Patents

Literature

1173 results about "Tunnel boring machine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

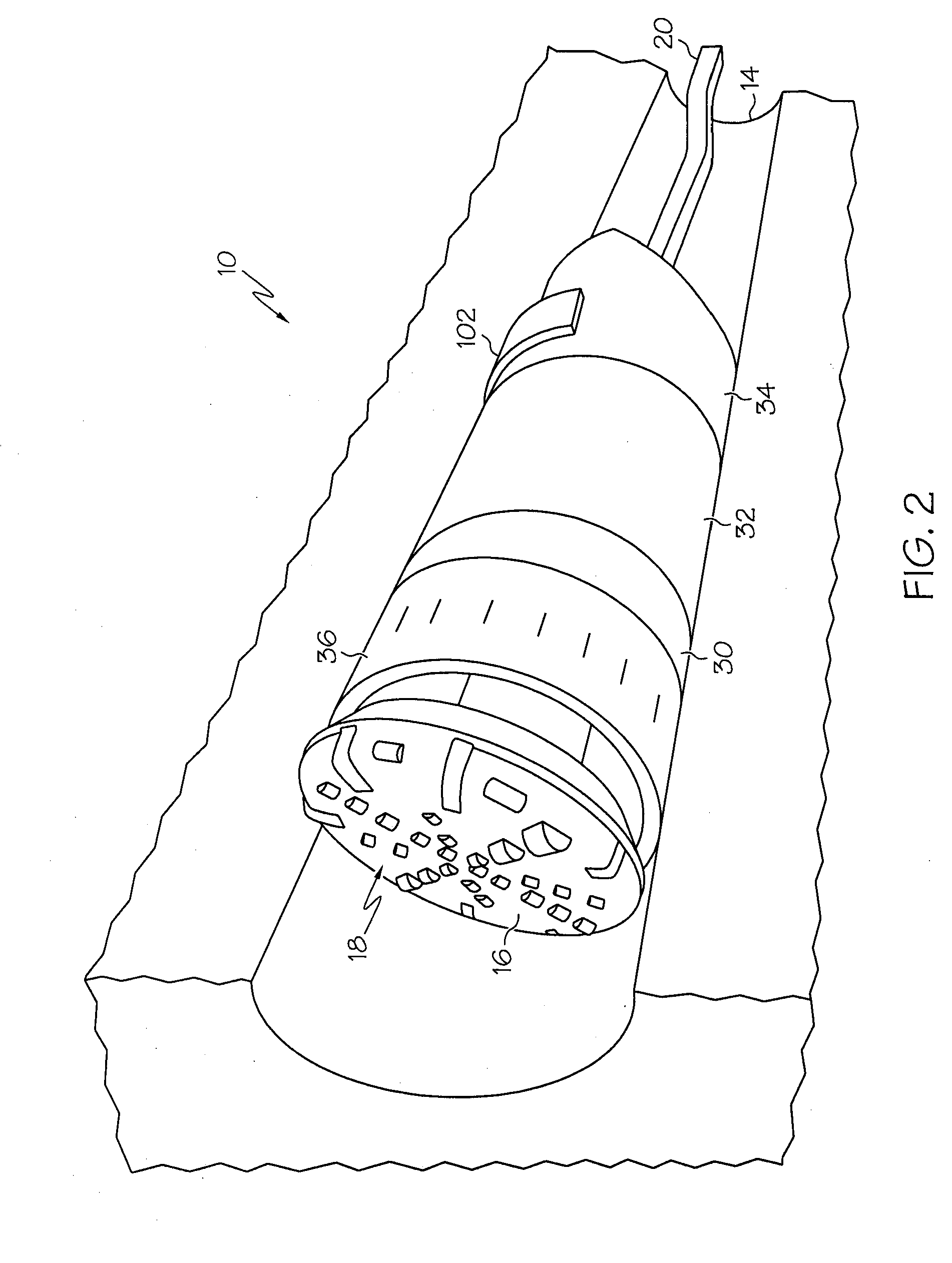

A tunnel boring machine (TBM), also known as a "mole", is a machine used to excavate tunnels with a circular cross section through a variety of soil and rock strata.They may also be used for microtunneling.They can bore through anything from hard rock to sand.Tunnel diameters can range from one metre (3.3 ft) (done with micro-TBMs) to 17.6 metres (58 ft) to date.

Abrasion detecting apparatus detecting abrasion of component of cutter head and tunnel boring machine including abrasion detecting apparatus

ActiveUS20110031017A1Efficient executionLabor savingEarth drilling toolsSurveyTunnel boring machineEngineering

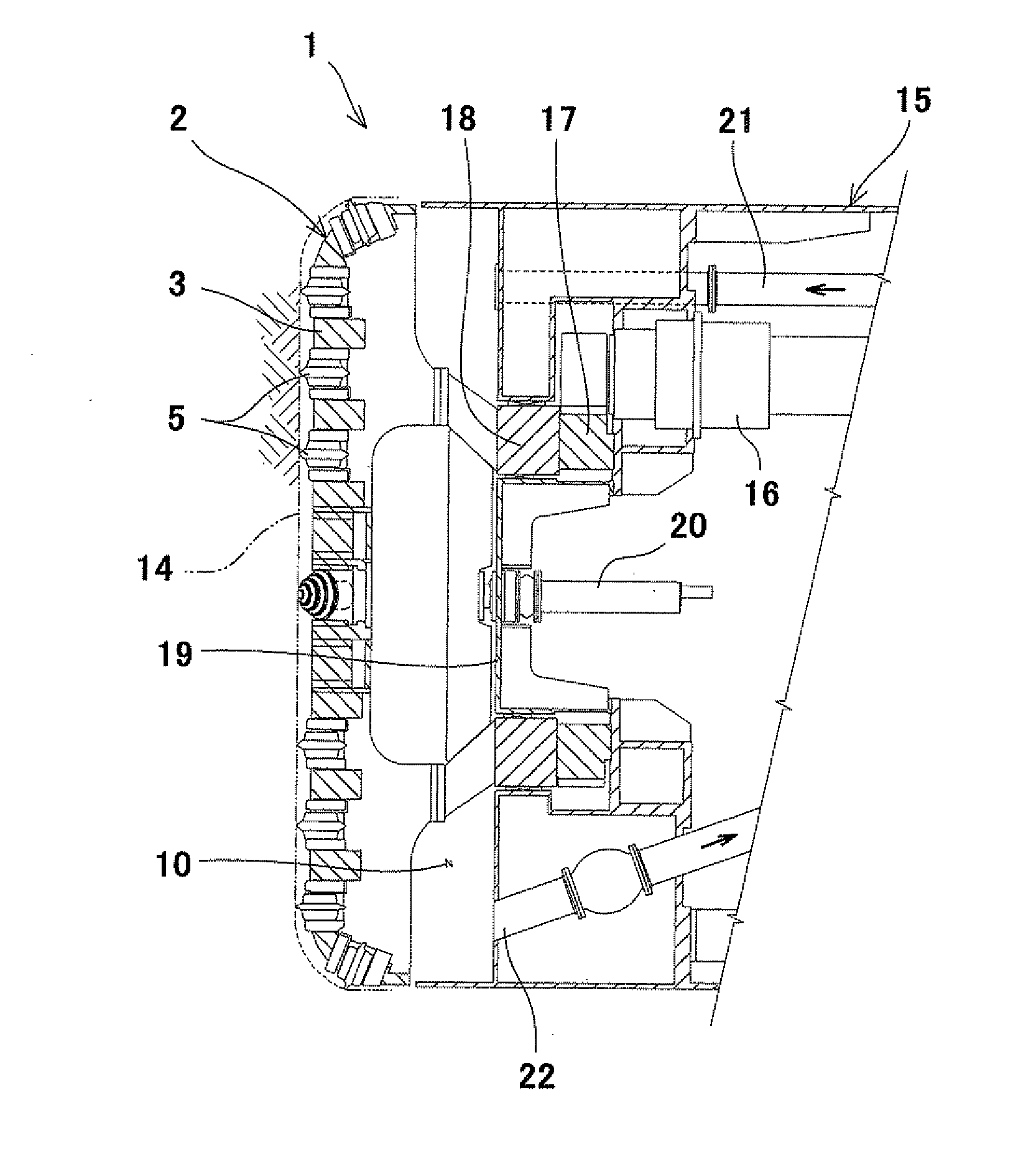

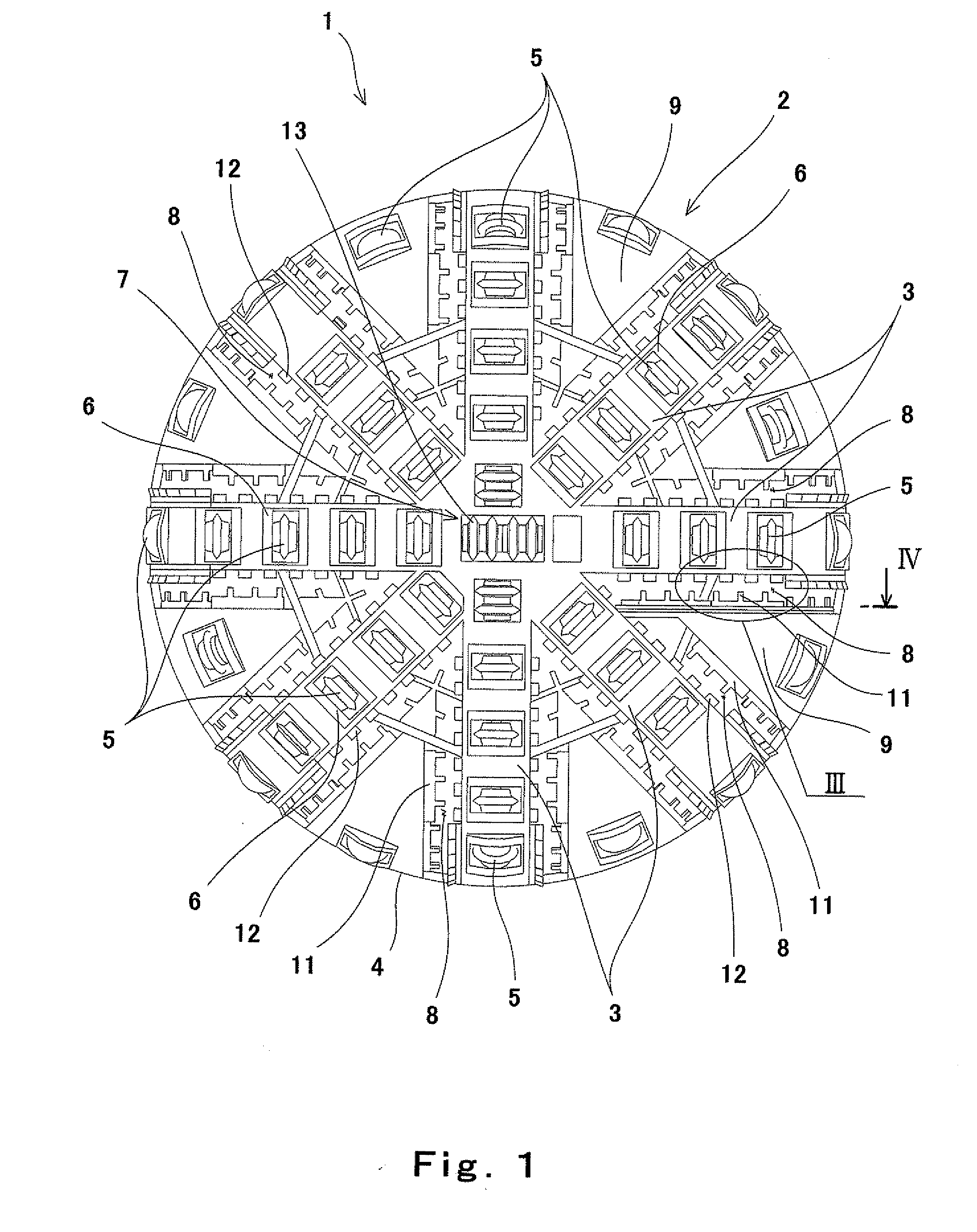

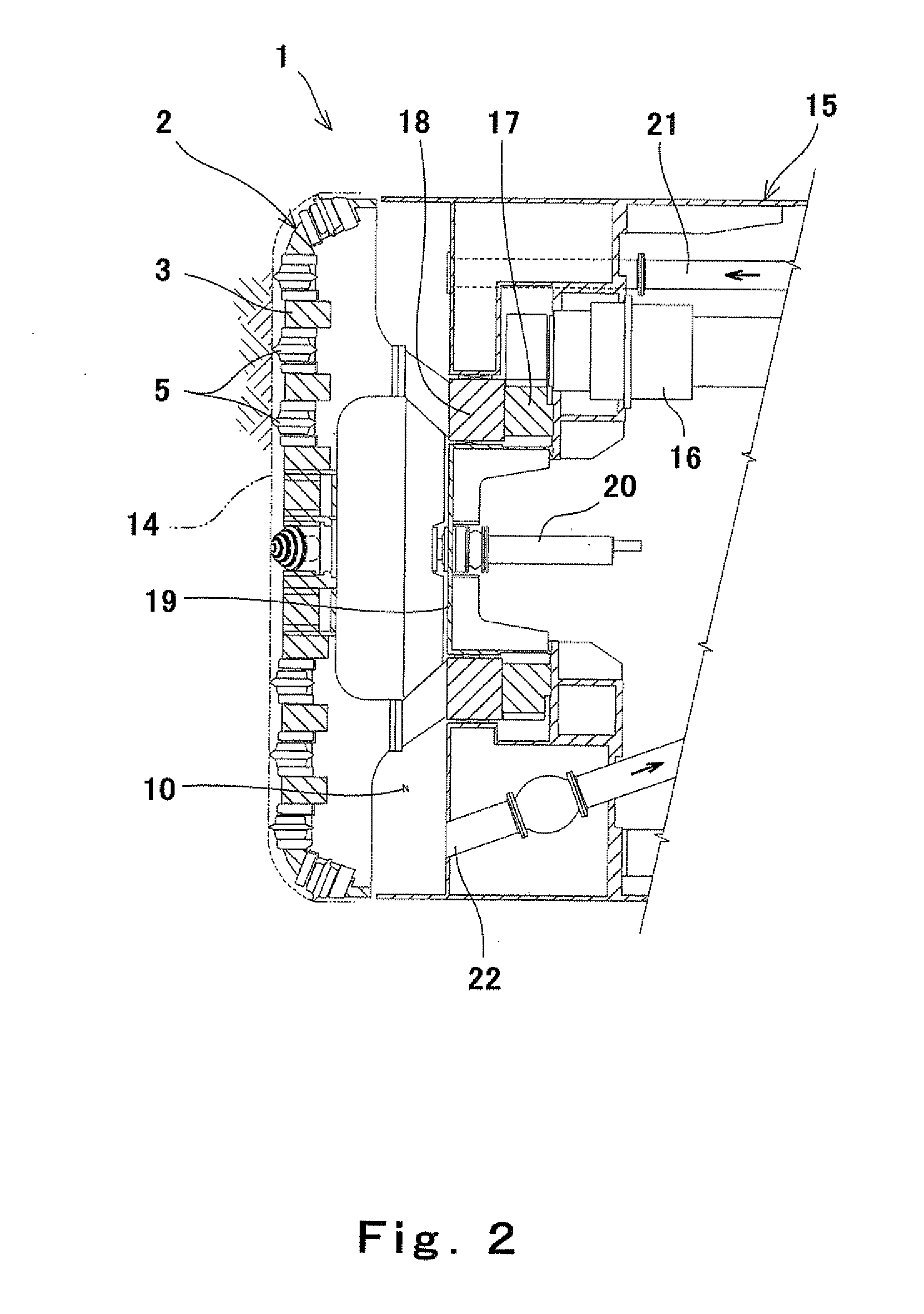

An abrasion detecting apparatus is configured to detect an abrasion of a component of a cutter head of a tunnel boring machine configured to excavate a ground using a cutter to bore a tunnel, the abrasion detecting apparatus including: an abrasion detection probe located rearward of a front end of the cutter by a certain distance and located forward or rearward of a front end of a component, whose abrasion needs to be detected, of the cutter head by a certain distance, the abrasion detection probe including an abrasion detecting portion at a front end portion thereof, the abrasion detecting portion abrading away by contact with the ground to be excavated; and a detecting device configured to detect an abrasion of the abrasion detecting portion.

Owner:UNDERGROUND INFRASTRUCTURE TECH CORP

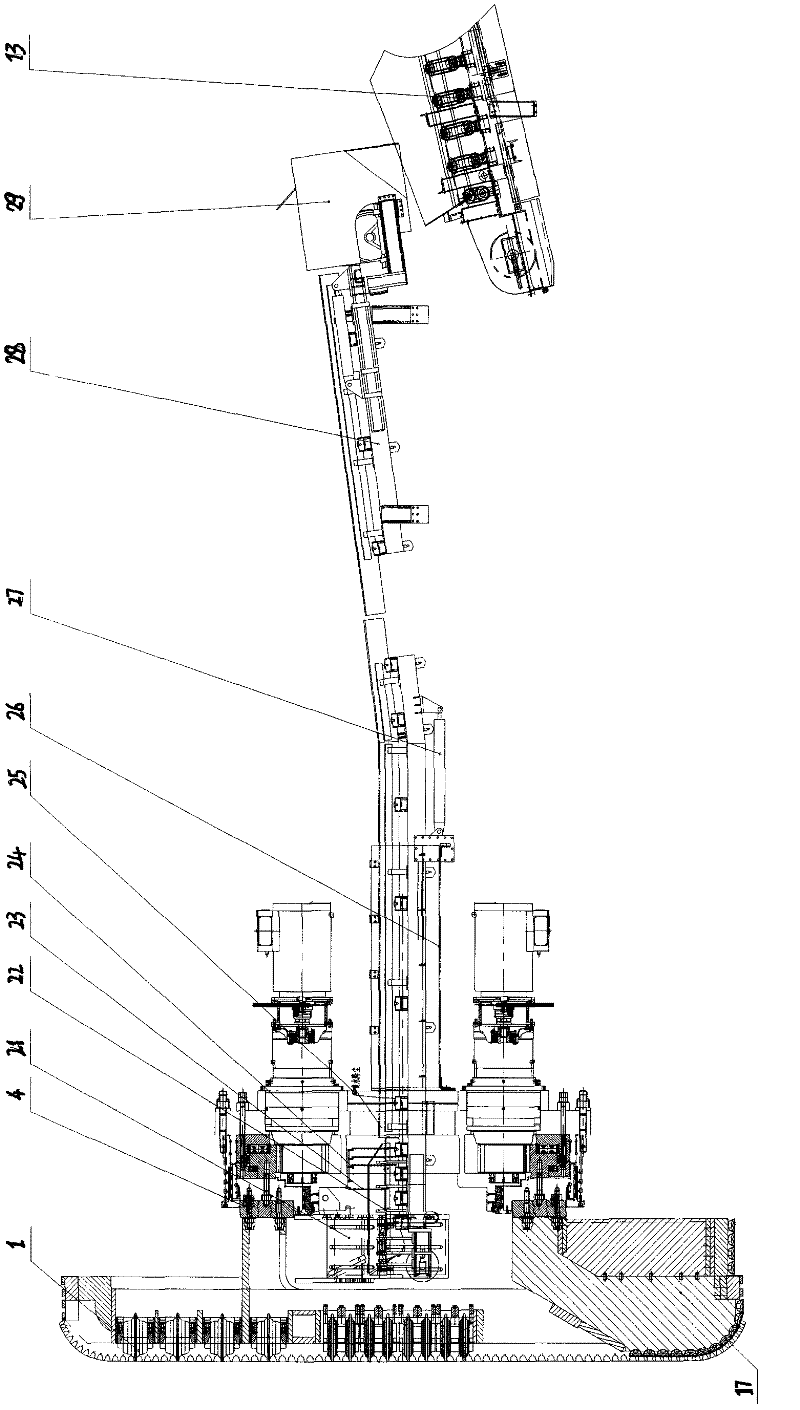

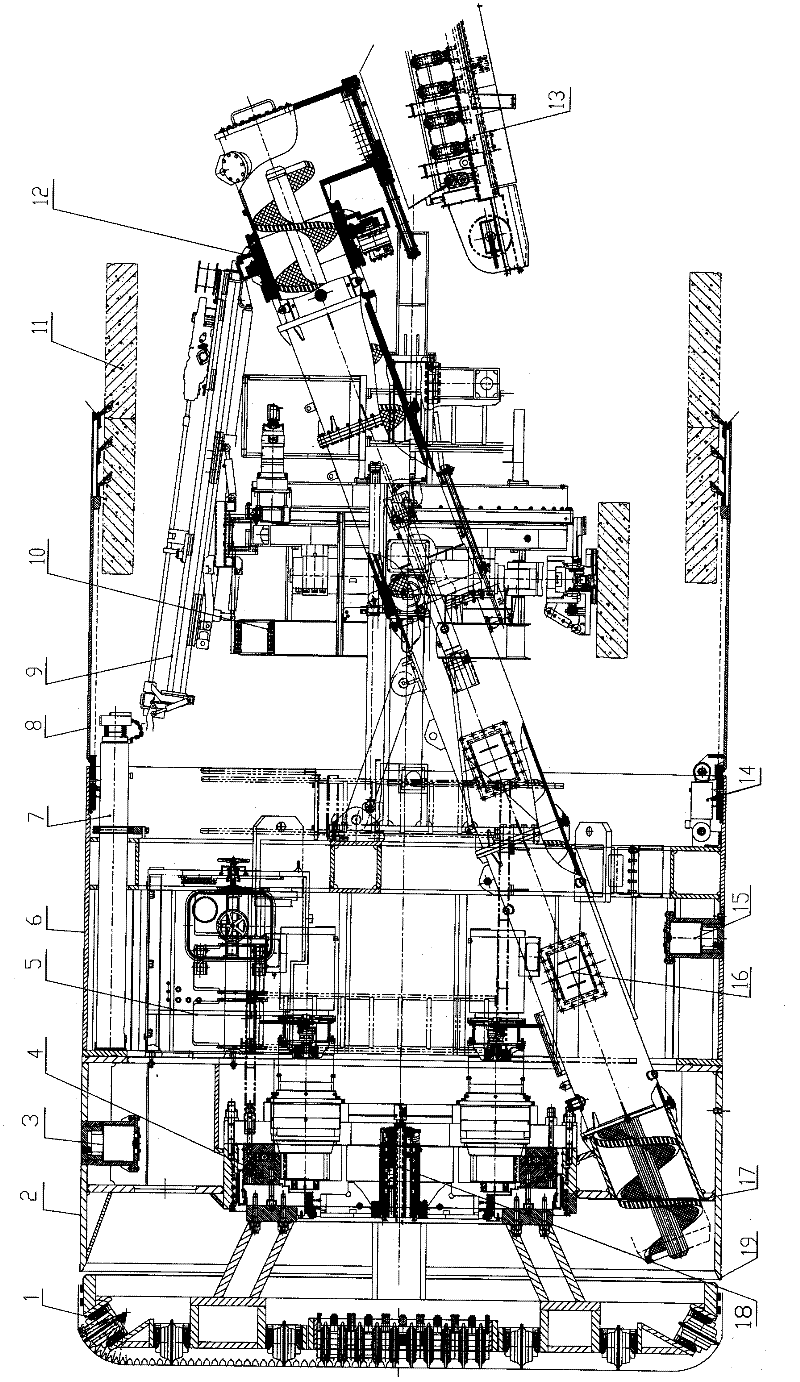

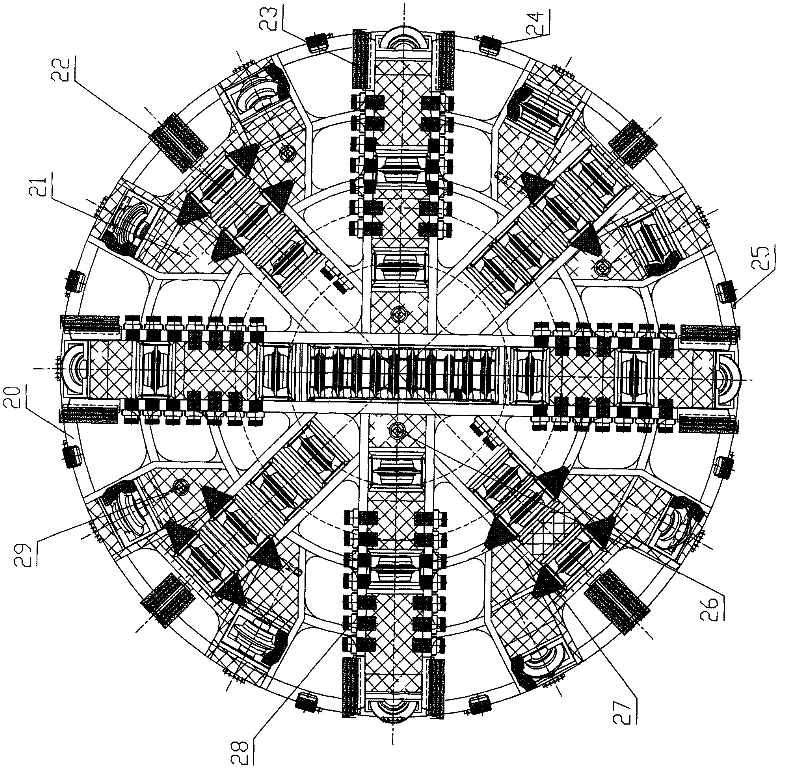

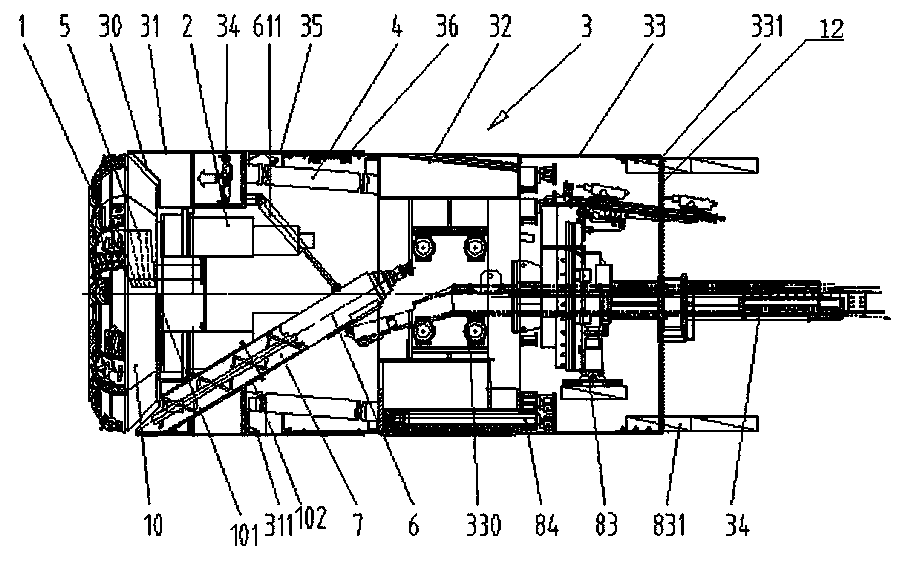

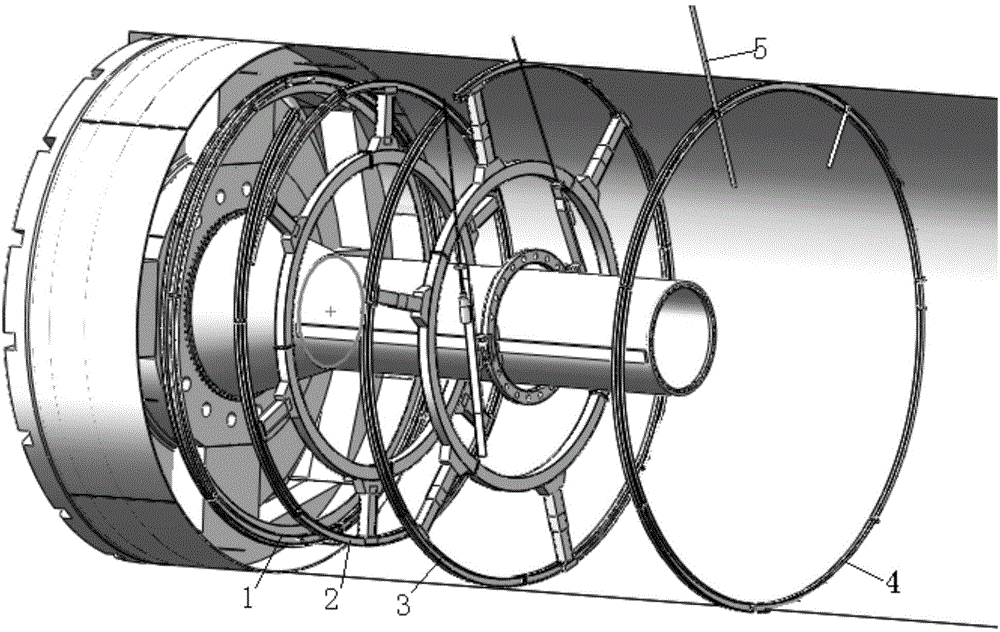

Novel dual-mode TBM (tunnel boring machine) and control method thereof

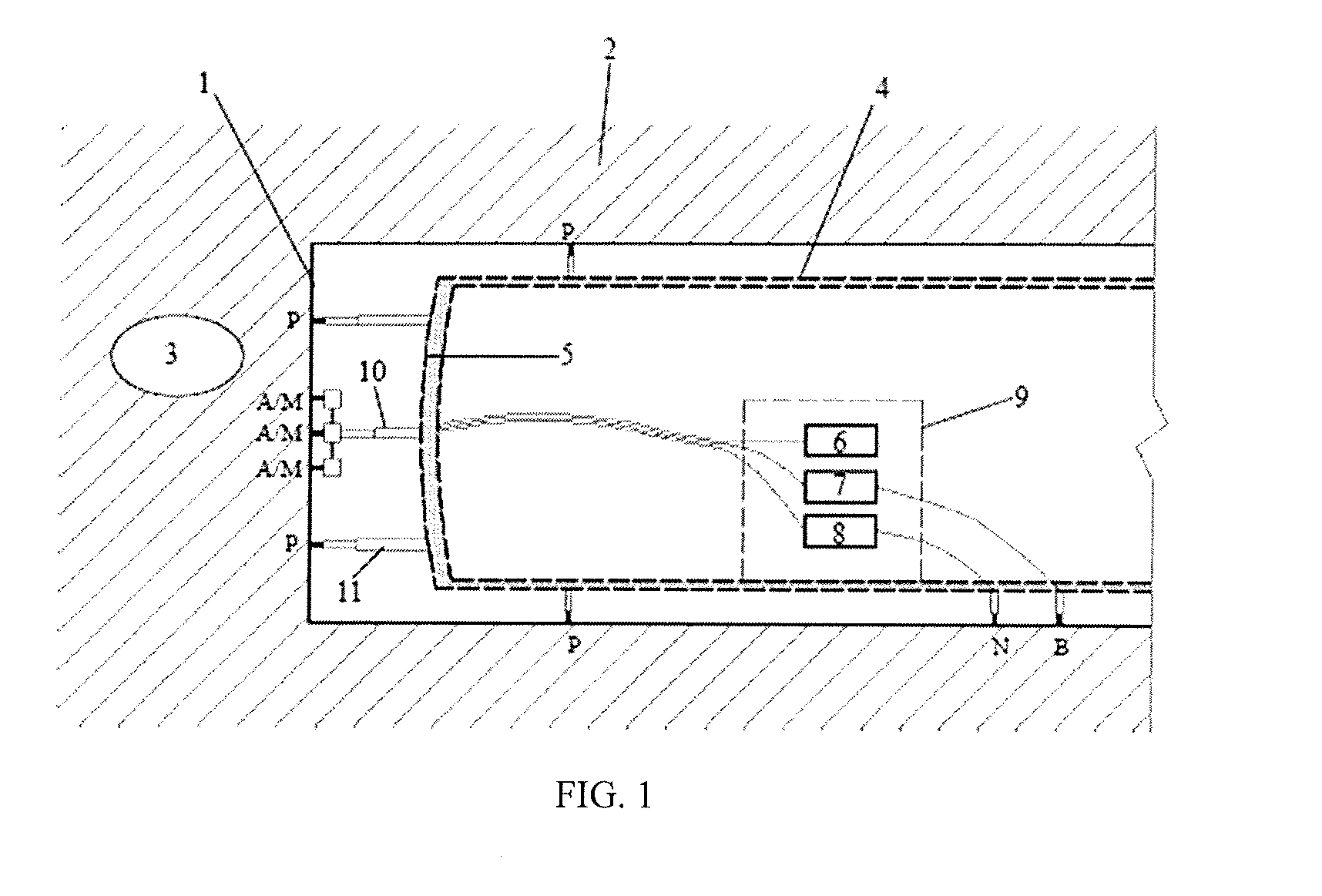

ActiveCN102410027AOvercome usabilityWith excavation face balancing functionUnderground chambersTunnel liningDual modeEngineering

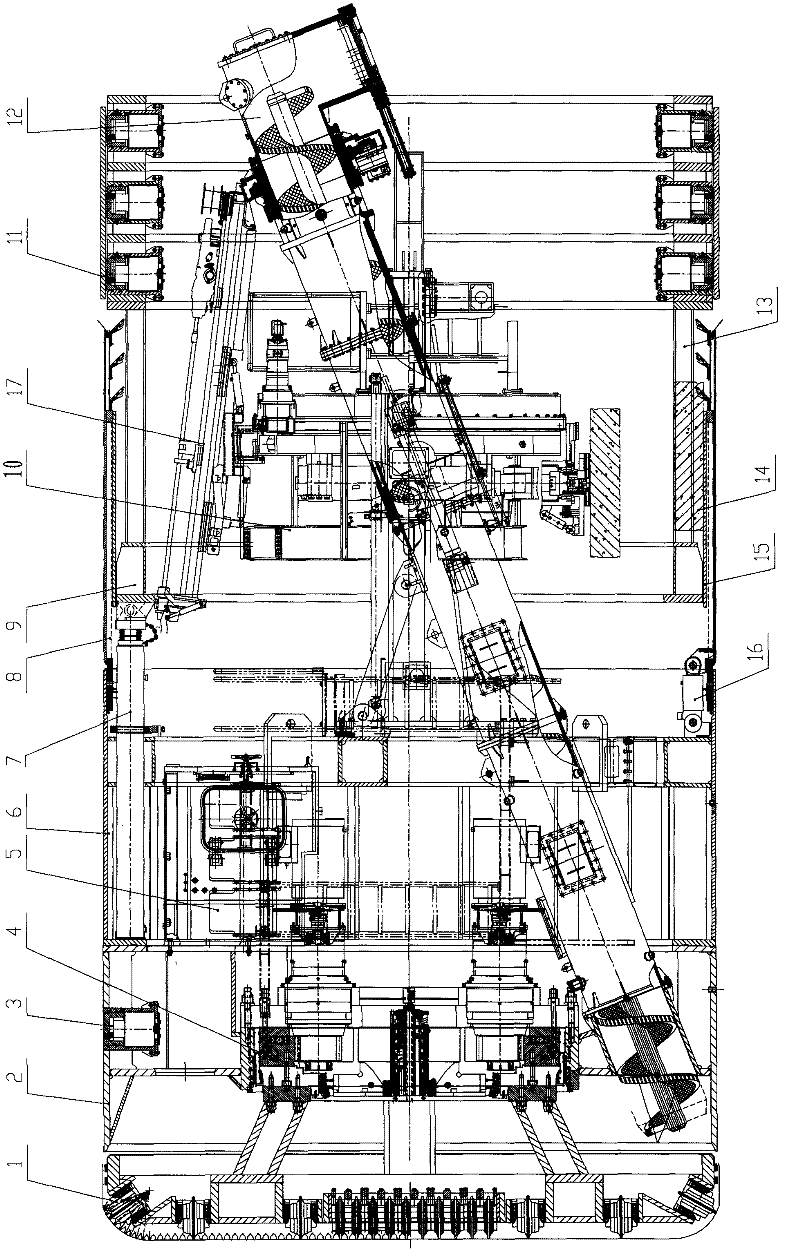

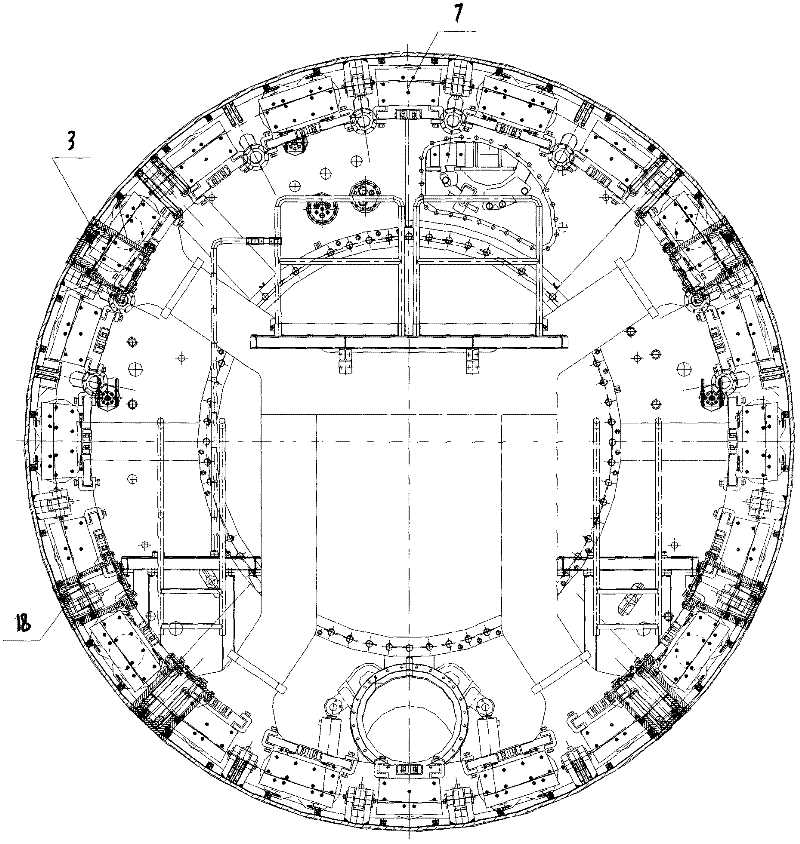

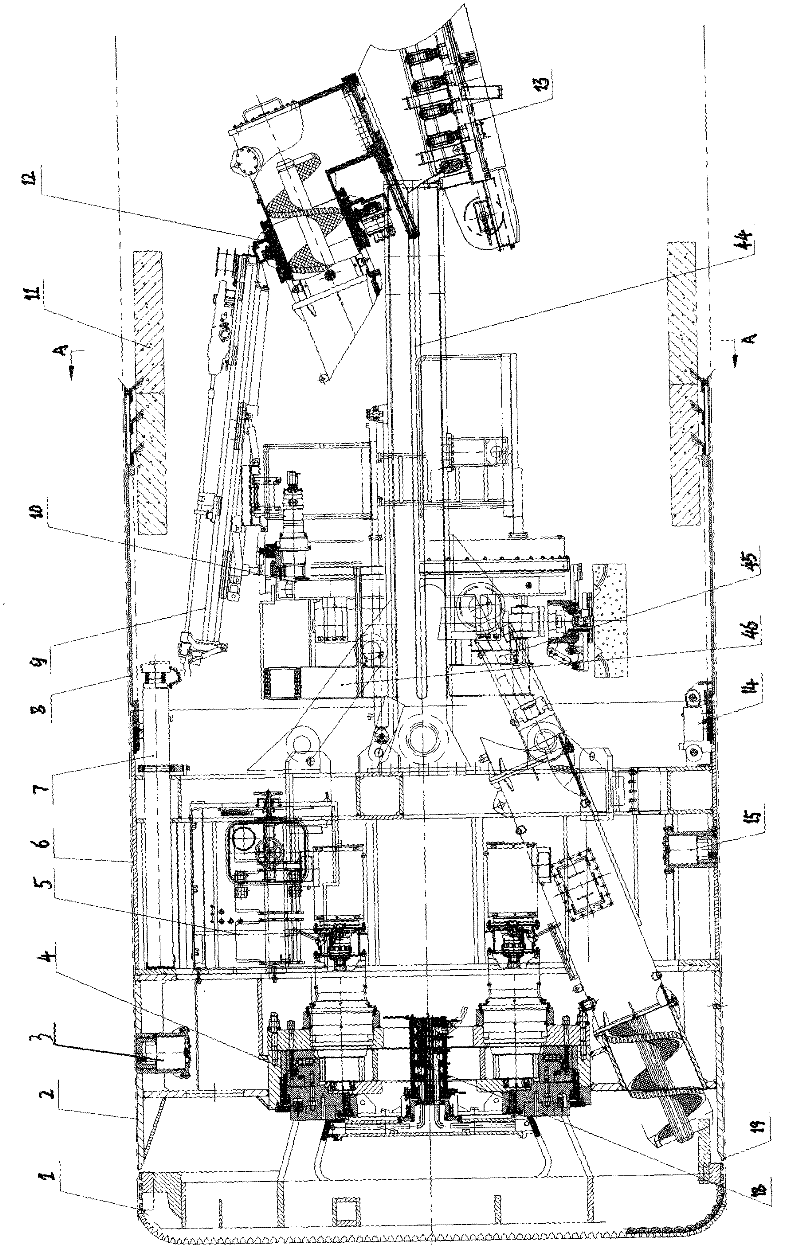

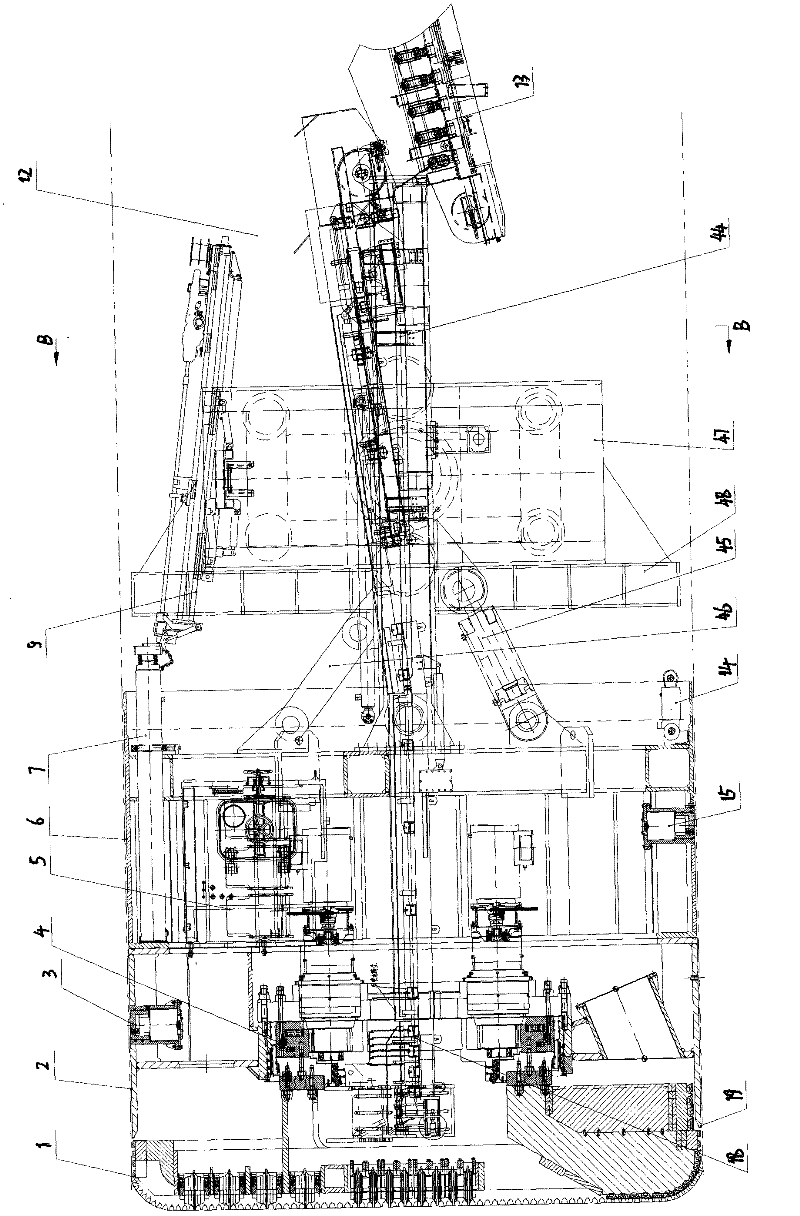

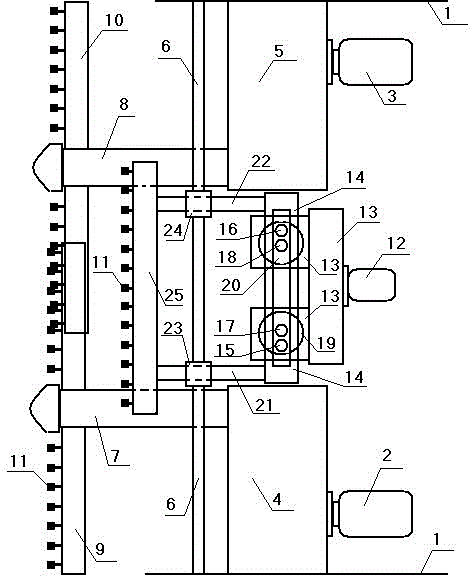

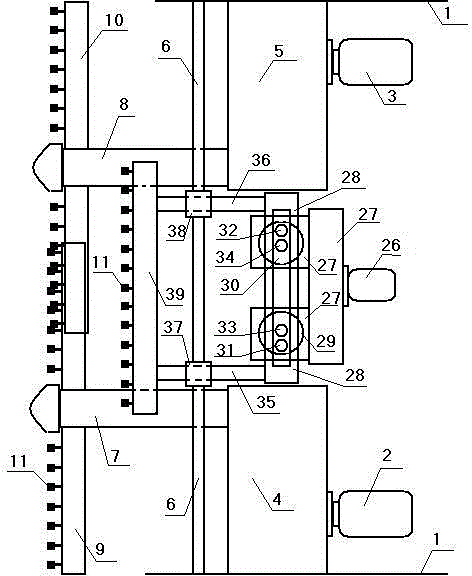

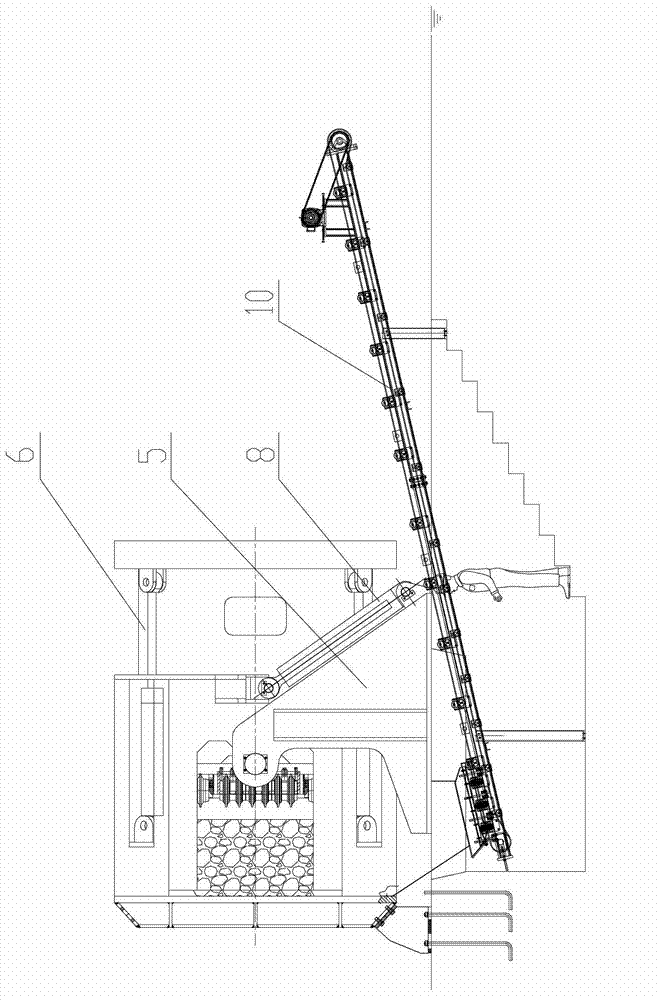

The invention discloses a novel dual-mode TBM (tunnel boring machine) and a control method thereof used for the field of tunnel shield and TBM construction. Two tunneling modes can be realized by the equipment. An EPB (Earth Pressure Balance) tunnel shield mode of soft rock tunneling is utilized when an excavated surface cannot be autostable; and a TBM mode of hard rock tunneling is utilized when the excavated surface is good in autostability; and the two modes are converted easily. According to the novel dual-mode TBM and the control method thereof disclosed by the invention, the problems that the traditional earth pressure balance tunnel shield is of limited use in encountering a complex rock soil stratum, the TBM does not adapt to a soft soil stratum and the like are solved; the two tunneling modes of hard rock and soft soil are realized, the advantages of two tunnel support technologies of segment erection and hole wall support are combined; the novel mixing type TBM which is integrated with a hard rock tunneler technology and a soft soil tunnel shield technology not only has a hard rock quick tunneling function but also has an excavated surface balancing function, so that the tunnel shield technology and the TBM technology are mutually integrated, the geological adaptation range of the equipment is broadened, the single tunneling equipment has wider geological adaptability, can effectively reduce the construction risk and is simple to operate and low in cost.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

Mixed TBM (Tunnel Boring Machine) with multiple-boring mode and tunnel supporting mode

ActiveCN102383805AControl face stabilityEnsure construction safetyTunnelsSludgeTunnel boring machine

The invention discloses tunnel construction equipment, in particular a mixed TBM (Tunnel Boring Machine) with a multiple-boring mode, which is suitable for sludge, clay, sand, grit, decomposed rock, hard rock and composite transition stratum. According to the invention, three modes of an earth pressure balance mode, a shield open mode and a TBM mode are adopted for construction according to different stratum geological conditions and construction tunnel supporting requirements; a deslagging mode is that a spiral conveyer or a TBM belt conveyor is adopted for deslagging; and simultaneously, a supporting mode can adopt a finned-tube lining or flexible post-supporting mode. The mixed TBM disclosed by the invention has very strong geological adaptability, is especially suitable for soft, hard and complex stratal construction of a mains underground engineering, and simultaneously, has the advantages that the whole machine has low manufacture cost, the mode conversion is relatively simple, the interference to mating construction is small, the control is convenient, the equipment manufacture cost is low, the economic property and practicability are achieved, and the use requirements of the flexible supporting mode of the construction can be met.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

Hard rock composite TBM (Tunnel Boring Machine) suitable for composite stratum and tunneling mode thereof

ActiveCN102364049AOvercome the shortcomings of limited use and the inability of TBM to be used in soft soil formationsWith excavation face balancing functionUnderground chambersTunnel liningGeomorphologyTunnel boring machine

The invention discloses hard rock shield construction equipment which is suitable for a single stratum of soft soil, soft rock, hard rock and the like and is simultaneously suitable for a soft and hard alternate stratum and a transition stratum, particularly silt, clay, powder, sand, gravel, decayed rock stratum. In the invention, two tunneling modes can be realized: an earth pressure balance tunneling mode and an open tunneling mode. When an excavated surface has poor stability or soft soil, a sand stratum and a sand gravel stratum with high water content are excavated, the earth pressure balance tunneling mode is used for construction; and when surrounding rock of the excavated surface can be self-stabilized, the open mode is used for construction when the rock stratum has high stability, particularly, a composite cutter head is used for tunneling. The equipment has extremely strong geological adaptability, is particularly suitable for construction of a soft and hard complex stratum of a municipal metro, and also has low construction interference and is convenient to control; and the overall manufacturing cost is greatly reduced compared with a hard rock tunneling machine.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

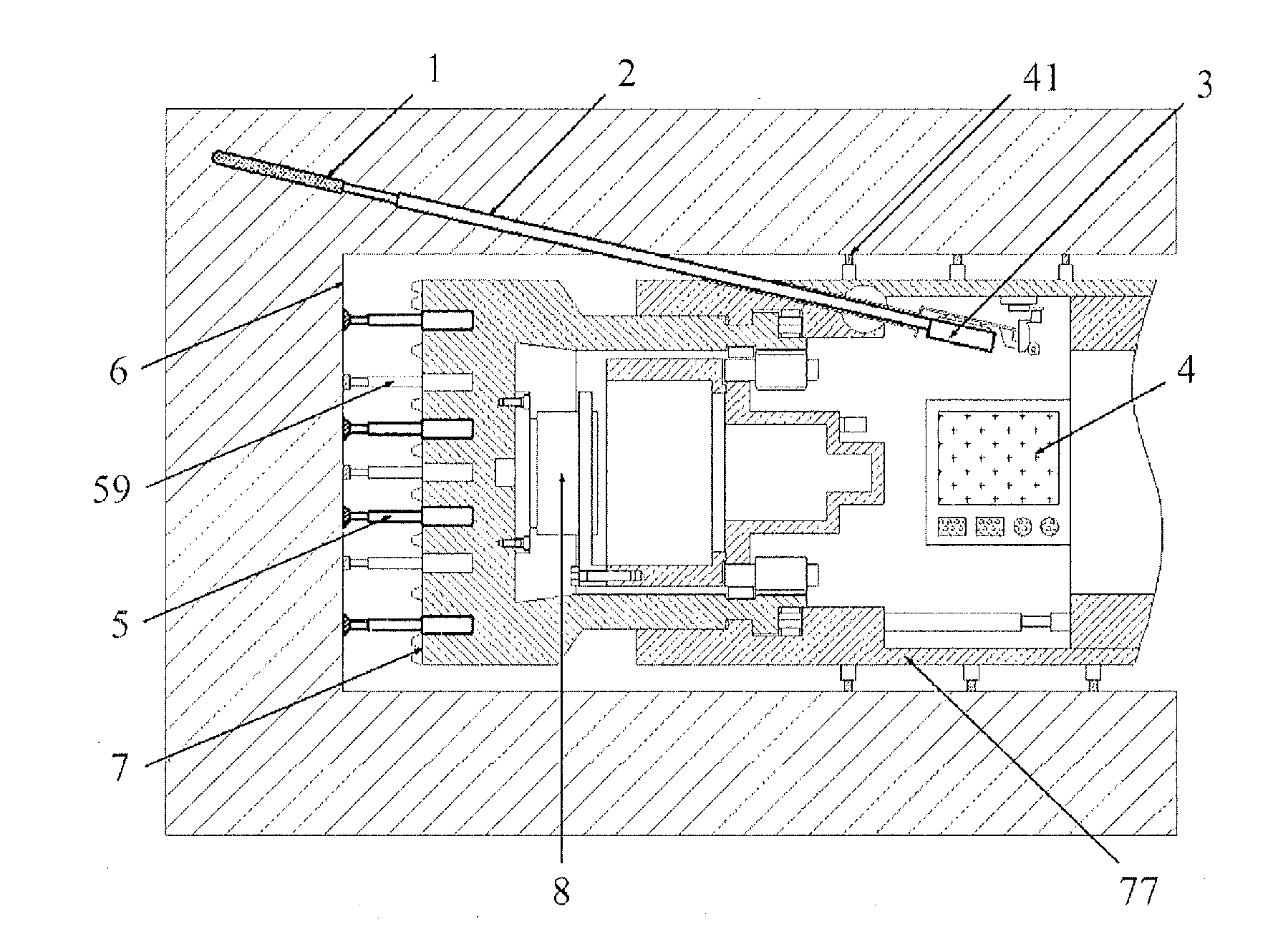

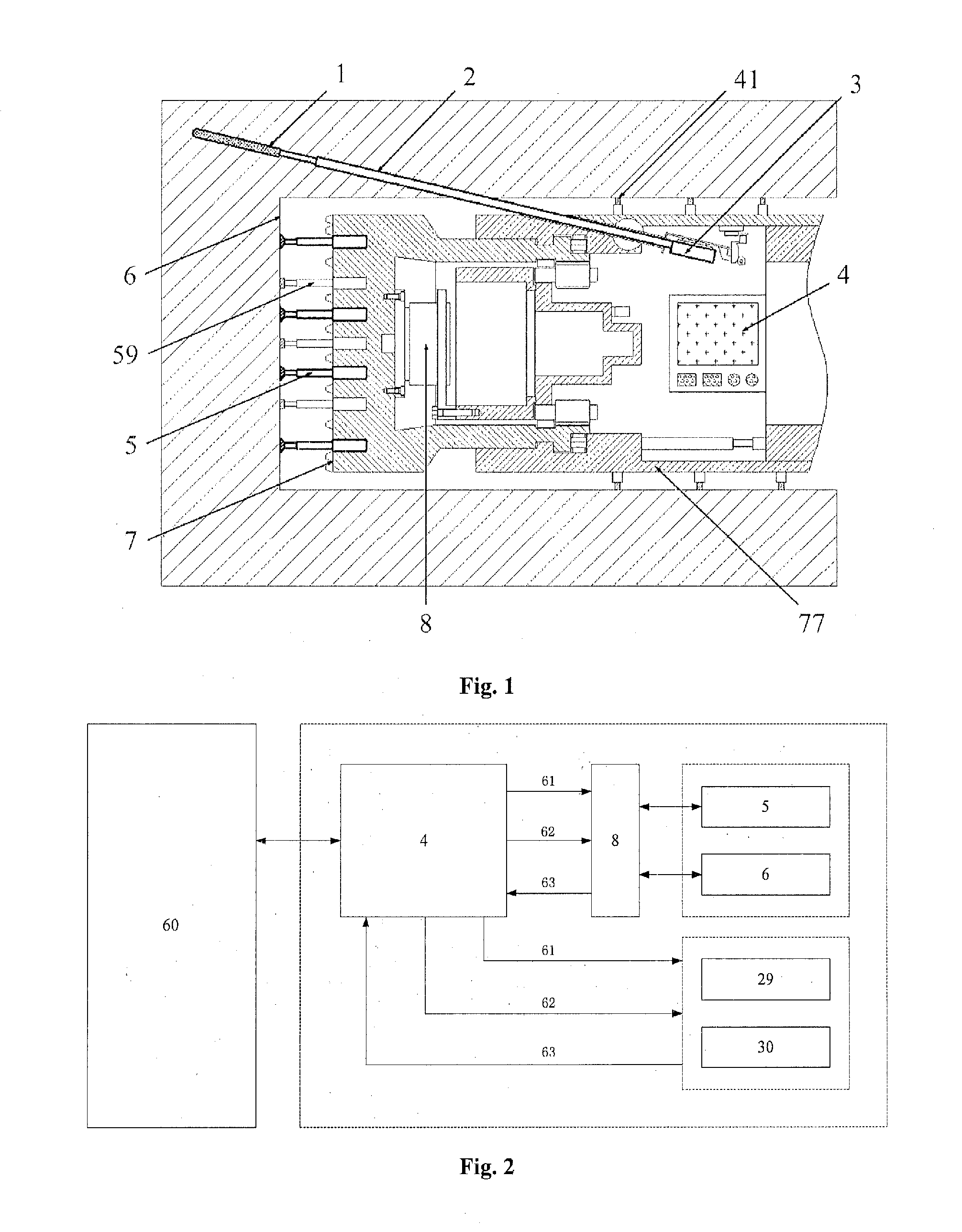

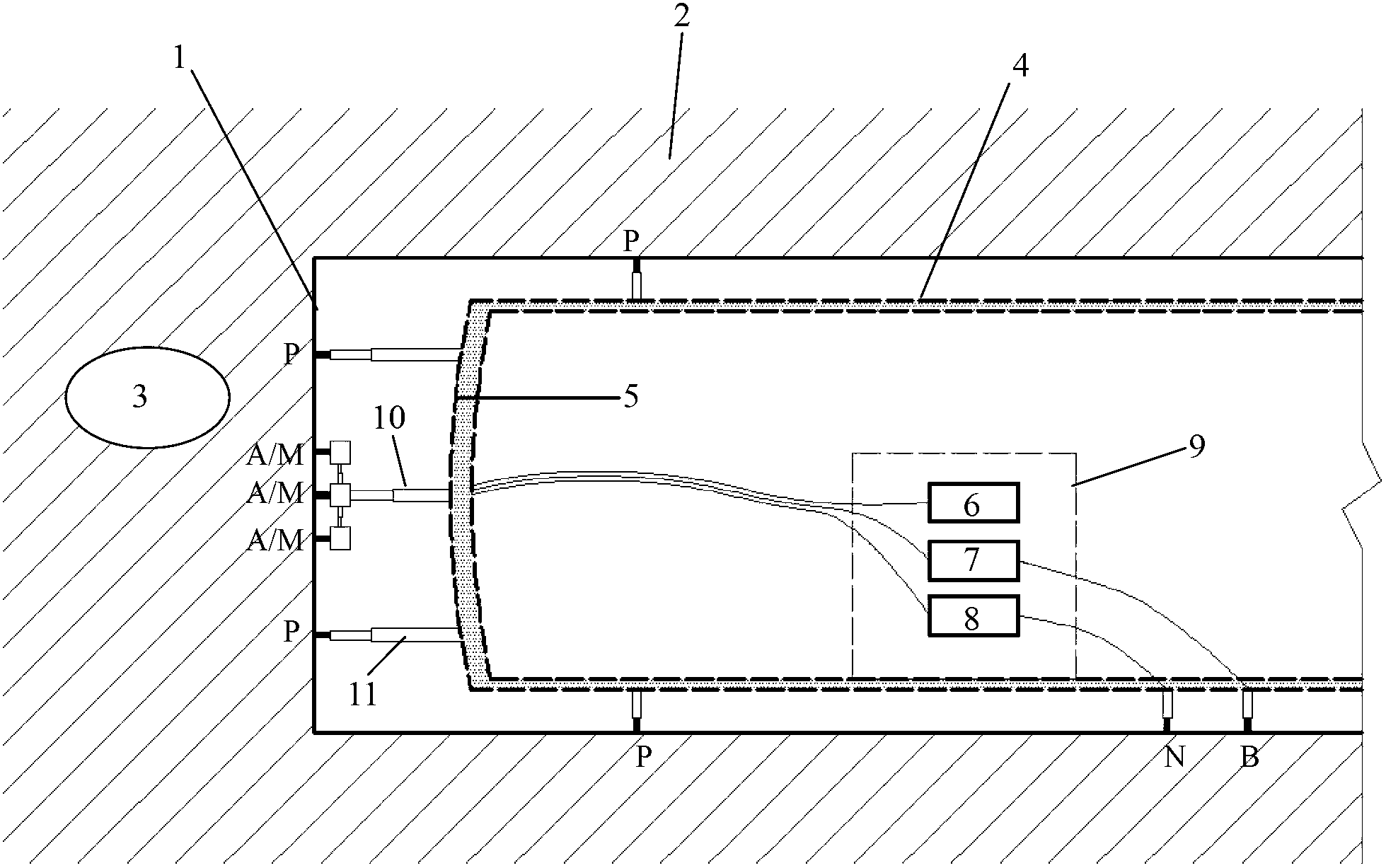

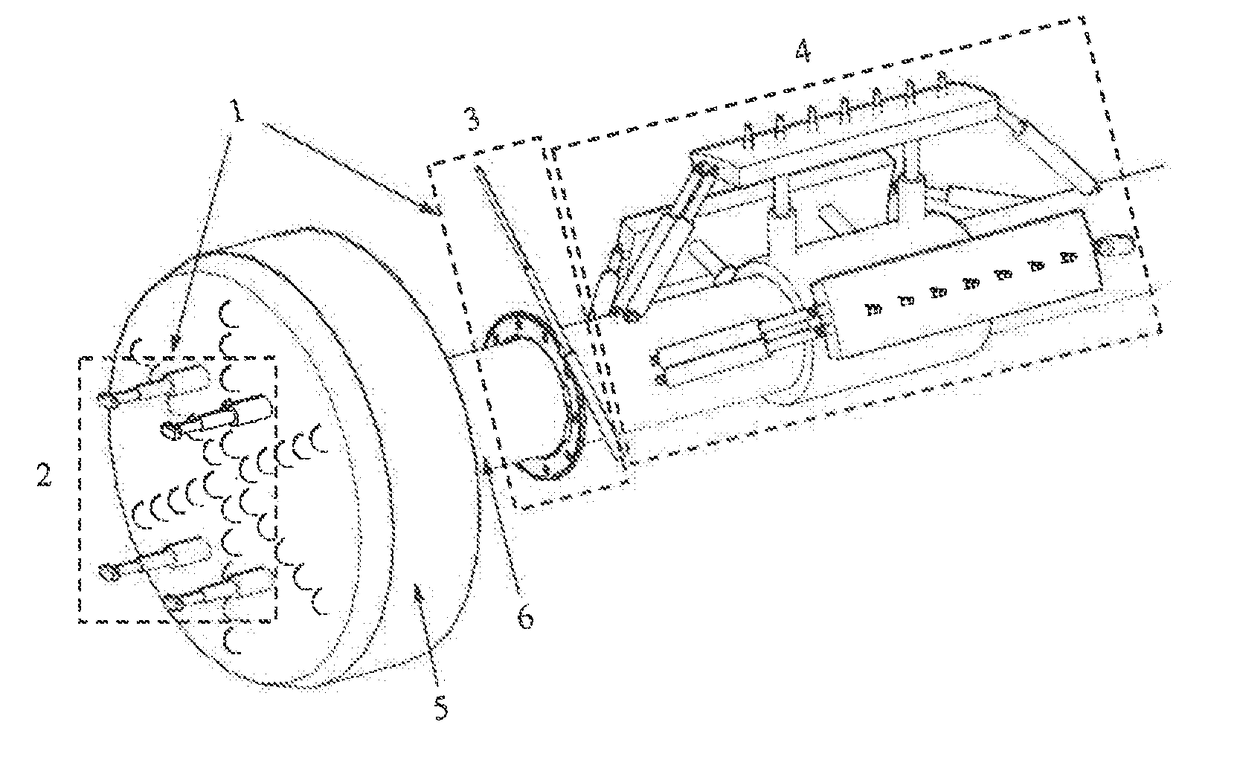

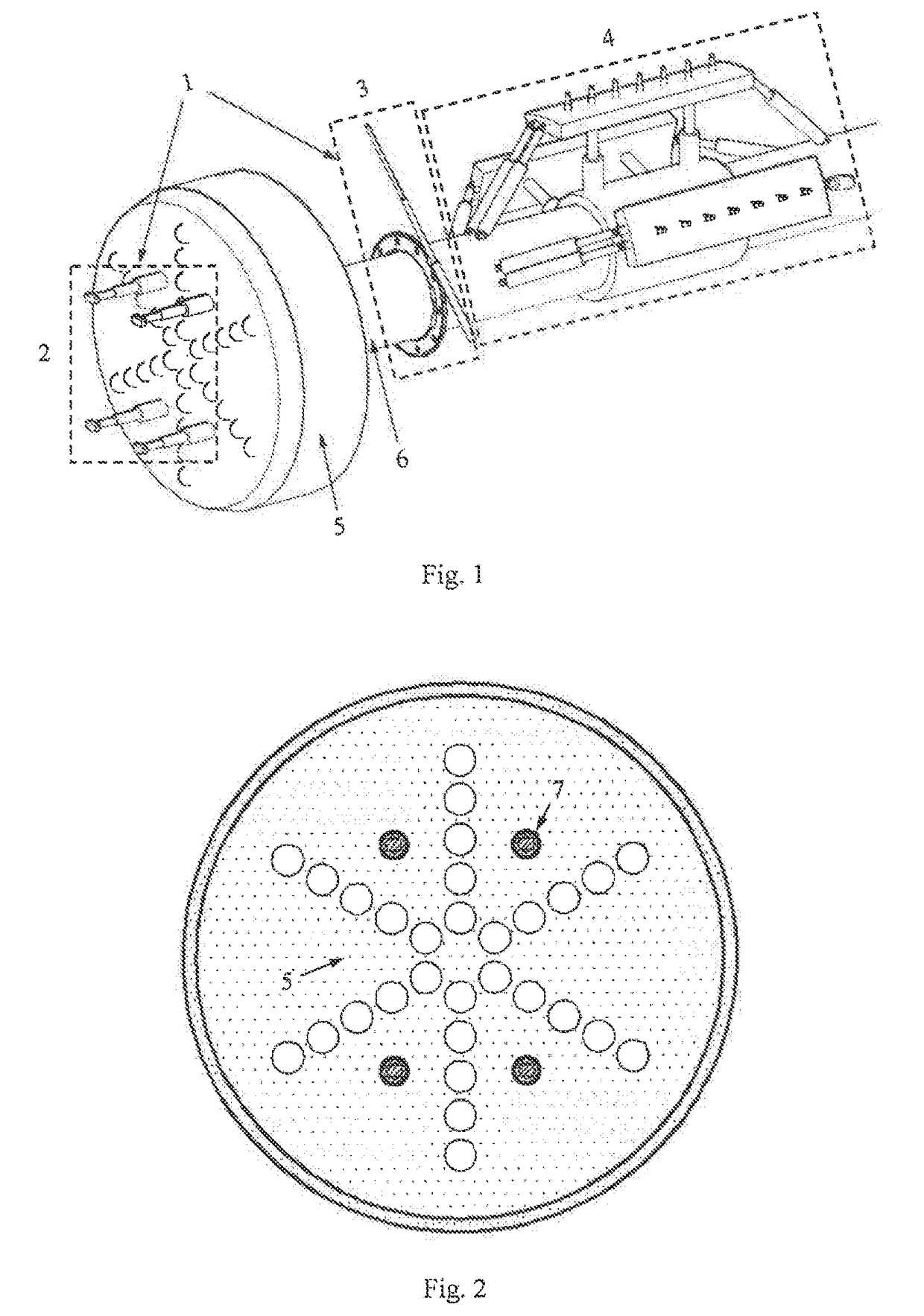

Comprehensive advanced geological detection system carried on tunnel boring machine

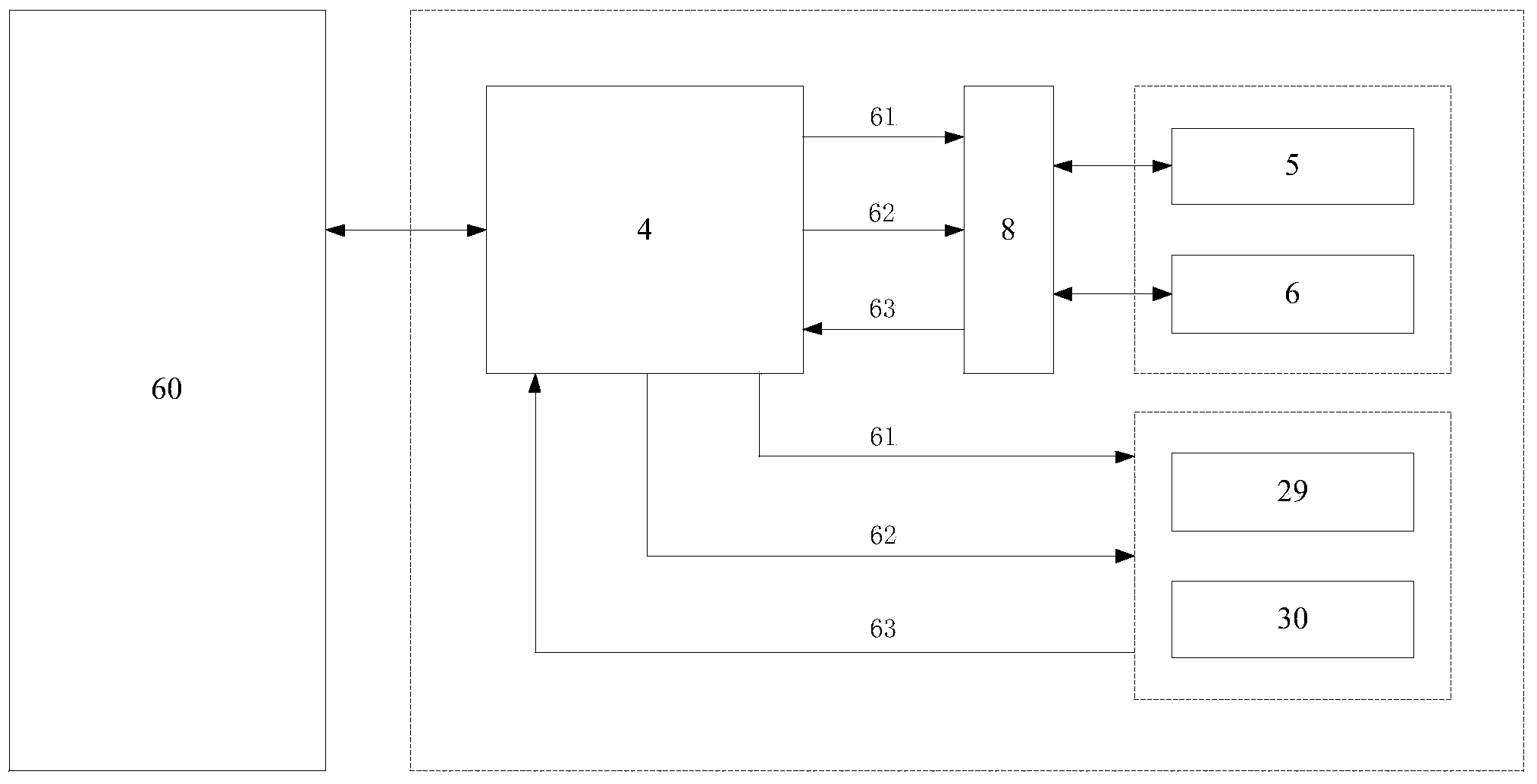

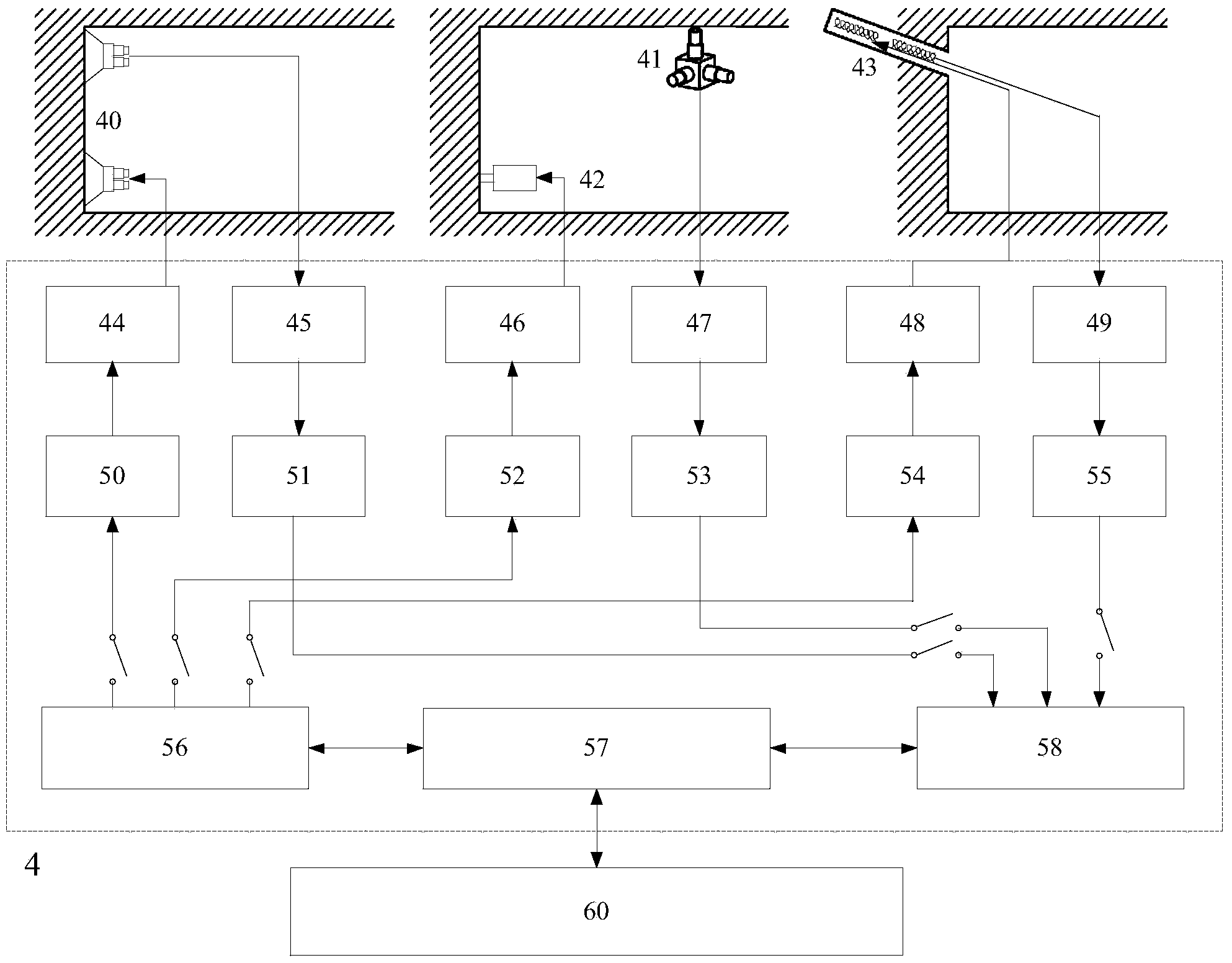

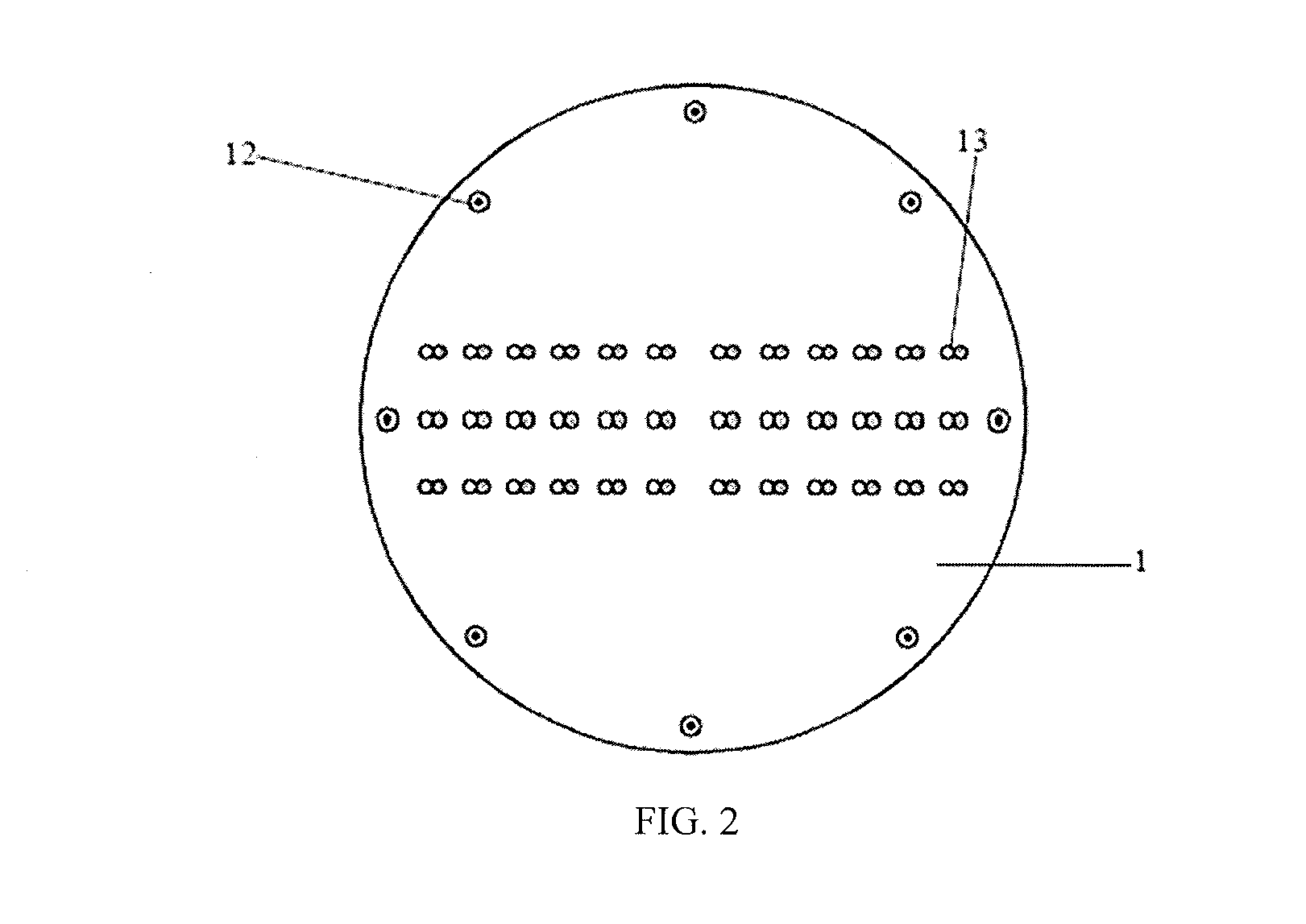

ActiveUS20150233242A1Improve accuracyImprove efficiencySeismic signal processingTunnelsDecision systemComputer module

The present invention presents a comprehensive advanced geological detection system carried on a tunnel boring machine. The comprehensive advanced geological detection system includes a multifunctional combination main frame, an induced polarization detection device, a seismic wave detection device, an integrated junction device, a borehole ground penetrating radar detection device and a comprehensive interpretation and decision system; the multifunctional combination main frame includes a time division multiplexing control module, an excitation source control module and a parallel data acquisition module; the excitation source control module outputs trigger signals to the three detection devices respectively, and the three detection devices respectively output measurement data and feedback signals to the time division multiplexing control module through the parallel data acquisition module; and the comprehensive interpretation and decision system supports geological interpretations and decisions through the inversion / migration imaging joint inversion of three detection methods.

Owner:SHANDONG UNIV

Comprehensive advance geological detection system carried by tunnel boring machine

ActiveCN103713335AImprove efficiencyImprove accuracyGeological measurementsDecision systemWave detection

The invention discloses a comprehensive advance geological detection system carried by a tunnel boring machine. The comprehensive advance geological detection system comprises a multifunctional combination main frame, an induced polarization detection device, an earthquake wave detection device, an integrated junction device, a drilling geological radar detection device and a comprehensive interpretation decision system. The multifunctional combination main frame comprises a time division multiplexing control module, an excitation source control module and a parallel data collecting module. The excitation source control module outputs trigger signals to the three detection devices respectively, the three detection devices respectively output measurement data and feedback signals to the time division multiplexing control module through the parallel data collecting module. The comprehensive interpretation decision system supports geological interpretations and decisions through the inversion / migration imaging joint inversion of three detection methods. The detection system greatly improves the automation degree and detection speed of detection equipment on the tunnel boring machine, and multiple kinds of detection equipment can be carried by the tunnel boring machine.

Owner:山东百廿慧通工程科技有限公司

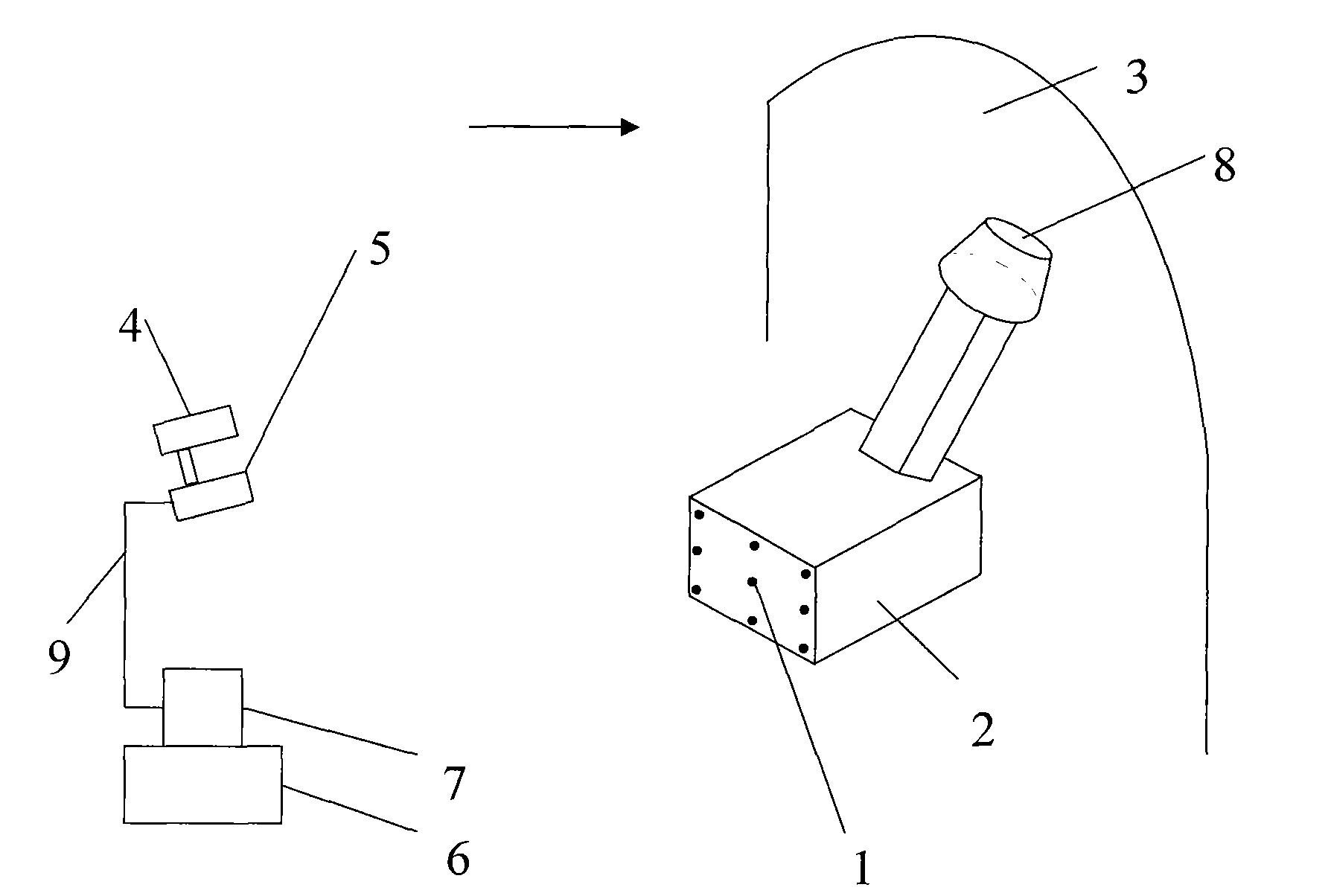

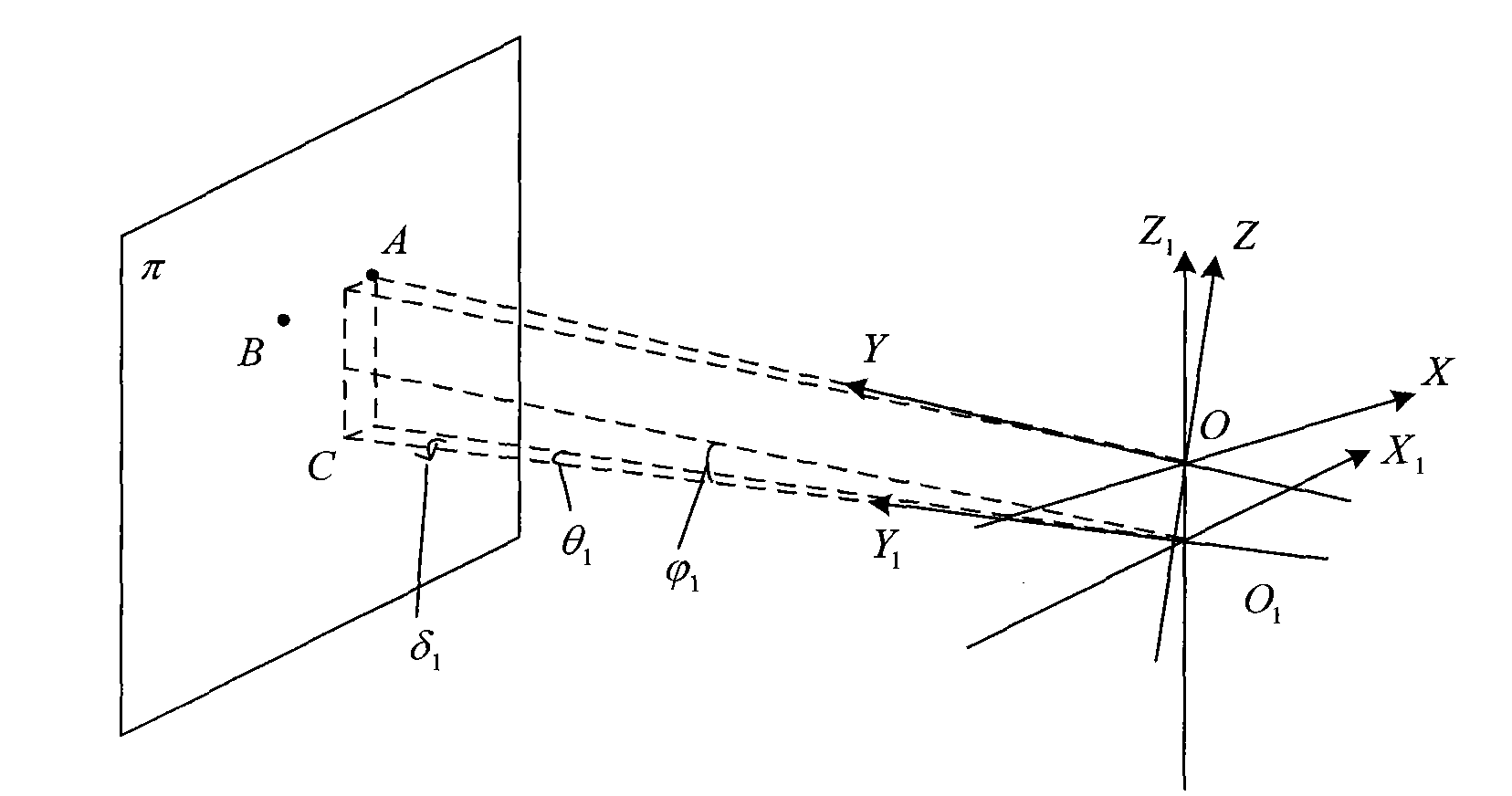

Method for automatically measuring special position of tunnel boring machine

ActiveCN101819036AIdeal mining pose measurement methodAdvancedAngle measurementView cameraTunnel boring machine

The invention relates to a method for automatically measuring the special position of a tunnel boring machine. According to the practical situation of the tunneling operation of the tunnel boring machine in a small underground space of a coal mine, an industrial view camera, an industrial computer, a laser orientation instrument and an image acquisition card are arranged on the back part of the tunnel boring machine. The position of the tunnel boring machine on a coal petrography cross section is measured and calculated, the most reasonable position of a machine body is determined, a command on an excavating operation is made and operators are far away from hazardous areas so as to reduce sudden accidents, enhance excavating safety and keep the tunnel boring machine on a best and most reasonable position and in a best and most reasonable state. A maximum cover angle is + / -60 degrees, a displacement detection deviation is less than 10 millimeters, the detection accuracy of a deflection angle is + / -12 gon, the detection accuracy of a pitch angle is + / -6 gon and the detection accuracy of a roll angle is + / -6 gon so as to improve excavating quality and efficiency. The method is advanced, reasonable and correct, is a very ideal method for measuring the excavation position of a coal extraction tunnel boring machine and can be used in tunnel excavation operation.

Owner:TAIYUAN INST OF COAL SCI RES INST +1

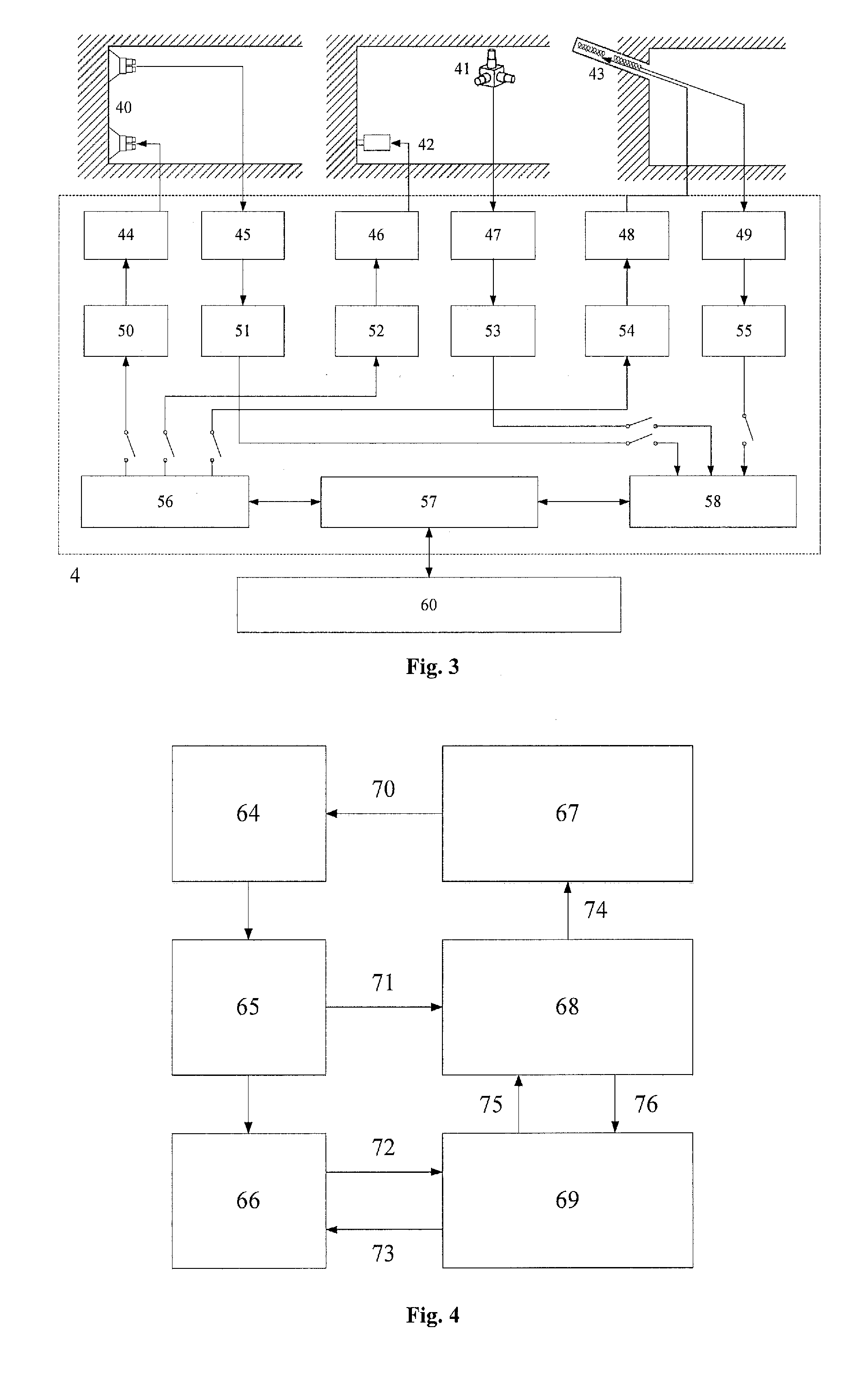

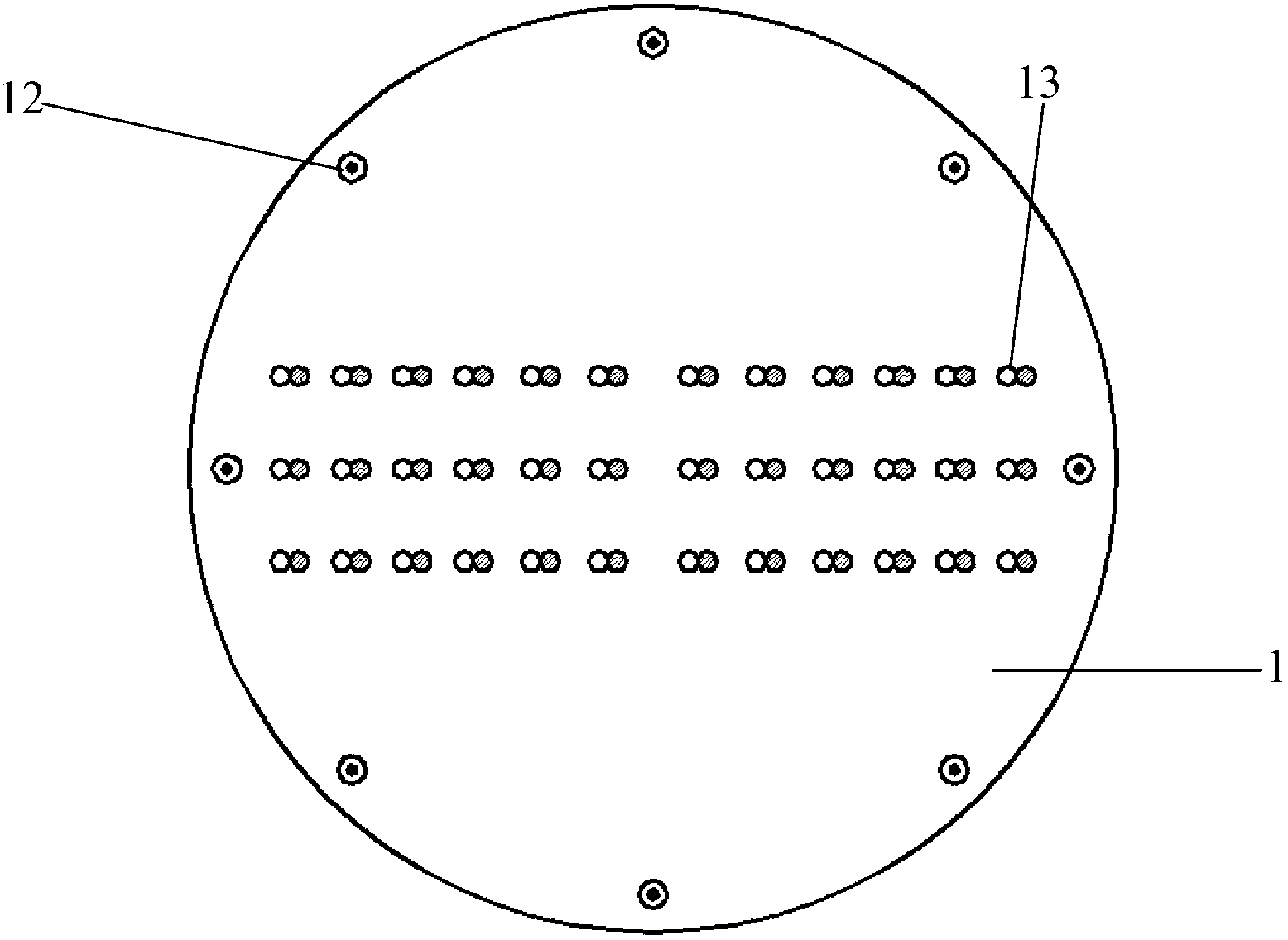

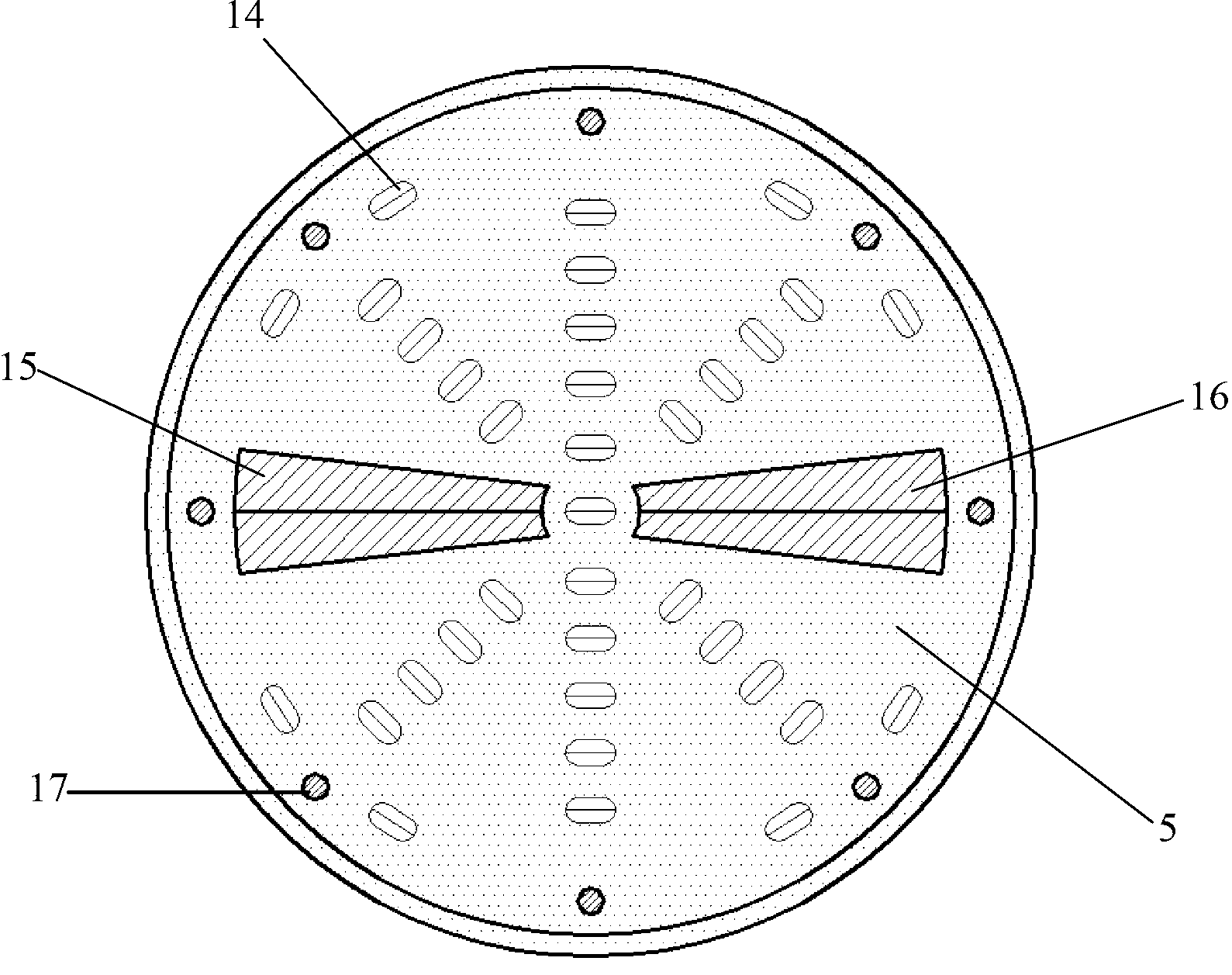

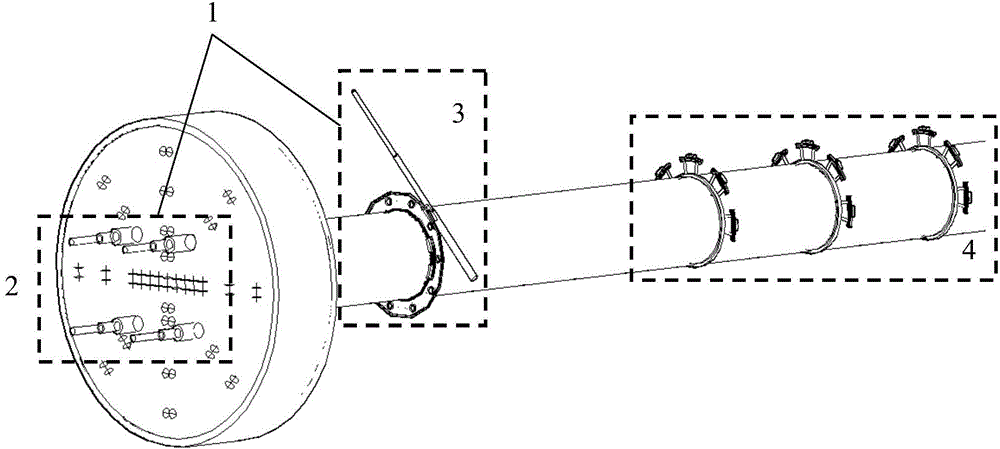

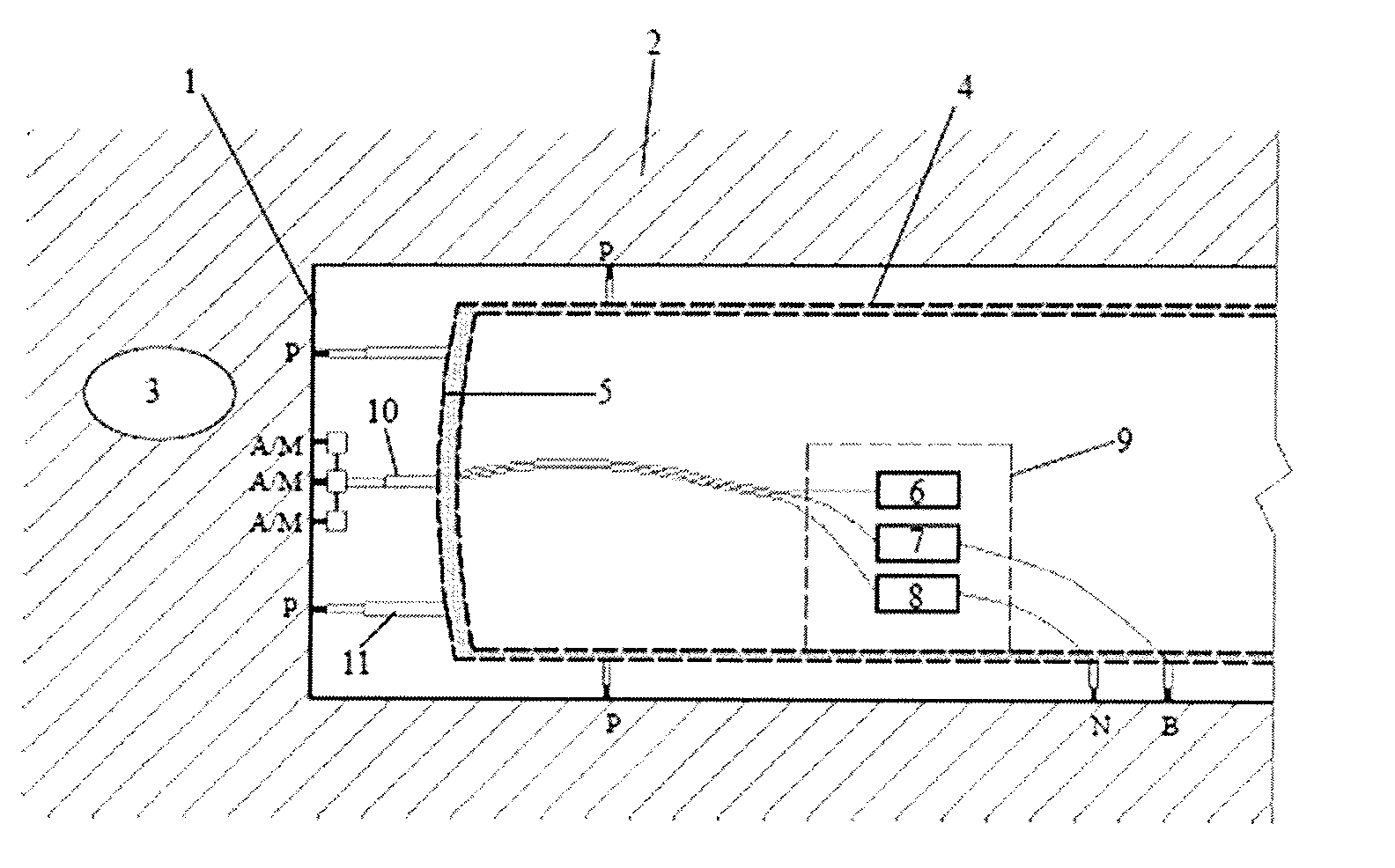

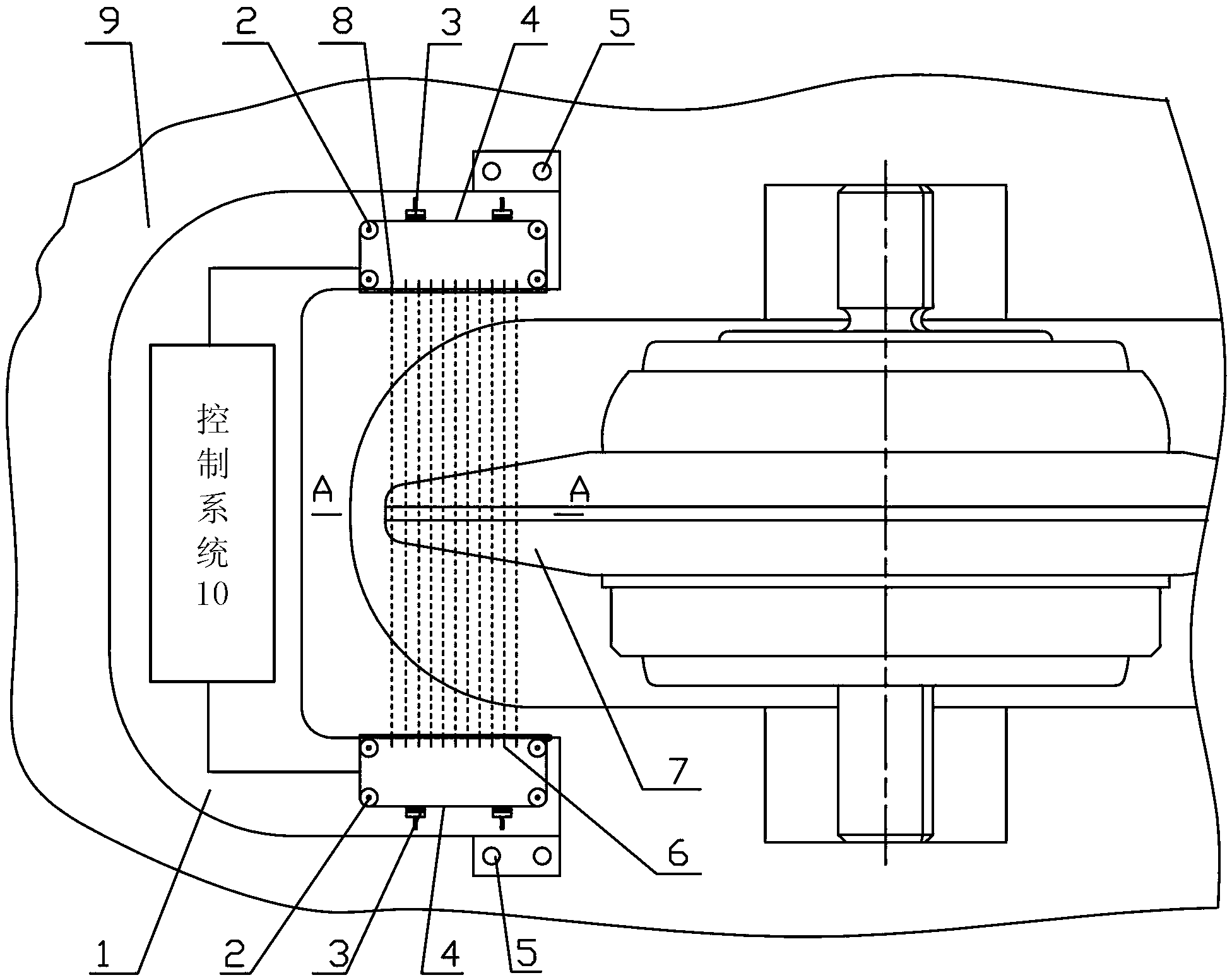

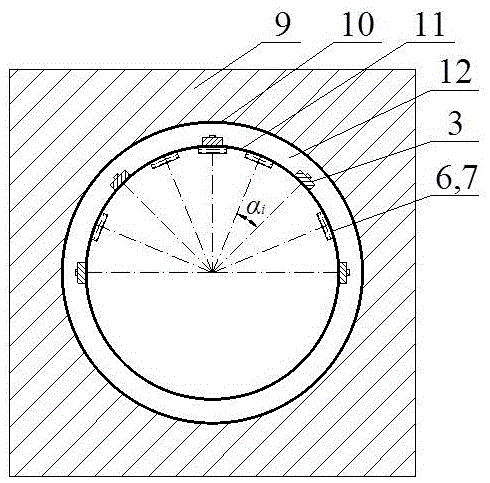

Advanced detection system and method for TBM (Tunnel Boring Machine) tunnel construction based on forward three-dimensional induced polarization

ActiveCN103076635ACompatibleAutomatically and quickly assign jobsElectric/magnetic detectionAcoustic wave reradiationBound waterWater flow

The invention discloses an advanced detection system and method for TBM (Tunnel Boring Machine) tunnel construction based on forward three-dimensional induced polarization. By fully utilizing a narrow detection space of a full-face excavated tunnel, controlling the opening of cabin doors of a power supply and measuring electrode cabin and a shielding electrode cabin through controllers, and controlling corresponding hydraulic transmission devices to automatically and rapidly arrange power supply, measurement and shielding electrode systems onto a TBM tunneling working face and side wall bottom plates at the rear of the TBM tunneling working face, under the effect of a shielding current system, tomographic detection power supply current points to the front of the working face. By using the detection method based on the forward three-dimensional induced polarization, the three-dimensional geological information of the front of the working face can be obtained. Moreover, by using a relation between induced polarization half-time difference and water flow, the magnitude of the water flow of a water body can be quantitatively forecasted. In addition, the parameter, i.e. the half-time difference has a stronger ability of distinguishing free water and bound water.

Owner:山东百廿慧通工程科技有限公司

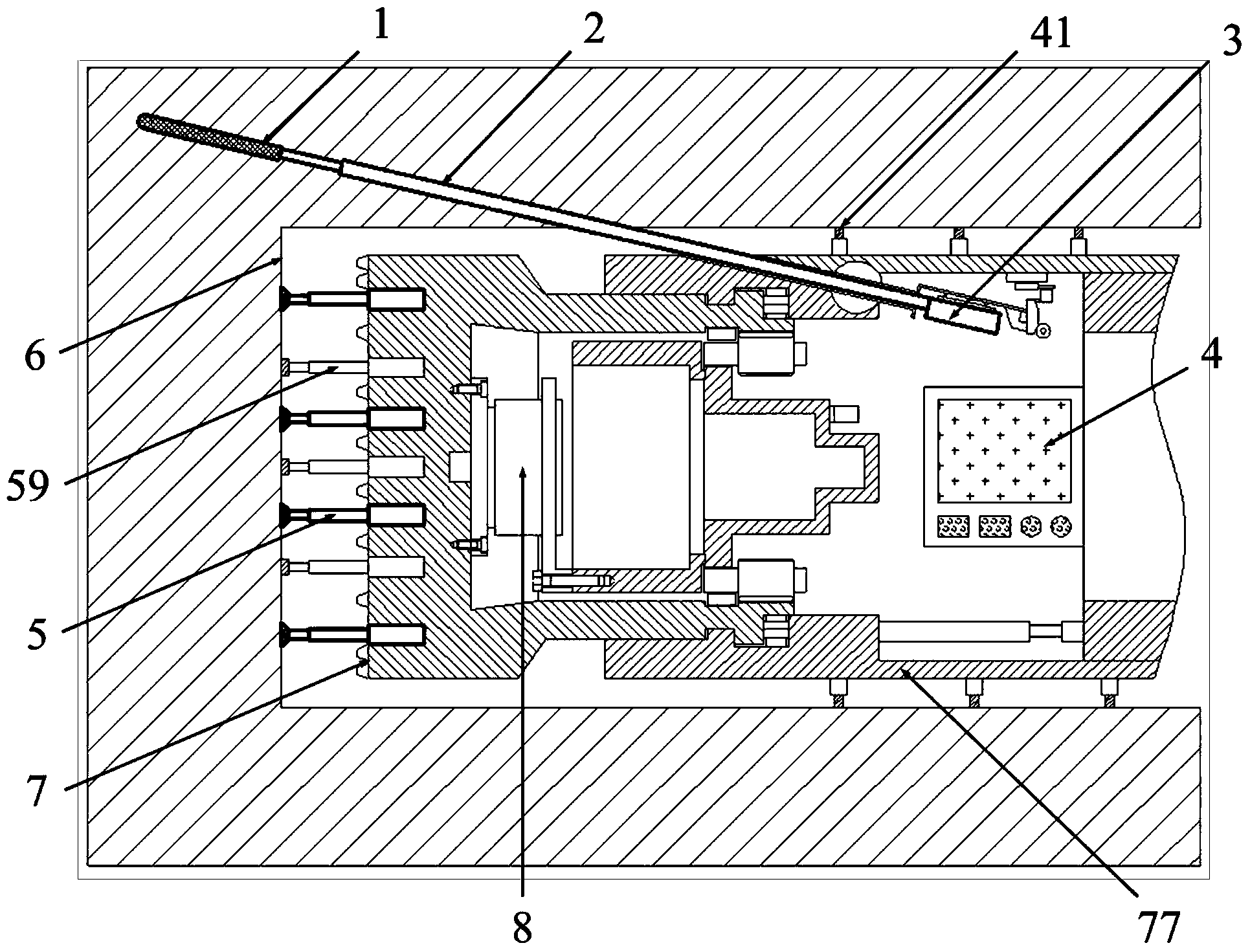

Rock breaking seismic source and active source three-dimensional seismic combined advanced detection system using tunnel boring machine

A rock breaking seismic source and active source three-dimensional seismic combined detection system uses a tunnel boring machine for three-dimensional seismic combined detection by active seismic source and rock breaking seismic source methods. Long-distance advanced prediction and position recognition of a geological anomalous body are realized using the active source seismic method. Machine construction is adjusted and optimized according to the detection result; real-time short-distance accurate prediction of the body is realized using the cutter head rock breaking vibration having weak energy but containing a high proportion of transverse wave components as seismic sources and adopting an unconventional rock breaking seismic source seism recording and handling method. An area surrounding rock quality to be excavated is represented and assessed. A comprehensive judgment is made to the geological condition in front of the working face with the results of active source and rock breaking seismic source three-dimensional seismic advanced detection.

Owner:SHANDONG UNIV

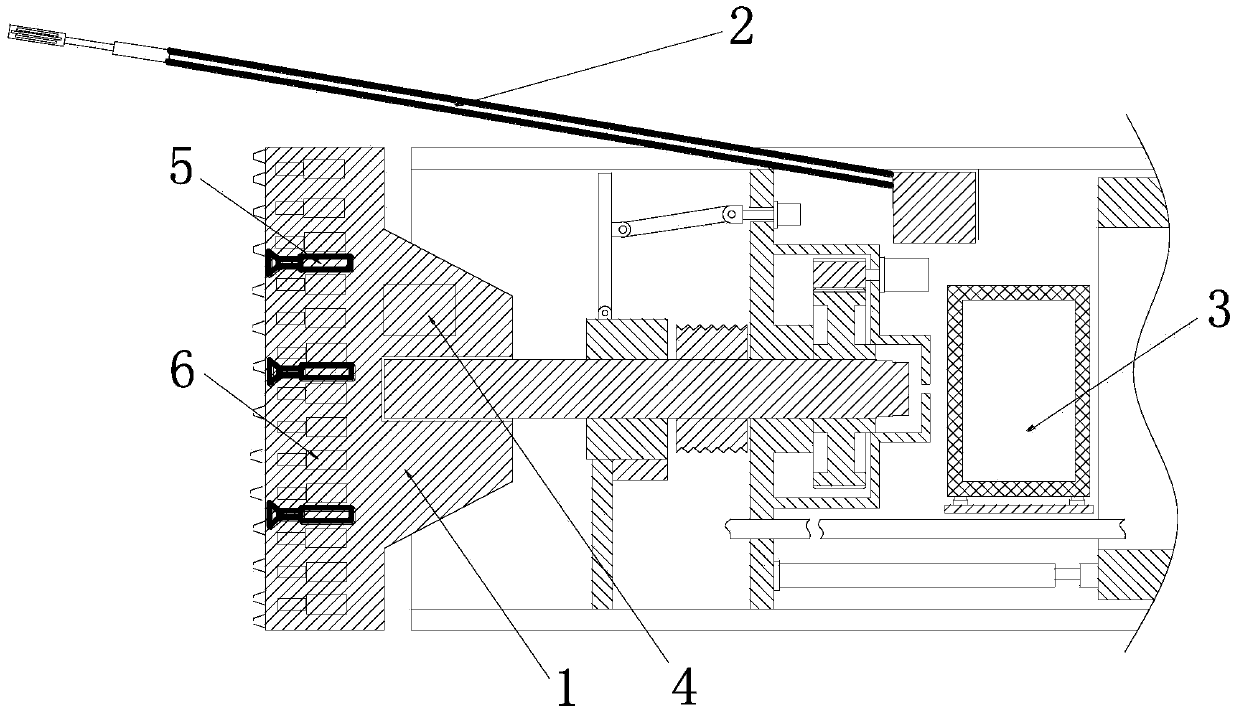

Tunnel boring machine active source three-dimensional seismic advanced detection device and method

ActiveCN104678426ADisplay clearly and accuratelyAccurate Velocity DistributionSeismic energy generationSeismic signal receiversEngineeringTunnel boring machine

The invention discloses a tunnel boring machine active source three-dimensional seismic advanced geology exploration device and method. The device comprises a tunnel boring machine cutterhead and a tunnel boring machine body connected with the cutterhead, wherein a main control room is arranged in the tunnel boring machine body; a controller and a multichannel seismic wave data collecting instrument are arranged in the main control room; seismic source systems are respectively arranged at the front ends of the tunnel boring machine cutterhead and the tunnel boring machine body; a data collecting system is arranged at the rear part of the working surface of the tunnel boring machine body according to certain space observation mode; the controller is respectively connected with the multichannel seismic wave data collecting instrument, the seismic wave systems and the data collecting system; the multichannel seismic wave data collecting instrument is connected with the data collecting system. The device has the benefits that rapid, flexible and automatic arrangement of a seismic wave and a detector system is realized, the maintenance time of the tunnel boring machine is sufficiently utilized, the work efficiency of geological advanced prediction is greatly improved, the normal construction is not disturbed, and time cost and economic cost are saved.

Owner:山东百廿慧通工程科技有限公司

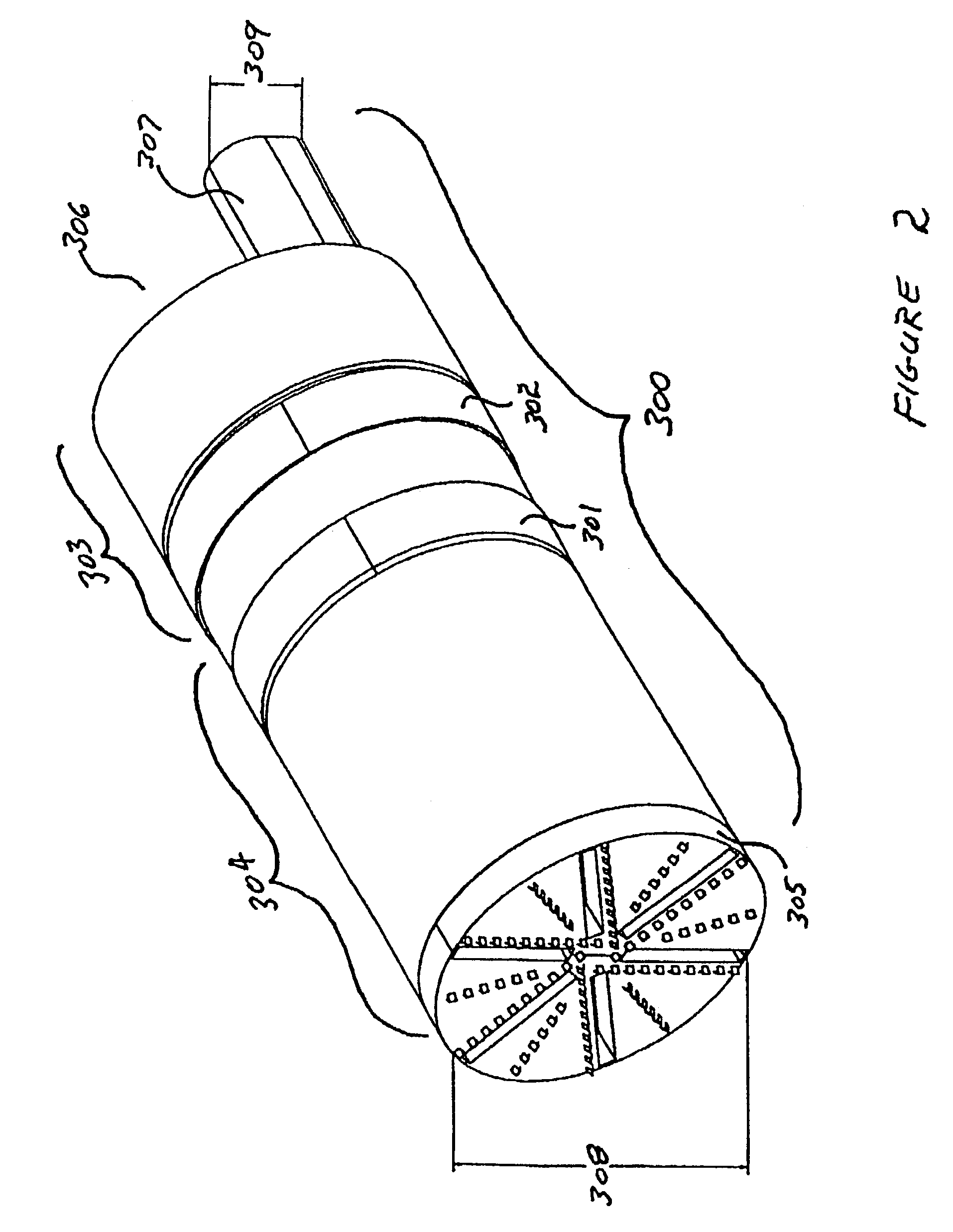

All-conditions tunnel boring machine

A tunnel boring machine is provided comprising a cutter head, a main beam, a first, second, and third shield; and a ground conditioning work zone within the first shield, a gripper assembly, a segment erector arm for lining the tunnel, and at least one propulsion mechanism. The ground conditioning work zone includes at least one probing device for probing the terrain ahead of the cutter head. The first shield is configured to be retracted relative to the second shield to provide access for the ground conditioning work zone to apply at least one ground support device. The at least one propulsion mechanism moves the cutter head, the first and the second shield forward while the third shield and the gripper assembly remain stationary. The ground support devices can include filling a hole with a ground conditioning agent; and placing a bolt, ring beam, mesh, or shotcrete in / on the tunnel wall.

Owner:THE ROBBINS CO

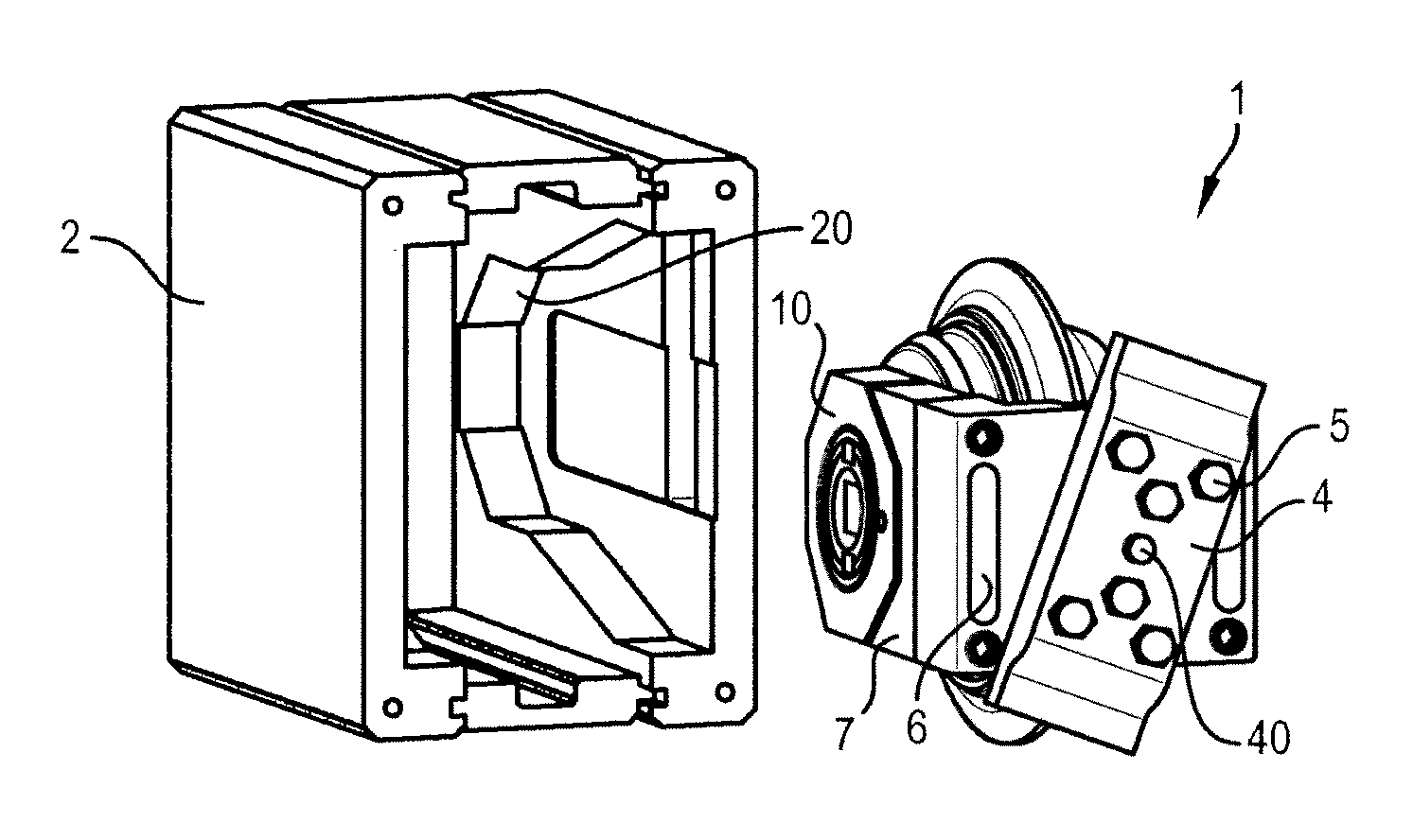

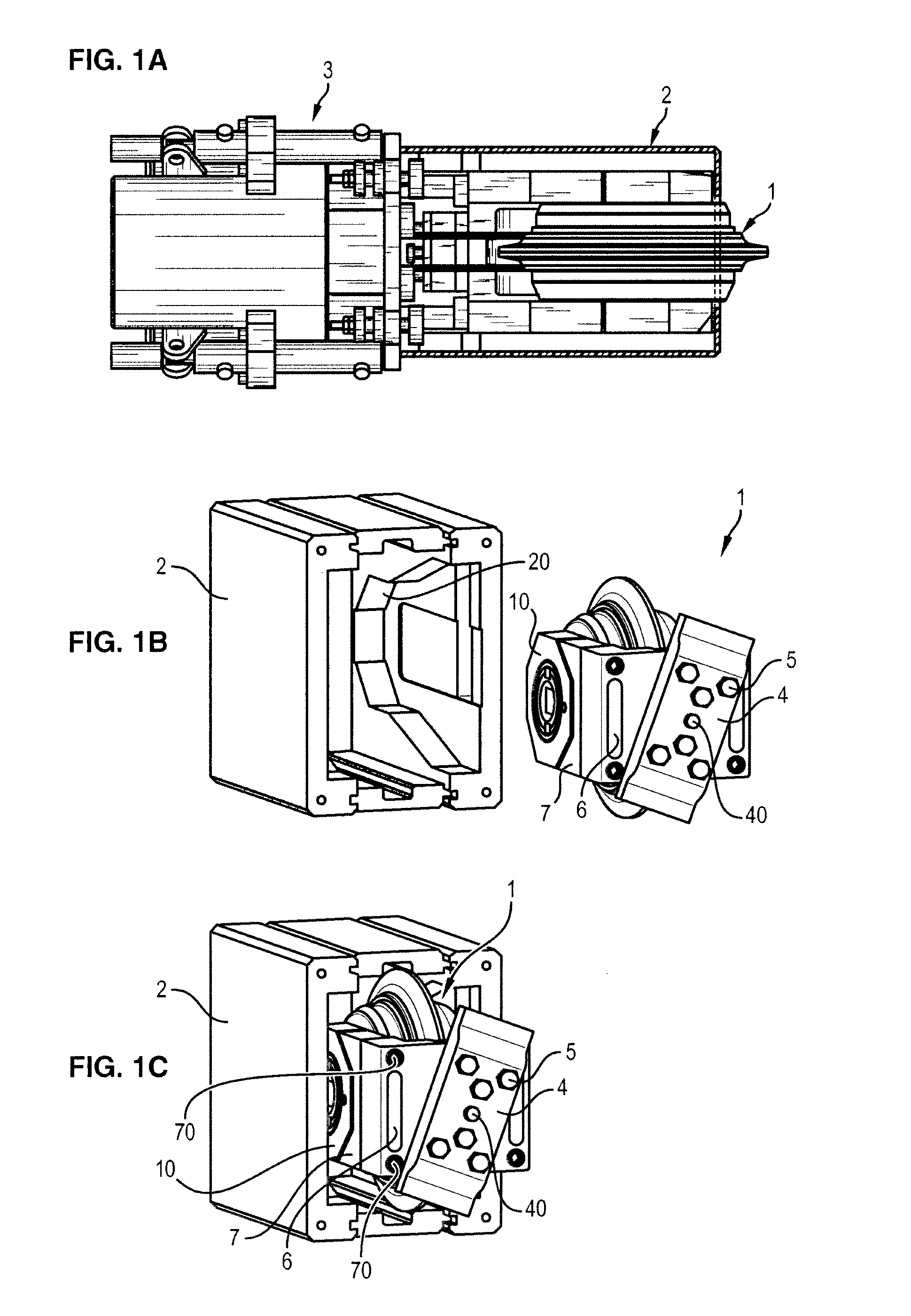

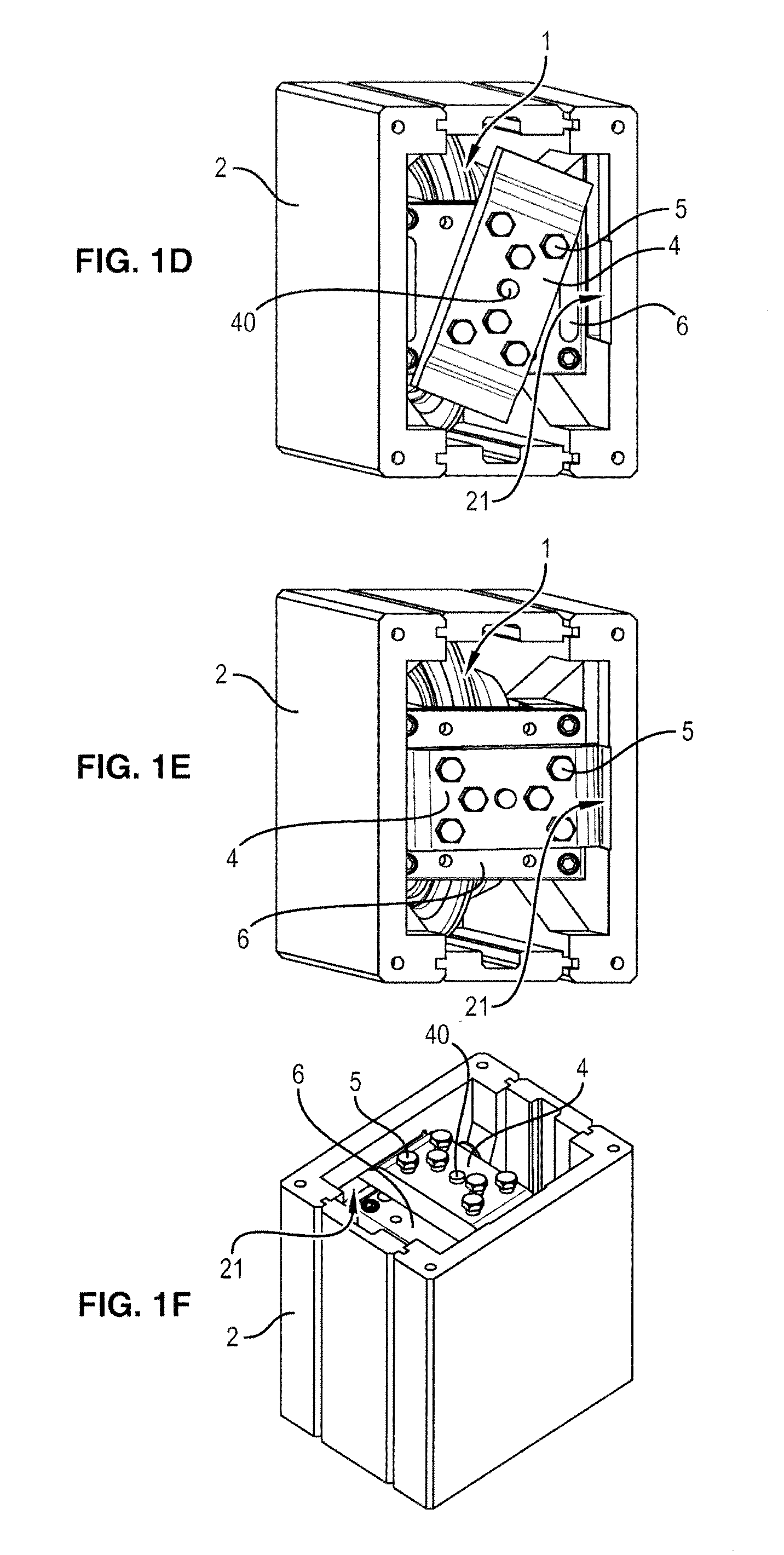

Method for replacing a tunnel boring machine roller cutter, handling device and roller cutter suited to such a method

The invention relates to a method for replacing a disk cutter (1) mounted with preload in a casing (2) attached to the cutting head of a tunnel boring machine, operated using a disk cutter (1) bearing, firmly attached thereto, an element (4) for locking into the housing (2) and preloading means (5), the method involving the steps of: a) removing a worn disk cutter (1) from said housing (2): • clamping a disk cutter (1) handling device (3) onto the housing (2); • taking hold of the disk cutter, • releasing the preload, • unlocking, • extracting the disk cutter (1), • unclamping the device (3), b) fitting a replacement disk cutter (1) in reverse order.

Owner:BOUYGUES TRAVAUX PUBLICS SA

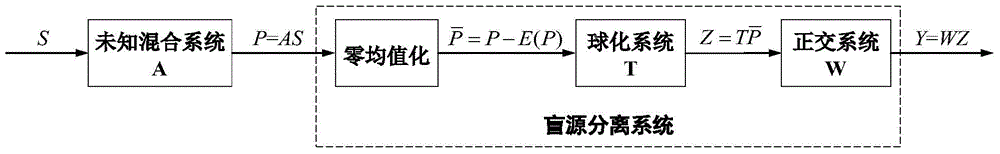

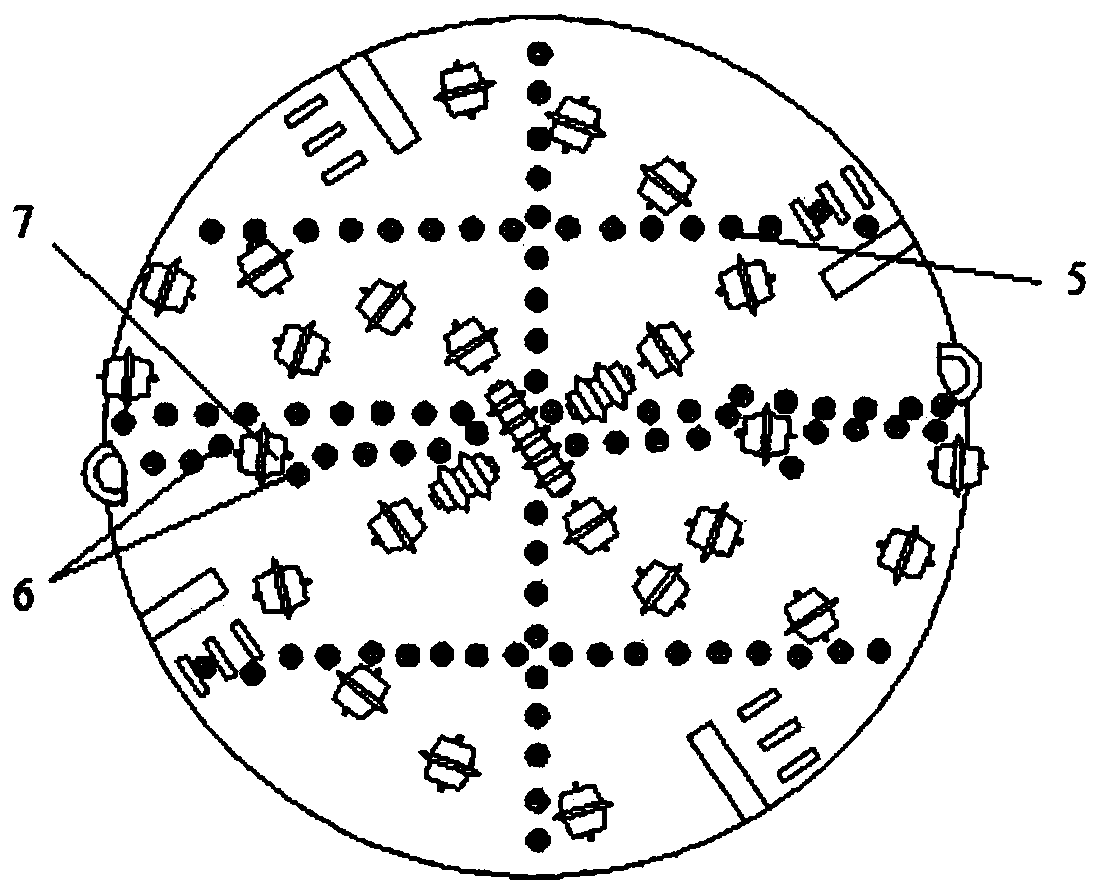

Tunnel boring machine rock breaking seismic source three-dimensional seismic advanced detection device and method

ActiveCN104678427ADoes not affect normal workflowQuick layoutSeismologySensor arrayIndependent component analysis

The invention discloses a tunnel boring machine rock breaking seismic source three-dimensional seismic advanced detection device and method. The device comprises a seismic source sensor array, a receiving sensor and a supporting device thereof, a noise sensor, and a multichannel seismic wave data collecting instrument, wherein the multichannel seismic wave data collecting instrument is connected with the seismic source sensor array, the receiving sensor and the noise sensor and receives seismic wave signals and noise signals of a noise source. Aiming at the special situation of the construction tunnel of a tunnel boring machine, the device adopts a seismic source signal blind source separation method based on an independent component analysis theory, a seismic source signal reconstruction method and a method for performing powerful interference signal degeneration on receiving sensor signals to finally obtain geological conditions in front of a working surface of the tunnel boring machine and the surrounding rock mass of a tunnel and corresponding mechanical parameters, can realize the advanced prediction of geological anomalous bodies, can further be used for evaluating the quality of surrounding rocks of a region to be excavated, and provides reference for the optimization of tunnel boring machine operating parameters and guarantee of construction safety.

Owner:山东百廿慧通工程科技有限公司

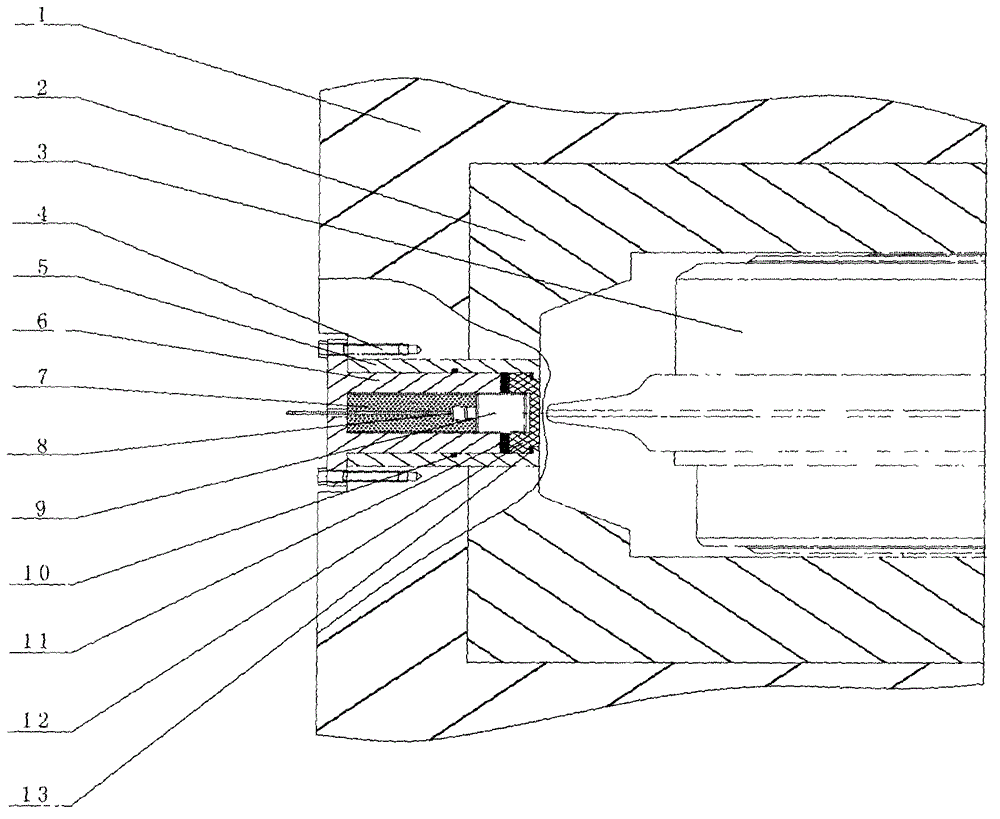

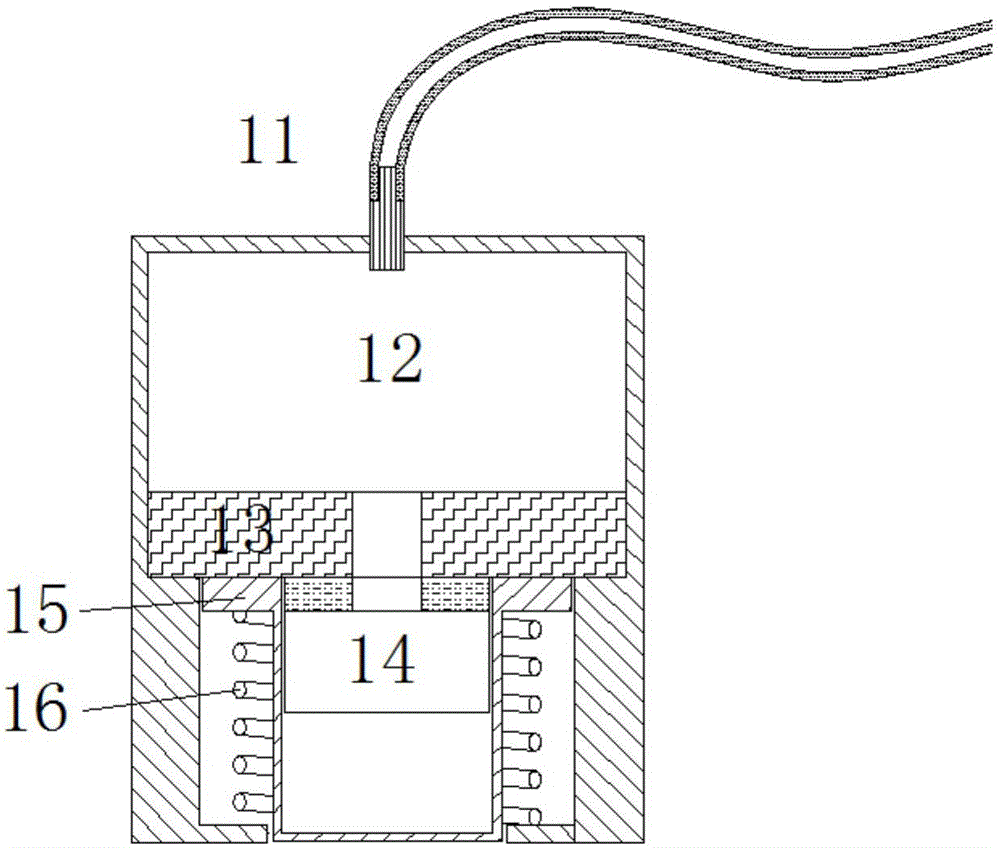

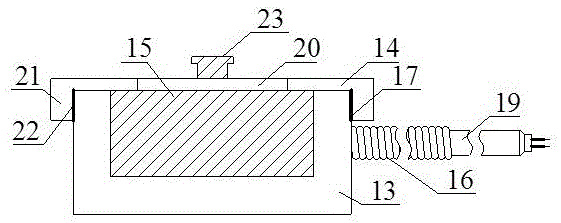

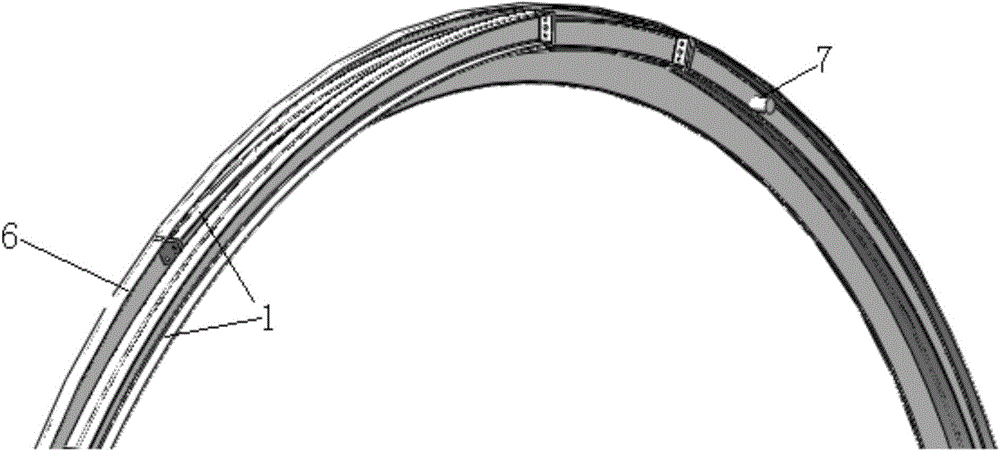

Real-time tunnel boring machine (TBM) hob abrasion monitoring device

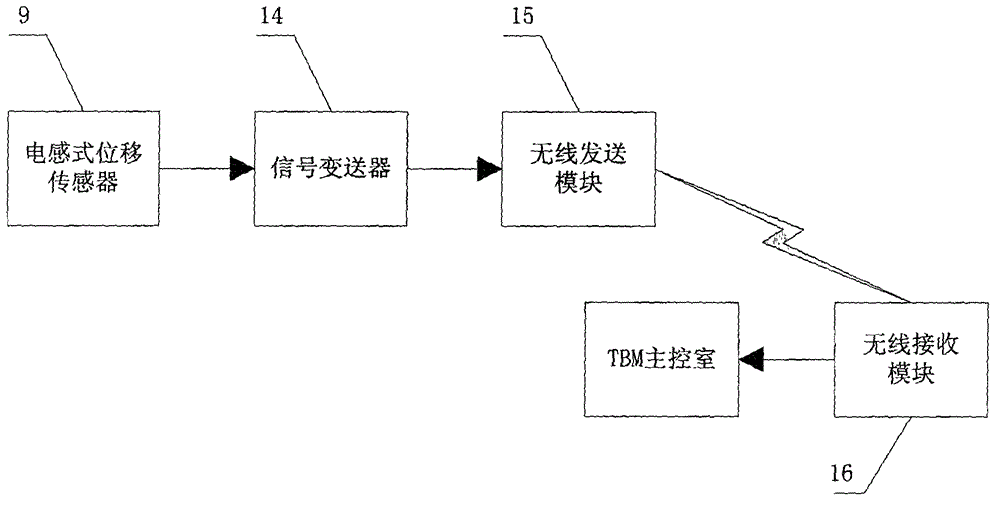

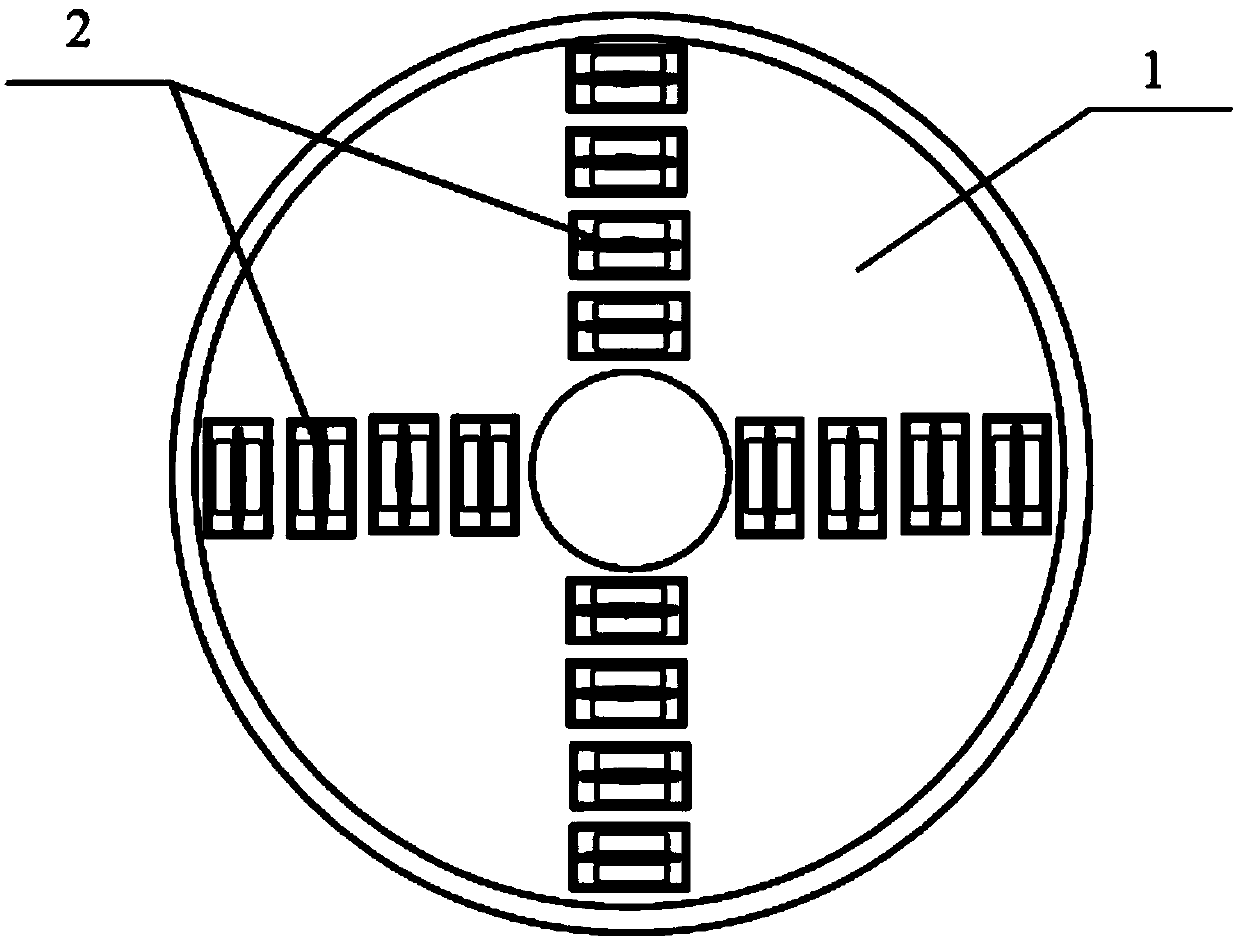

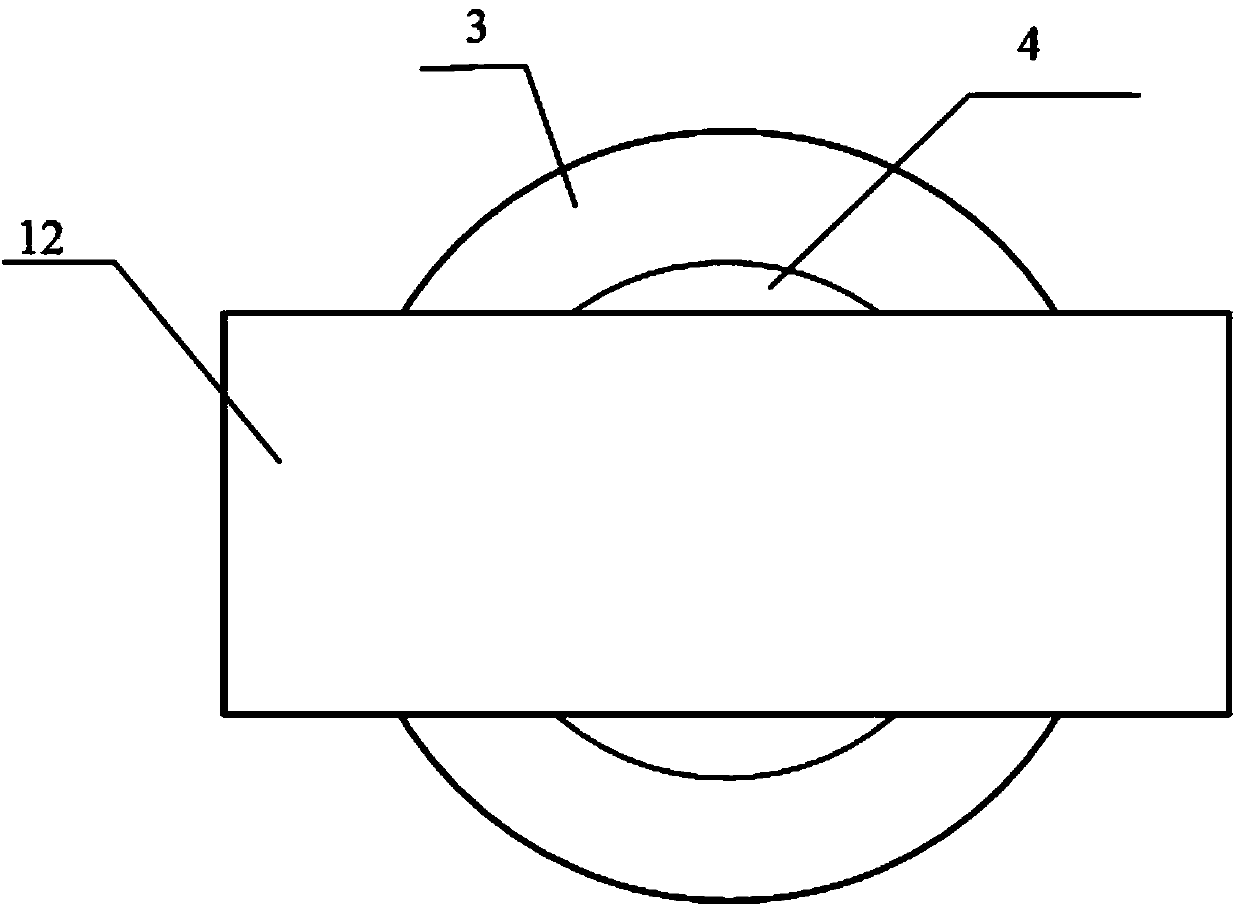

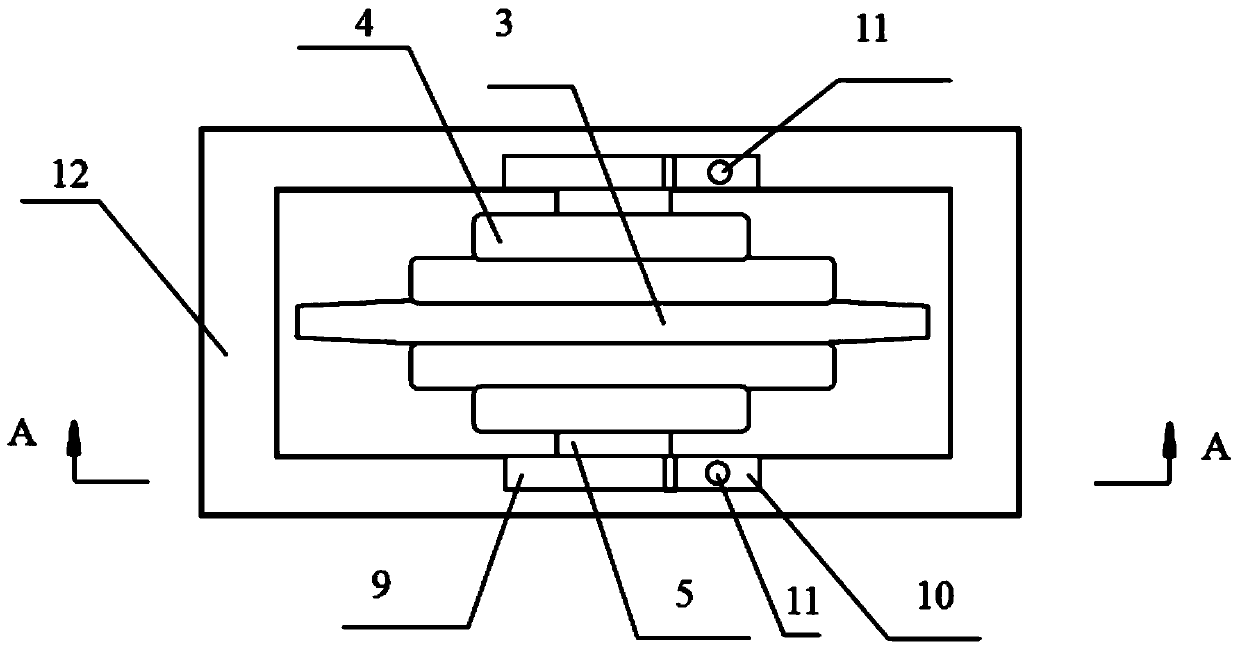

ActiveCN103148771AReal-time monitoring of wear statusKeep abreast of the operation status in timeUsing electrical meansRubber ringTransformer

The invention discloses a real-time tunnel boring machine (TBM) hob abrasion monitoring device based on an inductive displacement transducer. The device is characterized in that the inductive displacement transducer is installed in a transducer base, a lead pin is connected onto the inductive displacement transducer, and the internal gap of the transducer base is filled by an AB glue. A zirconia protection sleeve and the transducer base are installed in a transducer positioning sleeve, and a waterproof rubber ring is assembled in a groove of the transducer positioning sleeve. A small waterproof rubber ring is sealed between the zirconia protection sleeve and the transducer positioning sleeve, and a large waterproof rubber ring is sealed between the zirconia protection sleeve and the transducer base. The transducer positioning sleeve is installed into round holes in the middle of the side surfaces of a cutter head reinforcing plate and a tool apron, and the transducer base and the cutter head reinforcing plate are fixed into a whole through bolts. Hob abrasion signals which are detected by the inductive displacement transducer are processed by a signal transformer and then transmitted in a wireless manner. The device can be suitable for severe working environments of a hob and monitors the hob abrasion in real time.

Owner:CENT SOUTH UNIV

Device for online detection for stress of hobbing cutter of tunnel boring machine

ActiveCN103698075AGrasp the working status in timeExtended service lifeMeasurement of force componentsElastomerAudio power amplifier

The invention discloses a device for online detection for stress of a hobbing cutter of a tunnel boring machine. The device comprises a shaft end supporting structure of a cutter central shaft, a sensor for detecting the stress of the hobbing cutter, a signal amplifier, a transmitting antenna, a signal receiving device and a monitoring computer, wherein the shaft end supporting structure of the cutter central shaft comprises a shaft end structure of the cutter central shaft, a supporting wedge and a locking wedge, and the sensor is formed on the supporting wedge. The supporting wedge is used as an elastomer, the sensor for detecting the stress of the hobbing cutter is formed through pasting a resistance strain piece on the elastomer, and when the heading machine works, the sensor can be used for online detecting stress in three directions borne by a cutting edge of the hobbing cutter, so that the tunneling operation scheme can be adjusted according to the condition, the service life of the cutter is prolonged, and further good tunneling efficiency can be obtained. The device can also be used for identifying whether string wear occurs or not and timely grasping the working state of the hobbing cutter, and the tunneling efficiency can be ensured due to the fact that when the cutting edge is subjected to string wear, the cutter can be timely replaced.

Owner:TIANJIN UNIV

Waist-form tunnel boring machine

Disclosed is a waist-form tunnel boring machine. A first impact cutter bar is arranged on the upper portions of a first spindle and a second spindle, a first square shaft and a second square shaft are fixed on the right of the first impact cutter bar, the right end of the first square shaft and the right end of the second square shaft are fixed at the front end and the rear end of a first rectangular plate respectively, the middle of the first rectangular plate is provided with a rectangular hole, a first pin shaft is inserted into the rectangular hole, the lower end of the first pin shaft is fixed on the radius of a first wheel, the circular center of the first wheel is fixed on a first auxiliary shaft, and a second pin shaft is inserted into the other end of the rectangular hole. A second impact cutter bar is arranged on the lower portions of the first spindle and the second spindle, a third square shaft and a fourth square shaft are fixed on the right of the second impact cutter bar, the right end of the third square shaft and the right end of the fourth square shaft are fixed at the front end and the right end of a second rectangular plate respectively, the second rectangular plate is provided with a rectangular hole in the middle, a third pin shaft is inserted into the rectangular hole and fixed on the radius of a third wheel, the circular center of the third wheel is fixed on a third auxiliary shaft, and a fourth pin shaft is inserted into the other end of the rectangular hole.

Owner:永春县产品质量检验所福建省香产品质量检验中心国家燃香类产品质量监督检验中心福建

Advanced detector system and method using forward three-dimensional induced polarization method for tbm construction tunnel

ActiveUS20140333308A1Improve work efficiencyLow costElectric/magnetic detection for well-loggingSurveyBound waterEngineering

Disclosed is an advanced detector system and method using a forward three-dimensional induced polarization method for a TBM (Tunnel Boring Machine) construction tunnel. A narrow detection space of a full-face excavated tunnel is fully used, a controller controls doors of a source and measuring electrode compartment and a shielding electrode compartment to open and controls a corresponding hydraulic delivery device to automatically and quickly arrange a source electrode system, a measuring electrode system and a shielding electrode system. Under the action of a shielding current system, tomography detection supply current is directed ahead of the working face. Three-dimensional geologic information can be obtained, and the relationship between an induced polarization half-decay time difference and a water quantity can be used to quantitatively forecast the water quantity of a water-bearing body, and meanwhile, the half-decay time difference parameter has a high capacity of distinguishing free water from bound water.

Owner:SHANDONG UNIV

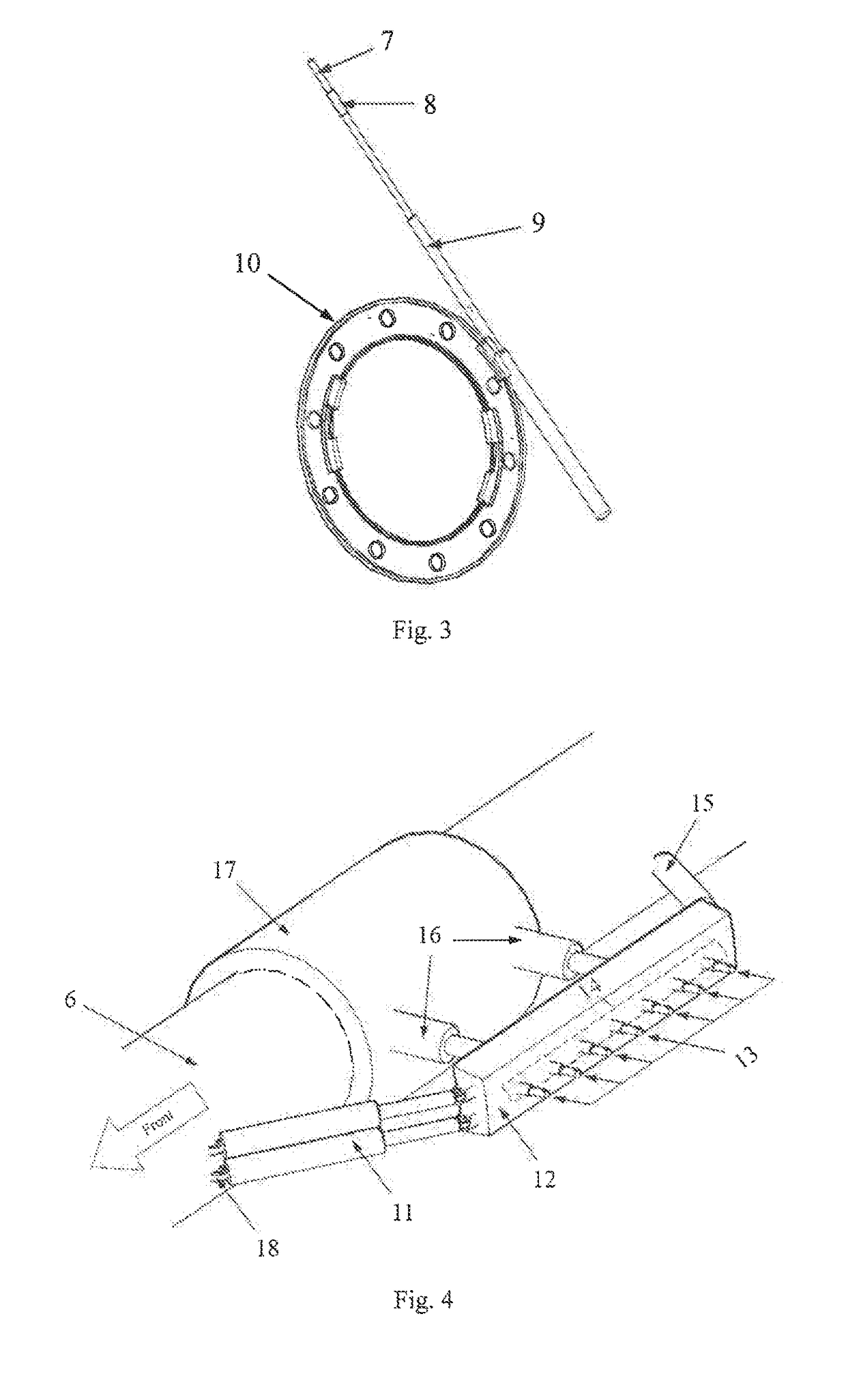

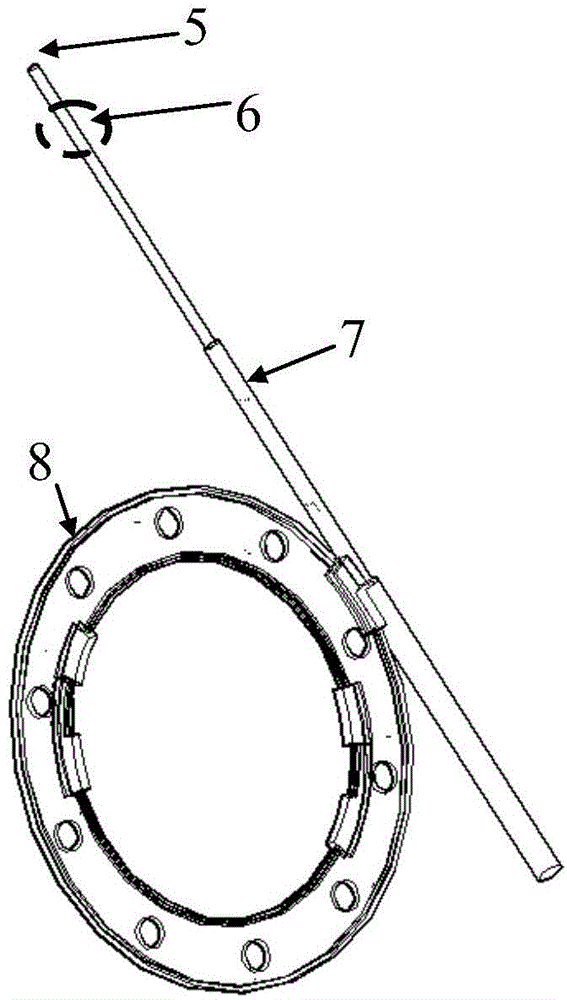

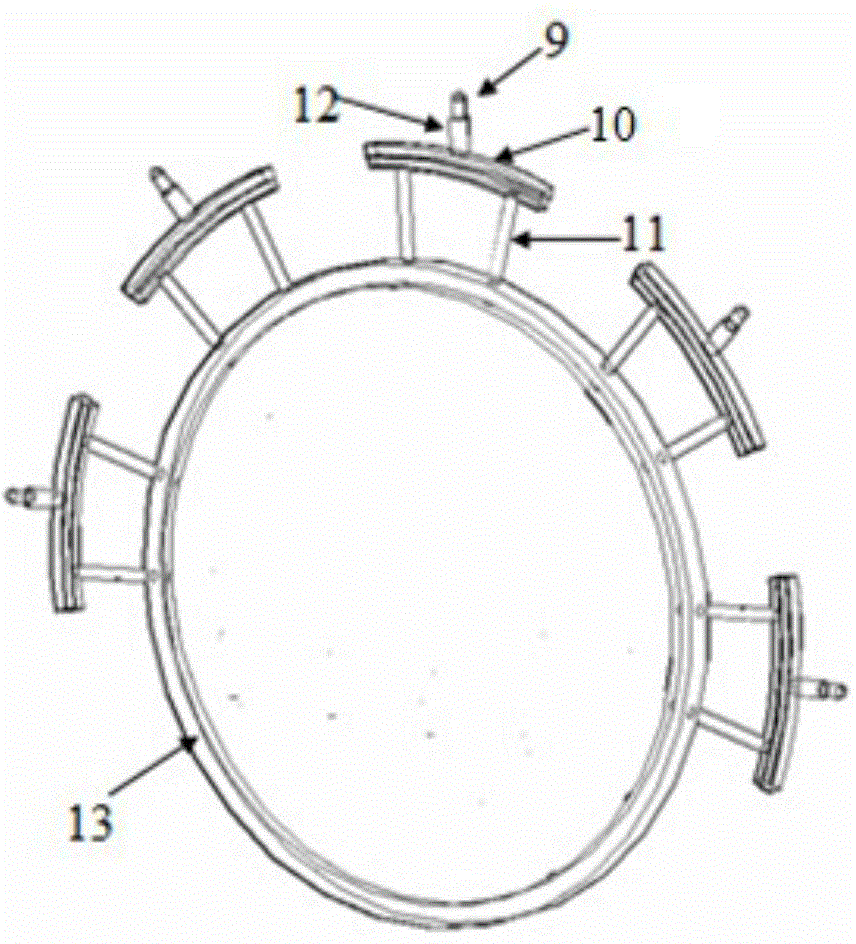

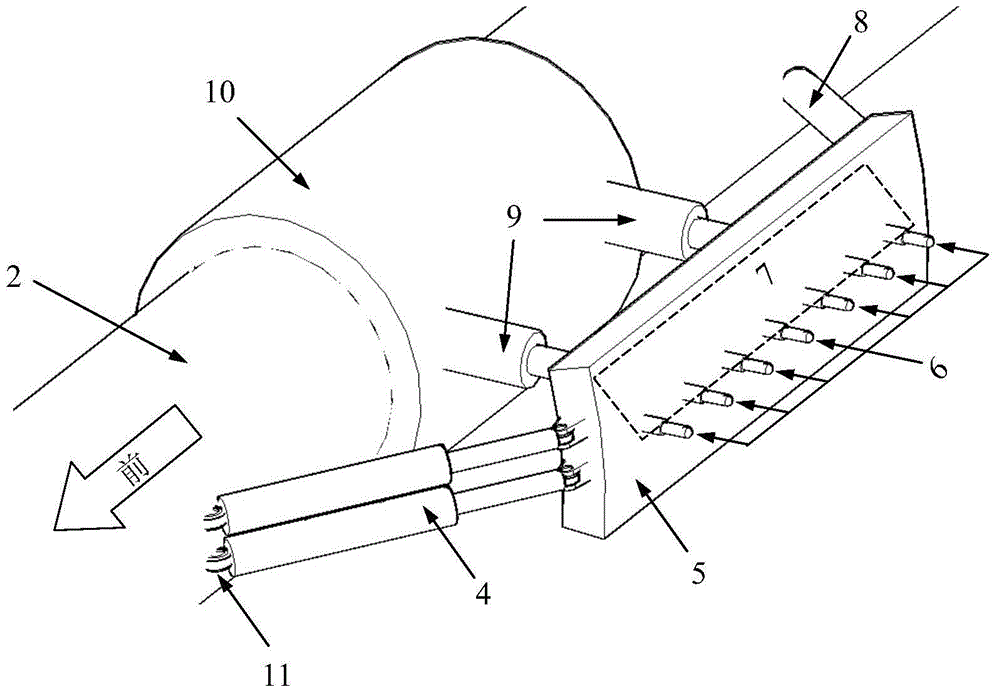

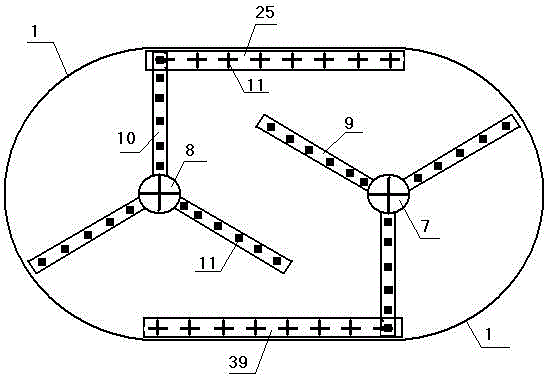

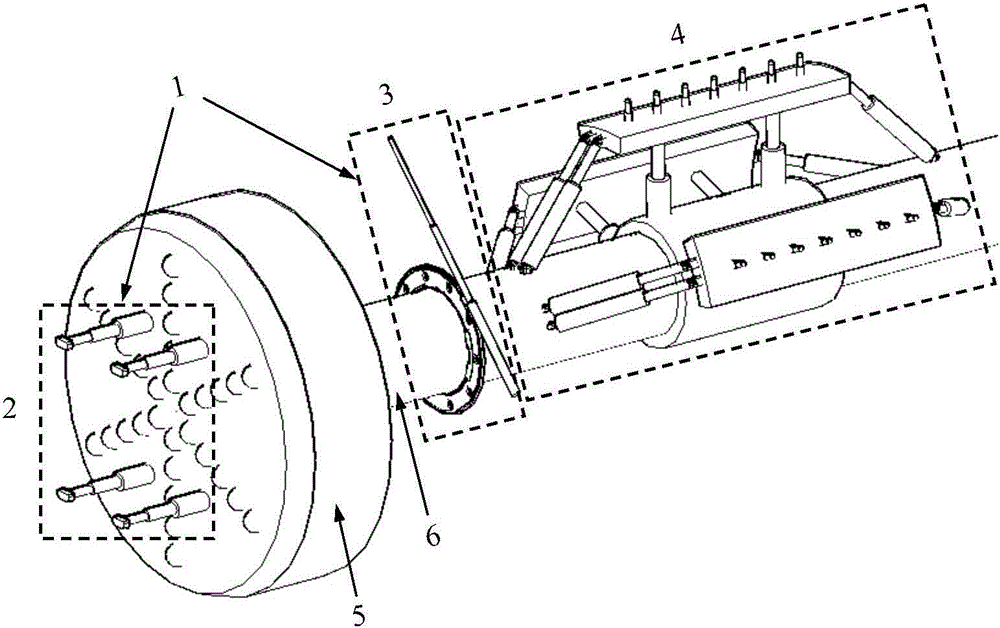

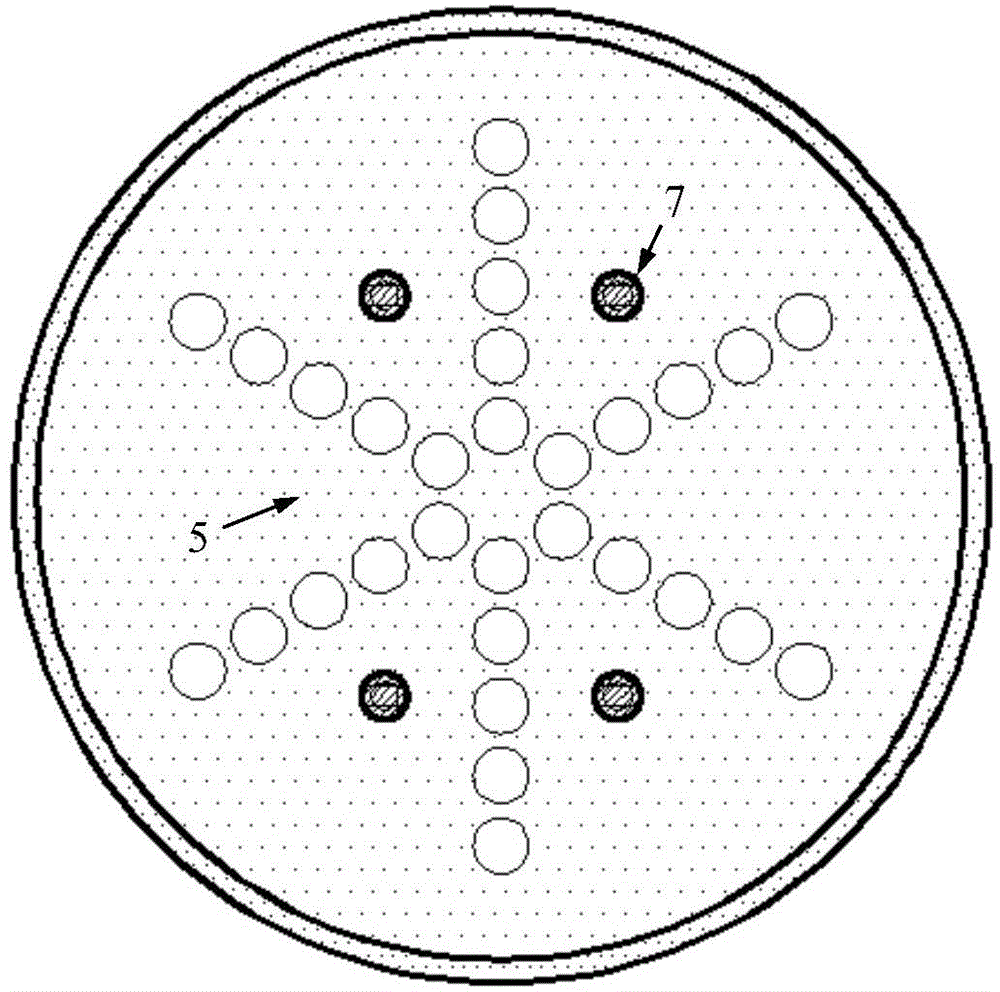

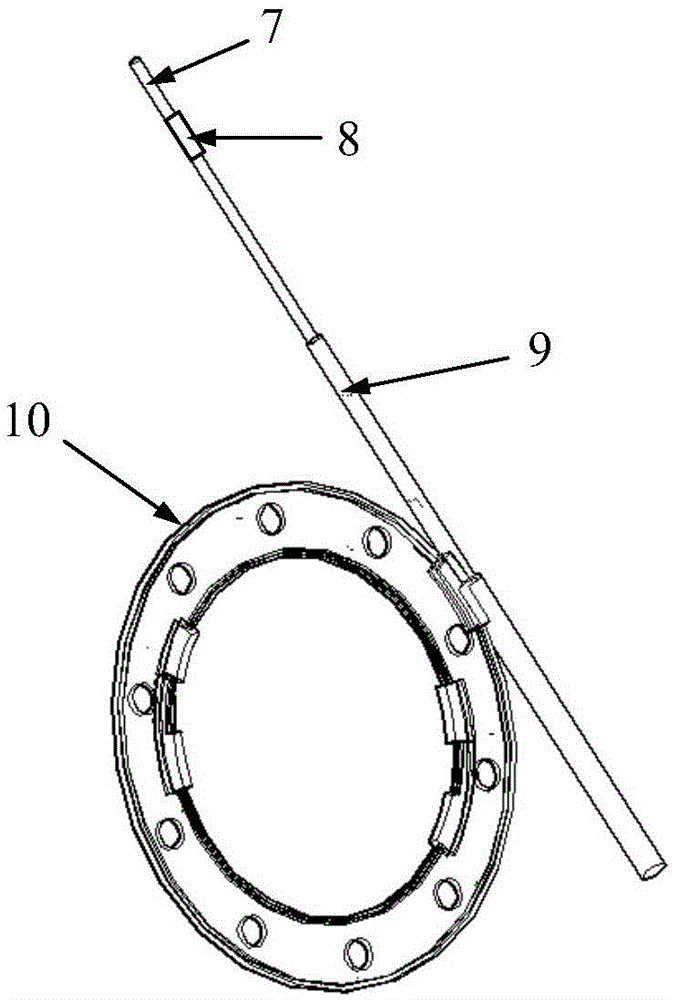

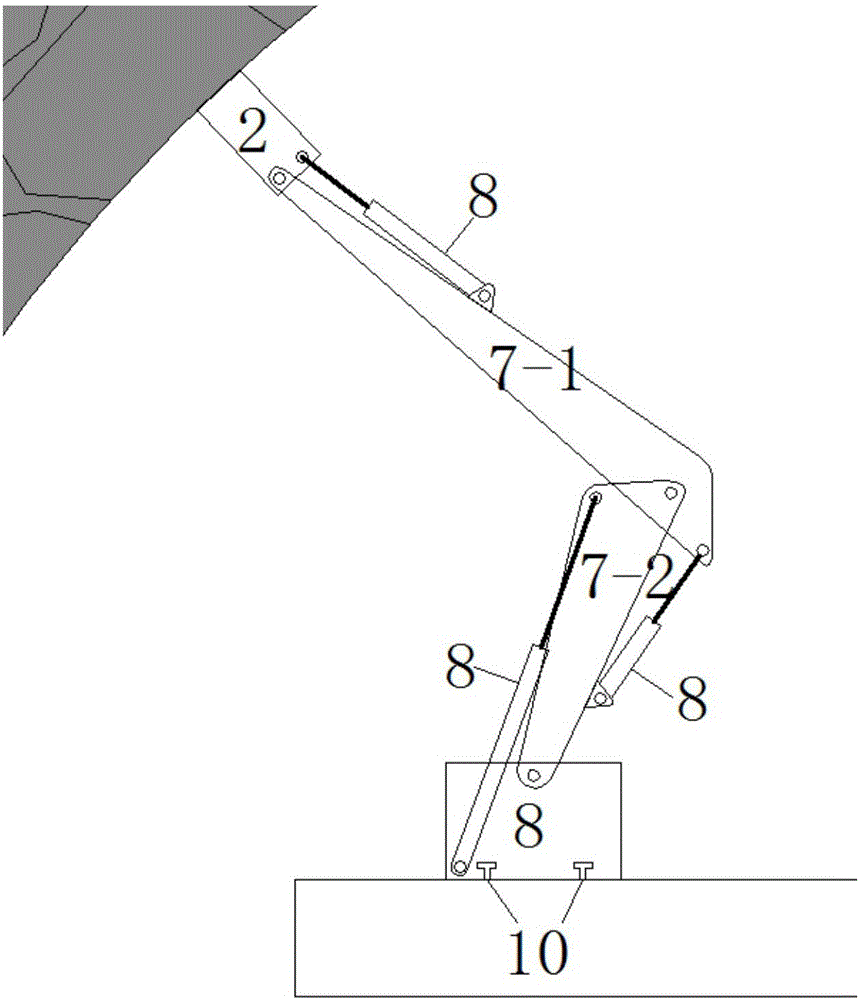

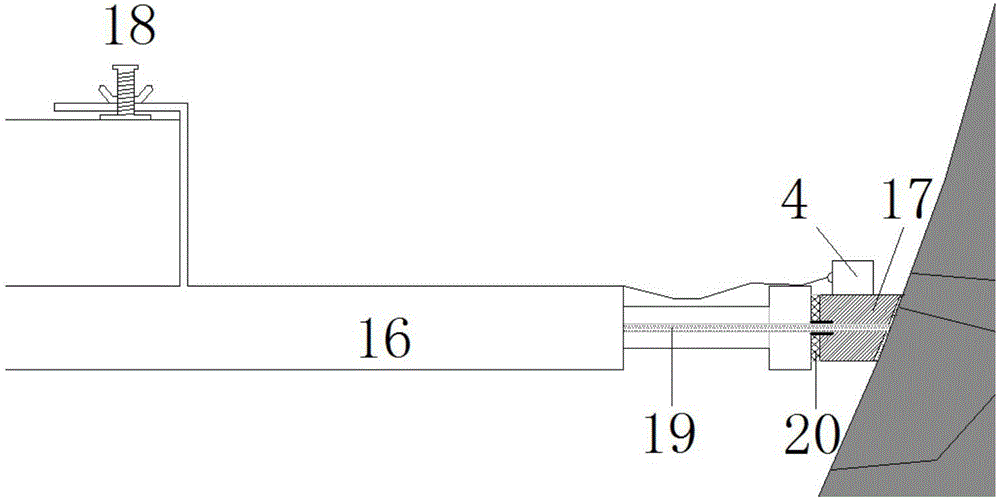

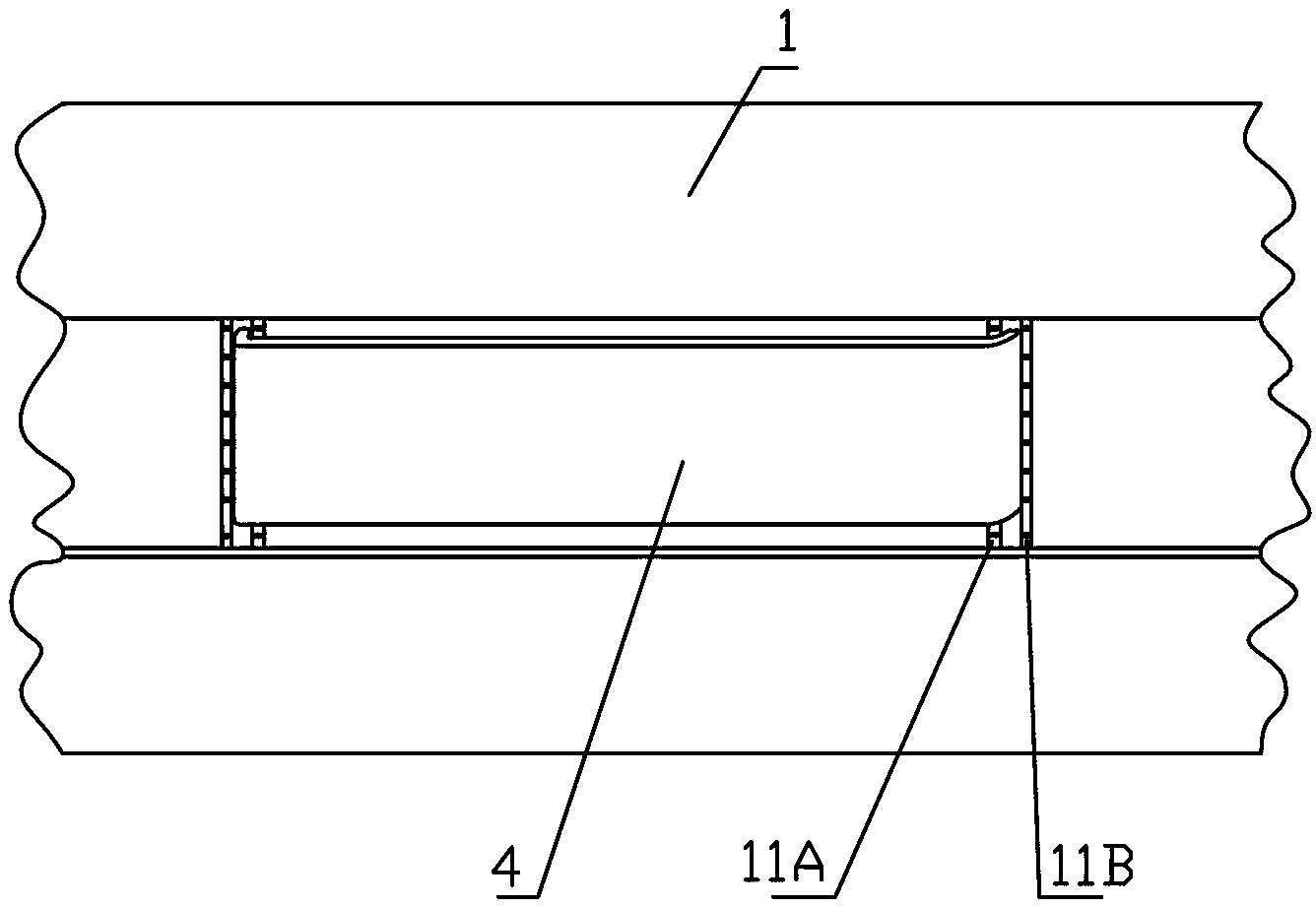

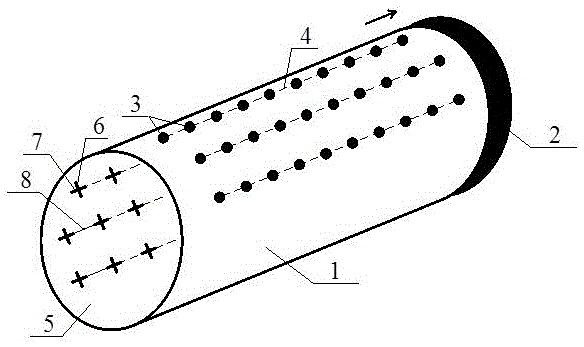

Carrying device of three advance geology forecasting instruments on TBM (Tunnel Boring Machine)

ActiveCN103698806AAdvancement of Geological Forecasting AbilitySimple structureSeismic signal receiversRadarEngineering

The invention discloses a carrying device of three advance geology forecasting instruments on a TBM (Tunnel Boring Machine). The carrying device comprises a transmission supporting and shock absorption device, a telescopic transmission system and an instrument cabin protection device, wherein the transmission supporting and shock absorption device is convenient for carrying power supplying / measuring electrodes, and installing seismic wave vibration exciters and a seismic wave sensor on a TBM cutter disk; the telescopic transmission system is convenient for carrying an oblique single-hole geology radar transmitting and receiving antenna above a TBM rear support; the instrument cabin protection device plays a protection role when the TBM is in boring operation and is convenient for carrying an instrument cabin controlling the whole detection work at the inner part of the TBM rear support. According to the carrying device disclosed by the invention, the integration of detection instruments and the TBM is realized, the detection space and the detection time of a full-face excavation tunnel are fully utilized, the detection instruments are automatically and quickly distributed on a working surface of the TBM, an advance detection hole is drilled, the three advance geology forecasting instruments are successfully carried, the detection efficiency of advance geology forecasting and the automation and rapidity level are increased, and the advance geology forecasting capacity of the TBM is obviously enhanced.

Owner:山东百廿慧通工程科技有限公司

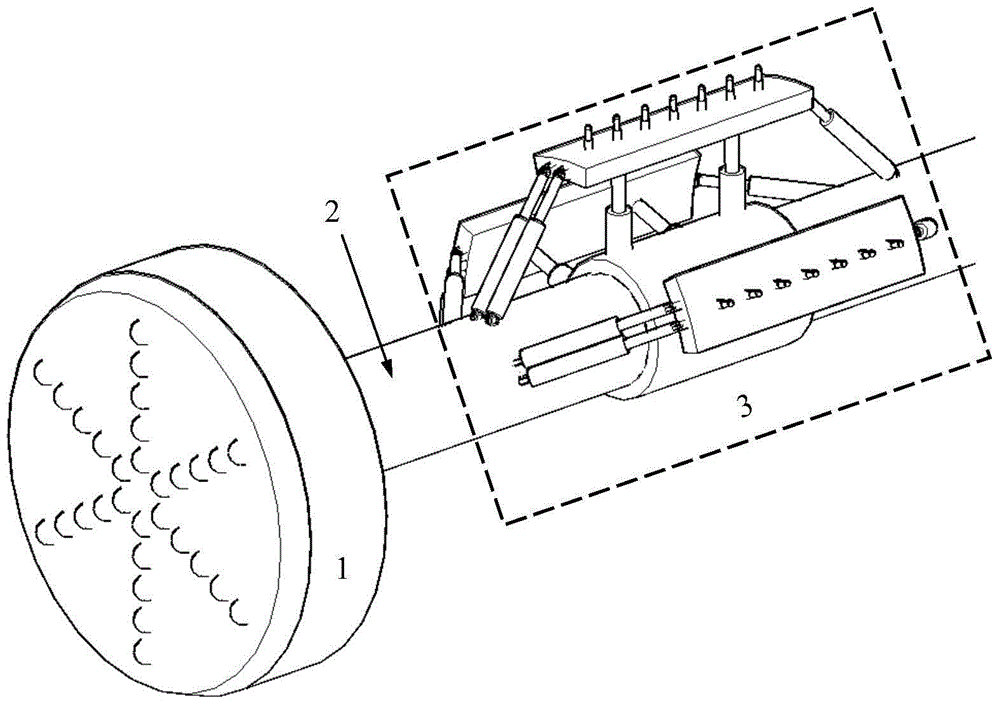

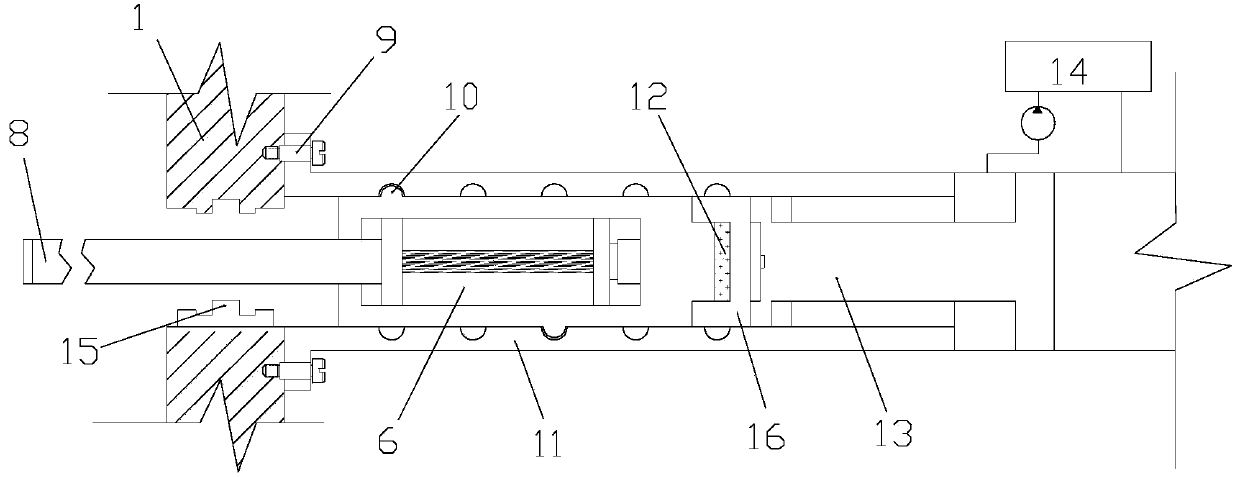

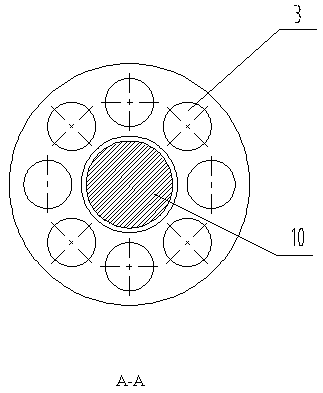

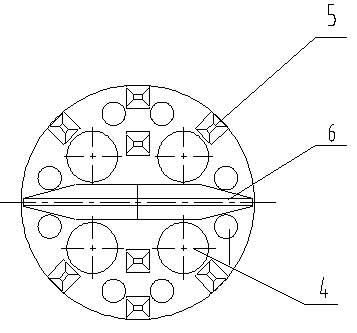

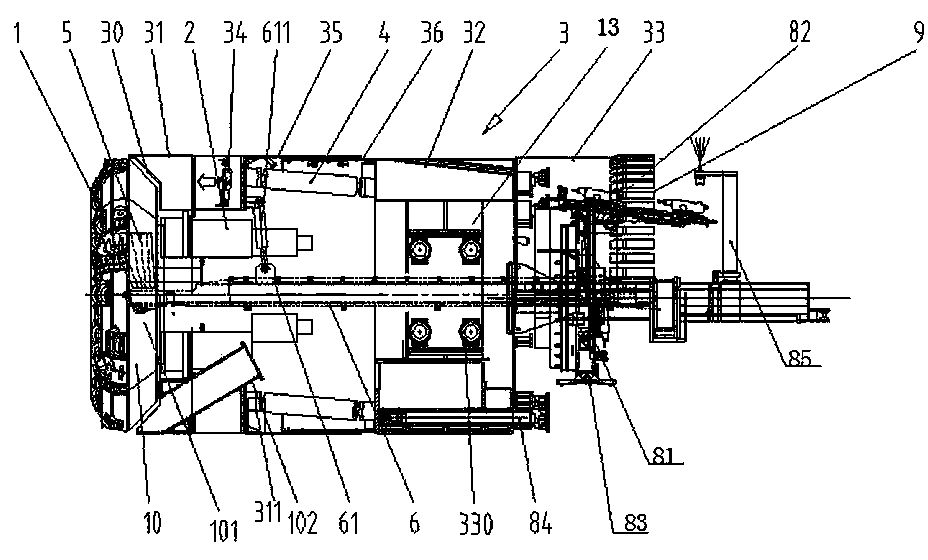

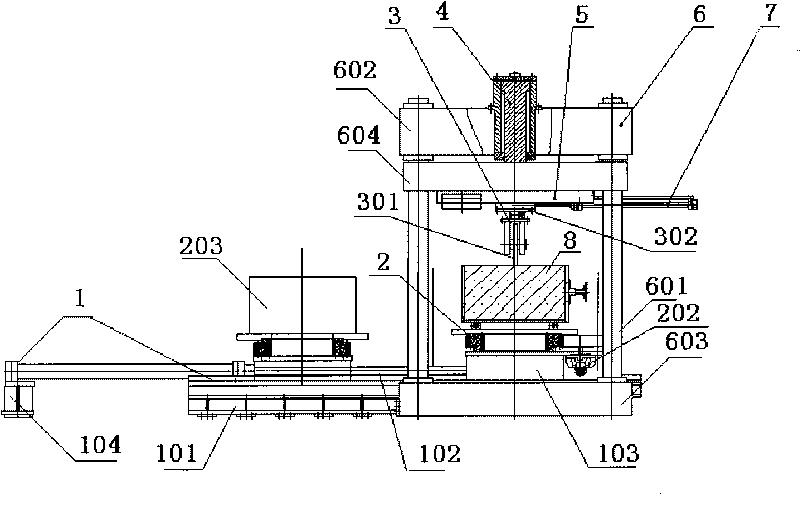

Miniature TBM (Tunnel Boring Machine) excavation system for tunnel excavation in physical simulation test

InactiveCN103364218AImprove excavation efficiencyImprove accuracyStructural/machines measurementTunnelsEngineeringRock tunnel

The invention relates to a miniature TBM (Tunnel Boring Machine) excavation system for tunnel excavation in a physical simulation test and belongs to the technical field of geotechnical engineering. The system comprises a cutter head, a protective shield, a gripper, a transmission shaft, a pulling jack, a guide rail, a motor, a base and the like; one end of the pulling jack is fixed to a support rack; a piston at the other end of the pulling jack is used for pulling the base and the motor to move forwards or backwards together; the motor is used for driving the transmission shaft to rotate to push the cutter head to move forwards to cut tunnel face rock mass; jacks on two sides of the gripper can push gripper arms to exert specified pressure to wall rock. The system can accurately simulate the rock breaking process of the cutter head, takes the interaction between the wall rock and the gripper, the interaction between the tunnel face and cutter head and the interaction between the wall rock and the protective shield into consideration, can be applied for simulating a shield TBM to excavate a soft rock tunnel, a subway or the like in a common geomechnical model test and can also be applied for simulating excavation of a TBM for a deep-lying hard rock tunnel to study the relationship between rock-machine interaction and rock burst.

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI

Tunnel boring machine rock breaking seismic source and active source three-dimensional seismic combined advanced detection system

ActiveCN104678428AFlexible layoutQuick layoutSeismic energy generationSeismic signal receiversShortest distanceSafety control

The invention discloses a tunnel boring machine rock breaking seismic source and active source three-dimensional seismic combined advanced detection system. The system comprehensively utilizes two modes of active source seismic source and rock breaking seismic source to perform three-dimensional seismic combined advanced detection, adopts an active source seismic method with high shock energy to realize long distance advanced prediction and positioning recognition of geological anomalous bodies before operation of a tunnel boring machine, performs adjustment and optimization on the following construction of the tunnel boring machine according to a detection result, adopts cutterhead rock breaking vibration with weak shock energy and high ratio of transverse wave components as a seismic source, adopts an unconventional rock breaking seismic source seismic record processing method to realize the real-time short-distance accurate prediction of the geological anomalous bodies, performs representation and evaluation on the quality of surrounding rock in a region to be excavated, finally comprehensively judges the geological condition of a part in front of a working surface according to combined results of active source and rock break seismic source three-dimensional seismic advanced detection, and provides a support for the optimization of tunnel boring machine operating parameters and construction safety control.

Owner:山东百廿慧通工程科技有限公司

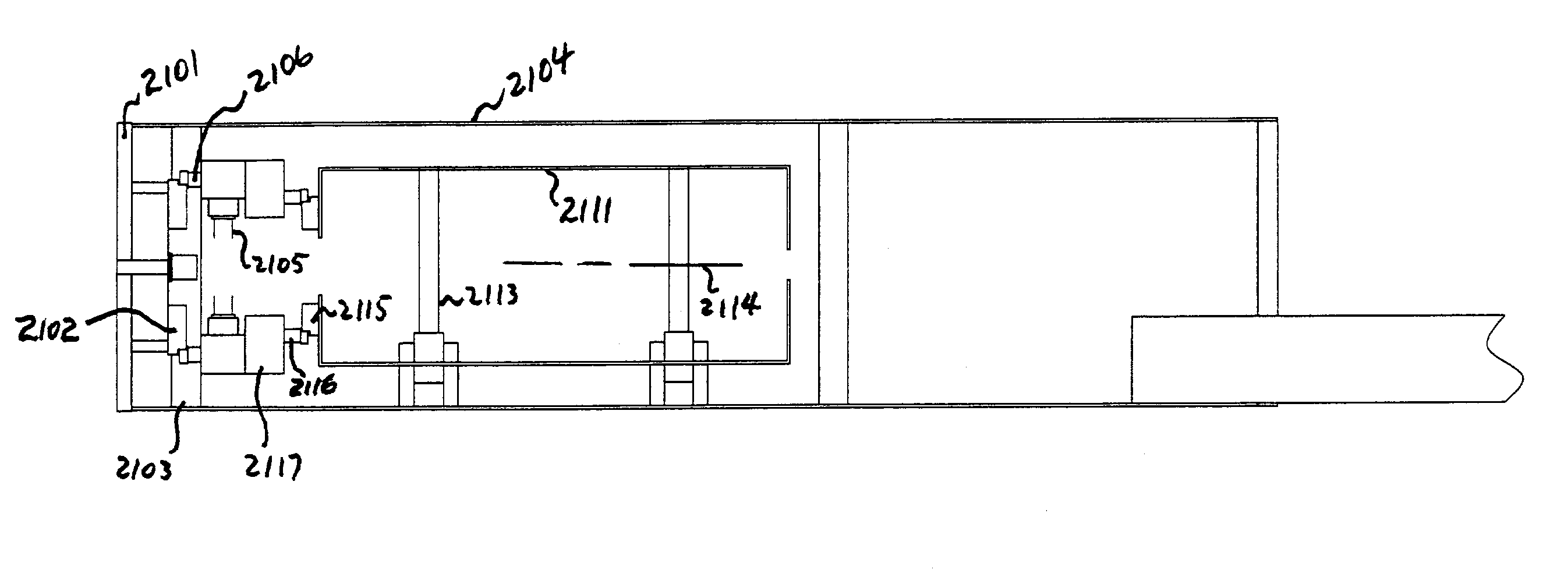

Device and method for carrying TBM (tunnel boring machine) seismic wave advanced prediction instruments

ActiveCN106772565AFast and flexible automatic layoutGuaranteed Detection PerformanceSeismic energy generationSeismic signal receiversClassical mechanicsTunnel boring machine

The invention discloses a device and a method for carrying TBM (tunnel boring machine) seismic wave advanced prediction instruments. The device for carrying the TBM seismic wave advanced prediction instruments comprises a seismic wave excitation machine carrying device and a seismic wave detector carrying device. The seismic wave excitation machine carrying device comprises bases, and the bases are arranged on slide rails axially arranged along tunnels, are connected with first driving mechanisms and can move along the slide rails under the driving effects of the first driving mechanisms; the first driving mechanisms are connected with a controller; an excitation machine is mounted at the tail end of a mechanical arm, the other end of the mechanical arm is mounted on the bases, the bases can move along the slide rails under the driving effects of the first driving mechanisms, and accordingly excitation can be carried out on different cross sections by the excitation machine; the mechanical arm is connected with second driving mechanisms, and angles of the excitation machine and angles of tunnel walls can be adjusted by the mechanical arm under the effects of the second driving mechanisms, so that excitation effects can be guaranteed; the first driving mechanisms and the second driving mechanisms are connected with the controller.

Owner:SHANDONG UNIV +1

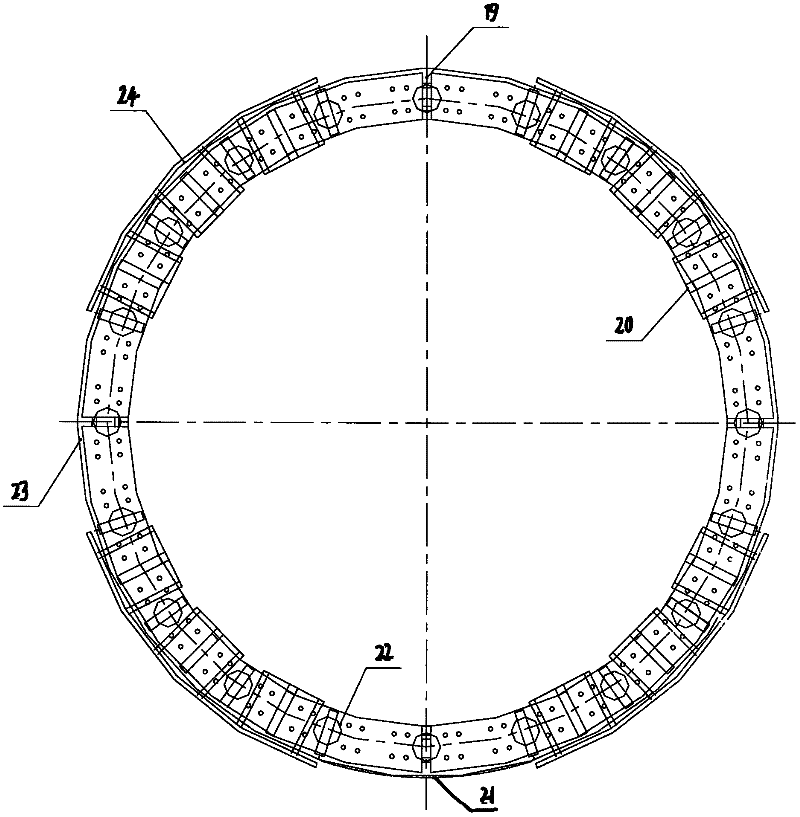

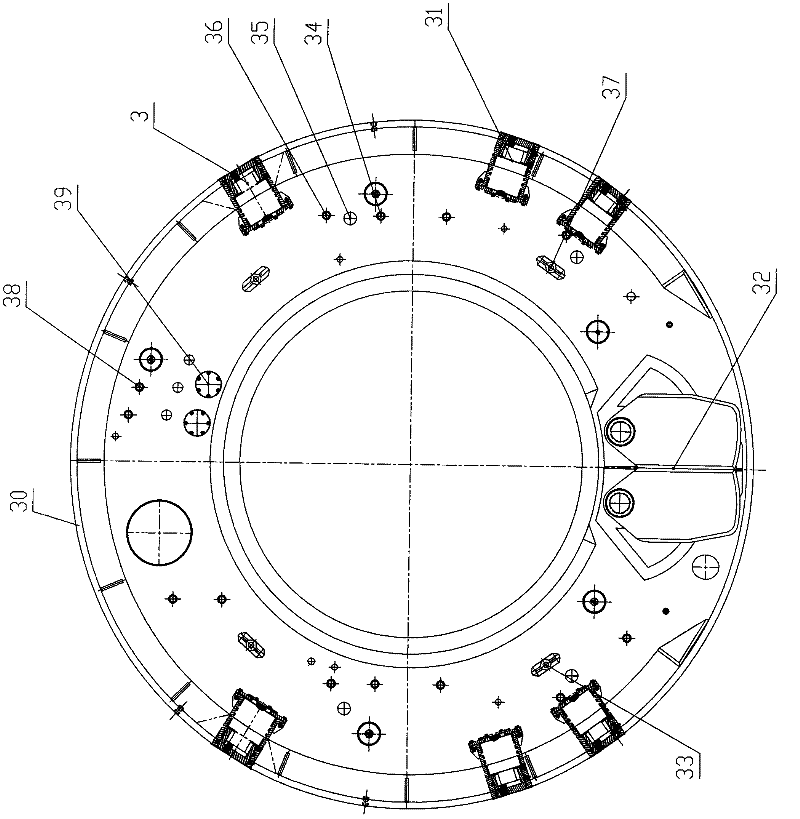

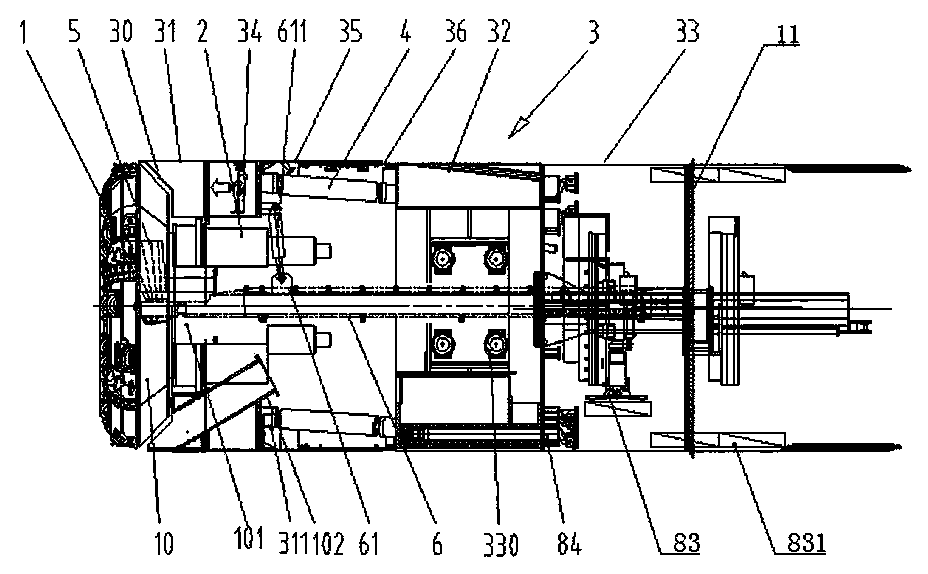

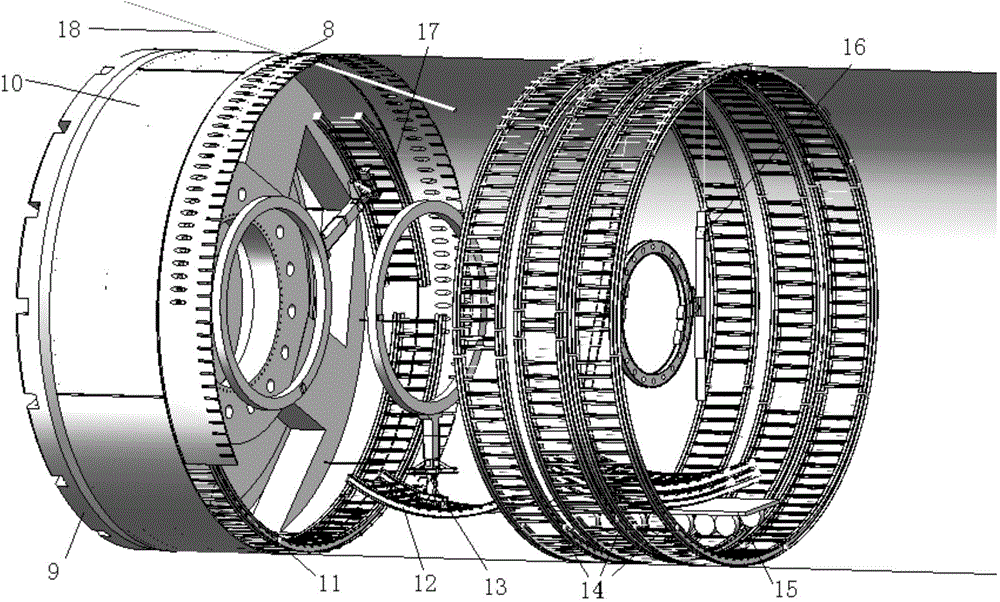

Combined type double-shield tunneling machine

ActiveCN104196538AIncrease the lengthShorten the lengthUnderground chambersTunnel liningSupporting systemDual mode

The invention discloses a combined type double-shield tunneling machine which comprises a cutter, an anterior shield, a cab, a main driving device, an inside-and-outside stretching shield, a V-shaped arrangement main propelling system, a hinge system, a supporting shield, a boot supporting system, a tail shield, an auxiliary propelling system, a dual-mode deslagging system, an integration supporting system and the like. Four working modes including of the double shielding modes including the support boot and segmental lining mode and the support boot and anchor-plate timbering mode, the single shielding mode and the ERB mode can be achieved, and efficient tunneling, efficient deslagging and efficient timbering are achieved under the hard rock, sandy soil and soft soil geological conditions. The combined type double-shield tunneling machine has the outstanding advantages that one device can meet various complex-geology tunneling construction requirements, the geology applicability of the tunneling machine is greatly improved, the frequency of tunneling machine replacement in tunnel construction is decreased, and production efficiency is greatly improved.

Owner:中船(青岛)轨道交通装备有限公司

TBM hob abrasion detection device

InactiveCN103234903ACompact structureEasy to assembleMaterial analysis by optical meansUsing optical meansControl systemEngineering

The invention discloses a TBM (tunnel boring machine) hob abrasion detection device comprising a concave shaped shell, the inward concave side wall of which is made of a transparent material. Two ends of the concave shaped shell inward concave side wall are an optical signal emission end and a receiving end respectively. The optical signal emission end can emit a set of parallel laser beams, and the optical signal receiving end is a set of photosensitive sensors, so that a plurality of parallel optical paths can be formed, and the on-off state of the optical paths can be determined by the abrasion degree of a hob ring. The device is also provided with a cleaning structure, a power supply and a control system. The control system receives data coming from the photosensitive sensors, and transmits the data to a TBM operation room host machine. With the advantages of simple structure, convenient installation, high efficiency and reliable work, strong practicality, cheapness, portability, easy control and the like, the TBM hob abrasion detection device provided in the invention also can eliminate the optical path breakover problem probably caused by rock powder during use, and is especially suitable for hard rock tunneling TBM hobs, thus making real time dynamic abrasion detection on the hob installed on a cutterhead become possible.

Owner:TIANJIN UNIV

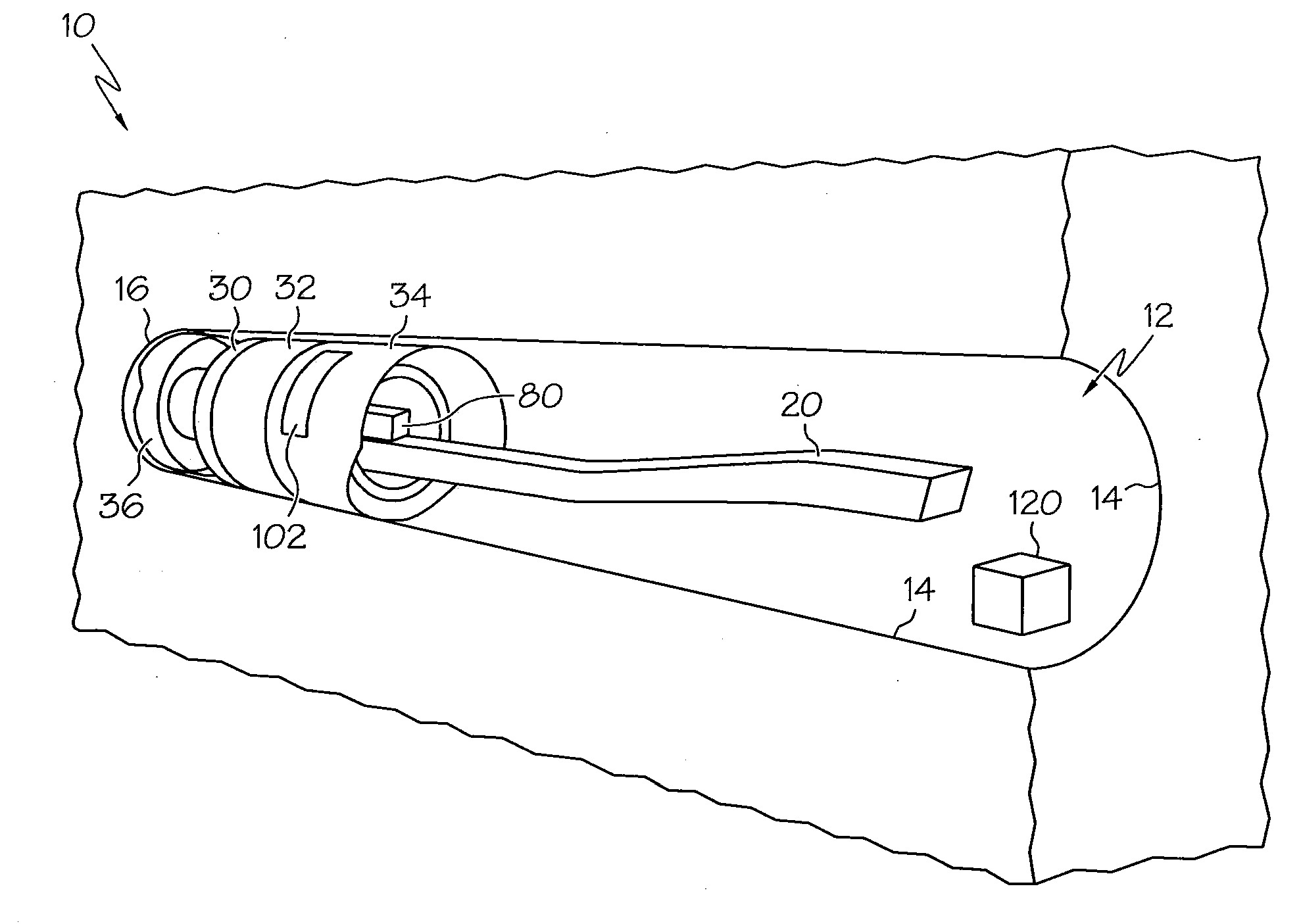

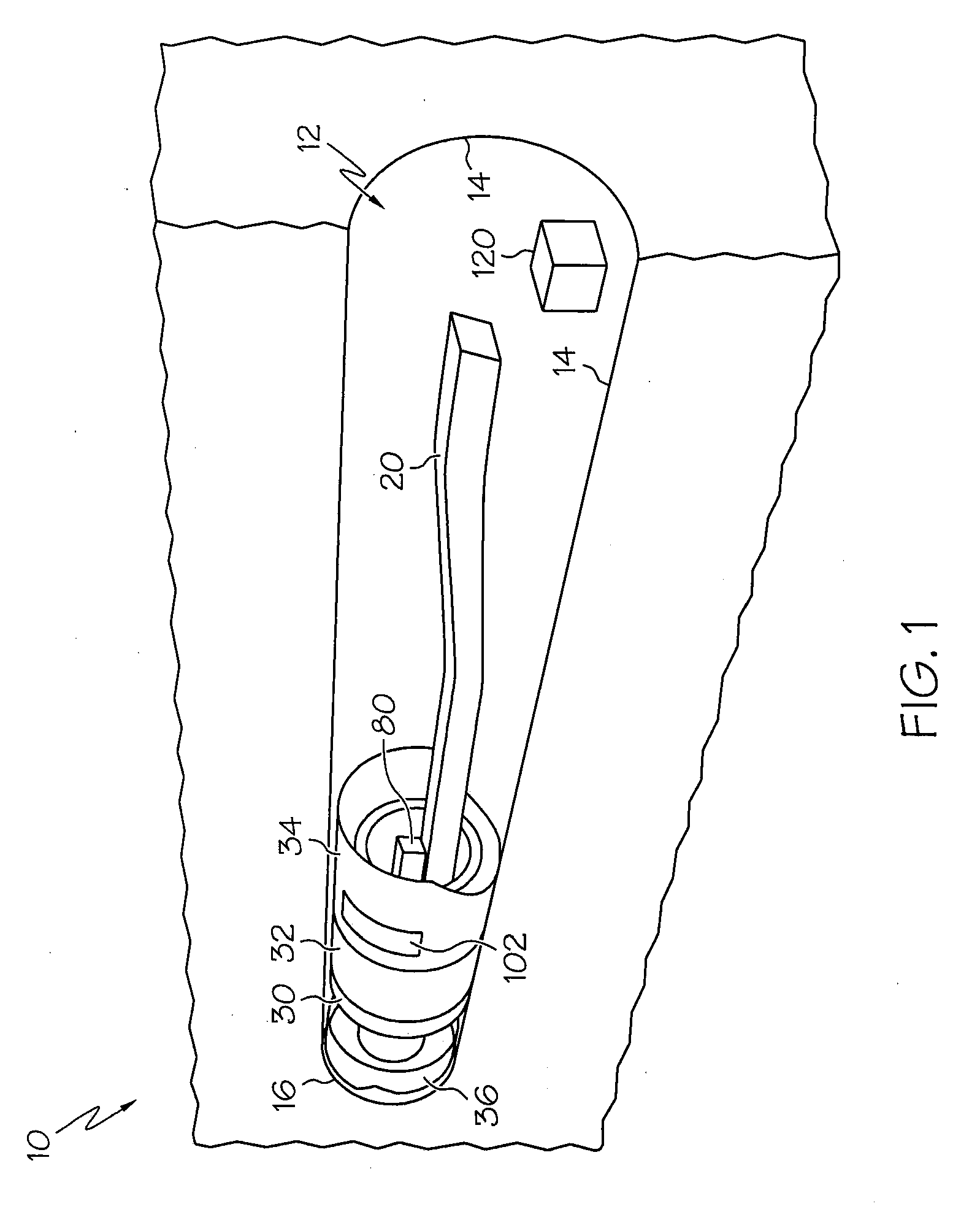

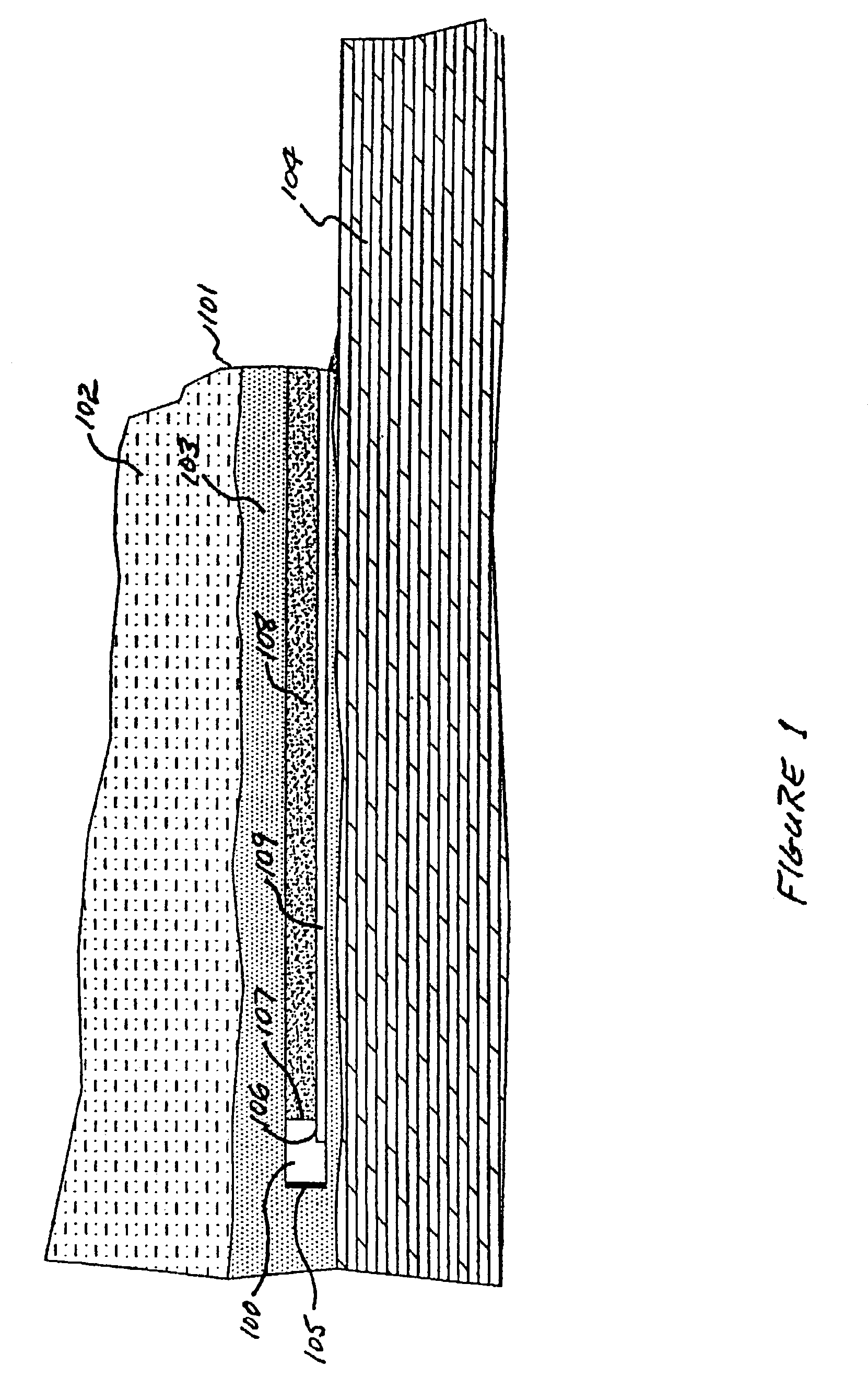

Method and means for processing oil sands while excavating

InactiveUS7097255B2Easy to separateReciprocating drilling machinesUnderground miningSanderTunnel boring machine

The present invention is directed to the separation of bitumen, such as by the Clark process or by a countercurrent de-sander, in an underground excavation machine, such as a tunnel boring machine.

Owner:OSUM OIL SANDS CORP

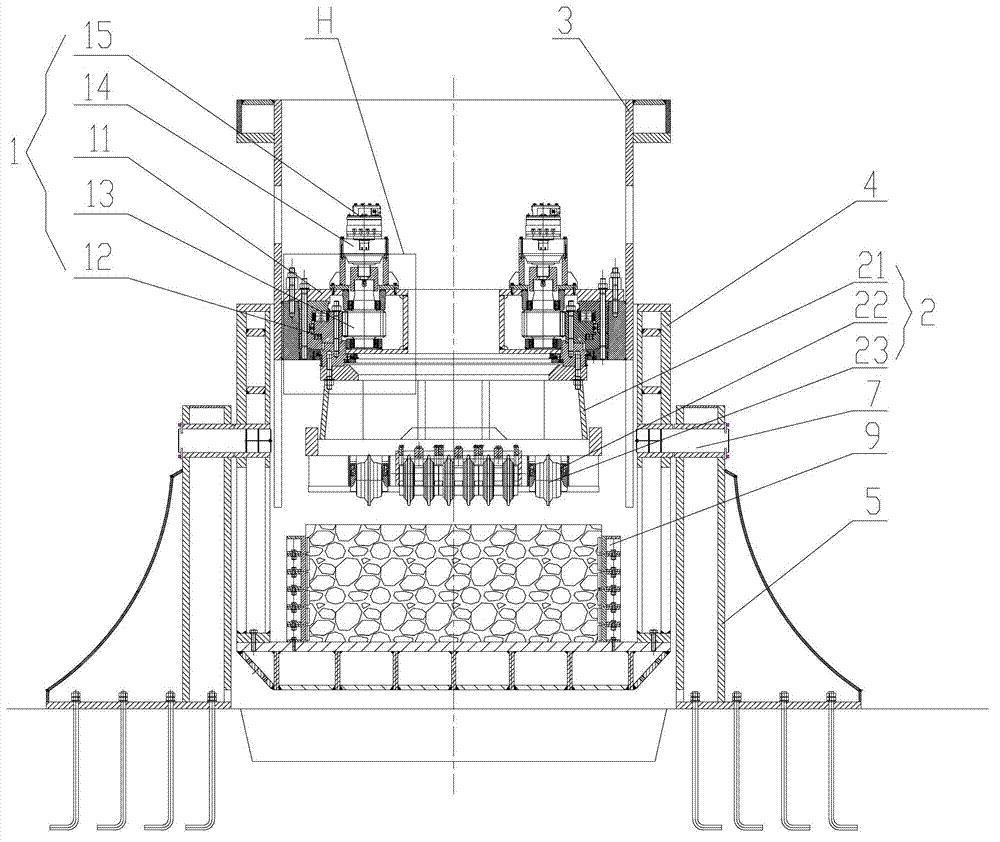

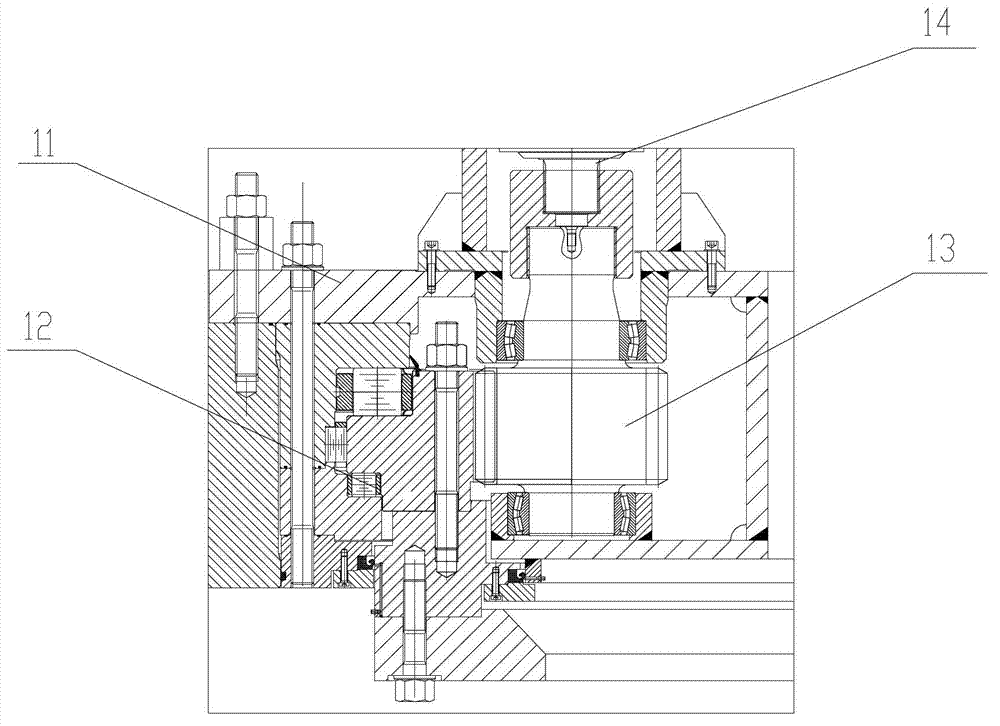

Shield and TBM (tunnel boring machine) hob test bed

InactiveCN102788693AAchieve regulationMachine part testingAutomotive engineeringTunnel boring machine

The invention discloses a shield and TBM (tunnel boring machine) hob test bed which comprises a test bed main unit and supports distributed symmetrically. The test bed main unit is rotatably connected with the supports, the rotation angle is at least 90 degrees, and accordingly the test bed main unit can be switched between a perpendicular state and a horizontal state. The test bed main unit is rotatably connected with the supports and can rotate at least 90 degrees, so that the test bed main unit can simulate actual moving conditions of a hob in the perpendicular state or horizontal state, cutting characteristics of the hob in different operation states can be researched, the hob is modified on the basis, and the service life of the hob is prolonged.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

A monitoring method for a surrounding rock and full face tunnel boring machine shield interaction process

ActiveCN105952465AEasy to installAccurate and reliable measurement resultsForce measurement by measuring frquency variationsForce measurement by measuring optical property variationRisk levelTunnel boring machine

The invention provides a monitoring method for a surrounding rock and full face tunnel boring machine shield interaction process. The method comprises the steps of: A, welding and installing pressure boxes to the outer surface of a shield for testing the extrusion force applied to the shield by surrounding rocks directly, placing cables of the pressure boxes in flexible cable-protecting casing pipes, and leading the cables into the shield and connecting the cables to a reading device; B, installing a surface strain sensor in each of the annular direction and the longitudinal direction of each monitoring point on the inner surface of the shield, and inversely calculating the extrusion force applied to the shield by the surrounding rocks according to the principle of elastic mechanics based on the tested annular and longitudinal strains of the inner surface of the shield; C, according to the acquired distribution rules of the extrusion force applied to the shield by the surrounding rocks, calculating the friction force borne by the shield on the premise of linear distribution of the extrusion force between two adjacent measuring points; D, according to the jamming state judging criteria and jamming risk coefficient calculation method, calculating whether the shield is jammed and giving early warning of a jamming risk level. The method solves the problem in monitoring of surrounding rock and shield interaction in a shield type TMB tunneling process, provides basis for the predictive analysis of jamming accidents and is of great importance for the safety of TBM tunneling.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI +1

Annular steel structure supporting construction method with open type TBM (tunnel boring machine)

InactiveCN103557013AAvoid manual cleaningReduce dependenceUnderground chambersTunnel liningGratingSlag

An open state is formed behind a shield of an open type TBM (tunnel boring machine), so that bolting and shotcreting with wire mesh and the like can be realized, when unfavorable geological conditions such as crushed zones are encountered, broken surrounding rock collapses and falls, which not only threatens the safety of operating personnel and equipment, but also greatly lowers the construction efficiency. The invention discloses an annular steel structure supporting construction method with the open type TBM. The supporting TBM is provided with a shield which has an annular steel structure installation space. When the unfavorable geological conditions are encountered, the annular steel structure can be fast erected in an assembly line mode under the protection of the shield, the shield is replaced with the annular steel structure for supporting the surrounding rock as the TBM tunnels; under the protection of the annular steel structure, an annular steel grating and a steel mesh hollow structure are used for carrying out the bolting and shotcreting supporting and the like, the previous extensive construction is changed to controllable standardized operation, the original open type unsafe environment is changed to a closed protected operation zone; the construction method disclosed by the invention is different from the passive supporting which is carried out after the surrounding rock collapses and falls; the annular steel structure actively close off the broken surrounding rock, then the surrounding rock becomes a part of the supporting structure, the work amount for backfilling concrete and removing slag is greatly reduced, and thus the method is more efficient and safer, the cost is reduced and the operation is easy to realize.

Owner:王静

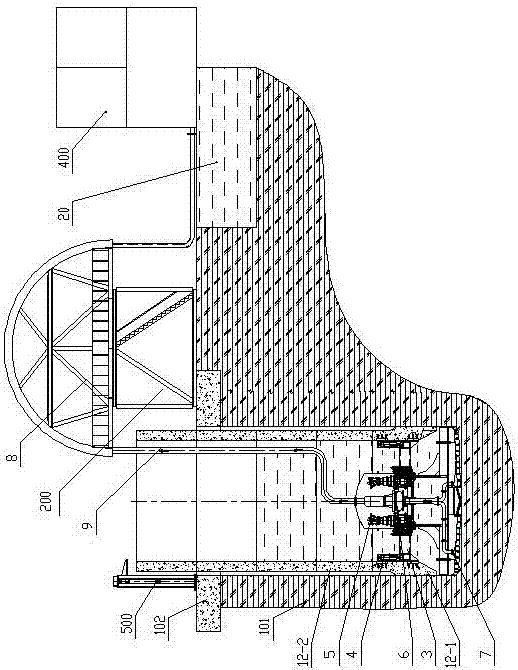

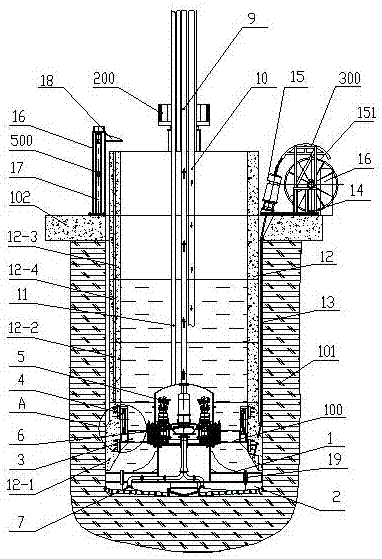

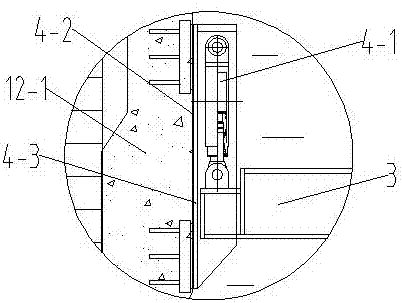

Vertical shaft tunnel boring machine by shaft sinking method and construction method of tunnel boring machine

ActiveCN107461197AChange the method of excavationReduce construction riskHydro energy generationShaft sinkingSludgeArchitectural engineering

The invention provides a vertical shaft tunnel boring machine by a shaft sinking method and a construction method of the tunnel boring machine, and solves the problems of low mechanization degree and efficiency, high risk and the like of devices and construction methods in the prior art. The tunnel boring machine comprises a tunneling mechanism, a pipe arrangement mechanism, a shaft lifting mechanism, a slurry separation system and an auxiliary pressure mechanism are mutually connected, the pipe arrangement mechanism, the shaft lifting mechanism, the slurry separation system and the auxiliary pressure mechanism are positioned on an over-ground wellhead ring beam, the tunneling mechanism comprises a tunneling shell, a cutter head is arranged at the front end of the tunneling shell, a driving fixing frame is arranged at the rear end of the tunneling shell, a feeding device and a driving device are arranged on the driving fixing frame, and the feeding device and the cutter head are connected with the driving device. The tunnel boring machine has mechanized excavation, sludge discharge and support functions and is operated on the ground, safe and reliable, underground operators are omitted in the working process of the vertical shaft tunnel boring machine, traditional shaft bottom excavation modes are changed, construction risks are greatly reduced, and operating efficiency is improved.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

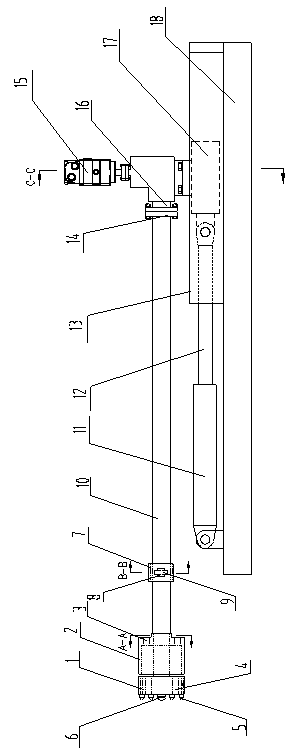

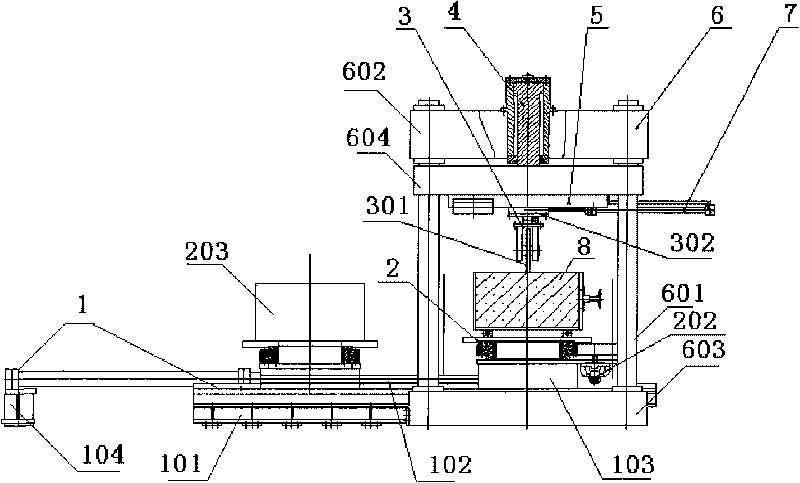

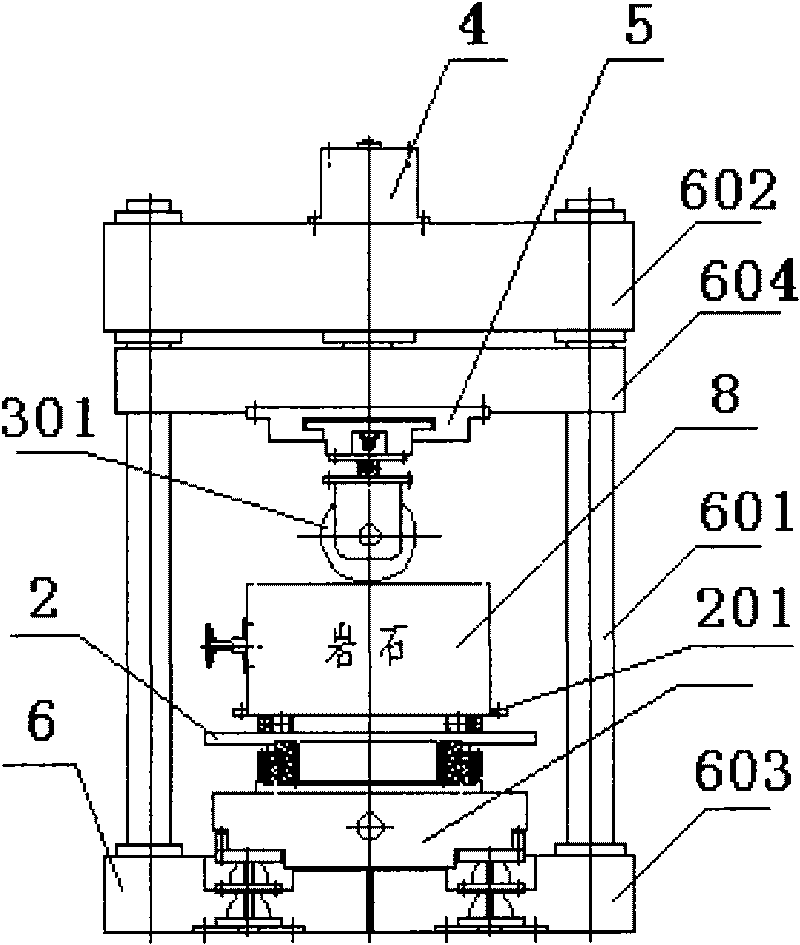

Cutting test method for rock-cutting tool

InactiveCN101713719AAffect the normal service lifeImprove stabilityInvestigating machinabilityHydraulic cylinderPresent method

The invention belongs to the field of hardware tools or tunnel boring machines, and in particular to a cutting test method for a rock-cutting tool. The cutting test method for the rock-cutting tool is characterized in that: a cutting test device for the rock-cutting tool comprises a storage box moving device, a storage box turning device, a cutting tool device, a screw-down oil cylinder device, a cutting tool moving device, a whole frame and a cutting tool locking device; the whole frame is formed by connecting an upper crossbeam, a lower crossbeam and a middle crossbeam by four prestressed pull rods; the whole frame is in rigid connection with the storage box moving device which is connected with a foundation; the storage box moving device at least comprises a pedestal, a guide rail, an operating platform and a hydraulic cylinder; the storage box turning device is arranged on the operating platform which is fixed on the guide rail on the pedestal; and the storage box turning device is moved to a working area to work by pushing the operating platform by the hydraulic cylinder. The cutting test method for the rock-cutting tool can really simulate the actual working condition of a tunnel boring machine (TBM) so as to systematically analyze the rock breaking and wearing processes of the rock-cutting tool.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

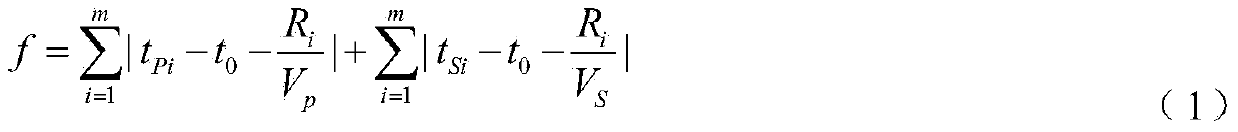

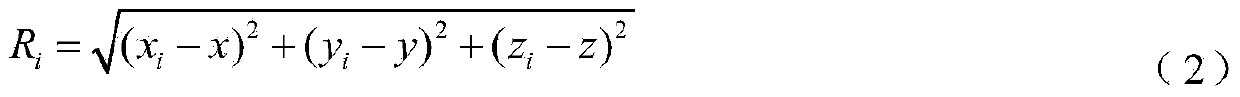

Method for acquiring micro seismic wave speed of high-stress hard rock TBM (Tunnel Boring Machine) construction tunnel in real time

InactiveCN103697999AGuaranteed accuracyThe method is economical and conciseAnalysing solids using sonic/ultrasonic/infrasonic wavesVelocity propogationTunnel boring machineWave speed

The invention relates to a construction tunnel micro seismic wave monitoring technology, in particular to a method for acquiring the micro seismic wave speed of a high-stress hard rock TBM (Tunnel Boring Machine) construction tunnel in real time. According to the technical scheme of the invention, the method comprises the following steps: arranging at least four micro seismic wave sensors in rock bodies behind the tunnel face of the high-stress hard rock TBM construction tunnel to acquire seismic signals generated by the breaking of rock bodies around the tunnel face; measuring the coordinates of a micro seismic source and the micro seismic sensors by taking the event of breaking of the rock bodies around the tunnel face as the micro seismic source, and acquiring a micro seismic wave speed by means of inversion when micro seismic source seismic signals monitored by the micro seismic sensors are extracted; inverting in real time along with TBM tunneling to obtain the micro seismic wave speed. By adopting the method, the micro seismic wave speed of the high-stress hard rock TMB construction tunnel can be acquired accurately in real time. The method is economical and simple, is practicable for operating, and is suitable for various high-stress hard rock TMB construction tunnels for use in water conservancy and hydropower, traffic and the like. The defects and impracticability of acquisition of wave speeds through positioning explosion and indoor sound waves are avoided.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com