Patents

Literature

46 results about "Modal coupling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Testing method for unmanned plane flight-control structure modal coupling

InactiveCN102566440AGuaranteed scope coverageAvoid Signal Amplitude CollapseSimulator controlModal couplingComputer science

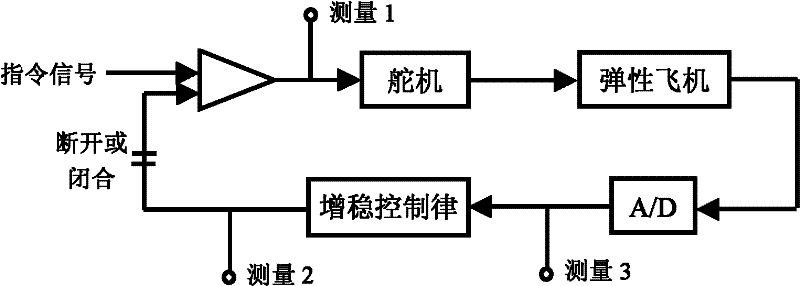

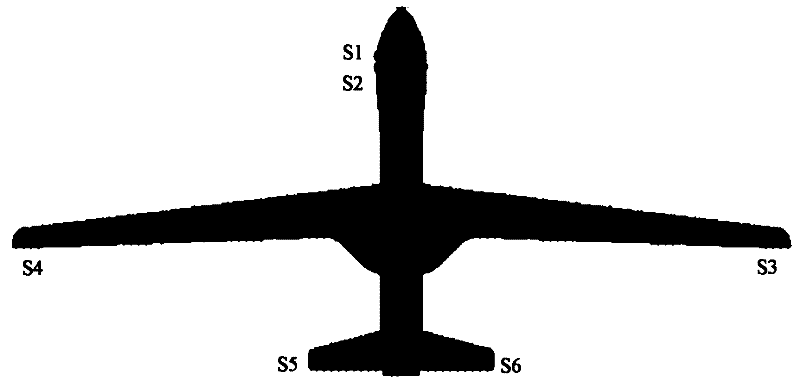

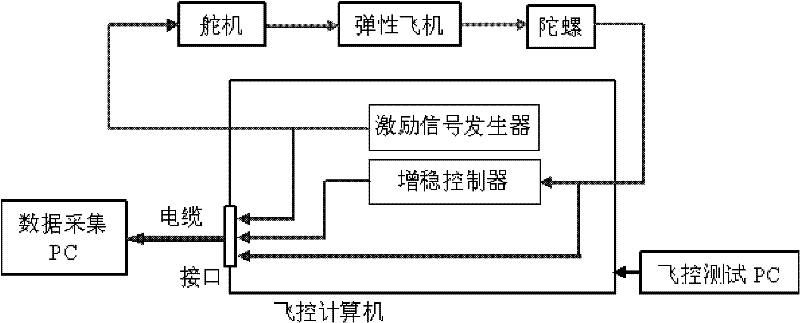

The invention discloses a testing method for unmanned plane flight-control structure modal coupling, and aims at providing a flight-control structure modal coupling testing method which can save resources, so as to solve the problems that stimulation signals are not injected, states of a plane cannot be effectively confirmed, a control loop cannot be divided reasonably in a unmanned plane flight-control structure modal coupling test. The method is realized by following measures that: a flight-control computer is adopted to compile software which can automatically generate stimulation signals, the flight-control computer uses received comprehensive inspection vehicle signals to generate agreement stimulation signals and plane control surface stimulation signals which are used as input of the test, ground states and air states are divided according to flight configuration conditions, vibration sensors used for monitoring plane vibration conditions are arranged on the head of the plane, the wing tip ends of swings and the wing tip end of a V-shaped tail wing, and parameters of the vibration sensors can be directly monitored by an oscilloscope.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

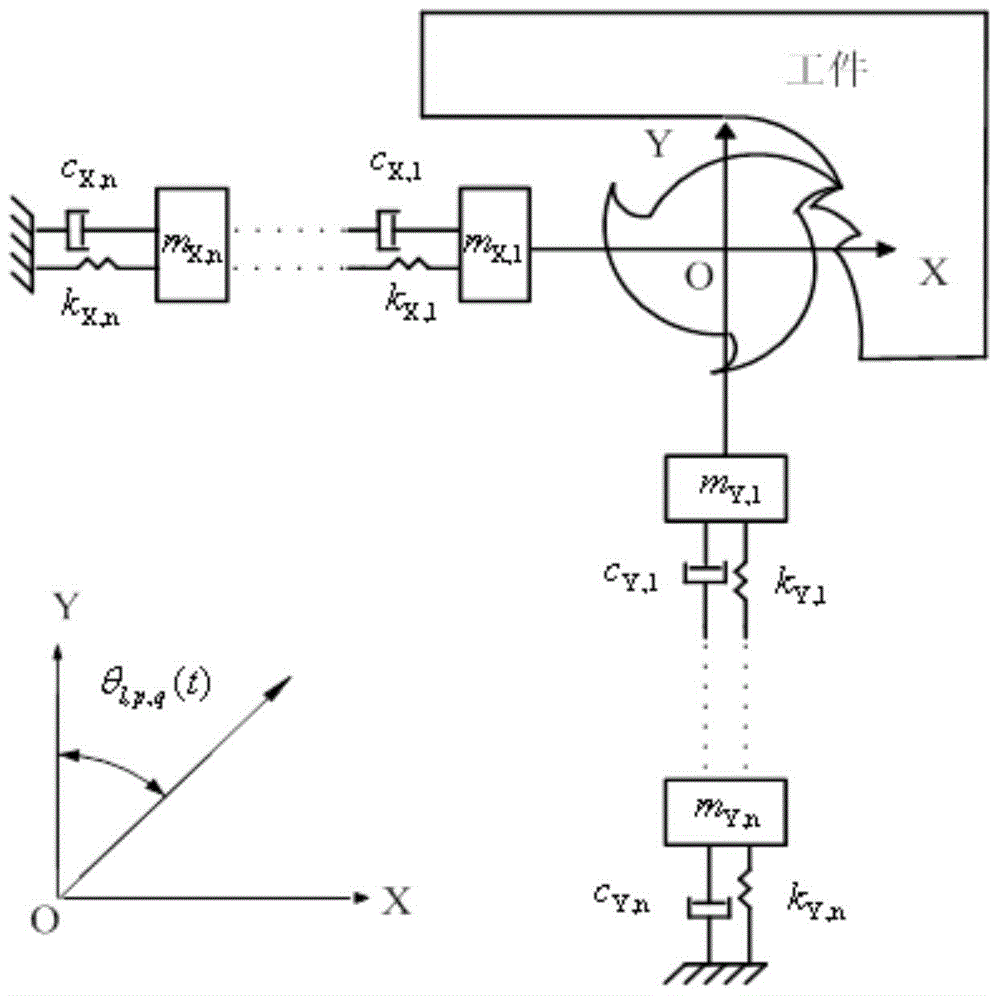

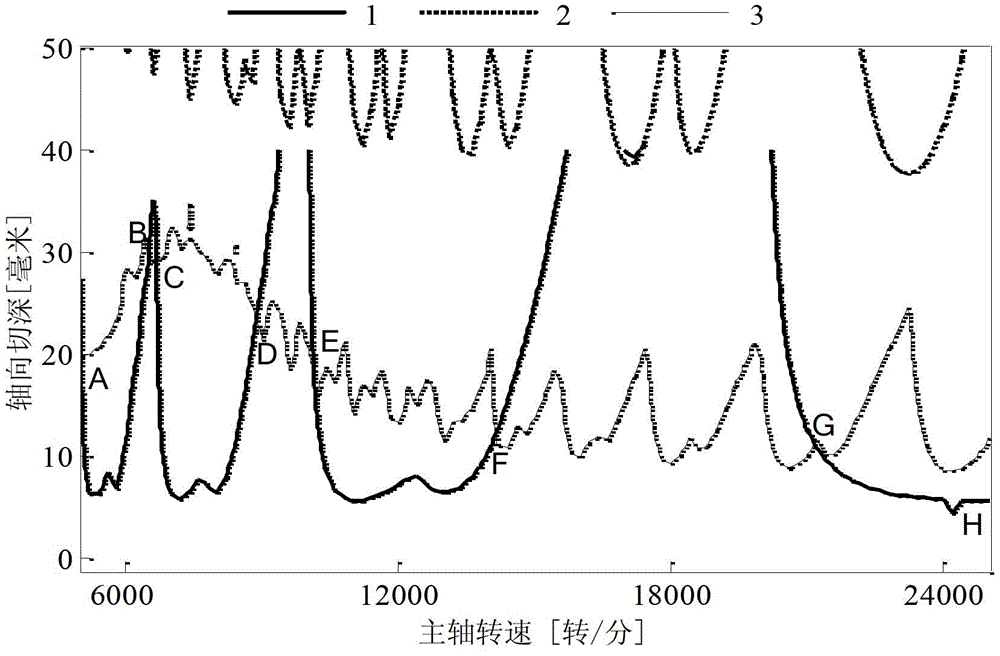

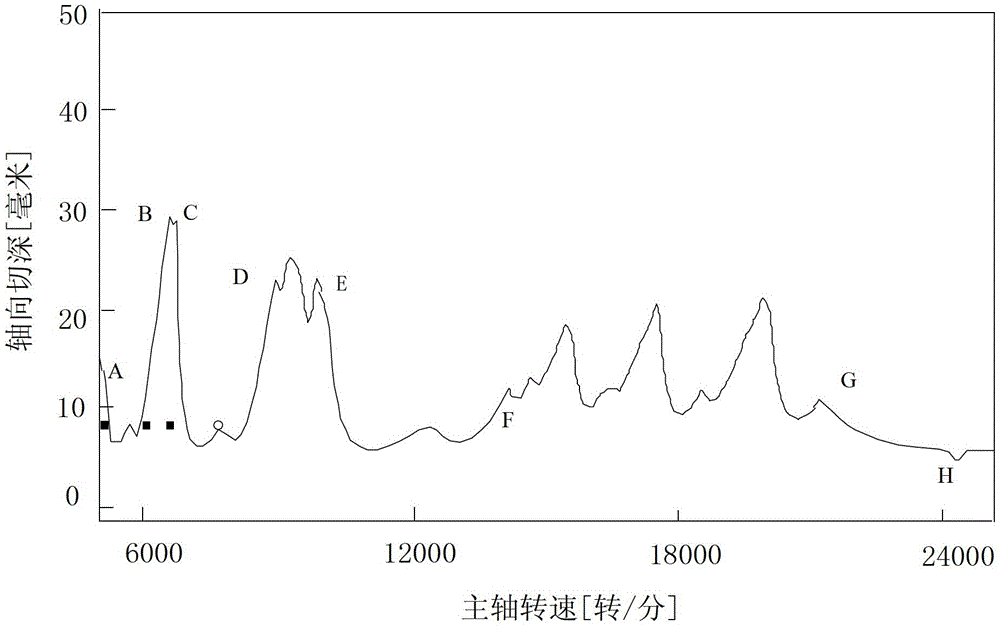

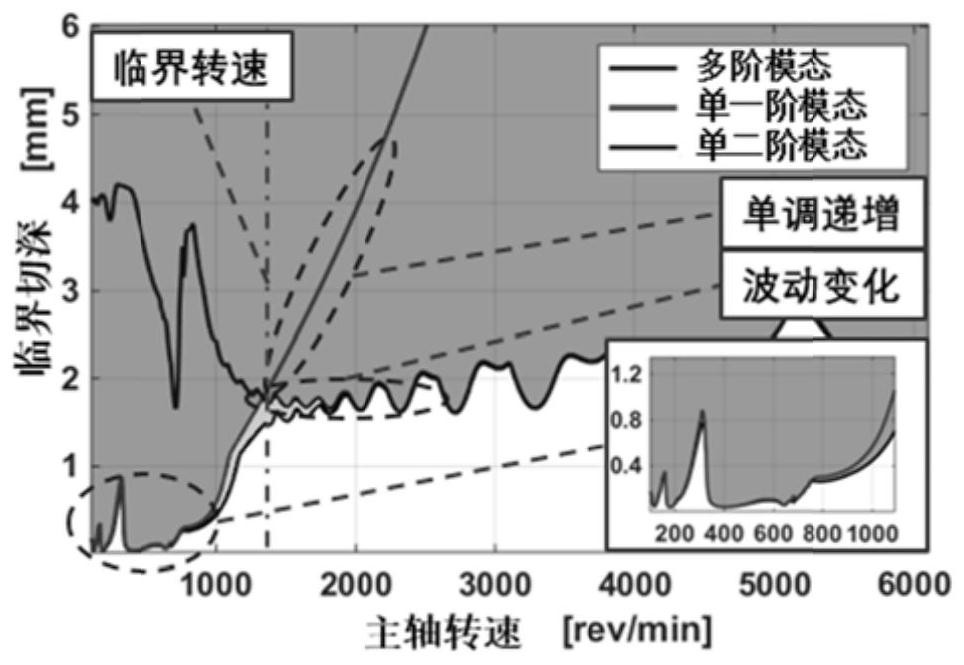

Milling stability domain prediction method under multi-modal coupling

ActiveCN103559550AImprove forecasting efficiencyImprove efficiencyForecastingProcess systemsModal testing

The invention discloses a milling stability domain prediction method under multi-modal coupling to solve a technical problem that the efficiency of an existing milling stability domain prediction method is low. The technical scheme is that firstly the transmission function of a process system is determined through a modal test experiment, then modal parameters are extracted from the transmission function and two orthogonal direction modal parameters are paired and combined, a milling test is carried out to calibrate a milling force coefficient, based on the milling force coefficient and each scale of modal parameters, an improved semi discrete method is employed to obtain a stability lobe diagram under each scale of modals, and finally lobe diagrams under obtained from each scale of modals are drawn in a same coordinate system to obtain a stable domain under multi modal coupling. Through a test, when a cutting cycle is divided into 40 sections, 80 sections and 120 sections, compared with a background technology method, the method can save time for 4949.6 seconds, 74200.4 seconds and 344699.5 seconds, and the efficiency is increased by 85.9%, 92% and 88.5%.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

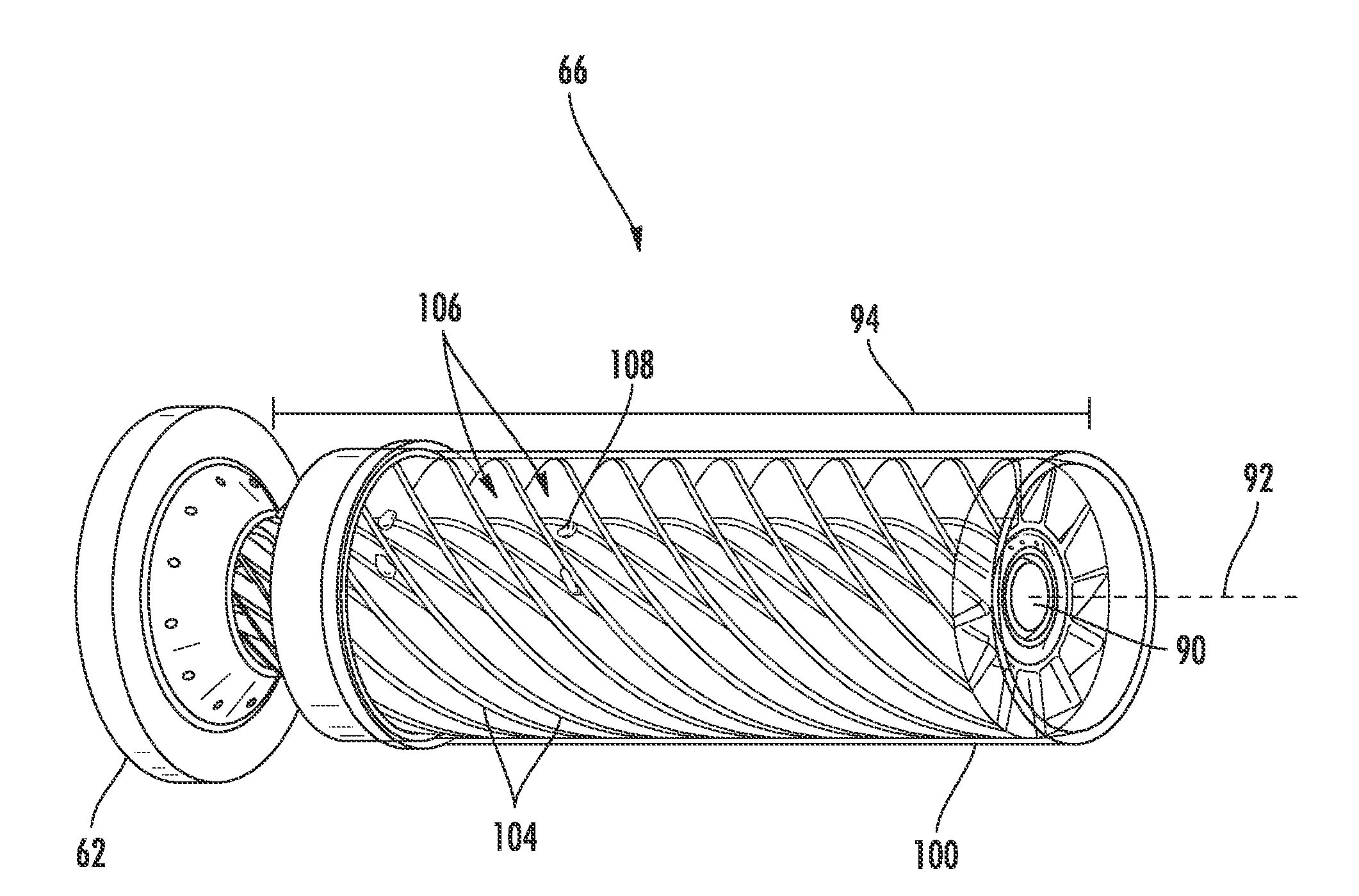

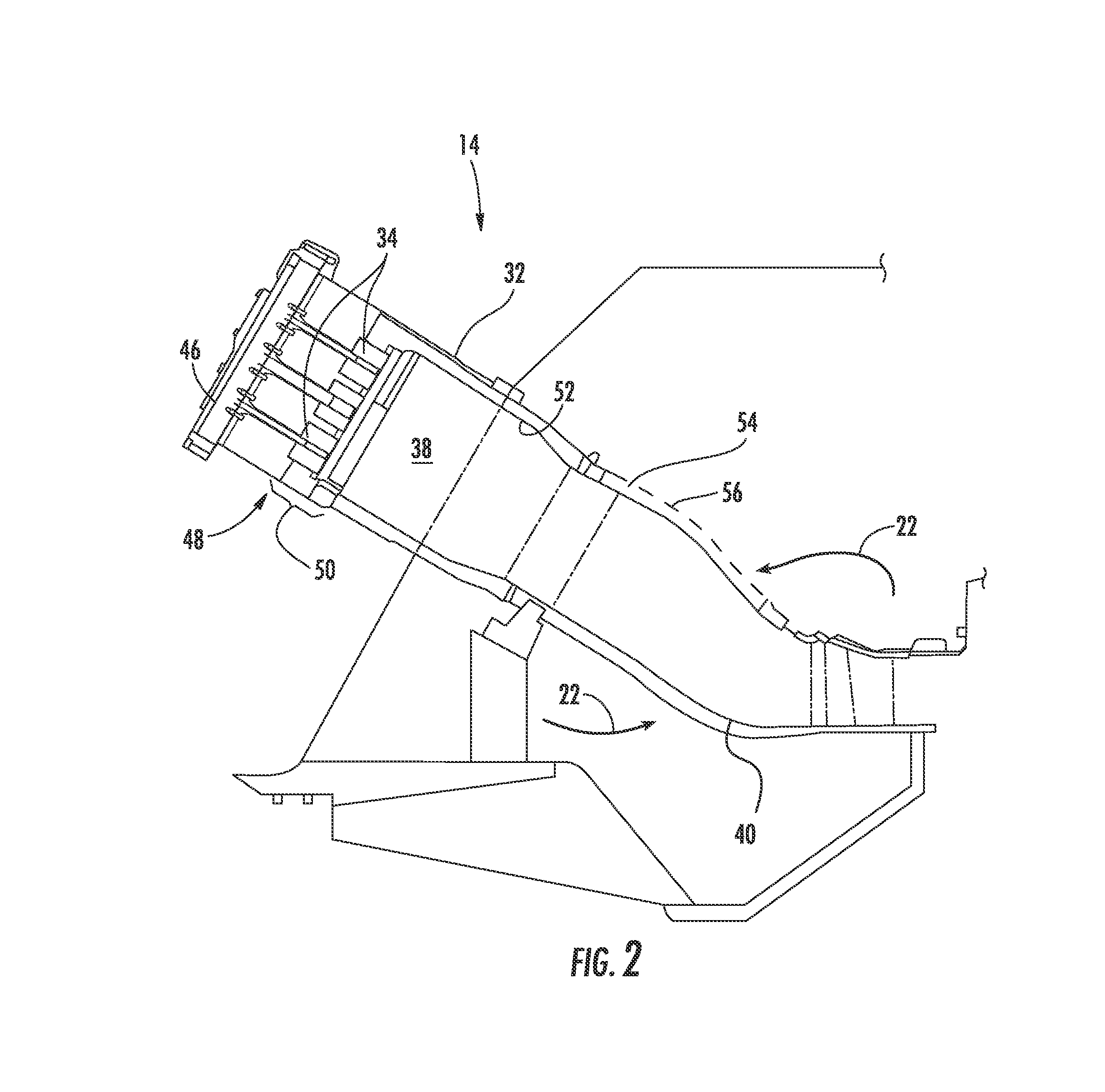

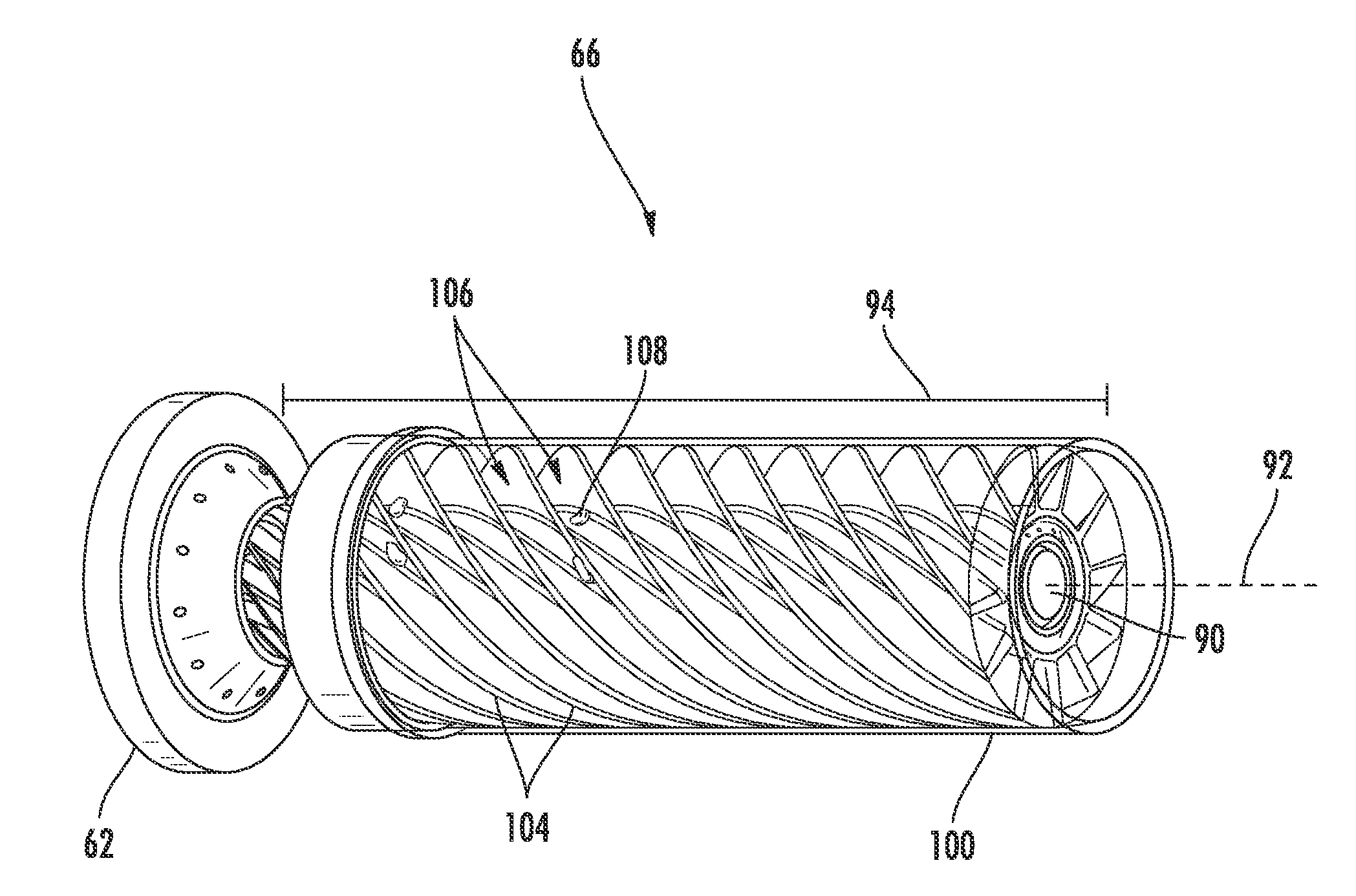

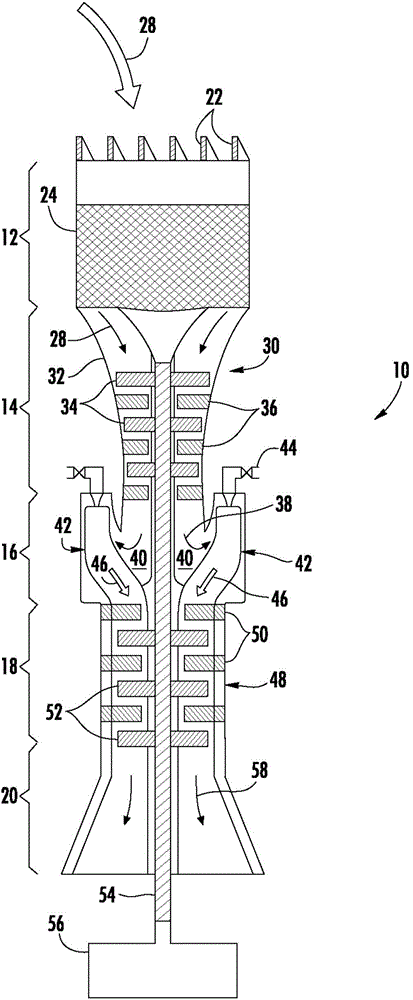

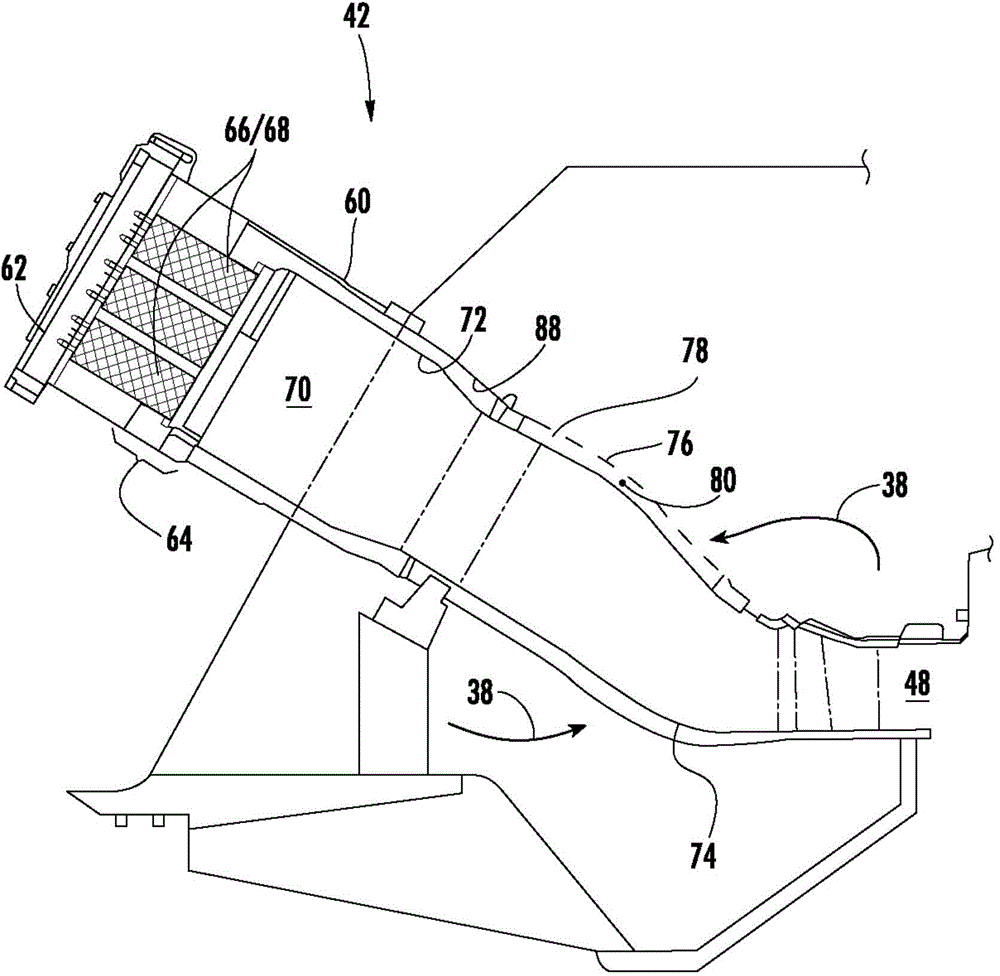

Fuel nozzle for reducing modal coupling of combustion dynamics

A fuel nozzle includes a center body that extends axially along an axial centerline for a length. A shroud circumferentially surrounds the center body for at least a portion of the length of the center body. A plurality of helical passages circumferentially surround the center body along at least a portion of the length of the center body, and a fuel port in each helical passage has a different convective time.

Owner:GENERAL ELECTRIC CO

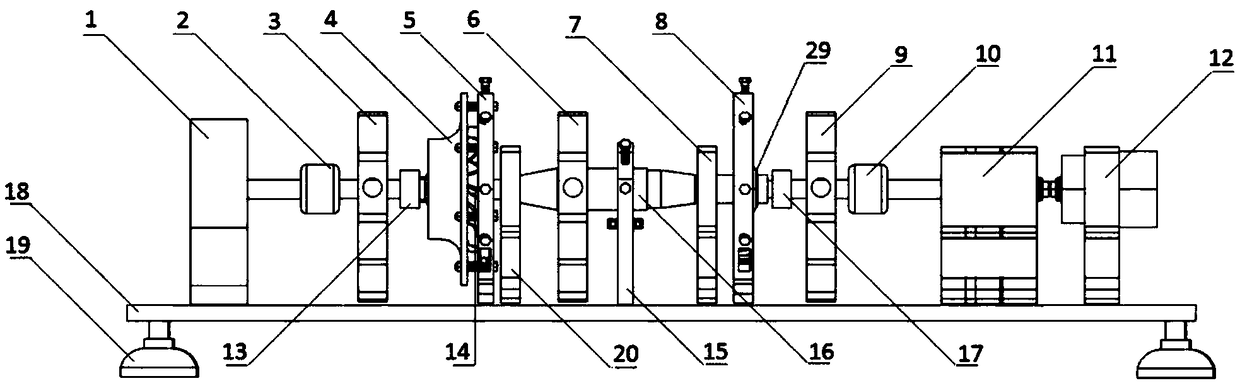

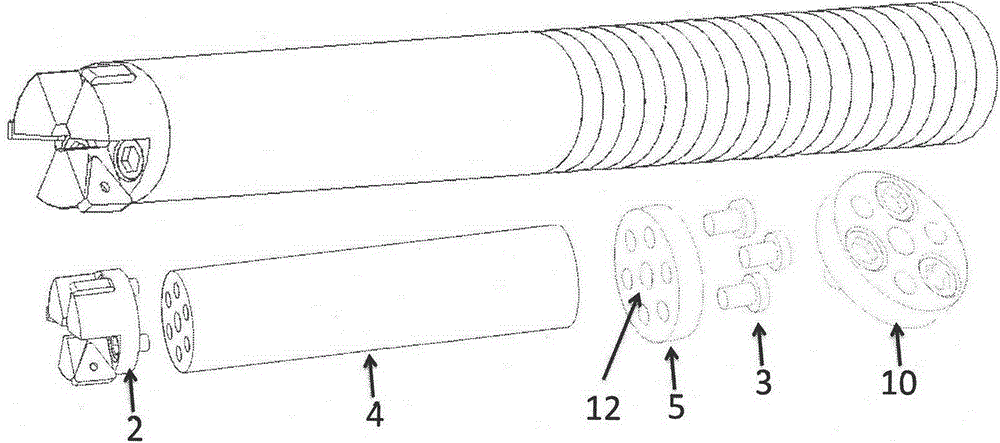

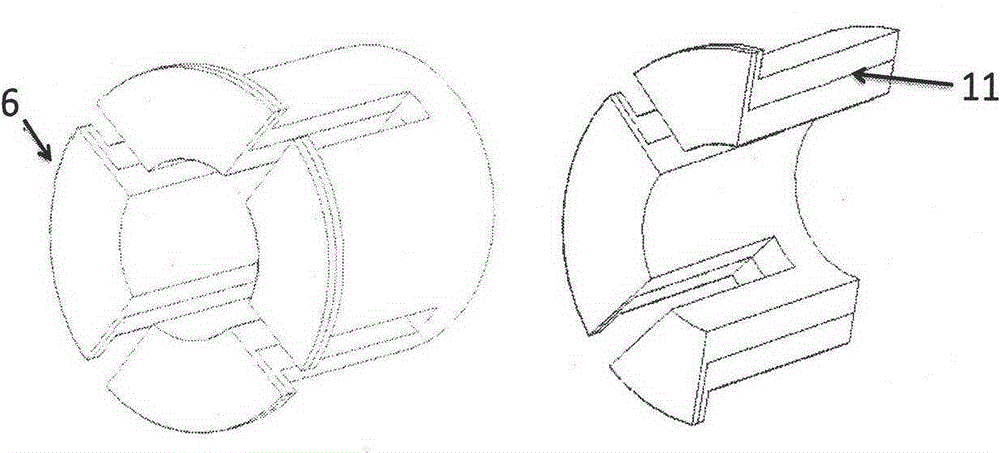

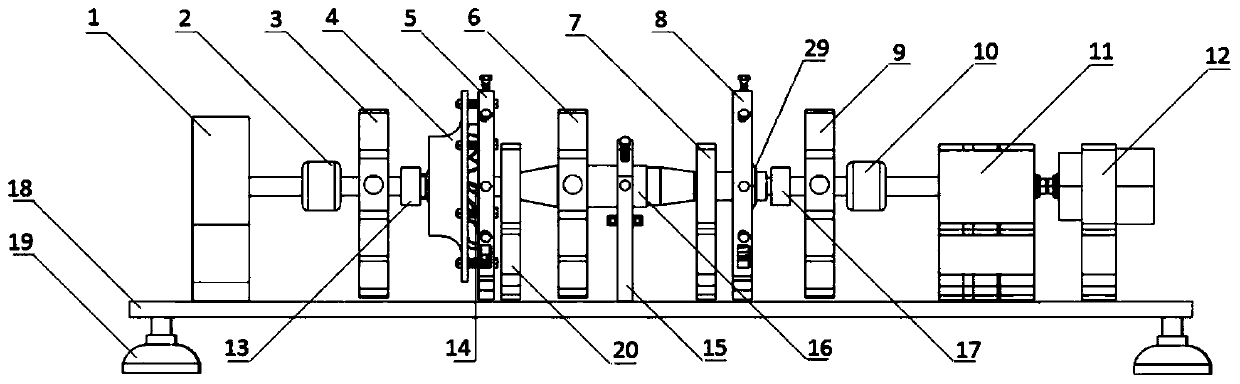

Small aircraft engine multi-point rubbing fault simulation experiment device

A small aircraft engine multi-point rubbing fault simulation experiment device includes a rotor system, a drive system, a rubbing system, a support system, and a measurement and control system. The rotor system adopts a centrifugal compressor and a leaf disc integrated structure axial flow turbine, which is consistent with the real structure of the small aircraft engine; the drive system includesa motor, a speed increaser and a magnetic powder brake; the rubbing system includes a compressor rubbing structure, a turbine rubbing structure and a rotating shaft rubbing structure, wherein each structure is an independent structure, and the structures can be combined with each other to realize multi-position and multi-modal coupling rubbing; the measurement and control system includes a motor rotating speed controller, a motor comprehensive protector, a data collector, a displacement sensor and a vibration acceleration sensor, wherein the motor comprehensive protector can prevent damage tothe motor under a high load. The invention can realistically simulate multi-type rubbing faults of the small aircraft engine rotor system at multiple locations, and can be used to study the vibrationresponse of the small aircraft engine under a plurality of frictional coupling effects.

Owner:南京领航智能航空科技有限公司

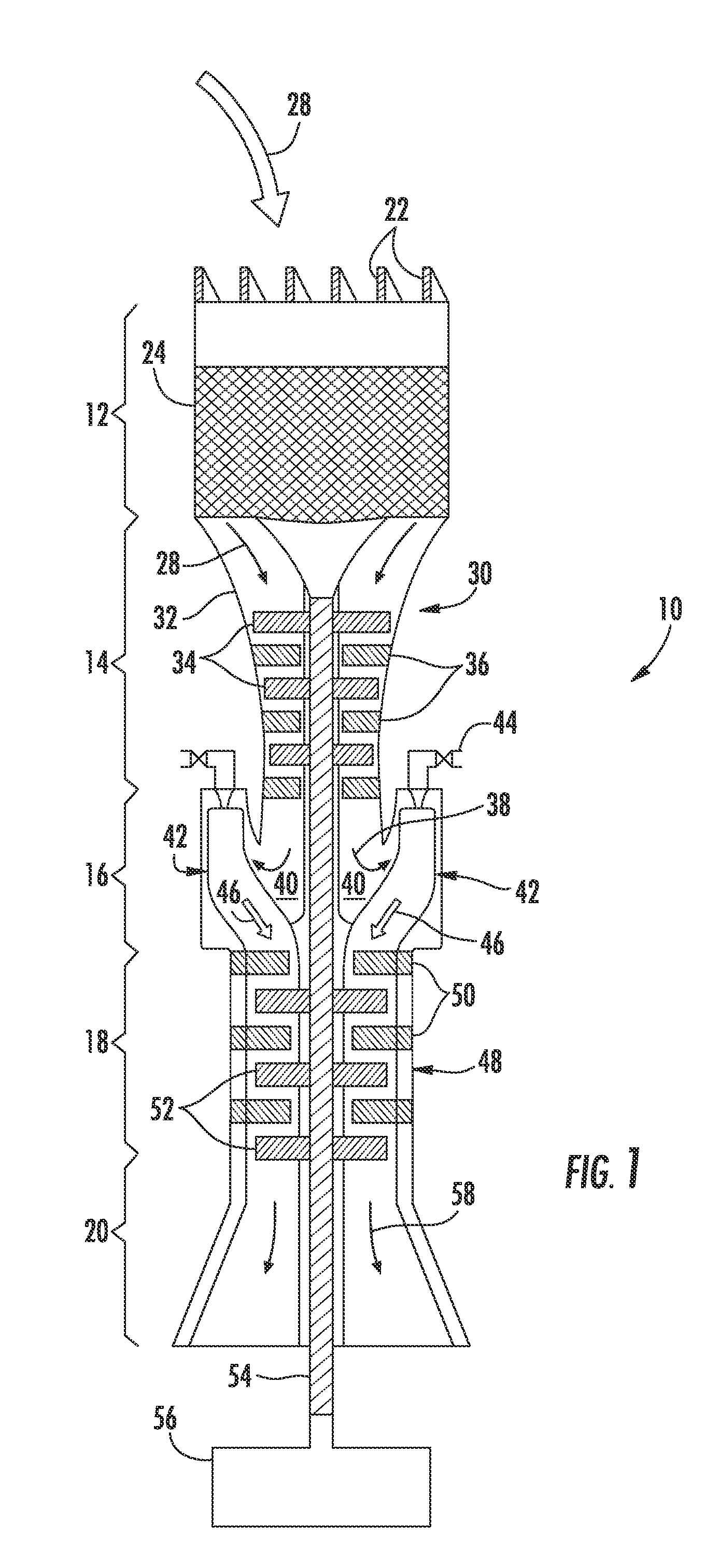

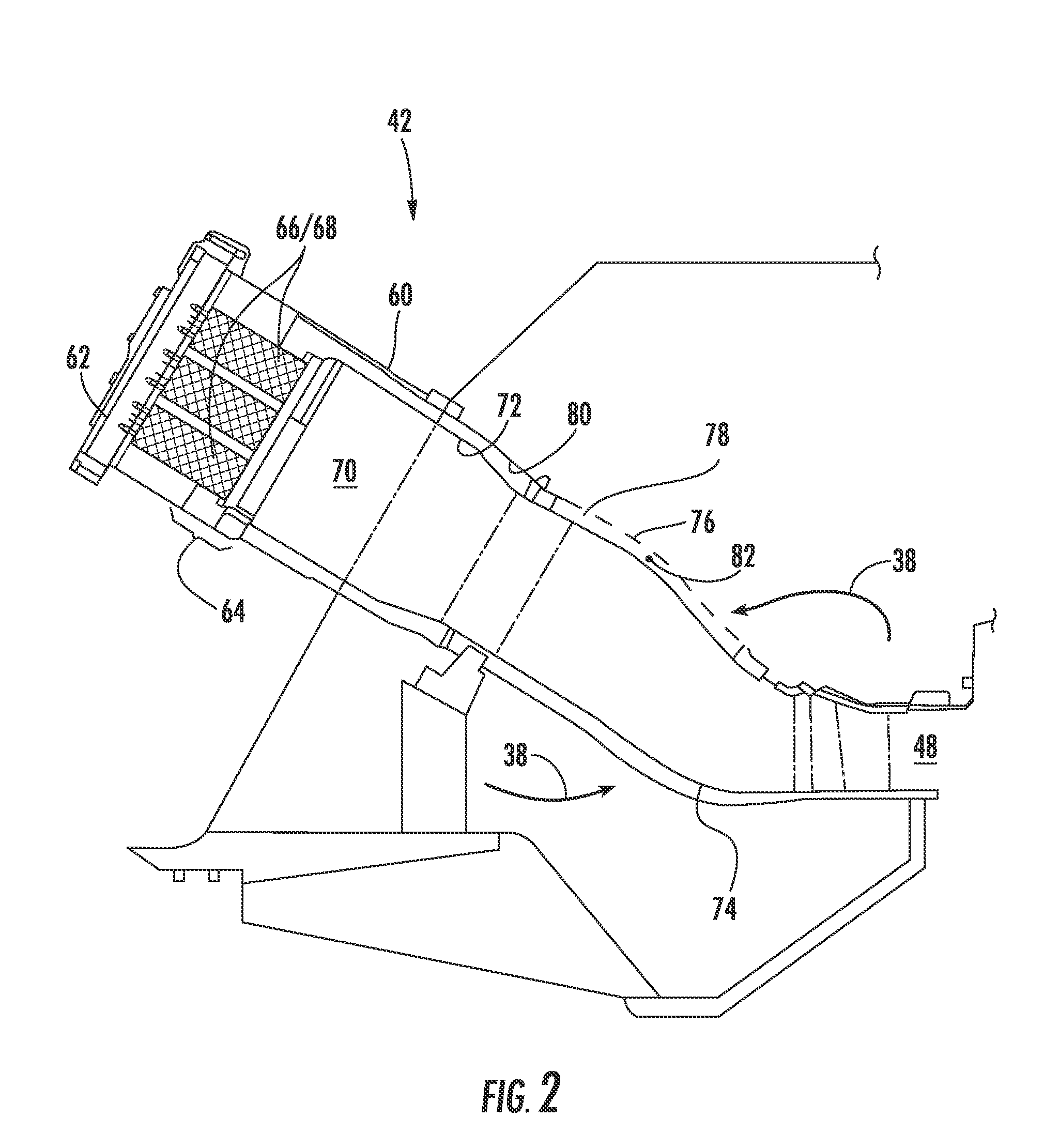

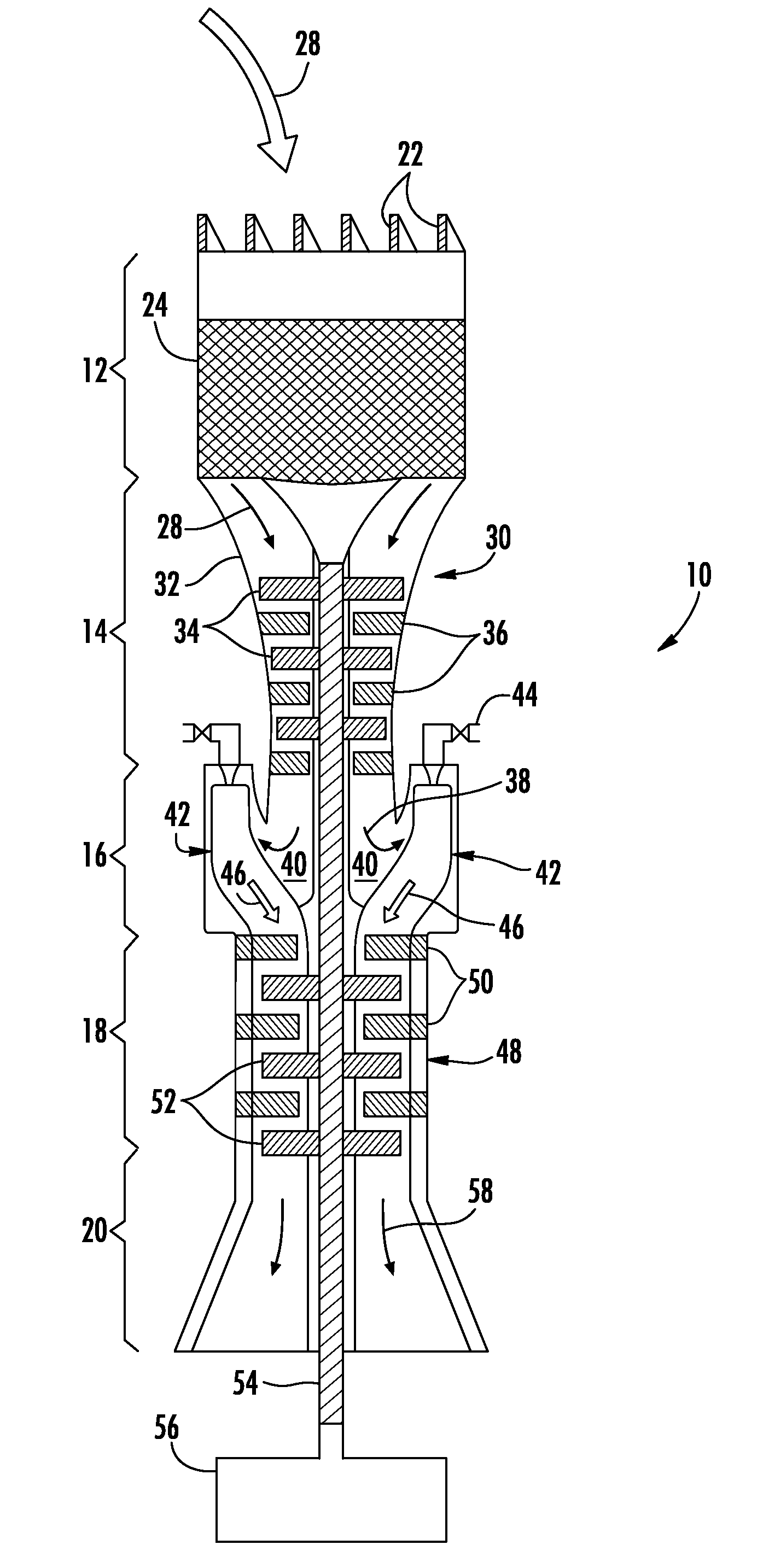

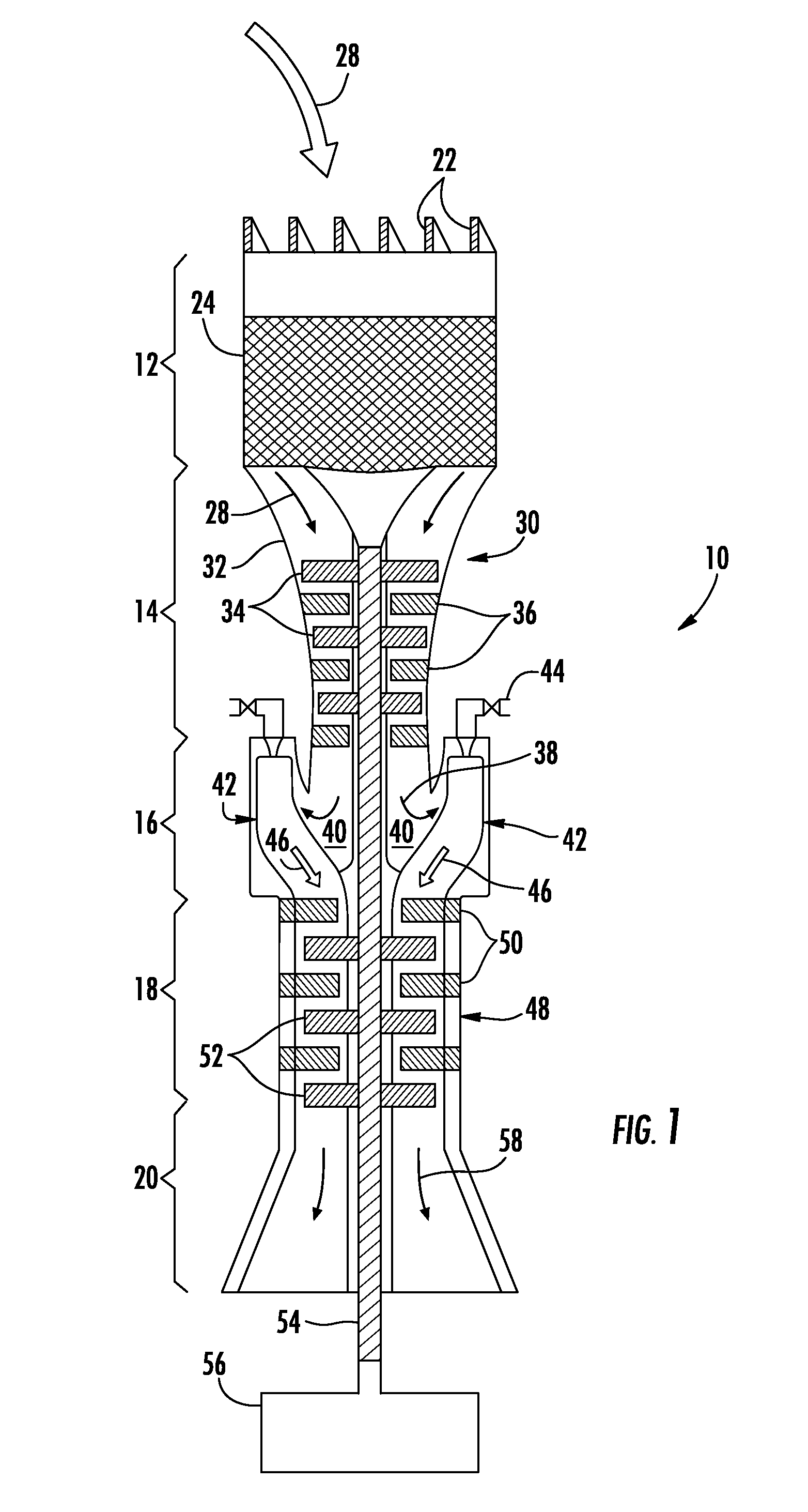

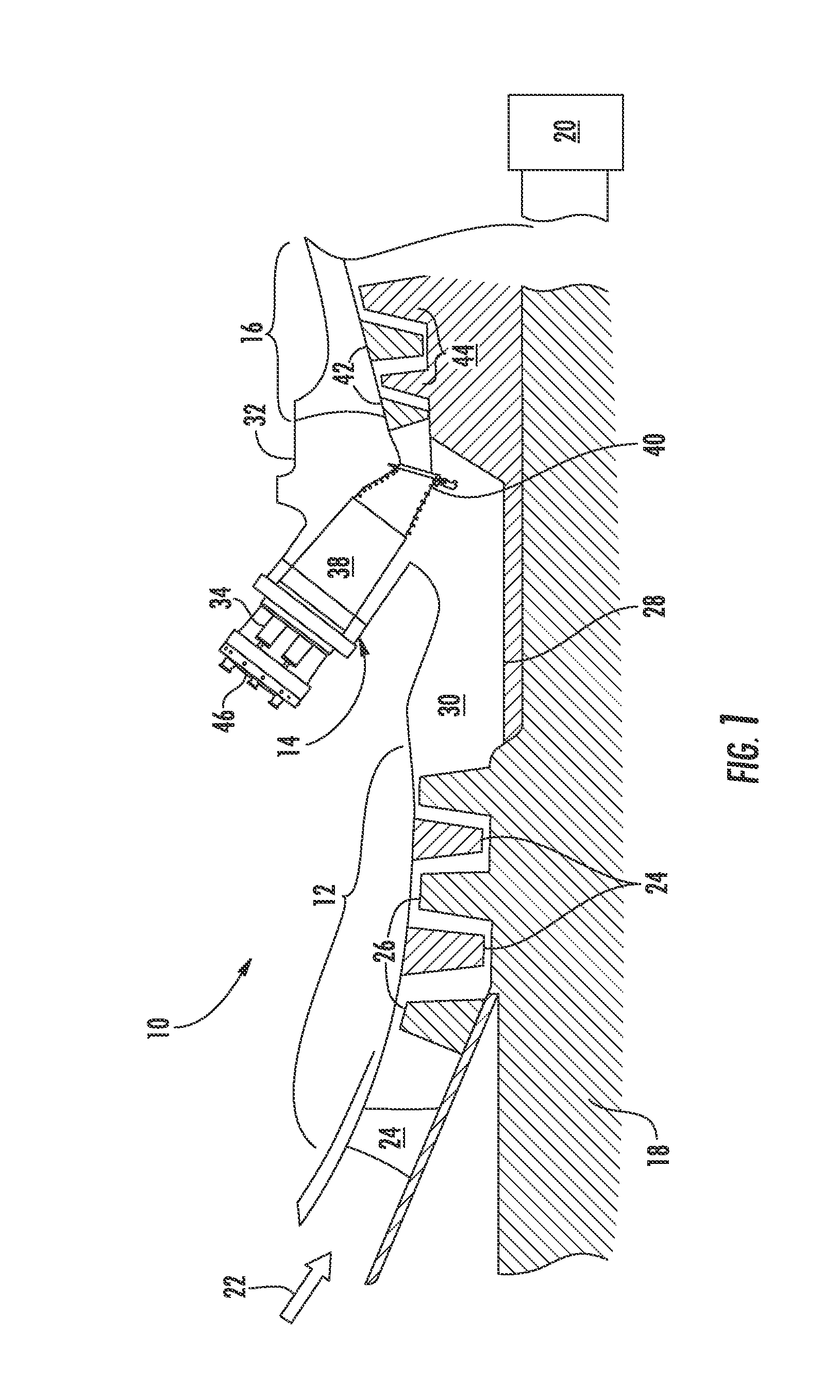

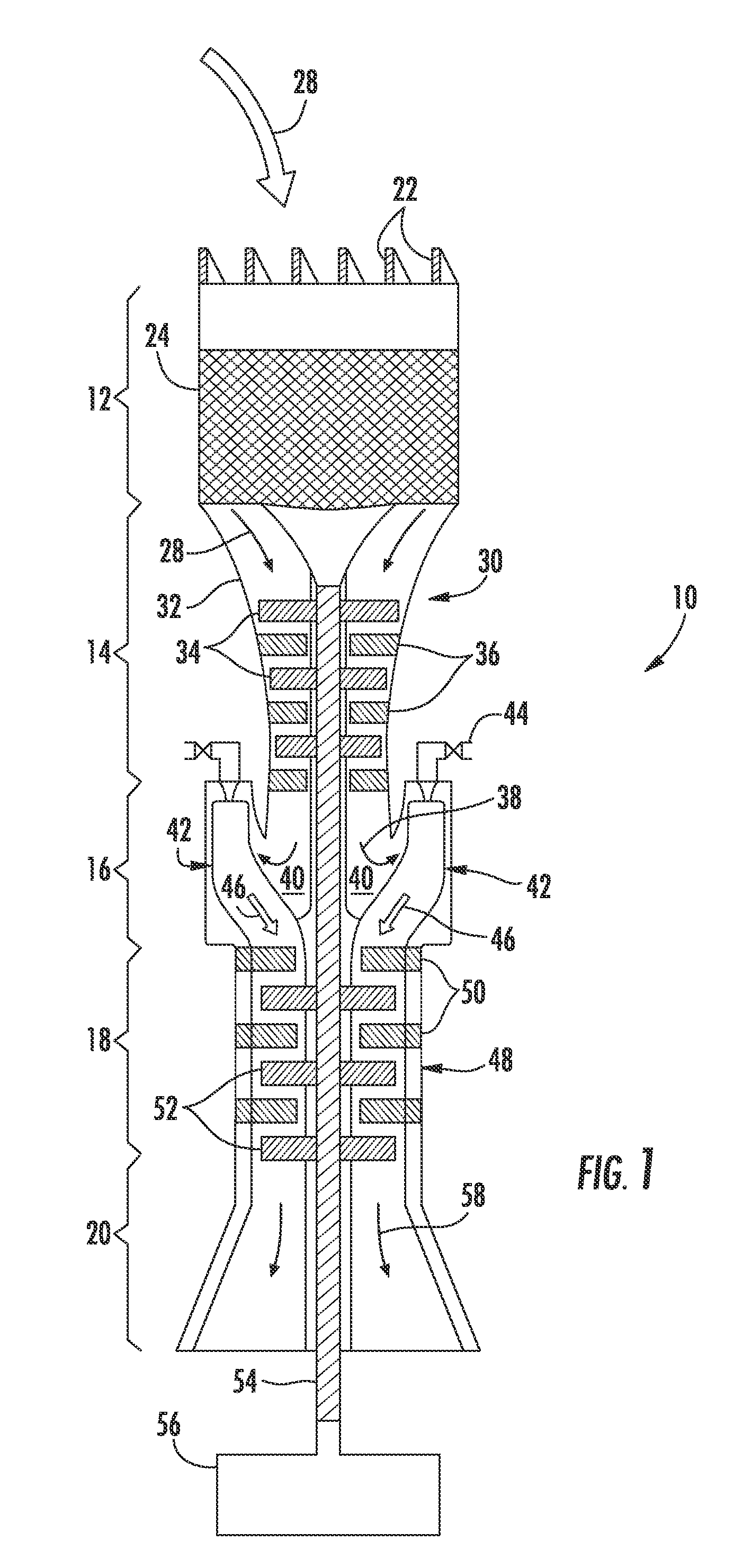

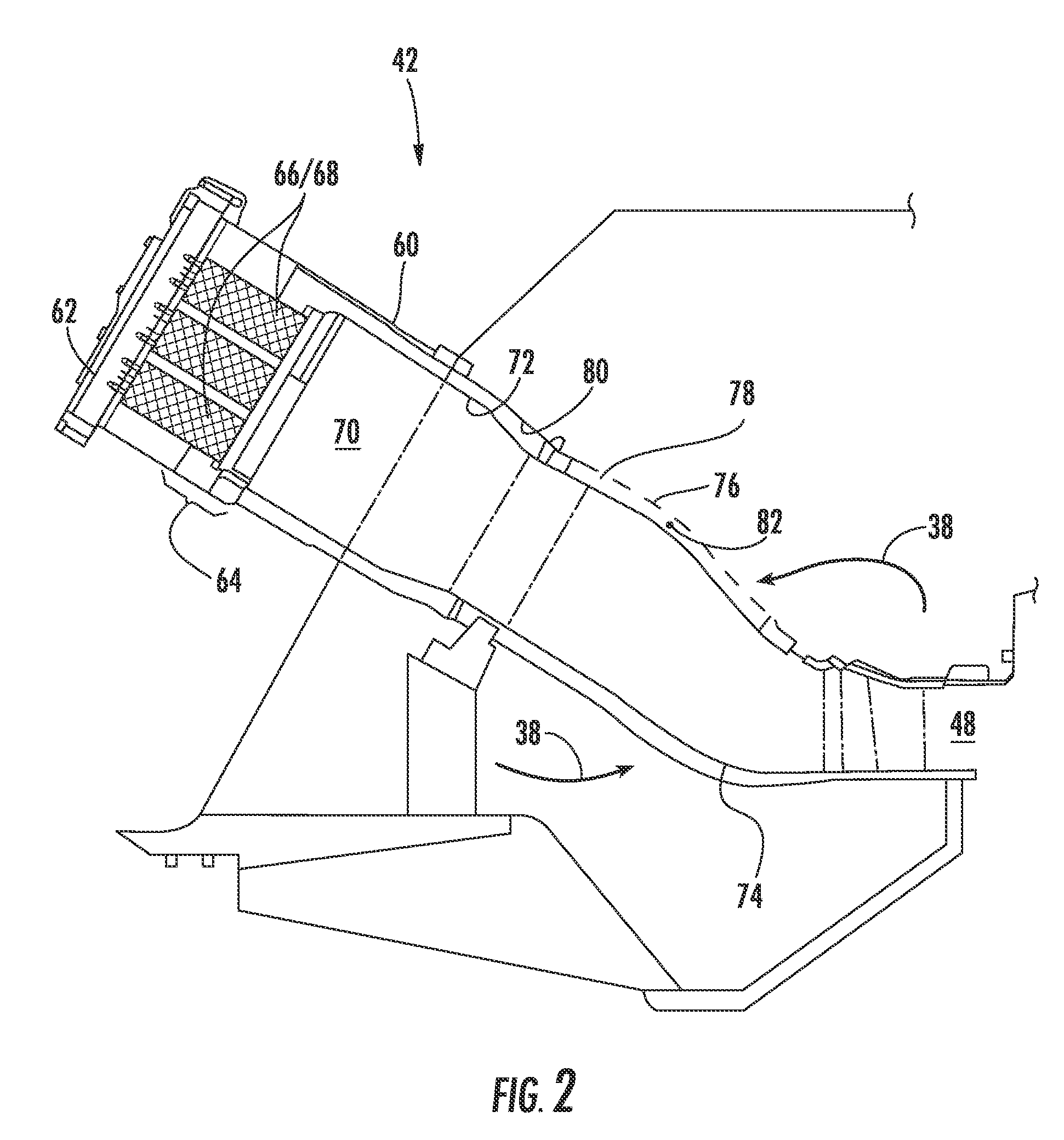

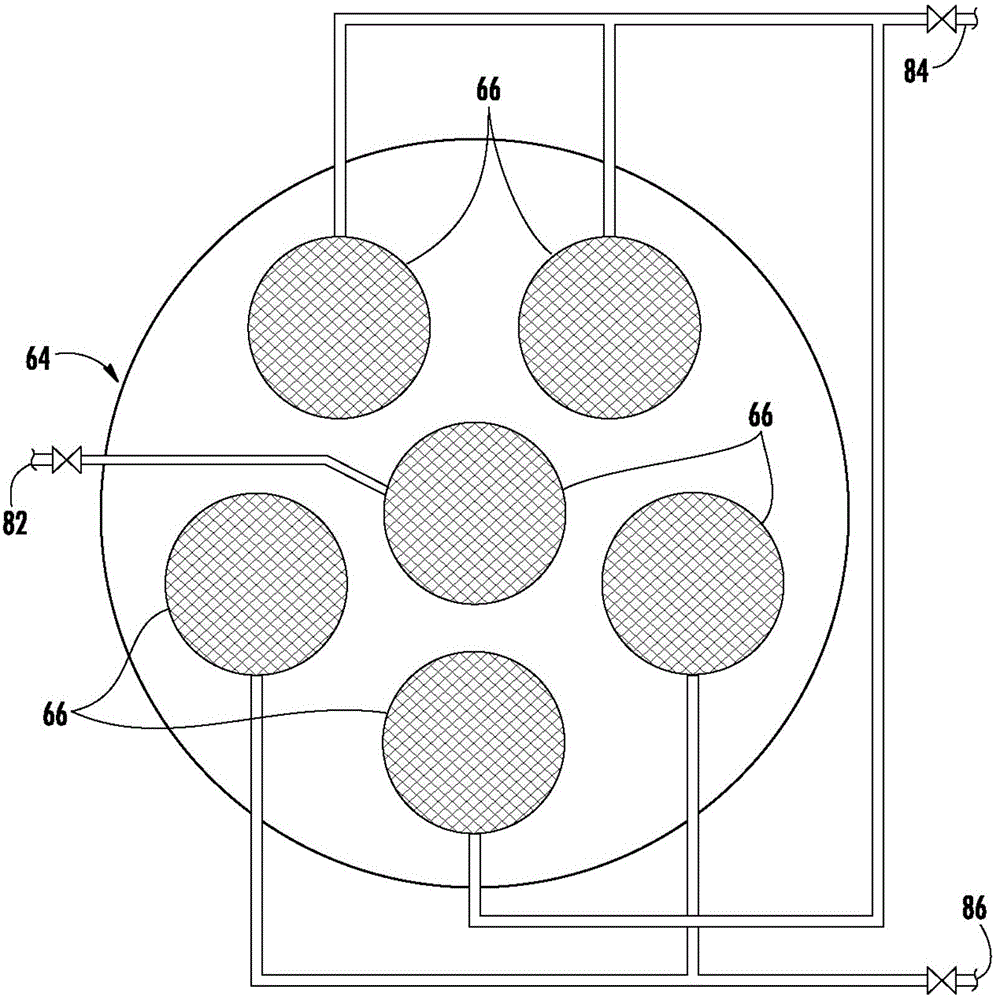

System and method for reducing modal coupling of combustion dynamics

InactiveUS20140137561A1Reducing modal coupling of combustion dynamicContinuous combustion chamberGas turbine plantsCombustion instabilityWorking fluid

A system for reducing modal coupling of combustion dynamics includes a plurality of combustors, and at least one fuel injector in each of the plurality of combustors. The system also includes structure for dithering a combustion instability frequency in at least one combustor in the plurality of combustors. A method for reducing modal coupling of combustion dynamics includes flowing a compressed working fluid at a temperature to a plurality of combustors and flowing a fuel to at least one fuel injector in each of the plurality of combustors. The method further includes dithering at least one of the temperature of the compressed working fluid flowing to the plurality of combustors or the fuel flow to the at least one fuel injector in at least one combustor in the plurality of combustors.

Owner:GENERAL ELECTRIC CO

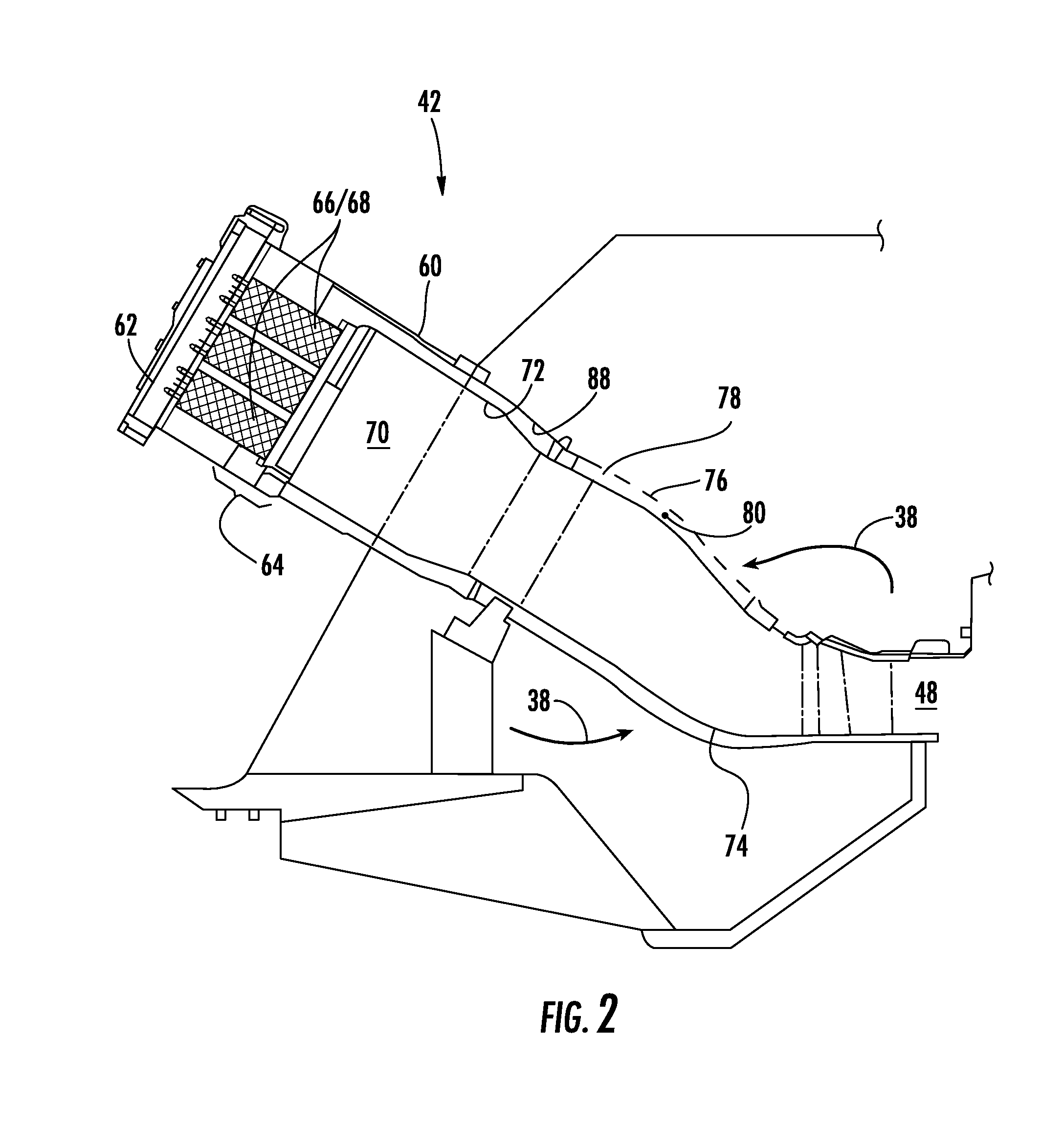

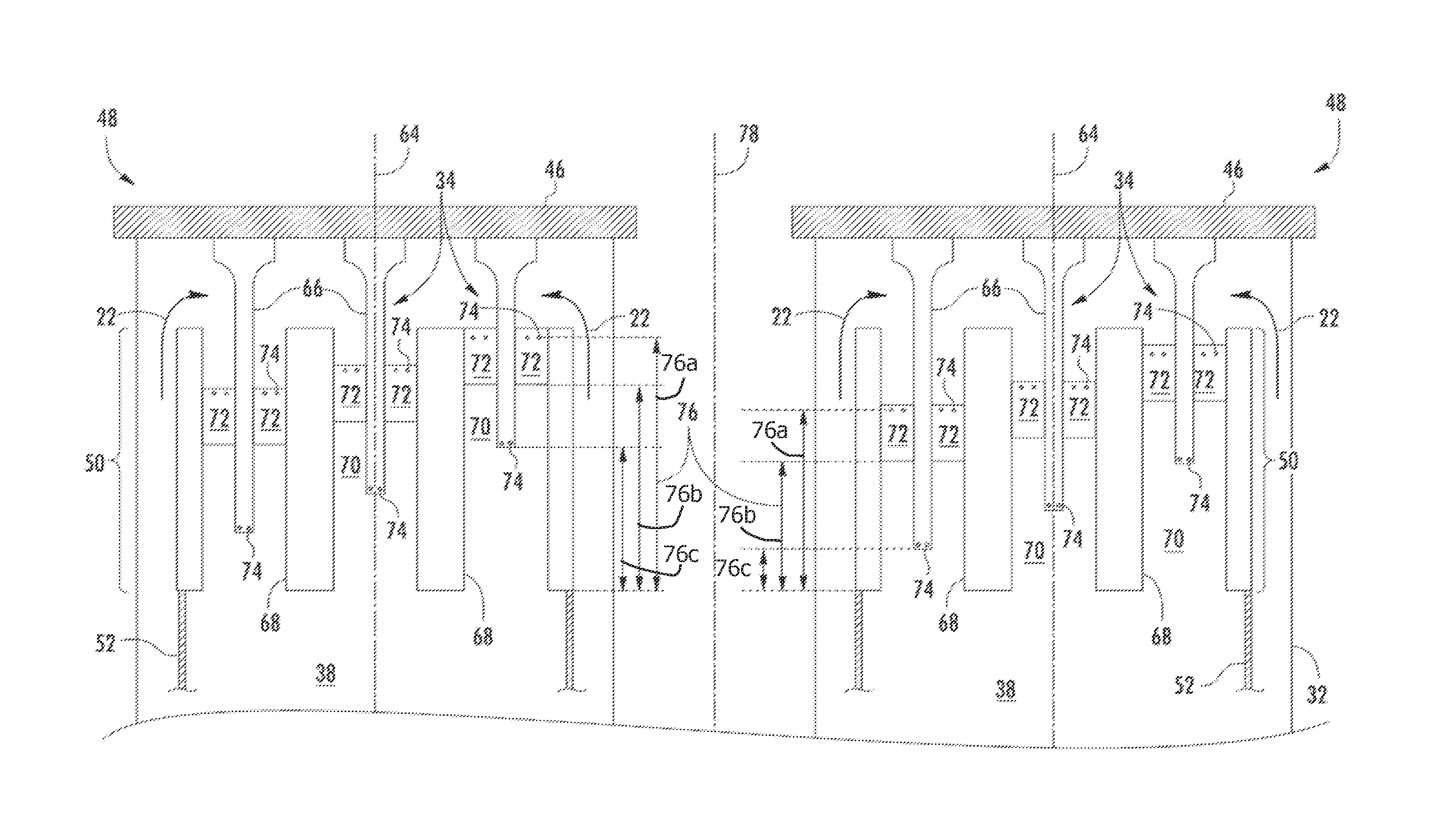

System and method for reducing modal coupling of combustion dynamics

ActiveUS9151502B2Reduce coherenceFrequency instabilityTurbine/propulsion fuel supply systemsContinuous combustion chamberCombustion instabilityCombustion chamber

A system and method for reducing combustion dynamics includes first and second combustors, and each combustor includes a fuel nozzle and a combustion chamber downstream from the fuel nozzle. Each fuel nozzle includes an axially extending center body, a shroud that circumferentially surrounds at least a portion of the axially extending center body, a plurality of vanes that extend radially between the center body and the shroud, a first fuel port through at least one of the plurality of vanes at a first axial distance from the combustion chamber, the plurality of vanes being located at a second axial distance from the combustion chamber. A second fuel port is provided through the center body at a third axial distance from the combustion chamber. The system further includes structure for producing a combustion instability frequency in the first combustor that is different from the combustion instability frequency in the second combustor.

Owner:GENERAL ELECTRIC CO

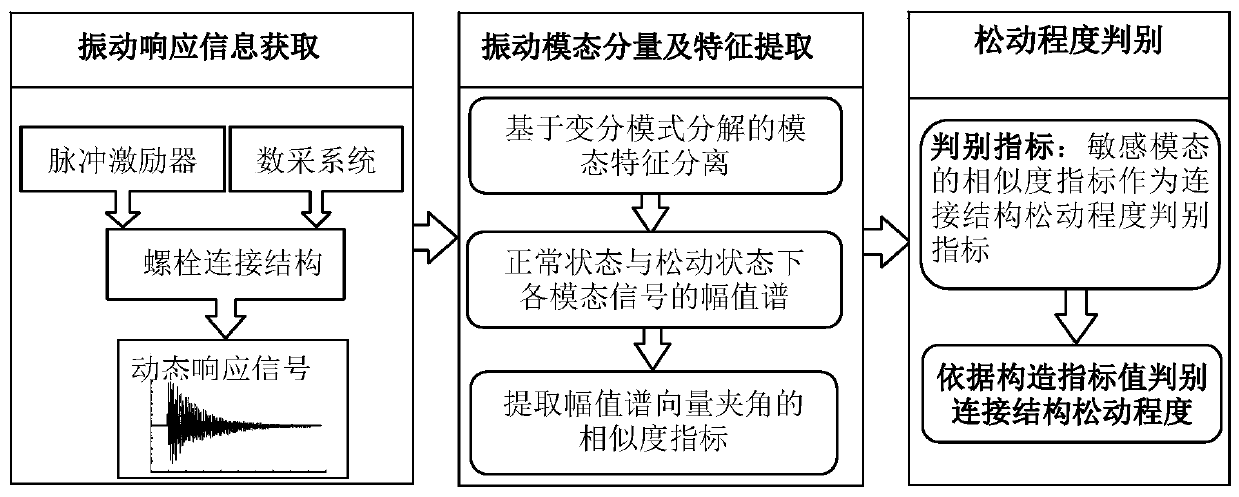

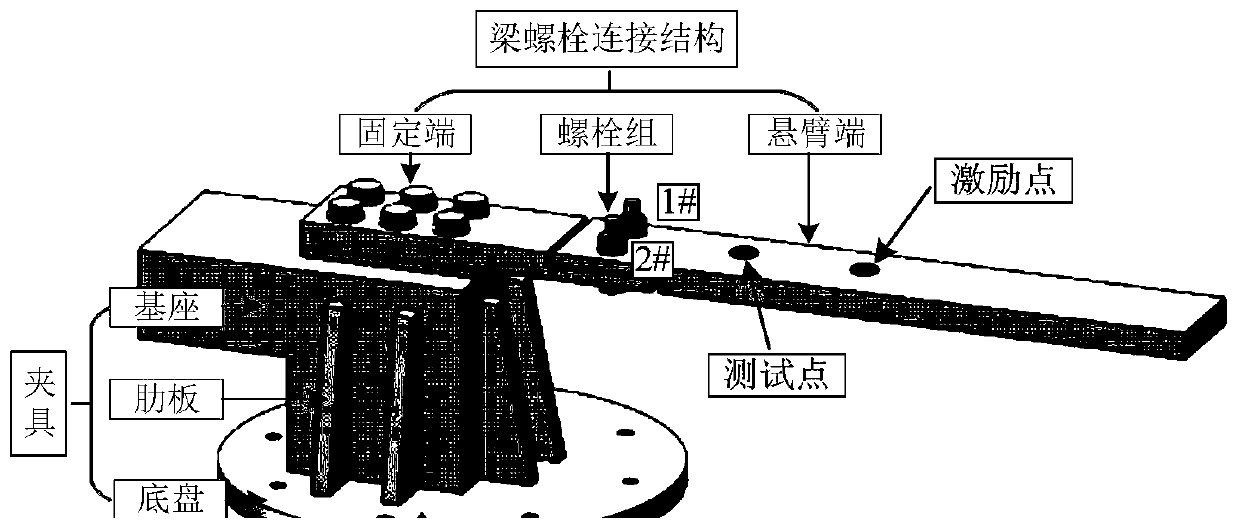

Method for judging degree of looseness of bolt based on vibration mode information

InactiveCN110044566ALow costStrong real-timeVibration testingNon destructiveVariational mode decomposition

Owner:XI AN JIAOTONG UNIV

Dynamic calibration method for high-frequency force balance

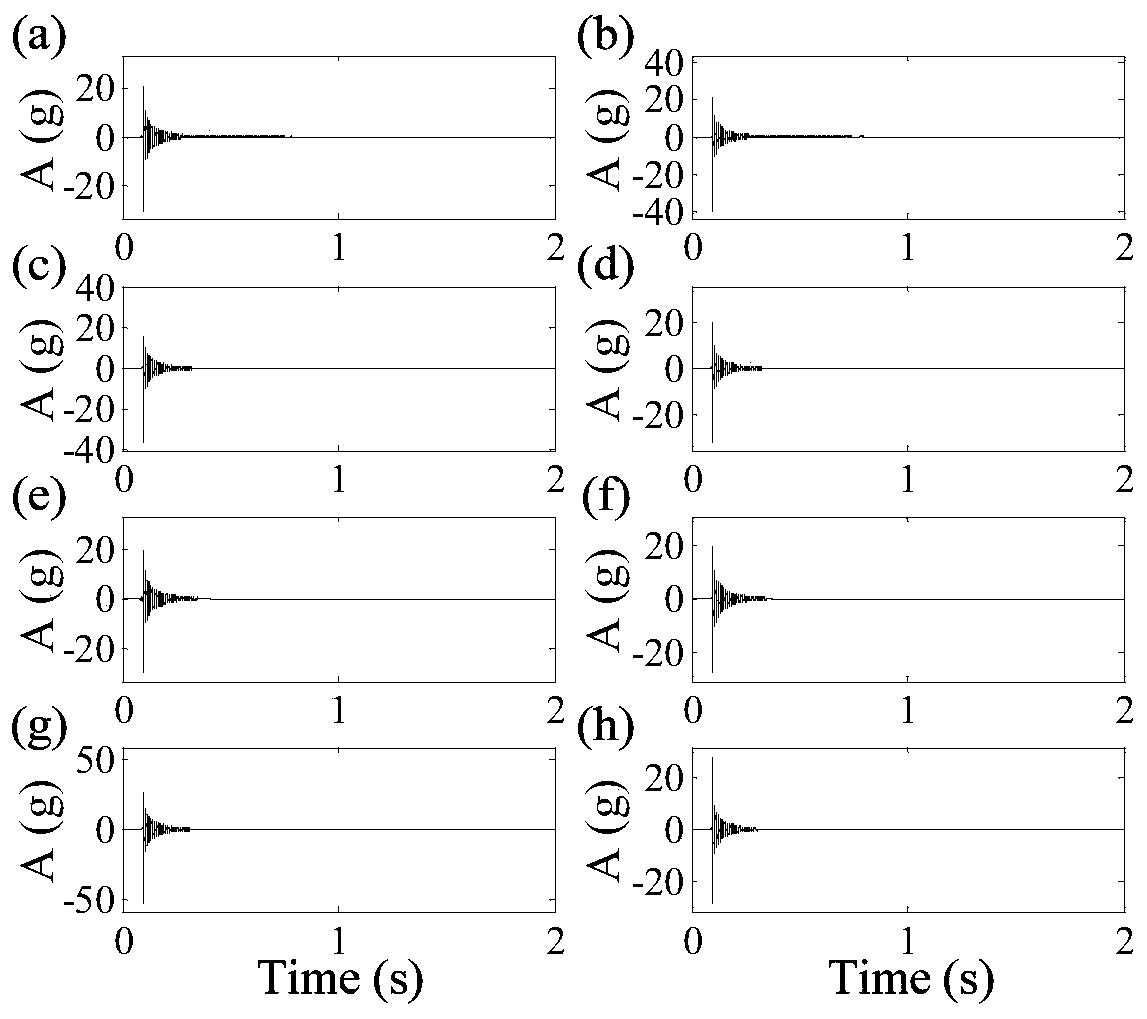

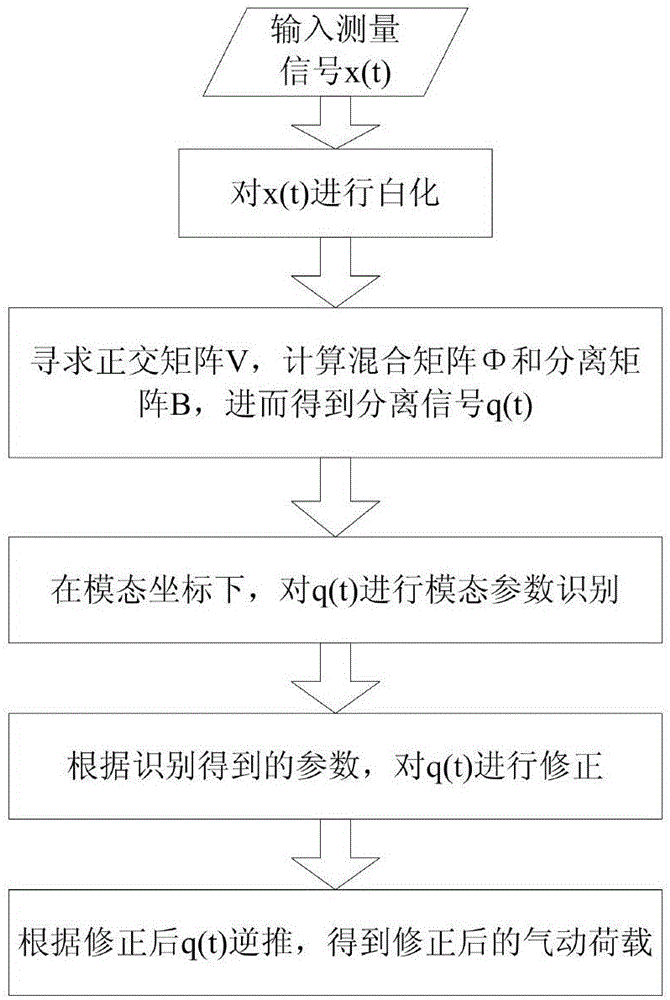

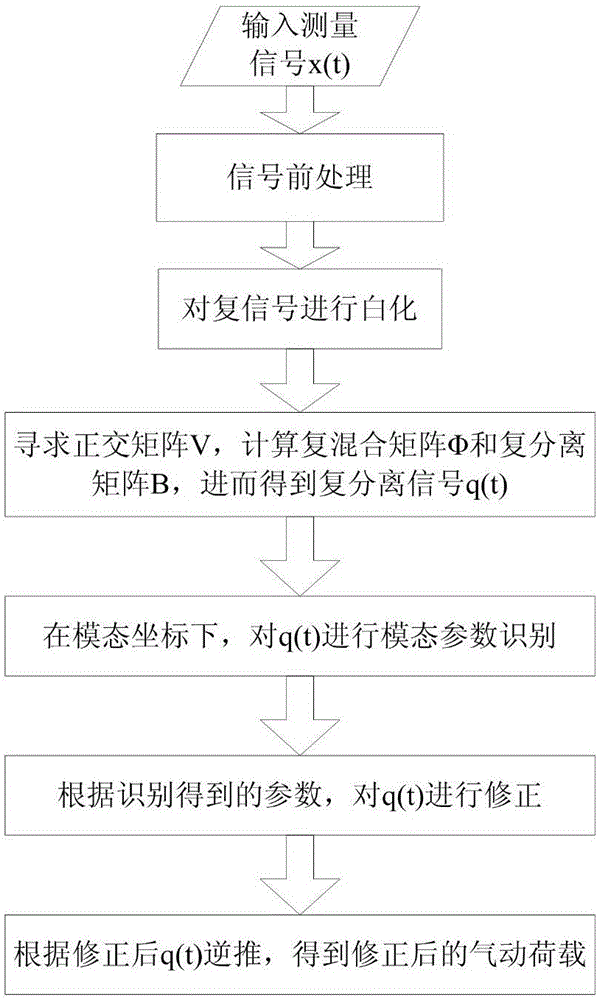

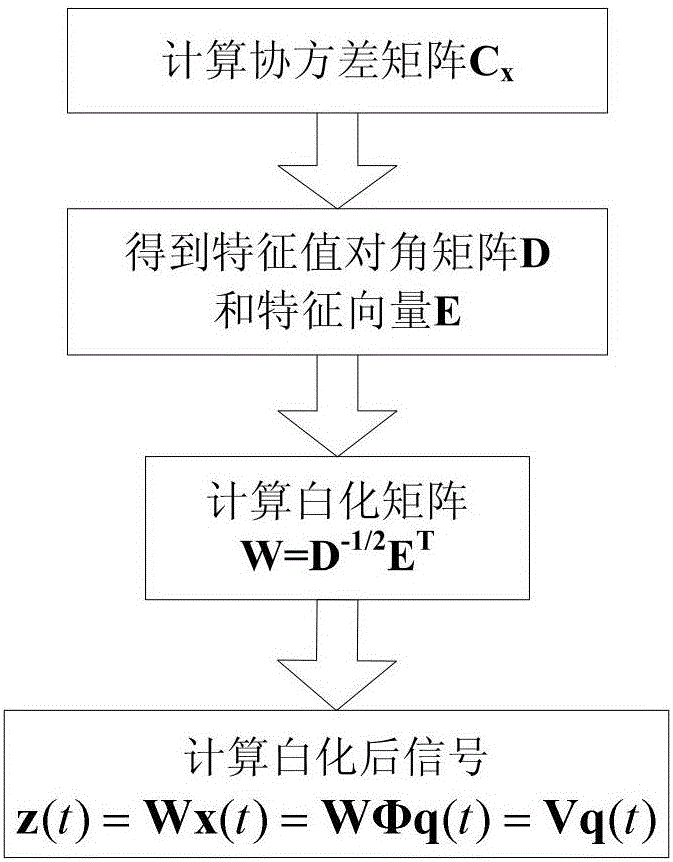

ActiveCN106709460ASimple test stepsEfficient separationAerodynamic testingCharacter and pattern recognitionCurve fittingParametric identification

The invention discloses a dynamic calibration method for a high-frequency force balance, which comprises the steps of performing whitening on a measurement signal x(t) to acquire a whitened signal z(t); seeking an orthogonal matrix V, enabling the whitened signal z(t) to equal to Vq(t), and thus acquiring a separated signal q(t); performing natural frequency and modal damping ratio recognition on the separated signal in modal coordinates; correcting the separated signal according to recognized parameters; and inversely deducing according to the separated signal to acquire a corrected pneumatic load. According to the invention, separation is performed on a coupling signal, and for independent components acquired by separation, natural frequency and modal damping ratio recognition is performed on the separated signals one by one by adopting a curve fitting method through combining aerodynamic characteristics, so that a dynamic amplification effect of a modal coupling system is corrected and eliminated, a real aerodynamic load spectrum density matrix is acquired finally, the reliability of parameter recognition and corresponding HFFB (High-Frequency Force Balance) dynamic signal calibration can be improved to the maximum extent, and an important basis is laid for subsequent accurate estimation for high-rise building prototype wind-induced responses.

Owner:SOUTH CHINA UNIV OF TECH

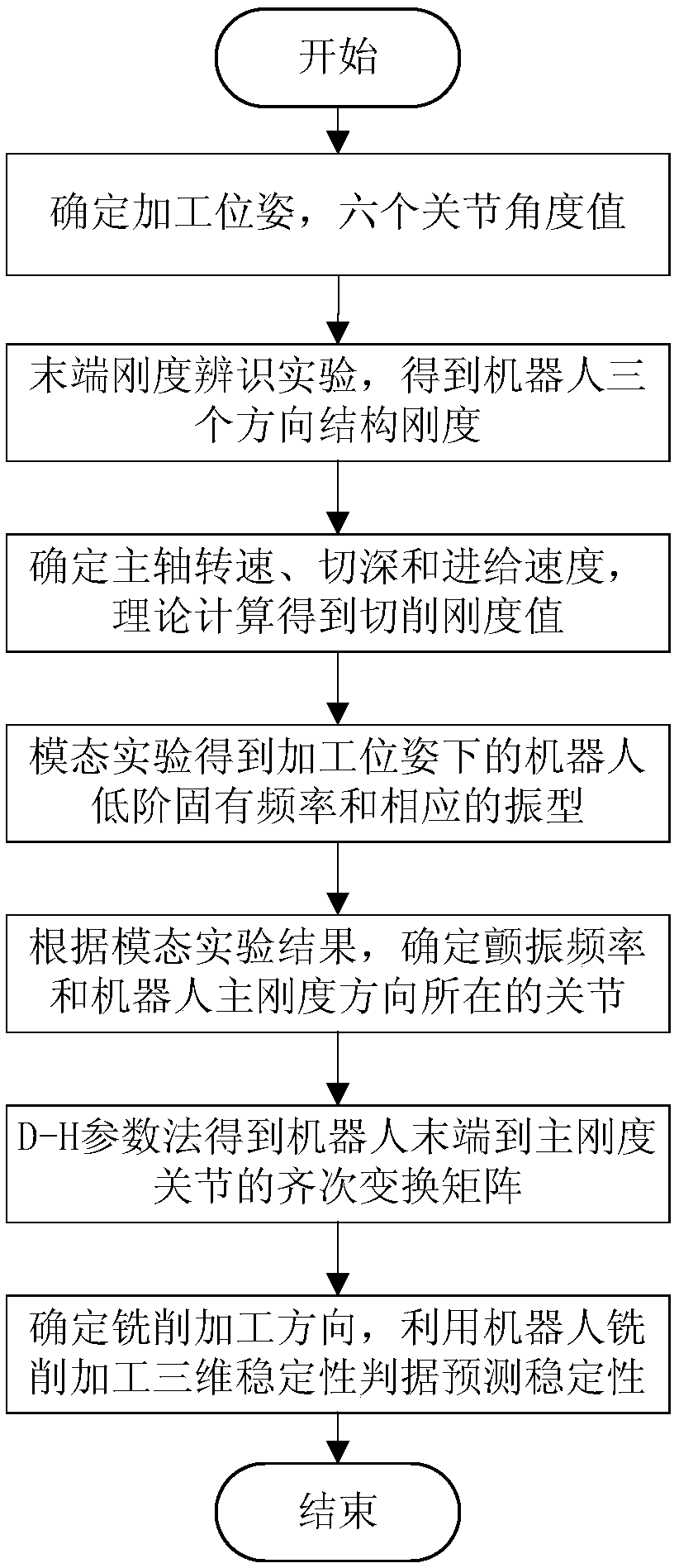

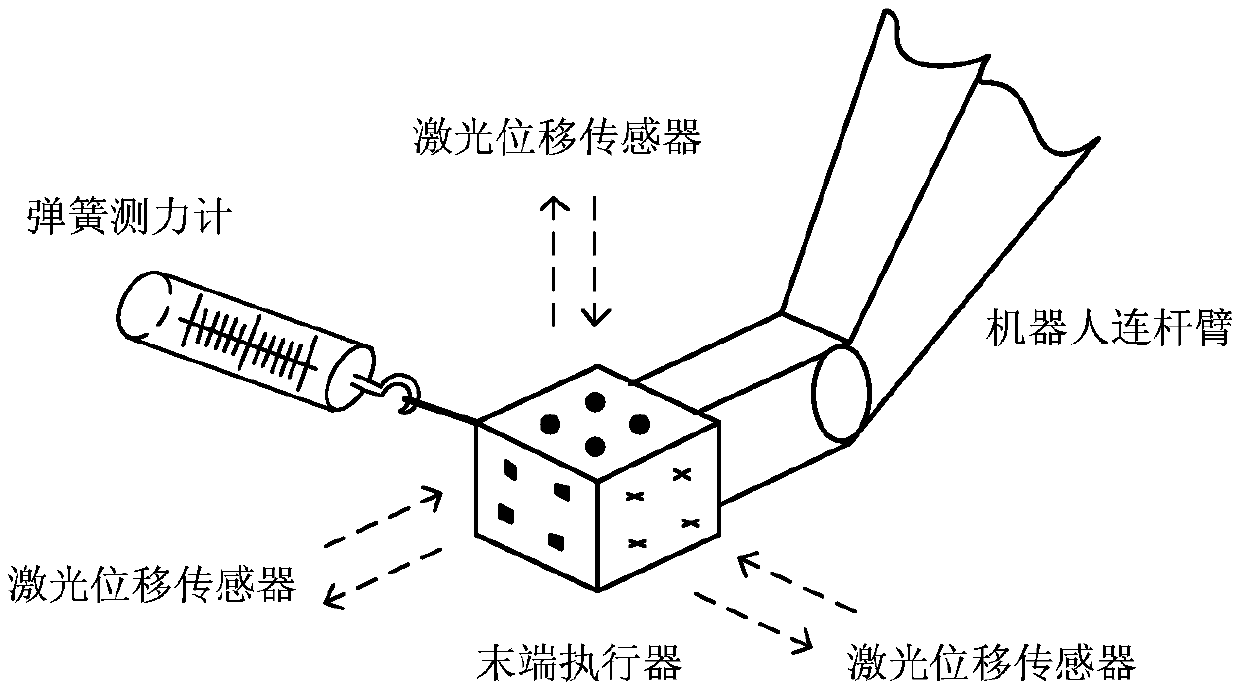

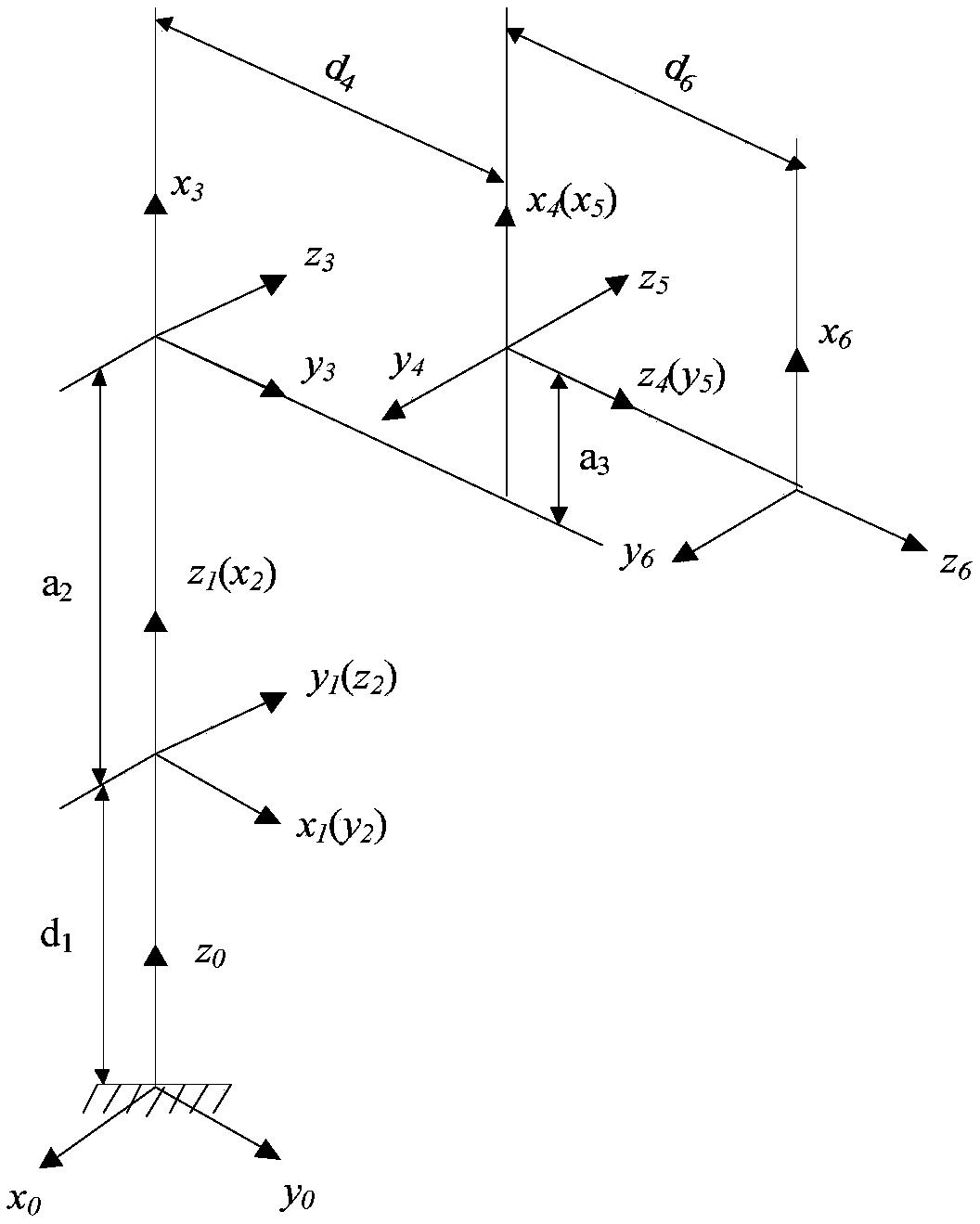

Milling three-dimensional stability forecasting method of six-freedom-degree series robot

ActiveCN108638076AAvoid Mode-Coupled FlutterImprove machined surface qualityProgramme-controlled manipulatorMachined surfaceStochastic matrix

The invention provides a milling three-dimensional stability forecasting method of a six-freedom-degree series robot and relates to the technical field of robot machining application. By means of themethod, the machining posture of the six-freedom-degree series robot is determined firstly, and the angle value of each joint of the robot is obtained; then the structural rigidity of the robot in three directions is obtained, and the milling cutting rigidity value of the robot is calculated and obtained; a homogeneous transformation matrix among all kinematics coordinate systems is obtained; theinherent frequency of various orders and corresponding modal shapes of the robot are obtained through analysis; the main rigidity direction of the robot is obtained, and the transfer matrix from cutting force to the main rigidity direction of the robot is determined; and finally, the machining direction is determined, and robot milling three-dimensional stability is used for judging and forecasting stability. By means of the milling three-dimensional stability forecasting method of the six-freedom-degree series robot, the machining feeding direction can be selected in advance, modal coupling fluttering in the milling process is avoided, and the quality of the machined surface is improved.

Owner:NORTHEASTERN UNIV

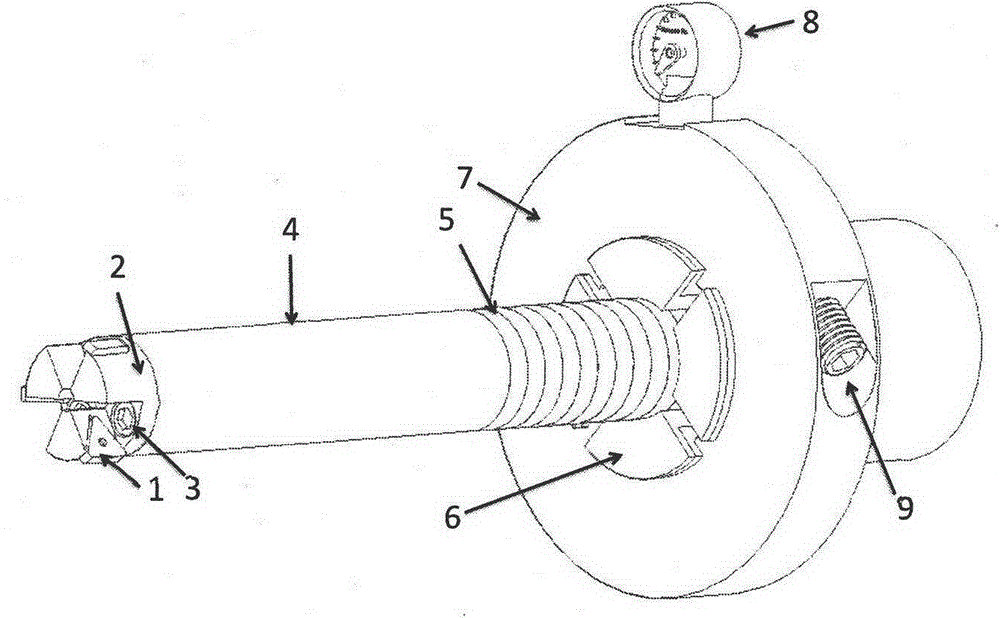

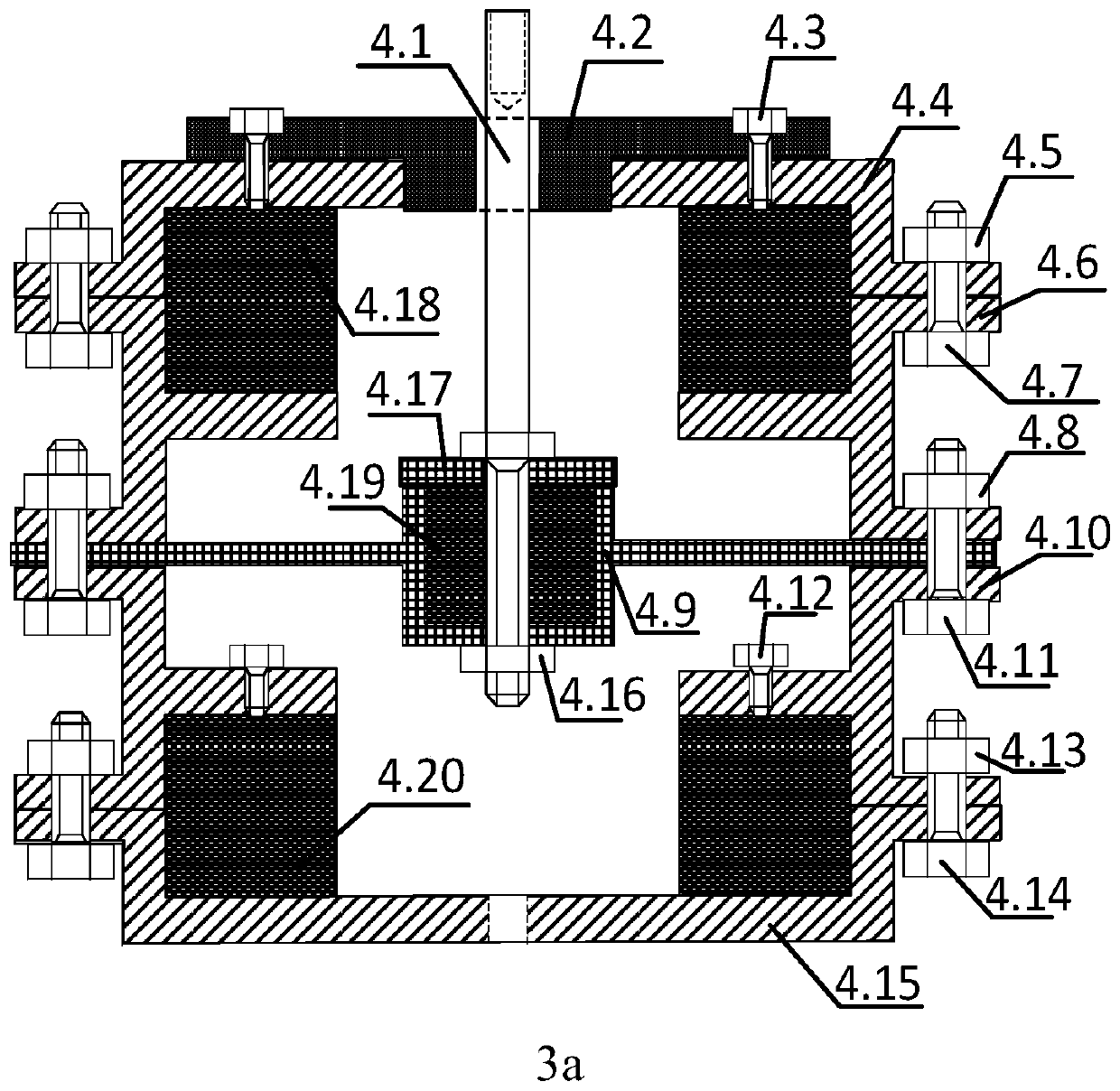

Numerical control tool system for providing vibration reduction by utilizing microcosmic friction and mass distribution

InactiveCN105081373AIncrease stiffnessEffective shock absorptionTransportation and packagingMilling cuttersNumerical controlHigh density

The invention discloses a clamp and tool bar system for providing the vibration reduction performance of a numerical control tool by utilizing a microcosmic friction phenomenon in combination with a modal coupling method for mass distribution and mass vibration reduction of the numerical control tool under the premise that macroscopic assembly sliding is not caused. By regulating forward pressure, static rigidity, a vibration reduction coefficient and dynamic rigidity on each assembly combination surface, the vibration reduction performance of an overall tool structure is optimized. A tool bar structural member 4 is made from a material with high elastic coefficient and high density ratio, and a tool bar connecting piece 5 is made from a material with high elastic coefficient, so that the vibration modal frequency and the vibration reduction efficiency are improved. By utilizing modal coupling, the vibration reduction performance of a mass vibration reduction unit is further improved, and the torsional vibration resistance and the bending vibration resistance of the tool are improved. According to the technical solution, by virtue of a modular tool bar, the ratio of extended length to diameter in a using process of the numerical control tool can be improved, and the vibration reduction performance of a tool structure is improved.

Owner:付麒麟

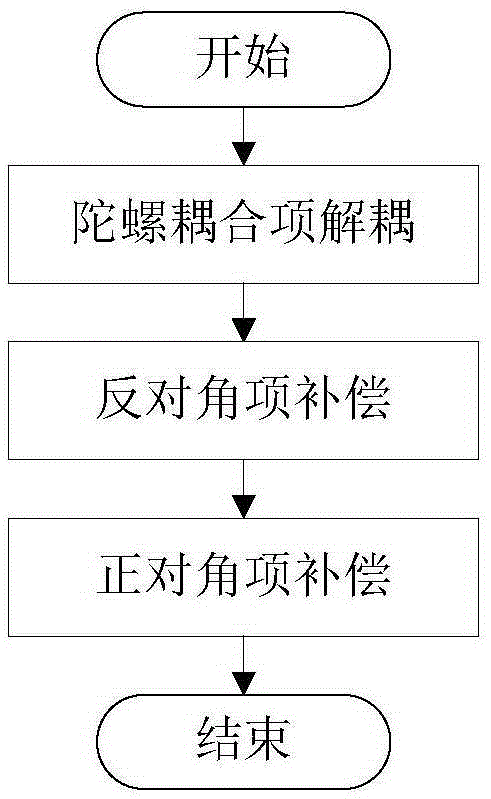

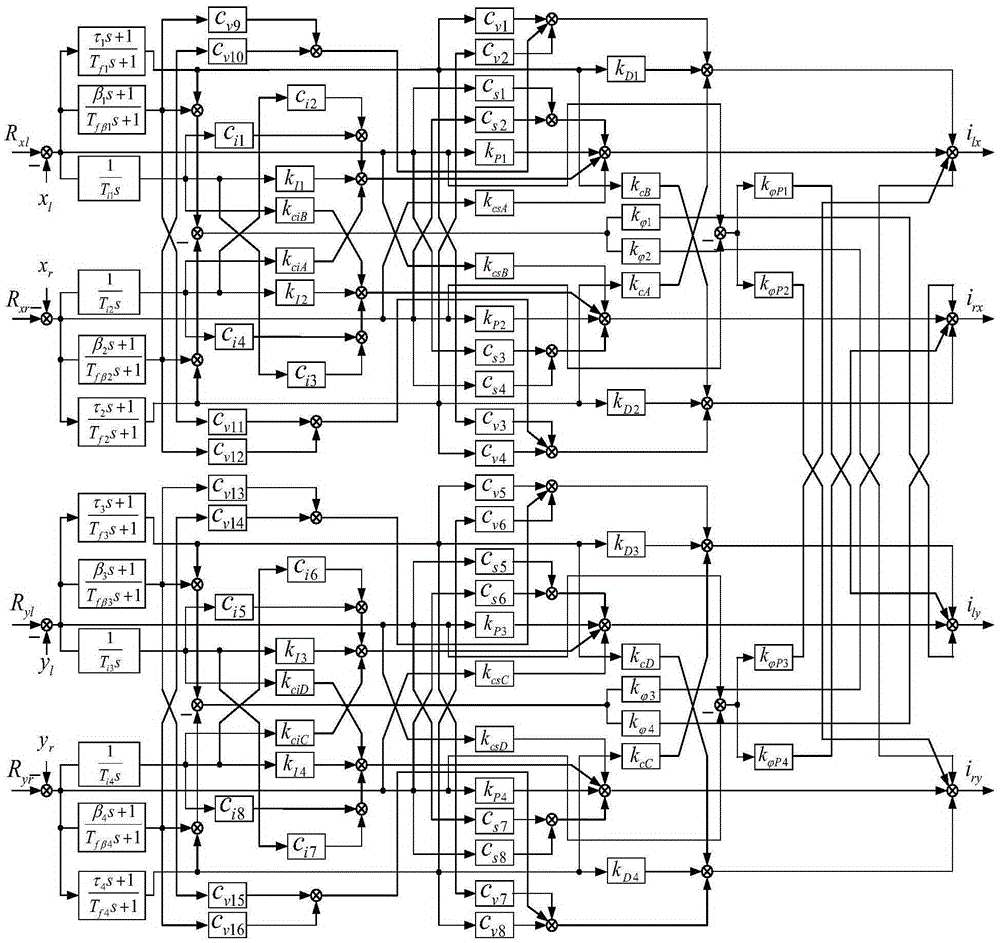

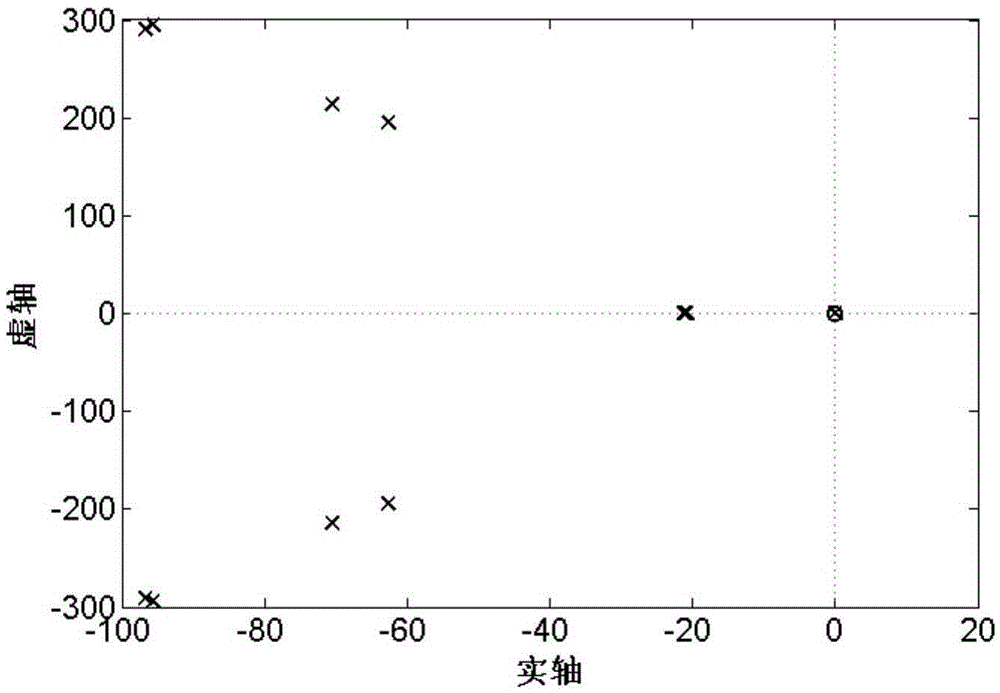

Modal decoupling decentralized control method used for magnetic bearing

InactiveCN105301964ARealize the modalityRealize modal quantity to controlAdaptive controlMagnetic bearingLinear quadratic

The invention provides a modal decoupling decentralized control method used for a magnetic bearing. The method comprises steps of 1: decoupling gyroscopic coupling of a magnetic bearing; 2: performing opposite angle items compensation on a differentiation element, a proportion element and an integration element; and 3: compensating positive angle items introduced by a differentiation coupling compensation controller, a differentiation coupling compensation controller and an integration coupling compensation controller. According to the invention, while gyroscopic effects of a rotator are restrained, modal coupling of a system can be compensated, so control on modal quantity of the rotator is achieved and stability of the system is improved; compared with the traditional PID control method, the cross feedback control and the linear quadratic type control, the modal decoupling decentralized control method is not affected by rotation speed of the rotator of a magnetic bearing, and the gyroscopic effects in the system can be well decoupled.

Owner:NANJING TECH UNIV

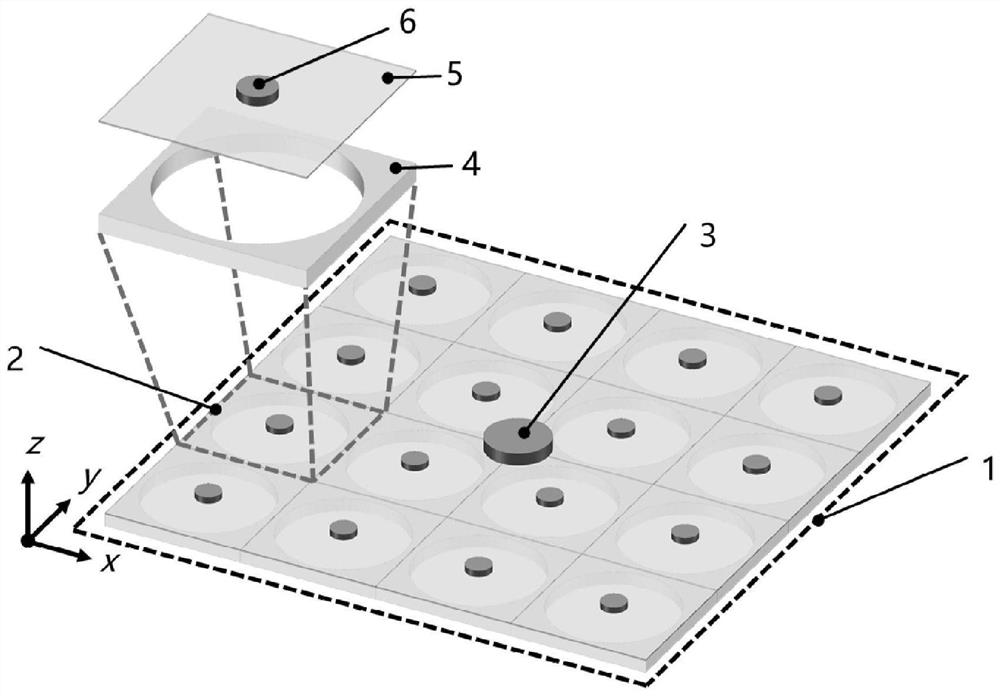

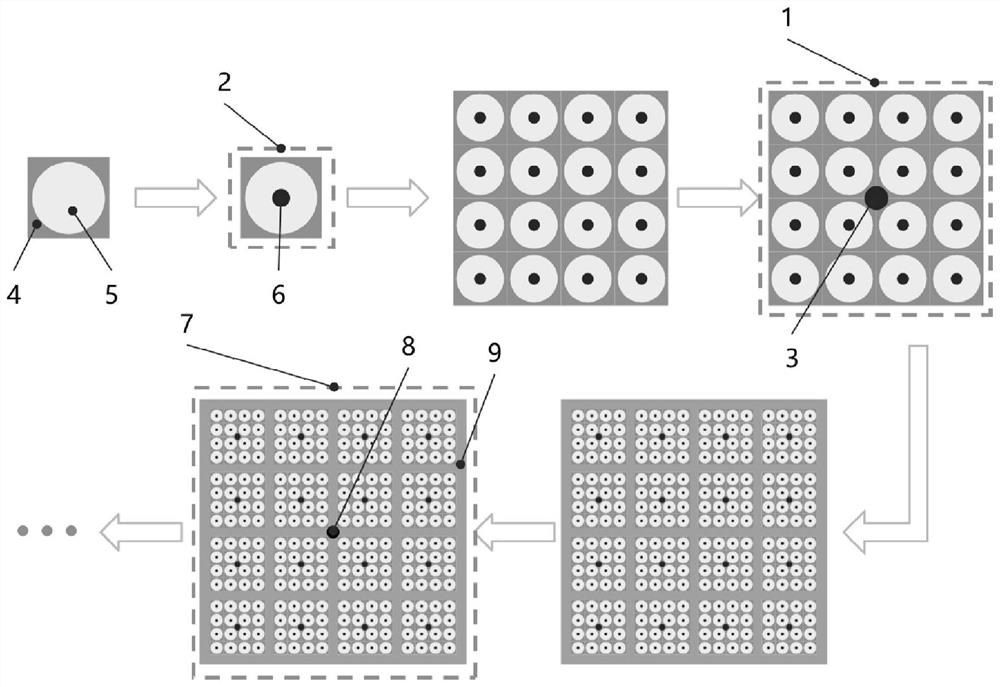

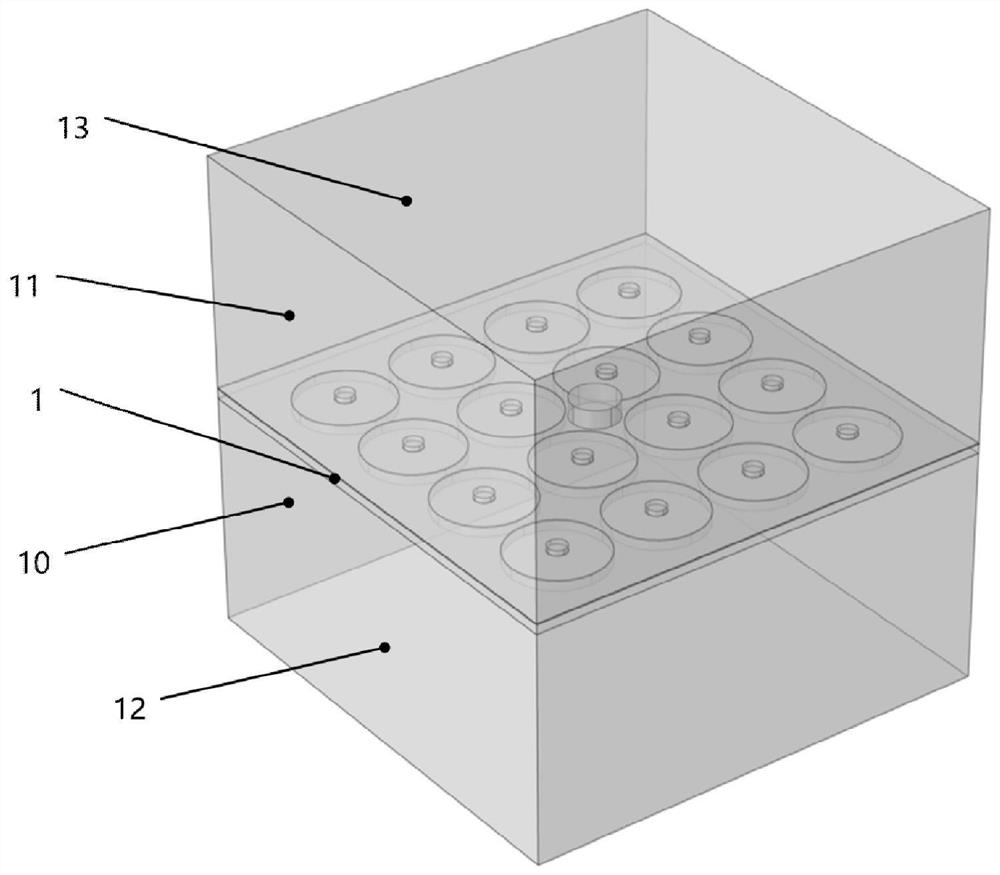

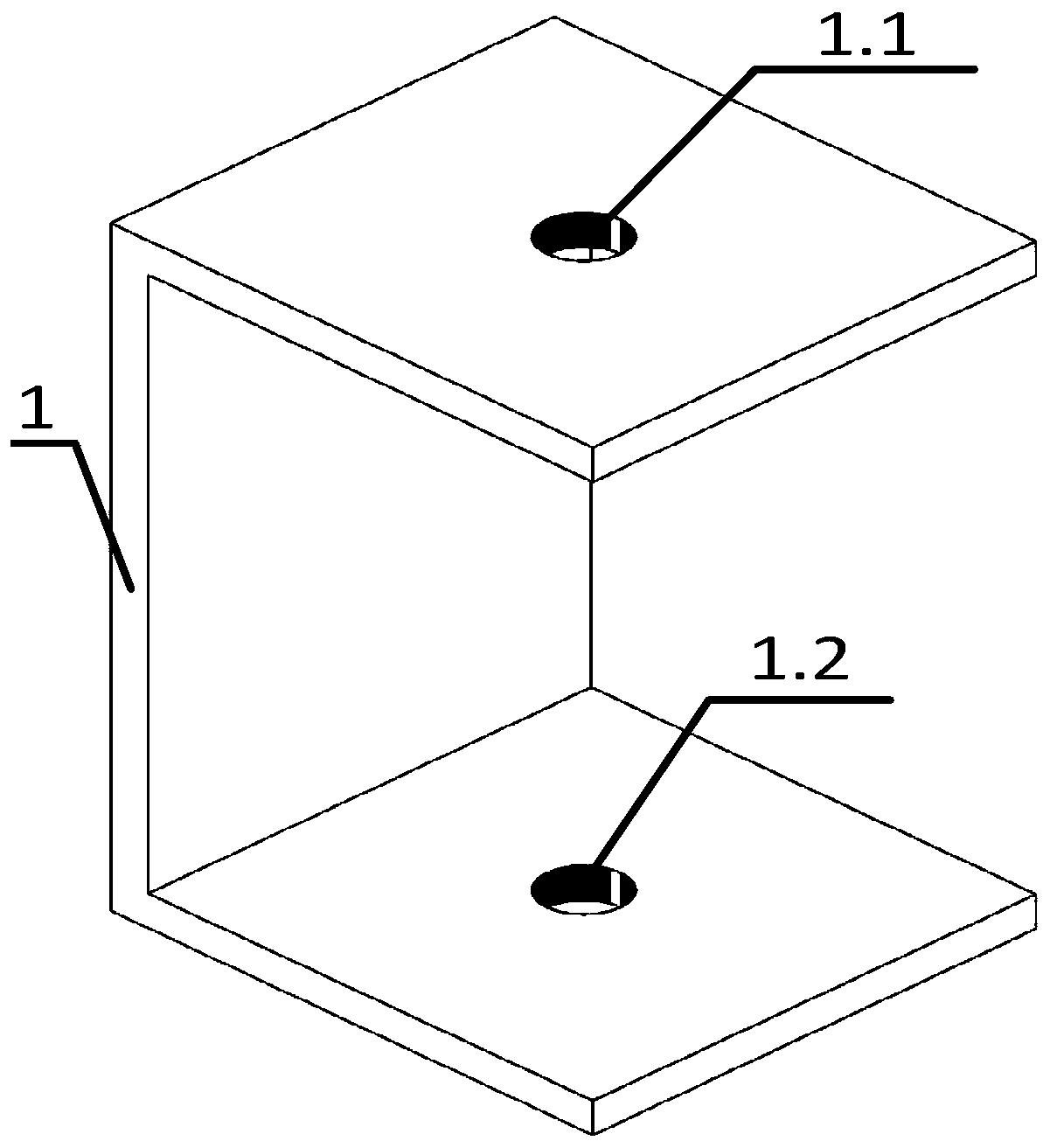

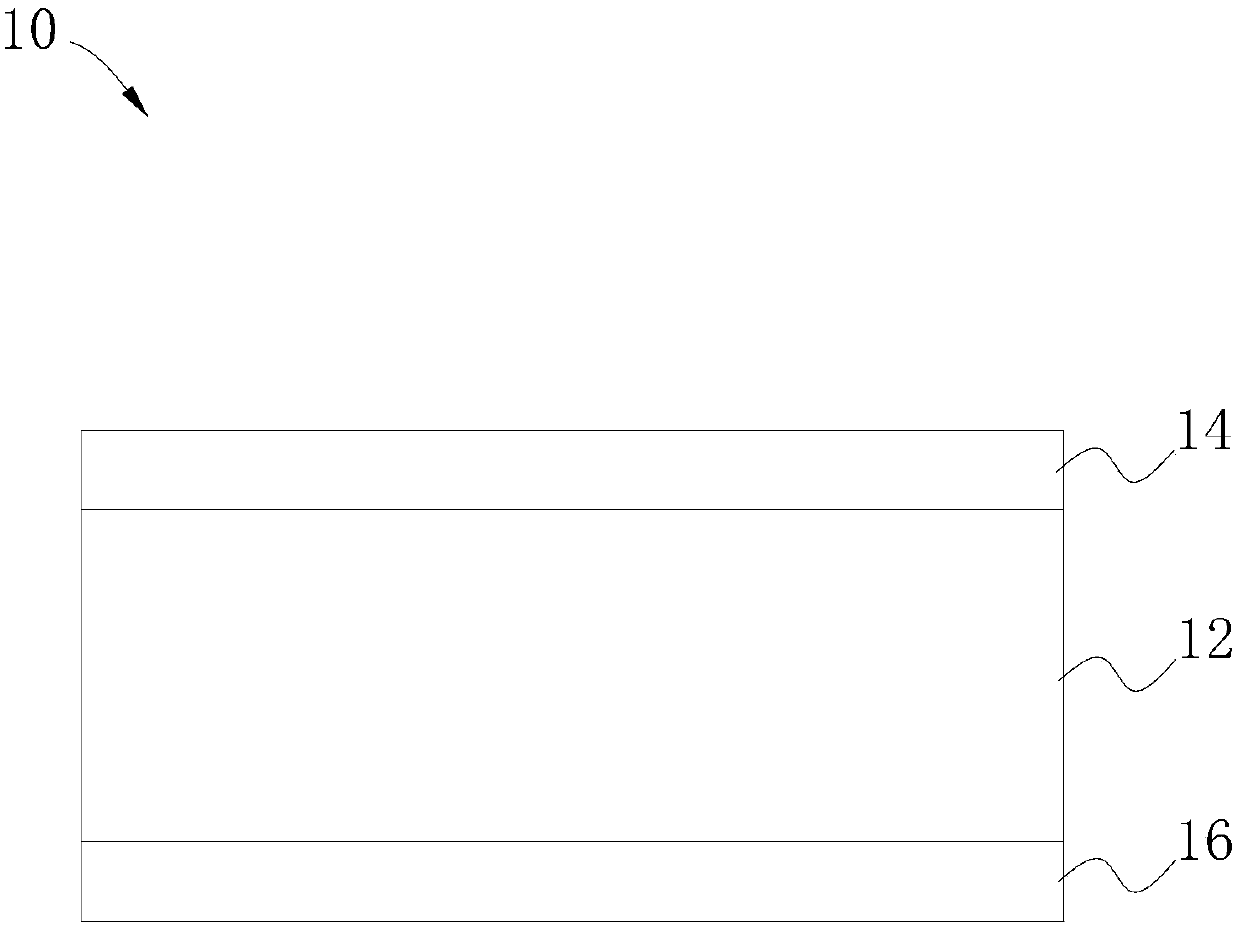

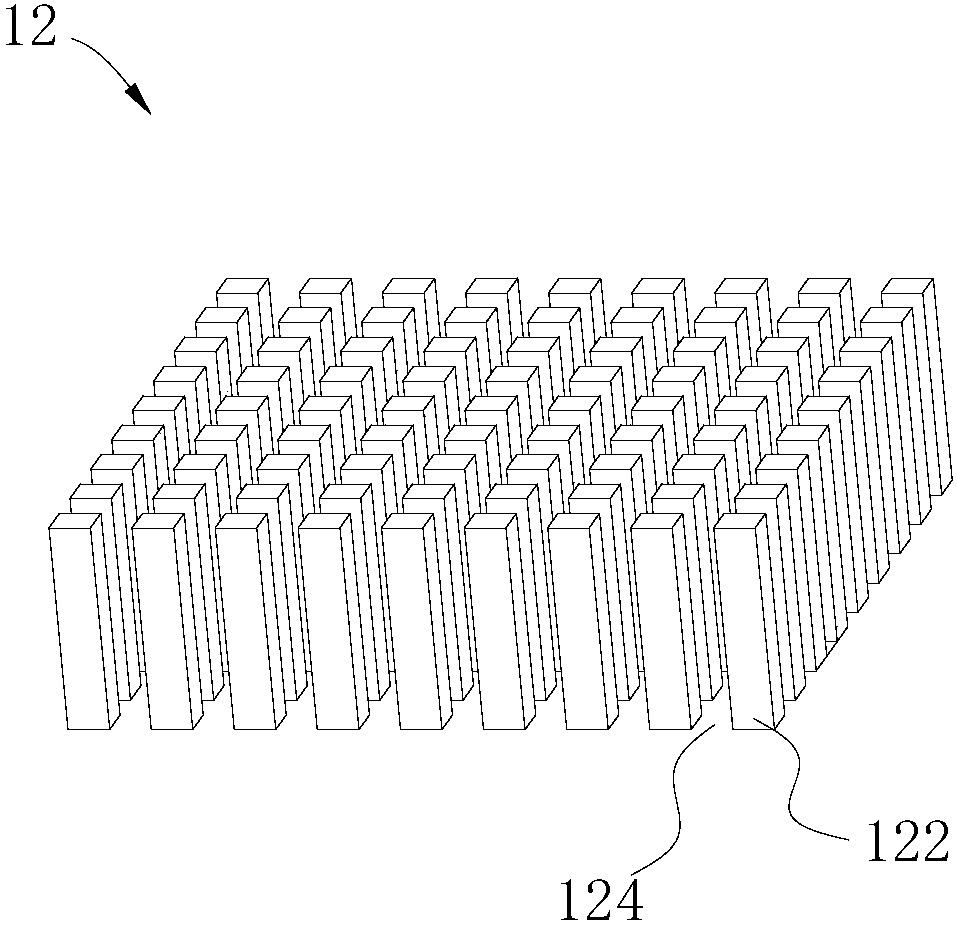

N-order acoustic meta-material low-frequency sound insulation structure

PendingCN112259066AImprove sound insulationEnhanced coupling anti-resonance effectSound producing devicesEnvironmental noiseNoise

The invention discloses an N-order acoustic meta-material low-frequency sound insulation structure, which relates to the technical field of mechanical noise and environmental noise control. The N-order acoustic meta-material low-frequency sound insulation structure comprises a plurality of (N-1)-order acoustic meta-material low-frequency sound insulation structures extending in an array mode in xand y directions, N-order mass blocks adhered to the centers of the (N-1)-order acoustic meta-material low-frequency sound insulation structures, and an external supporting frame, wherein N>=2; when Nis equal to 2, the second-order acoustic meta-material low-frequency sound insulation structure comprises a plurality of acoustic meta-material unit cells extending in an array mode in the x direction and the y direction and the second-order mass blocks attached to the center of the extending structures; and a sound insulation peak generated by the N-order acoustic meta-material low-frequency sound insulation structures is generated by a modal coupling anti-resonance effect of acoustic meta-materials of adjacent orders, and the N-order mass block is used for enhancing the modal coupling anti-resonance effect. The N-order acoustic meta-material low-frequency sound insulation structure has the advantages of being simple in structure, easy to adjust and the like, meanwhile, the structure haslarge expansion space, and potential application prospects are achieved for multi-frequency sound insulation within the low-frequency range.

Owner:XI AN JIAOTONG UNIV

Fuel nozzle for reducing modal coupling of combustion dynamics

A fuel nozzle includes a center body that extends axially along an axial centerline for a length. A shroud circumferentially surrounds the center body for at least a portion of the length of the center body. A plurality of helical passages circumferentially surround the center body along at least a portion of the length of the center body, and a fuel port in each helical passage has a different convective time.

Owner:GENERAL ELECTRIC CO

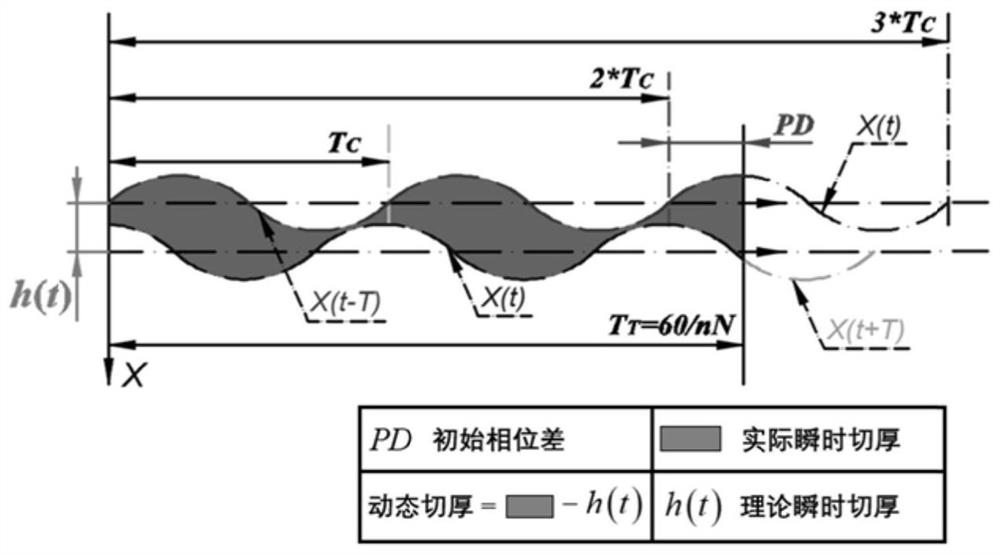

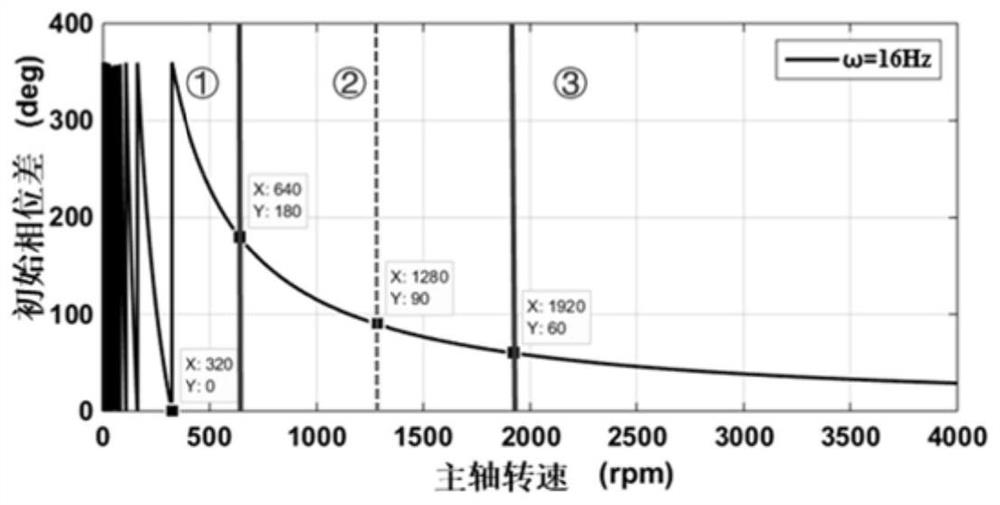

Robot milling flutter prediction and main modal analysis method

PendingCN112069664AShorten operation timePrecise positioningDesign optimisation/simulationSpecial data processing applicationsClassical mechanicsEngineering

The invention belongs to the technical field related to robot milling, and discloses a robot milling chatter prediction and main modal analysis method, which comprises the following steps: (1) constructing a dynamic cutting force model considering a regeneration chatter effect, and combining the dynamic cutting force model with a robot dynamic model considering a modal coupling effect to obtain adynamic cutting force model considering a regeneration chatter effect; carrying out modal space quality normalization conversion to obtain a final kinetic model; (2) analyzing the change of the dynamic cutting thickness of the robot along with the rotating speed under different modes according to the kinetic model, determining a mode influence factor, and judging the dominant mode of the milling flutter stability of the robot under a certain working condition by adopting the mode influence factor so as to provide a mode selection basis for predicting the milling stability of the robot, whereinthe modal influence factor is the phase difference of two times of blade ripples. According to the invention, operation data is saved, and the stability prediction efficiency is improved.

Owner:HUAZHONG UNIV OF SCI & TECH

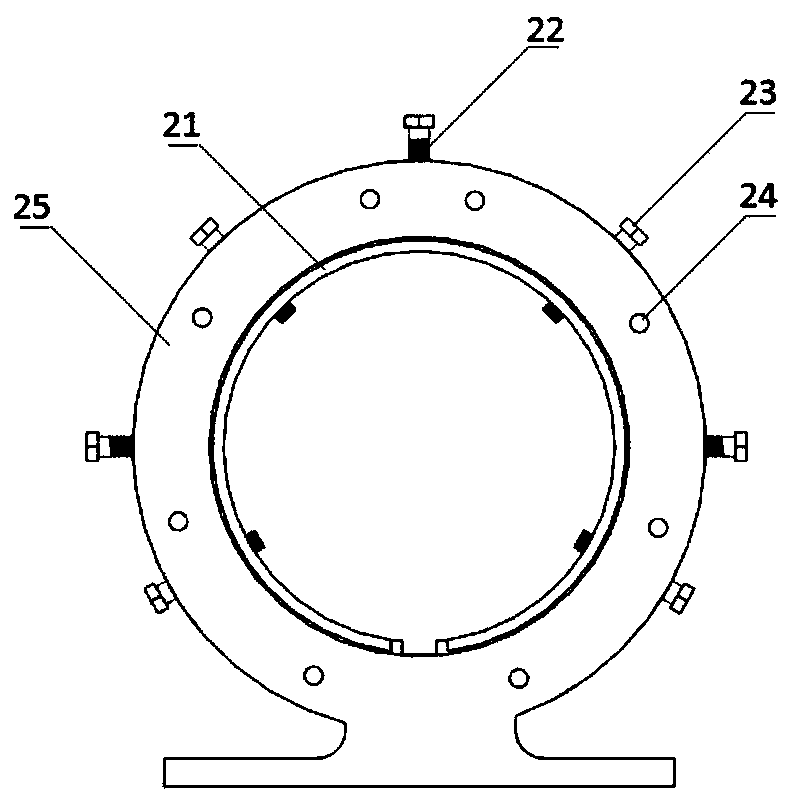

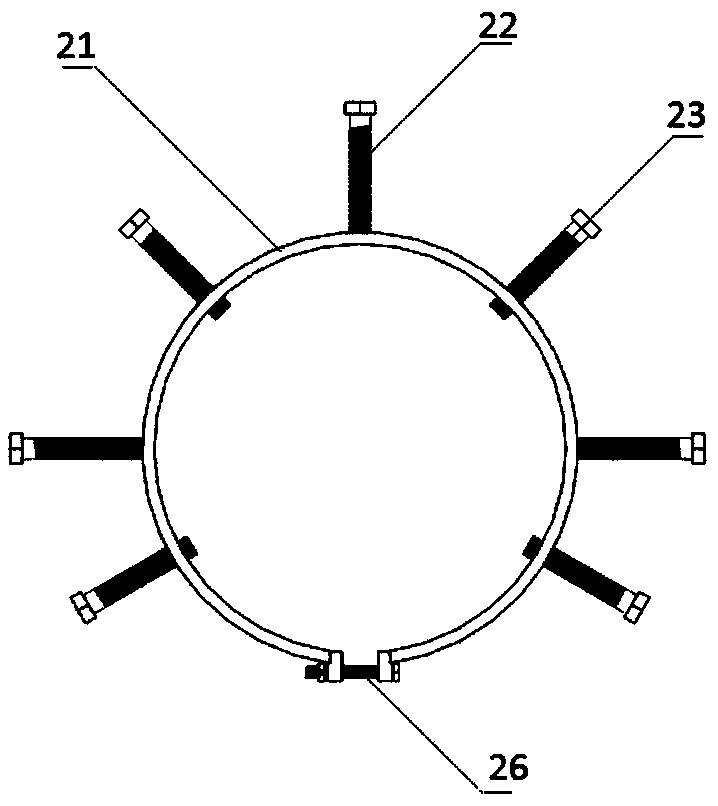

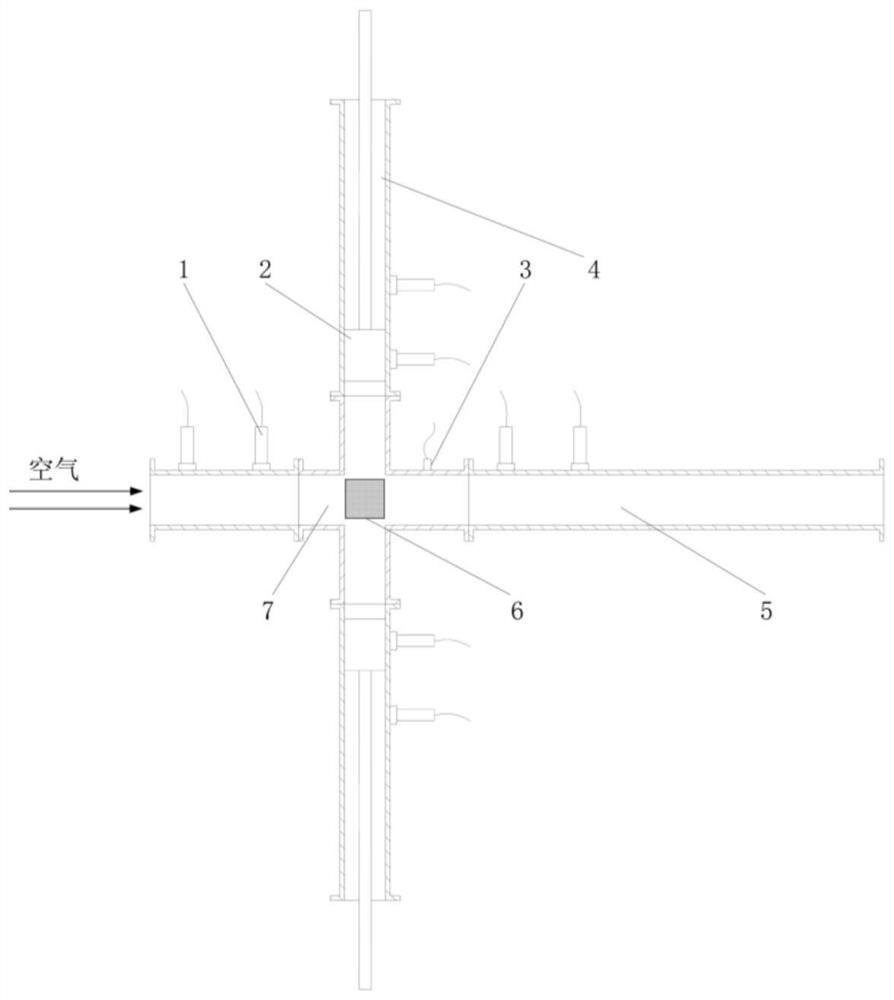

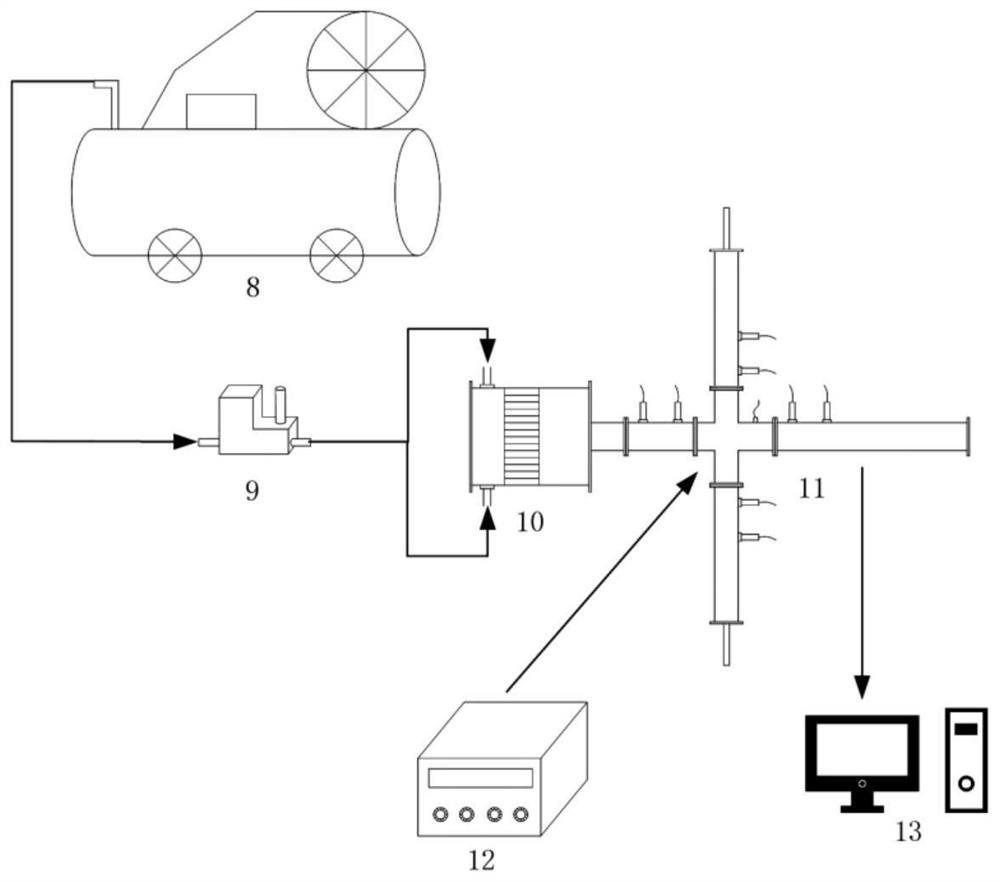

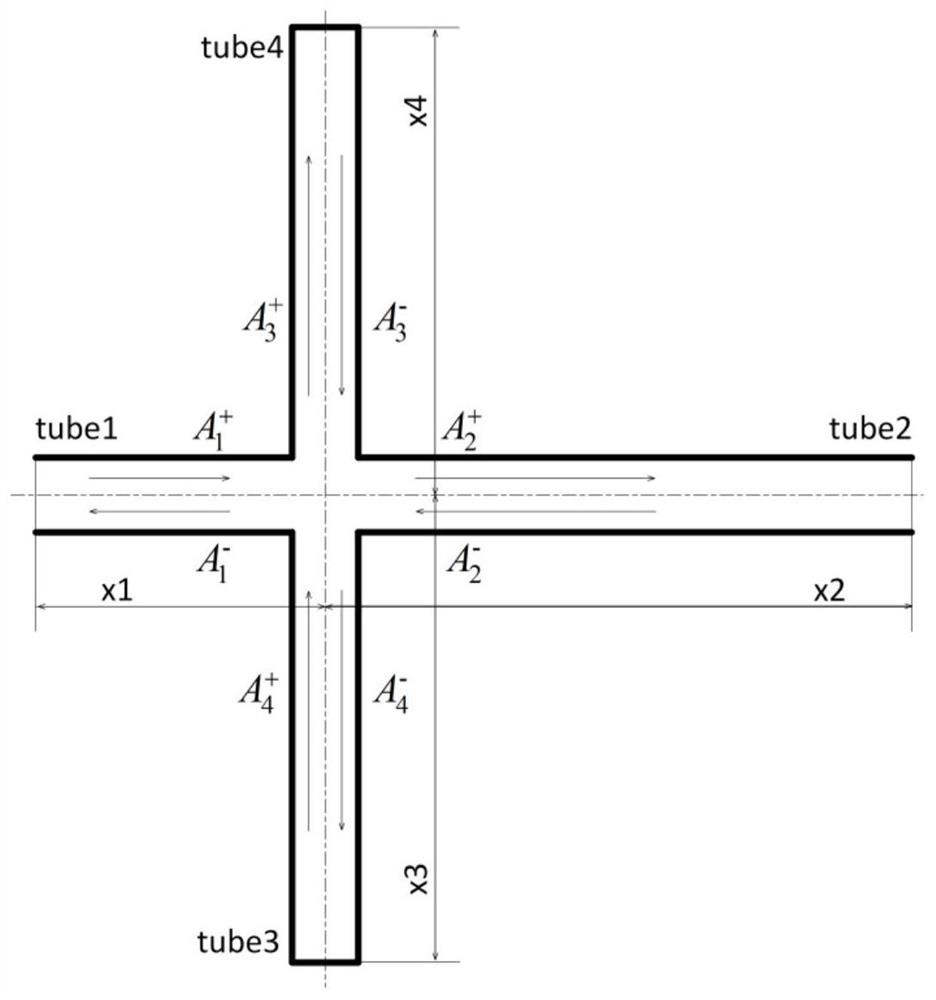

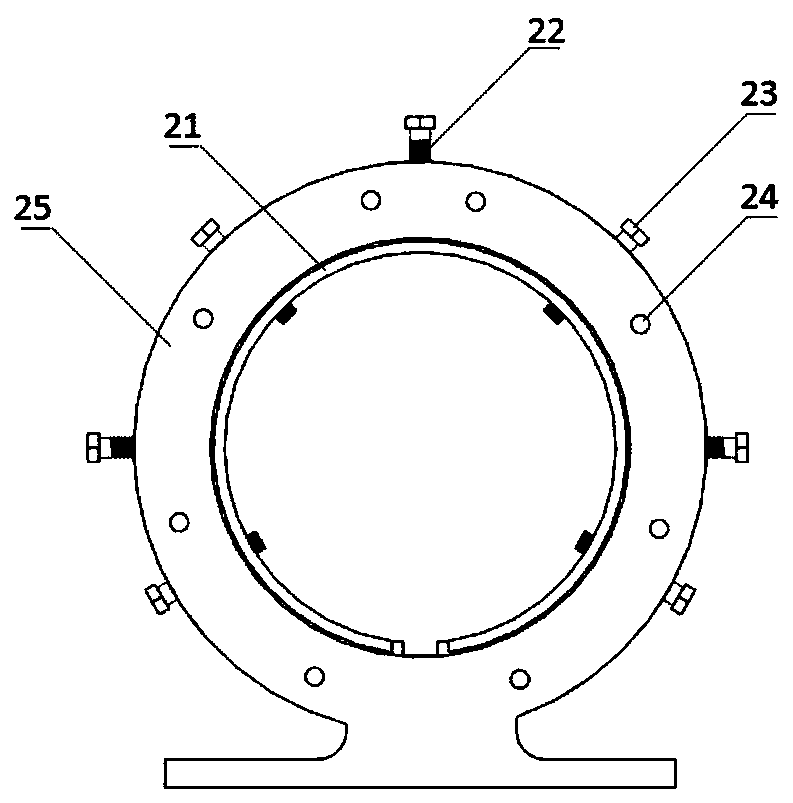

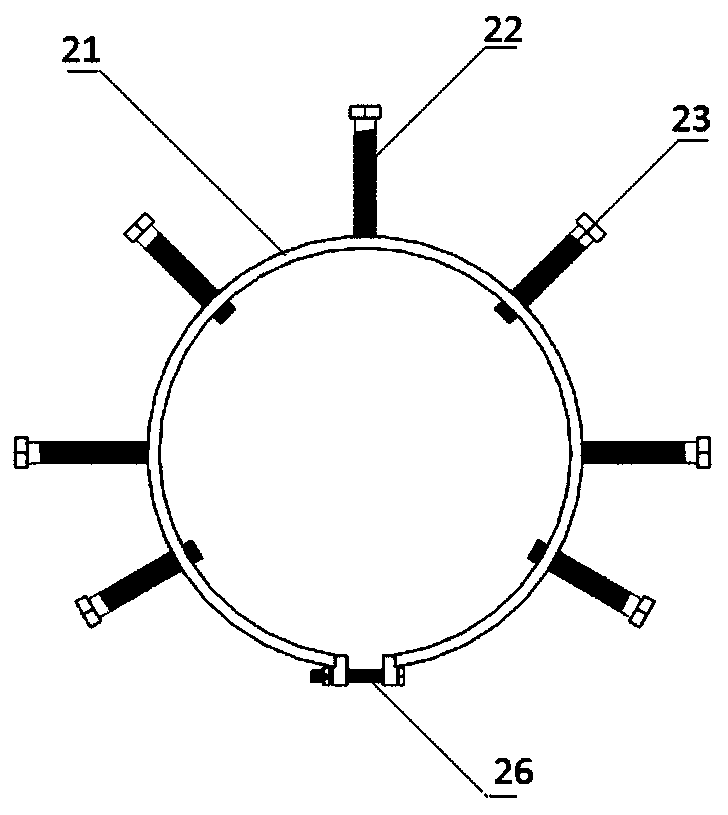

Experimental device and method for researching thermo-acoustic instability longitudinal and tangential mode coupling mechanism

PendingCN113959724AEasy to achieve quantitative adjustmentRealize quantitative adjustmentInternal-combustion engine testingCombustion chamberEngineering

The invention relates to an experimental device and method for researching a thermo-acoustic instability longitudinal and tangential modal coupling mechanism. The experimental device and method are used for researching thermo-acoustic instability modal coupling phenomena of combustion systems such as aerospace engines and ground gas turbines. The device is mainly an electric heating single-heat-source cross-shaped combustion chamber with a variable combustion chamber structure size, longitudinal and tangential mode coupling thermo-acoustic instability which simultaneously exists in a real engine is simulated, and heat source power and flow velocity control is facilitated. The longitudinal and tangential lengths of the combustion chamber may be achieved by modularly increasing or decreasing the number of tube segments and changing the position of the piston within the tangential tube, thereby achieving thermo-acoustic instability of longitudinal and tangential modal coupling at different resonant frequencies. Herein, quick response thermocouple and a pressure sensor are used in an experiment to obtain temperature data and sound pressure signals. By combining analysis methods such as power spectral density calculation, signal filtering, short-time Fourier transform and signal reconstruction, the characteristics and mechanism of thermo-acoustic unstable longitudinal and tangential mode coupling under different combustion chamber structures and sizes, different heat source powers and different air average flow rates can be researched. The experimental device is low in cost and simple in structure, and facilitates understanding and utilization of the thermo-acoustic unstable mode coupling phenomenon.

Owner:BEIHANG UNIV

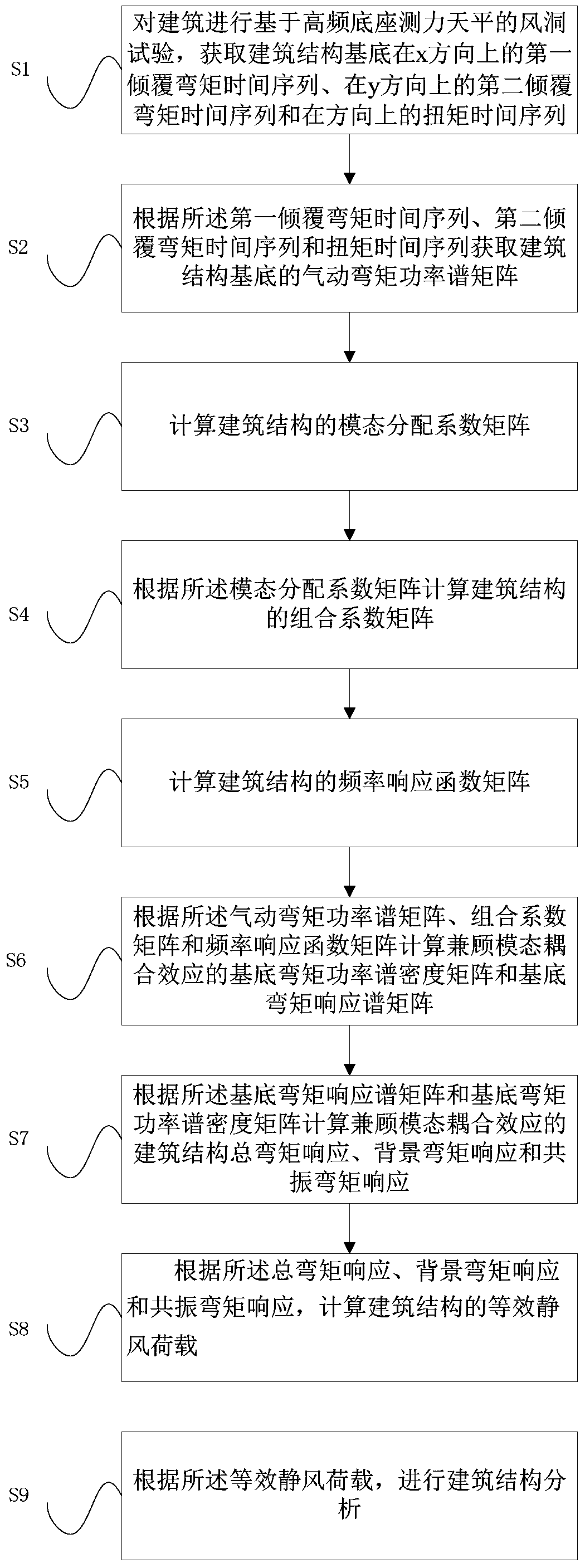

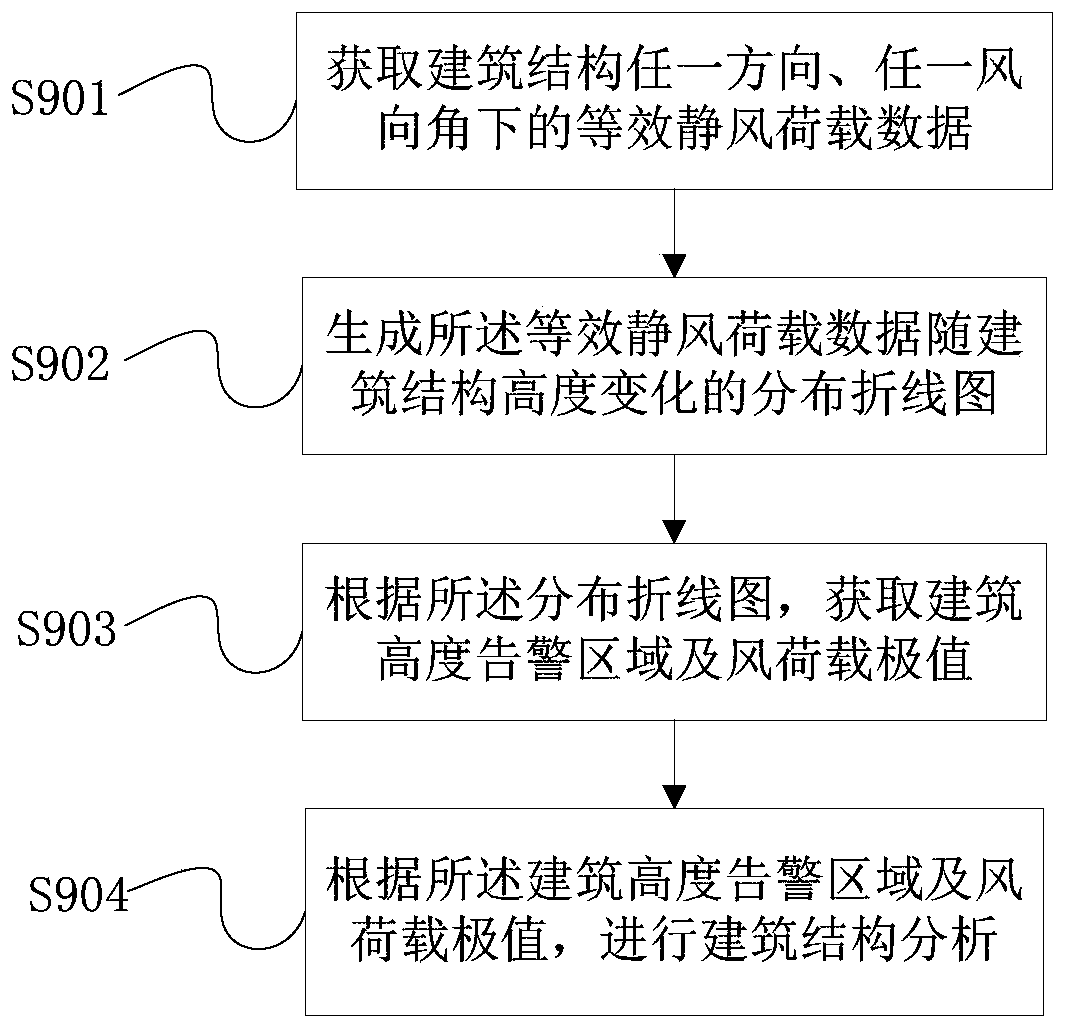

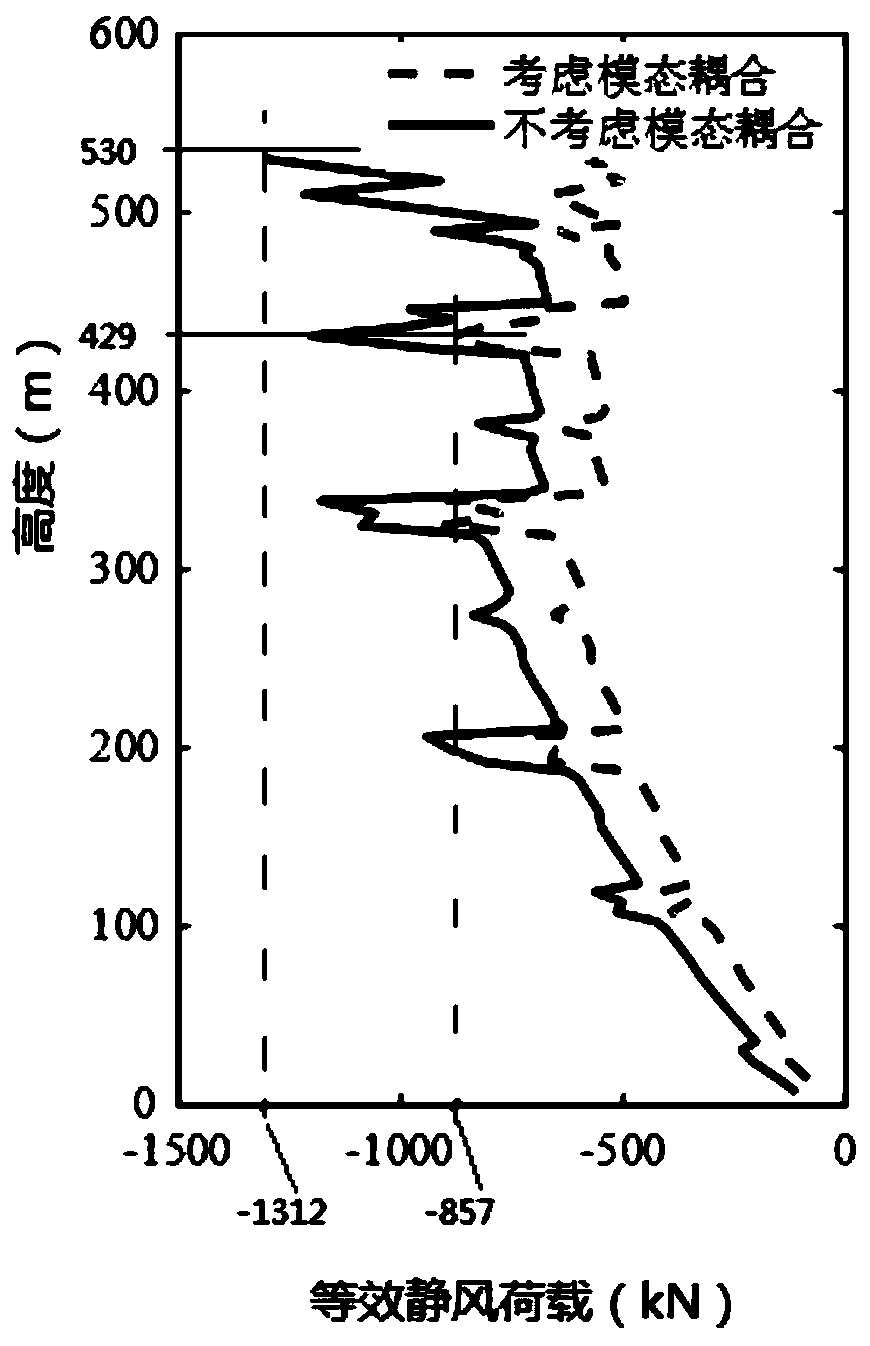

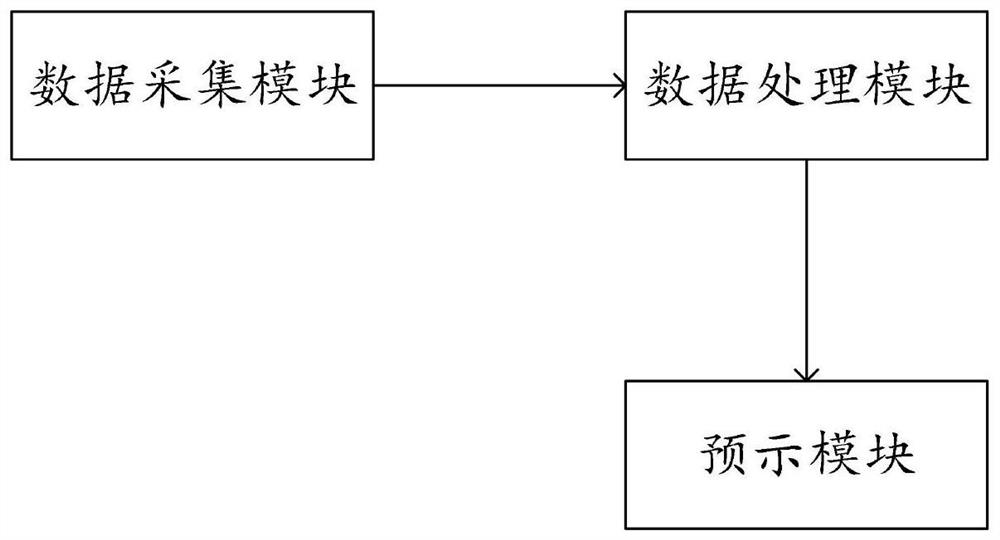

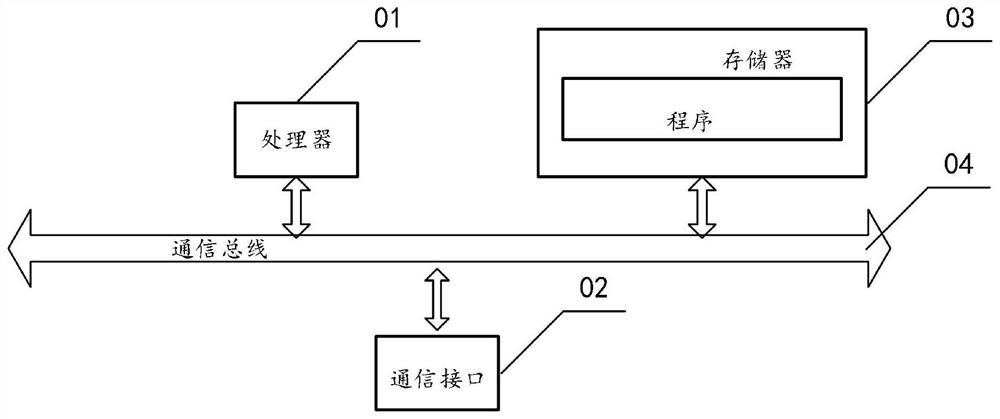

Load analysis method and device considering modal coupling effect and storage medium

ActiveCN110619150AAvoid safety accidentsGuarantee safety and reliabilitySpecial data processing applicationsStructure analysisEngineering

The invention discloses a load analysis method and device considering a modal coupling effect and a storage medium. The method comprises the following steps: 1, preparing raw materials; carrying out adynamometric balance wind tunnel test on the building; acquiring an overturning moment time sequence and a torque time sequence; and establishing an aerodynamic bending moment power spectrum matrix of a building structure base, analyzing to obtain a total bending moment response, a background bending moment response and a resonance bending moment response considering a modal coupling effect through the modal distribution coefficient matrix and the frequency response function matrix which are obtained through calculation, and calculating an equivalent static wind load of the building structure. The device comprises a memory for storing a program and a processor for loading the program to execute the analysis method. The storage medium stores instructions for executing the analysis method by a processor. By using the analysis method provided by the invention, the equivalent static wind load data precision can be higher, and the safety and reliability of a building can be ensured when the method is applied to building structure analysis. The method can be widely applied to the technical field of building analysis.

Owner:GUANGZHOU UNIVERSITY

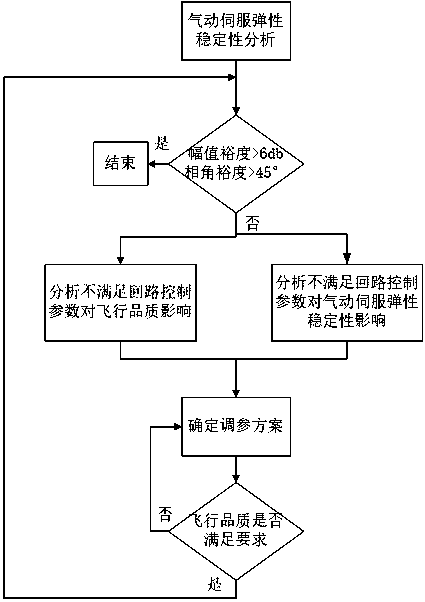

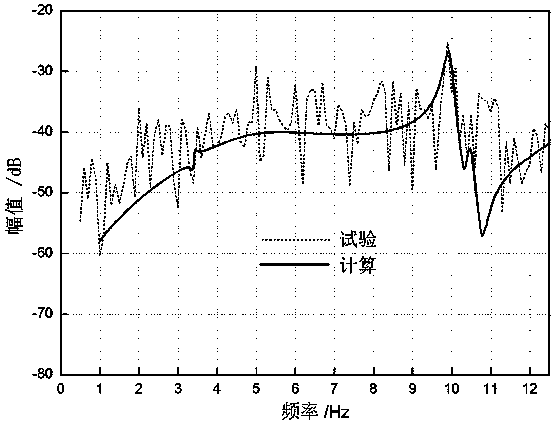

Method for improving elastic stability of pneumatic servo

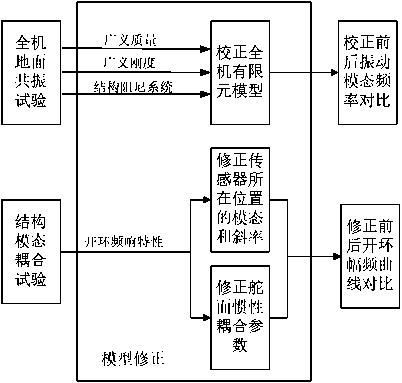

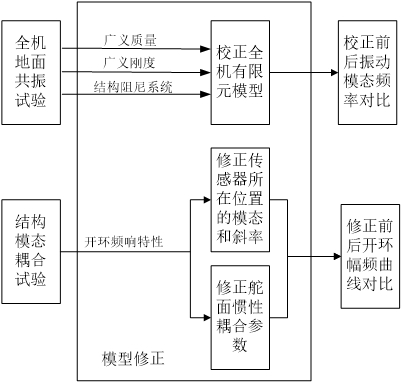

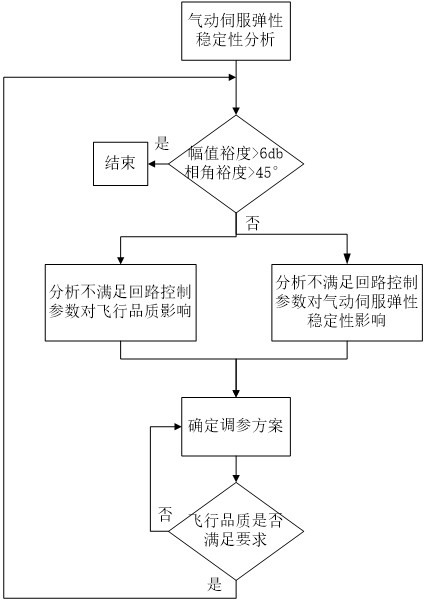

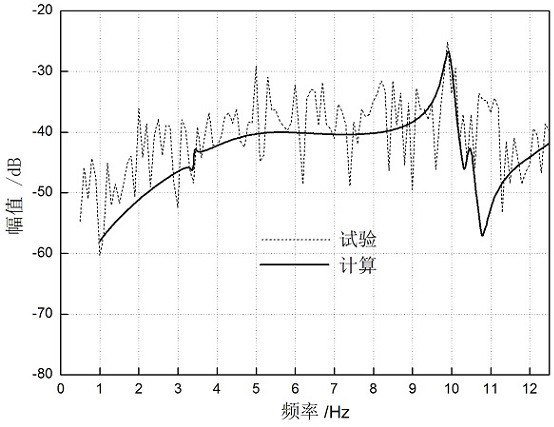

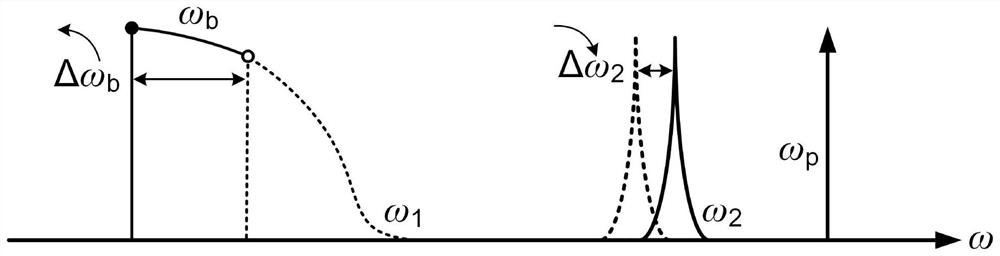

ActiveCN111332491ATaking into account the coupling relationshipPneumatic servo elastic stability analysis is accurateSustainable transportationGround installationsFly controlData design

The invention discloses a design method for improving the elastic stability of an aerodynamic servo. The method comprises the steps: correcting a body elastic model and a transfer function through employing a whole-plane ground resonance test or whole-plane ground structure modal coupling test data design optimization technology, and then improving the elastic stability of the aerodynamic servo through employing a flight control law dynamic parameter adjustment technology; the aerodynamic force, the structural elasticity and the coupling relation between control systems can be well considered,so that the flight quality requirement, the stability margin requirement of the control systems and the pneumatic servo elastic stability requirement are met within the full envelope range, and the method is already applied and verified in the multi-control-surface unmanned aerial vehicle. The problem that the pneumatic servo elastic stability of a multi-control-surface unmanned aerial vehicle isdifficult to control is solved.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

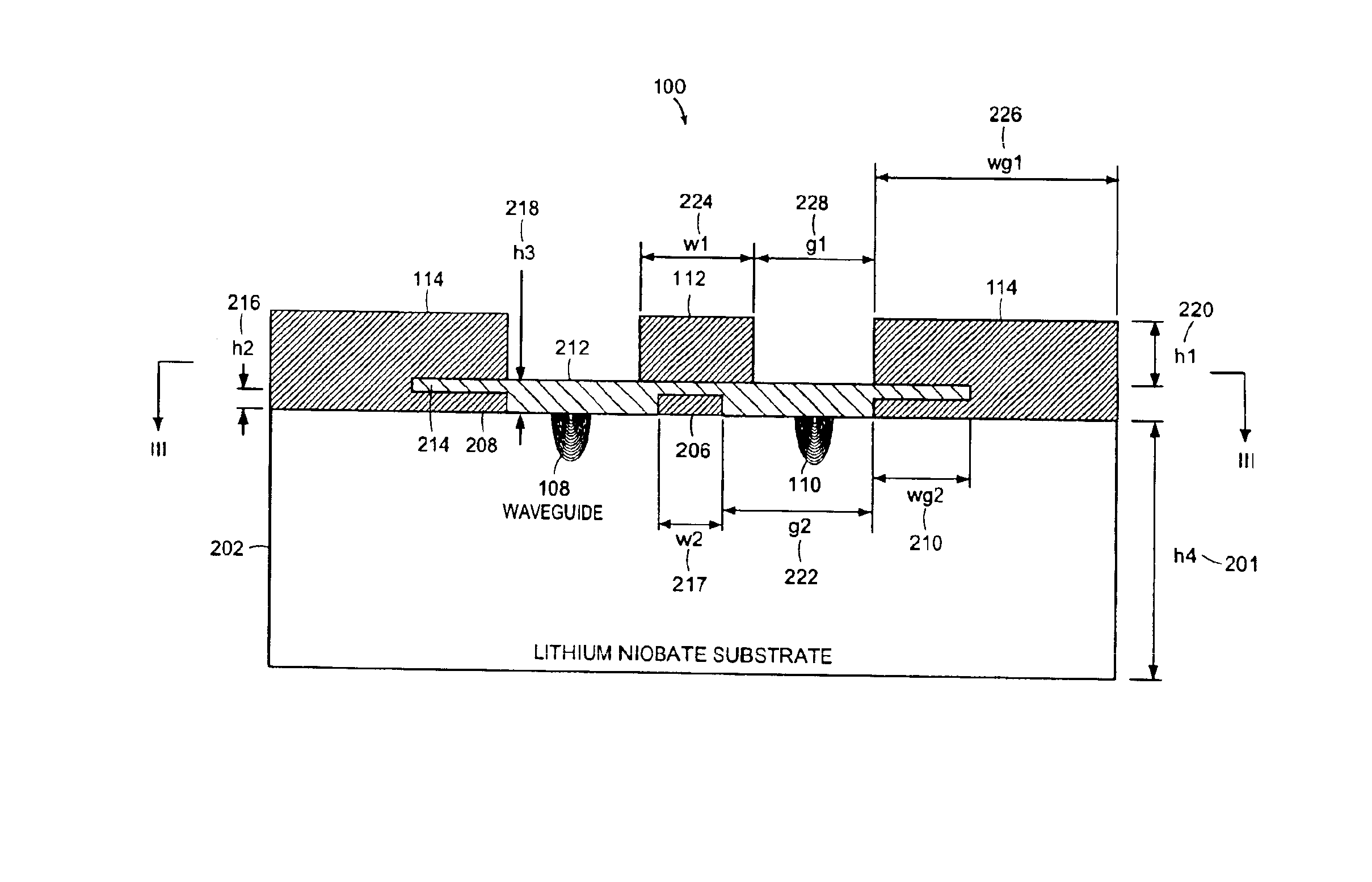

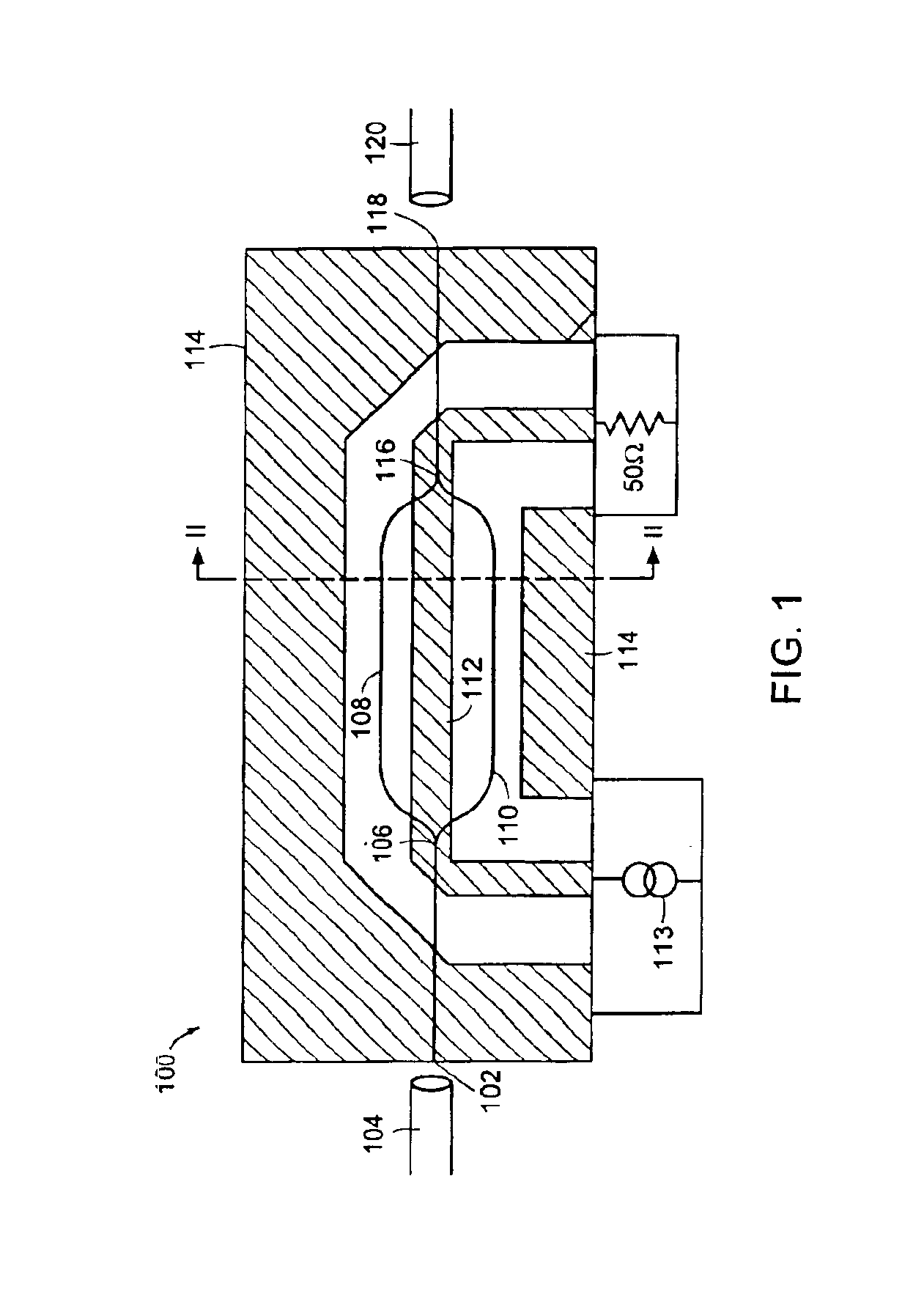

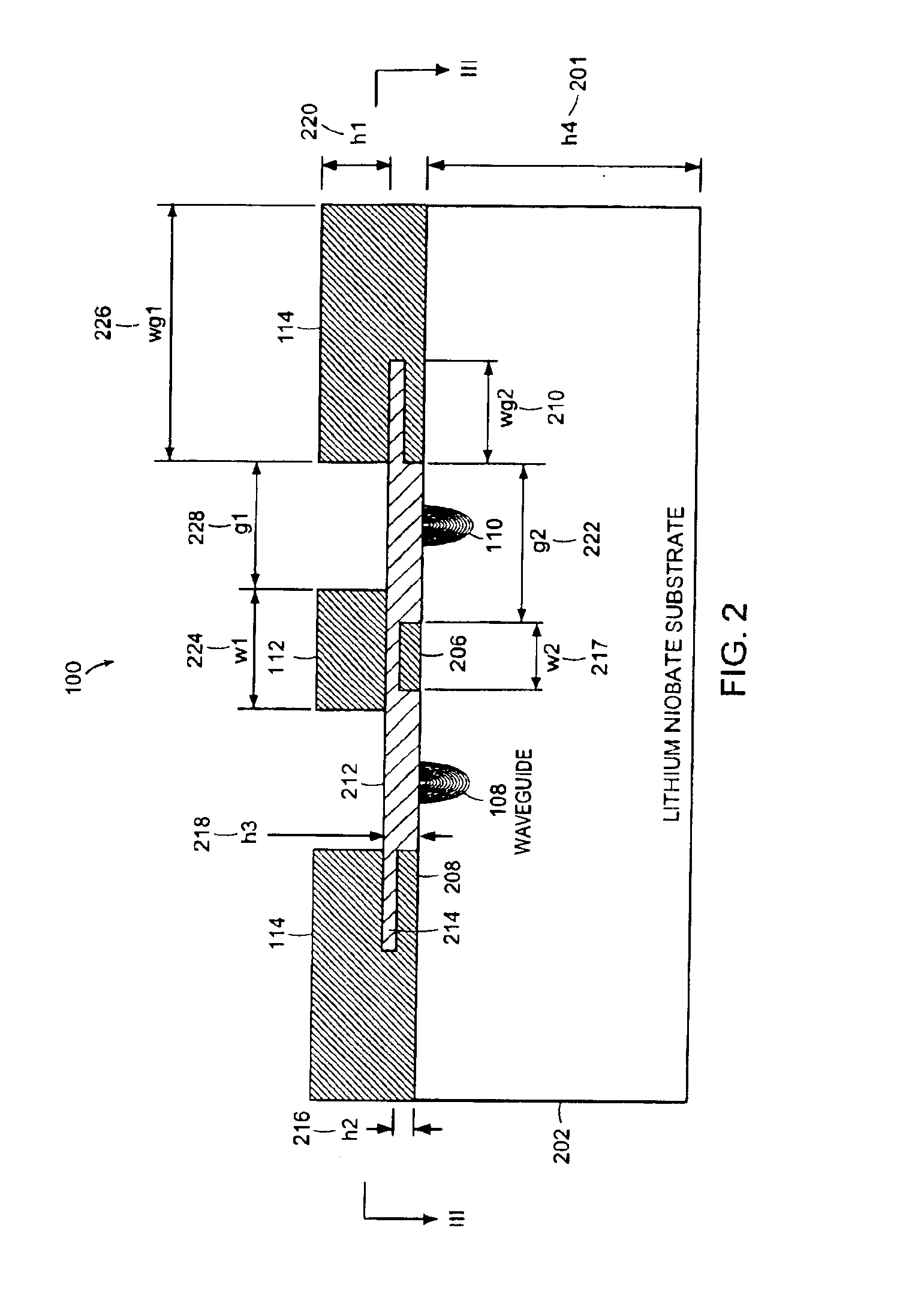

Suppression of high frequency resonance in an electro-optical modulator

InactiveUS6885780B2Suppresses modal couplingReduced insertion lossCoupling light guidesNon-linear opticsFloating electrodeWaveguide

The invention relates to suppression of high frequency resonance in an electro-optical device. The electro-optical device includes an optical waveguide formed in a substrate and a plurality of electrically floating electrode segments that are positioned on the substrate to intensify an electric field in the optical waveguide. The device also includes a RF ground electrode that is positioned on the substrate. The RF ground electrode defines a slot having a shape that suppresses modal conversion and propagation of high order modes in the RF ground electrode and in the plurality of electrically floating electrode segments, thereby suppressing modal coupling to the substrate. The device further includes a buffer layer formed on the upper surface of the substrate, on the plurality of electrically floating electrode segments, and in the slot. A driving electrode receives a RF signal that induces-the electric field in the optical waveguide.

Owner:LUMENTUM OPERATIONS LLC

System and method for reducing modal coupling of combustion dynamics

InactiveCN103822227AContinuous combustion chamberTurbine/propulsion fuel controlCombustion instabilityWorking fluid

The present invention provides a system and a method for reducing modal coupling of combustion dynamics. The system includes a plurality of combustors, and at least one fuel injector in each of the plurality of combustors. The system also includes structure for dithering a combustion instability frequency in at least one combustor in the plurality of combustors. A method for reducing modal coupling of combustion dynamics includes flowing a compressed working fluid at a temperature to a plurality of combustors and flowing a fuel to at least one fuel injector in each of the plurality of combustors. The method further includes dithering at least one of the temperature of the compressed working fluid flowing to the plurality of combustors or the fuel flow to the at least one fuel injector in at least one combustor in the plurality of combustors.

Owner:GENERAL ELECTRIC CO

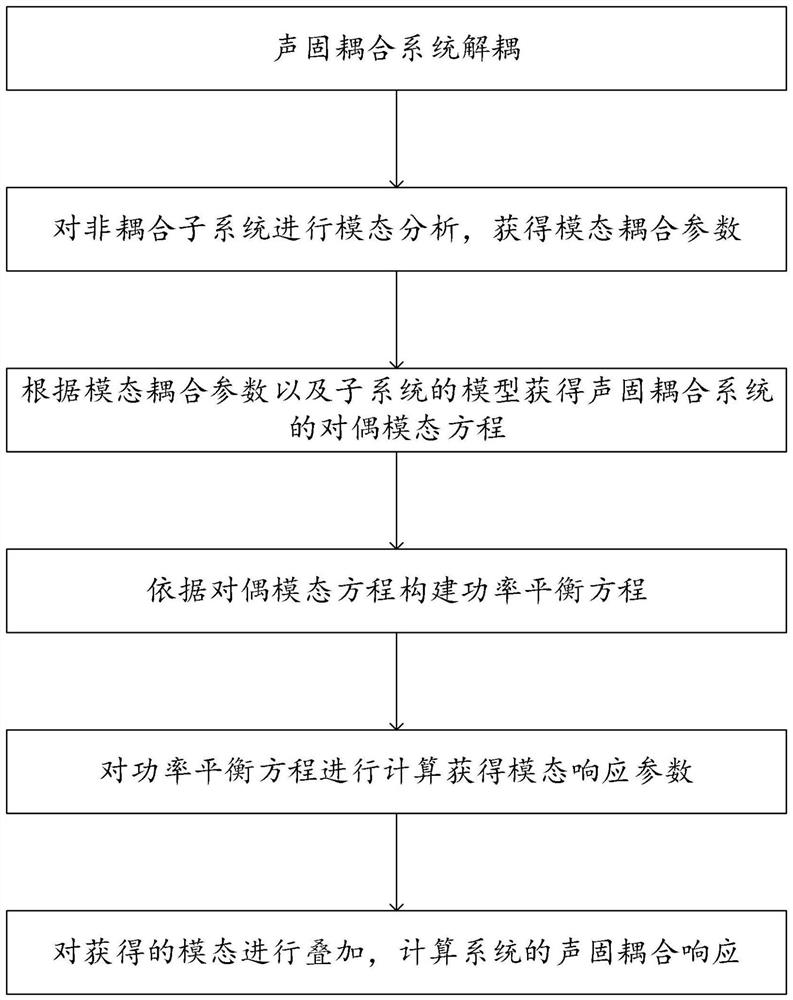

Sound-structure interaction system structure vibration response prediction method, system and storable medium

PendingCN113836773AImprove efficiencyImprove factory speedDesign optimisation/simulationComplex mathematical operationsNoise controlDual mode

The invention discloses a sound-structure-structure coupling system structure vibration response prediction method, a system and a storable medium, and relates to the related technical field of mechanical vibration noise analysis. The specific steps of the method are as follows: decoupling a sound-structure-structure coupling system into a sound cavity subsystem and a structure subsystem, and respectively establishing a model of each subsystem; performing modal analysis on the uncoupled subsystem, respectively extracting modal data of the structure subsystem and the acoustic cavity subsystem, and calculating modal coupling parameters between the two subsystems by using the modal data of the structure subsystem and the acoustic cavity subsystem; obtaining a dual mode equation of the acoustic-solid coupling system according to the mode coupling parameters and the models of the subsystems; obtaining a system acoustic-structure coupling response according to the dual-mode equation; According to the invention, the finite element and the dual mode are combined, so that the efficiency of the prediction method is improved, data support can be provided for noise control of the engine, the research and development period is shortened, the delivery speed is increased, and the competitive advantage is increased.

Owner:JIUJIANG UNIVERSITY

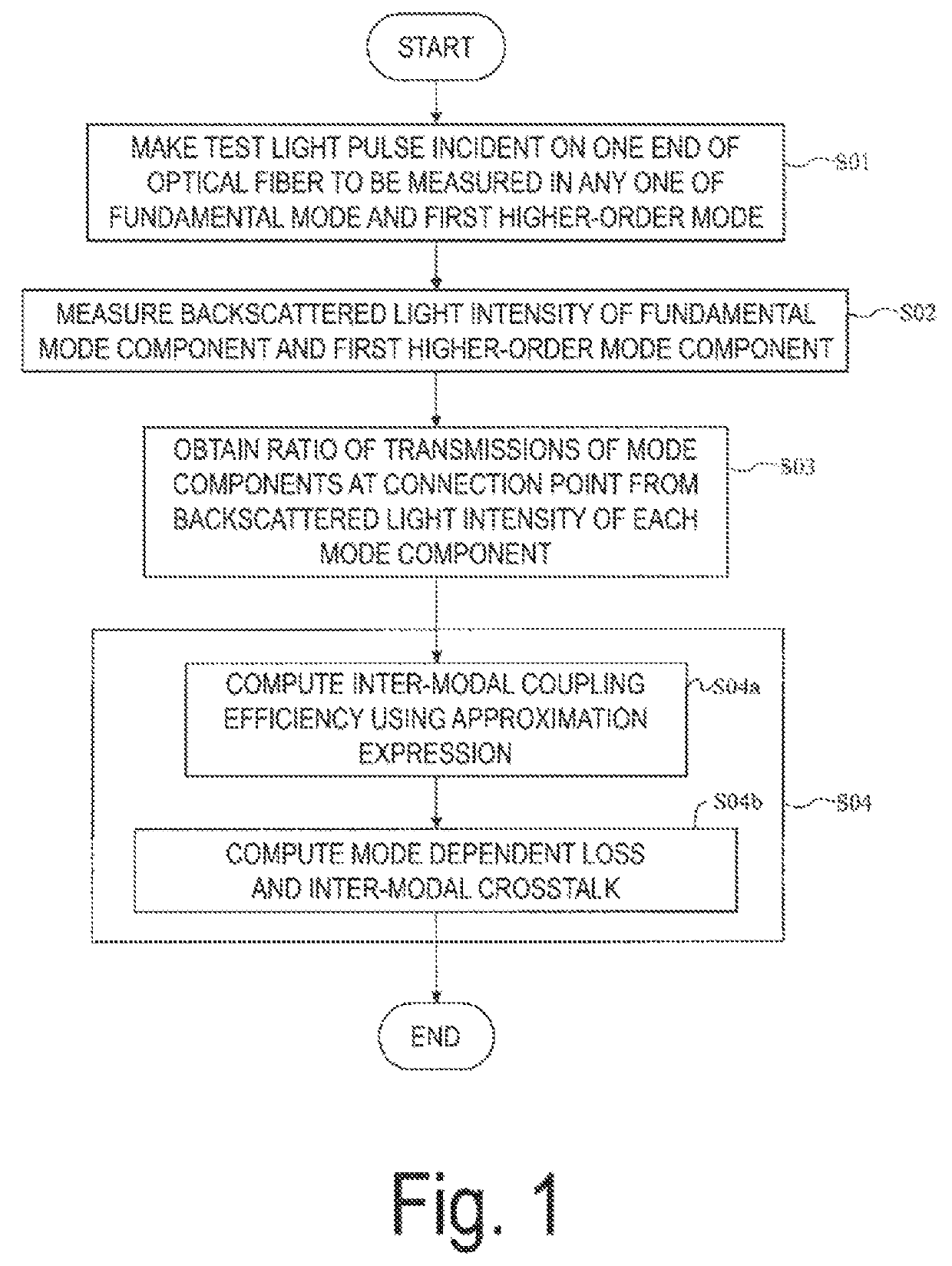

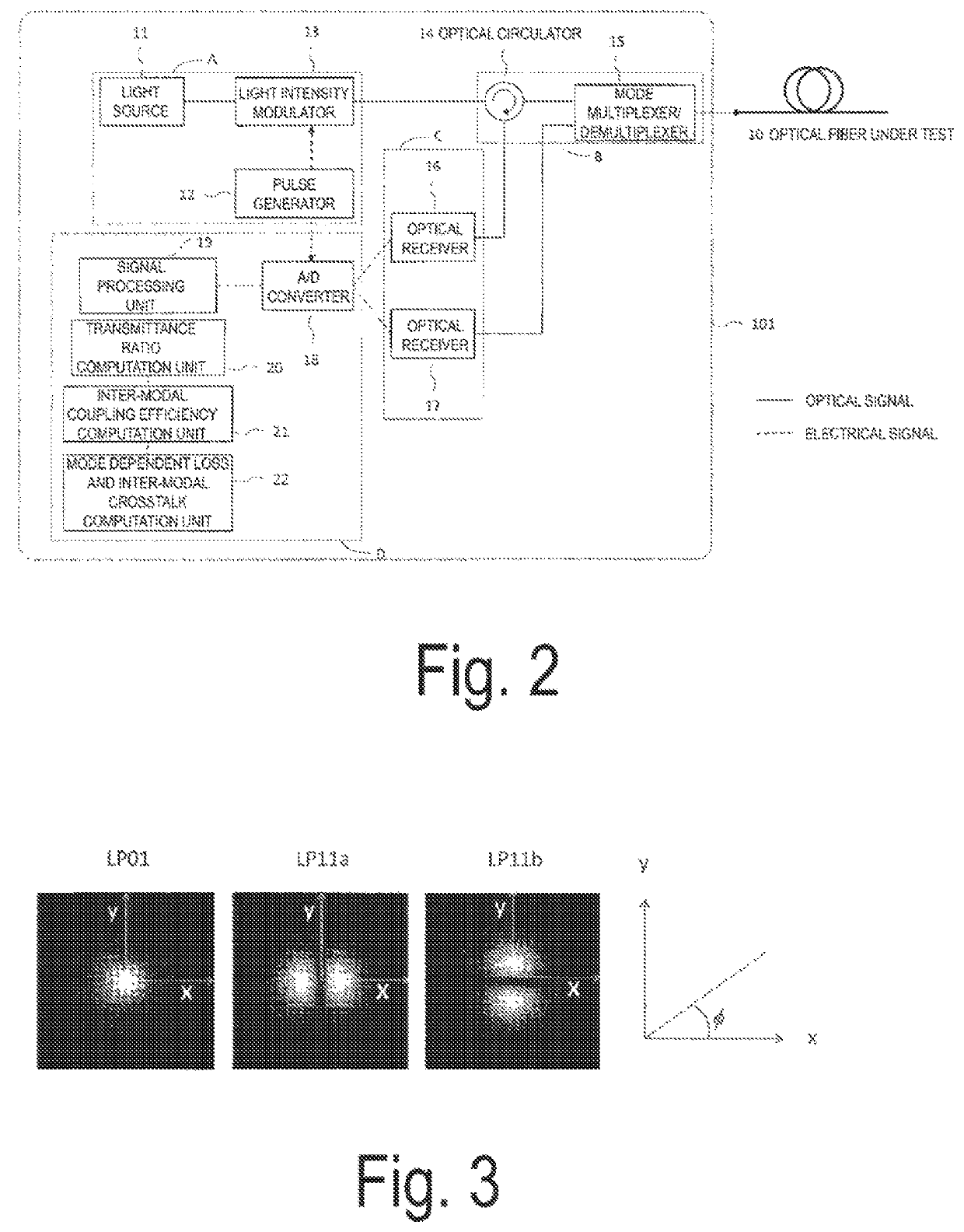

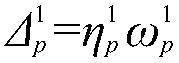

Optical fiber testing method and optical fiber testing device

ActiveUS11391644B2Reflectometers detecting back-scattered light in time-domainFiberGaussian function

The present invention has an object to provide an optical fiber test method and an optical fiber test apparatus for measuring a mode dependent loss and an inter-modal crosstalk in a fundamental mode and a first higher-order mode at a connection point of a few-mode fiber. In the optical fiber test method and test apparatus according to the present invention, the mode dependent loss and the inter-modal crosstalk in the fundamental mode and the first higher-order mode at the connection point are calculated by using an approximation expression of an inter-modal coupling efficiency that is obtained in approximating electric field distributions of the fundamental mode and the first higher-order mode in a few-mode fiber by Gaussian function and Hermite Gaussian function.

Owner:NIPPON TELEGRAPH & TELEPHONE CORP

High-frequency local response indication method for sound-solid coupling structure

ActiveCN108491595ADesign optimisation/simulationSpecial data processing applicationsBi-isotropic materialStrain energy

The invention provides a high-frequency local response indication method for a sound-solid coupling structure. A finite element method, a modal power flow equilibrium equation and a local energy indication theory are combined to indicate the high-frequency local response of the sound-solid coupling structure, the finite element method is used for obtaining the displacement modal vibration mode ofa structure subsystem on a coupling edge, the stress modal vibration mode of a sound cavity subsystem on the coupling edge and the inherent frequency and the modal quality of the subsystem, a modal coupling loss factor between subsystems is calculated, and the modal power flow equilibrium equation is established and solved to obtain the modal energy of the structure subsystem. Finally, the local energy indication theory is used for solving the local energy response of the structure subsystem, and a local stress / strain response is solved through a relationship between the strain energy and thestress strain of an isotropy material. By use of the method, the high-frequency local response indication method for the sound-solid coupling structure can be accurately indicated, and the problems that discretization methods including a traditional finite element method, a boundary element method and the like are low in calculation efficiency and each hypothesis of a statistical energy analysismethod can not be completely satisfied usually in engineering application and is difficult to obtain the local energy of the subsystem can be solved.

Owner:SOUTHEAST UNIV

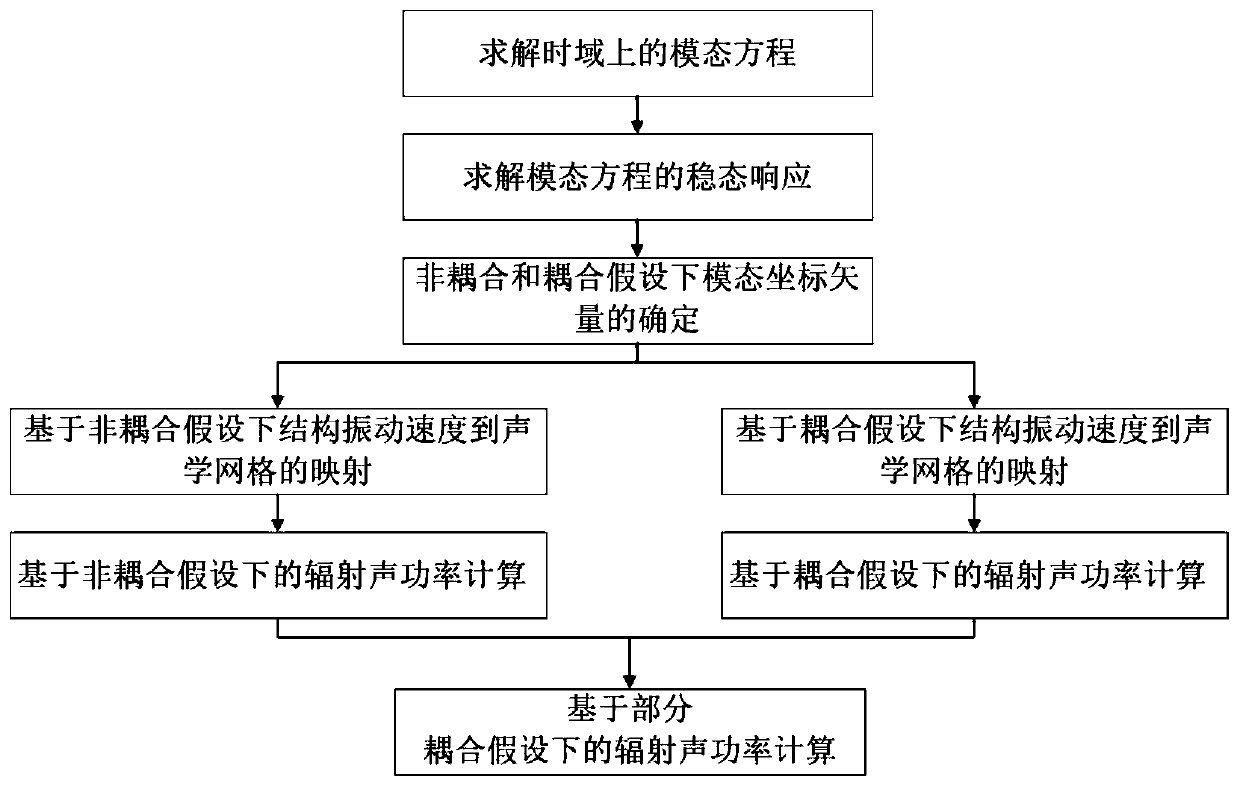

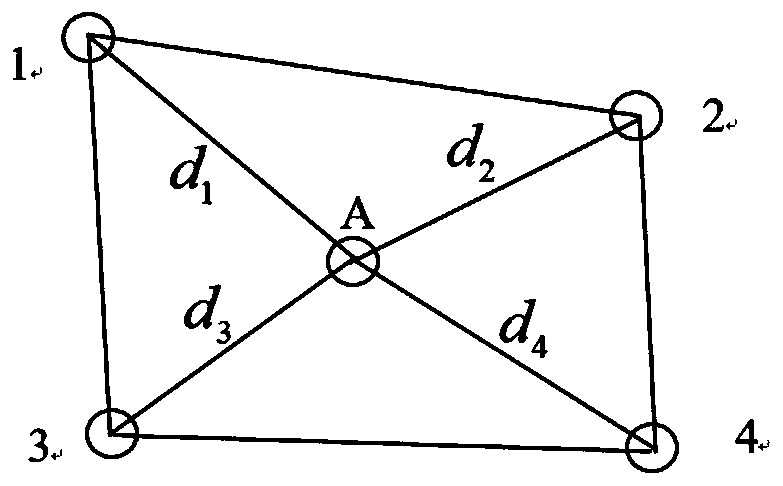

Radiation acoustic power calculation method based on modal partial coupling hypothesis

InactiveCN110162738AEliminate theoretical energy errorsVibration measurement in fluidComplex mathematical operationsVibration accelerationHypothesis

The invention discloses a radiation acoustic power calculation method based on a modal partial coupling hypothesis. The method mainly comprises the steps of structure modal calculation, structure vibration response solving, vibration acceleration mapping to a surface air layer and radiation acoustic power calculation based on the modal partial coupling hypothesis. Compared with a radiation acoustic power calculation method based on a modal uncoupling hypothesis and a modal coupling hypothesis, the radiation acoustic power calculation method based on the modal partial coupling meets the requirement for energy conservation, achieves complementation of the uncoupling hypothesis and the coupling hypothesis, and achieves the purpose of eliminating theoretical energy errors.

Owner:ZHEJIANG UNIV

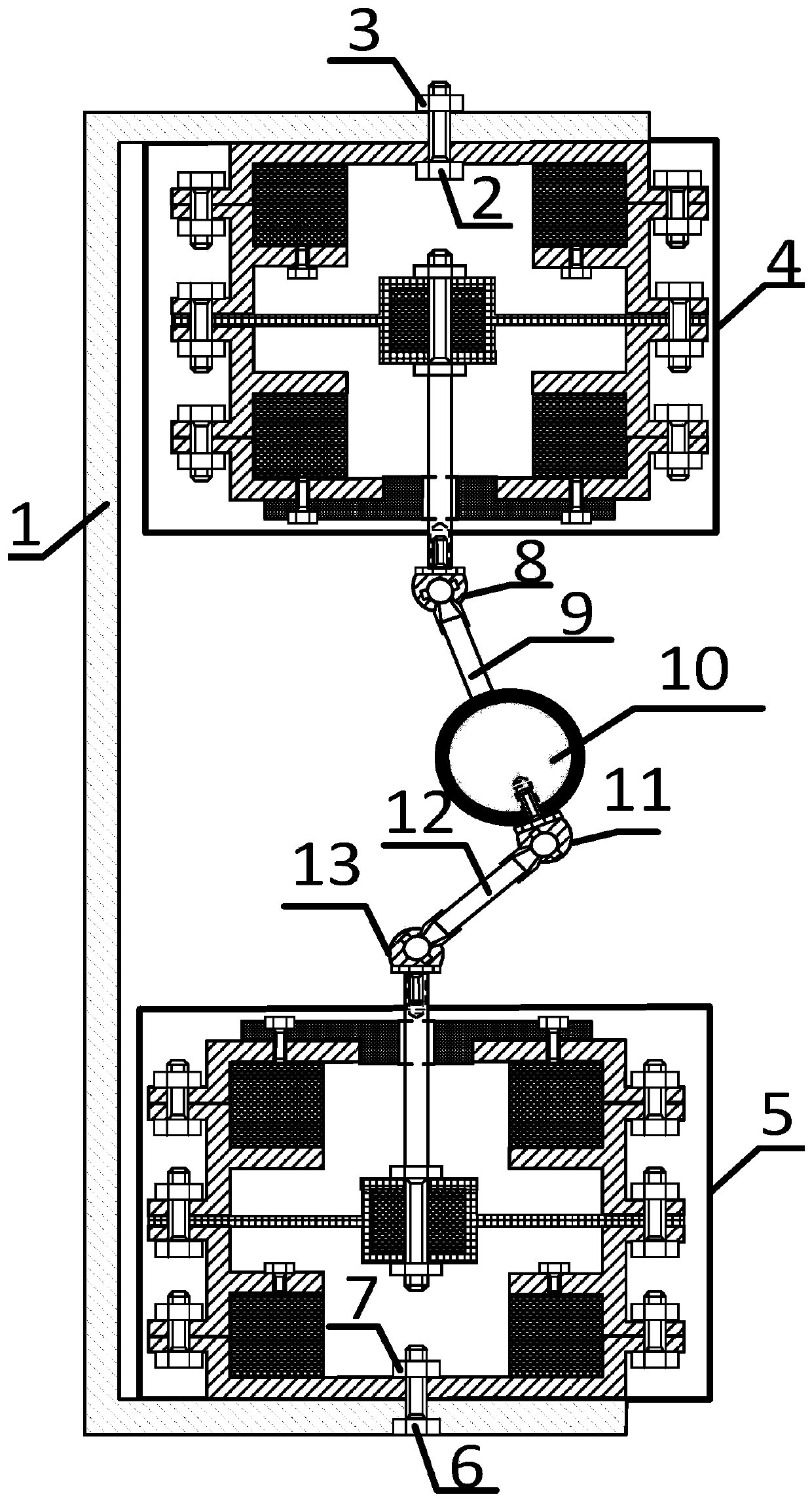

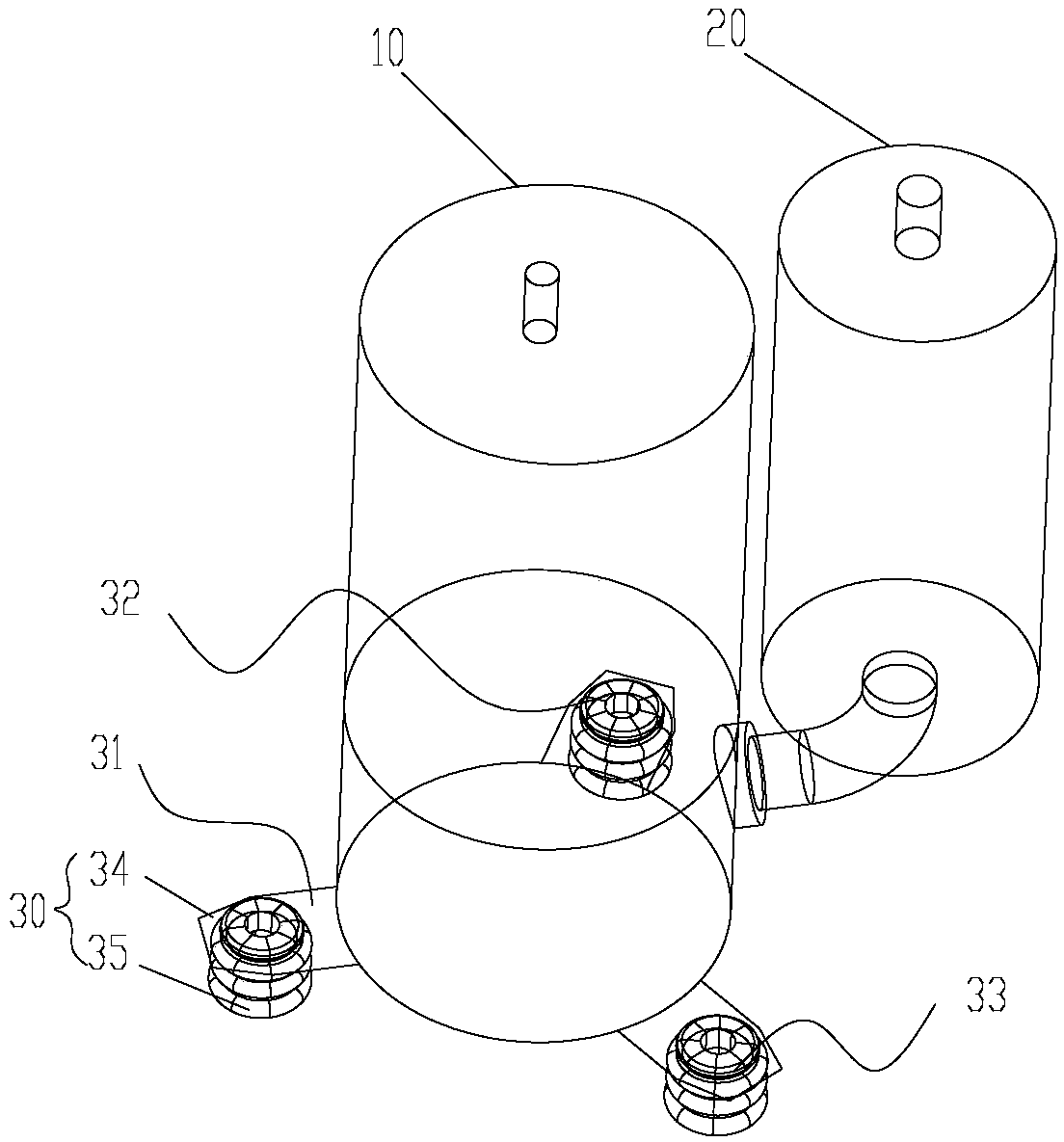

A multi-degree-of-freedom low-frequency vibration isolator based on the coupling of vibration mode and pendulum mode

The invention relates to a multi-degree-of-freedom low frequency vibration isolator based on vibration mode and swing mode coupling. The multi-degree-of-freedom low frequency vibration isolator mainlycomprises a high static state stiffness vibration isolator body and a low dynamic state stiffness vibration isolator body which are the same and are symmetrically arranged up and down, and supportingrods of the high static state stiffness vibration isolator body and the low dynamic state stiffness vibration isolator body are connected with a space swing mechanism through two spherical hinges; the high static state stiffness vibration isolator body and the low dynamic state stiffness vibration isolator body are each provided with a spiral spring and a magnetic negative stiffness mechanism; each spiral spring provides positive stiffness supporting along an axial support; each magnetic negative stiffness spring is formed by three attracted annular permanent magnets and provides nonlinear resilience and negative stiffness characteristics in the vertical direction; and the high static state stiffness vibration isolator body and the low dynamic state stiffness vibration isolator body achieve motion coupling with the space swing mechanism, quasi-zero stiffness characteristics and geometric nonlinearity damping in the horizontal direction are achieved, and low-frequency vibration of an object subject to vibration isolation in three transverse movement directions is effectively isolated. The multi-degree-of-freedom low frequency vibration isolator has the beneficial effects of high bearing capacity and low resonant frequency, and the good inhibitory effect on the low frequency vibration in multiple degree-of-freedom directions is achieved.

Owner:XI AN JIAOTONG UNIV

Compressor and air conditioner with same

ActiveCN108661882AConsistent compressionReduced modal coupling vibrationPositive displacement pump componentsPump installationsEngineeringModal coupling

The invention provides a compressor and an air conditioner with the same. The compressor comprises a compressor shell, a liquid storage barrel and supporting parts; the liquid storage barrel is connected with the compressor shell, the supporting parts are arranged at the bottom of the compressor shell, the plurality of supporting parts are provided, one of the plurality of supporting parts is located on the extension line of a first connecting line between the axis of the compressor shell and the axis of the liquid storage barrel, and the other supporting parts are located on the two sides ofthe first connecting line and are symmetrically arranged with respect to the first connecting line. One of the plurality of supporting parts is located on the extension line of the first connecting line between the axis of the compressor shell and the axis of the liquid storage barrel, and the other supporting parts are located on the two sides of the first connecting line and are symmetrically arranged with respect to the first connecting line, so that the compression amount of the supporting parts is consistent, the multi-direction modal coupled vibration caused by the vibration excitation of the compressor is reduced, and the noise of the compressor is reduced.

Owner:格力电器(南京)有限公司 +1

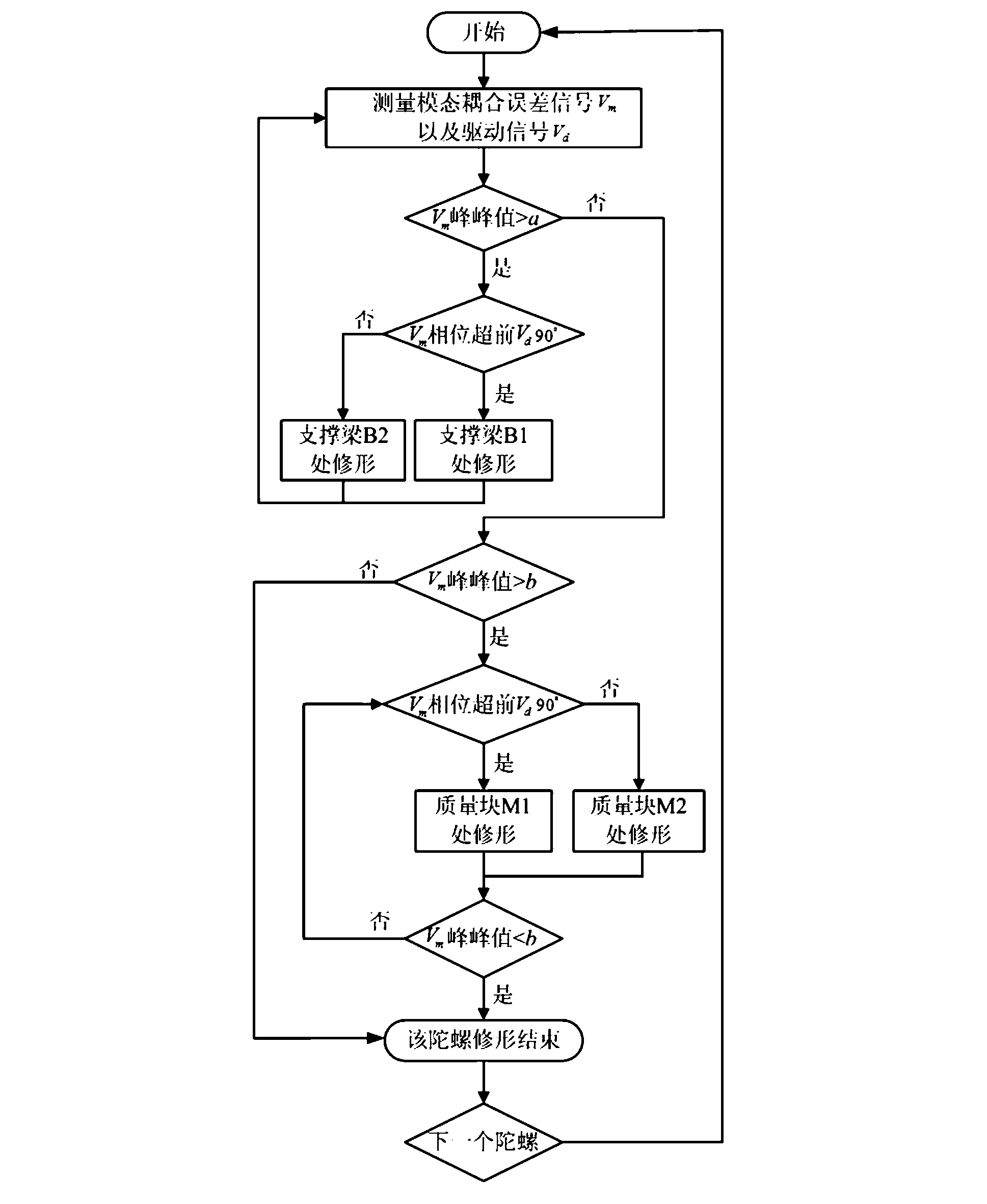

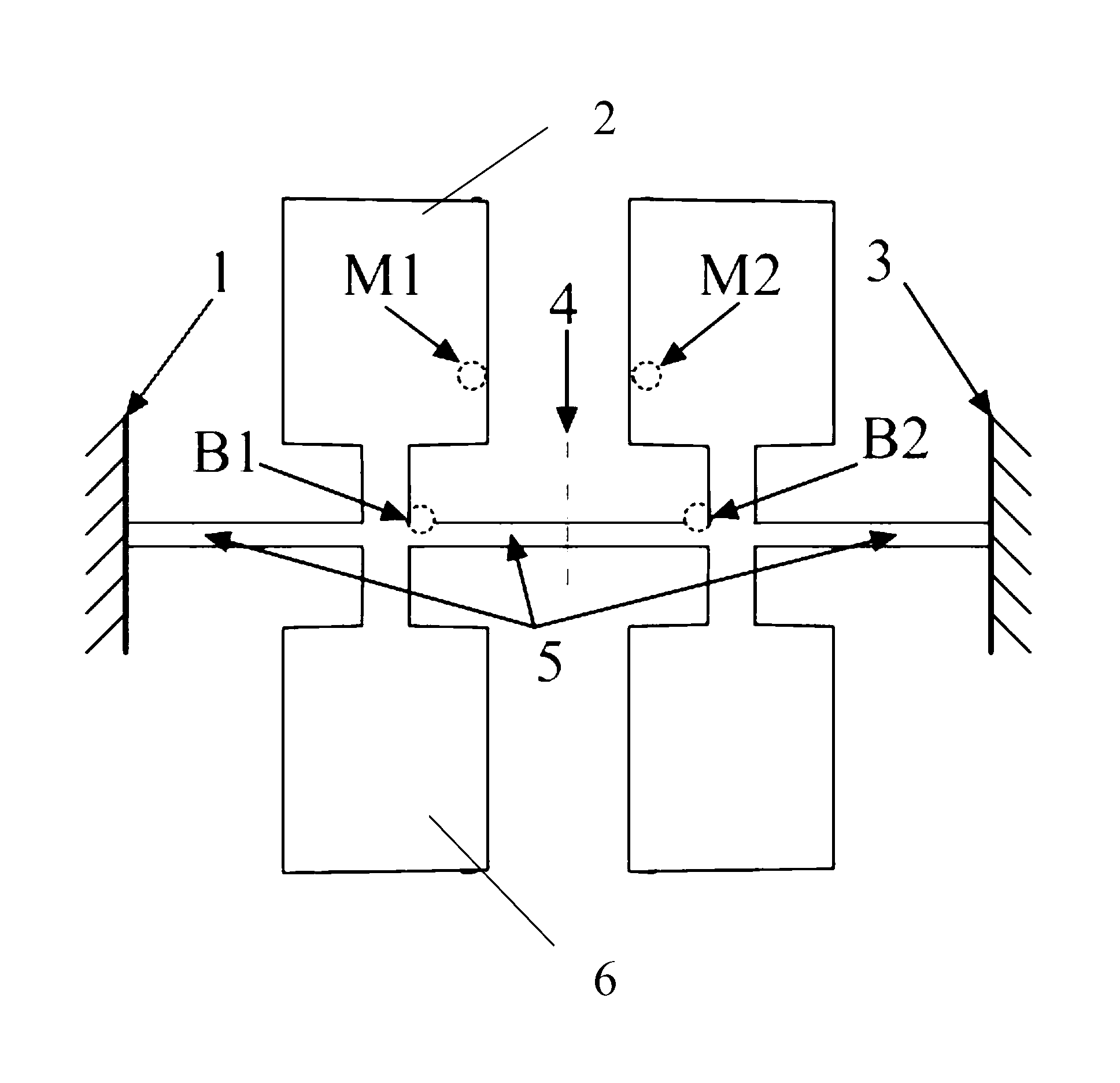

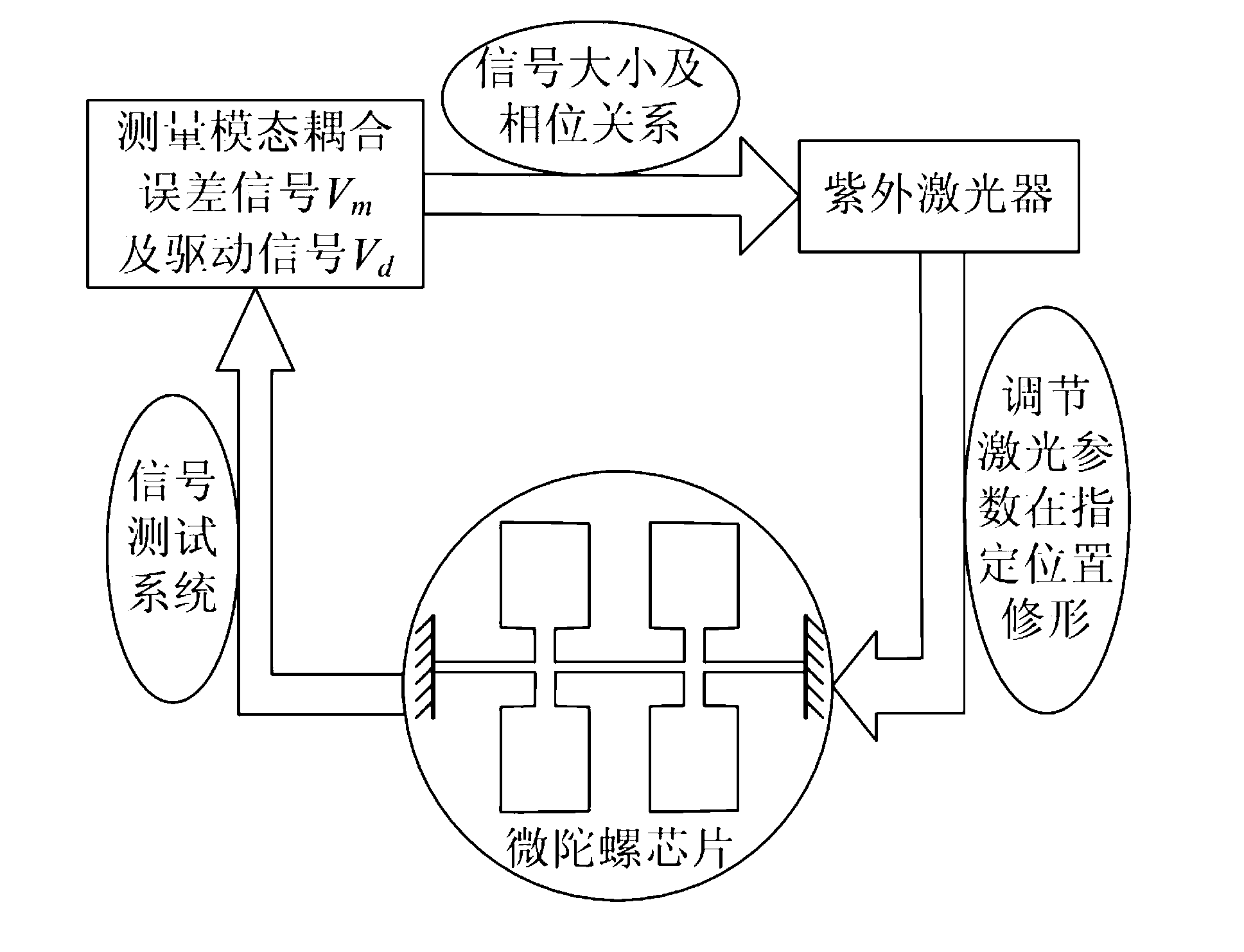

Laser profile modification method for reducing modal coupling error of vibratory silicon micro-machined gyroscope

ActiveCN102980591AEase of industrial productionImprove work performanceMeasurement devicesLaser beam welding apparatusGyroscopePeak value

The invention discloses a laser profile modification method for reducing the modal coupling error of a vibratory silicon micro-machined gyroscope. The method comprises the following steps: 1, signal test: testing the driving signal Vd and the modal coupling error signal Vm of a silicon micro-machined gyroscope chip, and determining the peak values and the phase relationships of the two signals; 2, determining the laser profile modification type according to the signals in step 1; 3, determining the profile modification position according to the signals in the step 1; and 4, carrying out laser profile modification according to the type obtained in step 2 and the position obtained in step 3. The laser profile modification method has the advantages of simple principle, simple operation, reduction of the modal coupling error, and improvement of the working performances of the silicon micro-machined gyroscope.

Owner:NAT UNIV OF DEFENSE TECH

Ultrasonic sensor and electronic device

InactiveCN108731716AHigh bandwidthConverting sensor ouput using wave/particle radiationUltrasonic sensorModal coupling

The invention discloses an ultrasonic sensor and an electronic device. The ultrasonic sensor includes a piezoelectric layer, a matching layer, and a backing layer; the matching layer is formed on onesurface of the piezoelectric layer; the matching layer is made of metal and a polymer; the backing layer is placed on the other surface of the piezoelectric layer; and the backing layer and the matching layers are respectively placed on the two opposite surfaces of the piezoelectric layer. According to the ultrasonic sensor and the electronic device provided by the embodiments of the present invention, the matching layer is additionally arranged on the piezoelectric layer of the ultrasonic sensor, so that the plurality of resonant frequencies of the ultrasonic sensor can undergo multi-modal coupling, so that the bandwidth of the ultrasonic sensor can be extended.

Owner:NANCHANG OUFEI BIOLOGICAL IDENTIFICATION TECH

Small aero-engine multi-point rubbing fault simulation experiment device

Owner:南京领航智能航空科技有限公司

A Method of Improving the Elastic Stability of Pneumatic Servo

ActiveCN111332491BTaking into account the coupling relationshipPneumatic servo elastic stability analysis is accurateGeometric CADSustainable transportationData designControl system

The invention discloses a design method for improving the elastic stability of aerodynamic servo, which adopts the whole machine ground resonance test or the whole machine ground structure modal coupling test data design optimization technology to correct the body elastic model and transfer function, and then uses the flight control law to dynamically adjust the parameters technology to improve the elastic stability of aerodynamic servo; the present invention can take into account the coupling relationship between aerodynamic force, structural elasticity and control systems, so as to meet flight quality requirements, control system stability margin requirements, and aerodynamic servo Elastic stability requirements have been applied and verified in multi-control surface UAVs. It solves the problem that the aeroservoelastic stability of a multi-control surface unmanned aerial vehicle is difficult to control.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

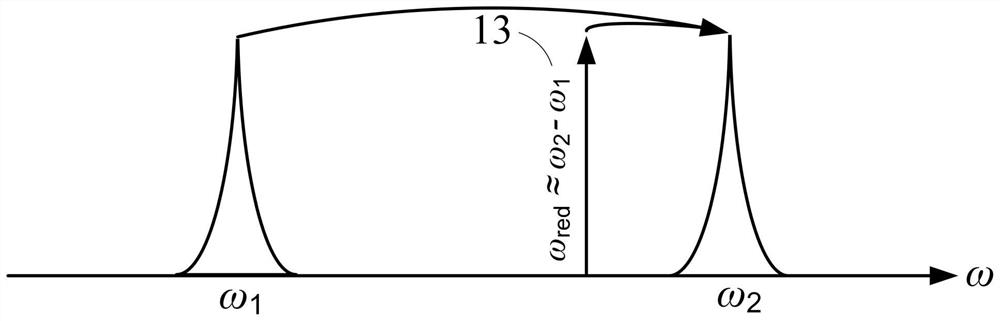

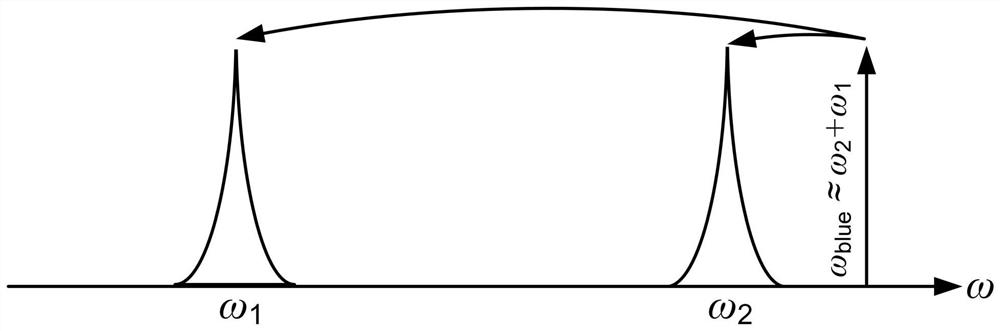

Sensor sensitivity improving method and system based on nonlinear domain modal coupling

ActiveCN114323081AEasy to operateEasy to integrateSustainable transportationConverting sensor output electrically/magneticallyLoop controlSoftware engineering

The invention discloses a sensor sensitivity improving method and system based on nonlinear domain modal coupling, and the method employs the coupling characteristic between at least two vibration modes in a resonator, employs a first mode in the two modes as a frequency output mode, and employs a second mode as a cavity mode to sense an external variable to be measured. In order to excite a coupling characteristic between the first mode and the second mode, the method entails the application of at least one pump. Meanwhile, in order to improve the sensitivity of the sensor, according to the method, the vibration state of the first mode needs to be excited to a nonlinear vibration area, the high-branch frequency of the second mode serves as final output, phase closed-loop control can be conducted on the first mode through a phase-locked loop, and rapid collection and measurement of the frequency are achieved. The invention is applied to a frequency output type sensor, can improve the sensitivity of the frequency output type sensor, does not need to introduce other auxiliary devices, and has the advantages of easy operation, convenient integration, stability, reliability, wide application range and the like.

Owner:NAT UNIV OF DEFENSE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com