Dimpled enhanced heat exchange tube

A technology of heat exchange tubes and small cells, applied in the direction of tubular elements, heat transfer modification, heat exchange equipment, etc., can solve the problems of inability to enhance heat transfer, unsatisfactory effect of heat transfer enhancement, and inability to generate longitudinal vortices in fluid, etc. Achieve the effect of improving comprehensive heat transfer performance, small fluid resistance, and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

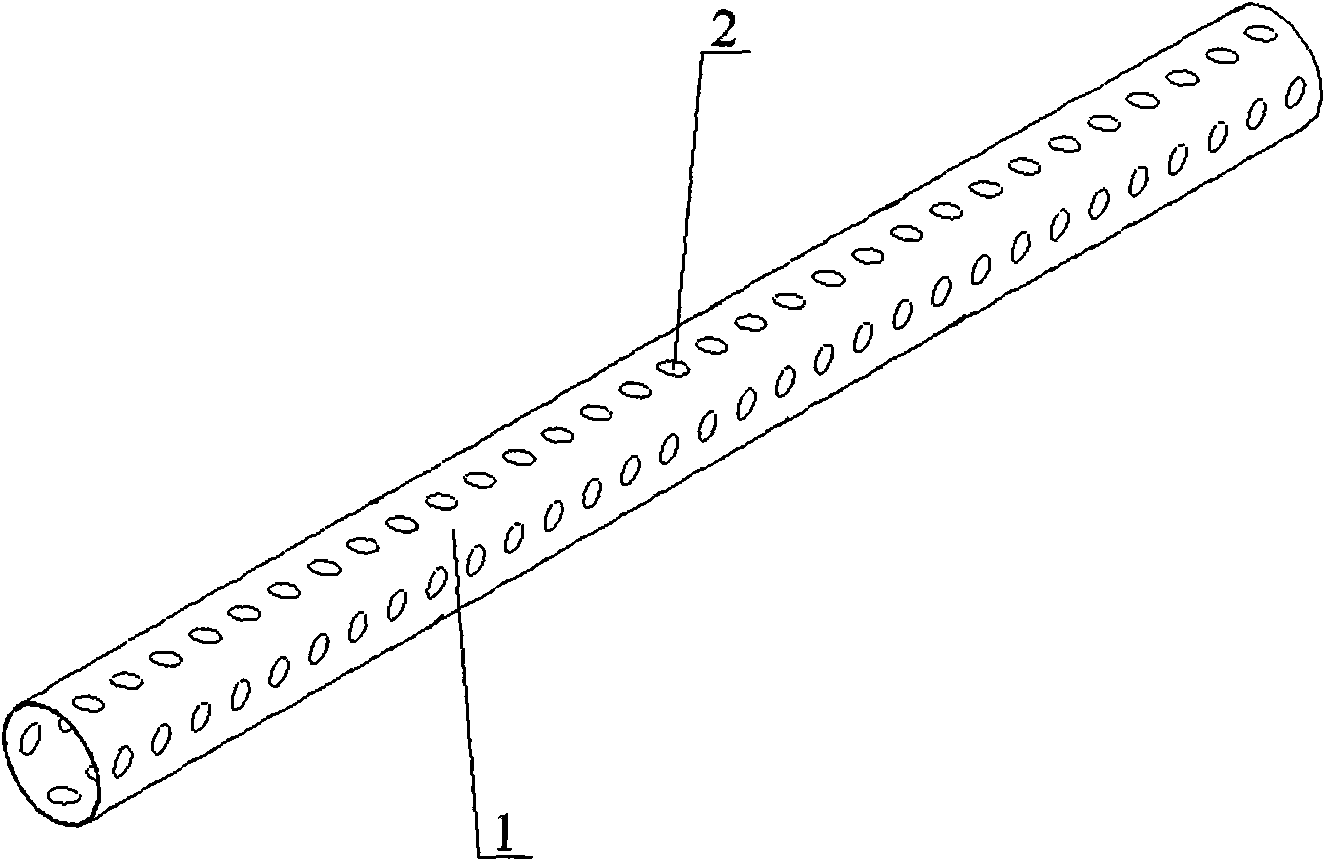

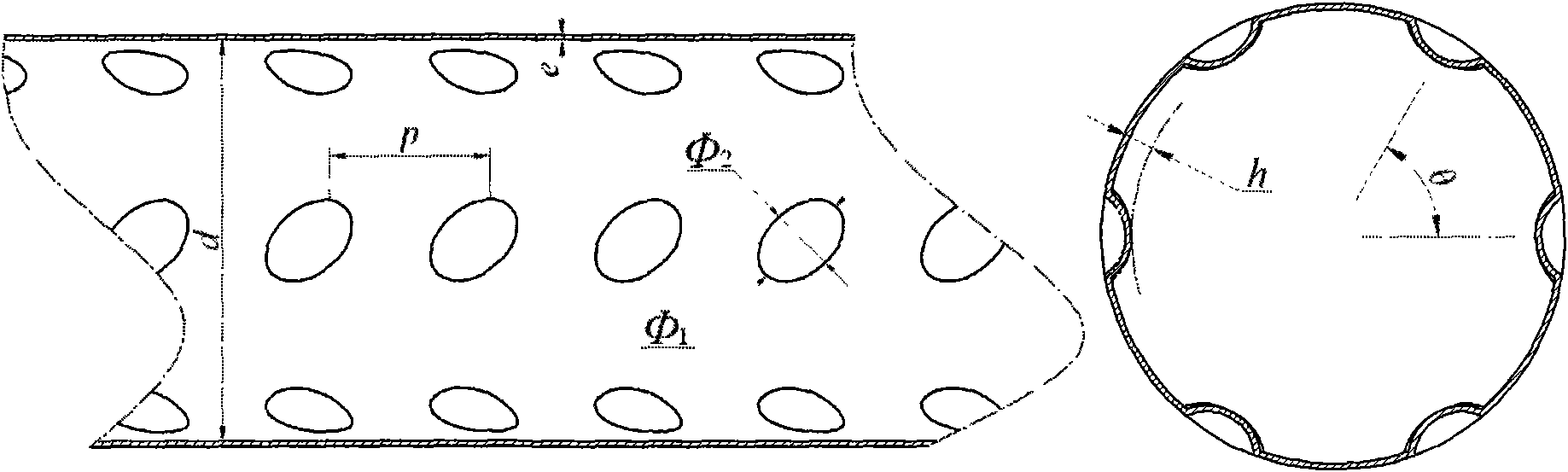

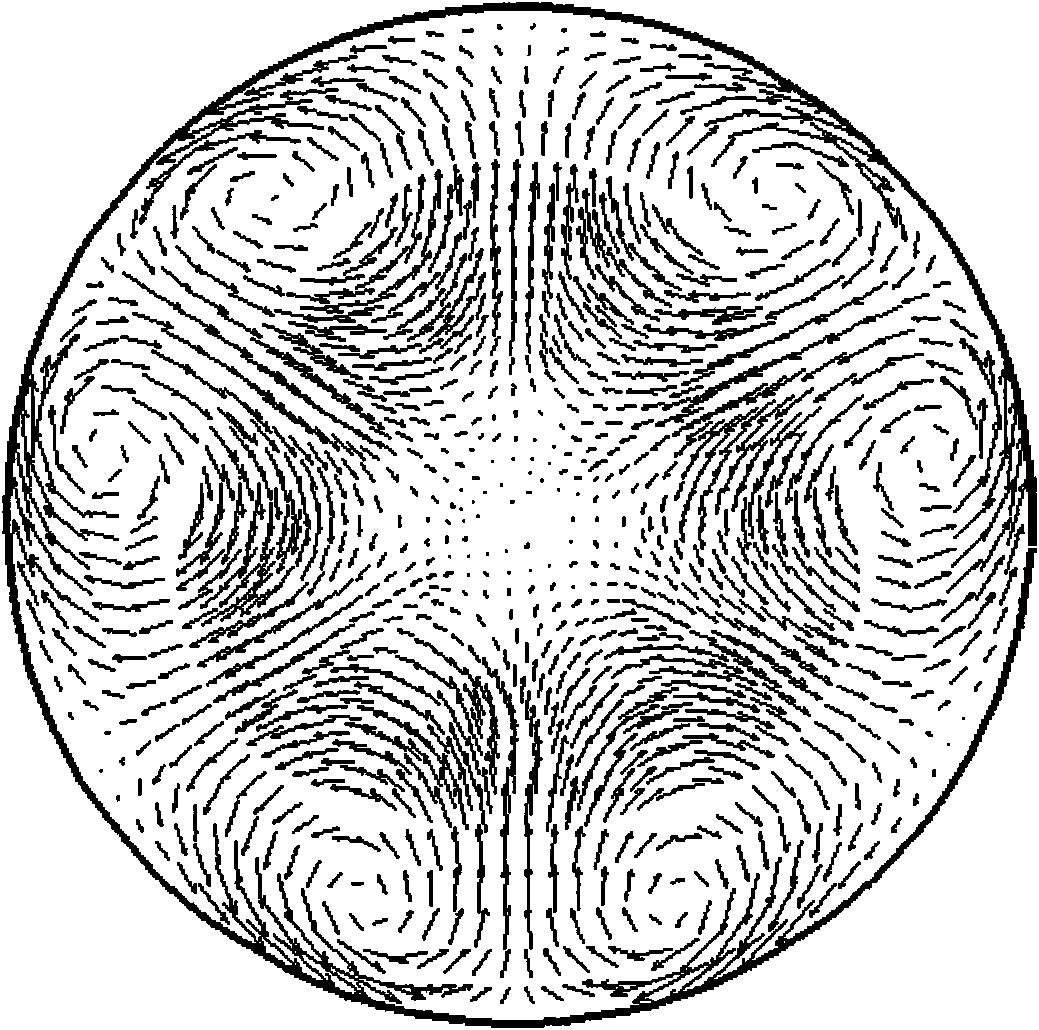

[0013] Example 1, see figure 1 , the present invention includes a base pipe 1 and a group of cytes composed of ellipsoidal crown-shaped cytes 2 protruding from the outer wall of the base pipe 1 to the inside of the base pipe 1 in a certain arrangement and circumferentially distributed on the wall of the base pipe 1, several Tetracyst groups are evenly distributed along the flow direction of the fluid in the base pipe 1 . The long axis of the ellipsoid crown-shaped cyte 1 forms an included angle of 45° with the flow direction of the fluid in the base pipe 1, and the directions of the long axes on the same circular section intersect each other; the projected length of the long axis of the ellipsoid-shaped cyte 1 is 8mm, and the projected length of the minor axis is 4mm; the angular interval θ between the ellipsoidal coronal cytes distributed in the circumferential direction of the base tube is 60°. The number of ellipsoidal corona-shaped tetracytes on the same circumferential s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com