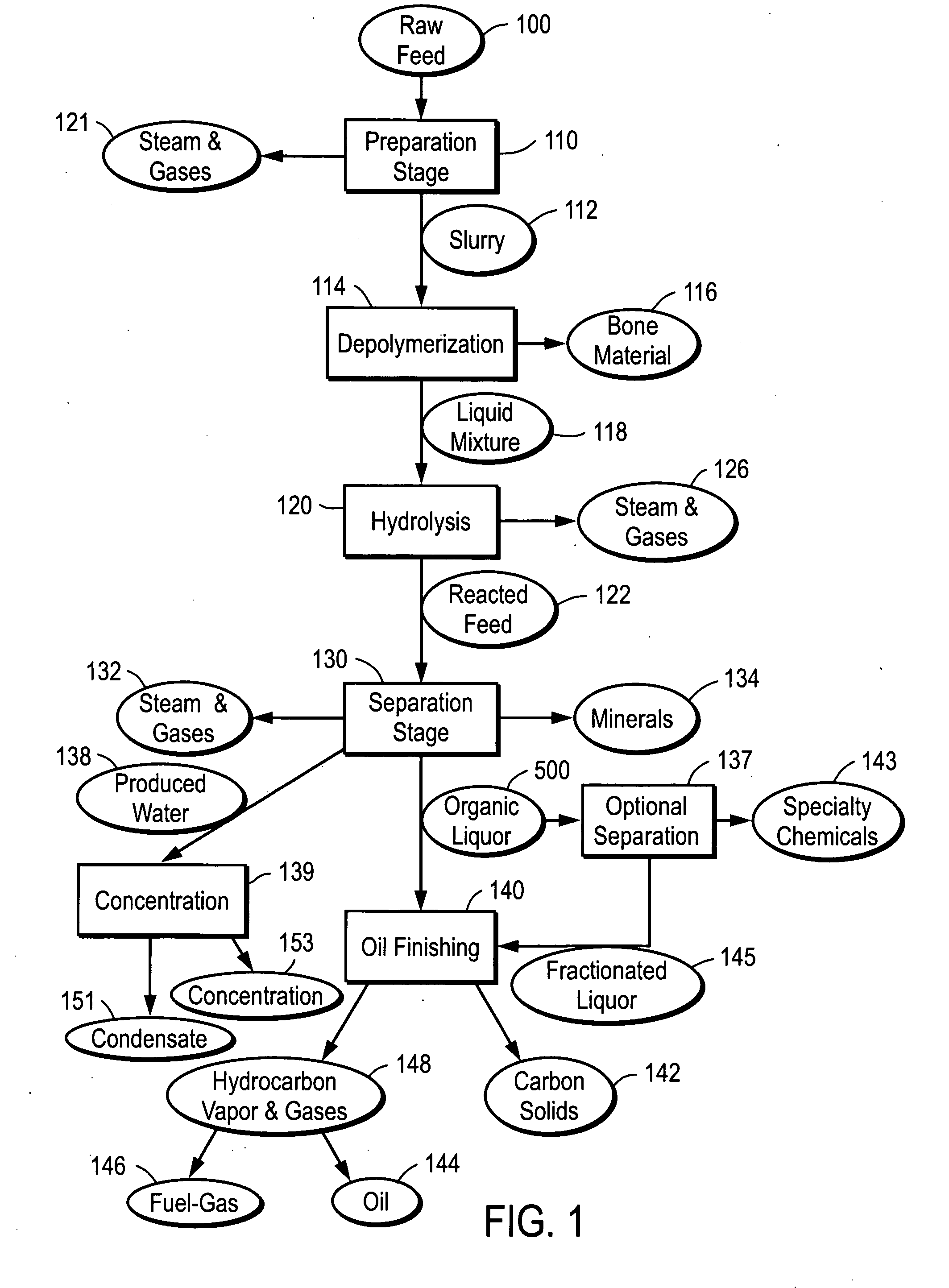

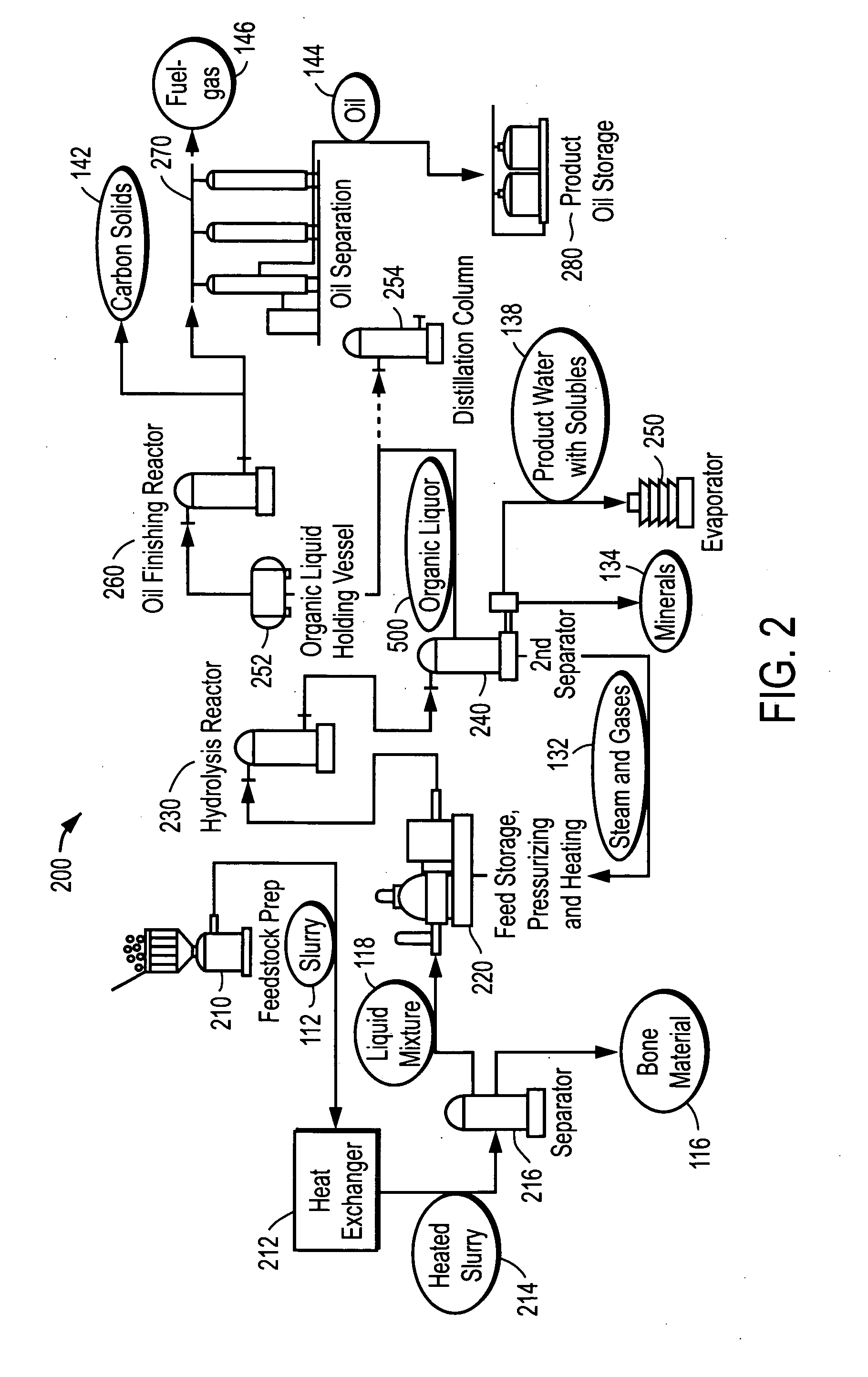

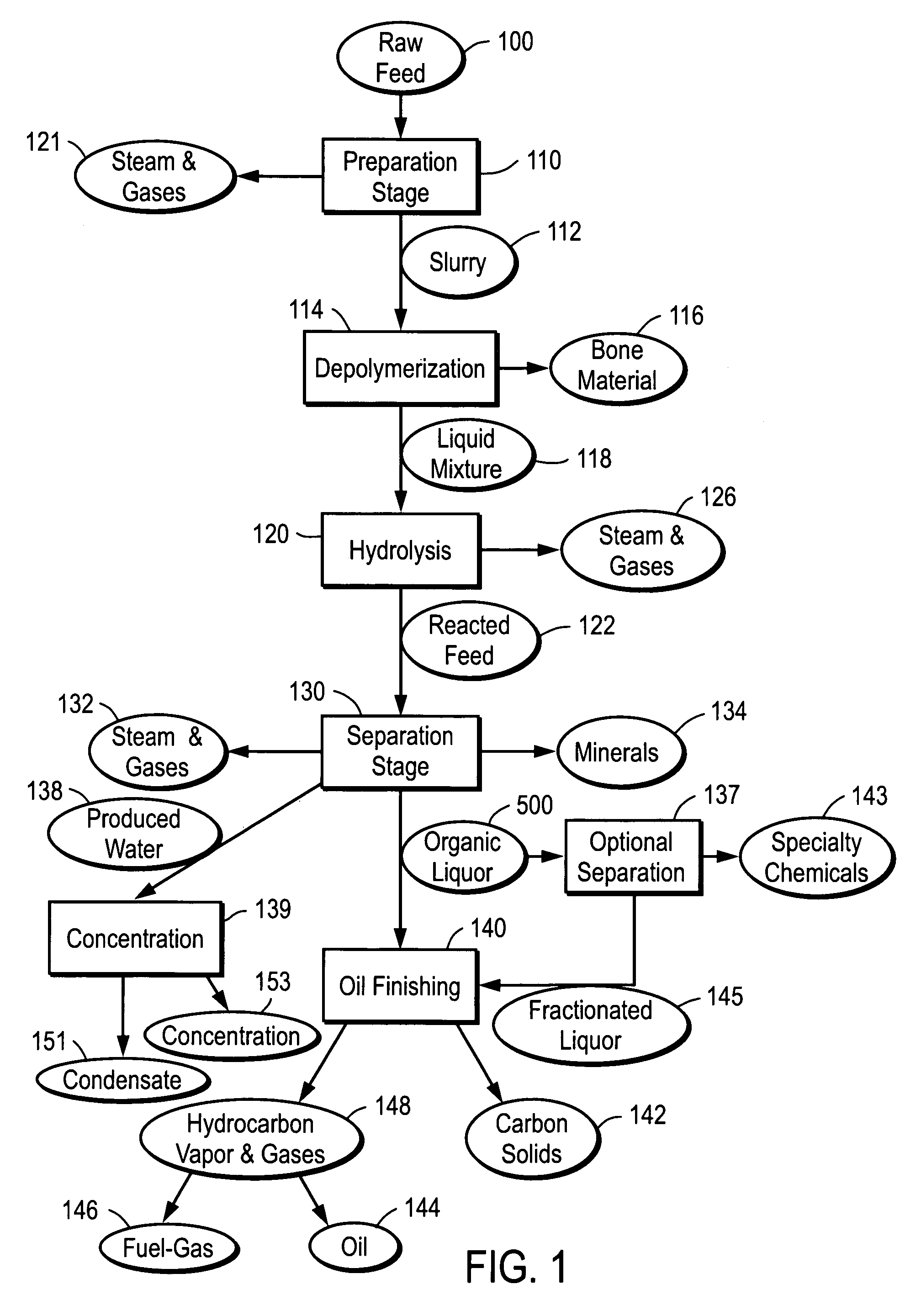

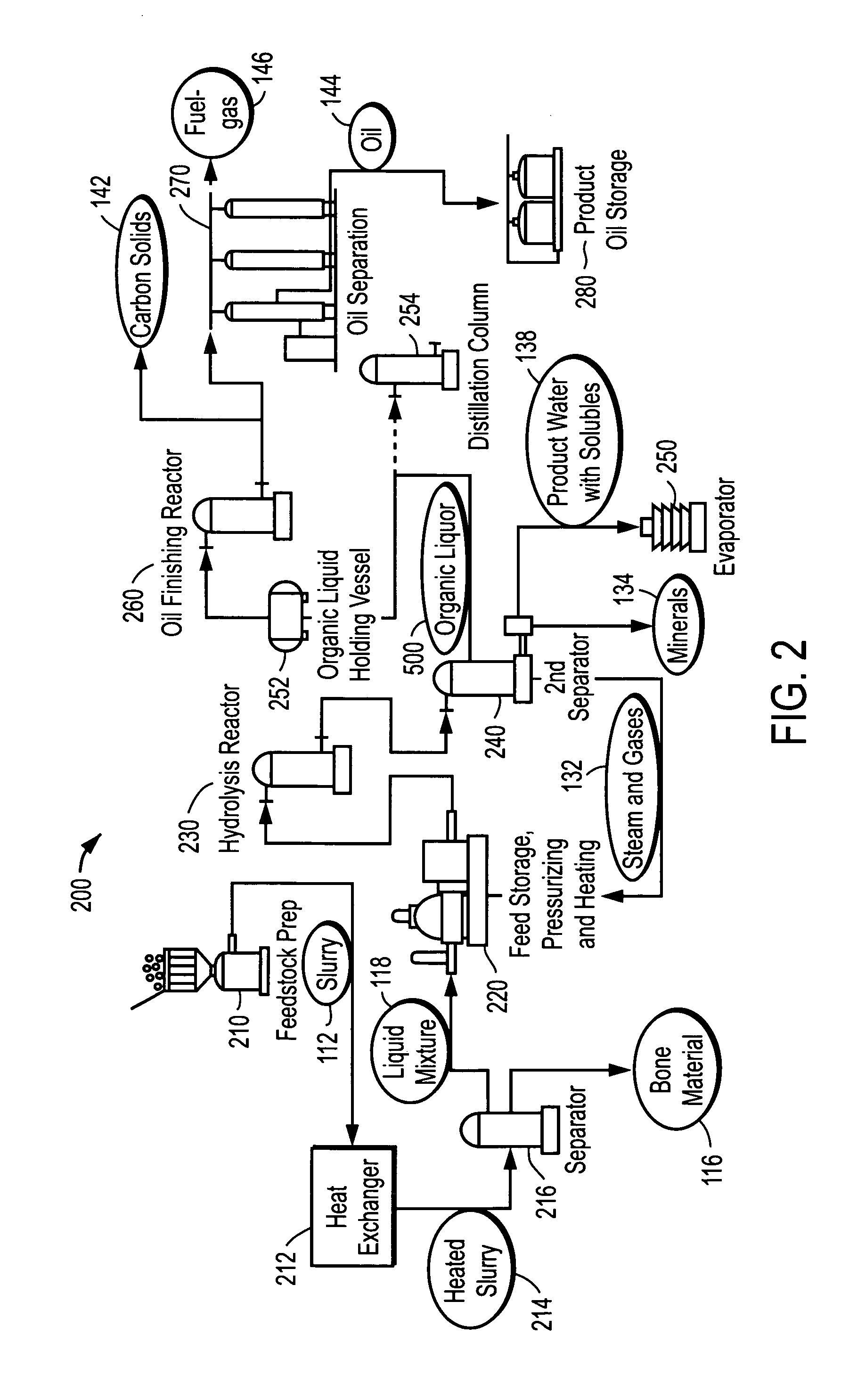

Depolymerization process of conversion of organic and non-organic waste materials into useful products

ActiveUS20070098625A1Improve energy efficiencyAcceptable costWaste based fuelLiquid hydrocarbon mixture productionDepolymerizationCost effectiveness

The present invention relates to the conversion of waste and low-value materials into useful products in reliable purities in a cost-effective and energy-efficient manner. More specifially, the invention provides processes that can handle mixed streams of various feedstocks, e.g. shredder residue, offal, animal manures, municipal sewage sludge, tires, and plastics, that otherwise have little commercial value, to useful products including gas, oil, specialty chemicals, and carbon solids. The process subjects the feedstock to heat and pressure, separates out various components, then further applies heat and pressure to one or more of those components, according to processes based on thermal or catalytic cracking. The invention further comprises an apparatus for performing a multi-stage process of converting waste materials into useful materials, and at least one oil product that arises from the process. Useful products can also be obtained or derived from materials diverted at different points of the process.

Owner:SYNPET TEKNOLOJI GELISTIRME

Biocidal compositions for treating water

InactiveUS6093422AEffective destructionEfficient Growth InhibitionOrganic active ingredientsBiocideCrosslinked chitosanSulfate zinc

The present invention is directed to a biocidal water treatment composition, water treatment apparatus, and method of treating water to reduce levels of pathogens. The composition contains sources of copper, zinc, and silver metal ions within a crosslinked polymer matrix. Examples of these ion sources include copper sulfate, zinc sulfate, and silver nitrate. An example of the crosslinked polymer matrix is crosslinked chitosan, which also serves to clarify the water and release the metal ions over time. The product is easy to manufacture, and allows the use of decreased halogen sanitizer, as well as decreased copper ion, thereby decreasing the likelihood of staining. The product simultaneously provides good bactericidal and algaecidal properties, despite low levels of copper ion and low chlorine levels.

Owner:ZODIAC POOL SYST

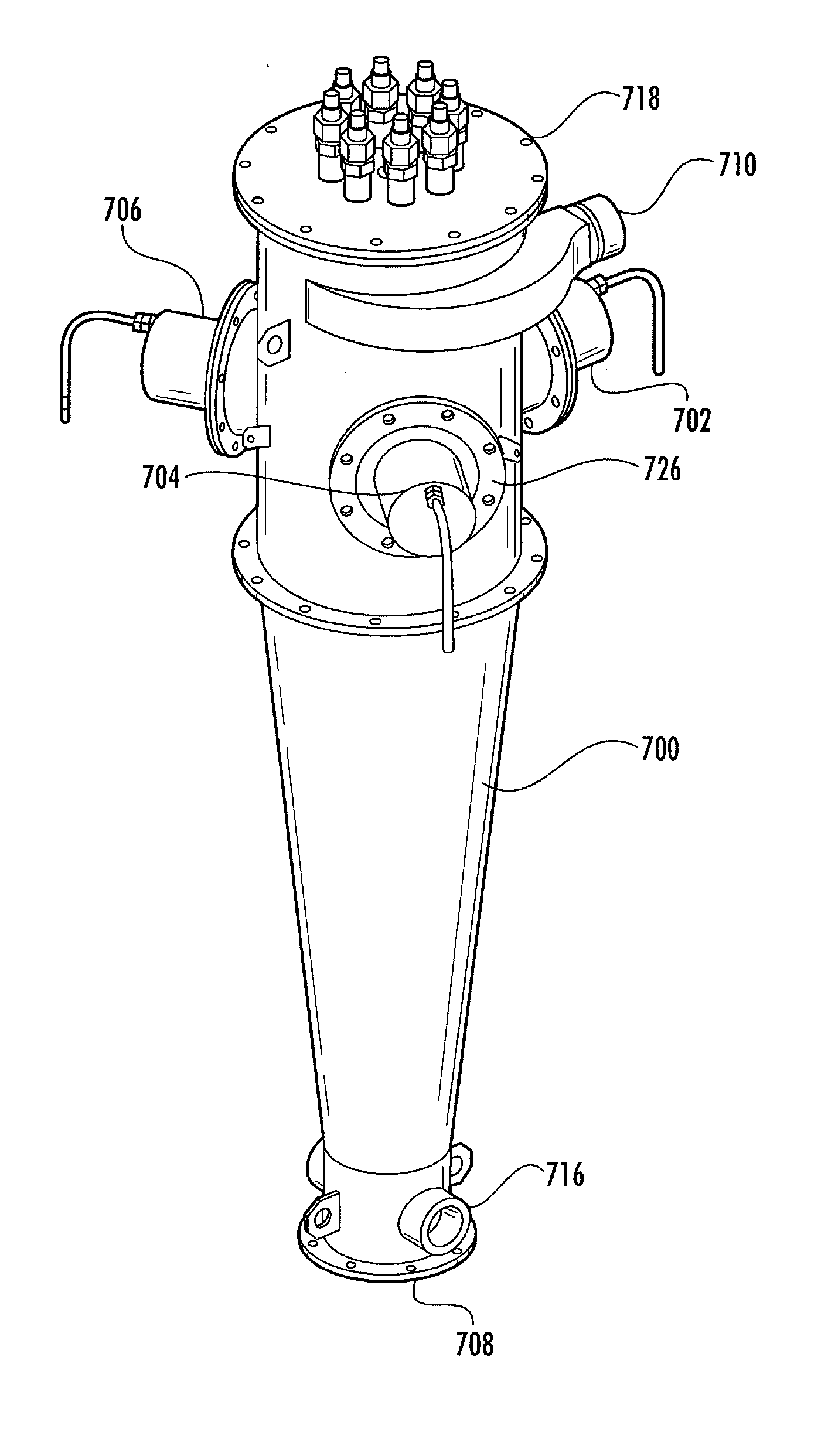

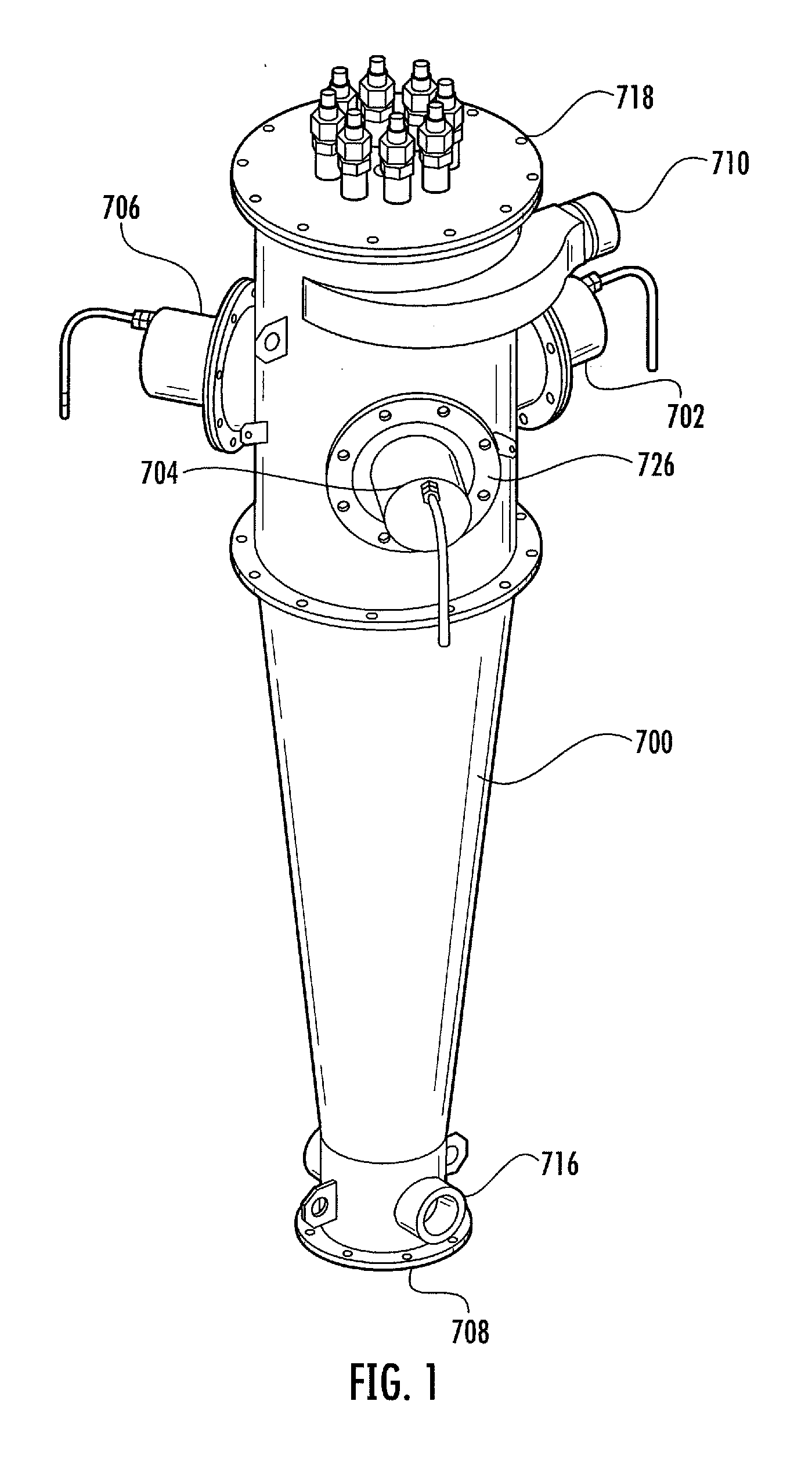

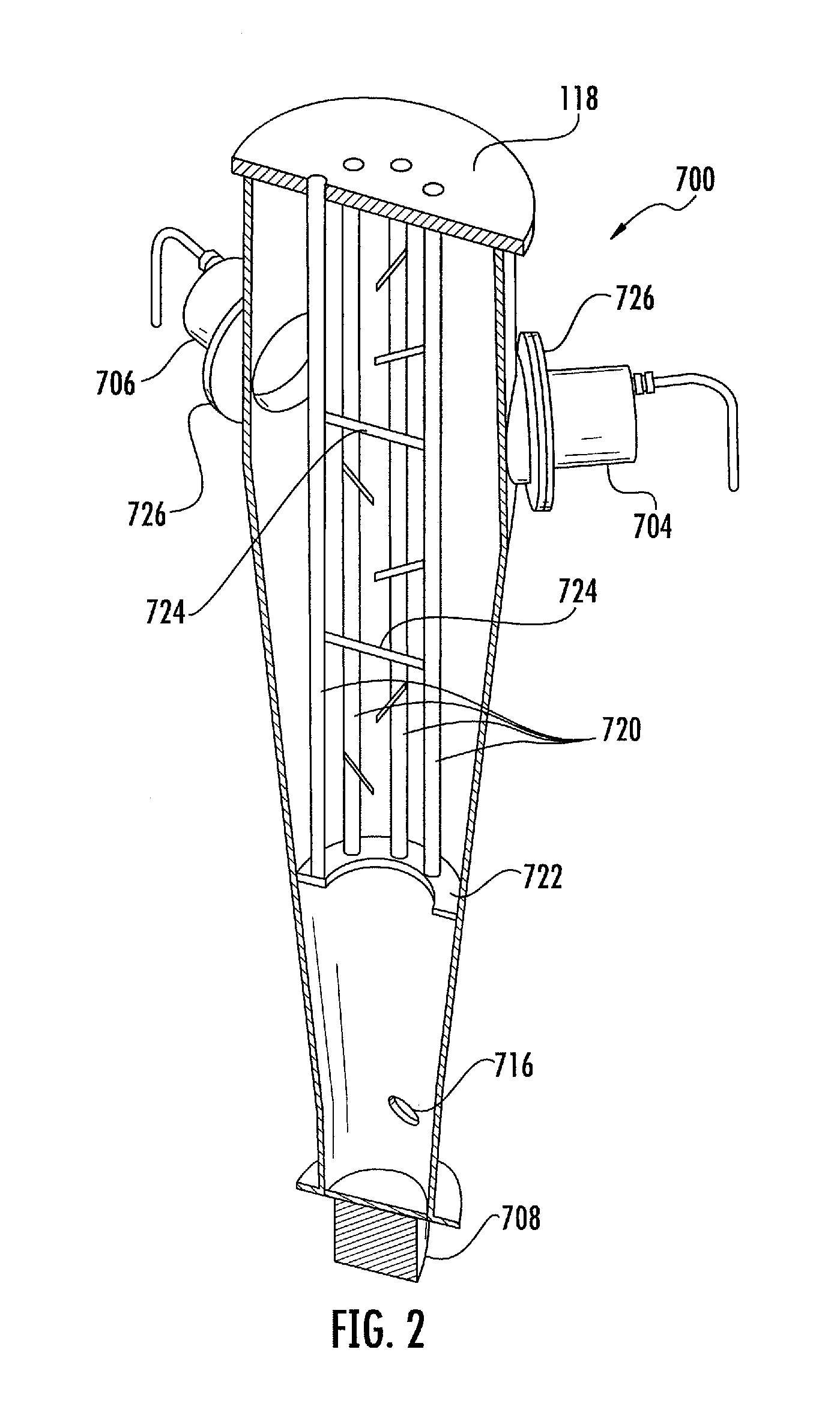

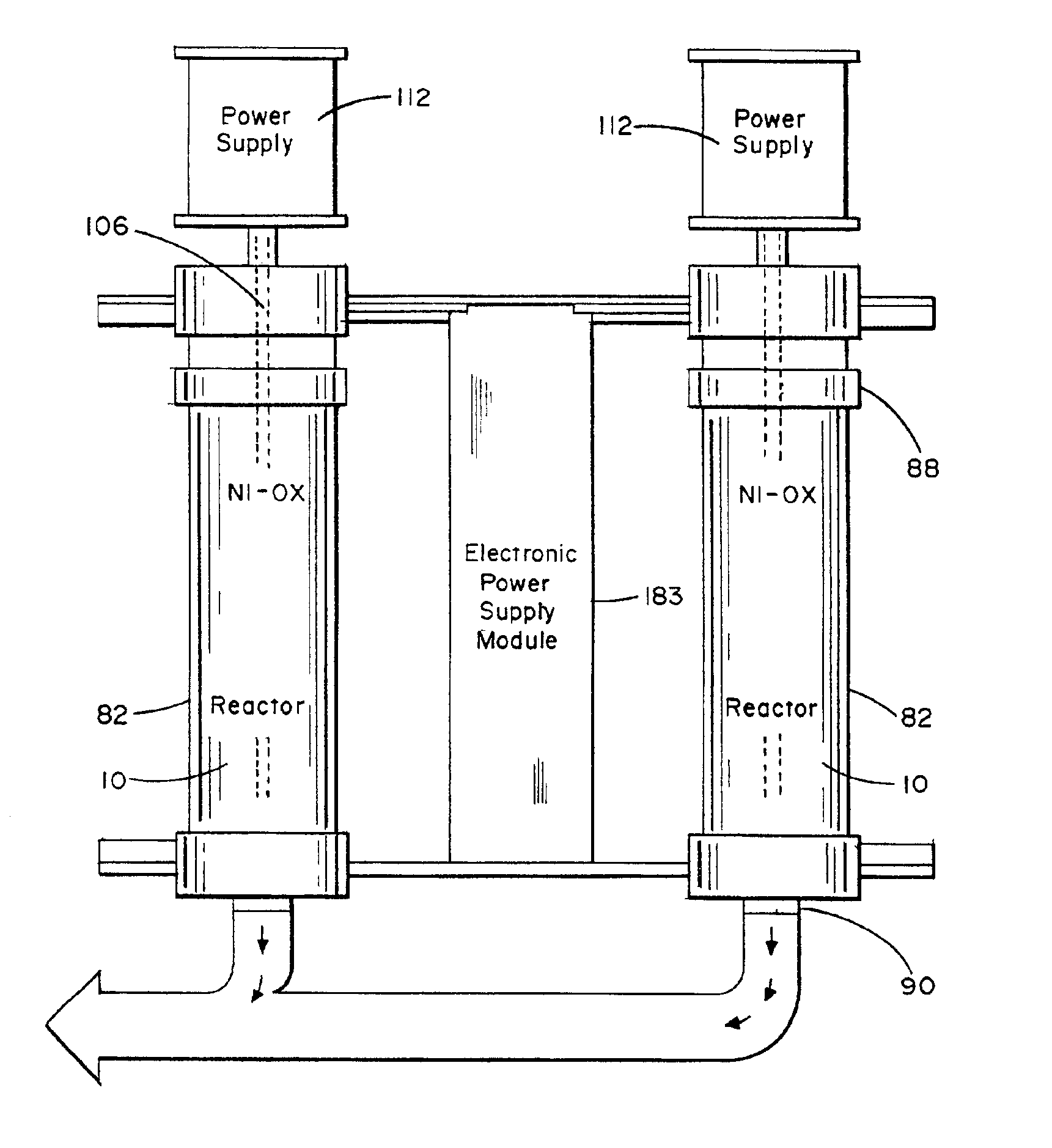

Reactor tank

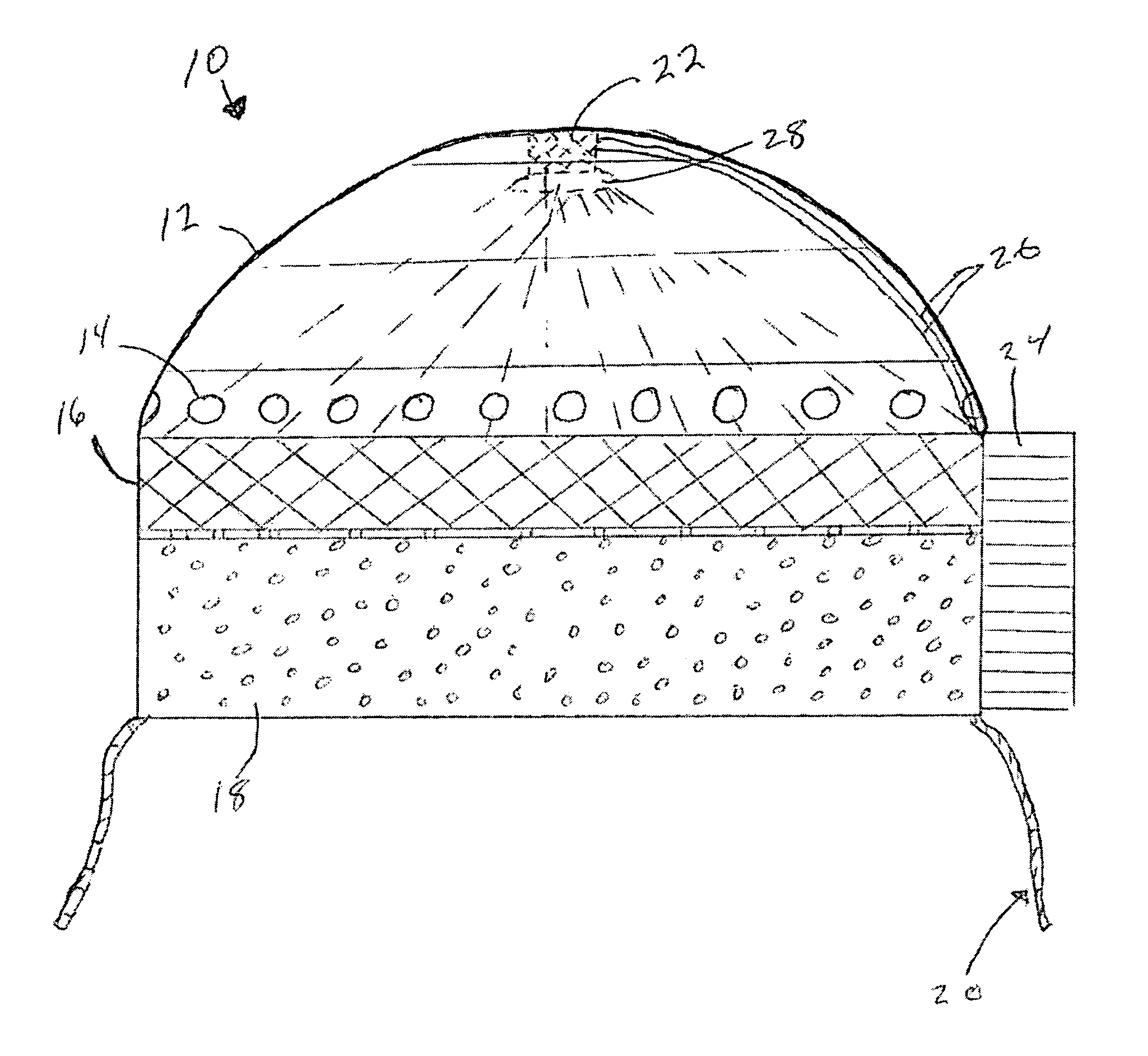

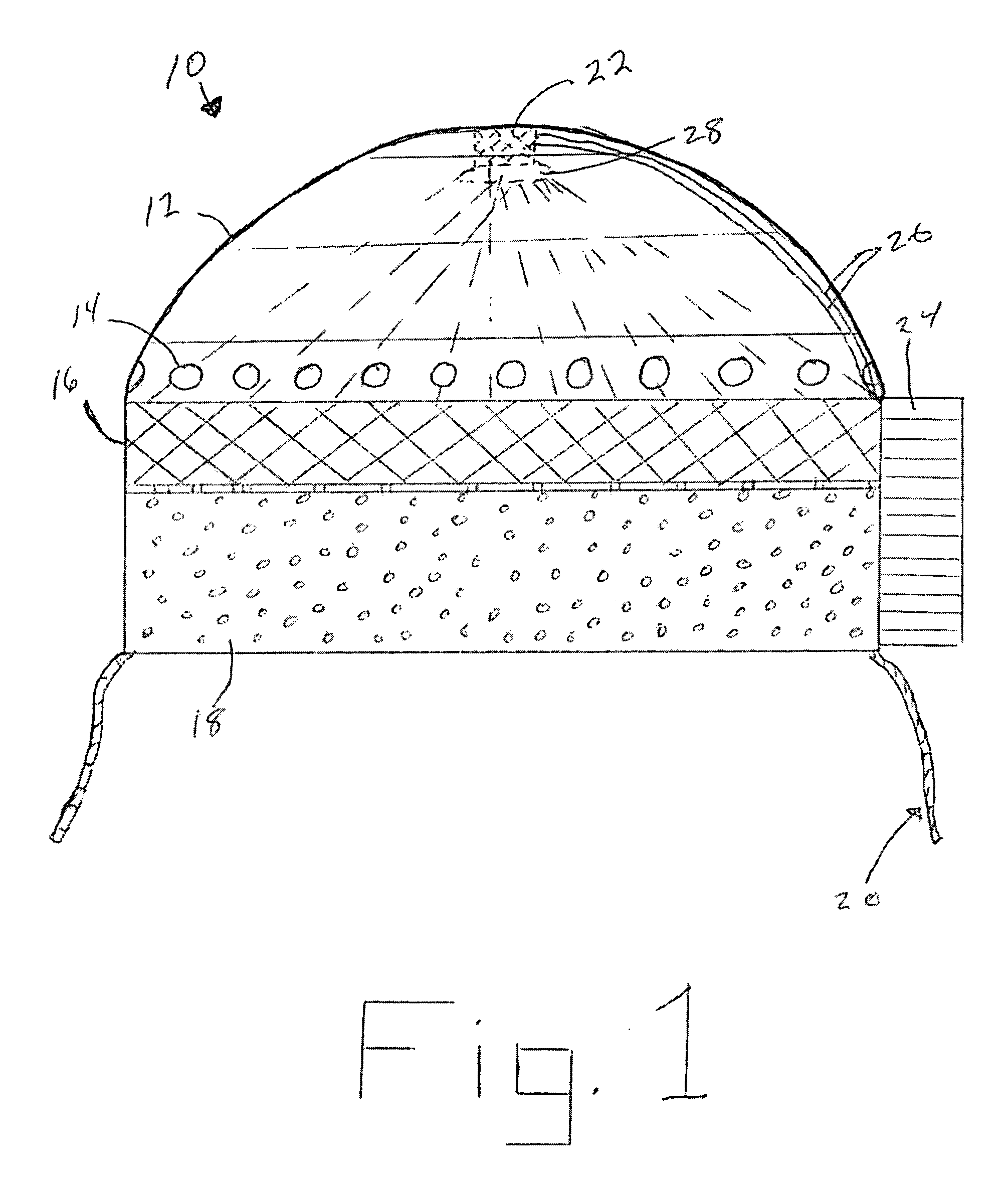

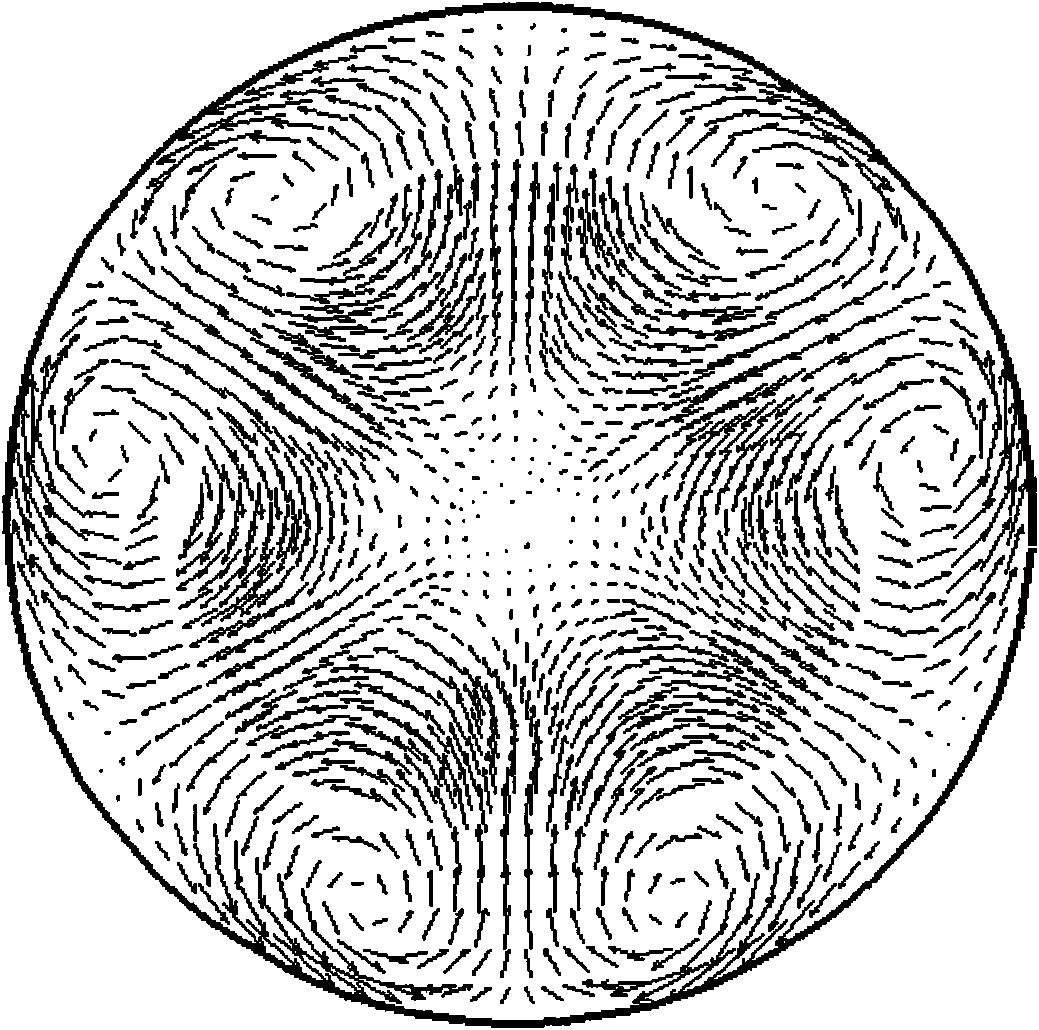

ActiveUS20100320147A1Faster rateEnhanced mass transferElectrostatic separatorsSedimentation separationCavitationAnaerobic bacteria

Disclosed is an improved water treatment cavitation reactor cone. The tank operates on a continuous flow of fluids which are subjected to ultrasonic waves in combination with a high level of injected ozone. The treatment tank includes a tangential inlet that induces a rotating flow into the tank thereby increasing the mixing of the ozone within the effluent. The effluent is further treated with DC current. The treatment tank provides a cost efficient and environmentally friendly process and apparatus for cleaning and recycling fluids as contaminated as frac water, used to stimulate gas production from shale formations, as well as other types of fluids having various levels of contaminants such as aerobic and anaerobic bacteria and suspended solids. The calcium carbonate scaling tendency is reduced to an acceptable level without the use of acids, ion exchange materials, or anti scaling chemicals which is of economical and environmental significance and benefit.

Owner:BRISBEN WATER SOLUTIONS

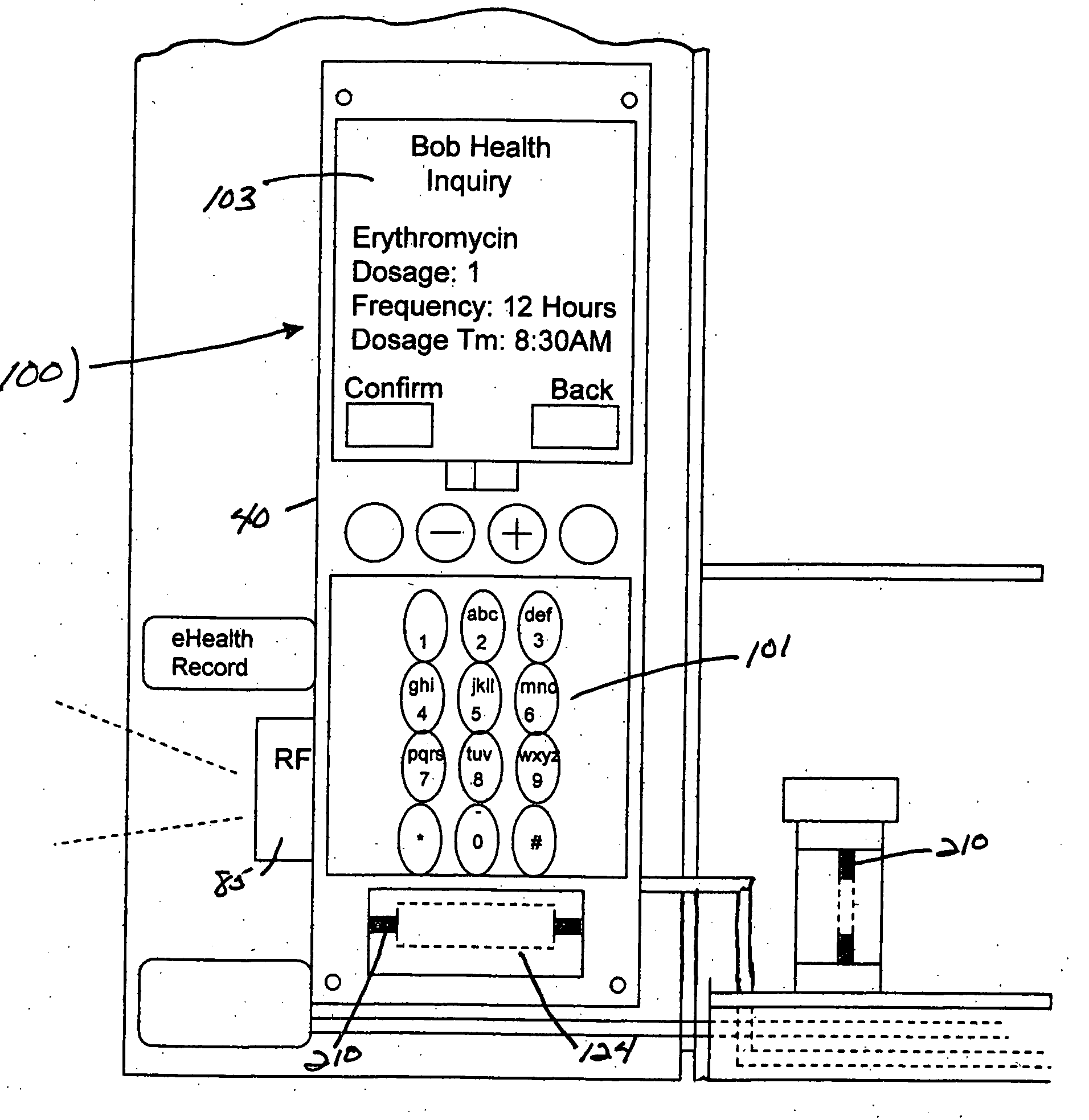

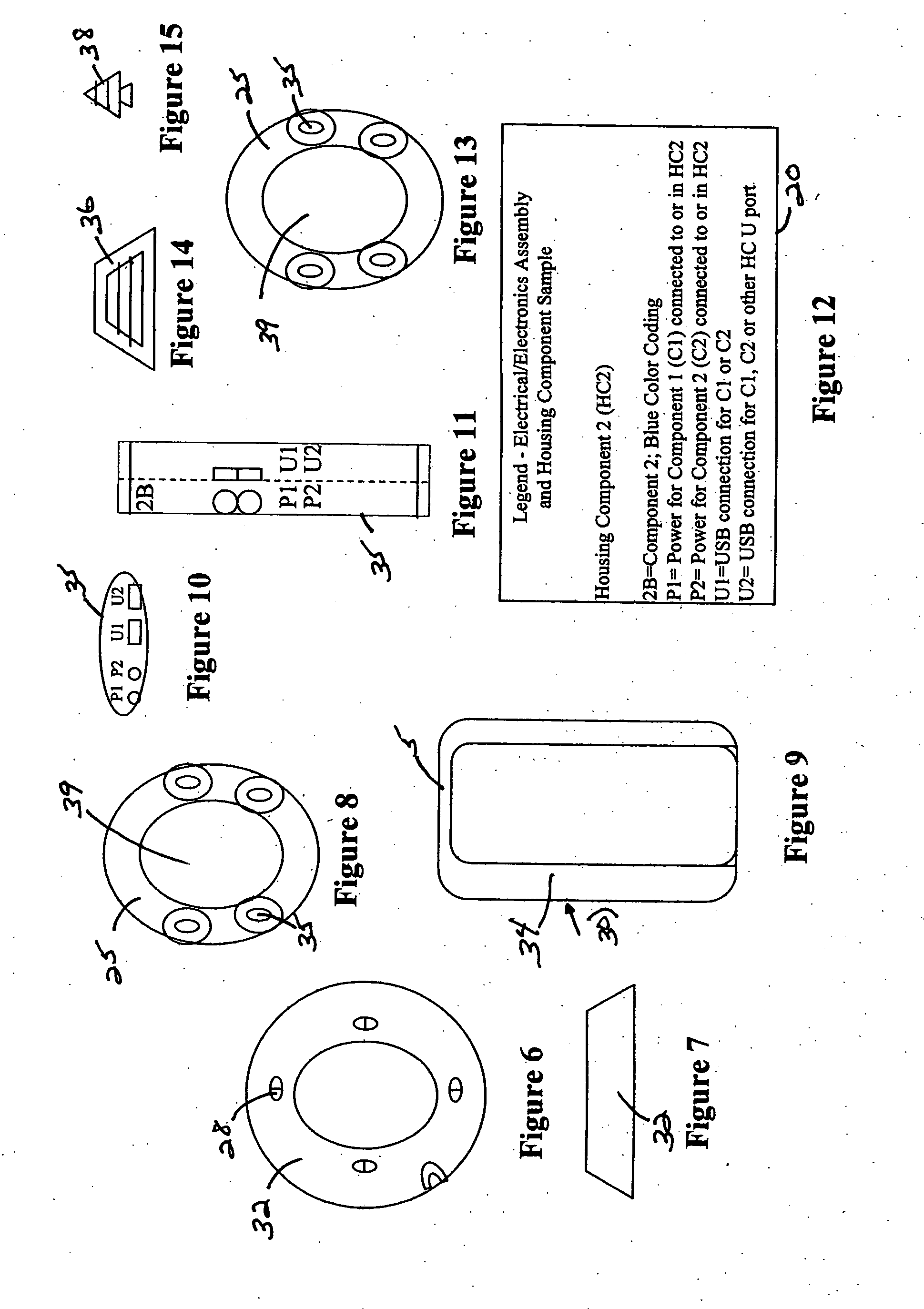

Multifunction-capable health related devices

InactiveUS20050188853A1Low incremental costImprove overall utilizationCombination devicesAuxillary pretreatmentBarcodeEngineering

Health and environmental devices such as air purifiers are adapted with components for multifunctional capabilities that involve electronic devices and associated housings containing at least one processor adapted to operate at least one component selected from the group consisting of air purifiers, sensors, local area and wide area networked components, and entertainment and electronic components. Health and safety related containers, covers and information input, processing, and output devices include one or more coded data readers for use with bar code, radio frequency identification (RFID) and other coded data technologies and comprise components to support at least one of the following: communications; networked sensors; and monitoring applications. Increased efficiencies in the use of coded data reader systems that include such coded readers and the associated items being read are supported by alignment indicia adapted for being on said items being read and on said reading devices.

Owner:SCANNELL ROBERT F JR

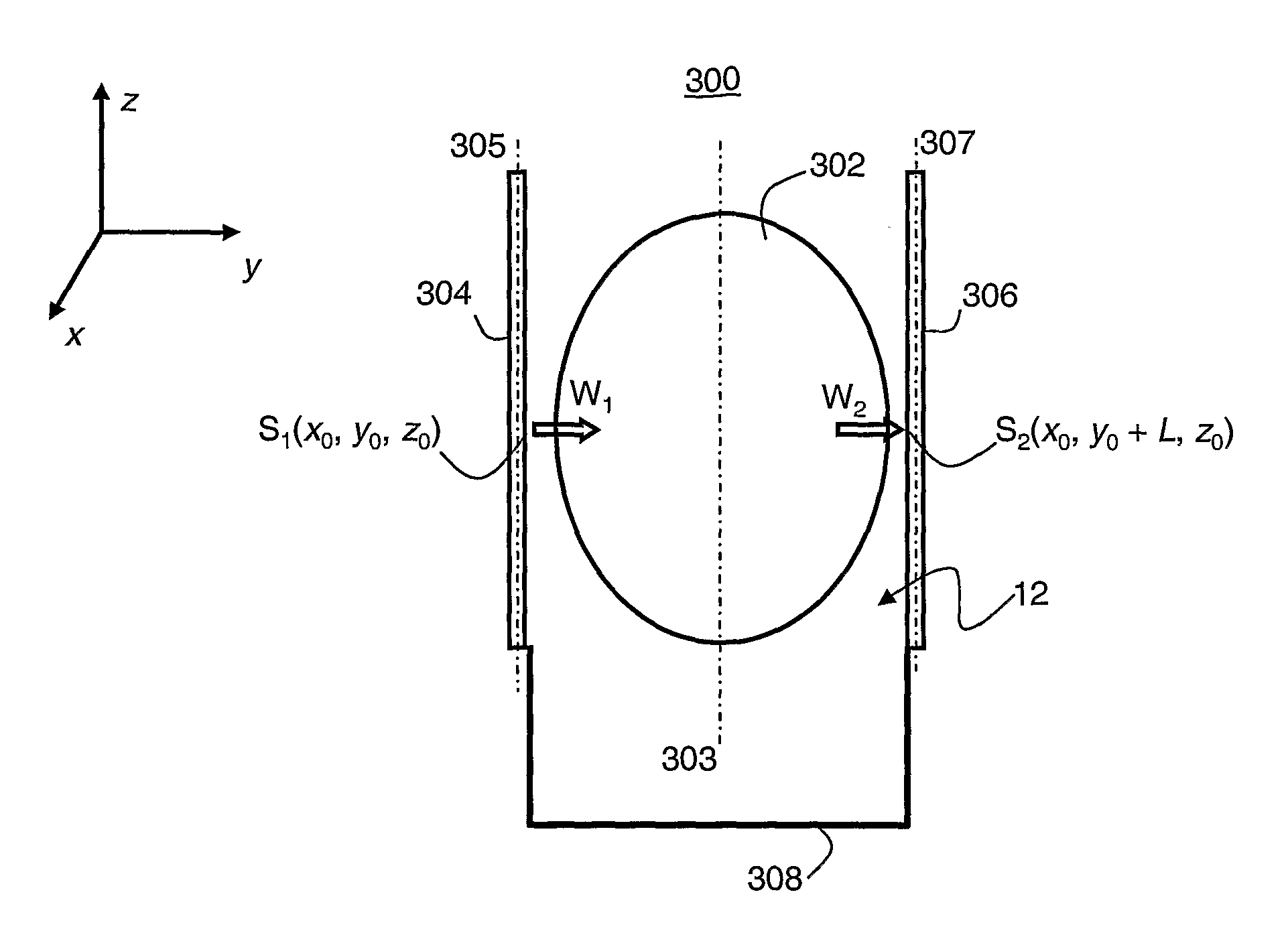

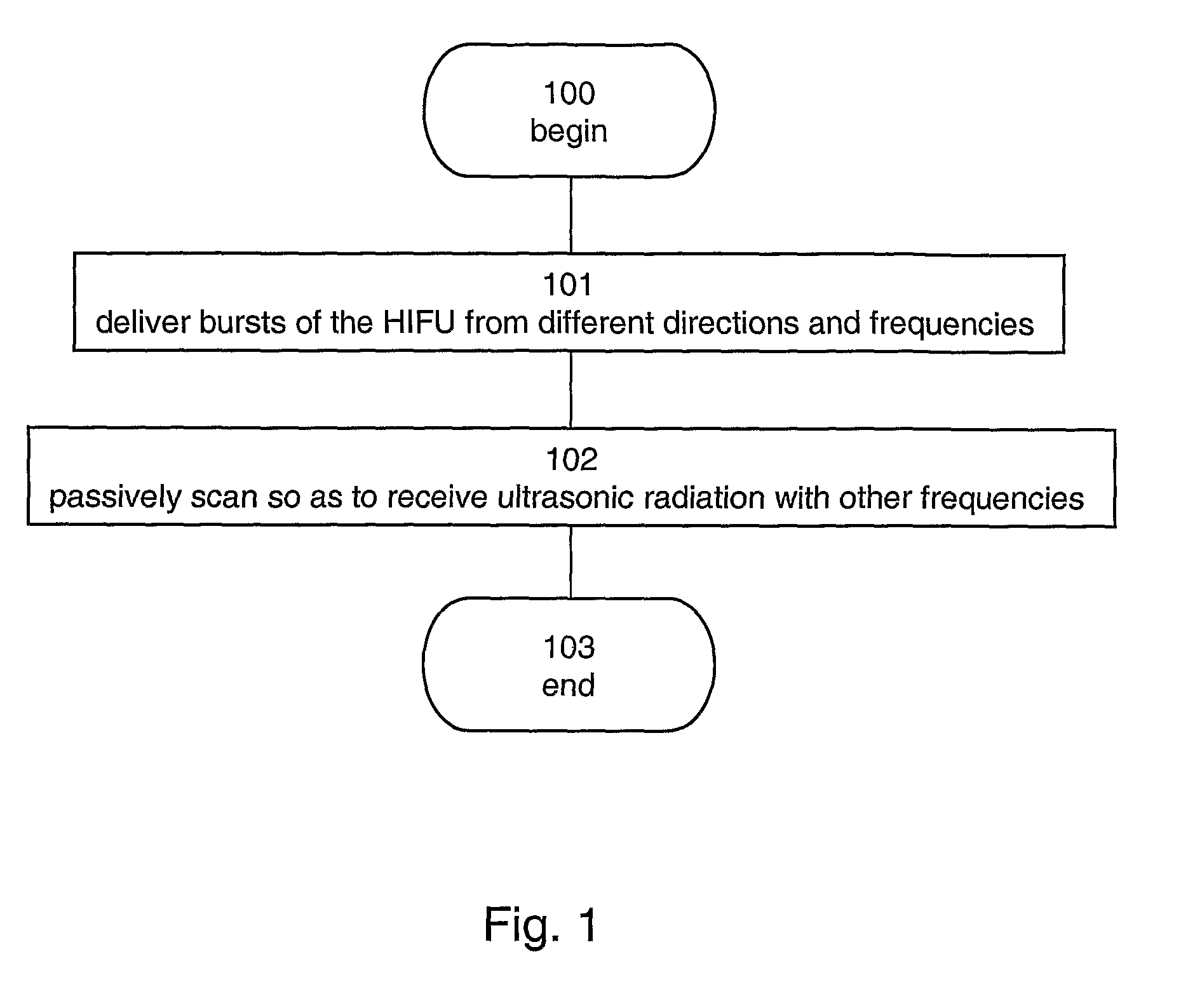

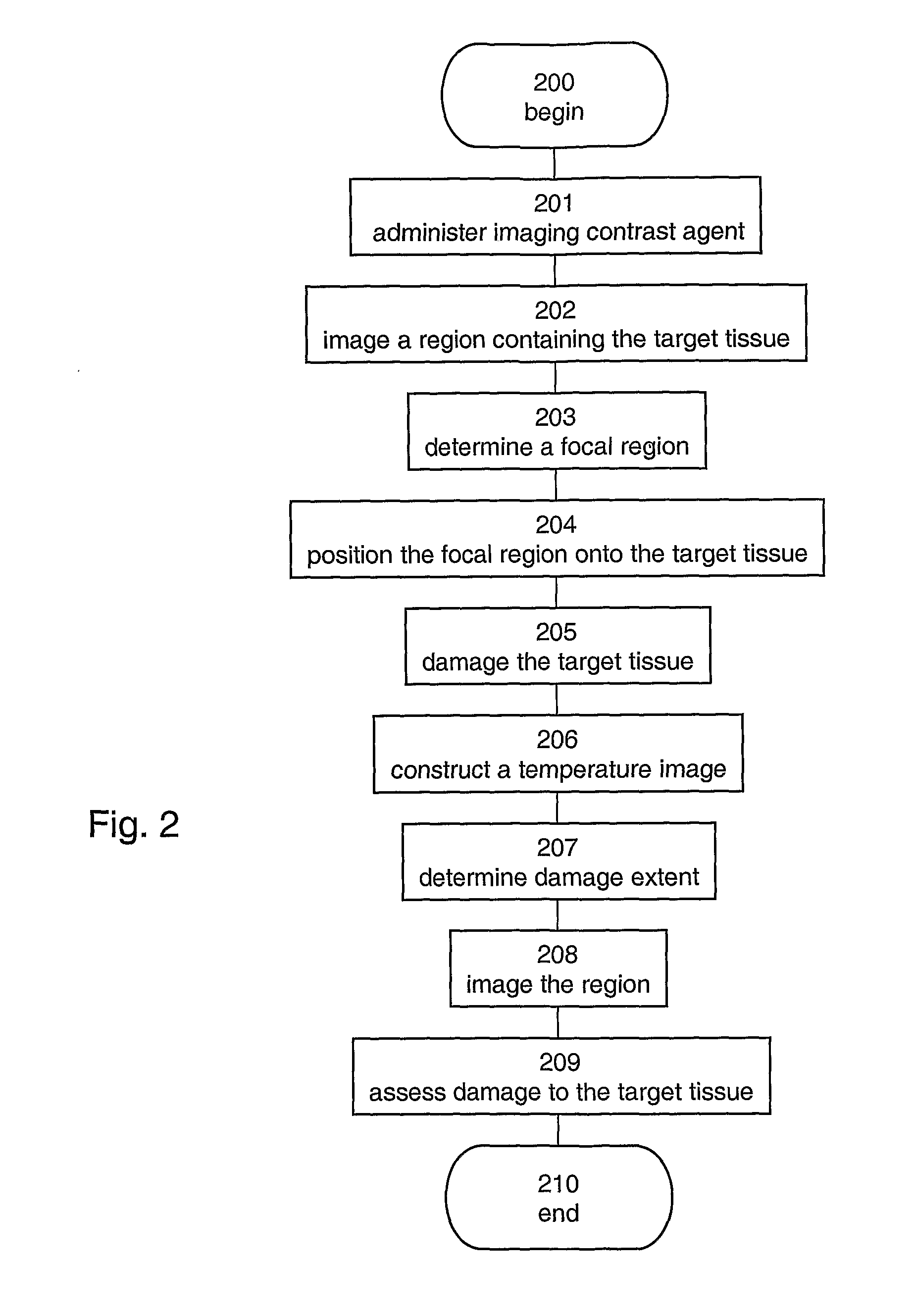

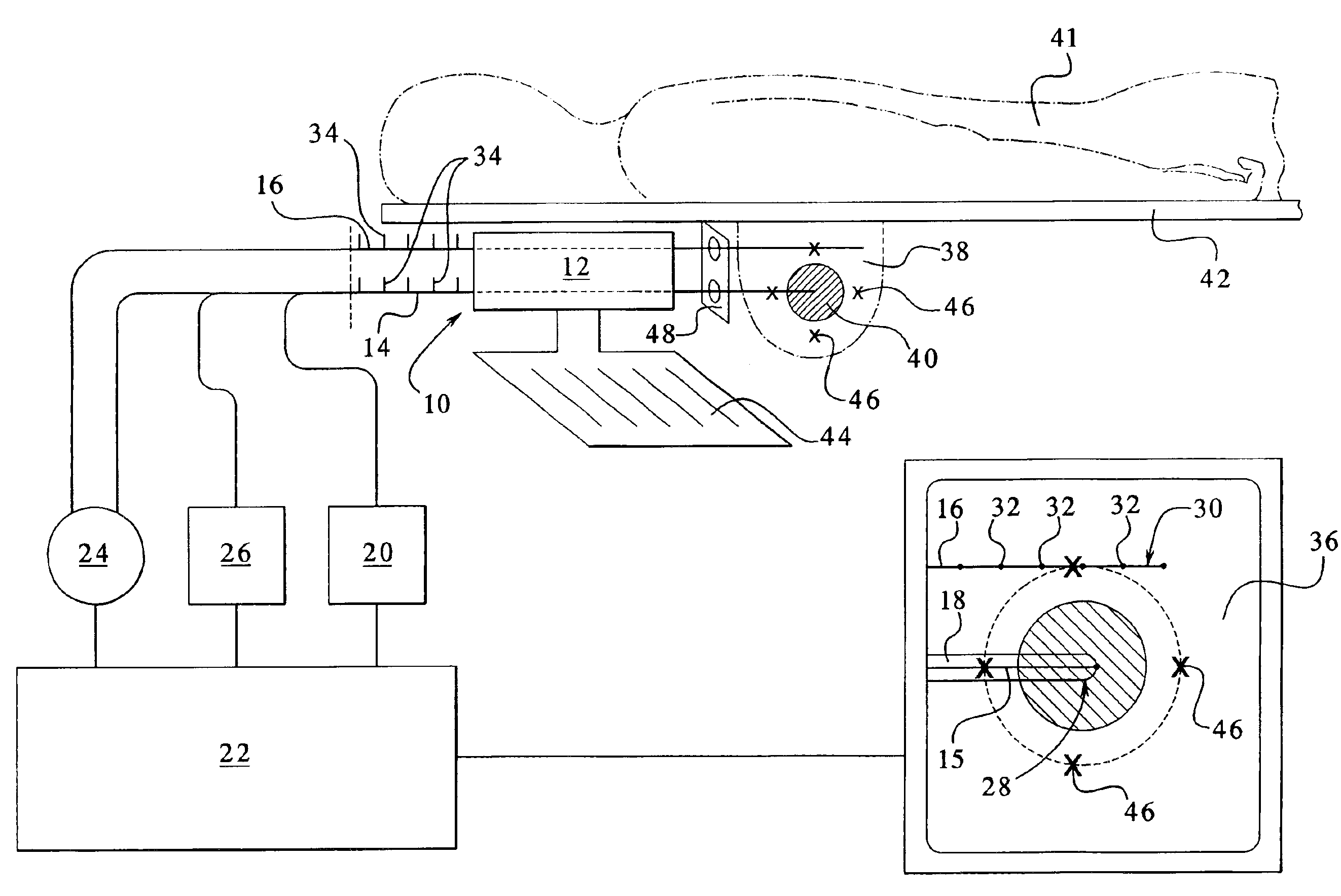

Ultrasonic Image-Guided Tissue-Damaging Procedure

InactiveUS20080177180A1Accurate imagingEffective destructionUltrasonic/sonic/infrasonic diagnosticsUltrasound therapyUltrasonic radiationRadiology

A method of damaging a target tissue of a subject is disclosed. The method comprises: (a) imaging a region containing the target tissue; (b) determining a focal region of a damaging radiation; (c) positioning the focal region onto the target tissue; and (d) damaging the target tissue by an effective amount of the damaging radiation. The determination of the focal region is by delivering to the region bursts of ultrasonic radiation from a plurality of directions and at a plurality of different frequencies, and passively scanning the region so as to receive from the region ultrasonic radiation having at least one frequency other than the plurality of different frequencies.

Owner:TECHNION RES & DEV FOUND LTD

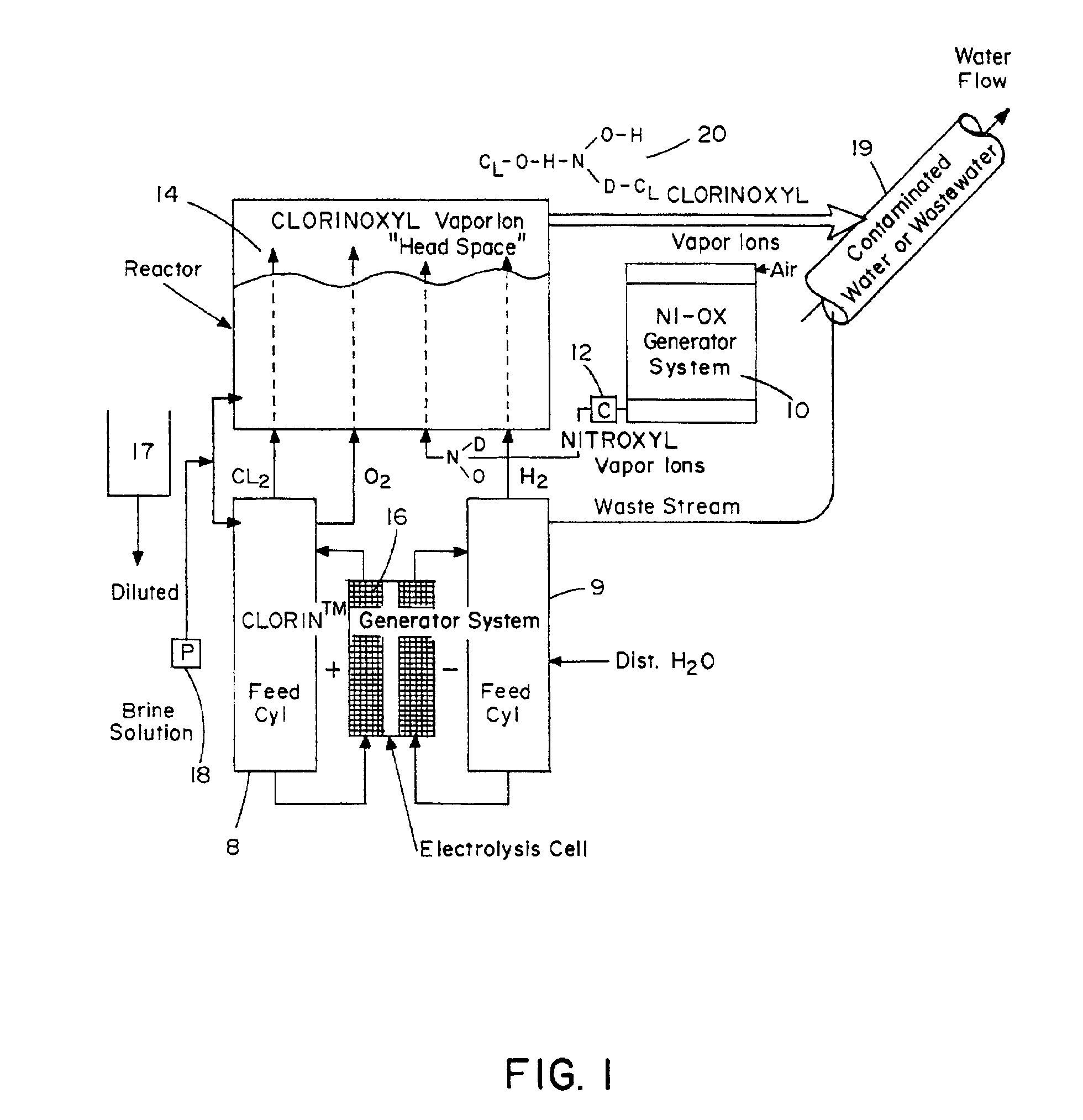

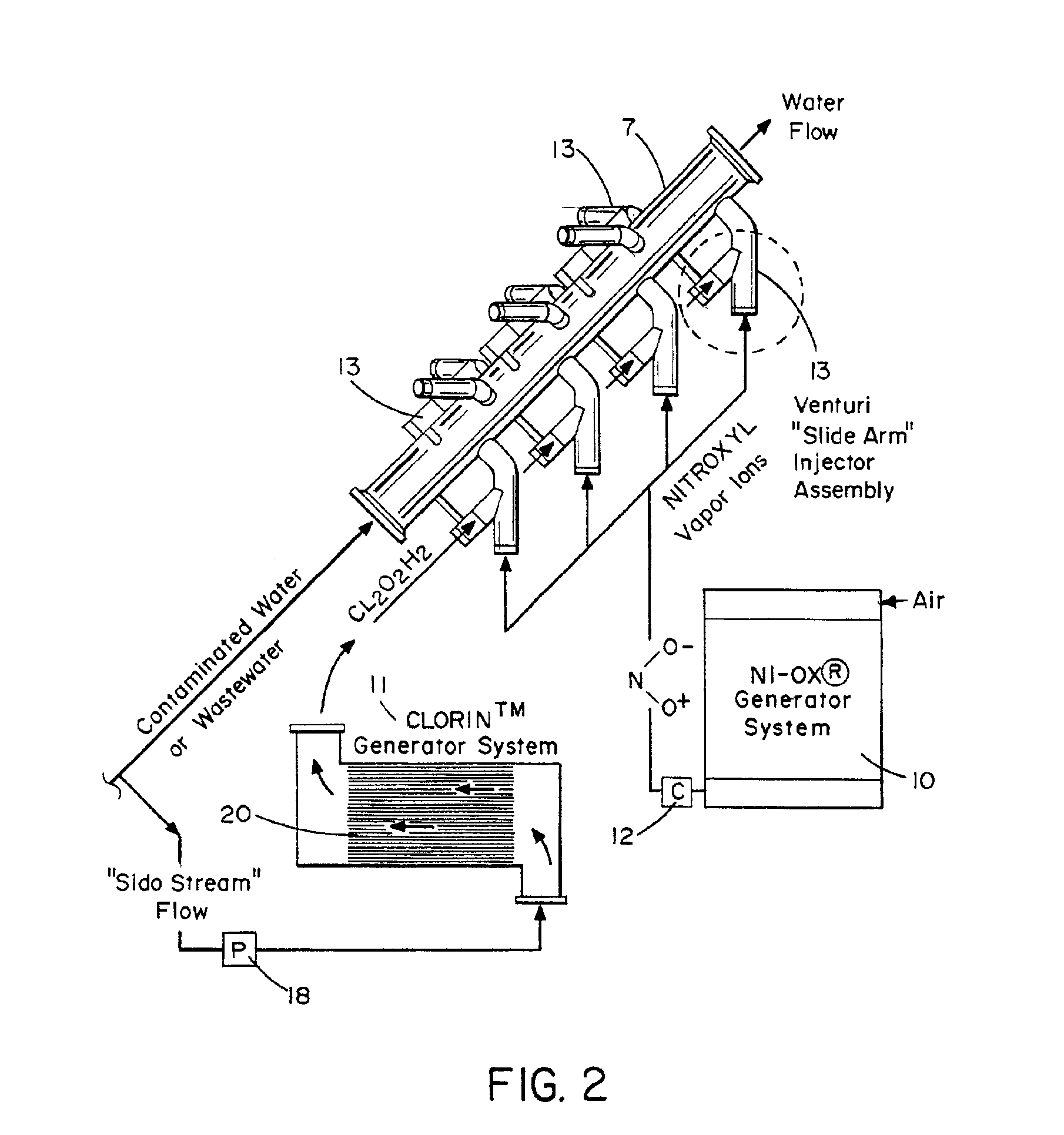

Non-chemical water treatment method and apparatus employing ionized air purification technologies for marine application

InactiveUS6923901B2Reduce maintenanceReduce energy costsCyanogen compoundsNitrogen compoundsElectrolysisDihydrogen oxide

Contaminated water, particularly, ballast water, blackwater, galley water, accommodation water, laundry water, fresh water and seawater, is disinfected by admixture of a highly reactive gas stream containing ions of oxygen and nitrogen, formed by exposure of air to short-wavelength ultraviolet radiation, and of chlorine, formed in situ by electrolysis of salt in the water. Solids removal can be accomplished by electrophoresis in the same unit employed for electrolysis to release chlorine, or in a separate unit. Heavy metals maybe removed by plating or sacrificing electrodes.

Owner:IONZ BLUEWATER SOLUTIONS +1

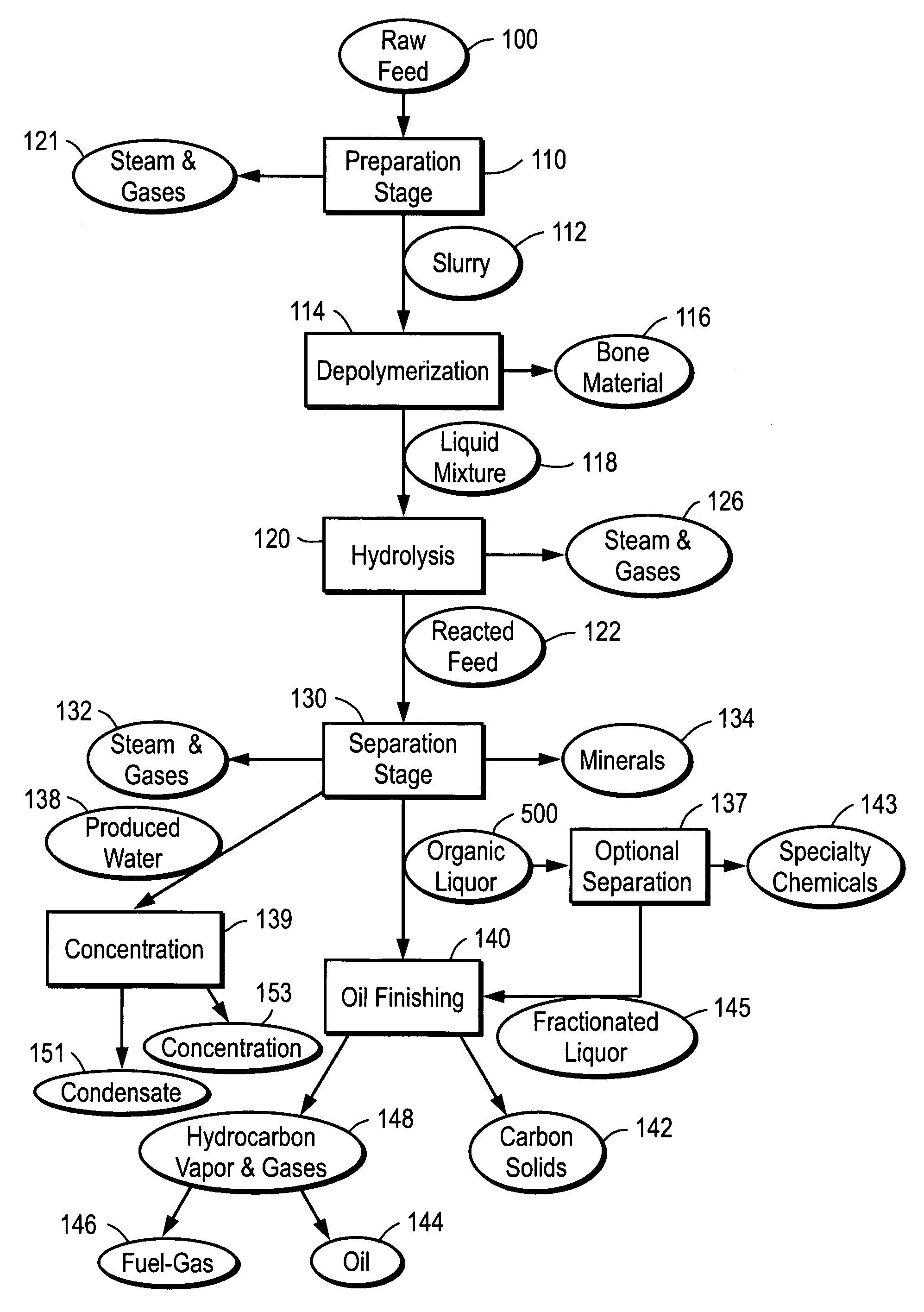

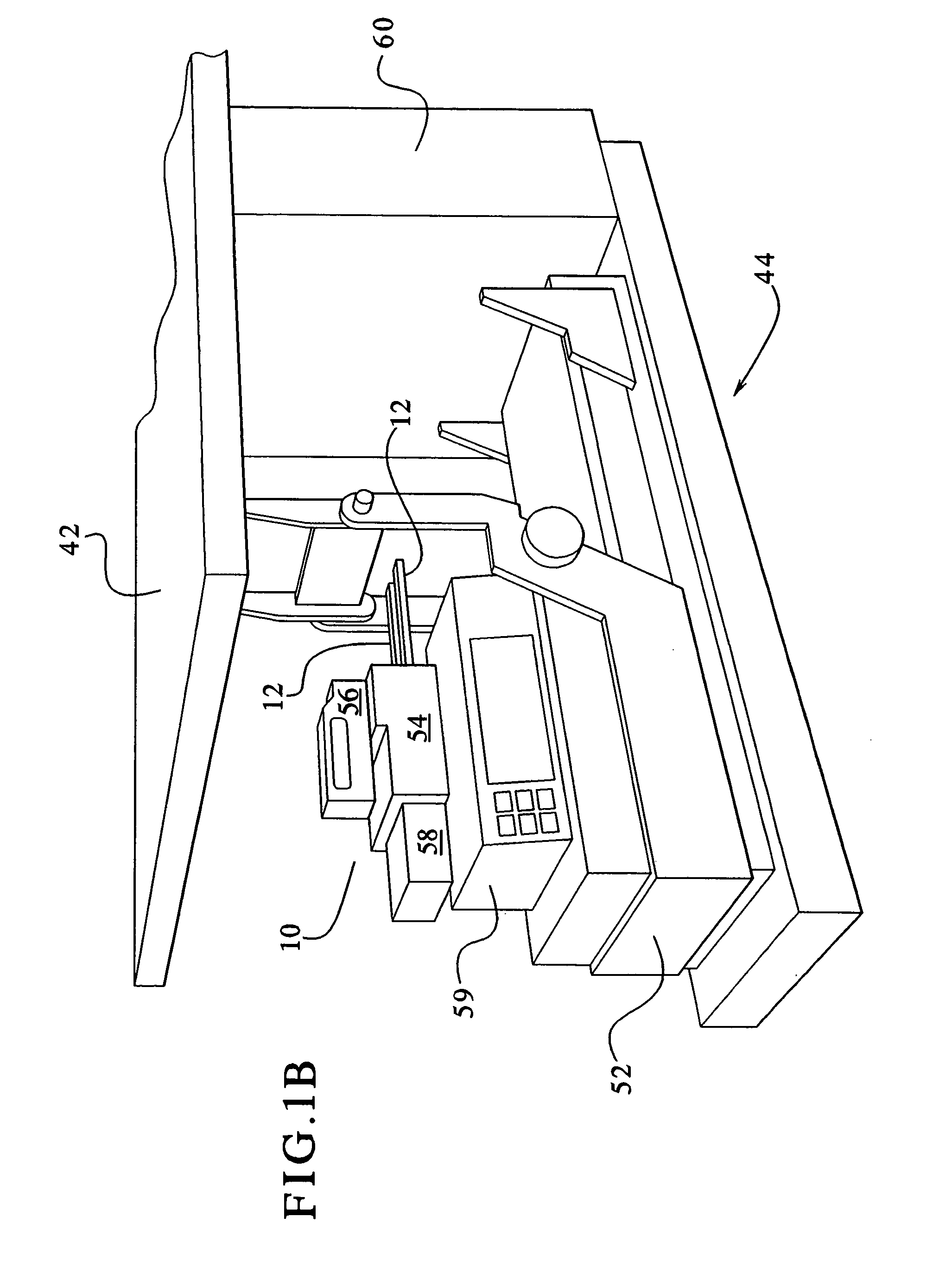

Depolymerization process of conversion of organic and non-organic waste materials into useful products

ActiveUS7771699B2Efficient processingSmooth connectionWaste based fuelLiquid hydrocarbon mixture productionSpeciality chemicalsDepolymerization

The present invention relates to the conversion of waste and low-value materials into useful products in reliable purities in a cost-effective and energy-efficient manner. More specifially, the invention provides processes that can handle mixed streams of various feedstocks, e.g. shredder residue, offal, animal manures, municipal sewage sludge, tires, and plastics, that otherwise have little commercial value, to useful products including gas, oil, specialty chemicals, and carbon solids. The process subjects the feedstock to heat and pressure, separates out various components, then further applies heat and pressure to one or more of those components, according to processes based on thermal or catalytic cracking. The invention further comprises an apparatus for performing a multi-stage process of converting waste materials into useful materials, and at least one oil product that arises from the process. Useful products can also be obtained or derived from materials diverted at different points of the process.

Owner:SYNPET TEKNOLOJI GELISTIRME

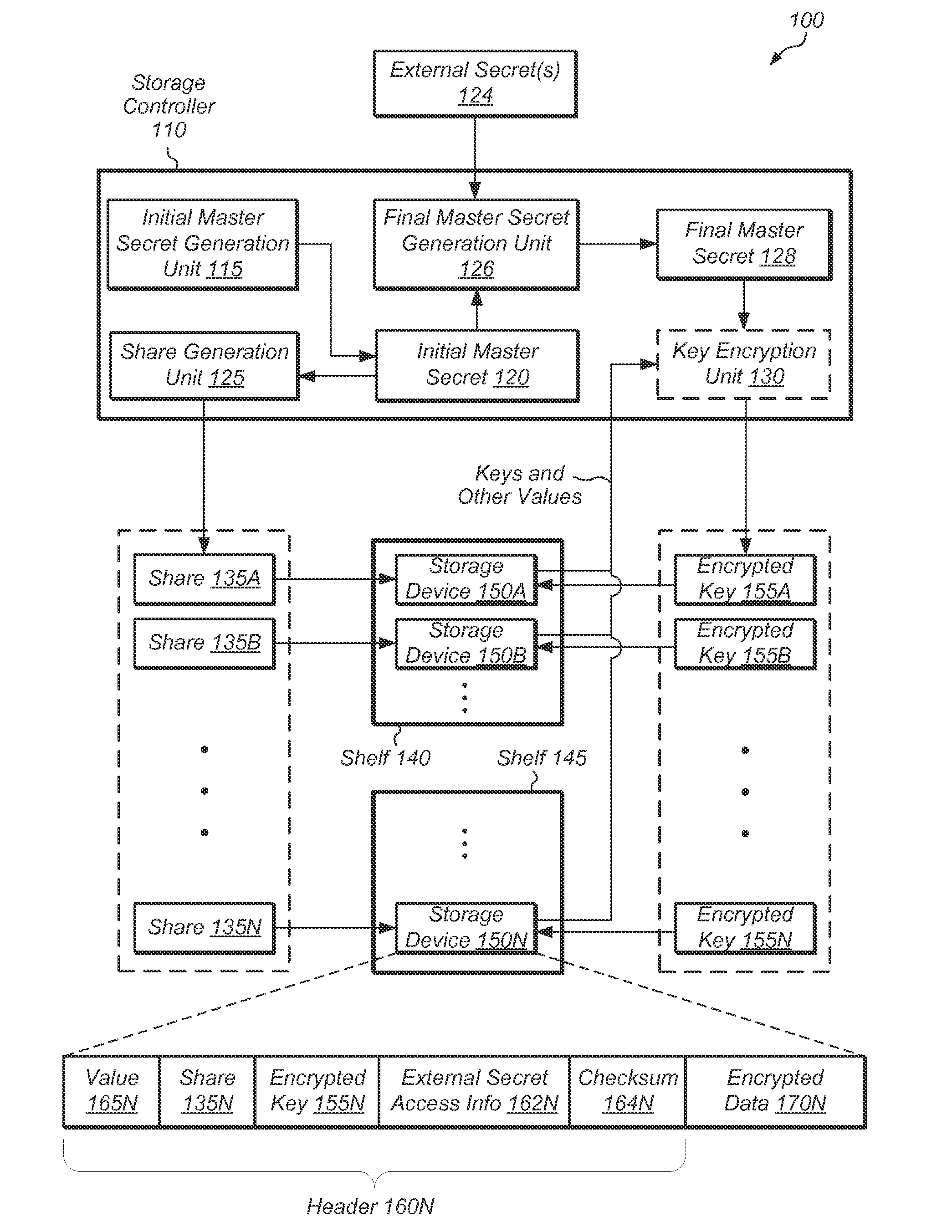

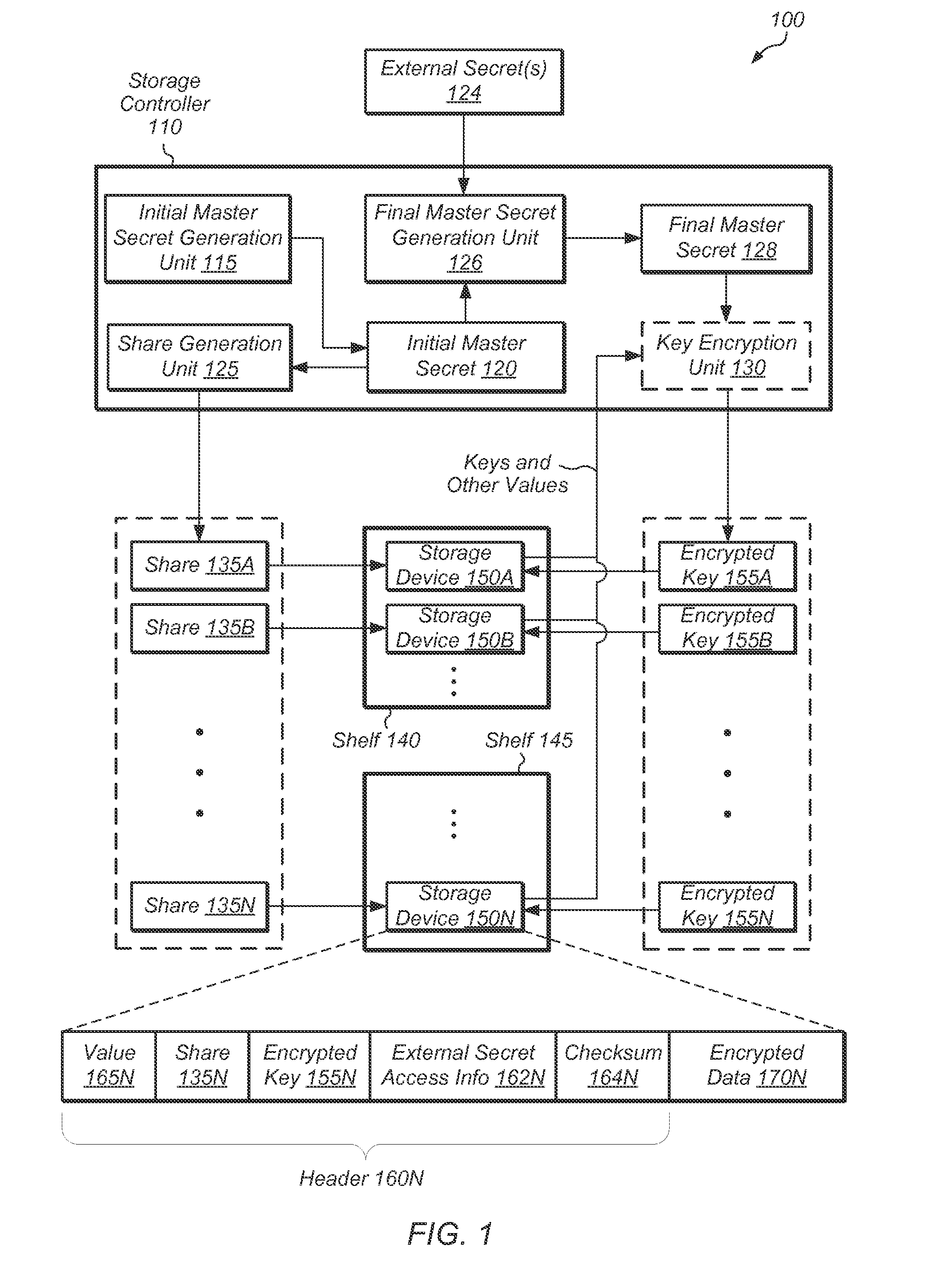

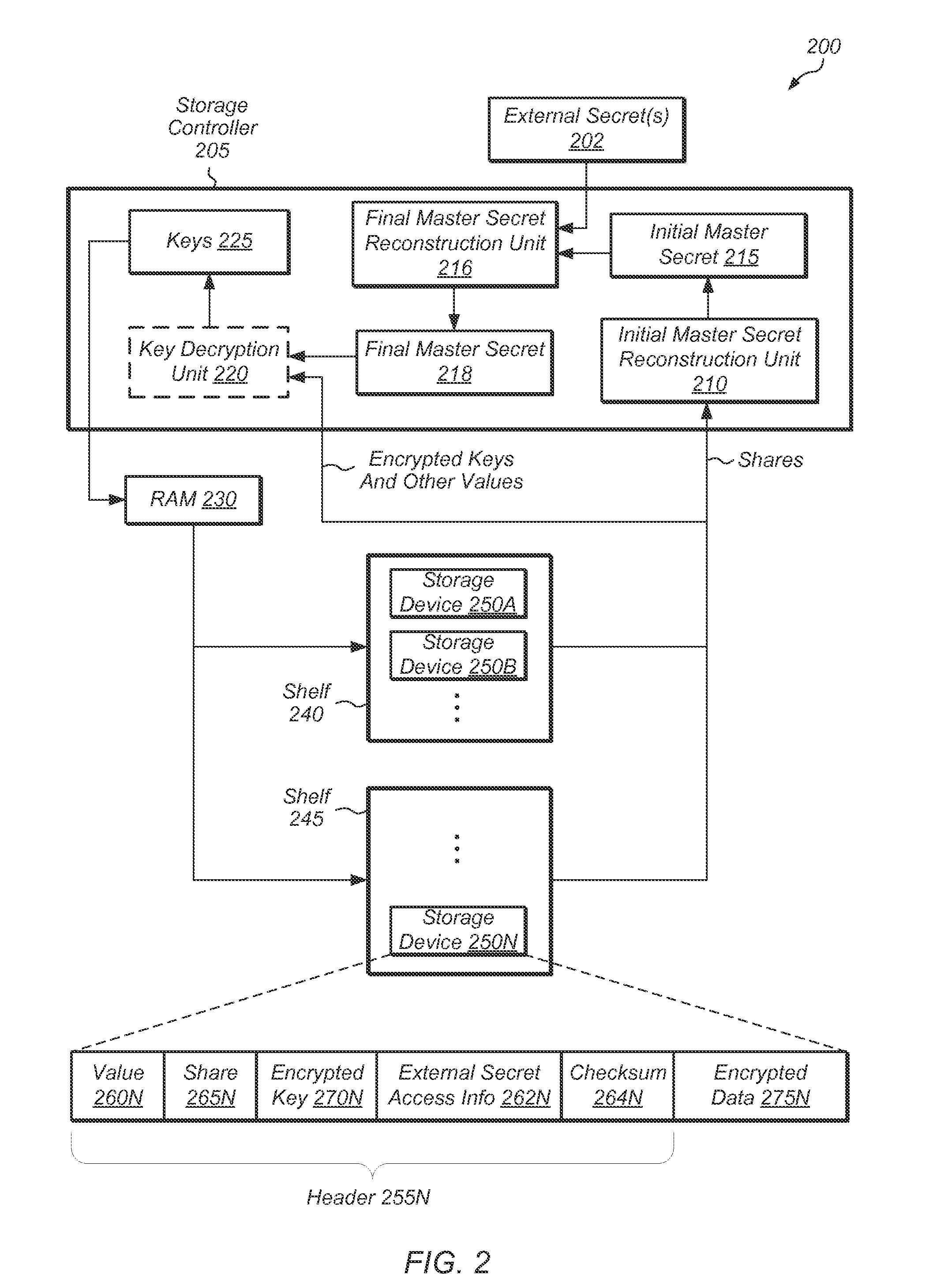

Data protection in a storage system using external secrets

ActiveUS20150127946A1Avoid dataEasy to destroyKey distribution for secure communicationUser identity/authority verificationKey generationThreshold number

A system, method, and computer-readable storage medium for protecting a set of storage devices using a secret sharing scheme in combination with an external secret. An initial master secret is generated and then transformed into a final master secret using an external secret. A plurality of shares are generated from the initial master secret and distributed to the storage devices. The data of each storage device is encrypted with a device-specific key, and this key is encrypted using the final master secret. In order to read the data on a given storage device, the initial master secret reconstructed from a threshold number of shares and the external secret is retrieved. Next, the initial master secret is transformed into the final master secret using the external secret, and then the final master secret is used to decrypt the encrypted key of a given storage device.

Owner:PURE STORAGE

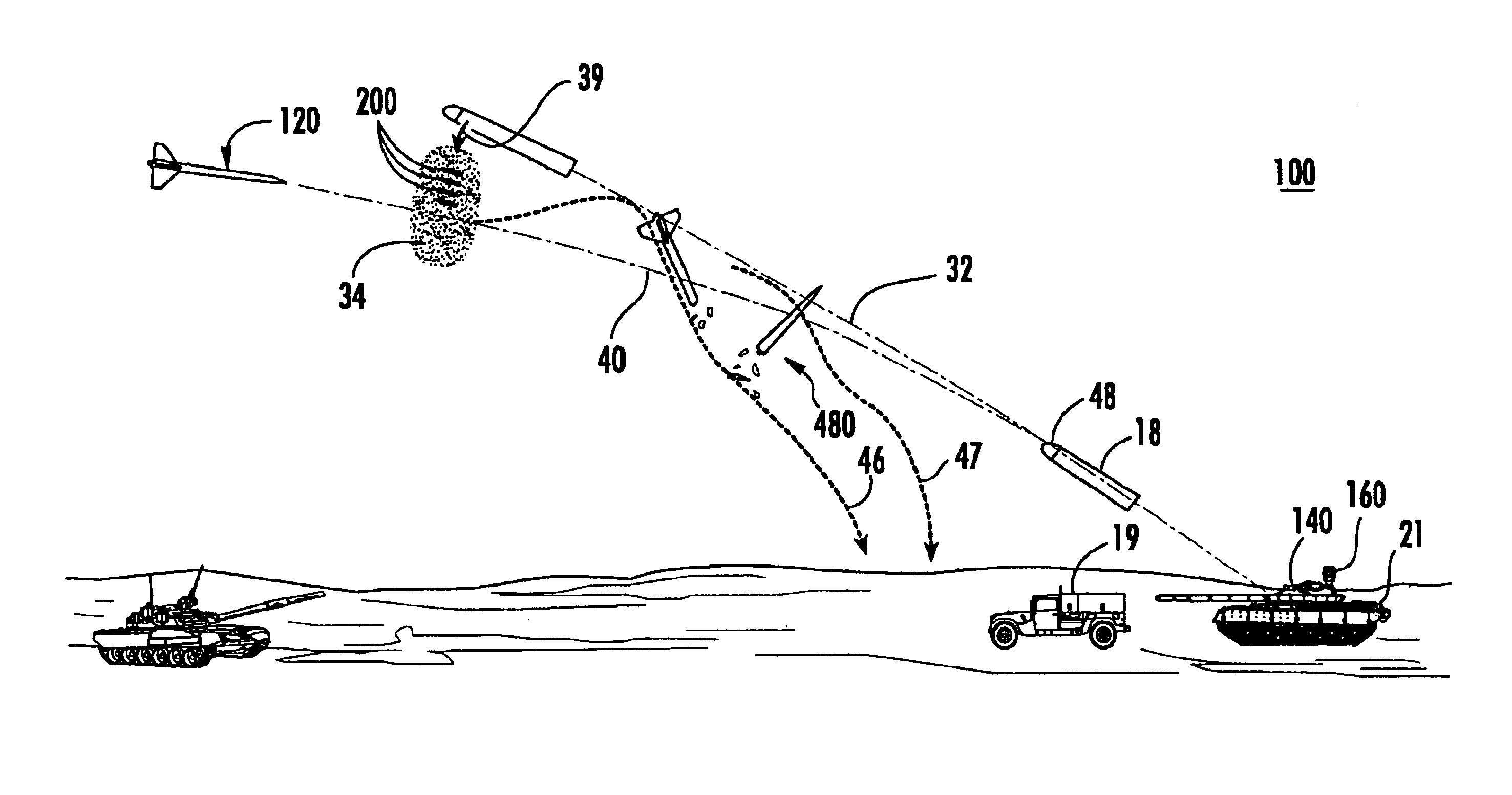

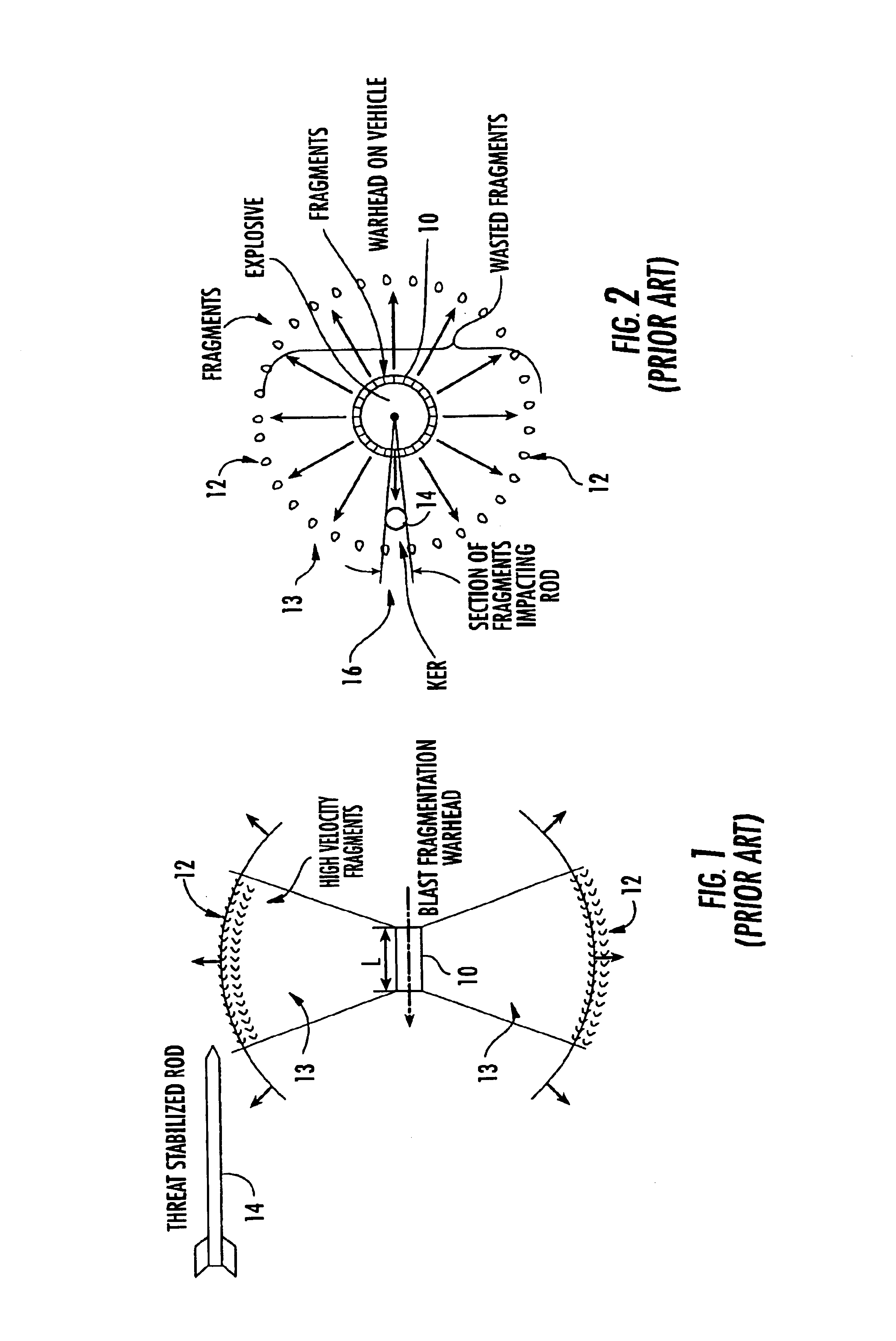

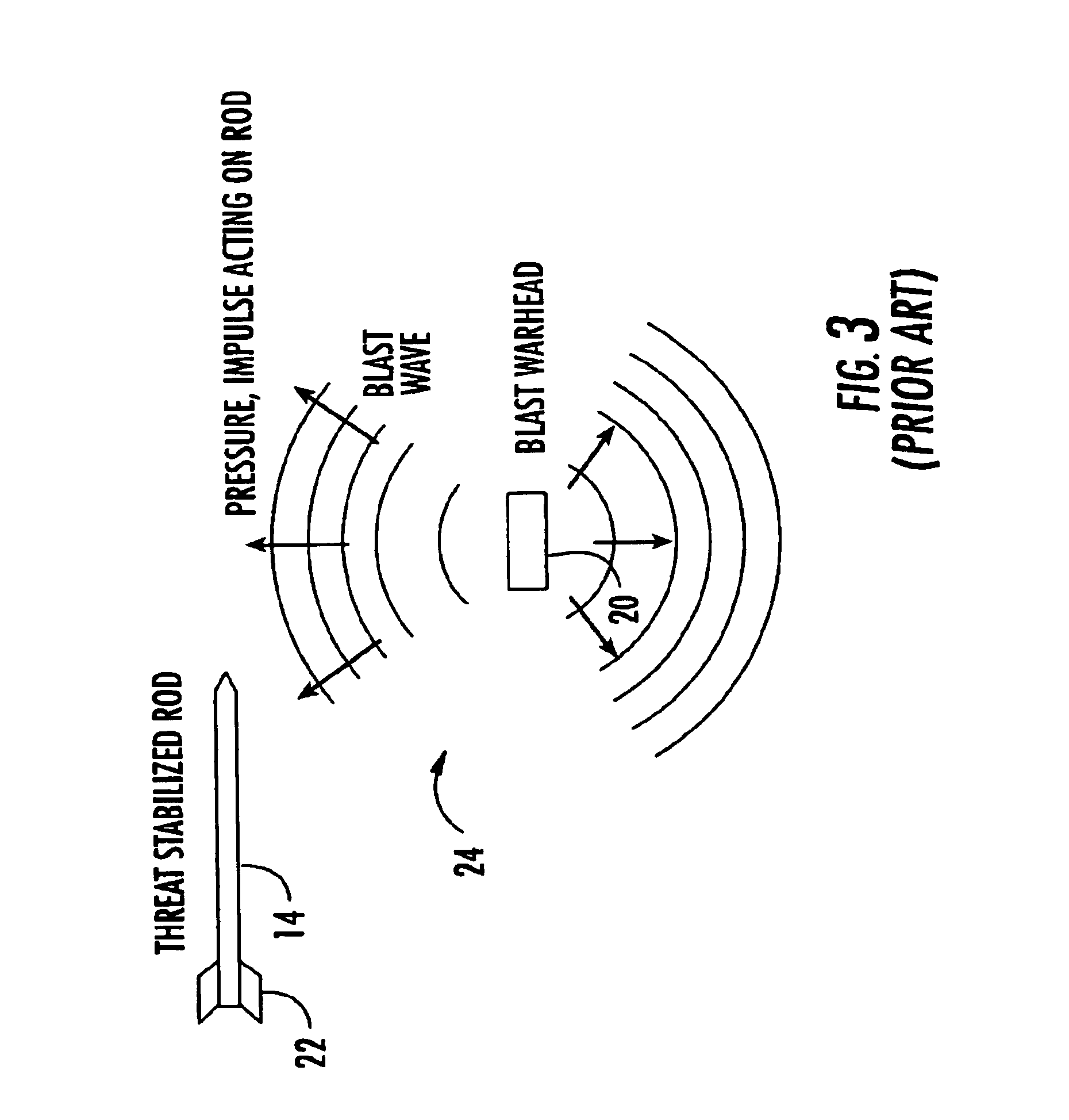

Vehicle-borne system and method for countering an incoming threat

InactiveUS6920827B2Effective destructionEffectively destroying and altering flight pathAmmunition projectilesProximity fuzesEngineeringProtection system

Owner:RAYTHEON CO

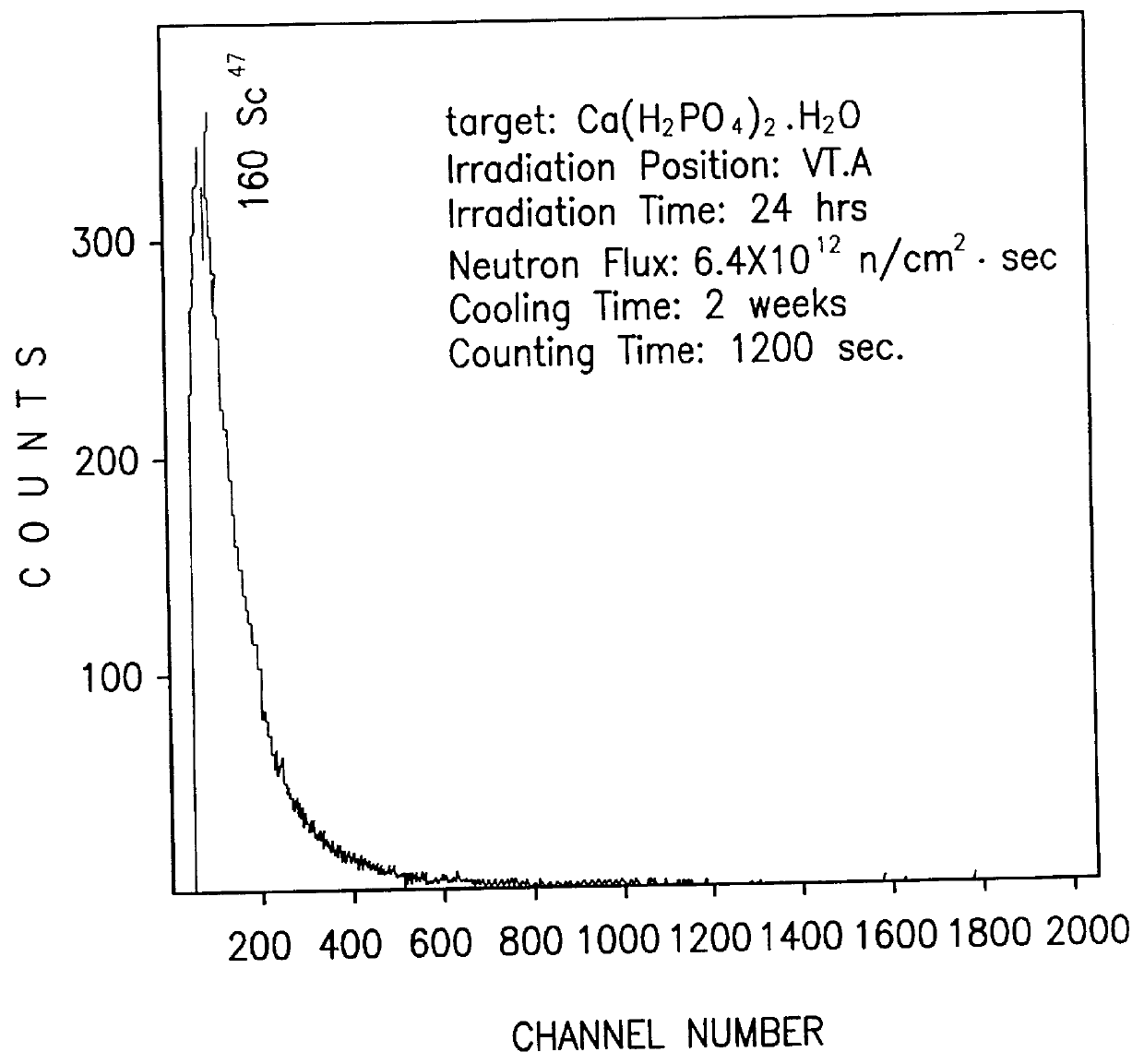

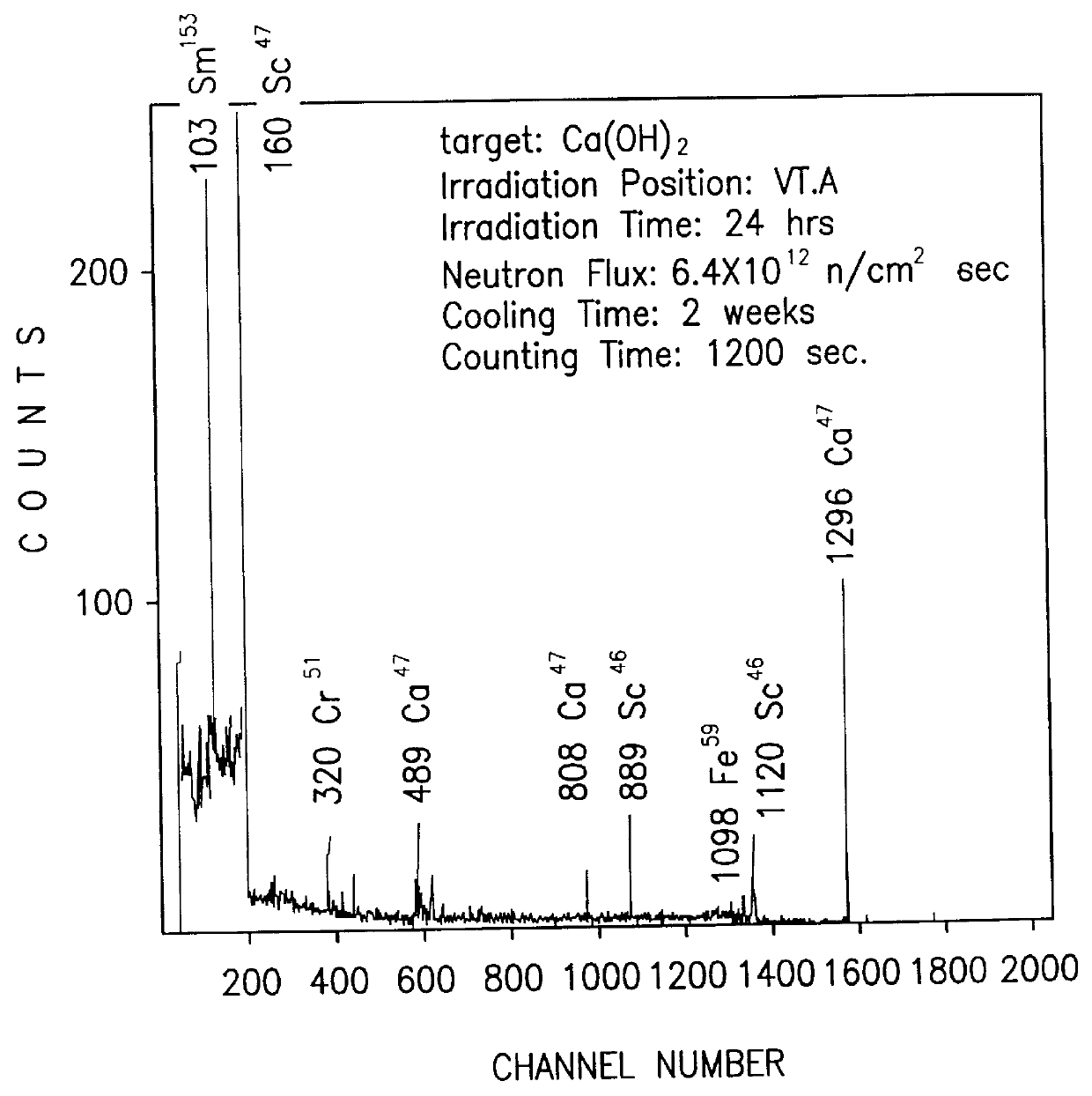

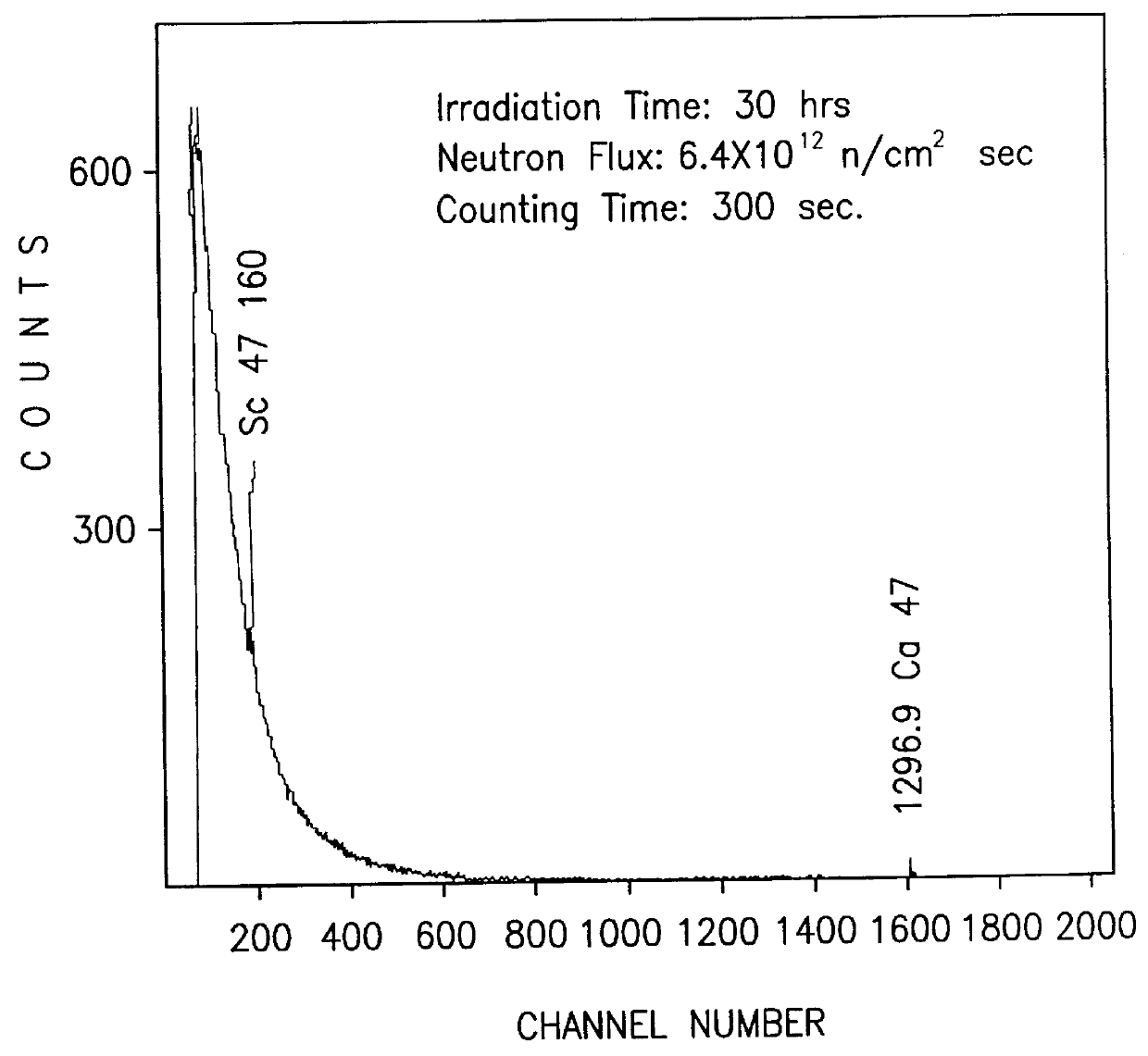

Radioactive particles and methods for preparing same

InactiveUS6149889AMinimizing damageLong lastingPowder deliveryRadioactive preparation carriersGlass particleRadioactive decay

A nuclear medical drug for localize radiotheraphy of a tumor and methods for its preparation. The drug includes a radioactive ceramic or glass particle having biocompatiblity. Ceramic or glass particles prepared by traditional processes become radioactive particles with pure beta -particle-emitting radionuclides after being irradiated with an appropriate flux of neutrons. The radioactive particle with suitable particle size can then be dispersed into a contrast medium for injection or can be implanted by operation.

Owner:DEPT OF HEALTH THE EXECUTIVE YUAN REPUBLIC OF CHINA

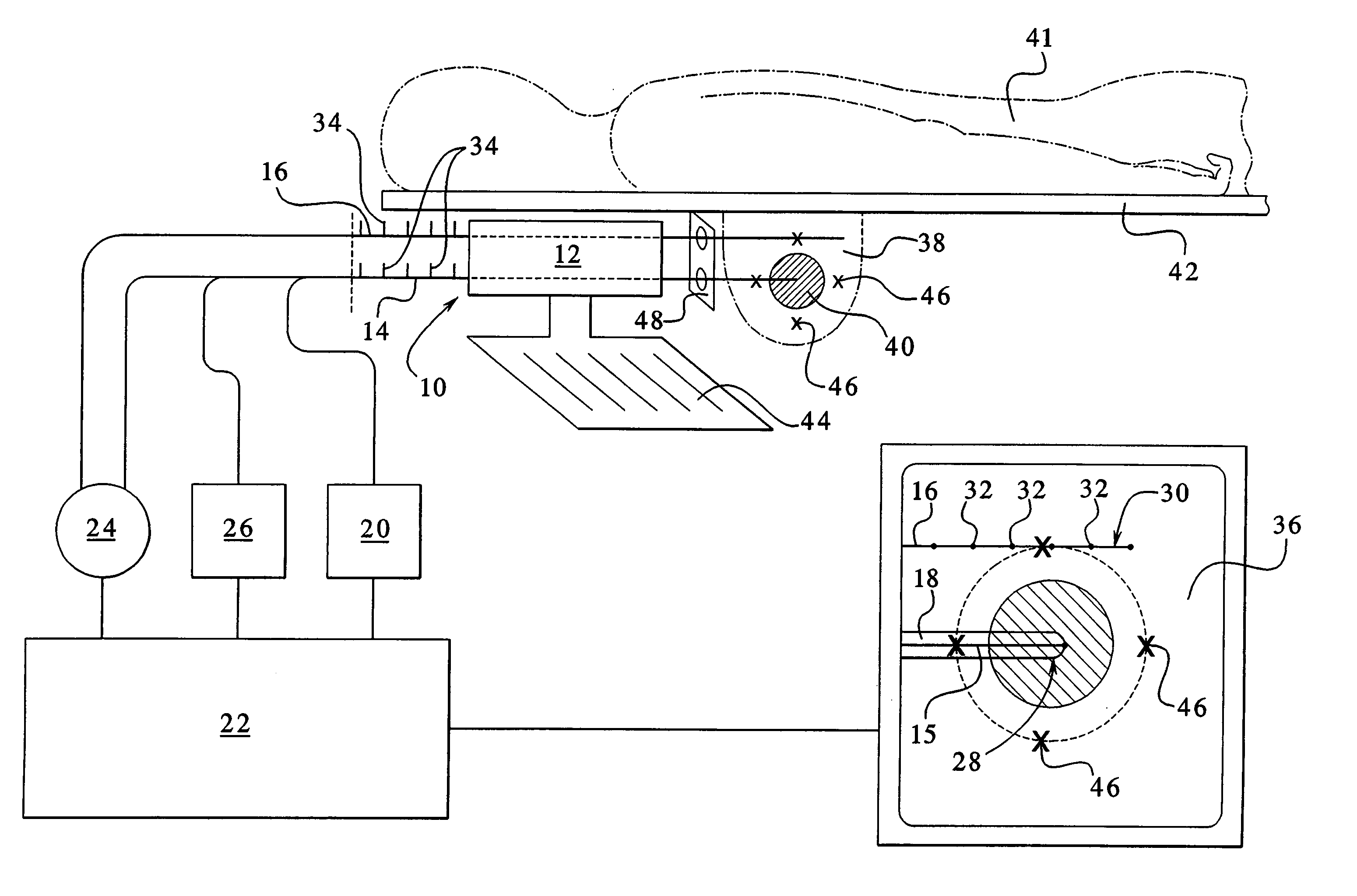

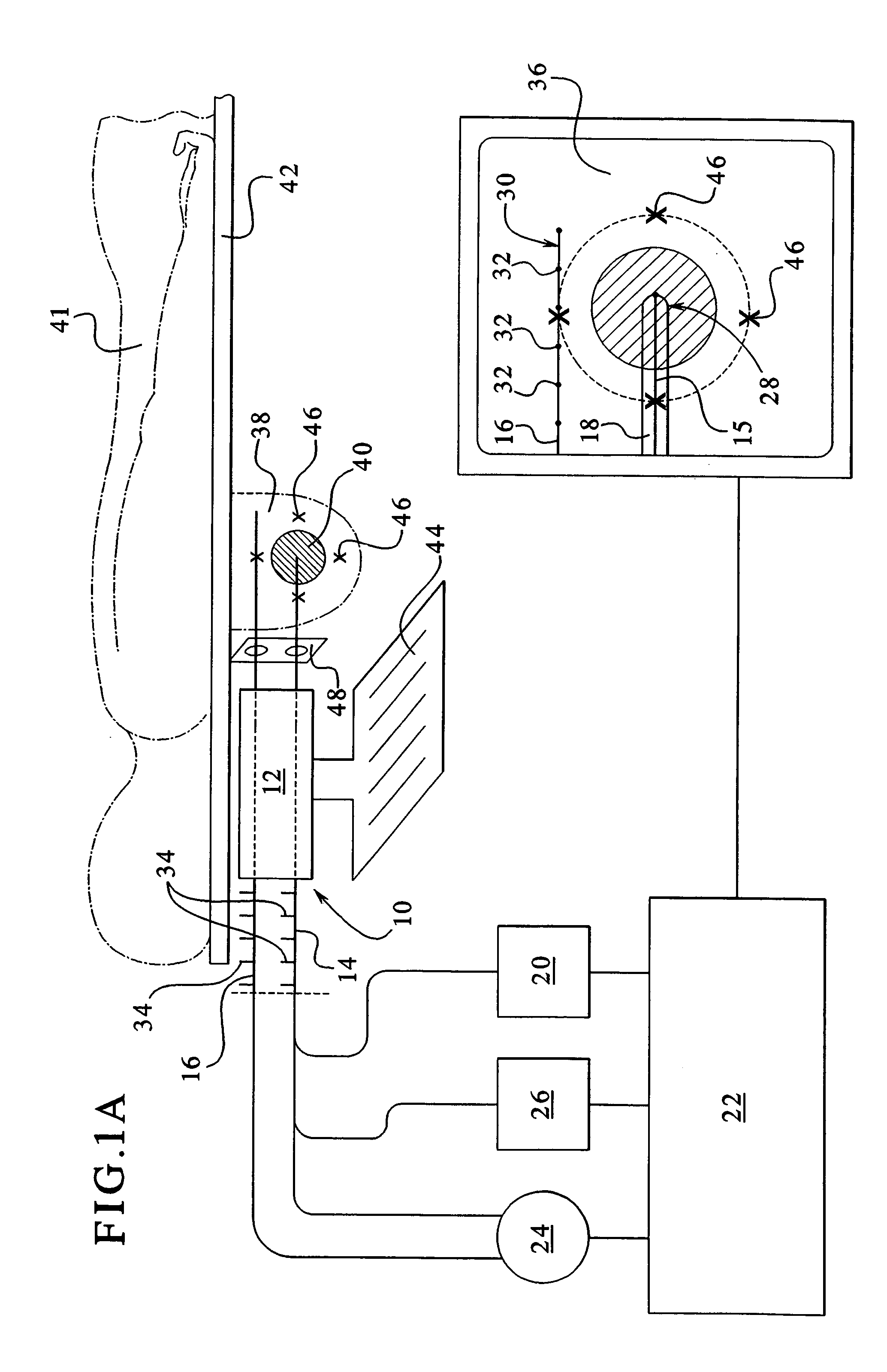

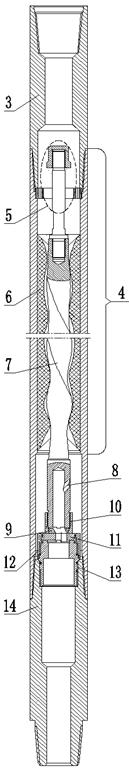

Apparatus and method for delivering ablative laser energy and determining the volume of tumor mass destroyed

InactiveUS7171253B2Complete efficientlyEffective destructionBlood flow measurement devicesSurgical needlesTumour volumeVisual monitoring

An apparatus and method for determining a volume of tumor mass destroyed. The present invention includes a temperature probe and a laser probe having a temperature sensor. The laser probe and temperature probe are inserted to measure a temperature of the tumor mass and a temperature of tissue mass surrounding the tumor mass. By determining the volume of tumor mass destroyed, a graphical representation of the volume of tumor mass destroyed is provided whereby real-time visual monitoring of the destruction of the tumor mass is achieved.

Owner:NOVIAN HEALTH INC

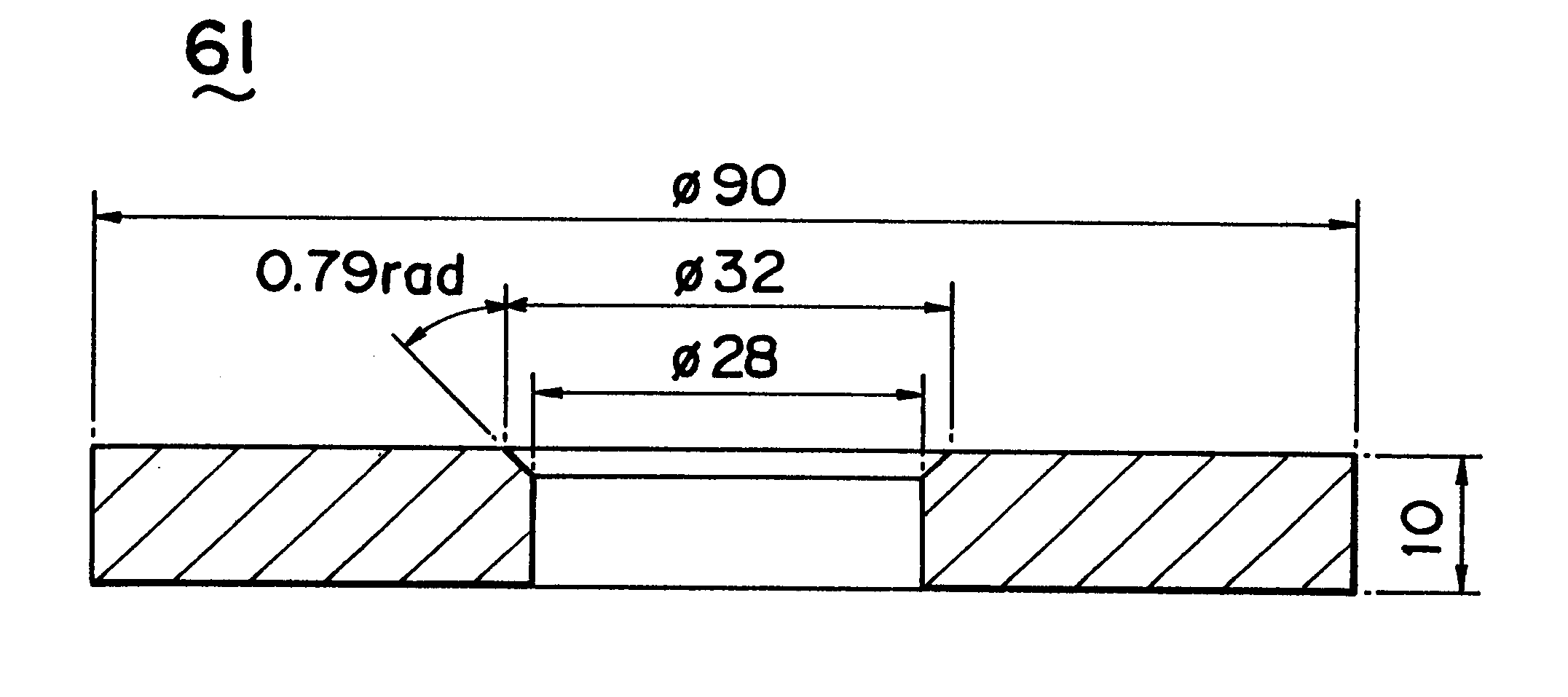

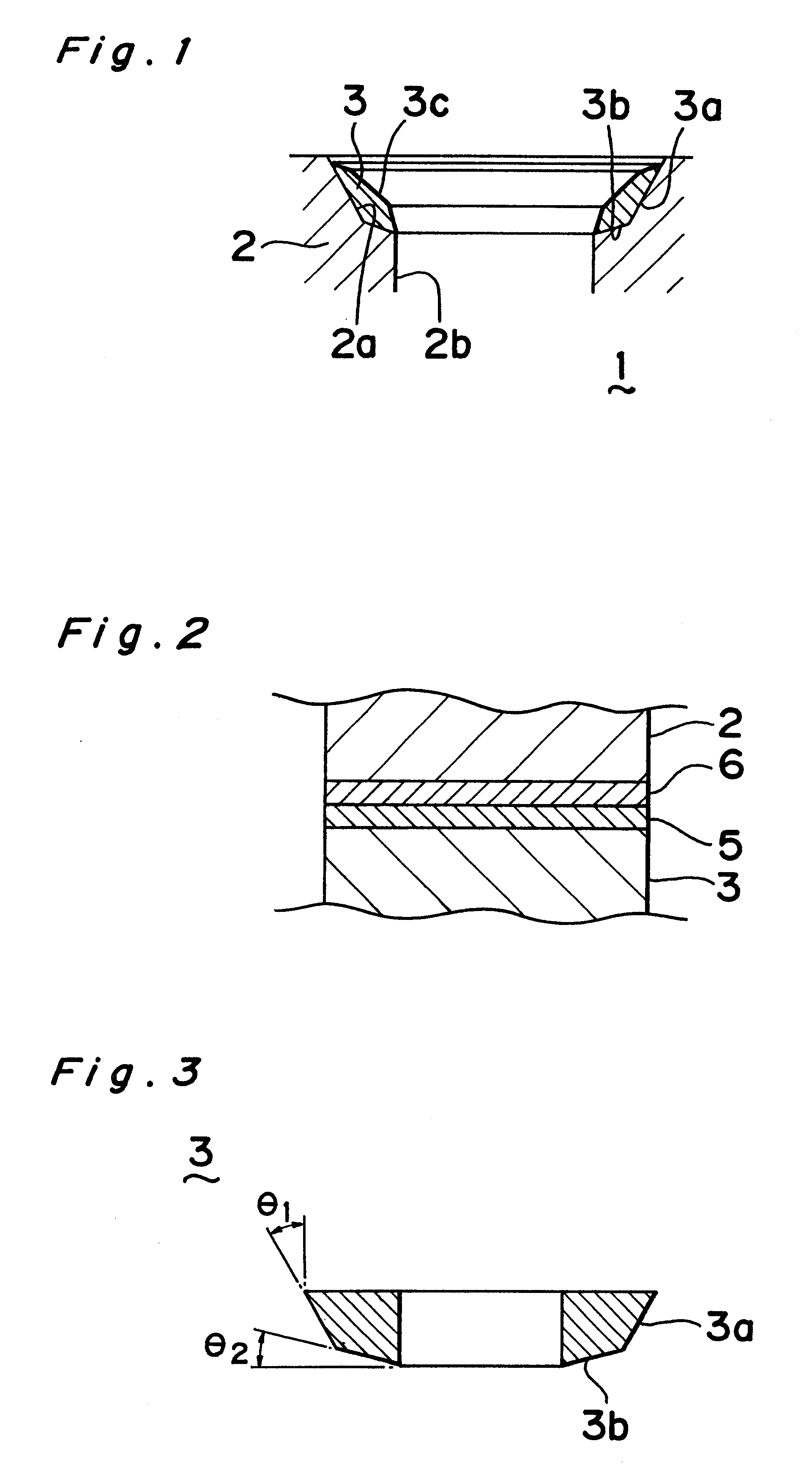

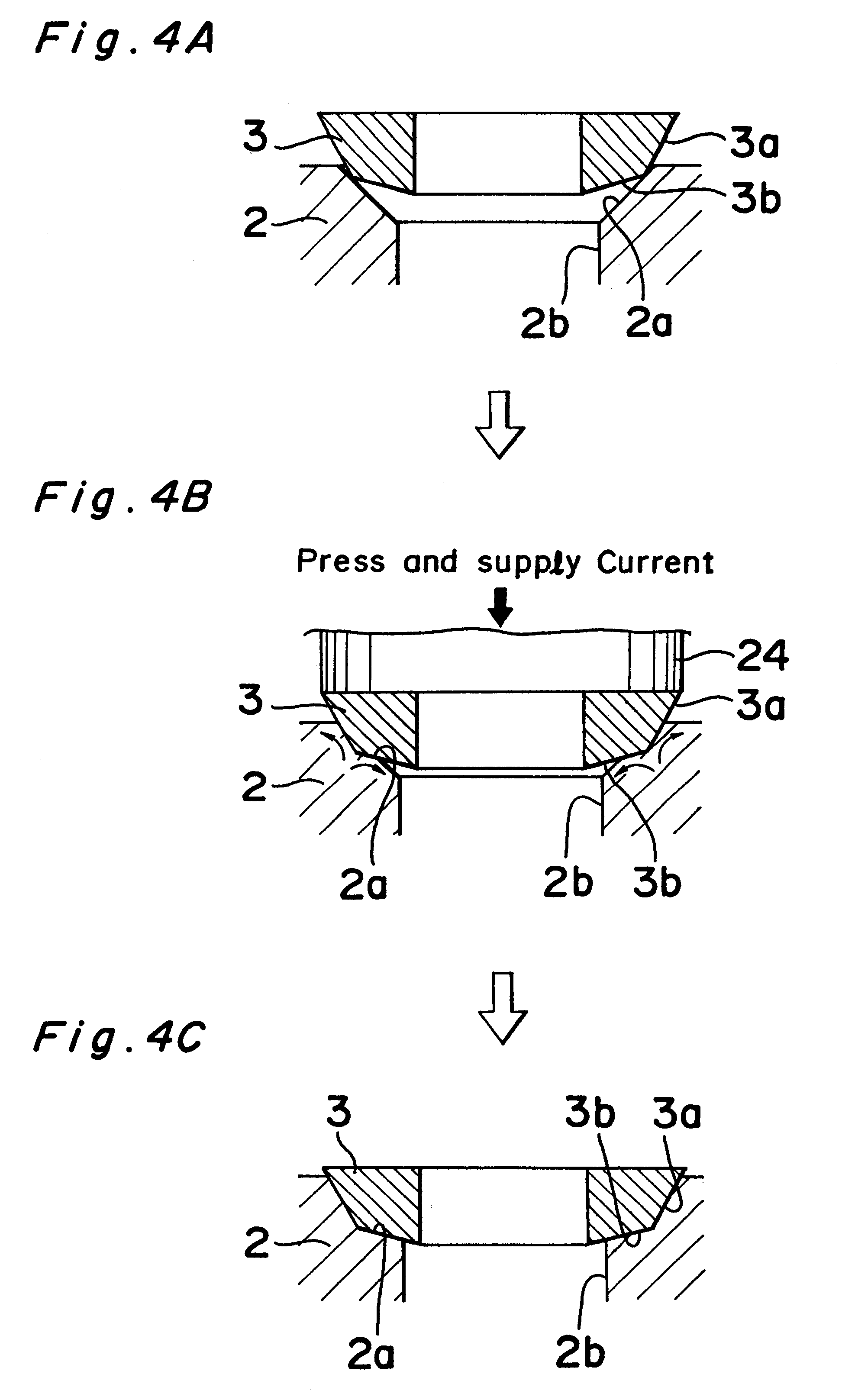

Joined metal member and method of joining said member

InactiveUS6323458B1Improve conductivityAvoid feverElectric heatingCylinder headsThermal conductivityEngineering

In order to provide a method of joining a cylinder head 2 and a valve seat 3 by press and heat generated on passing an electrical current through both members 2, 3, to achieve satisfactory joining with minimized heat generated inside when the current is supplied, while eliminating the need for an infiltration step and reduce the production cost, inhibiting an increase in thermal conductivity of the valve seat 3 and improving the wear resistance thereof. The valve seat 3 is made of a sintered material made from a powdery material with a high electrical conductivity element such as Cu dispersed therein. The current and the pressure are applied with a first joining surface 3a of the valve seat 3 and a joining surface 2a of the cylinder head body 2 being put into surface contact with each other in advance.

Owner:MAZDA MOTOR CORP

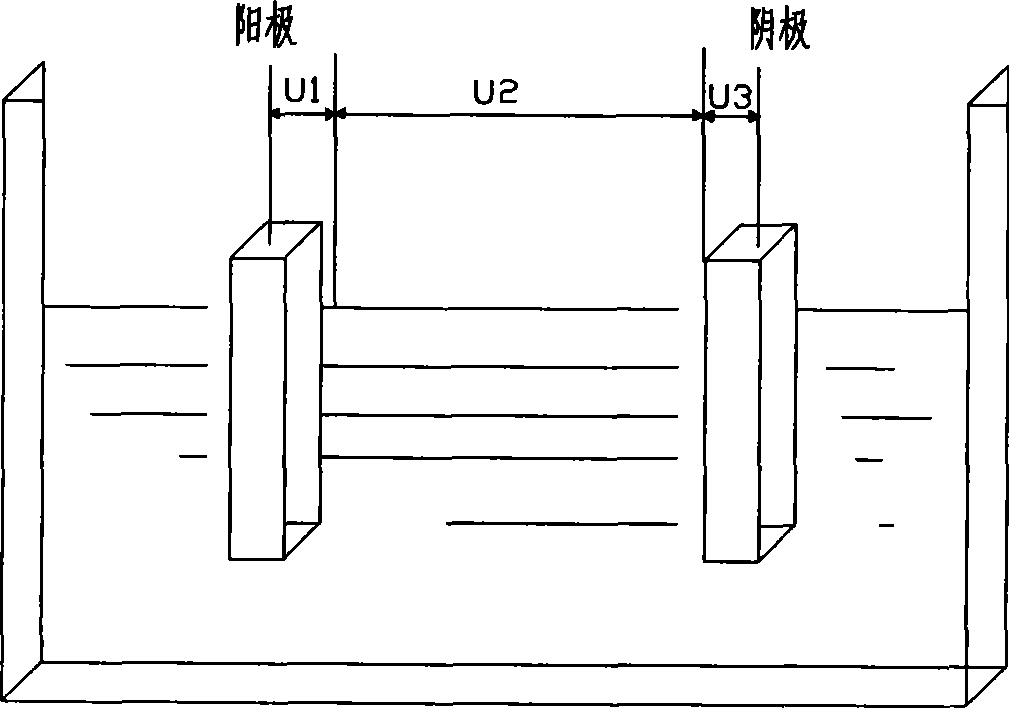

Micro-current electrolysis sterilization algae removing apparatus

ActiveCN101434430AEffective destructionGood sterilization and algae removalWater/sewage treatment using germicide/oligodynamic-processElectrolysisElectrical polarity

The invention discloses a micro-current electrolytic sterilization and algae removal device, which comprises a detector that is arranged on the intake pipe of a box body and is used for sensing solution electrical conductivity, wherein, at least more than one group of electrodes are arranged in the box body according to the order of an anode, an auxiliary electrode and a cathode, and a controller is used for judging the degree of the electrical conductivity and controlling the polarity of the electrodes in the box body and circuit connection; and the controller comprises a judging unit which is used for judging the degree of the electrical conductivity and triggering a corresponding seawater electrolytic mode unit, a fresh water electrolytic mode unit and a reversal-electrode electrolytic mode unit to operate according to judging results. The device can be simultaneously applied to sterilization and algae removal in seawater or fresh water, has good sterilization and algae removal effect, can realize automatic desludging and can be applied widely; moreover, an ultrasonicator is added, which effectively destroys various bacteria and algal cells by ultrasonic waves; and the device has simple structure and wide application range.

Owner:QINGDAO HEADWAY TECH

Apparatus and method for delivering ablative laser energy and determining the volume of tumor mass destroyed

InactiveUS6865412B2Complete efficientlyEffective destructionBlood flow measurement devicesSurgical needlesPhysicsTumour volume

An apparatus and method for determining a volume of tumor mass destroyed. The present invention includes a temperature probe and a laser probe having a temperature sensor. The laser probe and temperature probe are inserted to measure a temperature of the tumor mass and a temperature of tissue mass surrounding the tumor mass. By determining the volume of tumor mass destroyed, a graphical representation of the volume of tumor mass destroyed is provided whereby real-time visual monitoring of the destruction of the tumor mass is achieved.

Owner:NOVIAN HEALTH INC

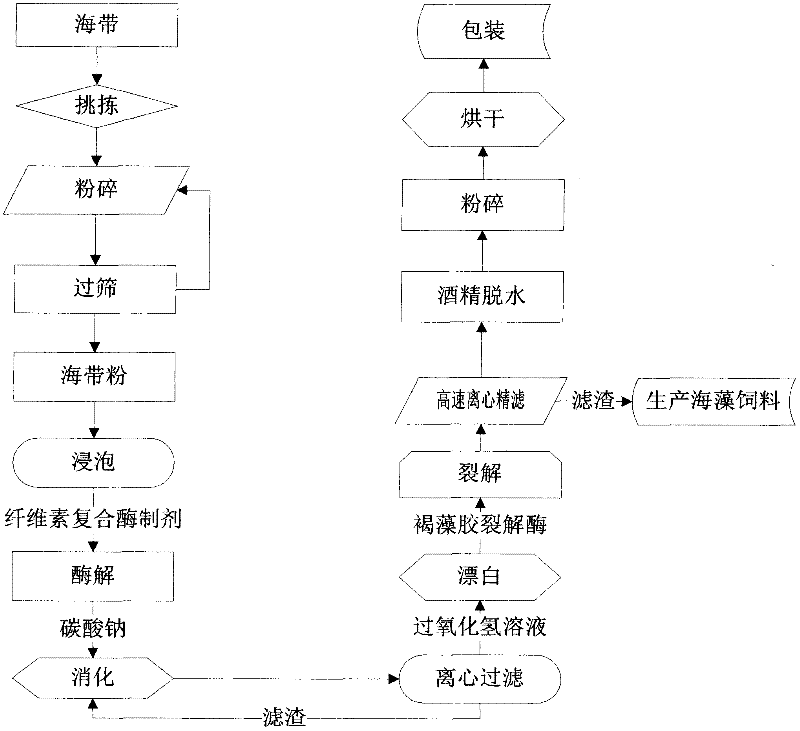

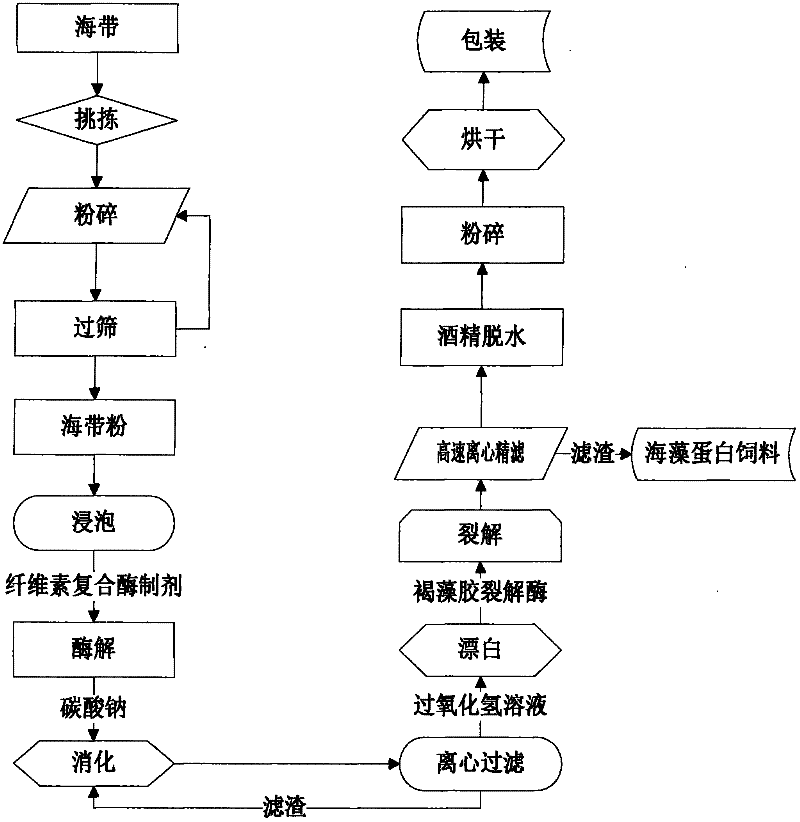

Novel process for extracting alginate-derived oligosaccharide from sea tangles by enzyme hydrolysis method

By aiming at the problems in the existing alginate-derived oligosaccharide extraction, the invention provides a production process for extracting alginate-derived oligosaccharide from sea tangles. A novel process for extracting alginate-derived oligosaccharide from sea tangles by an enzyme hydrolysis method comprises the nine steps of sea tangle powder preparation, soaking, cellulose enzymolysis, digestion, centrifugal filtration, bleaching, sodium alginate lyase enzymolysis, high-speed centrifugal fine filtration and alcohol dehydration. Compared with the existing alginate-derived oligosaccharide extraction process with the yield being 14-15 percent, the novel process has the advantages that the yield is 17-18 percent and is improved by 3 to 4 percent, meanwhile, the process steps are simplified, the use of chemical reagents is reduced, and the product appearance is more attractive.

Owner:青岛聚大洋藻业集团有限公司

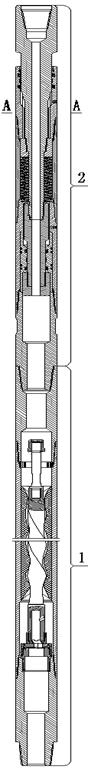

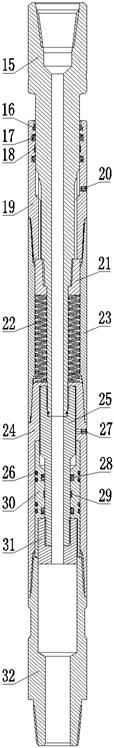

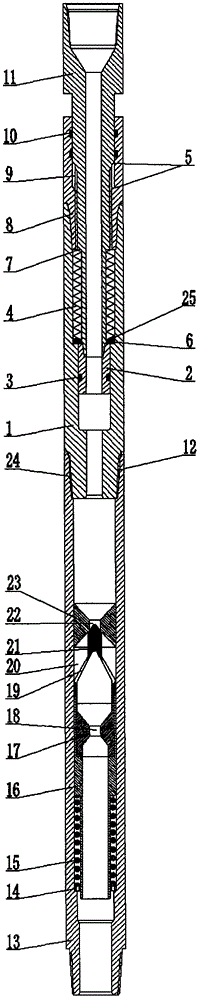

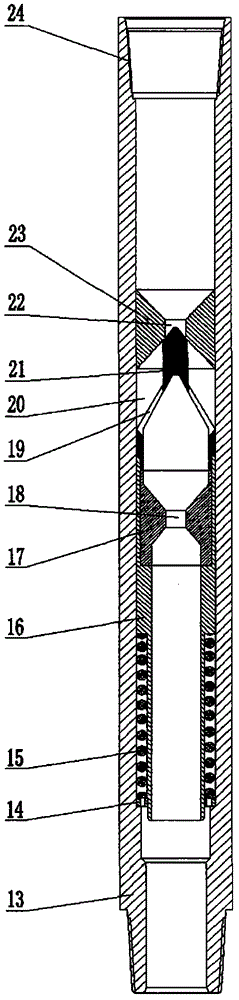

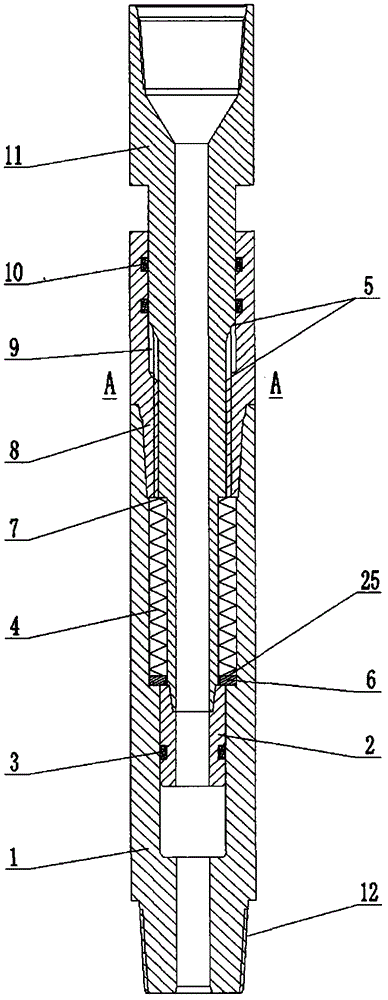

Pressure resistant tool for reducing frictional resistance of horizontal well section

ActiveCN102587832AStrong axial vibration capabilityEffective destructionDirectional drillingBorehole drivesUpper jointDrive shaft

The invention relates to a pressure resistant tool for reducing frictional resistance of a horizontal well section, which is used for reducing the frictional resistance of the horizontal well section and improving horizontal section extending and drilling capacity. The technical scheme includes: the pressure resistant tool for reducing the frictional resistance of a whole well consists of a pulse part and a vibration part. The pulse part mainly comprises an upper joint, a power part, an upper abrasion-resistant block, an upper fixing sleeve, a lower abrasion-resistant block, a lower fixing sleeve, a lower valve and a lower joint. The vibration part mainly comprises a spline transmission shaft, a spline righting tube, a locking nut, a disk spring, a supporting shell, a piston rod, a piston bush, a piston nut and a pulse pup joint. The vibration part is in threaded connection with the upper end of the pulse part. The overall overflowing area of a valve part driven by a motor rotor is gradually reduced, and fluid energy is converted into a series of pulse pressure to be transmitted to the vibration part. The pressure resistant tool has the advantages of high axial vibration capacity and simple structure, the frictional resistance between a drill stem and the well wall can be reduced, and the horizontal well and large-displacement well horizontal section extending and drilling capacity is improved.

Owner:SOUTHWEST PETROLEUM UNIV

Cold Plasma Sterilization Devices and Associated Methods

InactiveUS20130071286A1Rapidly sterilizing surgical instrumentsSimple methodElectrotherapyElectric discharge tubesNoble gasPlasma sterilization

A cold plasma sterilization device for sterilization of objects such as medical instruments. Gas is fed to a plasma chamber where it is energized by one or more electrodes coupled to a pulse source to thereby generate a cold plasma inside the plasma chamber. A dielectric barrier is sandwiched between the gas compartment and the electrodes to form a dielectric barrier discharge device. Inside the plasma chamber, one or more conductive stands that are coupled to ground hold the object to-be-sterilized. The cold plasma exits the plasma chamber, where it is recirculated for further use as a plasma source in subsequent cycles. Gases that can be used include noble gases such as helium, or combinations of noble gases.

Owner:COLD PLASMA MEDICAL TECH

Light-mediated air purification system and method

A system and method for cleaning air of harmful chemical and biological agents comprises a UV light source and photoactivatable catalyst impregnated in a porous material. Photoactivation of the catalyst generates hydroxyl radicals in the presence of water vapor, which destroy microbes and harmful chemicals. Representative devices include gas masks, respirators, and commercial air purification systems.

Owner:ALLEN SUSAN DAVIS

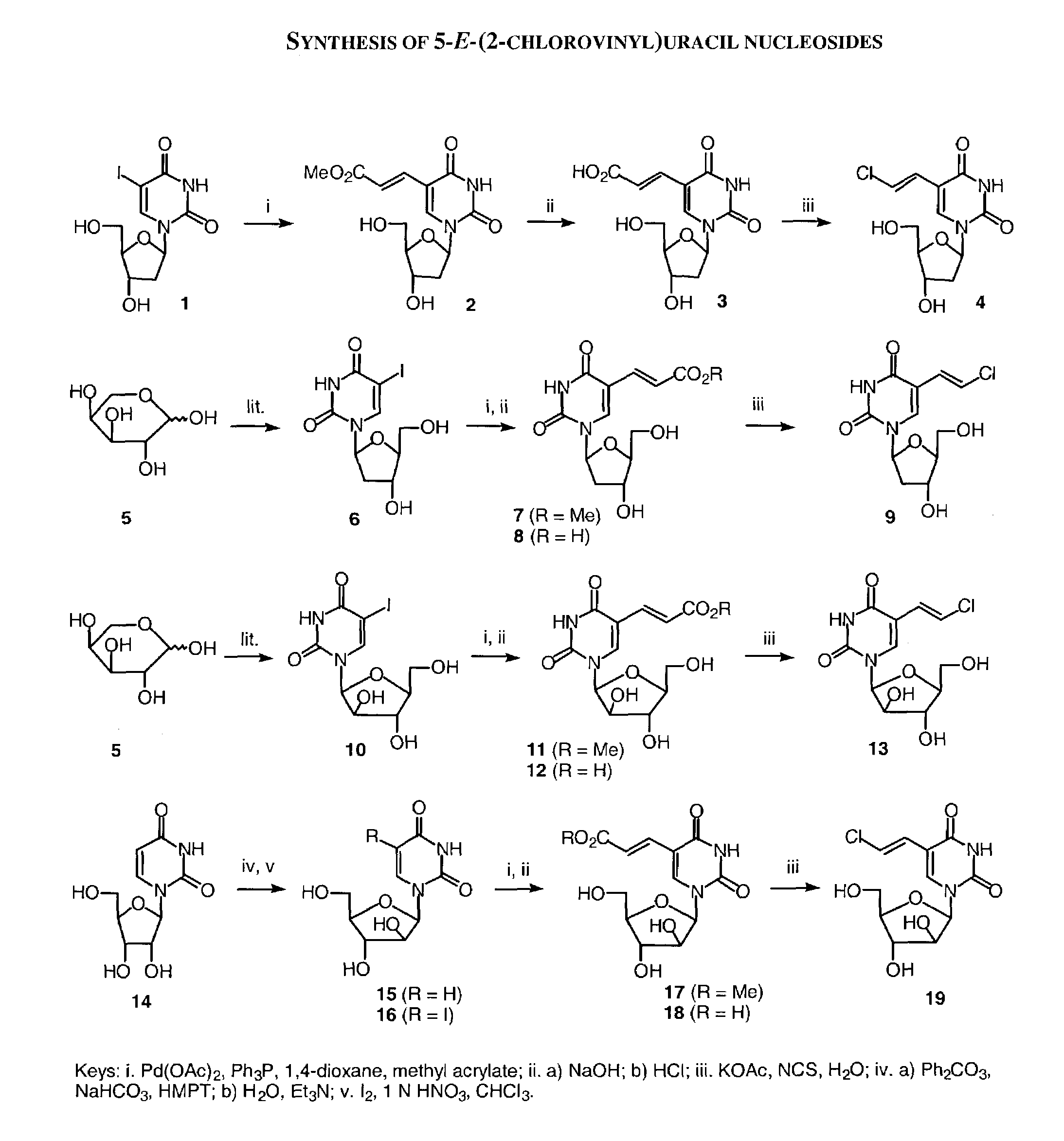

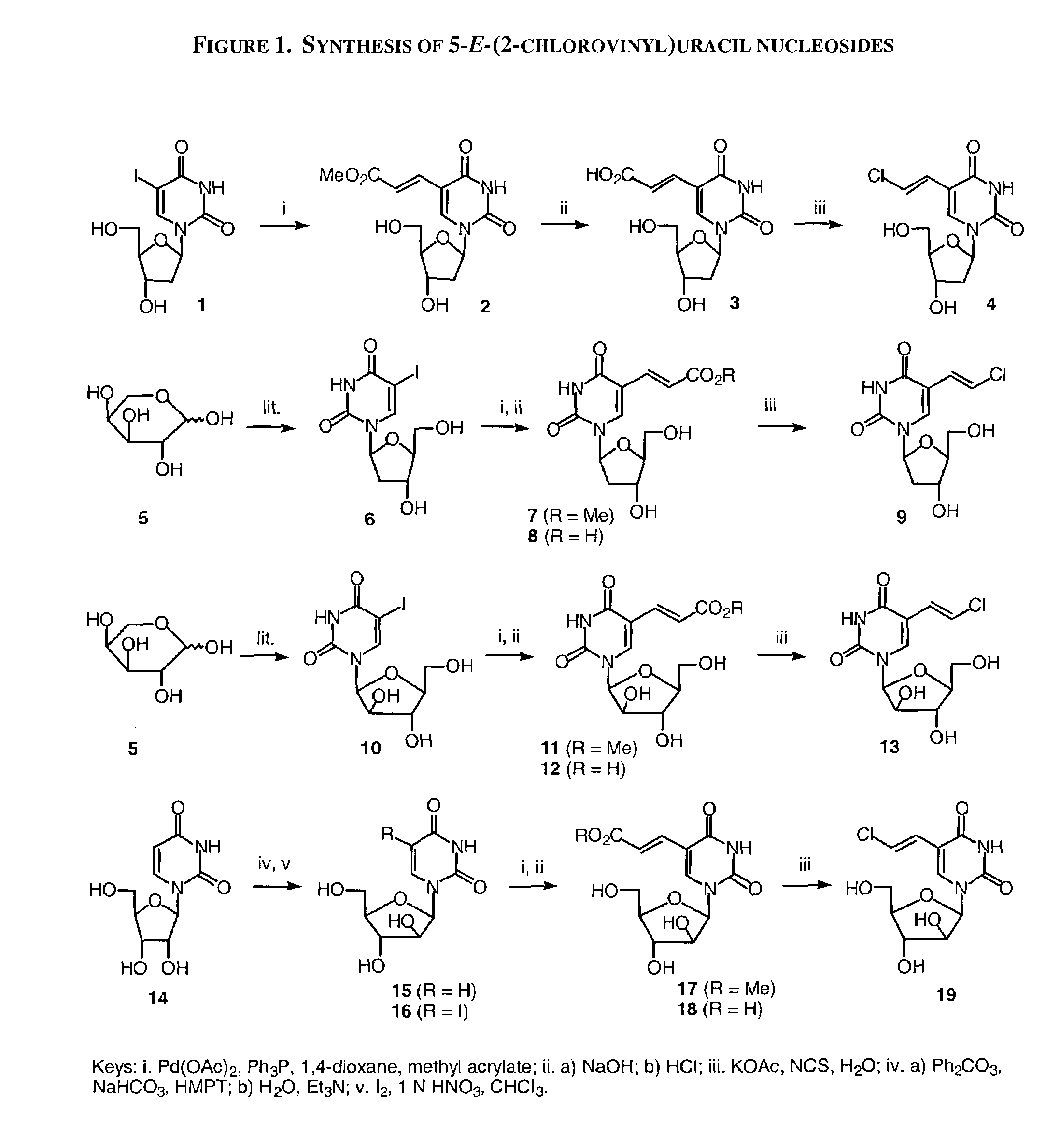

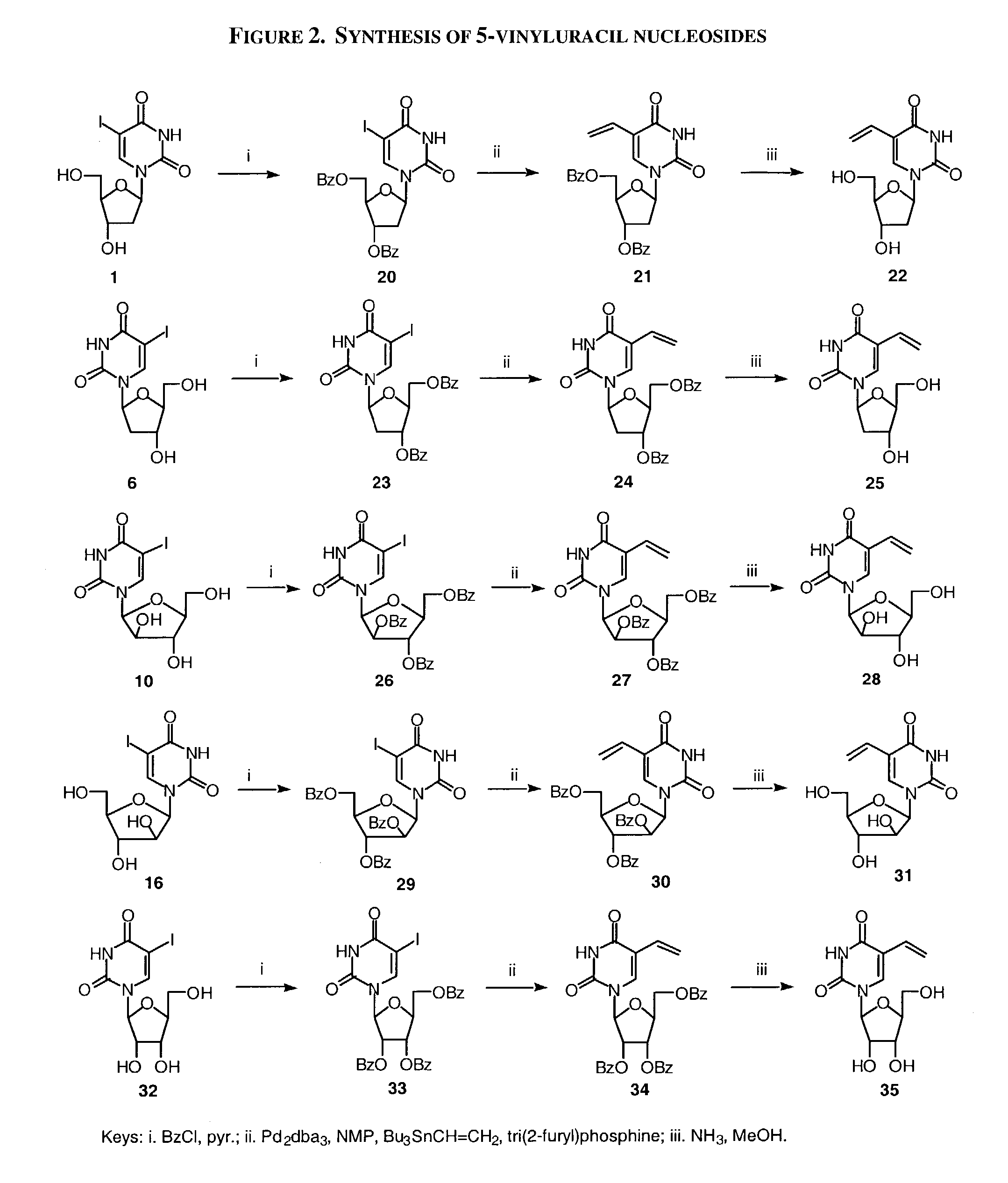

Treatment of EBV and KHSV infection

InactiveUS7211570B2Growth inhibitionIncreases activity and bioavailability and stabilityBiocideGenetic material ingredientsMedicineDiluent

A method and composition for the treatment, prevention and / or prophylaxis of a host, and in particular, a human, infected with Epstein-Barr virus (EBV), is provided that includes administering an effective amount of a 5-substituted uracil nucleoside or its pharmaceutically acceptable salt or prodrug, optionally in a pharmaceutically acceptable diluent or excipient.

Owner:EMORY UNIVERSITY +1

Clean manufacturing technique of extracting vanadium pentoxide from vanadium-contained stone coal

InactiveCN101597697AEffective destructionImprove leaching rateProcess efficiency improvementSlurrySolvent

The invention discloses a clean manufacturing technique of extracting vanadium pentoxide from vanadium-contained stone coal, comprising the following steps: grinding the vanadium-contained stone coal until the granularity is less than 2mm, baking in the industrial microwave device at temperature of 700 to 800 DEG C for 1h to 2h, fine grinding the clinker after baking until the granularity is less than 0.15mm, adding water to prepare ore slurry, in which the volume mass ratio of water to vanadium-contained stone coal is 1-1.5 to 1, adding sulphuric acid to leach at temperature of 80 to 95 DEG C for 2h to 20h, in which the amount of sulphuric acid is 10% to 25% of vanadium-contained stone coal, adding ferrous powder in the extract to reduce ferric ion, adjusting the pH value with lime and ammonia water to be 2.8 to 3.0, and obtaining ammonium polyvanadate precipitate after solvent extraction, oxidization and adding ammonia water. The ammonium polyvanadate is calcined to prepare powdery vanadium pentoxide product. The invention has beneficial effects of 1. effectively breaking structures of minerals such as vanadium-contained mica and kaolin by using microwave device to roast the vanadium-contained stone coal; 2. compared with stone coal direct acid leaching technique, reducing sulphuric acid amount by 10% to 15%, as the sulphuric acid amount when acid leaching is 10% to 25% of mineral mass; and 3. without any additive in the baking process or air pollution, belonging to clean manufacturing technique.

Owner:XIANGTAN UNIV

Soil firming agent

InactiveCN1442465AAdaptableStrong soil effectOrganic fertilisersSoil conditioning compositionsFirming agentMaterials science

A soil solidifying agent is prepared from calcium carbide dregs (25-90 portions), granualr slags (10-75 portions) of blast furnace and chemical trigger (0.1-5 portions) through grinding, and proportional mixing. Its advantages are broad spectrum, and high effect and durability.

Owner:TIANZHUJIE SPECIAL BUILDING MATERIAL TECH DEV BEIJING

Well drilling vibrator of horizontal well

InactiveCN102747974AStrong axial vibration capabilitySimple structureVibration devicesVibration drillingPistonEngineering

The invention relates to a well drilling vibrator of a horizontal well. The well drilling vibrator comprises a shell, a piston head, a disc spring, an upper shoulder, a fixed sleeve, a sliding shaft, a valve shell, a spring, a central pipe, a sliding valve body, a nozzle, a water hole, a second flow passage, a valve plug, a first flow passage and a fixed valve seat, wherein the shell is in threaded connection with the fixed sleeve; the sliding shaft is arranged in a central hole formed by the shell and the fixed sleeve; the fixed sleeve is matched with the sliding shaft through a spline; the fixed valve seat is fixedly arranged in the valve shell through thread; the valve plug is matched with the fixed valve seat; when water pressure at the upper end of the valve plug reaches a limited value, the valve plug is separated from the fixed valve seat, the spring is compressed downwards by the central pipe, and drilling fluid flows by the first flow passage and then flows by the second flow passage; when pump capacity changes, the water pressure at the upper end of the valve plug also changes, the compression of the spring changes, the distance from the valve plug to the fixed valve seat changes, the flow area of the first flow passage also changes, and pulsating pressure is caused to change the compression amplitude of the disc spring by the upper shoulder of the sliding shaft, so that vibration is caused.

Owner:CHINA PETROLEUM & CHEM CORP +1

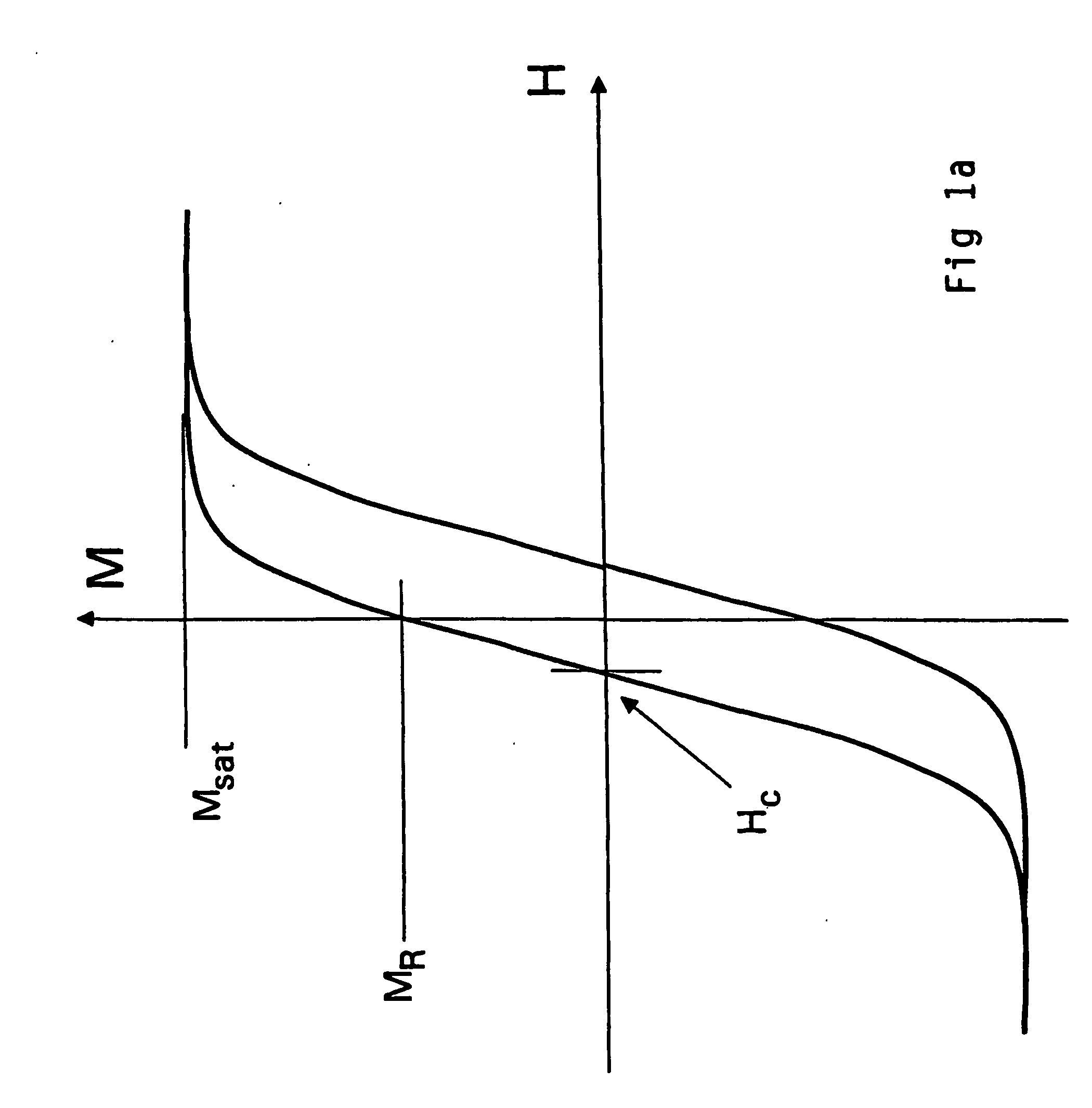

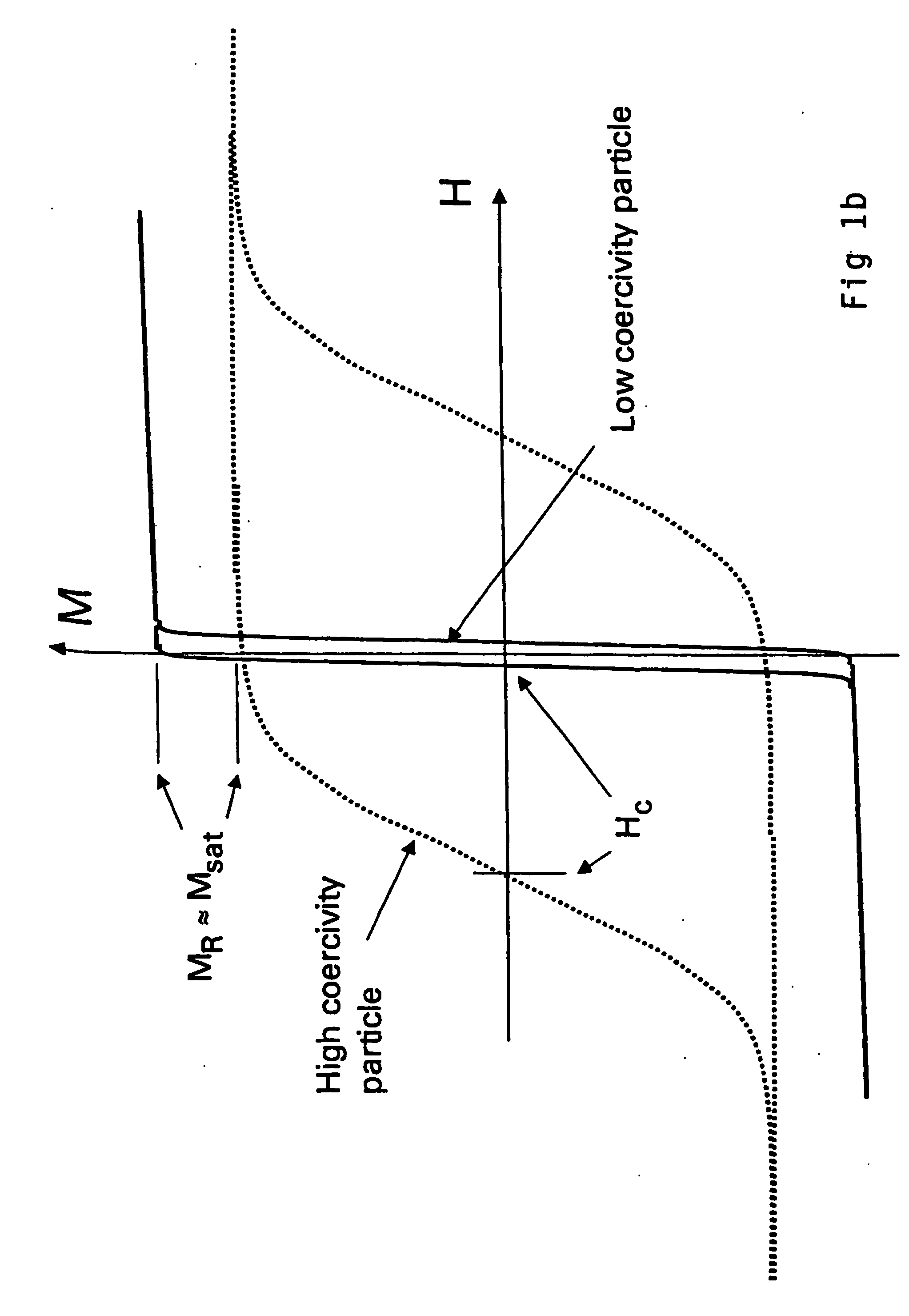

Magnetic particles for therapeutic treatment

InactiveUS20070197953A1Reduce magnetic field strengthReduce the oscillation frequencyPowder deliveryElectrotherapyMagnetizationTherapeutic treatment

Magnetic particles are used in therapeutic applications to disrupt a biological material. The particles have intrinsic magnetization, said magnetization being stabilised by inherent magneto-crystal line anisotropy and / or by shape anisotropy. By applying a magnetic field, the magnetic particles are induced to rotate when localised at the target biological material, thereby disrupting the material.

Owner:OXFORD INSTR SUPERCONDUCTIVITY +3

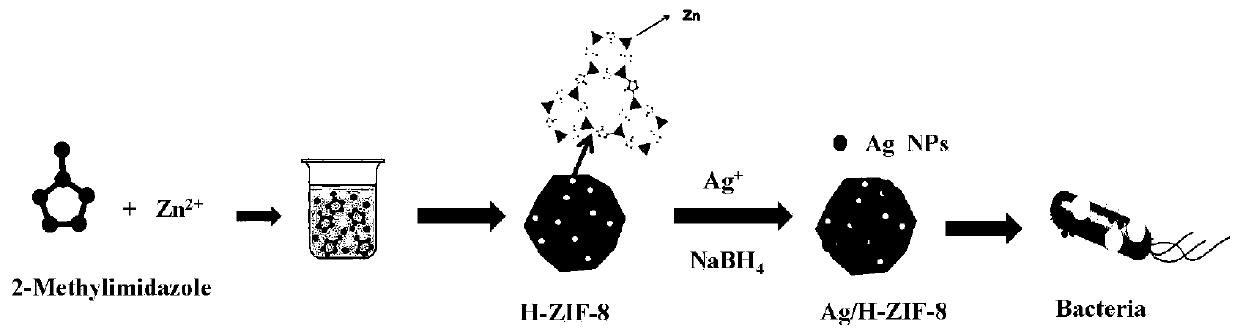

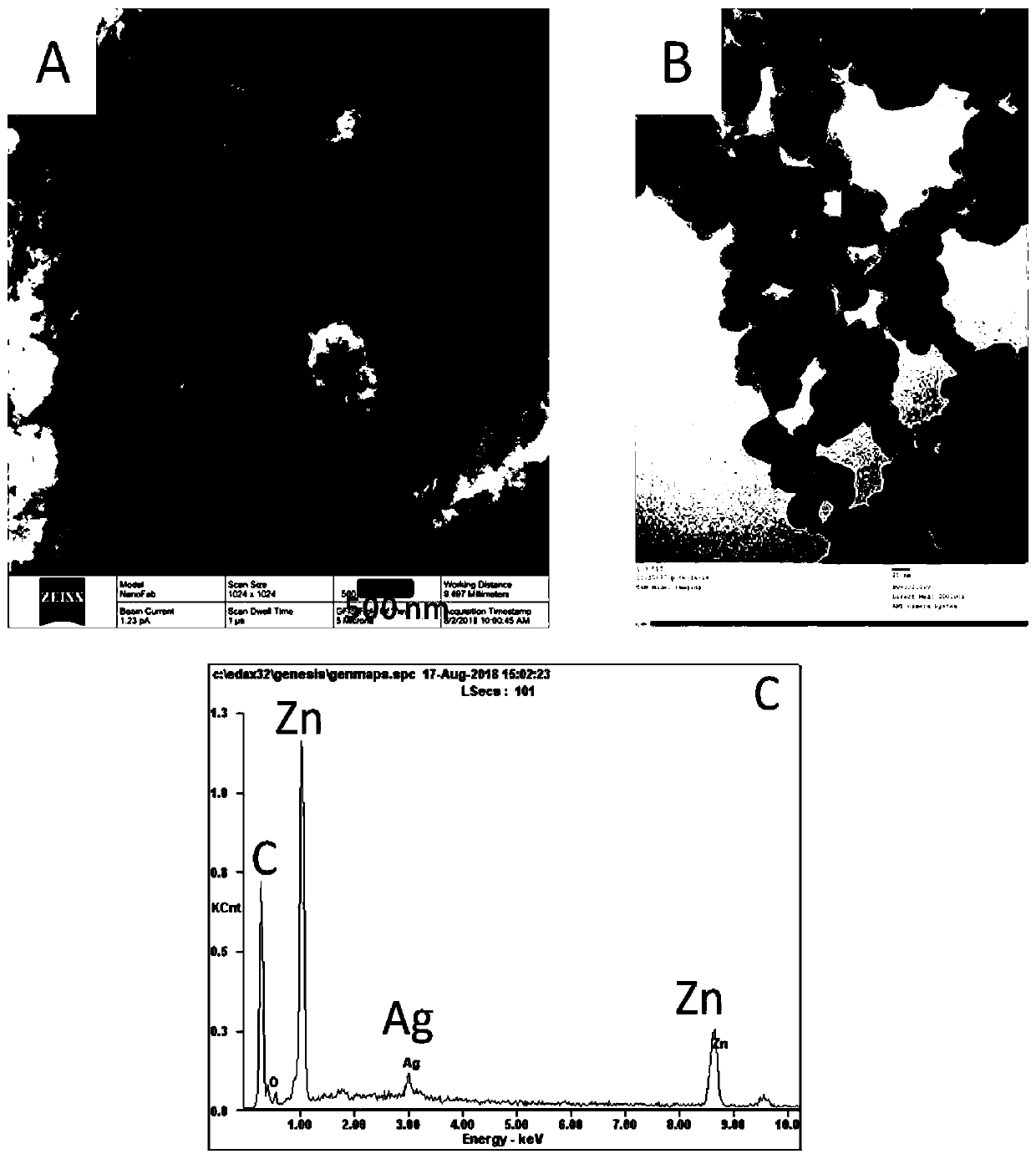

Ag/ZIF-8 anti-bacterial agent and preparation method thereof

InactiveCN109758474AImprove stabilityFacilitated DiffusionAntibacterial agentsPowder deliveryNanoparticleAnti bacterial

The invention relates to an Ag / ZIF-8 antibacterial agent and a preparation method thereof, and belongs to the technical field of nano materials. The invention provides the Ag / ZIF-8 composite anti-bacterial agent and the preparation method. The Ag / ZIF-8 composite anti-bacterial agent is prepared by dispersing Ag nanoparticles onto ZIF-8 by impregnation and reduction. The used ZIF-8 material has a multi-stage pore structure and a large specific surface area, and has good stabilization and dispersion effects on Ag nanoparticles. According to the Ag / ZIF-8 anti-bacterial agent, the provided Ag / ZIF-8 nano anti-bacterial agent has small particles and a spherical or polyhedral structure with the particle diameter of 10-200nm, thereby being beneficial to increasing the adhesion of the Ag / ZIF-8 anti-bacterial agent to bacteria; the Ag nanoparticles and the ZIF-8 have a synergetic anti-bacterial effect, multiple indicating bacteria present efficient and board spectrum anti-bacterial effects; thepreparation method is simple in process, economical and feasible.

Owner:DALIAN NATIONALITIES UNIVERSITY

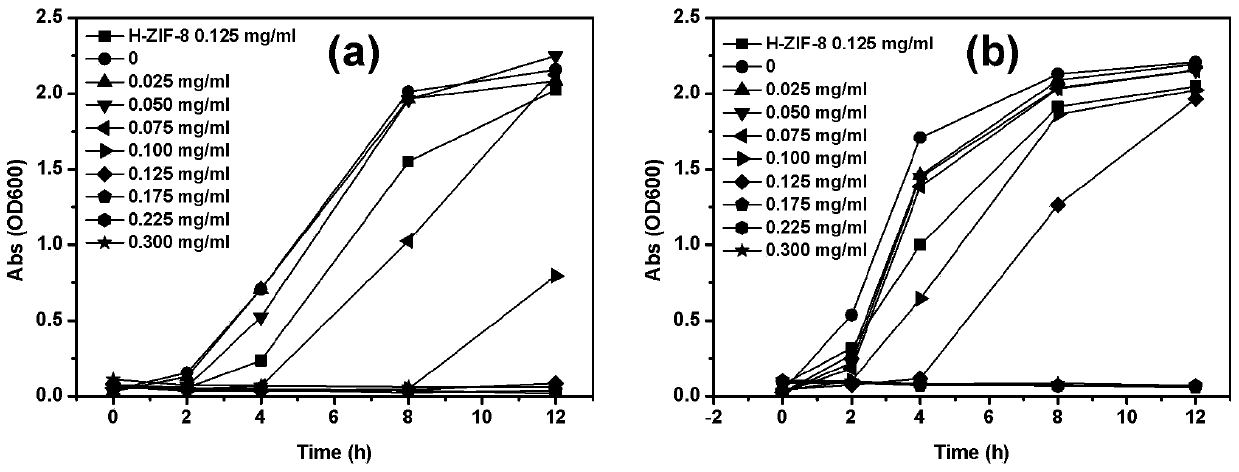

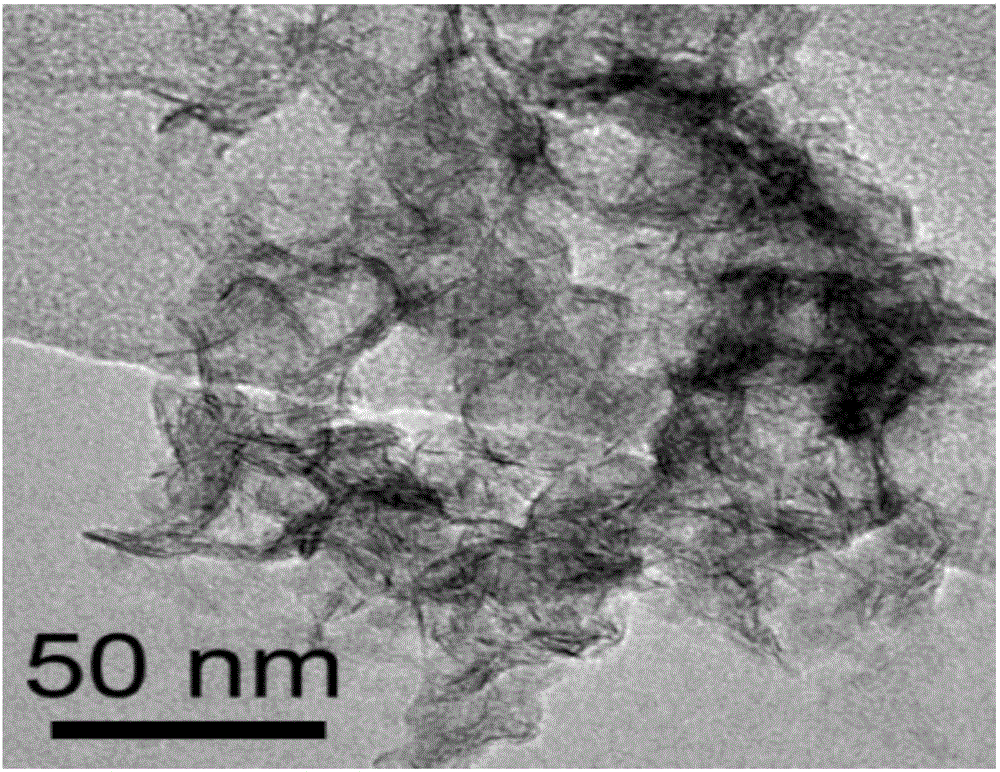

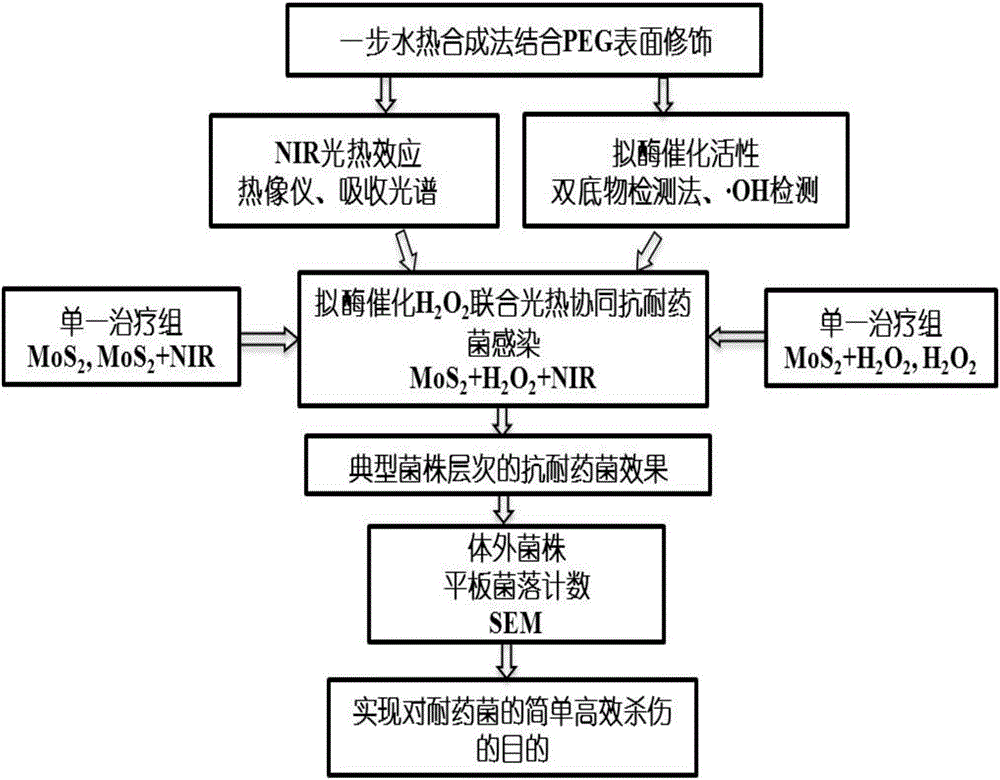

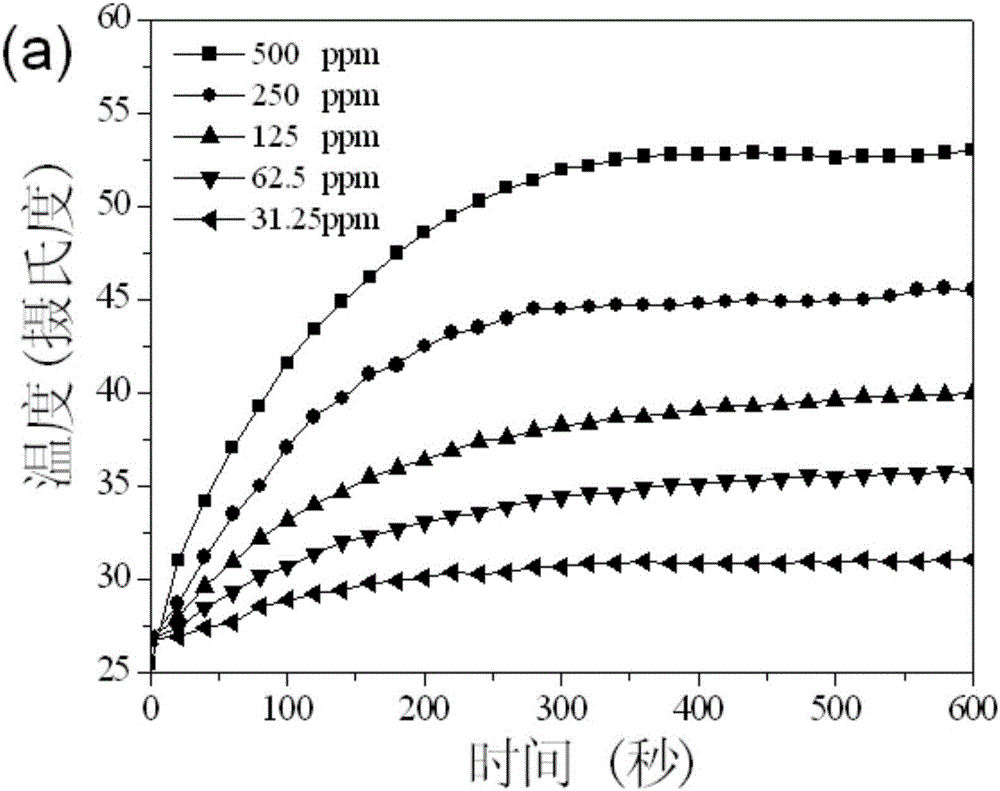

Nano-molybdenum sulfide antibacterial material and synthetic method thereof and application thereof

InactiveCN105948124AHigh yieldGood biocompatibilityAntibacterial agentsMaterial nanotechnologyThioureaPolyethylene glycol

The invention discloses a nano-molybdenum sulfide antibacterial material and a synthetic method thereof and application thereof. The synthetic method comprises the following steps: (1) dissolving polyethylene glycol solid in water, performing ultrasonic processing in an ultrasonic pool until the polyethylene glycol is dissolved completely, adding ammonium heptamolybdate solid, and performing ultrasonic processing until the ammonium heptamolybdate is dissolved completely to obtain a mixed solution; and (2) dissolving thiourea solid in water, dissolving the thiourea with stirring, adding the dissolved thiourea into the mixed solution, stirring the mixture, putting the mixture into a hydrothermal reactor having a polytetrafluoroethylene inner container, sealing the reactor, and performing heating reaction to obtain a black precipitate which is the nano-molybdenum sulfide antibacterial material. The invention also provides the nano-molybdenum sulfide antibacterial material which is prepared by the synthetic method. The invention also provides application of the nano-molybdenum sulfide antibacterial material on synergistic anti-microbial combining biomimetic catalysis hydrogen peroxide and near-infrared optothermal. The nano-molybdenum sulfide antibacterial material prepared by the synthetic method in the invention has high yield, and can be captured easily by bacteria. Moreover, the antibacterial effect of the material is obviously better than that of single biomimetic catalysis anti-microbial or single near-infrared optothermal anti-microbial.

Owner:INST OF HIGH ENERGY PHYSICS CHINESE ACADEMY OF SCI

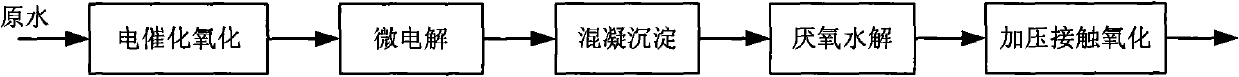

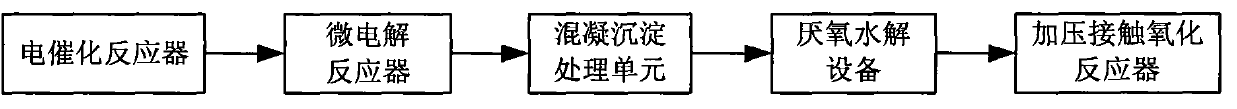

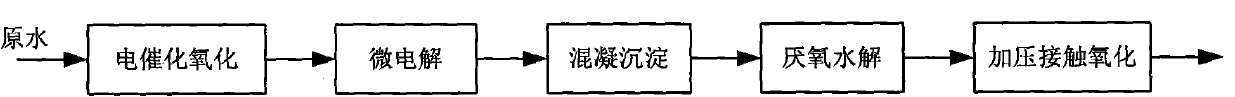

Process and equipment for treating high-concentration pyridine waste water

InactiveCN102139992AStrong resistance to shock loadsEfficient decompositionMultistage water/sewage treatmentWater/sewage treatment by oxidationChemical treatmentHigh concentration

The invention relates to a process for treating high-concentration pyridine waste water, which comprises the following steps of: regulating raw water of waste water to be acidic, and treating the raw water in electro-catalytic oxidation equipment; leading effluent to a micro-electrolysis device for treatment under the condition of maintaining the acidity and oxygen enrichment of the waste water; regulating the effluent to be meta-alkalescent, and adding chemicals to perform coagulating sedimentation; and controlling the salinity of the waste water to be below 2 percent, and performing biochemical treatment in an anaerobic hydrolyzing device and a pressurizing biological contact oxidation device, so that the effluent reaches the conventional first-level standards for sewage discharge. Due to the adoption of a physico-chemical treatment process serving electro-catalytic oxidation as a core, pyridine pollutants can be decomposed effectively, the toxicity of the waste water can be reduced, and the biodegradability of the waste water can be improved; for biochemical treatment is realized by a combination process of anaerobic hydrolysis and pressurizing biological contact oxidation, the organic loads, treatment efficiency and salt-tolerant capacity of the biochemical treatment are improved; and the process has the characteristics of high impact load resistant capacity, good treatment effect and low operating cost, and the treated high-concentration pyridine waste water can reach the standard stably before discharge.

Owner:JIANGSU PROVINCIAL ACAD OF ENVIRONMENTAL SCI +1

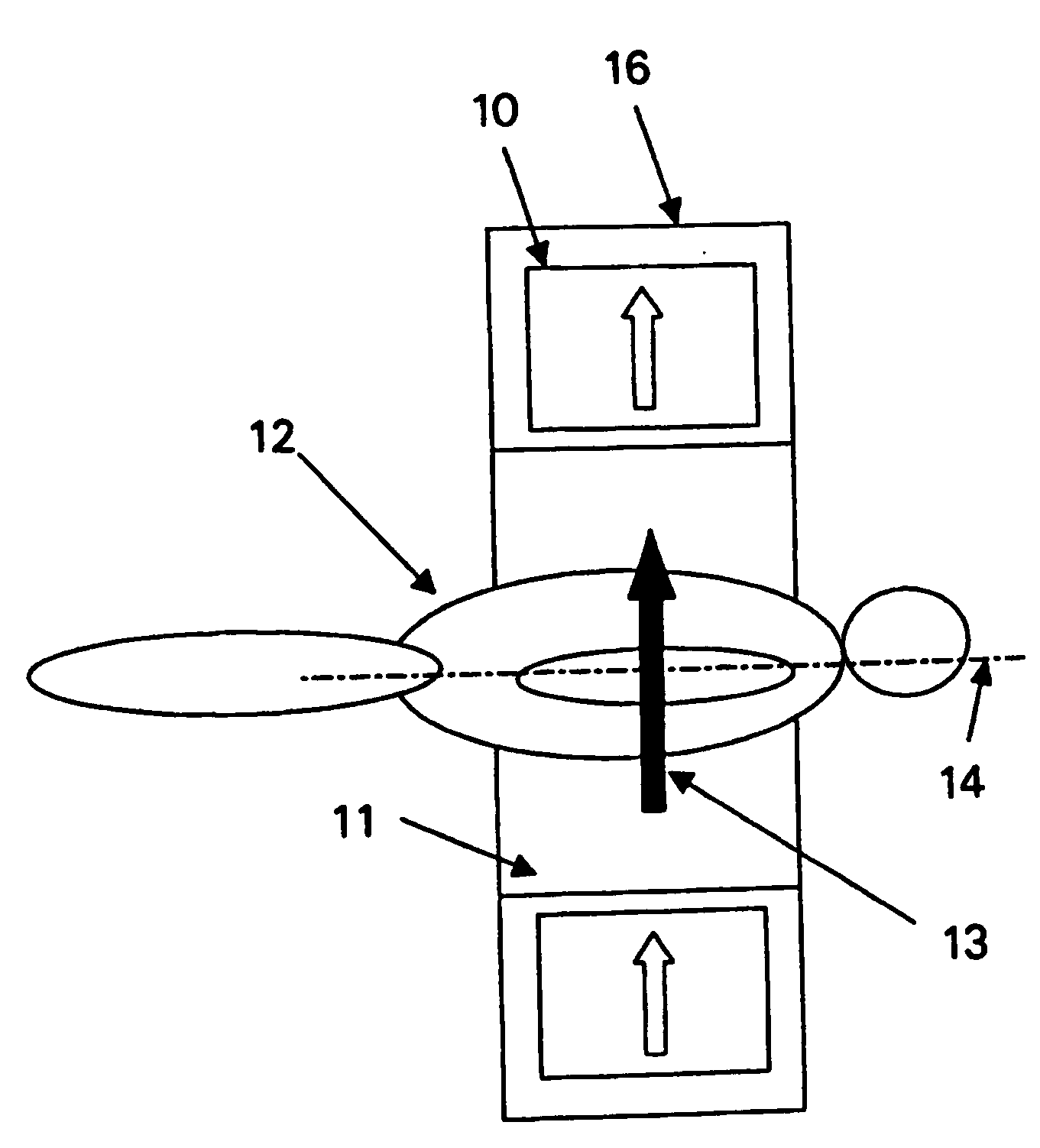

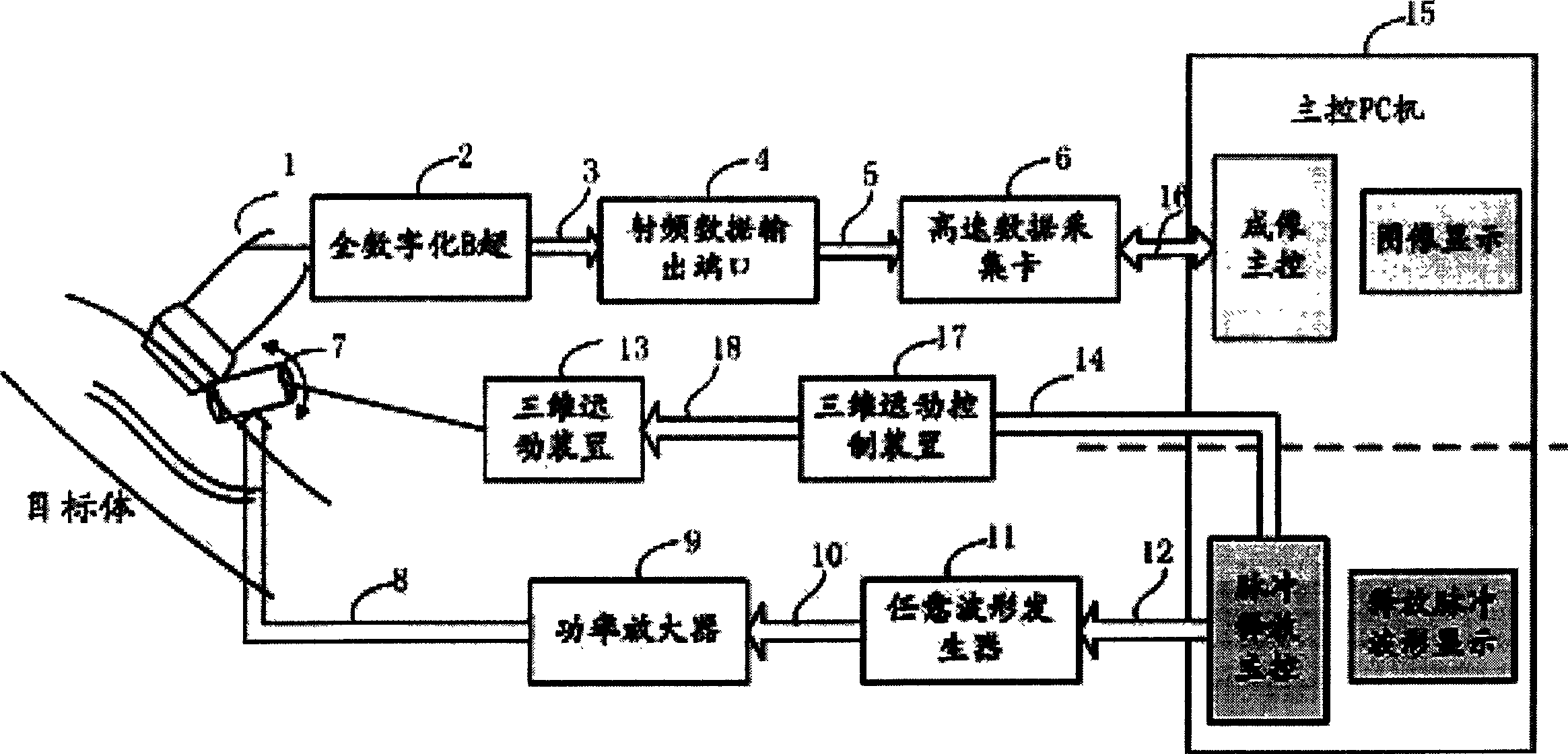

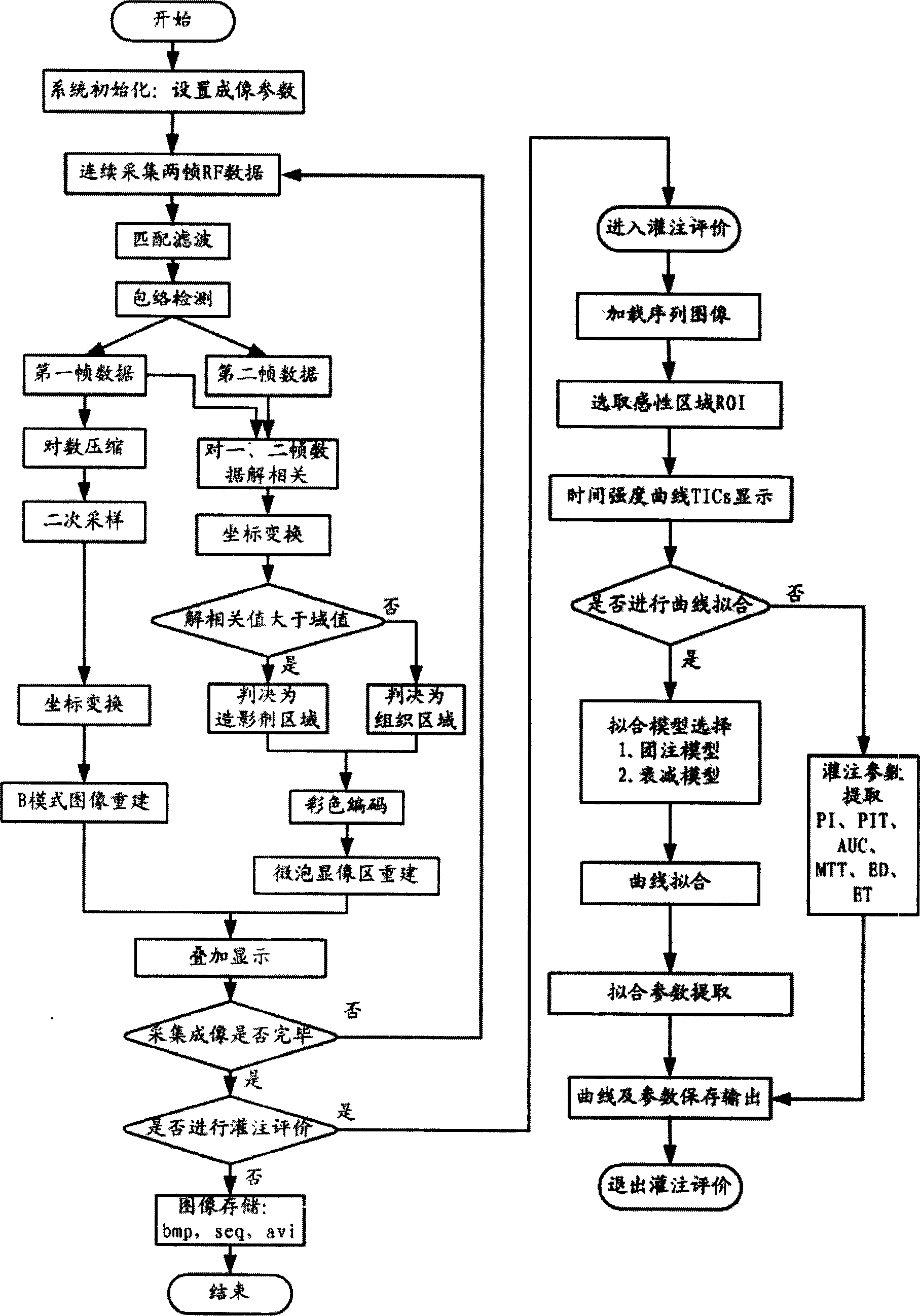

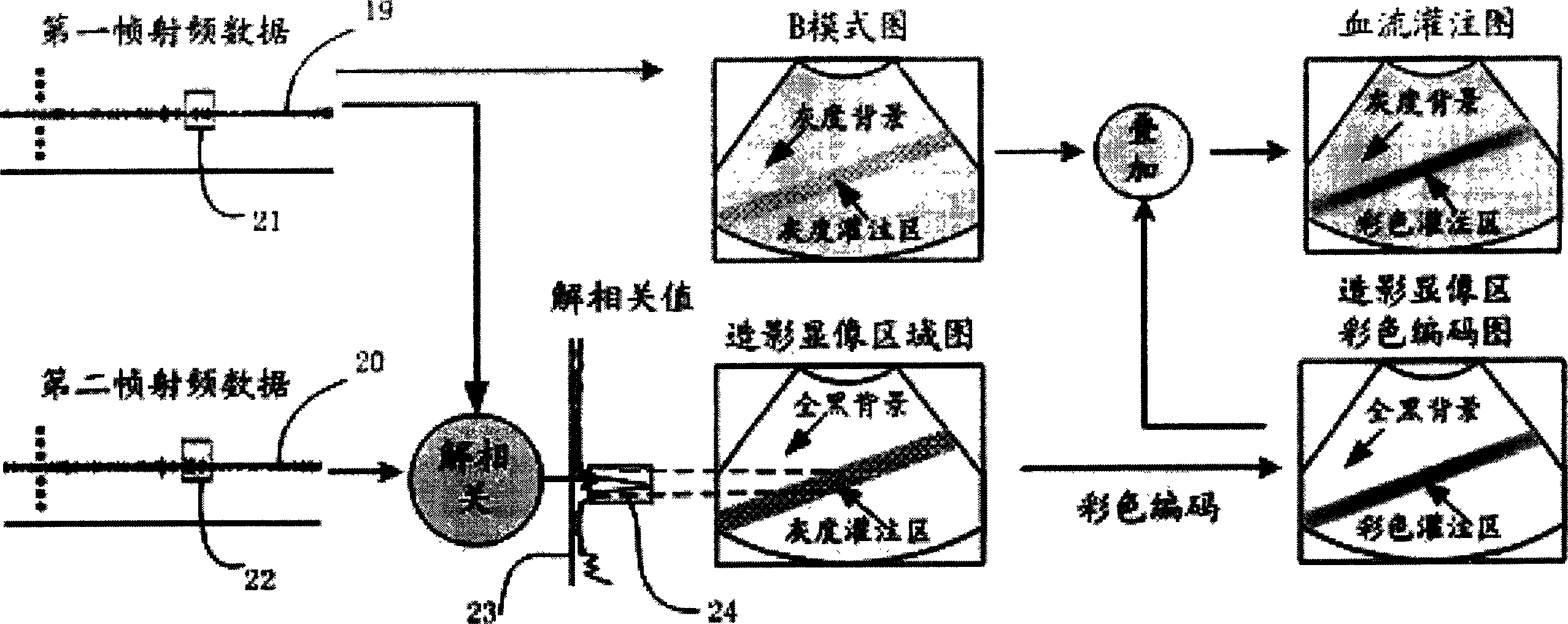

System and method of perfusion imaging and ultrasonic control releasing based-on capsule microbubble

InactiveCN1792334AAggregation easeOvercome attractionUltrasonic/sonic/infrasonic diagnosticsUltrasound therapyMicrovesicleSonification

A system based on envelope microvesicle for perfusion imaging and ultrasonic controlled release is composed of ultrasonic imaging probe, fully digitalized ultrasonography B, RF data output port, high-speed data acquisition card, PC as main controller, any waveform generator, 3D moving unit, moving controller and single-cell transducer. On the basis of fully digitalized ultrasonography B, a blood perfusion imaging algorithm is used for making a decision to obtained original RF data and performing real-time imaging. Under the guide of perfusion image, the release of envelope microvesicles is controlled.

Owner:XI AN JIAOTONG UNIV

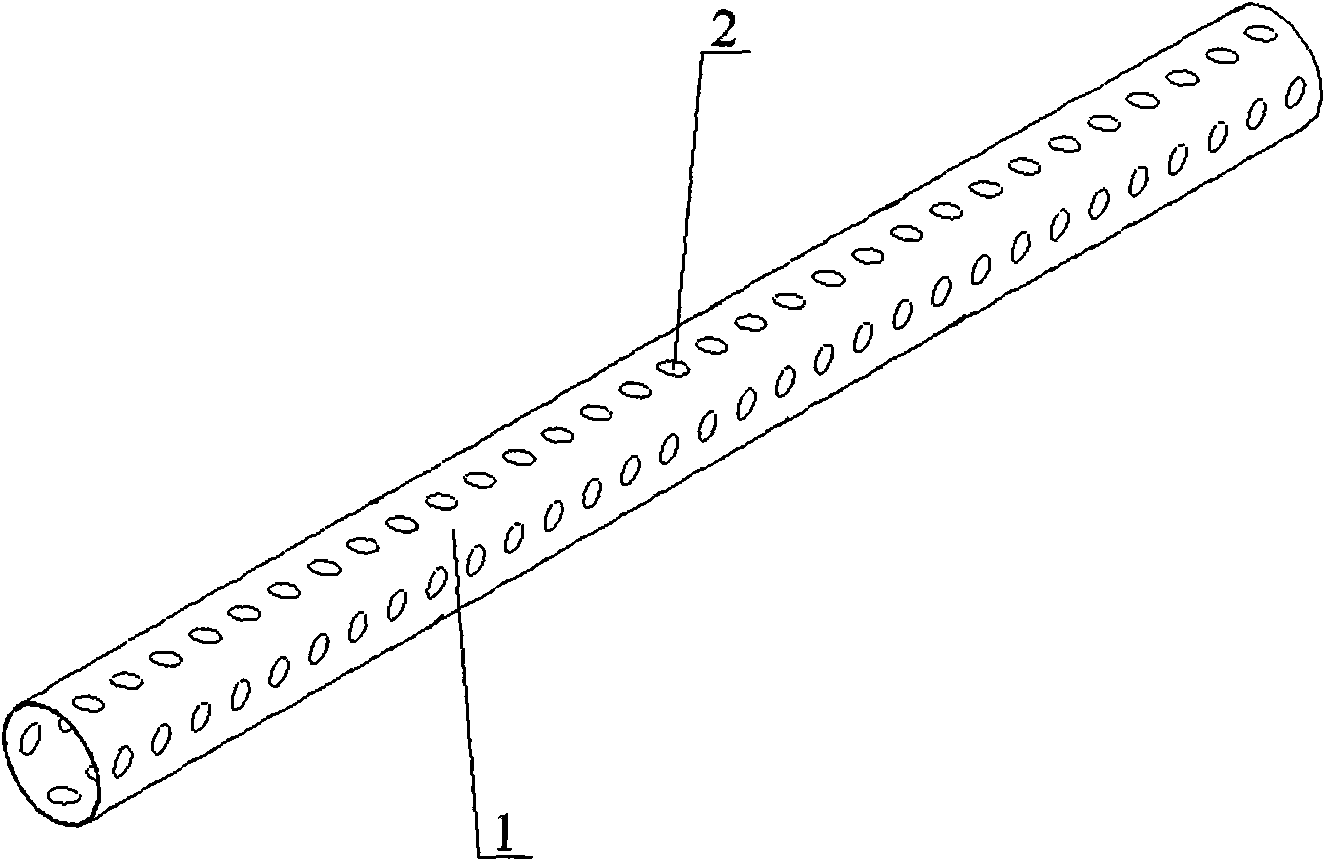

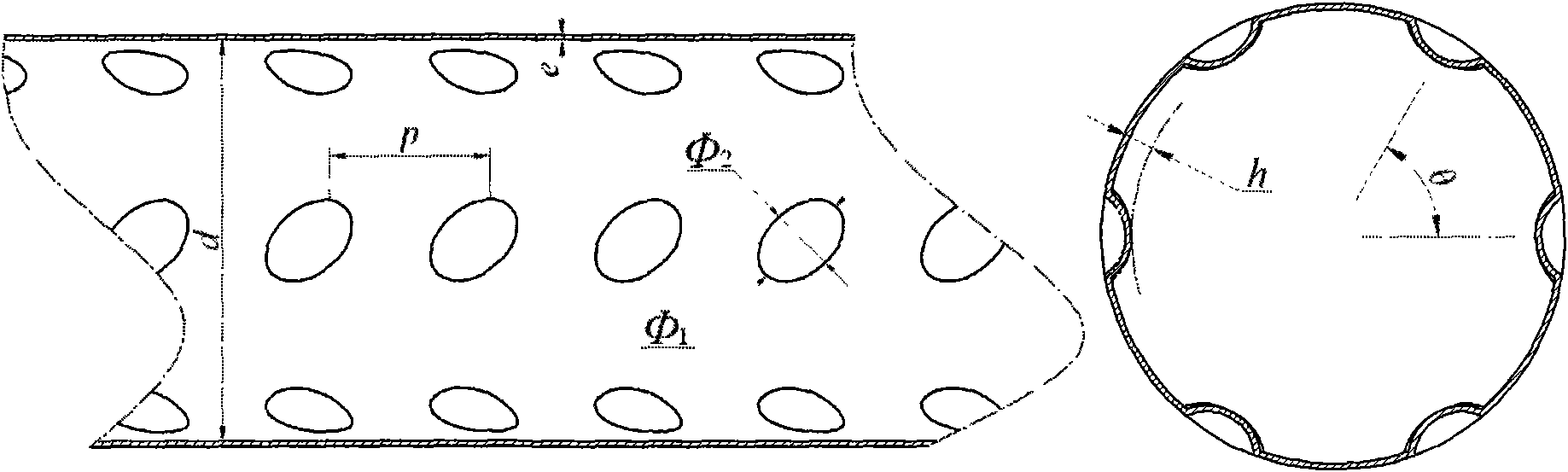

Dimpled enhanced heat exchange tube

InactiveCN101566445AReduce resistanceIncrease heat transfer areaHeat transfer modificationTubular elementsTrombe wallEngineering

The invention relates to a dimpled enhanced heat exchange tube, which comprises a base tube and dimple groups formed by ellipsoid crown type dimples which are processed from the external wall of the base tube to the inside according to certain array on the tube wall of the base tube, wherein the dimple groups are evenly distributed along the axial direction of the base tube according to certain cycle and separation distance. Because the base tube is processed with the novel dimples, the comprehensive performance of the heat exchange tube is improved compared with the former similar heat exchange tubes. The dimpled enhanced heat exchange tube has the following characteristics: 1, the ellipsoid crown type dimples increase the heat transfer area in the tube and increase the flow velocity of fluid; 2, boundary layers of the inner wall of the tube are destroyed more effectively; 3, the ellipsoid crown type dimples having certain included angle with the axial direction make the fluid generate longitudinal vortexes; and 4, the continuous changes of the cross section of the tube and the generated pressure changes increase the turbulivity of the fluid in the tube to further improve the tube side heat exchange coefficient, and while the tube side heat exchange coefficient is improved, the ellipsoid crown type dimples having certain included angle with the axial direction make the fluid generate secondary flow which has smaller increase to the fluid resistance, thus the effect of improving the comprehensive heat exchange performance is achieved.

Owner:XI AN JIAOTONG UNIV

Method for making high performance cement mixed material from flyash

InactiveCN1401606AImprove performanceAvoid using lessSolid waste managementCement productionPolymer scienceMixed materials

A flyash mixture used for preparing high-performance cement is prepared from 11 raw materials including alkaline lime material, gypsum, flyash, sodium sulfate, calcium carbonate, etc through mixing them with water, grinding, sieving, and spray drying or baking. Its advantages are high activity, multiple functions, low cost and high performance.

Owner:李国栋

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com