Device and method for testing torsional rigidity and mode of shafting

A technology of torsional stiffness and torsional mode, applied in measurement devices, vibration testing, testing of mechanical components, etc., can solve the problems of difficulty in measuring excitation torque and difficulty in implementing the frequency response method, and achieve easy implementation, high precision, and easy operation. convenient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] To make the above-mentioned purposes, features and advantages of the present invention more obvious and understandable, below in conjunction with the attached Figure 1 to Figure 5 The present invention will be further described in detail with specific embodiments.

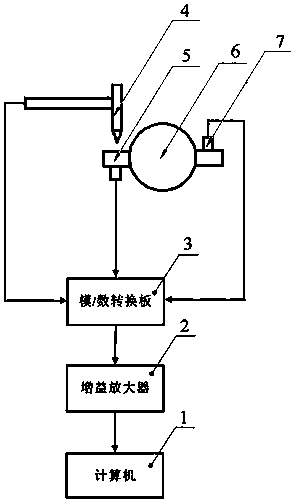

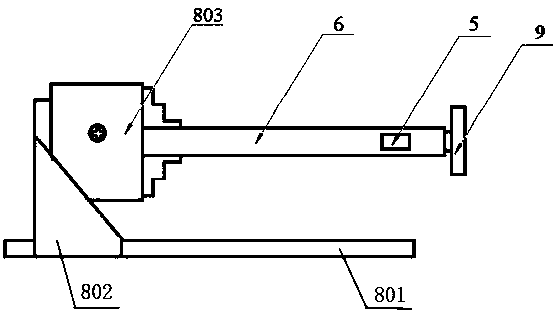

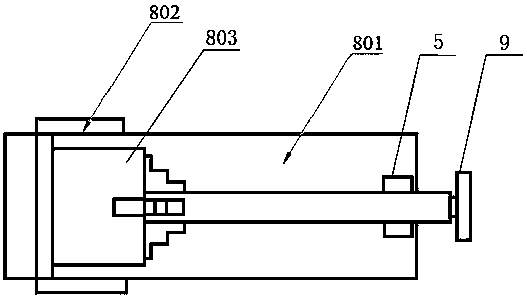

[0034] The device used in this embodiment to indirectly test the torsional stiffness and mode of the shaft system, such as figure 1 As shown, it includes an acceleration sensor 7 , an analog / digital conversion board 3 , a gain amplifier 2 and a computer 1 , a fixed stand 8 , a shaft to be measured 6 , an additional block 5 and a force hammer 4 . Among them, the acceleration sensor 7 is used to collect the acceleration signal of the additional block 5 on the shaft 6 and convert it into a voltage signal; the hammer 4 is used to excite the shaft 6 to generate modal vibration and generate a corresponding voltage according to the excitation force Signal, according to the material and weight of the shaft to be t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com