Patents

Literature

773results about "Alkali titanates" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Anode active material, manufacturing method thereof, and non-aqueous electrolyte secondary battery

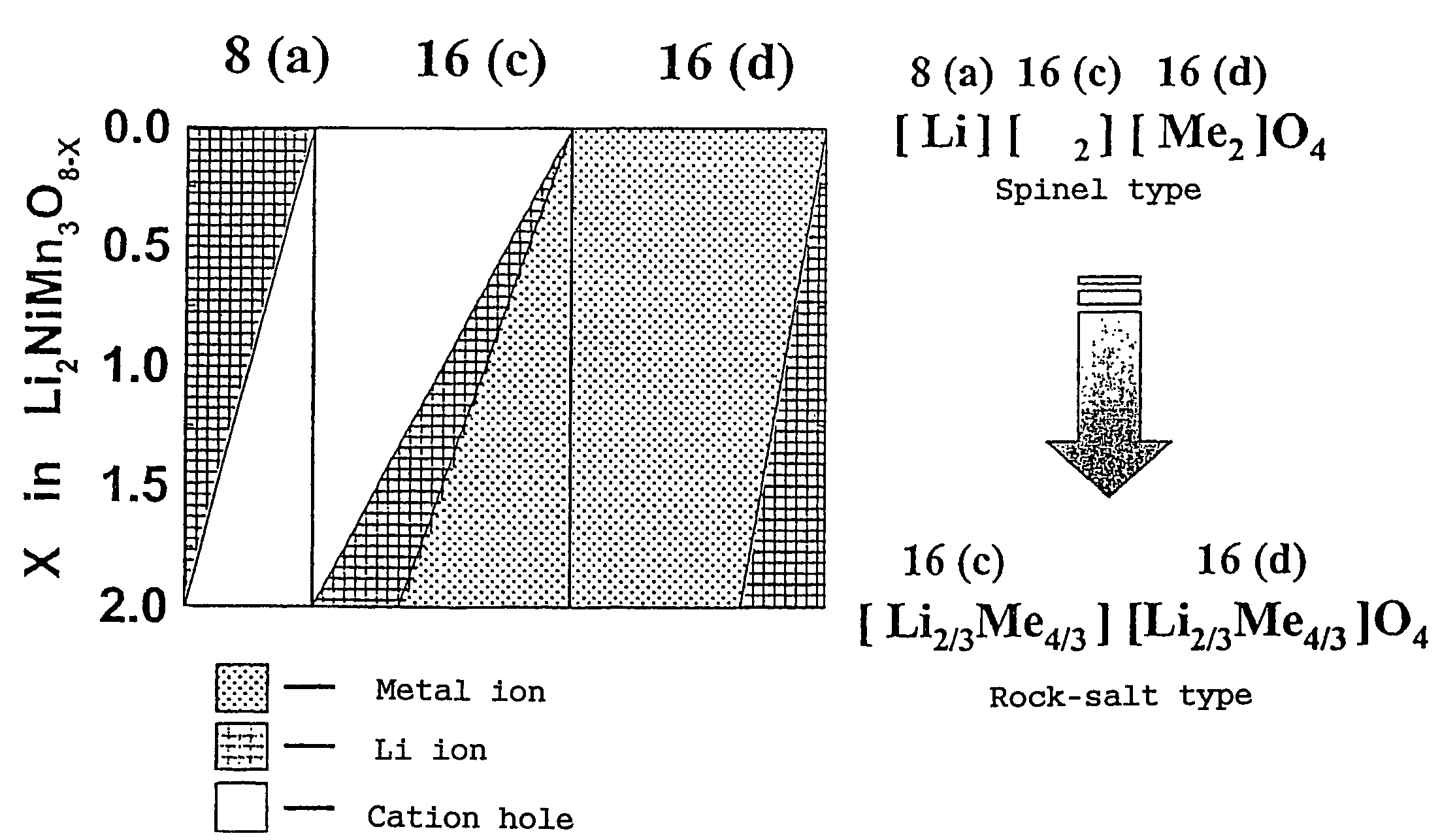

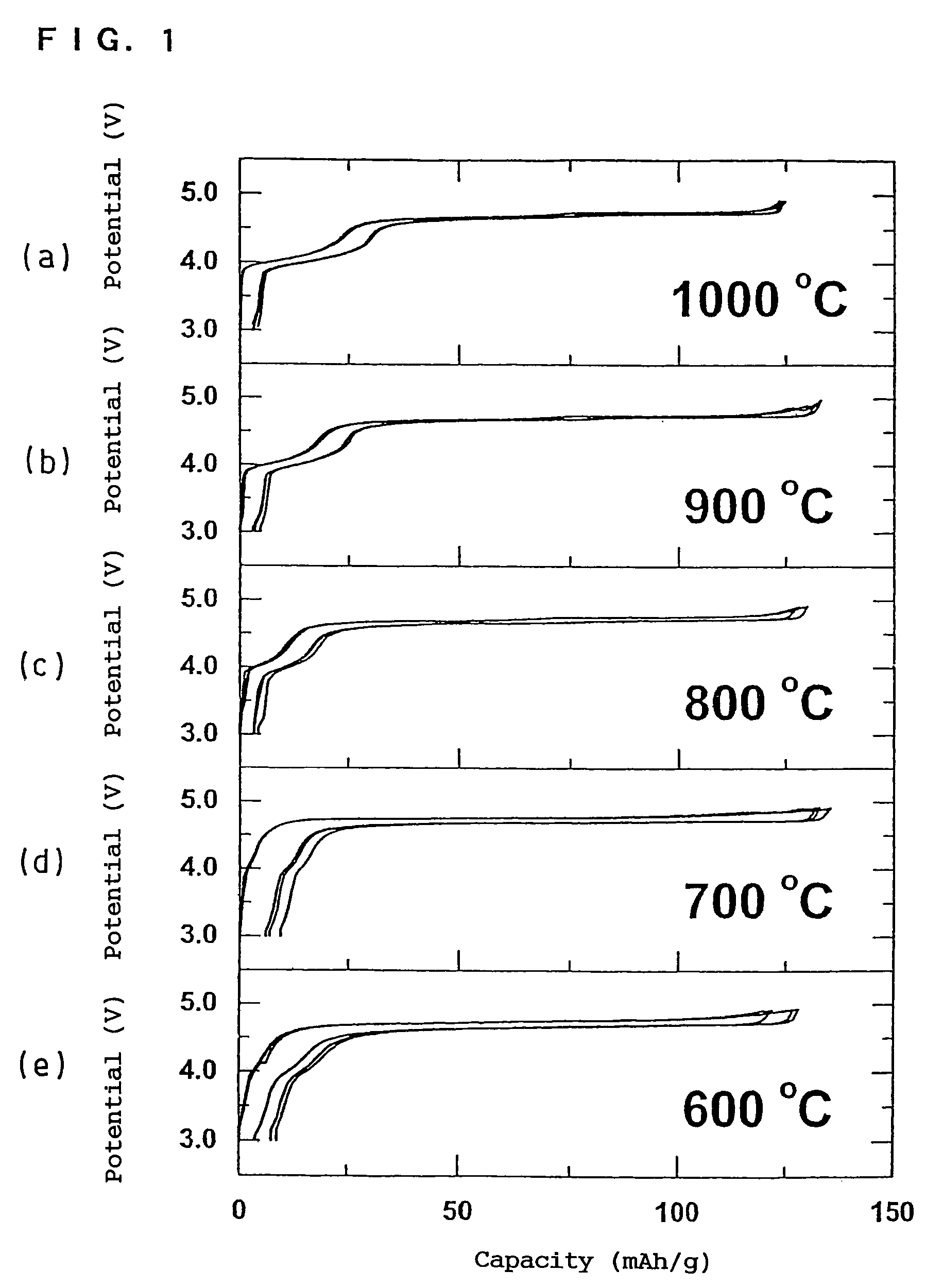

In order to provide a 3V level non-aqueous electrolyte secondary battery with a flat voltage and excellent cycle life at a high rate with low cost, the present invention provides a positive electrode represented by the formula: Li2±α[Me]4O8−x, wherein 0≦α<0.4, 0≦x<2, and Me is a transition metal containing Mn and at least one selected from the group consisting of Ni, Cr, Fe, Co and Cu, said active material exhibiting topotactic two-phase reactions during charge and discharge.

Owner:OSAKA CITY UNIV +1

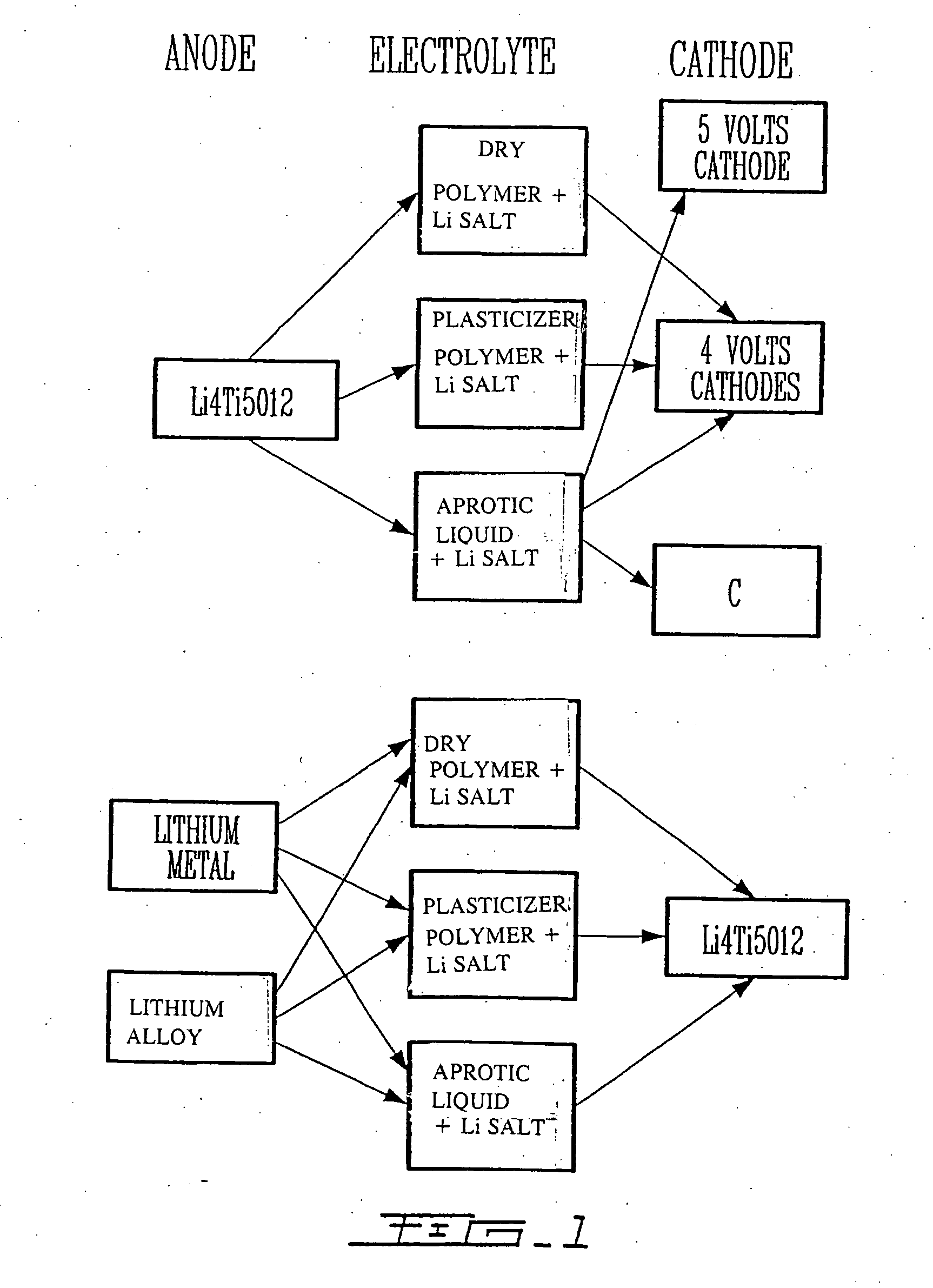

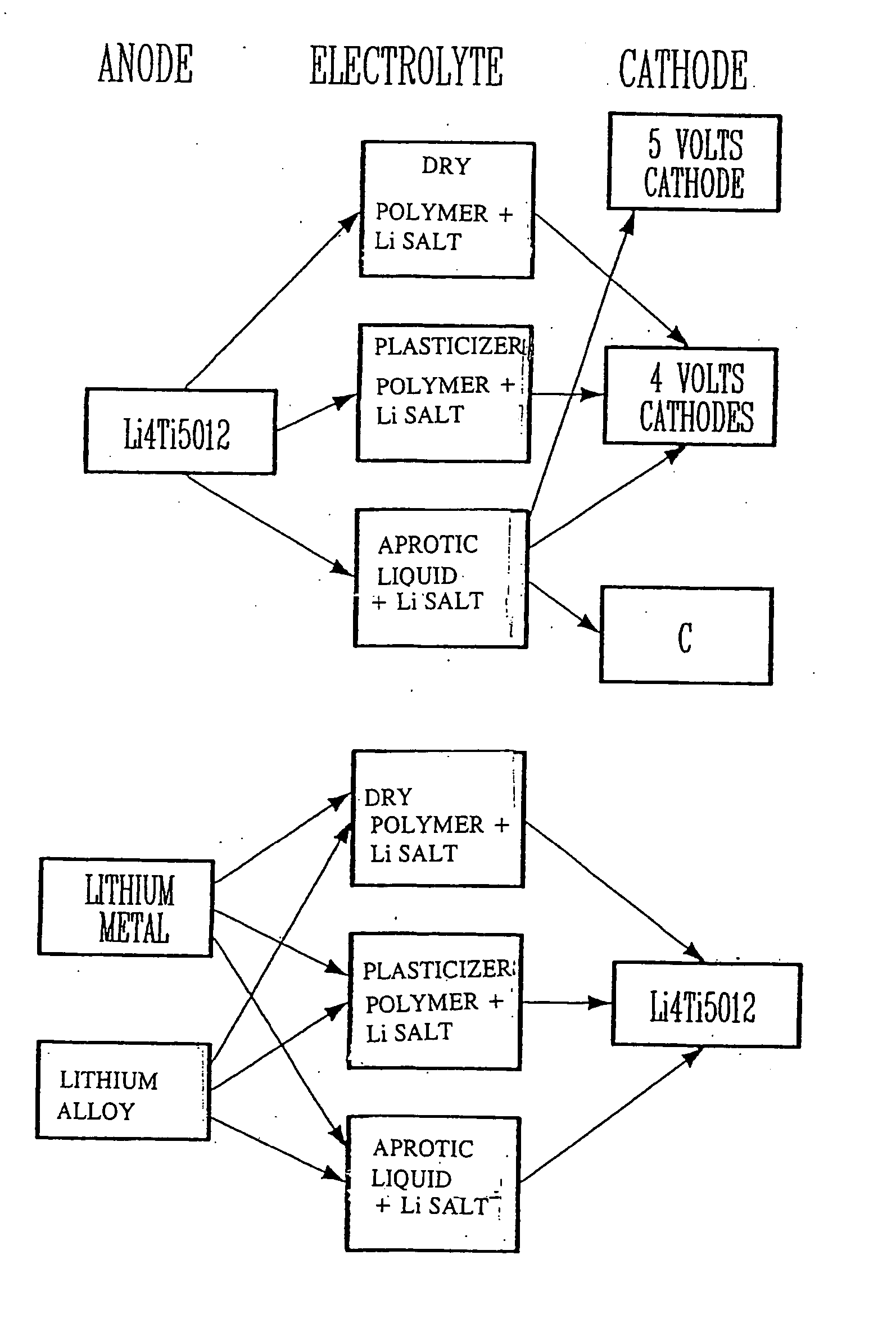

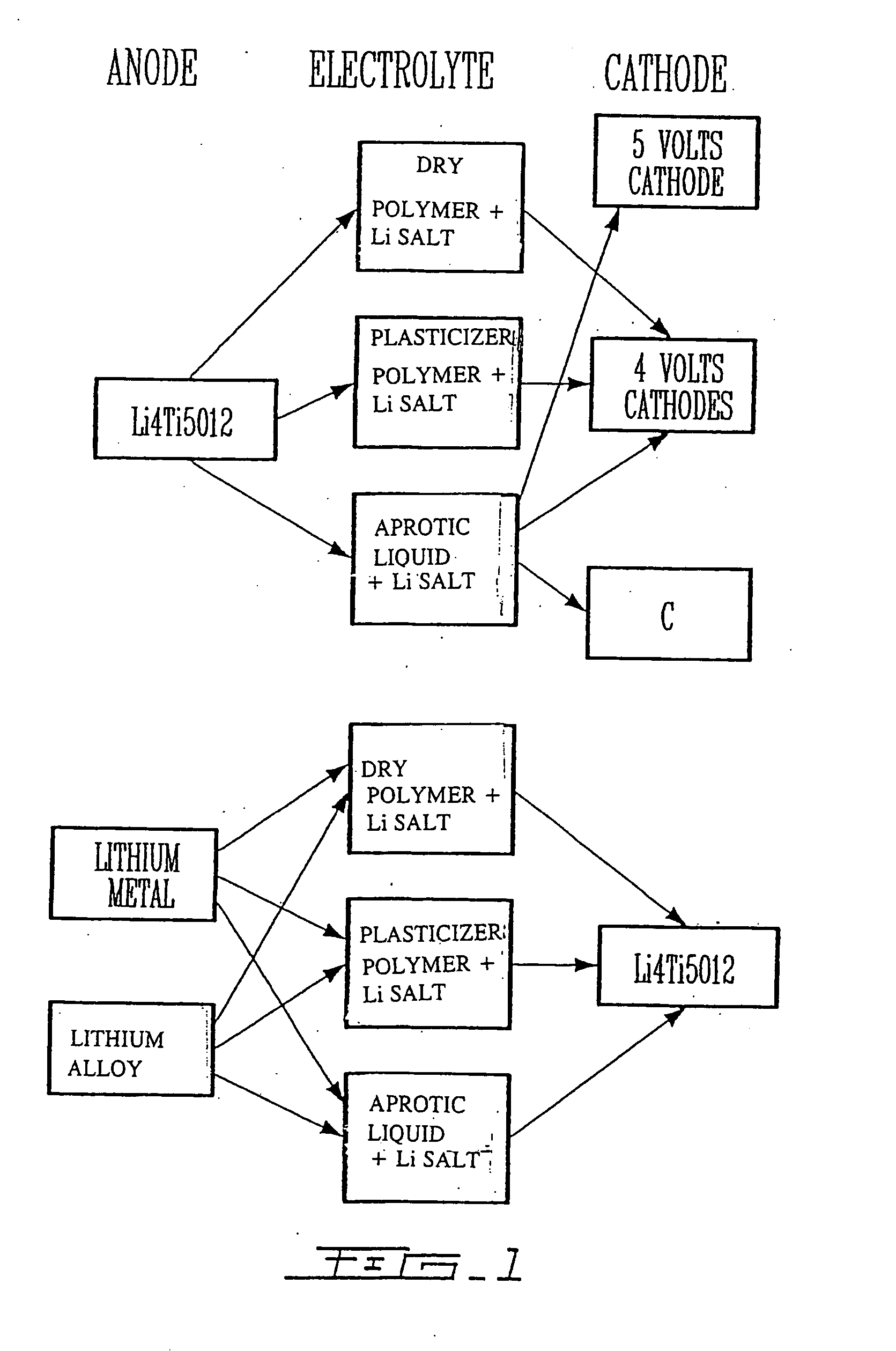

Li4Ti5O12, Li(4-alpha)Zalpha Ti5O12 or Li4ZbetaTi(5-beta)O12 particles, processes for obtaining same and use as electrochemical generators

Synthesis process for new particles of Li4Ti5O12, Li(4-alpha)ZalphaTi5O12 or Li4ZbetaTi(5-beta)O12, preferably having a spinel structure, wherein beta is greater than 0 and less than or equal to 0.5 (preferably having a spinel structure), alpha representing a number greater than zero and less than or equal to 0.33, Z representing a source of at least one metal, preferably chosen from the group made up of Mg, Nb, Al, Zr, Ni, Co. These particles coated with a layer of carbon notably exhibit electrochemical properties that are particularly interesting as components of anodes and / or cathodes in electrochemical generators.

Owner:HYDRO QUEBEC CORP

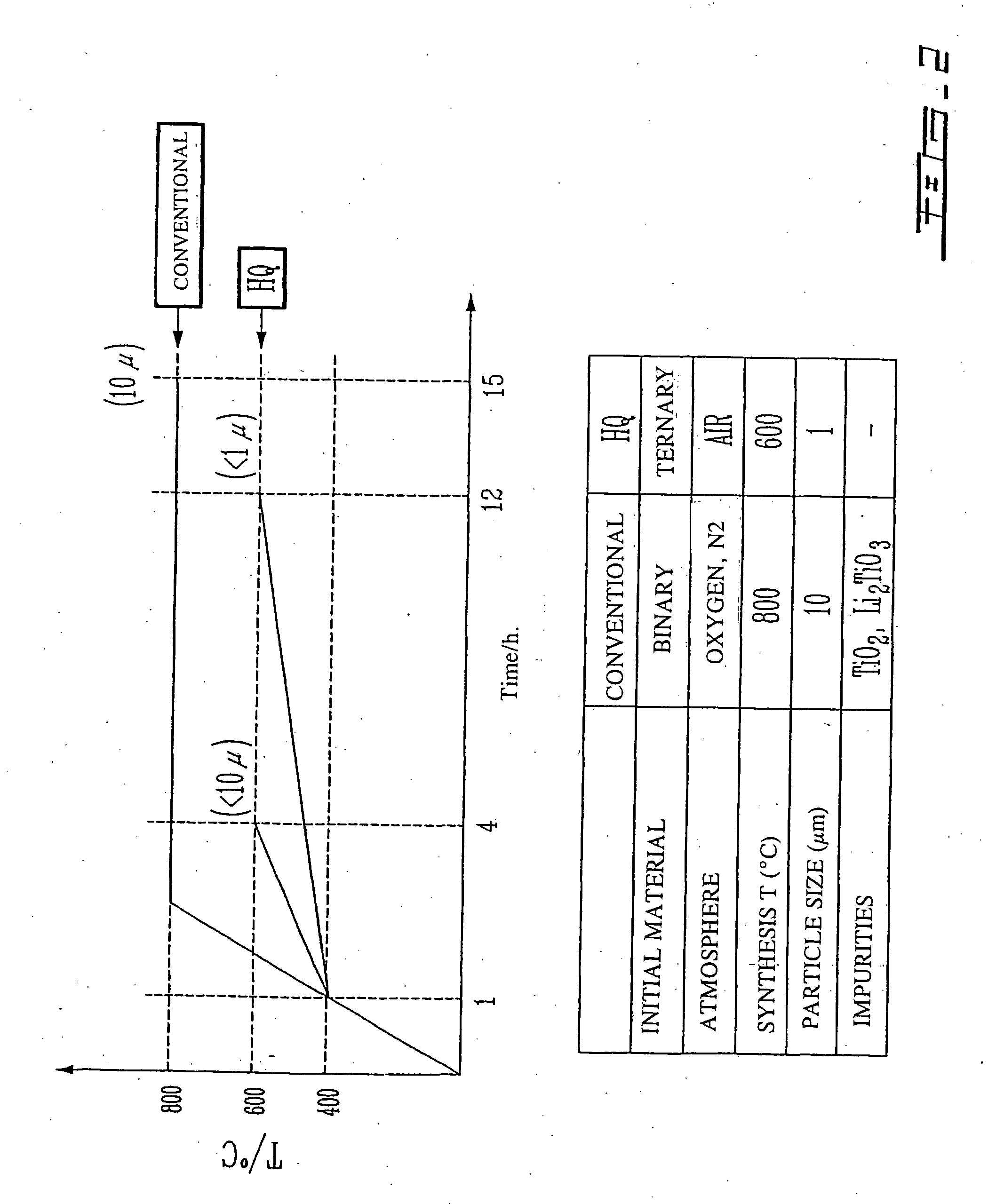

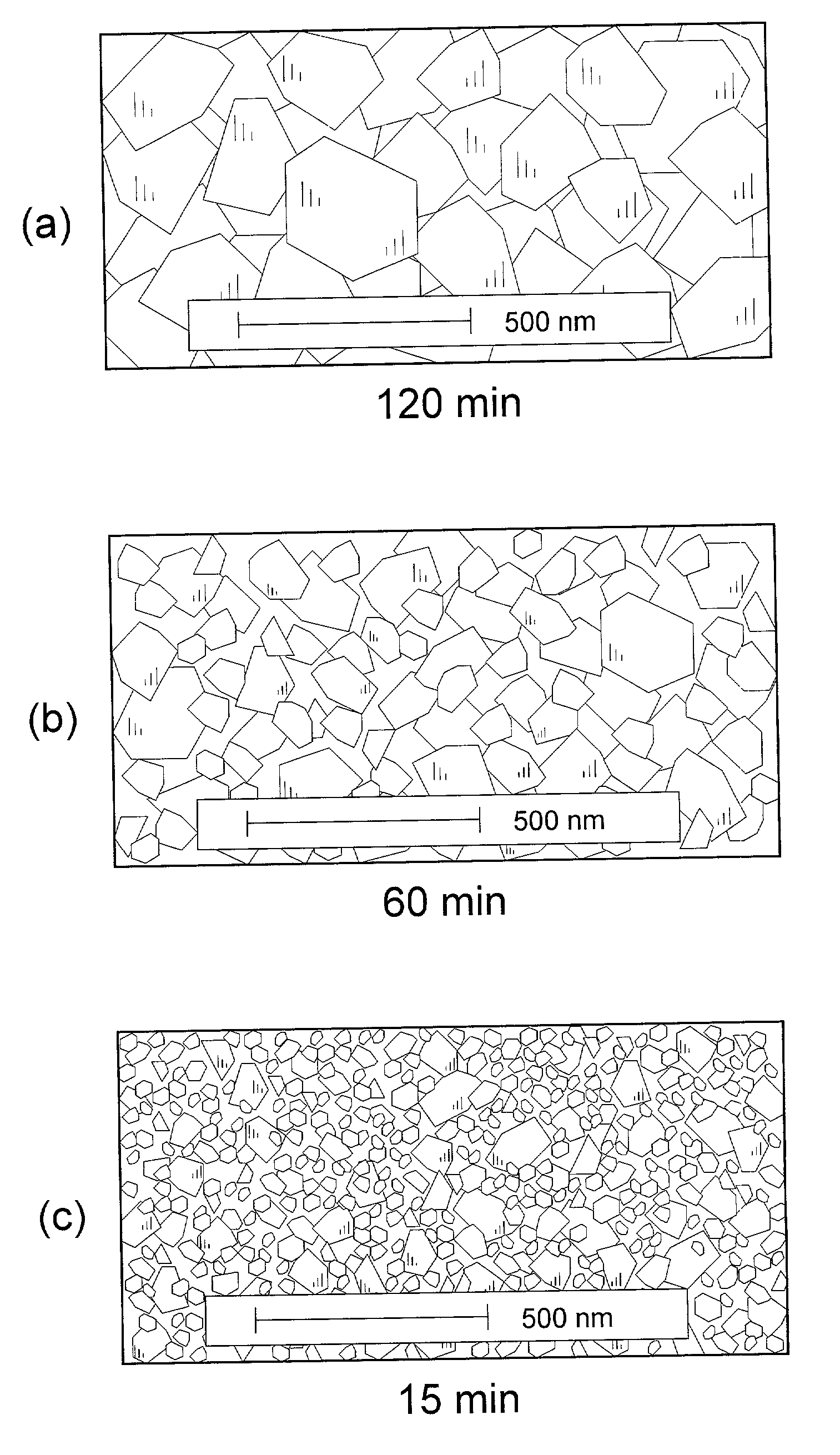

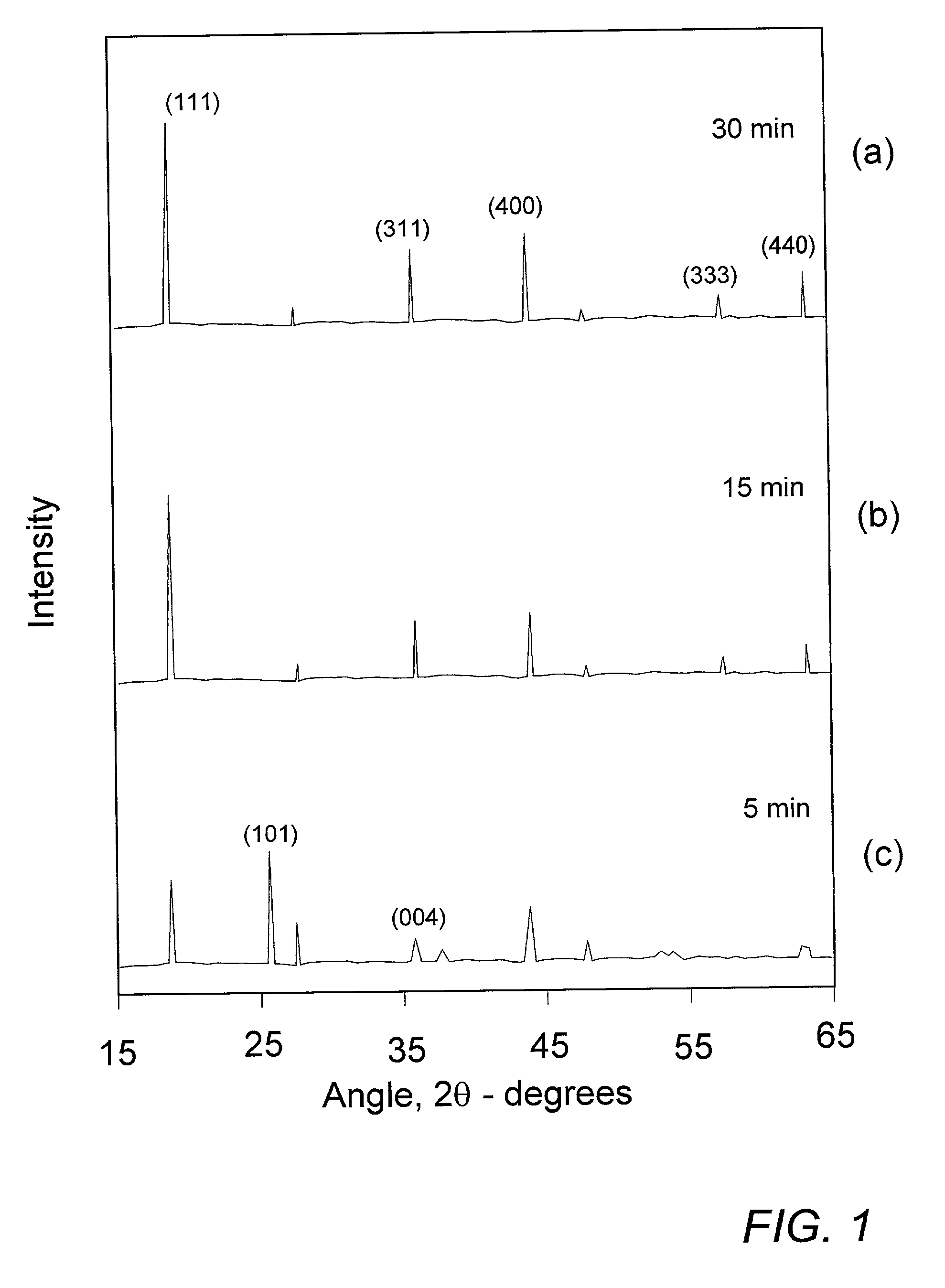

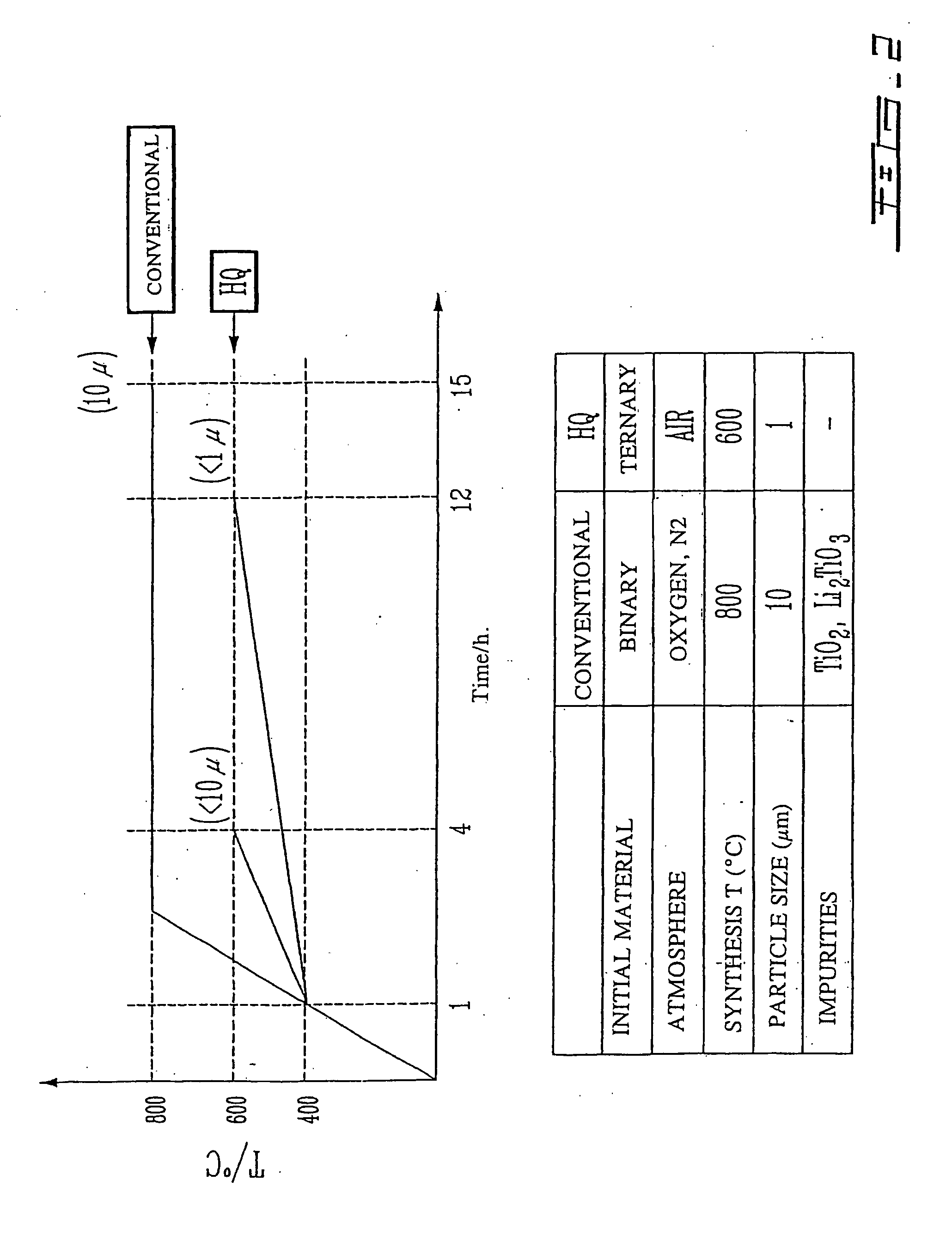

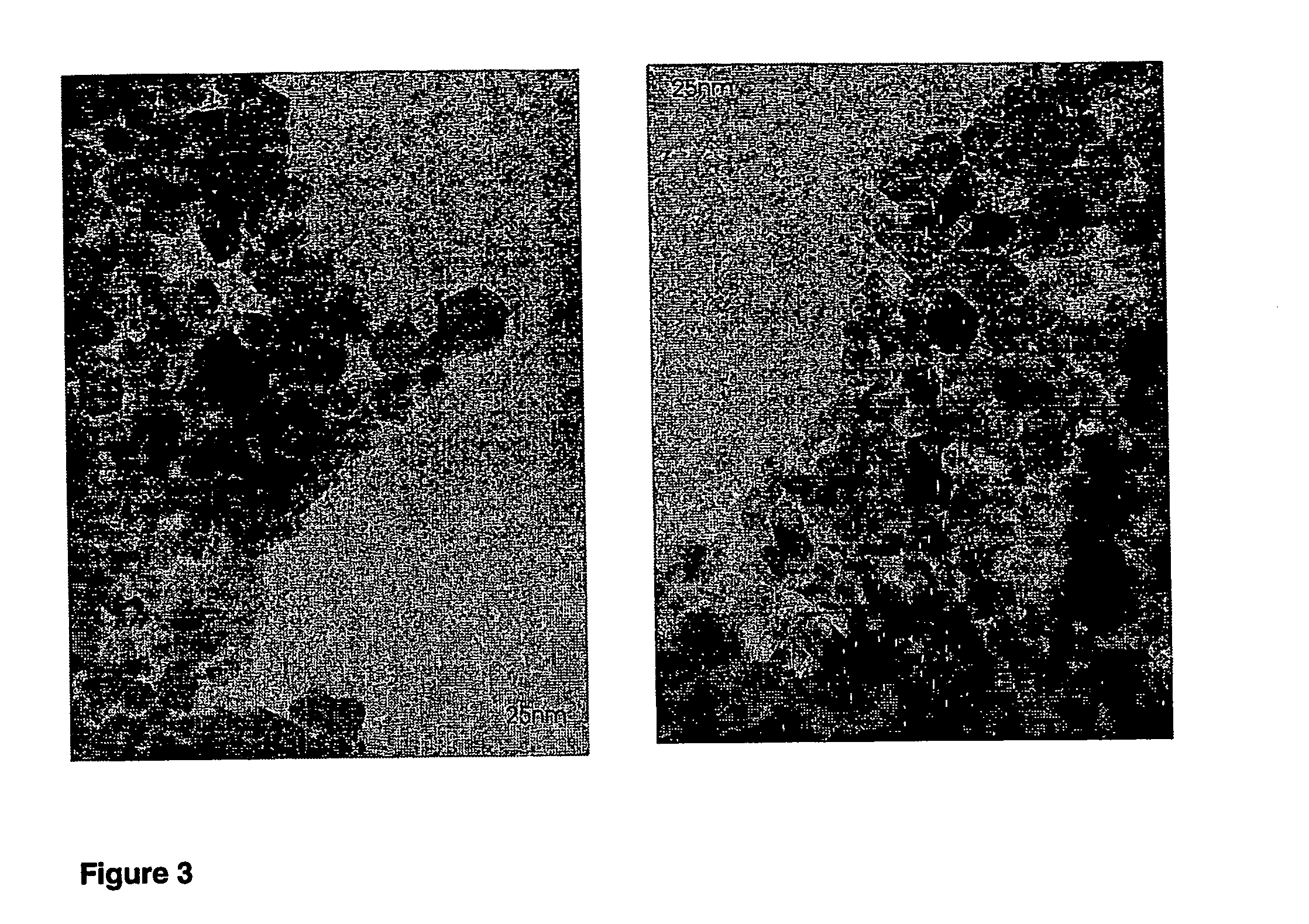

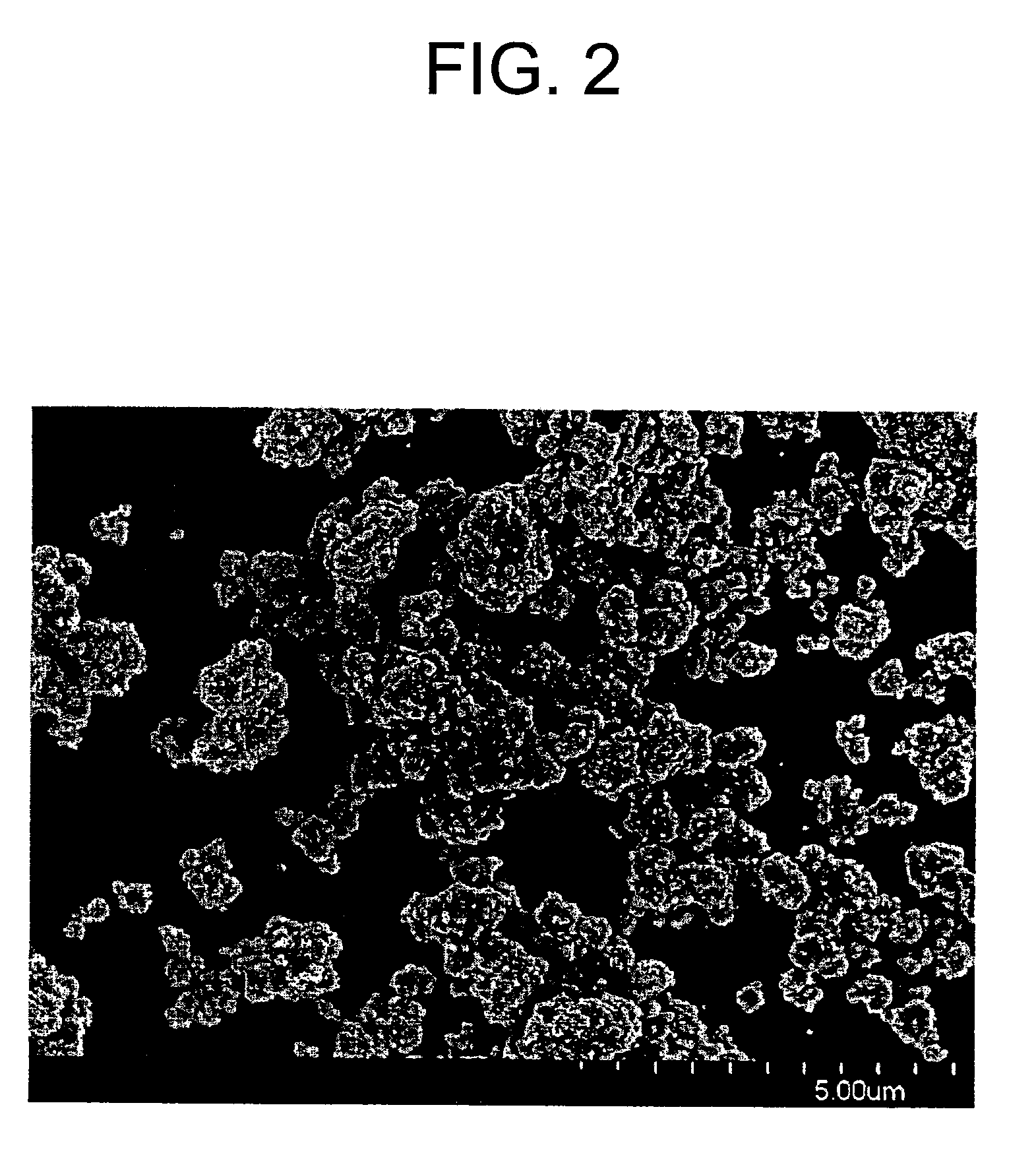

Nanostructure lithium titanate electrode for high cycle rate rechargeable electrochemical cell

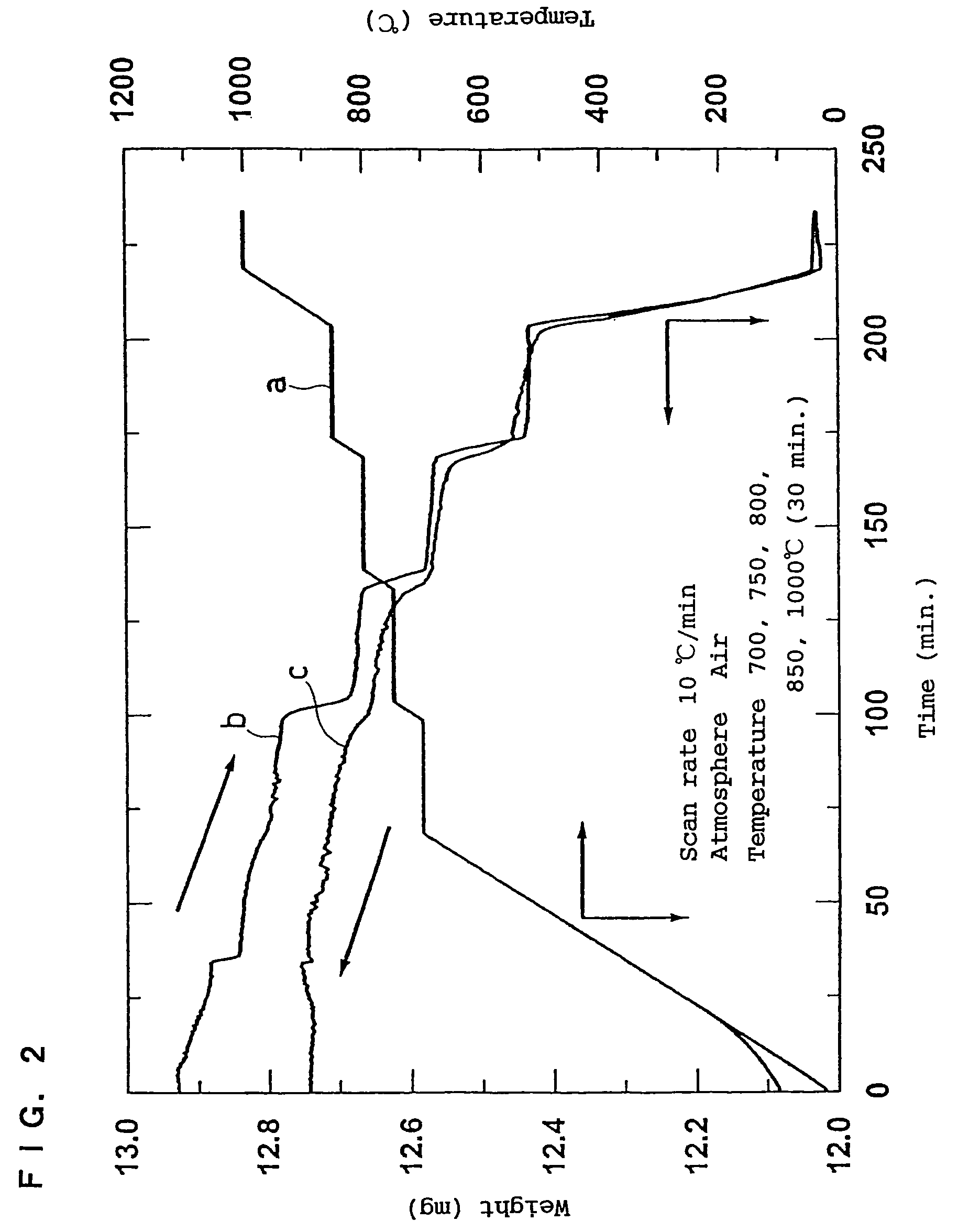

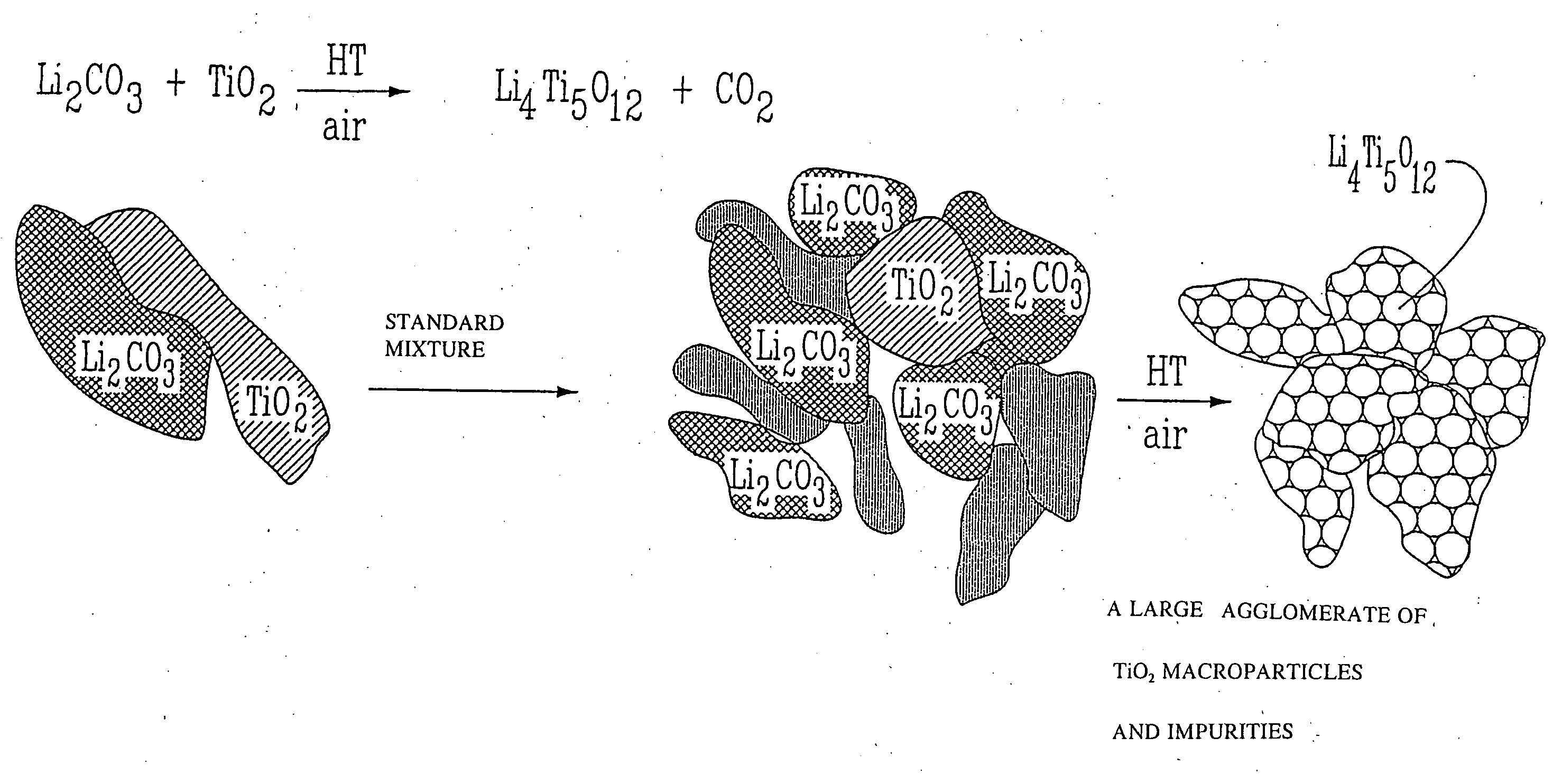

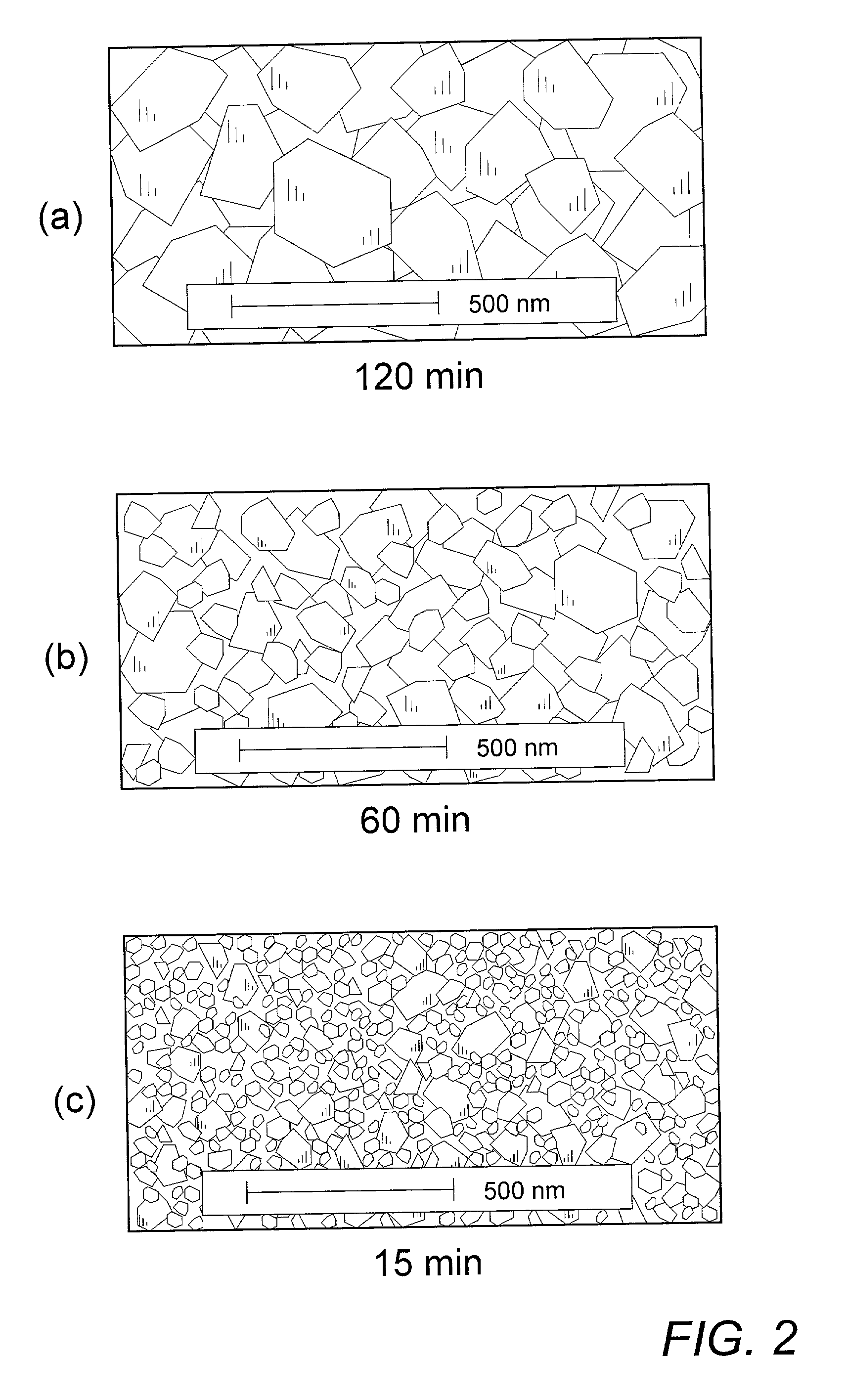

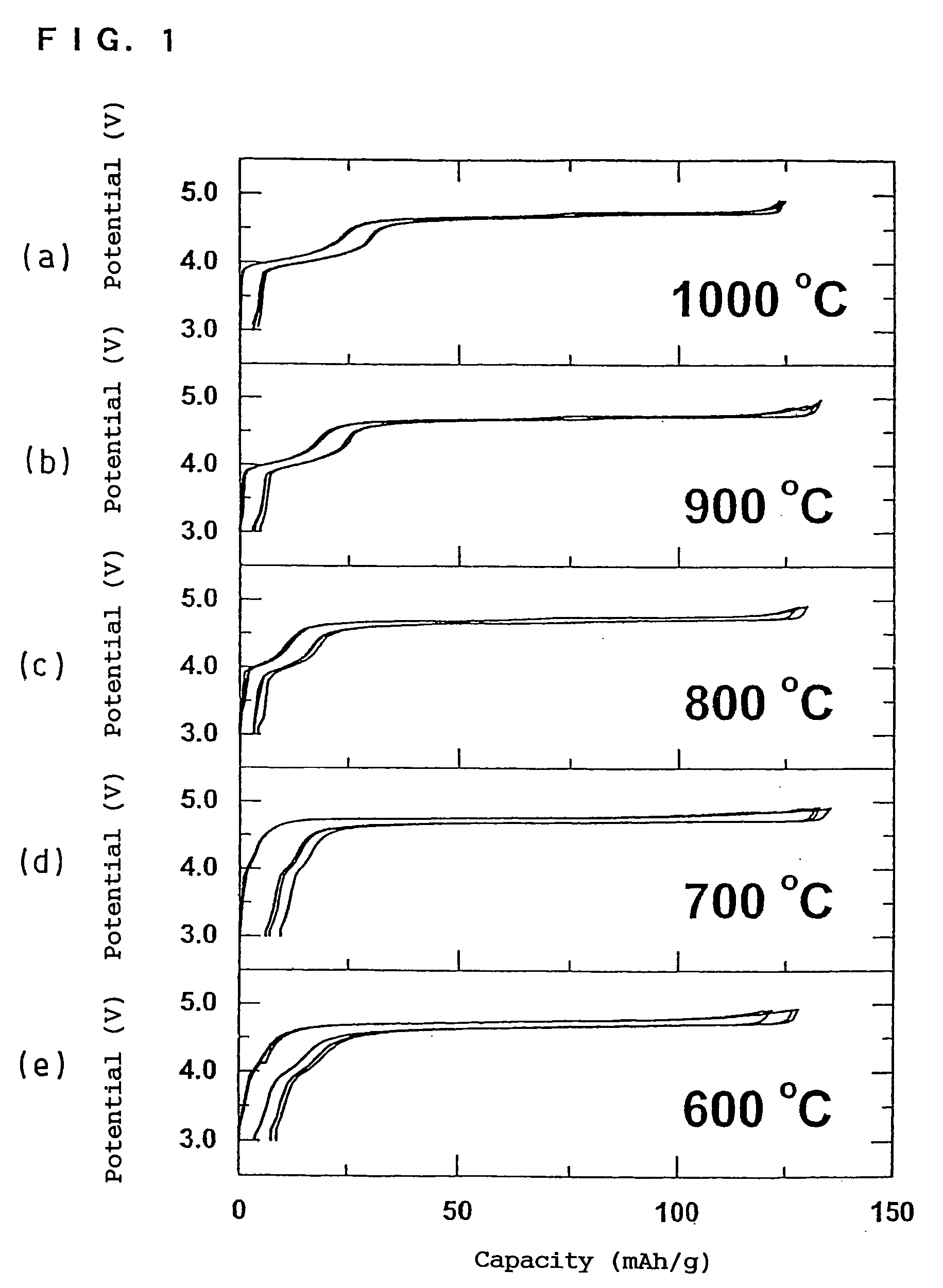

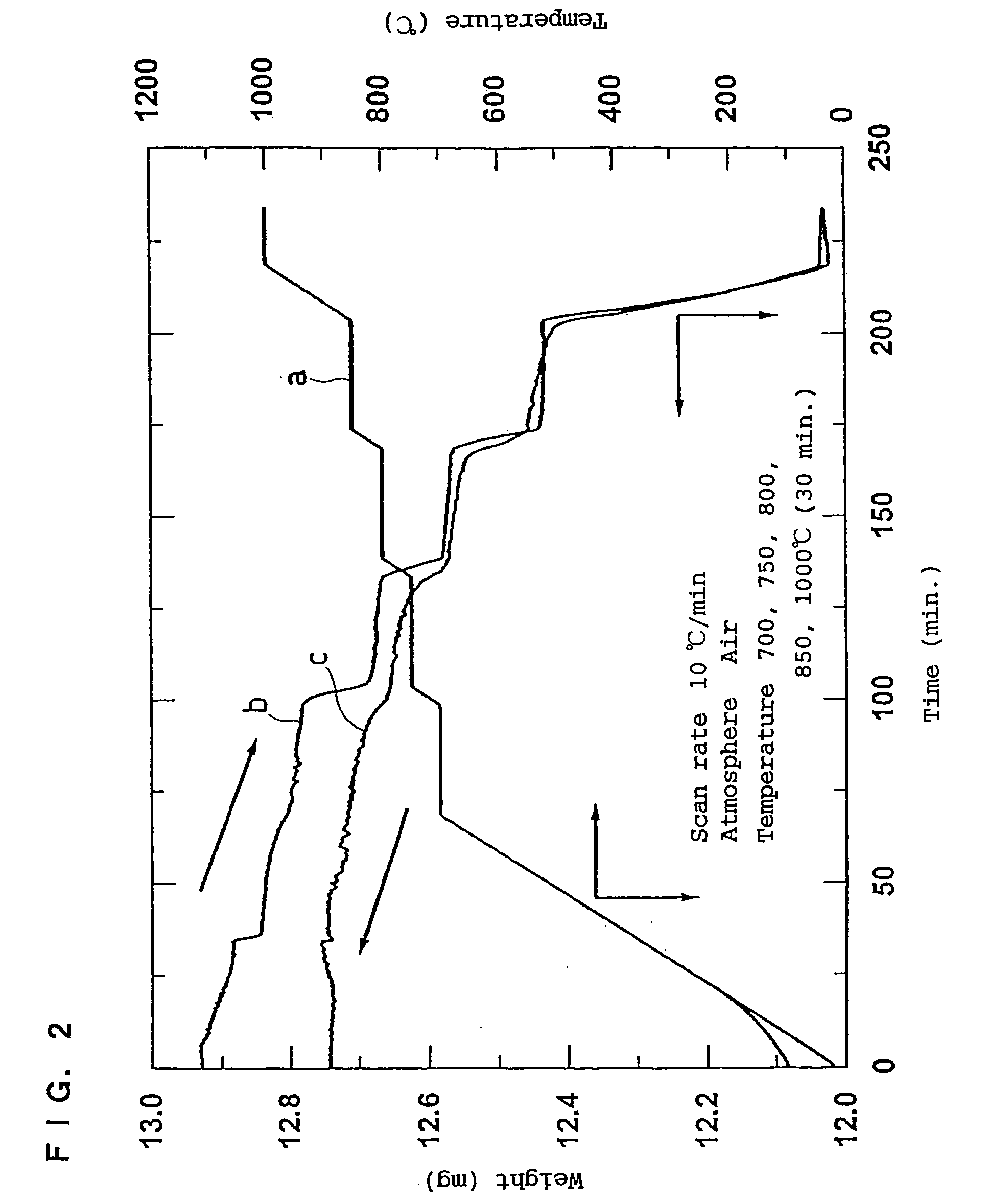

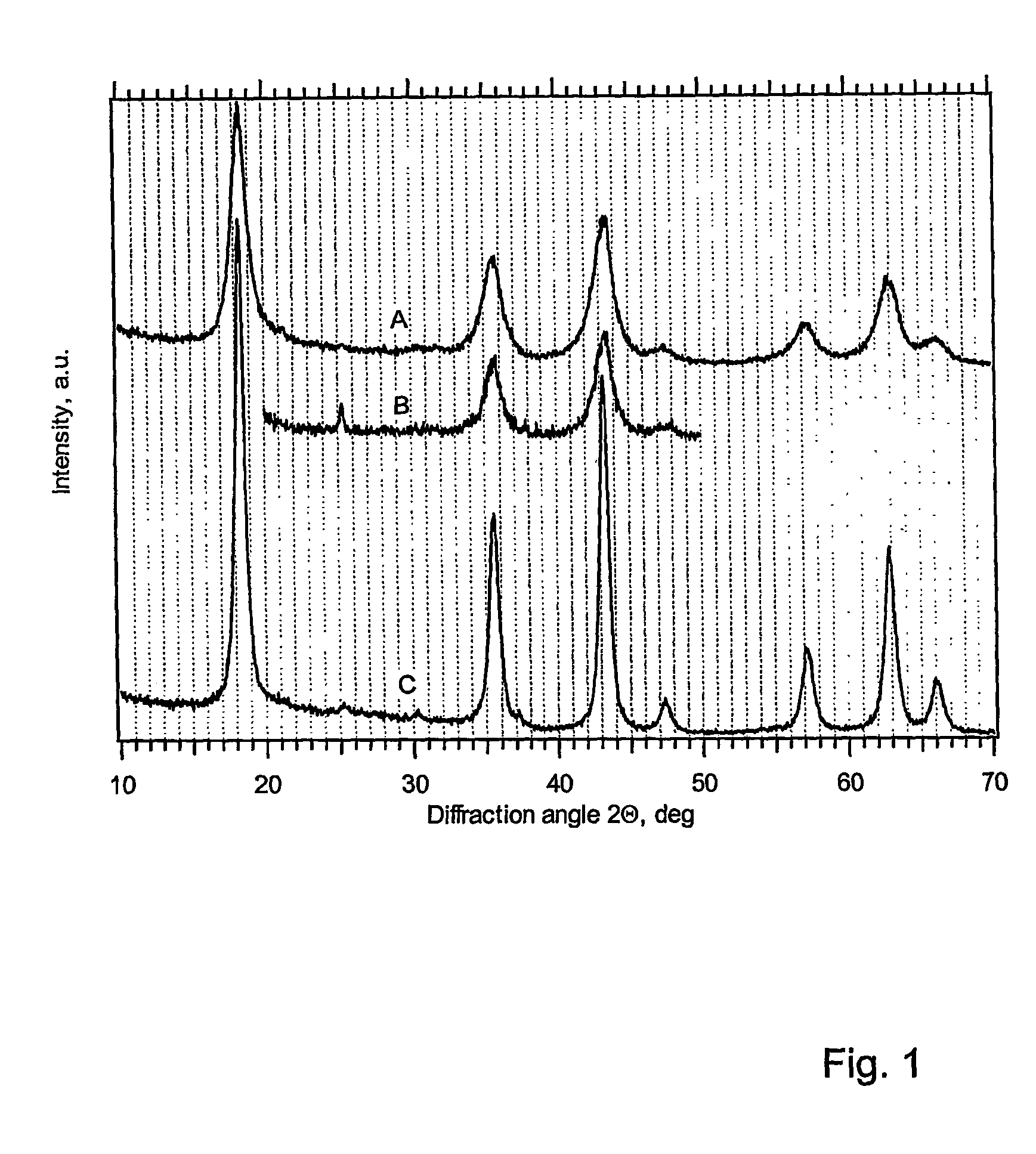

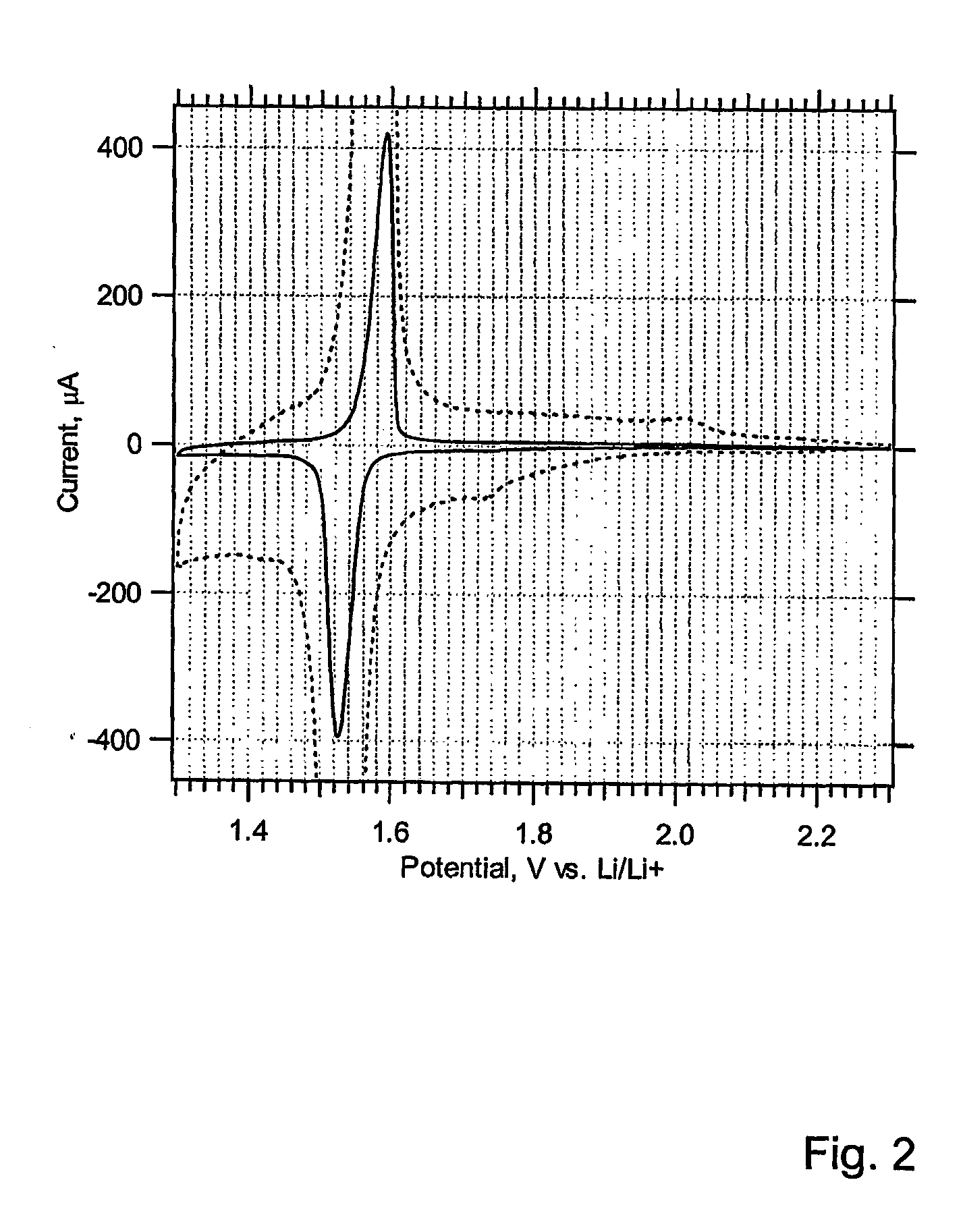

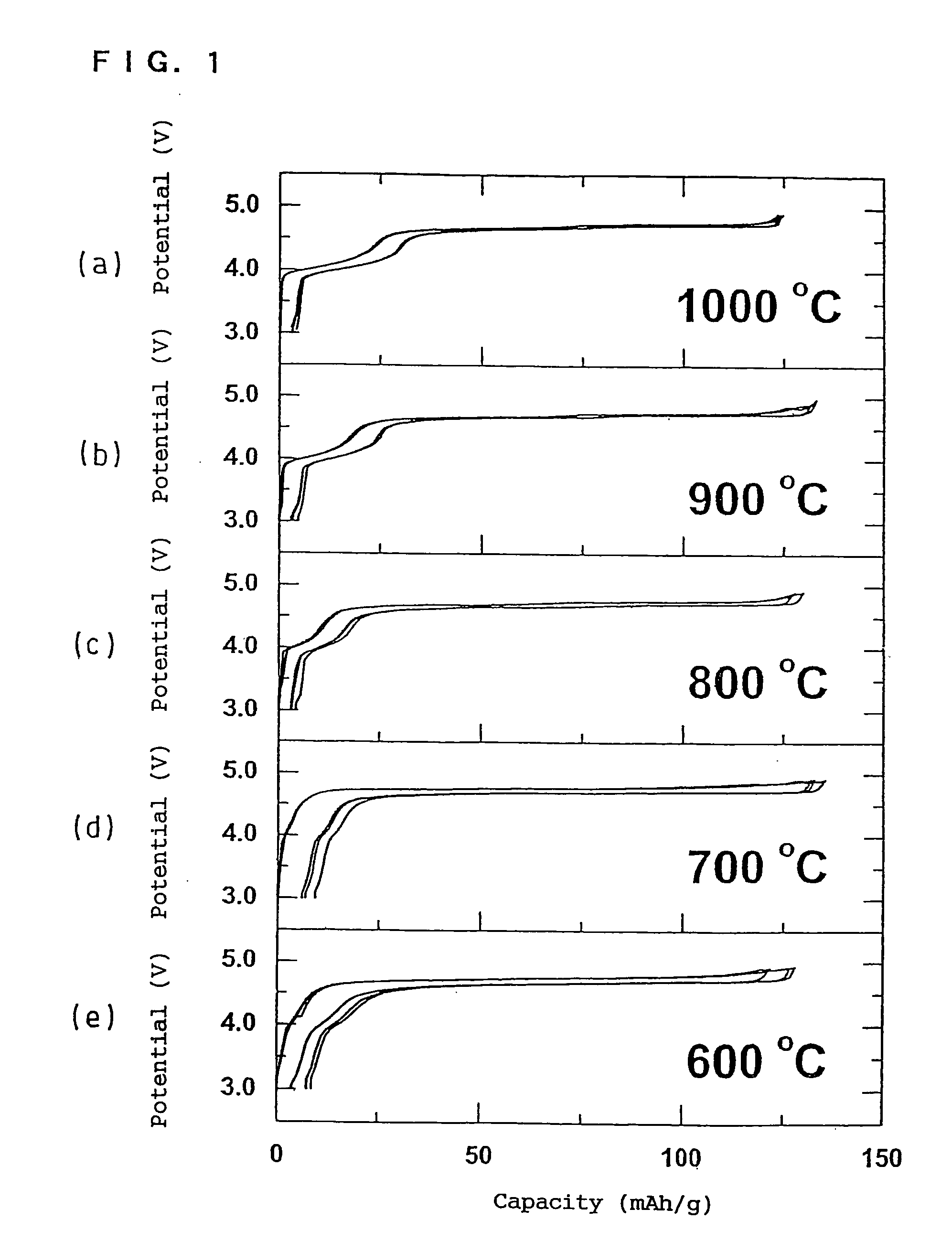

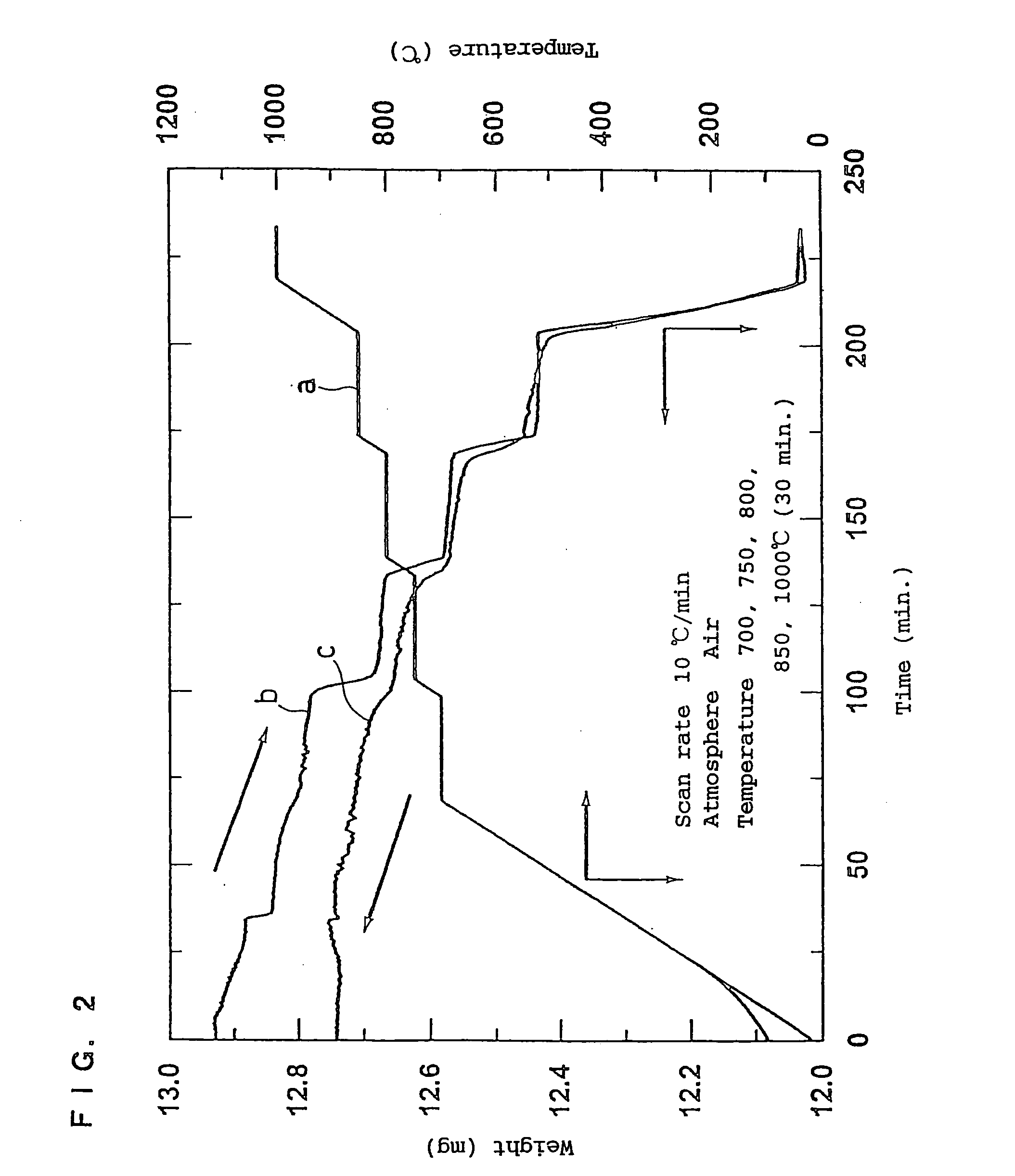

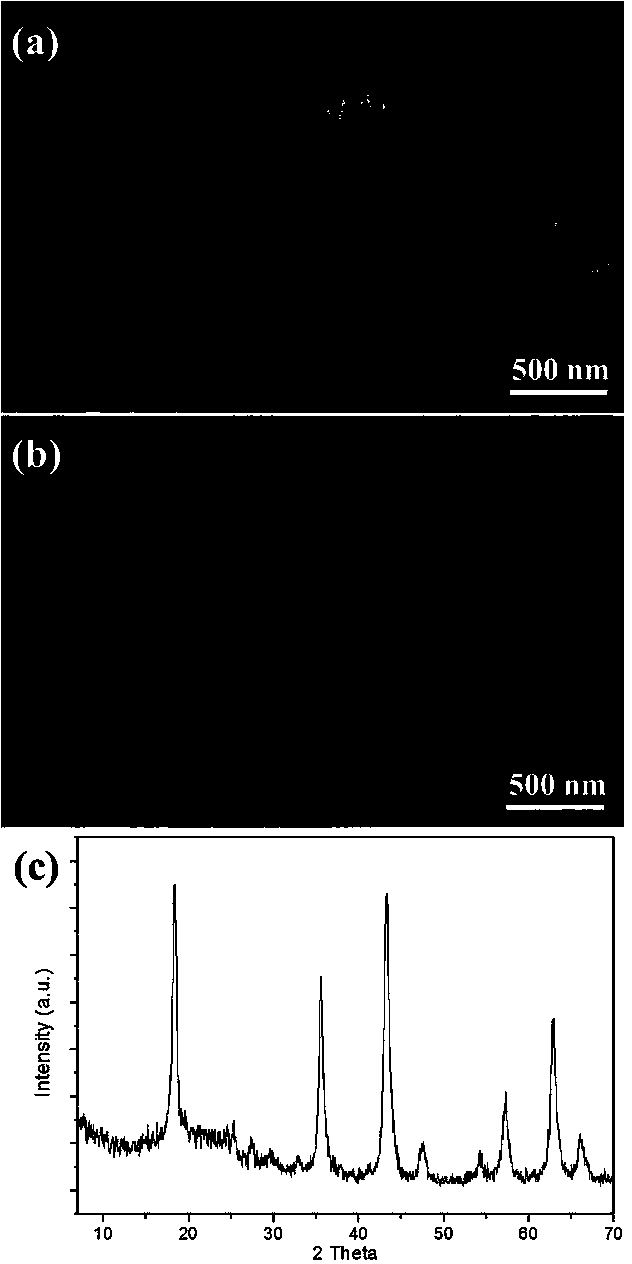

Rechargeable electrochemical cells, such as lithium batteries and asymmetric hybrid battery / supercapacitor systems, exhibiting exceptional specific capacity levels and stability over extended high-rate recharge cycling comprise nanostructure zero strain Li4Ti5O12 intercalation electrode material synthesized in a short duration process of annealing mixed TiO2 and Li-source precursor compounds at about 800° C. for a time of about 15–30 min which is not substantially longer than that required to effect maximum available reaction between the precursors, thereby substantially eliminating the growth of synthesized Li4Ti5O12 particles beyond nanostructure size. The process reduces by order of magnitude the time and energy required for synthesis of the active electrode material and fabrication of utilizing cell devices, and provides such nanostructure material which enables repeated, high-rate recharge cycling without loss of cell capacity or efficiency.

Owner:RUTGERS THE STATE UNIV

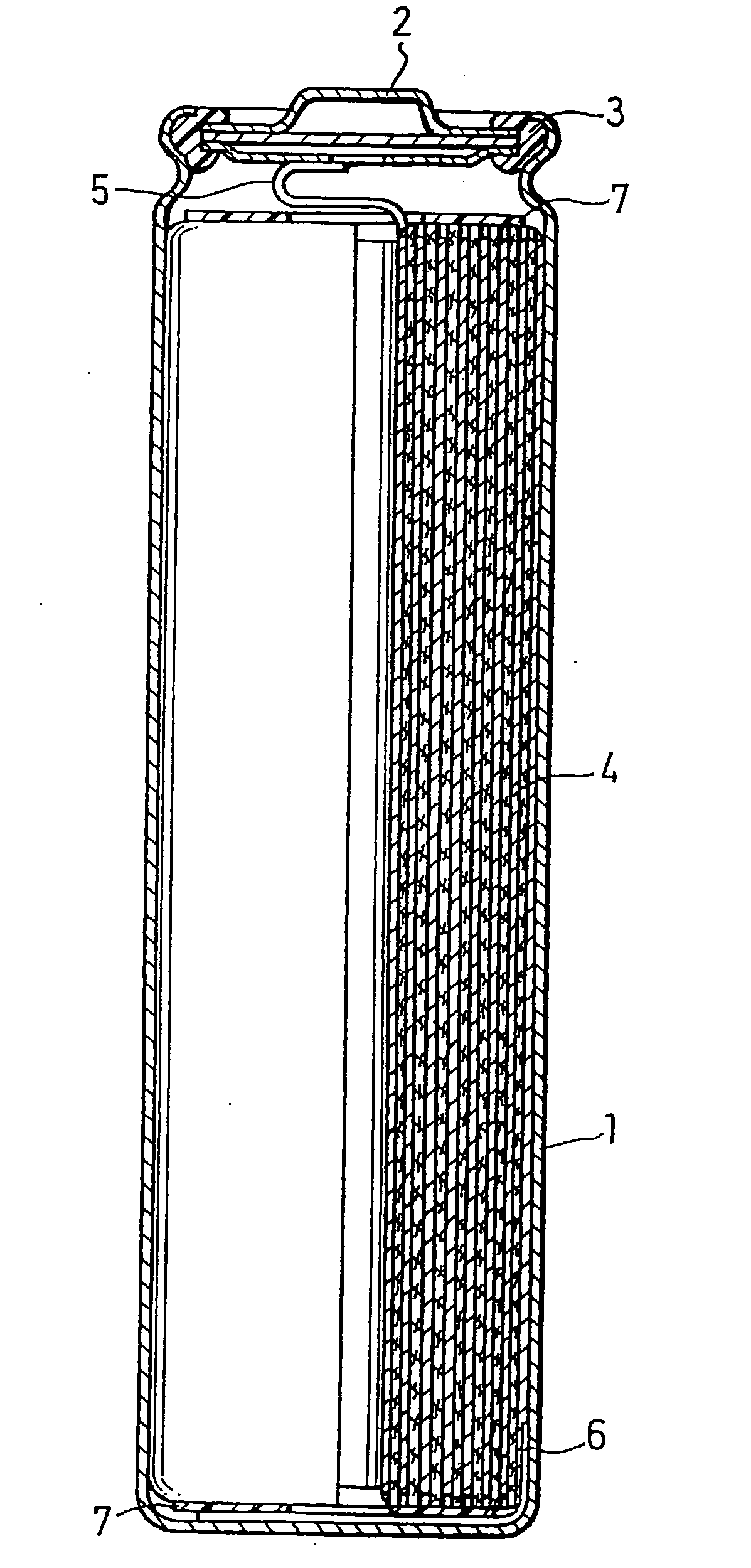

Anode active material, manufacturing method thereof, and non-aqueous electrolyte secondary battery

In order to provide a 3V level non-aqueous electrolyte secondary battery with a flat voltage and excellent cycle life at a high rate with low cost, the present invention provides a positive electrode represented by the formula: Li2±α[Me]4O8−x, wherein 0≦α<0.4, 0≦x<2, and Me is a transition metal containing Mn and at least one selected from the group consisting of Ni, Cr, Fe, Co and Cu, said active material exhibiting topotactic two-phase reactions during charge and discharge.

Owner:OSAKA CITY UNIVERSITY +1

High performance lithium titanium spinel li4t15012 for electrode material

The invention concerns a process for producing a spinel compound of formula Li4Ti5O12, comprising a step of preparing a mixture of an organo-lithium compound selected from lithium alcoholates with an organo-titanium compound selected from titanic acid esters, in a liquid medium, and a step of hydrolyzing the mixture of said compounds. The invention also concerns a Li4Ti5O12 particulate material which may be produced according to the previous cited process and which has a BET surface area of at least 10 m<2> / g. The material is particularly useful in the manufacture of Lithium Ion batteries.

Owner:FRANCOIS SUGNAUX +1

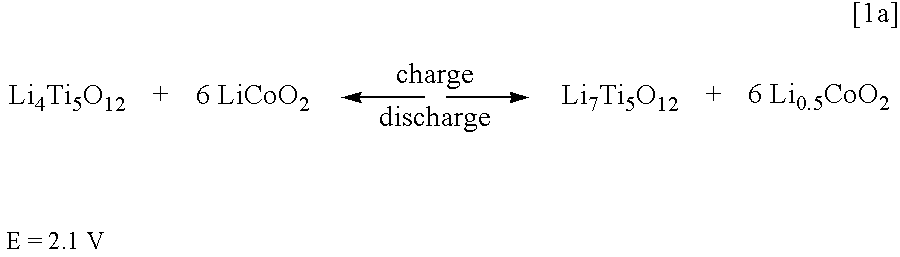

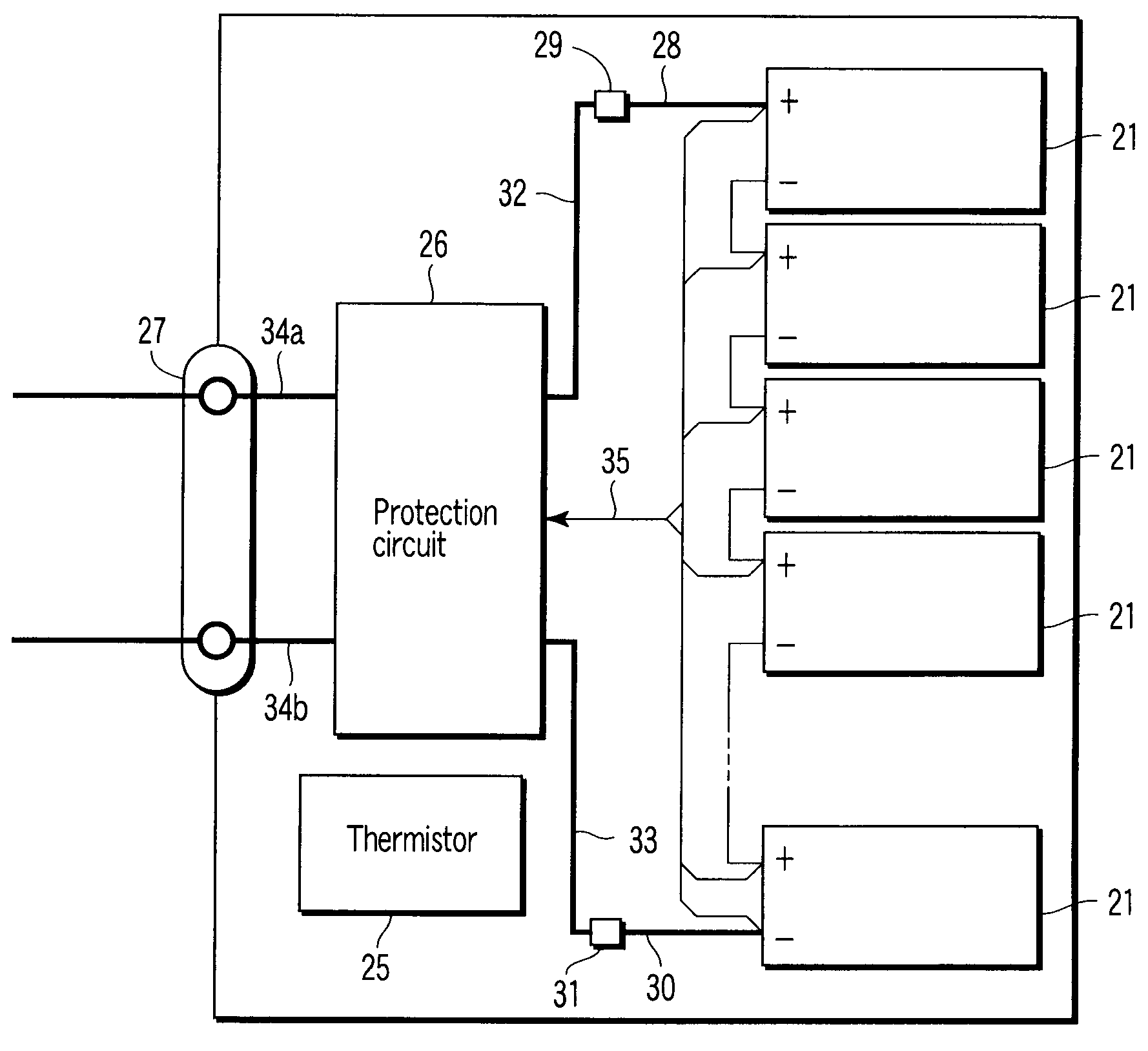

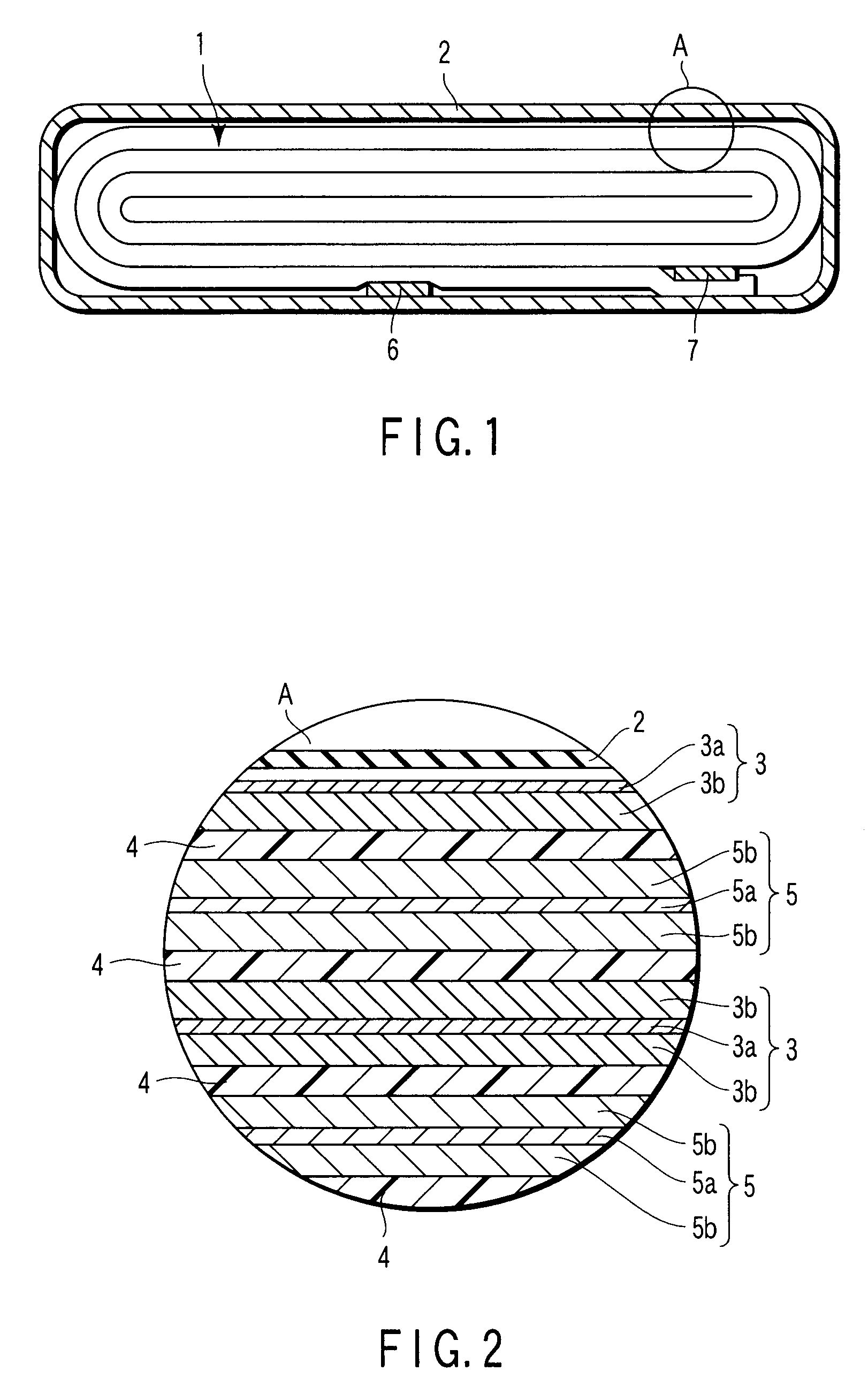

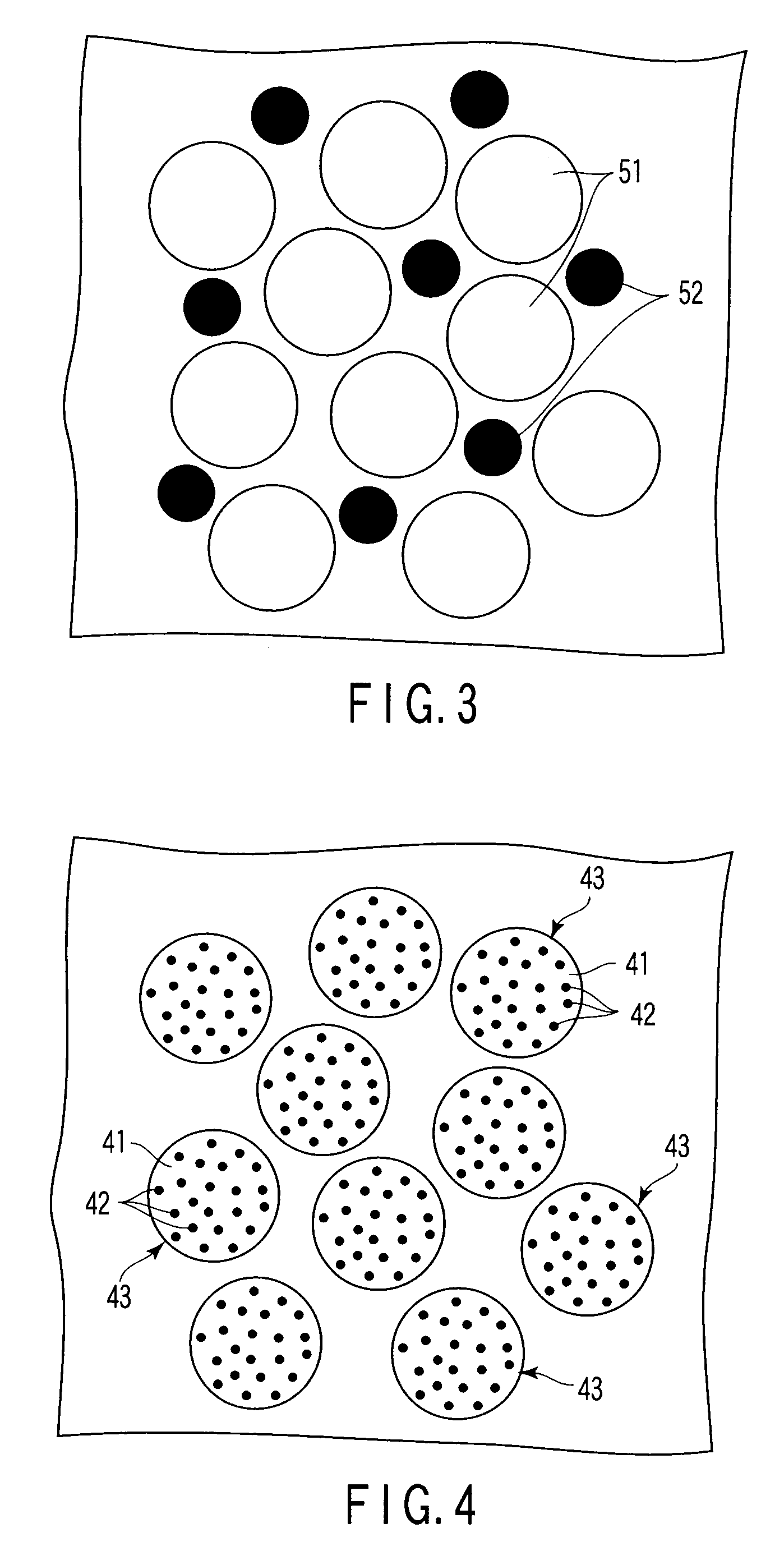

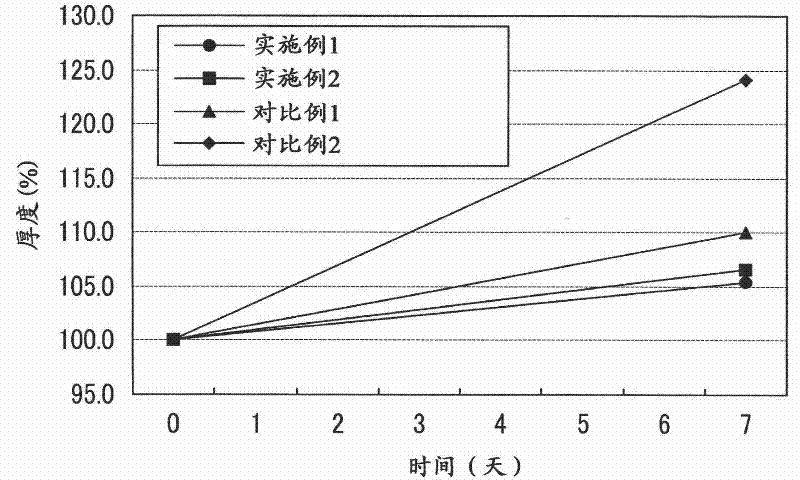

Active material for battery, manufacturing method of the same, non-aqueous electrolytic battery and battery pack

InactiveUS20090042095A1Easy to manufactureImprove performanceAlkali titanatesElectrode manufacturing processesDesorptionTitanium

An active material for a battery includes a mixed phase includes a lithium titanium composite oxide phase and a nonstoichiometric titanium oxide phase. This active material is excellent in lithium absorption / desorption performance, exhibiting high electric potentials in lithium absorption / desorption and high conductivity.

Owner:KK TOSHIBA

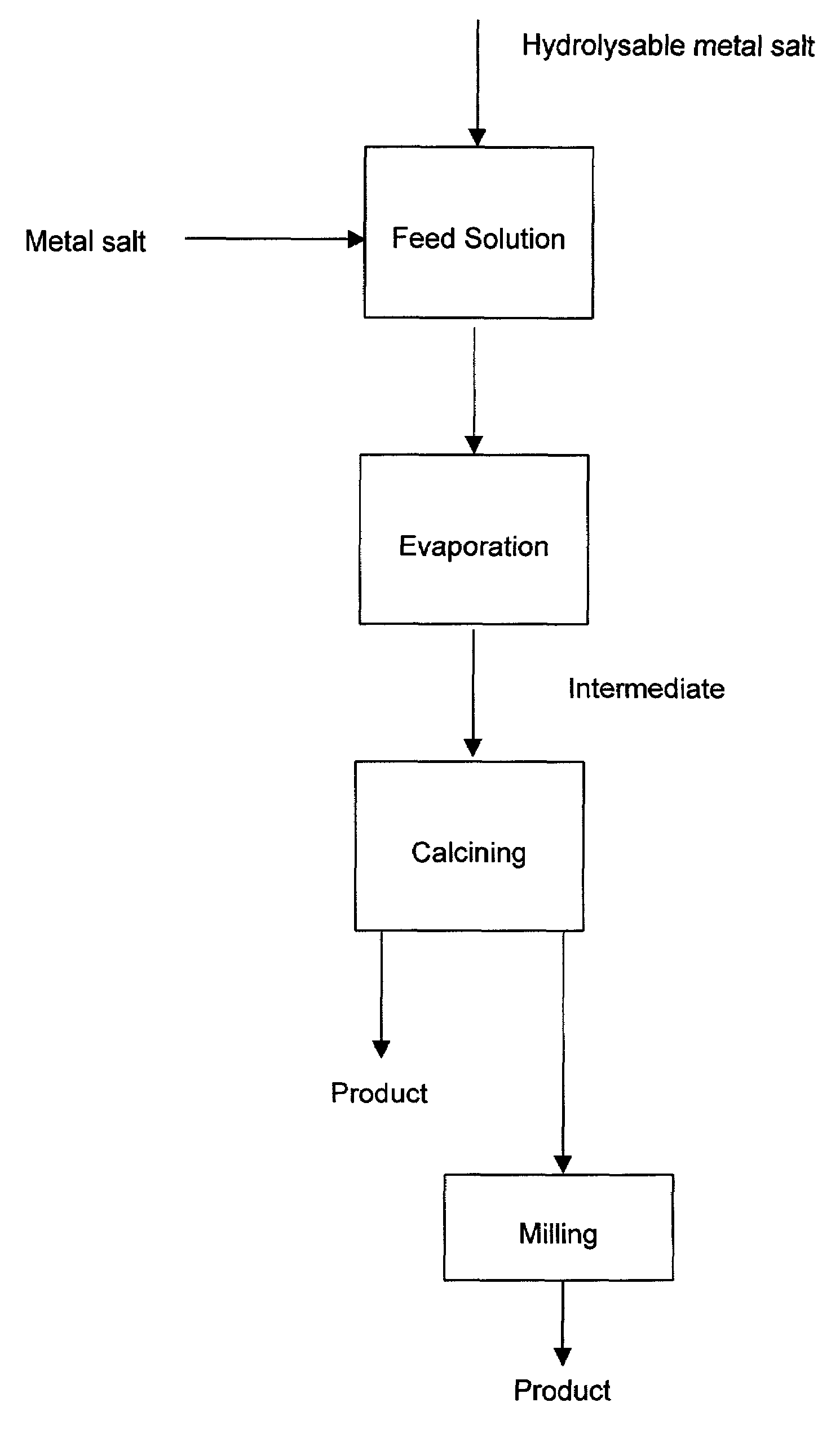

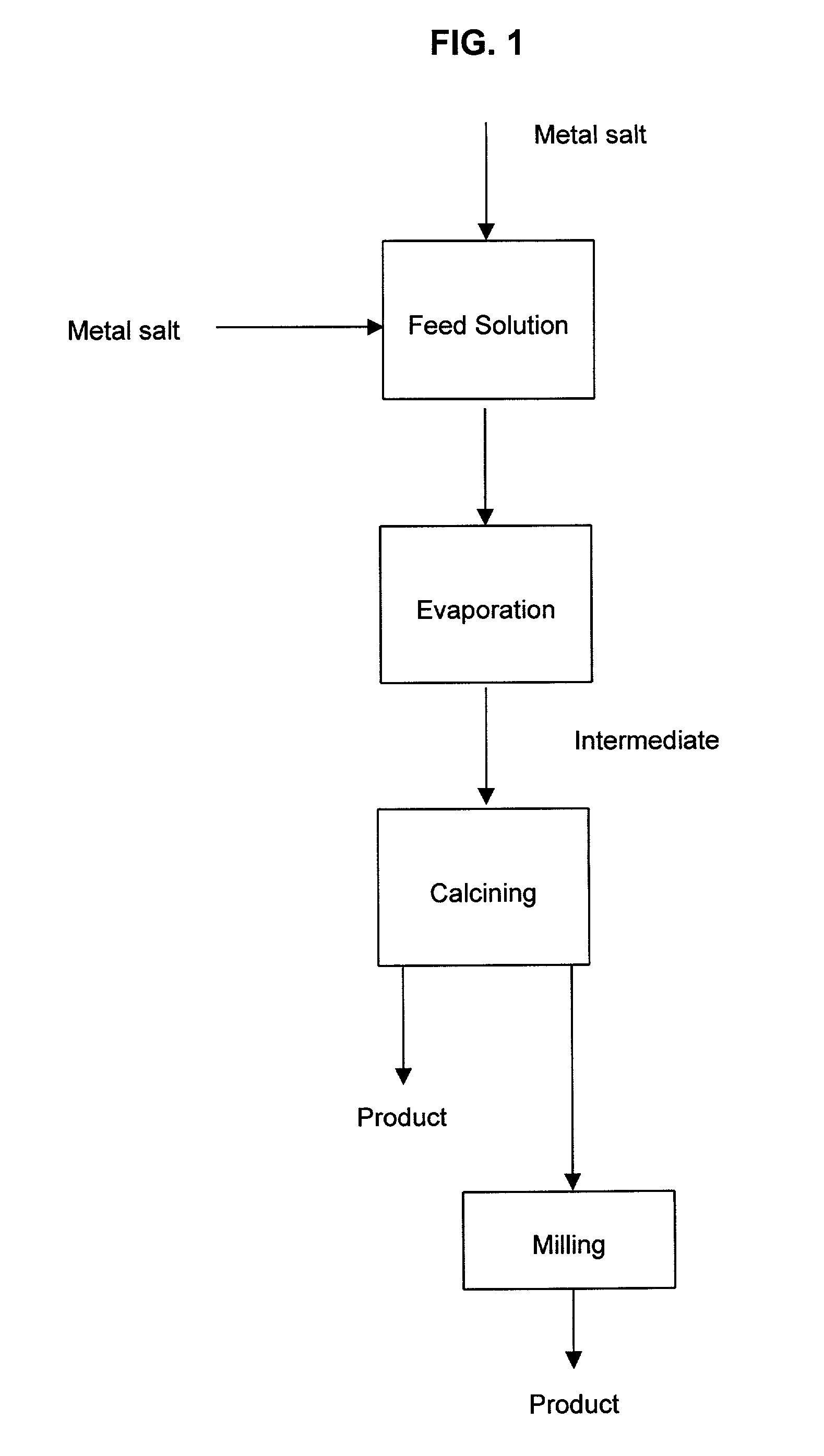

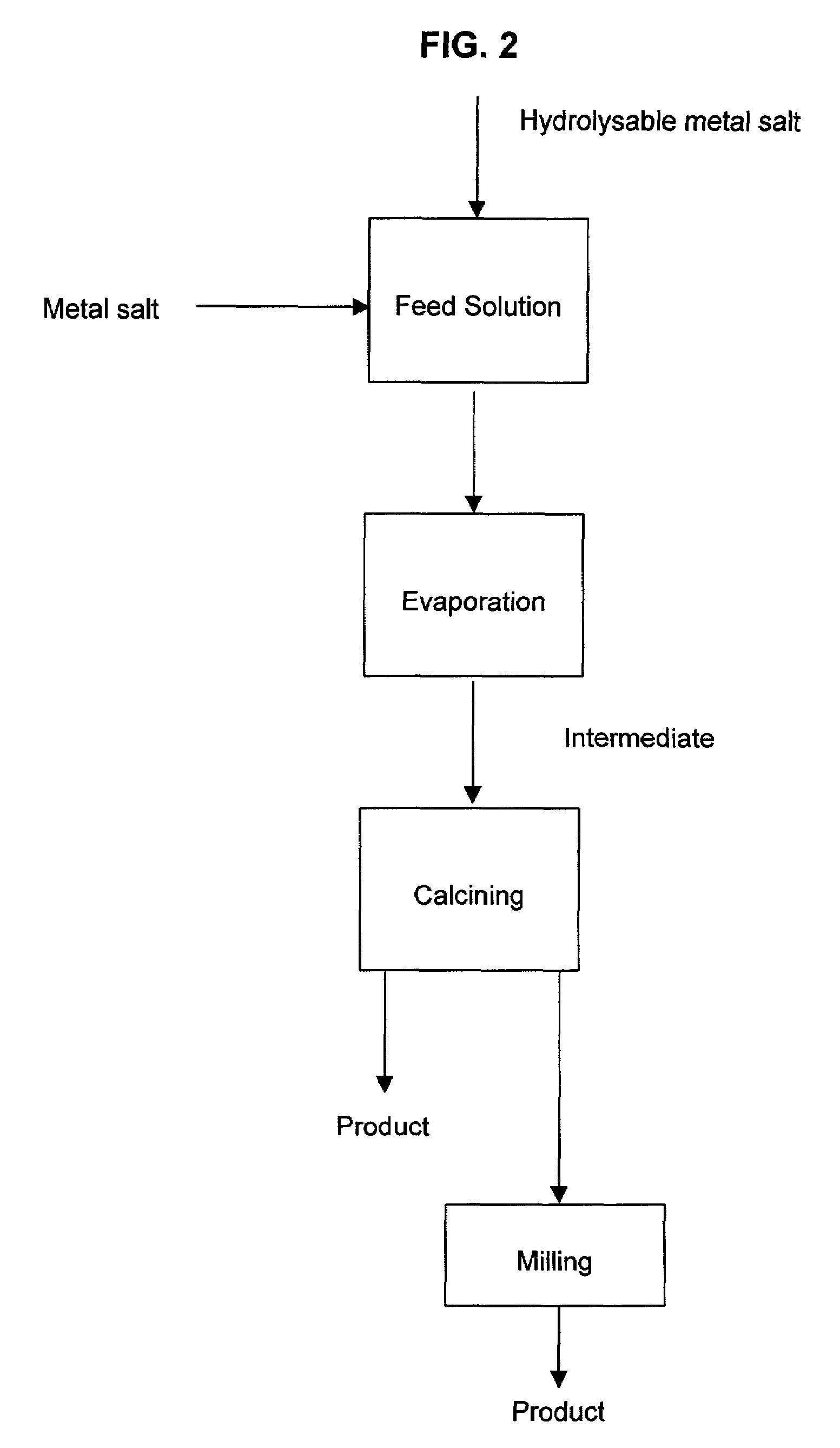

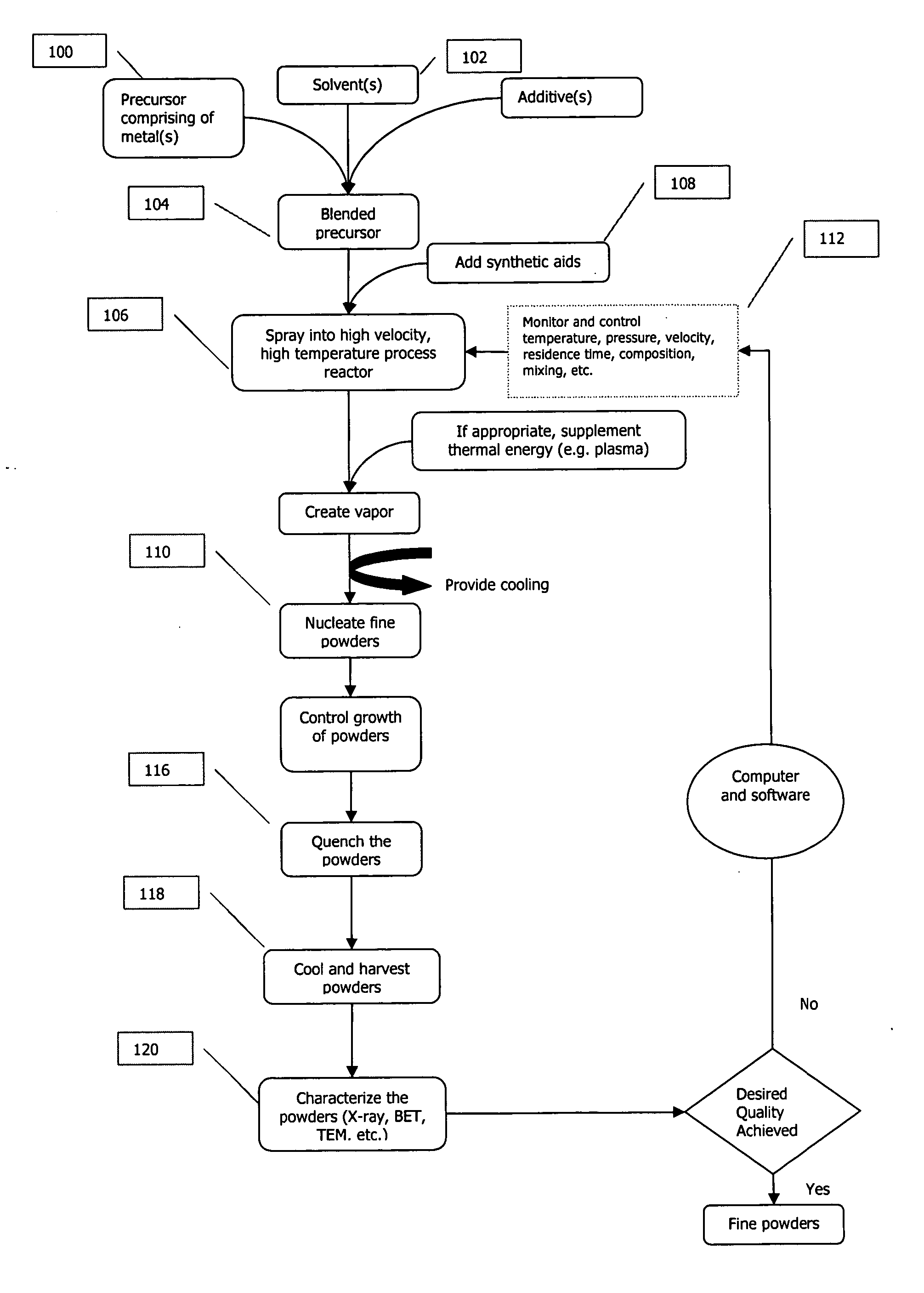

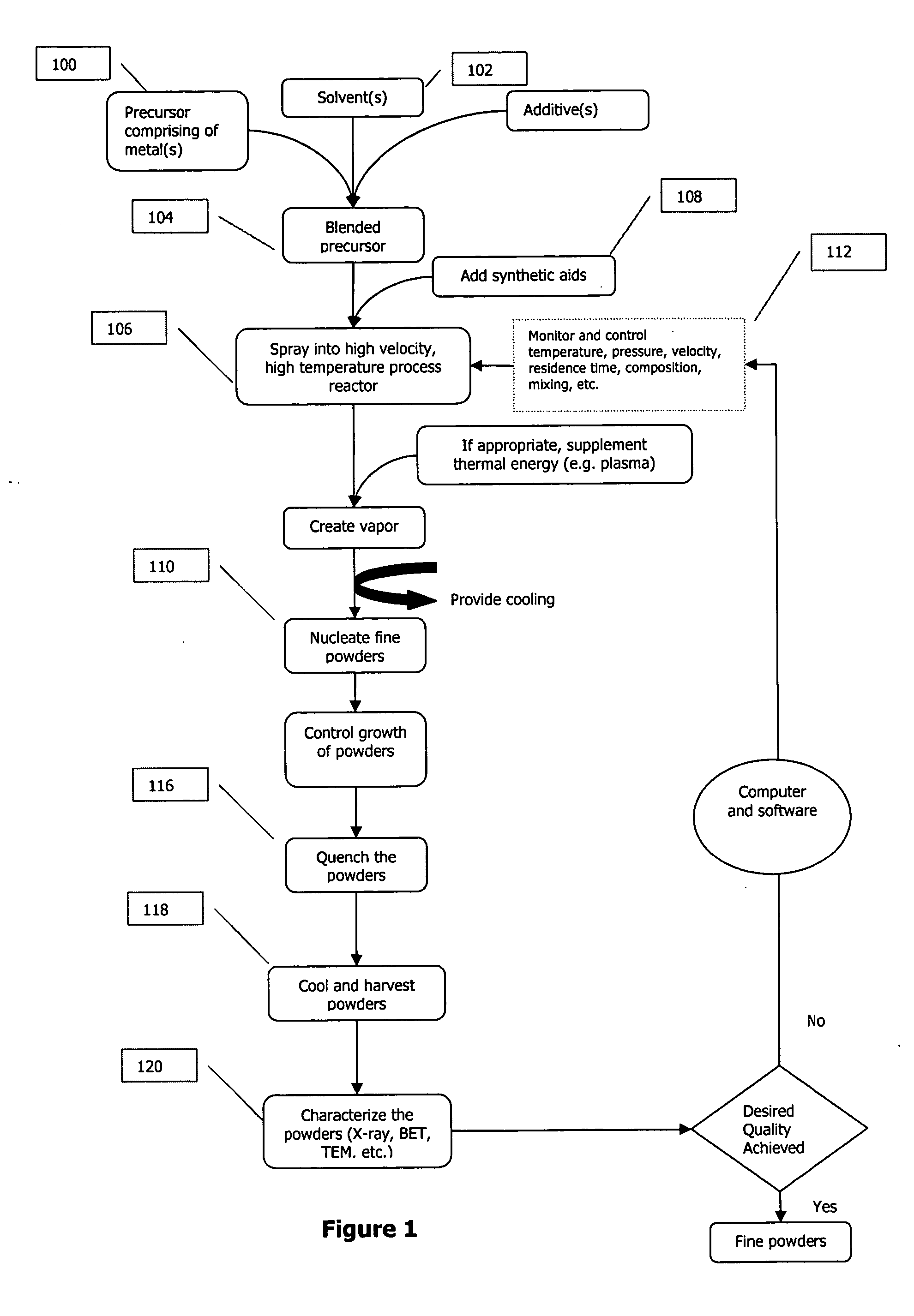

Method for producing mixed metal oxides and metal oxide compounds

A process to produce mixed metal oxides and metal oxide compounds. The process includes evaporating a feed solution that contains at least two metal salts to form an intermediate. The evaporation is conducted at a temperature above the boiling point of the feed solution but below the temperature where there is significant crystal growth or below the calcination temperature of the intermediate. The intermediate is calcined, optionally in the presence of an oxidizing agent, to form the desired oxides. The calcined material can be milled and dispersed to yield individual particles of controllable size and narrow size distribution.

Owner:ALTAIR NANOMATERIALS INC

Lithium Titanate And Method Of Forming The Same

InactiveUS20070238023A1Improve electronic conductivityAvoid lostAlkali titanatesZirconium compoundsMixture formationReducing agent

A lithium titanate has the following formula:Li4Ti5O12-x wherein x is greater than 0. The lithium titanate is formed by providing a mixture of titanium dioxide and a lithium-based component. The mixture is sintered in a gaseous atmosphere comprising a reducing agent to form the lithium titanate having the above formula. A lithium-based cell includes an electrolyte, an anode, and a cathode, with at least one of the anode and the cathode comprising the lithium titanate having the above formula. The lithium titanate is deficient of oxygen, which increases electronic conductivity of the lithium titanate by at least three orders over electronic conductivity of a stoichiometric lithium titanate, while avoiding loss of reversible electric power-generating capacity that typically occurs when doping is used to replace titanium in the lithium titanate with atoms that provide higher electronic conductivity.

Owner:ENERDEL

Positive electrode active materials for secondary batteries and methods of preparing same

InactiveUS6878490B2Deliver in short periodRetake in short periodAluminium compoundsAlkali titanatesPower capabilityLithium metal

The present invention is a positive electrode active material that can be used in secondary lithium and lithium-ion batteries to provide the power capability, i.e., the ability to deliver or retake energy in short periods of time, desired for large power applications such as power tools, electric bikes and hybrid electric vehicles. The positive electrode active material of the invention includes at least one electron conducting compound of the formula LiM1x−y{A}yOz and at least one electron insulating and lithium ion conducting lithium metal oxide, wherein M1 is a transition metal, {A} is represented by the formula ΣwiBi wherein Bi is an element other than M1 used to replace the transition metal M1 and wi is the fractional amount of element Bi in the total dopant combination such that Σwi=1; Bi is a cation in LiM1x−y{A}yOz; 0.95≦x≦2.10; 0≦y≦x / 2; and 1.90≦z≦4.20. Preferably, the lithium metal oxide is LiAlO2 or Li2M2O3 wherein M2 is at least one tetravalent metal selected from the group consisting of Ti, Zr, Sn, Mn, Mo, Si, Ge, Hf, Ru and Te. The present invention also includes methods of making this positive electrode active material.

Owner:UMICORE AG & CO KG

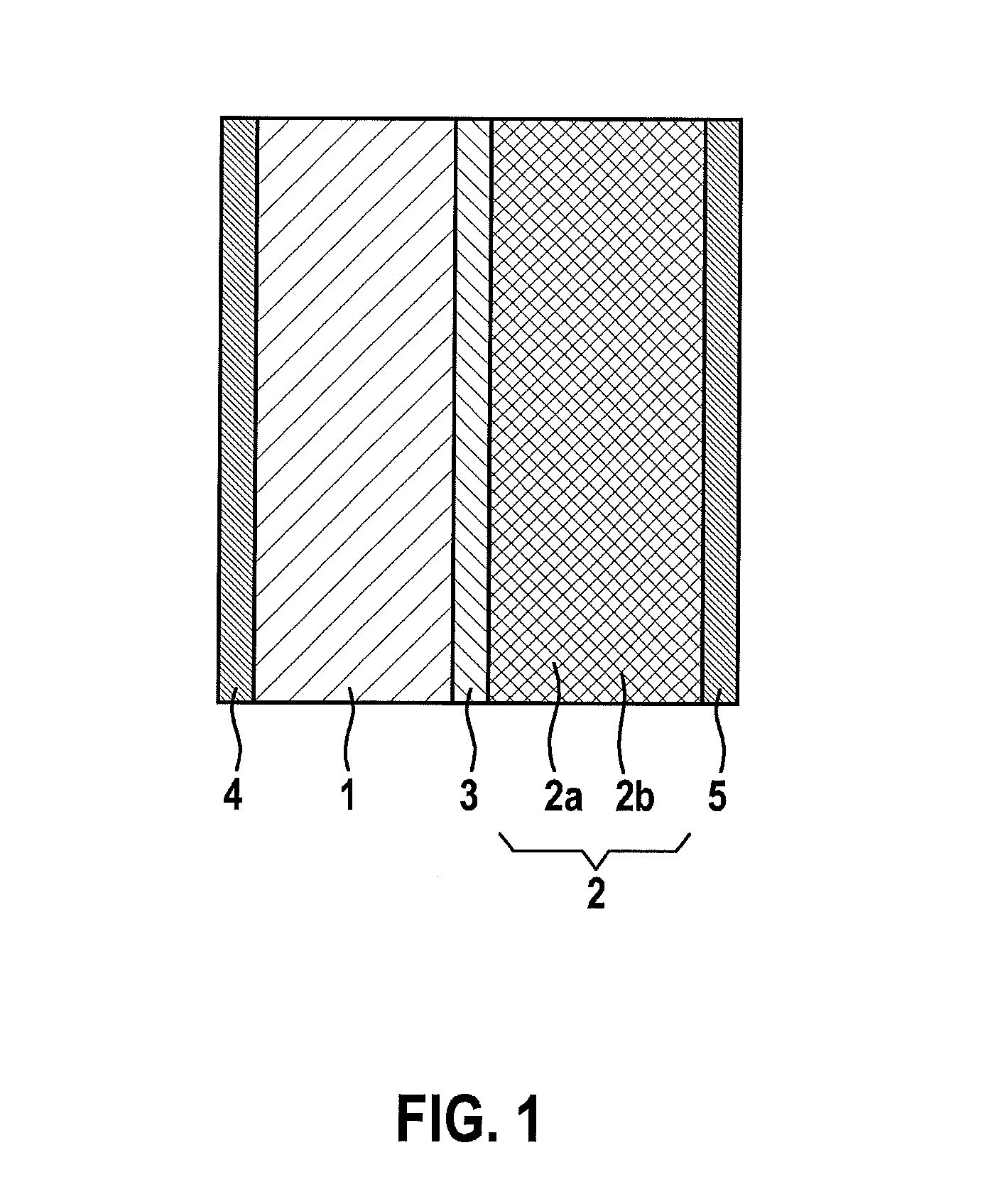

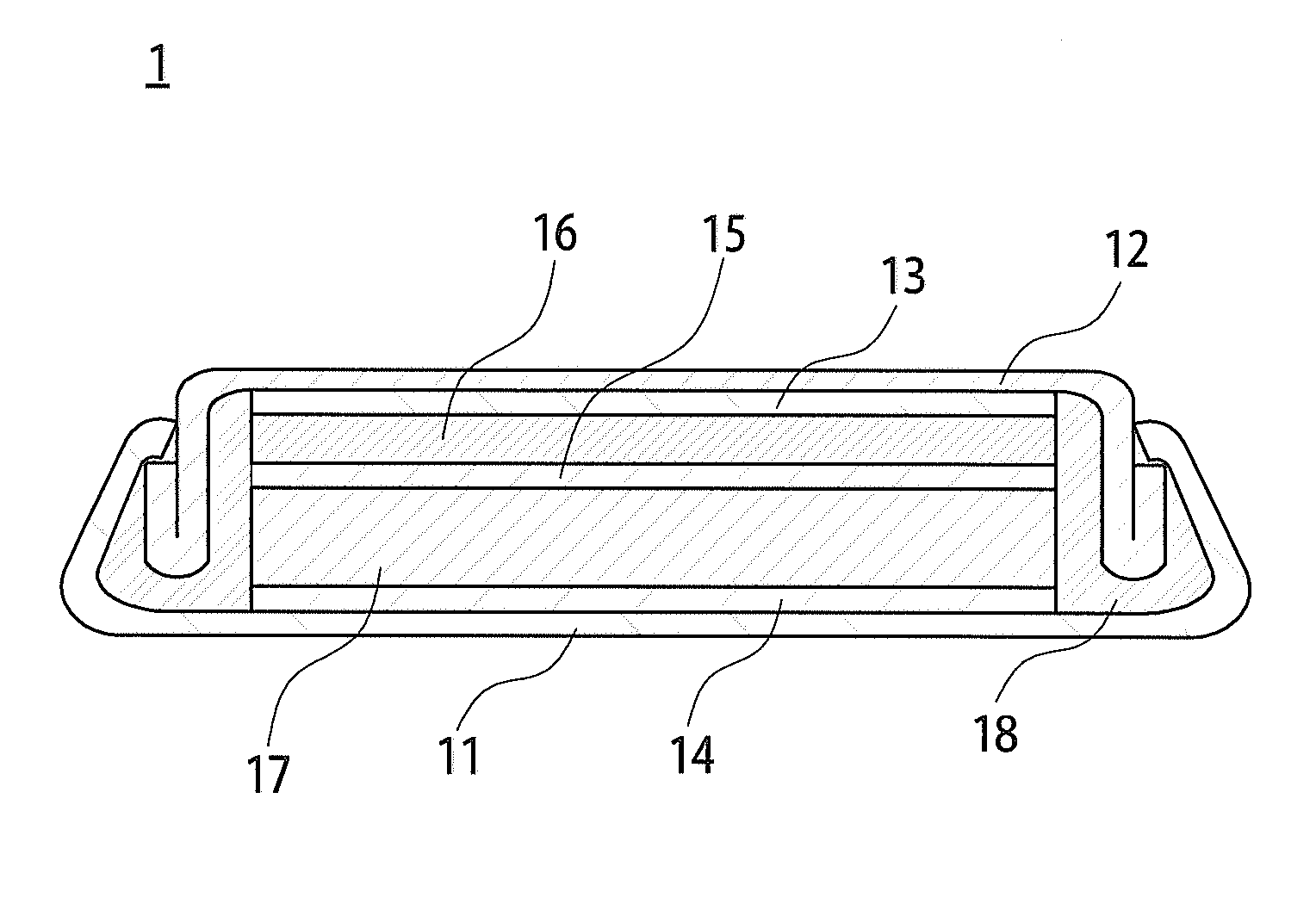

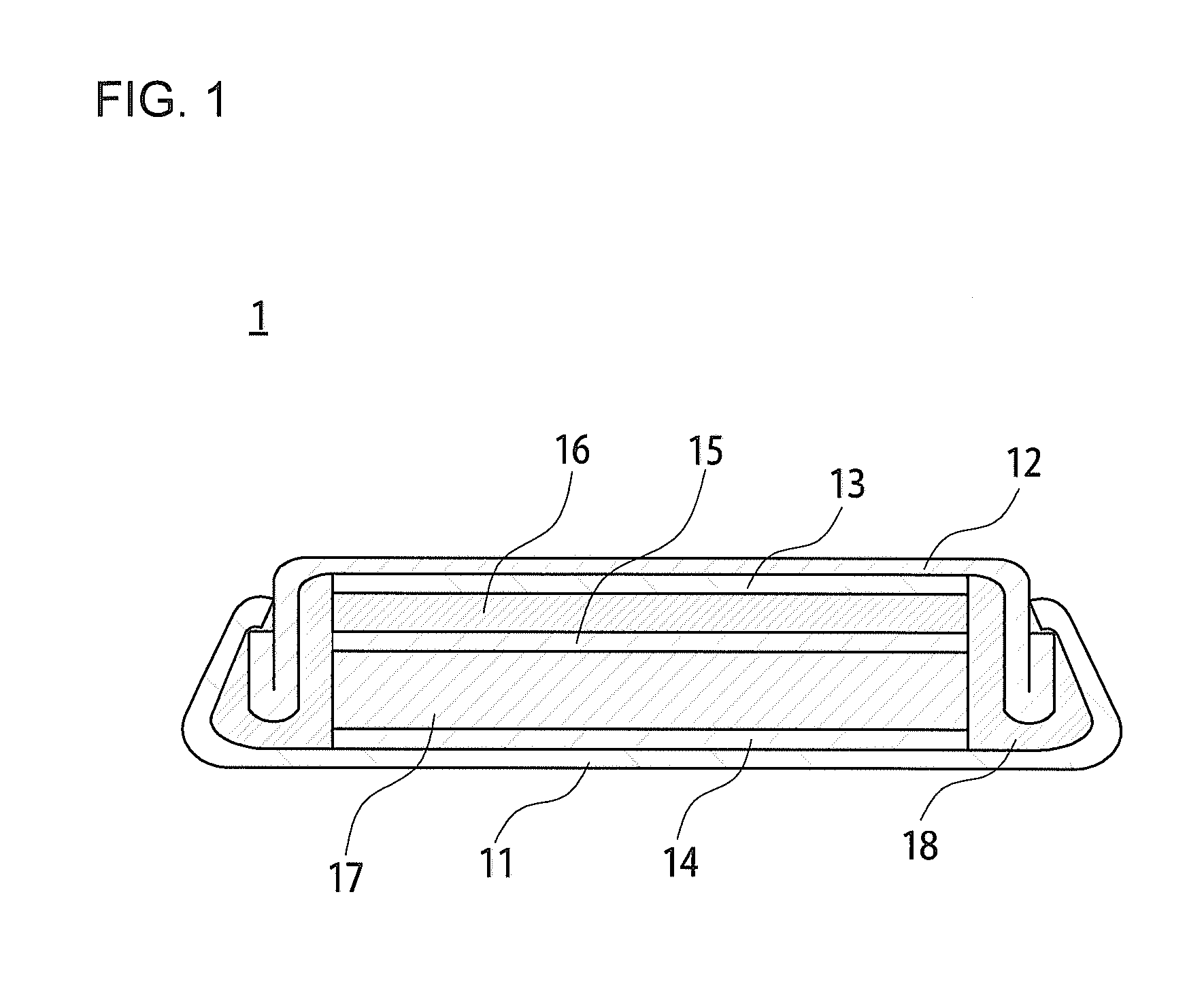

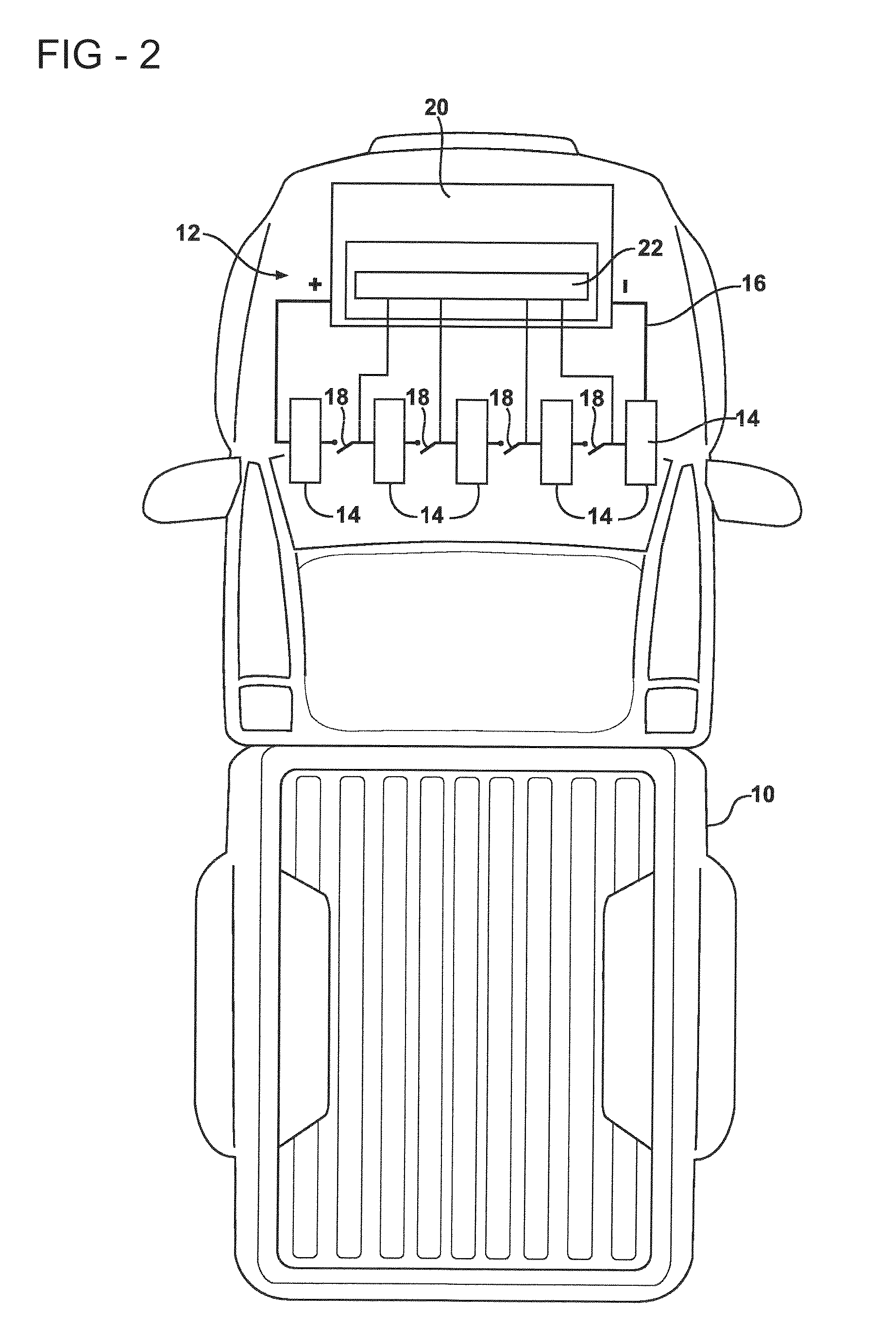

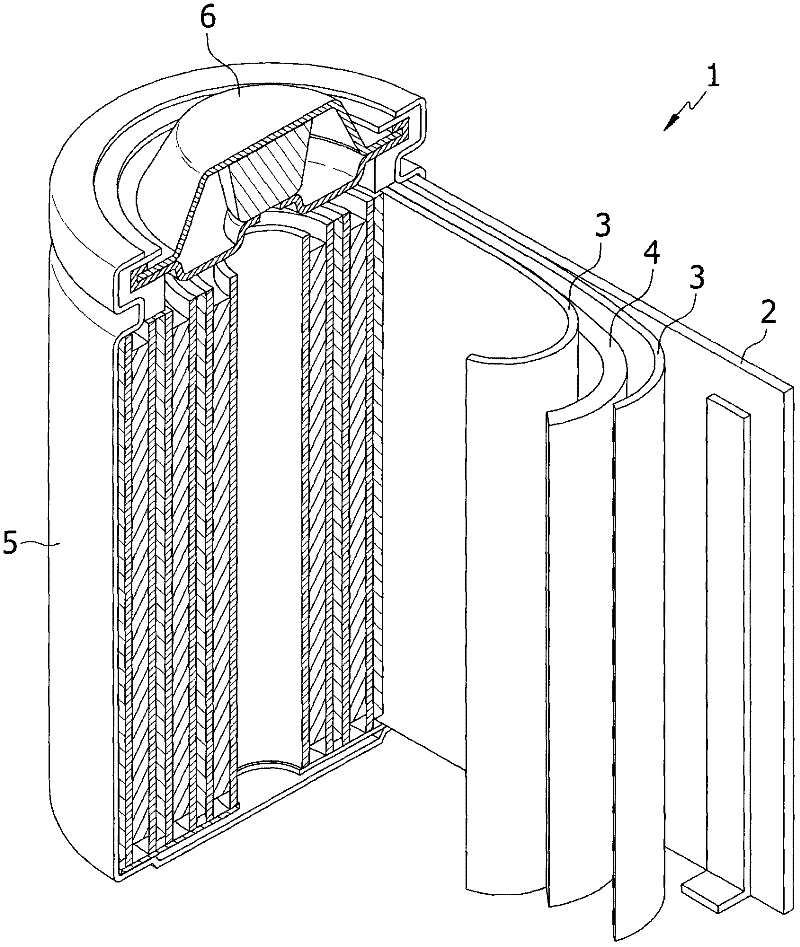

All-solid-state cell

ActiveUS20150044576A1Transportation is highImprove cycle stabilityAlkali titanatesTantalum compoundsAll solid stateSolid state electrolyte

An all-solid-state cell, which includes a lithium-containing anode, a cathode and a lithium ions-conducting solid-state electrolyte separator situated between the anode and the cathode. To improve the safety and cycle stability of the cell, the cathode includes a composite material including at least one lithium titanate and at least one lithium ions-conducting solid-state electrolyte. Furthermore, the invention relates to a corresponding all-solid-state battery and a mobile or stationary system equipped with it.

Owner:ROBERT BOSCH GMBH

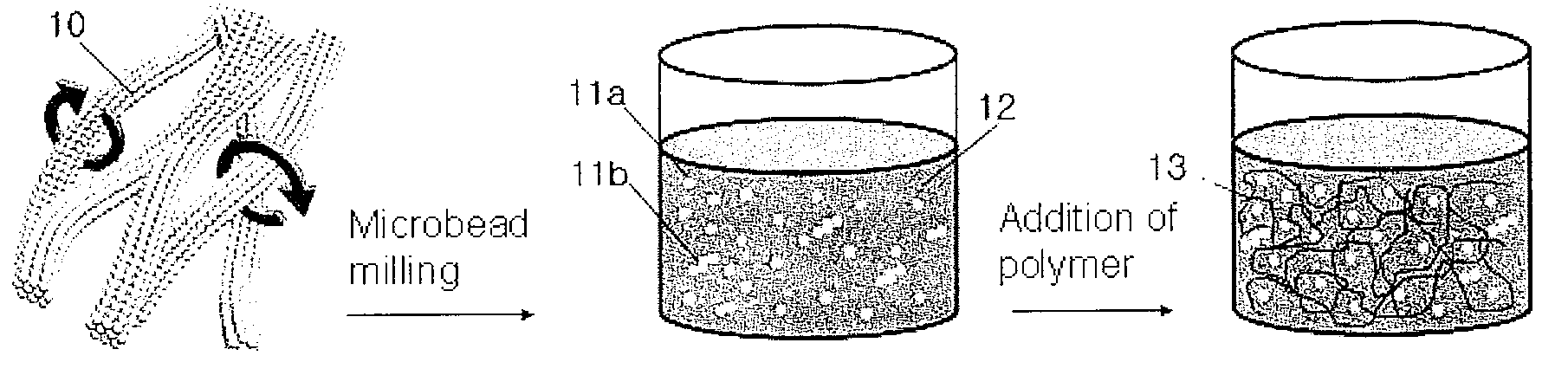

NANO powder, NANO ink and micro rod, and the fabrication methods thereof

InactiveUS20100167078A1Easy to makeOvercome problemsAlkaline earth titanatesPigmenting treatmentFiberMicro rods

Disclosed are a method for fabricating nanopowders, nano ink containing the nanopowders and micro rods, and nanopowders containing nanoparticles, nano clusters or mixture thereof, milled from nano fiber composed of at least one kind of nanoparticles selected from a group consisting of metal, nonmetal, metal oxide, metal compound, nonmetal compound and composite metal oxide, nano ink containing the nanopowders and microrods, the method comprising spinning a spinning solution containing at least one kind of precursor capable of composing at least one kind selected from a group consisting of metal, nonmetal, metal oxide, metal compound, nonmetal compound and composite metal oxide, crystallizing or amorphizing the spun precursor to produce nano fiber containing at least one kind of nanoparticles selected from a group consisting of metal, nonmetal, metal oxide, metal compound, nonmetal compound and composite metal oxide, and milling the nano fiber to fabricate nanopowders containing nanoparticles, nano clusters or mixture thereof.

Owner:KOREA INST OF SCI & TECH

Positive electrode active material, production method thereof and non-aqueous electrolyte secondary battery

In order to provide a 3V level non-aqueous electrolyte secondary battery with a flat voltage and excellent cycle life at a high rate with low cost, the present invention provides a positive electrode represented by the formula: Li2±α[Me]4O8−x, wherein 0≦α<0.4, 0≦x<2, and Me is a transition metal containing Mn and at least one selected from the group consisting of Ni, Cr, Fe, Co and Cu, said active material exhibiting topotactic two-phase reactions during charge and discharge.

Owner:PANASONIC CORP +1

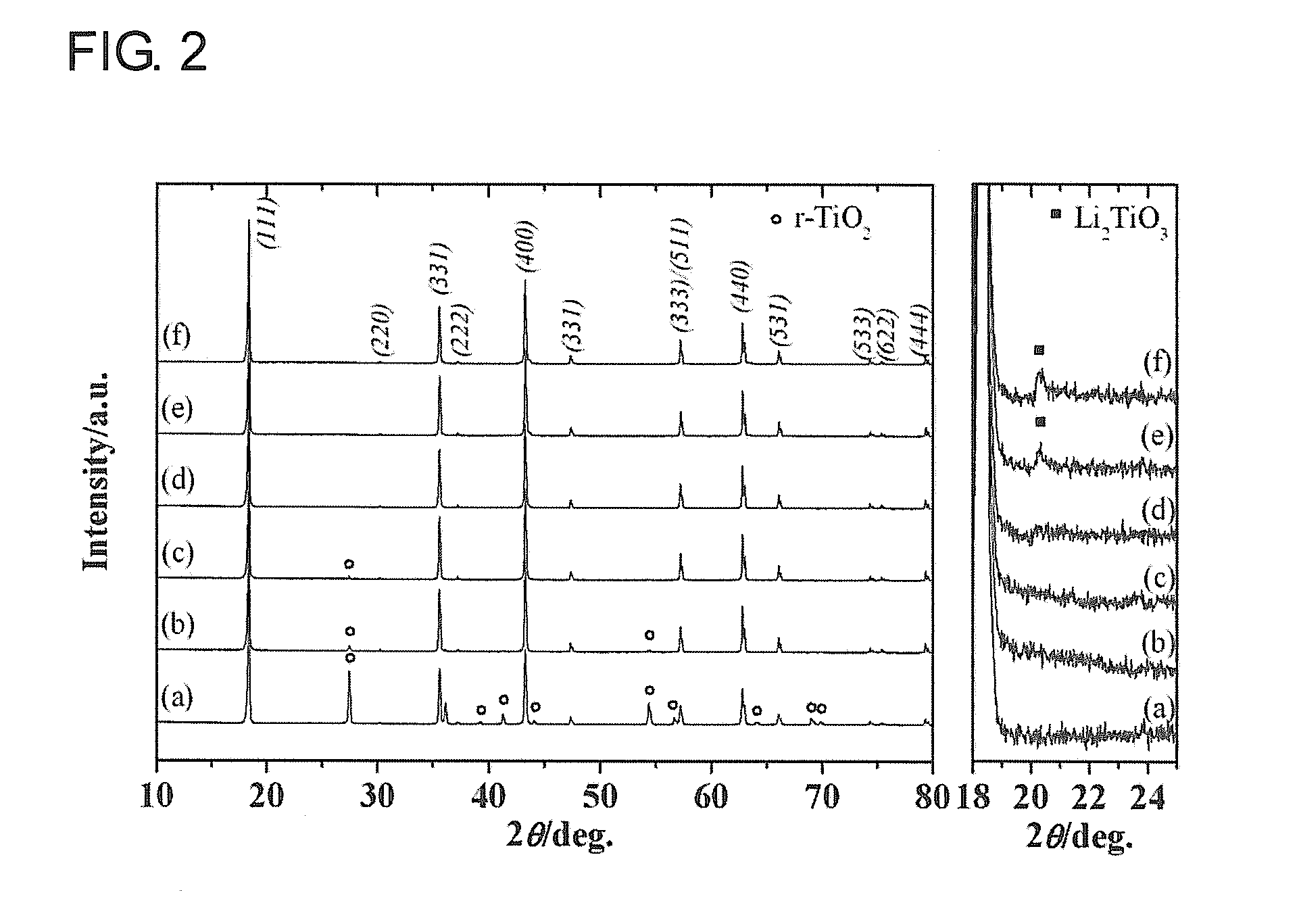

Non-stoichiometric titanium compound, carbon composite of the same, manufacturing method of the compound, active material of negative electrode for lithium-ion secondary battery containing the compound, and lithium-ion secondary battery using the active material of negative electrode

InactiveUS20110262809A1High crystallinityImprove featuresAlkali titanatesElectrode manufacturing processesTitaniumVoltage

Provided is a highly safe lithium-ion secondary battery with a gradual voltage decrease, high charge / discharge capacity, and ease of handling, in which explosion due to expansion, heat generation, ignition, and the like is prevented.A non-stoichiometric titanium compound represented by a chemical formula Li4+xTi5−xO12 (where 0<x<0.30), a non-stoichiometric titanium compound represented by a chemical formula Li4+xTi5−x−yNbyO12 (where 0<x<0.30, 0<y<0.20), and carbon-composite non-stoichiometric titanium compounds Li4+xTi5−xO12 / C (where 0<x<0.30) and Li4+xTi5−x−yNbyO12 / C (where 0<x<0.30, 0<y<0.20) obtained by applying a carbon composite-forming process thereto, an active material of negative electrode for a lithium-ion secondary battery using the compound, and a lithium-ion secondary battery using the active material of negative electrode.

Owner:IWATE UNIVERSITY

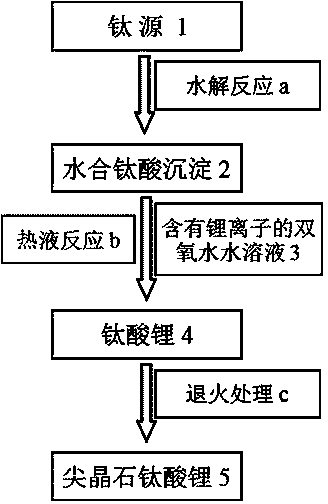

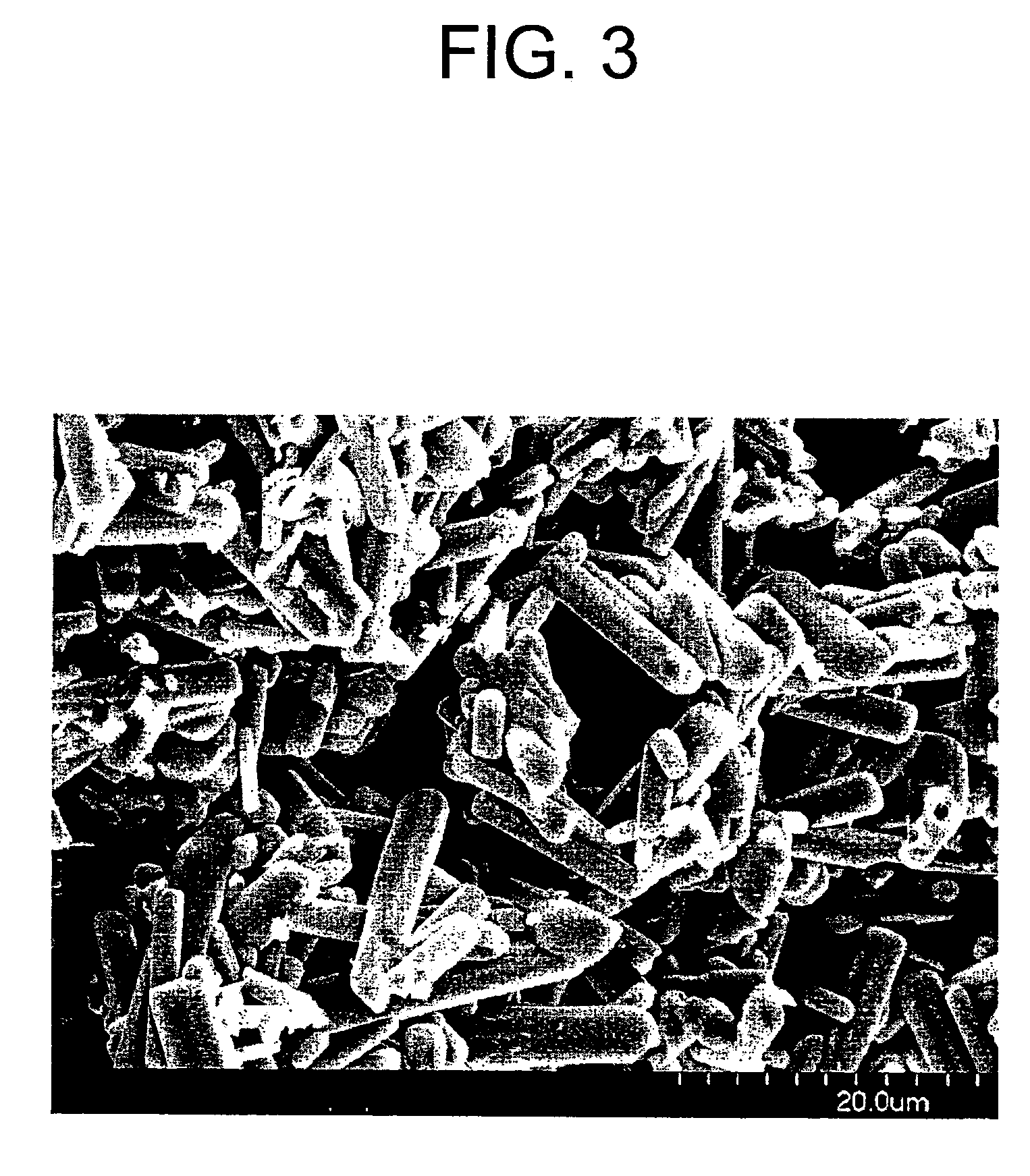

Method for preparing spinel lithium titanate

InactiveCN104201364AOvercome conductivityLow priceMaterial nanotechnologyAlkali titanatesLithiumNanowire

The invention discloses a method for preparing spinel lithium titanate. The method is characterized by comprising the steps of S1, performing hydrolysis reaction on a titanium source to obtain hydrated titanium acid sediments; S2, dispersing the hydrated titanium acid sediments into lithium ion-containing hydrogen peroxide aqueous solution to obtain a mixture; S3, performing hydrothermal reaction on the mixture to obtain nanowire type lithium titanate and / or lithium titanate with a nano differential level structure; S4, annealing the nanowire type lithium titanate and / or the lithium titanate with the nano differential level structure to obtain nanowire type spinel lithium titanate and / or the spinel lithium titanate with the nano differential level structure. According to the method, both spinel lithium titanate nanowires and the spinel lithium titanate with the nano differential level structure can be prepared.

Owner:李建明

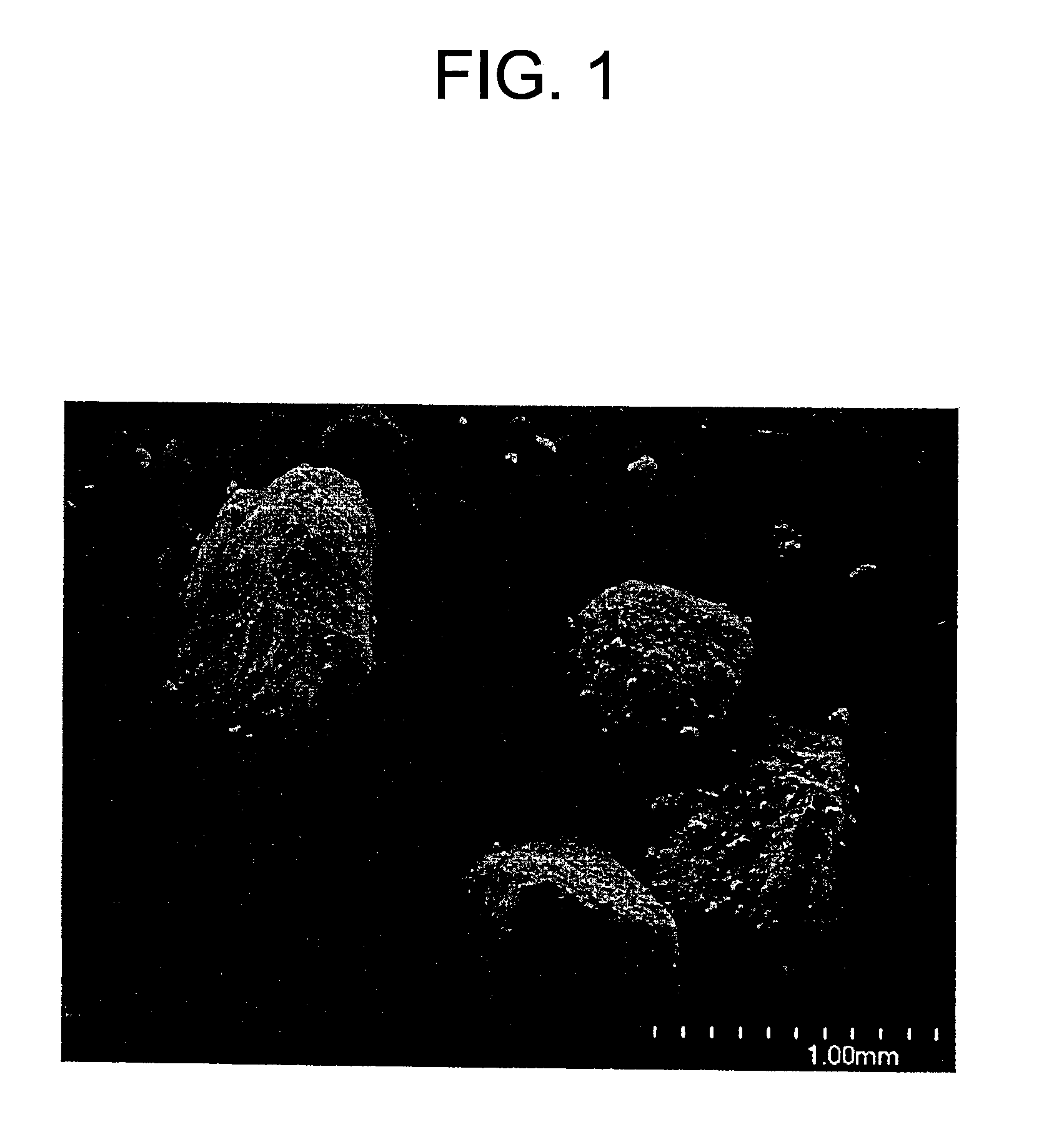

Potassium titanate, method for manufacturing the same, friction material and resin composition

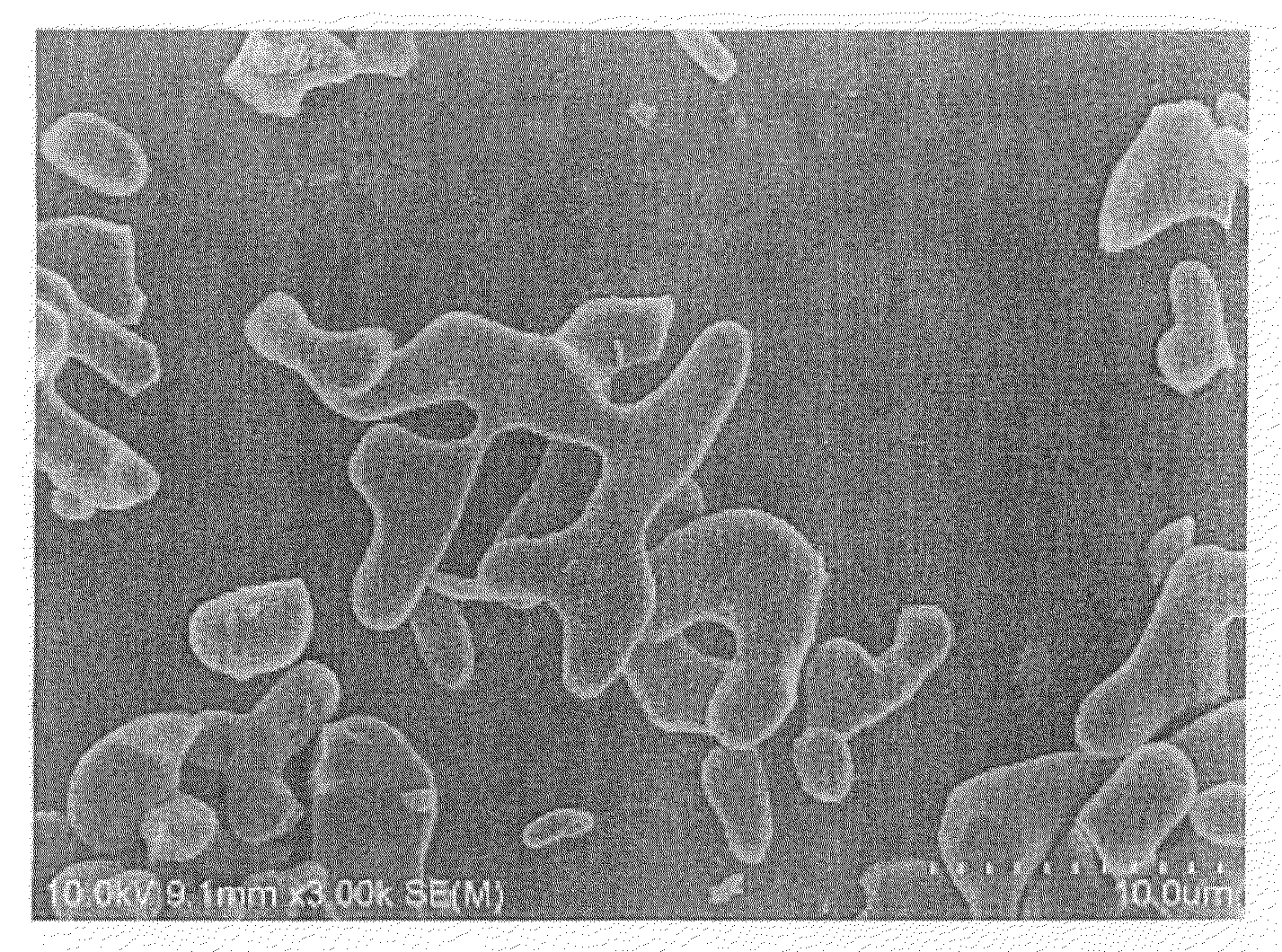

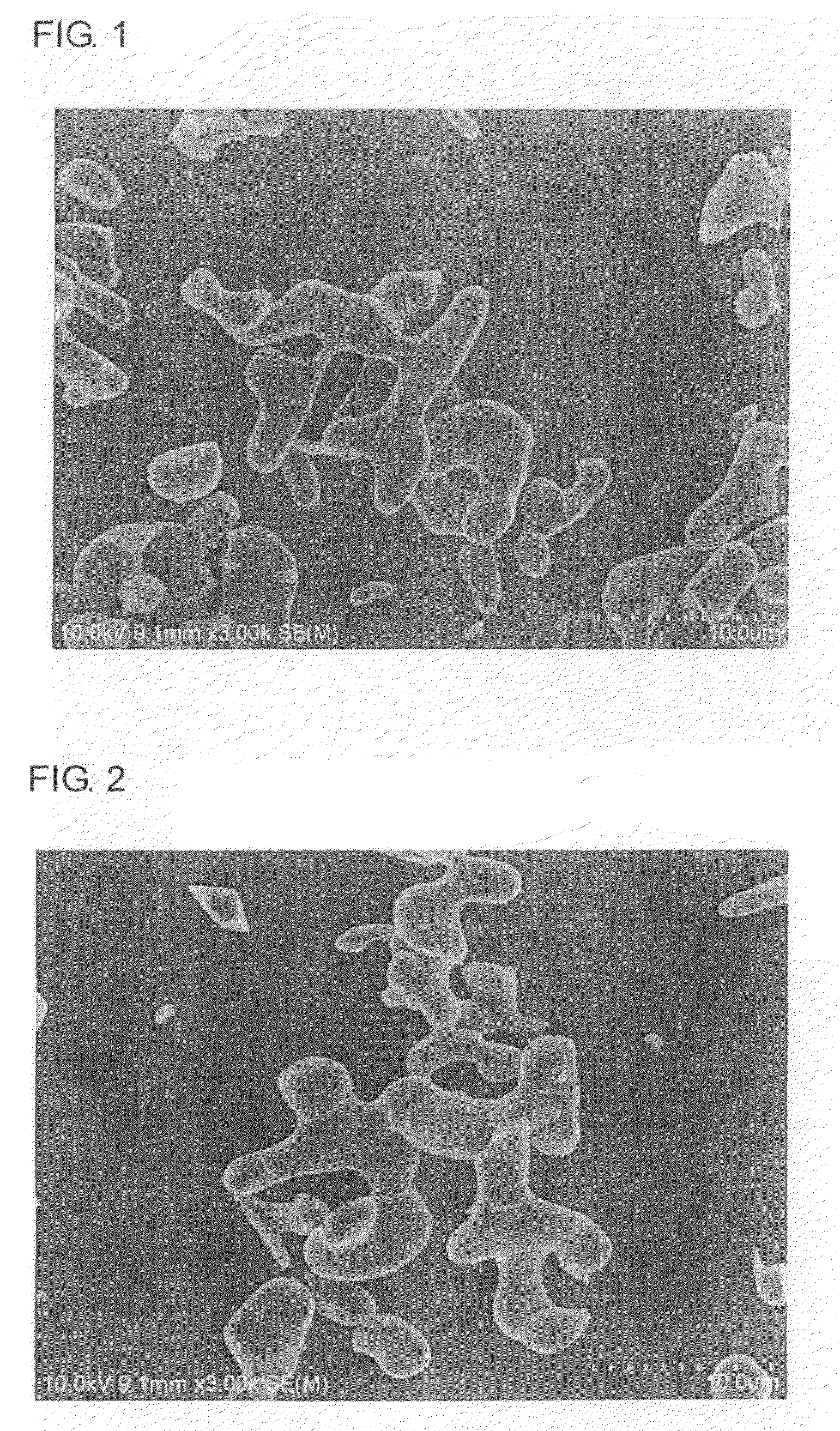

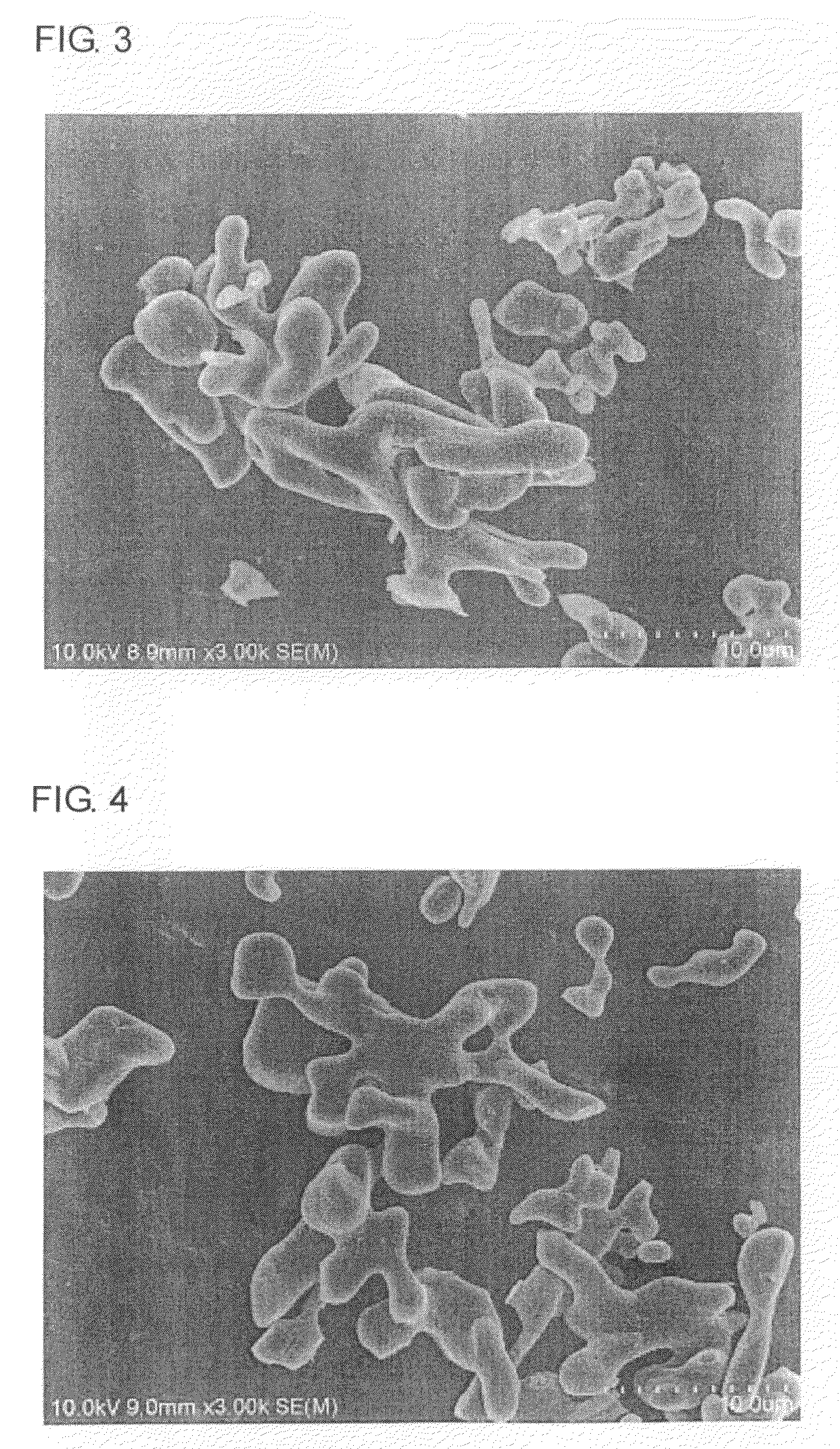

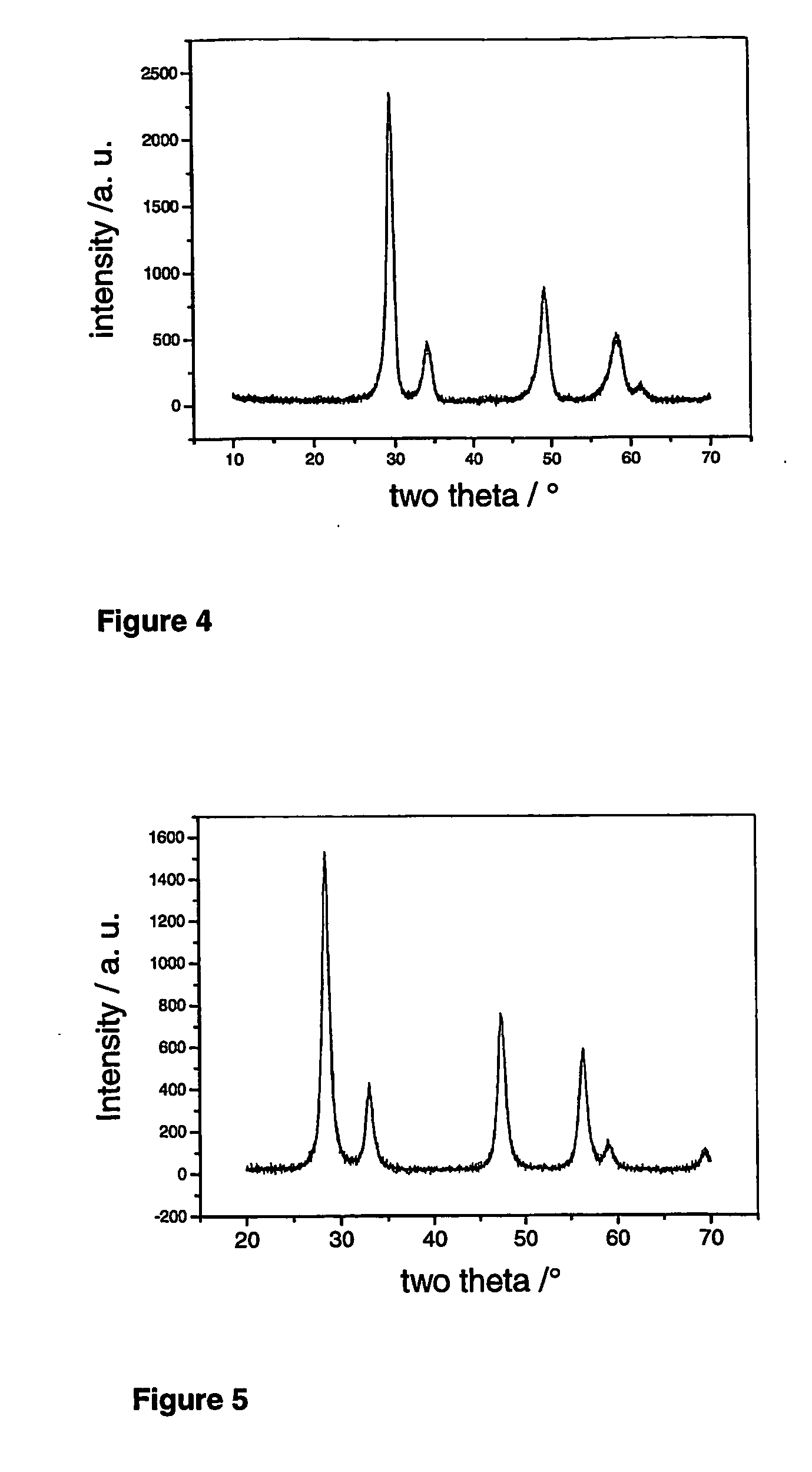

ActiveUS20080249222A1Improve reinforcementNovel shapePigmenting treatmentAlkali titanatesX-rayWear resistance

Potassium titanate is obtained which has a novel configuration, exhibits excellent wear resistance when incorporated in a friction material and shows an excellent reinforcement performance when incorporated in a resin composition. A manufacturing method of the potassium titanate, a friction material using the potassium titanate and a resin composition using the potassium titanate are also obtained. The potassium titanate is represented by K2TinO(2n+1) (n=4.0-11.0) and has the highest X-ray diffraction intensity peak (2θ) in the range of 11.0°-13.5° with its half width being not less than 0.5°.

Owner:OTSUKA CHEM CO LTD

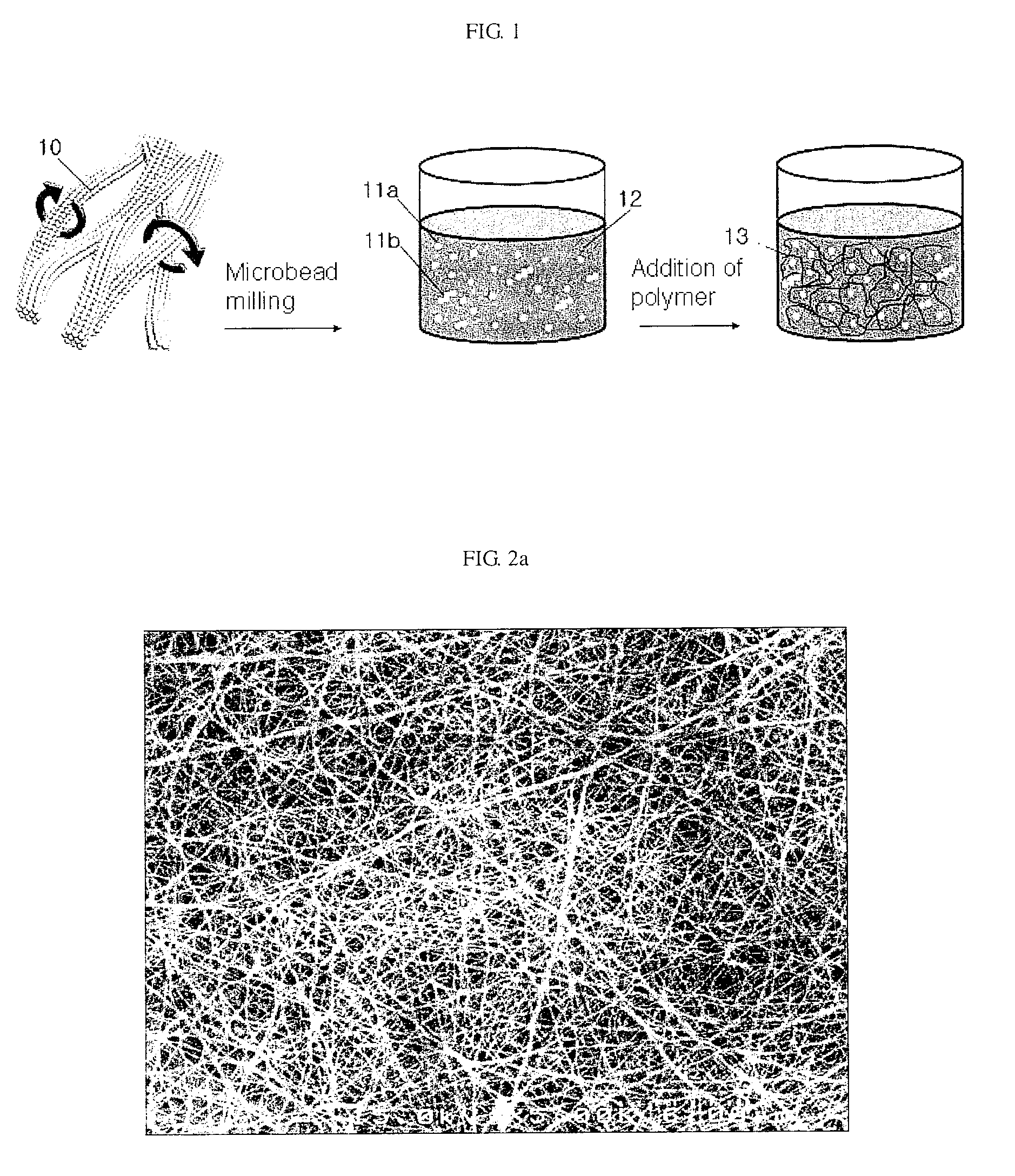

Manufacturing methods for nanomaterial dispersions and products thereof

InactiveUS20060016371A1Increase volumeLow cost productionMaterial nanotechnologyAlkaline earth titanatesManufactured nanomaterialsApplications of nanotechnology

Methods for manufacturing nanomaterial dispersions, such as nanomaterial concentrates, and related nanotechnology are provided. The nanomaterial concentrates provided can be more cheaply stored and transported compared to non-concentrate nanomaterial forms.

Owner:PPG IND OHIO INC

Lithium titanate cell with reduced gassing

InactiveUS20110067230A1Sufficient durationAvoid decompositionAlkali titanatesFinal product manufactureElectrolyteOperating voltage

A method of manufacturing a lithium cell is disclosed. The method can include providing a lithium cell having an operating voltage range, where the lithium cell includes a negative electrode, a positive electrode, and an electrolyte in contact with, and between, the negative electrode and the positive electrode. The negative electrode can include lithium titanate and the electrolyte can include an additive. The method can also include reducing the additive to form a coating on a surface of the negative electrode in contact with the electrolyte. The reducing step can include overcharging the lithium cell to a voltage greater than an upper limit of the operating voltage range and dropping a voltage of the negative electrode to 0.2-1V vs. lithium.

Owner:ENERDEL

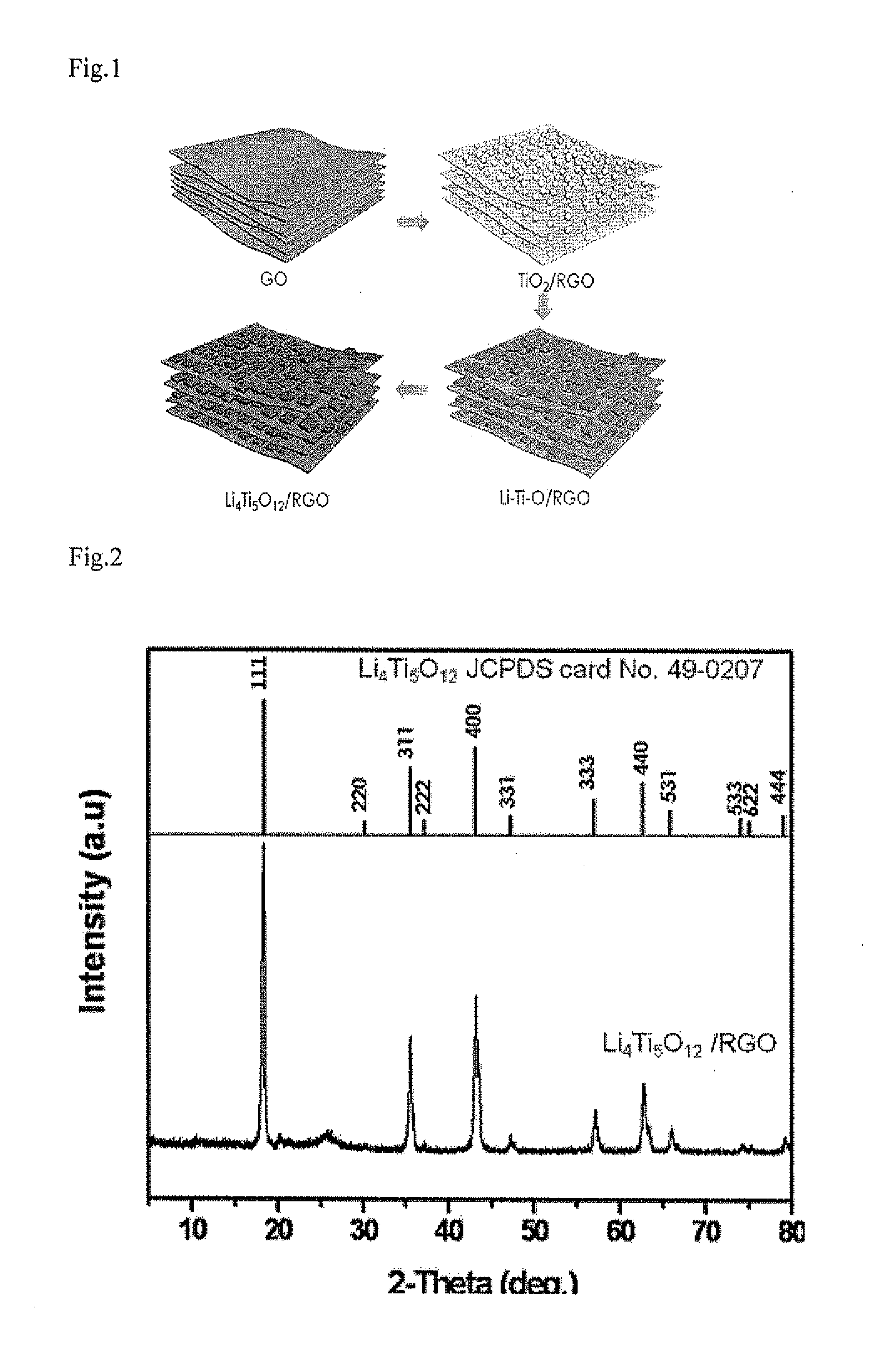

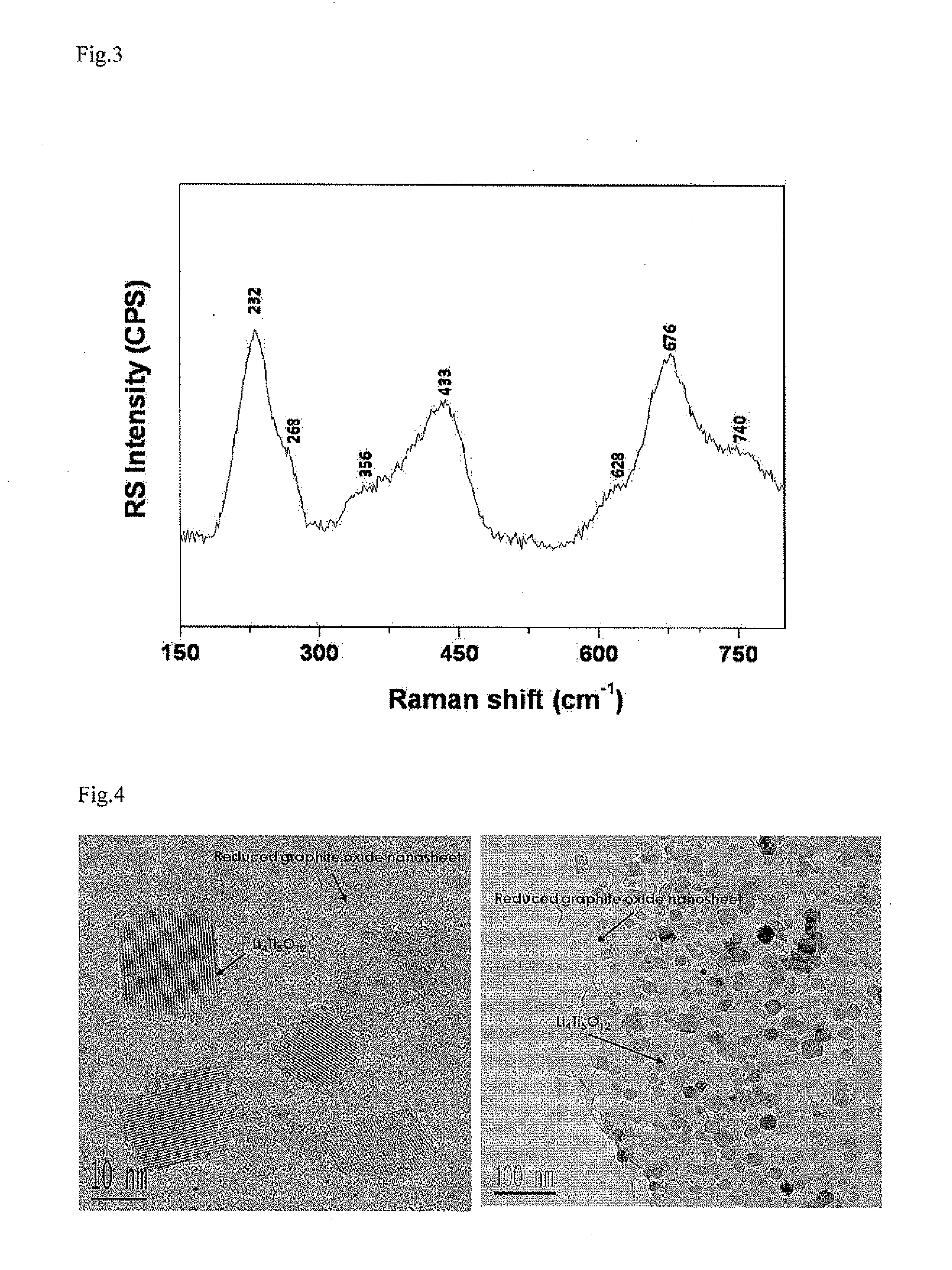

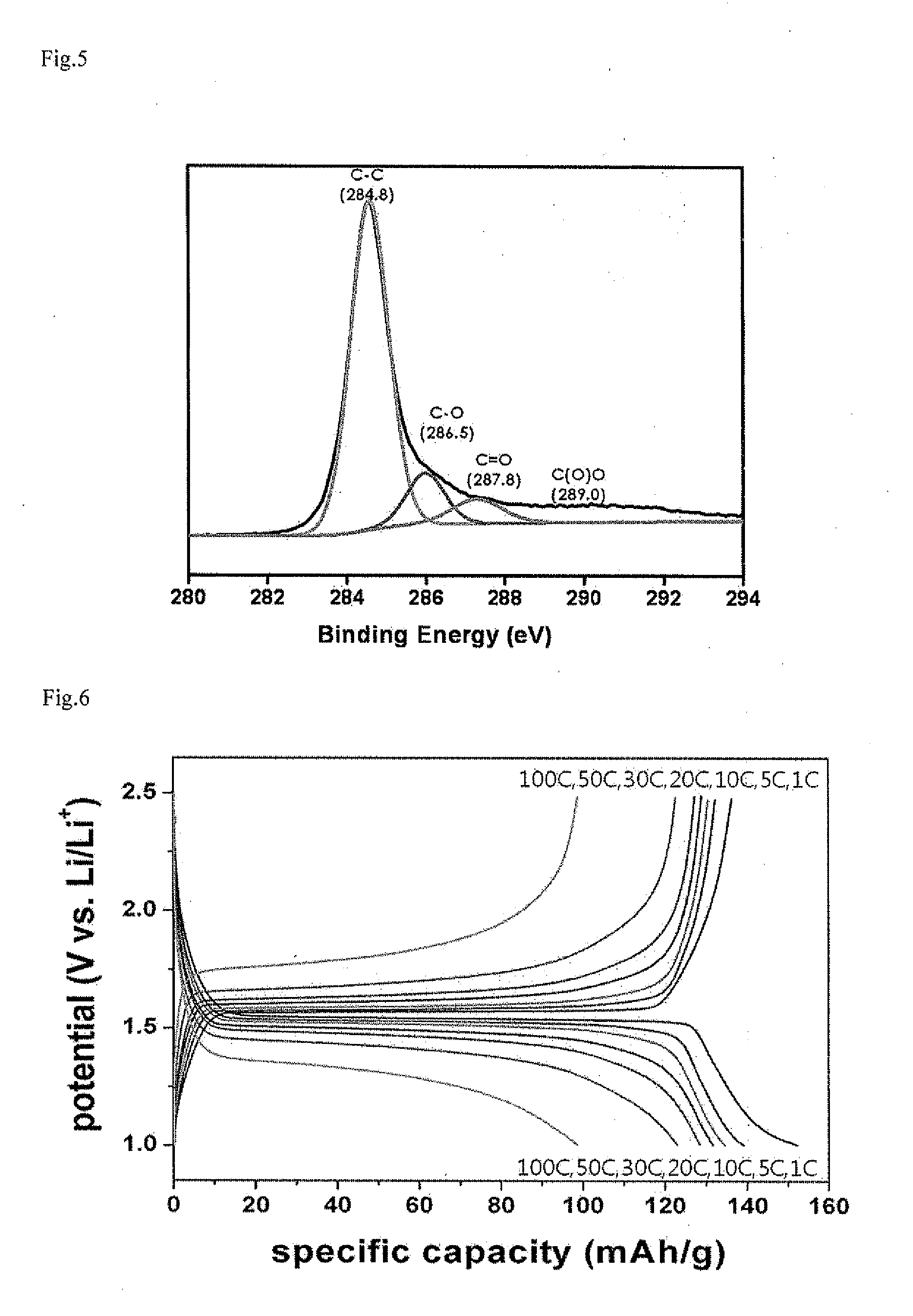

Spinel-Type Lithium Titanium Oxide/Graphene Composite and Method of Preparing the Same

InactiveUS20120104327A1Uniformly formedIncrease capacityMaterial nanotechnologyNon-metal conductorsLithiumMicrowave

A spinel-type lithium titanium oxide / graphene composite and a method of preparing the same are provided. The method can be useful in simplifying a manufacturing process and shortening a manufacturing time using microwave associated solvothermal reaction and post heat treatment, and the spinel-type lithium titanium oxide / graphene composite may have high electrochemical performances due to its excellent capacity and rate capability and long lifespan, and thus be used as an electrode material of the lithium secondary battery.

Owner:IND ACADEMIC CORP FOUND YONSEI UNIV

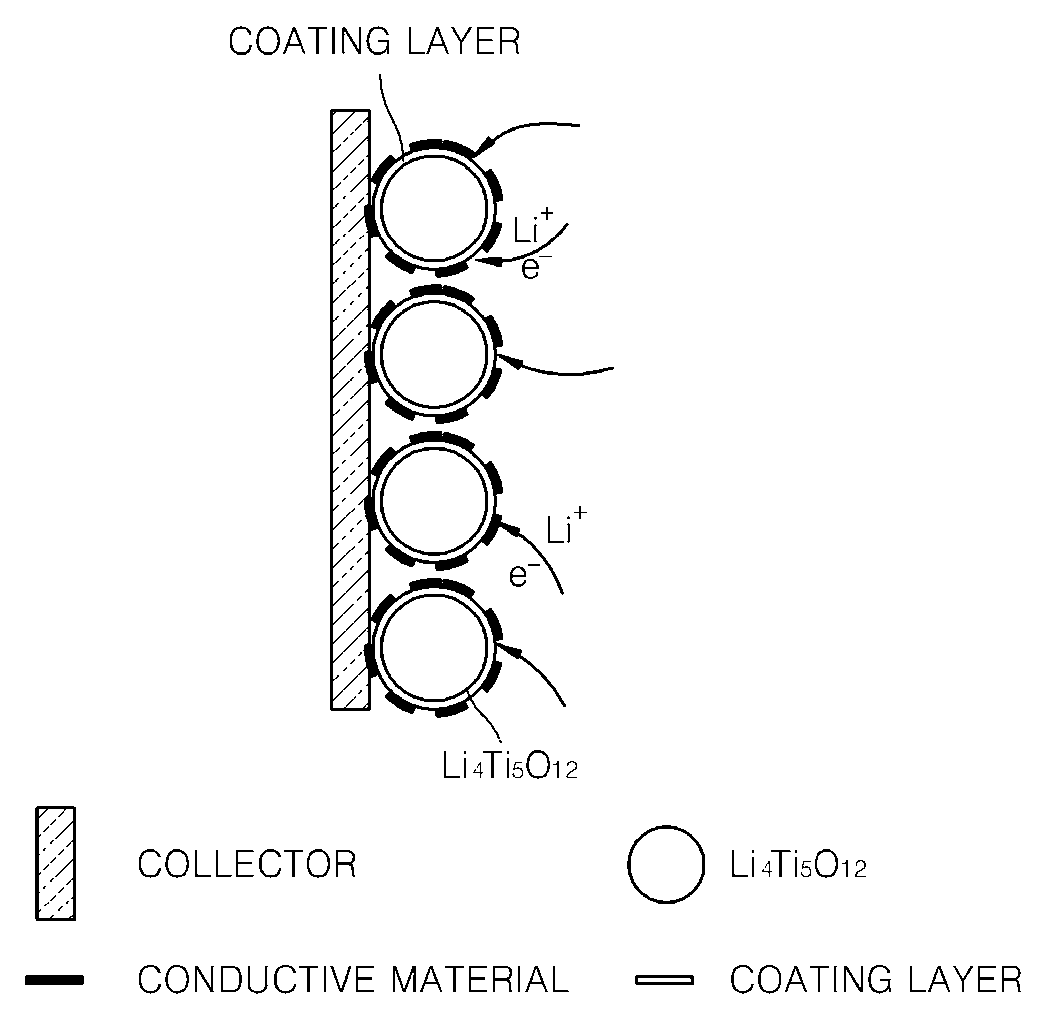

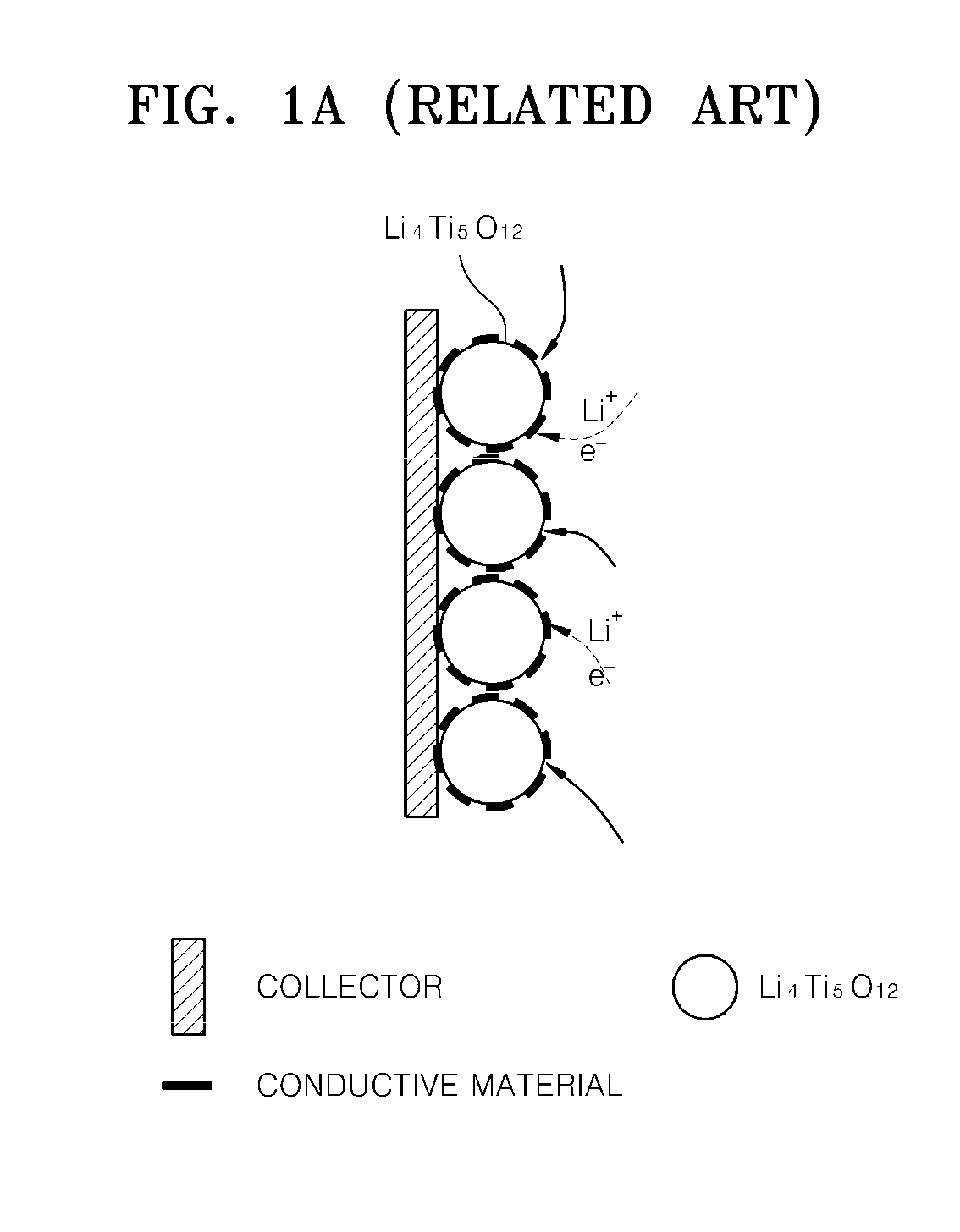

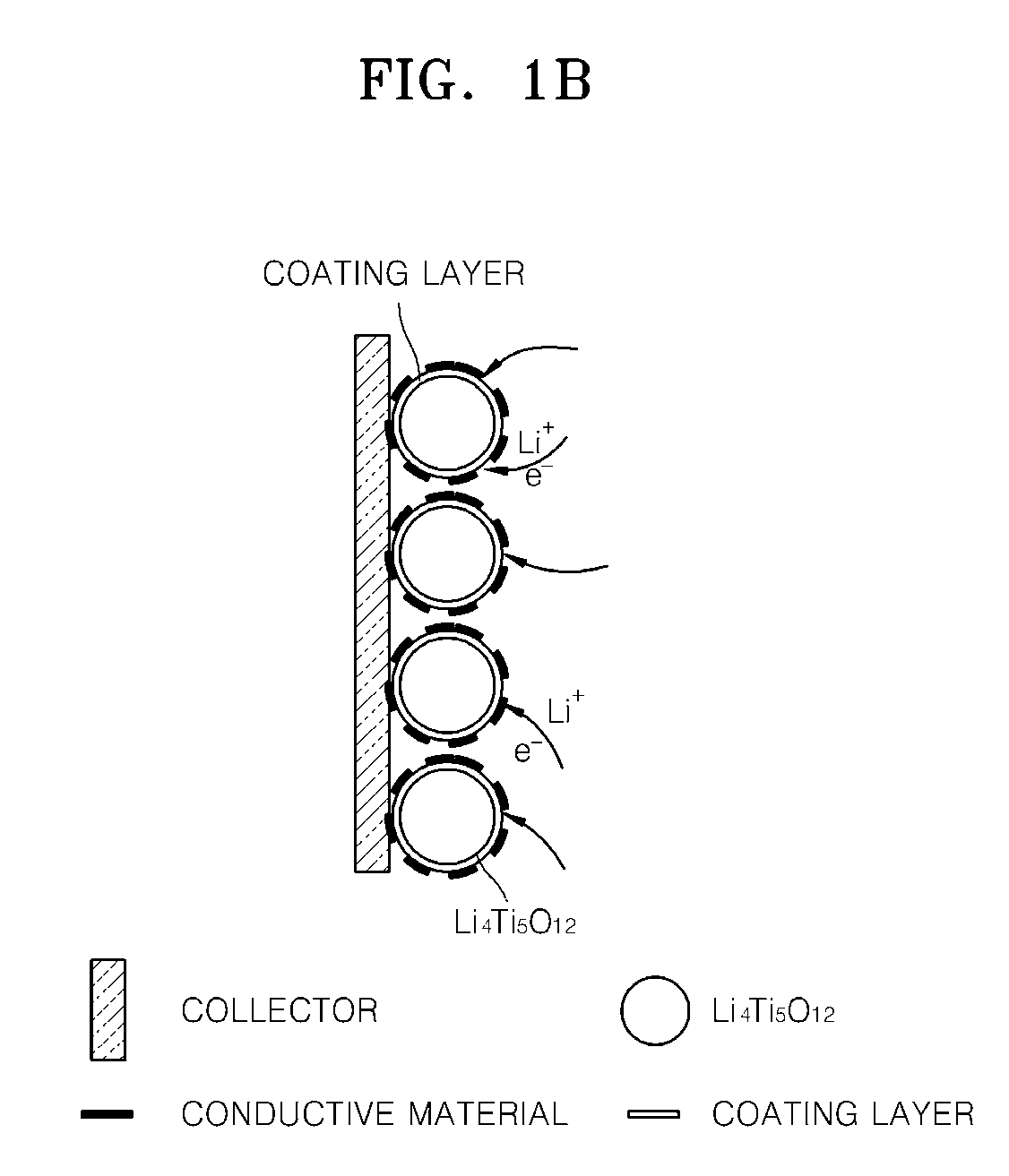

Surface treated anode active material and method of making the same, anode including the same, and lithium battery including the same

ActiveUS20090155692A1Improve efficiencyImprove cycle performanceAlkali titanatesActive material electrodesLithium oxideHigh rate

An anode includes a collector; and an anode active material layer disposed on the collector comprises an anode active material, which is lithium oxide coated Li4Ti5O12, a conductive material, and a binder, wherein the lithium oxide intercalates and / or deintercalates lithium ions into and from the lattice structure of Li4Ti5O12. By coating the surface of the anode active material with lithium oxide, an anode including the surface-treated anode active material has a high capacity, high-rate properties, and a high initial efficiency.

Owner:SAMSUNG SDI CO LTD

Li4Ti5O12, Li(4-a)ZaTi5O12 OR Li4ZbetaTi(5-beta)O12 particles, process for obtaining same and use as electrochemical generators

Synthesis process for new particles of Li4Ti5O12, Li(4-α)ZαTi5O12 or Li4ZβTi(5-β)O12, preferably having a spinel structure, wherein β is greater than 0 and less than or equal to 0.5 (preferably having a spinel structure), a representing a number greater than zero and less than or equal to 0.33, Z representing a source of at least one metal, preferably chosen from the group made up of Mg, Nb, Al, Zr, Ni, Co. These particles coated with a layer of carbon notably exhibit electrochemical properties that are particularly interesting as components of anodes and / or cathodes in electrochemical generators.

Owner:HYDRO QUEBEC CORP

Metal delivery system for nanoparticle manufacture

ActiveUS20060229197A1Improve productivityWell mixedRare earth metal oxides/hydroxidesMolten spray coating2-Ethylhexanoic acidMetallacarboxylic acid

Described is a method for the production of pure or mixed metal oxides, wherein at least one metal precursor that is a metal carboxylate with a mean carbon value per carboxylate group of at least 3, e.g. the 2-ethyl hexanoic acid salt, is formed into droplets and e.g. flame oxidized. The method is performed at viscosities prior to droplet formation of usually less than 40 mPa s, obtained by heating and / or addition of one or more low viscosity solvents with adequately high enthalpy.

Owner:ETH ZURICH THE SHORT NAME OF EID GENOSSISCHE TECHN HOCHSCHULE ZURICH

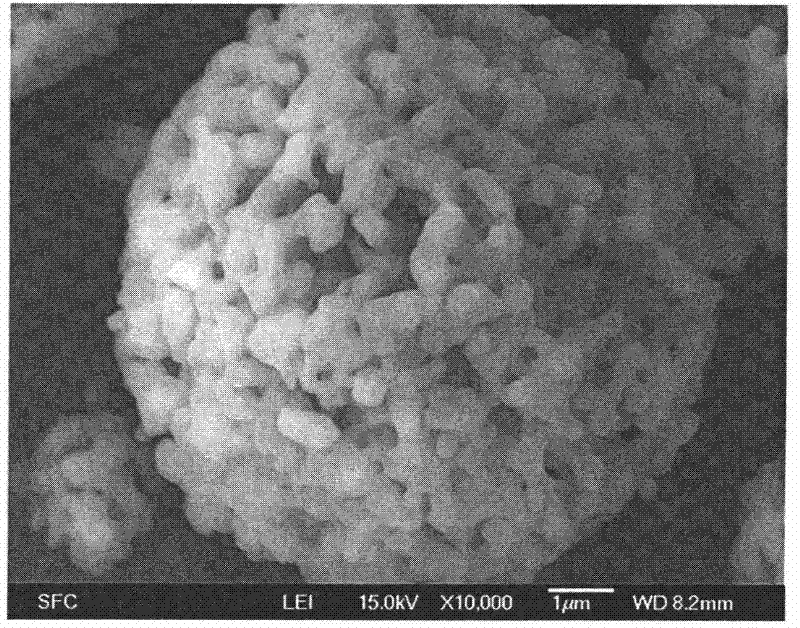

Negative active material, method of preparing same, and rechargeable lithium battery including same

The present invention relates to a negative electrode active material for a rechargeable lithium battery, a method of manufacturing the same, and a rechargeable lithium battery including the same. The negative active material has a specific surface area of 2 m<2> / g or more and less than 5 m<2> / g and includes secondary particles composed of assembled primary particles of a compound represented by Chemical Formula 1: [Chemical Formula 1] Li4-x-yMyTi5+x-zM'zO12 wherein, x is 0 or 1, or 0 to 1, y is 0 or 1, or 0 to 1, z is 0 or 1, or 0 to 1, M is La, Tb, Gd, Ce, Pr, Nd, Sm, Ba, Sr, Ca, Mg, or a combination thereof, and M' is V, Cr, Nb, Fe, Ni, Co, Mn, W, AI, Ga, Cu, Mo, P, or a combination thereof.

Owner:SAMSUNG SDI CO LTD

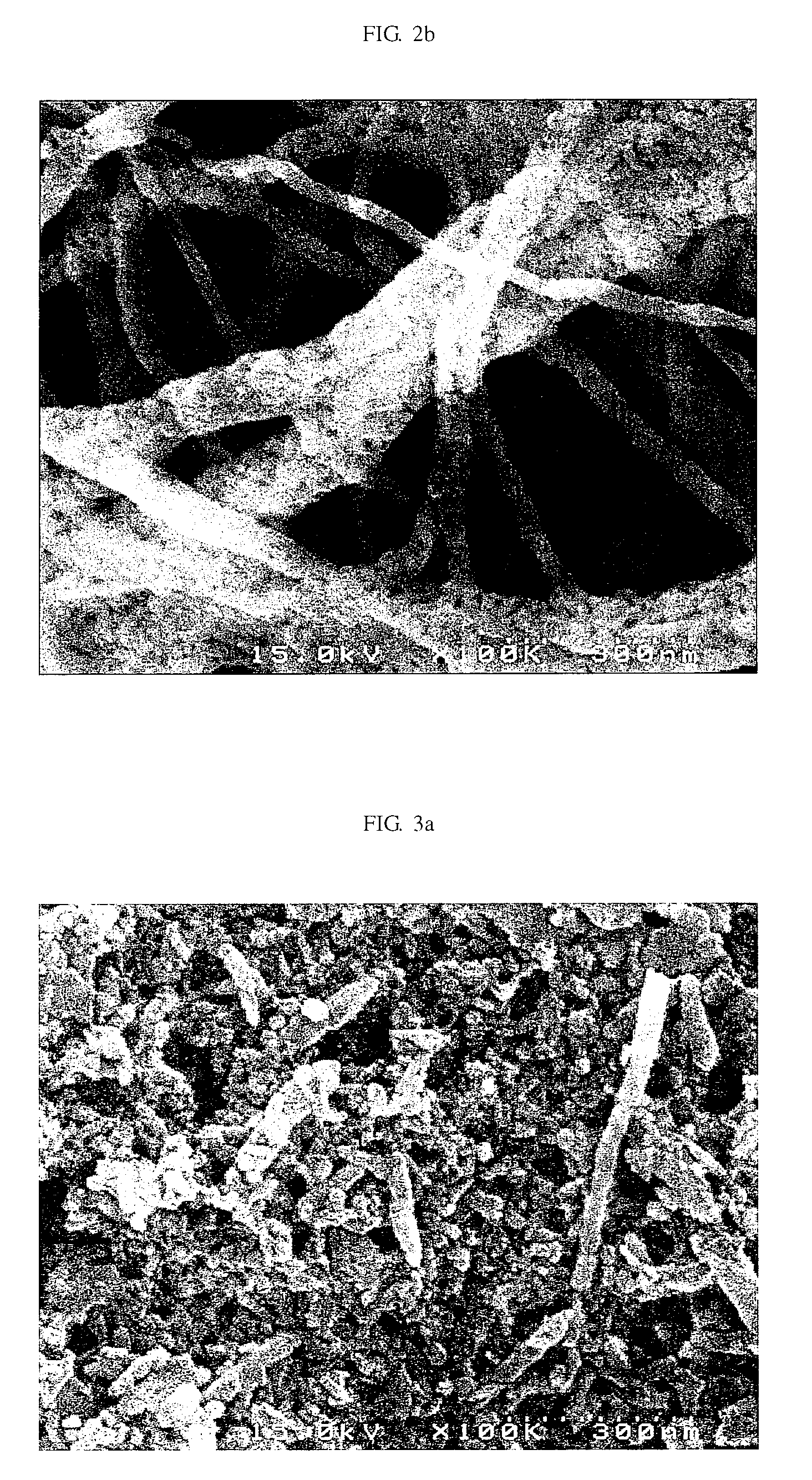

Electrode material and electrode containing the electrode material

InactiveUS20120132861A1Small particle sizeInhibit aggregationNon-metal conductorsAlkali titanatesChemical reactionMetal oxide nanoparticles

The electrode material includes metal oxide nanoparticles formed by applying shear force and centrifugal force to reactants containing a reaction inhibitor in a rotating reaction vessel during a chemical reaction; and carbon nanotubes with a specific area of 600 to 2600 m2 / g to which shear force and centrifugal force are applied for dispersion in the rotating reaction vessel during the chemical reaction. The metal oxide particles are highly dispersed and carried on the carbon nanotubes. Preferably, the metal oxide is lithium titanate.

Owner:NIPPON CHIMI CON CORP +1

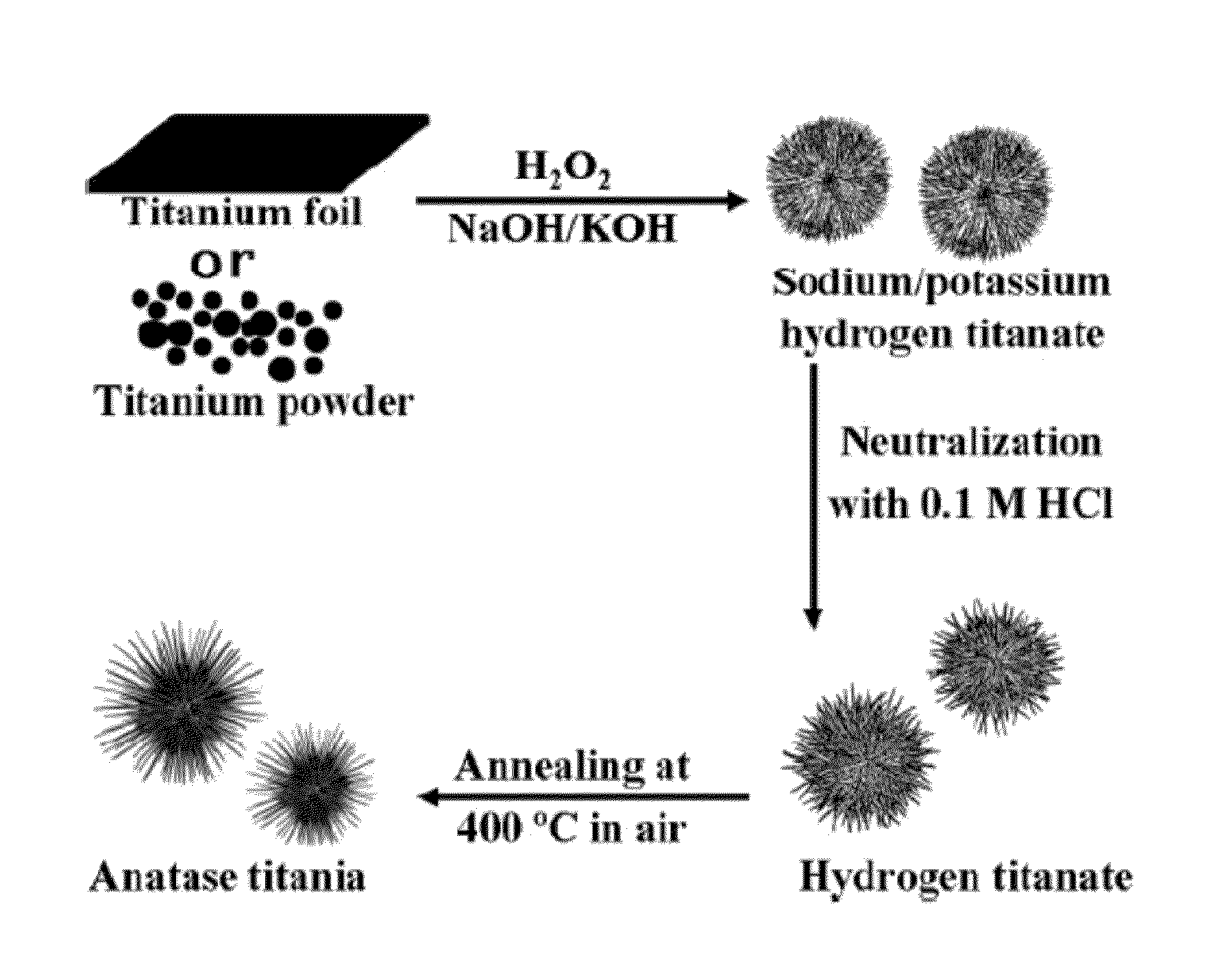

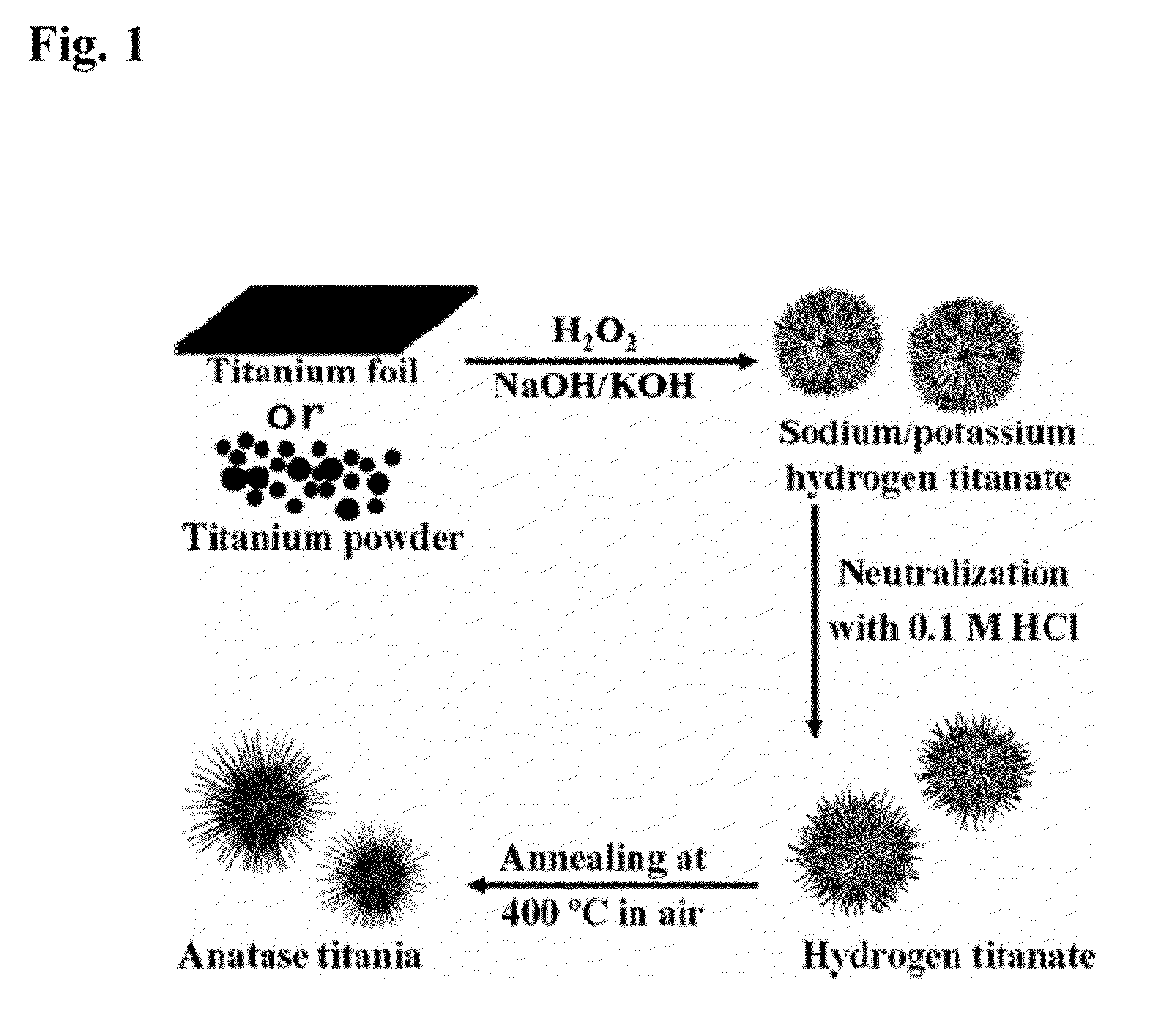

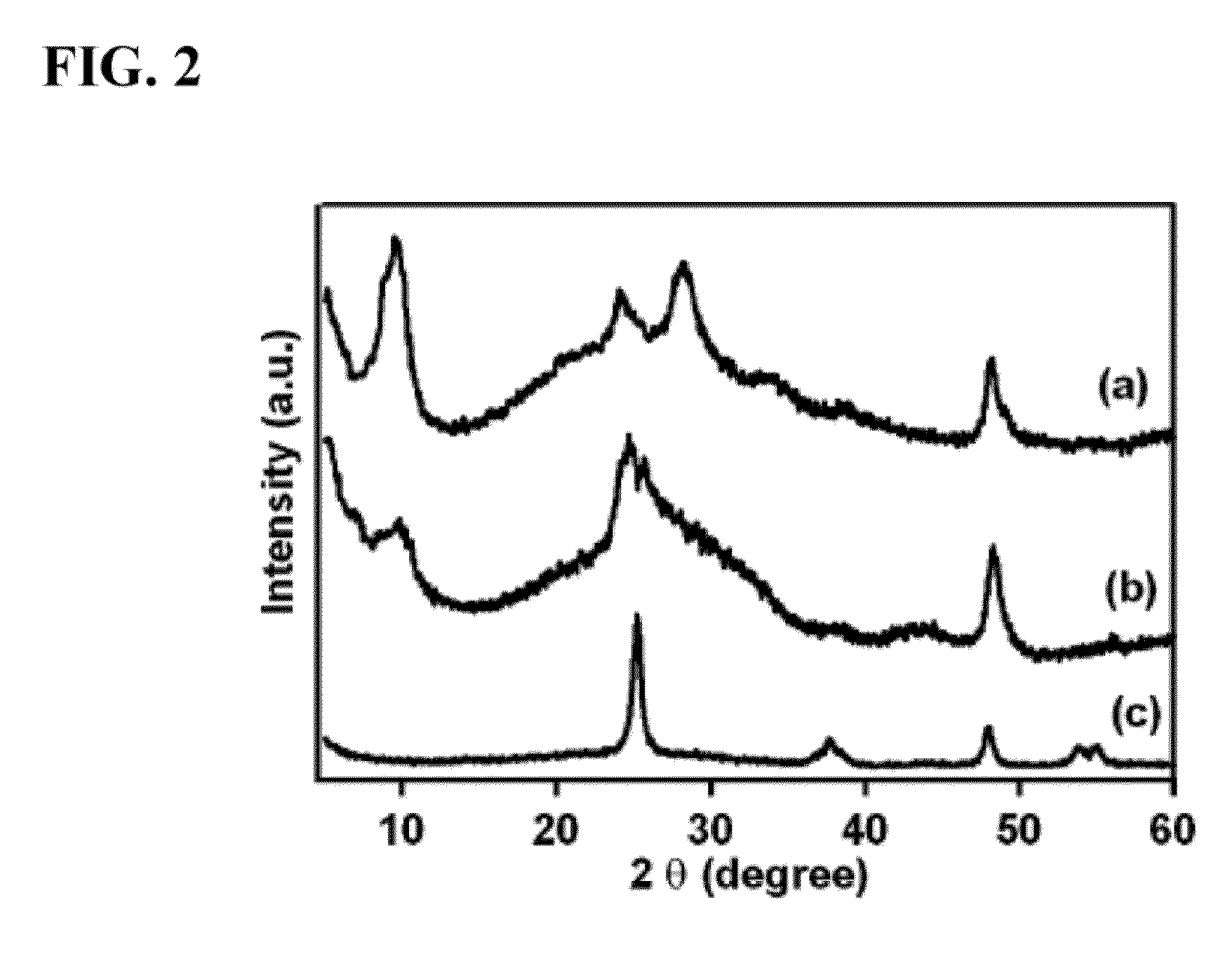

Titanate and titania nanostructures and nanostructure assemblies, and methods of making same

ActiveUS20130102458A1Improve scalabilityImprove photocatalytic performanceMaterial nanotechnologyHydrogenMicrometer scaleTitanium

The invention relates to nanomaterials and assemblies including, a micrometer-scale spherical aggregate comprising: a plurality of one-dimensional nanostructures comprising titanium and oxygen, wherein the one-dimensional nanostructures radiate from a hollow central core thereby forming a spherical aggregate.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

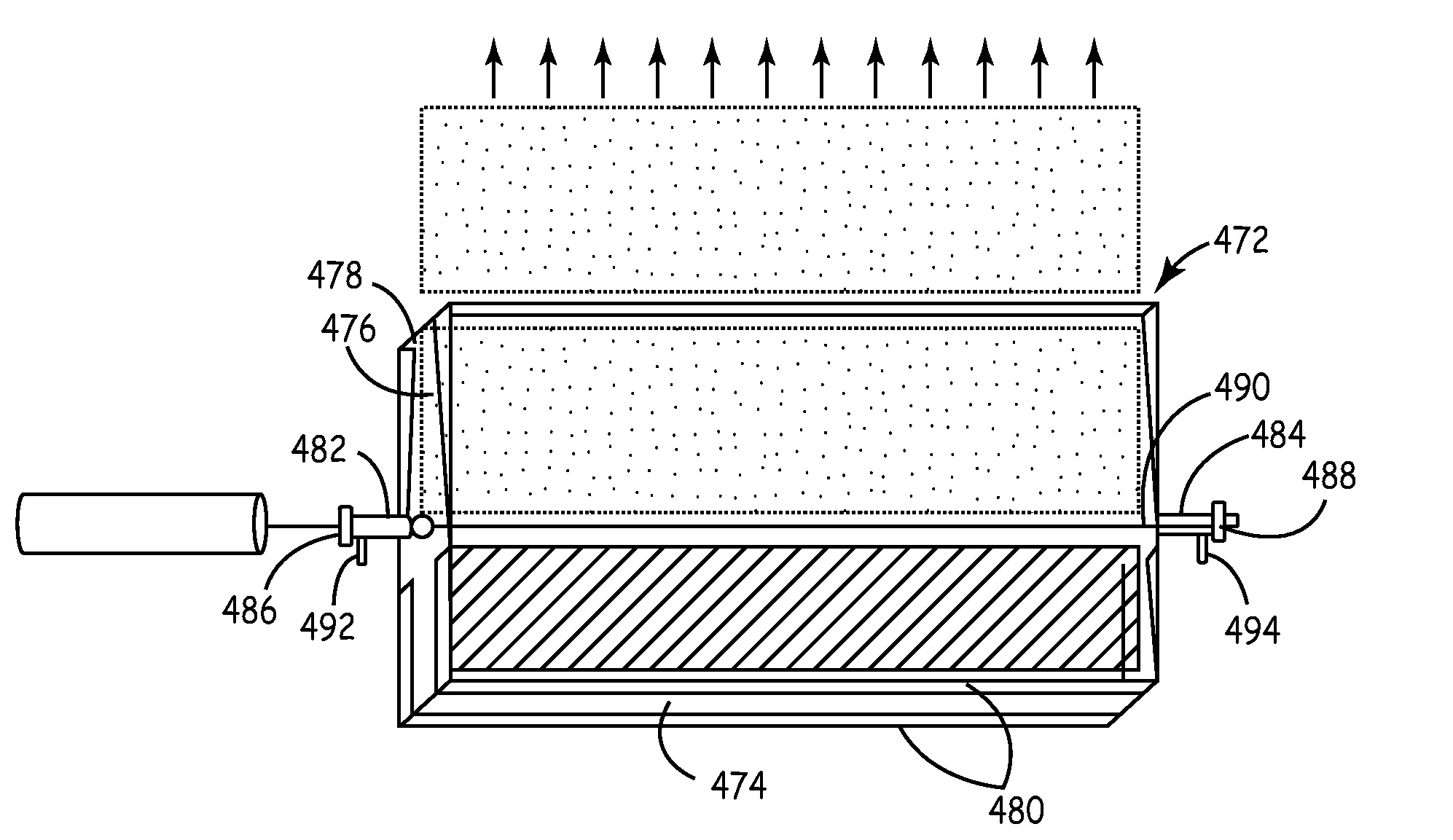

Process for the preparation of lithium metal oxides involving fluidized bed techniques

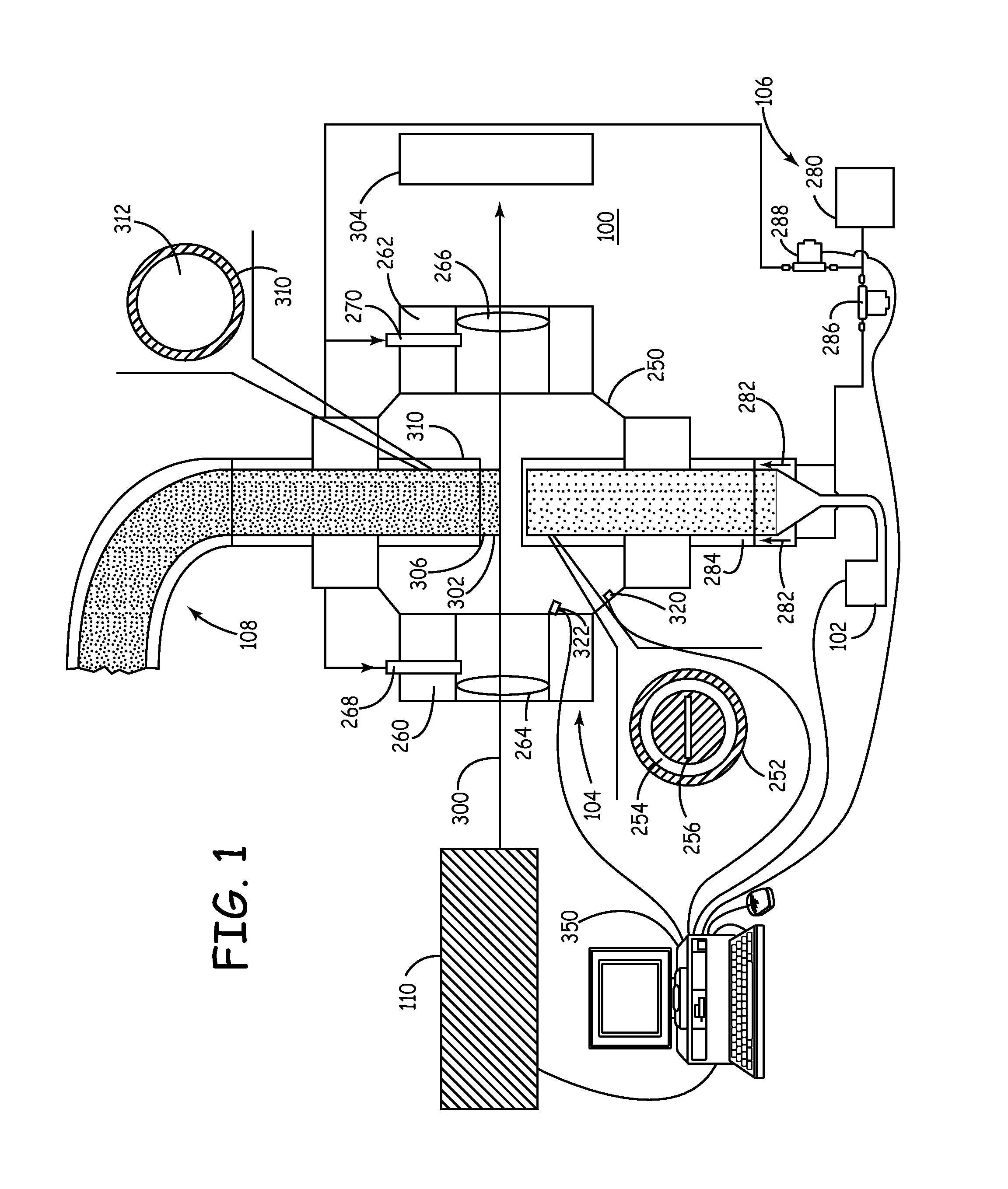

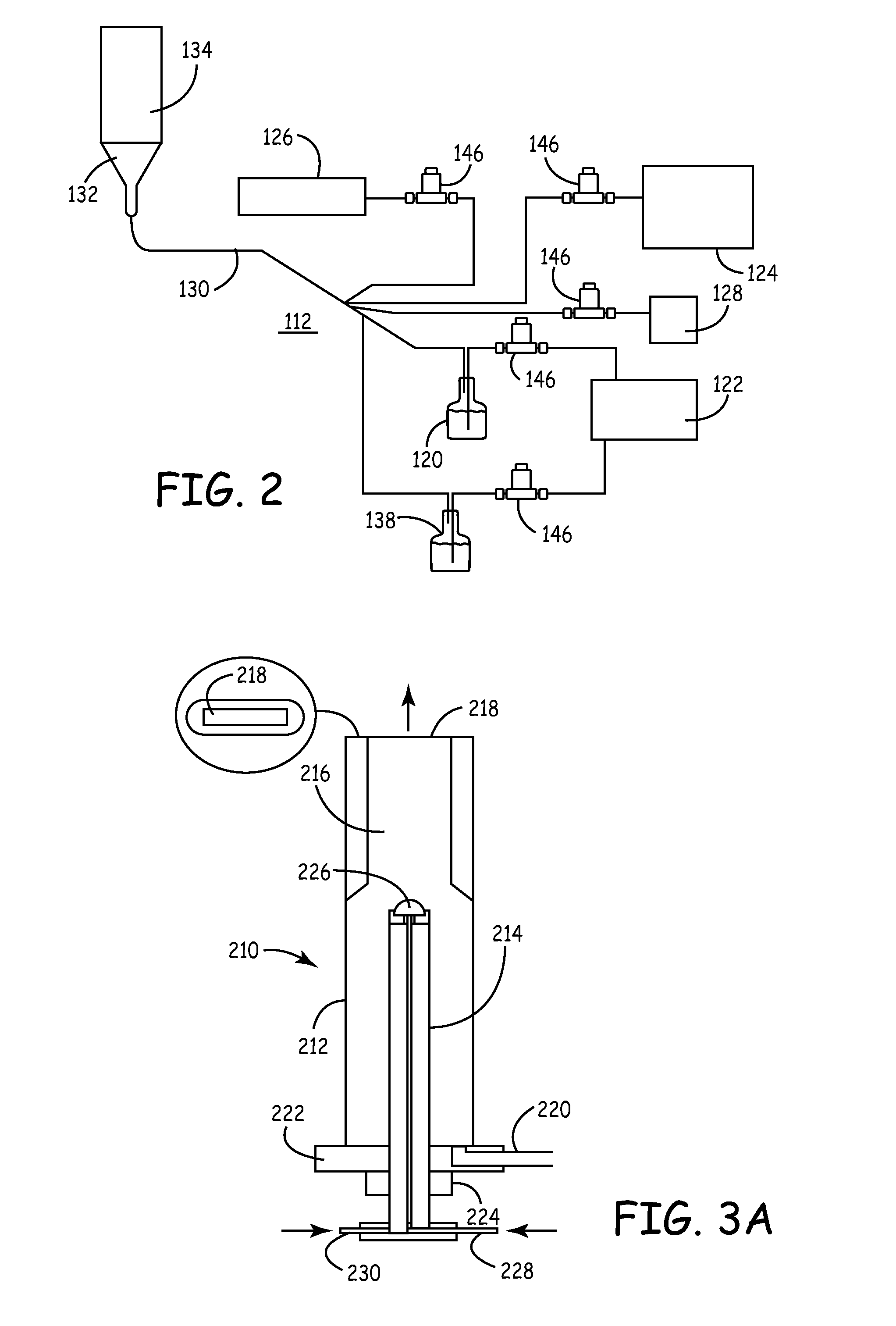

A method of producing lithium metal oxides can include mixing lithium salt and a metal oxide to form a composition, heating the composition in a first reactor, transferring the composition to a second reactor, and passing the composition through the second reactor to anneal the composition to form lithium metal oxides. The second reactor can be a fluidized bed reactor. The lithium metal oxide can have an average crystal size of between about 5 microns and about 20 microns.

Owner:HONEYWELL INT INC

Method of manufacturing alkali metal titanate and hollow body particle thereof, product thereof, and friction material containing the product

ActiveUS20100112350A1Improve braking performanceImproved braking stabilityAlkali titanatesZirconium compoundsPotassiumTitanium

The present invention is to provide a method of manufacturing a potassium titanate adapted for a friction material of a friction slide member. The present invention includes the steps of uniformly mixing an aggregate or a granulation of a titanium compound and a potassium compound with a vibration rod mill to form a mixture and sintering the mixture for reaction one another in order to manufacture a desired potassium titanate with ease and low cost.

Owner:TOHO TITANIUM CO LTD

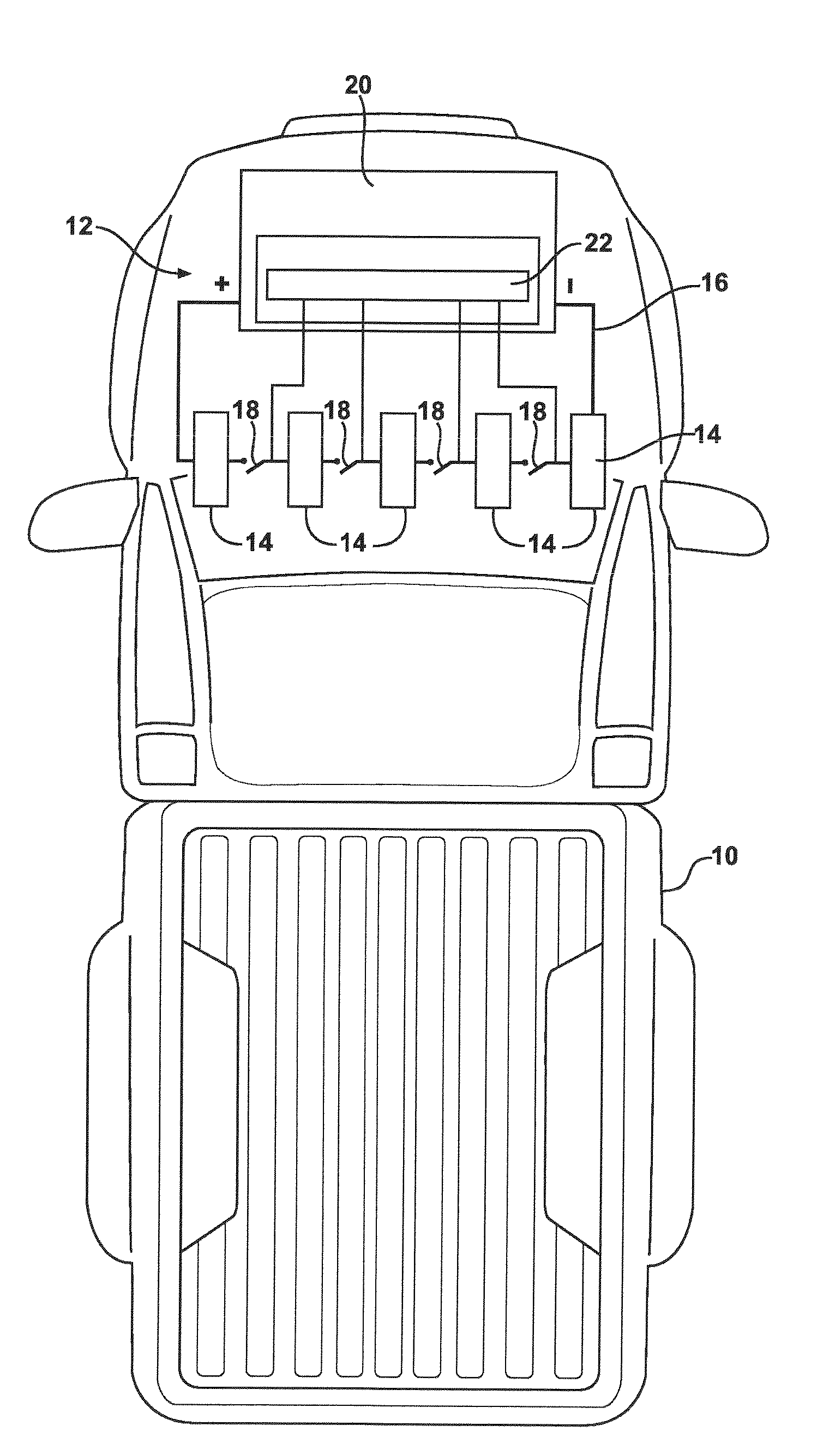

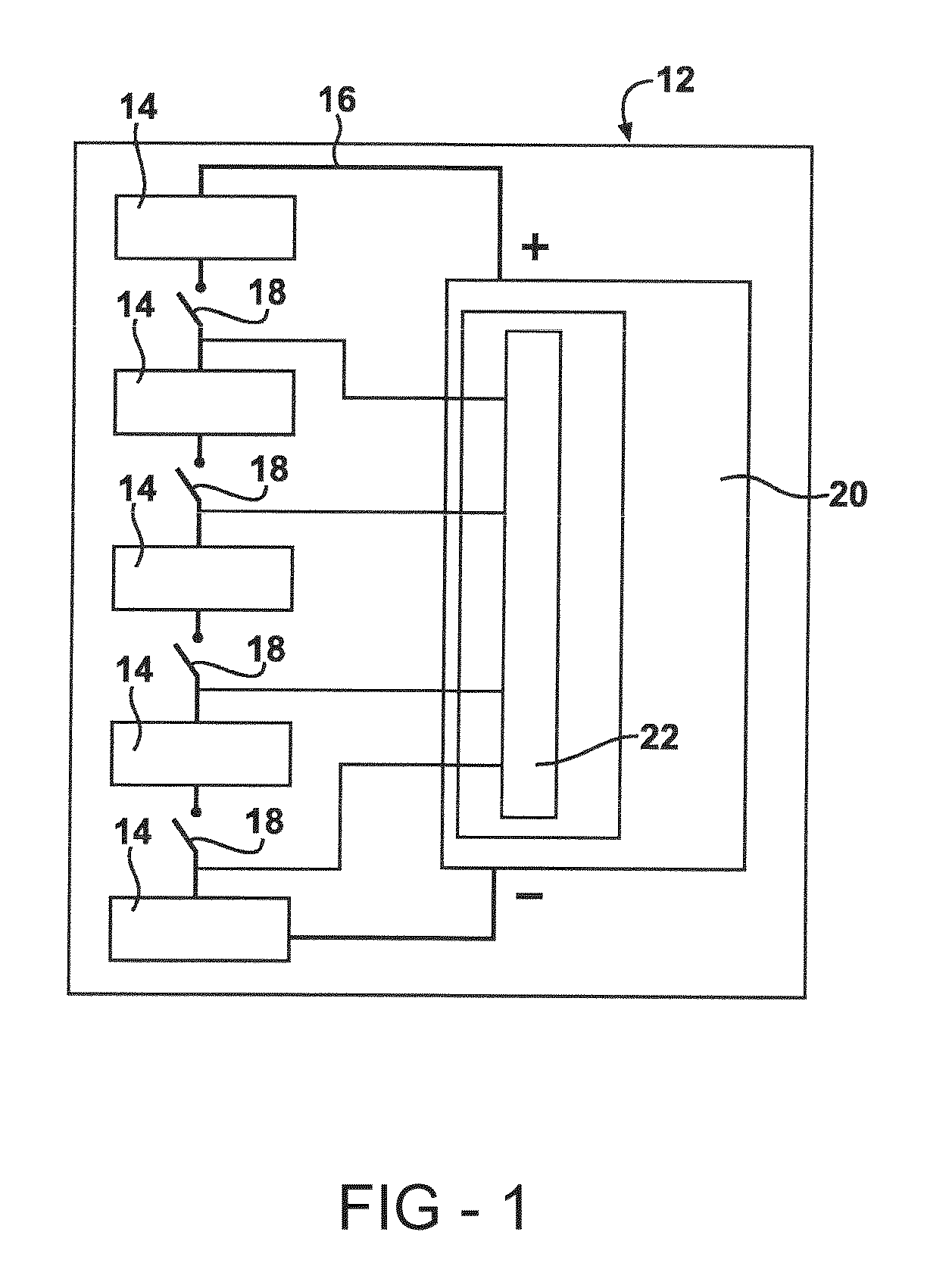

Methods for synthesizing submicron doped silicon particles

Methods are described that have the capability of producing submicron / nanoscale particles, in some embodiments dispersible, at high production rates. In some embodiments, the methods result in the production of particles with an average diameter less than about 75 nanometers that are produced at a rate of at least about 35 grams per hour. In other embodiments, the particles are highly uniform. These methods can be used to form particle collections and / or powder coatings. Powder coatings and corresponding methods are described based on the deposition of highly uniform submicron / nanoscale particles.

Owner:NANOGRAM

Lithium titanate and method of forming the same

InactiveUS7541016B2Improve electronic conductivityAvoid lostAlkali titanatesZirconium compoundsOxygenElectronic conductivity

A lithium titanate has the following formula:Li4Ti5O12−x wherein x is greater than 0. The lithium titanate is formed by providing a mixture of titanium dioxide and a lithium-based component. The mixture is sintered in a gaseous atmosphere comprising a reducing agent to form the lithium titanate having the above formula. A lithium-based cell includes an electrolyte, an anode, and a cathode, with at least one of the anode and the cathode comprising the lithium titanate having the above formula. The lithium titanate is deficient of oxygen, which increases electronic conductivity of the lithium titanate by at least three orders over electronic conductivity of a stoichiometric lithium titanate, while avoiding loss of reversible electric power-generating capacity that typically occurs when doping is used to replace titanium in the lithium titanate with atoms that provide higher electronic conductivity.

Owner:ENERDEL

Fabrication method for electrode active material and lithium battery comprising electrode active material fabricated therefrom

ActiveUS20090117464A1Great life-spanImprove performanceMaterial nanotechnologyAlkali titanatesSolventAqueous solution

Disclosed is a fabrication method for an electrode active material, and a lithium battery comprising an electrode active material fabricated therefrom. The fabrication method for an electrode active material comprises preparing an aqueous solution by dissolving a precursor that can simultaneously undergo positive ion substitution and surface-reforming processes in water; mixing and dissolving raw materials for an electrode active material with a composition ratio for a final electrode active material in the aqueous solution, thereby preparing a mixed solution; removing a solvent from the mixed solution, thereby forming a solid dry substance; thermal-processing the solid dry substance; and crushing the thermal-processed solid dry substance.

Owner:KOREA INST OF SCI & TECH

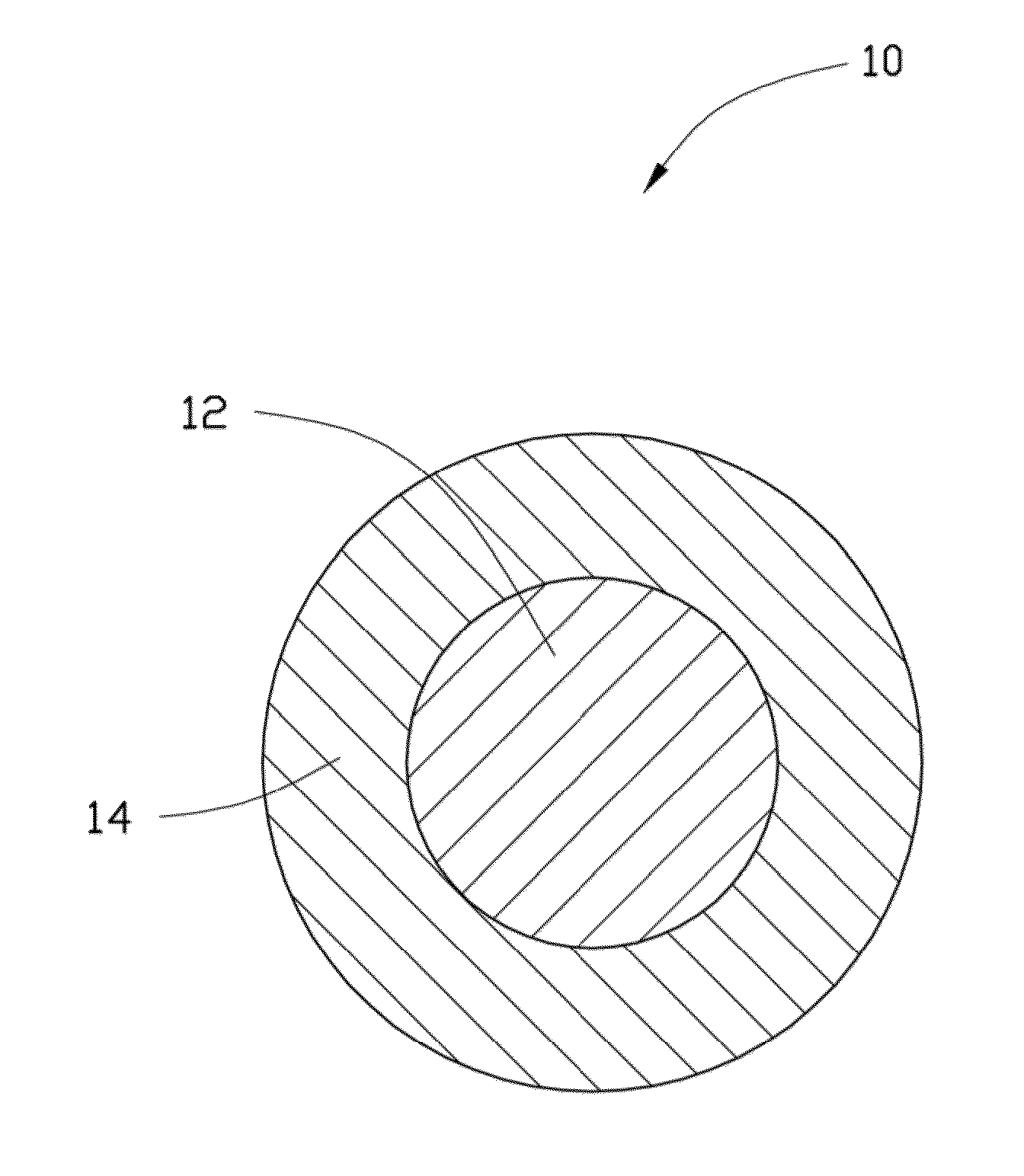

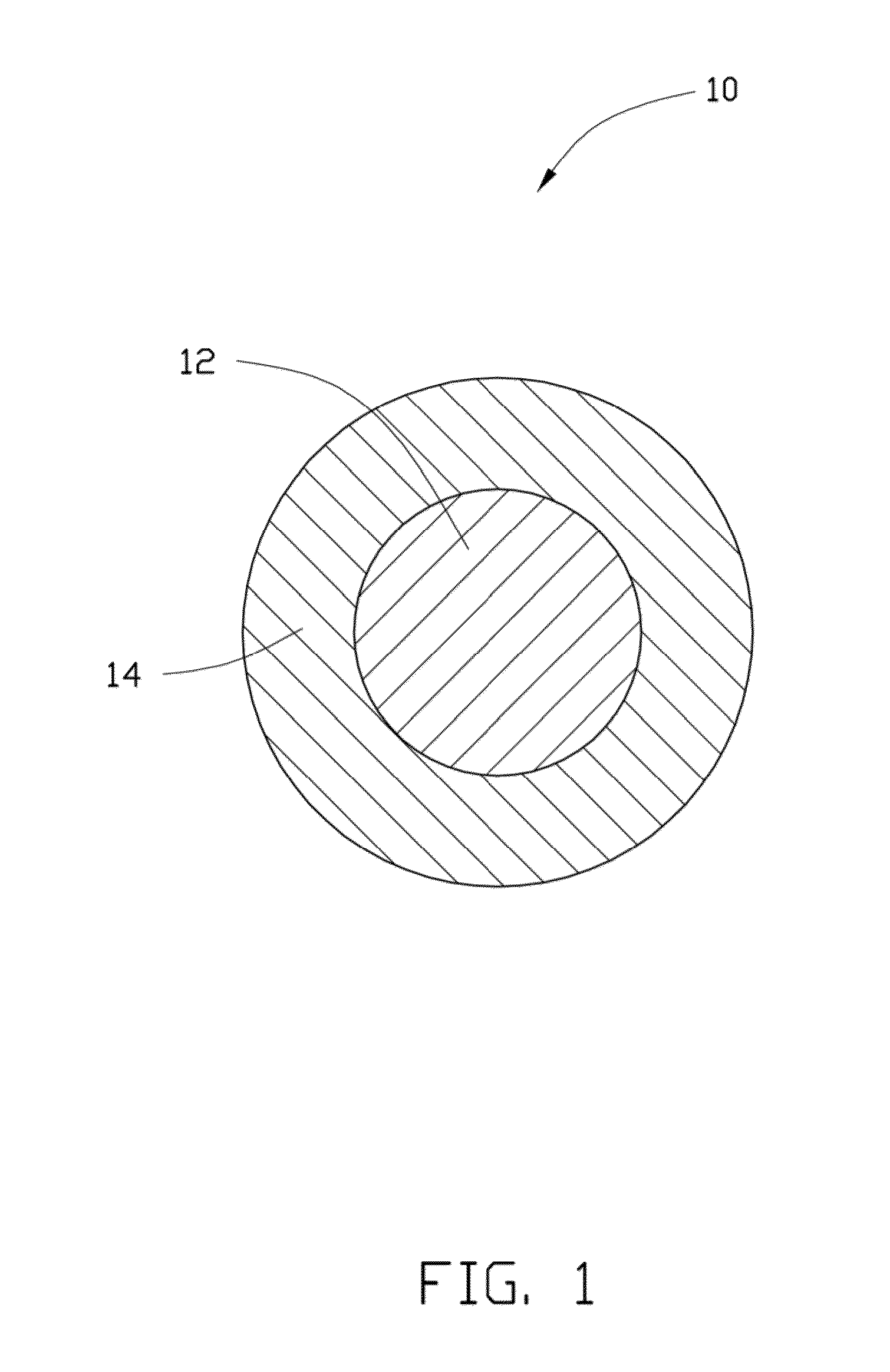

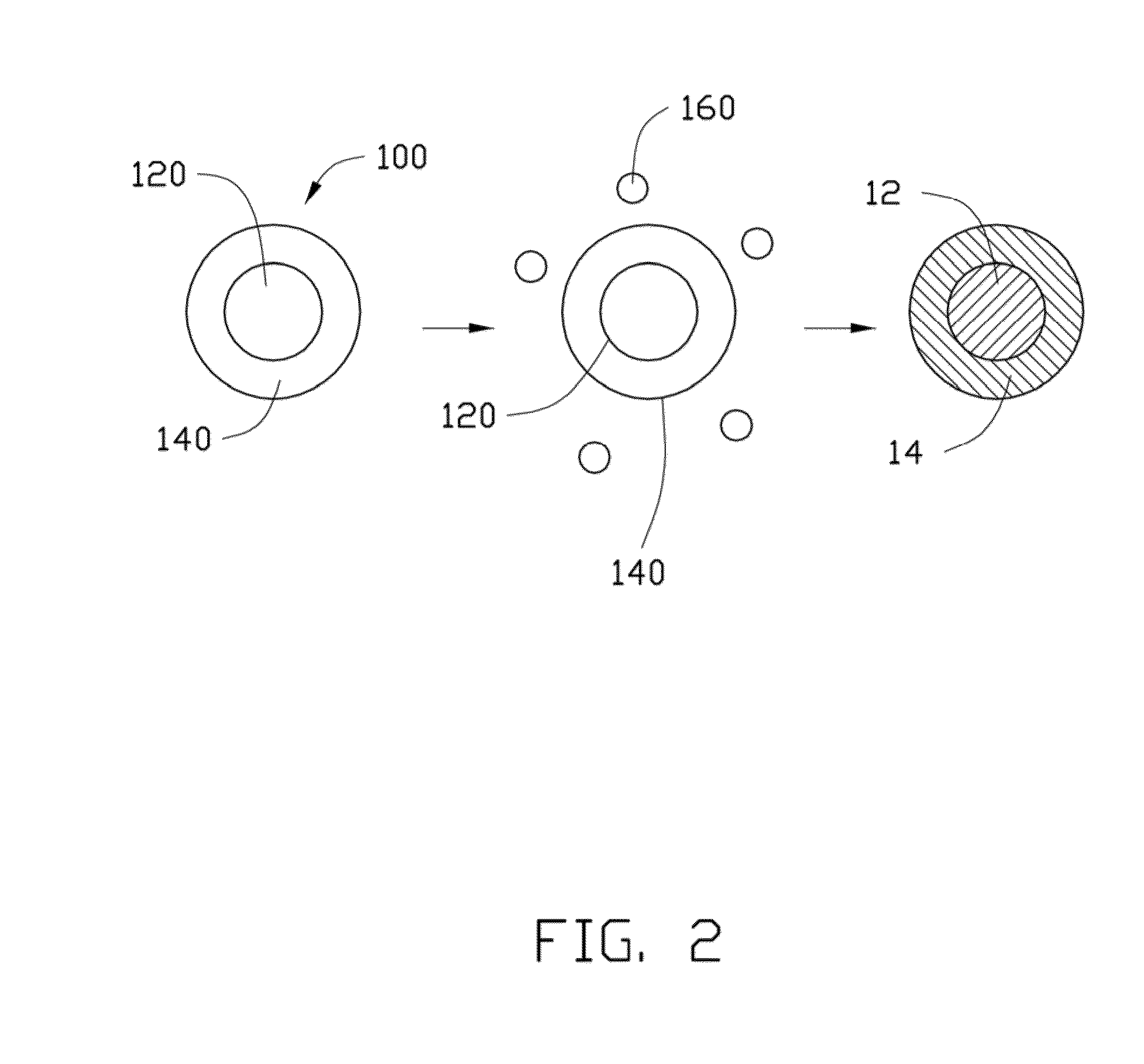

Cathode composite material, method for making the same, and lithium ion battery using the same

ActiveUS20140087256A1Improved chemical and thermal stabilityAlkali titanatesZirconium compoundsLithium metalLithium-ion battery

A cathode composite material includes a cathode active material and a coating layer coated on a surface of the cathode active material. A material of the coating layer is a lithium metal oxide having a crystal structure belonging to C2 / c space group of the monoclinic crystal system. The present disclosure also relates to a lithium ion battery including the cathode composite material.

Owner:TSINGHUA UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com