Bead type turbine blade trailing edge slit cooling structure

A technology of turbine blades and cooling structures, which is applied to the supporting elements of blades, engine elements, machines/engines, etc., can solve the problems of reducing the temperature level of the trailing edge area of the blade, and it is difficult to meet the cooling requirements of the trailing edge of the turbine blade. Cooling effect, increased convective heat transfer area, effect of increased convective heat transfer area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

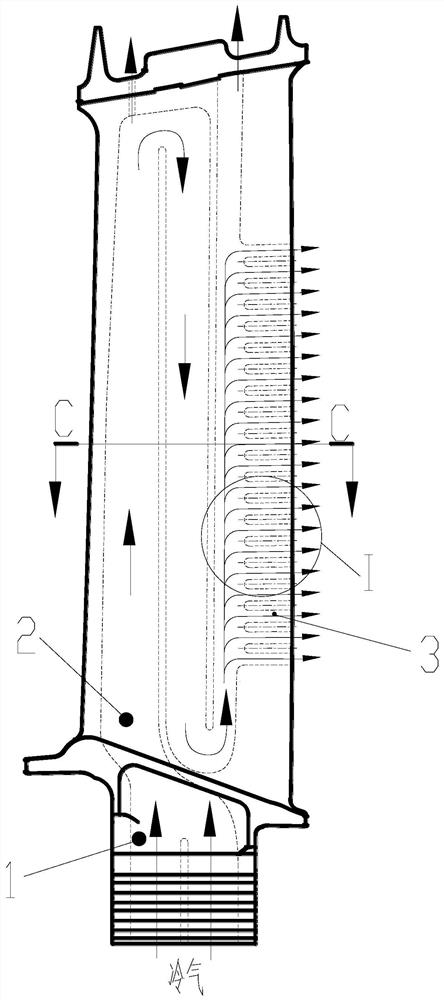

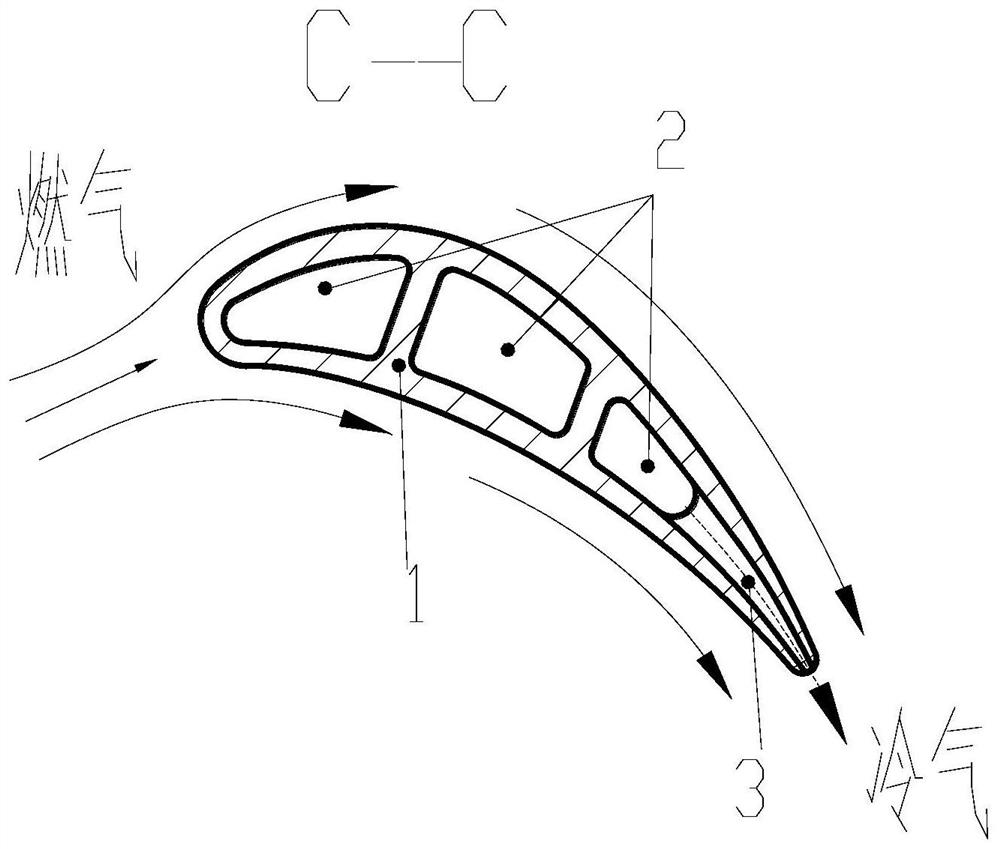

[0031] Please refer to Figure 2, a rosary-style turbine blade trailing edge split cooling structure, including a hollow turbine blade 1, an inner cavity cold air passage 2 and a trailing edge exhaust split passage 3;

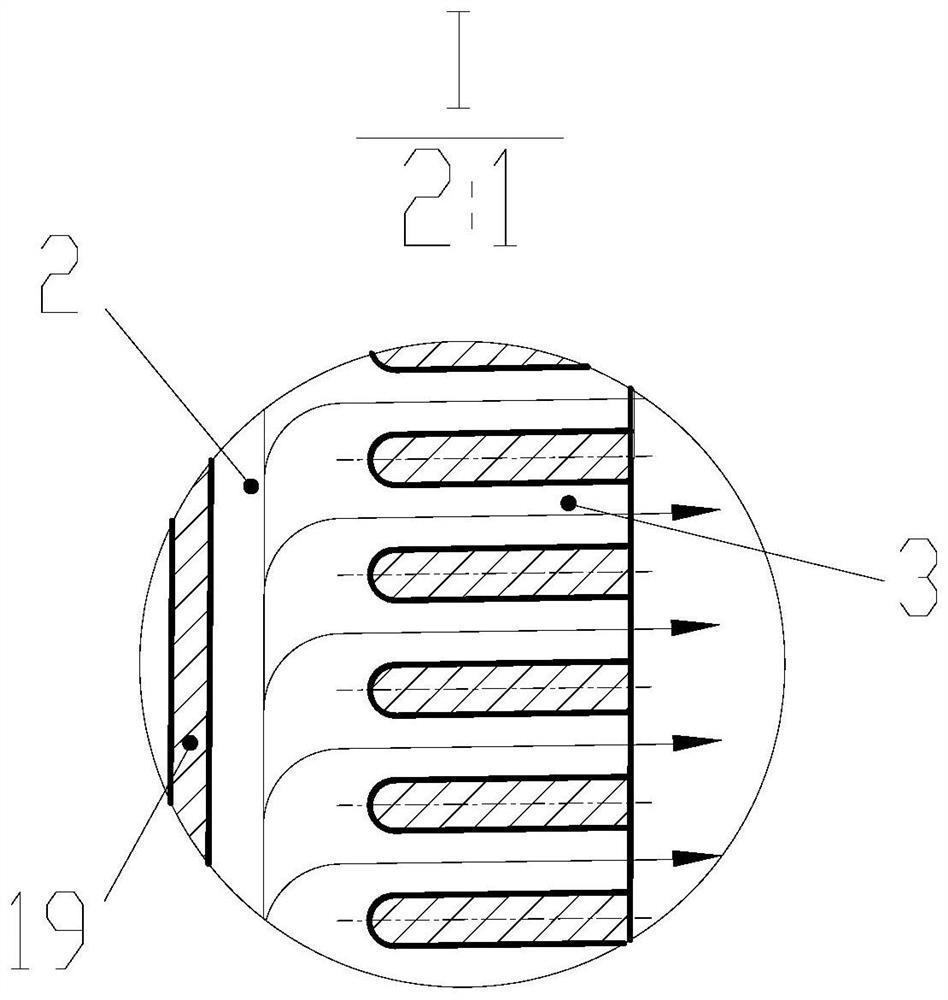

[0032] The interior of the hollow turbine blade 1 is provided with a cold air channel 2 in the inner cavity, and a plurality of discrete rosary-shaped trailing edge exhaust slit channels 3 are opened along the chord direction at the trailing edge, and its cross-sectional shape is circular or elliptical. The area changes continuously and alternately between the maximum value and the minimum value along the central line 4 of the slit channel, forming a rosary-like channel structure. Minor axis radius R of channel section x and major axis radius R y Controlled by the A-type wave curve 8 and the B-type wave curve 9 respectively. Typically, as shown in Figure 2(c), the centerline 4 of the split channel is a horizontal straight line in the front view of the blade, t...

Embodiment 2

[0034] Please refer to Figure 2, a rosary-style turbine blade trailing edge split cooling structure, including a hollow turbine blade 1, an inner cavity cold air passage 2 and a trailing edge exhaust split passage;

[0035] The interior of the hollow turbine blade 1 is provided with a cold air channel 2 in the inner cavity, and a plurality of discrete rosary-shaped trailing edge exhaust slit channels 3 are opened along the chord direction at the trailing edge, and its cross-sectional shape is circular or elliptical. The area changes continuously and alternately between the maximum value and the minimum value along the central line 4 of the slit channel, forming a rosary-like channel structure. Minor axis radius R of channel section x and major axis radius R y Controlled by the A-type wave curve 8 and the B-type wave curve 9 respectively. Typically, such as Figure 4 As shown, the center line 4 of the splitting channel is an inclined straight line in the front view of the bla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com