Patents

Literature

969results about "Velocity propogation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

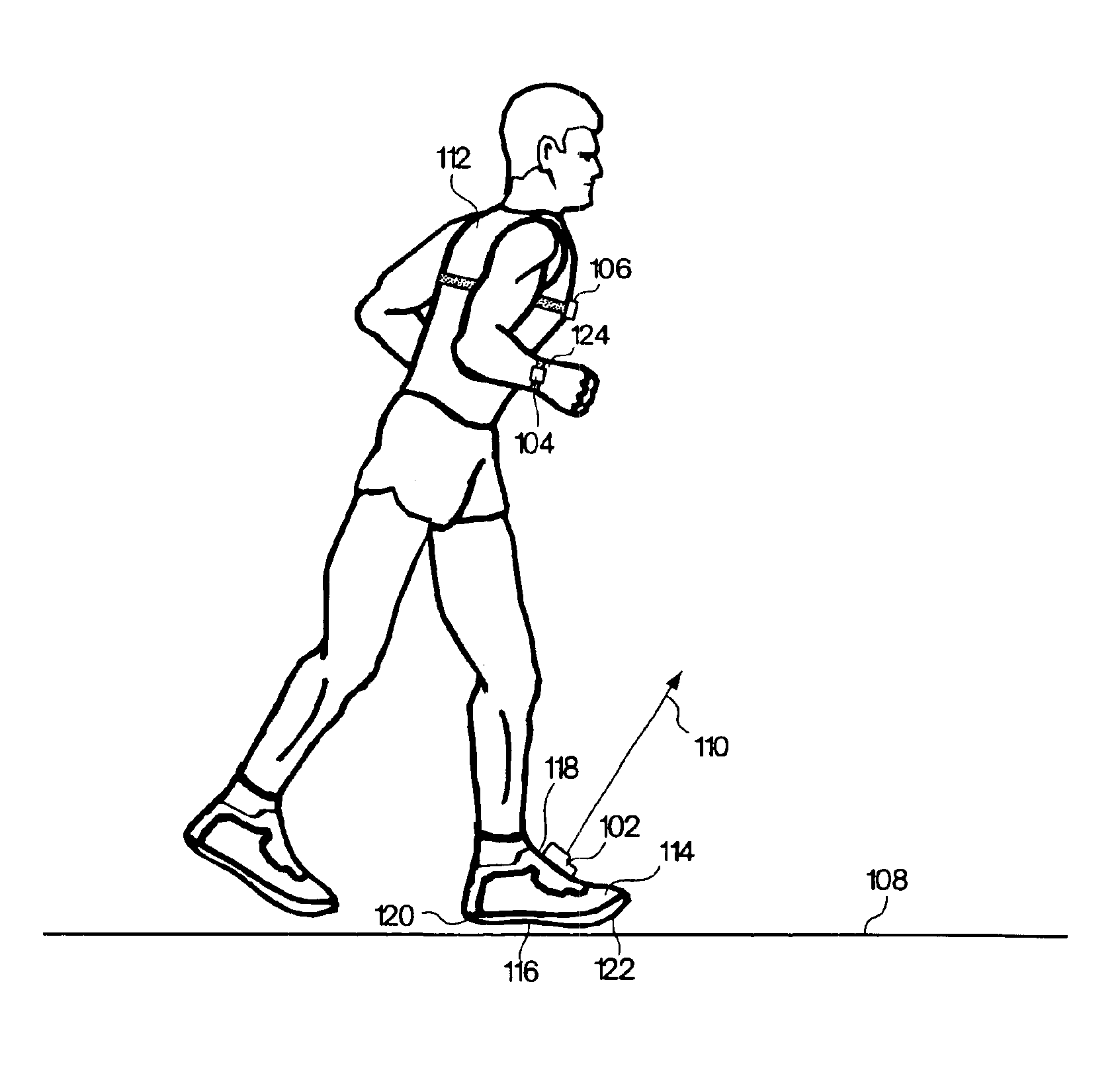

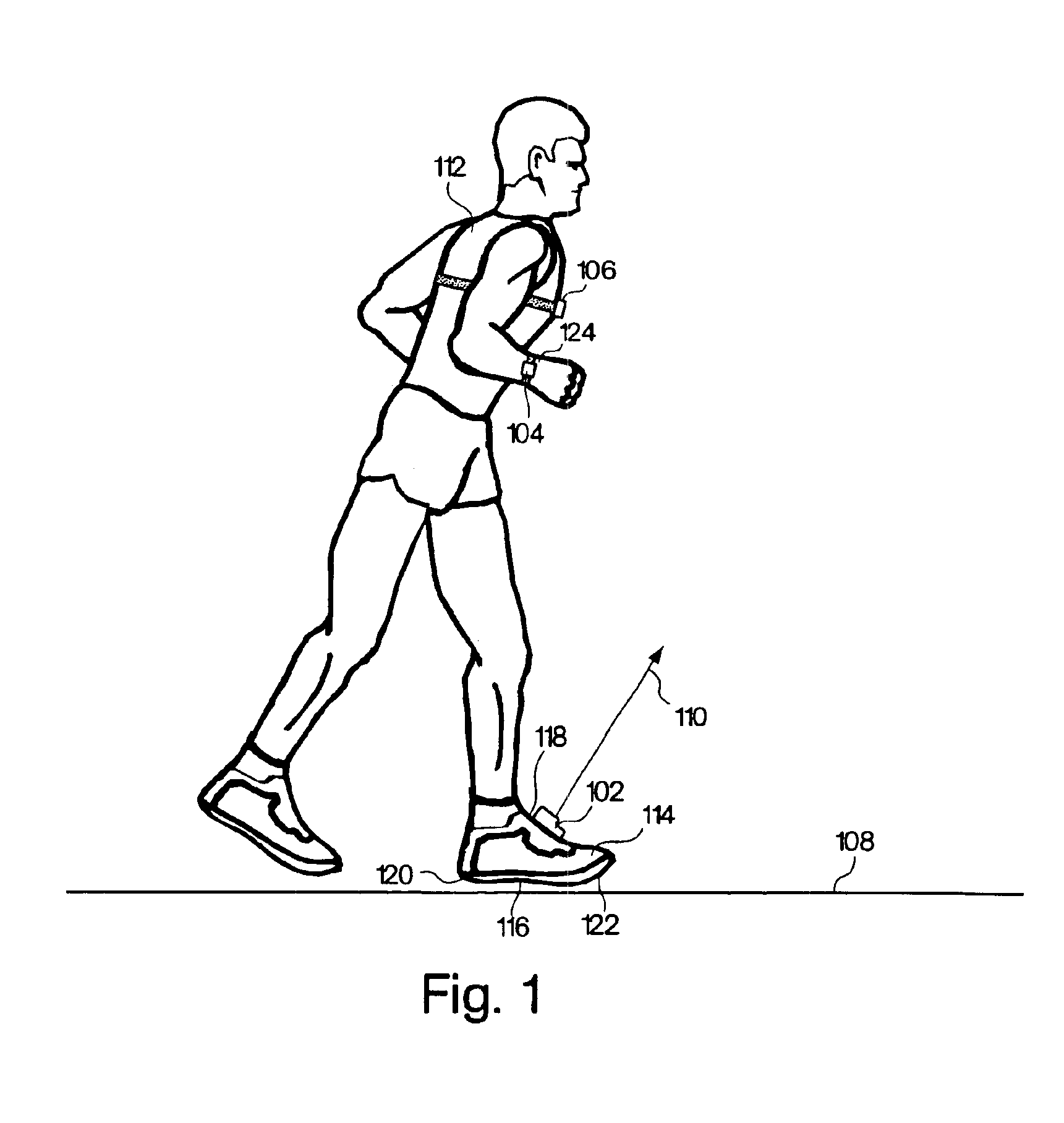

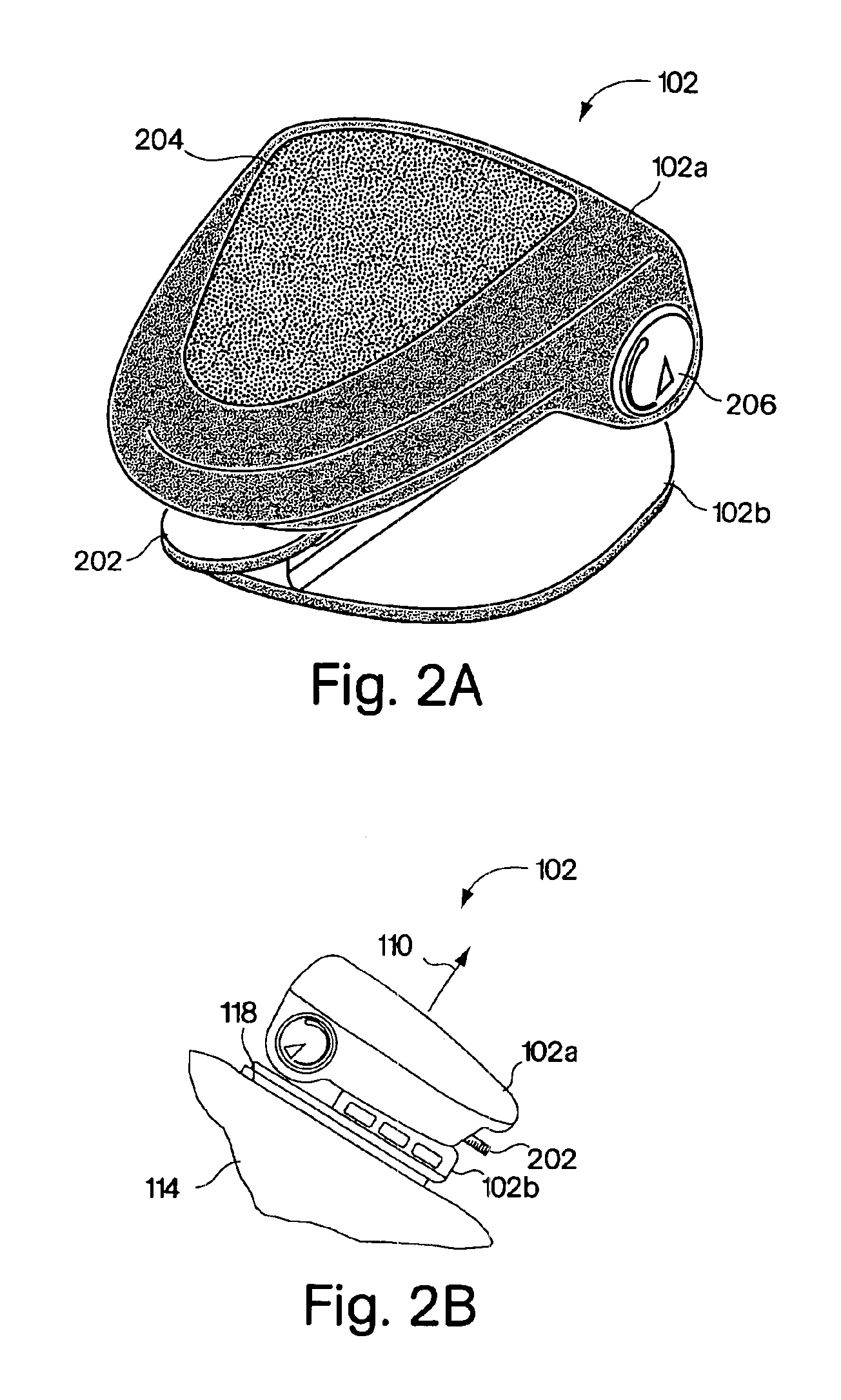

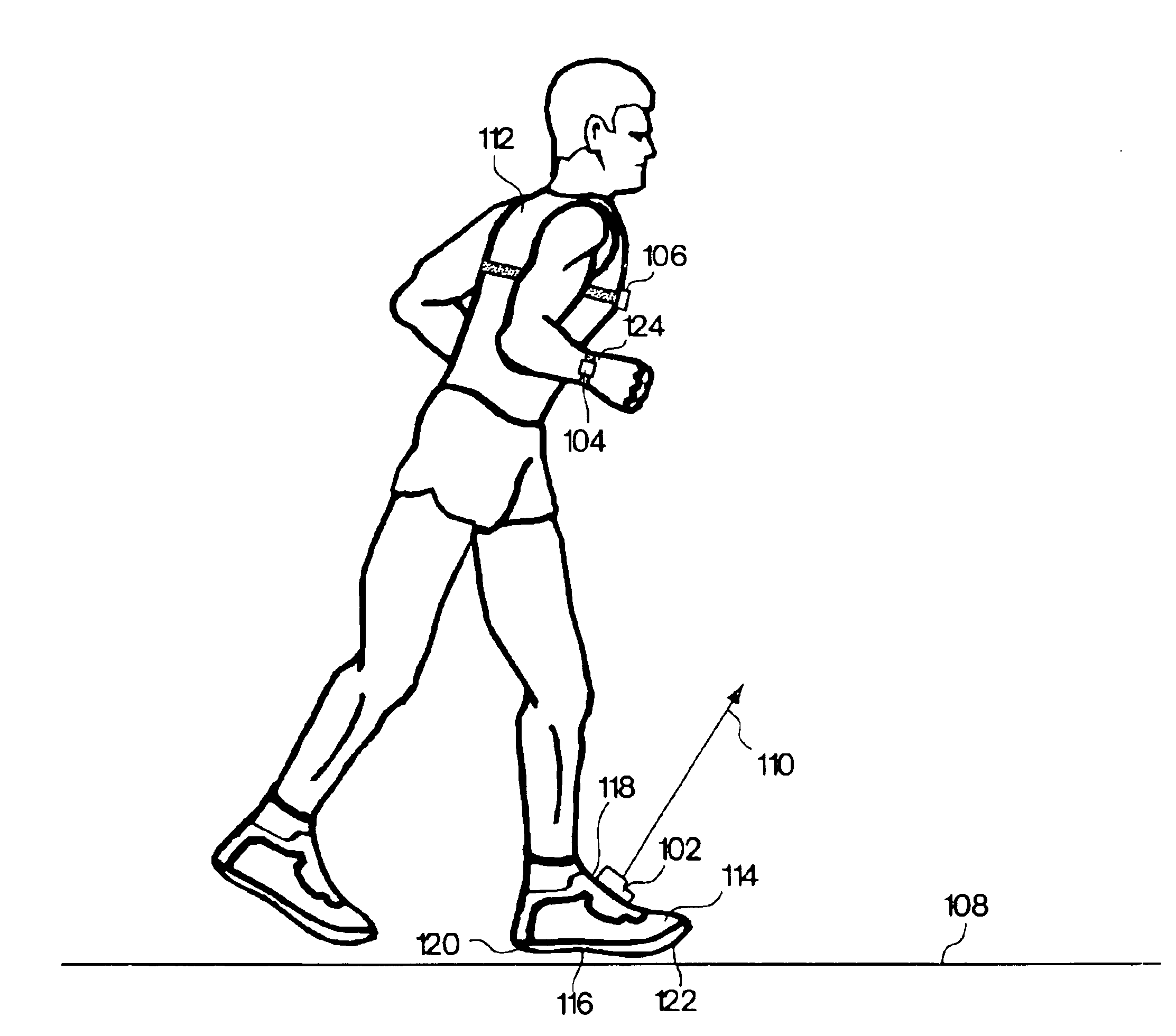

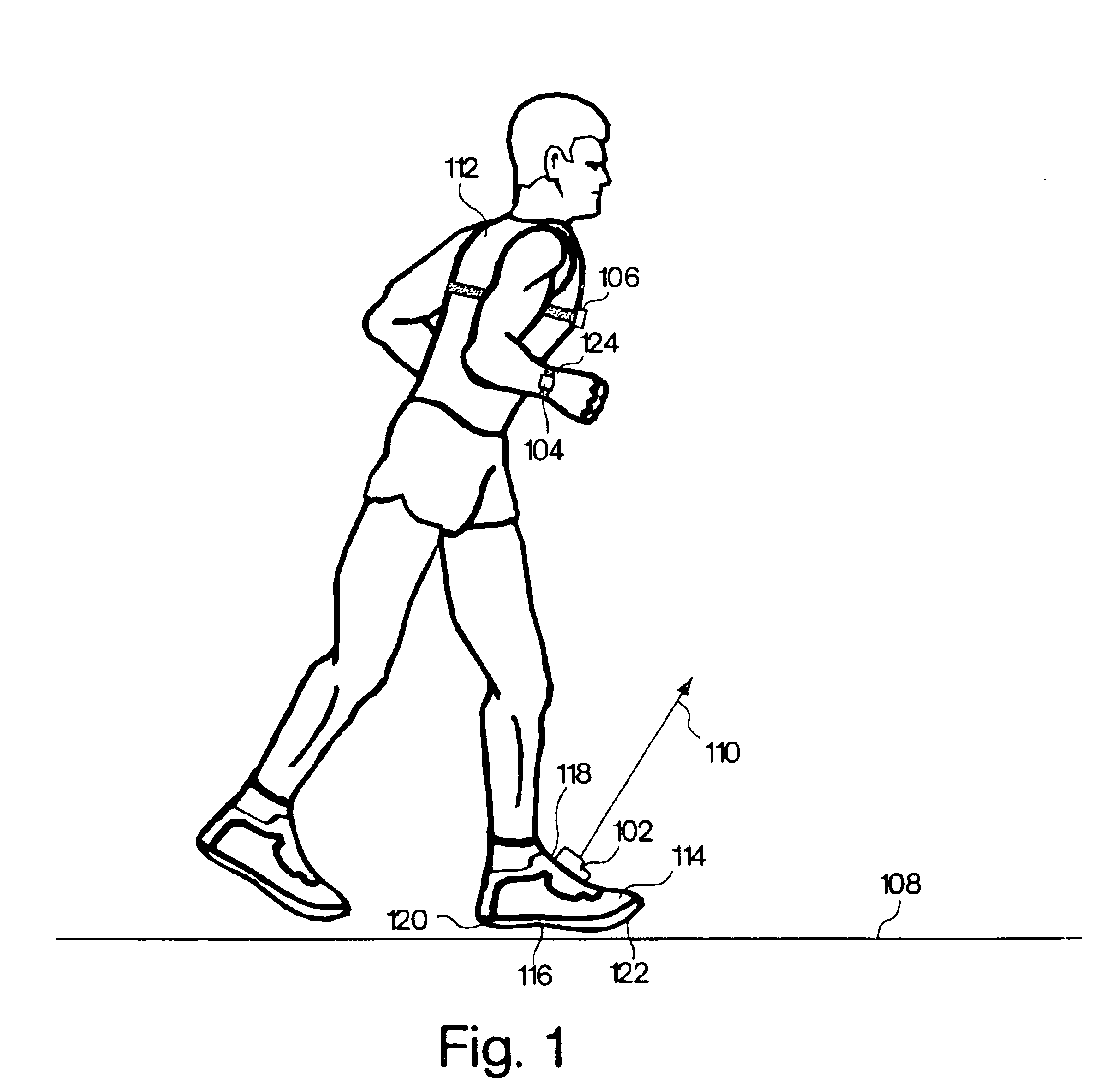

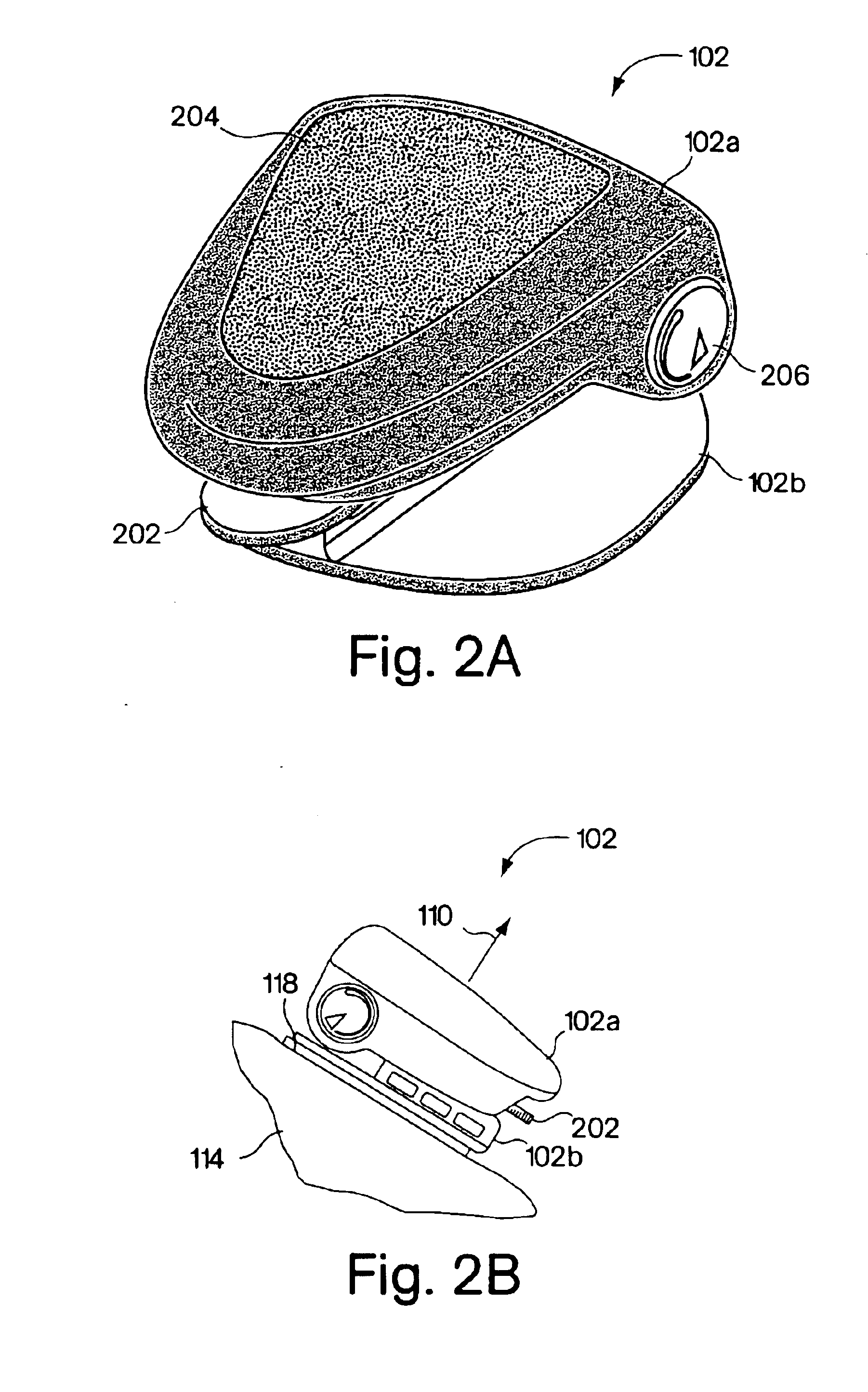

Monitoring activity of a user in locomotion on foot

InactiveUS6876947B1Physical therapies and activitiesTime indicationPacePhysical medicine and rehabilitation

In one embodiment, a method includes steps of: (a) identifying an average foot contact time of a user during a first outing; (b) identifying an average pace of the user during the first outing; (c) defining a relationship between foot contact times of the user and corresponding paces of the user, wherein the relationship is based upon the average foot contact time and the average pace identified during the first outing, and wherein no other average foot contact times and no other average paces identified during any different outings by the user are used to define the relationship; and (d) calibrating at least one device that monitors activity of the user in locomotion on foot based upon the defined relationship between foot contact times of the user and corresponding paces of the user. In another embodiment, a method includes steps of: (a) determining a single user-specific calibration constant that defines a relationship between foot contact times of a user and corresponding paces of the user, wherein no other user-specific calibration constants are used to define the relationship; and (b) calibrating at least one device that monitors activity of the user in locomotion on foot based upon the relationship between foot contact times of the user and corresponding paces of the user that is defined by the single user-specific calibration constant.

Owner:NIKE INC +1

Monitoring activity of a user in locomotion on foot

InactiveUS6898550B1Physical therapies and activitiesTime indicationPhysical medicine and rehabilitationSimulation

Owner:NIKE INC +1

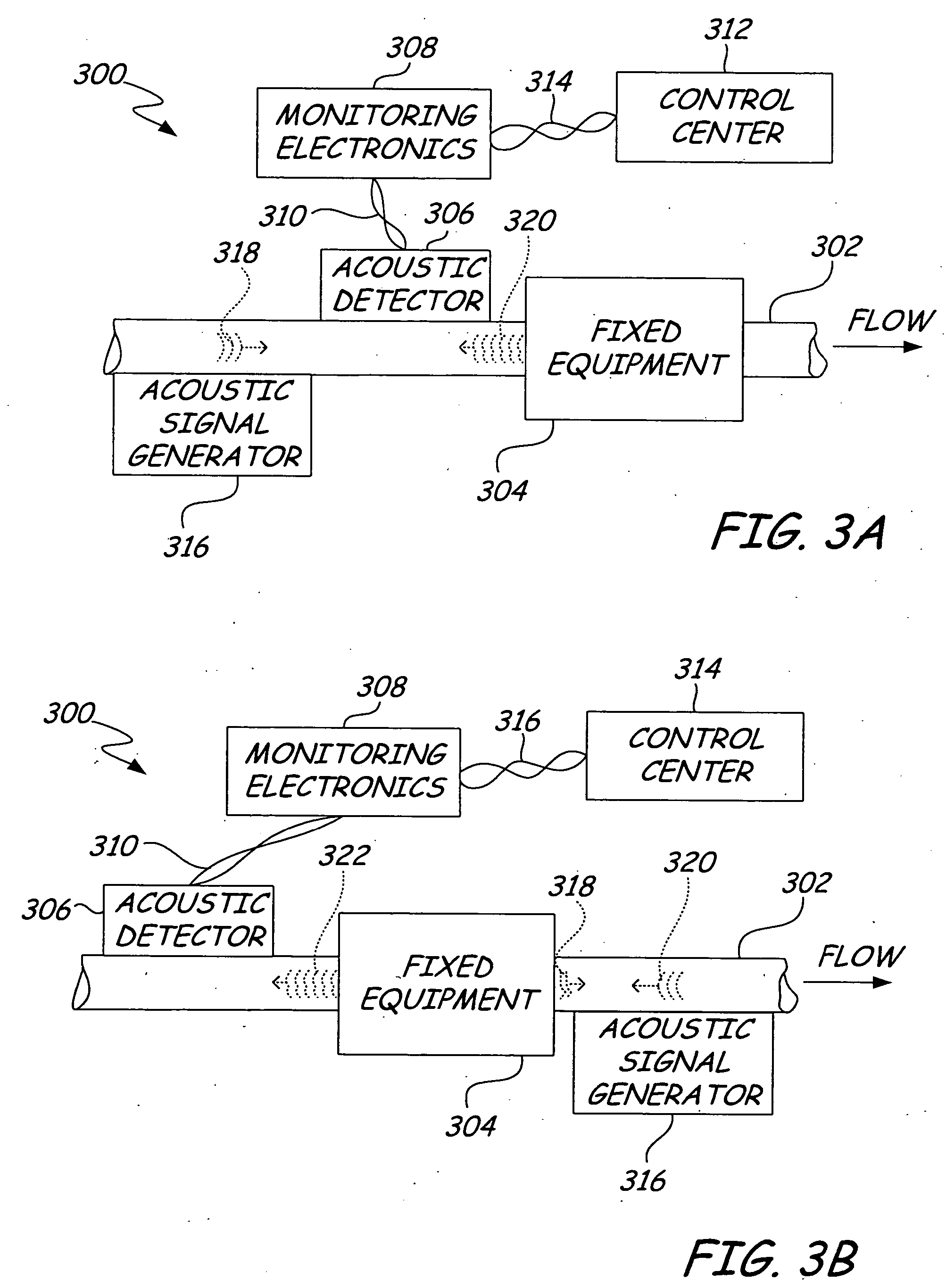

Process diagnostics

ActiveUS20050011278A1Improve abilitiesEasy to useVibration measurement in solidsAnalysing fluids using sonic/ultrasonic/infrasonic wavesTransducerEngineering

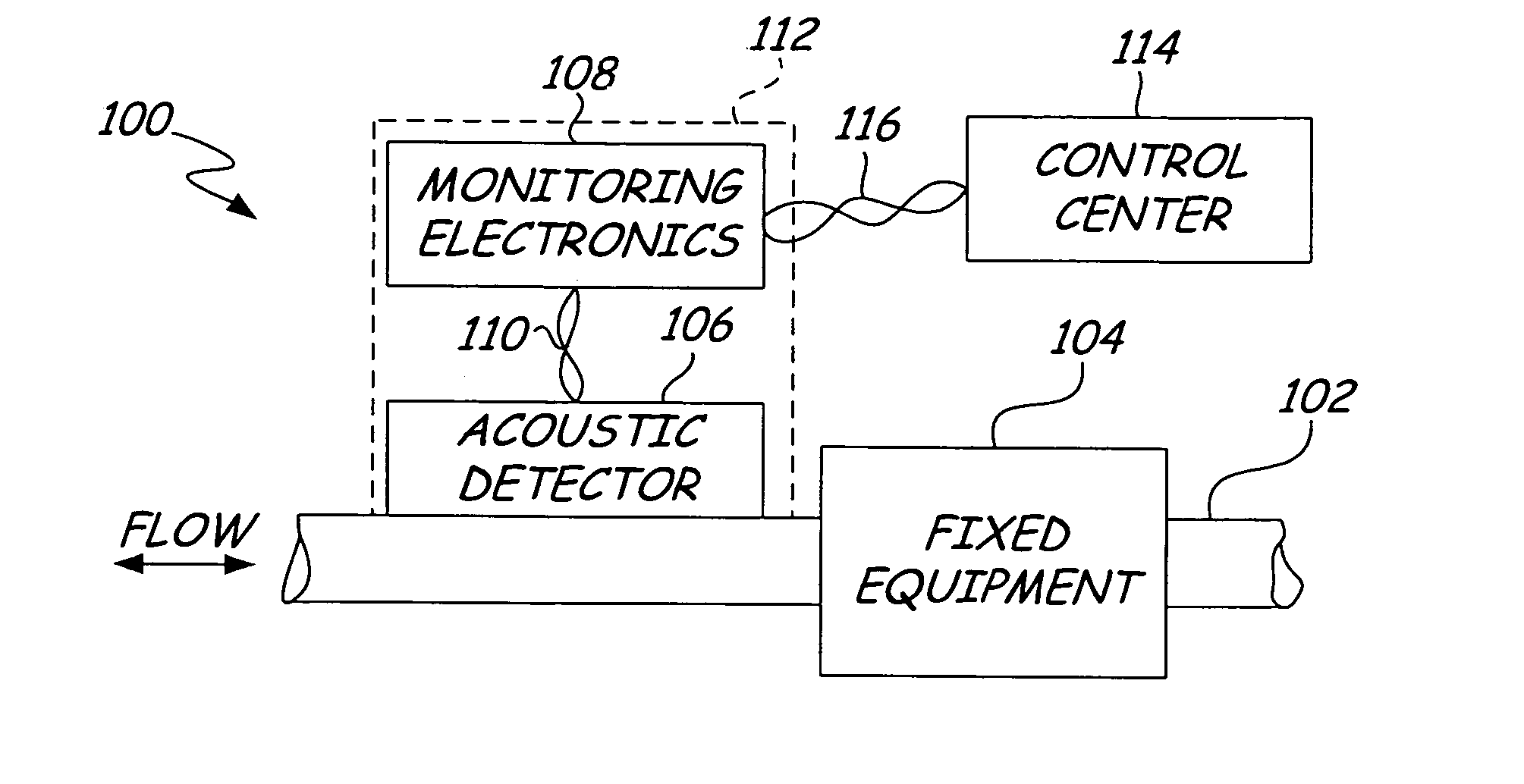

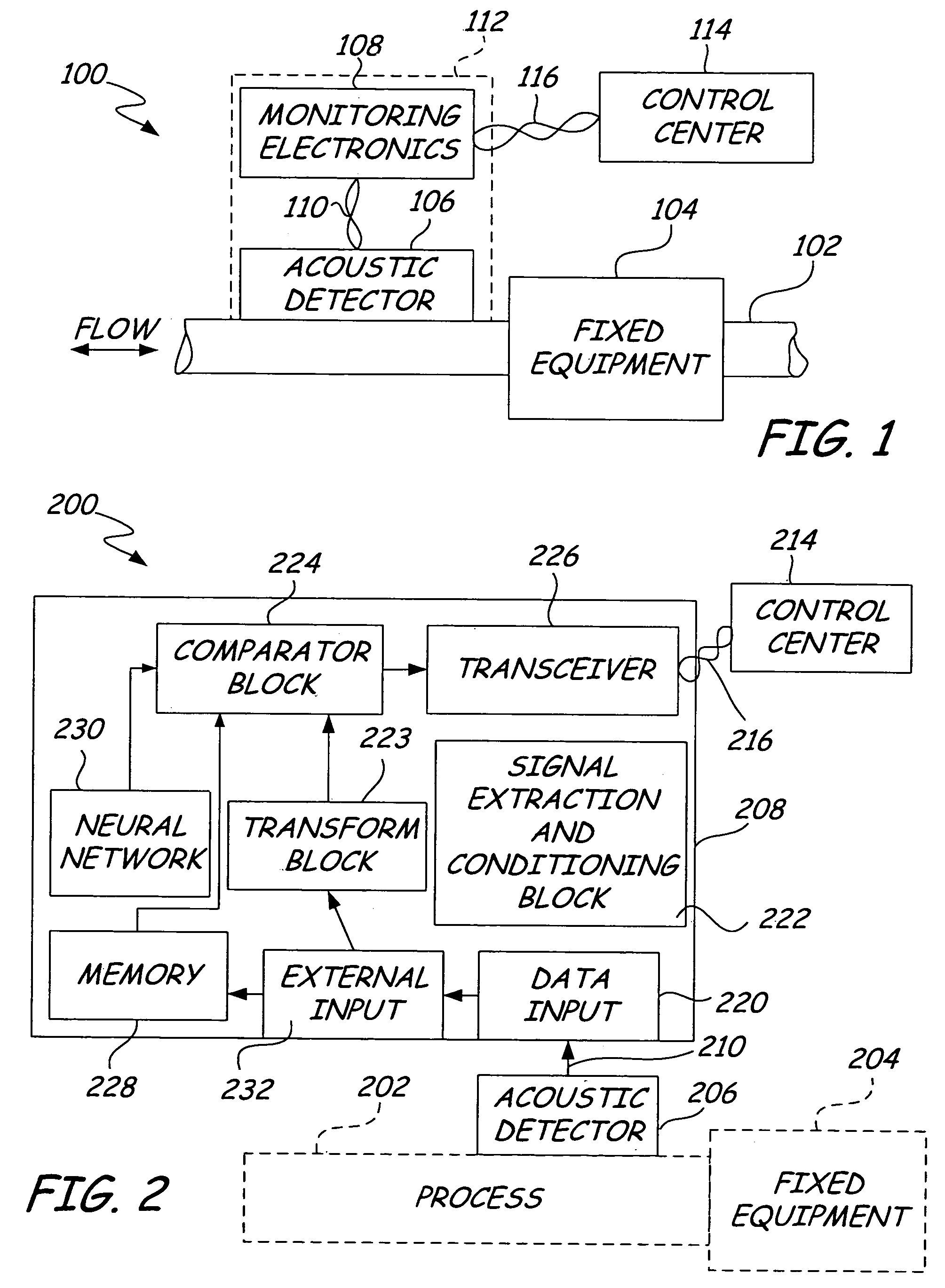

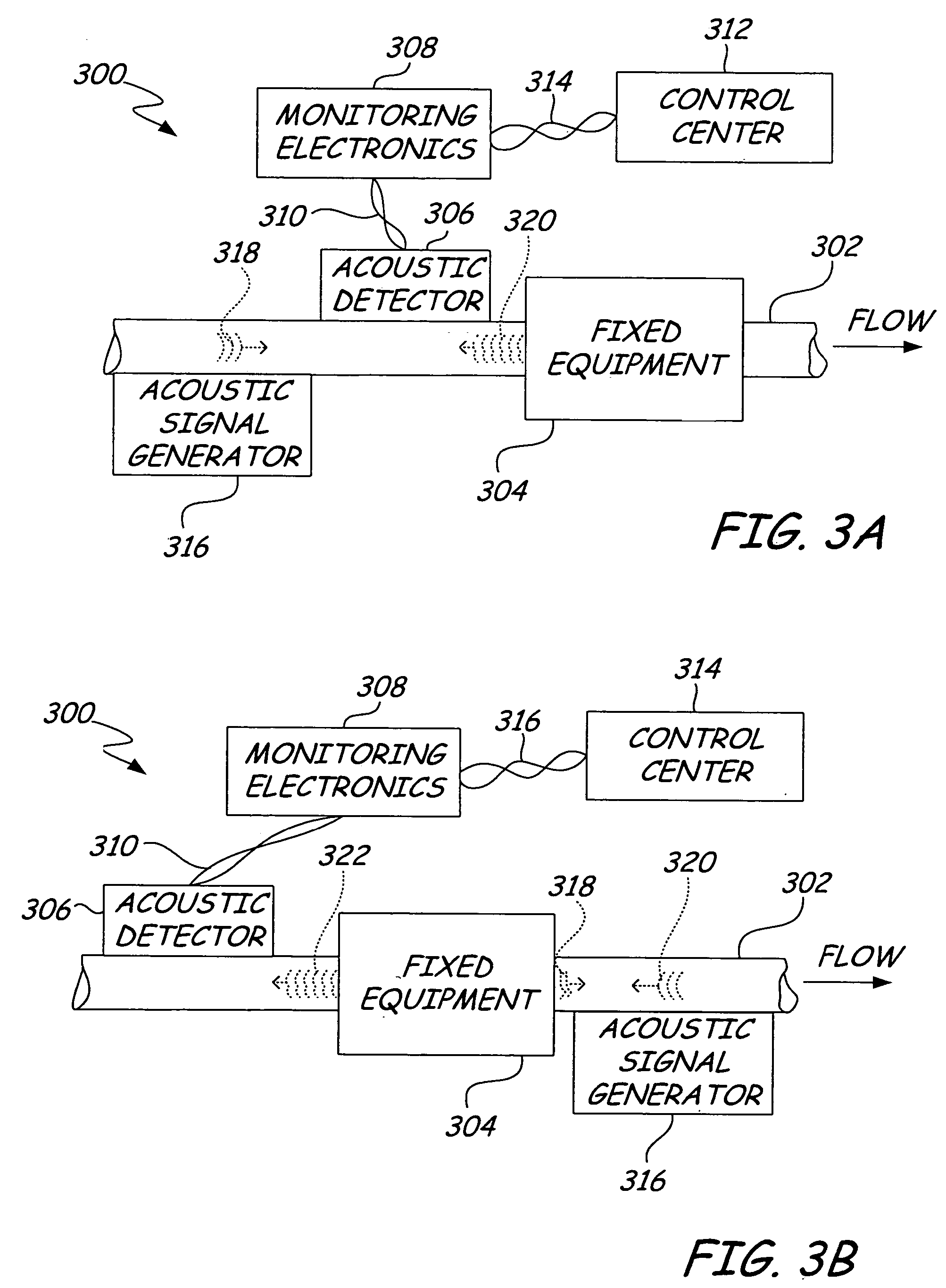

A diagnostic device for use in a industrial process includes monitoring electronics or diagnostic circuitry configured to diagnose or identify a condition or other occurrence in the industrial process. The system can be implemented in a process device such as a flowmeter, and in one example an acoustic flowmeter. A transducer can also be used and a frequency response, such as resonant frequency, can be observed.

Owner:ROSEMOUNT INC

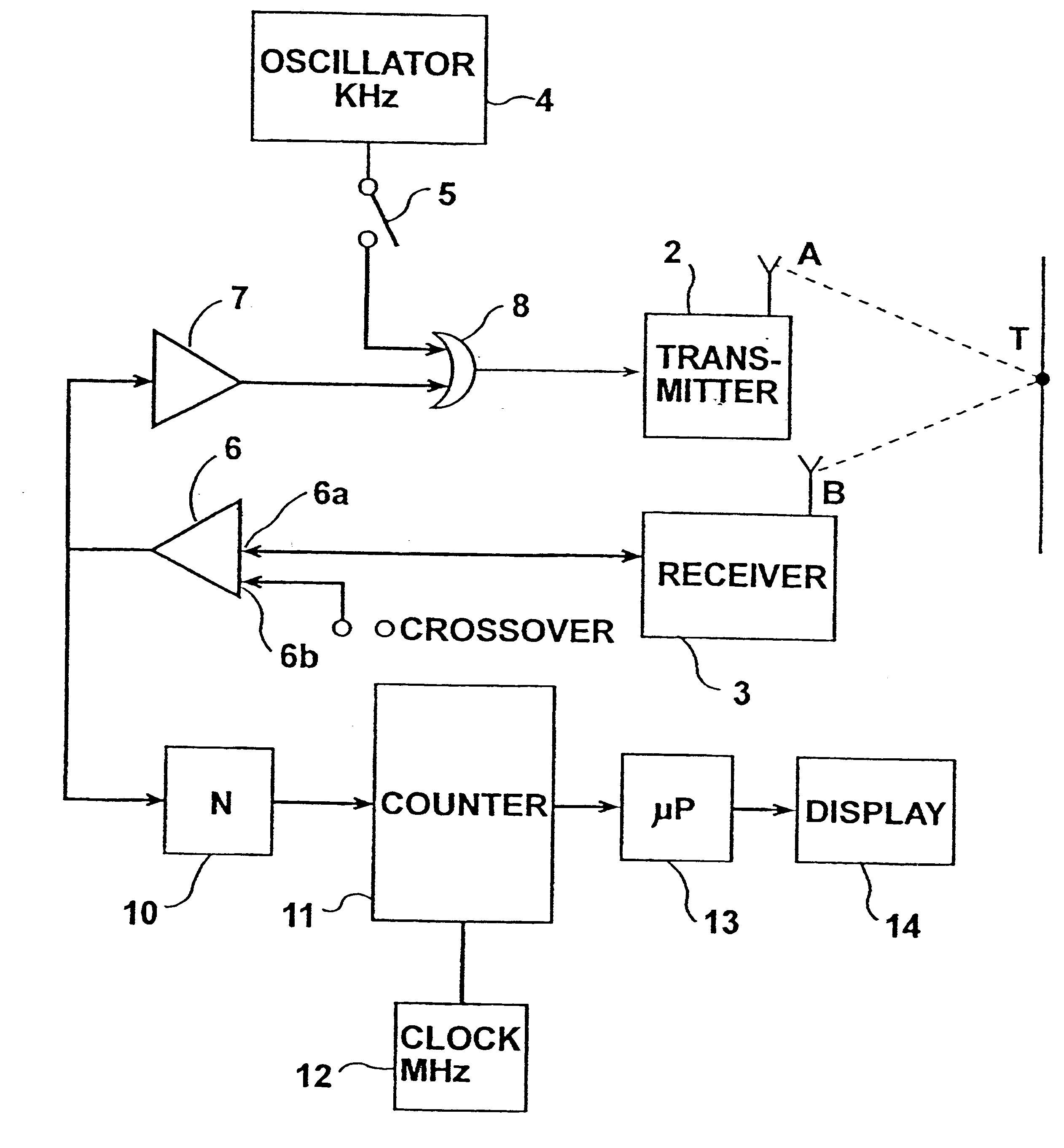

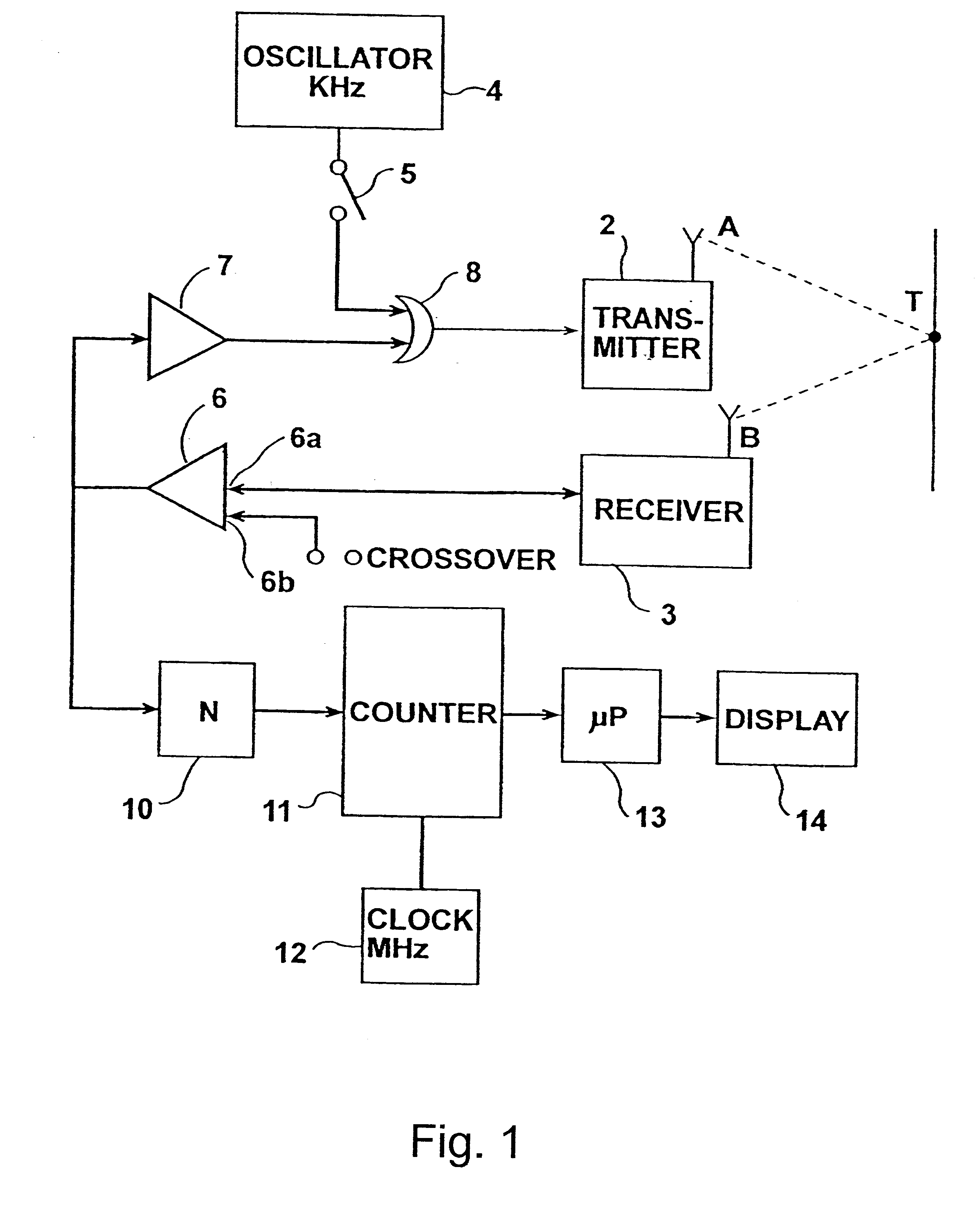

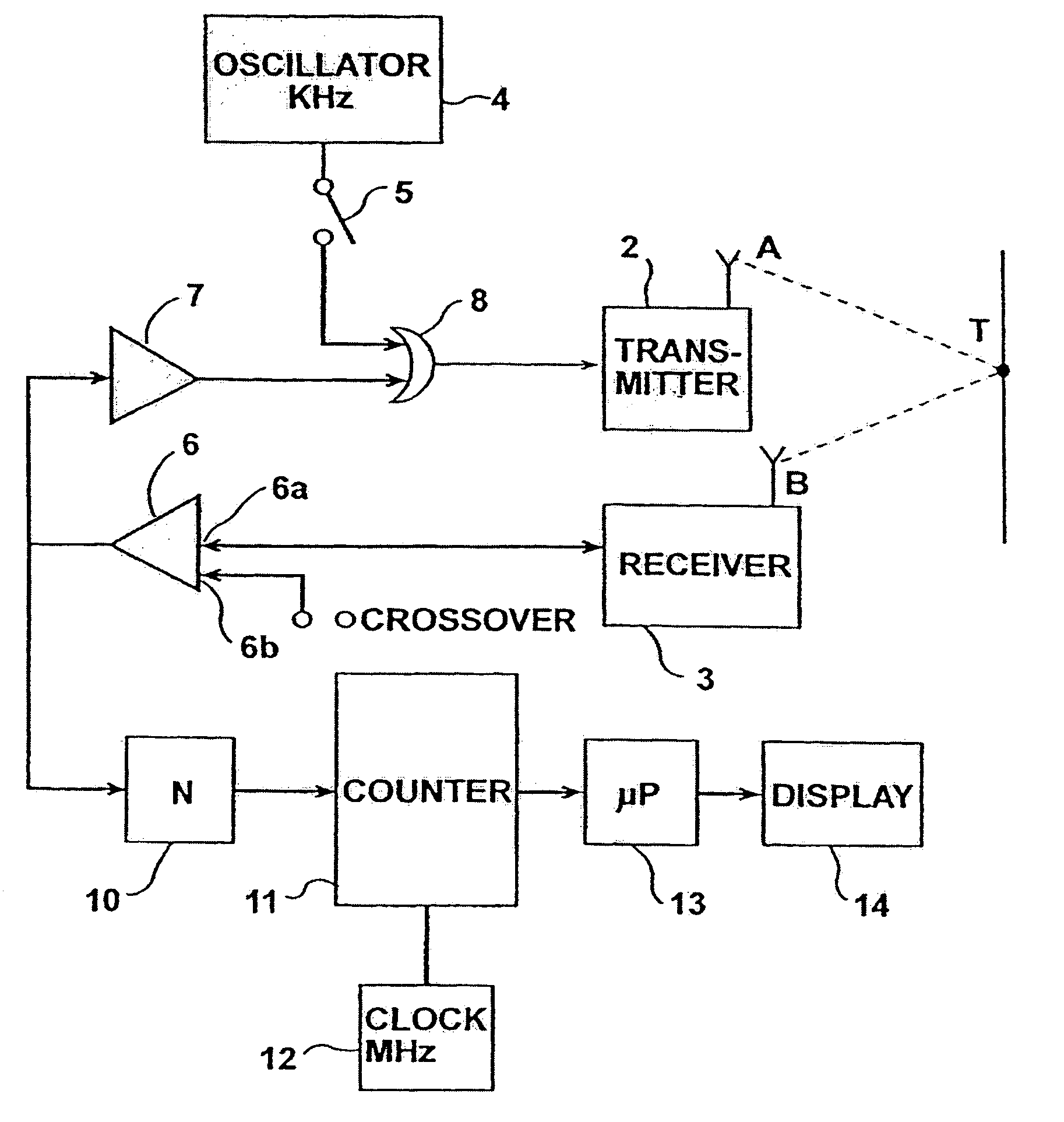

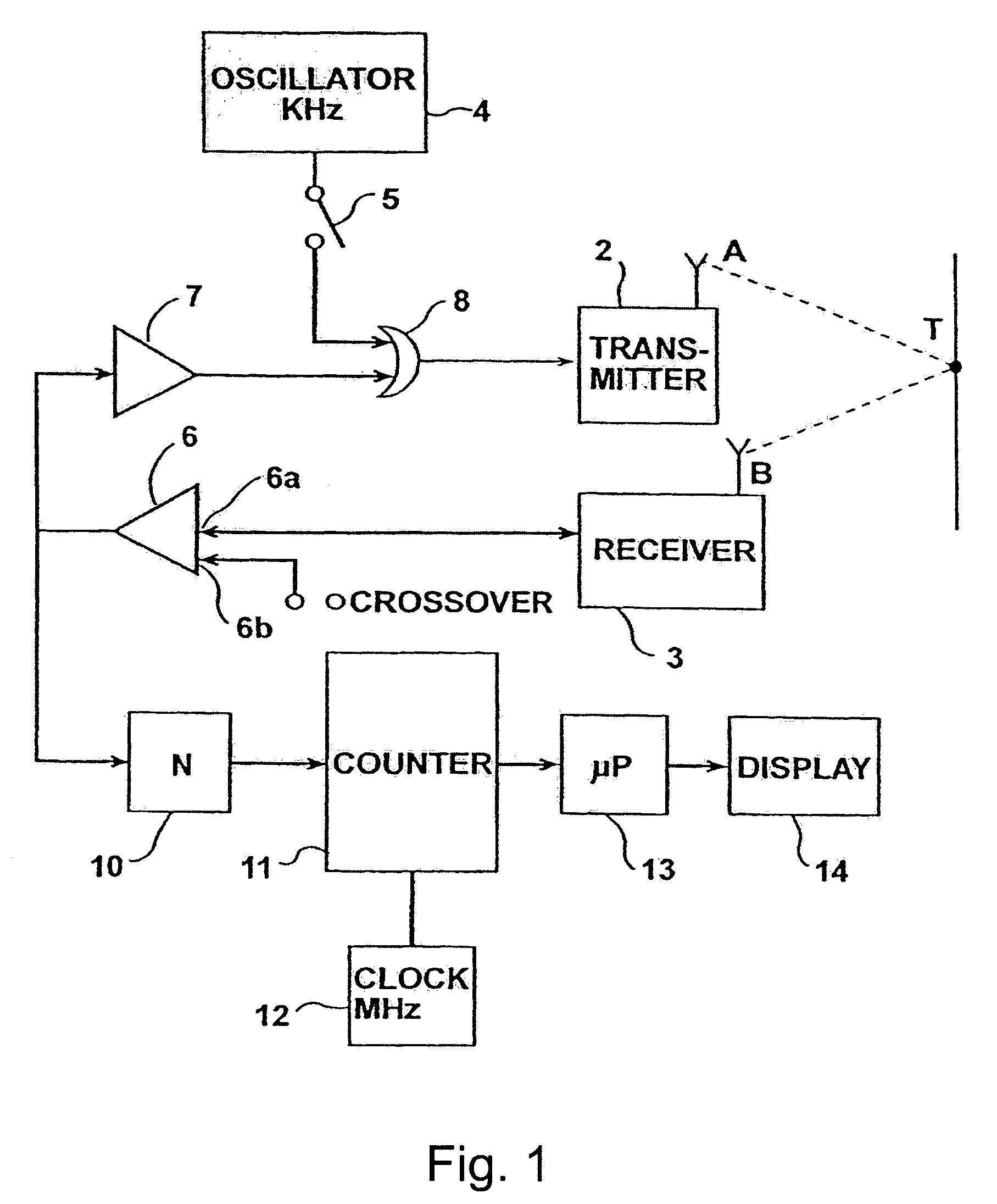

High-precision measuring method and apparatus

InactiveUS6621278B2Low-cost equipmentHigh precisionUltrasonic/sonic/infrasonic diagnosticsAnalysing fluids using sonic/ultrasonic/infrasonic wavesEngineeringFiducial points

A method and apparatus of measuring a predetermined parameter having a known relation to the transit time of movement of an energy wave through a medium, by transmitting from a first location in the medium a cyclically-repeating energy wave; receiving the cyclically-repeating energy wave at a second location in the medium; detecting a predetermined fiducial point in the cyclically-repeating energy wave received at the second location; continuously changing the frequency of transmission of the cyclically-repeating energy wave from the first location to the second location in accordance with the detected fiducial point of each received cyclically-repeating energy wave received at the second location such that the number of waves received at the second location from the first location is a whole integer; and utilizing the change in frequency to produce a measurement of the predetermined parameter.

Owner:NEXENSE

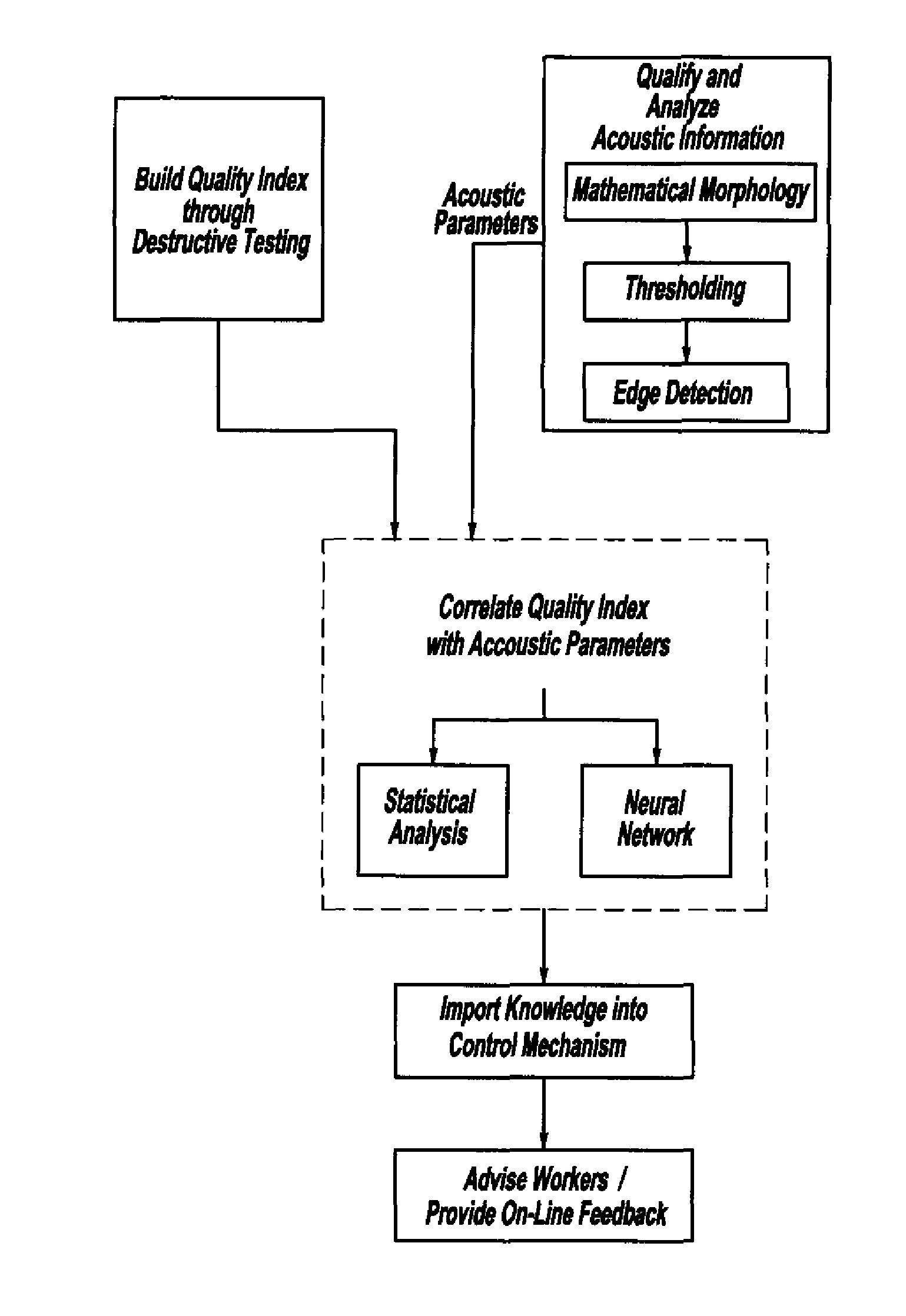

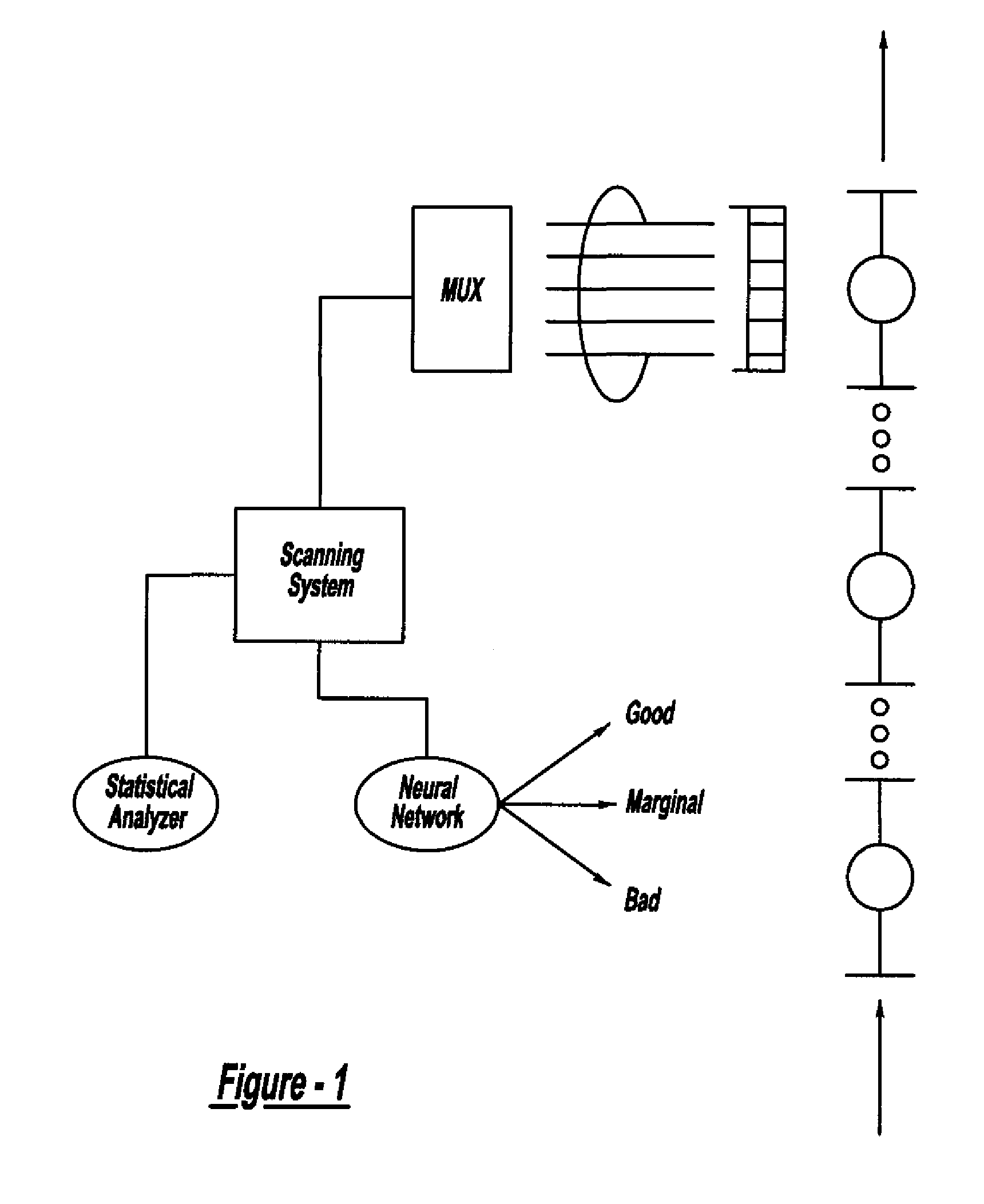

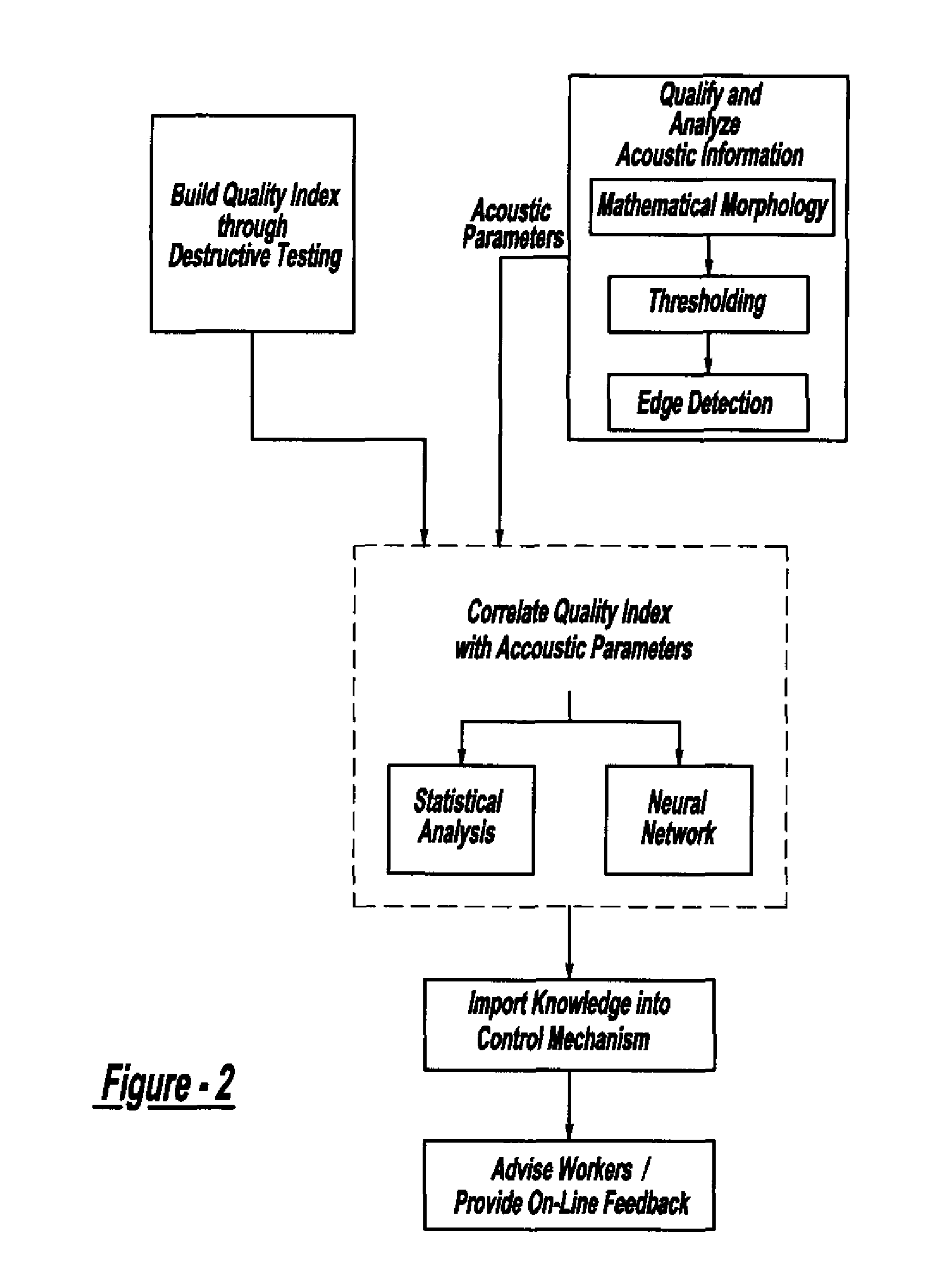

Method And System For Assessing Quality Of Spot Welds

InactiveUS20070038400A1Reduce in quantityReduce manufacturing costMultiple-port networksMagnetic property measurementsDigital dataSonification

A system and method for assessing the quality of spot weld joints between pieces of metal includes an ultrasound transducer probing a spot weld joint. The ultrasound transducer transmits ultrasonic radiation into the spot weld joint, receives corresponding echoes, and transforms the echoes into electrical signals. An image reconstructor connected to the ultrasound transducer transforms the electrical signals into numerical data representing an ultrasound image. A neural network connected to the image reconstructor analyzes the numerical data and an output system presents information representing the quality of the spot weld joint. The system is trained to assess the quality of spot weld joints by scanning a spot weld joint with an ultrasound transducer to produce the data set representing the joint; then physically deconstructing the joint to assess the joint quality.

Owner:FCA US

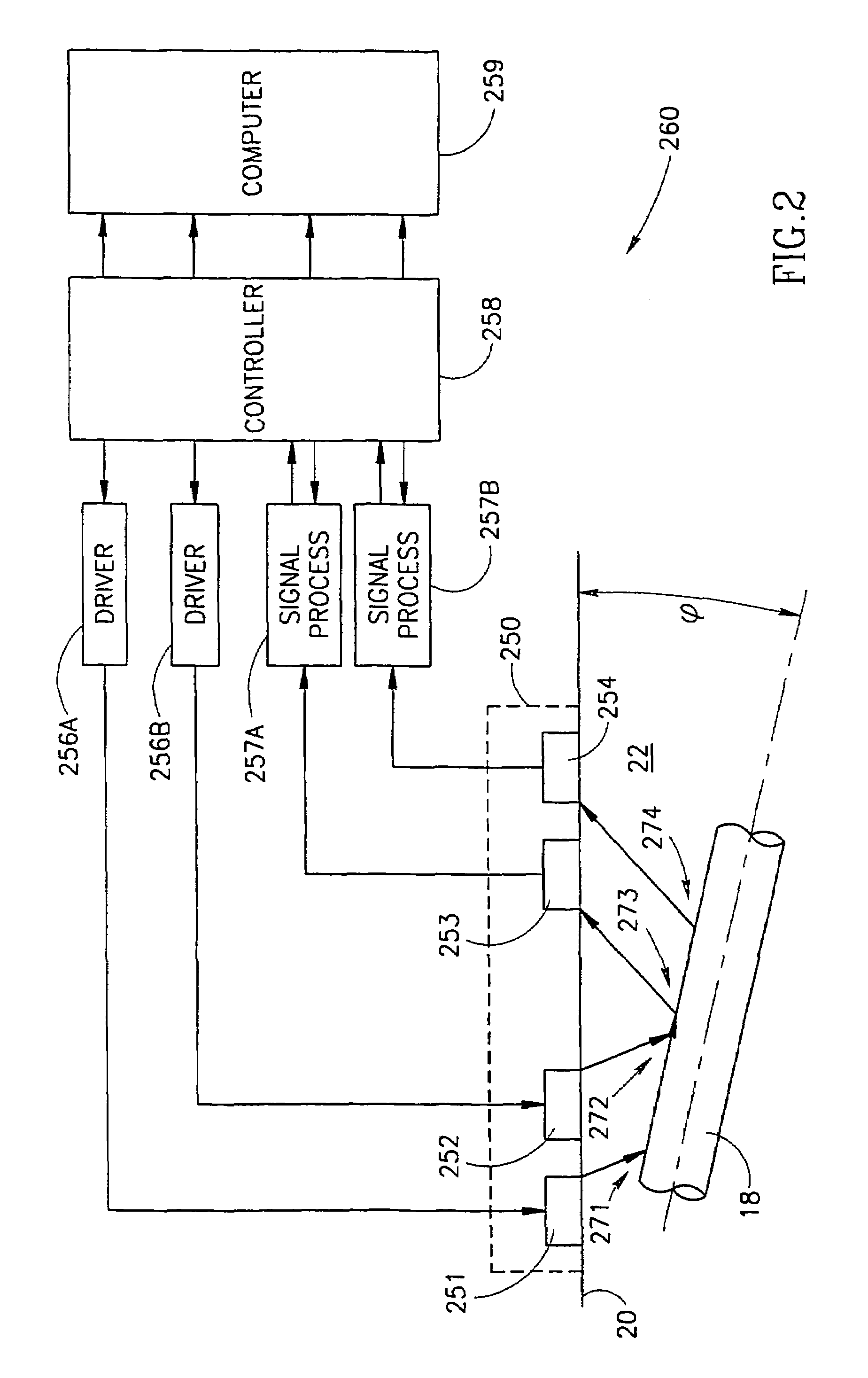

Fluid parameter measurement in pipes using acoustic pressures

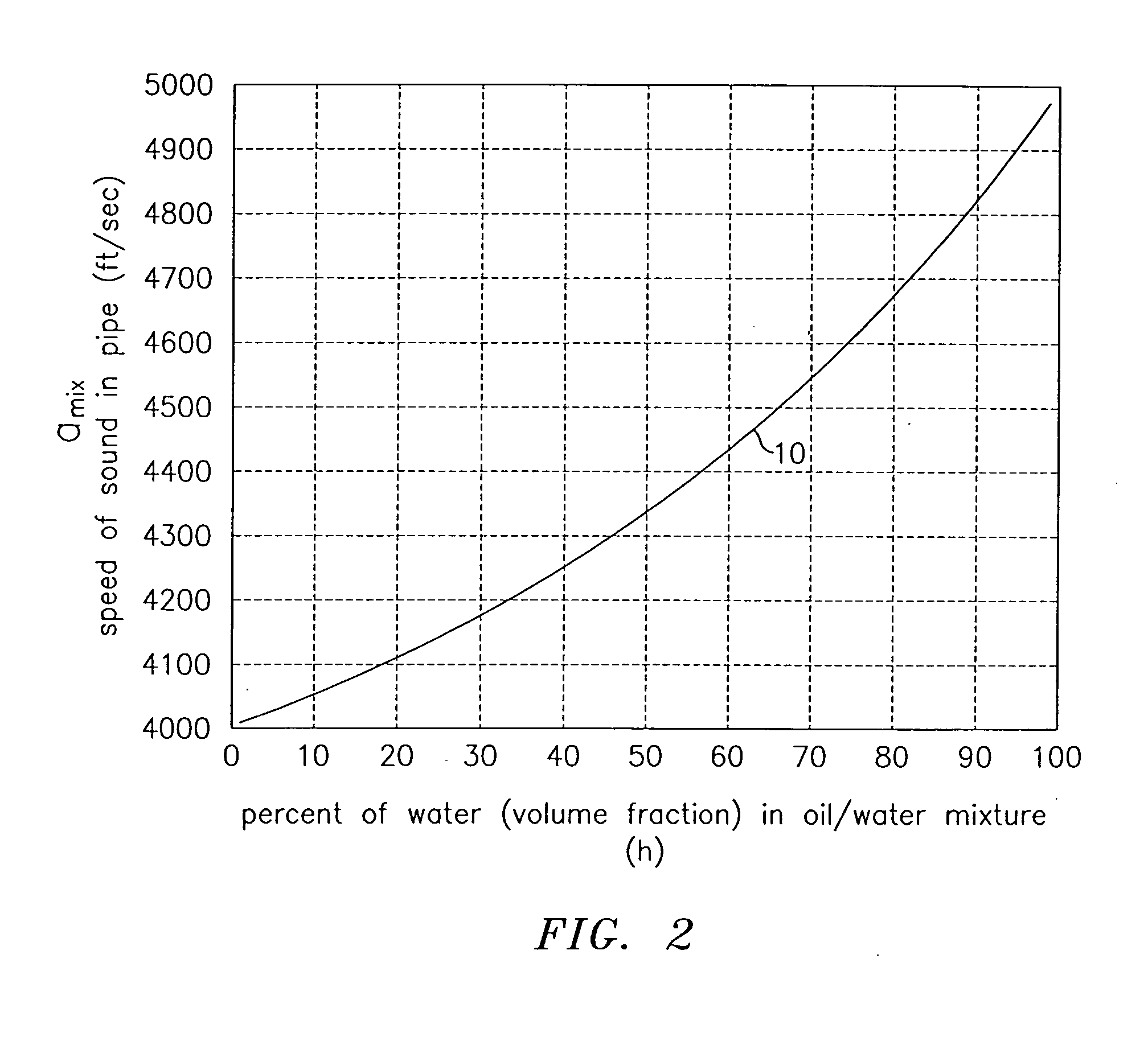

InactiveUS6862920B2Less sensitive to static shifts (or errors) in sensingImprove measurement reliabilityAnalysing fluids using sonic/ultrasonic/infrasonic wavesAnalysing solids using sonic/ultrasonic/infrasonic wavesEngineeringWater fraction

At least one parameter of at least one fluid in a pipe is measured using a spatial array of acoustic pressure sensors placed at predetermined axial locations along the pipe 12. The pressure sensors provide acoustic pressure signals, which are provided to a signal processing system that determines the speed of sound amix of the fluid (or mixture) in the pipe 12 using acoustic spatial array signal processing techniques. Numerous spatial array processing techniques may be employed to determine the speed of sound amix. The speed of sound amix is provided to another logic system that calculates the percent composition of the mixture, e.g., water fraction, or any other parameter of the mixture or fluid which is related to the sound speed amix. The signal processing system may also determine the Mach number Mx of the fluid. The acoustic pressure signals measured are lower frequency (and longer wavelength) signals than those used for ultrasonic flow meters, and thus are more tolerant to inhomogeneities in the flow. No external source is required and thus may operate using passive listening. The invention will work with arbitrary sensor spacing and with as few as two sensors if certain information is known about the acoustic properties of the system.

Owner:WEATHERFORD TECH HLDG LLC

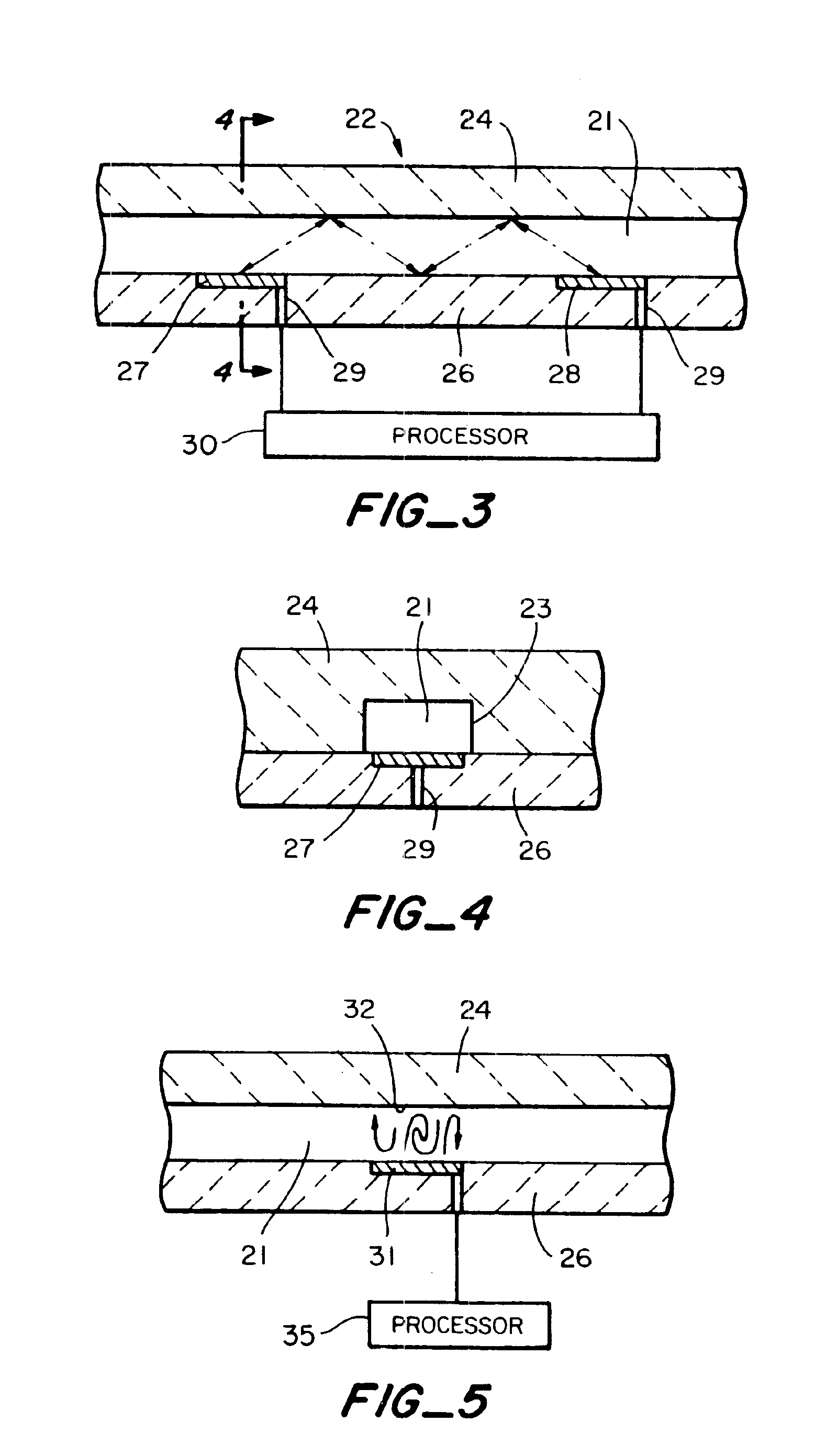

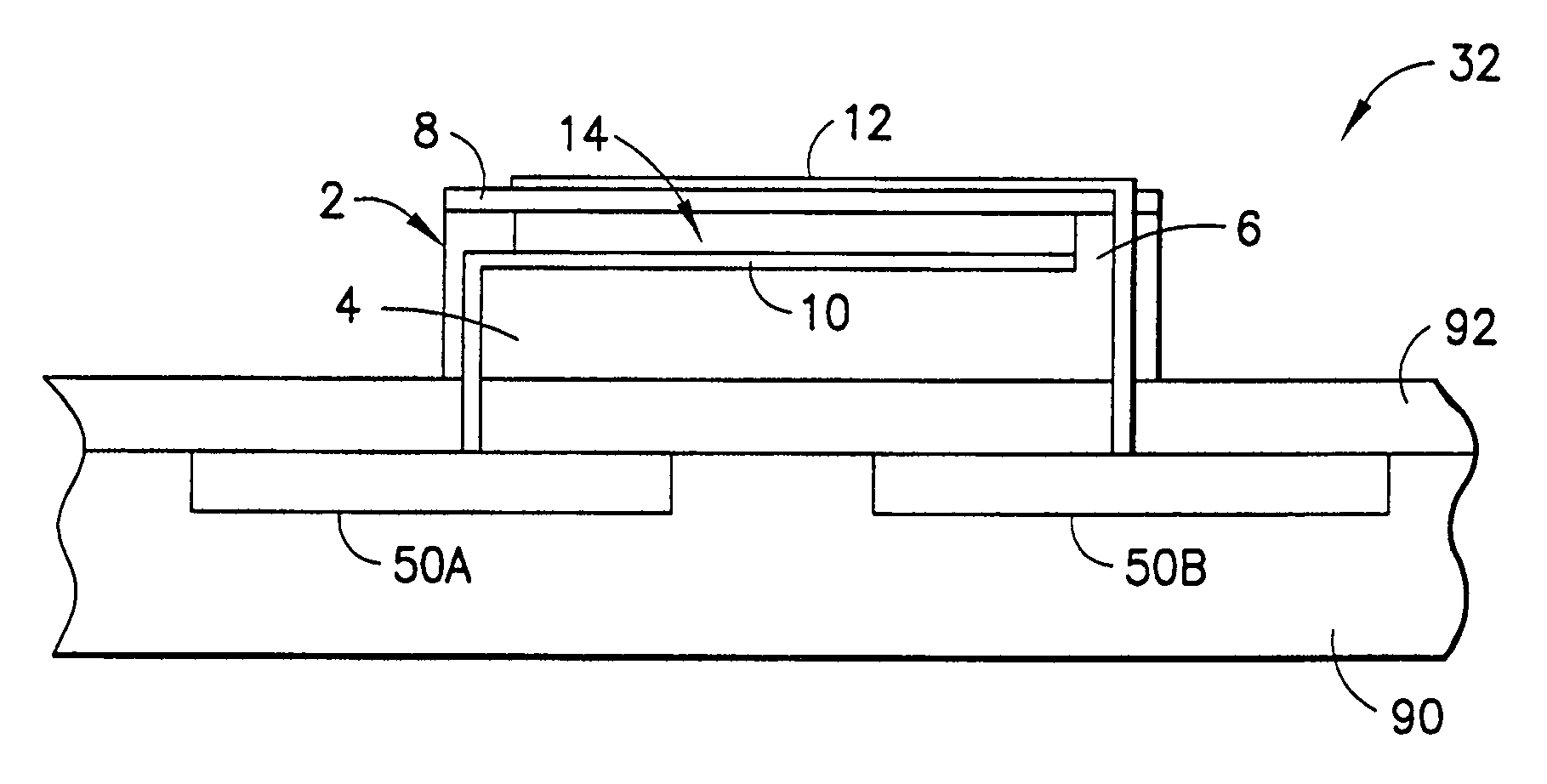

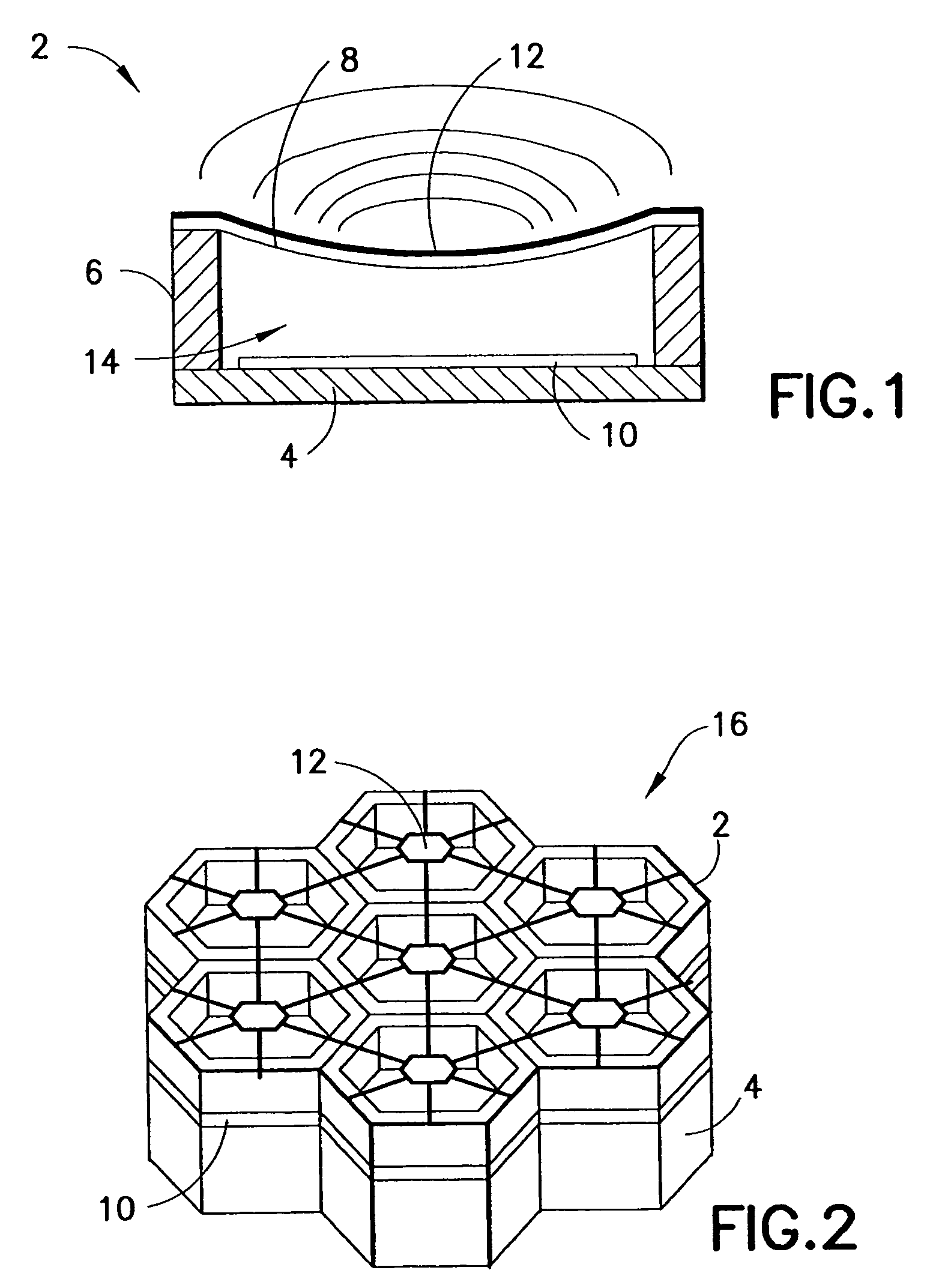

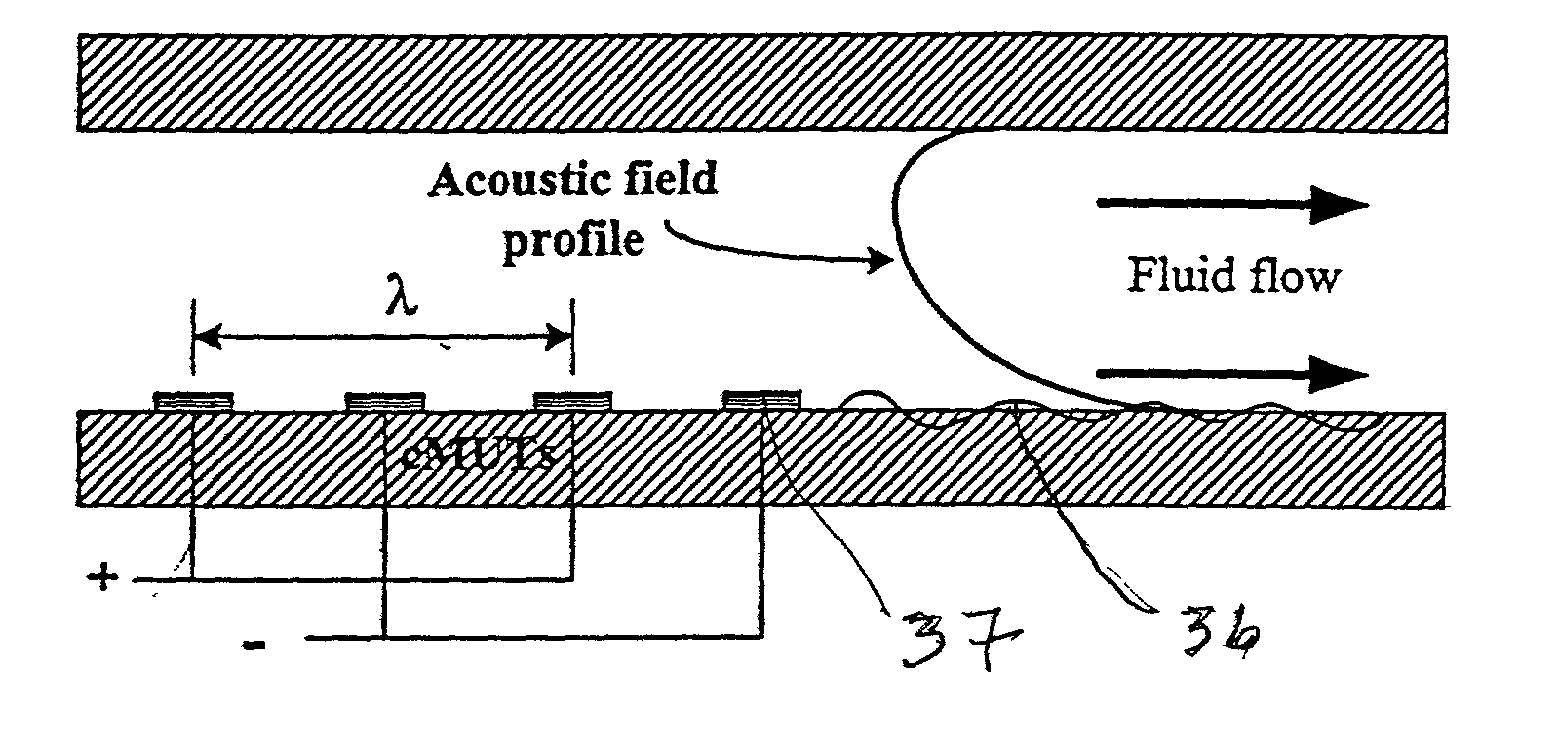

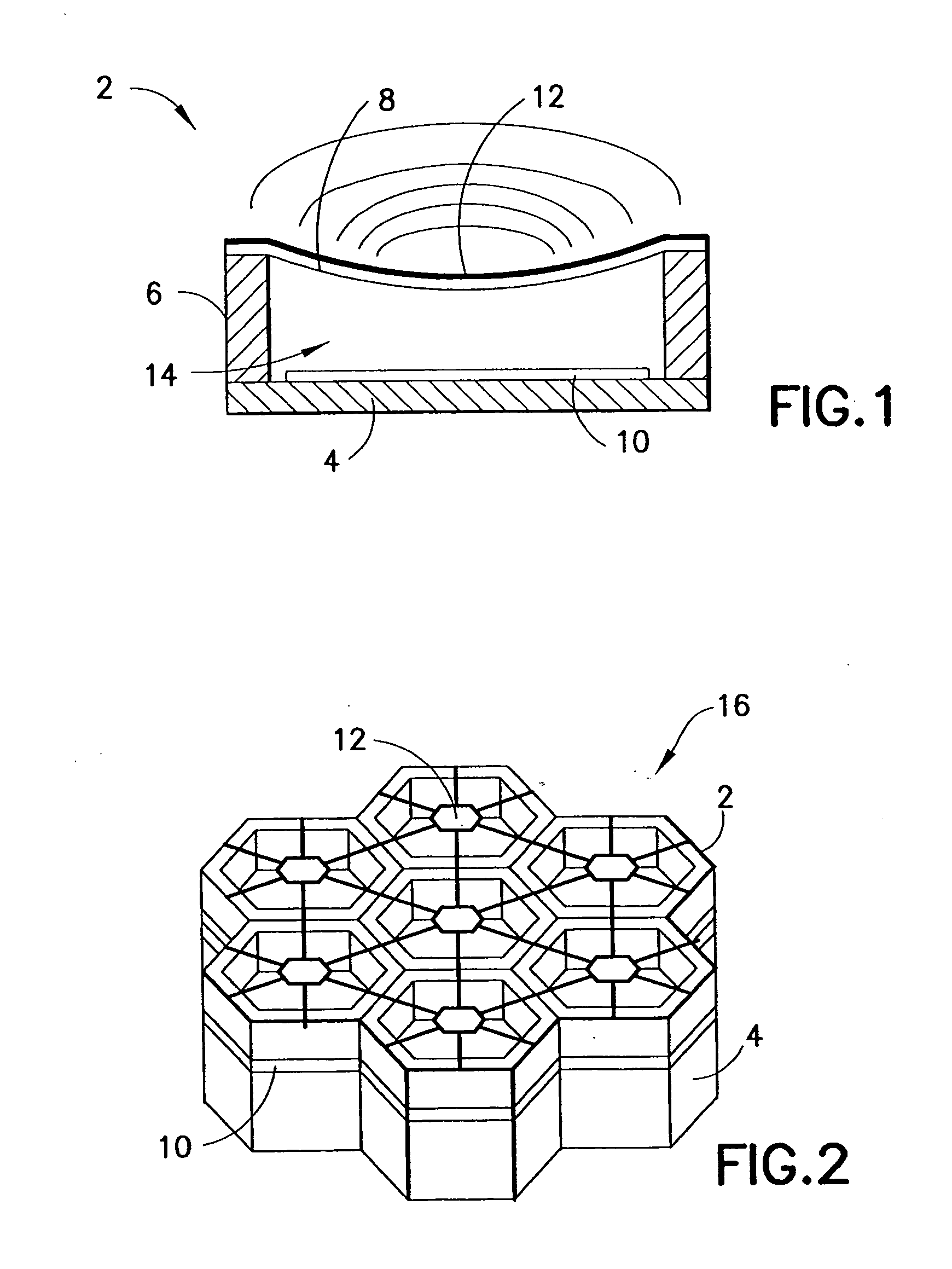

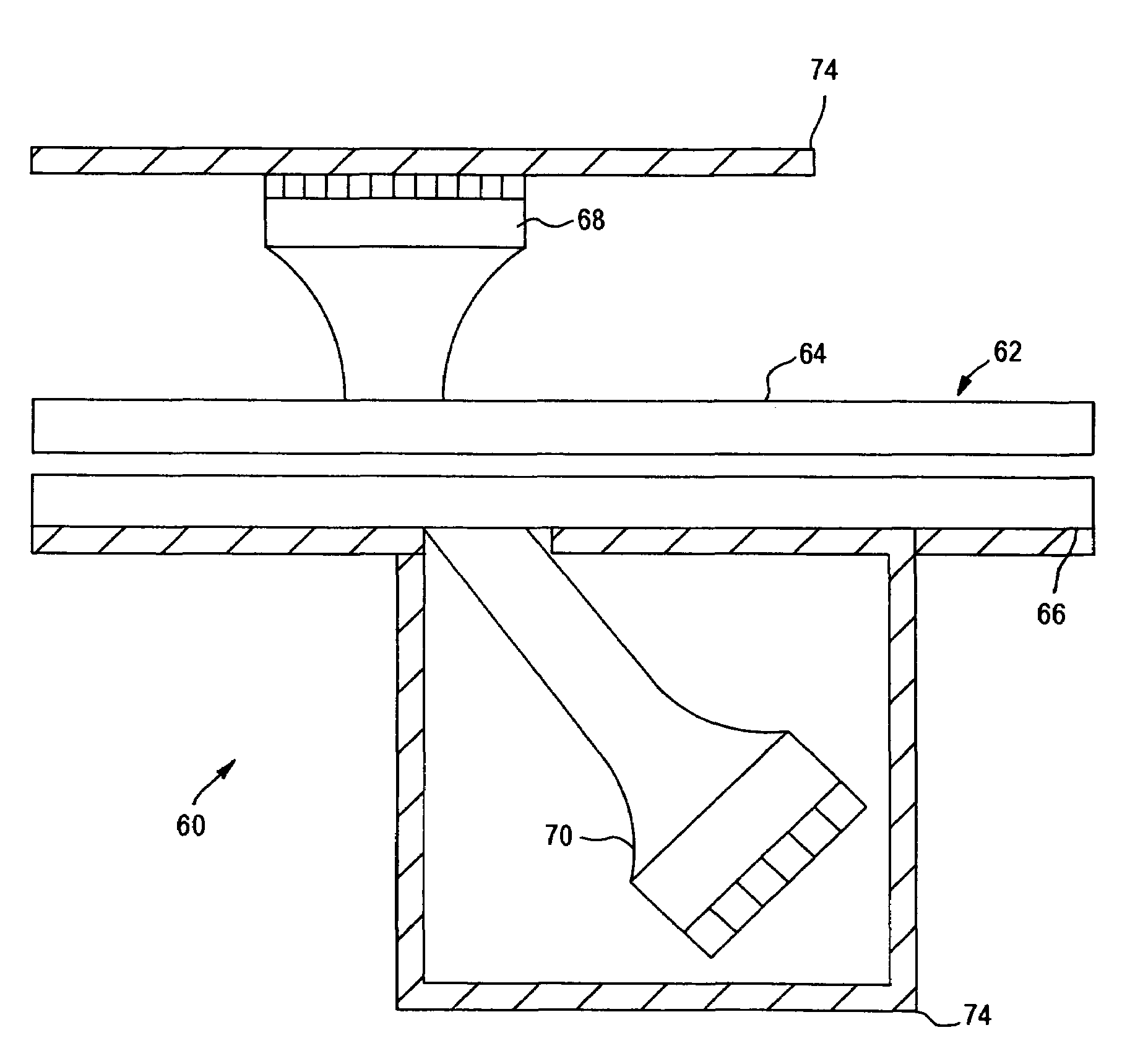

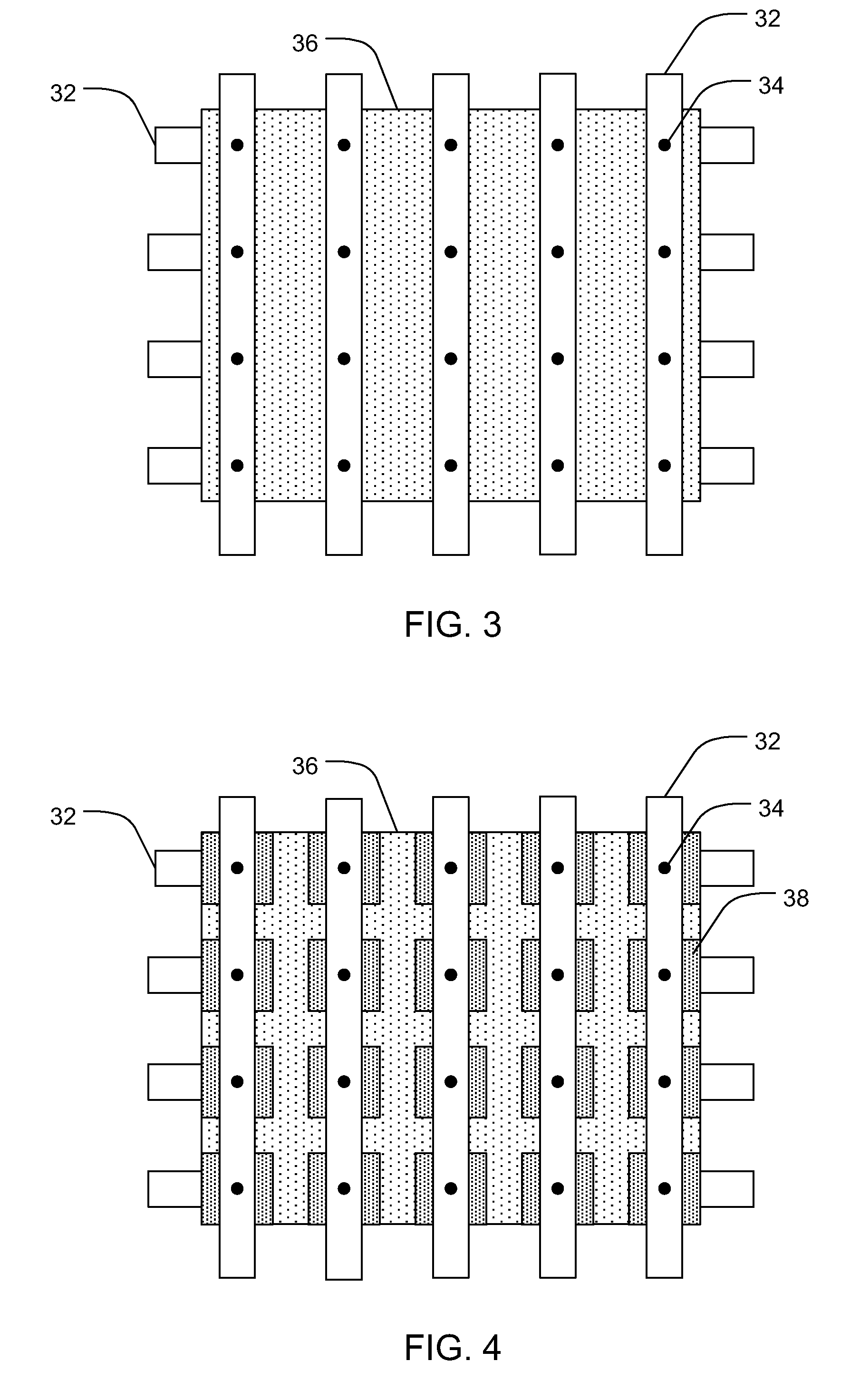

Fluidic device with integrated capacitive micromachined ultrasonic transducers

InactiveUS6854338B2Analysing fluids using sonic/ultrasonic/infrasonic wavesShaking/oscillating/vibrating mixersCapacitive micromachined ultrasonic transducersSonification

The present invention provides fluidic devices and systems which have micromachined ultrasonic transducers integrated into microchannels. The ultrasonic transducers generate and receive ultrasonic waves. The transducers can be disposed and operated to measure fluid characteristics such as pressure, density, viscosity, flow rate and can also be used to mix and pump fluids.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

Imaging method and device employing sherar waves

ActiveUS7252004B2Mitigate such drawbackEasy to implementAnalysing fluids using sonic/ultrasonic/infrasonic wavesAnalysing solids using sonic/ultrasonic/infrasonic wavesFocus ultrasoundTransducer

An imaging method for observing the propagation of a shear wave simultaneously at a multitude of points in a diffusing viscoelastic medium. The shear wave is caused to be generated by firing at least one focused ultrasound compression wave into the viscoelastic medium by means of an array of transducers, and then emitting at a fast rate and using the same array of transducers, unfocused ultrasound compression waves serving to obtain a succession of images of the medium, and processing the images obtained in this way in deferred time in order to determine the movements of the medium during the propagation of the shear wave.

Owner:SUPER SONIC IMAGINE

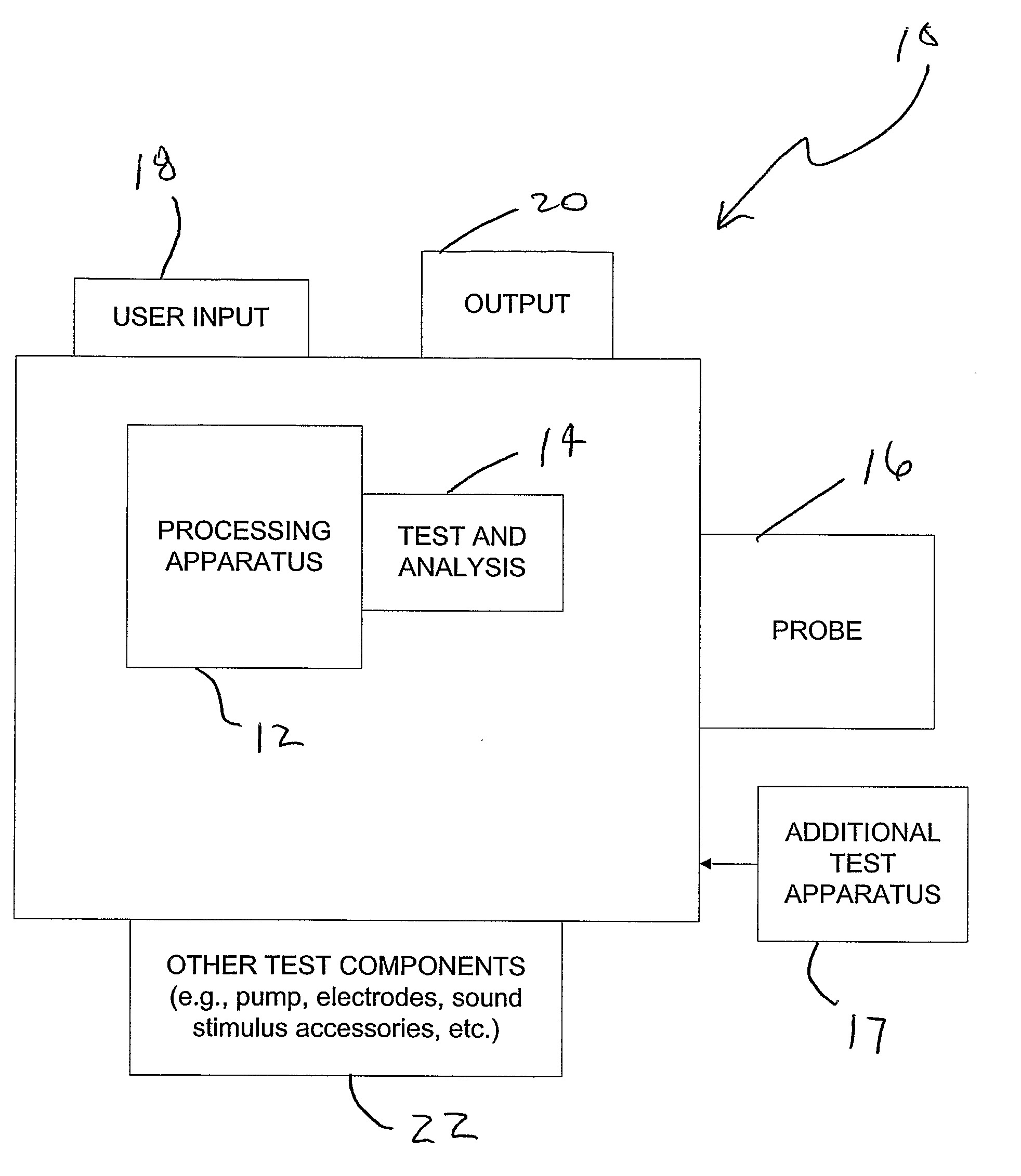

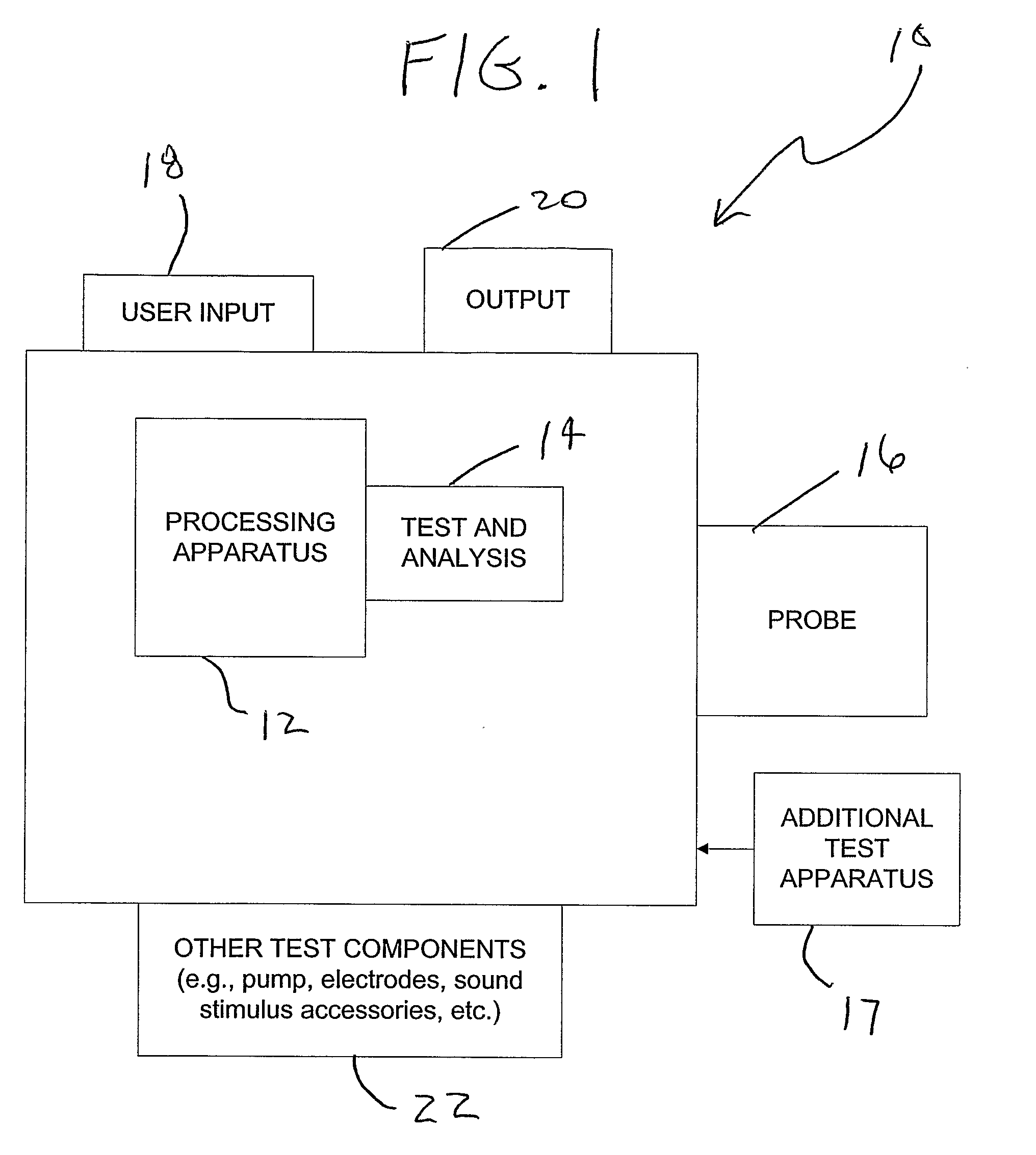

Test Battery System and Method for Assessment of Auditory Function

ActiveUS20080194984A1Improve accuracyImprove reliabilityVibration measurement in solidsMaterial analysis using sonic/ultrasonic/infrasonic wavesReflexTest battery

A test battery method and system (10, 100, 200, 225) for use in assessing auditory function (e.g., the screening or diagnosis of impairments, fitting of hearing aids, etc.) is provided which performs one or more auditory tests including, for example, an acoustic reflectance test. Such an acoustic reflectance test may be a reflectance tympanometry test that includes a feedback system to control static pressure in the ear canal. Such acoustic reflectance tests may be used alone or in combination with one or more other auditory tests. Further, for example, such a battery of tests may include middle-ear muscle reflex tests in combination with one or more other auditory or hearing tests.

Owner:SONICOM

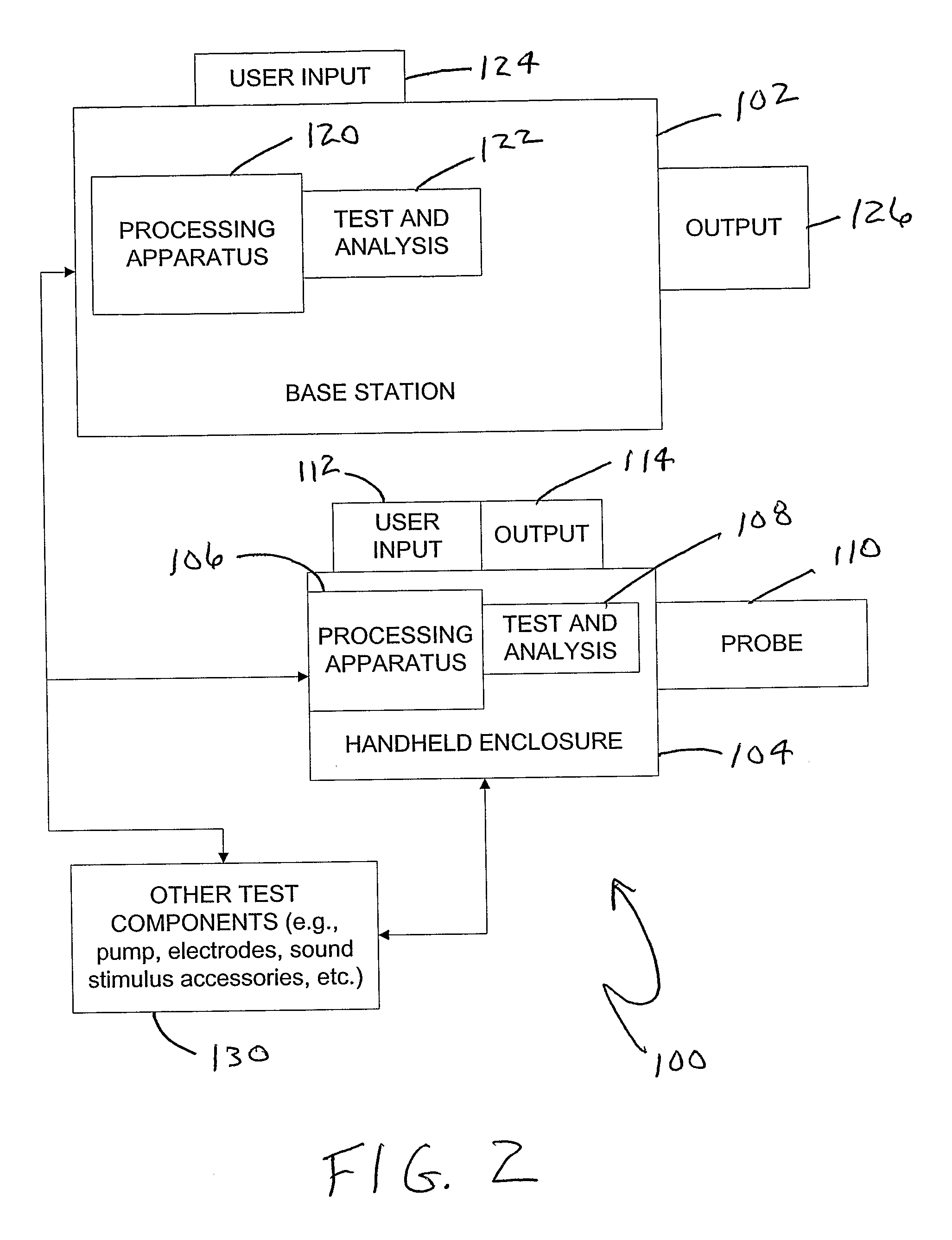

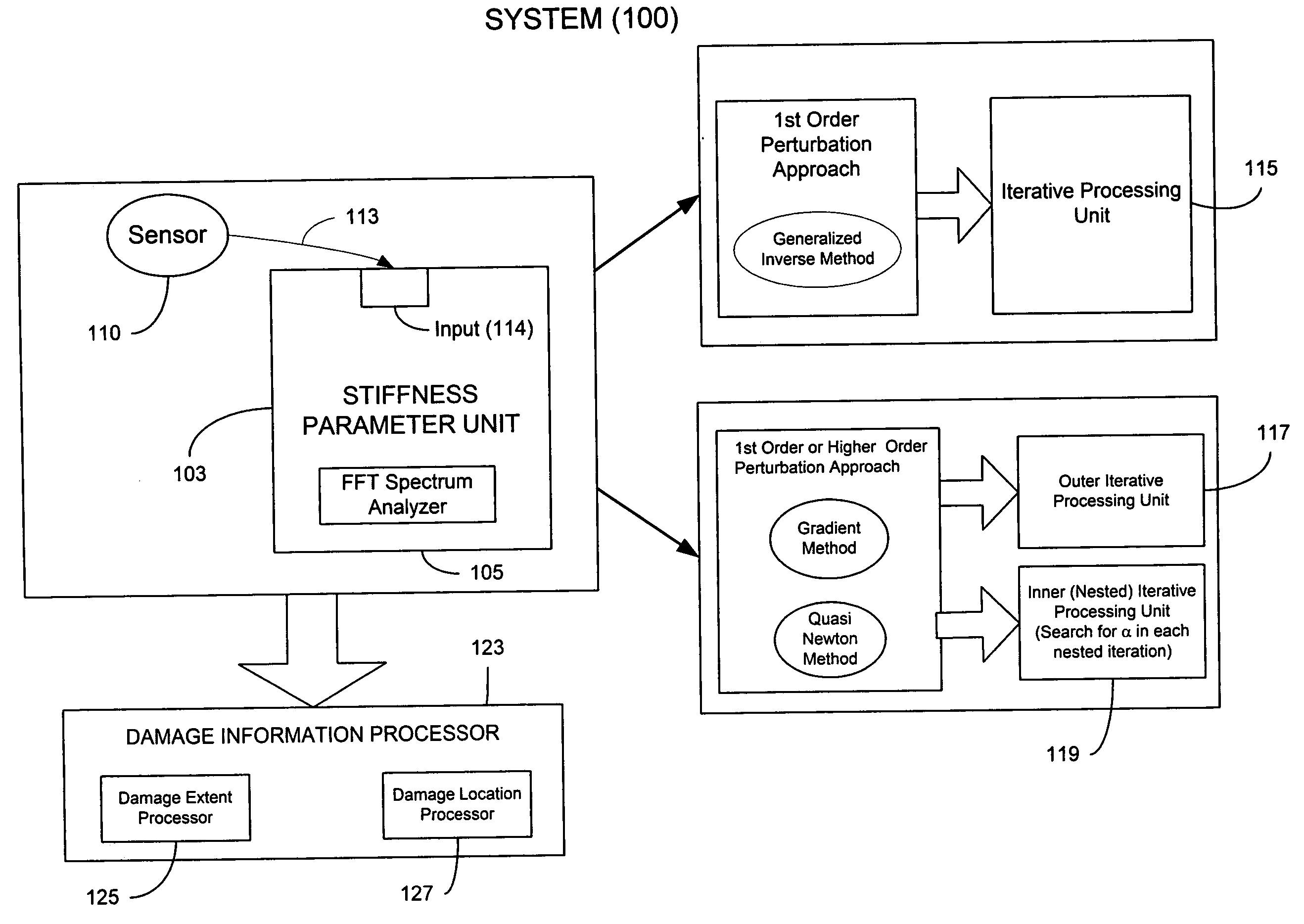

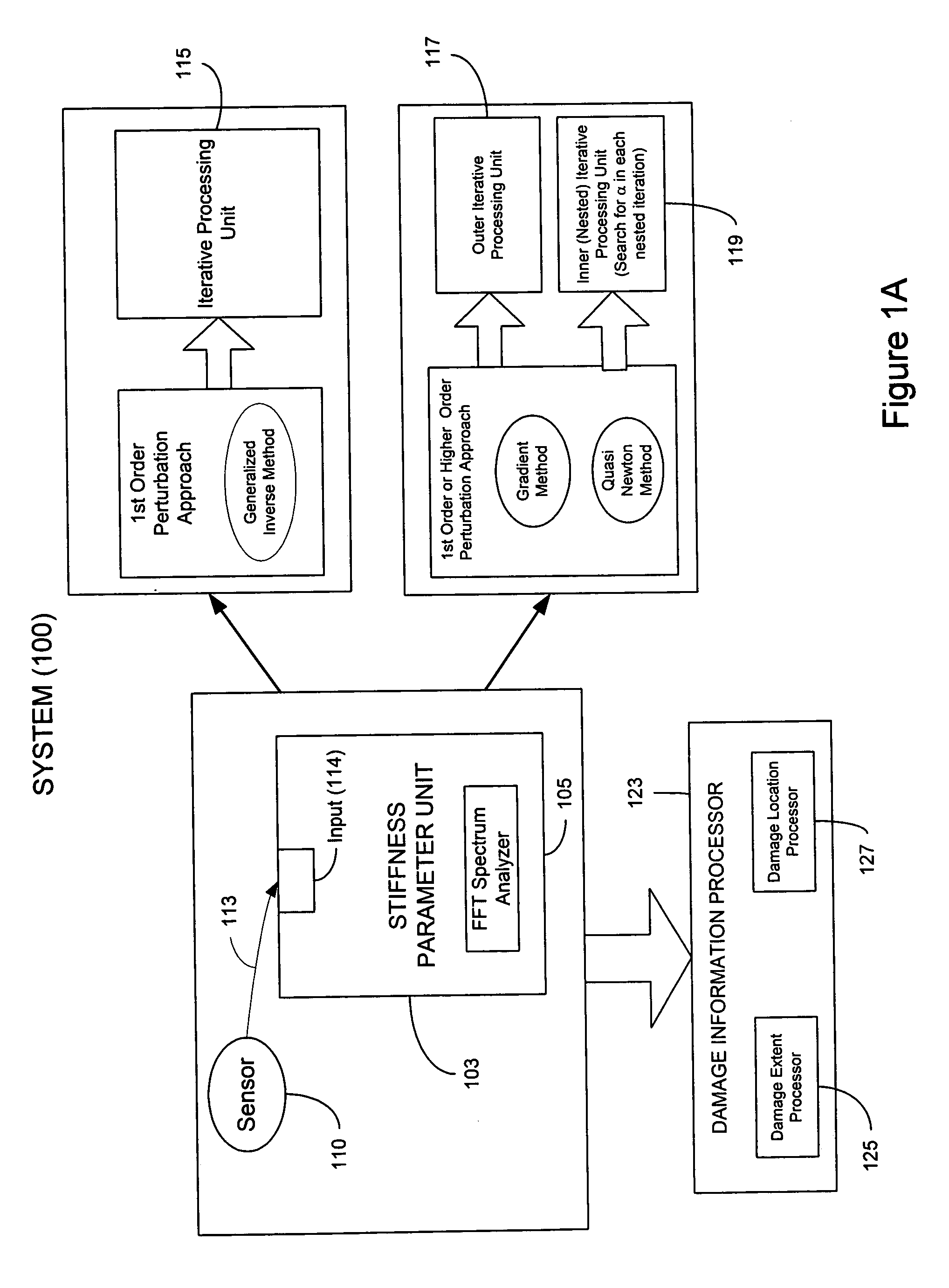

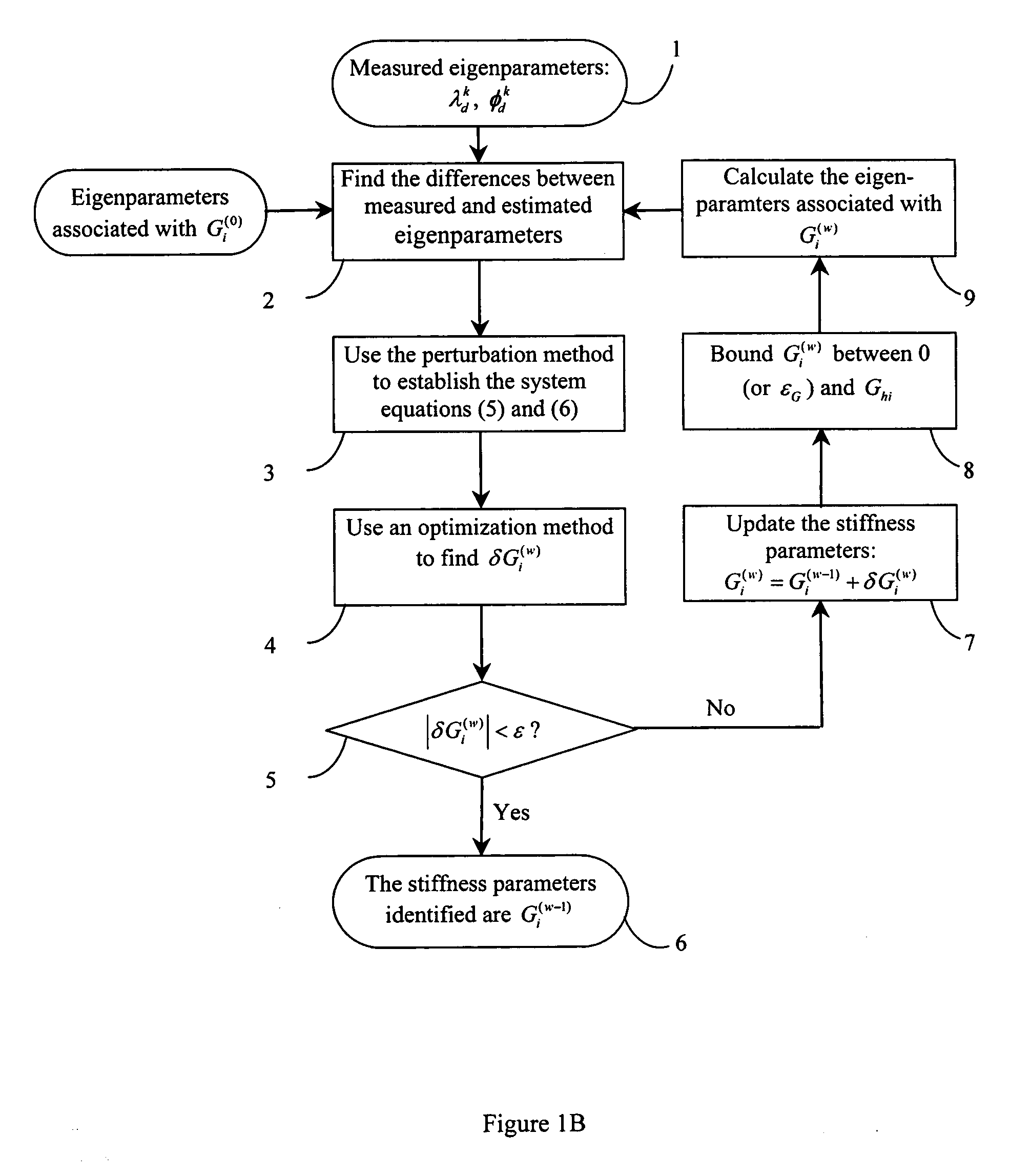

System and method for detecting structural damage

InactiveUS20050072234A1Vibration measurement in solidsAnti-theft devicesModal testingSignal-to-noise ratio (imaging)

A system and method for detecting structural damage is provided that utilizes a general order perturbation methodology involving multiple perturbation parameters. The perturbation methodology is used iteratively in conjunction with an optimization method to identify the stiffness parameters of structures using natural frequencies and / or mode shape information. The stiffness parameters are then used to determine the location and extent of damage in a structure. A novel stochastic model is developed to model the random impact series produced manually or to generate a random impact series in a random impact device. The random impact series method or the random impact device can be used to excite a structure and generate vibration information used to obtain the stiffness parameters of the structure. The method or the device can also just be used for modal testing purposes. The random impact device is a high energy, random, and high signal-to-noise ratio system.

Owner:UNIV OF MARYLAND BALTIMORE COUNTY

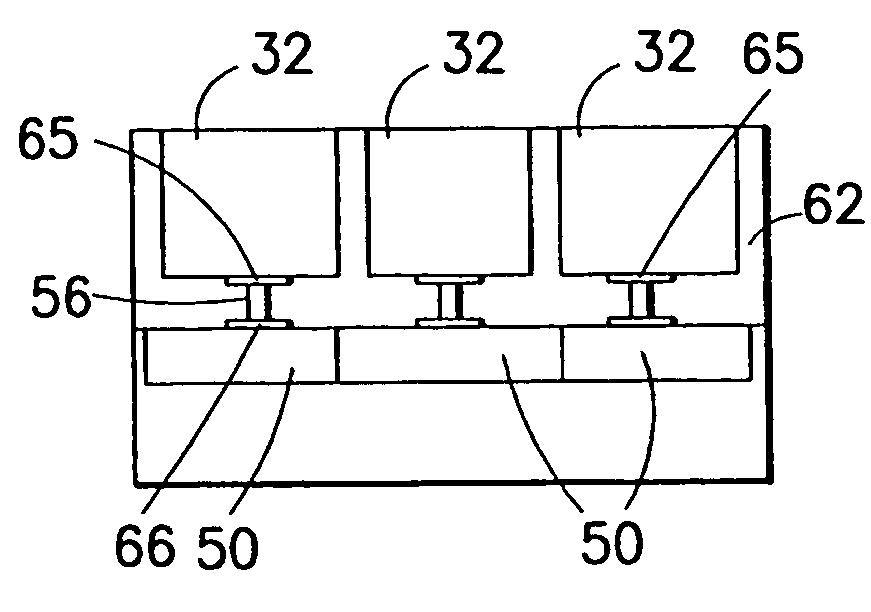

Integrated interface electronics for reconfigurable sensor array

ActiveUS7257051B2Ultrasonic/sonic/infrasonic diagnosticsAnalysing solids using sonic/ultrasonic/infrasonic wavesElectricitySensor array

Owner:GENERAL ELECTRIC CO

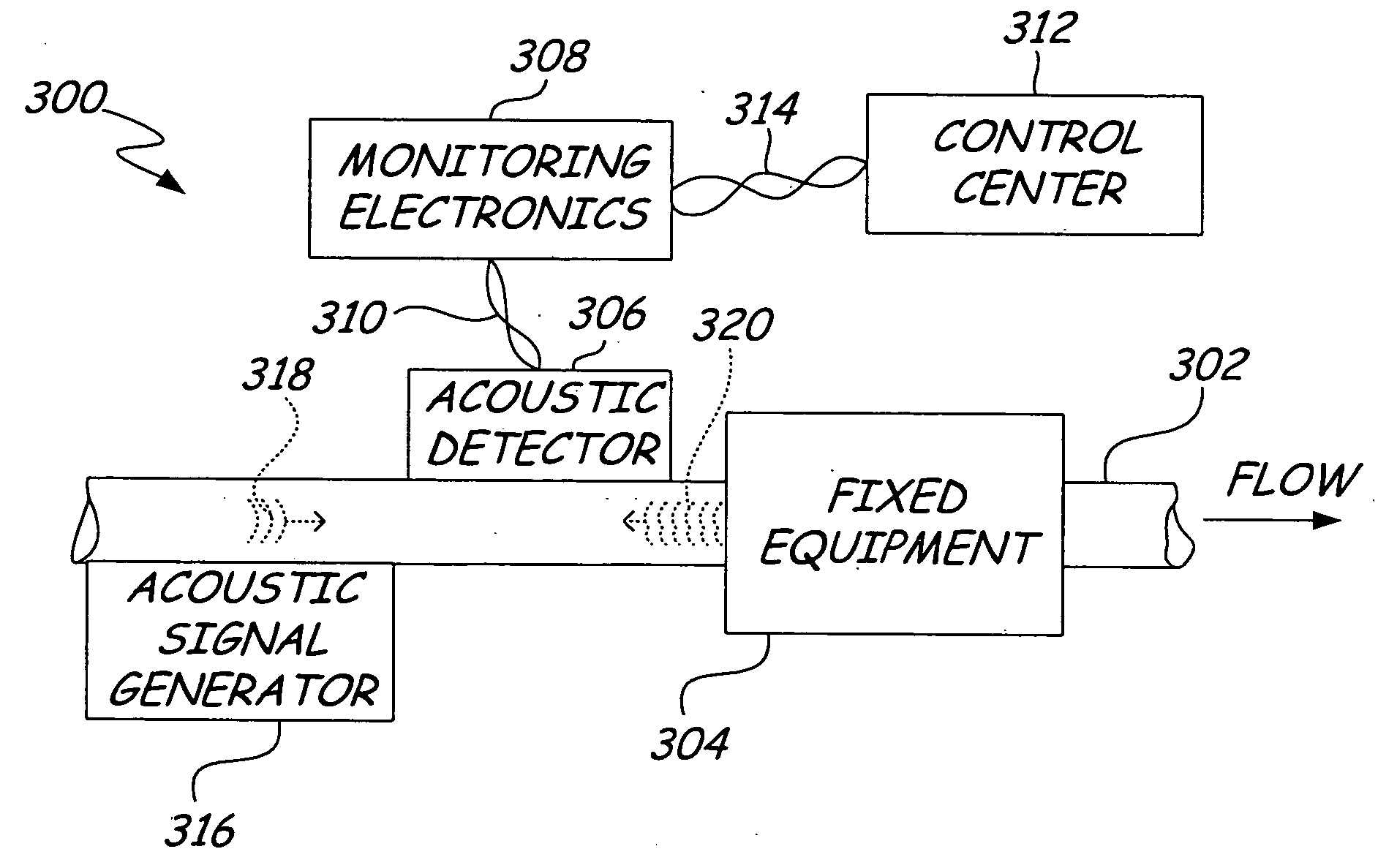

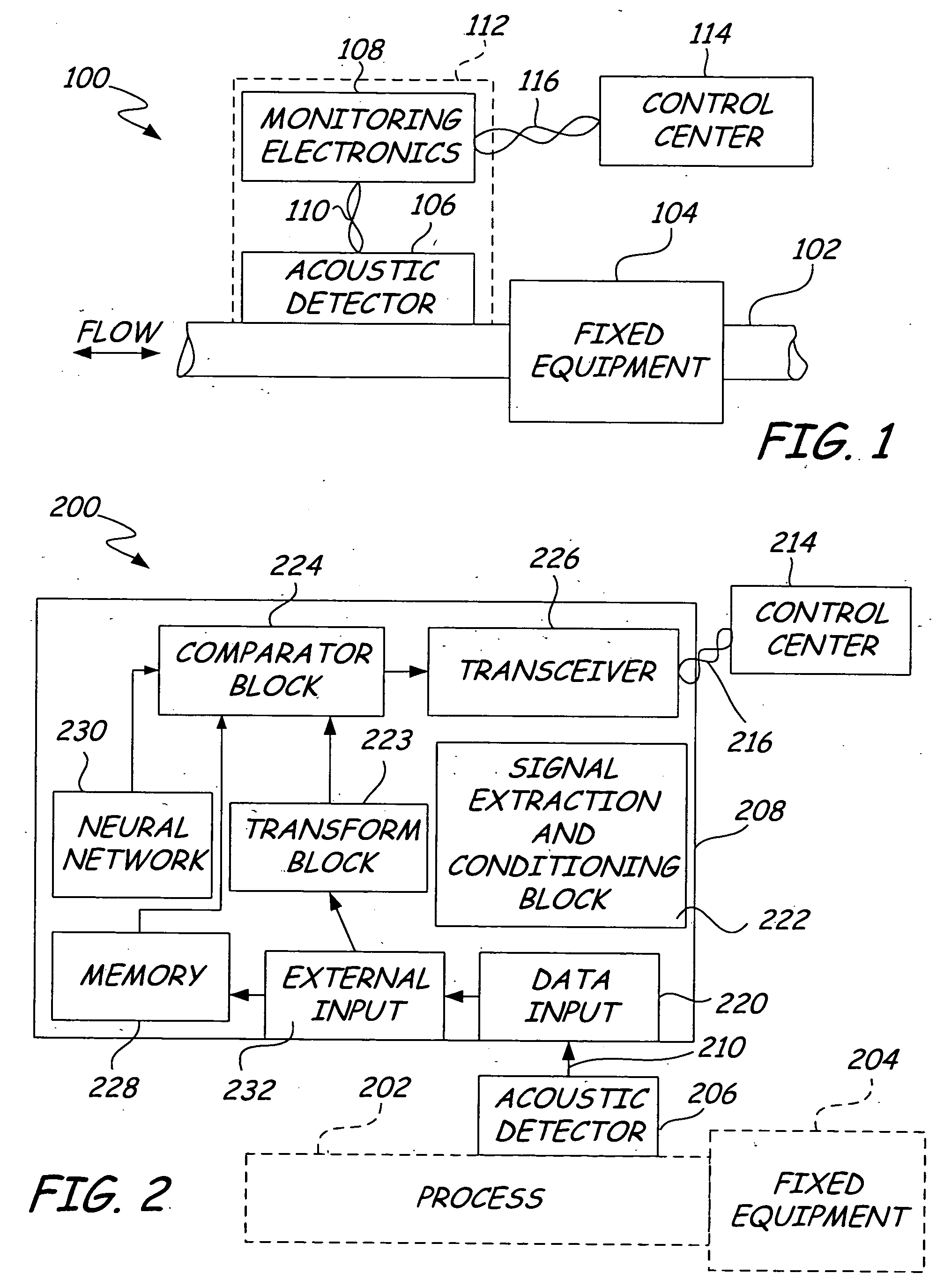

Process diagnostics

ActiveUS7290450B2Improve abilitiesEasy to useVibration measurement in solidsAnalysing fluids using sonic/ultrasonic/infrasonic wavesTransducerEngineering

A diagnostic device for use in a industrial process includes monitoring electronics or diagnostic circuitry configured to diagnose or identify a condition or other occurrence in the industrial process. The system can be implemented in a process device such as a flowmeter, and in one example an acoustic flowmeter. A transducer can also be used and a frequency response, such as resonant frequency, can be observed.

Owner:ROSEMOUNT INC

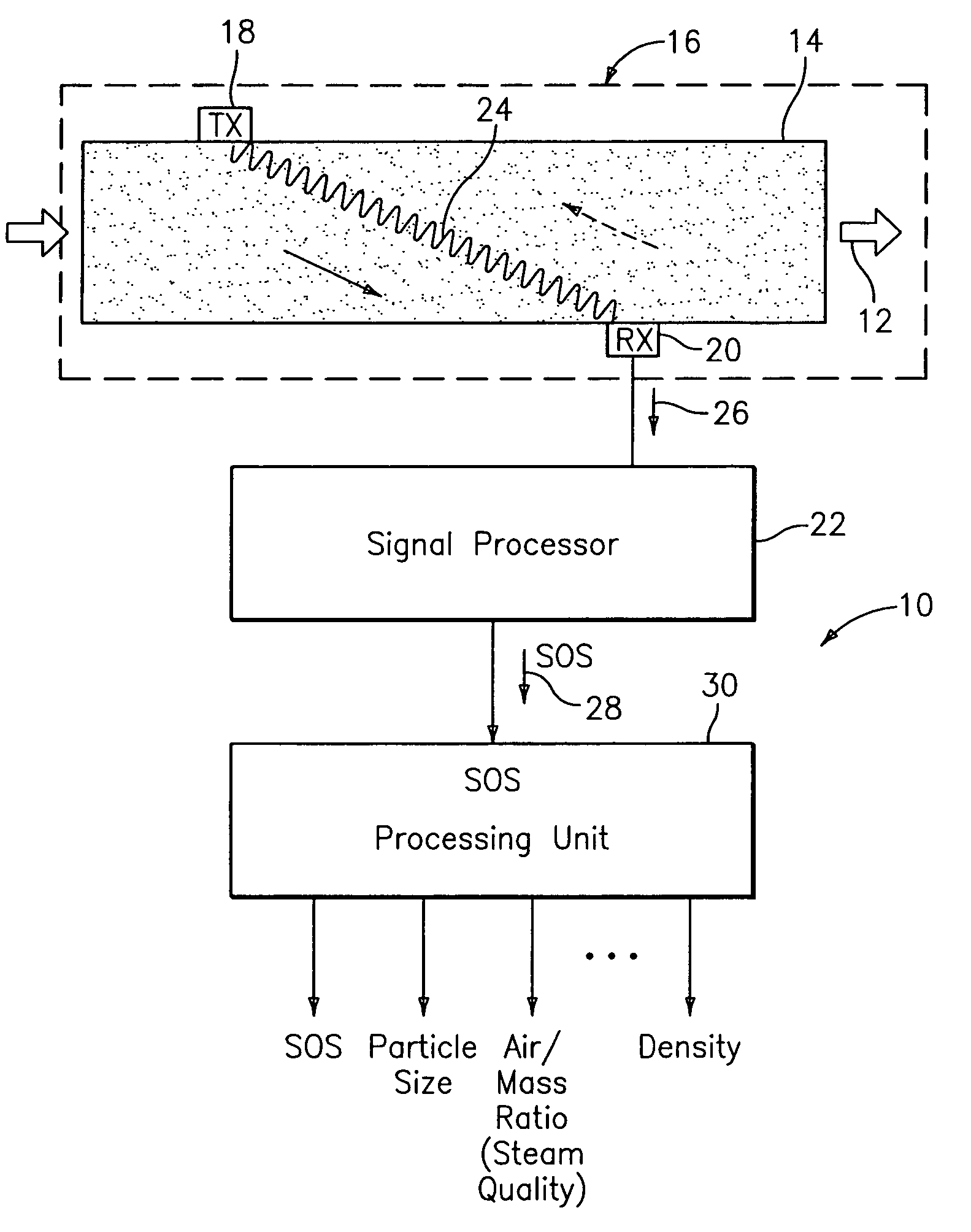

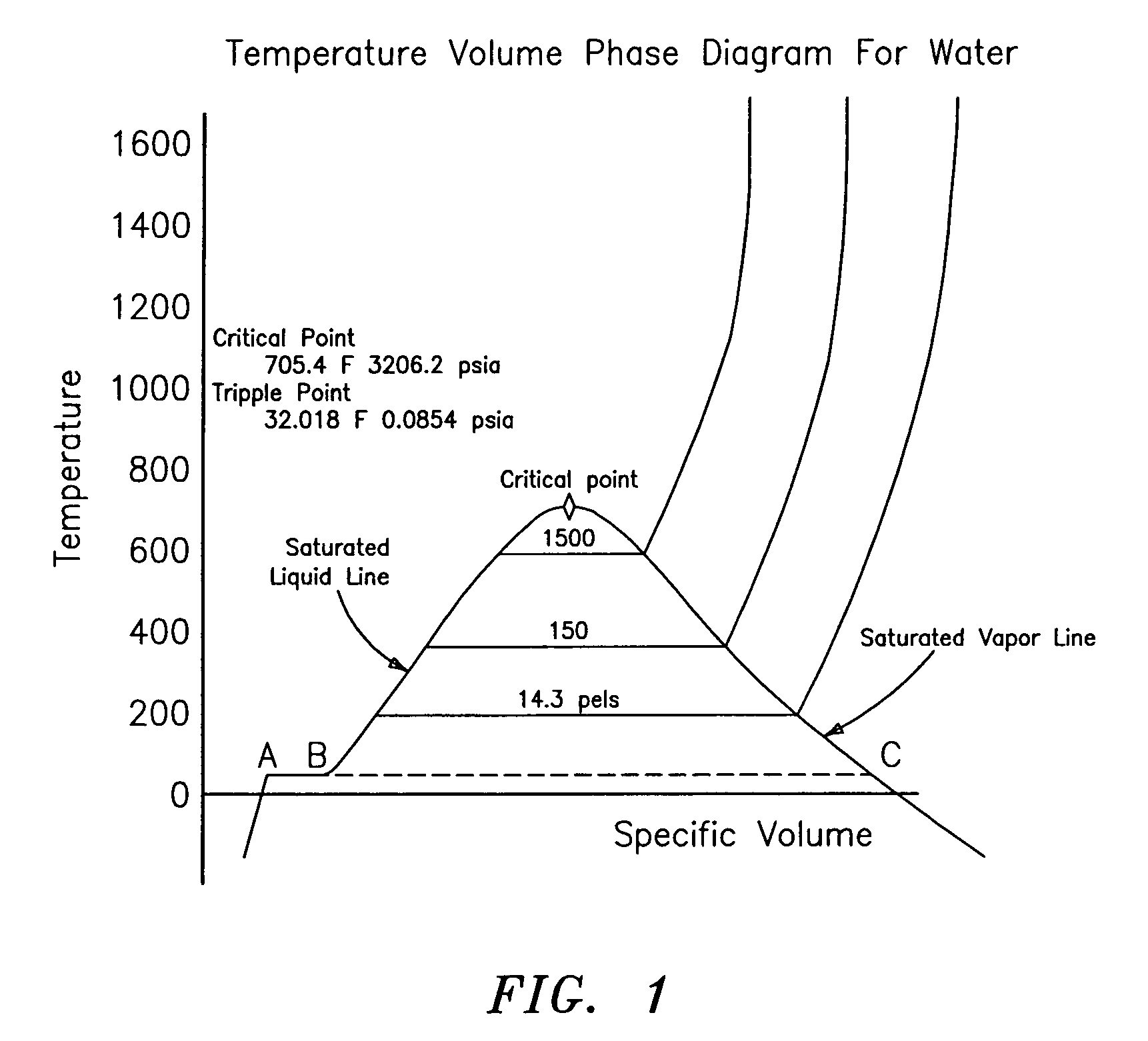

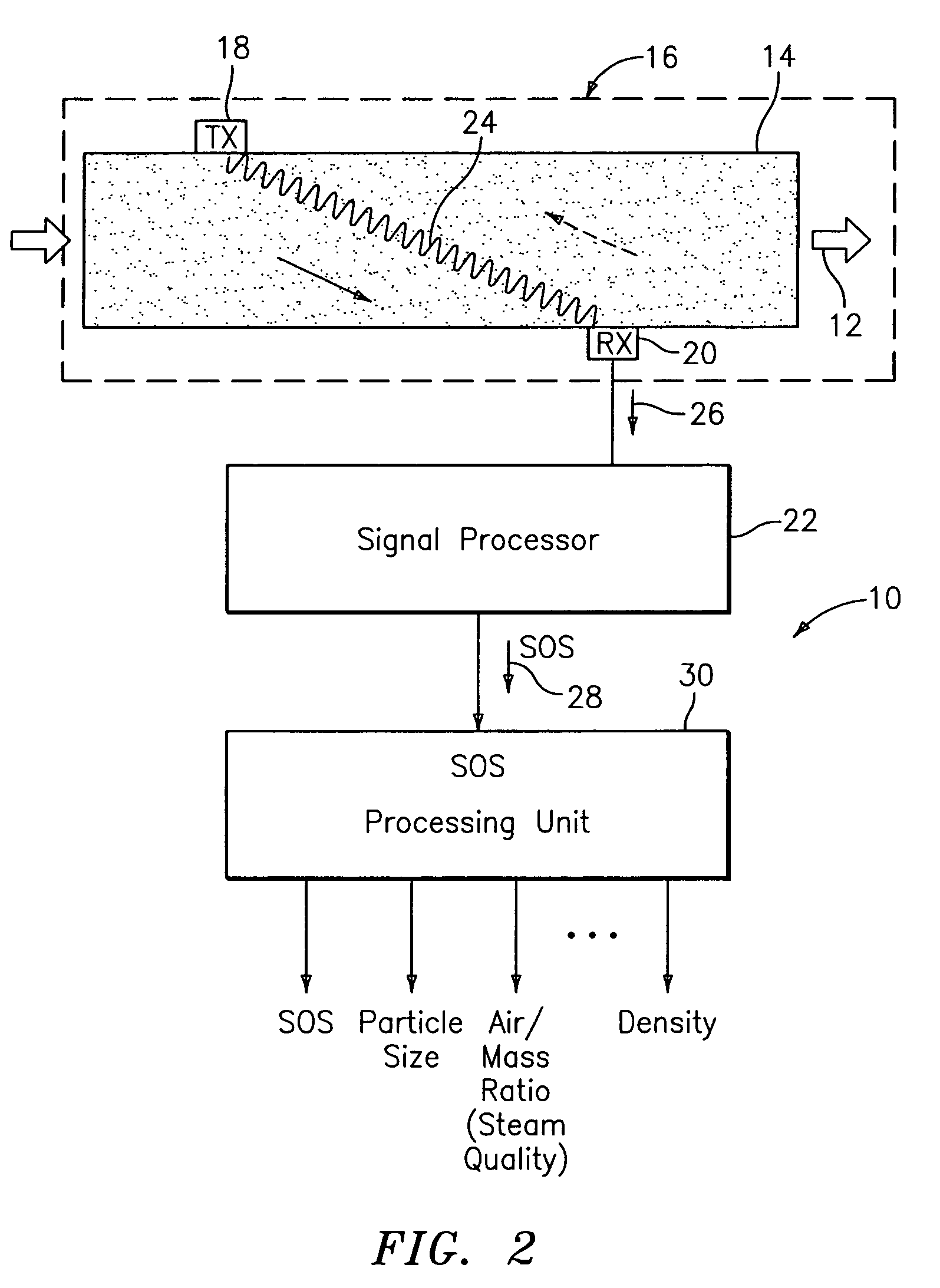

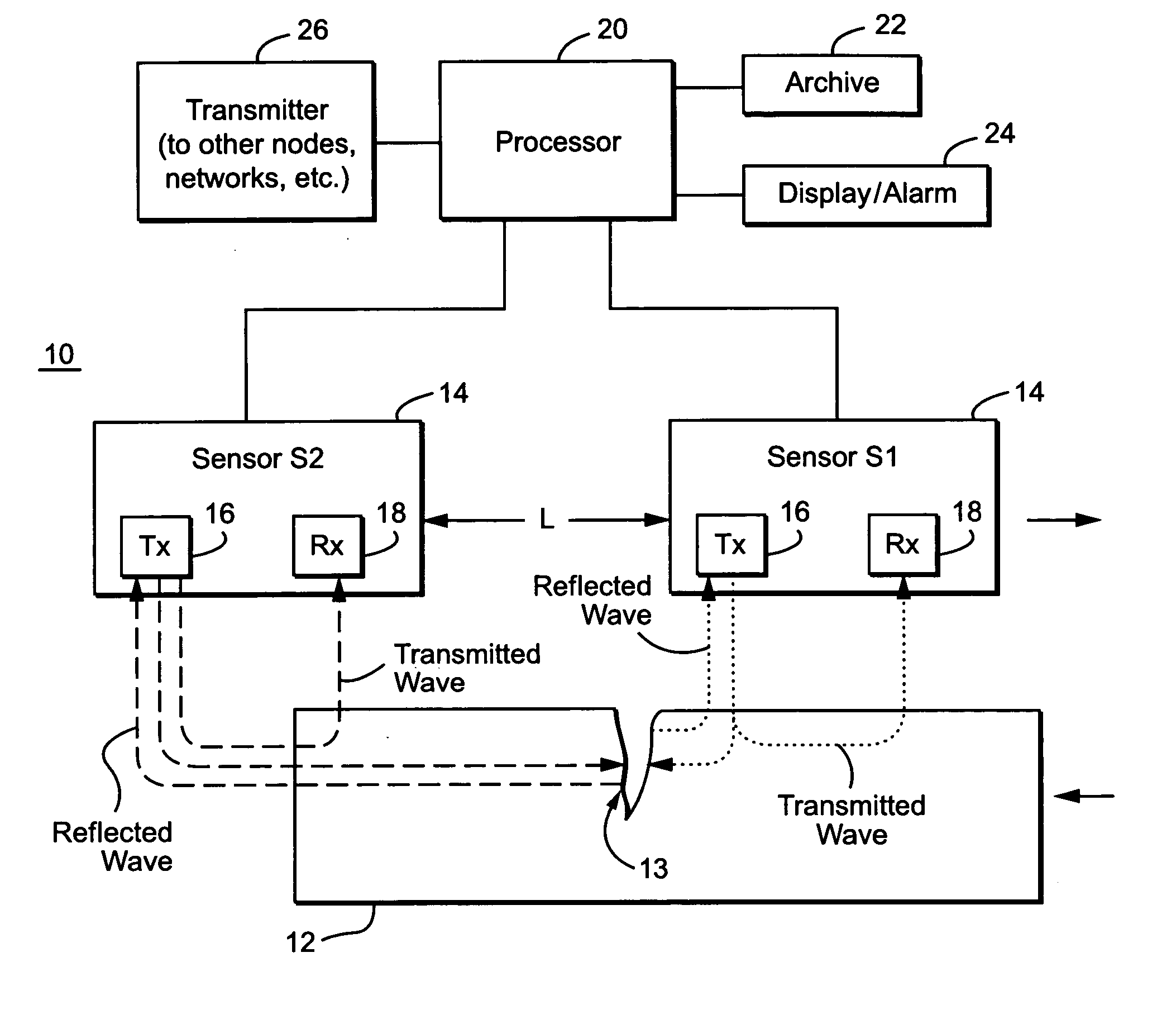

Apparatus for measuring parameters of a flowing multiphase mixture

ActiveUS7096719B2Analysing fluids using sonic/ultrasonic/infrasonic wavesAnalysing solids using sonic/ultrasonic/infrasonic wavesUltrasonic sensorMass ratio

An apparatus 10 is provided that measures the speed of sound propagating in a multiphase mixture to determine parameters, such as mixture quality, particle size, vapor / mass ratio, liquid / vapor ratio, mass flow rate, enthalpy and volumetric flow rate of the flow in a pipe or unconfined space, for example, using acoustic and / or dynamic pressures. The apparatus includes a pair of ultrasonic transducers disposed axially along the pipe for measuring the transit time of an ultrasonic signal to propagate from one ultrasonic transducer to the other ultrasonic transducer. A signal process, responsive to said transit time signal, provides a signal representative of the speed of sound of the mixture. An SOS processing unit then provides an output signal indicative of at least one parameter of the mixture flowing through the pipe. The frequency of the ultrasonic signal is sufficiently low to minimize scatter from particle / liquid within the mixture. The frequency based sound speed is determined utilizing a dispersion model to determine the at least one parameter of the fluid flow and / or mixture.

Owner:CIDRA CORP SERVICES

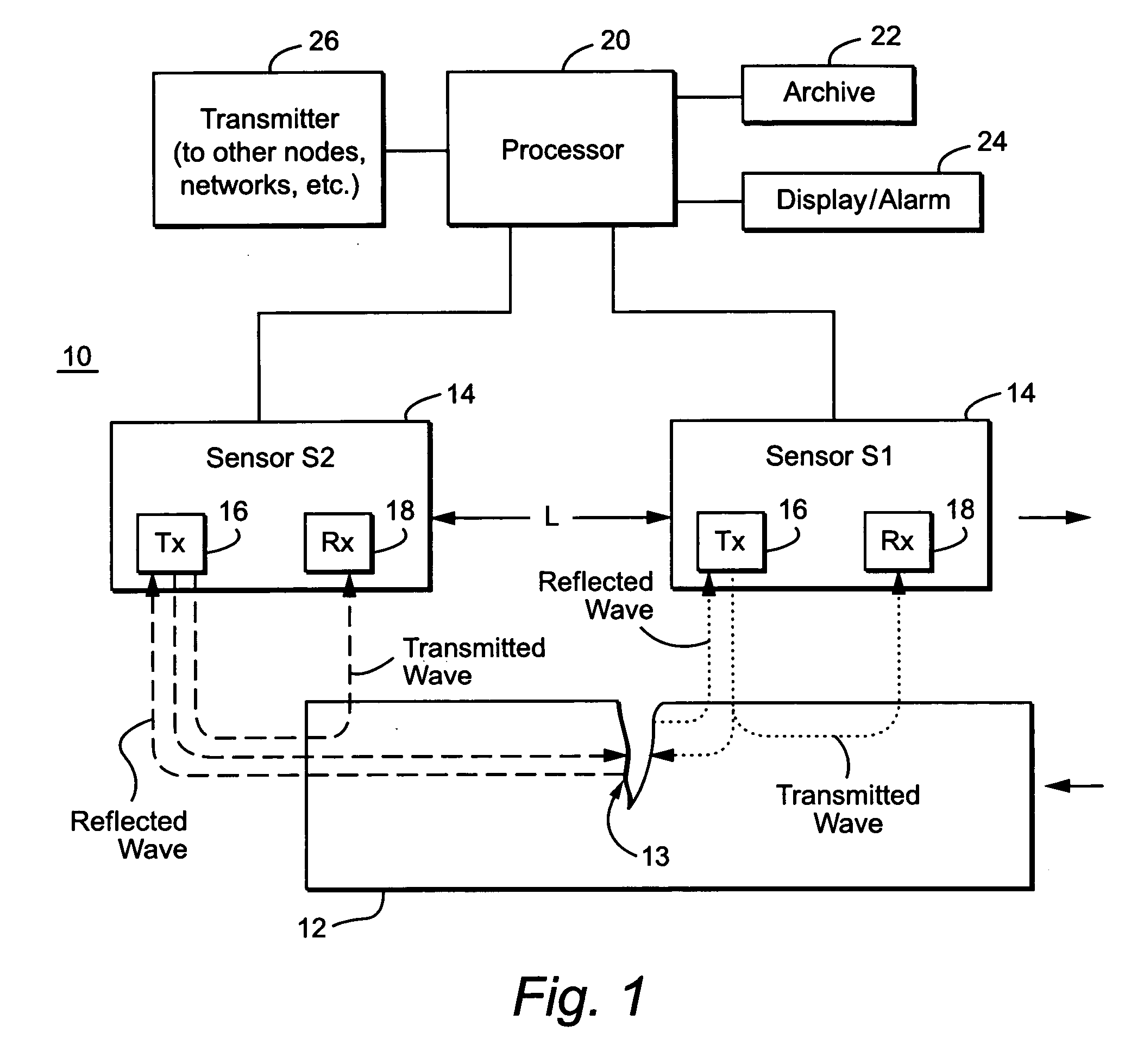

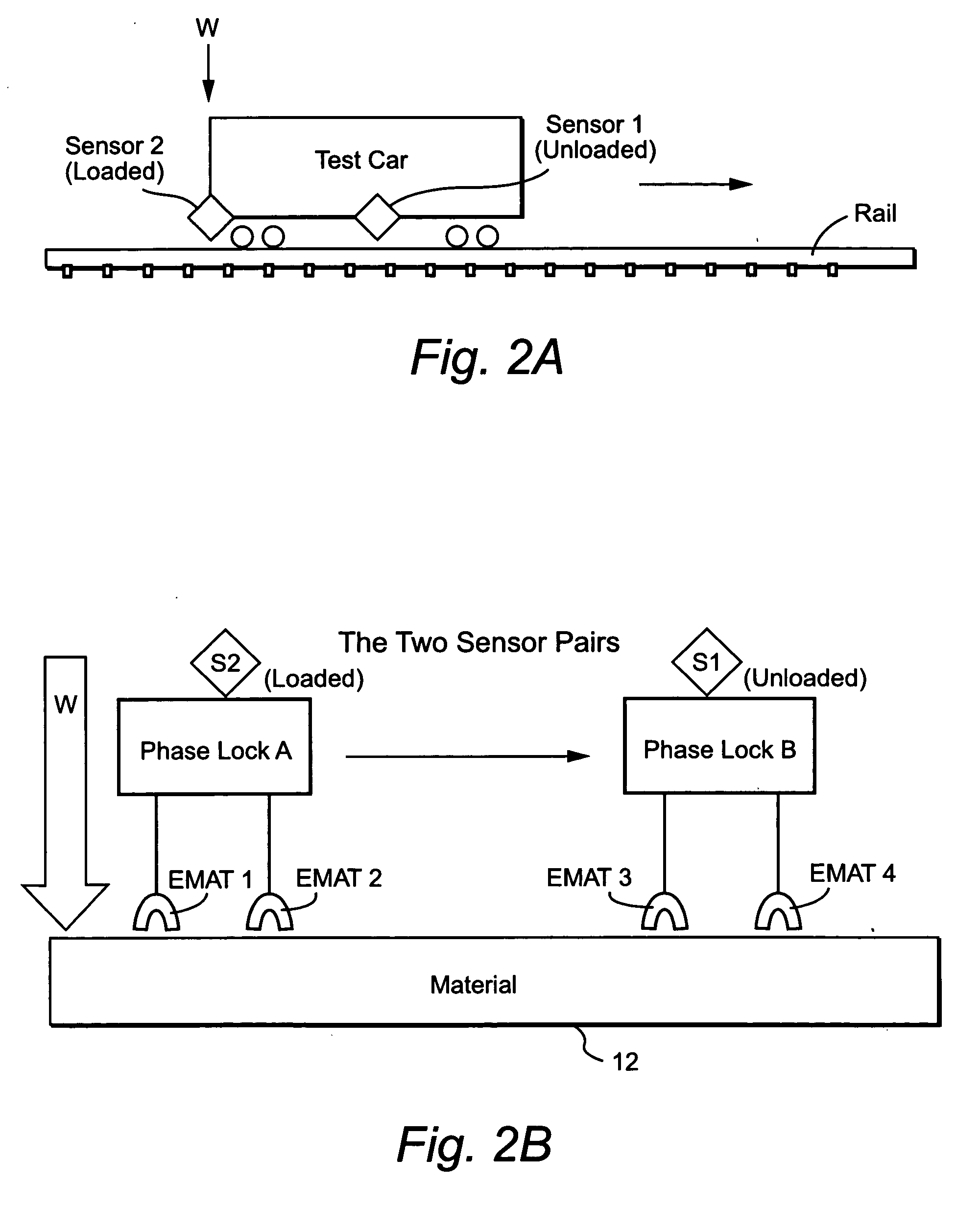

Method and apparatus for determining and assessing a characteristic of a material

InactiveUS20050072236A1Low costImprove accuracyAnalysing fluids using sonic/ultrasonic/infrasonic wavesAnalysing solids using sonic/ultrasonic/infrasonic wavesDifferential measurementCrazing

An acoustic energy-based, non-contact or contact testing approach provides low cost, highly accurate, and reliable information to (a) identify flaws and anomalies and (b) assess the integrity of a particular material. This approach is not hindered by surface conditions or impediments, and indeed, looks beneath the surface of the material by propagating an acoustic wave through the material using two differential transducers. A dynamic differential measurement is made of the material under a load condition and an unloaded condition that allows identification and assessment of various characteristics of the material. Multiple “windows” of information may be generated that permit (a) direct detection of flaws, defects, and anomalies using a scattering technique, (b) detection of crack closure and opening used to assess the stability of the material, (c) determination of strain on the material which relates to its performance, and (d) determination of defect dynamics linked to the defect size and stability.

Owner:LUNA INNOVATIONS

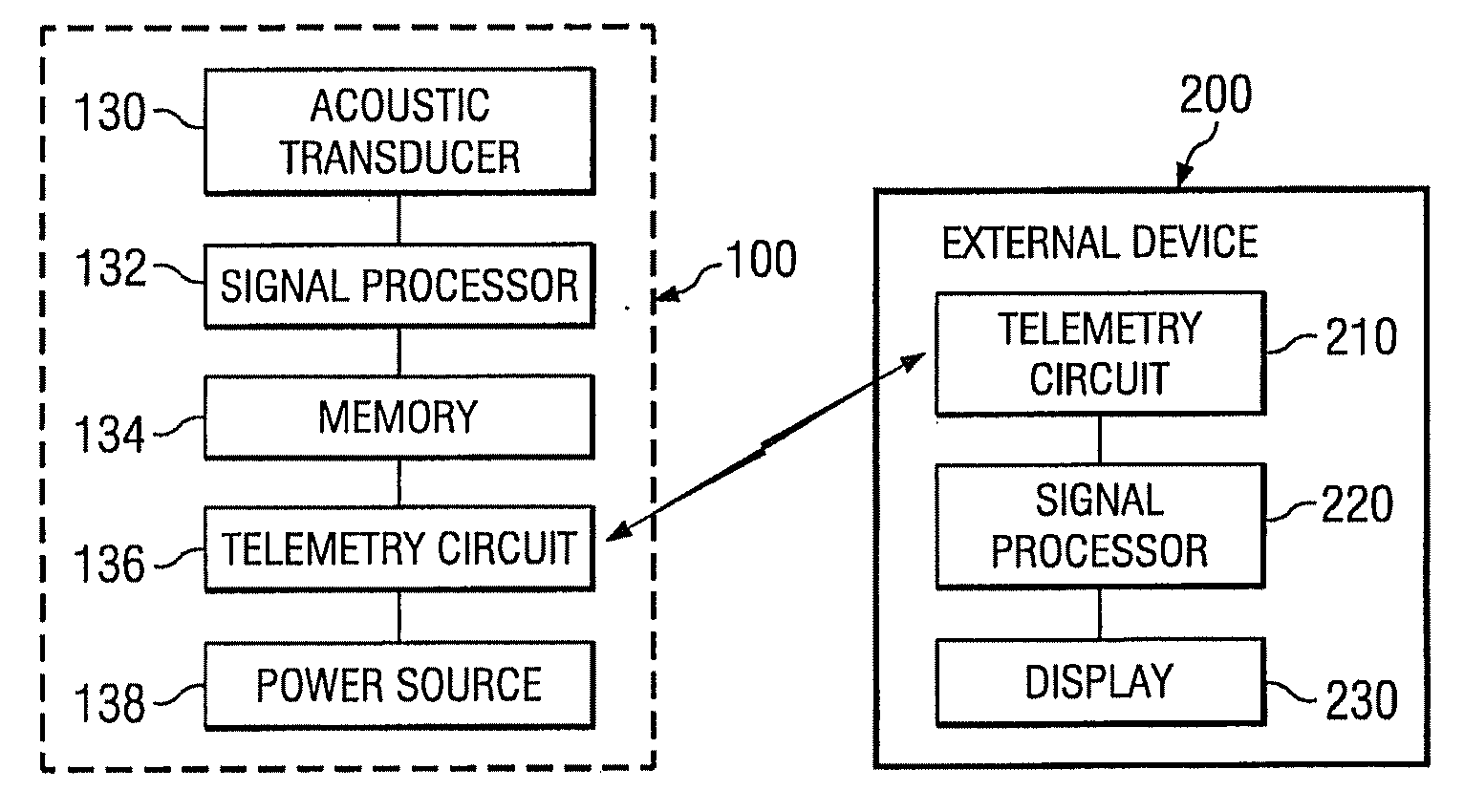

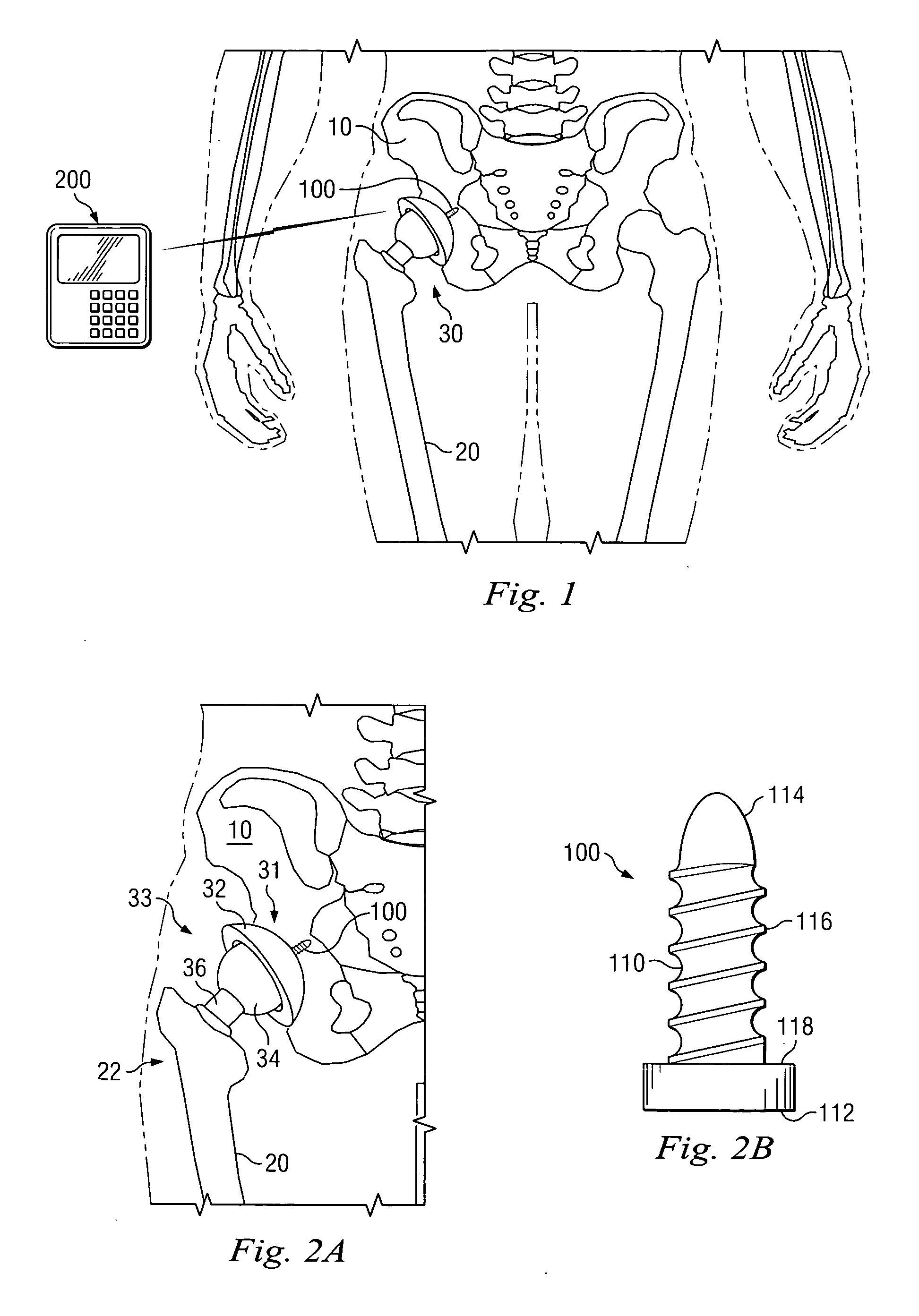

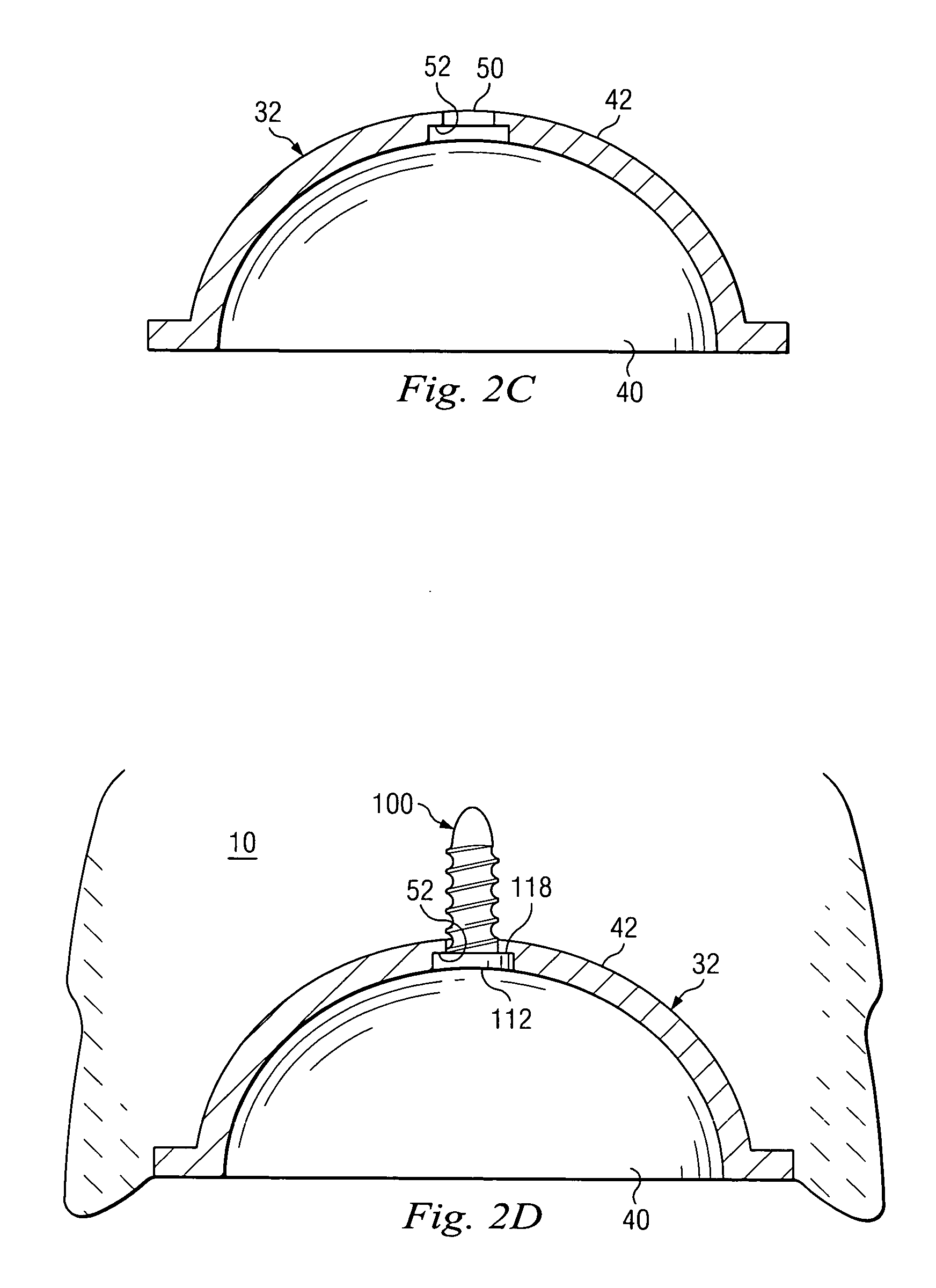

Implantable pedometer

InactiveUS20070179739A1Vibration measurement in solidsVibration measurement in fluidPedometerTelemetry Equipment

An implantable pedometer for measuring the amount of joint use is disclosed. The implantable pedometer includes a sensor adapted for detecting indicators of joint usage. A counter is configured for storing count data corresponding to the number of indicators detected by the sensor and a telemetry circuit is configured for transmitting the count data outside of the body.

Owner:WARSAW ORTHOPEDIC INC +1

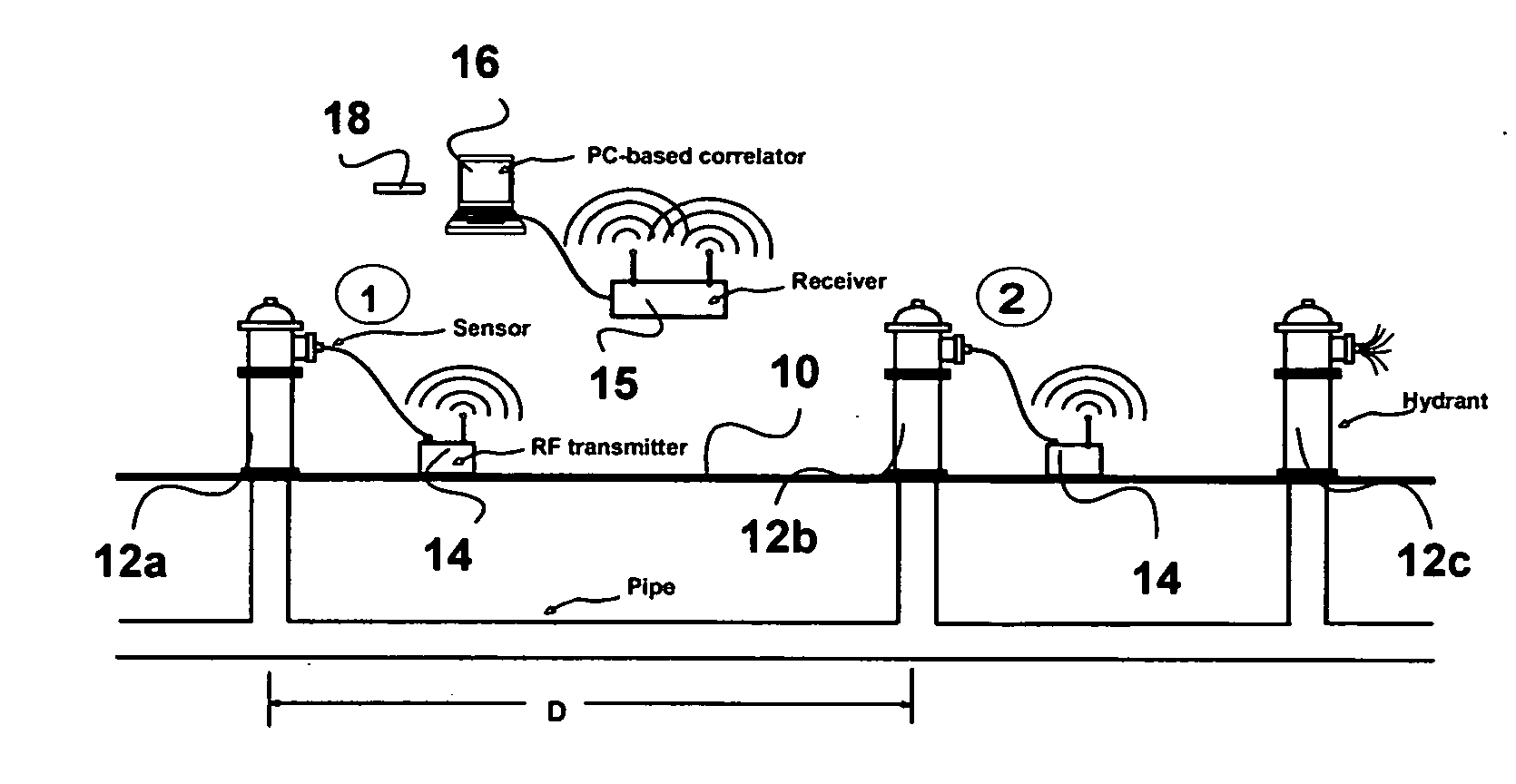

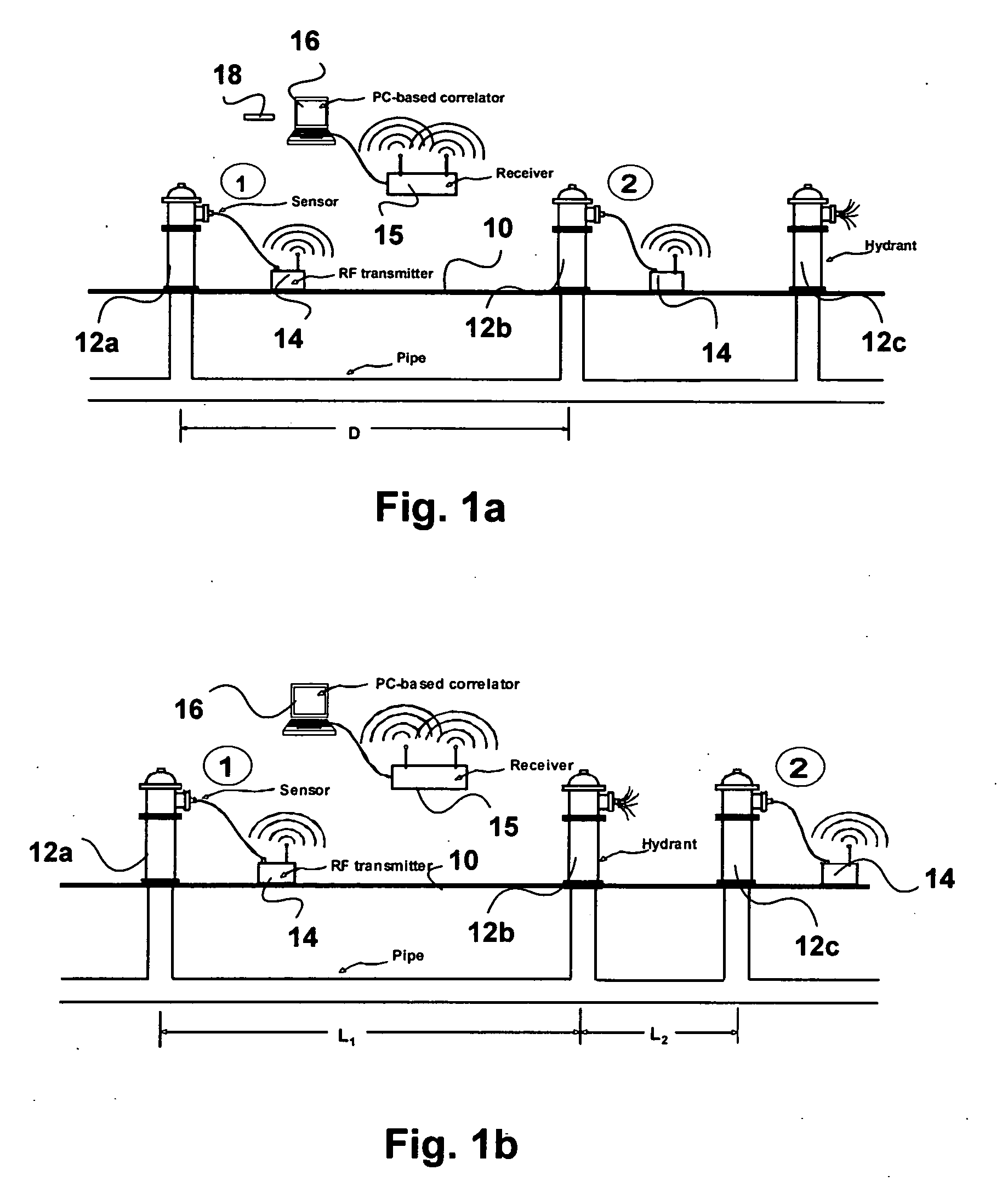

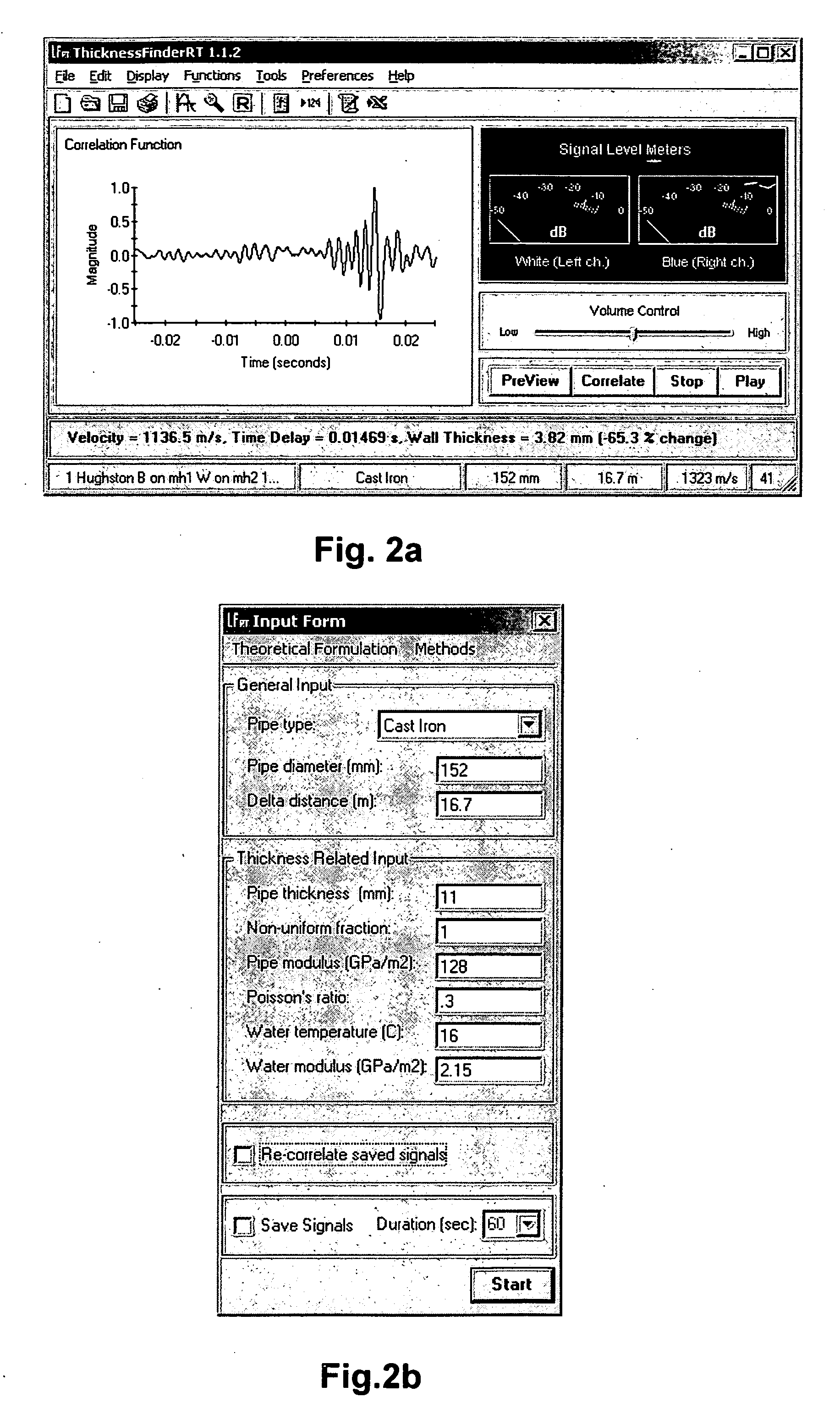

Non-destructive testing of pipes

ActiveUS20060283251A1Easy to measureEasy to calculateAnalysing fluids using sonic/ultrasonic/infrasonic wavesAnalysing solids using sonic/ultrasonic/infrasonic wavesNon destructiveEngineering

To perform a non-destructive condition assessment of a pipe carrying a fluid, an actual value representative of the propagation velocity of an acoustic disturbance propagating between two longitudinally separated points on the pipe is determined. A corresponding predicted value for the propagation velocity is computed as a function of at least one wall thickness parameter of the pipe by using a theoretical model for the propagation of acoustic waves in the pipe that assumes said pipe has a finite wall thickness with a predetermined circumferential thickness profile. The wall thickness parameter is then computed by matching the actual value with the predicted value, for example, by substituting the actual value in a formula predicting the theoretical value.

Owner:MUELLER INT LLC

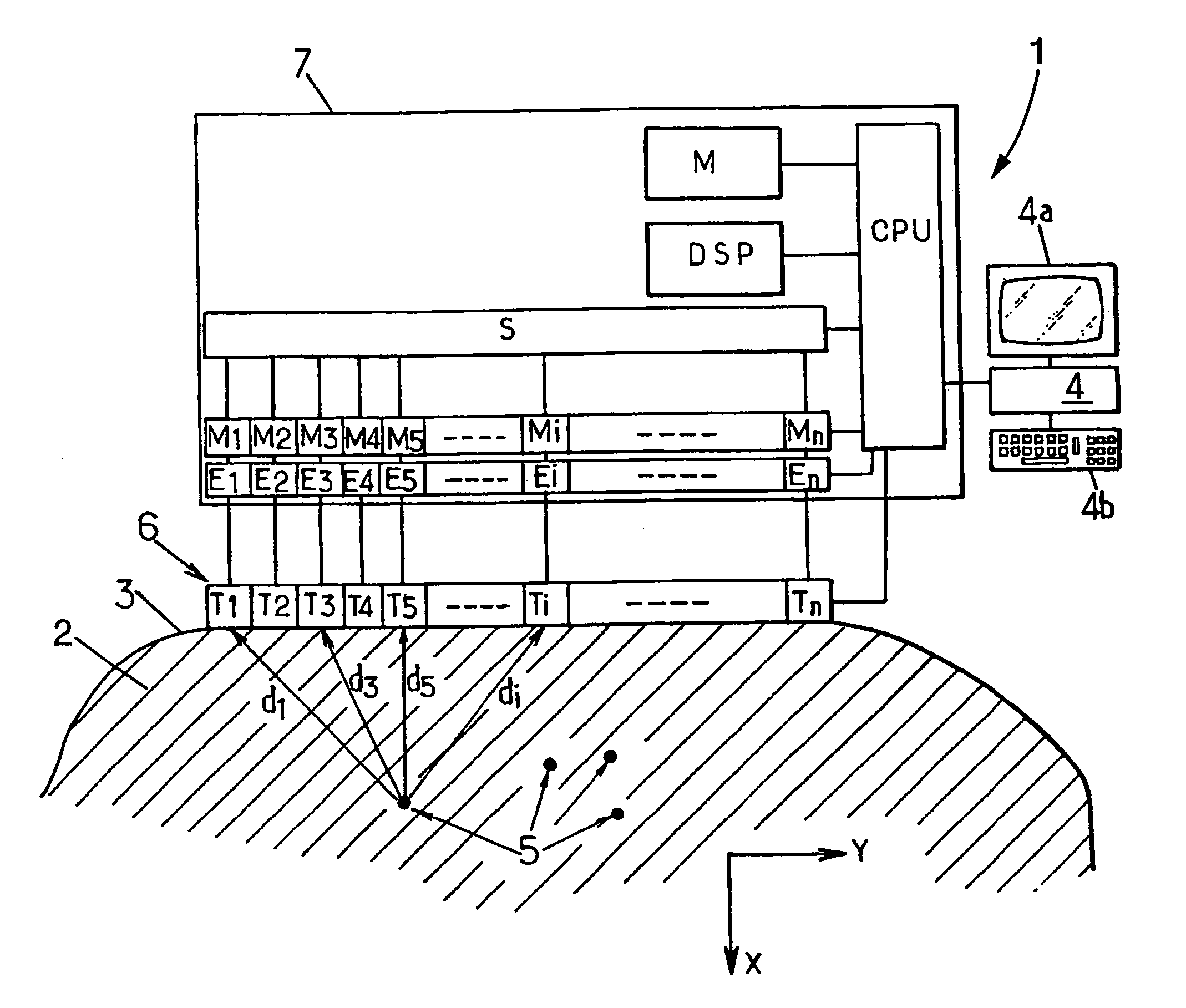

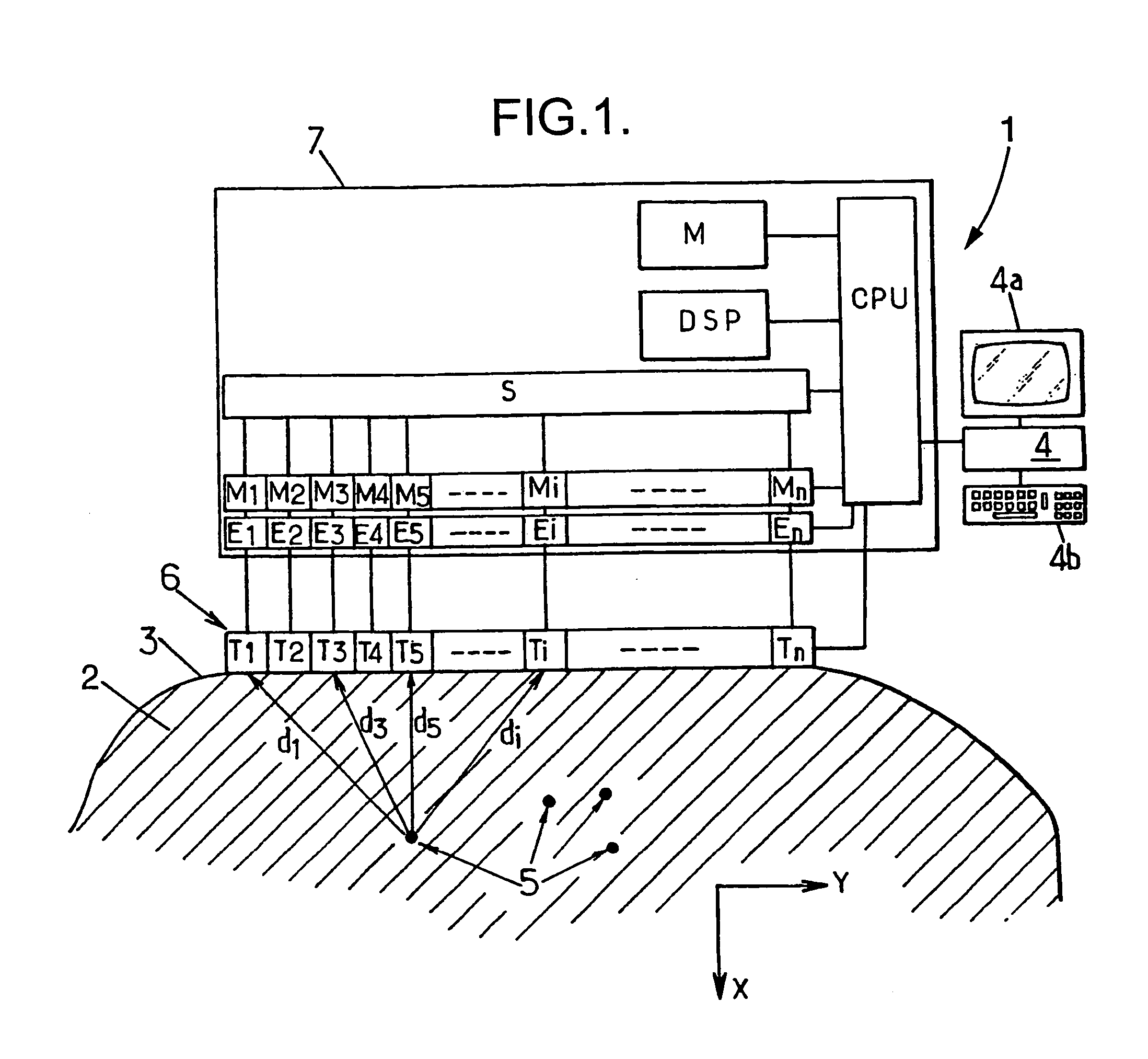

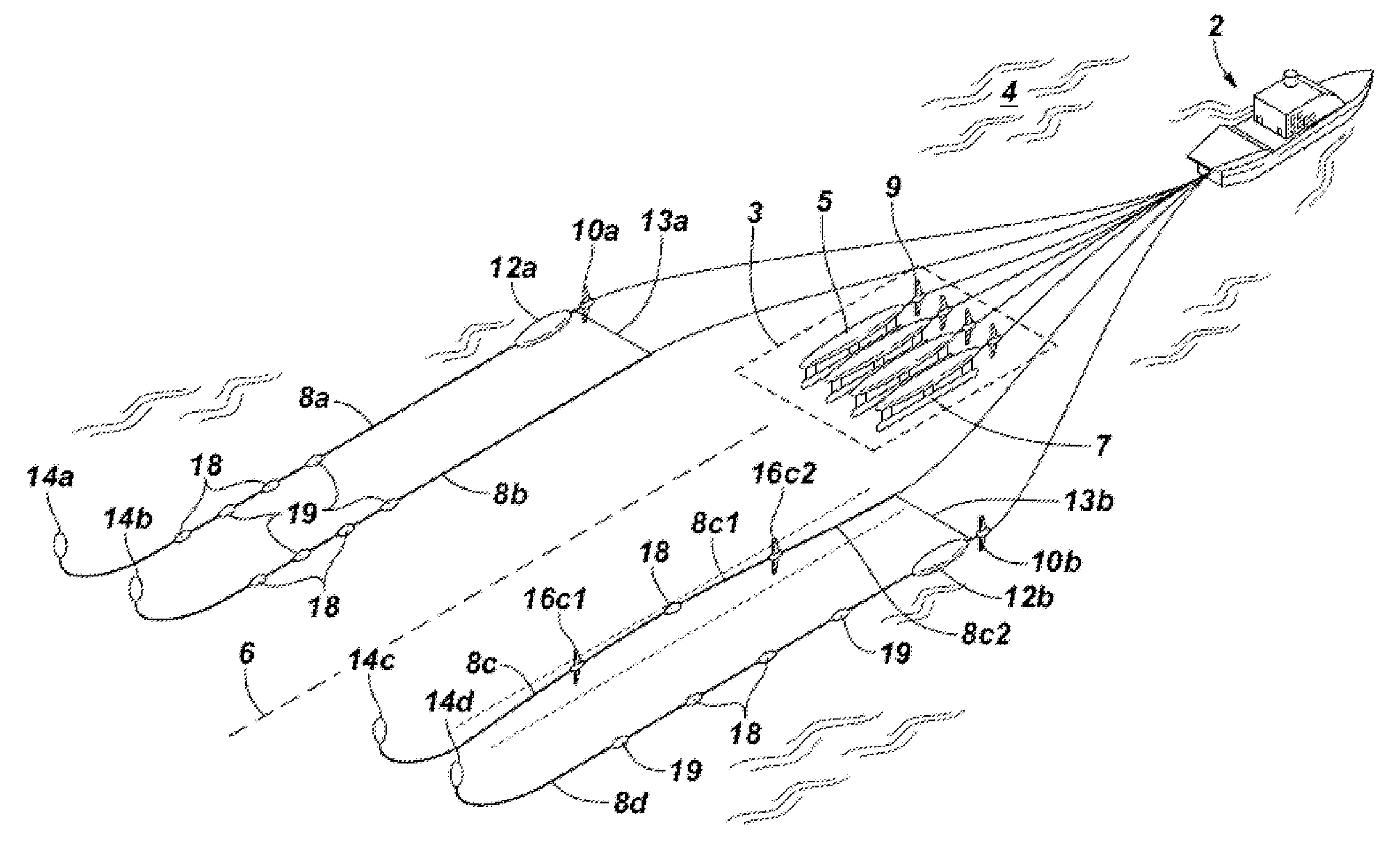

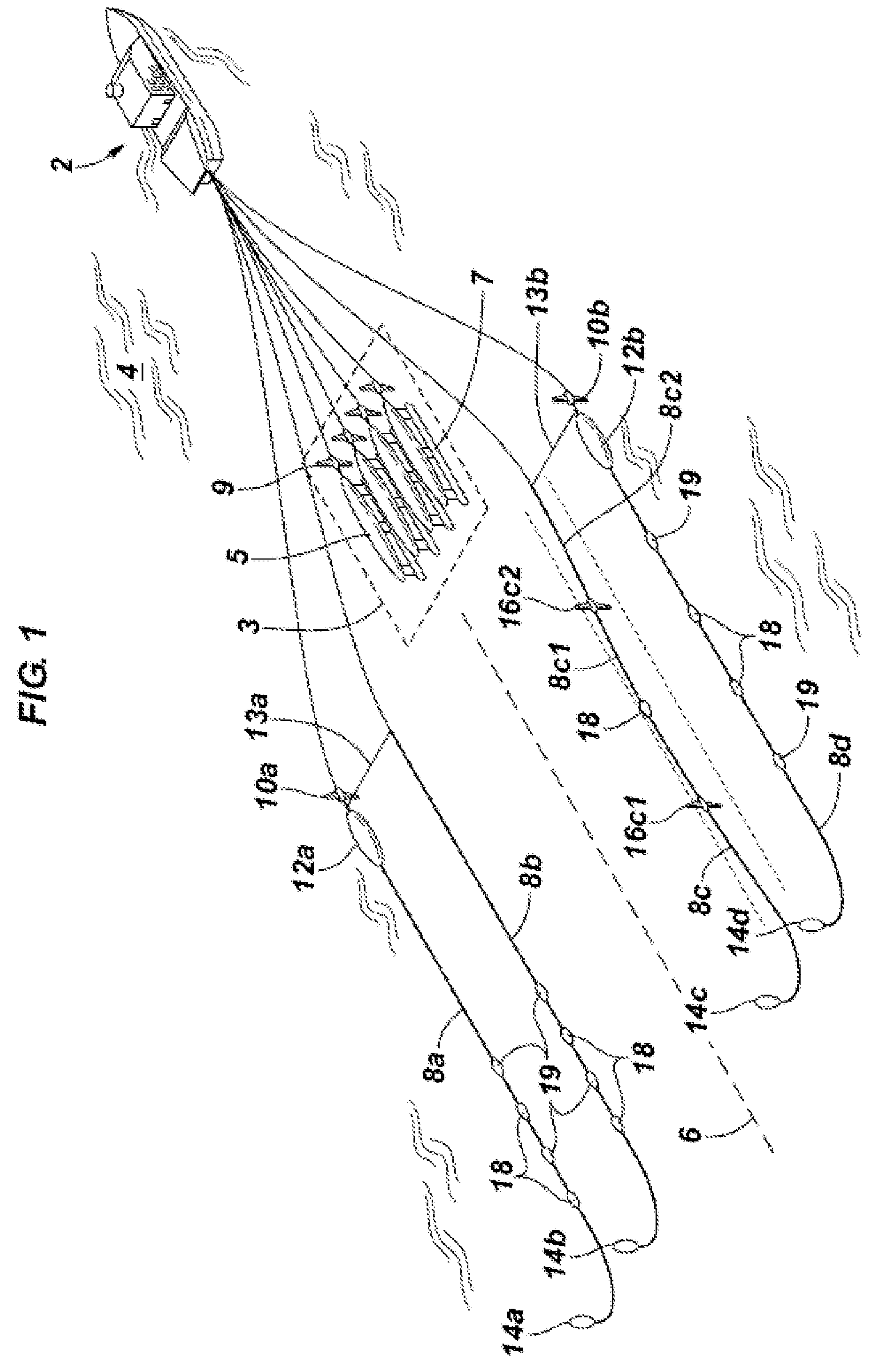

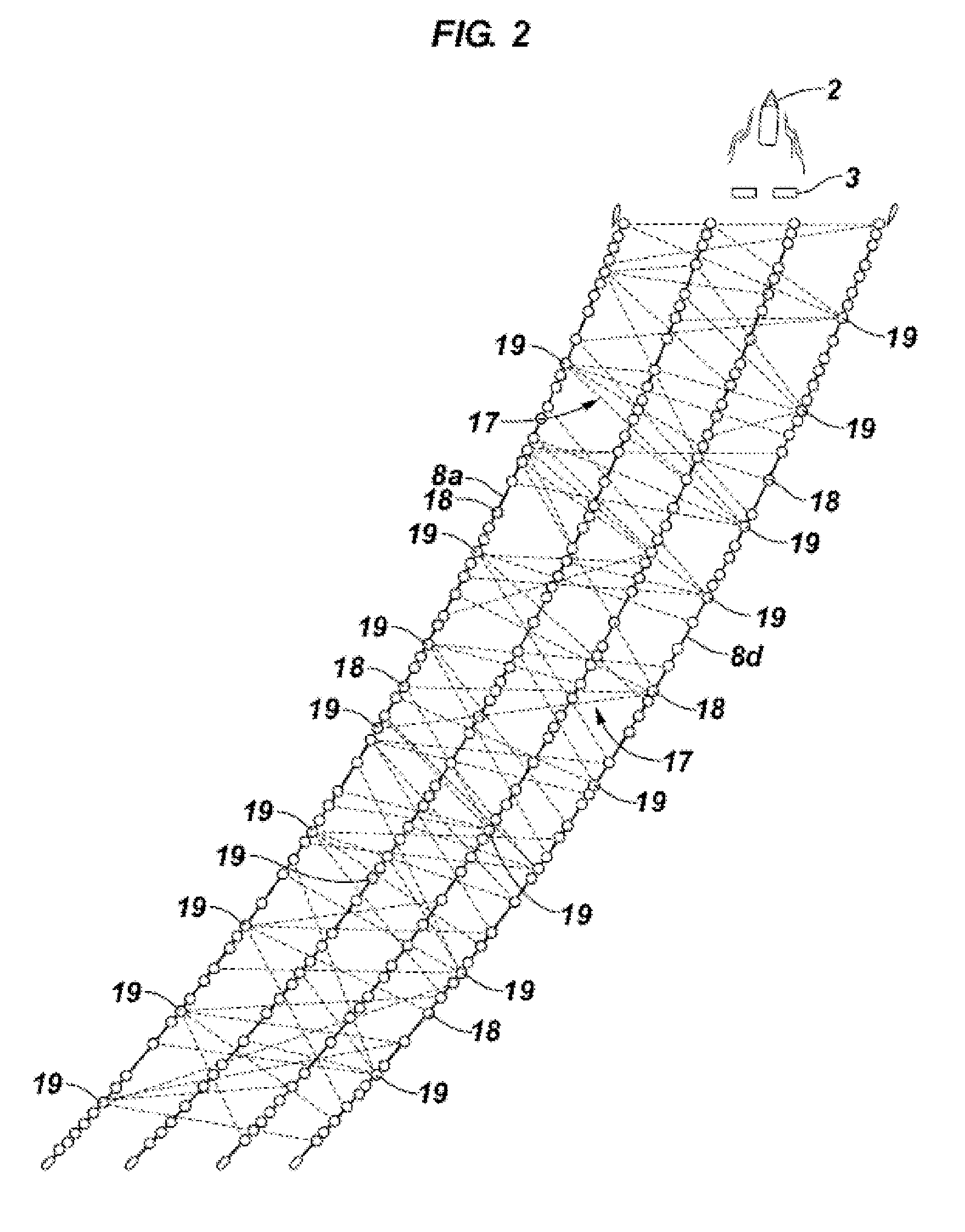

Acoustic propagation velocity modeling methods, apparatus and systems

InactiveUS20080008037A1Easy assessment processSimple structureSeismology for water-covered areasVelocity propogationMathematical modelPropagation time

Methods, apparatus, and systems for accurately estimating acoustic propagation velocity are described. One method comprises deploying in a marine environment a towed seismic spread comprising a plurality of acoustic positioning transmitters and a plurality of positioning point receivers, and using travel times for signals between at least some of the transmitters and point receivers to derive a mathematical model describing acoustic propagation velocity for the marine environment as a function of at least one spread spatial dimension, distances between transmitters and receivers, and any combination thereof. This abstract is provided to comply with the rules requiring an abstract, and allows a reader to quickly ascertain the subject matter of the technical disclosure. It is submitted with the understanding that it will not be used to interpret or limit the scope or meaning of the claims.

Owner:WESTERNGECO LLC

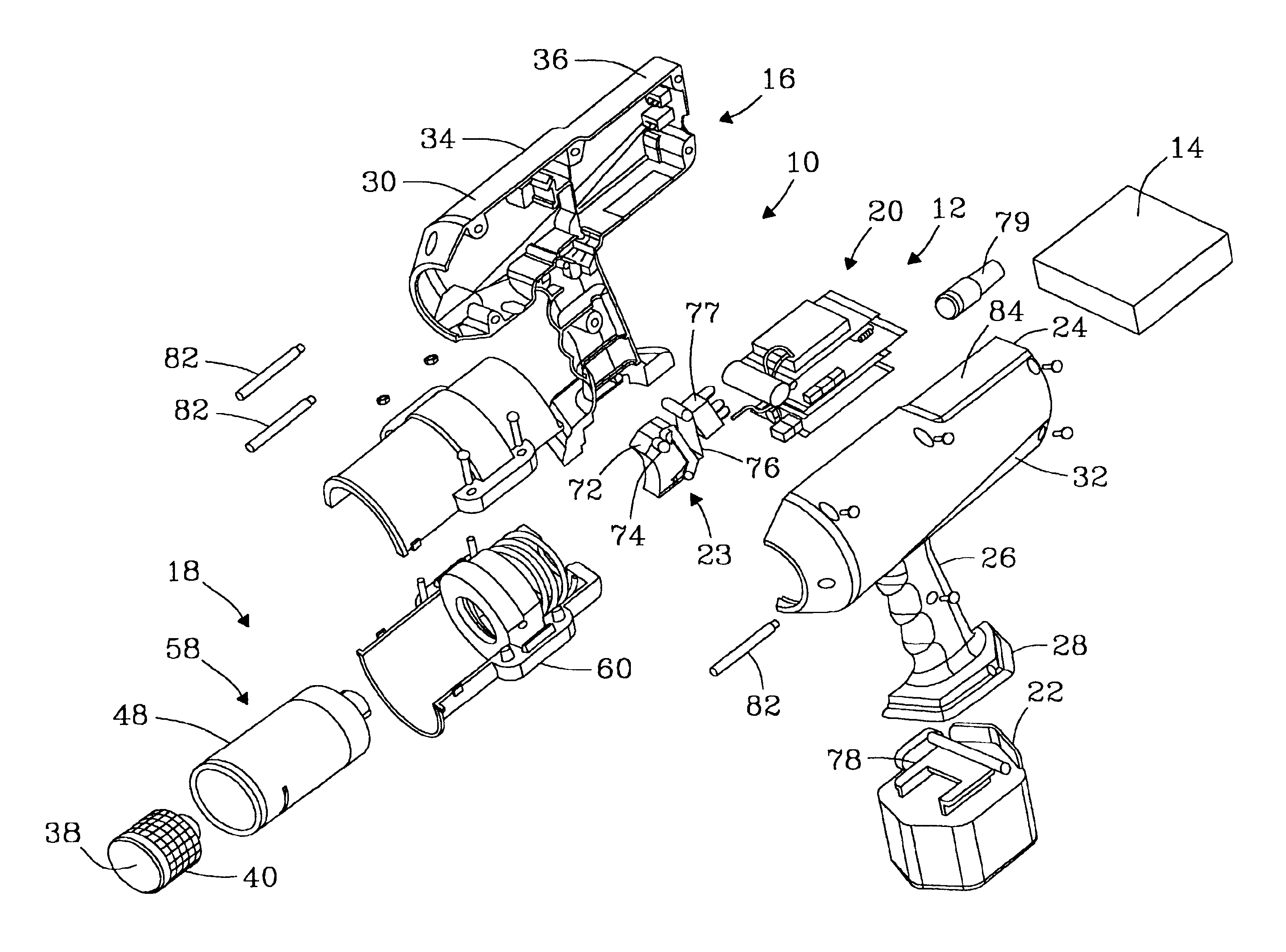

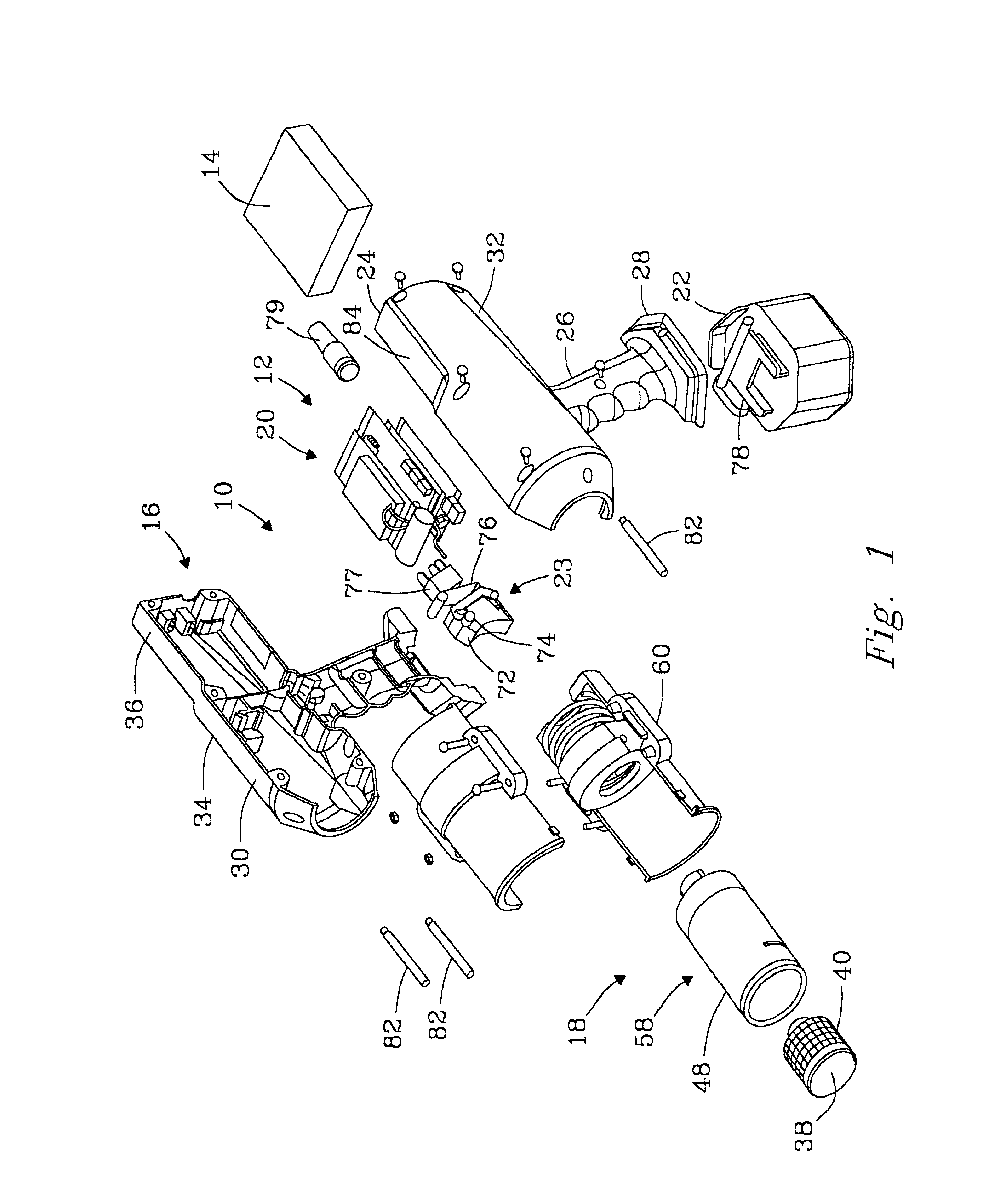

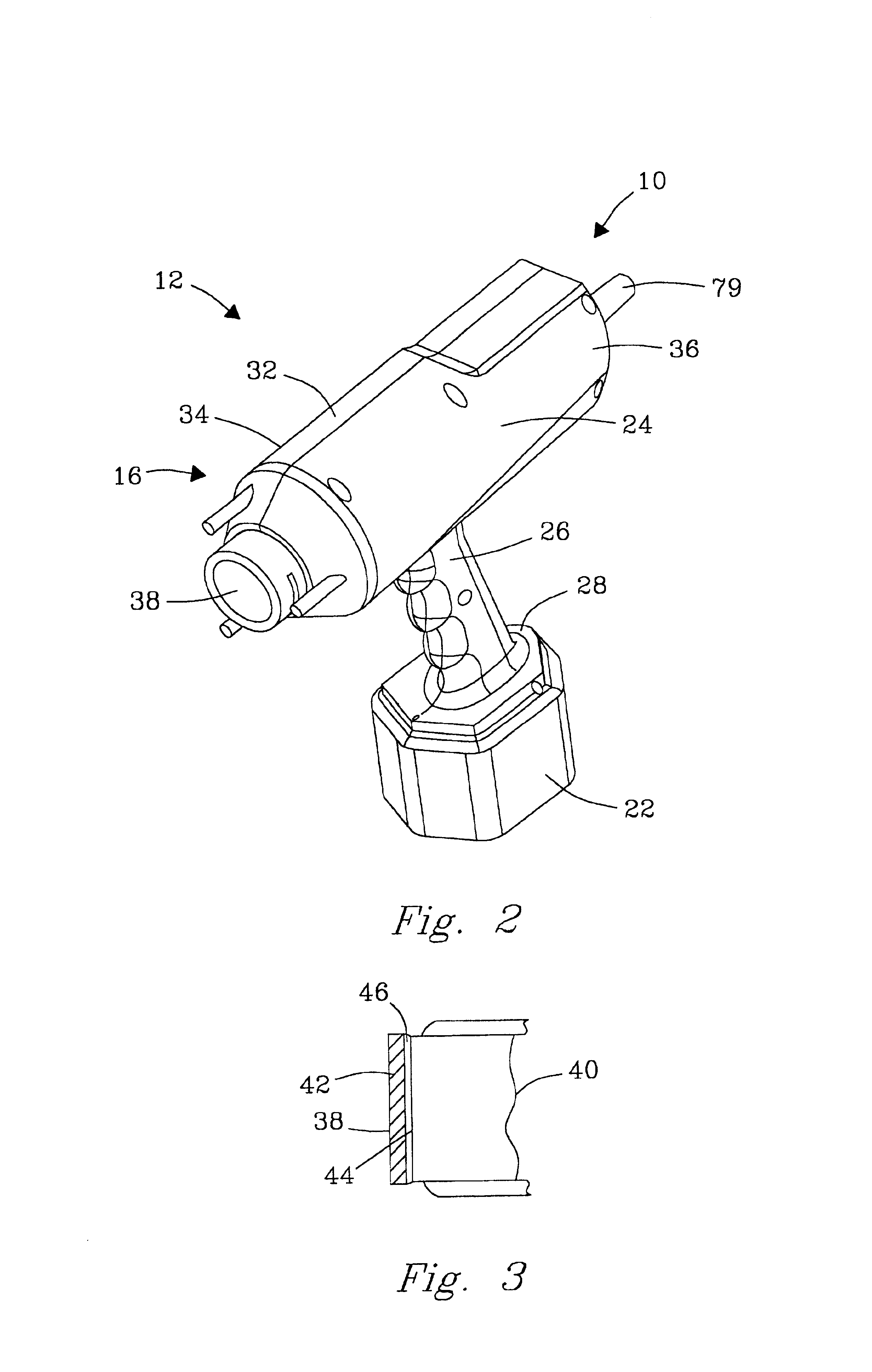

Acoustic inspection device

InactiveUS6938488B2Minimal noise figureRapid determinationUsing subsonic/sonic/ultrasonic vibration meansMagnetic property measurementsUltrasound sonographyTransducer

An ultrasound inspection apparatus particularly adapted to examine containers (sealed or unsealed) containing a liquid or solid bulk material. The apparatus has an overall configuration of a hand held pistol with a front transducer contact surface that is positioned against a front wall of the container. An ultrasound pulse is transmitted from the apparatus to be reflected from a back wall of a container being investigated. The received echo pulse is converted to a digital waveform. The waveform is analyzed relative to temperature, travel distance of the pulse(s), and time of travel to ascertain characteristics of the liquid or other materials and to provide identification of the same.

Owner:BATTELLE MEMORIAL INST

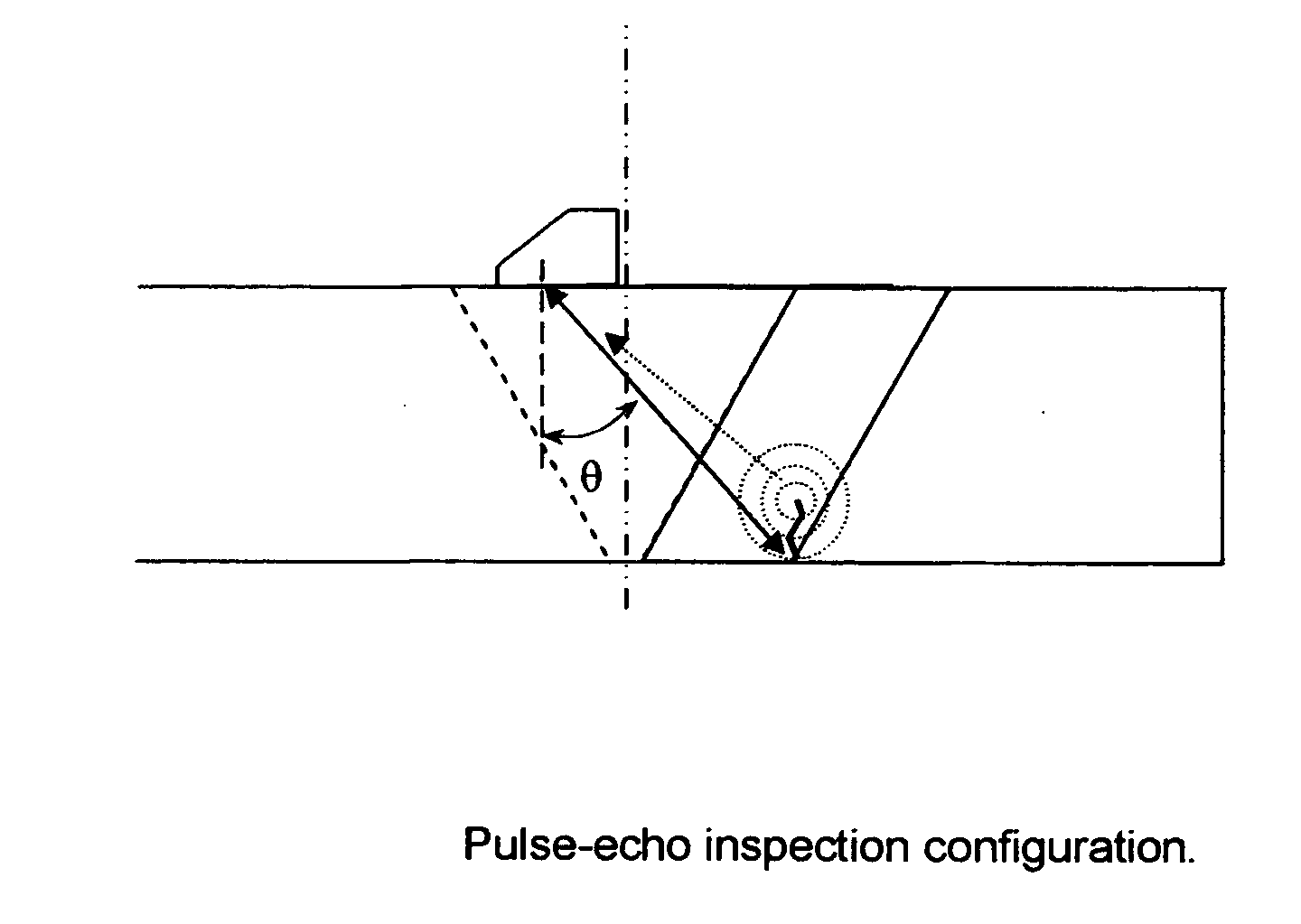

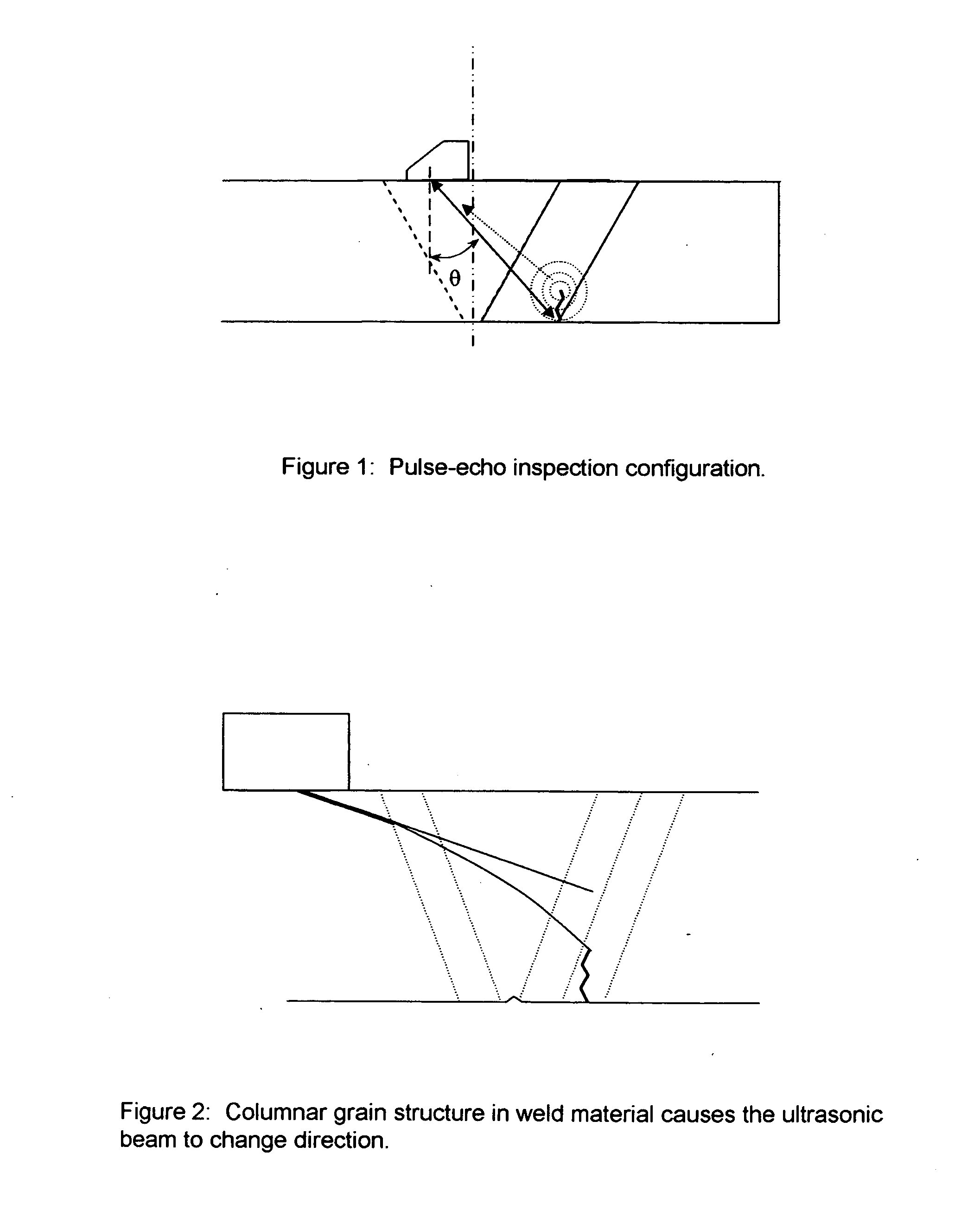

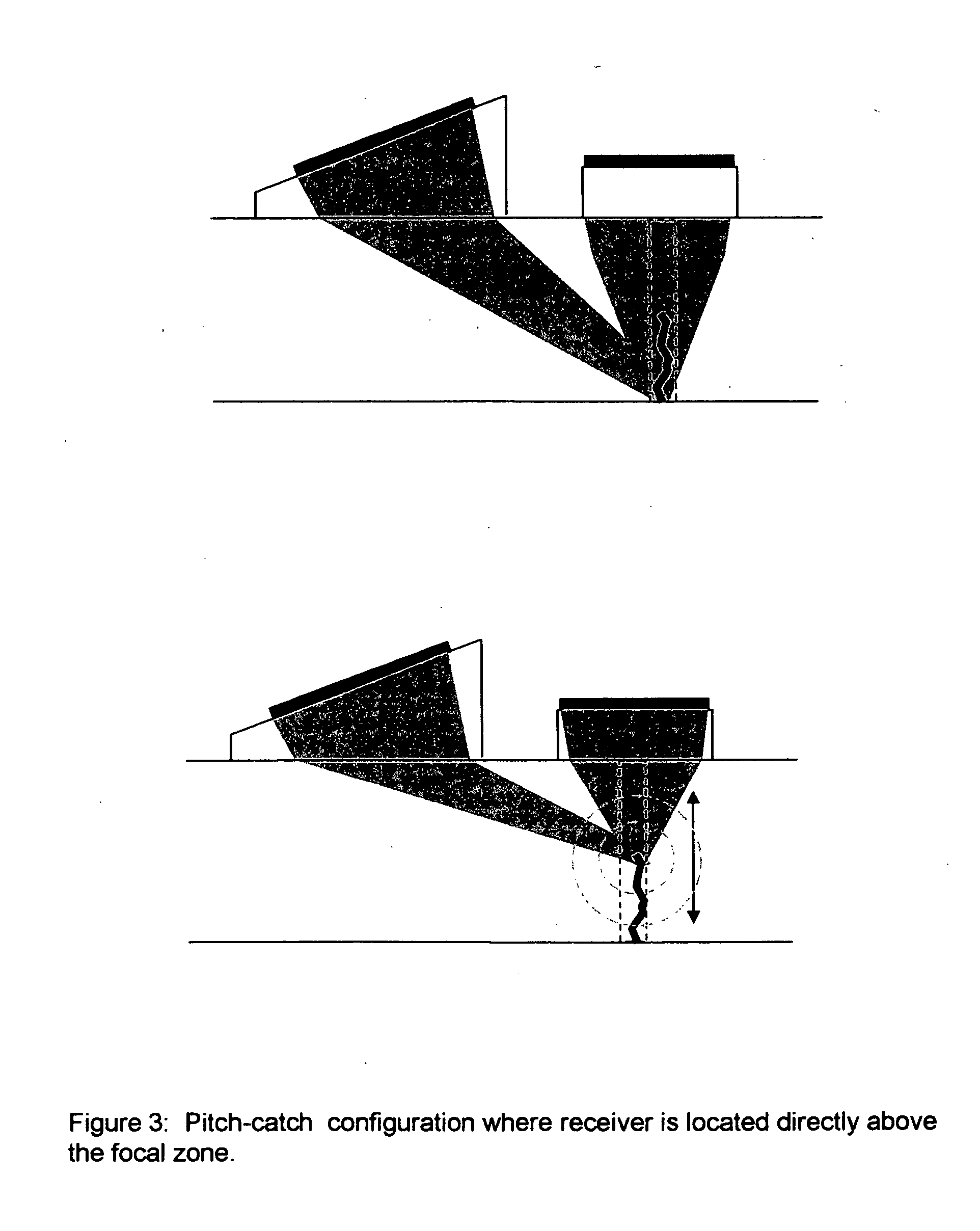

Ultrasonic method for the accurate measurement of crack height in dissimilar metal welds using phased array

InactiveUS20070000328A1Guaranteed normal transmissionEfficient receptionAnalysing fluids using sonic/ultrasonic/infrasonic wavesAnalysing solids using sonic/ultrasonic/infrasonic wavesLight beamPhased array

An ultrasonic method and apparatus utilizing phased array technology for obtaining accurate crack height measurements in materials where crystallographic structure creates beam reduction effects.

Owner:BUTSTREETCAR JONATHAN

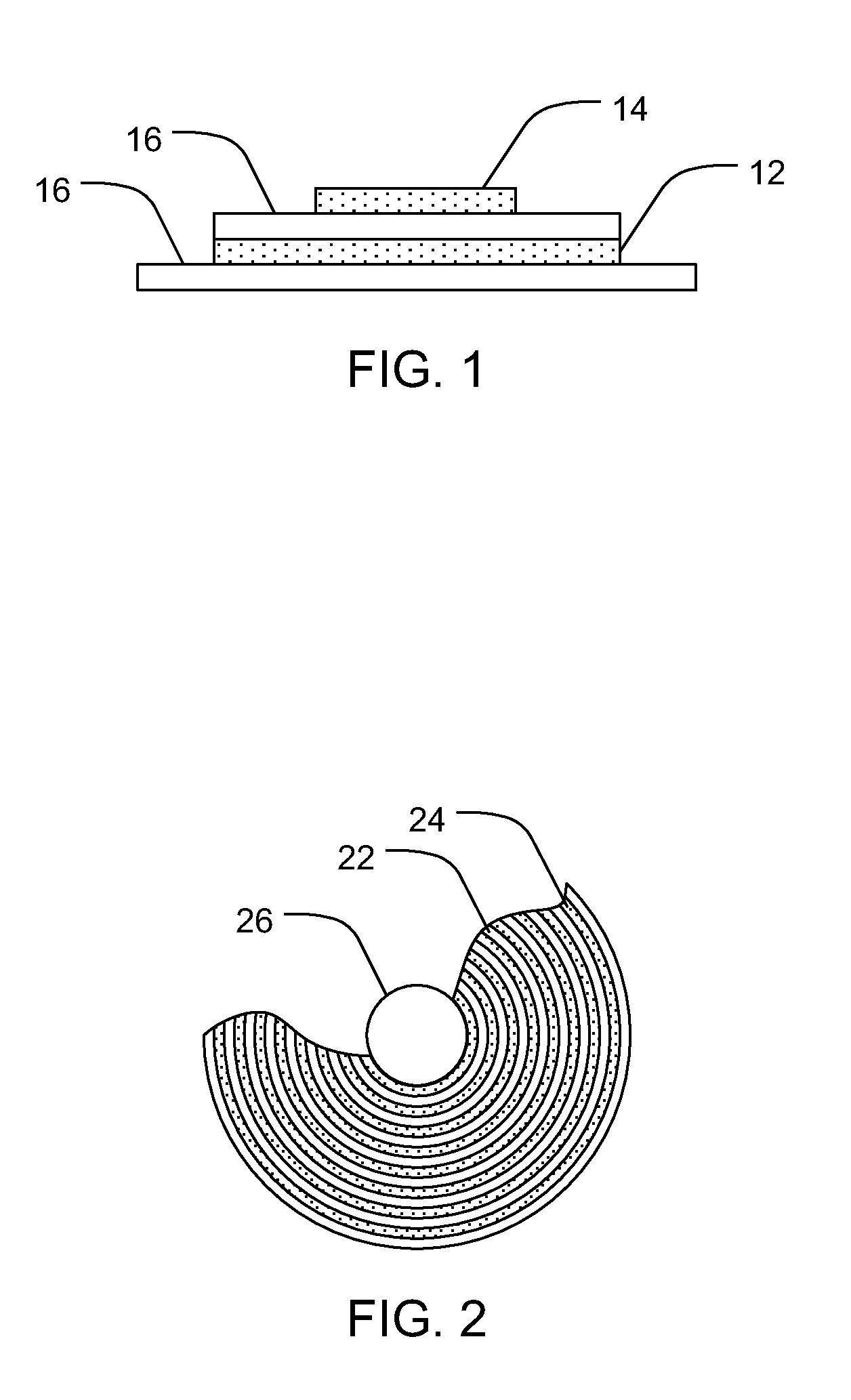

Fluidic device with integrated capacitive micromachined ultrasonic transducers

InactiveUS20020083771A1Analysing fluids using sonic/ultrasonic/infrasonic wavesAnalysing solids using sonic/ultrasonic/infrasonic wavesCapacitive micromachined ultrasonic transducersSonification

The present invention provides fluidic devices and systems which have micromachined ultrasonic transducers integrated into microchannels. The ultrasonic transducers generate and receive ultrasonic waves. The transducers can be disposed and operated to measure fluid characteristics such as pressure, density, viscosity, flow rate and can also be used to mix and pump fluids.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

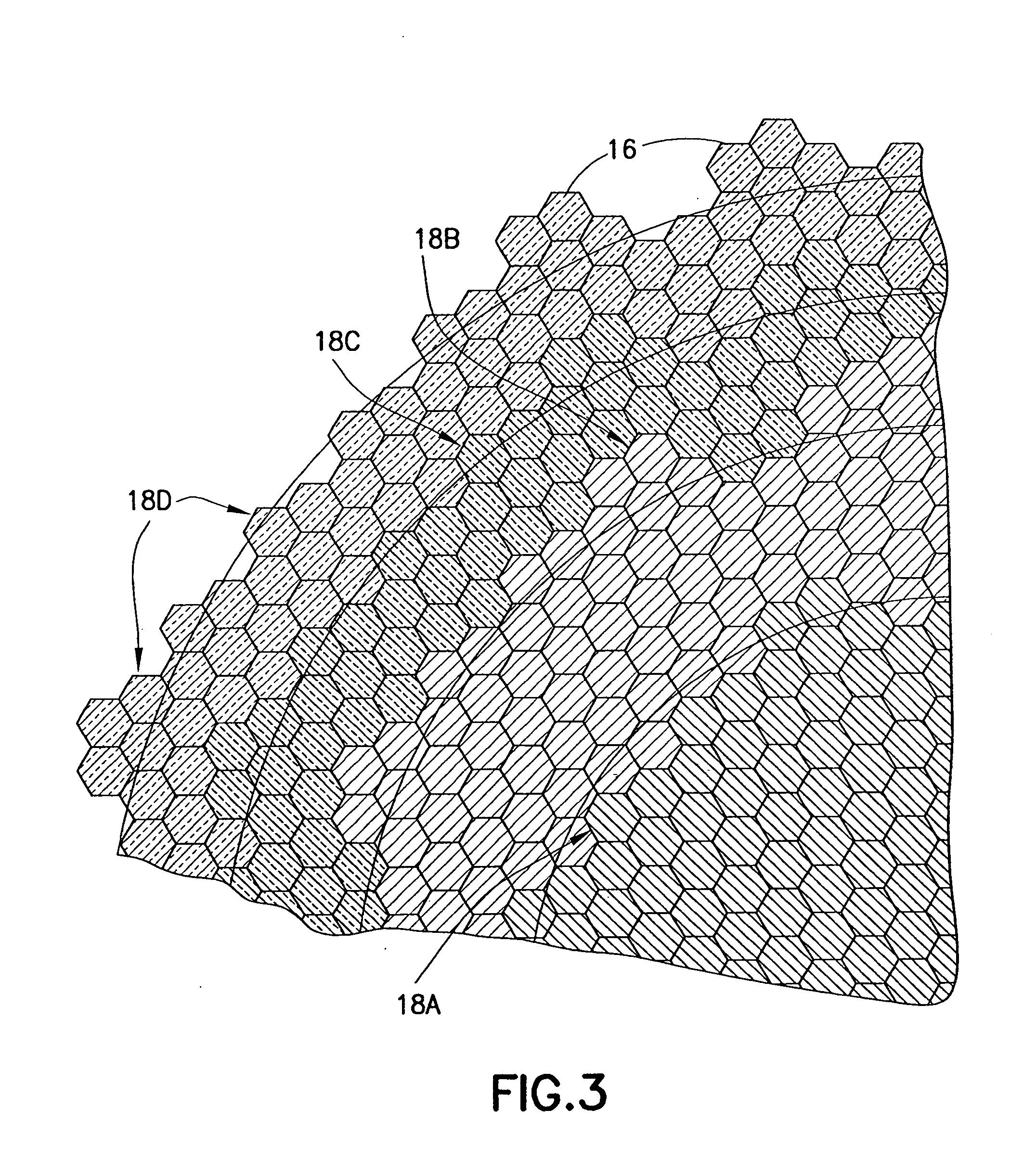

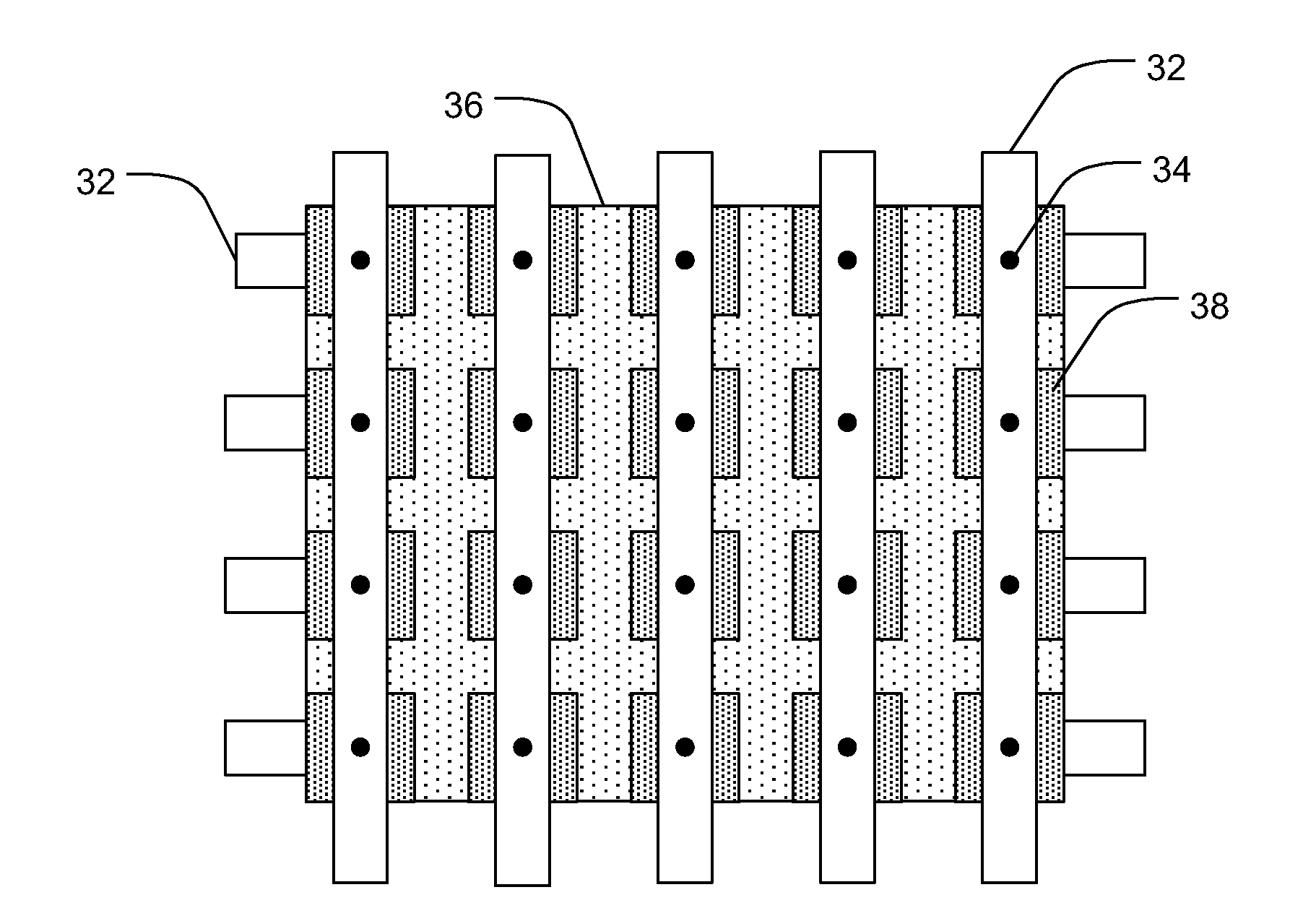

Integrated interface electronics for reconfigurable sensor array

ActiveUS20050094490A1Quickly reconfiguredUltrasonic/sonic/infrasonic diagnosticsAnalysing solids using sonic/ultrasonic/infrasonic wavesElectricitySensor array

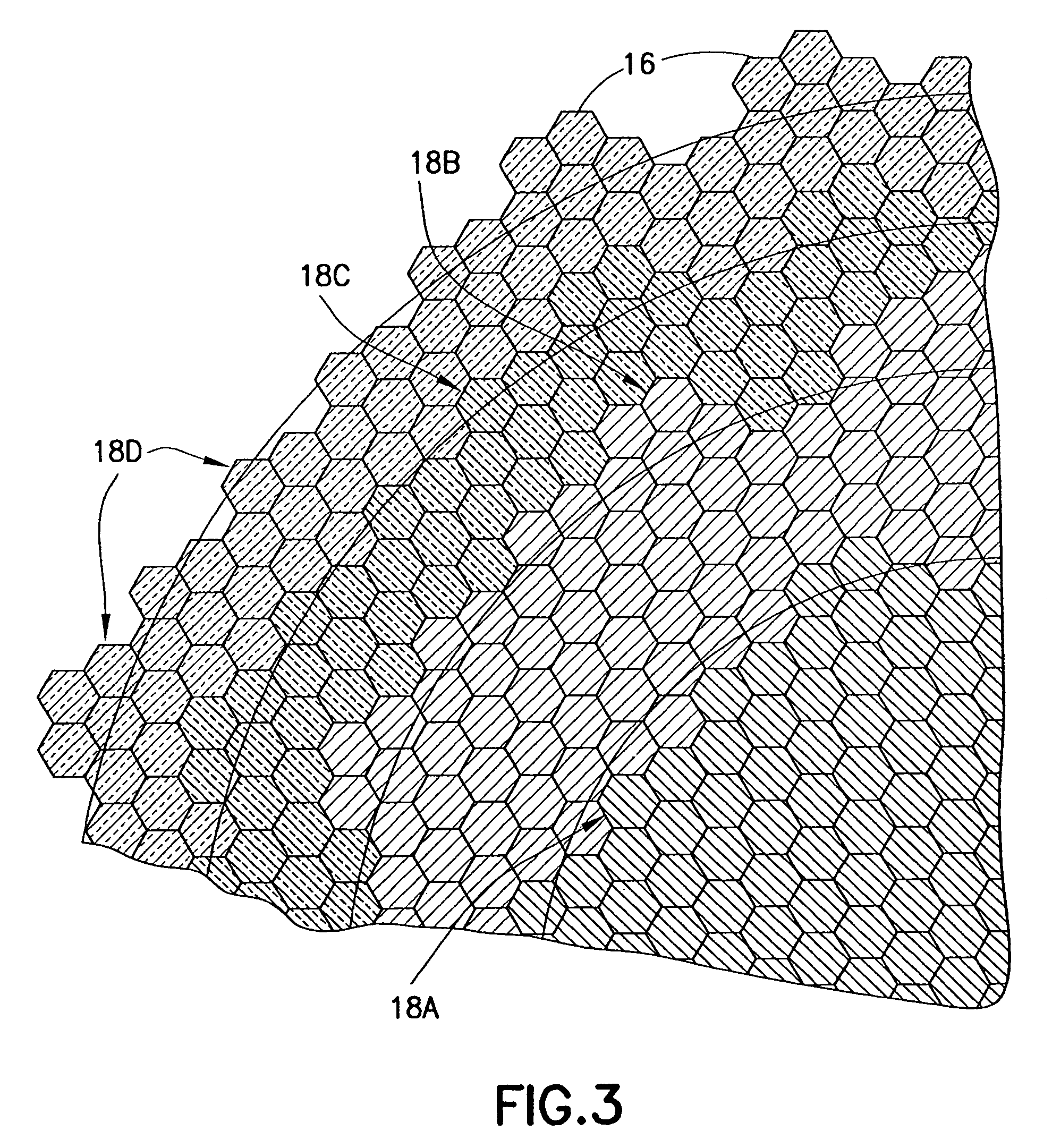

An integrated switch matrix for reconfiguring subelements of a mosaic sensor array to form elements. The configuration of the switch matrix is fully programmable. The switch matrix includes access switches that connect subelements to bus lines and matrix switches that connect subelements to subelements. Each subelement has a unit switch cell comprising at least one access switch, at least one matrix switch, a respective memory element for storing the future state of each switch, and a respective control circuit for each switch. The access and matrix switches are of a type having the ability to memorize control data representing the current switch state of the switch, which control data includes a data bit input to turn-on / off circuits incorporated in the control circuit. The sensor array and the switching matrix may be built in different strata of a co-integrated structure or they may be built on separate wafers that are electrically connected. If the sensors are arranged on a hexagonal grid, the unit switch cells may be arranged on either a hexagonal or rectangular grid.

Owner:GENERAL ELECTRIC CO

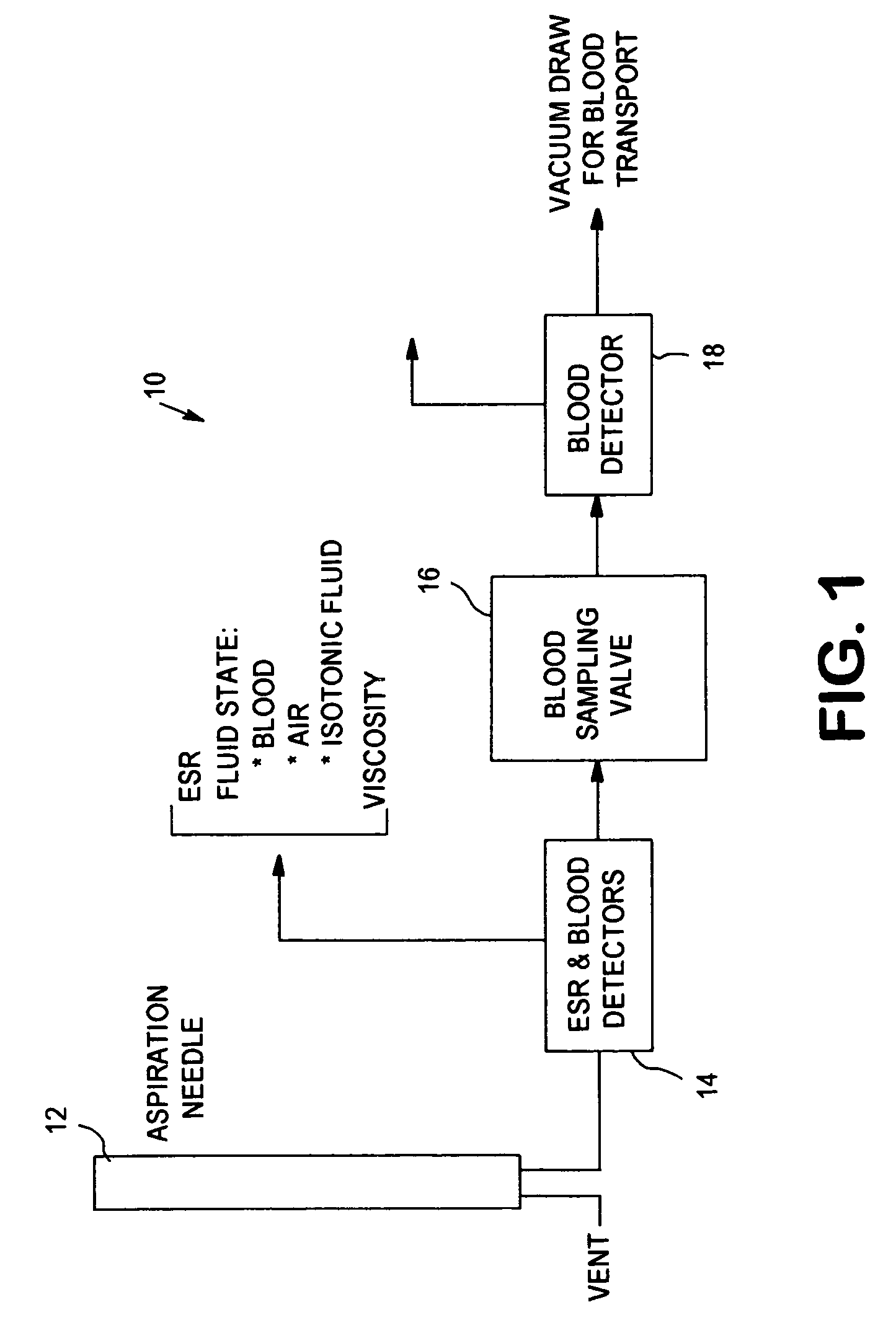

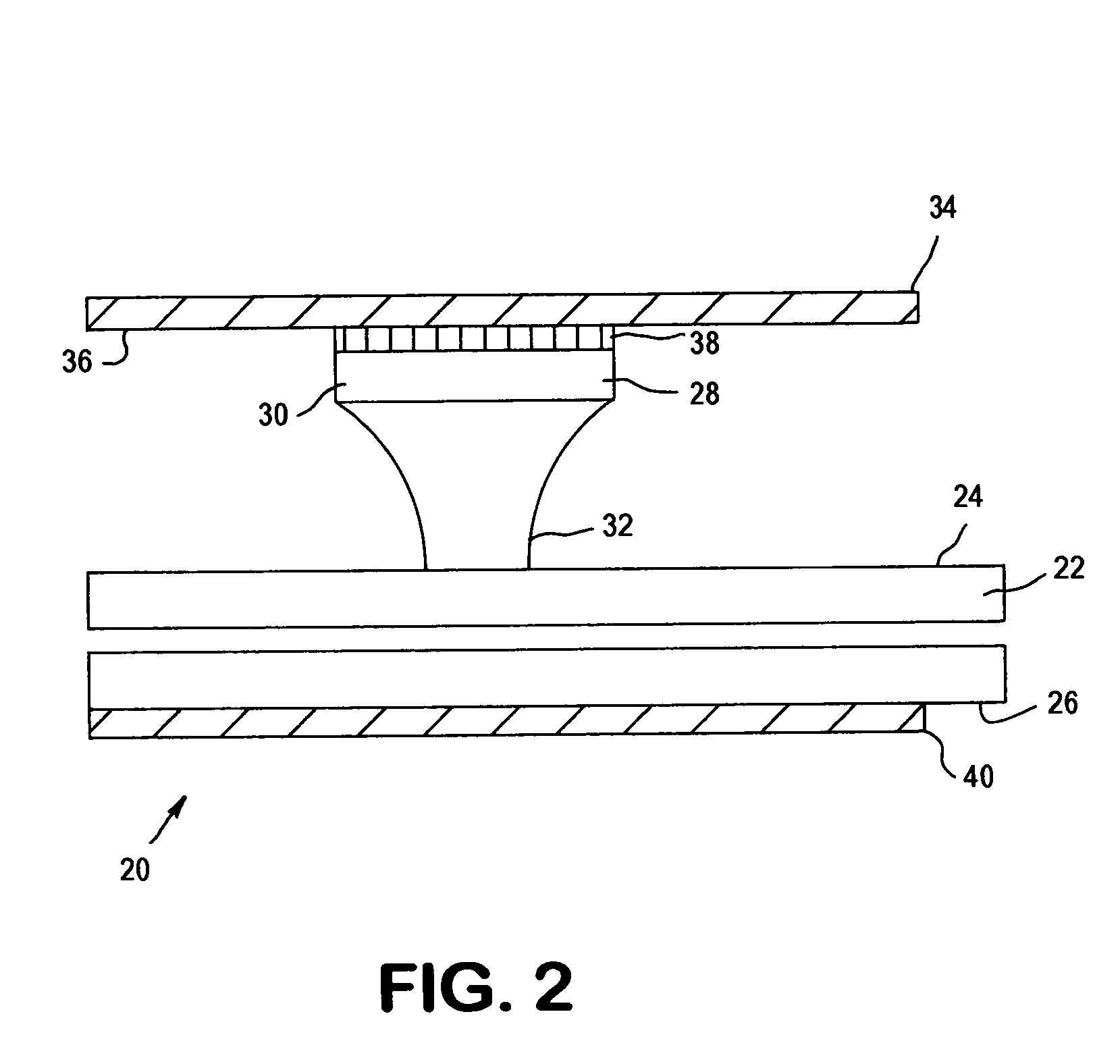

Apparatus and method for analyzing a liquid in a capillary tube of a hematology instrument

InactiveUS7207939B2Ultrasonic/sonic/infrasonic diagnosticsAnalysing fluids using sonic/ultrasonic/infrasonic wavesBlood capillaryHematology

An apparatus and method for determining the density and fluid-type of a fluid flowing in a capillary tube, the velocity and viscosity of a blood sample flowing in a capillary tube, the erythrocyte sedimentation rate (ESR) of a blood sample after flow has been brought to an abrupt stop in a capillary tube, and / or the zeta sedimentation rate (ZSR) of a blood sample after flow has been brought to an abrupt stop in a capillary tube. These measurements are accomplished by directing a waveform pulse, such as an ultrasound pulse, at a pre-determined frequency transversely across the capillary tube and sample fluid, and by determining the flight of time of the pulse through the capillary tube and sample fluid and / or the Doppler shift of the echo signals reflecting off cells moving forwardly or transversely within a flowing, or stationary, blood sample.

Owner:COULTER INTERNATIONAL CORPORATION

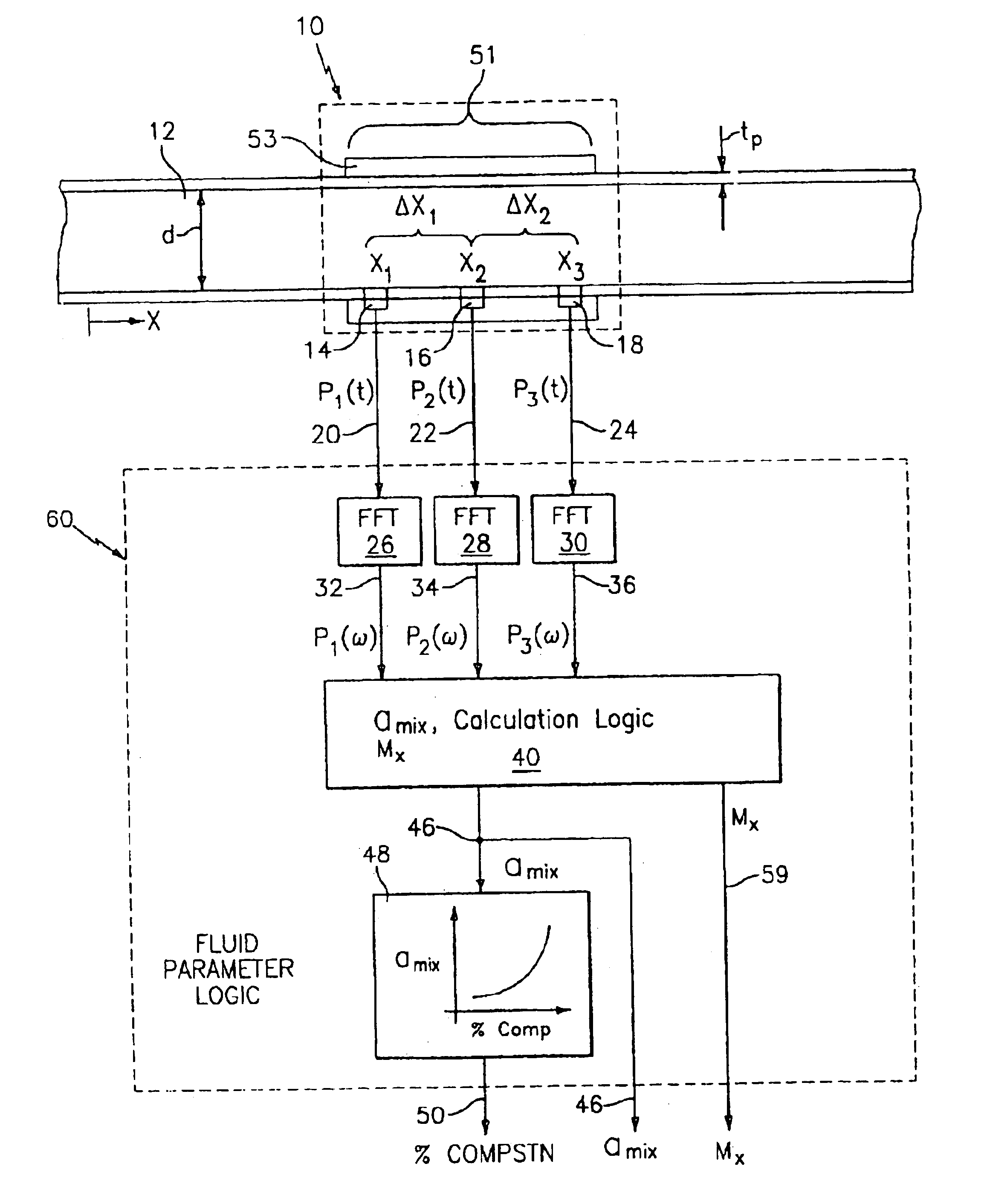

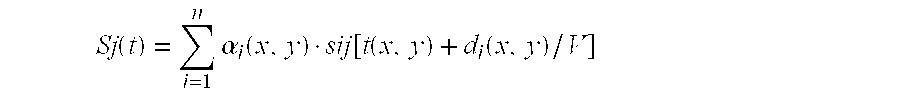

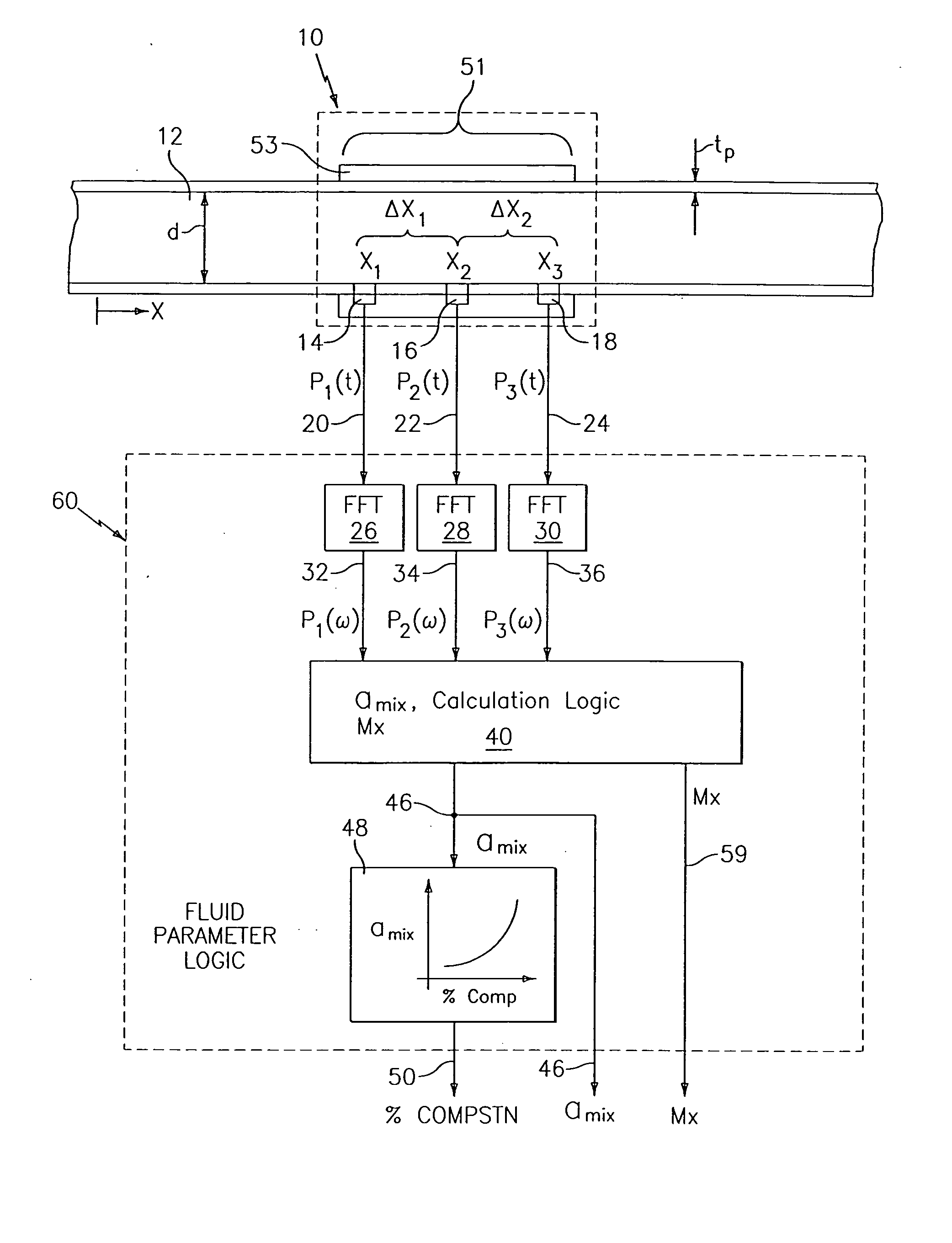

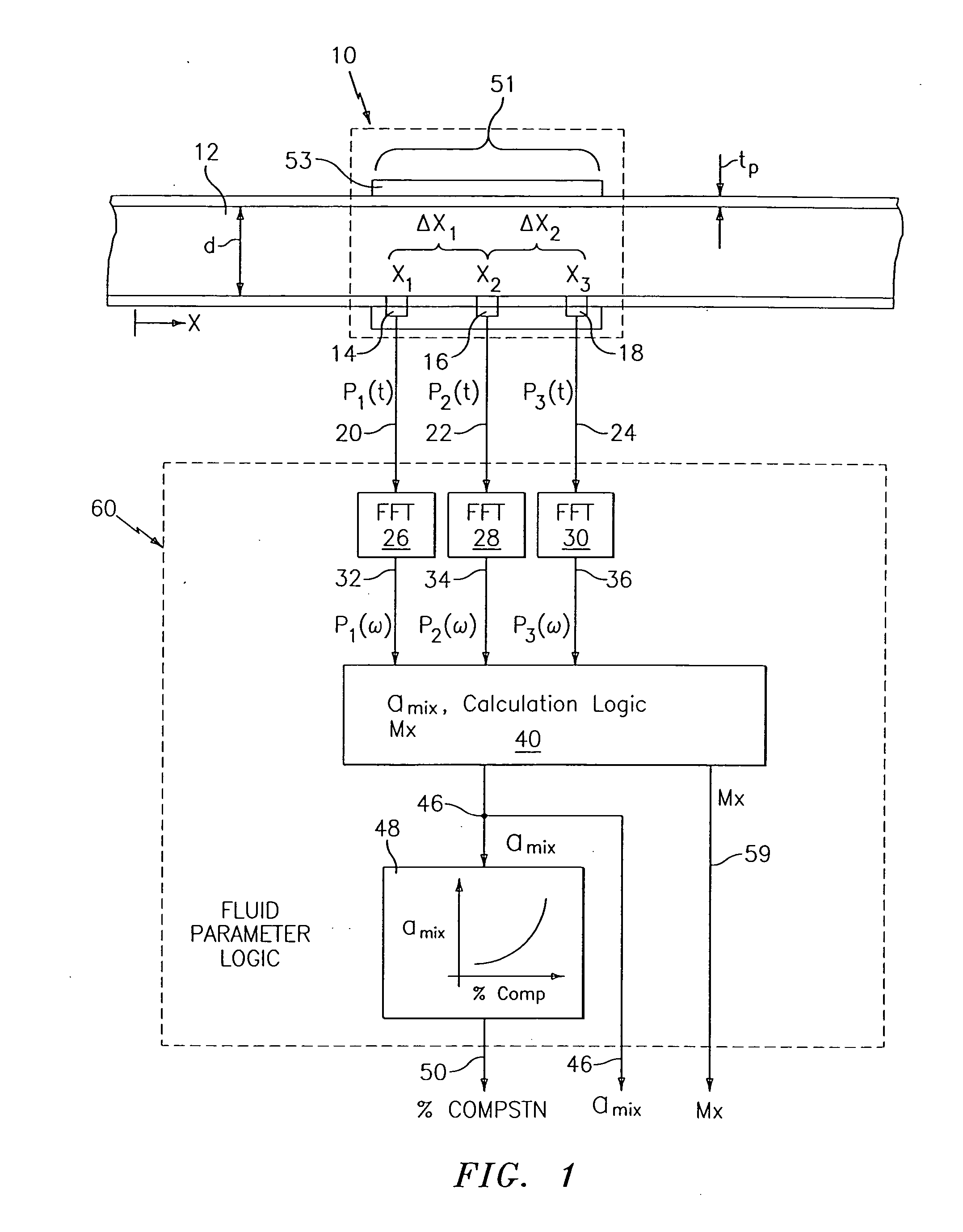

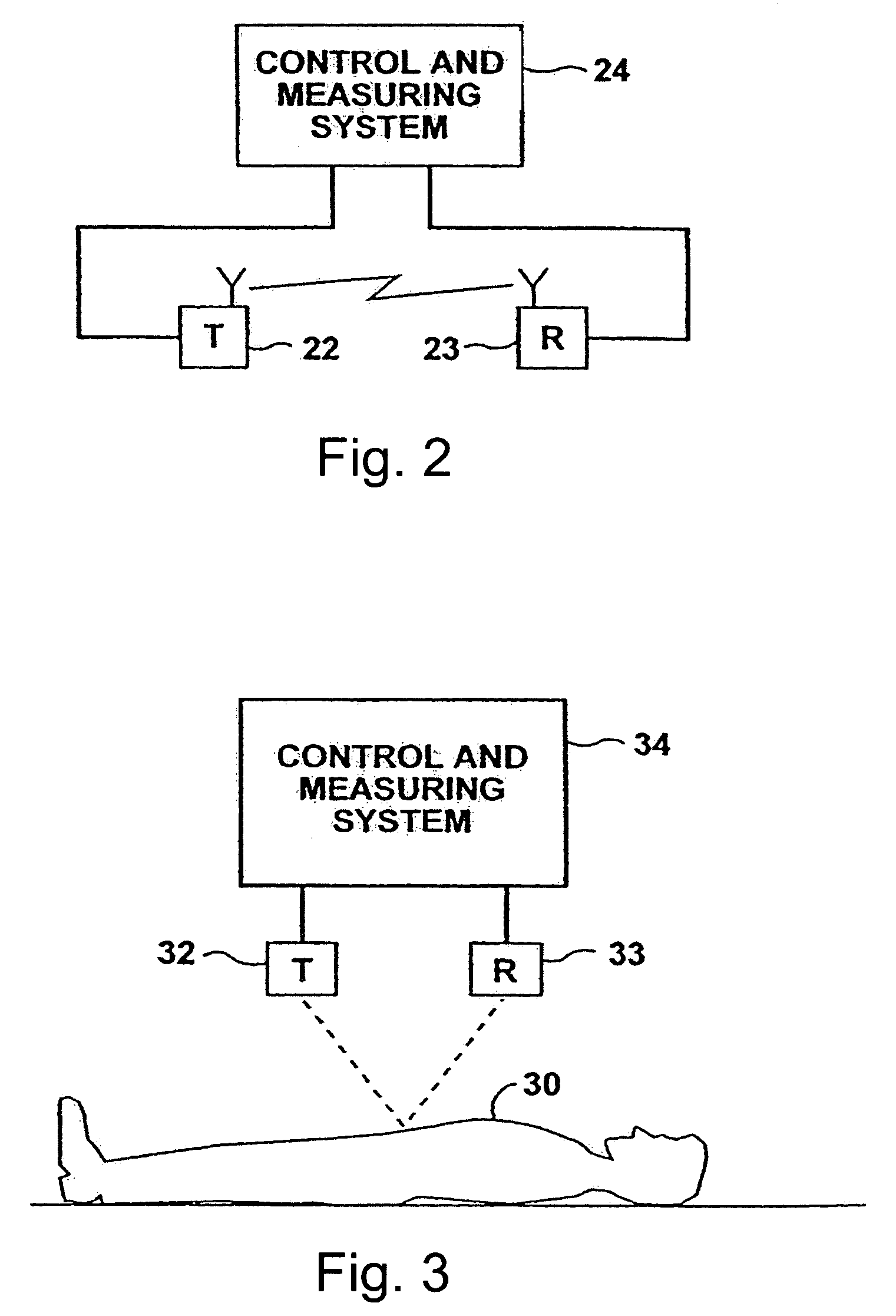

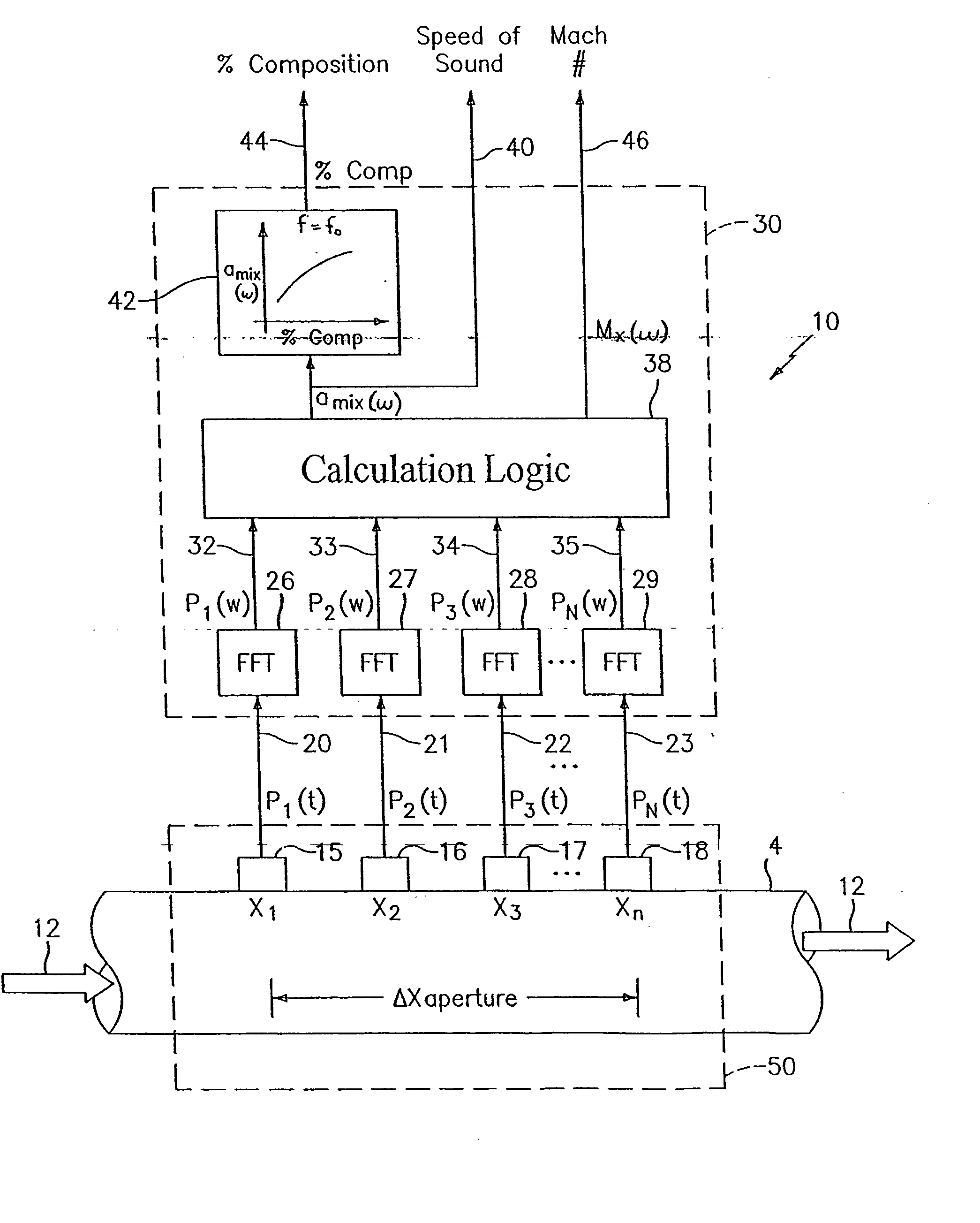

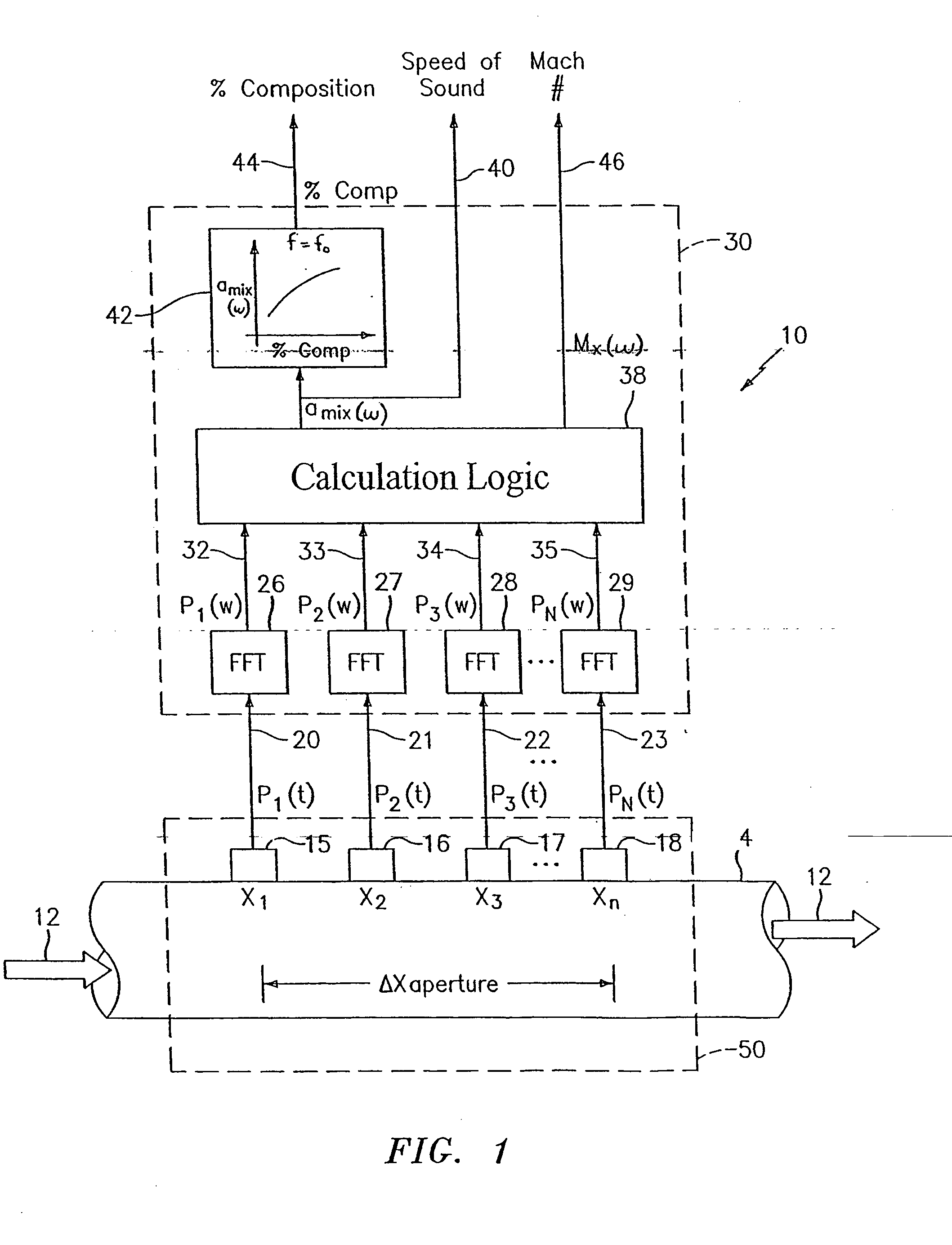

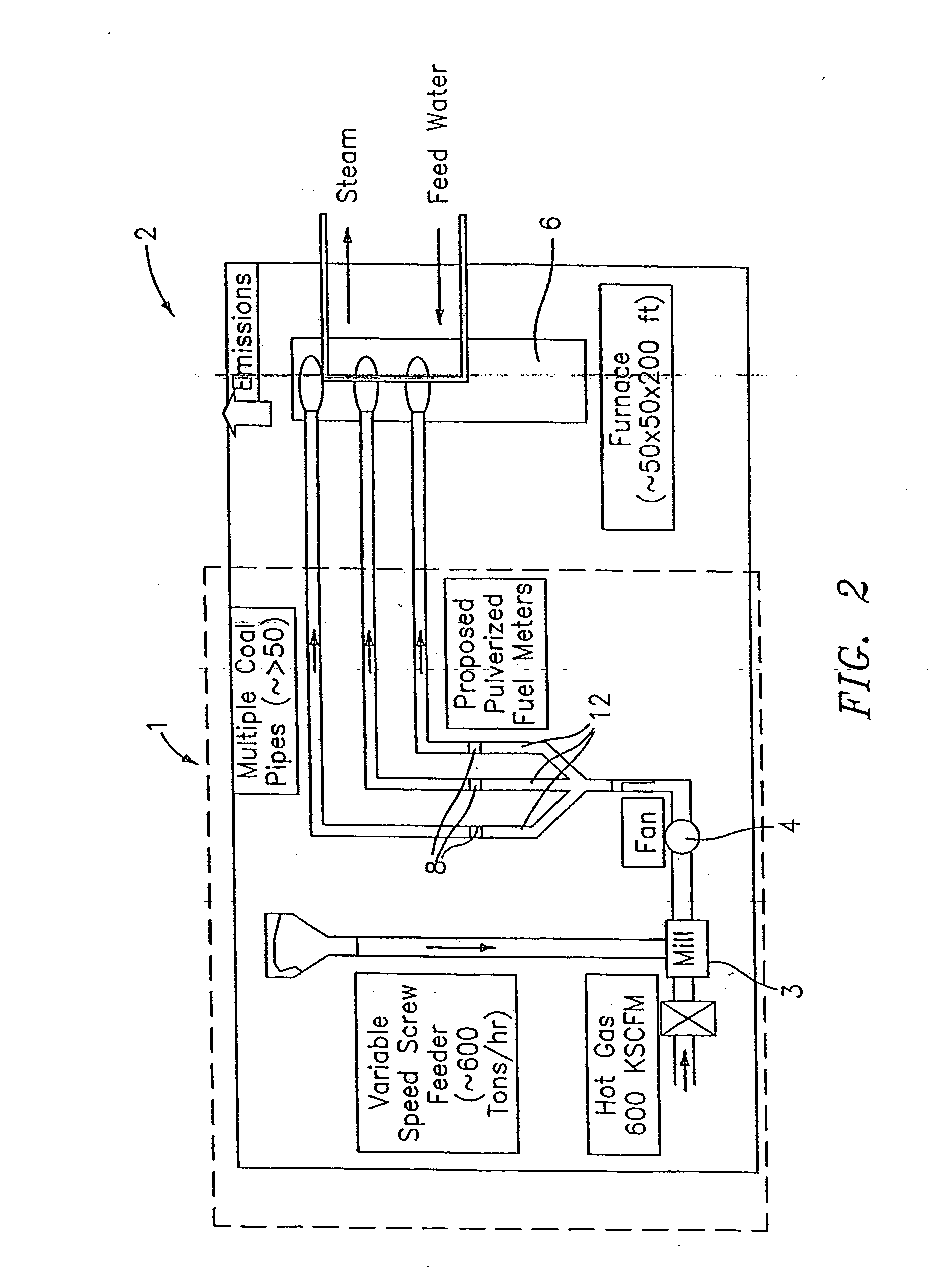

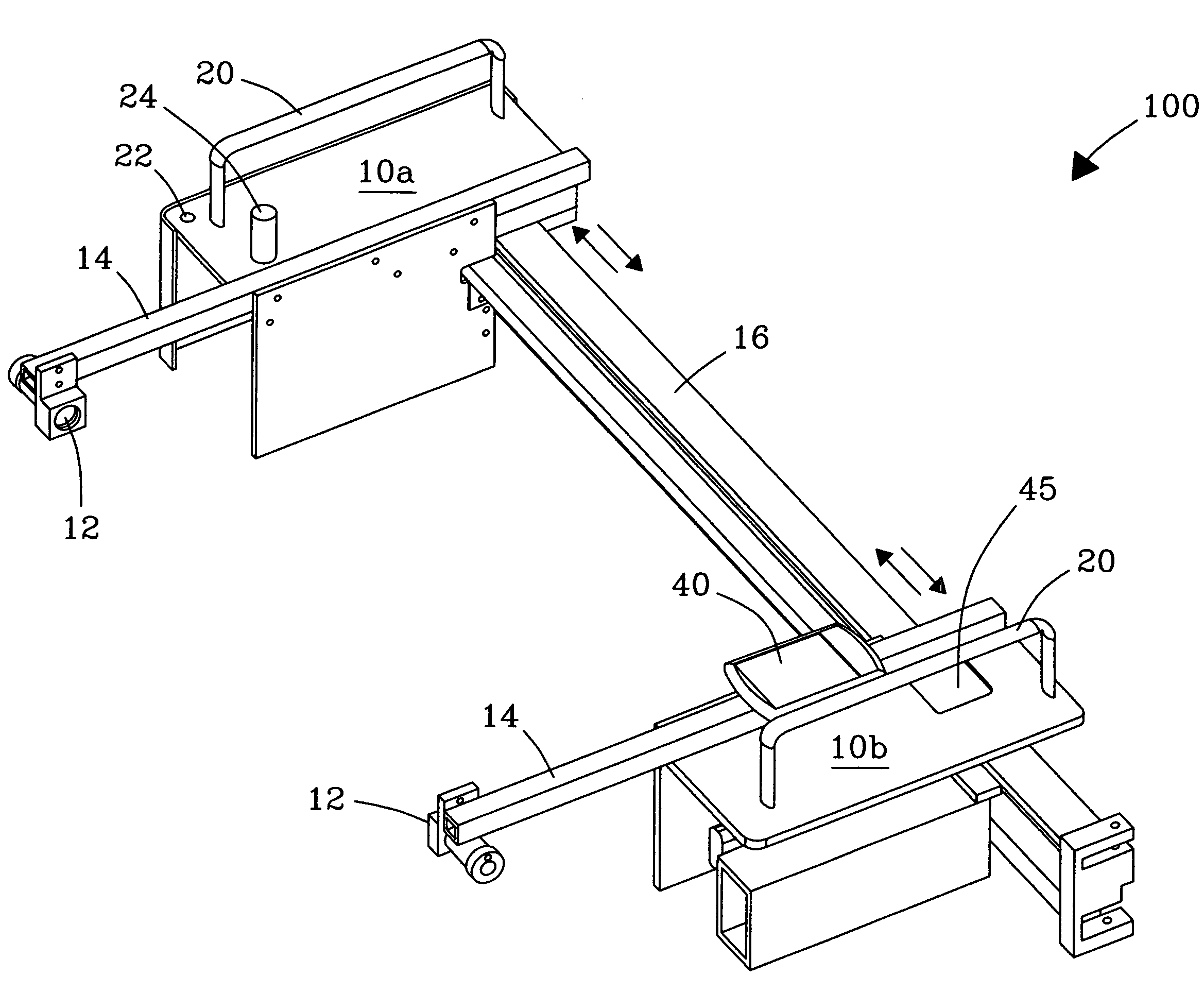

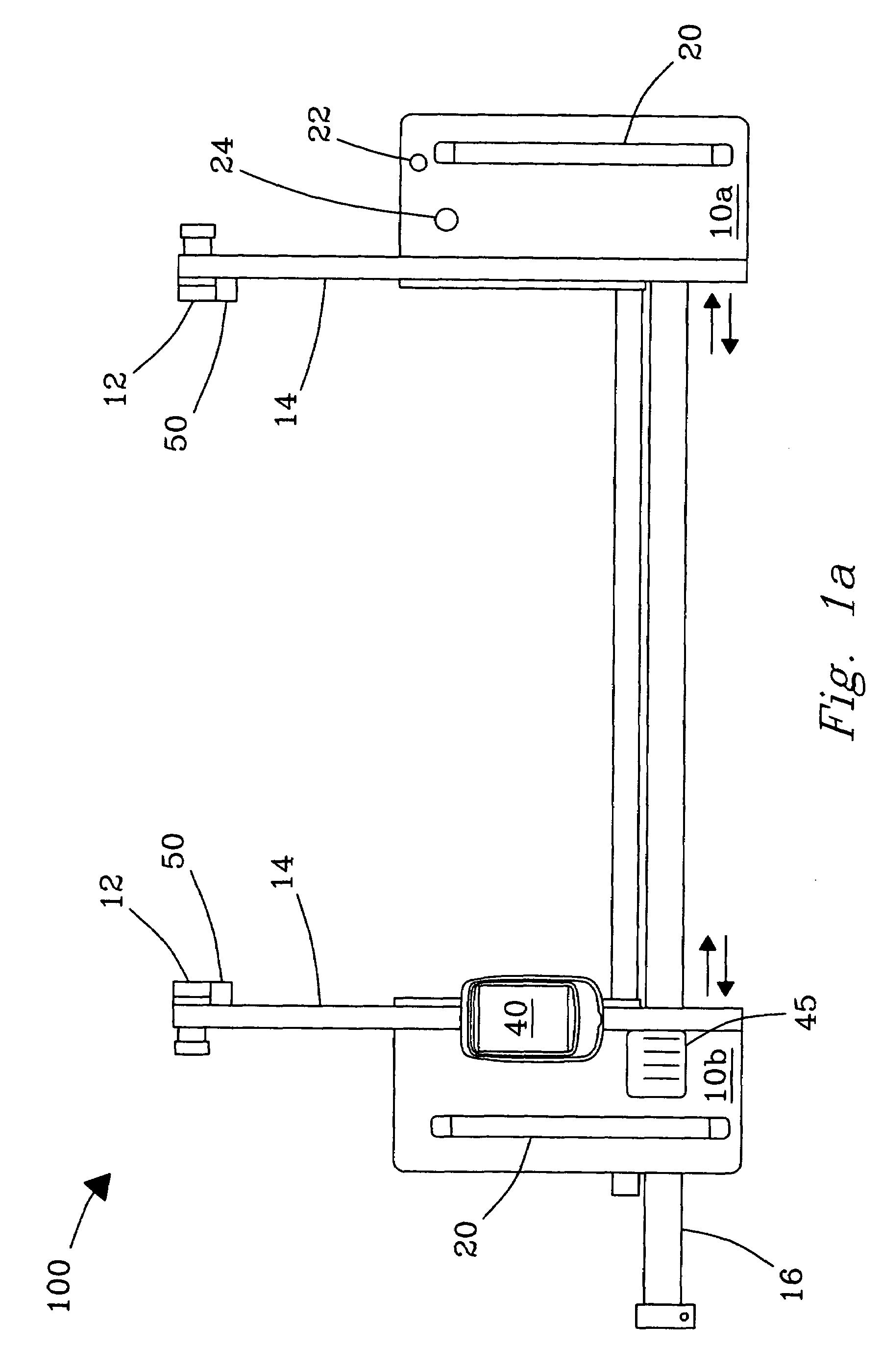

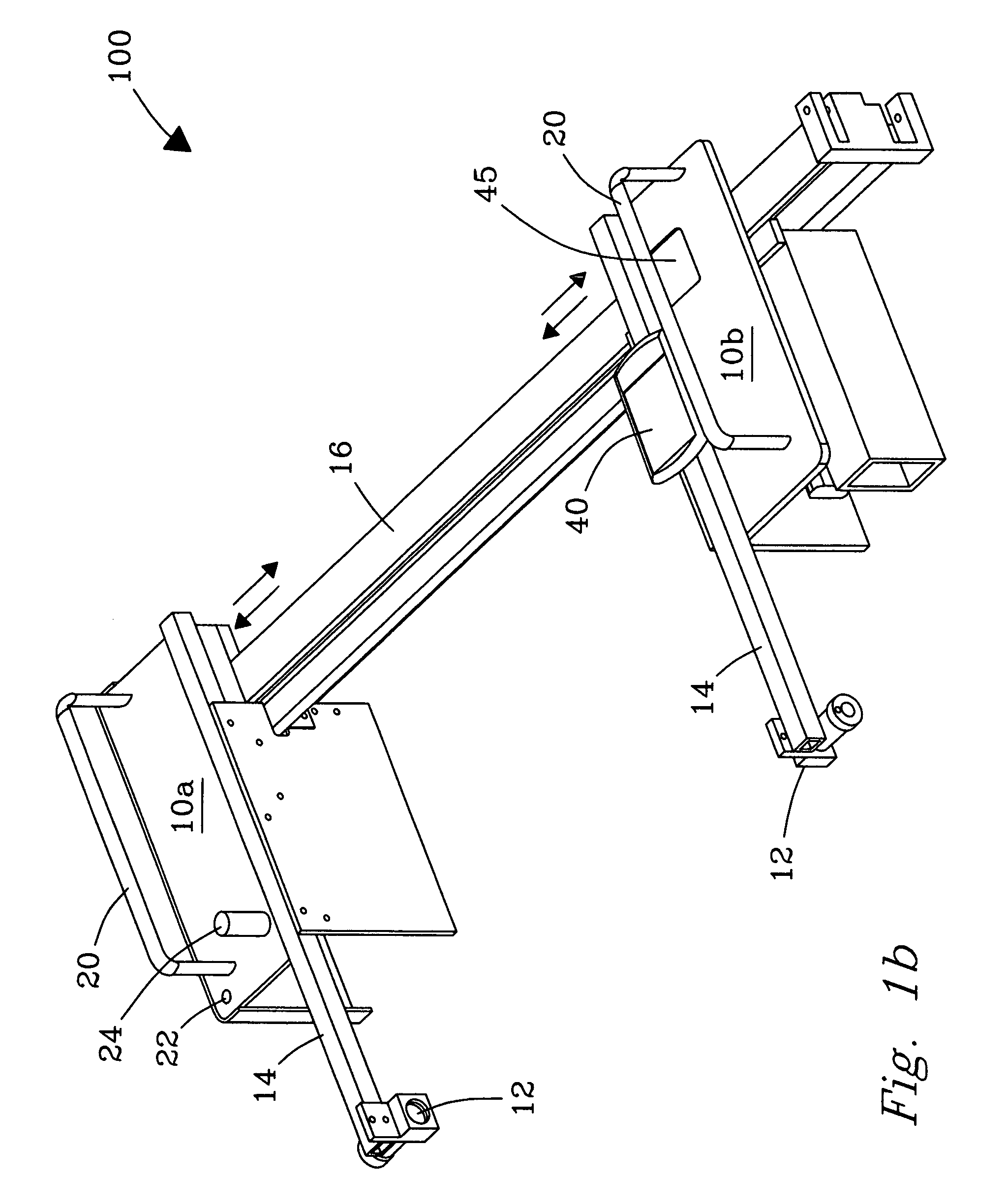

Fluid parameter measurement for industrial sensing applications using acoustic pressures

InactiveUS20050000289A1Less sensitiveImprove measurement reliabilityVibration measurement in solidsVibration measurement in fluidEngineeringOpto electronic

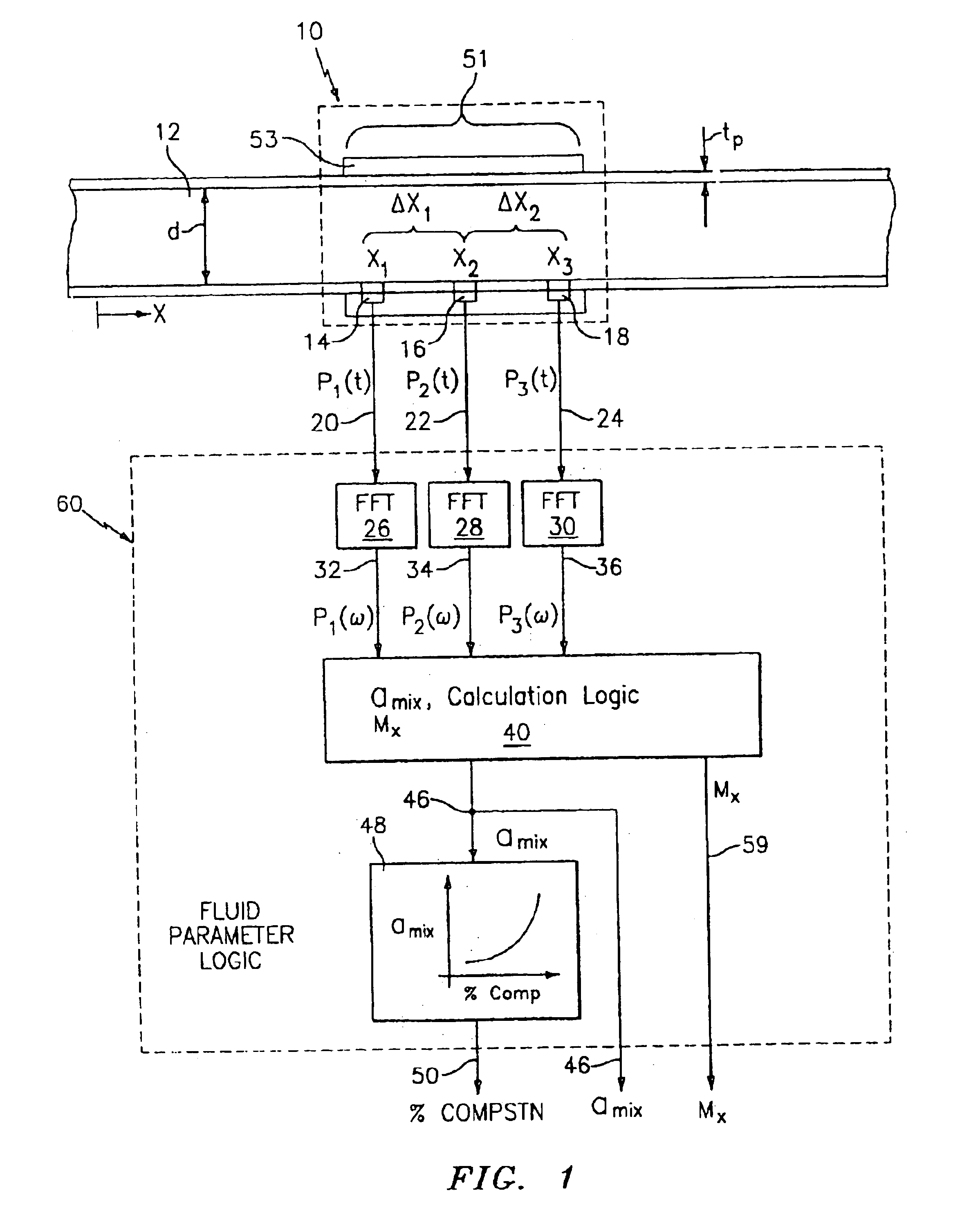

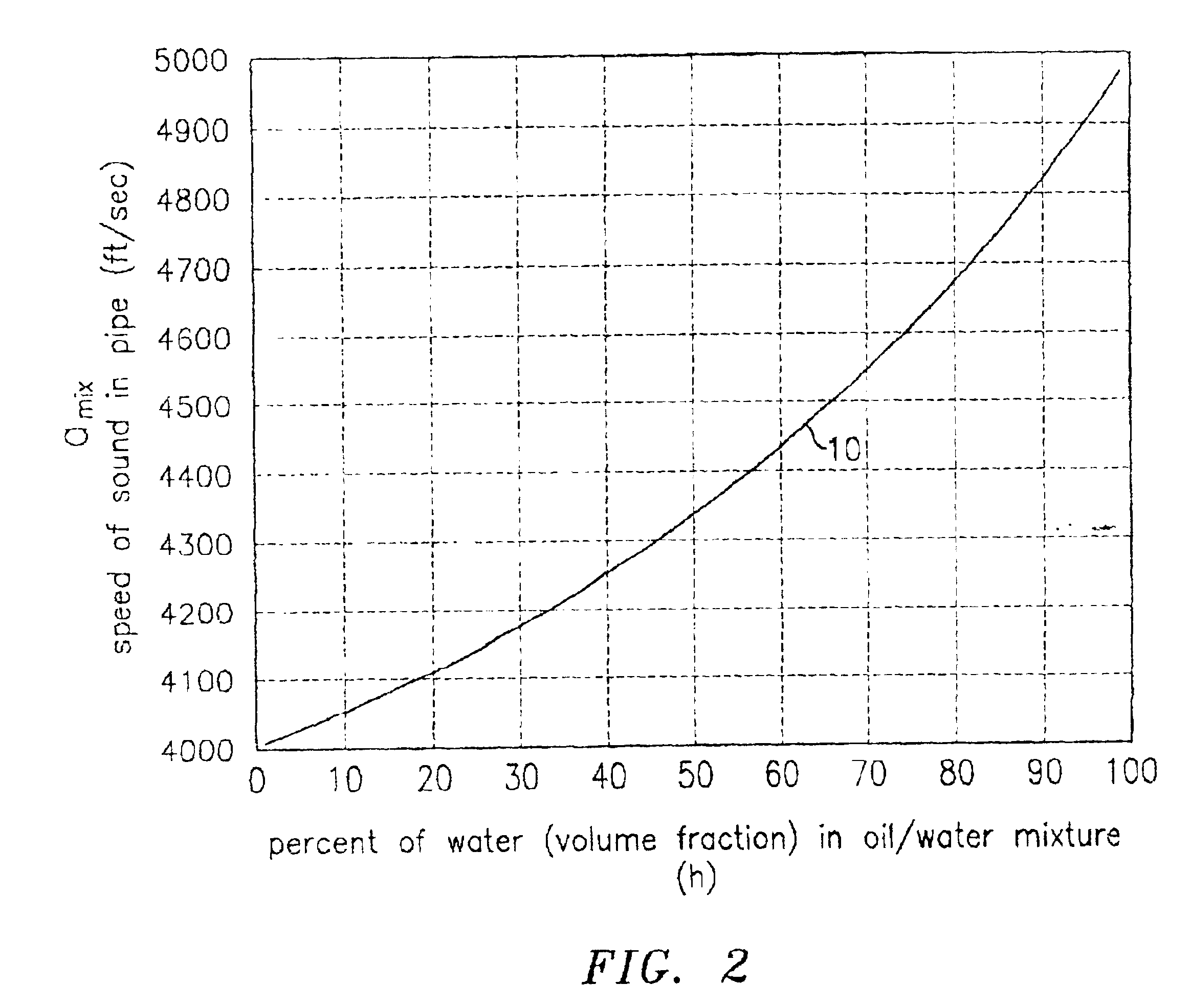

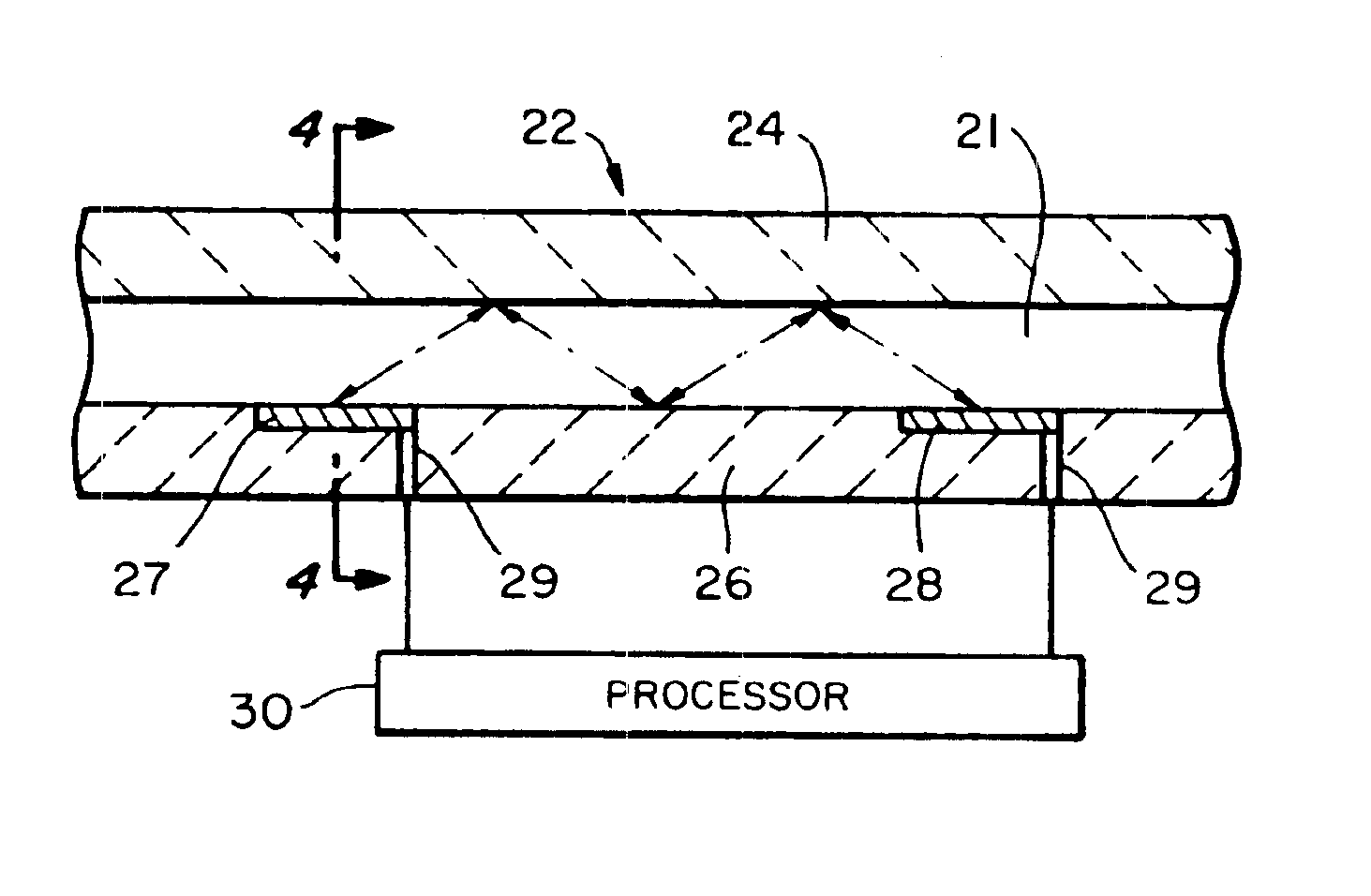

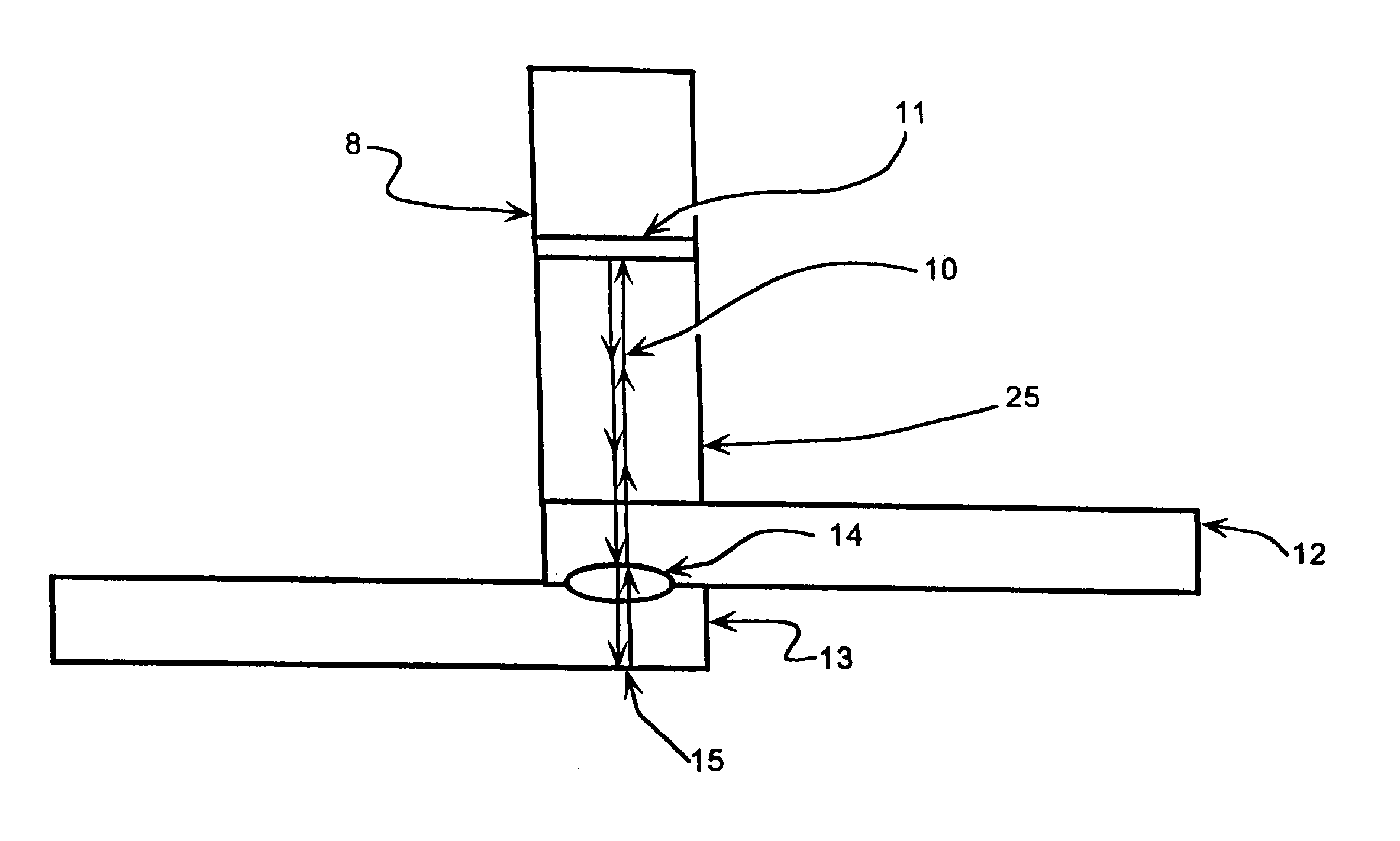

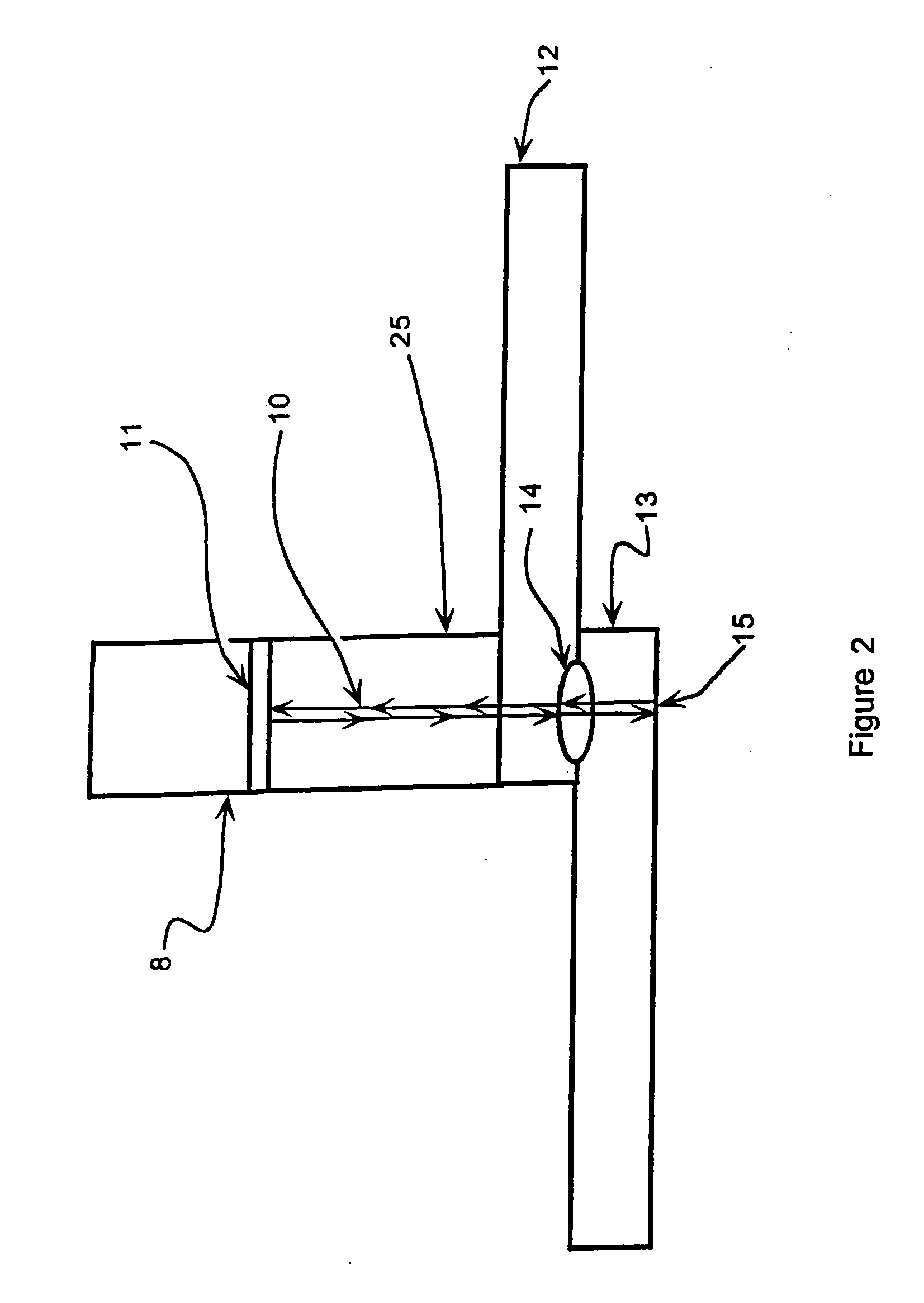

In industrial sensing applications at least one parameter of at least one fluid in a pipe 12 is measured using a spatial array of acoustic pressure sensors 14,16,18 placed at predetermined axial locations x1, x2, x3 along the pipe 12. The pressure sensors 14,16,18 provide acoustic pressure signals P1(t), P2(t), P3(t) on lines 20,22,24 which are provided to signal processing logic 60 which determines the speed of sound amix of the fluid (or mixture) in the pipe 12 using acoustic spatial array signal processing techniques with the direction of propagation of the acoustic signals along the longitudinal axis of the pipe 12. Numerous spatial array-processing techniques may be employed to determine the speed of sound amix. The speed of sound amix is provided to logic 48, which calculates the percent composition of the mixture, e.g., water fraction, or any other parameter of the mixture, or fluid, which is related to the sound speed amix. The logic 60 may also determine the Mach number Mx of the fluid. The acoustic pressure signals P1(t), P2(t), P3(t) measured are lower frequency (and longer wavelength) signals than those used for ultrasonic flow meters, and thus is more tolerant to inhomogeneities in the flow. No external source is required and thus may operate using passive listening. The invention will work with arbitrary sensor spacing and with as few as two sensors if certain information is known about the acoustic properties of the system. The sensor may also be combined with an instrument, an opto-electronic converter and a controller in an industrial process control system.

Owner:EXPRO METERS

Methods for ultrasonic inspection of spot and seam resistance welds in metallic sheets and a spot weld examination probe system (SWEPS)

InactiveUS20050132809A1Allow flexibilityAnalysing fluids using sonic/ultrasonic/infrasonic wavesAnalysing solids using sonic/ultrasonic/infrasonic wavesNon destructiveElectrical resistance and conductance

An external focused ultrasonic beam, non-destructive, open-air, inspection method of sheet metal spot and seam weldments using a probe in combination with motion measurement of the probe over the weldments during inspection without immersion of the material. Reflected ultrasonic waves are received and signals produced and processed or displayed as A-scan, B-scan and C-scan images that are easily recognized. An A-Scan is based on the time-of-flight difference between the outer surface, the weldment and inner and opposite surfaces of the component. B-scan and C-scan indicate the degree of weld fusion and provide data relative to fused thickness and defects sheet metal or welds. A special purpose scanner that enables ultrasonic examination welds. Scanner is pencil like ultrasonic probe with bearing face and position sensing device disposed adjacent a weld position. Scanner collects data for method to determine various characteristics of welded items.

Owner:APPLIED METRICS

High-precision measuring method and apparatus

InactiveUS7080554B2Vibration measurement in solidsAnalysing fluids using sonic/ultrasonic/infrasonic wavesPhase locked loop circuitTransmission channel

Owner:NEXENSE

Apparatus and method for measuring parameters of a mixture having solid particles suspended in a fluid flowing in a pipe

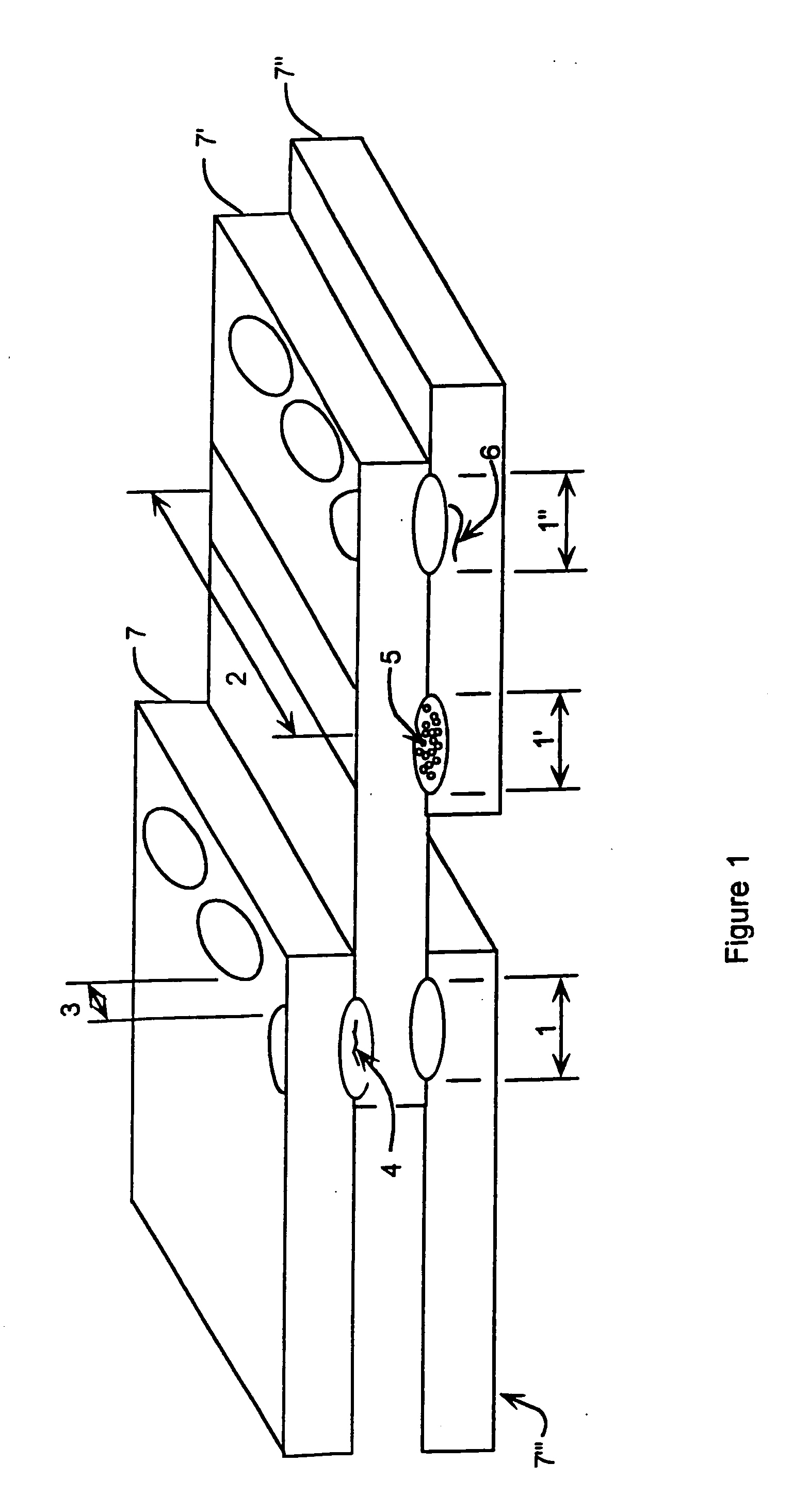

InactiveUS20050171710A1Analysing fluids using sonic/ultrasonic/infrasonic wavesAnalysing solids using sonic/ultrasonic/infrasonic wavesEngineeringSolid particle

An apparatus 10 and method is provided that includes a spatial array of unsteady pressure sensors 15-18 placed at predetermined axial locations x1-xN disposed axially along a pipe 14 for measuring at least one parameter of a solid particle / fluid mixture 12 flowing in the pipe 14. The pressure sensors 15-18 provide acoustic pressure signals P1(t)-PN(t) to a signal processing unit 30 which determines the speed of sound amix(ω) of the particle / fluid mixture 12 in the pipe 14 using acoustic spatial array signal processing techniques. The primary parameters to be measured include fluid / particle concentration, fluid / particle mixture volumetric flow, and particle size. Frequency based sound speed is determined utilizing a dispersion model to determine the parameters of interest. the calculating the at least one parameter uses an acoustic pressure to calculate

Owner:EXPRO METERS

Graphene and Hexagonal Boron Nitride Devices

InactiveUS20110163298A1Vibration measurement in solidsOptical rangefindersHexagonal boron nitrideBoron nitride

Graphene layers, hexagonal boron nitride (hBN) layers, as well as other materials made of primarily sp2 bonded atoms and associated methods are disclosed. In one aspect, the present invention provides graphene and hBN devices. In one aspect, for example, an electronic device is provided including a graphene layer and a planar hBN layer operably associated with the graphene layer and forming a functional interface therebetween. Numerous functional interfaces are contemplated, depending on the desired functionality of the device.

Owner:SUNG CHIEN MIN

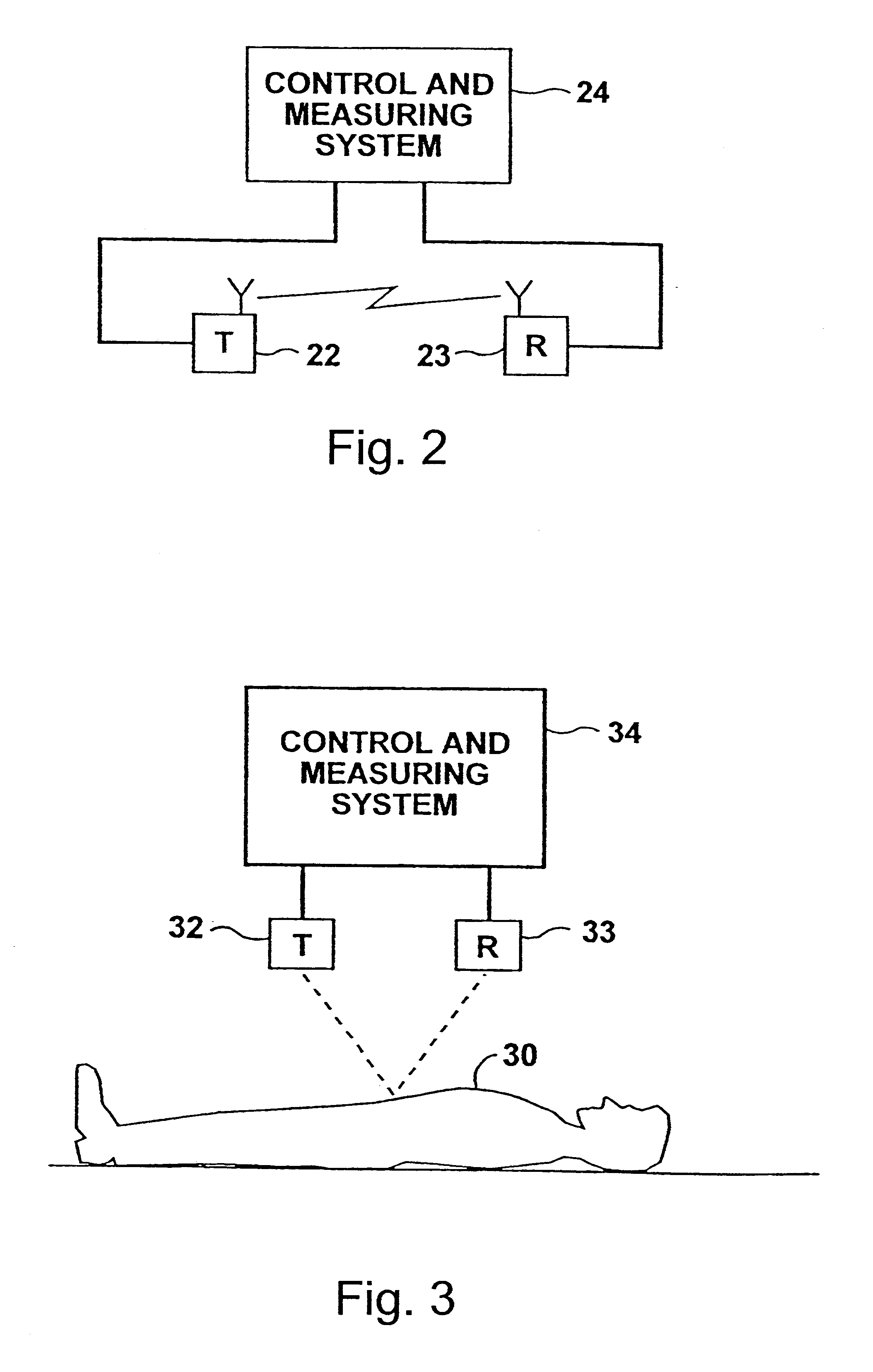

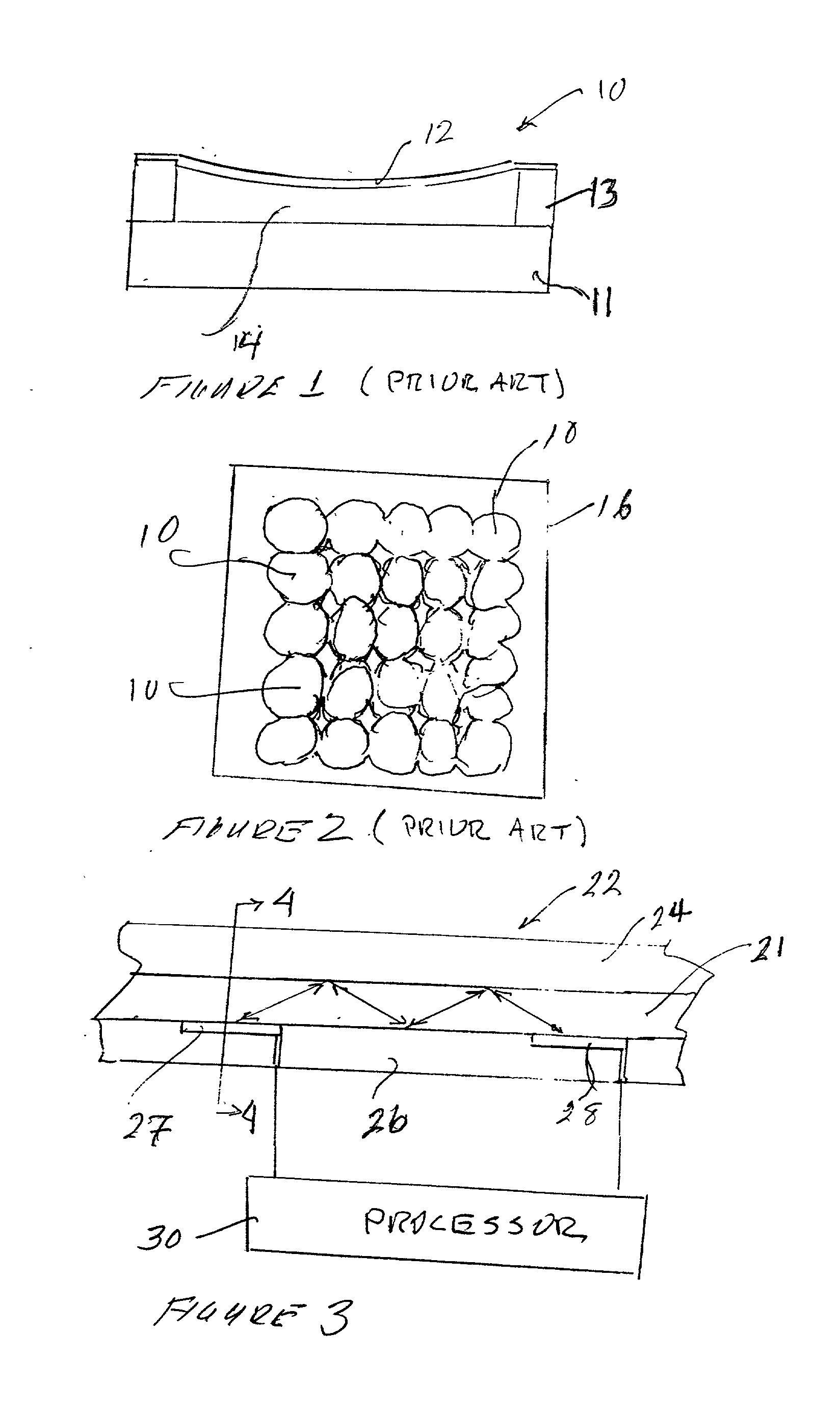

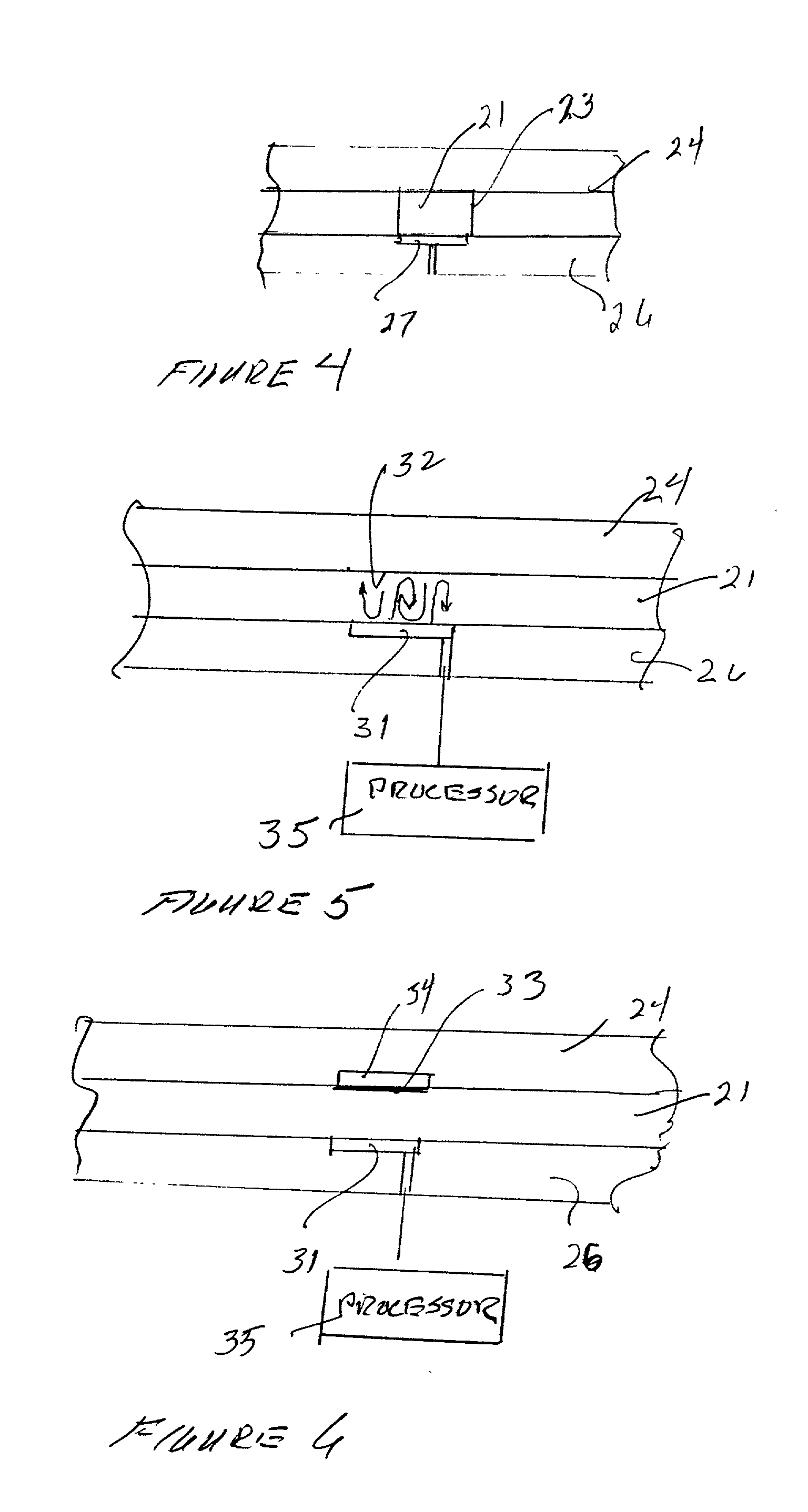

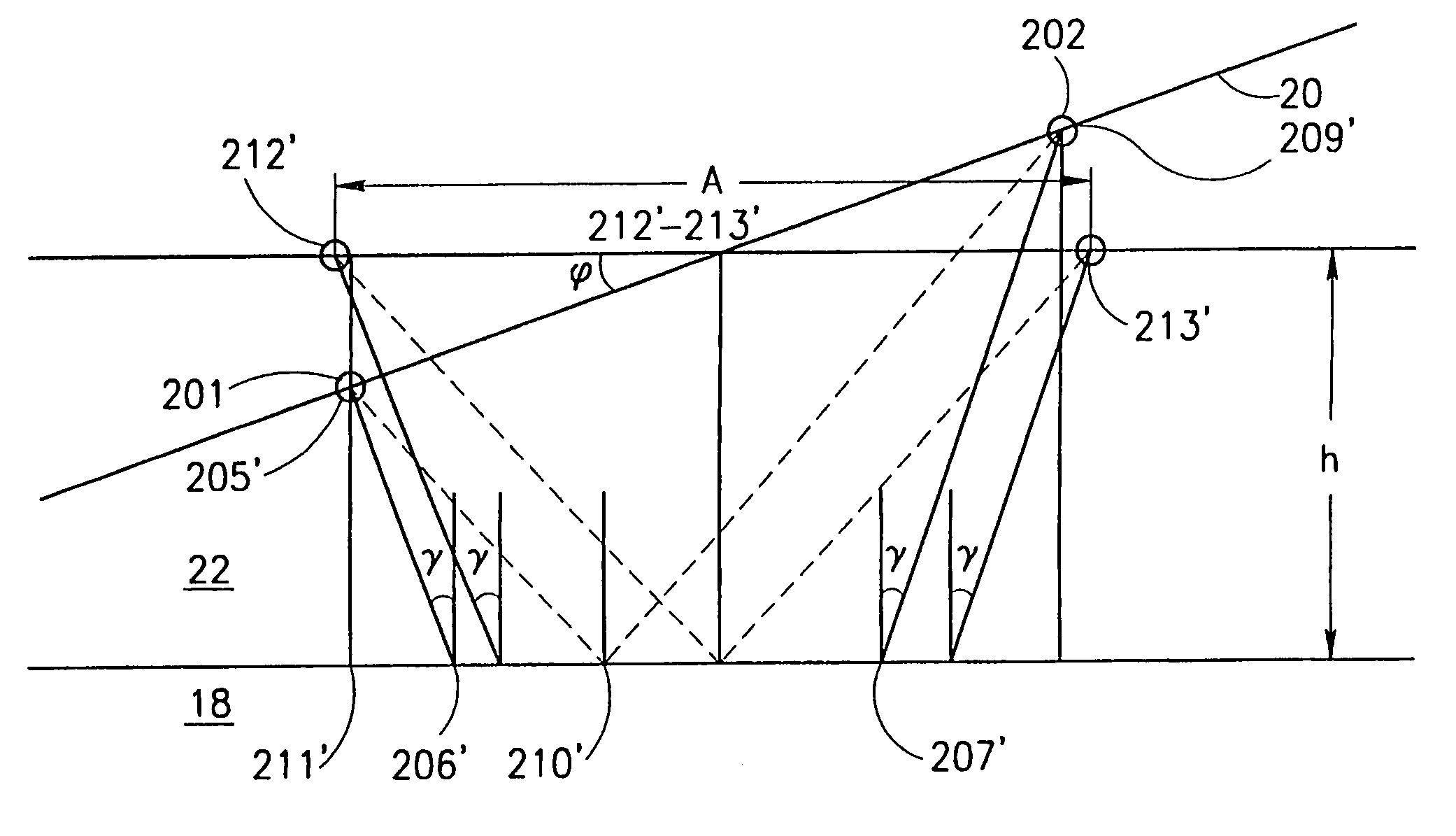

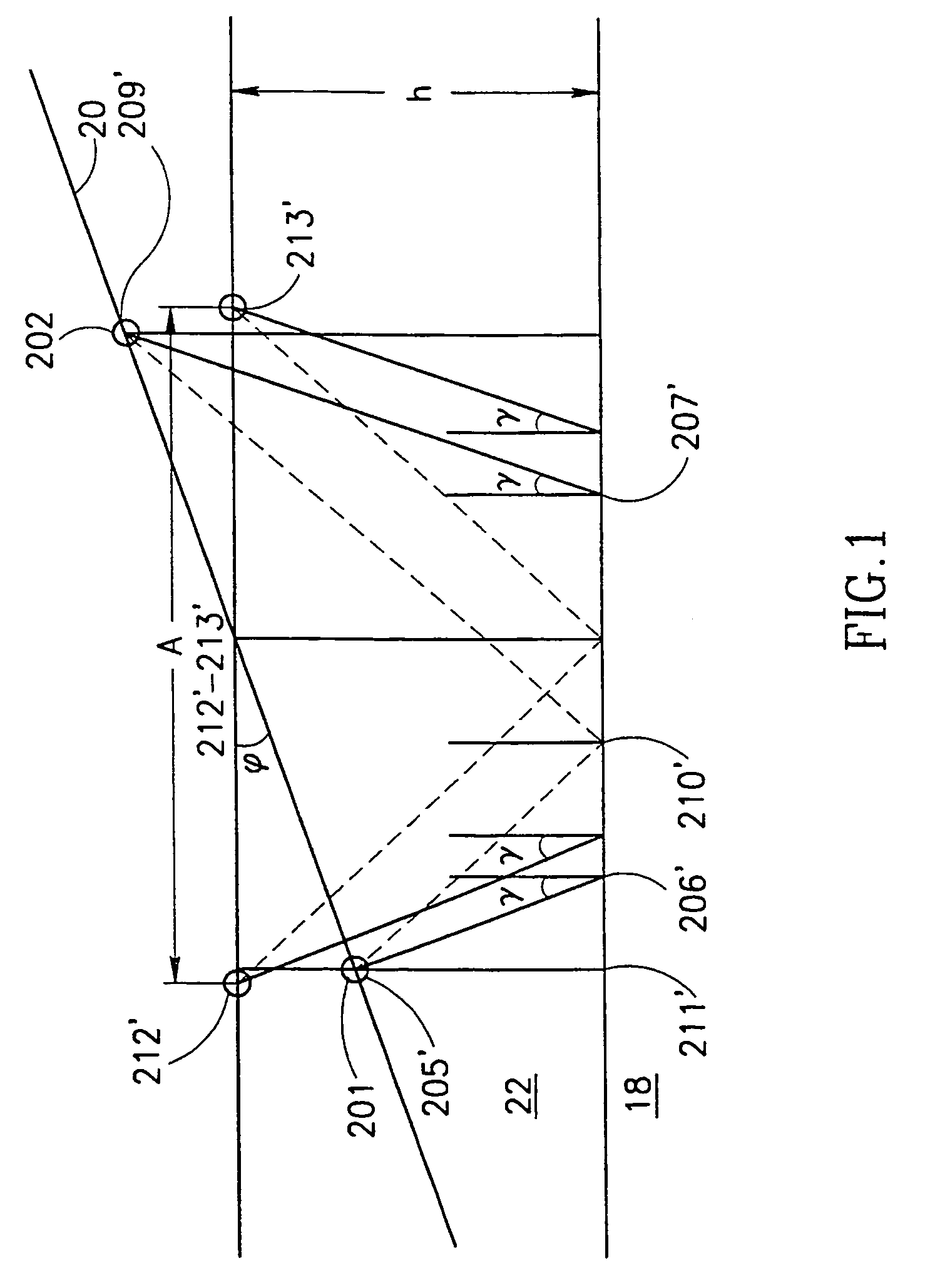

Determination of acoustic velocity in bone

InactiveUS7112173B1Improve spatial resolutionMinimum amount of interferenceHeart/pulse rate measurement devicesVelocity propogationSpeed of soundSoft tissue

A method for determining an acoustic velocity in a segment of a bone covered with a layer of soft tissue having an outer surface, which includes determining a first travel time of a first ultrasonic wave along a first path from the outer surface back to the outer surface which path includes at least a first part of the bone segment together with determining a second travel time of a second ultrasonic wave along a second path from the outer surface back to the outer surface, which path includes at least a second part of the bone segment and also determining a third travel time of a third ultrasonic wave along a third path from the outer surface back to the outer surface which path includes at least a third part of the bone segment, and deriving the acoustic velocity in the segment of bone from the three determined travel times.

Owner:BEAM MED

Methods and apparatus for multi-parameter acoustic signature inspection

ActiveUS7246522B1Quick switchAnalysing fluids using sonic/ultrasonic/infrasonic wavesAnalysing solids using sonic/ultrasonic/infrasonic wavesAcoustic signatureNon invasive

A multiparameter acoustic signature inspection device and method are described for non-invasive inspection of containers. Dual acoustic signatures discriminate between various fluids and materials for identification of the same.

Owner:BATTELLE MEMORIAL INST

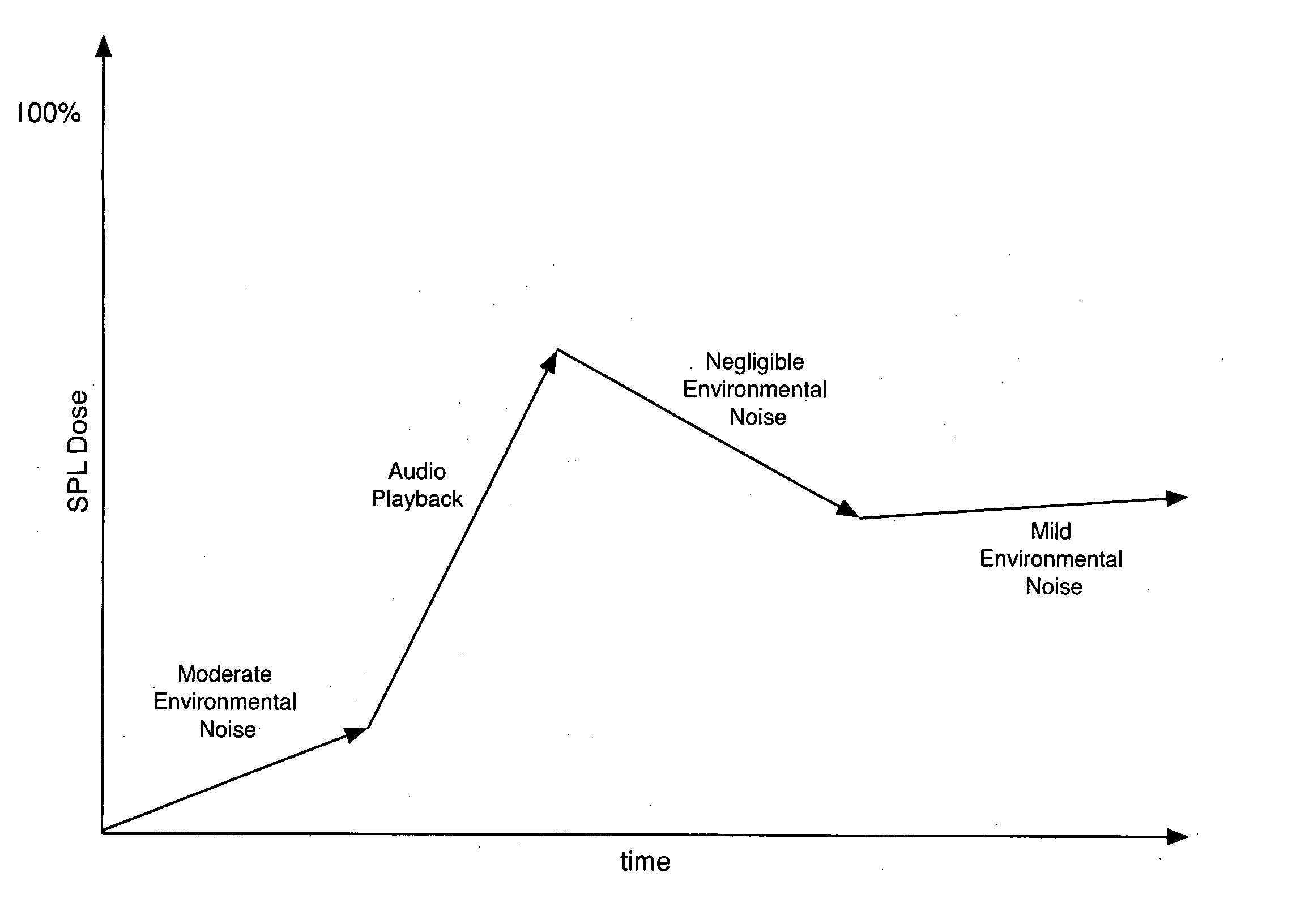

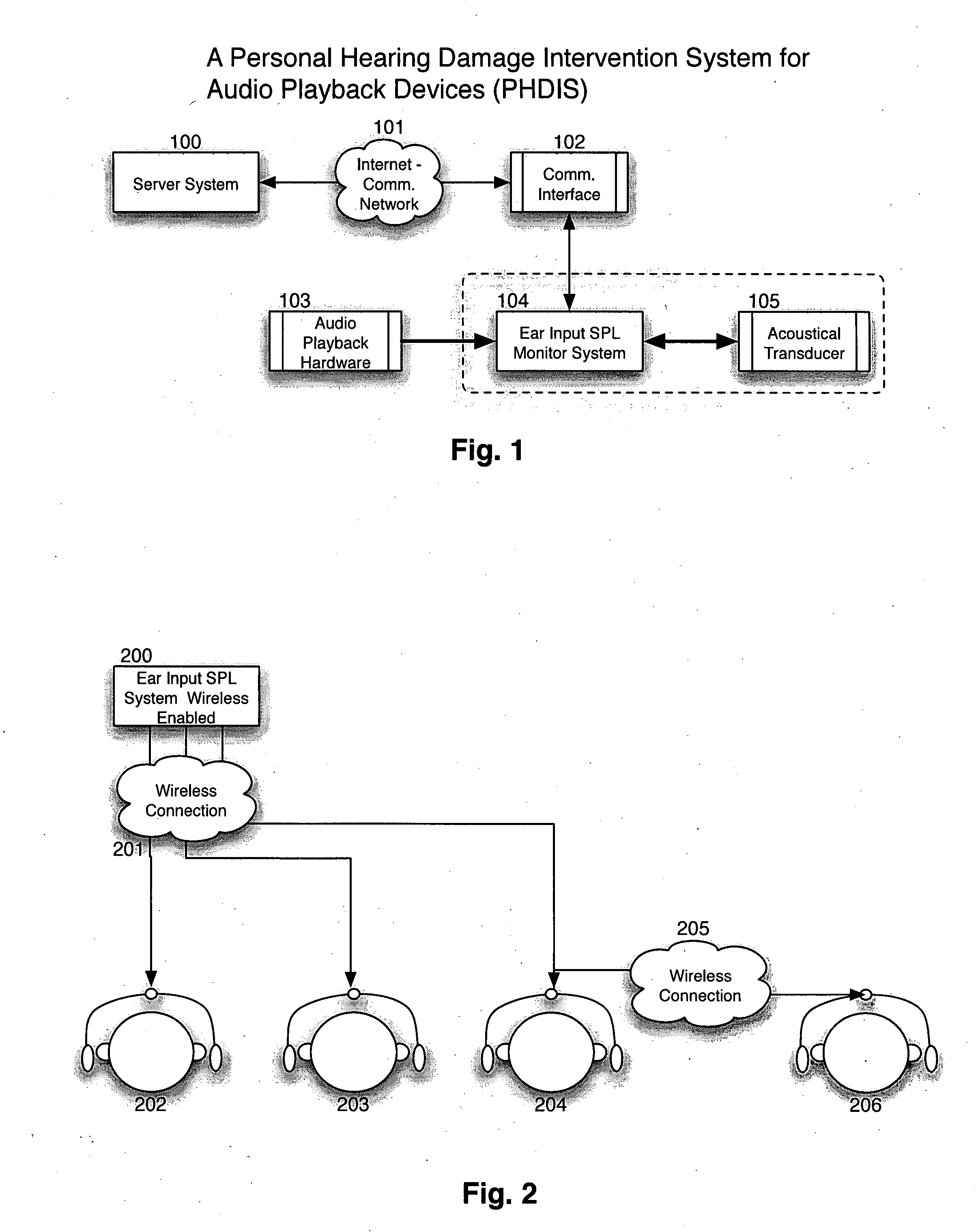

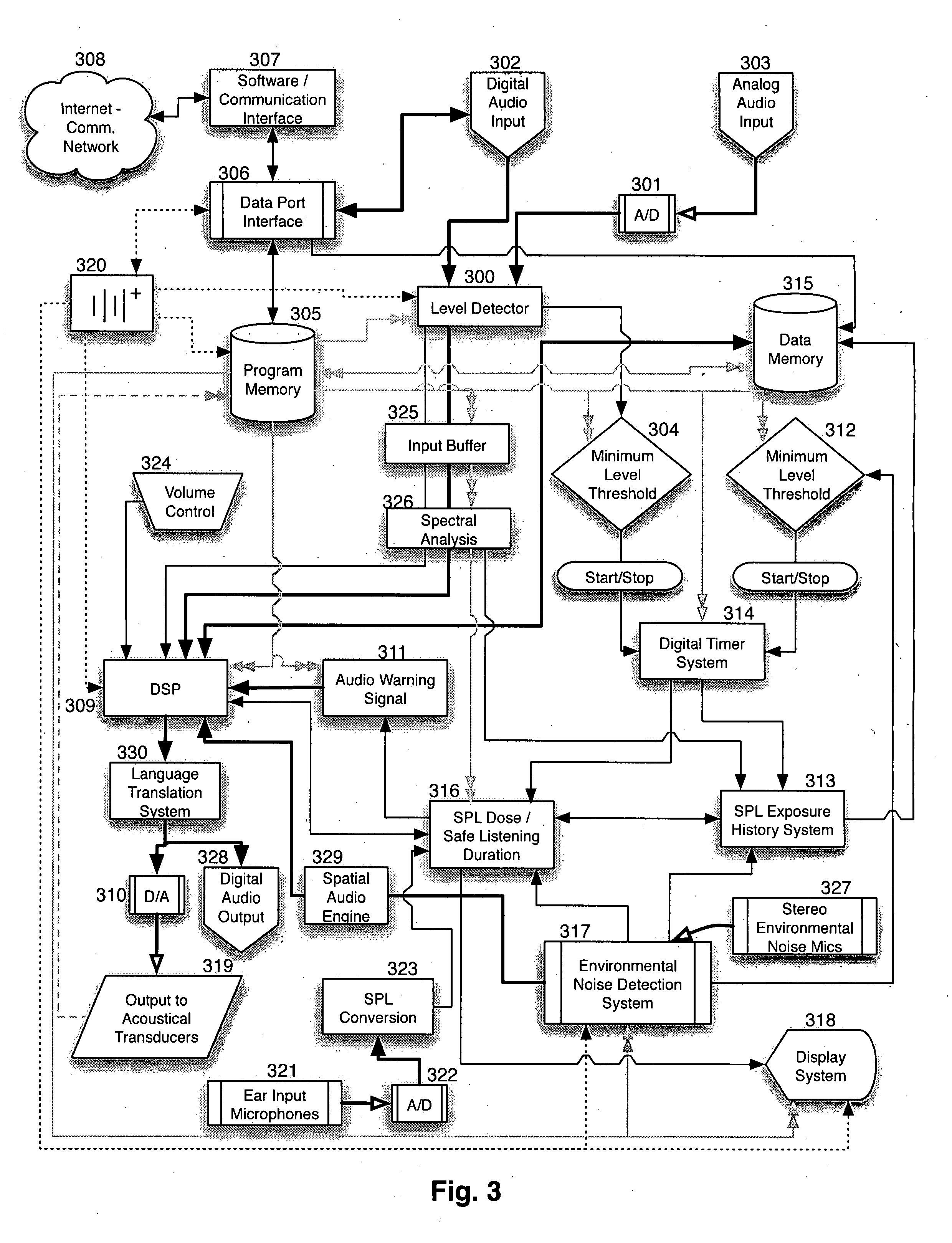

Methods and devices for hearing damage notification and intervention

ActiveUS20080205660A1Potential for hearing damageMinimize Hearing DamageVibration measurement in solidsOptical rangefindersMedicineLoudspeaker

At least one exemplary embodiment is directed to a method of monitoring hearing health comprising: measuring a first acoustic sound pressure level due to an ambient audio signal; measuring a second acoustic sound pressure level due to an emitted audio signal from a speaker; calculating a total sound pressure level dosage, where the total sound pressure level dosage is calculated using the first acoustic sound pressure level and a first time span, and the second acoustic sound pressure level and a second time span associated, where the first time span is the time associated with the measured first acoustic sound pressure level and second time span is the time associated with the measured second acoustic sound pressure level; and sending a notification signal when total sound pressure level dosage is greater than a threshold value.

Owner:STATON TECHIYA LLC

Popular searches

Synchronous motors for clocks Electric unknown time interval measurement Linear/angular speed measurement Time-pieces with integrated devices Speed/acceleration/shock instrument details Computer-assisted treatment prescription/delivery Fluid speed measurement Average speed measurement Digital computer details Speed measurement using gyroscopic effects

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com