Patents

Literature

226 results about "Modal testing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Modal testing is the form of vibration testing of an object whereby the natural (modal) frequencies, modal masses, modal damping ratios and mode shapes of the object under test are determined. A modal test consists of an acquisition phase and an analysis phase. The complete process is often referred to as a Modal Analysis or Experimental Modal Analysis.

System and method for detecting structural damage

InactiveUS20050072234A1Vibration measurement in solidsAnti-theft devicesModal testingSignal-to-noise ratio (imaging)

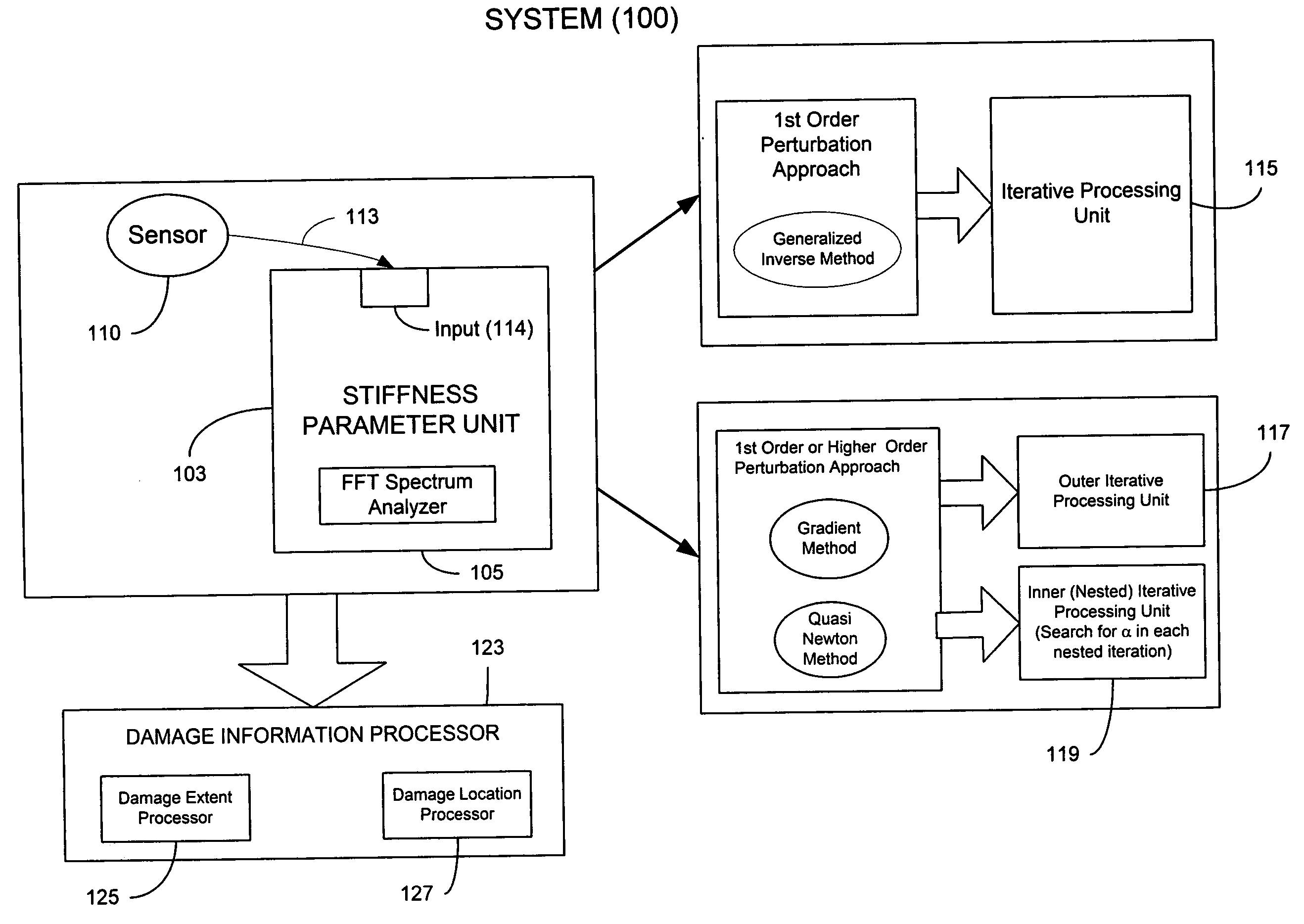

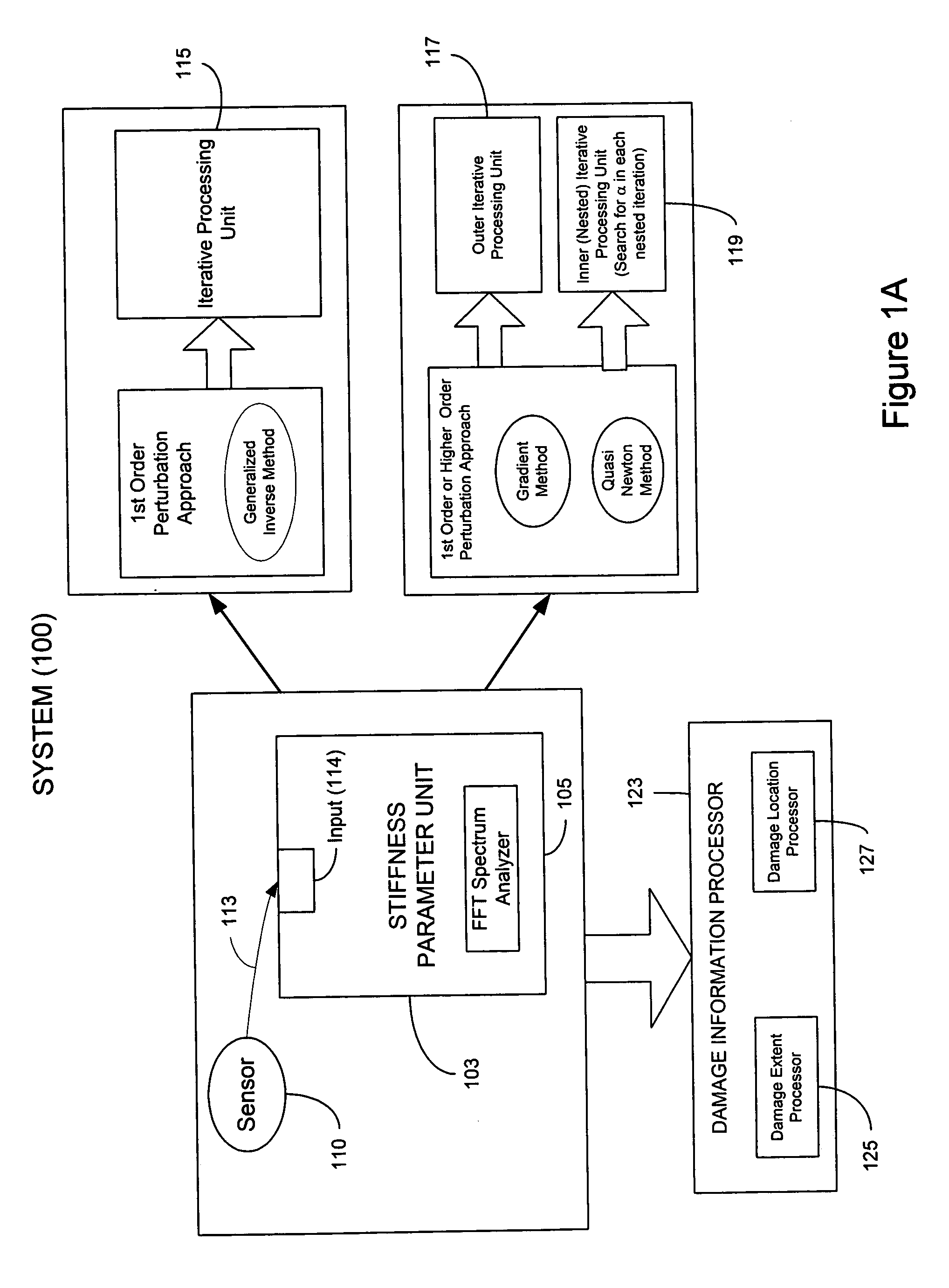

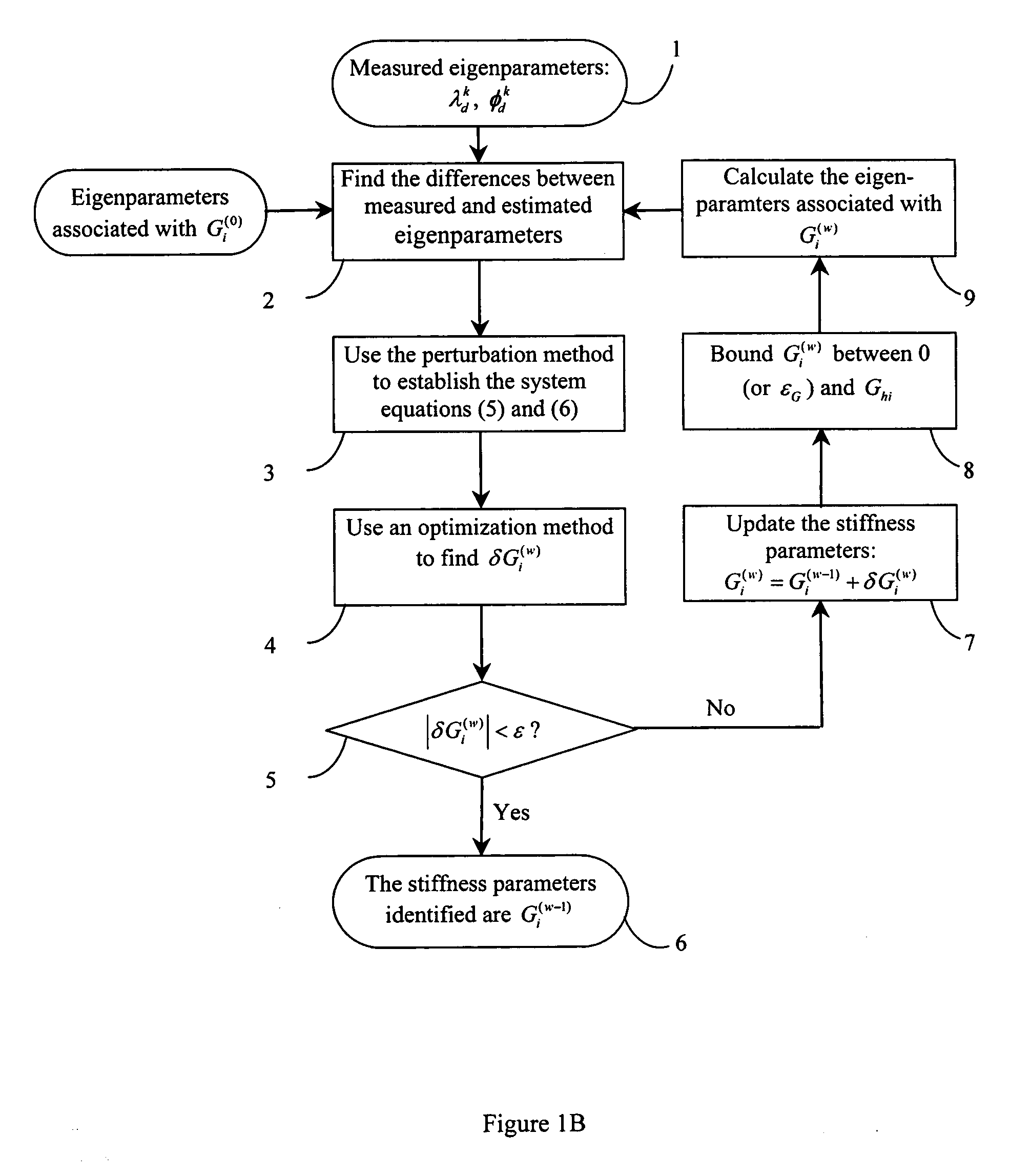

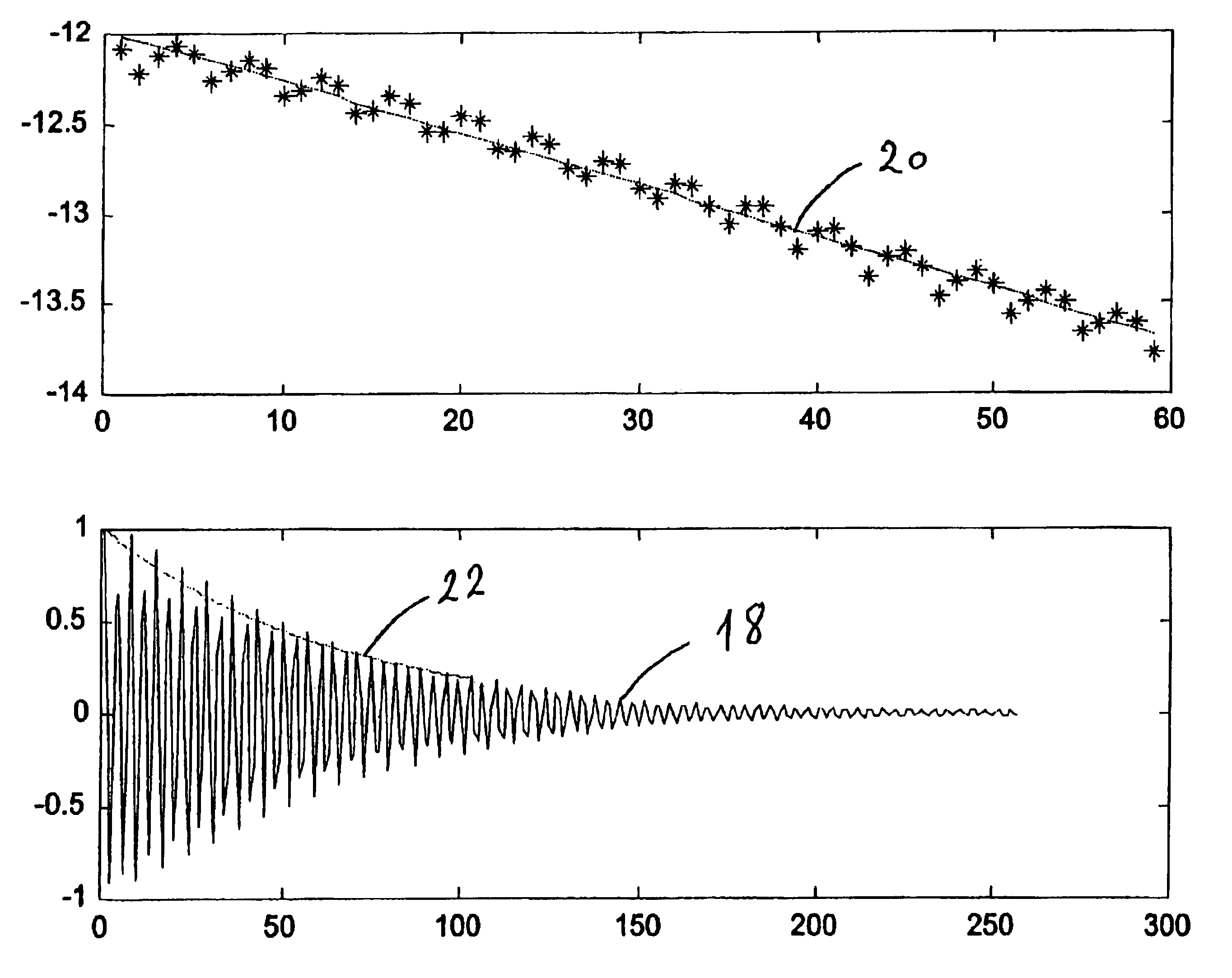

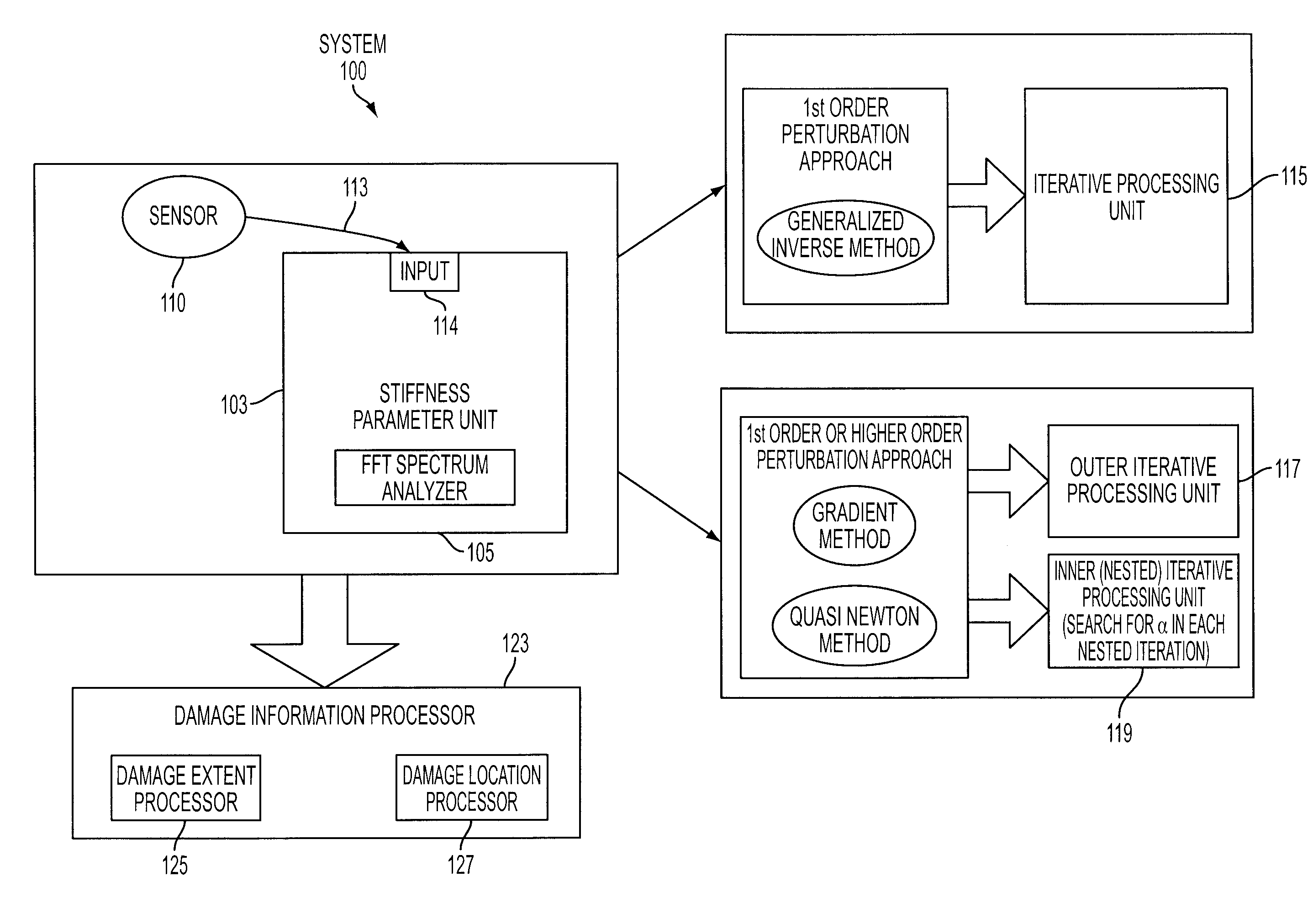

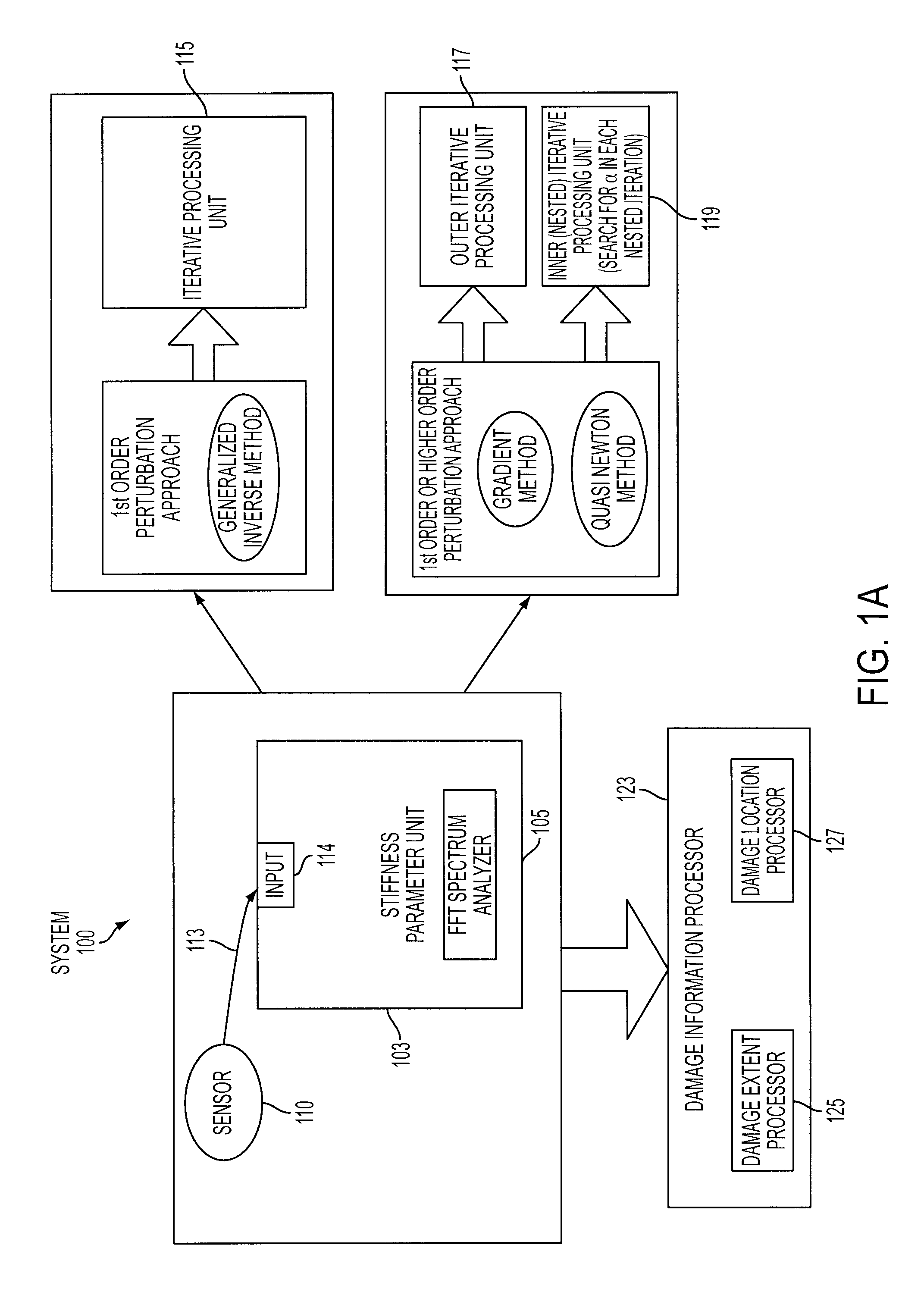

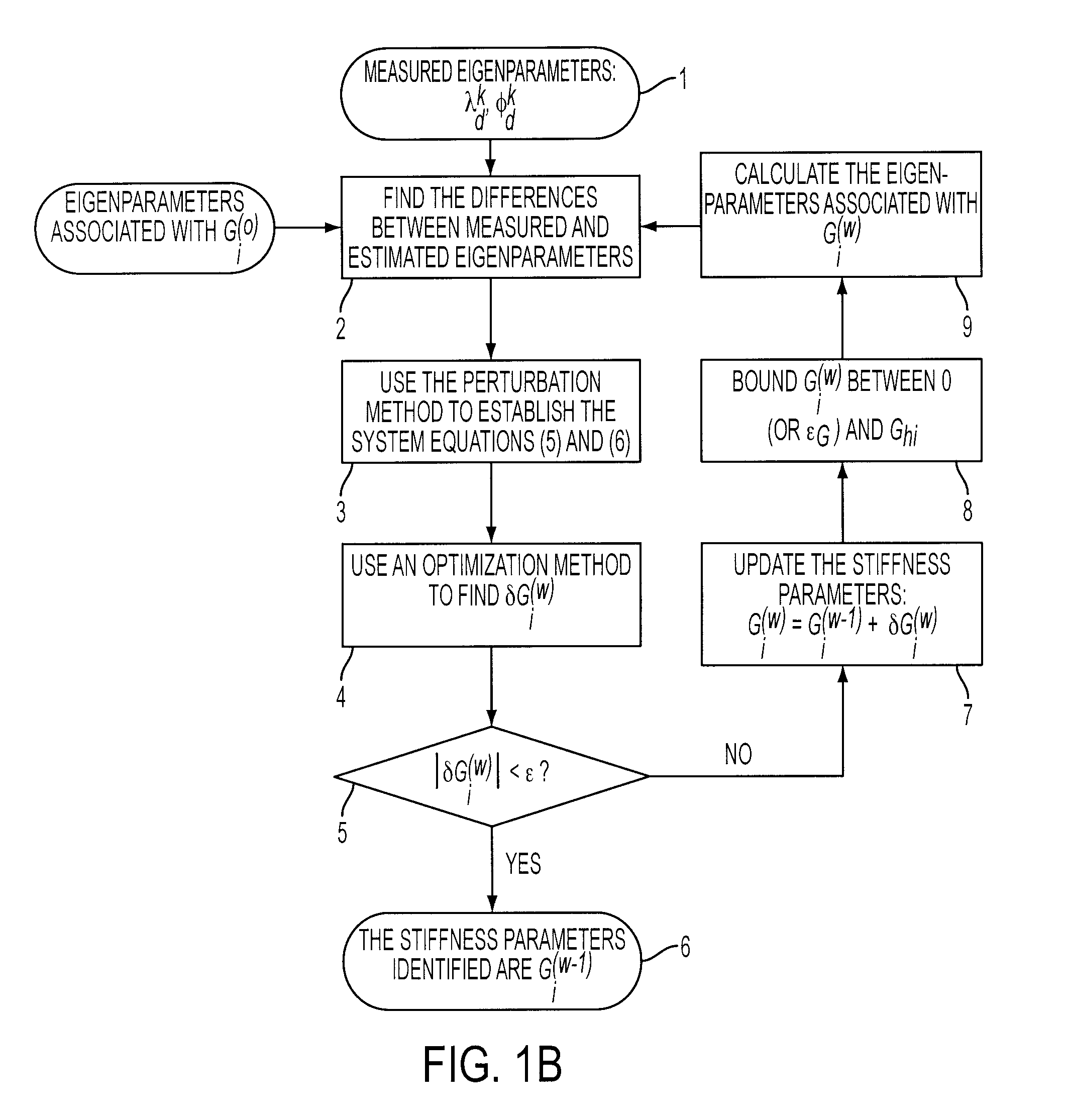

A system and method for detecting structural damage is provided that utilizes a general order perturbation methodology involving multiple perturbation parameters. The perturbation methodology is used iteratively in conjunction with an optimization method to identify the stiffness parameters of structures using natural frequencies and / or mode shape information. The stiffness parameters are then used to determine the location and extent of damage in a structure. A novel stochastic model is developed to model the random impact series produced manually or to generate a random impact series in a random impact device. The random impact series method or the random impact device can be used to excite a structure and generate vibration information used to obtain the stiffness parameters of the structure. The method or the device can also just be used for modal testing purposes. The random impact device is a high energy, random, and high signal-to-noise ratio system.

Owner:UNIV OF MARYLAND BALTIMORE COUNTY

Method for vibration analysis

InactiveUS6779404B1Vibration measurement in solidsMachine part testingSingular value decompositionModal testing

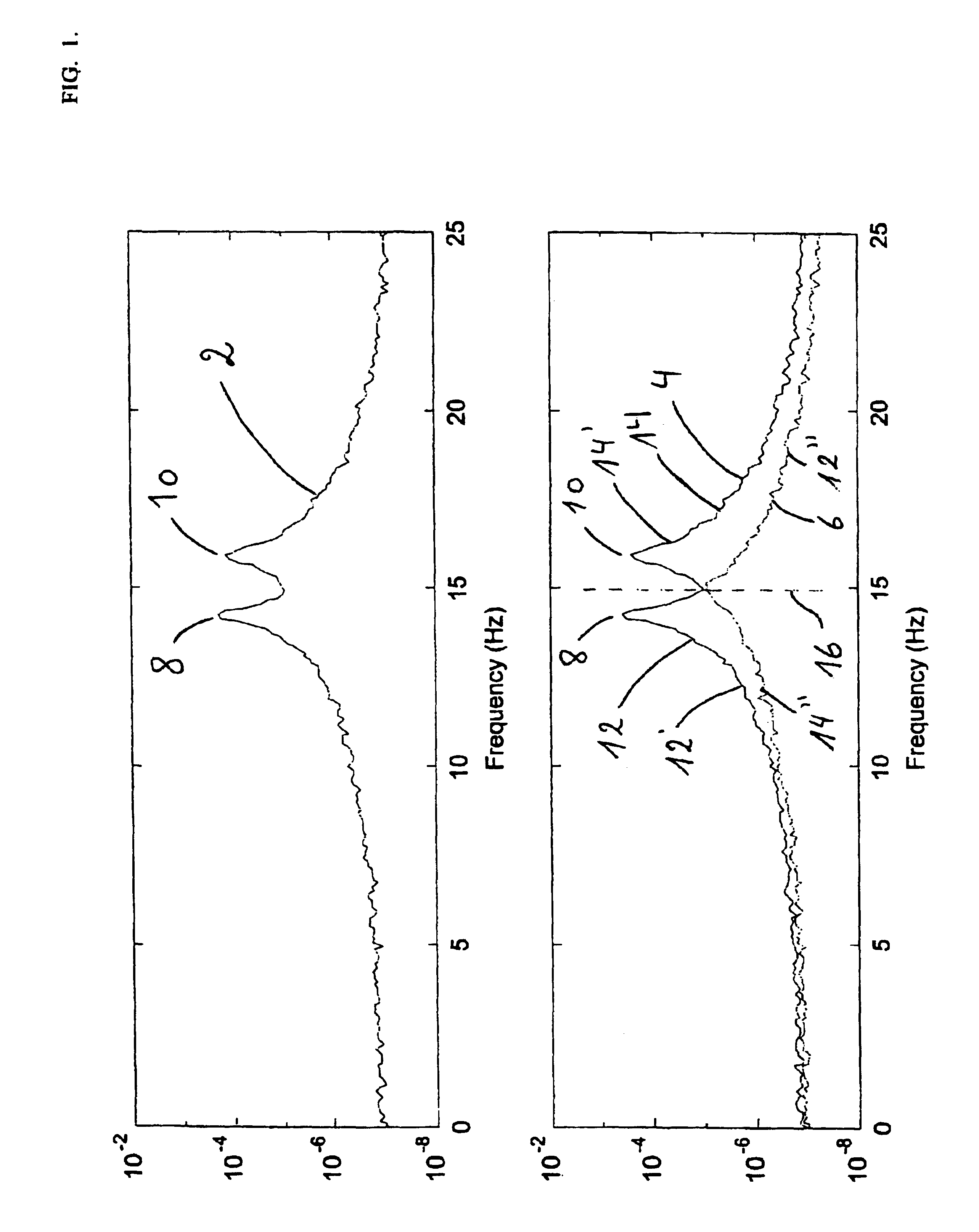

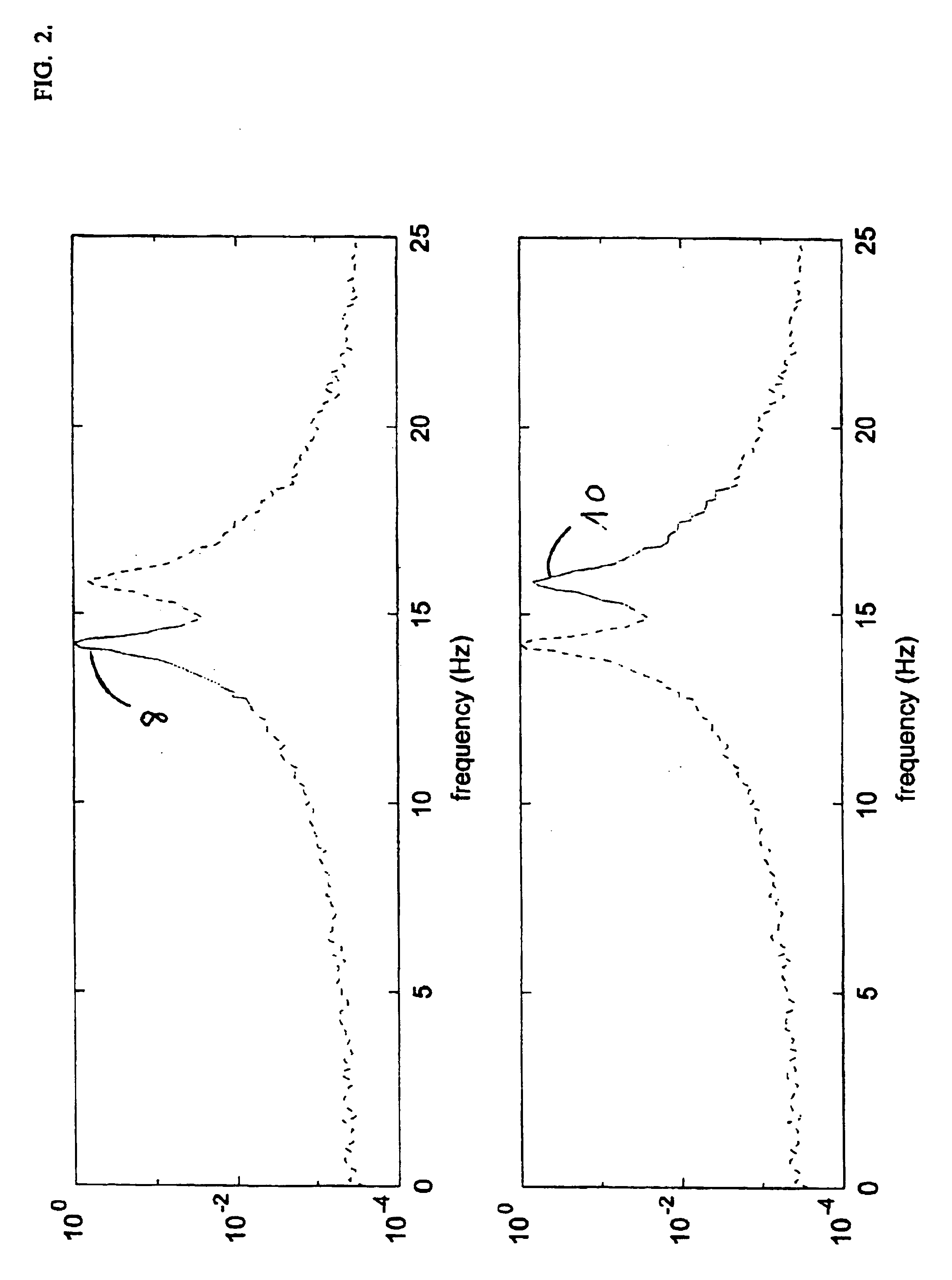

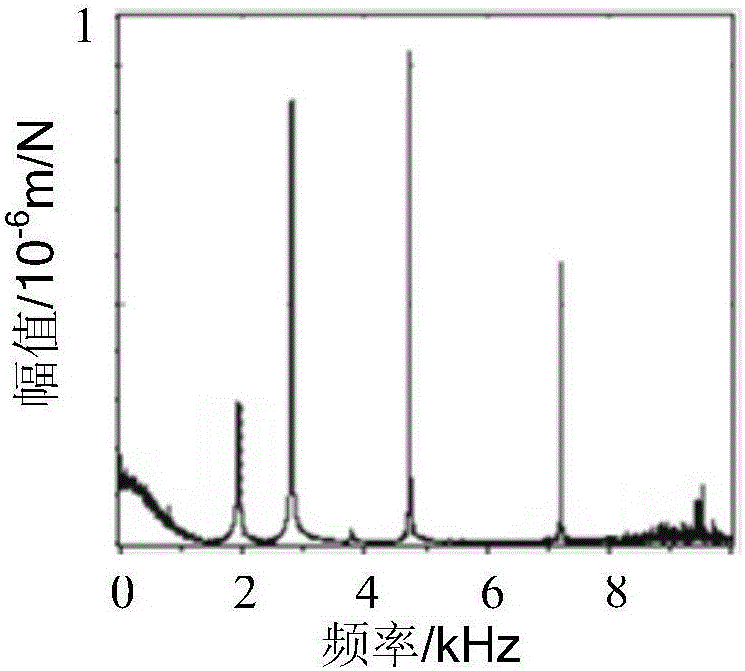

Output-only modal testing of an object. Vibrations are excited in said object and measured by a number of vibration sensitive detectors. From the data of the measurements, a spectral density matrix function is determined. From this density matrix, auto spectral densities for the individual modes are identified performing a decomposition based on the Singular Value Decomposition technique. From the auto spectral densities of the individual modes, natural frequencies and damping ratios for the modes can be estimated, and from the singular vectors of the Singular Value Decomposition, the modes shapes can be estimated.

Owner:STRUCTURAL VIBRATIONS SOLUTIONS

Thin-walled structure part vibration test device and method based on piezoelectric ceramic vibration exciter

ActiveCN103528782AEfficient collectionMeet the modal testSubsonic/sonic/ultrasonic wave measurementUsing wave/particle radiation meansDiagnostic Radiology ModalityModal testing

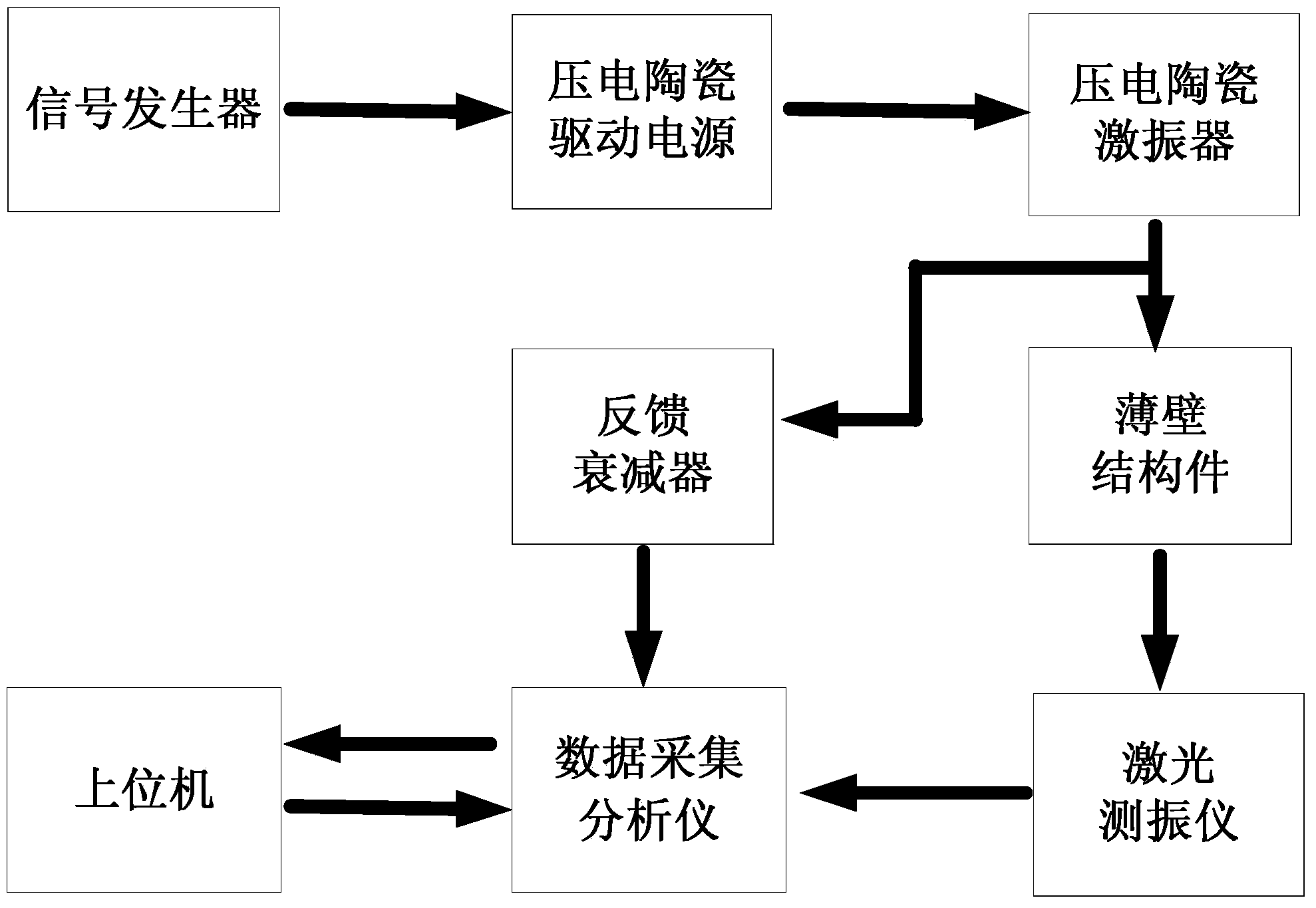

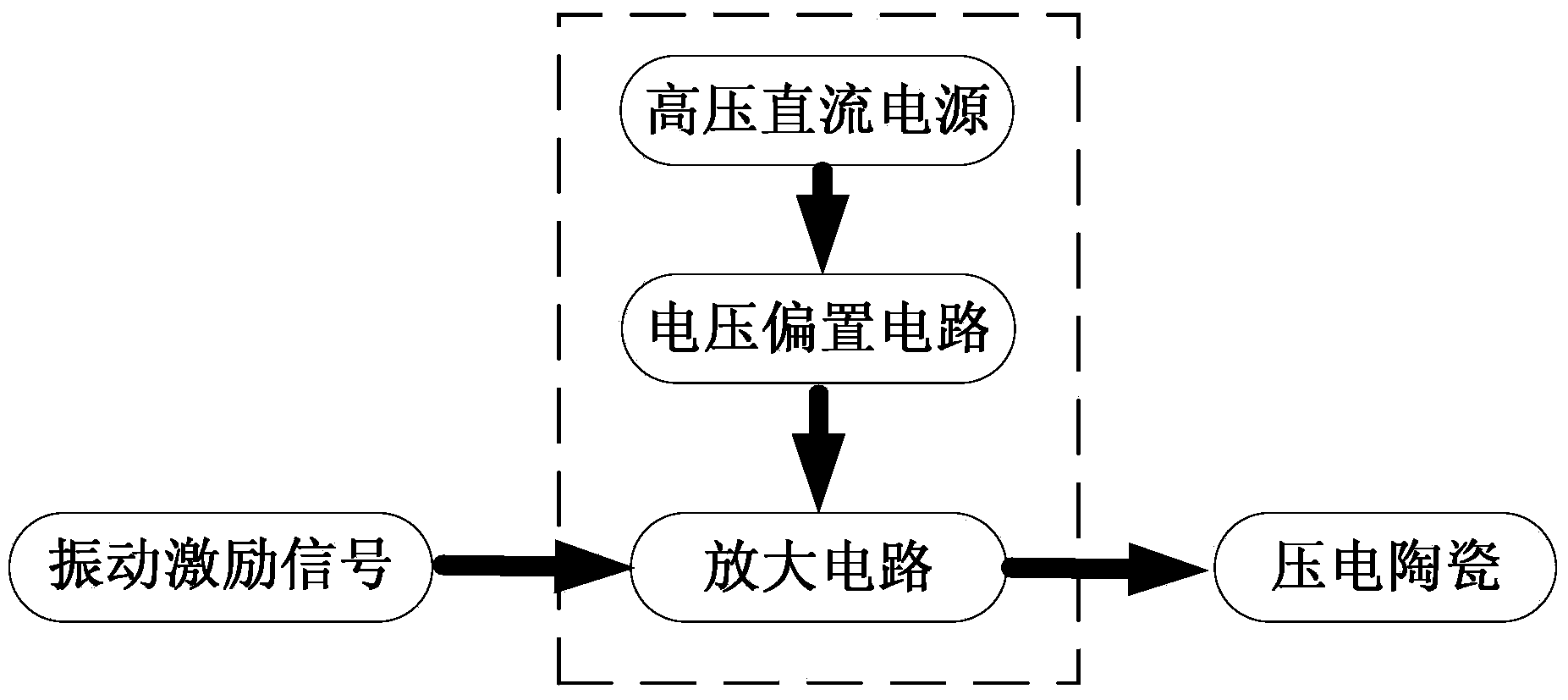

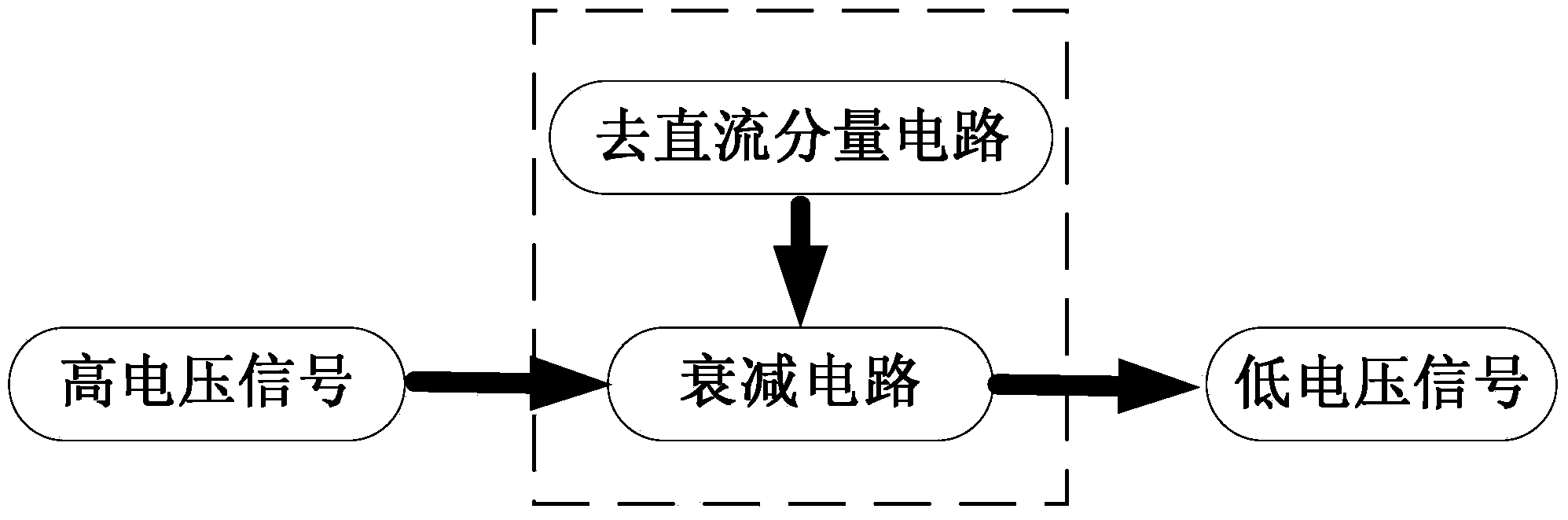

The invention belongs to the technical field of vibration test, in particular to a thin-walled structure part vibration test device and a method based on a piezoelectric ceramic vibration exciter. The device comprises a signal generator, a piezoelectric ceramic drive power supply, a piezoelectric ceramic vibration exciter, a feedback attenuator, a laser vibration meter, a data acquisition analyzer and an upper computer. The method comprises the steps of performing modality test on a thin-walled structure part, determining a linear relationship between excitation voltage and critical excitation frequency of the signal generator and calibrating an excitation force of the piezoelectric ceramic vibration exciter based on a cantilever theory. According to the device and the method, an excitation signal can be effectively acquired; the magnitude of the excitation force when the piezoelectric ceramic vibration exciter excites the structure part is defined; the stable designated excitation force and the linear excitation signal of the excitation frequency can be generated; influencing factors of non-linear piezoelectric ceramic excitation are effectively eliminated; the piezoelectric ceramic vibration exciter is adopted to realize high-frequency vibration excitation; additional mass is low; and the device is convenient to use.

Owner:NORTHEASTERN UNIV

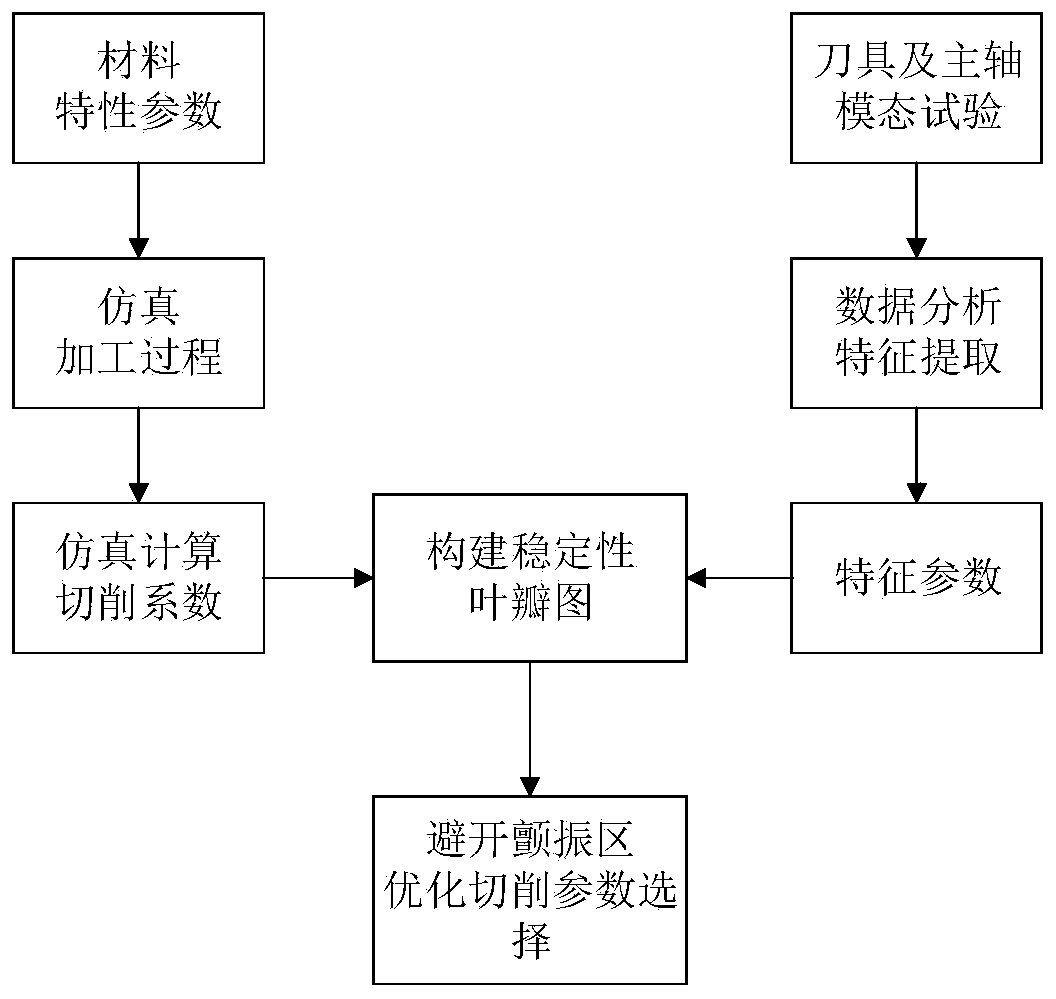

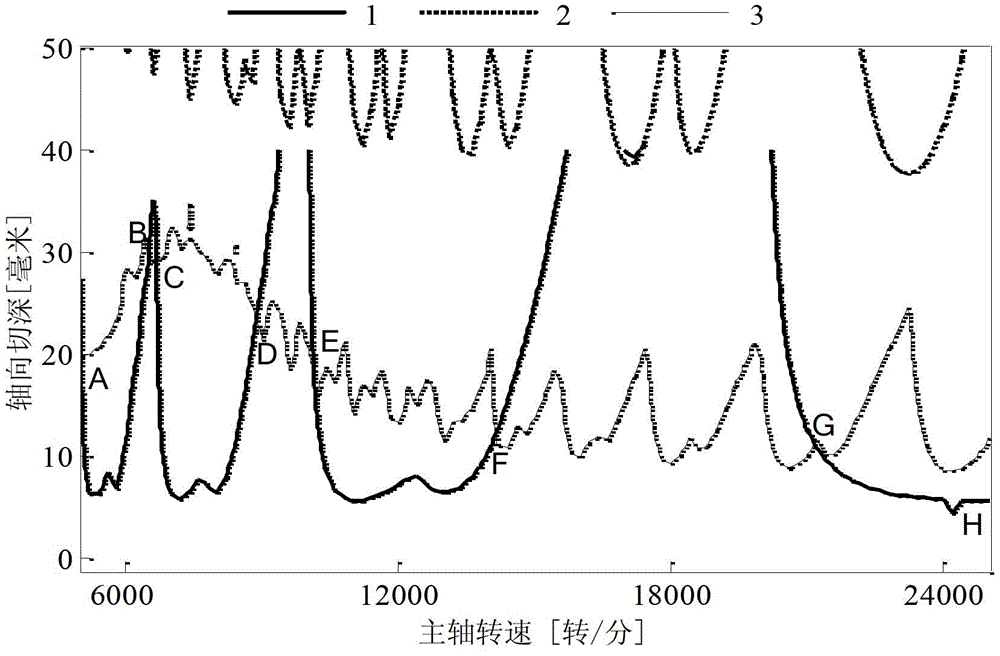

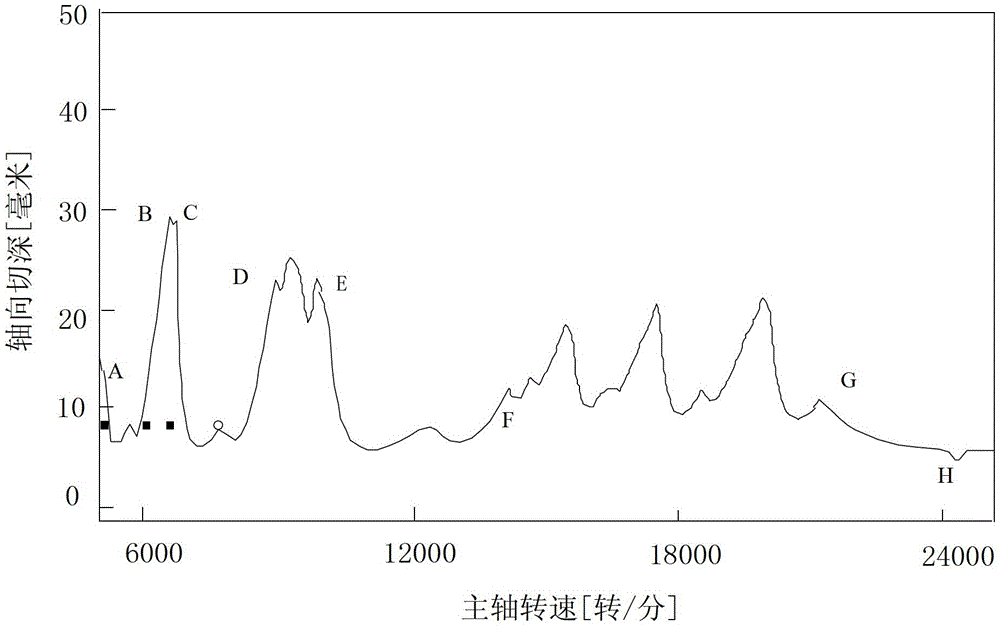

Flutter stability domain modeling approach for face cutting process

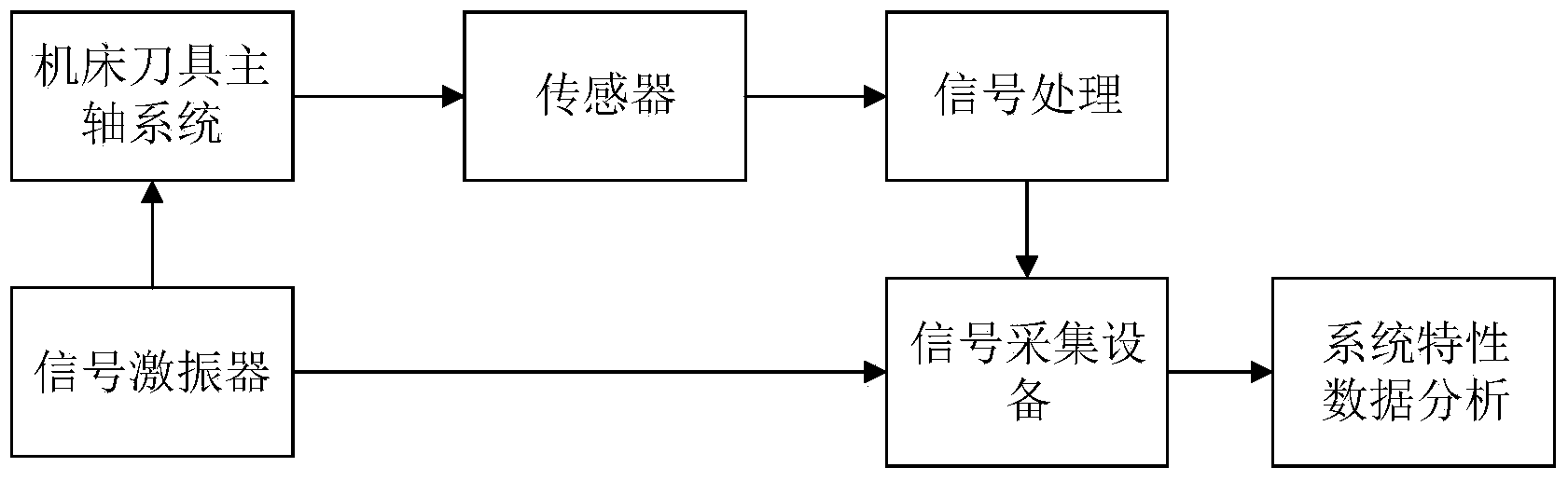

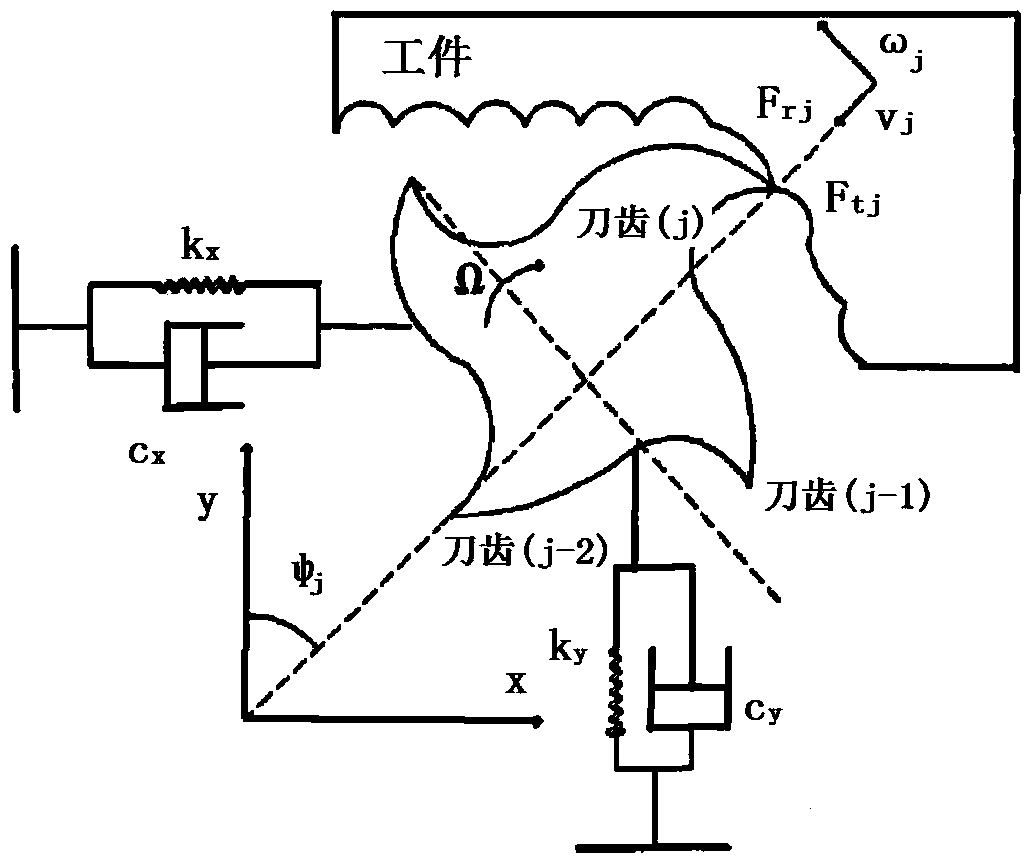

The invention belongs to the technical fields of simulating computational analysis and modal testing, and relates to a flutter stability domain modeling approach for a face cutting process. After all kinds of characteristic parameters of a material are known, a computer simulates a machining cutting process, calculates the cutting force in the machining process and analyzes the corresponding cutting coefficient. After the cutting coefficient is obtained, a modal experiment is utilized, modal testing is carried out on a machine tool spindle tool system, and the modal characteristic parameters of the machine tool spindle tool system are analyzed and comprise a multiple-order inherent frequency, a damping ratio, dynamic stiffness and the like. According to a flutter cutting theory, a stability lobe graph is drawn through combining the cutting coefficient and the system characteristic parameters and utilizing a computer assemble program, and is used for selecting the reasonable cutting parameter to avoid a flutter region, the processing precision and quality are improved, and a machine tool system is protected.

Owner:DALIAN UNIV OF TECH +1

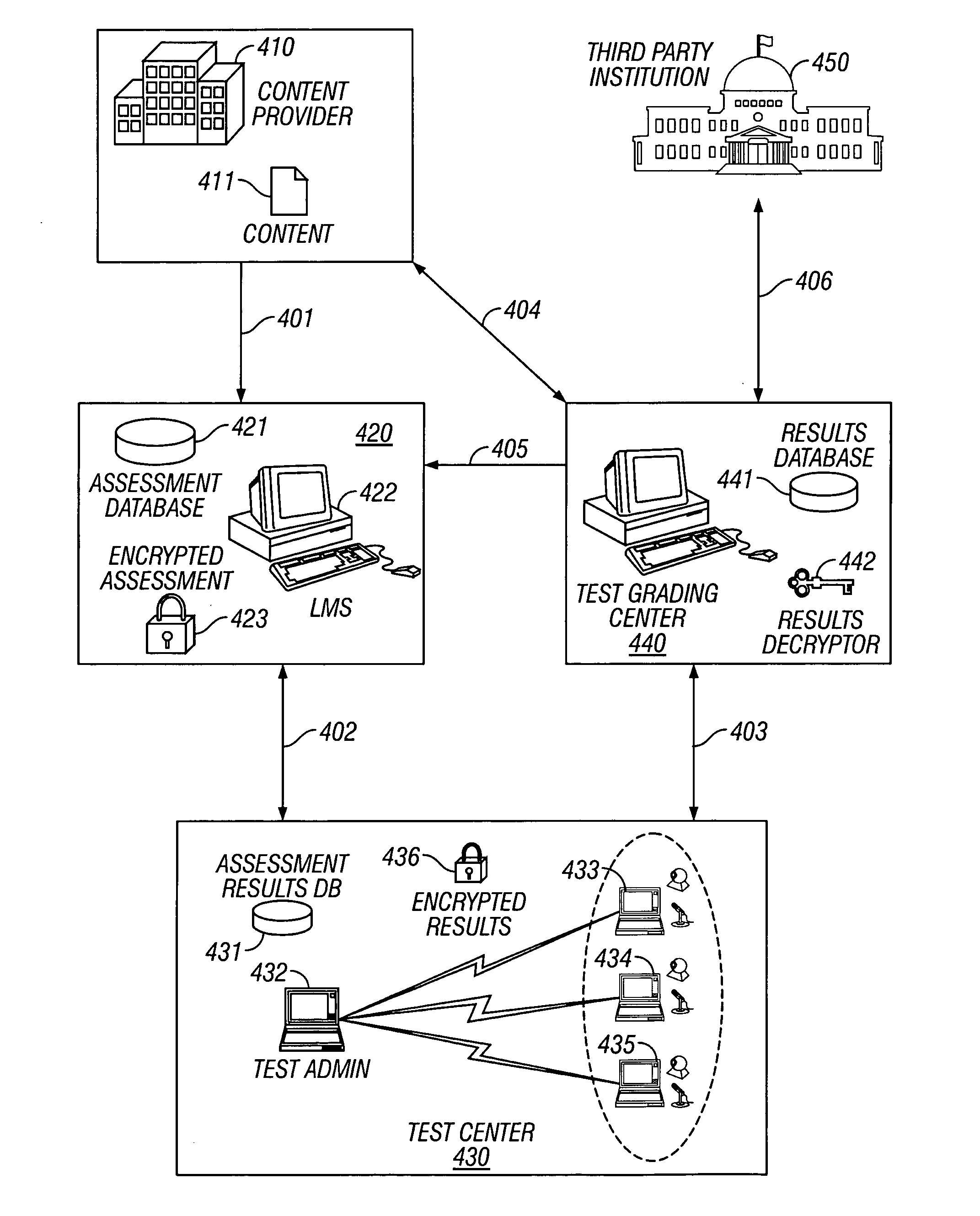

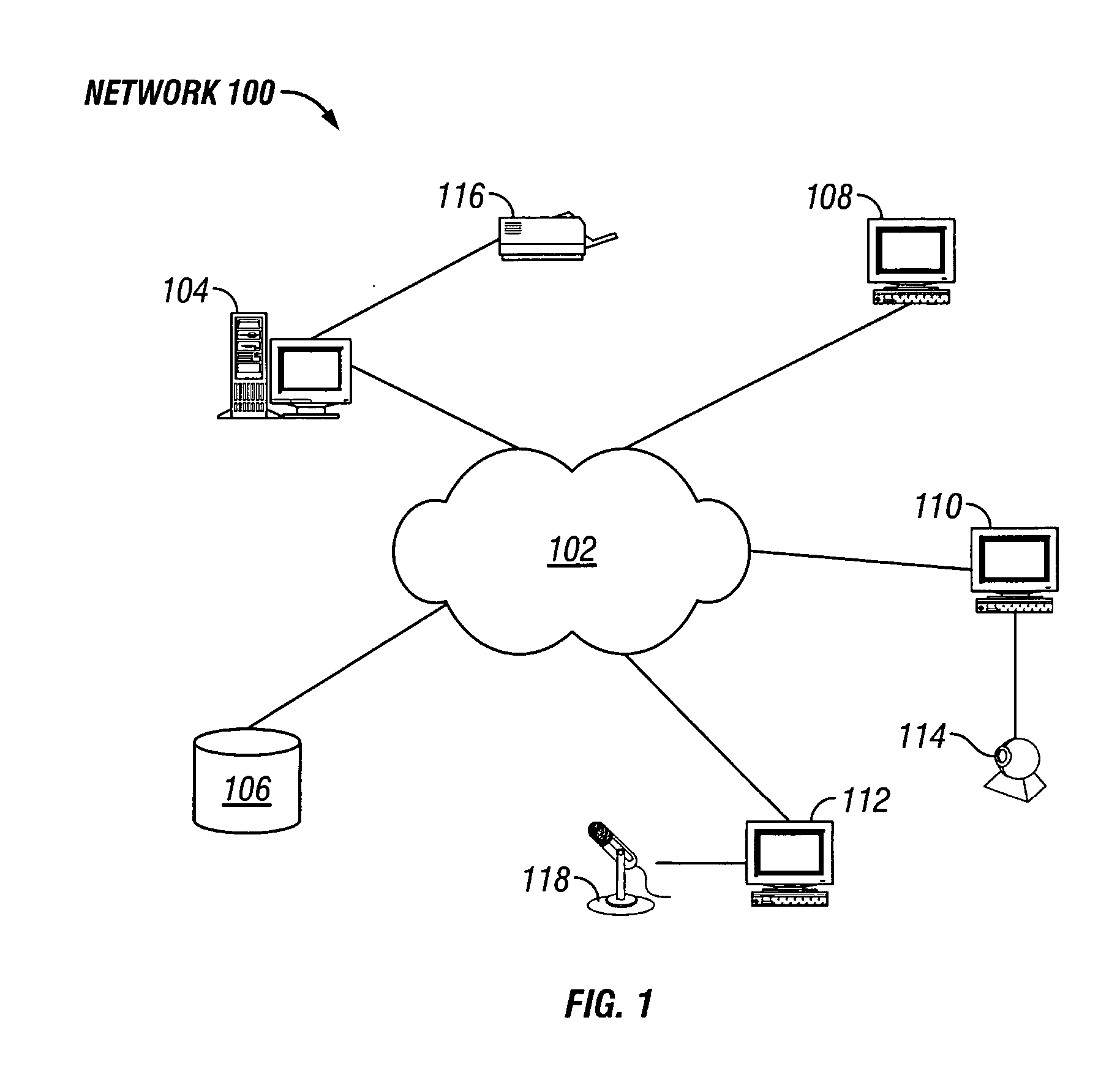

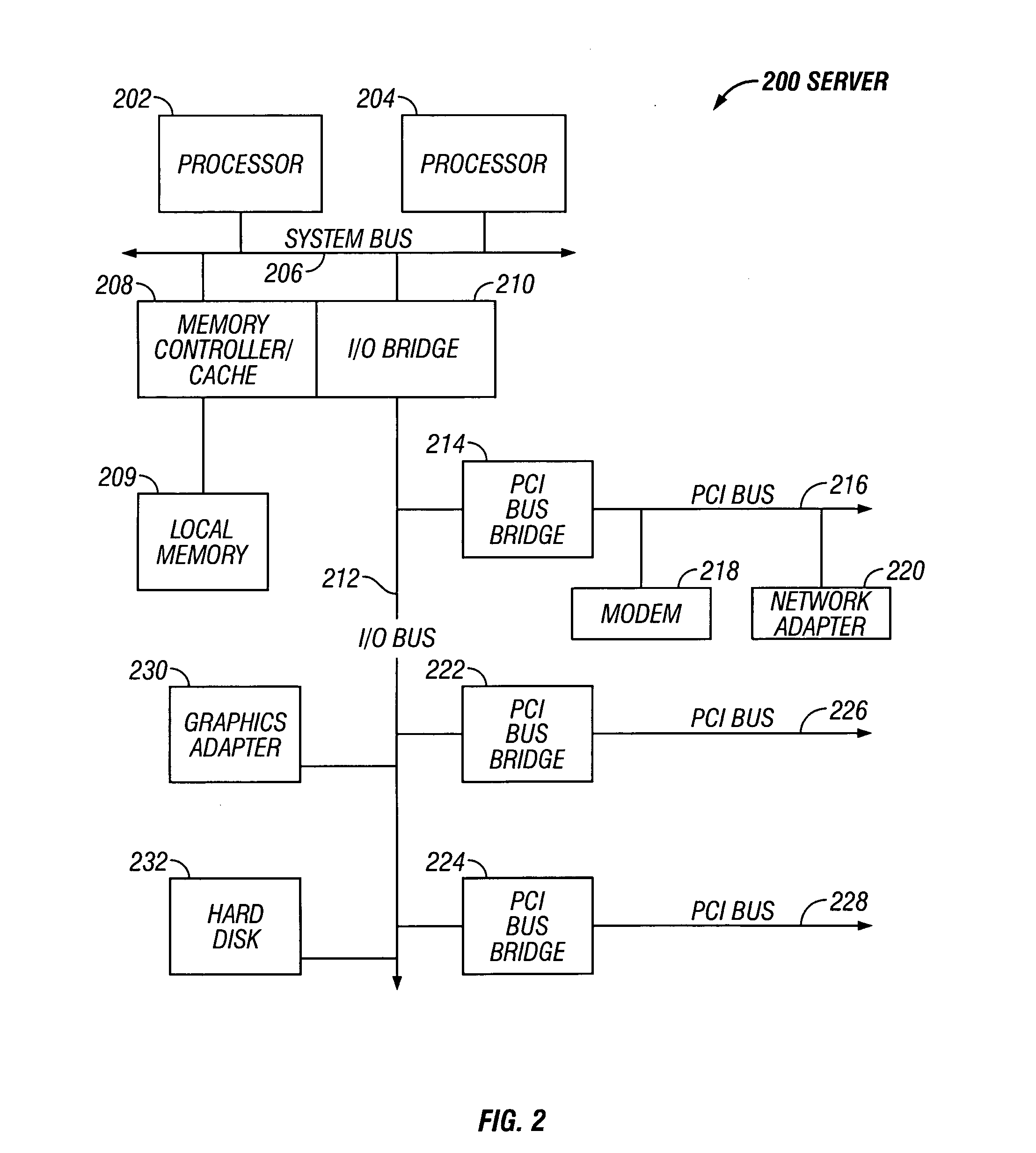

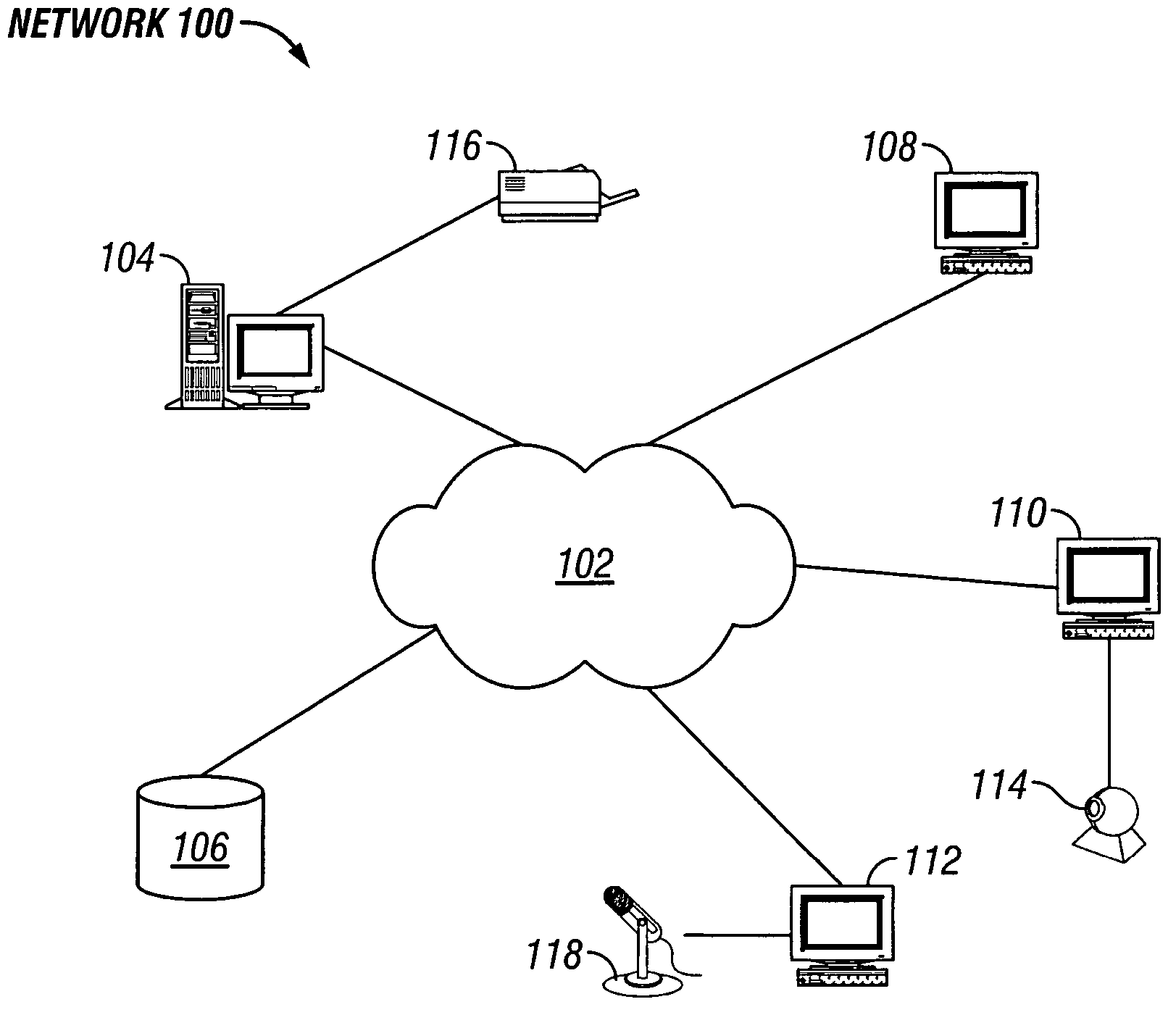

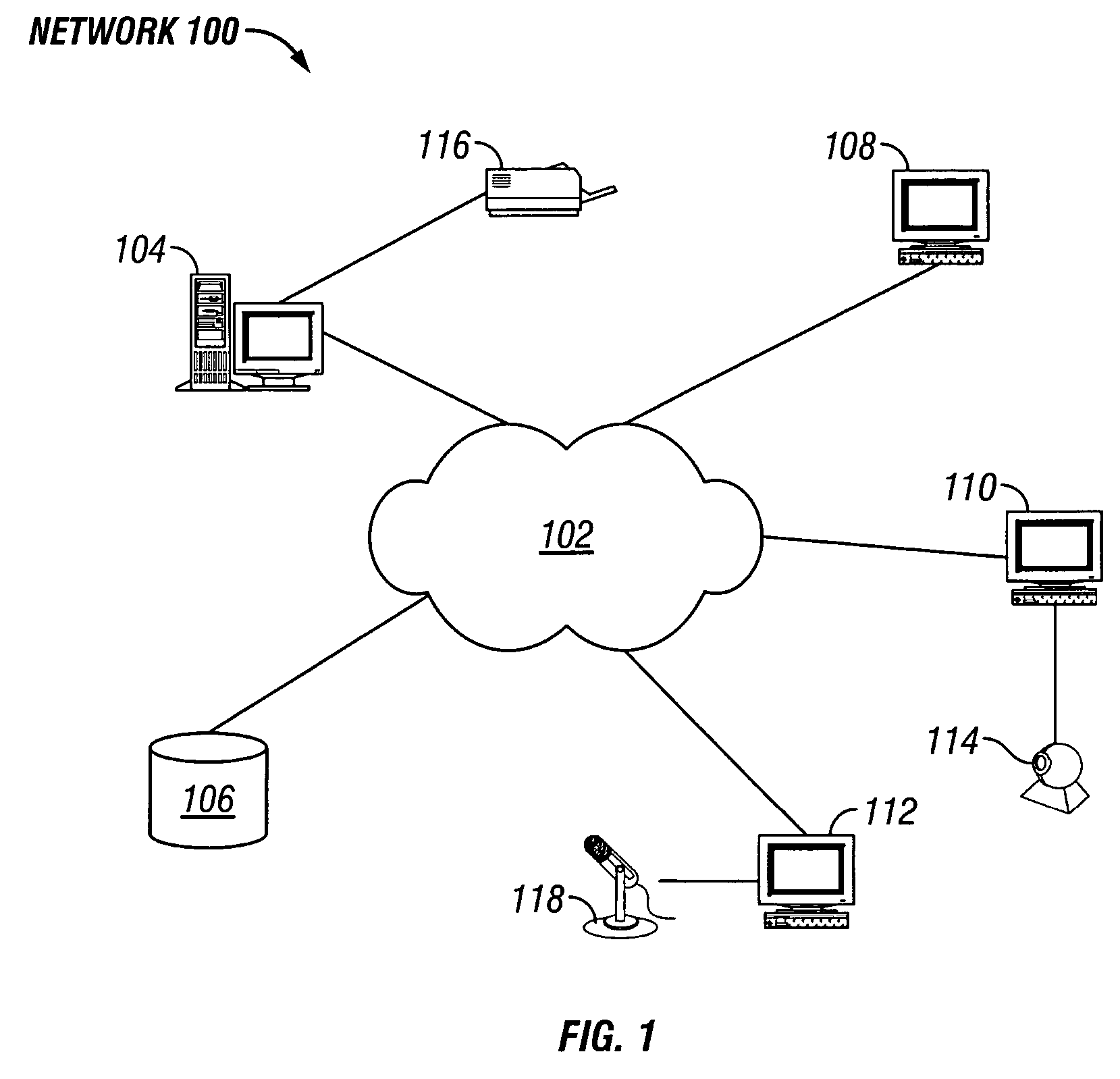

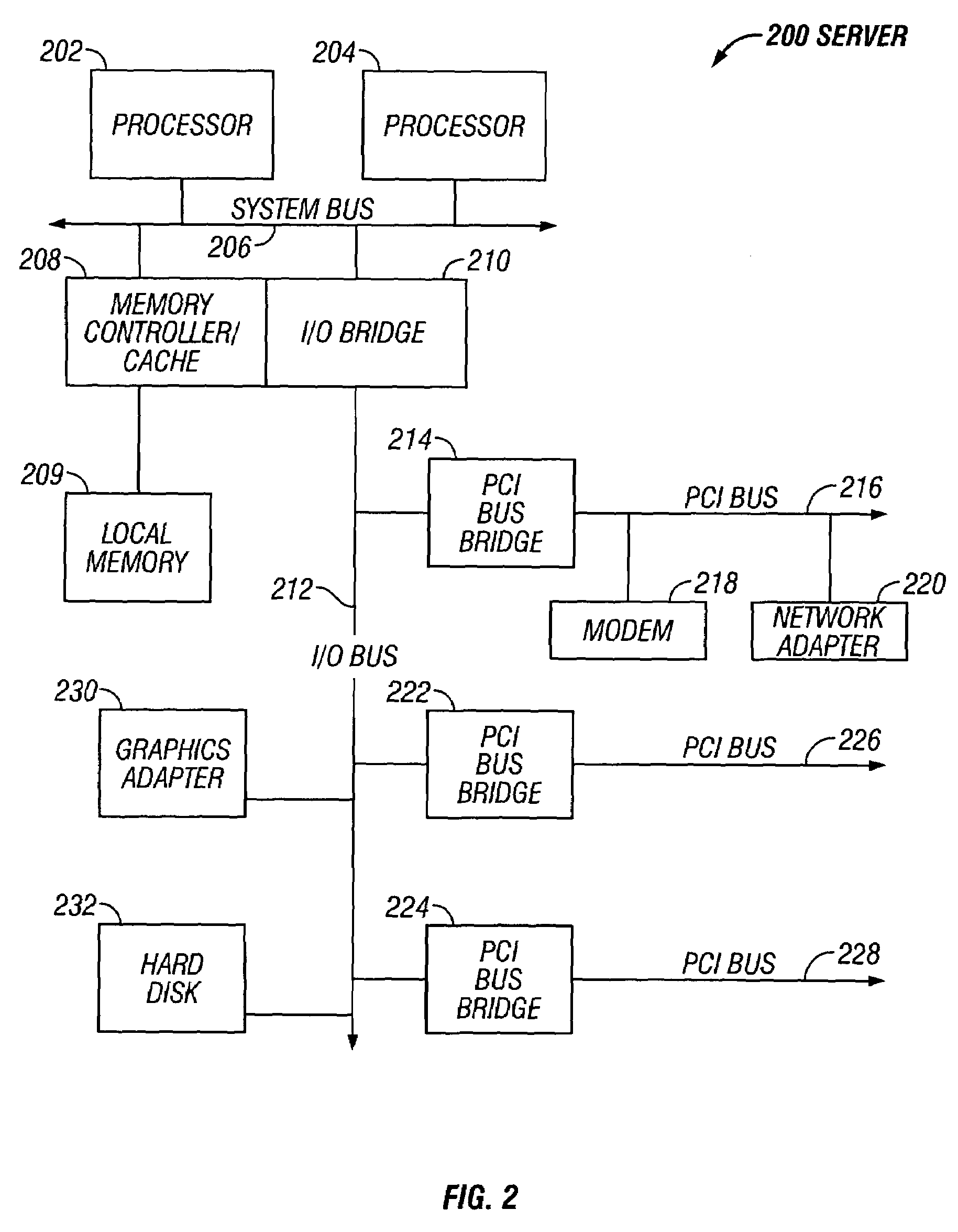

Multi-modal testing methodology

InactiveUS20050086498A1User identity/authority verificationComputer security arrangementsComputer hardwareModal testing

A method, program and system for administering tests in a distributed data processing network are provided by the present invention. The invention includes combining predetermined test content and multimedia support material into a single encrypted test file. The multimedia support may include visual and audio files for presenting test questions. The invention then exports the encrypted test file to at least one remote test location. The test locations import and decrypt the encrypted test file and load the test content and multimedia support material into a local database. The test is administered on a plurality of client workstations at the testing location, wherein the test may include audio questions and verbal responses by participants. During the course of testing biometric data about test participants is recorded and associated with the test files and participant identification. After the test is completed, the invention combines the completed test results, including verbal responses and biometric data, into a single encrypted results file and exports the encrypted results file to a remote evaluation location. The evaluation location imports and decrypts the encrypted results file and loads the test results into a local database for grading.

Owner:IP KNOWLEDGE VENTURES LLC

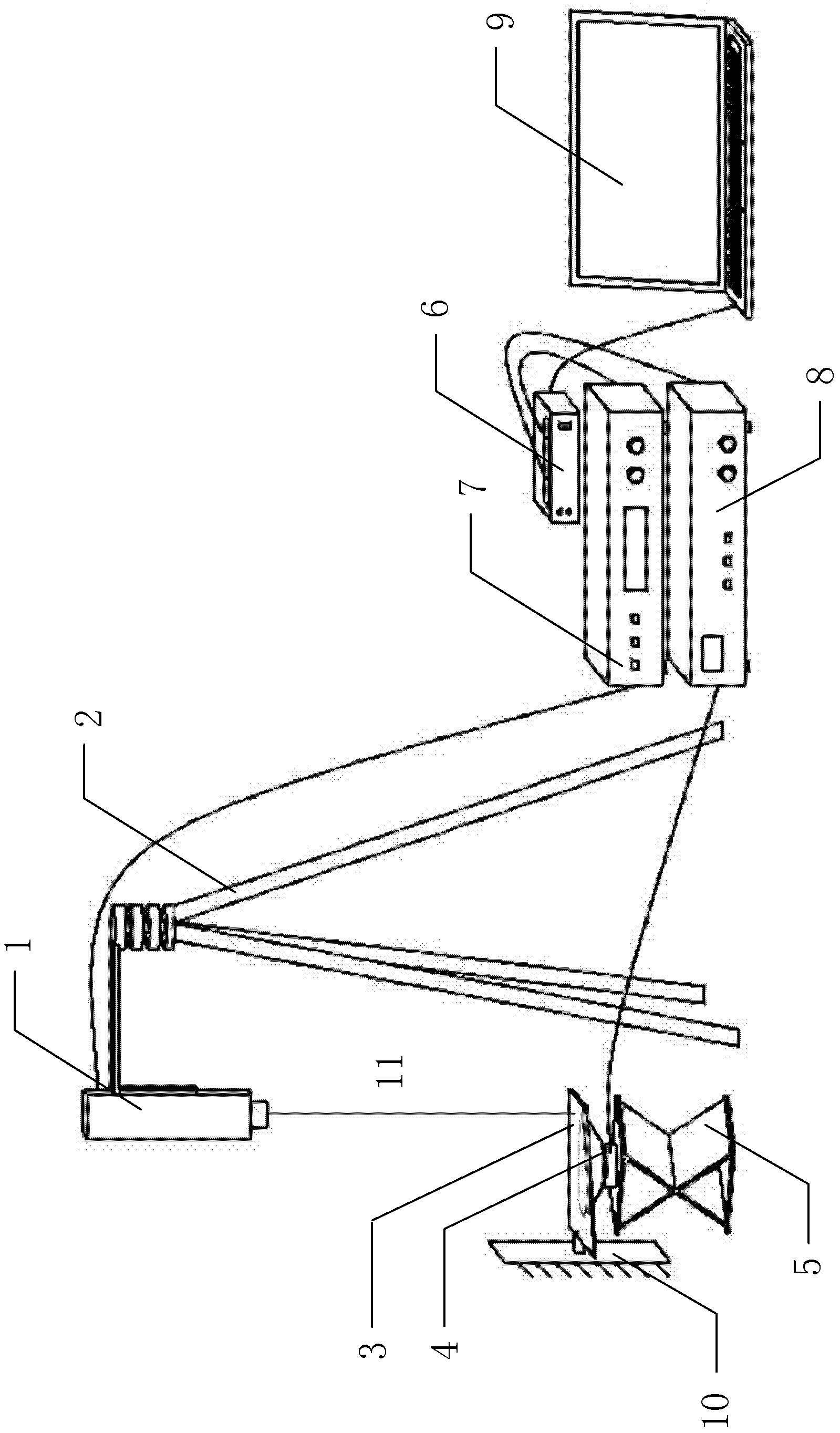

Non-contact modal test system and method

InactiveCN103048103ASubsonic/sonic/ultrasonic wave measurementUsing wave/particle radiation meansModal testingAcoustic wave

The invention relates to a non-contact modal test system and method. The method comprises the following steps: driving a shock excitation loudspeaker (4) to emit a sound wave and arousing a to-be-tested structure (3) to vibrate, wherein the shock excitation loudspeaker (4) is arranged under the to-be-tested structure (3), an upper surface of the shock excitation loudspeaker (4) is generally parallel to the to-be-tested structure (3) and a clearance is formed; and emitting laser through a laser head (1) and detecting a laser signal reflected by a to-be-tested point on the to-be-tested structure (3), wherein the laser head (1) is arranged above the to-be-tested structure (3). The non-contact modal test system and method provided by the invention have the advantages that a shock excitation source is not in contact with the to-be-tested plate structure, so that no additional mass and additional rigidity are brought to the system; a sensor (laser head) is not in contact with the to-be-tested plate structure, so that no additional mass is brought to the system; when the excitation is a sinusoidal signal, a sand molding method (placing quartz sand on the structure) is adopted for determinatively obtaining the modal frequency and vibration mode of the structure (macroscopic); and when the excitation is a white noise signal, the modal frequency and vibration mode of the structure can be analyzed and obtained by only collecting vibration signals.

Owner:BEIHANG UNIV

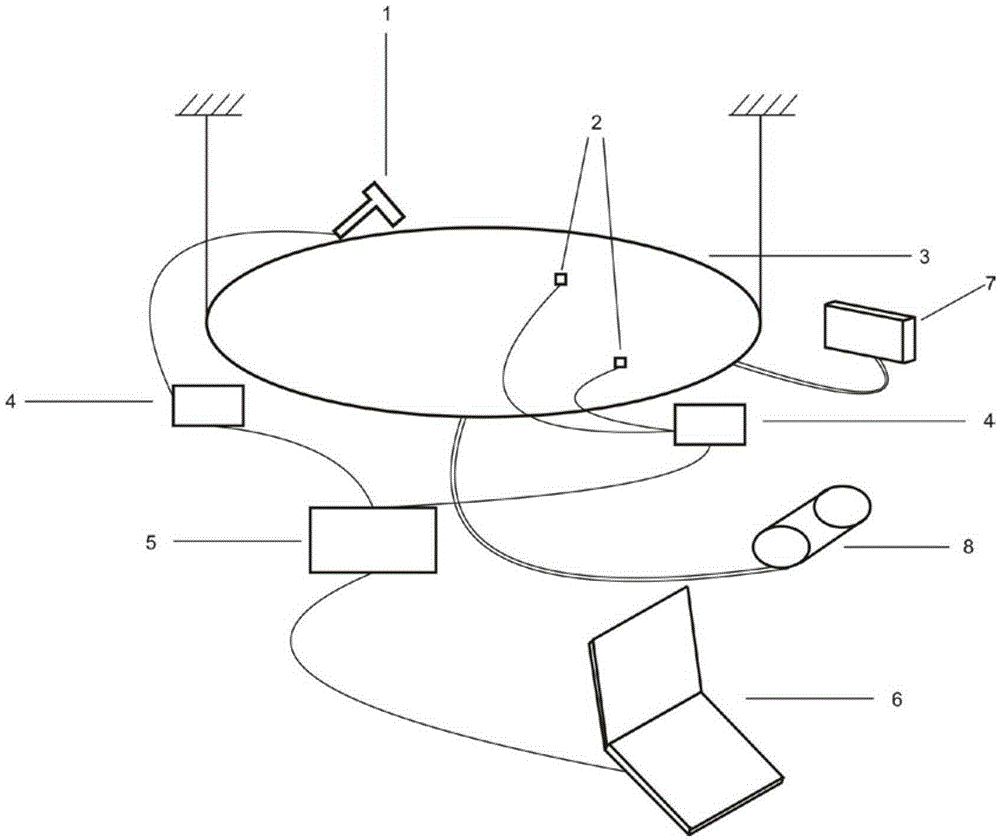

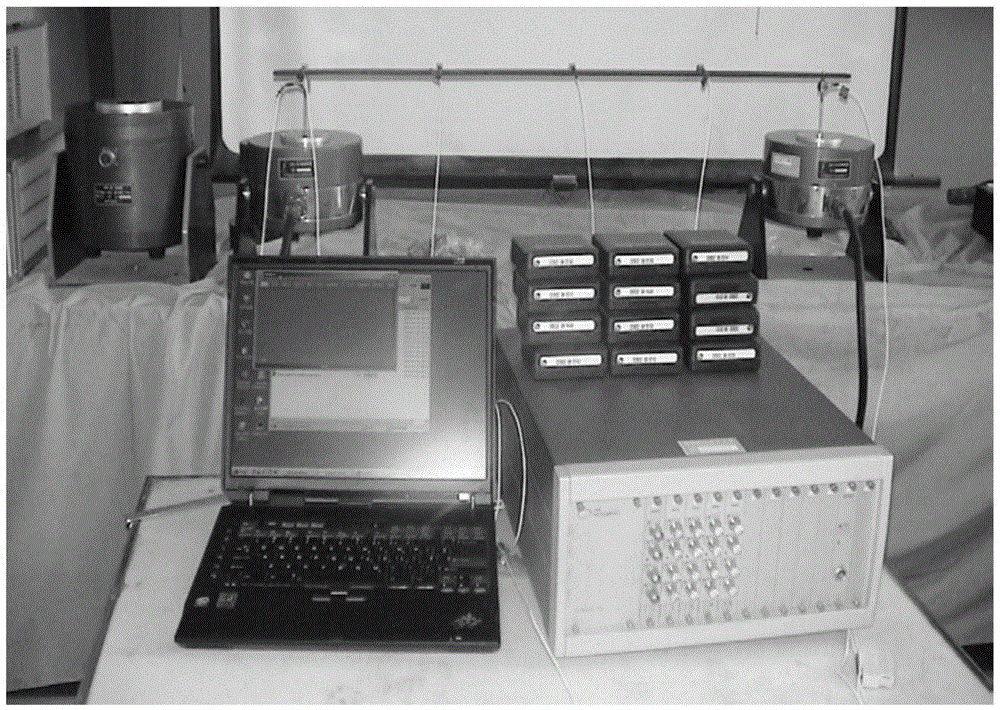

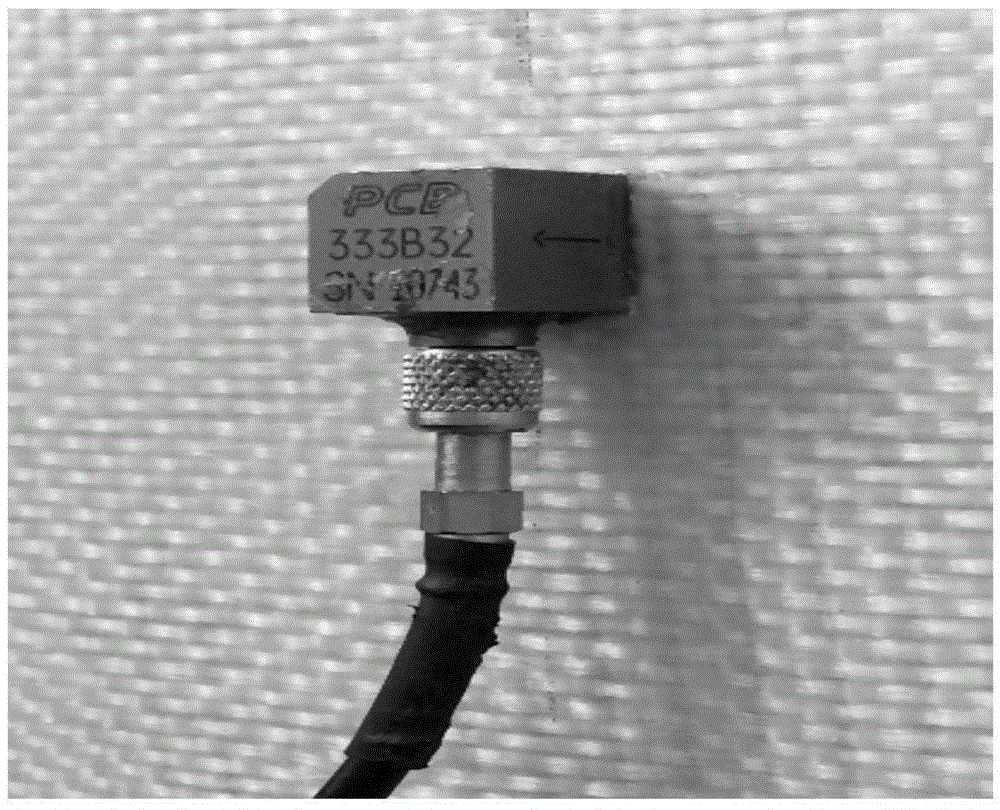

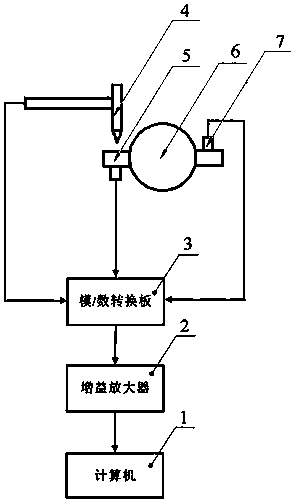

Device and method for performing modal testing on inflatable flexible film structure based on hammering excitation method

InactiveCN105424797AHigh precisionImprove reliabilityAnalysing solids using sonic/ultrasonic/infrasonic wavesModal testingAudio power amplifier

The invention discloses a device and method for performing modal testing on an inflatable flexible film structure based on a hammering excitation method. A force hammer is used for knocking a marked excitation point of the inflatable flexible film structure so as to apply vibrational excitation, a force sensor installed on the force hammer receives force signals, and an acceleration sensor installed on the surface of the inflatable flexible film structure receives acceleration signals; after the force signals and the acceleration signals are amplified by a charge amplifier, a data acquisition instrument inputs received acceleration electrical signals and force electrical signals into a computer, the computer performs digital-to-analogue conversion on the signals and obtains a frequency response function matrix according to the force signals and the acceleration signals, and finally modal vibration shapes of all orders and related modal parameters of the structure are obtained through parameter identification. Thus, modal numerical simulation of the inflatable flexible film structure can be verified and provided with reference. The device is simple in structure, convenient to operate and wide in application range.

Owner:BEIHANG UNIV +2

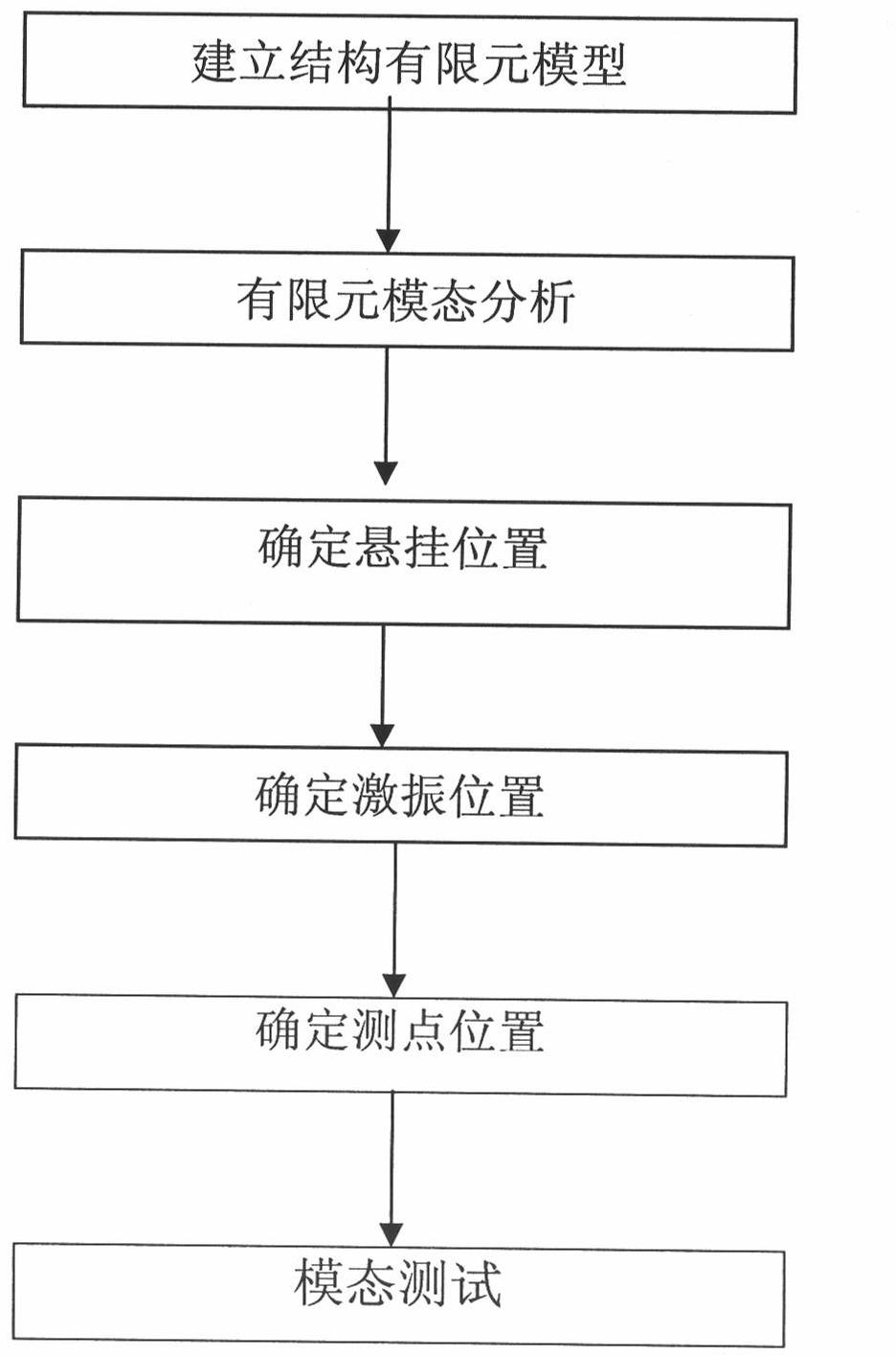

Method for testing vibration mode

InactiveCN102135466AImprove recognition accuracyImprove reliabilityVibration testingSpecial data processing applicationsModal testingElement model

The invention discloses a method for testing a vibration mode. The method comprises the following steps of: determining the optimal hanging position, the optimal excitation position and the optimal testing point during structure mode test by establishing a finite element model of the structure and analyzing the finite element model; during excitation position determination, providing two corresponding methods for determining the excitation position respectively as for excitation by an exciter method and excitation by a hammering method; and finally, hanging the structure to be tested at the determined optical hanging position, exciting the structure at the determined excitation position by the hammering method or the exciter method, and arranging a sensor to perform the mode test on the structure at the determined testing point position. By the method, the identification precision and the reliability of mode parameters can be improved effectively, the test cost is reduced, and the test cycle is shortened.

Owner:AECC AVIATION POWER CO LTD

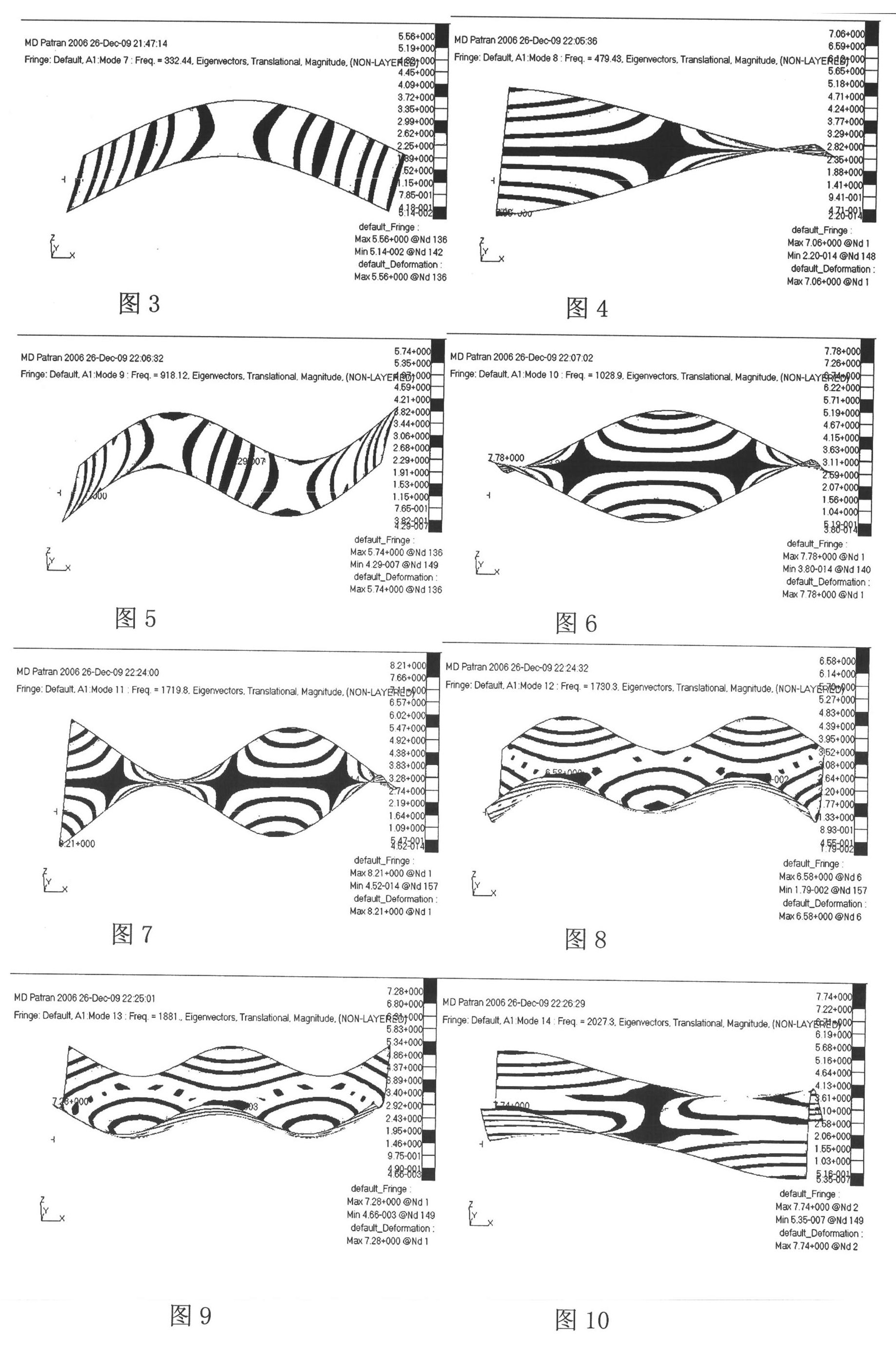

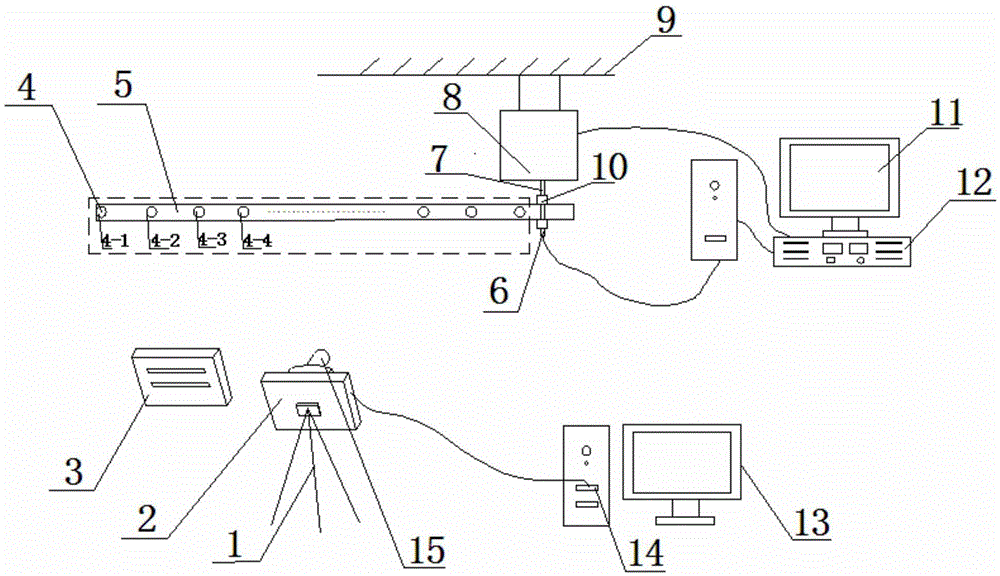

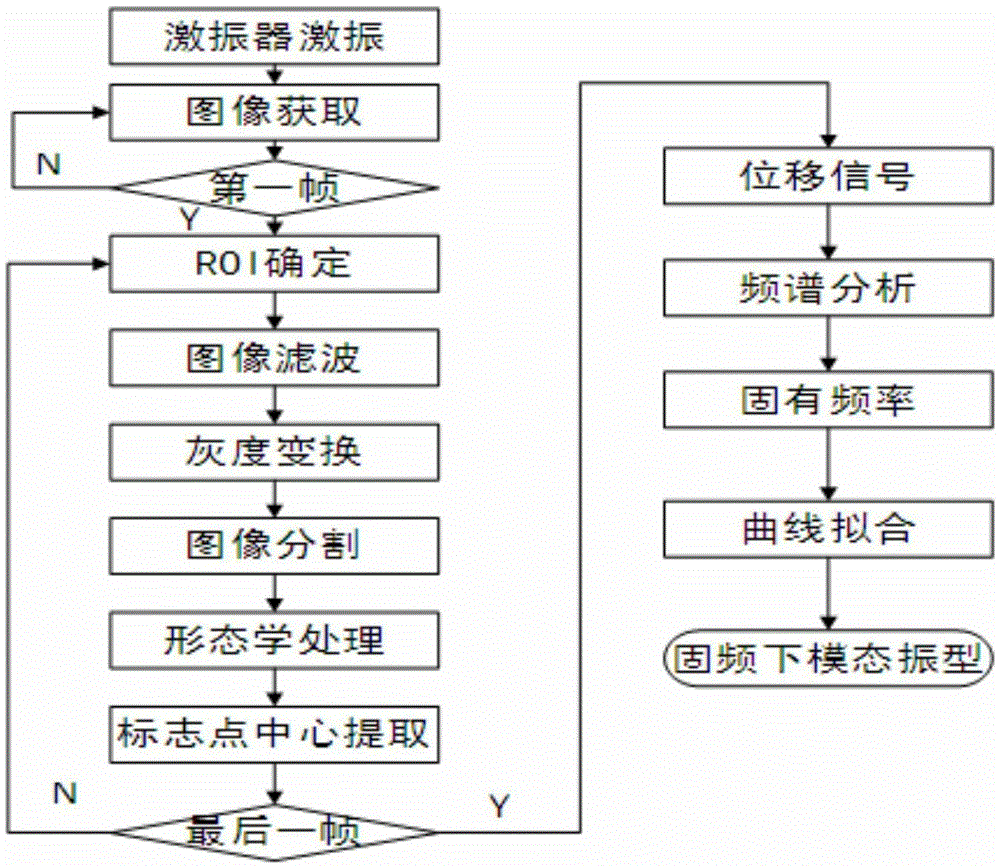

Method and system for thin-wall part modal testing based on machine vision

ActiveCN105424350AGuaranteed accuracyImprove spatial resolutionMachine part testingSubsonic/sonic/ultrasonic wave measurementModal testingConstant frequency

The invention discloses a method and system for thin-wall part modal testing based on machine vision. The method for the thin-wall part modal testing comprises the steps that a to-be-tested thin-wall part is fixed on an excitation head of an exciter and the to-be-tested thin-wall part is driven to perform equal-frequency vibration; meanwhile, a CCD industrial camera is used to continuously collect images of a vibration course of the thin-wall part; image processing is carried out to acquired sequence images so as to obtain an inherent frequency; the constant-frequency vibration of the thin-wall part is carried out under the inherent frequency; the continuous sequence images under the constant-frequency vibration are acquired; the image processing is carried out to the acquired continuous sequence images; and further a modal shape under the inherent frequency is obtained. The system disclosed by the invention has the advantages of a flexible structure; a complicated debugging course is not required; only low requirements are proposed for surface quality of the thin-wall part; non-contact measurement is carried out; vibration characteristics of a tested object are not changed; and the system has the advantages of high measurement precision and high efficiency, etc.

Owner:HUNAN UNIV OF SCI & TECH

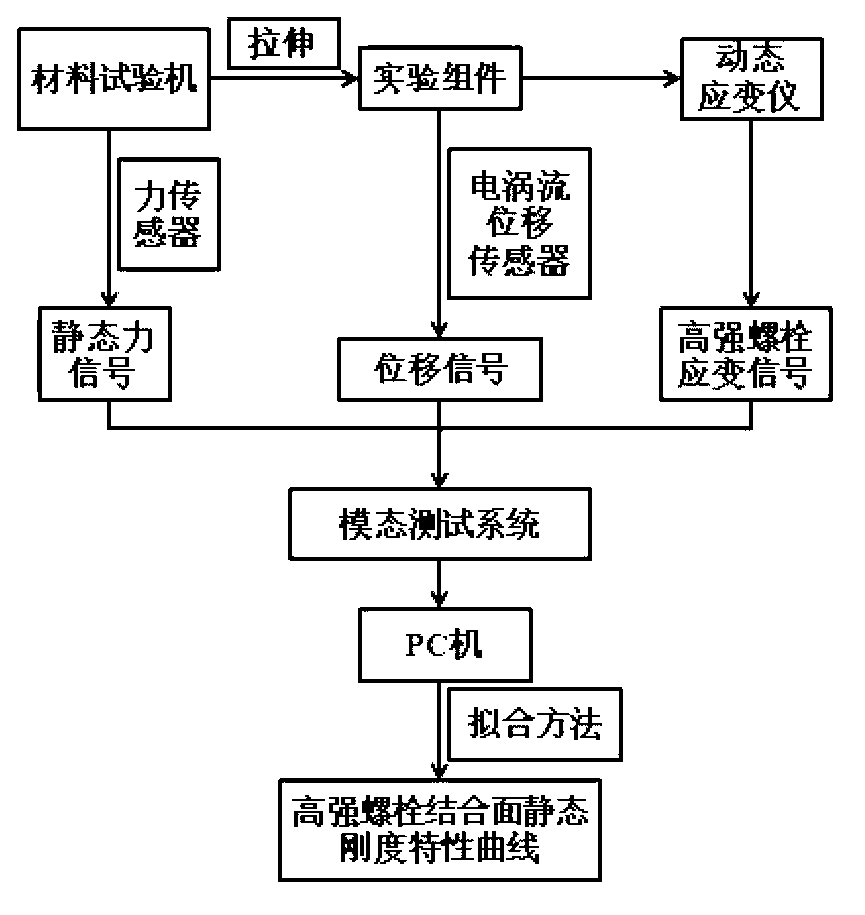

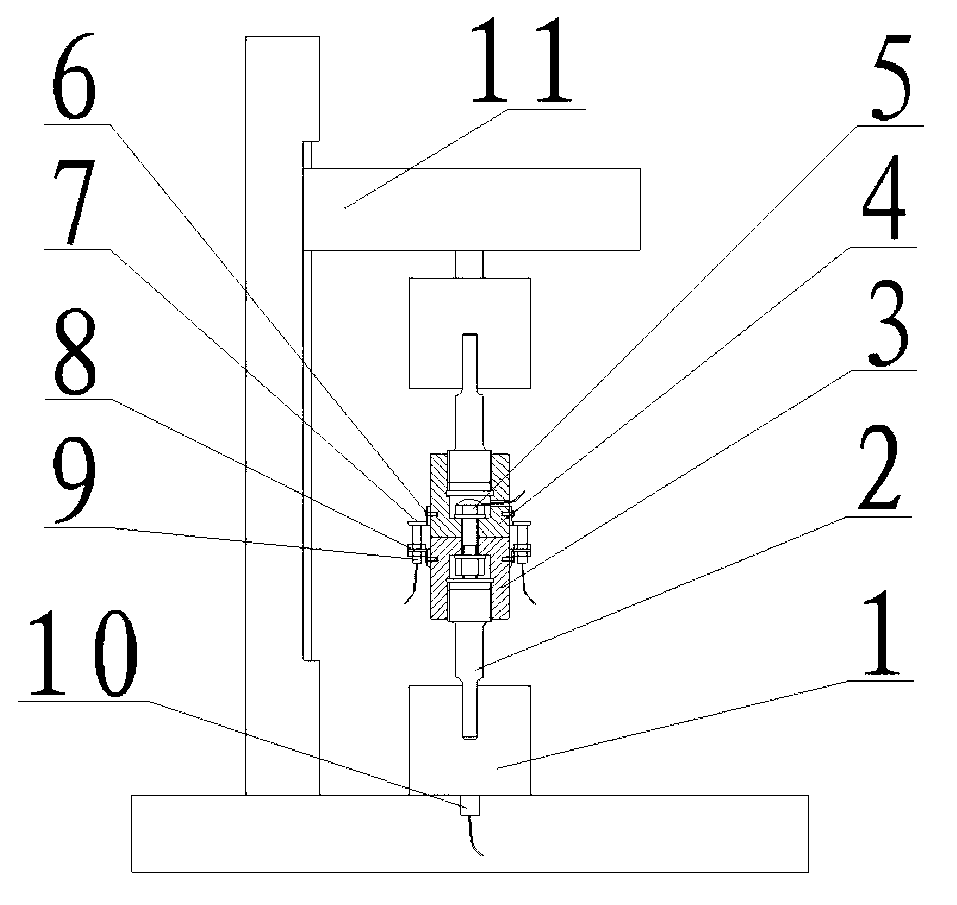

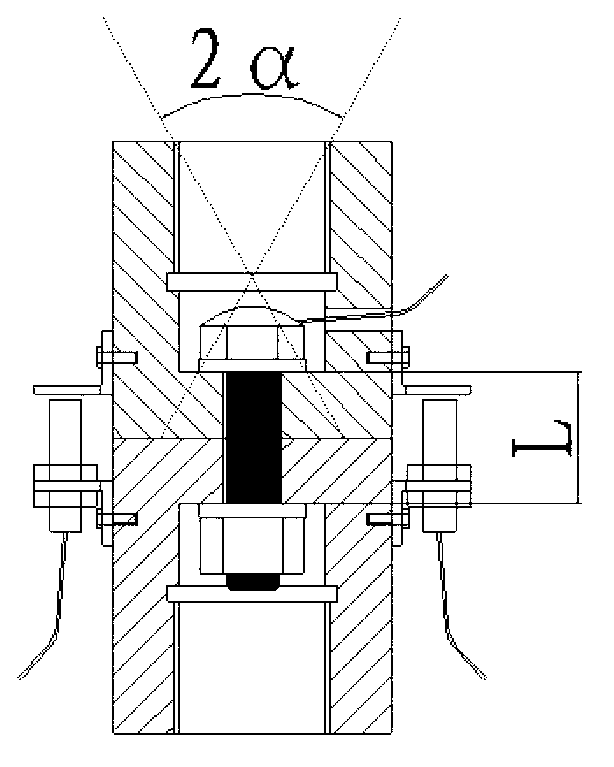

Device and method for testing normal static characteristics of junction surface of high-strength bolt

The invention discloses a device and a method for testing normal static characteristics of a junction surface of a high-strength bolt. The device for testing the normal static characteristics of the junction surface of the high-strength bolt comprises a material testing machine, two screws, a lower test piece, an upper test piece, the high-strength bolt, a slotless locating support, a slotted locating support, an eddy current displacement sensor, a force sensor, a dynamic strain indicator, a modal testing system and a personal computer (PC) machine. The high-strength bolt penetrates through the upper test piece and the lower test piece in a vertical mode so that the upper test piece and the lower test piece are mutually attached to form the junction surface, and a strain gage is embedded in the high-strength bolt. The eddy current displacement sensor is used for measuring the normal displacement variable quantity of the junction surface. The upper test piece and the lower piece are respectively connected with the material testing machine through the two screws. The material testing machine carries the force sensor and exerts static tensile force on the upper test piece and the lower test piece along the longitudinal direction. The dynamic strain indicator for measuring the pretightening force and a strain signal of the high-strength bolt, the eddy current displacement sensor for measuring the normal displacement variable quantity of the junction surface, and the force sensor for measuring a static force signal output self-signals to the modal testing system, and then the signals are transmitted to the PC machine.

Owner:BEIJING UNIV OF TECH

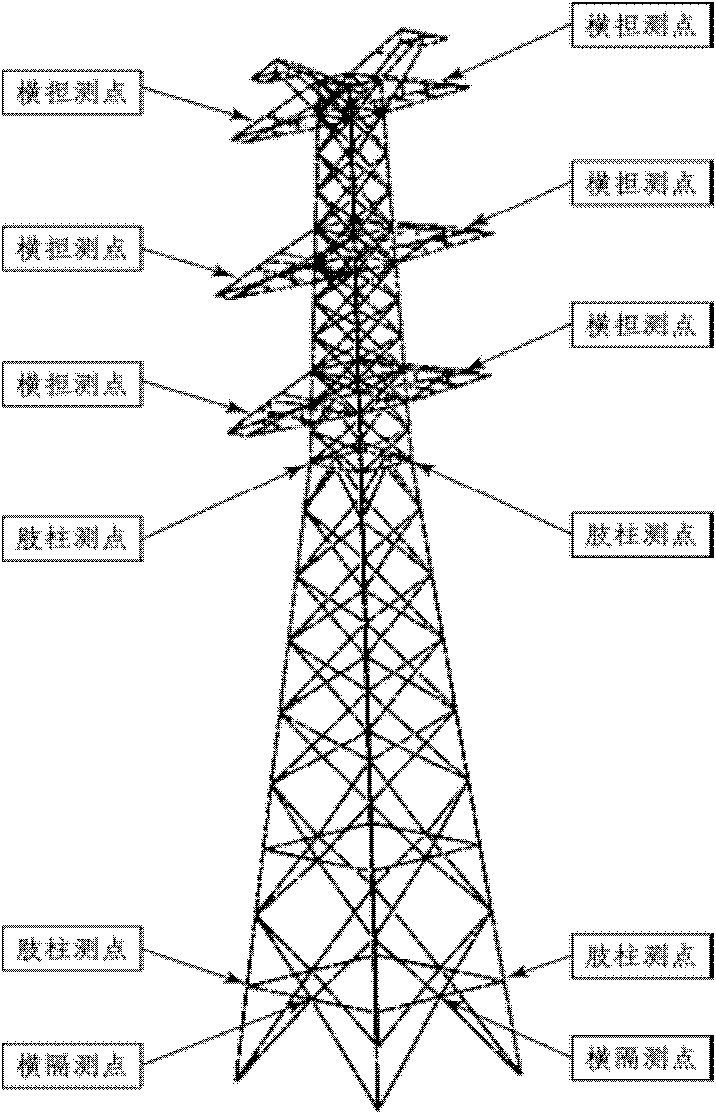

Test system and method for mode and vibration of self-supporting tower and large-span power transmission tower

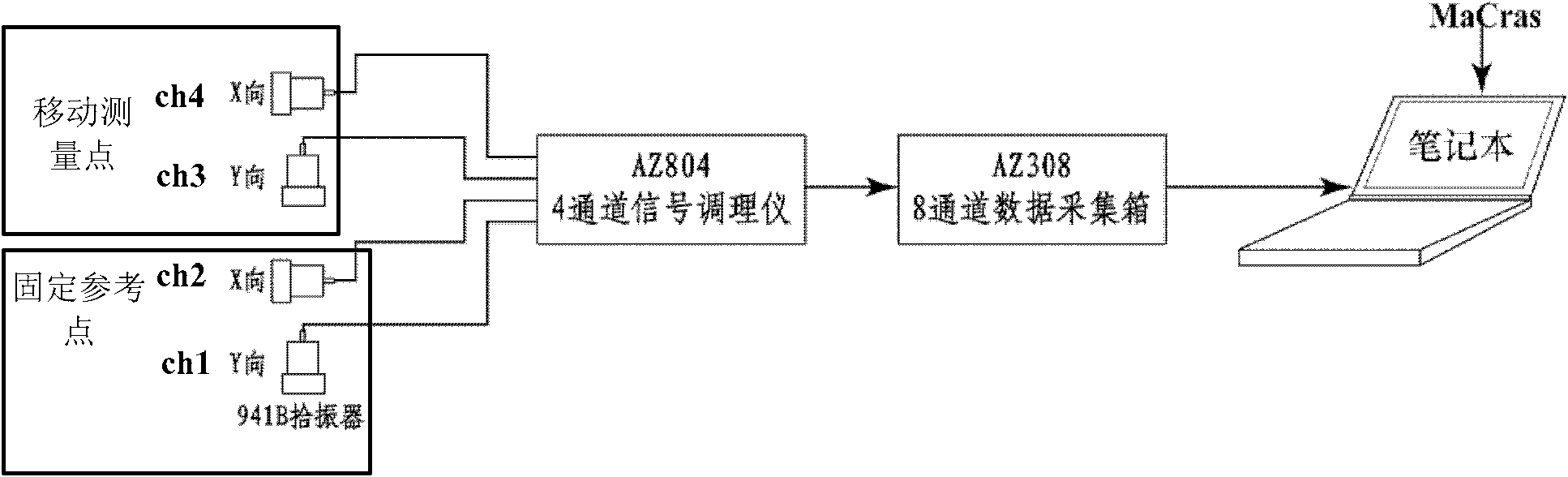

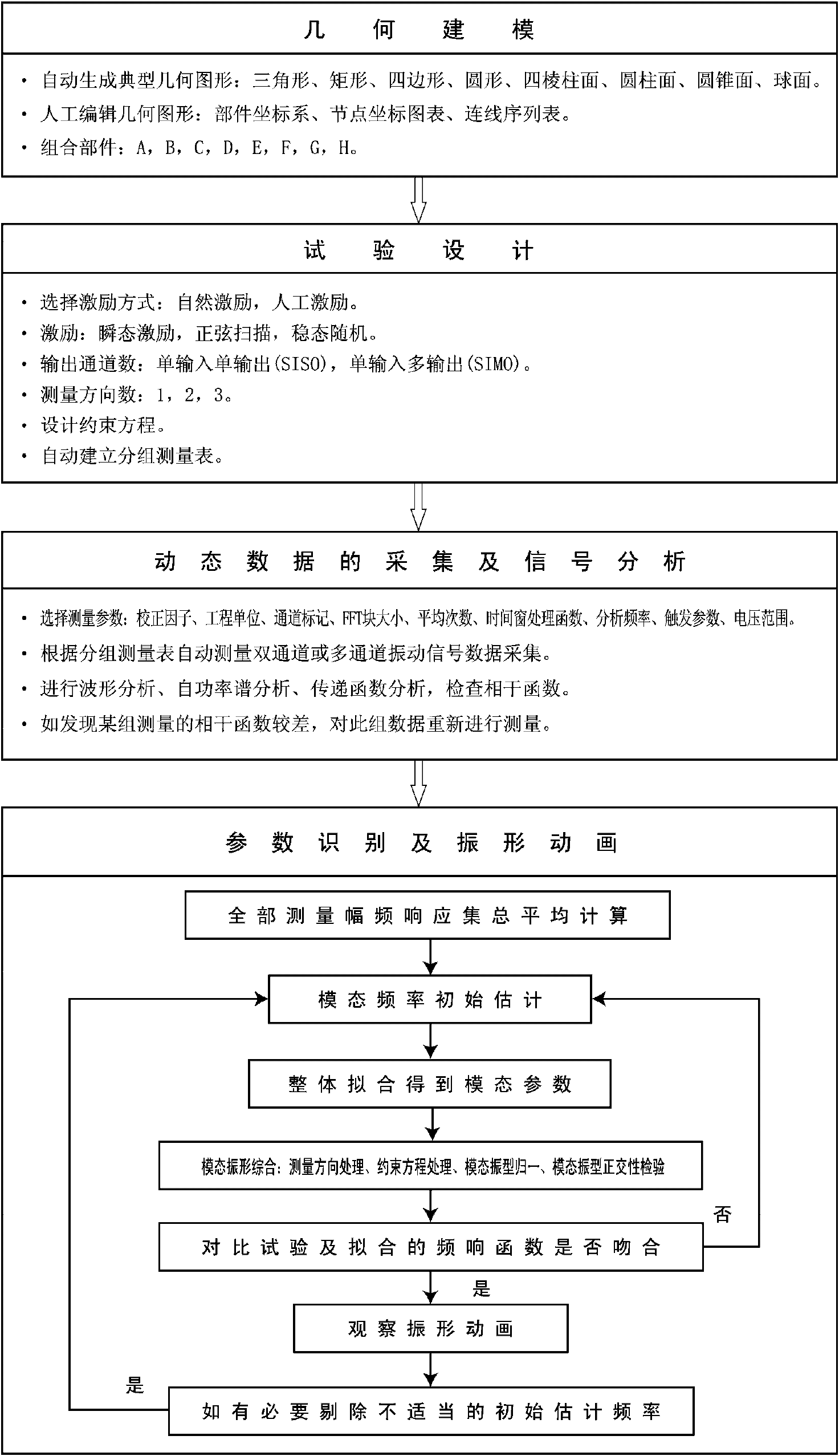

The invention discloses a test system and method for mode and vibration of a self-supporting tower and a large-span power transmission tower. The test system is characterized by comprising a sensor, wherein the sensor is connected with a signal conditioner; the signal conditioner is connected with a digital signal collecting box; a digital signal collector is connected with a computer; the digital signal collector is provided with eight channels; and an auto-power spectrum analysis module, a cross-power spectrum analysis module and an environmental motivation mode analysis module are arranged in the computer. On the basis of an environmental motivation method, a method for fixing a reference point and moving a measured point is utilized to test mode parameters and vibration of a soaring power transmission tower. Besides, corresponding hardware equipment and software programs are utilized to ensure that the environmental motivation method can be used for performing off-line mode test and analysis for a power transmission tower model.

Owner:JIANGSU FRONTIER ELECTRIC TECH +2

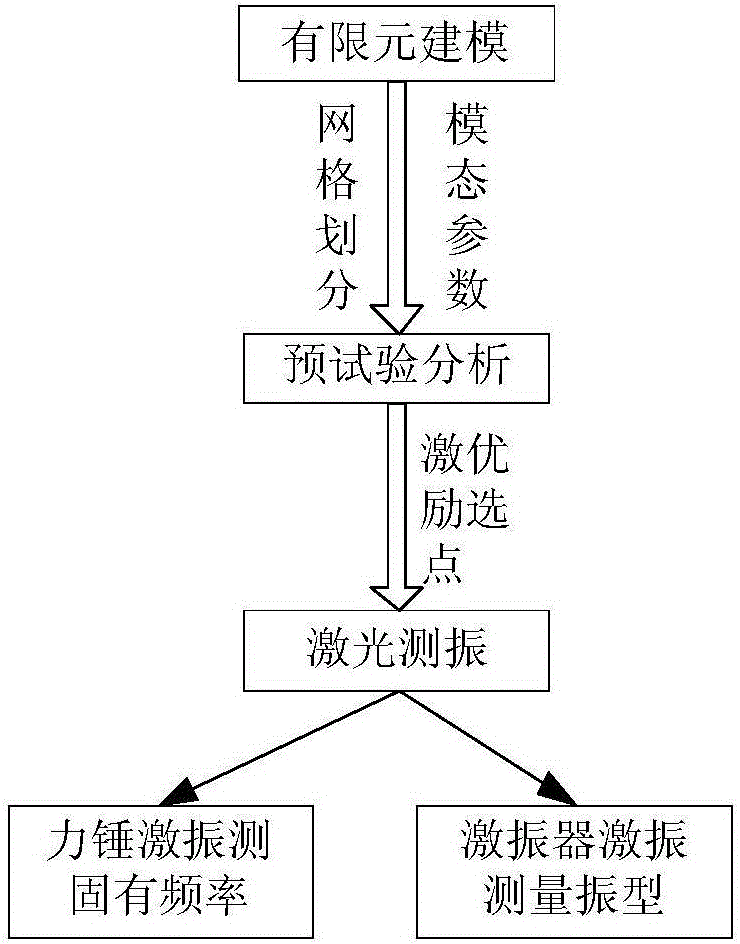

Small impeller mode testing method based on exciting point optimization and vibration measurement with laser

InactiveCN106596011ASolving Modal Testing ChallengesOvercome the problem of additional quality impactVibration testingVibration measurementModal testing

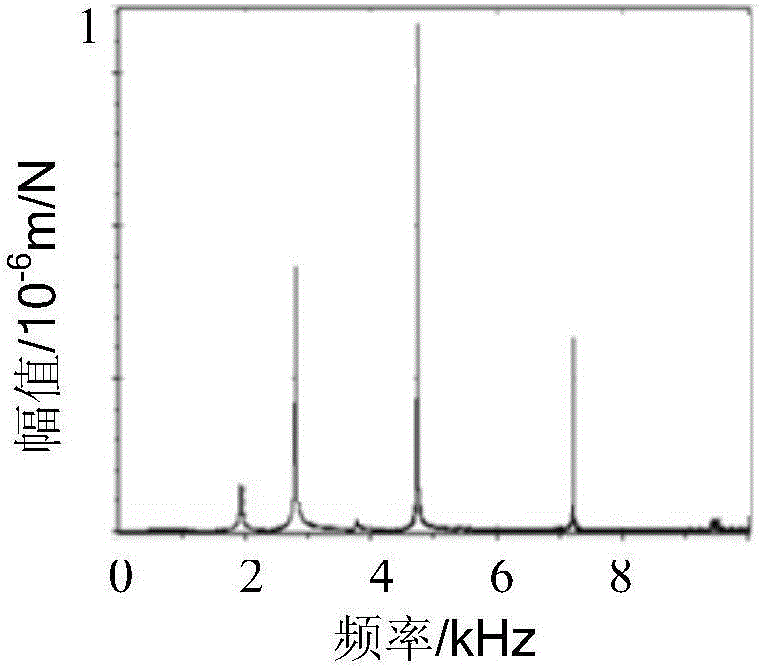

The invention discloses a small impeller mode testing method based on exciting point optimization and vibration measurement with laser. With the method, a technical problem of low testing precision of the existing small impeller mode testing method can be solved. The method is characterized in that an inherent frequency and a vibration mode of an impeller are obtained by finite element stimulation calculation; a mesh division model and a mode calculation result of the impeller are introduced into LMS Virtual.lab software to carry out a preliminary test analysis; and an impeller mode exciting position is selected preferably by using a driving point residue (DPR) method. An impeller is fixed at a support elastically; morphological data of a plate and blades are obtained by using a morphological scanning unit of a laser vibration measurement instrument; and a scanning region is defined at an image directly and point distribution is carried out. With a single-point hammering method, a vibration response signal on the free boundary condition is obtained; the inherent frequency of the impeller is measured; and point-to-point scanning is carried out by using an exciter on the condition of single-frequency shock excitation so as to obtain all-order vibration. Therefore, the testing precision can be improved.

Owner:中国船舶重工集团公司第七0五研究所

System and method for detecting structural damage

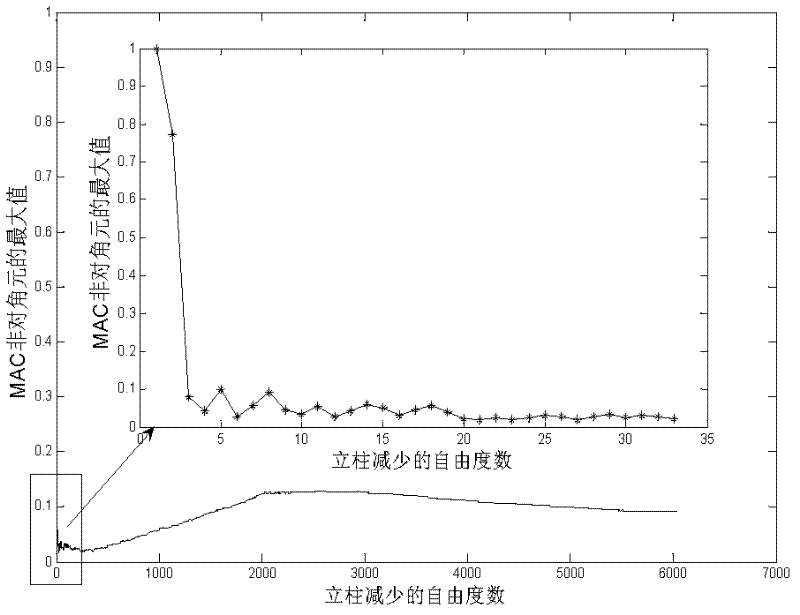

ActiveUS20080294354A1The degree of freedom becomes largerVibration measurement in solidsAnalysing solids using sonic/ultrasonic/infrasonic wavesModal testingSignal-to-noise ratio (imaging)

A system and method for detecting structural damage is provided that utilizes a general order perturbation methodology involving multiple perturbation parameters. The perturbation methodology is used iteratively in conjunction with an optimization method to identify the stiffness parameters of structures using natural frequencies and / or mode shape information. The stiffness parameters are then used to determine the location and extent of damage in a structure. A novel stochastic model is developed to model the random impact series produced manually or to generate a random impact series in a random impact device. The random impact series method or the random impact device can be used to excite a structure and generate vibration information used to obtain the stiffness parameters of the structure. The method or the device can also just be used for modal testing purposes. The random impact device is a high energy, random, and high signal-to-noise ratio system.

Owner:UNIV OF MARYLAND BALTIMORE COUNTY

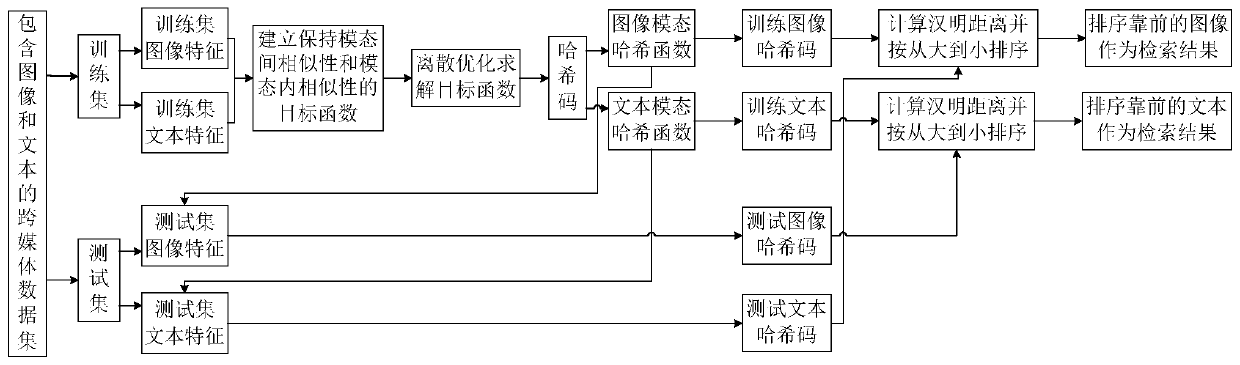

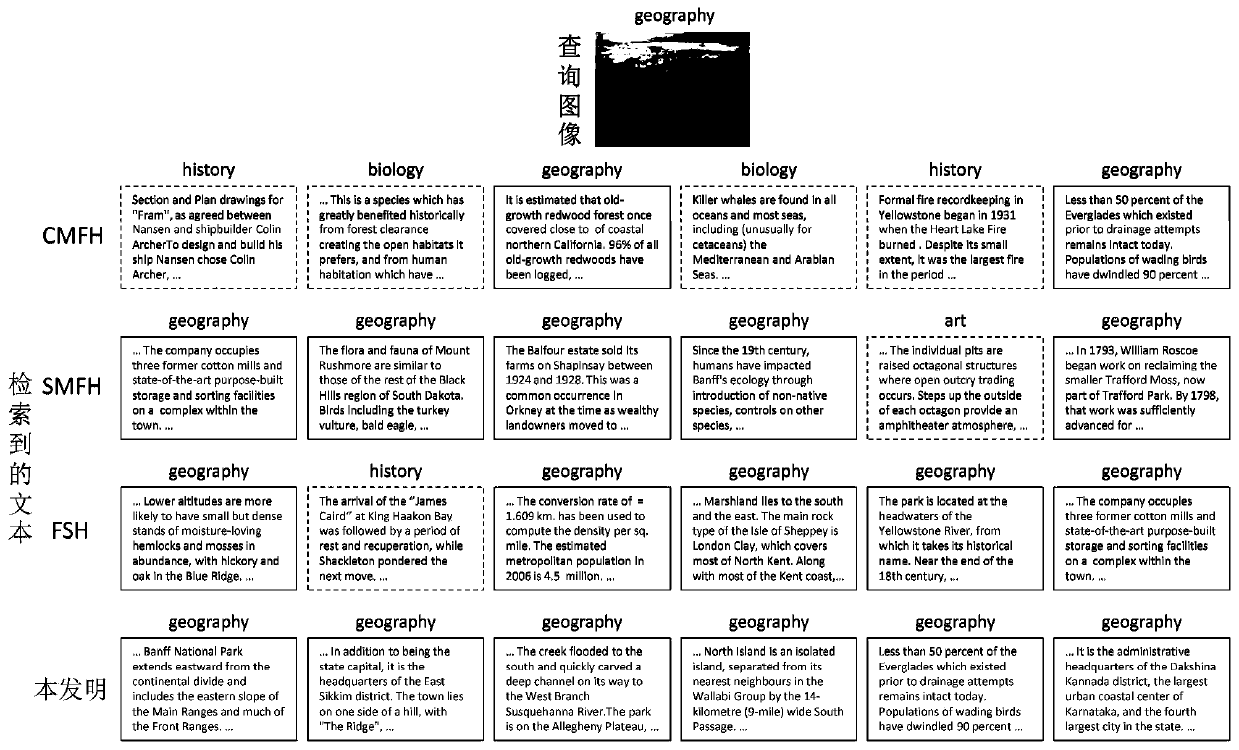

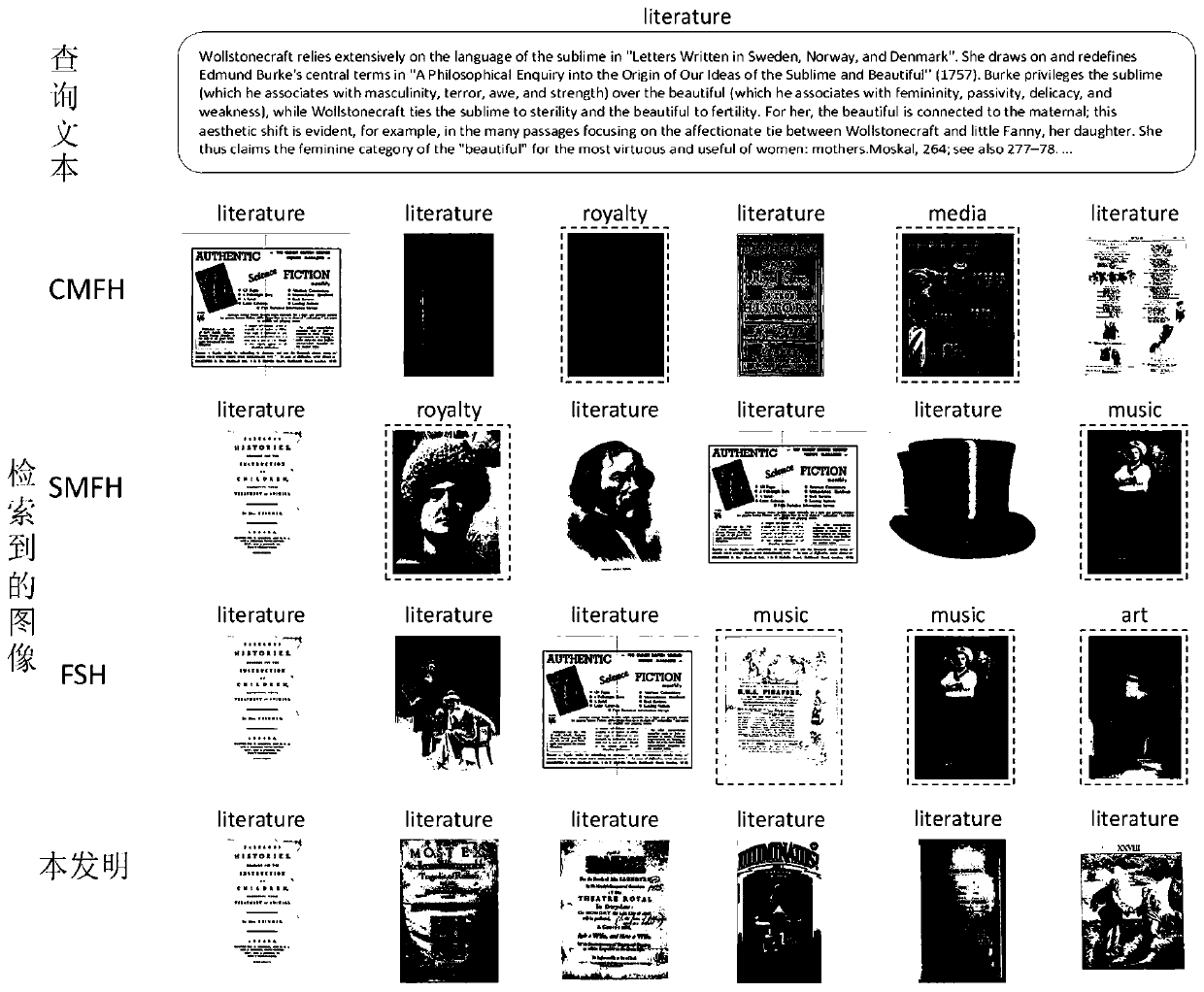

Cross-modal data discrete hash retrieval method based on similarity maintenance

ActiveCN110059198ATroubleshoot data retrieval issuesImprove accuracyMultimedia data indexingMultimedia data queryingModal testingCross modality

The invention discloses a cross-modal data discrete hash retrieval method based on similarity preservation. The method comprises the following steps of establishing a cross-modal retrieval data set composed of samples containing two modalities, and dividing the cross-modal retrieval data set into a training set and a test set; establishing an objective function for keeping similarity between modalities and similarity in modalities, and solving the objective function through a discrete optimization method to obtain a hash code matrix; learning a Hash function of each mode according to the Hashcode matrix; calculating Hash codes of all samples in the training set and the test set by using a Hash function; wherein one modal test set serves as a query set and the other modal training set serves as a retrieval set, calculating the Hamming distance between the Hash codes of the samples in the query set and the Hash codes of the samples in the retrieval set, wherein the sequence serves as aretrieval result. According to the method, the similarity between modalities and the similarity in the modalities can be effectively kept, the discrete characteristics of the Hash codes are considered, a discrete optimization method is adopted for solving the objective function, and therefore the cross-modality retrieval accuracy is improved.

Owner:ZHEJIANG UNIV +1

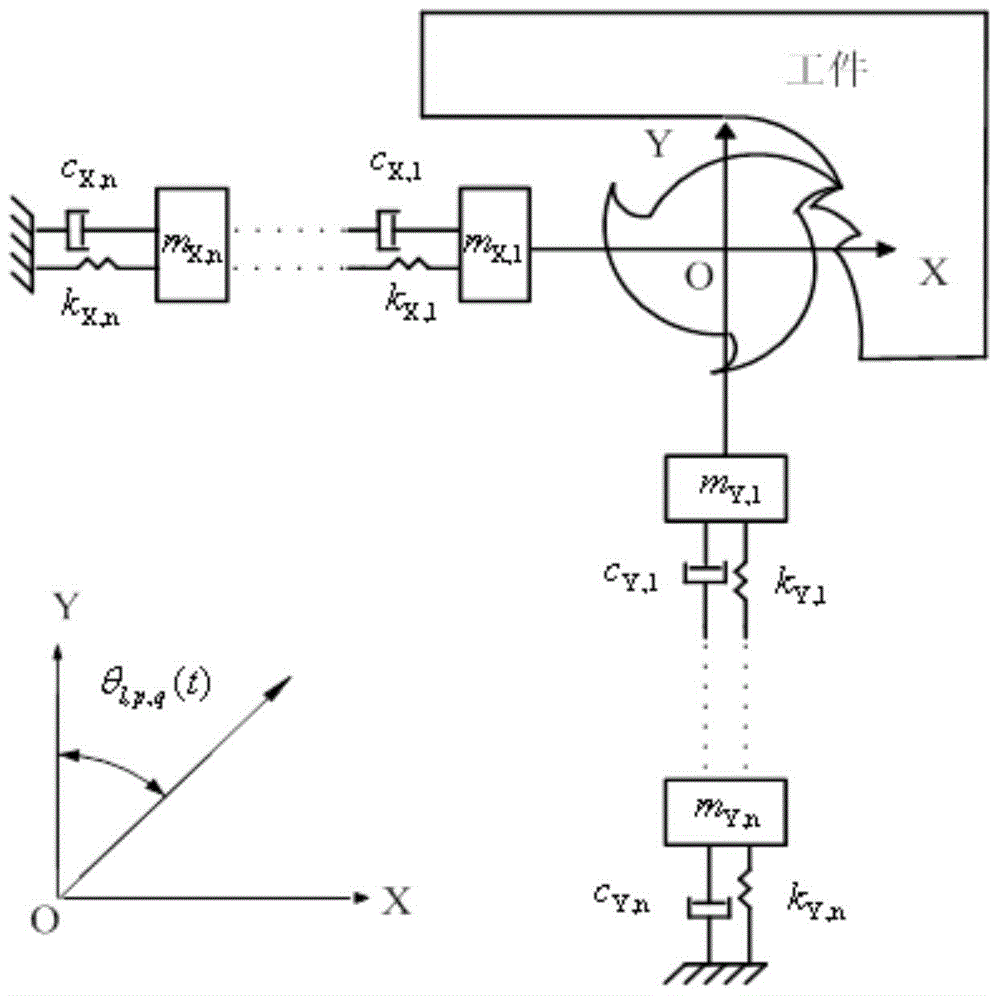

Milling stability domain prediction method under multi-modal coupling

ActiveCN103559550AImprove forecasting efficiencyImprove efficiencyForecastingProcess systemsModal testing

The invention discloses a milling stability domain prediction method under multi-modal coupling to solve a technical problem that the efficiency of an existing milling stability domain prediction method is low. The technical scheme is that firstly the transmission function of a process system is determined through a modal test experiment, then modal parameters are extracted from the transmission function and two orthogonal direction modal parameters are paired and combined, a milling test is carried out to calibrate a milling force coefficient, based on the milling force coefficient and each scale of modal parameters, an improved semi discrete method is employed to obtain a stability lobe diagram under each scale of modals, and finally lobe diagrams under obtained from each scale of modals are drawn in a same coordinate system to obtain a stable domain under multi modal coupling. Through a test, when a cutting cycle is divided into 40 sections, 80 sections and 120 sections, compared with a background technology method, the method can save time for 4949.6 seconds, 74200.4 seconds and 344699.5 seconds, and the efficiency is increased by 85.9%, 92% and 88.5%.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

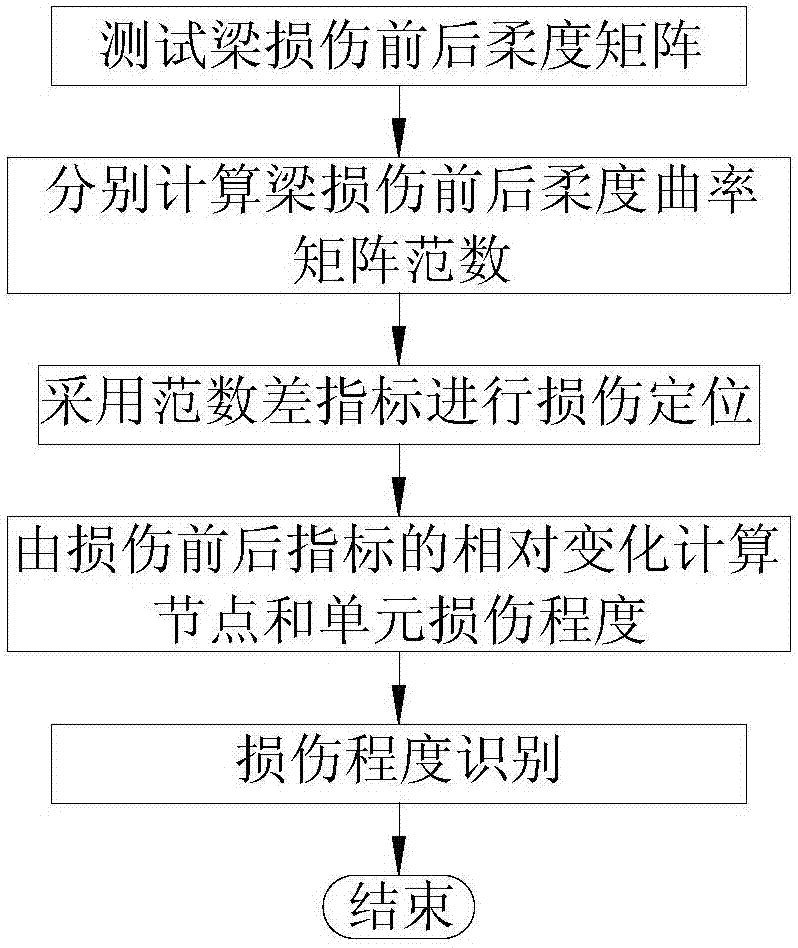

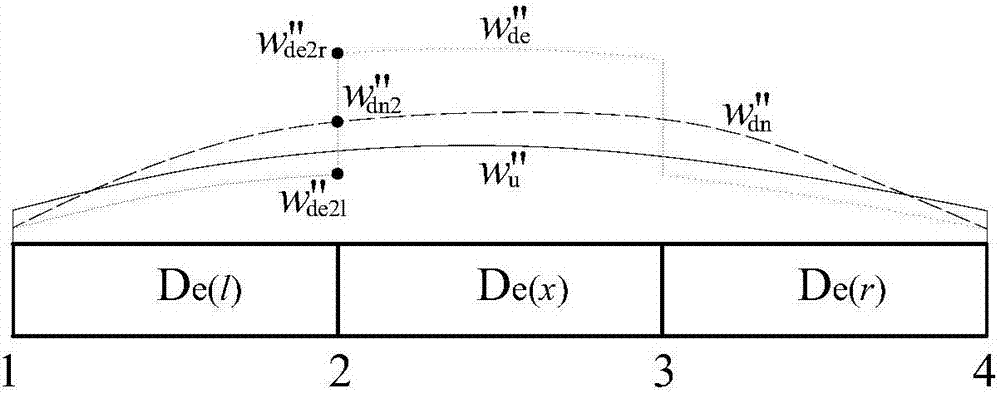

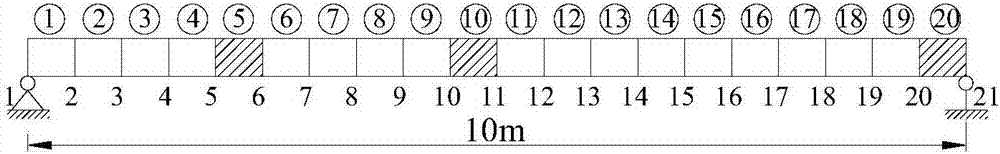

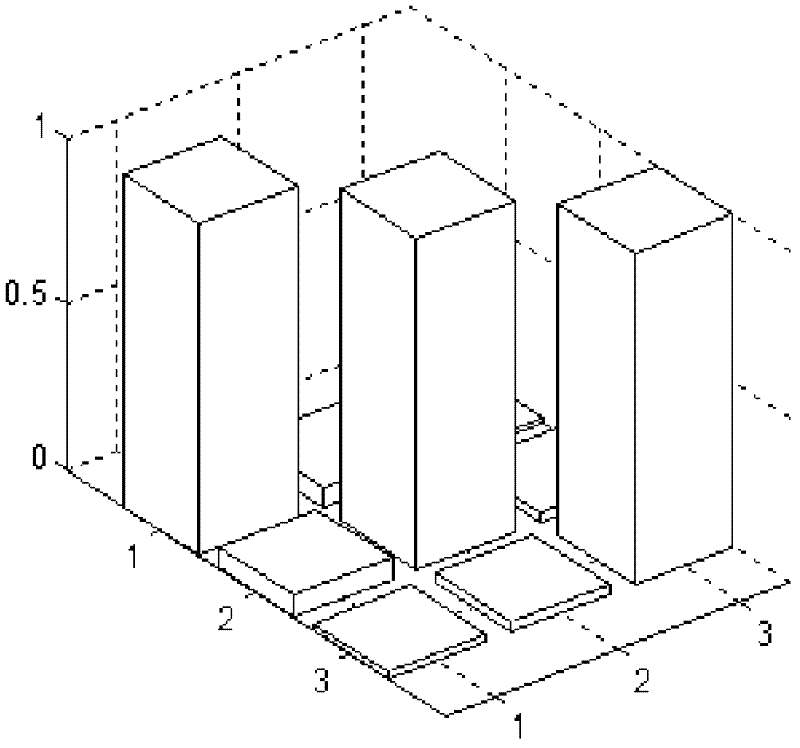

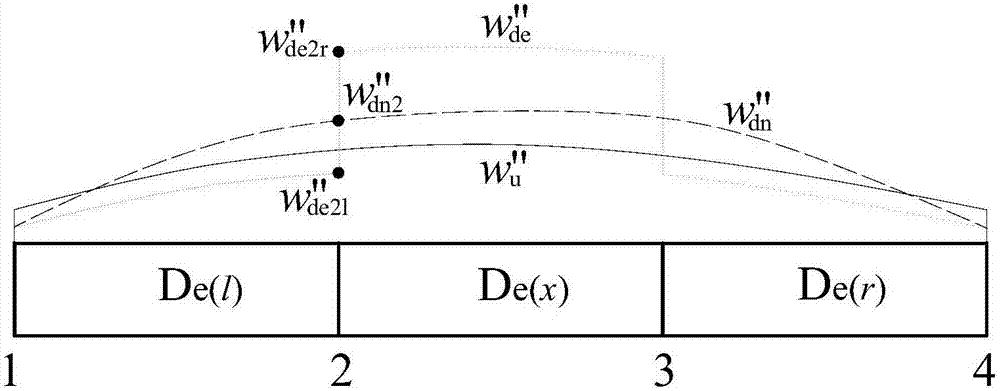

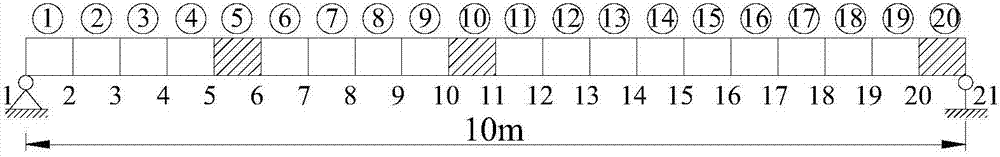

Beam structure damage identification method based on modal flexibility curvature matrix norms

ActiveCN106897543AEffective damage localizationAccurately identify the degree of damageGeometric CADDesign optimisation/simulationModal testingJoint damage

The invention discloses a beam structure damage identification method based on modal flexibility curvature matrix norms. The beam structure damage identification method includes the steps of conducting modal testing to obtain modal flexibility matrixes before and after beam structure damage respectively; acquiring curvatures of the flexibility matrixes before and after beam structure damage, sequentially acquiring the norms of column vectors of flexibility curvature matrixes and utilizing norm differences to position structure damage; computing a beam structure joint damage degree according to relative change of the flexibility curvature matrix norms so as to obtain a unit damage degree through computation. The beam structure damage identification method is capable of positioning single-damage and multi-damage working conditions of a beam structure effectively and capable of identifying the damage degree precisely, well overcomes the defect that existing modal flexibility curvature indexes cannot be used for damage degree identification, and can be applied to nondestructive testing and damage degree evaluation of the beam structure.

Owner:XIANGTAN UNIV

Multi-modal testing methodology

InactiveUS7257557B2User identity/authority verificationComputer security arrangementsModal testingComputer hardware

A method, program and system for administering tests in a distributed data processing network are provided by the present invention. The invention includes combining predetermined test content and multimedia support material into a single encrypted test file. The multimedia support may include visual and audio files for presenting test questions. The invention then exports the encrypted test file to at least one remote test location. The test locations import and decrypt the encrypted test file and load the test content and multimedia support material into a local database. The test is administered on a plurality of client workstations at the testing location, wherein the test may include audio questions and verbal responses by participants. During the course of testing biometric data about test participants is recorded and associated with the test files and participant identification. After the test is completed, the invention combines the completed test results, including verbal responses and biometric data, into a single encrypted results file and exports the encrypted results file to a remote evaluation location. The evaluation location imports and decrypts the encrypted results file and loads the test results into a local database for grading.

Owner:IP KNOWLEDGE VENTURES LLC

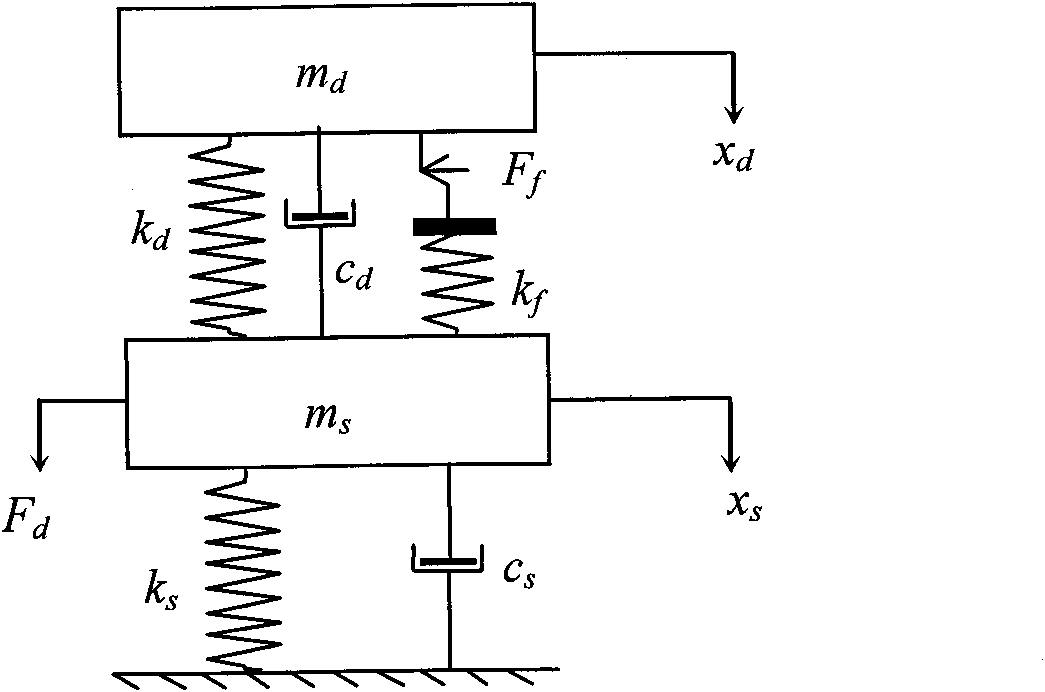

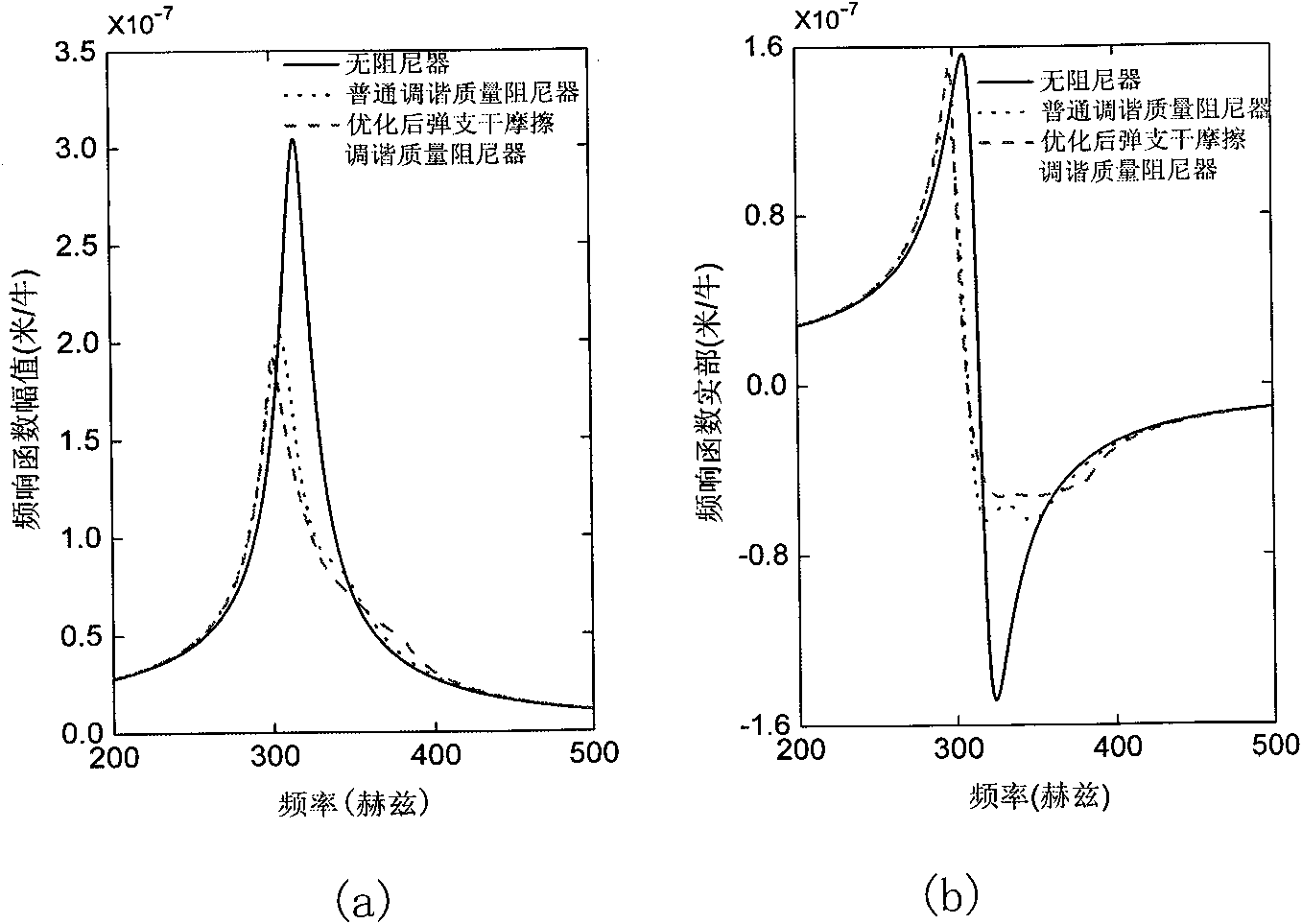

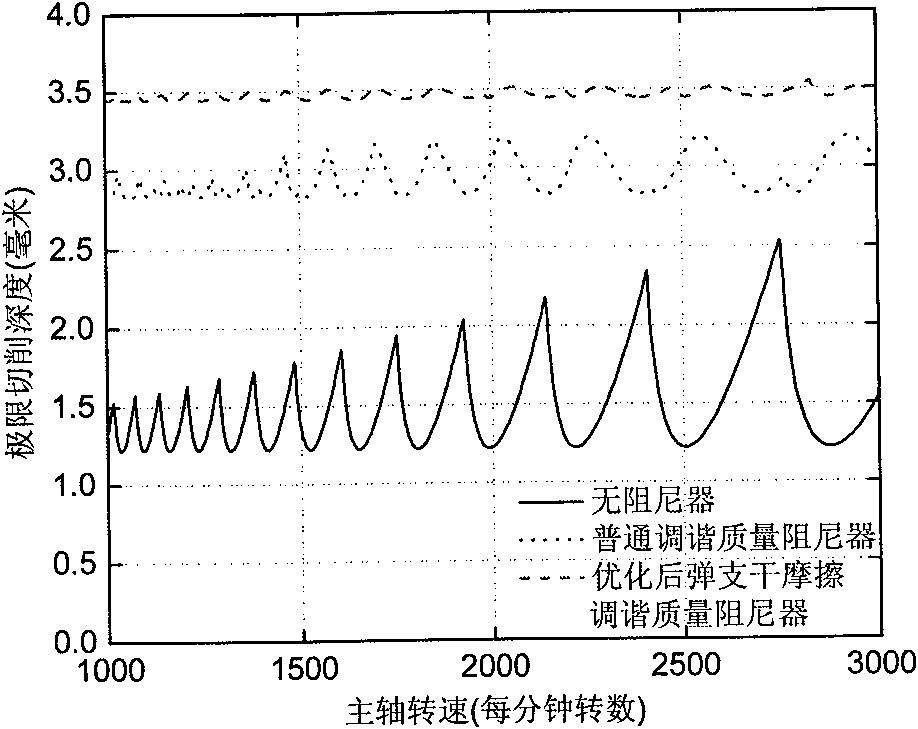

Optimization method of tuned mass damper of elastic support dry friction

InactiveCN101832359AImprove cutting stabilityNon-rotating vibration suppressionDamping factorModal testing

The invention relates to an optimal design method for a tuned mass damper of elastic support dry friction for controlling cutting vibration, relating to an optimization method of structural parameters for inhibiting a cutting vibration processing damper. The invention, aiming at an elastic support serial dry friction damper, provides the optimization method of structural parameters thereof, comprising the following steps of: firstly, acquiring the primary module state mass, the rigidity and the damping coefficient in a weak loop of a controlled cutting system through the module state testing technology; then establishing module dynamically for the cutting system additionally provided with the tuned mass damper of elastic support dry friction and acquiring the frequency responding function of the controlled cutting system through the numerical calculation method; and finally, carrying out the optimal design by adopting the numerical optimization method, and taking maximum negative real part of the frequency responding function of the controlled cutting system as the optimal object and fixed frequency, elastic support rigidity of the tuned mass damper of elastic support dry friction as the optimal parameters of the damper. The optimum design can exert two energy consumption abilities of friction damping and oscillator vibration at the same time to maximum extend so that the cutting stability is optimized.

Owner:BEIJING UNIV OF TECH

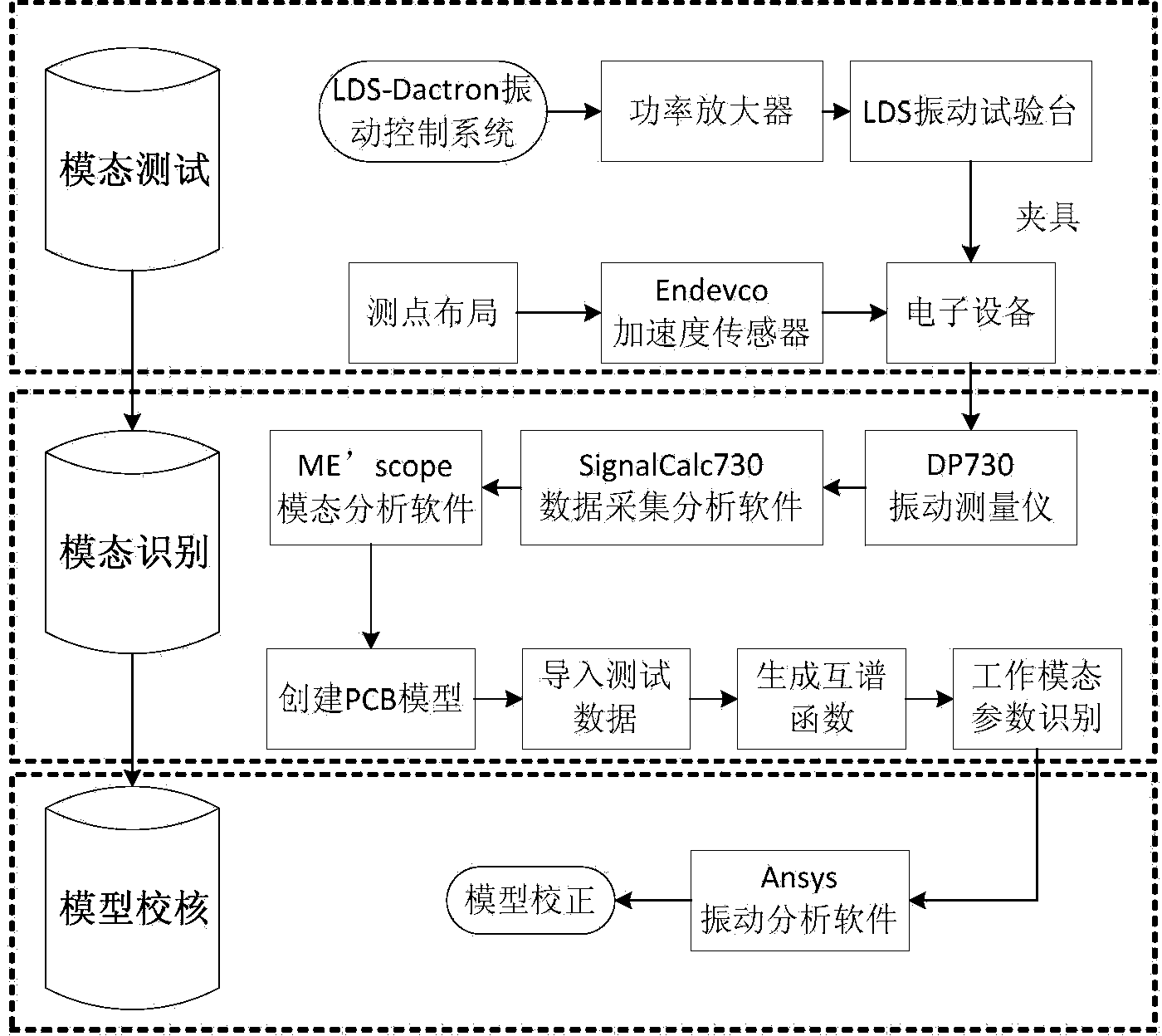

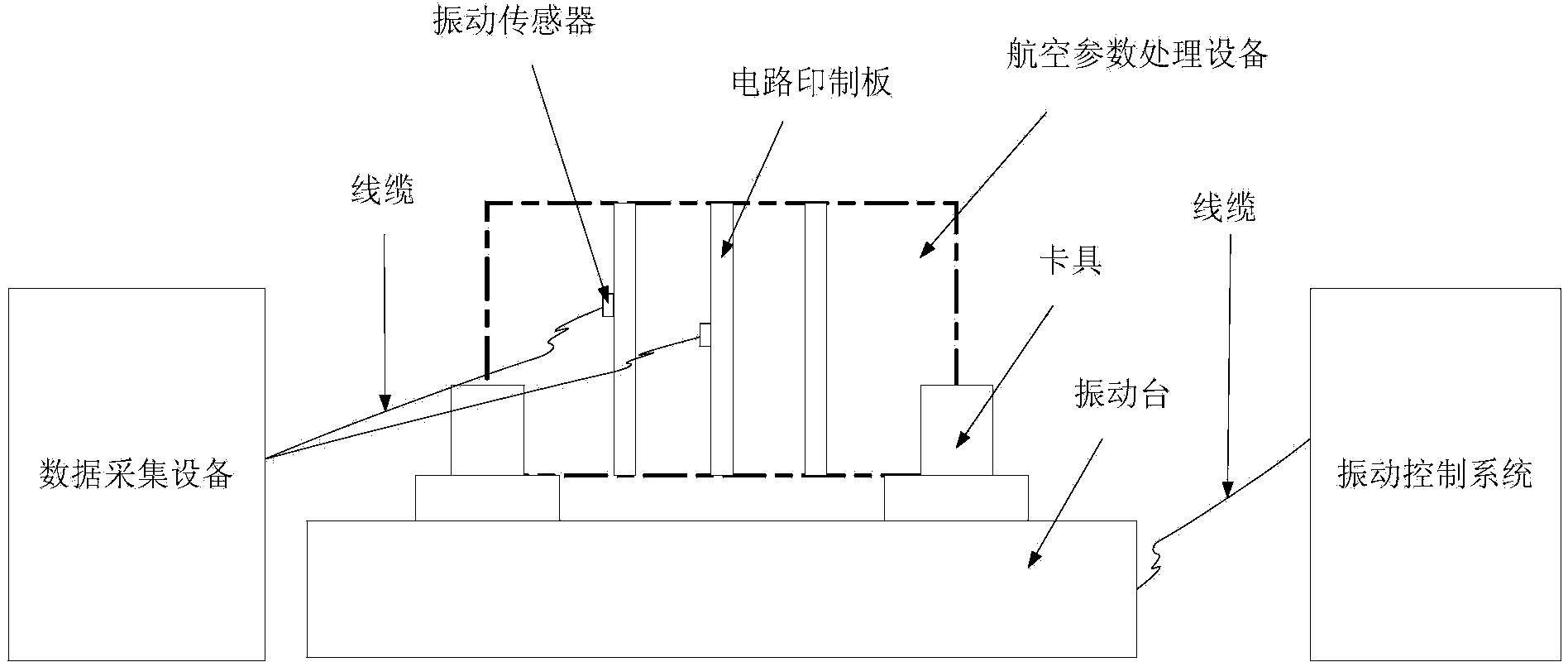

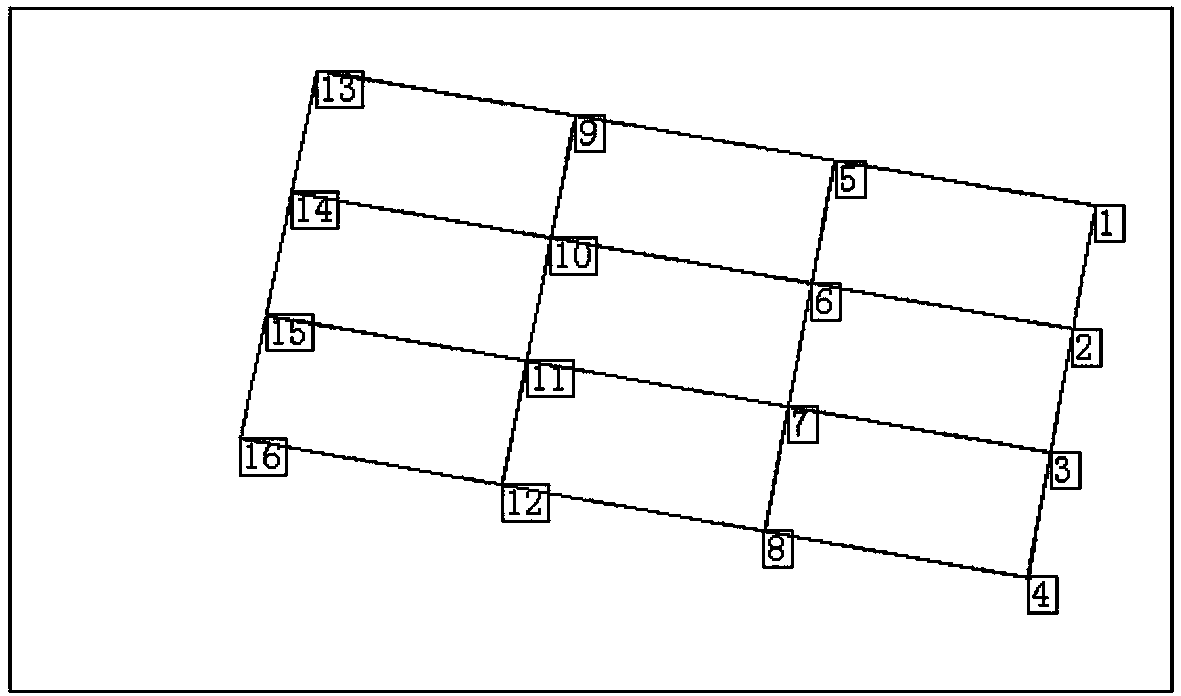

Avionic device operating modal measuring method for vibration finite element model correction

ActiveCN103983412ASpeed up the development processSave testing timeVibration testingModal testingElement model

The invention provides an avionic device operating modal measuring method for vibration finite element model correction. The method includes the following steps that firstly, response test points are arranged, and piezoelectric acceleration transducers are pasted, wherein the n response test points are arranged on a circuit board, and the piezoelectric acceleration transducers are pasted on the response test points respectively; secondly, an avionic device and a test device are installed, and an operating modal test platform is built; thirdly, time domain response data of the avionic device under the random vibration condition are acquired; fourthly, data processing is conducted through modal recognition software, and operating modal parameters of the avionic device are acquired. Through the steps, an avionic device operating modal measuring system for vibration finite element model correction is established, and the overall process from generation of random vibration signals to acquisition of the time domain response data and from generation of a time domain response data sample and a cross-spectrum function to recognition of the operating modal parameters of the avionic device is finished. According to the method, online modal recognition is achieved, and test time is saved and test cost is reduced.

Owner:BEIHANG UNIV

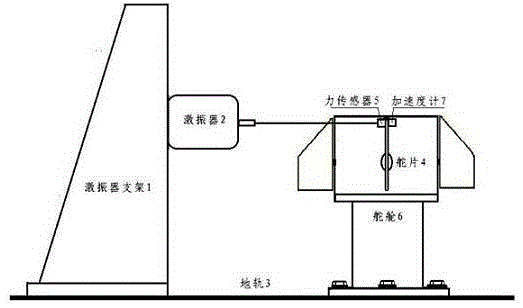

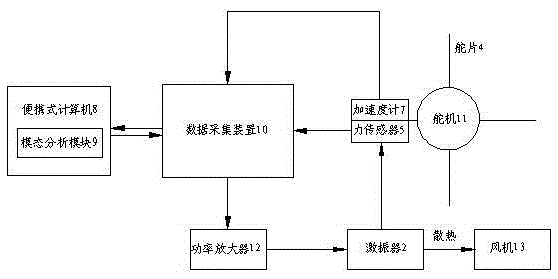

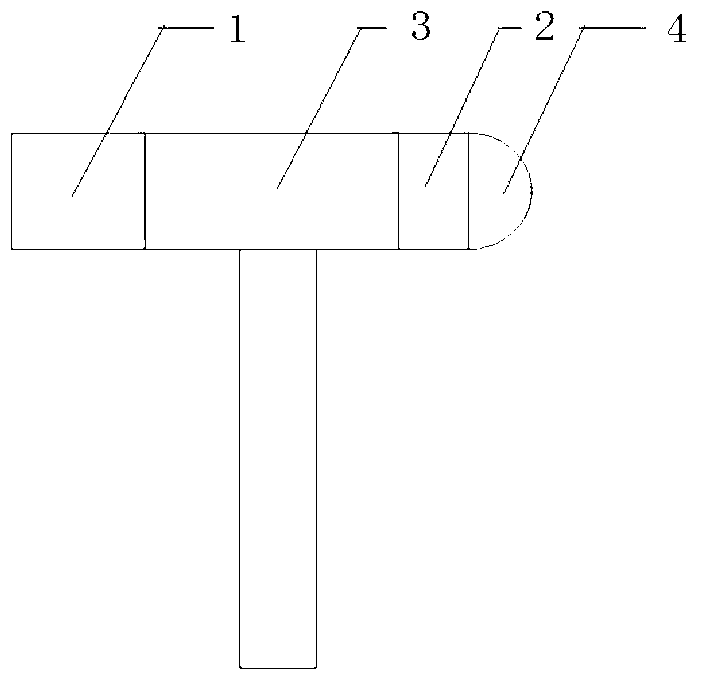

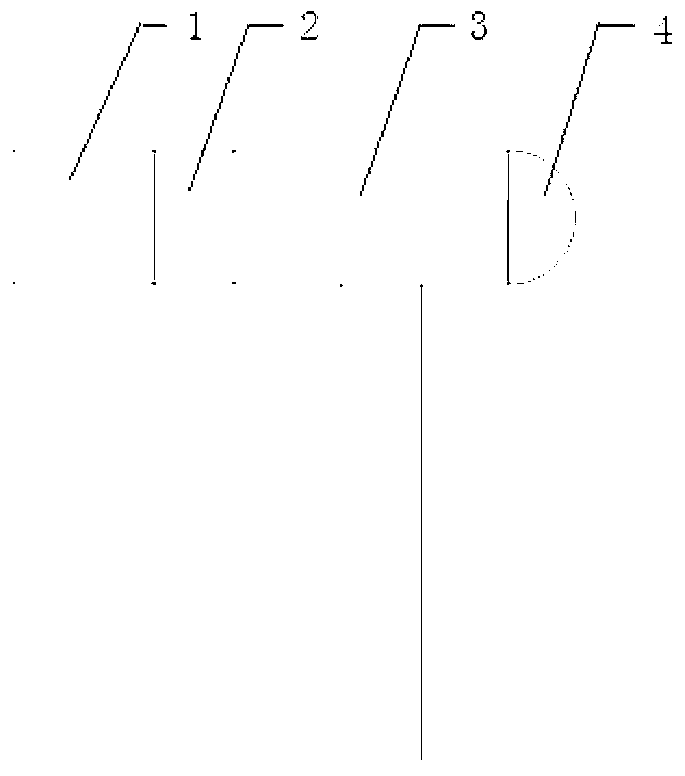

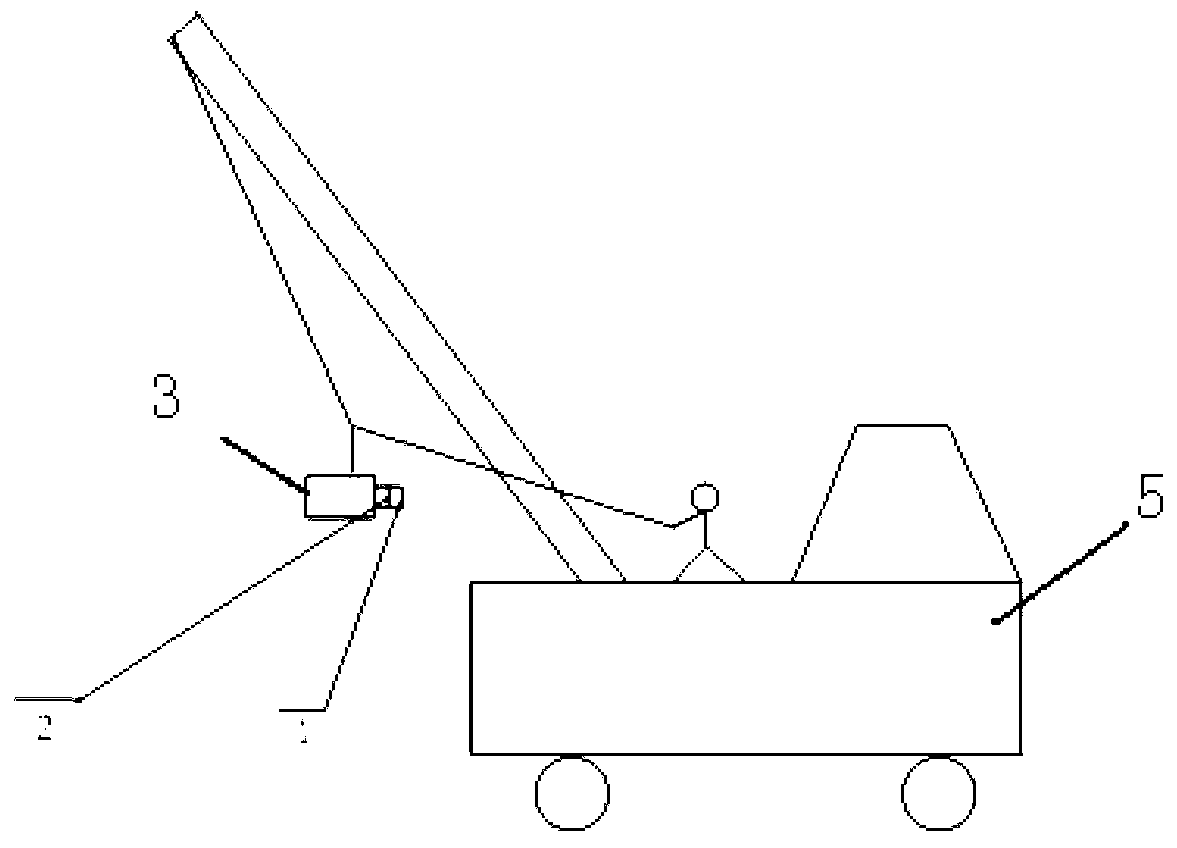

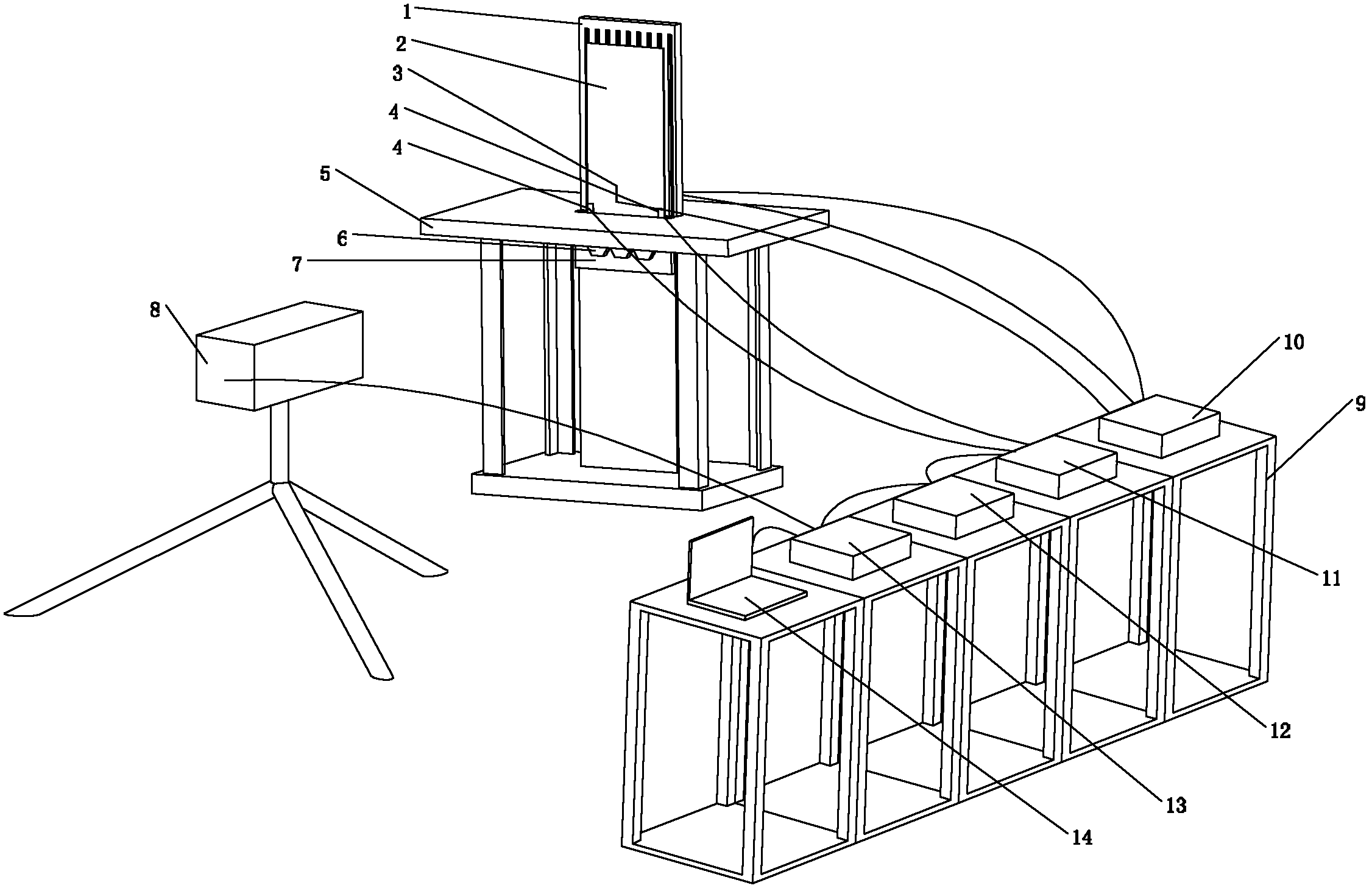

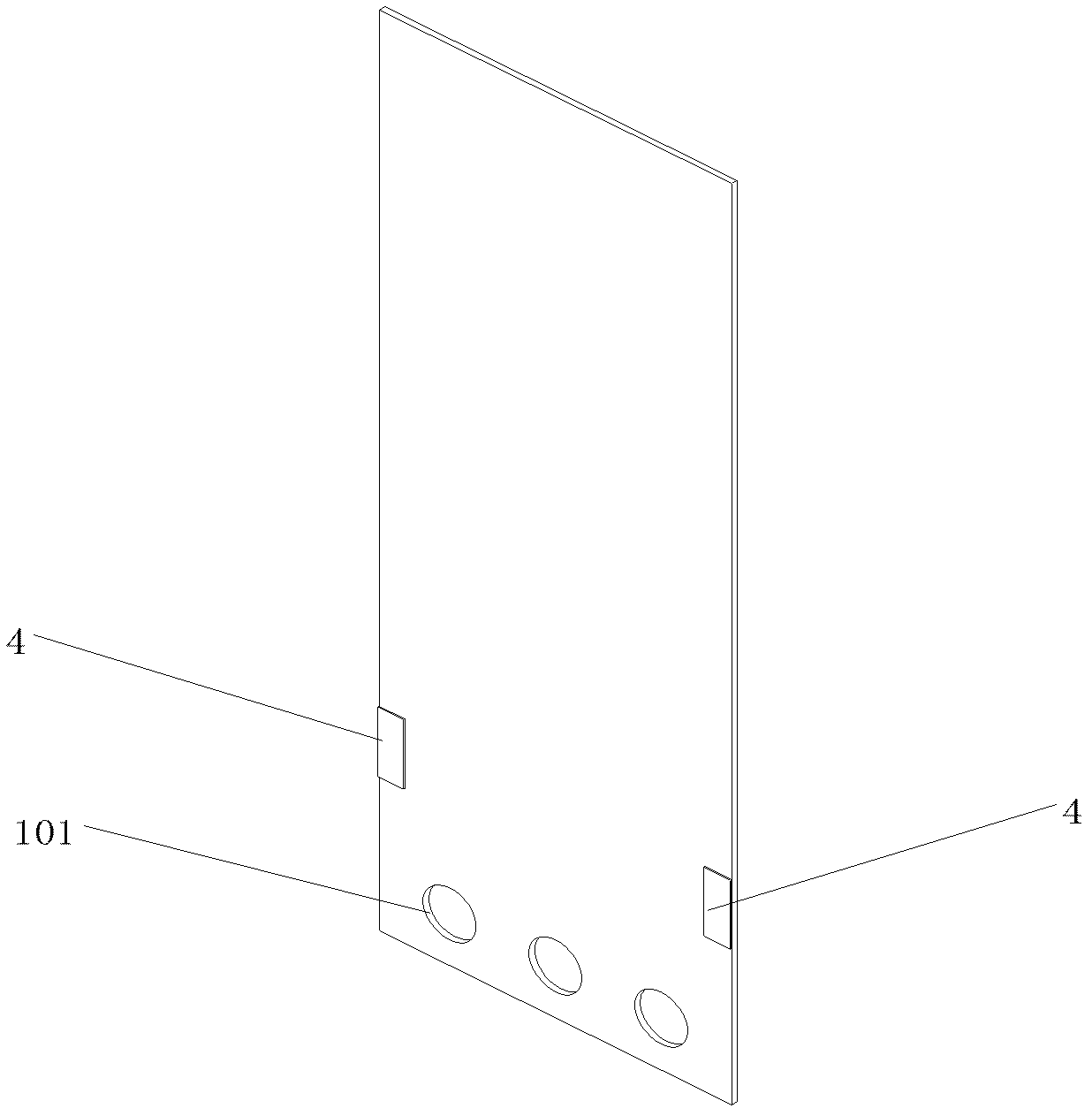

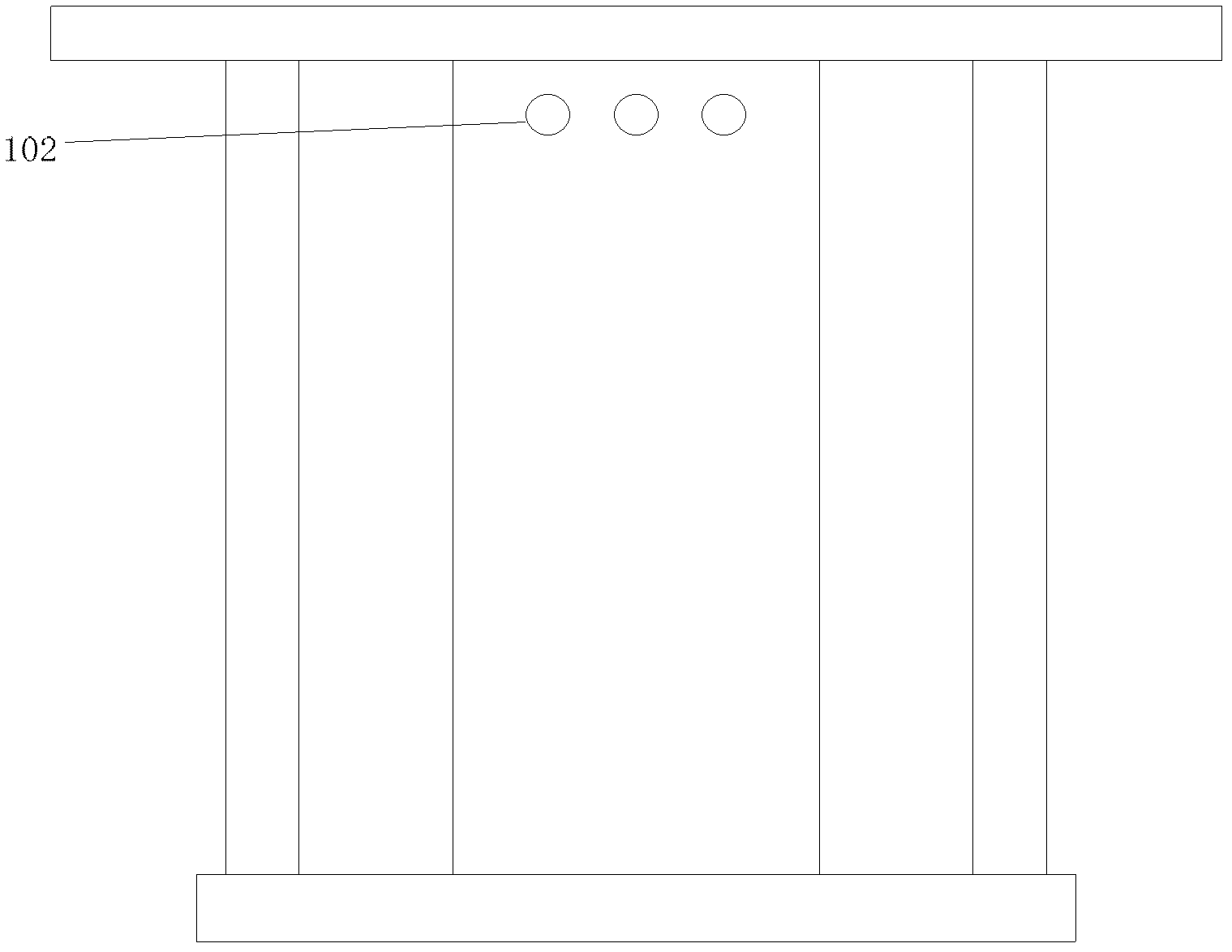

Modal analysis method based on folding control surface rudder system

The invention discloses a modal analysis method based on a folding control surface rudder system. The method comprises following steps: a modal test and analysis system comprising a vibration exciter support (1), a vibration exciter (2), a ground rack (3), a rudder piece (4), a force sensor (5), a rudder room (6), an accelerometer (7), a portable computer (8), a data acquisition device (10), a steering engine (11), a power amplifier (12), and a blower fan (13) is constructed; modal parameters of the rudder system are pre-estimated by a modal analysis module (9); the rubber system is stimulated by the vibration exciter (2), test data is collected by the data acquisition device (10), test results are interpreted by the modal analysis module (9), and the modal purity is verified by the modal analysis module (9). By use of the modal analysis method, the main modal of the rudder system can be accurately recognized and bending modals can be distinguished, modal parameters such as natural frequency, damping ratio, and vibration mode which describe dynamic characteristics of a structural system are determined, and modal recognition reliability and accuracy are increased.

Owner:BEIJING MECHANICAL EQUIP INST

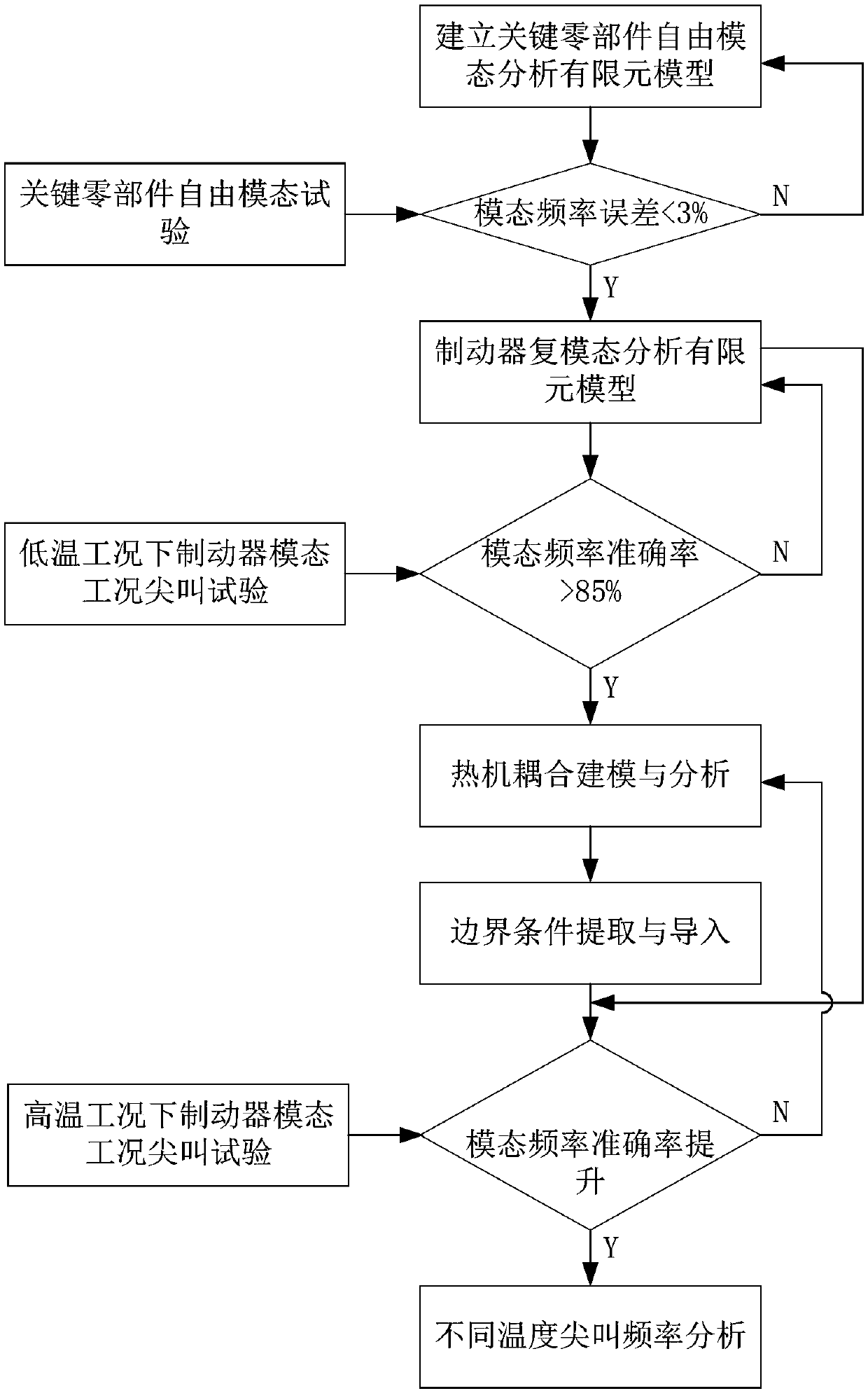

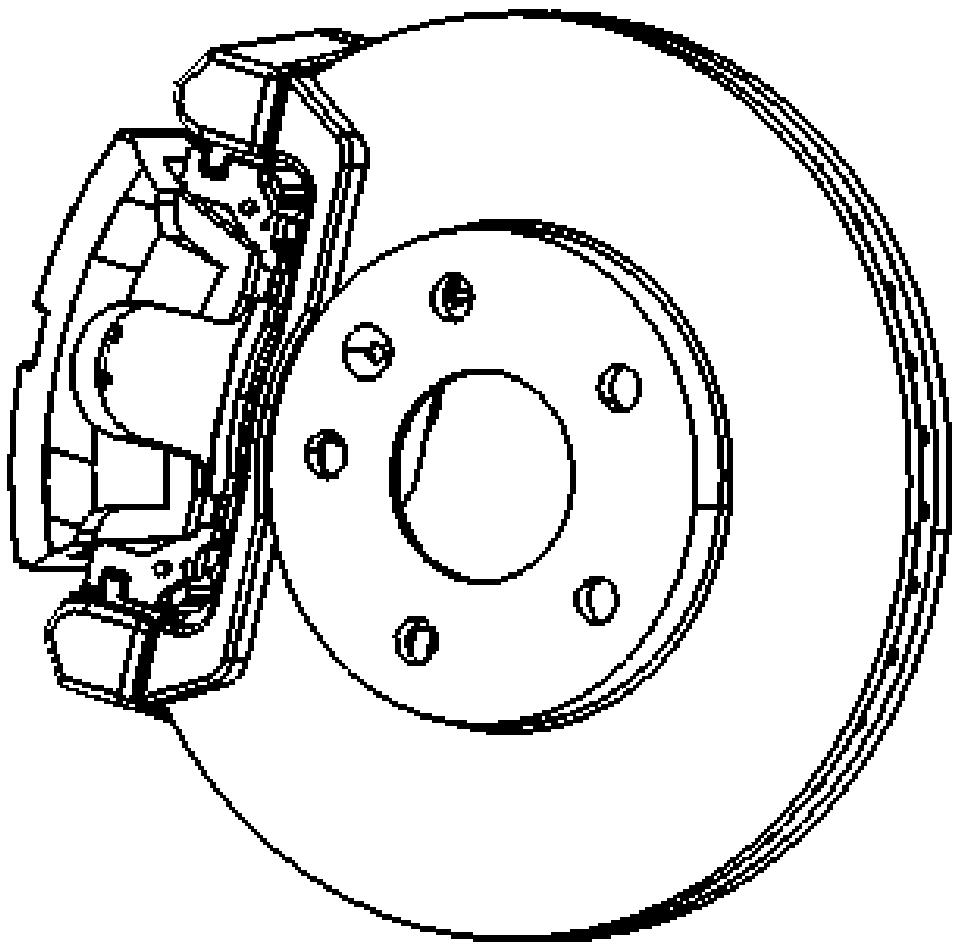

Brake squeal prediction method of considering thermal-mechanical coupling effect

ActiveCN107704644AImprove accuracyHigh precisionGeometric CADDesign optimisation/simulationModal testingElement model

The invention relates to a brake squeal prediction method of considering a thermal-mechanical coupling effect. The method includes the following steps: A, establishing a finite element model of free modal analysis of key parts; B, carrying out free modal testing and comparison of the key parts; C, establishing a finite element model of complex modal analysis of a brake; D, carrying out model working-condition squeal testing of the brake under a low-temperature working condition; E, carrying out model correction based on testing data of the low-temperature working condition; F, carrying out thermal-mechanical coupling modeling and analysis; G, carrying out boundary condition extraction and analysis; H, carrying out model working-condition squeal testing of the brake under a high-temperatureworking condition; I, carrying out model correction based on testing data of the high-temperature working condition; and J, carrying out different-temperature squeal frequency prediction. Compared with the prior art, the method helps to improve precision of brake squeal prediction, can particularly predict high-frequency noises of the automobile brake under the high-temperature working condition,and can reflect time-varying features of a brake squeal tendency caused by the thermal-mechanical coupling effect.

Owner:TONGJI UNIV

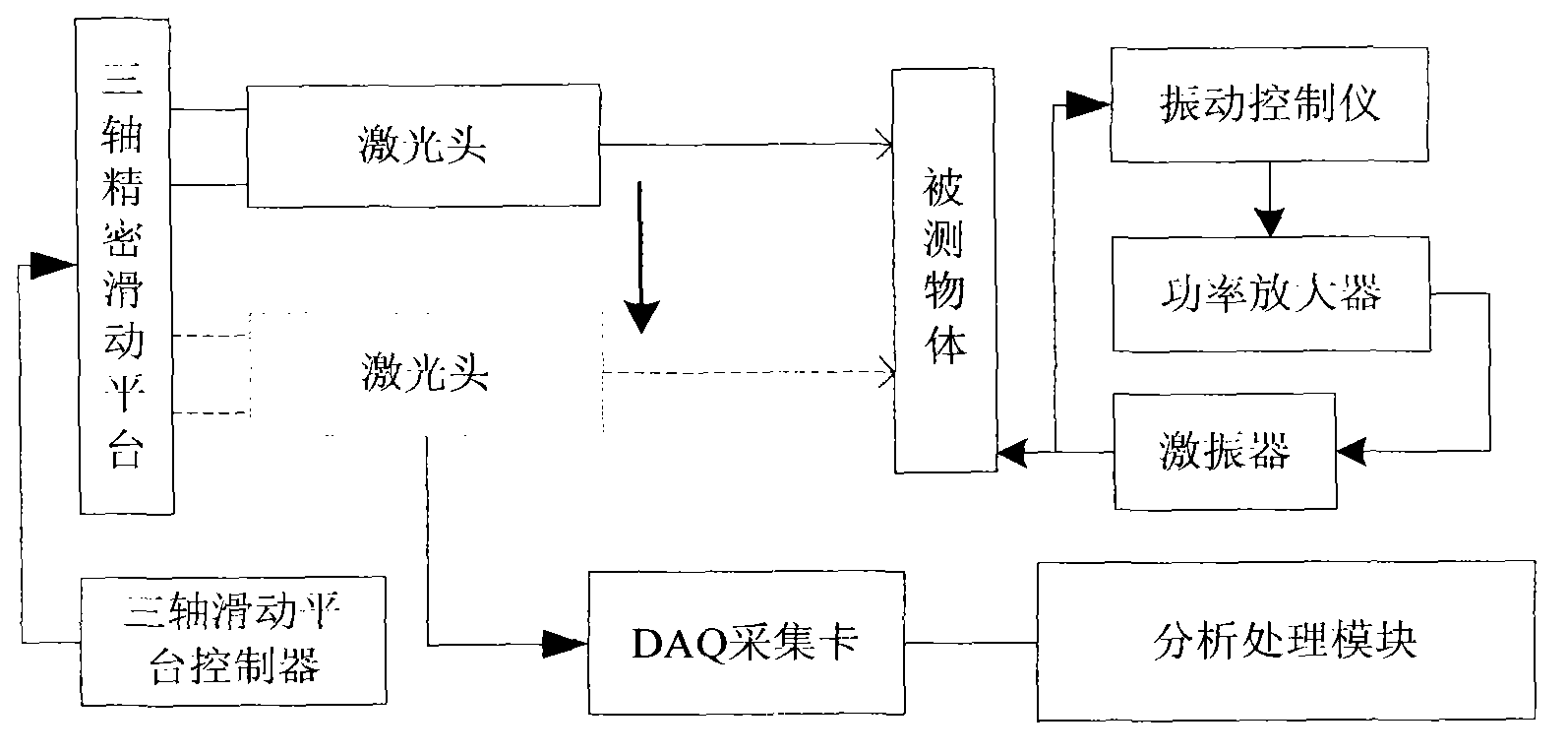

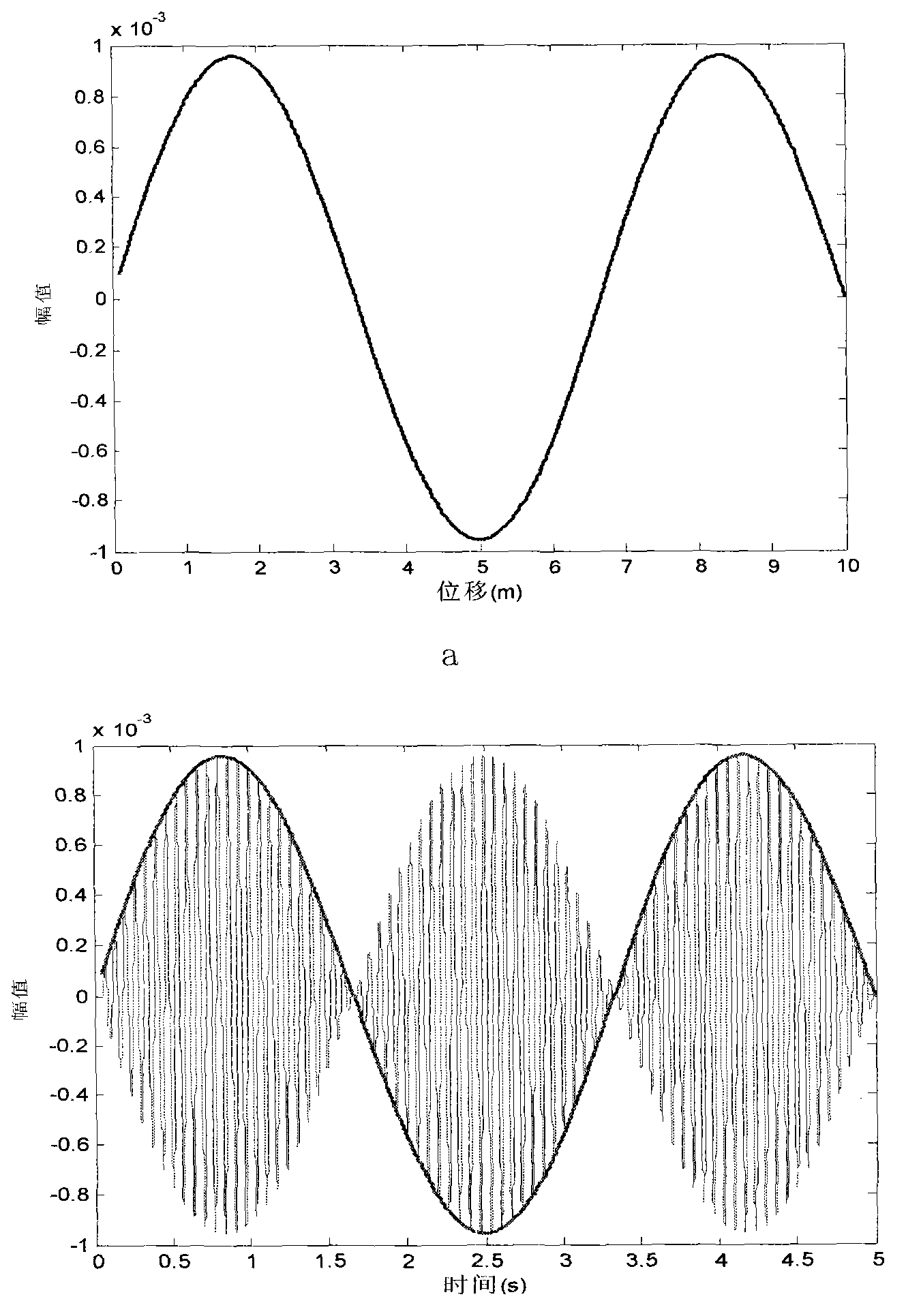

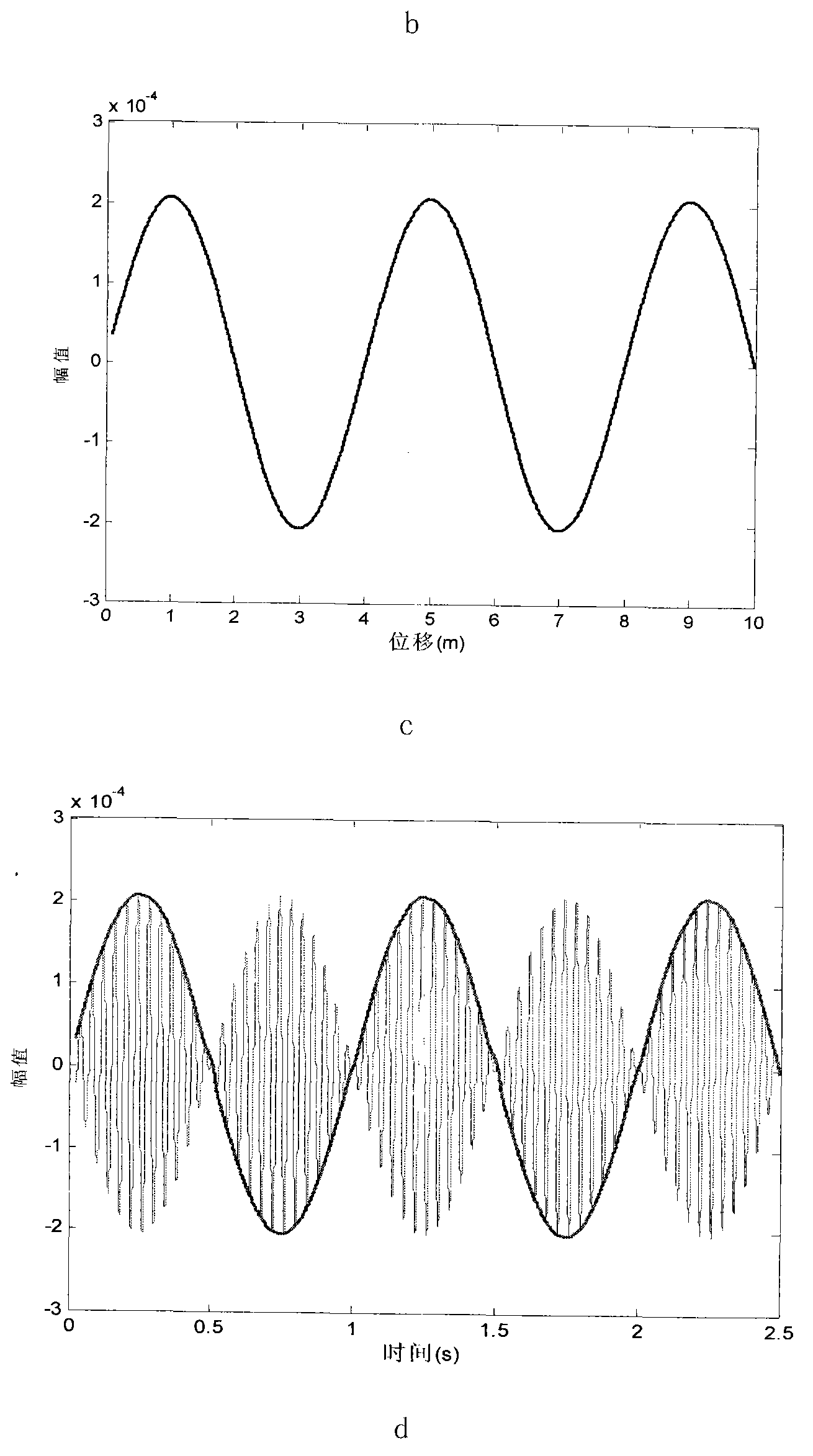

Modal testing system and modal testing method on basis of single-point laser continuous plane-scanning vibration measurement

InactiveCN103175602ASubsonic/sonic/ultrasonic wave measurementUsing wave/particle radiation meansModal testingVibration measurement

The invention discloses a modal testing system and a modal testing method on the basis of single-point laser continuous plane-scanning vibration measurement. A workpiece to be tested is fixed on a vibration measurement probe of a vibration measurer so as to be driven to vibrate. The vibration measurer is used for performing sweep frequency analysis to the workpiece to be tested so as to find an inherent frequency of the workpiece; at the corresponding inherent frequency, vibration conditions of the workpiece are tested by means of continuously constant-speed plane-scanning vibration measurement through laser; the vibration data are processed by an analysis processing module; and further a modal vibration mode at the corresponding inherent frequency can be solved. According to finite element analysis and tests of thin-walled beams by the modal testing system and the modal testing method, the result that finite element models and test models are consistent basically is concluded.

Owner:HUNAN UNIV OF SCI & TECH

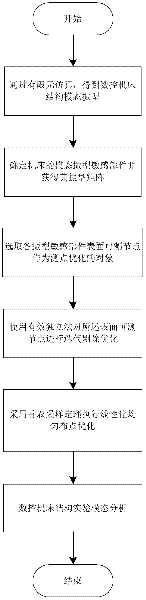

Method for executing layout optimization on model analysis measurable nodes of numerical control machining equipment

ActiveCN102566424AImprove test efficiencyOptimize locationAdaptive controlNumerical controlModal testing

The invention discloses a method for executing layout optimization on experimental model analysis measurable nodes of numerical control machining equipment, which comprises the following steps: (1) obtaining the overall structure modal shape of the equipment and a corresponding modal shape matrix through finite element simulation; (2) determining and selecting a modal shape sensitive component of the equipment and a corresponding shape matrix by utilizing the overall structure modal shape; (3) selecting surface measurable nodes from the modal shape sensitive component, wherein the surface measurable nodes are used as objects to be optimized in layout; (4) performing iteration elimination on the surface measurable nodes by using an effective independence method; and (5) executing linear even node distribution on the modal shape sensitive component by adopting the Shannon's sampling theorem. Through the method for executing the layout optimization on the experimental model analysis measurable nodes of the numerical control machining equipment, the defects in the aspects that the traditional modal testing efficiency is low, the time is long and the like can be overcome, and the number of the measurable nodes and the positions of the measurable nodes can be optimized, and the testing efficiency can be increased on the premise of ensuring natural frequency and shape identification in numerical control machine structure modal testing.

Owner:HUAZHONG UNIV OF SCI & TECH

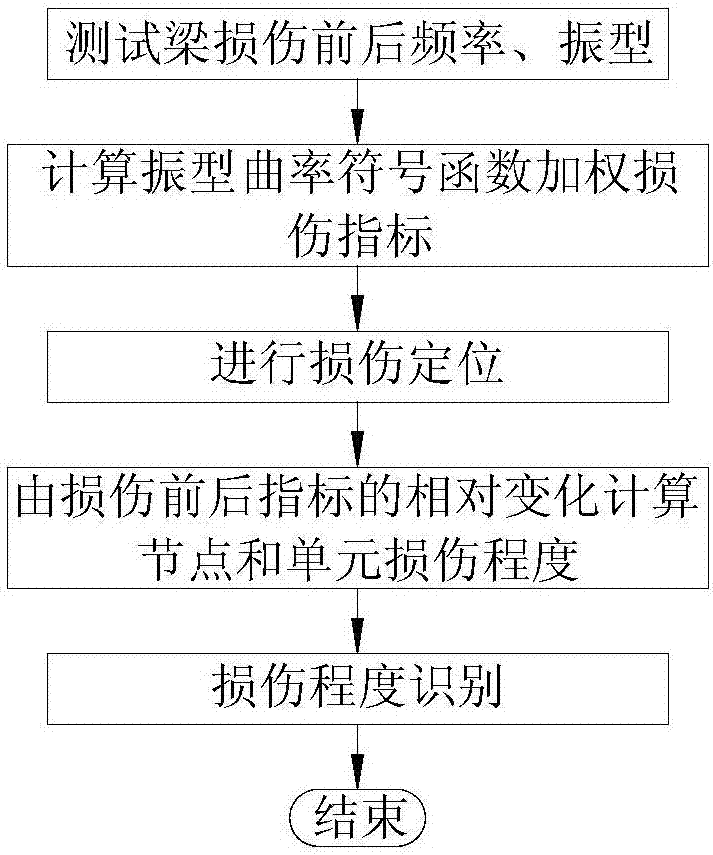

Identification method for beam structure damage of vibration mode weighing modal flexibility

ActiveCN107085037AEffective damage localizationAccurately identify the degree of damageAnalysing solids using sonic/ultrasonic/infrasonic wavesModal testingStatically indeterminate

The invention discloses an identification method for beam structure damage of vibration mode weighing modal flexibility. The method comprises the following steps: obtaining frequency and the vibration mode of the beam structure before and after the damage through a modal test; calculating vibration mode curvature sign function weighing damage index based on the frequency and the vibration mode before and after the damage to locate the damaged structure, calculating a beam structure node damage degree according to a relative change of the vibration mode curvature sign function weighing damage index before and after the damage, and then calculating a unit damage degree. The identification method for the beam structure damage of the vibration mode weighing modal flexibility can effectively determine a damage location of a single-damage and multi-damage working condition for the beam structure, the calculation method of the damage degree of the corresponding index under a statically determinate structure and a statically indeterminate structure can be used to identify the damage degree accurately, the shortcomings that the existing modal flexibility curvature index cannot be used to identify the damage degree are overcome, and the method can be applied to the nondestructive testing and damage degree assessment of the beam structure.

Owner:XIANGTAN UNIV

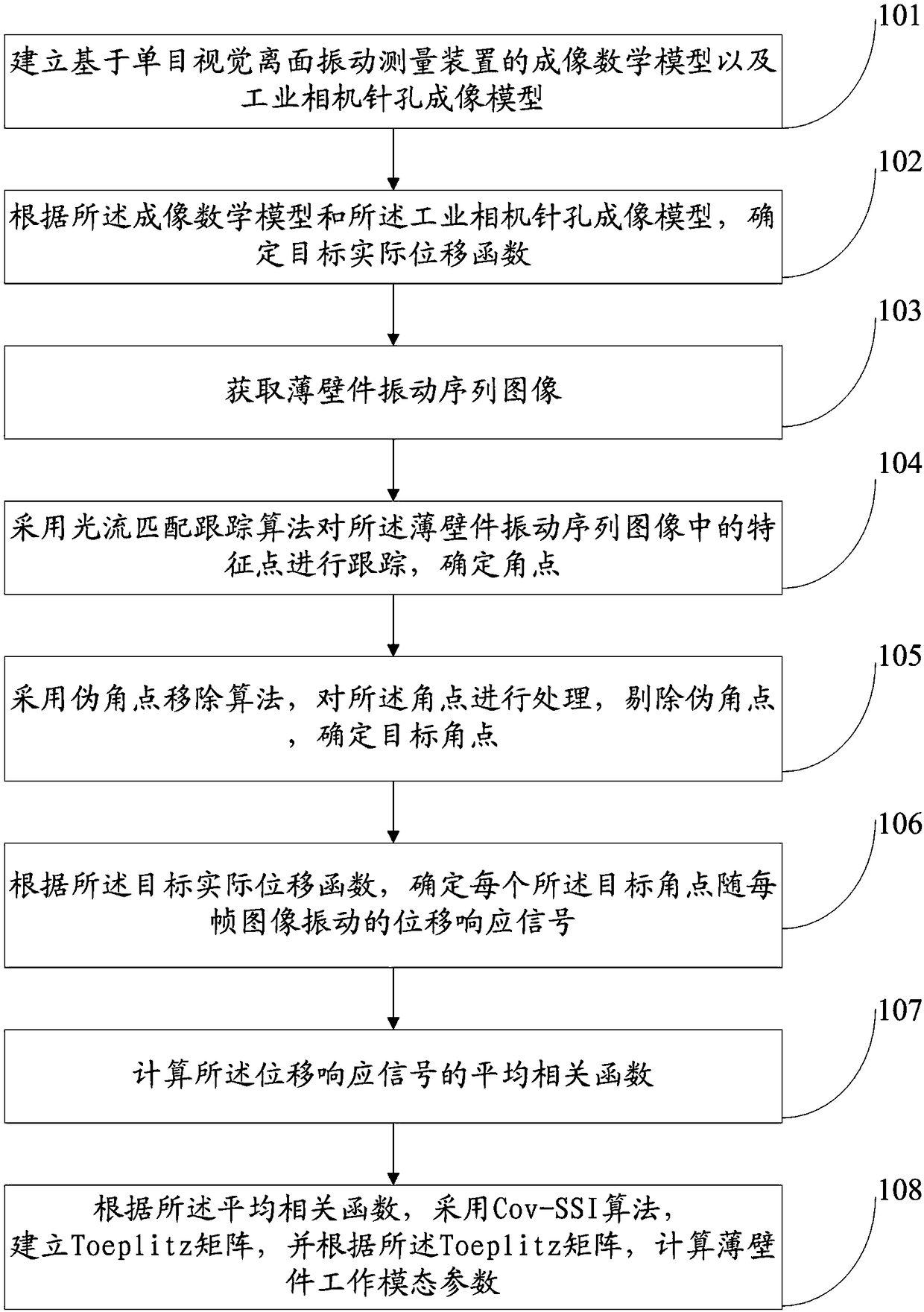

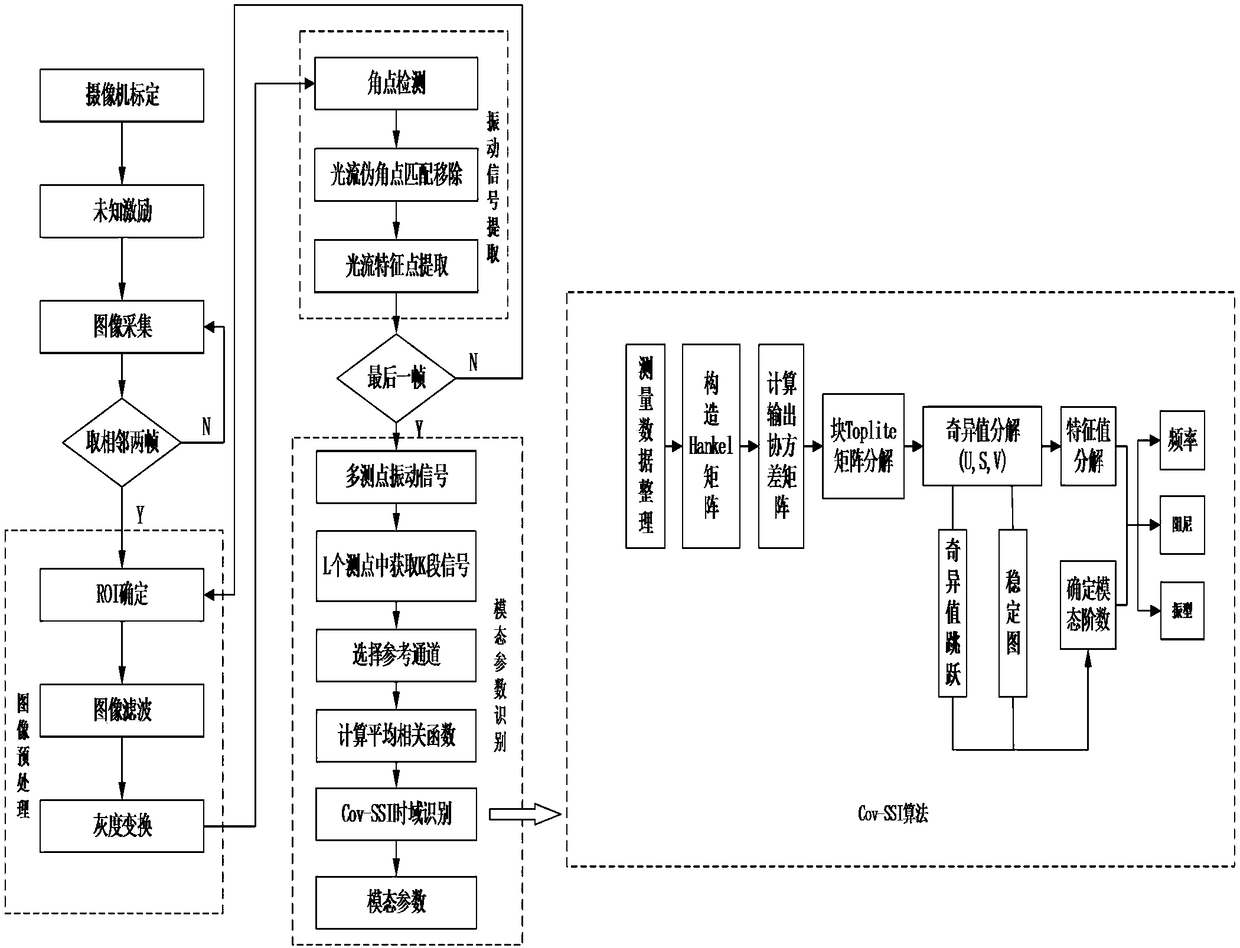

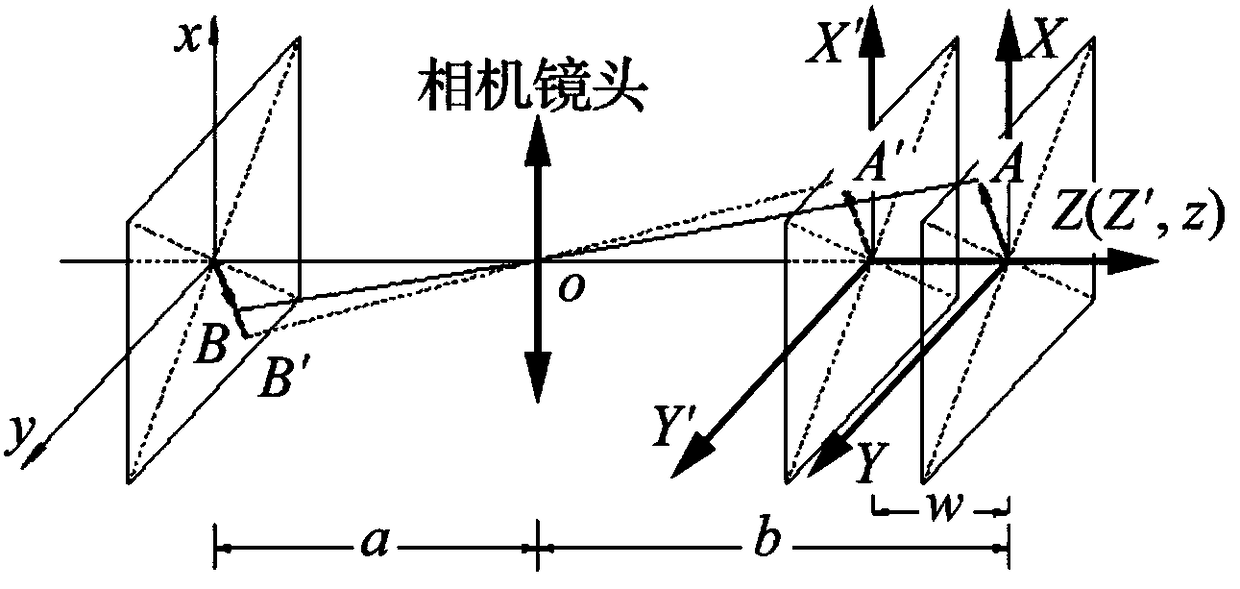

Thin-wall part working modal parameter determining method and system

InactiveCN108593087AImprove computing efficiencyImprove calculation accuracyImage enhancementImage analysisModal testingMathematical model

The invention discloses a thin-wall part working modal parameter determining method and system. The method comprises the following steps: establishing an imaging mathematical model based on a monocular vision off-plane vibration measuring device, and an industrial camera pinhole imaging model, determining a target actual displacement function, continuously tracking target angle points by utilizingan optical flow matching tracking algorithm with the pseudo-angle point removal, and obtaining a displacement response signal for each target angle point to vibrate along with each frame of image, calculating the average correlation function of each displacement response signal, and replacing the displacement response signal with the mean correlation function to serve as the Cov-SSI algorithm input item to carry out the working modal parameter identification, so that the working modal test of the thin-walled part is realized. According to the method, auxiliary structure light is not needed, any labels or marks are not needed to be pasted, and multi-view non-contact vibration mode measurement can be achieved, the problem that the calculation efficiency and the measurement precision of themachine vision vibration mode measurement method are low is effectively solved, and the problem that a low signal-to-noise ratio working mode parameter is difficult to identify is well solved.

Owner:HUNAN UNIV OF SCI & TECH

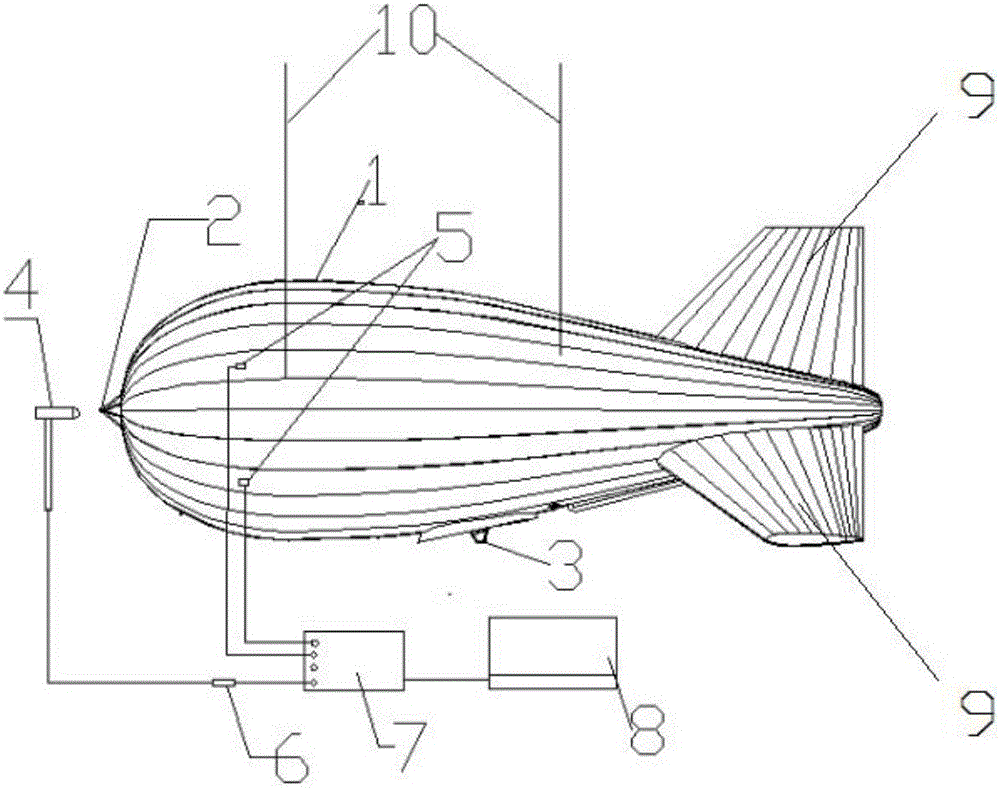

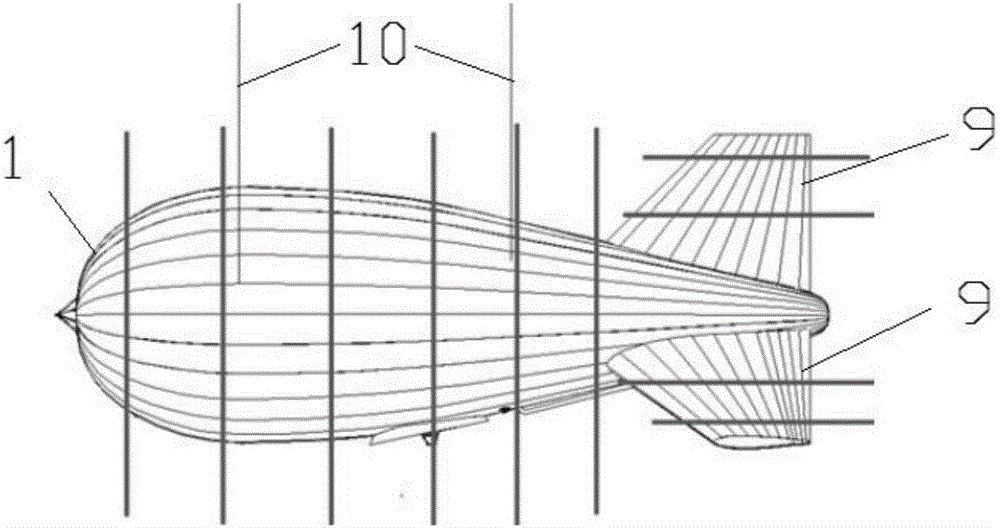

Aerostat modal testing method and system

The invention relates to the technical field of aerostat modal tests, in particular to an aerostat modal testing method and an aerostat modal testing system. The aerostat modal testing method at least comprises the steps of: lifting and suspending an aerostat in an enclosed space; respectively selecting a nose cone position and a nacelle position of the aerostat as excitation points; dividing the aerostat into a plurality of cross sections; arranging a plurality of sensors on each cross section; exciting the excitation points at the nose cone position and the nacelle position respectively; and acquiring an excitation signal and a vibration signal generated during the excitation process. The aerostat modal testing system at least comprises an exciter, sensors, an acquisition instrument and a computer. The aerostat modal testing method and the aerostat modal testing system are used for determining the inherent frequency and vibration mode of the aerostat so that the aerostat can avoid resonance during the design process, and making clear of the responding situations of the aerostat to different dynamic loads.

Owner:ACAD OF OPTO ELECTRONICS CHINESE ACAD OF SCI

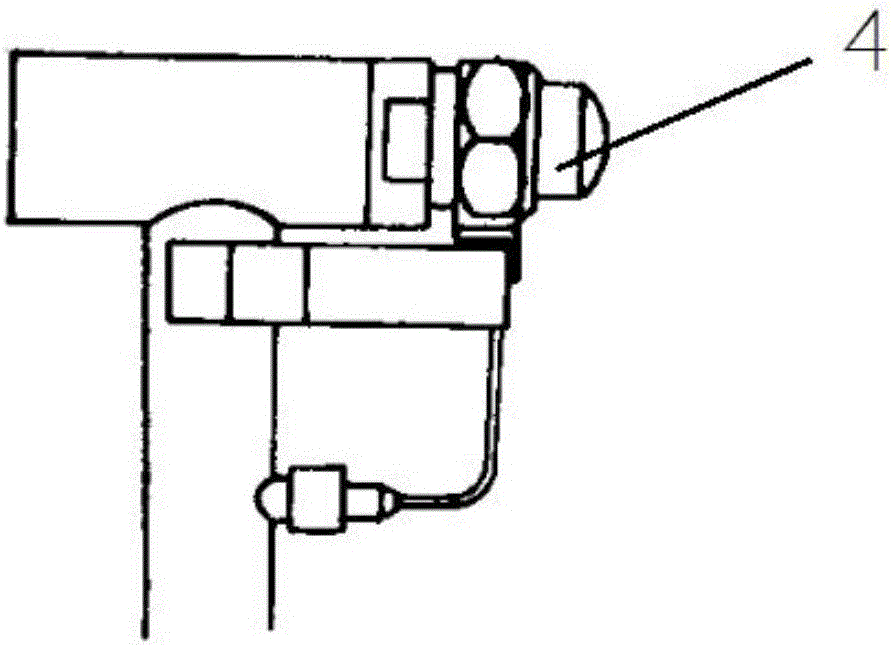

Exciting device for testing modal of large structural component

The invention relates to an exciting device for testing the modal of a large structural component. The exciting device comprises a force sensor, a hammer body and a counterweight, wherein the force sensor is arranged behind the hammer body; and the counterweight is arranged behind the force sensor. In order to overcome the defects of universal modal testing methods of the modal of the large structural component, such as a hammer method and a vibration exciter method, the invention provides the exciting device for testing the modal of the large structural component. The device plays a certain role in protecting the force sensor and can also prevent damaging the force sensor by too high vibration exciting force used for striking the large structural component.

Owner:HARBIN ENG UNIV

Device and method for testing torsional rigidity and mode of shafting

PendingCN108072488AEasy to implementEasy to operateMachine part testingStatic/dynamic balance measurementModal testingAccelerometer

The invention relates to a device and method for testing the torsional rigidity and mode of shafting, and belongs to the field of rigidity and mode test. In the device, a mass disc is bonded to the free end of a shaft to be tested, additional square blocks are bonded to the two sides, opposite to each other, in the side arm of the shaft to be tested respectively, and accelerometers are mounted onthe additional square blocks respectively. The device is easy to realize, convenient to operate and high in test precision, and fills the blanks in the field of torsional rigidity and mode test of theshafting. According to the method, the characteristic that the additional square blocks can act torsional moment excitation and test response of the tested shaft in the torsional direction is used, the mass disc is used to change the mass characteristic of the shaft, the torsional rigidity and moment of inertia of the tested shaft are calculated, the torsional rigidity and mode measured by the method can reflect the torsional oscillation characteristic of the shafting visually, and the method further has the advantage of high precision.

Owner:BRILLIANCE AUTO

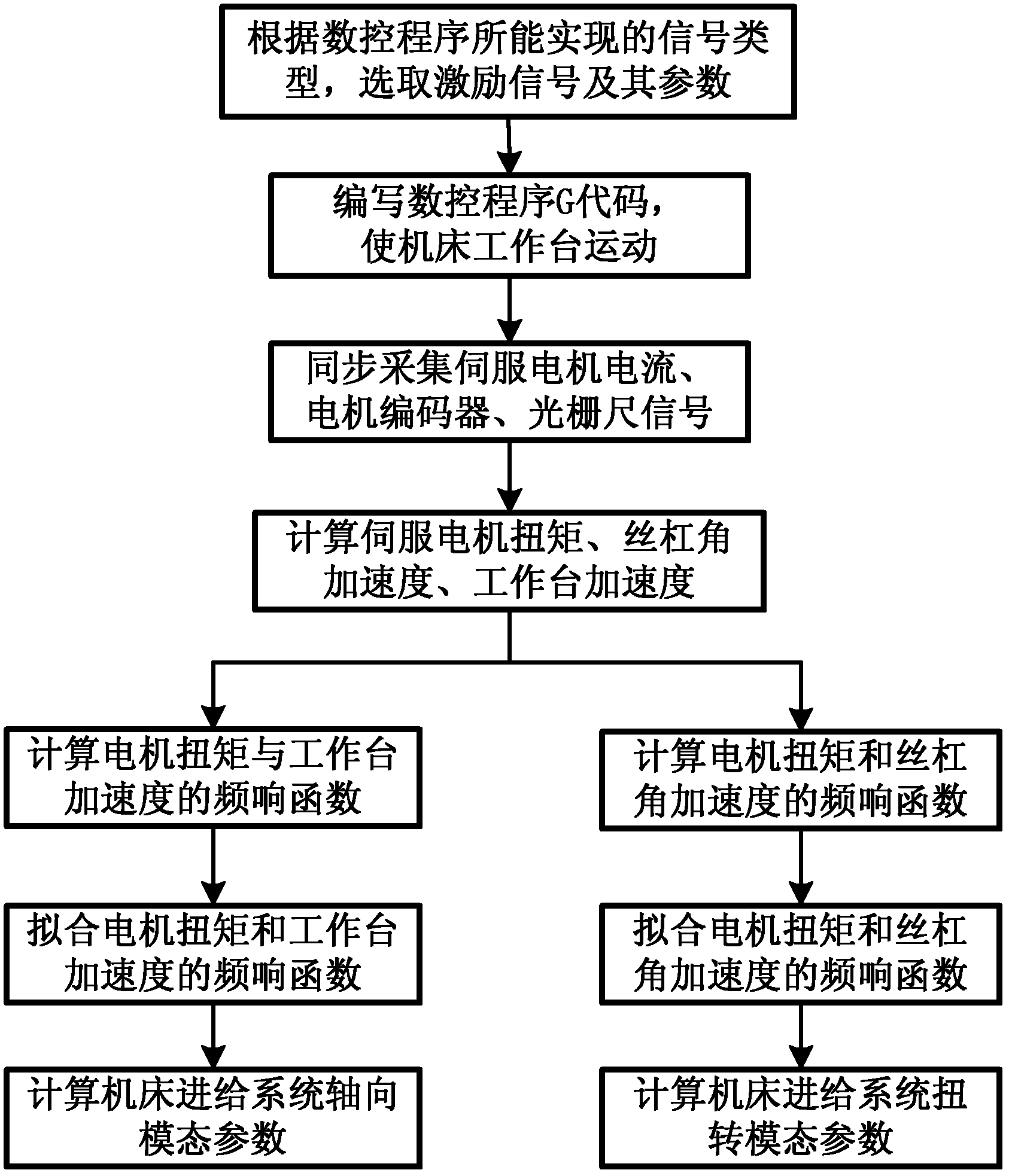

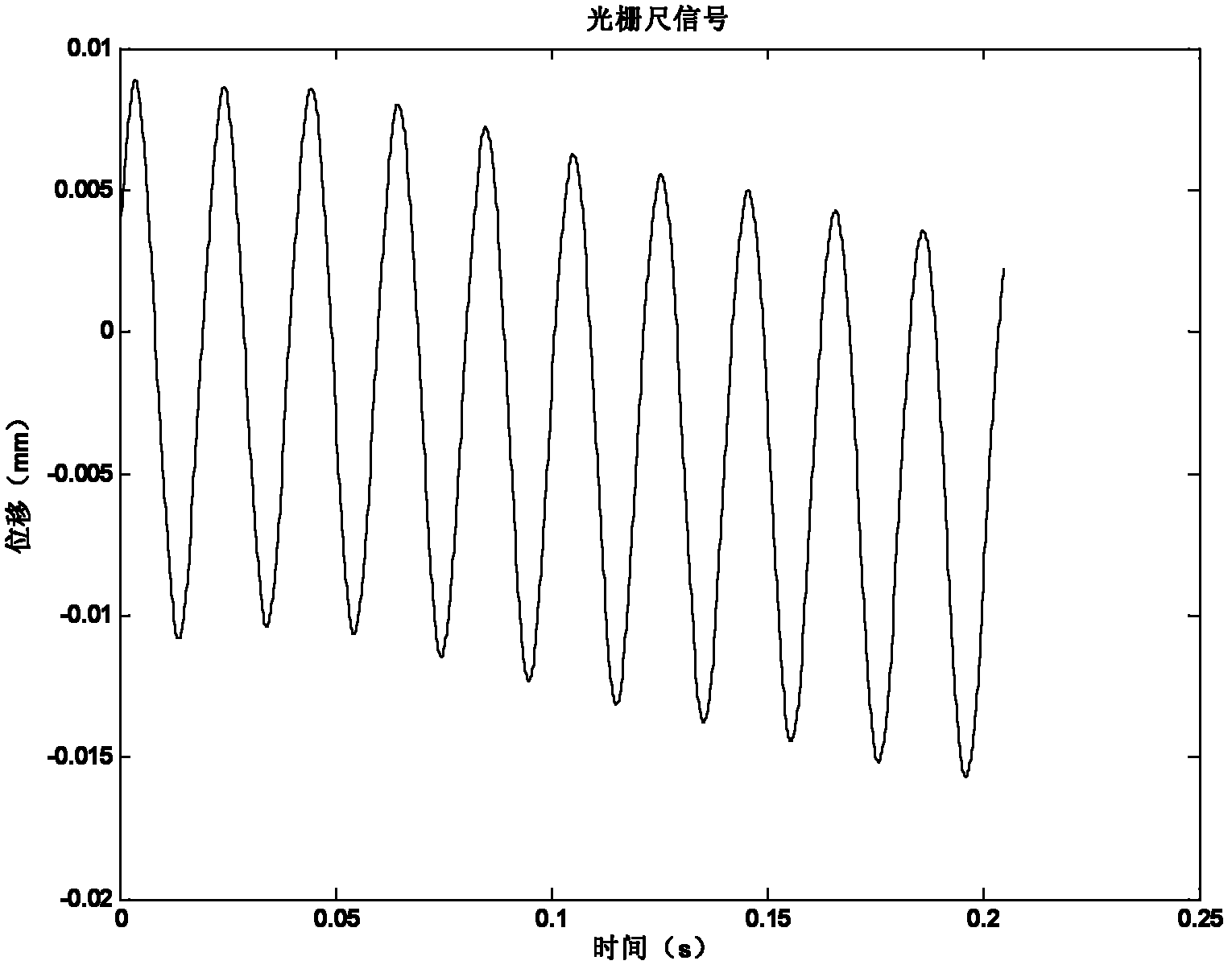

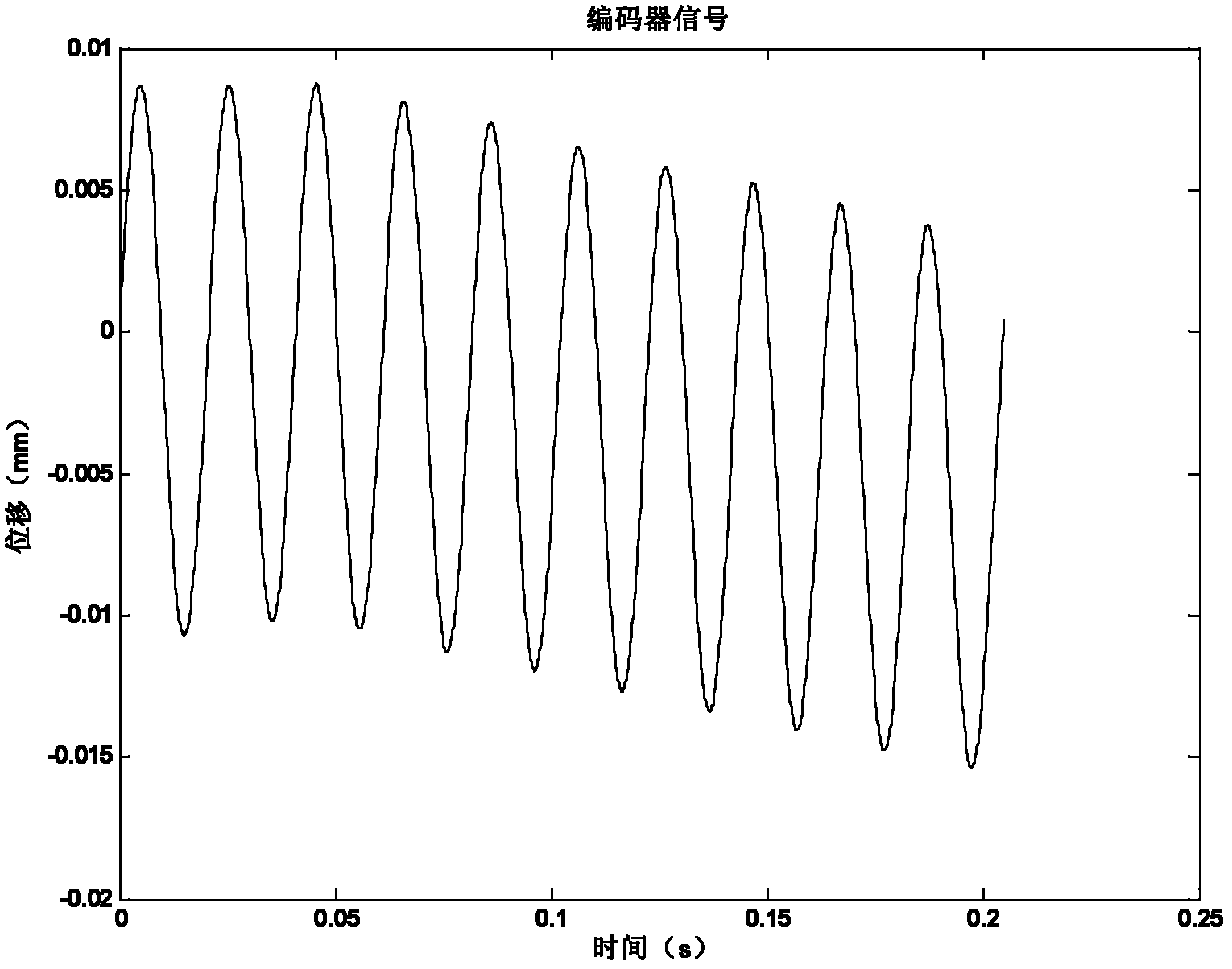

Modal testing method of numerical control machine tool feed system based on built-in sensors

ActiveCN102658503AReduce testing costsRealize online testMeasurement/indication equipmentsNumerical controlModal testing

The invention discloses a modal testing method of a numerical control machine tool feed system based on built-in sensors. The method comprises the following steps: a numerical control machine tool worktable is moved in accordance with given excitation signals, and at the same time servo motor current signals, motor coder signals and grating scale signals are acquired synchronously by using a signal acquisition device; the motor current signals are multiplied by the torque constant of a motor to produce the torque of the motor; second order difference is performed on the coder signals and the grating scale signals to produce acceleration signals of the worktable and angular acceleration of a screw rod; a frequency response function of the torque of the motor and an acceleration of the worktable and a frequency response function of the torque of the motor and an angular acceleration of the screw rod are calculated; fitting is performed on the two frequency response functions to obtain a fitted frequency response function; and axial modal parameters and torsional modal parameters are calculated finally. Compared with conventional modal testing methods, the novel method provided in the invention reduces cost of tests, and can realizes on-line testing of feed system modal parameters.

Owner:XI AN JIAOTONG UNIV

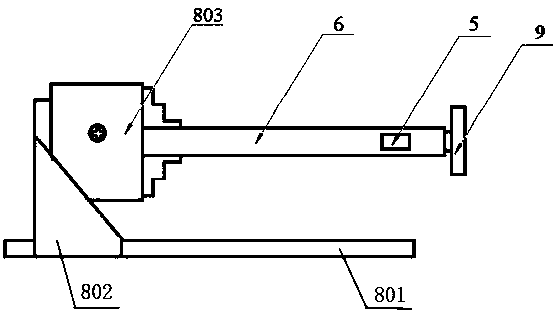

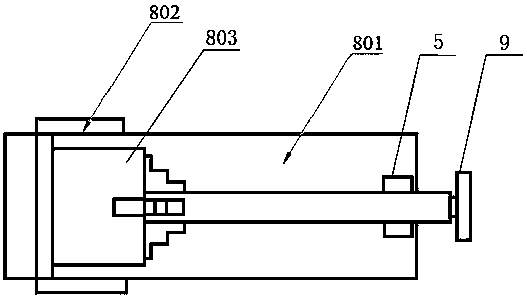

Device and method for measuring dynamic elasticity modulus in temperature environment

InactiveCN102620984AFree from destructionStable vibration effectStrength propertiesModal testingDynamic modulus of elasticity

The invention discloses a device and a method for measuring dynamic elasticity modulus in the temperature environment. The technical scheme of the device includes that a beam-shaped test piece is clamped on a fixed rigidity table in a manner of a cantilever state with one end fixed and the other end free; by the aid of a resistance heating device, a thermocouple feeds back temperature and a temperature controller controls heating and temperature of the test piece, a piezoelectric ceramic vibration exciter mounted on the test piece receives excitation signals amplified by a signal amplifier toexcite the test piece, a laser vibration measurer performs modal tests on the test piece in the temperature environment, a computer receives signals of the laser vibration measurer, acquires fixed frequency and modal of each step in the controlled temperature environment through signal analysis and calculates dynamic elasticity modulus of materials in the controlled temperature environment by tested fixed frequency according to the relation between the fixed frequency and the elasticity modulus. The device has the advantages of nondestructive testing, convenience in use and operation, high measuring accuracy and the like.

Owner:BEIHANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com