Patents

Literature

487 results about "Nickel electrode" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

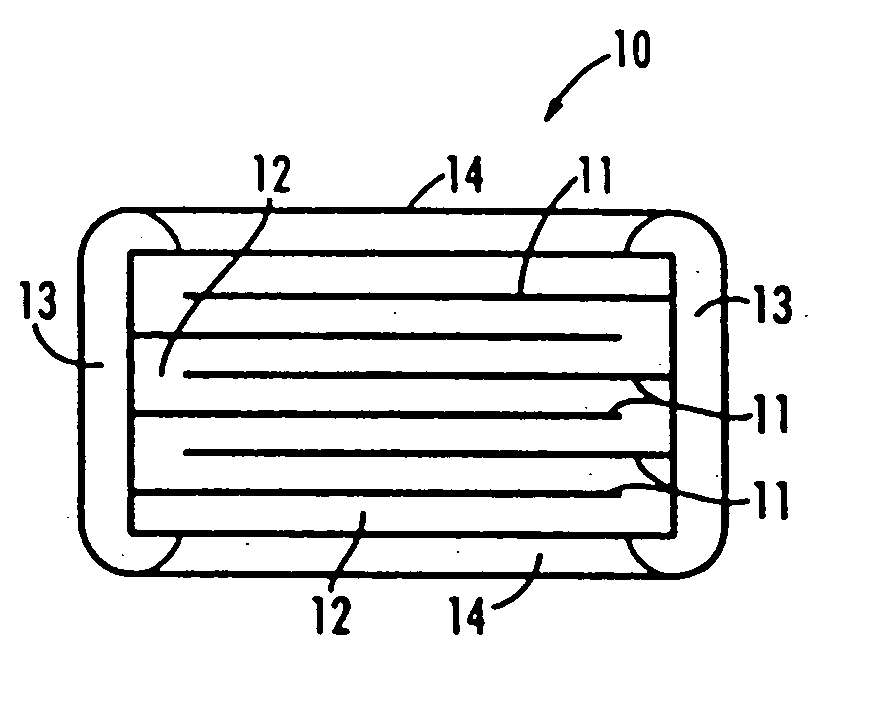

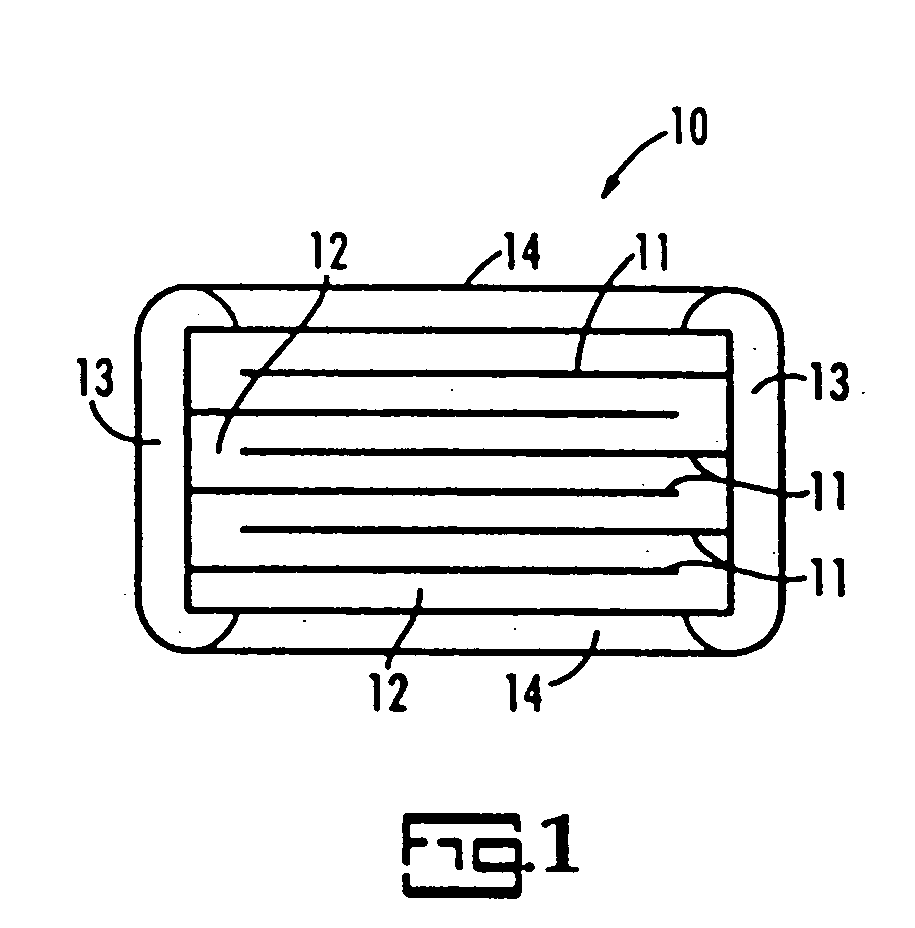

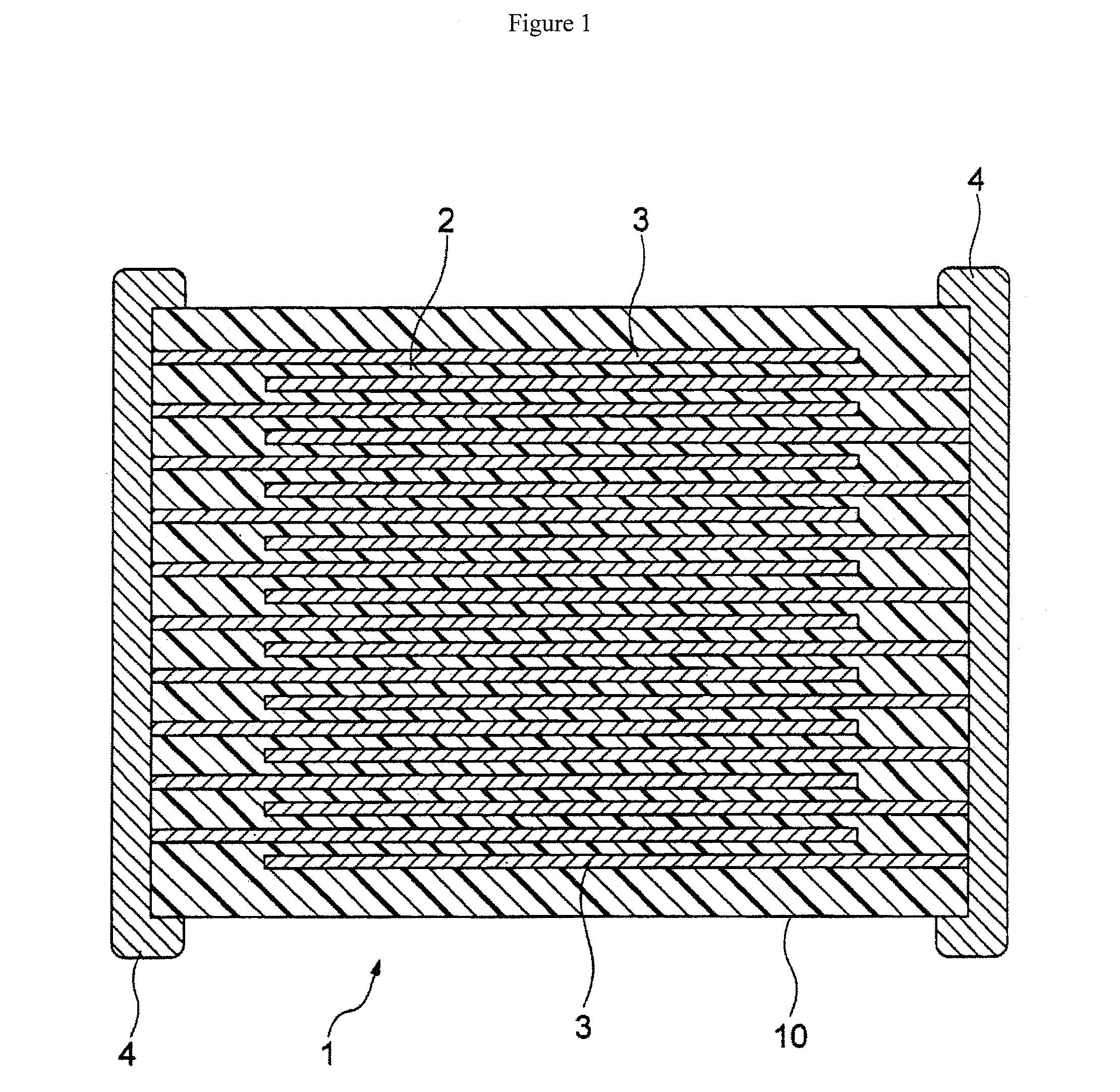

Electrical-energy-storage unit (EESU) utilizing ceramic and integrated-circuit technologies for replacement of electrochemical batteries

InactiveUS7033406B2Reduce sinteringLowering hot-isostatic-pressing temperatureElectrical storage systemFixed capacitor electrodesBarium titanatePermittivity

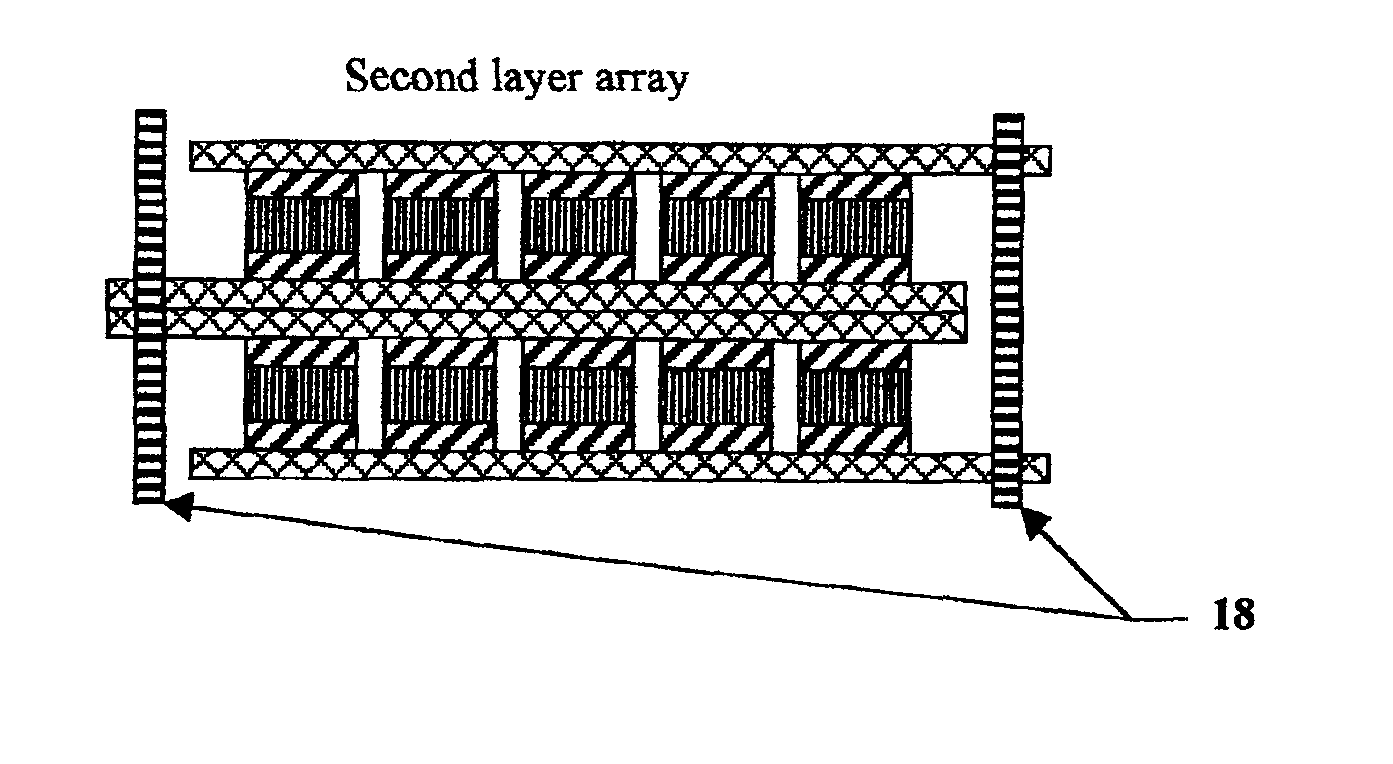

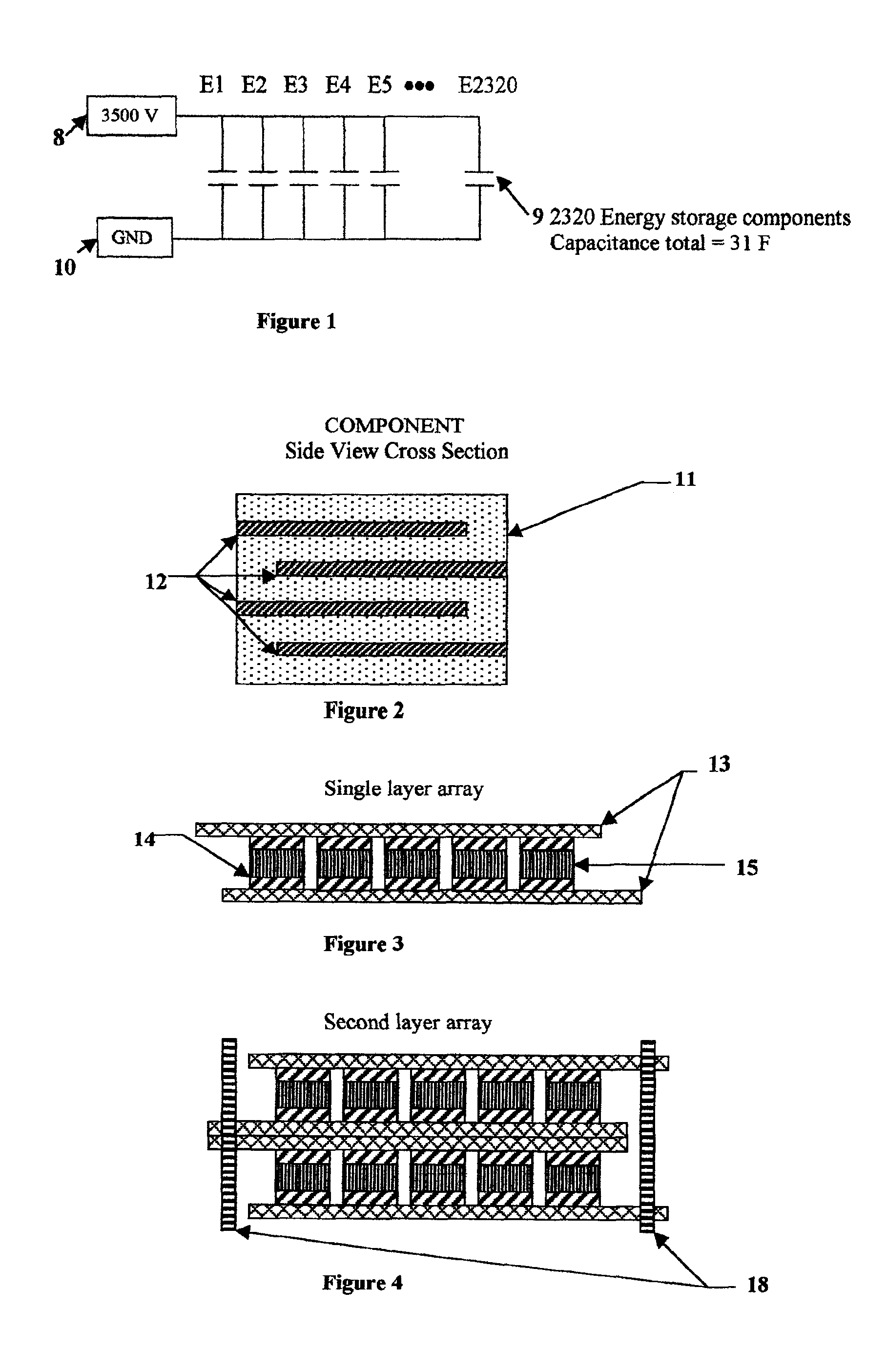

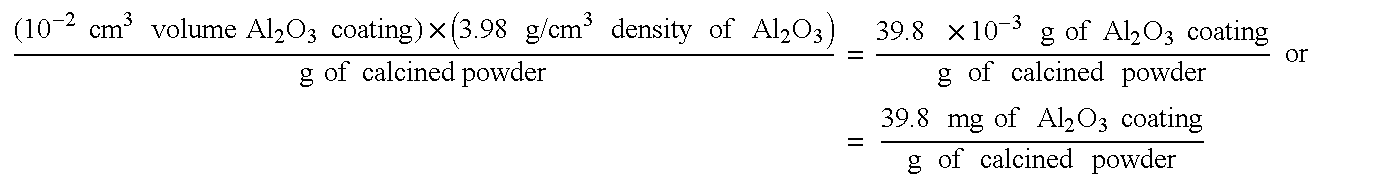

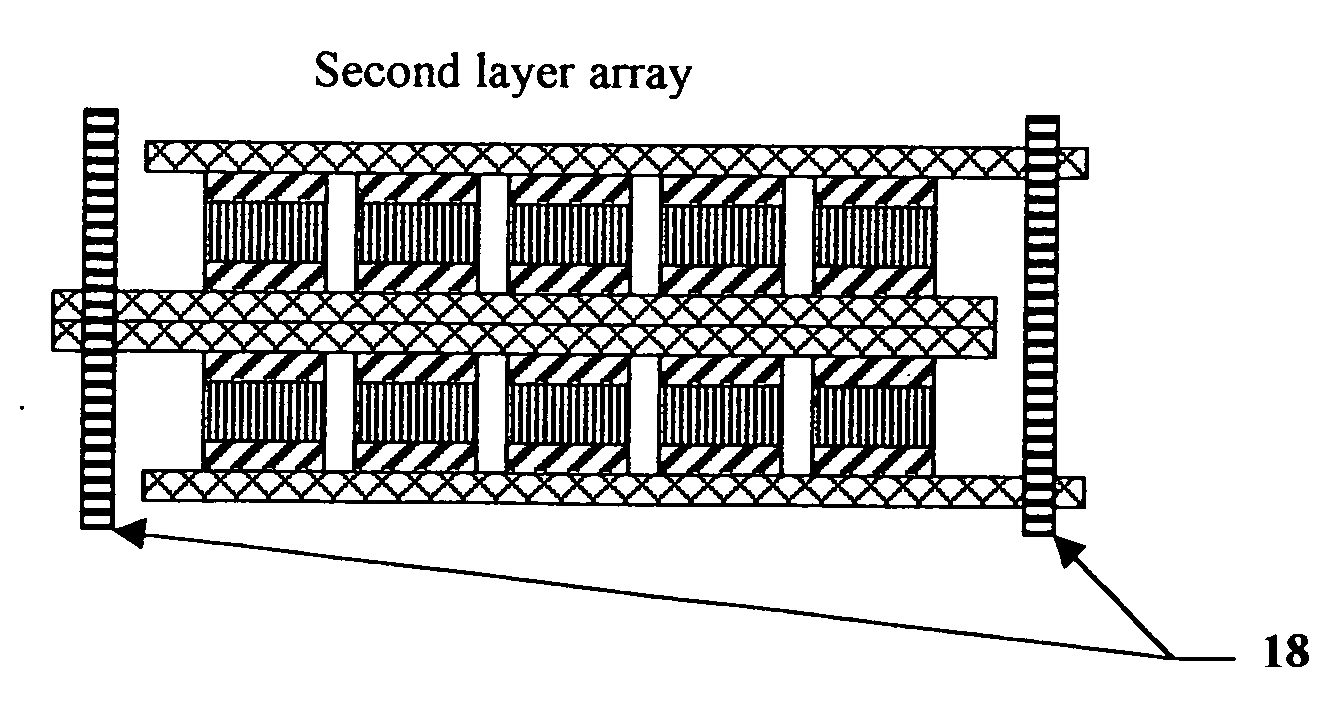

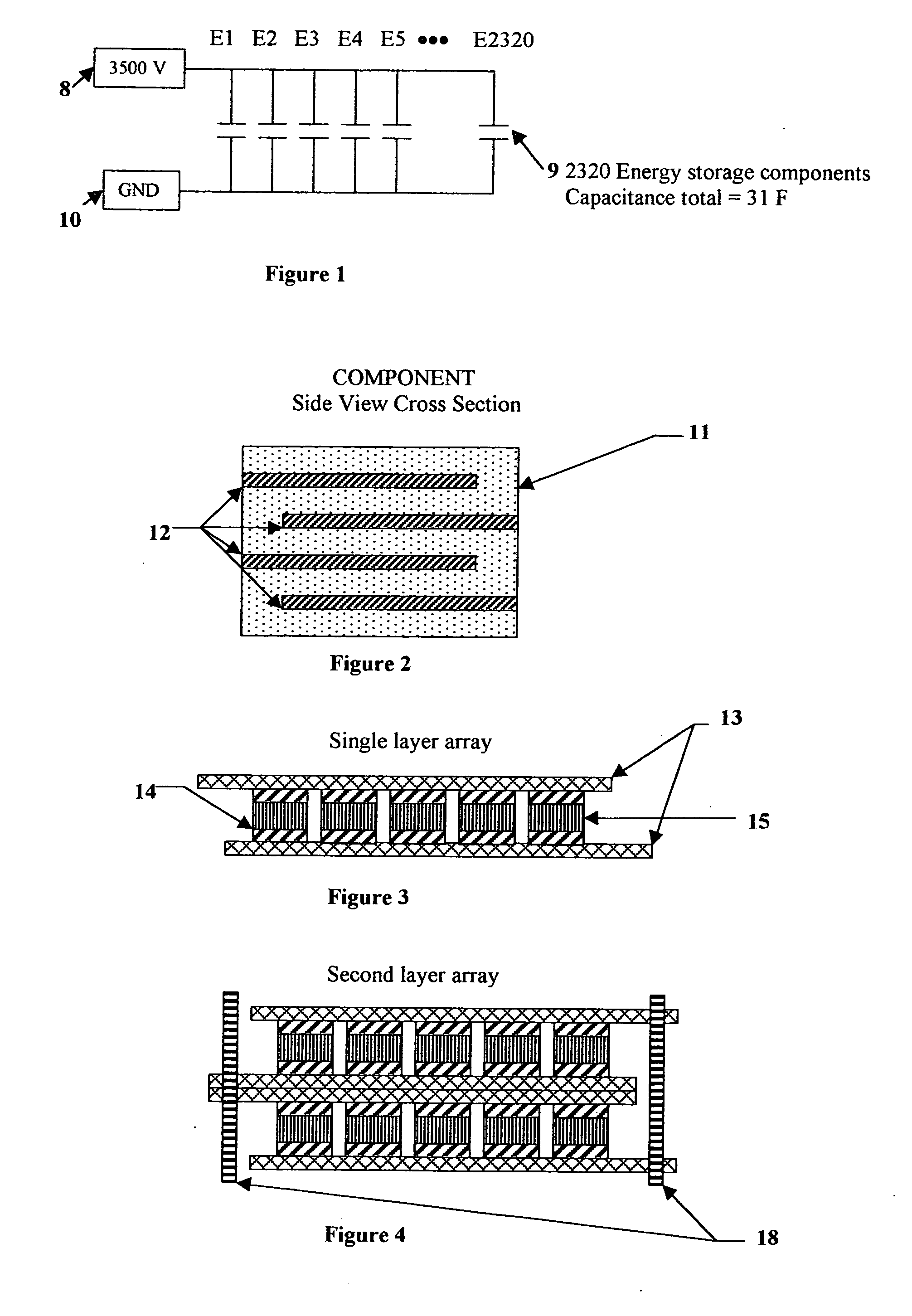

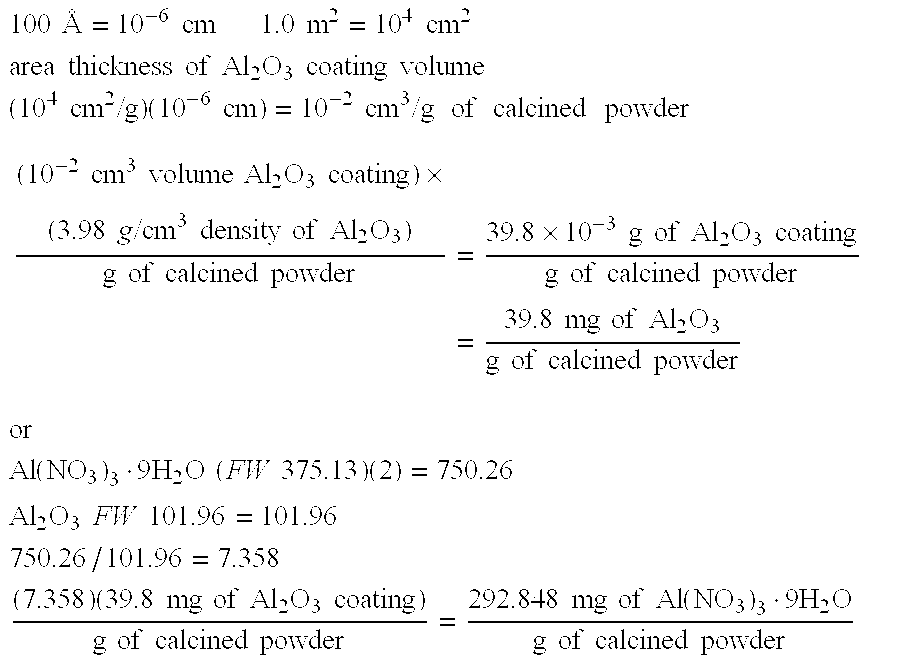

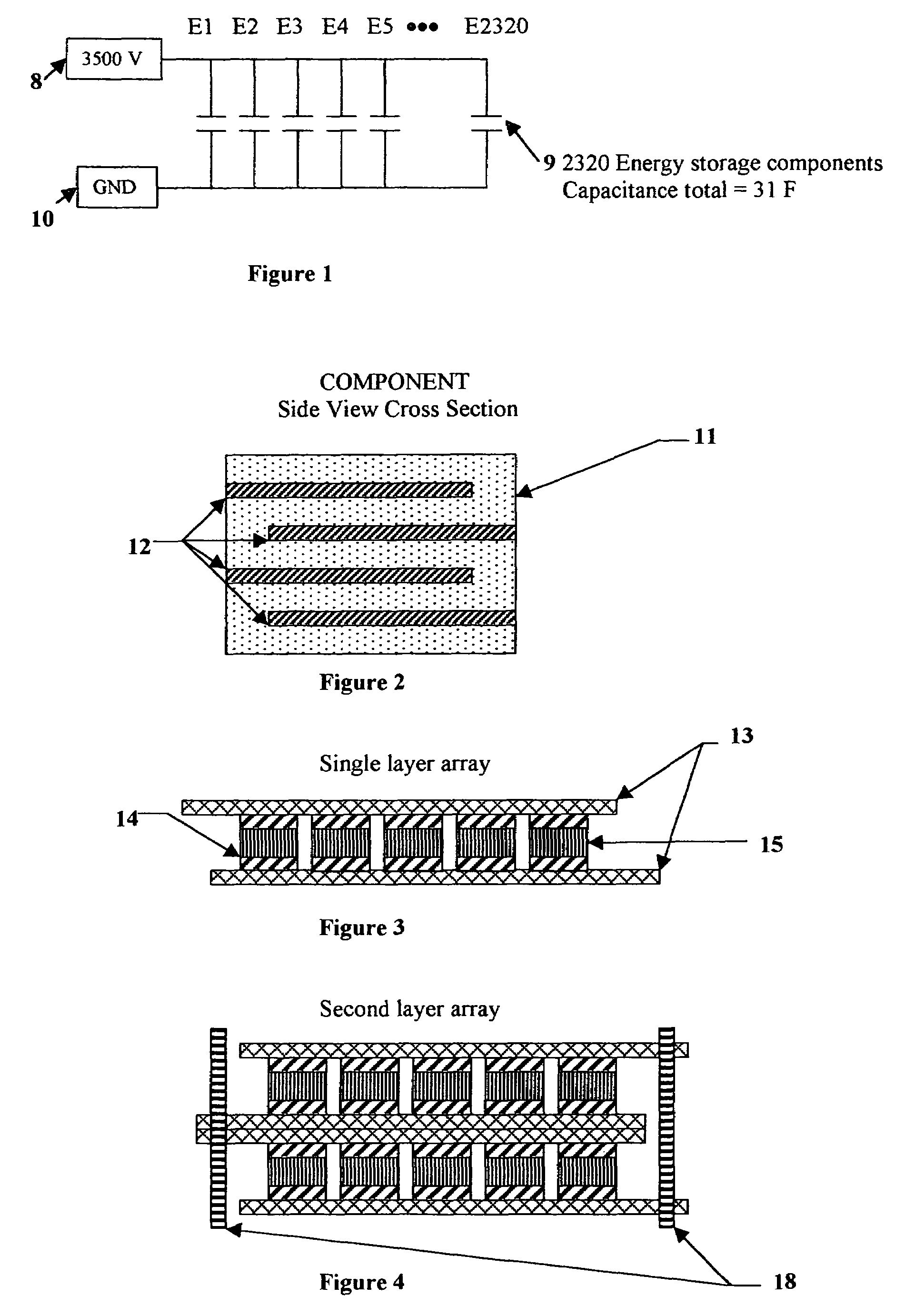

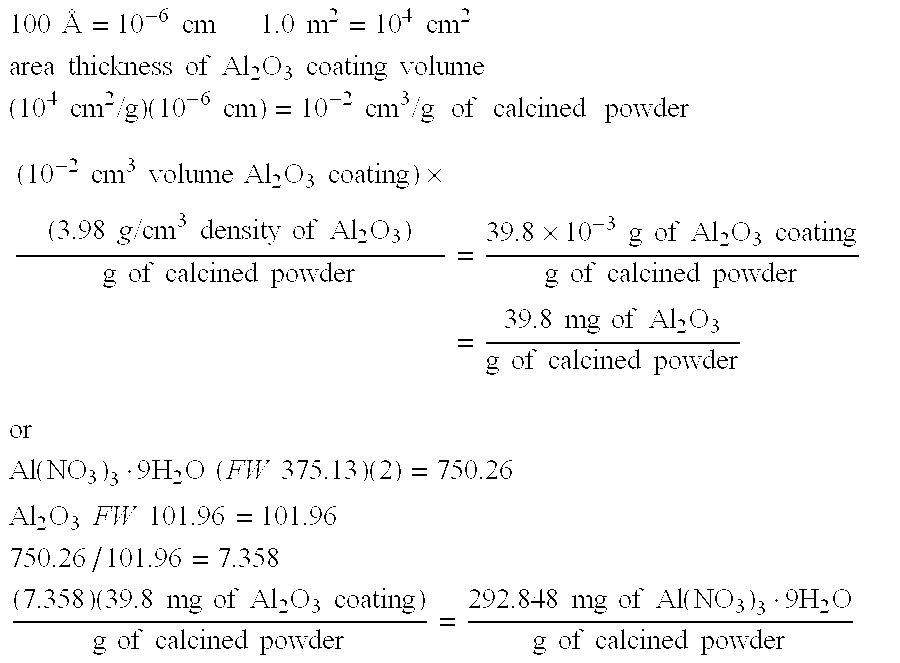

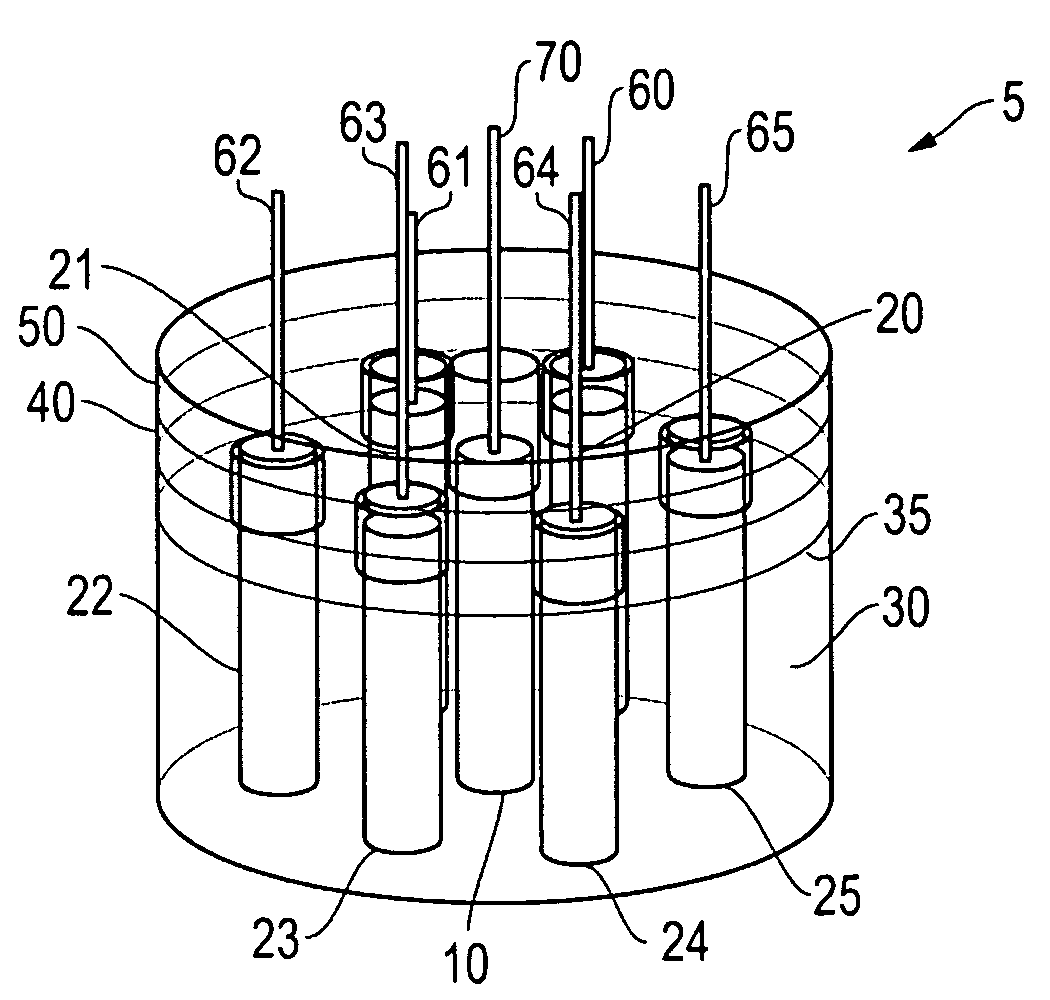

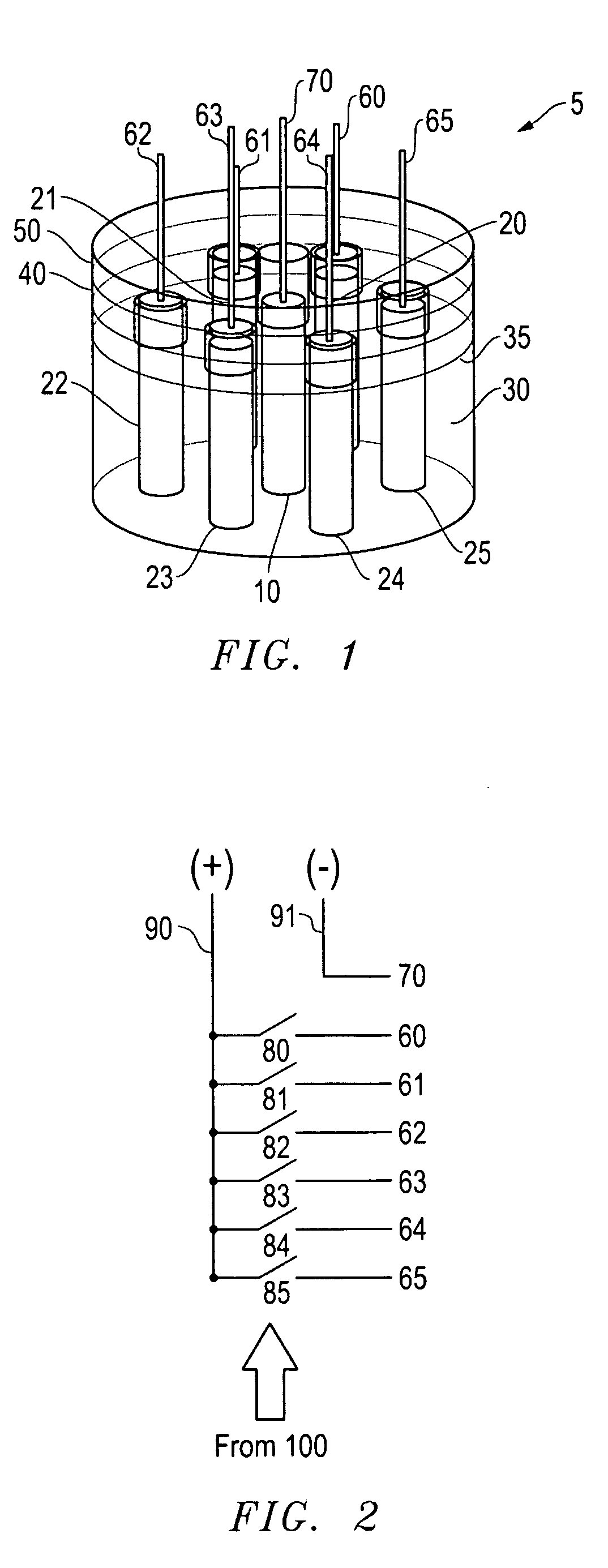

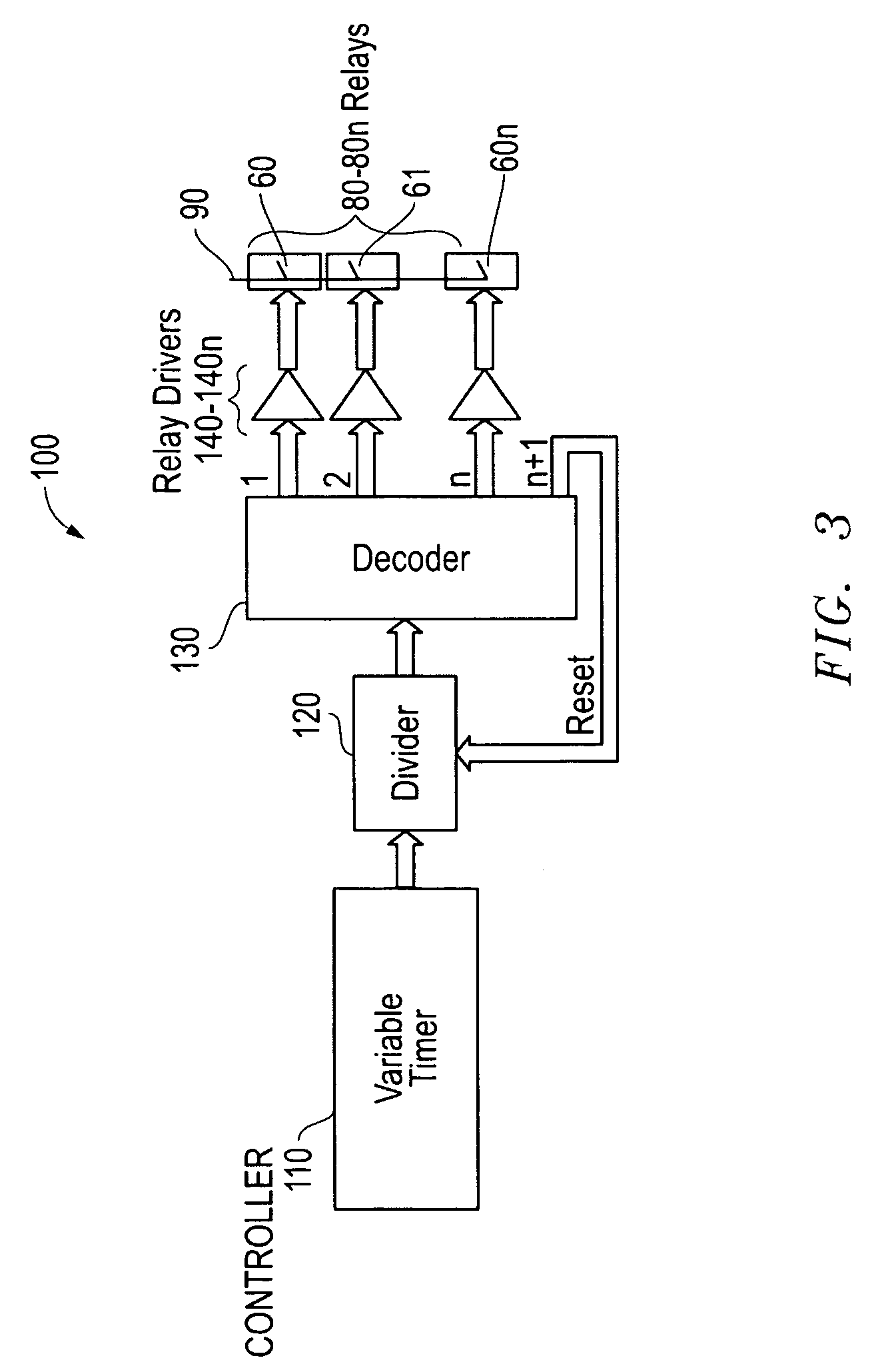

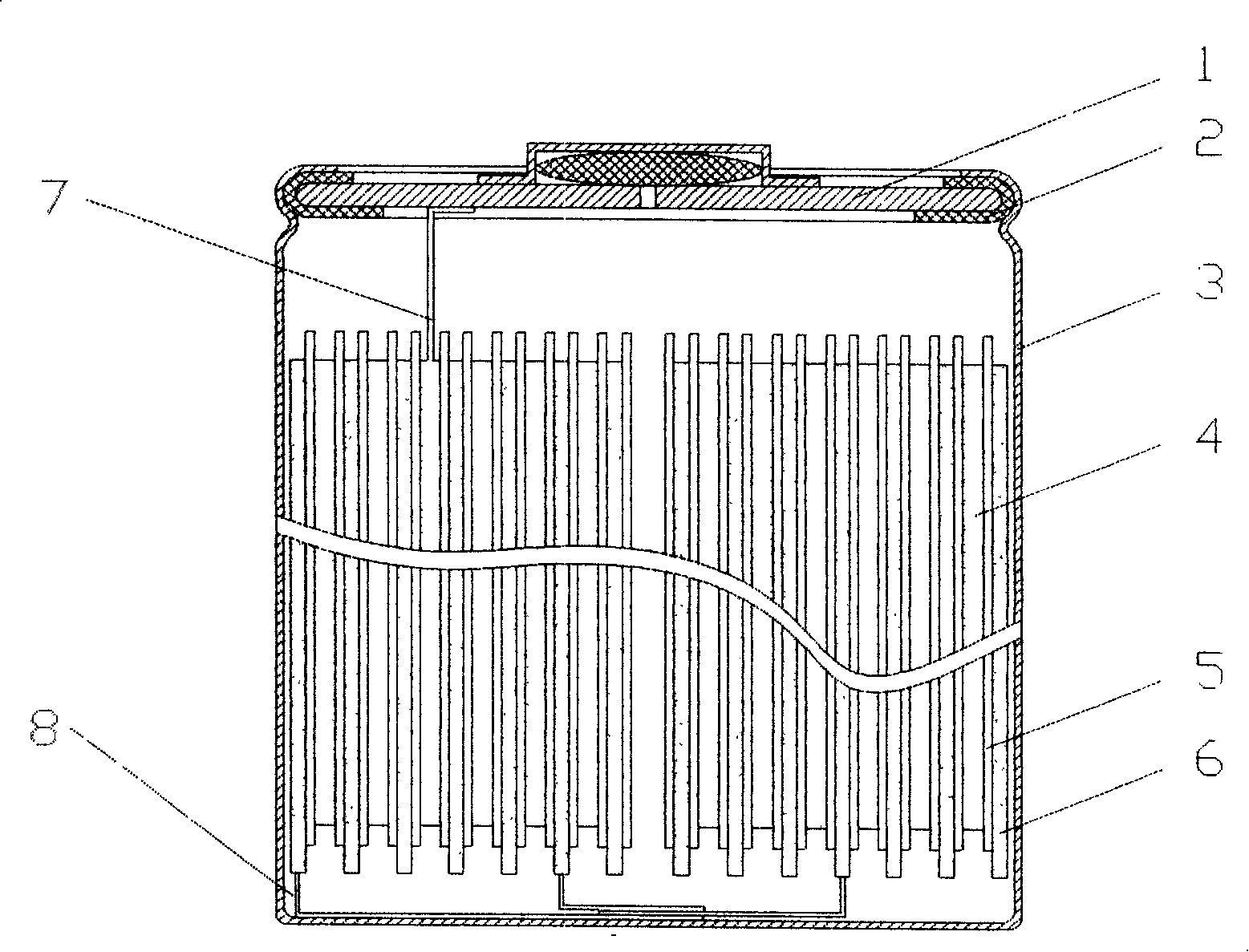

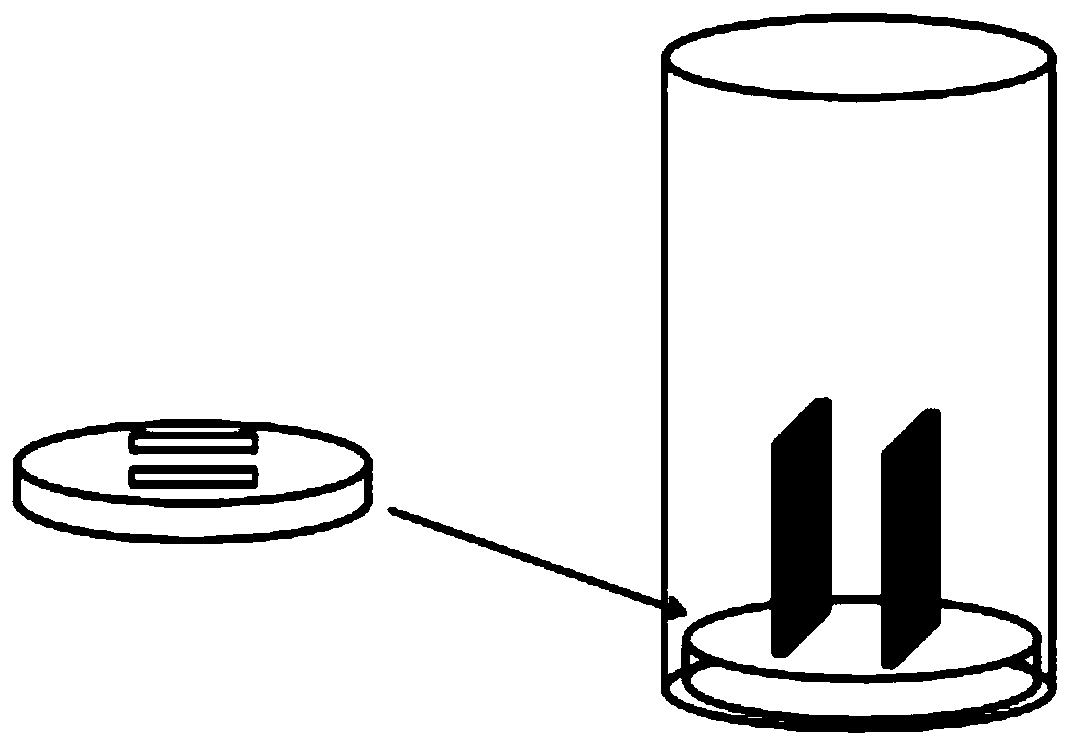

An electrical-energy-storage unit (EESU) has as a basis material a high-permittivity composition-modified barium titanate ceramic powder. This powder is double coated with the first coating being aluminum oxide and the second coating calcium magnesium aluminosilicate glass. The components of the EESU are manufactured with the use of classical ceramic fabrication techniques which include screen printing alternating multilayers of nickel electrodes and high-permittivitiy composition-modified barium titanate powder, sintering to a closed-pore porous body, followed by hot-isostatic pressing to a void-free body. The components are configured into a multilayer array with the use of a solder-bump technique as the enabling technology so as to provide a parallel configuration of components that has the capability to store electrical energy in the range of 52 kW·h. The total weight of an EESU with this range of electrical energy storage is about 336 pounds.

Owner:EESTOR

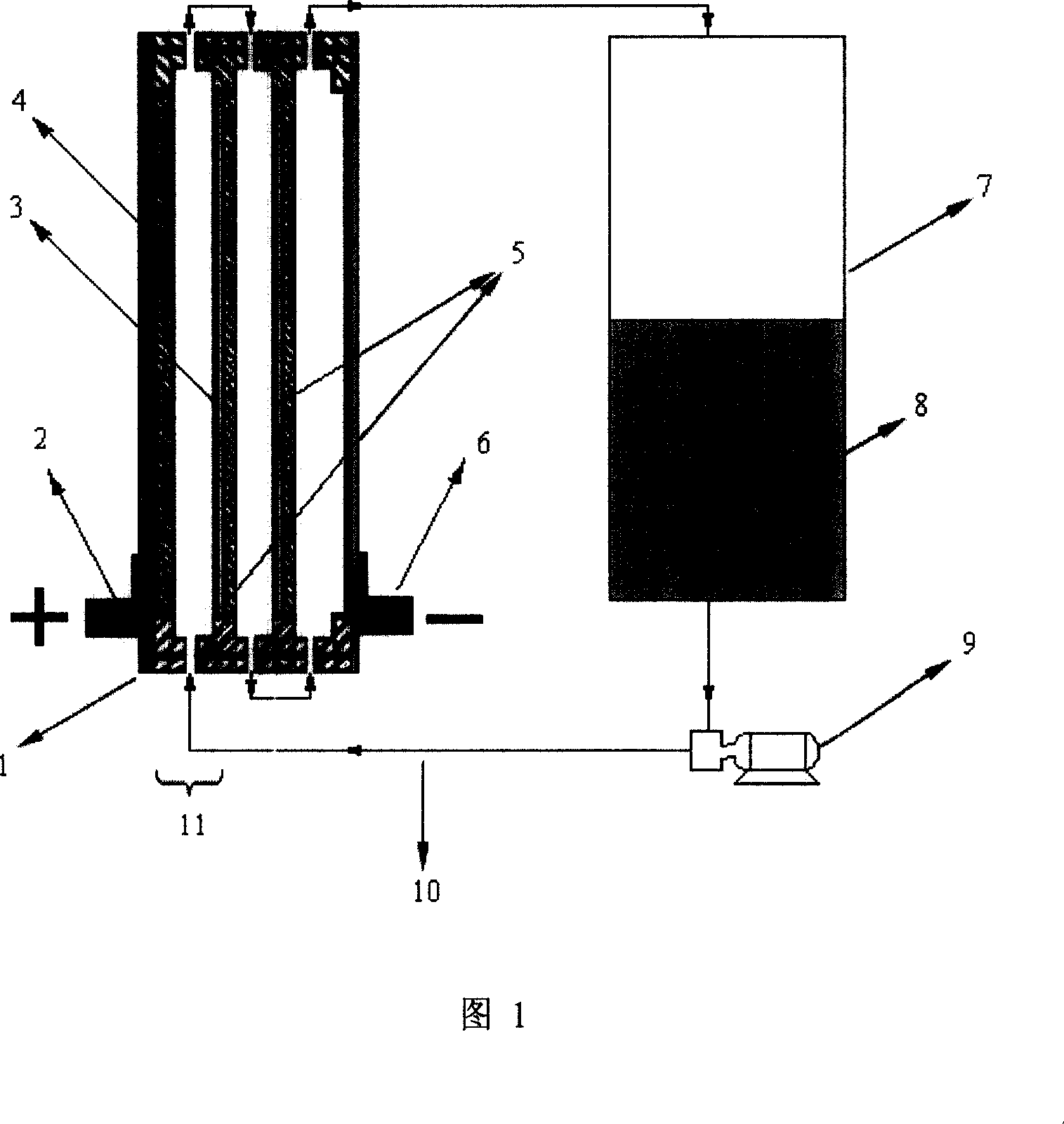

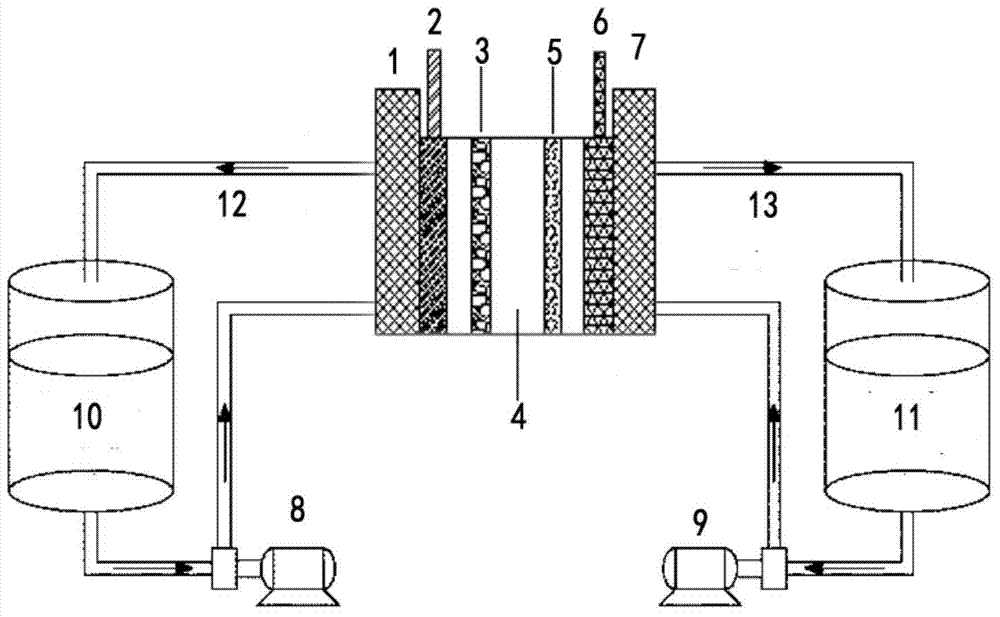

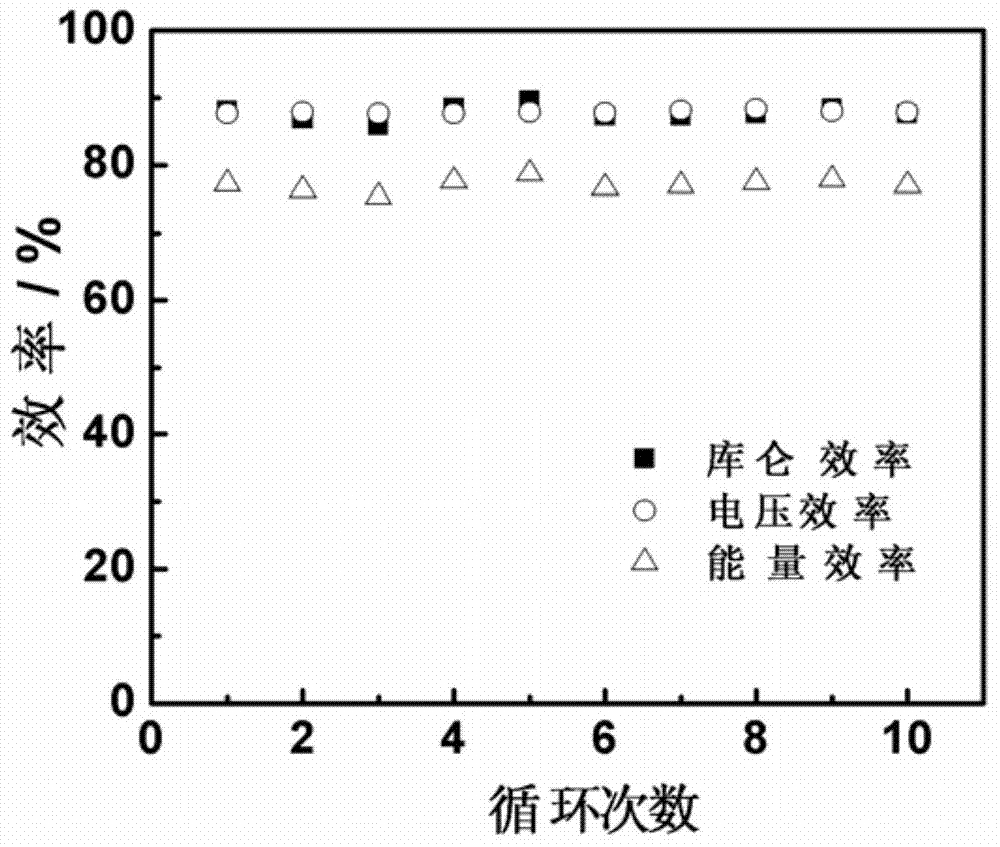

A Zn-Ni liquid battery

ActiveCN101127393AIncrease transfer speedDetoxificationElectrolyte moving arrangementsAlkaline accumulatorsEngineeringNickel electrode

The utility model relates to a zinc-nickel sap fluid cell, which comprises a galvanic pile which is a multi-section series connection of cell monomers, electrolyte, a storage tank, a liquid pump and a plurality of pipelines; wherein, the cell monomer comprises a nickel electrode anode, a cathode current collector of deposit zinc, and electrolyte; wherein, the electrolyte is a zincous alkaline solution, and two cell monomers are connected in series via a bipolar plate. In the process of charge and discharge, the electrolyte continuously flows between the storage tank and the galvanic pile via the pipelines driven by the liquid pump. Zinc settles onto the cathode current collector and becomes a cathode active substance from the electrolyte at the time of charging, while zinc dissolves into the electrolyte from the cathode current collector at the time of discharging. The utility model has the advantages of simple fabrication technology, low cost, high cycle life and other advantages.

Owner:NO 63971 TROOPS PLA +1

Electrical-energy-storage unit (EESU) utilizing ceramic and integrated-circuit technologies for replacement of electrochemical batteries

InactiveUS20060210779A1Fast chargingSolution to short lifeStacked capacitorsPrimary cellsBarium titanateElectrical battery

An electrical-energy-storage unit (EESU) has as a basis material a high-permittivity composition-modified barium titanate ceramic powder. This powder is double coated with the first coating being aluminum oxide and the second coating calcium magnesium aluminosilicate glass. The components of the EESU are manufactured with the use of classical ceramic fabrication techniques which include screen printing alternating multilayers of nickel electrodes and high-permittivitiy composition-modified barium titanate powder, sintering to a closed-pore porous body, followed by hot-isostatic pressing to a void-free body. The components are configured into a multilayer array with the use of a solder-bump technique as the enabling technology so as to provide a parallel configuration of components that has the capability to store electrical energy in the range of 52 kW·h. The total weight of an EESU with this range of electrical energy storage is about 336 pounds.

Owner:EESTOR

Super lead carbon battery with active carbon negative electrode and preparation method thereof

InactiveCN101764263AAlleviate salinizationImprove low temperature performanceFinal product manufactureLead-acid accumulator electrodesSulfationActivated carbon

The invention discloses a super lead carbon battery with an active carbon negative electrode and a preparation method thereof. The negative electrode of the supper lead carbon battery comprises the active carbon negative electrode and a lead negative electrode which are internally parallel. A positive electrode of the battery adopts PbO2 as an active substance. A separator adopts an AGM diaphragm. Electrolyte adopts 1.0-1.4g / cm<3> sulfuric acid. By introducing the active carbon negative electrode into the lead negative electrode in parallel internally to act as the active substance, the invention can greatly promote the charge acceptance ability of the negative electrode, effectively improve the low temperature property of the super lead carbon battery, and greatly mitigate sulfation phenomenon in the negative electrode, so that the deep-cycle life can reach more than 1,800 times. Compared with cost of an inorganic system carbon-carbon symmetric mode and a nickel electrode-carbon mixed alkali system, the invention can greatly reduce the material cost of products. Compared with a traditional lead-acid battery, the invention can greatly prolong recycling lifetime of products and have obvious performance price ratio advantage.

Owner:NANJING SHUANGDENG SCI TECH DEV RES INST

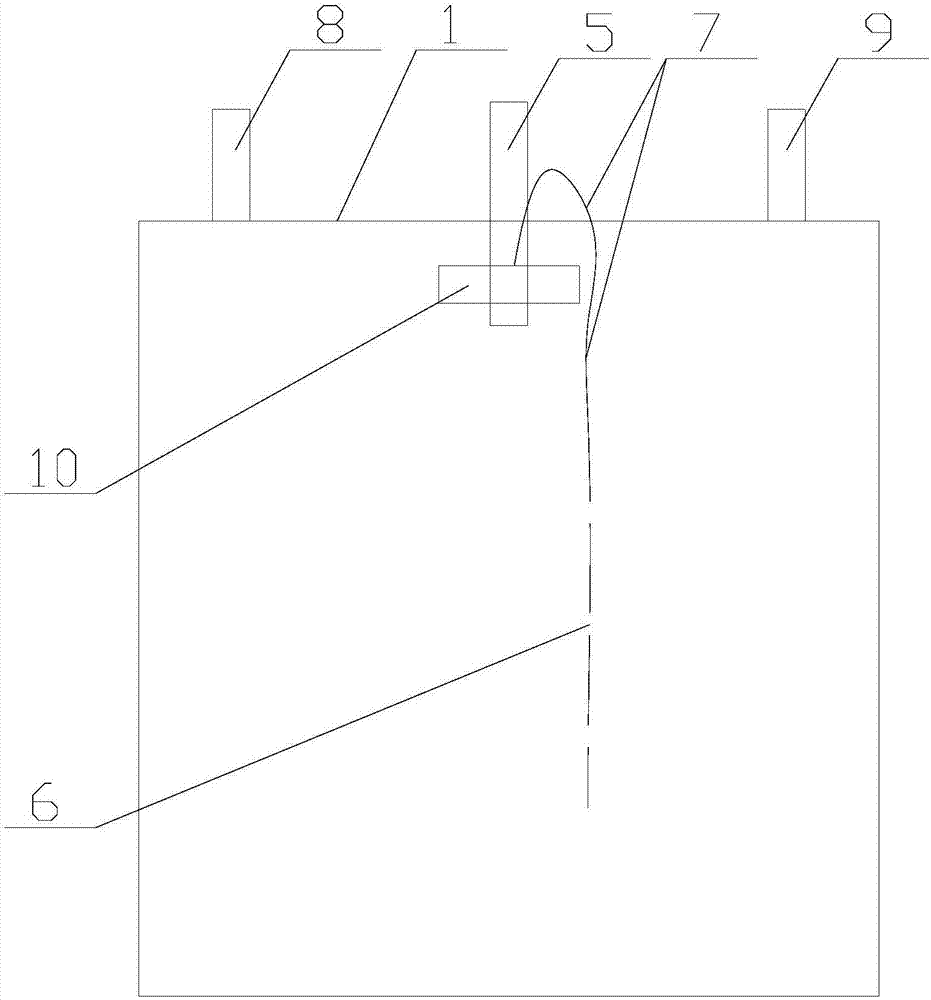

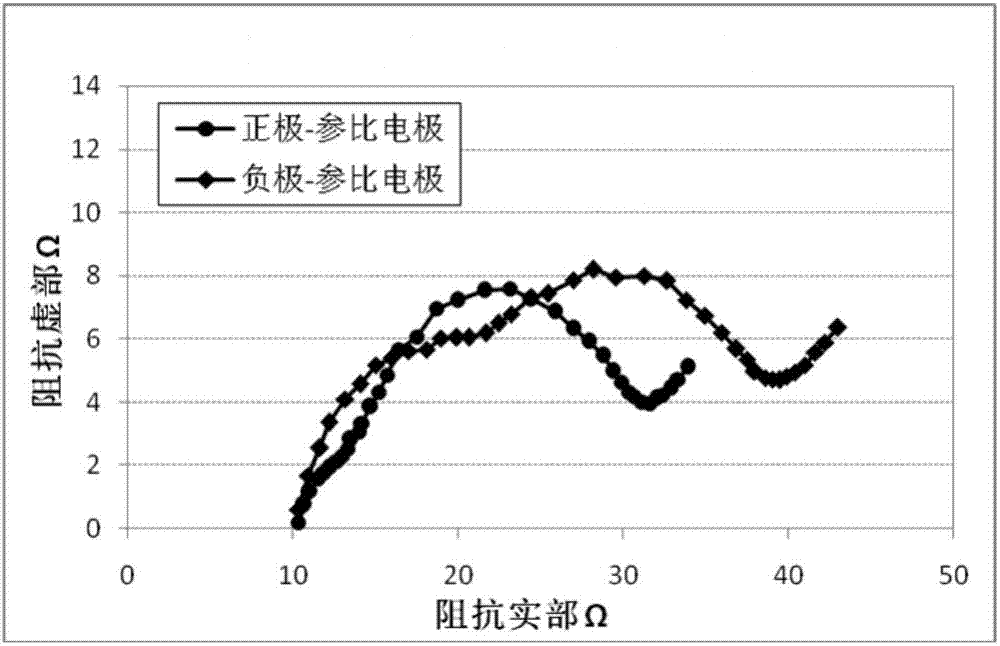

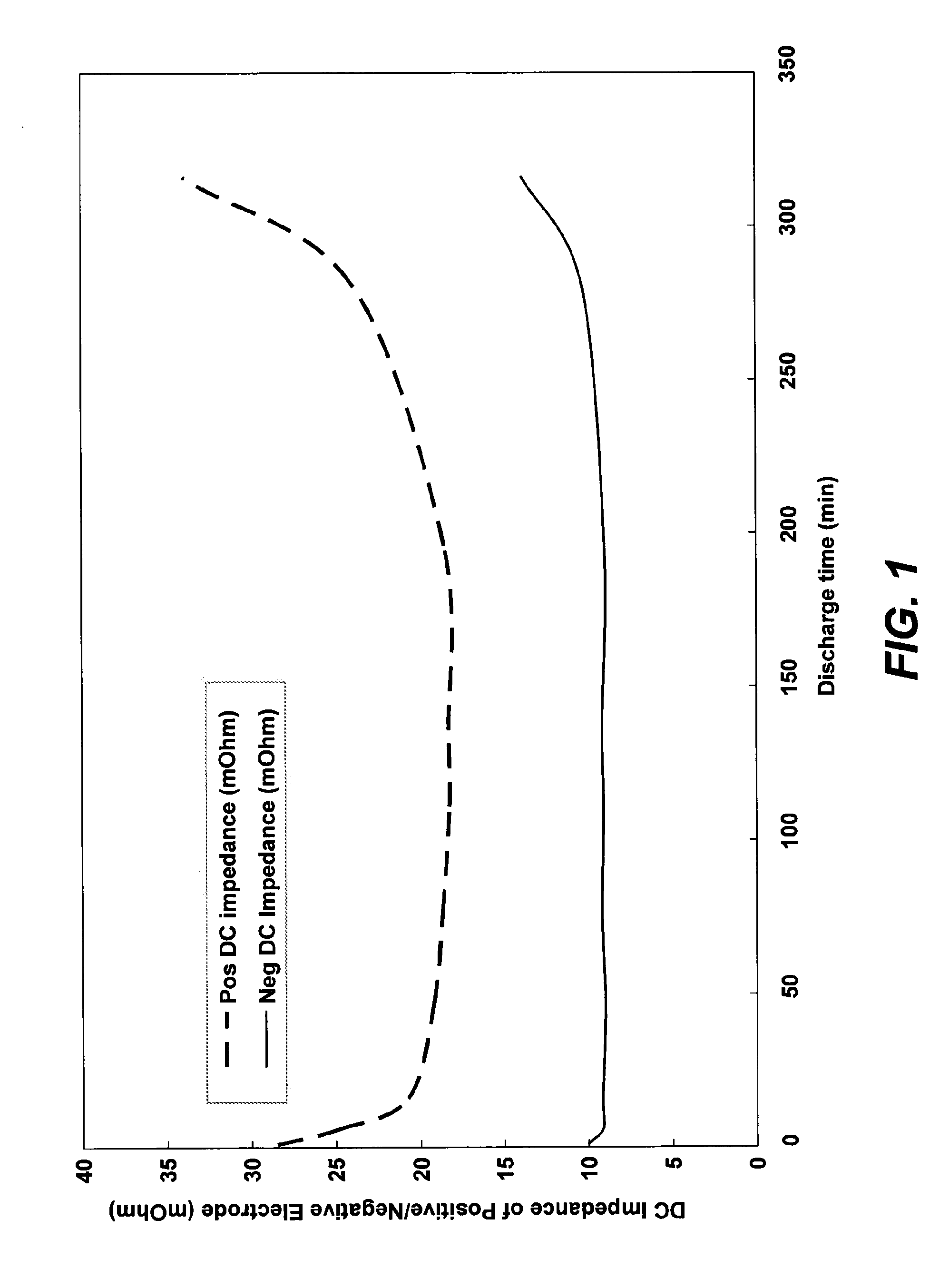

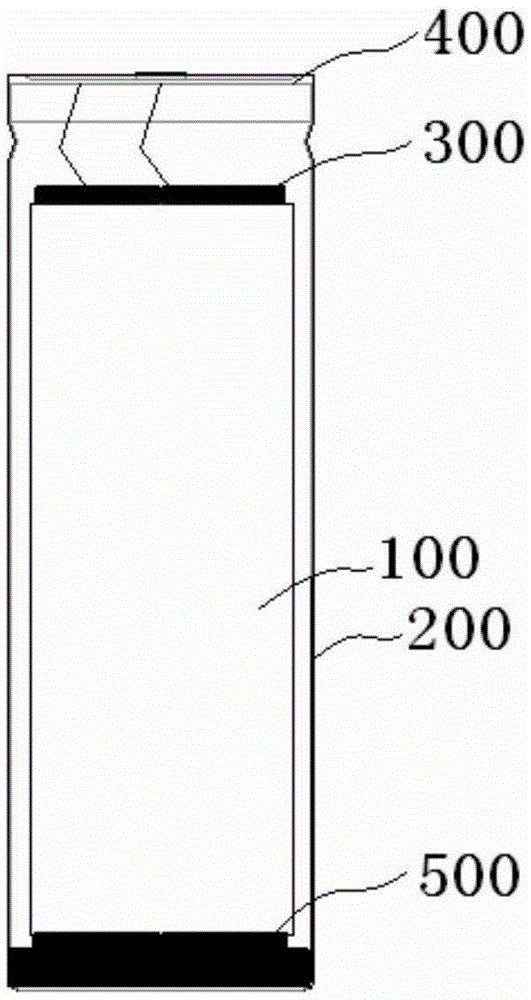

Three-electrode battery and manufacturing method thereof

PendingCN107293778AGuaranteed normal transmissionAdvancing Lifespan ResearchFinal product manufactureElectrolyte accumulators manufactureCopper wireEngineering

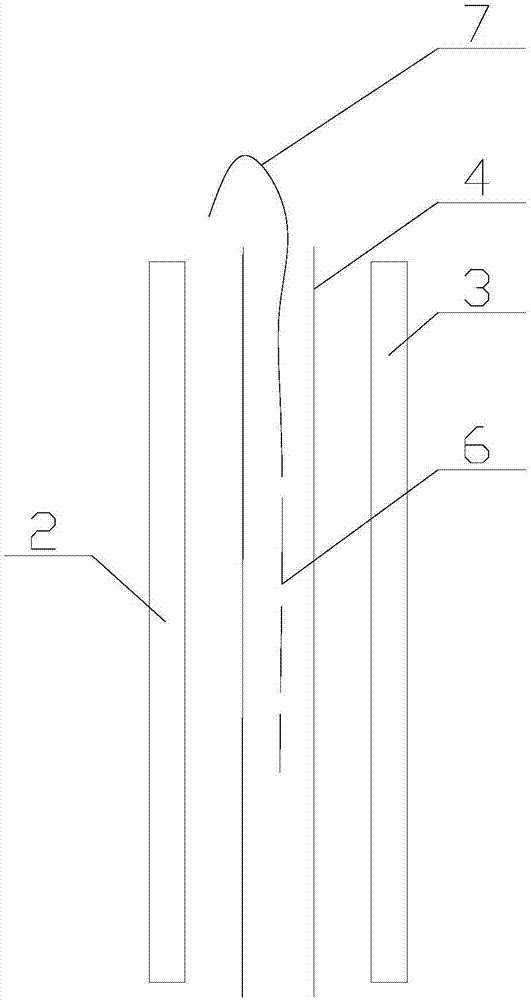

The invention discloses a three-electrode battery. The three-electrode battery comprises an outer shell, a positive electrode, a negative electrode, diaphragms, electrolyte, a reference electrode and a nickel electrode lug; the reference electrode is arranged between the positive electrode and the negative electrode; the diaphragms are arranged respectively between the positive electrode and the reference electrode and between the reference electrode and the negative electrode; the whole three-electrode battery is packaged in the outer shell; and the outer shell is filled with the electrolyte. One end of the reference electrode is a naked copper wire which is completely arranged between the positive electrode and the negative electrode, and the three electrodes are subjected to lithium plating before an AC impedance test; the other end of the reference electrode is a varnished wire; one portion of the varnished wire is immerged in the electrolyte, and the other portion of the varnished wire is located outside the positive electrode and the negative electrode and extends to the outer side of the outer shell to be connected with the nickel electrode lug; and the nickel electrode lug is fixed with the outer shell. The invention also discloses a preparation method of the three-electrode battery. The three-electrode battery has the advantages that the signal interference resistance is strong, the manufacturing cost is low, transmission of the lithium ions between the positive electrode and the negative electrode is guaranteed, in-situ monitoring for the electric potential of the positive electrode, the electric potential of the negative electrode and the impedance of the lithium ion battery in a use process is carried out, the detection accuracy is improved obviously, and the detection efficiency is improved.

Owner:ETRUST POWER ETP GRP LTD

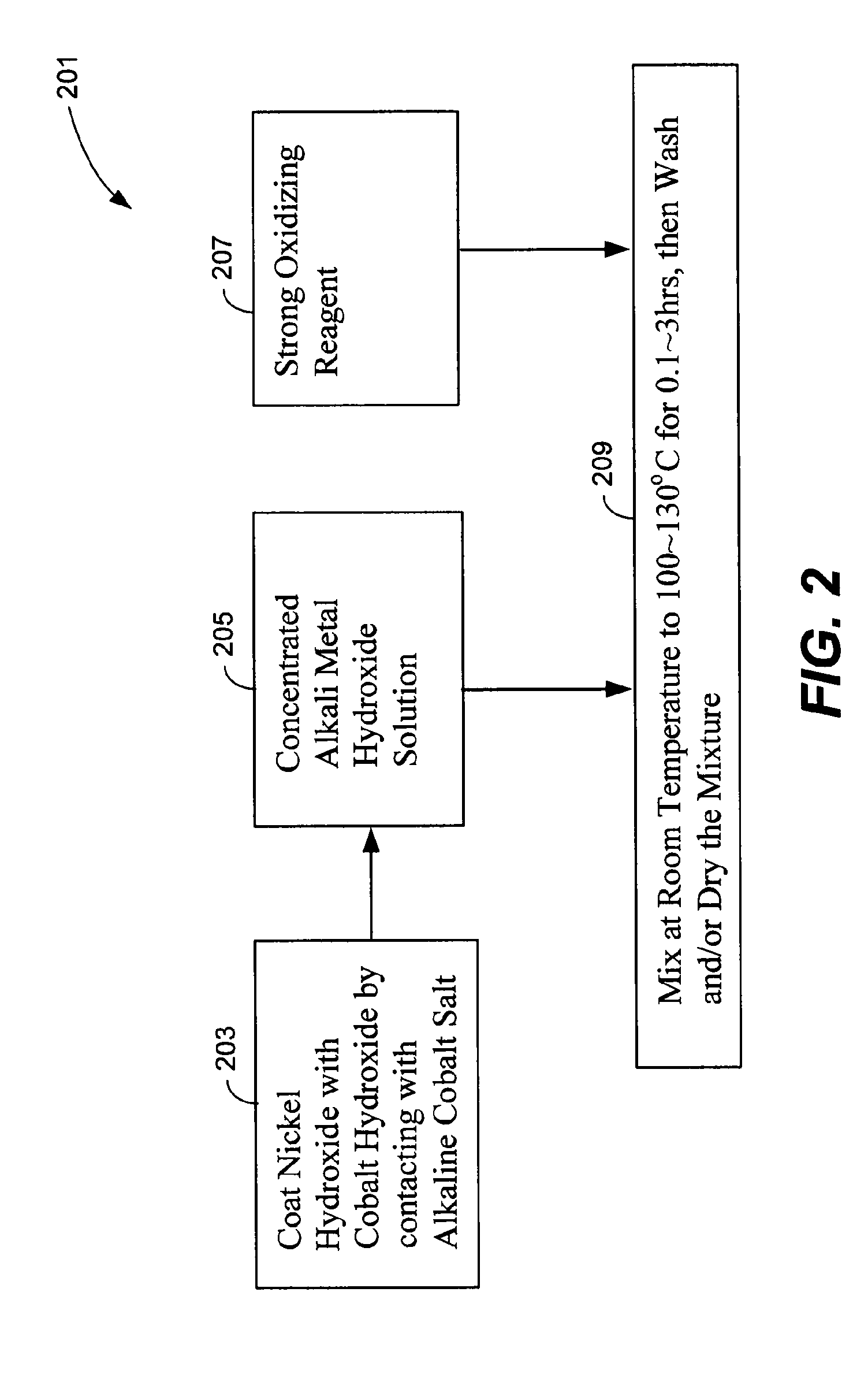

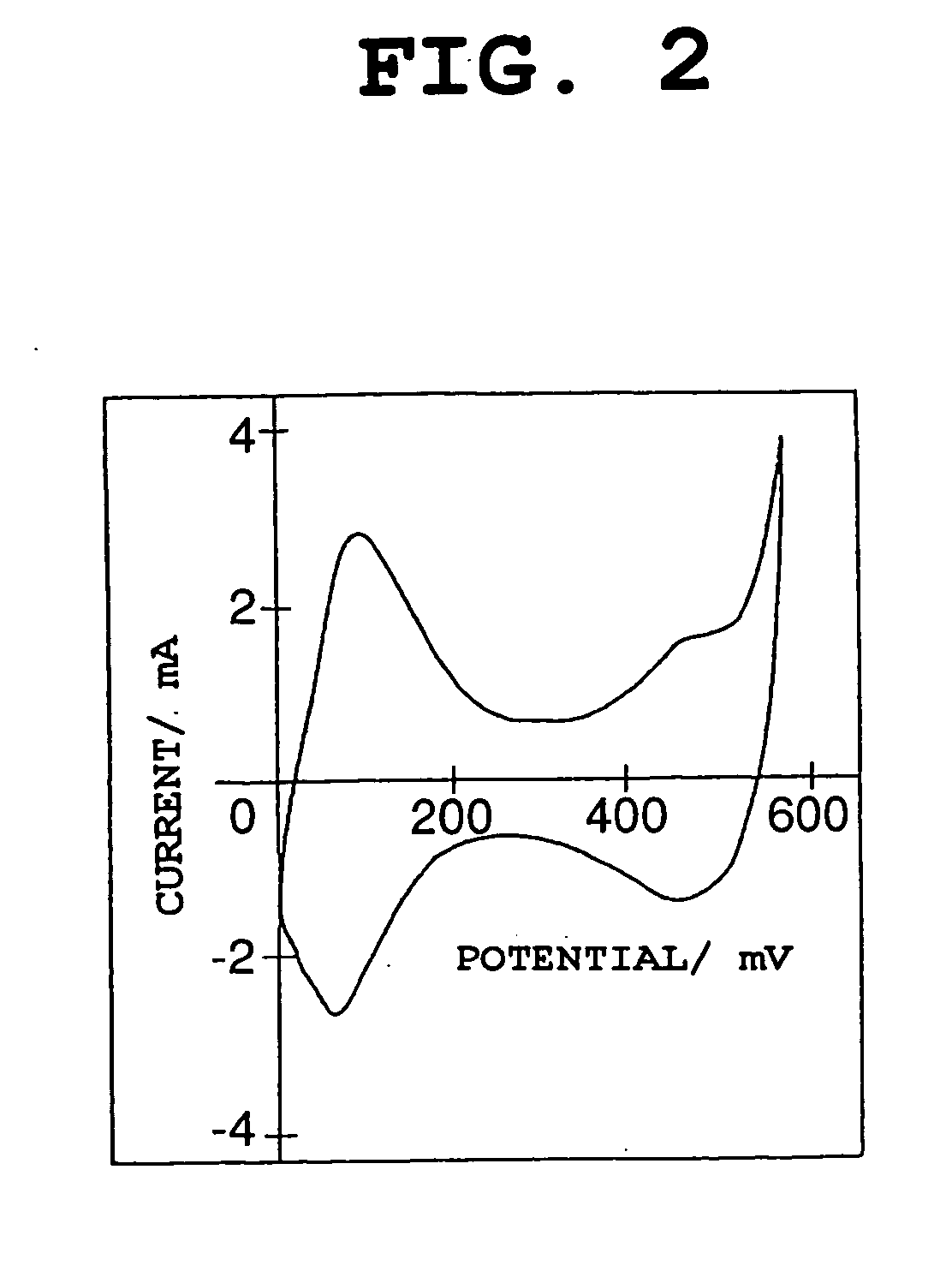

Nickel hydroxide electrode for rechargeable batteries

ActiveUS20090208839A1Facilitate interface reactionImprove reliabilityMaterial nanotechnologyHybrid capacitor electrodesPotassium persulfateNickel oxide hydroxide

The nickel hydroxide particles for a nickel hydroxide electrode may be treated using an alkaline solution of a strong oxidizing agent such as sodium or potassium persulfate to modify the surface nickel hydroxide structure. The resulting modified surface structure has been found to impart various benefits to electrodes formed from the nickel hydroxide. It is believed that the oxidation of cobalt compounds at the surface of the nickel hydroxide particles results in a highly conductive cobalt compound that plays an important role in the high reliability, high stability and high capacity utilization of nickel electrodes as described herein.

Owner:ZINCFIVE POWER INC

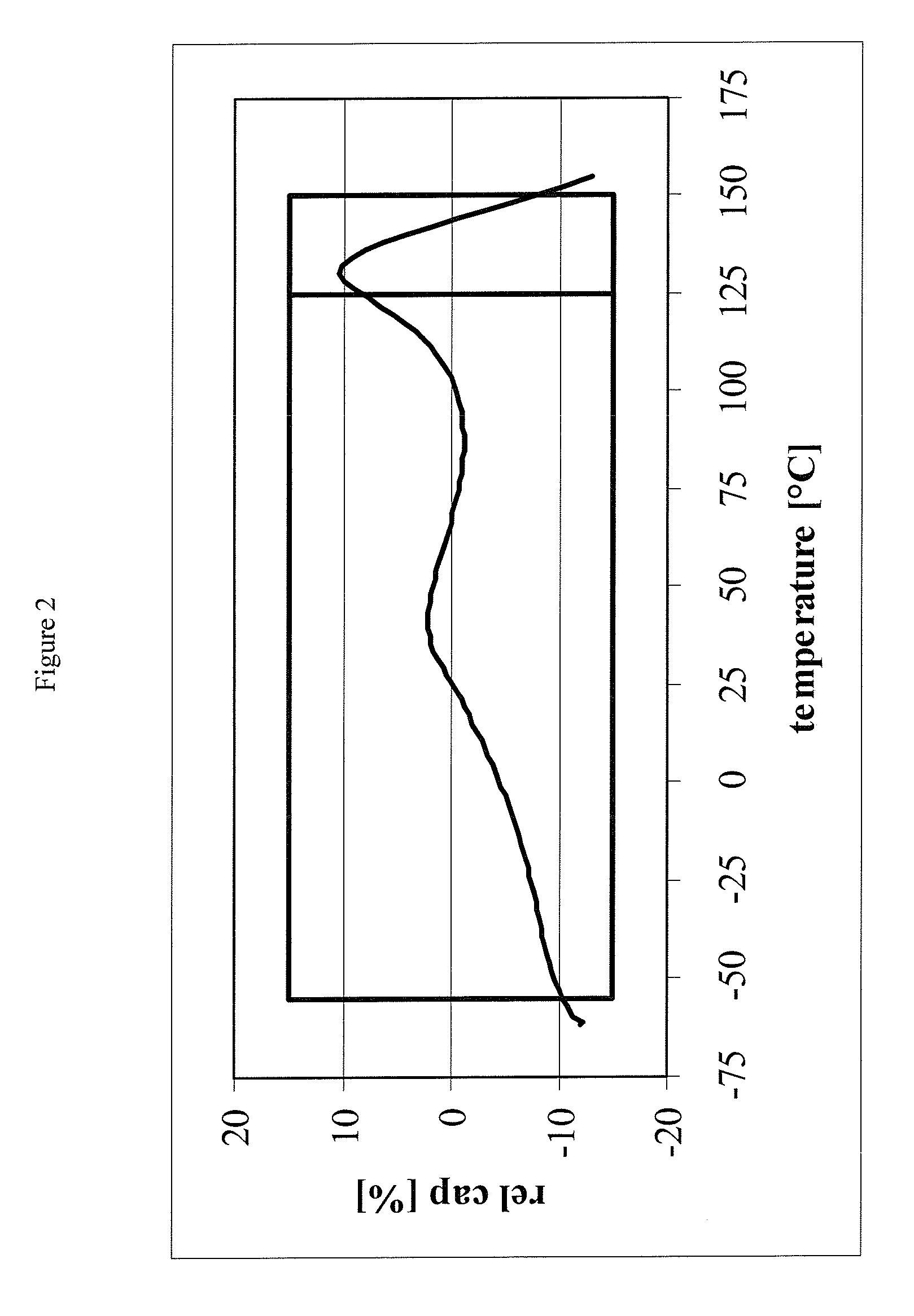

Super-wide-temperature-range nickel-hydrogen battery and manufacturing method therefor

ActiveCN105390755AImprove conductivityLower ohmic resistanceCell seperators/membranes/diaphragms/spacersFinal product manufacturePotassiumNickel electrode

The invention discloses a super-wide-temperature-range nickel-hydrogen battery. The battery comprises an iron shell as well as a nickel electrode, a hydrogen electrode, a diaphragm and an electrolyte solution mounted in the iron shell, wherein the nickel electrode takes foam nickel as a substrate material; the space in foam nickel is filled with a positive electrode active substance Ni(OH)2, a conductive agent, an additive and a binder; the hydrogen electrode takes a porous nickel-plated steel belt, a copper net or foam nickel as a substrate material; the porous nickel-plated steel belt, the copper net or foam nickel is coated with a negative electrode active substance, namely, hydrogen storage alloy powder, the conductive agent, the additive or the binder; and the electrolyte solution is a mixture of a potassium-rich alkaline aqueous solution and sodium tungstate or tungstic acid crystals. The invention furthermore discloses a manufacturing method for the super-wide-temperature-range nickel-hydrogen battery. According to the super-wide-temperature-range nickel-hydrogen battery disclosed by the invention, the ratio of 0.2C discharge capacity to normal-temperature capacity maximally can reach 70-80% in an environment with the temperature of -45 DEG C; and the ratio of 0.2C discharge capacity to normal-temperature capacity of the nickel hydrogen battery maximally can reach 85-95% in an environment with the temperature of 70 DEG C. Moreover, the manufacturing method is simple and suitable for large-scale production.

Owner:HENGYANG BST POWER

Process of forming a nickel electrode

InactiveUS6193871B1High areaHighly structuredElectrode carriers/collectorsAlkaline accumulator electrodesNickel electrodeZinc salts

Owner:EAGLE PICHER TECH LLC

Nonreducible dielectric ceramic composition

InactiveUS20030125192A1Quality improvementImprove reliabilityFixed capacitor dielectricCeramicsDielectric lossReducing atmosphere

Disclosed is a nonreducible dielectric composition. Provided is a highly reliable TC based dielectric composition prepared by adding a sintering additive having excellent qualities to a conventional (Ca1-xSrx)m(Zr1-yTiy)O3 based dielectric composition, so that it can be sintered under a reducing atmosphere to be used in formation of a nickel electrode, can be sintered at a temperature of less than 1,300° C., and even more, at a low temperature of 1,250° C., and has a small dielectric loss and a high resistivity. The composition of the present invention includes a nonreducible dielectric composition comprising a main component expressed by the general formula, (Ca1-xSrx)m(Zr1-yTiy)O3, which has the ranges of 0<=x<=1, 0<=y<0.09, and 0.7<=m<=1.05; and 0.5-10 wt % of a minor component expressed by the general formula, aMnO-bSiO2-dR1O-eR2O2 (a+b+d+e=100, R1 is at least one element selected from the group consisting of Mg, Ca, Sr and Ba, and R2 is at least one element of Zr and Ti), which has the ranges of 20<=a<=60, 10<=b<=65, and 0<(d+e)<=65.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Method for manufacturing lead-carbon ultracapacitor battery cathode

ActiveCN101667637AIncrease specific energyImprove discharge capacityElectrochemical generatorsElectrode manufacturing processesCapacitanceActivated carbon

The invention discloses a method for manufacturing a lead-carbon ultracapacitor battery cathode, comprising the following steps: active substances taking lead powder as a main component and active substances taking active carbon as a main component are respectively coated on different areas of an electrode matrix, and then are dried to obtain the lead-carbon ultracapacitor battery cathode. The invention provides a manufacturing technology of lead-carbon ultracapacitor battery cathode, which takes a pure lead sheet or lead alloy sheet as a matrix, and adopts the active carbon and the lead powder as active substances. Compared with the cathode taking the pure active carbon as cathode active substance, the cathode piece manufactured by the method can greatly improve discharge capacity of thelead-carbon ultracapacitor batteries, the specific energy can reach more than 16wh / kg, the cycle life can reach more than 1500 times, working potential window can reach 2.0V, and the cost is only onethird to one fifth of that of the current inorganic system carbon-carbon symmetric form and nickel electrode-carbon mixed alkaline system.

Owner:SHUANGDENG GRP

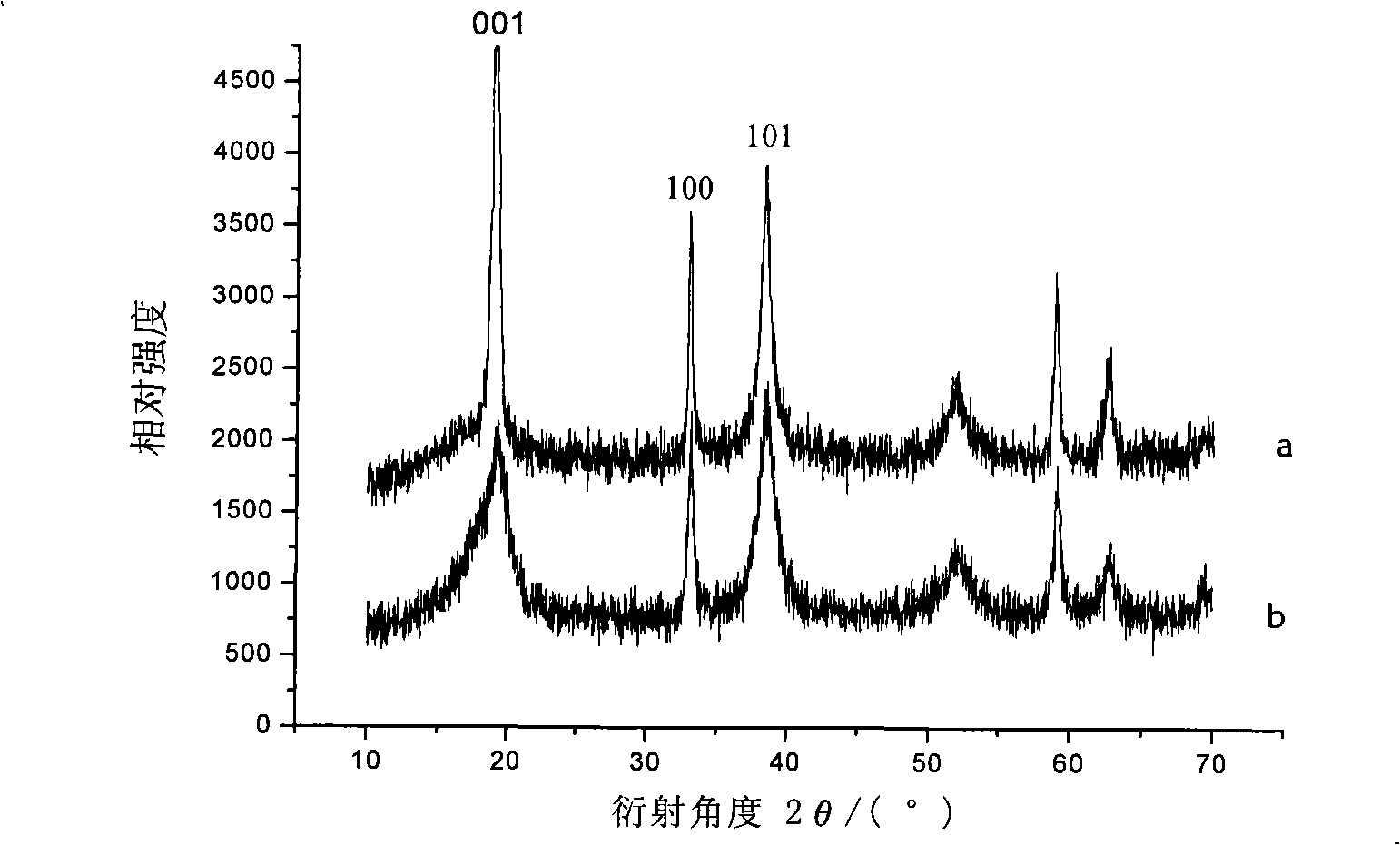

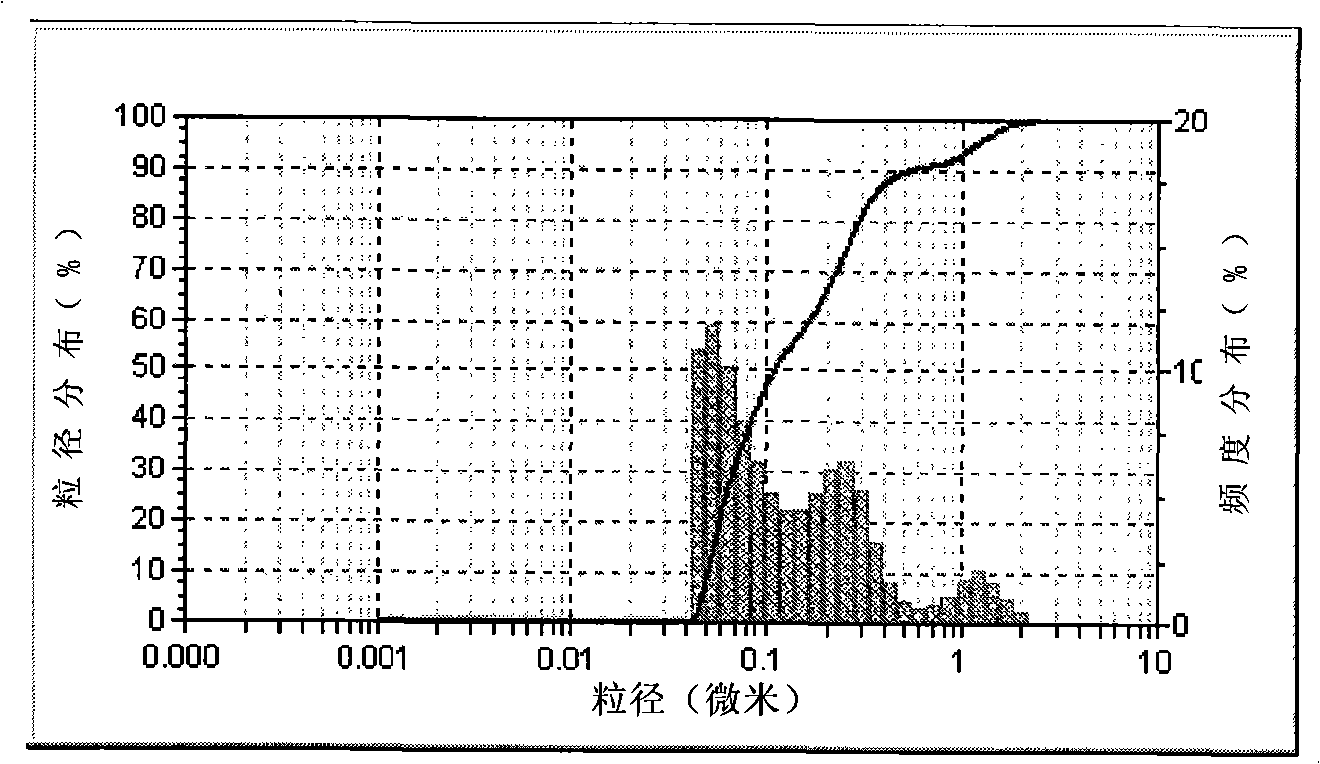

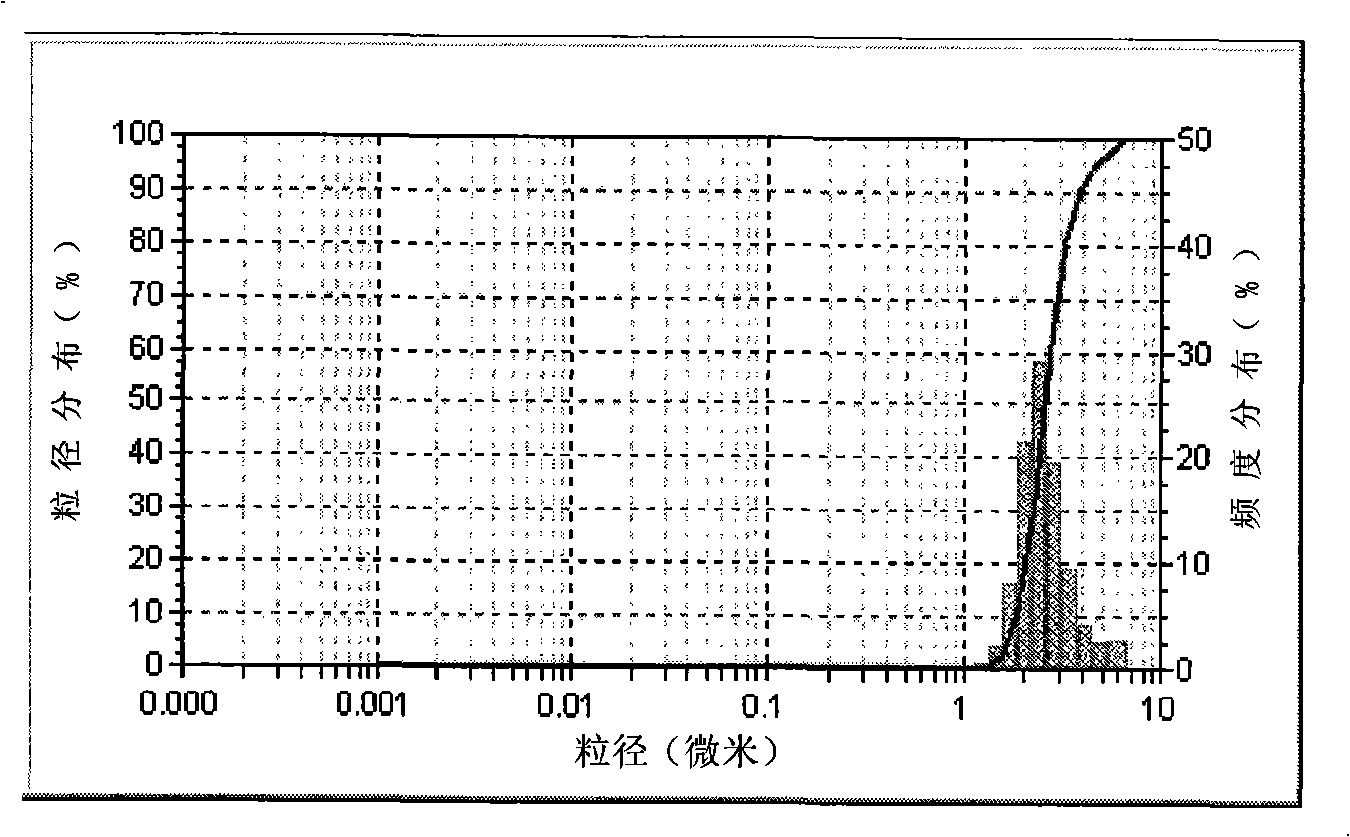

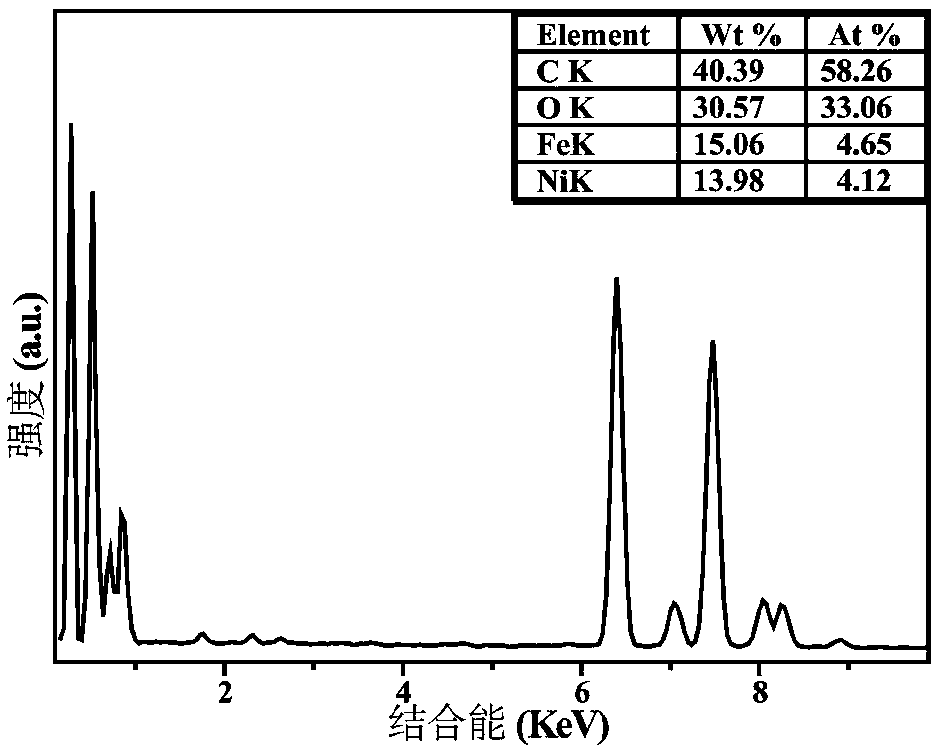

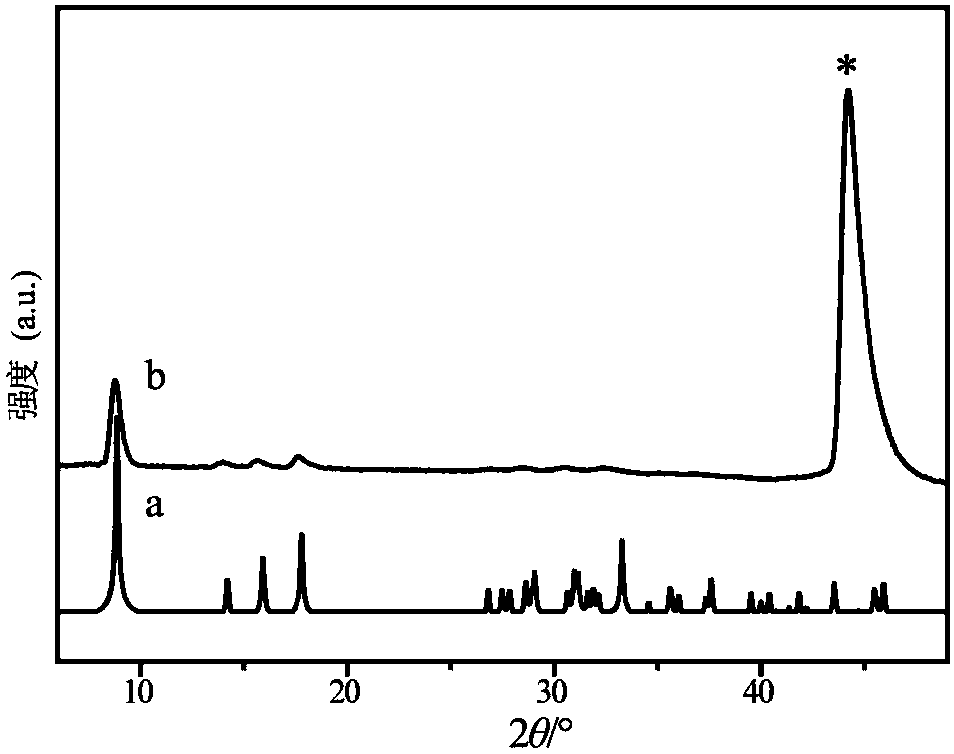

Preparation method and application of nanometer nickel hydroxide and composite electrode thereof

InactiveCN101525160AUniform particle sizeGood dispersionElectrode manufacturing processesNickel oxides/hydroxidesNickel saltNickel electrode

The invention discloses a preparation method and an application of nanometer nickel hydroxide and a composite electrode thereof. The preparation method comprises the following steps: adopting nickel salt and alkali liquor as raw materials, synthesizing nanometer nickel hydroxide by a direct precipitation method under the cooperation of ultrasonic waves, dispersant and pH value buffering agent, doping the nanometer nickel hydroxide into industrial micron-size spherical nickel hydroxide by a certain proportion and preparing a high-capacity composite nickel electrode. The whole reaction process is always carried out in the environment of ultrasonic vibration; the microcosmic appearance of the prepared nanometer nickel hydroxide is of a needle shape or a mixed shape of the needle shape and a torispherical shape and has uniform particles, good dispersivity and high activity; the discharging capacity of the composite nickel electrode prepared by doping the nanometer nickel hydroxide into the spherical nickel hydroxide according to the proportion of 3 percent to 11 percent is improved by 2 percent to 16 percent compared with that of the pure spherical nickel electrode; and the preparation method is applicable to be used for improving the electrochemical property of the positive electrode of a nickel-hydrogen battery.

Owner:GUANGDONG UNIV OF TECH

Electrical-energy-storage unit (EESU) utilizing ceramic and integrated-circuit technologies for replacement of electrochemical batteries

InactiveUS7595109B2Cost-effectiveSolve insufficient storage spacePrimary cellsStacked capacitorsElectrical batteryBarium titanate

Owner:EESTOR

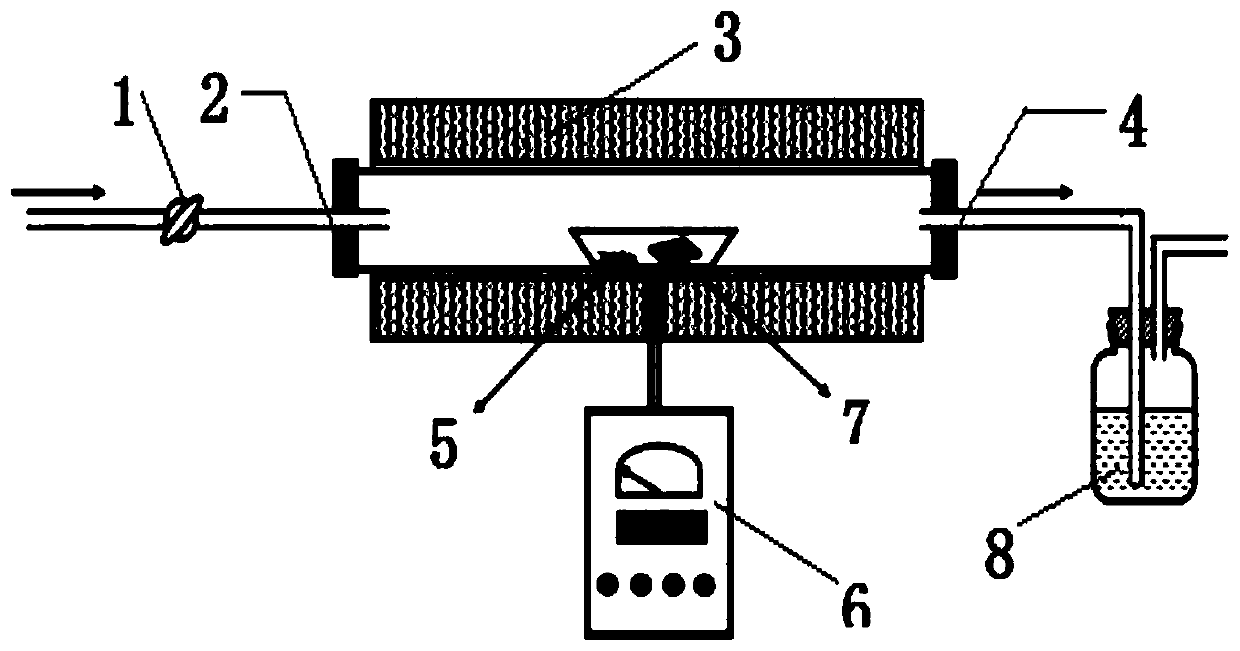

Gas Production Through Pulsed Electrolysis

Cells and methods of producing hydrogen and oxygen from an aqueous solution at about 90% of the Faraday Limit are provided. An exemplary method includes the steps of placing a graphite electrode and a nickel electrode in an alkaline solution comprising colloidal silver, colloidal magnesium and a powdered metal such as aluminum, and applying a constant positive voltage to the nickel electrode. Further, the example includes cyclically applying a negative voltage potential to the graphite electrode by turning on the negative applied voltage for a first time period and switching off the negative voltage for a second time period. The second time period should be sufficient to permit removal of substantially all or at least some of any aluminum or zinc deposited on the graphite electrode. Graphite-containing electrodes may be pretreated to infuse with a precious metal.

Owner:G & M ENERGY SYST

Nonreducible dielectric ceramic composition

InactiveUS6790801B2Quality improvementImprove reliabilityFixed capacitor dielectricCeramicsDielectric lossHigh resistivity

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

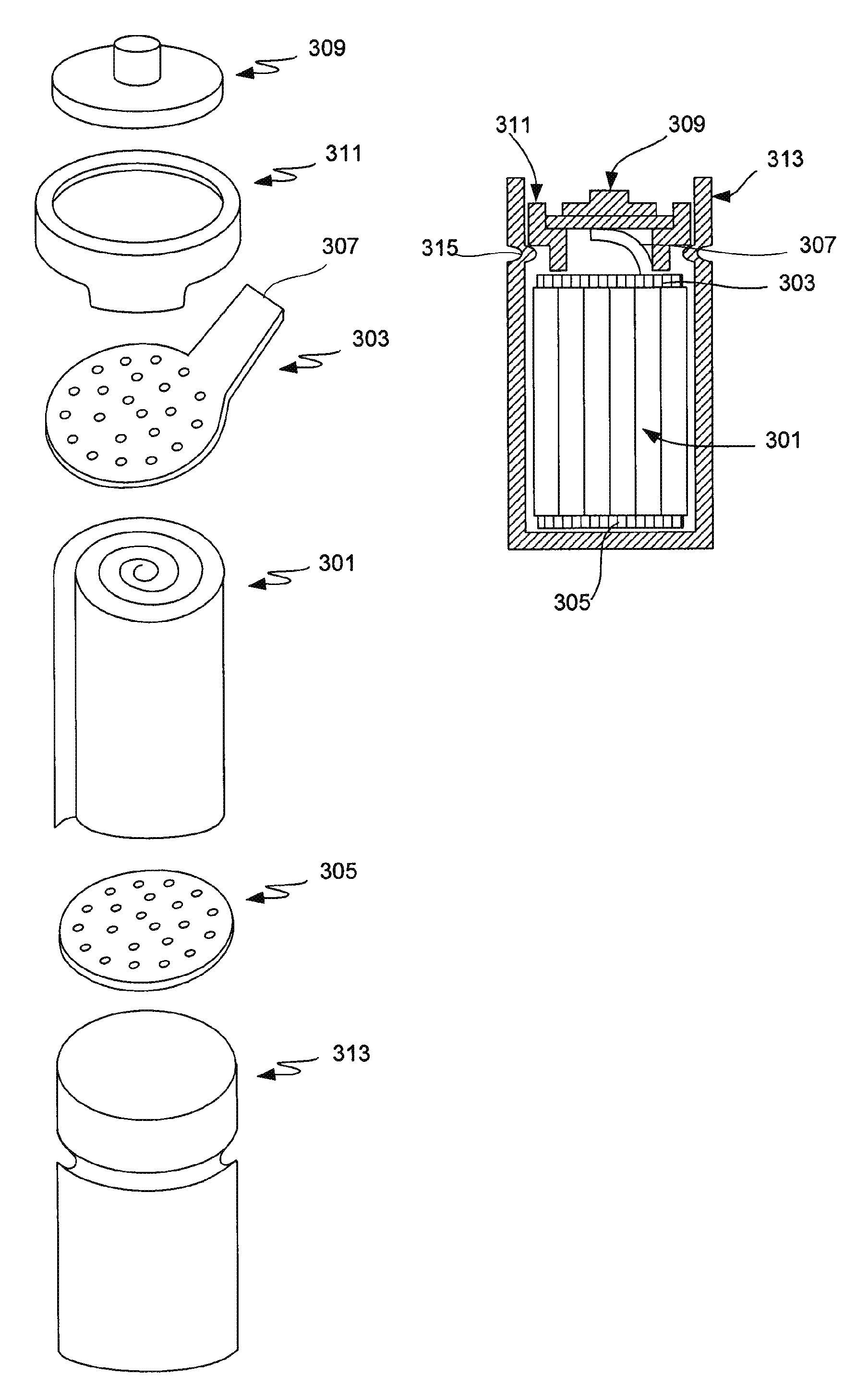

Cylinder type zinc-nickel storage battery

InactiveCN101202357AIncrease specific energyLow costFinal product manufactureSmall-sized cells cases/jacketsIndiumNickel electrode

The invention belongs to cylindrical zinc-nickel accumulators, comprising an anode in a battery shell, a polar plate group which is winded by a septum and a cathode, and a battery cover. The invention is characterized in that the cathode is a flexible zinc electrode and the anode is a nickel electrode; the battery shell and the battery cover are both made of copper or copper alloy material; the flexible zinc electrode consists of a cathode framework and cathode active matter on the cathode framework; the cathode framework is a netting or perforation belt or mesh grid, which is made of copper or copper alloy; the cathode active matter is the admixture of zinc or zinc oxide powder which takes one or more compounds out of calcium, lead, indium and tantalum as additive. As the flexible zinc electrode is taken as the cathode, the nickel electrode is taken as the anode and the copper or copper alloy material is taken as the battery shell and the shell cover, the specific energy of the battery is improved, the cost is reduced, and the invention can be taken as all power supplies.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST +1

Ceramic dielectric material matched with nickel inner electrode and production method of capacitor produced by ceramic dielectric material

ActiveCN101786864ASolve the problem of co-firingResistantFixed capacitor dielectricStacked capacitorsCeramic capacitorReducing atmosphere

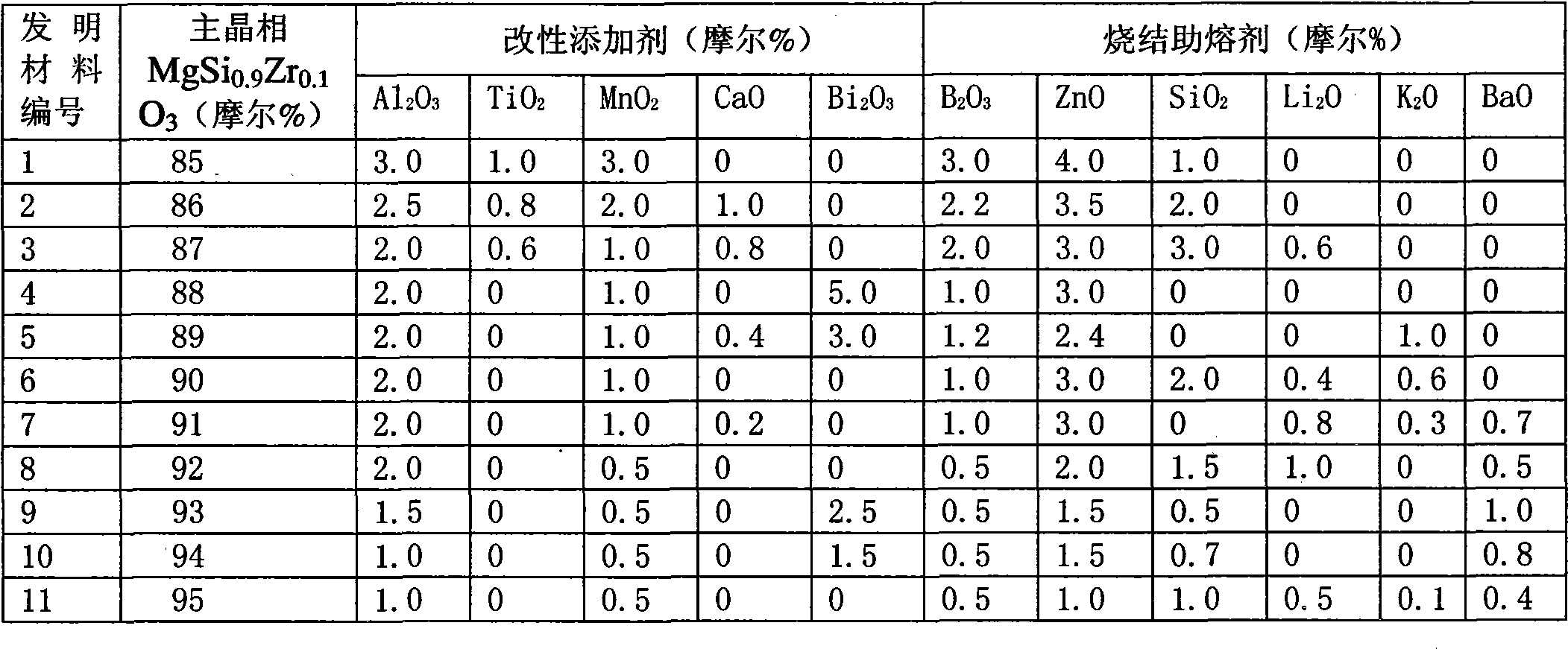

The invention discloses a ceramic dielectric material matched with a nickel inner electrode and a production method of a capacitor produced by the ceramic dielectric material. The ceramic dielectric material consists of a main crystal phase, a property-modifying additive and a sintered fluxing agent, wherein the main crystal phase is MgZrxSi(1-x)O3, and x is more than or equal to 0.05 and less than or equal to 0.15; the property-modifying additive is one or more of MnO2, Al2O3, CaO, Bi2O3 and TiO2; and the sintered fluxing agent is one or more of B2O3, SiO2, ZnO, Li2O, K2O and BaO. The ceramic dielectric material can meet the COG characteristic in the EIA standard, has good uniformity, uniform particle size distribution, high dispersibility, good molding technique and excellent dielectricproperty and meets the environmental requirement. When the material is used for making a multi-layer chip ceramic capacitor (MLCC), the material and the nickel electrode can be matched and sintered under the reducing atmosphere, the crystal particles of a ceramic body after sintering can grow uniformly and densely, the dielectric layer can be well matched with the inner electrode, and the productperformance is stable.

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG

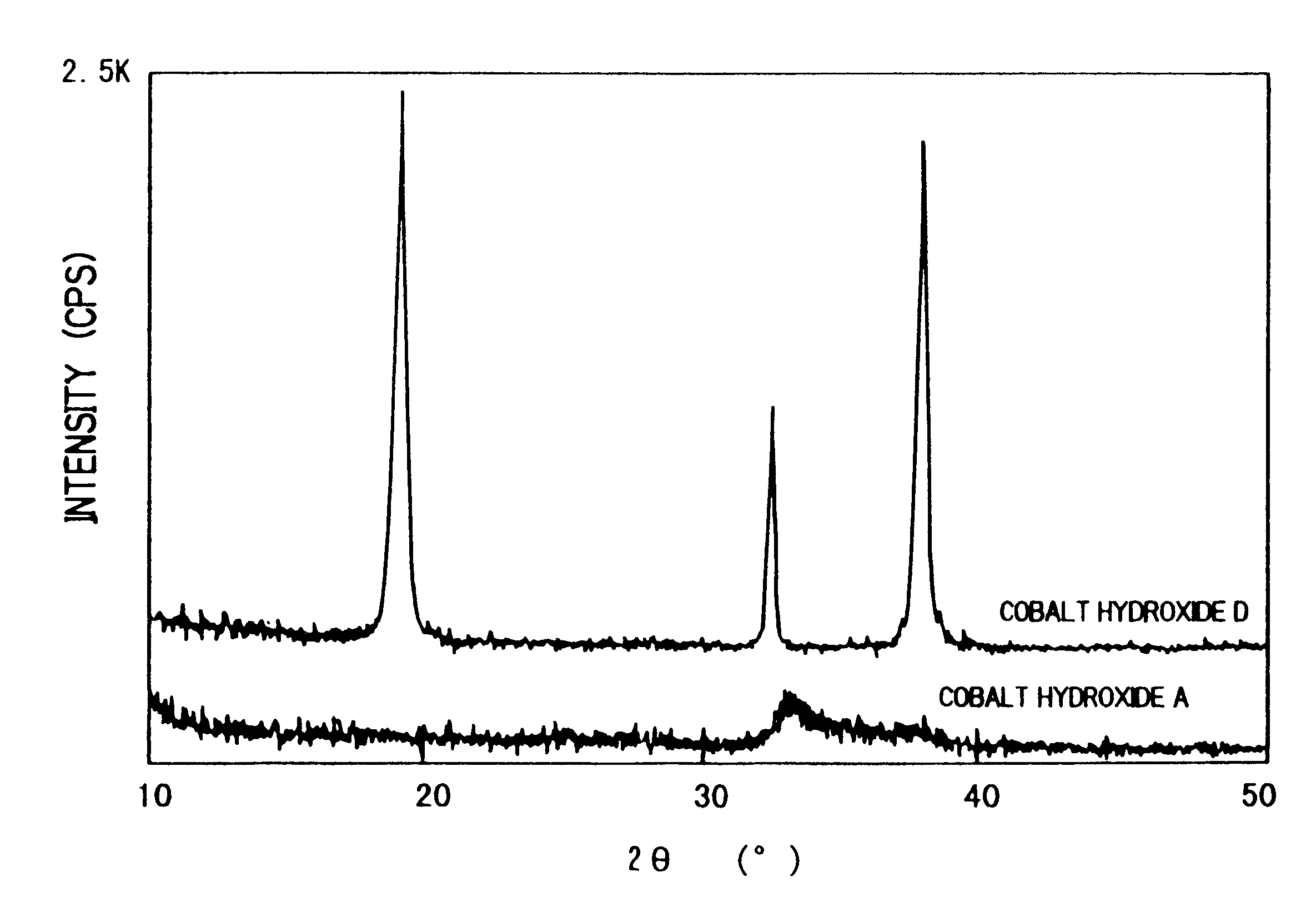

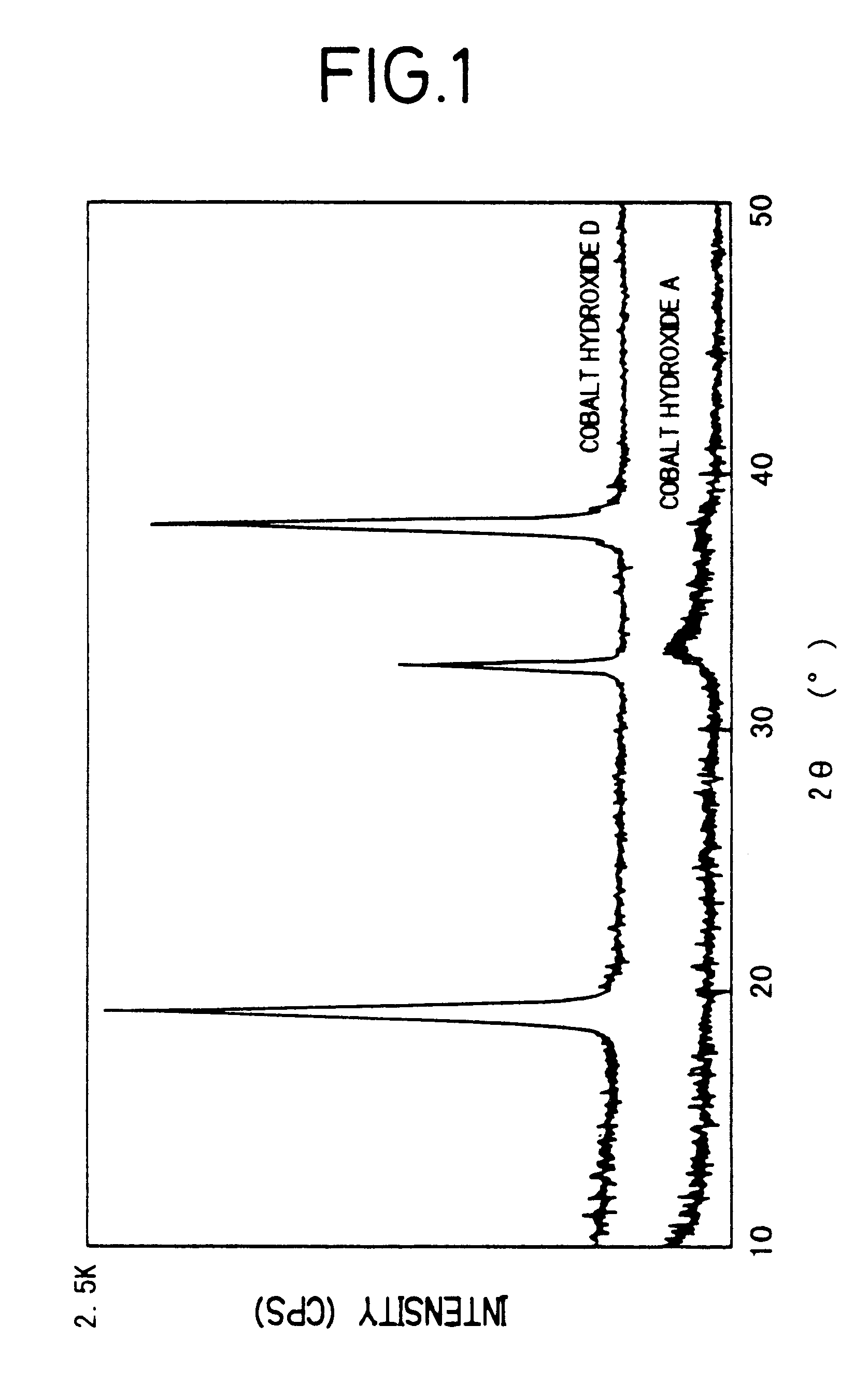

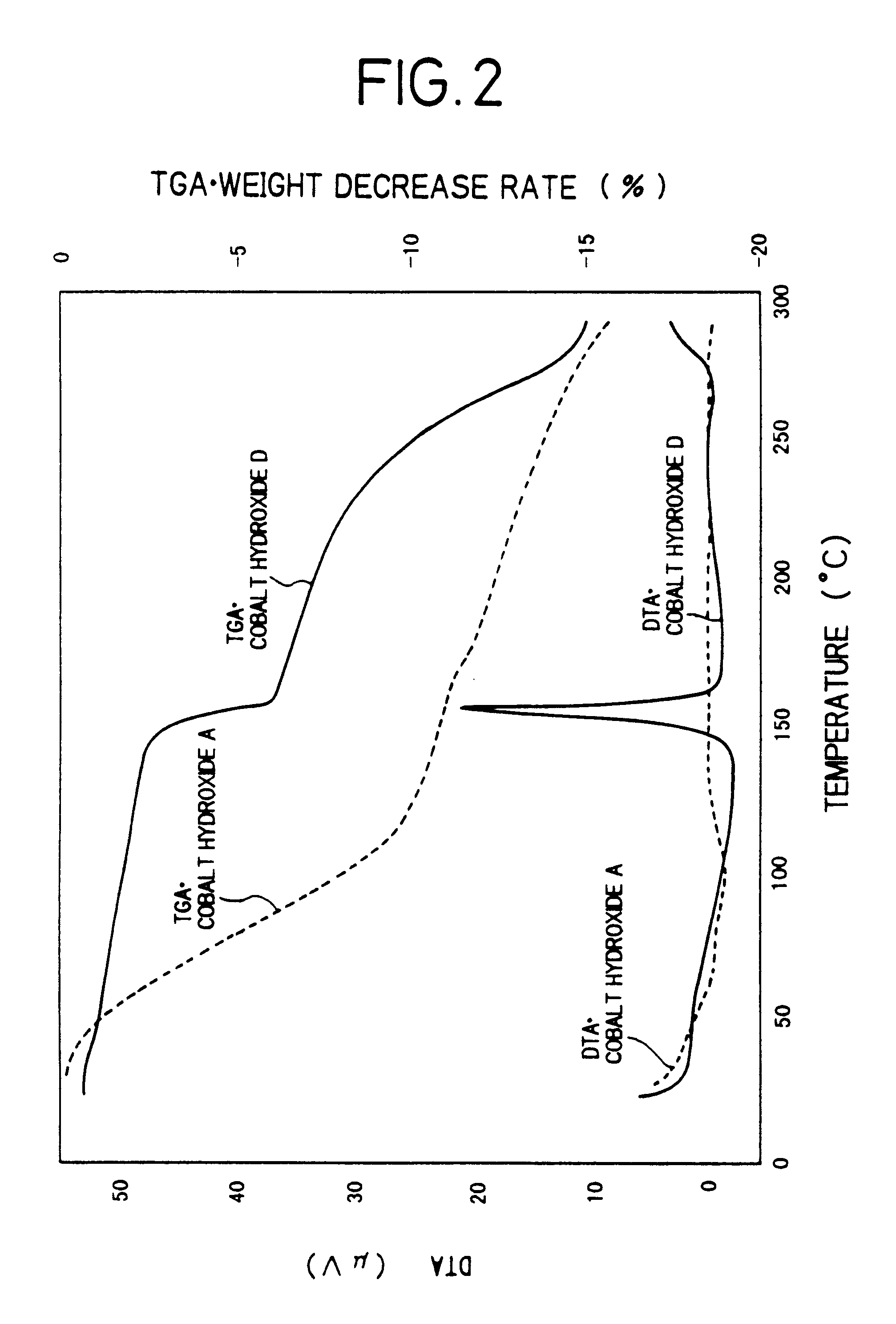

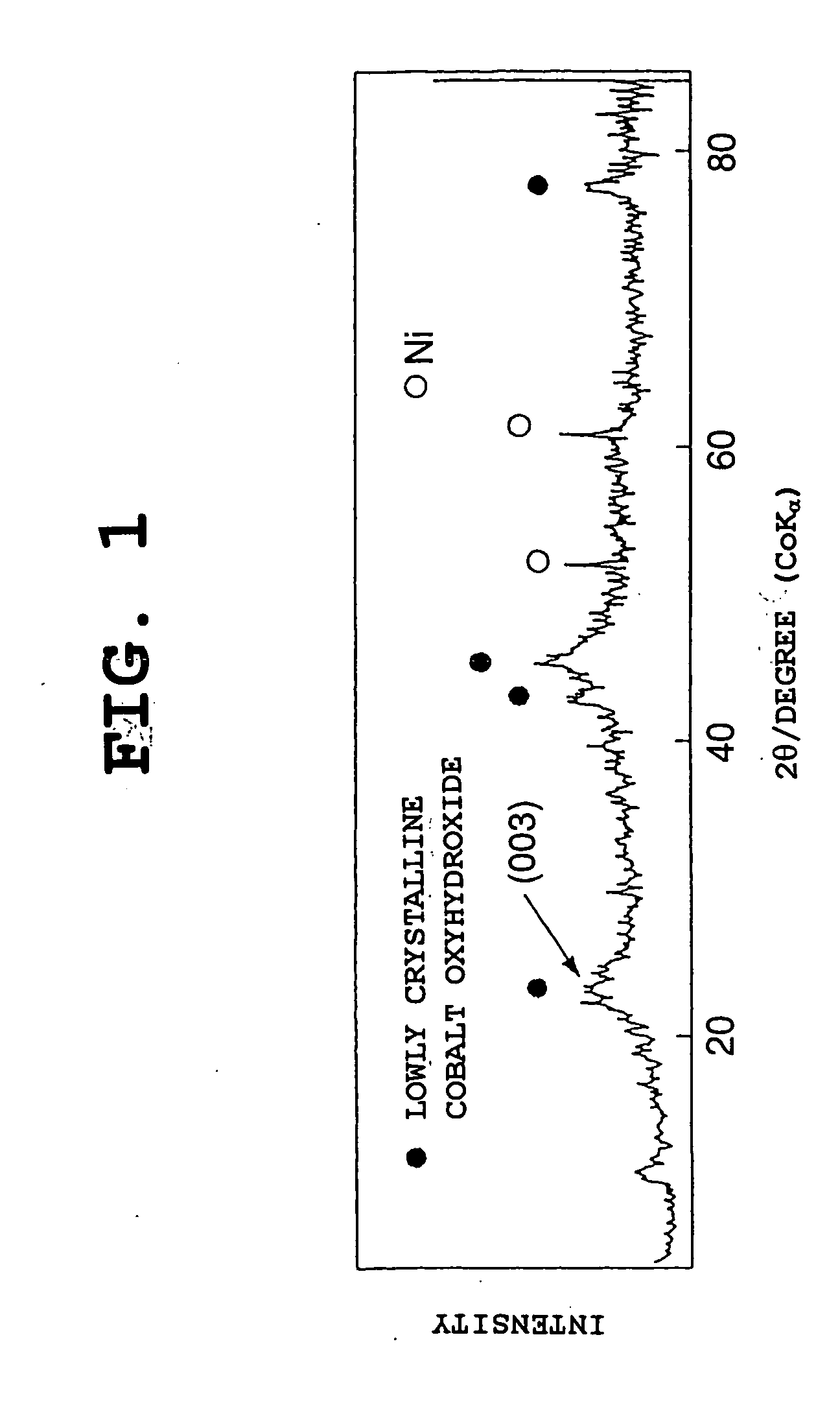

Method for manufacturing positive pole active material for alkaline secondary battery, paste nickel pole, and alkaline secondary battery and method for manufacturing thereof

InactiveUS6258483B1Convenience to workGuaranteed to workFinal product manufactureElectrode carriers/collectorsElectrical batteryNickel oxide hydroxide

There is provided a method of producing an active material of a positive electrode used for an alkaline secondary battery which is difficult to be oxidized, and high in its reactivity with an alkaline electrolyte to form a cobalt electric conductive matrix improved in electric conductivity. The method of producing thereof is characterized in that nickel hydroxide powder is dispersed in an aqueous solution of a strongly acidic cobalt salt and the dispersed solution thereof is, while being stirred, added gradually with an aqueous alkali solution to made to react one with another to precipitate a cobalt hydroxide while maintaining the reaction solution in the region of acidity to neutrality, and a solid part in which the cobalt hydroxide is mixed in the nickel hydroxide is separated from the reaction solution which is in the region of acidity to neutrality after the completion of the reaction, and is then washed with water. By this method of producing, there is obtained an active material of a positive electrode used for an alkaline secondary battery in which the amorphous to microcrystal cobalt hydroxide is mixed in the nickel hydroxide. Thus, using this active material of the positive electrode, a paste-type nickel electrode improved in utilization rate is obtained, and using the nickel electrode, an alkaline storage battery which has a high capacity and is excellent in the battery characteristics such as discharging characteristics, etc. is obtained.

Owner:THE FURUKAWA BATTERY CO LTD

Nonreducible dielectric ceramic composition

InactiveUS6858554B2Improve reliabilityQuality improvementFixed capacitor dielectricCeramicsDielectric lossReducing atmosphere

Disclosed is a nonreducible dielectric composition. Provided is a highly reliable TC based dielectric composition prepared by adding a sintering additive having excellent qualities to a conventional (Ca1-xSrx)m(Zr1-yTiy)O3 based dielectric composition, so that it can be sintered under a reducing atmosphere to be used in formation of a nickel electrode, can be sintered at a temperature of less than 1,300° C., and even more, at a low temperature of 1,250° C., and has a small dielectric loss and a high resistivity. The composition of the present invention includes a nonreducible dielectric composition comprising a main component expressed by the general formula, (Ca1-xSrx)m(Zr1-yTiy)O3, which has the ranges of 0<=x<=1, 0<=y<0.09, and 0.7<=m<=1.05; and 0.5-10 wt % of a minor component expressed by the general formula, aMnO-bSiO2-dR1O-eR2O2 (a+b+d+e=100, R1 is at least one element selected from the group consisting of Mg, Ca, Sr and Ba, and R2 is at least one element of Zr and Ti), which has the ranges of 20<=a<=60, 10<=b<=65, and 0<(D+E)&LE;65.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

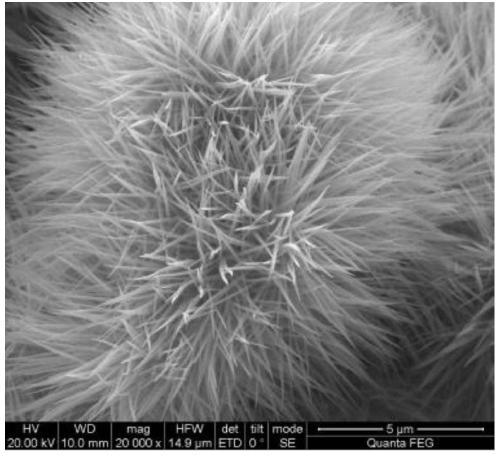

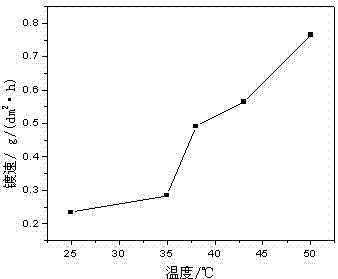

Phosphorus-doped nickel cobaltate/foam nickel electrode, preparation method and applications thereof

InactiveCN110195235AIncrease transfer rateExcellent electrocatalytic oxygen evolutionElectrode shape/formsElectrolysisNickel electrode

The invention belongs to the field of electrode materials, and particularly relates to a phosphorus-doped nickel cobaltate / foam nickel electrode, a preparation method and applications thereof. The preparation method comprises: sequentially carrying out cutting treatment, ultrasonic cleaning treatment and drying treatment on foam nickel so as to be spare; dissolving Co(NO3)2.6H2O, Ni(NO3)2.6H2O andurea in deionized water, and uniformly stirring to obtain a hydrothermal solution; inserting the foam nickel into a polytetrafluoroethylene mold base, wherein the foam nickel is maintained in a vertical state; maintaining the 120 DEG C for 5-8 h, cooling to a room temperature, washing, drying, calcining, and cooling to a room temperature to obtain a nickel cobaltate / foam nickel electrode; and placing the nickel cobaltate / foam nickel electrode and NaH2PO2.2H2O in a quartz boat, placing the quartz boat in a tubular furnace, and phosphating to obtain the phosphorus-doped nickel cobaltate / foam nickel electrode. According to the present invention, the obtained phosphorus-doped nickel cobaltate / foam nickel electrode can be used as the cathode for hydrogen evolution in water electrolysis, can further be used as the anode for oxygen evolution, is a dual-function electrode, and has good economy and environmental protection.

Owner:YANCHENG INST OF TECH

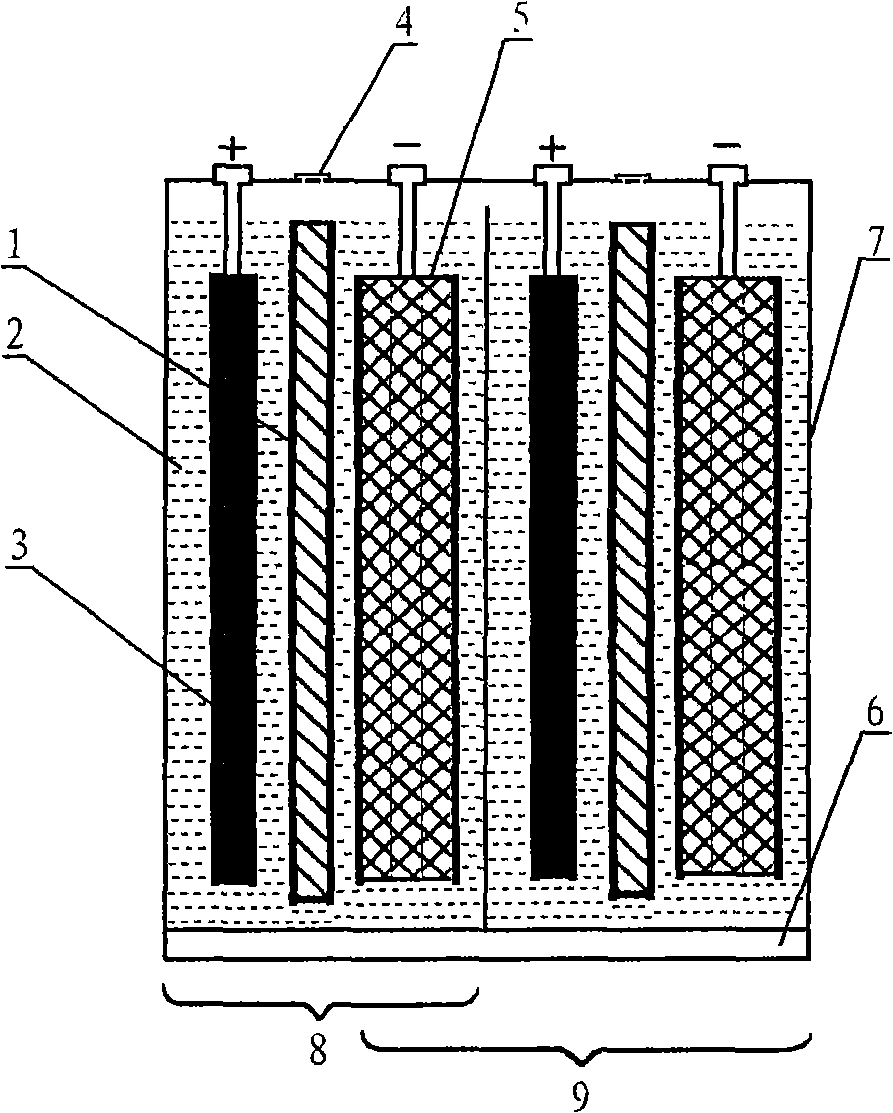

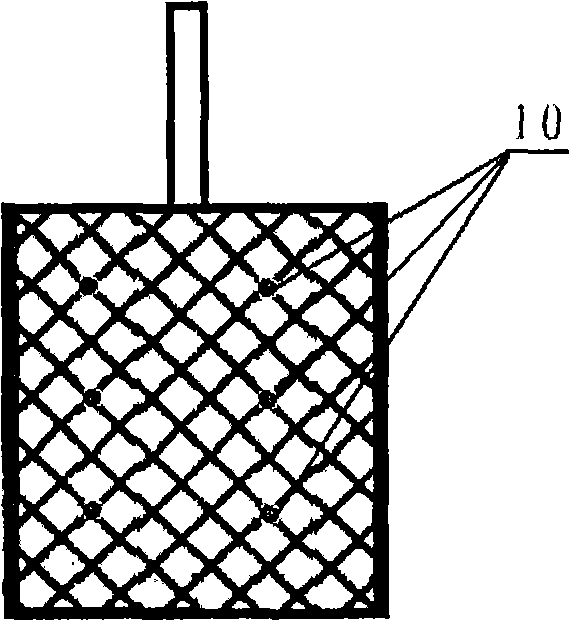

Zinc-nickel static single fluid flow battery

InactiveCN101299476ASmall self-dischargeRelieve internal pressureAlkaline accumulatorsFuel and secondary cellsEngineeringNickel electrode

A copper nickel statical single fluid stream battery is composed of a battery pile coupled by multi-section of battery monomers, electrolyte, a battery container and a sediment tank, wherein the battery monomers comprise a nickel electrode anode, a cathode current collector of the sediment zinc, a baffle plate and a liquid injection cover. The cathode active materials are dissolved and stored in the electrolyte, and two battery monomers of the series battery pile are connected in series by the positive and negative electrode connectors. In the charging and discharging processes, the active material dissolvable zinc salt in the electrolyte is converted with the metallic zinc on the cathode current collector backwards and forwards. The invention eliminates the solution storage tank and the liquid pump in the traditional fluid stream battery, realizes the dynamic loop of the active materials in the inner of the battery electrolyte, with small volume, high working pressure, long service life, convenient carrying, which is suitable to be used as the movable power with low cost.

Owner:CENT SOUTH UNIV

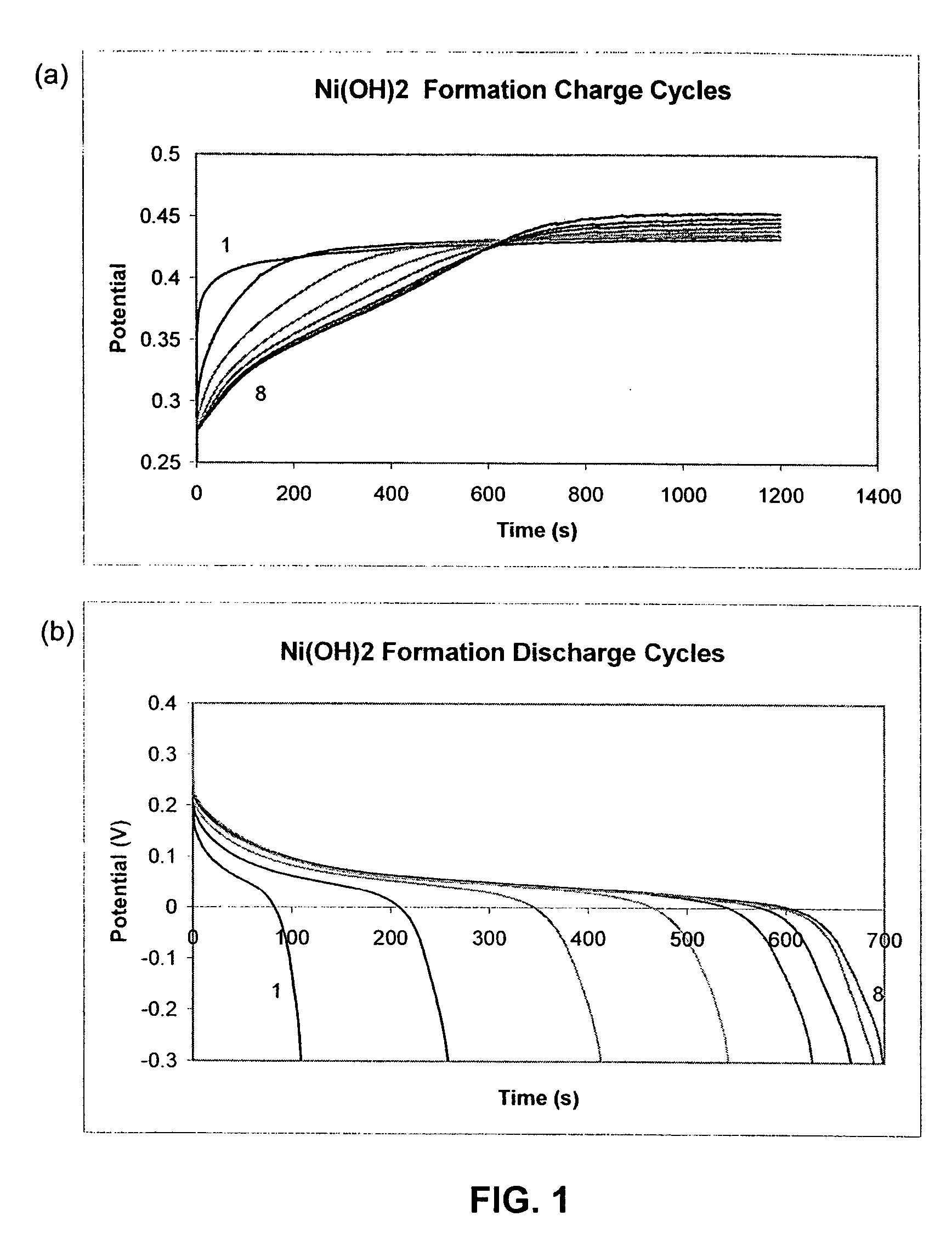

Nickel electrode material,and production method therefor, and nickel electrode and alkaline battery

ActiveUS20040241545A1Improved cycle life characteristicsHigh degreeElectrochemical processing of electrodesLayered productsInternal pressureNickel oxide hydroxide

Subjects for the invention are to provide a nickel electrode material having a satisfactory tap density and capable of attaining a sufficient reduction in discharge reserve and a process for producing the nickel electrode material, and to provide a nickel electrode and an alkaline storage battery having a high capacity and excellent internal-pressure characteristics. For accomplishing the subjects, the invention provides a nickel electrode material for use in a nickel electrode, wherein the positive-electrode material constituting the electrode material comprises: positive active material particles which comprise as the main component either a nickel hydroxide or a solid solution in a nickel hydroxide of one or more other elements and in which part of the nickel hydroxide has been oxidized; and a coating layer formed on the surface of the positive active material particles and comprising as the main component a high-order cobalt compound in which the cobalt has an oxidation number larger than 2, the average oxidation number of the nickel in the positive active material particles and the cobalt in the coating layer being from 2.04 to 2.40, and the positive-electrode material having a tap density of 2.0 g / cm<3 >or higher. The invention further provides a process for producing the electrode material, a nickel electrode employing the electrode material, and an alkaline storage battery having the nickel electrode.

Owner:GS YUASA INT LTD

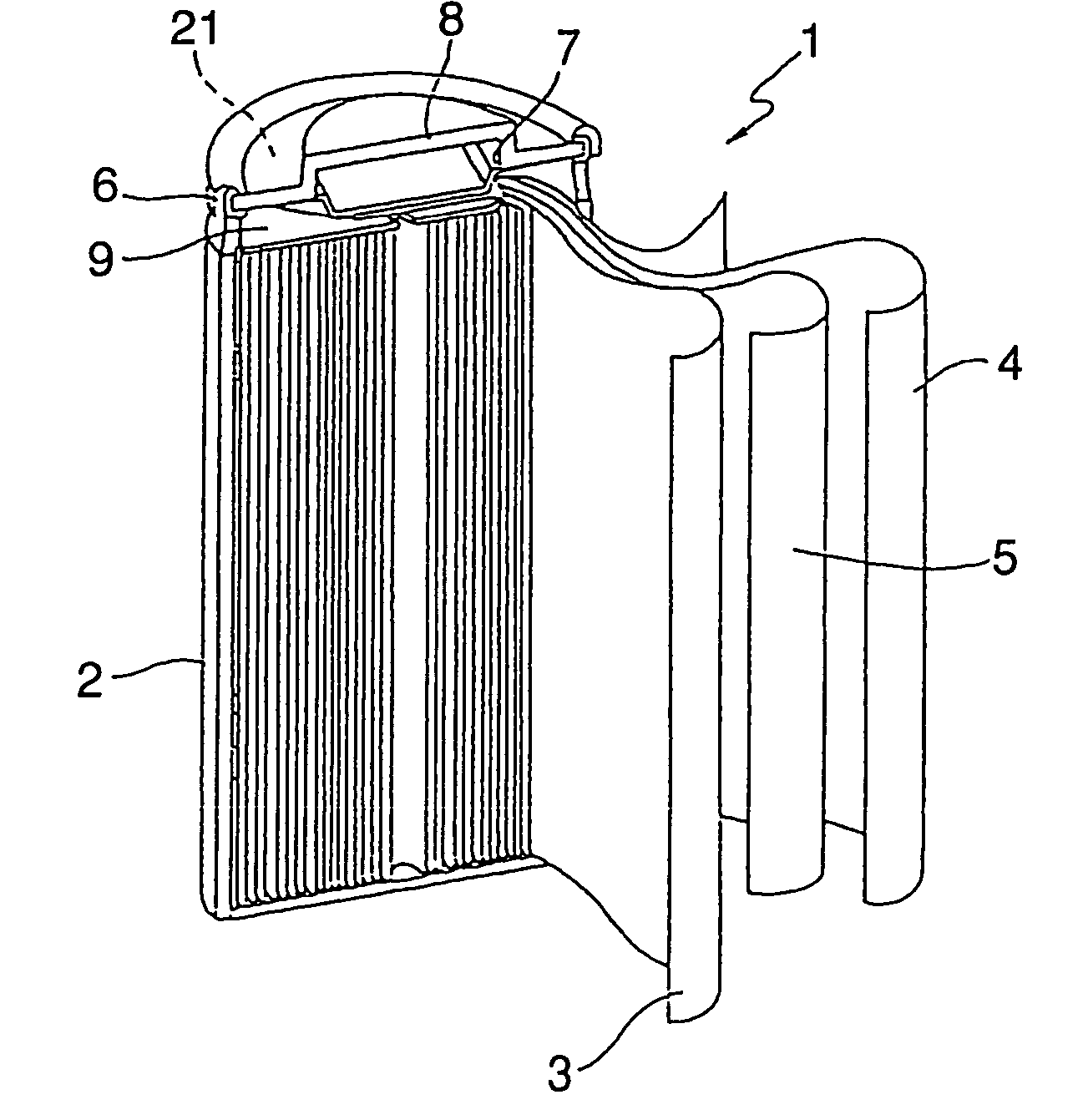

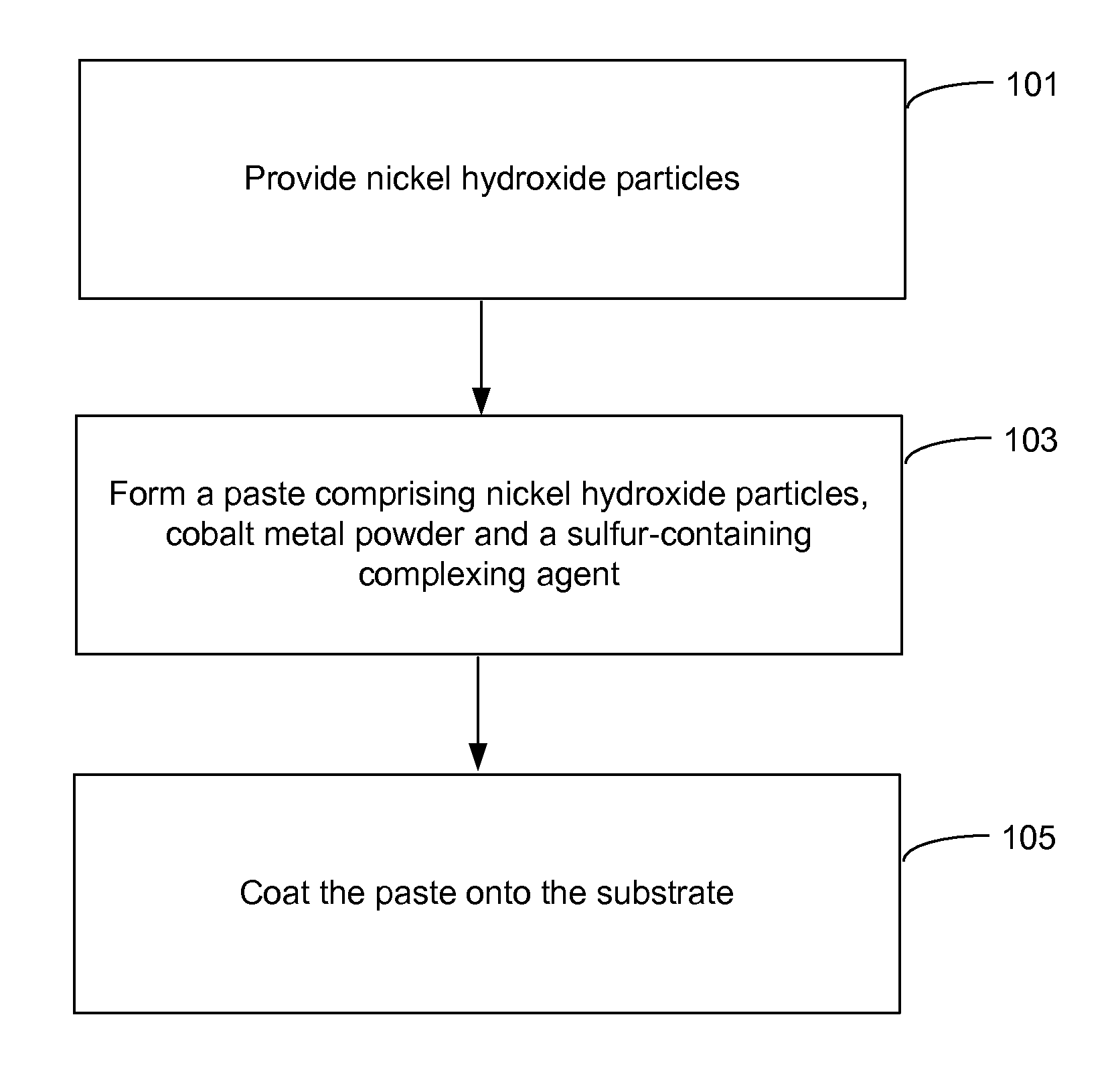

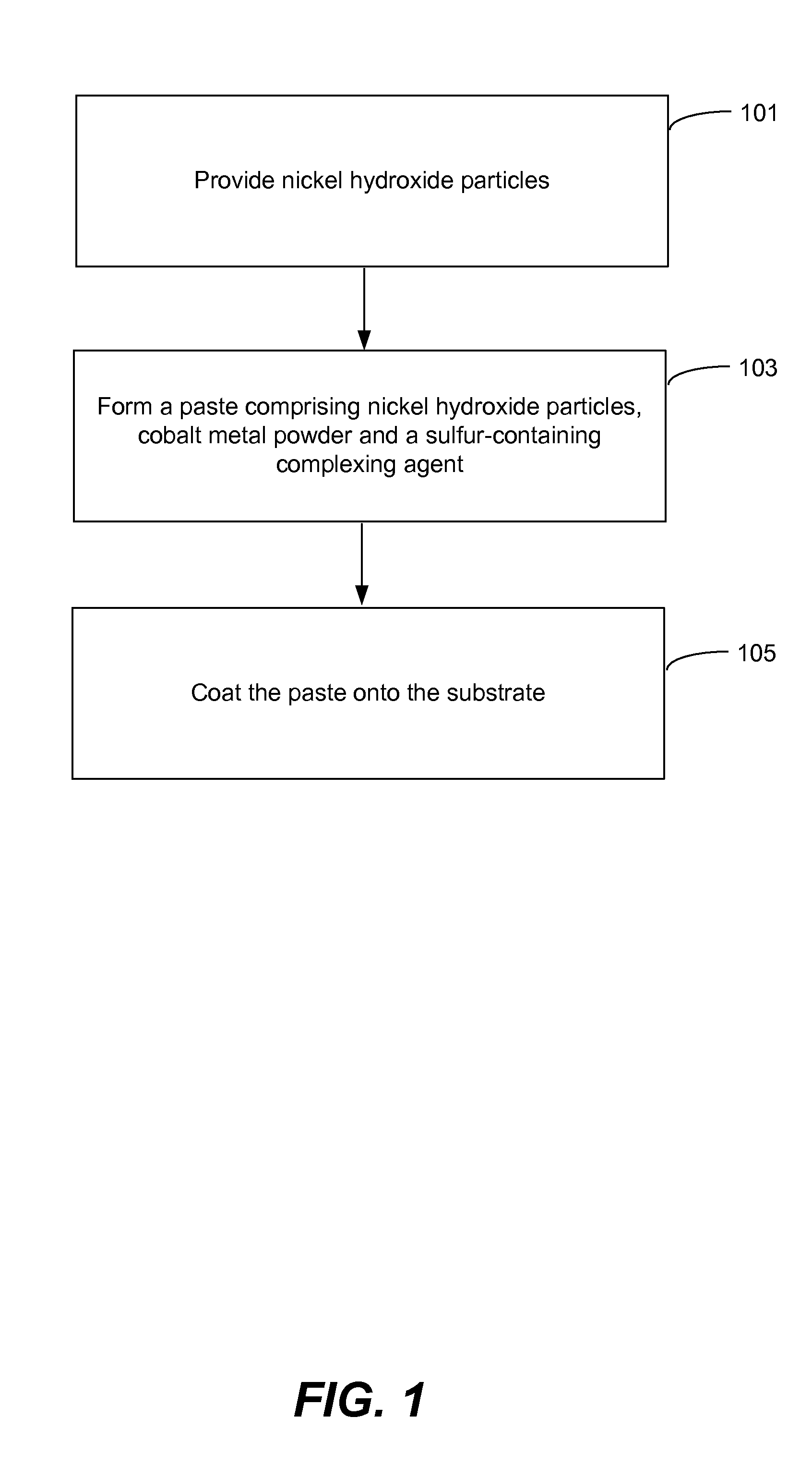

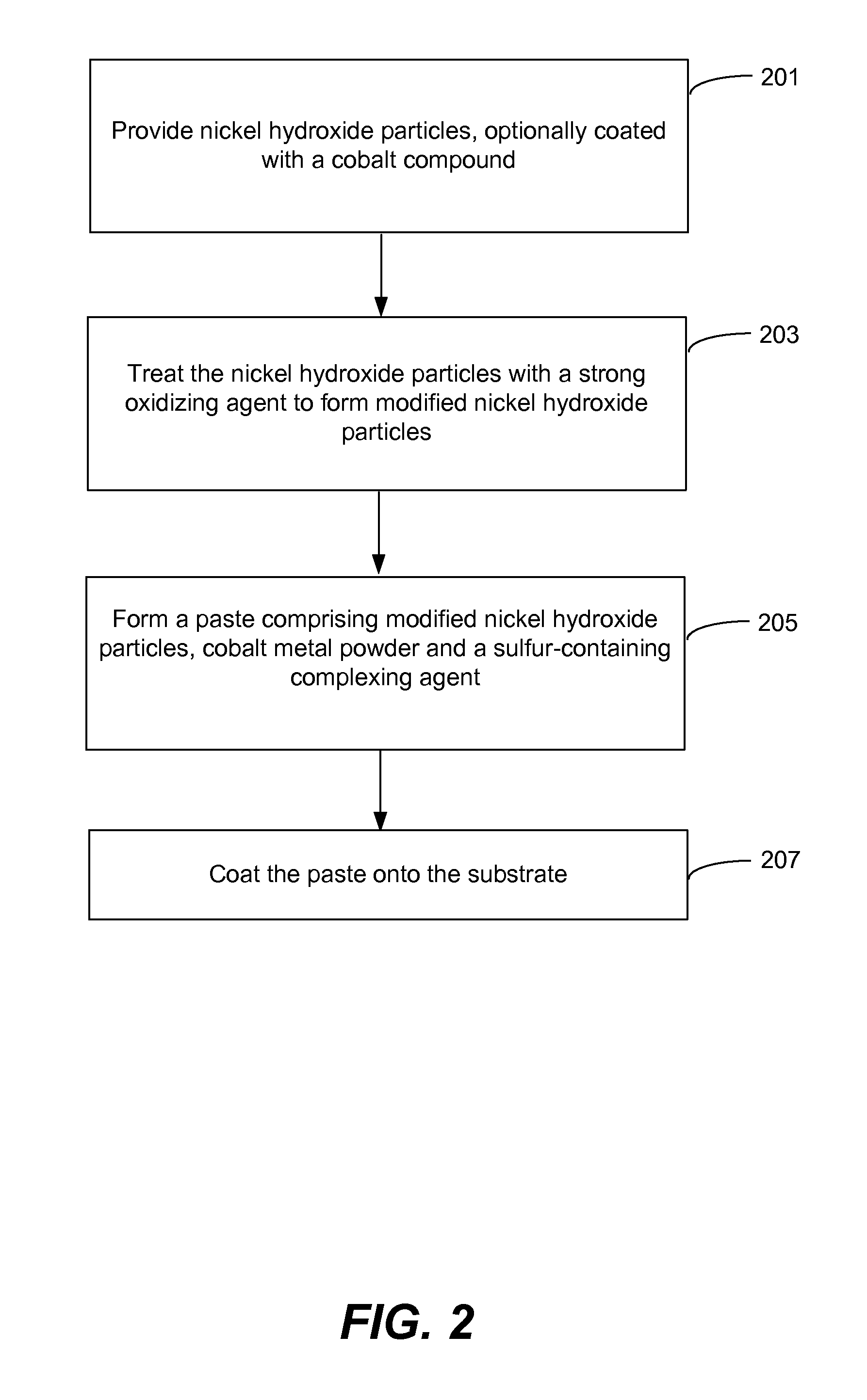

Pasted nickel hydroxide electrode and additives for rechargeable alkaline batteries

ActiveUS20140199591A1Prevent peelingMinimize migrationFinal product manufactureConductive materialNickel electrodeNickel zinc

A pasted positive nickel hydroxide electrode for use in battery cells (e.g., in nickel zinc cells, and nickel metal hydride cells) includes nickel hydroxide particles, a cobalt metal and / or cobalt compound and a sulfur-containing complexing agent capable of forming a complex with cobalt. The presence of the sulfur-containing complexing agent, such as dialkyldithiocarbamate (e.g., sodium diethyldithiocarbamate) improves lifetime and capacity utilization of the nickel electrode. The resulting pasted nickel hydroxide electrode includes a CoOOH conductive matrix after formation. The surface of the nickel hydroxide particles in the electrode is modified in some embodiments by providing a cobalt-containing coating onto the surface of the nickel hydroxide particles, followed by oxidation with a strong oxidizing agent. The complexing agent can be added before, after, or during the oxidation.

Owner:ZINCFIVE POWER INC

Iron-nickel storage battery adopting steel-strip iron electrode as cathode and preparation method of iron-nickel storage battery

ActiveCN102623757AIncrease profitReduce distanceFinal product manufactureElectrode carriers/collectorsPolyolefinSlurry

The invention relates to an iron-nickel storage battery adopting a steel-strip iron electrode as a cathode and a preparation method of the iron-nickel storage battery. The iron-nickel storage battery comprises a vessel with electrolyte, a cathode and an anode, wherein the cathode and the anode are arranged inside the vessel, the anode is a sintered nickel electrode, the cathode is a steel-strip iron electrode, the steel-strip iron electrode comprises a burr steel-strip base body and active substance slurry which is arranged on the surface of the burr steel-strip base body, the active substance slurry is prepared from the following ingredients by weight percent: 85 to 95 percent of ferroferric oxide, 1 to 5 percent of additive, 3 to 7 percent of conductive agent and 1 to 3 percent of binder, the anode and the cathode are assembled in a lamination-type structure, and a polyolefin diaphragm is arranged between the anode and the cathode; and since the sintered nickel electrode is adopted as the anode, the steel-strip iron electrode is adopted as the cathode, and a positive plate and a negative plate are isolated by the thin polyolefin diaphragm in a lamination-type structure when in assembling, the iron-nickel storage battery has the advantages of large capacity, strong large-current discharging capacity and long service life.

Owner:河南创力新能源科技股份有限公司

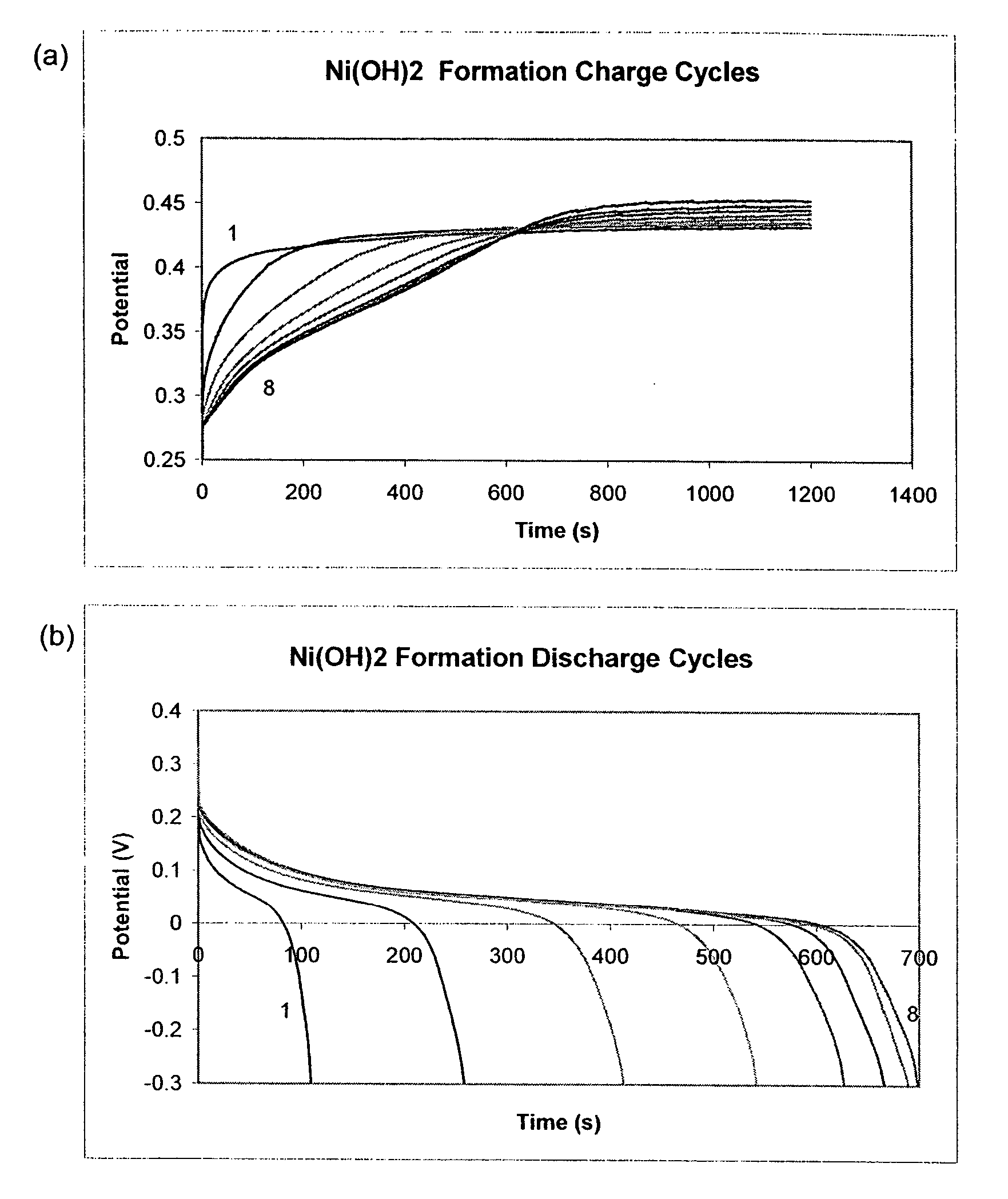

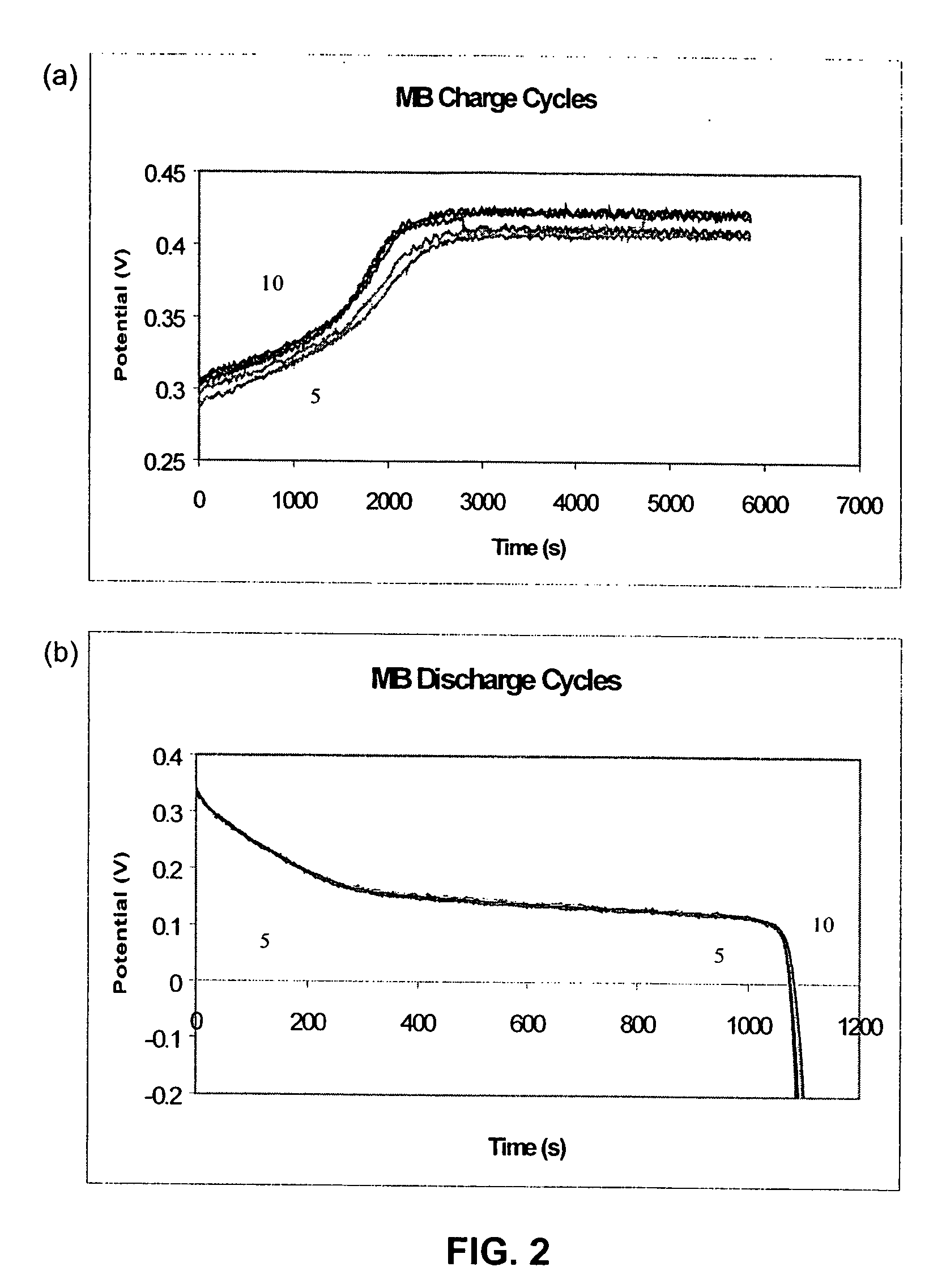

Nickel hydroxide impregnated carbon foam electrodes for rechargeable nickel batteries

InactiveUS20060024583A1Electrochemical processing of electrodesFinal product manufactureElectrical batteryCharge discharge

A novel nickel-carbon electrode, and methods for making the same, have been developed. The nickel-carbon electrode comprises an active mass (e.g., a nickel oxyhydroxide, hydroxide or oxide) deposited to a carbon foam using any one of chemical deposition, thermal deposition or electrochemical deposition. The nickel-carbon electrode is formed or “activated” through a series of charge-discharge cycles. The nickel-carbon electrode is comparable in volumetric capacities (mAh / cc) with commercial nickel electrodes but higher in gravimetric capacities (mAh / g). The nickel-carbon electrode may be used in rechargeable nickel-based batteries which have applications in cordless appliances, portable devices, standby power systems, the aerospace industry, and hybrid electric vehicles.

Owner:MICHIGAN TECHNOLOGICAL UNIVERSITY

Electrode paste for thin nickel electrodes in multilayer ceramic capacitors and finished capacitor containing same

InactiveUS20060171099A1Without loss of conductivityFixed capacitor dielectricStacked capacitorsCeramic capacitorNickel electrode

A method for forming a capacitor and capacitor formed thereby. The method comprises a) forming a capacitor precursor with green ceramic layers separated by conductive precursor layers wherein the conductive precursor layers have 30-80 wt % nickel precursor; up to 20 wt % grain growth inhibitor and 20-70 wt % organic vehicle; and b) heating the capacitor precursor to convert the green ceramic layers to ceramic dielectric layers and the conductive precursor layers to conductive layers.

Owner:BARBER DANIEL E +3

Zinc-nickel double-fluid flow battery

ActiveCN104716304ASolve the disadvantages of corrosionThere is no obvious attenuation in the charge-discharge cycle performanceAlkaline accumulator electrodesHigh concentrationAlkalinity

The invention relates to a zinc-nickel double-fluid flow battery. A single battery sequentially comprises a nickel electrode anode, a cation exchange membrane, an annular frame, an anion exchange membrane and a cathode that are superimposed in order. Both sides of the annular frame are respectively attached to the cation exchange membrane and the anion exchange membrane, two side opening ends of the annular frame are sealed by the cation exchange membrane and the anion exchange membrane, and the central cavity of the annular frame is enclosed into an electrolyte solution storage cavity. A third solution is loaded in the electrolyte solution storage cavity to conduct ions so as to form an ion conducting loop. Two different ion exchange diaphragms are used between the anode and cathode of the battery, by introducing the annular frame into the center, acidity and alkalinity of the electrolyte solutions at the anode and cathode are designed separately and independently, so that the anode electrolyte solution of the zinc-nickel fluid flow battery can use a low concentration alkali fluid, and the cathode electrolyte solution can use a zinc ion containing neutral aqueous solution, thus effectively solving the corrosion defect caused by the need of conventional nickel-zinc fluid flow batteries for a high concentration alkaline zincate aqueous solution.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

X8R dielectric composition for use with nickel electrodes

ActiveUS7541306B2Small dielectric lossImprove reliabilityStacked capacitorsSemiconductor/solid-state device manufacturingLow dissipationBarium titanate

Multilayer ceramic chip capacitors which satisfy X8R requirements and which are compatible with reducing atmosphere sintering conditions so that non-noble metals such as nickel and nickel alloys thereof may be used for internal and external electrodes are made in accordance with the invention. The capacitors exhibit desirable dielectric properties (high capacitance, low dissipation factor, high insulation resistance), excellent performance on highly accelerated life testing, and very good resistance to dielectric breakdown. The dielectric layers comprise a barium titanate base material doped with other metal oxides such as BaO, Y2O3, ZrO2, SiO2, MgO, MnO, MoO3, CaO, Lu2O3, Yb2O3, or WO3 in various combinations.

Owner:FERRO CORP

Preparation method of nickel electrode made of piezoelectric composite material

InactiveCN102337526ALow costReduce the temperatureLiquid/solution decomposition chemical coatingNickel saltChemical plating

The invention discloses a preparation method of a nickel electrode made of a piezoelectric composite material. The nickel electrode is prepared by using a chemical plating method. The preparation method comprises steps of roughening, sensitizing and activating the piezoelectric composite material, and putting the piezoelectric composite material in a nickel plating liquid to be plated with nickelto obtain the nickel electrode, wherein the activating solution used in the activation procedure is a palladium salt activating solution or nickel salt activating solution, the palladium salt activating solution is prepared by dissolving PdCl2 in certain hydrochloric acid, the PdCl2 content is 0.3-0.5 g / L and the content of the concentrated HCl is 9.9-11 ml / L; the nickel salt activating solution is prepared by dissolving nickel acetate and sodium borohydride in absolute methanol, the content of the nickel acetate is 64-68 g / L, and the content of the sodium borohydride is 64-68 g / L. The invention has the advantages of high nickel plating speed, easiness in regulating and controlling the thickness of a plating layer, uniform and dense thickness of the plating layer of a nickel plate, strongcombination force of the plating layer, good uniformity and wearing resistance, remarkable erosion resistance, excellent welding property and long service life, so that the application demand of the composite material is met.

Owner:UNIV OF JINAN

Metal organic framework/foamed nickel electrode material and preparation method and applications thereof

ActiveCN108315760AThe design is scientific, reasonable and simpleStrong process controllabilityElectrode shape/formsFerrous saltsMetal-organic framework

The invention discloses a metal organic framework / foamed nickel electrode material and a preparation method and applications thereof. The preparation method comprises following steps: taking a foamednickel sheet as the nickel source and basic material, placing the foamed nickel sheet in a reactor, adding a mixed solution of ferrous salts and terephthalic acid ligands into the reactor, sealing thereactor, heating the reactor to carry out reactions, cooling, taking out the foamed nickel sheet, washing, and drying to obtain the metal organic framework / foamed nickel electrode material. The chemical formula of prepared metal organic frame is Fe2Ni2(OH)2(C8H4O4), and the electrode material belongs to a triclinic system and a P1(1) space group. The provided method has the advantages of scientific and reasonable design, simple and controllable technology, easily available and cheap raw materials, low production cost, and high efficiency, is suitable for massive production, and has a wide commercial prospect. In an alkaline solution, the electrode material has an extremely high electro-catalytic activity on oxidation reactions of water, moreover, the catalytic effect is long lasting and stable, and the theoretical meaning and actual meaning are significant.

Owner:CAPITAL NORMAL UNIVERSITY

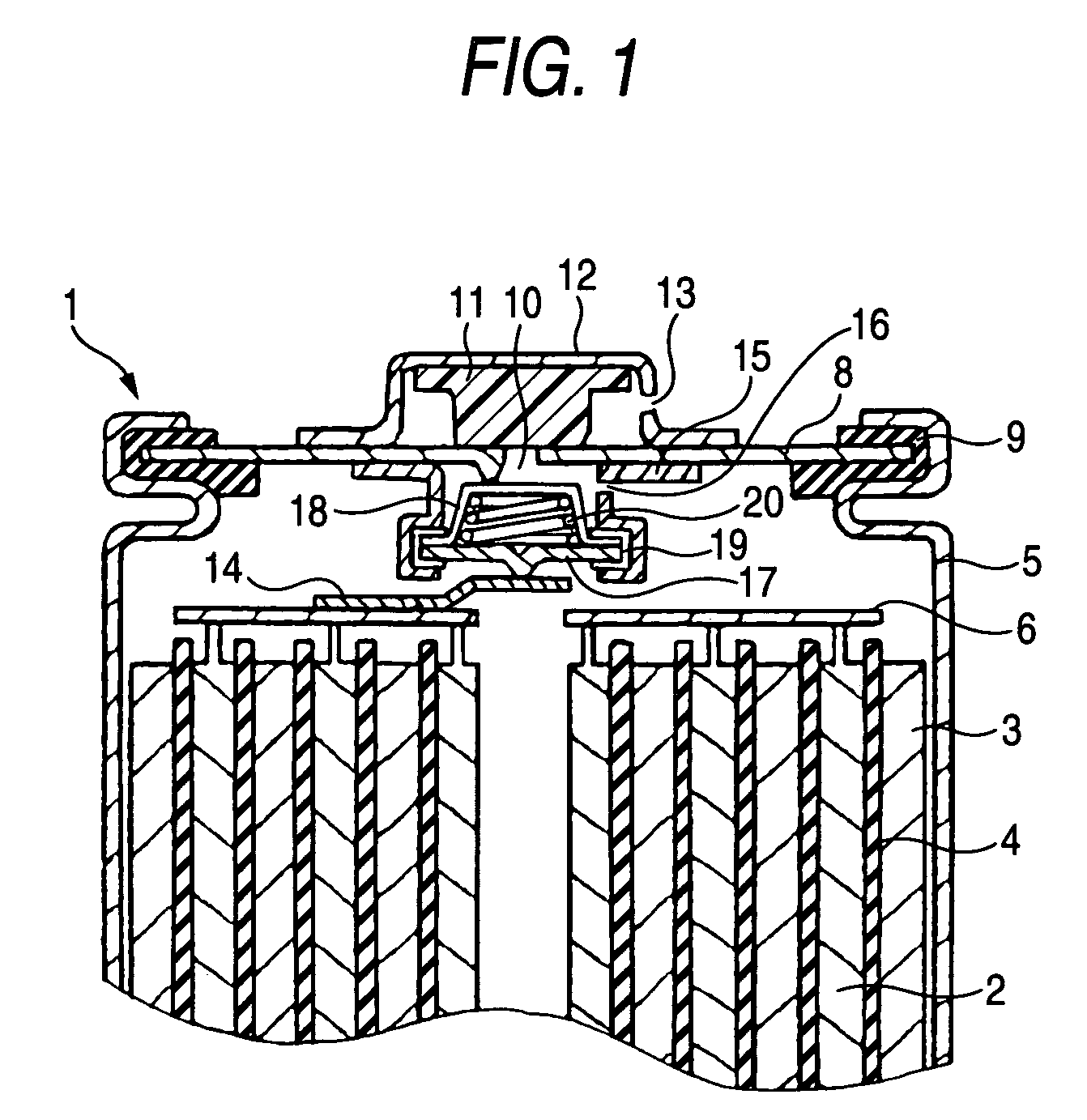

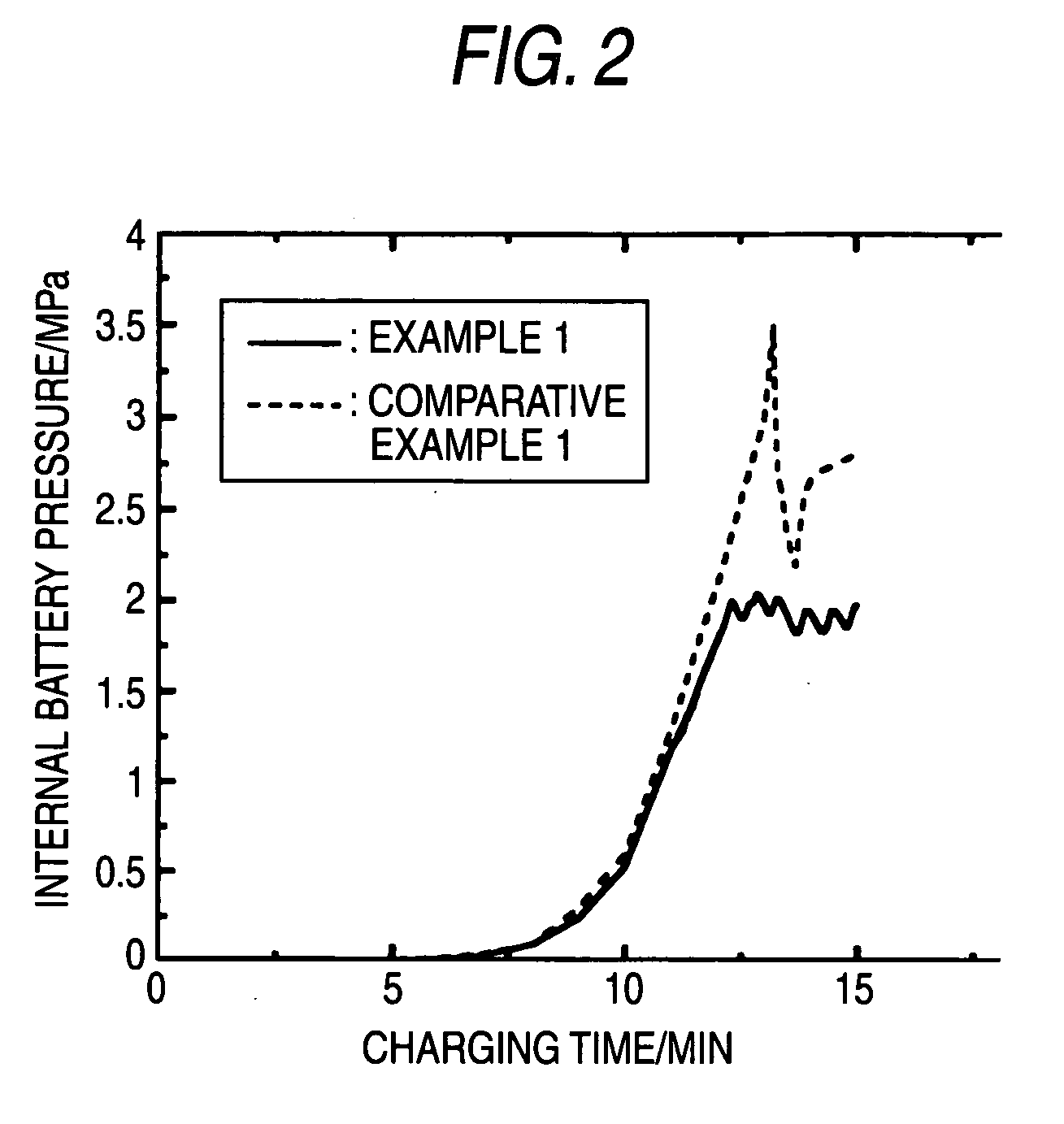

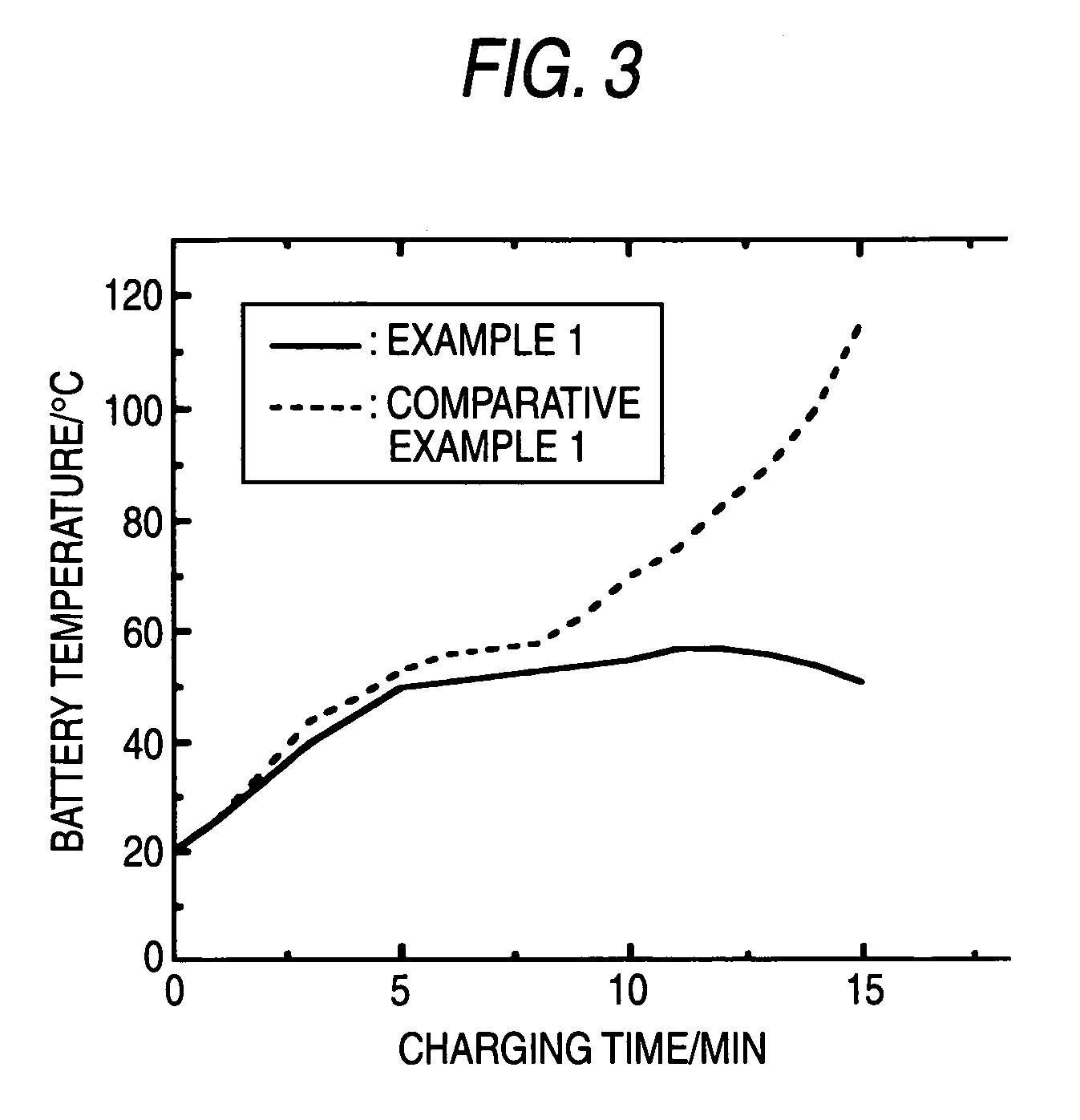

Sealed alkaline storage battery, electrode structure and charging method for the same, and charger for sealed alkaline storage battery

ActiveUS20060097701A1Remarkable effectBatteries circuit arrangementsFinal product manufactureEngineeringNickel electrode

A sealed alkaline storage battery including a nickel electrode as a positive electrode, characterized by having the function of being capable of charge when the gas pressure in the battery and / or the battery temperature is not higher than a specified value and of being incapable of charge when the gas pressure in the battery and / or the battery temperature exceeds the specified value.

Owner:GS YUASA INT LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com