Method for acquiring micro seismic wave speed of high-stress hard rock TBM (Tunnel Boring Machine) construction tunnel in real time

A high-stress, micro-seismic wave technology, applied in the direction of measuring propagation velocity, measuring ultrasonic/sonic/infrasonic waves, using sound waves/ultrasonic/infrasonic waves to analyze solids, etc., can solve the problem that the wave velocity is difficult to obtain accurately in real time, to avoid manpower and material resources consumption, Ensure accuracy and operationally feasible results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

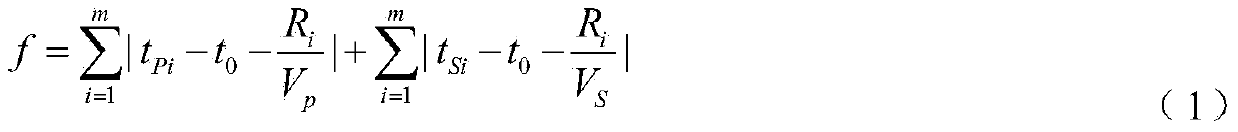

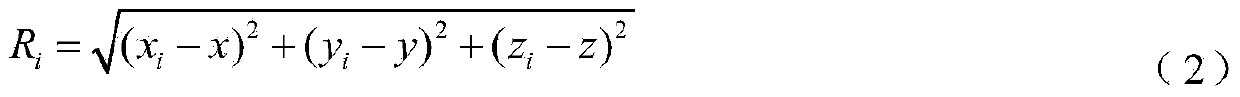

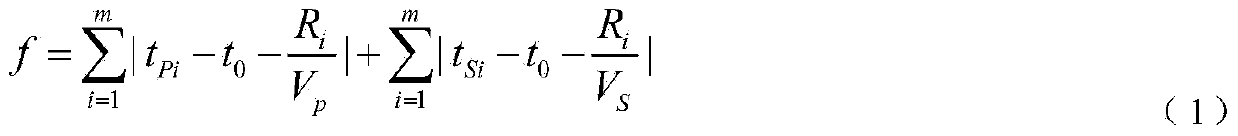

Method used

Image

Examples

specific Embodiment

[0030] The rock mass of a high-stress hard rock TBM construction tunnel is relatively complete, the tunnel section is circular, and full-section excavation is adopted. During the TBM construction process, rock mass collapse, rock burst or rock mass cracking often occur near the tunnel face.

[0031] a. Six microseismic sensors are arranged in the rock body behind the face of the high-stress hard rock TBM construction tunnel to capture the micro-vibration signals generated when the tunnel rock mass ruptures. The microseismic sensor is separated from the face by a certain distance, and it is arranged in the rock mass within 70-150m behind the face to prevent the microseismic sensor from being easily damaged by the excavation of the face if the distance is too close, and the microseismic sensor will exceed the microvibration collected by the microseismic sensor if it is too far away. range of the signal. The captured micro-vibration signals include micro-vibration signals generat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com