Fine adjustment measurement method, system and equipment for box culvert in tunnel and storage medium

A measurement method and technology in the tunnel, which is applied in image analysis, image enhancement, instruments, etc., can solve the problem that the box culvert installation accuracy cannot be considered as a whole and the overall planning of the box culvert installation position and posture, so as to improve accuracy, improve accuracy and efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

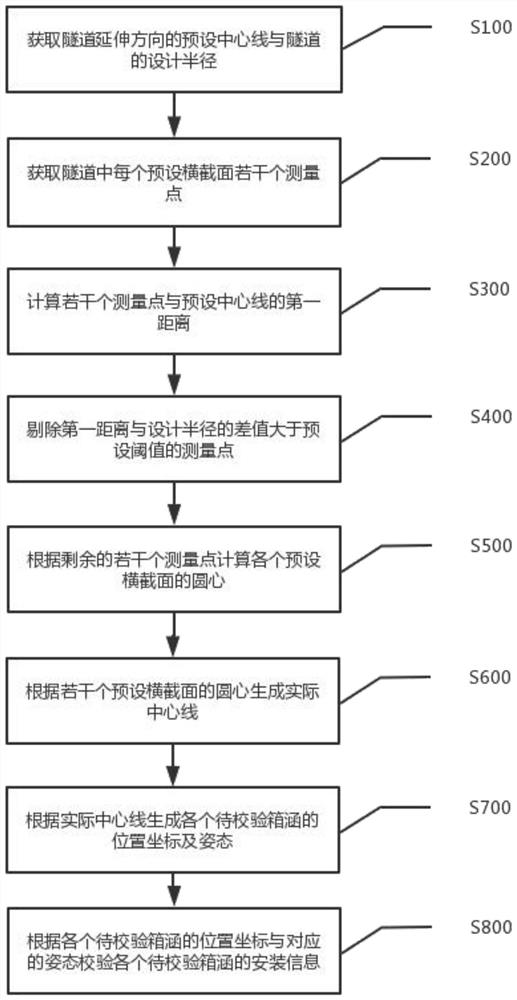

[0071] An embodiment of the present invention, such as figure 1 As shown, the present invention provides a fine-tuning measurement method for box culverts in tunnels, including several box culverts to be checked installed in the tunnel, including steps:

[0072] S100 obtains the preset centerline of the tunnel extension direction and the design radius of the tunnel.

[0073] Specifically, the design centerline at the time of tunnel design and the historical centerline measured before are acquired.

[0074] S200 acquires several measurement points on each preset cross-section in the tunnel.

[0075] Specifically, the preset cross-section refers to taking a tunnel cross-section at every preset distance in the tunnel as the preset cross-section, and the preset distance can be 5 cm, 10 cm, 20 cm and so on. Several measuring points can be acquired on the circular edge of each preset cross-section by means of a scanning mechanism.

[0076] S300 Calculate a first distance between ...

Embodiment 2

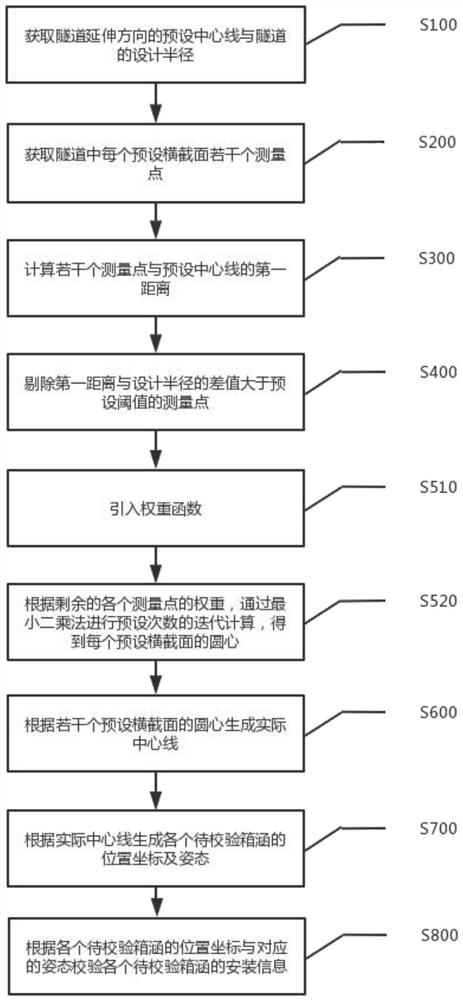

[0091] Based on Example 1, such as figure 2 As shown, the present invention also provides a fine-tuning measurement method for box culverts in tunnels. Step S500 calculates the center of each preset cross-section according to the remaining several measurement points, which is based on the remaining several measurement points through the weighted least squares method. Calculates the center of each preset cross section.

[0092] Specifically include steps: S510 introduce a weight function.

[0093] Specifically, the weight function is used to define the weight of several measurement points.

[0094] Exemplarily, the Tukey weight function is introduced, and the specific function is as follows:

[0095]

[0096] Where γ is a clipping function, which defines which measurement points are outlier measurement points.

[0097] S520 , according to the weights of the remaining measurement points, perform a predetermined number of iterative calculations by the least square method t...

Embodiment 3

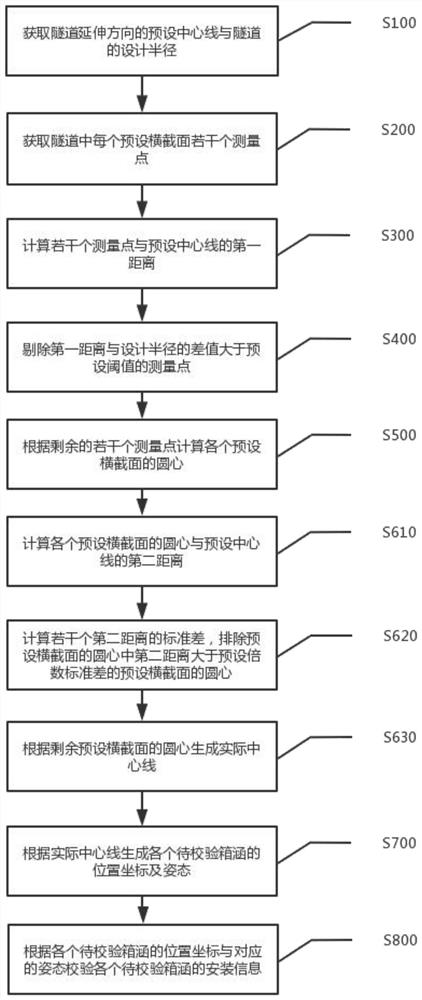

[0107] Based on any one of embodiments 1 to 2, such as image 3 As shown, the present invention also provides a fine-tuning measurement method for box culverts in tunnels. Step S600 generates actual centerlines according to the centers of several preset cross-sections, specifically including:

[0108] S610 Calculate a second distance between the centers of the several preset cross-sections and the preset centerline.

[0109]S620 Calculate standard deviations of a plurality of second distances, excluding circle centers of preset cross sections whose second distance is greater than a preset multiple standard deviation.

[0110] Exemplarily, the preset multiple may be double, triple or quadruple, and so on. Usually, the center of the circle when the distance is judged to be greater than three times the standard deviation is the error amount, and the error amount should be eliminated when the center line is obtained according to the center of the circle before calculation.

[01...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com