Preparation method of complex lithium negative pole of solid state battery

A solid-state battery and lithium-composite technology, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as poor wettability and high temperature environment, battery thermal failure, easy formation of lithium metal dendrite electrode volume, etc., to achieve the carrier Rich and cheap raw materials, stable electrode volume change, and the effect of inhibiting the growth of lithium dendrites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

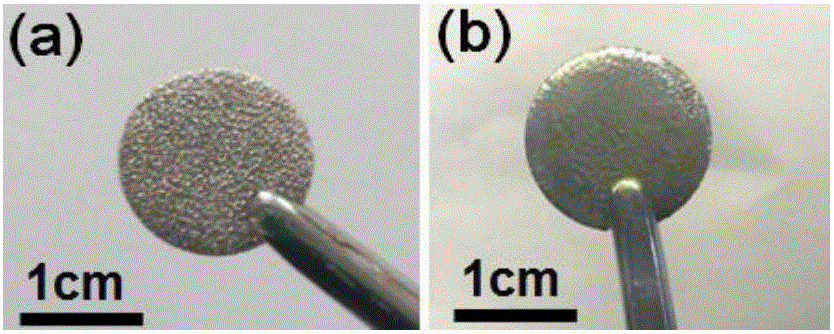

[0024] Example 1: Preparation of composite lithium negative electrode by hot melt infusion method using nickel foam as carrier

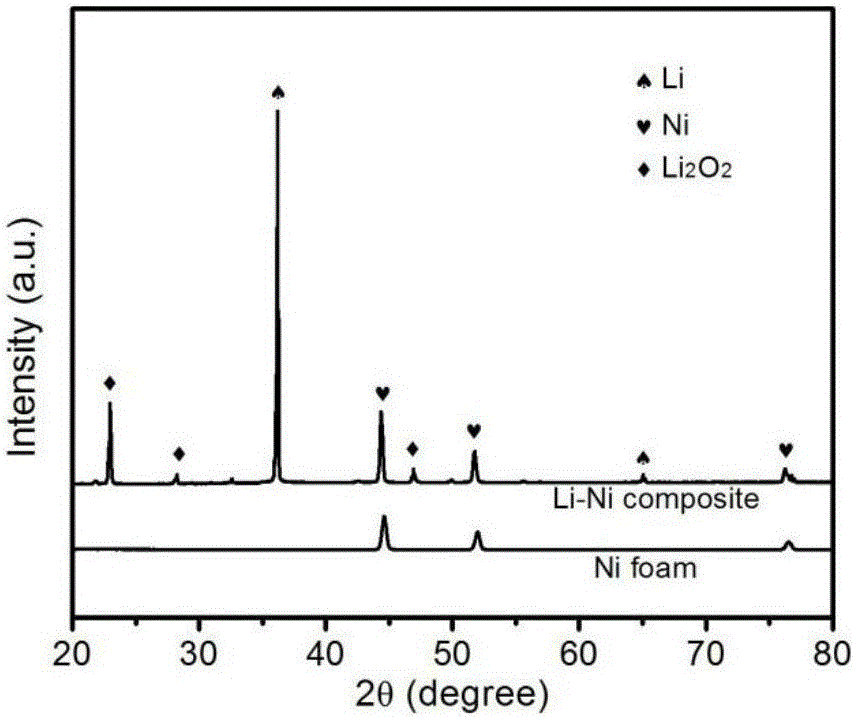

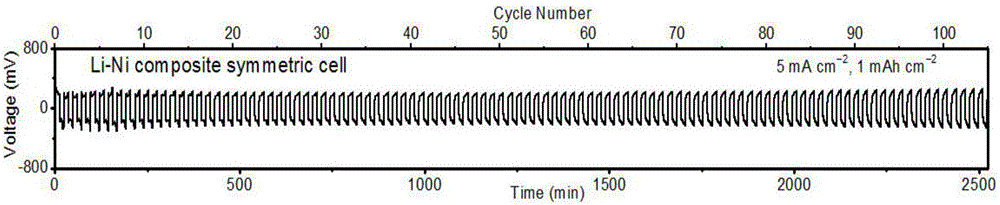

[0025] The steps of preparing the composite lithium negative electrode with nickel foam as the carrier are mainly divided into two steps. The first step is to punch and prepare the foam nickel with the size of the electrode sheet, and then use acetone, ethanol, and deionization to sonicate for 10 minutes, and finally place it in a freeze dryer for vacuum Drying; in the second step, set the temperature of the hot-melted lithium sheet to 700°C, completely melt the lithium sheet into a lithium metal liquid, and then put the foamed nickel electrode sheet prepared in the first step into the metal lithium liquid until it is completely infiltrated , and finally take out and naturally cool to form a composite lithium negative electrode. in, figure 1 The photo shown in a is the nickel foam electrode sheet prepared in the first step, figure 1 The photo shown...

Embodiment 2

[0027] Example 2: Preparation of composite lithium negative electrode by hot melt infusion method with copper foam as carrier

[0028] The steps of preparing the composite lithium negative electrode with copper foam as the carrier are mainly divided into two steps. The first step is to punch and prepare the foam copper with the size of the electrode sheet, and then use acetone, ethanol, and deionization to sonicate for 10 minutes, and finally place it in a freeze dryer for vacuum Drying; in the second step, set the temperature of the hot-melted lithium sheet to 500°C, completely melt the lithium sheet into a lithium metal liquid, and then put the foamed copper electrode sheet prepared in the first step into the metal lithium liquid until it is completely infiltrated , and finally take out and naturally cool to form a composite lithium negative electrode. The composite negative electrode was assembled into a solid-state symmetrical battery. Electrochemical tests showed that at ...

Embodiment 3

[0029] Example 3: Preparation of composite lithium negative electrode by hot melt infusion method using foamed carbon as carrier

[0030]The steps of preparing the composite lithium negative electrode with foamed carbon as the carrier are mainly divided into two steps. The first step is to punch and prepare the foamed carbon with the size of the electrode sheet, then use ethanol and deionization to sonicate for 10 minutes, and finally place it in a freeze dryer for vacuum drying; In the second step, set the temperature of the hot-melted lithium sheet to 300°C, completely melt the lithium sheet into a lithium metal liquid, and then put the foamed carbon electrode sheet prepared in the first step into the metal lithium liquid until it is completely infiltrated, and finally Take out and cool naturally to form a composite lithium negative electrode. The composite negative electrode was assembled into a solid-state symmetrical battery. Electrochemical tests showed that at a certain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com