Preparation method for carbon-coated nickel oxide NiO/C as supercapacitor electrode material

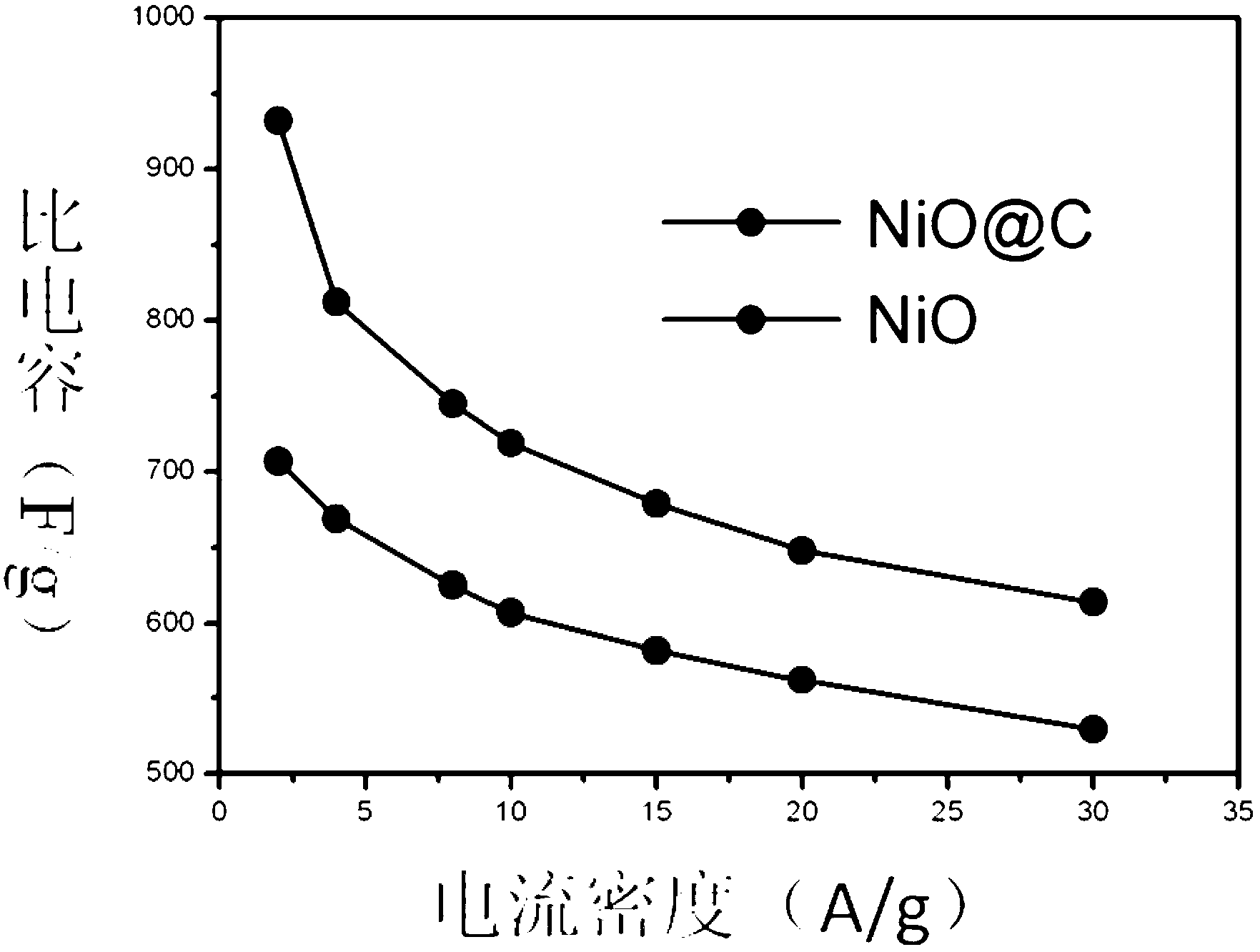

A technology for supercapacitors and electrode materials, which is used in the manufacture of hybrid capacitor electrodes and hybrid/electric double-layer capacitors, etc., can solve the problems of inability to uniformly coat NiO electrode materials, and achieves problems such as solving large-scale application difficulties, improving rate specific capacitance, Simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Weigh the raw material nickel acetate (Ni(CH 3 COO) 2 ·4H 2 O) 5mmol, urea (2g) and polyvinylpyrrolidone (PVP) 1g are dissolved in absolute ethanol and water and stirred to prepare a mixed solution; wherein the volumes of the absolute ethanol and water are 10ml and 40ml respectively;

[0025] (2) Pour the above-mentioned mixed solution into a polytetrafluoroethylene hydrothermal reactor to maintain 80% filling degree, put the hydrothermal reactor into a blast drying box, and react for 8 hours under hydrothermal conditions at 180°C , And then cool the reactor to room temperature.

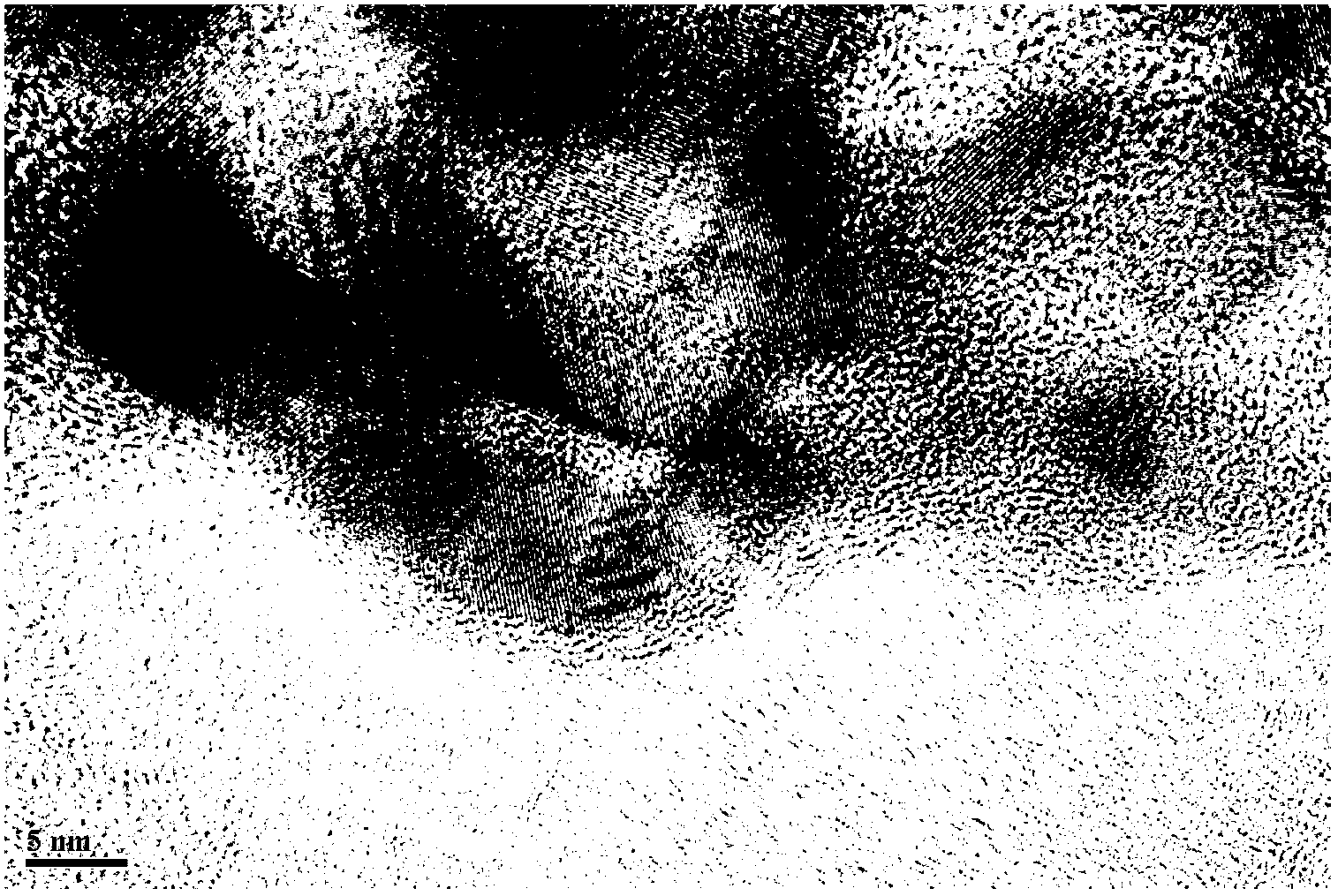

[0026] (3) The products obtained by centrifugation were washed with deionized water and ethanol solvents respectively, and dried; the dried samples were placed in a muffle furnace at 1°C / min to 450°C and calcined for 40 minutes.

[0027] (4) Weigh 0.2g of NiO sample, dissolve it in 36ml glucose solution, and stir to prepare a mixed solution; wherein the concentration of the glucose solution is 0....

Embodiment 2

[0031] (1) Weigh the raw material nickel acetate (Ni(CH 3 COO) 2 ·4H 2 O) 5mmol, urea (3g) and polyvinylpyrrolidone (PVP) 1g are dissolved in absolute ethanol and water and stirred to prepare a mixed solution; wherein the volumes of the absolute ethanol and water are 10ml and 40ml respectively;

[0032] (2) Pour the above-mentioned mixed solution into a polytetrafluoroethylene hydrothermal reactor to maintain 80% filling degree, put the hydrothermal reactor into a blast drying box, and react for 3 hours under hydrothermal conditions at 200°C , And then cool the reactor to room temperature.

[0033] (3) The products obtained by centrifugation were washed with deionized water and ethanol solvents respectively, and dried; the dried samples were placed in a muffle furnace at 1°C / min to 450°C and calcined for 40 minutes.

[0034] (4) Weigh 0.3 g of NiO sample and dissolve it in 36 ml of glucose solution and stir to prepare a mixed solution; wherein the concentration of the glucose solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com