Patents

Literature

538 results about "Exchange coefficient" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Exchange coefficient. [iks′chānj ‚kō·i‚fish·ənt] (fluid mechanics) A coefficient of eddy flux in turbulent flow, defined in analogy to those coefficients of the kinetic theory of gases.

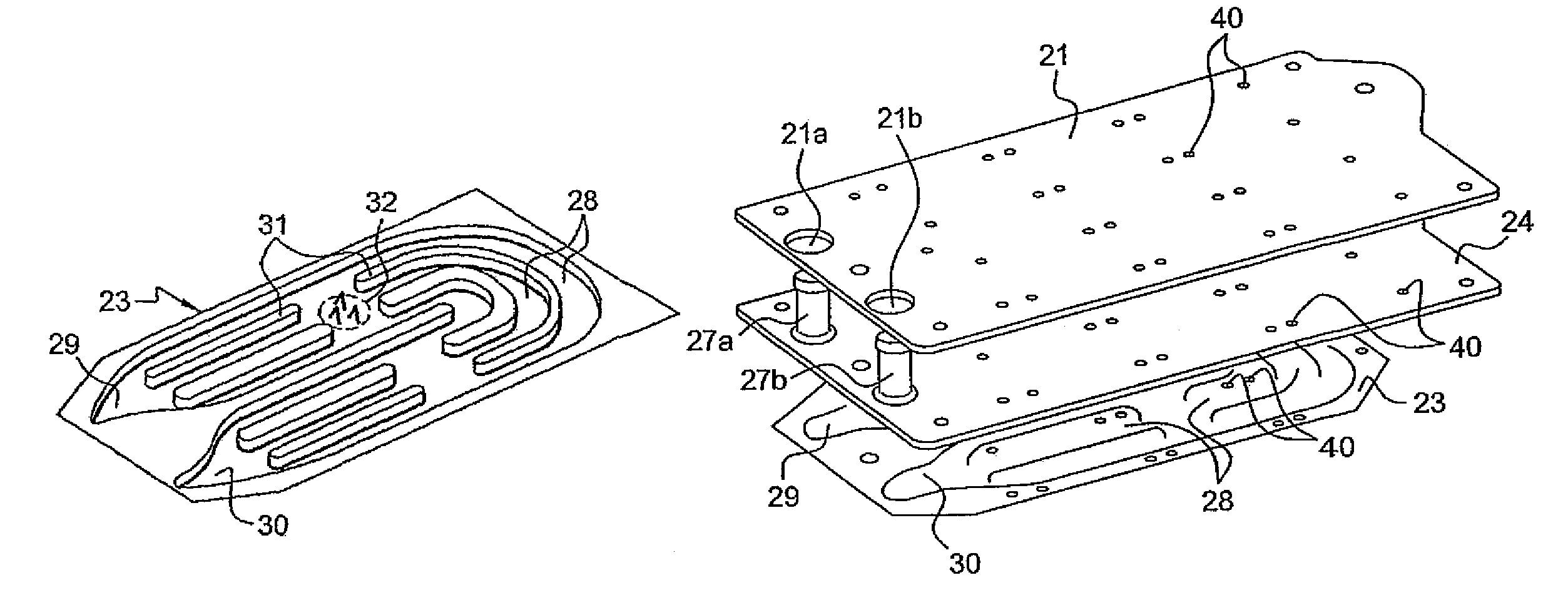

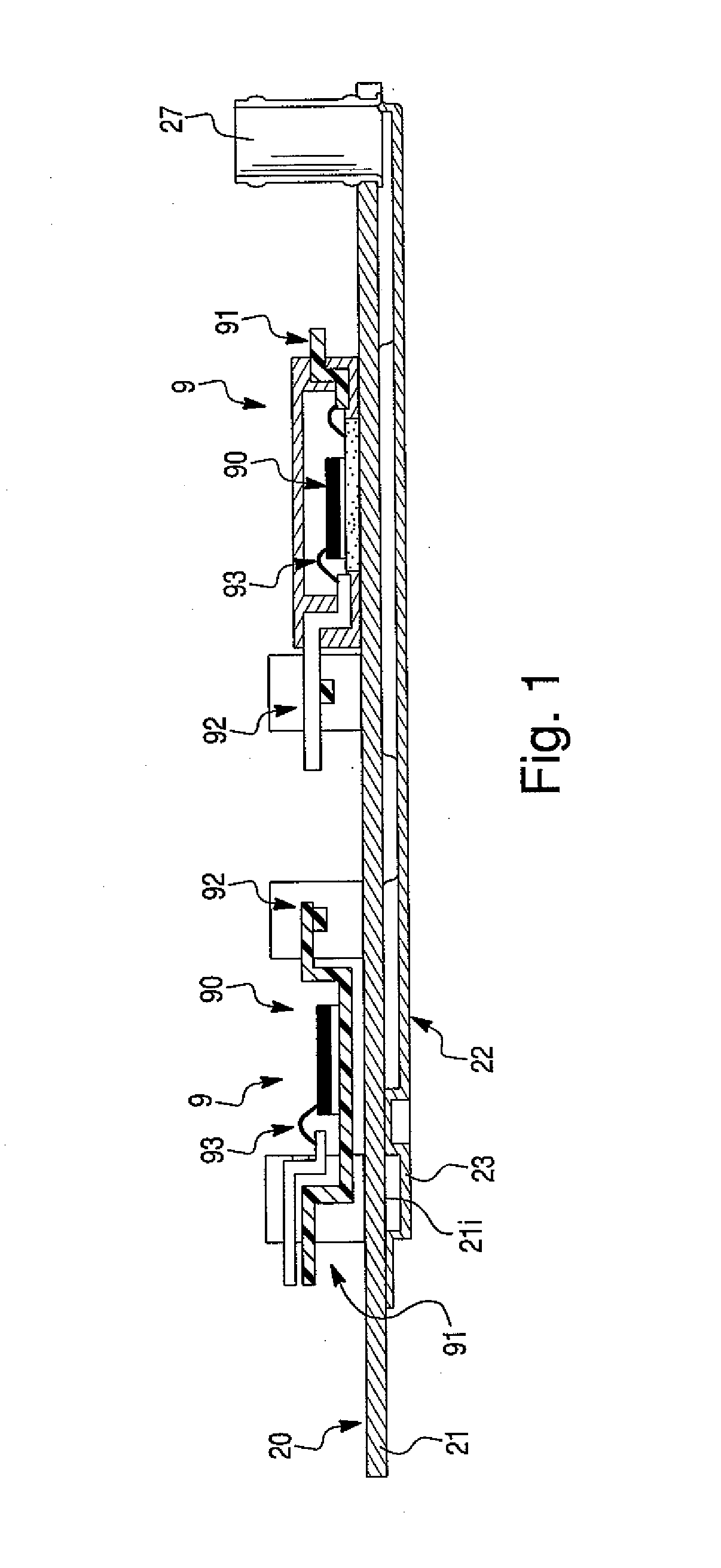

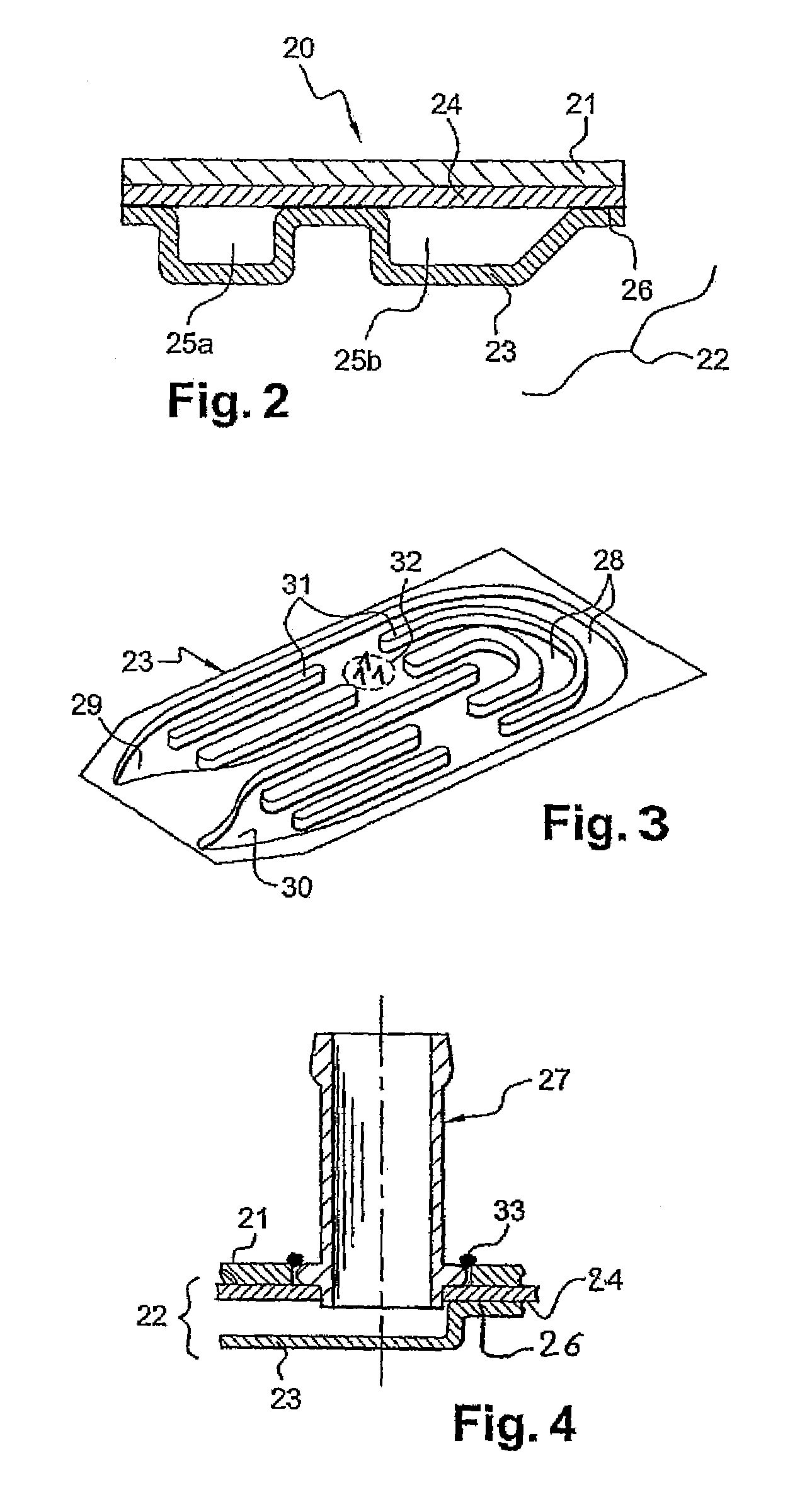

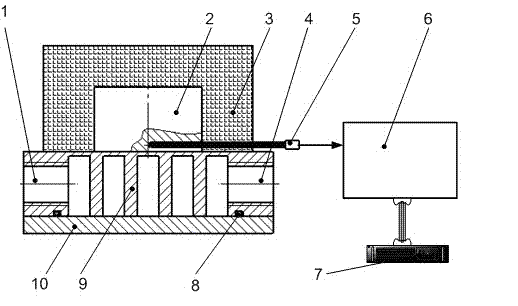

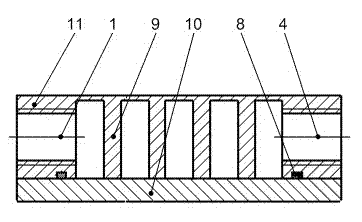

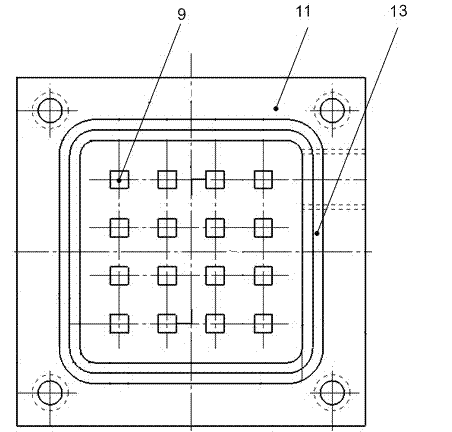

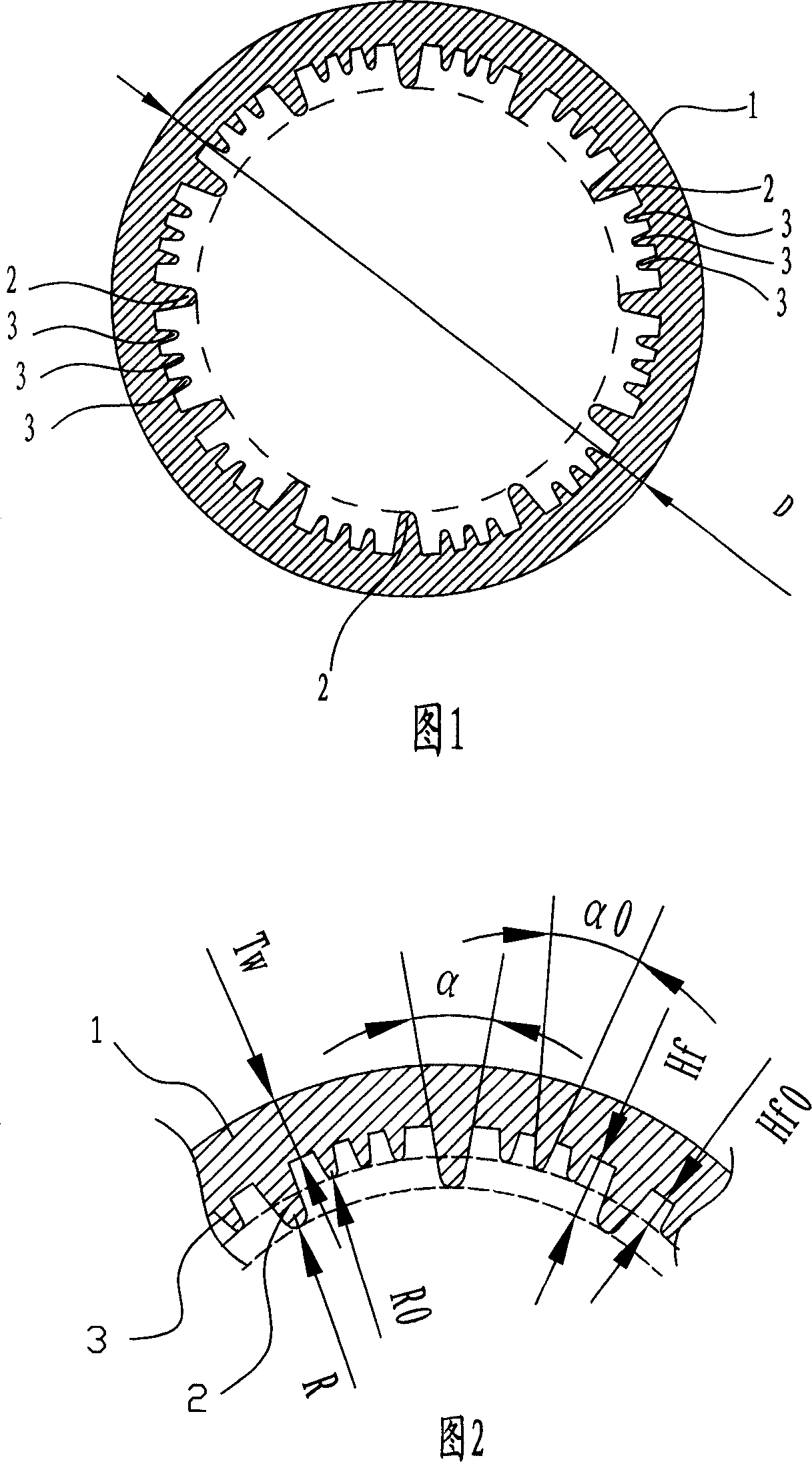

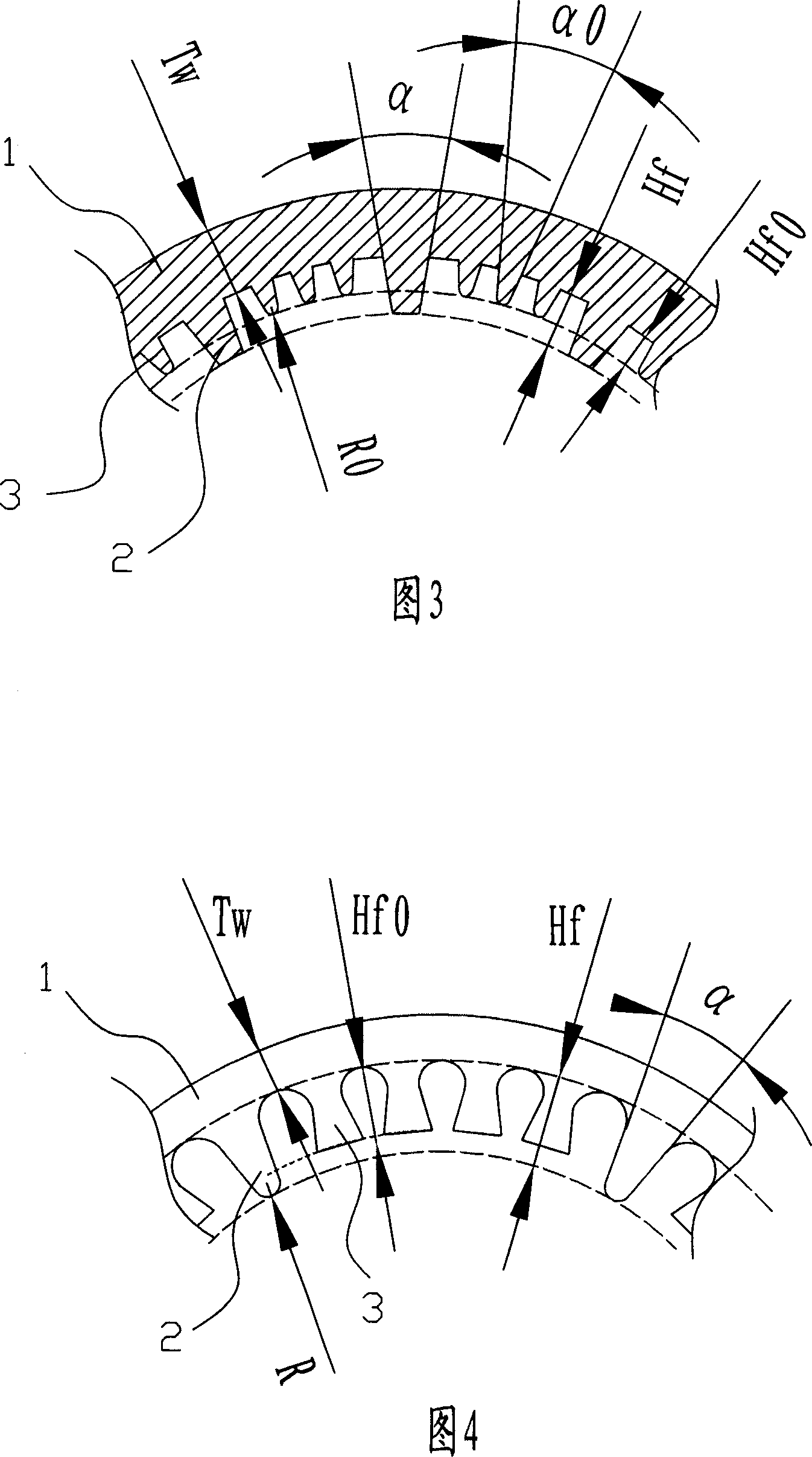

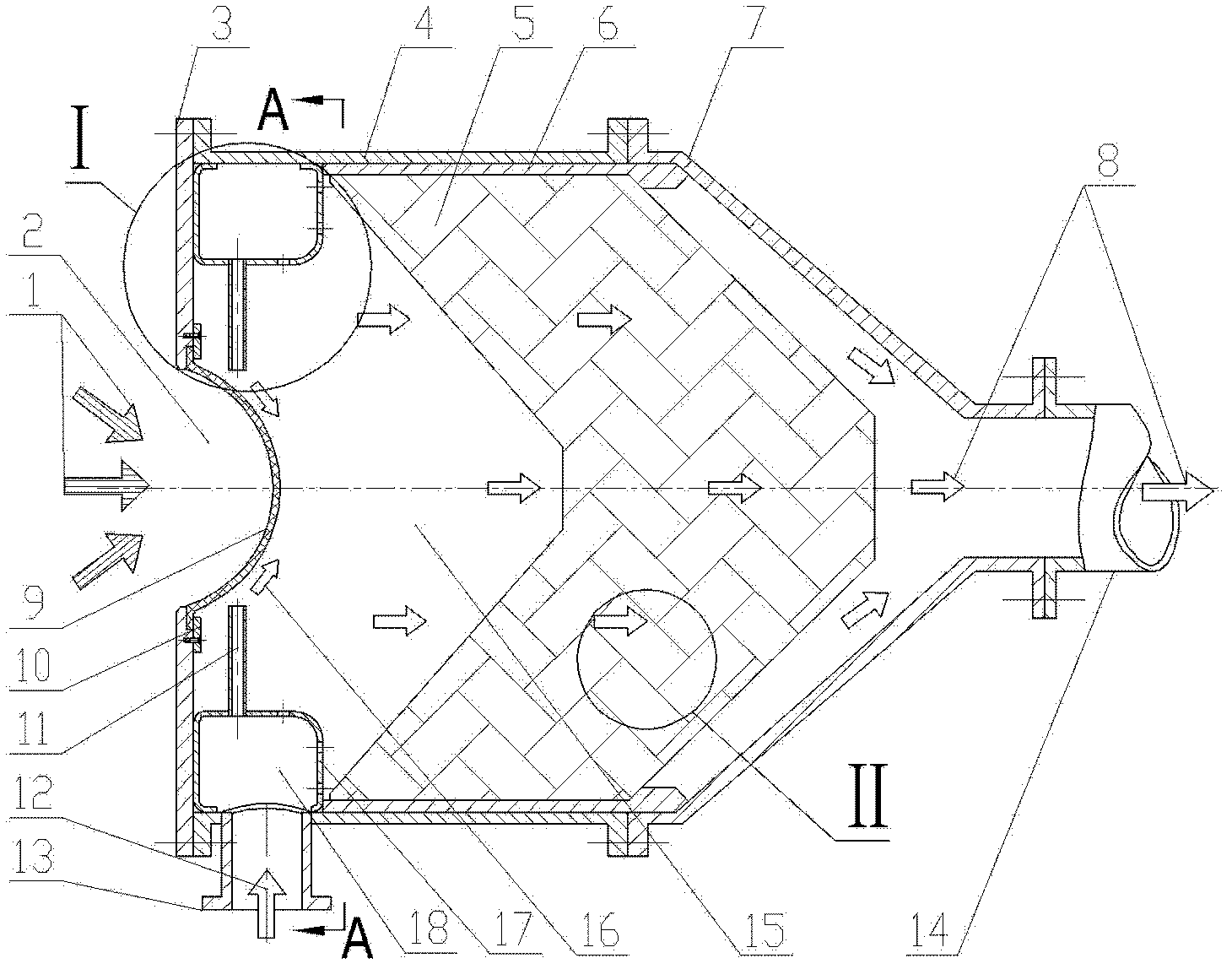

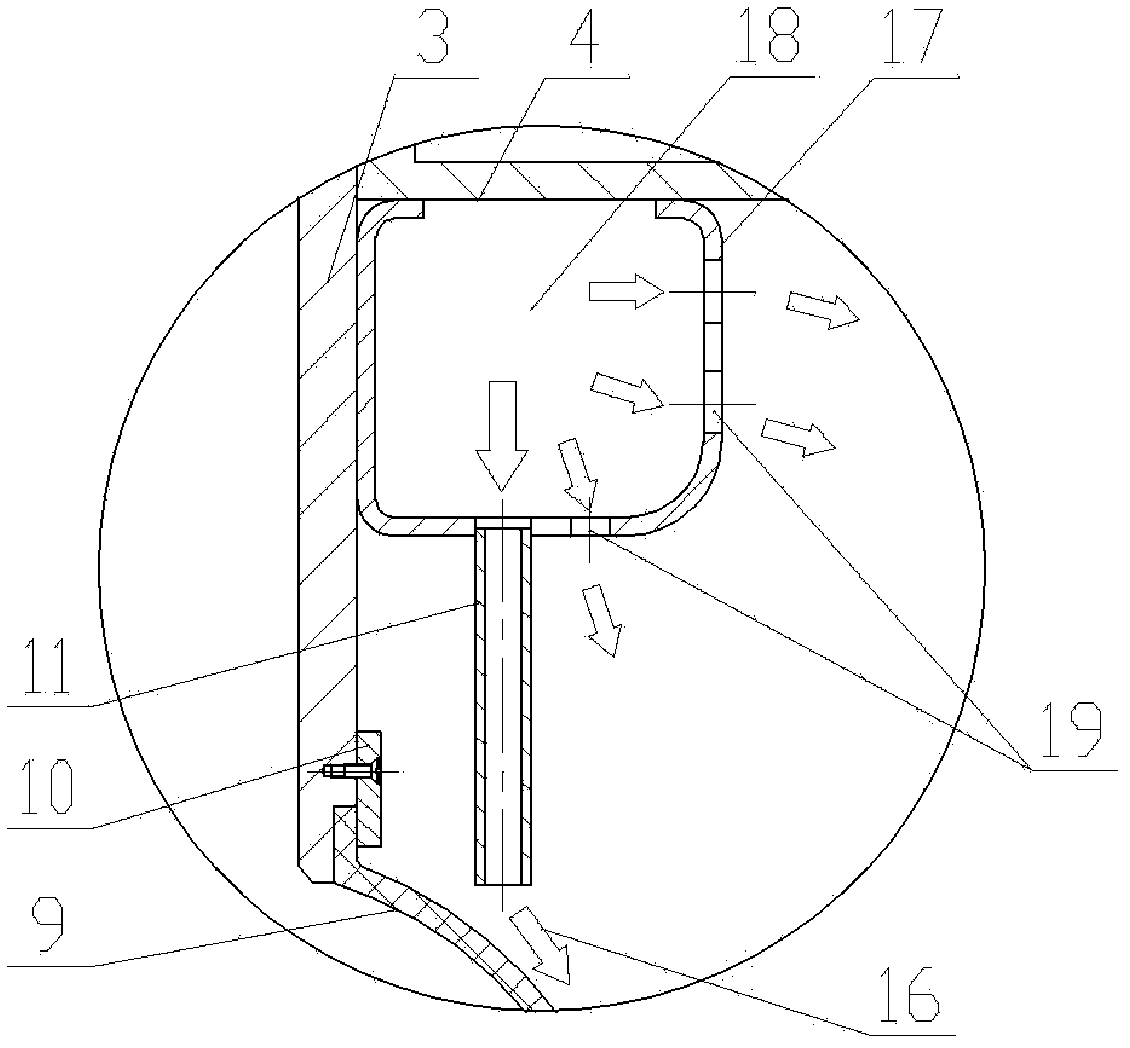

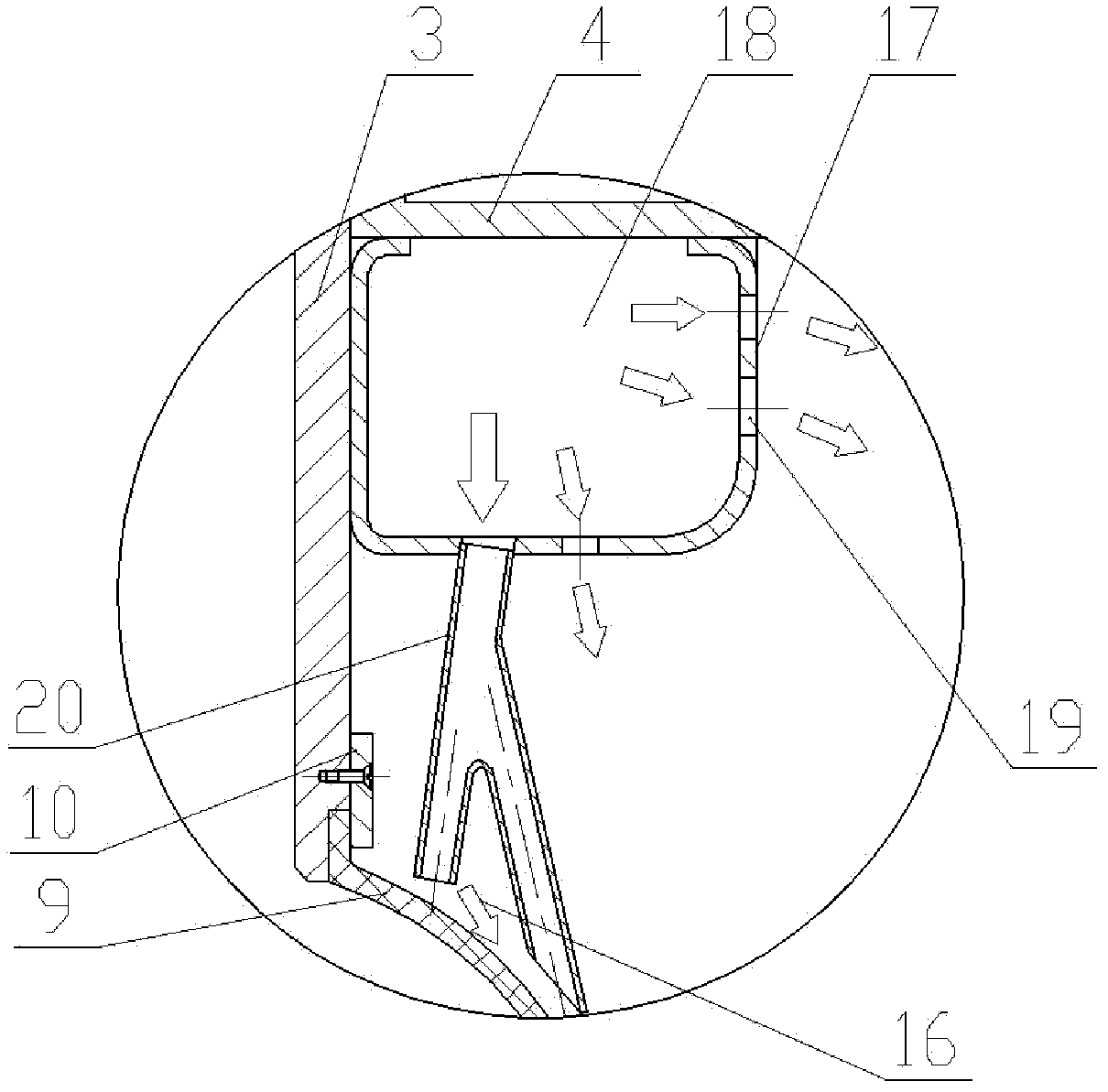

Power-electronic-cooling device

ActiveUS7417857B2Lower overall pressure dropImprove cooling effectSemiconductor/solid-state device detailsSolid-state devicesElectronics coolingEngineering

Owner:VALEO EQUIP ELECTRIC MOTEUR

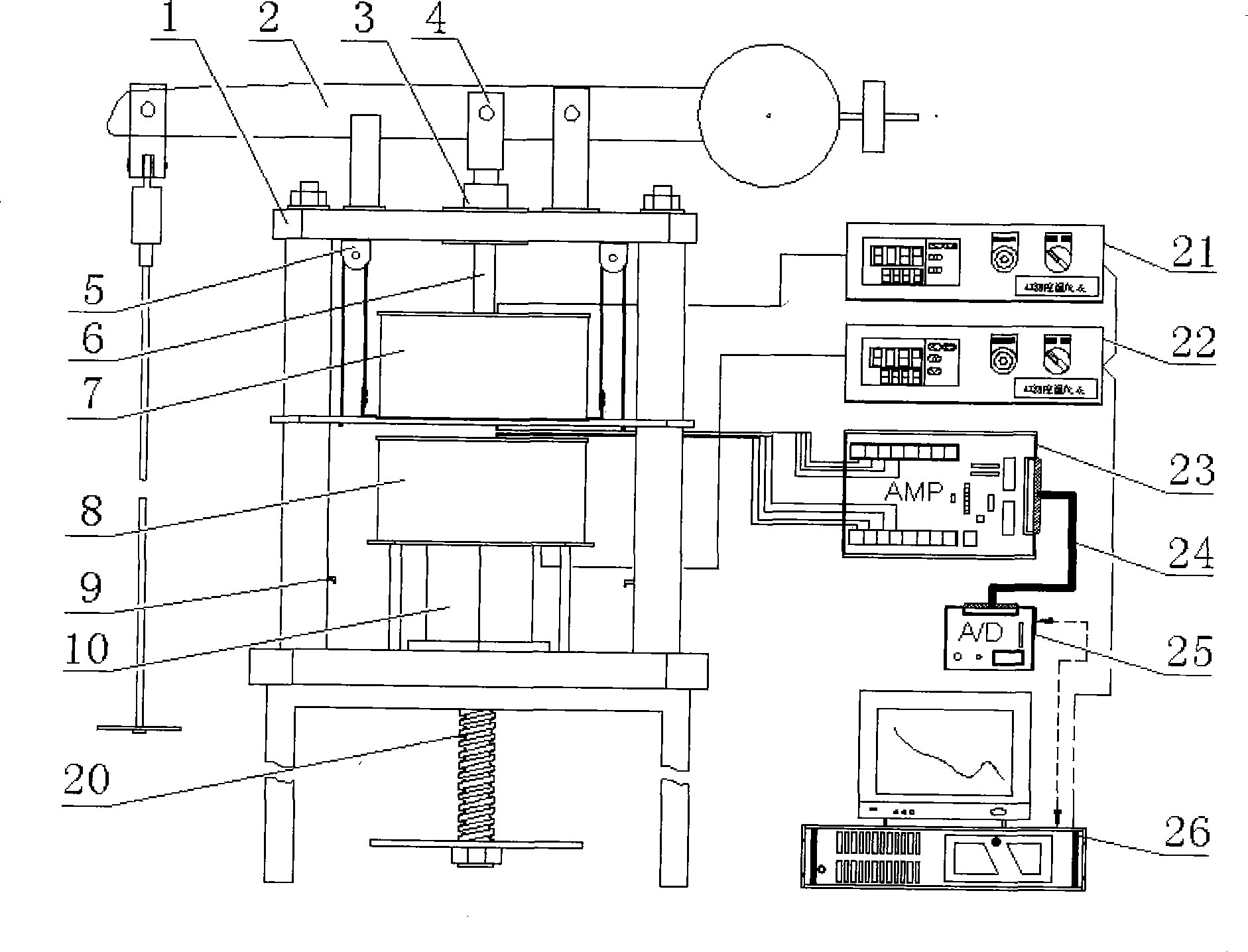

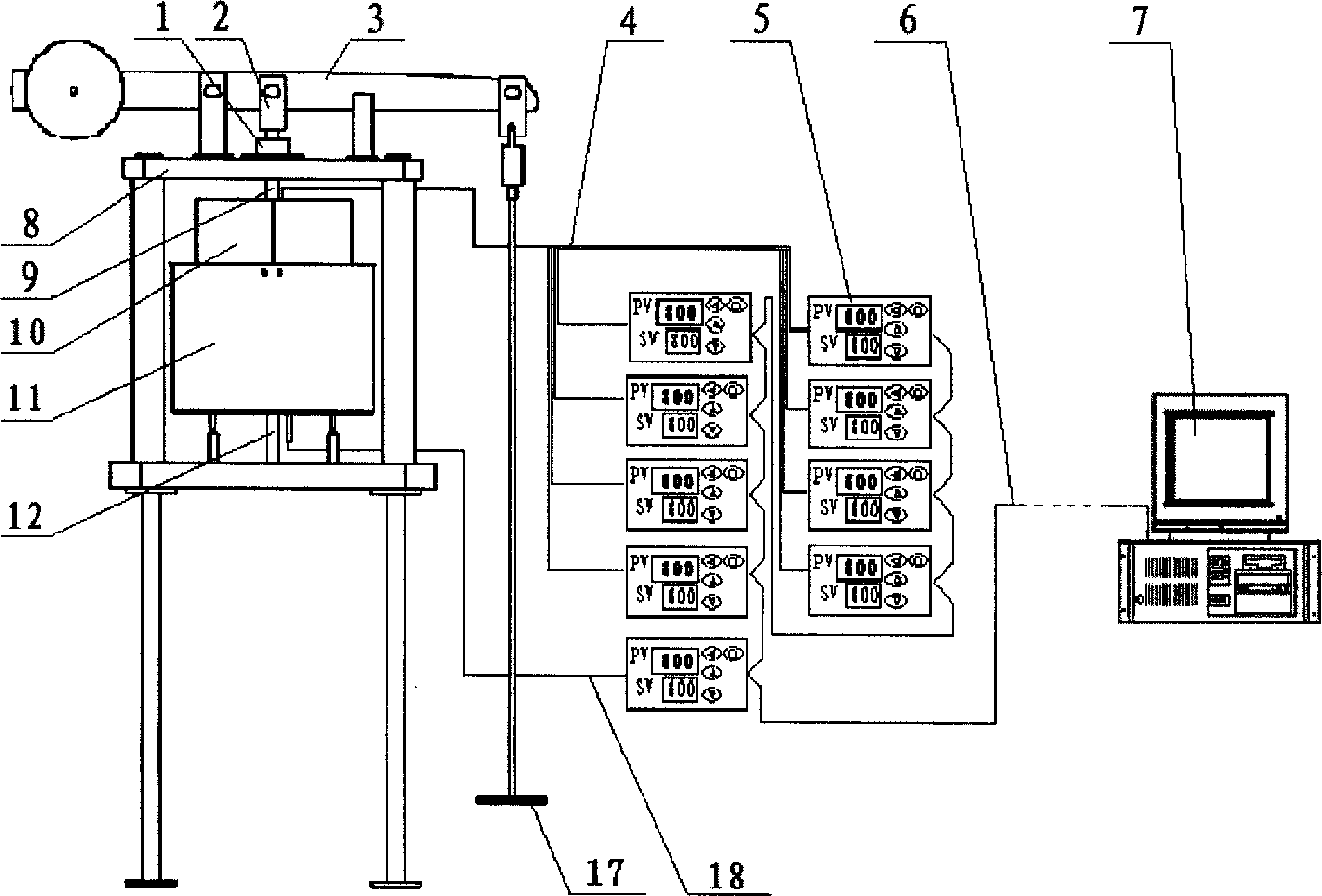

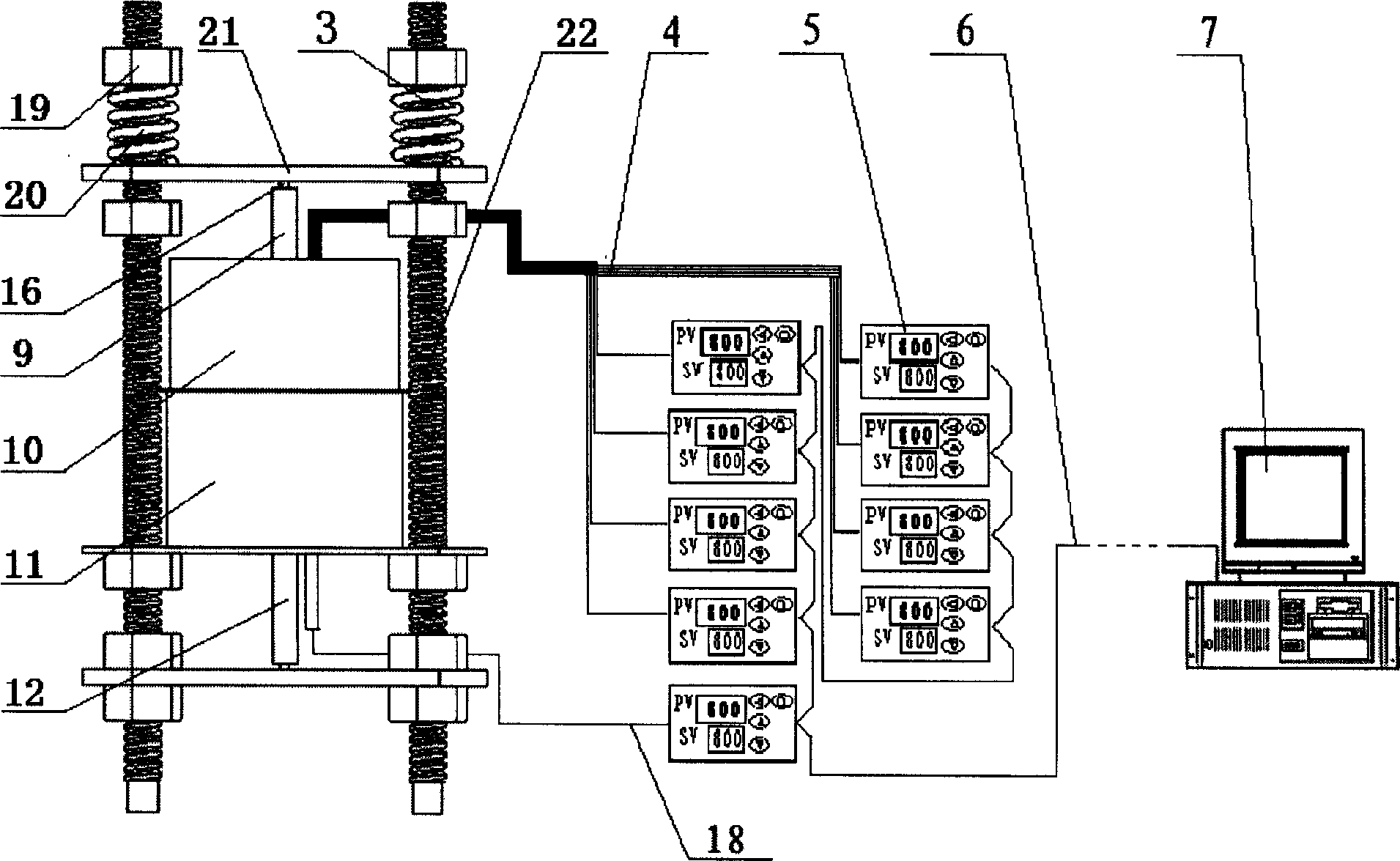

Solid interface contact heat exchange coefficient measurement method and apparatus based on transient method

InactiveCN101393150ARealize dynamic contactHigh heating temperatureMaterial thermal conductivityMaterial heat developmentEngineeringHigh heat

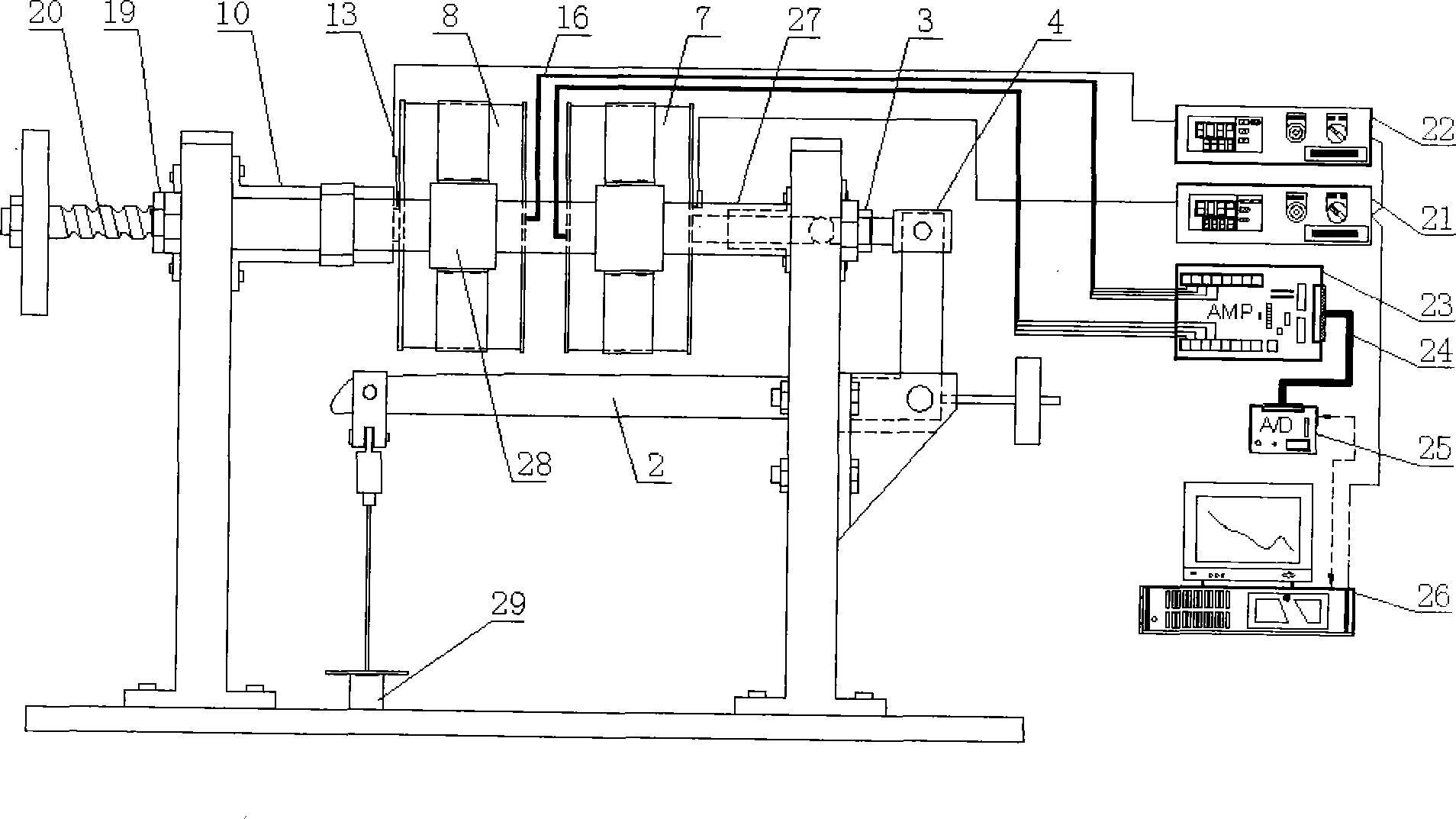

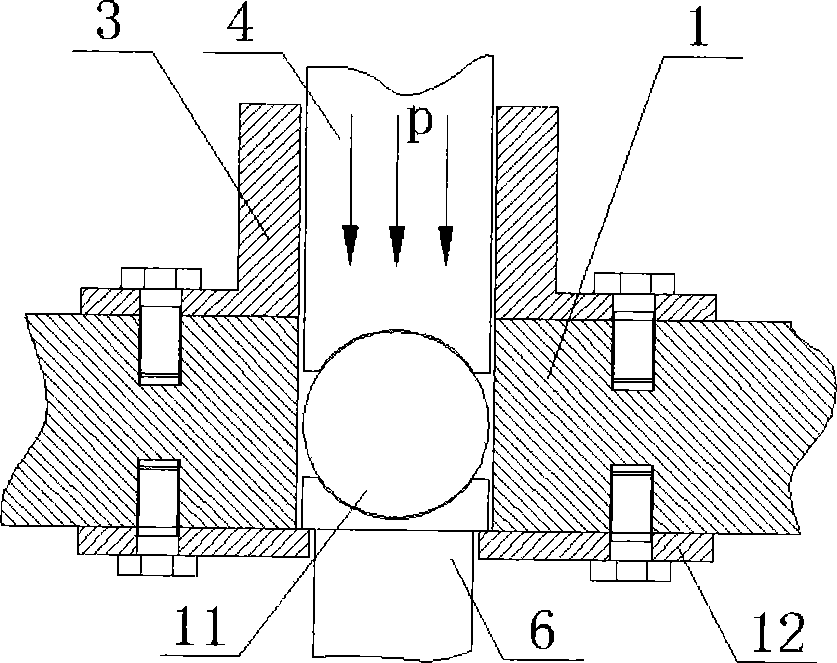

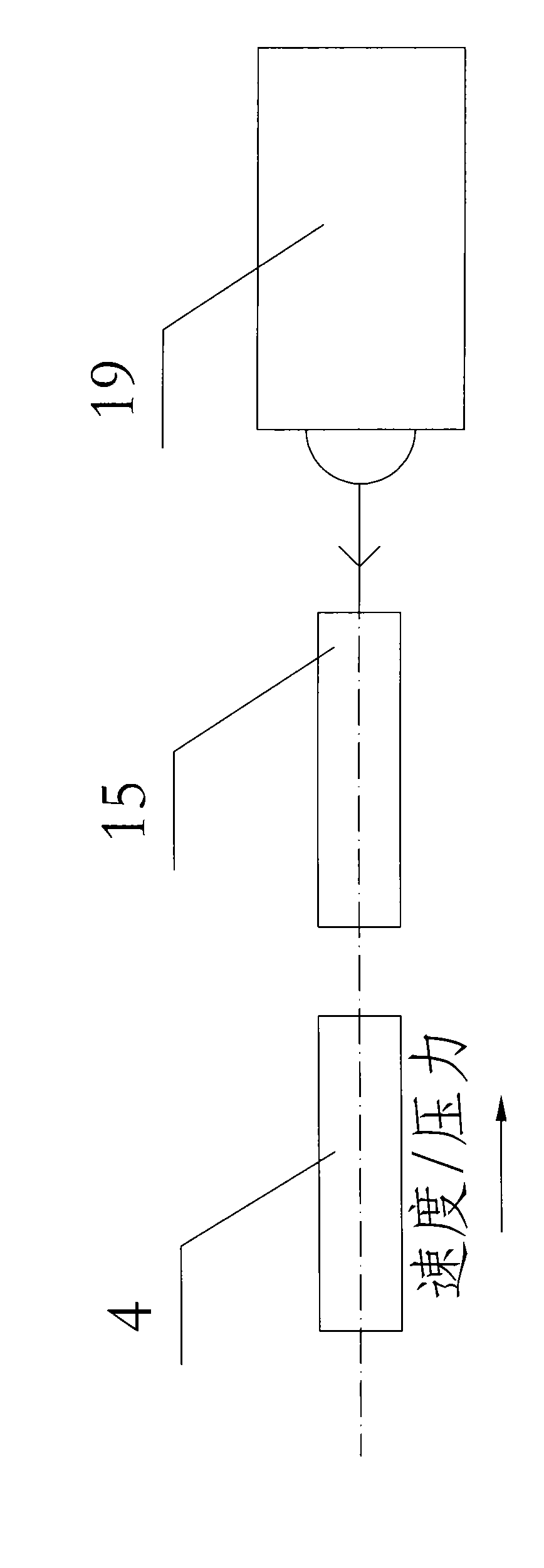

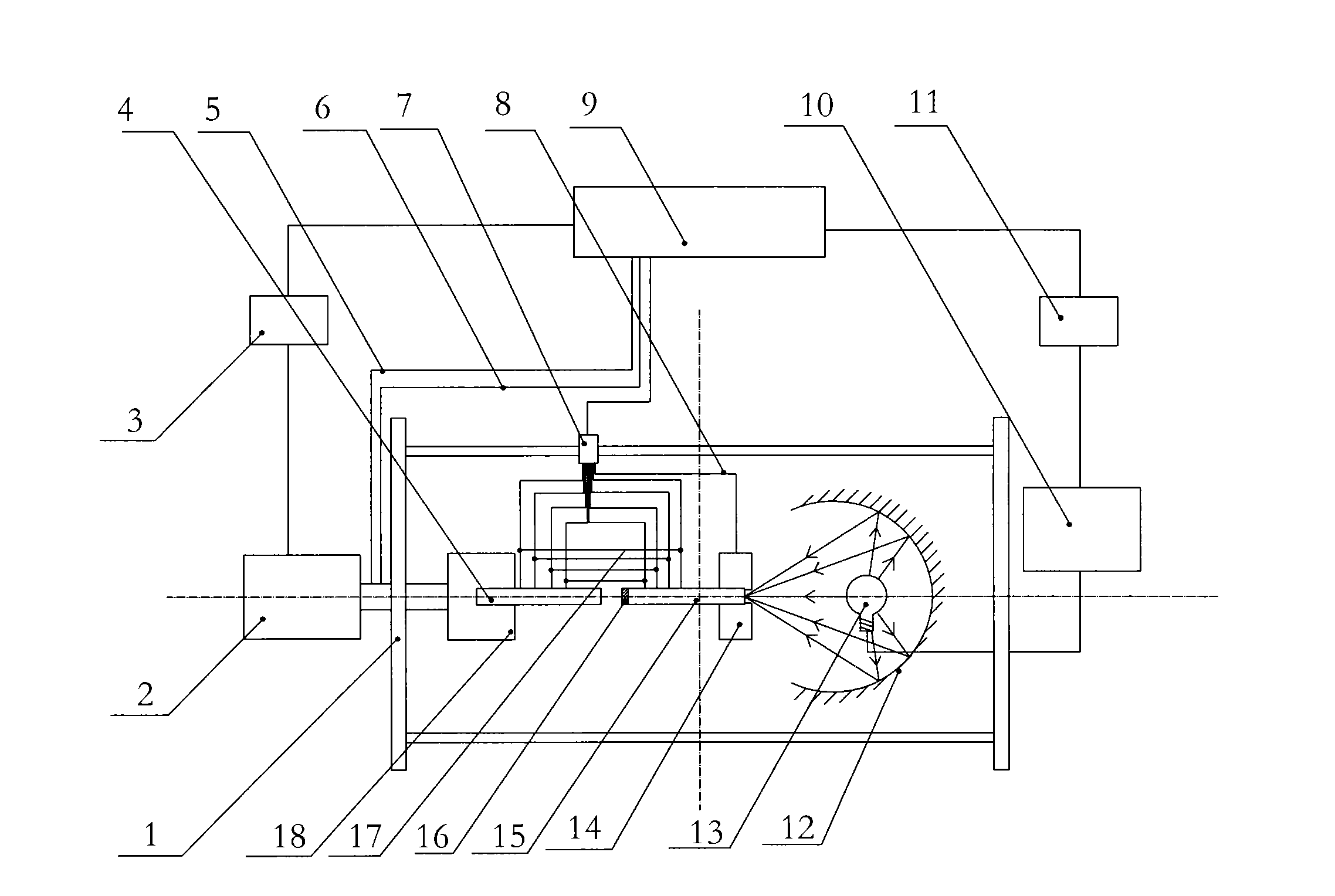

The invention relates to a method and a device for measuring solid interface contacted heat transfer coefficient based on a transient method. The method comprises the following steps: a lever loading device 2 is connected with a pressure turning joint 4, a centering ball 11, a low temperature sample connecting rod 6 and a low temperature sample 14 in turn from the top to the bottom; a positioning block bears pressure in advance; and a thread transmission shaft 20 pushes a high temperature sample 15 out of a heating furnace through a high temperature sample supporting rod 17, contacts and jacks up the low temperature sample 14 to transfer the pressure to the contact surface. A temperature control thermocouple 13 of the heating furnace is connected with a program control meter, the output end of the program control meter is connected in parallel and then is connected with an industrial computer 26 through an RS232 converter, a temperature detecting thermocouple 16 is connected with a preposition multi-path gate amplifier 23 and an A / D converter plate 25 in turn to acquire and process temperature signals of measured points in real time as well as compile a FORTRAN calculation module by applying a counter heat transfer arithmetic. The method has the advantages of high measuring temperature, quick acquisition and practical measuring principle, and is suitable for the research field of solid thermal processing.

Owner:DALIAN UNIV OF TECH

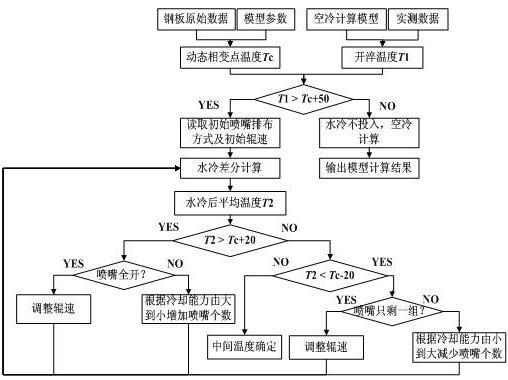

Method for controlling medium plate quenching technology

ActiveCN102399950AImprove calculation accuracyFlexible cooling strategyFurnace typesHeat treatment process controlHeat conductingModel parameters

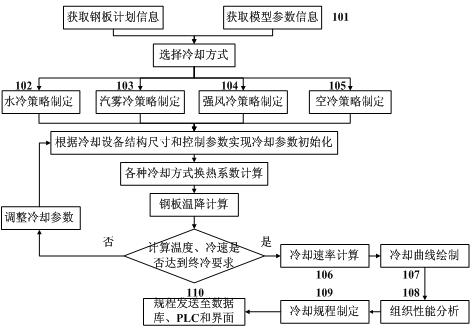

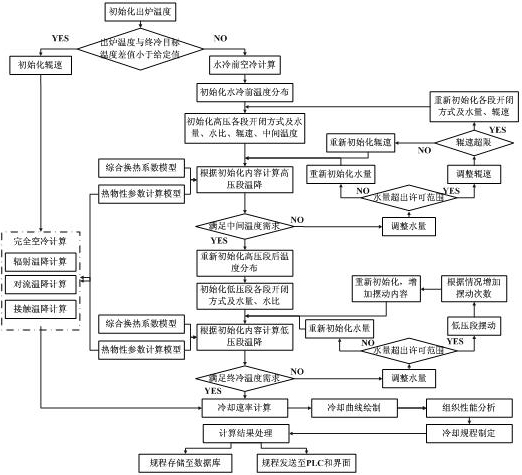

The invention discloses a method for controlling a medium plate quenching technology. The method comprises formulation of steel plate quenching strategies, model calculation of quenching parameters and formulation of quenching regulations, namely comprises the following steps of: according to steel plate planning information and model parameter information, automatically selecting one of four quenching manners, namely water cooling, haze cooling, strong wind cooling and air cooling, and formulating corresponding cooling strategies; calculating a comprehensive heat exchange coefficient of the surface of the steel plate according to the structural size of cooling equipment and control parameter initialized cooling parameters; calculating the temperature drop of the steel plate according to a heat conducting equation by combining a thermo-physical parameter model, and continually optimizing the quenching parameters till the cooling rate and the final cooling temperature reach target values; and finally performing structure property analysis and cooling regulation formulation, and sending the calculated regulations to a database, a programmable logic controller (PLC) and an interface. The method is flexible in cooling strategy formulation and high in cooling regulation calculation precision, and well solves the problems that the control precision of the medium plate quenching process is low, the performance of the quenched steel plate is unqualified and the like.

Owner:NORTHEASTERN UNIV

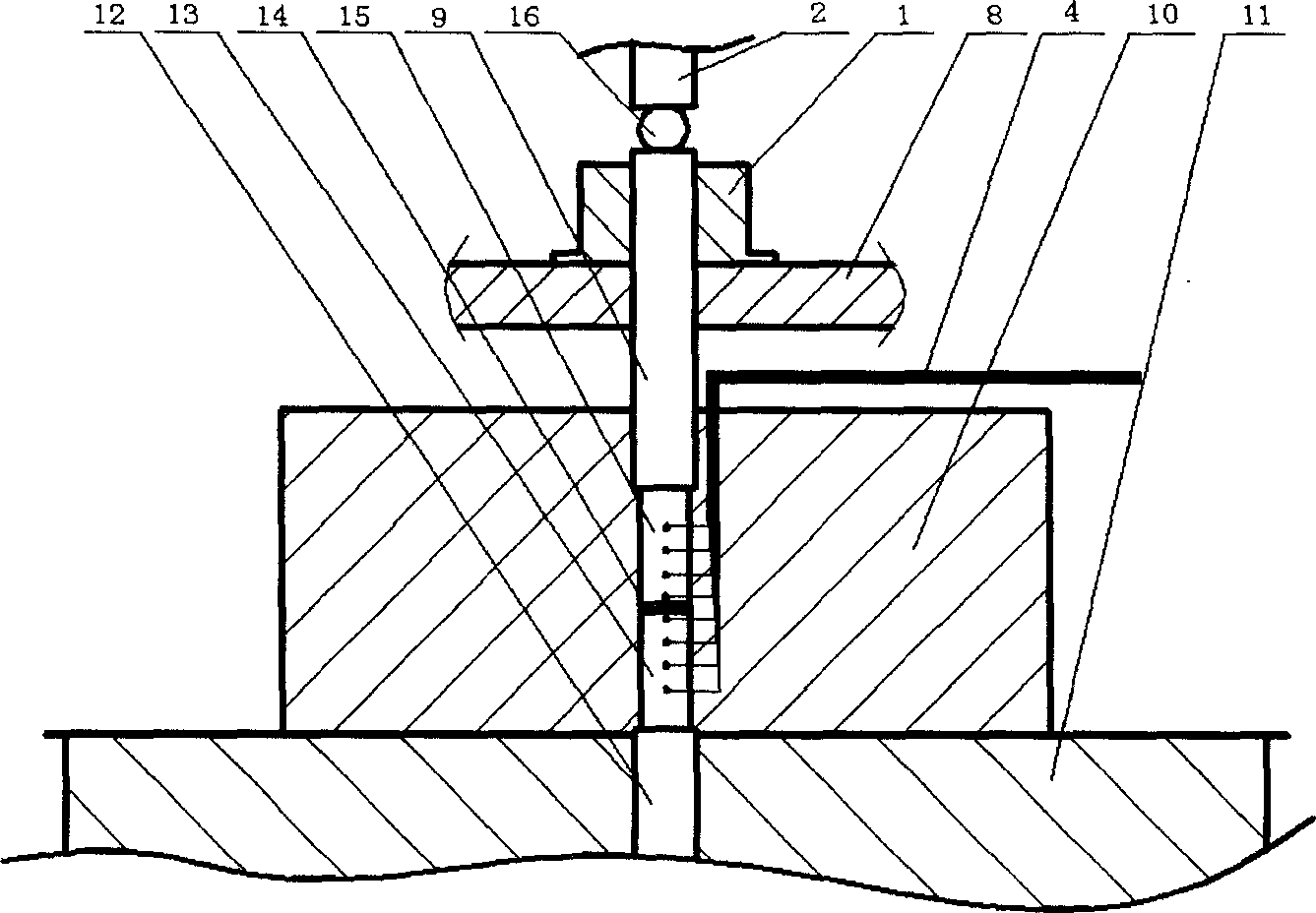

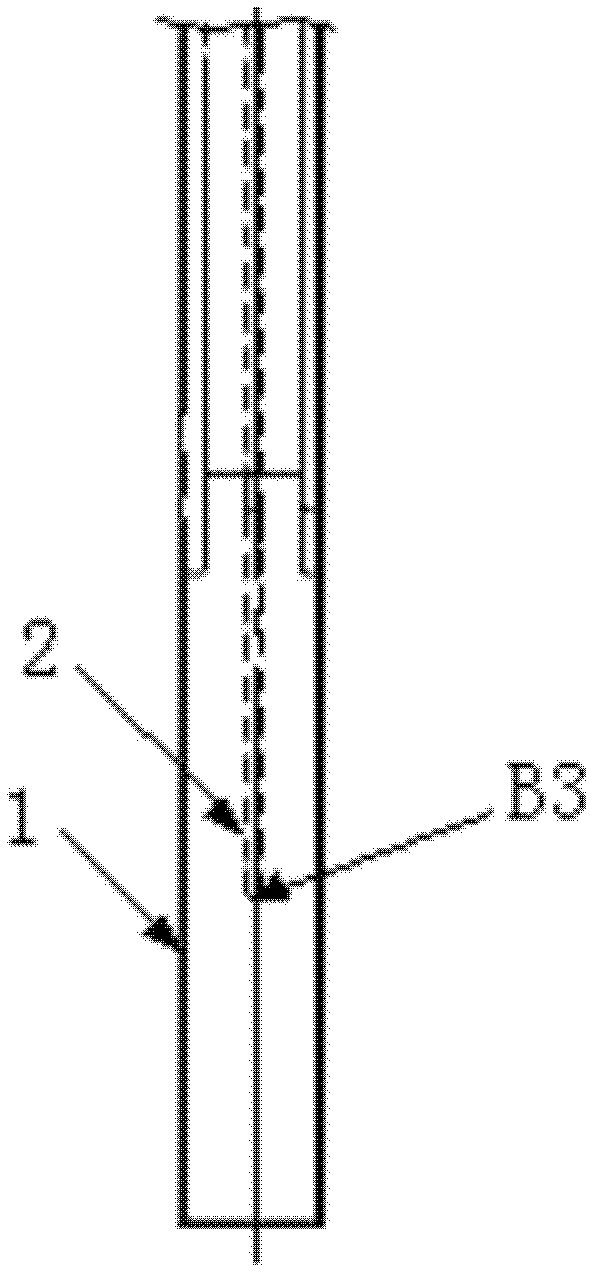

Method and apparatus for measuring solid interface contact heat exchange coefficient

InactiveCN1877313ANo added precision requiredLow costMaterial thermal conductivityMaterial heat developmentTemperature controlTemperature difference

Disclosed are a method and a device for measuring contact heat transfer coefficient on the solid interface. The method comprises connecting heating bar 12, the first sample 13, thin slice 14, the second sample 15, cold-trim bar 9, centring steel ball 16, pressure device 3 in sequence; adding corresponding thin slice 14 between the contacting surface of the two samples; increasing the number of contacting surface and enlarging temperature difference of the contacting surface; connecting the input terminals of thermal couple 4 and temperature control meter 5, and parallel the output terminal of the temperature control meter 5 with the industrial control machine 7 via the RS232 converter; heating the heating bar 12 with the heating stove 11, adding an asbestos heat insulating layer 10 around the sample to insulate heat; the industrial control machine 7 collecting temperature signal via the temperature control meter 5, displaying and analyzing.

Owner:DALIAN UNIV OF TECH

Regenerative dehumidification heat exchange device

ActiveCN101699177AImprove utilization efficiencyImprove qualityLighting and heating apparatusCoatingsDesiccantEngineering

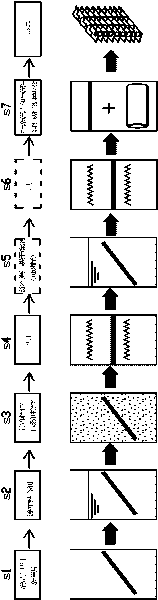

The invention relates to a regenerative dehumidification heat exchange device belonging to the technical field of refrigeration. The dehumidification heat exchange device comprises a cooling system, a heating system and a dehumidification heat exchange system, wherein the dehumidification heat exchange system is divided into a processing zone and a regeneration zone; the three systems are connected through pipelines; the processing zone of the dehumidification heat exchange system is connected with the cooling system through a pipeline, and the regeneration zone of the dehumidification heat exchange system is connected with the heating system through a pipeline; and continuous dehumidification can be realized by switching between the dehumidification zone and the regeneration zone. In the invention, a drying agent is coated on the heat exchange device or metal sheets to obtain the regenerative dehumidification heat exchange device; the dehumidification heat exchange device adopts cooling water and hot water in an inner pipe to cool and heat the drying agent, wherein the convection heat exchange coefficient of water is greatly higher than the convection heat exchange coefficient of gas, thereby being favorable to dehumidification and regeneration of the drying agent; the device is more compact; and the comprehensive performance of the dehumidification heat exchange device can be improved.

Owner:SHANGHAI JIAO TONG UNIV

Finite element method for on-line board temperature calculation in course of hot rolling

InactiveCN101221416AImprove calculation accuracyTotal factory controlAdaptive controlTime domainElement model

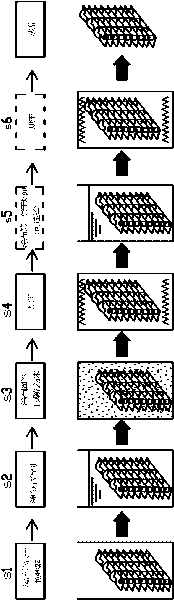

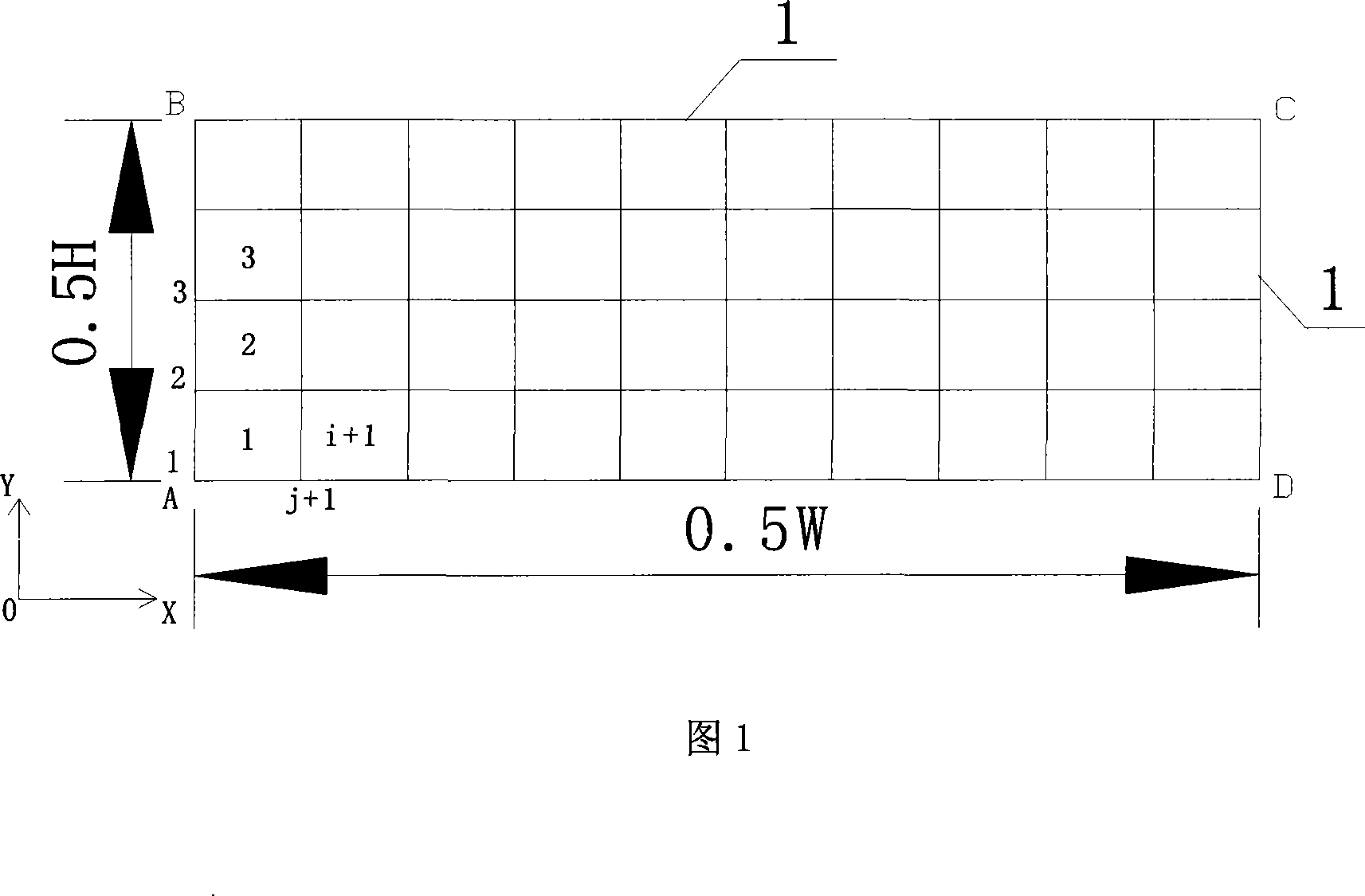

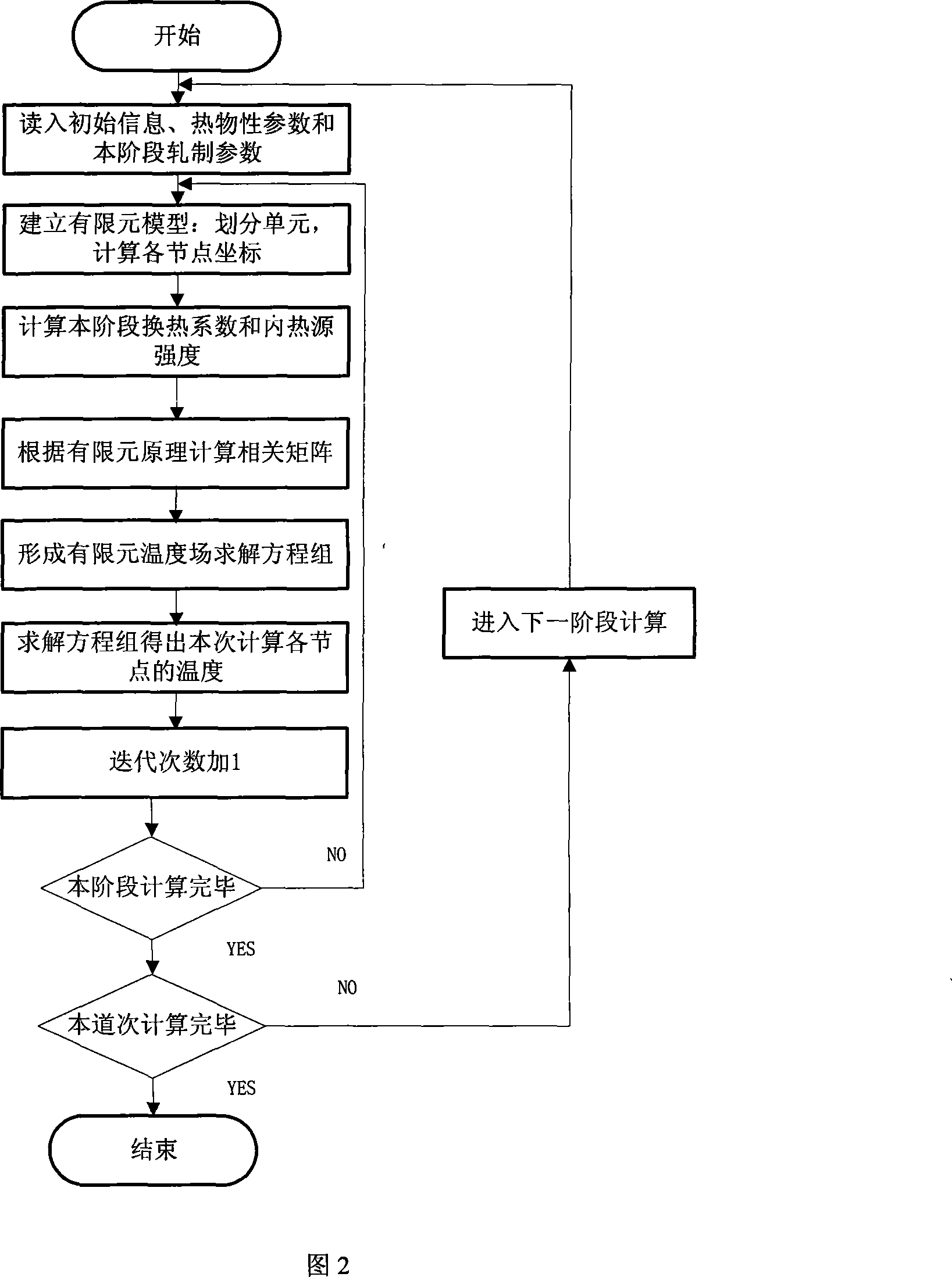

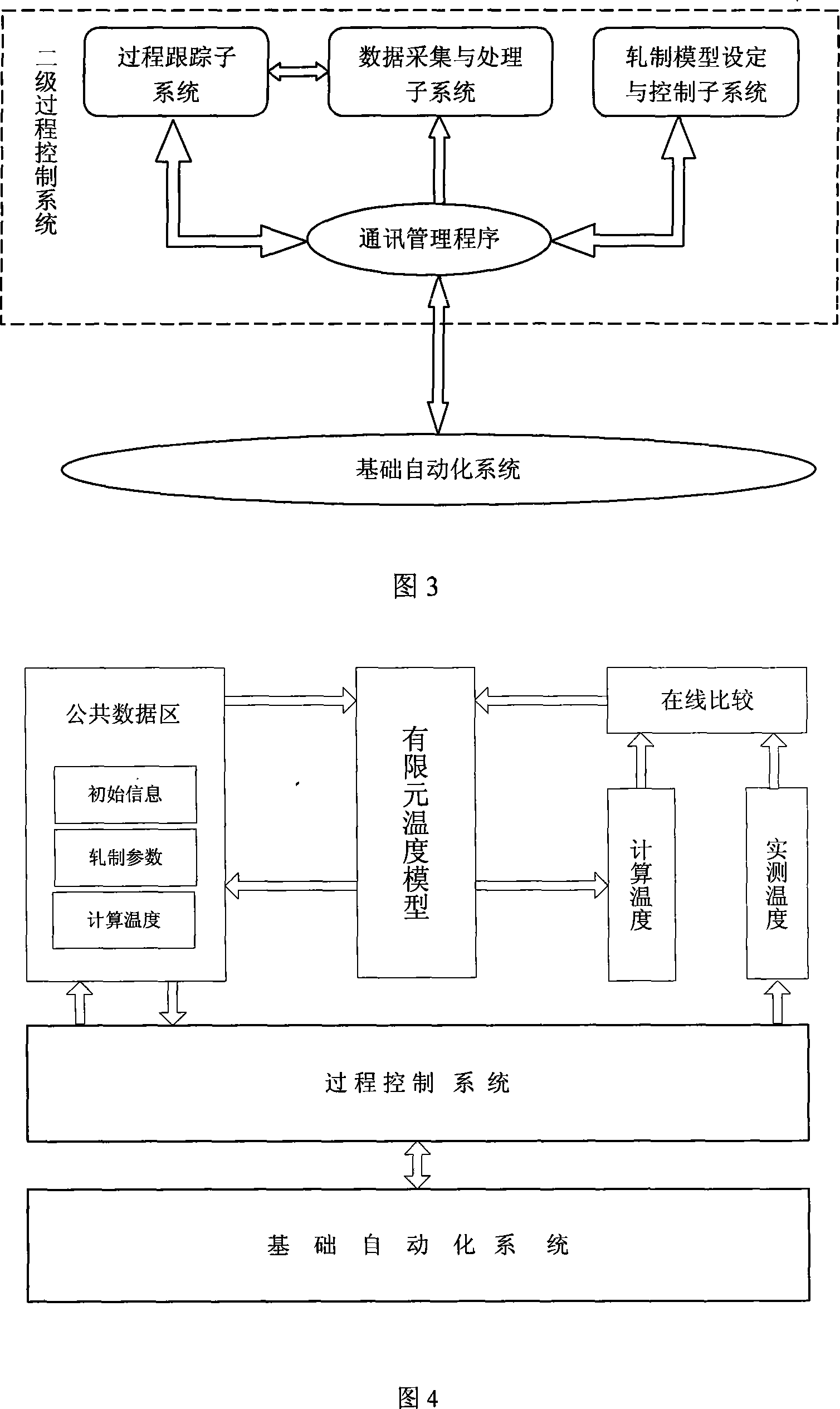

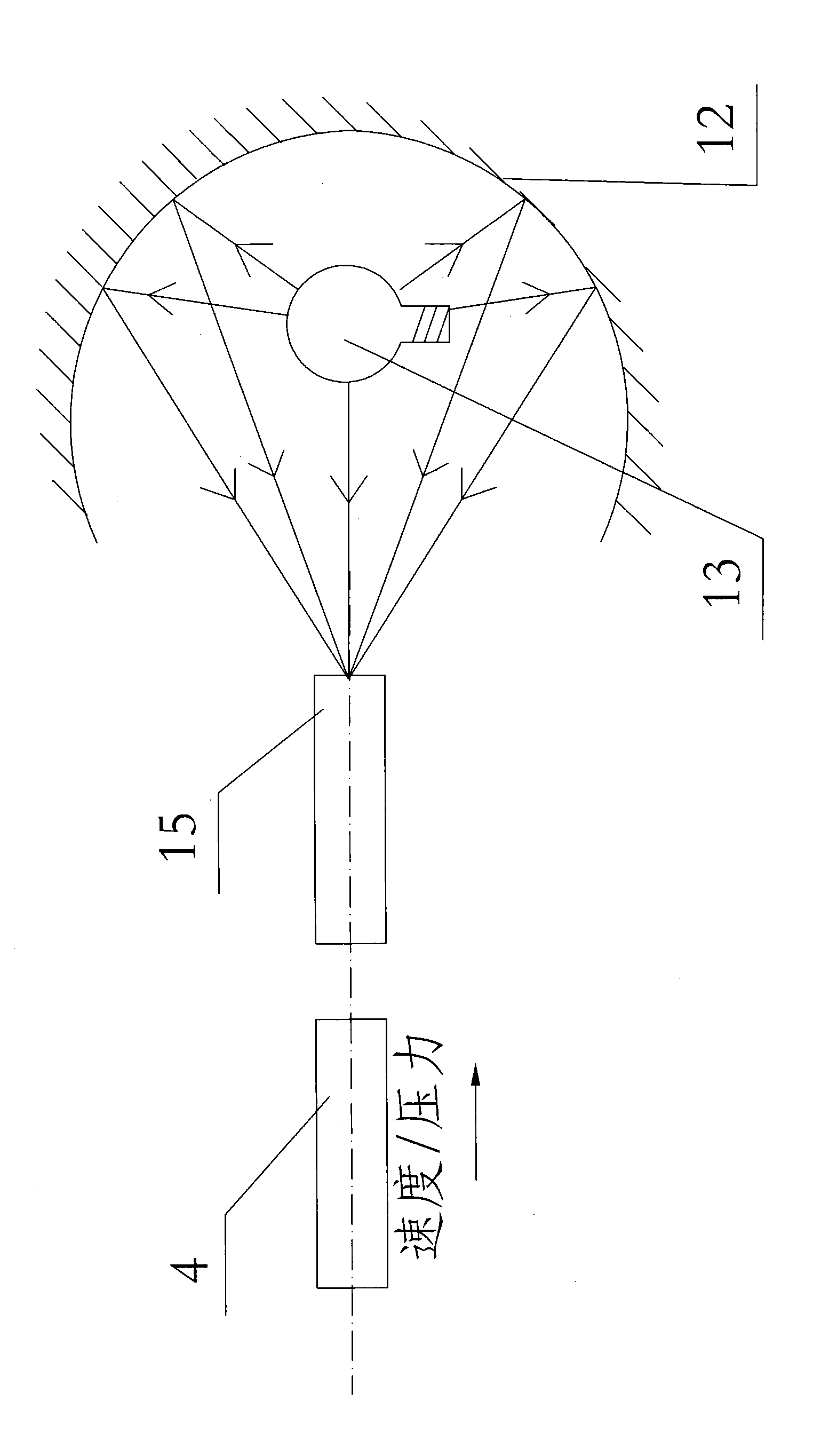

A finite element method for on-line calculation of slab band temperature during hot rolling belongs to the rolling technical field, and comprises the following steps that: (1) the establishment of a finite element model: unit division of the cross section of a rolling piece is carried out to set up a finite element analysis model; unit node numbering is carried out to calculate nodal coordinate; (2) the determination of parameters during calculation: the data needed during calculation includes initial information, rolling parameters, thermal physical property parameters of material, unit division information, control parameters and heat exchange coefficient; (3) the establishment of finite element solving equations set: through combining spatial domain finite element discretization and time domain finite difference, the solving linear equations set of temperature field finite element is set up; (4) pass rolling starting temperature is calculated; (5) on-line application is carried out. The invention has the advantages that: the invention can obtain high temperature calculation precision and the detailed information of slab band temperature distribution during entire hot rolling, thereby providing set parameters and optimized parameters for the rolling process; meanwhile, with strong practicality, the invention reduces calculation time and improves calculation efficiency; moreover, the invention is suitable for online application and optimization.

Owner:NORTHEASTERN UNIV LIAONING

Method and device for measuring dynamic contact heat exchange coefficient of high-temperature solid interface

InactiveCN101661009ARealize measurementEfficient heatingMaterial thermal conductivityMaterial heat developmentContact pressureMeasurement device

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

T cell type reinforced heat exchanging tube

InactiveCN101281005AIncrease heat transfer areaIncreased turbulenceTubular elementsEngineeringExchange coefficient

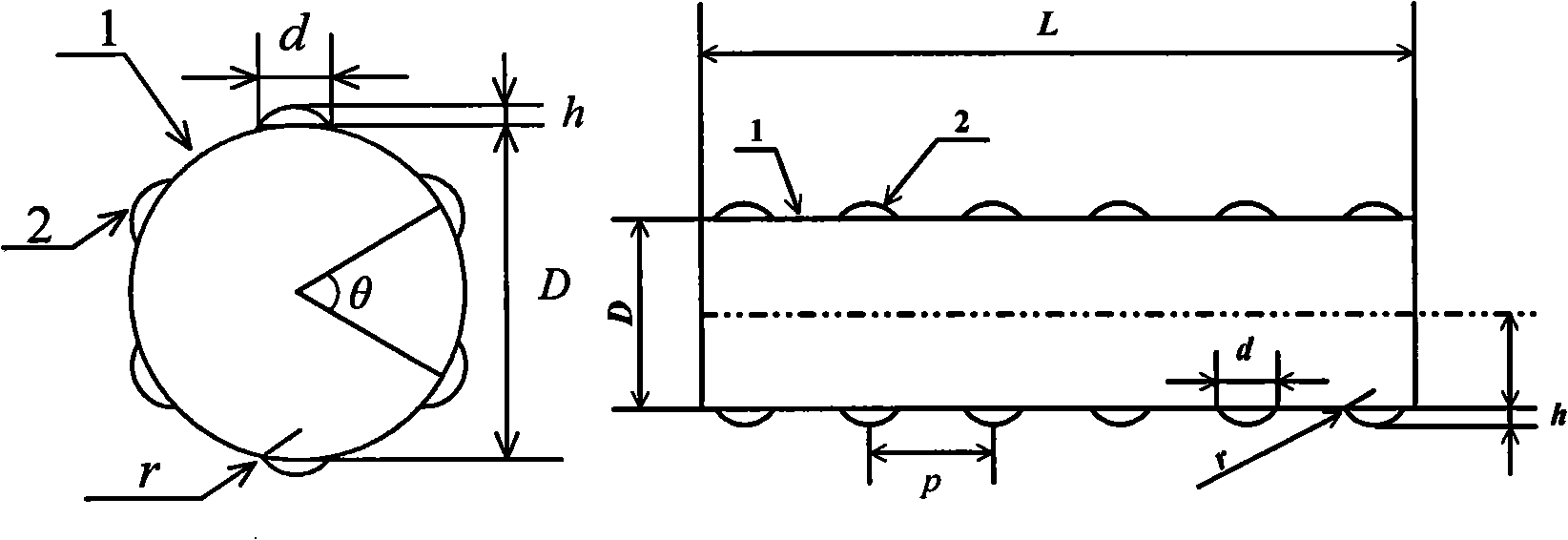

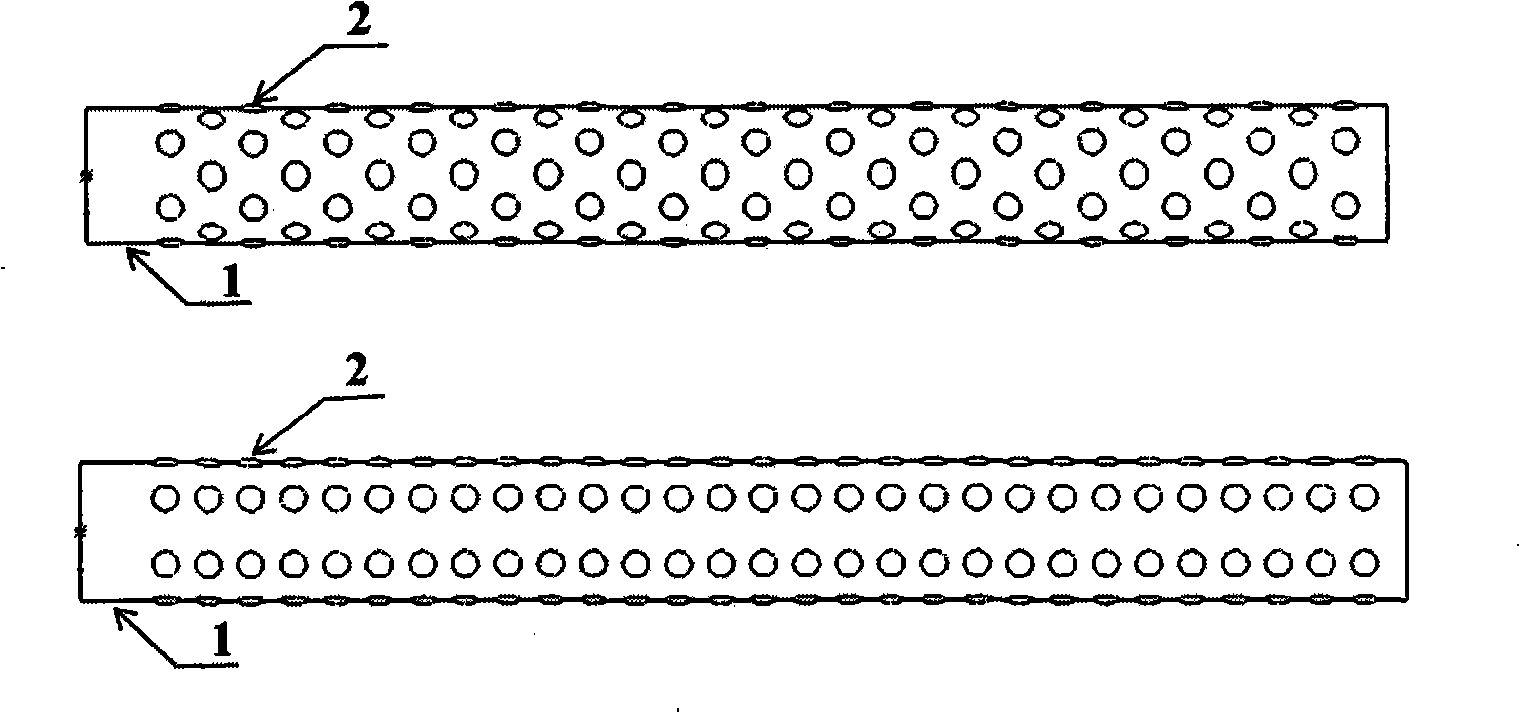

A cell intensifying heat exchanging pipe comprises a base pipe and a cell group composed of projected spherical crown cell from an inner wall to an outer side and distributed evenly along circle of the base pipe. A plurality of the cell group is distributed along the base pipe flowing direction. Because the invention is provided with projected cell on the base pipe that effectively enhances heat transporting area in the pipe, a border layer of the inner wall of the pipe is regularly destroyed and overflow degree of the fluid in the pipe is enhanced to a great extent, which improves heating exchanging coefficient of the pipe side; At the same time, proportion of the heat exchanging amount is greater than that of the resistance addition, which further realizes the effect of improving synthesized heat exchanging performance.

Owner:XI AN JIAOTONG UNIV

Automobile engine thermal management system modeling and control method

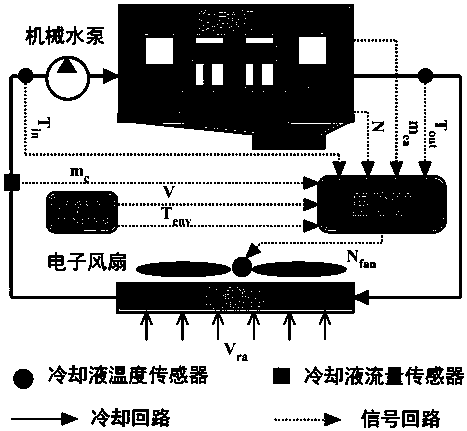

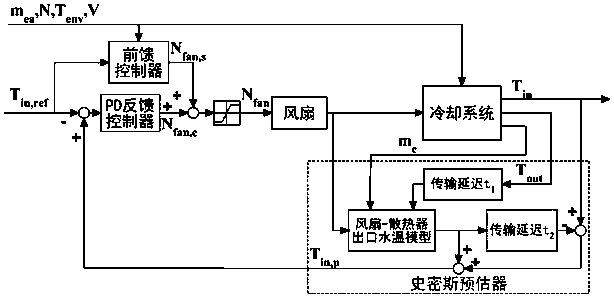

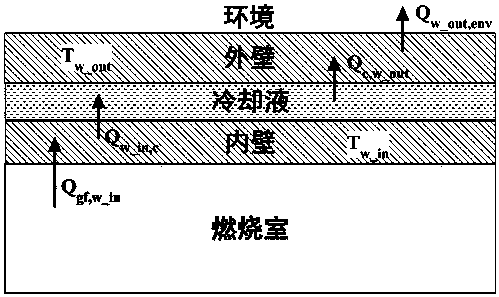

ActiveCN107869383ASolving Modeling Problems of Forced Convection Heat Transfer CoefficientsHigh control precisionGeometric CADCoolant flow controlDynamic modelsSystem dynamics model

The invention relates to an automobile engine thermal management system modeling and control method, and belongs to the technical field of control. The aim is to provide an engine thermal management system dynamic modeling method and a water temperature control method. In the system dynamic modeling method, an accurate heating power model of an air cylinder to an inner wall, a heat exchange coefficient model of a water jacket and cooling liquid and a radiating power model of a radiator are built. The research method of the method comprises the following steps that according to the structure, the principle and measurable signals of an engine thermal management system, a system dynamic model is built; seen from the heat convection heat exchange and radiation heat exchange mechanisms, three intermediate variables in the dynamic model are derived; a system inverse dynamic model is derived according to the system dynamic model; a Smith predictor is designed according to the system dynamic model; and a PD feedback controller is designed. The dynamic model of the engine thermal management system is accurately built, and the control accuracy is improved.

Owner:JILIN UNIV

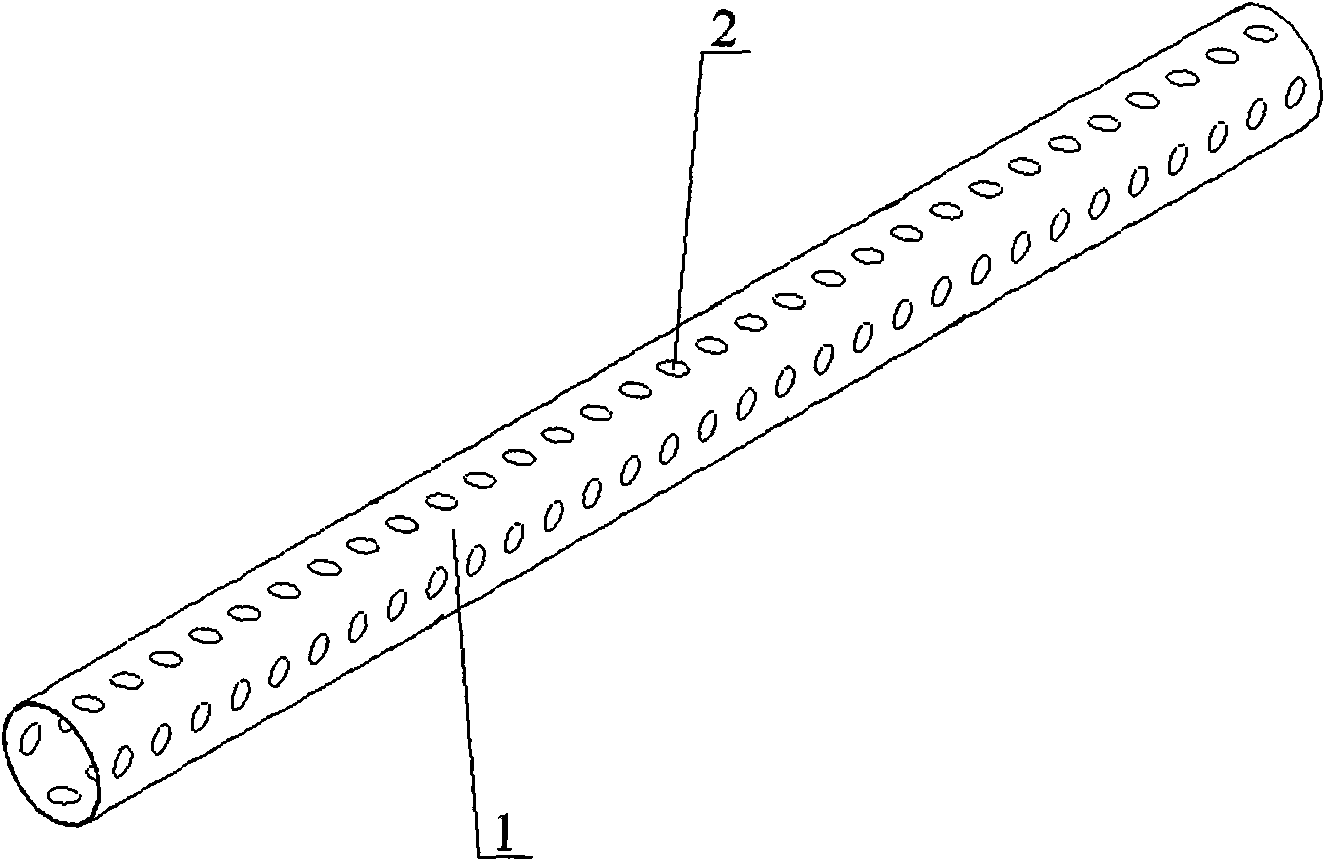

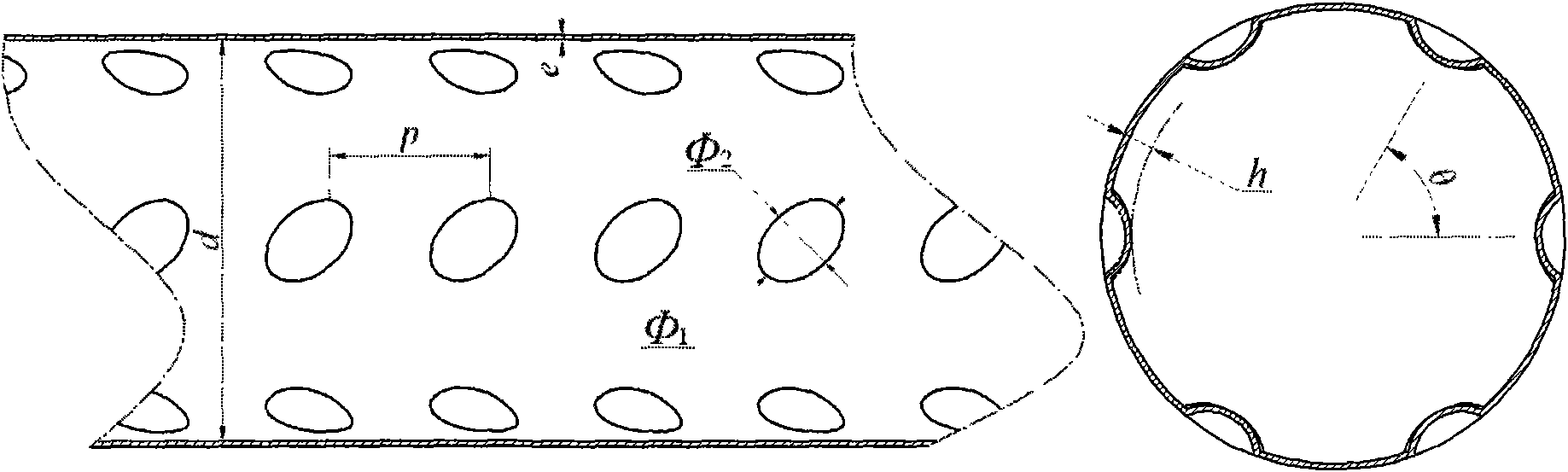

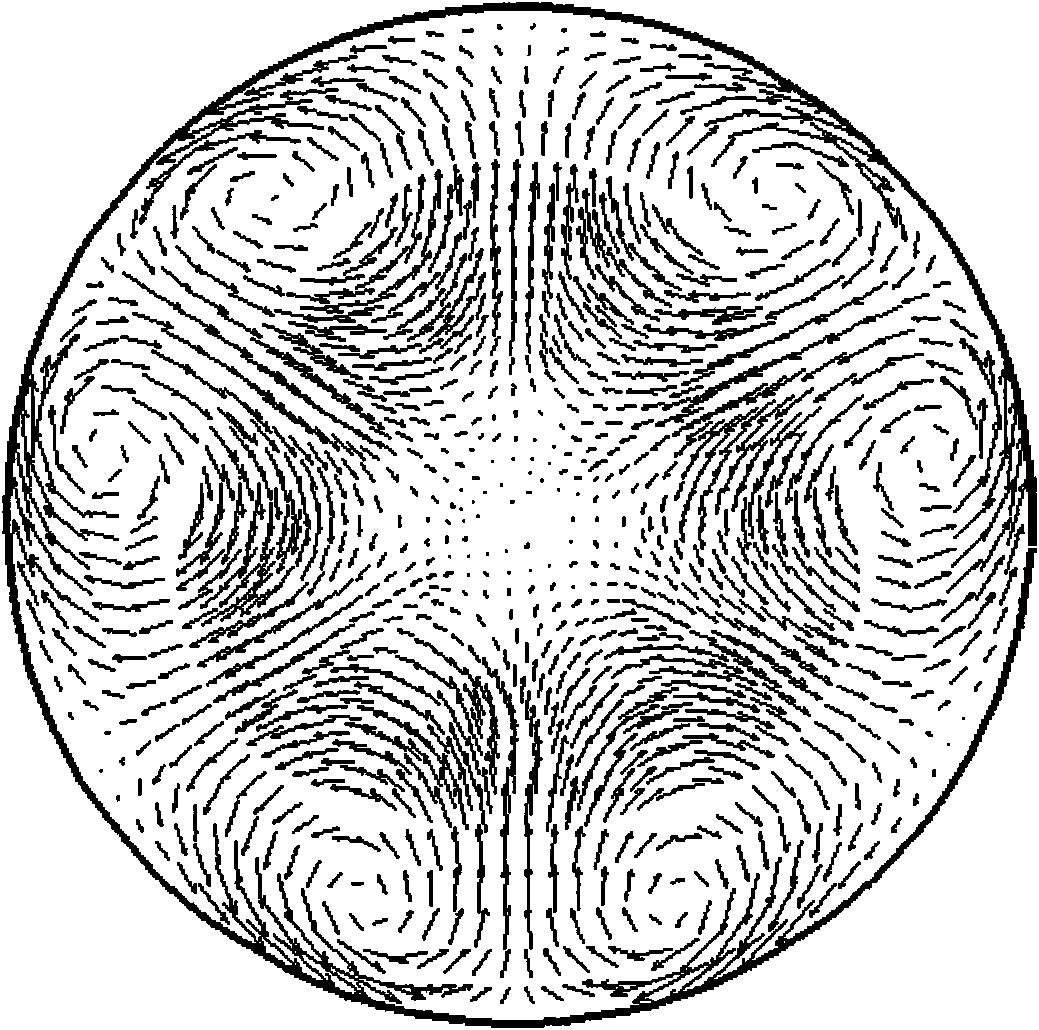

Dimpled enhanced heat exchange tube

InactiveCN101566445AReduce resistanceIncrease heat transfer areaHeat transfer modificationTubular elementsTrombe wallEngineering

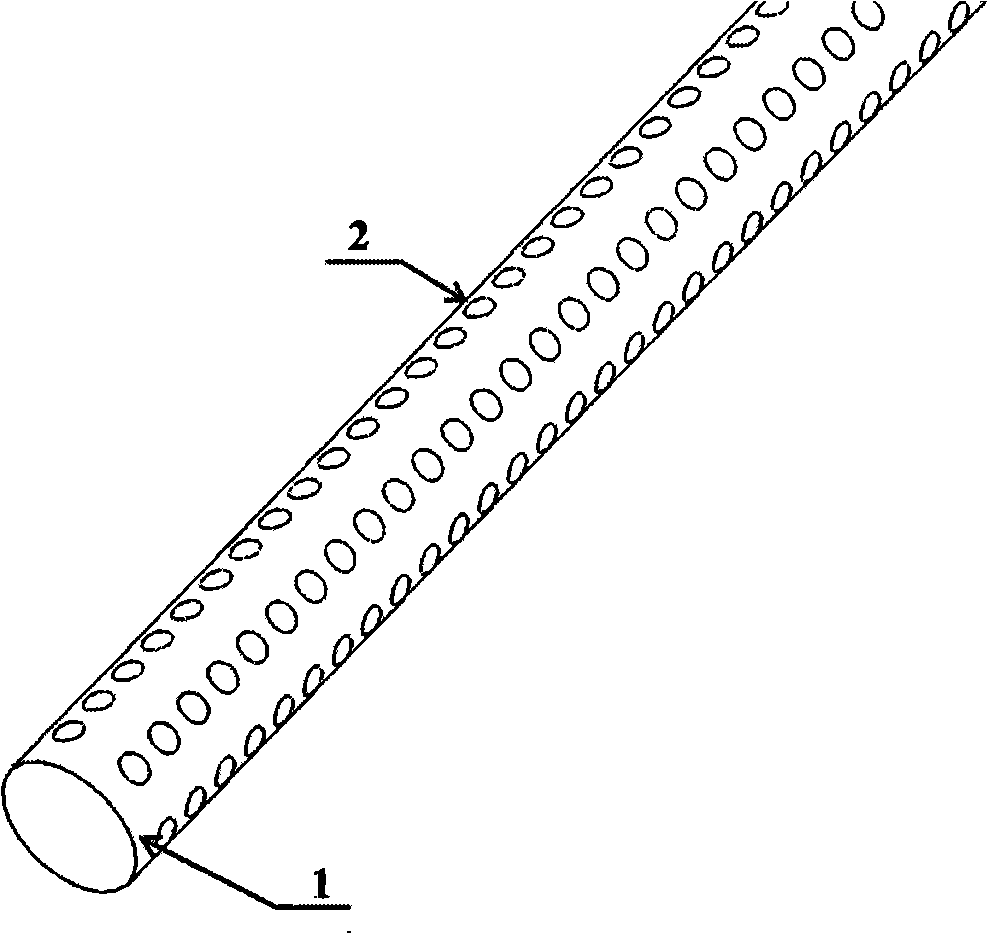

The invention relates to a dimpled enhanced heat exchange tube, which comprises a base tube and dimple groups formed by ellipsoid crown type dimples which are processed from the external wall of the base tube to the inside according to certain array on the tube wall of the base tube, wherein the dimple groups are evenly distributed along the axial direction of the base tube according to certain cycle and separation distance. Because the base tube is processed with the novel dimples, the comprehensive performance of the heat exchange tube is improved compared with the former similar heat exchange tubes. The dimpled enhanced heat exchange tube has the following characteristics: 1, the ellipsoid crown type dimples increase the heat transfer area in the tube and increase the flow velocity of fluid; 2, boundary layers of the inner wall of the tube are destroyed more effectively; 3, the ellipsoid crown type dimples having certain included angle with the axial direction make the fluid generate longitudinal vortexes; and 4, the continuous changes of the cross section of the tube and the generated pressure changes increase the turbulivity of the fluid in the tube to further improve the tube side heat exchange coefficient, and while the tube side heat exchange coefficient is improved, the ellipsoid crown type dimples having certain included angle with the axial direction make the fluid generate secondary flow which has smaller increase to the fluid resistance, thus the effect of improving the comprehensive heat exchange performance is achieved.

Owner:XI AN JIAOTONG UNIV

Excellent carbon-steel on-line forecasting and tissue sorbitizing controlling method

InactiveCN101168797AQuality Objection Loss DeclineReduce lossesFurnace typesHeat treatment process controlHigh carbonPerformance index

The invention discloses a method for on-line prediction and control of microstructure sorbite of high-quality carbon steel, which comprises the following steps: according to the material parameters and chemical composition, the cooling temperature of the air-cooling section is adjusted in the air-cooling section of Stelmo control cooling ; In the water-cooling section that controls the cooling, according to the different cooling methods of each section, at each time step, according to the position of the node, select the corresponding heat exchange coefficient, and continuously correct the heat exchange coefficient according to the self-learning method ; In the phase change process of Stelmore controlled cooling, according to the change of phase change heat, adjust the phase change process of Stelmore controlled cooling; in the process of Stelmore controlled cooling, provide parameter detection, online prediction and Control various performance indicators, and constantly monitor the proportion of sorbite in the production process of U-Carbon wire rod. It makes the high-quality carbon steel wire rod have good pulling performance.

Owner:CHONGQING IRON & STEEL CO LTD

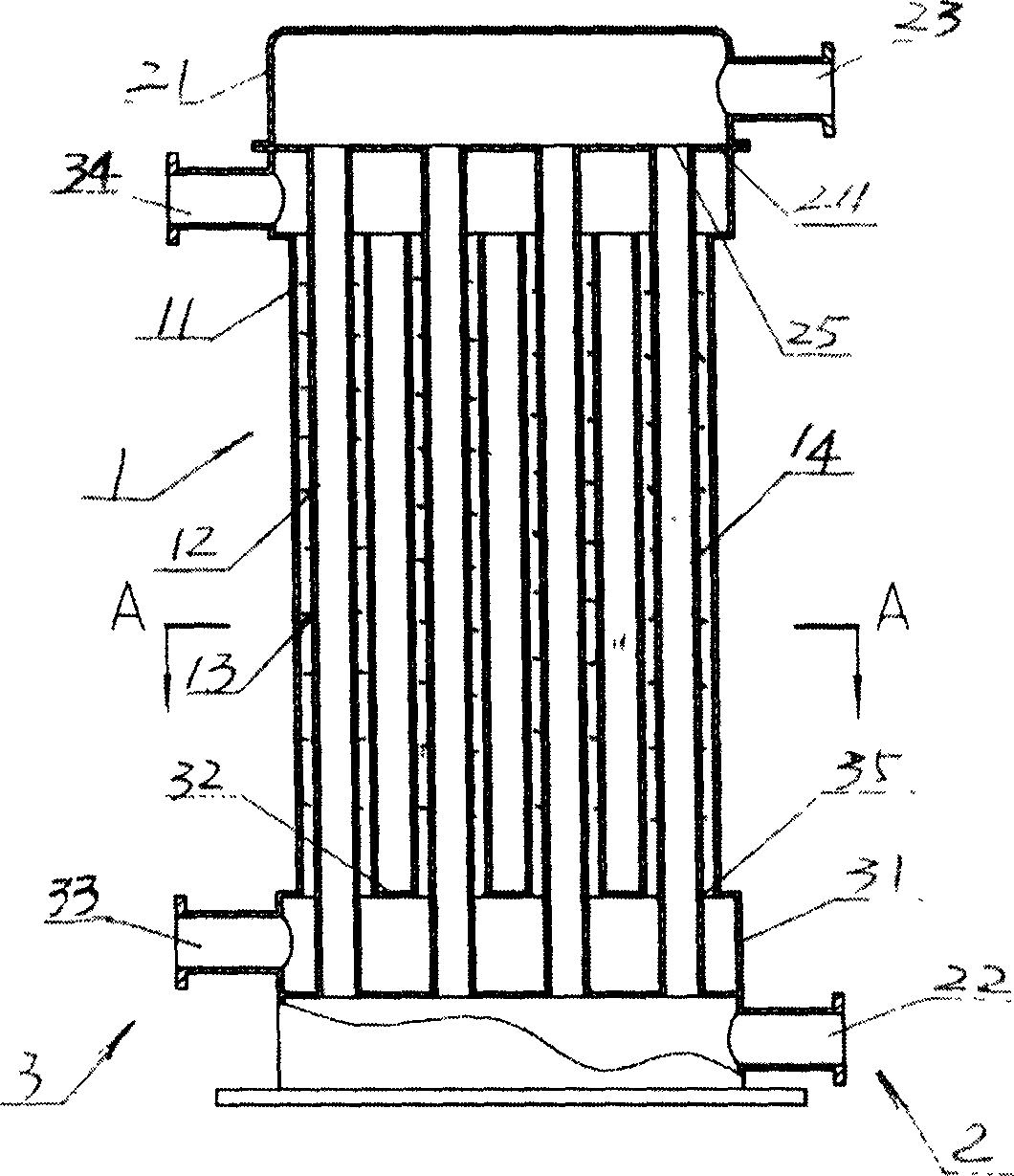

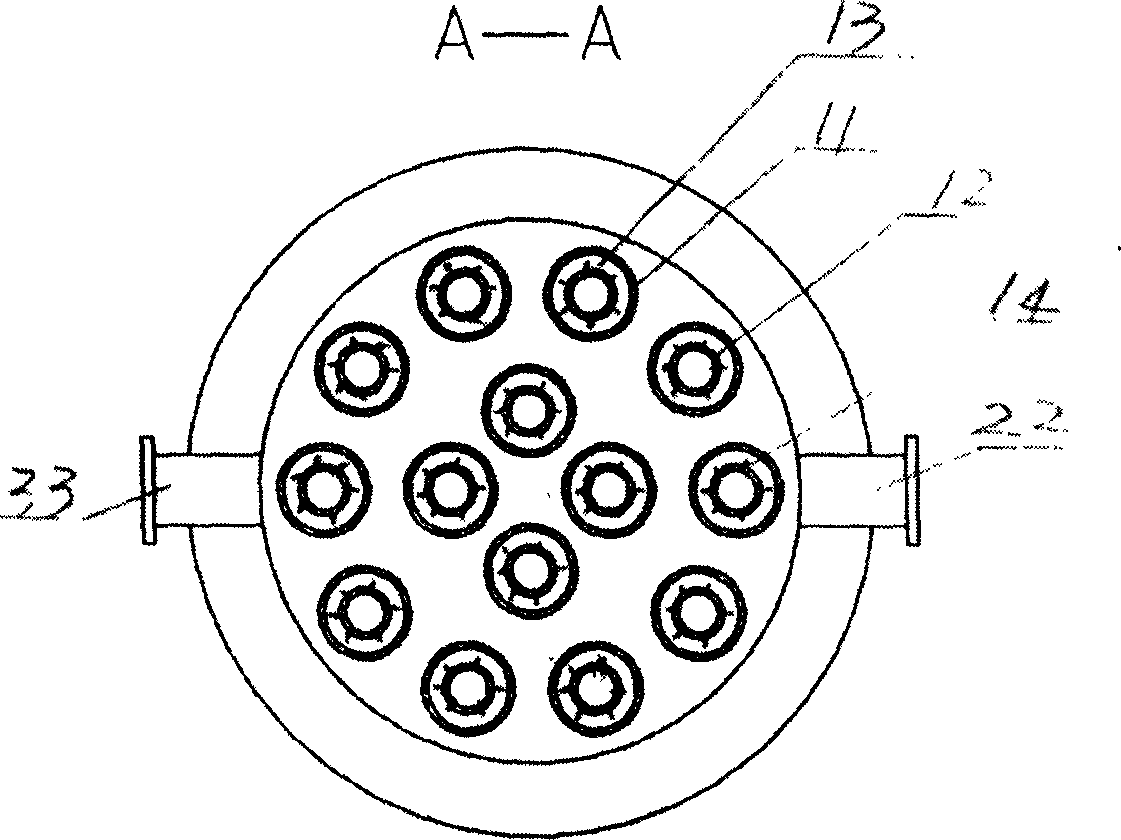

Pipe heat exchanger

InactiveCN1719179AImprove heat exchange efficiencyImprove heat transfer coefficientStationary tubular conduit assembliesEngineeringExchange coefficient

The present invention relates to a pipe-type heat exchanger. Said heat exchanger includes two portions of pipe sleeve group and pipe header group including first pipe header for making first medium circularly flow and second pipe header for making second medium circularly flow. Said invention can make the fluid be quickly flowed in the pipe sleeve so as to can obtain higher heat exchange coefficient.

Owner:刘庆久

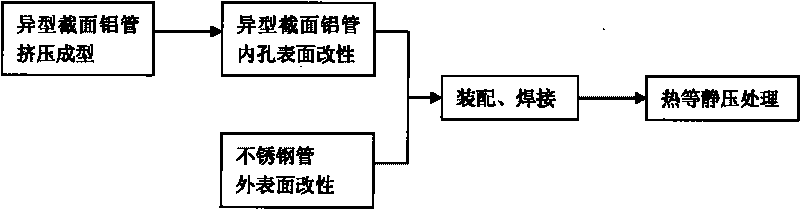

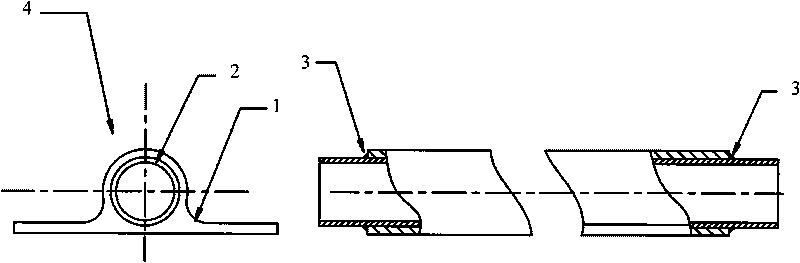

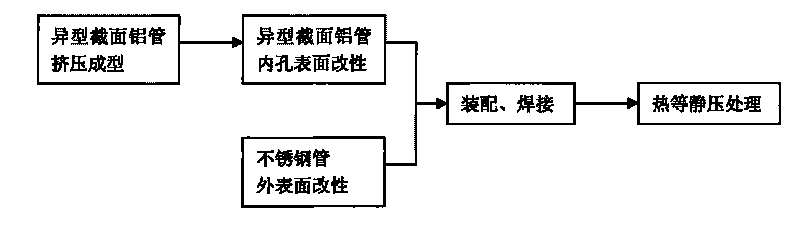

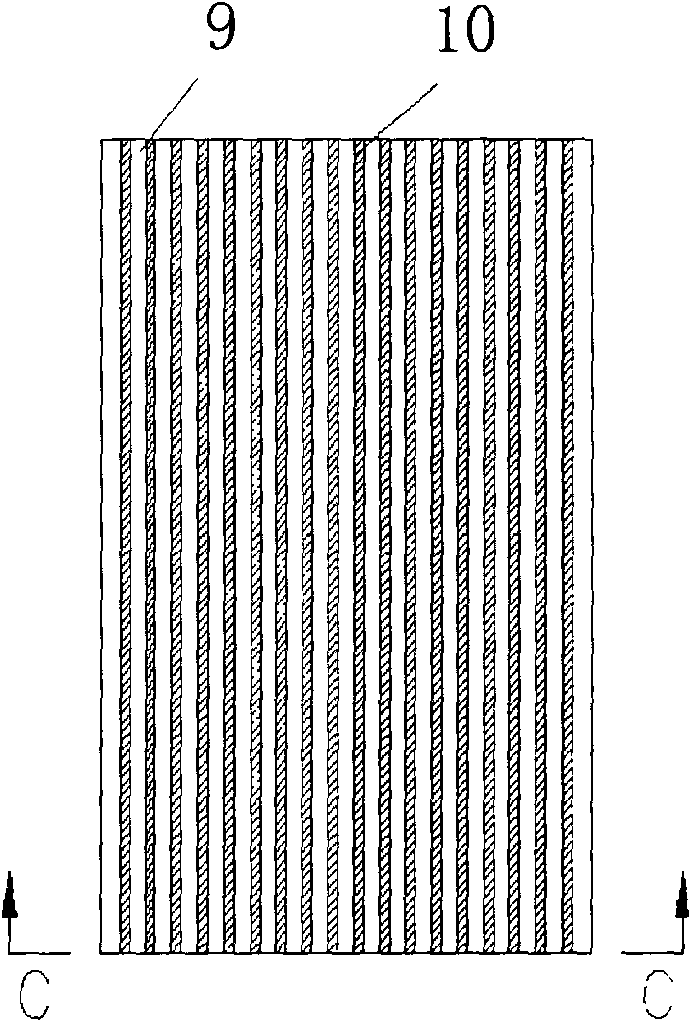

Method for producing irregular-section composite pipe

InactiveCN101745793AEfficient heat expansionHigh interface heat transfer coefficientFurnace typesLiquid/solution decomposition chemical coatingThermal expansionElectric power

The invention discloses a method for producing irregular-section composite pipes, belonging to the technical field of metal composite materials. The method comprises the following steps: an irregular-section aluminum pipe is extruded and formed, the surface of the inner hole of the irregular-section aluminum pipe is modified, the external surface of a stainless steel pipe is modified, the surface-modified stainless steel pipe is inserted into the inner-hole-surface-modified irregular-section aluminum pipe, the assembling end parts of the stainless steel pipe and the irregular-section aluminum pipe are sealed after the assembling is completed, and the welded part of the irregular-section aluminum pipe and the stainless steel pipe is put into a hot isostatic pressure furnace for heat treatment to obtain an irregular-section composite pipe. The irregular-section composite pipes produced through the invention have the advantages that the weight is light, the strength is high, the thermal expansion efficiency is high, the interfacial metallurgical bonding ratio is close to 100 percent, the interfacial heat exchange coefficient is high, the bonding strength is high, the service life in severe cold-and-hot-alternation environment and the like, can be used in heat pipe systems which are key technical hardware of aircrafts, aerospacecrafts and other spacecrafts, and can be widely used in fields such as power, electronics, ships, nuclear energy and the like.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

Improved high-efficiency unidirectional heat transfer pipe used for heat dissipation of microelectronics

InactiveCN102022936ATake away in timeIncrease boiling heat transfer coefficientIndirect heat exchangersEvaporationEngineering

The invention provides an improved high-efficiency unidirectional heat transfer pipe used for heat dissipation of microelectronics, belonging to the technical field of heat pipes, relating to a strictly unidirectional conductive gravity assisted heat pipe. The heat pipe of the invention is a seal chamber applied to the top of an heat dissipation object and is composed of a condensation section at the upper part, a heat insulation section at the middle part and an evaporation section at the lower part, the interior of the heat pipe is filled with a working medium, and the heat pipe is characterized in that the bottom of the chamber is matched with the shape of the top of the heat dissipation object, and the inner surface is distributed with scratch shallow slots; the top of the chamber is subject to superhydrophobic surface treatment; the inner wall of the chamber is provided with vertically arranged groove channels and capillary column channels separated with rib channels and is subject to superhydrophobic surface treatment; gasification is easier to realize on the surface of the scratch shallow slots at the bottom; the capillary column channels make condensation working medium fluid rapidly reflux, thus avoiding that the working medium of the heat pipe is dried up; and the top of the condensation section is subject to superhydrophobic surface treatment, thus realizing dropwise condensation. Thus, the invention improves condensation heat exchange coefficient and enables the heat pipe to operate normally and stably.

Owner:BEIJING UNIV OF TECH

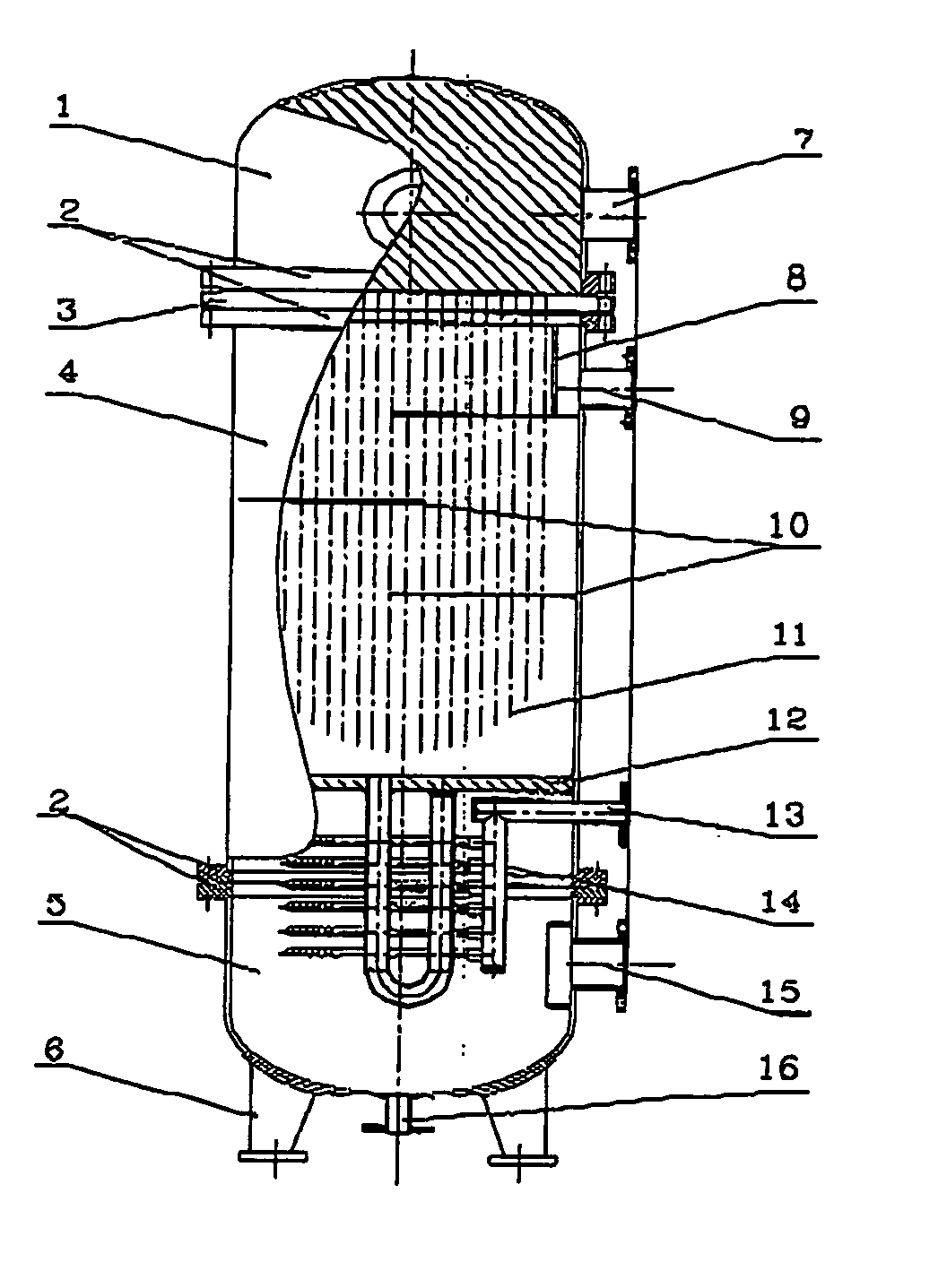

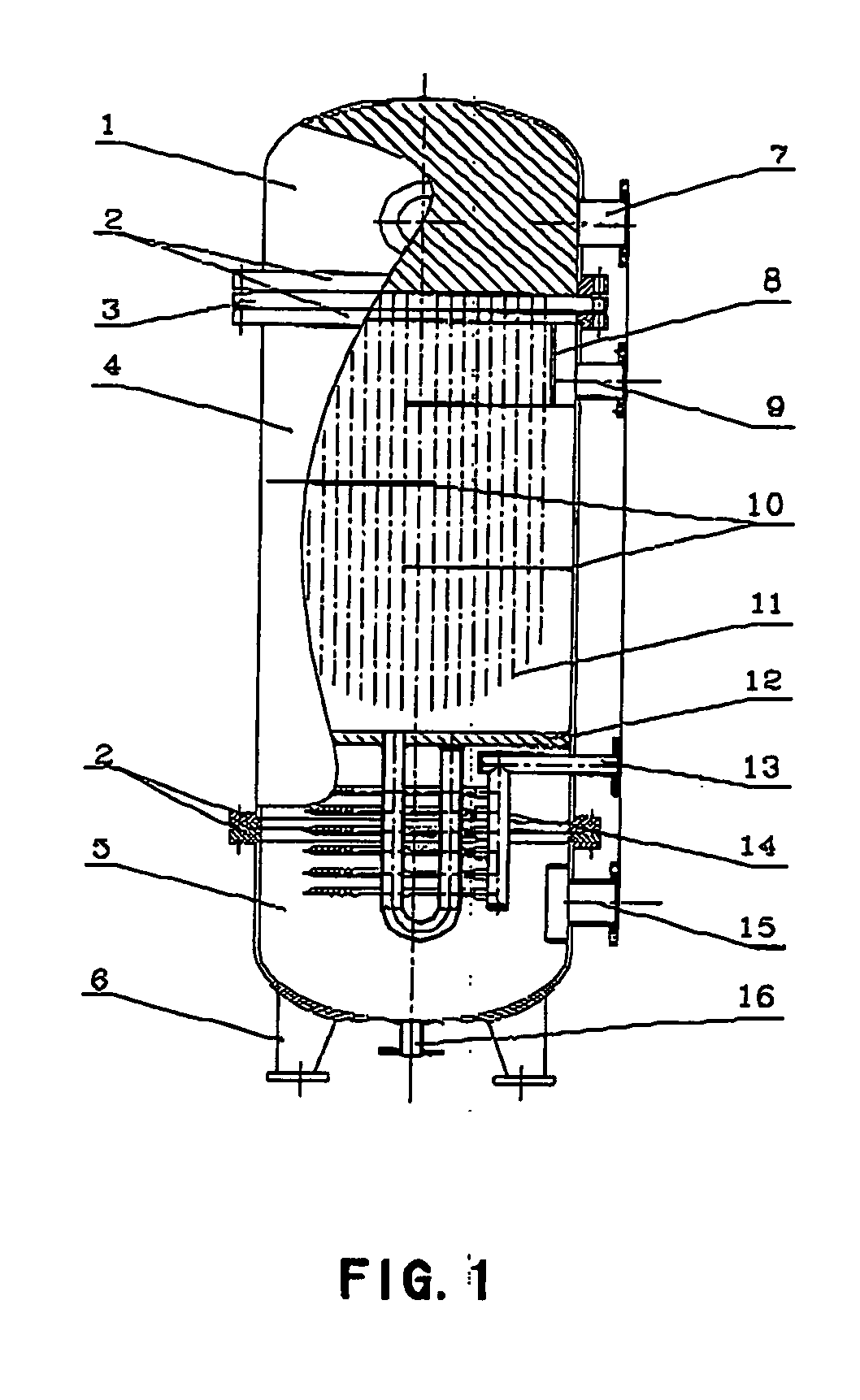

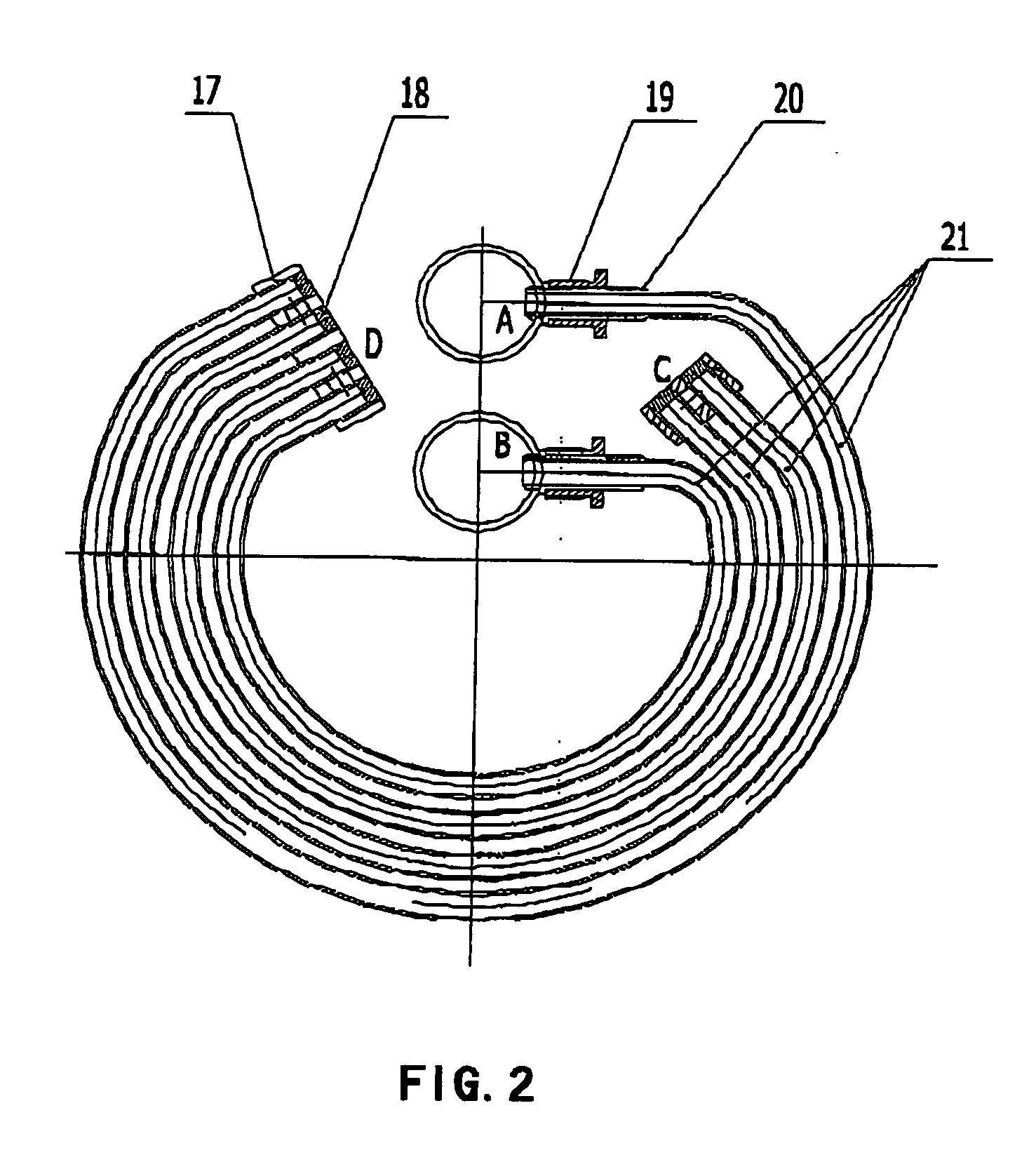

Complex flow-path heat exchanger having U-shaped tube and cantilever combined coil

InactiveUS20050109495A1Small flow resistanceIncrease water speedStationary conduit assembliesStationary tubular conduit assembliesWater flowEngineering

A complex flow-path heat exchanger having U-shaped tube and cantilever combined coil, which can achieve, in this type heat exchanger, a simple construction, a complex flow of steam within the same one heat exchange shell body, a high heat exchange efficiency, and a low energy loss. The technical gift of the present invention is that, after entering into the heat exchanger, steam firstly effects heat exchange on the U-shaped tube flow path shell side to be cooled and condensed, thereafter entering into flow path tube side of the cantilever combined coil, which are disposed within the same one shell, for a secondary heat exchange, and subsequently flowing out of the heat exchanger after being subcooled. Such steam-water heat exchanger having a complex flow path are advantageous in a small steam flow resistance of the U-shaped tube flow path shell side; a higher condensate water flow velocity in the cantilever combined coils flow path tube; a high heat exchange coefficient; good coordination of the temperature difference fields of the hot and cold fluids in the heat exchanger; and a high heat exchange efficiency. Therefore, the present heat exchanger can be a new generation product relative to the currently-used conventional low-temperature, low-pressure and corrosion-free heat exchangers.

Owner:SHANDONG UNIV

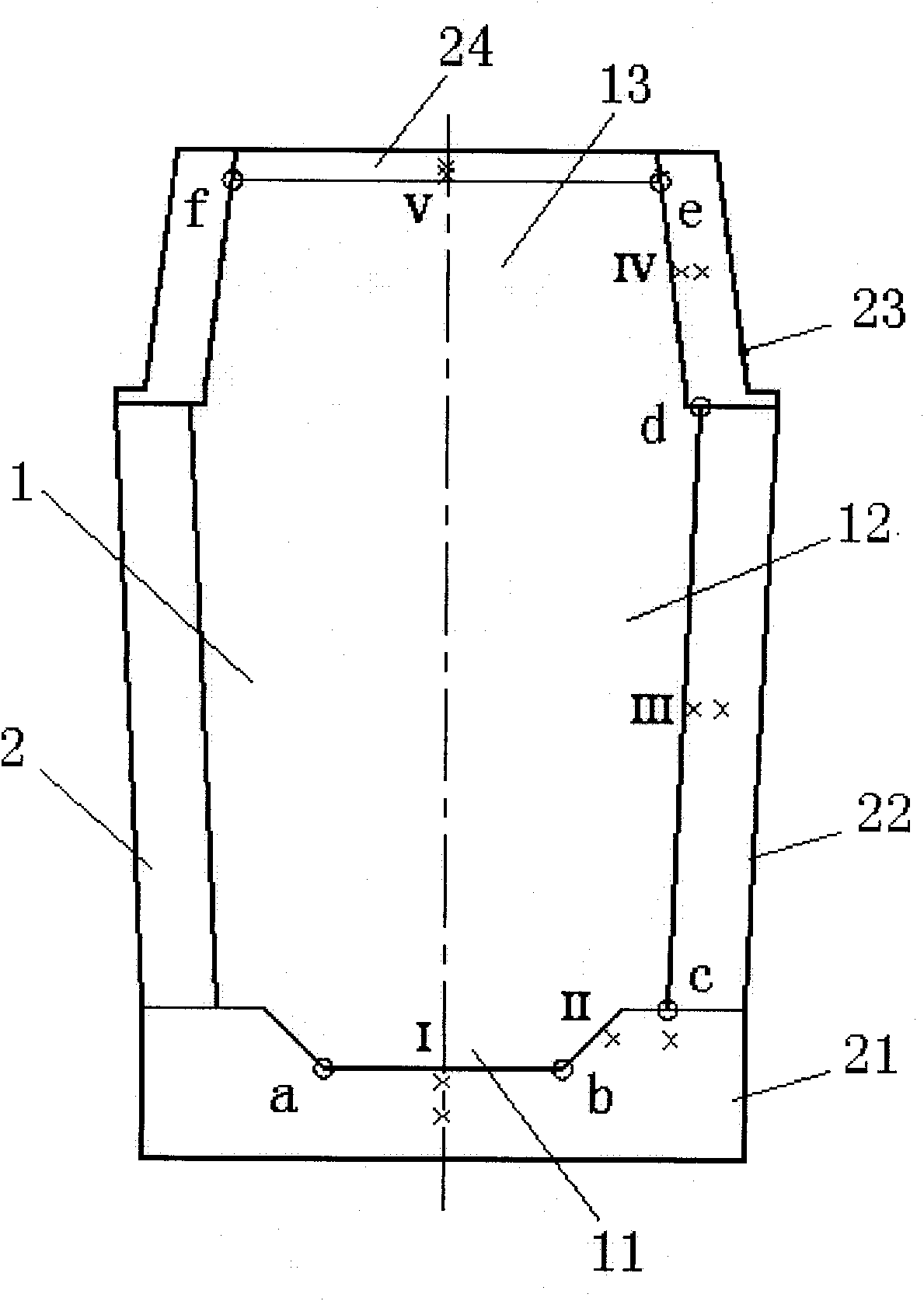

Device and method for evaluating relation of interface temperature and interface heat exchange coefficient

ActiveCN103033277AGuaranteed accuracyEliminate the effects ofMaterial heat developmentThermometers using electric/magnetic elementsData processing systemHot stamping

Provided is a device for evaluating relation of interface temperature and an interface heat exchange coefficient between a die and a sample in a hot stamping process. The device for evaluating the relation of the interface temperature and the interface heat exchange coefficient comprises a cooling device, a sample fixing device, a temperature detecting device and a data processing system. The cooling device comprises an upper tool and a lower tool, the sample fixing device is arranged on the upper surface of the upper tool, and the temperature detecting device is arranged on one side, close to the upper tool, of the sample fixing device. A plurality of support poles are arranged inside the upper tool, the cavities among the support poles are cooling water channels, and the cooling water channels are connected with a cooling water inlet and a cooling water outlet respectively. The invention further discloses a method for evaluating the relation of the interface temperature and the interface heat exchange coefficient between the die and the sample in the hot stamping process, and supplies corresponding theoretical basis to the test of interface coefficient.

Owner:滕州市产品质量监督检验所

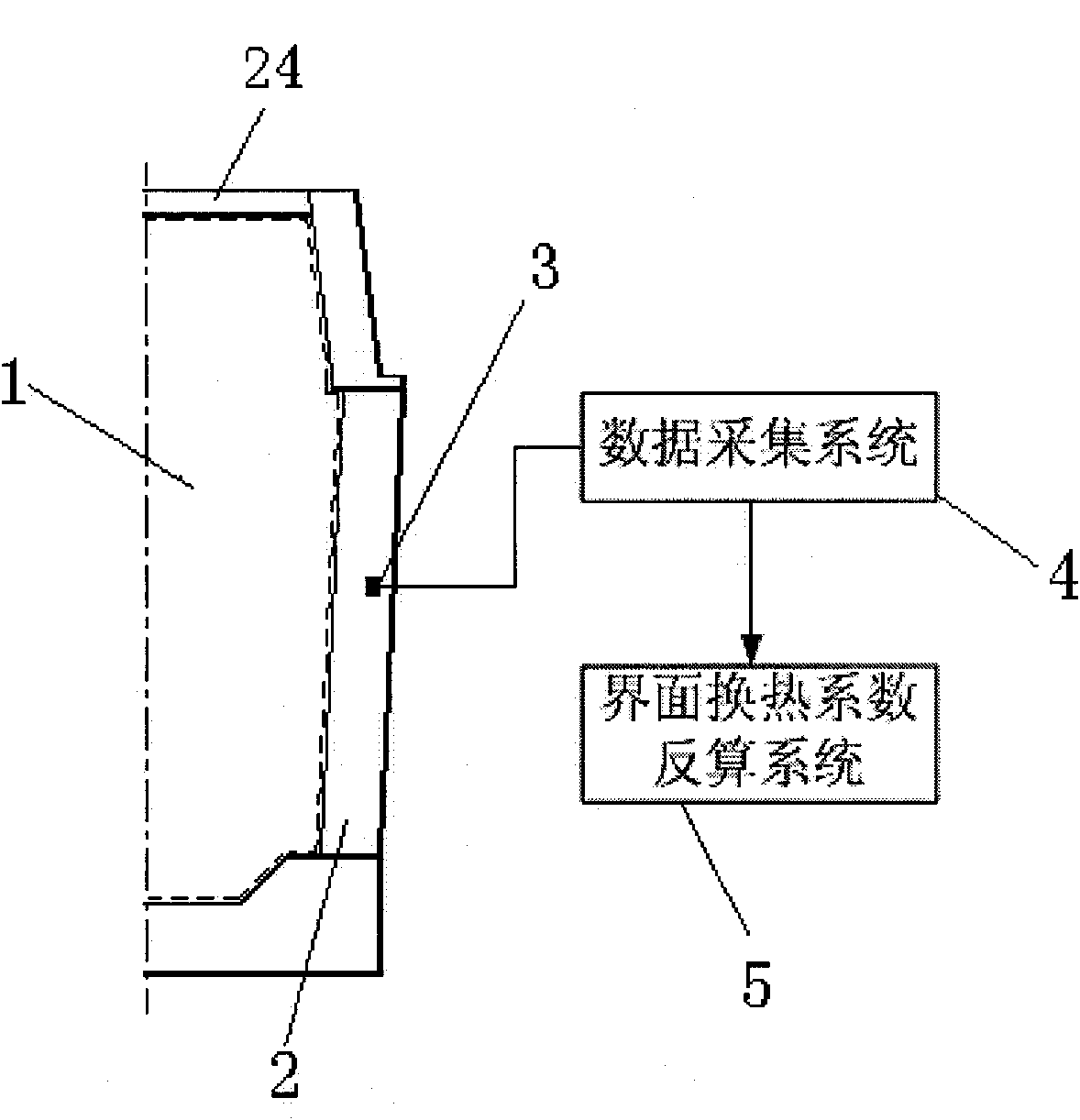

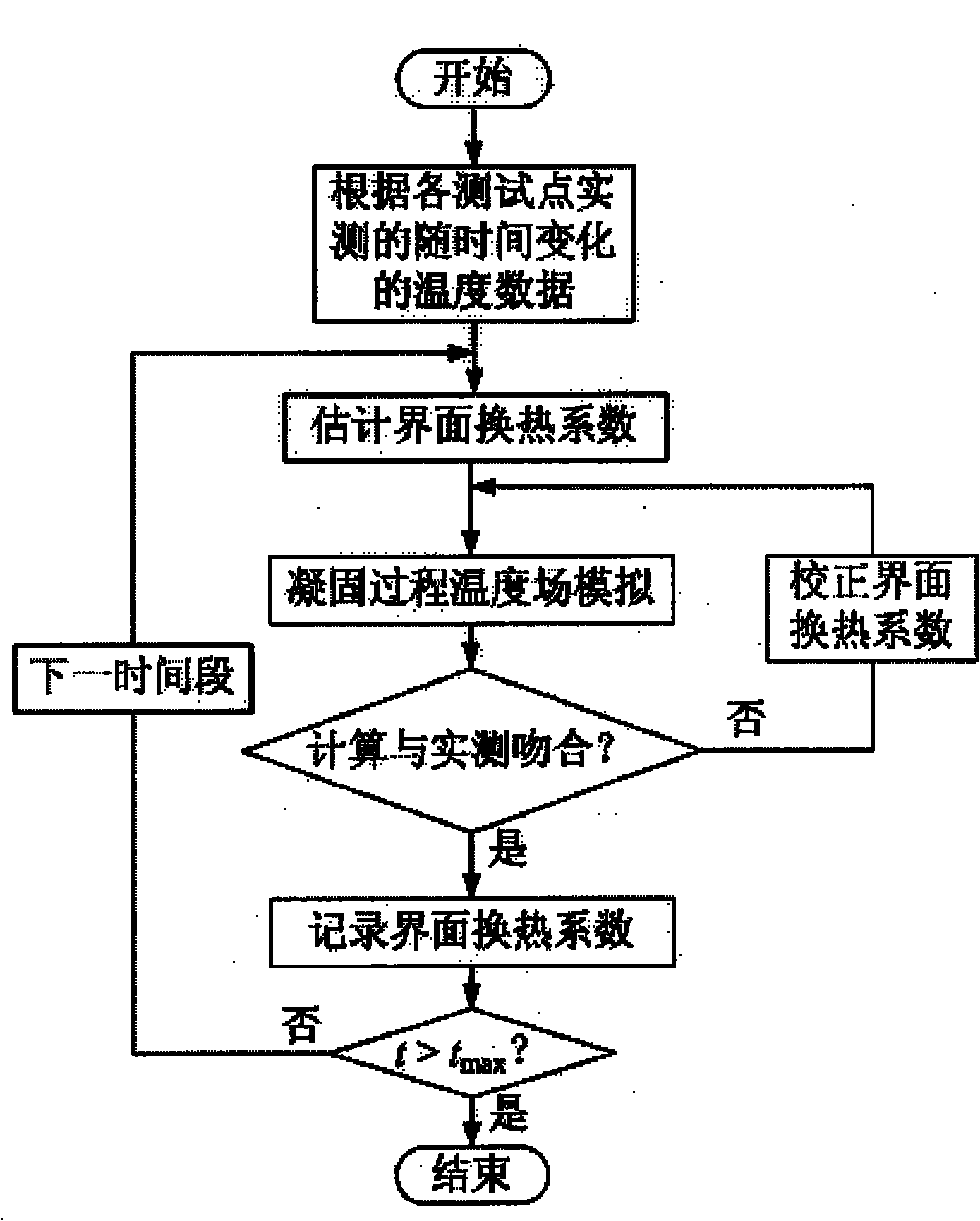

Method for determining interface heat exchange coefficient of large-sized steel ingot

InactiveCN101871903AThe testing process is simpleEasy to operateMaterial thermal conductivityMaterial heat developmentHeat flowHeat flux

The invention relates to a method for determining an interface heat exchange coefficient of a large-sized steel ingot. The method comprises the following steps of: 1) simplifying a contact interface between the steel ingot and an ingot mould into a plurality of test subsections, determining a plurality of test points in each subsection, setting a sensor on each test point, connecting the sensors to a data acquisition system together through respective leads, and connecting an interface heat exchange coefficient inverse calculation system at the output end of the data acquisition system; 2) when molten steel is solidified to form the steel ingot, acquiring temperature or heat flux information during molten steel solidification and transmitting the acquired signals to the data acquisition system through the sensors; 3) after the molten steel is fully solidified into the steel ingot, reading the data of each test point through the data acquisition system, acquiring the actually measured temperature or heat flux information of each test point along with time change, and importing the data and the information into the interface heat exchange coefficient inverse calculation system between the steel ingot and the ingot mould; and 4) solving the interface heat exchange coefficient between the steel ingot and the ingot mould by inverse calculation of the interface heat exchange coefficient inverse calculation system.

Owner:TSINGHUA UNIV

Female screw heat-transfer pipe

InactiveCN101004336AImprove heat transfer coefficientUniform extrusion forceTubular elementsScrew threadMaterials science

A heat conduction tube of internal thread type is prepared for forming said heat conduction tube by aluminum or aluminum alloy material, setting multiple parallel-arranged tooth ribs with high tooth and low tooth being set alternatively at internal surface of heat conduction tube to increase area of internal surface on heat conduction tube as large as possible for raising heat exchange coefficient of heat conduction tube and for maintaining excellent heat exchange effect of heat conduction tube.

Owner:GOLDEN DRAGON PRECISE COPPER TUBE GROUP

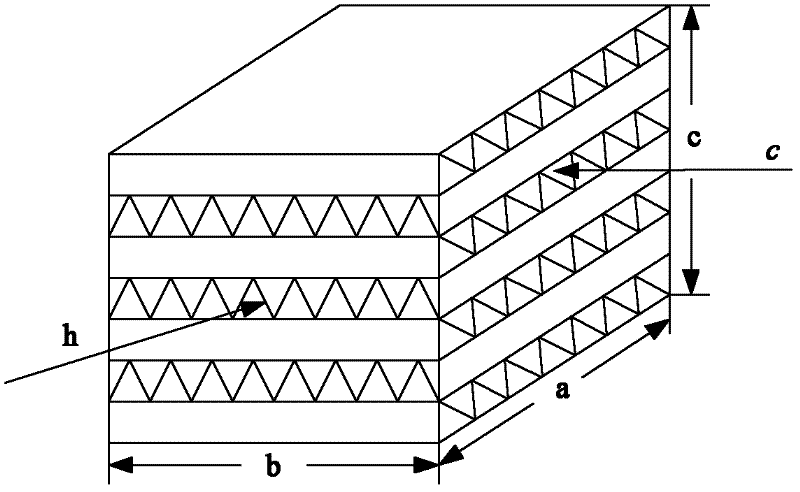

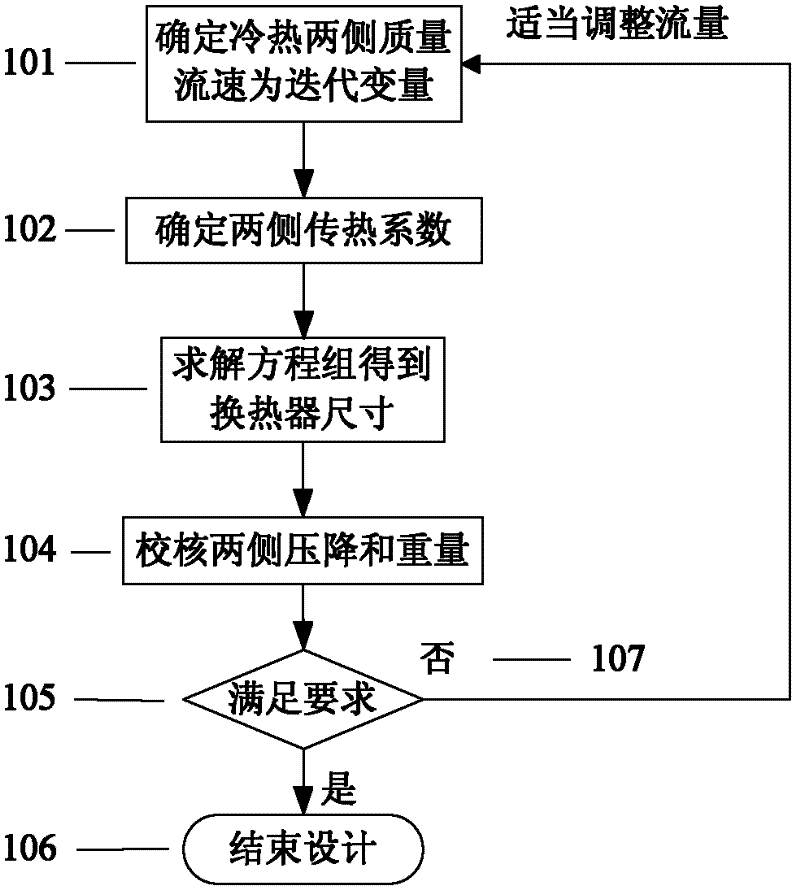

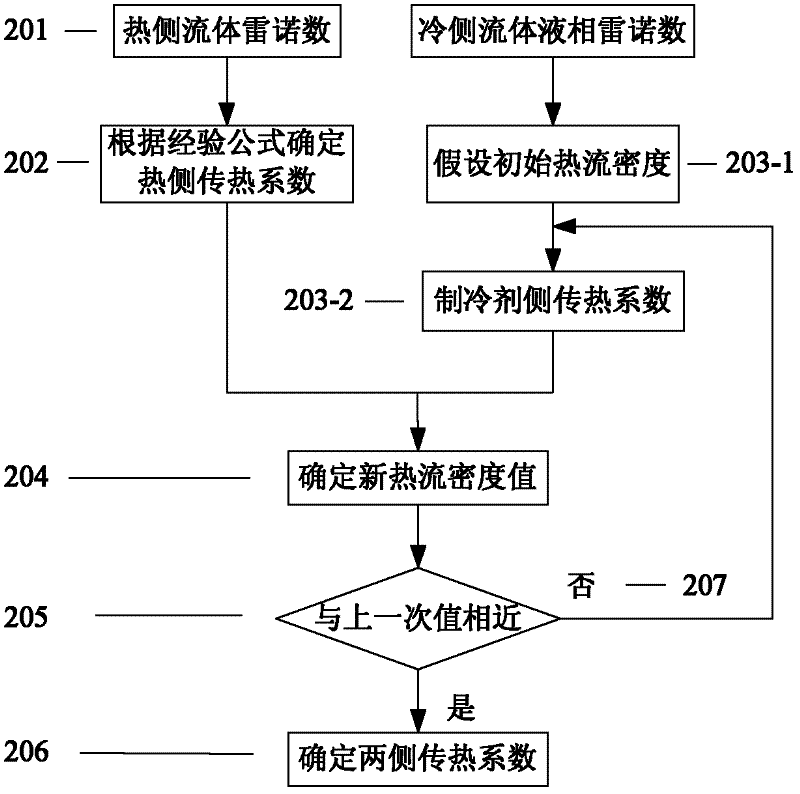

Optimal parameter determination method for plate-fin evaporator

InactiveCN102508958AEvaporators/condensersSpecial data processing applicationsEngineeringRefrigerant

The invention provides an optimal design method for a plate-fin evaporator. The method has the following beneficial effects: based on the design theory of the heat exchanger, the heat exchange coefficient of the refrigerant side of the evaporator is used instead of the heat exchange coefficient of the single phase fluid and then the size of the evaporator core is obtained by solving the equation set; the evaporator designed by the method can meet the efficiency requirement and the fluid on the two sides can simultaneously meet the pressure drop requirement; and when the equation set is solved by an iterative method, the new iteration variable needs to be reasonably selected so as to ensure the numerical solution to converge faster.

Owner:BEIHANG UNIV

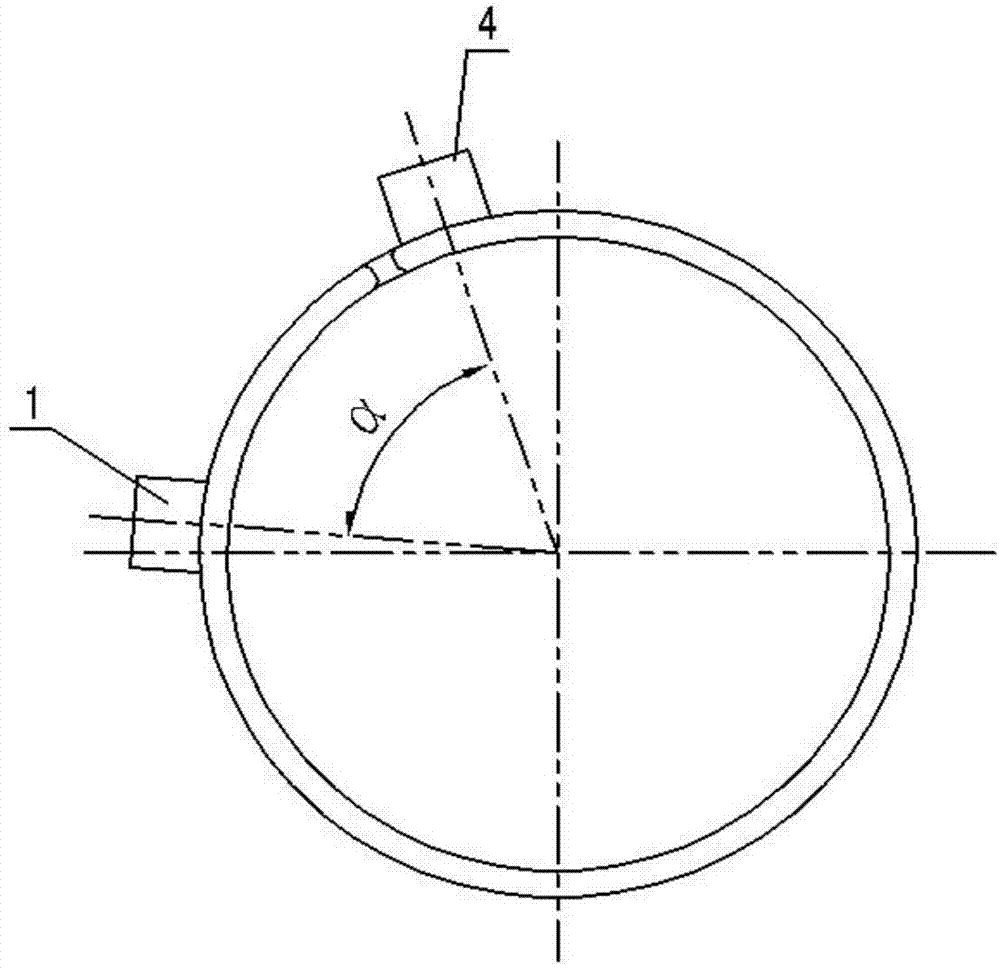

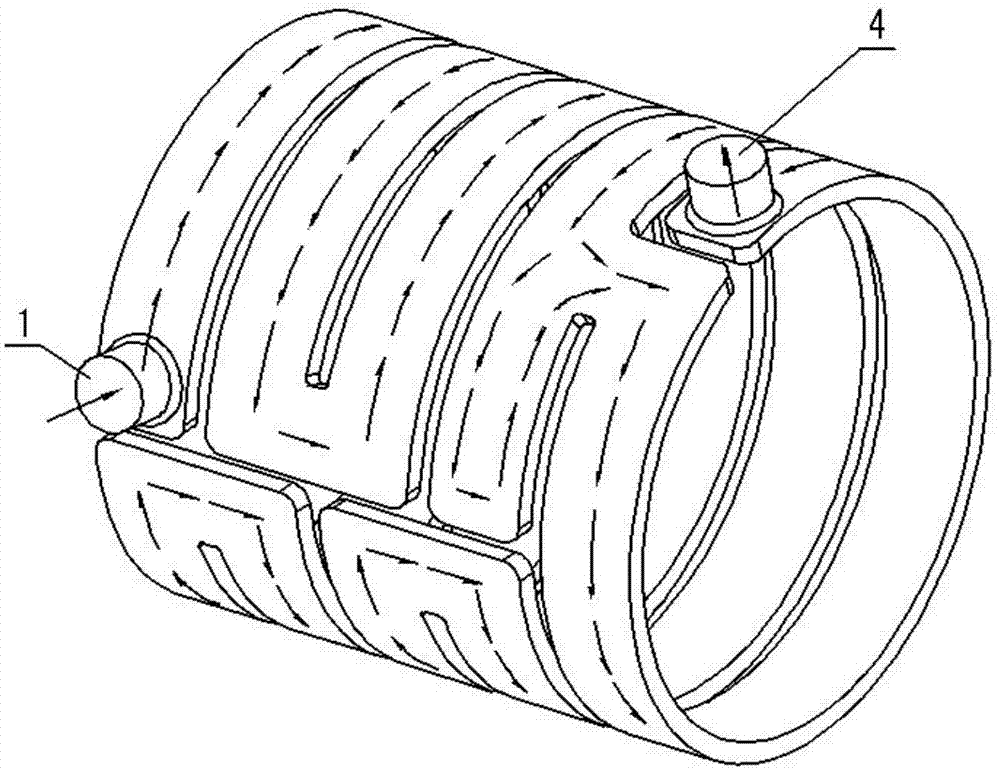

Equal-interval ring type motor cooling water channel

InactiveCN103490559AReduce temperature riseHigh working reliabilityCooling/ventillation arrangementSupports/enclosures/casingsWater channelWater flow

The invention discloses an equal-interval ring type motor cooling water channel. The motor cooling water channel is characterized in that all ring-shaped cavities which are distributed at equal intervals along the axial direction are communicated to form a continuous water flow channel, a cooling water inlet and a cooling water outlet of the water flow channel are respectively formed in a water inlet end ring and a water outlet end ring at the two ends, each ring-shaped cavity is in the shape of an opened ring with a flat rectangular surface, the adjacent ring-shaped cavities are connected end to end, i.e., the outlet of one ring-shaped cavity is communicated with the inlet of the next ring-shaped cavity, so that the water flows in the adjacent ring-shaped cavities oppositely flow along the circumference of the surface of a motor casing. The heat exchange coefficient and the heat exchange rate of a cooling system can be effectively improved, the temperature rise of a motor is reduced and the reliability of the motor is enhanced.

Owner:ANHUI JEE AUTOMATION EQUIP CO LTD

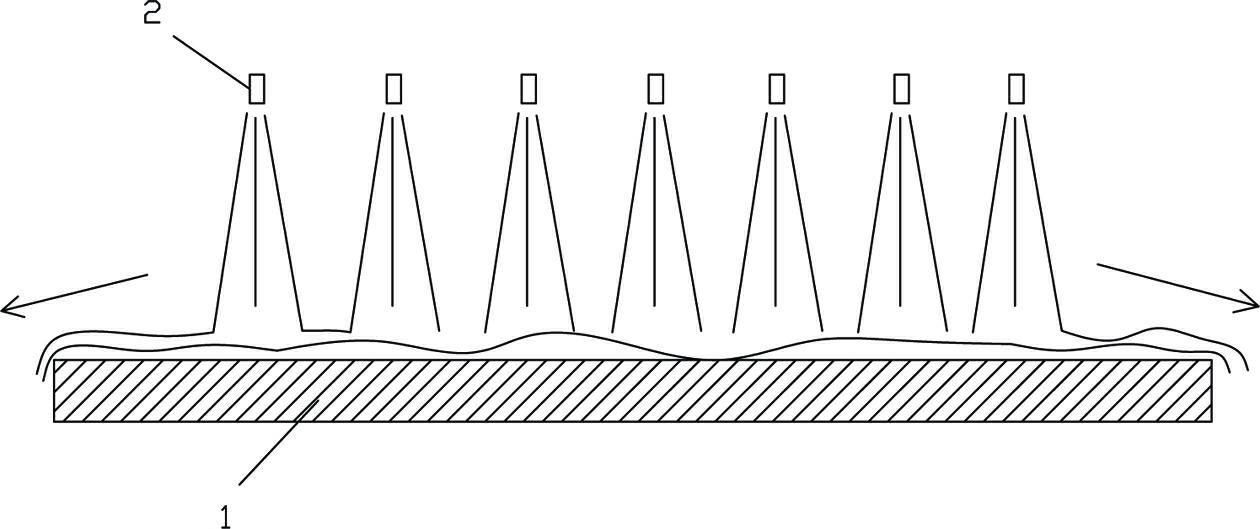

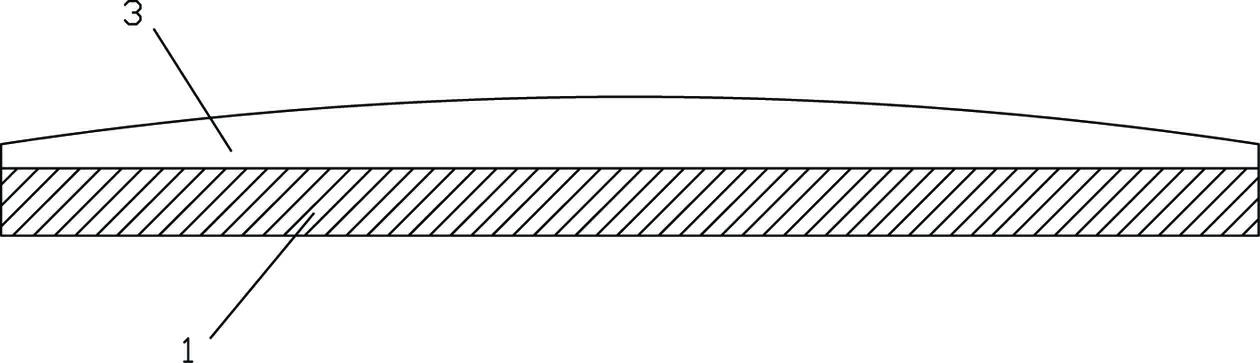

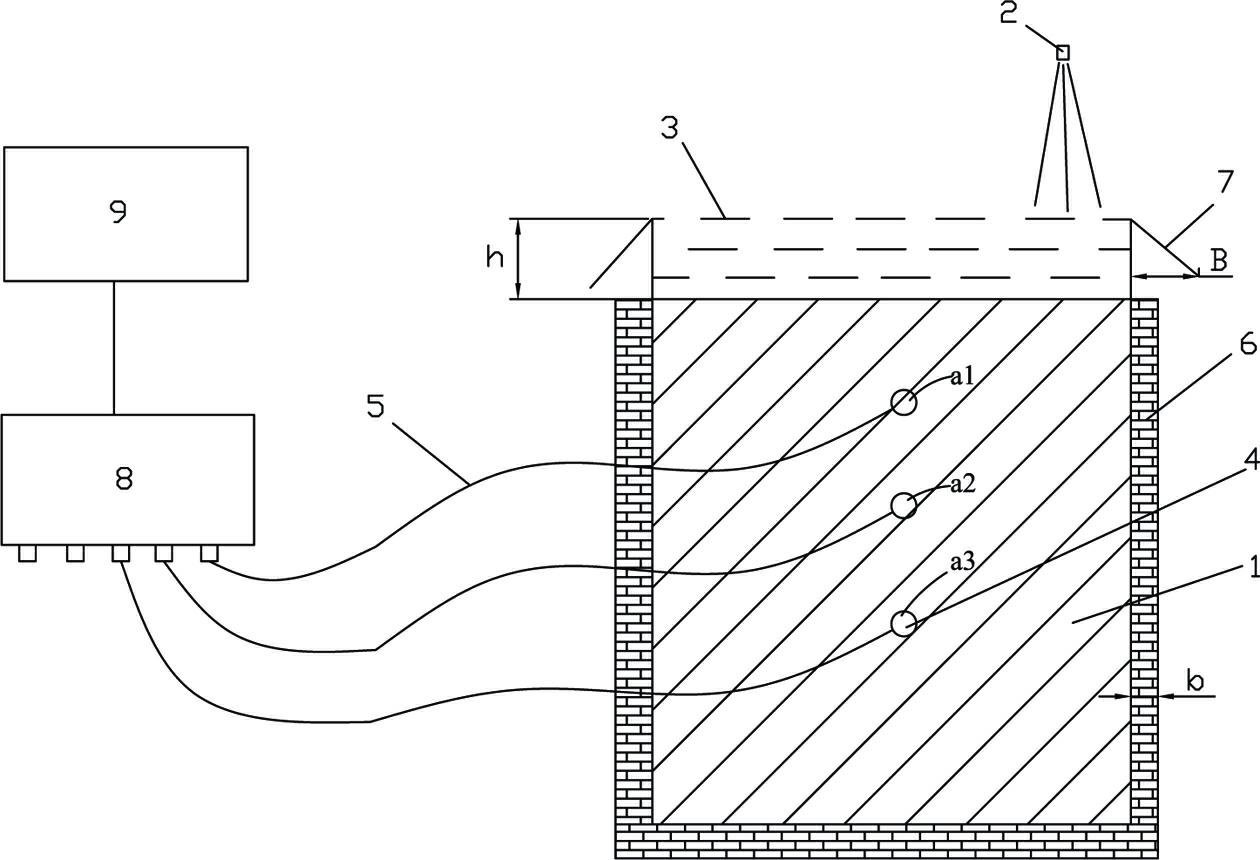

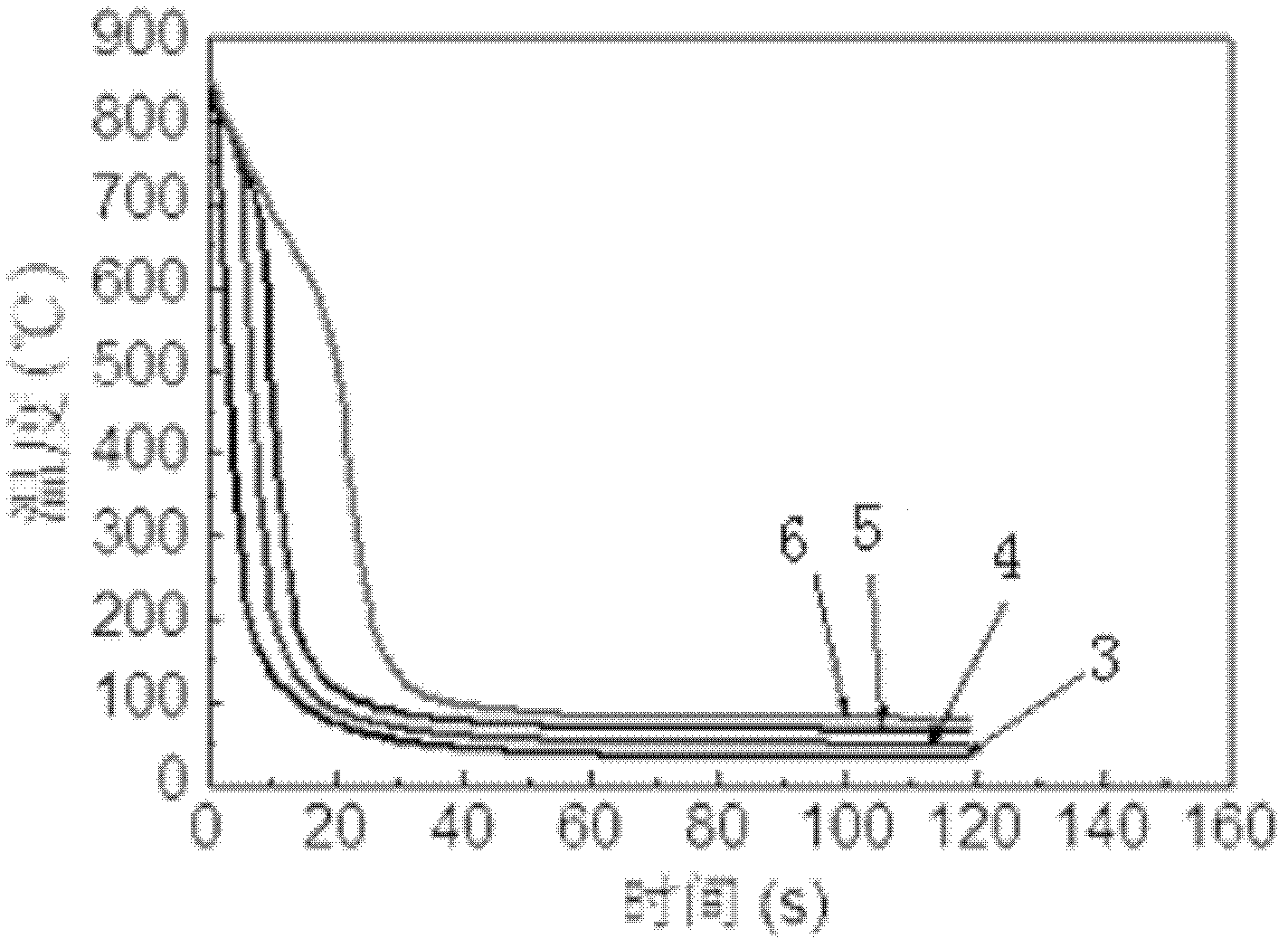

Method and device for testing heat exchange coefficients of steel plate with different water film thickness

InactiveCN102661969AAccurate Cooling ControlAvoid errorsMaterial heat developmentCooling curveData acquisition

The invention provides a method and a device for testing heat exchange coefficients of steel plates with different water film thicknesses. A cylindrical water film cofferdam is welded on the surface of a cylindrical steel plate, the height h of a cofferdam is equal to the tested thickness of the water film; three temperature measuring points are set in a direction perpendicular to cylindrical steel plate at a distance interval x, holes are drilled on the side face of the cylindrical steel plate at positions which are x / 2, x3 / 2 and x5 / away from the upper end face of the cylindrical steel plate, thermocouples are then placed in the holes, and the cold ends of the thermocouples are connected to a multi-channel data acquisition device; during experiment, a steel sample is placed in a heating furnace, then the data acquisition device is started to acquire the temperature; when the steel plate reaches an initial cooling temperature, the steel sample is taken out and placed in a heat-insulation tank which is placed under a spray nozzle, later the spray nozzle is opened to spray water onto the water film cofferdam and thus, and a water film is covered on the surface of the steel plate; and when the steel plate reaches a final cooling temperature, the temperature acquisition is stopped, and thus, the steel plate cooling curve T (t) based on different positions at the upper end face of the cylindrical steel plate is obtained. Therefore, the method and the device can test the heat exchange coefficient of the surface of the steel plates under a condition of different thicknesses of water films.

Owner:BAOSHAN IRON & STEEL CO LTD

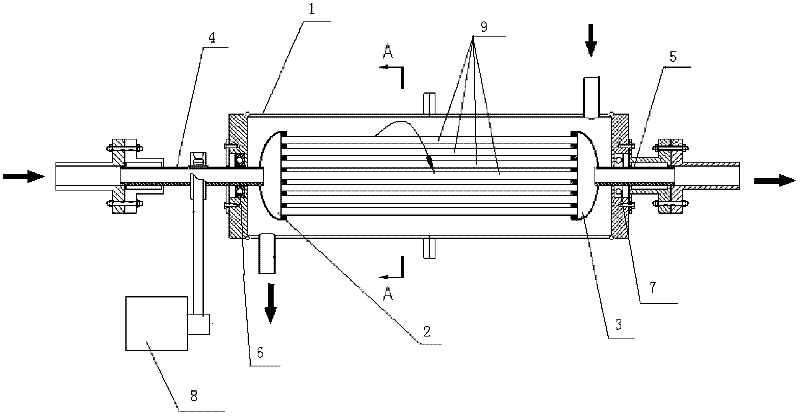

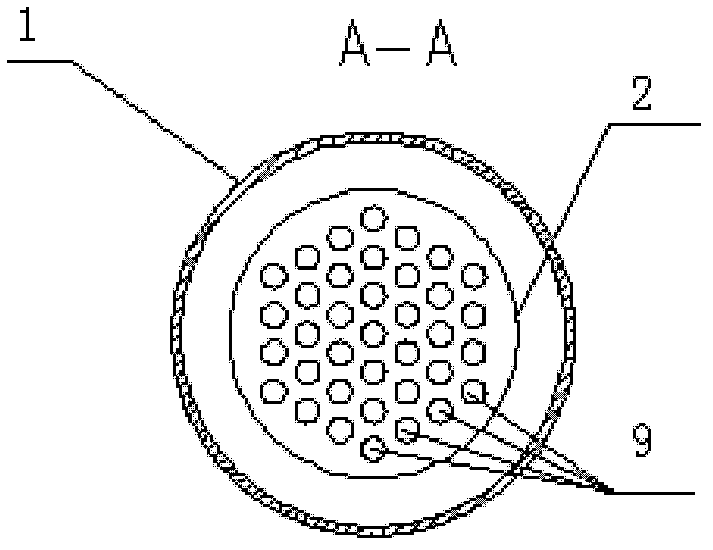

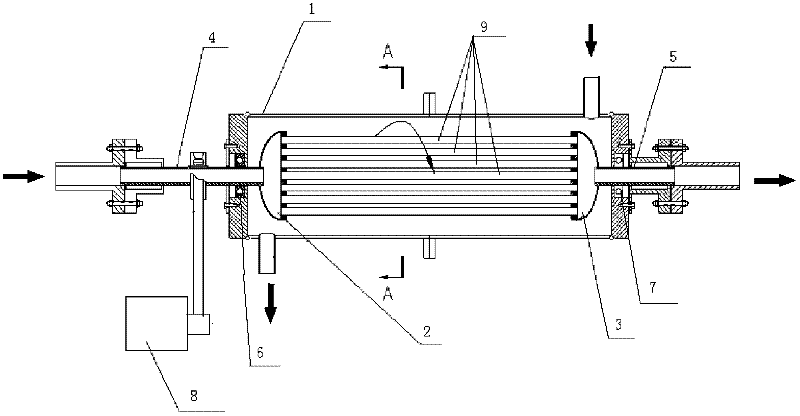

Rotary tube bundle heat exchanger

InactiveCN102538515AImprove heat transfer coefficientReduce volumeStationary tubular conduit assembliesHeat exchange apparatusEngineeringExchange coefficient

The invention belongs to the technical field of machinery, and relates to a rotary heat exchanger, in particular to a rotary tube bundle heat exchanger, which comprises a shell, a left tube plate, a right tube plate, a tube nest bundle, a motor, a rotating pipeline a, a rotating pipeline b, a bearing a and a bearing b. A fluid inlet and a fluid outlet are arranged at the upper end and the lower end of the shell respectively, through holes are arranged at the left end and the right end of the shell, annular grooves are arranged on the through holes, the left tube plate and the right tube plate are hemispherical, and the axis of the tube nest bundle is parallel to that of the shell. As the heat exchange coefficient of the rotary tube bundle heat exchanger is obtained without increasing the flow velocity of media, both a heat exchange medium a in an inner cylinder and a heat exchange medium b between the inner cylinder and an outer cylinder can enter the heat exchanger at a low speed, fluid resistance is greatly reduced, power needed for conveying fluids is remarkably decreased, and energy is saved.

Owner:NO 711 RES INST CHINA SHIPPING HEAVY IND GRP

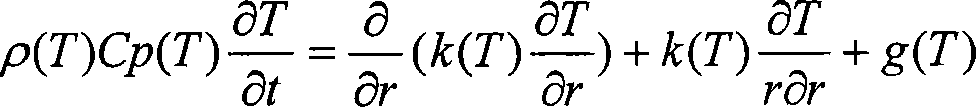

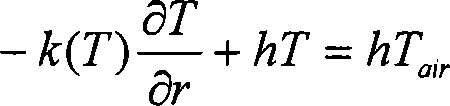

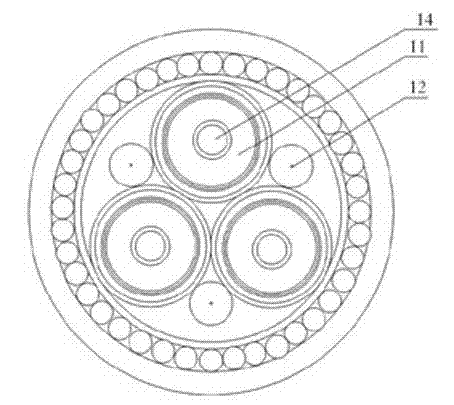

Method for modeling, calculating and analyzing temperature fields of photoelectric composite submarine cable

InactiveCN102880747AImprove accuracySpecial data processing applicationsElectrical conductorSteady state temperature

The invention discloses a method for modeling, calculating and analyzing temperature fields of a photoelectric composite submarine cable. The method comprises the following steps of: 1, establishing a geometric model of the photoelectric composite submarine cable in finite element analysis software ANSYS; 2, inputting material parameters of each composition material of the photoelectric composite submarine cable into the finite-element analysis software ANSYS, and establishing a finite element model of the photoelectric composite submarine cable; 3, setting the value range of hot load working current, environment temperature and convection heat exchange coefficients of the photoelectric composite submarine cable; 4, modeling an integral steady-state temperature field of the photoelectric composite submarine cable; 5, modeling a local heating steady-state temperature field of the photoelectric composite submarine cable; and 6, modeling a transient-state temperature field of the photoelectric composite submarine cable. The calculation accuracy of the temperature fields of the photoelectric composite submarine cable under complex structure and environment conditions is extremely high, a nonlinear mapping relation between a conductor and optical fiber temperature of the photoelectric composite submarine cable can be obtained without a large number of experiment data, and the method is simple and convenient.

Owner:SHANGHAI MARITIME UNIVERSITY

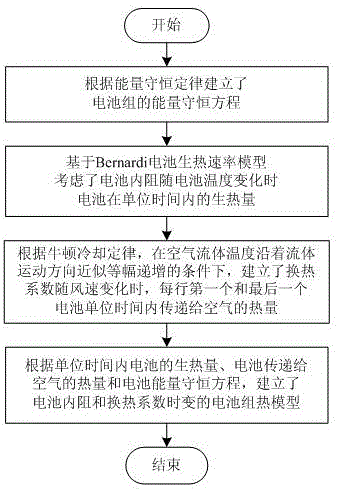

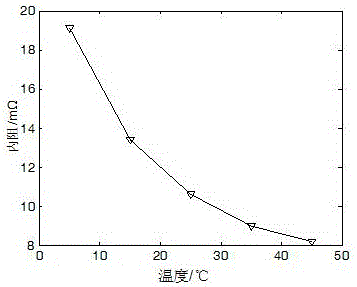

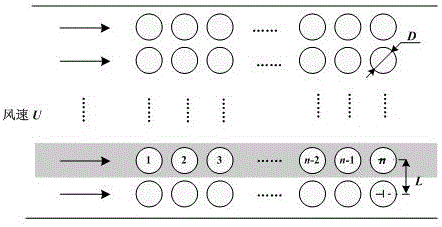

Thermal model modeling method for lithium ion battery pack based on air-cooling heat dissipating mode

InactiveCN106021810AGuaranteed accuracyReduce the difficulty of solvingComputer aided designSpecial data processing applicationsReduced modelInternal resistance

The invention relates to a thermal model modeling method for a lithium ion battery pack based on an air-cooling heat dissipating mode, and belongs to the technical field of batteries. According to the purpose, the thermal model modeling method for the lithium ion battery pack based on the air-cooling heat dissipating mode considers battery internal resistance and heat exchange coefficient time-varying condition, ensures model precision and reduces model solution difficulty. According to an energy conservation equation of the lithium ion battery pack, battery internal resistance data within the temperature range of 25-45 DEG C is fitted to obtain a linear function relational expression between the battery internal resistance and battery temperature, and finally a heat model of the monomer lithium ion battery is finally obtained. The defects that analytical solution cannot be obtained from an existing battery pack heat model, model accuracy is low, and the number of variables to be solved is large are overcome. The battery internal resistance and the heat exchange coefficient time-varying condition are considered, the analytical solution of the battery pack temperature can be obtained, model accuracy is ensured, the model solution difficulty is reduced, the number of variables to be solved is reduced, and a theoretical basis is provided for online estimating temperature of the lithium ion battery pack.

Owner:JILIN UNIV

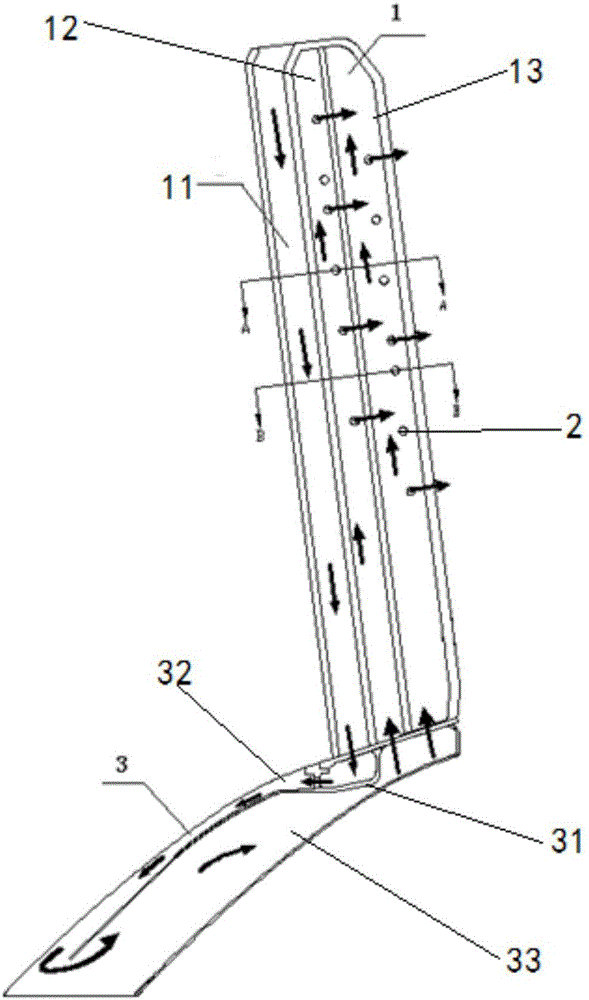

Anti-icing system of engine

ActiveCN106762147AHot air temperature is highGuaranteed heat transfer coefficientGas turbine plantsJet propulsion plantsLeading edgeEngineering

The invention discloses an anti-icing system of an engine. The anti-icing system of the engine comprises a rectifying supporting plate and a rectifying cover hood. The rectifying supporting plate comprises a first cavity, a second cavity and a third cavity. The first cavity, the second cavity and the third cavity are adjacent to one another. Exhaust holes are formed in the second cavity and the third cavity of the rectifying supporting plate. The rectifying cover hood communicates with the rectifying supporting plate. A partition plate is arranged in the rectifying cover hood. The rectifying cover hood is divided into a first partitioned cavity and a second partitioned cavity through the rectifying cover hood. The first partitioned cavity communicates with the second partitioned cavity. The first partitioned cavity communicates with the first cavity. The second partitioned cavity communicates with the second cavity and the third cavity. According to the anti-icing system of the engine, ice prevention is conducted through the pipe flow heat exchange mode, the hot air is high in temperature and flow, the heat exchange coefficient of the supporting plate leading edge and the side wall of the first cavity of the rectifying supporting plate is guaranteed, and the heat exchange effect from the top to the bottom of the whole first cavity of the rectifying supporting plate is guaranteed.

Owner:AECC SHENYANG ENGINE RES INST

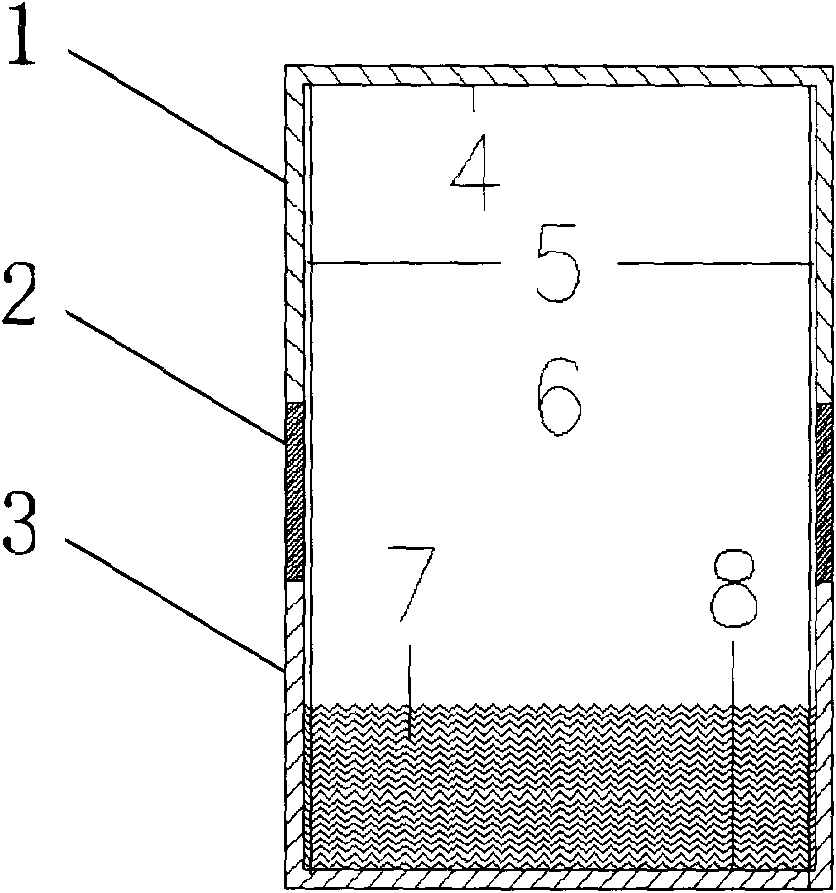

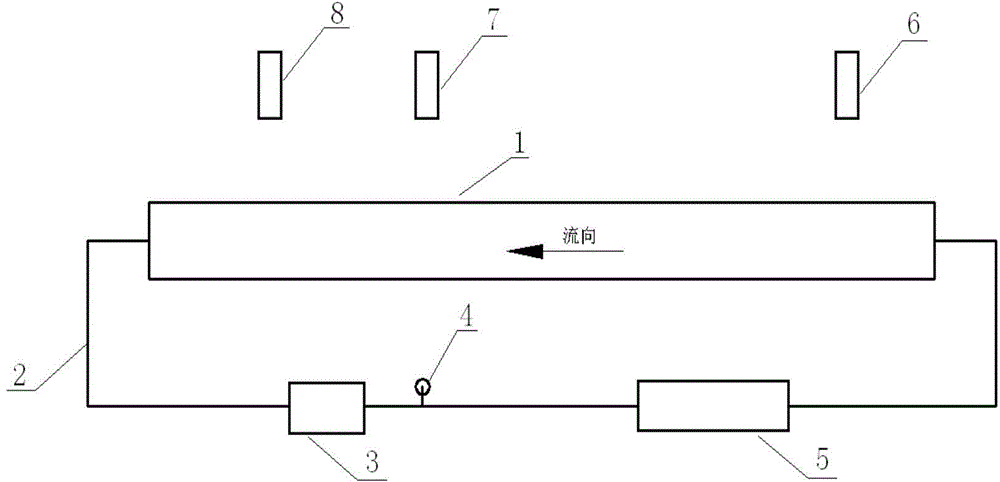

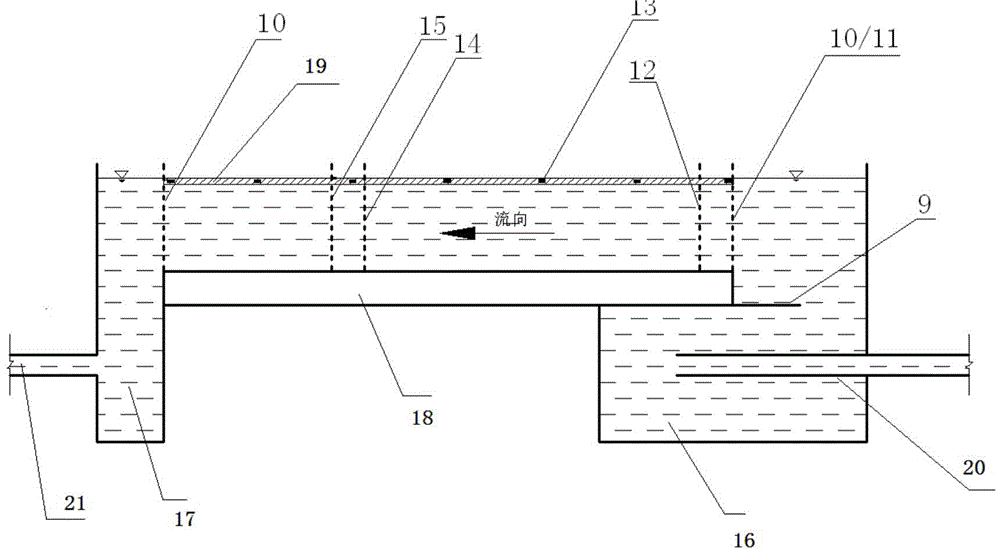

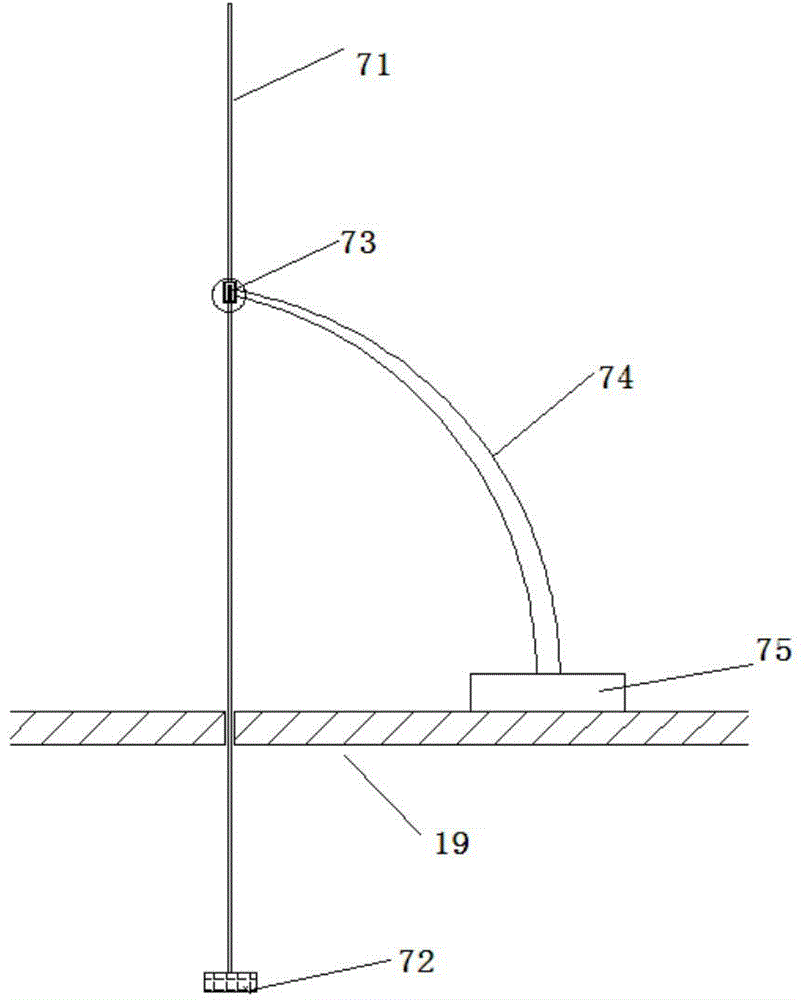

Ice water heat exchange coefficient experimental apparatus and measurement method

The invention provides an ice water heat exchange coefficient experimental apparatus which comprises a water tank 1, a water pump 3, a gate valve 4, a thermoregulator 5, a current meter 6, an ice thickness change measuring instrument 7 and a temperature recorder 8, wherein the water pump 3, the gate valve 4 and the thermoregulator 5 are sequentially connected through a pipeline 2 and form a loop; measurement probes of the current meter 6 and the temperature recorder 8 are positioned in the water tank 1; a measurement probe of the ice thickness change measuring instrument 7 is positioned in an ice layer 19 and water in the water tank. The invention also provides a method for measuring an ice water heat exchange coefficient by utilizing the device. The device well simulates reservoir icing and low-flow speed water flow conditions, acquires an ice water heat exchange coefficient of a corresponding reservoir and provides a design basis for water conservancy projects, also avoids the difficulty of developing reservoir ice water heat exchange coefficient prototype measurement in a rushing frigid zone reservoir area and provides great convenience and implementation possibility for research.

Owner:SICHUAN UNIV

Volume heat exchange heat absorber for solar heat generation system

InactiveCN102353153AIncrease the convective heat transfer areaImprove heat transfer effectSolar heating energySolar heat devicesCold airGlass cover

Owner:HUNAN UNIV

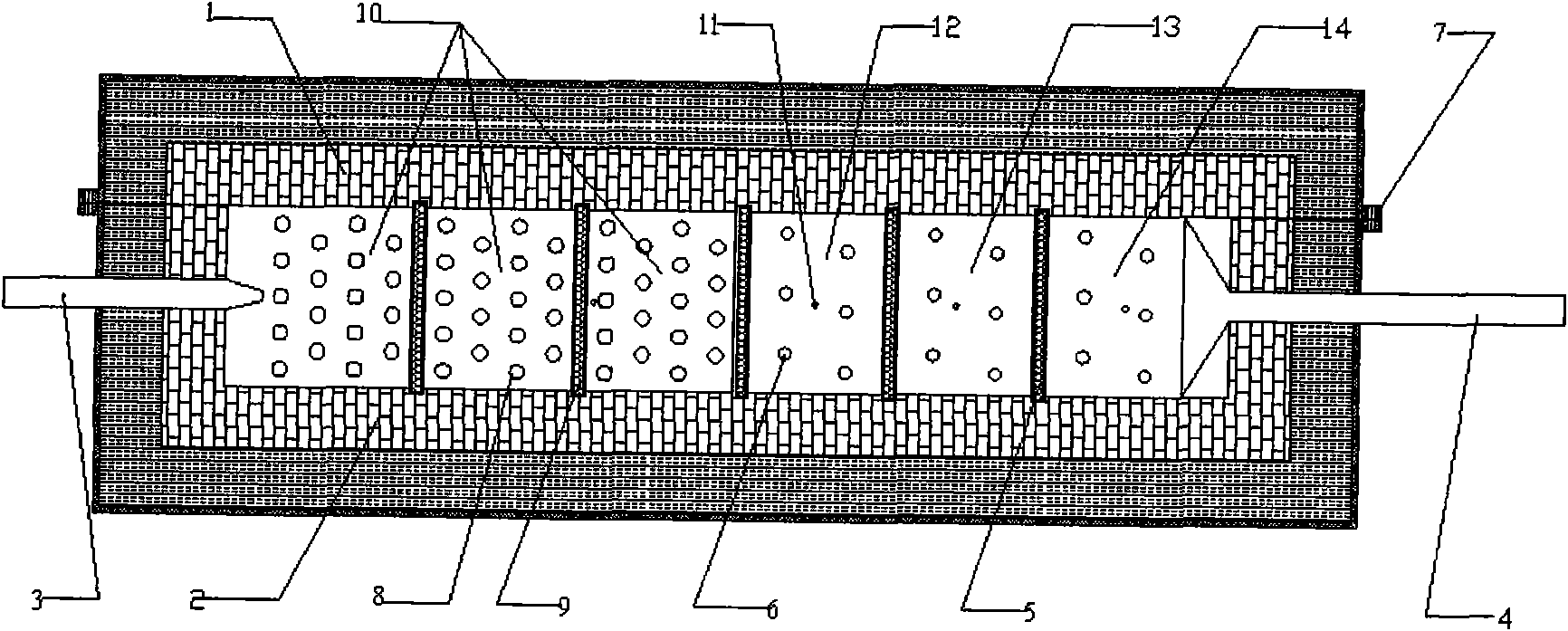

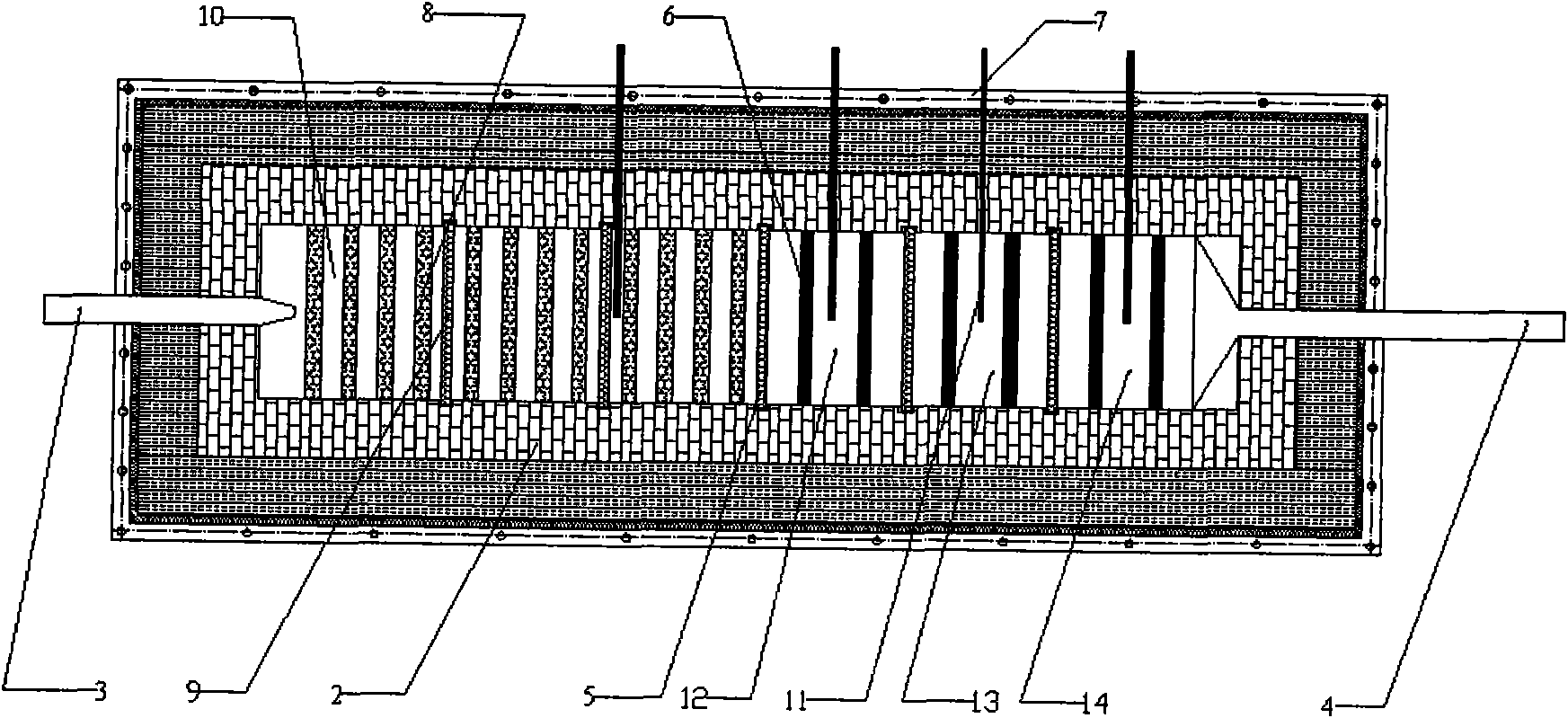

High-temperature air resistance furnace using silicon carbide foamed ceramic to enhance radiation absorption

InactiveCN101922796AIncrease heat transfer areaIncrease the heat exchange areaAir heatersTemperature resistanceCeramic foam

The invention provides a high-temperature air resistance furnace using silicon carbide ceramic foam to enhance radiation absorption, and a heating source is supplied for the high-temperature air resistance furnace by adopting a mode of combined heating of an electric filament heat rod (6) and a silicon carbide rod (8). By using the characteristic that the silicon carbide foamed ceramic absorbs heat radiation and has high temperature resistance and large specific surface area, a silicon carbide foamed ceramic body (5) with certain thickness and porosity and a silicon carbide ceramic foam sheet (9) are inserted in a high-temperature air resistance furnace body (2) to increase the heat transfer area of the high-temperature air resistance furnace, improve the convective heat exchange coefficient of the air, obtain high-temperature air, and reduce the volume of the air resistance furnace. The high-temperature air resistance furnace body (2) is divided into four heating regions by the silicon carbide foamed ceramic body (5), namely a pre-heating region, a medium-low temperature heating region, a medium-high temperature heating region and a high temperature heating region. The silicon carbide foamed ceramic sheet (9) and the silicon carbide foamed ceramic body (5) absorb heat radiation of the electric filament heat rod (6) and the silicon carbide rod (8).

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

Method for calculating quenching medium heat exchange coefficient by combining finite element method with inverse heat conduction method

ActiveCN102521439AGuaranteed credibilityGuaranteed accuracySpecial data processing applicationsCooling curveElement model

The invention discloses a method for calculating a quenching medium heat exchange coefficient by combining a finite element method with an inverse heat conduction method, which relates to a method for calculating a quenching medium heat exchange coefficient. The method comprises the following steps of: using a probe body, testing by an experiment to obtain the cooling curve of an internal point of the body, establishing a finite element model of the probe body, simulating a temperature field, and verifying the one-dimensional property of a problem; establishing a one-dimensional heat conduction micro equation and a sensitive coefficient equation under a coordinate system, and solving the heat-flow density value of the surface of the body surface by using the inverse heat conduction method; and verifying the measured temperature of the internal point of the probe in comparison to a calculated value, namely the heat exchange coefficient of the quenching medium calculated according to the Newton heat exchange law, so that the solution accuracy is ensured. The method is used for calculating the heat exchange coefficient of quenching medium.

Owner:HARBIN INST OF TECH

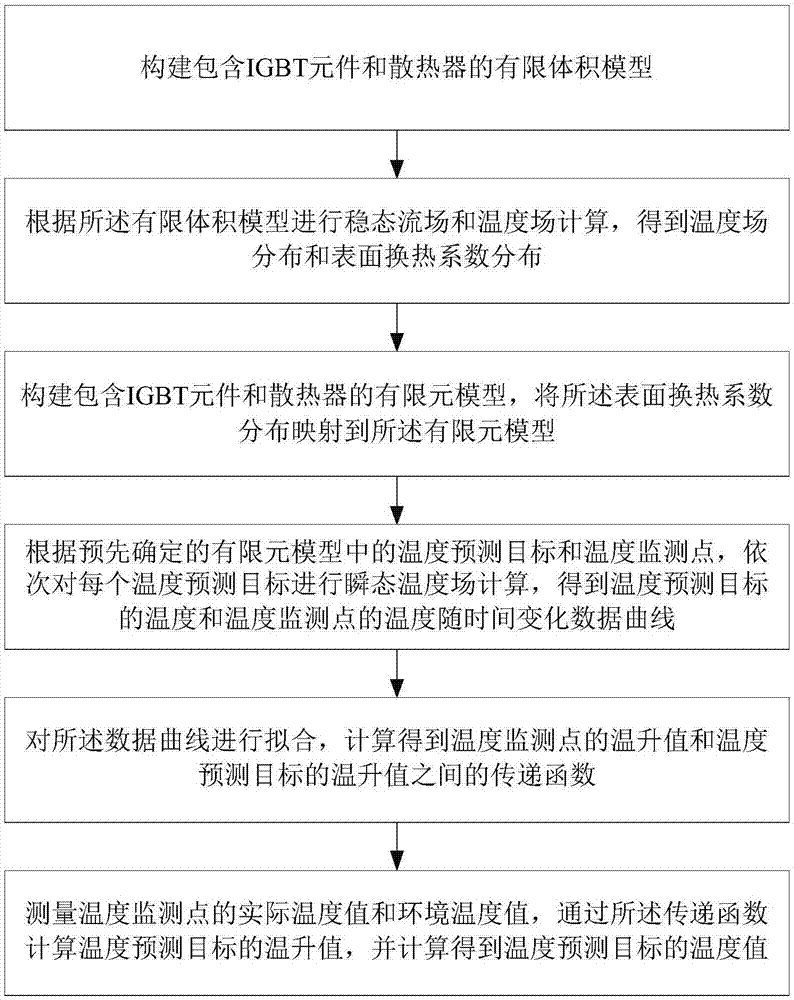

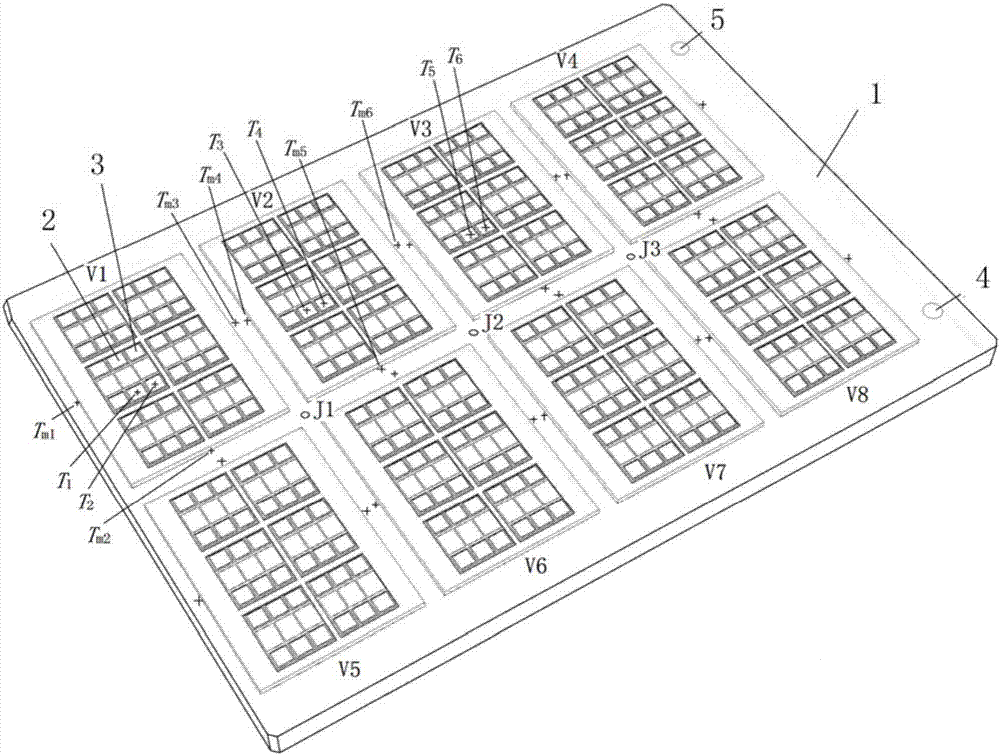

Method for online estimation of IGBT element junction temperature

InactiveCN106960085ACompleteness is not requiredFast predictionDesign optimisation/simulationSpecial data processing applicationsElement modelTemporal change

The invention discloses a method for online estimation of IGBT element junction temperature. The method comprises the steps that S1, a finite volume model is constructed; S2, temperature field distribution and surface heat exchange coefficient distribution are calculated according to the finite volume model; S3, a finite element model is constructed, and the surface heat exchange coefficient distribution is mapped to the finite element model; S4, according to predetermined temperature prediction targets and temperature monitoring points, transient temperature field calculation is performed on all the temperature prediction targets in sequence, and a data curve of changes of temperature of the temperature prediction targets and temperature of the temperature monitoring points over time is obtained; S5, the data curve is fitted, and a transfer function between temperature rise values of the temperature monitoring points and temperature rise values of the temperature prediction targets is obtained; and S6, actual temperature values and environment temperature values of the temperature monitoring points are measured, the temperature rise values of the temperature prediction targets are calculated through the transfer function, and temperature values of the temperature prediction targets are obtained through calculation. The method has the advantages that the integrity of elements does not need to be damaged, prediction speed is high, and accuracy is high.

Owner:ZHUZHOU CSR TIMES ELECTRIC CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com