Patents

Literature

597 results about "Nickel acetate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for producing semiconductor device

InactiveUS6479329B2Semiconductor/solid-state device manufacturingSemiconductor devicesSingle crystalLaser light

Owner:SEMICON ENERGY LAB CO LTD

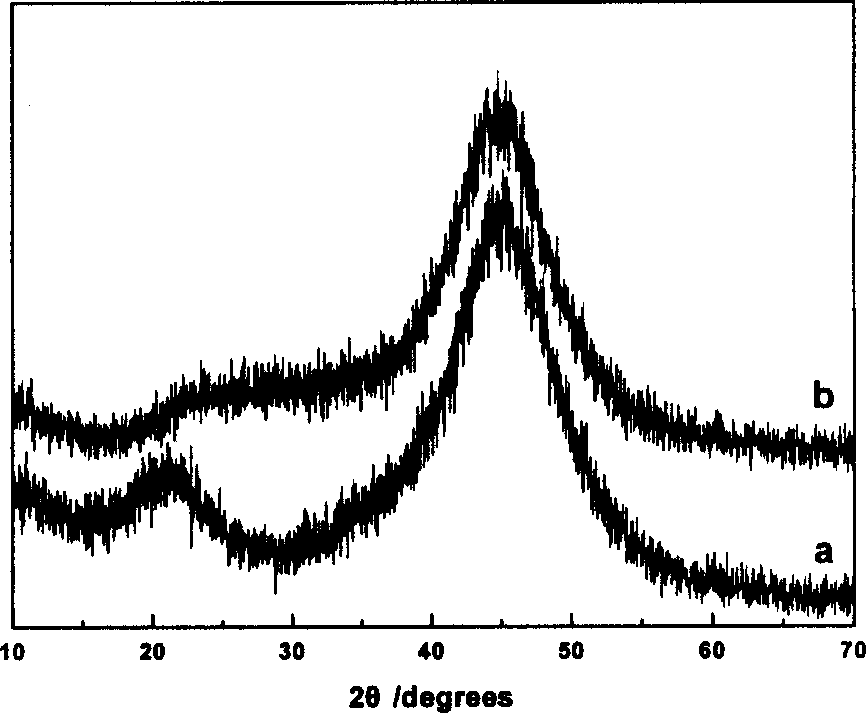

Aromatic saturated hydrogenation catalyst and its preparing process

ActiveCN101099934AHigh catalytic activityMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsBimetalChemistry

The present invention relates to one kind of arene saturation hydrogenating metal nitride catalyst, which consists of gamma-Al2O3 carrier and supported bimetal Ni-Mo nitride. Of the active components, Ni accounts for 2.5-10 wt%, Mo accounts for 6-25 wt%, and Ni and Mo co-exist as Ni2Mo3N, Ni, Mo2N and small amount of oxides. The catalyst is prepared through the following steps: roasting gamma-Al2O3 powder at 500-550 deg.c for 4-5 hr; dissolving nickel acetate, ammonium molybdenum and HMT in the molar ratio of 14 to 3 to 17.2-27 in 13 % ammonia water solution to form immersion solution; soaking the gamma-Al2O3 powder in the solution via stirring for 2-4 hr, filtering, air drying, vacuum drying at 60-100 deg.c for 5-8 hr, tabletting and sieving; roasting first in Ar flow to 650-680 deg.c for 2 hr and then in H2 flow for 2 hr, and cooling to room temperature in H2; and final deactivating in N2 containing O2 in 1 % for 4 hr. It has high catalytic activity and other features.

Owner:PETROCHINA CO LTD

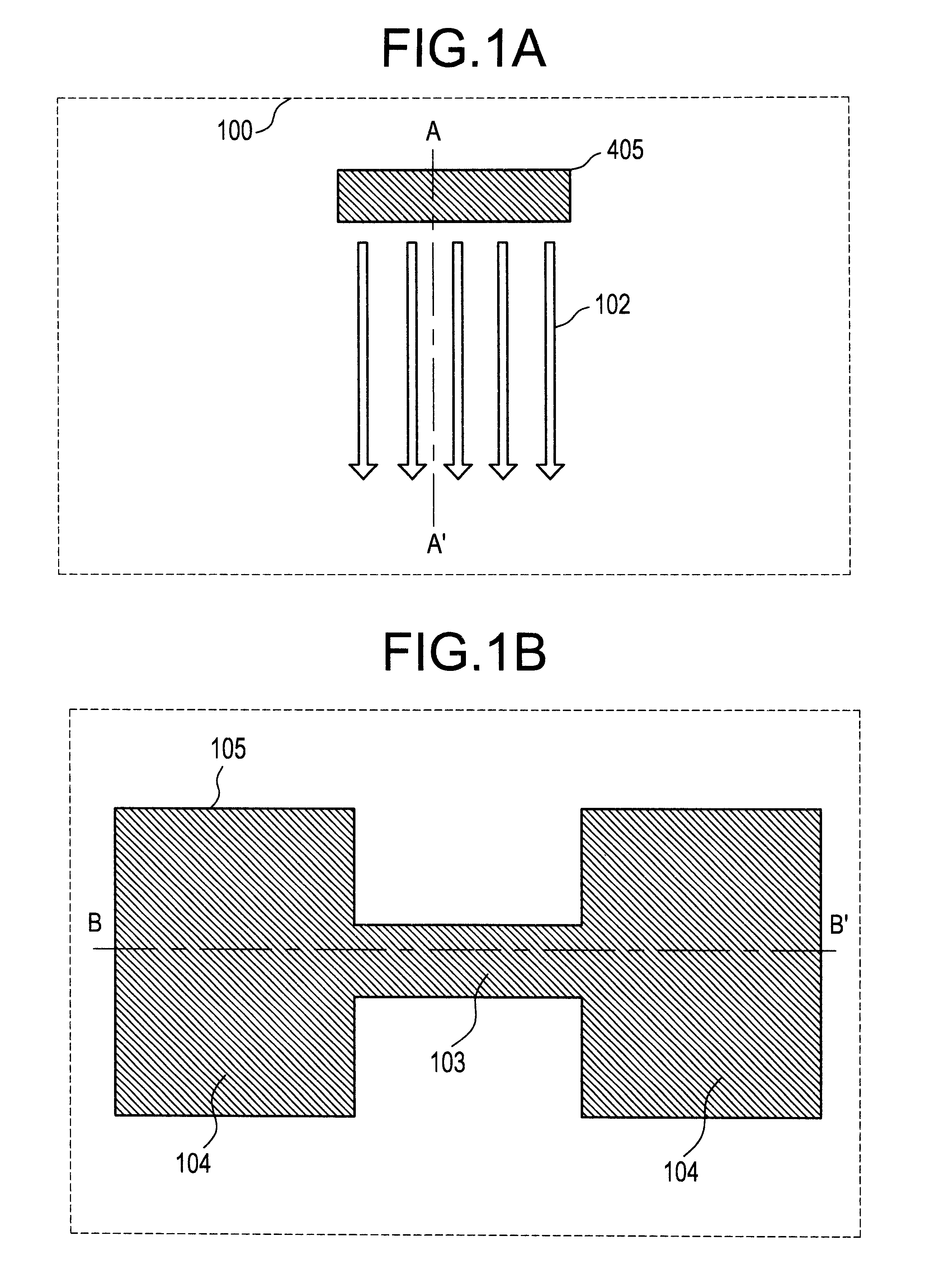

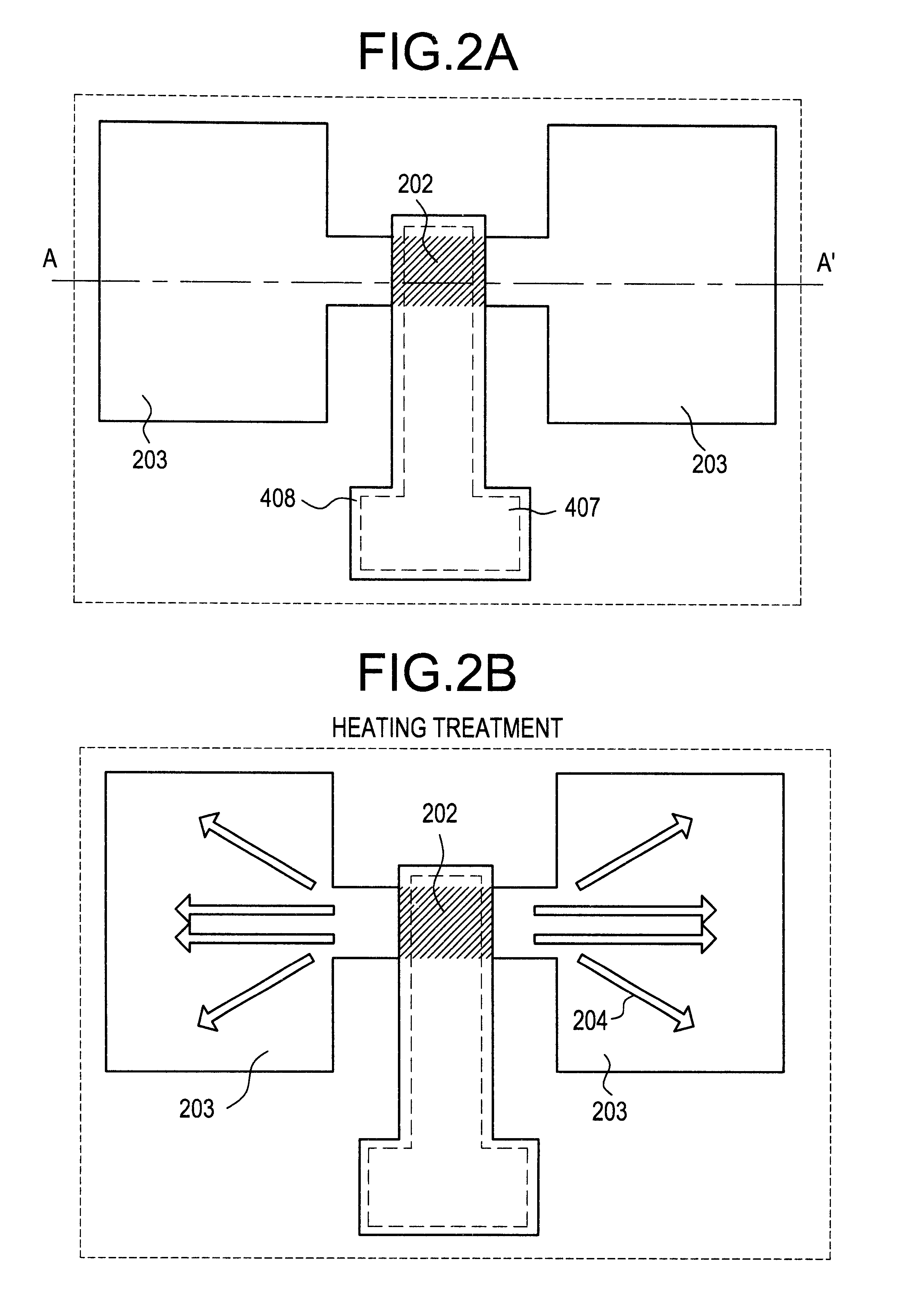

Semiconductor device and method for producing the same

InactiveUS6316789B1Improve crystallizationPromote crystallizationTransistorSolid-state devicesAmorphous siliconNickel acetate

The solution (for example, a nickel acetate solution) containing a metal element such as nickel which accelerates the crystallization of silicon is applied to an amorphous silicon film by spin coating using a mask, to retain nickel in contact with the surface of the amorphous silicon film. Then, heating treatment is performed to crystallize selectively the amorphous silicon film, so that an amorphous region and a crystalline region are formed in the silicon film. In this state, the silicon film is heated to diffuse the metal element from the crystalline region to the amorphous region, thereby decreasing a concentration of the metal element in the crystalline region.

Owner:SEMICON ENERGY LAB CO LTD

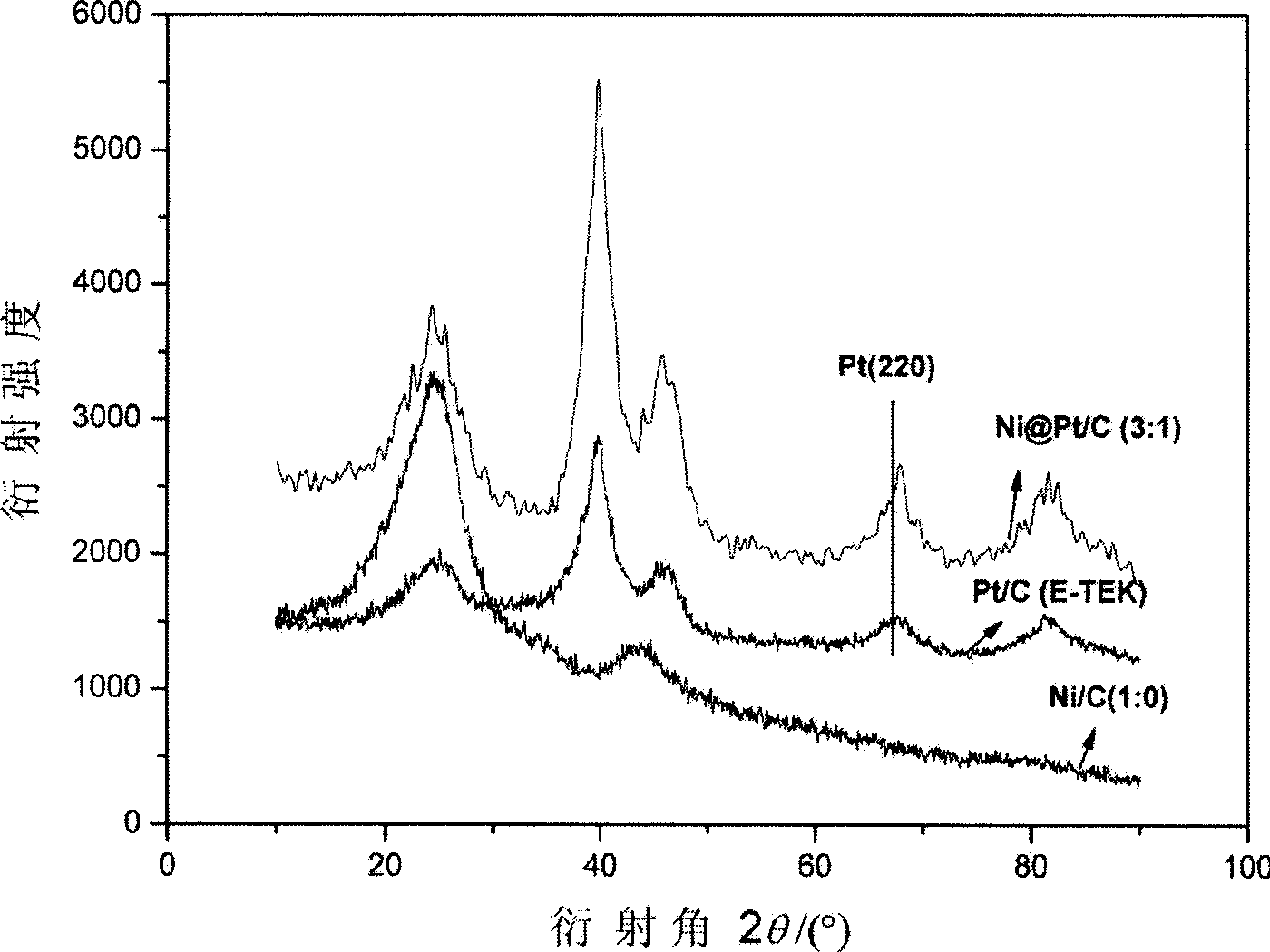

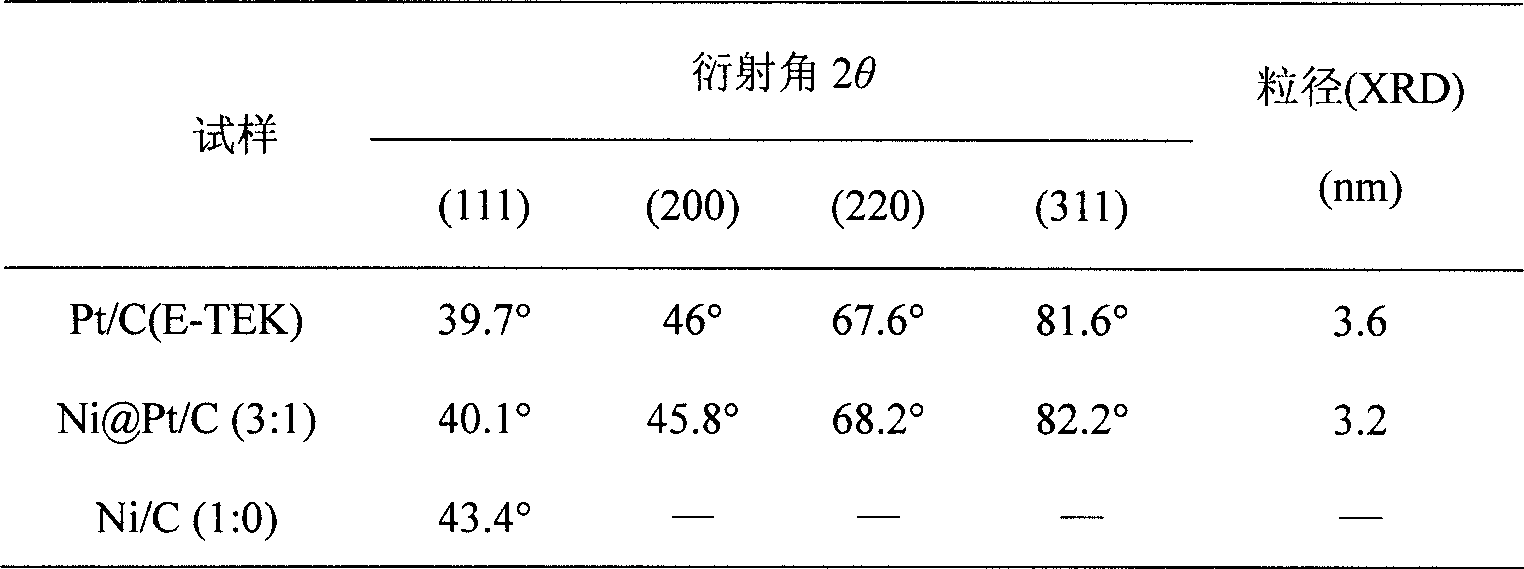

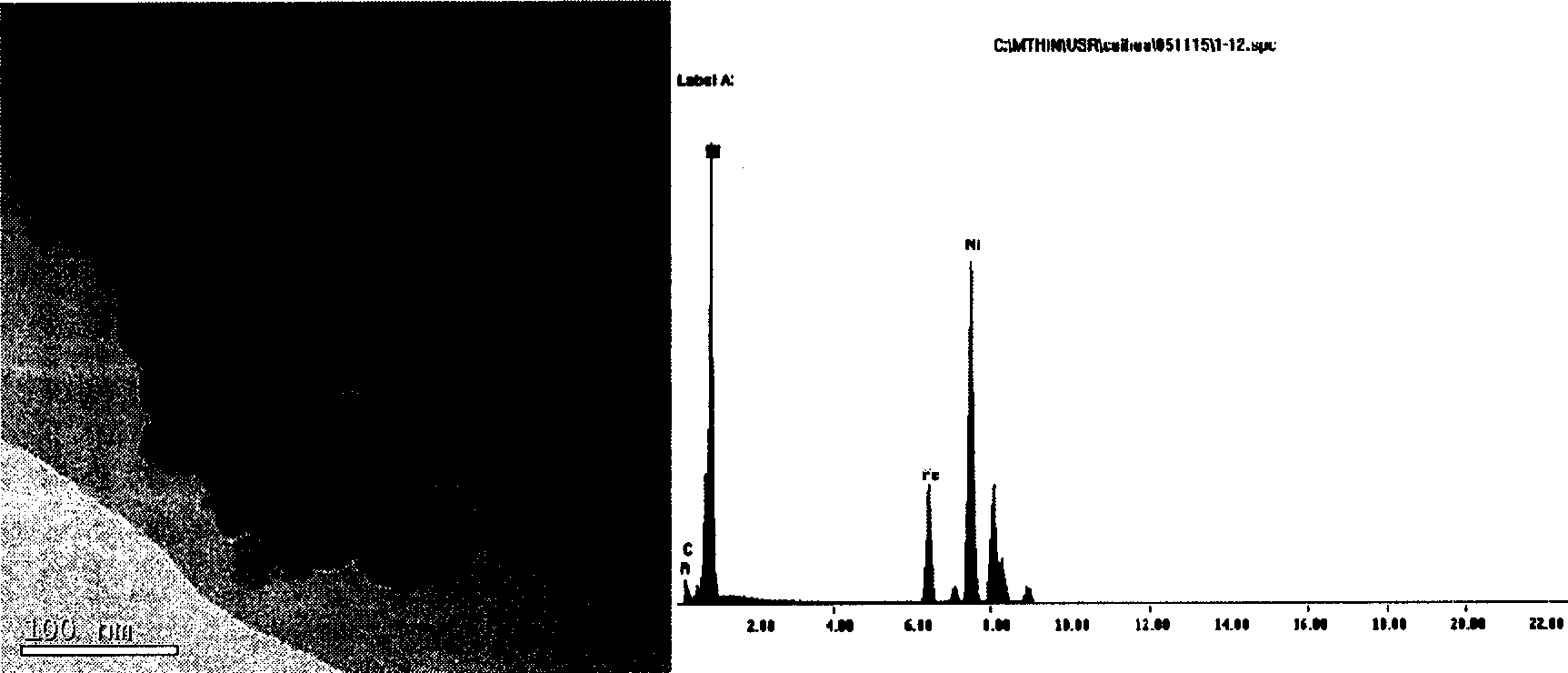

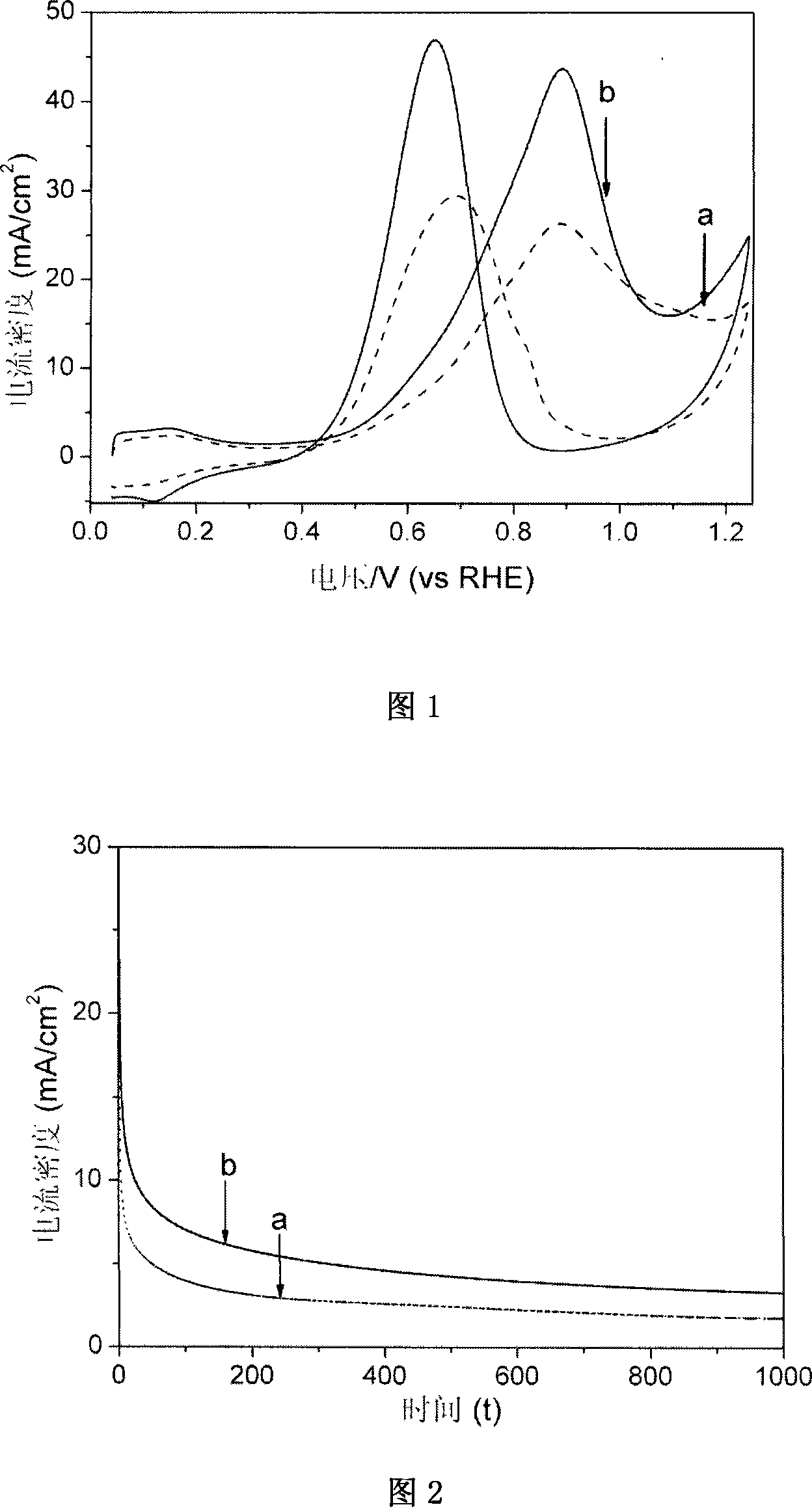

Preparation method of carbon supported core-shell Ni-Pt particles for direct methanol fuel cells

ActiveCN101455970AImprove catalytic performanceLow priceCell electrodesMetal/metal-oxides/metal-hydroxide catalystsChemistryInorganic chemistry

The invention provides a method for preparing carbon-supported nucleocapsid type Ni-Pt particles for direct methanol fuel cell catalysts, which belongs to a preparation process of direct methanol fuel cell catalysts. The method comprises the steps of adopting sodium citrate as a stabilizer, adopting cationic surfactant CTAB as dispersant, using sodium hypophosphite to reduce nickel acetate, generating a Ni kernel on the surface of Vulcan XC-72 or mesoporous carbon treated with sodium borohydride, washing superfluous sodium hypophosphite and generating a Pt shell on the surface of the Ni kernel through chemical replacement. The catalyst has a structure with the Ni kernel and the Pt shell, and has the advantages of low Pt support amount and high catalytic activity.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Catalyst for preparing mixing alcohol with low carbon from synthesis gas and its preparing method

InactiveCN1431049AGuaranteed stabilityGuaranteed lifeOrganic compound preparationHydroxy compound preparationHigh resistanceMANGANESE ACETATE

A catalyst for preparing low-carbon alcohol mixture from synthetic gas contains Mo (2-40 %), Ni (4-10%), Mn (0.1-5.0%), K (5-15%), S (20-40%) and bentone, and is prepared through reaction of ammoniumsulfide solution or hydrogen sulfide gas on ammonium molybdate, adding concentrated acetic acid, thermal stirring, cooling for deposition, adding deionized water for dissolving doposit to obtain solution of ammonium thiomolybdate, dropping the solution along with the mixed solution of nickel acetate and manganese acetate in acetic acid to form black deposit, filtering, washing, baking, mixing with bentone, and tabletting. Its advantages are high resistance to S and no carbon deposit.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

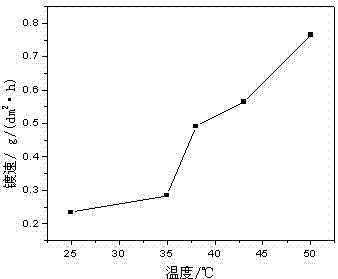

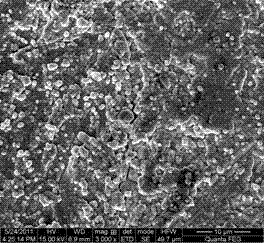

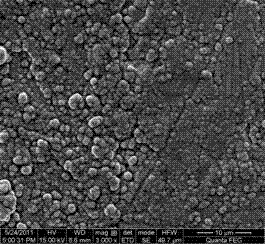

Mixed acid anodizing and hole sealing method of magnesium-containing high-silicon-content wrought aluminum alloy surface

The invention belongs to the technical field of alloy surface treatment, and particularly relates to a mixed acid anodizing and hole sealing method of a magnesium-containing high-silicon-content wrought aluminum alloy surface, which comprises the following steps that: after a magnesium-containing high-silicon-content wrought aluminum alloy workpiece with the silicon content of up to 10-15wt% is pre-treated, a mixed acid liquid of 150-180g / L of H2SO4 and 5-15g / L of organic acid is used as an electrolytic liquid, the magnesium-containing high-silicon-content wrought aluminum alloy workpiece is subjected to DC (direct current) anodic oxidation for 20-25min at room temperature at the current density of 1.2-1.8A / dm<2>, and then is subjected to boiling water sealing, cold sealing, nickel acetate sealing or stearic acid hole sealing. In the acid anodizing and hole sealing method, a layer of anodic oxide film is prepared on the surface of magnesium-containing high-silicon-content wrought aluminum alloy by controlling anodizing process parameters and hole sealing process conditions, thereby improving the corrosion resistance of the surface of the magnesium-containing high-silicon-content wrought aluminum alloy.

Owner:NORTHEASTERN UNIV

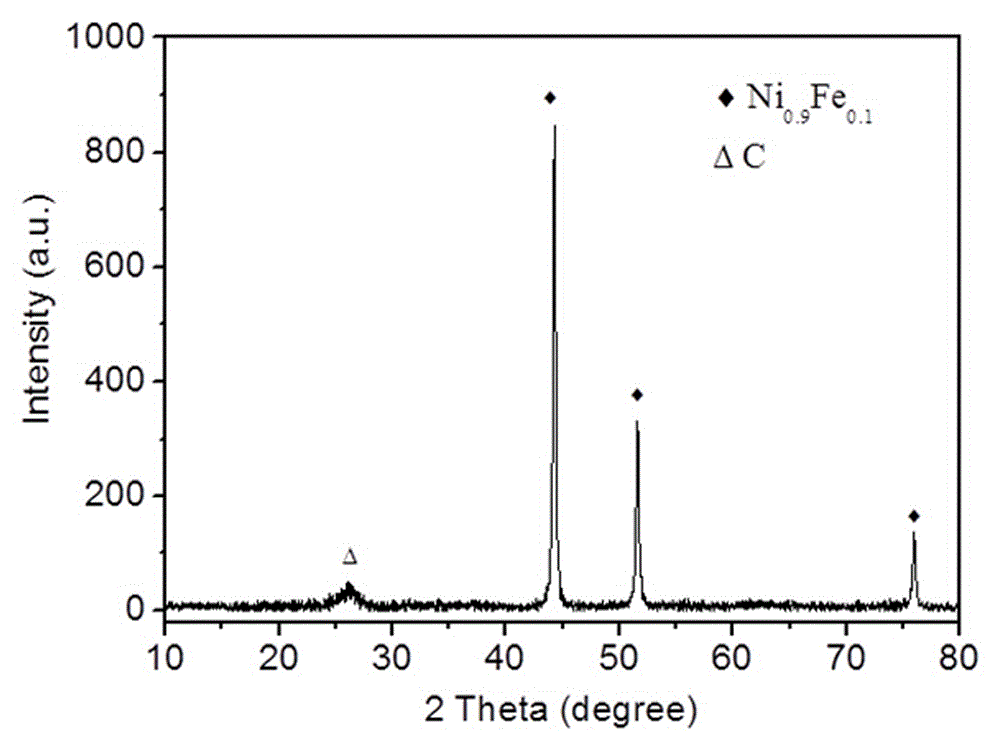

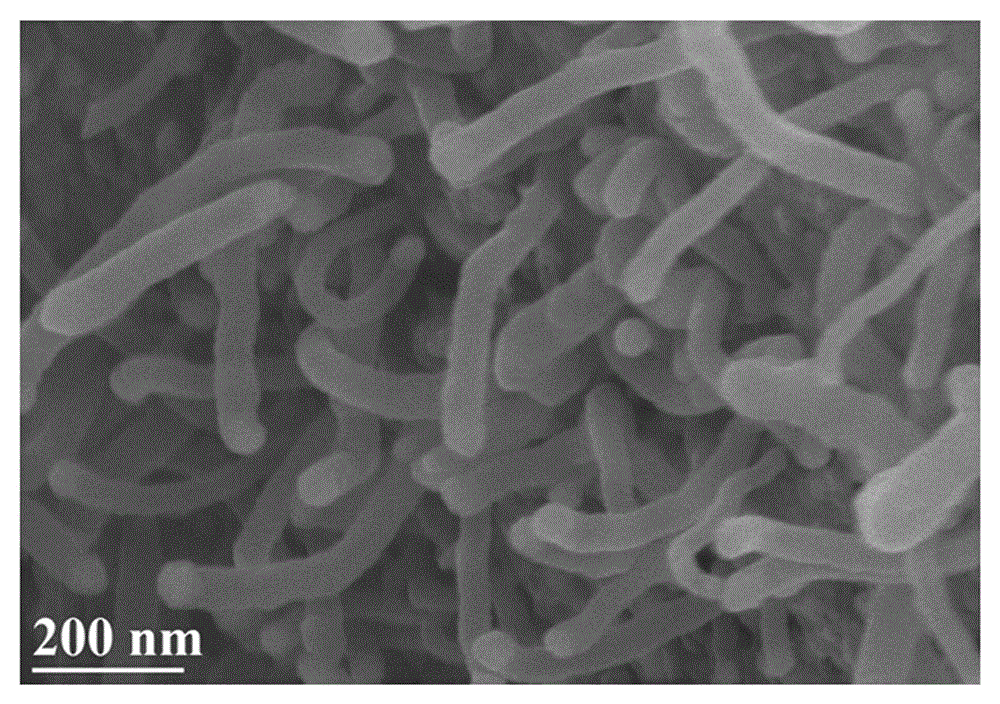

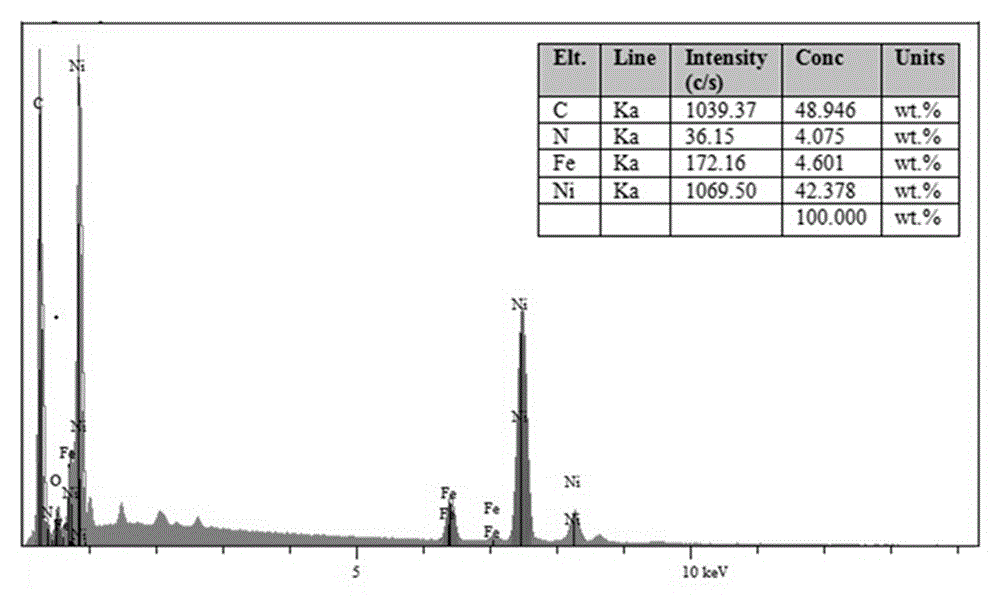

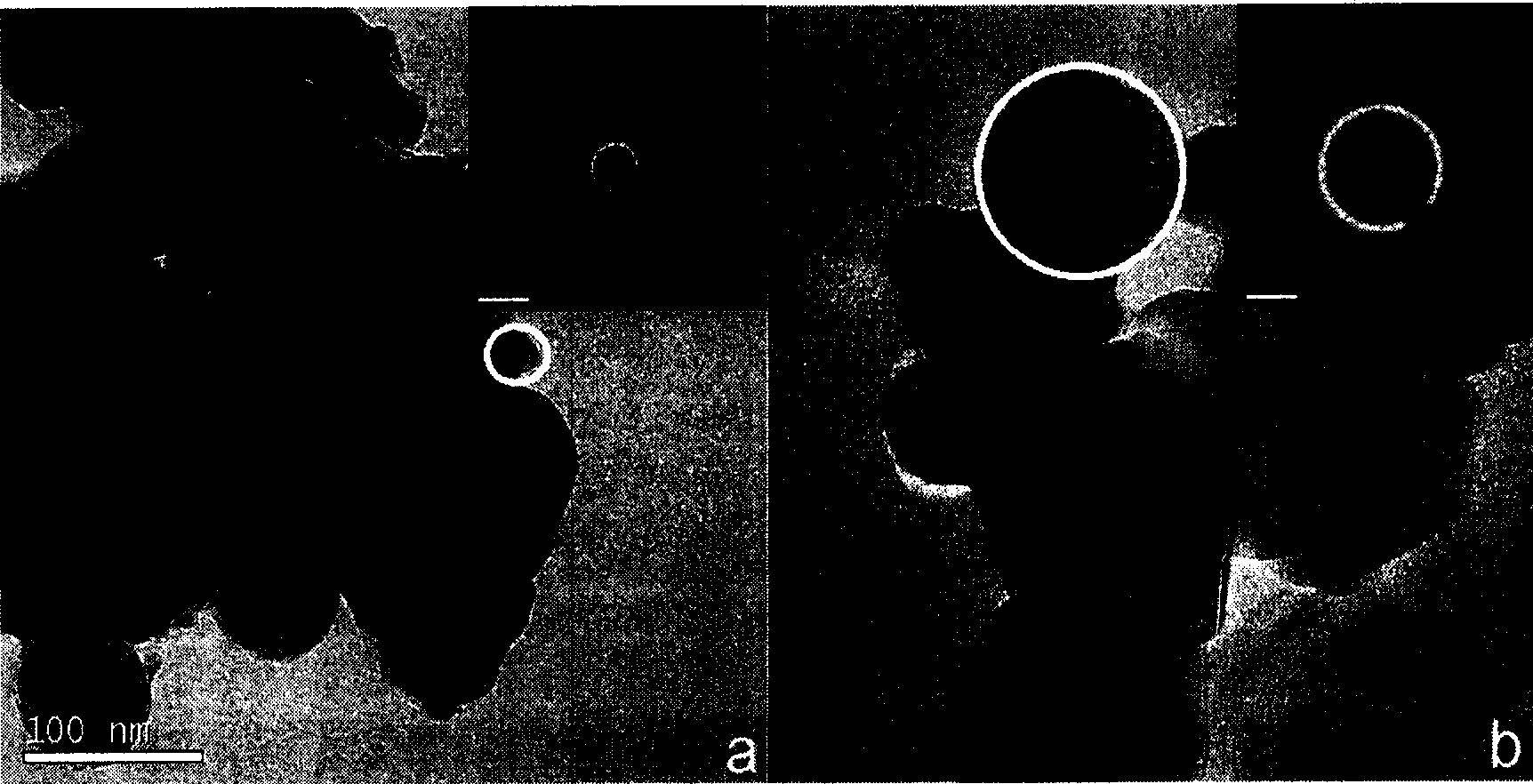

Nitrogen-doped carbon nanotube nickel-iron coated oxygen evolution catalytic material for water electrolysis and application

ActiveCN105107540ALarge specific surface areaImprove performanceElectrolysis componentsPhysical/chemical process catalystsThioureaEthylic acid

The invention relates to preparation and application of a nitrogen-doped carbon nanotube nickel-iron coated oxygen evolution catalytic material for water electrolysis. A general formula of the composite electrode material is Ni0.9Fe0.1@CNx, wherein CN is nitrogen-doped carbon, and x is greater than or equal to 0.01 and less than or equal to 0.1. The specific preparation method of the catalytic material comprises the steps of uniformly mixing nickel acetate and ferric chloride with citric acid and thiourea according to certain molar percentages, and then carrying out calcinations for 1-10h under an N2 gas flow rate of 10-100 mL / min at 600-900 DEG C to prepare the catalytic material. The preparation method provided by the invention effectively achieves one-step preparation of the Ni0.9Fe0.1@CNx oxygen evolution catalytic material with set ratios of Ni, Fe, C and N by an in-situ solid-phase method, and the product is nanotube-shaped, porous and large in specific surface area, and has excellent performance when being used as an oxygen evolution electrode material for water electrolysis. The method provided by the invention is convenient to operate, the process is simple and easy to control, raw materials are low in price and easy to obtain, and the catalytic material is suitable for large-scale production.

Owner:TAIYUAN UNIV OF TECH

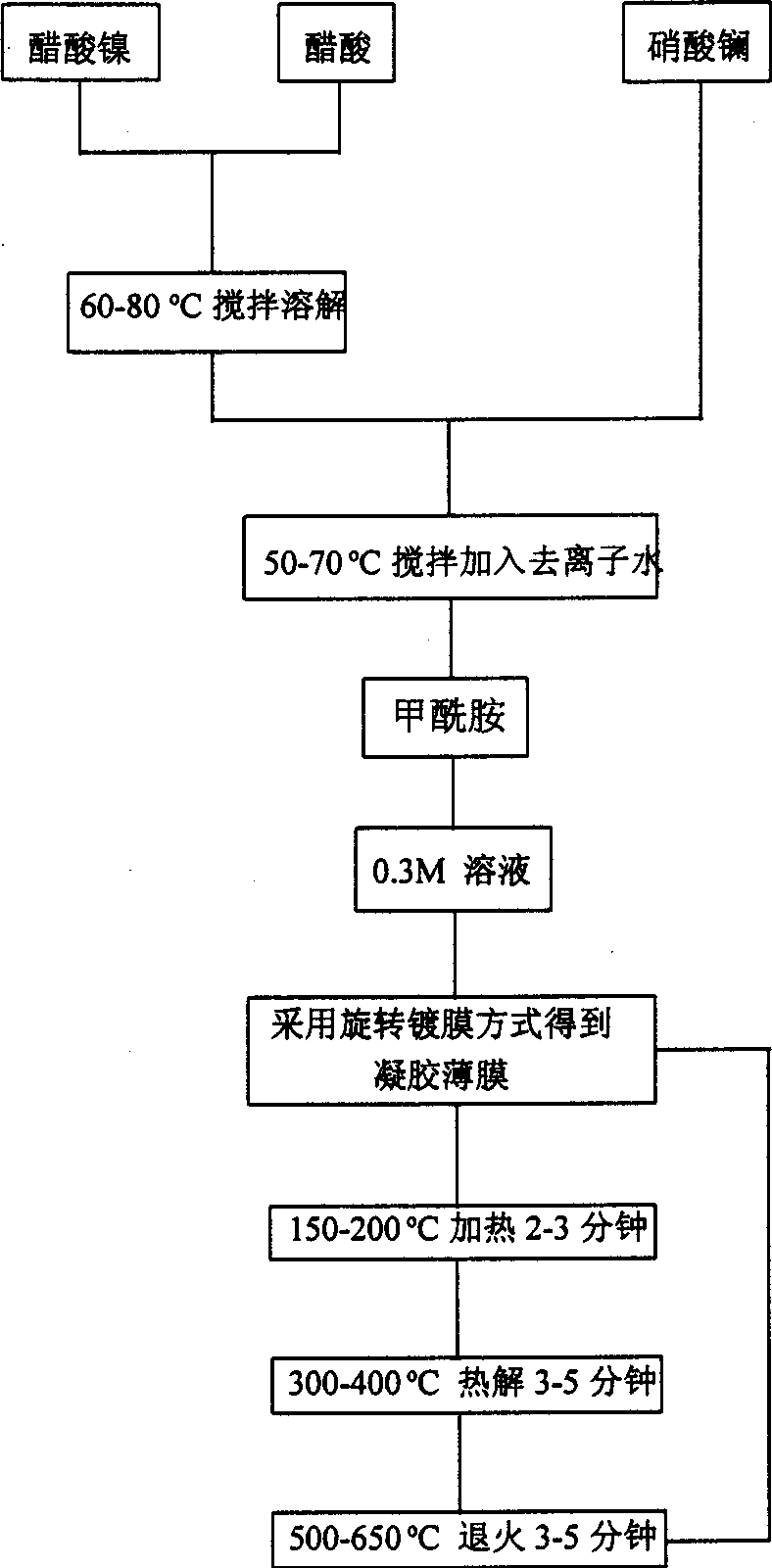

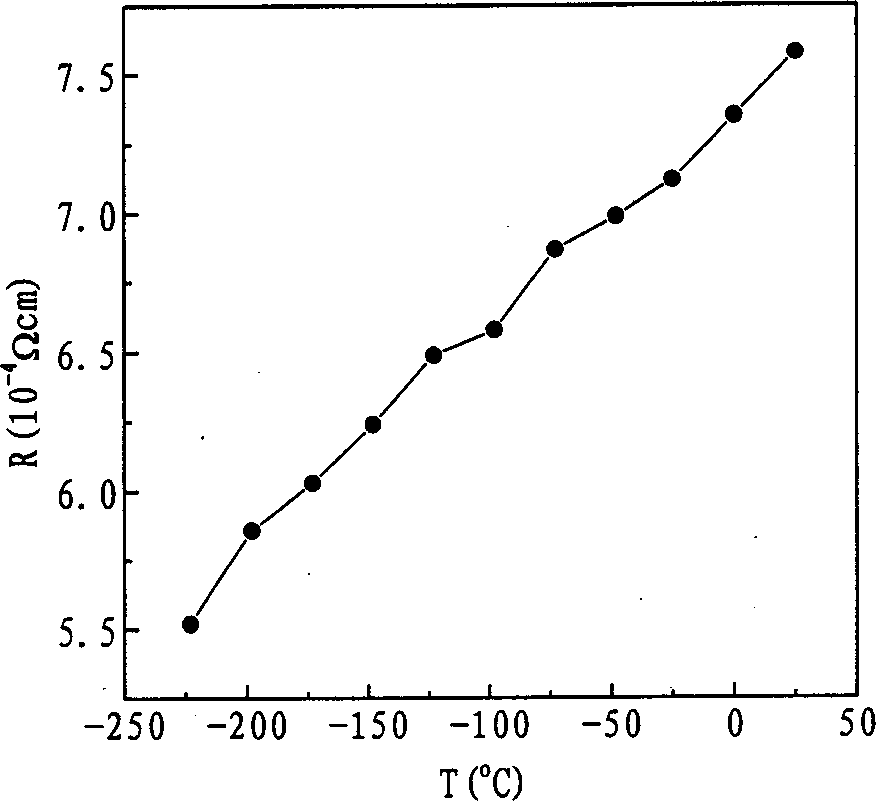

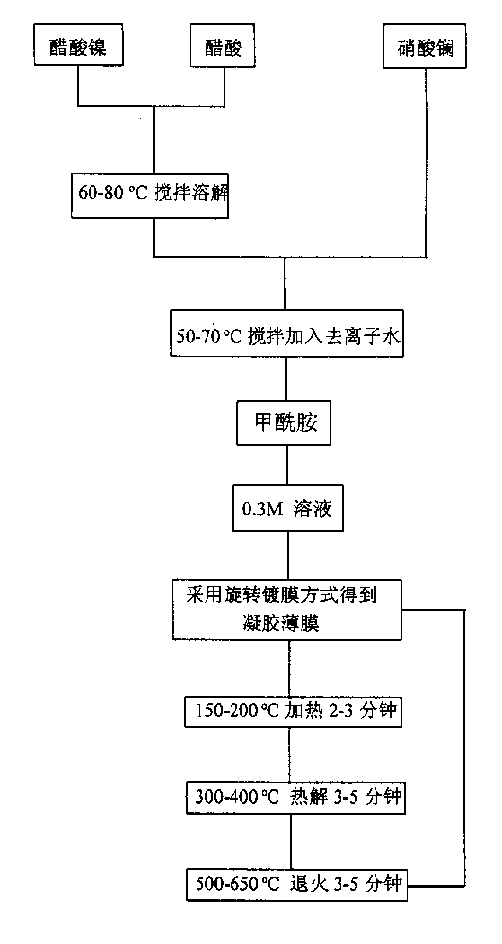

Prepn of lanthanum nickelate-conducting metal oxide film material

InactiveCN1362749ALow costEasy to operatePiezoelectric/electrostrictive/magnetostrictive devicesSolventFilm material

The preparation method for lanthanum nickelate conductive metal oxide film material includes: preparing precursor solution, mixing solvent acetic acid, deionized water and additive methanamide and solute nickel acetate and lanthanum nitrate at a certain temperature in the concentration of 0.3 M to obtain precursor solution, and preparing film material, making the prepared precursor solution form gel film on the substrate by adopting rotating coating mode, then making heat treatment by sections in quick annealing furnace to form film material. Said film material possesses high selective orinetation and good metal characteristics, and its room temp. electric resistivity is about 7.6X10 to the minus fourth ohm cm. Said film material can be used to prepare high-quality ferroelectric film material on it or can be used as bottom electrode of ferroelectric film device.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

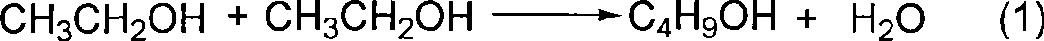

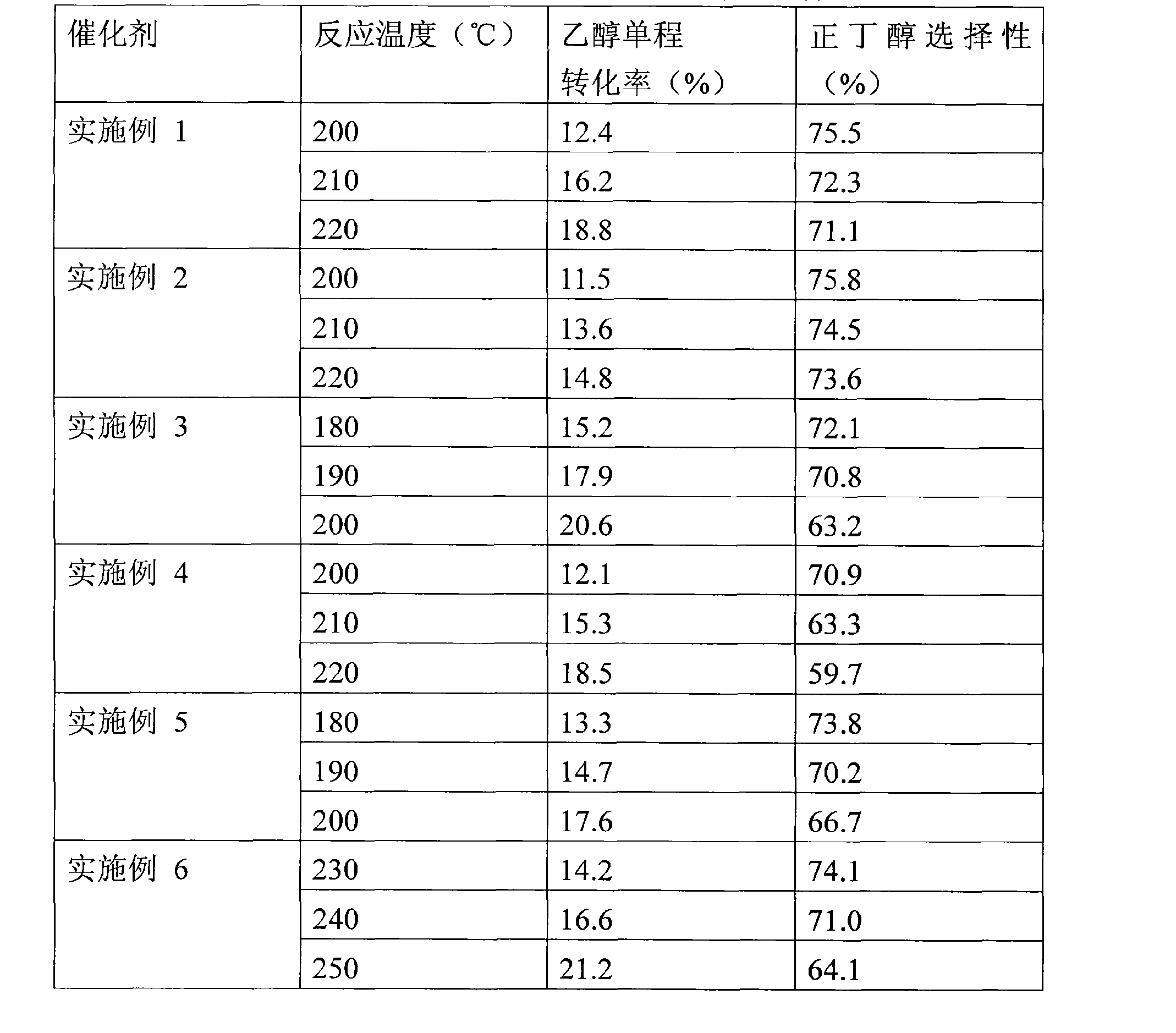

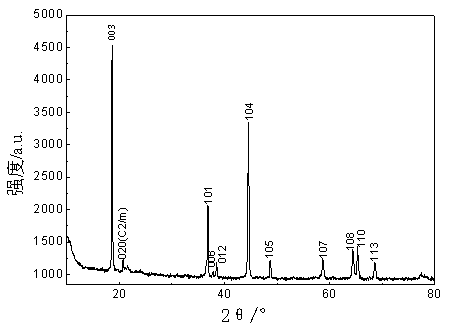

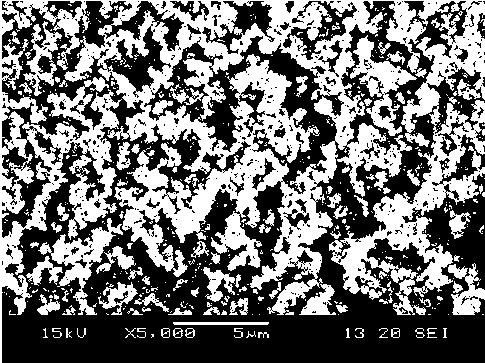

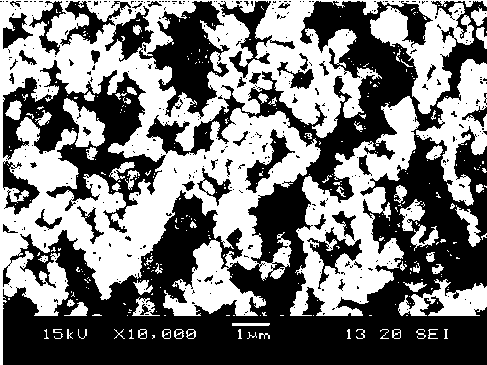

Bi-component supported catalyst of ethanol condensed n-butanol and a method of preparing thereof

InactiveCN101530802ASimple methodLow costOrganic compound preparationHydroxy compound preparationPotassium fluorideGram

The invention discloses a bi-component supported catalyst of ethanol condensed n-butanol and a method of preparing thereof. The main active ingredients of the catalyst are as follows by weight percentage content: 2%-10% nickel, 0.5%-9% cocatalyst MgO or KF. The preparing method comprises the steps of: directly dipping 30-50 grams of granulose gamma-Al2O3 into nickel acetate or nickel nitrate aqueous solution with consistency being 0.5-1.0 mol / L, dipping for 2 to 4 days, occasionally stirring, evaporating, drying under 130 degrees centigrade, then dipping into magnesium nitrate or potassium fluoride aqueous solution with consistency being 0.1-1.0 mol / L for 2 to 3 days, evaporating, drying under 130 degrees centigrade to prepare the bi-component supported catalyst of ethanol condensed n-butanol. The method of preparing bi-component supported catalyst in the invention is simple and has low cost; the catalytic activity is higher than that of the single component nickel supported catalyst; the selectivity of the n-butanol in the products can achieve above 70% and has wildly industrialized application prospect.

Owner:ZHEJIANG UNIV

Lithium-enriched ternary anode material of power lithium-ion battery and preparation method of lithium-enriched ternary anode material

InactiveCN103280574AIncrease capacityPromote circulationCell electrodesMANGANESE ACETATEPhysical chemistry

The invention discloses a lithium-enriched ternary anode material of a power lithium-ion battery and a preparation method of the lithium-enriched ternary anode material. The molecule formula of the lithium-enriched ternary anode material of the power lithium-ion battery is Li1.2Ni0.13Co0.13Mn0.54O2. The preparation method comprises the following steps of: dissolving lithium acetate, cobaltous acetate, nickel acetate and manganese acetate in deionized water according to the molar ratio of Li: Co: Ni: Mn: O being 1.2: 0.13: 0.13: 0.54: 2 to obtain a solution 1; adding citric acid according to the ratio of the molar weight of the citric acid to the total molar weight of Ni, Co and Mn being 1:1 to obtain a solution 2; dropwise adding the solution 2 into the solution 1, and then adjusting the pH value to 9, continuously stirring the solution at the temperature of 80 DEG C until purple gel is formed, and then sequentially drying, ball milling, calcining segment by segment and grinding to obtain the lithium-enriched ternary anode material of the power lithium-ion battery with large discharging specific capacity and good cycling performance.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

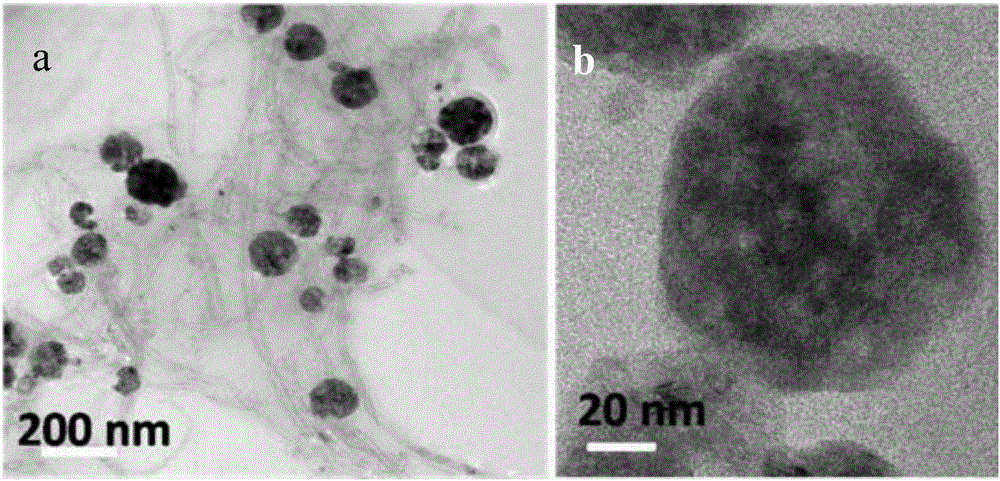

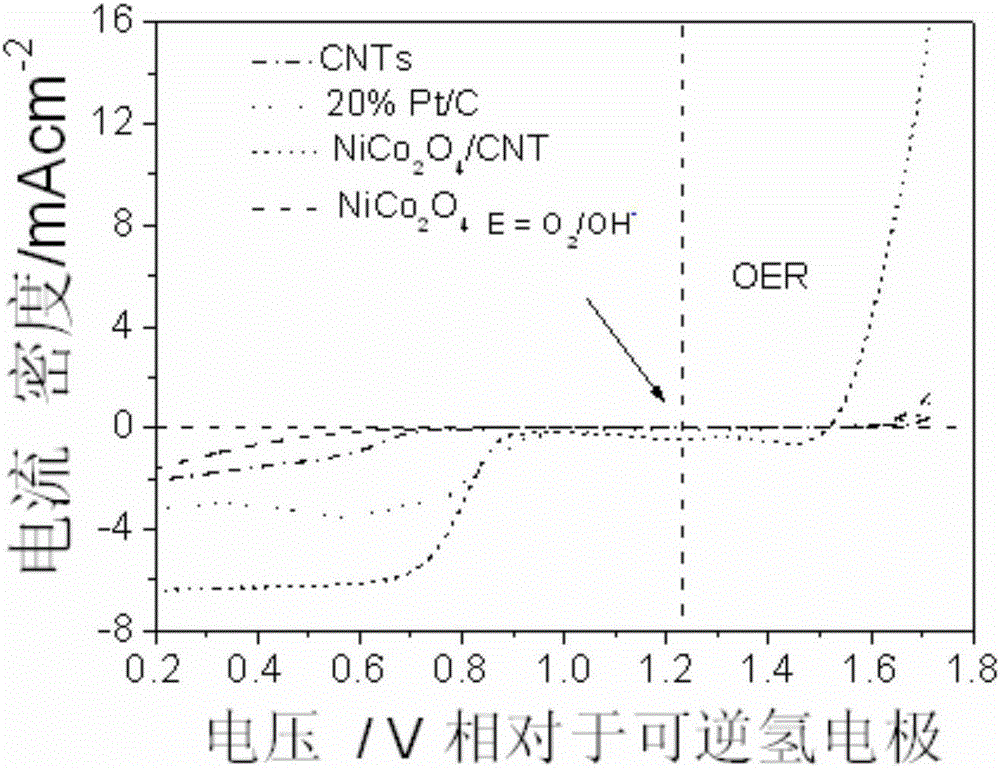

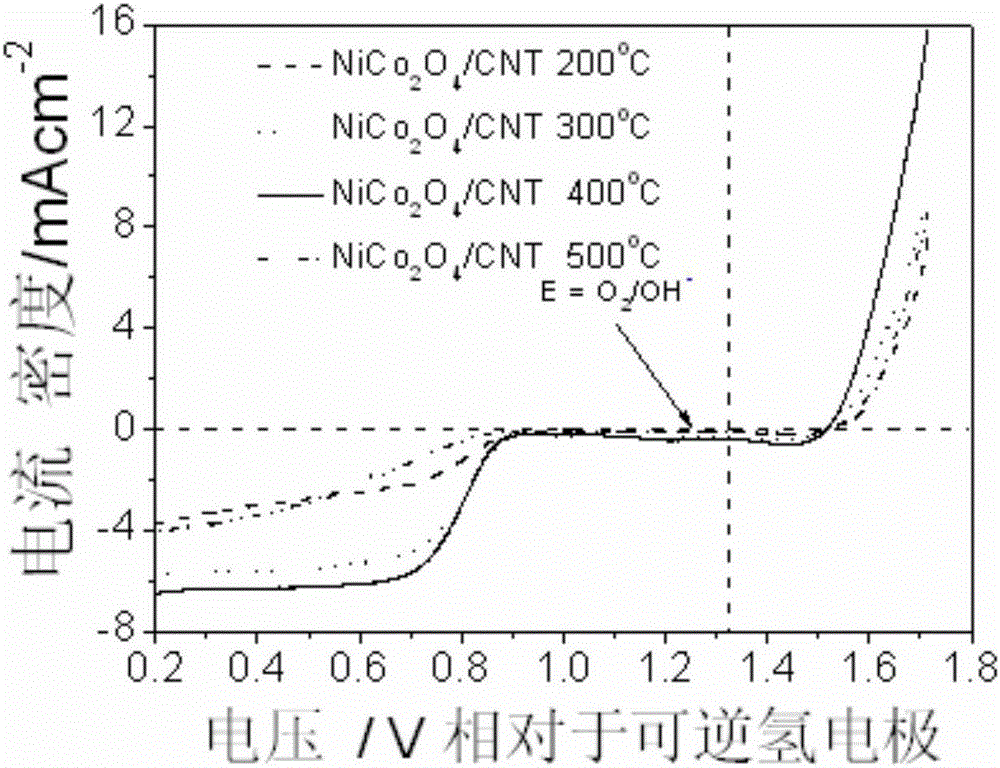

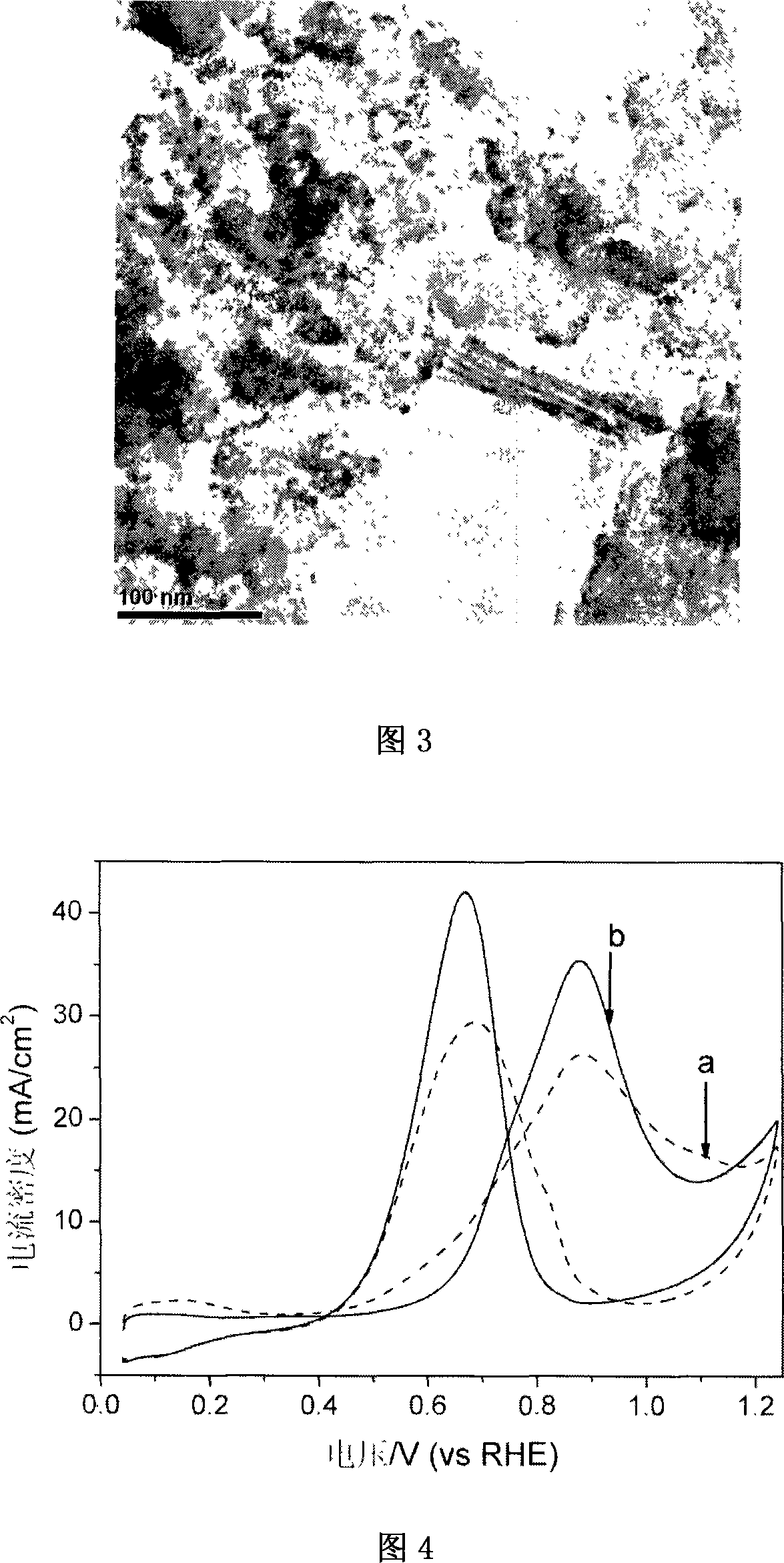

Nickel cobalt oxide/carbon nanotube composite catalyst, preparation and application thereof

InactiveCN105289617AImprove electrochemical performanceImprove charge and discharge stabilityCell electrodesMetal/metal-oxides/metal-hydroxide catalystsCarbon nanotubeCarbon nanotube supported catalyst

The invention relates to a nickel cobalt oxide / carbon nanotube composite catalyst, a preparation and an application thereof. The bi-functional catalyst comprises carbon nanotube and nickel cobalt oxide NiCo2O4 spinel; according to the preparation, nickel acetate, cobalt nitrate and carbon nanotube are respectively weighed, and then dissolved in ammoniacal liquor and the obtained material is performed with ultrasonic dispersion, then is subjected to a hydrothermal reaction at temperature of 140-160 DEG C for 3-6 hours, the obtained product is cooled to room temperature, cleaned and dried, calcined and ground to obtain the bi-functional catalyst. The invention also provides an application of the bifunctional catalyst in preparation of an air electrode of a metal air battery. The bi-functional catalyst has efficient oxygen reduction performance and efficient oxygen evolution performance in air.

Owner:DONGHUA UNIV

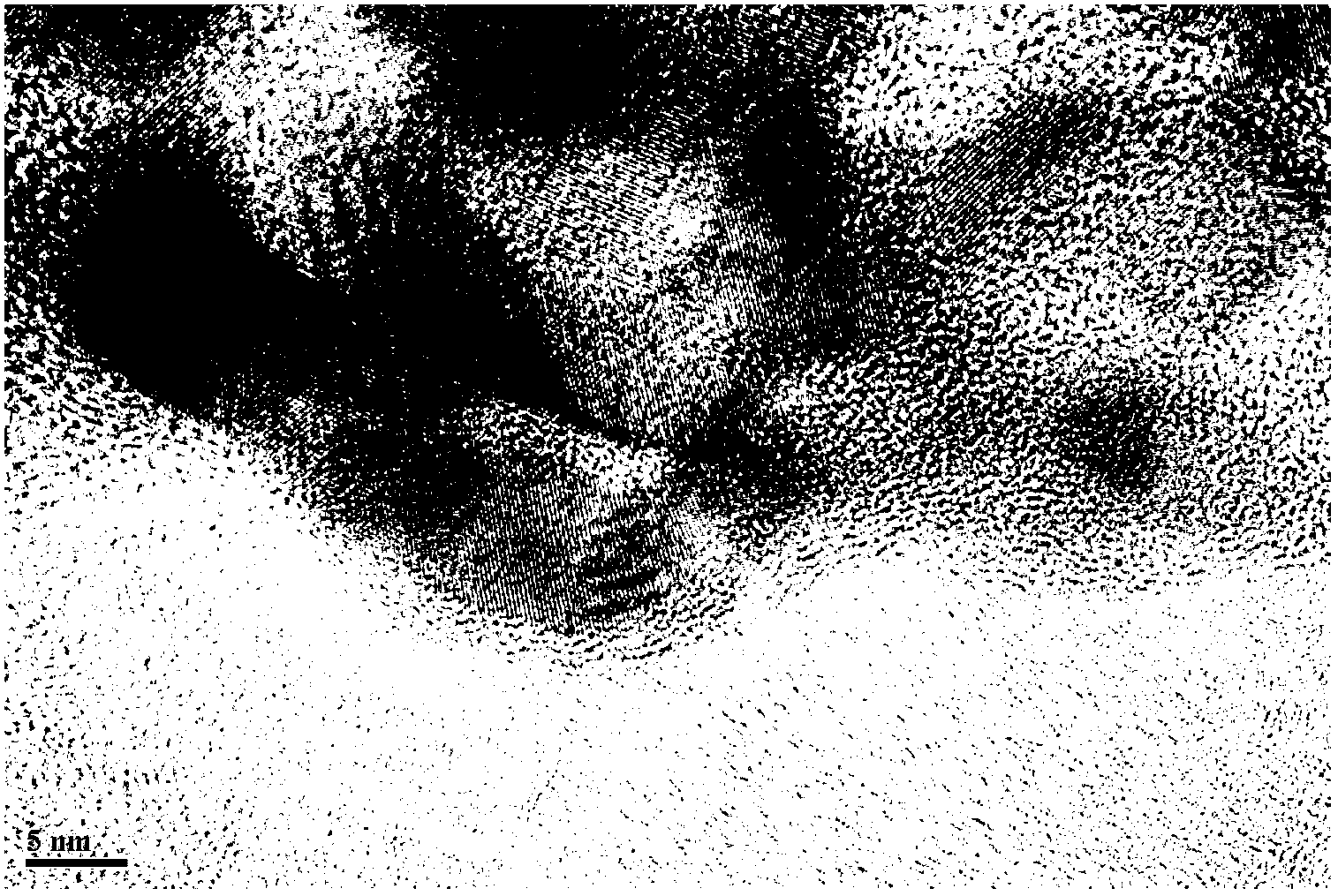

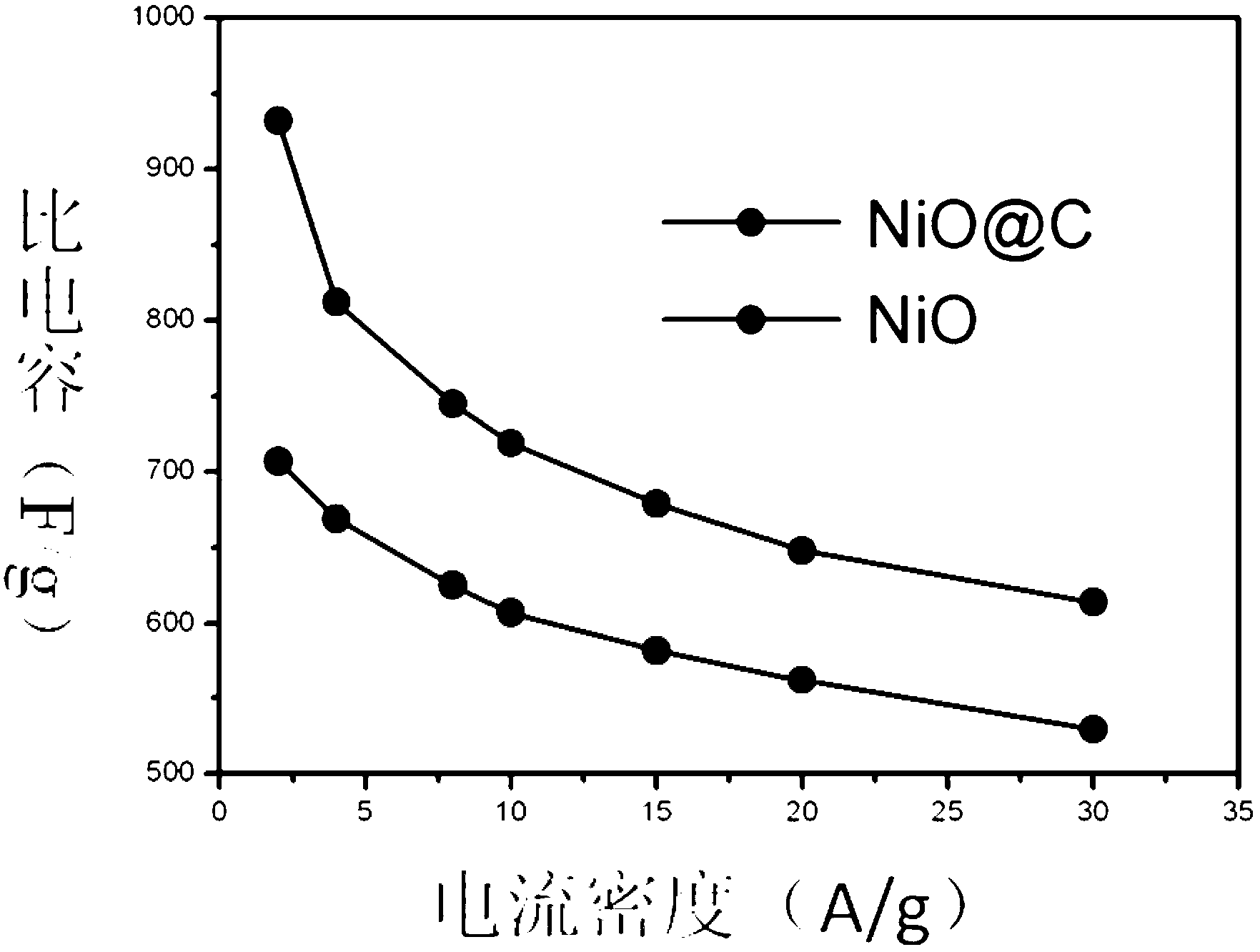

Preparation method for carbon-coated nickel oxide NiO/C as supercapacitor electrode material

InactiveCN103219169ALarge specific surface areaImprove conductivityHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceCarbon layer

The invention relates to a preparation method for carbon-coated nickel oxide NiO / C as a supercapacitor electrode material, comprising the steps that (1) nickel acetate Ni (CH3COO)2.4H2O, urea and polyvinylpyrrolidone are dissolved in absolute ethyl alcohol and water and stirred, so that a mixed solution is obtained; (2) the mixed solution is subjected to hydrothermal reaction, and after the reaction is finished, the mixed solution is cooled, centrifuged, rinsed, dried and calcined, so the NiO material is obtained; (3) the NiO is dissolved in a glucose solution and stirred, to obtain a mixed solution, the mixed solution is subjected to hydrothermal reaction, and after the reaction is finished, the mixed solution is cooled, centrifuged, rinsed, dried and calcined, so that the carbon-coated nickel oxide NiO / C is obtained. The NiO / C electrode material prepared by the method disclosed by the invention is in porous structure and has high specific surface area, meanwhile the overall conductivity of the NiO electrode material can be improved due to the carbon layer, and the carbon and the NiO have synergistic effect, so that the specific capacitance and speed ratio capacitance, and the NiO / C is an excellent supercapacitor electrode material.

Owner:DONGHUA UNIV

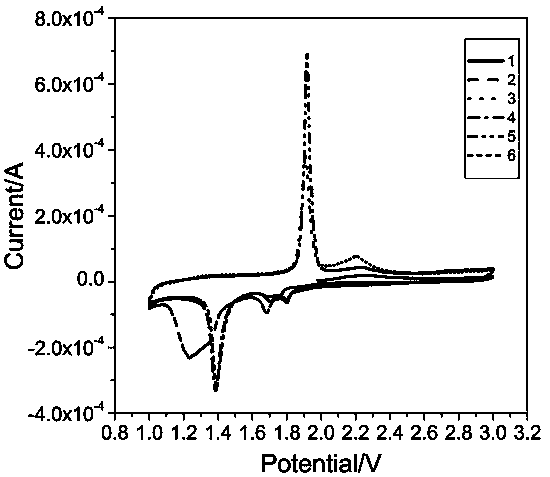

Graphene/nickel sulphide nano composite electrode material and preparation method thereof

InactiveCN104183848AEasy to synthesizeEasy to operateMaterial nanotechnologyCell electrodesSolventNickel sulfide

The invention discloses a graphene / nickel sulphide nano composite electrode material and a preparation method thereof. The graphene / nickel sulphide nano composite electrode material is prepared under the crosslinked action of graphene with graphene oxide as a carrier, nickel acetate as a nickel source and carbon disulphide as a sulphur source. The graphene / nickel sulphide nano composite electrode material comprises graphene nanosheets and nickel sulphide flower-type submicrostructure ingredients in a mass ratio of (5-35%): (95-65%). The preparation method of the graphene / nickel sulphide nano composite electrode material has the advantages that graphene oxide, nickel acetate and carbon disulphide are taken as raw materials and the graphene / nickel sulphide nano composite electrode material is obtained by adopting a one-pot solvothermal method in an organic solvent, and the graphene / nickel sulphide nano composite electrode material has good electrochemical lithium storage property and can serve as a cathode material for a lithium ion battery.

Owner:NANCHANG HANGKONG UNIVERSITY

Ni-Zn ferrite/SiO2 composite nano-fiber and preparation method thereof

InactiveCN101914821AControl shapeWide variety of sourcesFilament/thread formingInorganic material magnetismFiberEthylic acid

The invention discloses a Ni-Zn ferrite / SiO2 composite nano-fiber and a preparation method thereof, belonging to the field of inorganic non-metal composite functional materials and the preparation thereof. In the preparation method, PVP (Polyvinylpyrrolidone) is taken as a complexing agent to react with nickel acetate, zinc acetate, ferric nitrate and tetraethoxysilane so as to prepare a precursor solution. Precursor fibers are prepared by an electrostatic spinning technique firstly; and then, the obtained precursor fibers are dried and roasted at a proper temperature to prepare NiO.5Zn0.5Fe2O4 / SiO2 composite nano-fiber, wherein the SiO2 exists in an amorphous form. The invention has the advantages of wide raw material source, easily controlled reaction process, simple technique, convenient operation and the like by adopting the technique solution of the invention to prepare the required target products; in addition, the invention can conveniently control the microstructure and appearance of the products by regulating process factors and chemical components so as to realize the controllability on the electromagnetism thereof. The preparation method is also applied to the preparation of other magnetic composite nano-fiber materials.

Owner:JIANGSU UNIV

Method for preparing NiB non-crystalline alloy catalyst with the aid of microwave

InactiveCN1792440ACluster size controllableGood dispersionCatalyst carriersHydrocarbon by hydrogenationChemical platingIron(II) chloride

A microwave aided process for preparing the catalyst of non-crystalline NiB alloy suitable for catalytic hydro-reaction with high catalytic active features that the chemical reduction and chemical plating in microwave field is used, KBH4 is used as reducer, its primary salt is chosen from nickel sulfate, nickel acetate, etc, its secondary salt is chosen from cobalt chloride, iron chloride, etc, its carrier is chosen from oxide, molecular sieve, etc, its solvent is chosen from water, tetrahydrofuran, etc and the complex agent, stabilizer and additive is used.

Owner:NANKAI UNIV

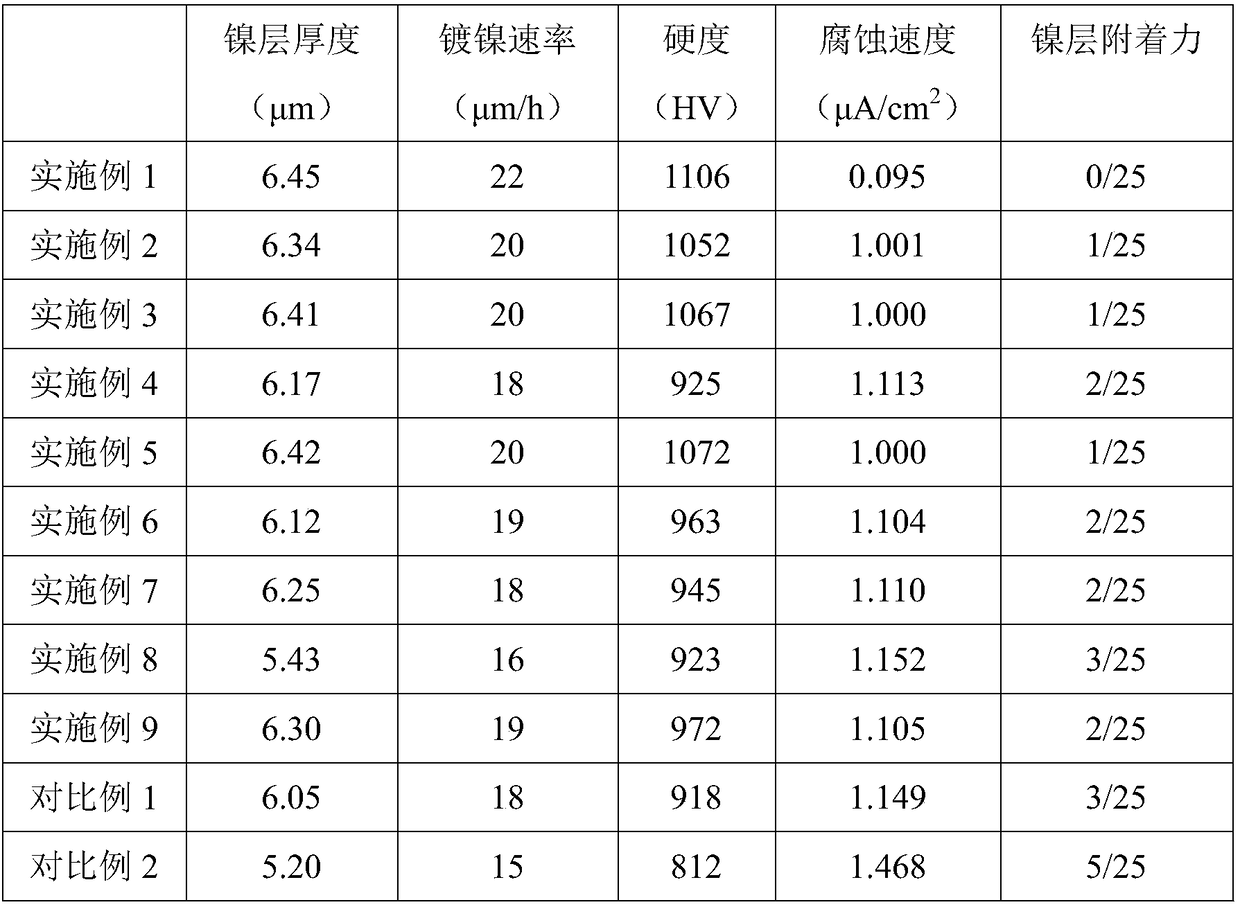

Chemical nickel plating liquid and preparation method

The invention provides chemical nickel plating liquid. The chemical nickel plating liquid is prepared from the following components: nickle salt, a reducing agent, a complexing agent, a buffering agent, a stabilizing agent, a surfactant and deionized water, wherein, the chemical nickel plating liquid is specially prepared from the components in parts by weight: 1000 parts of deionized water, 20 to35 parts of nickel salt, 15 to 32 parts of a reducing agent, 10 to 30 parts of a complexing agent, 2 to 12 parts of a buffering agent, 1 to 15 parts of a stabilizing agent, and 0.01 to 0.2 part of asurfactant. The nickel salt is one or more of nickel sulfate, nickel chloride, nickel acetate, nickel carbonate and nickel aminosulfonate.

Owner:WINSTAR CHEM SHANGHAI

N-doped carbon-coated cobalt-nickel sulfide/graphene composite electrode material

InactiveCN108075128ASimple preparation processImprove controllabilityHybrid capacitor electrodesCell electrodesCapacitanceThiourea

The invention discloses an N-doped carbon-coated cobalt-nickel sulfide / graphene composite electrode material and a preparation method thereof, belonging to the field of preparation of an electrode material for super capacitors. The preparation method comprises the following processes: adding graphene oxide (GO) into an ethylene glycol solution, and performing ultrasonic dispersion to enable the GOto be uniformly dispersed in the ethylene glycol solution; adding polyvinylpyrrolidone (PVP), cobaltous acetate tetrahydrate and nickel acetate into a GO dispersion solution prepared above, after ultrasonic dispersion and dissolution, transferring to a round bottom flask to perform oil bath reaction and performing centrifugal washing and drying; enabling a product, which is dried via centrifugalwashing after oil bath, to calcine with thiourea to obtain the N-doped carbon-coated cobalt-nickel sulfide / graphene composite electrode material. According to the prepared electrode material, N-dopedcarbon is coated outside cobalt-nickel sulfide particles which have uniform sizes in microstructure, the electrode material is uniformly loaded on the substrate of graphene, and meanwhile, the electrode material has relatively high specific capacitance, excellent rate capability and cycling stability.

Owner:FUZHOU UNIV

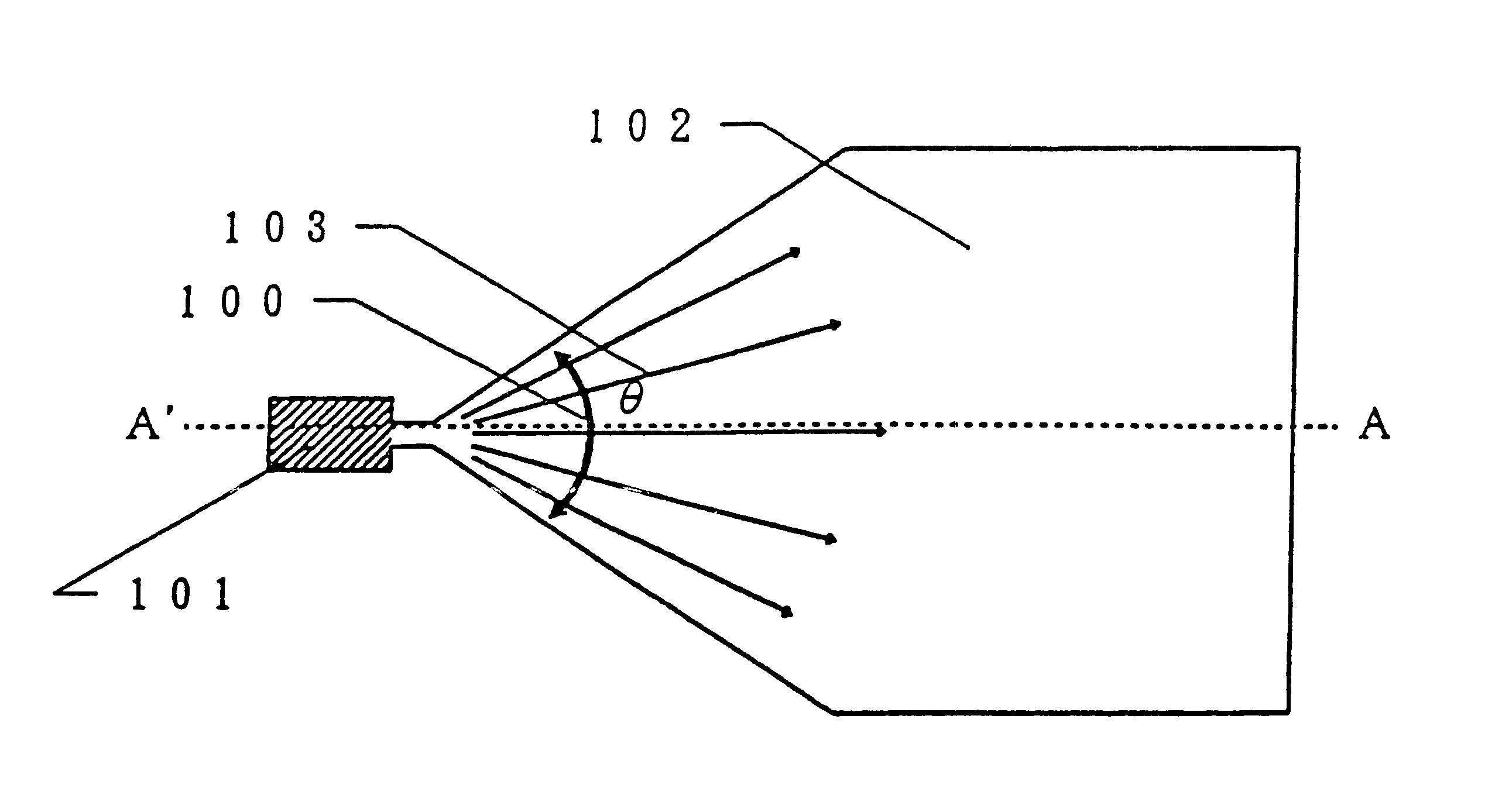

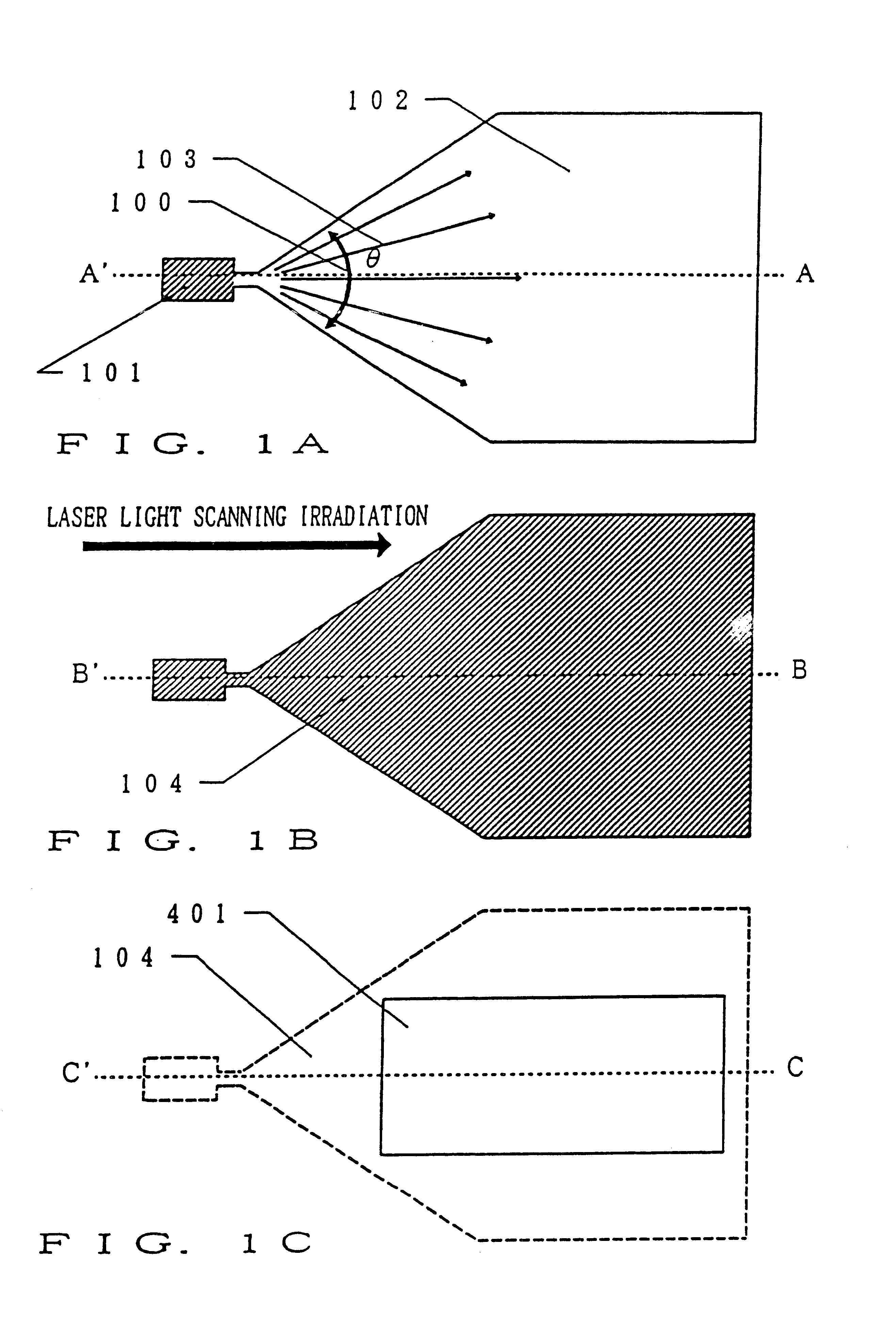

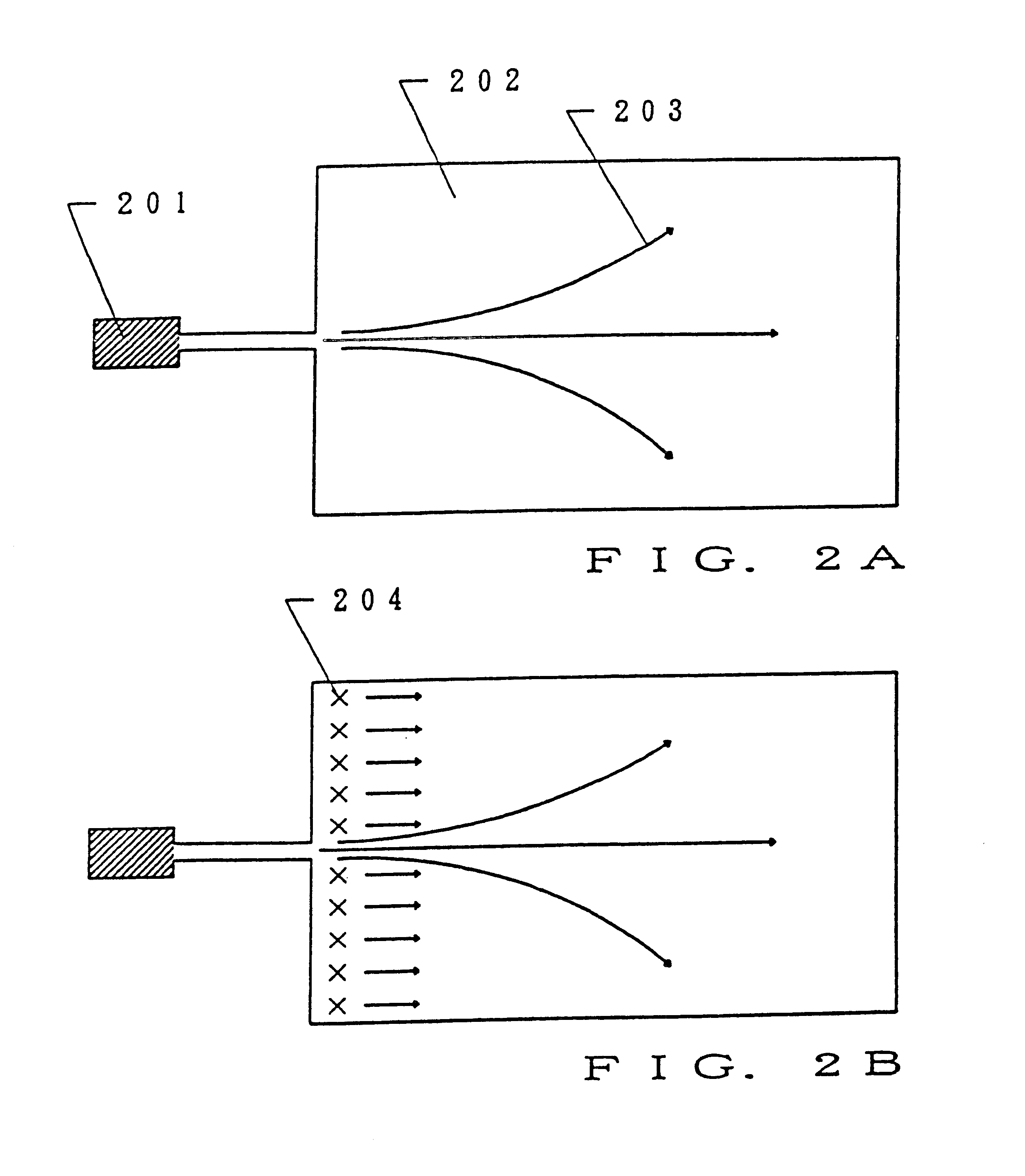

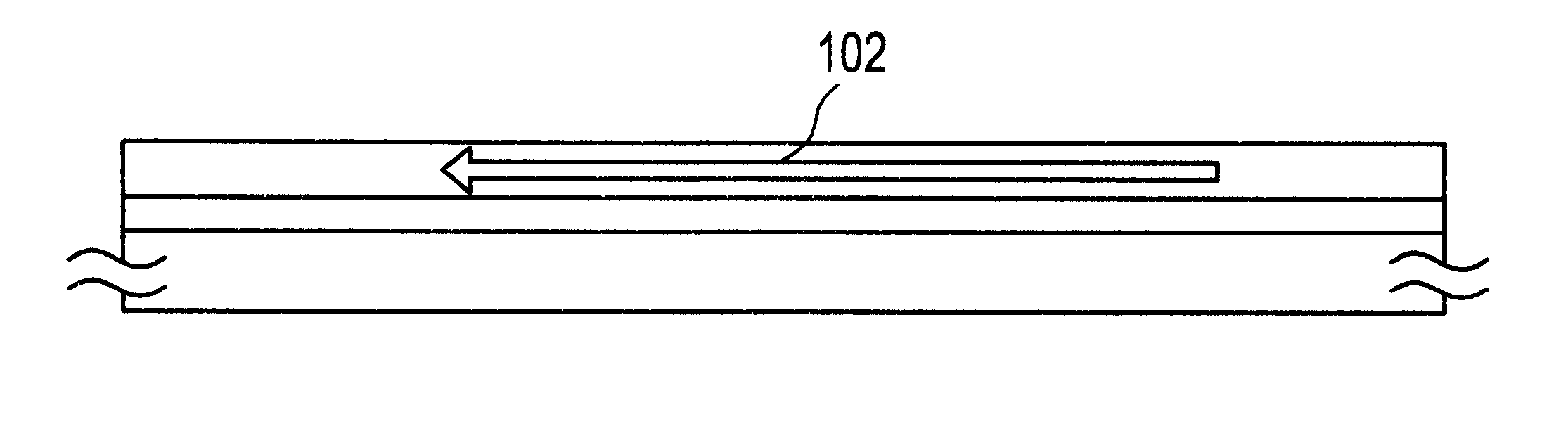

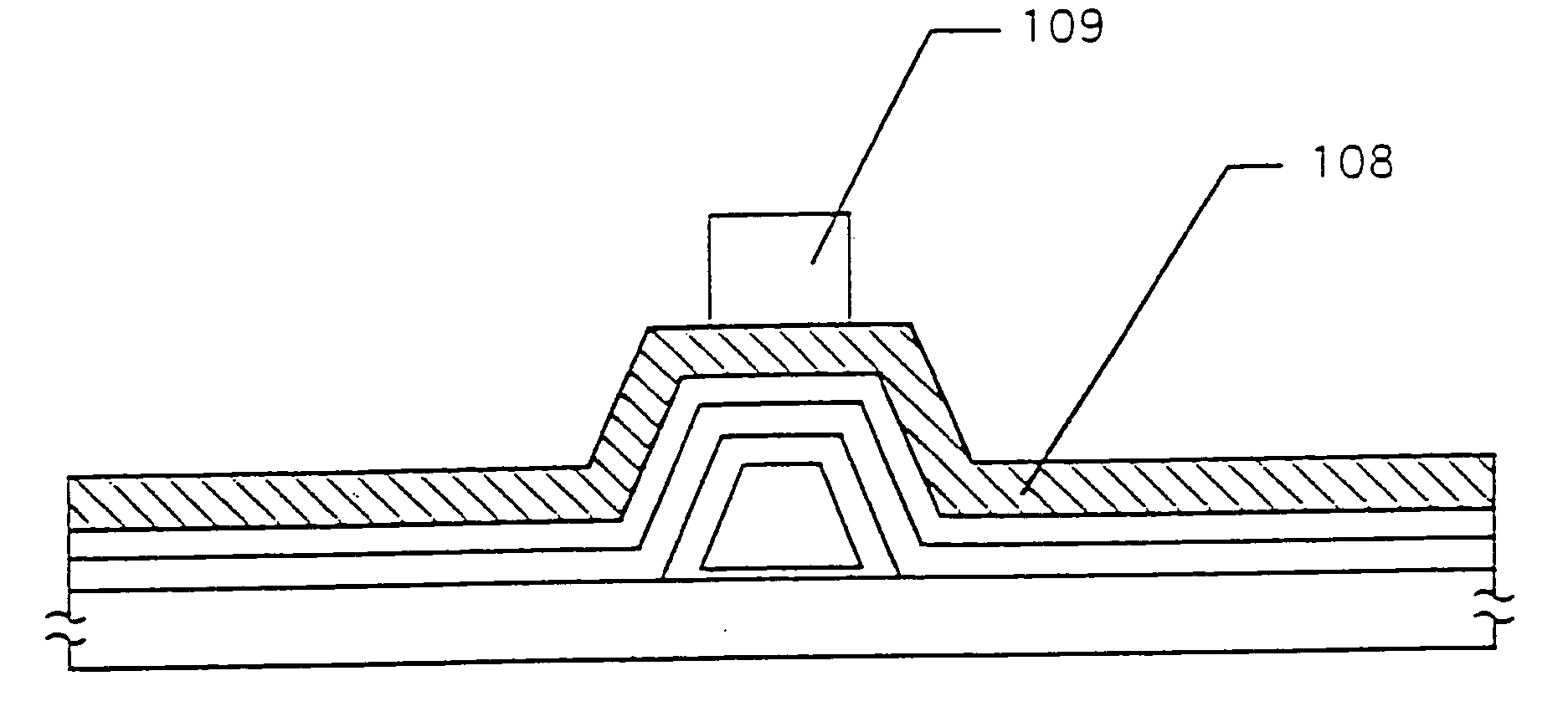

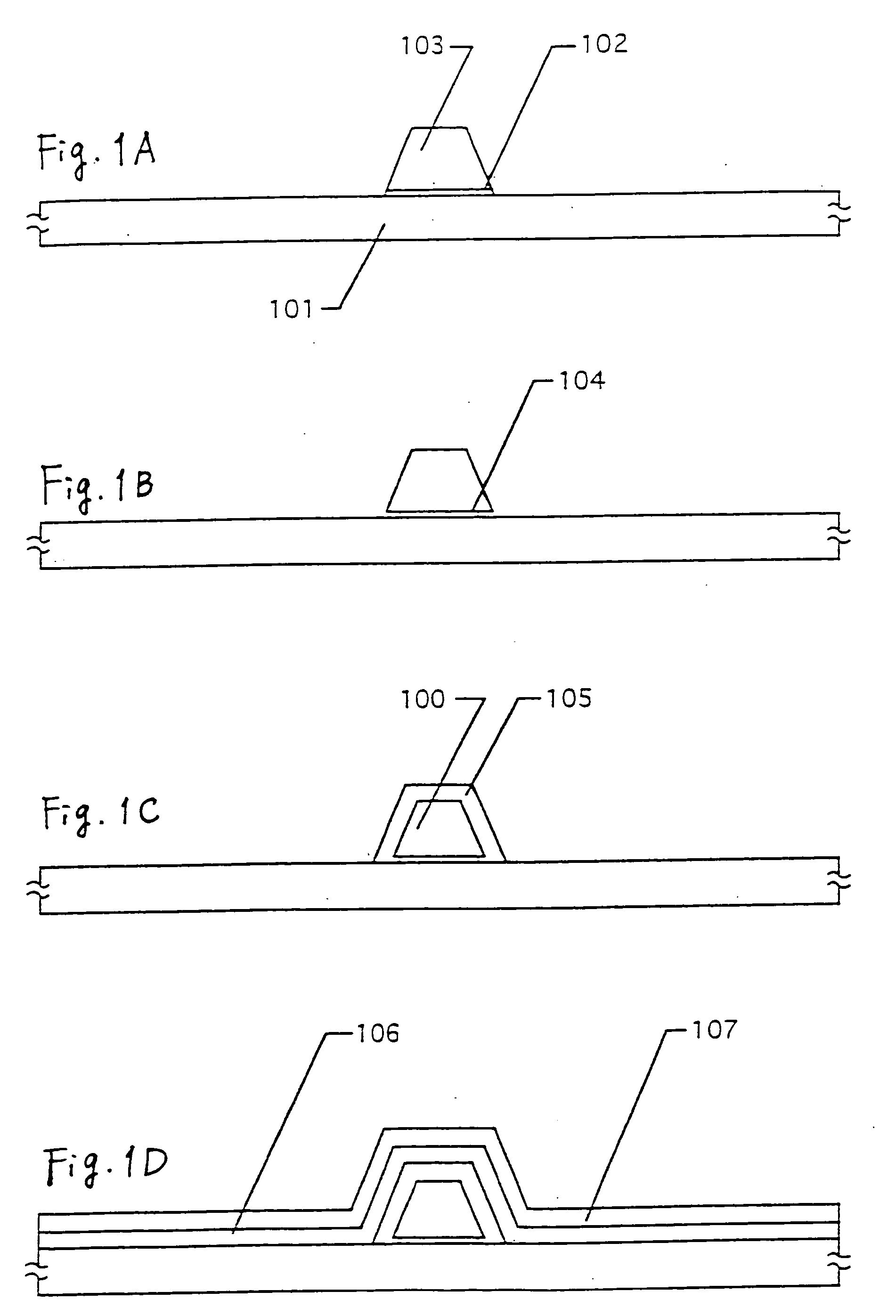

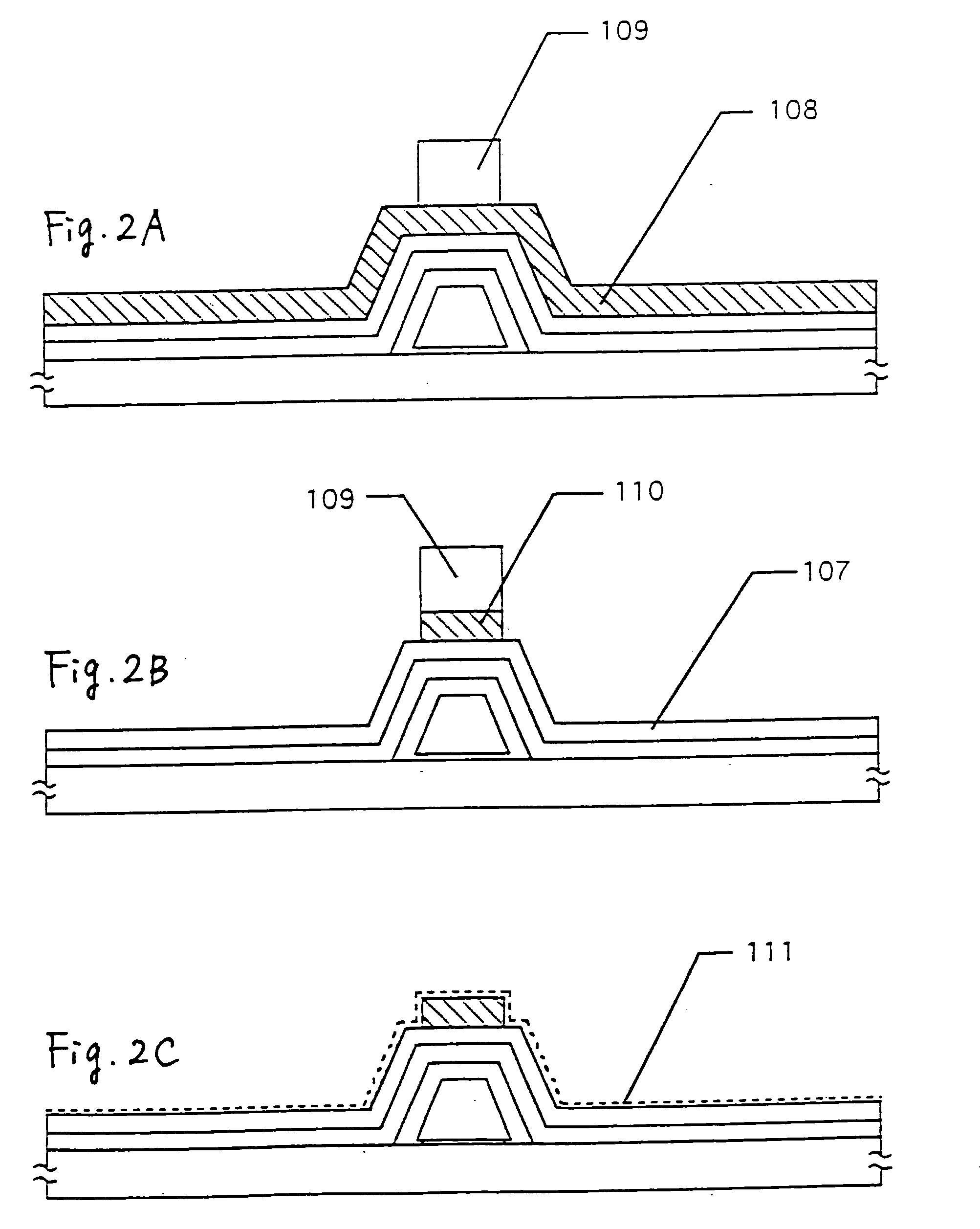

Semiconductor device and method for producing it

InactiveUS20050012096A1Promote formationSolid-state devicesSemiconductor/solid-state device manufacturingBottom gateLayered structure

Disclosed is a technique of improving the heat resistance of the aluminum gate electrode in bottom-gate-type TFT of which the active layer is made of a crystalline silicon film. A pattern of a laminate of a titanium film 102 and an aluminum film 103 is formed on a glass substrate 101. The pattern is to give a gate electrode 100. Then, the titanium film 102 is side-etched. Next, the layered substrate is heated to thereby intentionally form hillocks and whiskers-on the surface of the aluminum pattern 103. Next, the aluminum pattern 103 acting as an anode is subjected to anodic oxidation to form an oxide film 105 thereon. The anodic oxidation extends to the lower edge of the aluminum pattern 103, at which the titanium layer was side-etched. Next, a gate-insulating film 106 and an amorphous silicon film are formed. A mask is formed over the pattern, which is to give -the gate electrode, and then a nickel acetate solution is applied to the layered structure. Thus, nickel is kept in contact with the surface of the structure. Next, this is heated to induce crystal growth in the silicon film from the region contacted with nickel to the masked region. In the bottom-gate-type TFT thus produced, the active layer is made of a crystalline silicon film. In this process, since the anodic oxide film is formed as in FIG. 1(C), aluminum does neither melt to flow away nor diffuse away. Thus, the heat resistance of the aluminum electrode formed is improved.

Owner:SEMICON ENERGY LAB CO LTD

Method for preparing lignin-based carbon fiber hydrogen storage material by electrostatic spinning process

ActiveCN104947246AWide variety of sourcesLow priceFilament/thread formingFibre chemical featuresAir atmosphereMicro nano

The invention relates to a method for preparing a hydrogen storage material, and particularly relates to a method for preparing a lignin-based carbon fiber hydrogen storage material by electrostatic spinning. The method comprises the following steps: preparing a sodium lignin sulfonate / polyacrylonitrile / nickel acetate / boric acid spinning solution; preparing sodium lignin sulfonate / polyacrylonitrile composite micro-nano fiber through electrostatic spinning; drying in a vacuum drying oven and pre-oxidizing in an air atmosphere in a muffle furnace; and gradually heating and calcining in a condition of continuously introducing an inert gas into the tubular furnace to obtain sodium lignin sulfonate / polyacrylonitrile composite carbon fiber containing a Ni-B catalyst, wherein Ni-B realizes an effect of catalytic graphitization. The prepared sodium lignin sulfonate / polyacrylonitrile composite carbon fiber has relatively high graphitization degree, and the hydrogen absorption capacity under the conditions of 298K and 95bar reaches 0.92wt% within 60s.

Owner:QUANGANG PETROCHEM RES INST OF FUJIAN NORMAL UNIV

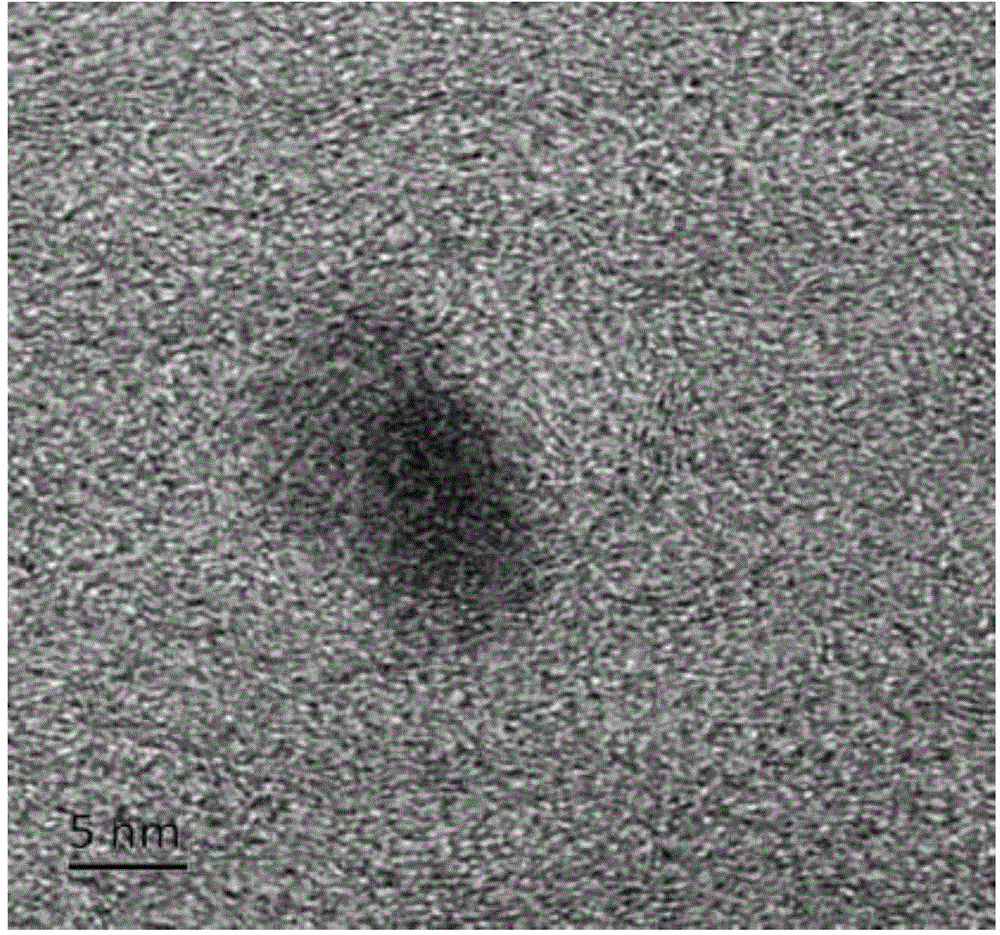

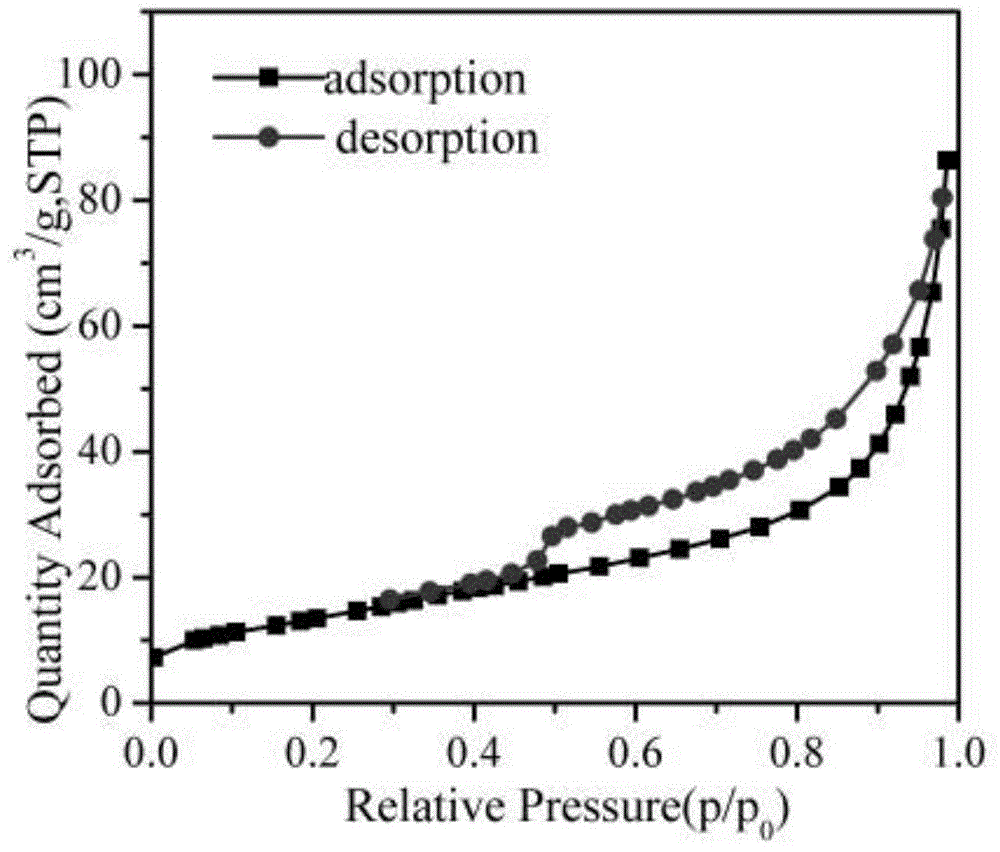

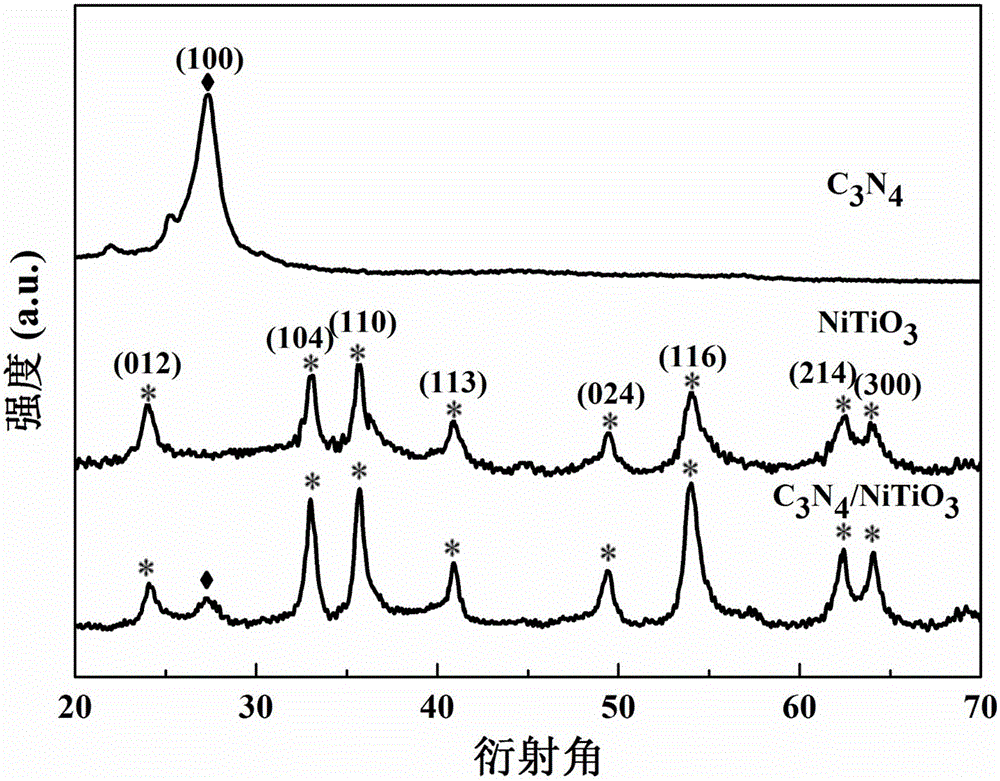

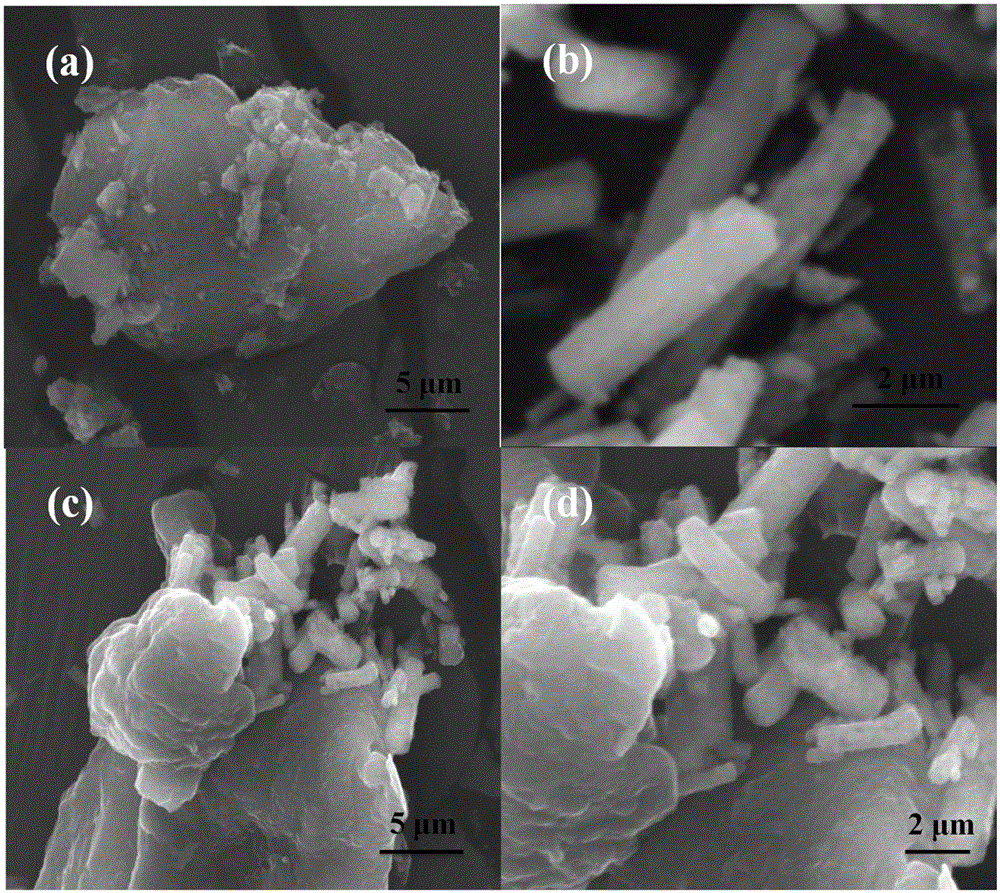

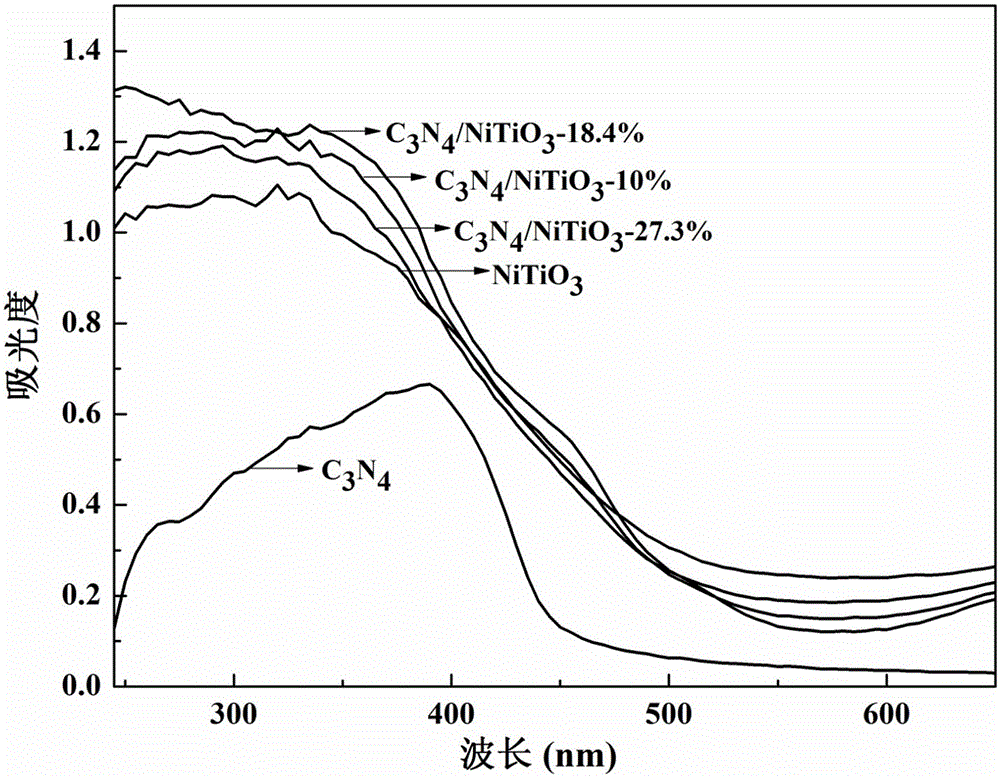

Carbon nitride-nickel titanate composite material and preparation method and application thereof

InactiveCN105032464AImprove stabilityImprove recycling effectPhysical/chemical process catalystsWater/sewage treatment by irradiationEthylic acidCarbon nitride

The present invention discloses a carbon nitride-nickel titanate composite material and a preparation method and application thereof. The carbon nitride-nickel titanate composite material comprises carbon nitride and nickel titanate. Nickel titanate is deposited on the surface of carbon nitride to form the carbon nitride-nickel titanate composite material. The preparation method comprises the steps of: dissolving dicyandiamide in ethylene glycol to obtain an ethylene glycol solution containing dicyandiamide; adding nickel acetate and tetrabutyl titanate into the ethylene glycol solution containing dicyandiamide, carrying out a polymerization reaction to obtain reaction products; calcining the reaction products to obtain the carbon nitride-nickel titanate composite material . The composite material of the present invention has the advantages of high stability, high recyclability, high specific surface area and sites with high photocatalytic activity. The preparation method is simple, high in maneuverability and low in cost; and the composite material has superior photocatalytic properties, and can be widely used in the field of photocatalytic degradation of dye wastewater.

Owner:湖南红普创新科技发展有限公司

Preparation method of nickel electrode made of piezoelectric composite material

InactiveCN102337526ALow costReduce the temperatureLiquid/solution decomposition chemical coatingNickel saltChemical plating

The invention discloses a preparation method of a nickel electrode made of a piezoelectric composite material. The nickel electrode is prepared by using a chemical plating method. The preparation method comprises steps of roughening, sensitizing and activating the piezoelectric composite material, and putting the piezoelectric composite material in a nickel plating liquid to be plated with nickelto obtain the nickel electrode, wherein the activating solution used in the activation procedure is a palladium salt activating solution or nickel salt activating solution, the palladium salt activating solution is prepared by dissolving PdCl2 in certain hydrochloric acid, the PdCl2 content is 0.3-0.5 g / L and the content of the concentrated HCl is 9.9-11 ml / L; the nickel salt activating solution is prepared by dissolving nickel acetate and sodium borohydride in absolute methanol, the content of the nickel acetate is 64-68 g / L, and the content of the sodium borohydride is 64-68 g / L. The invention has the advantages of high nickel plating speed, easiness in regulating and controlling the thickness of a plating layer, uniform and dense thickness of the plating layer of a nickel plate, strongcombination force of the plating layer, good uniformity and wearing resistance, remarkable erosion resistance, excellent welding property and long service life, so that the application demand of the composite material is met.

Owner:UNIV OF JINAN

Preparation method of nickel-based silver conductive slurry

InactiveCN102723142APrevent oxidationLow costNon-conductive material with dispersed conductive materialCable/conductor manufactureHydrazine compoundSlurry

The invention relates to a preparation method of nickel-based silver conductive slurry, belonging to the technical field of conductive slurry. With a reducing agent of hydrazine hydrate and a protective agent of PVP, nickel acetate as a nickel source is reduced at the normal pressure in liquid phase to obtain nano-nickel metal powder, which is characterized in that raw materials is easy to obtain, that both equipment and operation are simple, and that products are high in yield and purity, small in particle size, and even in particle distribution, etc. With a reducing agent mixed by glucose and tartrate, a silver-ammonia solution is reduced at the normal temperature to coat surface of the nano nickel metal with silver to obtain nickel-based compound metal powder, which is convenient in operation and simple in technology. Thickness of coating is even and is easy to control, and appearance of the coating is good. Prepared slurry is characterized by compact sintering films, strong adhesive force, good conductivity, low cost, and the like, which can greatly reduce production cost of electronic elements.

Owner:JIANGSU UNIV +1

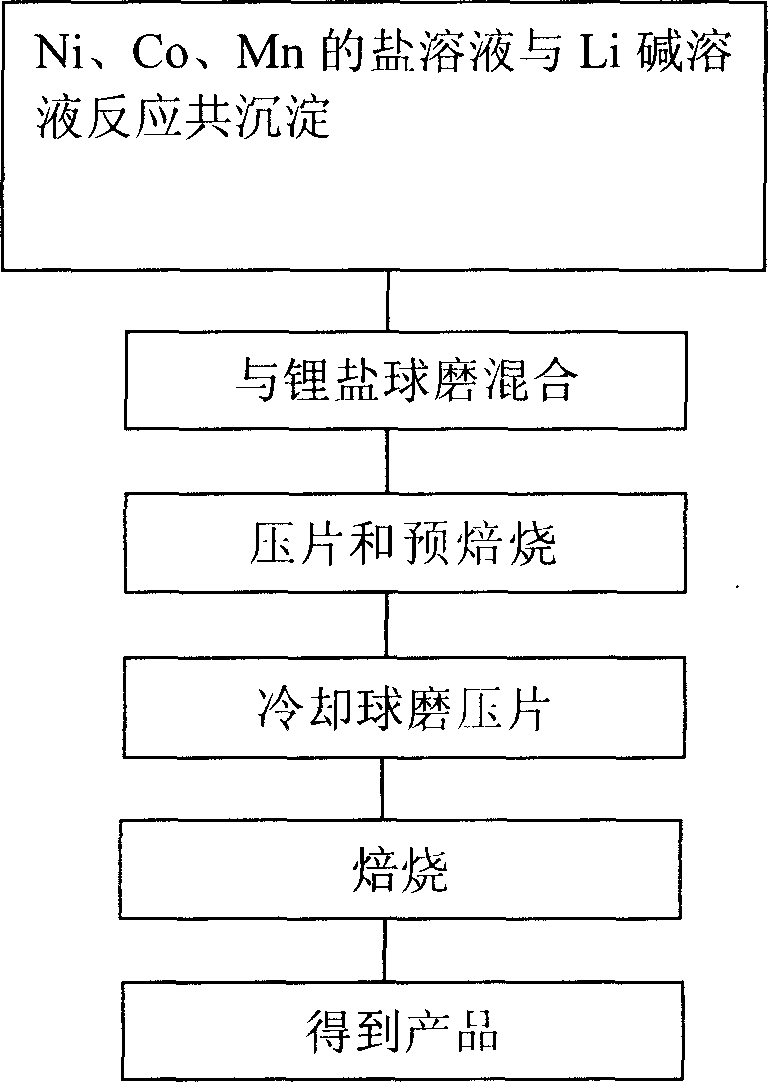

Method for producing anode active material containing lithium, magnesium compound oxide

InactiveCN1741302AStructural Precise TailoringSimple structureElectrode manufacturing processesLithium compoundsMANGANESE ACETATENickel salt

A method for preparing positive electrode multielement active material containing lithium / manganese composite oxide includes directly using lithium hydroxide coprecipitation to prepare M ( OH )2 , mixing it with lithium salt in grinding , forming plate by pressing , prebaking , cooled ball grinding , forming plate by pressing and backing . In the method , applied nickel salt is nickel acetate or nickel nitrate , applied cobalt salt is cobalt acetate or cobalt nitrate, applied manganese salt is manganese nitrate or manganese acetate and applied lithium salt is lithium carbonate or lithium acetate .

Owner:HEBEI UNIV OF TECH

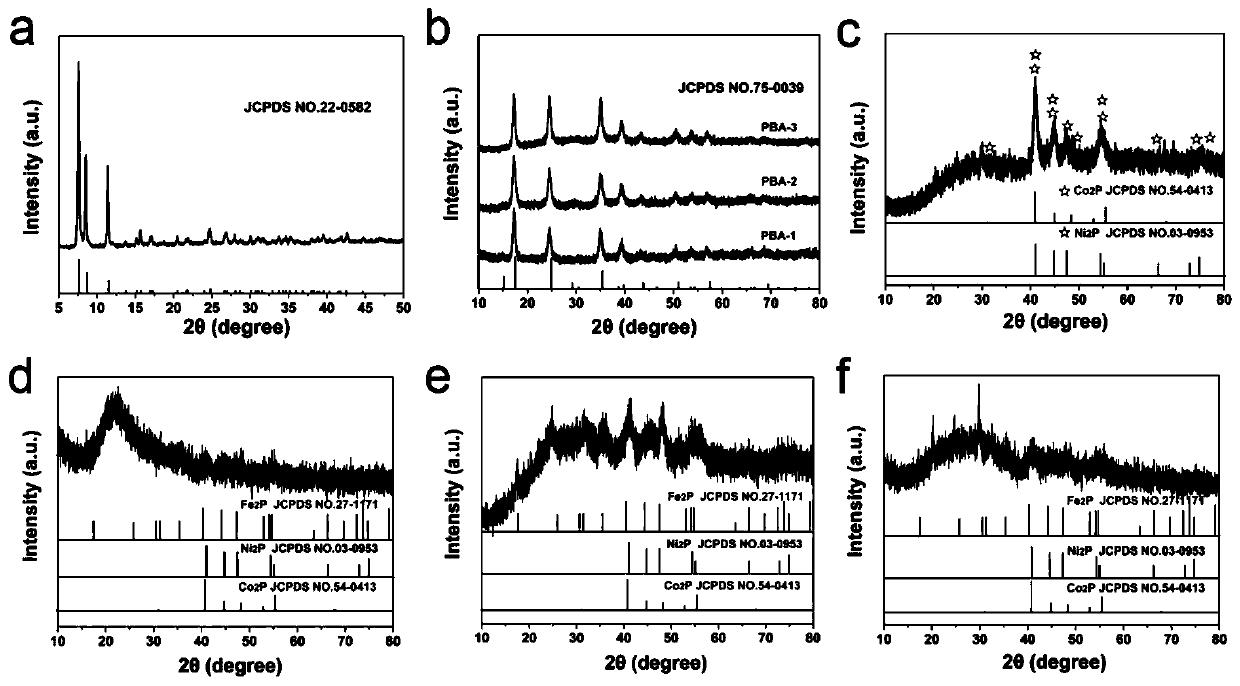

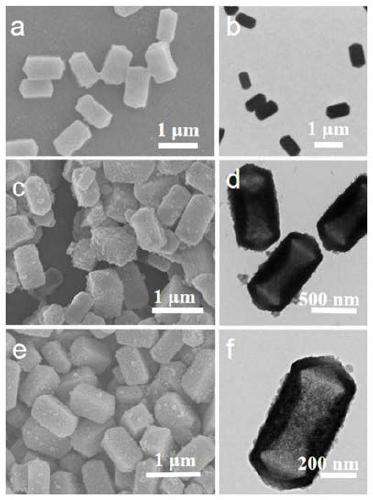

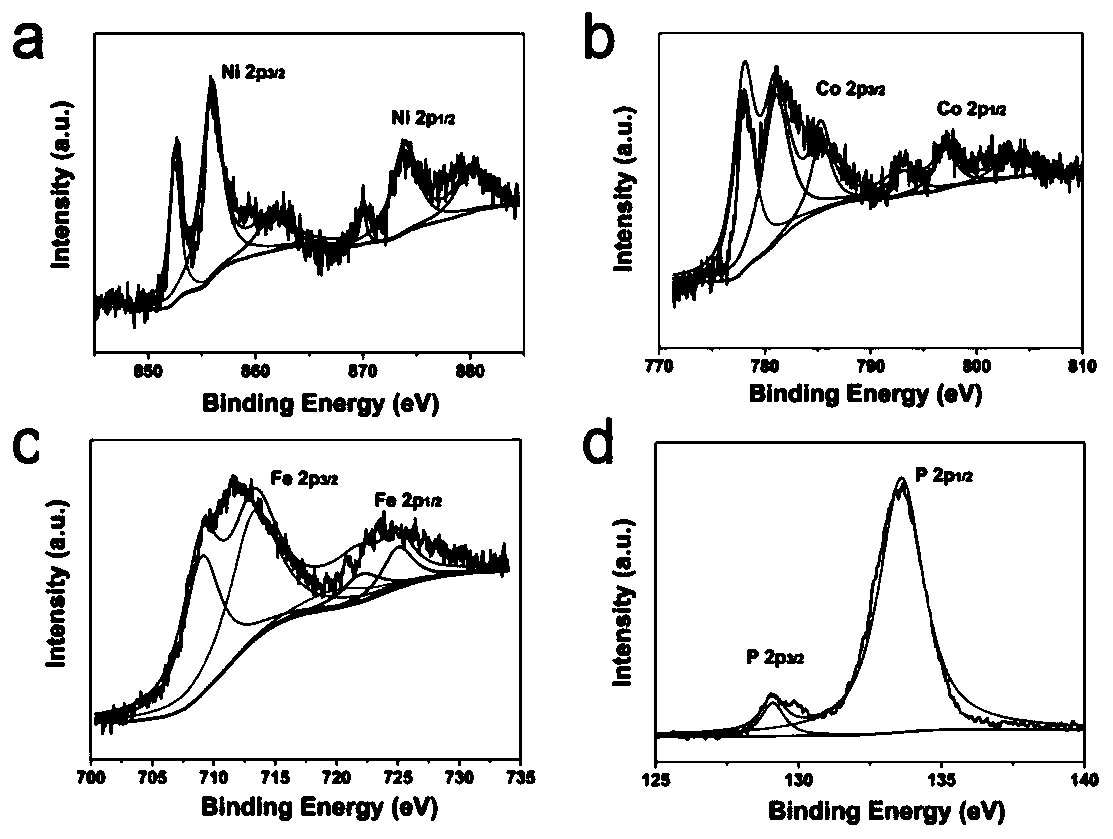

Preparation method of hollow Ni2P/Co2P/Fe2P nano-composite electrocatalyst

ActiveCN110354876AGood repeatabilityImprove electrocatalytic performancePhysical/chemical process catalystsElectrodesPotassium ferricyanideOxygen

The invention discloses a preparation method of a hollow Ni2P / Co2P / Fe2P nano-composite electrocatalyst. The method comprises the following steps: preparing a nickel-cobalt precursor, used as a template, by using nickel acetate, cobalt acetate and polyvinylpyrrolidone as reaction materials and ethanol as a reaction solvent, adding potassium ferricyanide, and preparing a hollow Prussian blue analogthrough room temperature stirring by using ethanol and water as reaction solvents; and phosphating PBA in a tubular furnace at a low temperature with sodium hypophosphite as a phosphorus source to prepare the hollow Ni2P / Co2P / Fe2P nano-composite material. The hollow Ni2P / Co2P / Fe2P nano-composite electrocatalyst prepared in the invention has the advantages of high repeatability, simple and high preparation process, and superior catalytic activity and stability in electrocatalytic oxygen evolution reactions.

Owner:NANJING UNIV OF SCI & TECH

No-palladium activating recipe for chemical nickel plating on plastic surface and its technological process

InactiveCN1772950AIncrease contentTightly boundLiquid/solution decomposition chemical coatingAcetic acidAlcohol

The present invention discloses no-palladium activating solution recipe for chemical nickel plating on plastic surface and its technological process. The recipe of the no-palladium activating solution for pre-treatment before chemical nickel plating includes mainly nickel acetate, sodium borohydride and methanol. The activating process includes the steps of: dissolving nickel acetate in methanol, dissolving sodium borohydride in methanol, setting plastic sheet inside methanol solution of nickel acetate, adding the methanol solution of sodium borohydride into the methanol solution of nickel acetate to activate, and final ageing for some time. The present invention prepares active nickel by means of reducing sodium borohydride at normal temperature, and the activating process with nickel to replace palladium has the advantage of low temperature operation.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Preparation method of hexamethylenediamine

InactiveCN107805203AReduce usageHigh yieldOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsHexamethylenediamineOxide composite

The invention discloses a preparation method of hexamethylenediamine. Hexane dinitrile is used as a raw material, and a nano-nickel and magnesium oxide composite material is used as a catalyst to prepare the hexamethylenediamine through liquid phase hydrogenation. The preparation method of the hexamethylenediamine comprises the following steps: dipping a porous carrier by using nickel acetate andmagnesium nitrate aqueous solutions at different concentrations at first, and carrying out in-situ reduction to obtain an immobilized nickel and magnesium oxide based composite catalyst under different conditions; adding raw materials, the catalyst and a solvent in a reaction kettle in proportion, sealing the reaction kettle, removing air in the kettle by a hydrogen substitution method, starting aheating power supply, applying set pressure to hydrogen after the temperature in the kettle is raised to the set reaction temperature, then starting a magnetic stirrer, and beginning to time reaction; and after the reaction is finished, filtering out the catalyst, and distilling and separating under reduced pressure. The yield of a target product is high, the yield of the hexamethylenediamine isgreater than 70%, and the solvent and the catalyst are recyclable.

Owner:SHANGHAI INST OF TECH

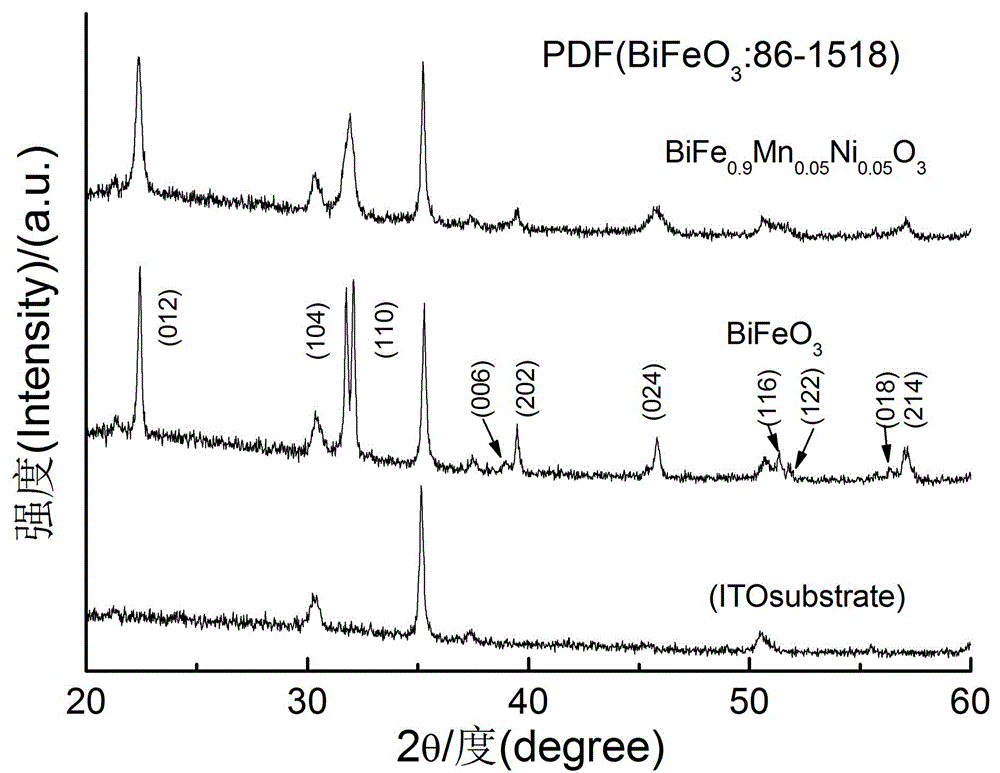

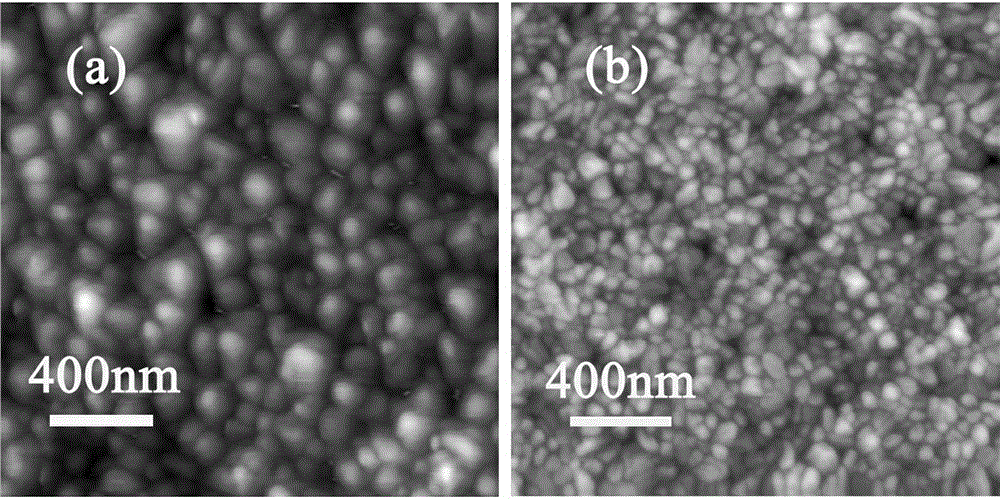

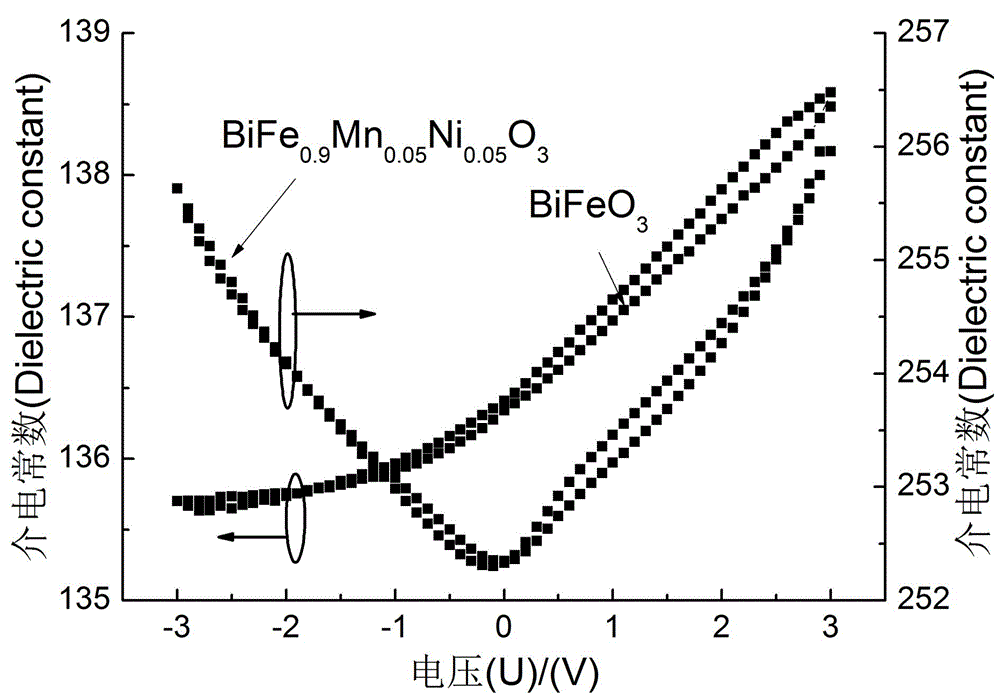

Method for preparing manganese, nickel codoped bismuth ferrite film by sol-gel process

The invention discloses a method for preparing manganese, nickel codoped bismuth ferrite film by a sol-gel process. The method comprises the steps of weighing material ferric nitrate, bismuth nitrate, manganese acetate and nickel acetate according to a general formula BiFe(1-2x)MnxNixO3 (x is smaller than or equal to 0.05 and greater than or equal to 0.0125); adding glacial acetic acid to agitate for 30 minutes at 80 DEG C; and adding ethylene glycol monomethyl ether to agitate for 180 minutes at room temperature to prepare into a liquid precursor of which the concentration is 0.1-0.2mol / L. The final sample is obtained by preparing a wet film on indium tin oxide / glass or a platinum substrate by a spin-coating method, pre-annealing, finally annealing the film, and repeating the pre-annealing and film annealing processes for 10-20 times. The method has the characteristics that the impurity phase in bismuth ferrite can be effectively restrained; the grain size and the root-mean-square roughness of the film surface are reduced; the insulating property, ferroelectric properties, the ferromagnetic property and the optical property of the sample are improved; and the method is simple in production technology, good in reproducibility, and low in cost.

Owner:XINJIANG UNIVERSITY

Method for producing low Pt content electro-catalyst by microwave

InactiveCN101176843APromote commercializationImprove performanceCell electrodesMetal/metal-oxides/metal-hydroxide catalystsHigh energyBall mill

The invention relates to a microwave preparation method of electro catalyst with low Pt content, belonging to electro catalysis for fuel cell field. The invention comprises following steps: 1 to 20 parts by weight(pbw) of carbon powder is high energy ball milled after being thoroughly dried, 20 to 400 pbw of H2O2 is then used for reflux, the carbon powder is dried after being washed with de-ionized water, and the carbon after pretreatment can be obtained after natural cooling; the precursor chloroplatinic acid, nickel acetate solution, TiO2 nano-tube powder and carbon are put into a flask, after the pH value is adjusted by adding glycol solution, the mixture is mixed uniformly by ultrasound, wherein, the mass content of Pt is 2.5 to 20%, the mass content of Ni is 2.5 to 20%, the mass content of TiO2 nano-tube powder is 5 to 30%; the mixed solution is then put into a microwave reactor with a condensation and reflux device for thermal reaction, when the reaction is finished, the electro catalyst can be obtained from the mixed solution after being laid aside, filtered, water washes, vacuum dried and grinded. The invention has the advantages of mild and controllable conditions, short reaction time, simple operation and green revolution.

Owner:SHANGHAI JIAO TONG UNIV

Direct chemical nickel-phosphate plating solution and chemical nickel-phosphate plating coating process for magnesium alloy

ActiveCN102994988ANo pollution in the processAvoid emissionsLiquid/solution decomposition chemical coatingNickel phosphateReducing agent

The invention relates to magnesium alloy surface treatment technology, in particular to a direct chemical nickel-phosphate plating solution and chemical nickel-phosphate plating coating process for magnesium alloy, belonging to the field of magnesium alloy surface treatment. A chemical nickel-phosphate plating coating takes nickel acetate or nickel sulfate as main salts, phosphinic acid as a reducing agent, sodium citrate, glycine or sodium succinate as a complexing agent, ammonium bifluoride as a corrosion inhibitor, sodium acetate as a buffering agent and cadmium chloride as a stabilizer, and the plating application temperature is 80-95 DEG C. The chemical nickel-phosphate plating coating process comprises the steps: organic solvent oil removal, blow-drying, alkaline washing, water washing, chemical nickel-phosphate plating, water washing and roasting in sequence. According to the process, the problems that the chemical nickel-phosphate alloy plating coating technology in the prior can not be directly applied to magnesium alloy and causes harm to the environment can be solved.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Modified nickel cobalt manganese ternary composite electrode material coated on oxide surface and preparation method thereof

ActiveCN107331852AAvoid corrosionReduce surface resistanceSecondary cellsPositive electrodesMANGANESE ACETATENiobium

The invention provides a modified nickel cobalt manganese ternary composite electrode material coated on an oxide surface and a preparation method thereof. A coating layer of the composite electrode material is prepared from two or three metal oxides MxOy, wherein M is niobium, zirconium or yttrium; the thickness of the coating layer is 0.5-50nm and the weight percent in the composite electrode material is 1%-10%; the prepared nickel cobalt manganese composite electrode material has an alpha-NaFeO2 layered structure. Nickel acetate, cobalt acetate, manganese acetate and lithium acetate are taken as raw materials, the metal oxides are served as surface coating matters and the high-temperature sintering and in-situ coating combined technology is adopted for preparing the high-performance composite electrode material. The coating layer of the composite electrode material can prevent the metal ions in active materials from dissolving, can resist against the corrosion of HF to active materials and can reduce the surface impedance and promote the cycling stability. The preparation process is simple, the operation is easy, the production period is short, the equipment requirement is low and industrial development and popularization and application are benefited.

Owner:ENERGY RESOURCES INST HEBEI ACADEMY OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com