Laser profile modification method for reducing modal coupling error of vibratory silicon micro-machined gyroscope

A silicon micro-gyroscope and modal coupling technology, which is applied in laser welding equipment, instruments, measuring devices, etc., can solve the problems that restrict the performance of micro-gyroscopes, and achieve the effect of low processing conditions, simple operation, and simple principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

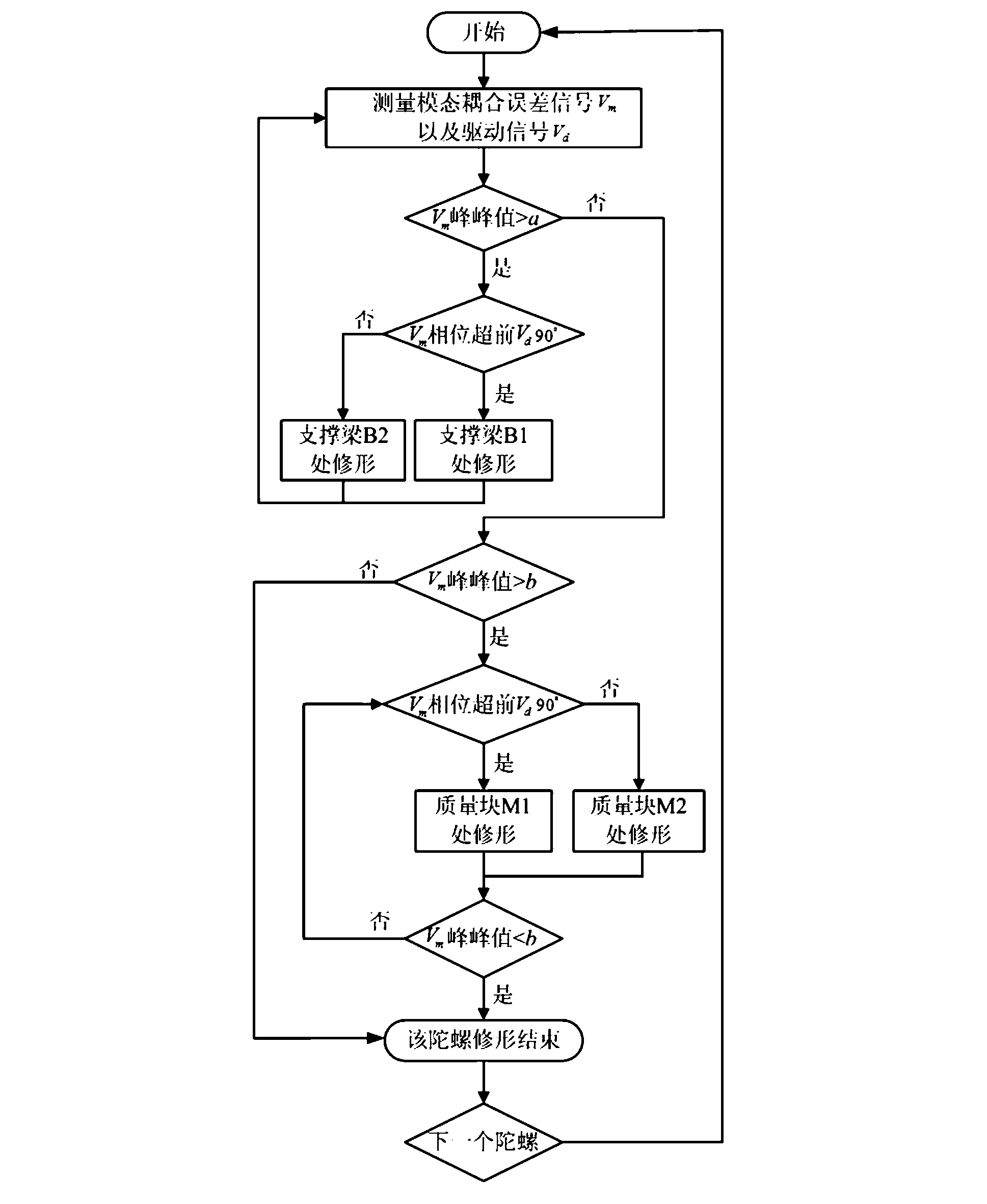

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

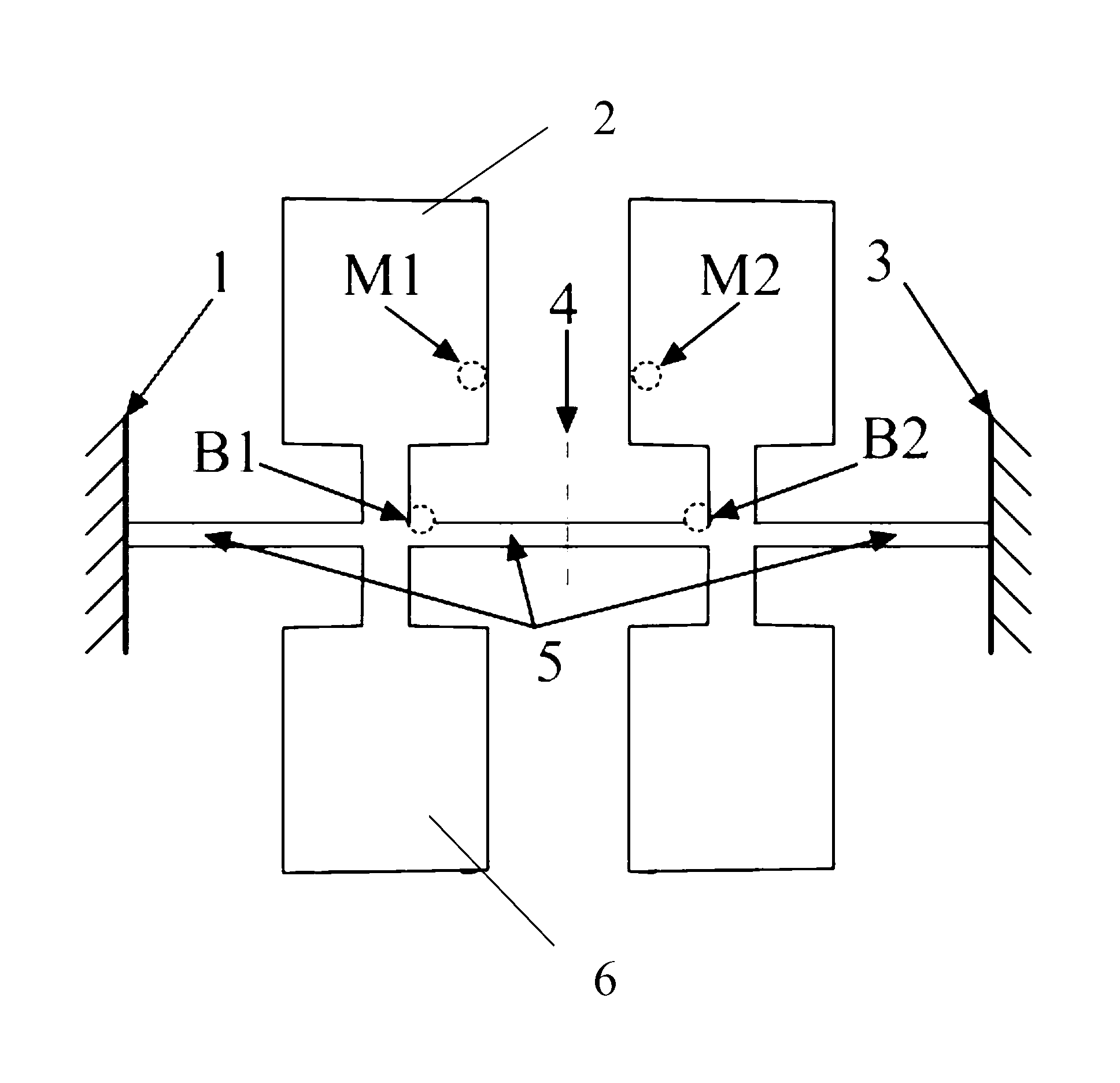

[0025] Such as figure 2 As shown, taking a silicon microgyro chip in a specific application example as an example, the silicon microgyro chip includes a support beam 5 and several mass blocks, and the two ends of the support beam 5 pass through the first anchor point 1 and the second anchor point respectively. 3 fixed, the first mass block 2 and the second mass block 6 form a group and are symmetrically arranged at both ends of the support beam 5 (two pairs of left and right in this example), and they are arranged correspondingly, forming two pairs during work The mass swing centerline 4 between the masses.

[0026] In an ideal situation, there is no processing error in the vibration structure of the silicon micro-gyroscope, and the modal coupling error of the micro-gyroscope is zero at this time. When there are machining errors in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com