Intelligent detection device of defects of mobile phone outer shell based on machine vision

A mobile phone shell and intelligent detection technology, which is applied in the direction of optical testing for flaws/defects, sorting, etc., can solve problems such as slow speed and easy fatigue, and achieve the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with specific examples, but the embodiments of the present invention are not limited thereto.

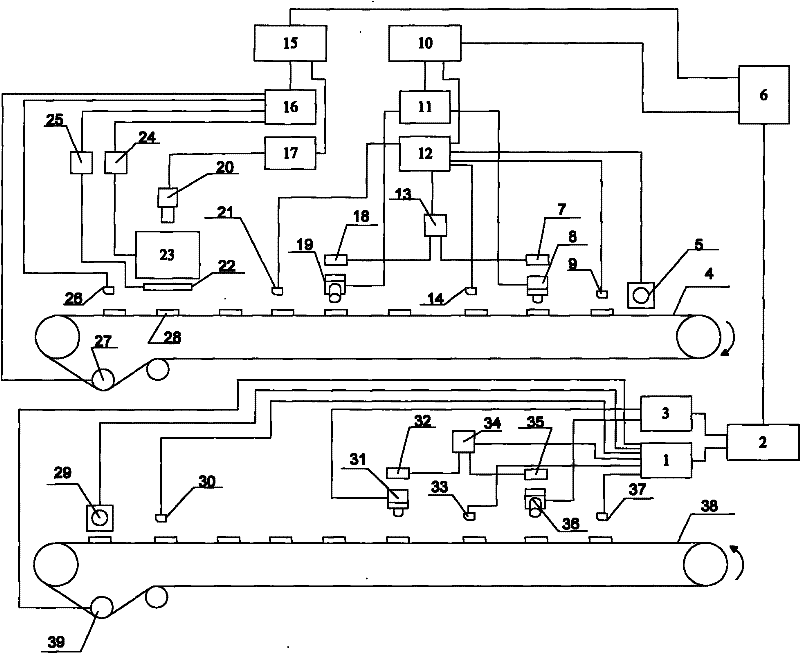

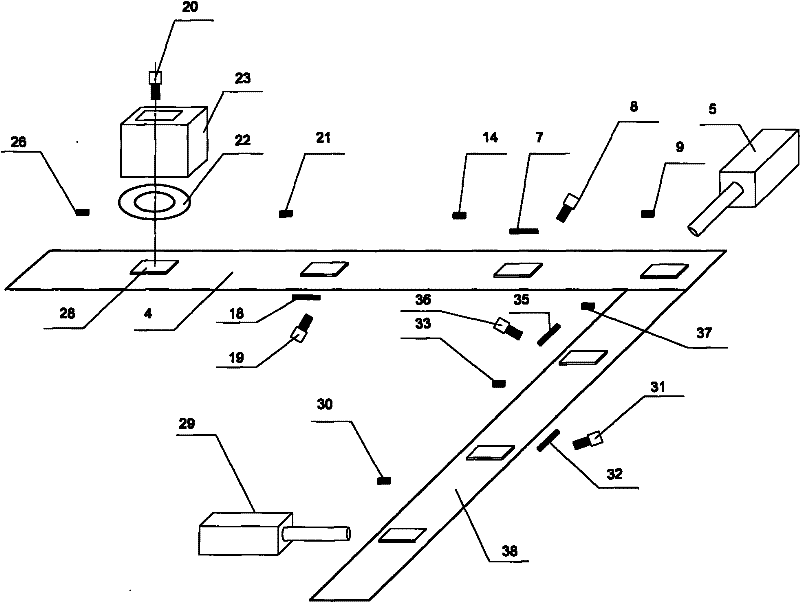

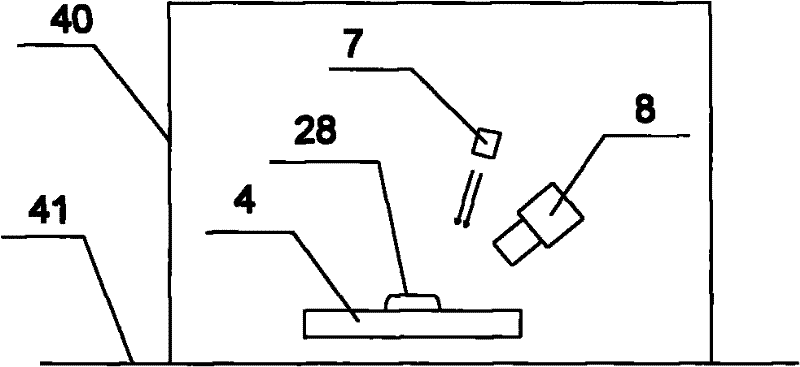

[0030] like figure 1 , the first industrial computer 15 is equipped with the first signal acquisition card 16 and the first image acquisition card 17, and this computer is responsible for the defect detection of the top surface of the mobile phone shell. The coaxial light source 23 is connected with the coaxial light source controller 24, the ring light source 22 is connected with the ring light source controller 25, the ring light source 22 is located directly below the coaxial light source 23, the axes of the two light sources coincide, and the first signal acquisition card 16 Respectively output control signals to the coaxial light source controller 24 and the ring light source controller 25, thereby respectively controlling the brightness of the coaxial light source 23 and the ring light source...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com