Patents

Literature

57 results about "Micro rods" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

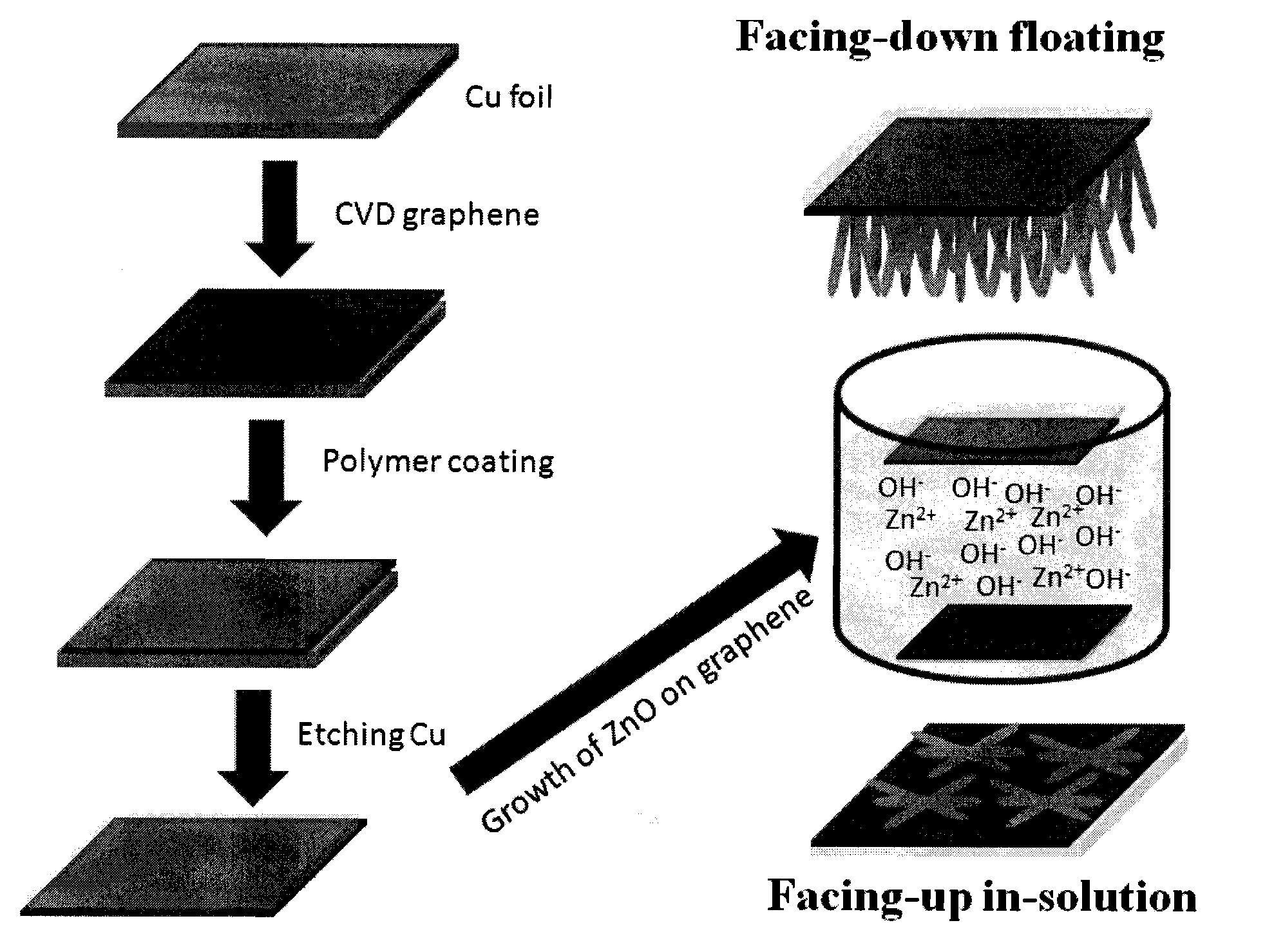

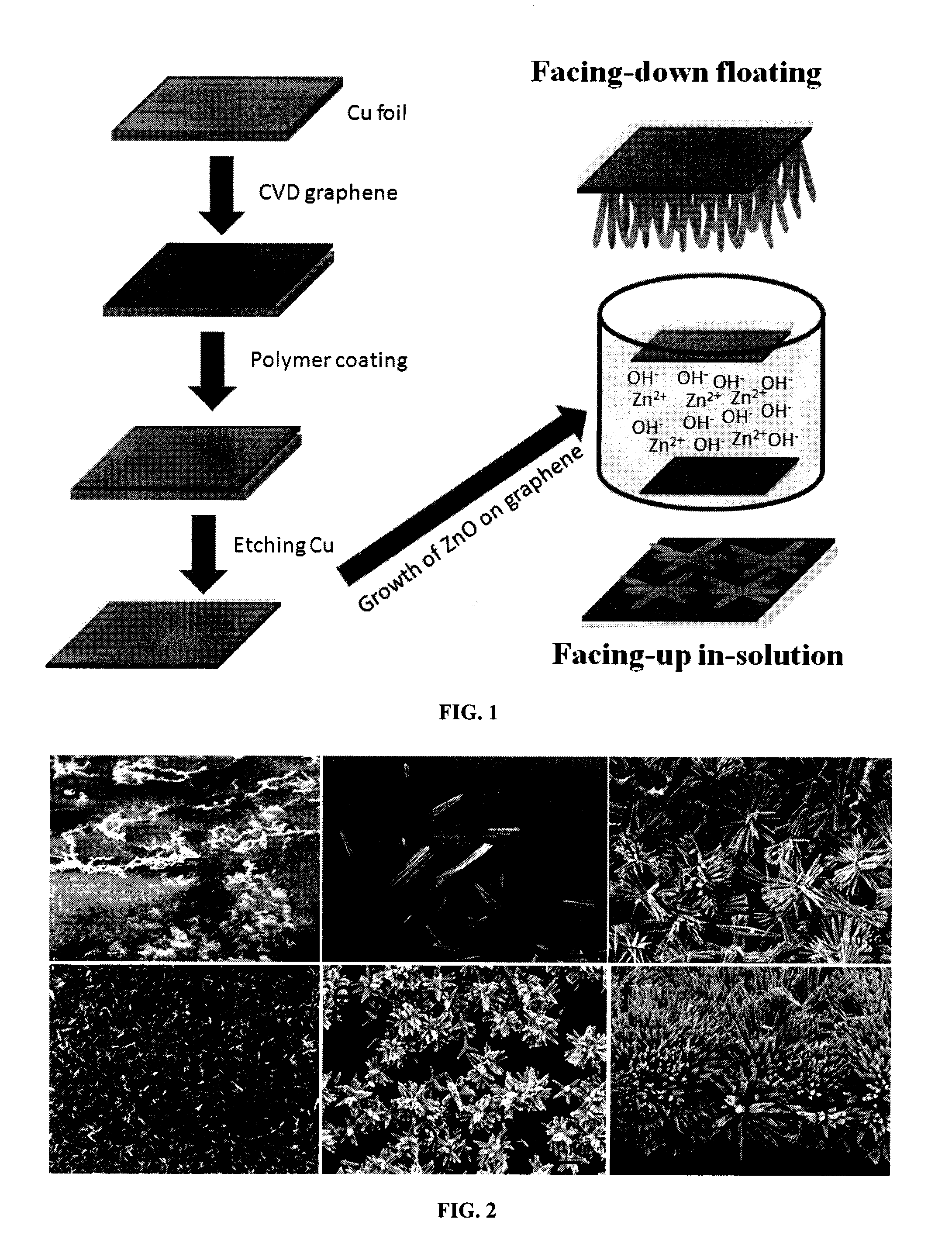

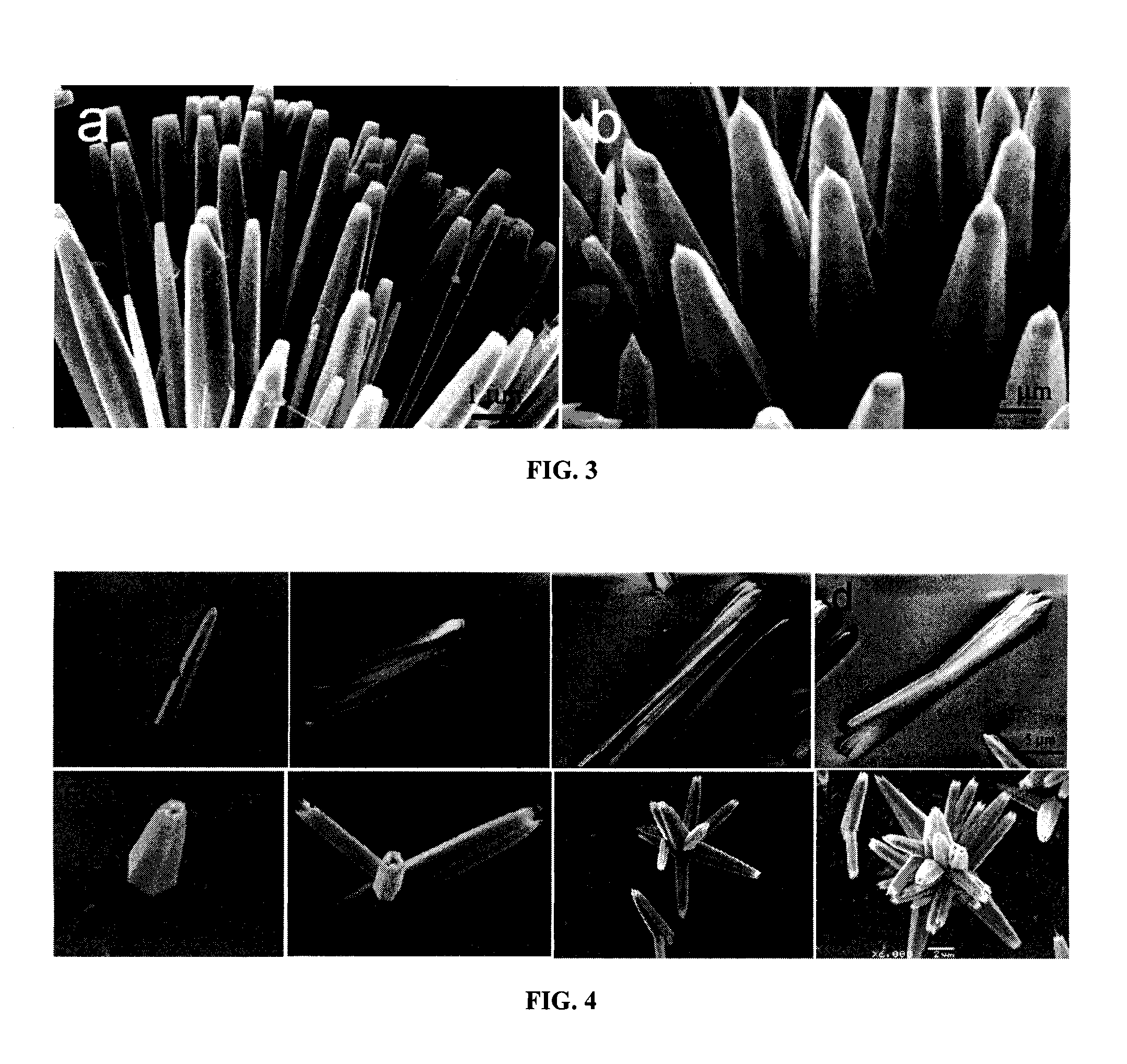

Semiconductor-Graphene Hybrids Formed Using Solution Growth

InactiveUS20130099196A1Improve mobilitySolve the thickerMaterial nanotechnologyPretreated surfacesNano structuringGas phase

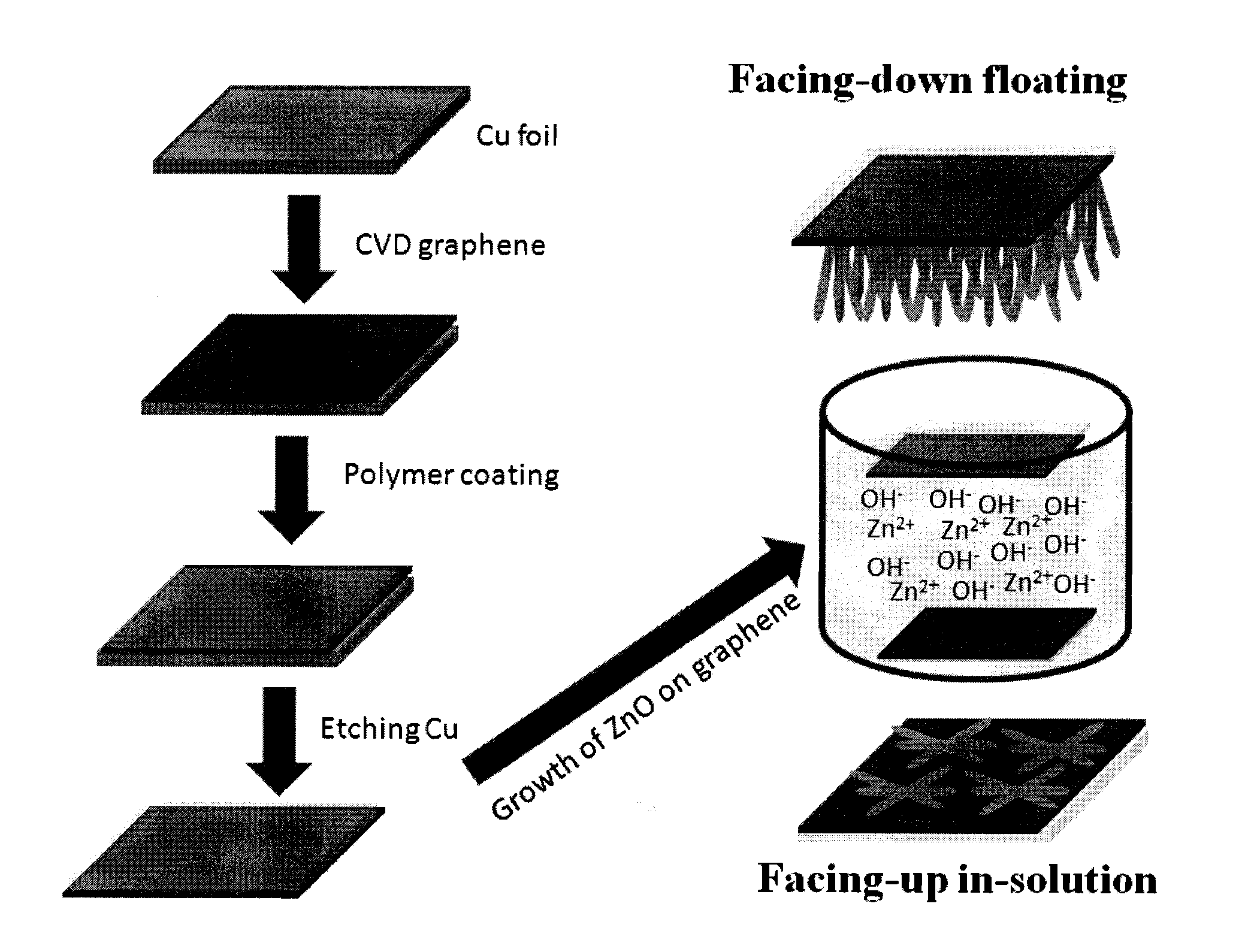

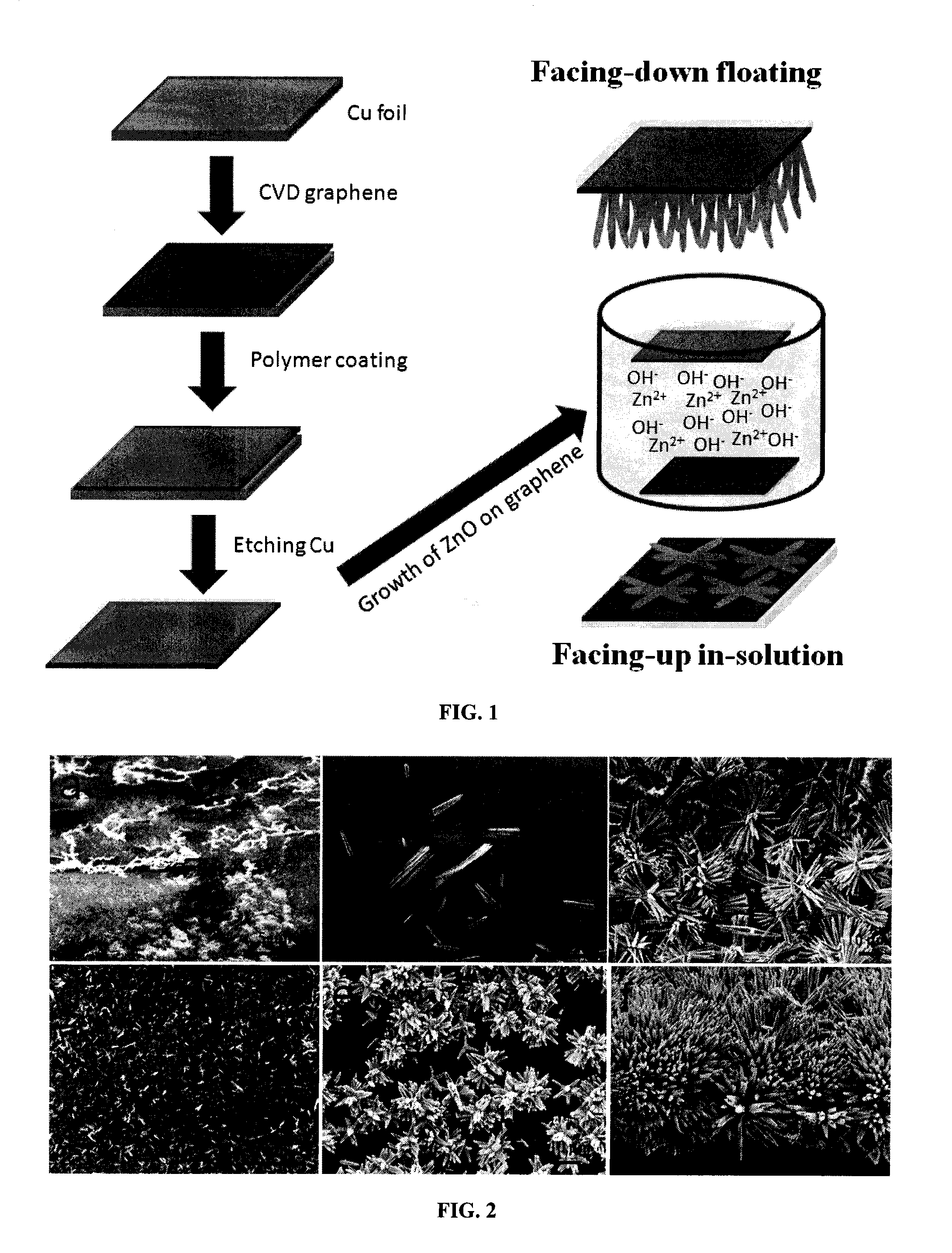

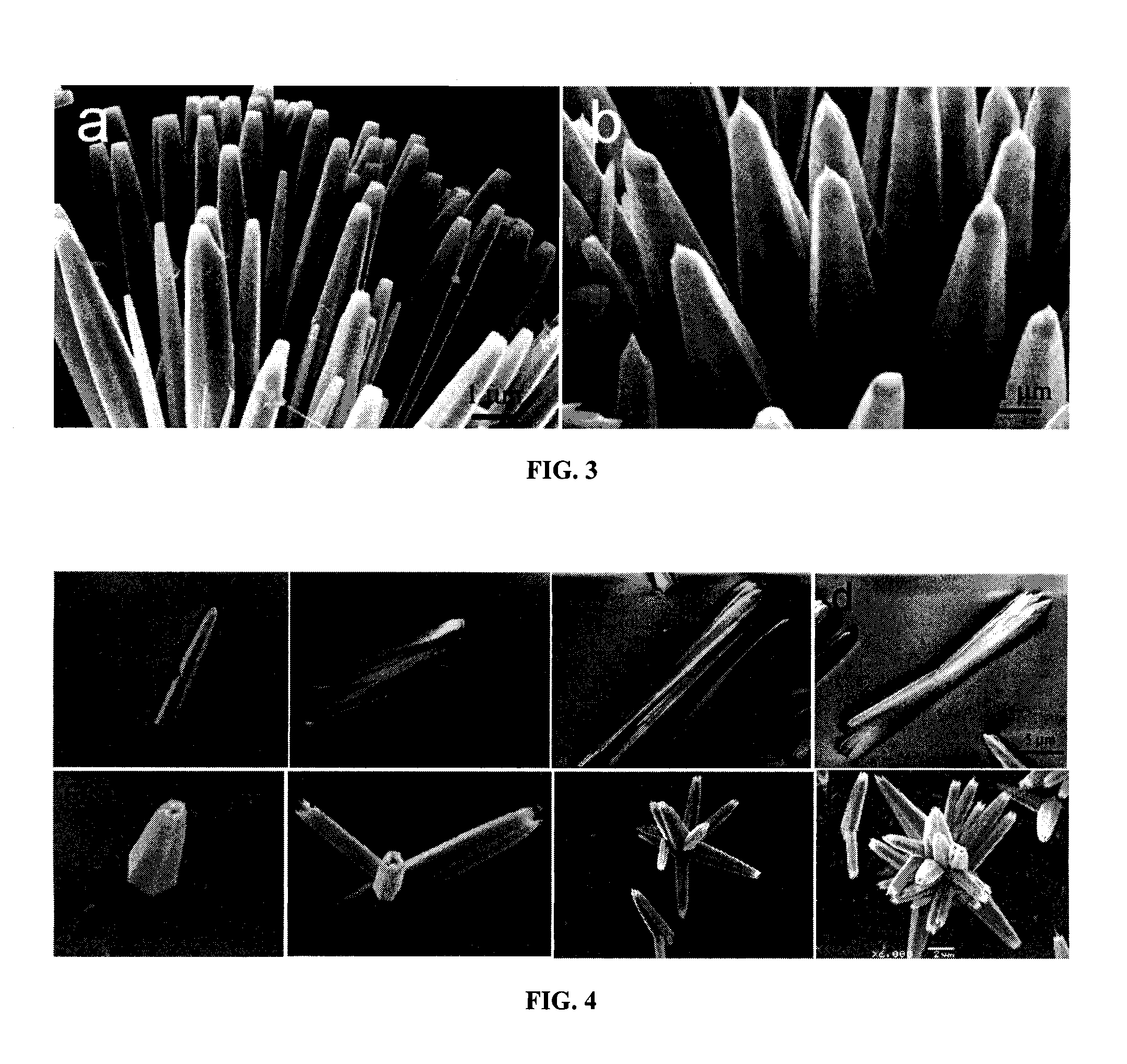

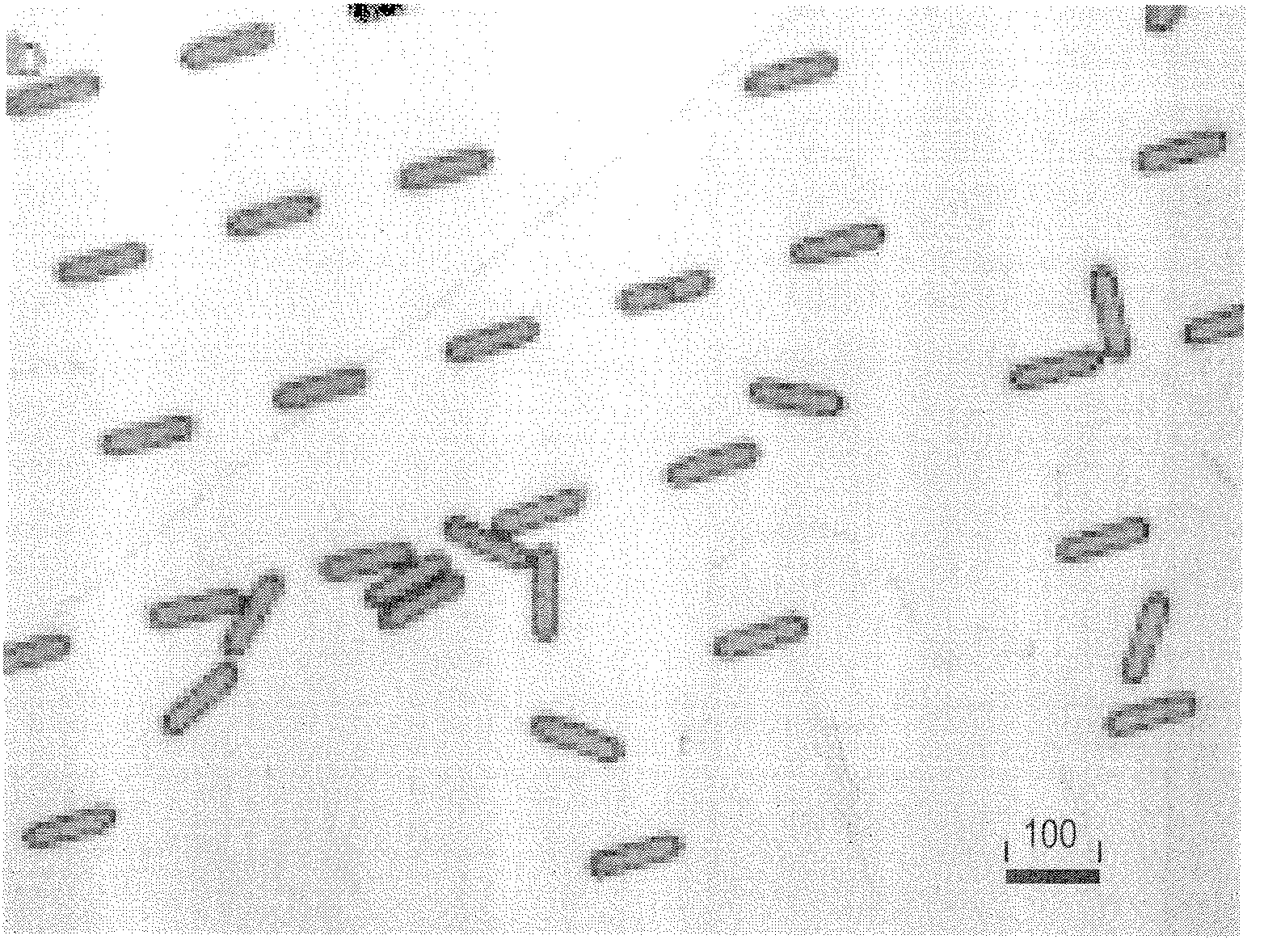

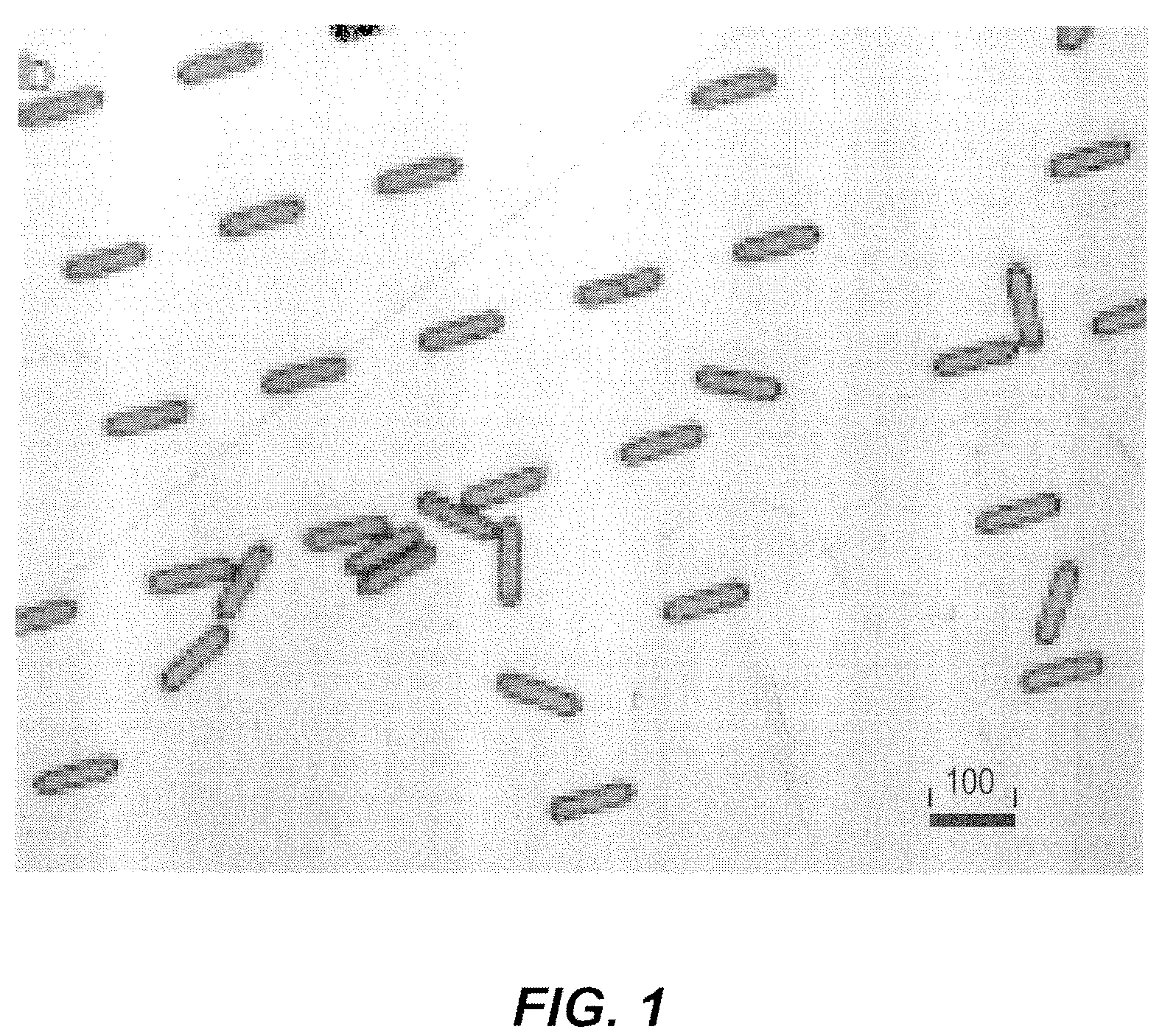

A novel method for fabrication of hybrid semiconductor-graphene nanostructures in large scale by floating graphene sheets on the surface of a solution is provided. Using this approach, crystalline ZnO nano / micro-rod bundles on graphene fabricated using chemical vapor deposition were prepared. UV detectors fabricated using the as-prepared hybrid ZnO-graphene nano-structure with graphene being one of the two electrodes show high sensitivity to ultraviolet light, suggesting the graphene remained intact during the ZnO growth. This growth process provides a low-cost and robust scheme for large-scale fabrication of semiconductor nanostructures on graphene and may be applied for synthesis of a variety of hybrid semiconductor-graphene nano-structures demanded for optoelectronic applications including photovoltaics, photodetection, and photocatalysis.

Owner:UNIVERSITY OF KANSAS

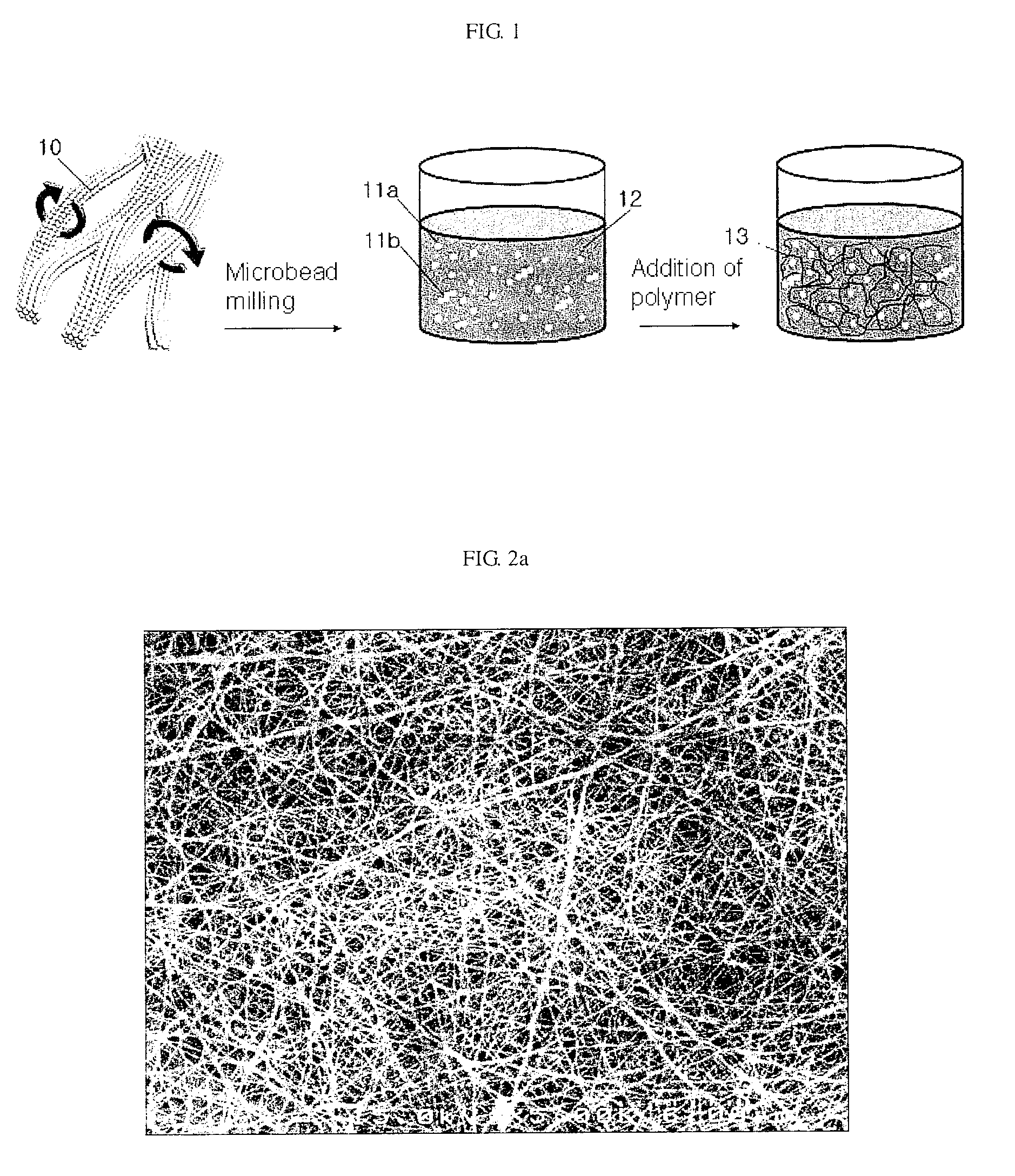

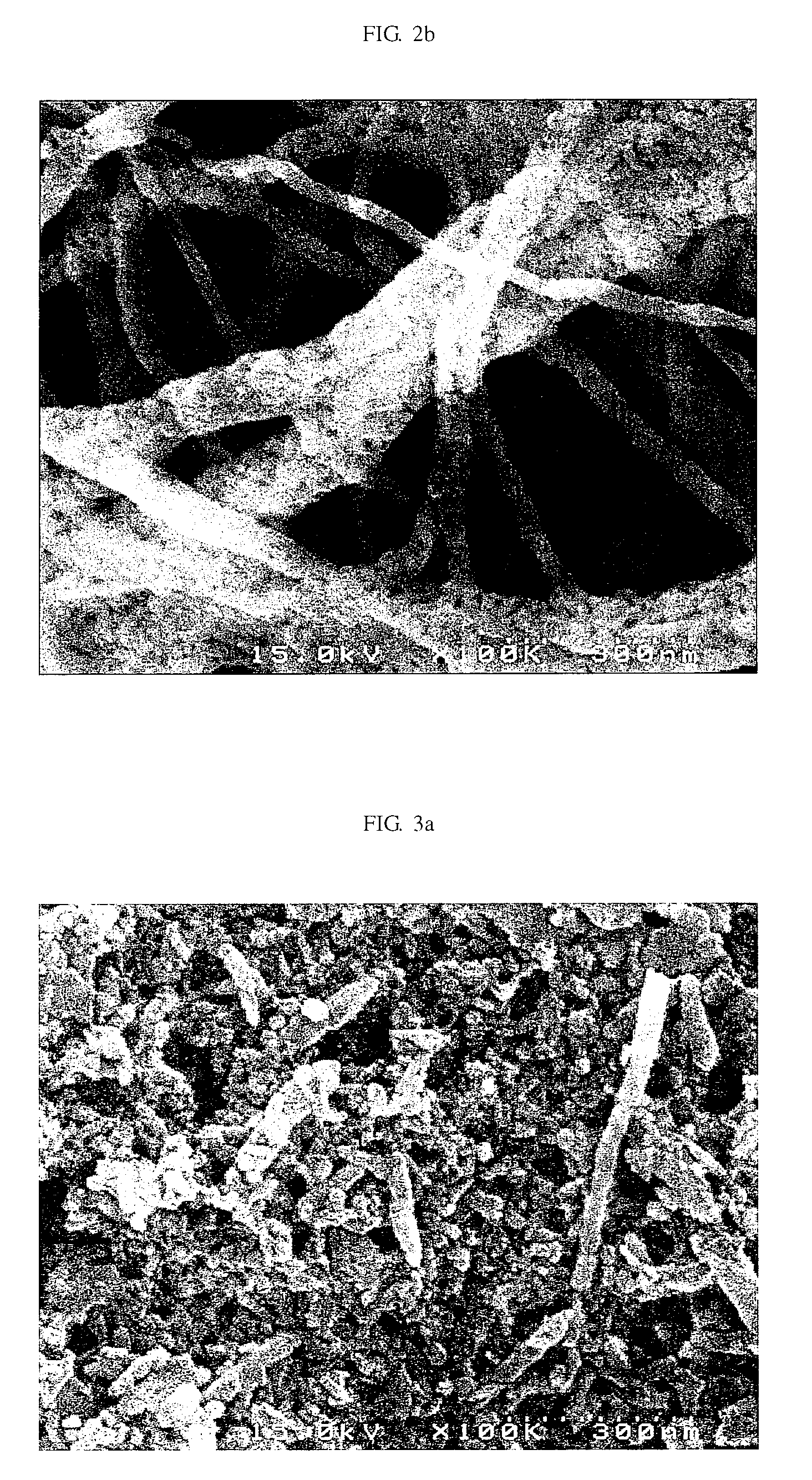

NANO powder, NANO ink and micro rod, and the fabrication methods thereof

InactiveUS20100167078A1Easy to makeOvercome problemsAlkaline earth titanatesPigmenting treatmentFiberMicro rods

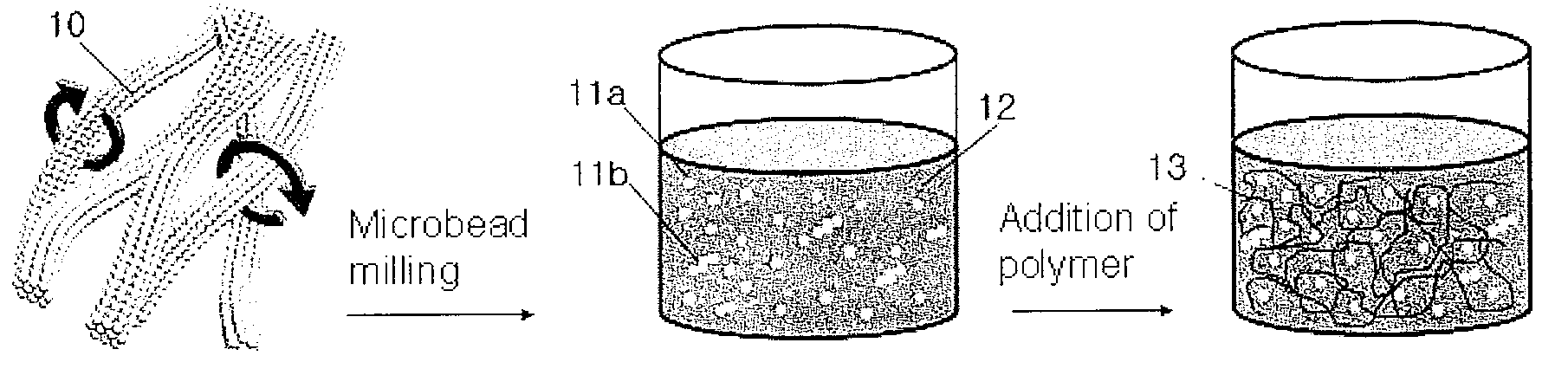

Disclosed are a method for fabricating nanopowders, nano ink containing the nanopowders and micro rods, and nanopowders containing nanoparticles, nano clusters or mixture thereof, milled from nano fiber composed of at least one kind of nanoparticles selected from a group consisting of metal, nonmetal, metal oxide, metal compound, nonmetal compound and composite metal oxide, nano ink containing the nanopowders and microrods, the method comprising spinning a spinning solution containing at least one kind of precursor capable of composing at least one kind selected from a group consisting of metal, nonmetal, metal oxide, metal compound, nonmetal compound and composite metal oxide, crystallizing or amorphizing the spun precursor to produce nano fiber containing at least one kind of nanoparticles selected from a group consisting of metal, nonmetal, metal oxide, metal compound, nonmetal compound and composite metal oxide, and milling the nano fiber to fabricate nanopowders containing nanoparticles, nano clusters or mixture thereof.

Owner:KOREA INST OF SCI & TECH

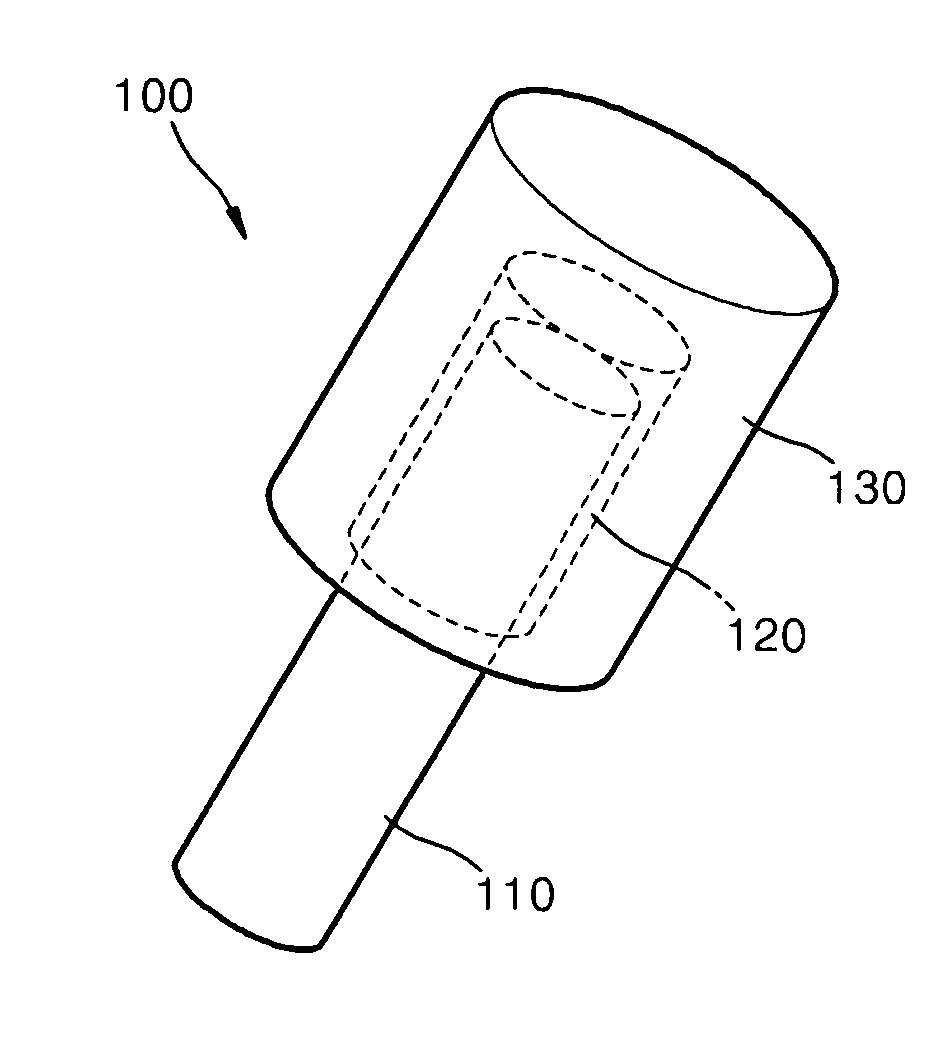

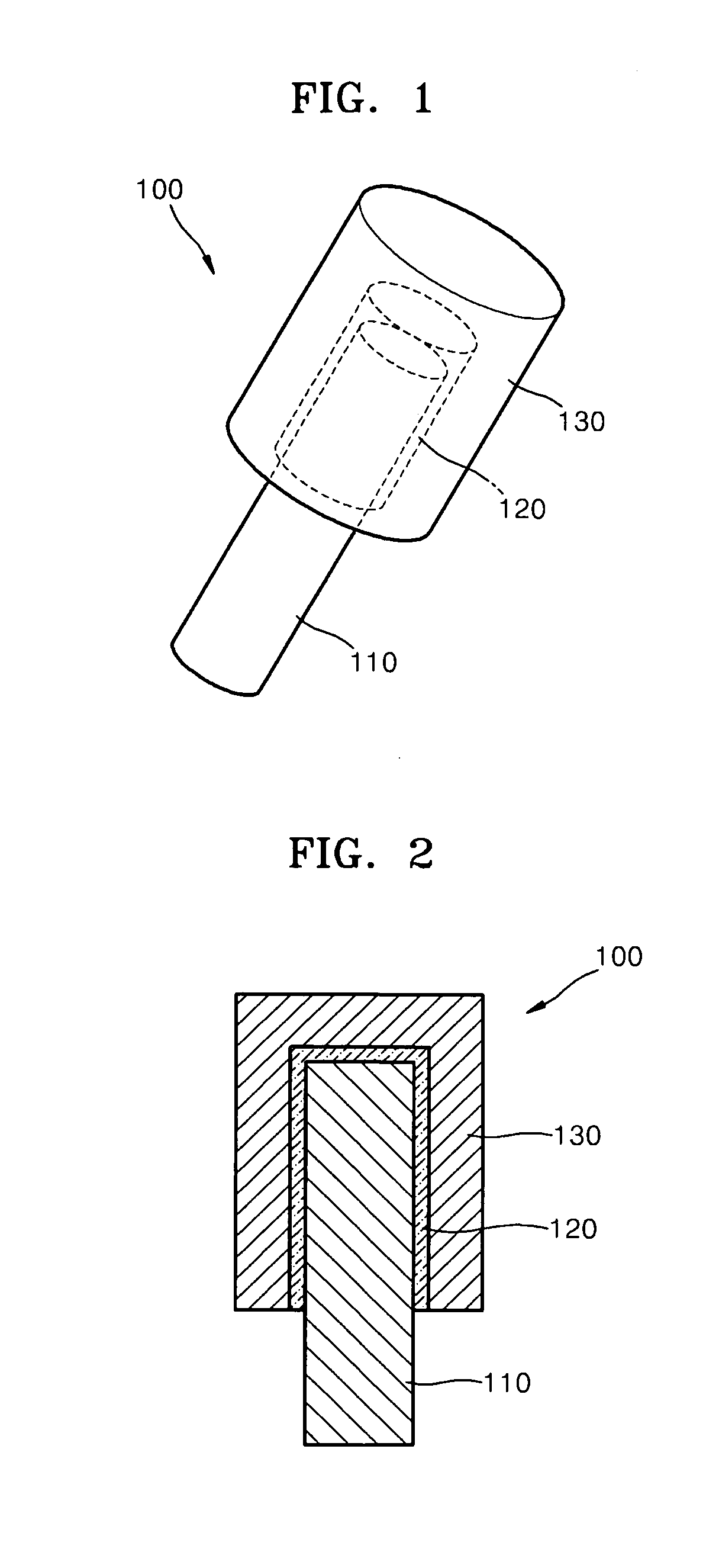

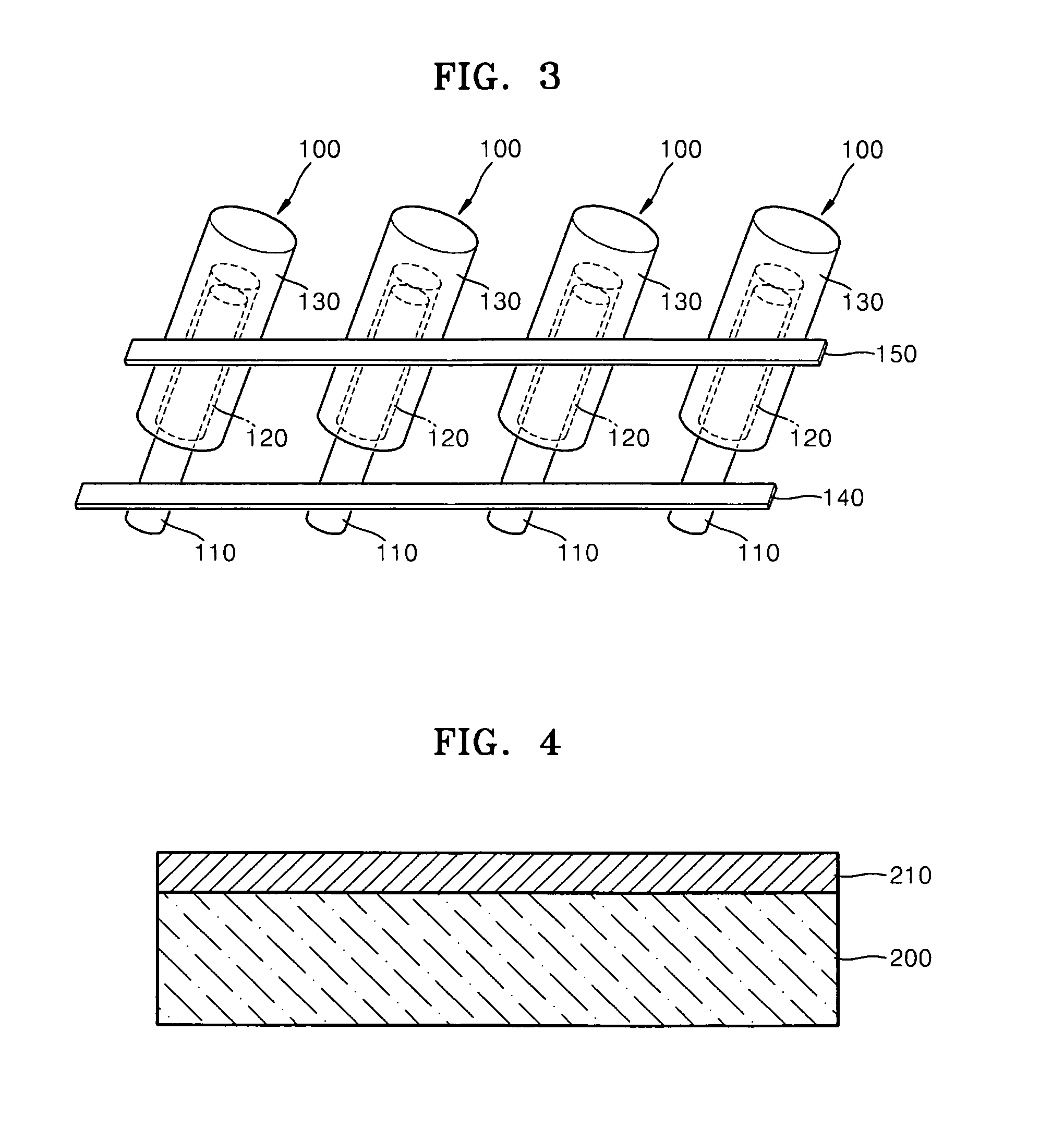

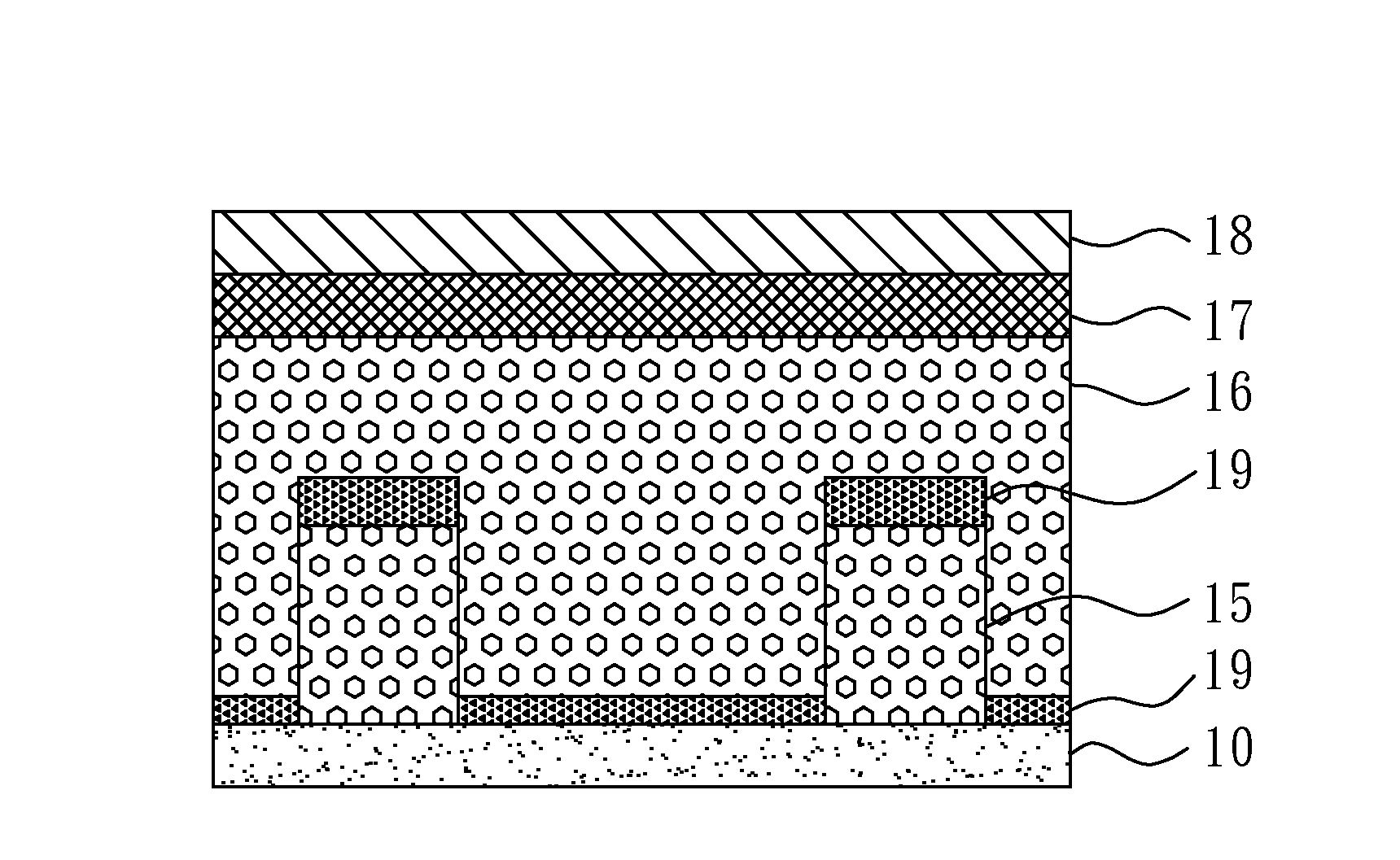

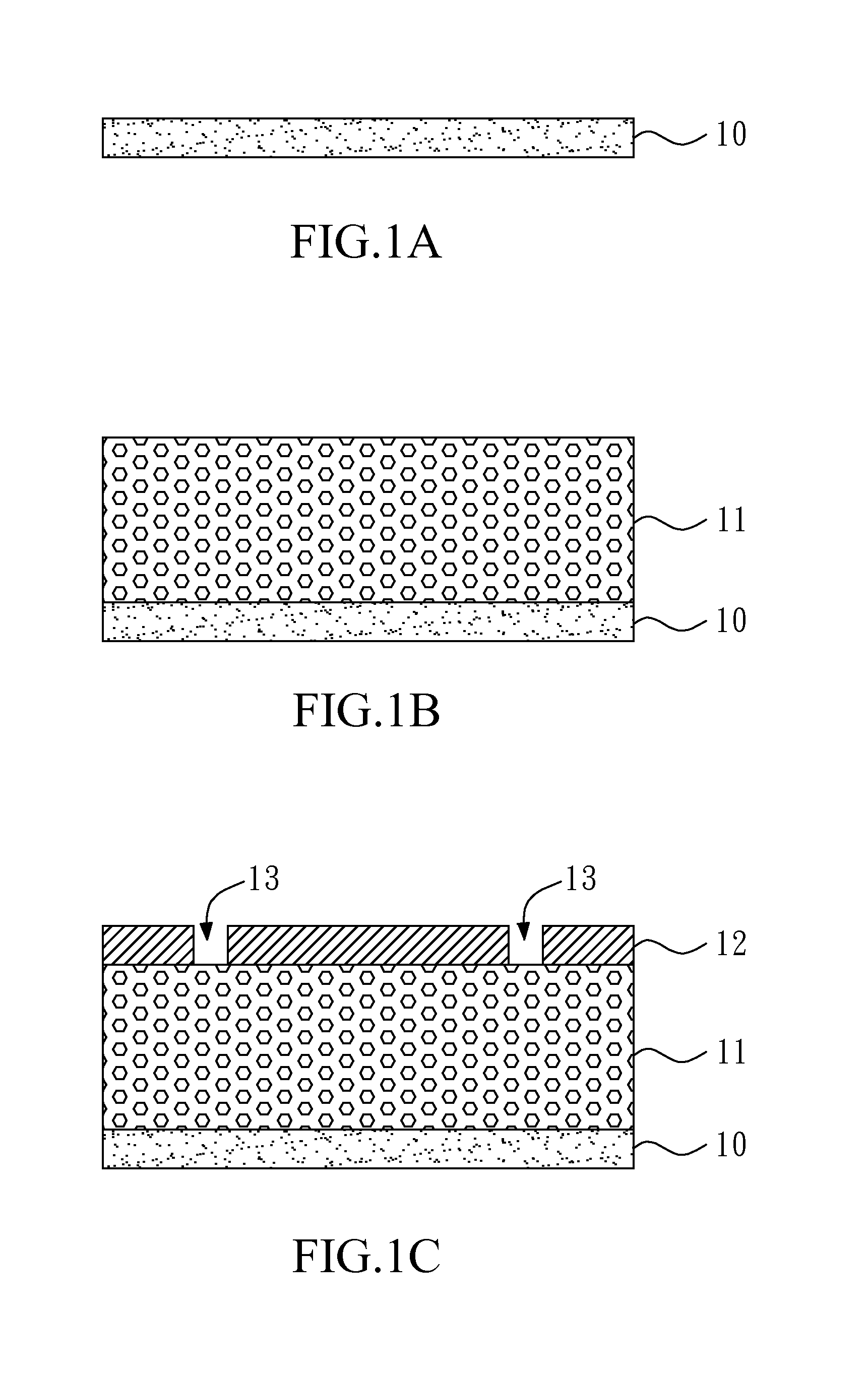

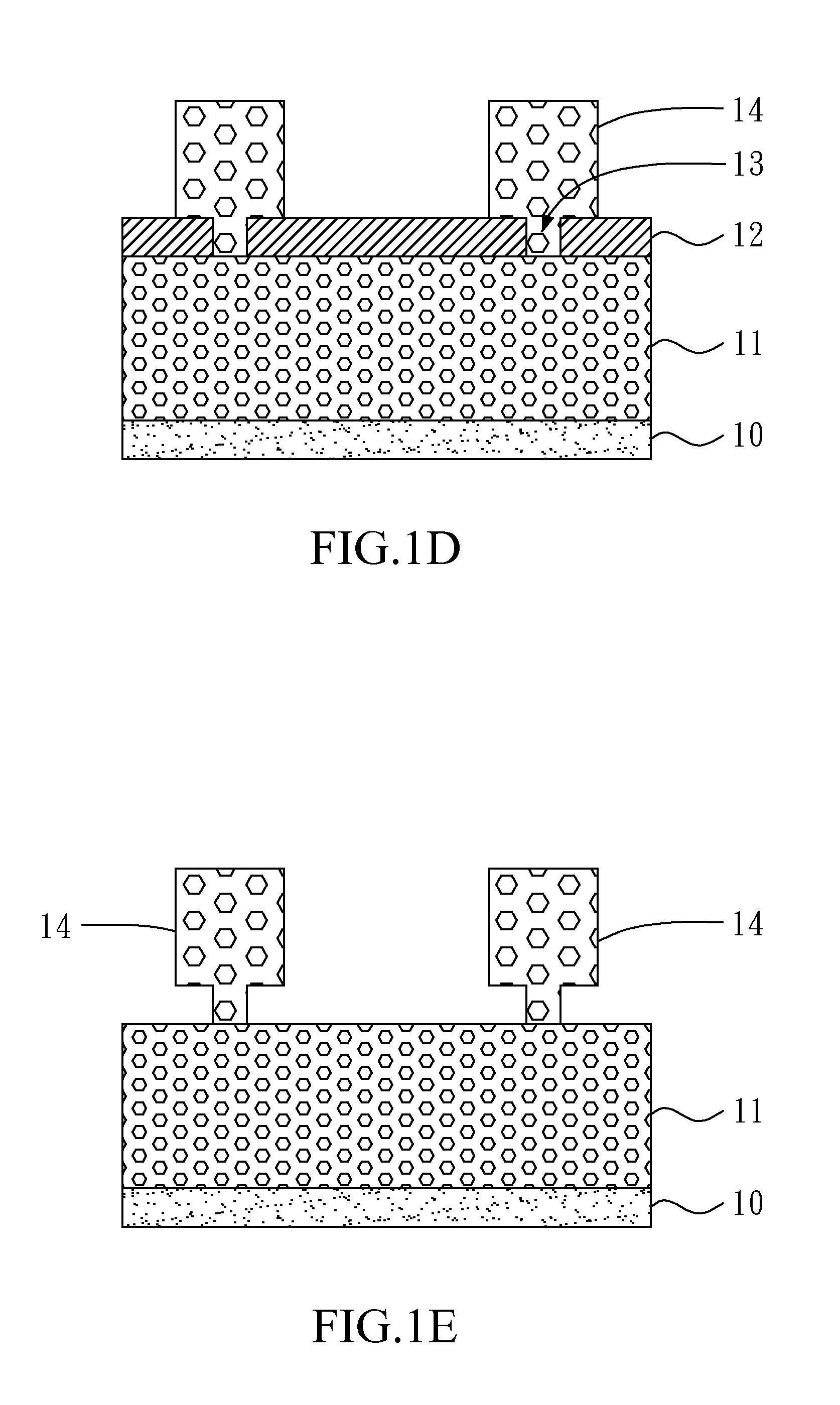

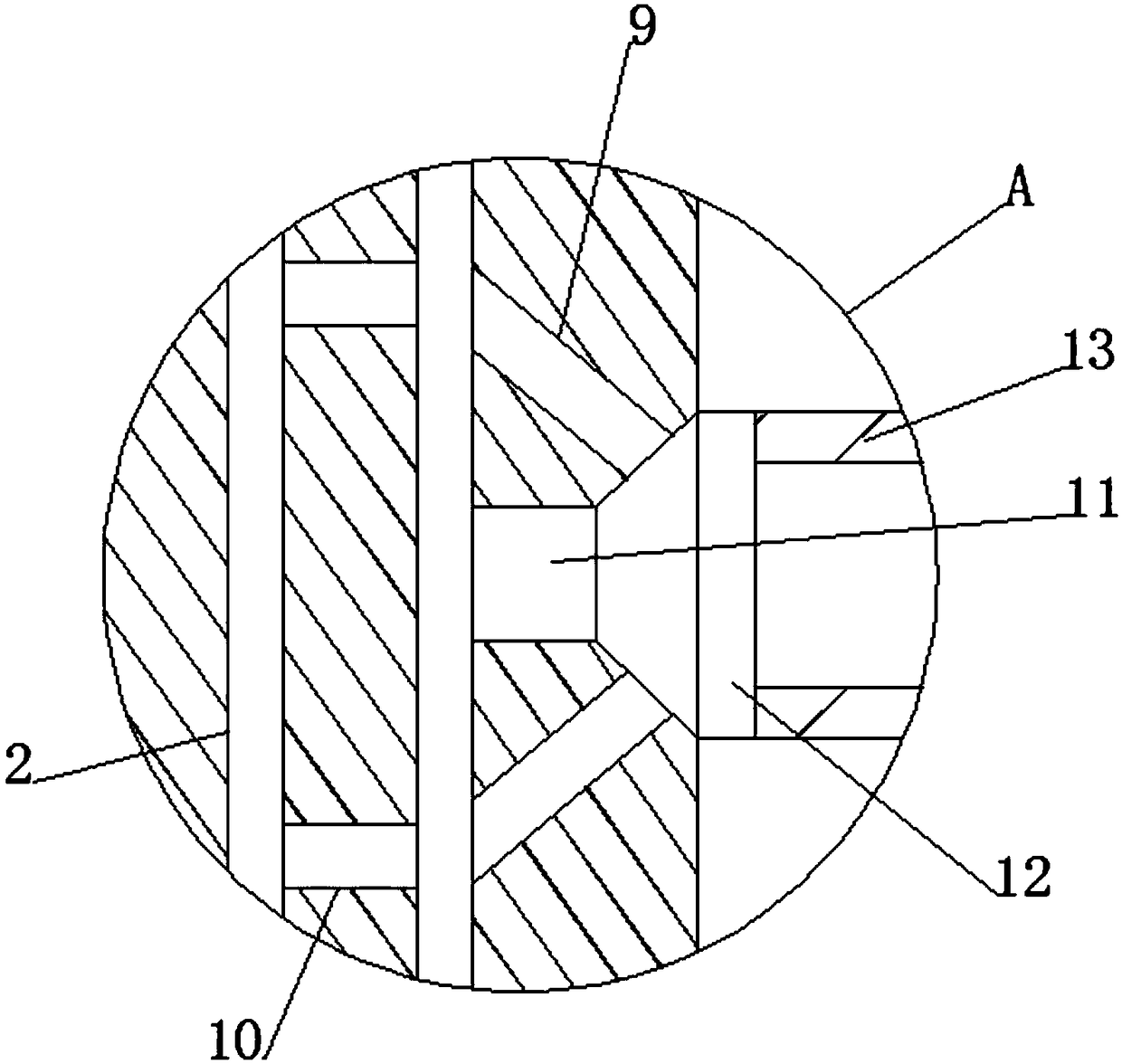

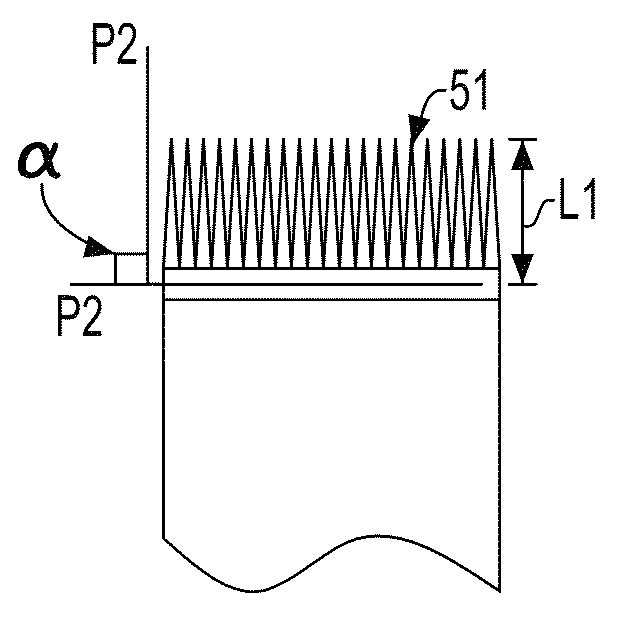

Light emitting device using a micro-rod and method of manufacturing a light emitting device

InactiveUS20100155767A1Semiconductor/solid-state device manufacturingSemiconductor devicesMicro rodsLight emitting device

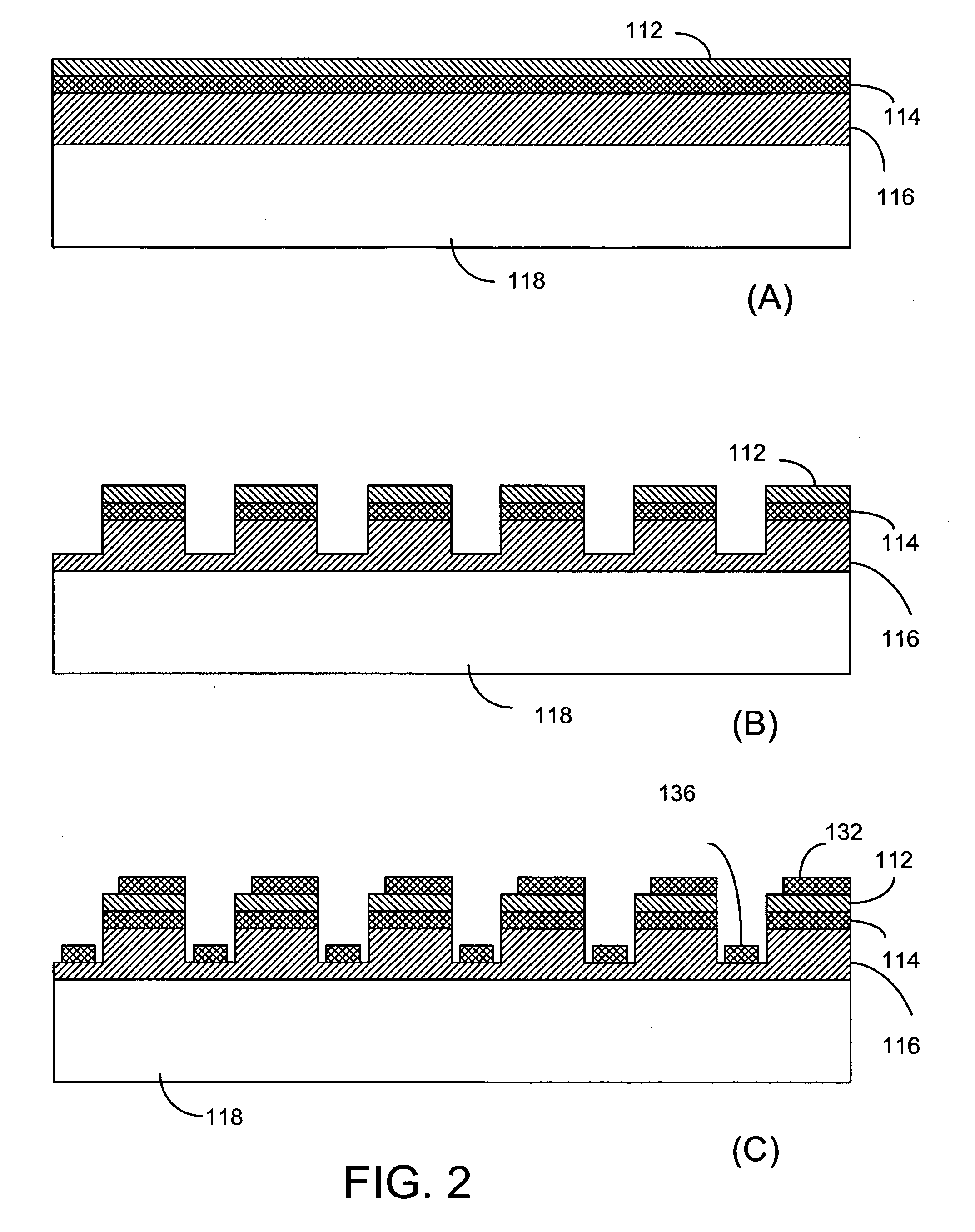

A light emitting device using a micro-rod and a method of manufacturing a light emitting device are provided, the method includes forming a material layer on a substrate. The material layer is patterned such that a hole is formed that exposes a surface of the substrate. A core is grown in the shape of a micro-rod on the surface of the substrate exposed through the hole. A light emitting layer is deposited on the core. A shell is grown on the light emitting layer.

Owner:SAMSUNG ELECTRONICS CO LTD

Semiconductor-graphene hybrids formed using solution growth

InactiveUS8878157B2Prevent orImprove mobilityMaterial nanotechnologySolid-state devicesNano structuringGas phase

Owner:UNIVERSITY OF KANSAS

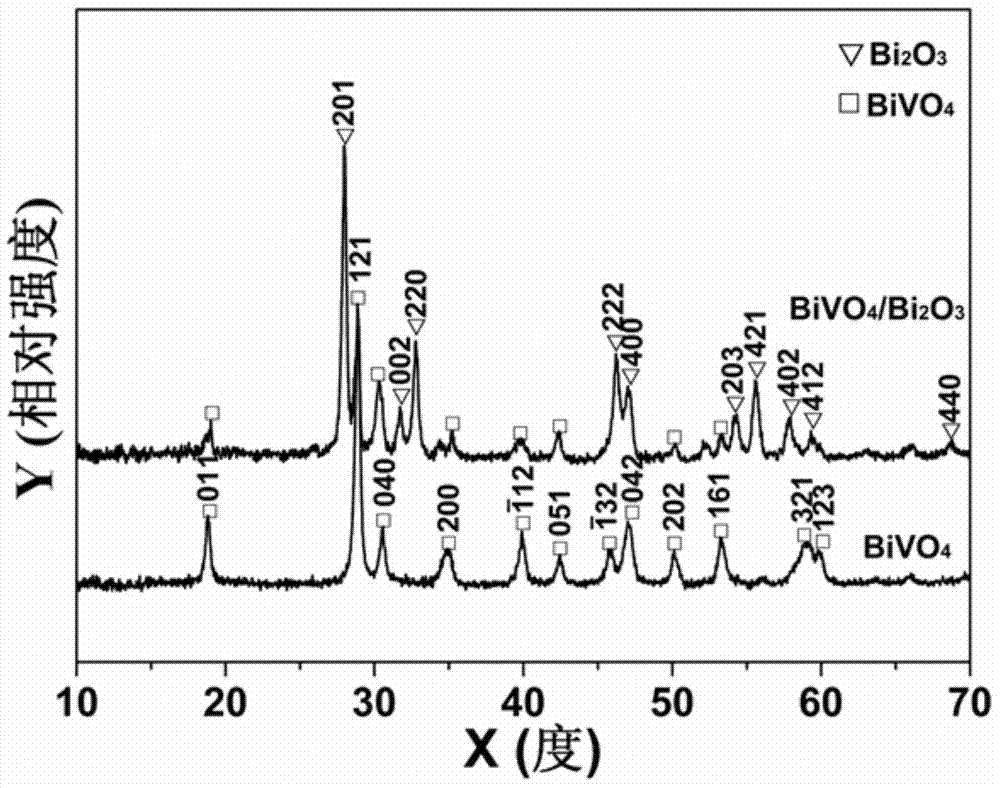

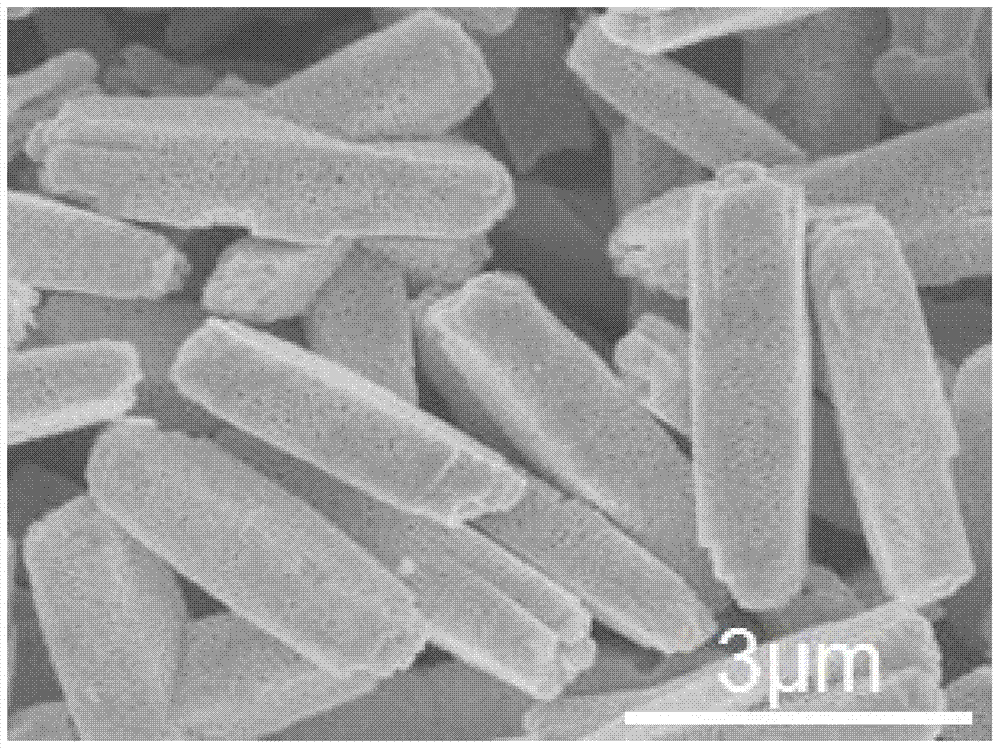

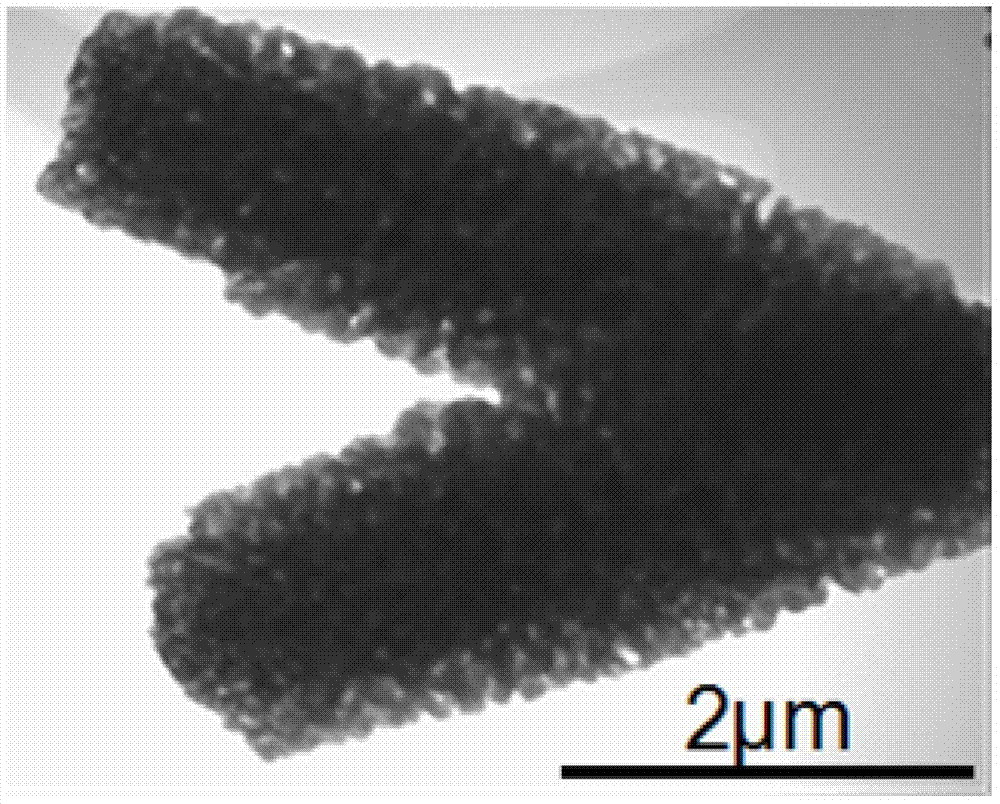

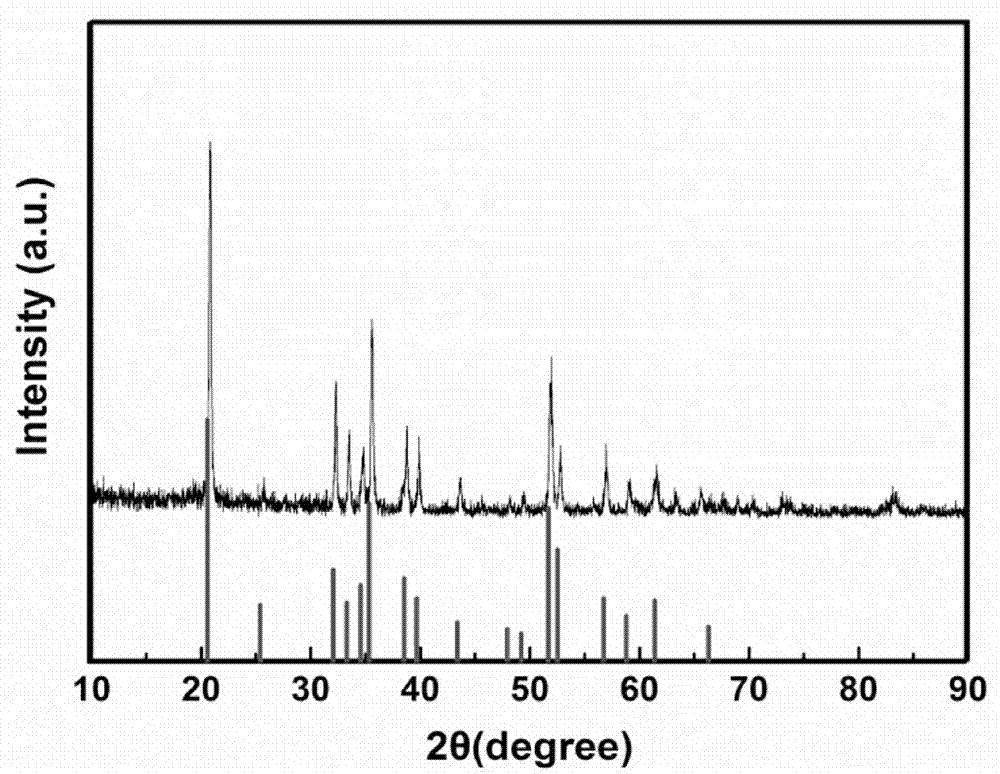

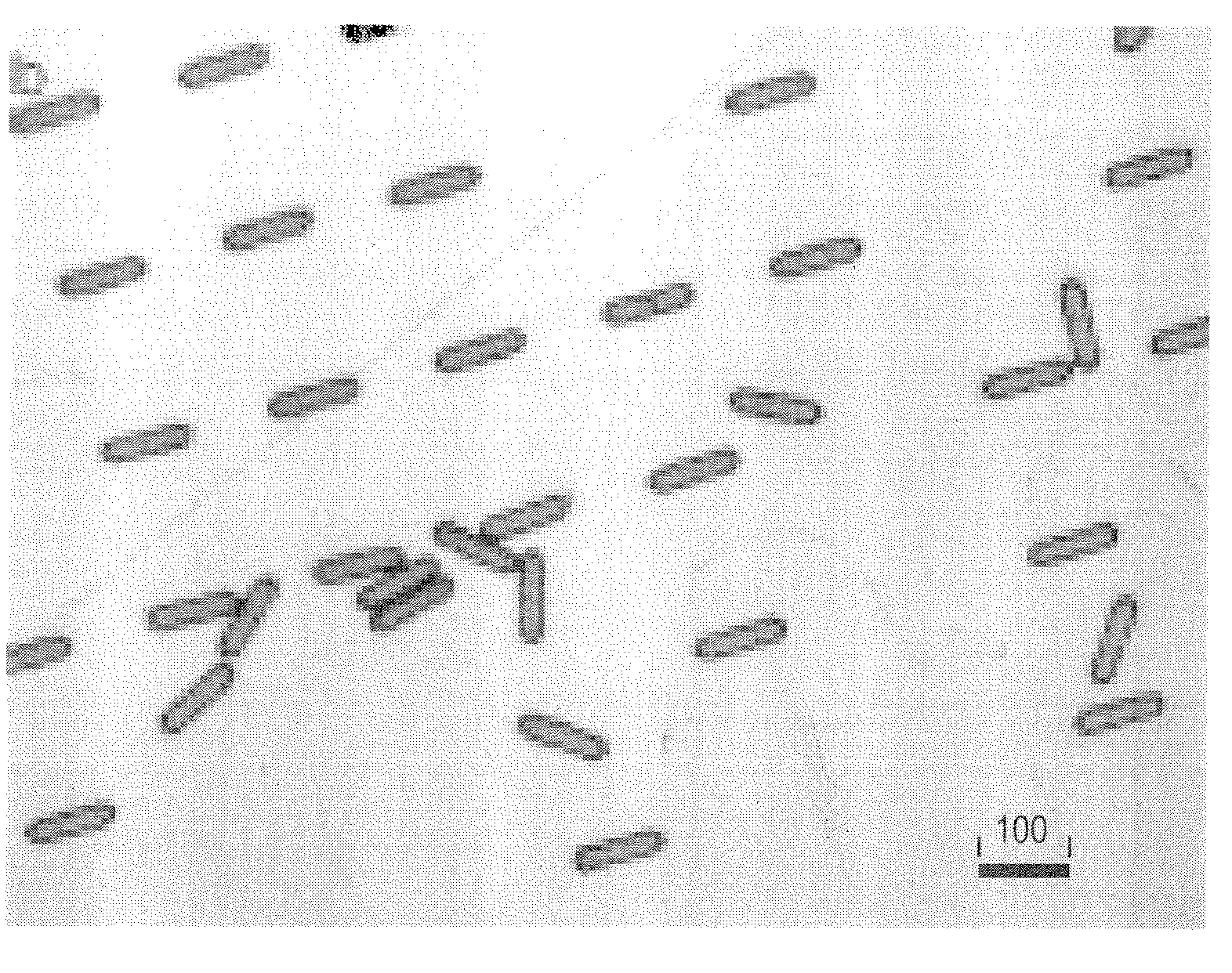

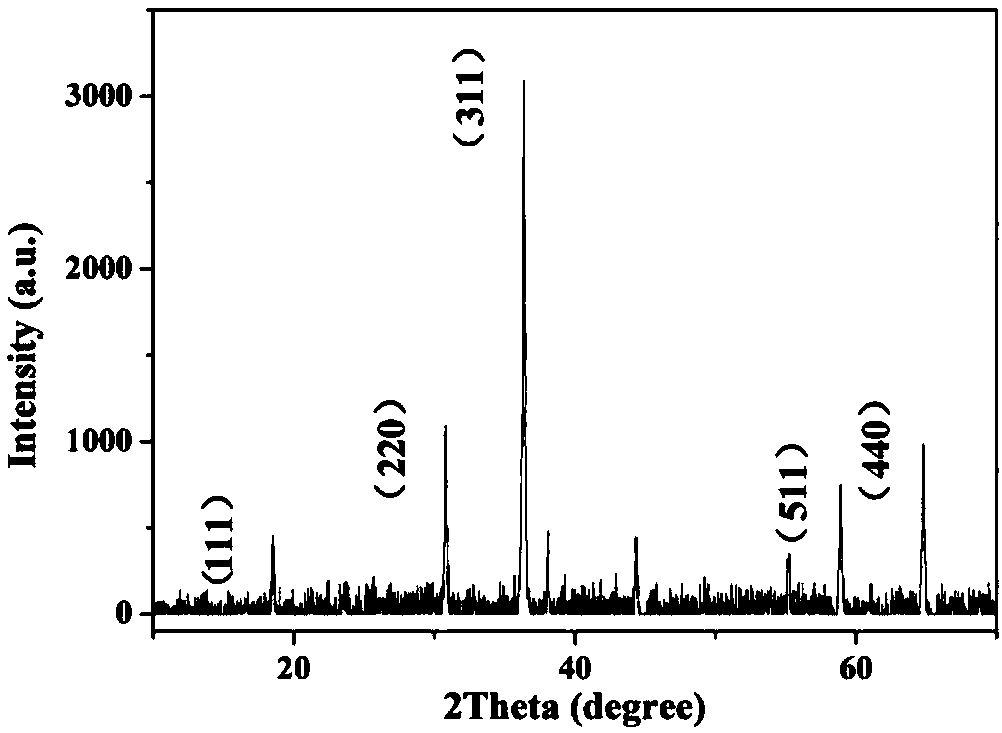

Method for massively preparing mesoporous BiVO4/Bi2O3 composite micro-rod p-n heterojunction photocatalyst

InactiveCN104772134ALow costEasy to controlMetal/metal-oxides/metal-hydroxide catalystsHeterojunctionSurface-active agents

The invention relates to a method for massively preparing a mesoporous BiVO4 / Bi2O3 composite micro-rod p-n heterojunction photocatalyst. The method for massively preparing the mesoporous BiVO4 / Bi2O3 composite micro-rod p-n heterojunction photocatalyst takes metal inorganic salt-bismuth nitrate pentahydrate (Bi (NO3) 3.5H2O) as a reaction precursor, polyvinylpyrrolidone (PVP) as a surface active agent as well as sodium oxalate (Na2C2O4) and sodium metavanadate (NaVO3) as reactants; the method comprises the steps of feeding the surface active agent into the reaction precursor, carrying out a solvothermal reaction, centrifuging, washing, drying, and carrying out solid-phase reaction calcination on the obtained product at the temperature of 300-400 DEG C to obtain the BiVO4 / Bi2O3 composite micro-rod p-n heterojunction photocatalyst. The prepared mesoporous BiVO4 / Bi2O3 composite micro-rod p-n heterojunction photocatalyst has the length of about 3.5-4.5mu m, the diameter of about 0.7-0.9mu m and the mesoporous average diameter of 30.0nm. The prepared mesoporous BiVO4 / Bi2O3 composite micro-rod p-n heterojunction photocatalyst has the characteristics of being low in cost, easy to control, good in repeatability, and the like.

Owner:ZHEJIANG NORMAL UNIVERSITY

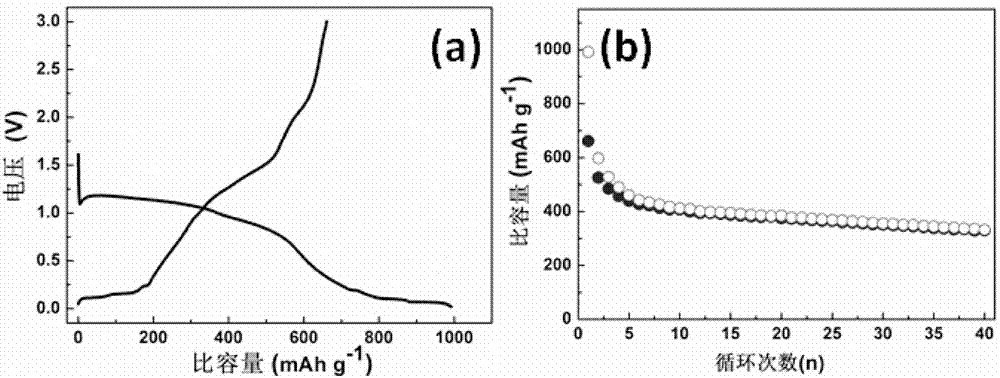

Method of in-situ synthesis of porous nano Co3O4/C anode material

The invention provides a method of in-situ synthesis of a porous nano Co3O4 / C anode material and belongs to the field of electrochemical. The method particularly includes steps of: synthesizing a rod-like porous cobalt-based metal organic framework through a solvothermal method, and washing, soaking and vacuum-drying a product to obtain a precursor; performing high-temperature carbonization decomposition to the precursor in a tubular furnace with an inert gas / oxygen mixture atmosphere, thus preparing a hierarchical porous nano / micro rod-like Co3O4 / C anode material. In the invention, with the porous and large-specific-surface-area cobalt-based metal organic framework, which has periodical network crystal structure, being a self-template precursor, the hierarchical porous nano / micro rod-likeCo3O4 / C anode material is prepared through the in-situ th ermal decomposition. The method has simple process. The anode material has high conductivity and specific capacity, and is excellent in cyclic stability.

Owner:JIANGSU UNIV

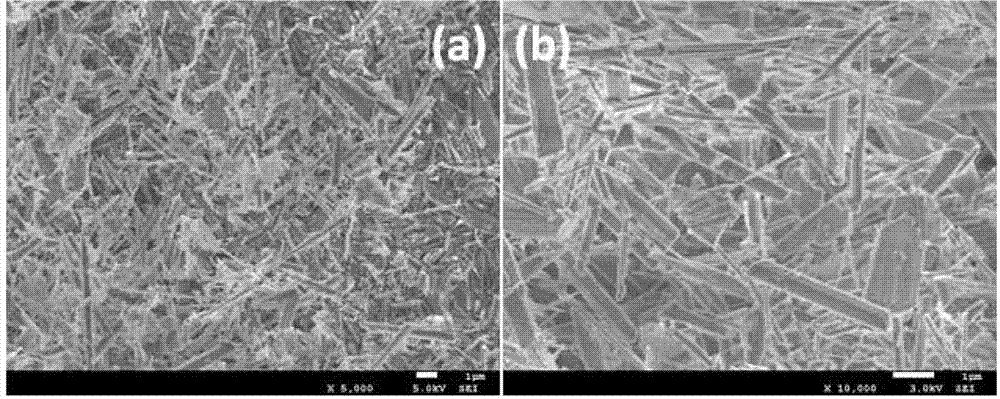

Novel Co(OH)F lithium ion battery negative electrode material and preparation method thereof

ActiveCN104124447AFacilitate chemical reactionsCell electrodesSecondary cellsChemical reactionMicro rods

The invention provides a novel lithium ion battery negative electrode material. The negative electrode material is rod-shaped; the length of a rod is 1-5 microns, and the diameter of the rod is 100 nanometers-1 micron. A preparation method of the rod-shaped Novel Co(OH)F lithium ion battery negative electrode material comprises the following steps: carrying out chemical reaction on cobaltous acetate, sodium fluoride and hexamethylenetetramine or glucose which are used as basic raw materials under the hydrothermal condition so as to obtain the rod-shaped Novel Co(OH)F lithium ion battery negative electrode material. A synthesis method of the negative electrode material is simple and easy to operate; a prepared sample is micro rod-shaped; the length of the micro rod is 1-5 microns, and the diameter of the micro rod is 100 nanometers-1 micron.

Owner:CHINA THREE GORGES UNIV

Method for forming semiconductor nano-micro rods and applications thereof

InactiveUS20120129290A1Reduce dislocation densitySemiconductor/solid-state device manufacturingNanoopticsMicro rodsEngineering

An embodiment of this invention utilizes ZnO rods as the etching mask to etch a GaN layer arranged below, so that GaN rods are formed. The GaN rods have similar patterns as the ZnO rods. The pattern, size, position, and height of the GaN rods are respectively controlled by the pattern, size, position, and height of the ZnO rods.

Owner:NAT TAIWAN UNIV

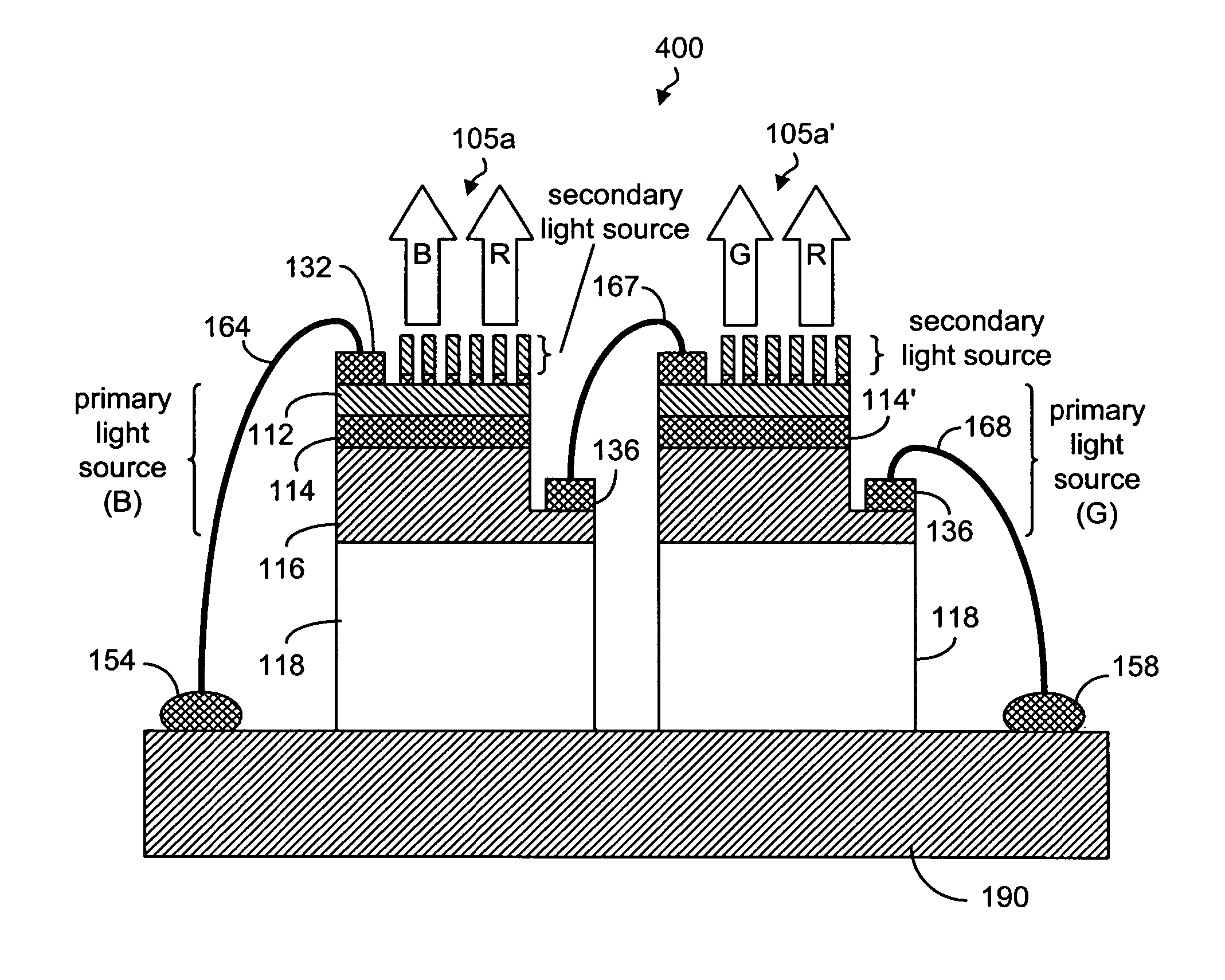

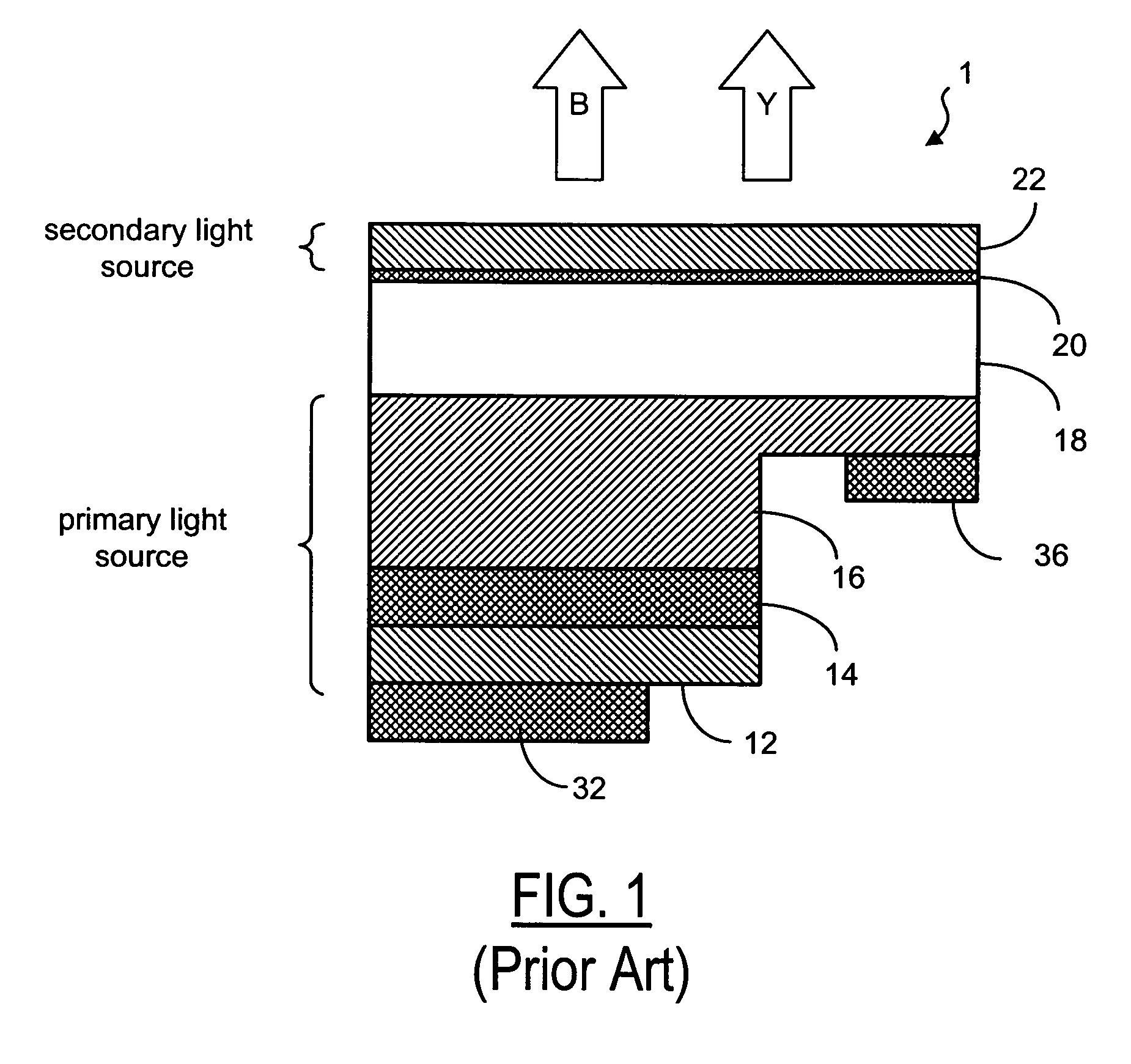

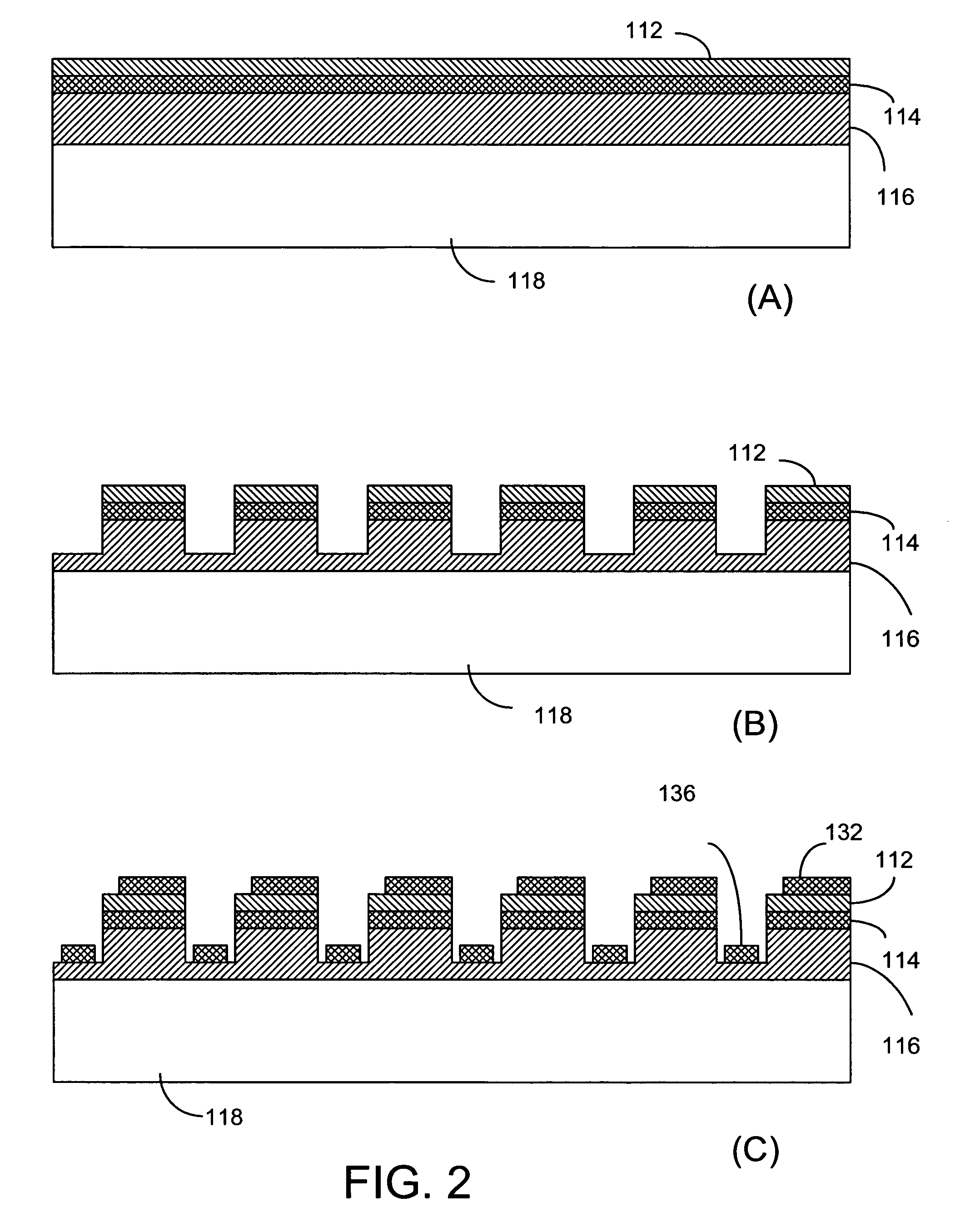

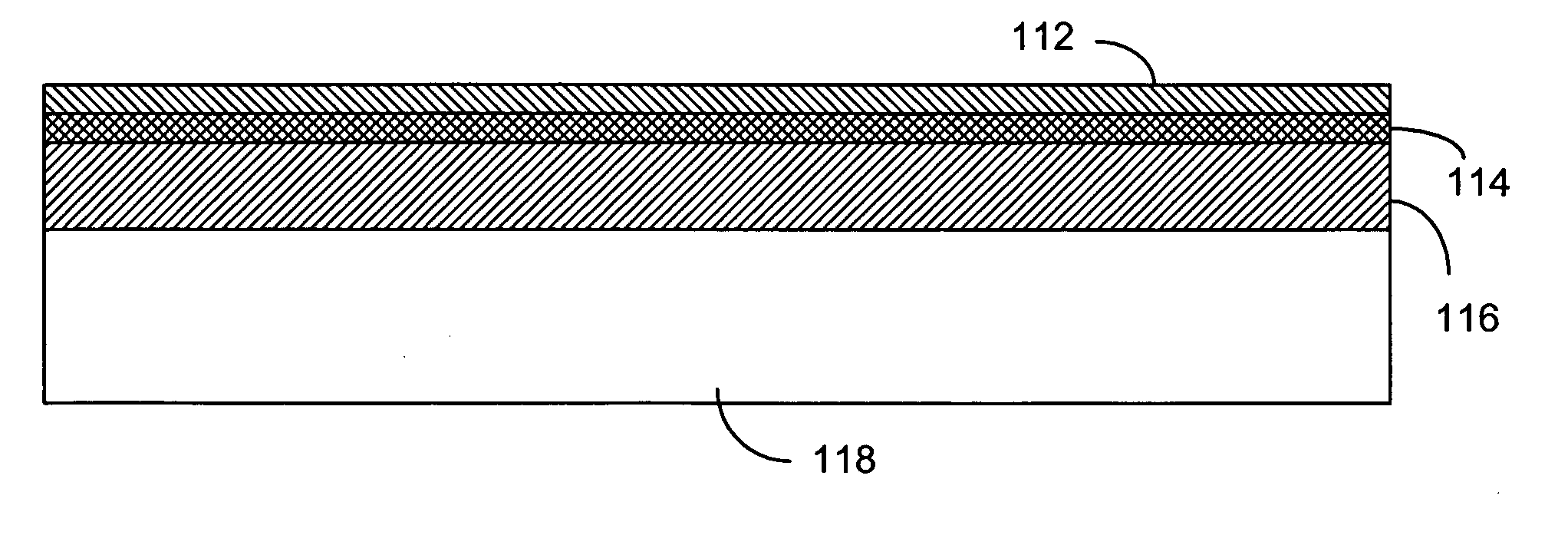

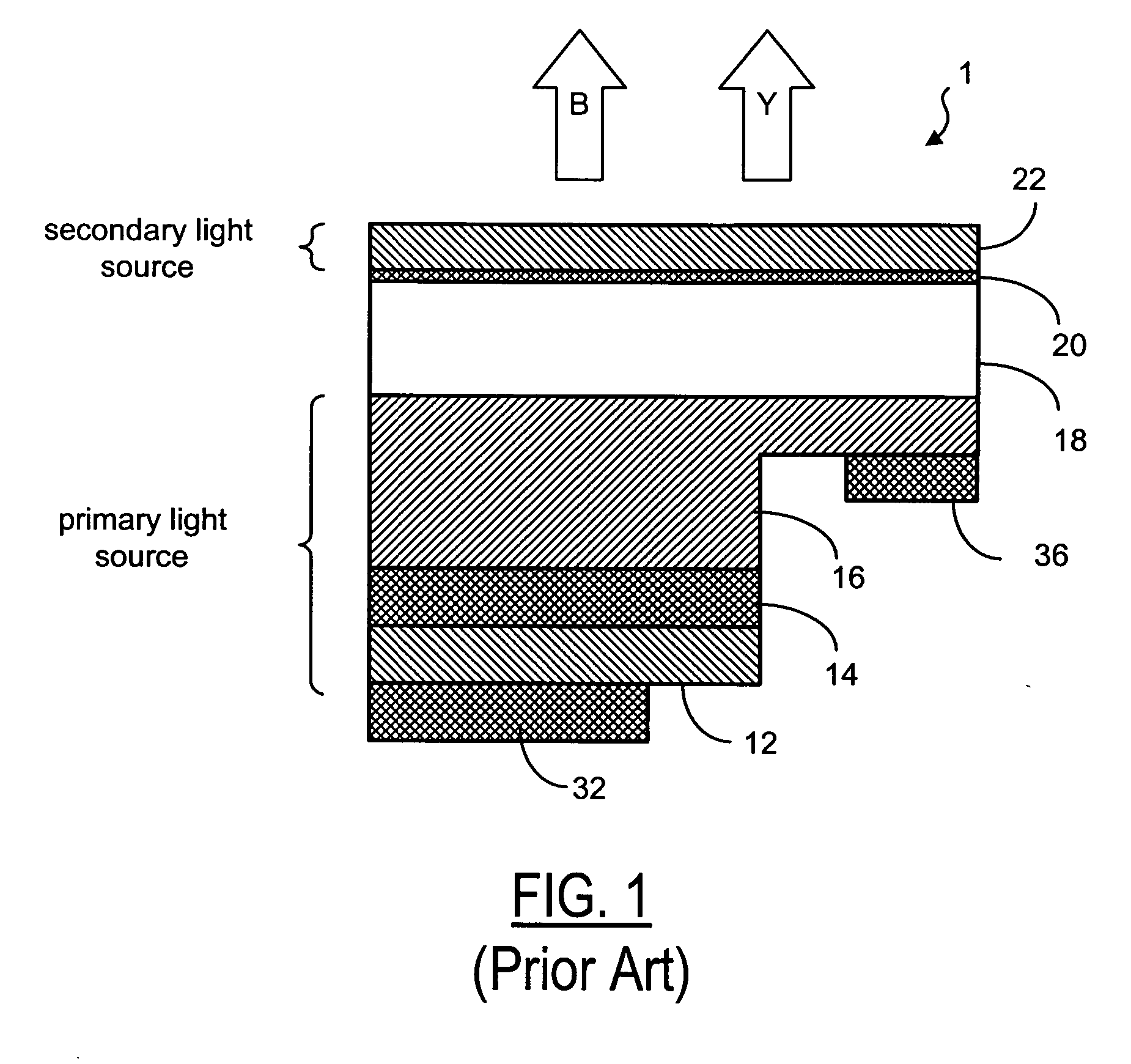

White light emitting device and method of making same

ActiveUS7208336B2Solid-state devicesSemiconductor/solid-state device manufacturingMicro rodsGreen-light

A white-light emitting device comprising a first PRS-LED and a second PRS-LED. The first PRS-LED has a primary light source to emit blue light and a secondary light source to emit red light responsive to the blue light; and the second PRS-LED has a primary light source to emit green light and a secondary light source for emitting red light responsive to the green light. Each of the primary light sources is made from an InGaN layer disposed between a p-type GaN layer and an n-type GaN layer. The secondary light sources are made from AlGaInP. The primary light source and the secondary light source can be disposed on opposite sides of a sapphire substrate. Alternatively, the second light source is disposed on the n-type GaN layer of the primary light source. The second light sources may comprise micro-rods of AlGaInP of same or different compositions.

Owner:OPTRONIC SCI LLC

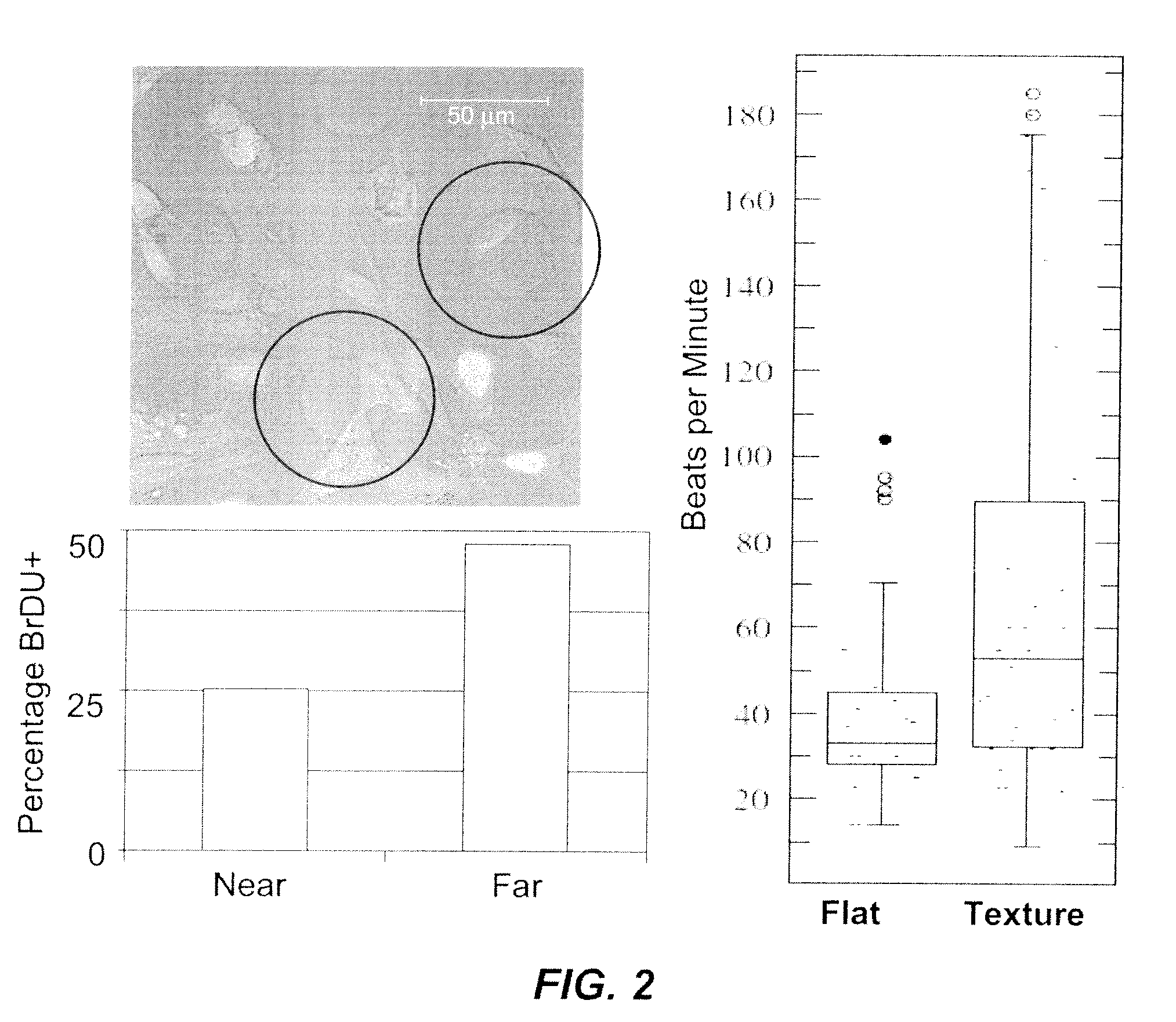

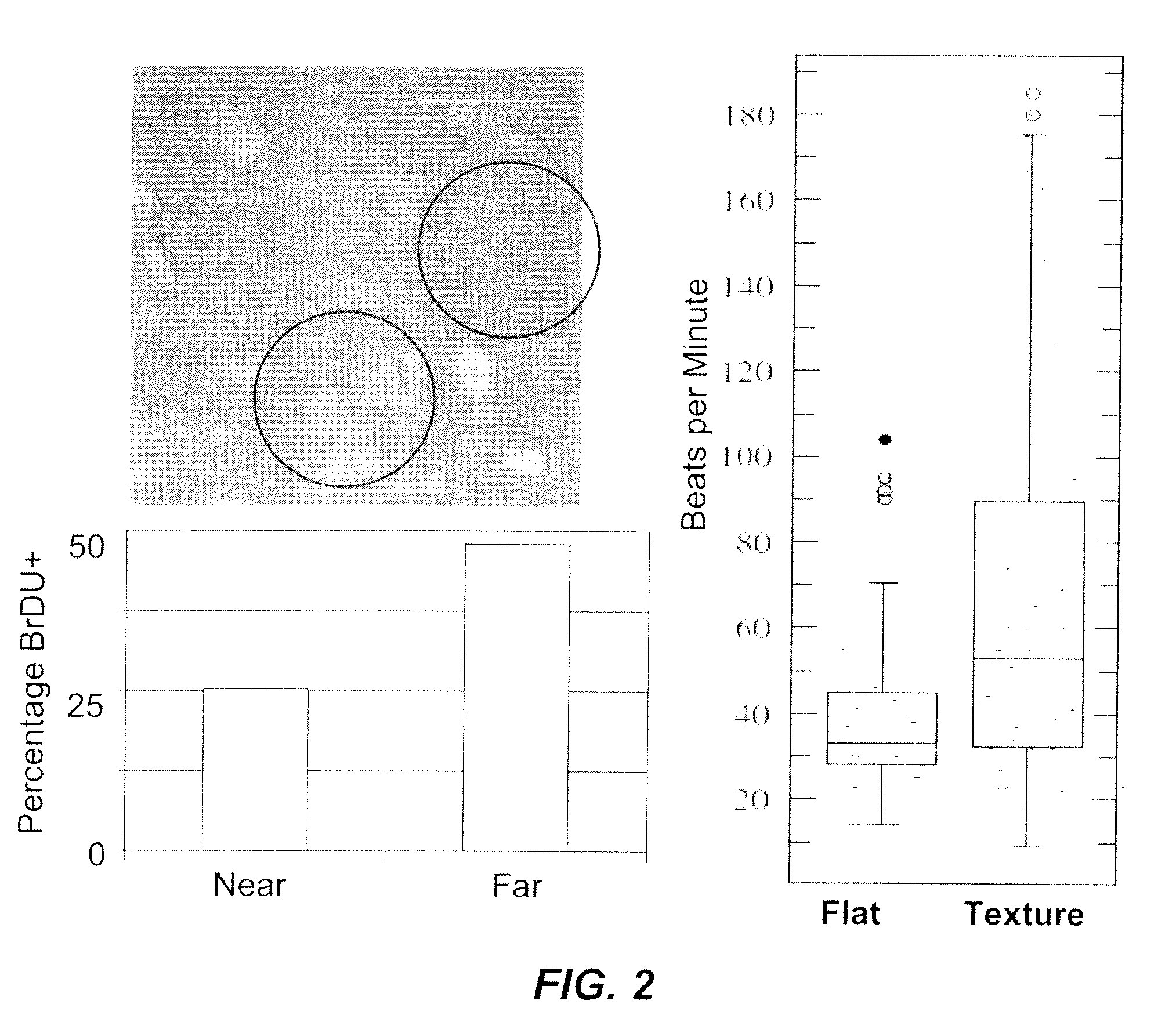

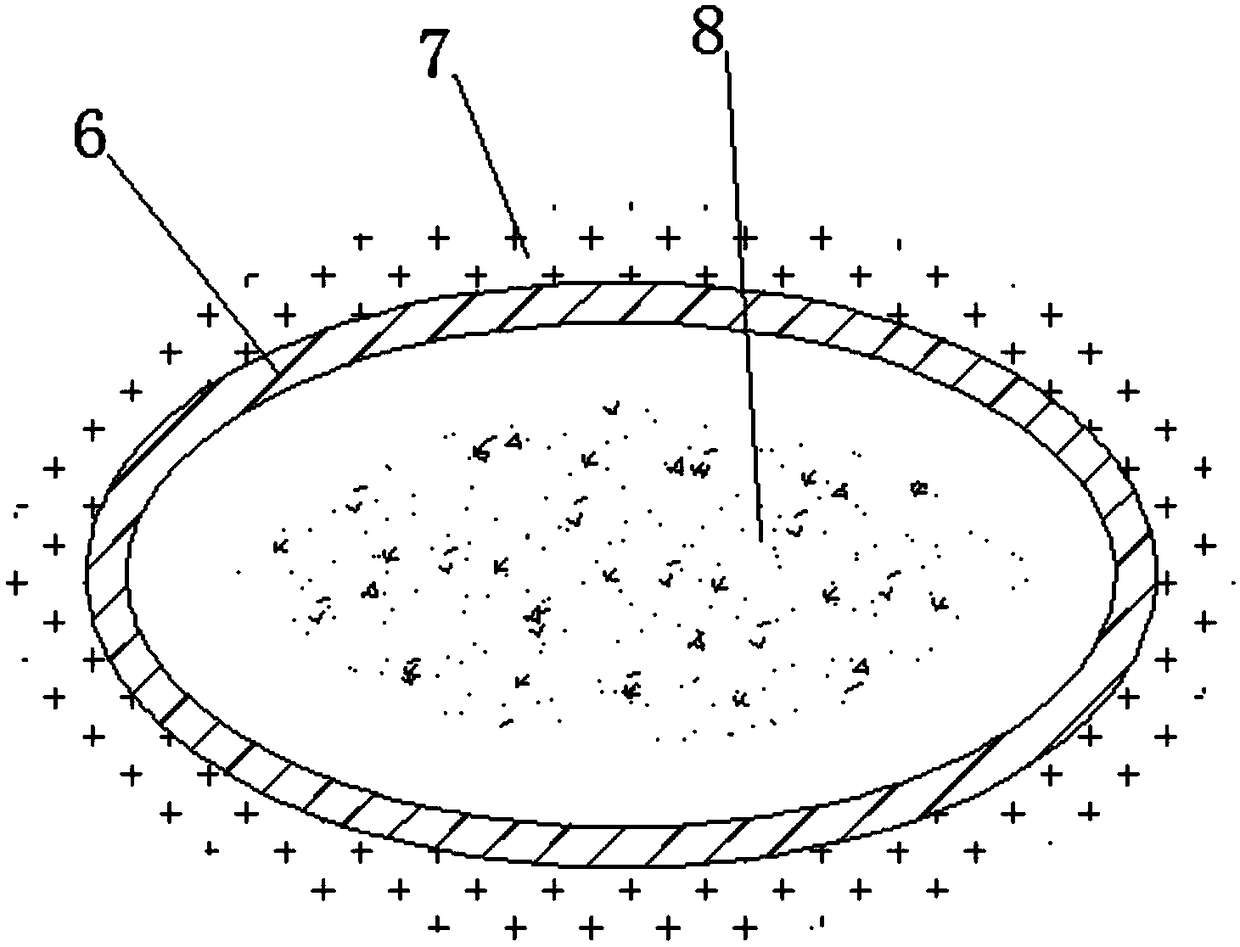

Temporal release of growth factors from 3D micro rod scaffolds for tissue regeneration

InactiveUS20100158979A1Efficient repairPeptide/protein ingredientsMuscular disorderDiseaseMicro rods

The present invention relates to the use of three-dimensional microrod scaffolds for the temporal release of growth factors useful in tissue regeneration, engineering and treatment of disorders.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

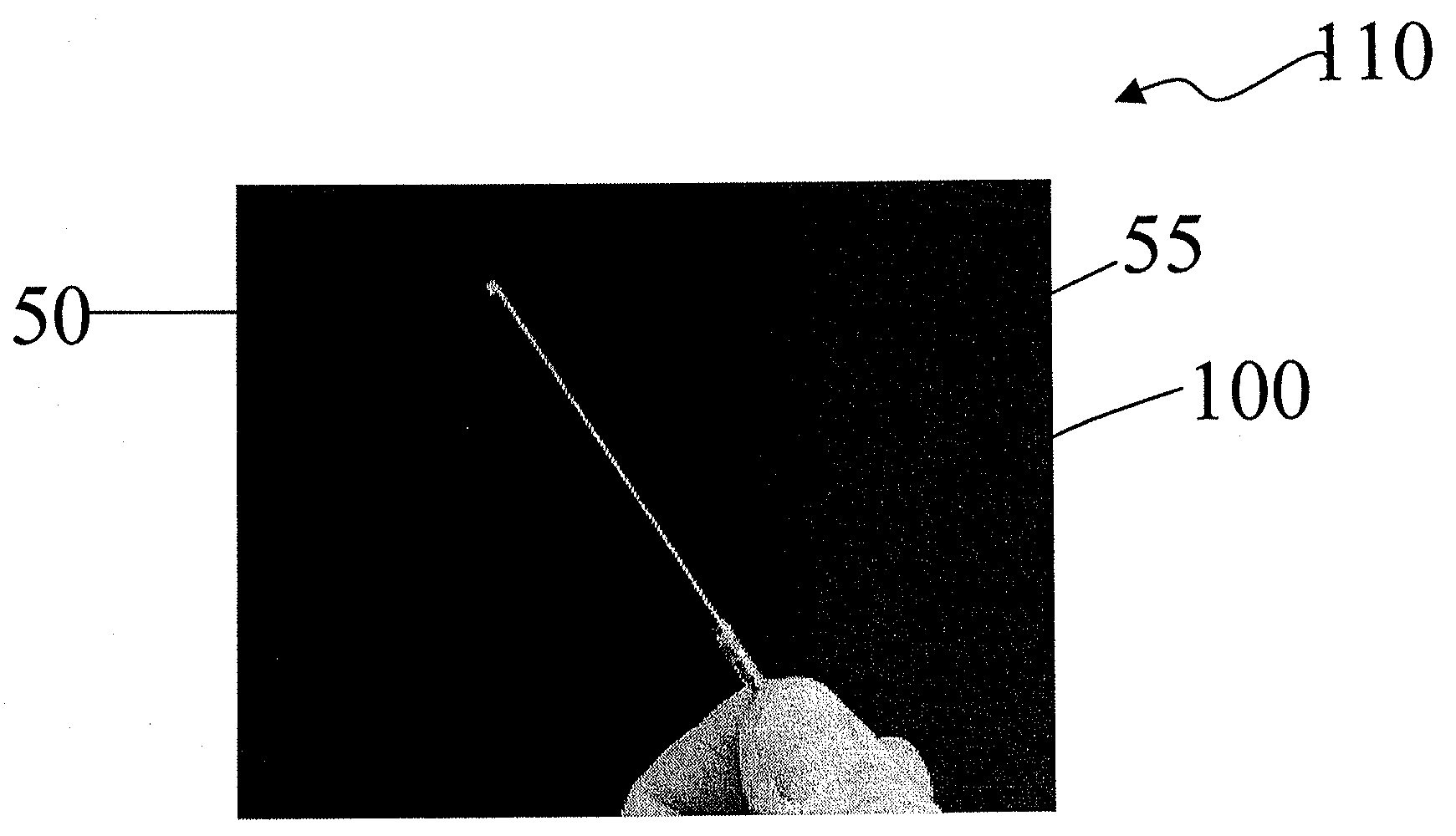

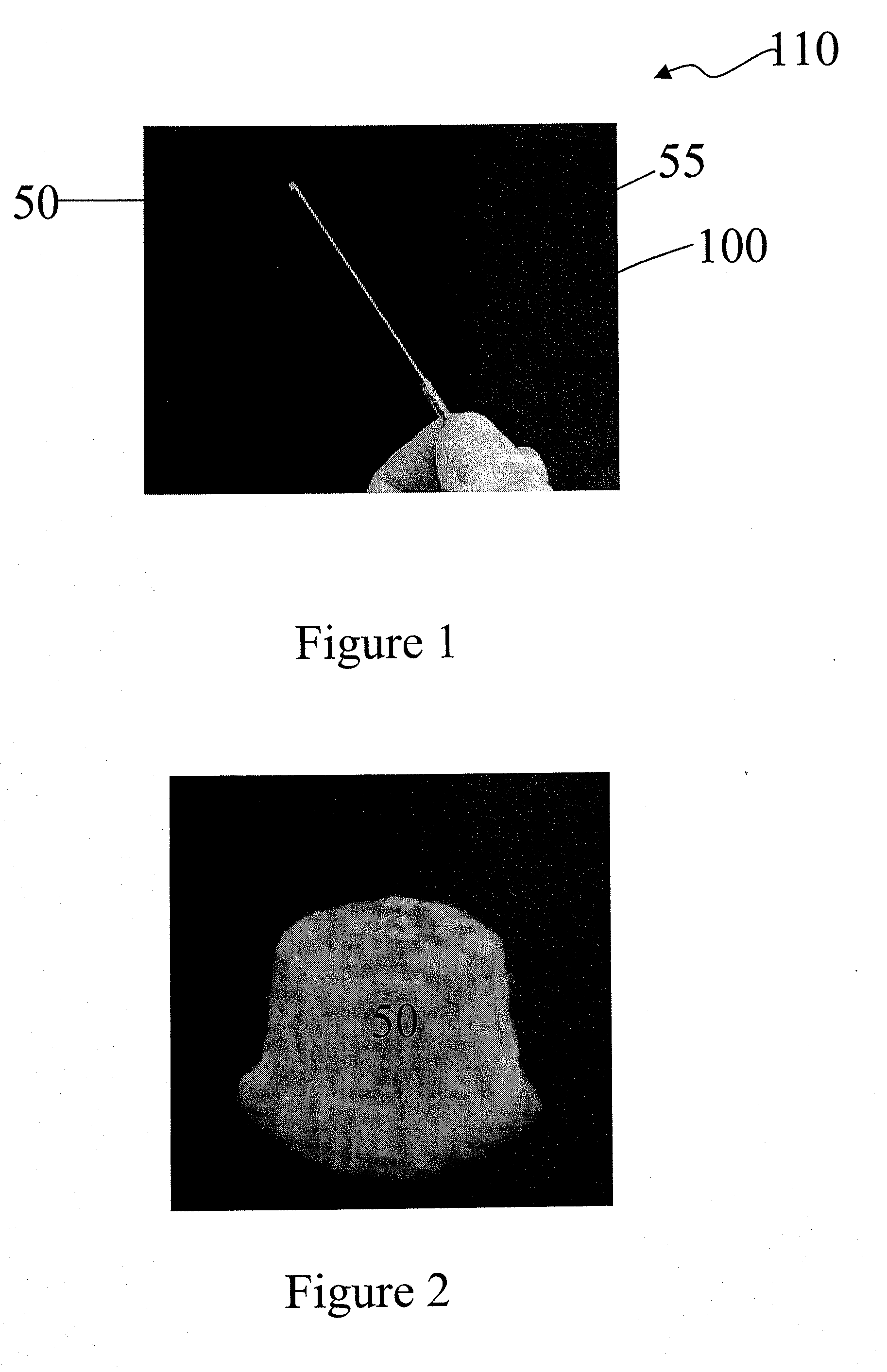

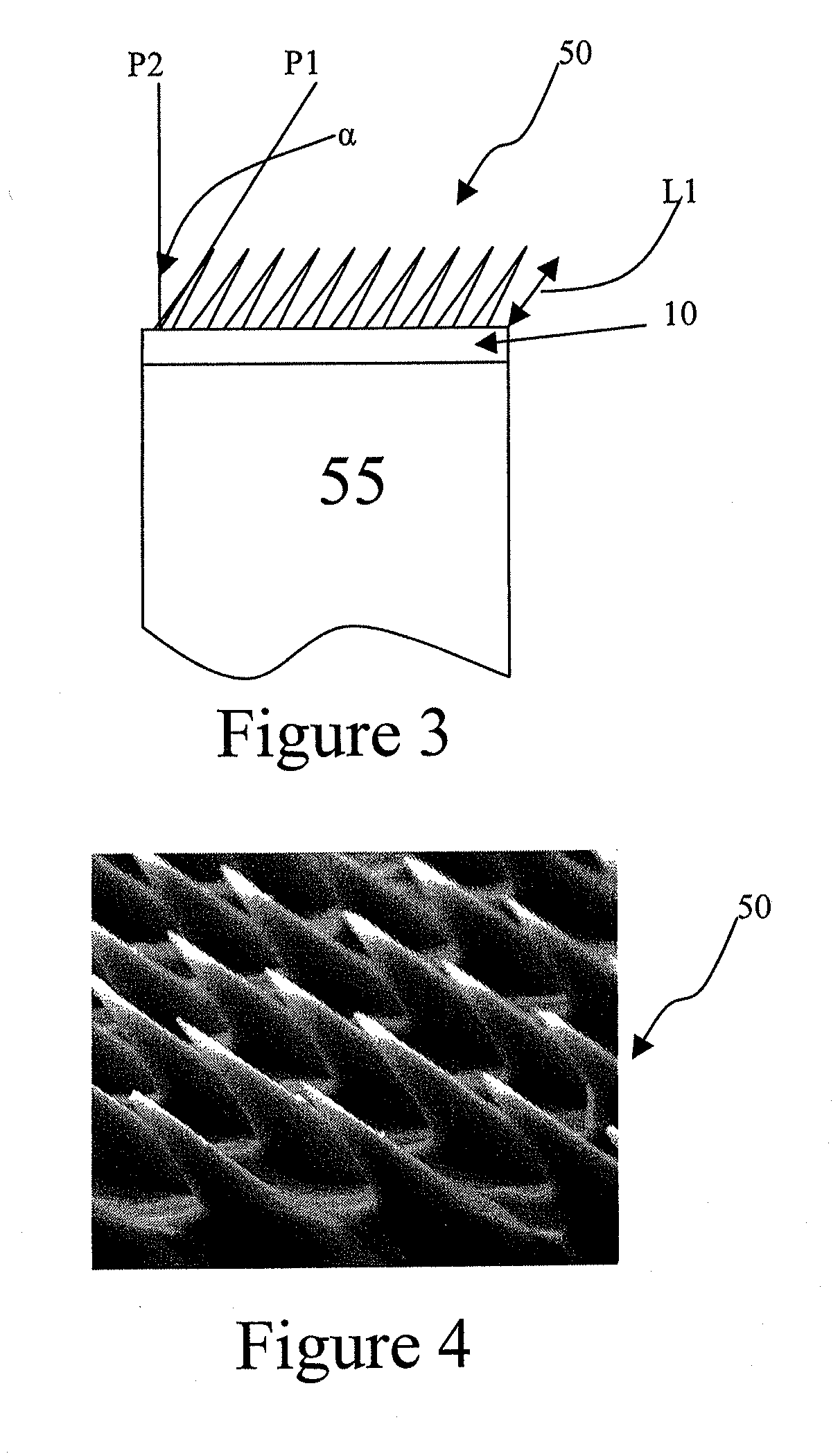

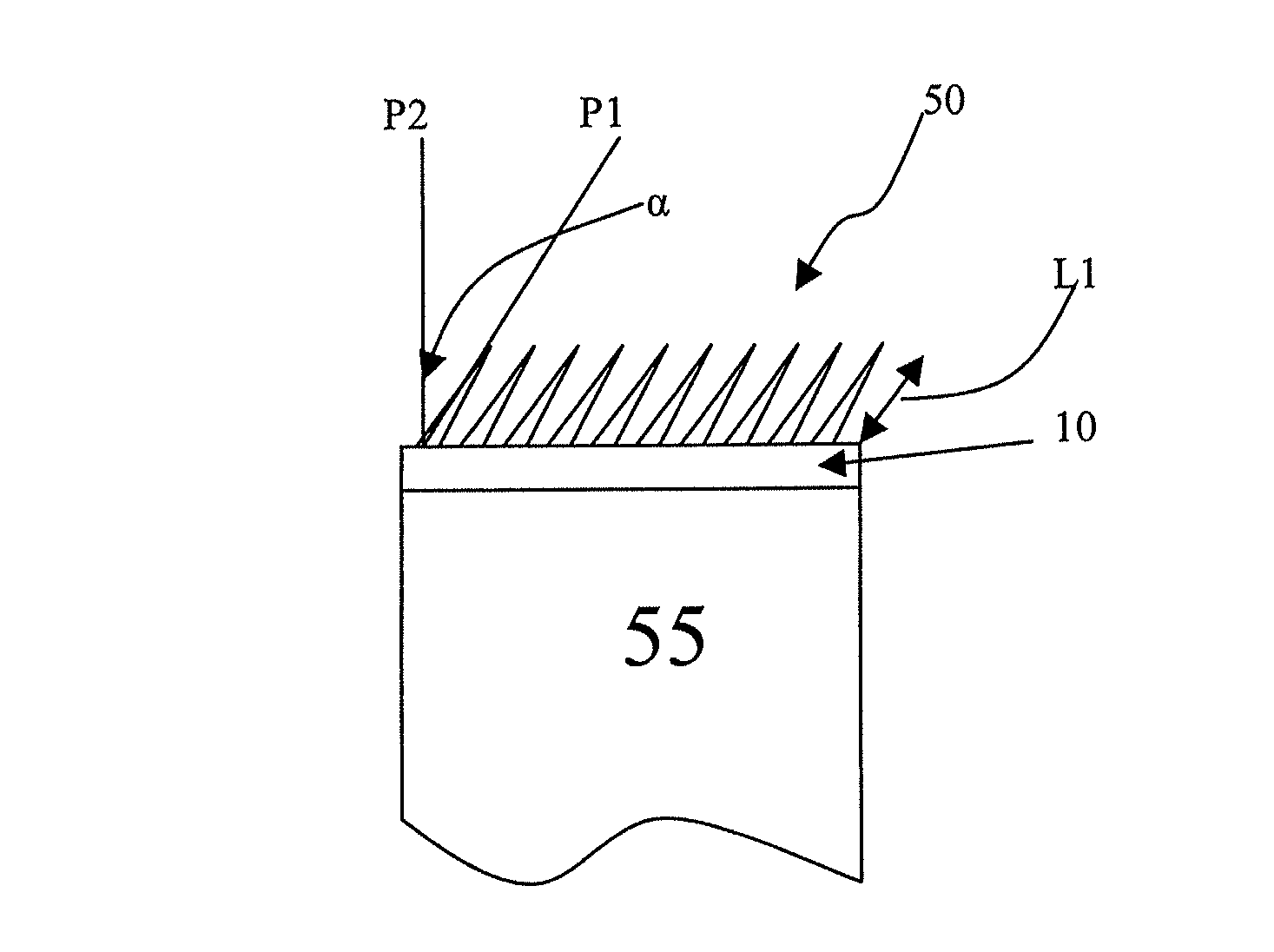

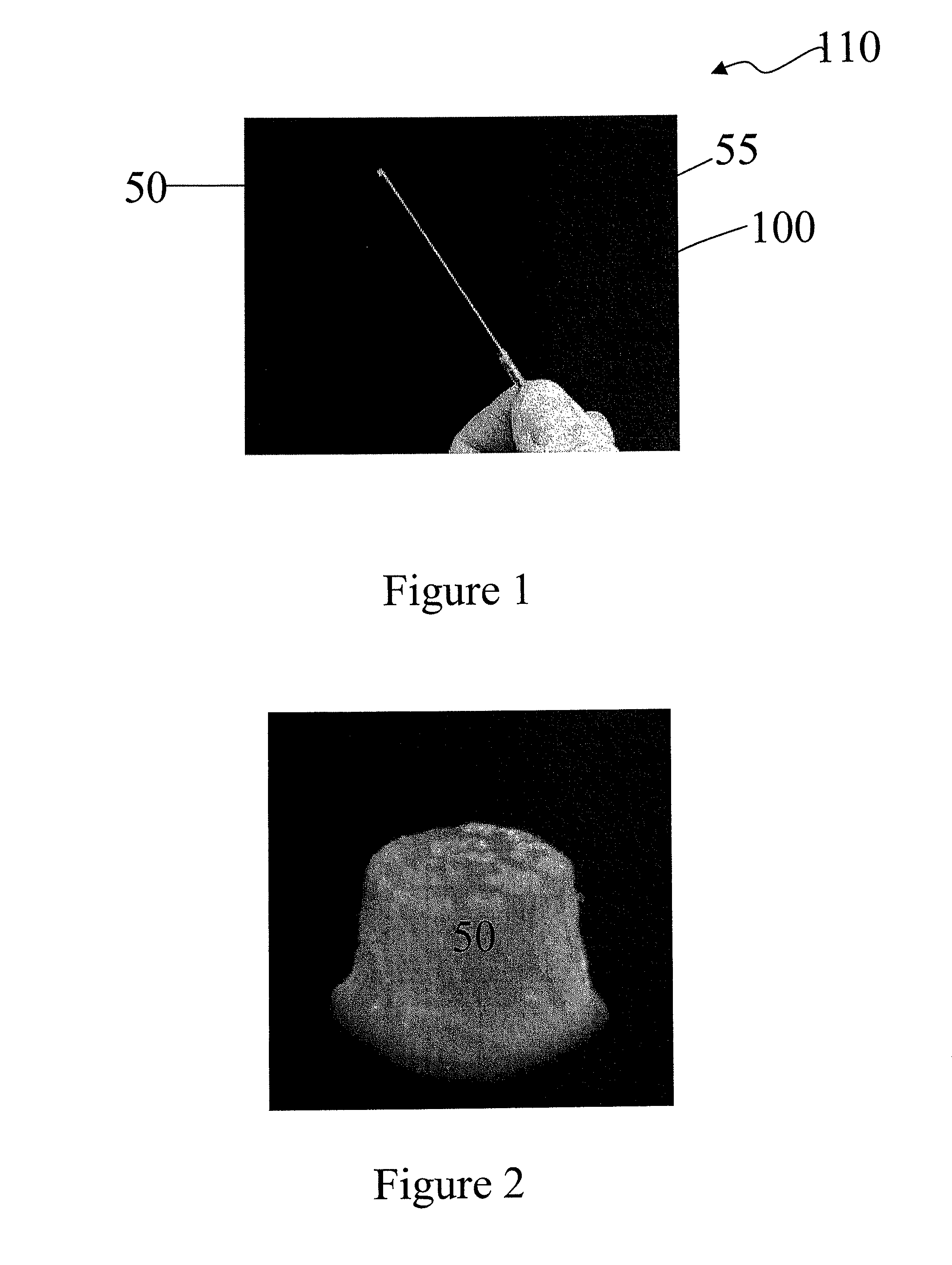

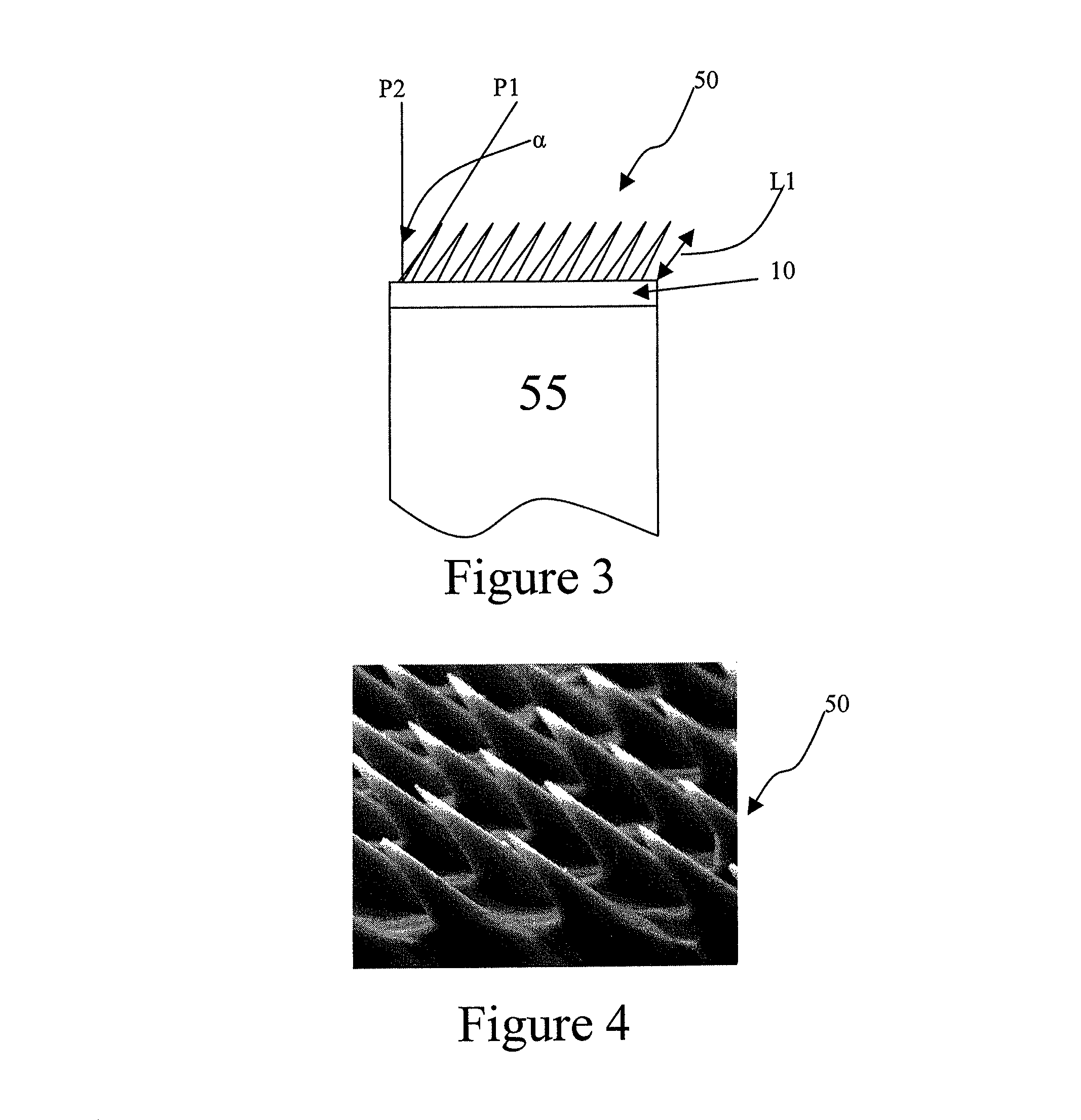

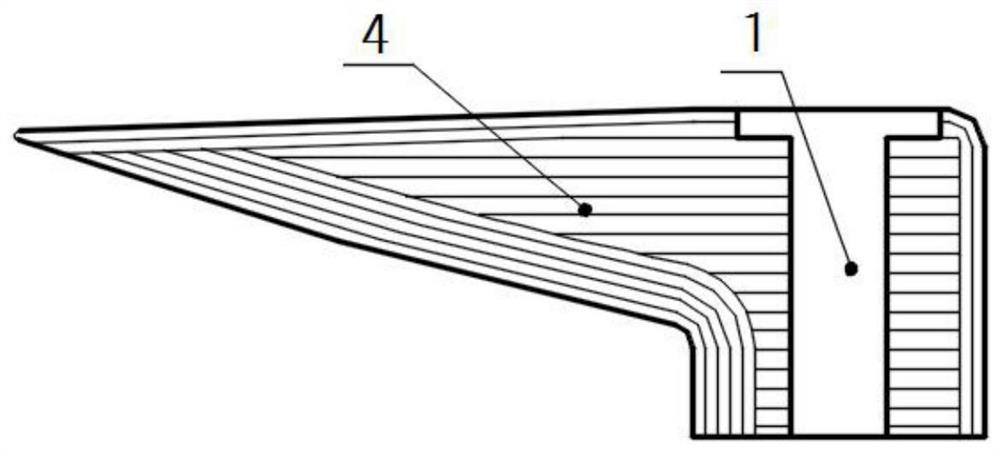

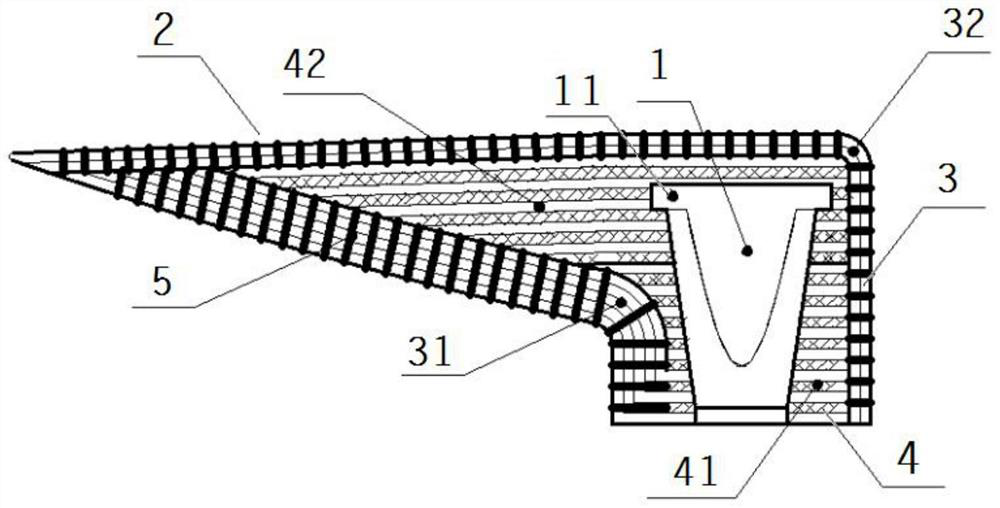

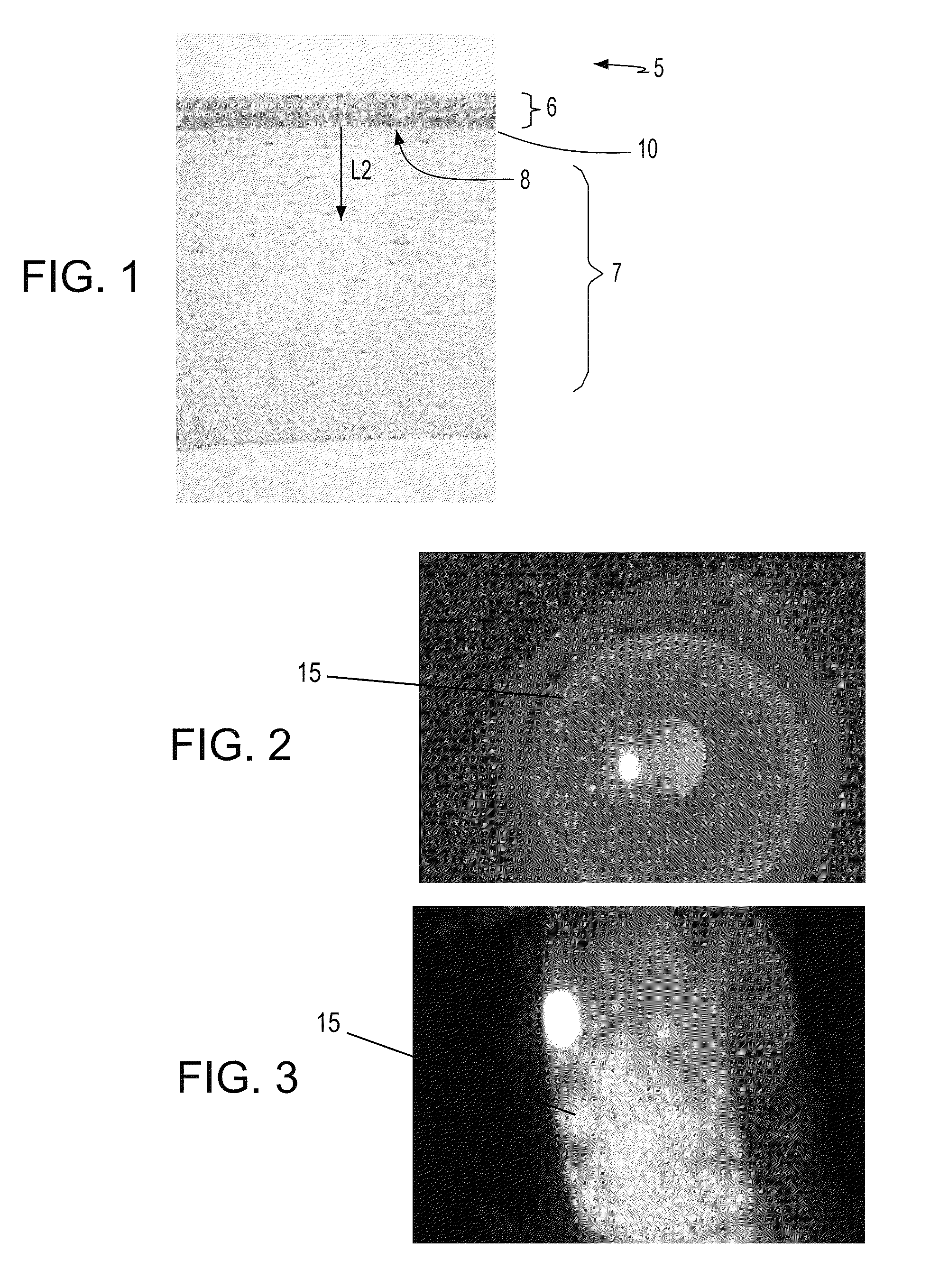

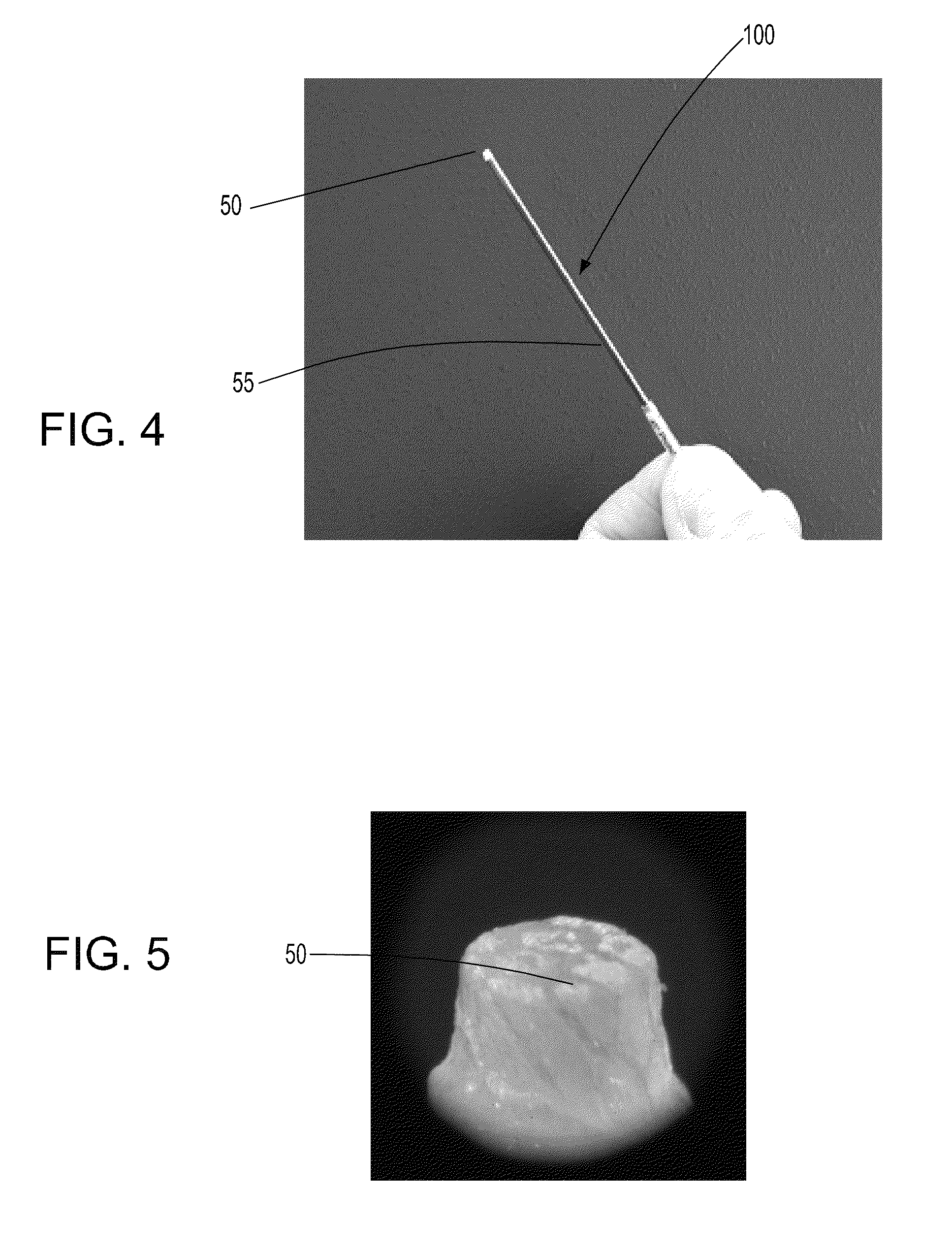

Retinal instrument

In one embodiment, the present invention provides a method of removing scar tissue from an eye that includes inserting a device including an array of micro-rods into an eye, wherein at least one glass micro-rod of the array of glass micro-rods includes a sharp feature; contacting a scar tissue with the array of micro-rods; and removing the array of micro-rods and the scar tissue from the eye. In another embodiment, the present invention provides a medical device for engaging a tissue including and an array of glass micro-rods, wherein at least one glass micro-rod of the array of glass micro-rods includes a sharp feature opposite a base of the array of glass micro-rods that is connected to the cannula, wherein the sharp feature of the at least one micro-rod is angled from a plane that is normal to a face of the base of the array of glass micro-rods.

Owner:UNIV OF TENNESSEE RES FOUND +1

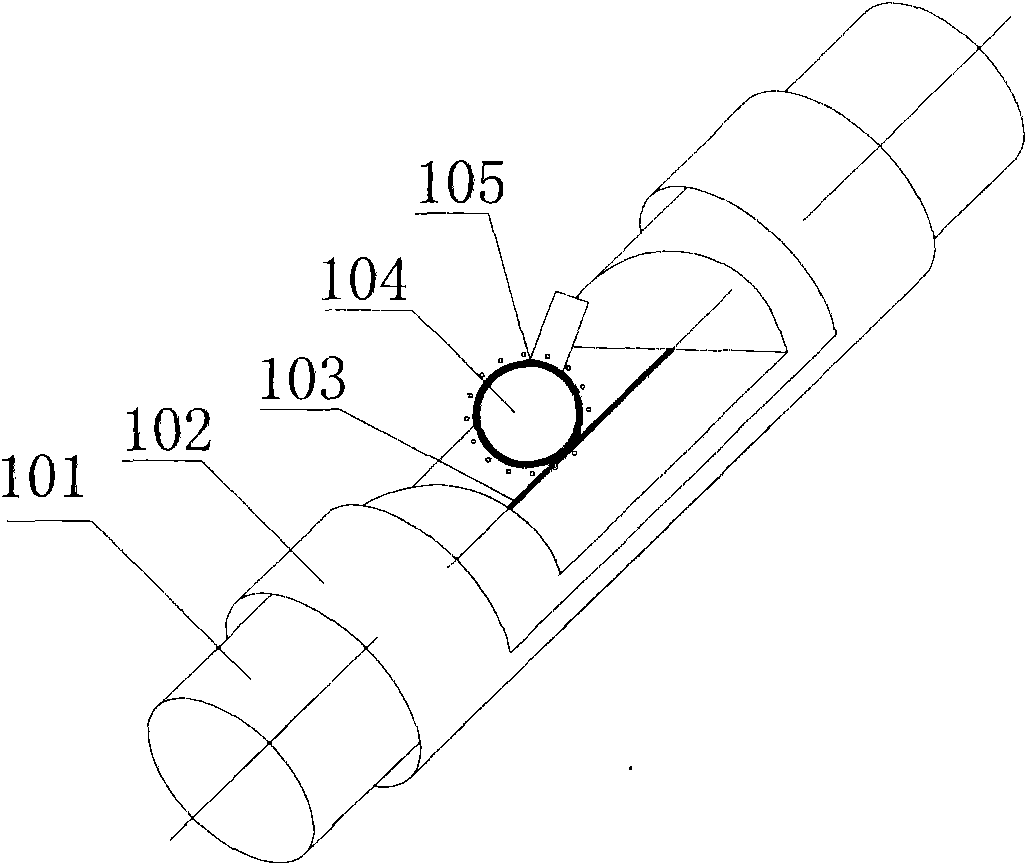

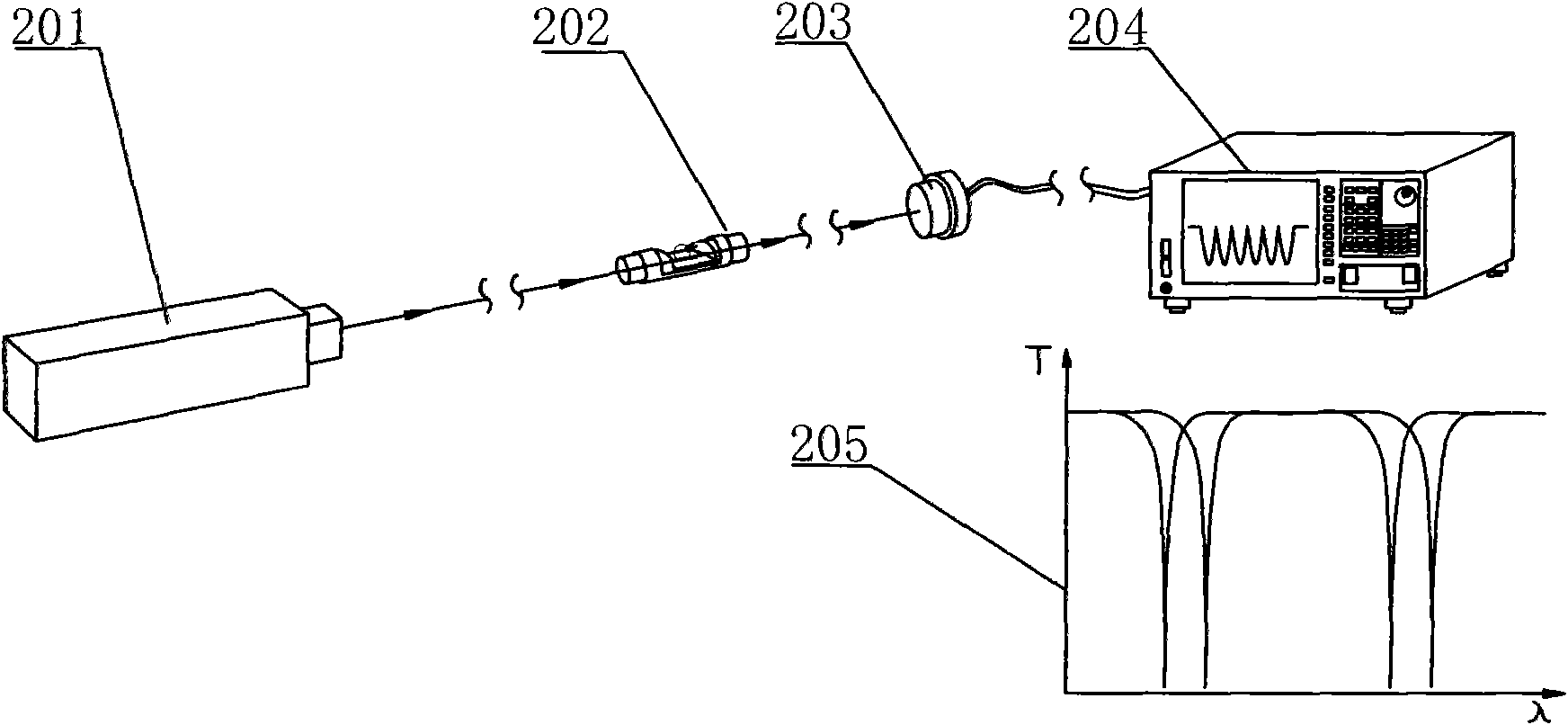

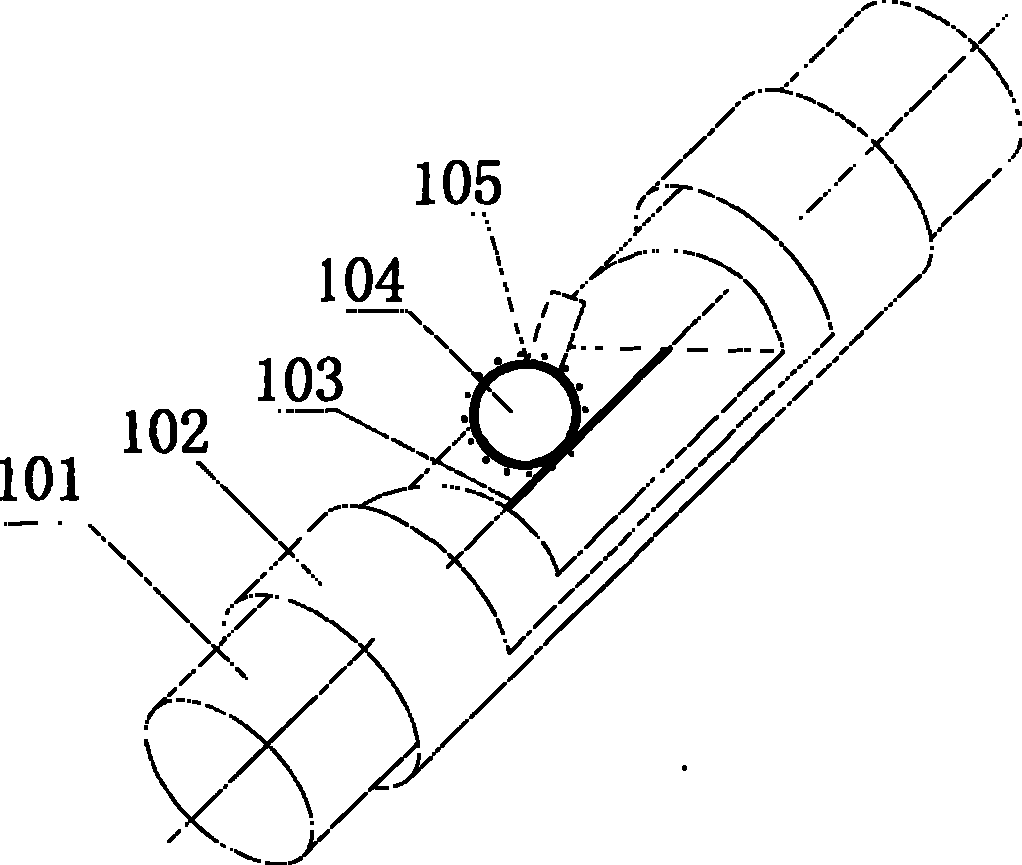

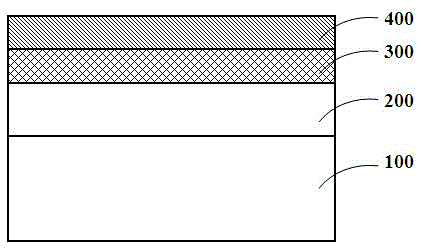

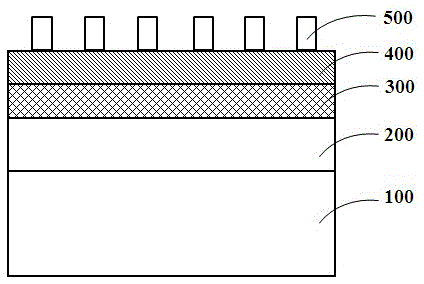

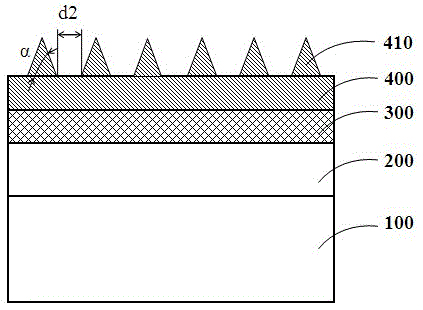

Optical fiber sensor based on zeolite molecular sieve film-plating microresonator and preparation method thereof

InactiveCN102042969AChange the refractive indexHigh sensitivityOptical fibre with multilayer core/claddingPhase-affecting property measurementsMicrosphereOptical medium

The invention relates to an optical fiber sensor based on a zeolite molecular sieve film-plating microresonator and a preparation method thereof. The optical fiber sensor comprises a fiber core 103, a coating layer 101, a protective layer 102, an optical medium microsphere resonator 104, and a zeolite molecular sieve film 105 for plating, wherein the outer part of the fiber core 103 is coated with the coating layer 101; the outer part of the coating layer 101 is covered by the protective layer 102; the coating layer 101, the protective layer 102 and the fiber core 103 form an optical fiber main body; a groove is processed in the middle of the optical fiber main body and the fiber core 103 is exposed; and the optical medium microsphere resonator 104 which is plated with the zeolite molecular sieve film 105 and is provided with a micro-rod is fixed on the side wall of the groove. In the invention, the structure of the optical medium microsphere resonator 104 is used for replacing the traditional microprobe processed by laser near field, under irradiation of femtosecond laser, the optical field around the optical medium microsphere resonator 104 is near-field distribution, and by near-field processing, the gap between the optical medium microsphere resonator 104 and the optical fiber main body reaches several nanometers to dozens of nanometers.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Retinal instrument

In one embodiment, the present invention provides a method of removing scar tissue from an eye that includes inserting a device including an array of micro-rods into an eye, wherein at least one glass micro-rod of the array of glass micro-rods includes a sharp feature; contacting a scar tissue with the array of micro-rods; and removing the array of micro-rods and the scar tissue from the eye. In another embodiment, the present invention provides a medical device for engaging a tissue including and an array of glass micro-rods, wherein at least one glass micro-rod of the array of glass micro-rods includes a sharp feature opposite a base of the array of glass micro-rods that is connected to the cannula, wherein the sharp feature of the at least one micro-rod is angled from a plane that is normal to a face of the base of the array of glass micro-rods.

Owner:UNIV OF TENNESSEE RES FOUND +1

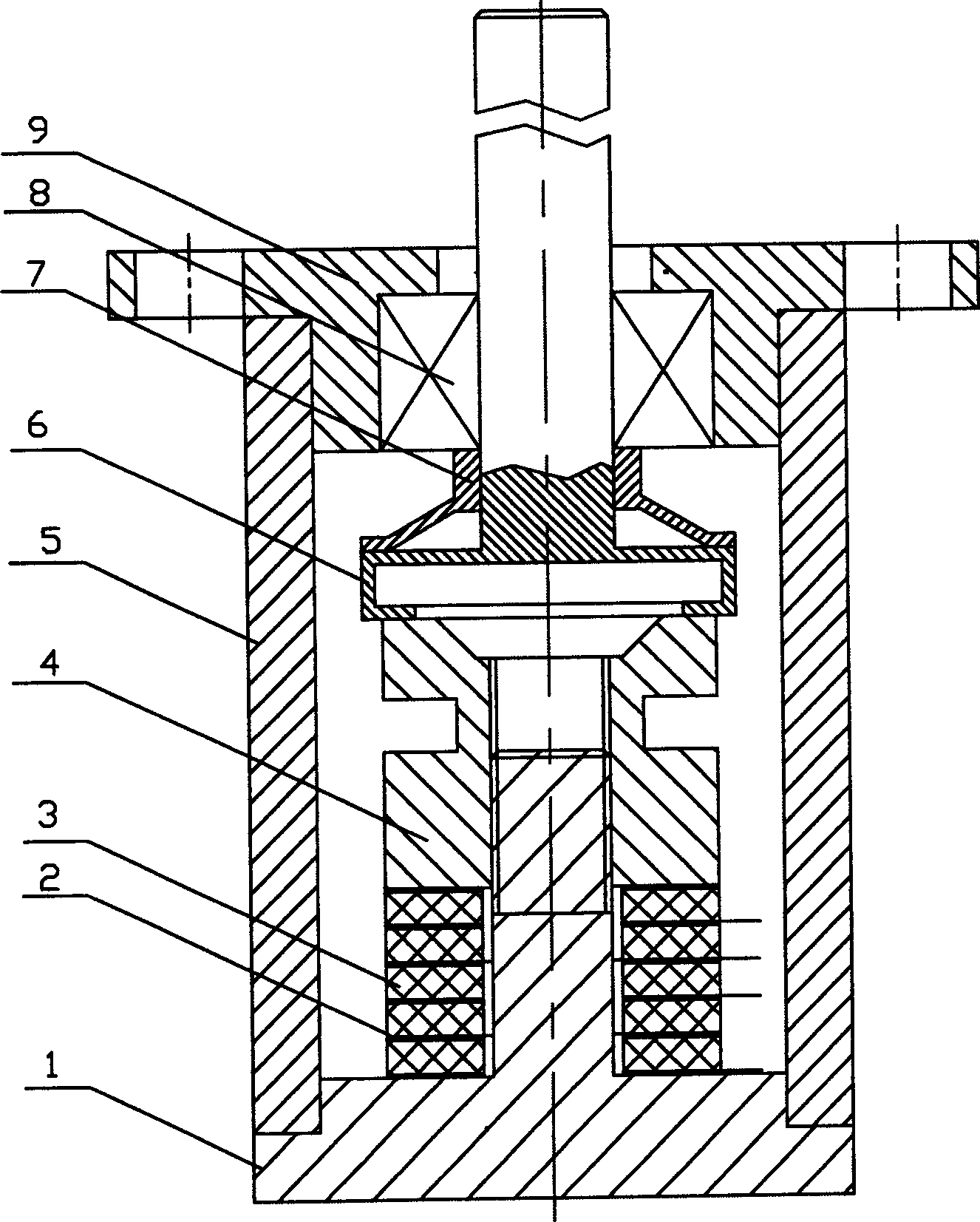

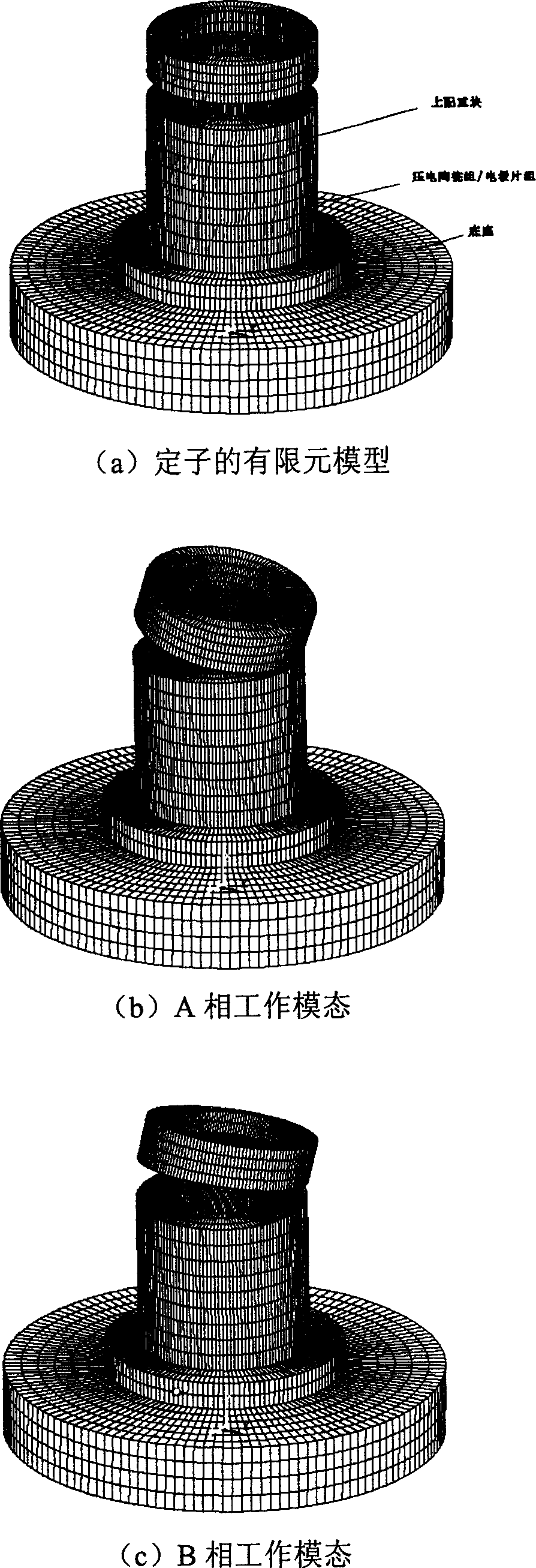

Minitype rod traveling wave type ultrasonic motor

InactiveCN1606227ACompact structureEasy to processPiezoelectric/electrostriction/magnetostriction machinesMicro rodsEngineering

A micro-rod traveling wave supersonic motor is composed of a stator part including screwing tightly the piezoelectric ceramic set and electrode plates by the base and the up balance block with a crew rod on the base. The rotor part is composed of a rotor, a bearing and a disk spring. The shell part is composed of a holddown and a shell. The pre-pressure of the stator and rotor is applied by pressing the disk spring with press blocks. When a certain AC voltage is inlet into the motor in supersonic frequency, the top surface mass points on the top balance block of the stator form elliptic movement, a friction is generated between the rotor and stator since pre-pressure exists between them. The power is output by the rotor shaft.

Owner:JIANGSU FENGKE ULTRASONIC MOTORS TECH

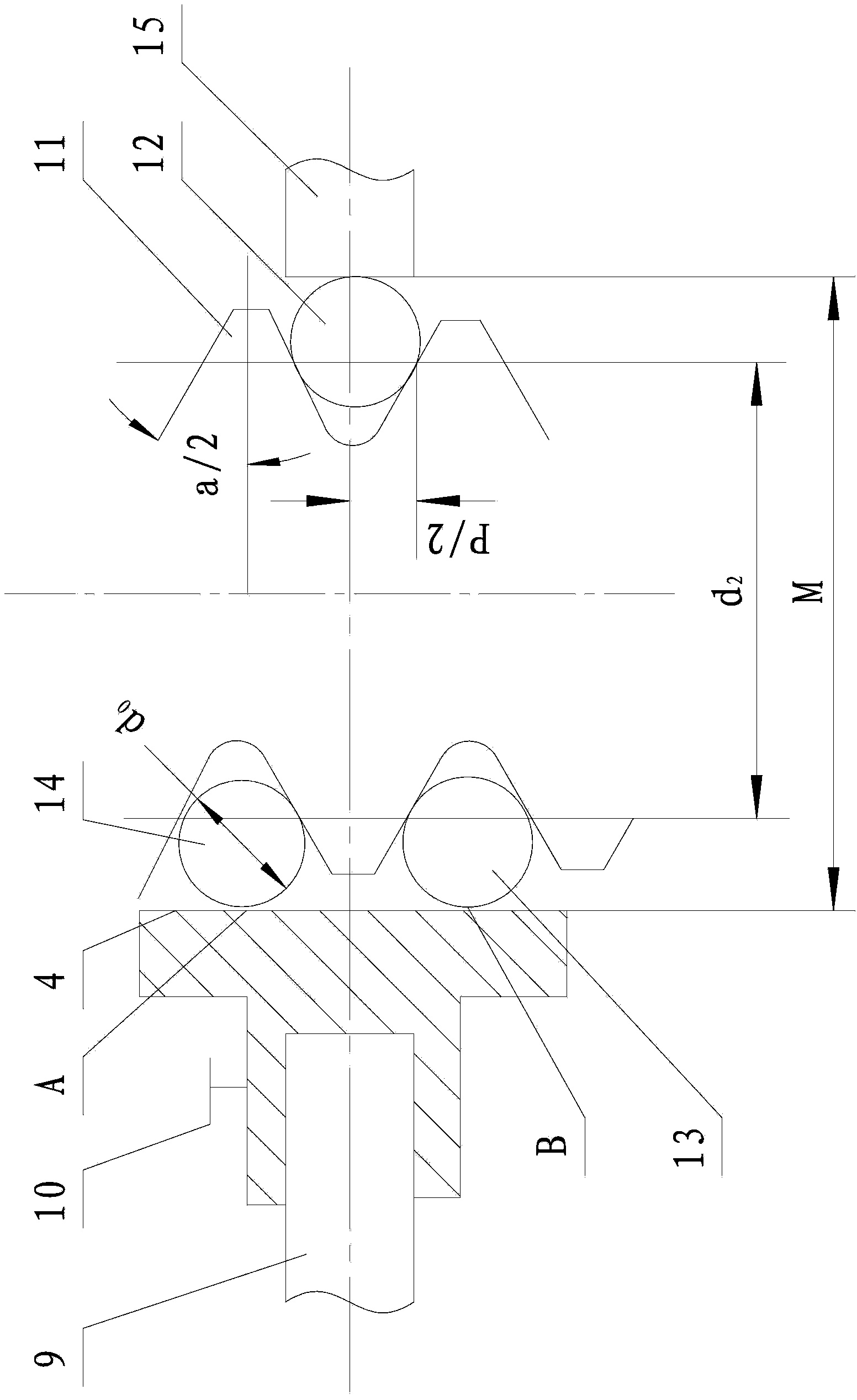

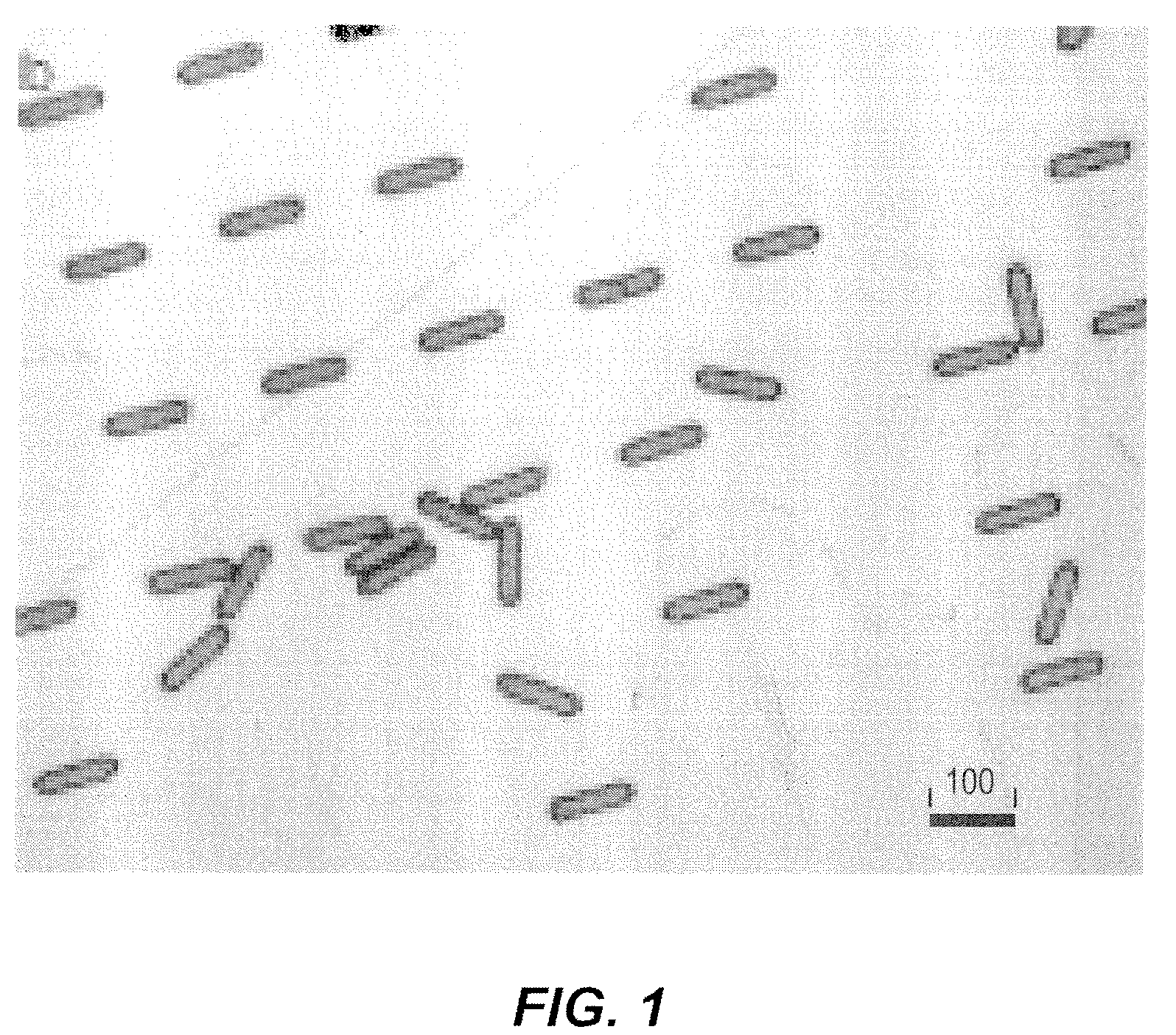

Method for producing ZnO nano-rods and micro-rods in mass

The invention provides a method for producing ZnO nano-rods and micro-rods in mass. The method comprises the following steps: firstly, adopting an easy chemical coprecipitation method to prepare ZnO precursors; putting the precursors in a constant-temperature and constant-humidity chamber; and obtaining ZnO nano-rods and micro-rods by controlling temperature, humidity and time in the constant-temperature and constant-humidity chamber. The method uses the constant-temperature and constant-humidity chamber to obtain the ZnO rod structures in different sizes and has the advantages of high purity,low cost, simple process, good controllability, high yield, mass production suitability, and the like. The invention is characterized in that (1) the nano-rods in different sizes can be obtained by controlling the humidity and the time in the constant-temperature and constant-humidity chamber; and (2) the micro-rods in different sizes can be obtained by controlling the temperature and the time inthe constant-temperature and constant-humidity chamber. The ZnO in the structures can be applied in different aspects, such as detectors, catalysts, sensors, piezoelectric transducers, superficial acoustic fluctuation devices, laser diodes, solar cells, and the like.

Owner:HARBIN INST OF TECH

Vertical structure light-emitting diode and production method thereof

ActiveCN105590995AMeet application needsImprove light extraction efficiencySemiconductor devicesMicro rodsEngineering

The invention provides a vertical structure light-emitting diode and a production method thereof. A mini-sized micron or nanometer rod-shaped vertical structure light-emitting diode having two hexagonal cone-shaped end surfaces can be produced by adopting the etching technology and the substrate stripping technology. The requirements of the biomedical field, the photoelectric field, and other fields related to the mini-sized light-emitting diode on the mini-sized light-emitting diode can be satisfied.

Owner:XIAMEN SANAN OPTOELECTRONICS TECH CO LTD

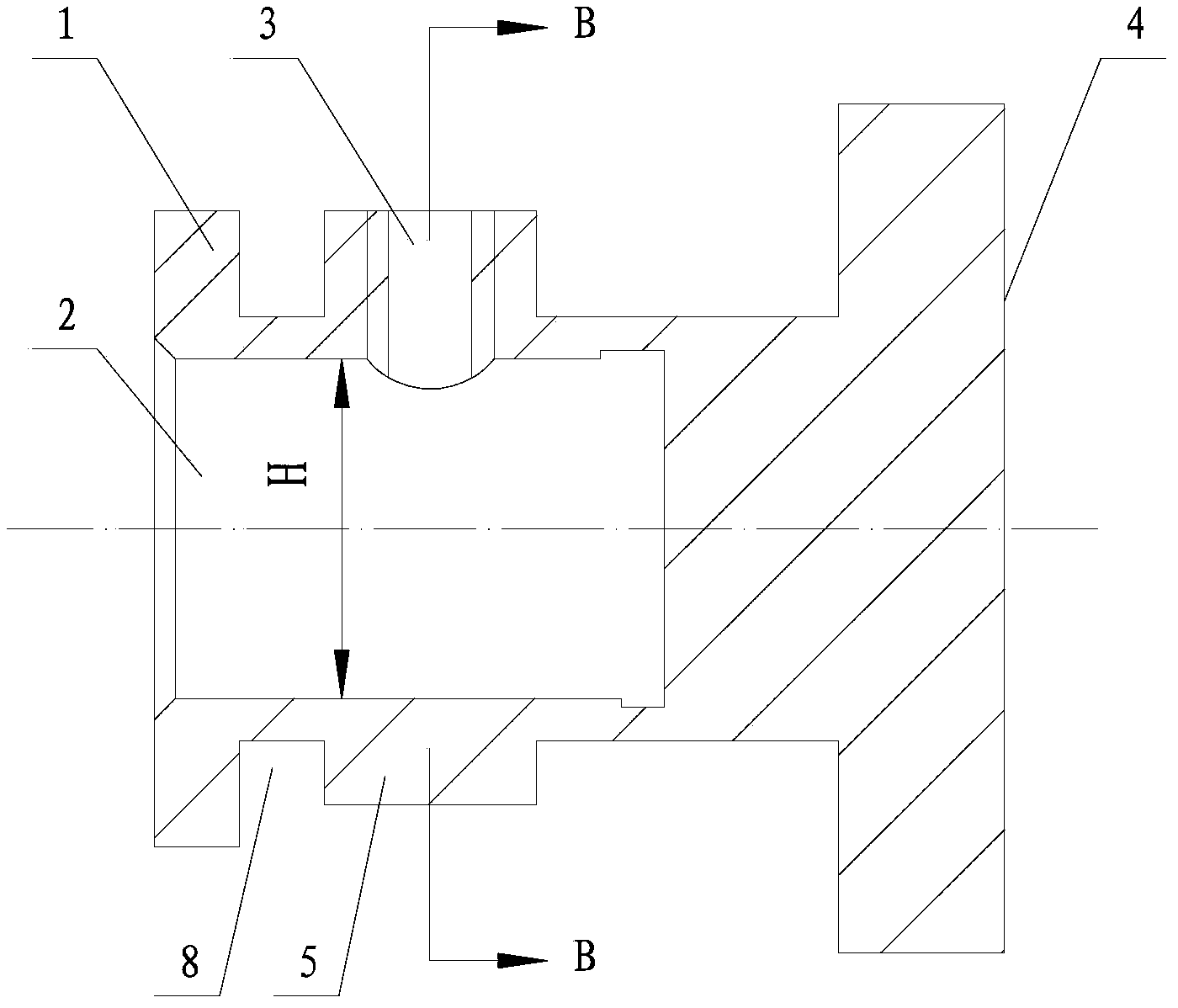

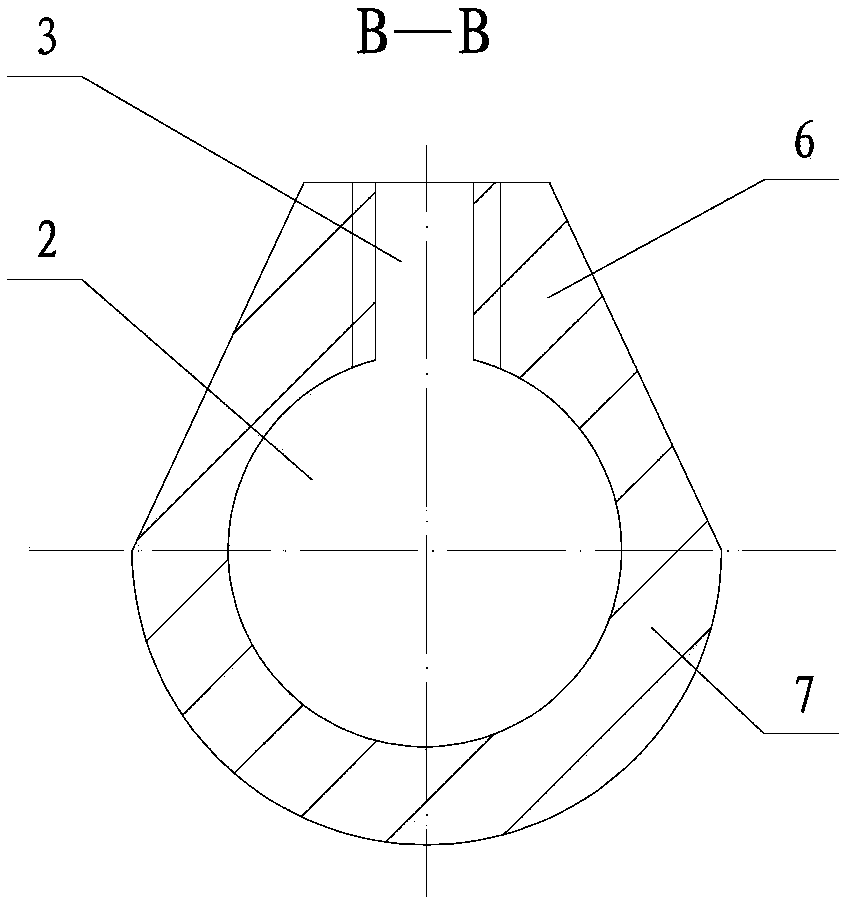

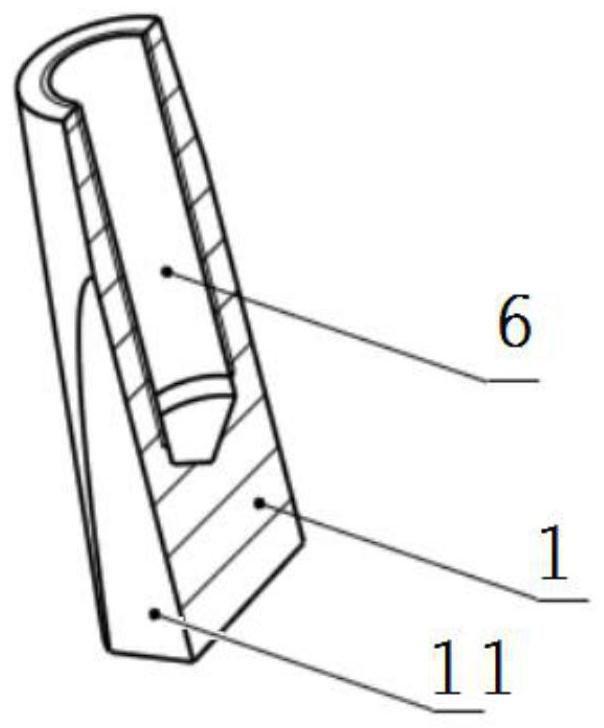

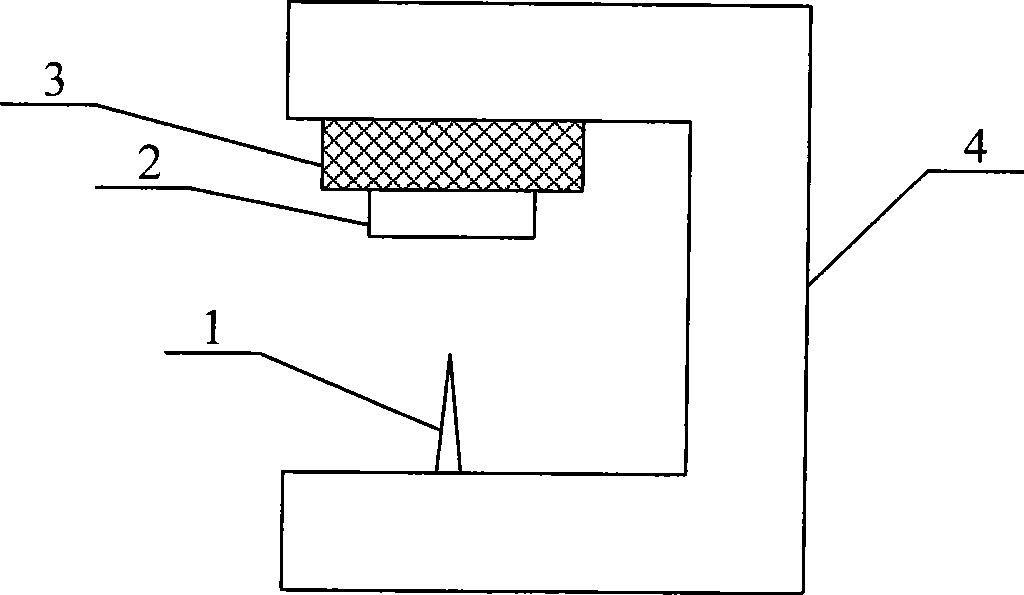

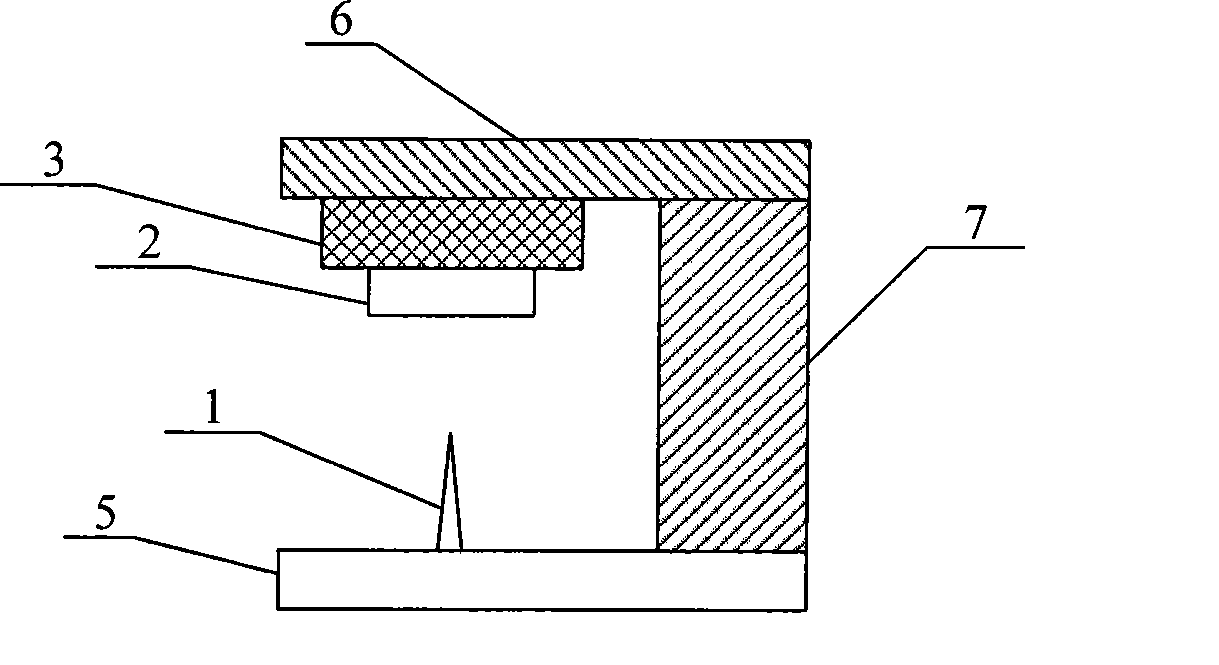

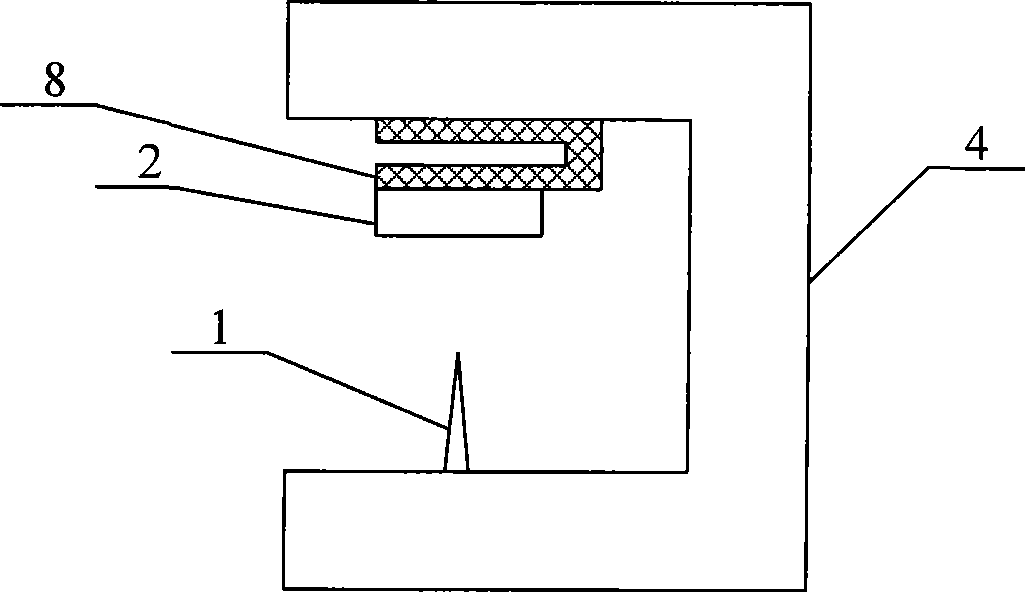

Auxiliary testing fixture for detecting geometric parameters of steep-pitch thread

InactiveCN103983155ASolve problems that cannot be measuredImprove product qualityMechanical diameter measurementsMicro rodsMicrometer

The invention belongs to the field of screw thread measuring, and specifically discloses an auxiliary testing fixture for detecting geometric parameters of a steep-pitch thread. One end of the testing fixture main body of the auxiliary testing fixture is provided with a positioning hole, the end surface of the other end is a contact surface, the micrometer measuring micro rod of an external diameter micrometer is inserted into the positioning hole, the contact surface abuts against a second needle and a third needle during thread measuring by use of a three-needle method, the second needle and the third needle are placed in a neighboring tooth groove at one side of the axial cross section of the detected thread, and a first needle for measuring the thread by use of the three-needle method is placed into a tooth groove at the other side of the axial cross section of the detected thread and abuts against the micrometer gauge button of the external micrometer. The auxiliary testing fixture provided by the invention solves the problem of measuring an intermediate diameter and a large diameter in the geometric parameters of the steep-pitch thread, overcomes one difficulty in length metering testing, and provides reliable measuring data for the product quality of a machinery industry; and the auxiliary testing fixture is used through cooperation with the external micrometer, is provided with quite high measuring precision, and expands the application scope of the external diameter.

Owner:SHENYANG TURBO MASCH CORP

Temporal release of growth factors from 3D micro rod scaffolds for tissue regeneration

The present invention relates to the use of three-dimensional microrod scaffolds for the temporal release of growth factors useful in tissue regeneration, engineering and treatment of disorders.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

Composite material joint and preparation method thereof

ActiveCN112571825AImprove connection reliabilityPrevent rotationWeight reductionDomestic articlesFiberCarbon fibers

The invention relates to a composite material joint and a preparation method thereof. The composite material joint comprises a metal insert and a joint body, wherein the metal insert is a table body of a non-axisymmetric structure, a mounting mechanism is arranged at the small end of the metal insert and is used for being connected with an external mechanism, the joint body comprises a base body and an outer panel skin laid on the surface of the base body, the base body coats the periphery of the metal insert and exposes the mounting mechanism, the base body is formed by alternately laying chopped fiber mold pressing layers and carbon fiber prepreg laying layers, and the chopped fiber mold pressing layers and the carbon fiber prepreg laying layers are all perpendicular to the axis of the metal insert, the outer panel skin is composed of the carbon fiber prepreg laying layers and micro rods, and the micro rods are perpendicular to the outer panel skin. According to the composite material joint and the preparation method thereof, by means of metal insert structure optimization, base body laying layer structure optimization and outer panel skin laying layer interlayer reinforcement, the composite material joint is prevented from losing efficacy in advance between layers when being loaded, and the bearing capacity of the composite material joint can be greatly improved, so that thepassive mass of the composite material joint can be further reduced through structure optimization.

Owner:THE GENERAL DESIGNING INST OF HUBEI SPACE TECH ACAD

Probe-fixing and example-oscillating non-micro rod scanning force microscope lens

InactiveCN101424611ANeedle shape is goodGood effectSurface/boundary effectInstrumental componentsSmall amplitudeScanning tunneling microscope

The invention relates to a non-microbot scanning force microscope body of a fixed probe and oscillated sample type, in particular to a scanning probe microscope which comprises a probe, a sample, a vibrator and a localizer, wherein the localizer is arranged between the probe and the vibrator, and the probe points to the sample fixed on the vibrator; the localizer comprises an XYZ positioning piezoelectric tube, a probe seat and a vibrator seat, the probe seat and the vibrator seat are respectively arranged at both ends of the XYZ positioning piezoelectric tube, and the probe and the vibrator are respectively fixed on the probe seat and the vibrator seat; the probe is a discrete non-microbot probe, and the vibrator is a piezoelectric vibrator, a crystal vibrator, a quartz crystal vibrator or a quartz micro fork. The invention has the advantages that the discrete non-microbot probe, such as an STM (Scanning Tunneling Microscope) probe, can be used, the cost of the probe is greatly decreased for benefiting the occurrence and the popularization of a microscope with better scanning force, the use of the crystal vibrator with high-quality factors can improve the frequency resolution and the measurement accuracy, and the addition of an auxiliary vibrator between the localizer and the vibrator can also obtain small-amplitude vibration so as to improve the measurement sensitivity of short range force and the atom resolution.

Owner:UNIV OF SCI & TECH OF CHINA

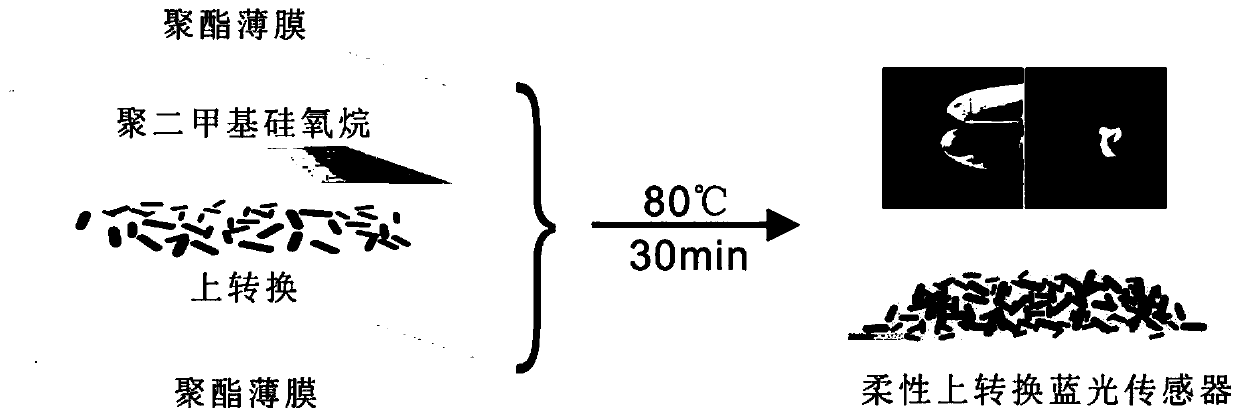

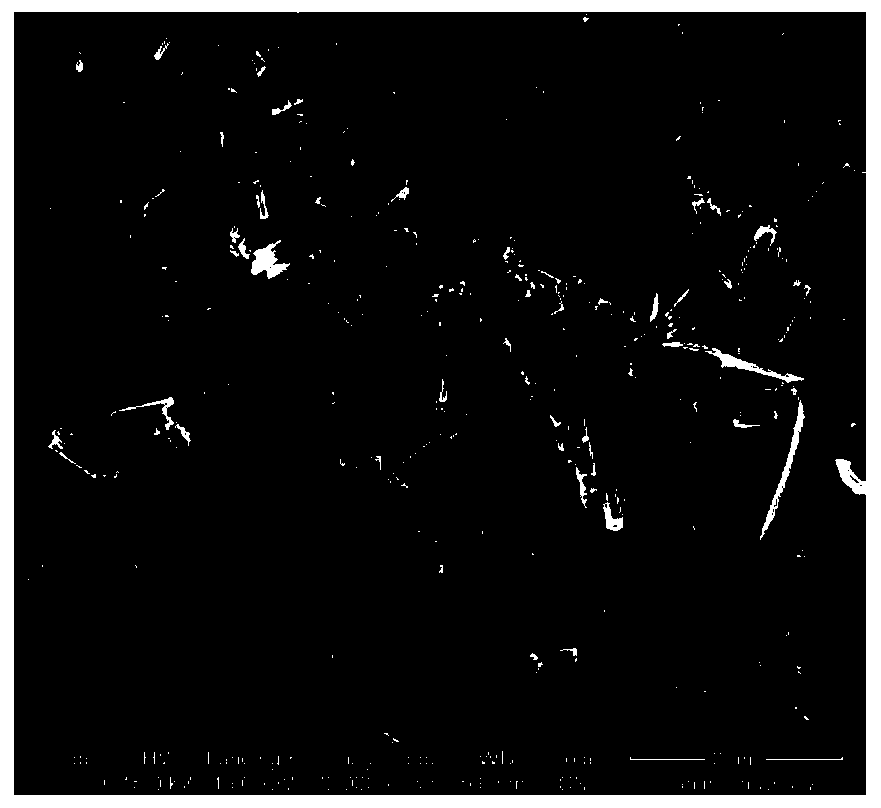

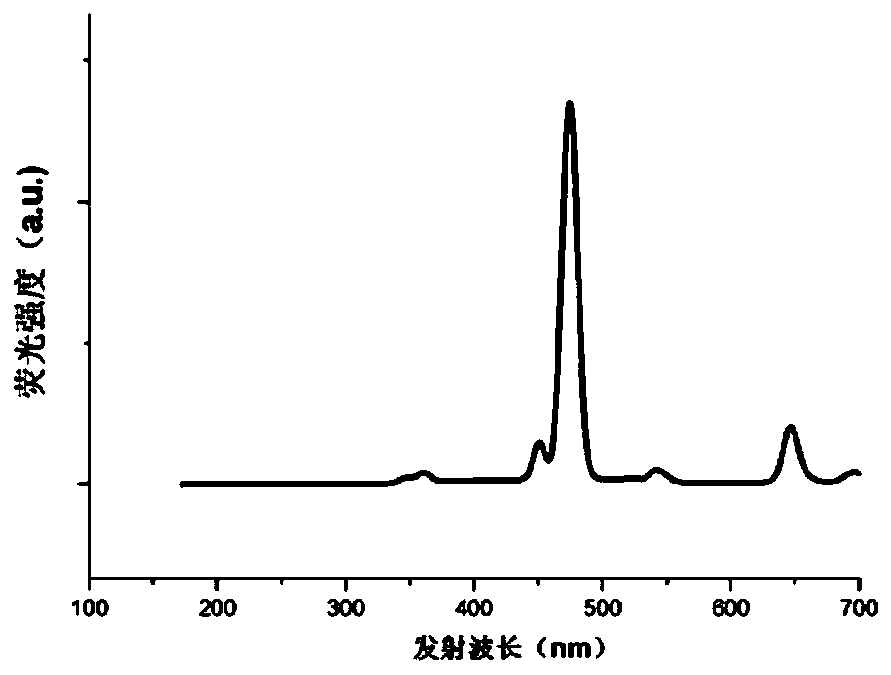

Flexible up-conversion blue light sensor capable of regulating cryptochrome CRY2 protein allosterism in vivo and preparation method thereof

InactiveCN109758589ASafe and efficient light conversionHigh blue light conversion efficiencyIn-vivo testing preparationsPolyesterRare earth

The invention discloses a flexible up-conversion blue light sensor capable of regulating morphochrome CRY2 protein allosterism in vivo and a preparation method thereof. The preparation method comprises the following steps of 1) preparation and characterization of a blue light up-conversion micro-rod doped with a rare earth thulium element; 2) preparation of the flexible up-conversion blue light sensor: (1) preparing a polydimethylsiloxane precursor of different ratios of 10:1-7:1, mixing the blue light up-conversion micro-rod doped with rare earth thulium element by 10-100mg / ml, vacuumizing for 30-40min at 0.03MPa-0.05MPa to remove bubbles and evenly spin coating the mixture on a polyester film; (2) after the liquid forms the film for 0.2mm-3mm, conducting vacuum curing at high temperatureof 80 DEG C for 30-60 min; (3) compacting the film after cooling to avoid generation of bubbles. The sensor has an area of 25mm<2>-1cm<2>, and can emit bright blue light with the wavelength of 470nmunder the excitation of 980nm near-infrared light, and the blue light emitted can change the structure phase of the cryptochrome CRY2 protein to achieve safe efficient light conversion of particles invivo.

Owner:TIANJIN UNIV

Embedded micro rod capable of accelerating plastic degradation

The invention discloses an embedded micro rod capable of accelerating plastic degradation, and belongs to the field of plastic degradation. The embedded micro rod comprises two micro rod bodies, wherein a sweet degradation hollow column is fixedly connected with a part between the two micro rod bodies; an elliptic annular cavity is cut in the inner end of the sweet degradation hollow column; the elliptic annular cavity is filled with fixed degradation bacteria; a plurality of vertical maze inlets are cut in the inner end of each of the two micro rod bodies; the vertical maze inlets are longitudinally communicated with one another; a plurality of horizontal maze connecting holes and inclined maze connecting holes are cut in the inner end of each of the two micro rod bodies; a Y-shaped outlet is formed in one end, close to the sweet degradation hollow column, of each of the two micro rod bodies; a vertical blocking diaphragm is communicated with a vertical maze inlet close to the sweet degradation hollow column. The embedded micro rod has the advantages that Ideonella sakaiensis 101-F6 bacteria can be carried to all positions through ants, so that PET plastic particles adjacent to the micro rod can be mixed with the bacteria, plastic degradation is accelerated, and labor resource investment is reduced through nature power mixing.

Owner:湖州伟乐医疗科技有限公司

White light emitting device and method of making same

ActiveUS20060216845A1Solid-state devicesSemiconductor/solid-state device manufacturingMicro rodsGreen-light

A white-light emitting device comprising a first PRS-LED and a second PRS-LED. The first PRS-LED has a primary light source to emit blue light and a secondary light source to emit red light responsive to the blue light; and the second PRS-LED has a primary light source to emit green light and a secondary light source for emitting red light responsive to the green light. Each of the primary light sources is made from an InGaN layer disposed between a p-type GaN layer and an n-type GaN layer. The secondary light sources are made from AlGaInP. The primary light source and the secondary light source can be disposed on opposite sides of a sapphire substrate. Alternatively, the second light source is disposed on the n-type GaN layer of the primary light source. The second light sources may comprise micro-rods of AlGaInP of same or different compositions.

Owner:OPTRONIC SCI LLC

Method for preparing modified micro-rods and reinforced plastic containing modified micro-rods

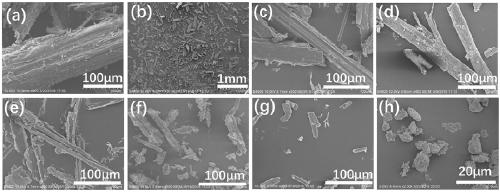

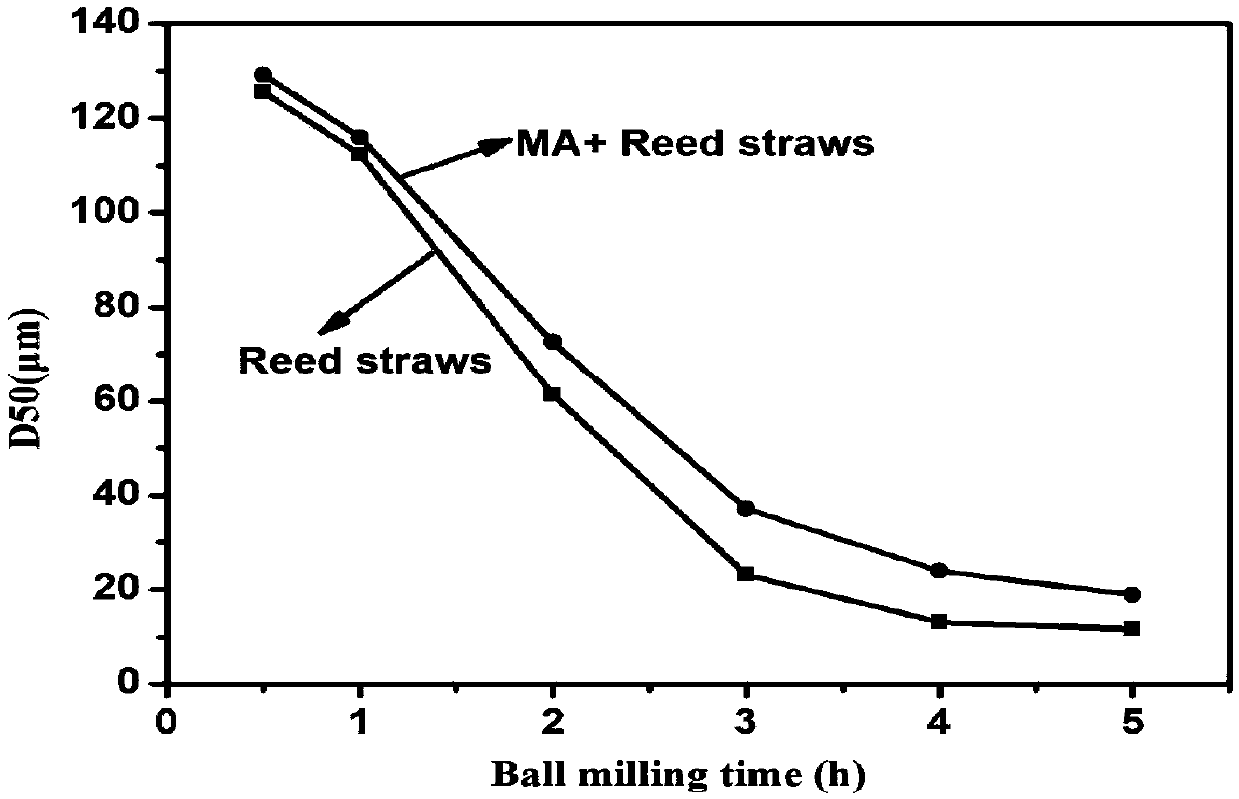

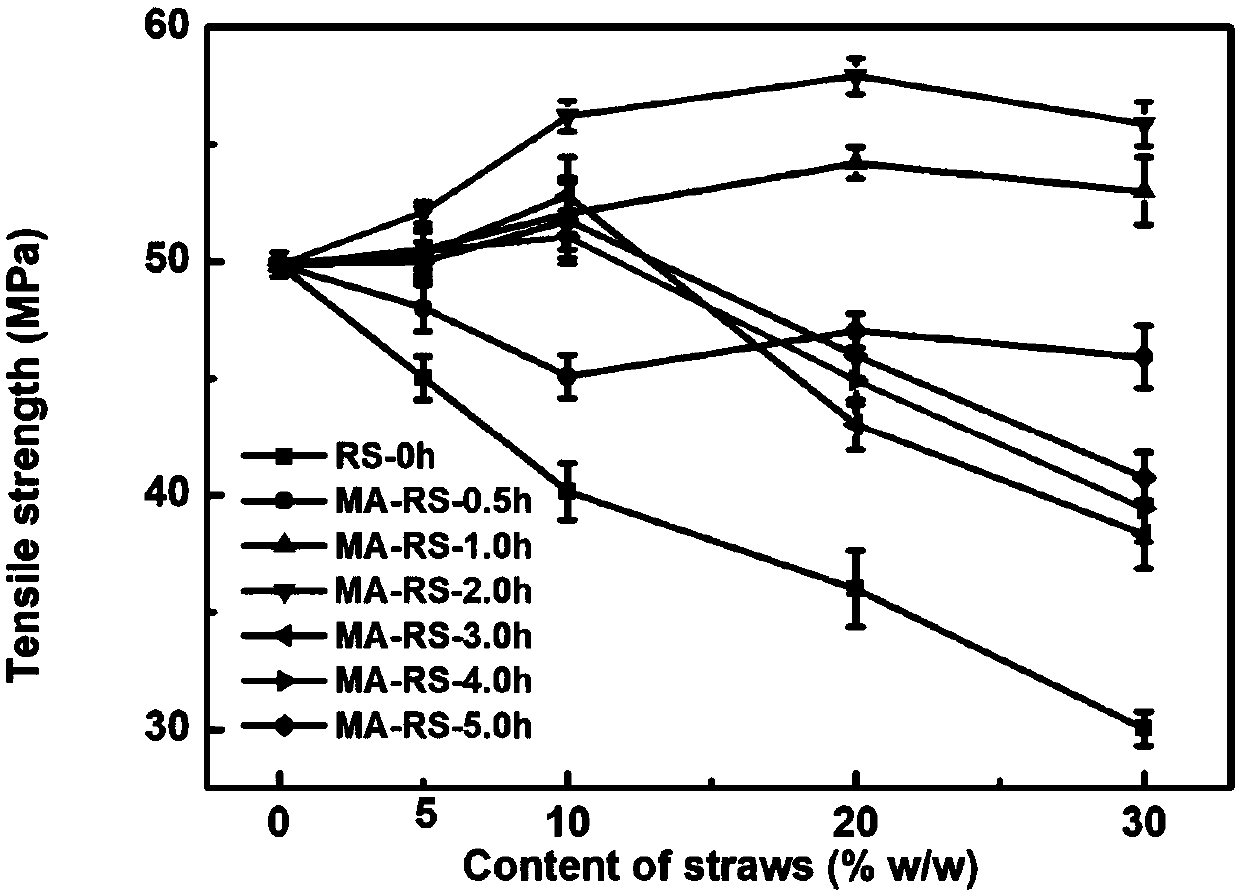

ActiveCN109629294AIncrease profitUniform structurePulping with acid salts/anhydridesPulp beating/refining methodsFiberSolvent free

The invention provides a method for preparing modified micro-rods. The method includes the operation steps that straw is mixed with organic acid or anhydride, and the mixture is ball-milled for 0.5-5h under the solvent-free condition, wherein the organic acid is selected from tartaric acid, citric acid, p-toluenesulfonic acid, adipic acid and stearic acid, and the anhydride is maleic anhydride. The invention further provides the modified micro-rods prepared with the method, and reinforced plastic containing the modified micro-rods. Modified fiber rods are directly prepared from the straw witha one-step ball-milling method, and modified corncob cellulose nano-fibers are applied to improving the mechanical performance of the plastic. On one hand, the method is efficient, environmentally friendly and free of solvents and completed at a step; on the other hand, the straw without being purified is directly used as the raw material, the modified micro-rods with uniform structures are prepared, the utilization rate of the straw is greatly increased, and high utilization value is also achieved on the aspect of industrialization. The obtained modified micro-rods are used for toughening the plastic, and the strength of the plastic is greatly improved.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

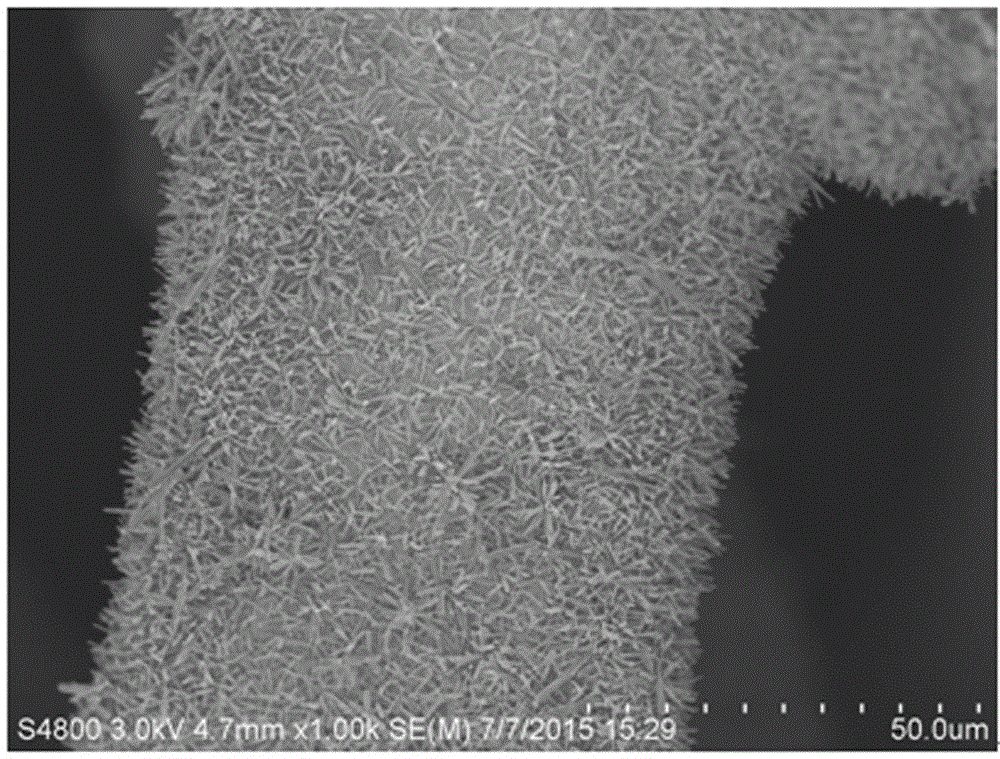

Preparation method of magnesium cobaltate porous micro-rod/ foamed nickel combined electrode material

InactiveCN105355467AImprove diffusion and mass transfer performanceLarge specific surface areaHybrid capacitor electrodesHybrid/EDL manufactureMagnesium saltMetallic materials

The invention belongs to the preparation field of inorganic non-metallic materials, and especially relates to a preparation method of a magnesium cobaltate porous micro-rod / foamed nickel combined electrode material. The method includes the steps: immersing clean foamed nickel into an oxalic acid aqueous solution, adding a mixed aqueous solution containing soluble magnesium salt and soluble cobalt salt into the above solution at a room temperature and in a stirring condition, stirring for reaction until a micrometer-structure precursor grows on the surface of the foamed nickel, taking out the foamed nickel, conducting cleaning, drying and calcining in sequence, and finally obtaining a magnesium cobaltate porous micro-rod / foamed nickel combined electrode material. The preparation method is simple and convenient, is low in manufacture cost, and produces products that have high purity. A combined magnesium cobaltate porous micro-rod has a nano-scale porous channel structure, and the dimension of the channel is 10-20nm. The magnesium cobaltate porous micro-rod is 200-500nm in diameter and 2-5[Mu]m in length.

Owner:BOHAI UNIV

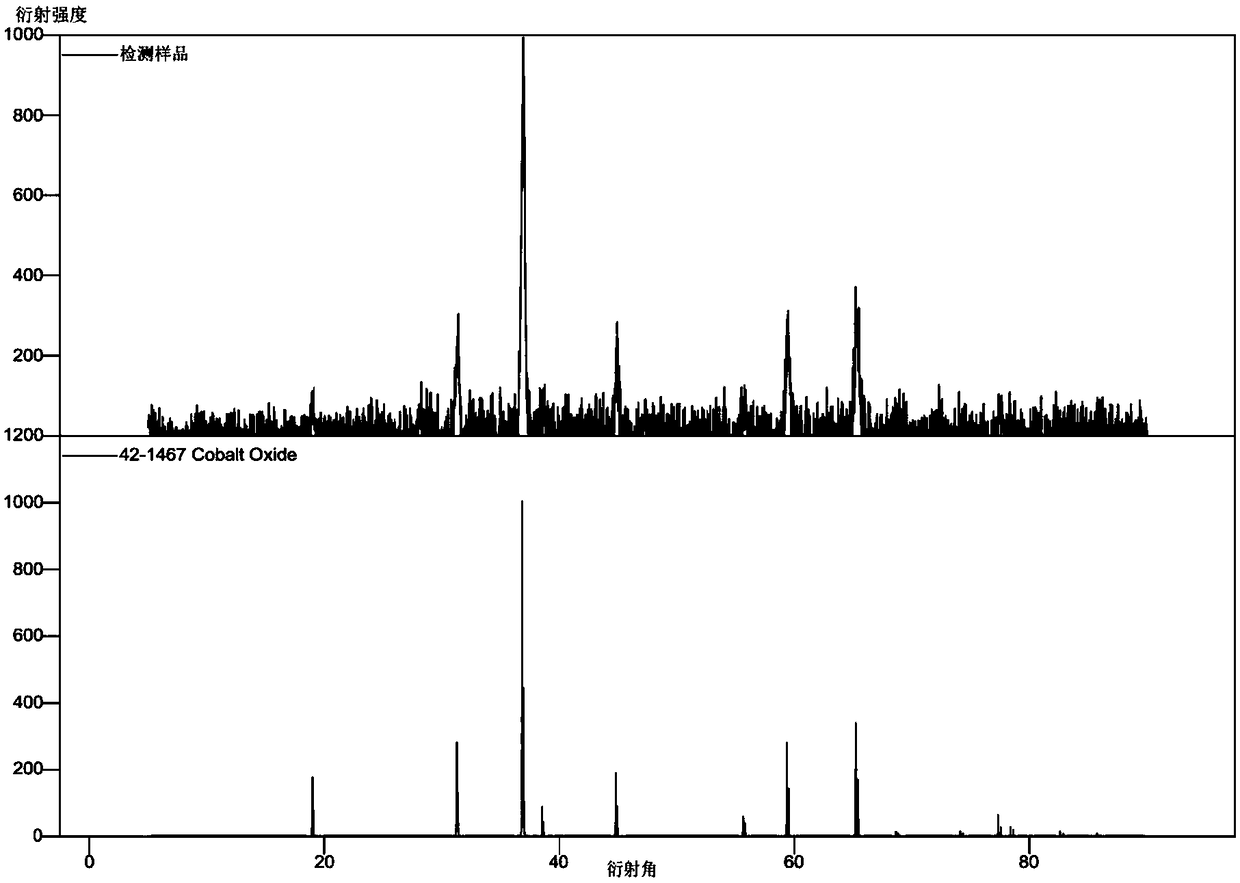

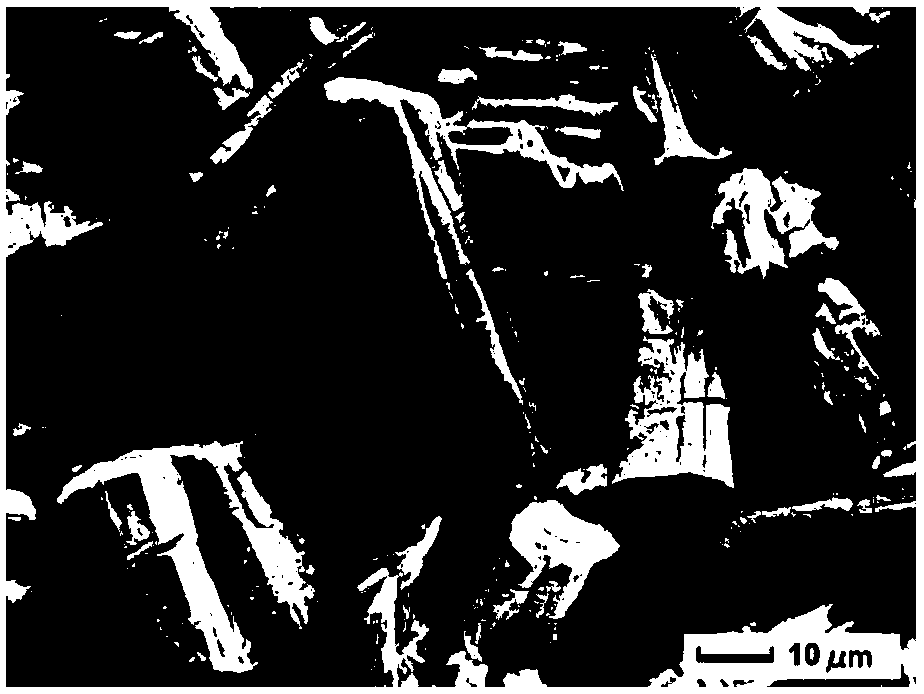

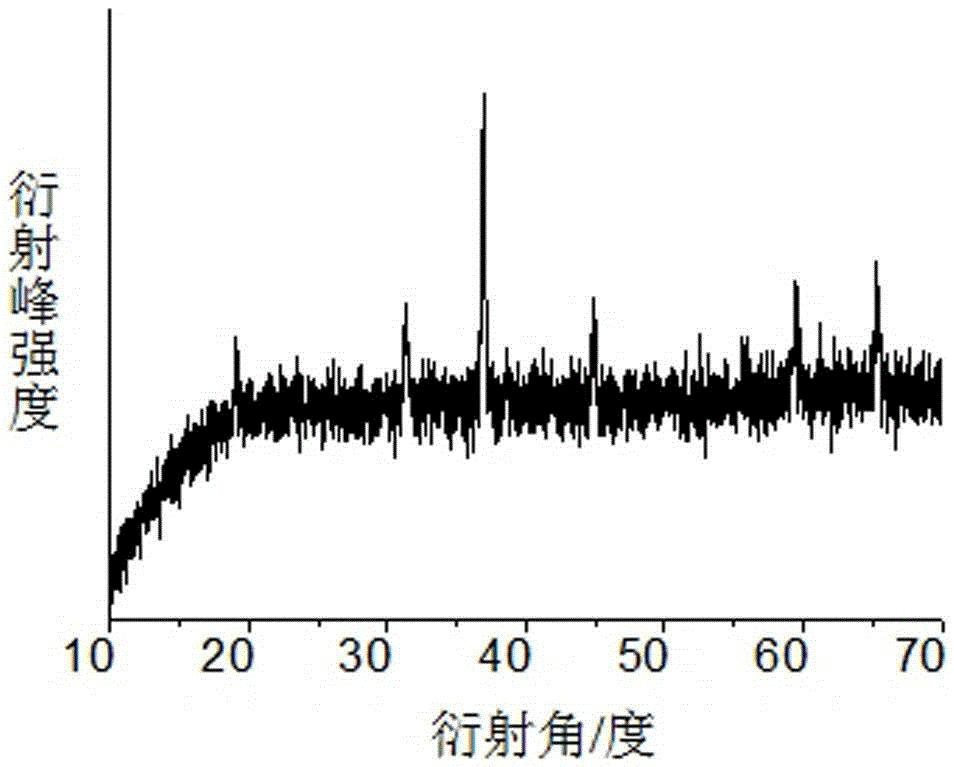

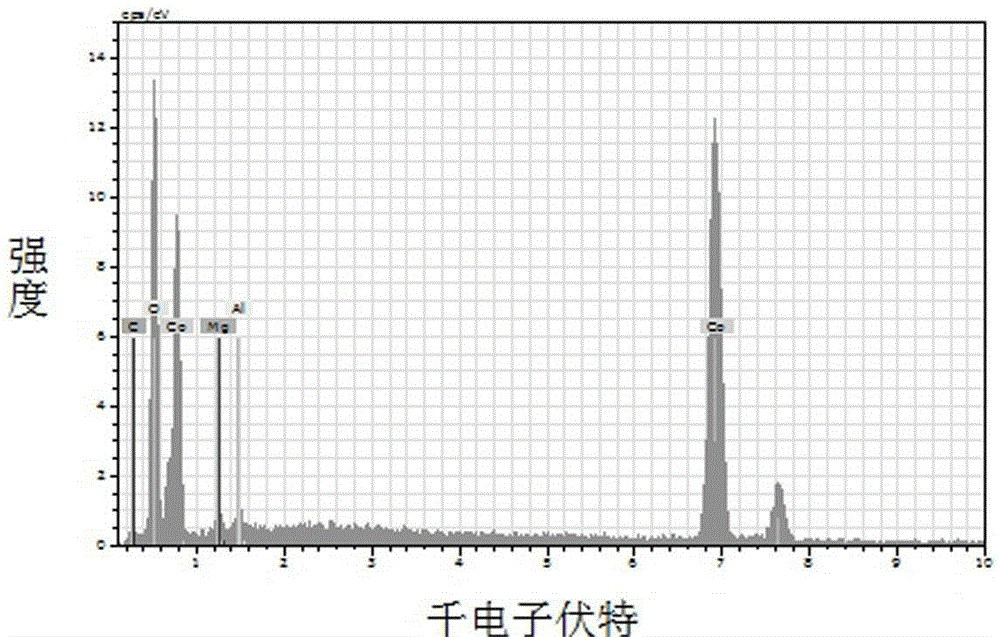

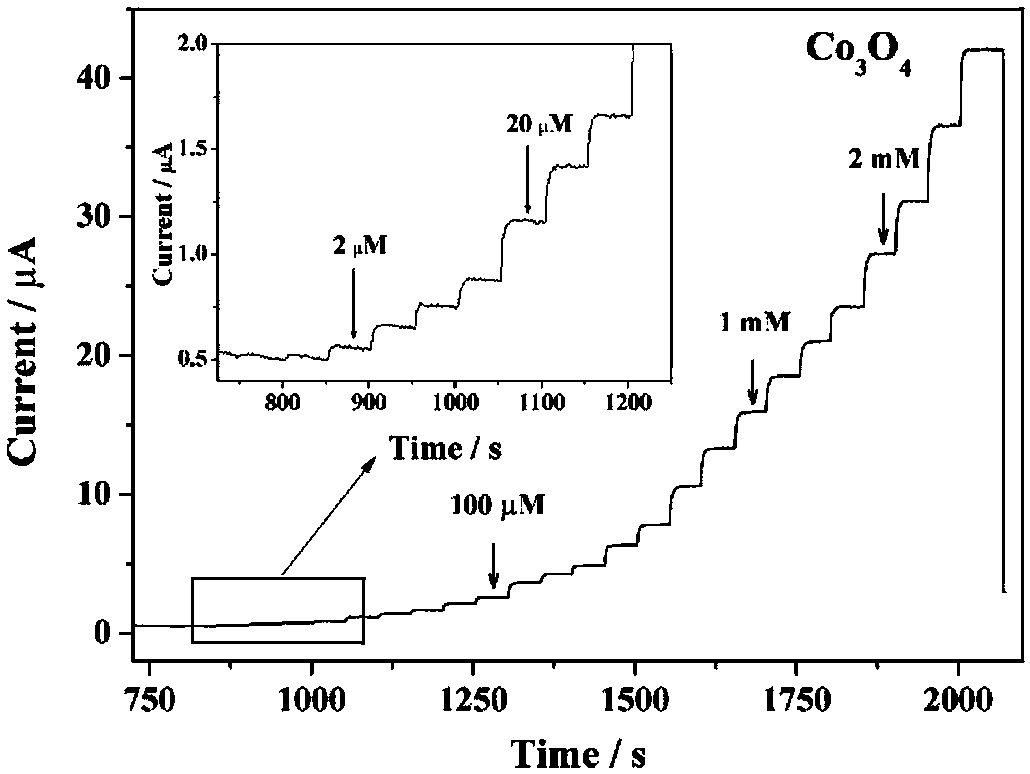

Preparation method of regularly octahedral cobalt oxide micro-nano-particle material

InactiveCN107827166AImprove electrochemical stabilityExcellent electrochemical sensing characteristicsCobalt oxides/hydroxidesMicro nanoMicro rods

The invention discloses a preparation method of a regularly octahedral cobalt oxide micro-nano-particle material. CoCl2.6H2O is taken as a raw material, CO(NH2)2 is taken as a precipitant, deionized water is taken as a solvent, a rod-like precursor grows into a micro-rod formed by octahedral Co3O4 firstly and then the micro-rod grows gradually until regularly octahedral particles are formed. According to the method, CoCl2.6H2O and CO(NH2)2 as two simple raw materials are adopted under a mild hydrothermal condition, the deionized water is taken as the solvent, the rod-like precursor grows intothe micro-rod formed by octahedral Co3O4 firstly and then the micro-rod grows gradually until the regularly octahedral particles are formed, so that regularly octahedral Co3O4 and the micro-rod structure formed by regularly octahedral Co3O4 are prepared in a controllable manner, and the material not only has higher electrochemical stability, but also shows excellent electrochemical sensing property on H2O2.

Owner:SHAANXI UNIV OF SCI & TECH

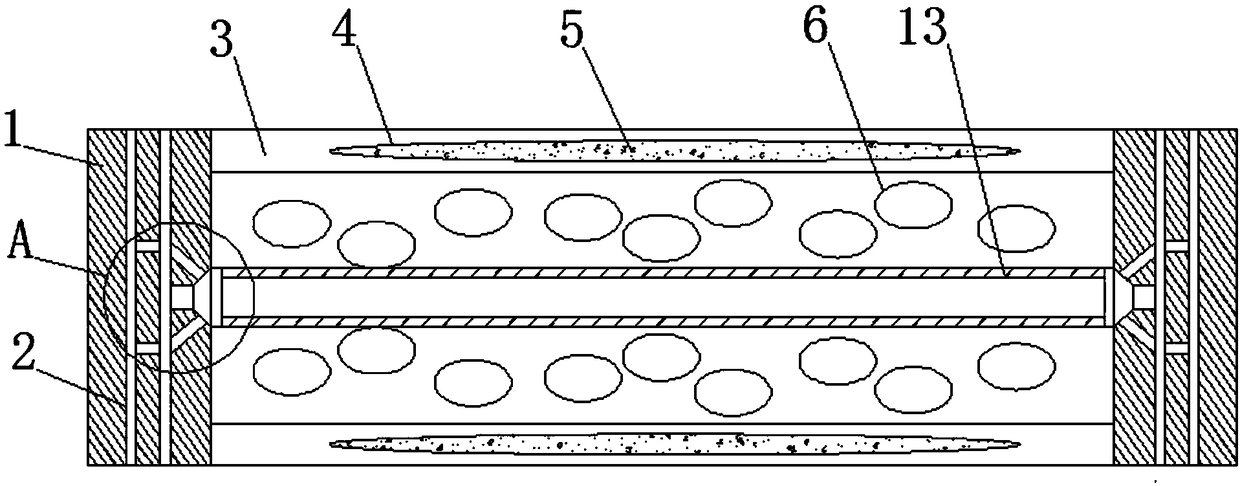

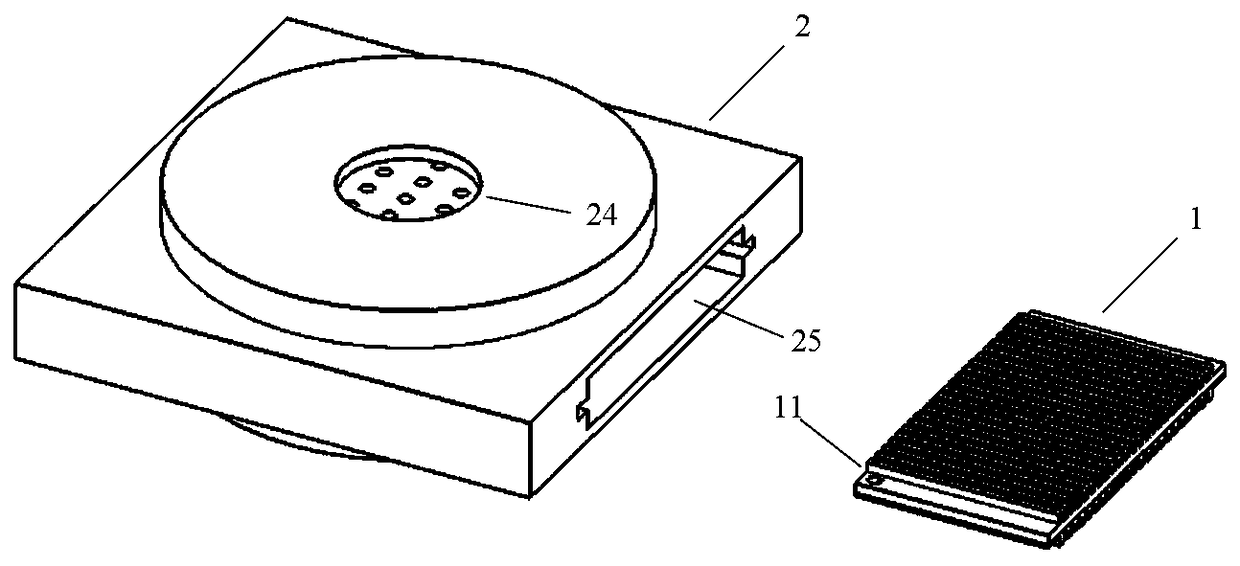

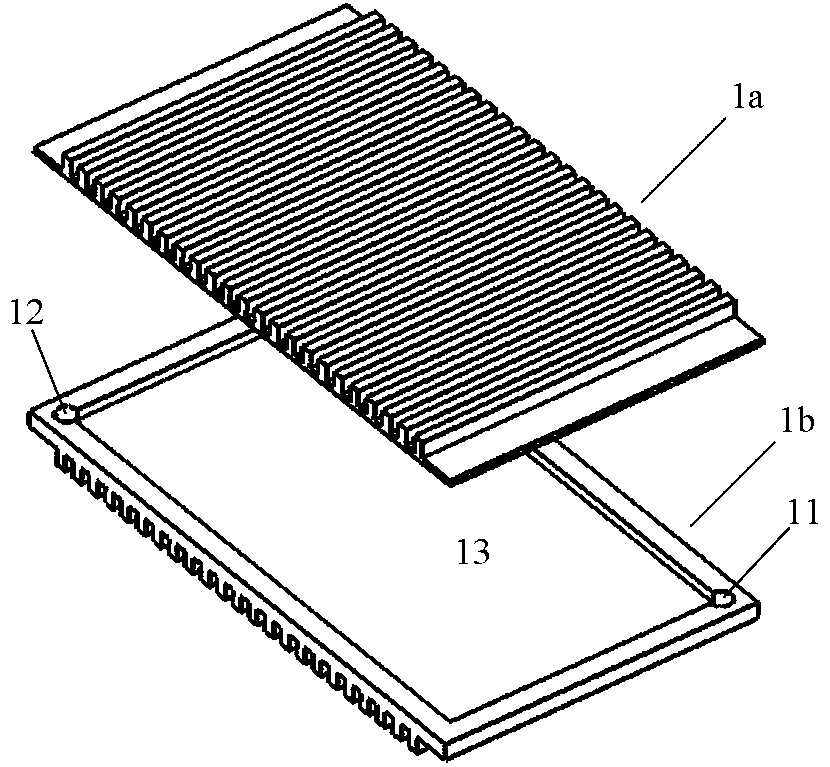

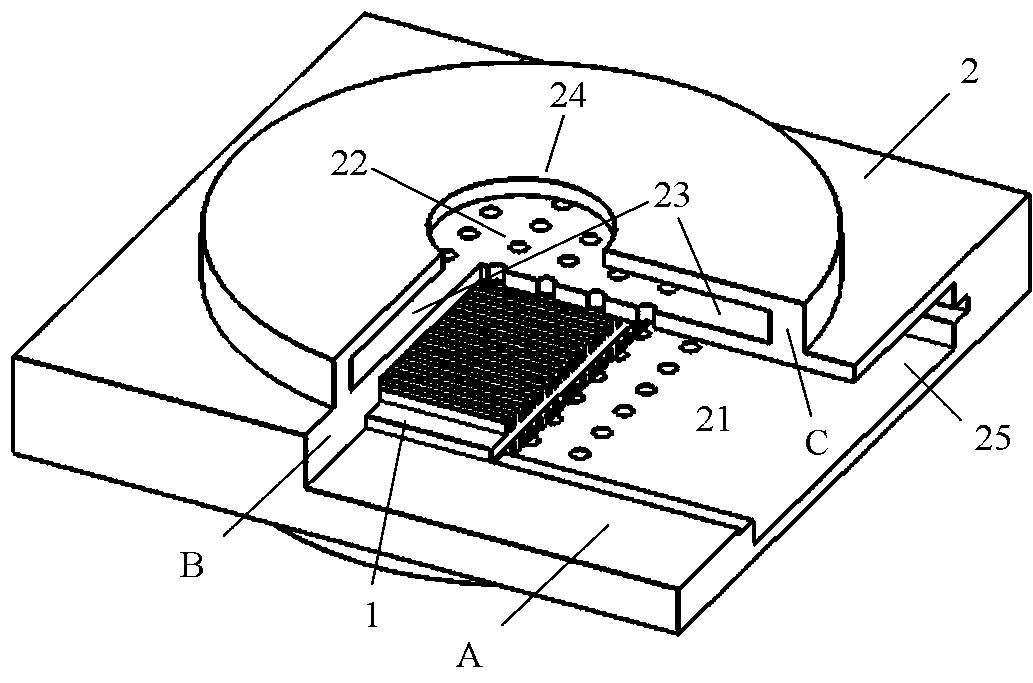

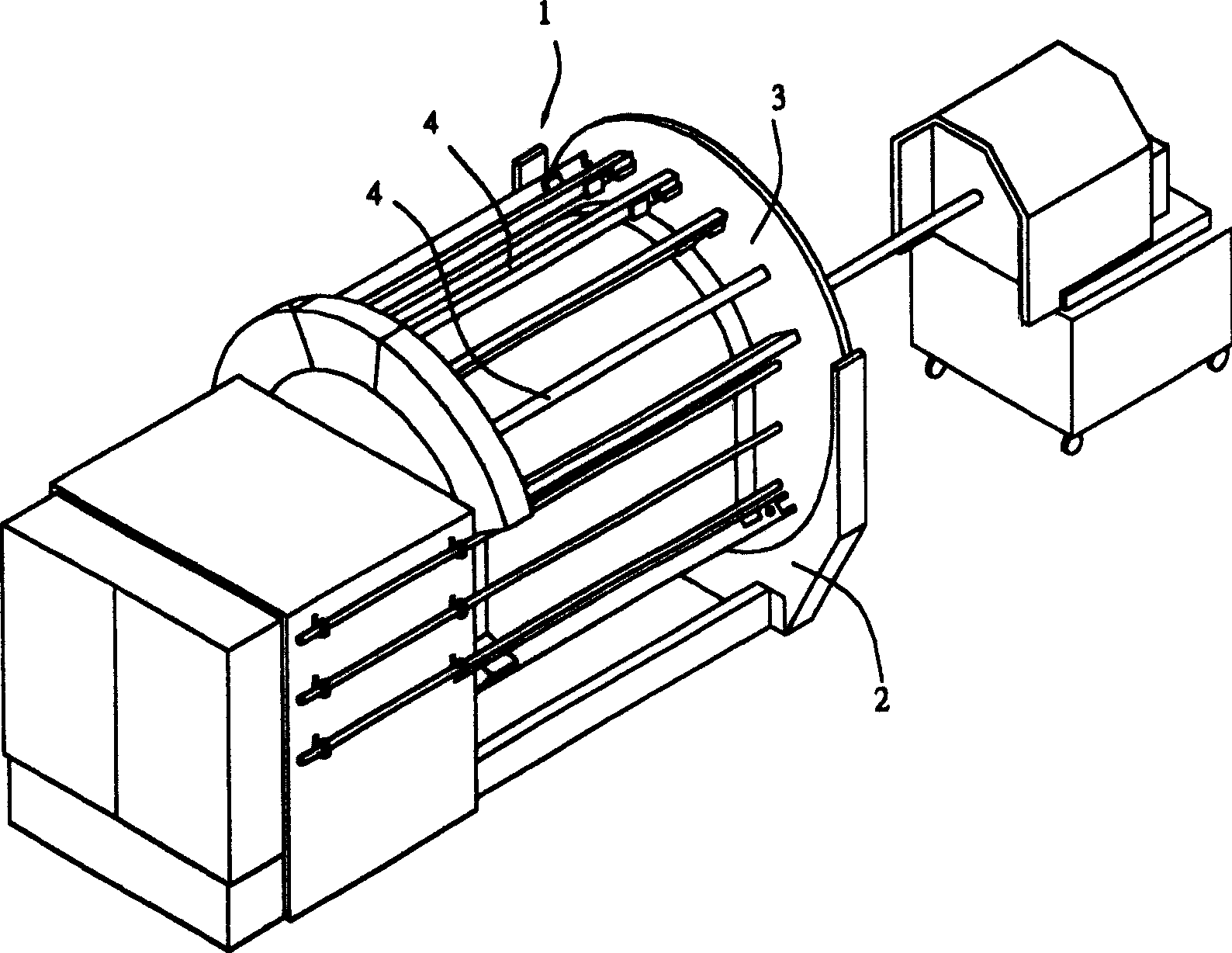

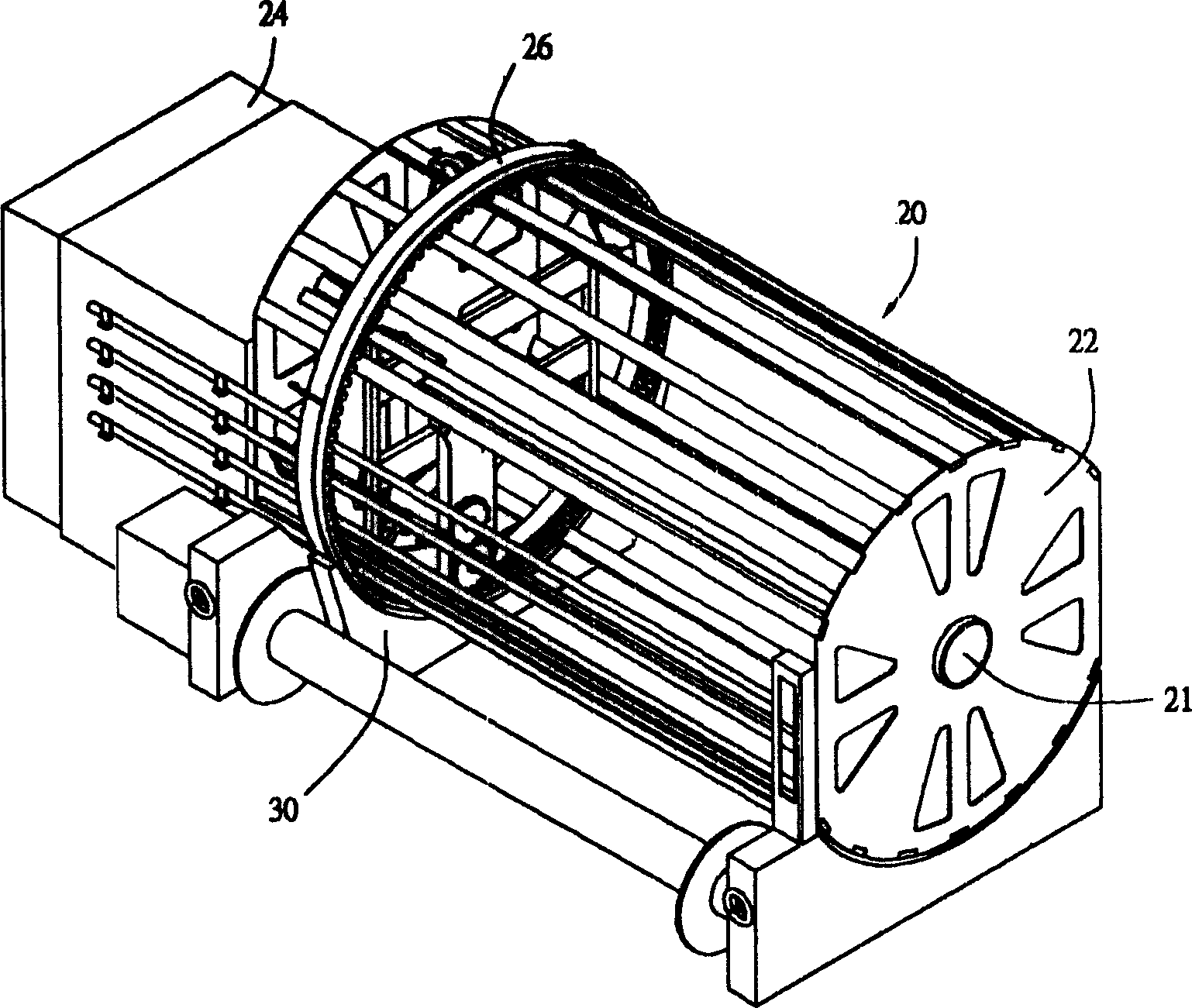

Ultrahigh-speed cooling and rewarming method and ultrahigh-speed cooling and rewarming device

PendingCN108917255AImprove heat transfer efficiencyHigh cooling and rewarming rateDomestic cooling apparatusDead animal preservationVitrificationUltra high speed

The invention relates to an ultrahigh-speed cooling and rewarming method and an ultrahigh-speed cooling and rewarming device, which are used for the glass-state storage of biological samples, such ascells and tissues. The device comprises a chip module and a case, and the chip module is arranged in the case. The chip module is of a flat hollow structure, and the interior is a sample micro-cavity,which is used for containing a to-be-stored biological sample; and a microchannel or micro-rod array is engraved on the external surfaces of the two sides with the largest area on the chip module, and are used for heat exchange. The case is also a flat hollow structure, and the interior is a chip cavity which is used for containing the chip module; one side of the chip cavity communicates with aworking medium inlet via a micropore array and a pressure-stabilizing cavity, and the other side communicates with a working medium outlet; the micropore array is aimed at the microchannel or micro-rod array on the surface of the chip module, and a jet gap exists between both. According to the invention, after being injected, working medium is jetted onto the chip module by the micro-rod array, asuperstrong surface heat exchange effect is generated under the dual function of the micro-jet and the microchannels, and thereby the ultrahigh-speed cooling and rewarming of the sample inside is realized.

Owner:成都酷卓生命科技有限公司

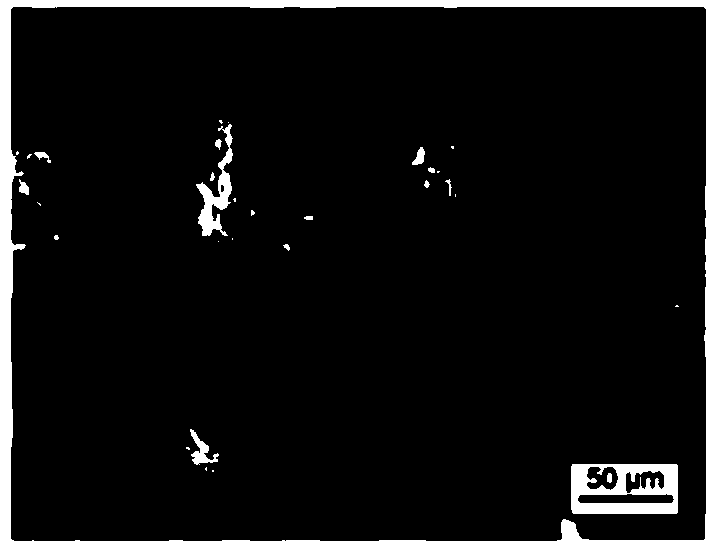

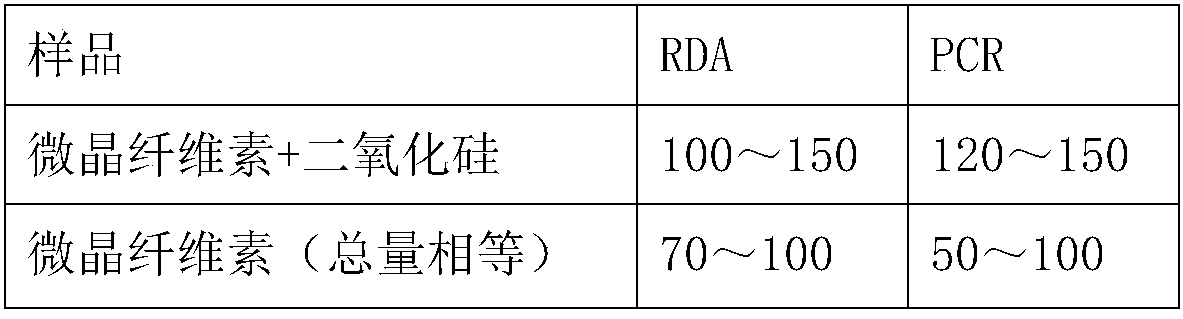

Oral care article and preparation method thereof

InactiveCN108721140AEfficient removalEasy to cleanCosmetic preparationsToilet preparationsFiberBlack tea

The invention discloses an oral care article which is prepared from the following components in parts by weight: 99-1 part of microcrystalline cellulose and 1-99 parts of silicon dioxide. The invention also provides a preparation method of the oral care article. The oral care article (toothpaste) and the preparation method thereof provided by the invention have the beneficial effects that the oralcare article is a composition containing microcrystalline cellulose and silicon dioxide, can effectively remove tooth stains caused by food pigments such as coffee, black tea and soy sauce, and simultaneously can not damage tooth enamel; the microcrystalline fiber which is micro rod-shaped structure fiber can gently wipe color stains on the surfaces of teeth; and the microcrystalline fiber and the silicon dioxide are compounded for use to obtain synergetic cleaning effects, so that the surfaces of the teeth can be more effectively cleaned.

Owner:WUXI QINGHE XIAOBEI TECH CO LTD

Microfabricated instruments and methods to treat recurrent corneal erosion

ActiveUS8591481B2Promote wound healingPromote healingEye surgeryMedical applicatorsEpitheliumMicro rods

Owner:UNIV OF TENNESSEE RES FOUND +1

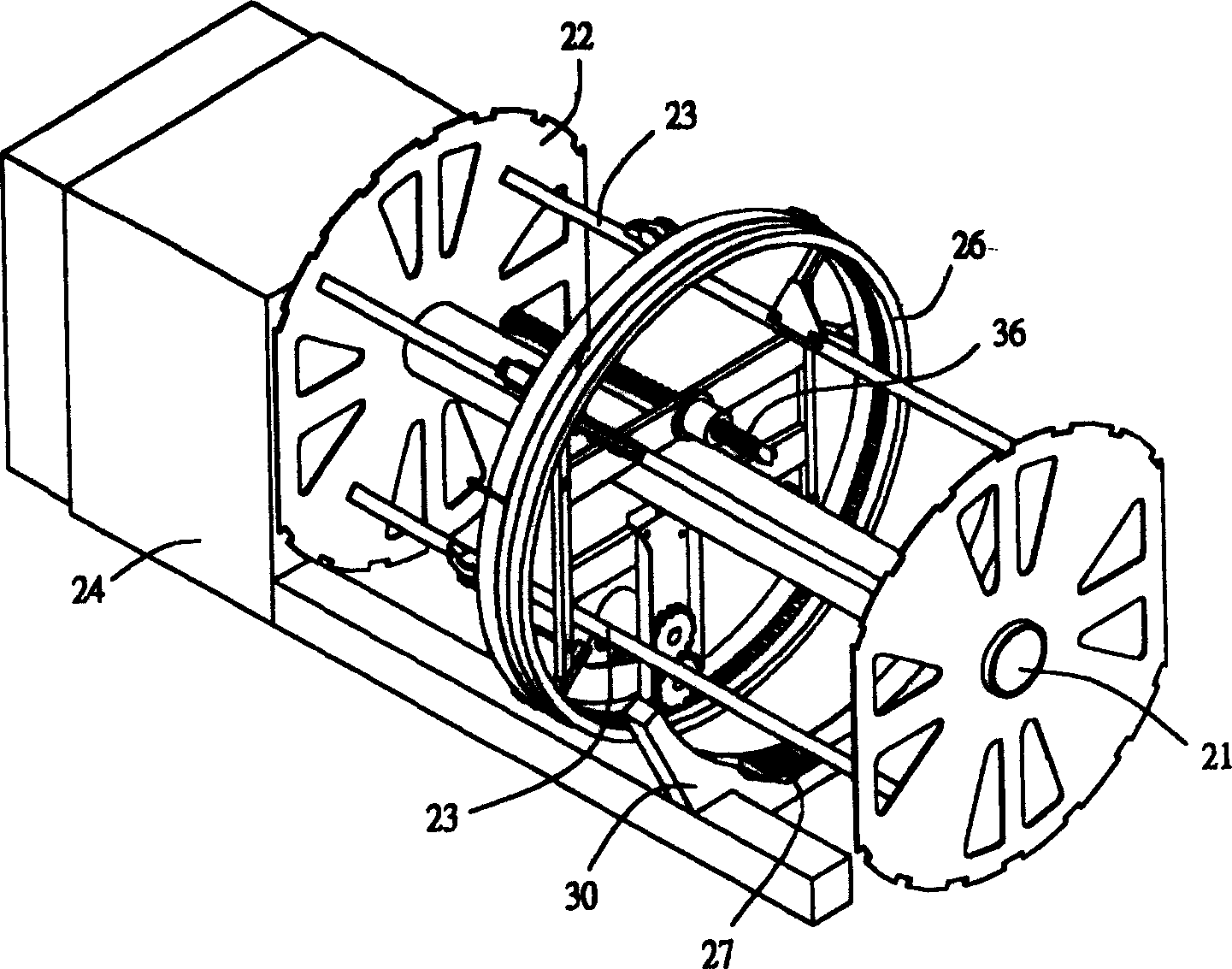

Automatic sample warping machine and its warping method

The automatic sample warping machine has structure including one transverse moving wheel with yarn hooking head to hook yarn led out by the string guiding frame; one first rack combination set inside the transverse moving wheel and comprising several auxiliary frames and one drive mechanism to rotate the transverse moving wheel; one micro wheel with several extending frames with bevel to twist yarn onto one drum in proper tension order; one second rack combination set inside the micro wheel and connected to the first rack combination for the micro wheel to reciprocate; several extending auxiliary rods for the auxiliary frames to move on the auxiliary rods; one transverse moving rod driven by one first servo motor to combine with the first rack combination for the transverse wheel to move back and forth; and one micro rod driven by one second servo motor to combine with the second rack combination for the transverse wheel to reciprocate back and forth.

Owner:本盟紡織股フン

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com