Patents

Literature

88results about How to "Increase the convective heat transfer area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

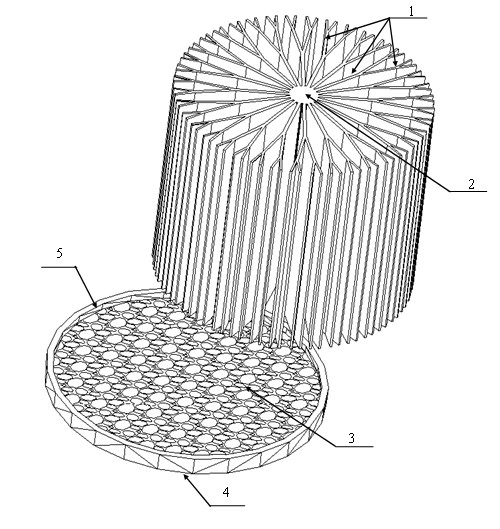

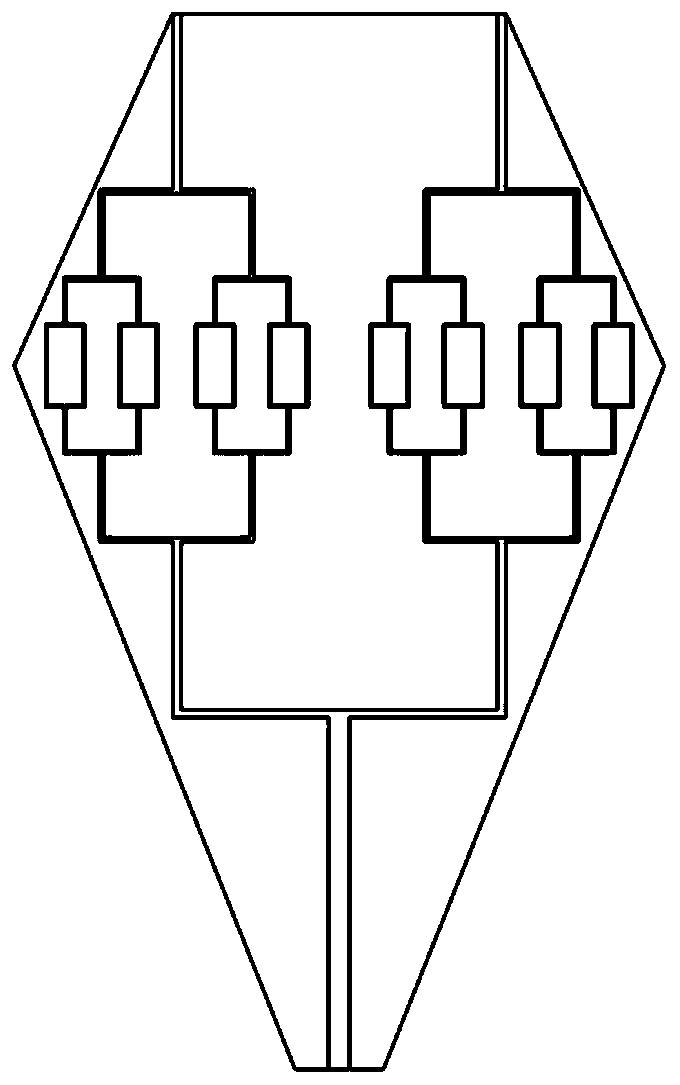

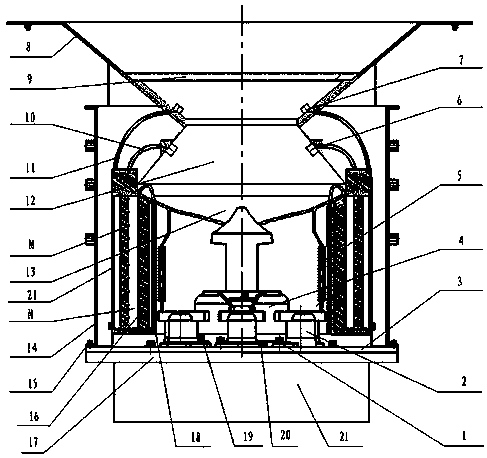

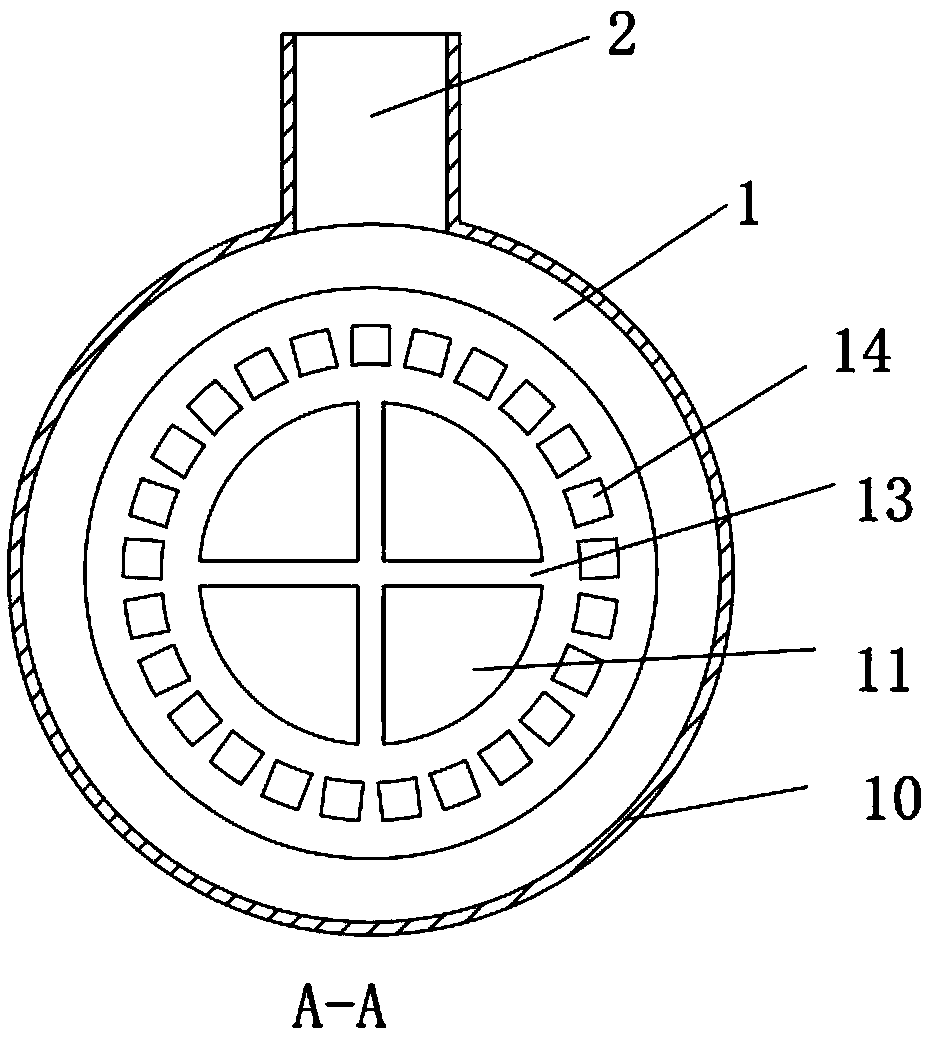

Configurational tree-shaped heat pipe radiator

ActiveCN102034773AImprove cooling effectReduce the temperature level of the heating surfaceSemiconductor/solid-state device detailsSolid-state devicesHeat flowEngineering

The invention discloses a configurational tree-shaped heat pipe radiator. The radiator consists of a high-thermal conductivity base plate, liquid-absorption cores, a radiating fin and working media, wherein narrow cavities are formed inside the base plate; the radiating fin is connected with the narrow cavities; communicated cavities are formed inside the radiating fin; the liquid-absorption cores are filled in the narrow cavities; the working media are filled in the narrow cavities and the communicated cavities; the radiating fin has a configurational tree-shaped structure and consists of a main communicated channel and at least two forked connection fins; the forked connection fins are arranged at the periphery of the main communicated channel circularly; and the communicated cavities inside the forked connection fins are communicated with the main communicated channel. The heat pipe radiator can quickly remove the heat which is generated by a plurality of (a single) local high-temperature heat flow heat source points (point) through phase change of the working media, so that local hot points are effectively eliminated, temperature of a heating surface of the heat pipe radiator is reduced, and safe, stable and efficient operation of electronic equipment is further guaranteed.

Owner:SOUTHEAST UNIV

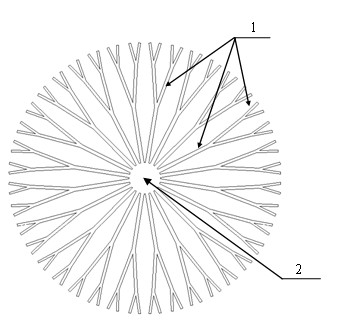

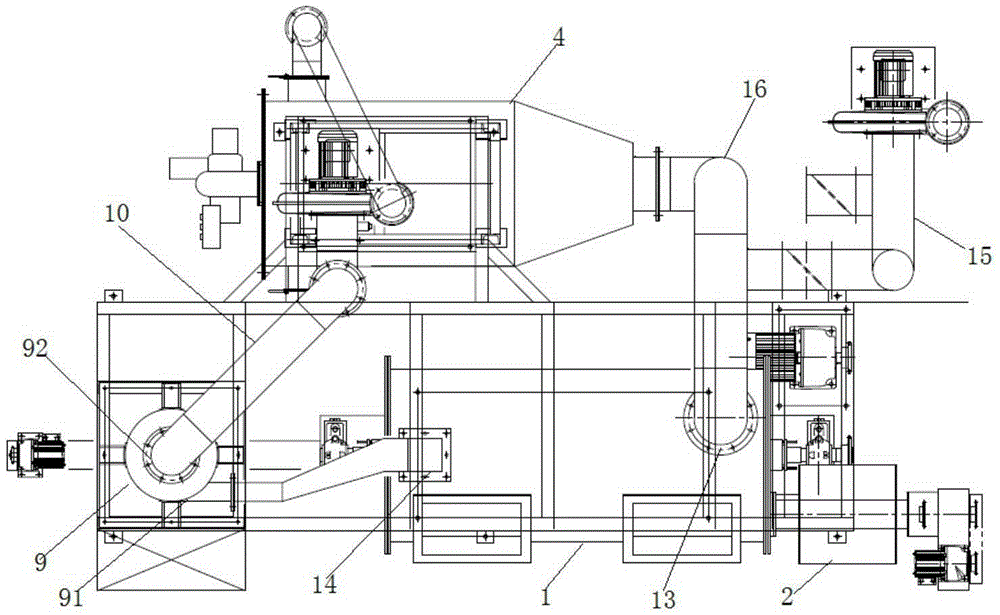

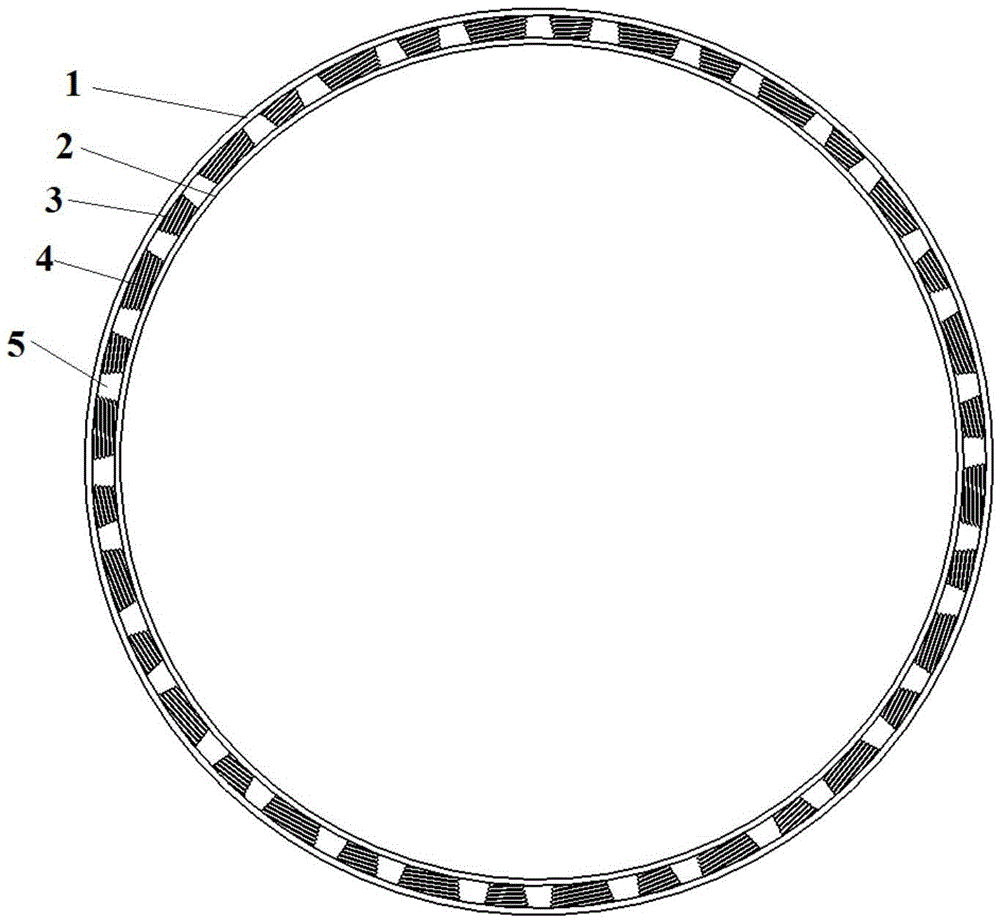

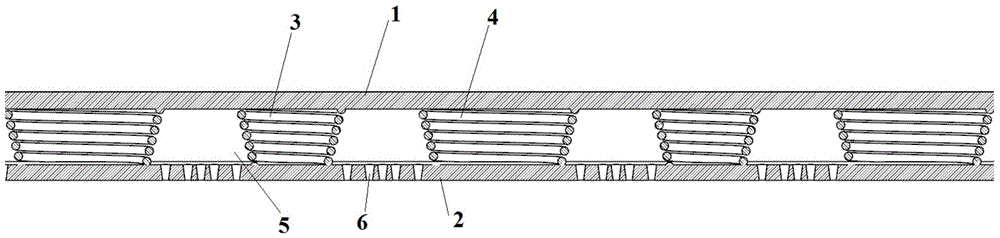

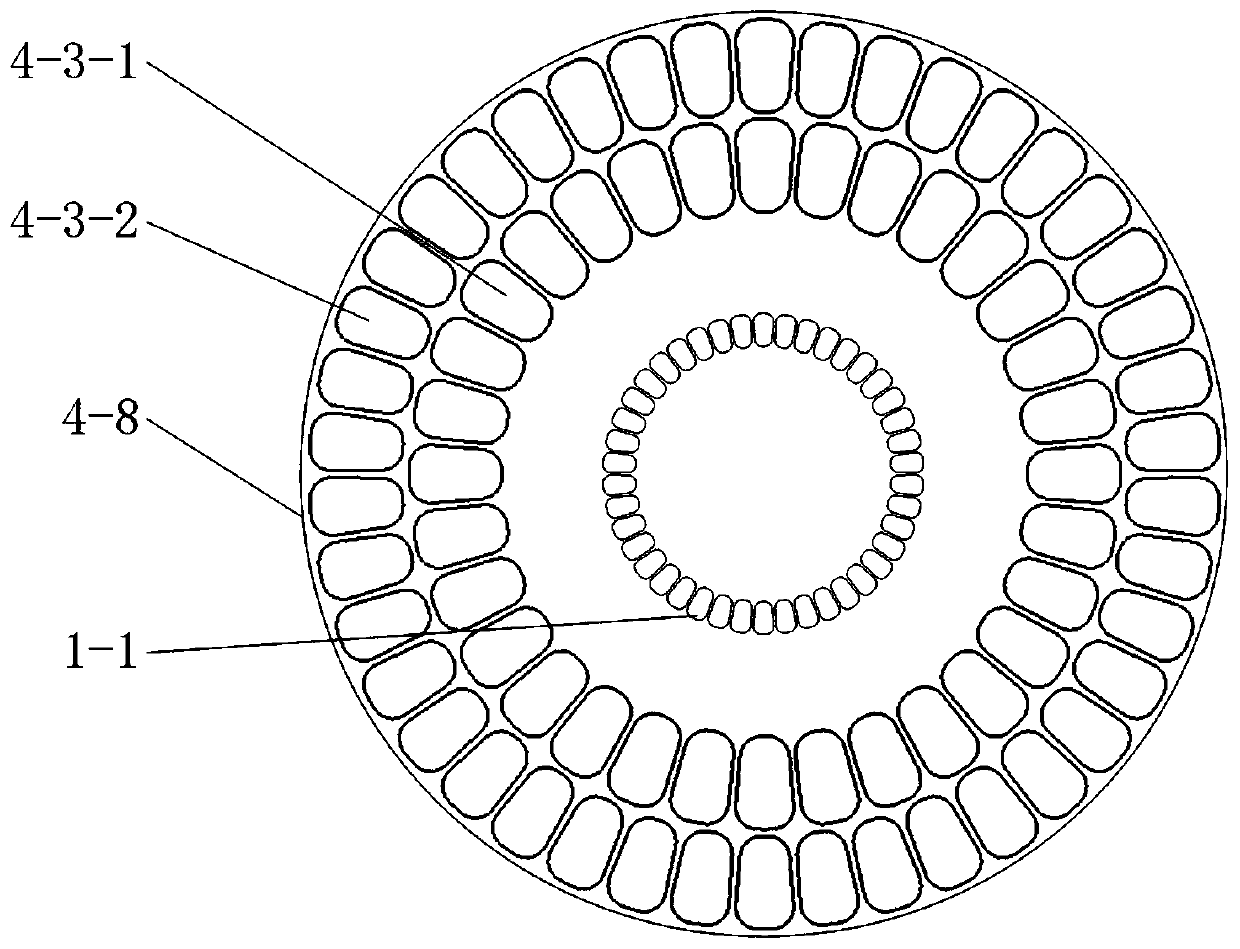

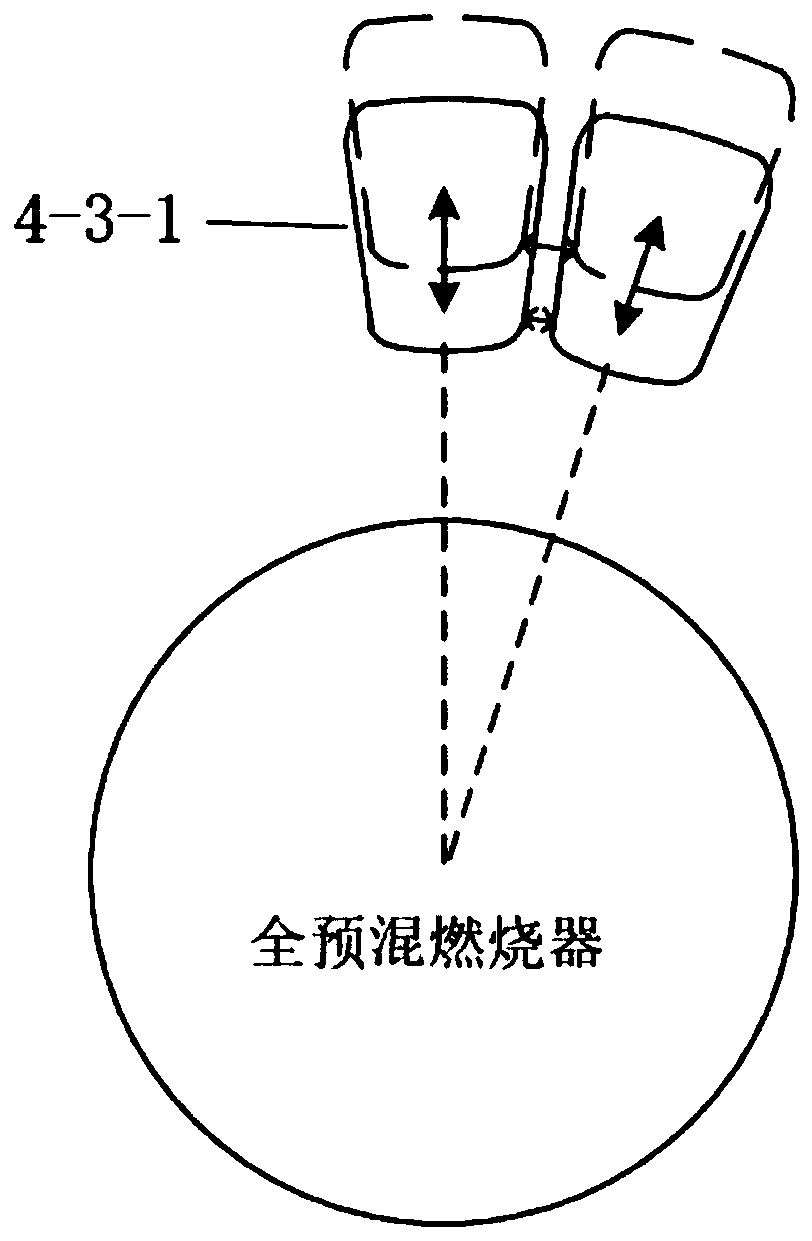

High-adjustment-ratio water-cooling premixed combustion high-strength heat exchange gas condensation boiler

PendingCN111141028AFully absorb radiation heat transferEnhanced radiation heat transferAir heatersGaseous fuel burnerCombustorAir blower

The invention provides a high-adjustment-ratio water-cooling premixed combustion high-strength heat exchange gas condensation boiler. The high-adjustment-ratio water-cooling premixed combustion high-strength heat exchange gas condensation boiler comprises a combustor and a heat exchanger, wherein the full-premixed combustor mounted in the center of a boiler top plate consists of a booster fan, a premixing chamber and a water-cooling combustion head; a flame stabilizing pipe and an anti-tempering column of the water-cooling combustion head can realize high-adjustment-ratio water-cooling premixed combustion; the heat exchanger consists of a lap of water-cooling wall and one or more laps of fins uniformly arranged in the peripheral direction by bent edge folding fin pipes; an air blower feedsair into the premixing chamber for fully mixing with gas to enter an inner cavity of a hole plate of the combustion head; the air flows out from a fire hole, and is sprayed out from narrow gaps amongthe water-cooling pipes distributed in the peripheral direction; after the air flows out from the flame stabilizing pipe, the air is ignited to uniformly combust in the peripheral direction and the axial direction, and radiates and releases heat to an inner pipe ring; smoke flushes base pipes and fins of inner and outer ring fin pipes in sequence to reinforce heat exchange; and the smoke downwards flows into a dew bearing disc through gaps between a housing and an outer layer fin pipe, and is exhausted into atmosphere from a smoke outlet. The high-adjustment-ratio water-cooling premixed combustion high-strength heat exchange gas condensation boiler is high in combustion load adjustment ratio, compact in heat exchange, low in nitrogen emission and high in heat efficiency.

Owner:XI AN JIAOTONG UNIV +1

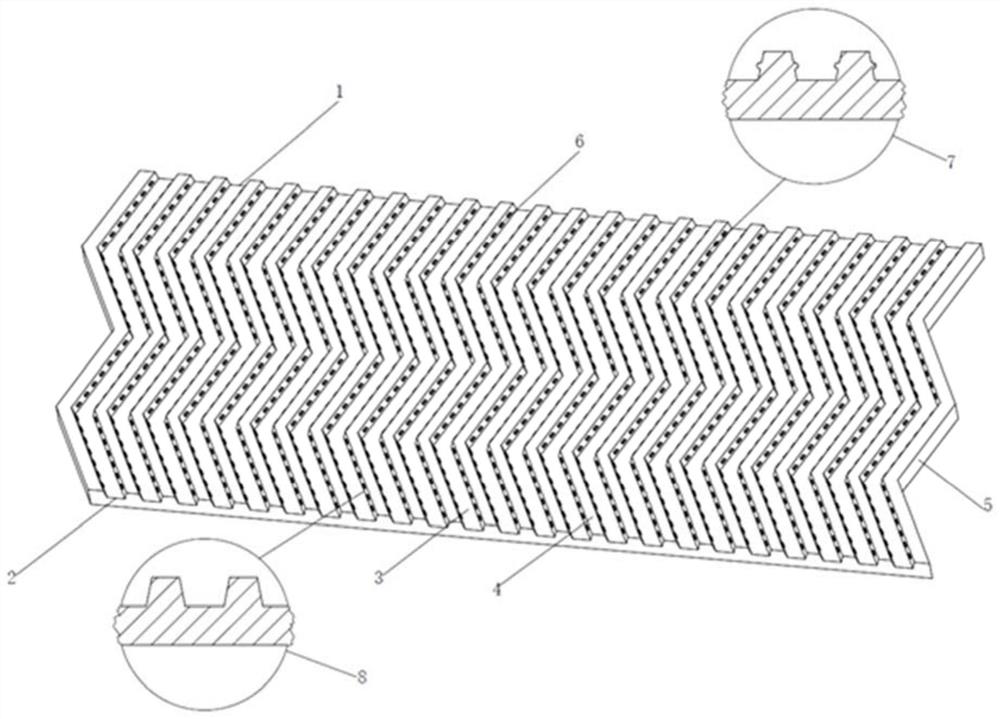

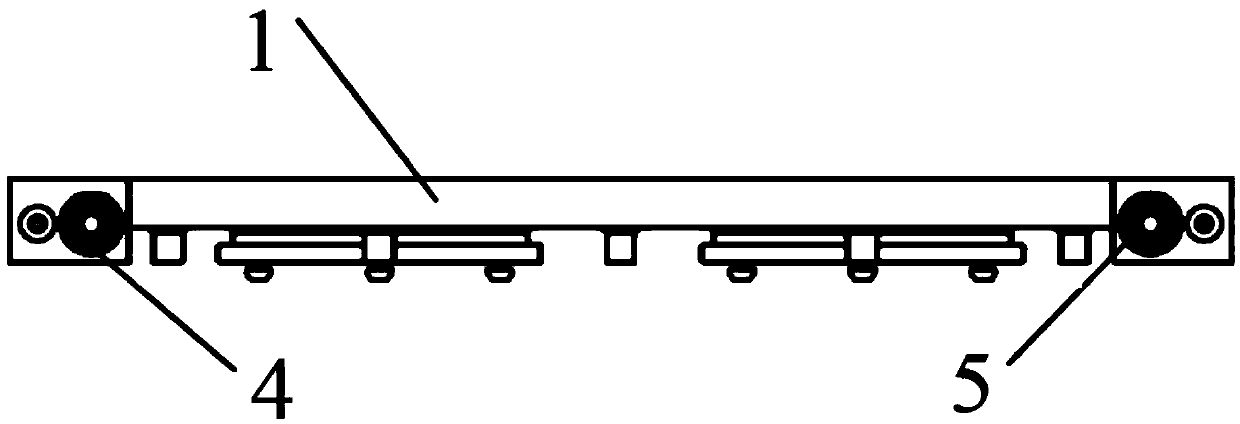

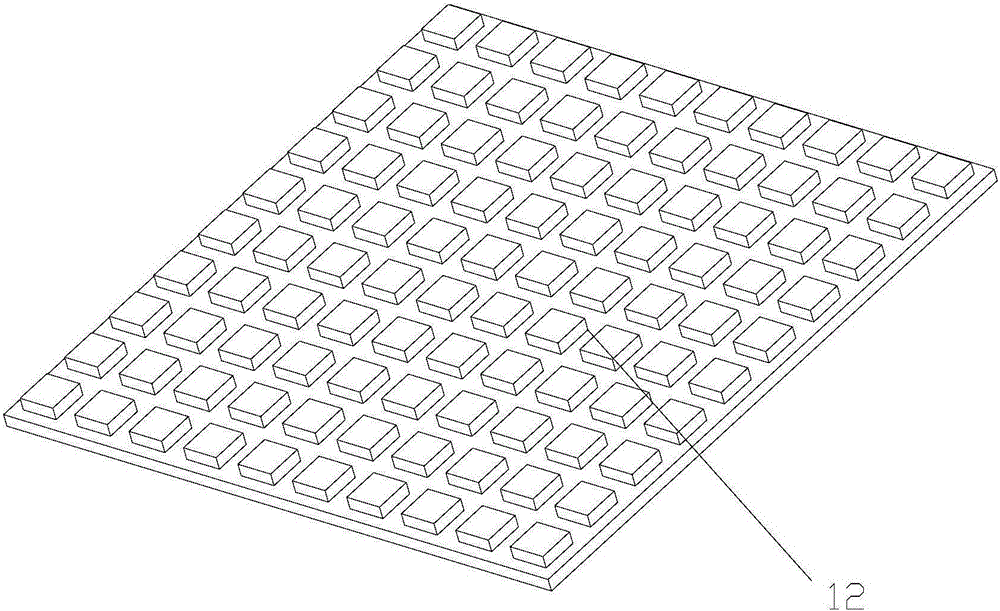

Fuel cell flow field plate and fuel cell

InactiveCN112133938AReduce accumulationEnhance the flow field mass transfer and heat conduction capacityCollectors/separatorsEngineeringEnvironmental geology

The invention provides a fuel cell flow field plate and a fuel cell, and relates to the field of fuel cells. The fuel cell flow field plate is mainly suitable for hydrogen-air fuel cells and hydrogen-oxygen fuel cells. The fuel cell flow field plate comprises a flow field plate body, an air inlet, an air outlet, a flow channel, flow channel ridges and bosses, and the flow channel and the flow channel ridges are both arranged on the flow field plate; fluid enters the flow channel from the air inlet and flows out from the air outlet; and the flow channel ridges are arranged on the two sides of the flow channel, and the bosses are arranged on the side faces of the flow channel ridges in the flow channel direction at certain intervals. By introducing the boss structure, local turbulence is generated, and mass transfer and heat transfer of reaction gas to a gas diffusion layer are enhanced; the wall surface of the flow channel is divided by the bosses, so that the effective contact area ofliquid drops and the wall surface of the flow channel is reduced, a continuous water film is prevented from being formed, liquid water in the flow channel is not easy to accumulate, and the phenomenonof 'flooding' is relieved; and the boss structure also increases the convective heat exchange area, so that the heat exchange capacity of the flow field is enhanced, and the temperature distributionof the flow field is improved.

Owner:SHANGHAI JIAO TONG UNIV

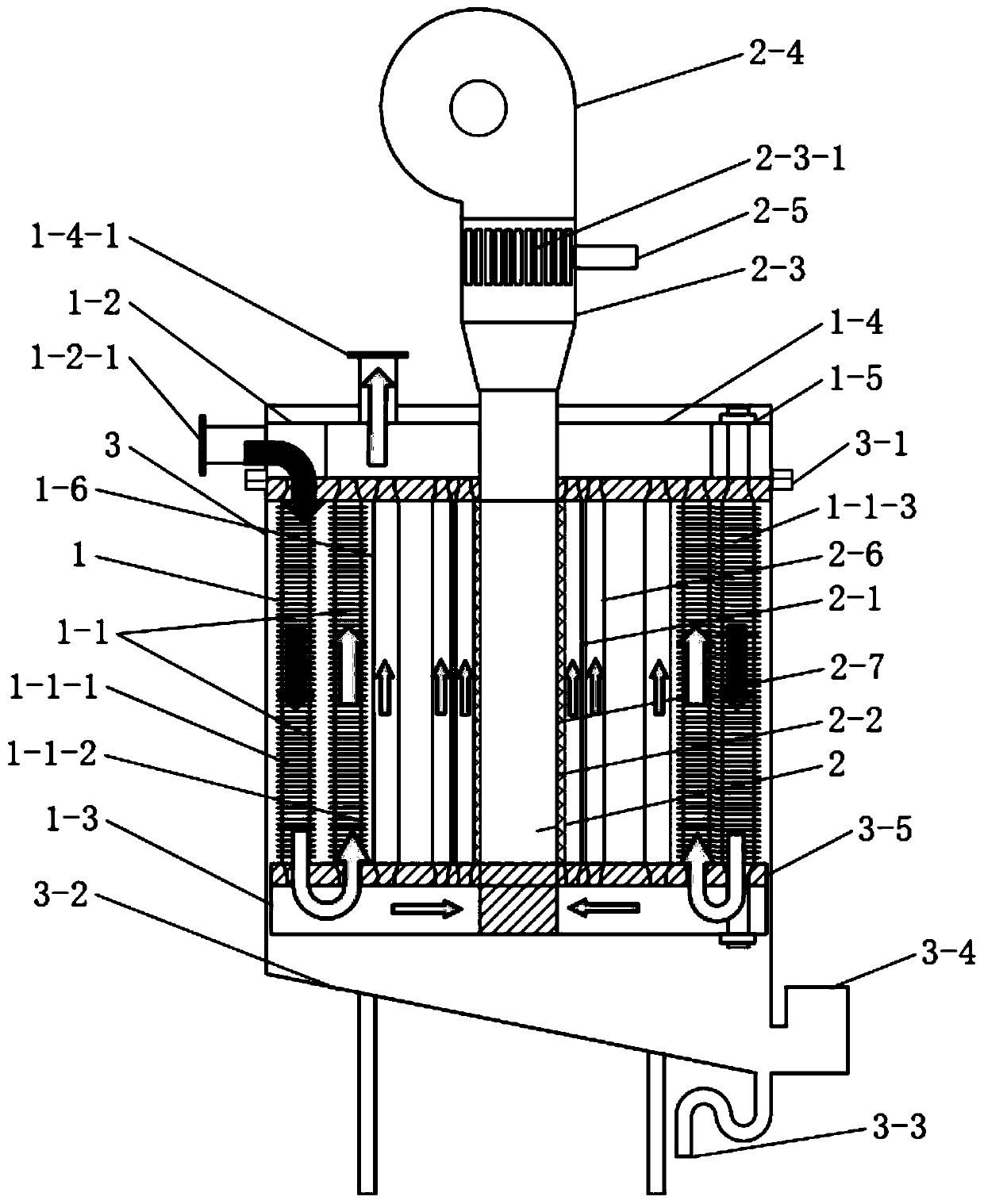

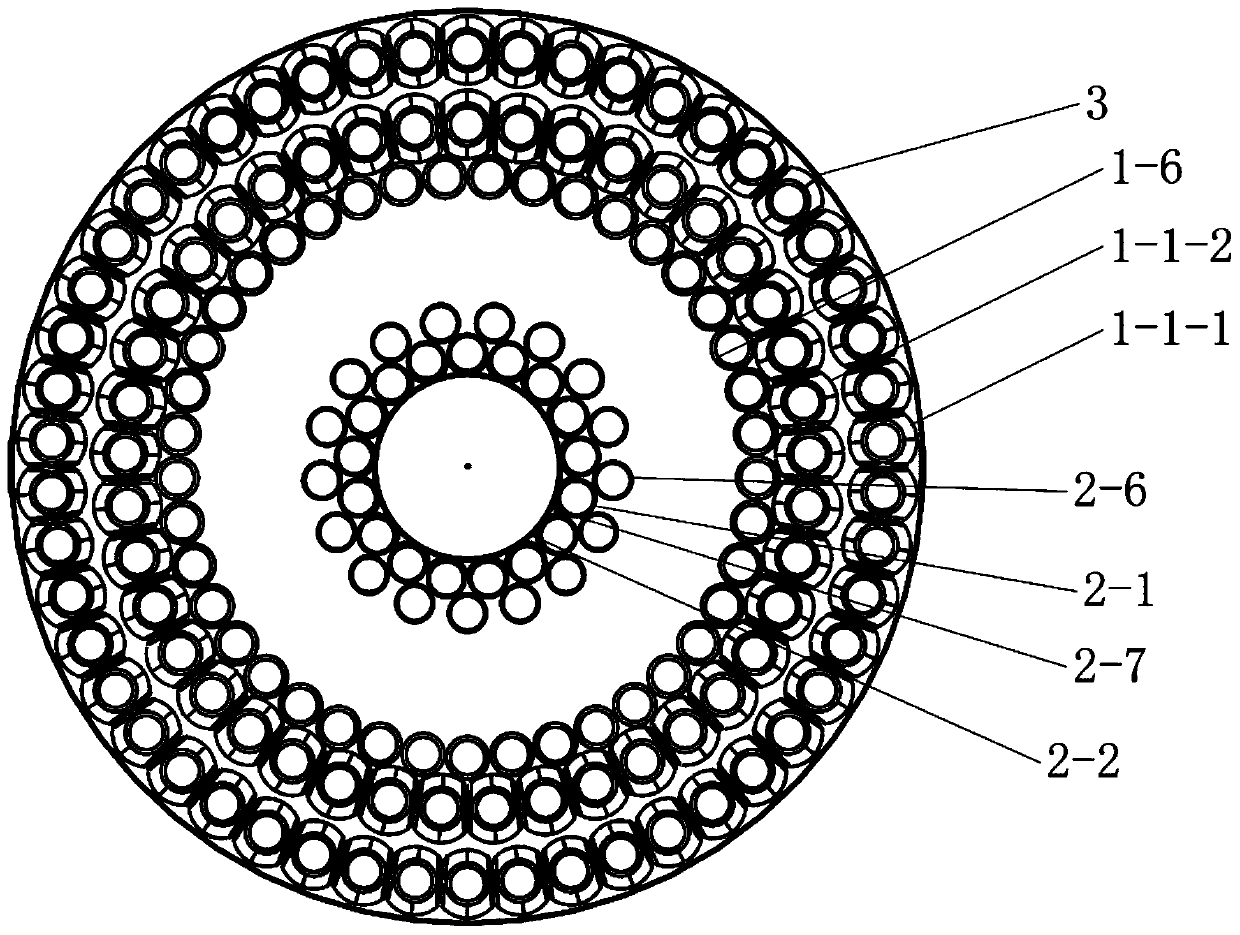

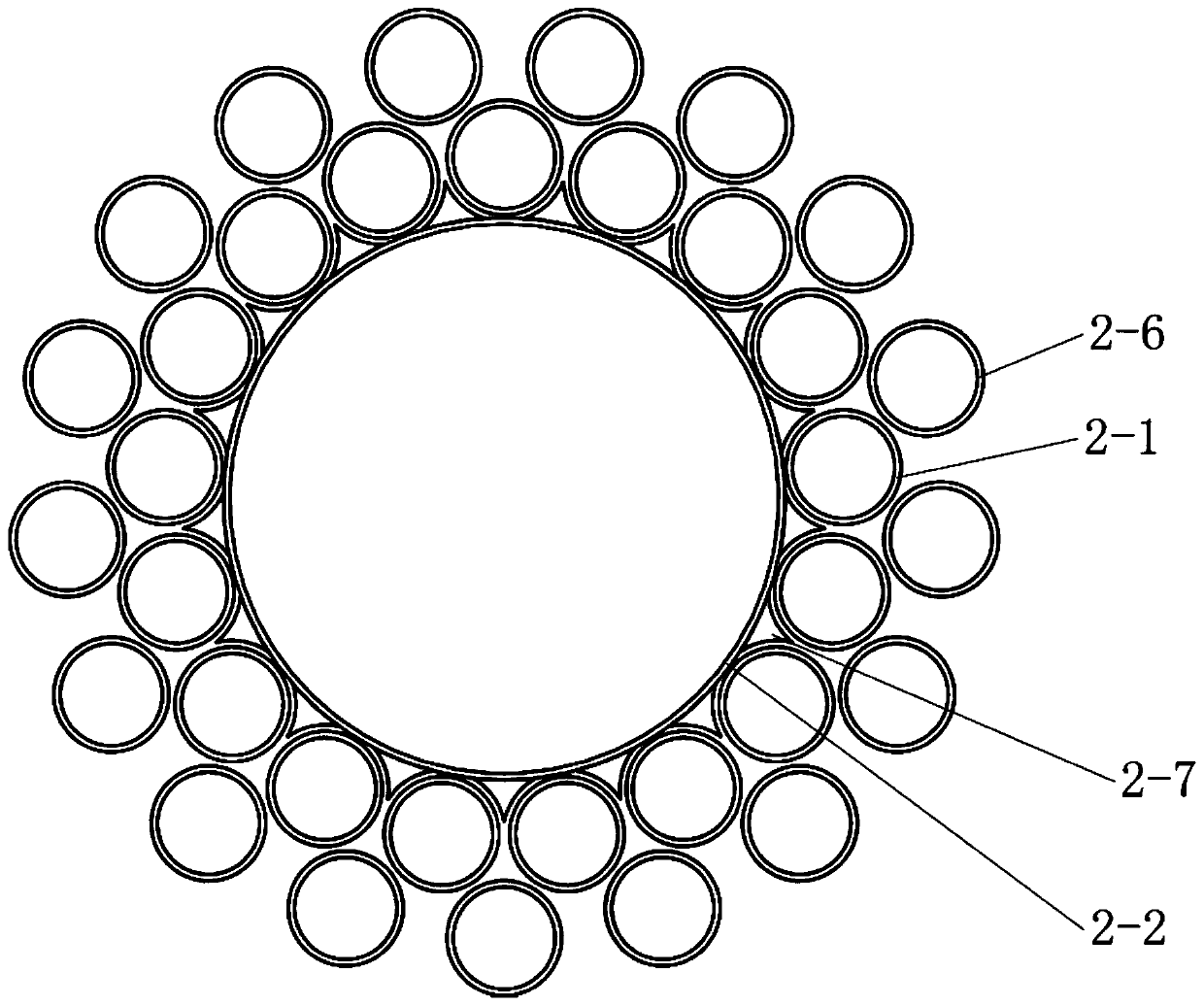

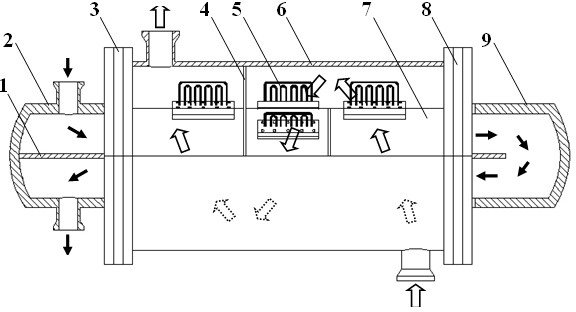

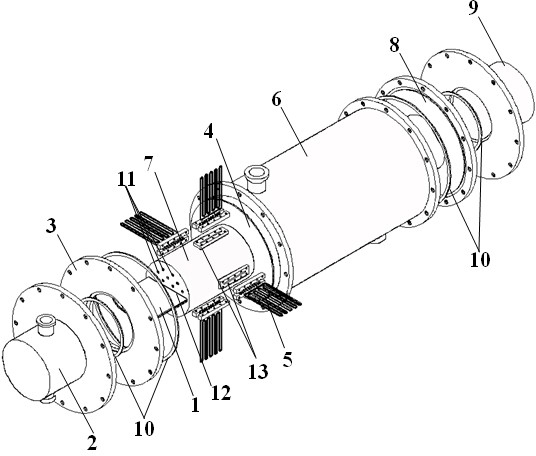

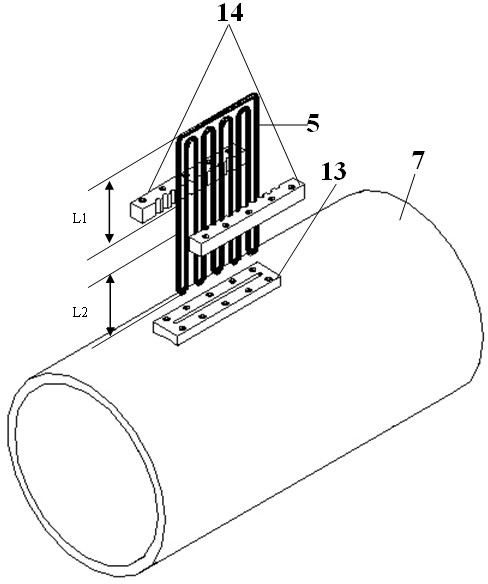

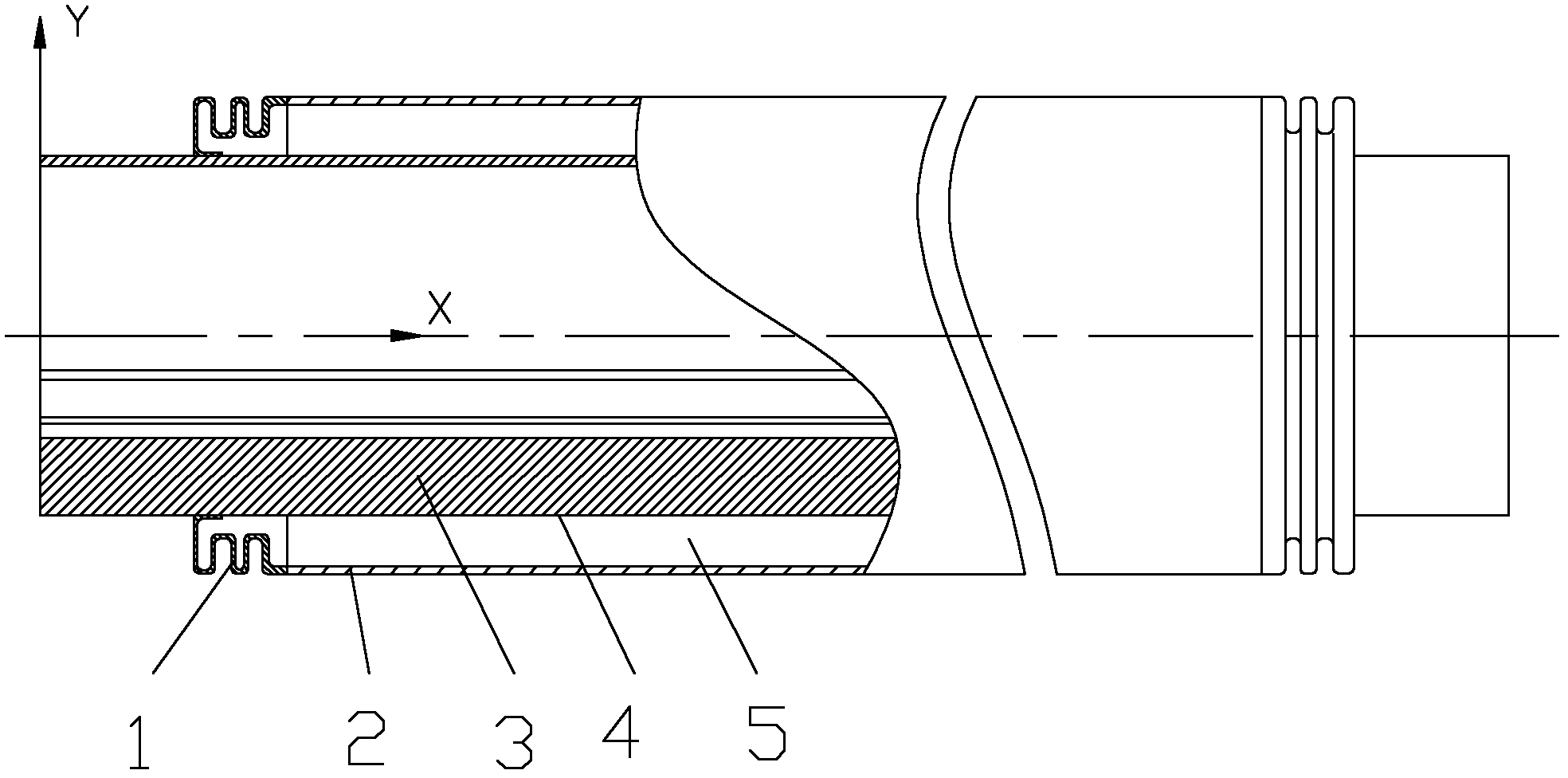

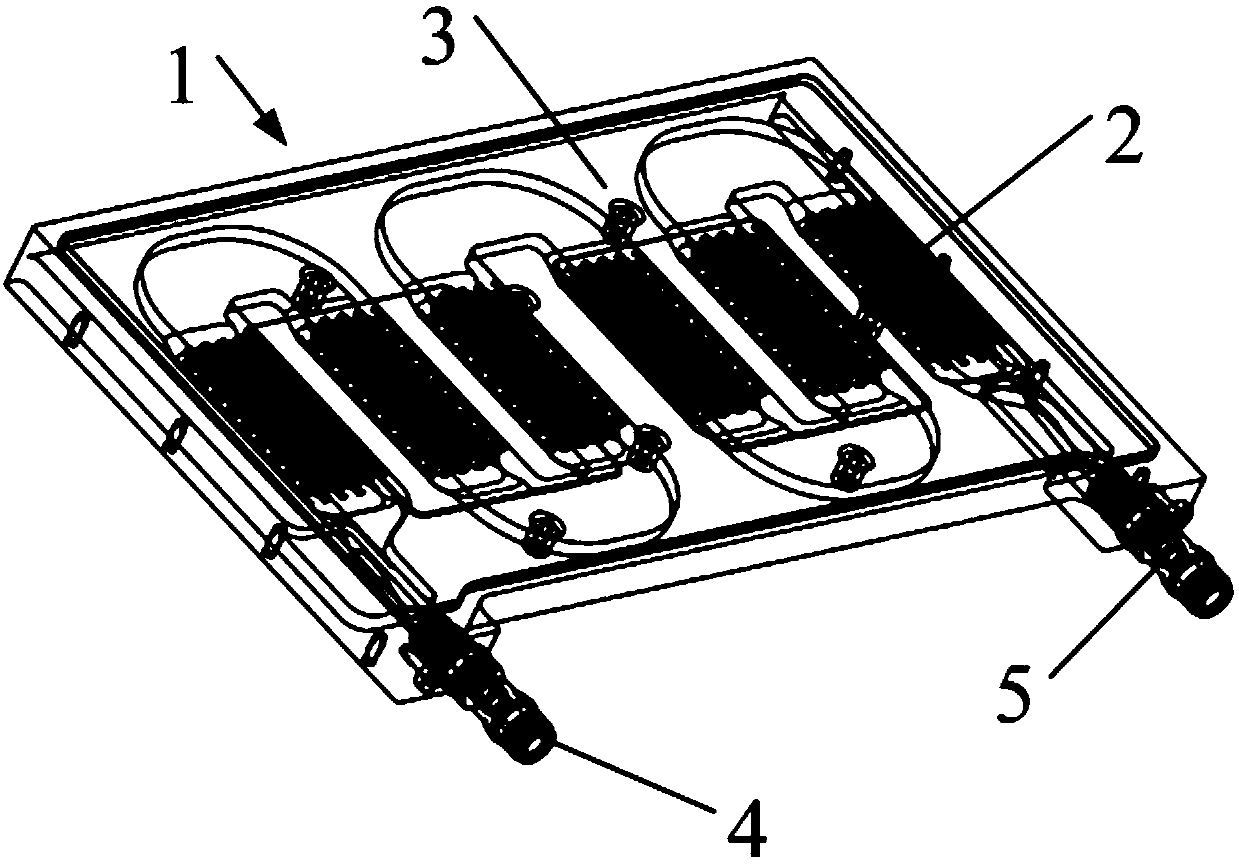

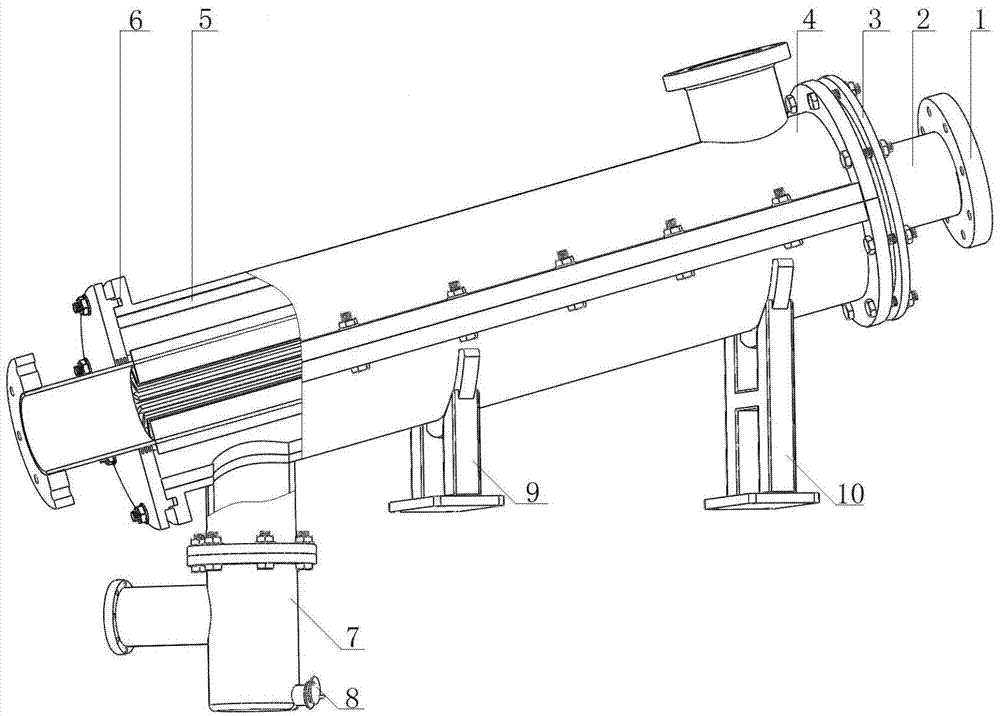

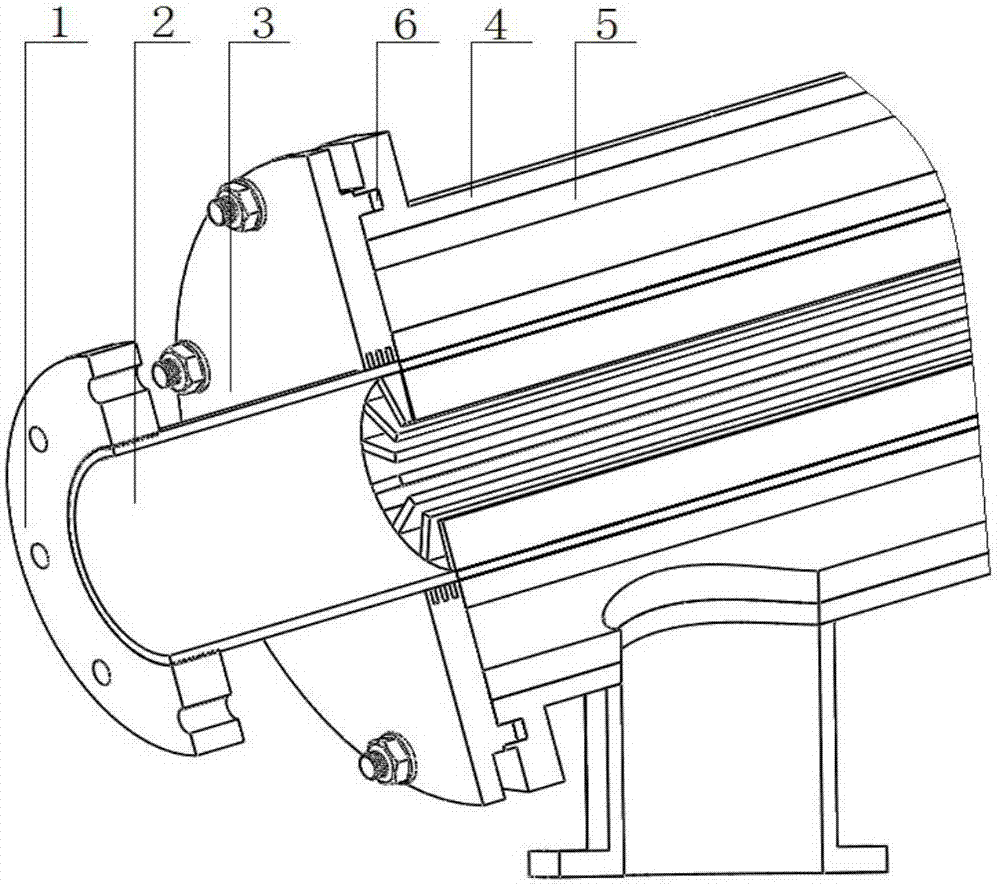

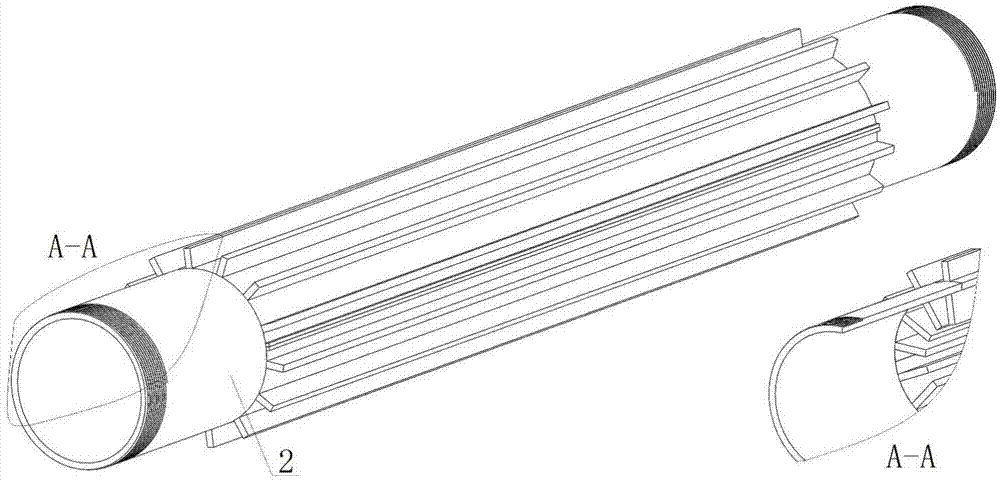

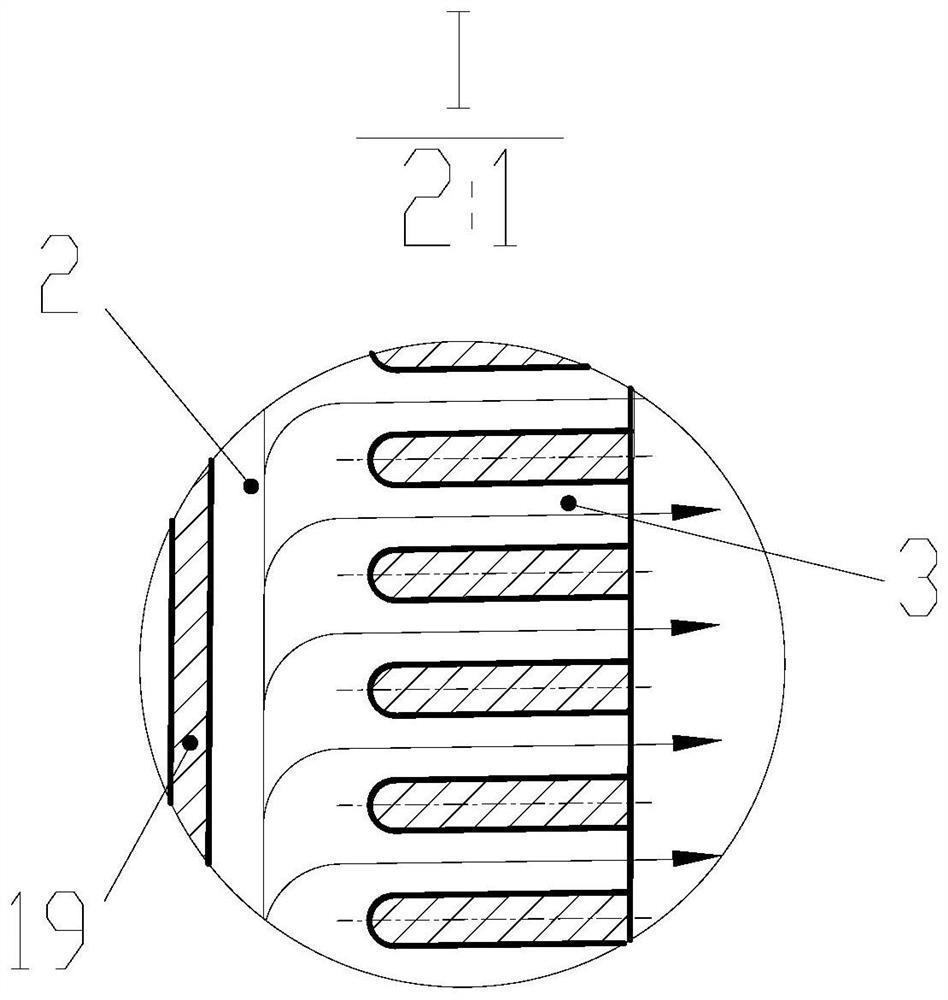

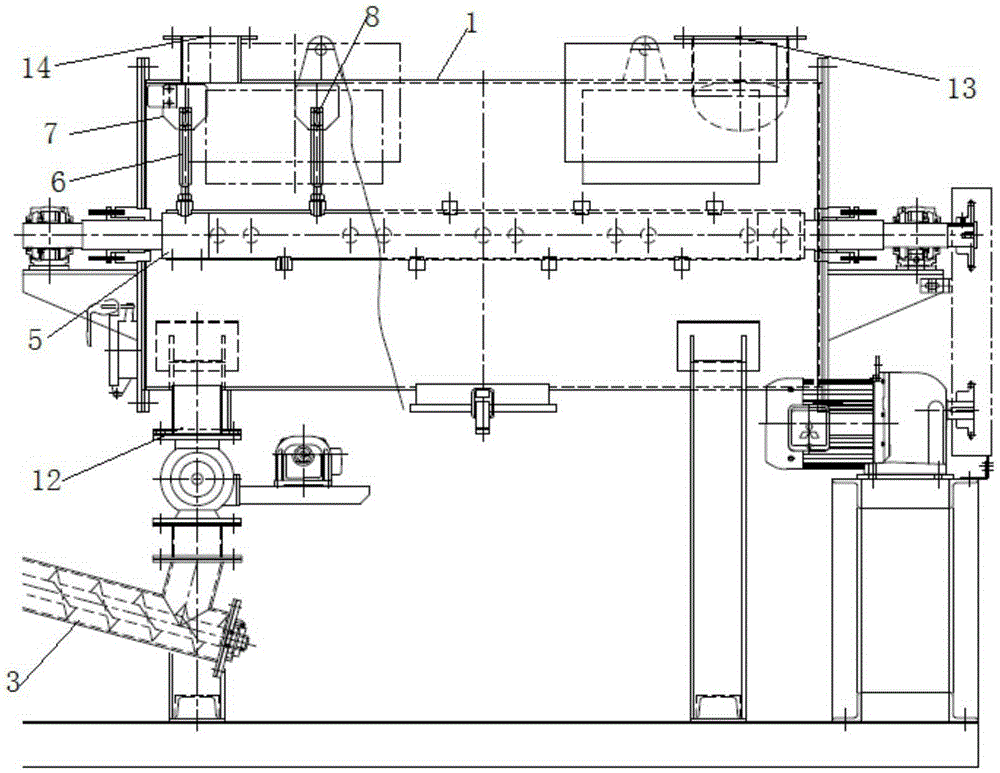

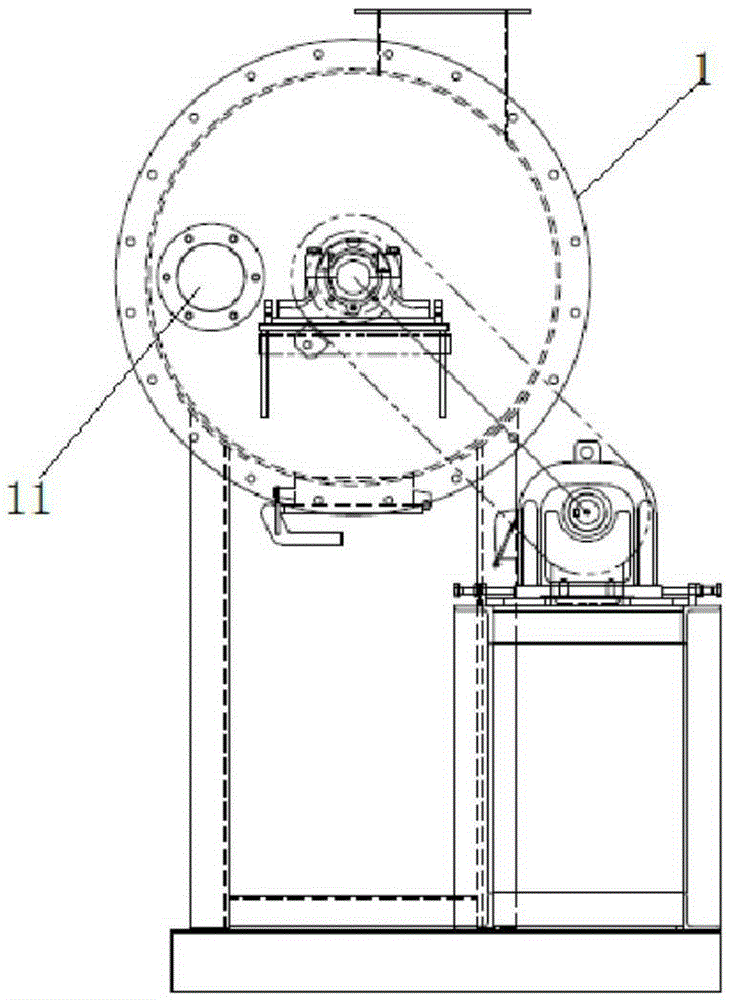

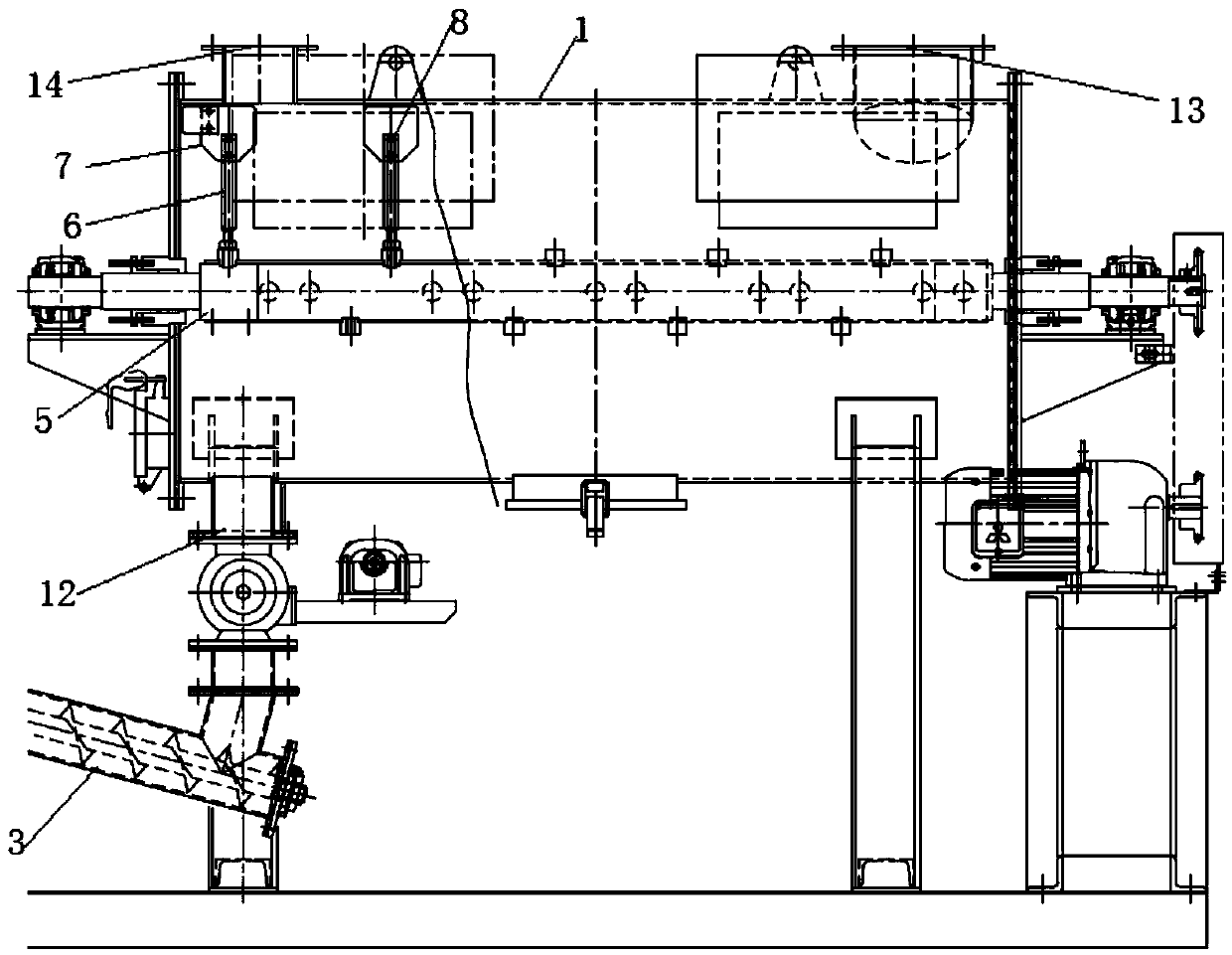

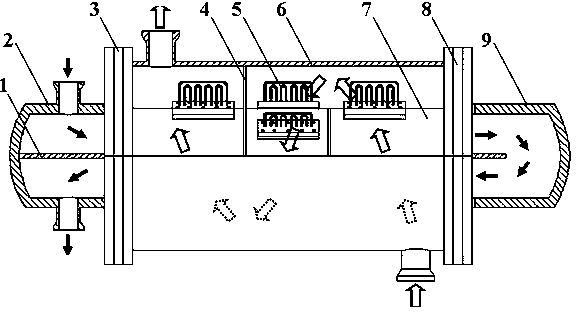

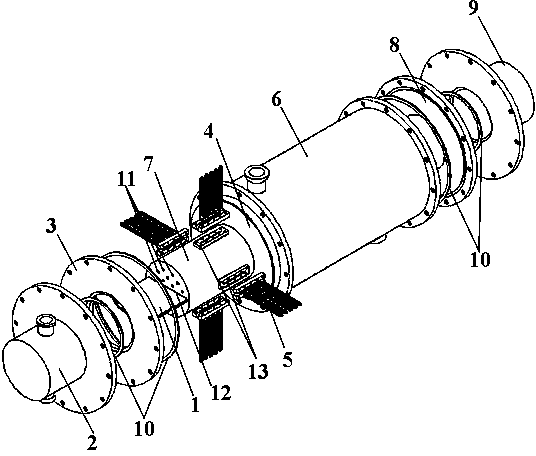

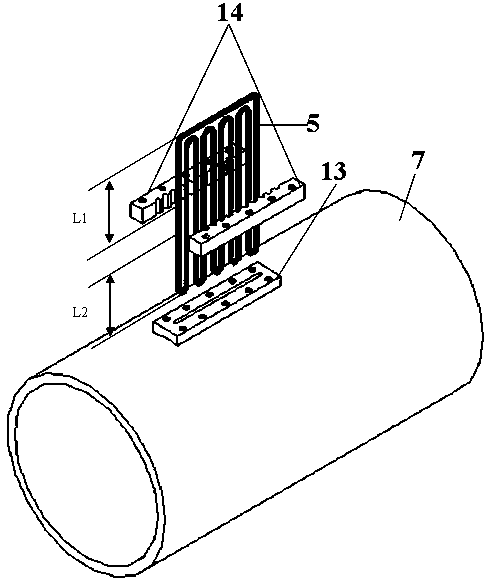

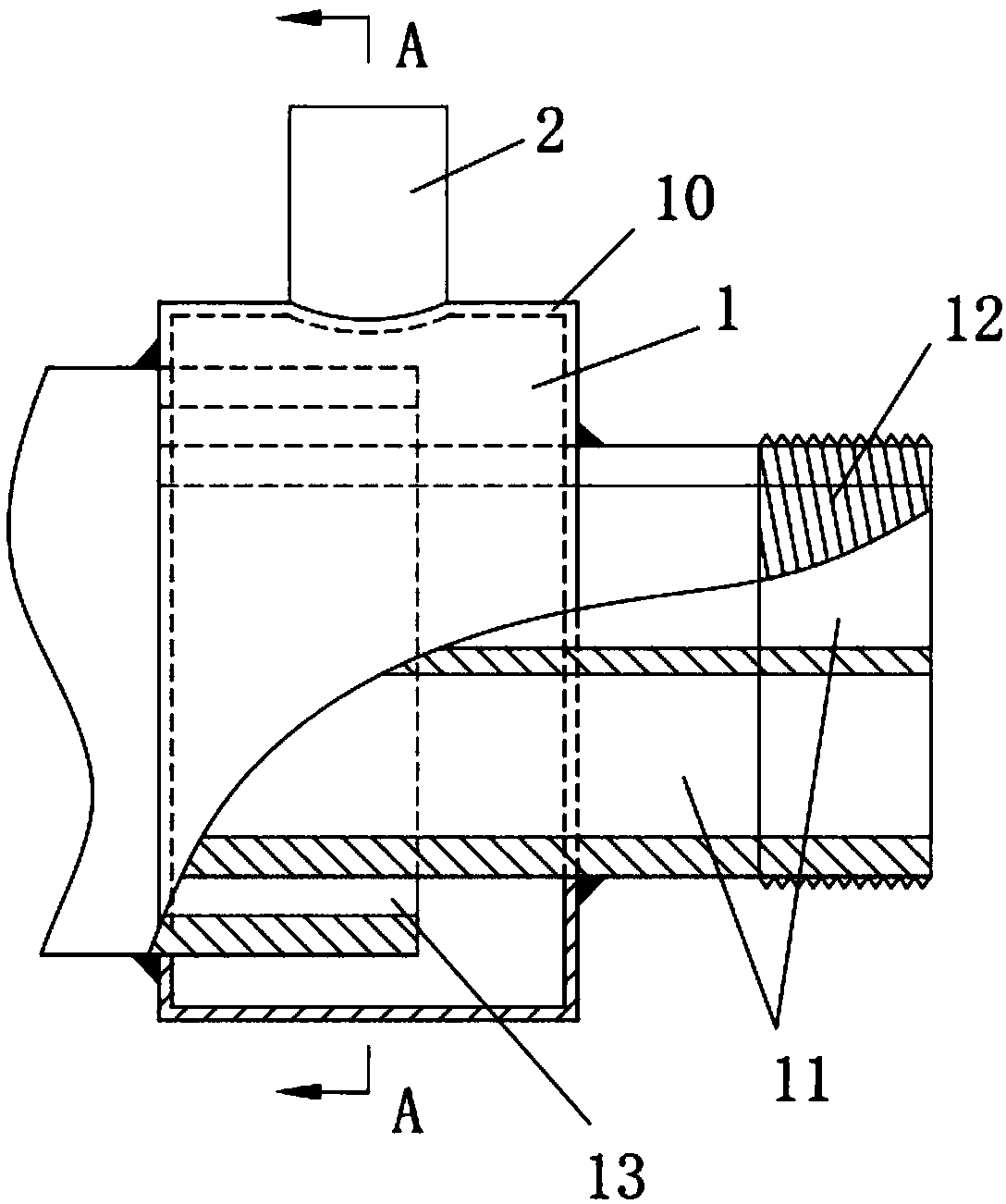

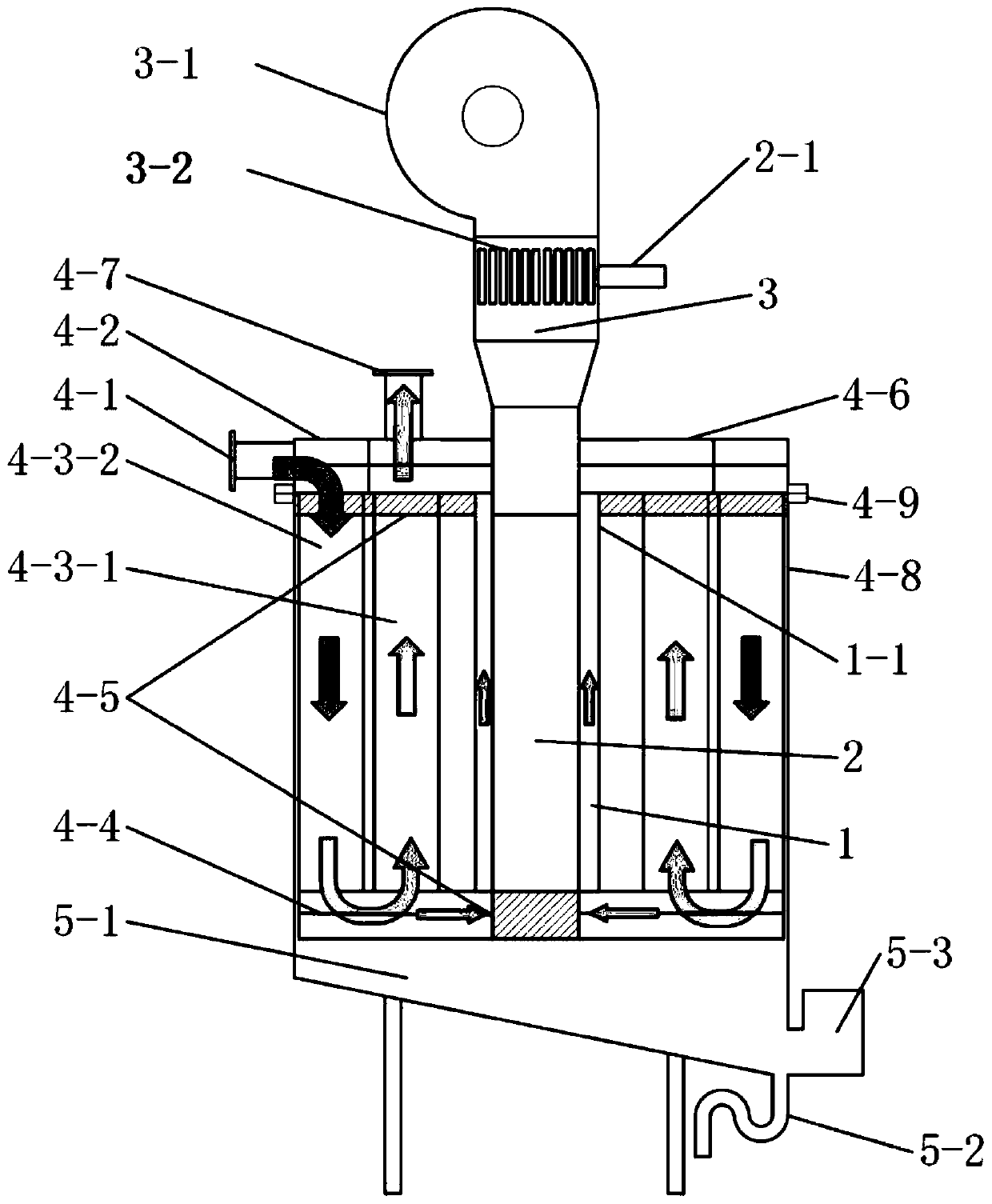

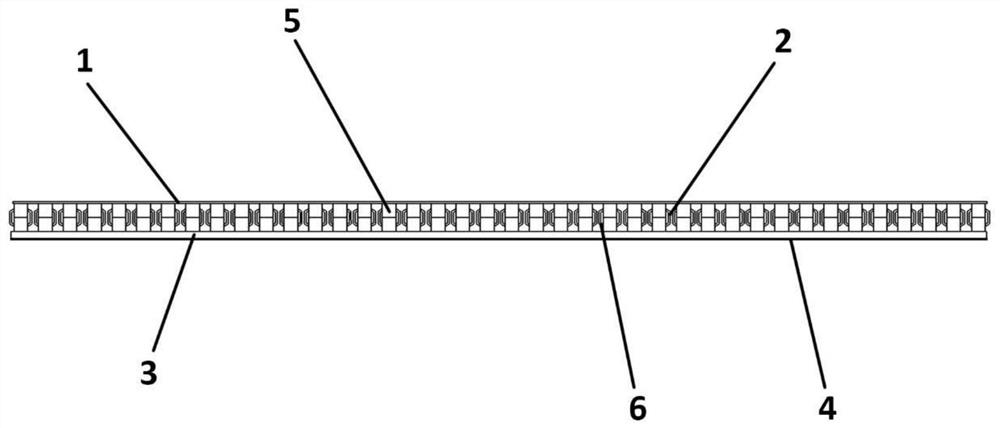

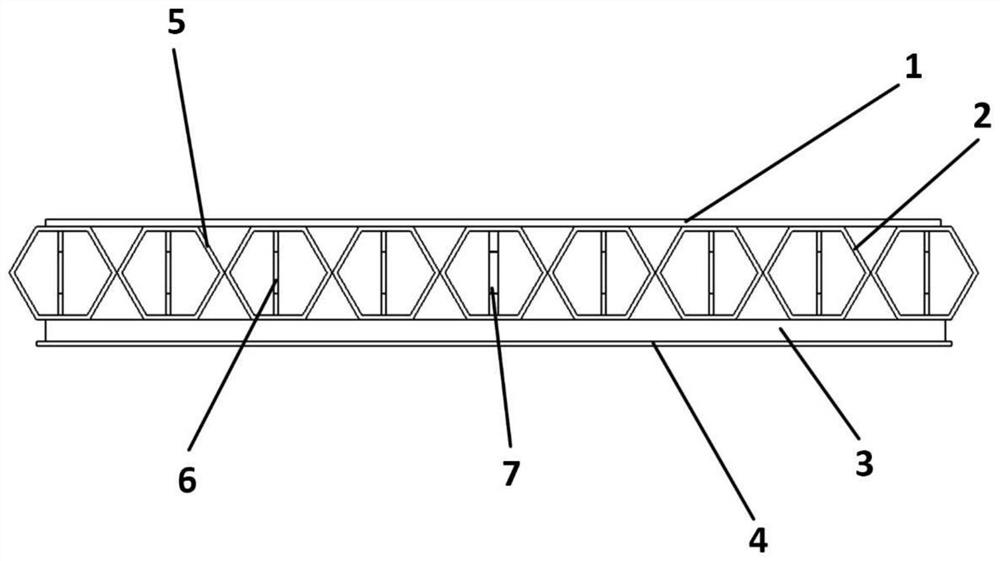

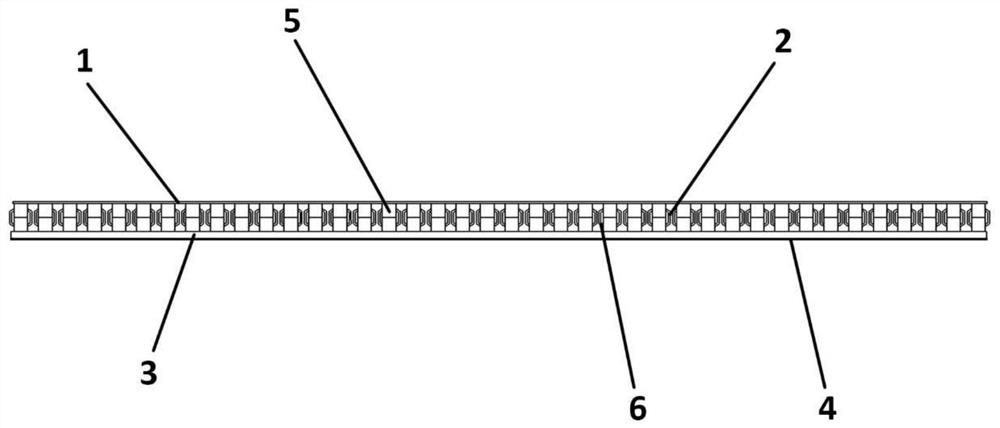

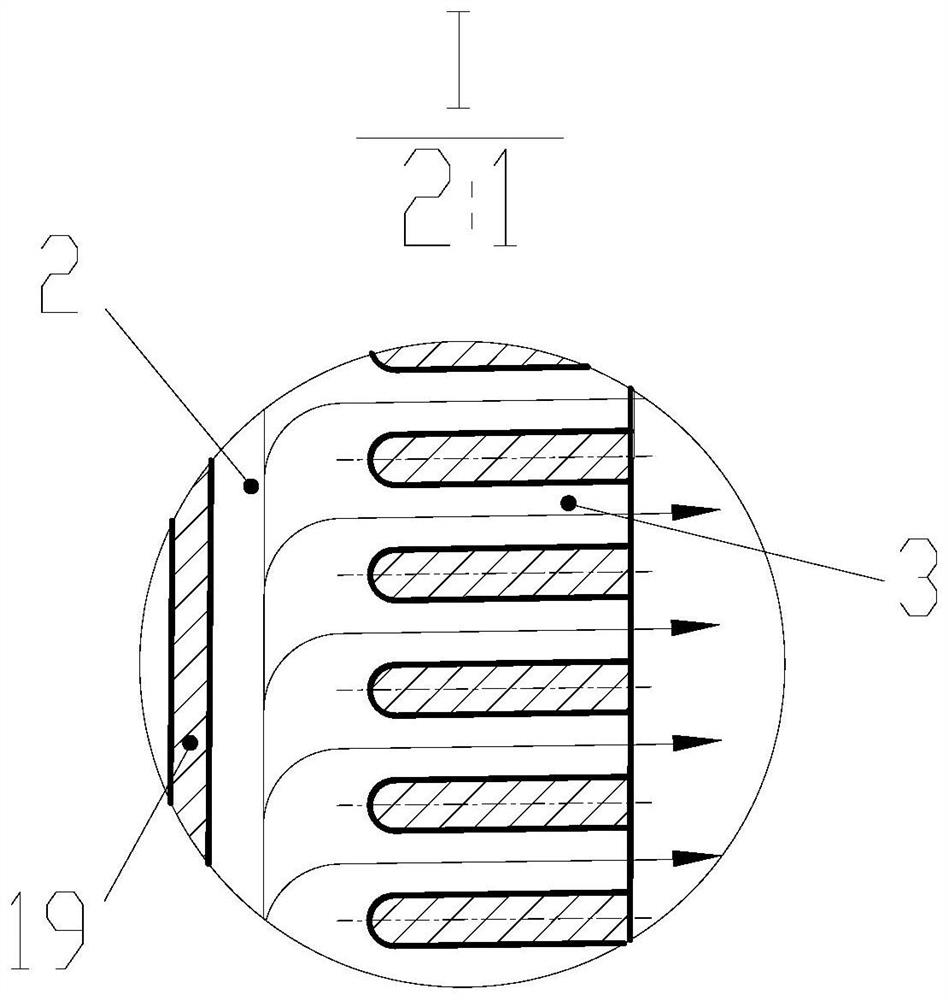

Tube shell type pulsating heat pipe heat exchanger

ActiveCN102620587AIncrease the convective heat transfer areaSpeed up evaporationIndirect heat exchangersHeat flowPlate heat exchanger

The invention discloses a tube shell type pulsating heat pipe heat exchanger, which comprises a shell pass, a tube pass, a sealing flange and a sealing head, wherein the sealing flange and the sealing head are arranged at the two ends of the shell pass; the tube pass is arranged in the shell pass and is divided into vertically communicated return fluid passages by a middle partition plate; a sealing flange and a sealing head at the two ends of the tube pass are fixed and hermetically connected with flange rings at the two ends of the shell pass; pulsating heat pipes are arranged on the tube pass and the shell pass; condensation sections of the pulsating heat pipes are positioned in the shell pass; and evaporation sections of the pulsating heat pipes are positioned in the tube pass. According to the tube shell type pulsating heat pipe heat exchanger, the pulsating heat pipes are inserted into the tube shell type heat exchanger in groups, so that the heat exchange space is fully utilized; and a corresponding heat pipe working medium is selected according to the size of a heat flow in a frictional heat exchange process, so that gradient utilization of energy is realized. In addition, the tube shell type pulsating heat pipe heat exchanger can be arranged in any direction and has the advantages of compact structure, small size, simple manufacturing process, convenience for assembly, disassembly and maintenance, no need of an external pump for driving flow, safety in use and excellent application prospect.

Owner:SOUTHEAST UNIV

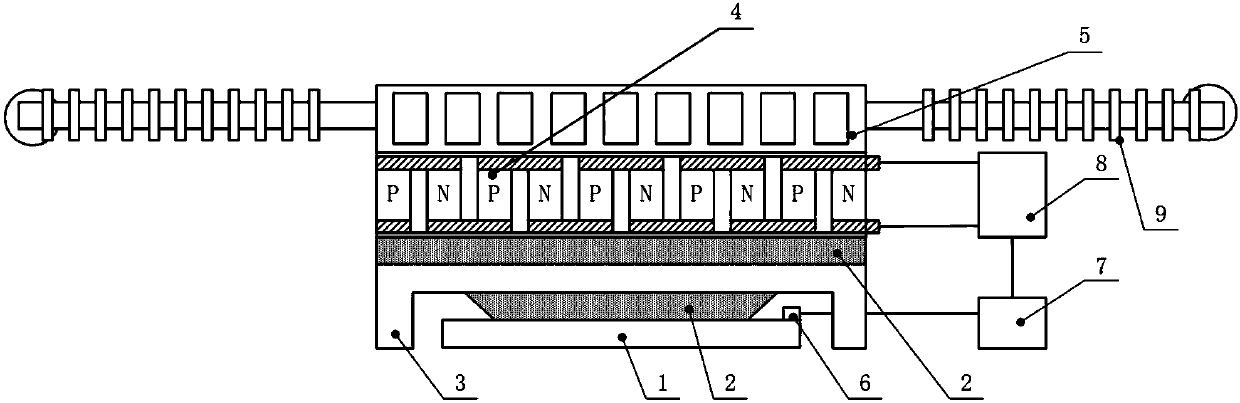

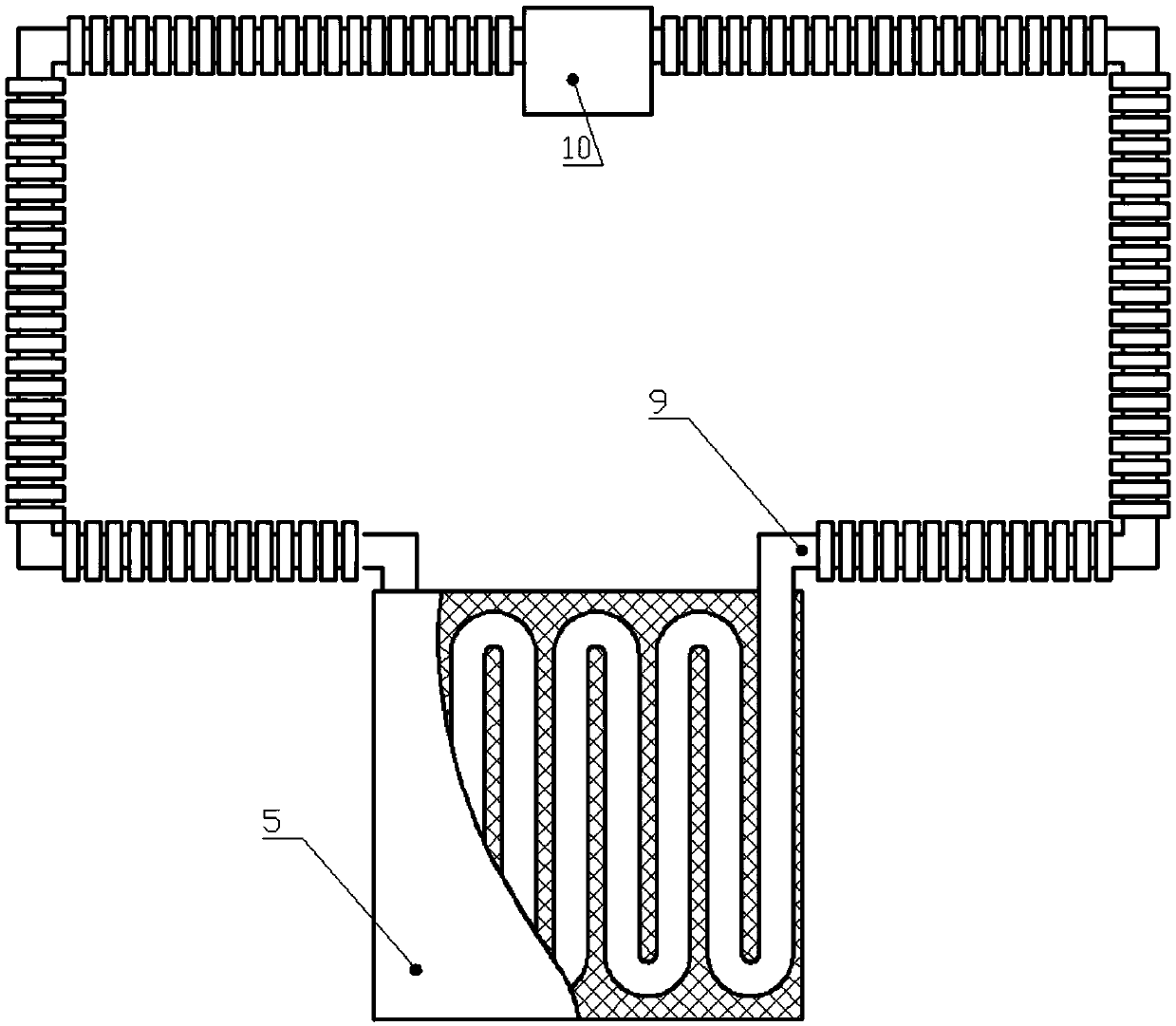

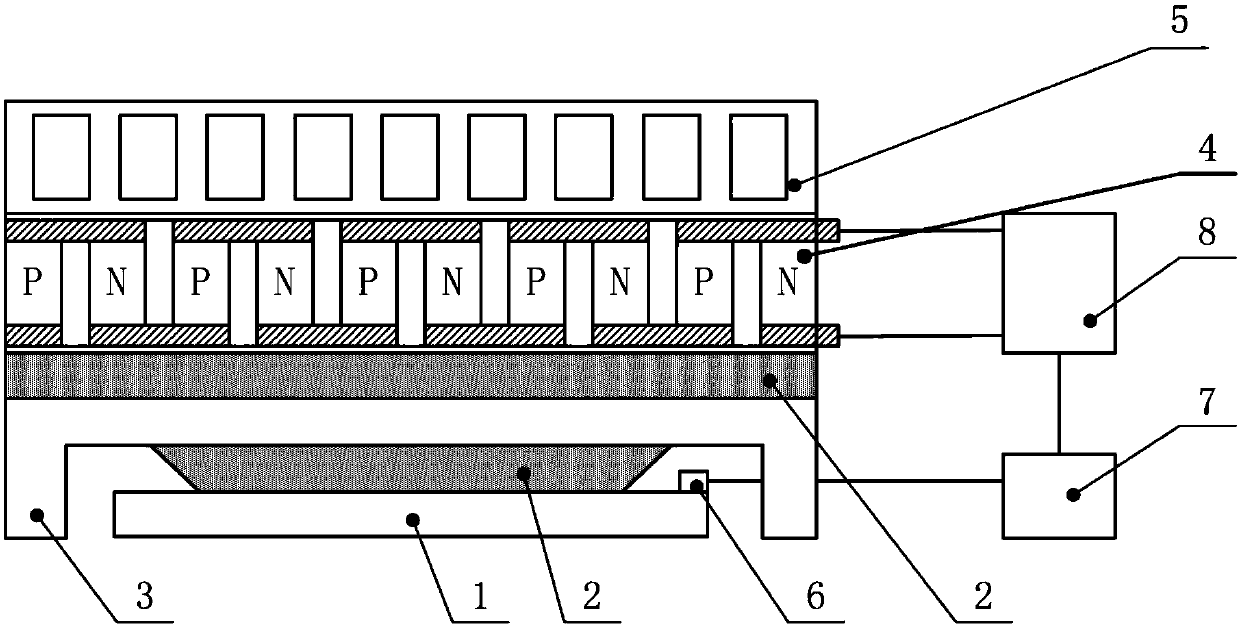

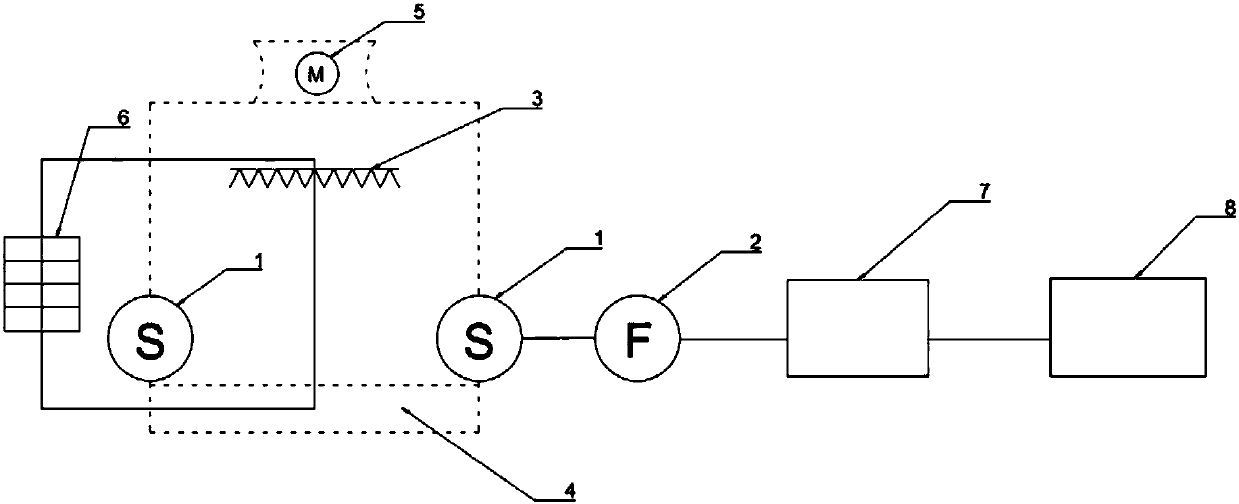

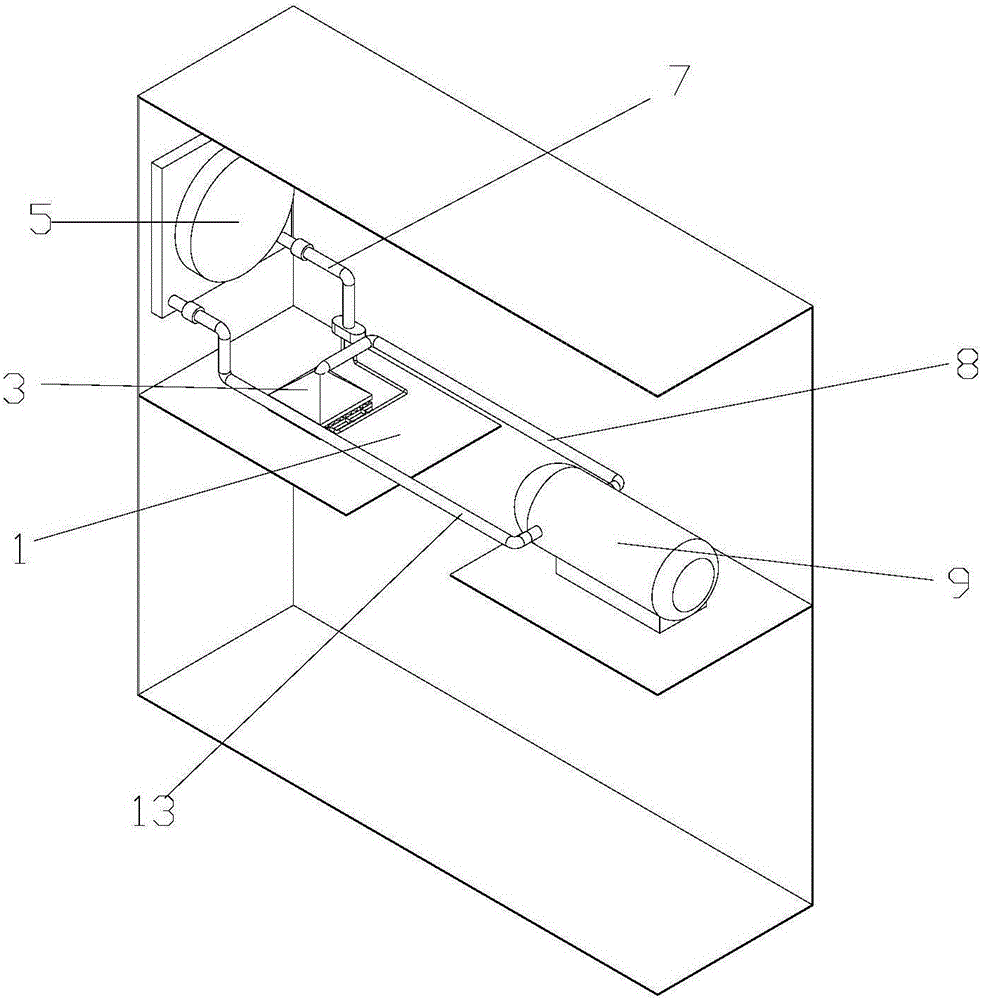

Chip cooling system

InactiveCN107678524ASmall thermal inertiaAbsorb in timeDigital data processing detailsMachines using electric/magnetic effectsHeat flowCooling effect

The invention relates to a chip cooling system comprising a semiconductor cooler used for actively exchanging heat in a transporting manner, and a chip radiator used for performing heat convection, wherein the semiconductor cooler is connected with a power supply; one side of the semiconductor cooler is a heating end while the other side is a cooling end, the heating end can be fit with a chip tobe cooled, and the cooling end is fit with the chip radiator; a superfine channel is arranged in the chip radiator, the chip radiator is connected with a circulating pipe with a power device to form acirculating loop, and cooling liquid is filled in the circulating loop. According to the system provided by the invention, the semiconductor cooler and the chip radiator are combined to form a two-stage heat exchange system, the semiconductor cooler provides relatively large heat dissipation heat-flow density through actively transporting heat energy, heat on the chip can be absorbed in time, andthe chip radiator dissipates heat to the external environment via the circulating pipe; the system is heat in heat dissipation efficiency, low in cost, free of noise, controllable in cooling capacityand good in cooling effect.

Owner:XI AN JIAOTONG UNIV

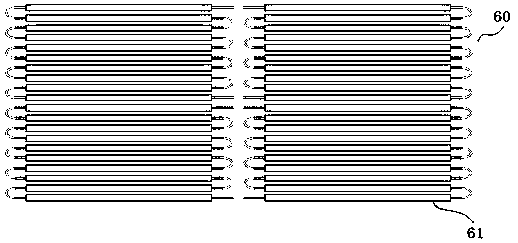

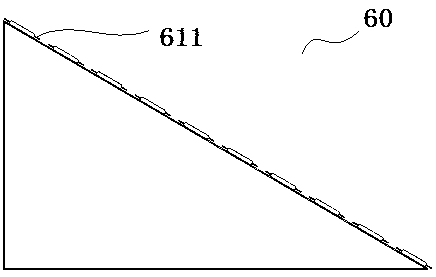

Tank type solar vacuum heat collecting tube with one-sided inner fin

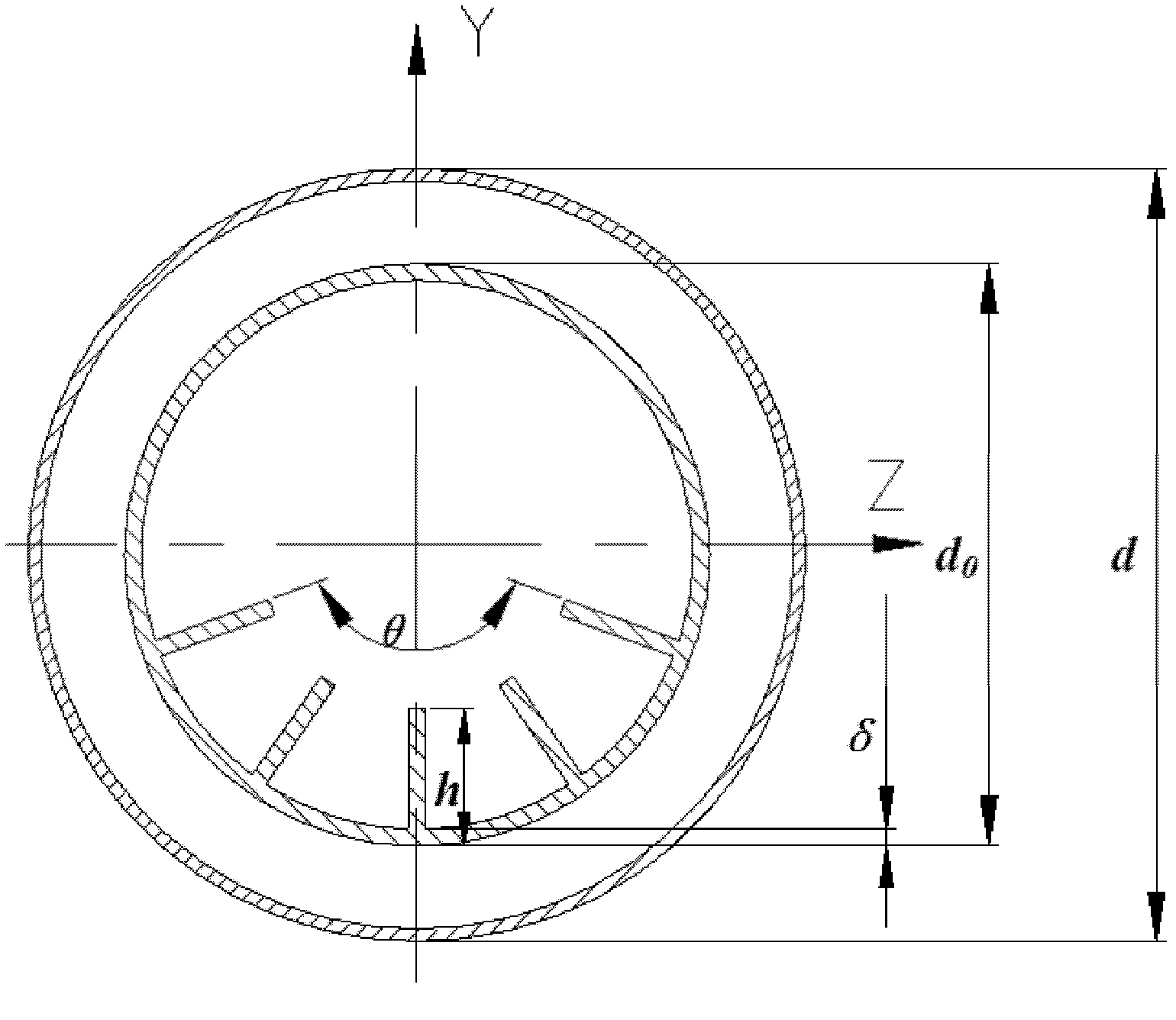

InactiveCN102425867AReduce windImprove reliabilitySolar heat devicesSolar thermal energy generationHeat conductingEnhanced heat transfer

The invention relates to a tank type solar vacuum heat collecting tube with a one-sided inner fin, comprising a glass outer tube and a metal inner tube with a one-sided inner fin enhanced heat transfer structure, wherein two ends of the glass outer tube are sealed with the metal inner tube through corrugated tubes; the space between the glass outer tube and the metal inner tube is vacuum; the external surface of the metal inner tube is coated with a selective sunlight absorption coating; the inner fin is arranged on the inner surface of one side of the metal inner tube which absorbs focalized solar energy; and the inner fin and the metal tube are integrated. The inner fin introduces heat to the center of the metal inner tube, increases the heat convection area, reduces the temperature difference between the metal inner tube and a heat-conducting fluid, and improves the cooperation degree between the velocity field of the heat-conducting fluid in the heat collecting tube and the temperature field of the heat collecting tube. Furthermore, the inner fin also increases the strength and reliability of the heat collecting tube.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

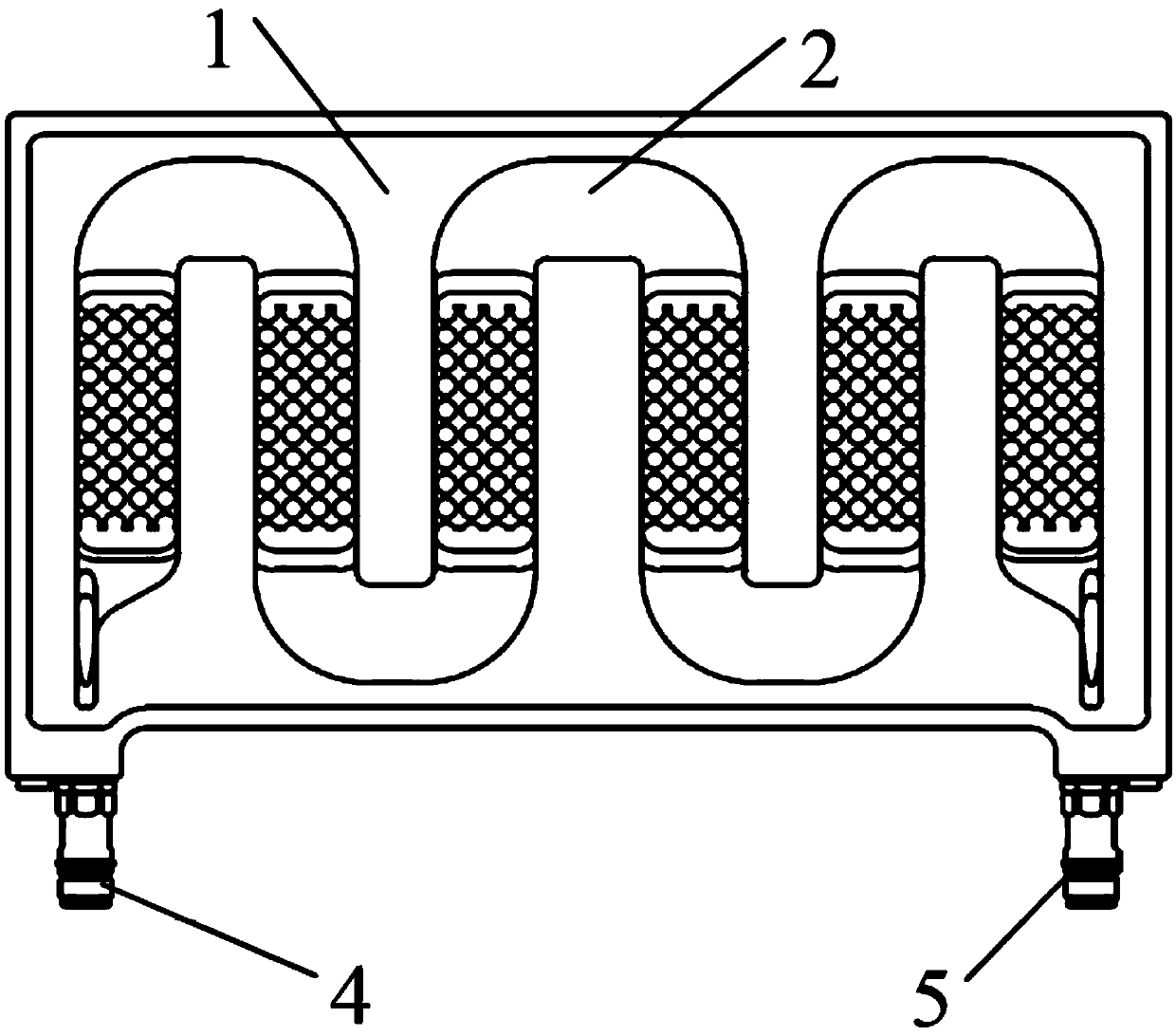

Porous medium liquid-cooling cooling device, manufacturing method and use method thereof

InactiveCN109548363AReduce thermal resistanceLarge specific surface areaCooling/ventilation/heating modificationsPorous mediumEngineering

The invention provides a porous medium liquid-cooling cooling device, a manufacturing method and a use method thereof. A heat dissipating medium diversion groove is arranged on a substrate, and the heat dissipating medium diversion groove is provided with a heat dissipating medium inlet joint and a heat dissipating medium outlet joint. A porous medium module is filled in the heat dissipating medium diversion groove, so that a heat dissipating medium generates disturbance in a flowing manner in the heat dissipating medium diversion groove. A cover plate is covered on the substrate, and is sealingly connected with the substrate, so that the heat dissipating medium diversion groove forms a heat dissipating medium diversion cavity, and the heat dissipating medium flows in the heat dissipatingmedium diversion cavity. Thermal resistance of heat conduction is effectively reduced. A fluid flows through the internal of a porous medium, and heat convection is generated among the porous medium and a skeleton structure of the porous medium. The porous medium is large in specific surface area, and large in heat convection area. The skeleton structure is arranged in an intricate manner so thata fluid boundary layer on the surface of a skeleton is thinned or damaged, so as to reduce thermal resistance of heat convection. A porous medium liquid-cooling cooling plate can reduce thermal resistance during a heat transfer and enhance heat dissipation.

Owner:SHANDONG CHAOYUE DATA CONTROL ELECTRONICS CO LTD

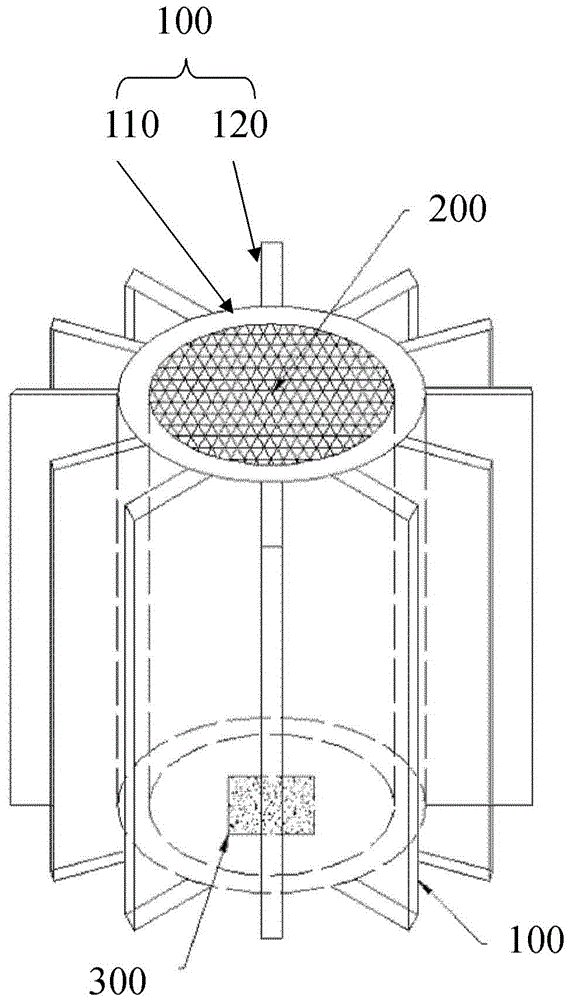

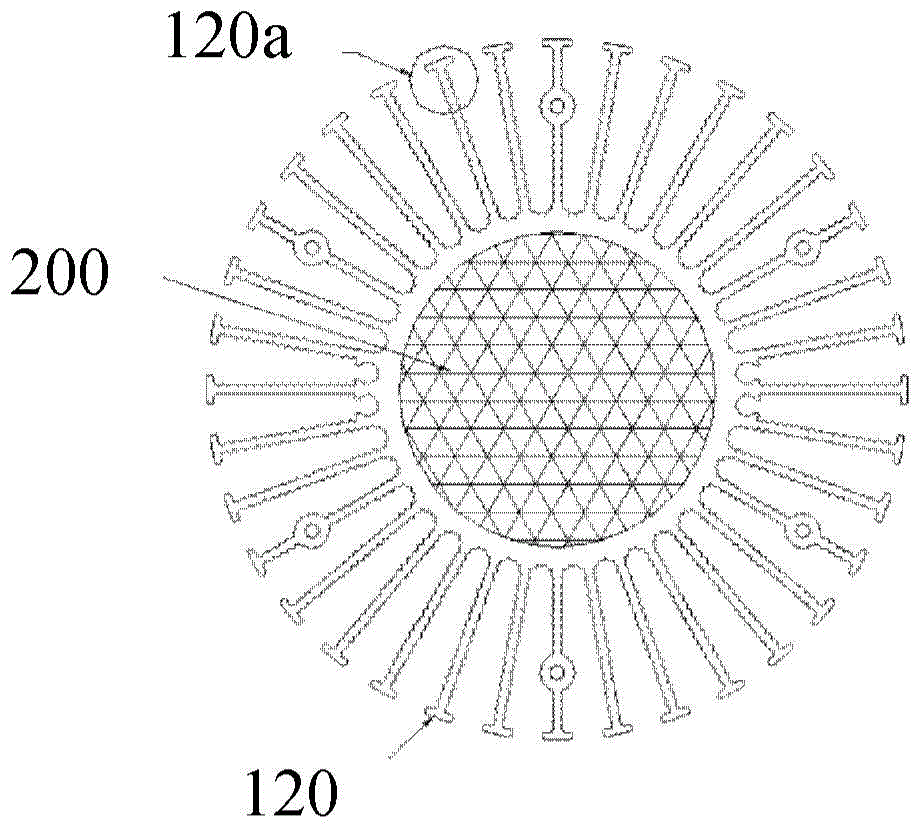

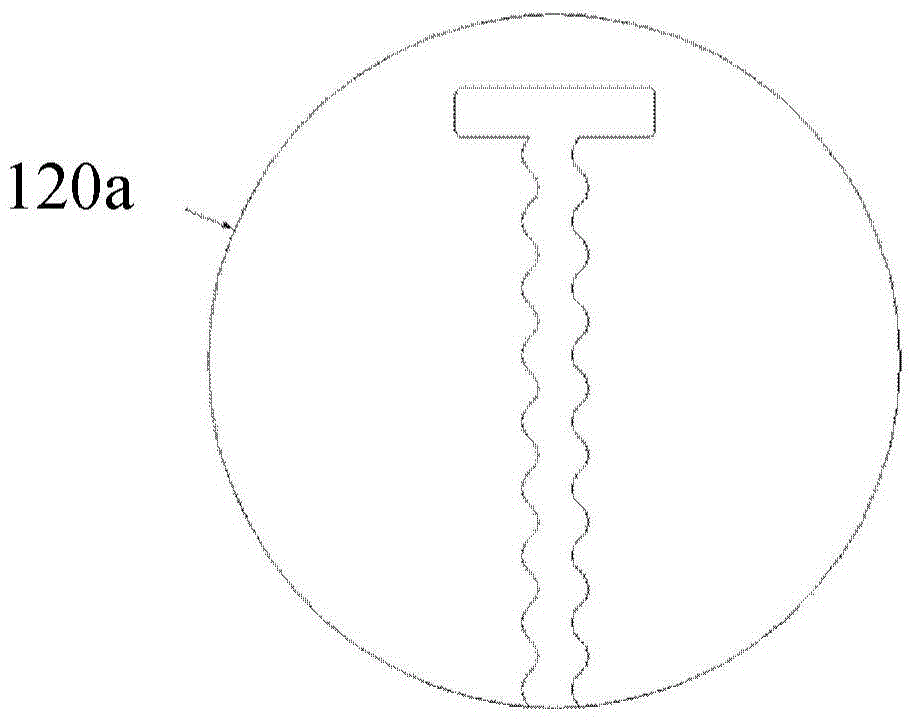

led radiator

ActiveCN103474566BOvercome the bottleneck problem that cannot be emitted from the LED chipEfficient releaseSemiconductor devicesGraphiteEngineering

The invention provides an LED radiator. The LED heat sink includes: a sunflower-shaped heat sink 100, including a cylindrical body 110 and a plurality of cooling fins 120 extending outward from the cylindrical body; In the cylindrical body of the heat sink, it is cylindrical, and its outer cylindrical surface is in close contact with the inner cylindrical surface of the sunflower-shaped heat sink cylindrical body. The LED chip 300 is attached to the graphite heating core. The upper surface or the lower surface is used to transfer the LED chips 300 to the sunflower-shaped heat sink 100 . Because the heat-taking core made of graphite is adopted, the heat dissipation efficiency of the LED radiator of the present invention is greatly improved, and the weight is greatly reduced.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

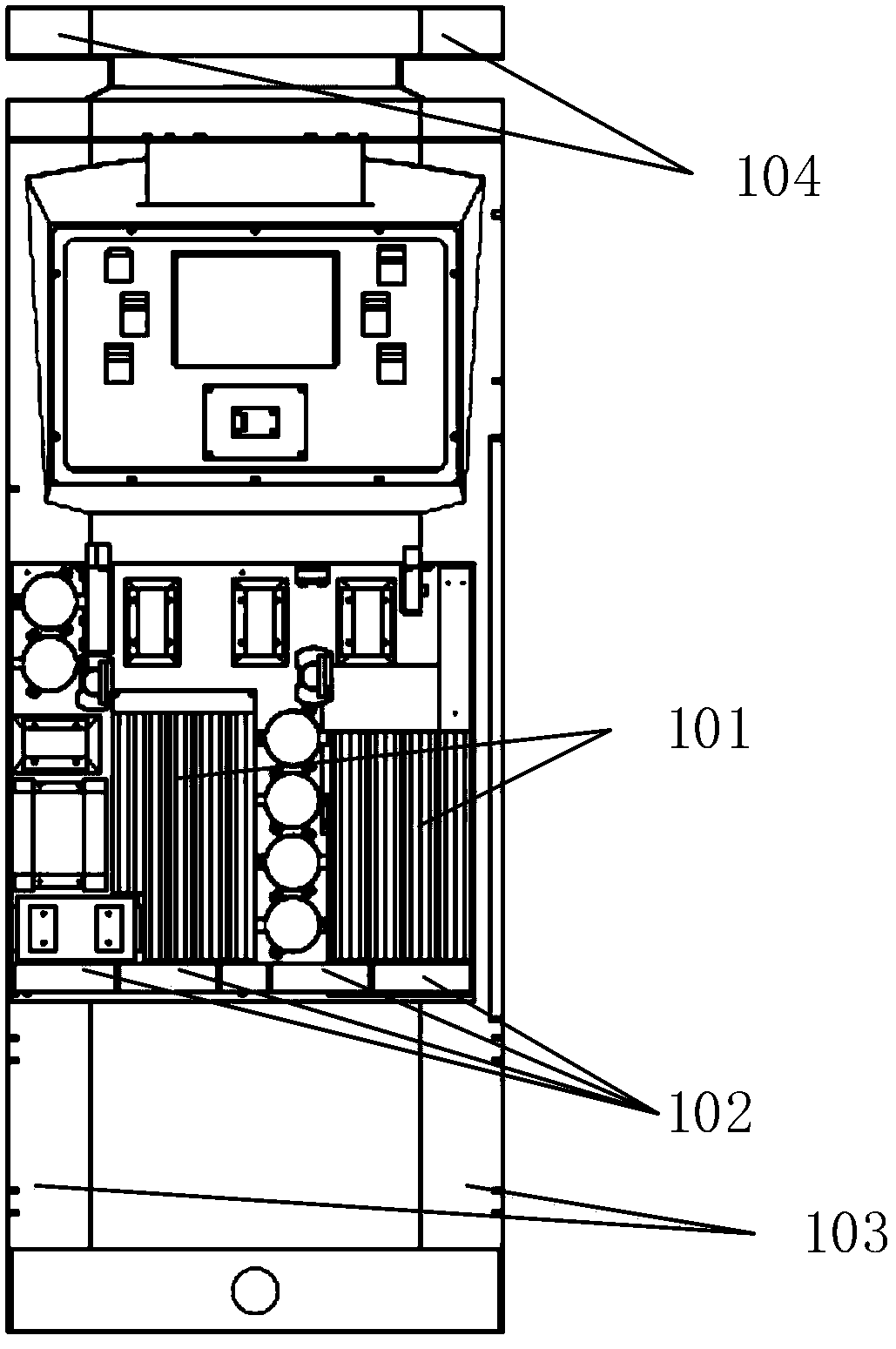

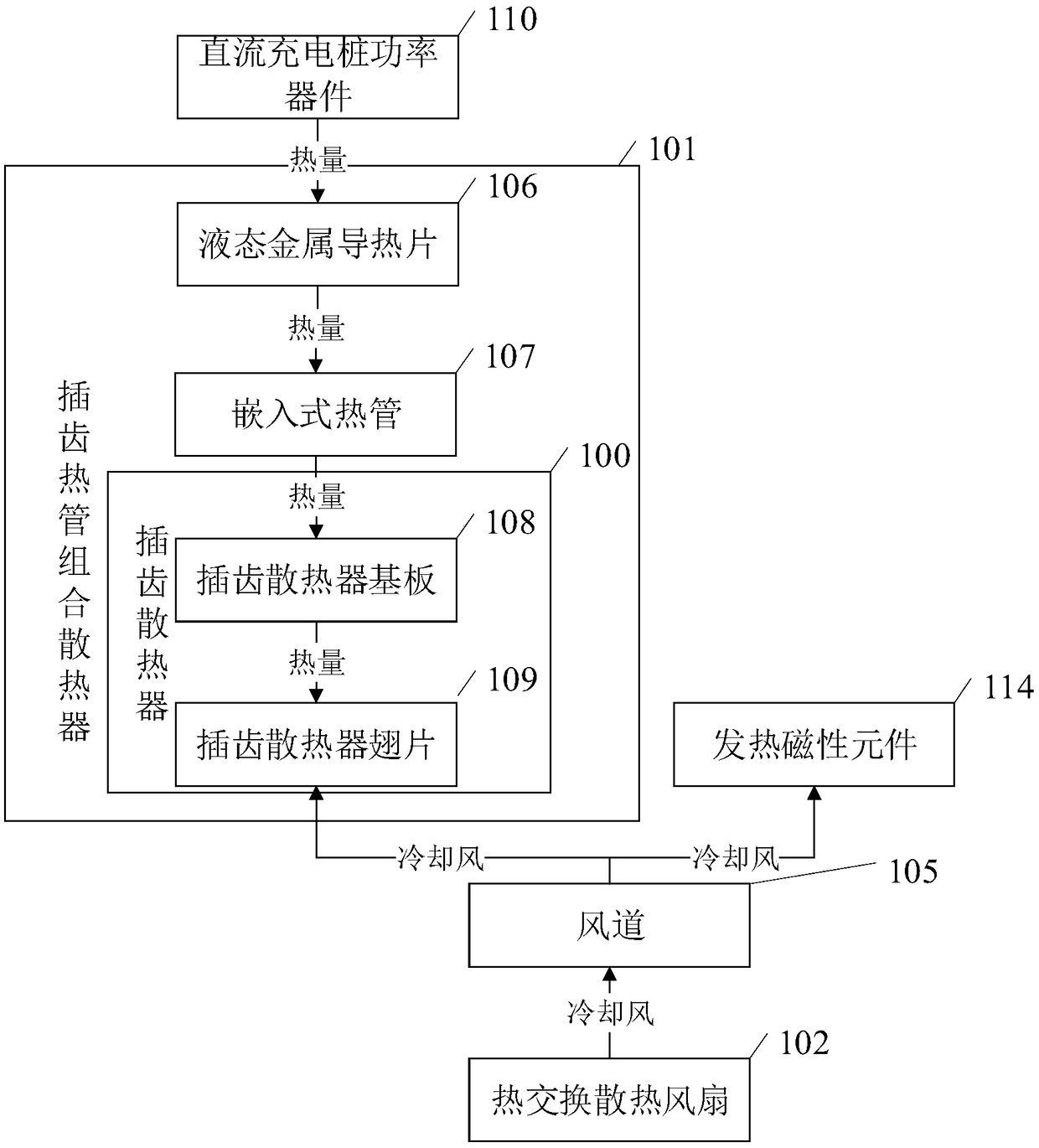

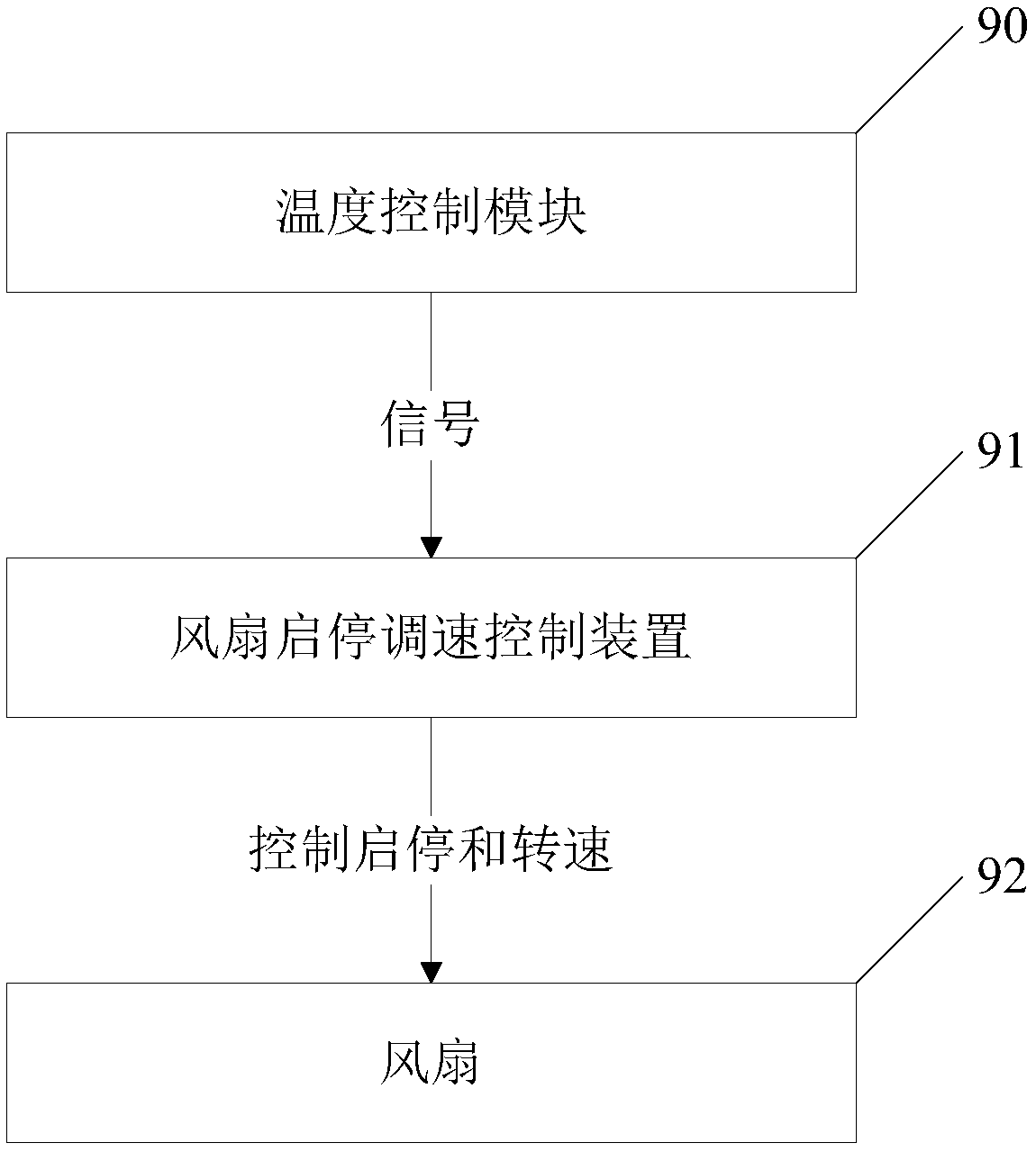

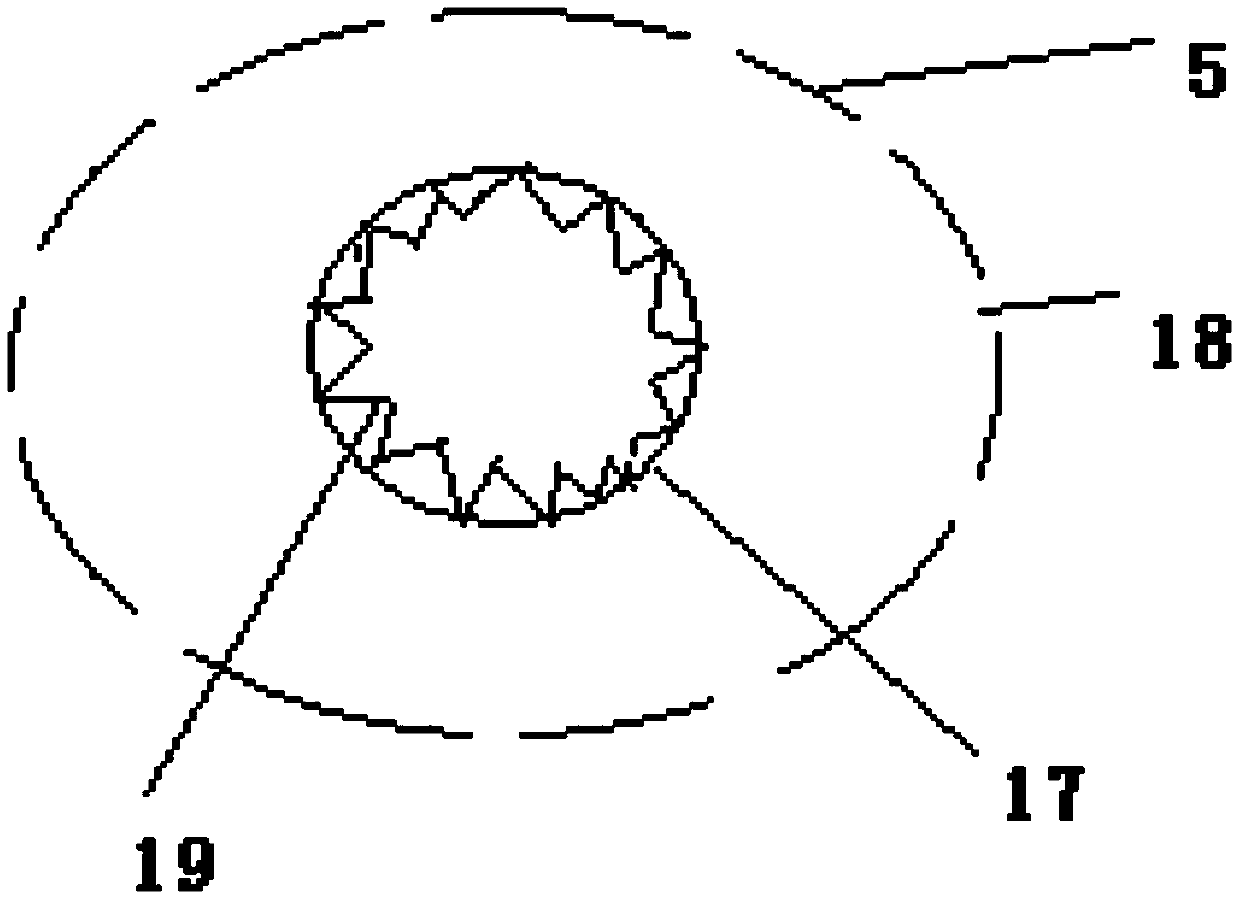

DC charging pile air-cooling circulation system

PendingCN109484228AImprove comprehensive convective heat transfer capacityGood effectCharging stationsModifications for power electronicsEngineeringElectrical and Electronics engineering

Provided is a DC charging pile air-cooling circulation system. The invention discloses a DC charging pile air-cooling heat dissipation system which solves the problem that an existing device is low inefficiency and high in consumption. The system includes an air-cooling heat dissipation module which is used for conveying cooling air to perform heat exchange with a heat-generating device and discharging hot air, thereby cooling a DC charging pile; the system can be divided into a duct, a gear-toothed heat pipe combined radiator and a fan; the duct is used for conveying cooling air to cool a power device and discharging hot air; the gear-toothed heat pipe combined radiator includes a gear-toothed radiator, an embedded heat pipe and a liquid metal heat-conducting fin and is used for conducting heat of the power device out to perform heat exchange with the cooling air; and the fan is used for sucking the cooling air from the outside of the system to make the cooling air flow in the duct.The system can effectively improve the comprehensive convective heat exchange capacity of the air cooling, and the air cooling effect is more obvious, ensuring that the heat generated inside the DC charging pile is effectively and timely discharged.

Owner:北京中科绿能科技有限公司

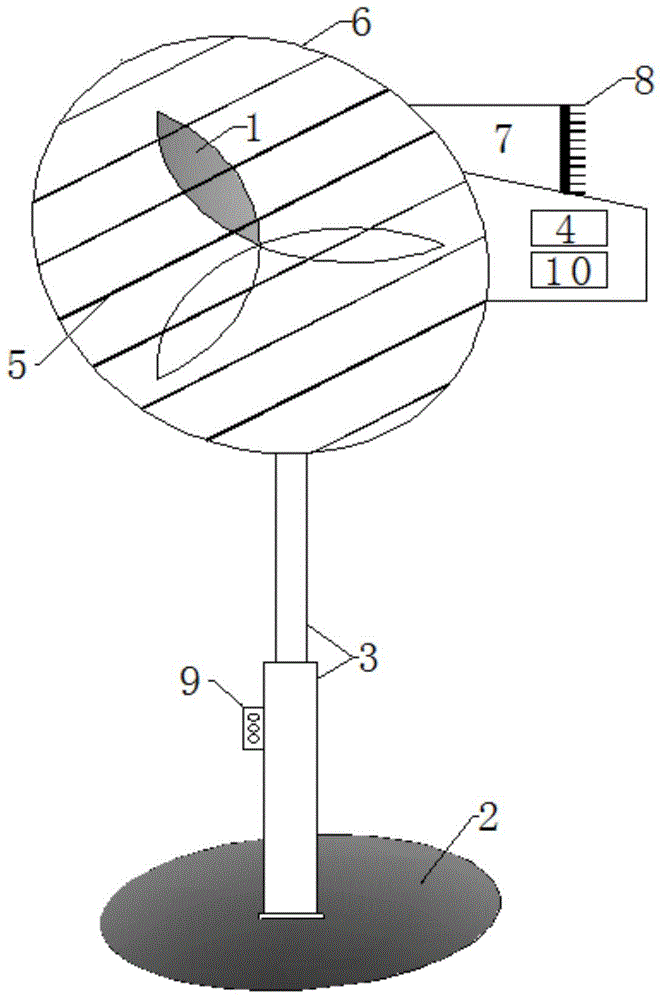

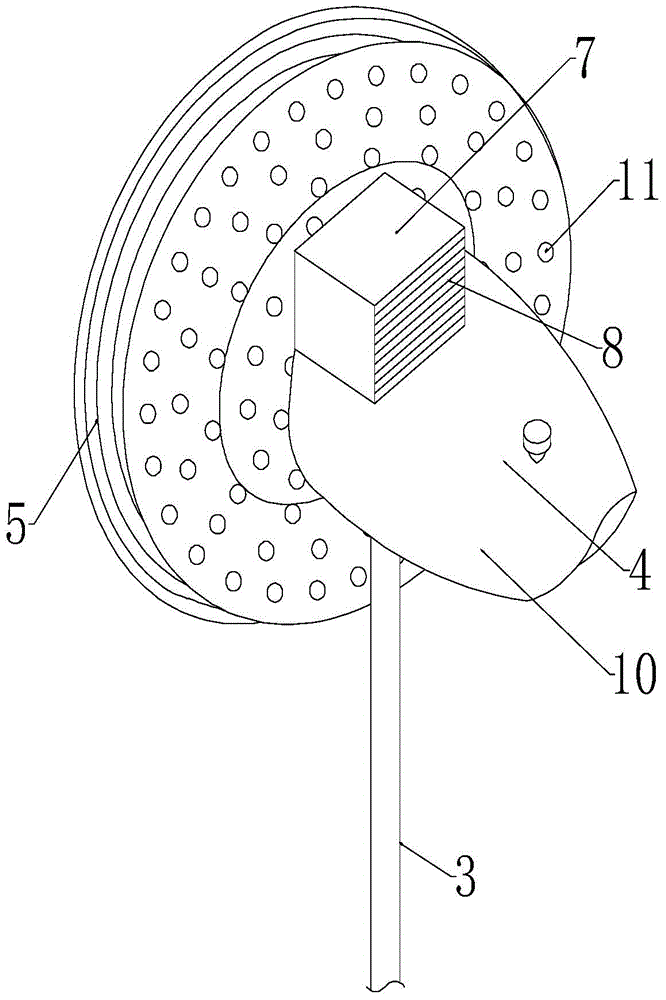

Multifunctional thermoelectric air conditioner fan

InactiveCN105042739ARealize multi-level controlIncrease the convective heat transfer areaLighting and heating apparatusAir conditioning systemsGratingEngineering

The invention discloses a multifunctional thermoelectric air conditioner fan which comprises an air conditioner fan component and a vertical rod component. The air conditioner fan component comprises a power component and a blade unit, and the power component comprises a power device and a rectifying circuit which are installed inside a cover; a heat conduction metal plate is installed on the front portion of the cover, a thermoelectricity module used for controlling the temperature of the heat conduction metal plate is arranged behind the heat conduction metal plate, one end of the thermoelectricity module is connected with the heat conduction metal plate, and the other end of the thermoelectricity module is connected with heat dissipation fins; the blade unit is arranged in front of the heat conduction metal plate and connected with the power device, and gratings is arranged outside the blade unit; the rectifying circuit provides direct currents for the thermoelectricity module and the power device; the vertical rod component comprises a vertical rod and a base, the vertical rod is connected with the cover, and switch buttons are arranged on the vertical rod; the base is arranged at the bottom end of the vertical rod. According to the air conditioner fan, a traditional fan is combined with the thermoelectricity module, refrigeration and heating can be achieved, the requirements in different seasons are satisfied, the indoor comfort is improved, the structure is simple, and no pollutants are generated.

Owner:HUAZHONG UNIV OF SCI & TECH

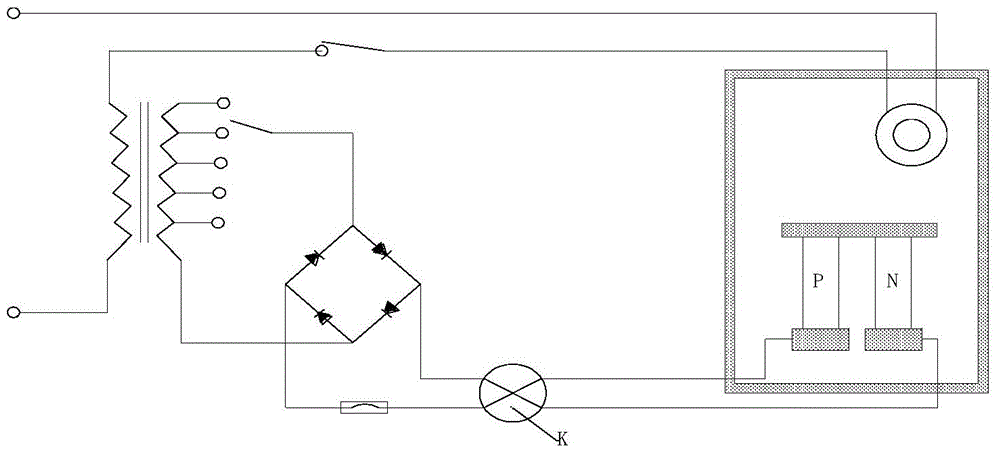

Device and method for utilizing cyclic cooling water in cooling tower of steel plant to generate power

PendingCN107795430AImprove cooling effectImprove shock absorptionHydro energy generationReaction enginesCooling towerNuclear engineering

The invention relates to a device and method for utilizing cyclic cooling water in a cooling tower of a steel plant to generate power. By improving the structure of the cooling tower, thegravitationalpotential energy of the cooling water is converted into mechanical energy, and then the mechanical energy is converted into electric-power kinetic energy to achieve the efficient utilization of resources. According to the method, by arranging a hydroelectric power generation unit above a water collection pool, the potential energy of the water is utilized to enable magnesium-aluminum lightweightcorrosion-resistant blades to rotate, the blades drive a power generator to generate power after accelerated by a speed changing gear, and the power is supplied to electrical equipment after output current is rectified and inverted. Compared with traditional cooling towers, the technology has the advantages that existing power generator equipment is utilized to convert the gravitational potentialenergy of the water freely falling into electric energy, the installation process is simple, the economic benefits are large, and meanwhile, the cooling efficiency of the cooling tower is improved.

Owner:UNIV OF SCI & TECH BEIJING

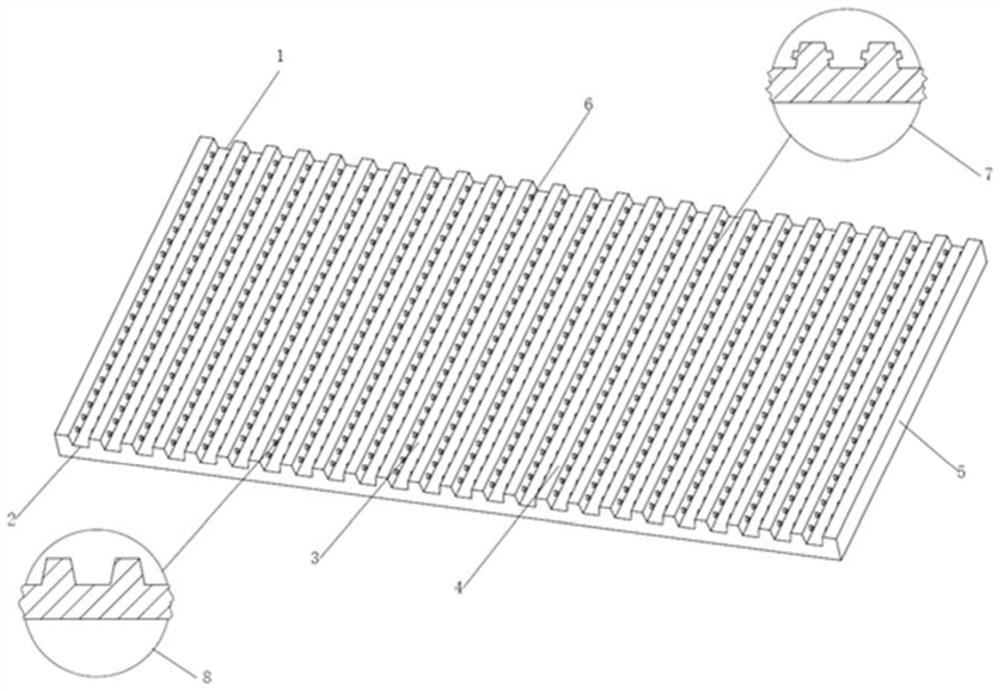

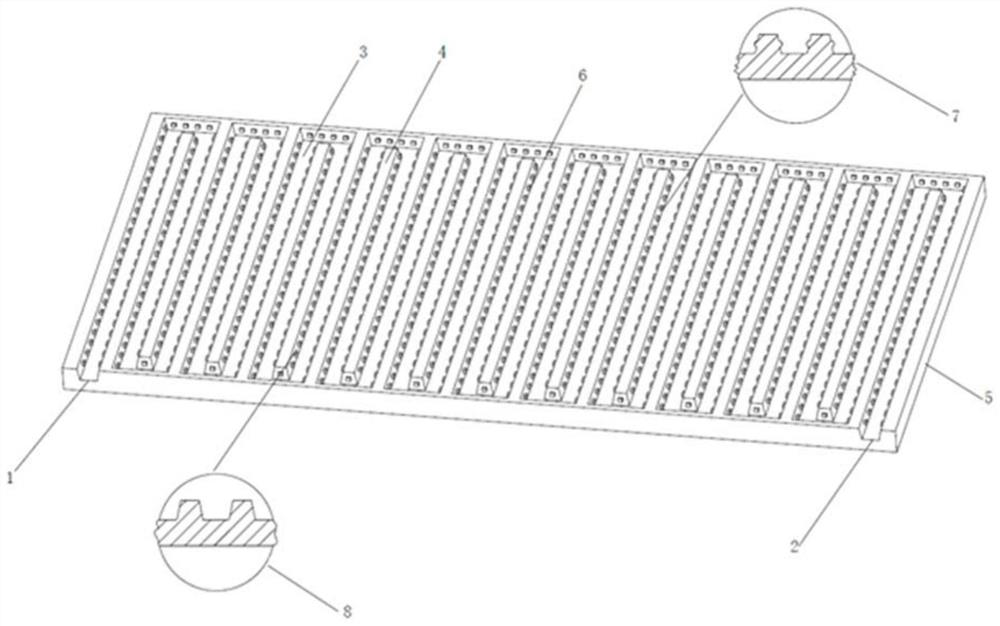

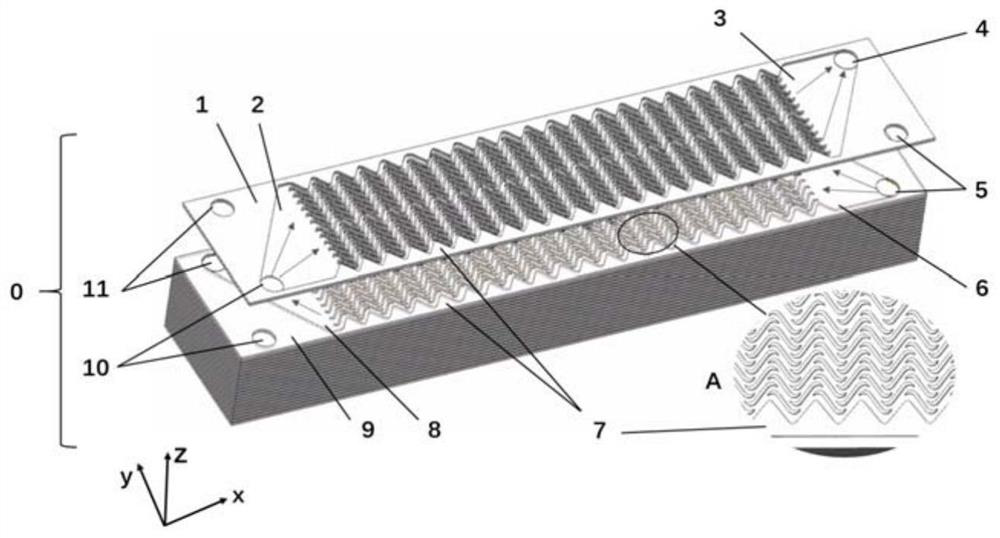

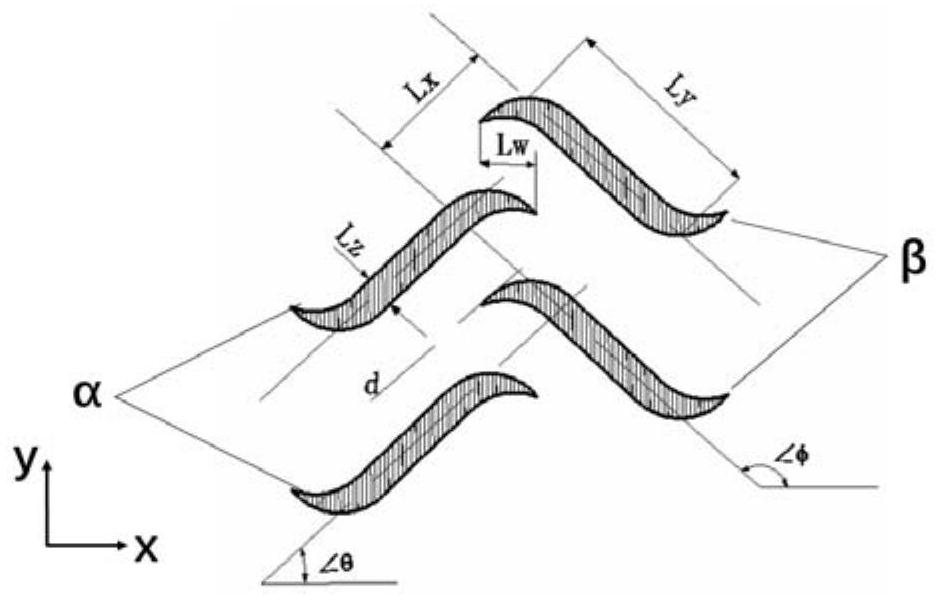

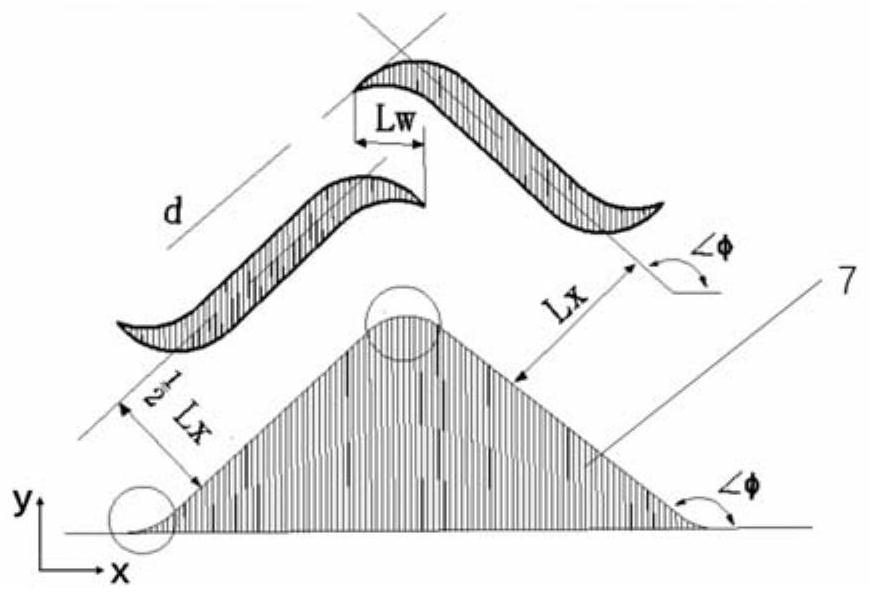

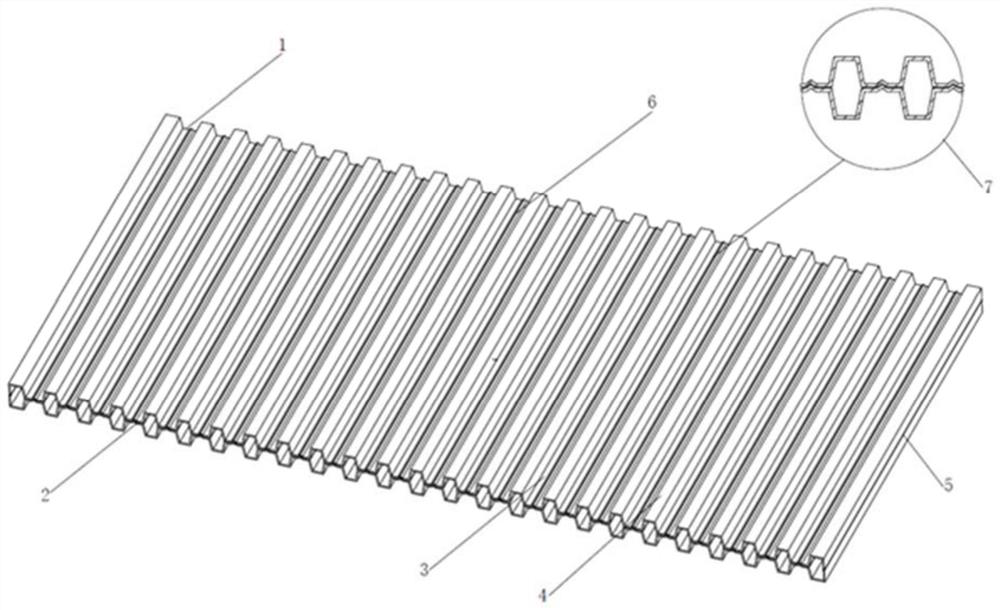

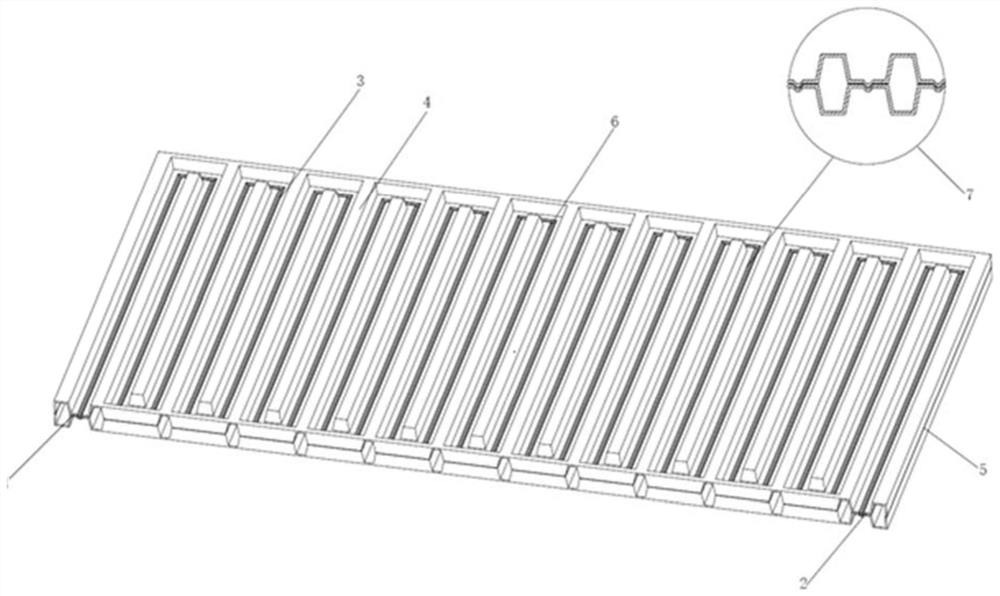

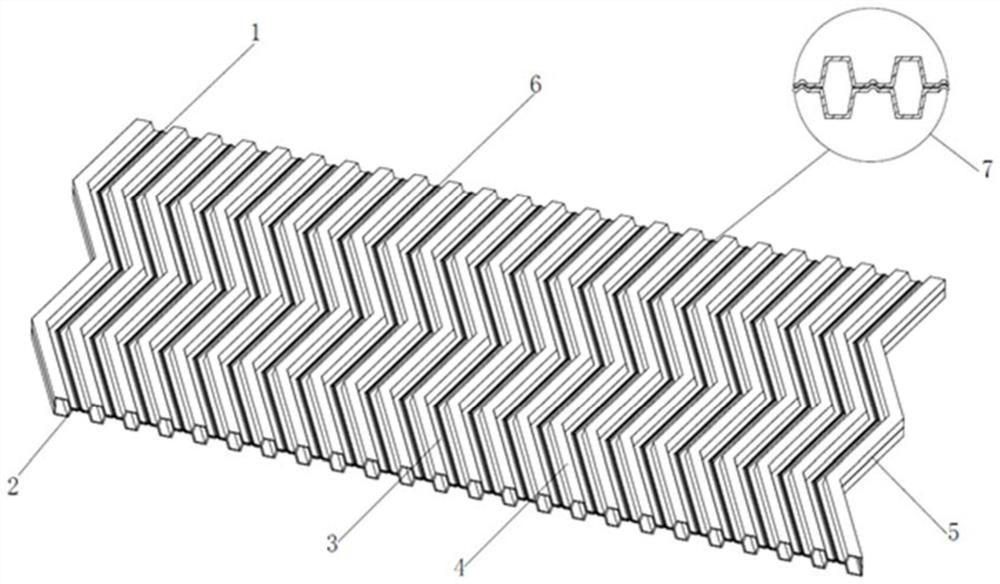

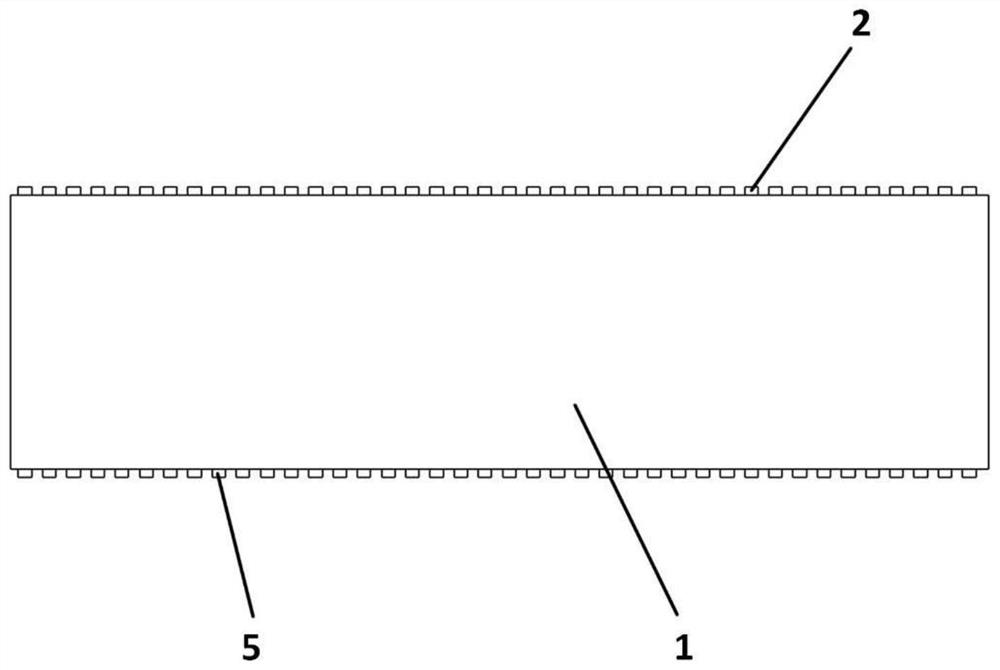

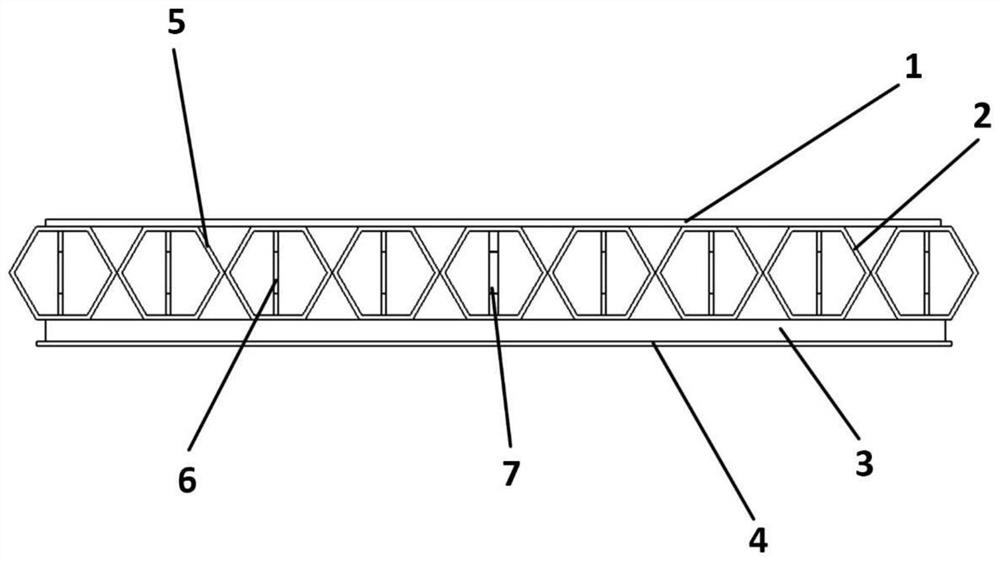

Discontinuous S-fin type heat exchange plate and PCHE core body

PendingCN113154915AIncrease the convective heat transfer areaReduce uniformityLaminated elementsStationary plate conduit assembliesThermodynamicsEngineering

The invention provides a discontinuous S-fin type heat exchange plate which is provided with a fluid inlet uniform distribution area, a fluid outlet contraction area and a discontinuous S-fin type area, the side edge of the heat exchange plate is of a sawtooth-like structure, and the discontinuous S-fin type area comprises a forward fin and a reverse fin which are the same in structure and different in arrangement position. According to the discontinuous S-fin type heat exchange plate, the fluid inlet and outlet flow channel form, the sawtooth-like structure and the forward and reverse S-shaped fin design are adopted, the convection heat exchange area of the heat exchange plate is increased, meanwhile, the flow distribution nonuniformity and the flow separation phenomenon of fluid are reduced, and the pressure loss of the fluid in the flow heat exchange process is reduced.

Owner:上海新奥节能技术有限公司

Device for using flue gas waste heat of rotary cement kiln to preheat air

InactiveCN104329948AImprove temperature riseEfficient SupplementCombustion processIncreasing energy efficiencyThermal energyEngineering

The invention discloses a device for using flue gas waste heat of a rotary cement kiln to preheat air, so as to effectively improve the heat energy utilization rate of the rotary cement kiln. The device comprises a threaded flange, a ribbed pipe, a flange, a shell, a refractory lining, a sealing ring, a gravity dust removal joint, a dust removal end cover, a low support and a high support. The device for using flue gas waste heat of the rotary cement kiln to preheat air has the advantages that the thermal efficiency is higher and the medium flowing resistance is smaller; since the flue gas and the air flow in reverse directions, reverse heat exchange is realized; the arranged refractory lining has the effect of heat preservation and heat storage, the temperature of the refractory lining is increased, the surface of the high-temperature refractory lining realizes radiative heat transfer to the ribbed pipe and the heat supply of the ribbed pipe is effectively supplemented; since fourteen long strip-shaped straight ribs are arranged on the inner and outer walls of the ribbed pipe, the ribs increase the convectional heat exchange area and the heat transfer is enhanced; the device also has a dust removal function; since the shell is embedded into two supports at different heights through arc-shaped convex blocks, the entire device and the horizontal plane form a certain inclination angle; since the gravity dust removal joint is arranged at a flue gas outlet of the steel shell, the dust removal is facilitated.

Owner:UNIV OF SCI & TECH LIAONING

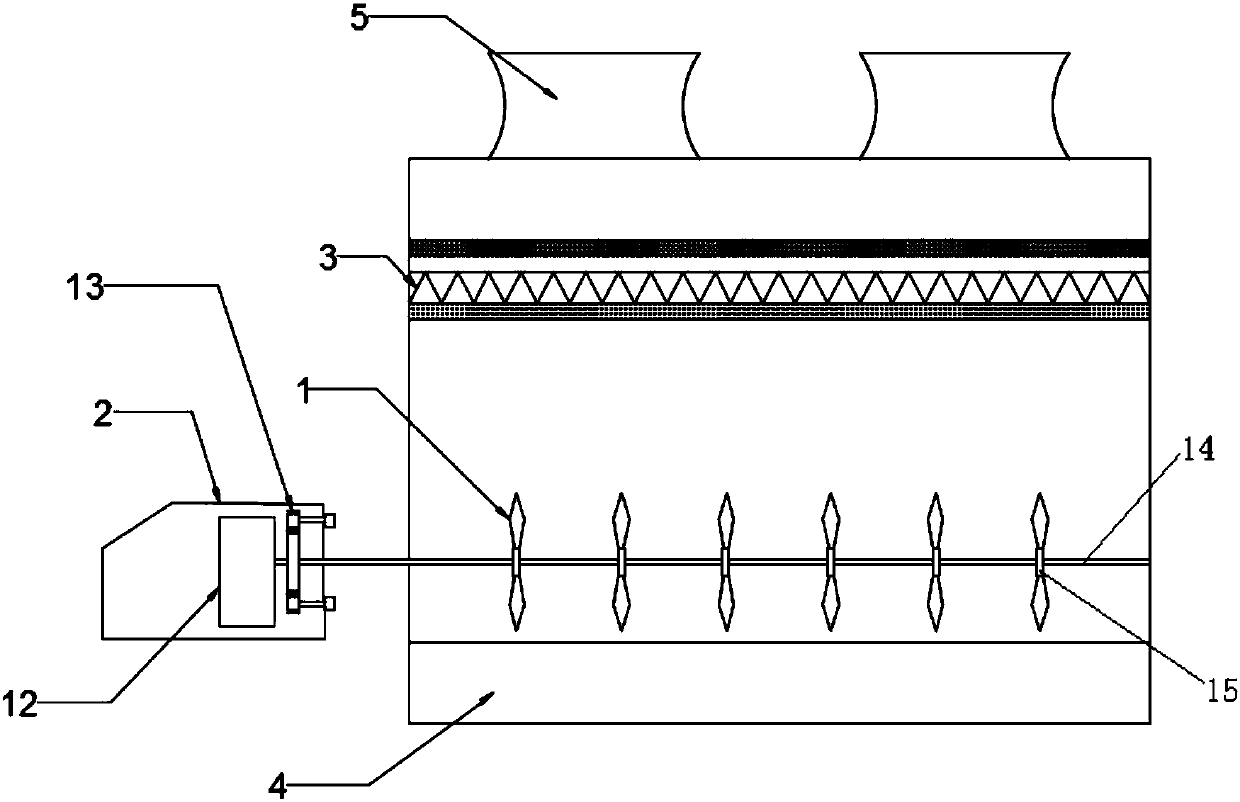

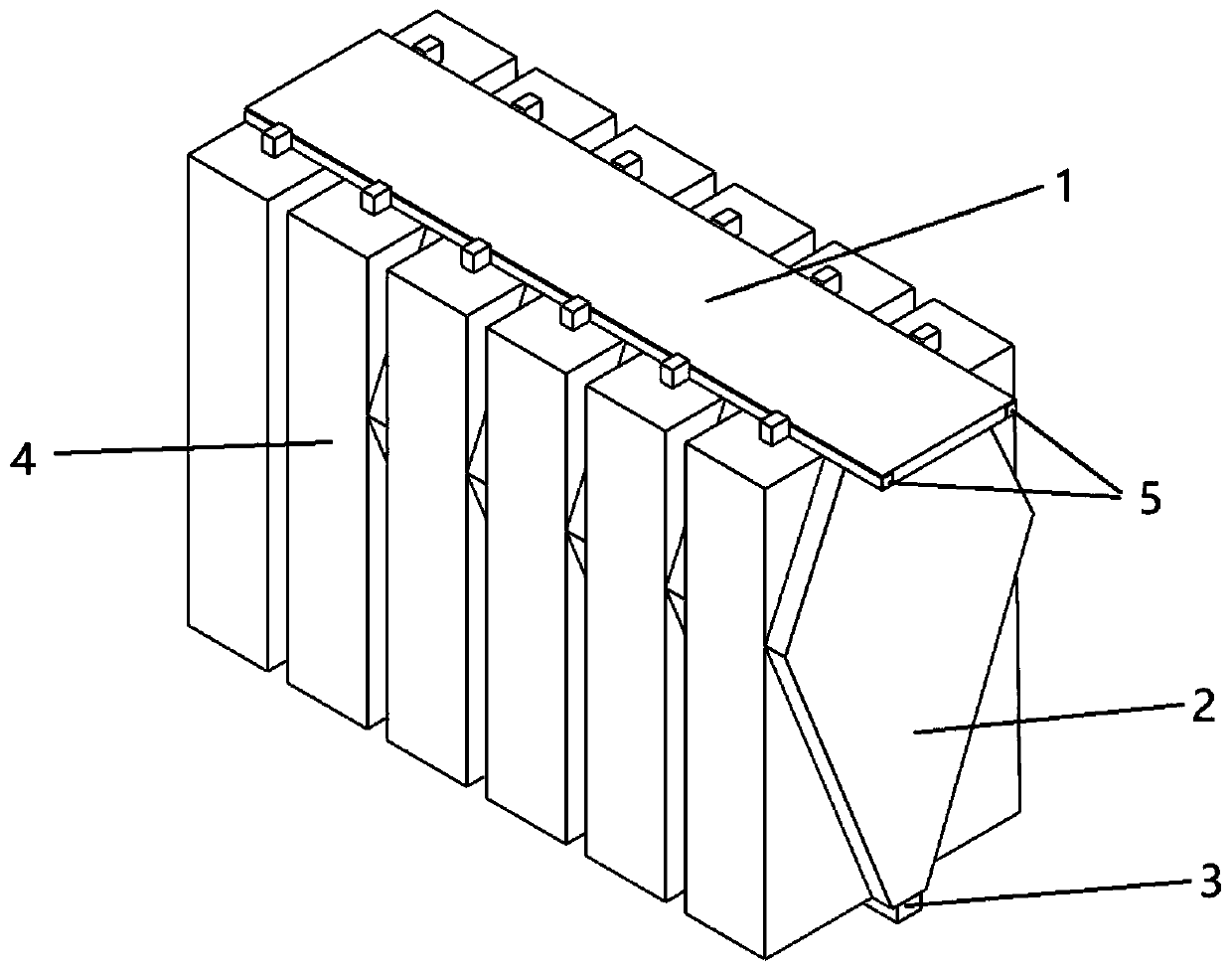

Heat dissipation module for battery thermal management

ActiveCN110534843AIncrease the convective heat transfer areaImprove cooling efficiencyAir-treating devicesSecondary cellsEngineeringBattery cell

The invention discloses a heat dissipation module for battery thermal management. The heat dissipation module comprises a top cover plate, a cooling plate and an outlet pipeline. The top cover plate is provided with two fluid passages. The top cover plate and the outlet pipe are respectively located at the upper and lower ends of the cooling plate. The cooling plate is intenrally provided with a fractal microchannel. The inlet of the fractal microchannel is connected with a fluid pipeline flowing through the pole lug, and the outlet of the fractal microchannel is connected with the outlet pipeline. The cooling plate and lithium iron phosphate battery cells are alternately distributed, and the two sides of each lithium iron phosphate battery cell are attached to the cooling plate. The temperature of the battery module can be accurately controlled, the temperature of the battery module is controlled within a safe range and the temperature distribution is uniform; and the heat dissipationmodule has a compact structure and is beneficial to realize the weight reduction of the whole vehicle.

Owner:CHANGAN UNIV

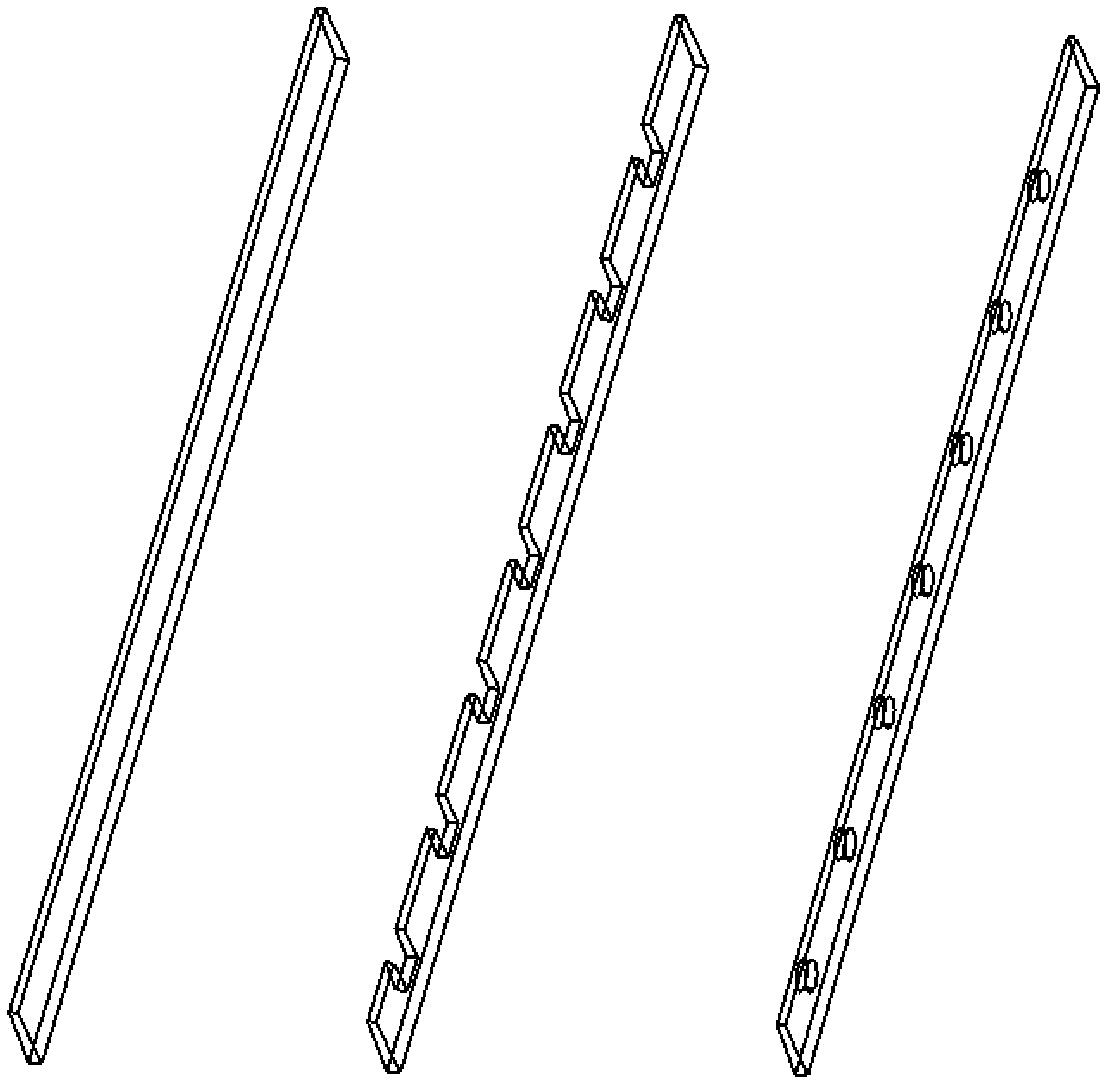

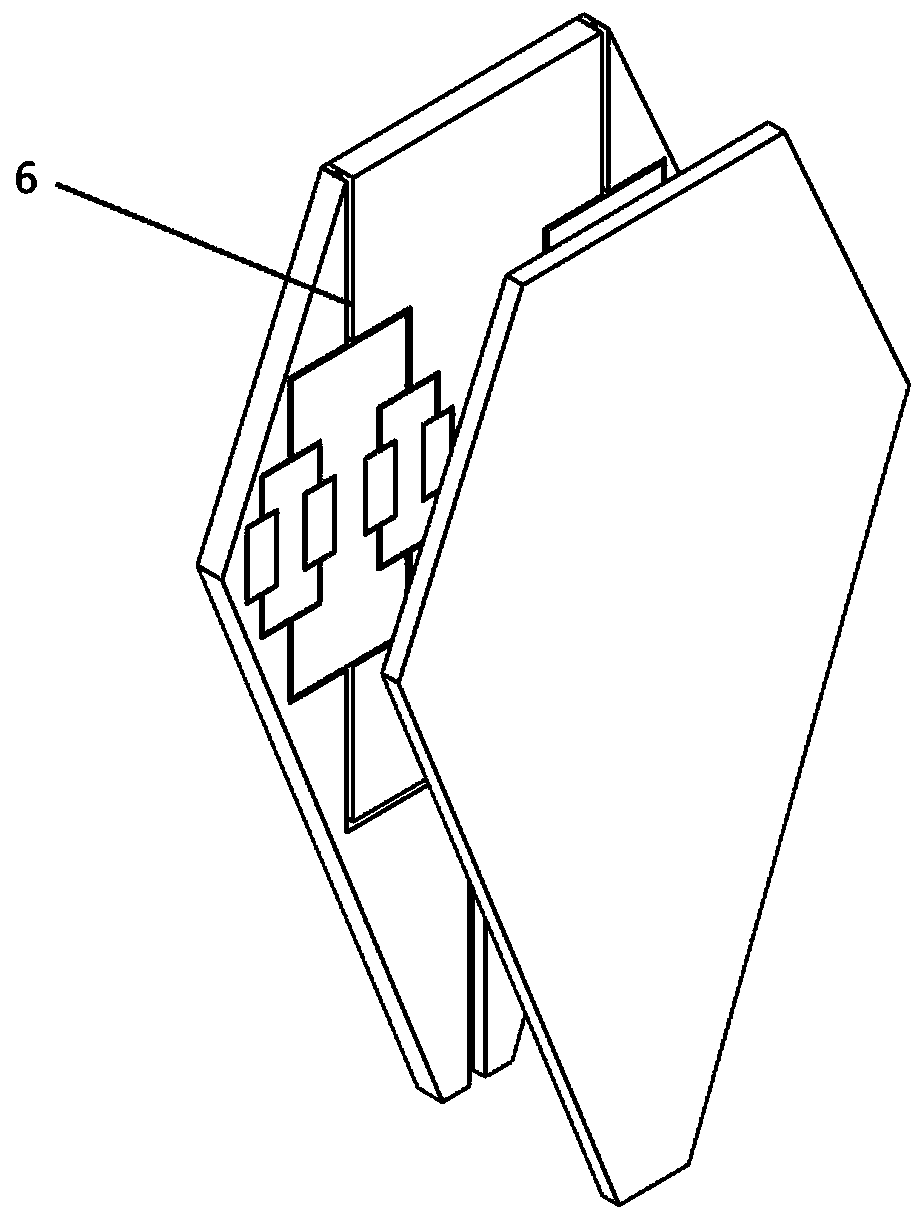

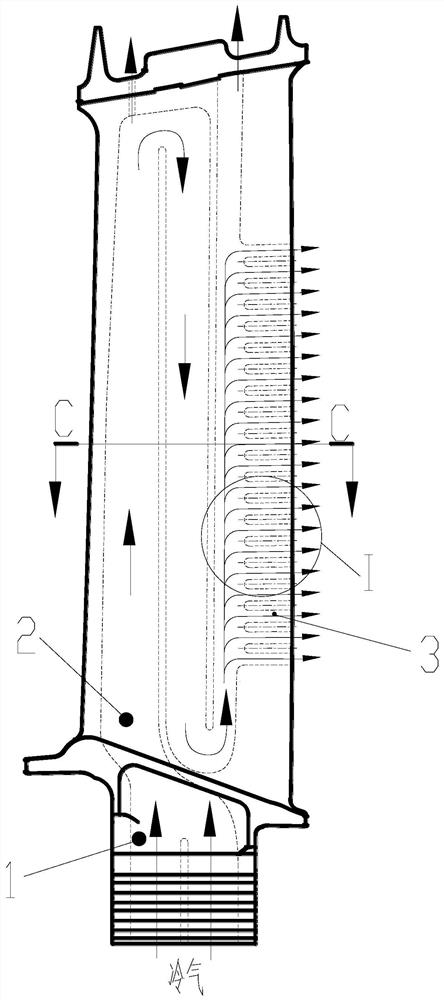

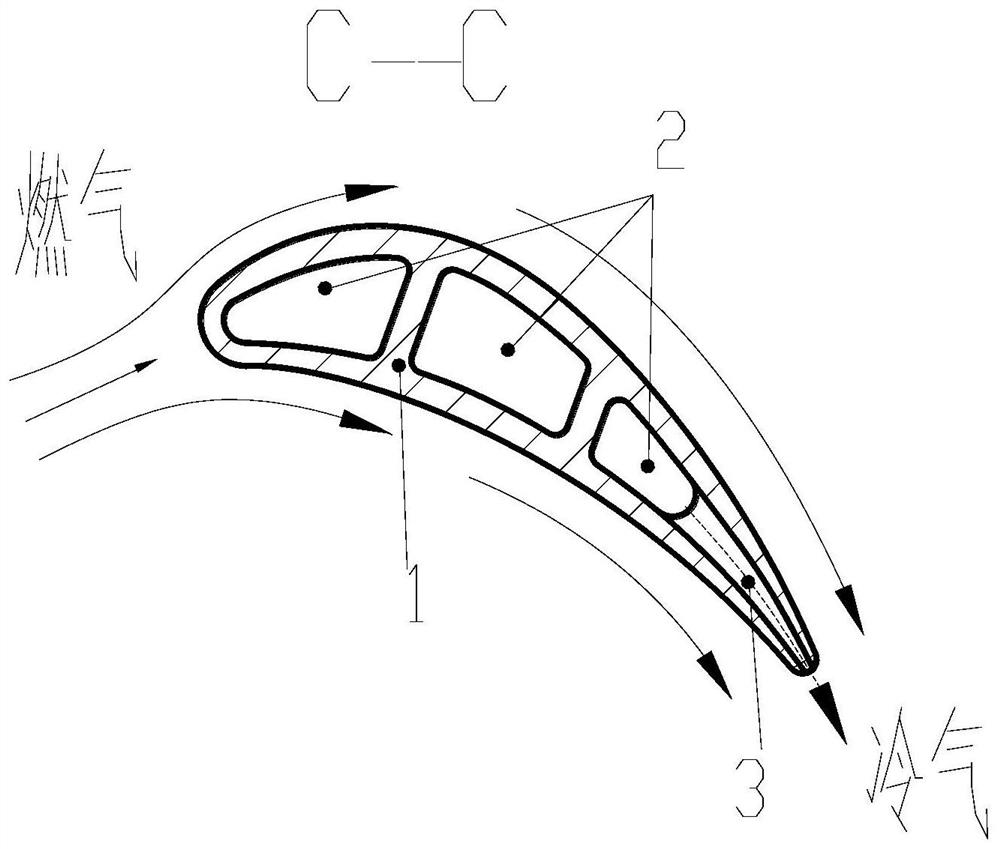

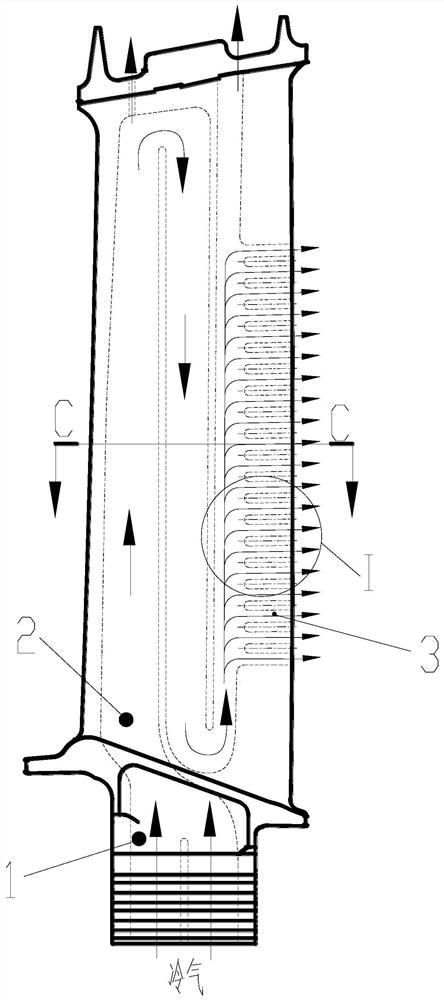

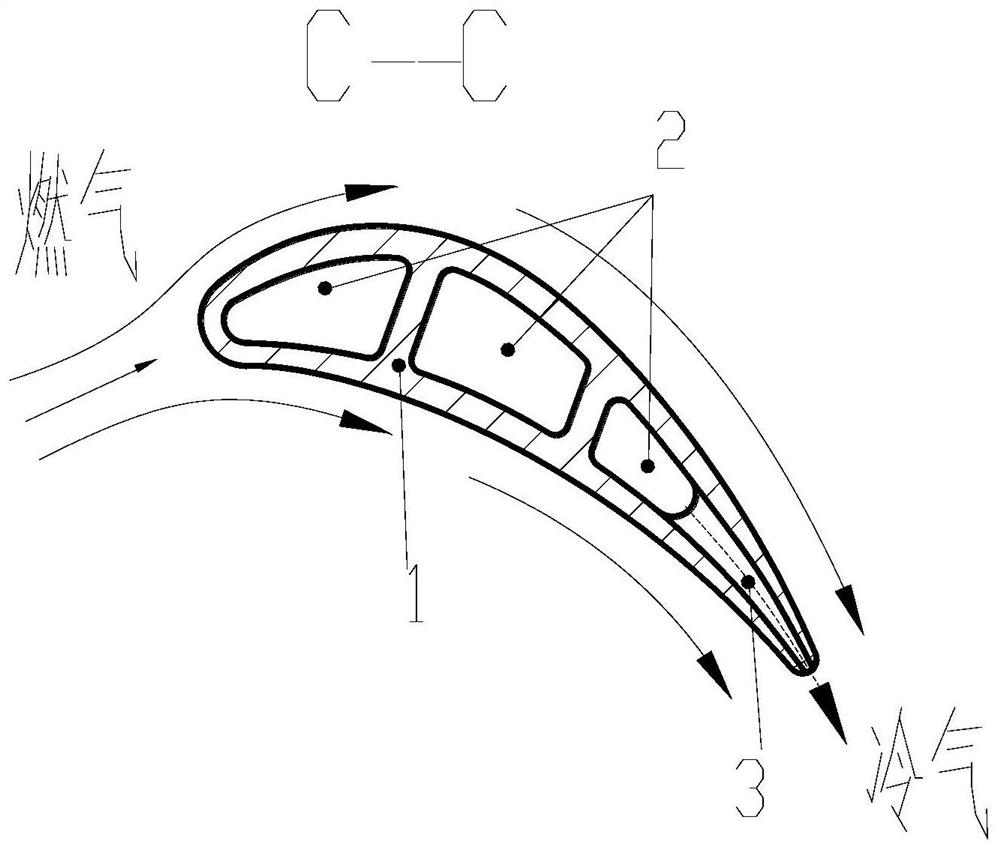

Bead type turbine blade trailing edge slit cooling structure

ActiveCN112177683AIncrease the convective heat transfer areaImprove heat transfer effectBlade accessoriesMachines/enginesTurbine bladeEngineering

The invention belongs to the technical field of aero-engine turbine cooling, and relates to a bead type turbine blade trailing edge slit cooling structure. The cooling structure comprises a hollow turbine blade, an inner cavity cool gas channel and trailing edge exhaust slit channels, the inner cavity cool gas channel is formed inside the hollow turbine blade and used for allowing low-temperaturecool gas to flow inside the blade to cool the blade; and the trailing edge of the hollow turbine blade is provided with the plurality of discrete bead type trailing edge exhaust slit channels in the chordwise direction so as to allow the cool gas to be exhausted out of the blade. The bead type trailing edge exhaust silt has a repeatedly contracted and expanded channel structure, the convective heat exchange area of the cool gas and a channel inside the trailing edge of the turbine blade is effectively increased, and compared with an existing trailing edge middle slit structure, the bead type trailing edge exhaust slit has the repeatedly contracted and expanded channel structure, and can blow off a boundary layer and inhibit the boundary layer from thickening, so that heat exchange is enhanced.

Owner:DALIAN UNIV OF TECH

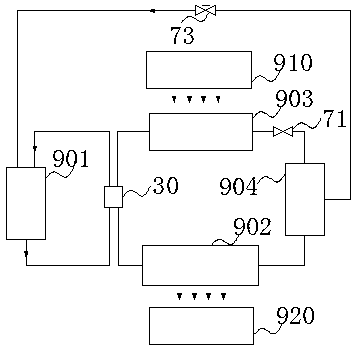

Heat pump unit with solar energy-air source direct expansion evaporator

PendingCN109579363AImprove heating effectReduce input powerMechanical apparatusHeat pumpsNew energyHigh energy

The invention provides a heat pump unit with solar energy-air source direct expansion evaporator, and belongs to the technical field of new energy utilization. The heat pump unit comprises a compressor, a condenser and an evaporator and is filled with working medium a heat pump circulating pipeline; the heat pump unit is characterized in that an evaporation tube is arranged in the evaporator, tooth grains and fins are arranged on the inner tube wall and the outer tube wall of the evaporation tube respectively, the tooth grains comprise convex tooth parts and groove parts which penetrate through the two ends of the evaporation tube and are alternately arranged; a solar heat absorbing surface with a wire drawing groove is arranged on the surface of the fins; the evaporation tubes are arranged in parallel and are connected in series to form an evaporation tube set; the evaporation tube set is connected to the two ends of the evaporator in parallel. Compared with other solar direct-expansion heat pump units, the heat pump unit has higher energy efficiency.

Owner:RENQIU HONGWANG HEATING EQUIP +1

Fuel cell flow field plate and fuel cell

PendingCN112086658AReduce the use effectReduced assembly effortCollectors/separatorsThermodynamicsFuel cells

The invention provides a fuel cell flow field plate and a fuel cell, relates to the field of fuel cells, and is mainly suitable for hydrogen-air fuel cells and hydrogen-oxygen fuel cells. The flow field plate comprises an air inlet, an air outlet, a flow channel, a ridge, a groove and a boss, wherein the groove and the boss are formed in the bottom of the flow channel, are distributed at the bottom of a flow channel ditch along the flow channel direction and are respectively positioned on two polar plates. According to the flow field plate, the grooves and the bosses are arranged on the wall surfaces of the bottoms of the flow channels of the two polar plates respectively, and when the fuel cell is assembled, the grooves and the bosses are meshed with each other, so that the two polar plates cannot move relatively. The groove and boss structures in the flow channels divide the interface of the liquid drop and the wall of the flow channel, so that the effective contact area of the liquid drop and the wall of the flow channel is reduced, liquid water is prevented from forming a continuous water film, the discharge of the liquid water is facilitated, and the flooding phenomenon is relieved. And meanwhile, due to the existence of the groove and boss structures, airflow disturbance is further enhanced, the convective heat exchange area is increased, and the mass transfer and heat exchange capacity of a flow field is improved.

Owner:SHANGHAI JIAO TONG UNIV

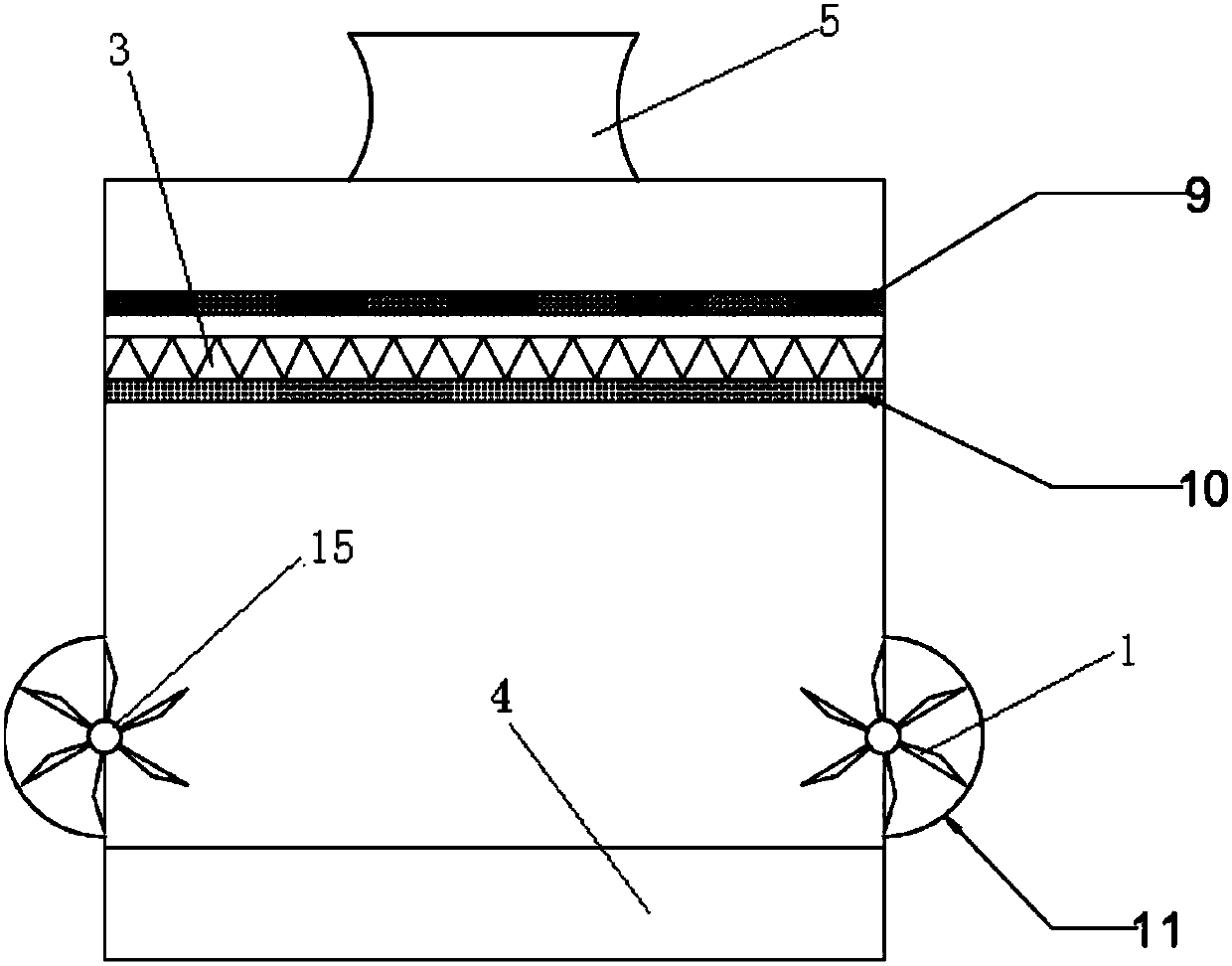

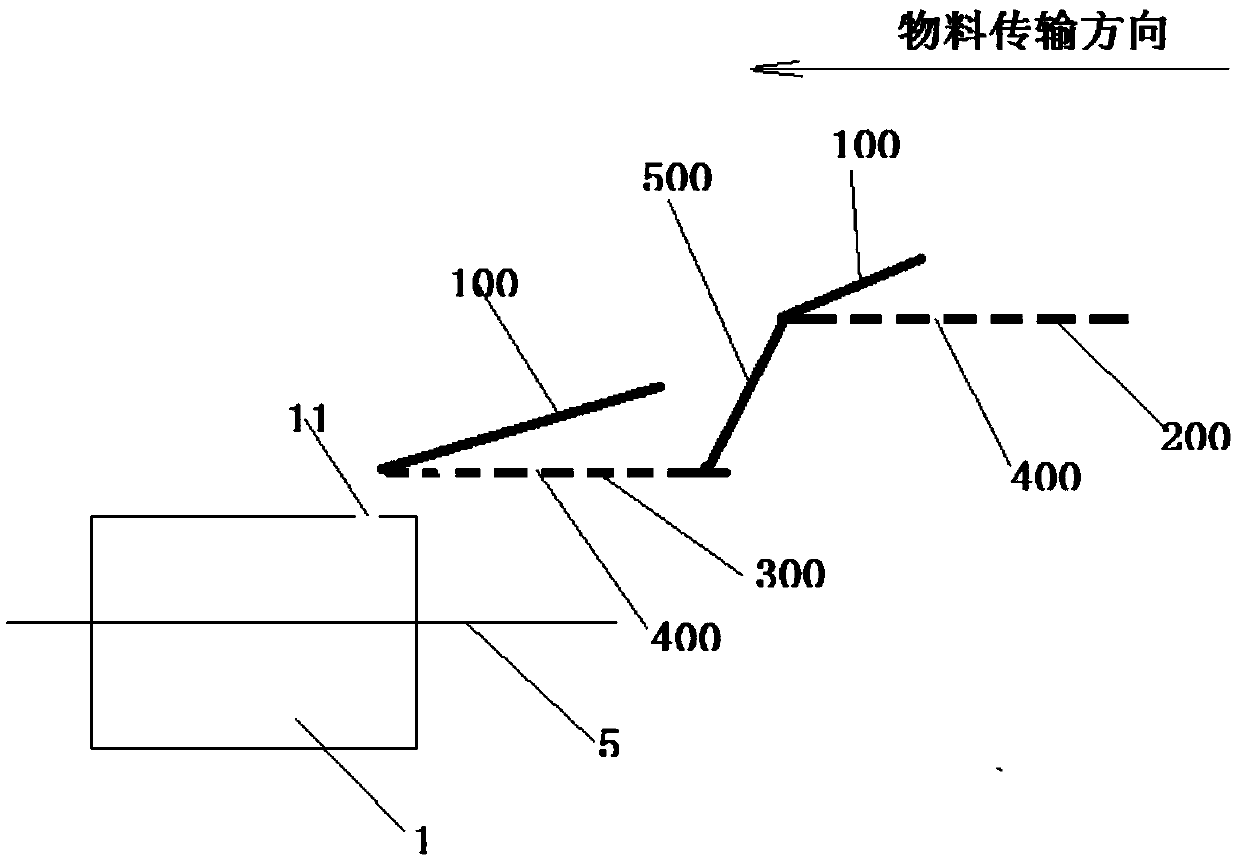

Drying device

ActiveCN105387712AKeep dryStir wellSludge treatment by de-watering/drying/thickeningSludge dryingEngineeringProduct gas

The invention discloses a drying device. The drying device comprises a furnace body, a charging device for charging a material into the furnace body, a collecting device for collecting a dried material in the furnace body, an air supply device for inducing external hot gas into the furnace body by a first gas inlet, and a stirring device for stirring and pulverizing the material, wherein the stirring device comprises a rotary shaft which penetrates through a cavity of the furnace body, the rotary shaft is provided with a venting cavity provided with a plurality of gas nozzles, the gas spraying direction of the gas nozzles is misaligned and not parallel with the stirring direction of the stirring device and the stirring direction of blades, during material drying, the hot gas is induced into the cavity of the furnace body by the first gas inlet, and the rotary shaft rotates to drive a stirring assembly on the rotary shaft to continuously stir the material along the axial direction and radial direction of the rotary shaft, so that the material is turned over in the furnace body along the axial direction and radial direction of the rotary shaft, the stirring time of the material is prolonged, and a convection heat exchange area between the material and the hot gas is increased. In addition, the stirring assembly can pulverize the material to form a material of smaller particles, thus further increasing the convection heat exchange area between the material and the hot gas and improving the drying efficiency and drying effect of the material.

Owner:汪振朴

Sludge treatment system

ActiveCN105502881ASmoothly fall intoImprove space utilizationSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningEngineeringTreatment system

The invention relates to a sludge treatment system which comprises a conveying device, a water removal structure and a drying device. The drying device comprises a furnace body, a feed device used for adding materials into the furnace body, a material collection device used for collecting the dried materials in the furnace body, an air supply device used for leading external hot air into the furnace body through a first air inlet, and a stirring device used for stirring and smashing the materials. When the materials are dried, hot air is led into a cavity of the furnace body through the first air inlet, a second rotating shaft rotates and drives a stirring assembly on the second rotating shaft to unceasingly stir the materials in the radial direction and the axial direction of the second rotating shaft, and therefore the materials can roll in the axial direction and the radical direction of the second rotating shaft in the furnace body, the time during which the materials are stirred is prolonged, and the convective heat exchange area of the materials and hot air is enlarged. In addition, the materials can be smashed through the stirring assembly, materials with smaller particles can be formed, the convective heat exchange area of the materials and hot air is further enlarged, and the material drying efficiency and effect are improved.

Owner:GUYUAN XINYUE HALAL FOOD +1

Enhanced heat abstractor employing pulsating flow and foam metal plate

ActiveCN105097735ALittle flow resistance lossIncrease contact areaSemiconductor/solid-state device detailsSolid-state devicesCavitationHeat transfer efficiency

The invention discloses an enhanced heat abstractor employing pulsating flow and a foam metal plate. The enhanced heat abstractor comprises a pulsating pump, a heat sink chamber, an accumulated liquid cavity and a cooler, wherein the pulsating pump conveys a cooling liquid into the accumulated liquid cavity through a liquid inflow pipe; the accumulated liquid cavity sprays the cooling liquid into the heat sink chamber; the heat sink chamber conveys the liquid which is subjected to heat transfer into the cooler to cool through a liquid discharge pipe; the pulsating pump sucks in the cooled cooling liquid from the cooler through a connecting pipe; the heat sink chamber comprises the foam metal plate, a heat transfer support plate and a cover board; the heat transfer support plate is connected with a high-heating flux device; the foam metal plate is fixedly connected with the heat transfer support plate; and a dispenser is vertically connected with the top of the cover board. The pulsating flow of the enhanced heat abstractor is matched with a dual-layer foam metal structure, so that transverse and longitudinal disturbance and mixing of working mediums can be increased; a thermal boundary layer is continuously recombined; and meanwhile, cavitation and vortex formation are caused by pressure change in the disturbance process, therefore, the heat transfer efficiency can be greatly improved.

Owner:常州贺斯特科技股份有限公司

Tube shell type pulsating heat pipe heat exchanger

ActiveCN102620587BIncrease the convective heat transfer areaSpeed up evaporationIndirect heat exchangersHeat flowPlate heat exchanger

The invention discloses a tube shell type pulsating heat pipe heat exchanger, which comprises a shell pass, a tube pass, a sealing flange and a sealing head, wherein the sealing flange and the sealing head are arranged at the two ends of the shell pass; the tube pass is arranged in the shell pass and is divided into vertically communicated return fluid passages by a middle partition plate; a sealing flange and a sealing head at the two ends of the tube pass are fixed and hermetically connected with flange rings at the two ends of the shell pass; pulsating heat pipes are arranged on the tube pass and the shell pass; condensation sections of the pulsating heat pipes are positioned in the shell pass; and evaporation sections of the pulsating heat pipes are positioned in the tube pass. According to the tube shell type pulsating heat pipe heat exchanger, the pulsating heat pipes are inserted into the tube shell type heat exchanger in groups, so that the heat exchange space is fully utilized; and a corresponding heat pipe working medium is selected according to the size of a heat flow in a frictional heat exchange process, so that gradient utilization of energy is realized. In addition, the tube shell type pulsating heat pipe heat exchanger can be arranged in any direction and has the advantages of compact structure, small size, simple manufacturing process, convenience for assembly, disassembly and maintenance, no need of an external pump for driving flow, safety in use and excellent application prospect.

Owner:SOUTHEAST UNIV

Solar energy and fuel mixed heating heat collector

InactiveCN109539584AEfficient use ofCompact structureSolar heating energyCombustion processCold airCombustion chamber

The invention relates to the technical field of new energy utilization, in particular to a solar energy and fuel mixed heating heat collector. The heat collector can realize solar power generation when sunlight meets the power generation conditions, and uses a gas power generation device when no sunlight can be used. The heat collector comprises a base plate; a heat collector shell covers the baseplate; an internal heat regenerator outer shell, a cold air channel, a hot exhaust channel, an internal heat exchanger and a heat collector inner sleeve are arranged in the heat collector shell in sequence in a sleeved mode; a heat regenerator and a cylinder are arranged at the upper part of the base plate in a heat collector inner sleeve; a heat collecting device is arranged at the upper part ofthe heat collector shell; the bottom of the heat collecting device is sealed; the bottom of the heat collecting device and the upper part of the heat collector inner sleeve form a combustion chamber;a finned heating pipe is arranged in the heat collector inner sleeve; one end of the finned heating pipe is connected with a cold end of the cylinder, and the other end is connected with a hot end ofthe cylinder; and the bottom of the base plate is connected with a Stirling engine shell through a cylinder base.

Owner:西安猎光新能源科技有限公司

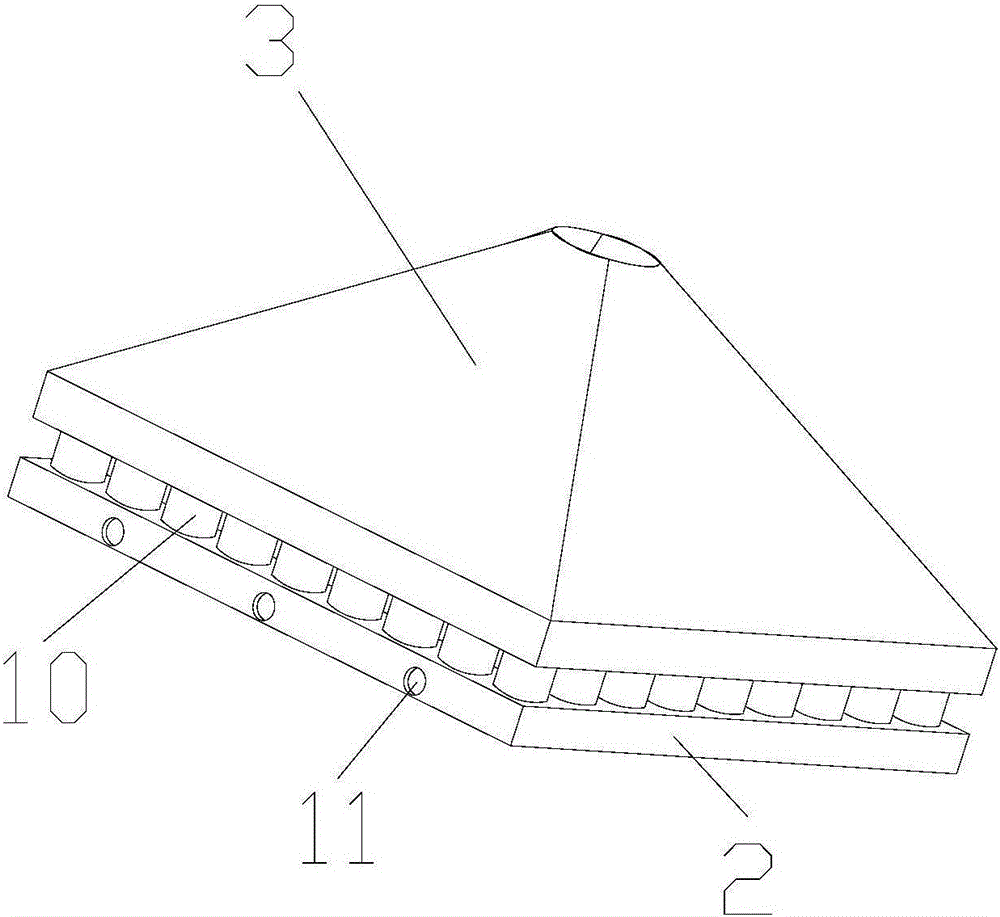

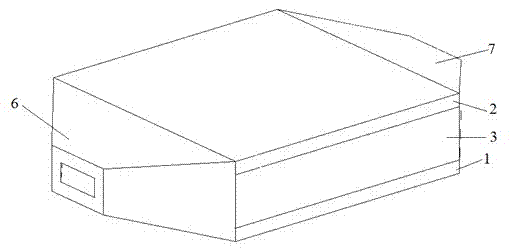

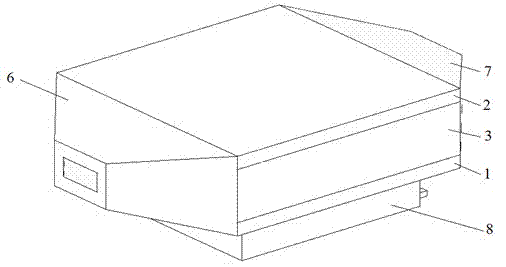

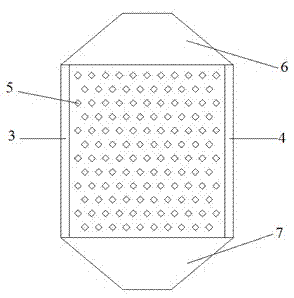

Micro convex array type thermoelectric generator heat exchange module

InactiveCN103580545AIncrease the convective heat transfer areaImprove heat exchange efficiencyGenerators/motorsEngineeringFront and back ends

The invention discloses a micro convex array type thermoelectric generator heat exchange module. A micro convex array is arranged on the upper end face of a heat exchange module base plate, the upper end of the micro convex array is in contact with the lower end face of an upper cover plate, a left side plate and a right side plate are arranged on the left side and the right side of the thermoelectric generator heat exchange module base plate respectively, and a flow inlet and a flow outlet are formed in the front end and the rear end of the thermoelectric generator heat exchange module respectively. Hot fluid enters the thermoelectric generator heat exchange module through the flow inlet, flows through the micro convex array for heat convection and flows out of the flow outlet. The whole thermoelectric generator heat exchange module is arranged on the upper portion of a thermoelectric power generation module, and is used as the hot end of a thermoelectric generator. The micro convex array structure is adopted, compared with a micro channel structure, the micro convex array type thermoelectric generator heat exchange module enables the heat convection area to be increased, and improves heat exchange efficiency. A rhombic staggered arrangement array is adopted in the micro convex array, the structure is more complex, the fluid is more disorganized, and the heat convection is severer. The micro convex array is simple in structure, easy to manufacture, low in production cost and suitable for mass production.

Owner:ZHEJIANG UNIV

Micro-channel pipeline heat exchanger

PendingCN108106174AImprove flexural strengthNot easy to crushEvaporators/condensersStationary tubular conduit assembliesWater flowEngineering

The invention provides a micro-channel pipeline heat exchanger. The micro-channel pipeline heat exchanger comprises a heat exchanger pipeline and an end connector of the heat exchanger pipeline; the heat exchanger pipeline comprises an outer wall and an inner pipe; the inner pipe is a water flow channel; a plurality of micro-channels used to enable refrigerants to pass are arranged between the outer wall and the inner pipe; the micro-channels extend along the inner pipe in the axial direction; the micro-channels are orderly arranged around the outer side of the inner pipe and each two adjacentmicro-channels are not connected with each other; the sections of the micro-channels are squares, circles, ovals or polygons; connecting ribs are arranged at the inner pipe in the radius direction and the inner pipe is divided into a plurality of pipelines by the connecting ribs; at least two connecting ribs are arranged and the two connecting ribs are arranged in a staggered manner; one end of the end connector is connected with the micro-channels and the other end of the end connector is connected with a refrigerant pipeline of a refrigeration circulation system; a plurality of connecting ribs are designed at the inner pipe, so that the convection heat exchanging area of water can be greatly increased by the connecting ribs and the heat exchanging efficiency can be high; meanwhile, thebending-resistant strength of the pipeline can be strengthened and the pipeline is not prone to flatten during bending.

Owner:GUANGDONG NEW ENERGY TECH DEV

Anti-vibration cooling wall of ground gas turbine combustion chamber

InactiveCN105605605AIncrease the heat exchange areaImprove cooling efficiencyContinuous combustion chamberCasings/liningsCombustion chamberPhase difference

The invention provides an anti-vibration cooling wall of a ground gas turbine combustion chamber. The anti-vibration cooling wall comprises an inner wall and an outer wall, wherein the inner wall and the outer wall are connected by using screw type spring steel with incremental diameter and are arranged in a certain manner; a communicated cavity is formed between the inner wall and the outer wall. According to the anti-vibration cooling wall, by changing the wall surface structure of a main combustion chamber flame tube, the propagation of sound wave in a main combustion chamber is absorbed and changed, and then the phase difference between oscillation of sound pressure and fluctuation of heat release rate cannot remain unchanged all the time; meanwhile, the spring has a trimmer pressure effect, so that the occurrence of thermo-acoustic oscillation is effectively prevented. Through the arrangement of the spring in the anti-vibration cooling wall, the heat convection area of cooling air is increased, the cooling efficiency of cooling air is improved, and the anti-vibration cooling wall has a wide application prospect.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

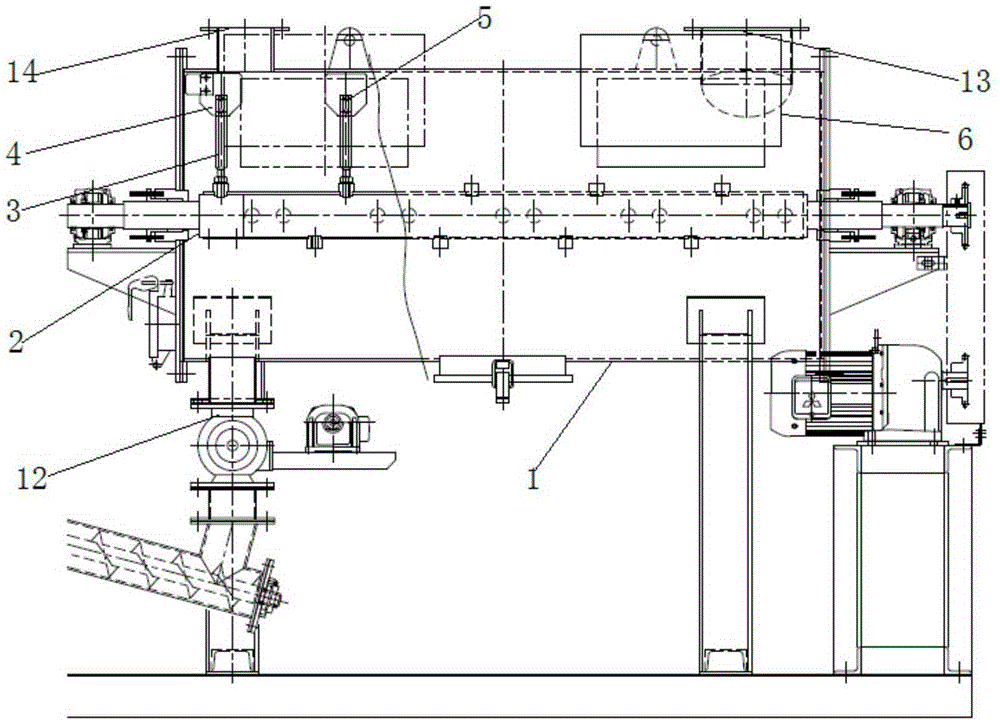

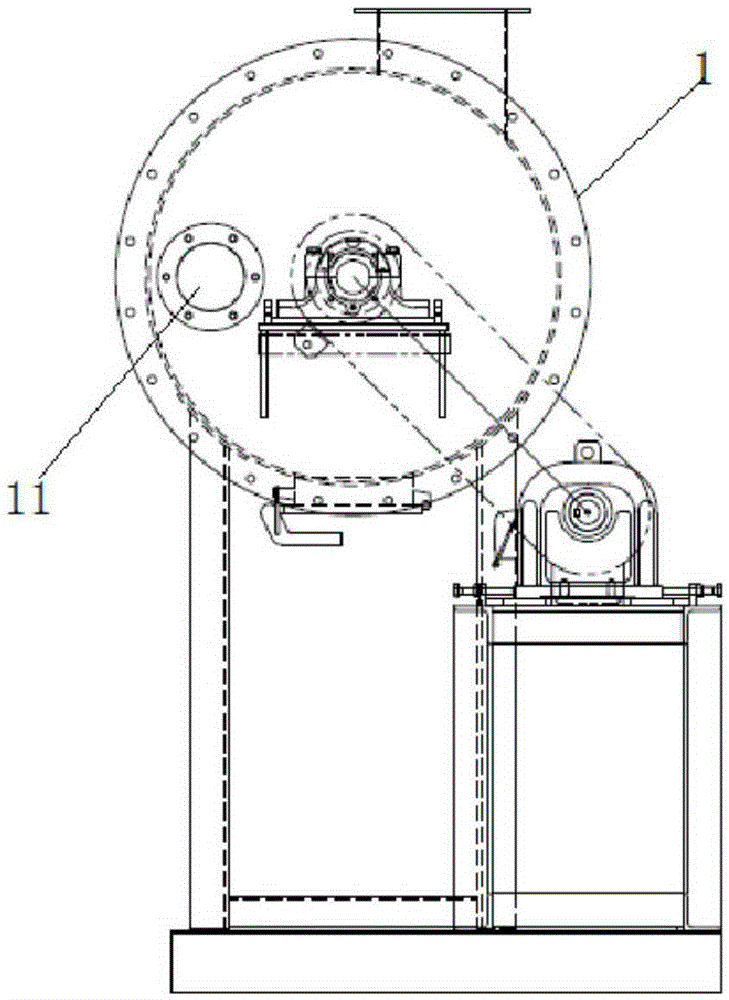

Gas condensation boiler with narrow gap combustion and heat exchange function

ActiveCN110822714AFully absorb radiation heat transferEnhanced convective heat transferStorage heatersAir heatersCombustorFlue gas

The invention discloses a gas condensation boiler with a narrow gap combustion and heat exchange function. The gas condensation boiler comprises a combustor and a heat exchanger, wherein the narrow gap combustor installed in the center of a boiler top plate is composed of a blower, a mixer and a water-cooled combustion head; the heat exchanger is formed by uniformly arranging three circles of corngrain-shaped straight pipes in the circumferential direction, wherein the inner circle of corn grain-shaped straight pipe and the outer circle of corn grain-shaped straight pipe are narrow in the inner sides and wide in the outer sides, and the third circle of corn grain-shaped straight pipe is coupled with the combustion head; the blower feeds air into the mixer to be fully mixed with gas, the mixture enters the combustion head cavity to be discharged from narrow gaps between the water cooling straight pipes which are uniformly distributed in the circumferential direction, after ignition, the mixture is uniformly combusted in the circumferential and axial directions and radiates heat towards the inner tube ring, the narrow gap between the inner and outer circles of straight pipes is washed by the flue gas in sequence to realize the intensified heat exchange of the narrow gap laminar flow, and the flue gas flows downwards into an exposed disc from the gaps between the outer shell andthe outer straight pipes and is discharged into the atmosphere from a flue gas outlet. The gas condensation boiler has the advantages of being simple in structure, capable of realizing laminar flow strengthening, compact in heat exchange, low in nitrogen emission and high in thermal efficiency.

Owner:XI AN JIAOTONG UNIV +1

Drying machine

ActiveCN105333706AIncrease the areaImprove heat transfer efficiencyDrying machines with non-progressive movementsDrying solid materialsSmall particleMechanical engineering

The invention discloses a drying machine. The drying machine comprises a furnace body, rotating shafts, and stirring components, wherein the furnace body is arranged in the horizontal direction; the furnace body is provided with a feed opening through which materials are added and a discharge opening through which the materials are taken out; the rotating shafts are arranged in the cavity of the furnace body in a penetrating manner; the stirring components are arranged on the rotating shafts; the stirring components are used for stirring and crushing the materials in the axial directions of the rotating shafts and in the radial directions of the rotating shafts. According to the drying machine disclosed by the invention, when the materials are dried, under the driving of the rotating shafts, the stirring components can stir the materials in the axial directions of the rotating shafts and in the radial directions of the rotating shafts, so that the materials can be rolled in the furnace body in the axial directions of the rotating shafts and in the radial directions of the rotating shafts; besides, when the materials are stirred, the materials can also be crushed to form the materials with smaller particles, so that the area of heat convection between the materials and external environment is increased, the drying efficiency of the materials is improved, and the drying effect of the materials is improved.

Owner:江苏碧诺环保科技有限公司

An m2 solid state hard drive cooling sticker

ActiveCN113380283BEnhance bending and compressive capacityAchieve protectionReducing temperature influence on carrierThermal insulationEngineering

The invention discloses a heat dissipation sticker applied to a notebook computer, a desktop computer or an external M2 solid state hard disk. The heat dissipation sticker comprises: a thin porous foam metal copper layer, a two-way regular hexagonal array heat dissipation layer, a specially treated fixed copper sheet and a Silicone insulating pad. The present invention designs each structural size for the M2 solid state hard disk on the market, and realizes both light weight and efficient heat dissipation by utilizing the design of an efficient bidirectional regular hexagonal array heat dissipation layer and the like. The fixed copper sheet acts as a support and a reference plane. The silicone thermal insulation pad is connected to the user's M2 solid-state hard disk, which can not only play the role of bonding, buffering and electrostatic shielding, but also reduce the contact thermal resistance between the thermally conductive solid surfaces. The heat dissipation sticker of the invention is easy to install, and only needs the user to closely attach the heat dissipation sticker to the hard disk, so that the heat dissipation capacity of the hard disk can be greatly enhanced, the working temperature can be greatly reduced, and the compression and bending resistance of the user's M2 hard disk can be improved. Easy to install.

Owner:XI AN JIAOTONG UNIV

Heat dissipation patch for M2 solid state disk

ActiveCN113380283AEnhance bending and compressive capacityAchieve protectionReducing temperature influence on carrierThermal insulationHexagonal array

The invention discloses a heat dissipation patch applied to a notebook computer, a desktop computer or an external M2 solid state disk. The heat dissipation patch comprises a thin porous foam metal copper layer, a bidirectional regular hexagon array heat dissipation layer, a specially-processed fixed copper sheet and a silica gel insulation pad. Various structural sizes are designed for the M2 solid state disk in the market, and the design of the efficient bidirectional regular hexagonal array heat dissipation layer and the like is utilized to realize the combination of light weight and efficient heat dissipation. And the fixed copper sheet plays a role of supporting and a reference surface. The silica gel heat-conducting insulation pad is connected with the user M2 solid state disk, so that the effects of bonding, buffering and electrostatic shielding can be achieved, and the contact thermal resistance between heat-conducting solid surfaces can be reduced. The heat dissipation patch is easy to install, the heat dissipation capacity of the hard disk can be greatly enhanced and the working temperature can be greatly reduced only by tightly attaching the heat dissipation patch to the hard disk by a user, the compression resistance and bending resistance of the M2 hard disk of the user can be improved, and the heat dissipation patch is light and easy to install.

Owner:XI AN JIAOTONG UNIV

A Beaded Turbine Blade Trailing Edge Slit Cooling Structure

ActiveCN112177683BIncrease the convective heat transfer areaImprove heat transfer effectBlade accessoriesMachines/enginesCold airTurbine blade

The invention belongs to the technical field of aero-engine turbine cooling, and relates to a rosary-type turbine blade trailing edge slit cooling structure. The cooling structure includes a hollow turbine blade, an inner cavity cold air channel and a trailing edge exhaust slit channel. The hollow turbine blade is provided with an inner cavity cold air channel for low-temperature cooling gas to flow inside the blade to cool the blade. The trailing edge of the hollow turbine blade has a plurality of discrete rosary-shaped trailing edge exhaust slot channels along the chord direction for cooling air to exit the blade. The rosary-type trailing edge exhaust slit of the present invention has a repeatedly contracted and expanded channel structure, which effectively increases the convective heat exchange area between the cold air and the inner channel of the turbine blade trailing edge, compared with the existing slit structure in the trailing edge. The rosary-type trailing edge exhaust slit of the present invention has a repeatedly contracting and expanding channel structure, which can blow off the boundary layer and inhibit its thickening, thereby enhancing heat exchange.

Owner:DALIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com