Cobalt-intercalated molybdenum sulfide secondary battery material and preparation method and application thereof

A secondary battery, molybdenum sulfide technology, applied in secondary batteries, nanotechnology for materials and surface science, battery electrodes, etc., can solve the problems of difficult to control product morphology, cumbersome preparation process, high system temperature, etc. Achieving good cycle stability, simple process, and improved electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

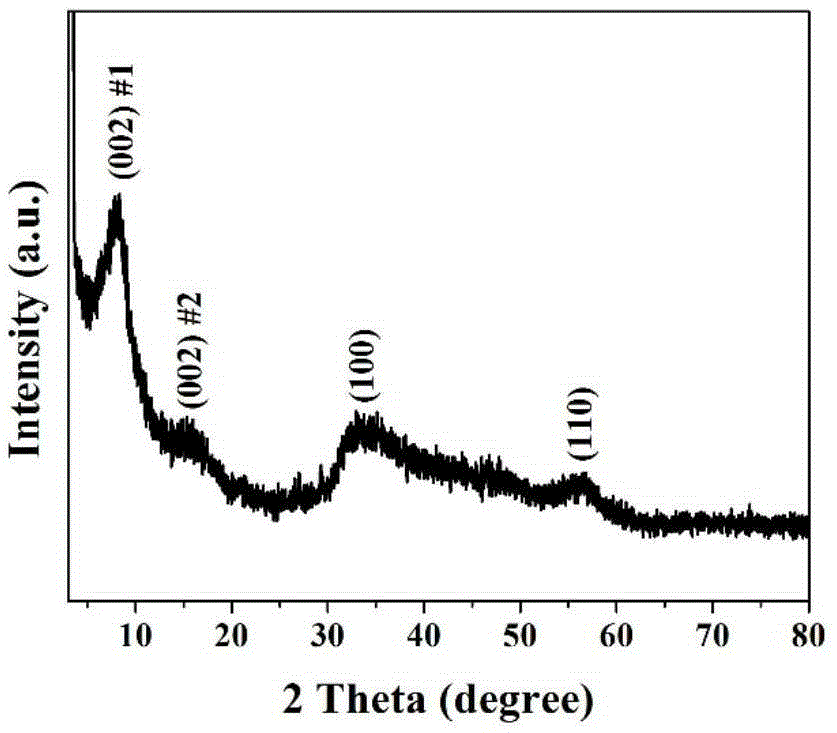

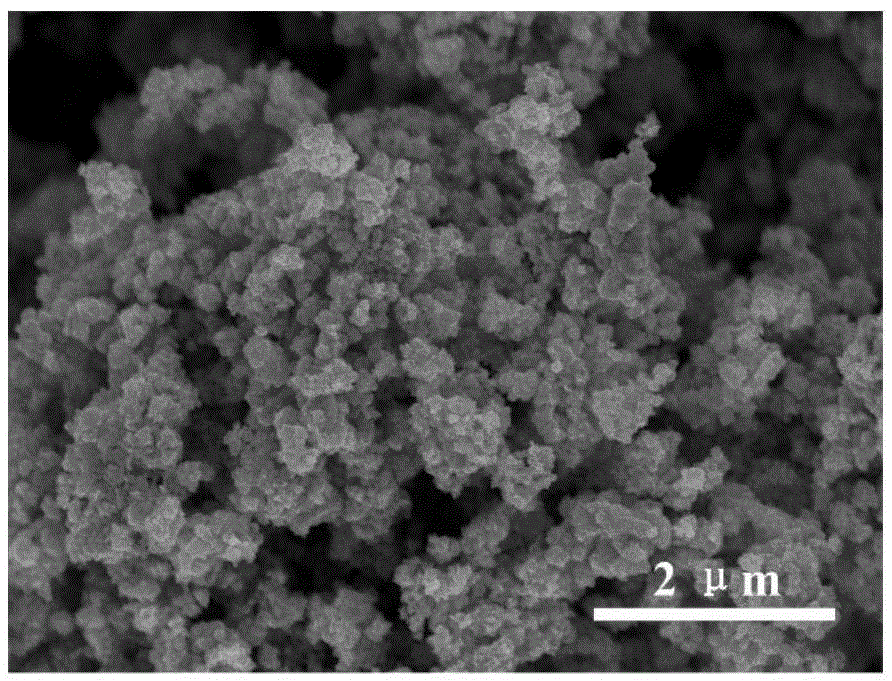

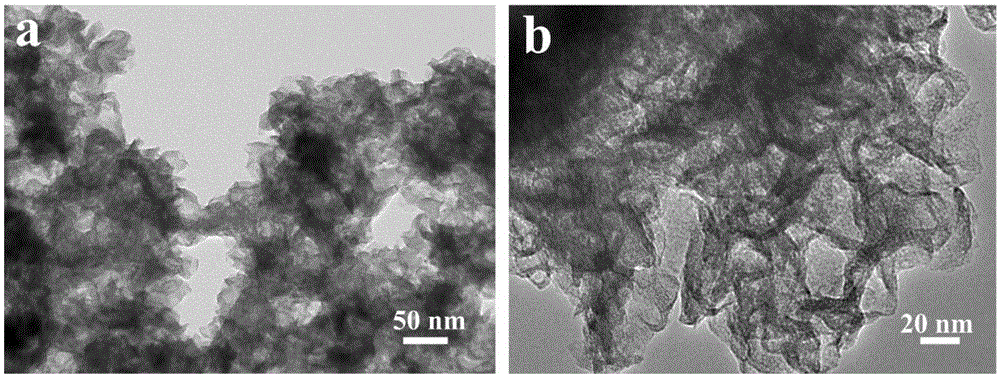

[0038] (1) In a 100ml flask, add 0.5mmol of cobalt acetate, 1.0mmol of sodium molybdate, and 4mmol of sublimed sulfur to 40ml of ethylene glycol, stir vigorously at room temperature and keep for 1 hour to prepare poly Reaction solution with hierarchical structure.

[0039] (2) move the reaction solution prepared according to step (1) into a high-pressure reactor with a 50ml polytetrafluoroethylene liner, and after reacting at 200°C for 24 hours, the reactor is naturally cooled to 20°C, and after centrifugation, use This was washed several times with absolute ethanol and water, and freeze-dried to obtain a three-dimensional cobalt-intercalated molybdenum sulfide hierarchical structure.

Embodiment 2

[0042] (1) In a 100ml flask, add 1.5mmol of sodium molybdate and 4mmol of sublimed sulfur to 40ml of ethylene glycol, stir vigorously at room temperature and keep for 1 hour to prepare a reaction solution with a multi-level structure.

[0043] (2) move the reaction solution prepared according to step (1) into a high-pressure reactor with a 50ml polytetrafluoroethylene liner, and after reacting at 200°C for 24 hours, the reactor is naturally cooled to 20°C, and after centrifugation, use This is washed several times with absolute ethanol and water, and freeze-dried to obtain molybdenum sulfide nanoparticles. Figure 9 is a scanning electron micrograph of the obtained molybdenum sulfide.

Embodiment 3

[0045] (1) In a 100ml flask, 1.5mmol of cobalt acetate and 4mmol of sublimed sulfur were added to 40ml of ethylene glycol, stirred vigorously at room temperature and kept for 1 hour to prepare a reaction solution with a hierarchical structure.

[0046] (2) move the reaction solution prepared according to step (1) into a high-pressure reactor with a 50ml polytetrafluoroethylene liner, and after reacting at 200°C for 24 hours, the reactor is naturally cooled to 20°C, and after centrifugation, use This was washed several times with absolute ethanol and water, and freeze-dried to obtain a molybdenum sulfide hierarchical structure similar to a three-dimensional cobalt intercalation. Figure 10 is the resulting CoS 2 Scanning electron micrographs of nanomaterials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com