Patents

Literature

3987 results about "Carbon layer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

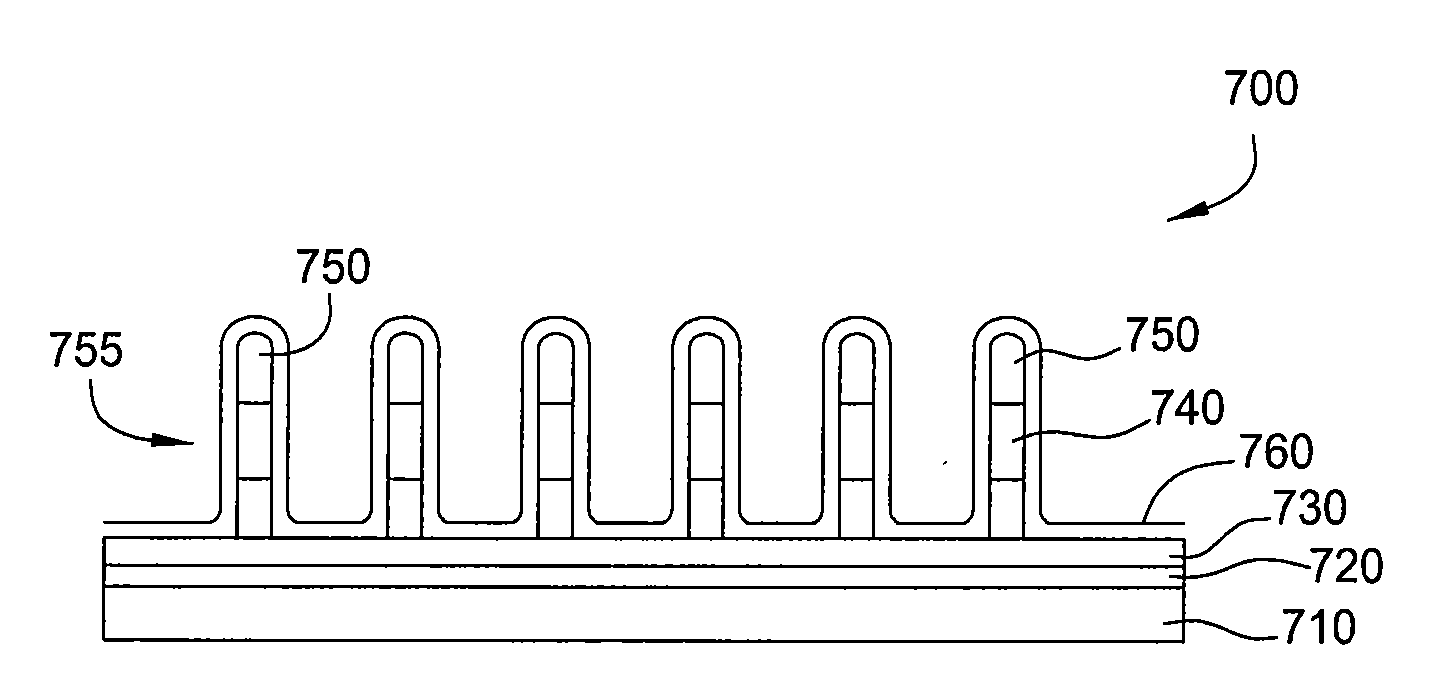

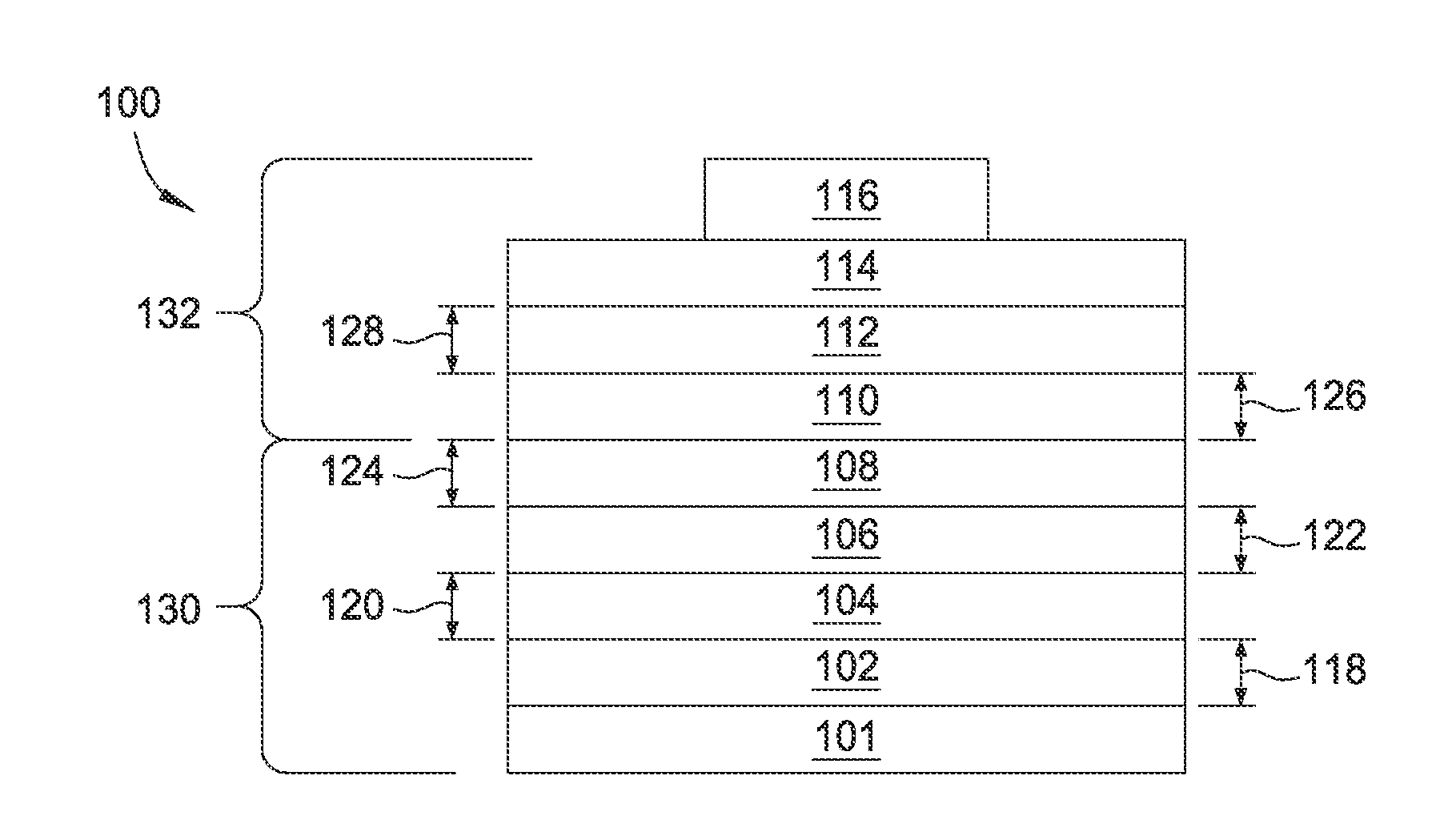

Method for Depositing Conformal Amorphous Carbon Film by Plasma-Enhanced Chemical Vapor Deposition (PECVD)

ActiveUS20100093187A1Good shape retentionHighly conformalSemiconductor/solid-state device manufacturingChemical vapor deposition coatingCarbon layerNitrogen gas

Methods and apparatus for depositing an amorphous carbon layer on a substrate are provided. In one embodiment, a deposition process includes positioning a substrate in a substrate processing chamber, introducing a hydrocarbon source having a carbon to hydrogen atom ratio of greater than 1:2 into the processing chamber, introducing a plasma initiating gas selected from the group consisting of hydrogen, helium, argon, nitrogen, and combinations thereof into the processing chamber, with the hydrocarbon source having a volumetric flow rate to plasma initiating gas volumetric flow rate ratio of 1:2 or greater, generating a plasma in the processing chamber, and forming a conformal amorphous carbon layer on the substrate.

Owner:APPLIED MATERIALS INC

Biocompatibly coated medical implants

InactiveUS20050079200A1Easy to controlProperty variableStentsHeart valvesCarbon layerBiocompatible coating

Implantable medical devices with biocompatible coatings and processes for their production are described. The present invention relates in particular to medical implantable devices coated with a carbon-containing layer which devices are produced by at least partially coating the device with a polymer film and heating the polymer film in an atmosphere which is essentially free from oxygen to temperatures in the region of 200° C. to 2500° C., a carbon-containing layer being produced on the implantable medical device.

Owner:CINVENTION AG

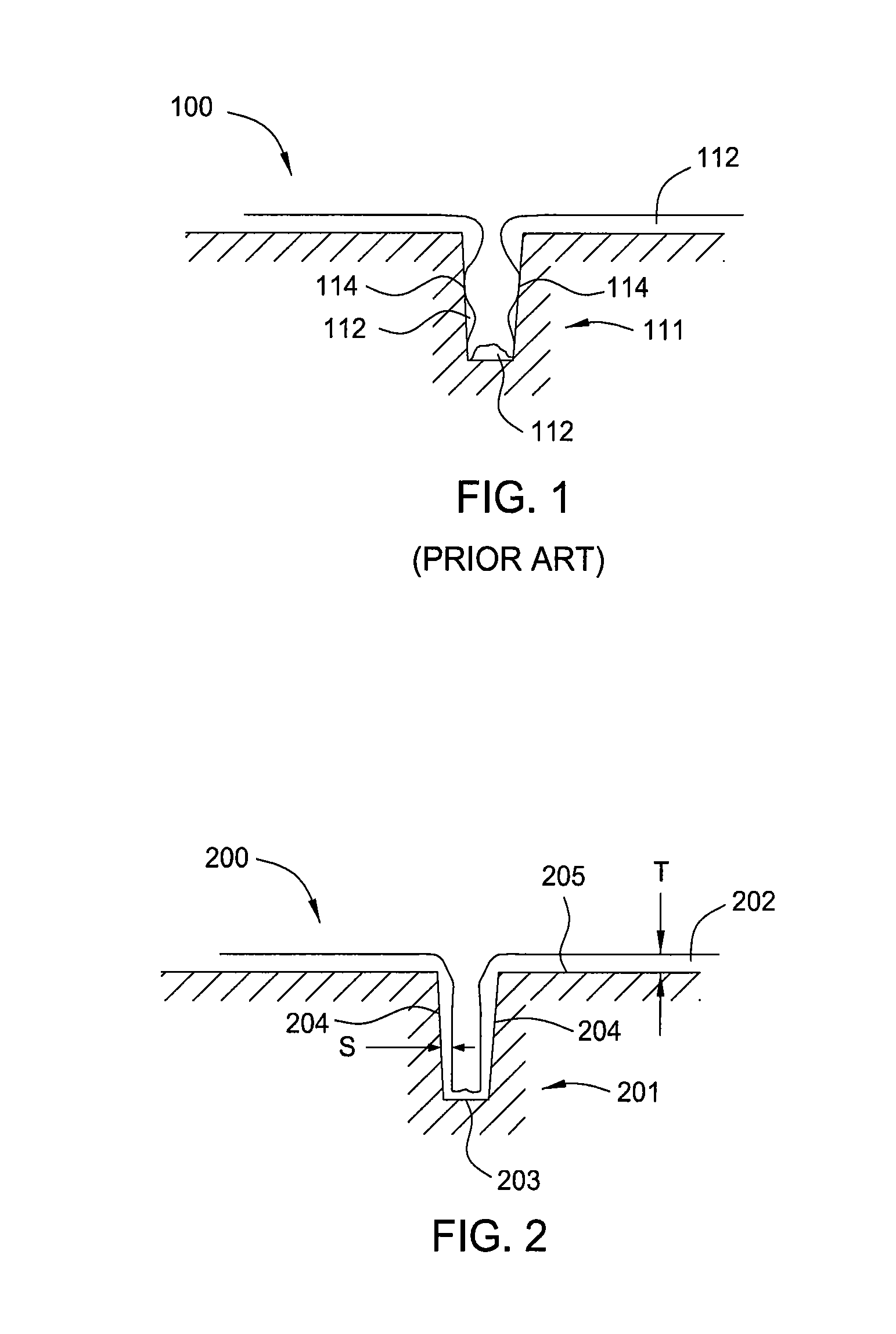

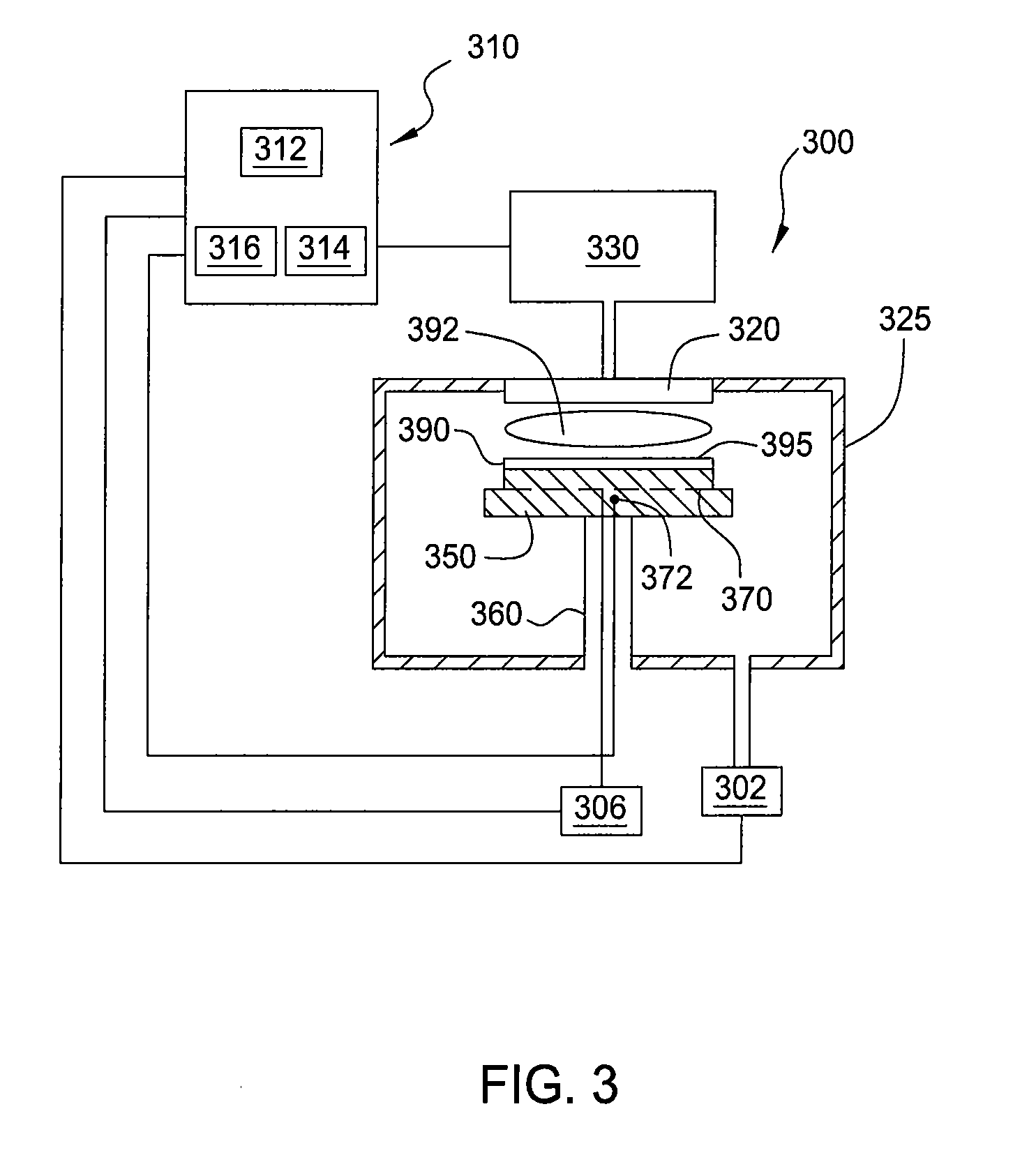

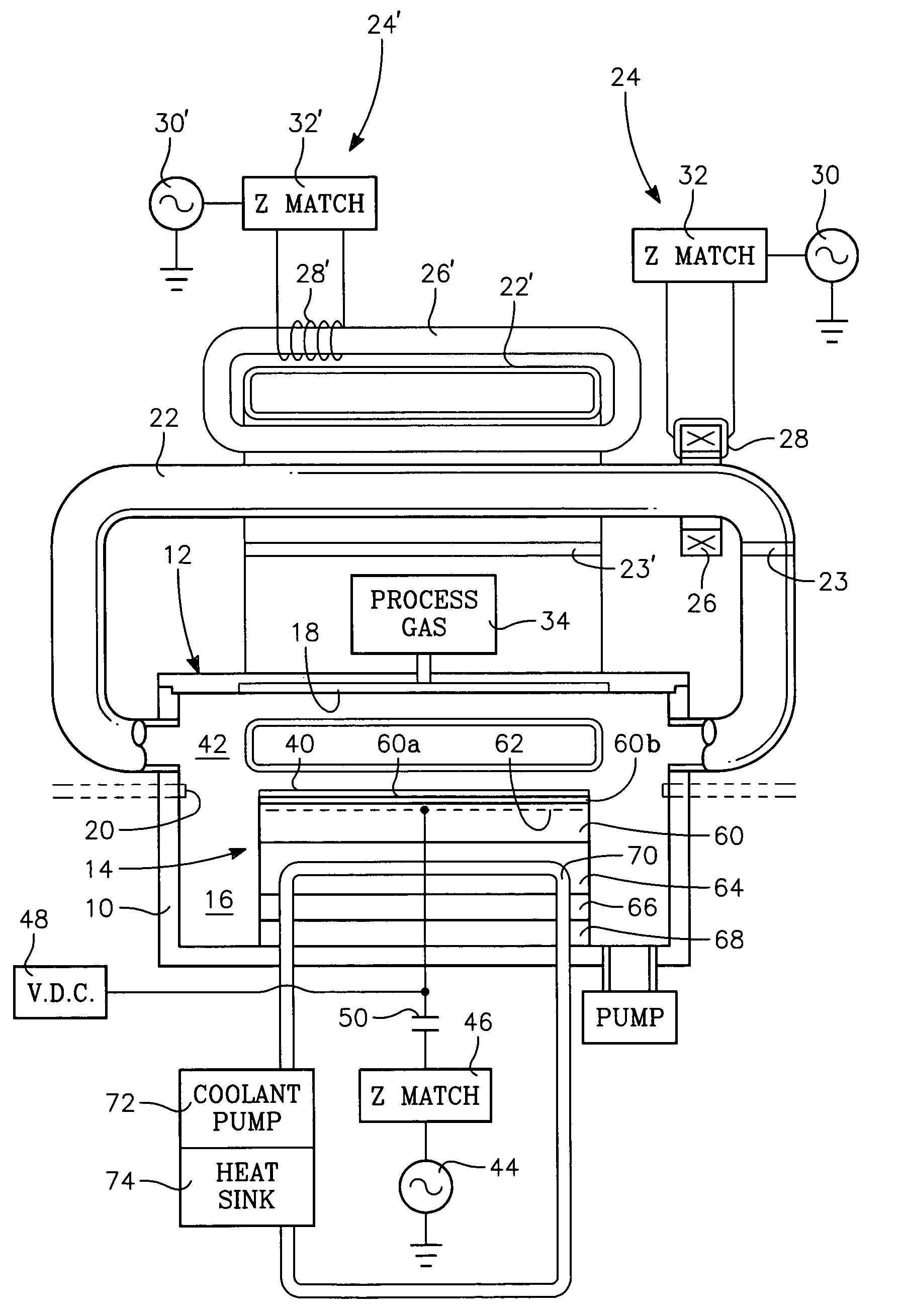

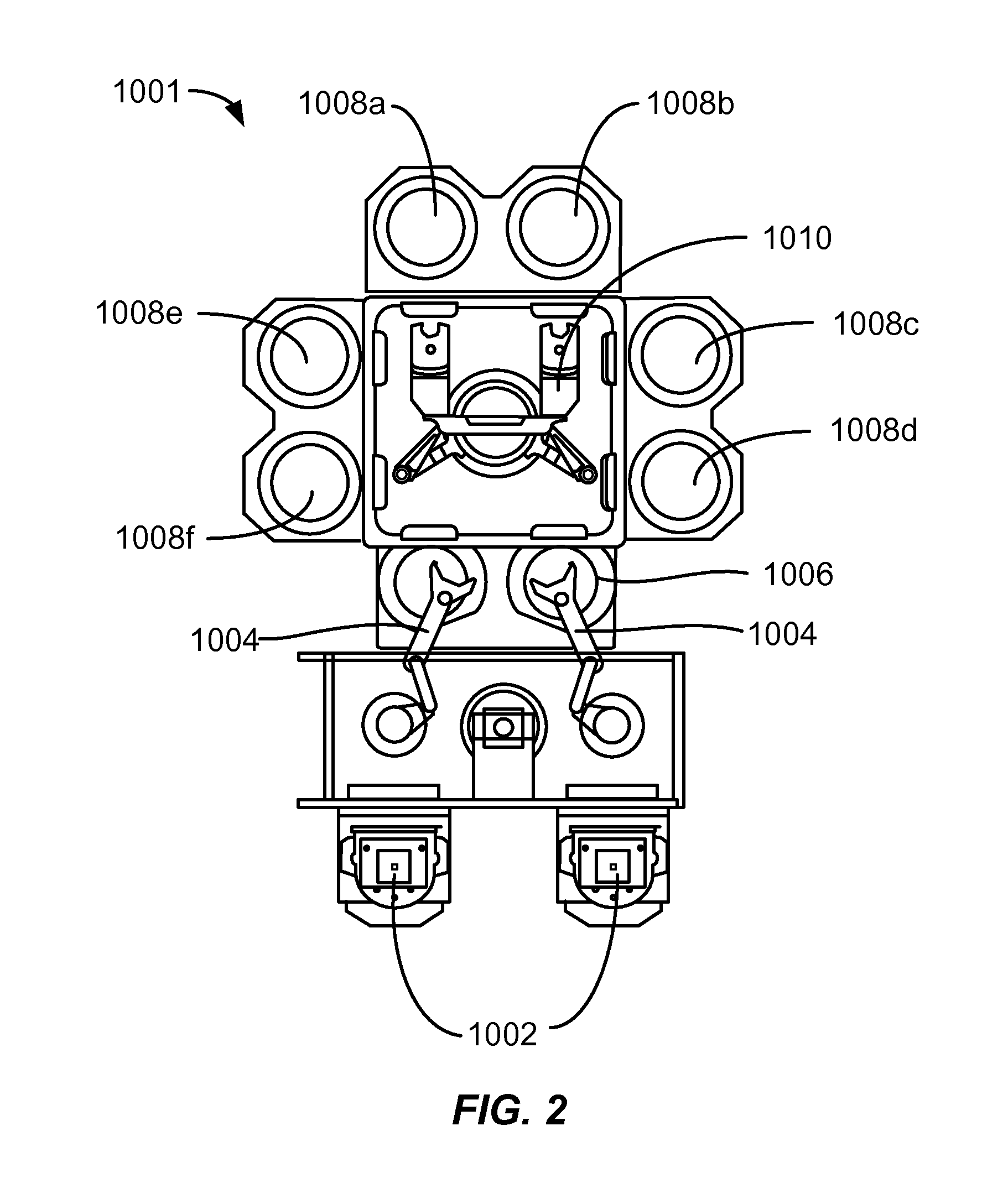

Low temperature plasma deposition process for carbon layer deposition

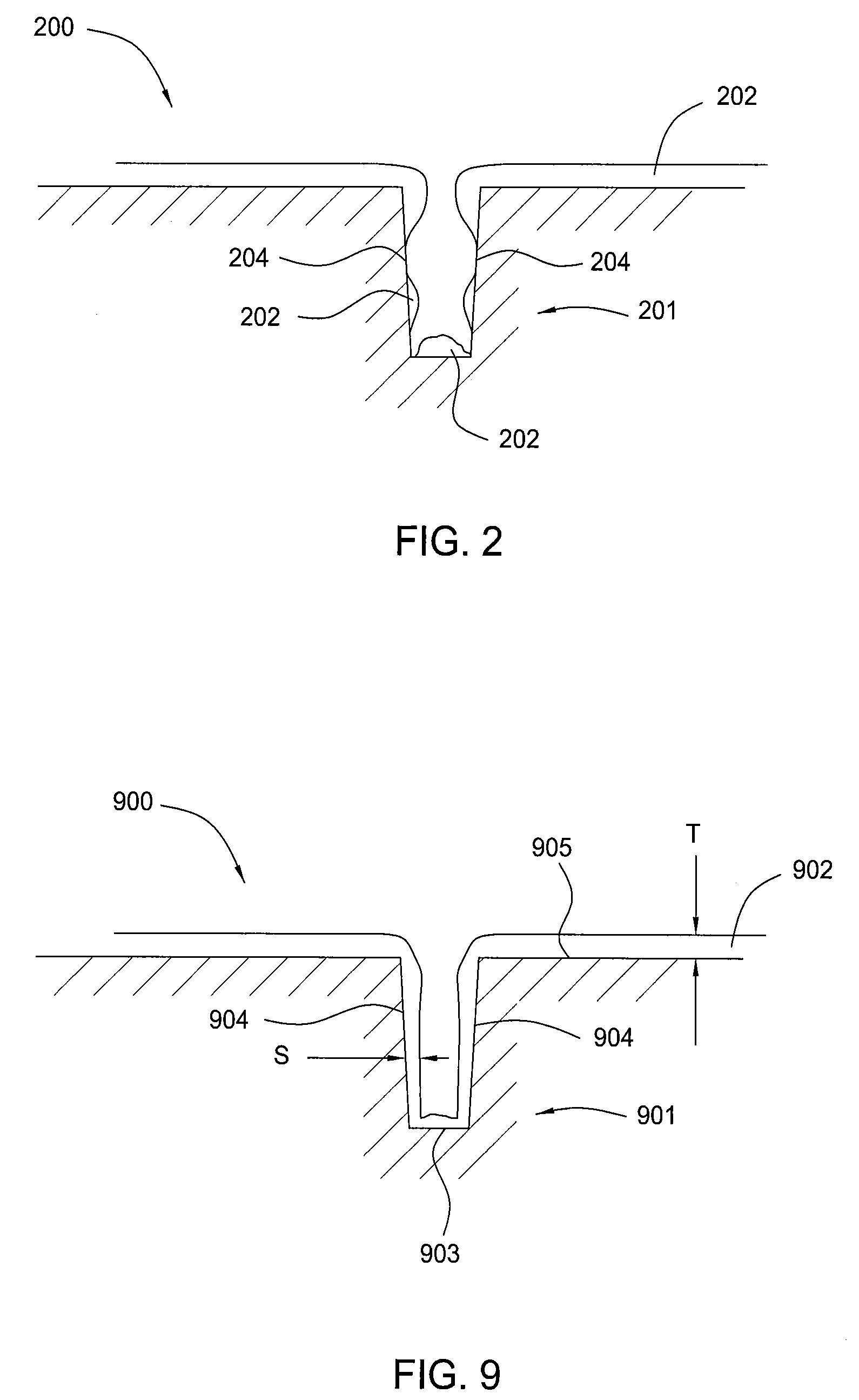

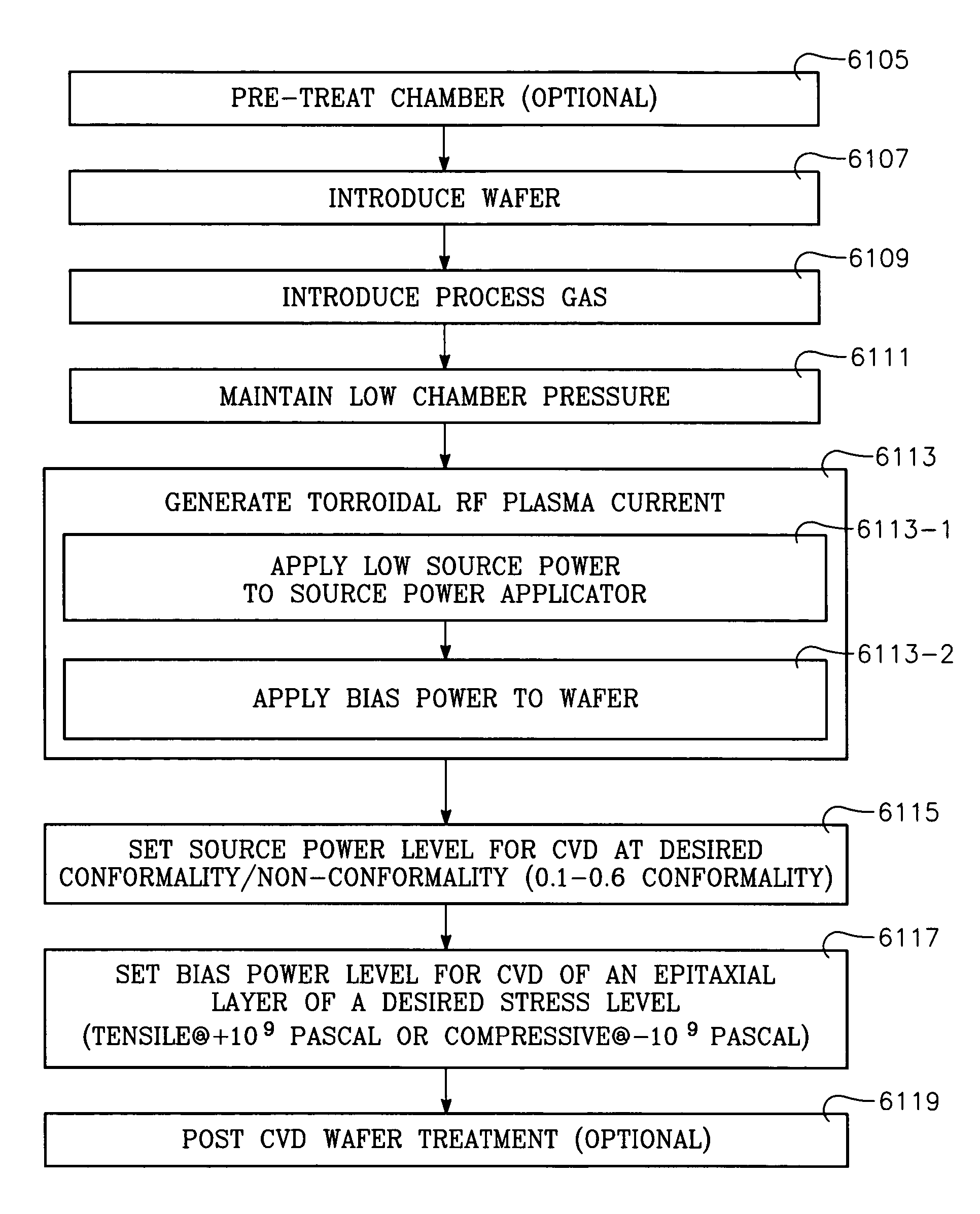

InactiveUS7312162B2Semiconductor/solid-state device manufacturingChemical vapor deposition coatingCarbon layerPlasma current

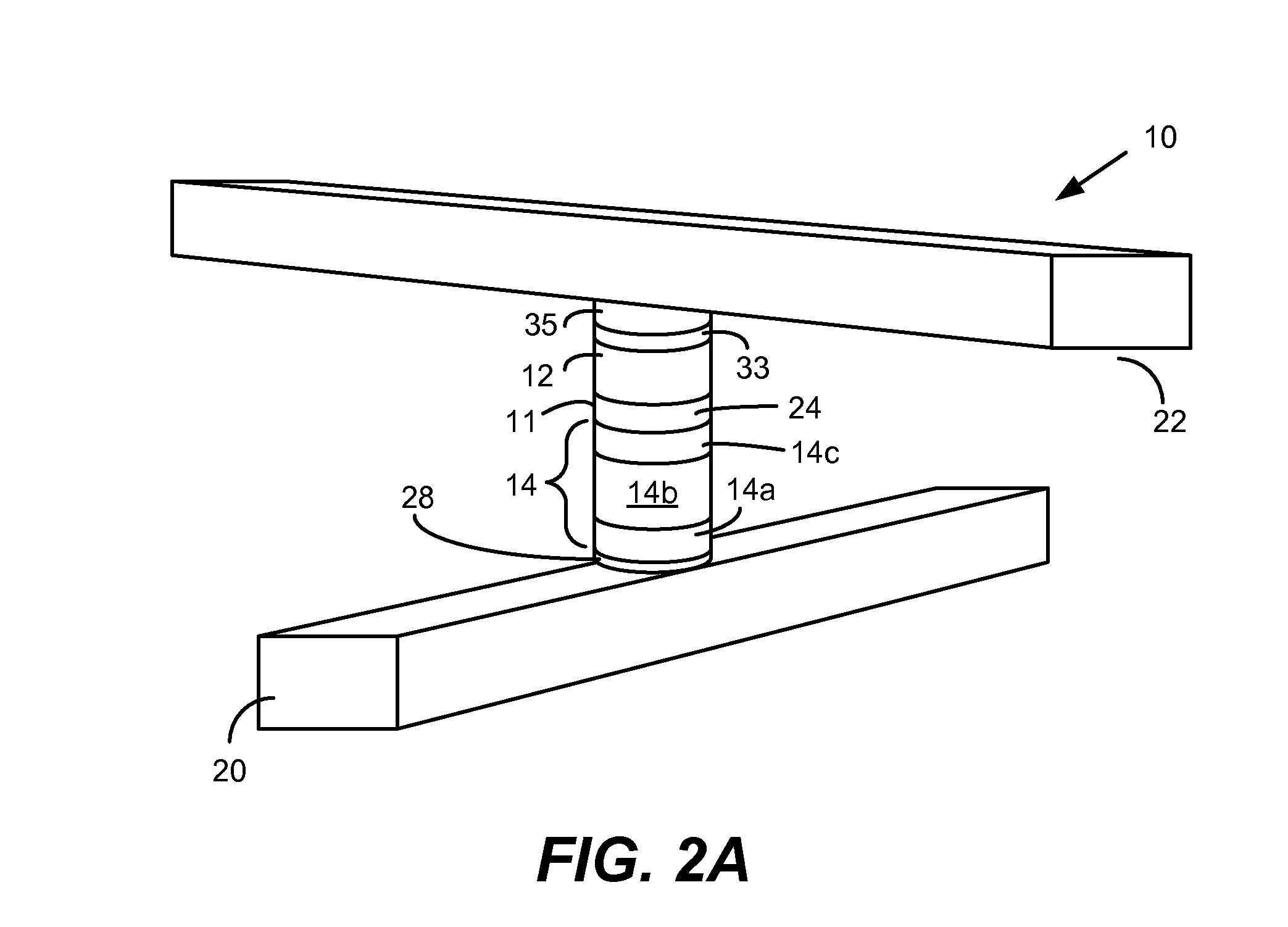

A method of depositing a carbon layer on a workpiece includes placing the workpiece in a reactor chamber, introducing a carbon-containing process gas into the chamber, generating a reentrant toroidal RF plasma current in a reentrant path that includes a process zone overlying the workpiece by coupling plasma RF source power to an external portion of the reentrant path, and coupling RF plasma bias power or bias voltage to the workpiece.

Owner:APPLIED MATERIALS INC

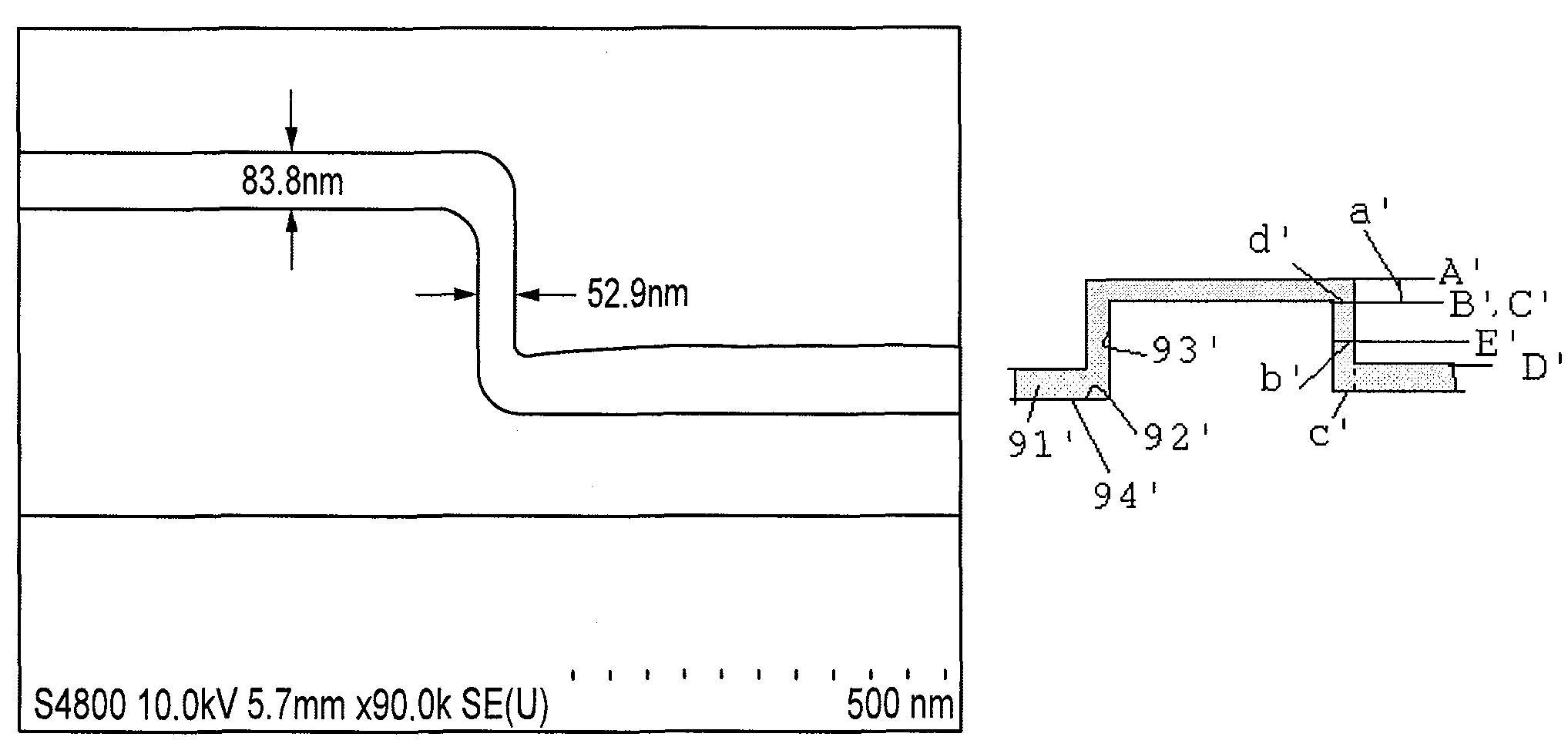

Method For Depositing an Amorphous Carbon Film with Improved Density and Step Coverage

ActiveUS20080003824A1High densityLower thermal budgetPretreated surfacesSemiconductor/solid-state device manufacturingCarbon layerKrypton

A method for depositing an amorphous carbon layer on a substrate includes the steps of positioning a substrate in a chamber, introducing a hydrocarbon source into the processing chamber, introducing a heavy noble gas into the processing chamber, and generating a plasma in the processing chamber. The heavy noble gas is selected from the group consisting of argon, krypton, xenon, and combinations thereof and the molar flow rate of the noble gas is greater than the molar flow rate of the hydrocarbon source. A post-deposition termination step may be included, wherein the flow of the hydrocarbon source and the noble gas is stopped and a plasma is maintained in the chamber for a period of time to remove particles therefrom.

Owner:APPLIED MATERIALS INC

Low temperature plasma deposition process for carbon layer deposition

InactiveUS20060264060A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingCarbon layerPlasma current

A method of depositing a carbon layer on a workpiece includes placing the workpiece in a reactor chamber, introducing a carbon-containing process gas into the chamber, generating a reentrant toroidal RF plasma current in a reentrant path that includes a process zone overlying the workpiece by coupling plasma RF source power to an external portion of the reentrant path, and coupling RF plasma bias power or bias voltage to the workpiece.

Owner:APPLIED MATERIALS INC

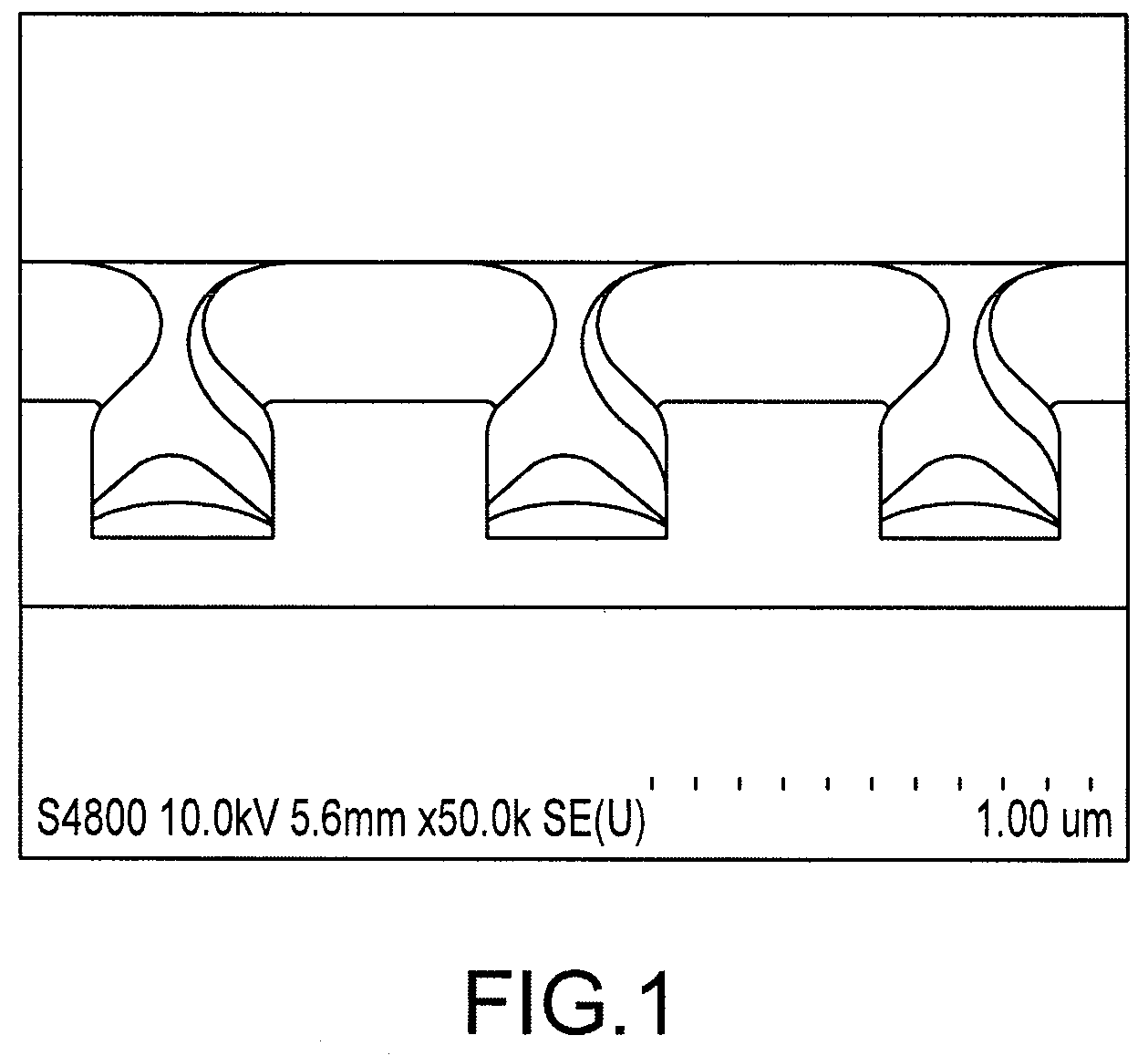

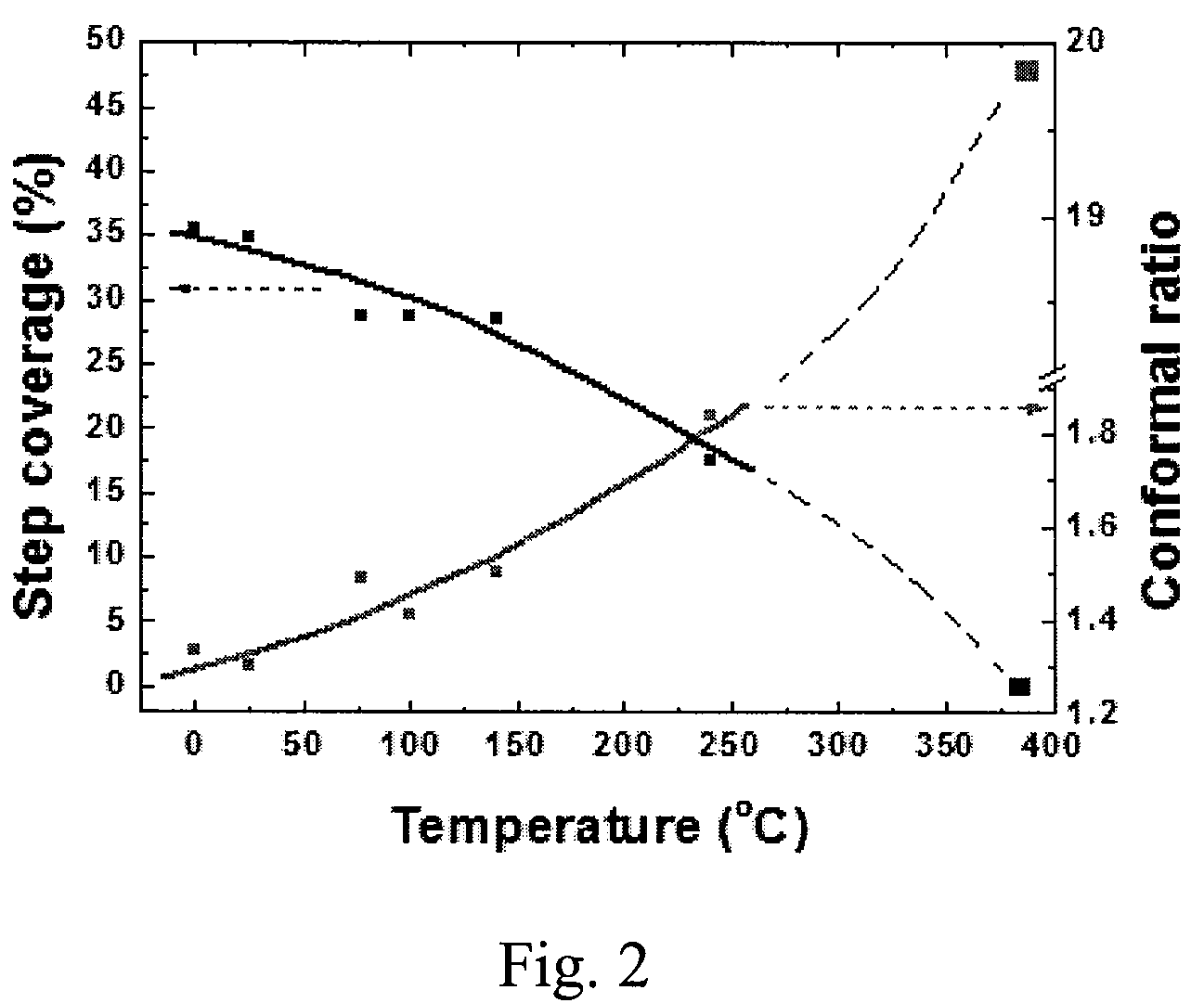

Method of forming highly conformal amorphous carbon layer

ActiveUS7842622B1Easily ionizedReduce riskSemiconductor/solid-state device manufacturingChemical vapor deposition coatingCarbon layerSemiconductor

A method of forming a conformal amorphous hydrogenated carbon layer on an irregular surface of a semiconductor substrate includes: vaporizing a hydrocarbon-containing precursor; introducing the vaporized precursor and an argon gas into a CVD reaction chamber inside which the semiconductor substrate is placed; depositing a conformal amorphous hydrogenated carbon layer on the irregular surface of the semiconductor substrate by plasma CVD; and controlling the deposition of the conformal ratio of the depositing conformal amorphous hydrogenated carbon layer. The controlling includes (a) adjusting a step coverage of the conformal amorphous hydrogenated carbon layer to about 30% or higher as a function of substrate temperature, and (b) adjusting a conformal ratio of the conformal amorphous hydrogenated carbon layer to about 0.9 to about 1.1 as a function of RF power and / or argon gas flow rate.

Owner:ASM JAPAN

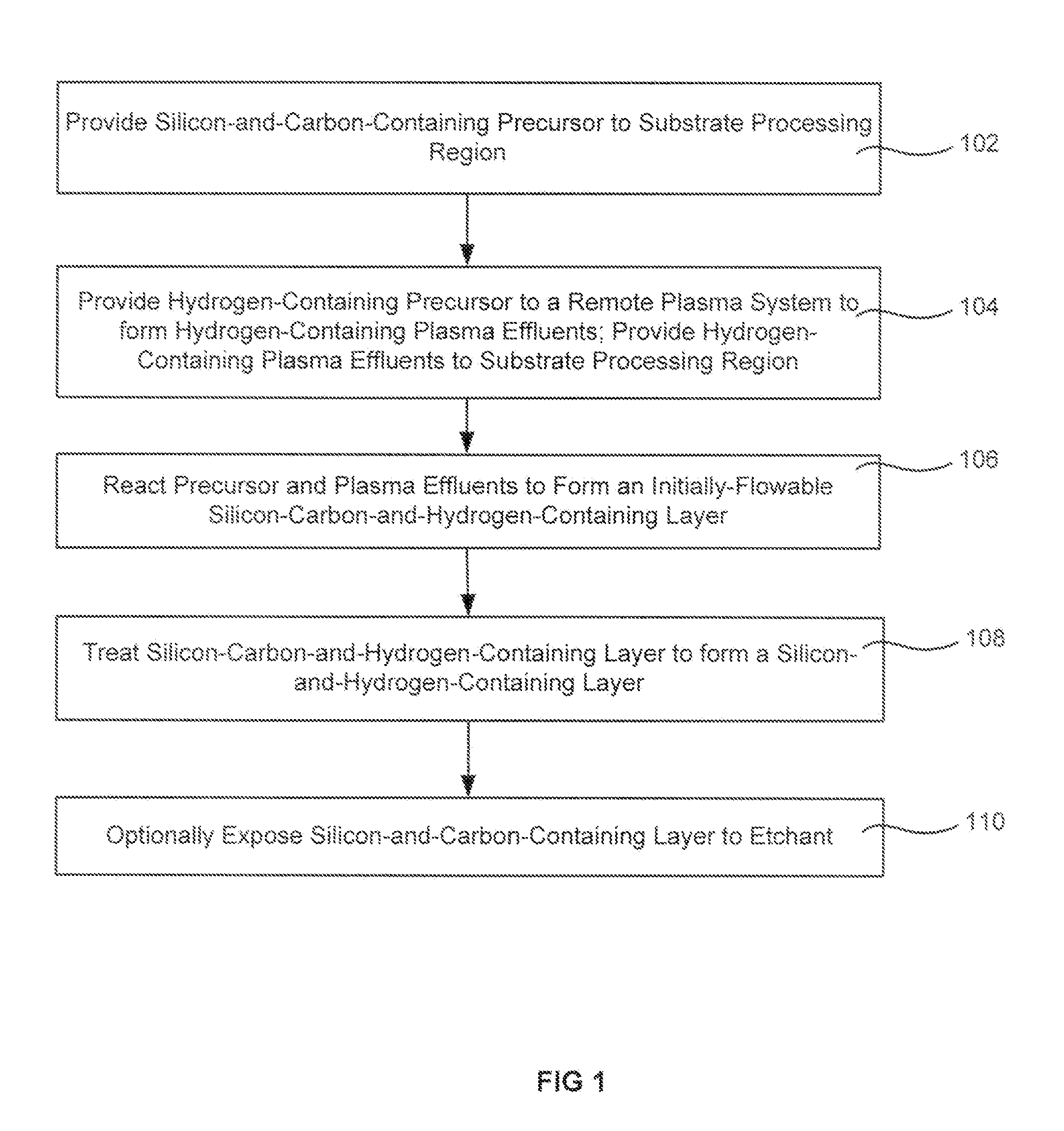

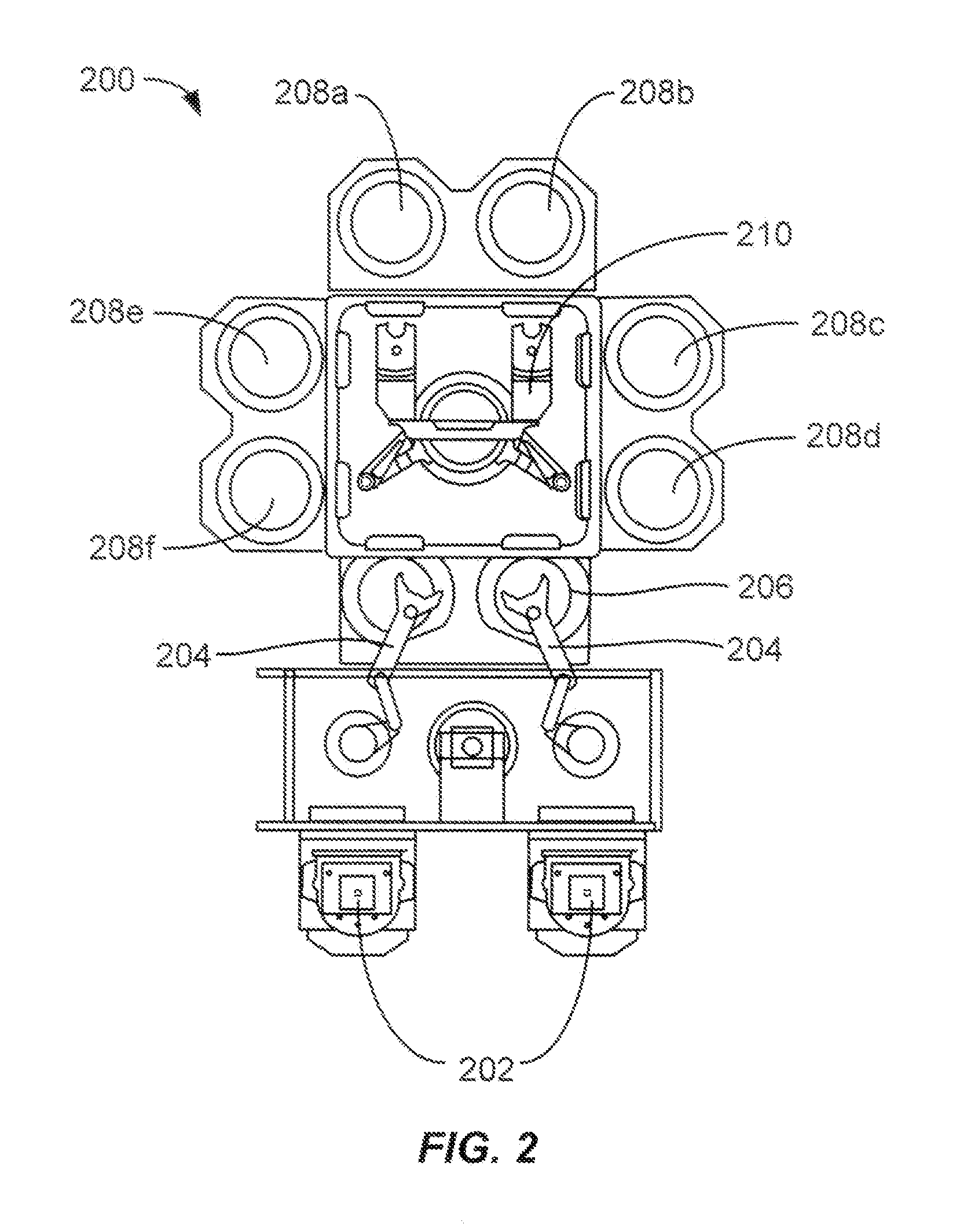

Flowable silicon-and-carbon-containing layers for semiconductor processing

InactiveUS20130217239A1Decreases beneficially low wet etch rateReduce hydrogen contentSemiconductor/solid-state device manufacturingCarbon layerHydrogen

Methods are described for forming and curing a gapfill silicon-and-carbon-containing layer on a semiconductor substrate. The silicon and carbon constituents may come from a silicon-and-carbon-containing precursor excited by a radical hydrogen precursor that has been activated in a remote plasma region. Exemplary precursors include 1,3,5-trisilapentane (H3Si—CH2—SiH2—CH2—SiH3) as the silicon-and-carbon-containing precursor and hydrogen (H2) as the hydrogen-containing precursor. The hydrogen-containing precursor may also be a hydrocarbon, such as acetylene (C2H2) or ethylene (C2H4). The hydrogen-containing precursor is passed through a remote plasma region to form plasma effluents (the radical hydrogen precursor) which are flowed into the substrate processing region. When the silicon-and-carbon-containing precursor combines with the plasma effluents in the substrate processing region, they form a flowable silicon-carbon-and-hydrogen-containing layer on the semiconductor substrate.

Owner:APPLIED MATERIALS INC

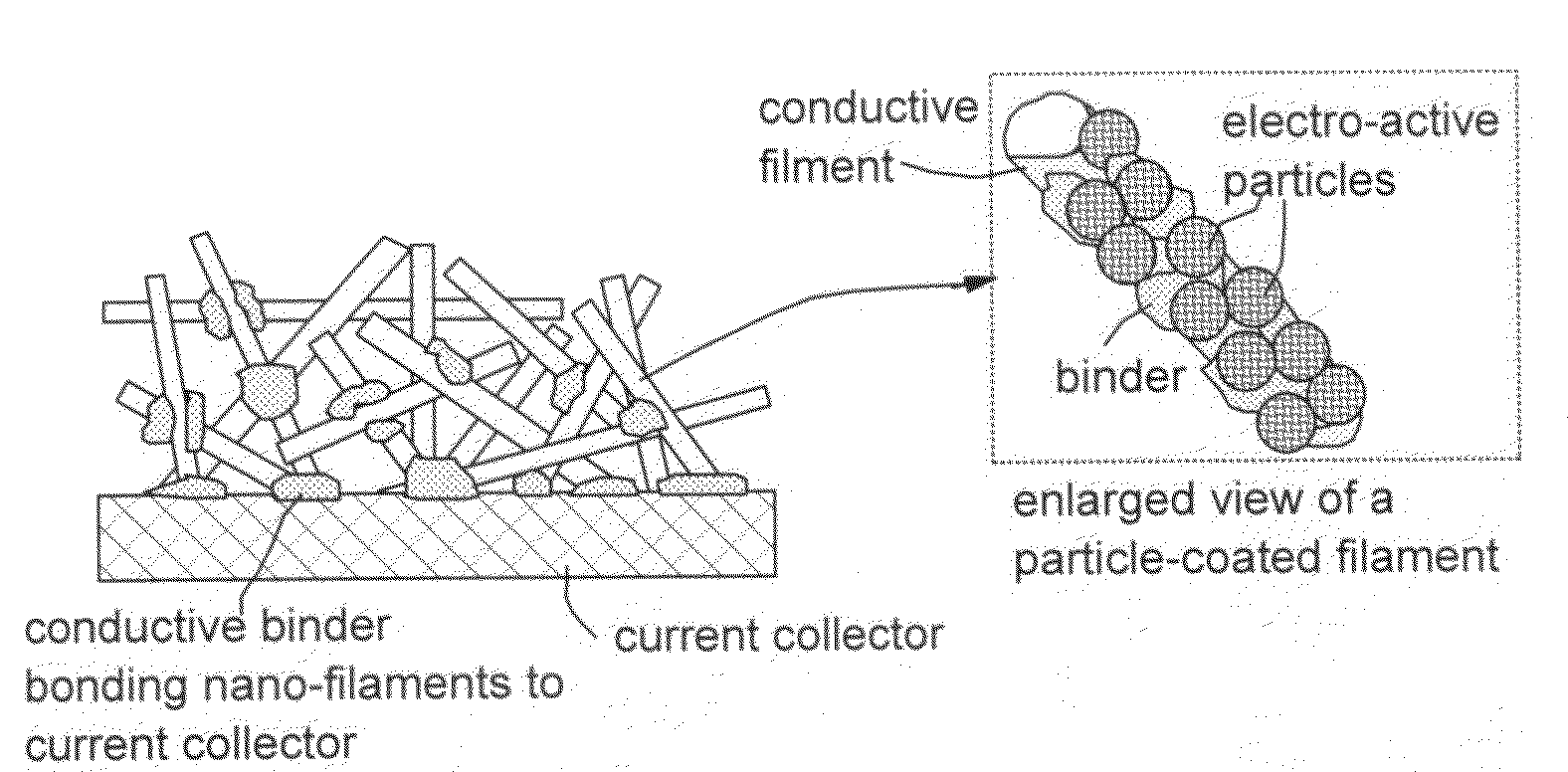

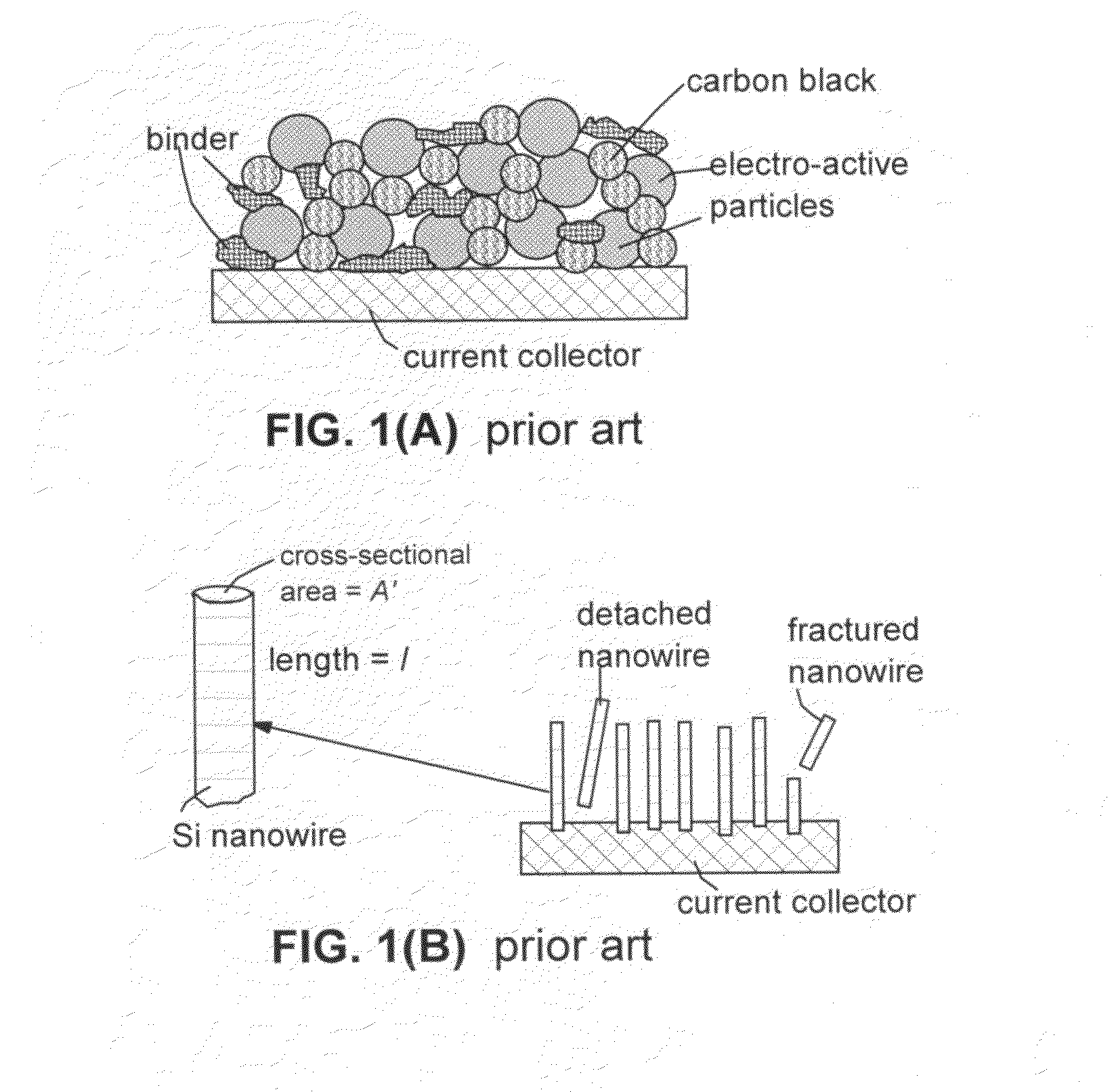

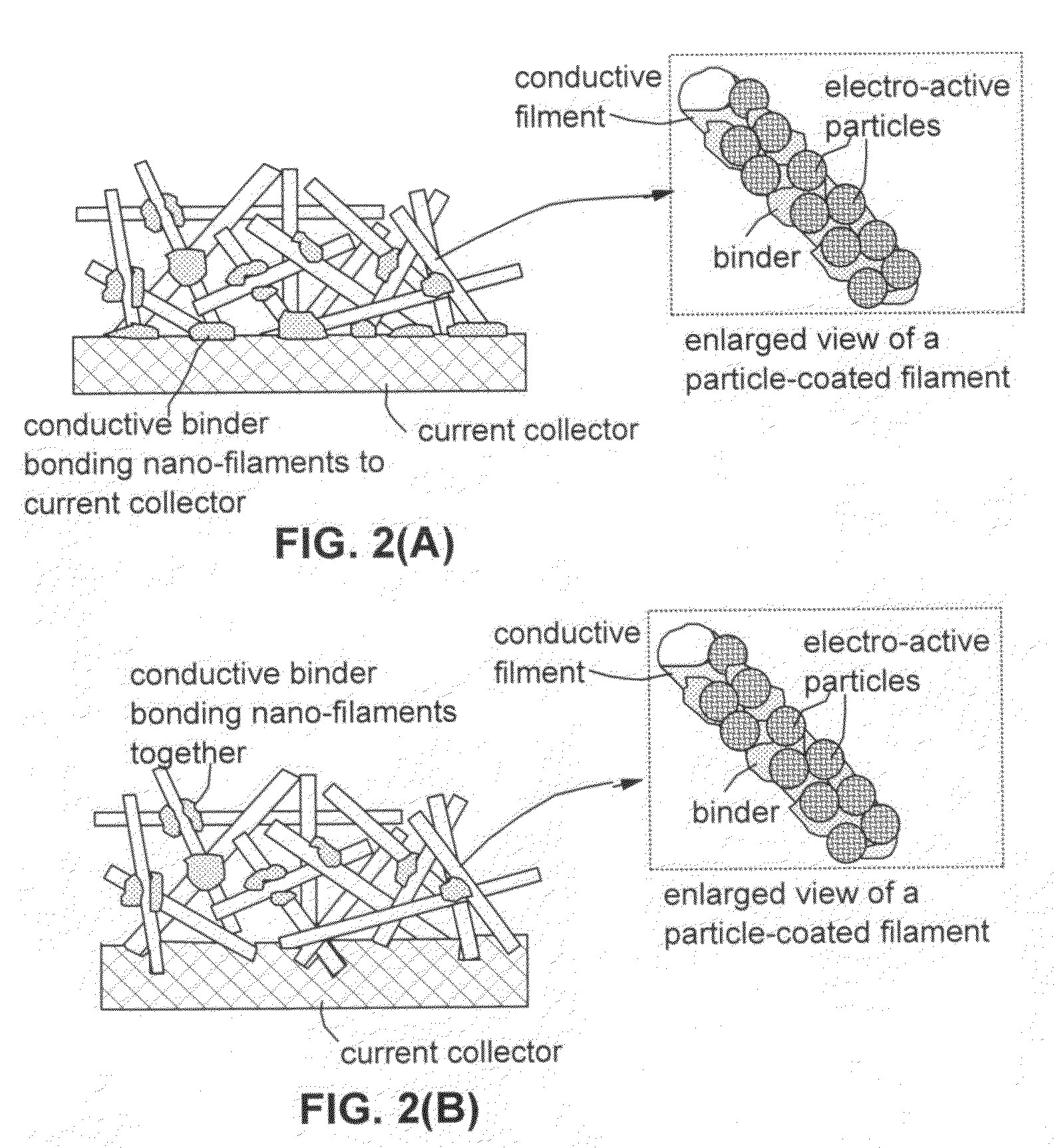

Conductive nanocomposite-based electrodes for lithium batteries

ActiveUS20090305135A1High specific capacityHigh reversible capacityMaterial nanotechnologyNon-aqueous electrolyte accumulator electrodesCarbon layerComposite electrode

This invention provides a nanocomposite-based lithium battery electrode comprising: (a) A porous aggregate of electrically conductive nano-filaments that are substantially interconnected, intersected, physically contacted, or chemically bonded to form a three-dimensional network of electron-conducting paths, wherein the nano-filaments have a diameter or thickness less than 1 μm (preferably less than 500 nm); and (b) Sub-micron or nanometer-scale electro-active particles that are bonded to a surface of the nano-filaments with a conductive binder material, wherein the particles comprise an electro-active material capable of absorbing and desorbing lithium ions and wherein the electro-active material content is no less than 25% by weight based on the total weight of the particles, the binder material, and the filaments. Preferably, these electro-active particles are coated with a thin carbon layer. This electrode can be an anode or a cathode. The battery featuring such an anode or cathode exhibits an exceptionally high specific capacity, an excellent reversible capacity, and a long cycle life.

Owner:GLOBAL GRAPHENE GRP INC

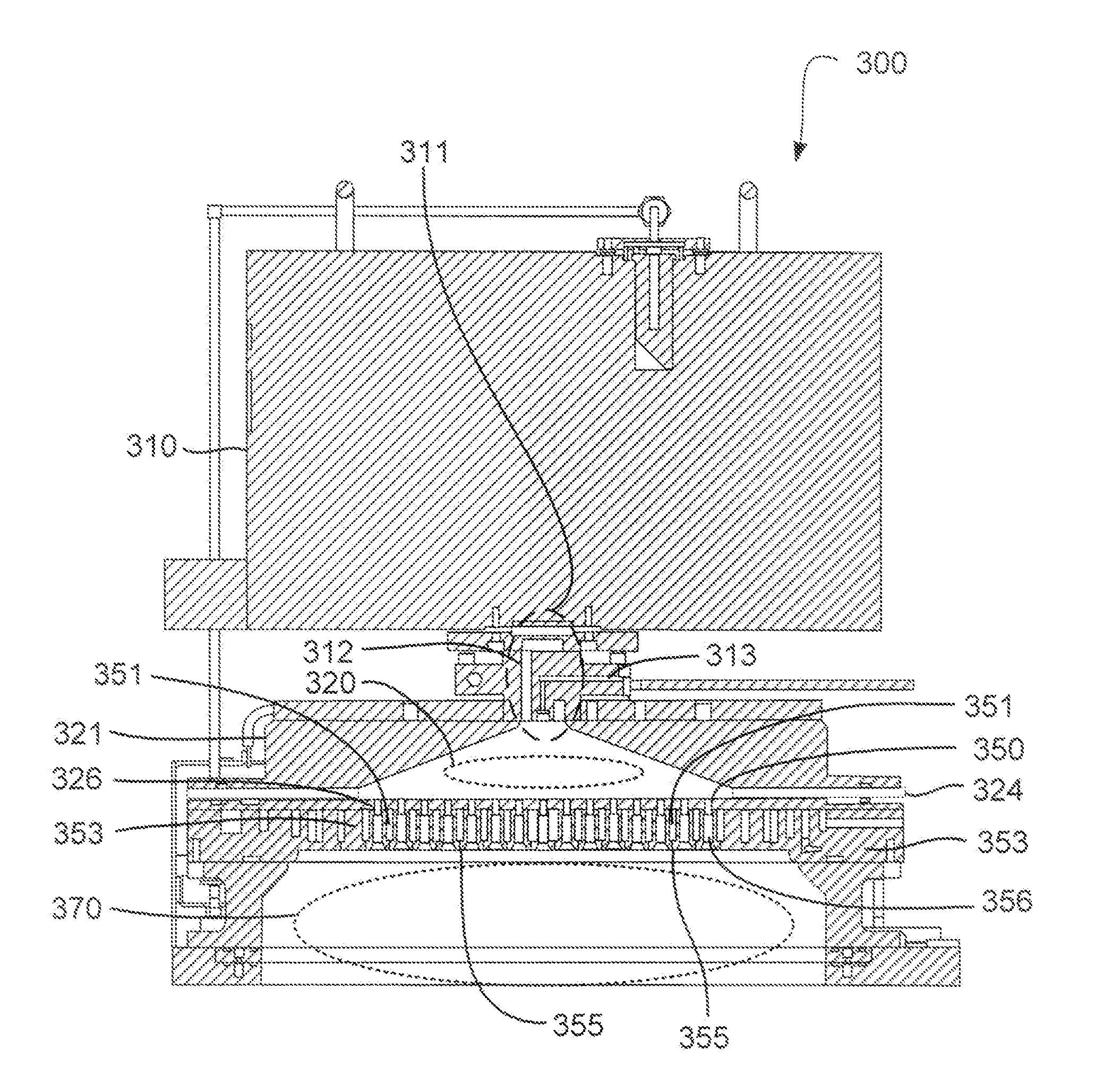

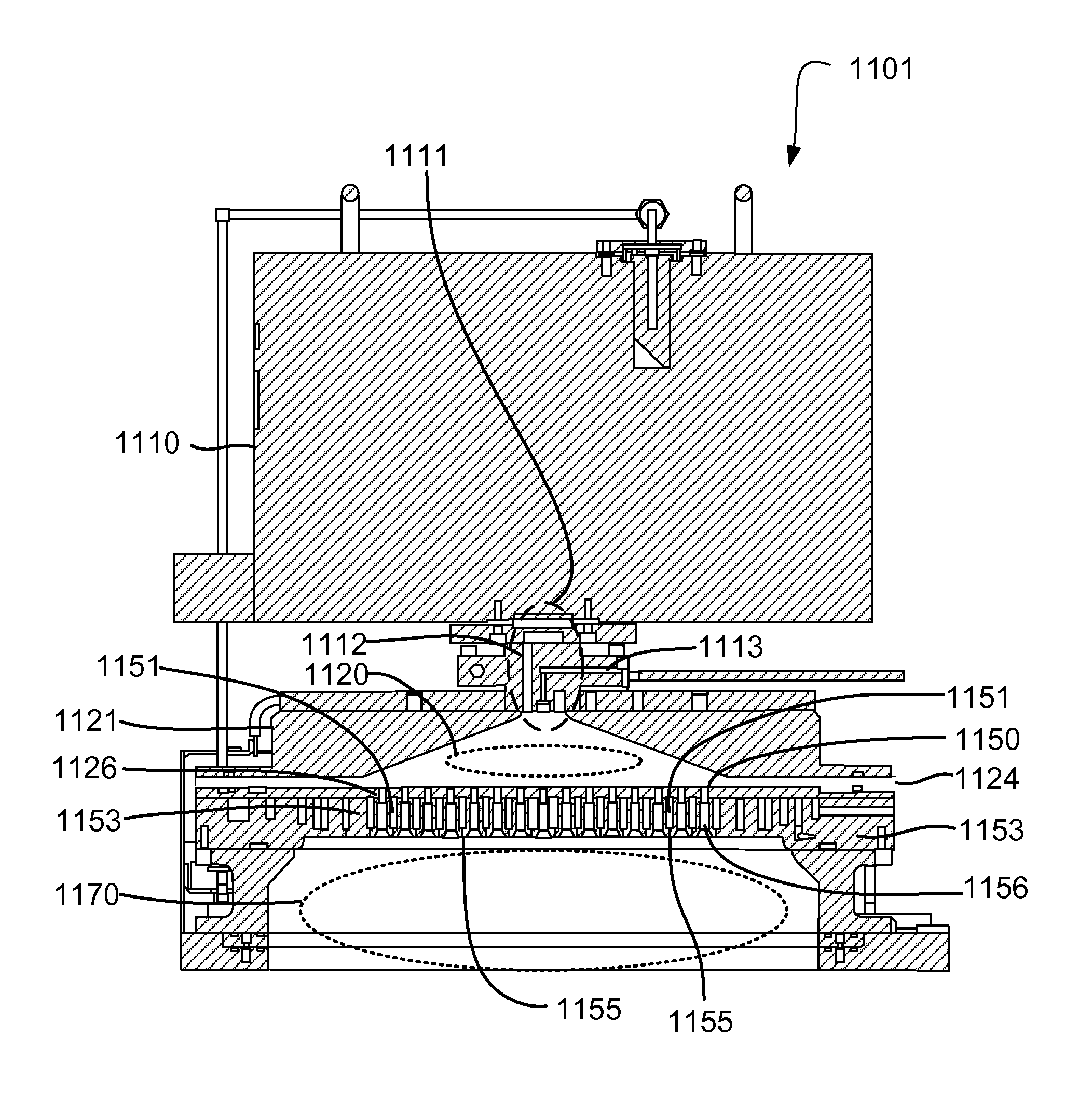

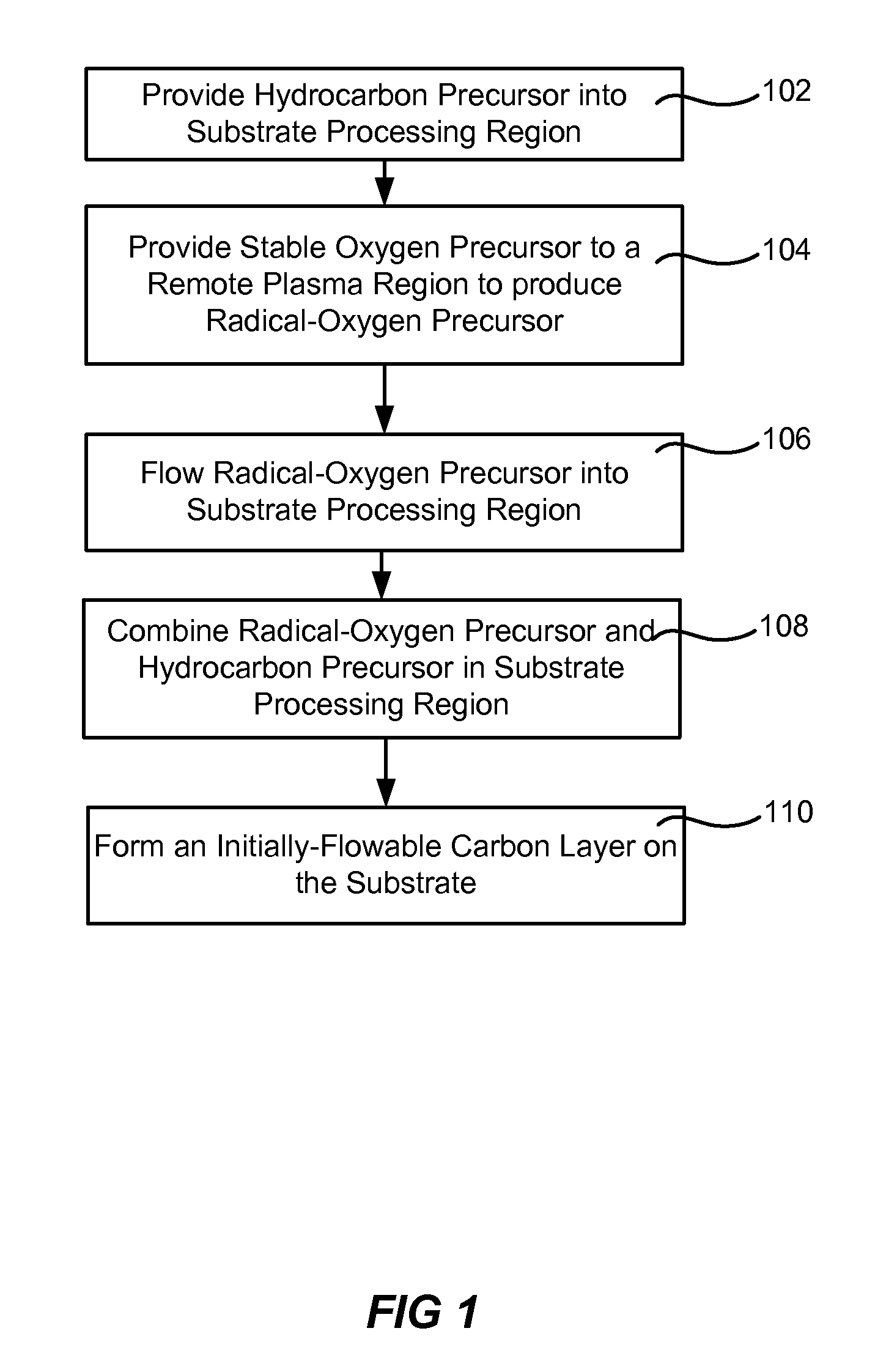

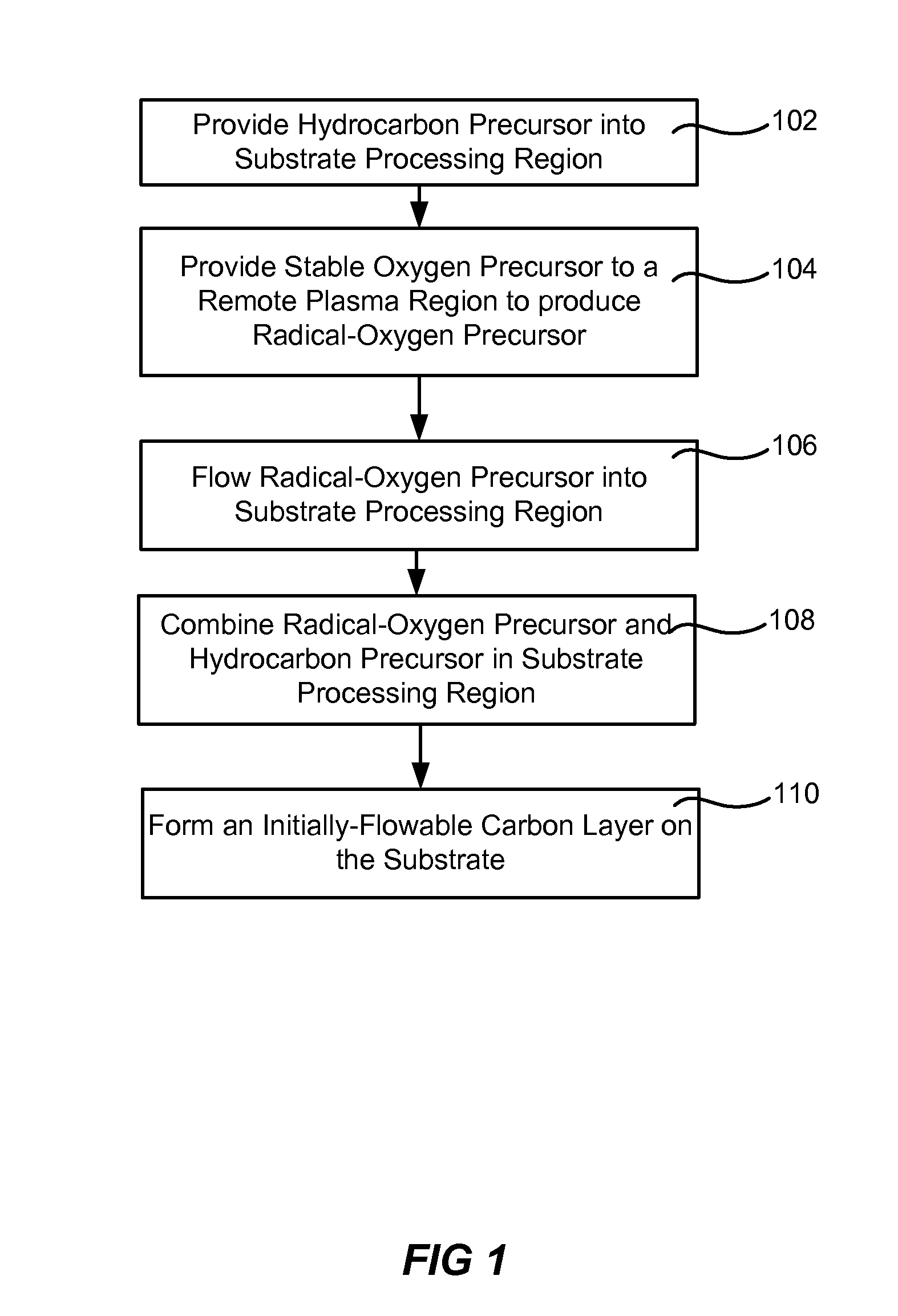

Flowable carbon for semiconductor processing

ActiveUS9514932B2Semiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingCarbon layerSemiconductor

Methods are described for forming flowable carbon layers on a semiconductor substrate. A local excitation (such as a hot filament in hot wire CVD, a plasma in PECVD or UV light) may be applied as described herein to a silicon-free carbon-containing precursor containing a hydrocarbon to form a flowable carbon-containing film on a substrate. A remote excitation method has also been found to produce flowable carbon-containing films by exciting a stable precursor to produce a radical precursor which is then combined with unexcited silicon-free carbon-containing precursors in the substrate processing region.

Owner:APPLIED MATERIALS INC

Flowable carbon for semiconductor processing

ActiveUS20140045342A1Semiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingCarbon layerSilicon

Methods are described for forming flowable carbon layers on a semiconductor substrate. A local excitation (such as a hot filament in hot wire CVD, a plasma in PECVD or UV light) may be applied as described herein to a silicon-free carbon-containing precursor containing a hydrocarbon to form a flowable carbon-containing film on a substrate. A remote excitation method has also been found to produce flowable carbon-containing films by exciting a stable precursor to produce a radical precursor which is then combined with unexcited silicon-free carbon-containing precursors in the substrate processing region.

Owner:APPLIED MATERIALS INC

Moisture barrier coatings

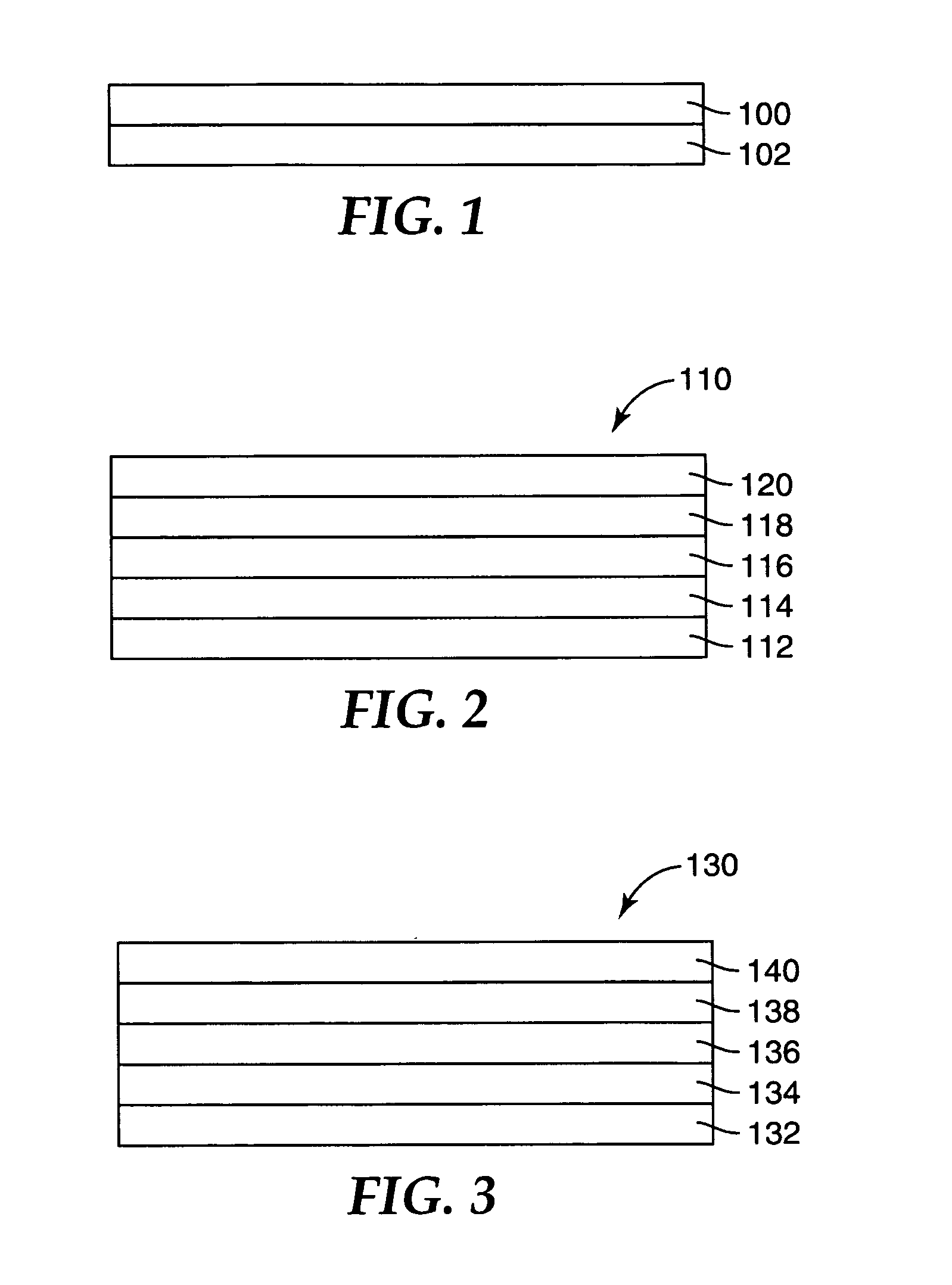

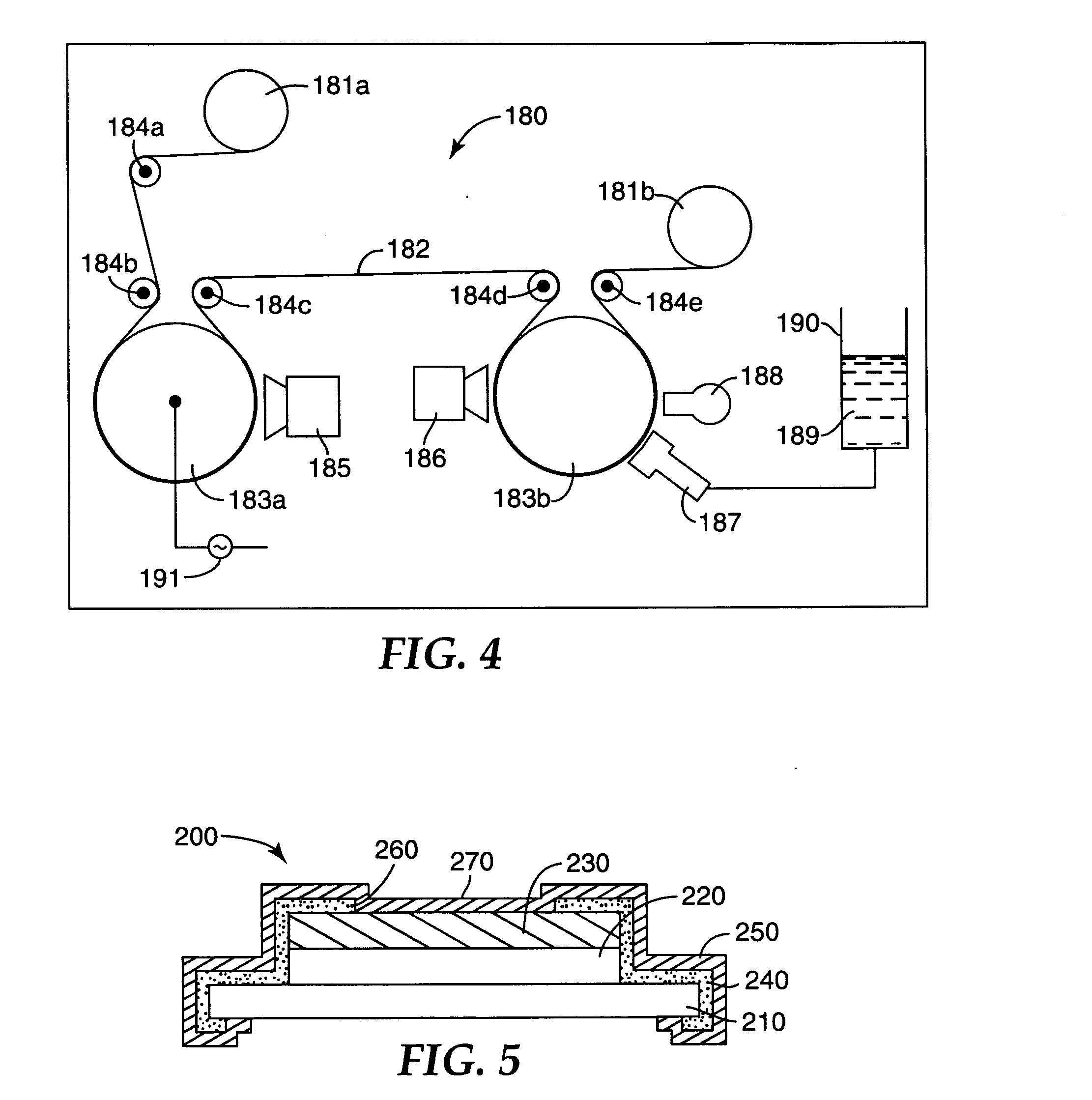

InactiveUS20070020451A1Liquid surface applicatorsSynthetic resin layered productsCarbon layerMoisture barrier

A barrier assembly having a flexible or rigid substrate overcoated with an all polymer multilayer stack. A multilayer on the substrate includes alternating diamond-like glass or carbon layers with polymer layers. Another multilayer includes alternating polymer layers using different types of polymers. The barrier layers can be used to mount, cover, encapsulate or form composite assemblies for protection of moisture or oxygen sensitive articles

Owner:3M INNOVATIVE PROPERTIES CO

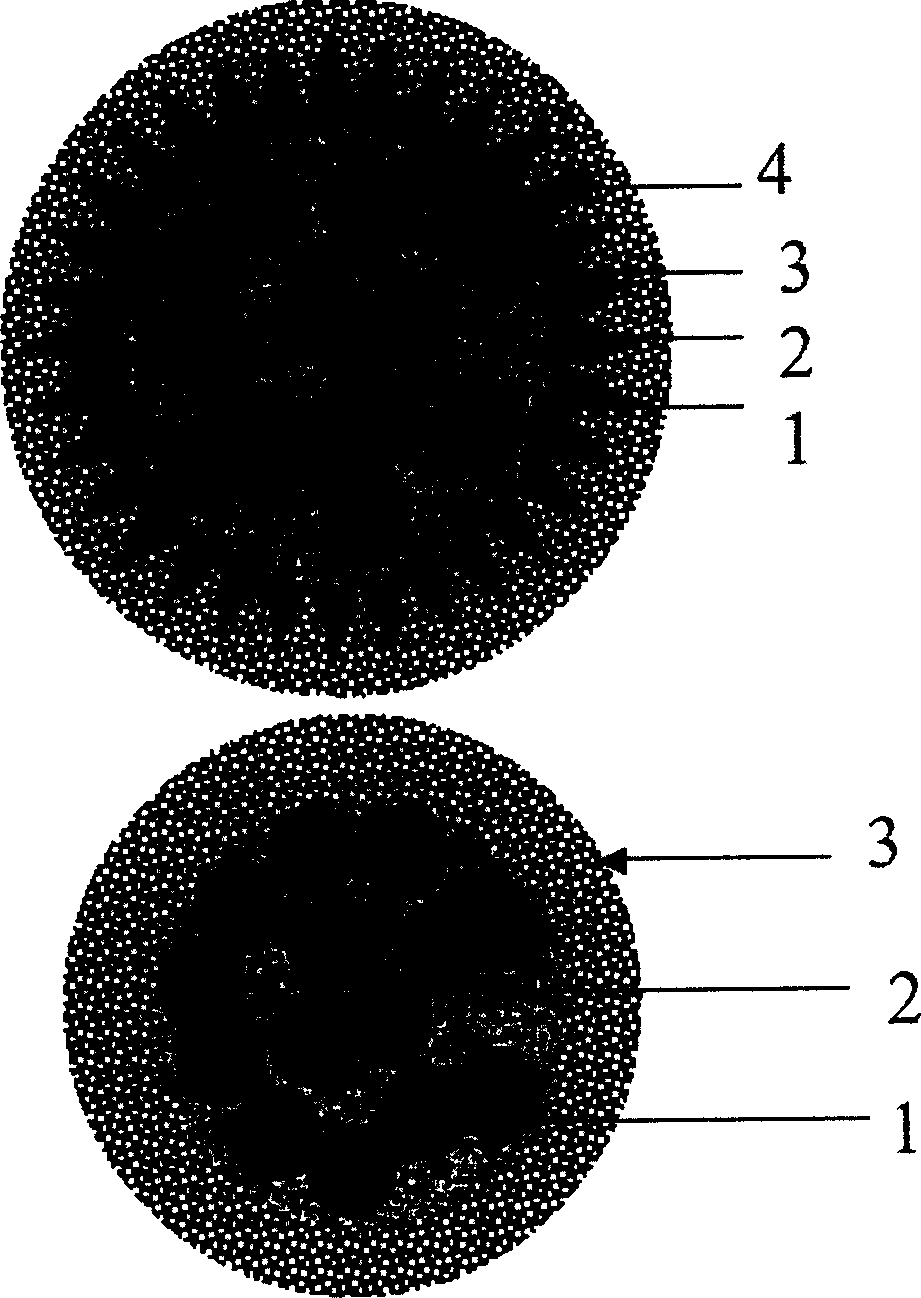

Silicon-carbon composite negative electrode material for lithium ion battery and preparation method thereof

ActiveCN103474667AImprove cycle performanceHigh charge and discharge capacityMaterial nanotechnologyCell electrodesCarbon compositesCarbon layer

The invention relates to a silicon-carbon composite negative electrode material and a preparation method thereof. The silicon-carbon composite negative electrode material successively comprises nano silicon / graphite particles, a first carbon coating layer and an organic cracking carbon layer from inside to outside. The nano silicon / graphite particles are globular or globular-like composite particles formed by employing graphite as an inner core of a volume expansion buffer substrate and coating a nano silicon particle layer; the first carbon coating layer comprises carbon nanotubes and / or amorphous carbon, the carbon nanotubes and / or amorphous carbon are interspersed in a gap network formed by gaps of the nano silicon particles and / or are coated outside the nano silicon particle layer, so that the nano silicon is tightly wrapped between the carbon nanotubes and / or between the carbon nanotubes and the graphite substrate, and besides, the material ion conductivity is effectively enhanced; the organic cracking carbon layer is an outermost coating layer of the silicon-carbon composite negative electrode material. The silicon-carbon composite negative electrode material has excellent cycle performance, excellent multiplying power charging and discharging performance and lower volume expansion effect.

Owner:BTR NEW MATERIAL GRP CO LTD

Method for making a lithium mixed metal compound having an olivine structure

ActiveUS20070207080A1Mitigate such drawbackNon-metal conductorsLiquid surface applicatorsLithiumCarbon layer

Owner:AQUIRE ENERGY CO LTD

Method of forming high aspect ratio features

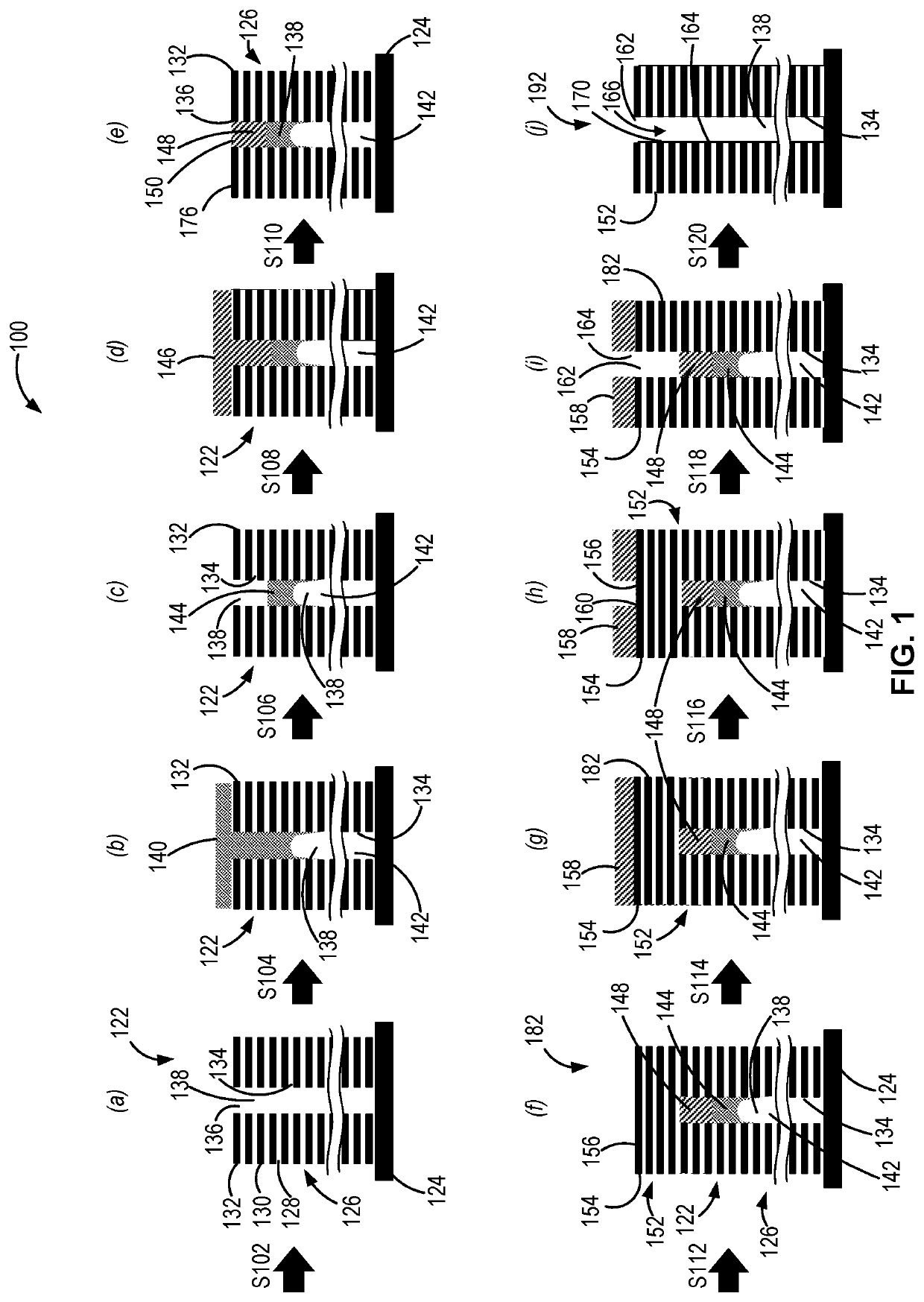

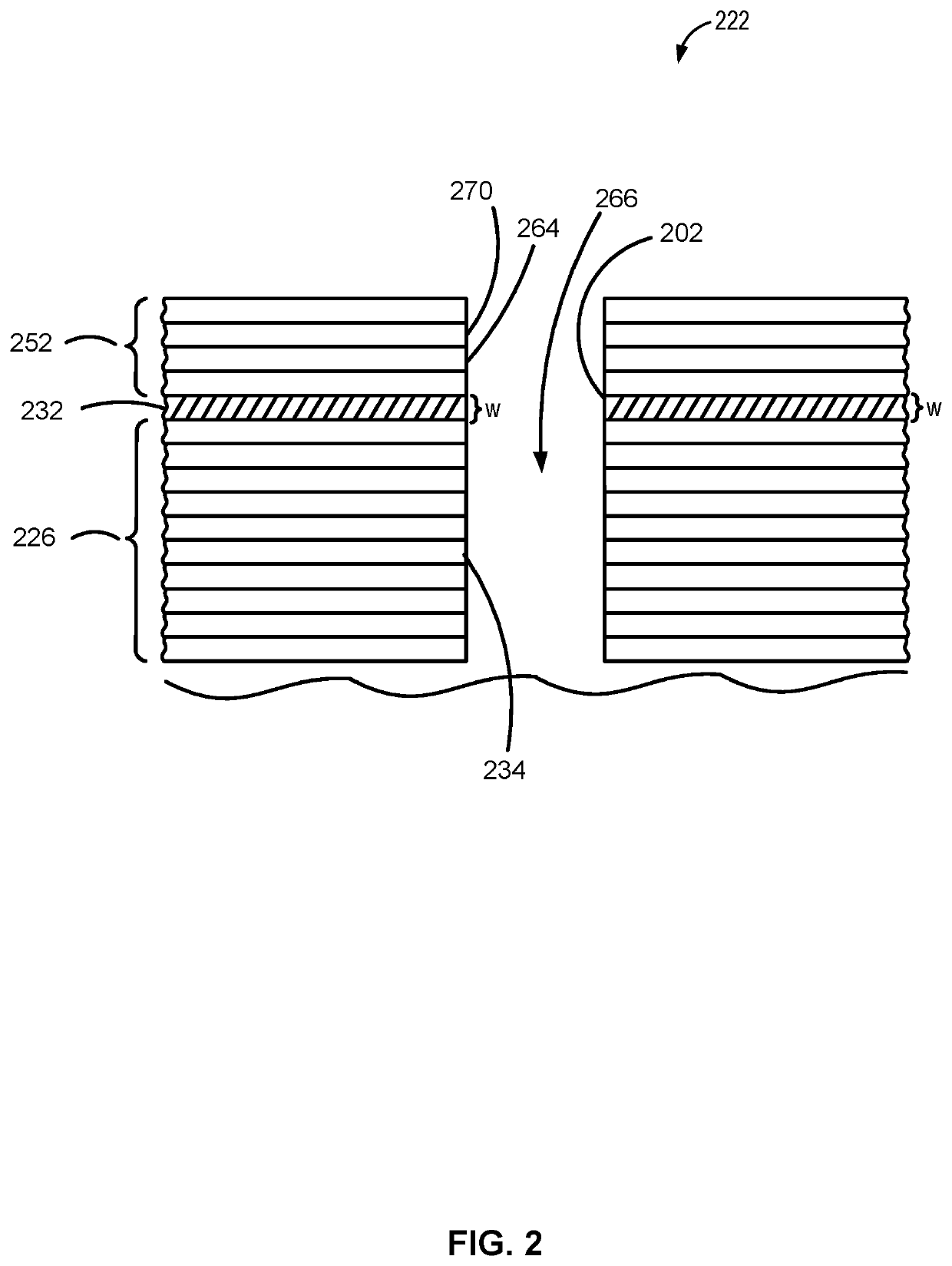

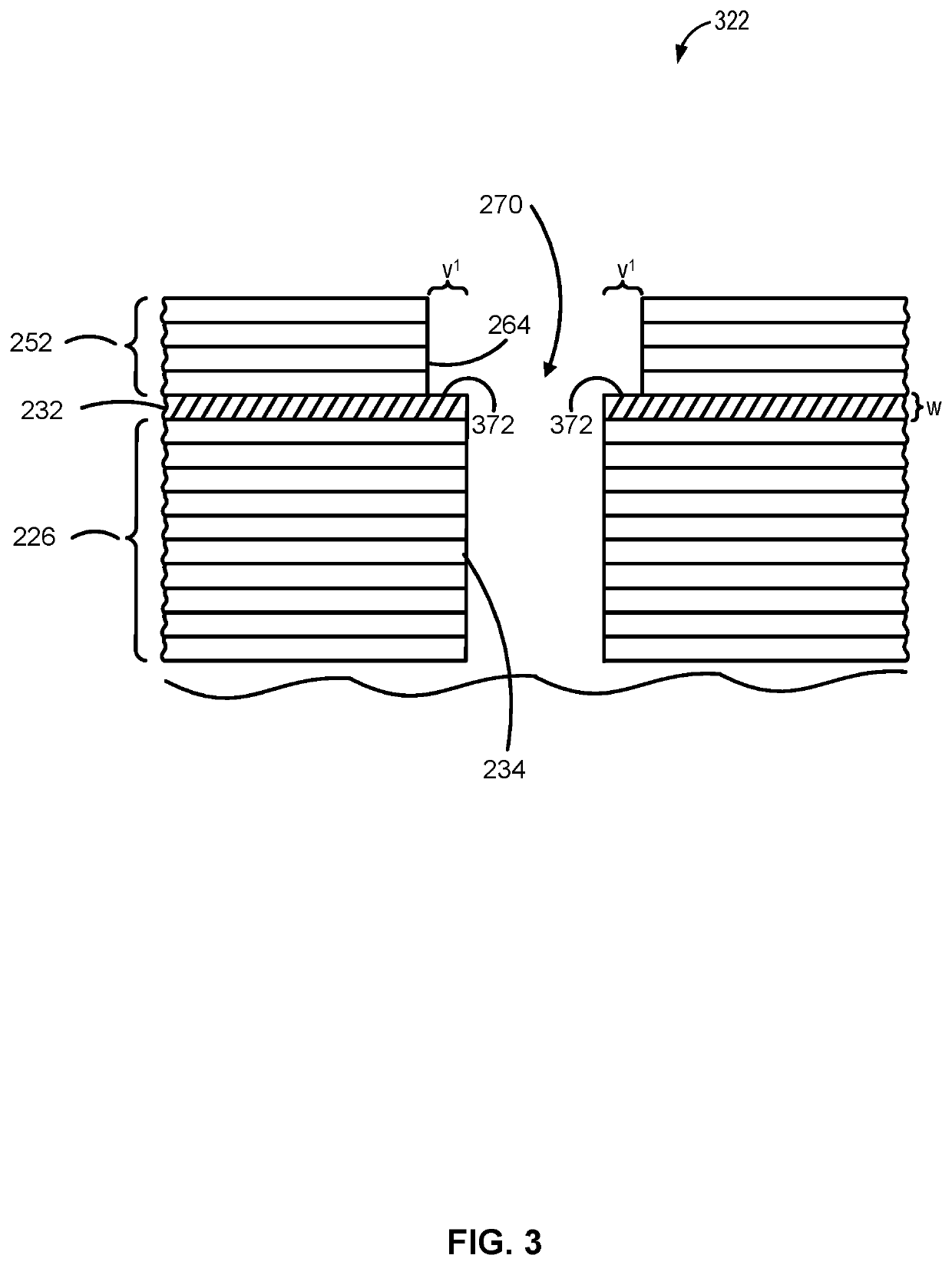

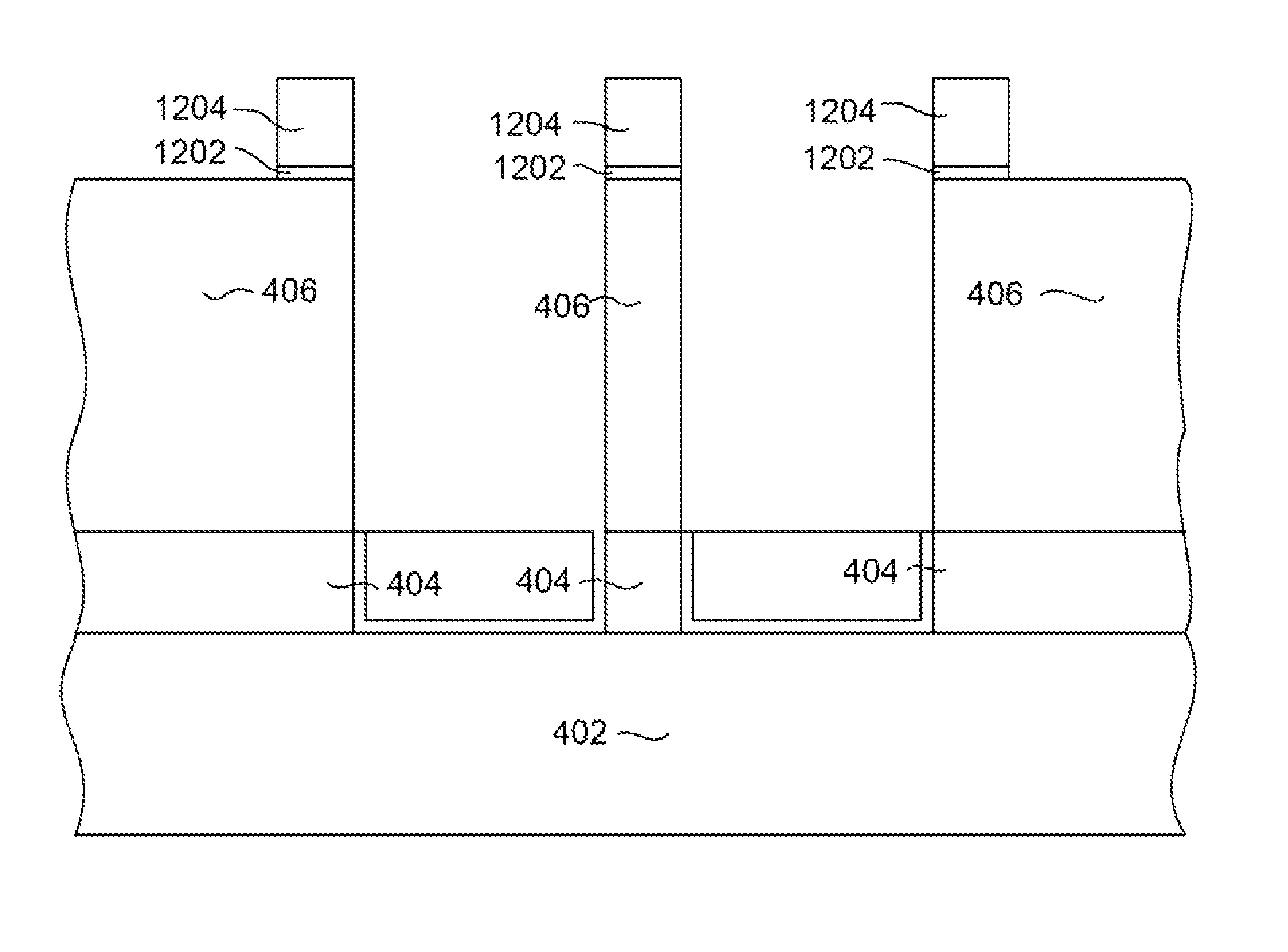

PendingUS20210225642A1Prevent and mitigate bowingReduce carbon depositionSemiconductor/solid-state device detailsSemiconductor/solid-state device manufacturingCarbon layerEngineering

Methods and systems for forming high aspect ratio features on a substrate are disclosed. Exemplary methods include forming a first carbon layer within a recess, etching a portion of the first carbon layer within the recess, and forming a second carbon layer within the recess. Structures formed using the methods or systems are also disclosed.

Owner:ASM IP HLDG BV

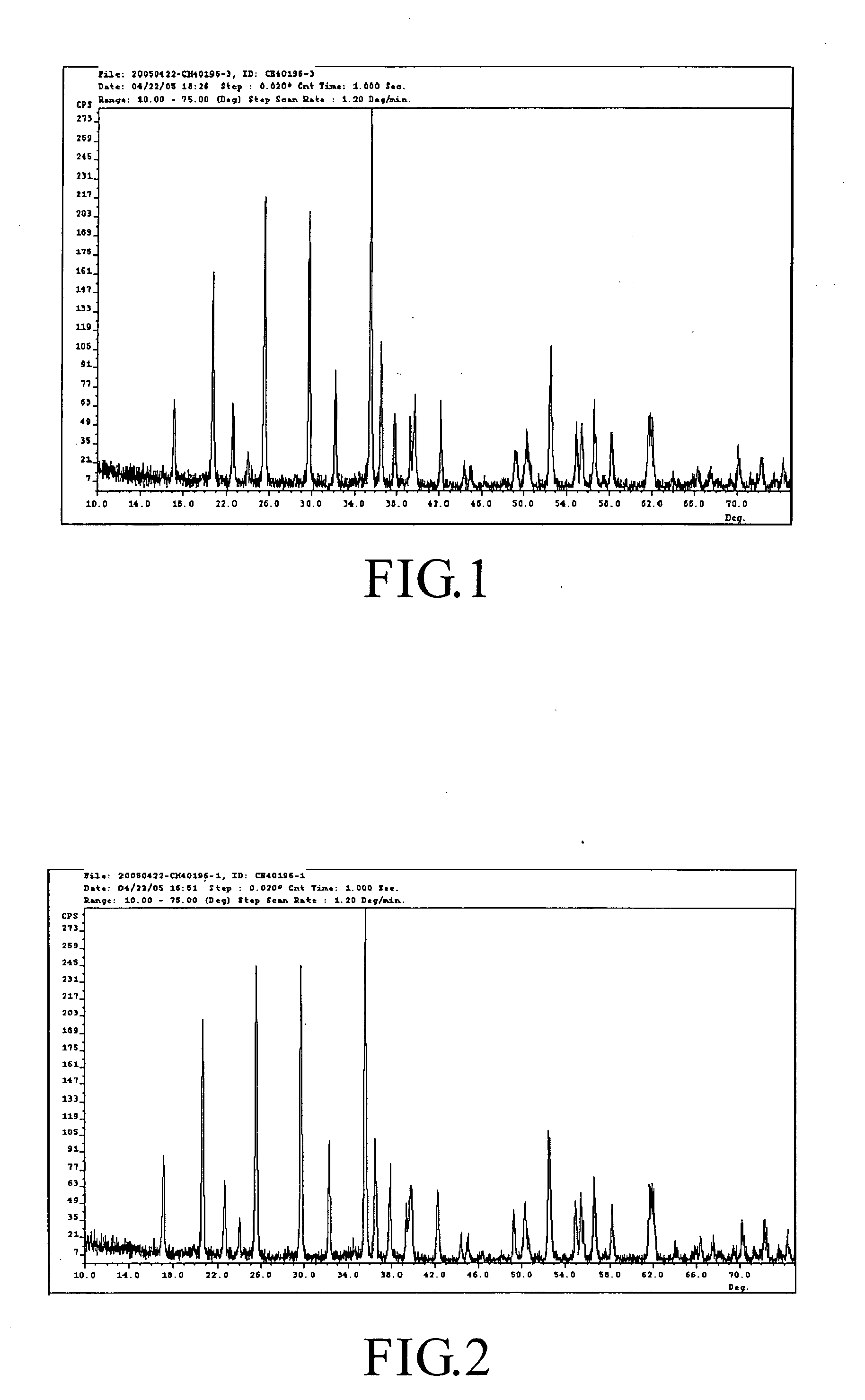

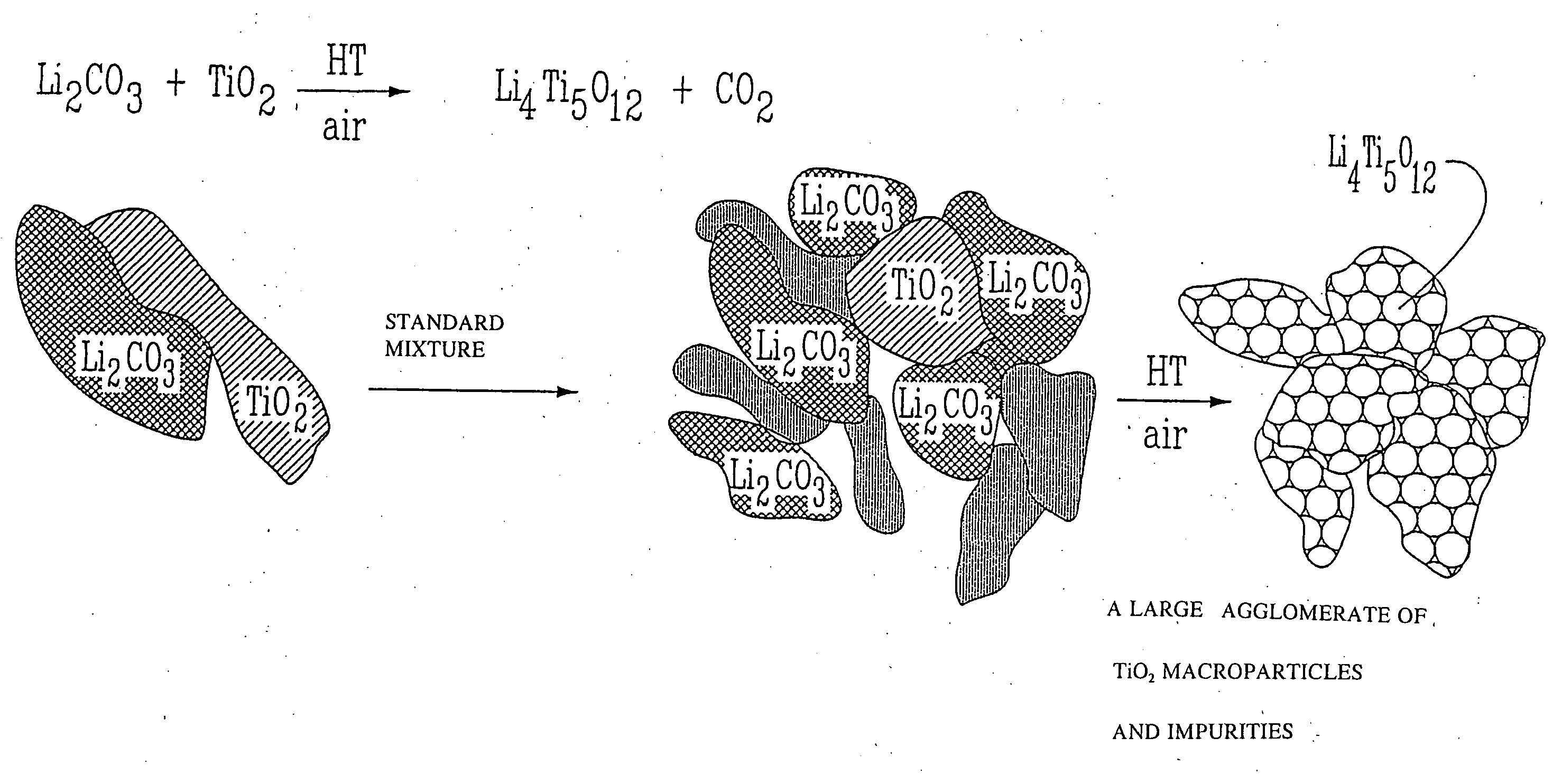

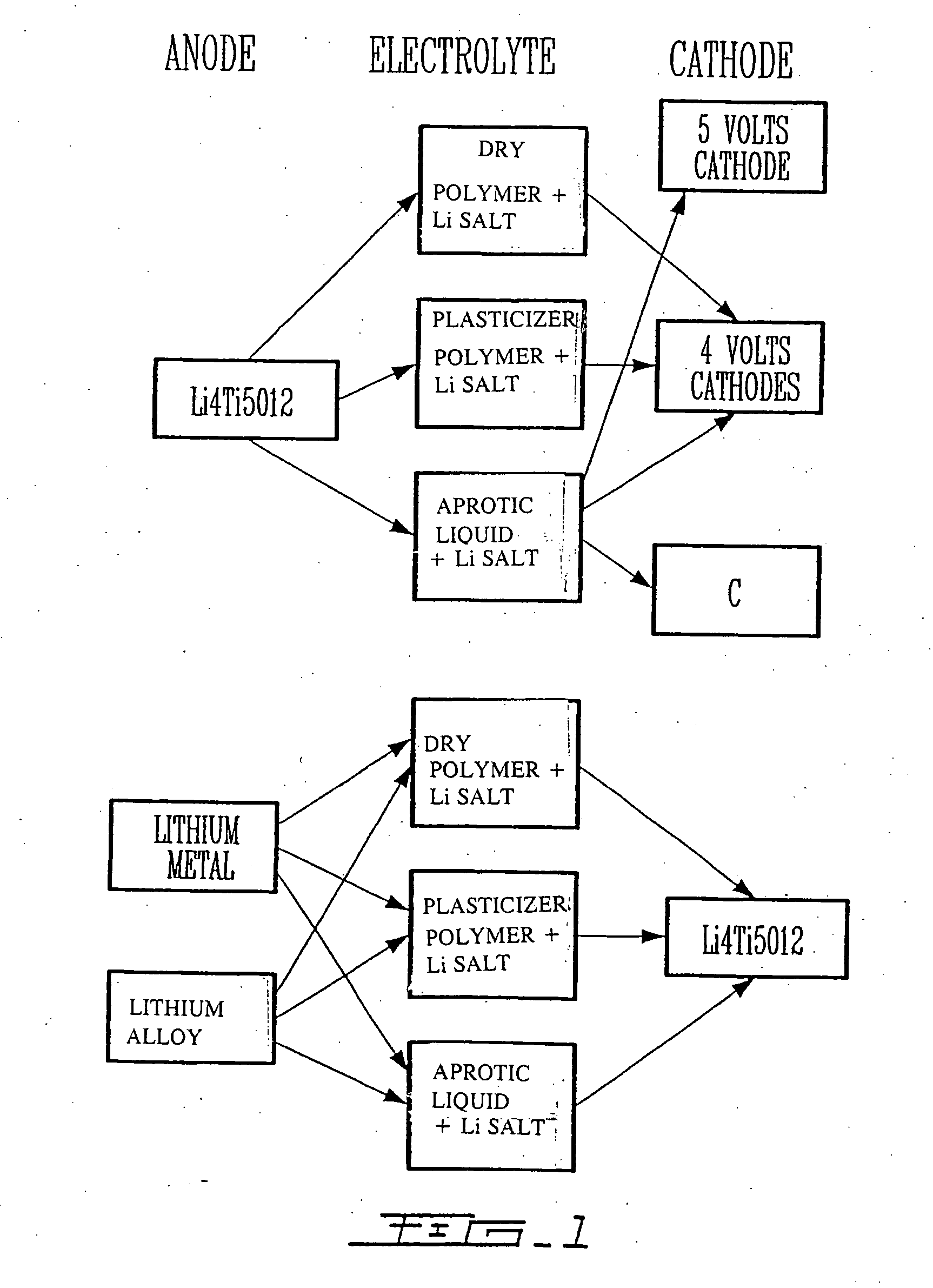

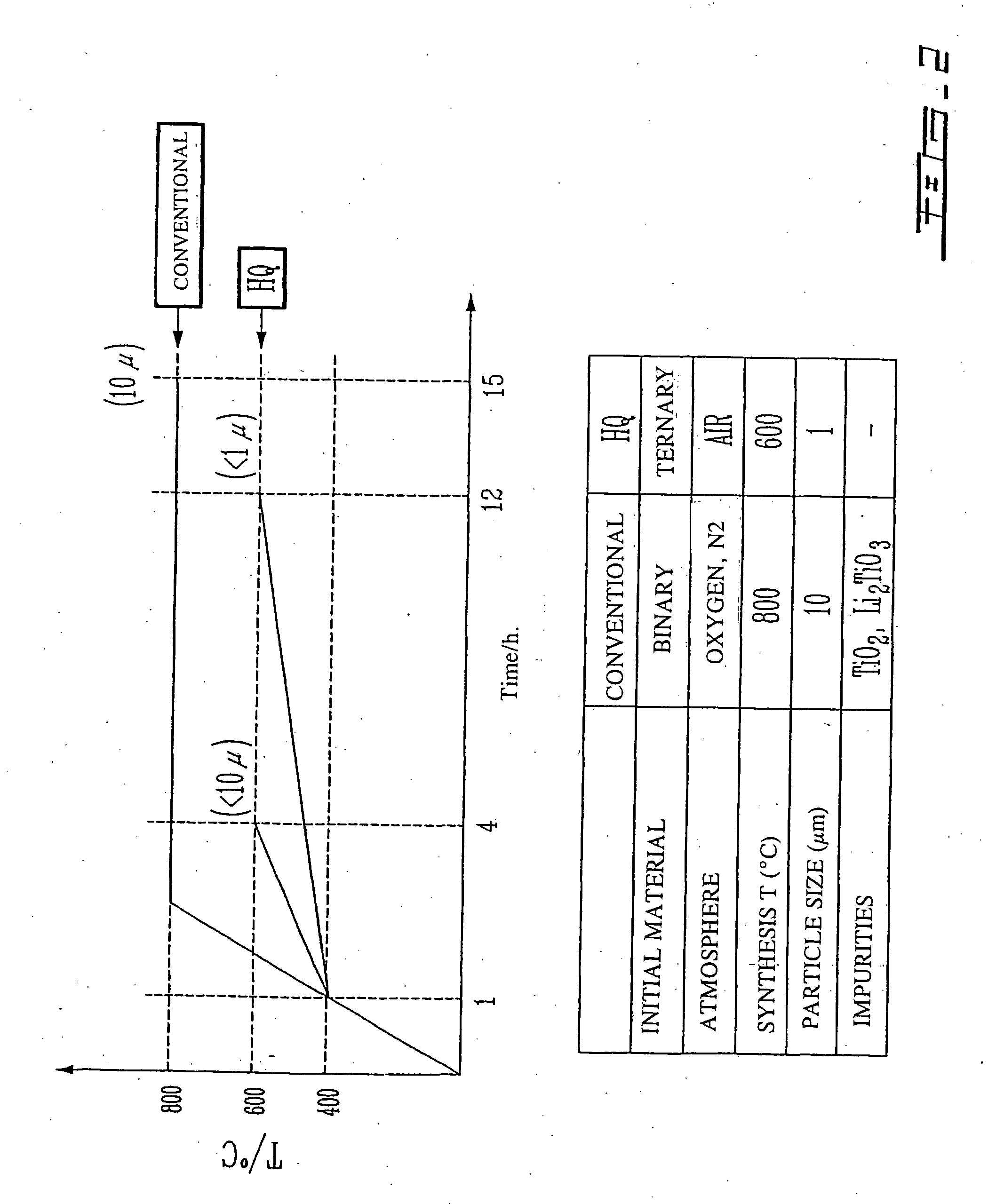

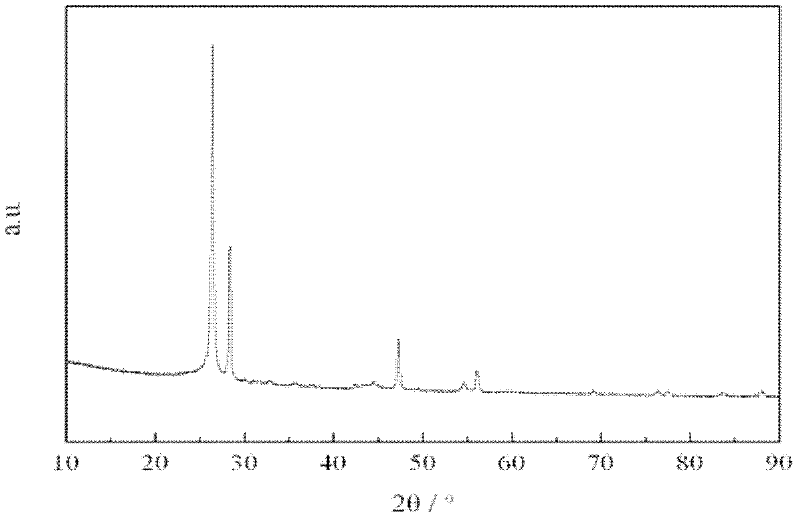

Li4Ti5O12, Li(4-alpha)Zalpha Ti5O12 or Li4ZbetaTi(5-beta)O12 particles, processes for obtaining same and use as electrochemical generators

Synthesis process for new particles of Li4Ti5O12, Li(4-alpha)ZalphaTi5O12 or Li4ZbetaTi(5-beta)O12, preferably having a spinel structure, wherein beta is greater than 0 and less than or equal to 0.5 (preferably having a spinel structure), alpha representing a number greater than zero and less than or equal to 0.33, Z representing a source of at least one metal, preferably chosen from the group made up of Mg, Nb, Al, Zr, Ni, Co. These particles coated with a layer of carbon notably exhibit electrochemical properties that are particularly interesting as components of anodes and / or cathodes in electrochemical generators.

Owner:HYDRO QUEBEC CORP

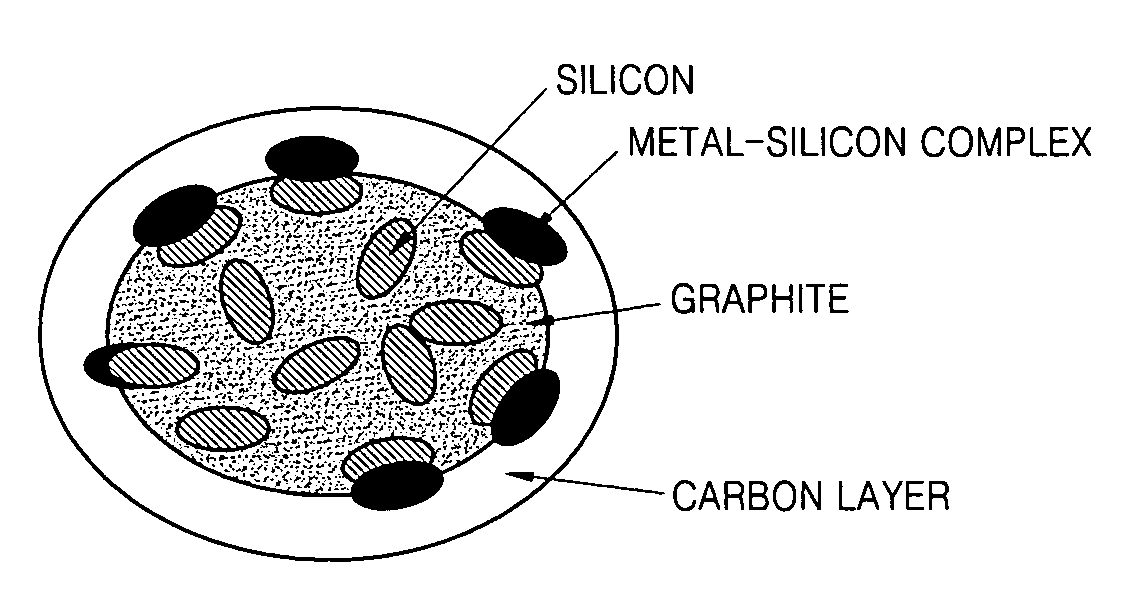

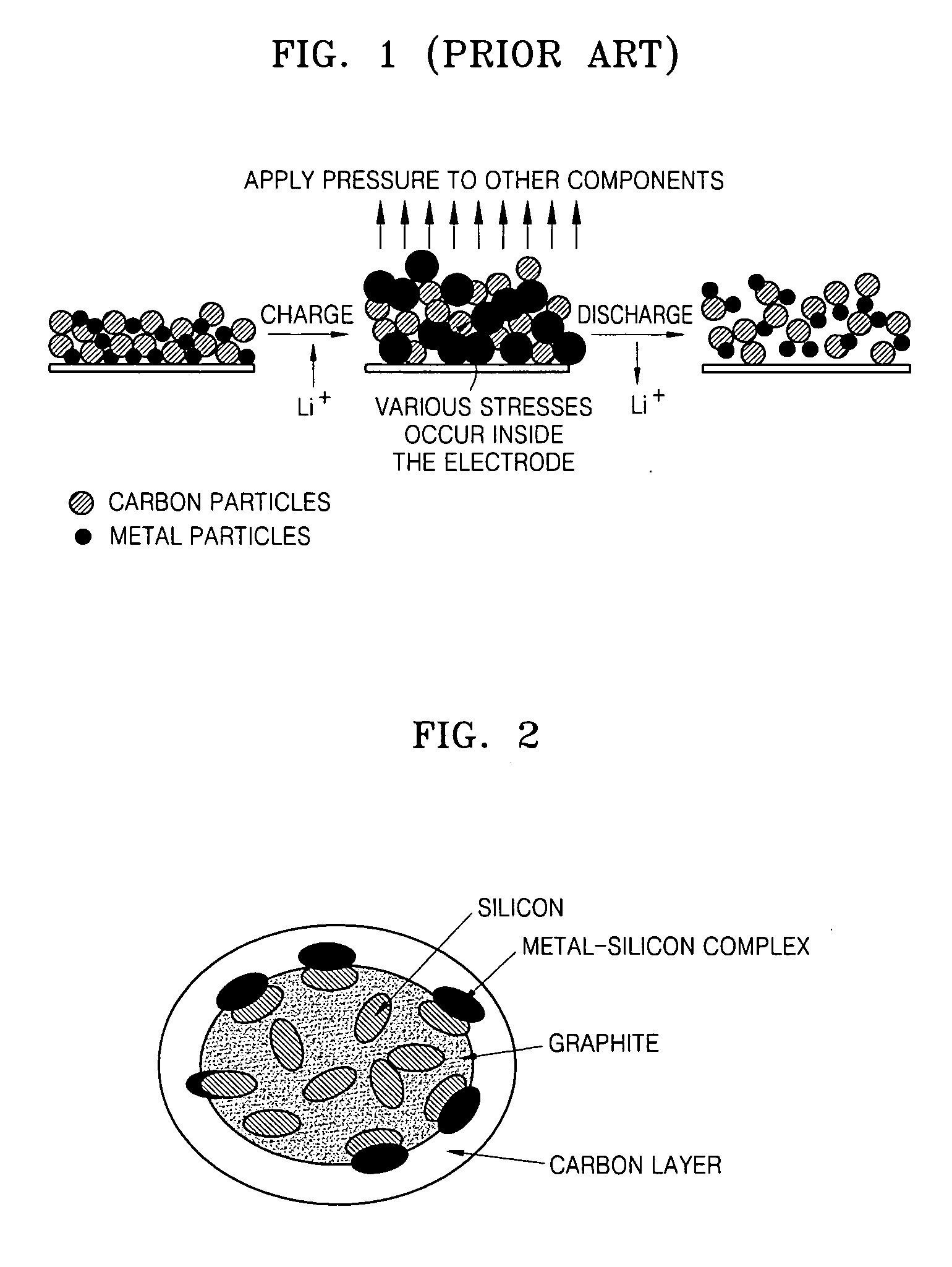

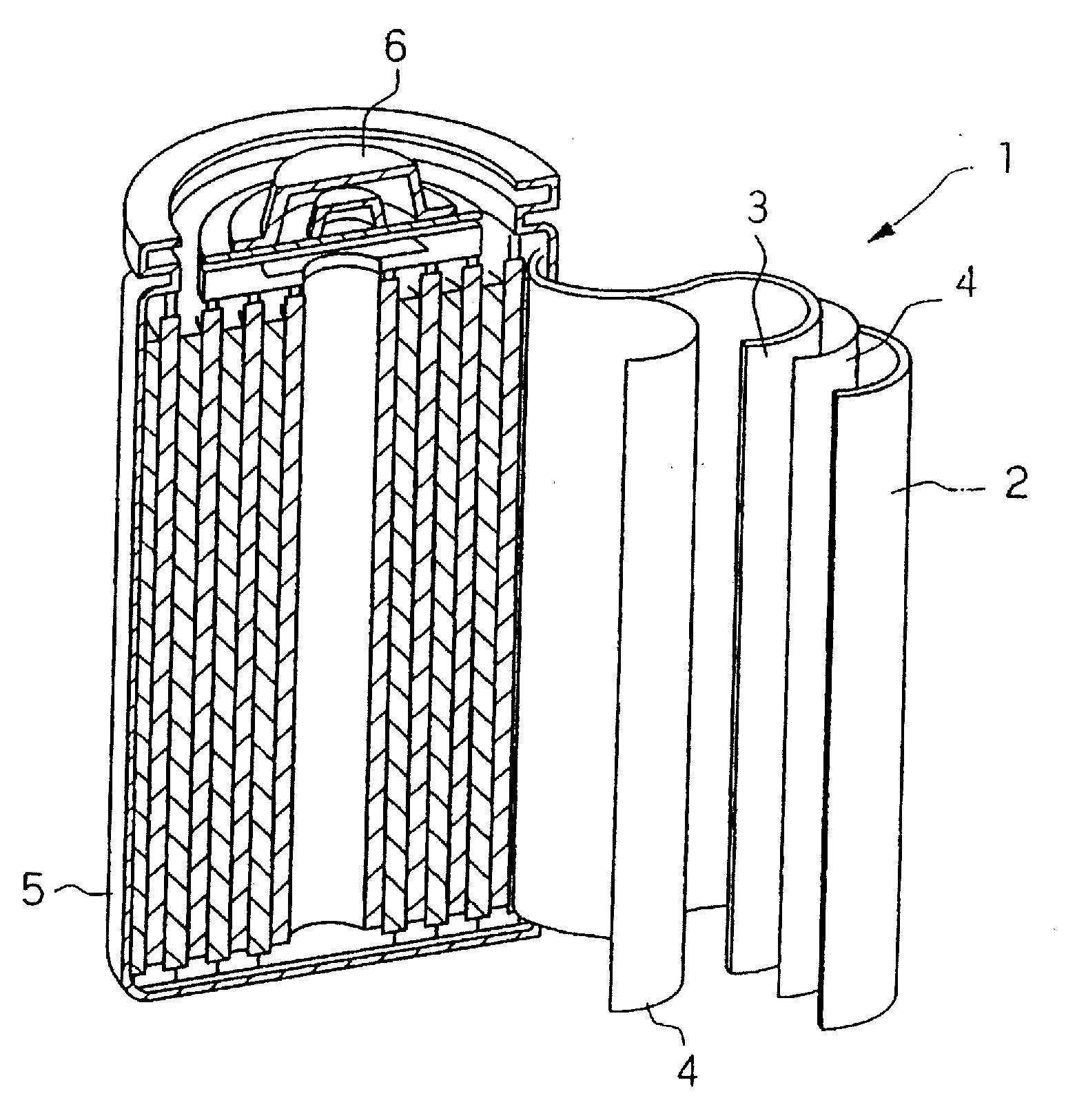

Anode active material, method of manufacturing the same, and lithium battery using the same

ActiveUS20070077490A1Large capacityGood capacity retentionNon-aqueous electrolyte accumulatorsElectrode thermal treatmentCarbon layerMetal alloy

Anode active materials, methods of producing the same and lithium batteries using the same are provided. More particularly, an anode active material having high capacity and excellent capacity retention, a method of producing the same and a lithium battery having a long lifespan using the same are provided. The anode active material comprises complex material particles comprising silicon and graphite, a carbon layer covering the surface of the complex material particles, and a silicon-metal alloy formed between the complex material particles and the amorphous carbon layer.

Owner:SAMSUNG SDI CO LTD

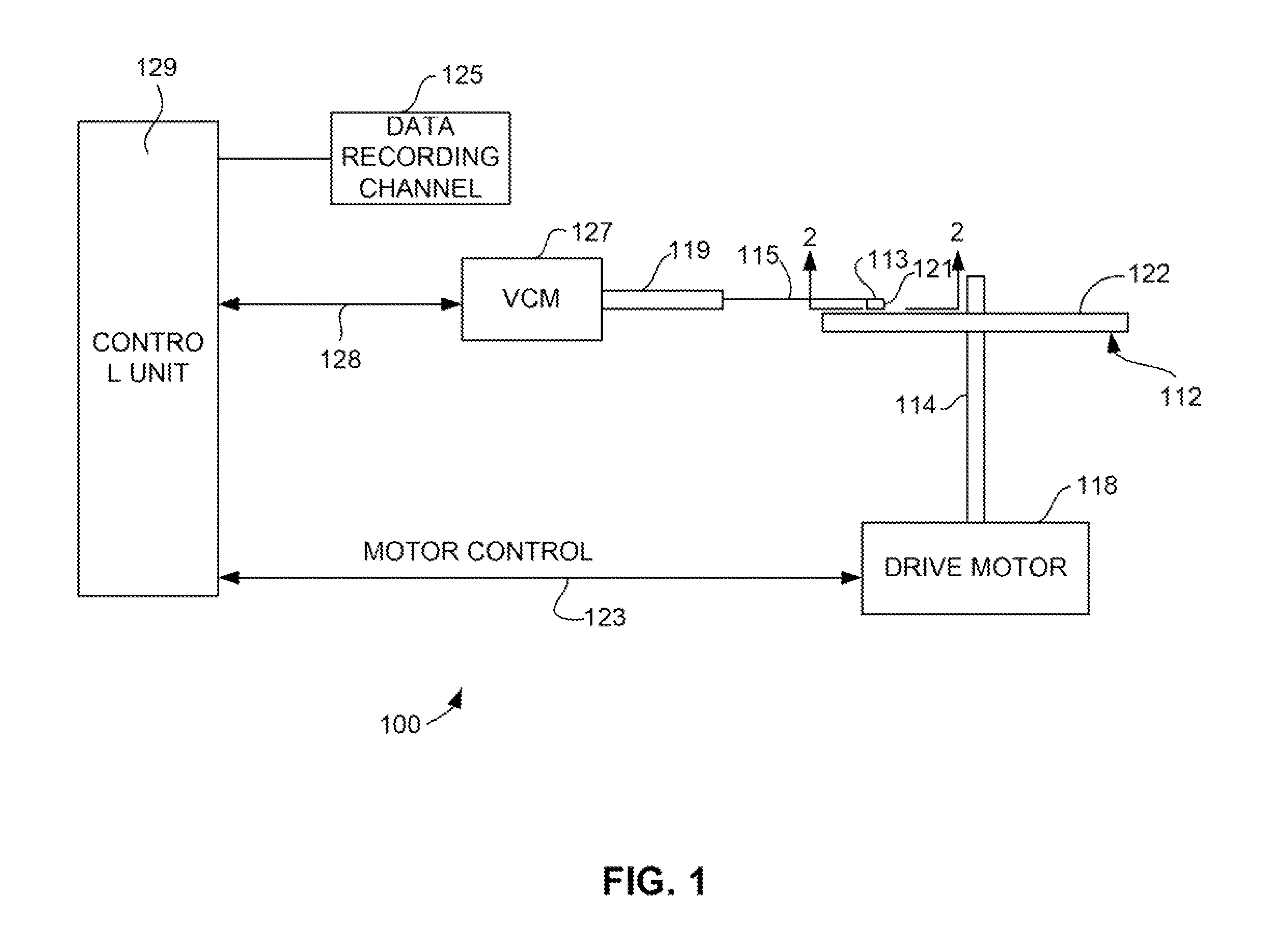

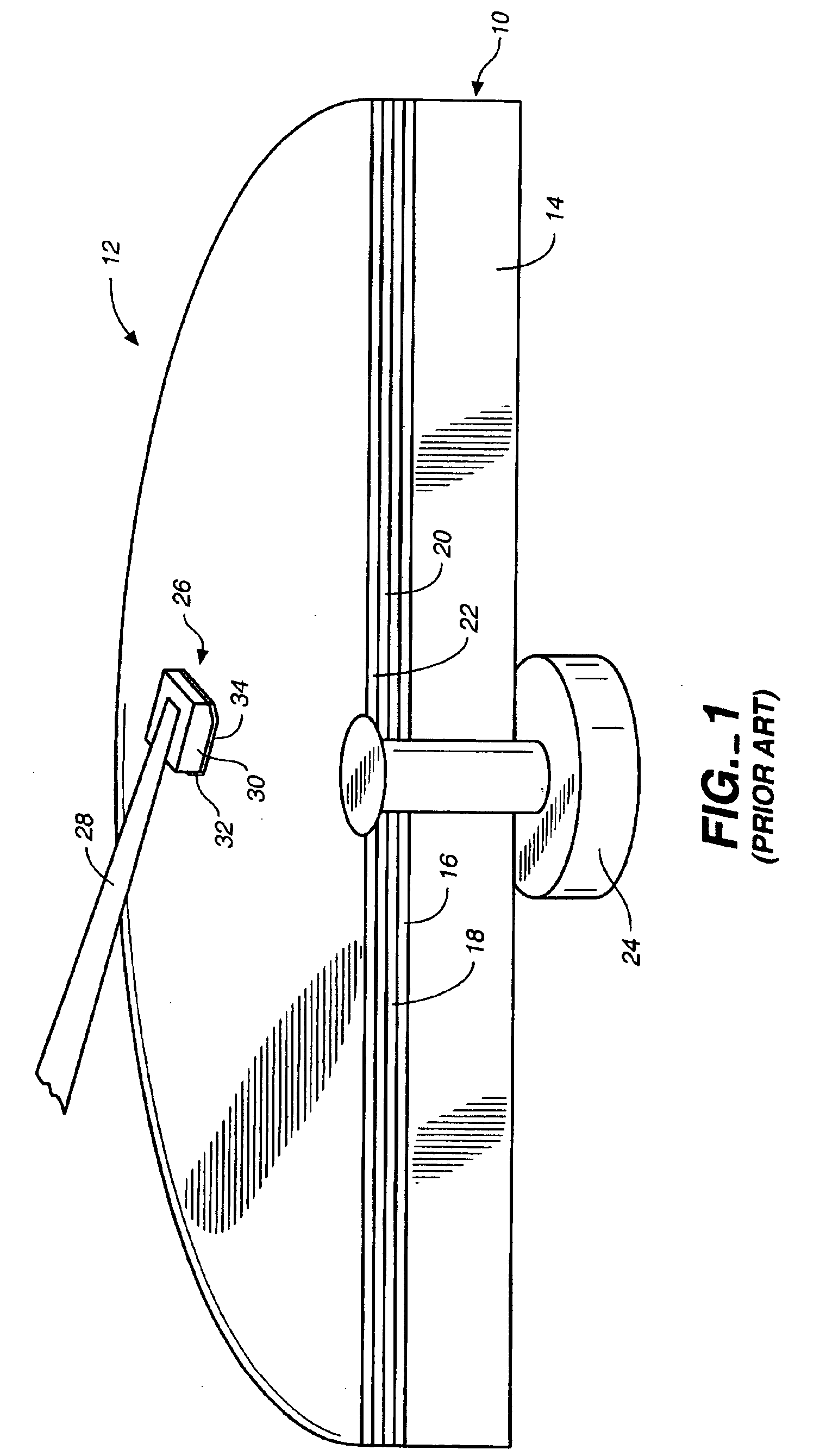

Method for manufacturing a magnetic read sensor with narrow track width using amorphous carbon as a hard mask and localized CMP

ActiveUS8617408B2Narrow widthTrack-width can be very smallElectrical transducersMagnetic measurementsCarbon layerInsulation layer

A method for manufacturing a magnetic read sensor at very narrow track widths. The method uses an amorphous carbon mask layer to pattern the sensor by ion milling, rather than a mask constructed of a material such as photoresist or DURIMIDE® which can bend over during ion milling at very narrow track widths. By using the amorphous carbon layer as the masking layer, the trackwidth can be very small, while avoiding this bending over of the mask that has been experienced with prior art methods. In addition, the track-width can be further reduced by using a reactive ion etching to further reduce the width of the amorphous carbon mask prior to patterning the sensor. The method also allows extraneous portions of the side insulation layer and hard bias layer to be removed above the sensor by a light CMP process.

Owner:WESTERN DIGITAL TECH INC

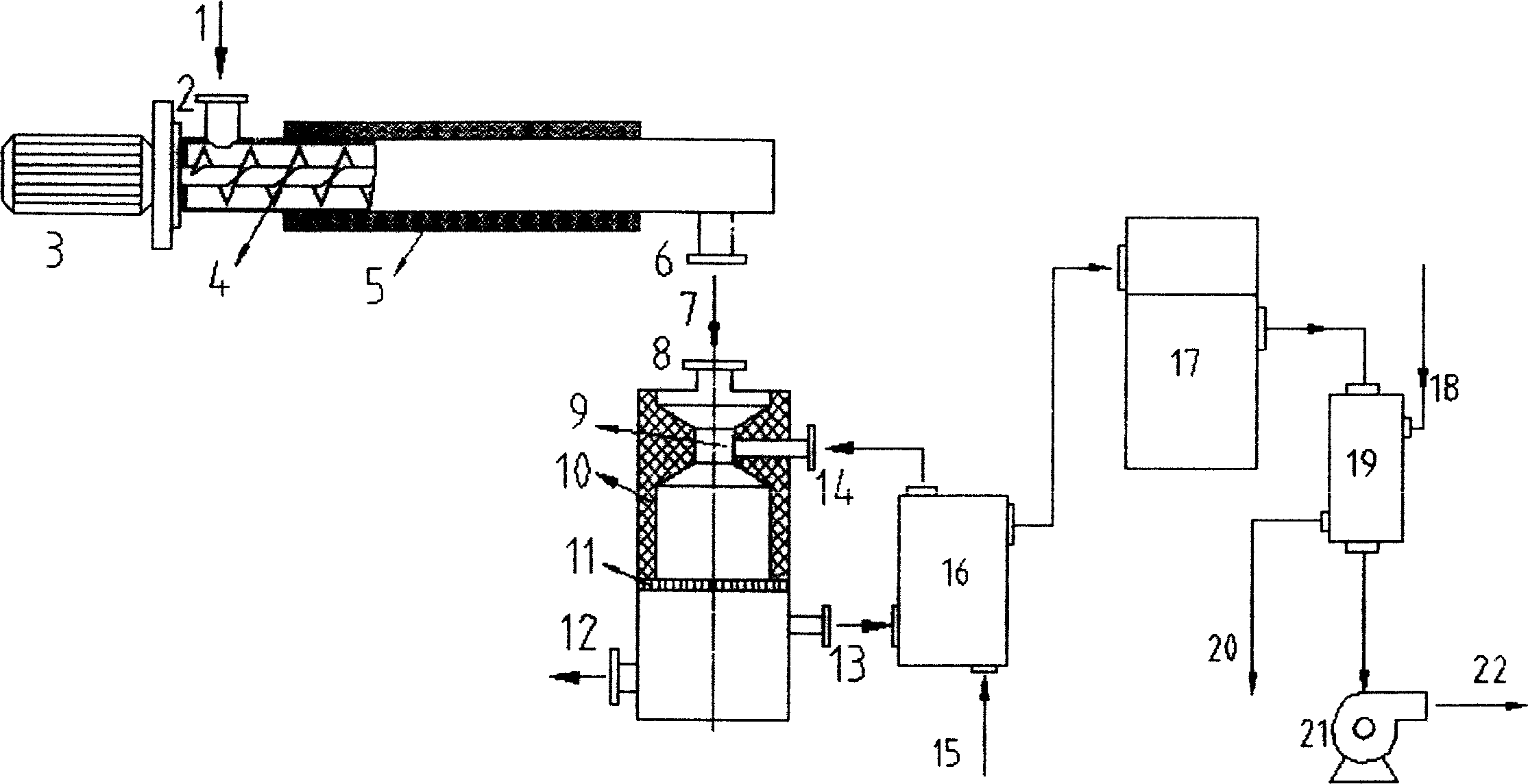

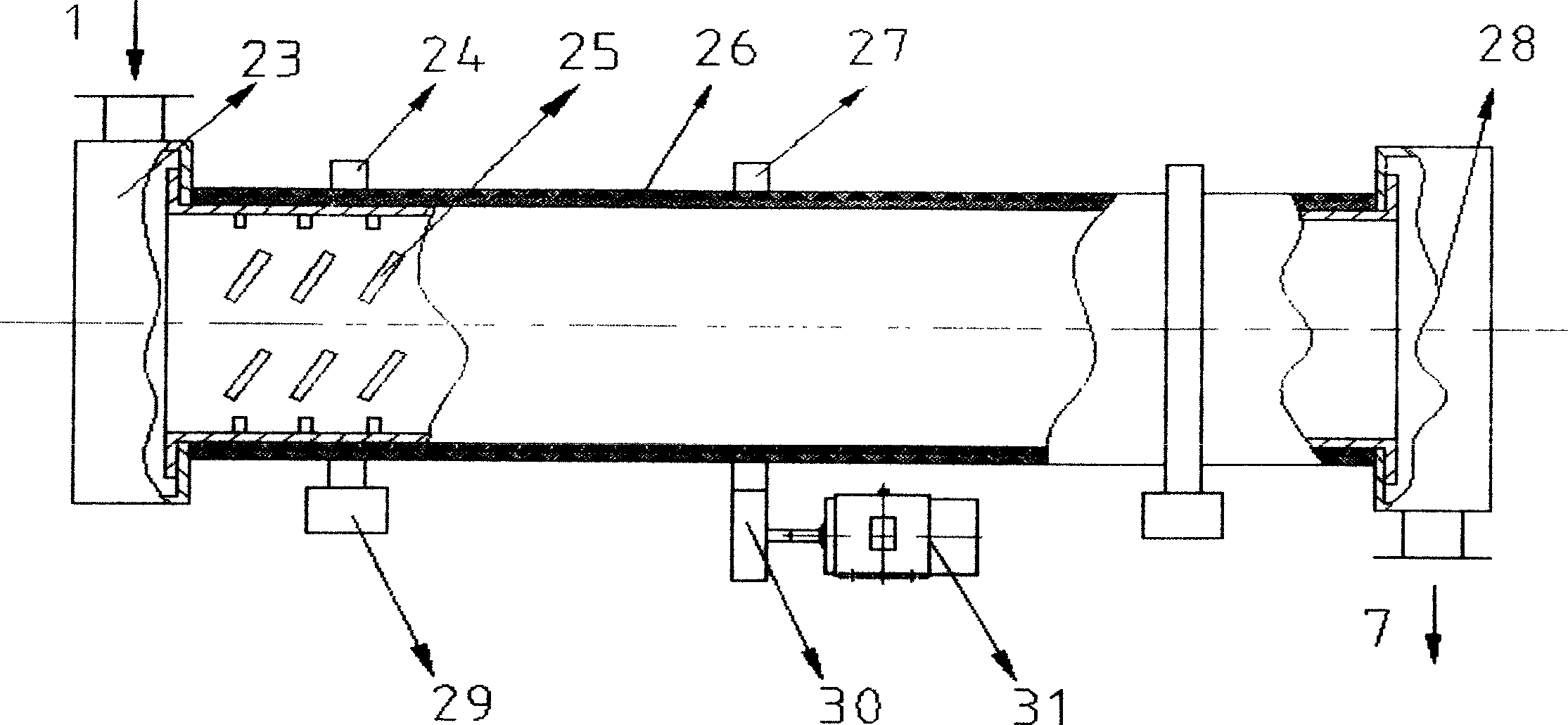

Low-tar biomass gasifying method and apparatus

InactiveCN1710023AWide adaptability of raw materialsSpecial form destructive distillationCarbon layerDecomposition

The invention discloses a kind of biomass gasifying method and device. The technology through separating the two courses of solid biomass pyrogenation and decomposition and gasification of the pyrogenation outcome, then transform the biomass into flammable gas of rather low tar content. Firstly send biomass into the pyrogenation reactor, without oxidant in; have pyrogenation reaction at 400 - 650 Deg. C, the pyrogenation outcome including pyrogenation gas and remaining charcoal gets into pyrogenation carburetor, and have incomplete oxidizing combustion reaction with sent oxidant, to form a high temperature of 900 - 1100 Deg. C. At the time, the heavy hydrocarbon substance of tar decomposes into small molecule gas, and the decomposed gas leaves out of the carburetor after having deoxidizing reaction with the nether blazing carbon layer. The high temperature gas is provided for consumers' use after depurated and cooled. The gas produced by the invention has very low tar content, which makes the following depurating equipment simple, won't produce second pollution and makes the raw materials widely used. The produced fuel gas can be used in civil filed and directly used for generating electricity.

Owner:ENERGY RES INST OF SHANDONG ACAD OF SCI

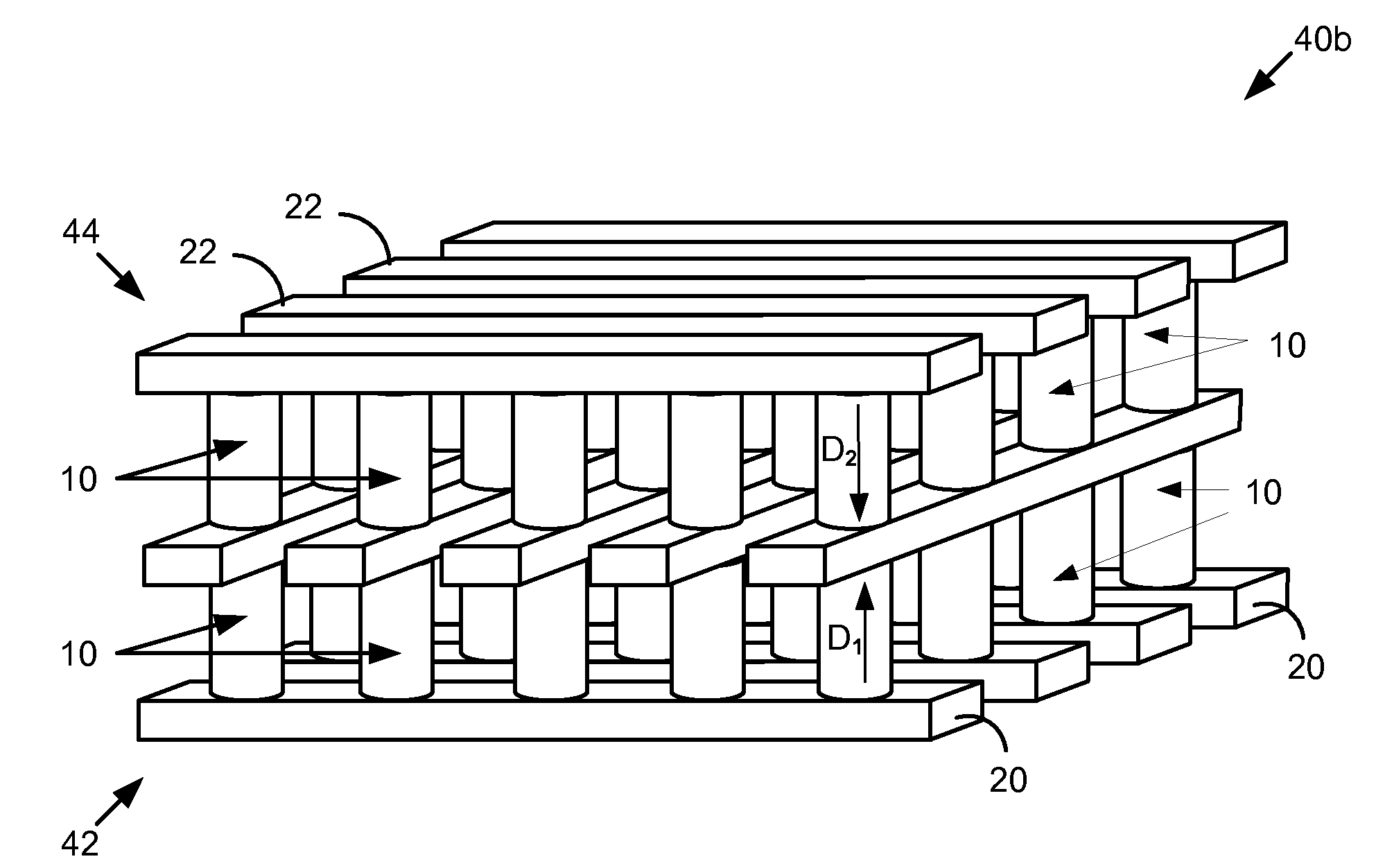

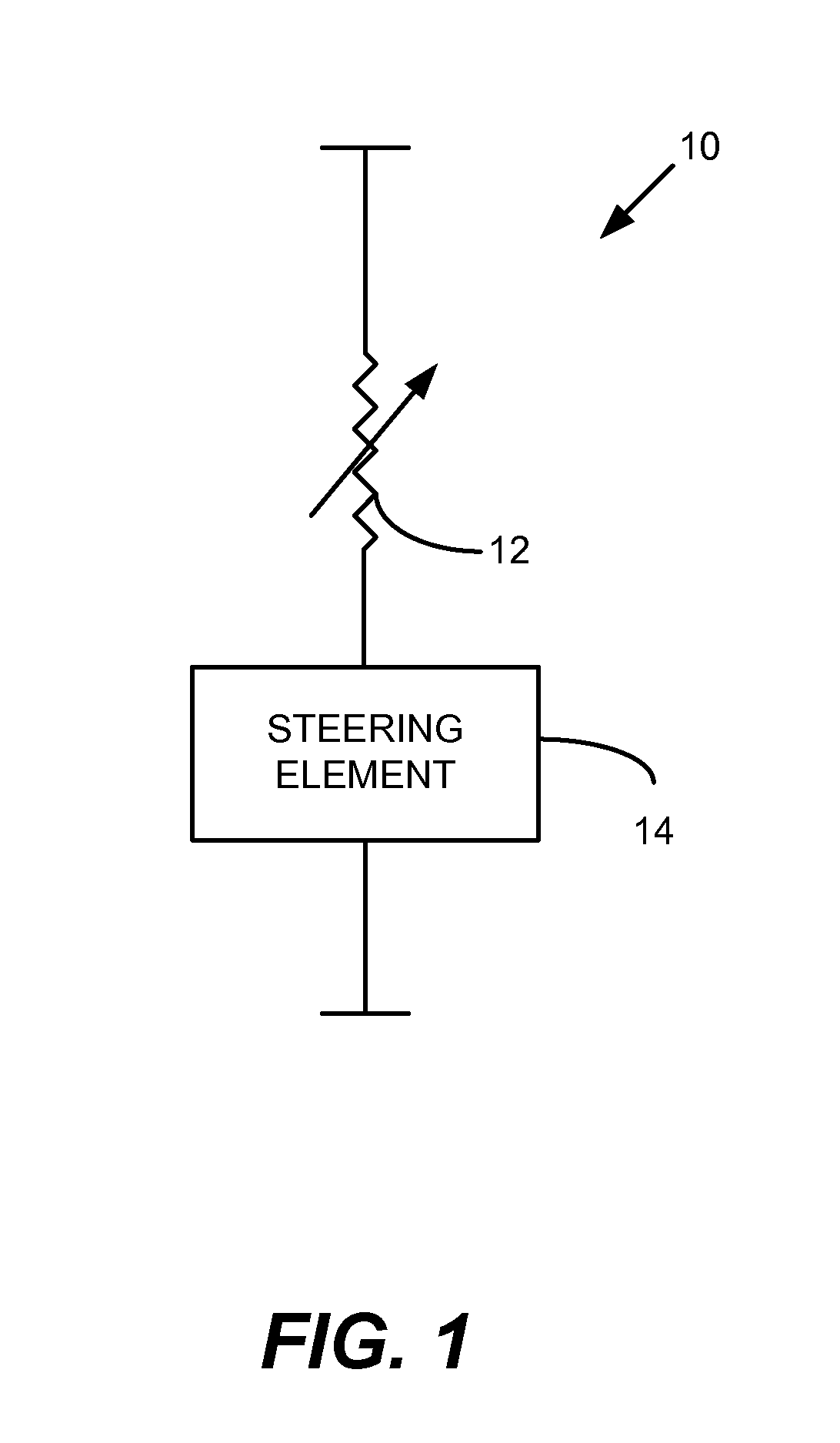

Memory cell that includes a carbon-based memory element and methods of forming the same

InactiveUS20100032640A1Solid-state devicesSemiconductor/solid-state device manufacturingResistCarbon layer

Memory cells, and methods of forming such memory cells, are provided that include a carbon-based reversible resistivity switching material. In particular embodiments, methods in accordance with this invention form a memory cell by forming a layer of carbon material above a substrate, forming a barrier layer above the carbon layer, forming a hardmask layer above the barrier layer, forming a photoresist layer above the hardmask layer, patterning and developing the photoresist layer to form a photoresist region, patterning and etching the hardmask layer to form a hardmask region, and using an ashing process to remove the photoresist region while the barrier layer remains above the carbon layer. Other aspects are also provided.

Owner:SANDISK TECH LLC

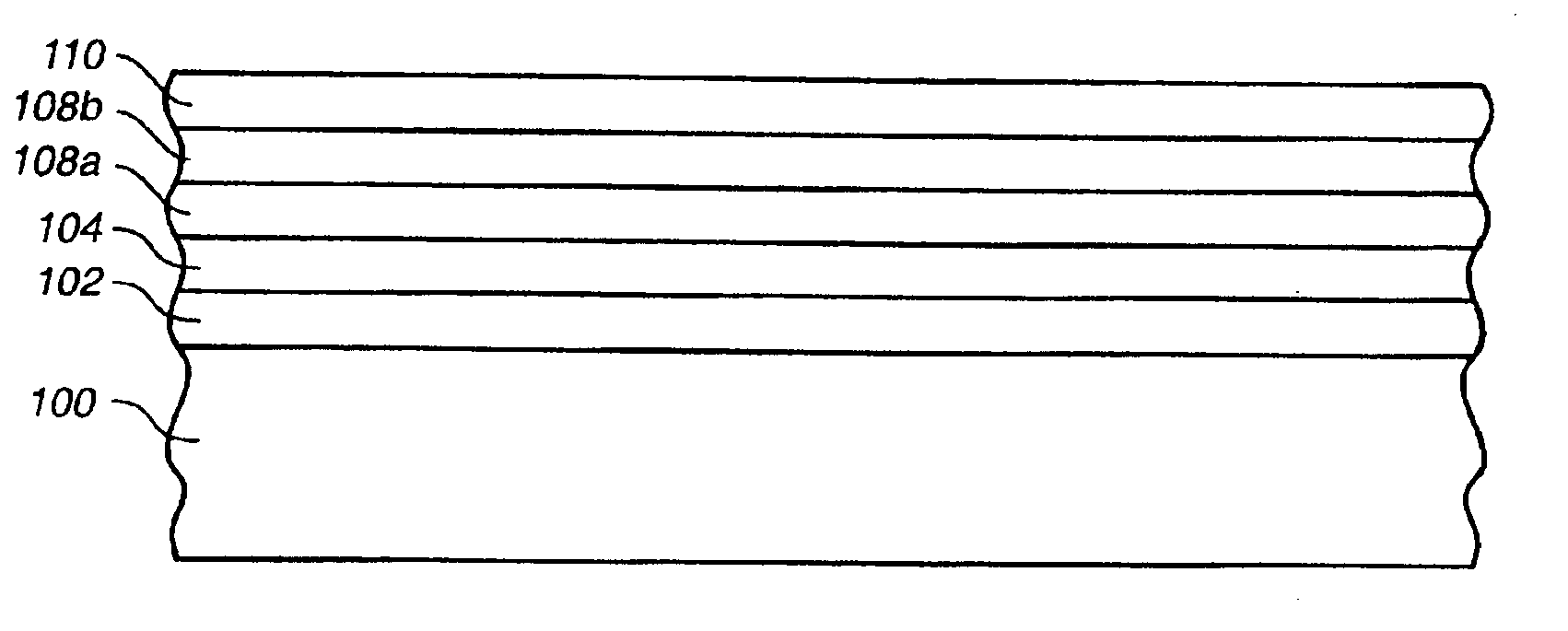

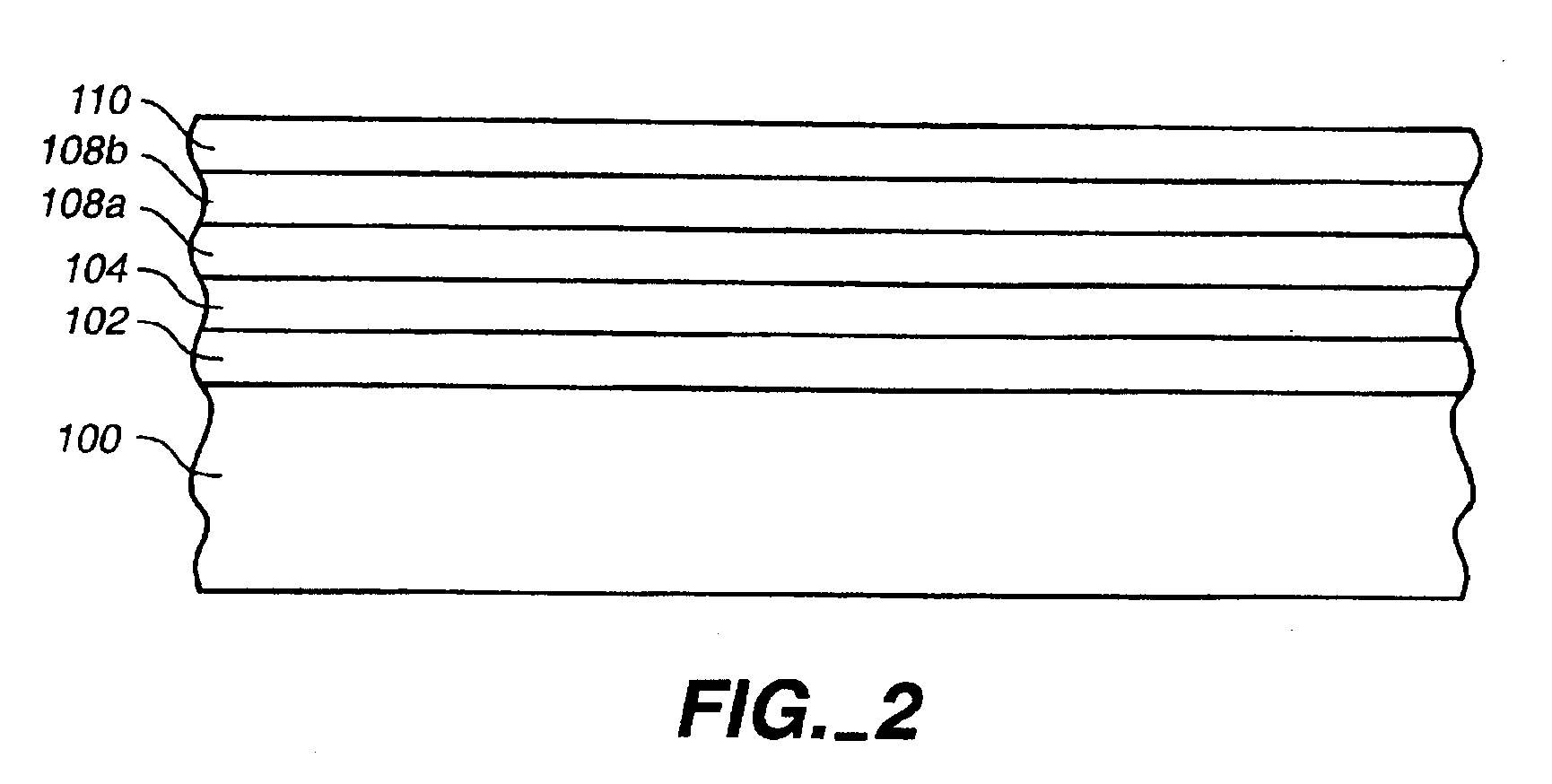

Magnetic disk comprising a first carbon overcoat having a high SP3 content and a second carbon overcoat having a low SP3 content

InactiveUS6855232B2Increase contentResists wearLayered productsVacuum evaporation coatingCarbon layerPerfluoropolyether

A method for making a magnetic disk comprises forming first and second protective carbon layers on a magnetic layer. The first protective carbon layer is predominantly SP3 carbon. The second protective carbon layer comprises about 50% or less SP3 carbon. The second protective carbon layer is very thin, e.g. between 0.1 and 1.0 nm thick. A lubricant layer (e.g. a perfluoropolyether lubricant) is applied to the second protective carbon layer. The second protective carbon layer facilitates improved cooperation between lubricant and the disk.

Owner:WESTERN DIGITAL TECH INC

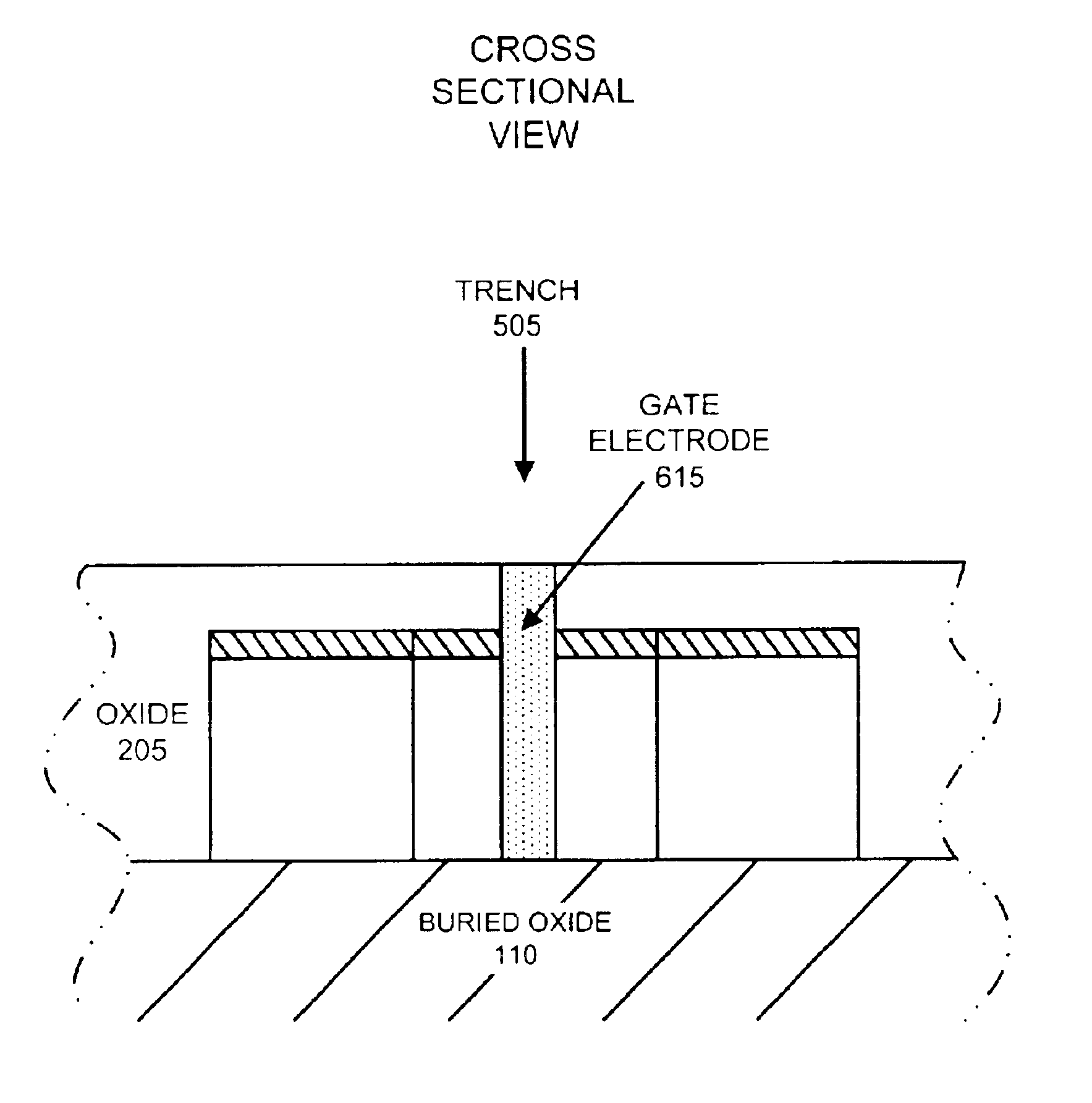

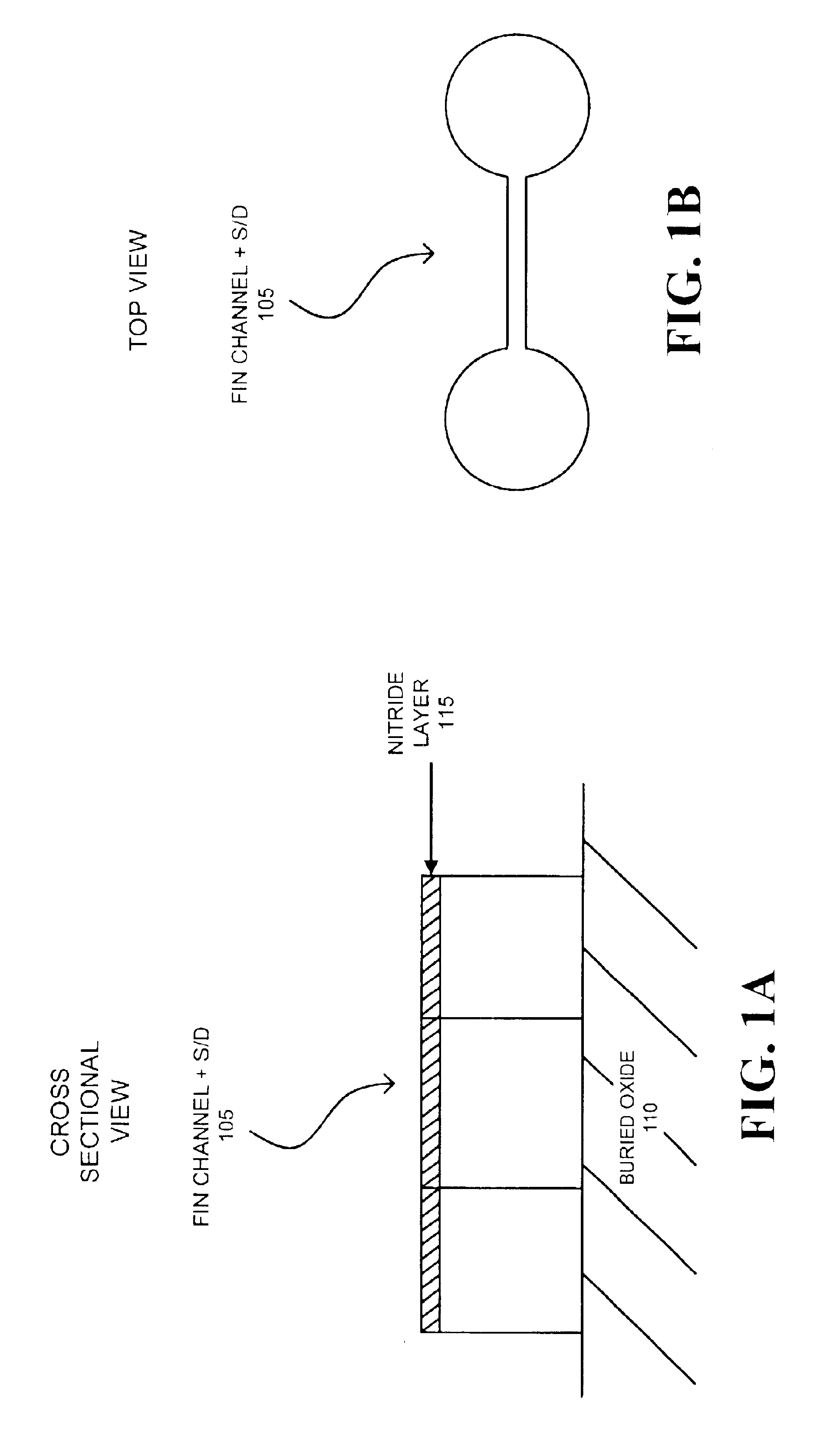

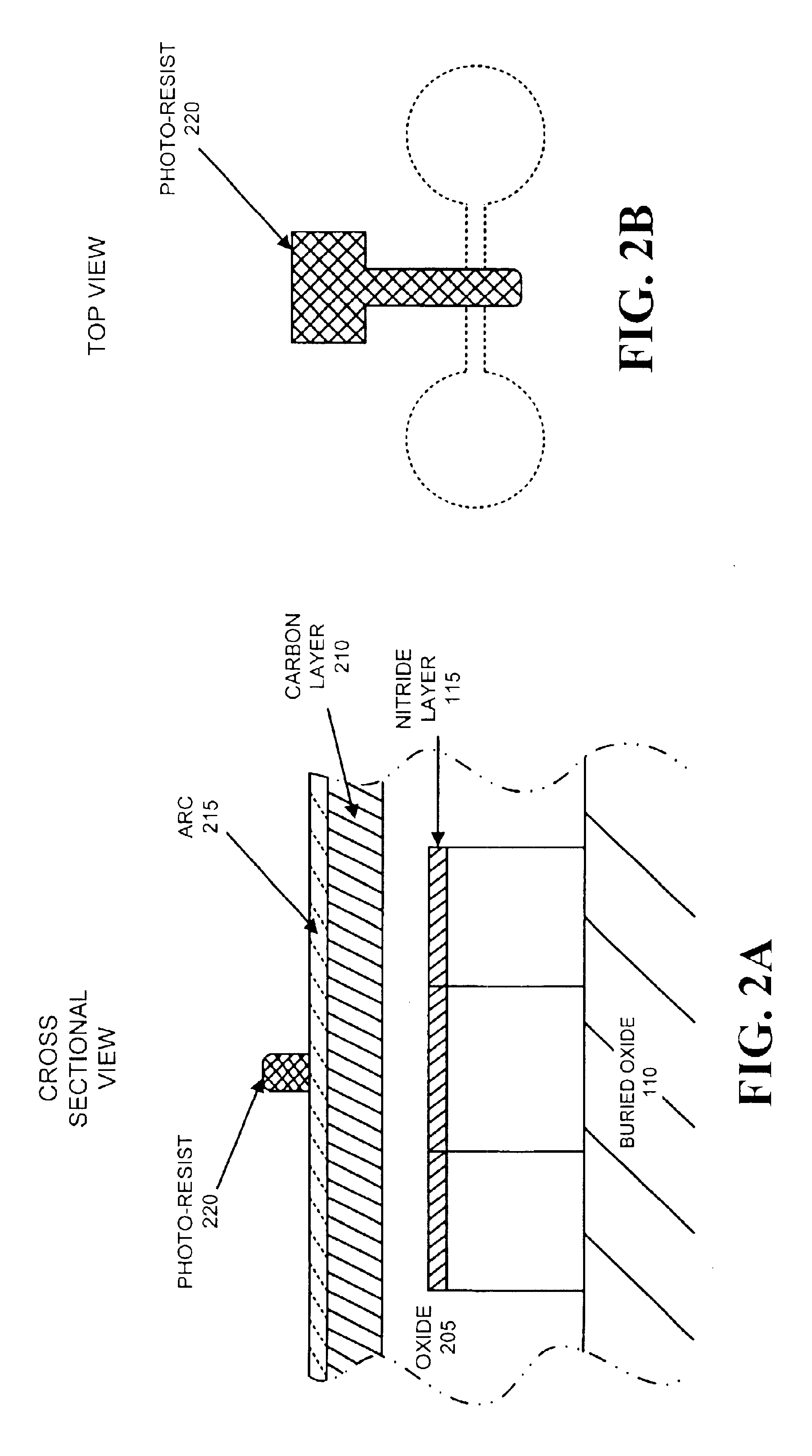

Finfet gate formation using reverse trim of dummy gate

InactiveUS6864164B1Wide photo marginIncreasing ability to printTransistorSemiconductor/solid-state device manufacturingCarbon layerEngineering

A method of forming a gate electrode for a fin field effect transistor (FinFET) includes forming a fin on a substrate and forming an oxide layer over the fin. The method further includes forming a carbon layer over the oxide layer and forming a trench in the oxide layer and the carbon layer, where the trench crosses over the fin. The method also includes filling the trench with a material to form the gate electrode.

Owner:GLOBALFOUNDRIES INC

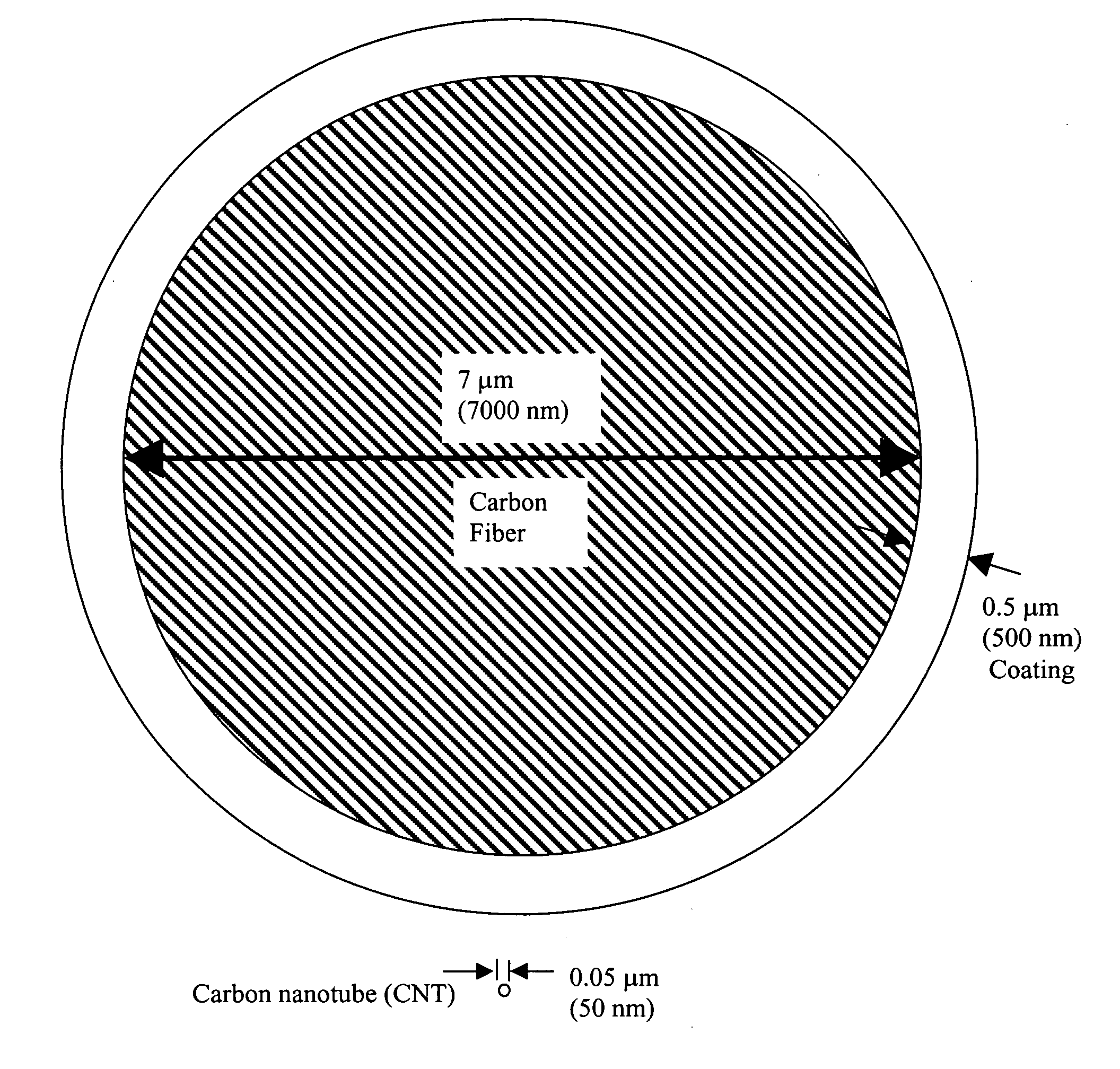

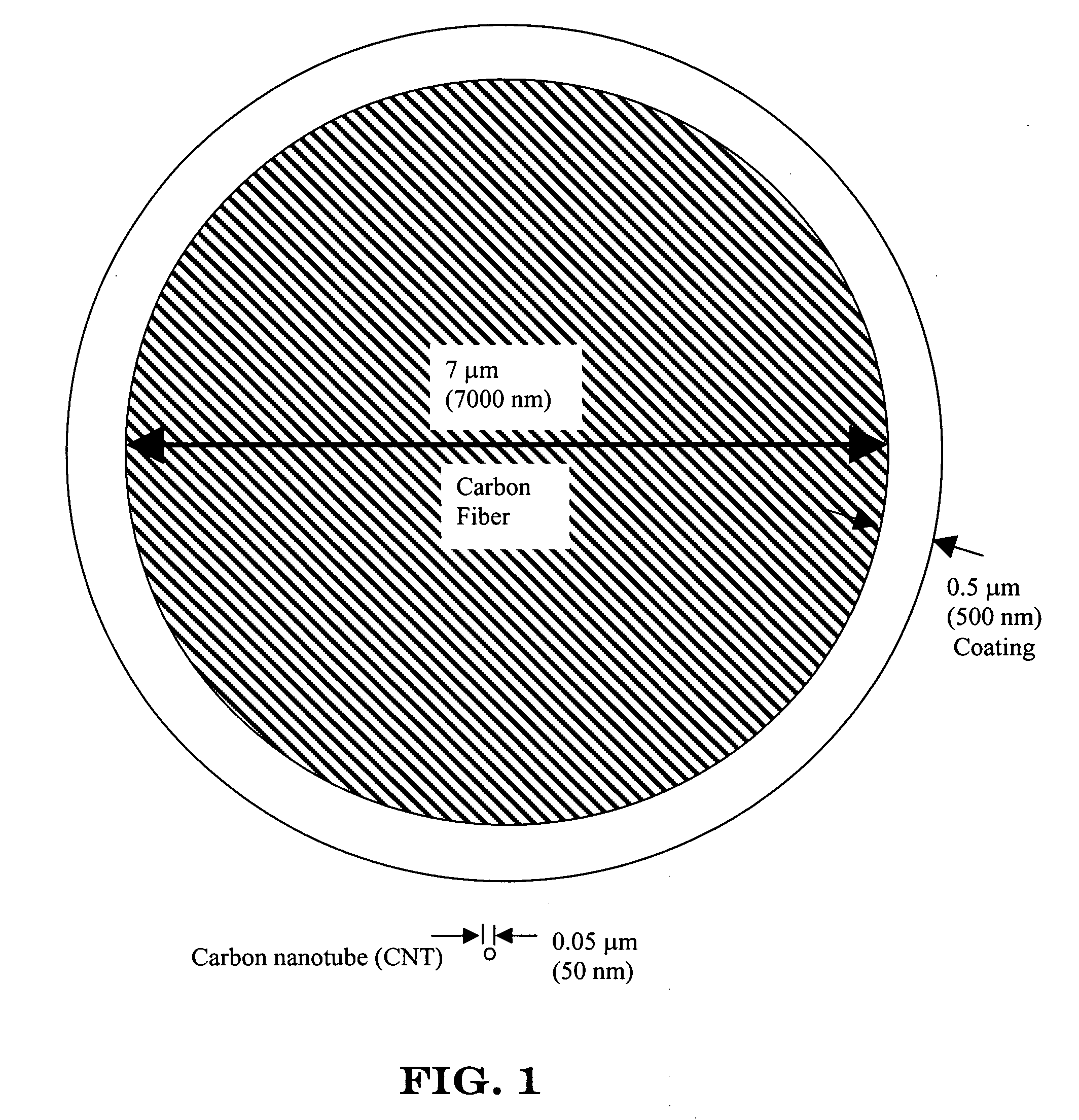

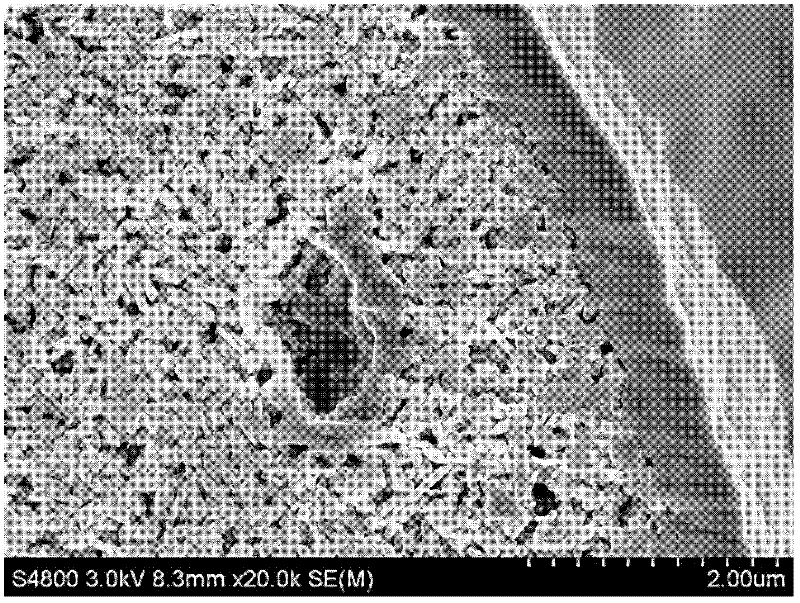

Nanotube-containing composite bodies, and methods for making same

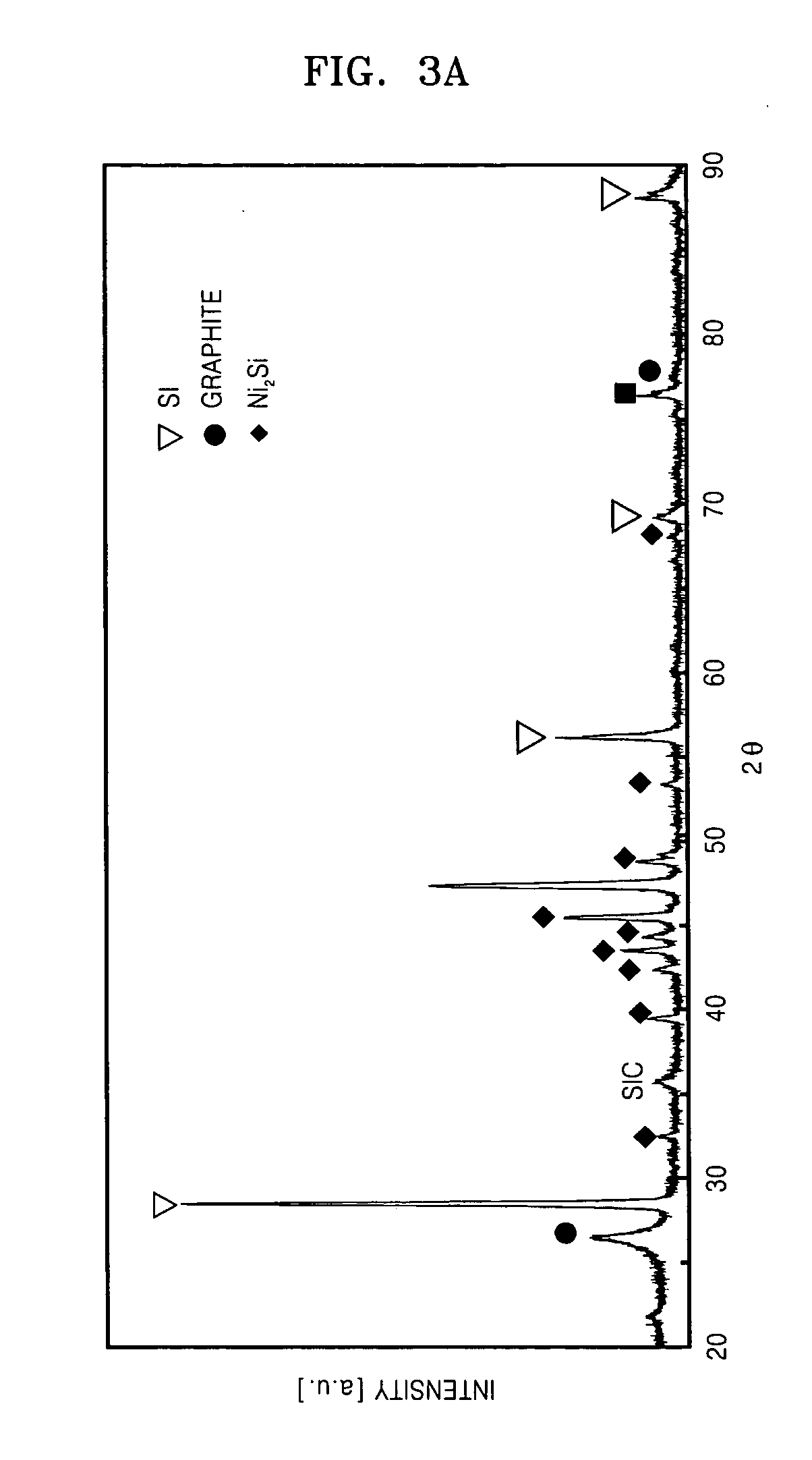

A composite material featuring carbon nanotubes reinforcing a matrix featuring metal or silicon carbide, or both. Such composites can be produced using a molten silicon metal infiltration technique, for example, a siliconizing or a reaction-bonding process. Here, the carbon nanotubes are prevented from chemically reacting with the silicon infiltrant by an interfacial coating disposed between the carbon nanotubes and the infiltrant. Preferably, the coating is free carbon or a carbonaceous precursor material added during preform processing, or after. The reaction-bonding system is designed such that the molten infiltrant of silicon metal or silicon alloy reacts with at least some of the interfacial carbon layer to form in-situ silicon carbide, and that the formed SiC is sufficiently dense that it effectively seals off the underlying carbon nanotube from exposure to additional molten infiltrant. A reaction-bonded composite body containing even a small percentage of carbon nanotubes possessed a significant increase in electrical conductivity as compared to a reaction-bonded composite not containing such nanotubes, reflecting the high electrical conductivity of the nanotubes.

Owner:KARANDIKAR PRASHANT G

Silicon-carbon negative electrode material of lithium ion battery and preparation method thereof

ActiveCN102394287AExcellent intercalation and delithiation abilityImprove cycle stabilityCell electrodesFiberCarbon composites

The invention discloses a silicon-carbon negative electrode material of a lithium ion battery and a preparation method thereof, and solves the technological problem of improving the charge and discharge cycling stability of the electrode material. The silicon-carbon negative electrode material is prepared by mixing a silicon-carbon composite material and a natural graphite material, wherein the weight of the silicon-carbon composite material is 7-20% and the silicon-carbon composite material is prepared by depositing carbon nanotube and / or carbon nanofiber on the surface of nanometer silica fume and / or embedding into the nanometer silica fume to form core, the surface of which is covered with 3-15wt% of a carbon layer. The preparation method provided by the invention comprises steps of: precursor silicon powder preparation; chemical vapor deposition; liquid-coating roasting; crushing; and mixing. In comparison with the prior art, the reversible specific capacity of the silicon-carbon composite negative electrode material is greater than 500mAh / g; the coulombic efficiency for a first cycle is greater than 80%; the capacity conservation rate of cycling for 50 weeks is greater than 95%. The preparation method is simple, is easy to operate, requires low cost and is suitable for a high-volume negative electrode material of lithium ion batteries used for various portable devices.

Owner:BTR NEW MATERIAL GRP CO LTD

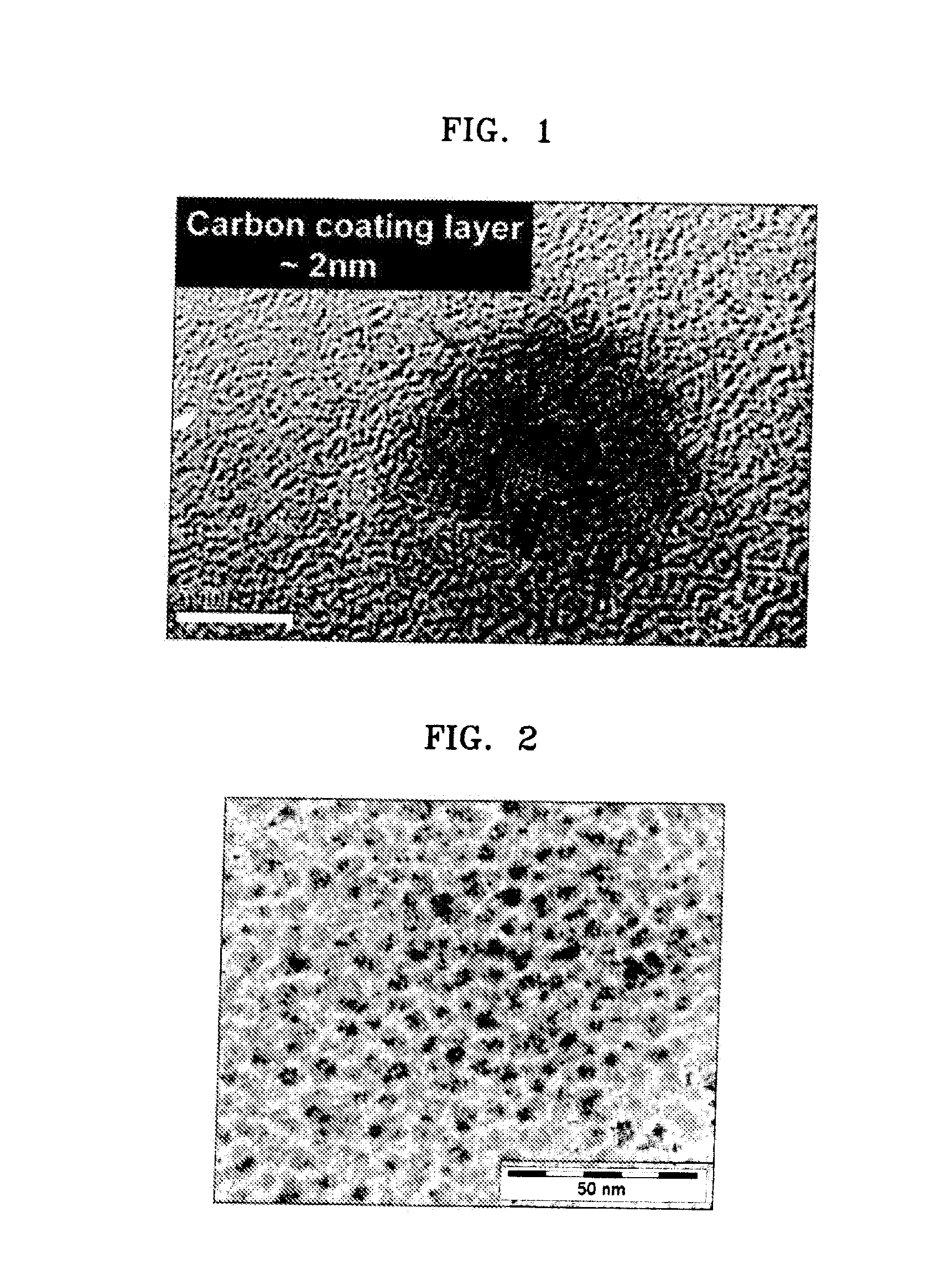

Negative active material including metal nanocrystal composite, method of preparing the same, and anode and lithium battery including the negative active material

InactiveUS20070264574A1Reduce formationHigh charge and discharge capacityMaterial nanotechnologyNon-aqueous electrolyte accumulator electrodesCarbon layerCarbon coating

Negative active materials including metal nanocrystal composites comprising metal nanocrystals having an average particle diameter of about 20 nm or less and a carbon coating layer are provided. The negative active material includes metal nanocrystals coated by a carbon layer, which decreases the absolute value of the change in volume during charge / discharge and decreases the formation of cracks in the negative active material resulting from a difference in the volume change rate during charge / discharge between metal and carbon. Therefore, high charge / discharge capacities and improved capacity retention capabilities can be obtained.

Owner:SAMSUNG SDI CO LTD

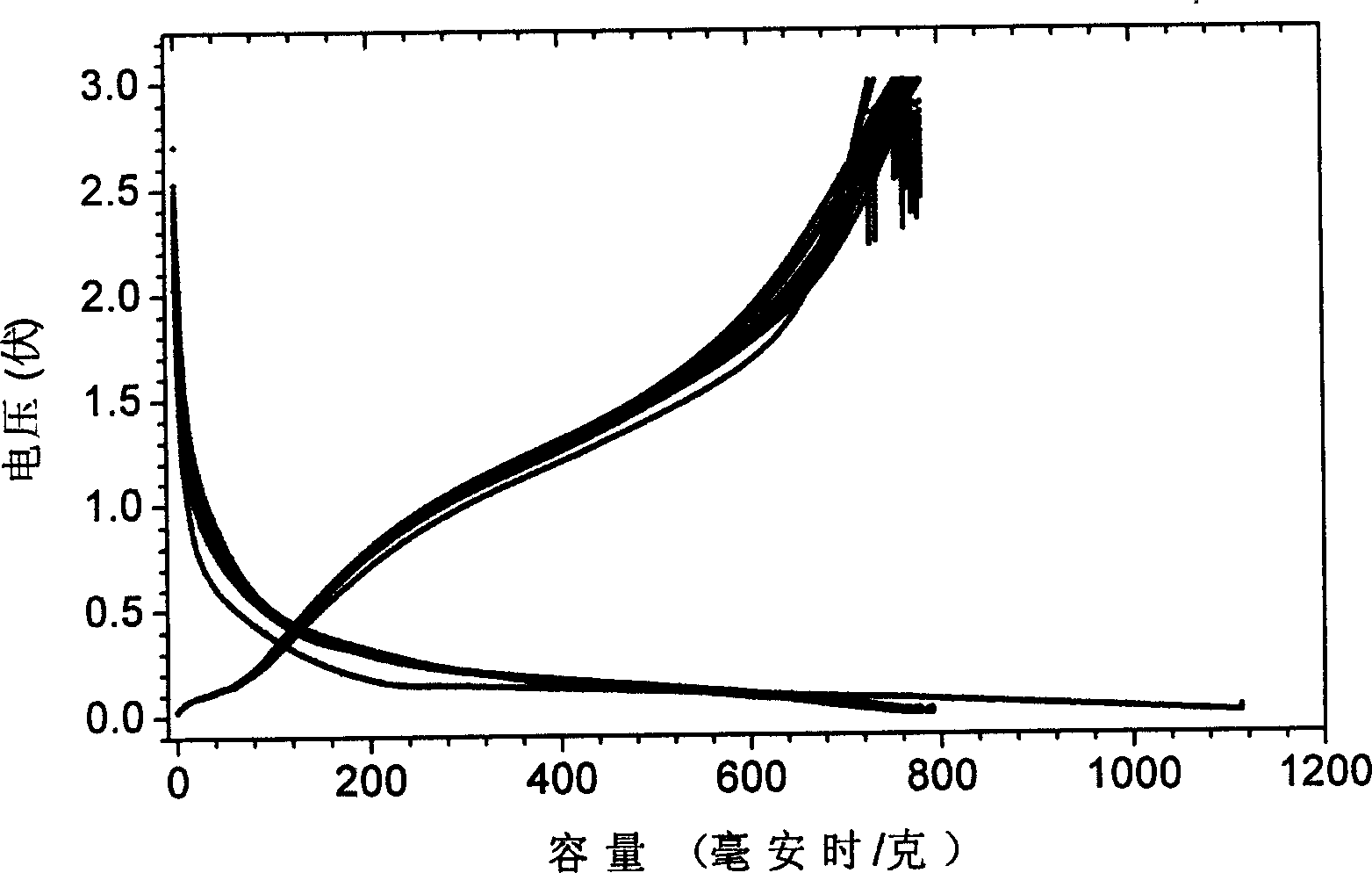

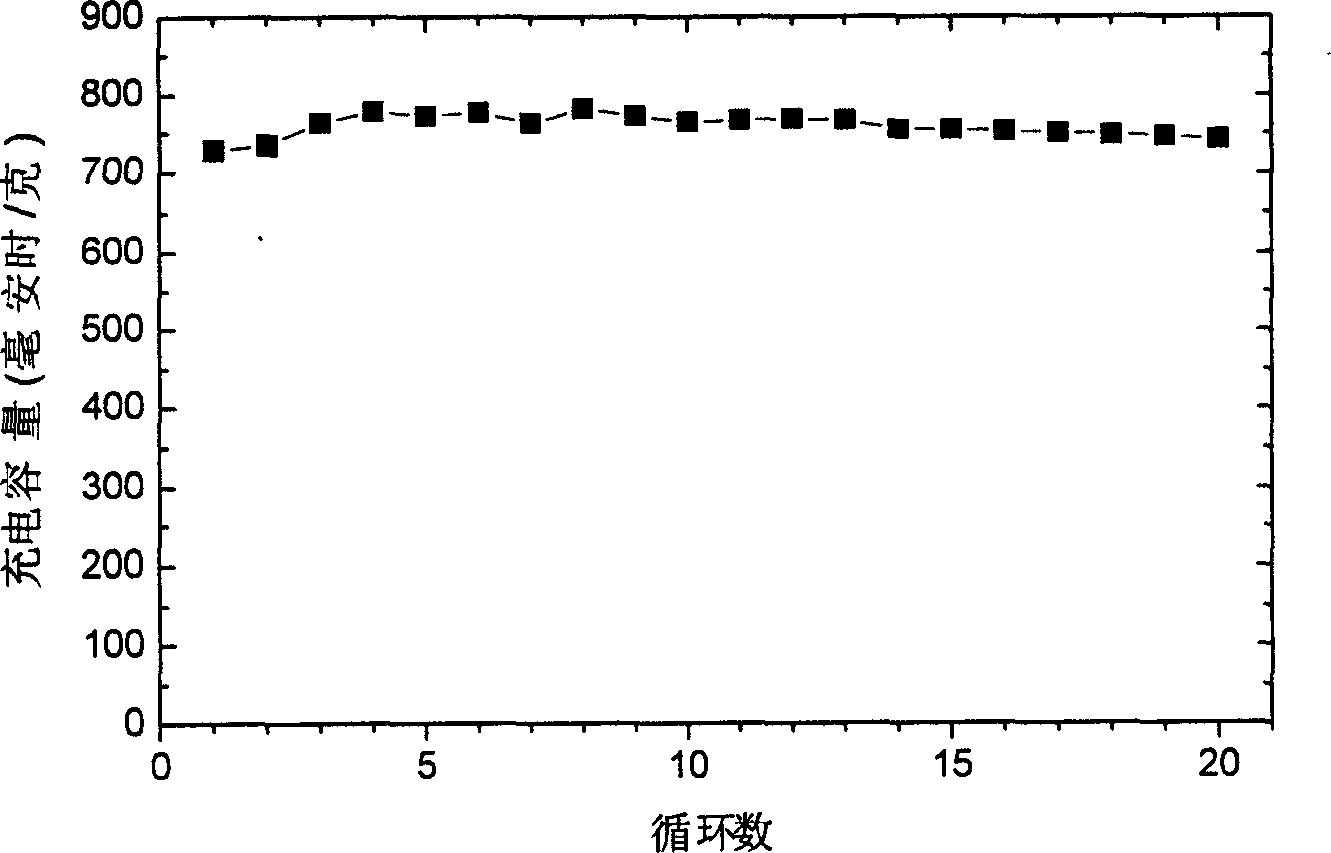

Negative electrode active material and use of secondary lithium battery

The invention has a grain structure with an outer shell and several inner cores. The grain size is from 100 nanometers to 100 microns. The inner cores are compound grain that includes active substance and conducting additive. The outer shell is a carbon layer. The active substance takes 20-95wt% of total cathode active material, and is mixture of one or several transition metallic compound selected from silicon and lithium storage whose thermodynamic equilibrium potential is less than 1.5v. The cathode material can be made by using mechanical process or thermal method, and can be directly used as cathode material or used with other existing cathode material.

Owner:LIYANG TIANMU PILOT BATTERY MATERIAL TECH CO LTD

Hard mask for patterning magnetic tunnel junctions

InactiveUS20160351799A1Magnetic-field-controlled resistorsGalvano-magnetic device detailsCarbon layerAnti-reflective coating

Device structures and methods for fabricating device structures are provided herein. Magnetic random access memory (MRAM) devices described herein may include a film stack comprising a magnetic tunneling junction layer, a dielectric capping layer, an etch stop layer, a conductive hard mask layer, a dielectric hard mask layer, a spin on carbon layer, and an anti-reflective coating layer. The film stack may be etched by one or more selected chemistries to achieve improved film stack sidewall verticality. Memory cells having increasingly uniform and reduced critical dimensions may be fabricated utilizing the methods and devices described herein.

Owner:APPLIED MATERIALS INC

Method for preparing fewer-layer graphene on basis of biomass waste

ActiveCN105060289AReduce pollutionAbundant and easy-to-obtain raw materialsCarbon layerArgon atmosphere

The invention discloses a method for preparing fewer-layer graphene on the basis of biomass waste, which comprises the following steps: carrying out hydrothermal treatment on the biomass waste, and carrying out carbonization by heating and calcination, thereby obtaining a carbonization material; immersing the carbonization material in an acid solution to remove impurities, thereby obtaining biomass carbon; and quickly heating the biomass carbon in an argon atmosphere, and carrying out high-temperature graphitization to obtain the biomass fewer-layer graphene. The hydrothermal process is combined with the high-temperature graphitization to directly strip the biomass waste, and the carbonization and high-temperature graphitization are carried out. Thus, the prepared biomass fewer-layer graphene has the advantages of fewer layers (2-10 layers), fewer defects, fewer oxy groups, high electric conductivity and small carbon layer interval. The method is simple to operate, has the advantages of low cost and high graphene yield, and can easily implement industrialized large-scale production. The prepared biomass fewer-layer graphene can be used in the fields of lithium ion batteries, supercapacitors and the like, is beneficial to green production of battery industry, and has important practical value and favorable application prospects.

Owner:湖南宸宇富基新能源科技有限公司

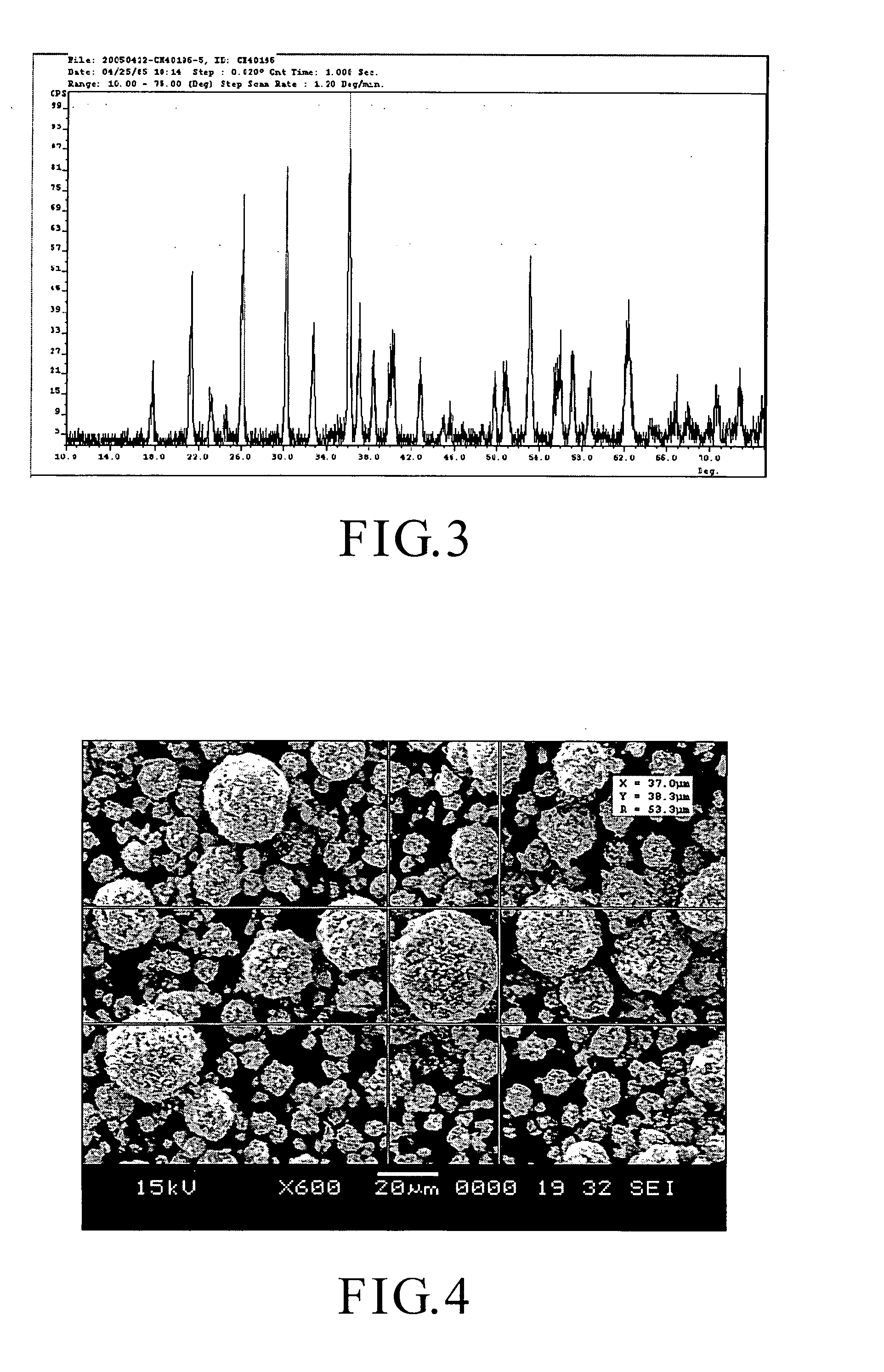

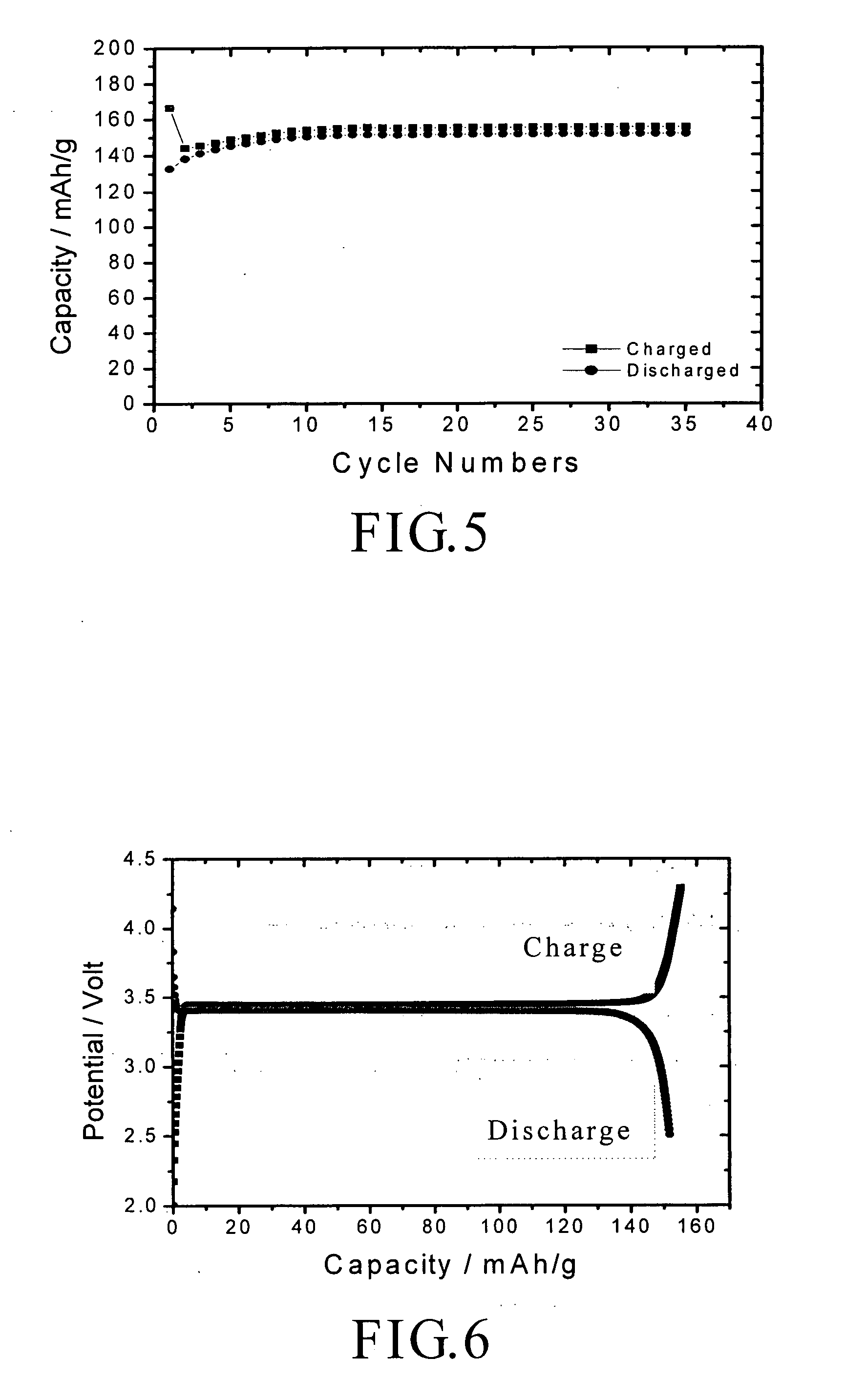

Ferric phosphate lithium material for lithium ion powder cell and preparation method thereof

ActiveCN101081696APromote crystallizationSingle structureElectrode manufacturing processesLithium compoundsCarbon layerLithium iron phosphate

The present invention discloses lithium iron phosphate material for lithium ion power cell and its preparation process, and dissolves the technological problem of raising the discharge power and safety performance. The lithium iron phosphate material is spherical or spheroid composite particle with one base body of lithium iron phosphate and doping and modifying agent and one coating carbon layer. Its preparation process includes wet ball milling the mixture comprising lithium salt, ferric salt, phosphoric acid, doping and modifying agent and dispersant, spraying to pelletize, heating for pre-treatment, maintaining temperature, cooling, pulverizing and shaping. Compared with available technology, the present invention has the features of high crystallization, single structure, average composite particle size of 5-60 microns, specific surface area of 8.0-15.0 sq m / g, bulk density of 1.4-1.7 g / cu cm, high specific capacity, high safety, etc.

Owner:BTR (TIANJIN) NANO MATERIAL MFG CO LTD

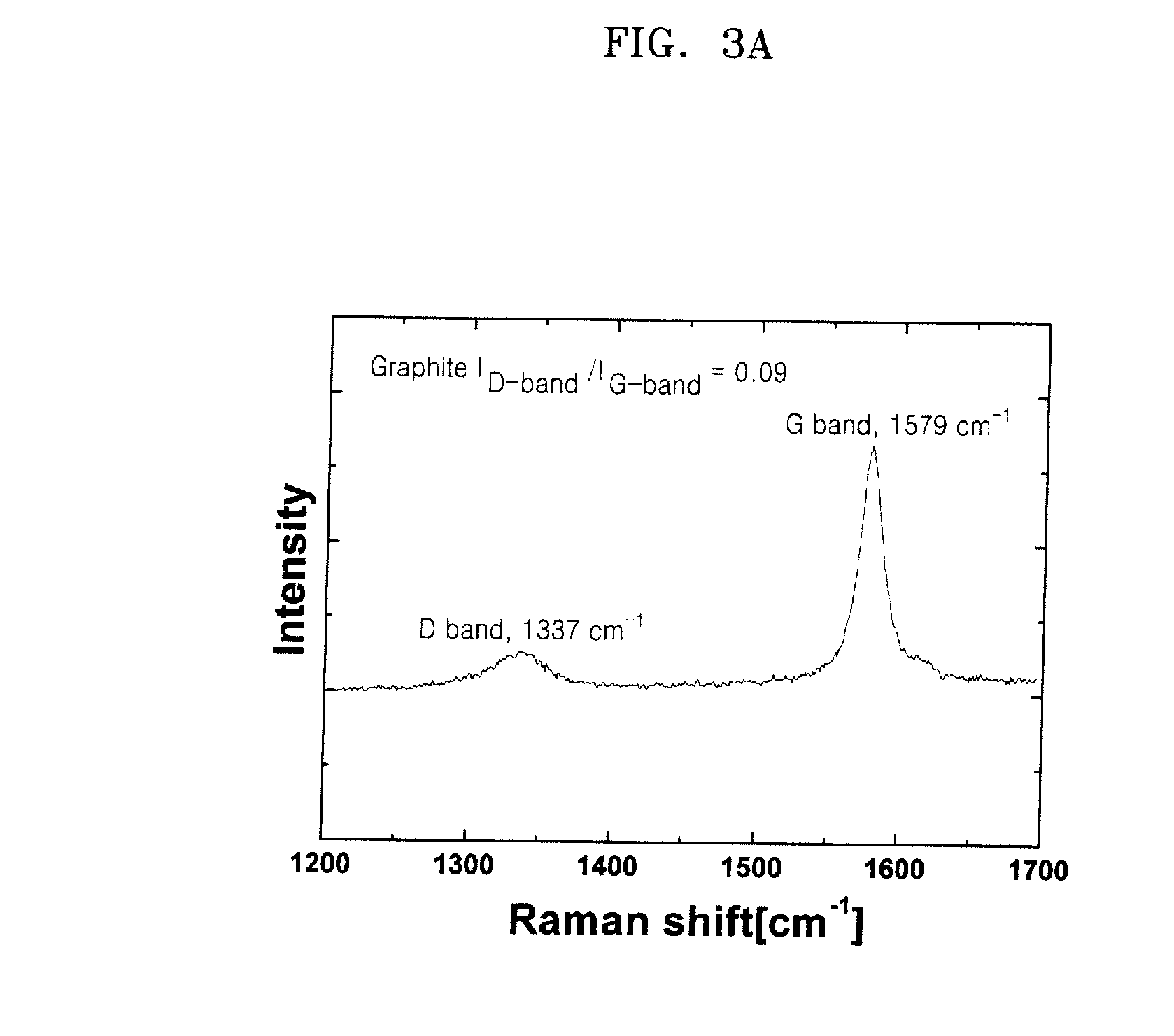

Conductive composite particle, method of manufacturing the same, electrode using the same, lithium ion secondary battery

In a manufacturing method of a conductive composite particle, a conductive composite particle is manufactured that is formed of an active material particle having a region capable of electrochemically inserting and desorbing lithium and a carbon layer joined to the particle surface. In the carbon layer, fine metal particles are dispersed. This method has the following three steps. In the first step, a polymer material containing the metal element composing the fine metal particles is prepared. In the second step, the active material particle surface is coated with the polymer material containing the metal element. In the third step, a carbon layer having a porous structure including a fibrous structure is formed as the surface layer section from the polymer material by a treatment where the active material particle coated with the polymer containing the metal element is heated in an inert atmosphere to carbonize the polymer material.

Owner:PANASONIC CORP

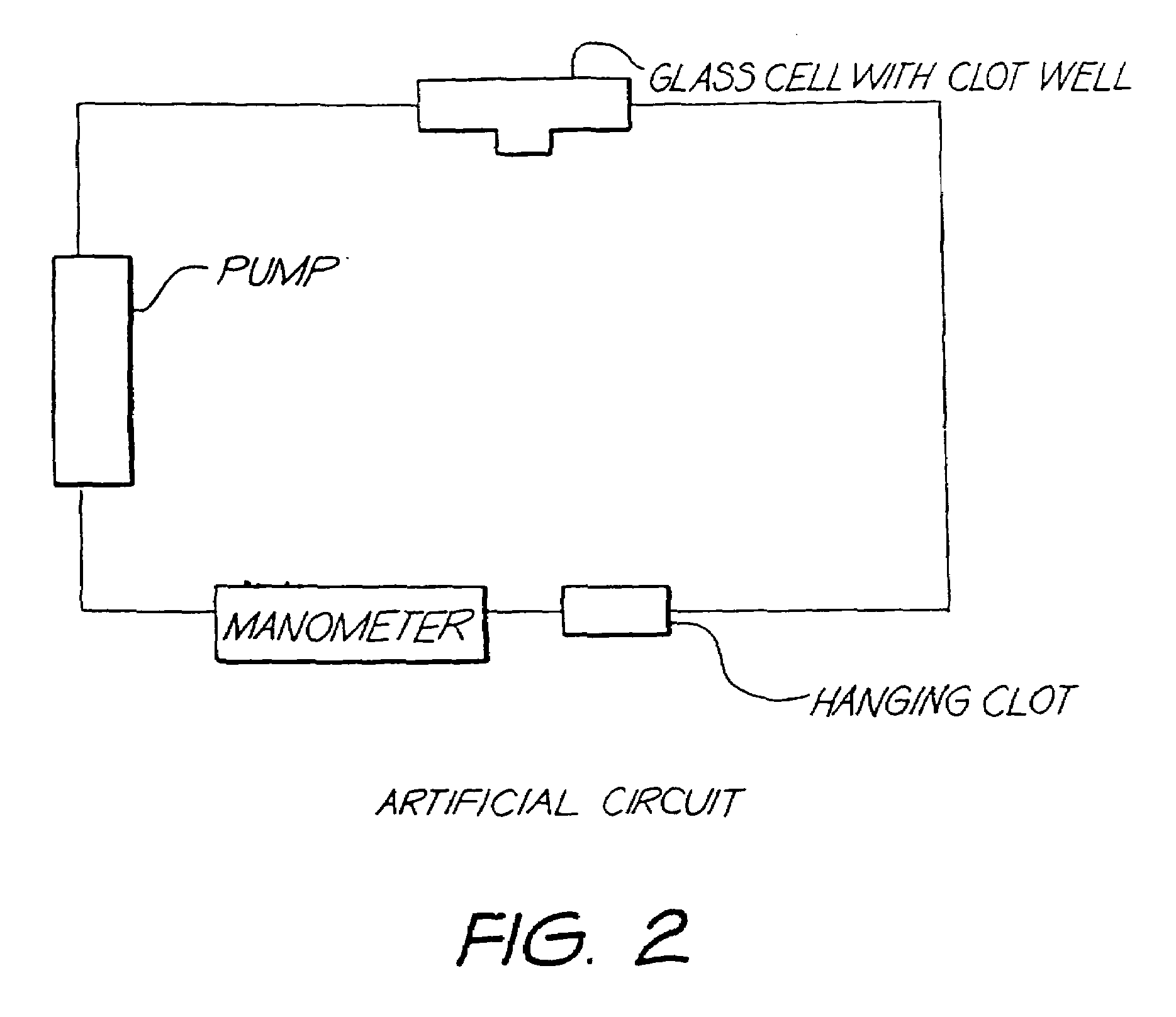

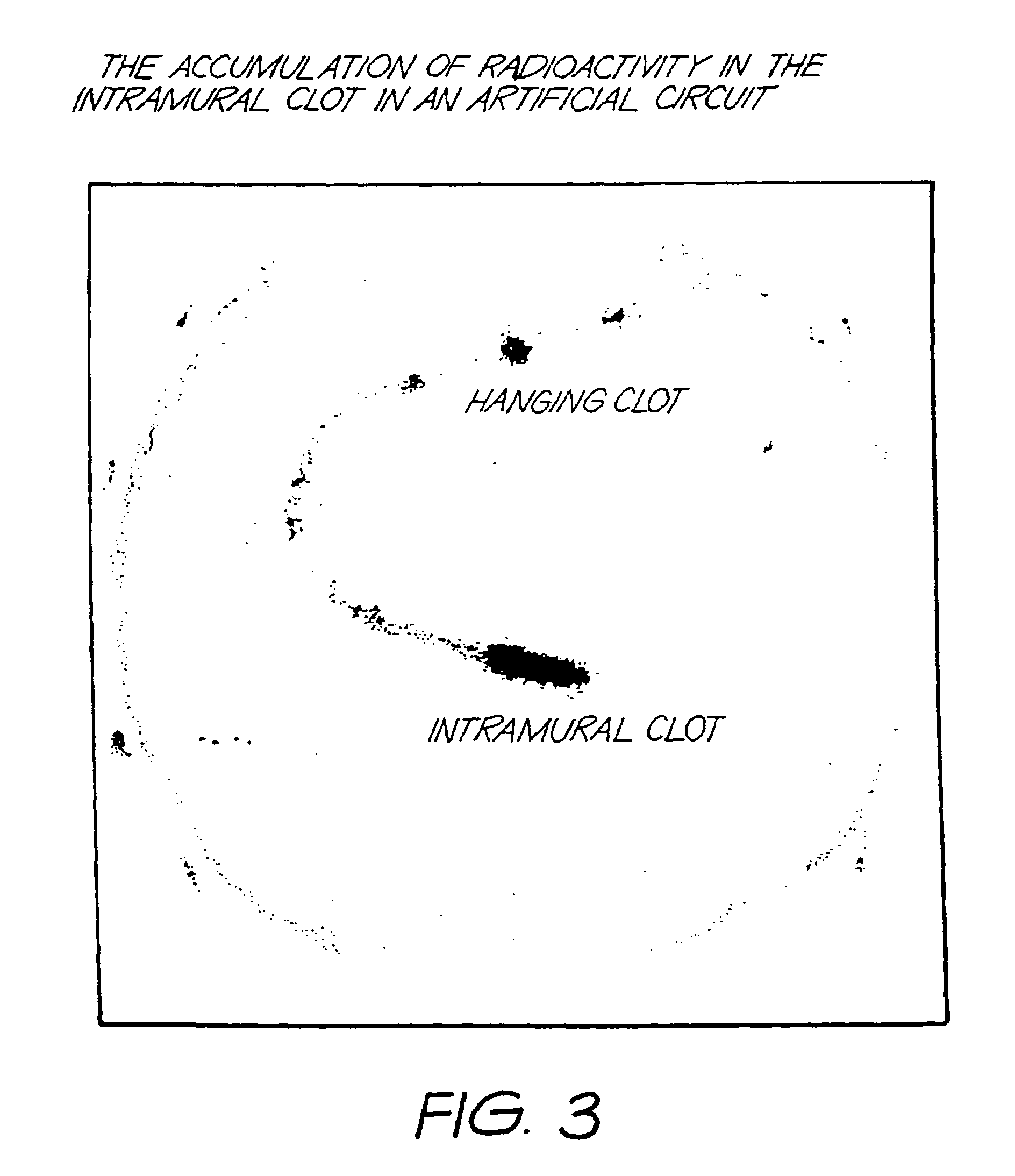

Method for detection of fibrin clots

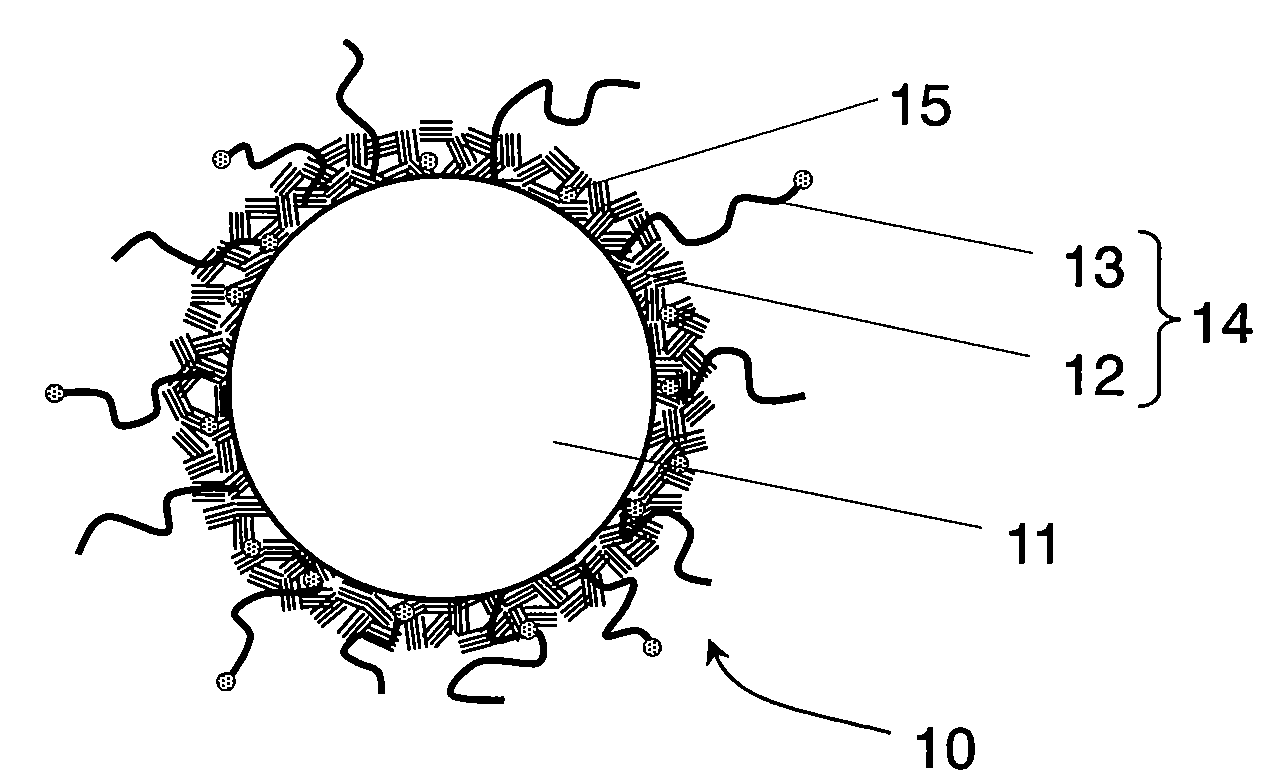

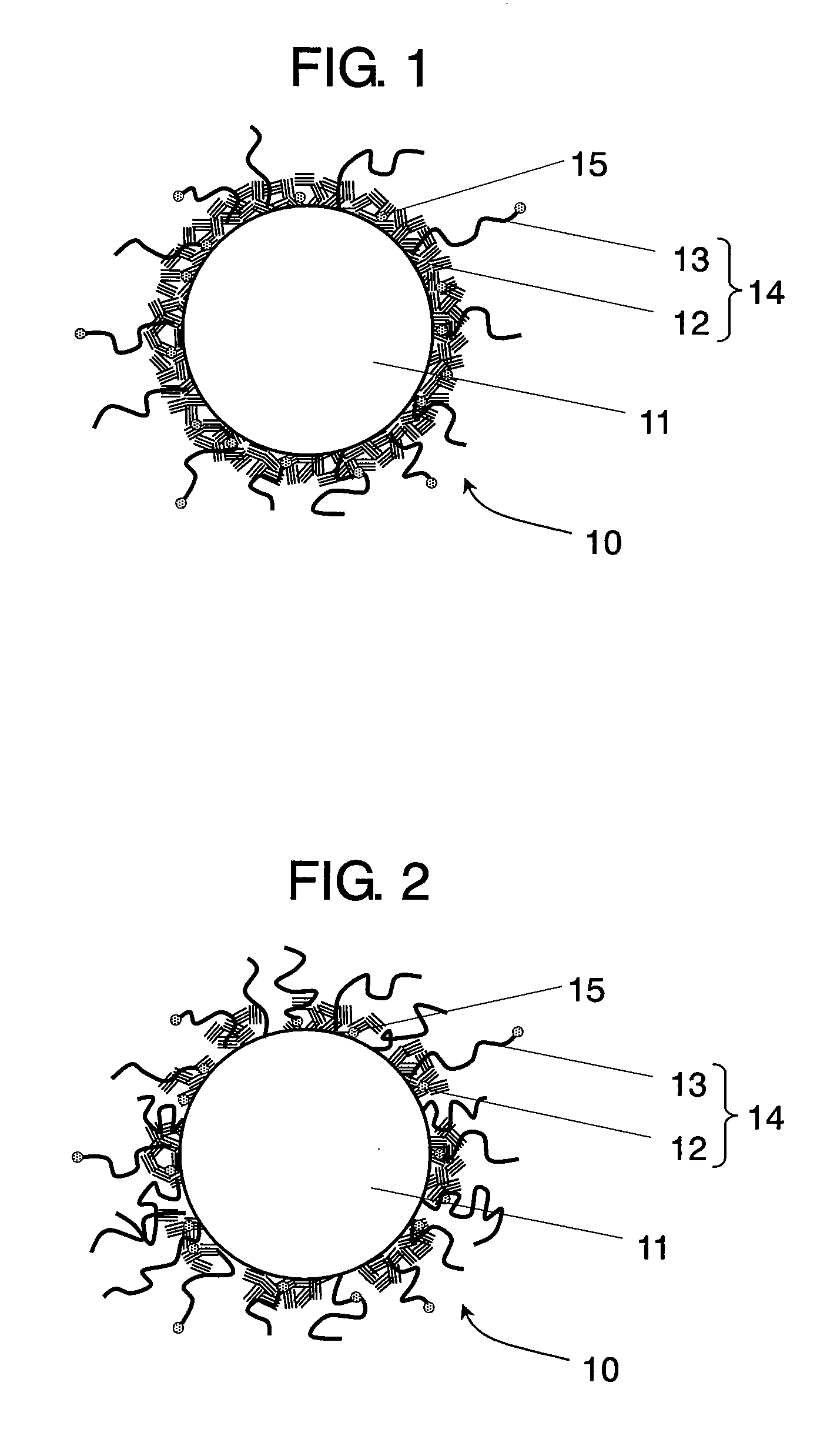

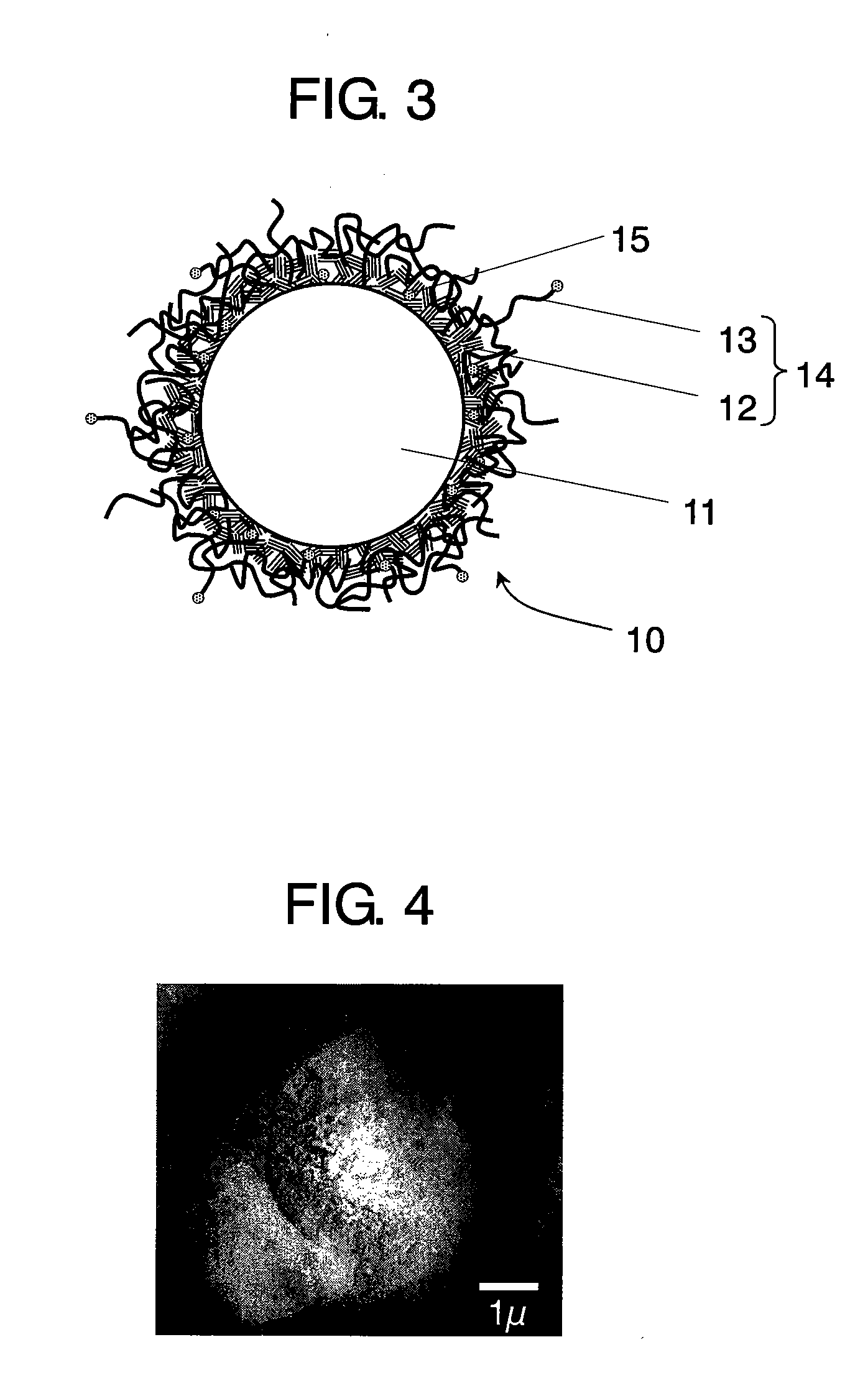

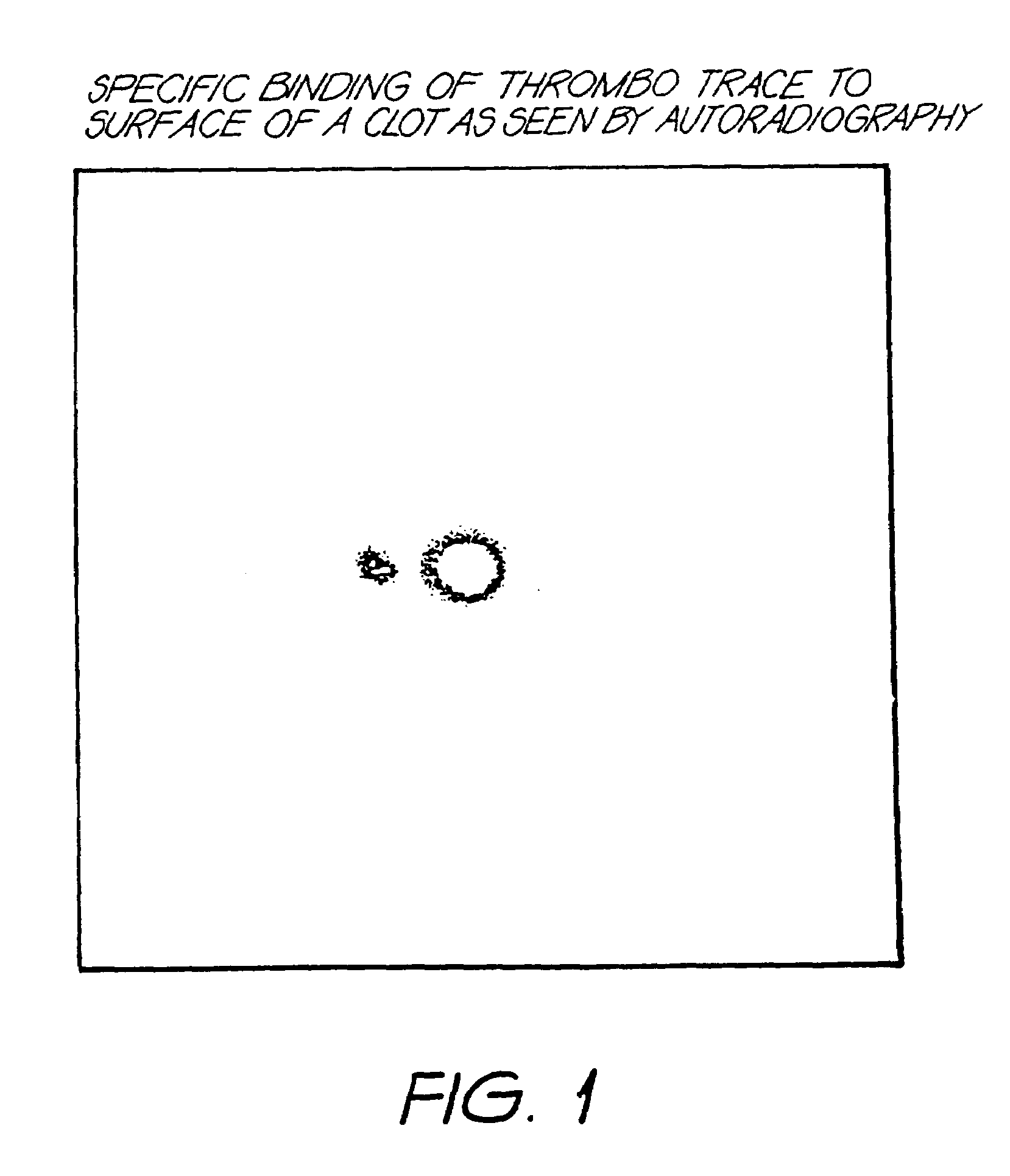

InactiveUS6977068B1Improve binding efficiencyEasy to producePowder deliveryRadioactive preparation carriersCarbon layerIn vivo

A method for the detection of fibrin in a source, in particular the in vivo detection of a fibrin in a patient, the method comprising supplying to the source or patient an amount of a detectable reagent comprising a plurality of discrete particles, each of the particles comprising a plurality of layers of carbon and being capable of binding to fibrin; and detecting the presence of the particles in the source. The particles may also comprise a detectable marker encased in said plurality of layers of carbon, the presence of said marker being capable of detection in said source.

Owner:AUSTRALIEN NAT UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com