Patents

Literature

78 results about "Central line" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In geometry central lines are certain special straight lines associated with a plane triangle and lying in the plane of the triangle. The special property that distinguishes a straight line as a central line is manifested via the equation of the line in trilinear coordinates. This special property is related to the concept of triangle center also. The concept of a central line was introduced by Clark Kimberling in a paper published in 1994.

Method of Controlling Gaussian Projection Deformation Based on Normal Section Meridian Ellipsoid

ActiveCN102288158AEfficient control of Gaussian length projection deformationControl Gaussian length projection distortionProfile tracingRectangular coordinatesComputational physics

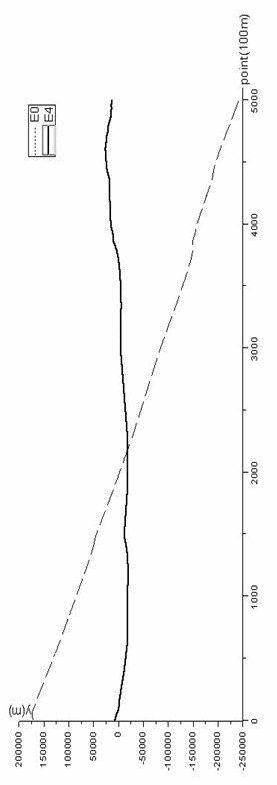

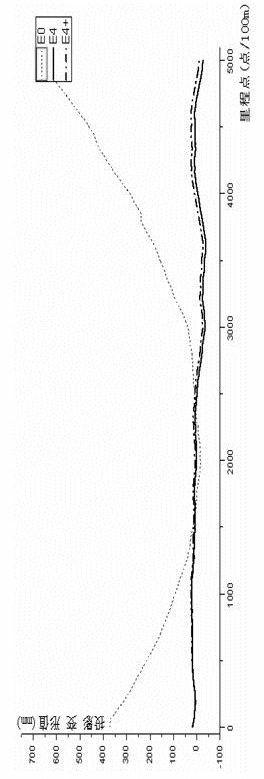

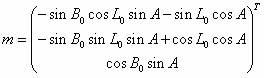

The invention discloses a method for controlling Gaussian projection deformation based on a normal section meridian ellipsoid. The basic technical thought is that: a new ellipsoid is constructed, so that the direction of a central meridian is basically consistent with a line extension direction, and projection deformation along a line central line extension direction is close to zero. The method comprises the following steps of: (1) constructing a normal section meridian ellipsoid E4; (2) converting the space rectangular coordinate of an ellipsoid E0 into the space rectangular coordinate of the ellipsoid E4; (3) converting the space rectangular coordinate of the ellipsoid E4 into a geodetic coordinate; (4) converting the geodetic coordinate of the ellipsoid E4 into a Gaussian plane coordinate; (5) calculating the Gaussian projection deformation value of the ellipsoid E4; and (6) comparing the Gaussian projection deformation value of the ellipsoid E4 with a projection deformation limitvalue, and verifying. By the method, the Gaussian length projection deformation of a long and large line can be effectively controlled, the number of projection zones is greatly reduced, and the method is particularly suitable for east, west, non-south and non-north long and large line engineering.

Owner:甘肃铁道综合工程勘察院有限公司

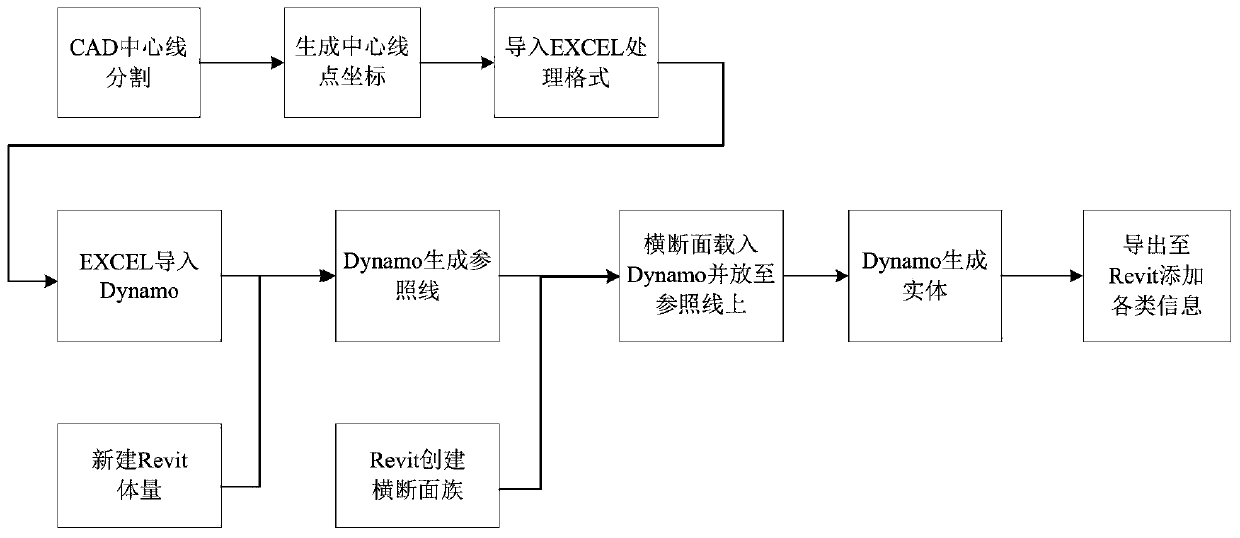

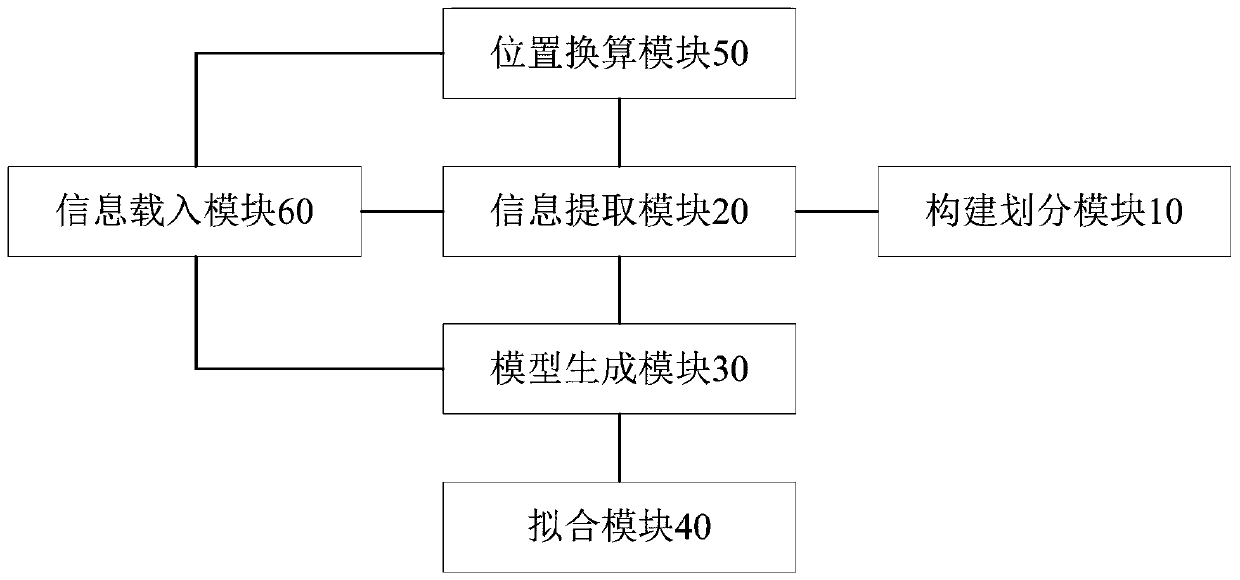

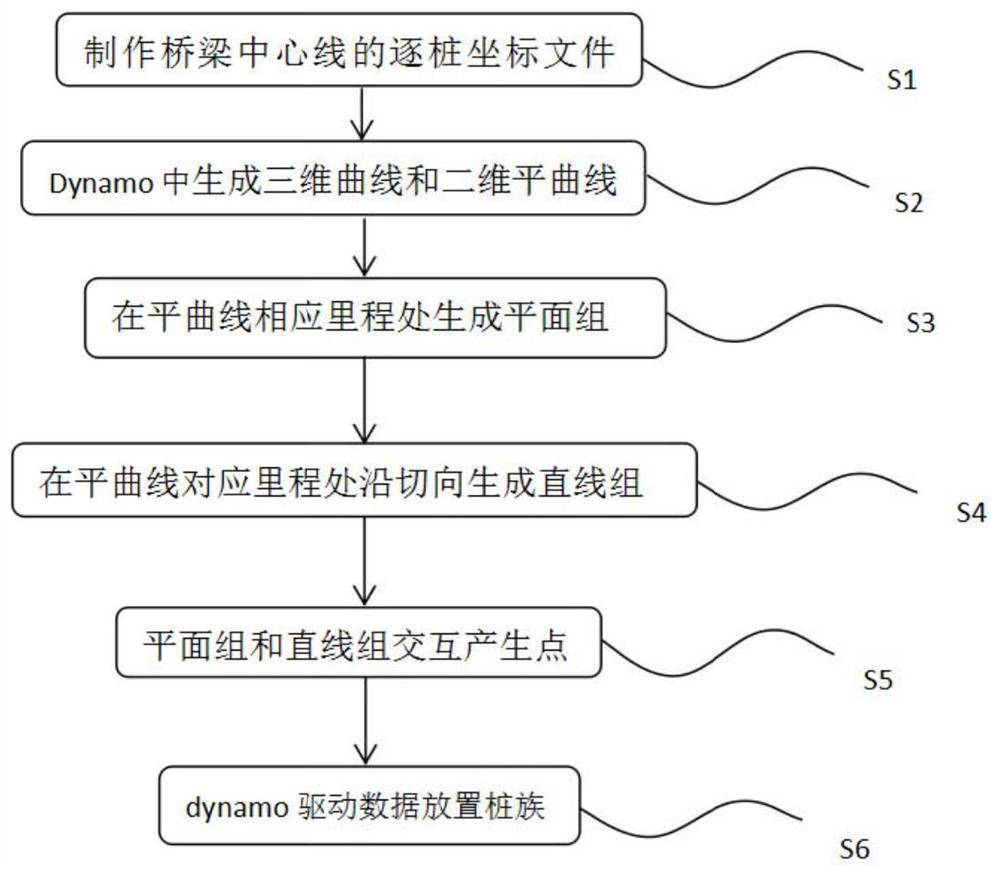

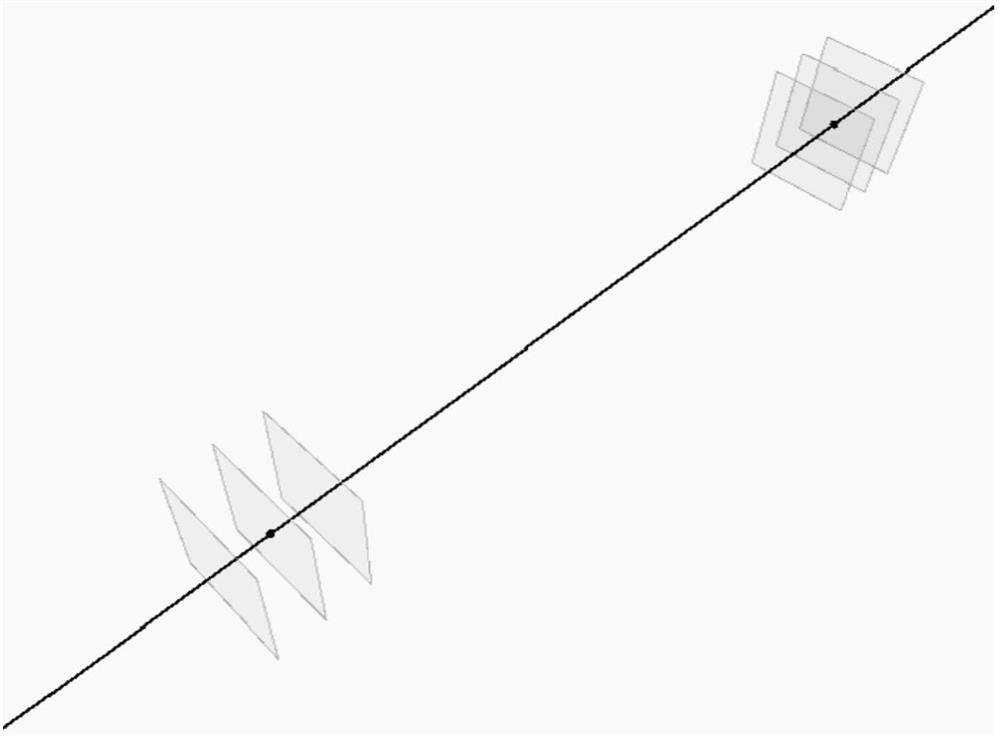

BIM parametric modeling method and device based on Dynamo

PendingCN111063030AParametric modeling is fastImprove visualization3D modellingAlgorithmIndustrial engineering

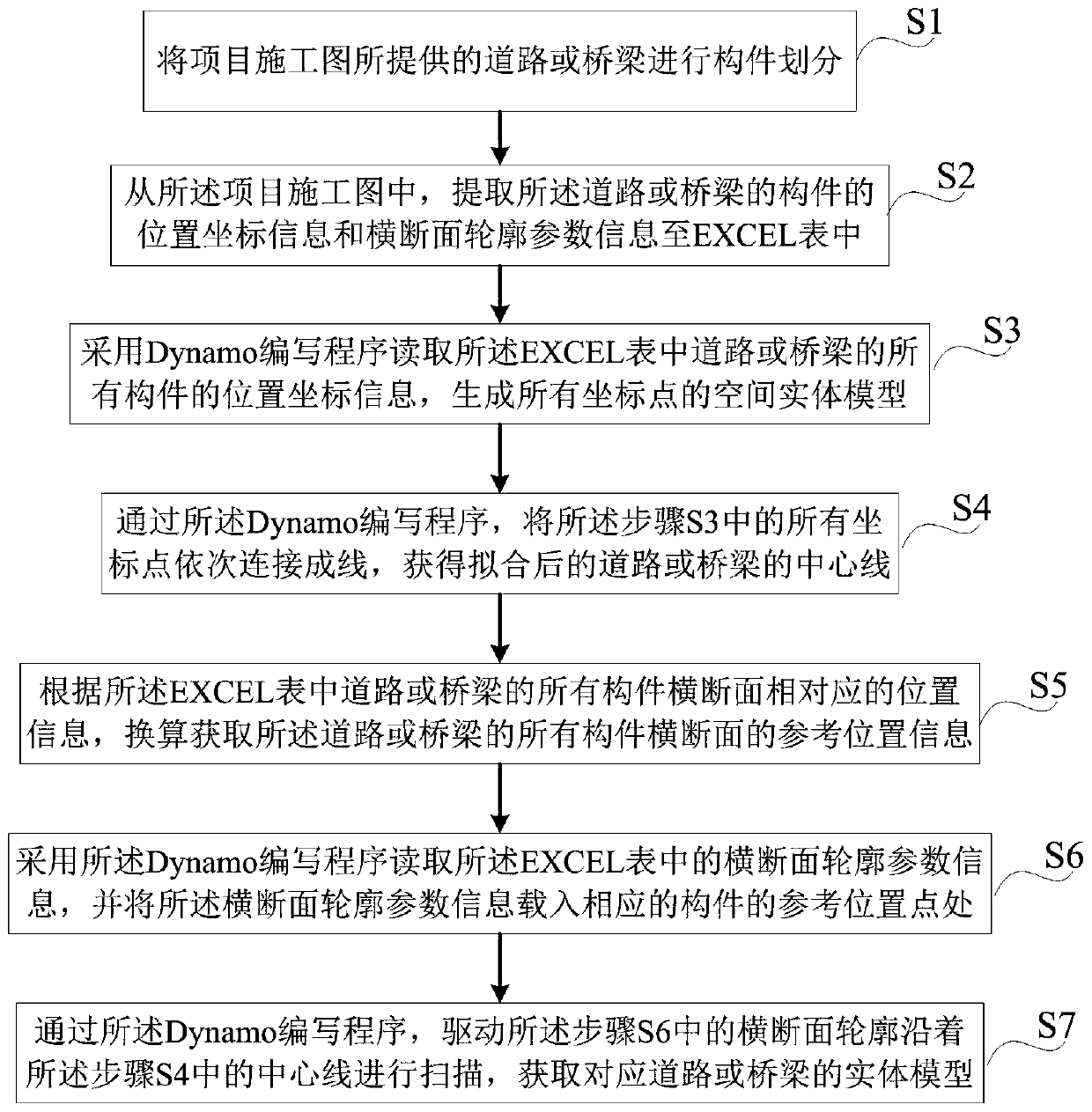

The invention discloses a BIM parametric modeling method and device based on Dynamo. The method comprises the steps of conducting component division on roads or bridges provided by a project construction drawing; extracting position coordinate information and cross section contour parameter information of the component into an EXCEL table; reading position coordinate information of all componentsin the EXCEL table to generate a space entity model of all coordinate points; sequentially connecting the coordinate points of all the components into a line to obtain a fitted center line of the roador the bridge; according to the position information corresponding to the cross sections of all the components in the EXCEL table, obtaining reference position information of the cross sections of all the components through conversion; reading cross section contour parameter information in the EXCEL table, and loading the cross section contour parameter information into a reference position pointof a corresponding component; and driving the cross section profile to scan along the center line to obtain a solid model of the corresponding road or bridge. According to the invention, rapid parametric modeling can be realized, and the working efficiency is improved.

Owner:SHANGHAI PUDONG ROAD & BRIDGE CONSTR

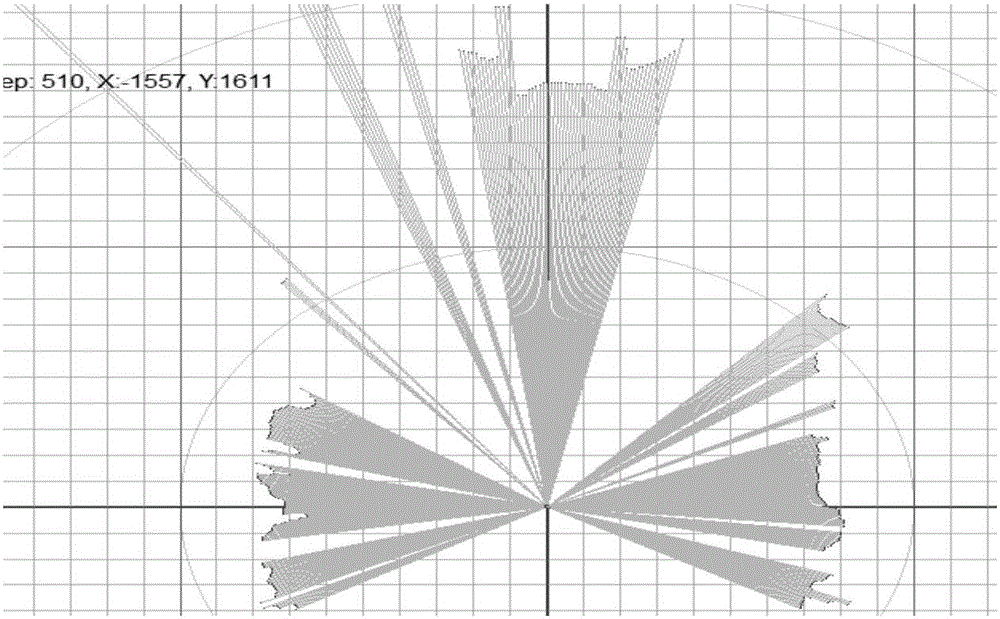

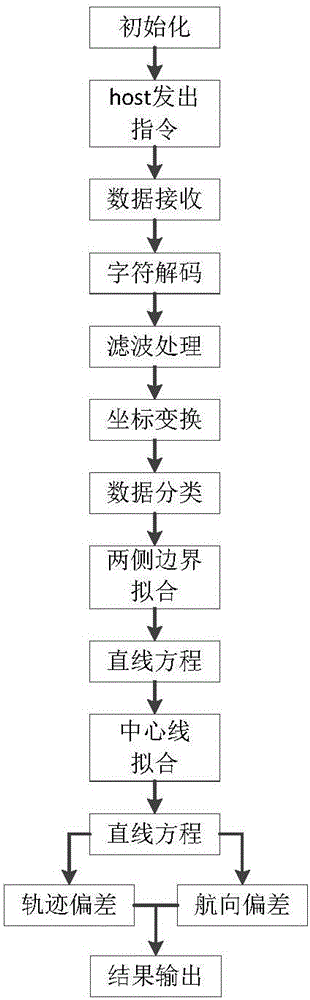

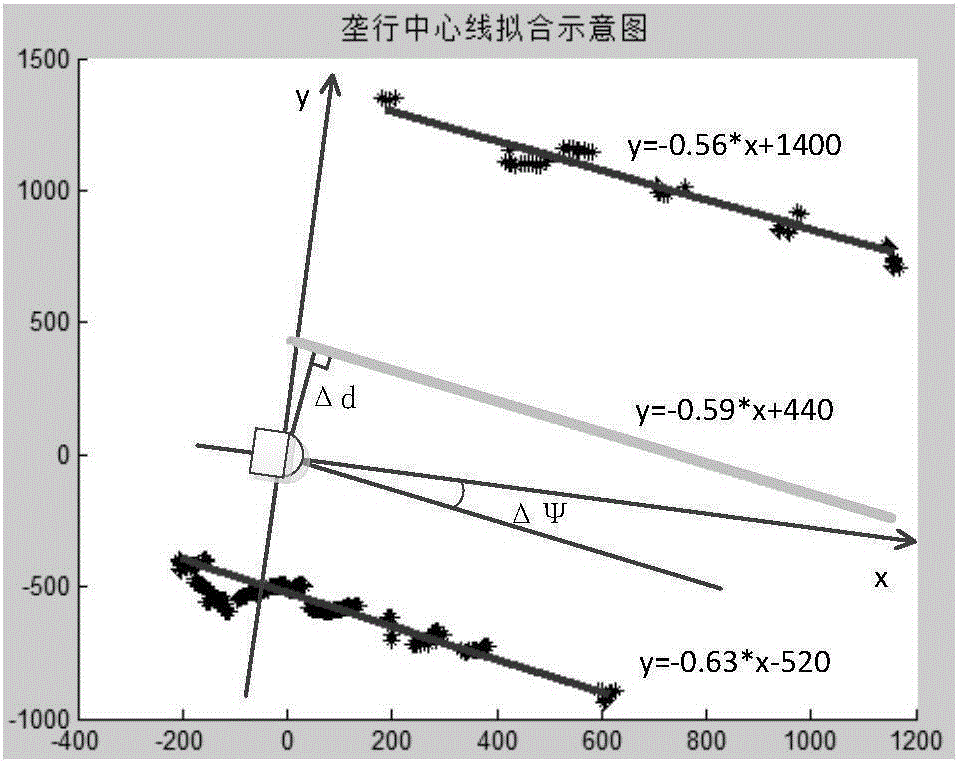

Method and system for realizing robot row identification and guiding based on laser radar detection

InactiveCN106249742AThe path identification method is simpleHigh precisionPosition/course control in two dimensionsGeomorphologyRectangular coordinates

The invention discloses a method and system for realizing robot row identification and guidance based on laser radar detection. The steps are: the laser radar carried by the robot collects the distance and polar angle from the left and right sides of the row to the plant protection robot; sets a critical value and uses extreme value filtering method to remove the interference information in the collected distance; carry out coordinate transformation, and transform the polar coordinates into rectangular coordinates; The classification data is used to fit straight lines to the envelopes on the left and right sides of the row, and the equations of the straight lines on both sides of the row are obtained; the center line fitting of the borders on both sides: according to the acquired straight line equations on both sides of the row, the equations of the two sides of the row are fitted. The linear equation of the row center line; using the row center line as the navigation line, calculate the course deviation and trajectory deviation of the robot; realize the guidance of the robot row recognition through the course deviation and trajectory deviation. The path identification method of the present invention is relatively simple and efficient.

Owner:UNIV OF JINAN

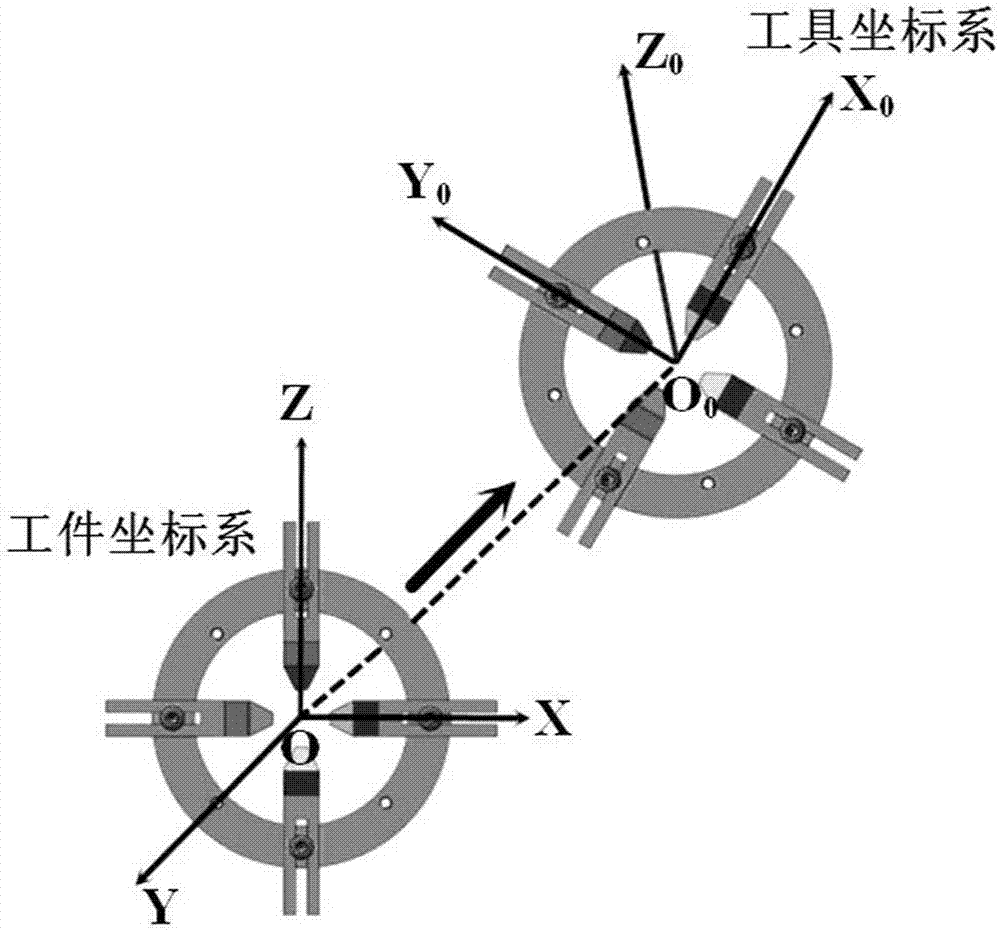

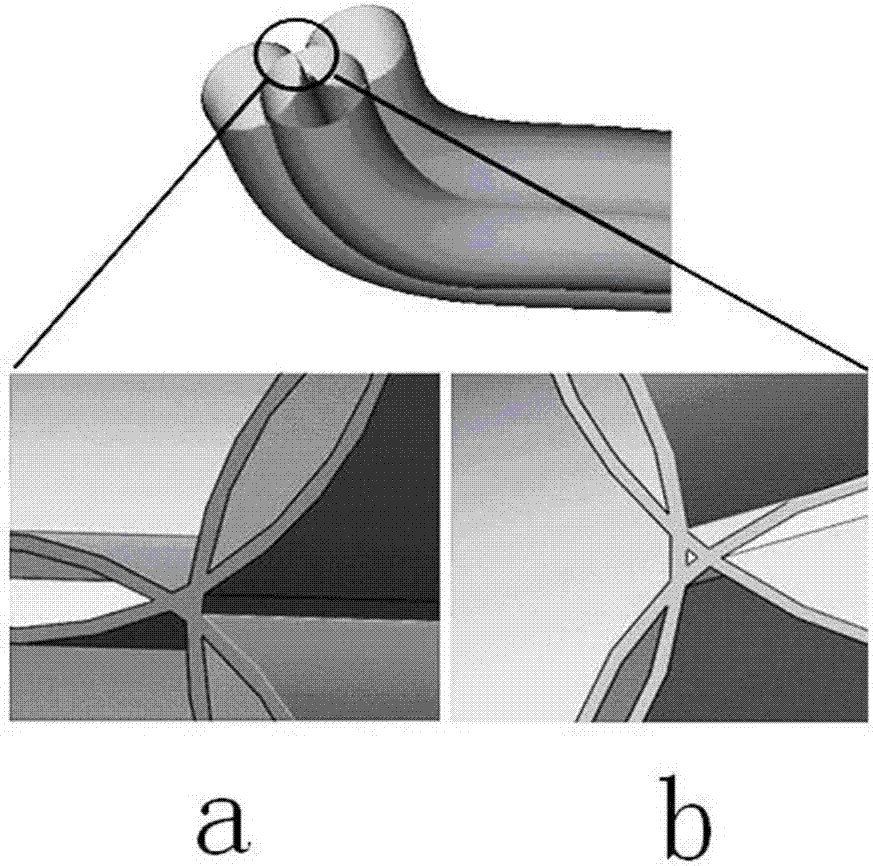

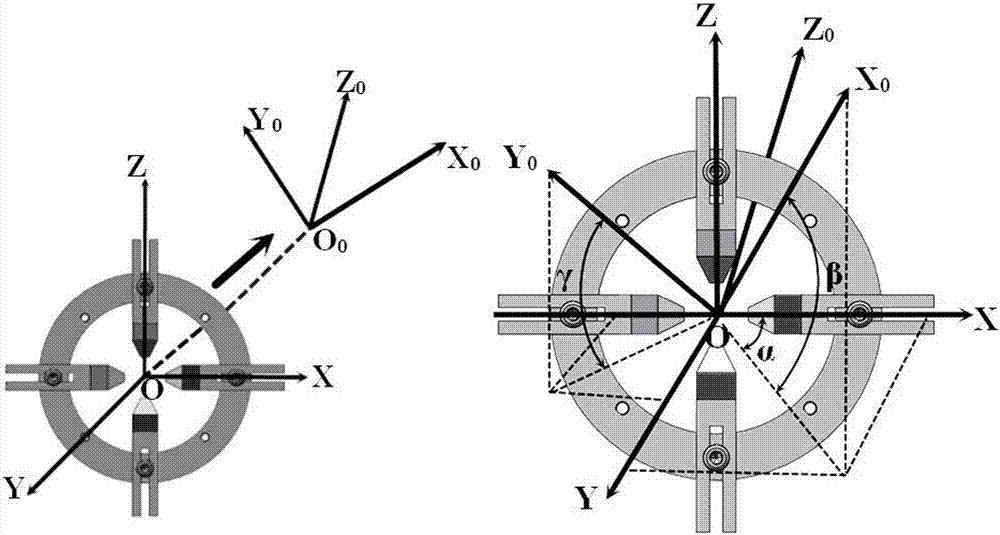

Method for generating inner surface polishing path of spatial bend pipe by c reconstruction

ActiveCN107422693AImprove work efficiencyLess preparationNumerical controlPoint cloudRectangular coordinates

The invention belongs to the technical field of magnetic grinding, and especially relates to a method for generating an inner surface polishing path of a spatial bend pipe by center line reconstruction. The method is characterized by comprising the following steps: step 1, obtaining outer contour point cloud of a spatial bend pipe; step 2, through curve fitting, obtaining three contour lines; step 3, generating a spatial bend pipe by using the fit outer contour line through a cross section intersection method; step 4, performing point discretization on the generated bend pipe center line and the outer contour line generated by measurement; step 5, establishing a space rectangular coordinate system O0X0Y0Z0, setting the rectangular coordinate system as a robot tool coordinate system; step 6, through translation and rotation, transforming a workpiece coordinate system to the tool coordinate system; step 7, through conversion of a homogeneous coordinate transformation matrix on the coordinate system, obtaining a pose coordinate in a processing path at the processing moment; step 8, obtaining a final machine polishing path. The method can accurately determine a processing path of a complex spatial bend pipe, and improves working efficiency.

Owner:UNIV OF SCI & TECH LIAONING

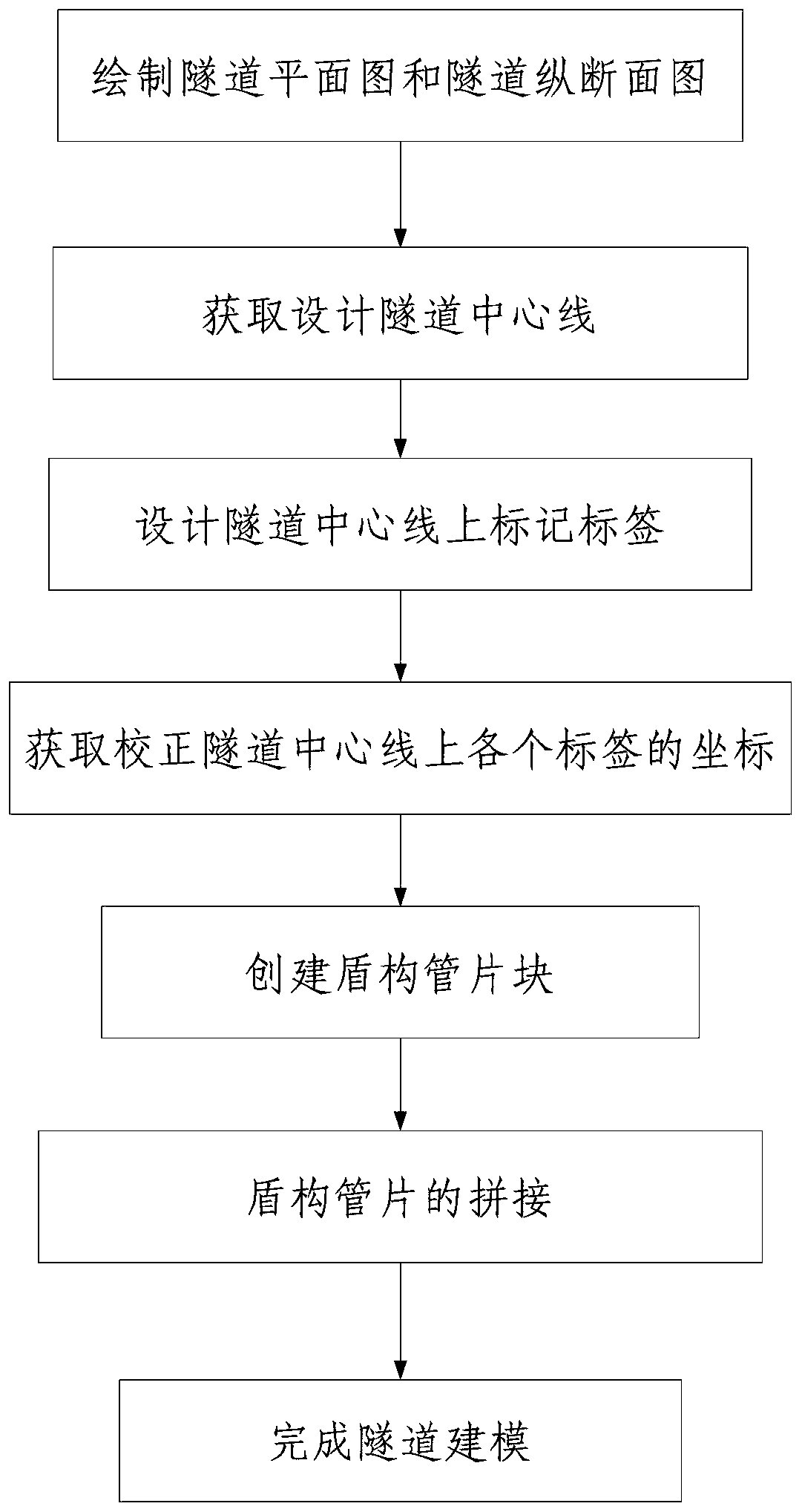

Tunnel BIM rapid modeling method

PendingCN110990930ASave excavation section sizeReduce construction costsGeometric CADDesign optimisation/simulationStructural engineeringMechanical engineering

The invention discloses a tunnel BIM rapid modeling method. The method comprises the following steps of: 1, drawing a tunnel planar graph and a tunnel longitudinal section graph; 2, acquiring a designed tunnel center line; 3, marking the designed tunnel center line with labels; 4, obtaining the coordinates of labels on a correction tunnel center line; 5, creating a shield segment block; and 6, splicing the shield segments to finish tunnel modeling. The method provided by the invention is simple in step and novel and reasonable in design. According to the tunnel BIM rapid modeling method of theinvention, the coordinates of all the labels on the designed tunnel center line are corrected, so that the method can effectively adapt to the existence of superelevation and over-distance on a bend;segment blocks are corrected when shield segment ring splicing is conducted on the curve section of the tunnel center line, and therefore, the method can effectively adapt to the actual situation ofa tunnel, tunnel model precision is improved, and efficiency is high.

Owner:CHINA RAILWAY FIRST GRP CO LTD +1

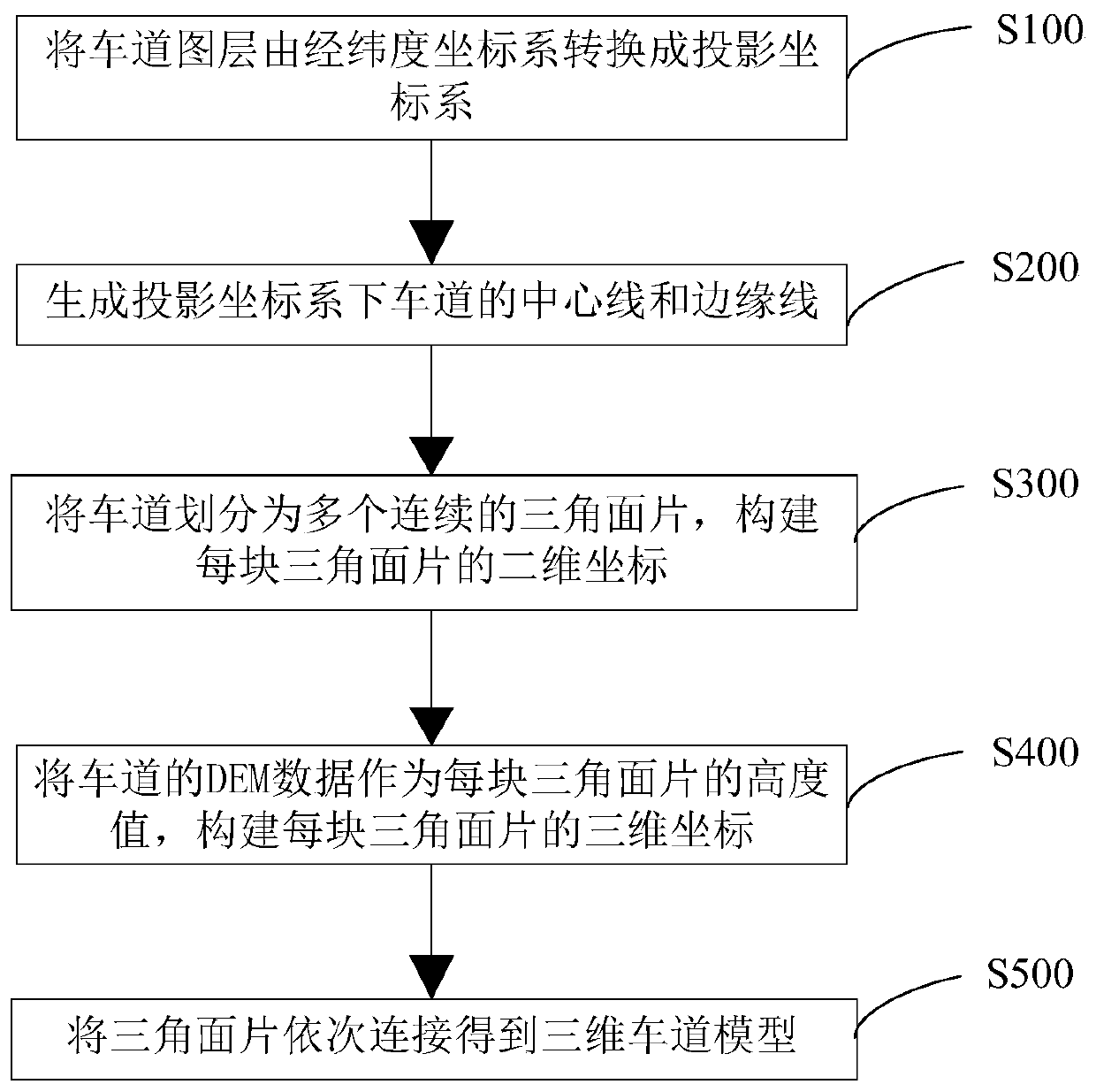

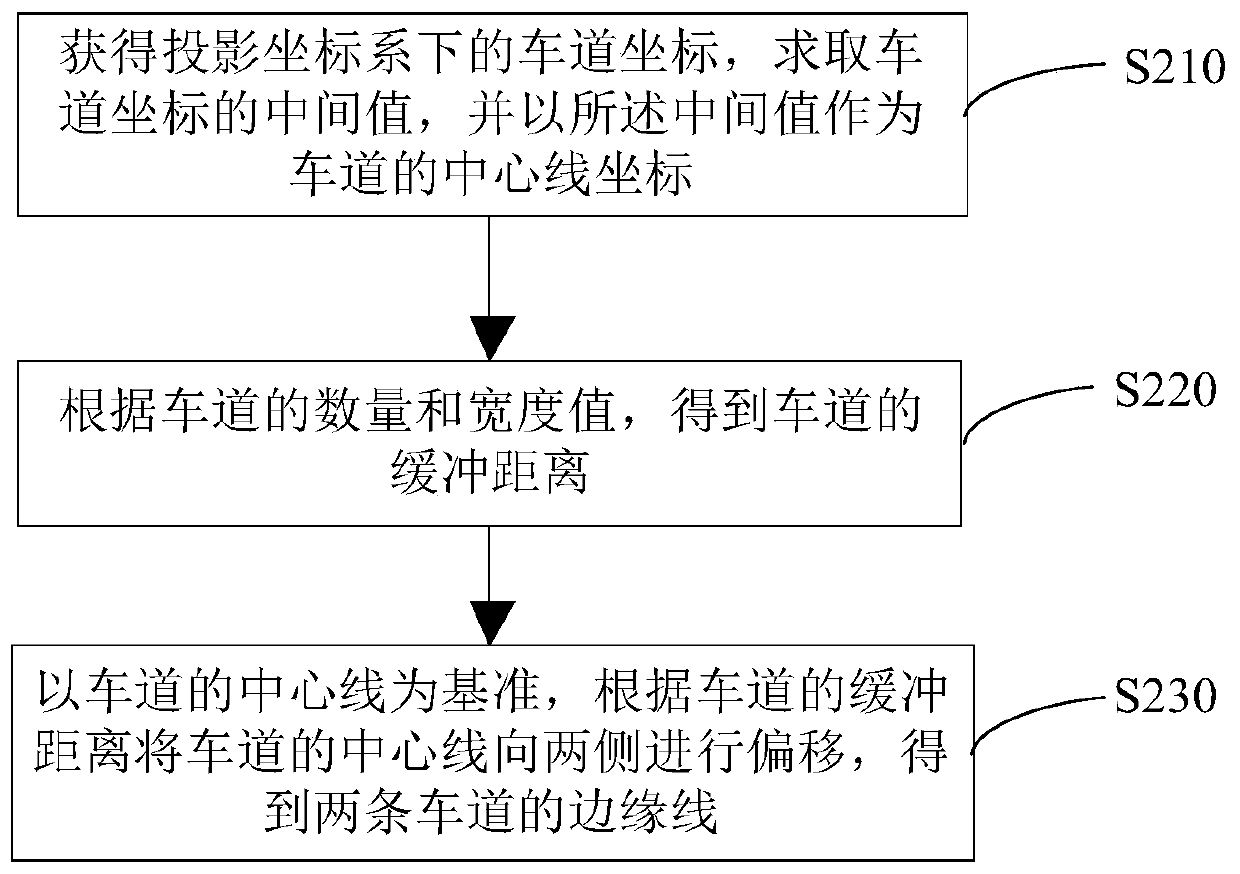

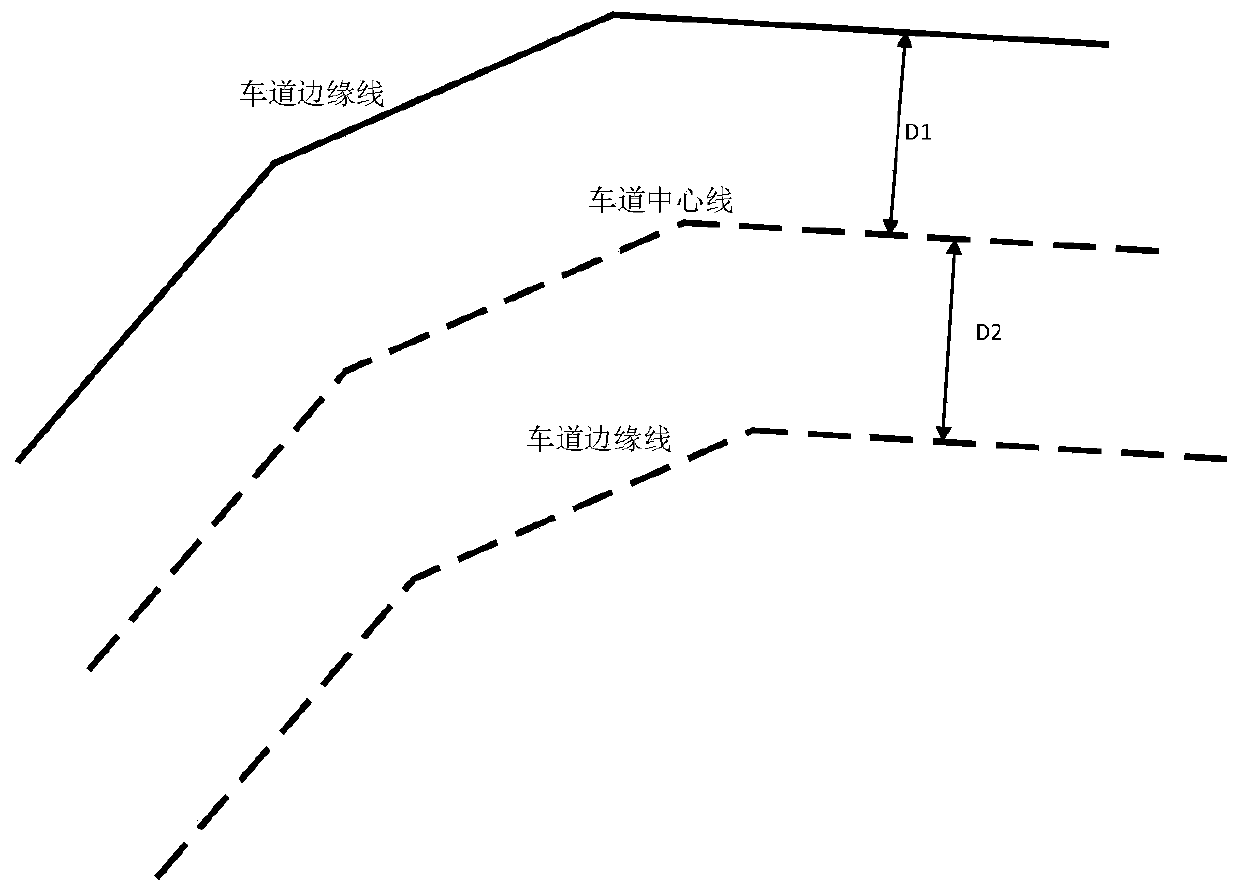

Three-dimensional lane model generation method and system

The invention relates to the technical field of three-dimensional road modeling, in particular to a three-dimensional lane model generation method and system, and the method comprises the steps: firstly enabling a lane layer to be converted into a projection coordinate system from a longitude and latitude coordinate system; generating a center line and an edge line of the lane under the projectioncoordinate system; dividing the lane into a plurality of continuous triangular patches, and constructing a two-dimensional coordinate of each triangular patch; constructing a three-dimensional coordinate of each triangular patch by taking DEM data of a lane as a height value of each triangular patch; sequentially connecting the triangular patches to obtain a three-dimensional lane model. According to the invention, the existing two-dimensional electronic map data can be fully utilized, and the three-dimensional model of the lane is automatically constructed, so that a large amount of acquisition work is saved, and the requirement of microscopic traffic simulation can be met.

Owner:FOSHAN UNIVERSITY

Lenticular lens sheet

InactiveUS6359736B1Suppress scrapingPressing forceSampled-variable control systemsProjectorsEngineeringLenticular lens

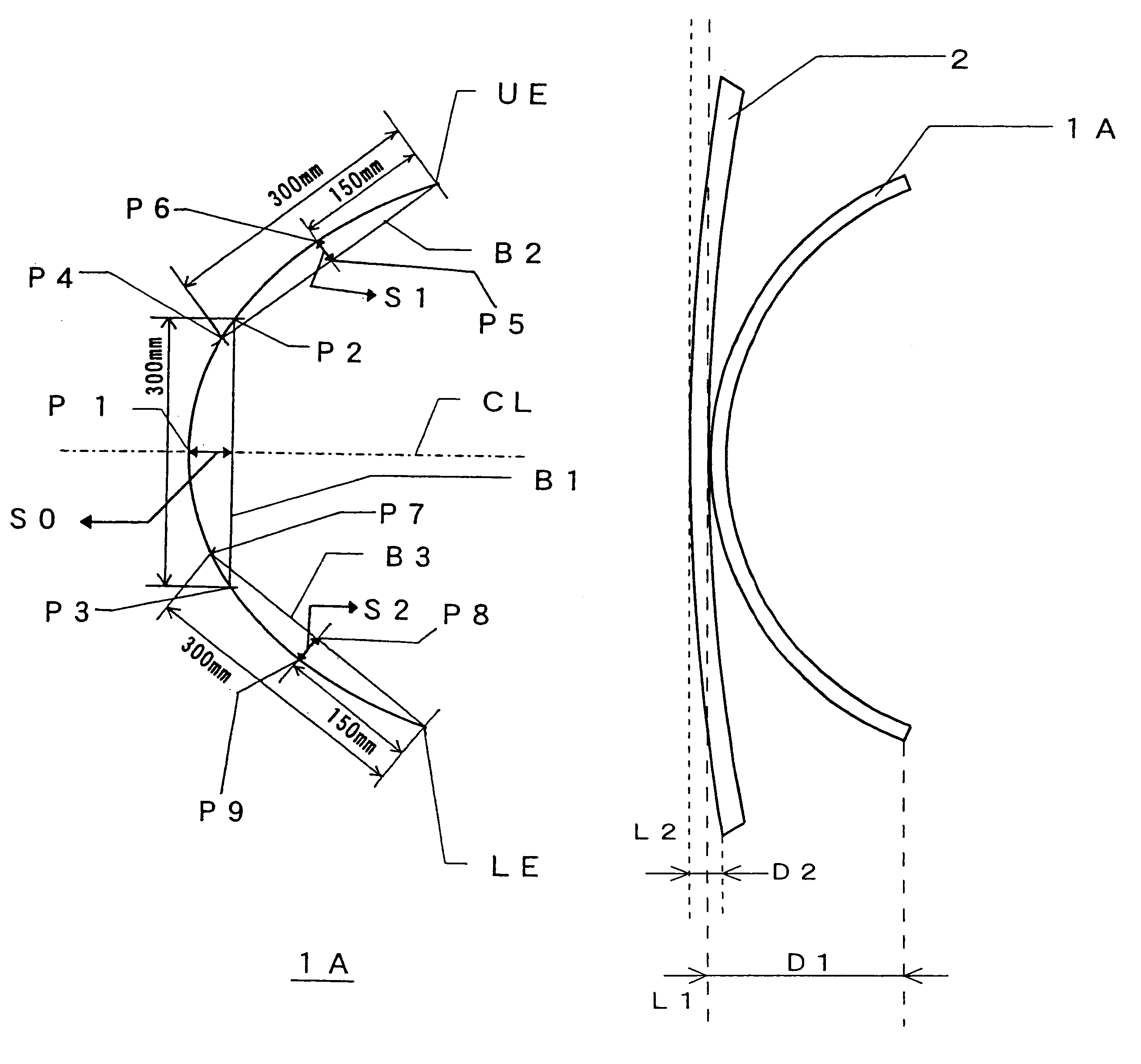

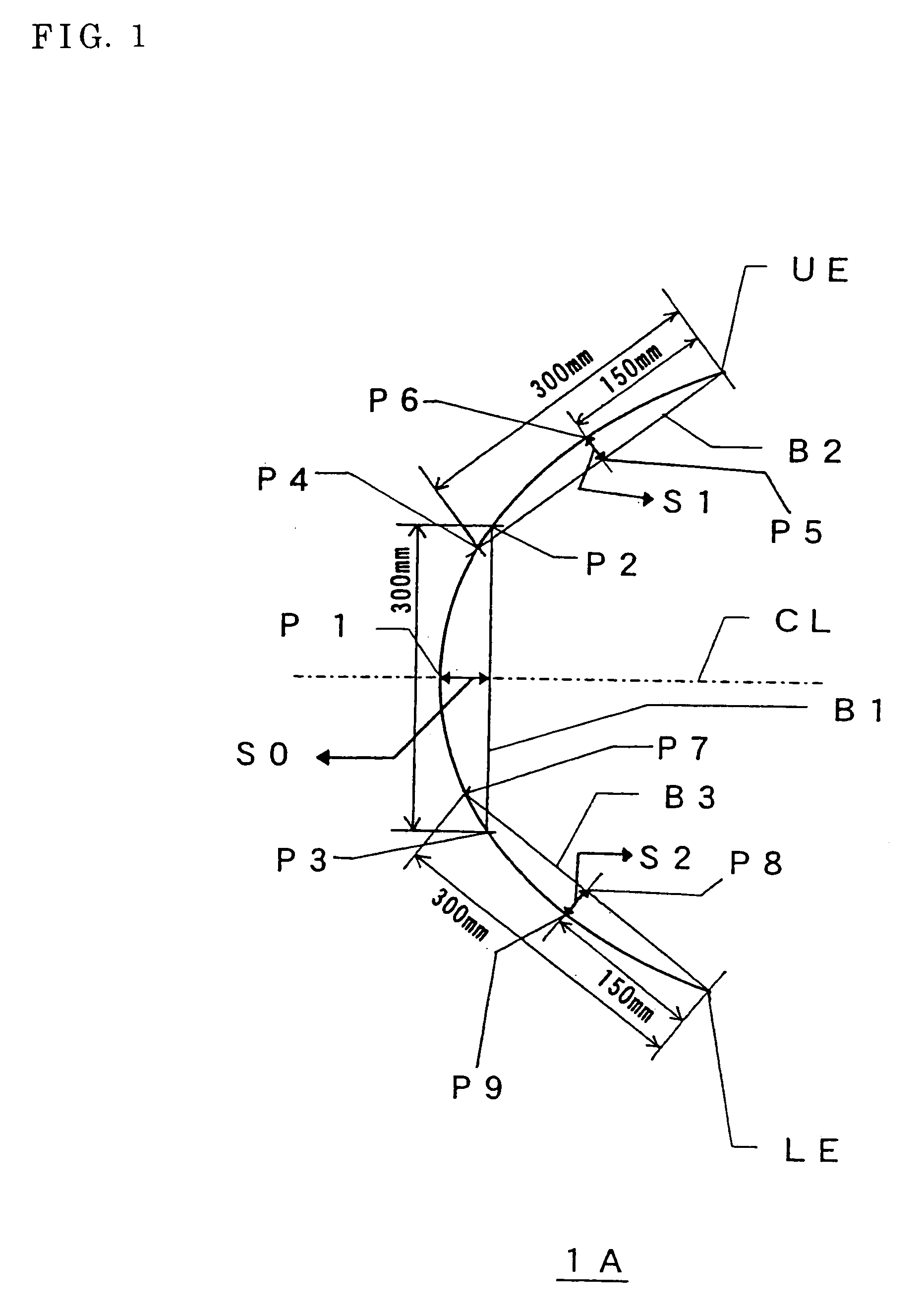

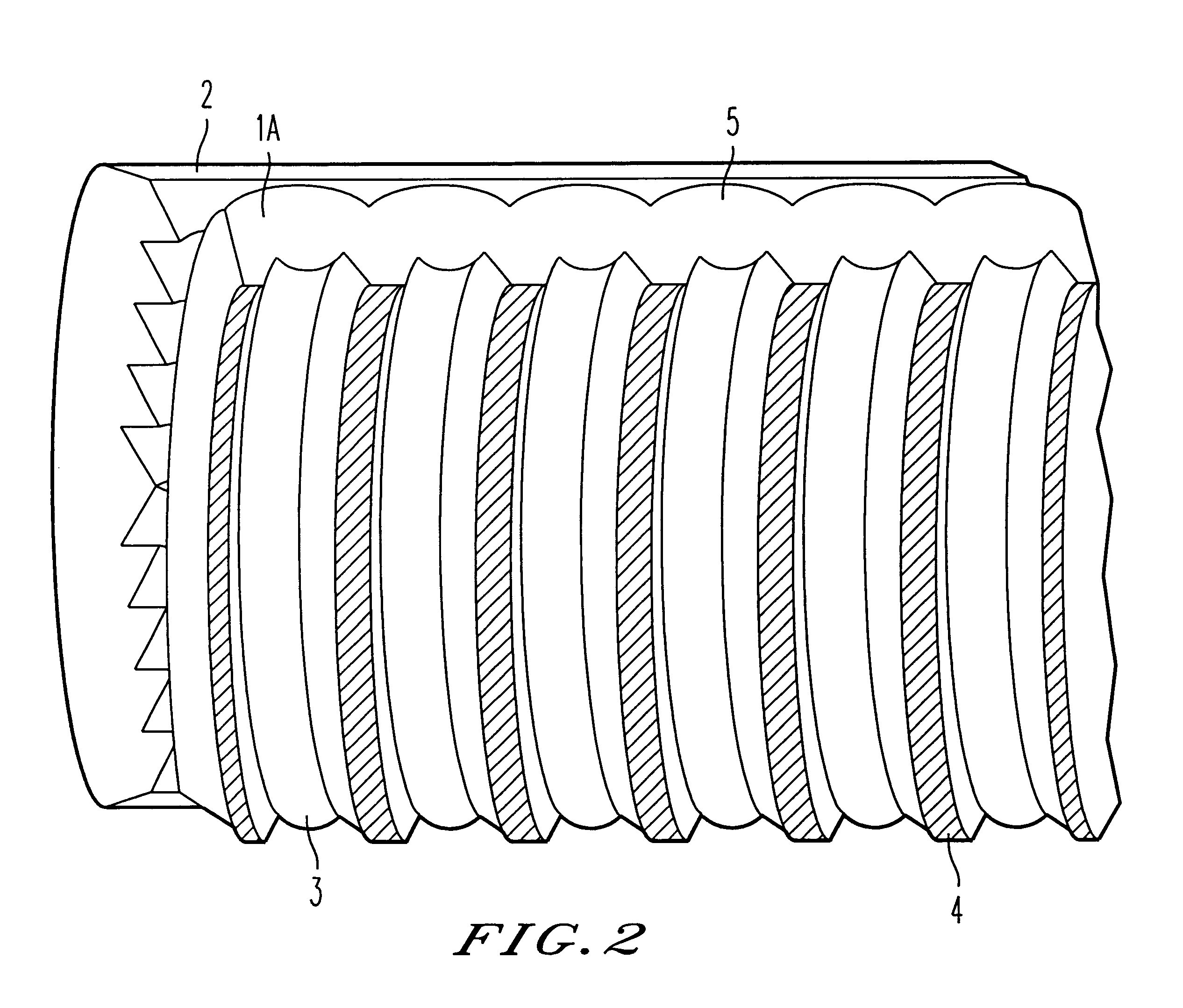

A lenticular lens sheet has arcuate-shaped warping such that the optical output lens side is the concave side, where, considering a chord B1 that connects points P2 and P3 to each other which are points on this approximate curve of arcurate shape and are of distance 150 mm from center line CL, and between which a distance is 300 mm, a distance to this chord B1 from the point P1 where this approximate curve and this center line intersect is represented by S0, and, considering a chord B2 that connects an upper edge UE of this approximate curve to a point P4 300 mm from the upper edge in the downwards direction, a distance to this chord B2 from the point P6 where the perpendicular from the central point P5 of this chord B2 intersects this approximate curve is represented by S1, and, considering a chord B3 that connects a lower edge LE of this approximate curve to a point P7 300 mm from the lower edge in the upwards direction, a distance to this chord B3 from the point P9 where the perpendicular from the central point P8 of this chord B3 intersects this approximate curve is represented by S2, respectively, there exists a relationship satisfying S0>S1>0 and S0>S2>0.

Owner:KURARAY CO LTD

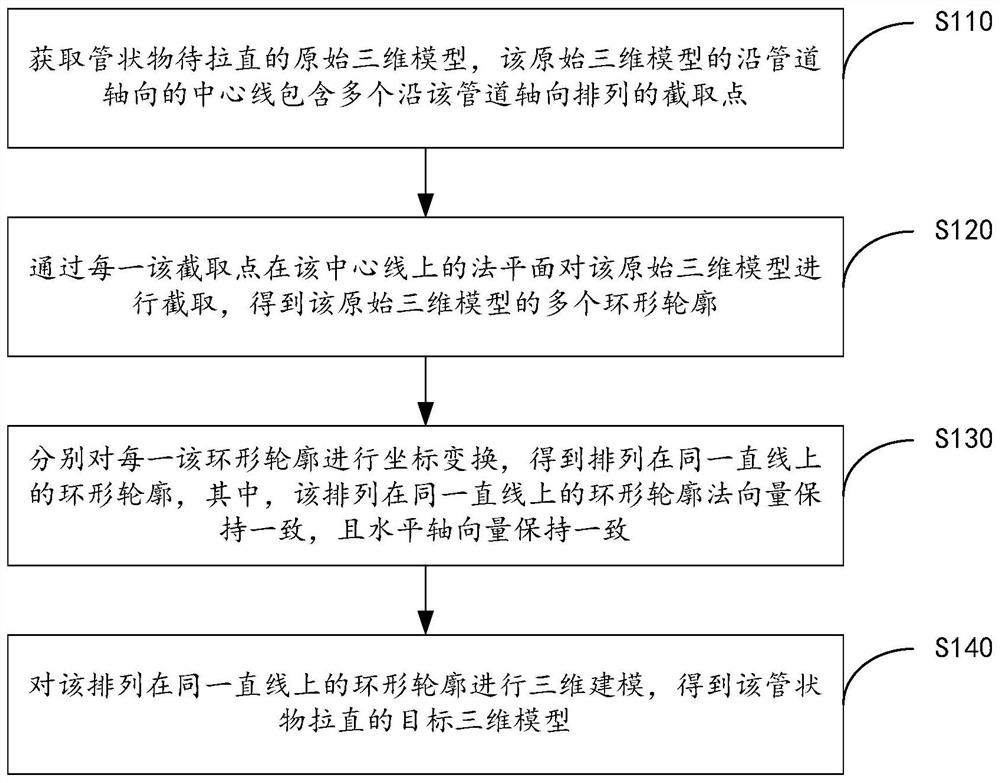

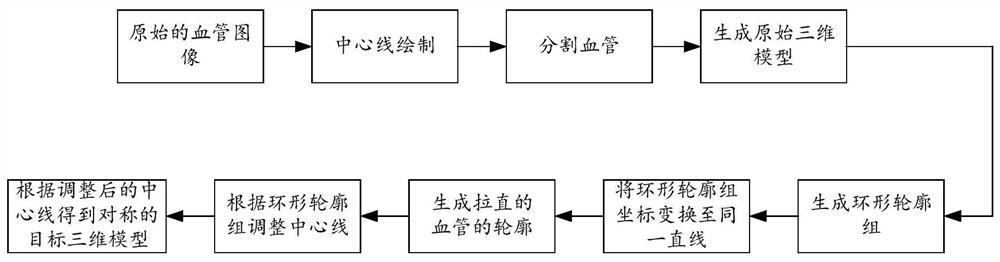

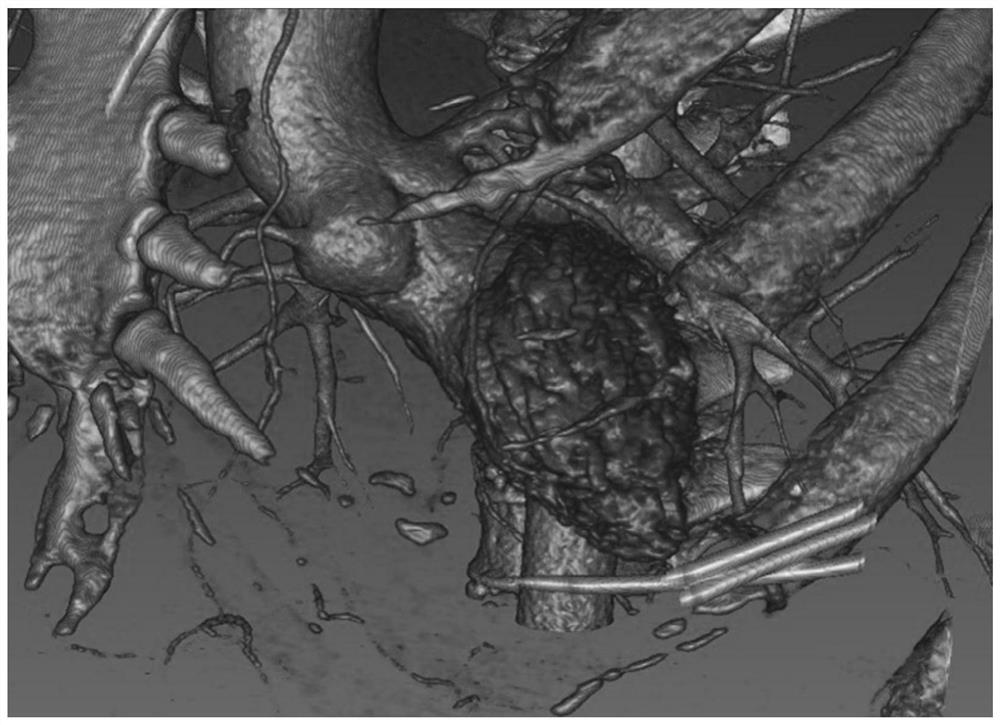

Straightening method and device for three-dimensional model of tubular object and electronic equipment

PendingCN112614217AIntegrity guaranteedImage analysisGeometric image transformationAlgorithmStructural engineering

The invention provides a straightening method and device for a three-dimensional model of a tubular object and electronic equipment, and the method comprises the steps: obtaining a to-be-straightened original three-dimensional model of the tubular object, and enabling a central line of the original three-dimensional model along the axial direction of a pipeline to comprise a plurality of interception points which are arranged along the axial direction of a pipeline; intercepting the original three-dimensional model through a normal plane of each interception point on the center line to obtain a plurality of annular contours of the original three-dimensional model; conducting coordinate transformation on each annular contour to acquire annular contours arranged on the same straight line, wherein normal vectors of the annular contours arranged on the same straight line are kept consistent, and horizontal axial vectors of the annular contours arranged on the same straight line are kept consistent; and performing three-dimensional modeling on the annular contours arranged on the same straight line to obtain a target three-dimensional model for straightening the tubular object. According to the embodiment of the invention, the integrity of the three-dimensional structure information of the straightened tubular object image can be ensured, and the three-dimensional model of tubular object straightening is obtained.

Owner:SHENZHEN RAYSIGHT INTELLIGENT MEDICAL TECH CO LTD

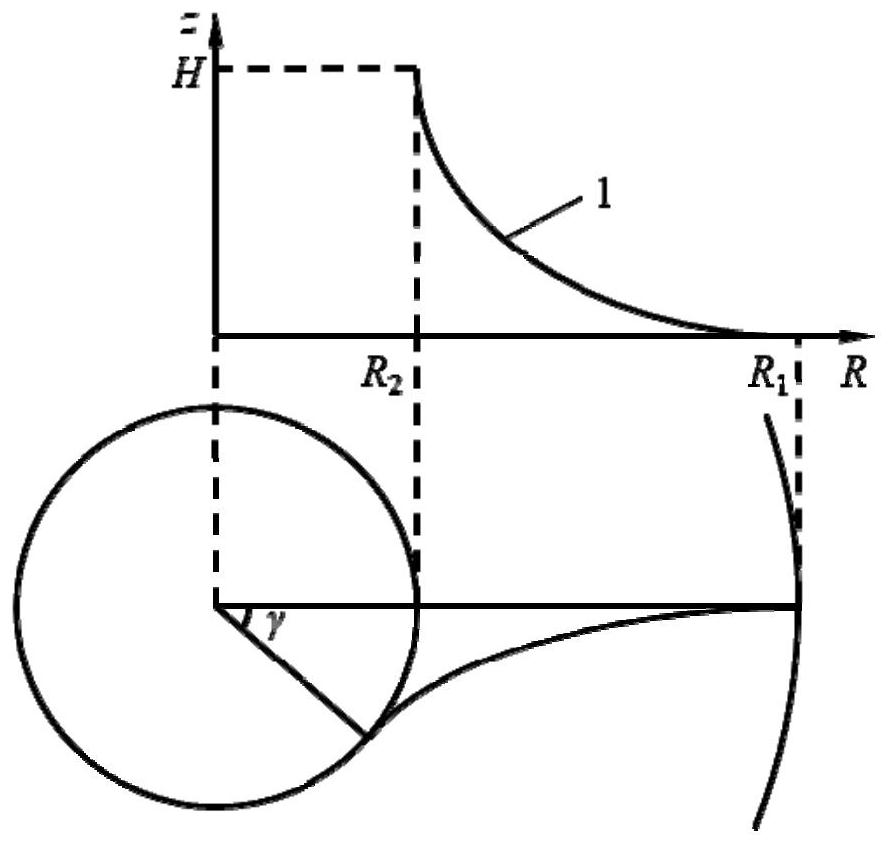

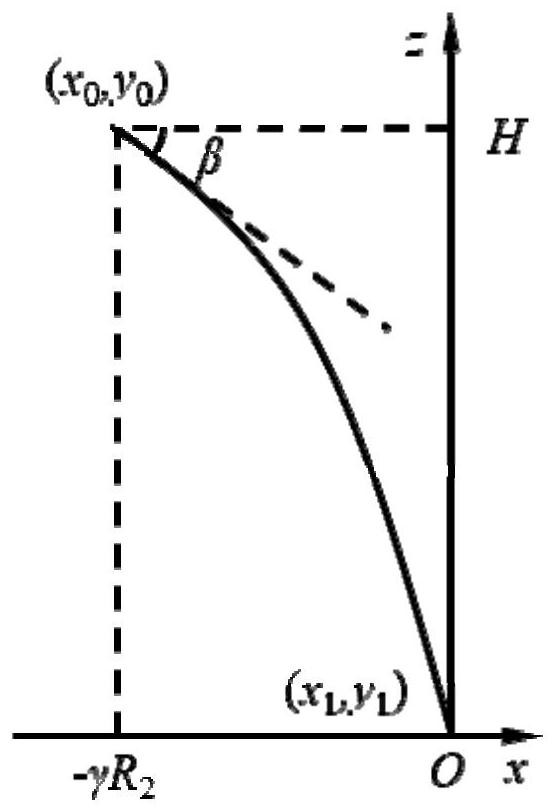

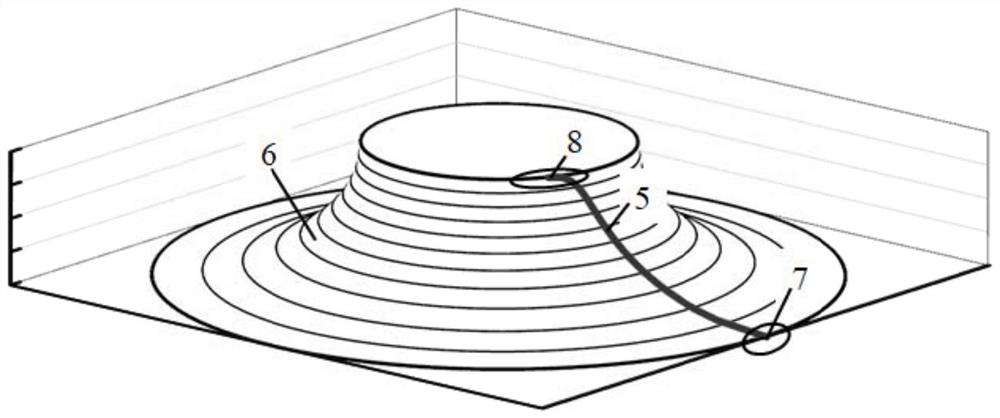

Streamline tunnel type rotating fluid machine runner design and forming method

The invention discloses a streamline tunnel type rotating fluid machine runner design and forming method. The method comprises the following steps: S1, obtaining relevant constraint parameters obtained through one-dimensional design; s2, obtaining a central line expansion projection curve and constructing the central line expansion projection curve into a cubic Hermite curve; s3, after a central line expansion projection curve is obtained, restoring an expansion plane into a cylindrical surface to obtain an equation of the cylindrical surface projection curve; s4, if the meridian form is known, easily obtaining an annular curved surface equation where the center line is located; s5, combining the cylindrical projection curve and the annular curved surface equation to obtain an equation ofan actual runner center line; s6, obtaining the inlet and outlet areas of the runner according to the flow characteristics and speed conditions of the rotary machine, thereby forming a complete runner. The method is easy to expand to streamline design of more fluid machines through a combined equation method, is suitable for media such as gas, liquid, solid powder and multi-phase mixed fluid, forms a design system from streamlines to runners and from low dimension to high dimension, and can make more reasonable prediction on mechanical properties.

Owner:科诺泰博(北京)科技有限公司

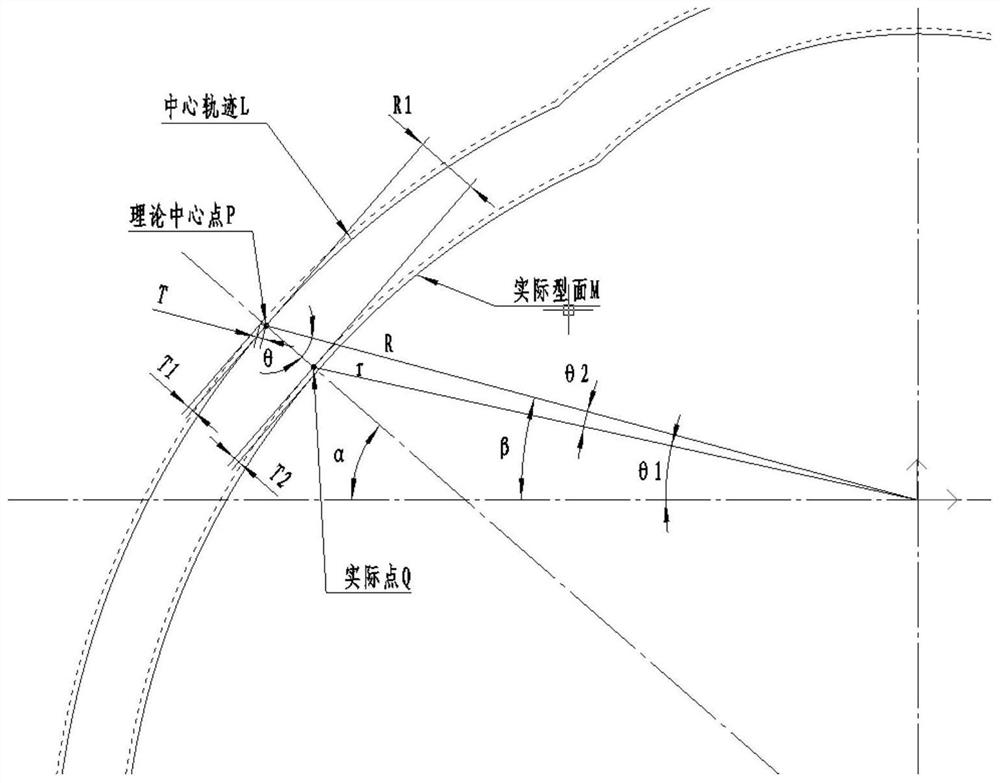

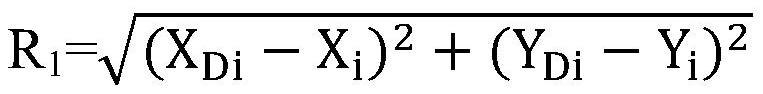

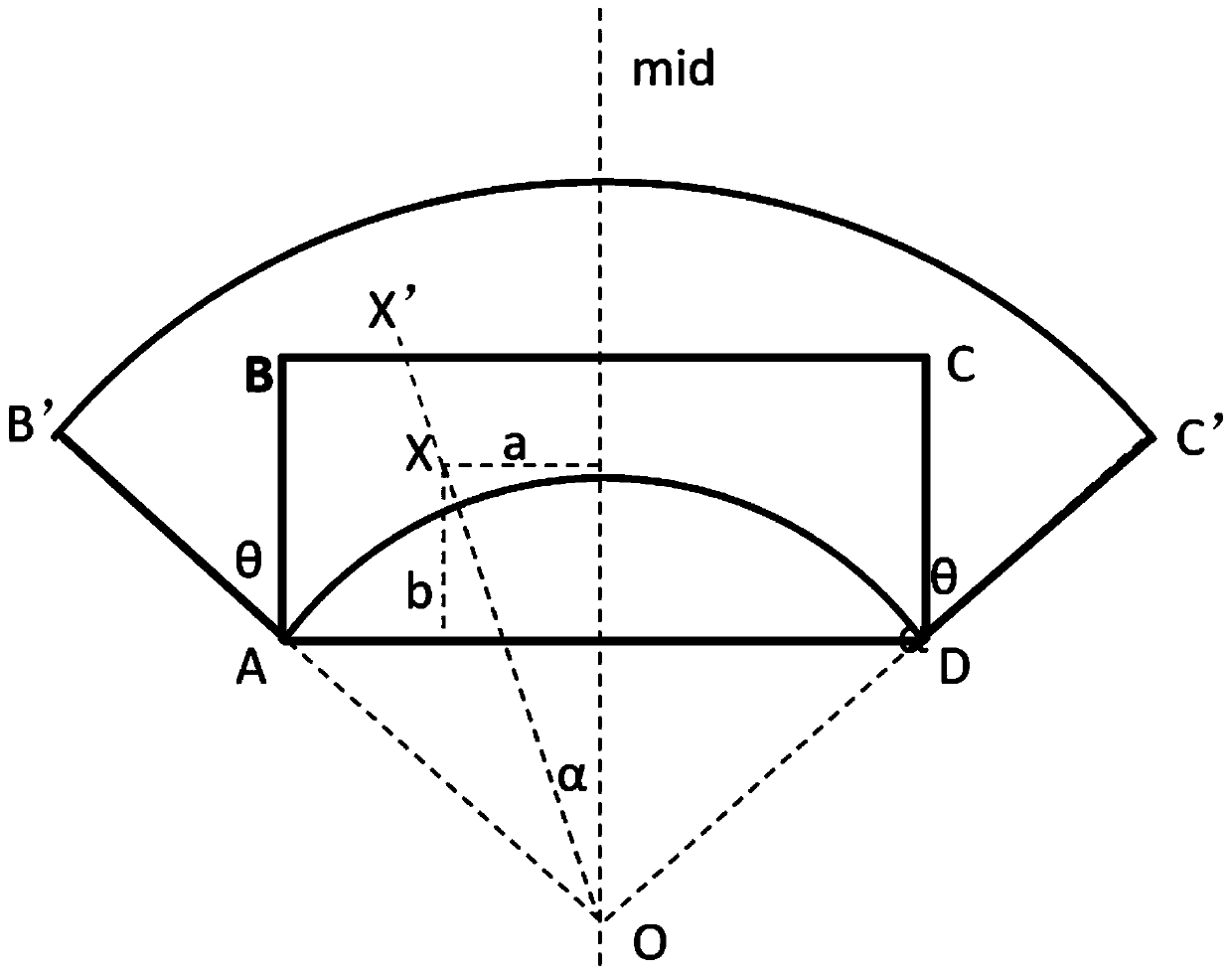

Method for converting normal tolerance into polar radius tolerance

ActiveCN112525133AImprove measurement efficiencyMeet the design requirementsMeasurement devicesMeasurement costEngineering

The invention belongs to the field of measurement, and relates to a method for converting normal tolerance into polar radius tolerance. The method comprises the following steps of: 1) taking any pointP on a molded surface center line of a part model; 2) performing normal bias R1 on the actual molded surface point Q to obtain a theoretical central point P; 3) performing comparison measurement according to the corresponding coordinate system and the model to obtain a normal deviation actual value T2 of the actual profile measurement point Q, the position of the actual profile measurement pointQ and a normal direction vector actual value of the actual profile measurement point Q; calculating to obtain a normal direction angle alpha of an actual profile measurement point Q and a polar radiusR and an angle beta of a theoretical central point P; 4) the deviation T of the theoretical central point P in the radial direction is approximately equal to T1 / cos (theta) = T1 / cos (alpha-beta); and5) comparing and measuring to obtain corresponding data, and performing formula operation to obtain the radial deviation T of the central point. According to the invention, the measurement efficiencyof the cam profile can be improved, the machining waiting period is shortened, and the measurement cost is reduced.

Owner:XIAN AERO ENGINE CONTROLS

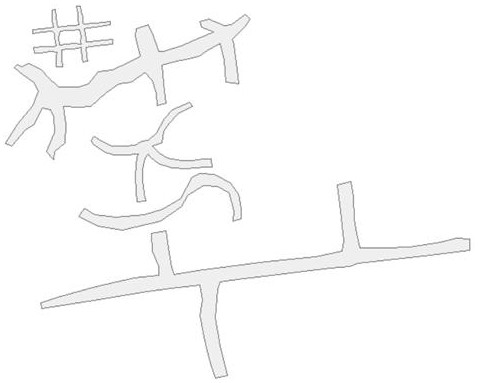

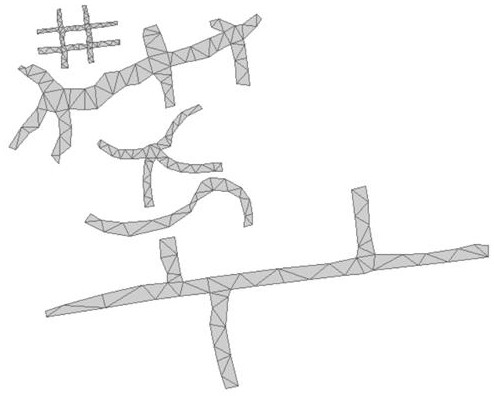

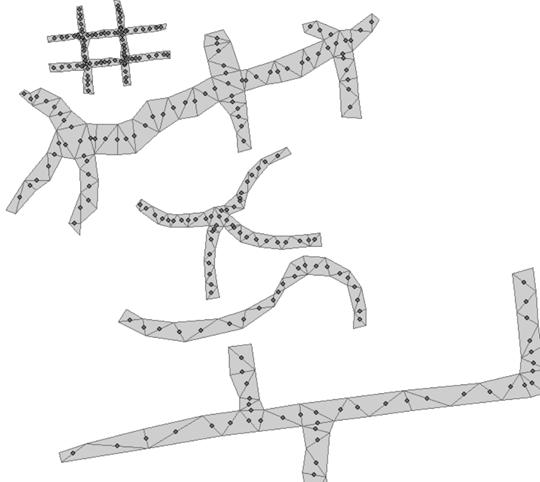

Improved planar element center line extraction method based on TIN

The invention provides an improved planar element center line extraction method based on TIN, and the method comprises the steps: obtaining a data set of vector data, and constructing an irregular triangulation network; screening triangles in the vector data from the irregular triangulation network according to the inclusion relation of the vector data; extracting a central point of each edge of the internal triangle; calculating the number of neighbors of the internal triangle and storing the neighbors to triangle attributes; acquiring a central point which is not on the boundary of the vector data according to the boundary relationship between the central point and the vector data; calculating the sum of the number of neighbors of the triangle adjacent to the central point which is not on the vector data boundary, and recording the sum into the central point attribute; connecting the points according to the central point attributes and the triangle attributes to obtain a line segmentset; determining an exit point of the vector data according to the line segment set; and adding a connecting line of the vector data outlet point and the outer end point of the line segment set to the line segment set to finally form a road network. Excessive encryption of boundary points is not needed, and extraction of the center line is completed through one-time calculation.

Owner:吉奥时空信息技术股份有限公司

A Pile Foundation Model Creation Method Based on Revit and Dynamo

Owner:ZHEJIANG UNIV

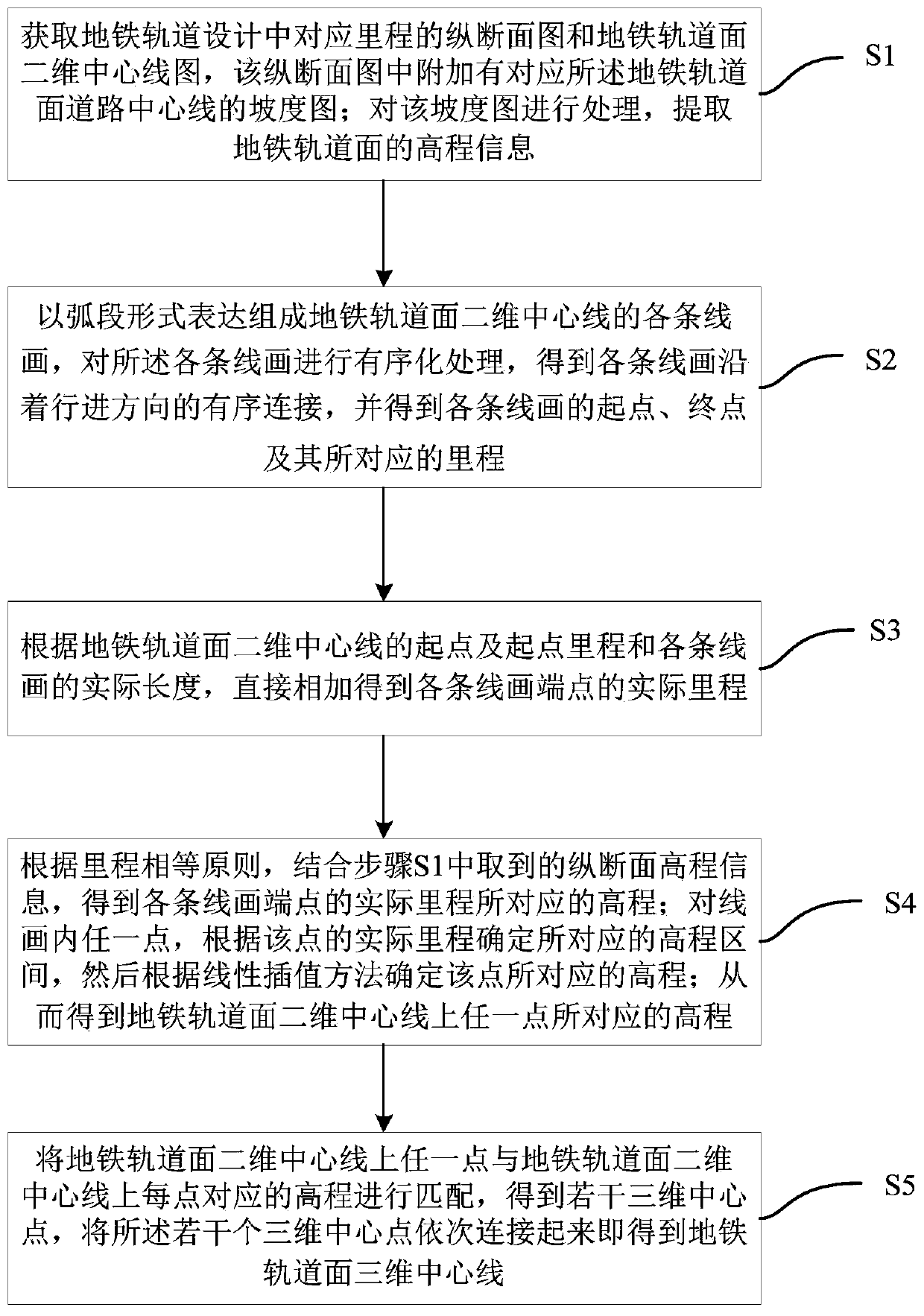

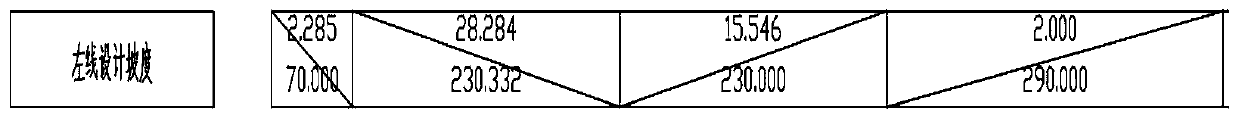

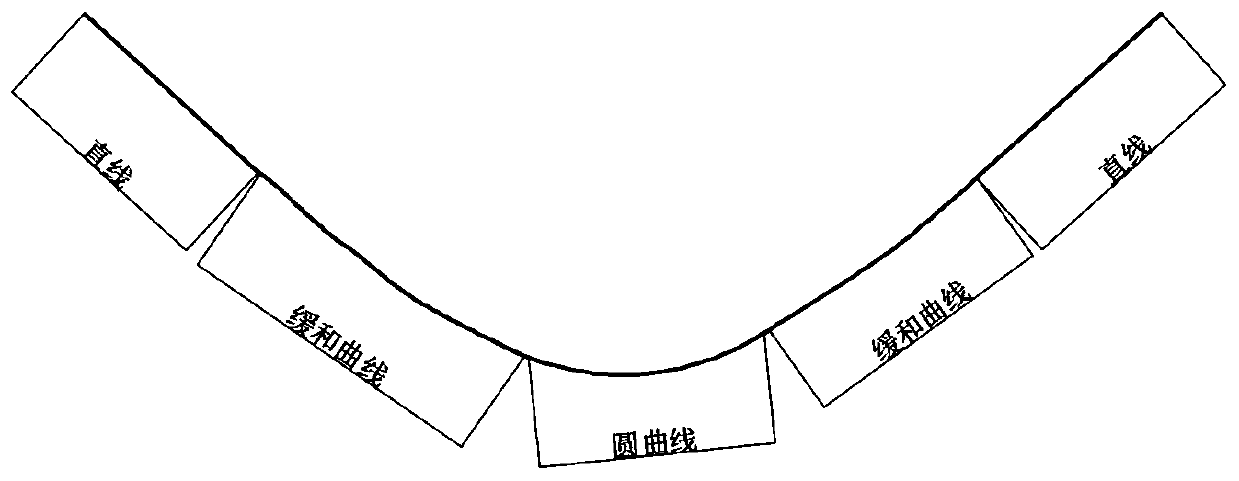

Subway track surface three-dimensional center line generation method

ActiveCN111199064ASimple methodEasy to operateGeometric CADData processing applicationsPoint cloudAlgorithm

The invention provides a subway track surface three-dimensional center line generation method, which comprises the following steps: processing an acquired longitudinal section diagram, and extractingcorresponding information of mileage and elevation of the center line of the subway track surface; carrying out ordering processing on each line drawing of the two-dimensional center line of the subway track surface to obtain a starting point of each line drawing along the line direction and a corresponding starting point mileage, and calculating the actual mileage of each line drawing end point according to the starting point mileage and the actual length of each line drawing; matching the line drawing endpoints with the longitudinal section information according to a mileage equality principle to obtain elevations corresponding to the line drawing endpoints; for any point in the line drawing, determining the elevation corresponding to the point according to the actual mileage of the point and a linear interpolation method; and further obtaining the three-dimensional center line of the subway track surface. The method has the advantages that the method is simple and easy to operate, the obtained three-dimensional center line can be combined with tunnel point cloud data to calculate various cross sections, and the production efficiency of tunnel clearance measurement, operation monitoring and other work is improved.

Owner:WUHAN DESIGN & RES INST OF CHINA COALTECH & ENG GROUP

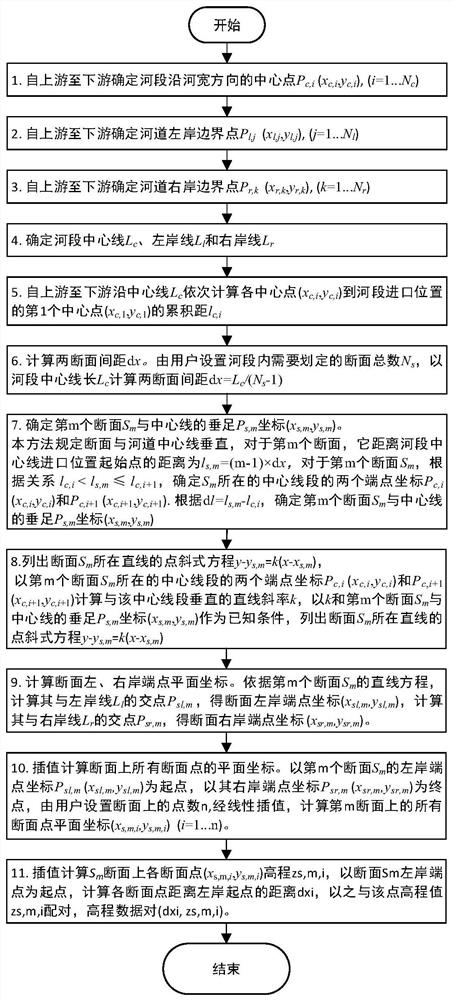

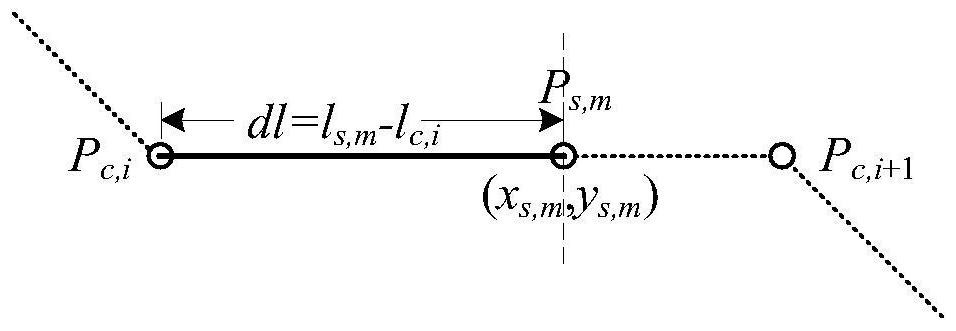

Automatic division method for element mathematical model section of water and sediment habitat of one-dimensional river network

ActiveCN112069696AReduce manual interventionImprove the efficiency of section divisionDesign optimisation/simulationSpecial data processing applicationsRiver networkRiver routing

The invention discloses an automatic division method for an element mathematical model section of a water and sediment habitat of a one-dimensional river network, which comprises the following steps of determining a central point, a river channel left bank boundary point and a river channel right bank boundary point of a river section along a river width direction from upstream to downstream, anddetermining a river section central line, a left bank line and a right bank line; then sequentially calculating cumulative distances lc, i from each central point Pc, i (xc, i, yc, i) to the first central point Pc, 1 (xc, 1, yc, 1) of the entrance position of the river reach along the central line Lc from upstream to downstream; setting the total number Ns of sections needing to be defined in theriver reach, and calculating the distance between every two adjacent sections; determining vertical feet Ps and m coordinates (xs, m, ys, m) of the mth section Sm and the center line; determining a point skew equation of a straight line where the section Sm is located; calculating plane coordinates of left and right bank end points of the section; and finally, performing interpolation calculationon the elevation zs, m, i, ys, m and i of each section point (xs, m, i) on the Sm section, calculating the distance dxi between each section point and the starting point of the left bank, and obtaining an elevation data pair (dxi, zs, m and i). The invention solves the problem of automatically dividing the section of a one-dimensional river network model.

Owner:CHINA INST OF WATER RESOURCES & HYDROPOWER RES

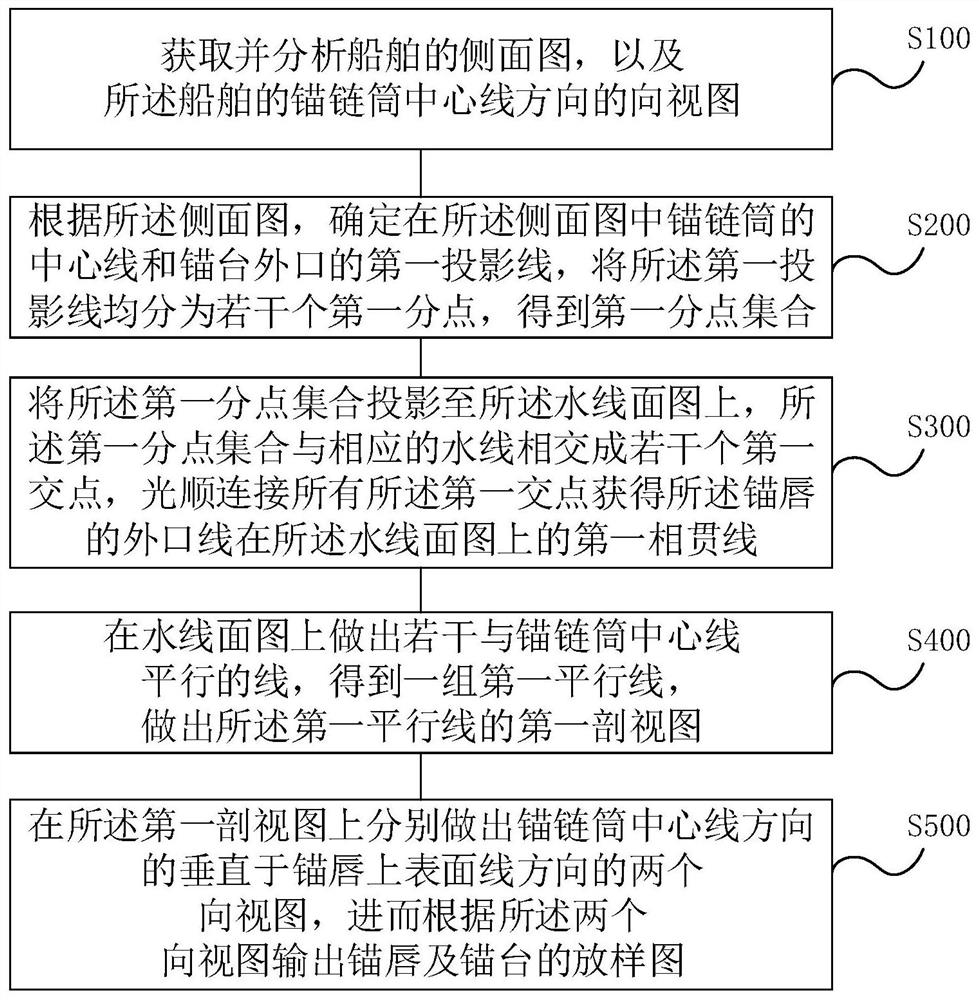

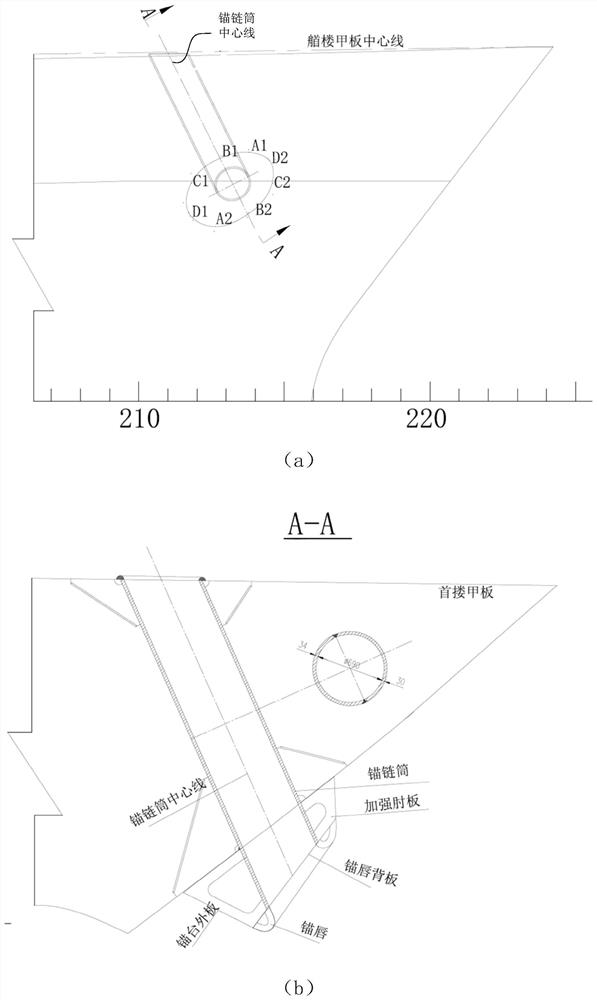

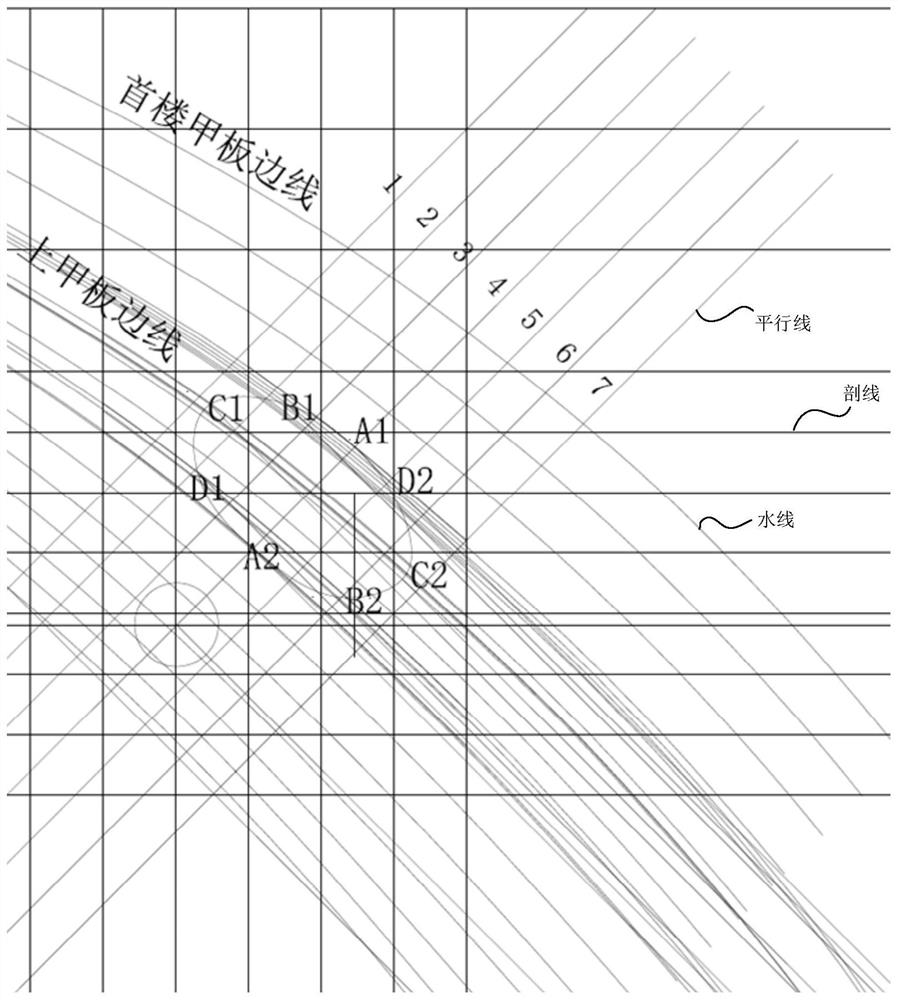

Lofting design method and system for anchor mouth and anchor chock

ActiveCN112319723ASimplify the stake out processImprove stakeout accuracyVessel designingMarine engineeringStructural engineering

The invention discloses a lofting design method and system for an anchor mouth and an anchor chock, and relates to the technical field of shipbuilding. The method comprises the steps of acquiring andanalyzing a side view of a ship and a direction view of a central line direction of a hawse pipe of the ship; projecting the center line of the hawse pipe and the outer opening of the anchor chock toa waterline plane drawing according to the side view; drawing a plurality of lines parallel to the center line of the hawse pipe on the waterline plane drawing to obtain a group of first parallel lines, and drawing a first sectional view of the first parallel lines; and making two directional views perpendicular to the upper surface line direction of the anchor mouth in the center line direction of the hawse pipe on the first sectional view, and then outputting lofting drawings of the anchor mouth and the anchor chock according to the two directional views. The contour shape, the lineation sample and the angle sample of the anchor mouth are obtained in a projection plane conversion mode, the lofting process can be simplified, the lofting precision is improved, and the working efficiency isimproved.

Owner:CSSC HUANGPU WENCHONG SHIPBUILDING COMPANY

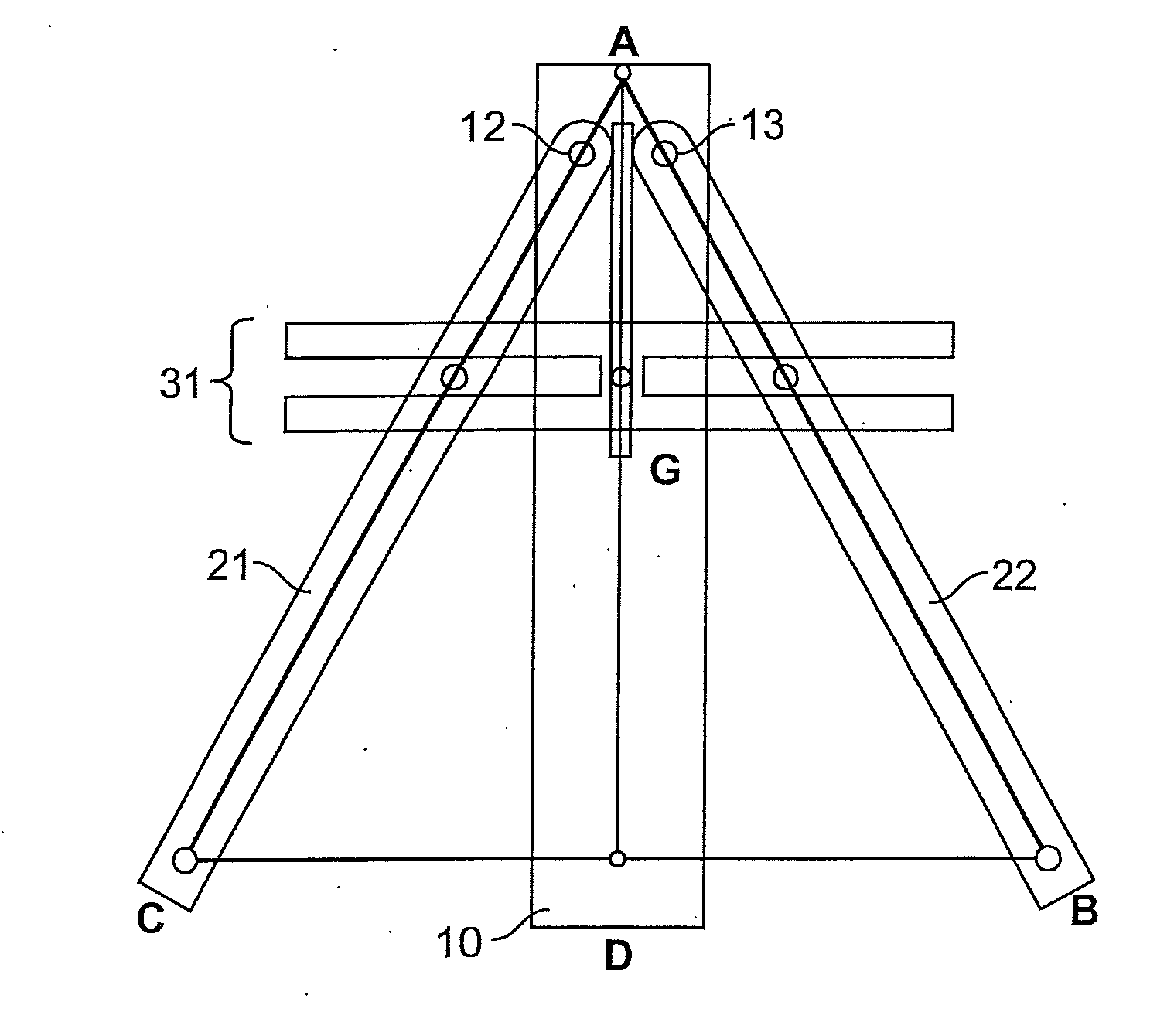

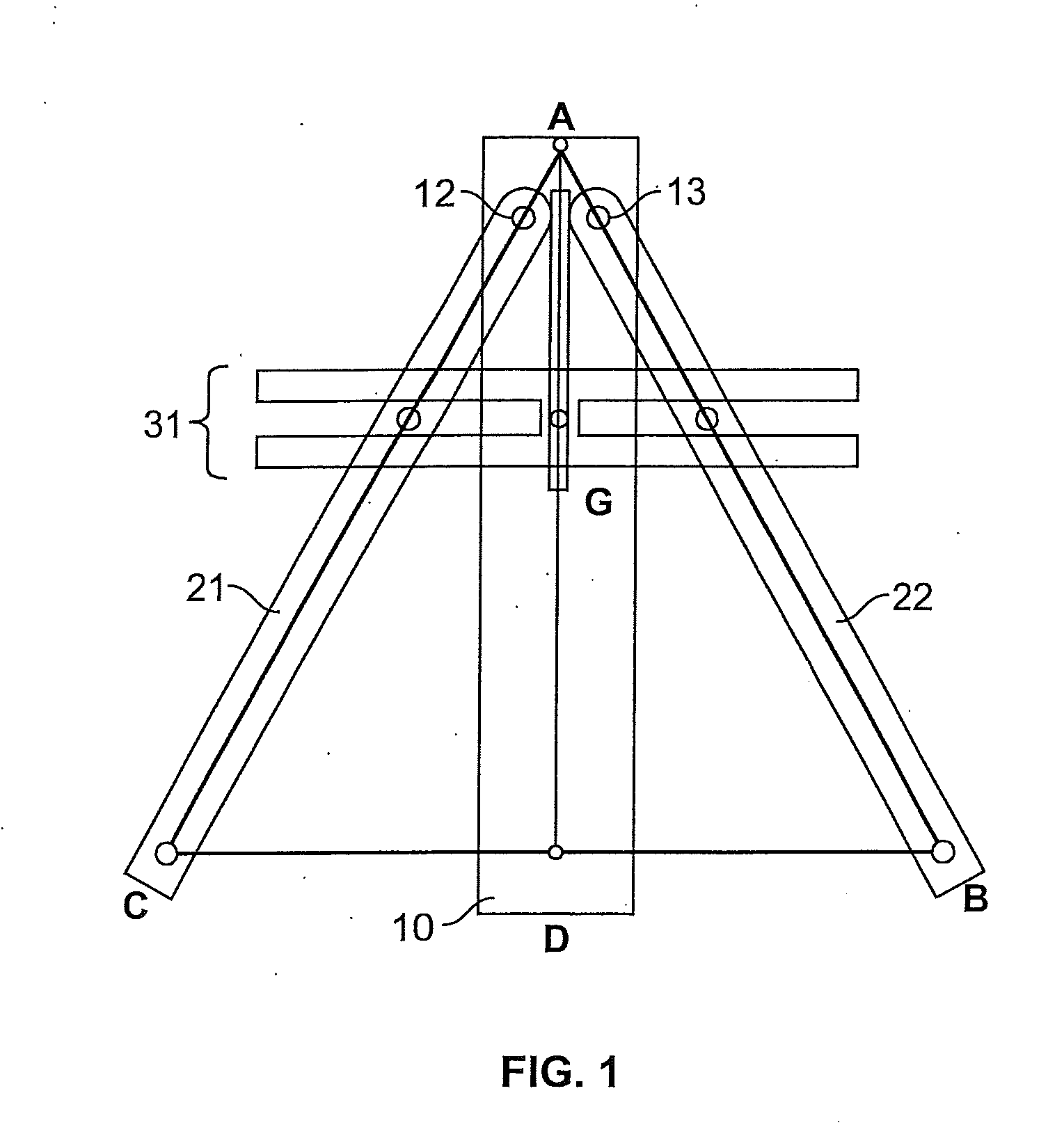

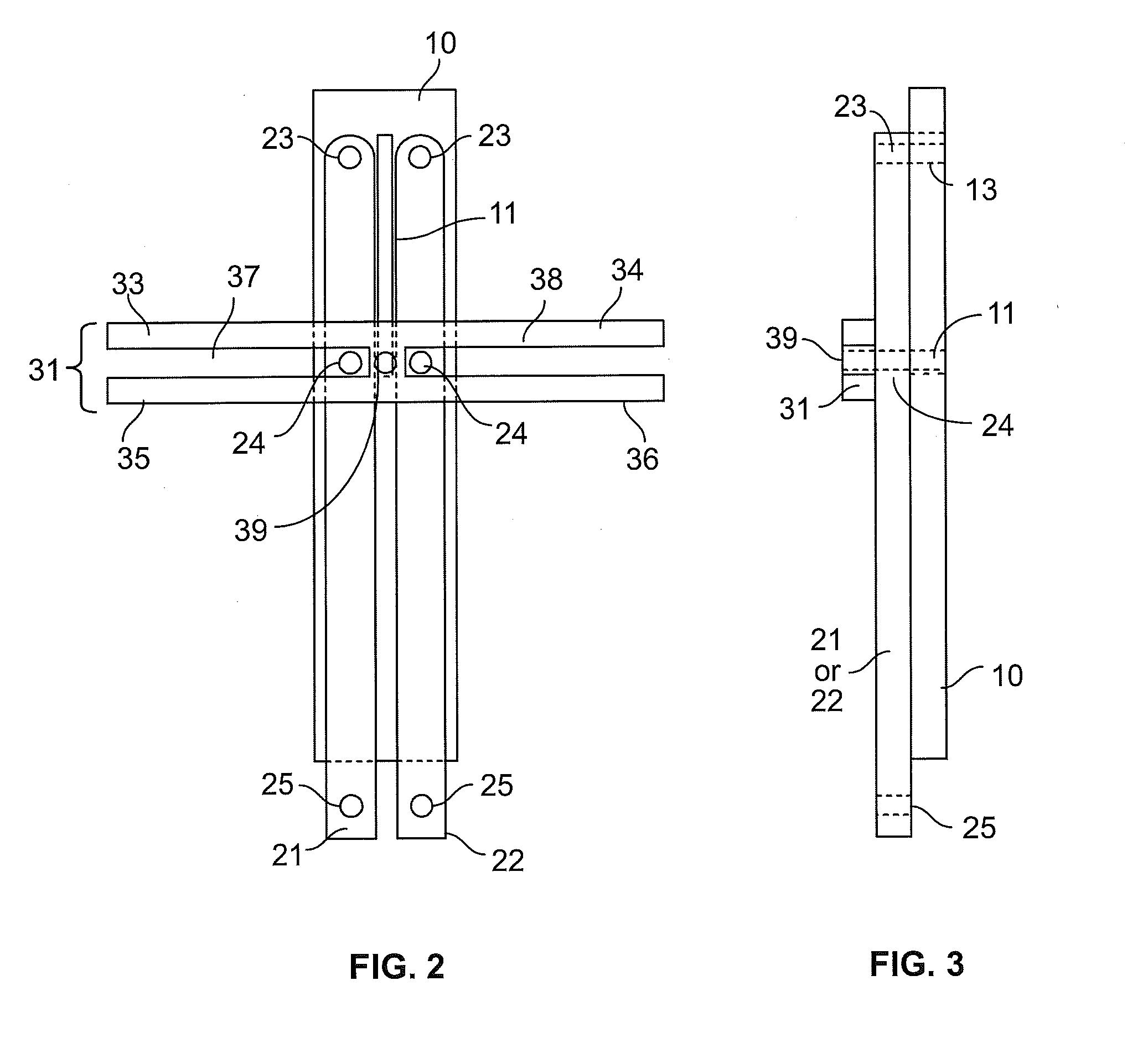

Precision tool for locating center lines in geometric shapes

ActiveUS20150176957A1Precise definitionPrecision can be ensuredMechanical clearance measurementsEngineeringMiddle line

Owner:JAMES J DANKOWSKI TRUST

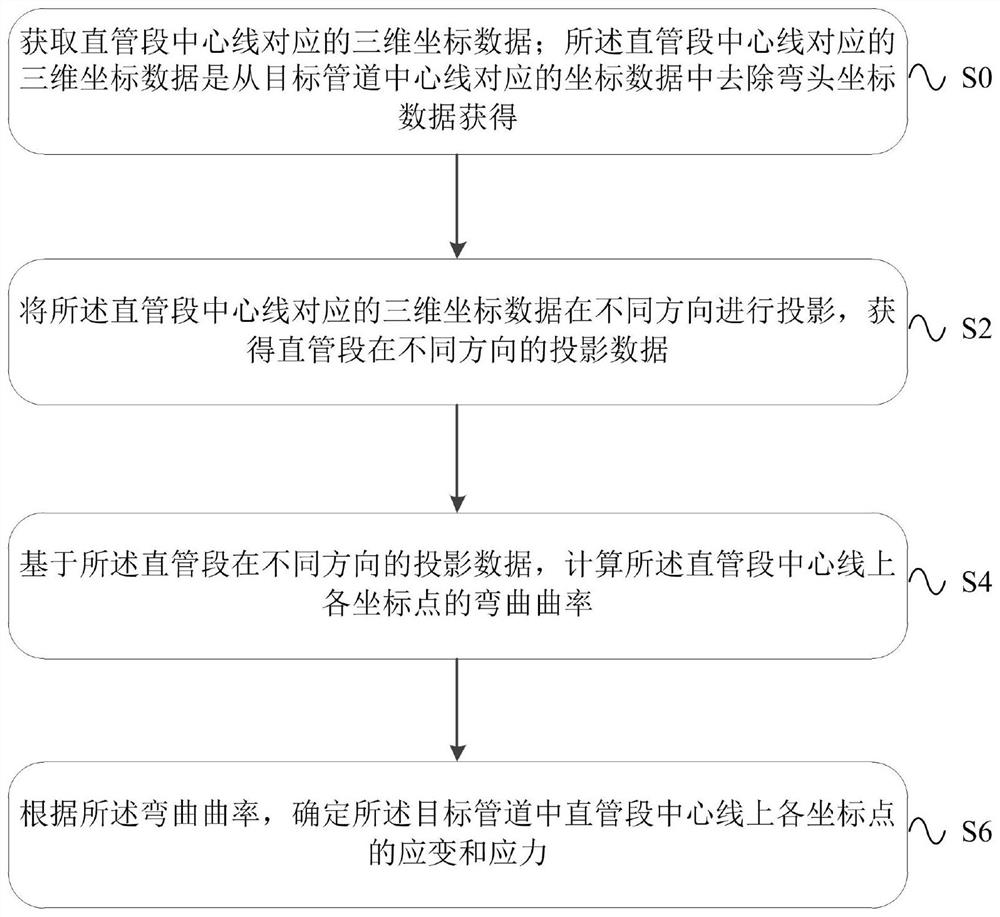

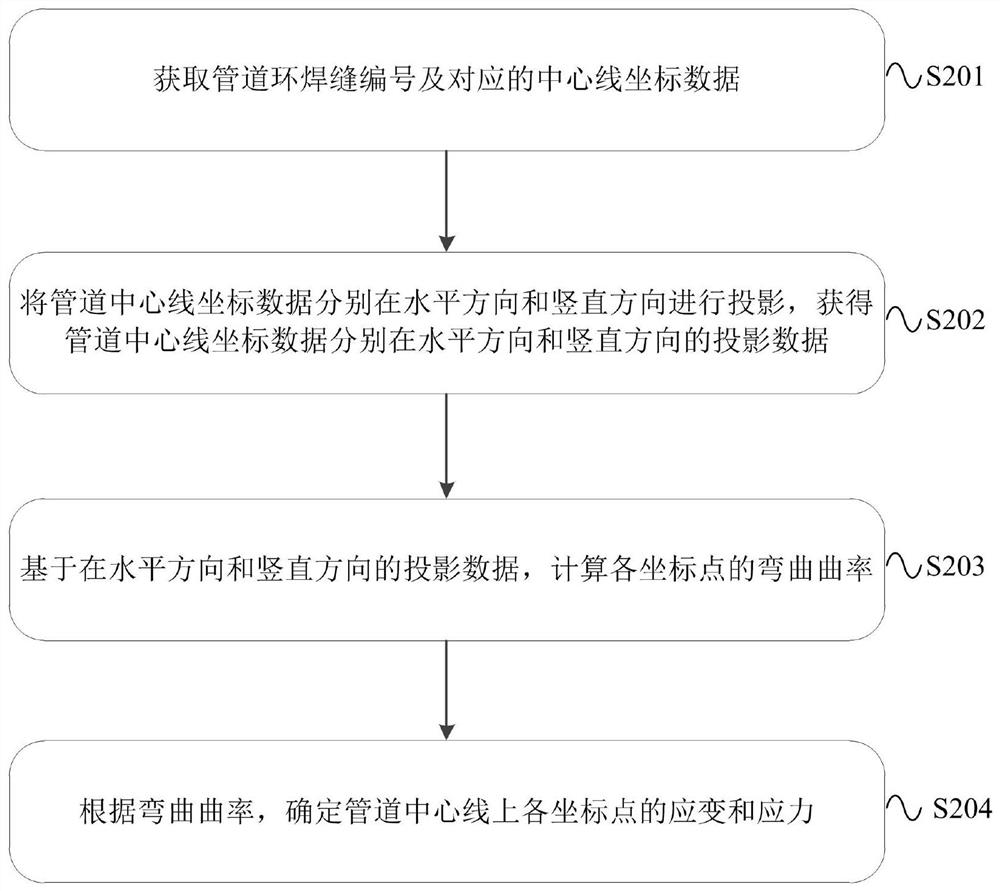

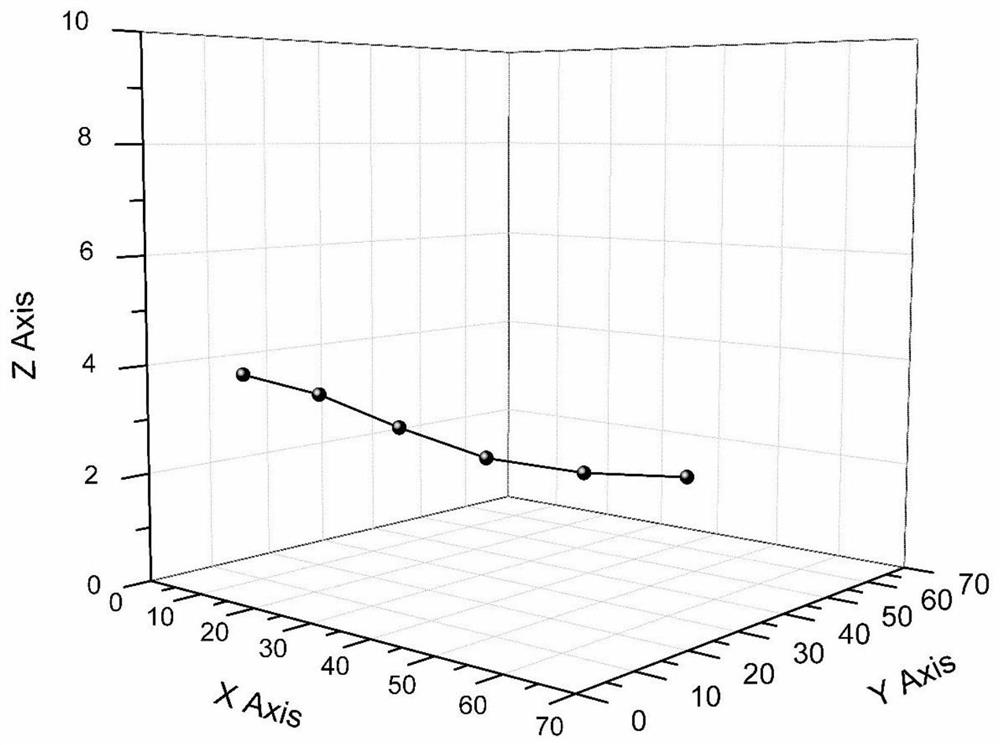

Method, device and apparatus for determining strain and stress of pipeline

ActiveCN112287496AStress-strain accuracyAccurate descriptionGeometric CADDesign optimisation/simulationStraight tubeClassical mechanics

The embodiment of the invention provides a method, a device and an apparatus for determining strain and stress of a pipeline. The method comprises the following steps: acquiring three-dimensional coordinate data corresponding to the center line of a straight pipe section, wherein the three-dimensional coordinate data corresponding to the center line of the straight pipe section is obtained by removing elbow coordinate data from coordinate data corresponding to the center line of a target pipeline; projecting the three-dimensional coordinate data corresponding to the center line of the straightpipe section in different directions to obtain projection data of the straight pipe section in different directions; calculating the bending curvature of each coordinate point on the center line of the straight pipe section based on the projection data of the straight pipe section in different directions; and determining the strain and stress of each coordinate point on the center line of the straight pipe section in the target pipeline according to the bending curvature. By utilizing the embodiment of the invention, the three-dimensional shape of the pipeline can be accurately described, sothat the calculated stress and strain of the pipeline are more accurate.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

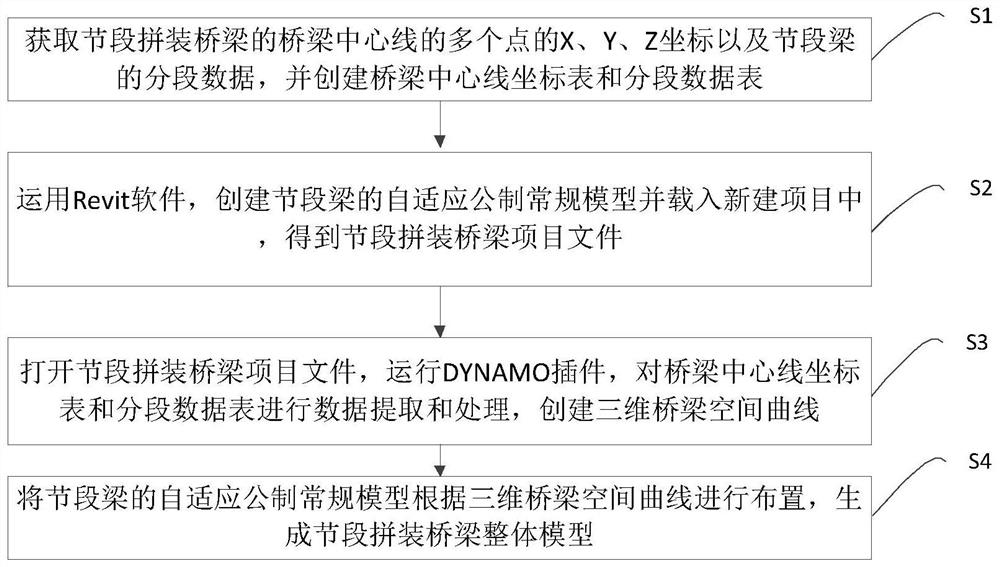

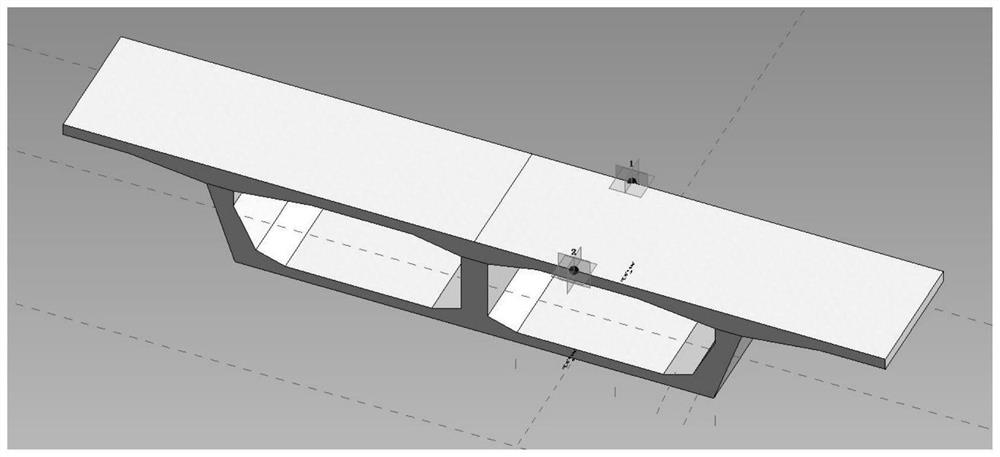

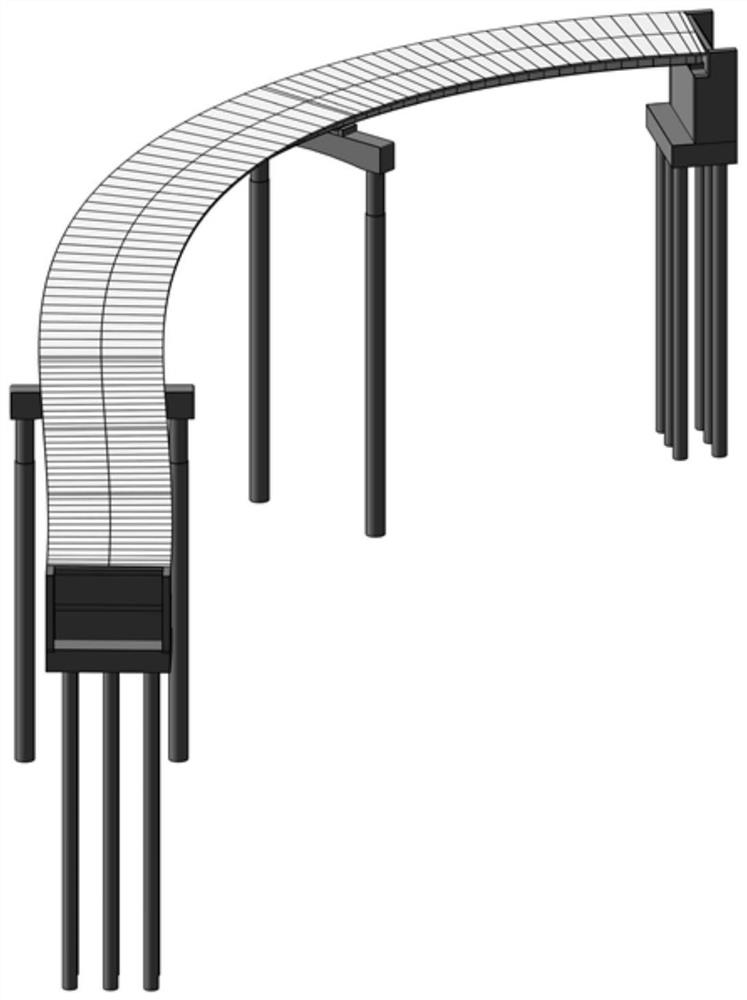

Revit-based segmental assembled bridge modeling method and system

PendingCN114065357AImprove modeling accuracyReal-time dynamic modification typeGeometric CADSpecial data processing applicationsAlgorithmModelSim

The invention provides a method and a system for modeling a segment assembled bridge based on Revit. The method comprises the following steps: creating a bridge center line coordinate table and a segment data table; creating a self-adaptive metric conventional model of the segmental beam and loading a new project; running a DYNAMO plug-in, and creating a three-dimensional bridge space curve; and arranging the self-adaptive metric conventional model of the segmental beam according to the three-dimensional bridge space curve to generate an overall model of the segmental assembled bridge. According to the method, the modeling precision is high, and the segmental assembled bridge model can be accurately established according to drawing data; the model can be used for data statistics and export, the workload of manual calculation is small, and the working efficiency can be remarkably improved; the modeling method is suitable for various straight-line and curve-form bridges; according to the modeling method, the flat curve and the longitudinal curve of the segmental beam can be formed by fitting high-precision broken lines; according to the modeling method, the type and size parameters of each segmental beam model can be dynamically modified in real time.

Owner:CHINA MCC20 GRP CORP +1

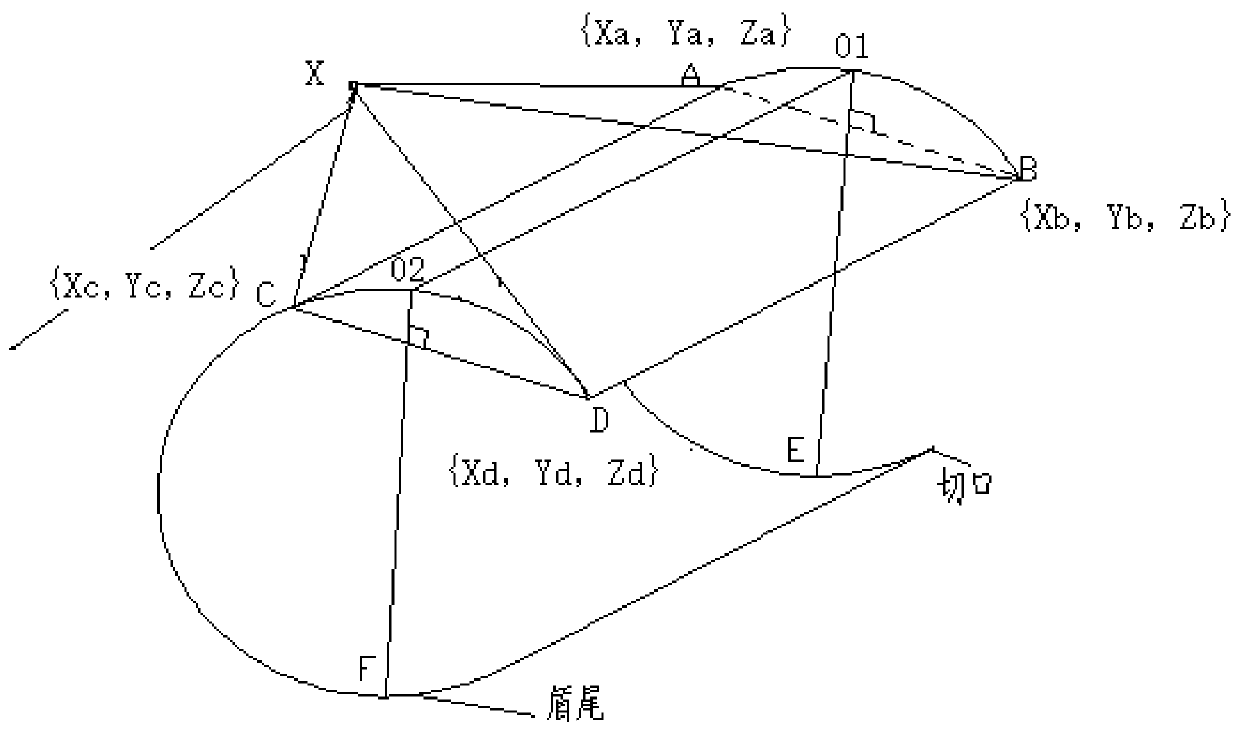

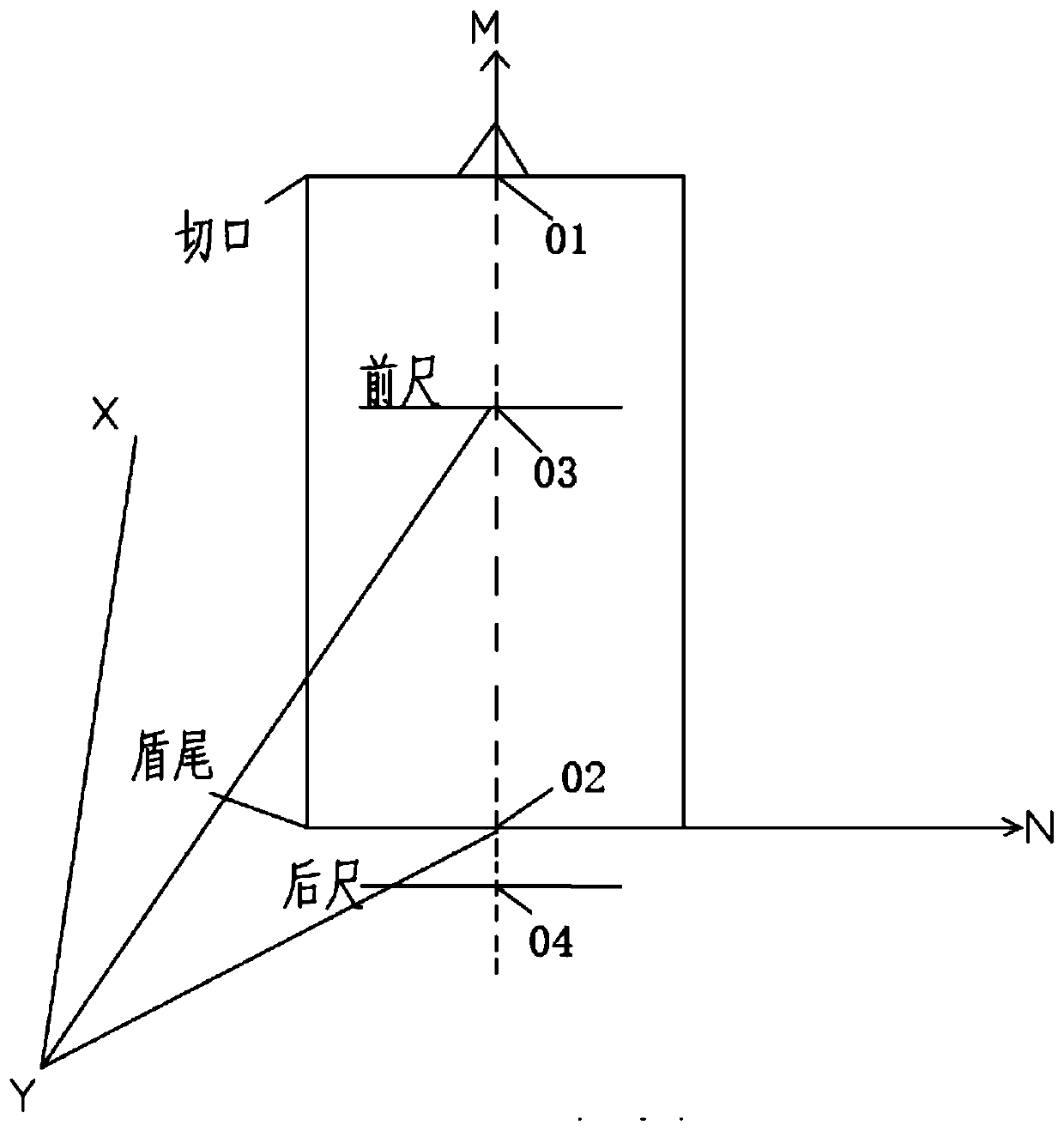

Initial positioning and rapid centering measurement method for shield tunneling machine

ActiveCN111578873AShorten the construction periodReduce the risk of working in underground spacesMeasurement devicesMachineShield tunneling

The invention relates to an initial positioning and rapid centering measurement method for a shield tunneling machine and is used for correcting the posture of the shield tunneling machine before theshield tunneling machine starts. The method is characterized in that an independent coordinate system is established, four points are taken from a cutter head and a shield tail of the shield tunnelingmachine, and the plane center line of the shield tunneling machine is obtained through calculation according to the vertical diameter theorem theory, and coordinates of the central points of measurement planes of a front ruler and a rear ruler in the shield tunneling machine are calculated by using a coordinate conversion formula by taking the coordinates as reference lines of the new independentcoordinate systems, the new independent coordinate systems are continuously established to enable the position coordinates of the central points of the planes measured by the front ruler and the rearruler in the shield tunneling machine to be zero, and finally plane accurate centering of the measurement marks in the shield tunneling machine is completed. Compared with a traditional method, the method is easy and convenient to operate, higher in measurement precision and higher in speed, a construction period of a project is greatly shortened, less manpower is needed, the risk of urban underground space operation is greatly reduced, and technical feasibility, working efficiency and the implementation effect are greatly higher than those of the traditional mode.

Owner:SHANGHAI FOUND ENG GRP

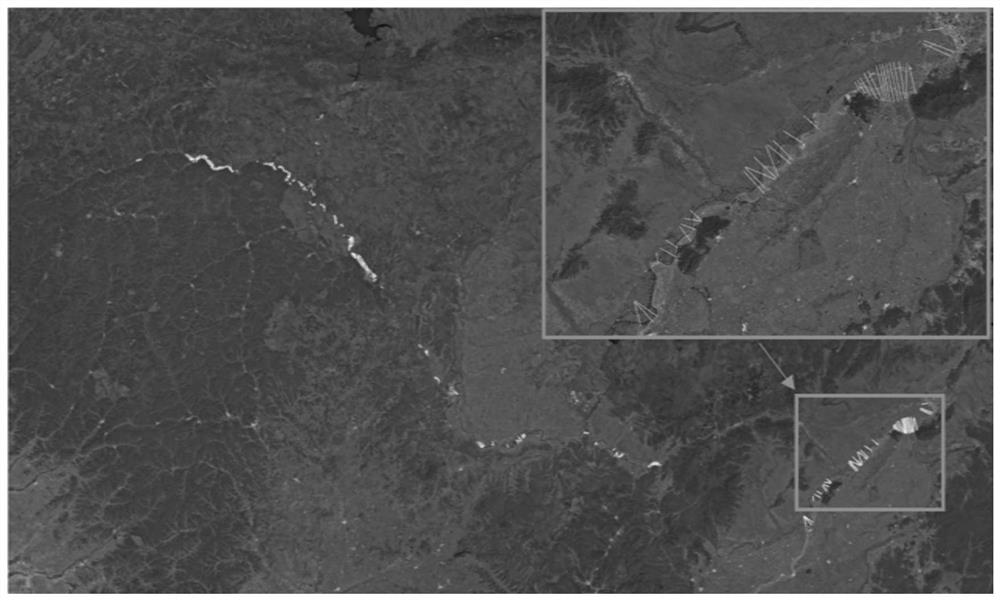

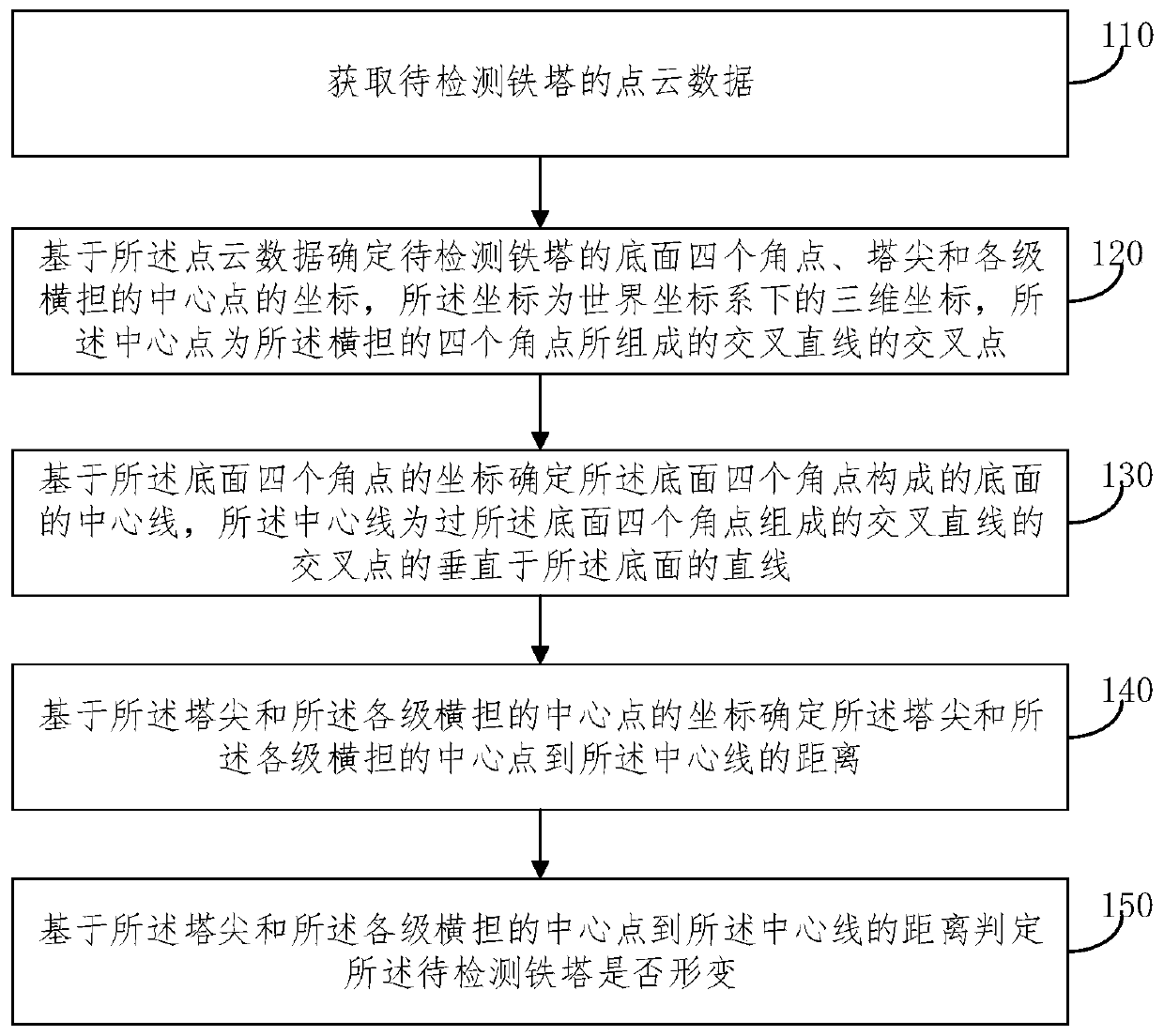

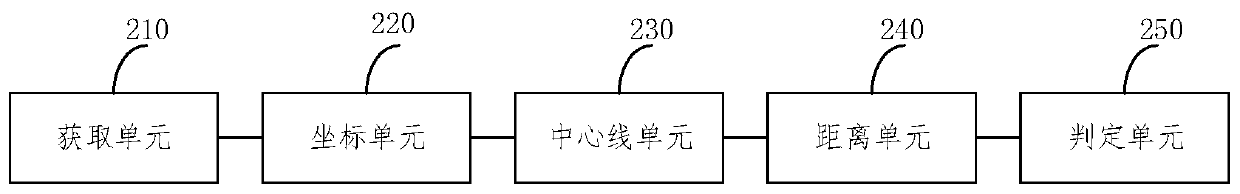

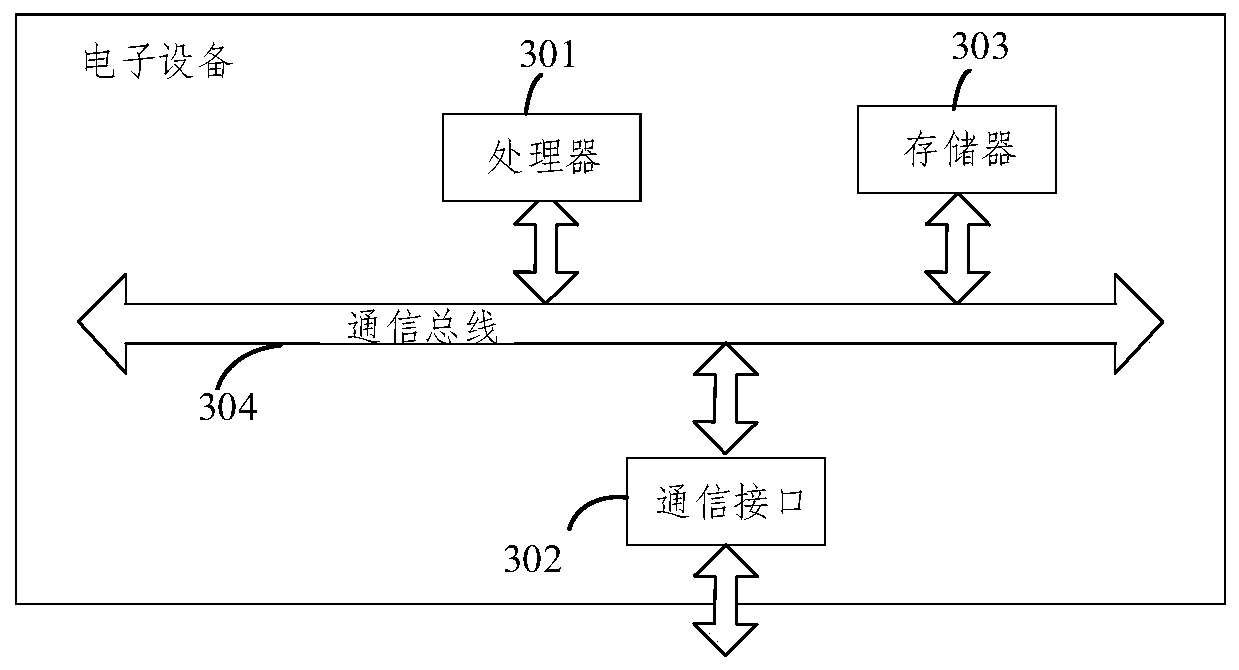

Method and system for detecting iron tower deformation based on point cloud data

ActiveCN111521125AImprove the efficiency of deformation detectionUsing optical meansPoint cloudClassical mechanics

The embodiment of the invention provides a method and system for detecting iron tower deformation based on point cloud data. The method comprises steps that the point cloud data of a to-be-detected iron tower are acquired; coordinates of four corners of a bottom surface of the to-be-detected iron tower, a tower tip and center points of all levels of cross arms are determined based on the point cloud data, the coordinates are three-dimensional coordinates under a world coordinate system, and the center points are intersection points of intersection straight lines formed by the four corners of the cross arms; based on the coordinates of the four corners of the bottom surface, a center line of the bottom surface formed by the four corners of the bottom surface is determined, the center line is a straight line perpendicular to a bottom surface and passing through the intersection point of crossed straight lines formed by the four corners of the bottom surface; distances from the central points of the tower tip and the cross arms to the central line are determined based on the coordinates of the central points of the tower tip and the cross arms; whether the to-be-detected iron tower deforms is determined based on the distances from the tower tip and the central points of the cross arms to the central line. The method is advantaged in that efficiency of iron tower deformation detection is improved, and the trouble that detection personnel need to measure on site is avoided.

Owner:武汉地大信息工程股份有限公司

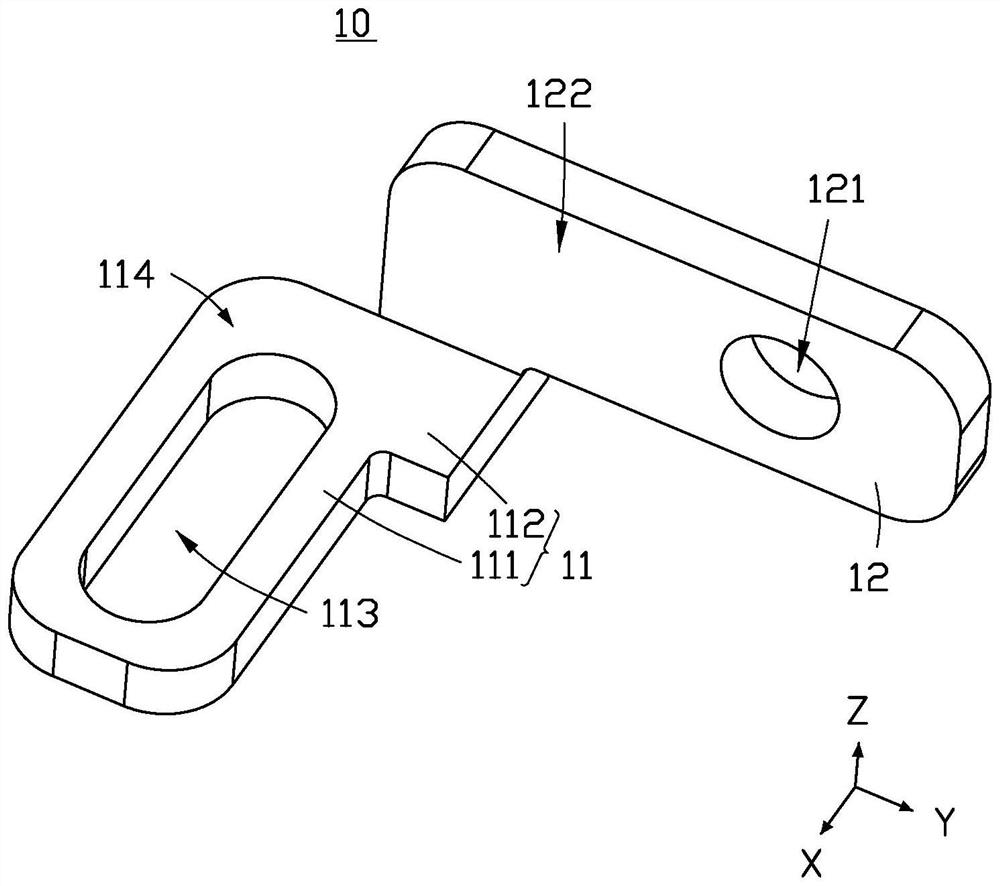

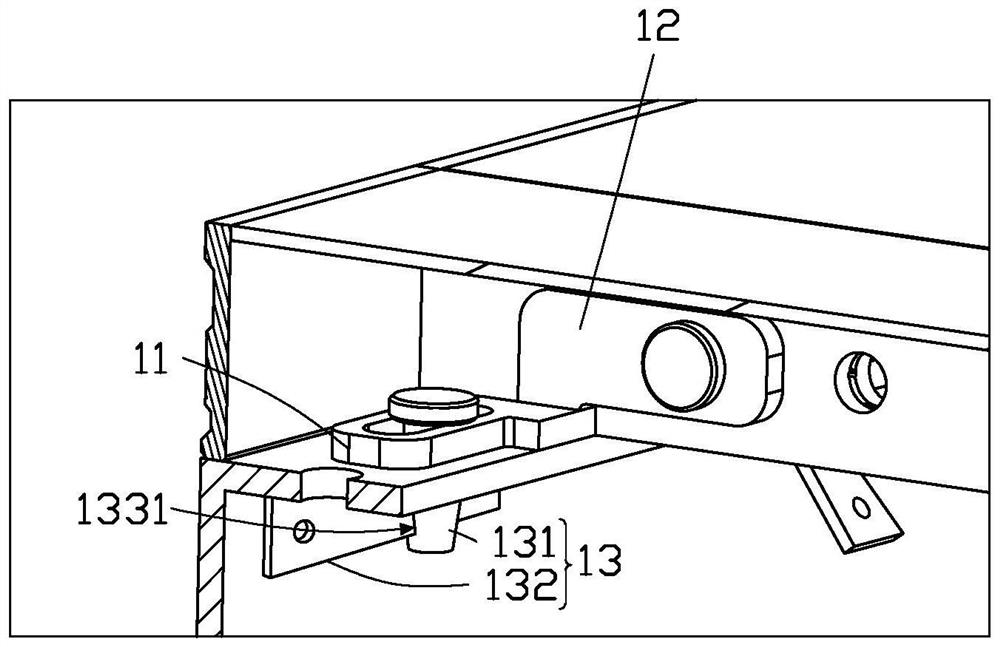

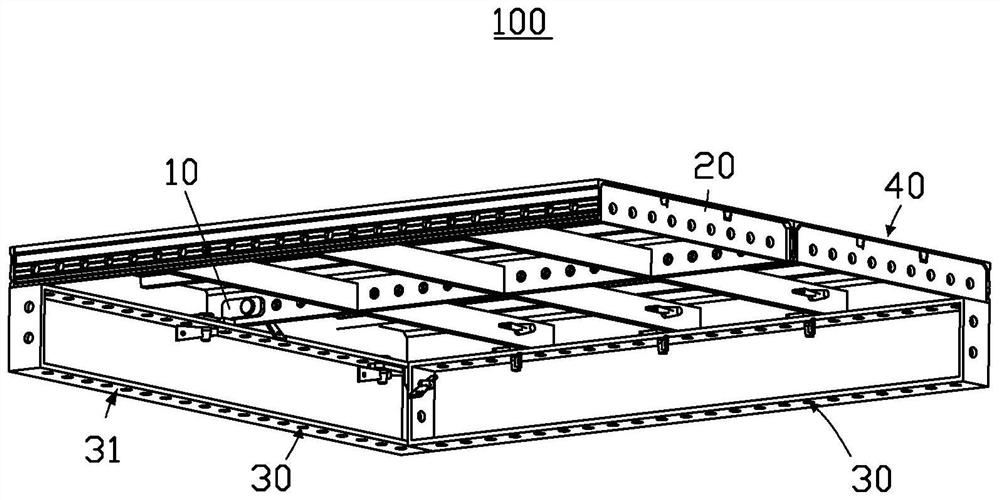

Connecting structure and formwork system

PendingCN113356578AReduce the difficulty of productionReduce typesForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksStructural engineeringMechanical engineering

The invention discloses a connecting structure and a formwork system. The connecting structure comprises a first connecting piece and a second connecting piece, wherein the first connecting piece comprises a first face, a first connecting hole is formed in the first connecting piece, the first connecting hole penetrates in the first direction perpendicular to the first face, the second connecting piece is connected to the first connecting piece, the second connecting piece comprises a second face, the second face is perpendicular to the first face, the second connecting piece is provided with a second connecting hole, the second connecting hole is formed in a penetrating mode in the second direction perpendicular to the second face, the second direction is perpendicular to the first direction, a geometric center line of the first connecting hole and a geometric center line of the second connecting hole are arranged in different planes, the first connecting piece is fixed to one formwork, the second connecting piece is fixed to the other formwork, and therefore an internal corner is formed, building of the formwork system can be completed only through a plane formwork, and the types of formworks needed for building the formwork system are few.

Owner:SNTO TECH GRP

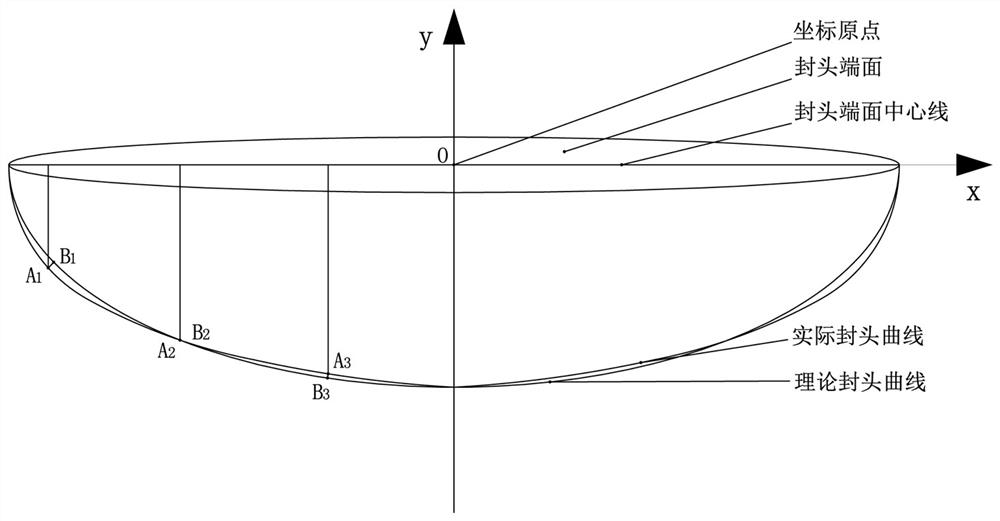

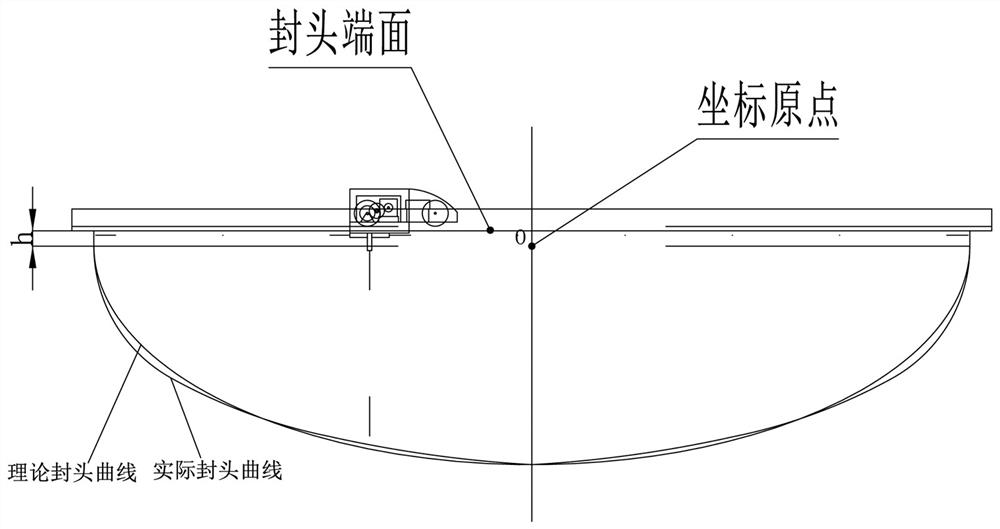

Method for measuring shape deviation of ellipsoidal seal head

ActiveCN112945062ASolve problems that require different templatesQuick fixMechanical counters/curvatures measurementsMeasurement costShape deviation

The invention relates to a measurement method, in particular to a method for measuring shape deviation of an ellipsoidal head, and aims to solve technical problems of high measurement cost and inconvenience in operation of an existing ellipsoidal head. According to the method, a plurality of positions of a center line of an end face of an oval end socket are selected for projection, projection distances in the vertical direction and the horizontal direction are detected, coordinates of each projection point and a corresponding point can be obtained by combining a theoretical curve equation of the end socket, the concave-convex condition and the specific deviation value of the seal head corresponding to each projection point position are obtained, and maximum shape deviation of the seal head and the simulated contour of the seal head are finally obtained.

Owner:SHANXI YANG MEI CHEM IND MACHINERY

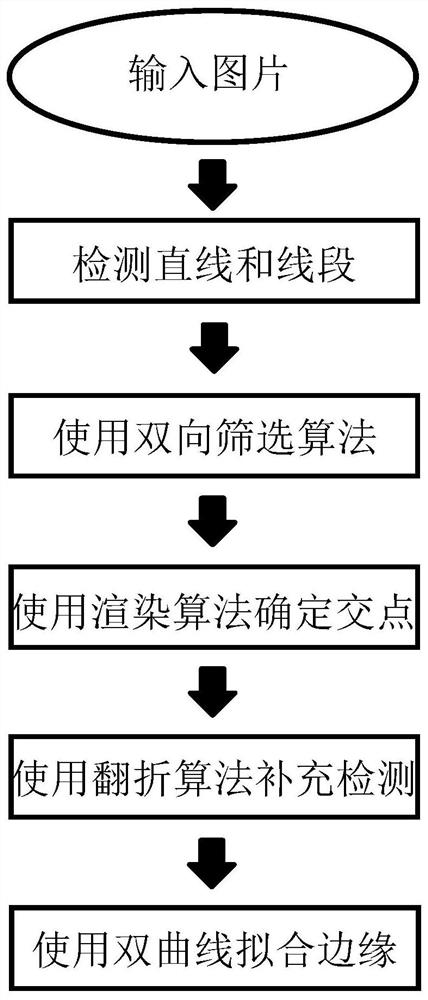

Chrysanthemum pool pattern geometrical information extraction method based on detection straight lines and line segments

ActiveCN111612738AAchieve acquisitionAchieve depictionImage enhancementImage analysisImage extractionAlgorithm

The invention discloses a chrysanthemum pool pattern geometrical information extraction method based on detection straight lines and line segments, and the method achieves the obtaining and drawing ofinformation in a material image through a computer image detection method. The method includes: firstly, extracting edges of an image, and carrying out straight line and line segment detection on anedge detection image; eliminating false results through a bidirectional screening algorithm to obtain a plurality of sets including a center line and a plurality of line segments, wherein the center line is obtained by combining two straight line detection results with the same angle and close distance; detecting and positioning intersection points of the chrysanthemum pool belts by utilizing a result graph obtained by applying a rendering algorithm through the generated center line; supplementing a detection result by using a turning method according to the detected intersection point and part of the single-side edge; and finally describing the pattern edge of the chrysanthemum pool through a hyperbolic curve. According to the method for detecting the patterns of the chrysanthemum pond, the patterns and the intersection points of the patterns of the material chrysanthemum pond can be detected, positioned and described, the research speed is increased, the research cost is reduced, andresearch and development of the disciplines are promoted.

Owner:SHANGHAI UNIV

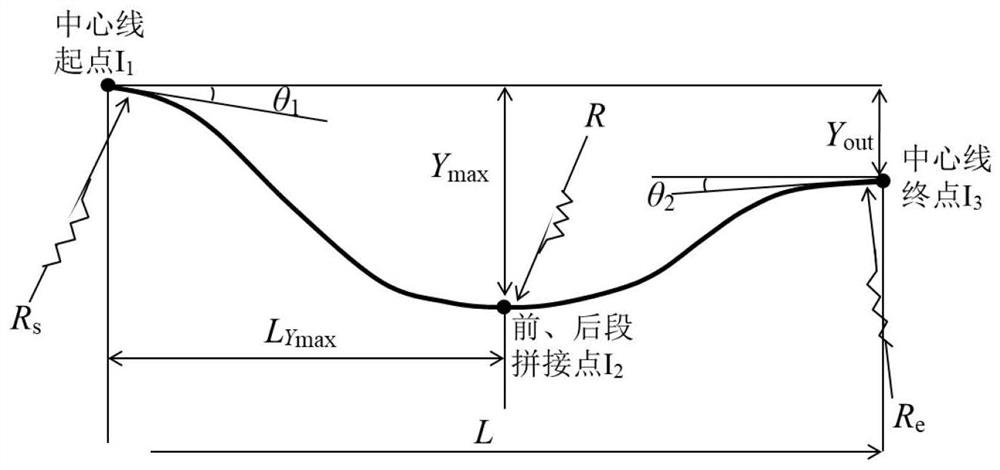

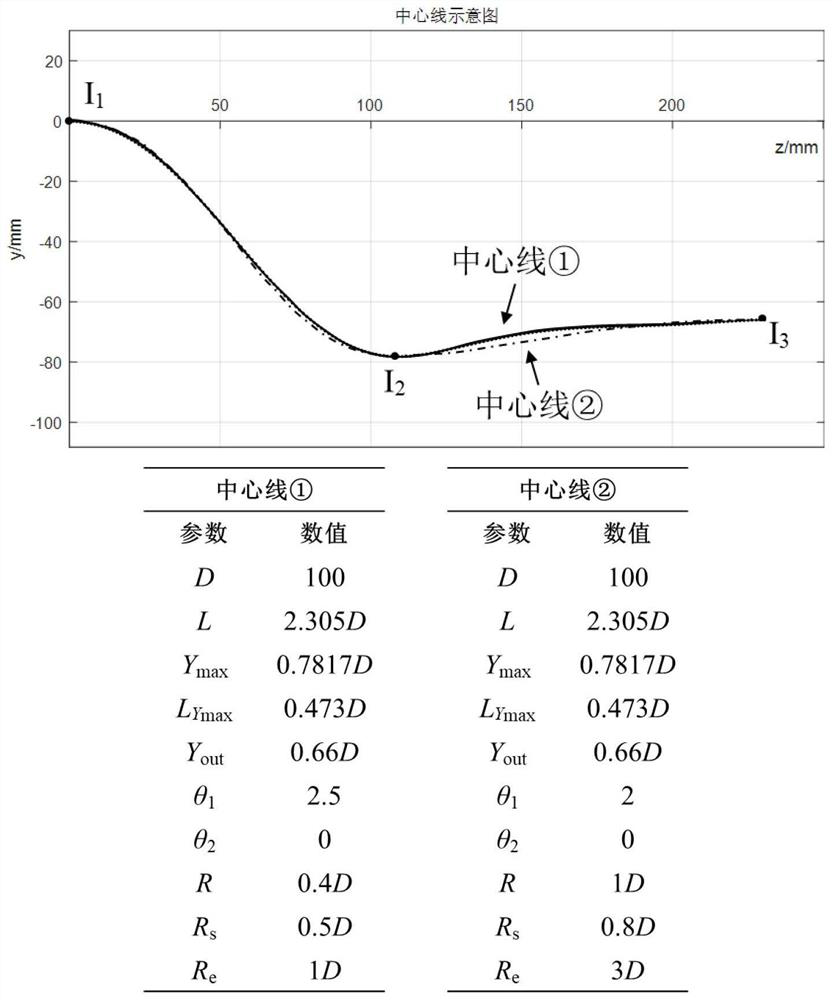

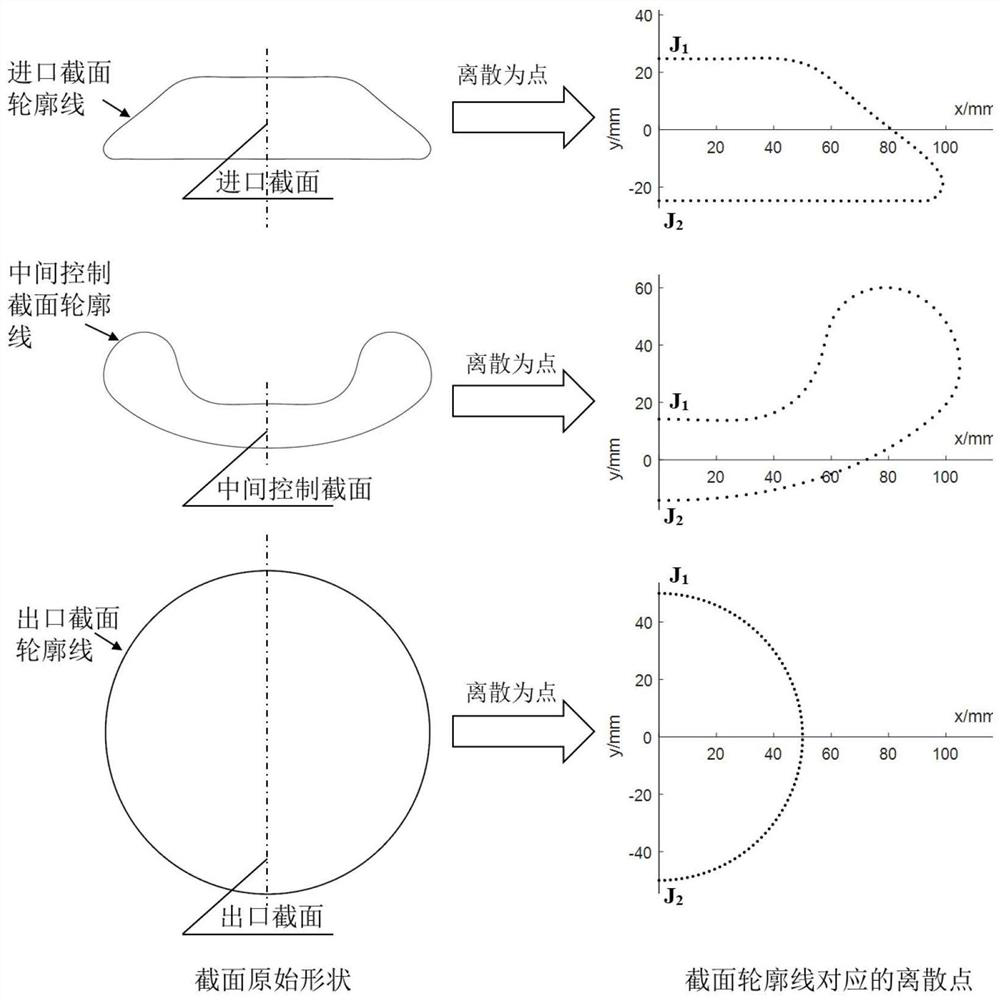

Invisible snakelike air inlet channel design method based on matrix transformation

ActiveCN114781078AAchieve smooth transitionAvoid errorsGeometric CADSustainable transportationInlet channelShape change

The invention discloses an invisible snakelike air inlet channel design method based on matrix transformation. According to the technical scheme, when the center line is designed, front and rear sections of quintic polynomials are spliced, so that the whole center line is second-order continuous; in the aspect of shape design of the cross sections of the pipeline, the contour line of each cross section is dispersed into a plurality of points, coordinates of the points are sequentially listed in the clockwise direction, and the contour line of each cross section can be represented by a matrix. Based on the method, the geometric shape change of the cross section contour line is converted into algebraic operation between matrixes. By designing a matrix transformation rule among an inlet section, a middle section and an outlet section, a shape change rule of a cross section contour line can be designed. By means of the design method, smooth transition between sections in any shape can be achieved, the starting point and the end point of each section curve generated in the design process are located on the symmetry plane, and therefore the more accurate air inlet channel profile can be obtained.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

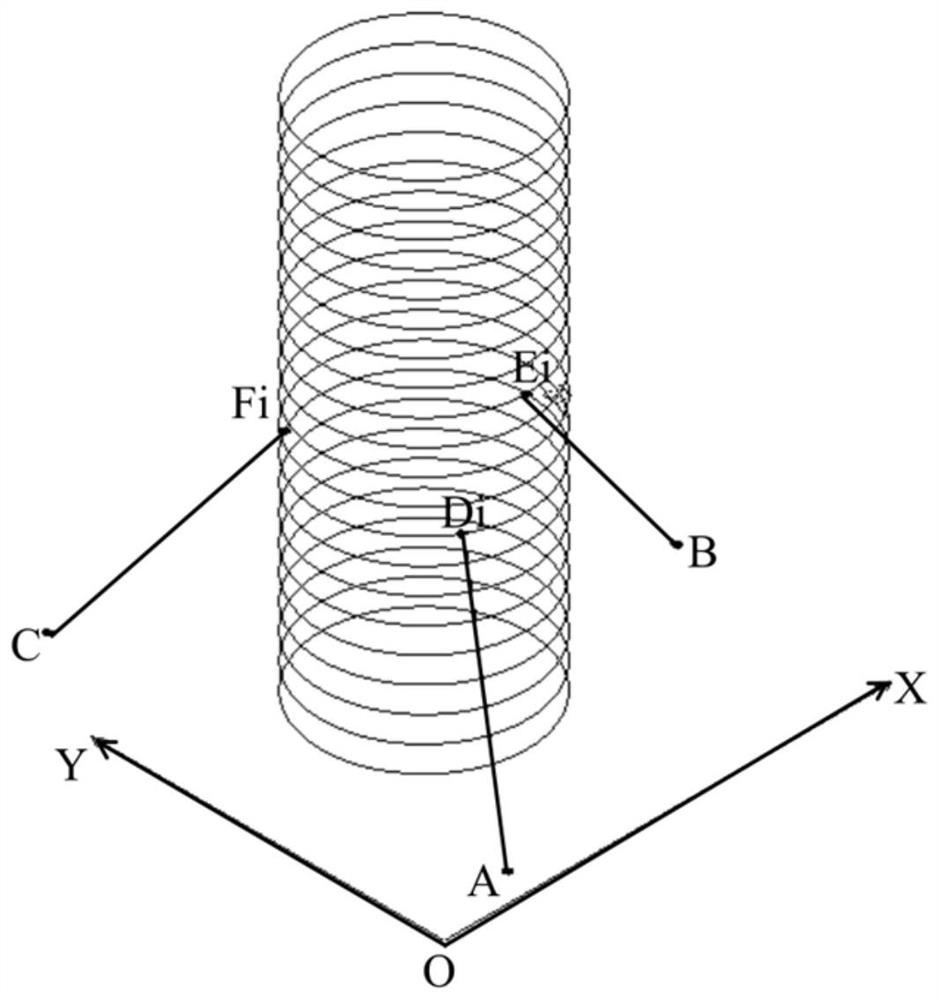

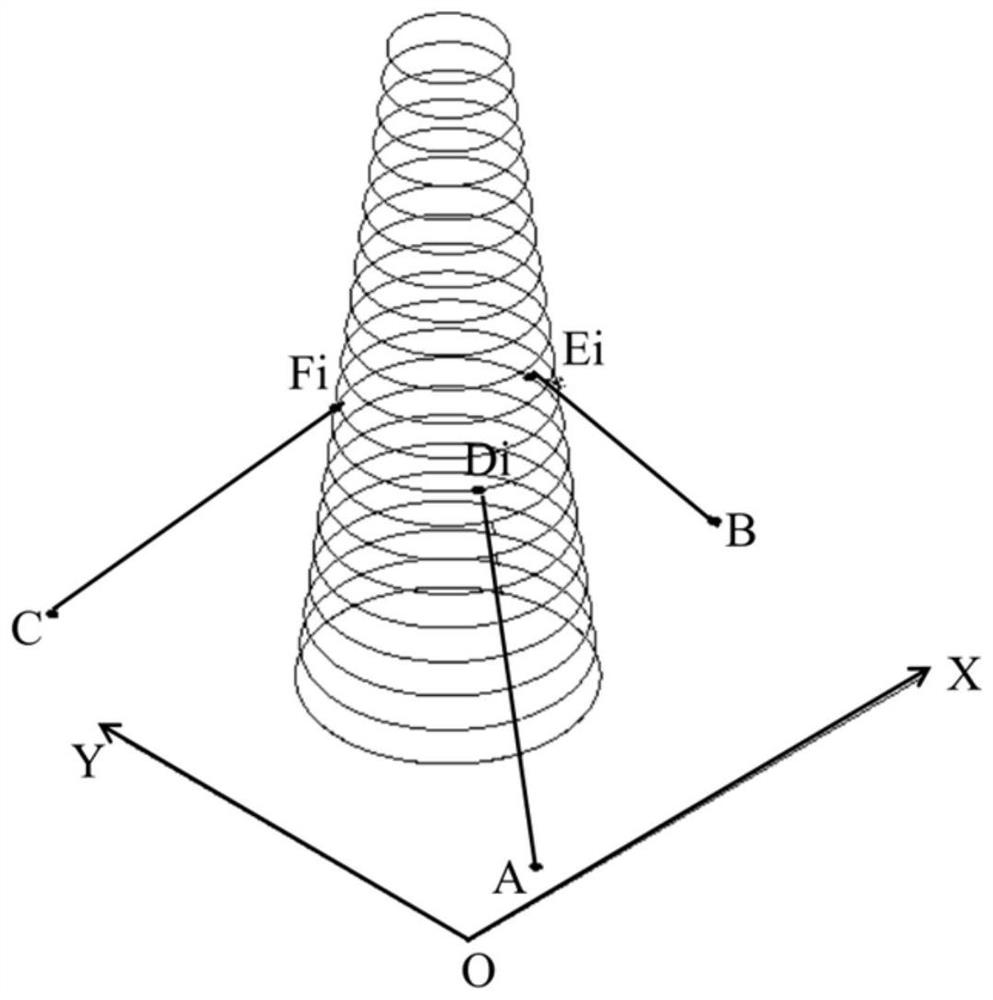

Inclination measuring method

InactiveCN111982069AHigh measurement accuracyEasy to operateIncline measurementStructural engineeringControl theory

The invention relates to the technical field of building measurement, and in particular relates to an inclination measuring method. The inclination measuring method comprises the steps of S1 establishing a three-dimensional coordinate system; S2 measuring coordinates of at least three measuring points in the circumferential direction of the sections of the building at different heights so as to determine circle centers of the sections of the corresponding different heights; and S3 determining the inclination of the building based on the measured circle centers of the sections with different heights. The invention discloses the inclination measuring method. The method is used for measuring the inclination of cylindrical and conical buildings. Coordinates of three measuring points in the circumferential direction of sections with different heights are measured, circle center coordinates of the sections with different heights are determined on the basis of a circle center formula, the center line of the building is obtained on the basis of the circle center coordinates, and therefore the inclination degree and the perpendicularity degree of the building are judged, operation is easy,measurement is convenient, and the measurement precision is high.

Owner:SHENZHEN YJY BUILDING TECH

A p-d path planning method for a large-scale intelligent mowing robot

ActiveCN107102643BEasy to generate automaticallyReduce complexityPosition/course control in two dimensionsVehiclesAlgorithmSimulation

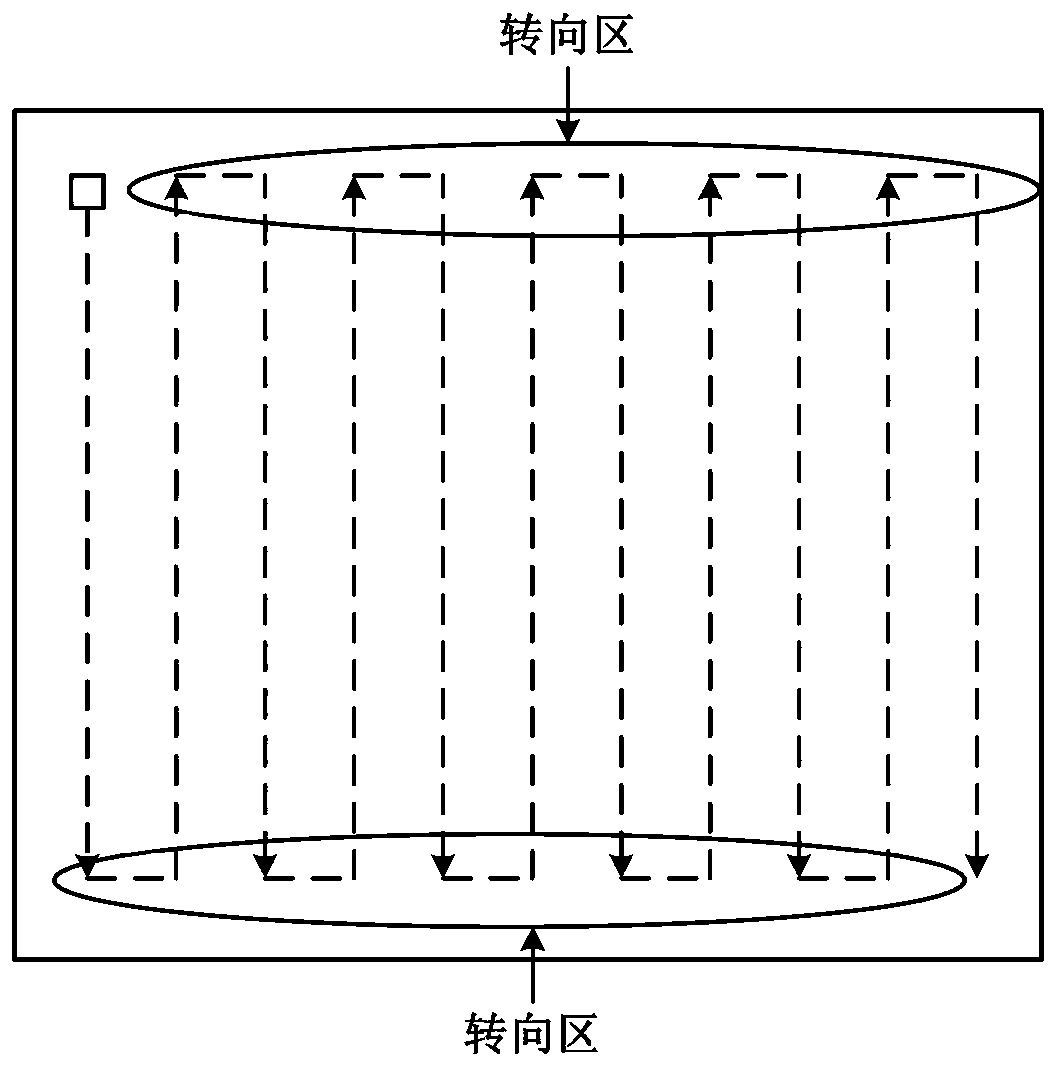

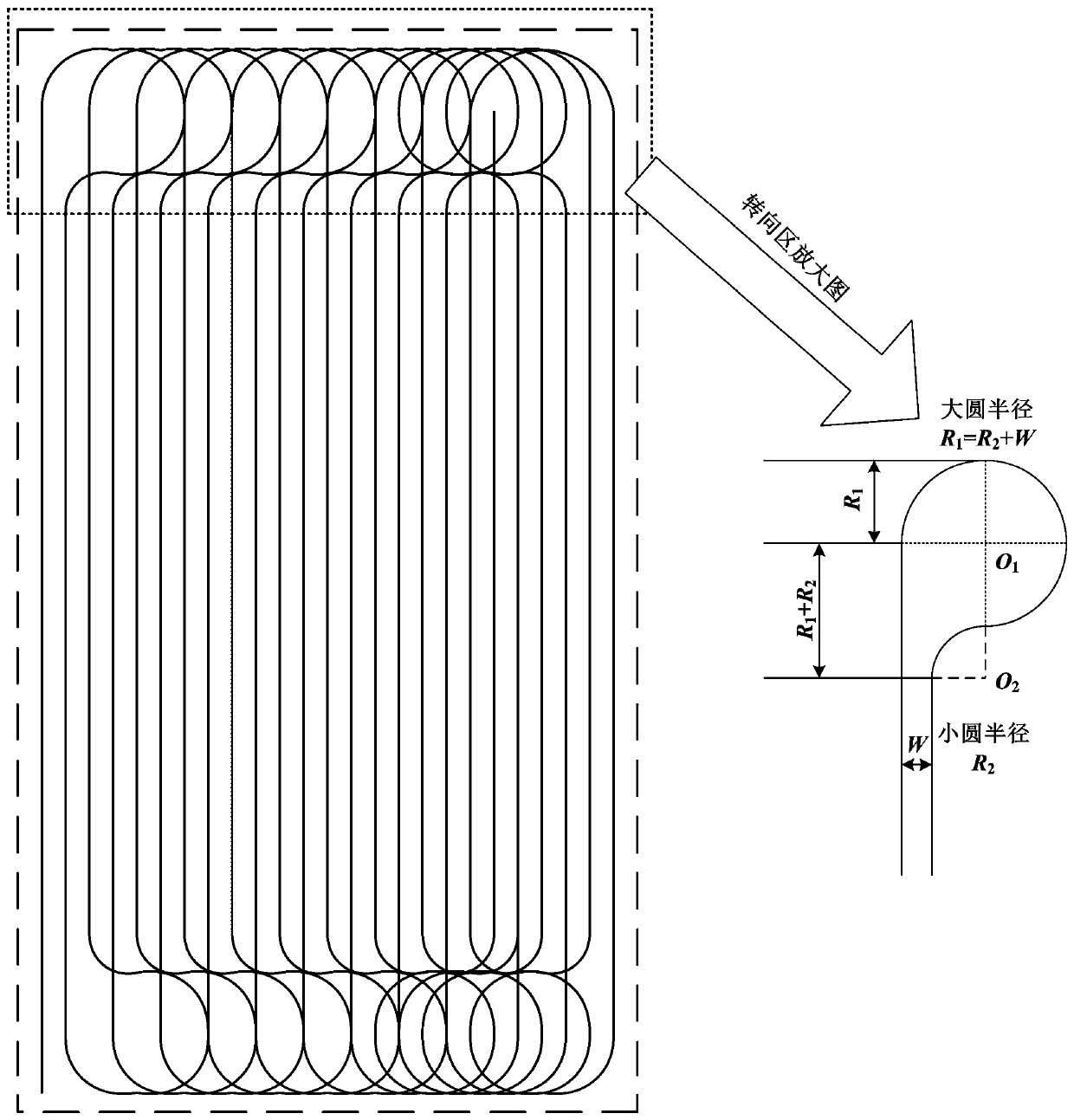

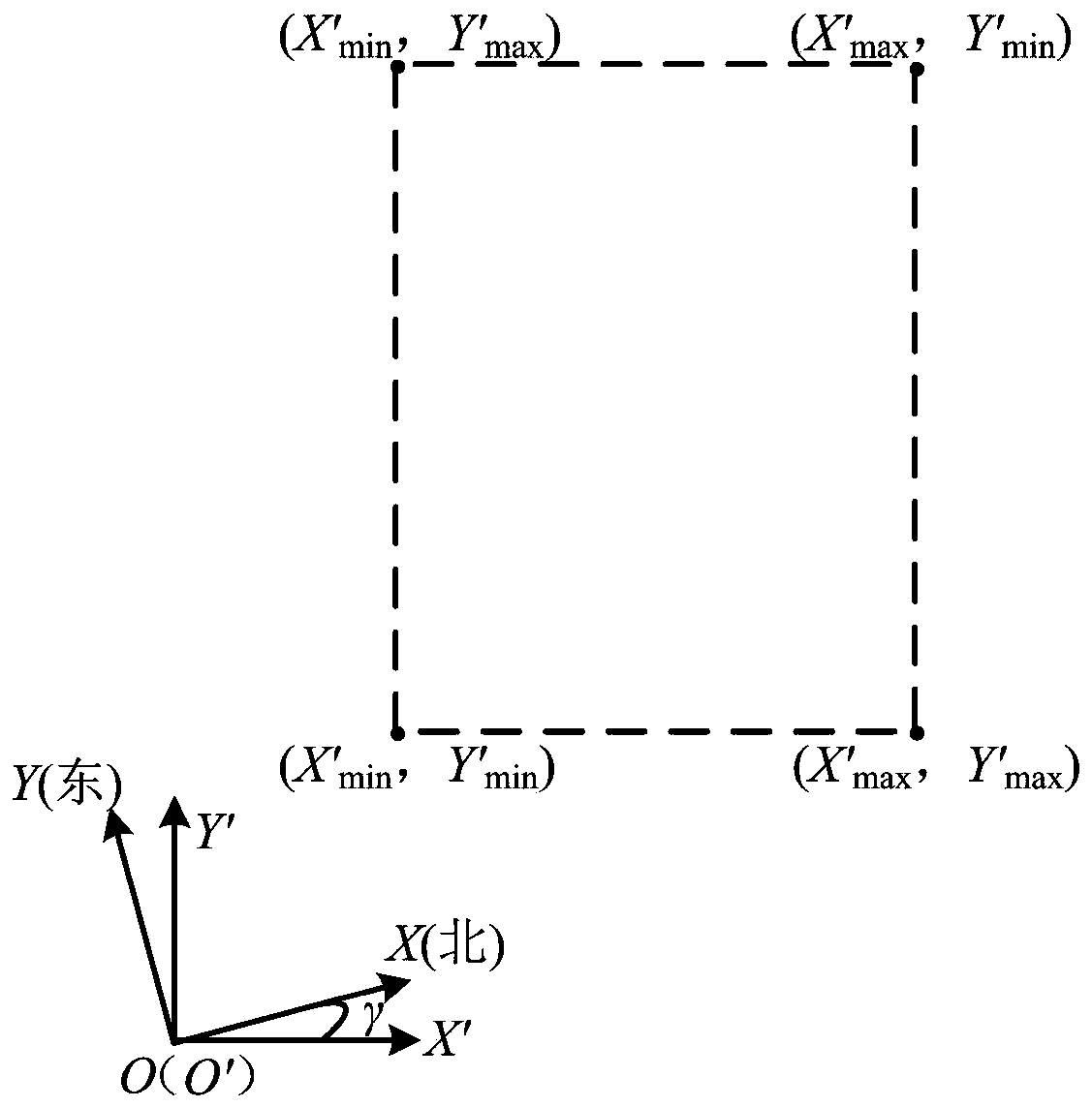

A p‑d path planning method for large-scale intelligent lawn mowing robots, which uses the tangent method of two circles in the turning area instead of the traditional straight-line turning method. According to the geometric size of the area to be cut, the performance indicators of the lawn mowing robot and the requirements of the grass coverage rate, , set the radius R of the great circle tangent to the adjacent path 1 , the radius R of the small circle tangent to the adjacent path 2 and the W size of the distance between the center line of the car body and the adjacent path, and then determine a straight line from two points and list the equations. Use the equations to calculate the straight-line paths of the left and right areas to be cut and the large and small circle paths tangent to the adjacent paths. This generates a p‑d path, which not only maintains the advantages of the circuitous path planning algorithm, but also overcomes the shortcomings of the circuitous path algorithm that easily misses cuts in the turning area.

Owner:JIANGXI HONGDU AVIATION IND GRP

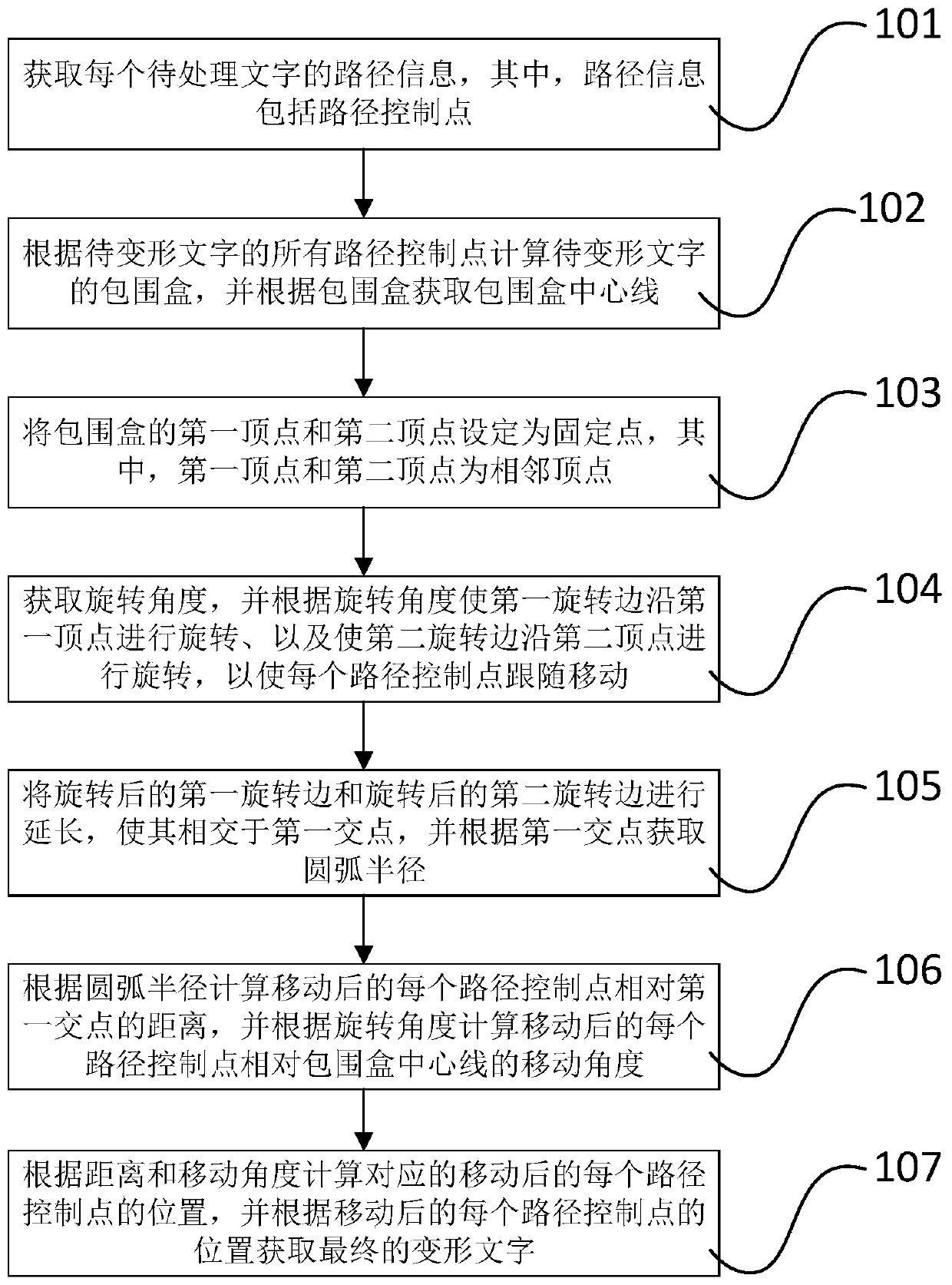

Character bending deformation method, medium, equipment and device

The invention discloses a character bending deformation method and device. The method comprises the steps of: obtaining path information of each to-be-processed character, calculating a bounding box according to a path control point in the path information, and obtaining a center line of the bounding box; setting a first vertex and a second vertex of the bounding box as fixed points; making a first rotation edge rotate along the first vertex and a second rotation edge rotate along the second vertex according to the rotation angle until each path control point follows to move; extending the rotated first rotating edge and the rotated second rotating edge to enable the first rotating edge and the second rotating edge to intersect at a first intersection point, and obtaining an arc radius; calculating the distance of each moved path control point relative to the first intersection point according to the arc radius, and calculating the moving angle of each moved path control point relativeto the center line of the bounding box according to the rotation angle; and calculating the position of each path control point after movement to obtain a final deformed character. Therefore, the controllability of a character bending deformation result is greatly improved.

Owner:GAODING XIAMEN TECH CO LTD

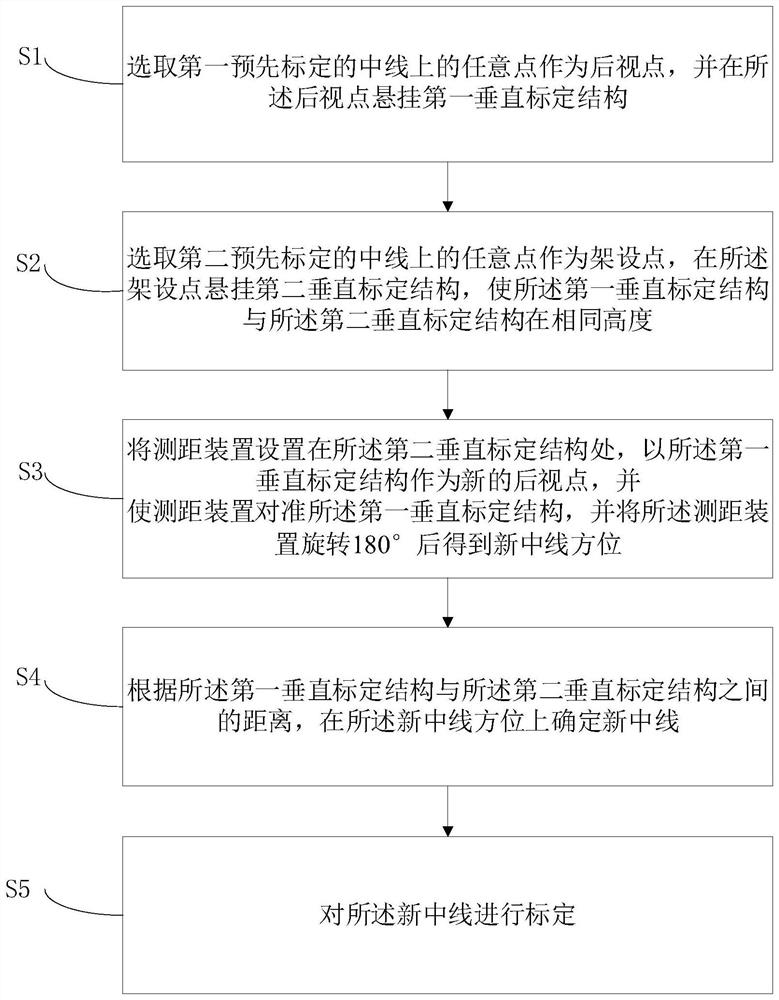

Center line calibration method for underground linear roadway

PendingCN112556664AShorten the timeReduced measurement processSurveying instrumentsEngineeringMechanical engineering

The invention provides a center line calibration method for an underground straight roadway, which comprises the following steps of: selecting any point on a first pre-calibrated center line as a rearview point, and suspending a first vertical calibration structure at the rear view point; selecting any point on a second pre-calibrated center line as an erection point, and suspending a second vertical calibration structure at the erection point; arranging a distance measuring device at the second vertical calibration structure, taking the first vertical calibration structure as a new rear viewpoint, enabling the distance measuring device to be aligned with the first vertical calibration structure, and rotating the distance measuring device by 180 degrees to obtain a new central line orientation; determining a new center line in the direction of the new center line according to the distance between the first vertical calibration structure and the second vertical calibration structure;and calibrating the new center line. The invention can solve the problems that at least two station instruments need to be erected, the measurement process is complicated, the working efficiency is low and the like in the process of carrying out center line calibration on a long-distance linear roadway in the prior art.

Owner:CHINA HUAYE GROUP

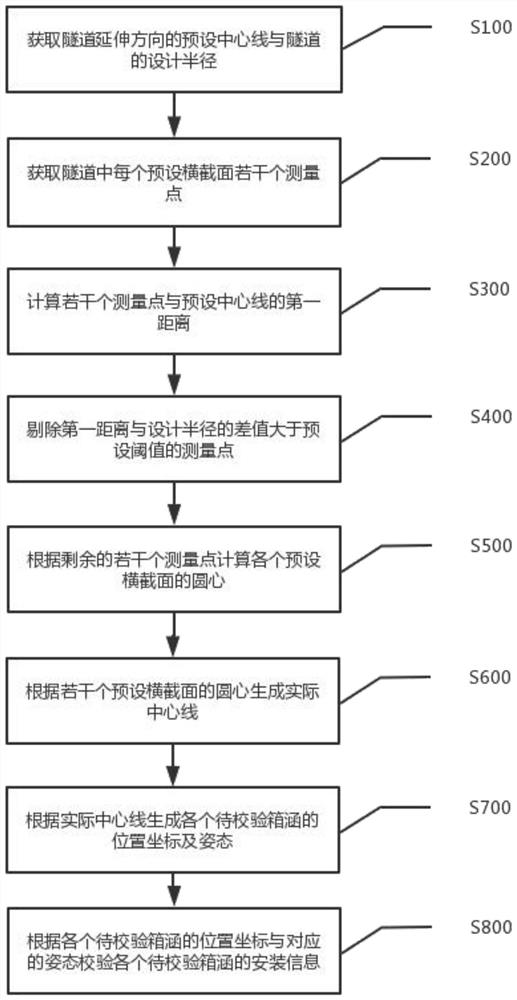

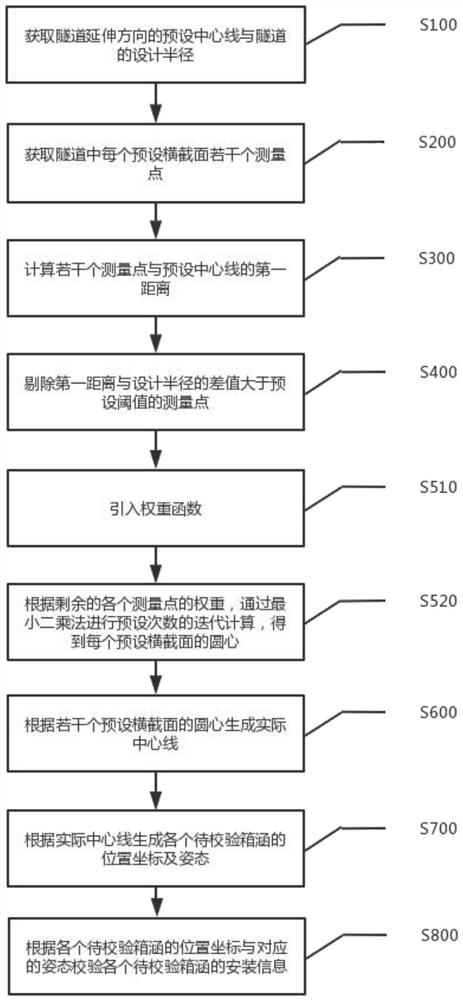

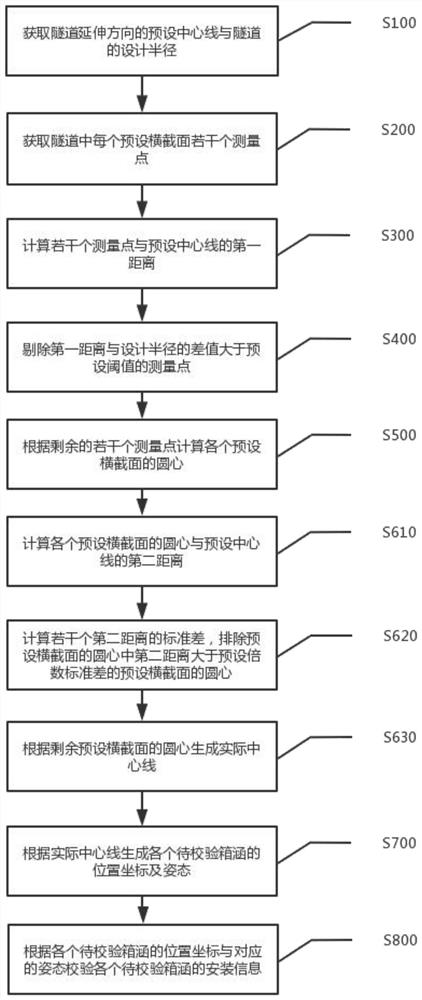

Fine adjustment measurement method, system and equipment for box culvert in tunnel and storage medium

PendingCN114387215AHigh precisionImprove efficiencyImage enhancementImage analysisControl theoryMechanical engineering

The invention discloses a fine adjustment measurement method, system and device for box culverts in a tunnel and a storage medium, and the method comprises a plurality of to-be-verified box culverts installed in the tunnel, and also comprises the steps: obtaining a preset center line in the extension direction of the tunnel and the design radius of the tunnel; acquiring a plurality of measurement points on each preset cross section in the tunnel; calculating a first distance between the plurality of measuring points and a preset center line; eliminating the measurement points of which the difference between the first distance and the design radius is greater than a preset threshold value; calculating the circle center of each preset cross section according to the plurality of remaining measurement points; generating an actual center line according to the circle centers of the plurality of preset cross sections; generating position coordinates and postures of the to-be-verified box culverts according to the actual center lines; and verifying the installation information of each box culvert to be verified according to the position coordinate of each box culvert to be verified and the corresponding attitude. The actual center line of the tunnel can be generated, and the accuracy and efficiency of position information verification of the box culvert in the tunnel are improved.

Owner:力信测量(上海)有限公司 +1

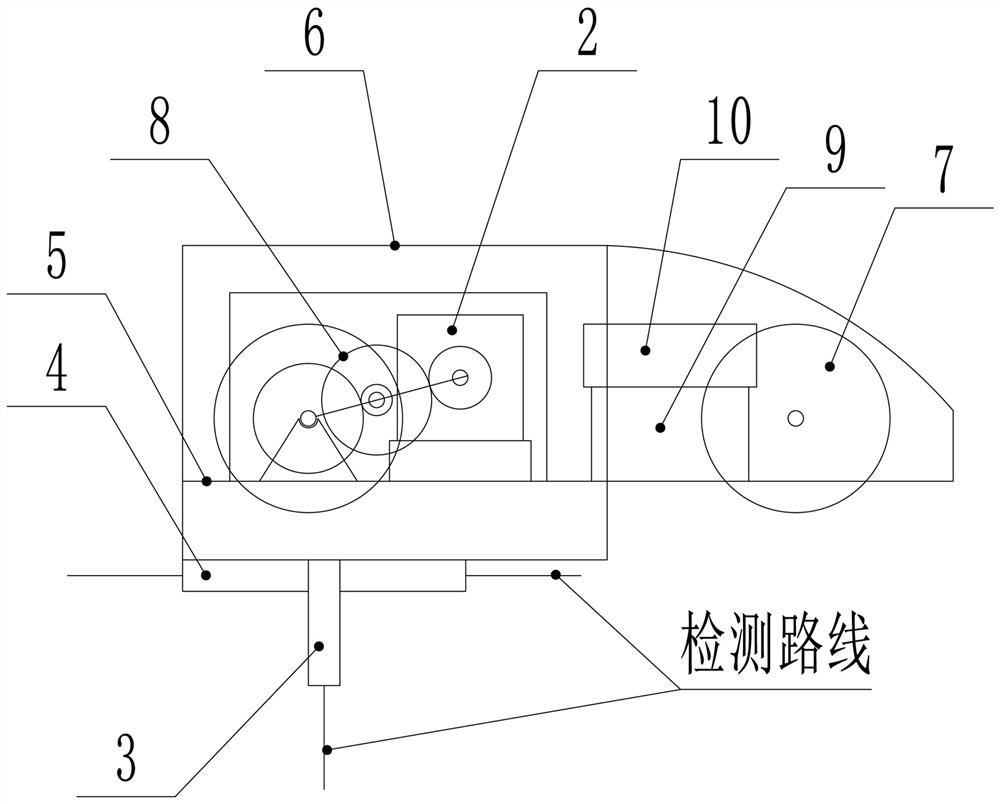

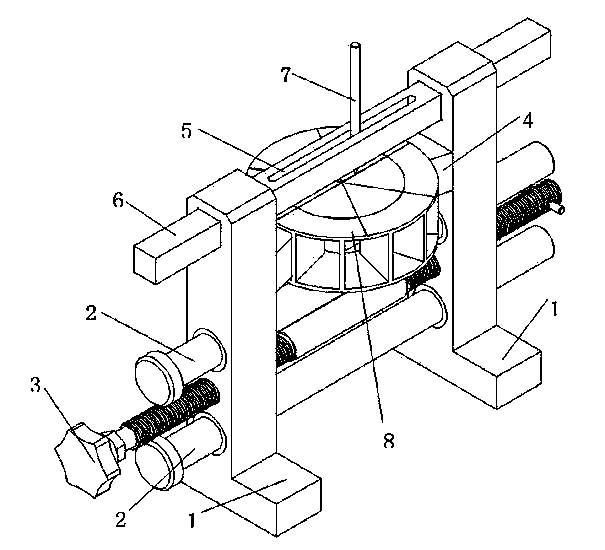

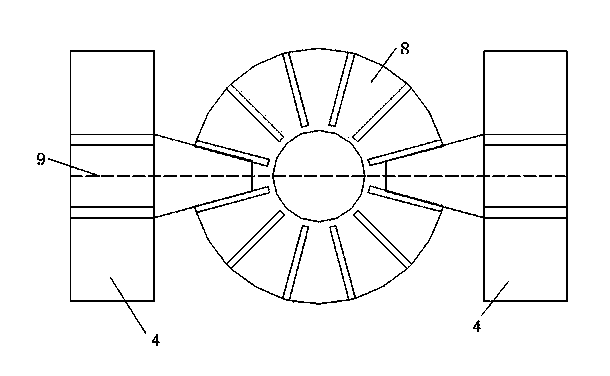

Method and apparatus for determining center of casting impeller

The invention discloses a method and an apparatus for determining the center of a casting impeller. The apparatus comprises two supports (1), and guide bars (2) horizontally penetrate through the two supports (1). An adjustment screw (3) is arranged to pass through the supports (1) in the middle. A movable wedge block (4) cooperating with a work piece (8) is disposed on the upper part of each support (1), and a cross bar (6) horizontally passing through the two supports is arranged above the wedge blocks (4). A central reference slot (5) is arranged in the cross bar (6), and a marking needle (7) can slide to the left and the right in the central reference slot (5). A plurality of theoretical central lines are marked on a casting impeller by means of the marking needle. Intersection points of the plurality of theoretical central lines form an intersection point zone, and a point in the zone is picked as the center of the casting impeller for carrying out subsequent finishing. According to the technical scheme, the number of unqualified products can be minimized, and the yield is maximized.

Owner:NANJING AUTOMOBILE GROUP CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com