Patents

Literature

9678 results about "Cyclic stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nano graphene reinforced nanocomposite particles for lithium battery electrodes

ActiveUS20100143798A1Increase stiffnessHigh strengthActive material electrodesSecondary cellsLithium metalNanocomposite

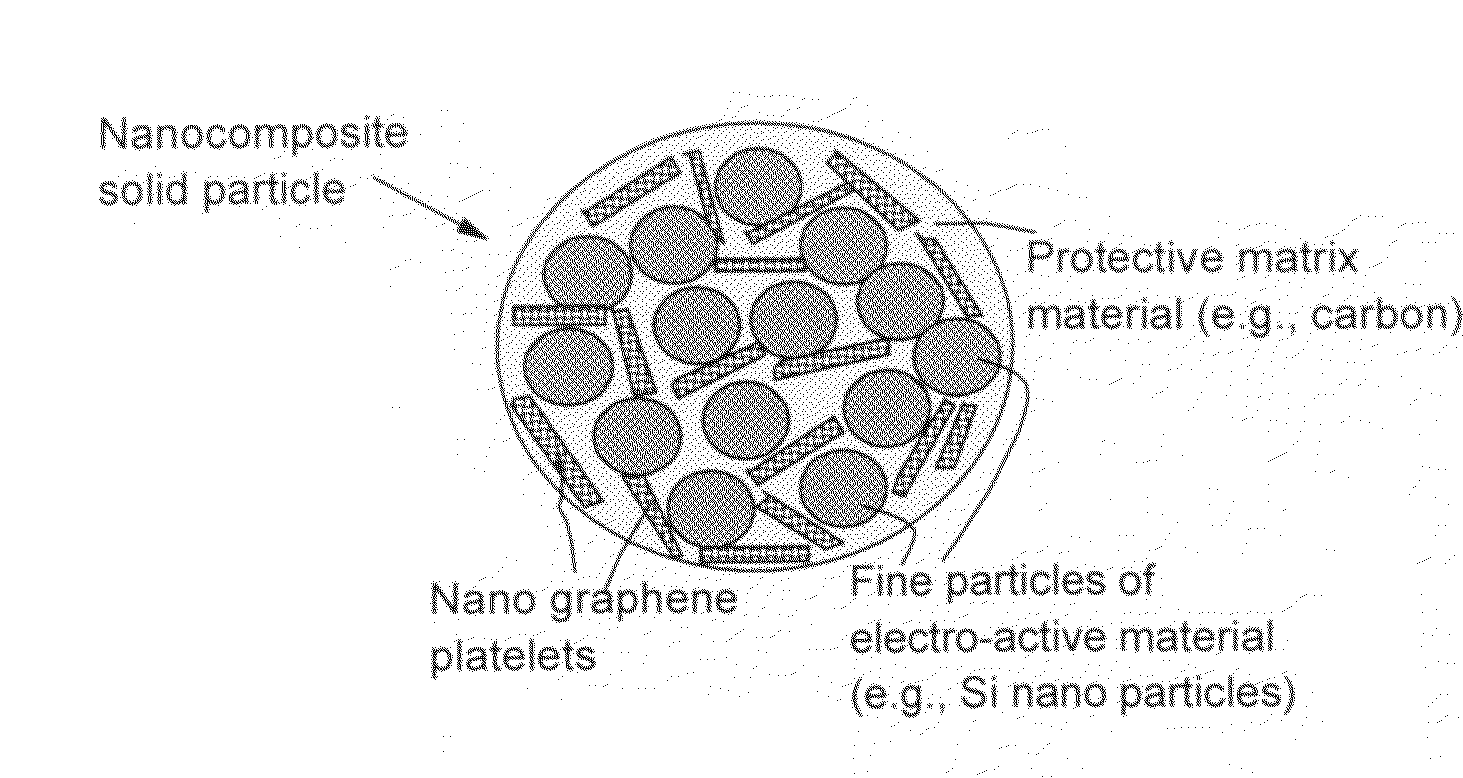

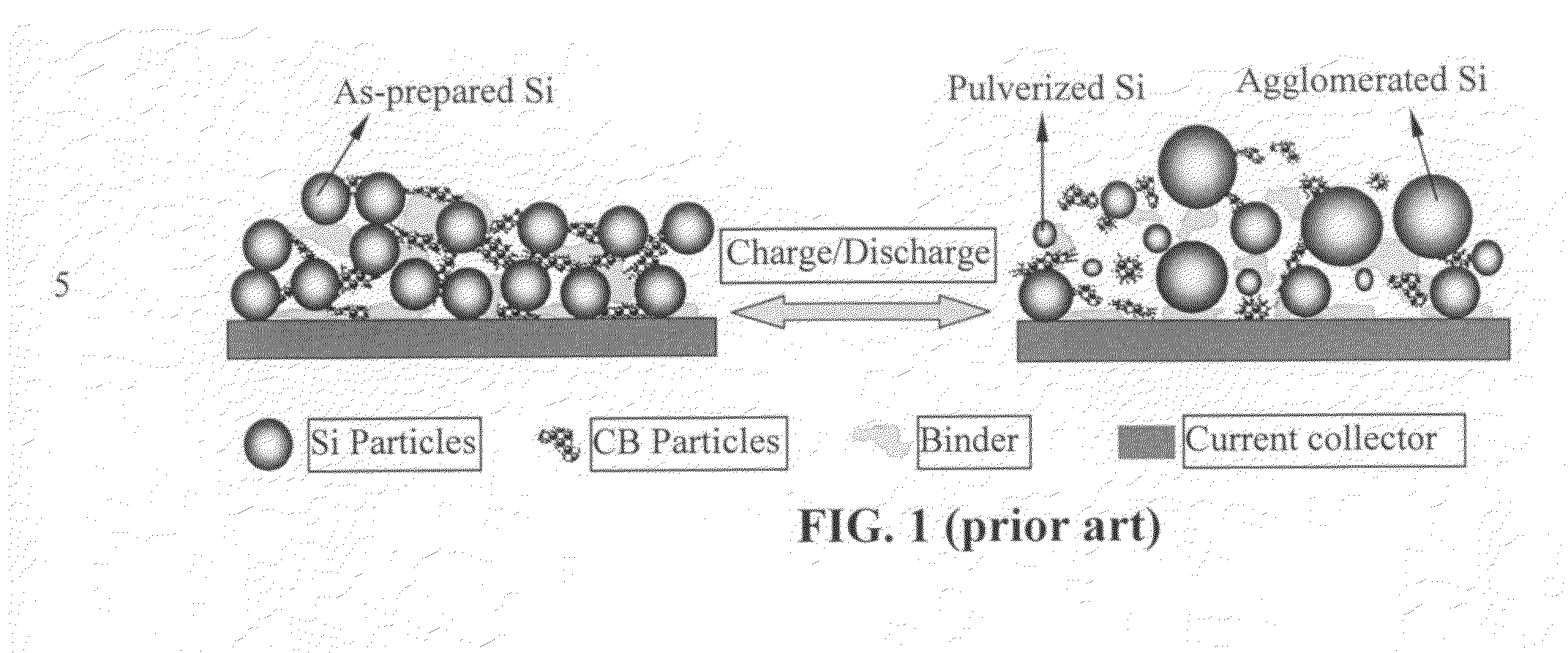

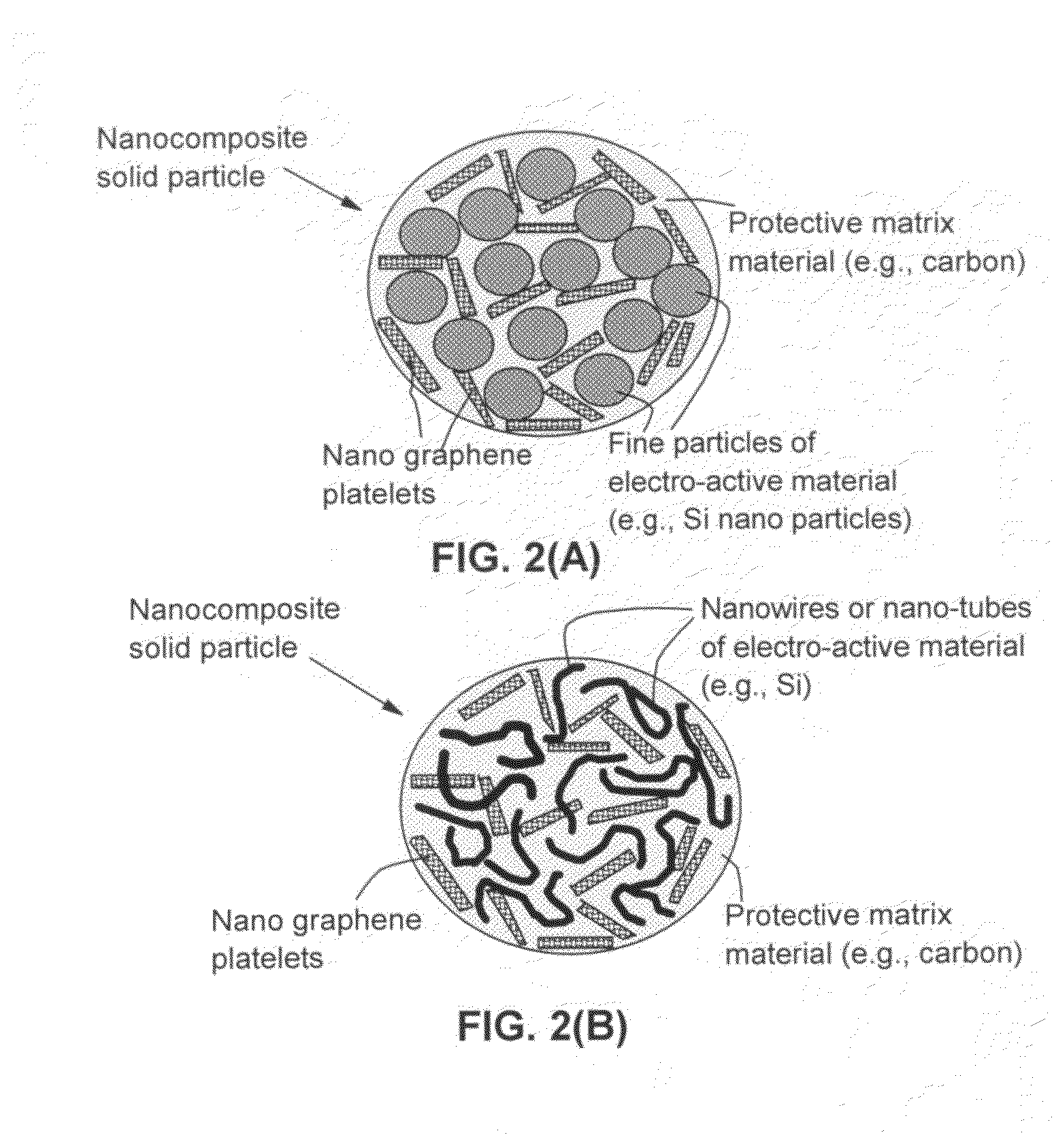

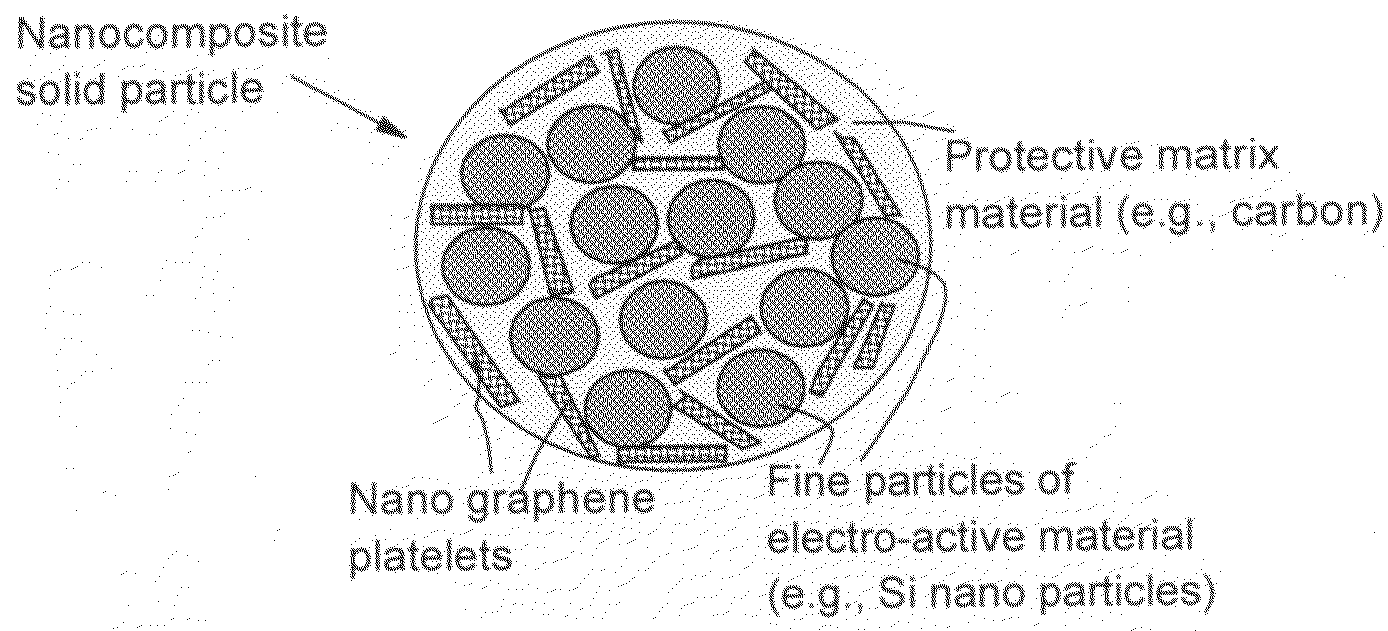

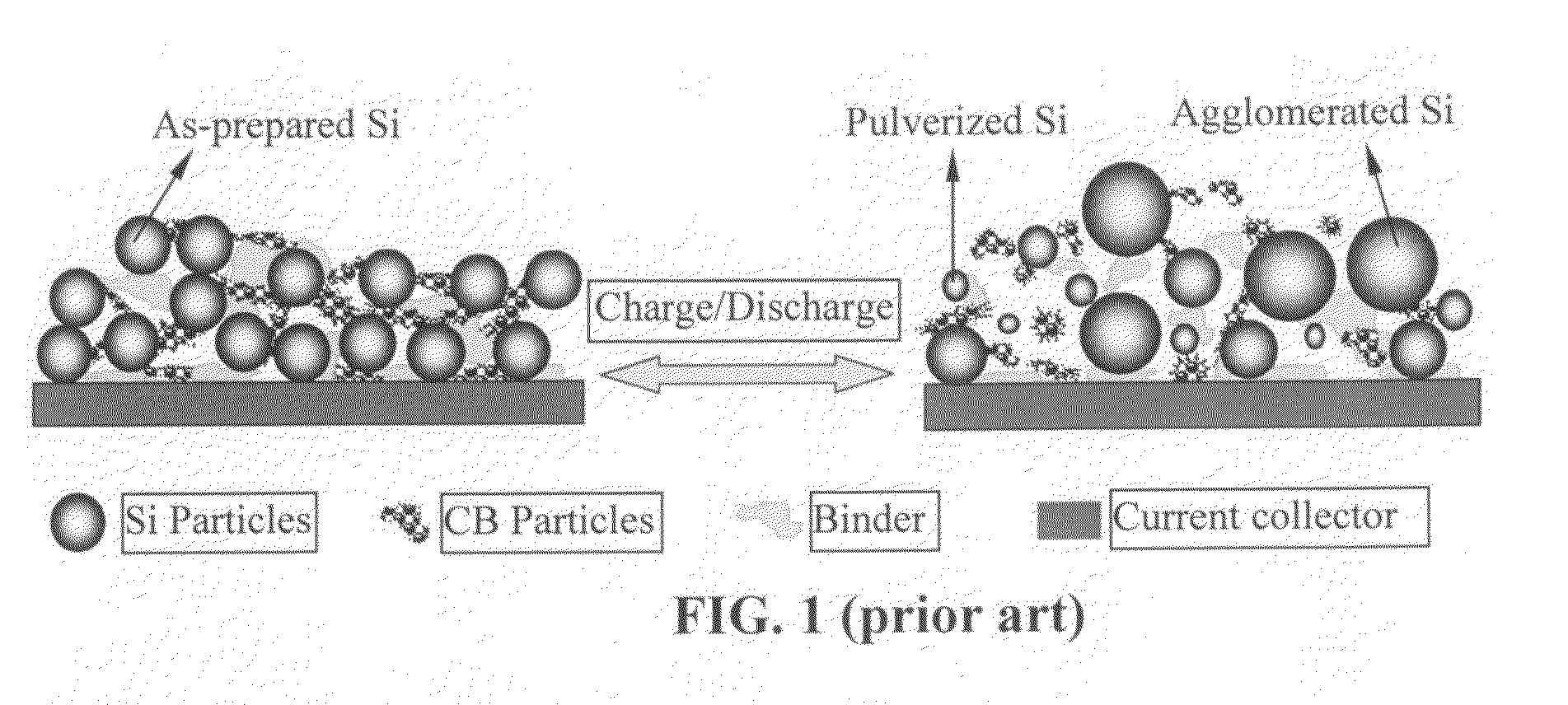

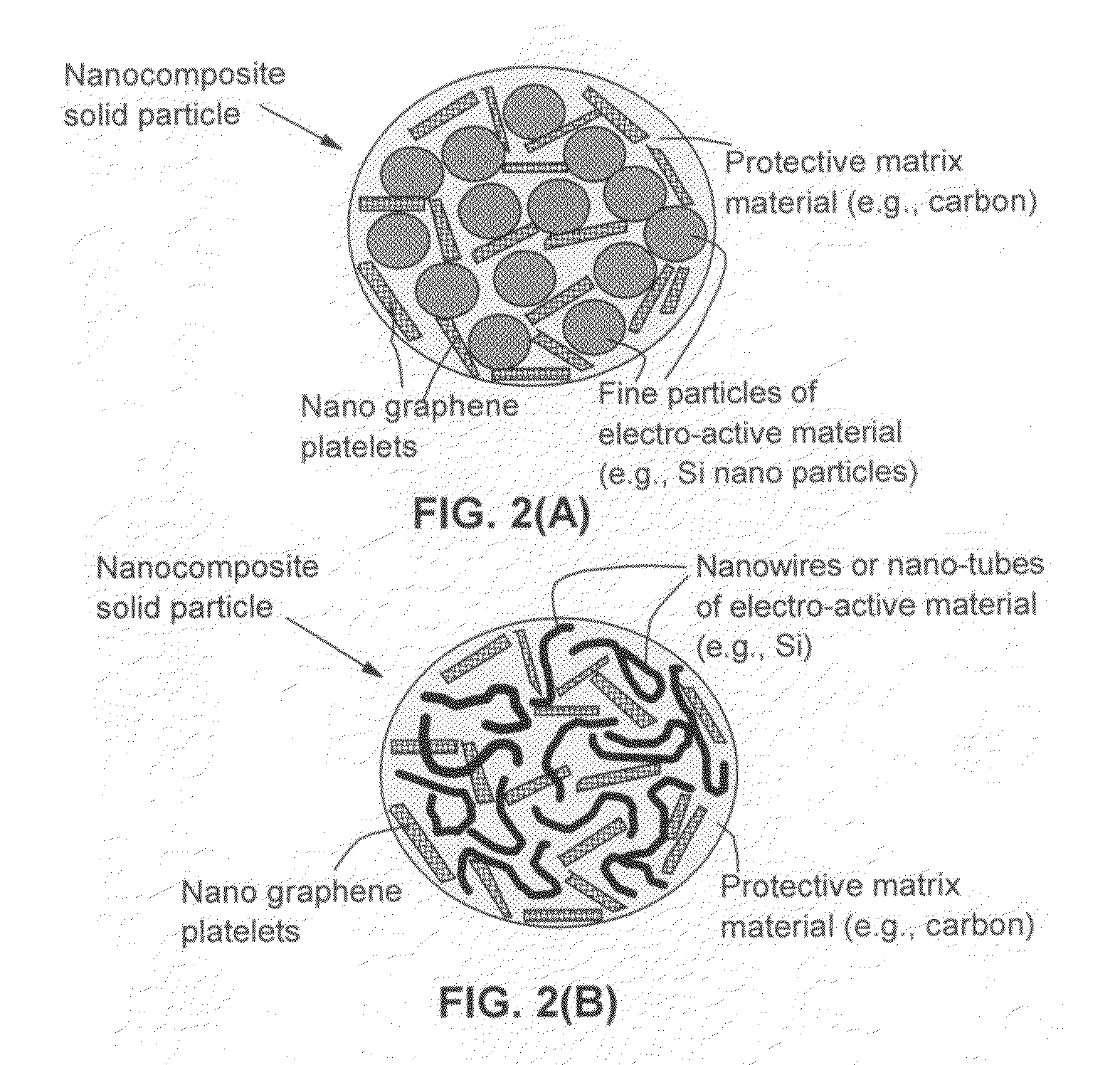

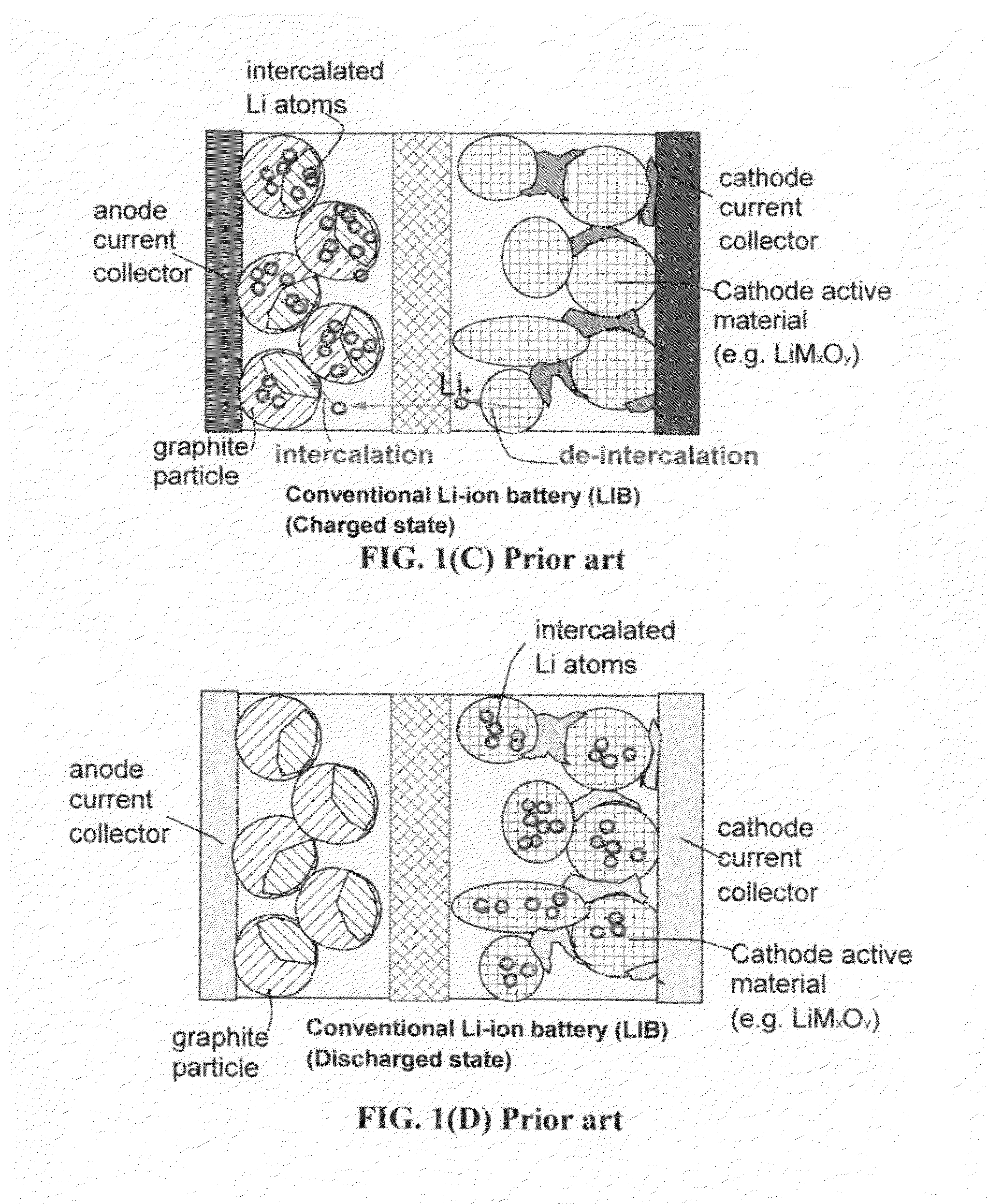

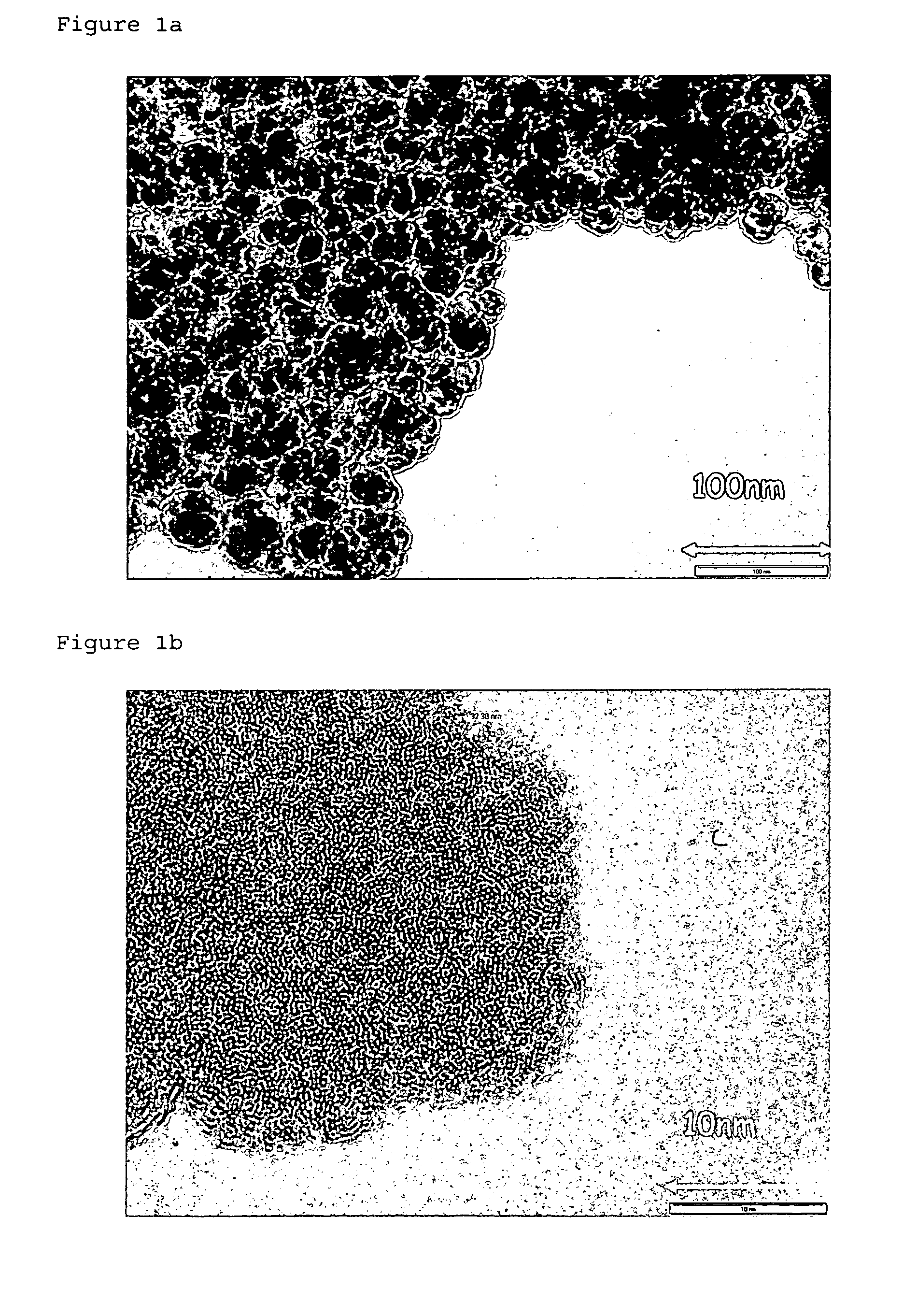

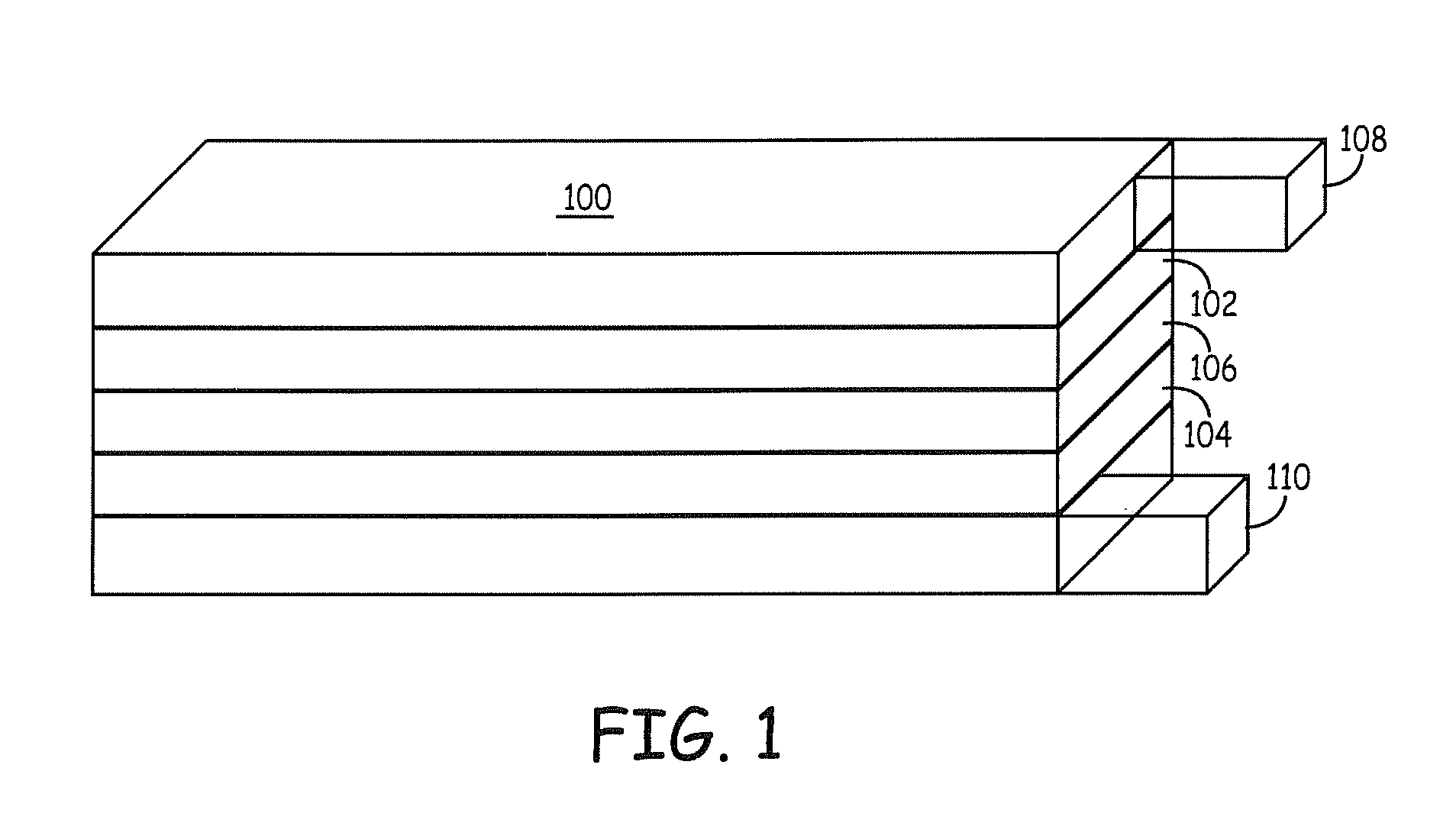

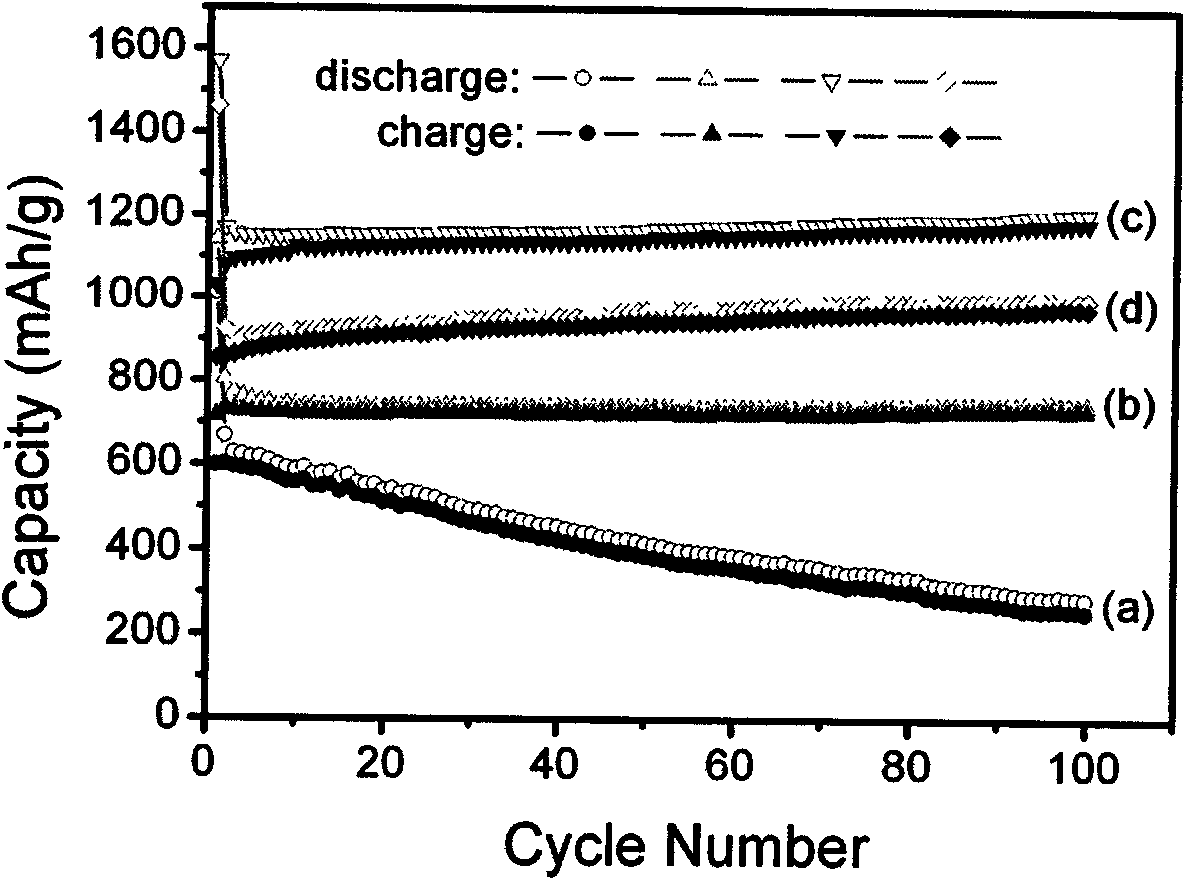

A solid nanocomposite particle composition for lithium metal or lithium ion battery electrode applications. The composition comprises: (A) an electrode active material in a form of fine particles, rods, wires, fibers, or tubes with a dimension smaller than 1 μm; (B) nano graphene platelets (NGPs); and (C) a protective matrix material reinforced by the NGPs; wherein the graphene platelets and the electrode active material are dispersed in the matrix material and the NGPs occupy a weight fraction wg of 1% to 90% of the total nanocomposite weight, the electrode active material occupies a weight fraction wa of 1% to 90% of the total nanocomposite weight, and the matrix material occupies a weight fraction wm of at least 2% of the total nanocomposite weight with wg+wa+wm=1. For a lithium ion battery anode application, the matrix material is preferably amorphous carbon, polymeric carbon, or meso-phase carbon. Such a solid nanocomposite composition provides a high anode capacity and good cycling stability. For a cathode application, the resulting lithium metal or lithium ion battery exhibits an exceptionally high cycle life.

Owner:SAMSUNG ELECTRONICS CO LTD

Process for producing nano graphene reinforced composite particles for lithium battery electrodes

ActiveUS20100176337A1Increase stiffnessHigh strengthCell electrodesLi-accumulatorsFiberLithium metal

Owner:SAMSUNG ELECTRONICS CO LTD

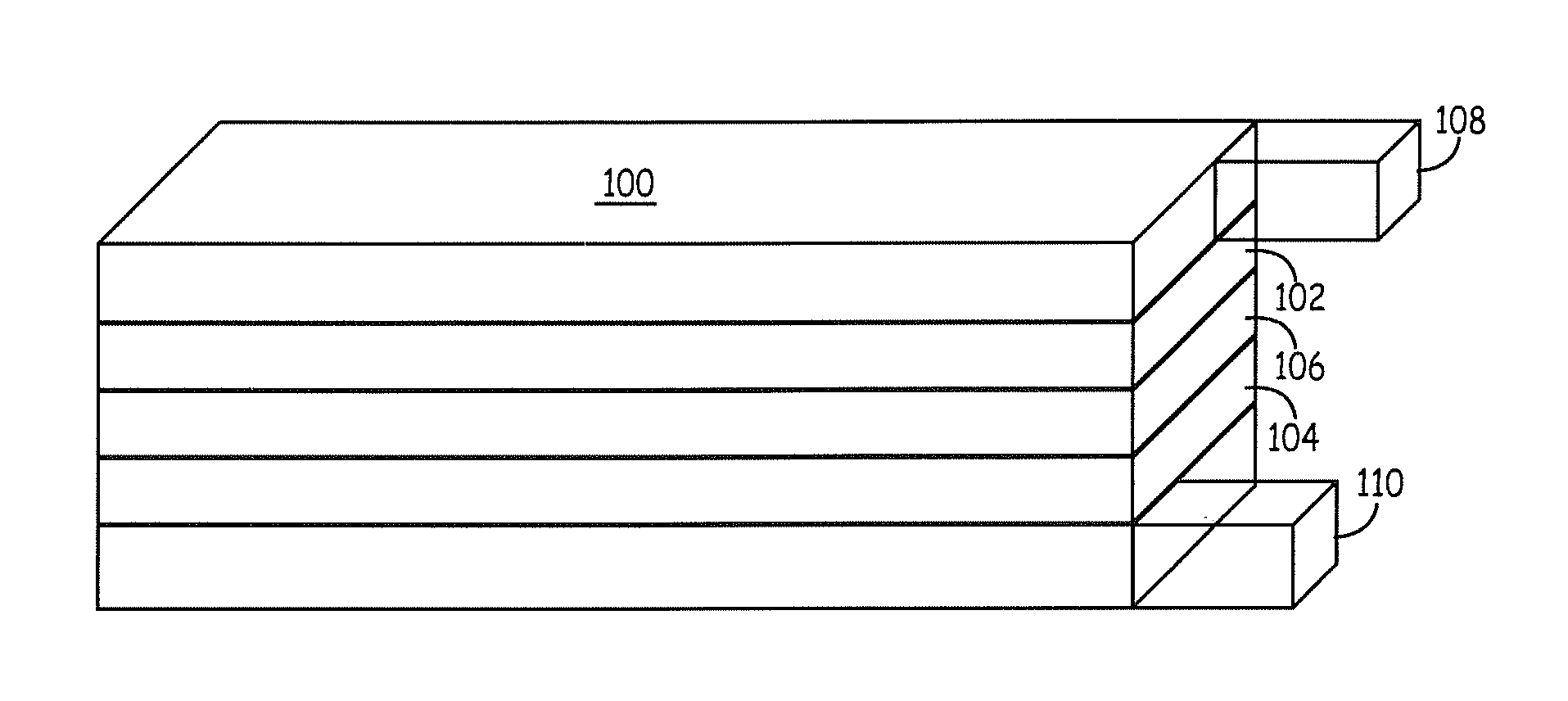

Hybrid electrode and surface-mediated cell-based super-hybrid energy storage device containing same

PendingUS20130171502A1Primary cell to battery groupingMaterial nanotechnologyHigh energyLithium metal

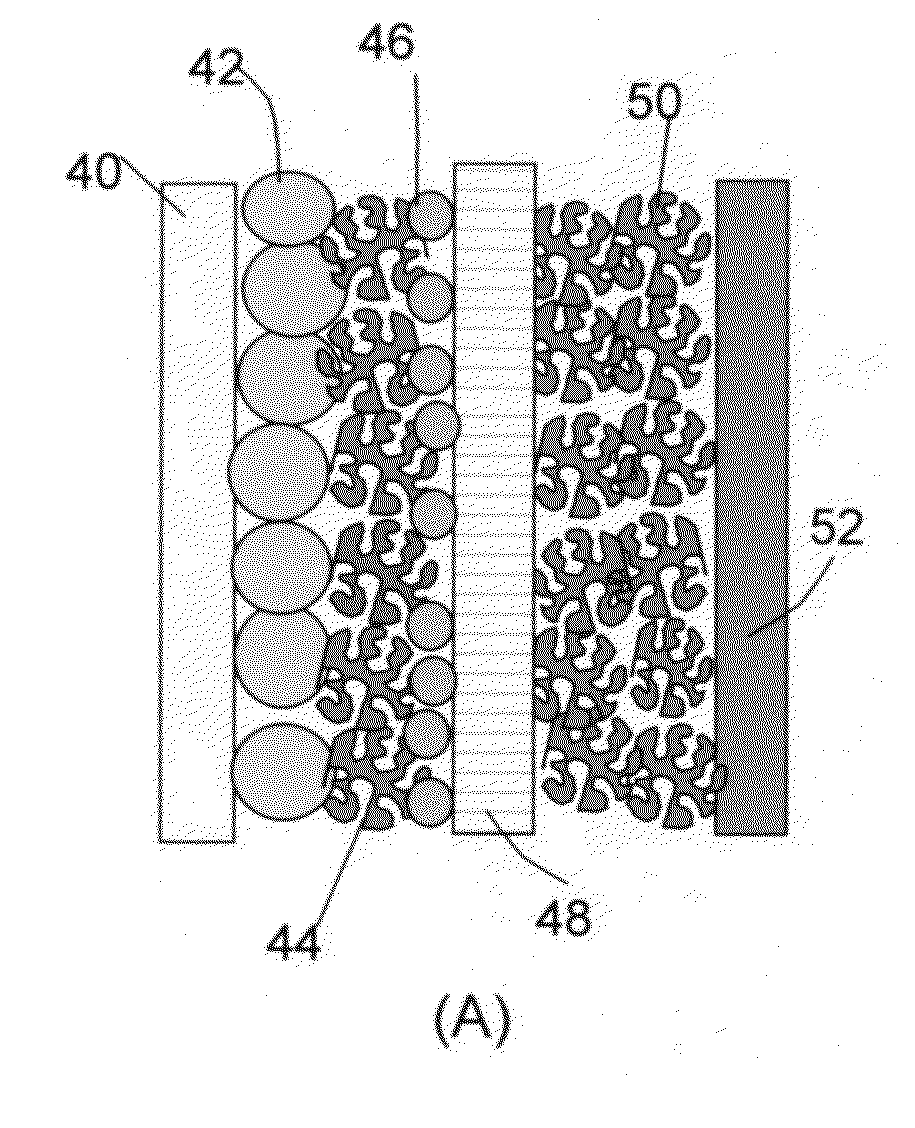

The present invention provides a multi-component hybrid electrode for use in an electrochemical super-hybrid energy storage device. The hybrid electrode contains at least a current collector, at least an intercalation electrode active material storing lithium inside interior or bulk thereof, and at least an intercalation-free electrode active material having a specific surface area no less than 100 m2 / g and storing lithium on a surface thereof, wherein the intercalation electrode active material and the intercalation-free electrode active material are in electronic contact with the current collector. The resulting super-hybrid cell exhibits exceptional high power and high energy density, and long-term cycling stability that cannot be achieved with conventional supercapacitors, lithium-ion capacitors, lithium-ion batteries, and lithium metal secondary batteries.

Owner:GLOBAL GRAPHENE GRP INC +1

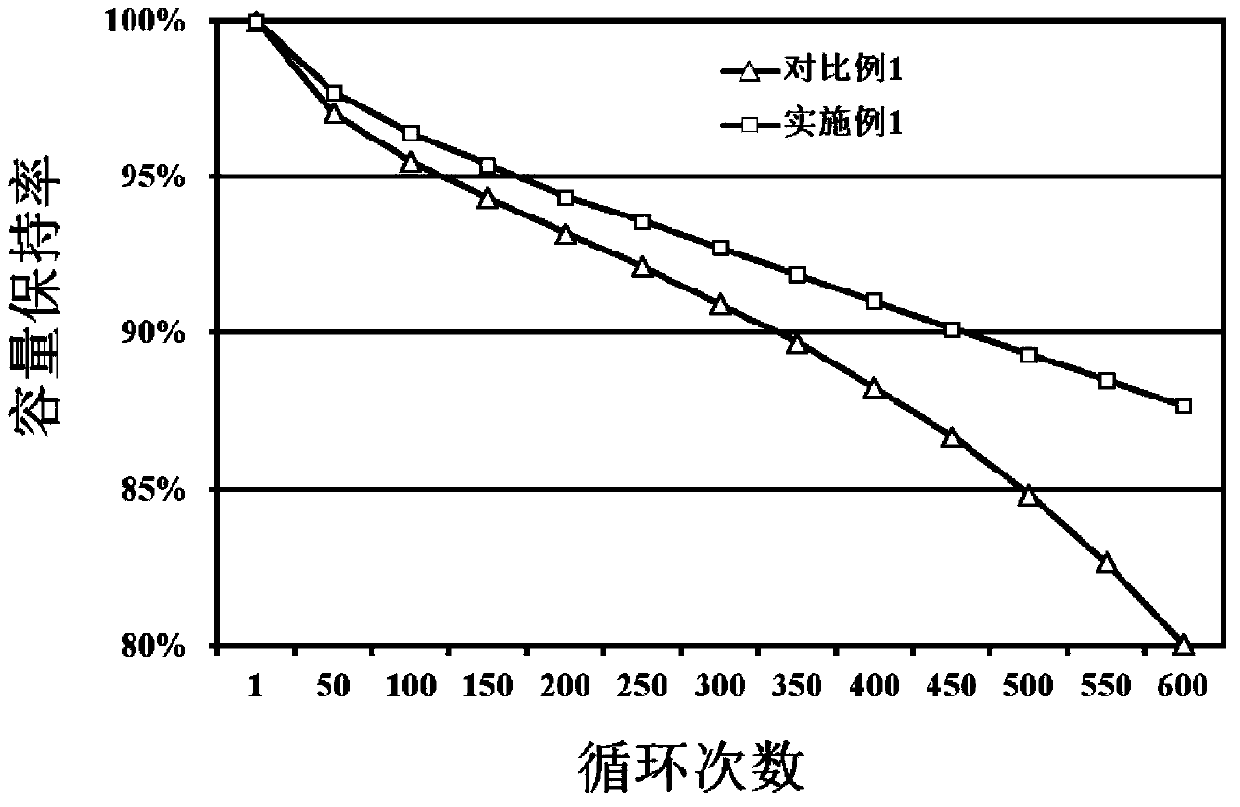

Graphite alkene iron lithium phosphate positive active material, preparing method thereof, and lithium ion twice battery based on the graphite alkene modified iron lithium phosphate positive active material

InactiveCN101752561AImprove conductivityImprove cycle stabilityLi-accumulatorsNon-aqueous electrolyte accumulator electrodesLithium-ion batteryCarbon coated

The present invention relates to graphite alkene iron lithium phosphate positive active material, a preparing method thereof, and a lithium ion twice battery based on the graphite alkene modified iron lithium phosphate positive active material. Graphite alkene and iron lithium phosphate are dispersed into water solution to be mixed evenly by stirring and ultra audible sound, then, are dried to obtain iron lithium phosphate material compounded by the graphite alkene and the iron lithium phosphate to be annealed by high temperature, and finally, the graphite alkene modified iron lithium phosphate positive active material is obtained. Compared with traditional carbon coated and conductive polymeric adulteration modified lithium batteries, the lithium ion twice battery based on the graphite alkene modified iron lithium phosphate positive active material has the advantages of high battery capacity, good charging-discharging circulating performance, long life and high circulating stability, and has great utility value.

Owner:宁波艾能锂电材料科技股份有限公司

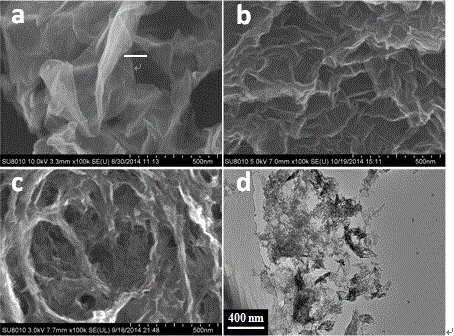

Graphene/metal oxide composite cathode material for lithium ion battery and preparation

InactiveCN102646817APromote circulationExcellent rate performanceCell electrodesHigh energyIn situ polymerization

The invention belongs to the fields of material synthesis and energy technology, and especially relates to a graphene / metal oxide composite cathode material for lithium ion batteries and a preparation method thereof. Grapheme is dispersed into various metal oxide precursor salt solutions; a graphene / metal oxide compound is obtained directly by a hydrothermal method, or an graphene / metal oxide compound is obtained by a liquid in-situ polymerization method or a coprecipitation process; and the graphene / metal oxide compound is obtained by heat treatment or hydrothermal treatment. In the invention, the novel three-dimensional composite cathode material of graphene-coated metal oxide or graphene-anchored metal oxide is prepared by carrying metal oxide particles with graphene as a carrier. The obtained composite material can be used as a lithium ion battery cathode, which has a high specific capacity, excellent cycle stability and rate capability, and is expected to be used as a lithium ion battery cathode material with a high energy density and a high power density.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

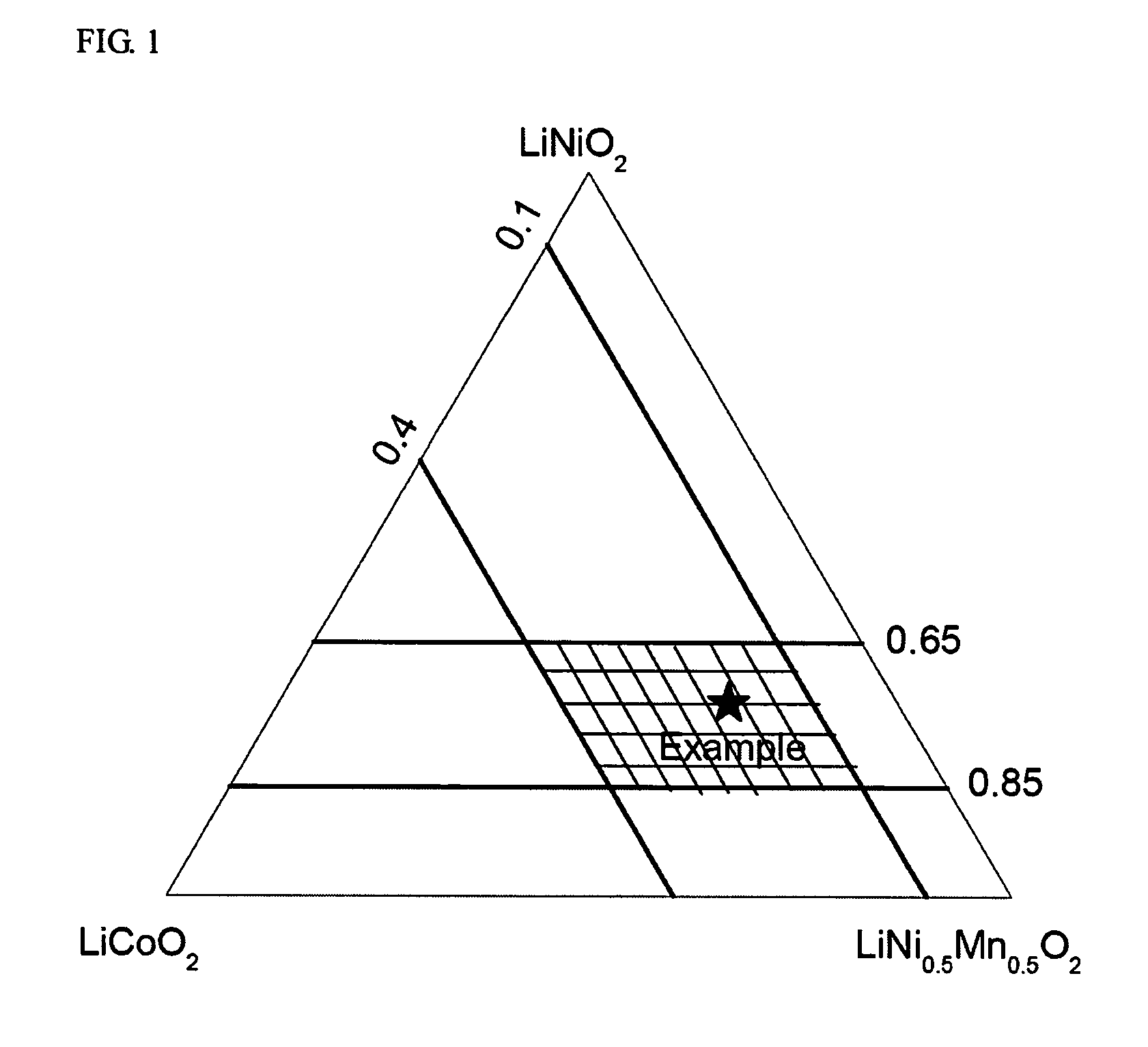

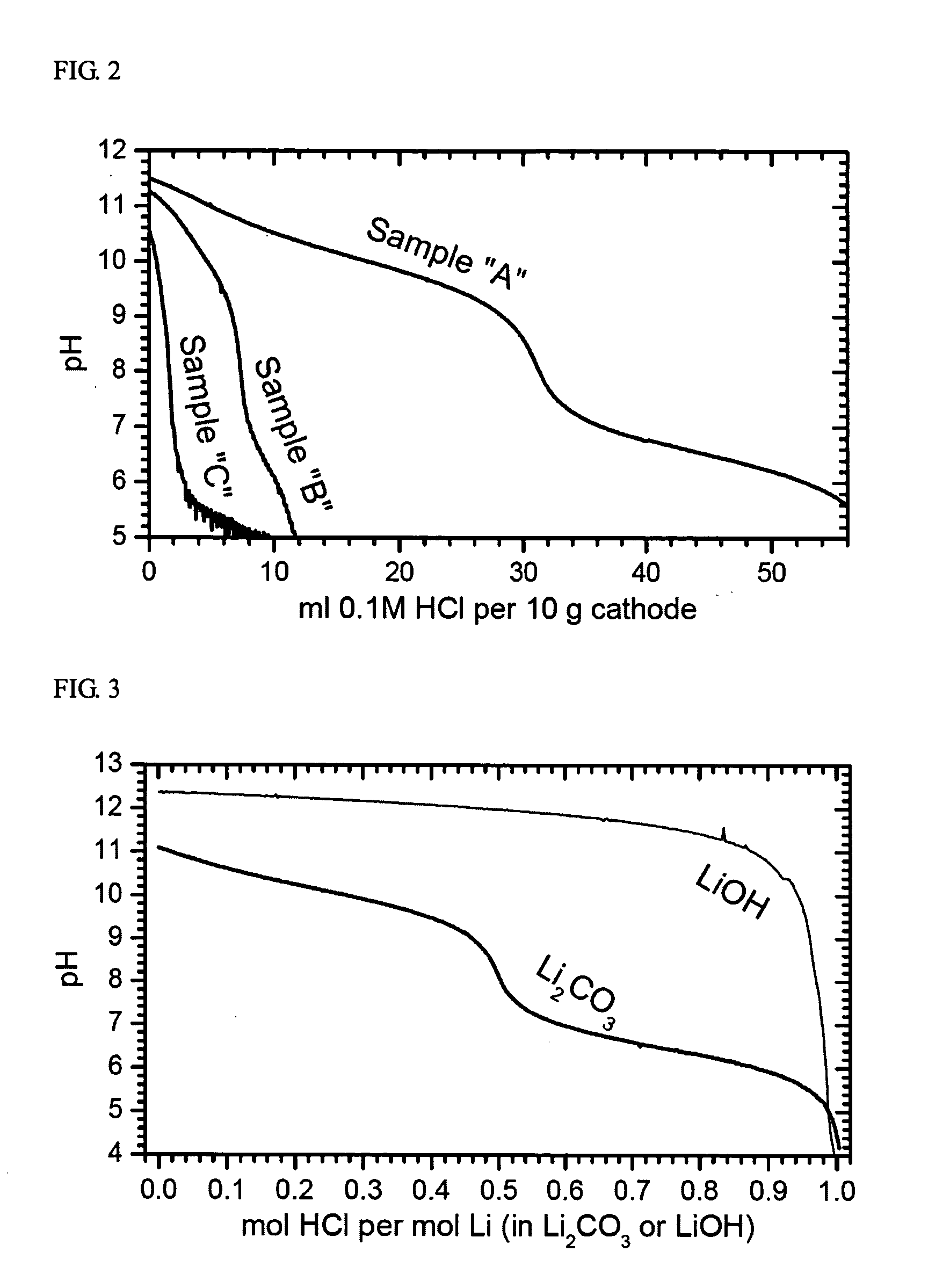

Ni-based lithium transition metal oxide

The present invention provides a powderous lithium transition metal oxide with the composition as represented by the below Formula and prepared by solid state reaction in air from a mixed transition metal precursor and Li2CO3, with being practically free of Li2CO3 impurity: LixMyO2 wherein M=M′l-kAk, where M′=Nil-a-b(Ni1 / 2Mn1 / 2)aCob on condition of 0.65≦a+b≦0.85 and 0.1≦b≦0.4; A is a dopant; and 0≦k≦0.05; and x+y=2 on condition of 0.95≦x≦1.05. The Ni-based lithium transition metal oxide according to the present invention has a well-layered structure, and also improved safety, cycling stability and stability against aging and low gas evolution during storage, when used as an active material for cathode of lithium secondary batteries, because it has a high sintering stability and is substantially free of soluble bases. Moreover, the lithium transition metal oxide of the present invention can be prepared by a low-cost process using a mixed transition metal precursor and Li2CO3 as raw stocks and under relatively unrestricted conditions.

Owner:LG ENERGY SOLUTION LTD

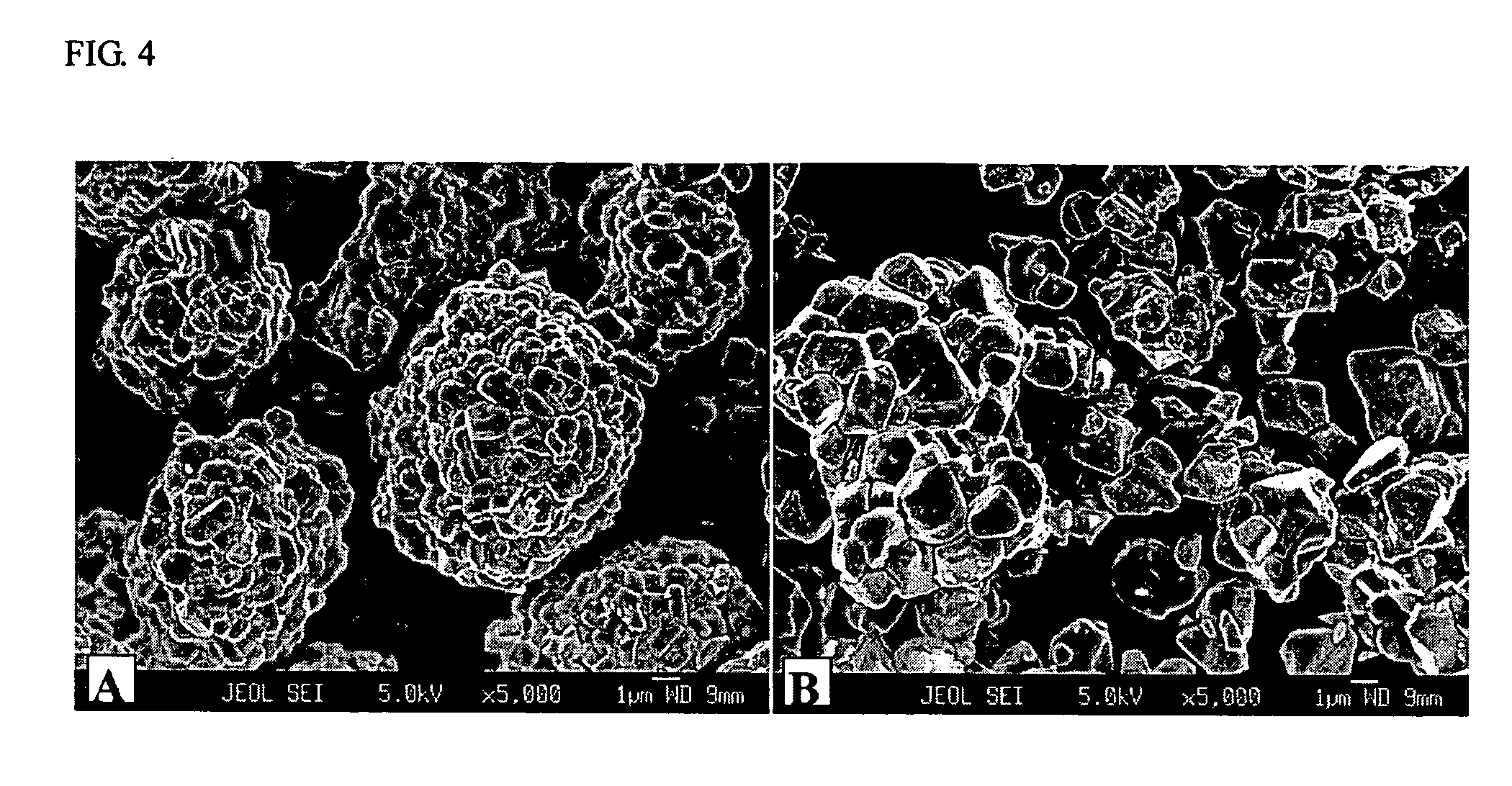

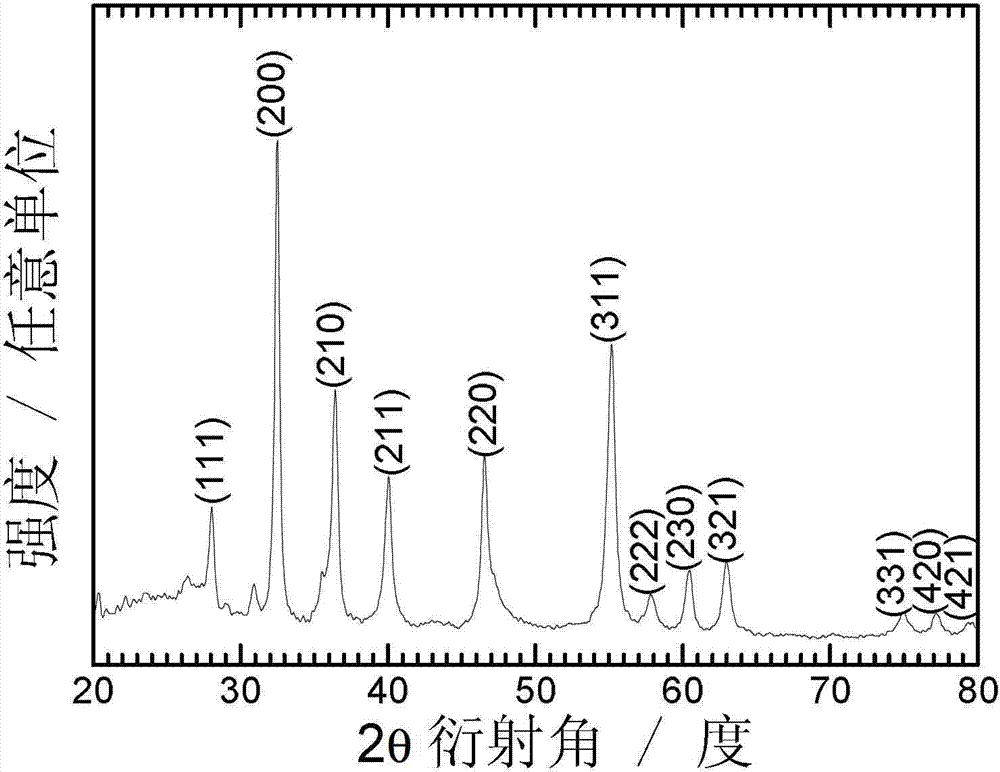

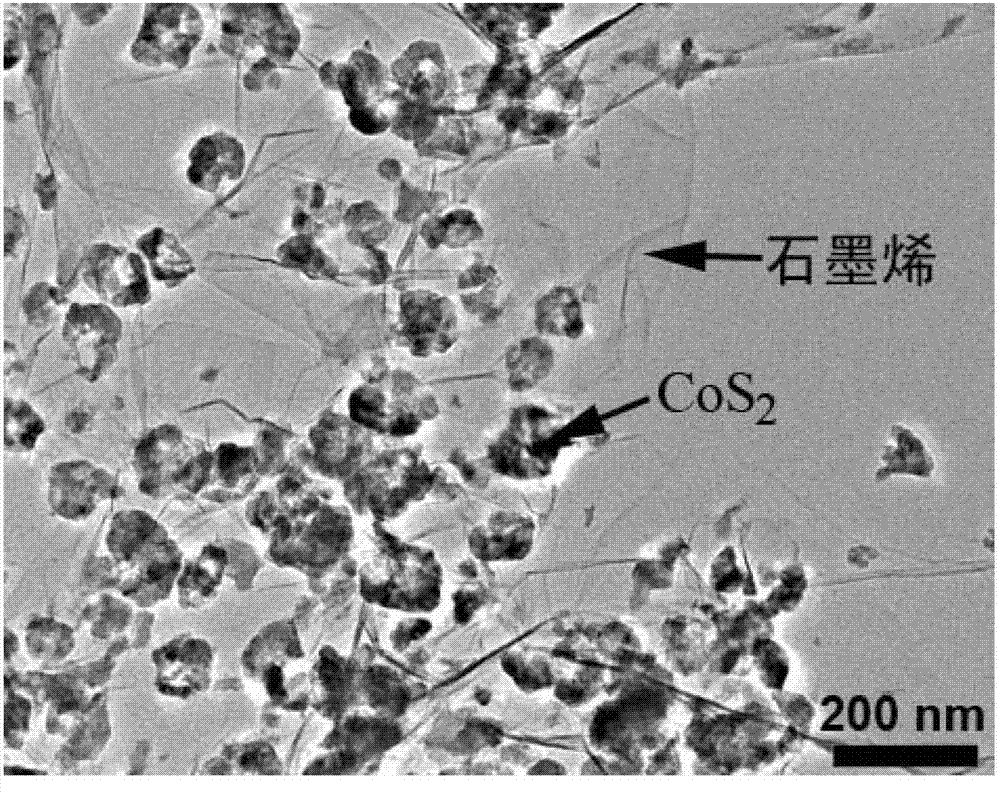

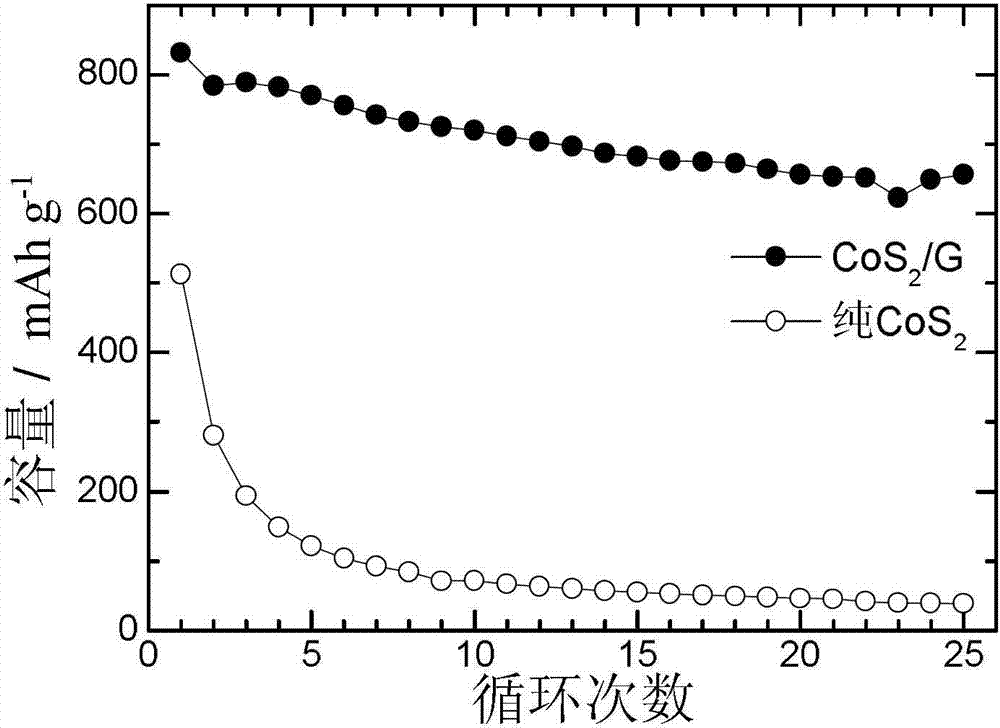

Transition metal sulfide/graphene composite material, and preparation method and application thereof

The invention discloses a transition metal sulfide / graphene composite material which is composed of a nano transition metal sulfide and graphene, wherein the transition metal sulfide is Ni2S3, NiS, FeS, FeS2, CoS, CoS2, CuS2, CuS, MnS or MnS2. Under the dispersion and loading actions of the graphene, the transition metal sulfide can be uniformly distributed and have small particle size, the stability and loop stability of the transition metal sulfide in the charging and discharging process can be effectively enhanced, and the composite material can be used as a lithium ion battery negative pole material. The invention also discloses a one-step low-temperature preparation method of the composite material, which has the advantages of simple technique, low cost, short cycle, low energy consumption and the like and is suitable for large-scale industrial production.

Owner:ZHEJIANG UNIV

Anode material for nickel-base lithium ion battery and preparation method of anode material

ActiveCN104409700AEasy to operateSuitable for industrial productionCell electrodesSecondary cellsOptoelectronicsOxygen

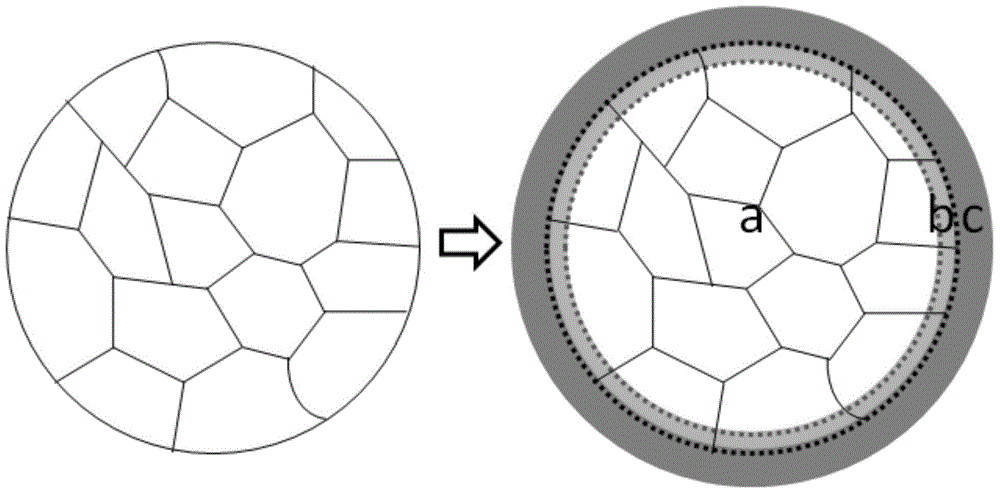

The invention provides an anode material for a nickel-base lithium ion battery and a preparation method of the anode material. The anode material comprises an inner core, a doping layer and a cladding layer, wherein the chemical formula of the inner core is LiaNixCoyMzO2; the doping layer is another inner core containing M'; at least M' and oxygen elements are contained in the cladding layer; the anode material is of a core-shell structure, and comprises the inner core, the doping layer and the cladding layer from inside to outside. The anode material for the nickel-base lithium ion battery provided by the invention is little in lithium-nickel mixing, and the cycling stability of the material is obviously improved.

Owner:BTR NEW MATERIAL GRP CO LTD

Composite lithium titanate electrode material and preparation method thereof

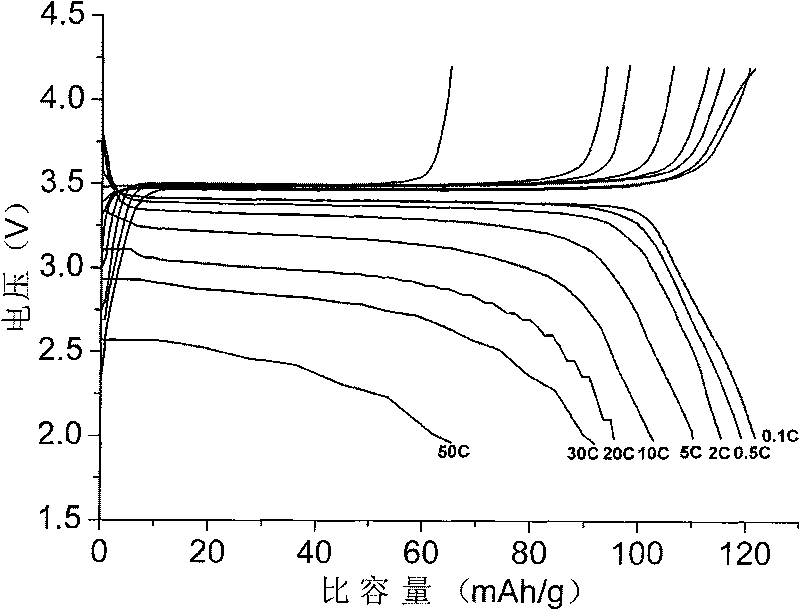

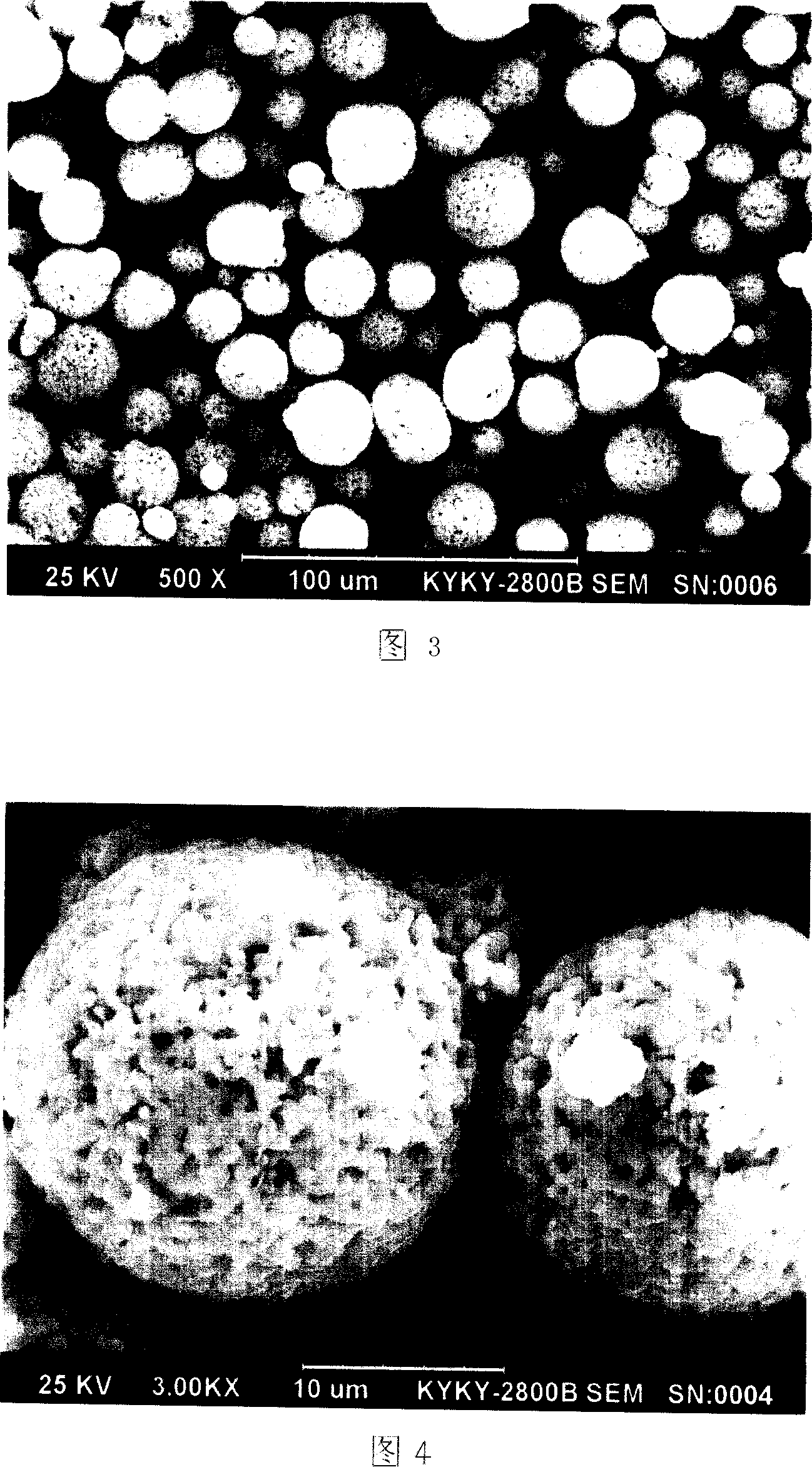

ActiveCN101000960AHigh reversible electrochemical capacityImproved magnification performanceElectrode manufacturing processesChemical/physical/physico-chemical processesHigh rateSpherical shaped

The invention discloses an electrode material of composite lithium titanate and its preparation method, which is secondary particles with spherical or similar spherical shape and porous nanometer channels, which is made from lithium titanate particles, nano-carbon coated materials and doped modifier. The preparation method includes: milling the inorganic lithium salt, titanium dioxide, nano-carbon coated material or doped modifier, scattering them into the organic solvent for further drying, processing heat treatment, and cooling. Comparing with the existing technologies, this electrode material has the high-rate performance, highly reversible electrochemical capacity, and smaller surface area to enhance its first Coulomb efficiency and cycle stability, applying to rechargeable and once-use lithium-ion battery.

Owner:BTR NEW MATERIAL GRP CO LTD

Multi-element composite nano-material, preparation method thereof and application thereof

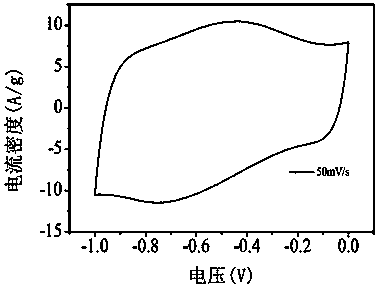

ActiveCN103117175AComponents are easy to controlImprove stabilityHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceHigh energy

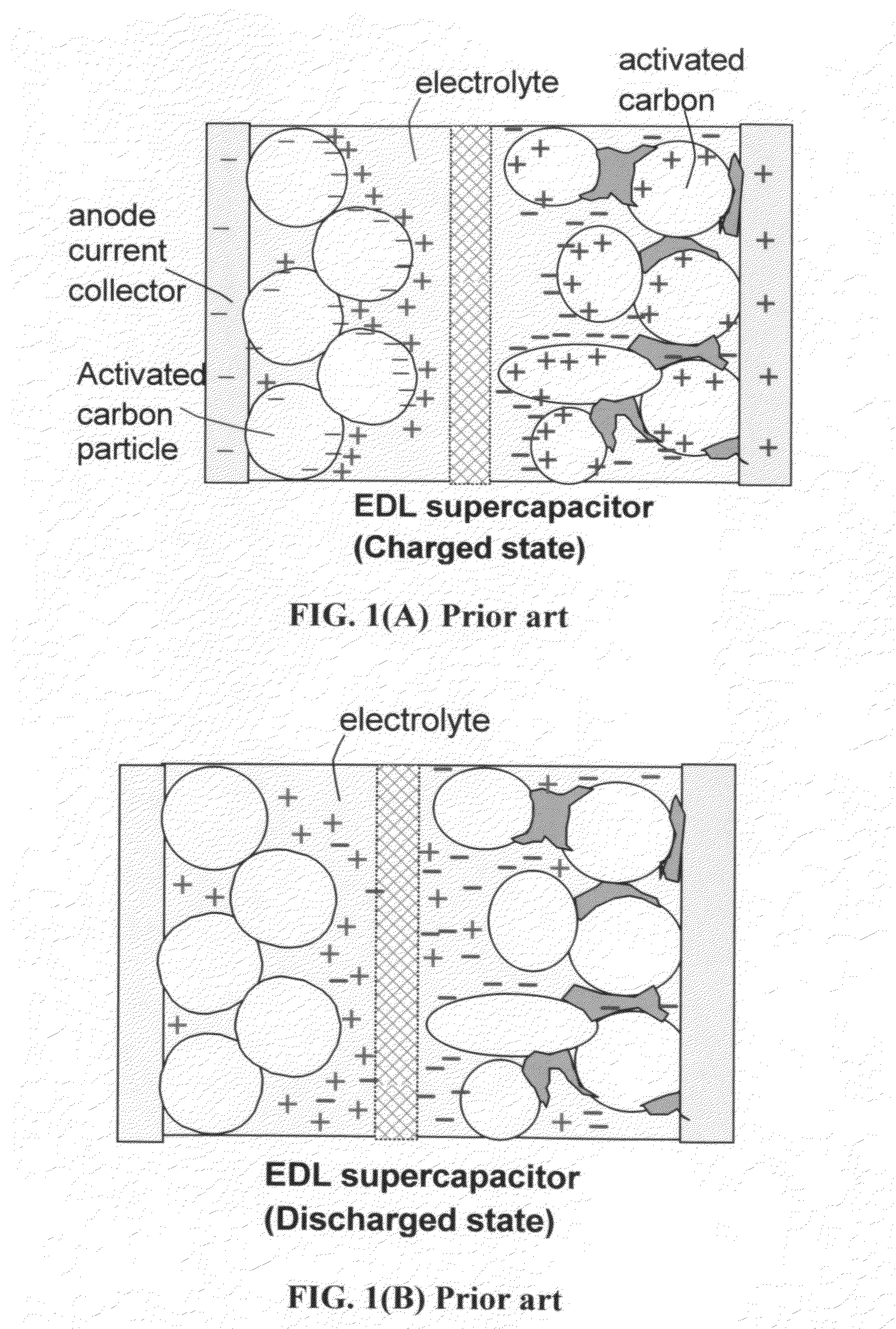

The invention provides a multi-element composite nano-material for a super capacitor, and a preparation method of the nano-material. The nano-material comprises a carbon material, metal oxide and conducting polymer, and components of the nano-material can be two or more than two materials. By the aid of the characteristics such as fine electrical conductivity, long cycle life and high specific surface area of the carbon material, high pseudo-capacitance of the metal oxide and low internal resistance, low cost and high operating voltage of the conducting polymer, different types of electrode materials generate synergistic effects, advantages are mutually combined, shortcomings are mutually weakened, the energy storage characteristics of an electric double-layer capacitor and a pseudo-capacitor are simultaneously made full use of, a composite electrode material with high power density, fine circulating stability and higher energy density is prepared, and the multi-element composite nano-material is excellent in comprehensive performance when used for an electrode of the super capacitor, has the advantages of simple preparation process, short cycle, low cost and the like, and is suitable for large-scale industrial production.

Owner:中科(马鞍山)新材料科创园有限公司

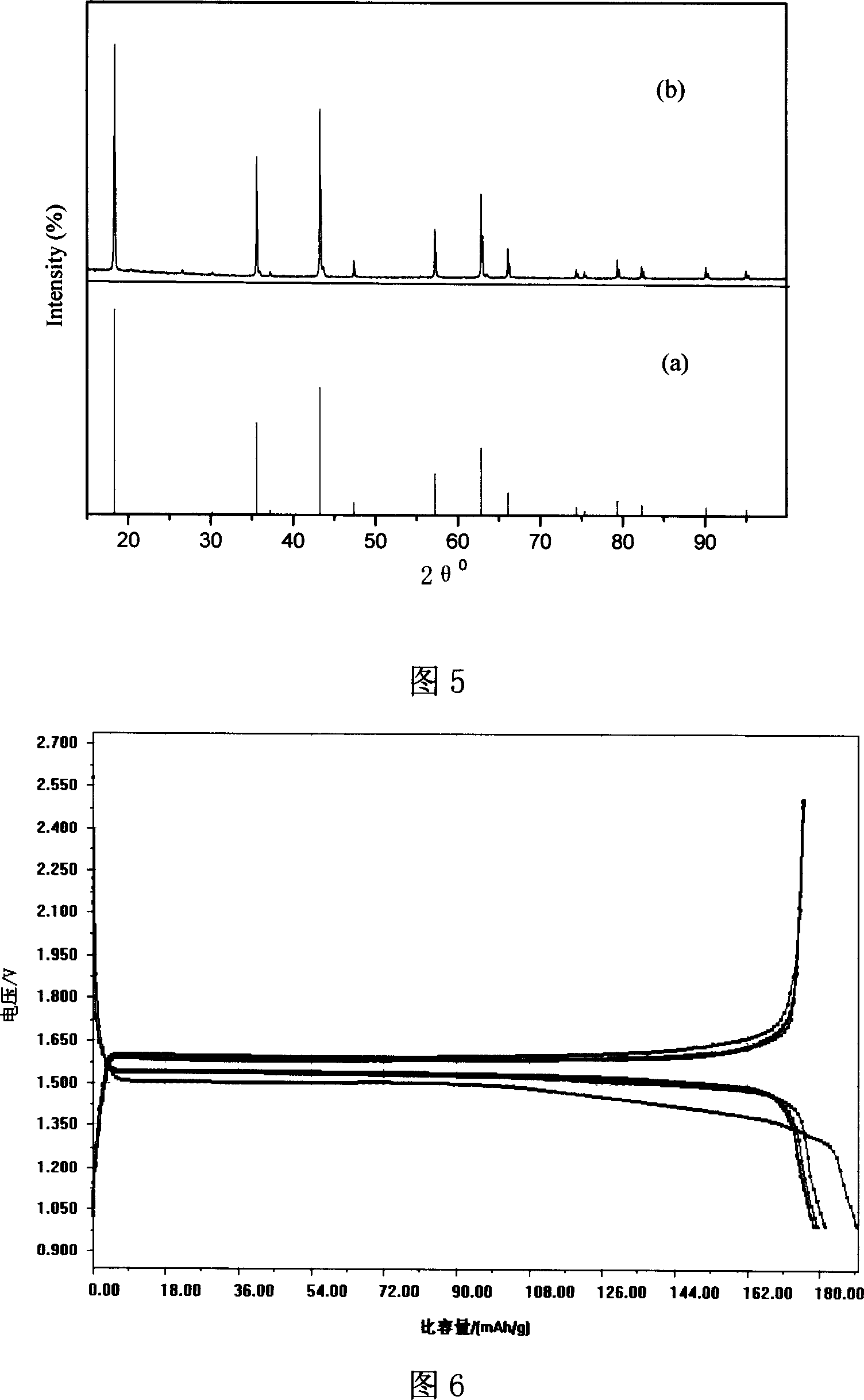

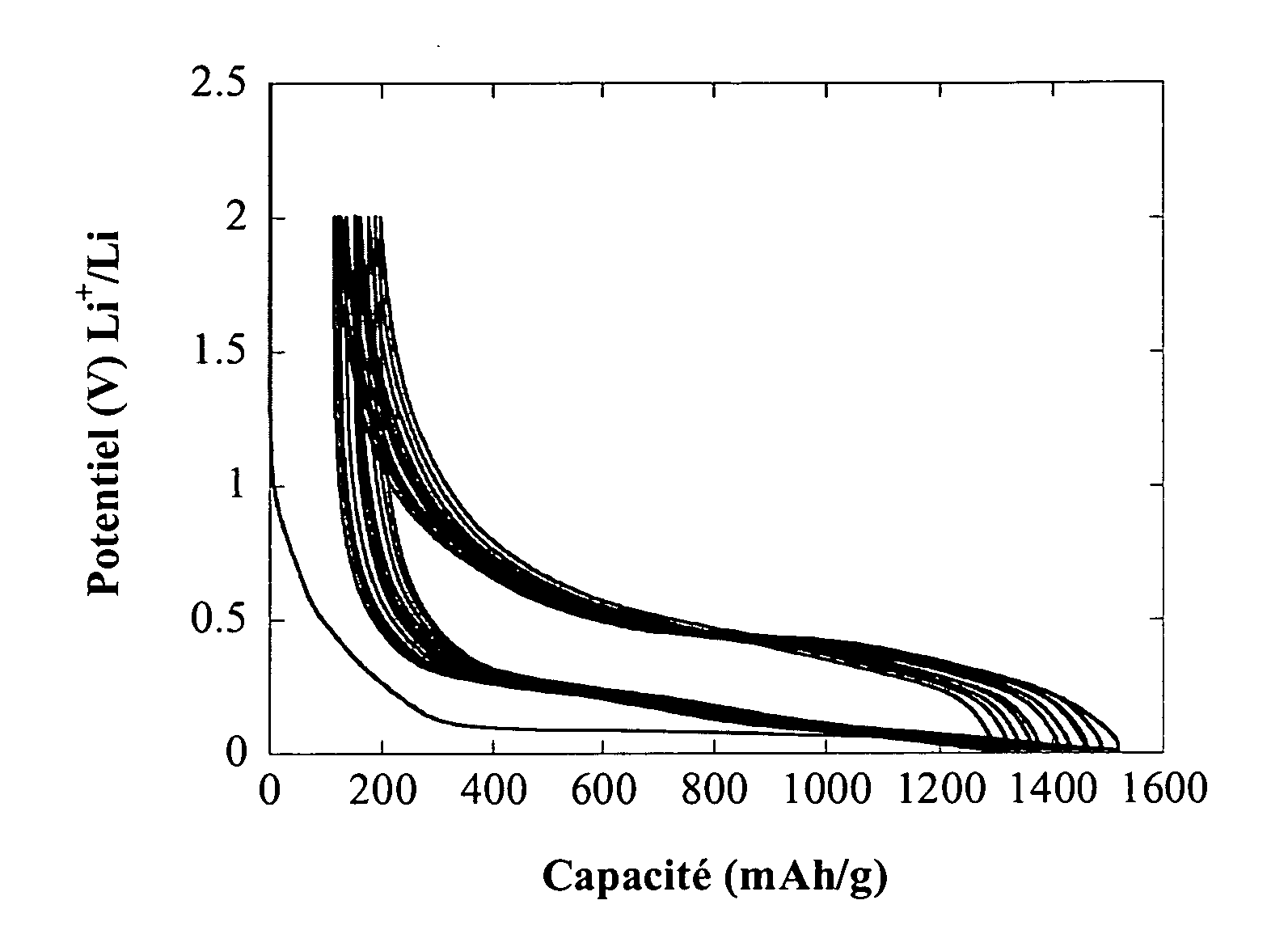

Nanocomposite material for the anode of a lithium cell

ActiveUS20060275668A1Material nanotechnologyLiquid surface applicatorsCarbon compositesChemical vapor deposition

The subject of the invention is an anode material of the silicon-carbon composite type, for a lithium cell, having a high mass capacity and good cycling stability. This material is obtained by a preparation method comprising the steps consisting of: a) providing a silicon powder obtained by the plasma-enhanced chemical vapour deposition (PECVD) technique or by CO2 laser, the size of the silicon particles being less than 100 nm; b) mixing the silicon powder with a carbon-containing polymer, and c) carrying out the pyrolysis of the mixture. The invention also proposes a lithium cell containing at least one anode the material of which contains the nanocomposite material produced by this method.

Owner:SAFT GRP SA

Graphene/silicon lithium ion battery cathode material and preparation method thereof

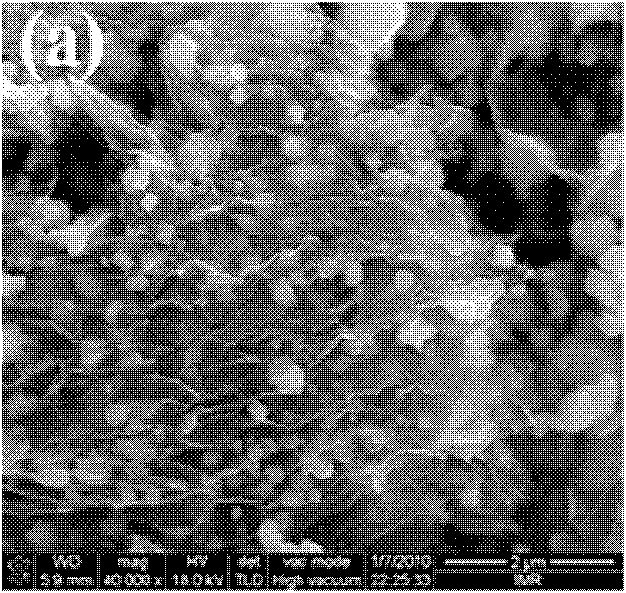

InactiveCN101924211AHigh specific capacityImprove cycle stabilityCell electrodesComposite filmNew energy

The invention discloses a grapheme / silicon composite material for a lithium ion battery cathode material and a preparation method thereof, belonging to the fields of electrochemistry and new energy materials. The method comprises the following steps of: using graphite as a raw material; oxidizing the graphite into oxidized graphite by adopting oxidants of concentrated sulfuric acid and potassium permanganate; then, ultrasonically stripping the oxidized graphite to prepare oxidized graphene; mixing oxidized graphene in different proportions with nano silicon powder; ultrasonically dispersing, filtering or directly drying into a cake / film; and roasting under a reduction atmosphere to prepare self-support graphene / silicon composite film materials in different proportions. Proved by electrochemistry tests, the graphene / silicon composite film material prepared by the method has higher specific capacity and cycle stability, simple preparation method and easy mass production and consequently is an ideal high-energy lithium ion battery cathode material.

Owner:UNIV OF SCI & TECH BEIJING +1

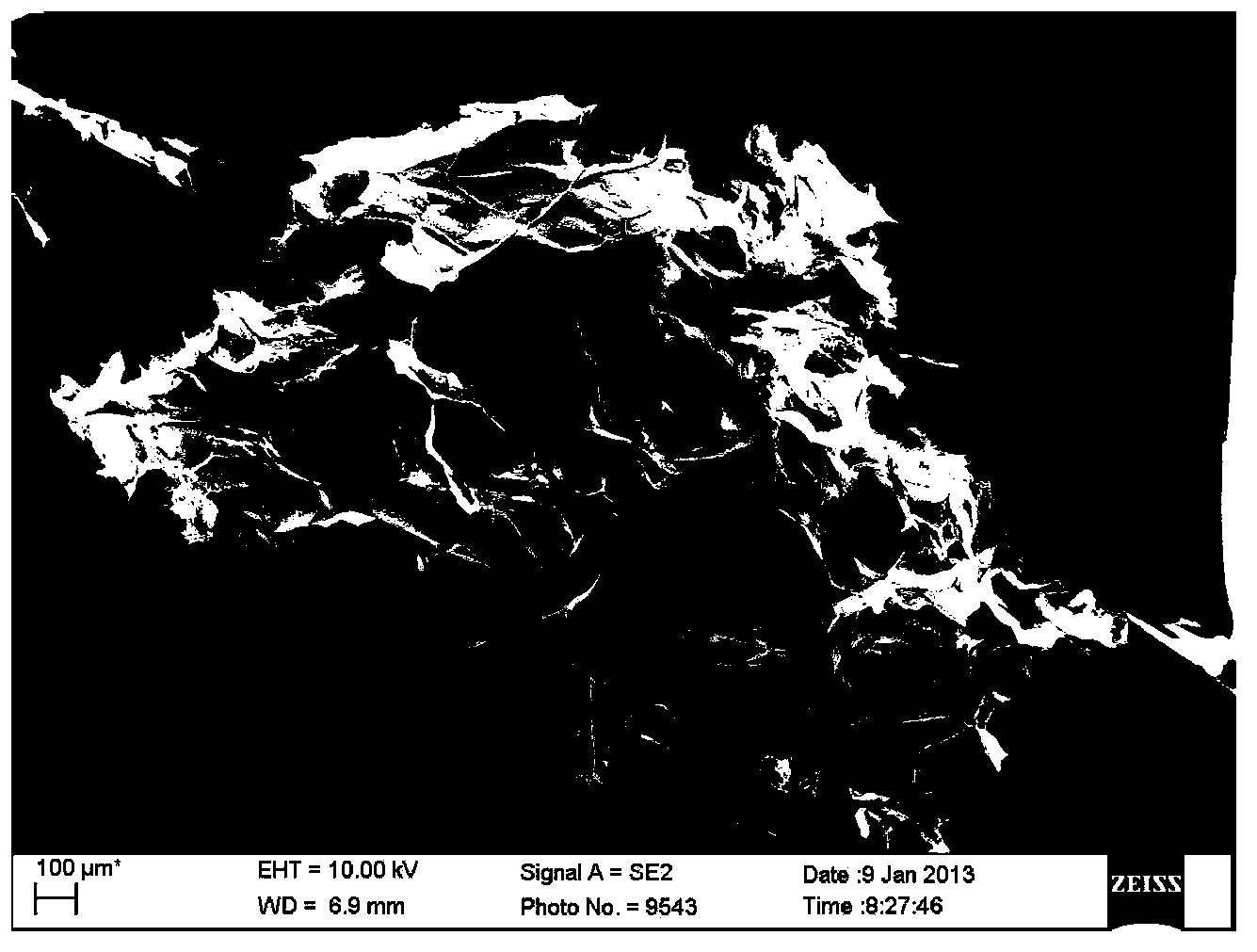

Method for preparing graphene aerogel and graphene/ metallic oxide aerogel

InactiveCN103413689ARich sourcesLow priceHybrid capacitor electrodesGrapheneSupercritical dryingCross-link

The invention discloses a method for preparing graphene aerogel and graphene / metallic oxide aerogel. The method is characterized in that graphite oxide aqueous solution serves as a raw material, alcohol serves as a cross-linking agent, a precursor solution is obtained through the simple mixing and dispersing processes, the hydrothermal method is adopted, the freeze drying method or a supercritical drying method is adopted, and then the graphene aerogel is obtained . The graphene / metallic oxide aerogel can be prepared by adding metallic oxide into the polymeric precursor solution. On one hand, the graphene vinyl aerogel material has the characteristic of the graphene aerogel, and on the other hand, the graphene vinyl aerogel material can have the physicochemical characteristic of the metallic oxide. In addition, the aerogel material has a large specific surface and good electrical conductivity, can directly serve as a supercapacitor electrode, and has large specific capacity, good rate capability and cycling stability. The materials used in the method are low in cost, the industrial process is simple, and the method is friendly to the environment.

Owner:UNIV OF SCI & TECH BEIJING

Very Long Cycling of Lithium Ion Batteries with Lithium Rich Cathode Materials

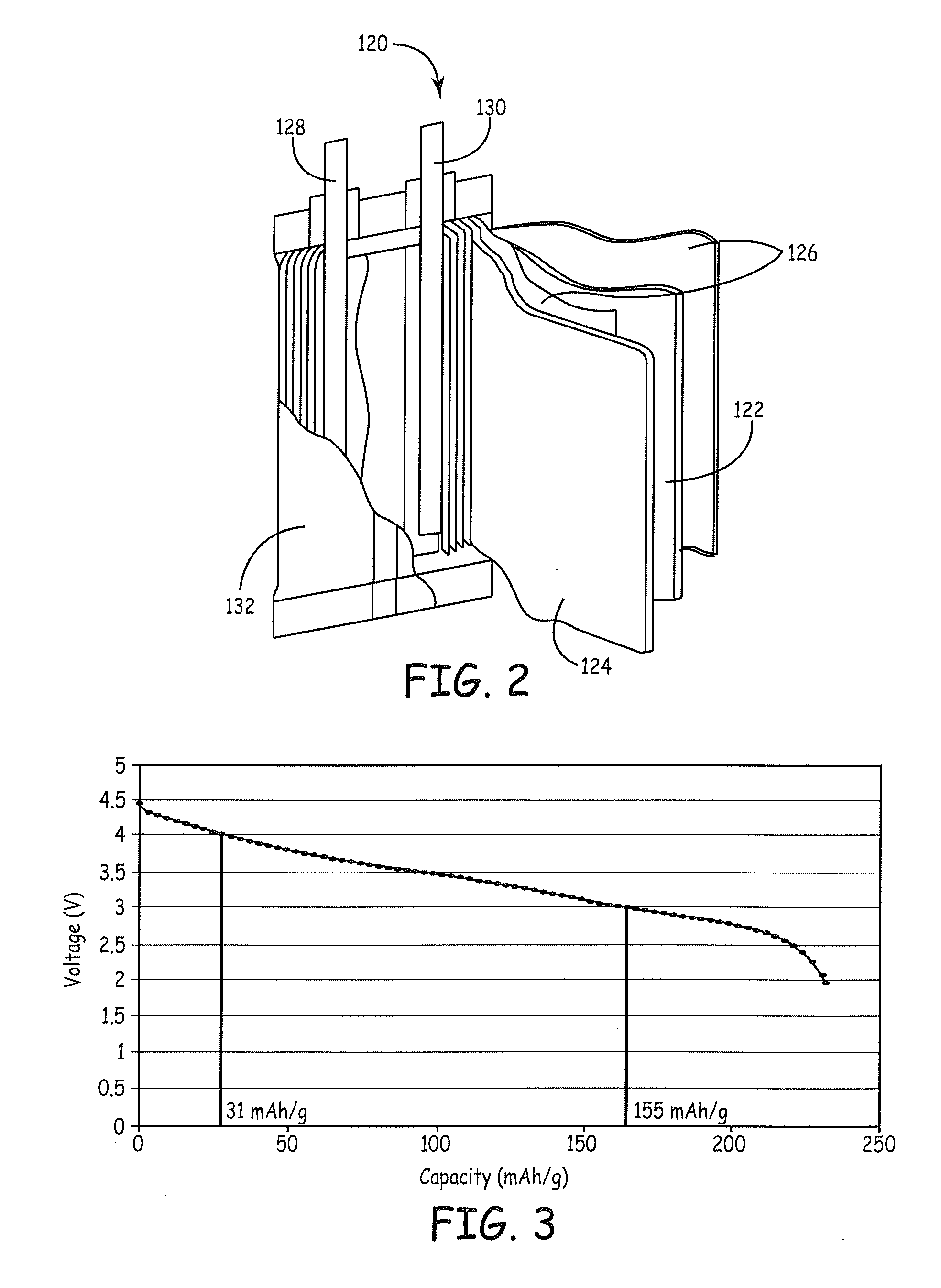

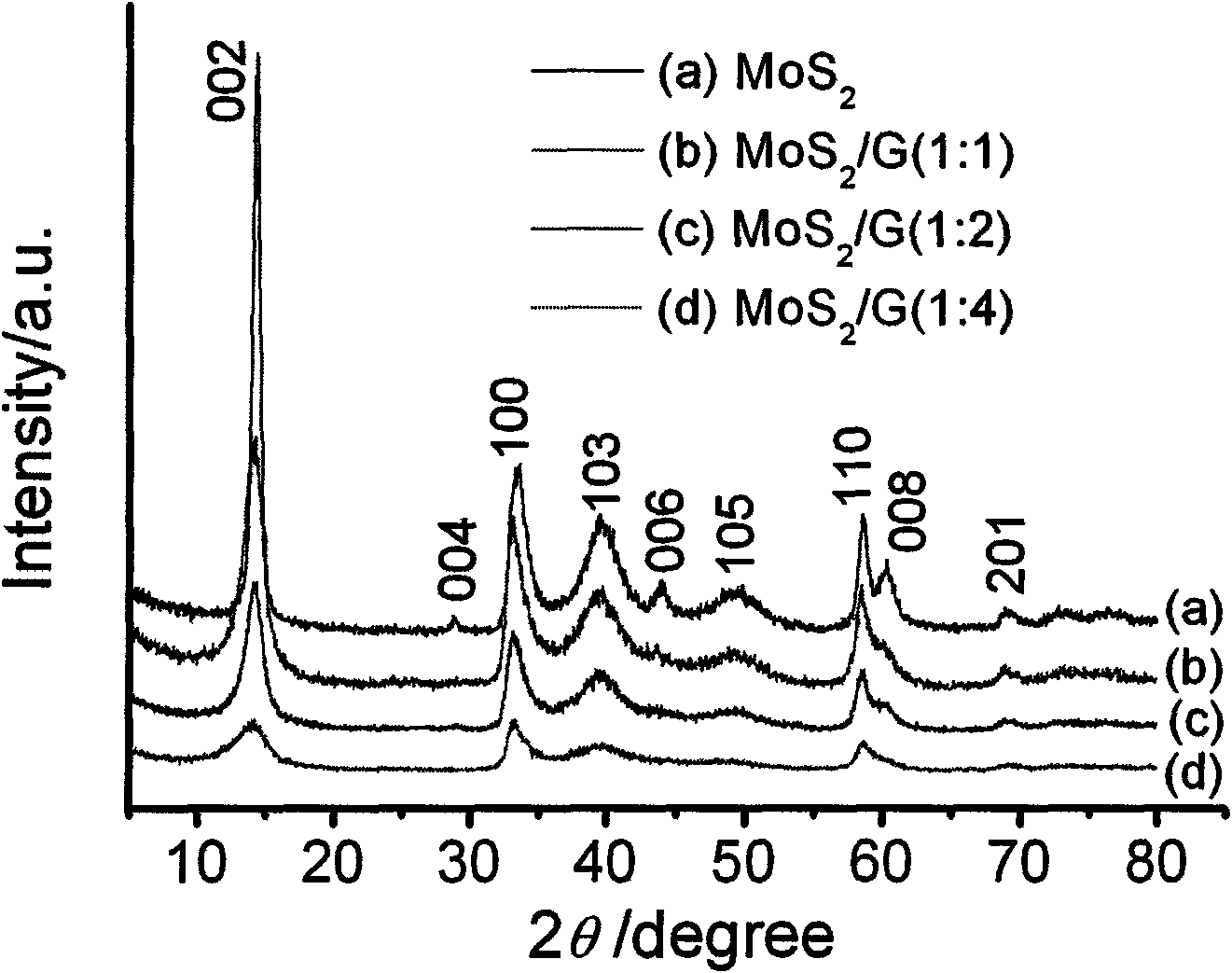

Lithium ion batteries can be activated and then cycled to exploit a moderate fraction of the discharge cycling capacity such that the discharge capacity and average discharge voltage stay within initial values for thousands of cycles. The superior cycling performance has been achieved at relatively high discharge rates and for practical battery formats. Lithium ion battery performance can also be achieved with superior cycling performance with partially activated batteries such that good discharge capacities can be exploited for many thousands of cycles before the discharge capacity and average discharge voltage drops more than 20% from initial values. The positive electrode active material can be a lithium rich metal oxide. The activation of the battery can comprise phase changes of the active materials. As described herein, the phase changes can be manipulated to exploit a reasonable fraction of the available high capacity of the material while providing outstanding cycling stability.

Owner:IONBLOX INC

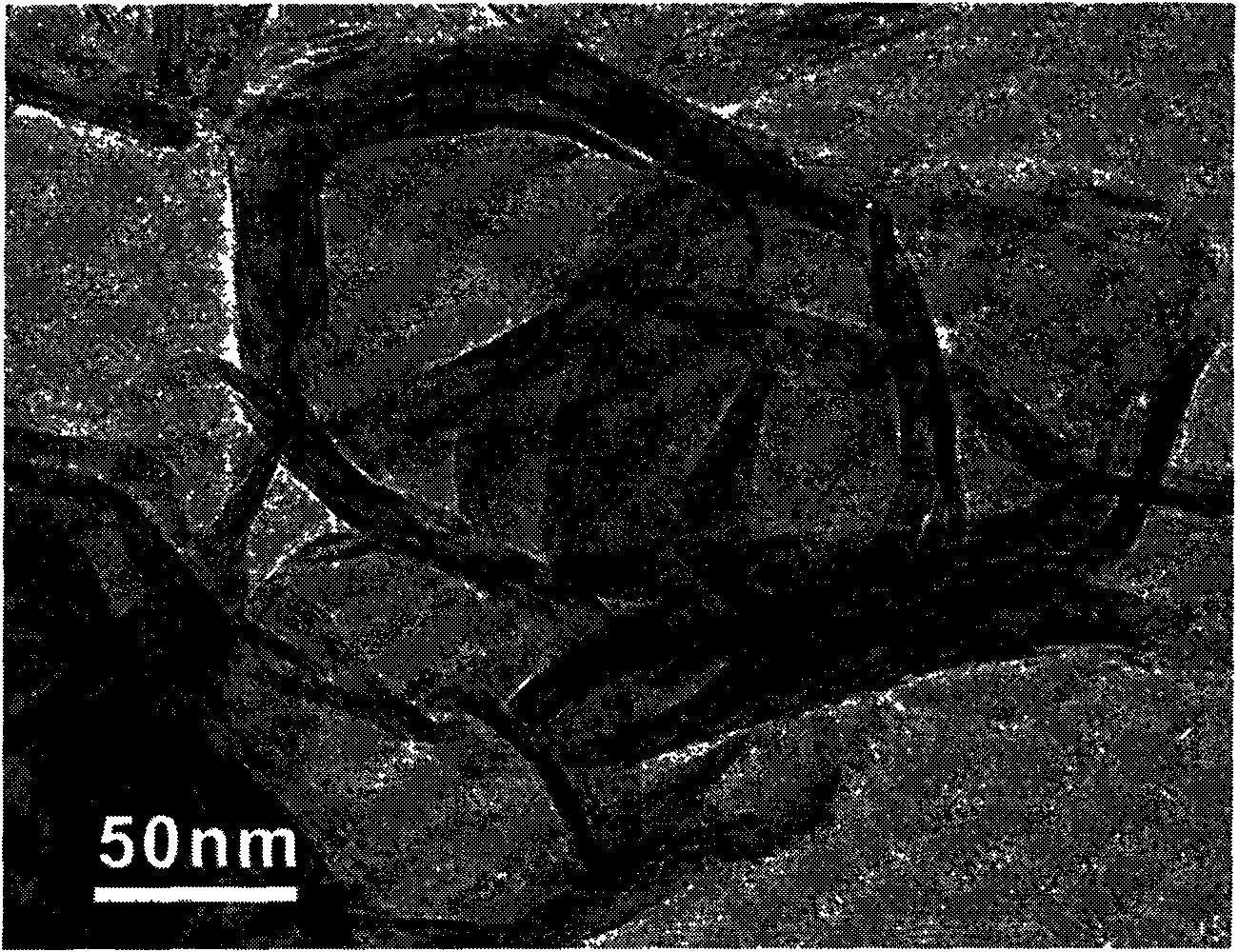

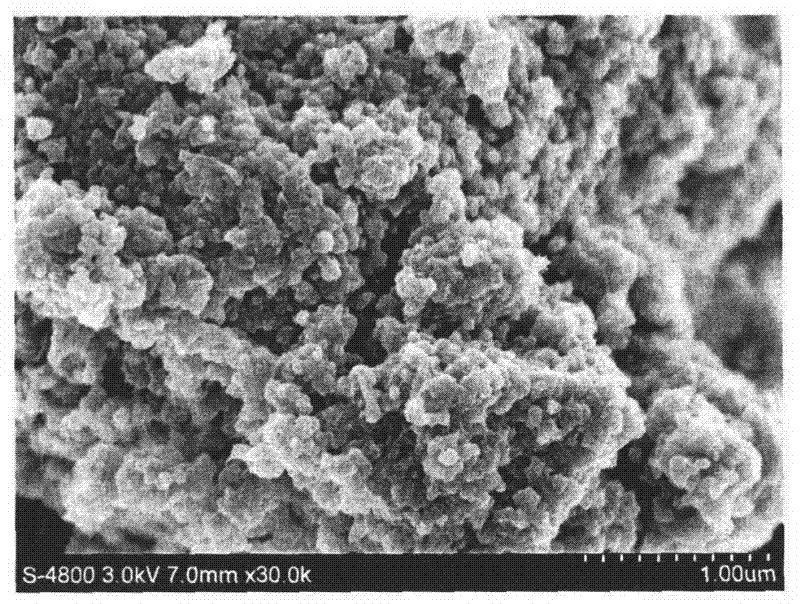

Graphene/MoS2 compound nano material lithium ion battery electrode and preparation method thereof

InactiveCN102142537ALarge specific surface areaImprove mechanical propertiesNon-aqueous electrolyte accumulator electrodesLithium-ion batteryMaterials science

The invention discloses a graphene / molybdenum disulfide (MoS2) compound nano material lithium ion battery electrode and a preparation method thereof. The electrode comprises the following components in percentage by mass: 75 to 85 percent of compound nano material serving as an active substance, of a graphene nano slice and MoS2, and 5 to 10 percent of acetylene black and 10 percent of polyvinylidene fluoride; and the mass ratio of the graphene nano slice to the MoS2 nano material in the compound nano material active substance is (1 to 1)-(4 to 1). The preparation method of the electrode comprises the following steps of: preparing an oxidized graphite nano slice by using graphite as a raw material by a chemical oxidization method; synthesizing by a one-step hydrothermal in-situ reduction method in the presence of the oxidized graphite nano slice to obtain a graphene nano slice / MoS2 compound nano material; and finally, preparing the electrode by using the graphene nano slice / MoS2 compound nano material as the active substance. The electrode has high electrochemical lithium storage reversible capacity and cyclic stabilization performance, and can be widely applied to new generation lithium ion batteries.

Owner:ZHEJIANG UNIV

Preparation method of high power capacity lithium ion battery cathode material

ActiveCN102769139AHigh specific capacityImprove cycle stabilityCell electrodesNanotechnologyCyclic stability

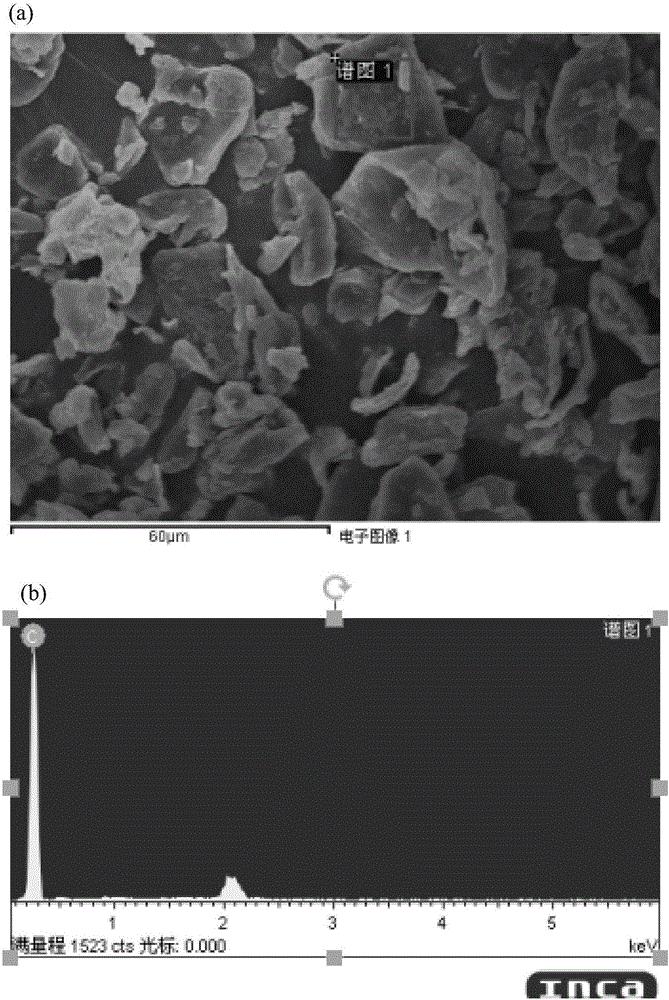

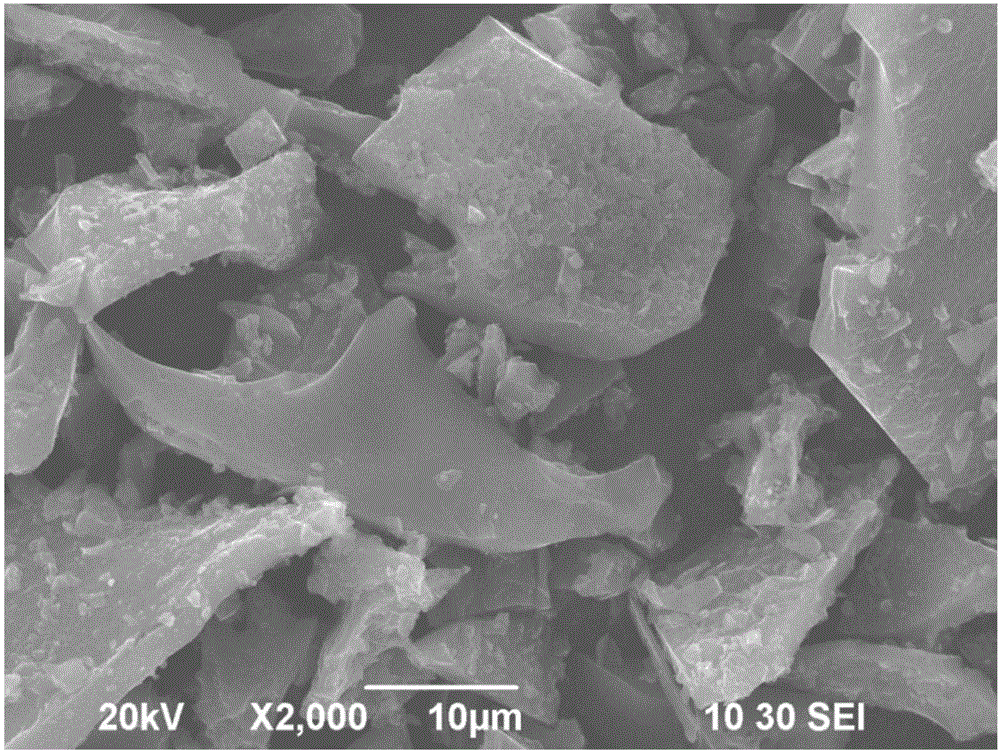

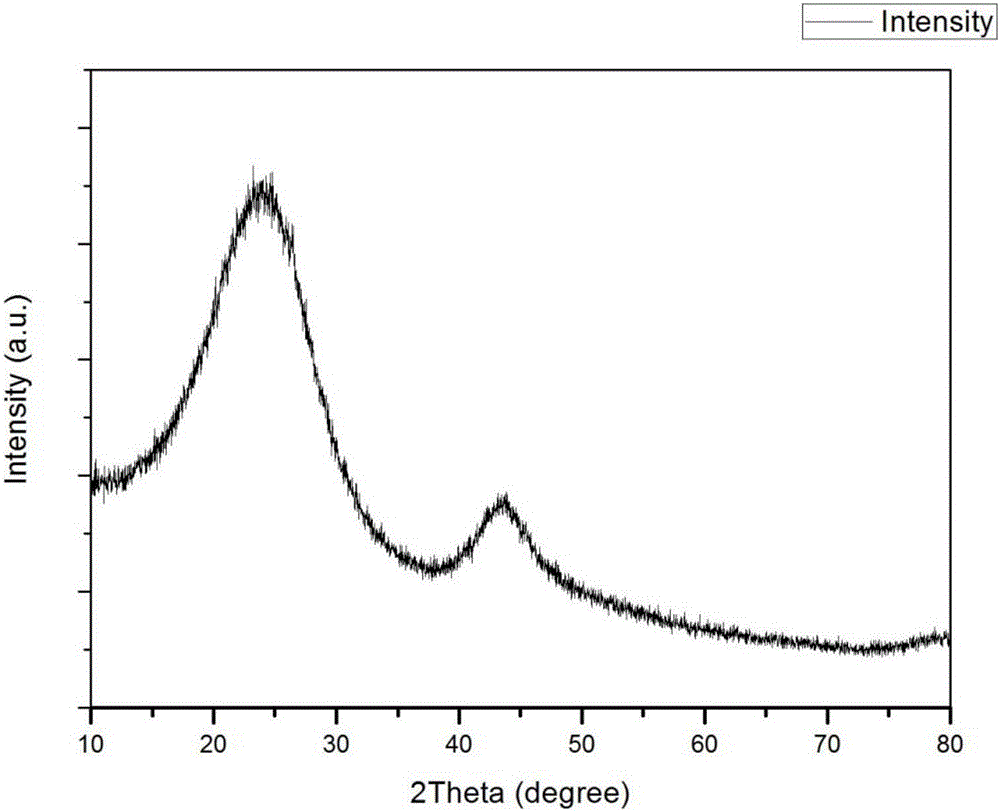

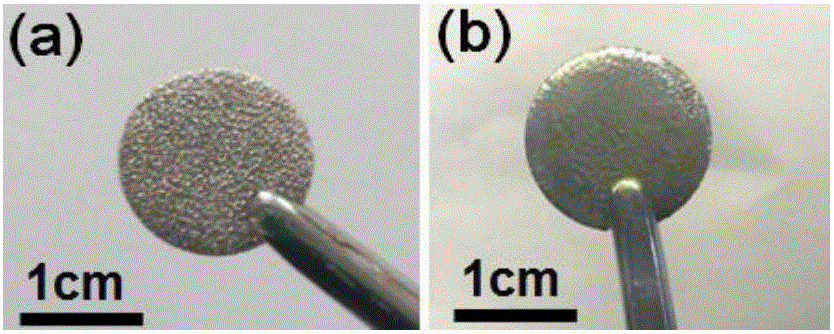

A preparation method of a high power capacity lithium ion battery cathode material uses natural spherical graphite to serve as raw materials, uses concentrated sulfuric acid to serve as an inserting layer agent, uses potassium permanganate to serve as an oxidizing agent, conducts expansion treatment at high temperature to obtain micro-expanded graphite, then enables the micro-expanded graphite in different proportions to be mixed with nanometer ganister sand, conducts ultrasonic dispersion, suction filtration and dying to obtain the micro-expanded graphite with the nanometer ganister sand inserted in layers, enables the micro-expanded graphite to be mixed and coated with carbon source carbon source according to certain proportion, and finally conducts carburizing sintering under inert gas shielding to prepare completely coated silicon carbon composite cathode material with sufficient obligated obligate inside. Electrochemistry shows that the silicon carbon composite material prepared by the preparation method has high specific capacity and cycling stability and is the ideal high power capacity lithium ion battery cathode material.

Owner:内蒙古斯诺新材料科技有限公司

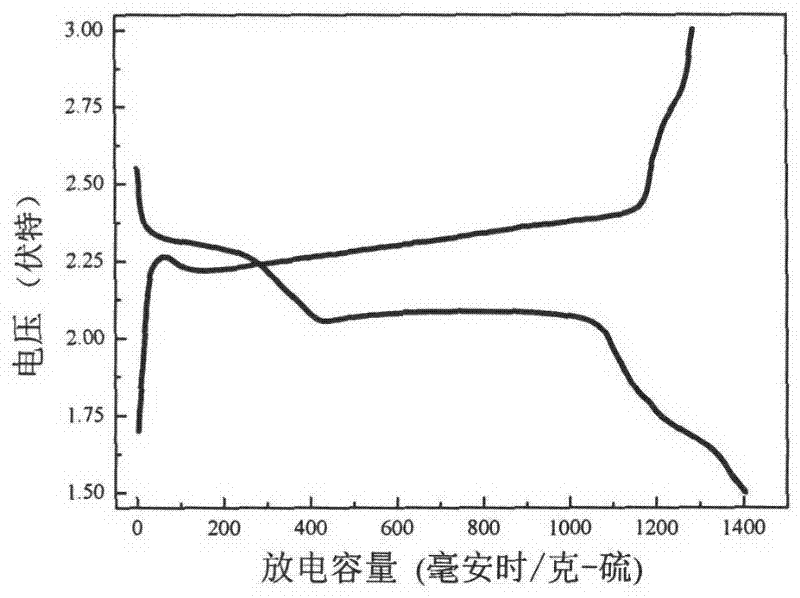

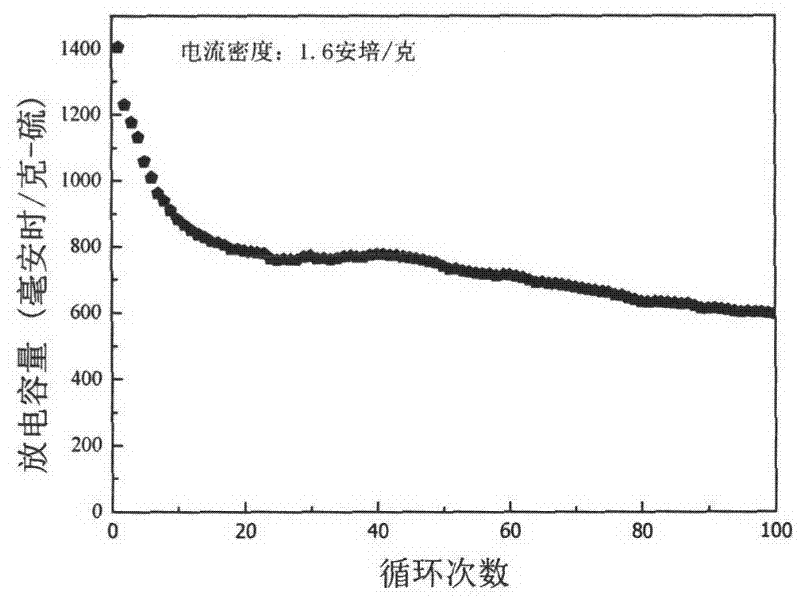

Lithium battery with polymer-coated sulfur/carbon composite material as anode

InactiveCN102447113AImprove cycle performanceImprove conductivityCell electrodesSecondary cellsCarbon compositesMass ratio

The invention relates to a lithium battery with a polymer-coated sulfur / carbon composite material as an anode. According to the invention, sublimed sulfur or sulfur powder and a conductive carbon material are mixed according to a mass ratio of 3:7-8:2; the mixture is subject to ball milling, such that a sulfur / carbon composite material is obtained; the composite material is dispersed in a solution, and a polymer monomer is added to the solution; under a low temperature and the protection of inert gas, an oxidizing agent is added for initiating polymerization; the material is centrifuged, washed, and dried; the obtained polymer-coated elemental sulfur / carbon composite material, acetylene black and PTFE are mixed; a dispersant is added to the mixture, and the mixture is sufficiently mixed by stirring; the mixture is rolled into a sheet, and is vacuum-dried under a temperature of 55 DEG C, such that an electrode sheet is obtained. The prepared electrode sheet is adopted as an anode, metal lithium is adopted as a cathode, and a solvent type organic solution system containing 0.2mol / L of a waterless lithium nitrate additive is adopted as electrolyte, and a battery is assembled. With the electrode material, the assembled lithium battery is advantaged in high specific capacity, good circulation stability, and excellent heavy-current charge / discharge performances. The preparation method is advantaged in simple process, low cost, and good repeatability.

Owner:NANKAI UNIV

All-solid state lithium ion battery composite positive electrode material and preparation method thereof, and all-solid state lithium ion battery

ActiveCN103633329AImprove cycle lifeImprove discharge capacityCell electrodesSecondary cellsSolid state electrolyteTitanium disulfide

Embodiments of the present invention provide an all-solid state lithium ion battery composite positive electrode material, which comprises a positive electrode active material and a cladding layer arranged on the surface of the positive electrode active material, the positive electrode active material is one or a plurality of materials selected from a lithium cobalt oxide, lithium nickelate, lithium manganate, lithium iron phosphate, lithium nickel cobalt manganese, vanadium pentoxide, molybdenum trioxide and titanium disulfide, and the cladding layer material is one or a plurality of lithium-containing transition metal oxides. According to the present invention, with the cladding layer, formation of the space charge layer can be effectively inhibited, the electrode / inorganic solid state electrolyte interface can be improved, and the interface resistance of the all-solid state lithium ion battery can be easily reduced so as to improve cycle stability and durability of the all-solid state lithium ion battery. Embodiments of the present invention further provide a preparation method for the all-solid state lithium ion battery composite positive electrode material, and an all-solid state lithium ion battery containing the all-solid state lithium ion battery composite positive electrode material.

Owner:泰州市海通资产管理有限公司

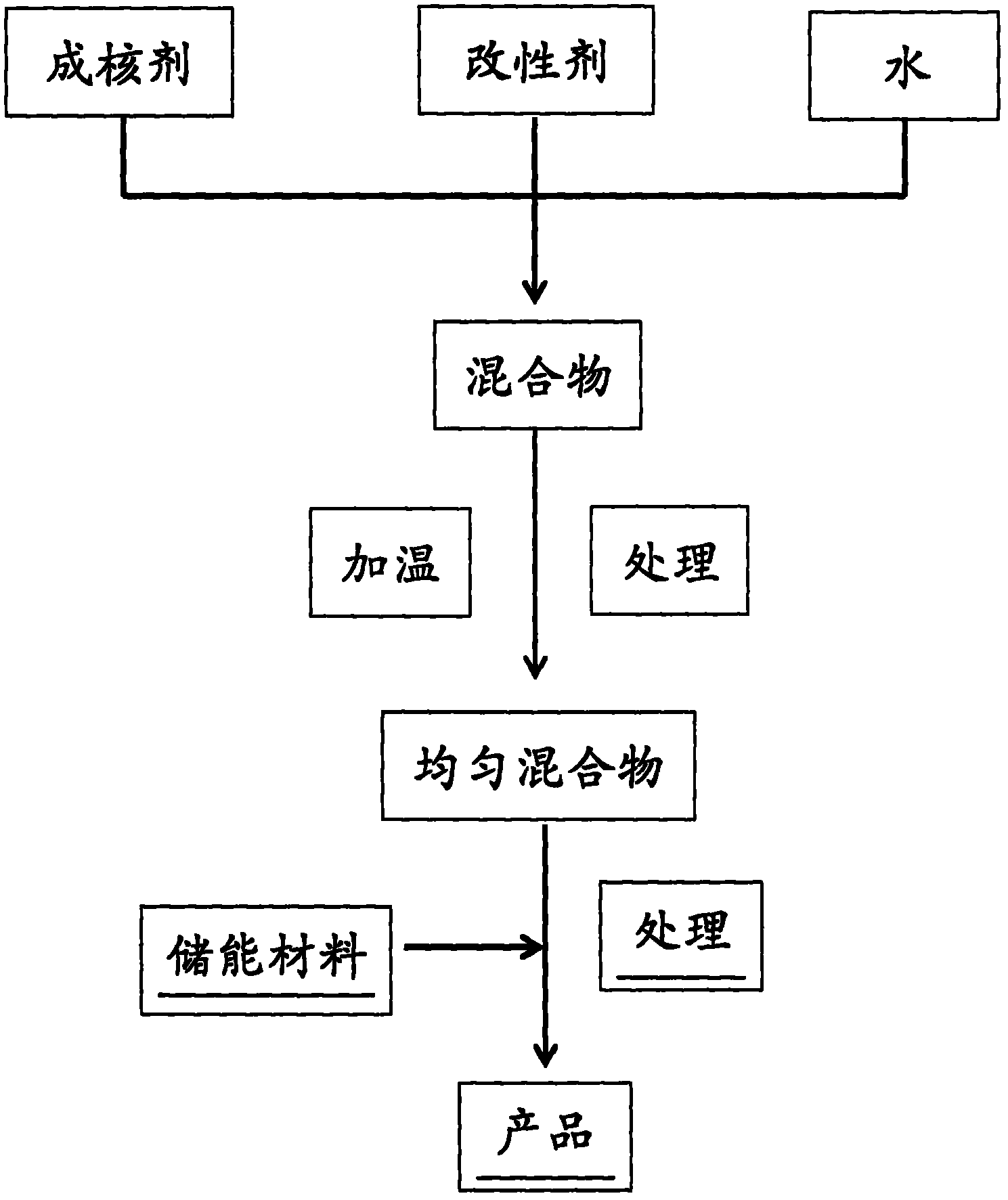

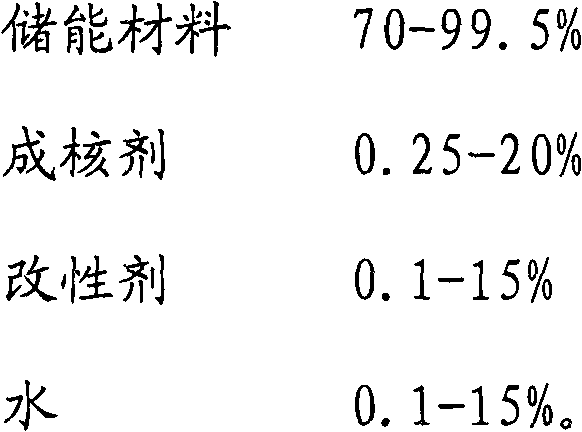

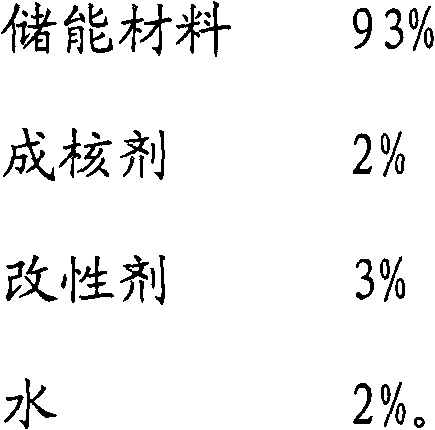

Inorganic phase change energy storage material

InactiveCN102604599AImprove liquidityPrevent Mutual AggregationHeat-exchange elementsPhase changeEnergy storage

The invention relates to the technical field of energy storage material, in particular to inorganic phase change energy storage material. The material comprises the following components by mass: 70 to 99.5 % of energy storage material, 0.25-20 % of nucleating agent, 0.1-15 % of modifying agent and 0.1-15 % of water. The bases hydrate or crystalline hydrous salt, especially the bases hydrate is adopted as energy storage material; the nucleating agent adopts carbonate; and the modifying agent is dispersant. According to the inorganic phase change energy storage material, by selecting proper nucleating agent and the ration of the nucleating agent, material phase separation can be effectively solved, especially the phase change energy storage material prepared by adding the dispersant into a system has good cycling stability, and simultaneously the potential heat value does not change after circulation for thousands of times.

Owner:SHANGHAI XUNENG NEW ENERGY TECH

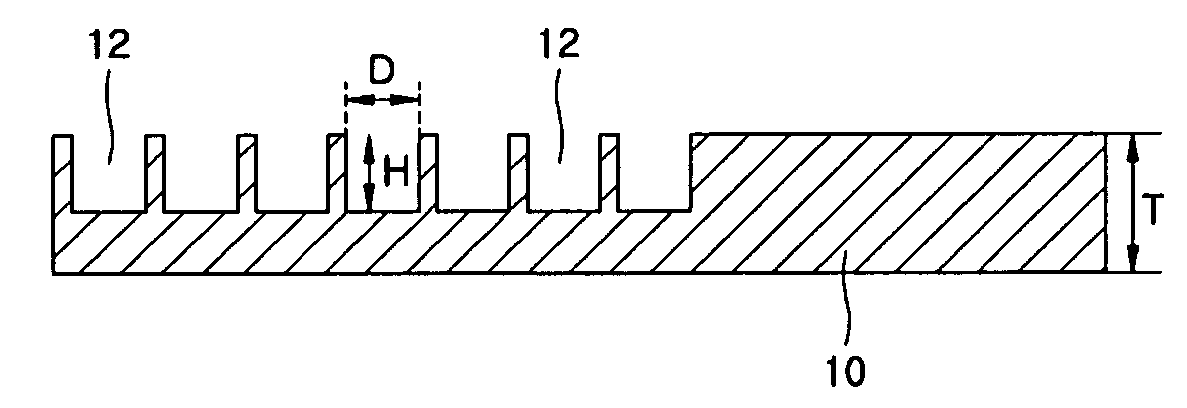

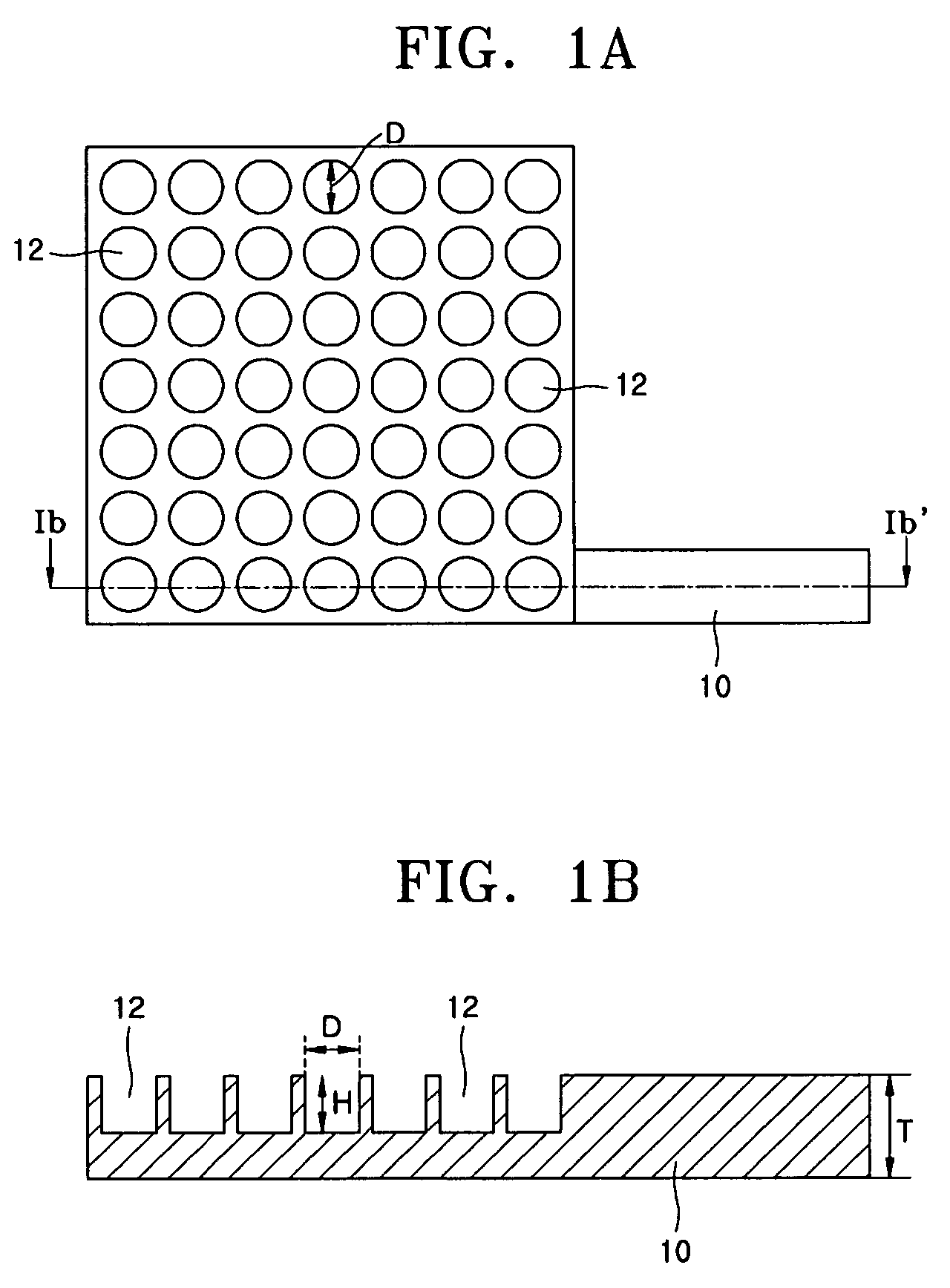

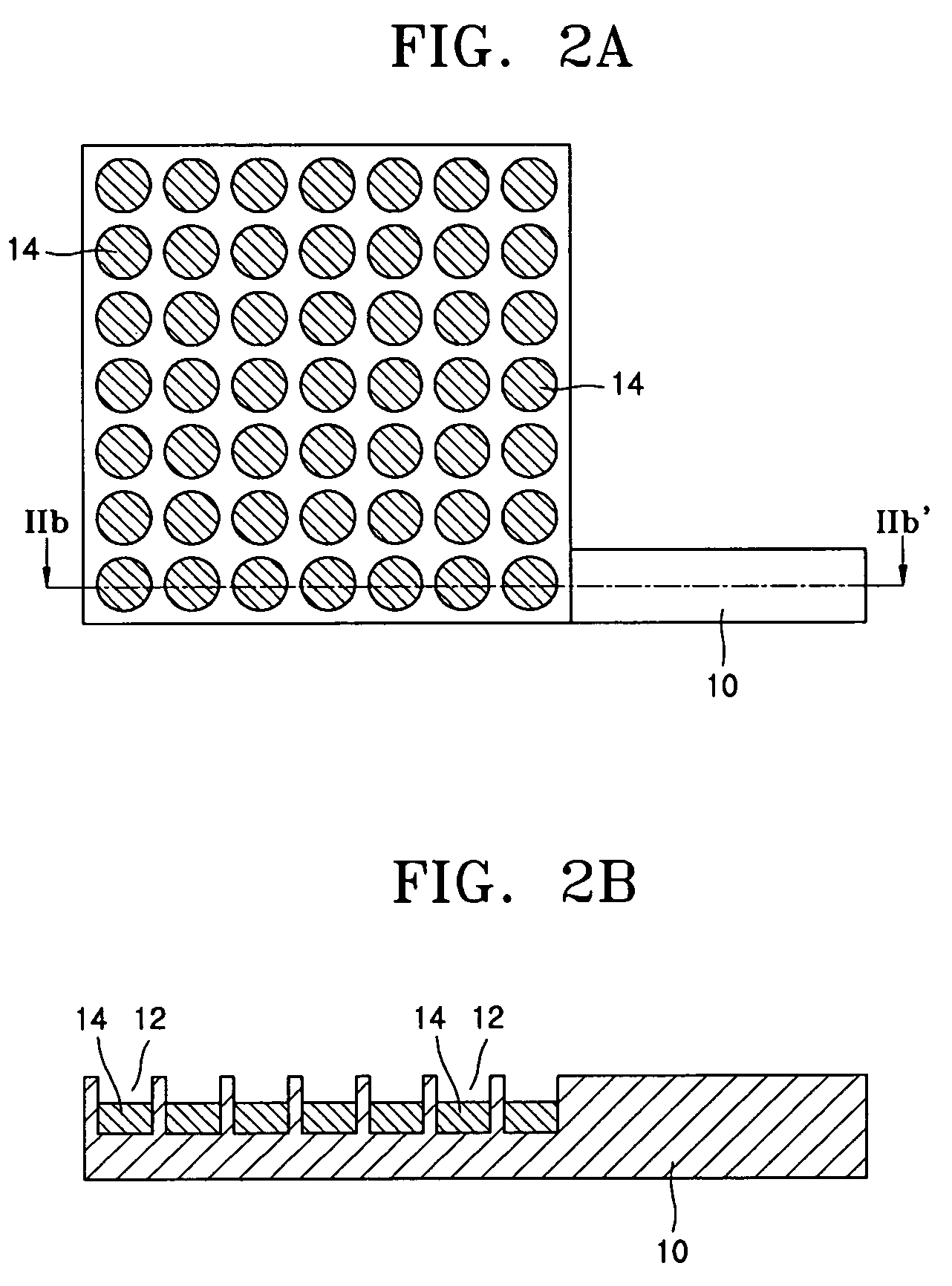

Anode for lithium metal polymer secondary battery comprising surface patterned anodic current collector and method of preparing the same

InactiveUS20060110661A1Cyclic stabilityExtend your lifeElectrode carriers/collectorsNon-aqueous electrolyte accumulator electrodesSurface patternLithium metal

There are provided an anode for a lithium metal polymer secondary battery comprising an anodic current collector having a surface on which a plurality of recesses having a predetermined shape are formed and a method of preparing the same. The plurality of recesses are formed on a surface of the anodic current collector using a physical method or a chemical method. In a lithium metal polymer secondary battery employing the anode, oxidation / reduction of lithium and the formation of dendrite occur only in the recesses formed by surface patterning of the anodic current collector. Thus, expanding and shrinking of a battery due to a change in the thickness of the lithium anode can be prevented and cycling stability and the lifespan of a battery can be improved.

Owner:ELECTRONICS & TELECOMM RES INST

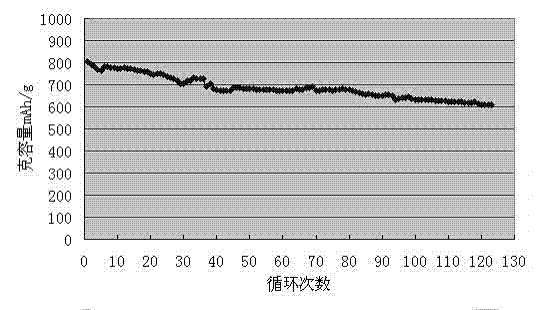

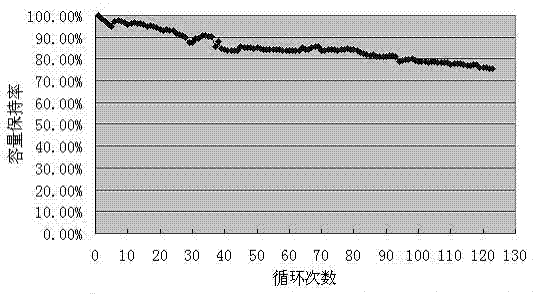

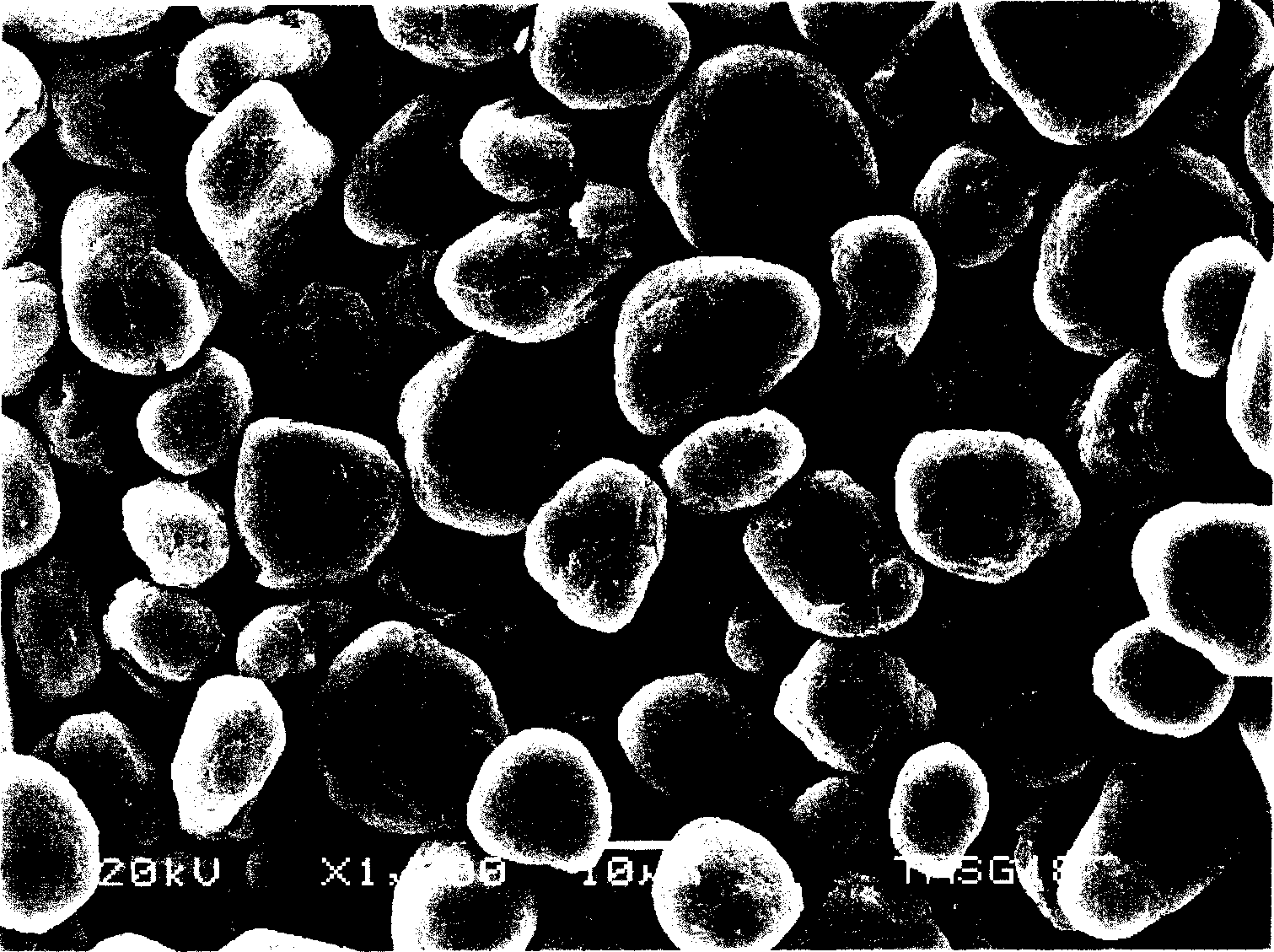

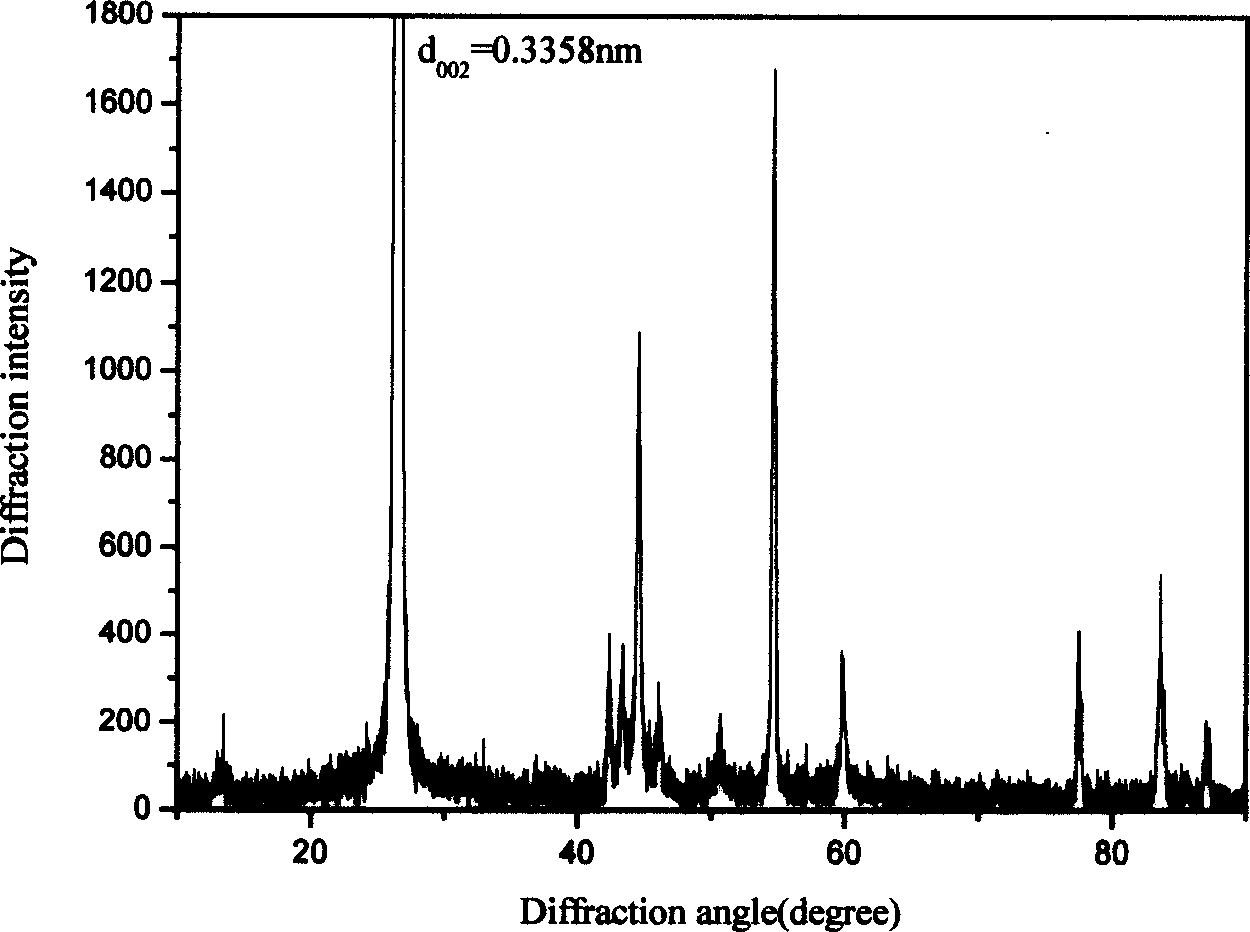

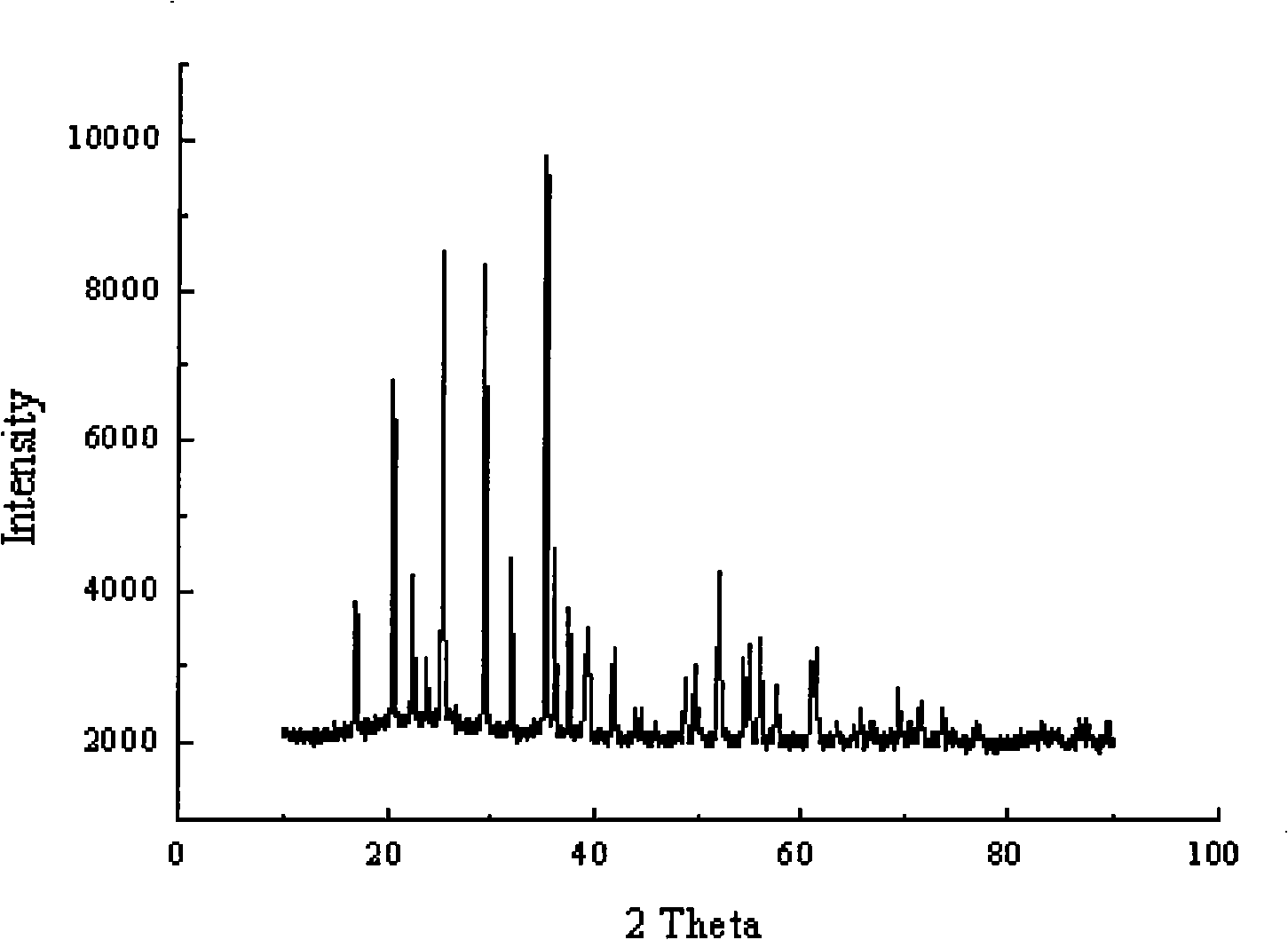

Cathode material of composite carbon in use for lithium ion battery and preparation method

ActiveCN1697215ASimple preparation processEasy to operateElectrode manufacturing processesActive material electrodesLithium-ion batteryMaterials science

The disclosed composite carbon material of negative pole in lithium ion cell is composite graphite including spherical graphite and covering layer, which is pyrolytic carbon of organic matter. Inserted transition metal elements are contained between layers of graphite crystal. Preparation method is as following: crushing graphite, shaping and sphericized, purifying treatment, washing, dewatering and drying, dipped in salt solution doped by transition metal in multivalence, mixed with organic matter, covering treatment, and carbonizing treatment or graphitization treatment. Comparing with prior art, the disclosed material of negative pole possesses advantages of fine capability of embedding lithium and taking off lithium, high cyclical stability, reversible specific capacity larger than 350mAh / g, coulomb efficiency higher than 94% at first cycle, conservation rate for capacity larger than 80% in 500 times of circulation.

Owner:BTR NEW MATERIAL GRP CO LTD

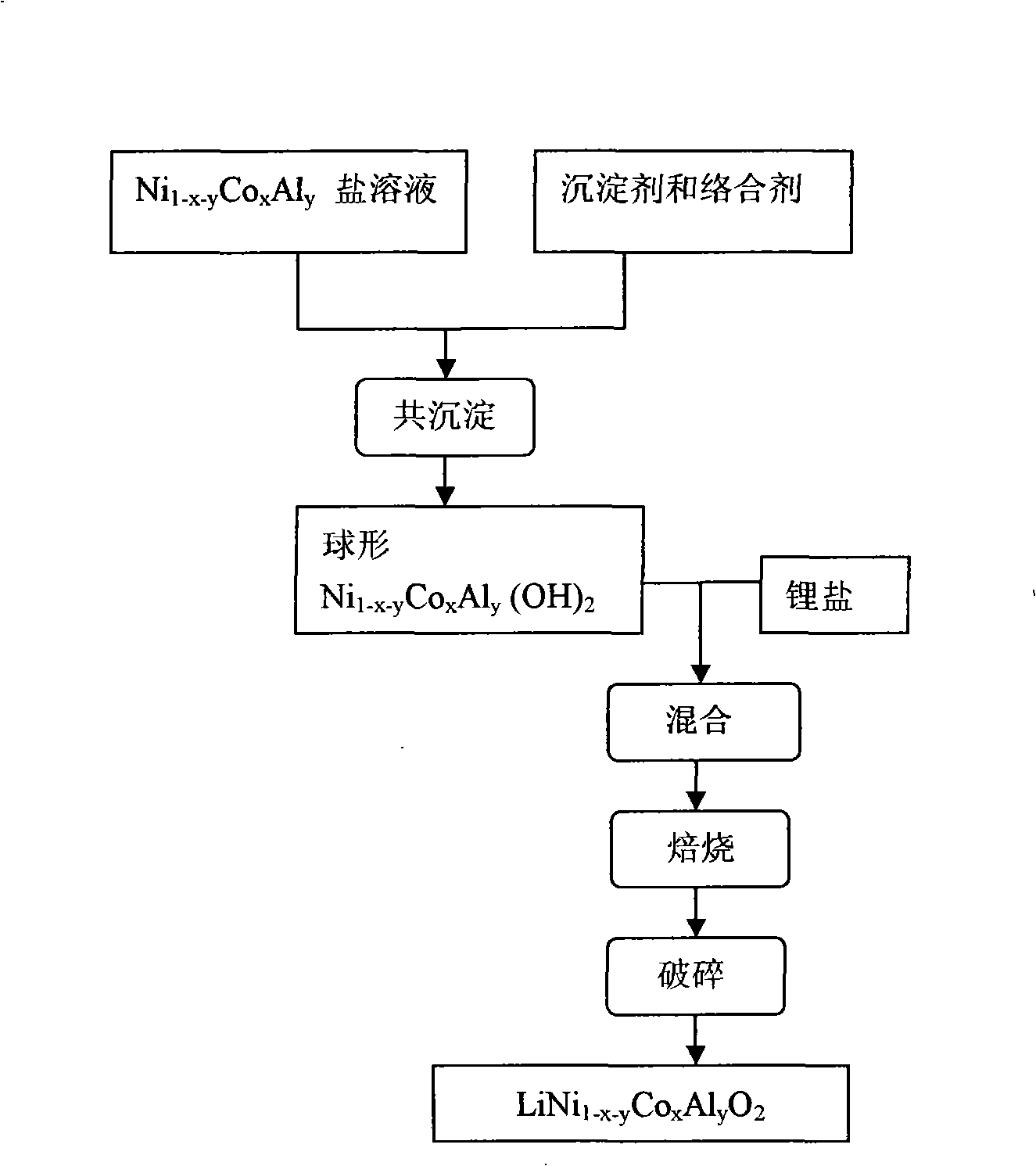

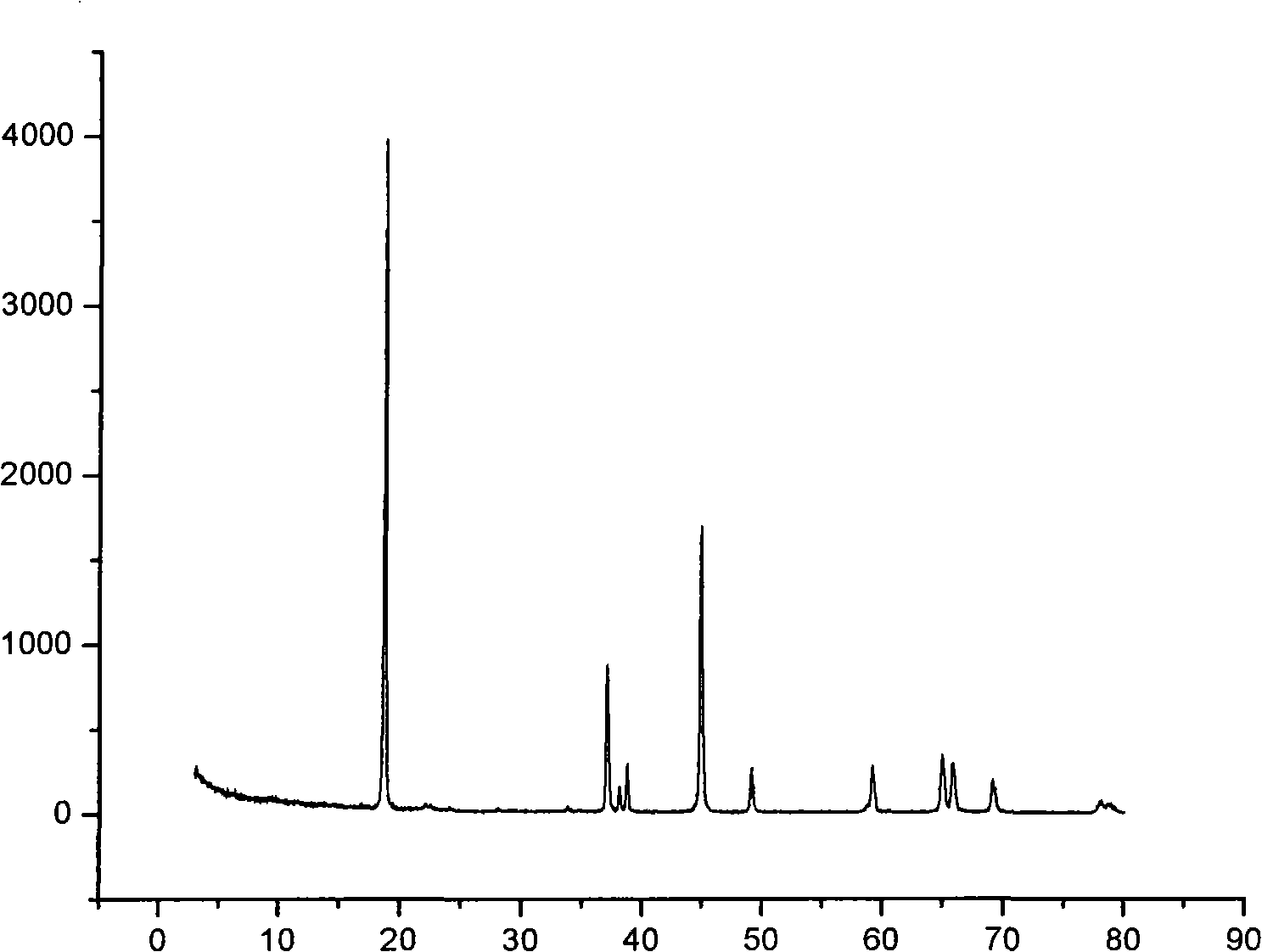

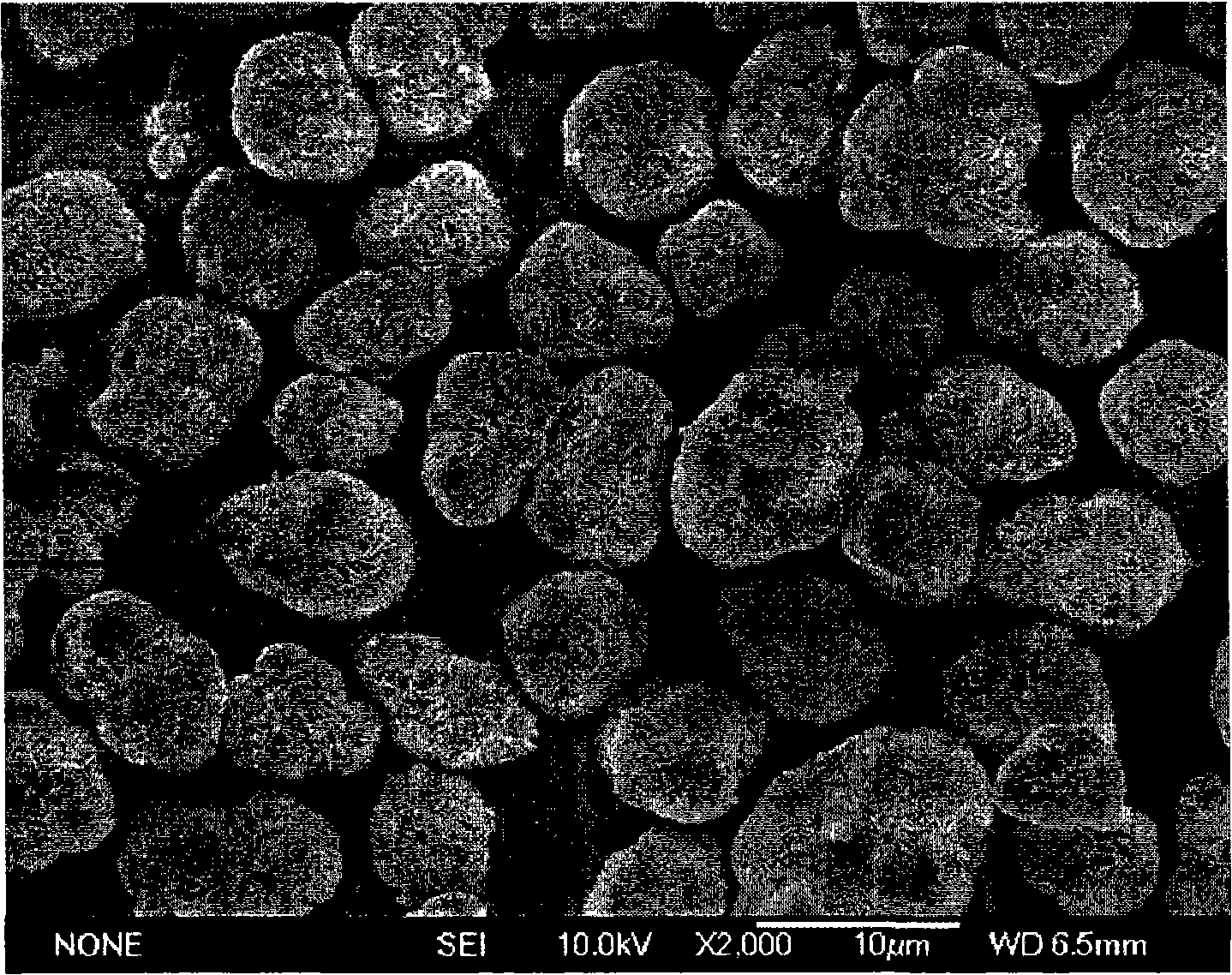

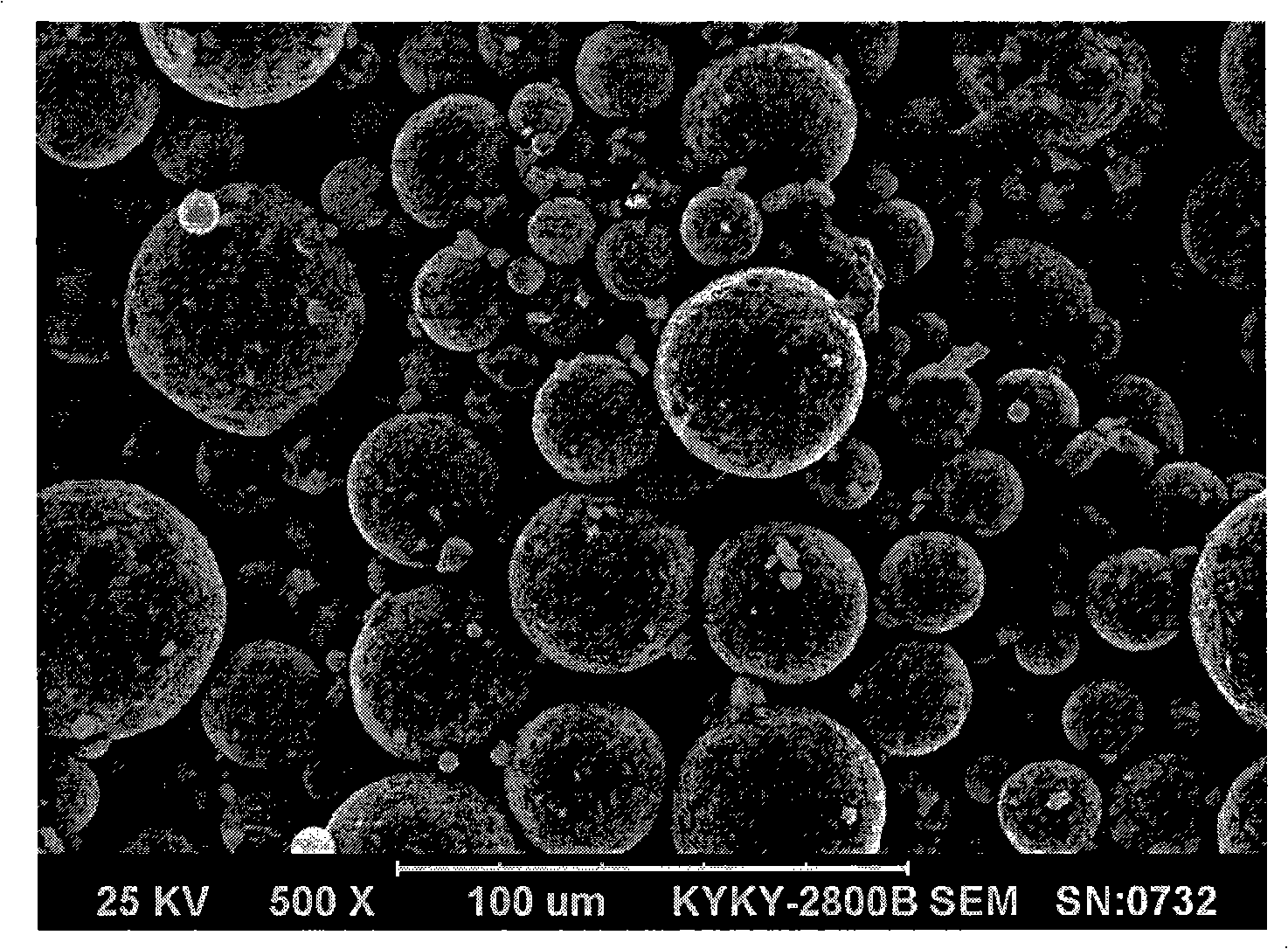

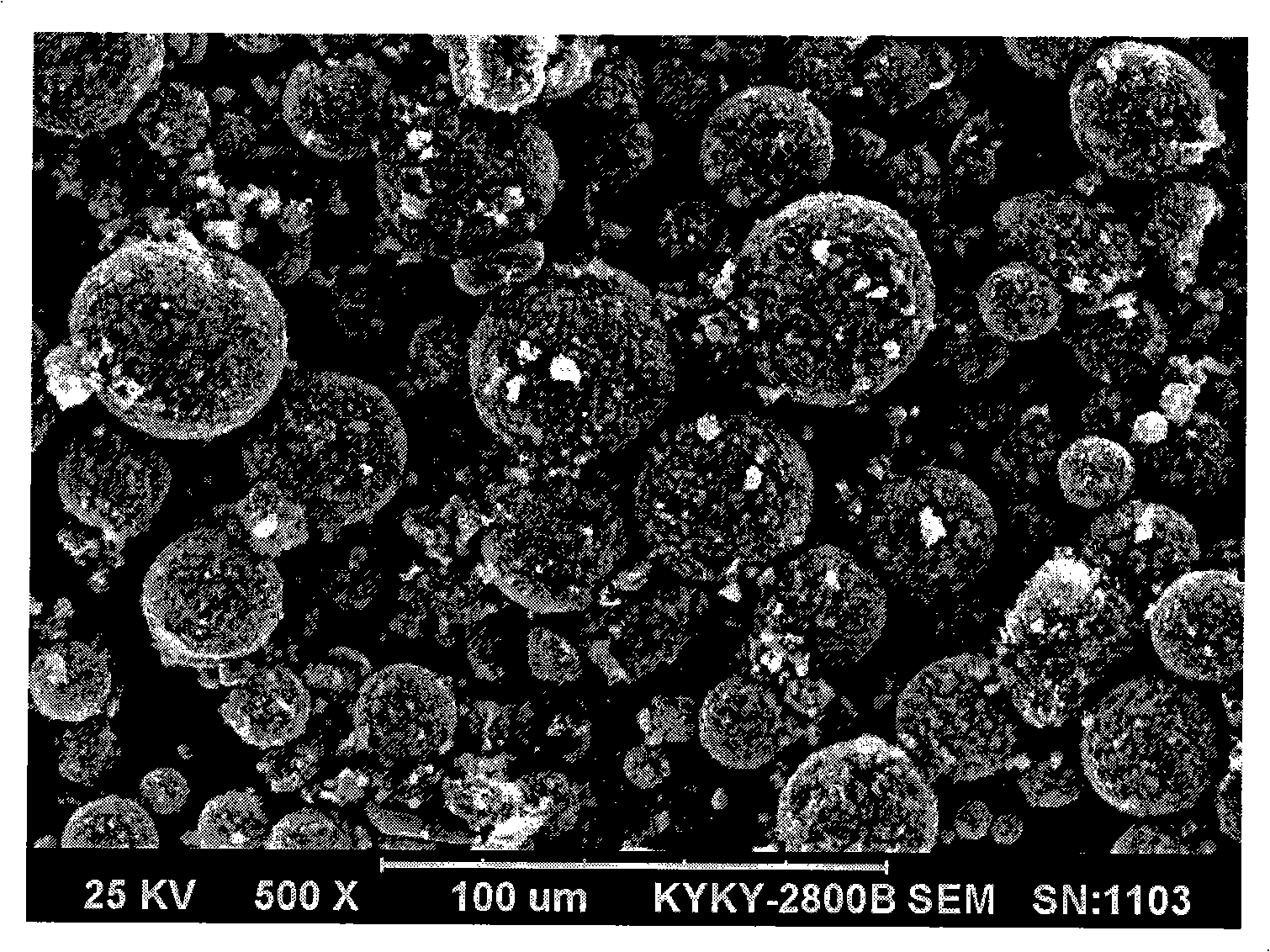

Spherical aluminum-doped nickel cobalt lithium for lithium ion battery and its making method

ActiveCN101262061AImprove liquidityImprove charge and discharge cycle stabilityElectrode manufacturing processesLithium compoundsDischarge efficiencyHigh rate

The invention discloses a preparation method of a spherical doped Al-Ni lithium cobalt oxide for lithium-ion battery. The preparation steps are that: first, sulfate, nitrate or chlorate of Al-Ni-Co react with strong alkali that is added with complex agent in liquid phase; the pH value, the temperature and the feeding speed of the reaction solution are controlled so as to produce a spherical precursor of Al-Ni-Co hydroxide; then the spherical precursor of Al-Ni-Co hydroxide is dried and evenly mixed with lithium hydroxide, lithium nitrate or lithium carbonate and dried; the obtained mixture is roasted into a spherical doped Al-Ni lithium cobalt oxide. The spherical doped Al-Ni lithium cobalt oxide has comparatively high tap density and remarkable cycle stability in the process of high-rate charge / discharge cycle, which improves over charge performance of Ni-Co substance and first obviously enhances charge / discharge efficiency; in addition, the preparation method of the spherical doped Al-Ni lithium cobalt oxide has the advantages of being simple, controllable and suitable for industrialized production with low energy consumption, high efficiency, short reaction time and low cost.

Owner:成都巴莫科技有限责任公司

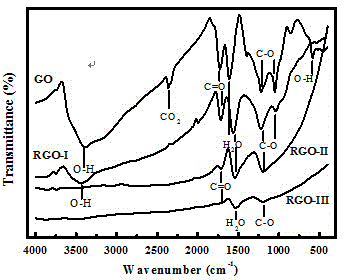

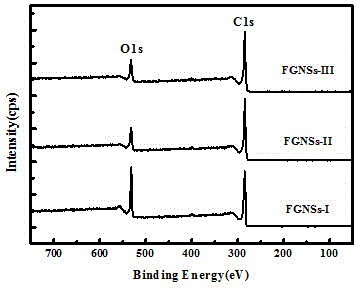

Method for preparing lithium ion battery anode/cathode material from reduced graphene oxide

The invention discloses a method for preparing a lithium ion battery anode / cathode material from reduced graphene oxide. The method comprises the following steps: performing ultrasonic dispersion on graphite oxide in an organic solvent, thereby obtaining a graphene oxide dispersion liquid; reducing by using an appropriate reducing agent or directly using a solvent, oxidizing graphene through oil bath backflow, a hydrothermal method or other reduction methods, thereby obtaining a reduced graphene oxide material containing part of oxygen-containing groups. When the prepared reduced graphene oxide material is used in a lithium ion battery anode material, a relatively high specific discharge capacity can be achieved, that is, is up to 280mAh / g, and good circulation stability and excellent rate performance are achieved. The prepared reduced graphene oxide material can be also used in a lithium ion battery cathode material, the specific discharge capacity can be kept being 900mAh / g and more than 900mAh / g after 100 rounds of charge / discharge circulation, and the circulation stability is relatively good. The method can be a significant study point of high-performance low-cost electrode materials of lithium ion batteries.

Owner:TIANJIN NORMAL UNIVERSITY

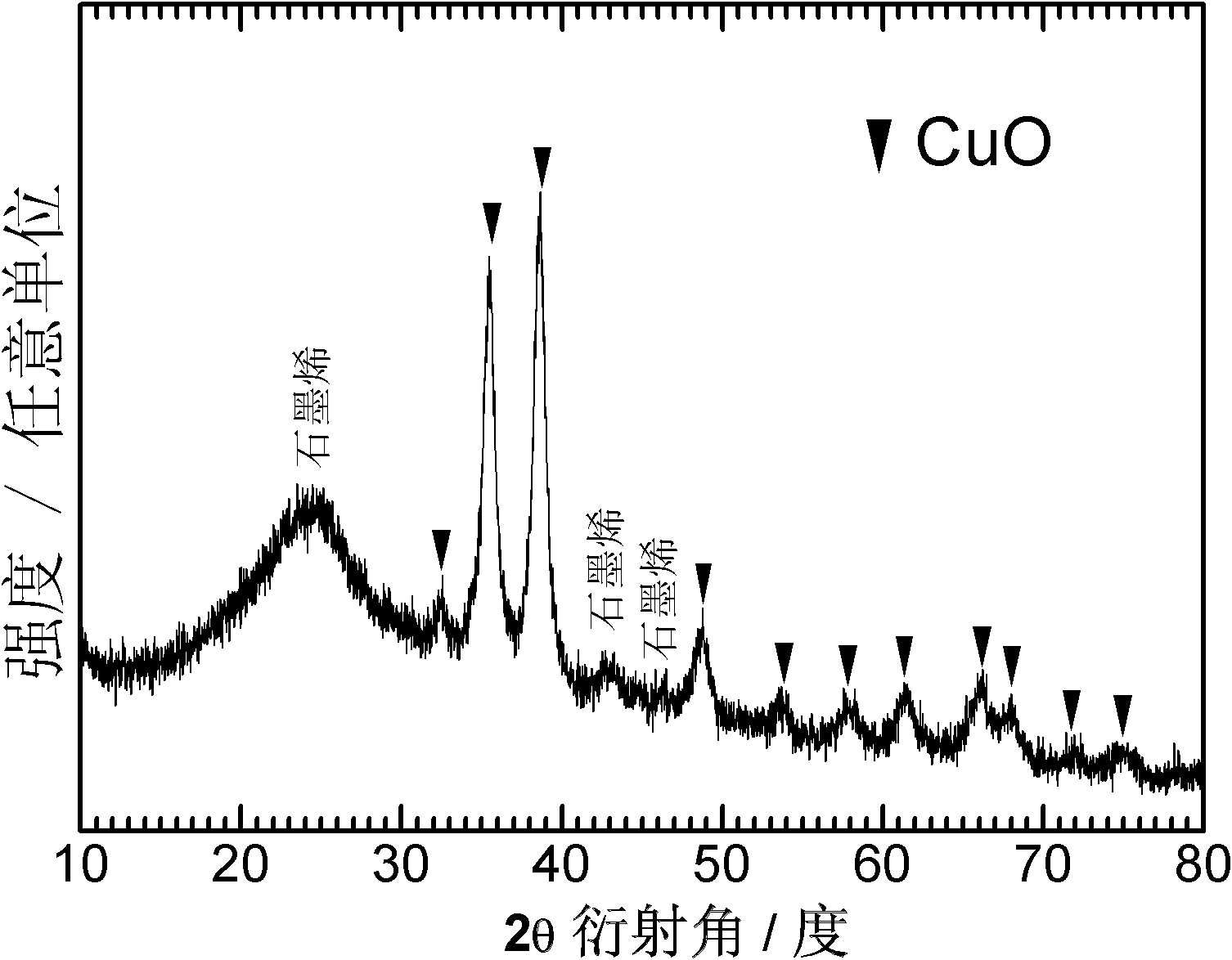

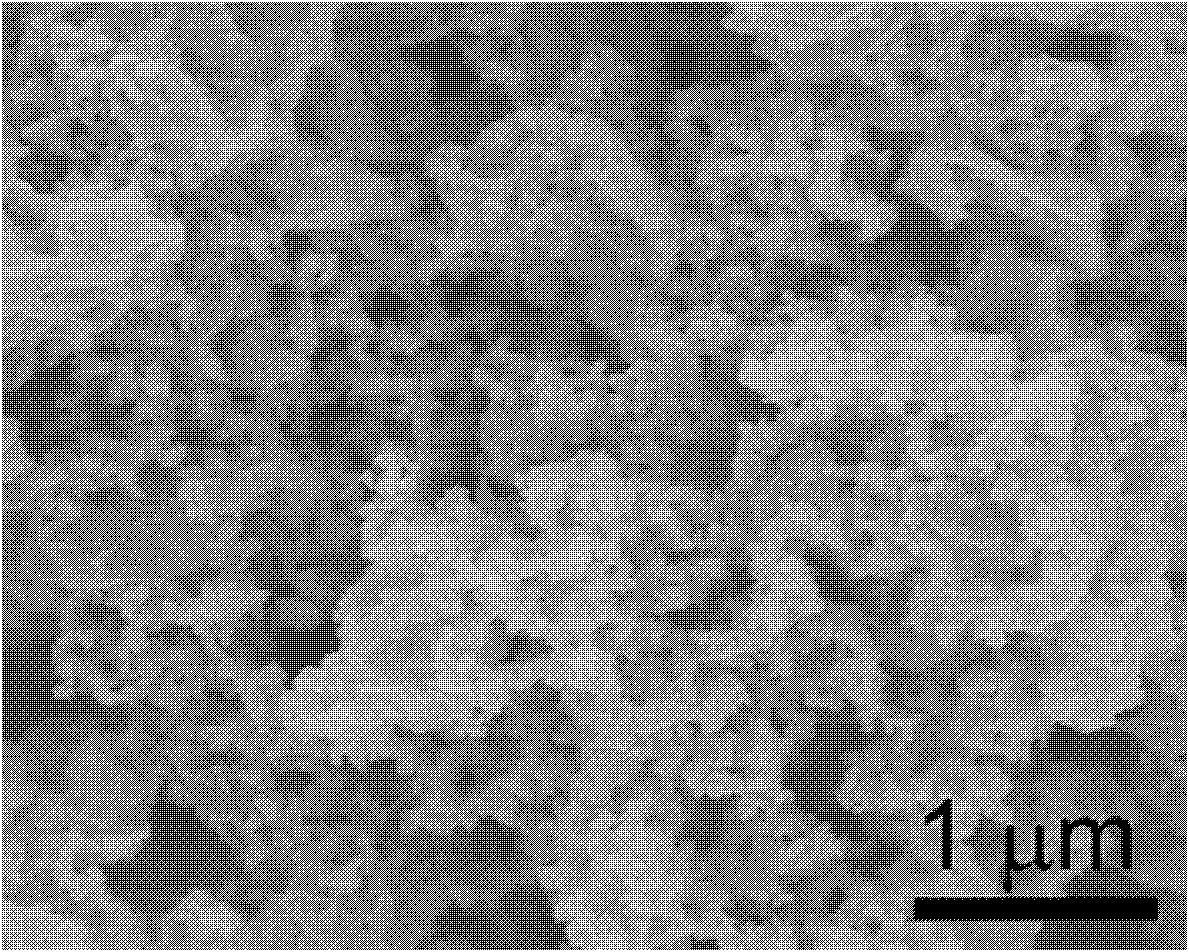

Transition metal oxide/ graphene composite material and preparation method thereof

The invention discloses a transition metal oxide / graphene composite material, which consists of a nanometer transition metal oxide and graphene, wherein the transition metal oxide is MnO, Fe2O3, Cr2O3, Cu2O, CuO or V2O5. Because of the dispersing and loading effects of the graphene, the transition metal oxide in the composite material can be distributed uniformly and is small in particle size, and the stability and the cyclical stability of the transition metal oxide in the process of charging and discharging can be effectively improved. The invention also discloses a one-step low-temperature preparation method of the composite material, which has the advantages of simple process, low cost, short cycle, low energy consumption and the like, and is suitable for large-scale industrial production.

Owner:ZHEJIANG UNIV

Biomass hard carbon negative electrode material for sodium ion battery, preparing method and sodium ion battery

ActiveCN106299365AImprove the first charge and discharge efficiencyImprove electrochemical performanceNon-aqueous electrolyte accumulatorsCell electrodesSodium-ion batteryLithium-ion battery

The invention relates to a biomass hard carbon negative electrode material for a sodium ion battery, a preparing method and the sodium ion battery and belongs to the technical field of sodium ion energy storage equipment. The biomass hard carbon negative electrode material is prepared through the method including the following steps that firstly, a biomass raw material is smashed, and precursor particles are obtained; secondly, in a protection atmosphere, the precursor particles are heated to 400-600 DEG C to be pre-sintered for 1.5-2.5 h, then cooled to the room temperature along with a furnace, then heated to 800-1600 DEG C to be sintered for 2-5 h and cooled, and an intermediate is obtained; thirdly, the intermediate is put into an alkali solution to be soaked, taken out, then put into an acid solution to be soaked, then washed with water to be neutral and dried, and a purified product is obtained; fourthly, the purified product is subjected to microwave vacuum activation for 3-15 s at the power of 1000-2000 W, and then the biomass hard carbon negative electrode material is obtained. The first-time charging and discharging efficiency of the obtained biomass hard carbon negative electrode material reaches up to 90% or above, the circulation stability is good, the reversible specific capacity is 300 mAh / g or above, and the biomass hard carbon negative electrode material has a good electrochemical property.

Owner:浙江瓦司特钠科技有限公司

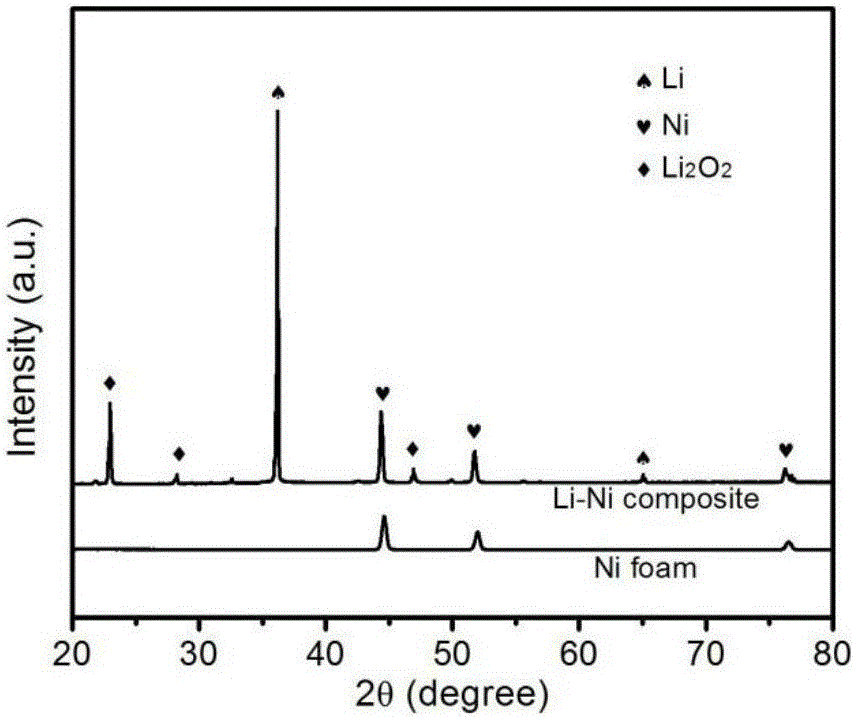

Preparation method of composite lithium metal anode

InactiveCN108365200AReduce chalkingImprove cycle stabilityCell electrodesLi-accumulatorsLiquid metalLithium-ion battery

The invention discloses a preparation method of a composite lithium metal anode and belongs to the technical field of lithium metal batteries. The preparation method of the composite lithium metal anode comprises steps as follows: firstly, the surface of a framework material is modified, the framework material with the lithiophilic surface is prepared, the framework material is contacted with liquid metal lithium, so that the liquid metal lithium is injected into the framework material with the lithiophilic surface, and the composite lithium metal anode is prepared after cooling. The lithiophilic surface can be obtained through modification of various framework materials (including a conductive framework material and an insulated framework material), the framework materials are efficientlycomposited with the liquid metal lithium, and the composite lithium metal anode material is obtained. When the obtained composite lithium metal anode material is assembled in a total battery, growthof lithium dendrites can be effectively inhibited, the volume expansion effect of the anode is relieved, the pulverization phenomenon of the lithium metal anode is reduced, and the cycling stability and the safety of the lithium metal battery are substantially improved, and the cycle life of the lithium metal battery is substantially prolonged.

Owner:TSINGHUA UNIV

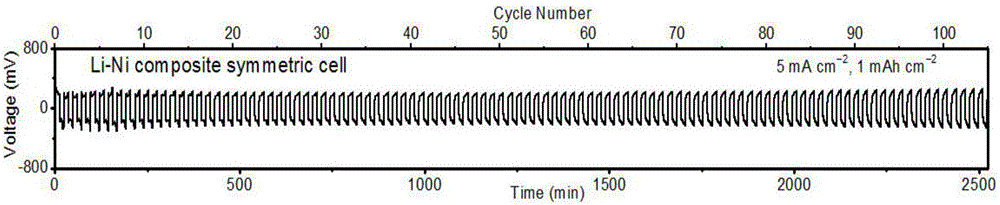

Preparation method of complex lithium negative pole of solid state battery

The present invention discloses a preparation method of a complex lithium negative pole of a solid state battery, and belongs to the technical field of electrochemistry and new energy resources. The preparation method mainly comprises the steps: depositing lithium metal on three-dimensional carbon material or foam porous material gaps by using a heat infusing melting method or an electrodeposition method to obtain the complex lithium negative pole, wherein the application of a three-dimensional framework plays two roles, namely, providing adequate space for pre-storing lithium in the preparation process; providing a carrier for receiving metal lithium in a battery circulation process. The complex lithium negative pole can be widely applied in lithium metal batteries such as lithium ion batteries, lithium-air batteries, lithium-sulfur batteries, and solid state batteries. In the assembled symmetric solid state battery, under large electric current density of 5mA cm-2, a stable voltage decay (200mV) can still be kept after circulation for 100 times, in the battery circulation, the growth of lithium dendrites can be inhibited and the pole volume change can be stabilized, and the advantages of being good in circulation stability, and long service life can be realized; in the present invention, a carrier material is rich, and low in price; the process is controlled, the cost is low, and the batch production can be realized.

Owner:UNIV OF SCI & TECH BEIJING

Lithium ion battery anode material manganese lithium phosphate and preparation method thereof

ActiveCN101320809AImprove electronic conductivityEvenly dispersedElectrode manufacturing processesPhosphorus compoundsCapacitanceLithium iron phosphate

The invention discloses a manganese / lithium phosphate of lithium iron battery positive pole material and a production method thereof, the technical issue to be solved is to improve electrochemical performances of the positive pole material. The material of the invention includes substrates of manganese / lithium phosphate which are covered by a carbon material covering layer, the lithium covering the manganese / lithium phosphate behind the carbon material covering layer is spherical and has microscopic characteristics of being near spherical, rhombic, tapered, tabular, layered or / and block-shaped as well as of having 0.5-30 mum long and short axles. The production method comprises the following steps of: production of nanometer particles, liquid phase mixed reaction, production of precursor, sintering treatment, covering organic substances. Compared with the prior art, the invention improves the electron conductivity of the manganese / lithium phosphate by covering with carbon liquid phase, the carbon sufficiently covers active materials to efficiently prevent particle aggregation, the invention has the characteristics of about 4V of discharge voltage, high discharge and charge capacitance, excellent circulation stability, high safety, simple process, low cost and little influence on the environment.

Owner:SHENZHEN CITY BATTERY NANOMETER TECH

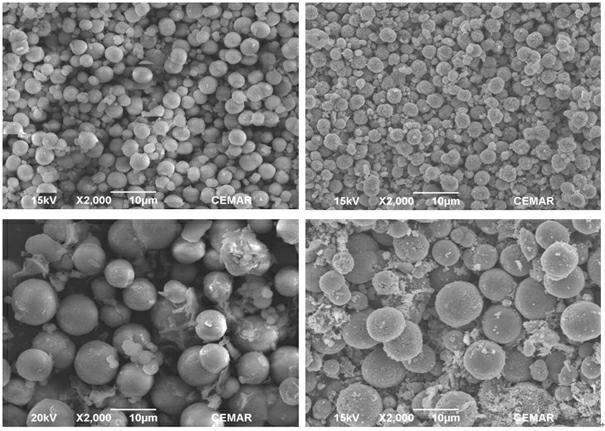

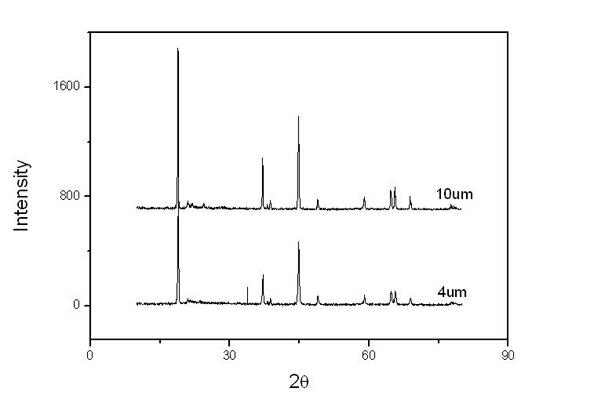

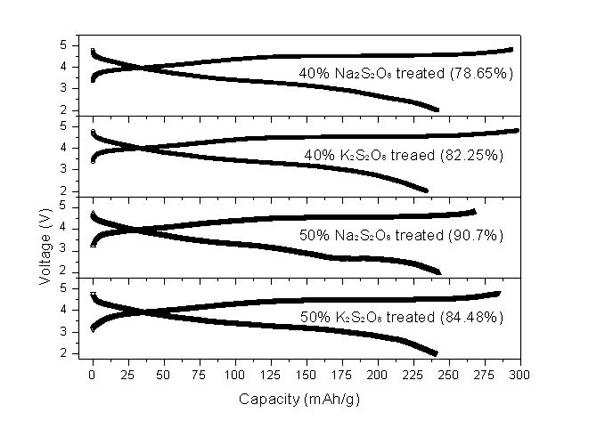

Synthesis and surface modification method of lithium excessive laminar oxide anode material

The invention relates to a synthesis and surface modification method of a lithium rich anode material Li1+xM1-xO2 (M is one or more of Ni, Co and Mn, and X is more than or equal to 0 and less than or equal to 1 / 3) for a lithium ion battery. The method comprises the following steps of: synthesizing a precursor by using a carbonate precipitation method, mixing the precursor and a lithium salt, and calcining for 2 to 20 hours at the temperature of between 800 and 1,100 EG C to obtain a lithium rich material, wherein the prepared lithium rich material has controllable particle size and higher reversible capacity; and dissolving persulfate or sulfate in an amount which is 5 to 80 mass percent of the lithium rich material into deionized water, adding the lithium rich material, stirring for 2 to 100 hours at the temperature of between 25 and 80 DEG C, heating the materials to the temperature of between 100 and 500 DEG C in a muffle furnace, calcining the materials for 2 to 20 hours, fully filtering the obtained materials, and washing off impurities to obtain the surface modified anode material Li1+x-yM1-xO2. The synthesized lithium rich material has controllable particle size; the first charge / discharge efficiency of the lithium rich material and the discharge specific capacity and the cyclical stability under high magnification can be improved; and the method is simple, low in cost, convenient for operation and suitable for industrialized production.

Owner:GUANGZHOU HKUST FOK YING TUNG RES INST

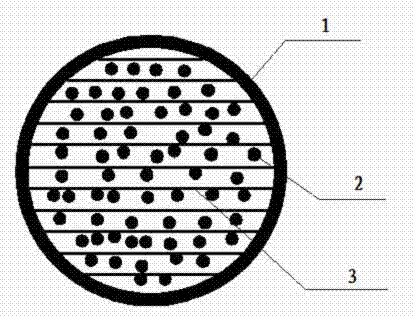

Lithium ion battery silicon carbide composite anode material and preparation method thereof

The invention discloses a lithium ion battery silicon carbide composite anode material and a preparation method thereof and aims to solve the technical problem of improving the cycling stability of a silicon carbide cathode. The lithium ion battery silicon carbide composite anode material consists of the following components in percentage by mass: 85 to 75 percent of graphite and 15 to 25 percent of silica particles, wherein the nano silica particles are dispersed on a graphite carrier to form a nuclear shell structure and are 5 to 16 mum in granularity. The preparation method comprises the following steps of: preparing a graphite dispersing agent and a silicon grinding dispersing agent; adding the silicon grinding dispersing agent into the graphite dispersing agent; and performing thermal treatment. When the method is compared with the prior art, silicon atoms are dispersed on a graphite atomic nucleus by a cation-anion charge absorption method, so that the silicon atoms can uniformly wrap the surface of the graphite, the dispersity of silicon is effectively improved in a silicon carbide composite material preparing process, the initial efficiency and the cycling stability of the silicon carbide composite anode material are improved, and a battery using the material as an anode material has relatively high safety, multiplying power performance and cycle performance.

Owner:BTR NEW MATERIAL GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com