Lithium ion battery cathode material and preparation method thereof as well as lithium ion battery

A lithium-ion battery and negative electrode material technology, applied in the field of electrochemistry, can solve the problems of poor electrode cycle performance, poor rate performance, easy cracking, pulverization, etc., to improve cycle stability, improve electrical conductivity, and prevent agglomeration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

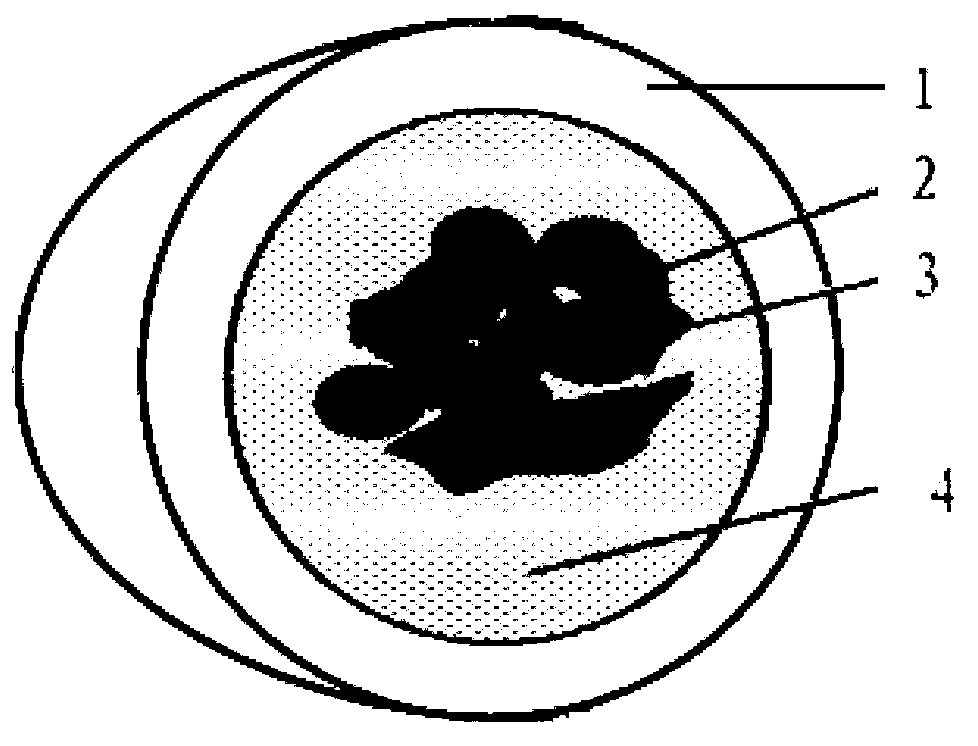

[0034] The present invention also provides a preparation method for the above lithium ion battery negative electrode material, comprising the following steps: a) mixing and ball milling silicon powder and carbon material to obtain a first mixture; b) mixing the first mixture, the first carbon coating material mixing with a foaming agent and ball milling to obtain a second mixture; c) mixing the second mixture with a second carbon coating material, ball milling, and then roasting under the protection of an inert gas to obtain a negative electrode material for a lithium ion battery.

[0035] Wherein, the silicon powder and the carbon material are mixed and ball-milled to obtain the first mixture, which is the core silicon-carbon particle of the negative electrode material of the lithium ion battery. The silicon powder can be silicon powder well known to those skilled in the art, and there is no special limitation. In order to make the silicon particles can be nano-dispersed among...

Embodiment 1

[0046] 1.1 Put 2g of nano-silica powder and 2g of mesocarbon microspheres in a ball milling jar, use absolute ethanol as the ball milling medium, and ball mill at 400 rmp for 8 hours to obtain the first mixture.

[0047] 1.2 Add 4 g of glucose and 0.004 g of urea to the first mixture obtained in 1.1, ball mill at 450 rpm for 4 h, and spray dry to obtain the second mixture.

[0048] 1.3 Add 40 g of glucose to the second mixture obtained in 1.2, ball mill at 450 rpm for 4 hours, then dry the resulting mixture in an oven at 80 °C, and then bake it in a tube furnace in an argon atmosphere at 800 °C for 5 hours to obtain a lithium-ion battery negative electrode material .

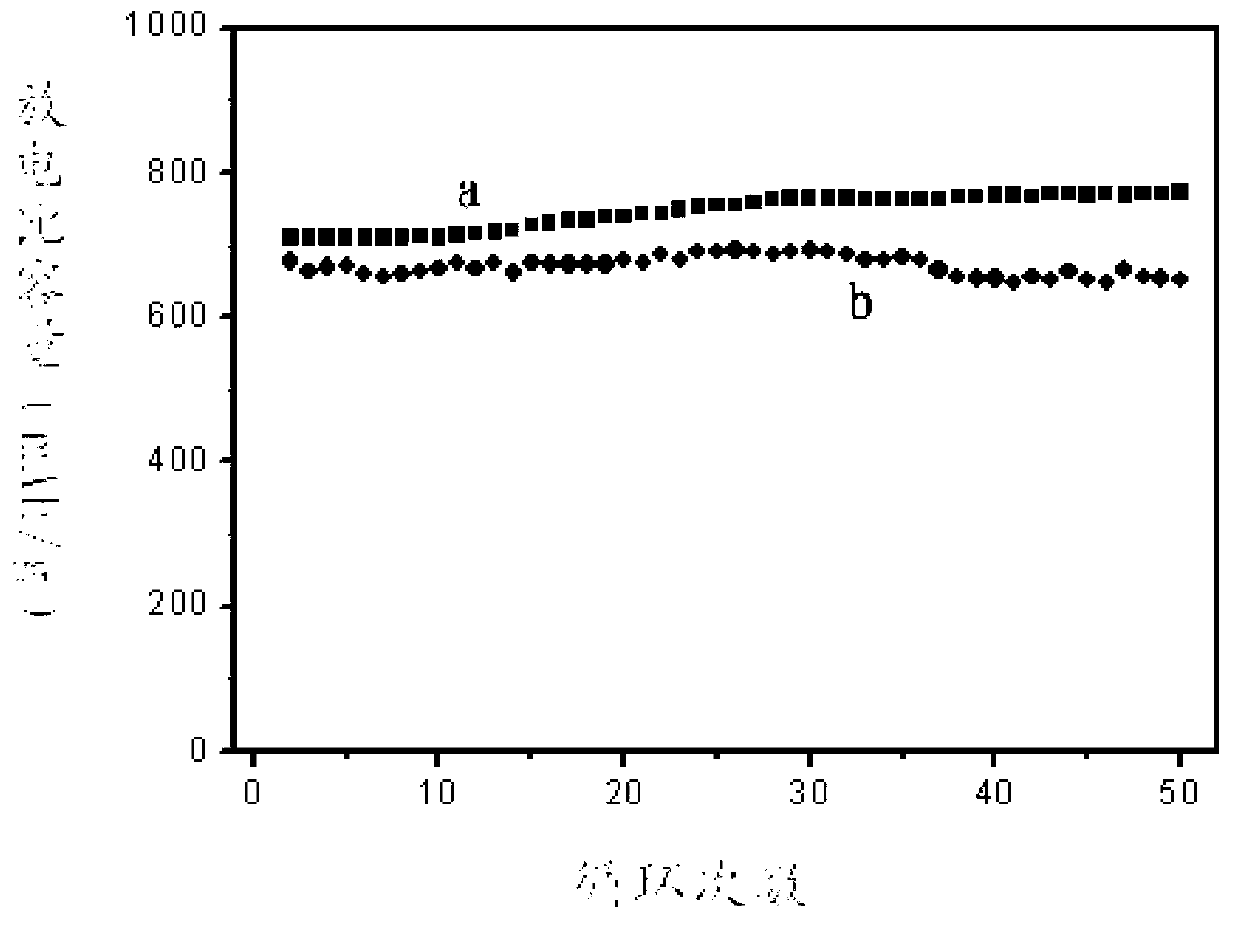

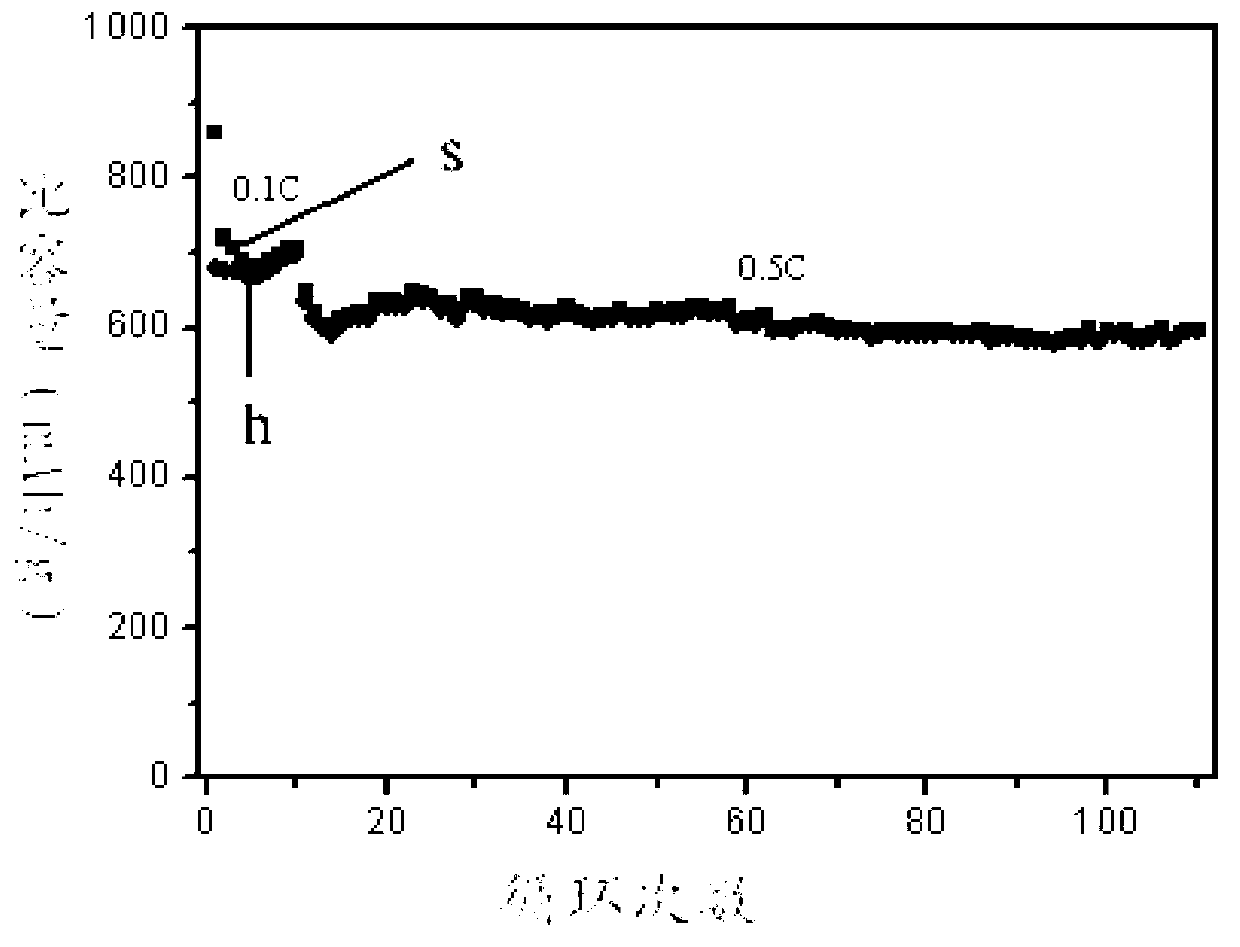

[0049] The lithium ion battery negative electrode material, Supper P and polyvinylidene fluoride binder obtained in 1.3 were prepared into a slurry in a ratio of 80:10:10, and then uniformly coated on the copper foil current collector to obtain a negative electrode pole piece , using lithium metal as the counte...

Embodiment 2

[0051] 2.1 Put 2g of nano-silica powder and 2g of mesocarbon microspheres in a ball milling jar, use absolute ethanol as the ball milling medium, and ball mill at 400 rmp for 8 hours to obtain the first mixture.

[0052] 2.2 Add 0.8 g of glucose and 0.004 g of urea to the first mixture obtained in 2.1, ball mill at 450 rpm for 4 hours, and spray dry to obtain a second mixture.

[0053] 2.3 Add 4.8 g of glucose to the second mixture obtained in 2.2, ball mill at 450 rpm for 4 hours, and then dry the resulting mixture in an oven at 80 °C, and then bake it in a tube furnace in an argon atmosphere at 800 °C for 5 hours to obtain a lithium-ion battery negative electrode Material.

[0054] The lithium-ion battery negative electrode material, Supper P and polyvinylidene fluoride binder obtained in 2.3 were prepared into a slurry in a ratio of 80:10:10, and then uniformly coated on the copper foil current collector to obtain a negative electrode pole piece , using lithium metal as th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com