Patents

Literature

1749results about "Pulp beating/refining methods" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method and apparatus for manufacturing microfibrillated cellulose fiber

ActiveUS7381294B2Efficient and stable productionQuality improvementNon-fibrous pulp additionNatural cellulose pulp/paperCellulose fiberSlurry

A method for producing a microfibrillated cellulose, which comprises subjecting a slurry containing a pulp having a solids concentration of 1 to 6 wt % to the treatment with a disc refiner repeatedly ten times or more, to thereby prepare a microfibrillated cellulose having a number average fiber length or 0.2 mm or less and an amount of water hold of 10 mL / g or more, the amount representing the volume of water capable of being held by a unit weight of the cellulose fiber. The method allows the production of a microfibrillated cellulose having high quality with stability and with good efficiency.

Owner:DSG INT LTD

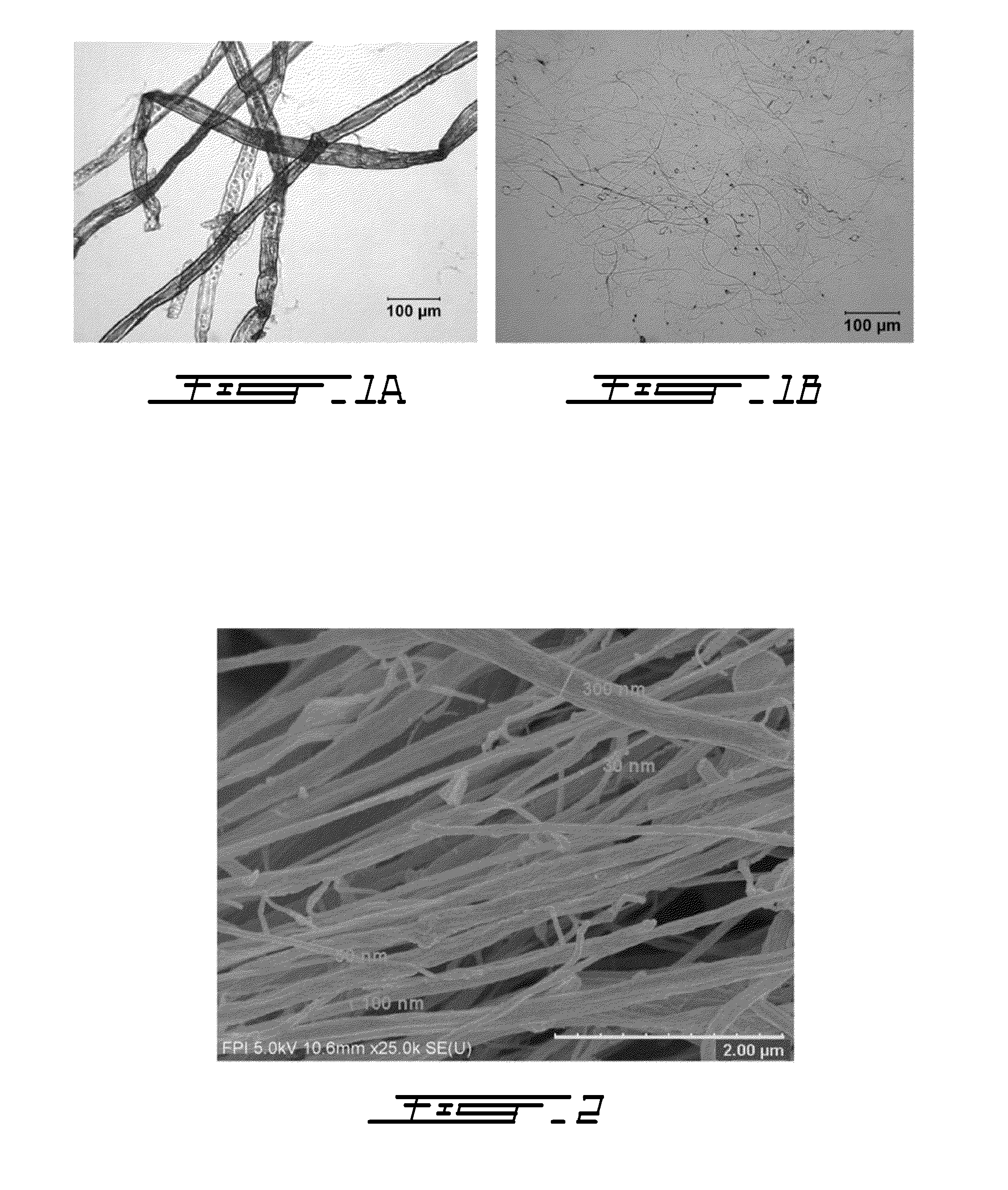

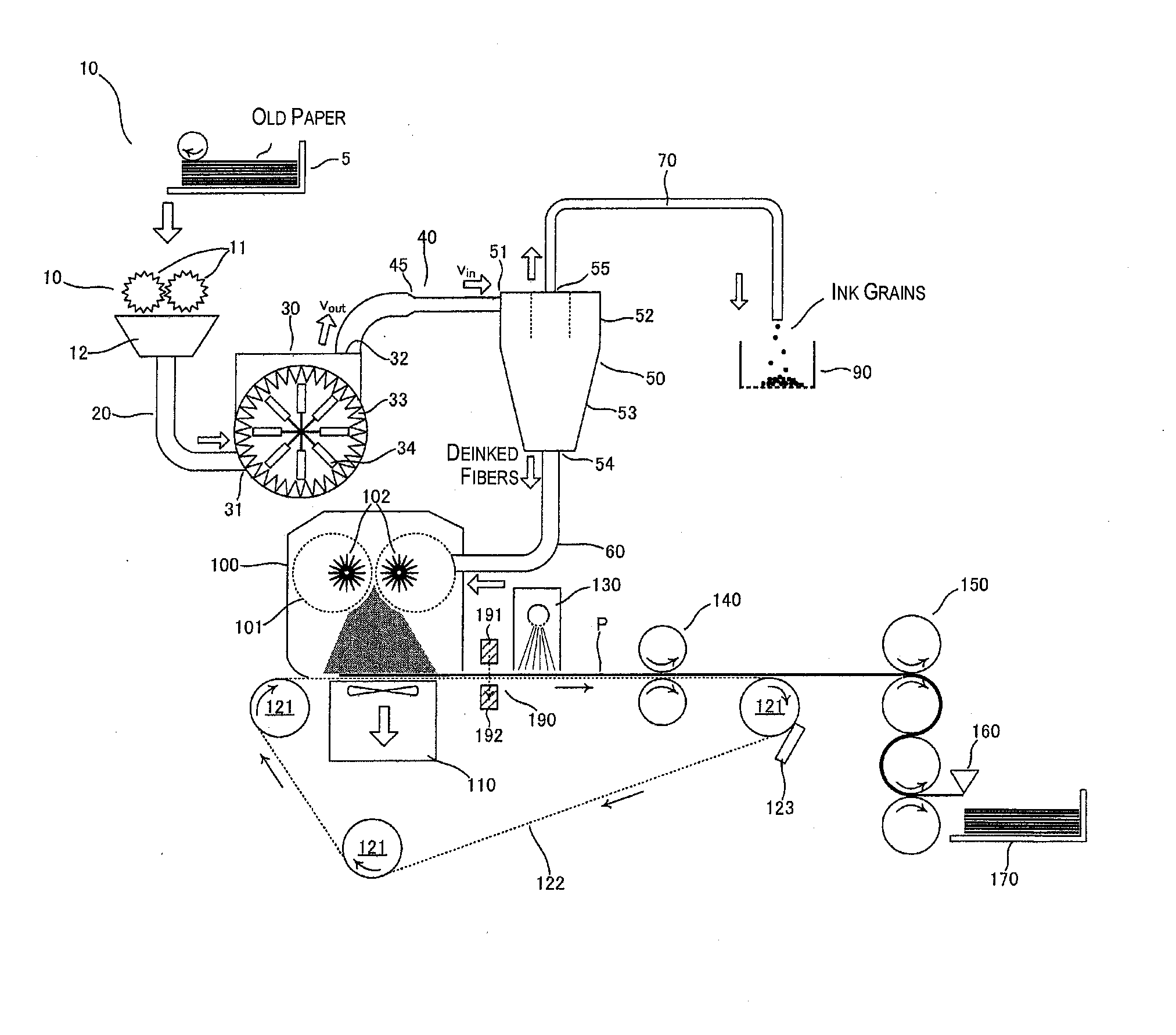

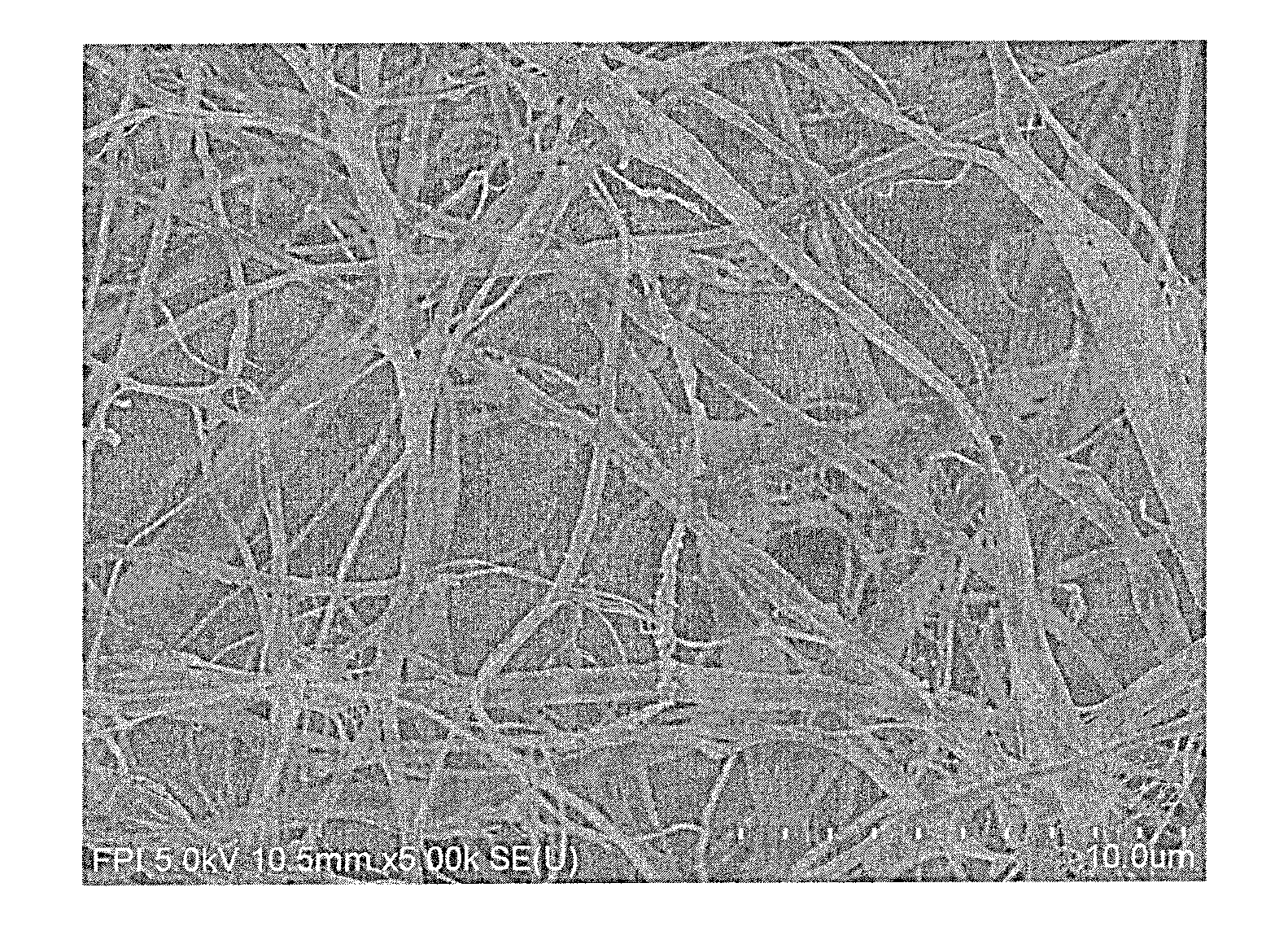

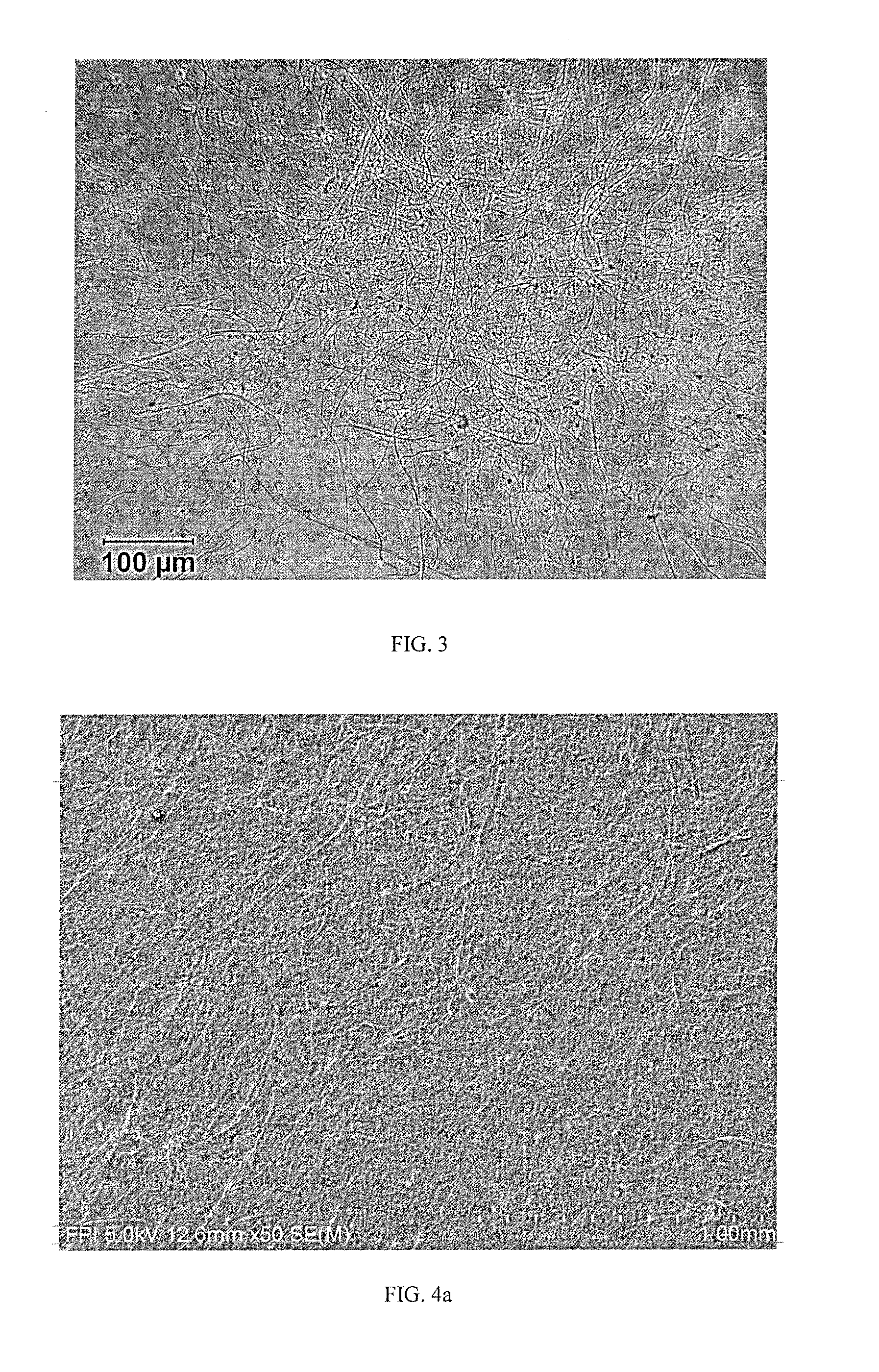

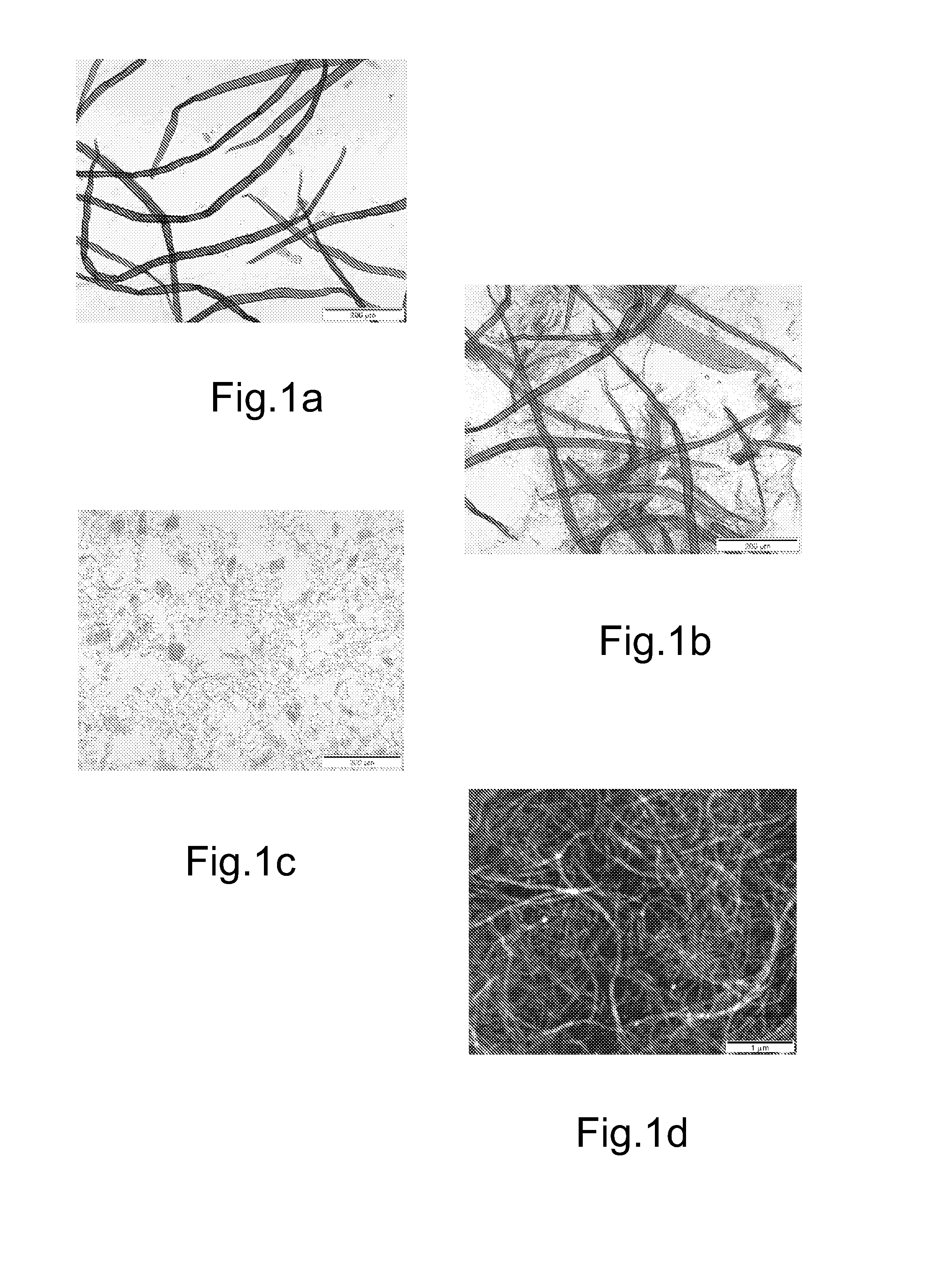

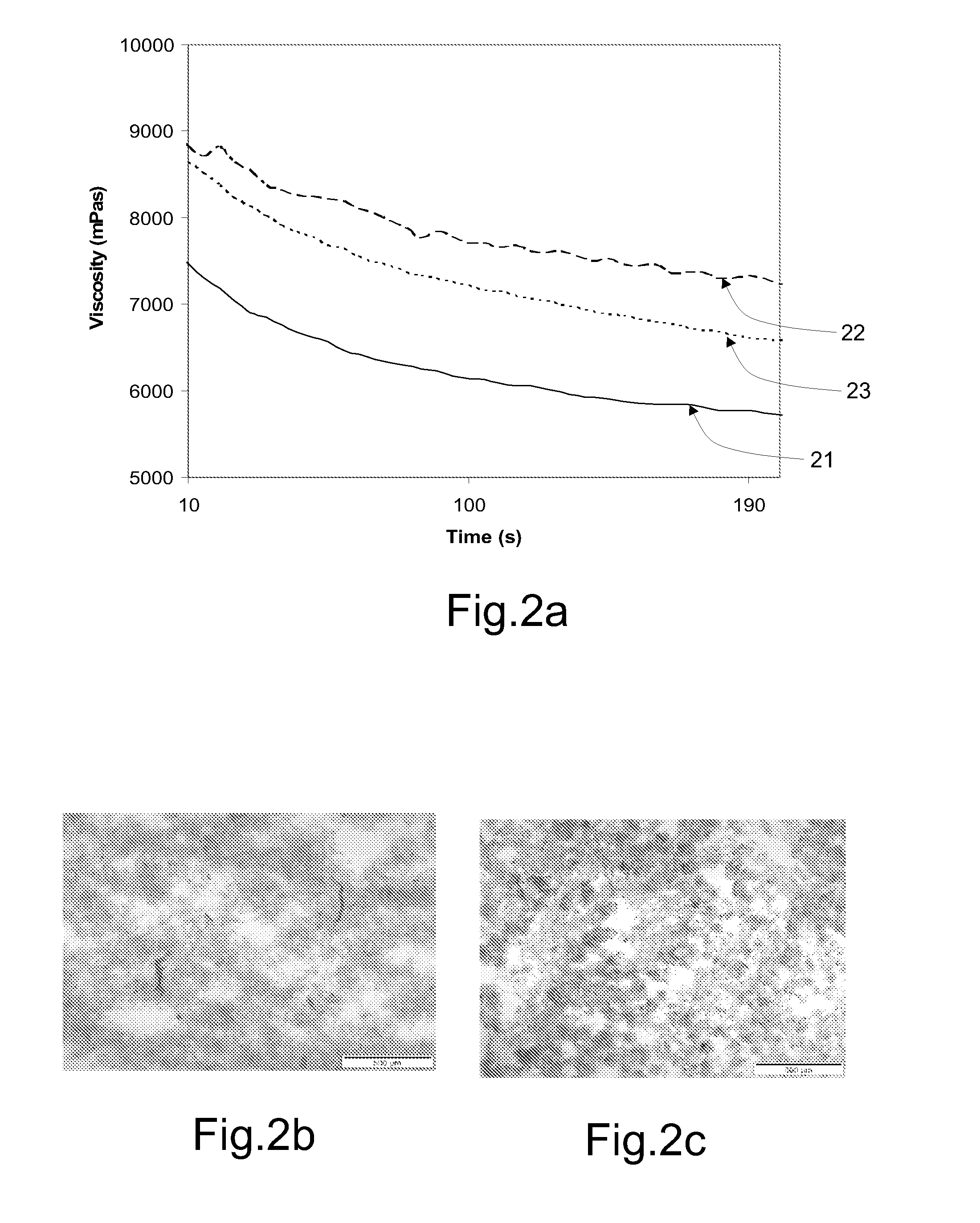

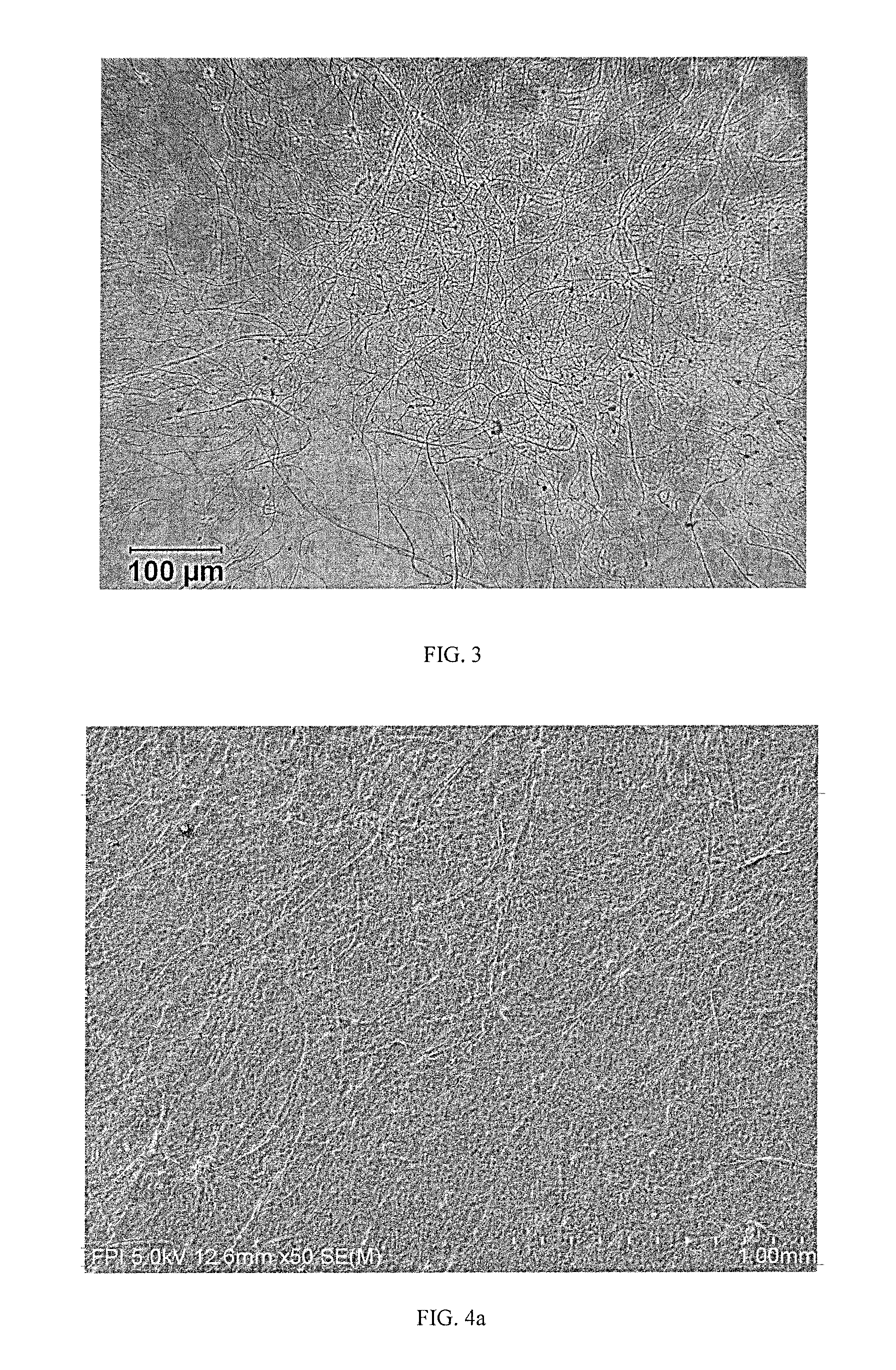

Cellulose nanofilaments and method to produce same

ActiveUS20110277947A1Improve strength propertiesMaterial nanotechnologyNatural cellulose pulp/paperPolymer sciencePaperboard

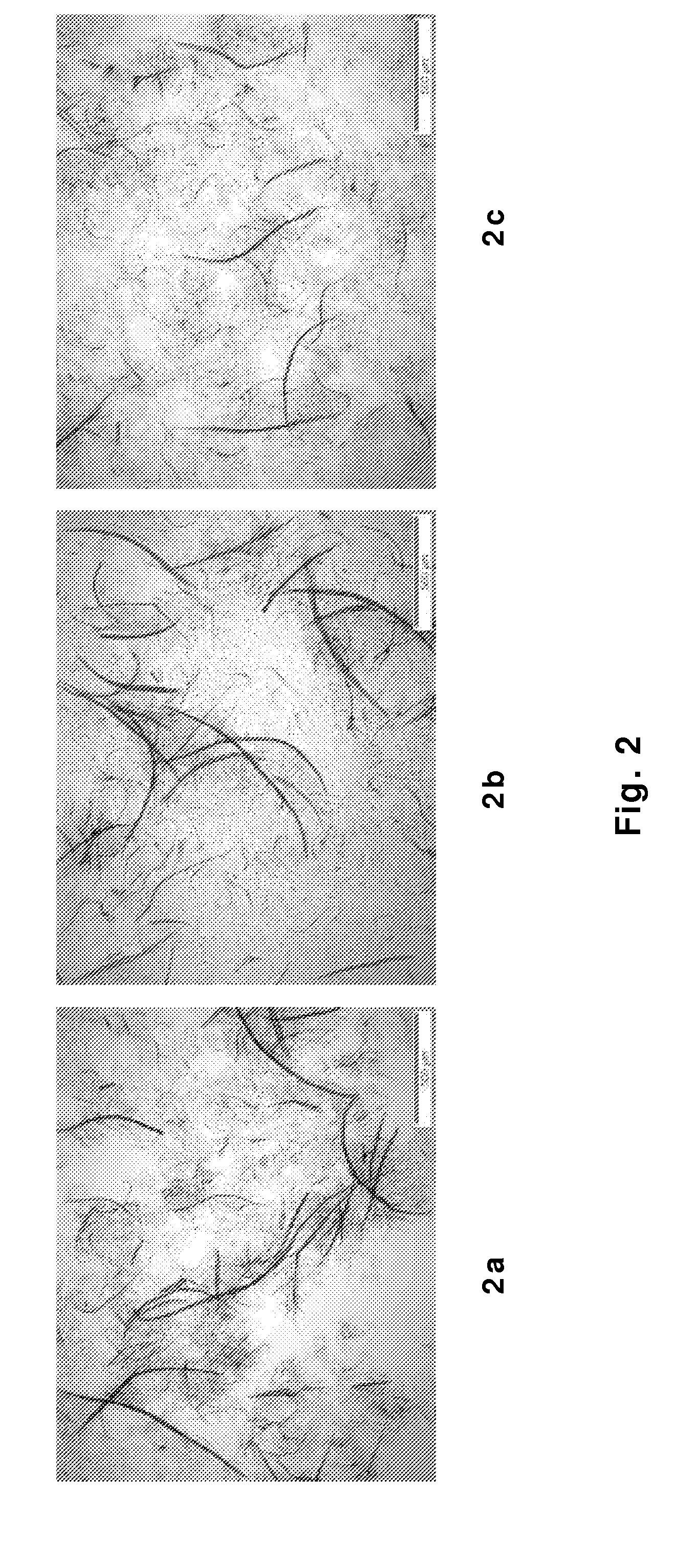

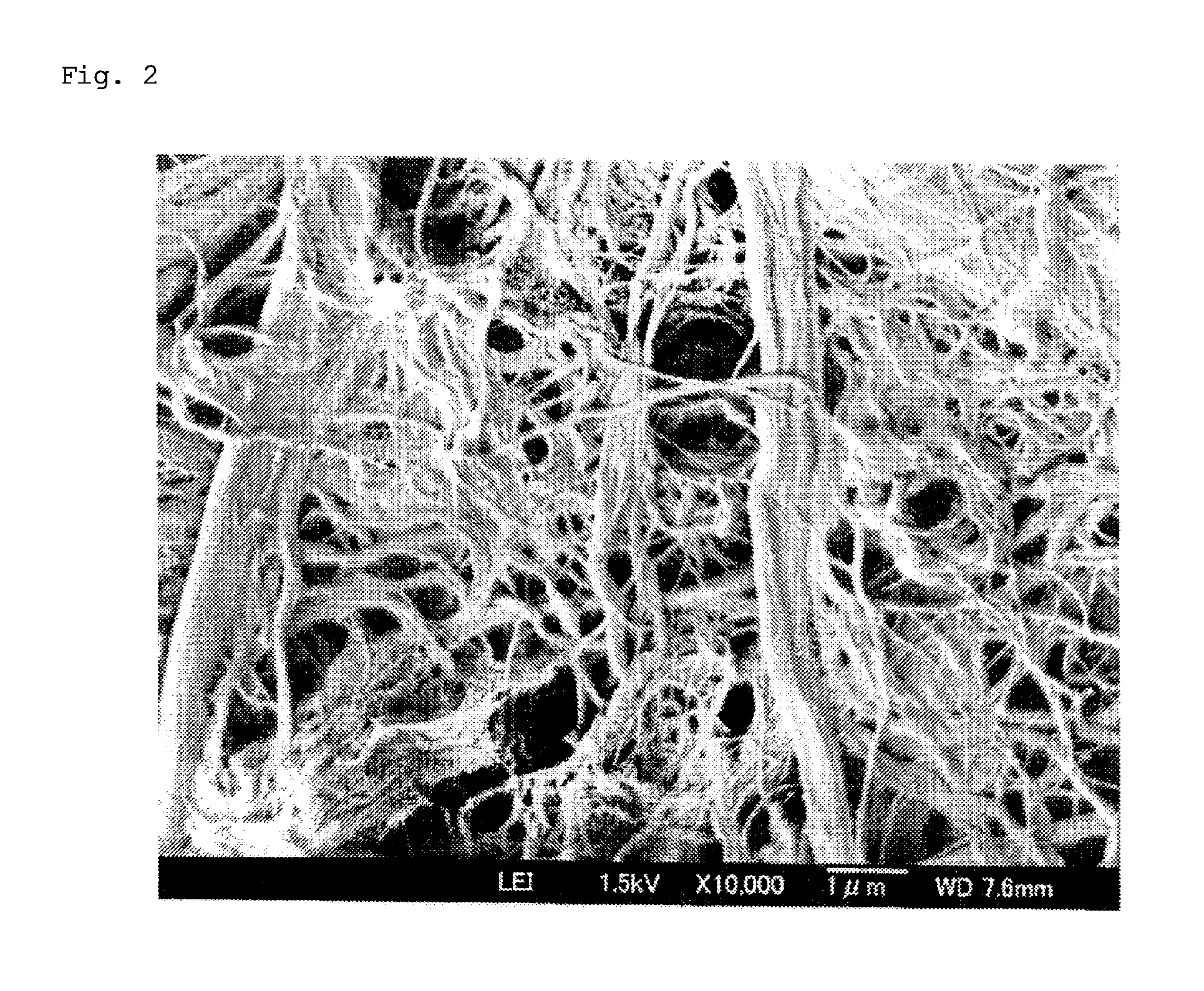

Cellulose nanofilaments from cellulose fibers, a method and a device to produce them are disclosed. The nanofilaments are fine filaments with widths in the sub-micron range and lengths up to a couple of millimeters. These nanofilaments are made from natural fibers from wood and other plants. The surface of the nanofilaments can be modified to carry anionic, cationic, polar, hydrophobic or other functional groups. Addition of these nanofilaments to papermaking furnishes substantially improves the wet-web strength and dry sheet strength much better than existing natural and synthetic polymers. The cellulose nanofilaments produced by the present invention are excellent additives for reinforcement of paper and paperboard products and composite materials, and can be used to produce superabsorbent materials.

Owner:FPINNOVATIONS INC

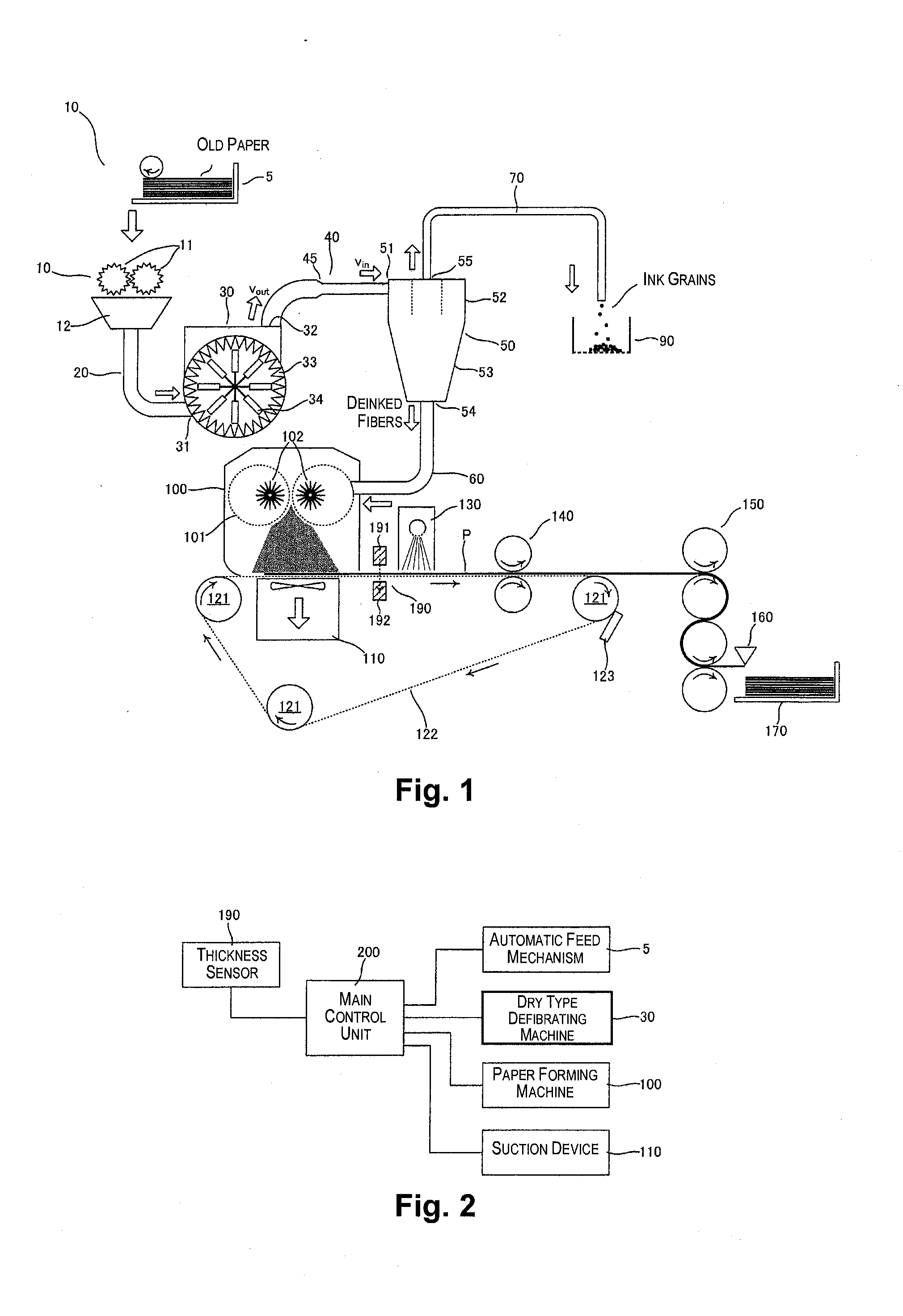

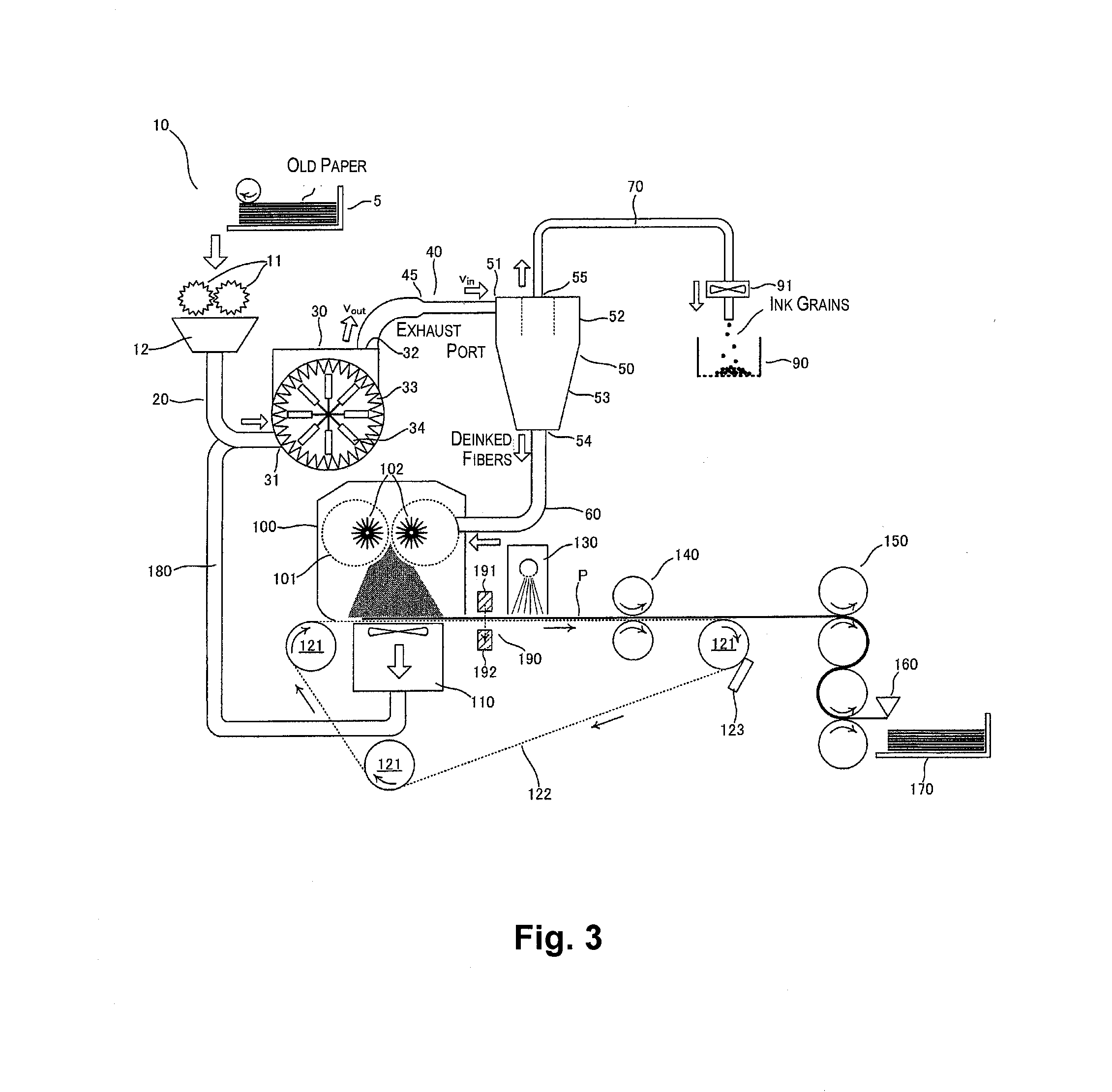

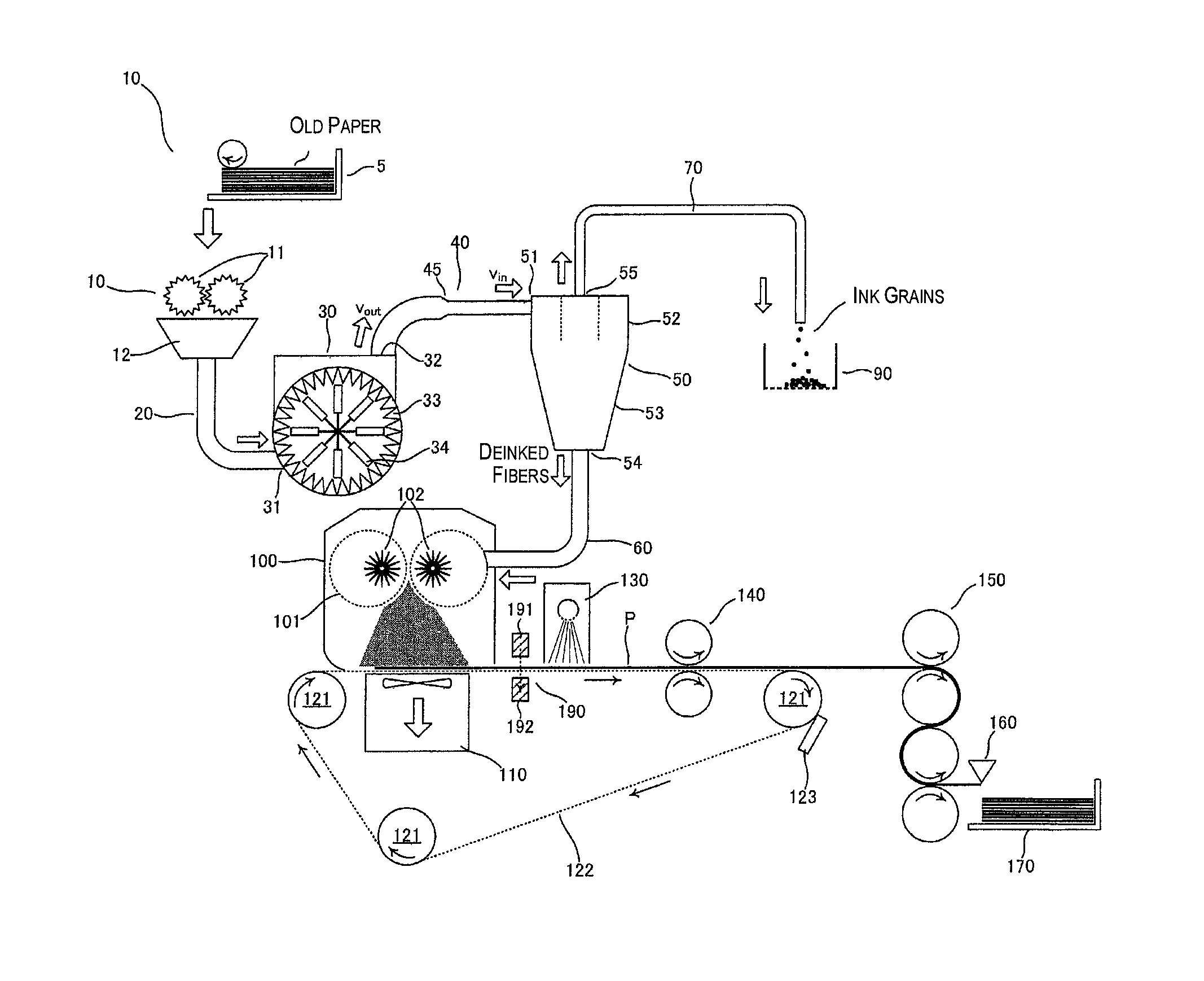

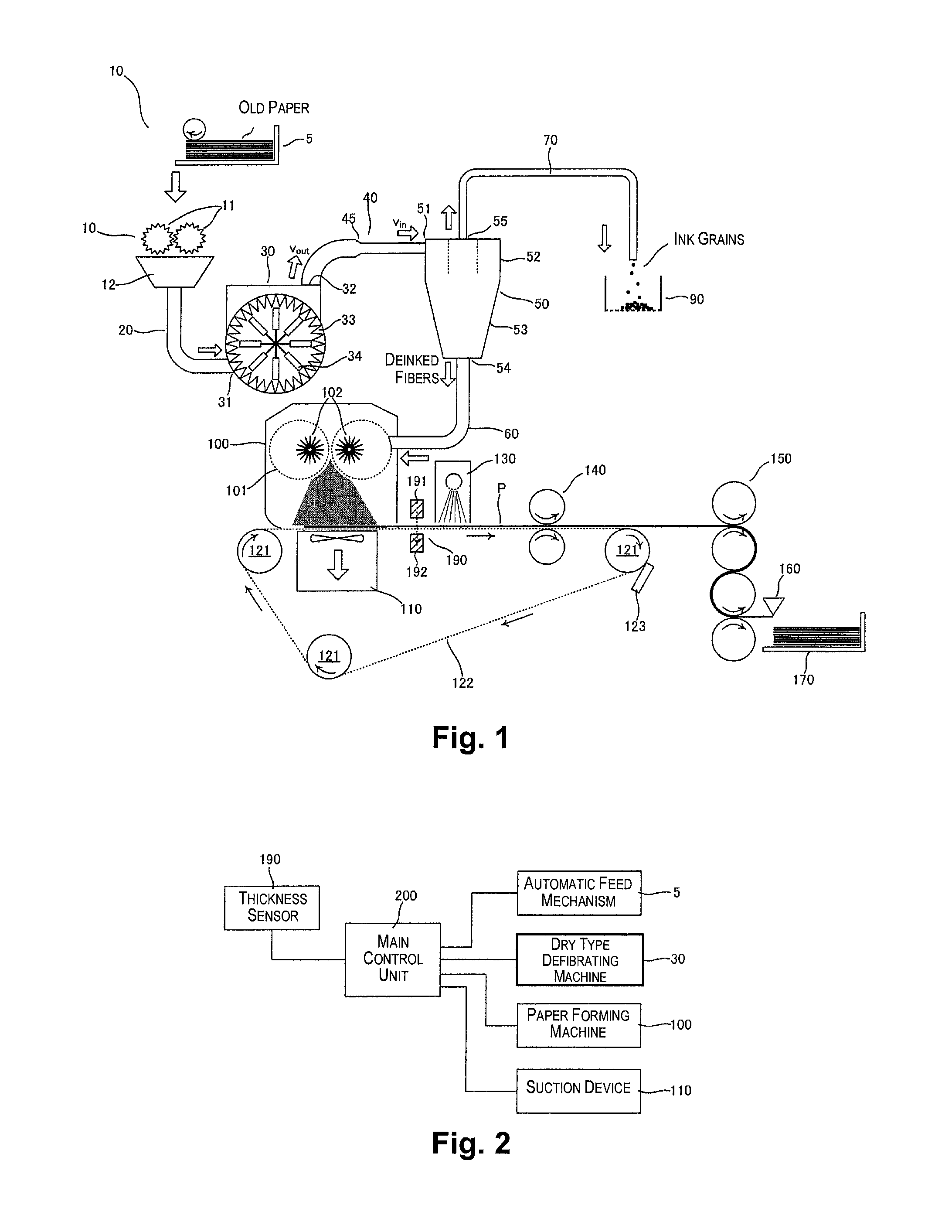

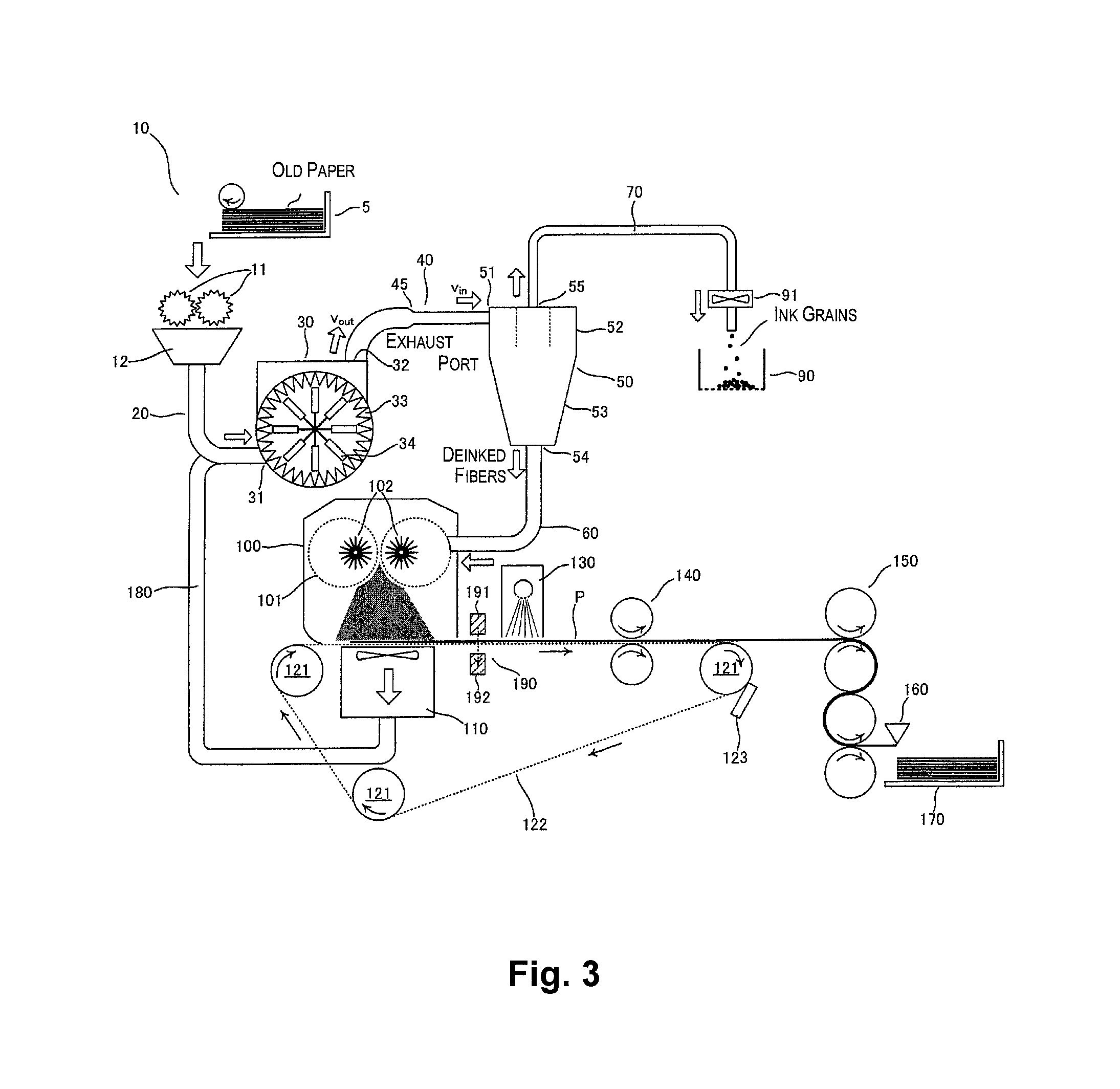

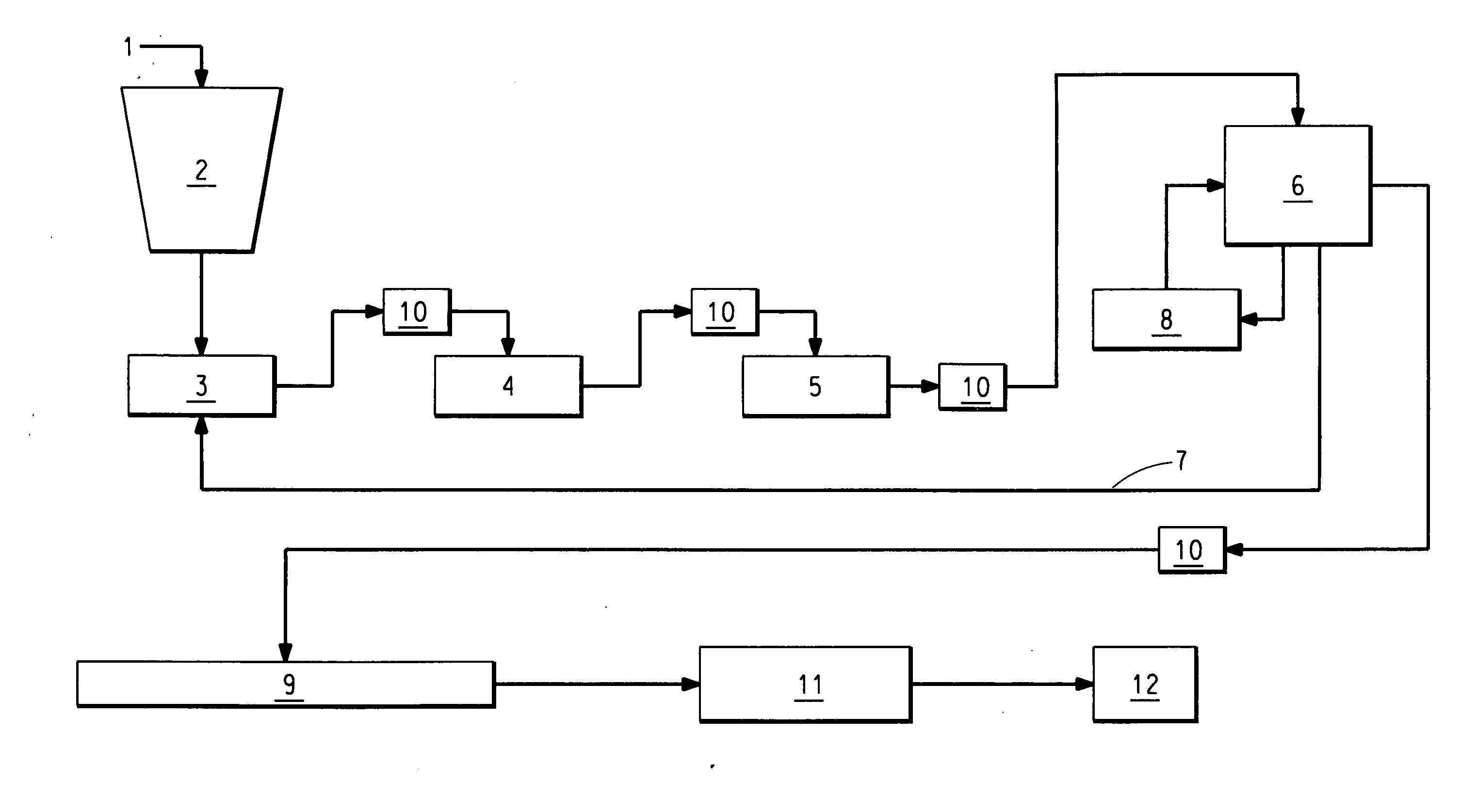

Paper recycling system and paper recycling method

InactiveUS20140027075A1Improve the level ofHigh whitenessPaper recyclingFlat articlesPaper recyclingPulp and paper industry

To provide a paper recycling device capable of recycling paper of increased whiteness level that can be widely used for applications other than paper for newspapers, the paper recycling device of the present invention has a dry type defibrator for crushing and defibrating paper, a first transport pipe for transporting defibrated material that was defibrated by the dry type defibrator, a cyclone for air classifying and deinking the defibrated material transported by the first transport pipe, a second transport pipe for transporting the defibrated material that was deinked by the cyclone, and a paper forming machine for forming paper with the defibrated material transported by the second transport pipe.

Owner:SEIKO EPSON CORP

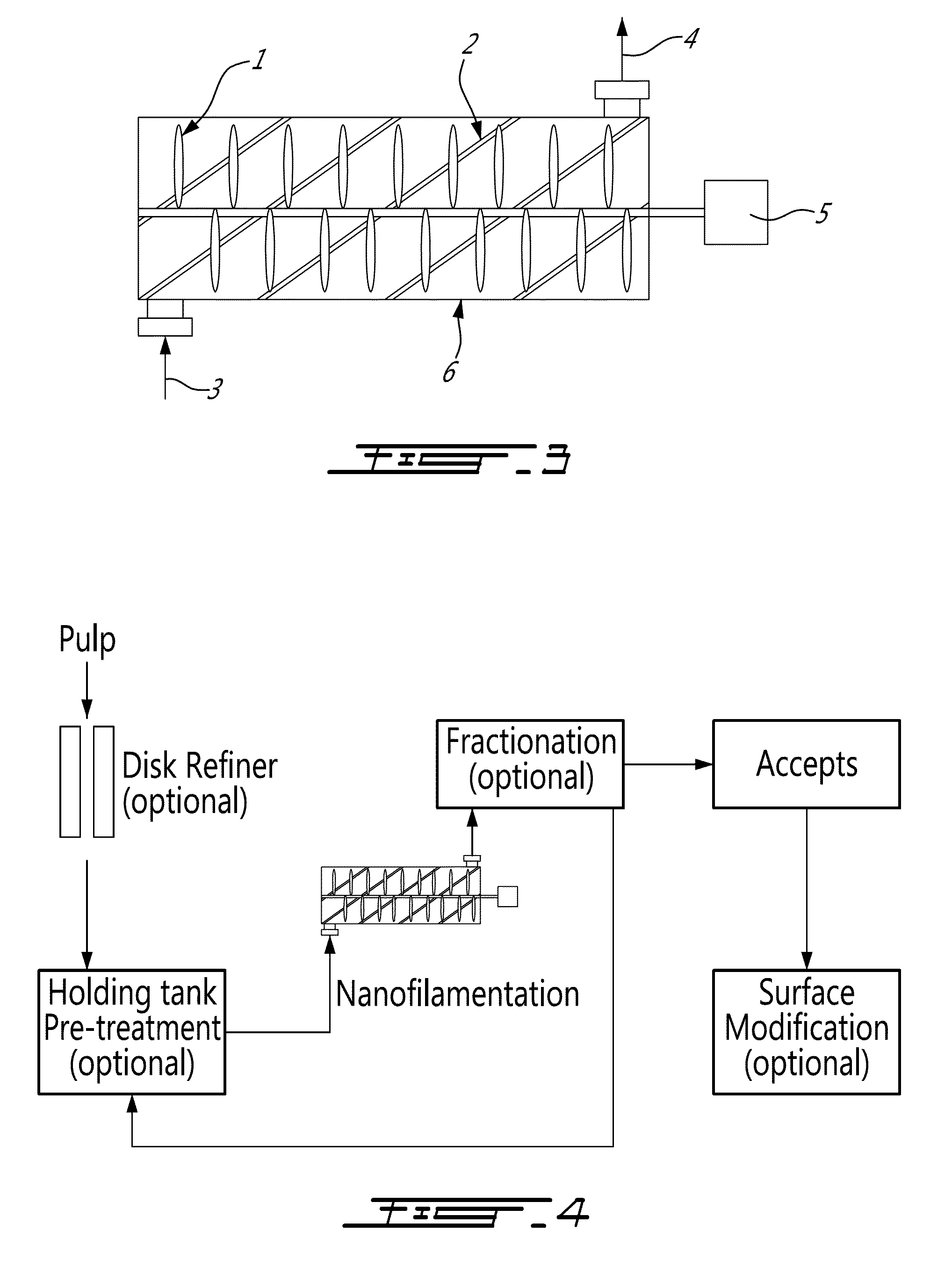

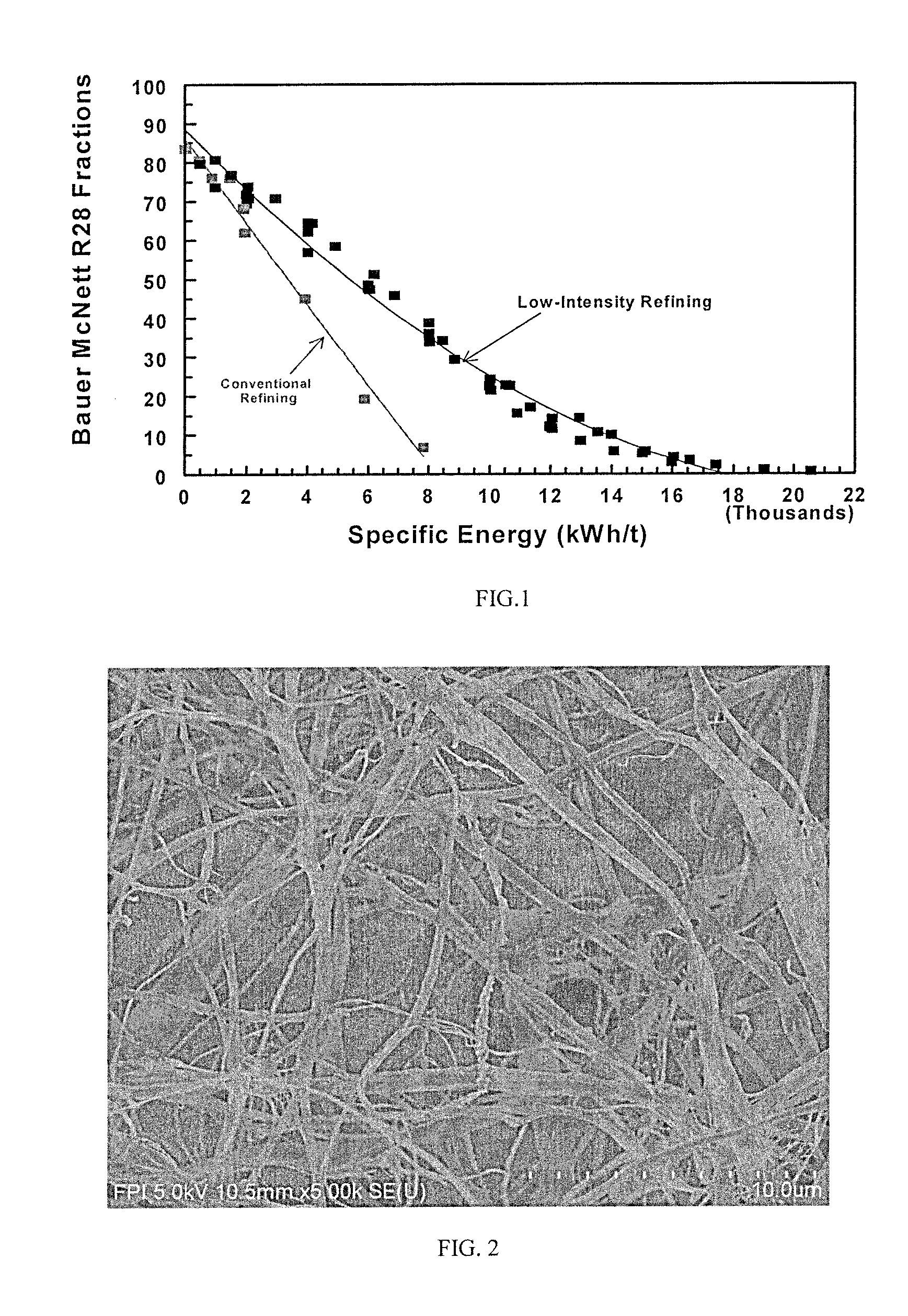

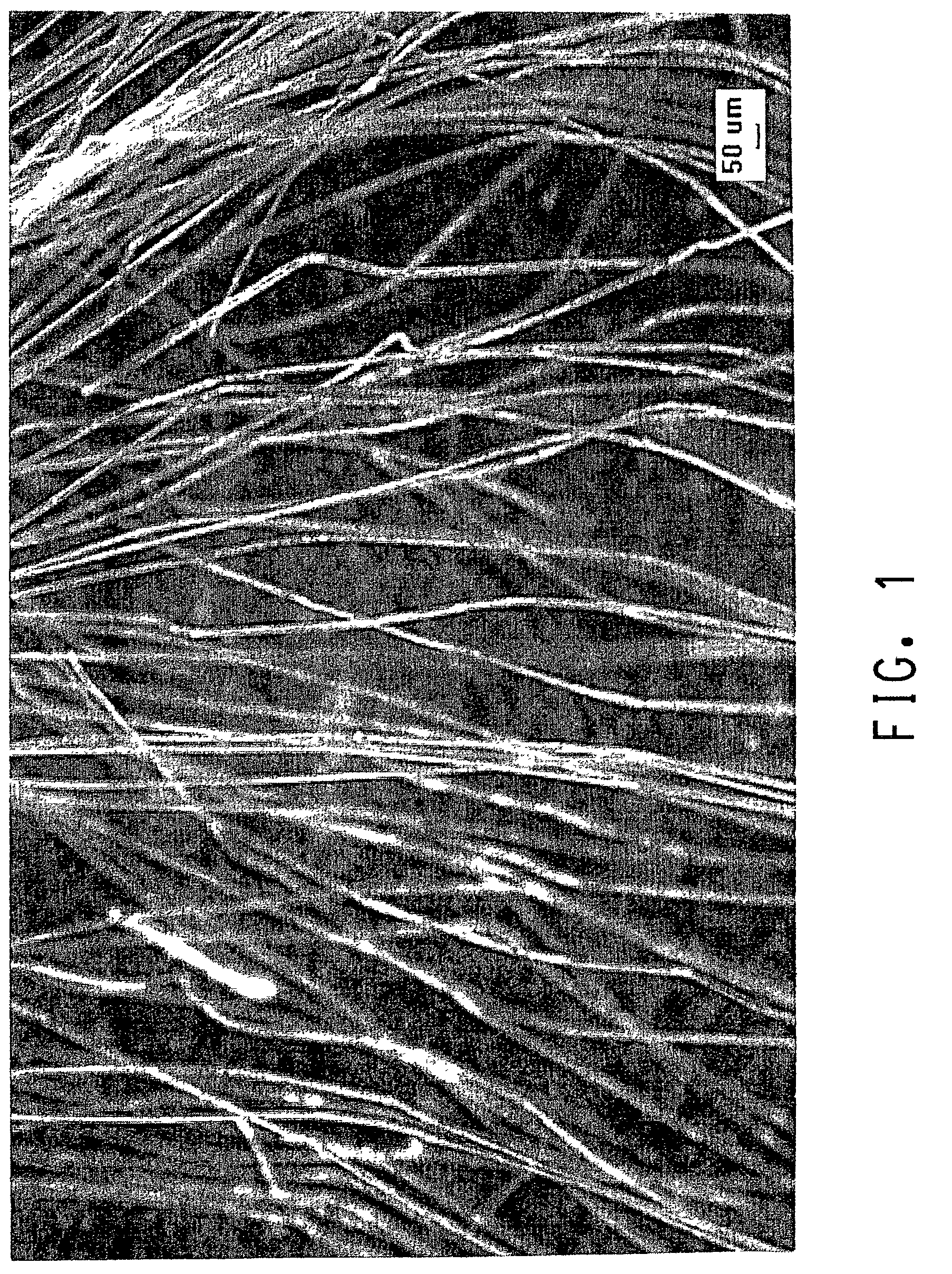

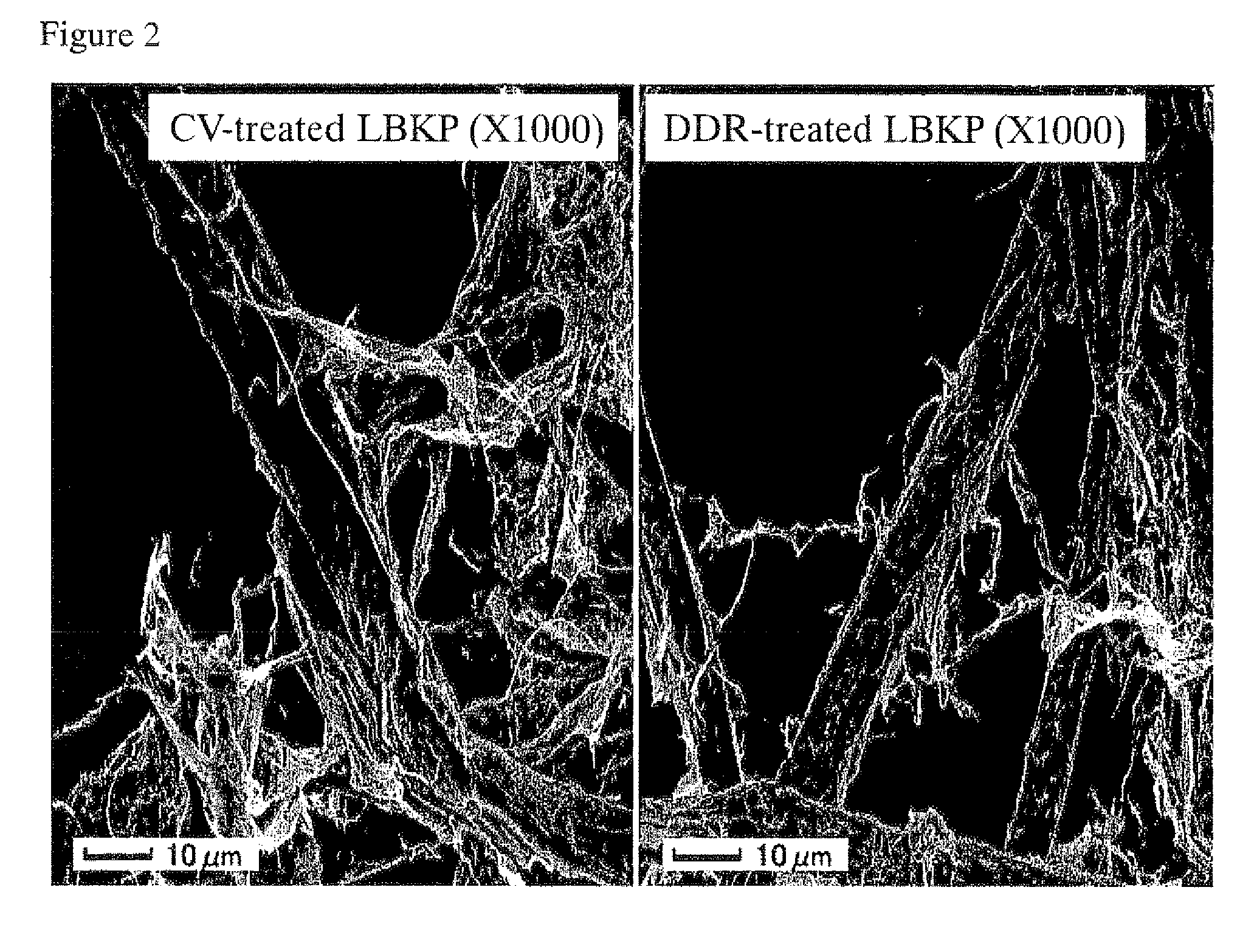

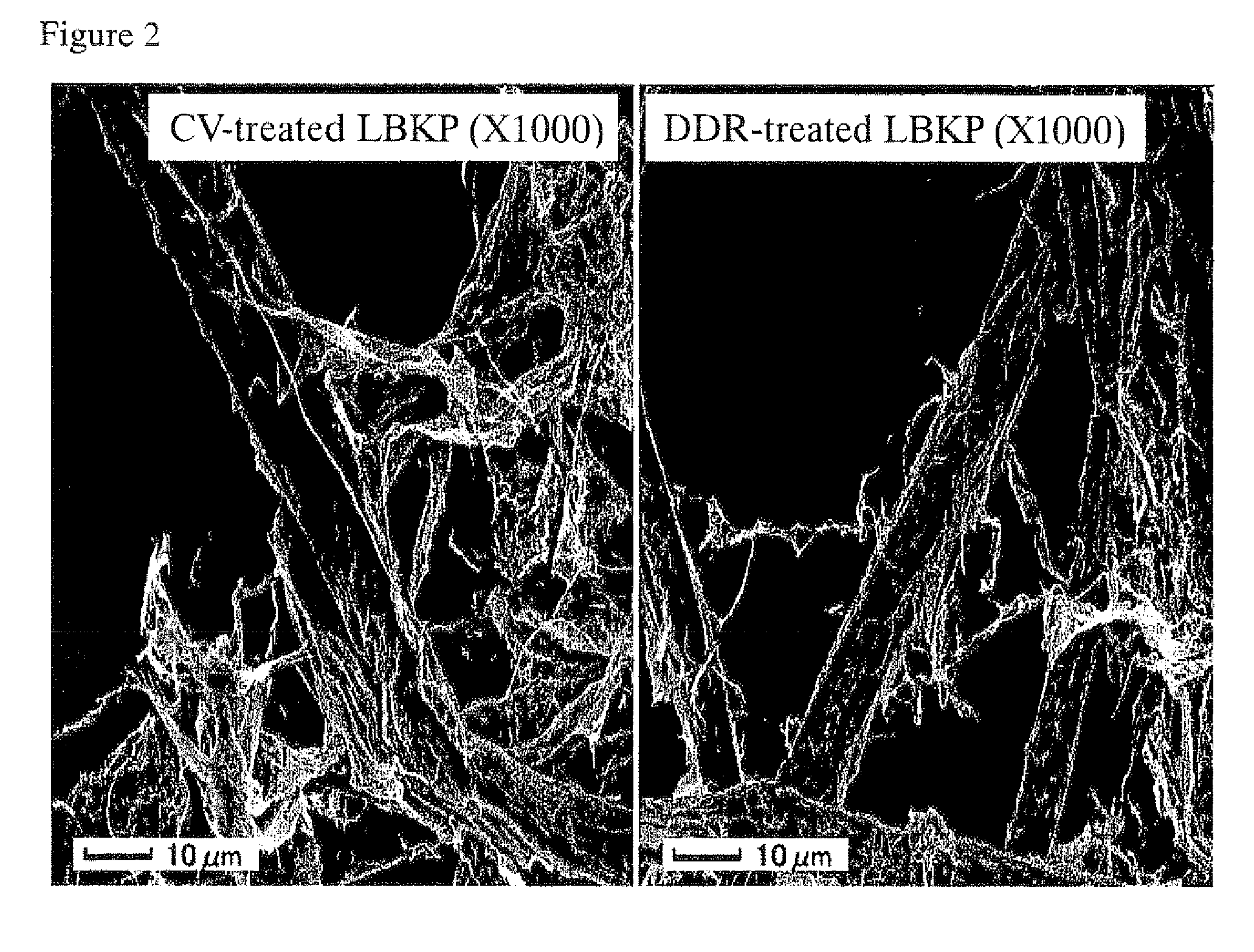

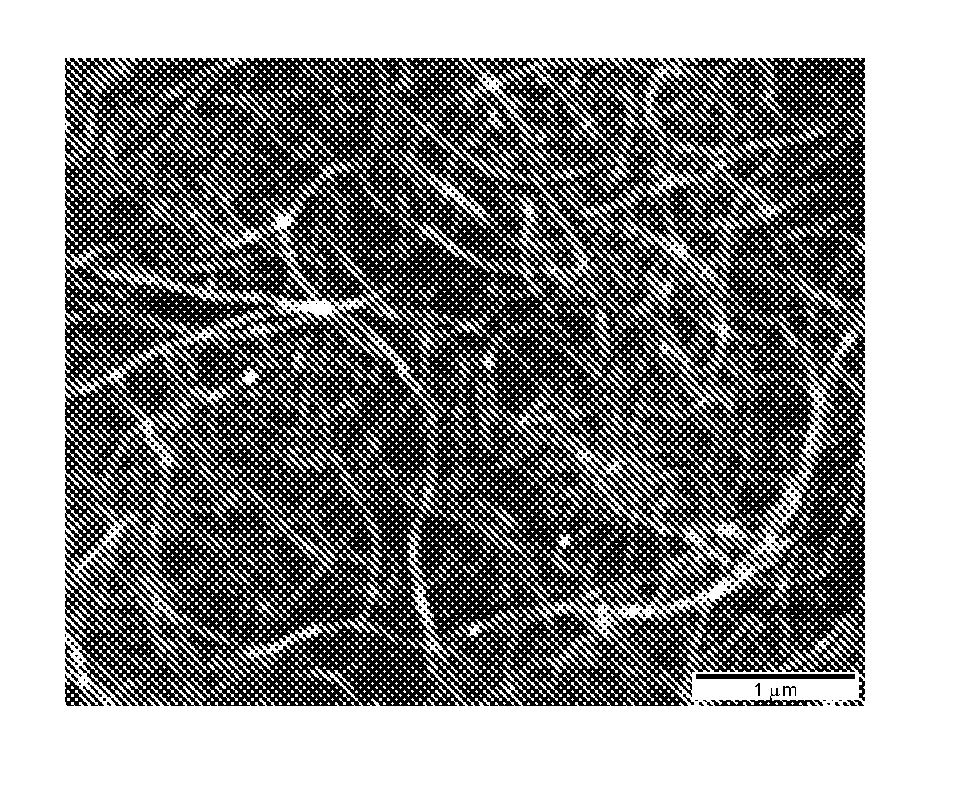

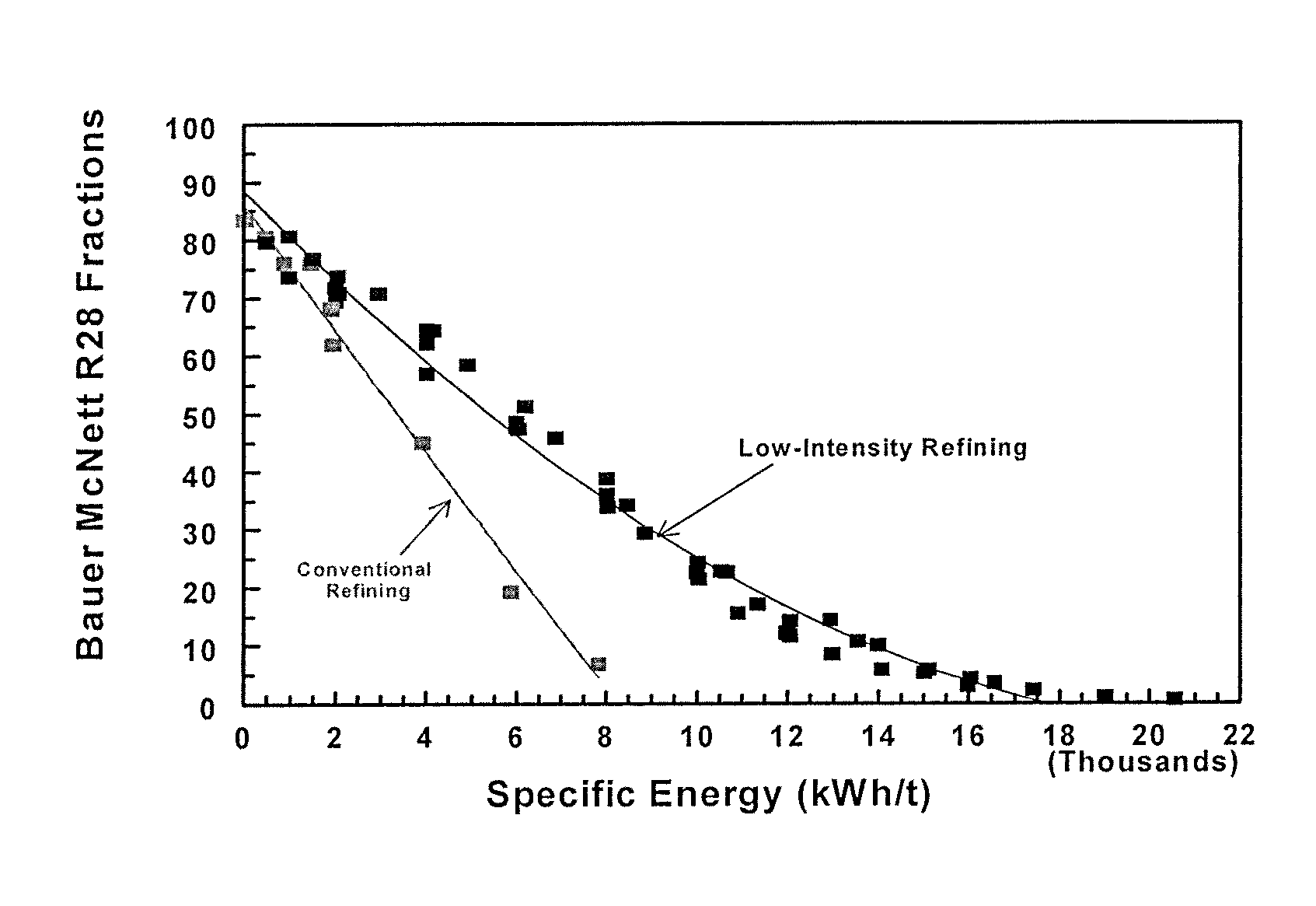

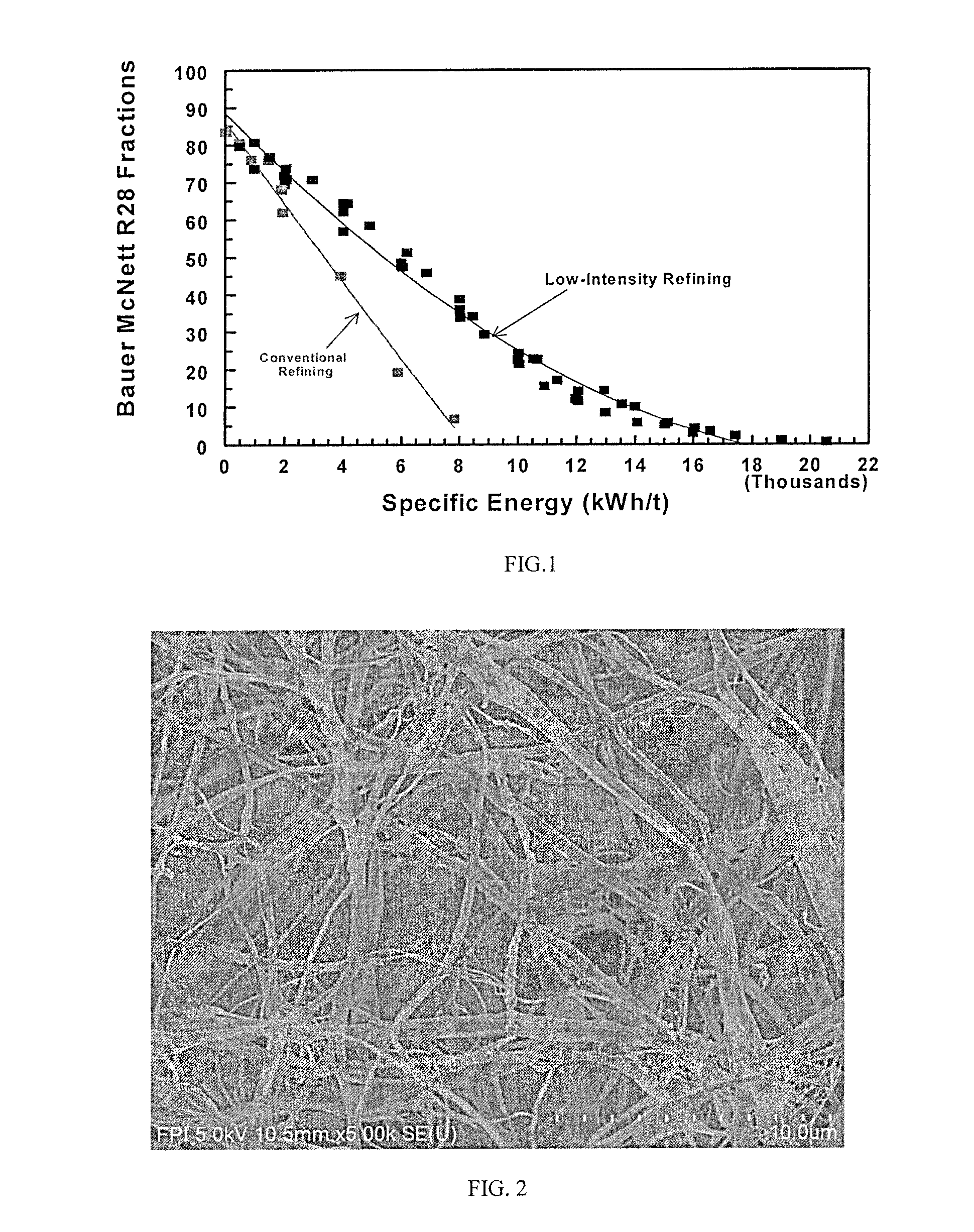

High aspect ratio cellulose nanofilaments and method for their production

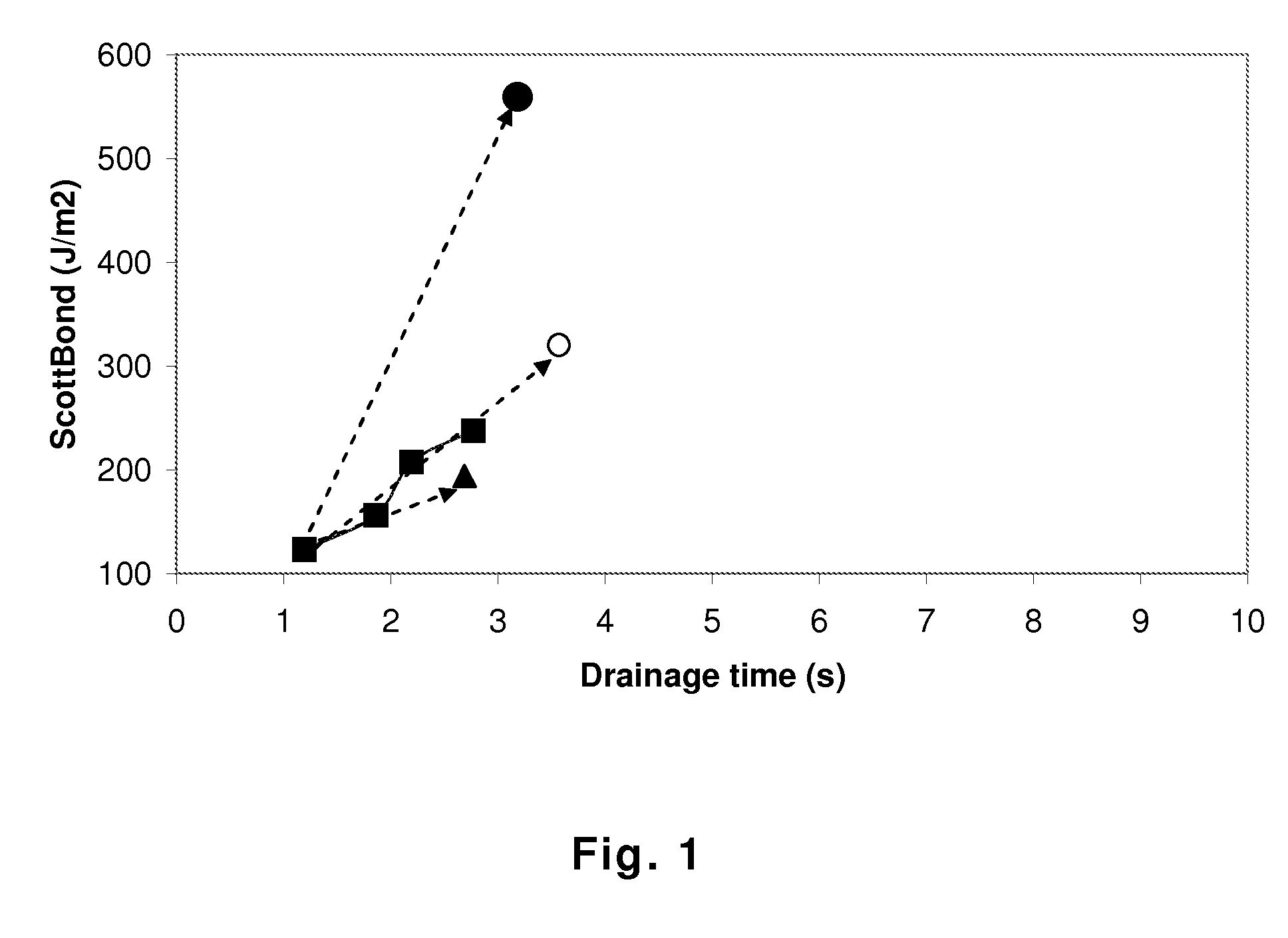

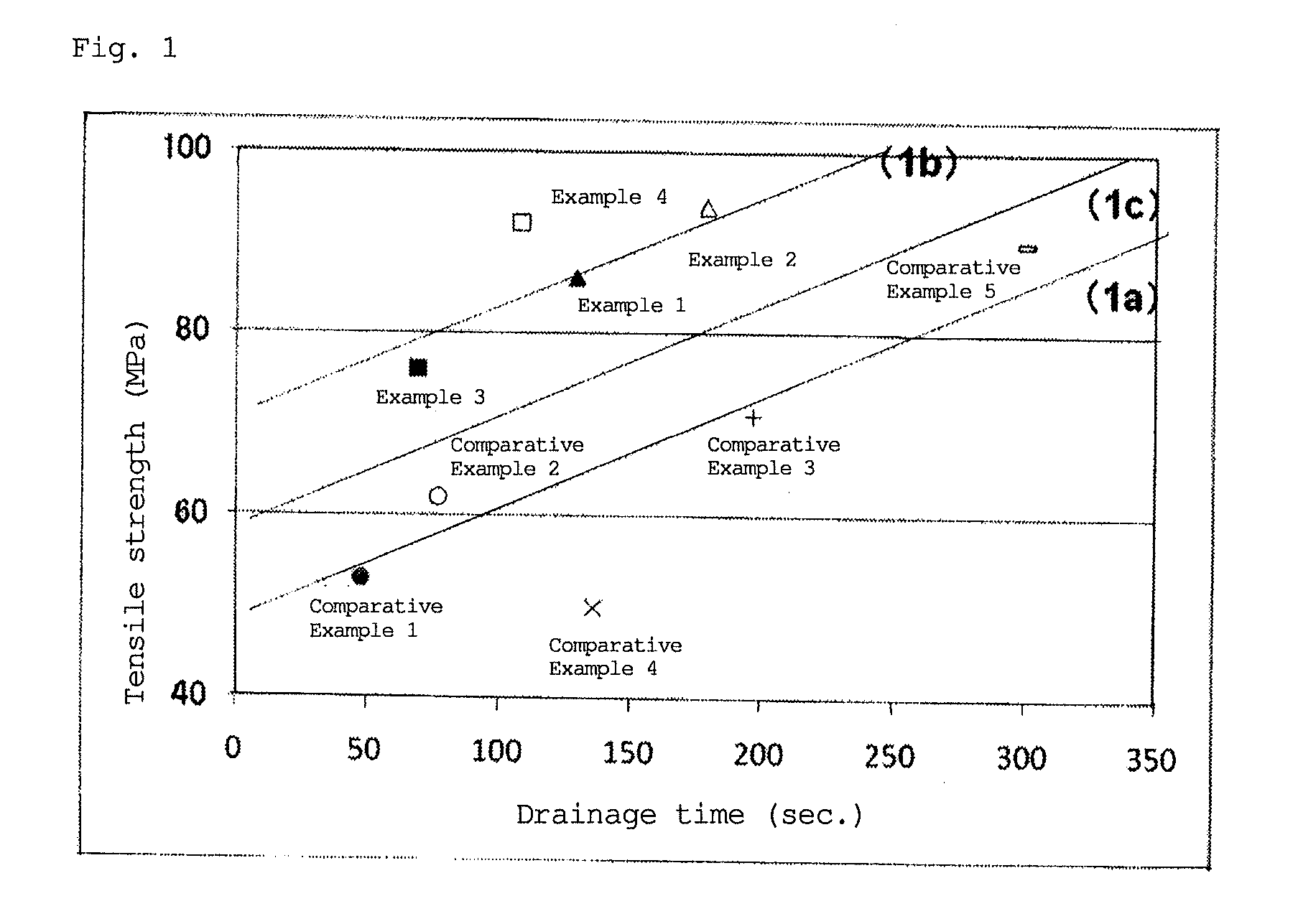

ActiveUS20130017394A1High consistency refiningIncrease surface areaMaterial nanotechnologyFinely-divided cellulose conservationMicrometerPaperboard

A method to produce on a commercial scale, high aspect ratio cellulose nanofilaments (CNF) from natural lignocellulosic fibers comprises a multi-pass high consistency refining (HCR) of chemical or mechanical fibers using combinations of refining intensity and specific energy. The CNF produced represents a mixture of fine filaments with widths in the submicron and lengths from tens of micrometers to few millimeters. The product has a population of free filaments and filaments bound to the fiber core from which they were produced. The proportion of free and bound filaments is governed in large part by total specific energy applied to the pulp in the refiner, and differs from other cellulose fibrillar materials by their higher aspect ratio and the preserved degree of polymerization (DP) of cellulose, and are excellent additives for the reinforcement of paper, tissue, paperboard and the like. They display exceptional strengthening power for never-dried paper webs.

Owner:FPINNOVATIONS INC

Process for manufacturing pulp, paper and paperboard products

InactiveUS20070277947A1Speed up the processReduce the amount requiredPulp bleachingPulping with organic solventsChlorine dioxidePaperboard

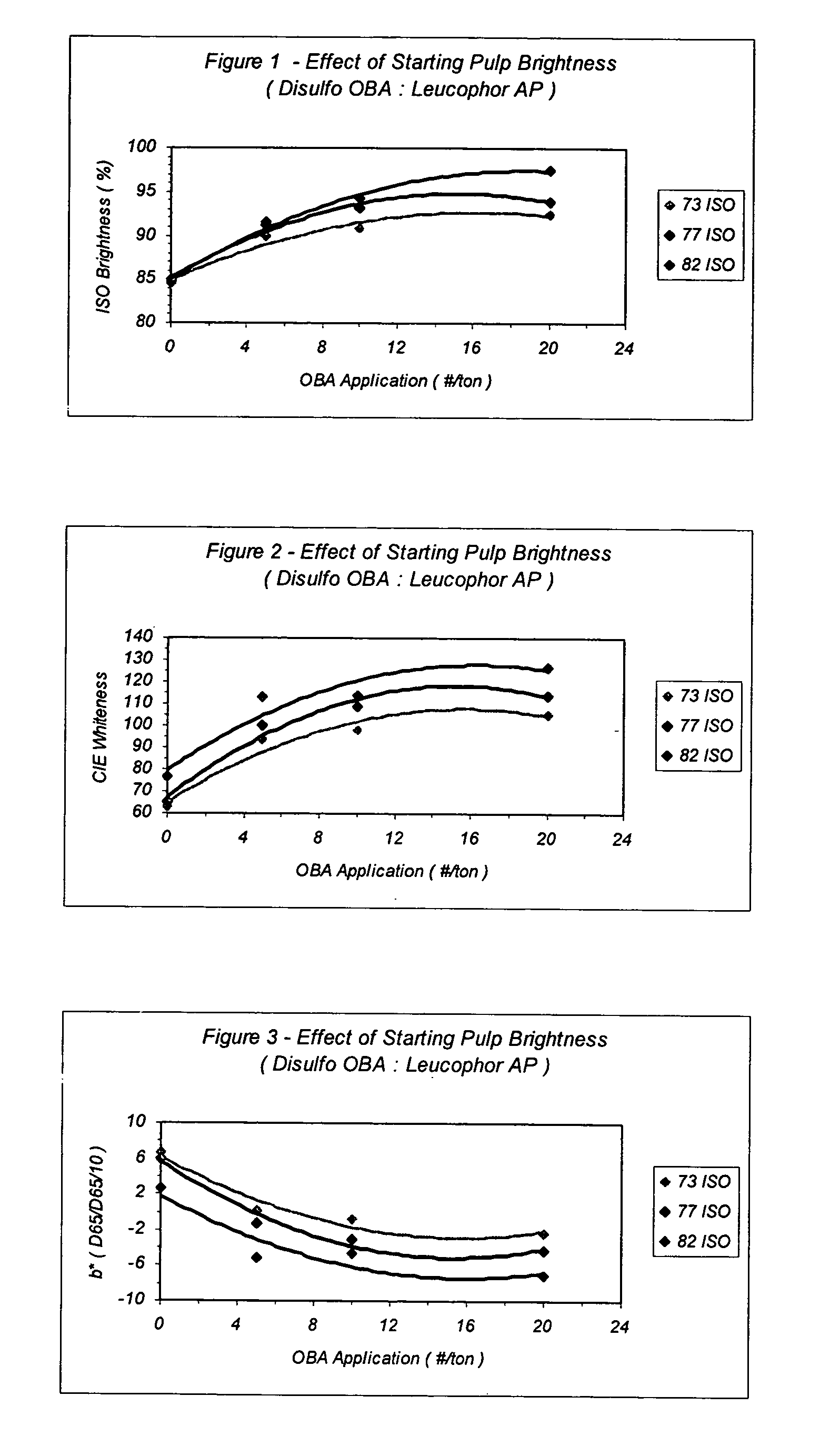

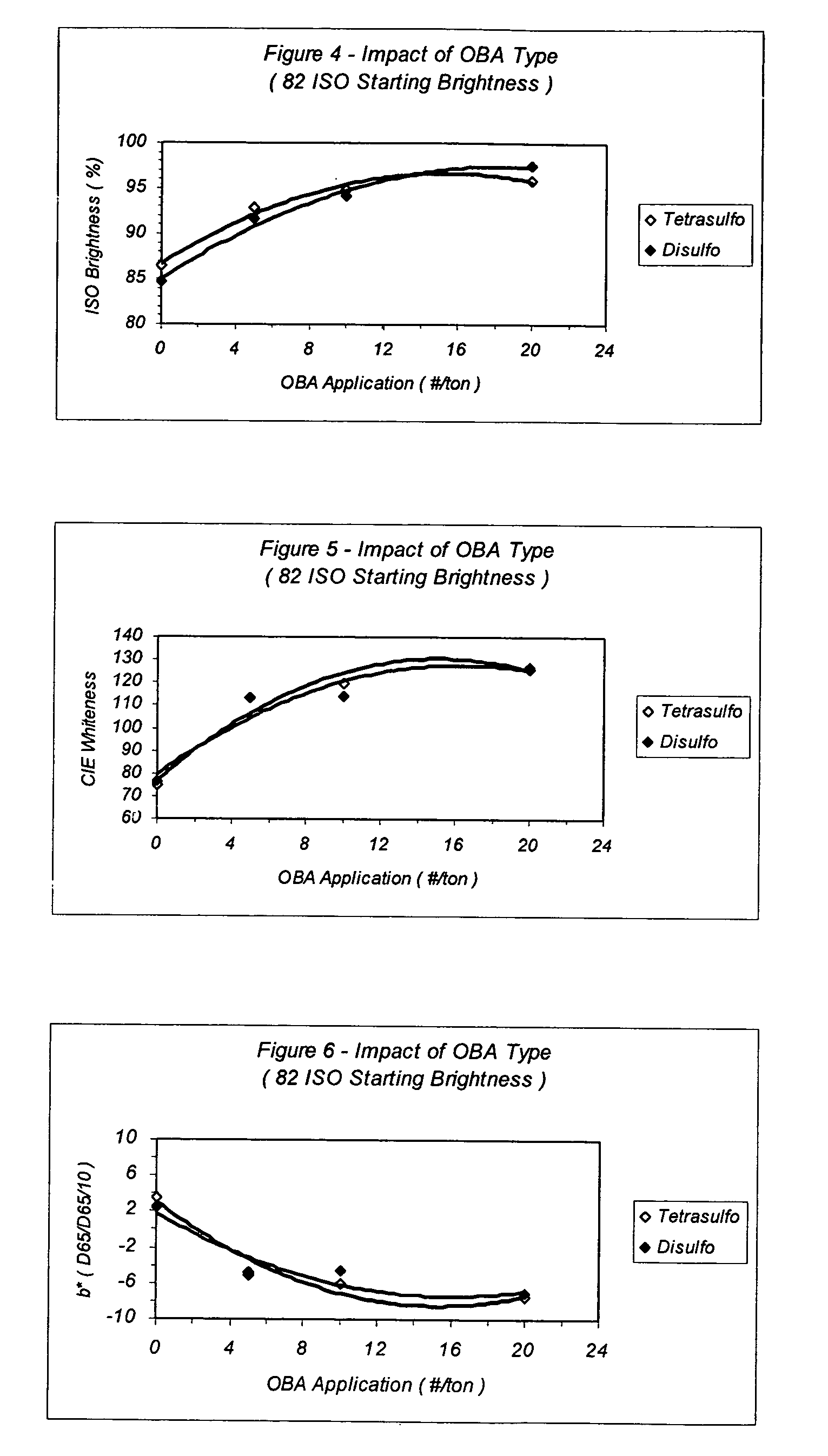

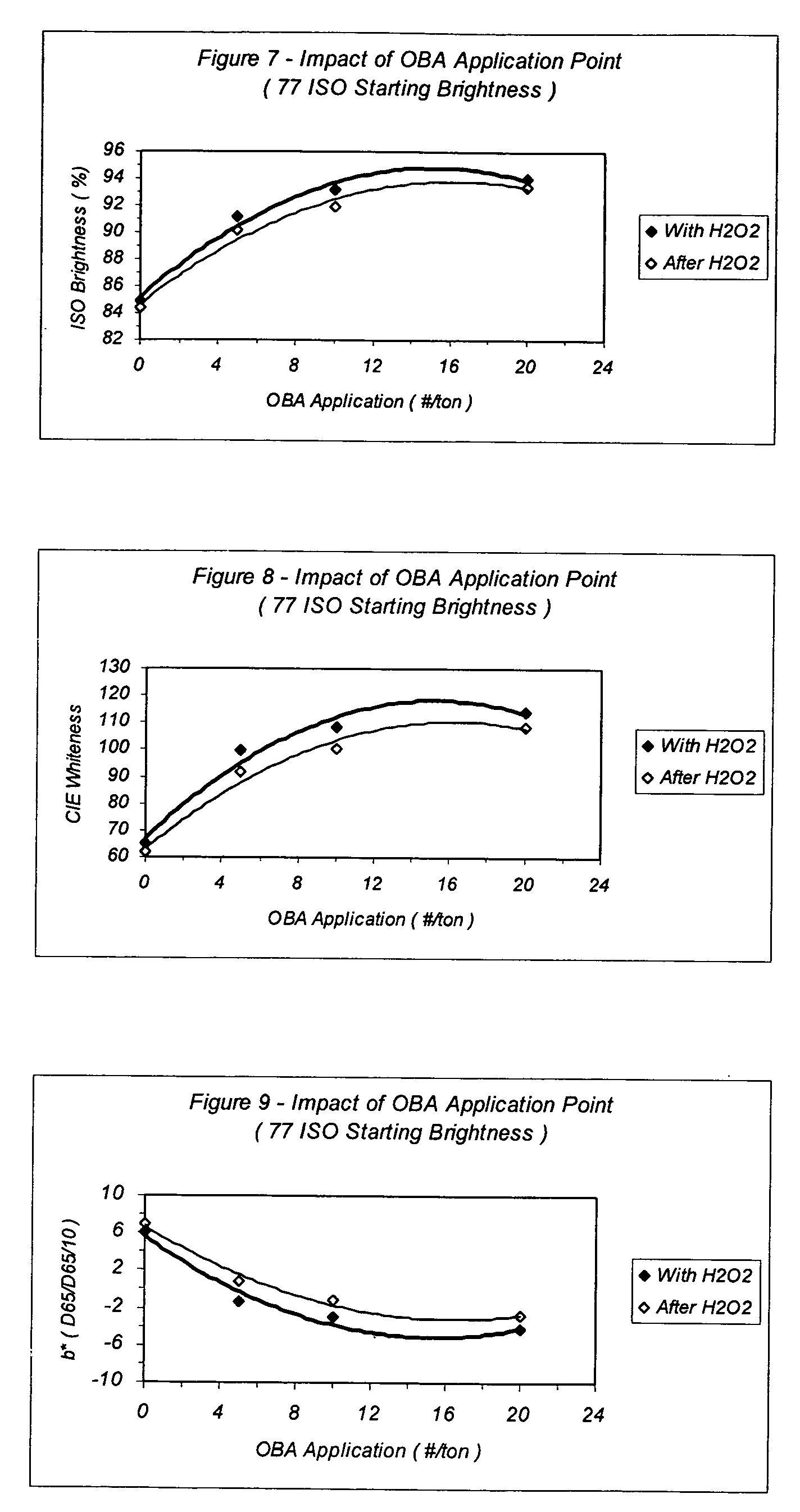

A process for bleaching mechanical wood pulp is provided comprising subjecting the wood pulp to at least one bleaching stage with one or more bleaching agents in the presence of one or more optical brightening agent, wherein the bleaching agents are selected from the group consisting of oxidative bleaching agents other than chlorine based bleaching agents such as chlorine dioxide, elemental chlorine or a combination thereof, reductive bleaching agents or any combination of two or more thereof.

Owner:INT PAPER CO

Method of producing micropulp and micropulp made therefrom

InactiveUS20030114641A1More cost-effectivelySmall sizeCellulose coatingsPaper/cardboardFiberSolid component

The present invention is directed to a process for producing micropulp. The process includes contacting organic fibers with a medium comprising a liquid component and a solid component, agitating the medium and the organic fibers to transform the organic fibers into the micropulp dispersed in the medium. If desired, the slurry of the micropulp in the liquid component can be used or the micropulp can be separated from the medium. The micropulp can be readily incorporated into coating compositions such as those used in automotive OEM or refinish applications. The micropulp can also be incorporated into powder coating applications or as a thixotrope or reinforcement in polymer formulations.

Owner:EI DU PONT DE NEMOURS & CO

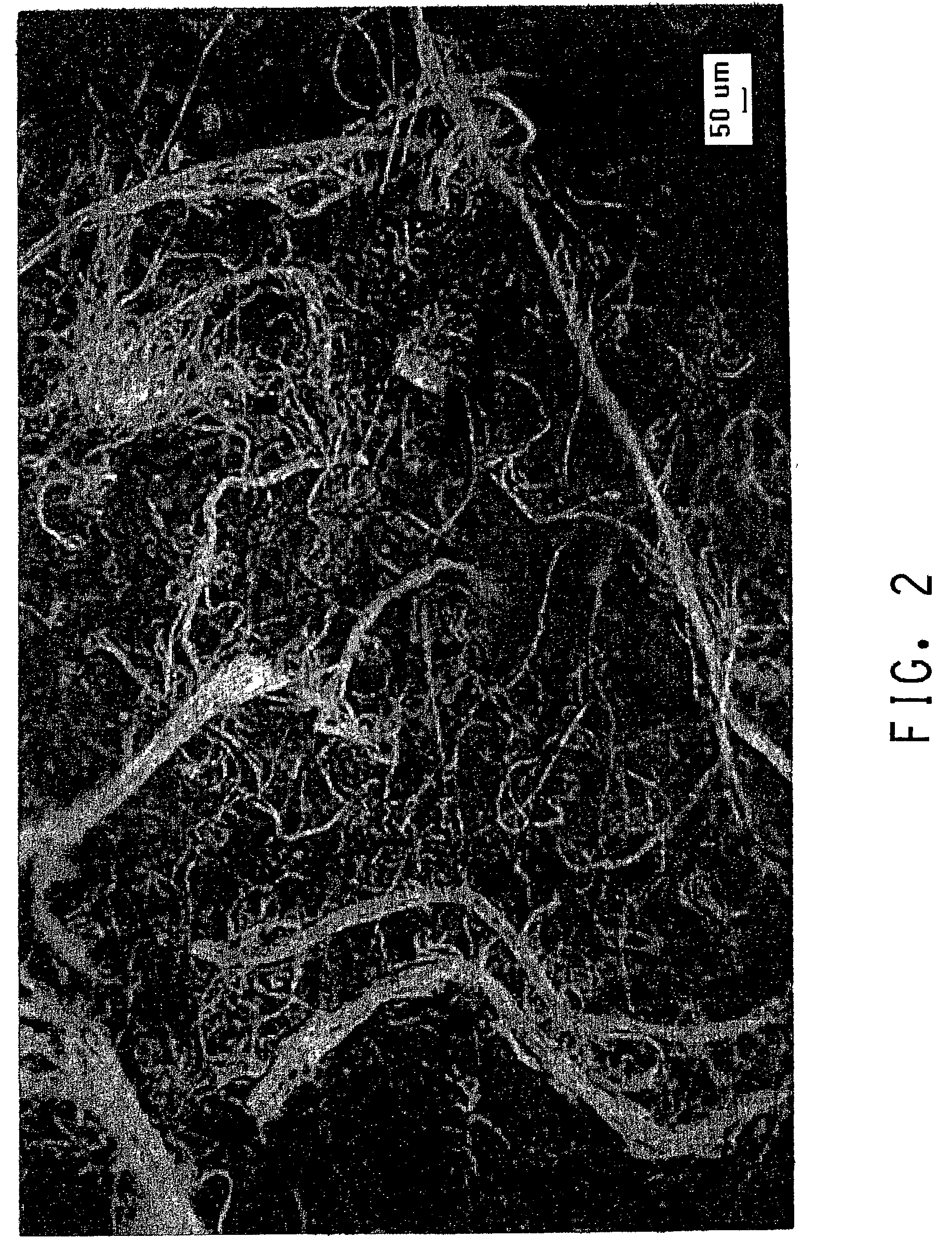

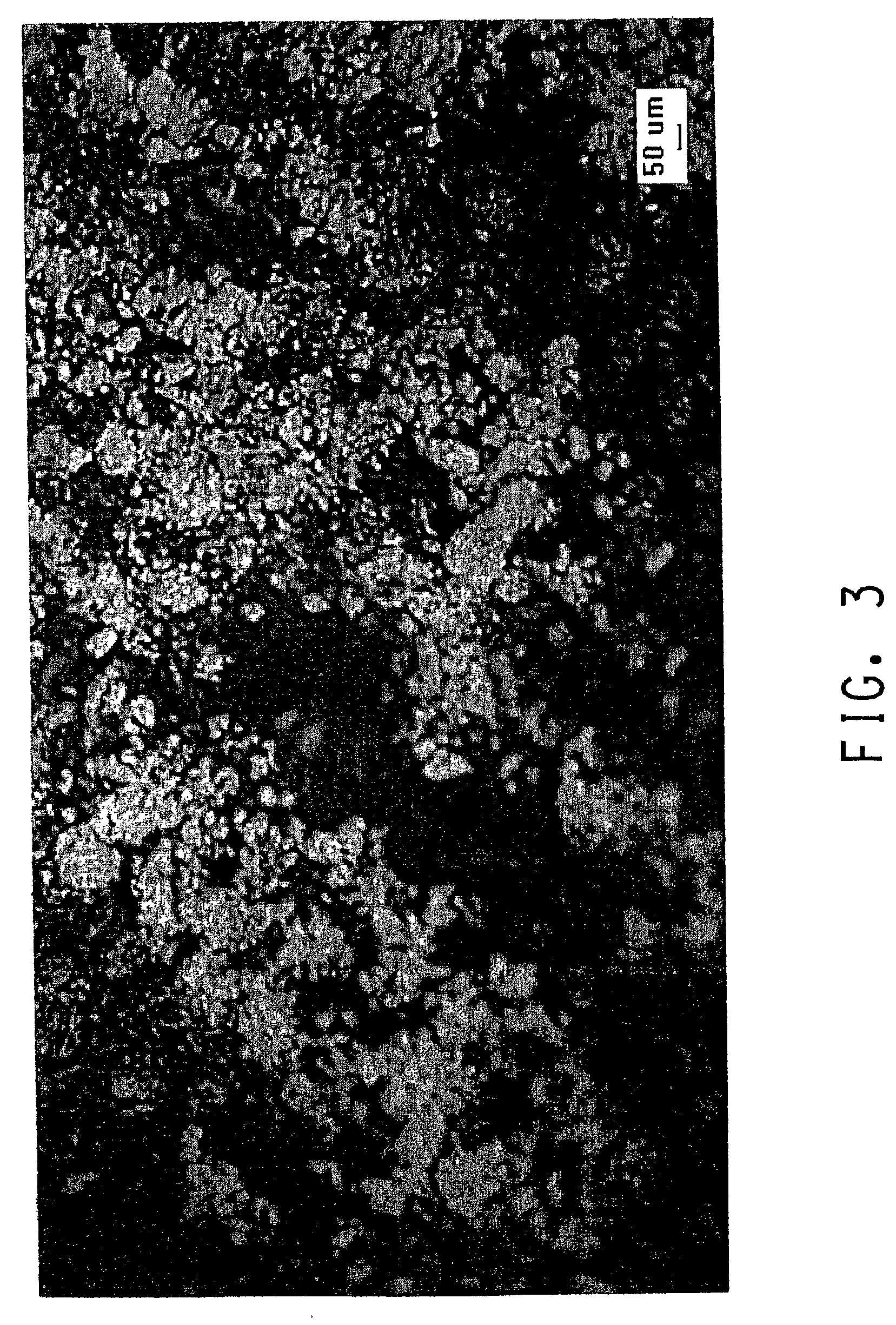

Cellulose-based fibrous materials

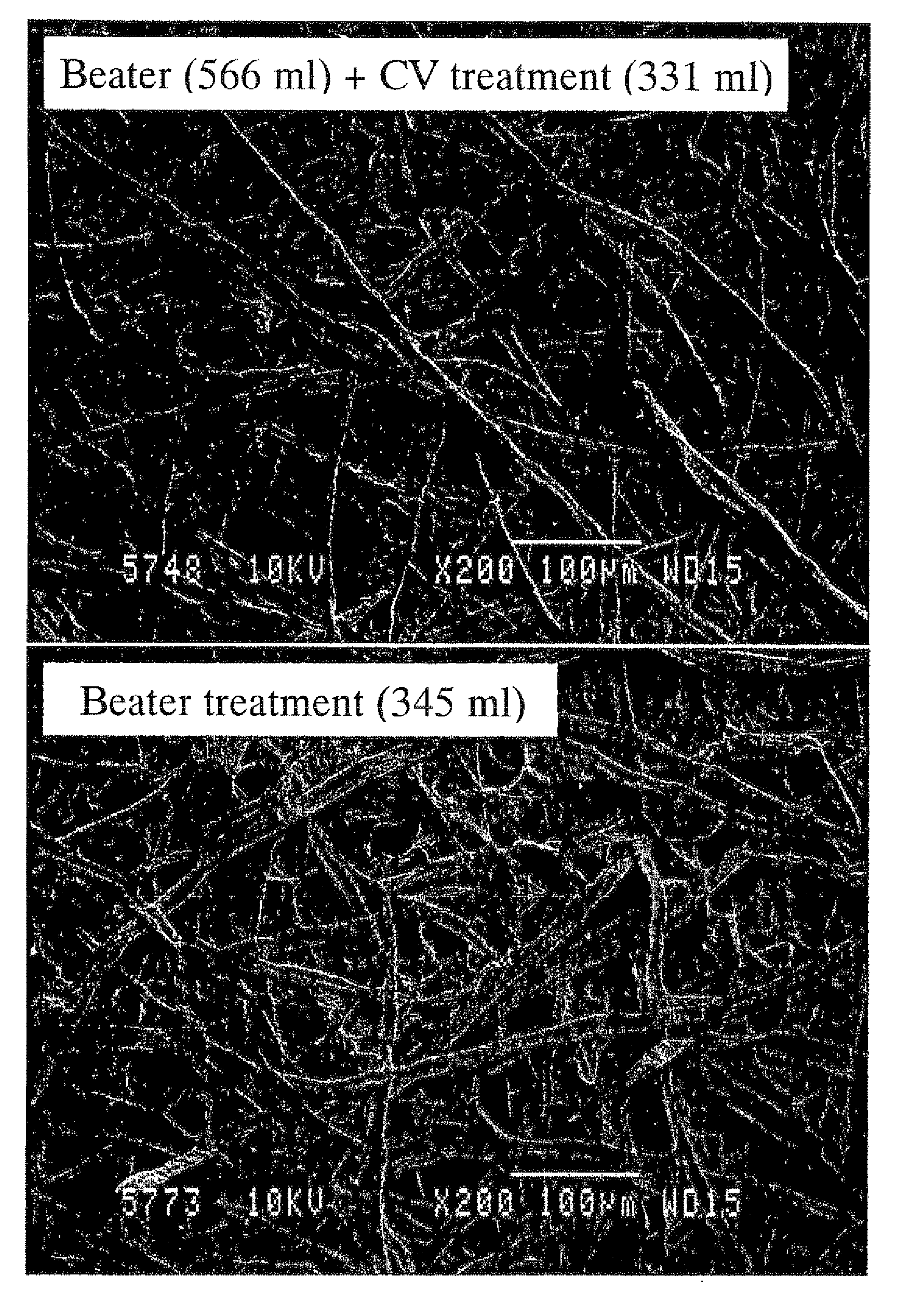

InactiveUS8012312B2Low densityImprove surface qualityCellulosic pulp after-treatmentCalendersFiberPolymer science

The present invention aims to provide cellulose-based fibrous materials for obtaining papers and sheets having low density, high surface quality, good size stability despite of high strength, and high opacity. Cellulose-based fibrous materials having external fibrils consisting of an assembly of scale-like microfibrils exhibit a higher fiber stiffness, a lower water retention value and a higher specific surface area as compared with fibrous materials having filamentous external fibrils at the same freeness. Papers and sheets having low density, high surface quality, good size stability and high opacity can be obtained by using such fibrous materials.

Owner:NIPPON PAPER IND CO LTD

Paper recycling system and paper recycling method

Owner:SEIKO EPSON CORP

Cellulose-based fibrous materials

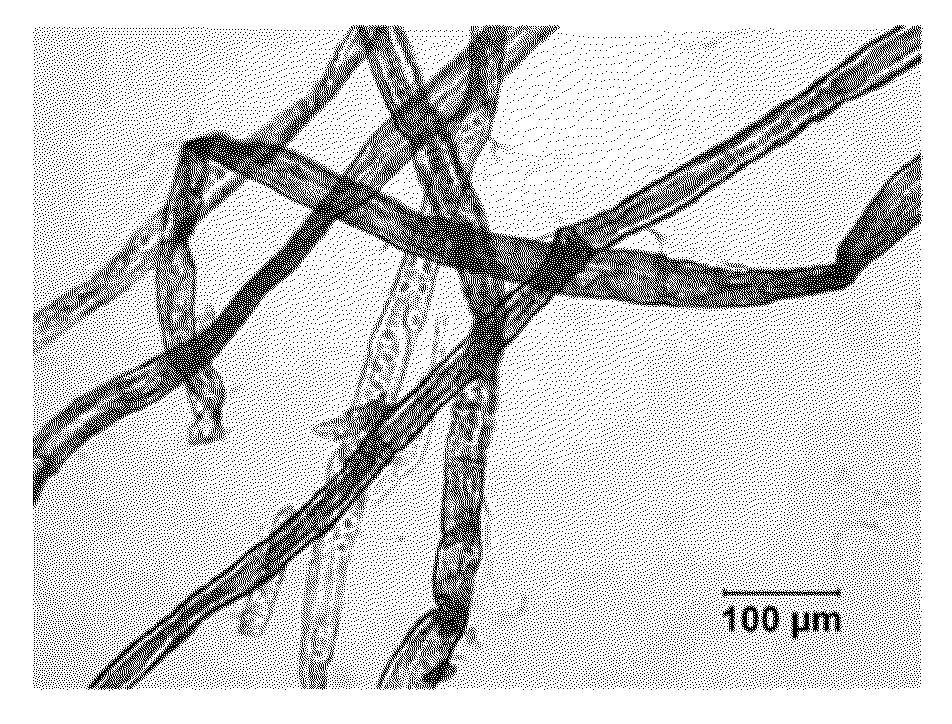

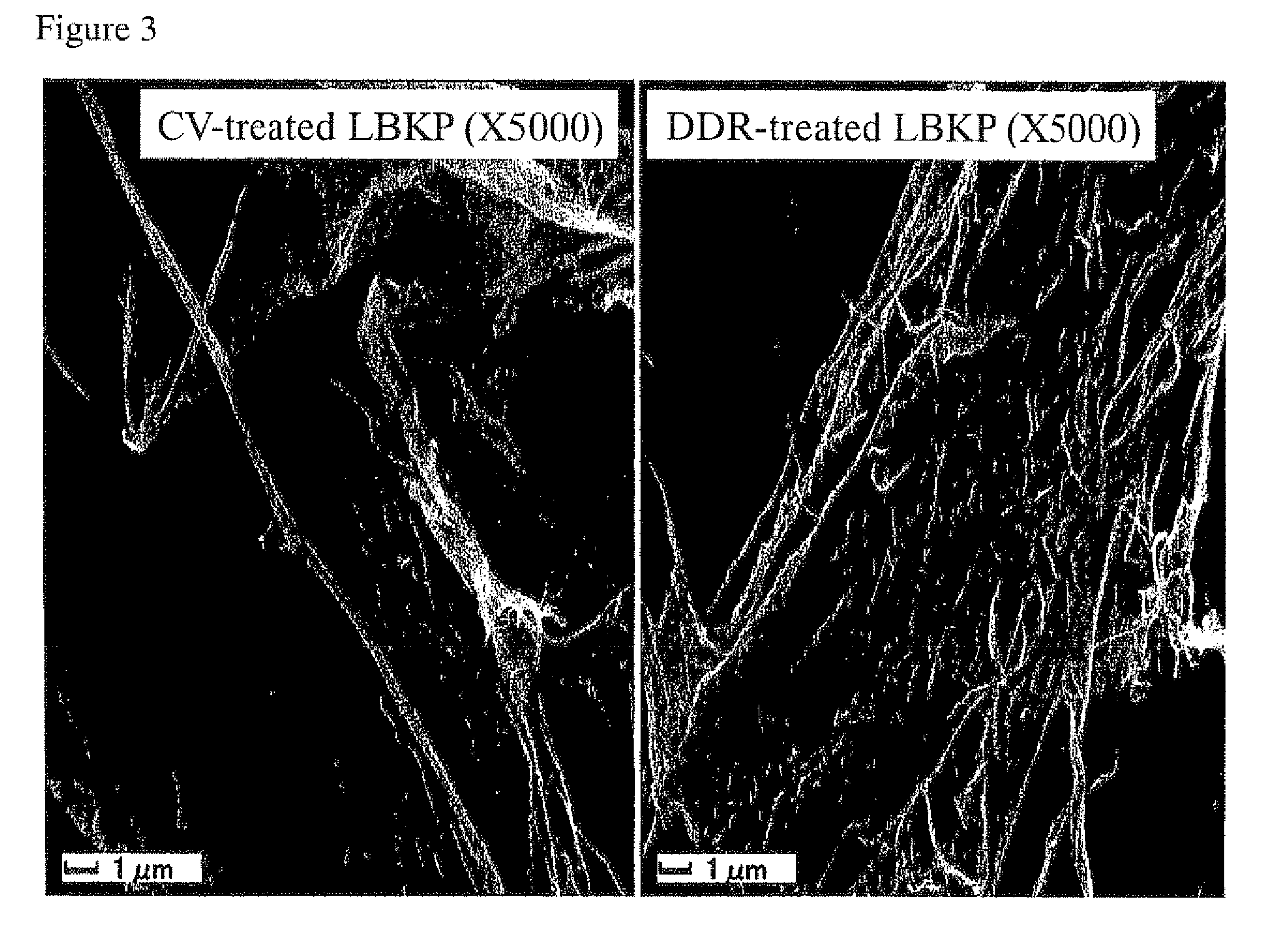

ActiveUS20090065164A1Low densityImprove surface qualityCellulosic pulp after-treatmentReinforcing agents additionFiberPolymer science

The present invention aims to provide cellulose-based fibrous materials for obtaining papers and sheets having low density, high surface quality, good size stability despite of high strength, and high opacity. Cellulose-based fibrous materials having external fibrils consisting of an assembly of scale-like microfibrils exhibit a higher fiber stiffness, a lower water retention value and a higher specific surface area as compared with fibrous materials having filamentous external fibrils at the same freeness. Papers and sheets having low density, high surface quality, good size stability and high opacity can be obtained by using such fibrous materials.

Owner:NIPPON PAPER IND CO LTD

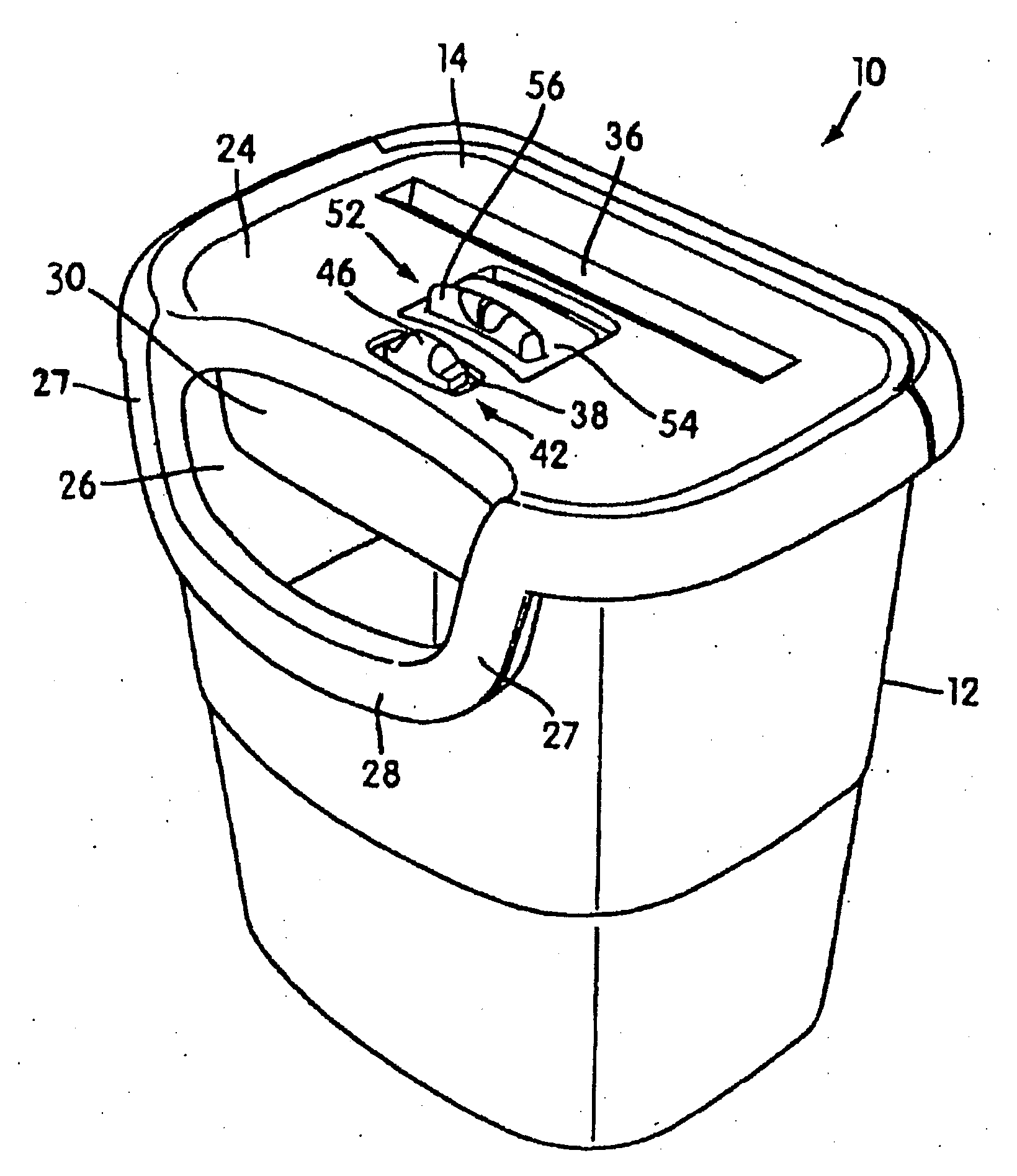

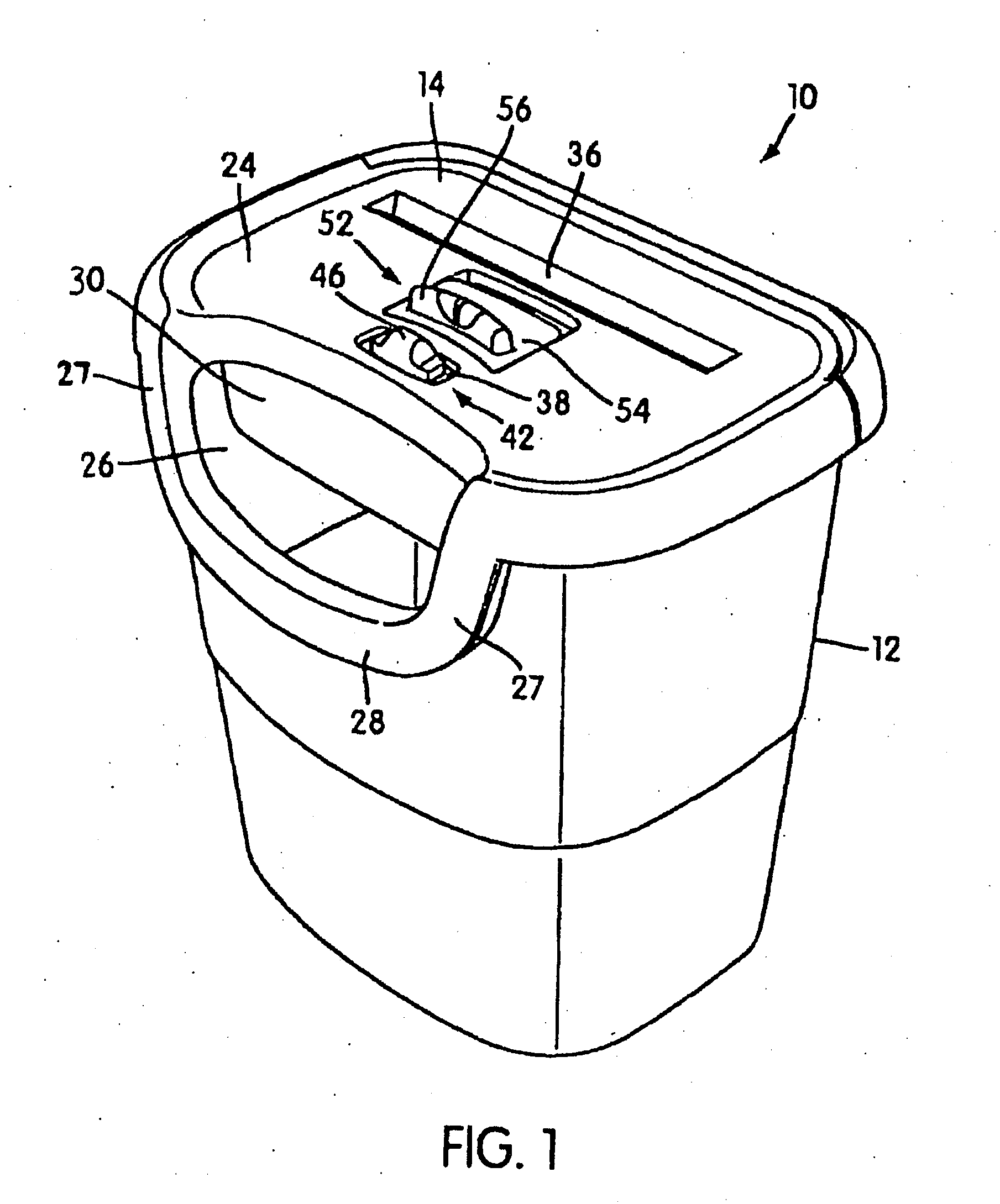

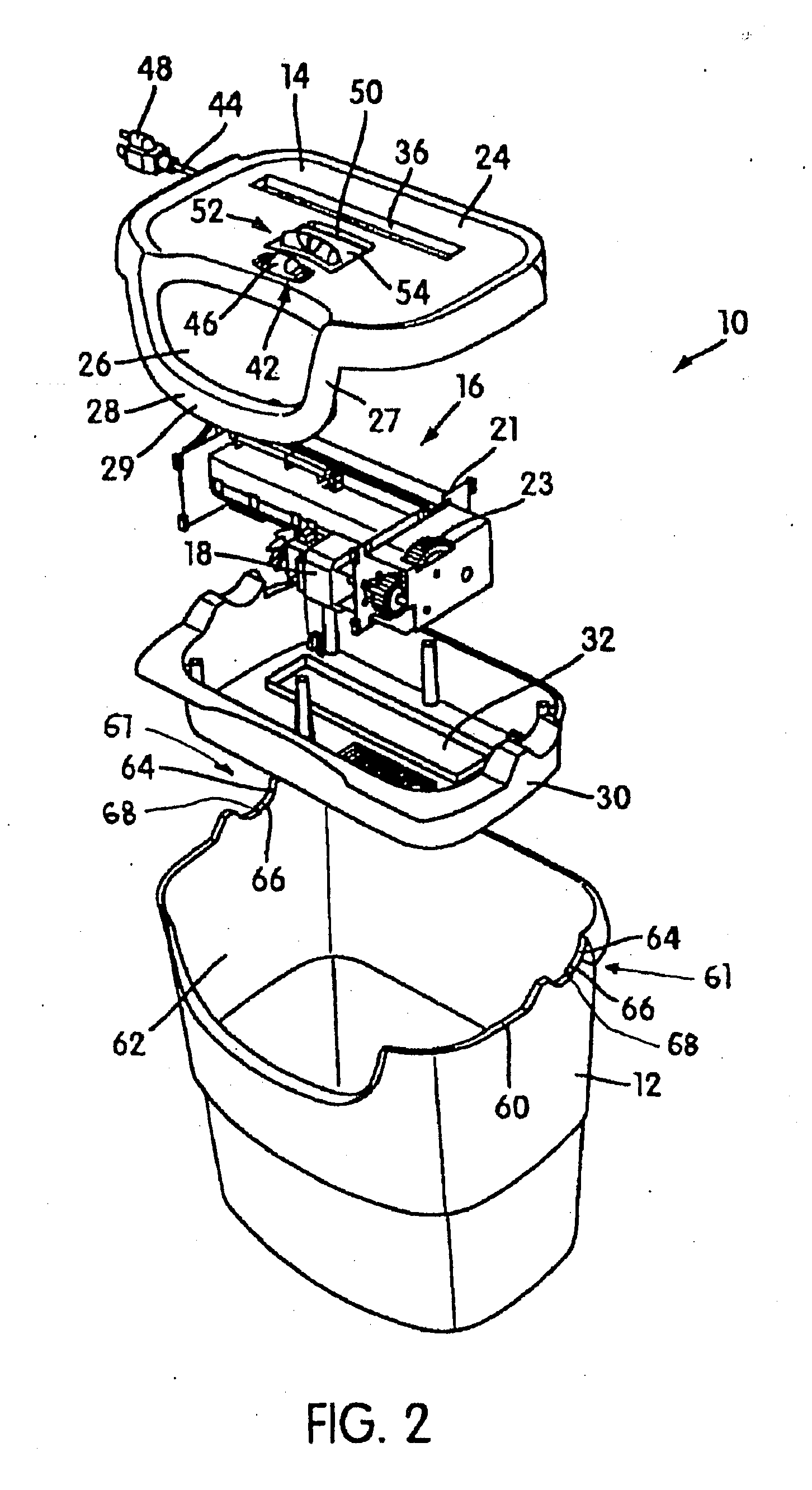

Shredder thickness with Anti-jitter feature

A shredder includes a housing having a throat for receiving at least one article to be shredded, and a shredder mechanism received in the housing and including an electrically powered motor and cutter elements. The shredder also includes a detector that is configured to detect a thickness of the at least one article being received by the throat, and a controller that is configured to operate the motor to drive the cutter elements to shred the at least one article and to set a flutter threshold higher than the predetermined maximum thickness threshold, if the detected thickness is less than a predetermined maximum thickness threshold. The controller is also configured to thereafter continuously detect the thickness of the at least one article being inserted into a throat of the shredder; and to perform a predetermined operation responsive to the thickness detector detecting that the thickness of the at least one article is greater than the flutter threshold.

Owner:FELLOWES INC

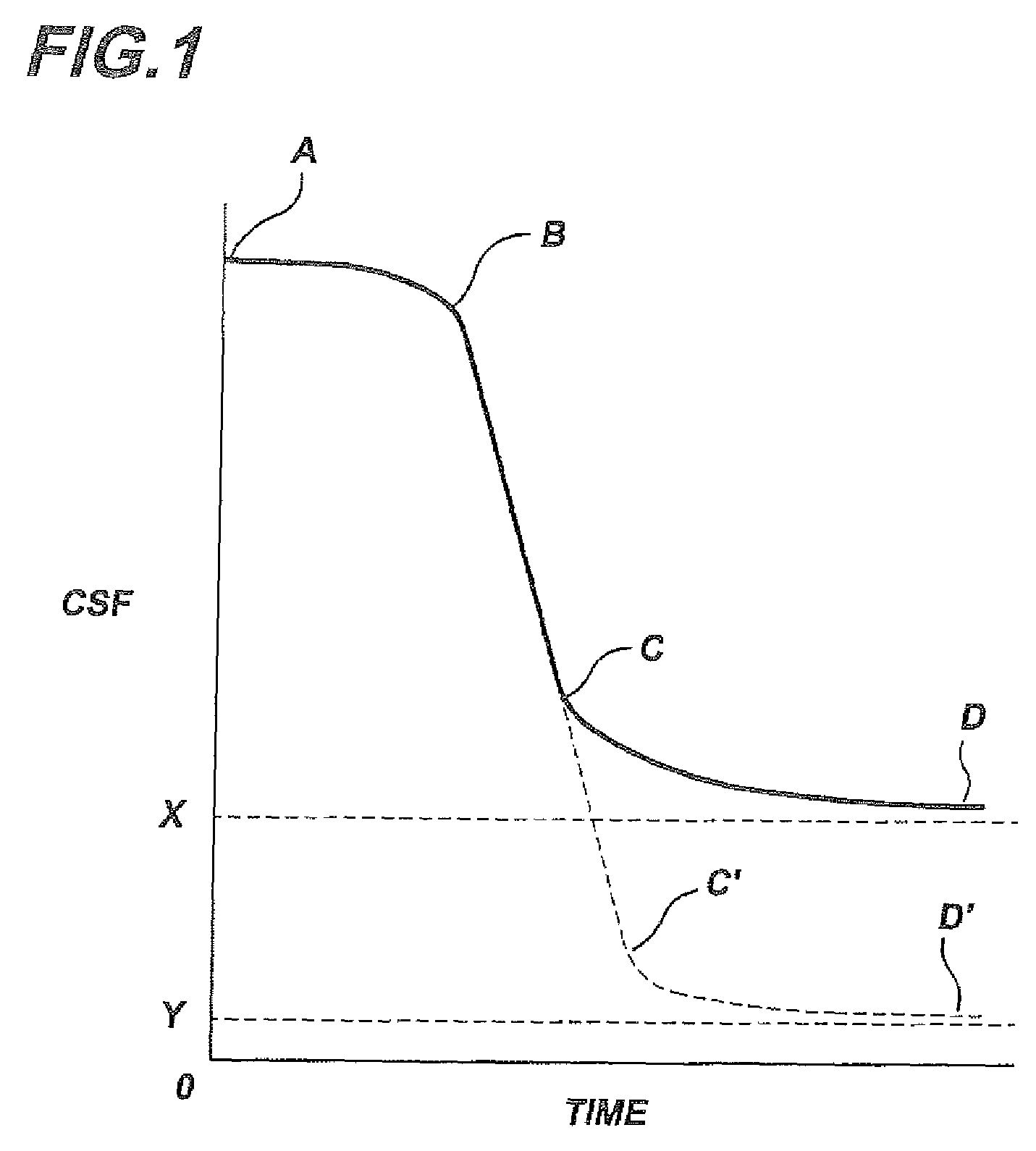

Process for producing fibrillated fibers

ActiveUS7566014B2Inhibit productionIncreased fiber lengthFilament/thread formingGrain treatmentsFiberShear rate

A process for making fibrillated fibers includes preparing a fluid suspension of fibers, low shear refining the fibers at a first shear rate to create fibrillated fibers having a reduced CSF, and subsequently higher shear refining the fibers at a second shear rate, higher than the first shear rate, to increase the degree of fibrillation of the fibers. The refining at the first shear rate may be with a rotor at a first maximum shear rate and the refining at the second shear rate may be with a rotor at a second maximum shear rate, higher than the first maximum shear rate. The process may further include pre-treating the fibers by high shear refining with impact to stress the fibers prior to low shear refining.

Owner:KX TECH LLC (DW US)

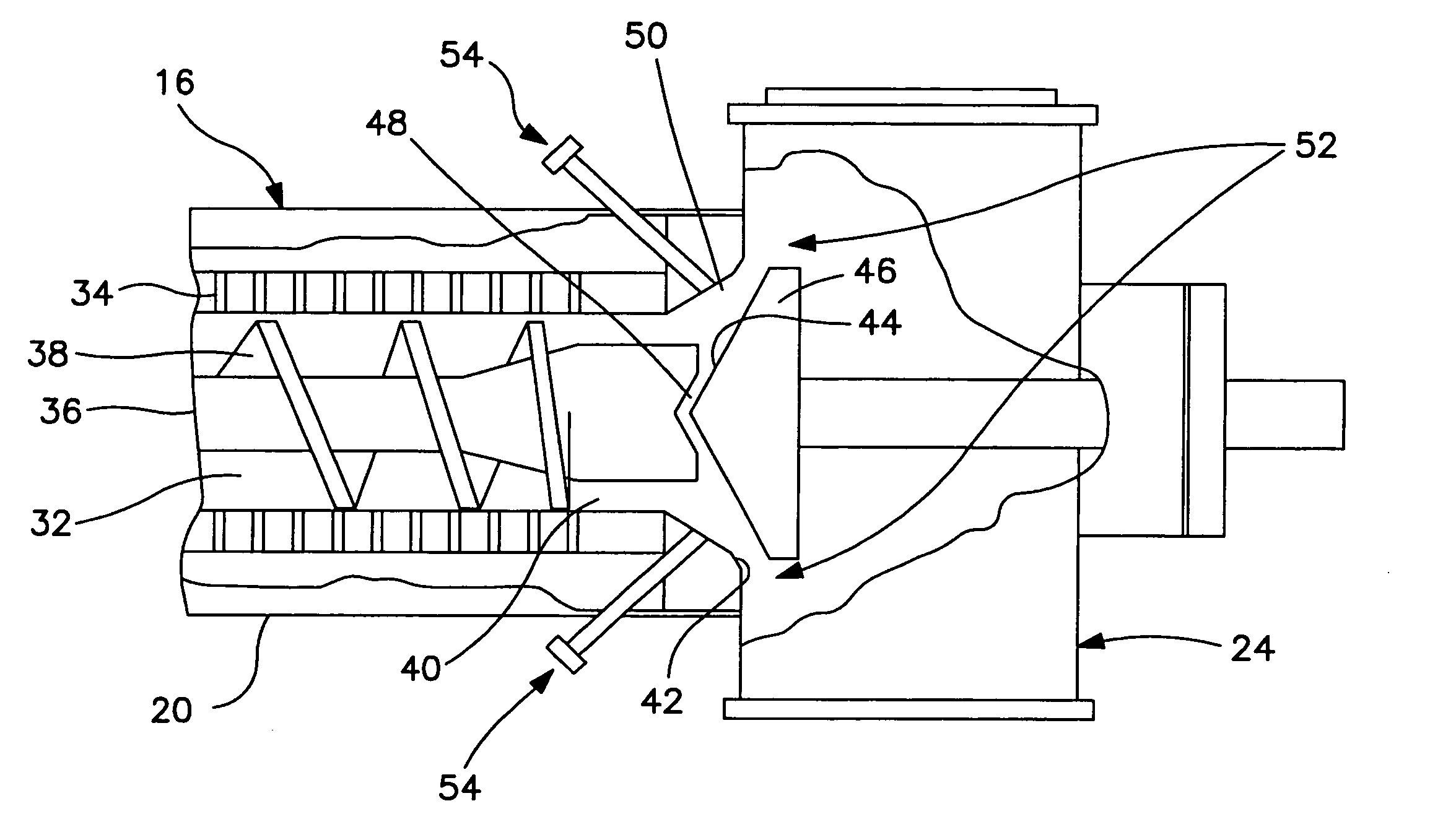

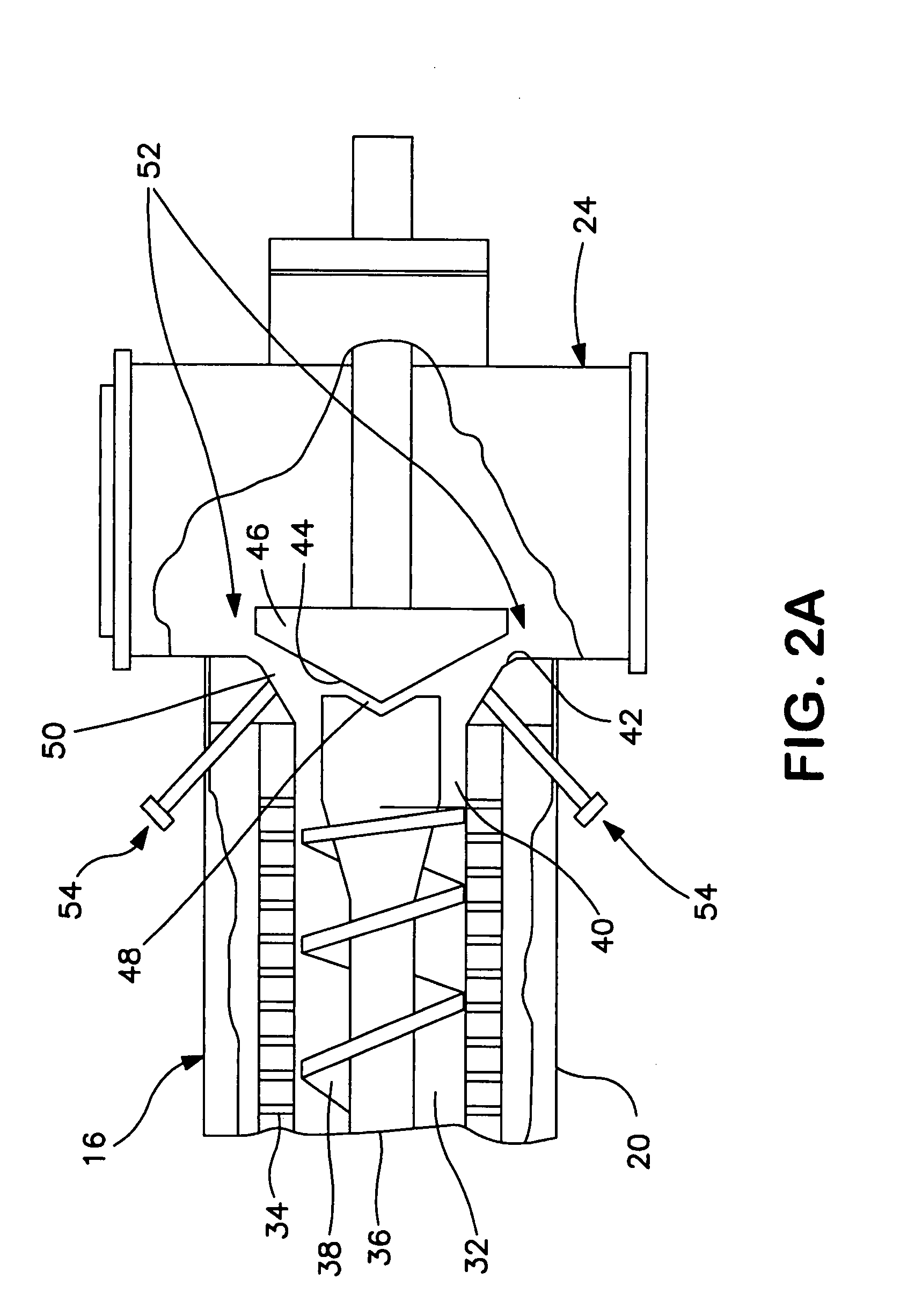

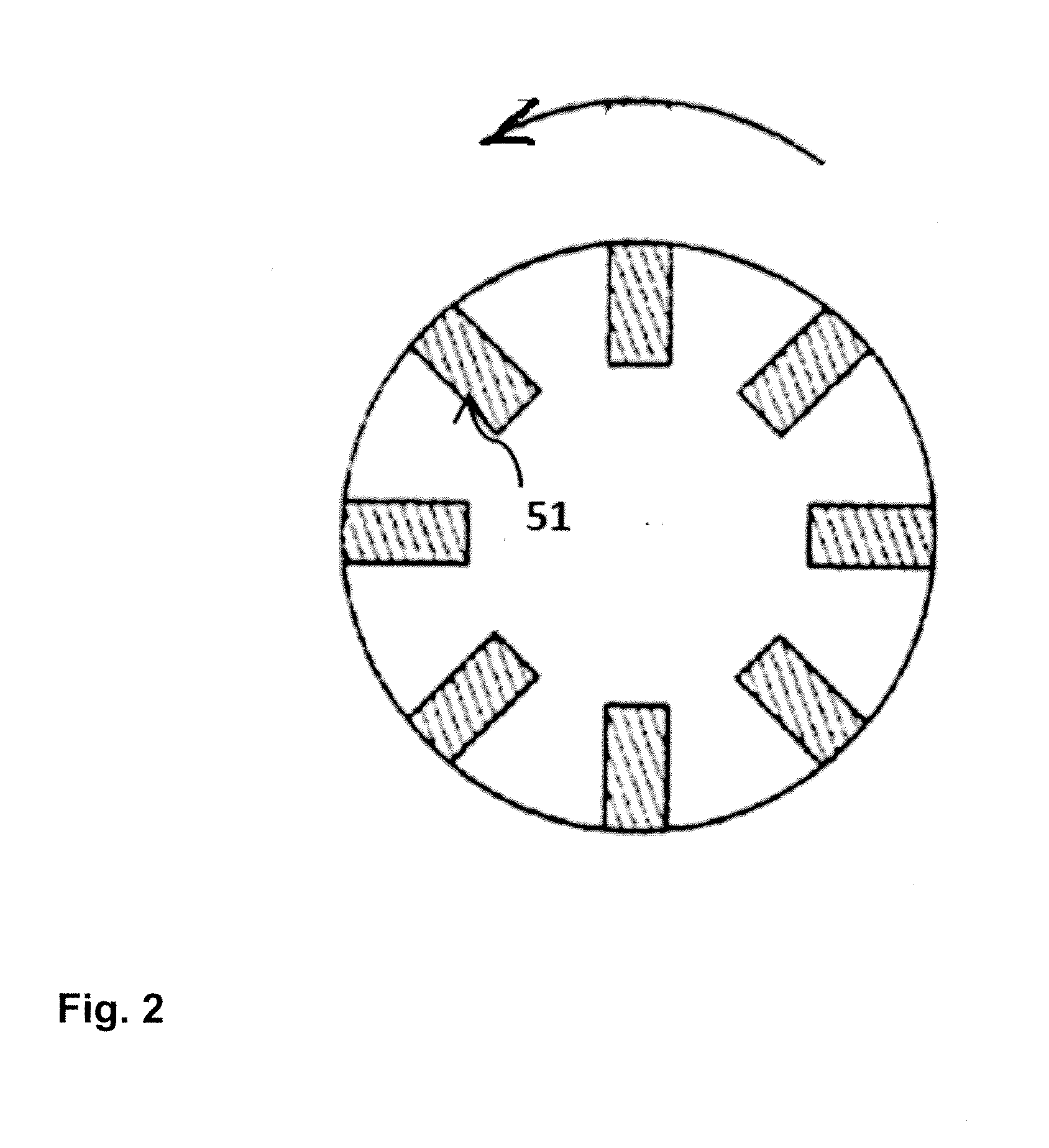

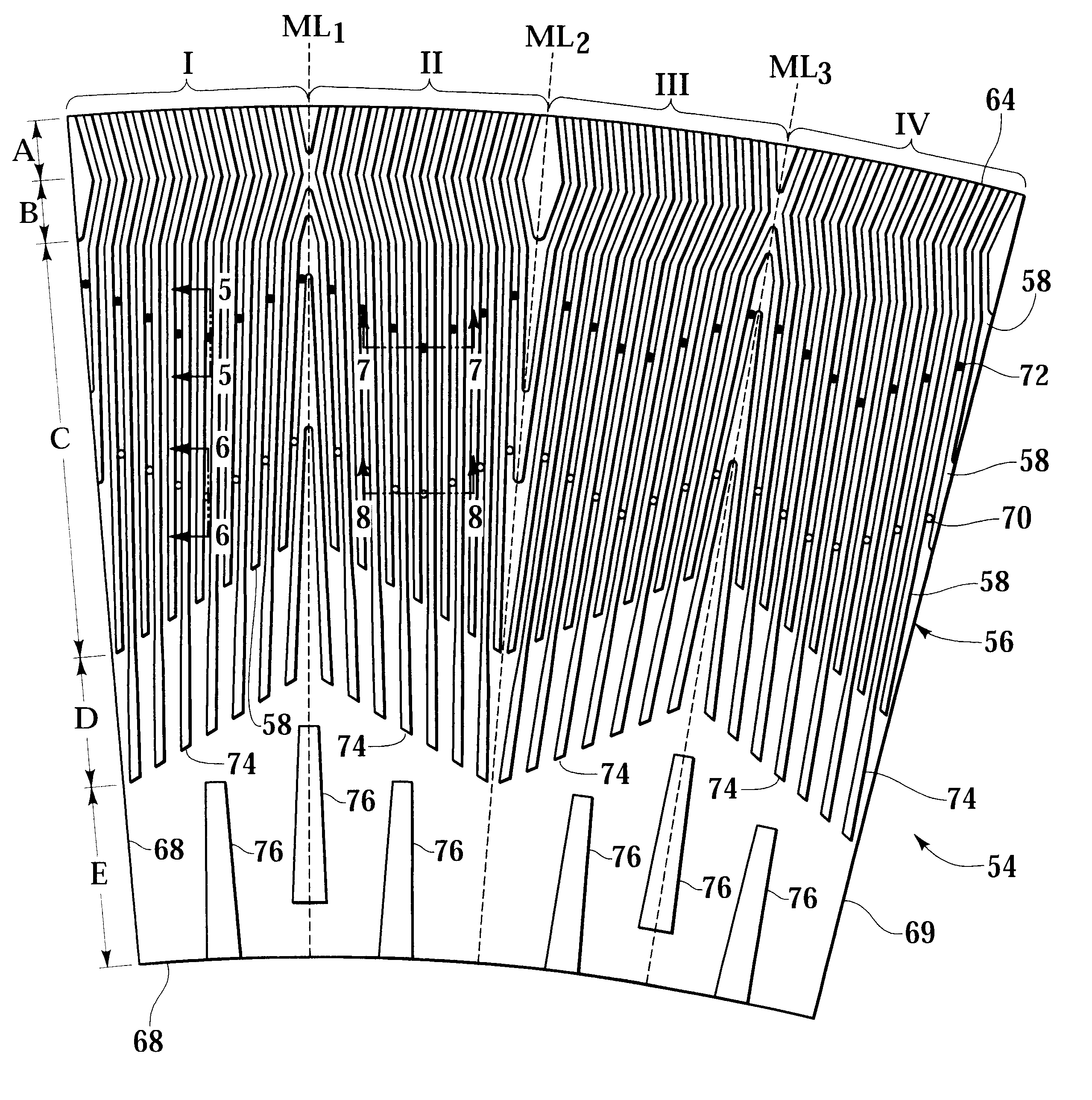

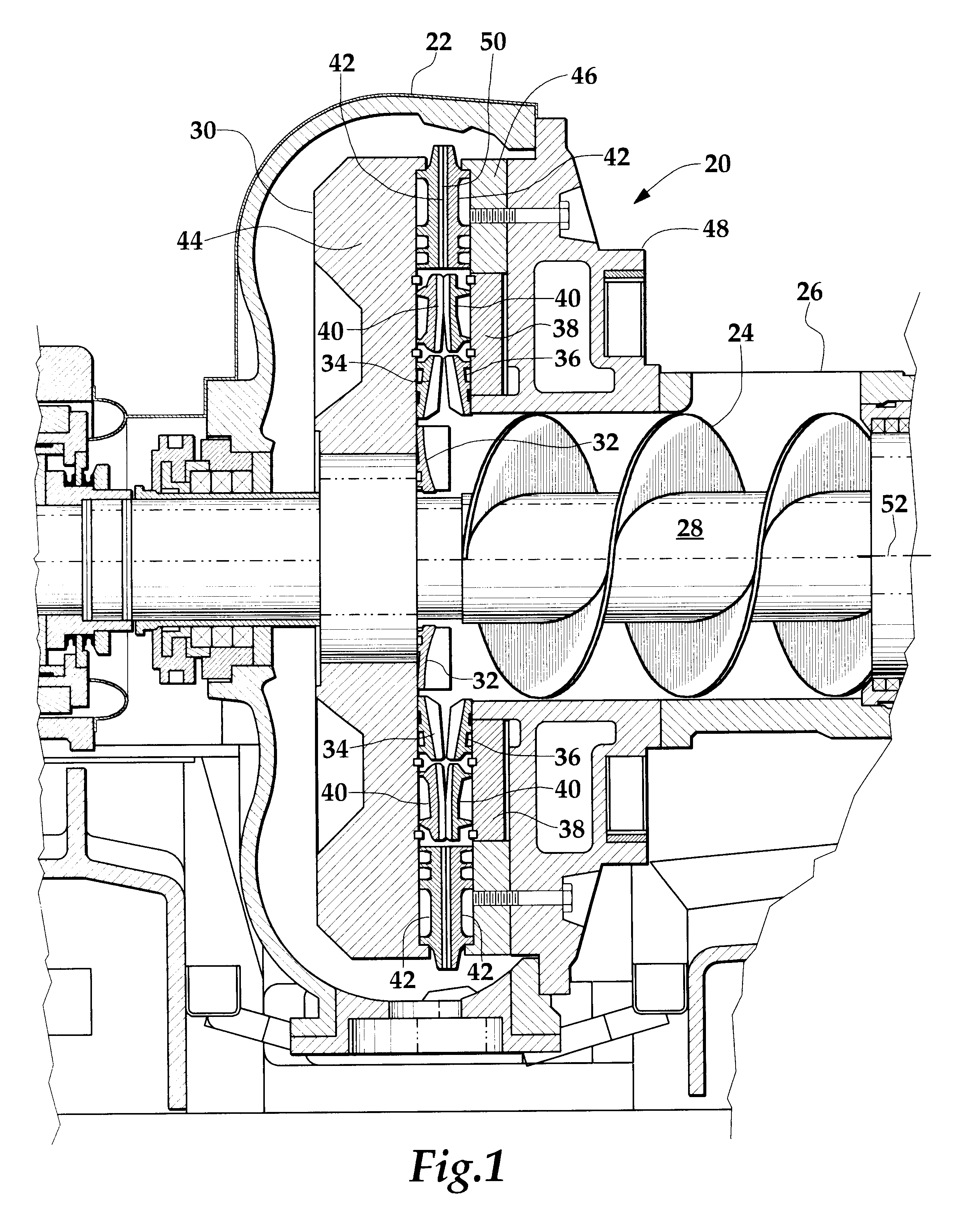

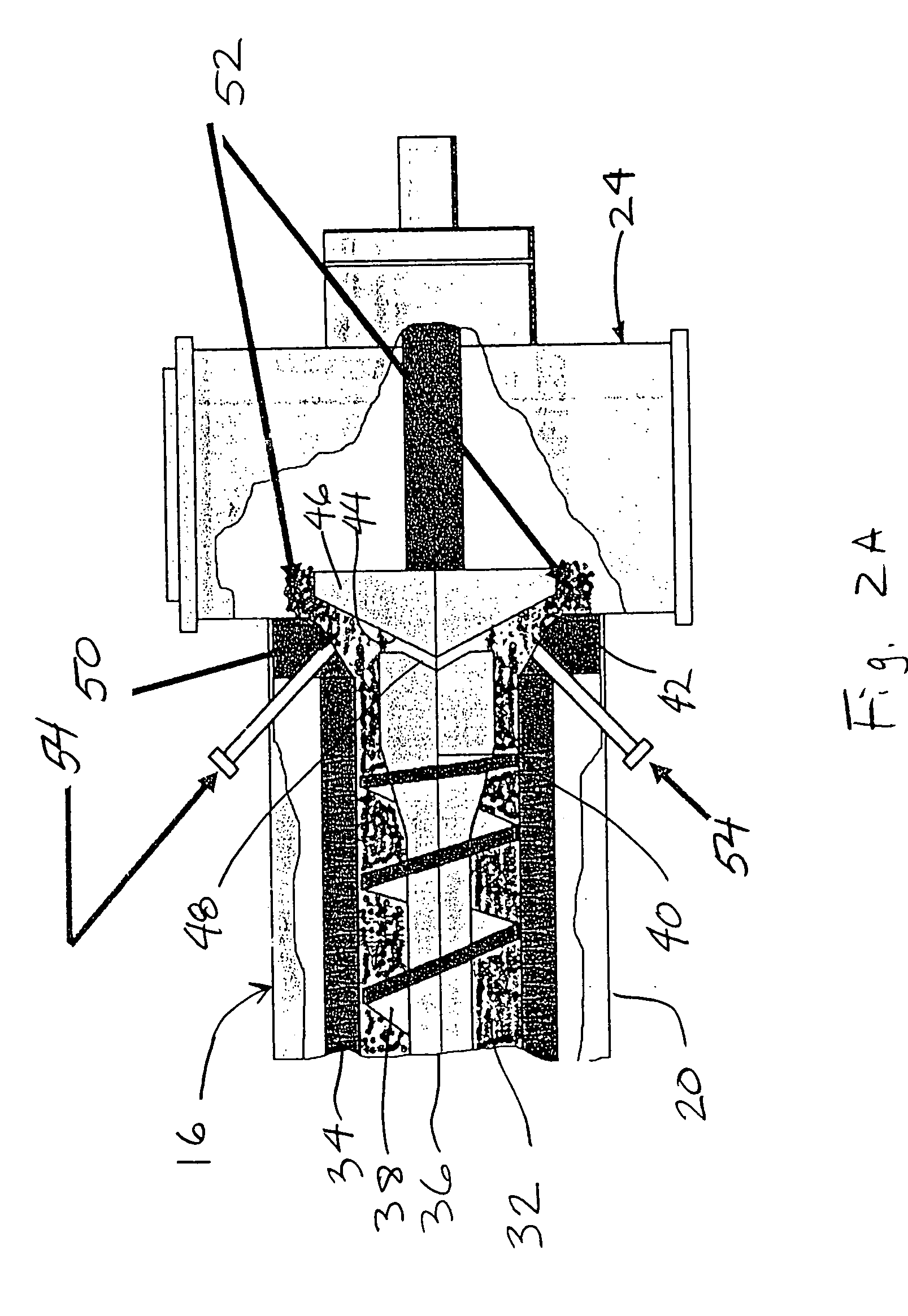

Disc refiner with increased gap between fiberizing and fibrillating bands

ActiveUS20070164143A1Minimizing componentSpace minimizationCocoaPulp beating/refining methodsFiberBand pattern

Plate elements, a plate configuration, and associated system for thermomechanical refining of wood chips wherein destructured and partially defibrated chips are fed to a rotating disc primary refiner, where opposed discs each have an inner band pattern of bars and grooves and outer band pattern of bars and grooves, such that substantially complete fiberization (defibration) of the chips is achieved in the inner band and the resulting fibers are fibrillated in the outer band. One embodiment is directed to a pair of opposed co-operating refining plate elements for a flat disc refiner wherein the bars and grooves on each of the inner bands form an inner feed region followed by an outer working region, the bars and groove on each of the outer bands form an inner feed region followed by an outer working region, and the gap and / or material flow area formed when the plates are placed in front of each other increases between the inner working region and the outer feed region.

Owner:ANDRITZ INC

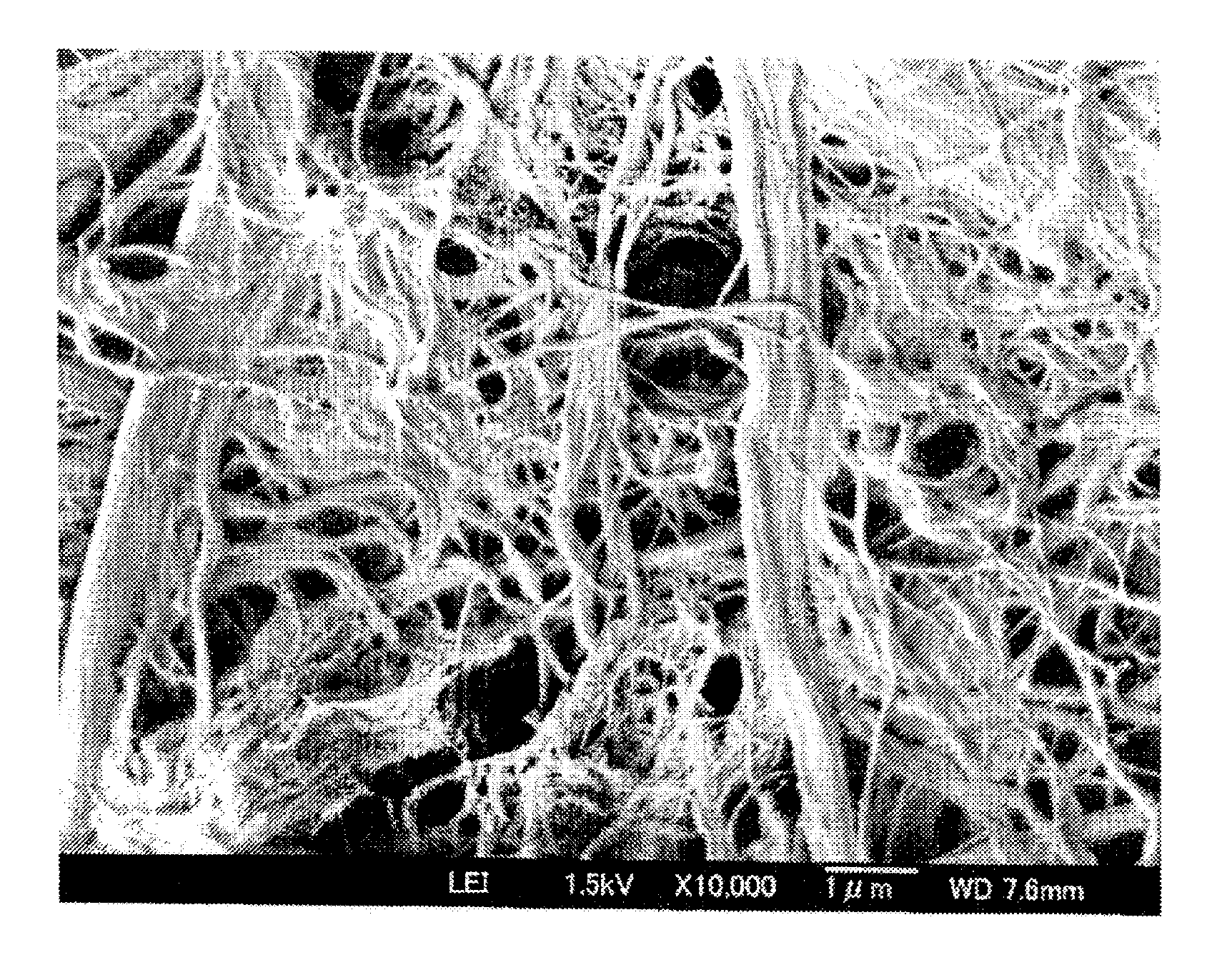

Method and apparatus for manufacturing microfibrillated cellulose fiber

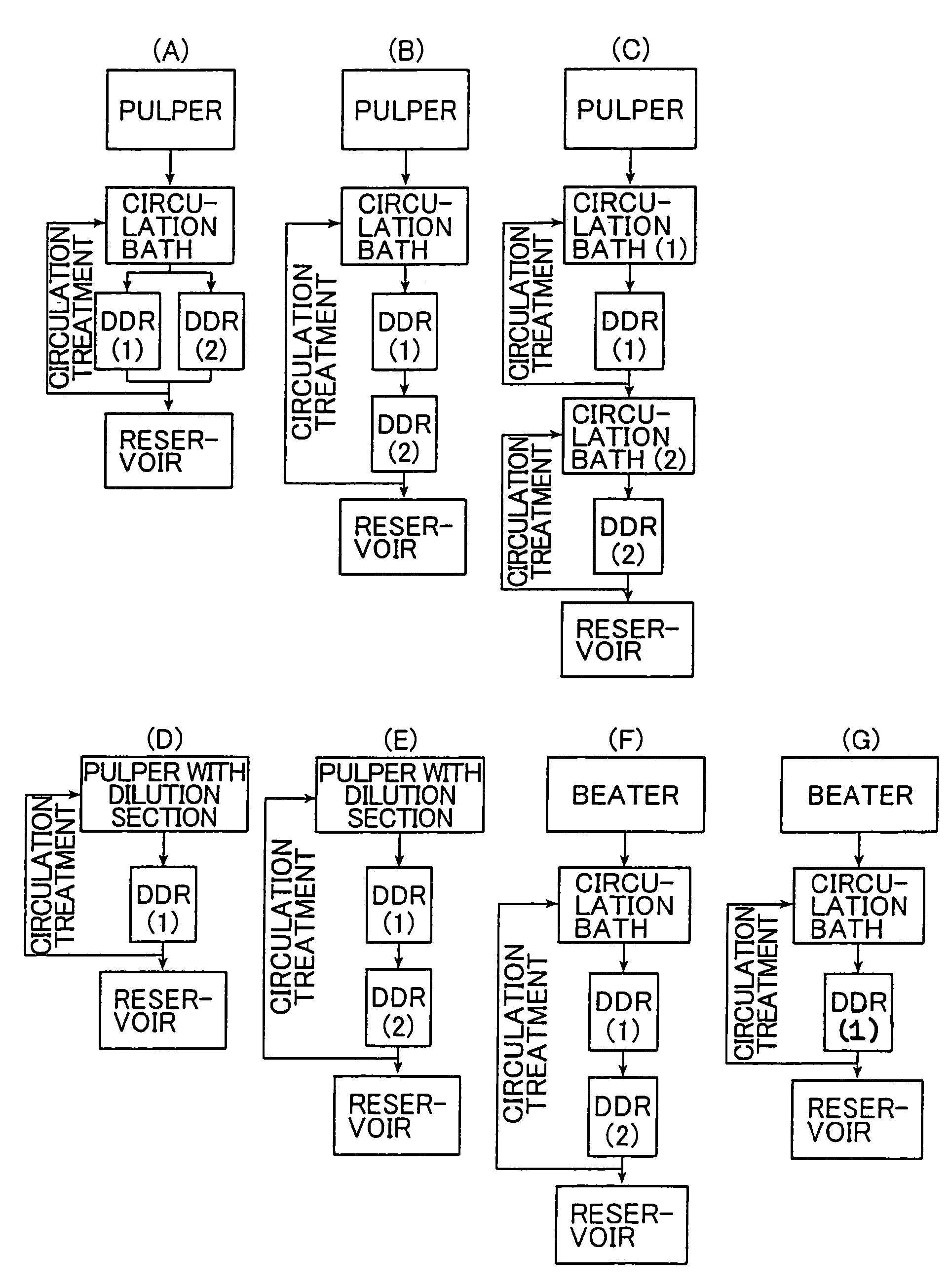

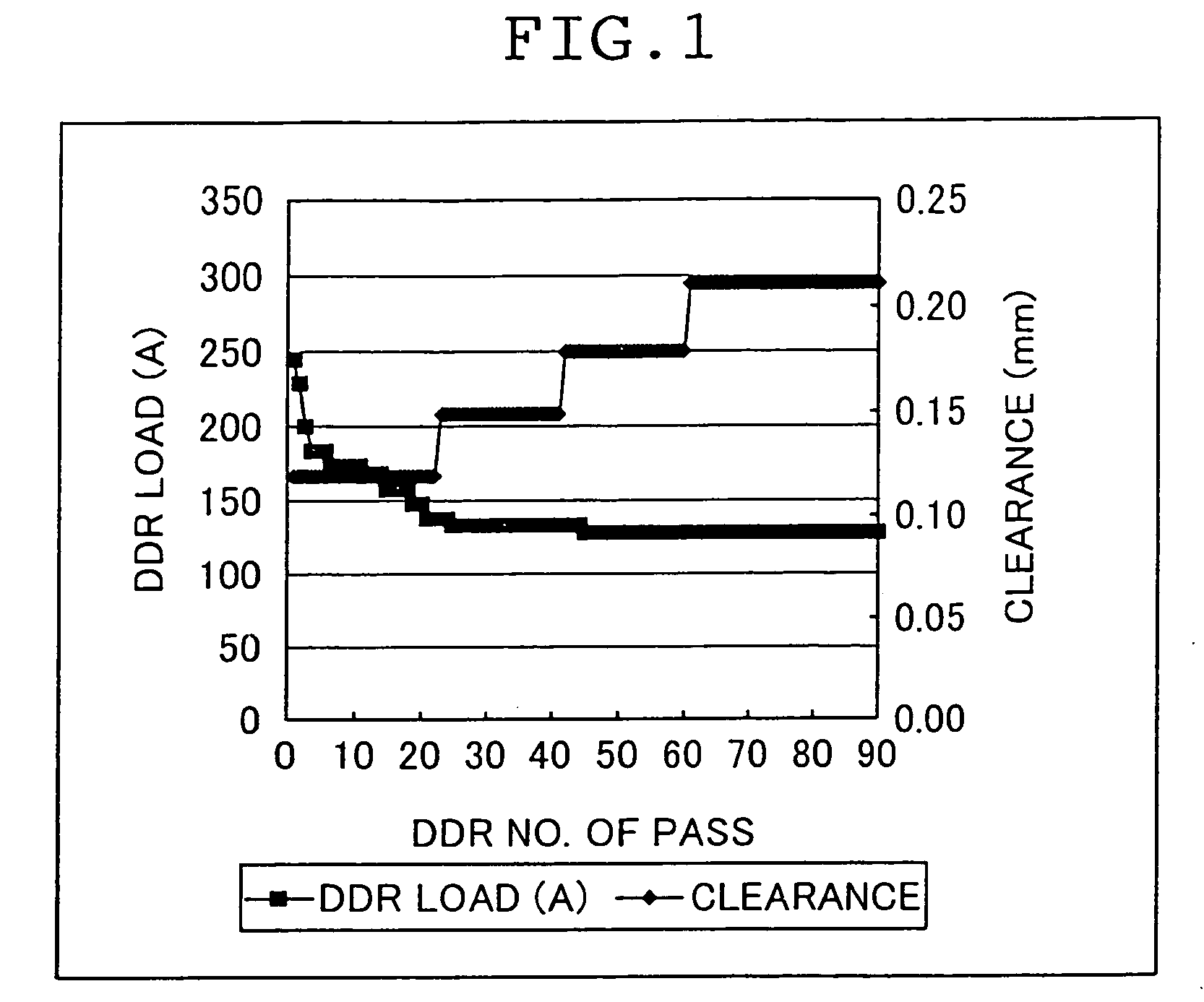

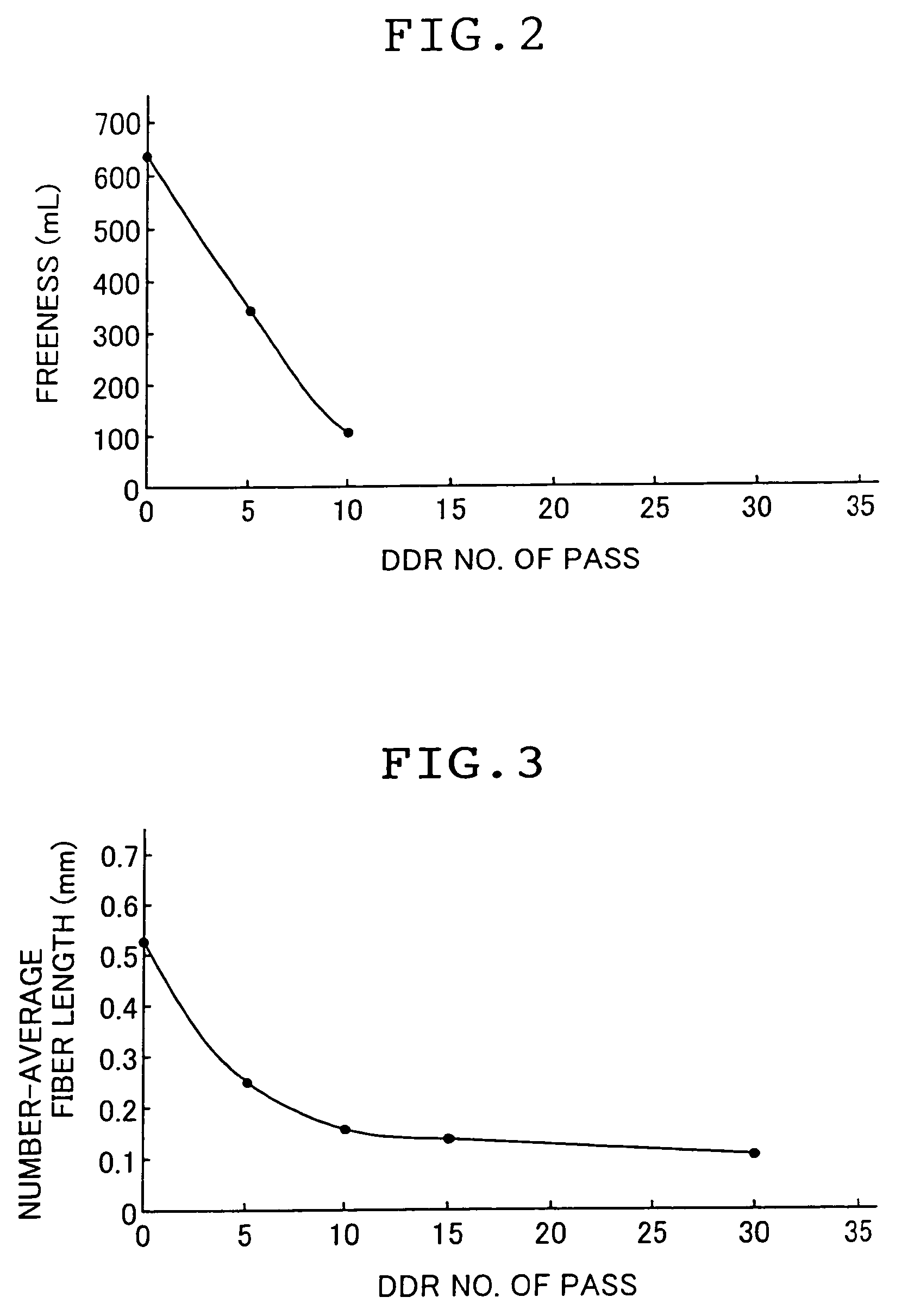

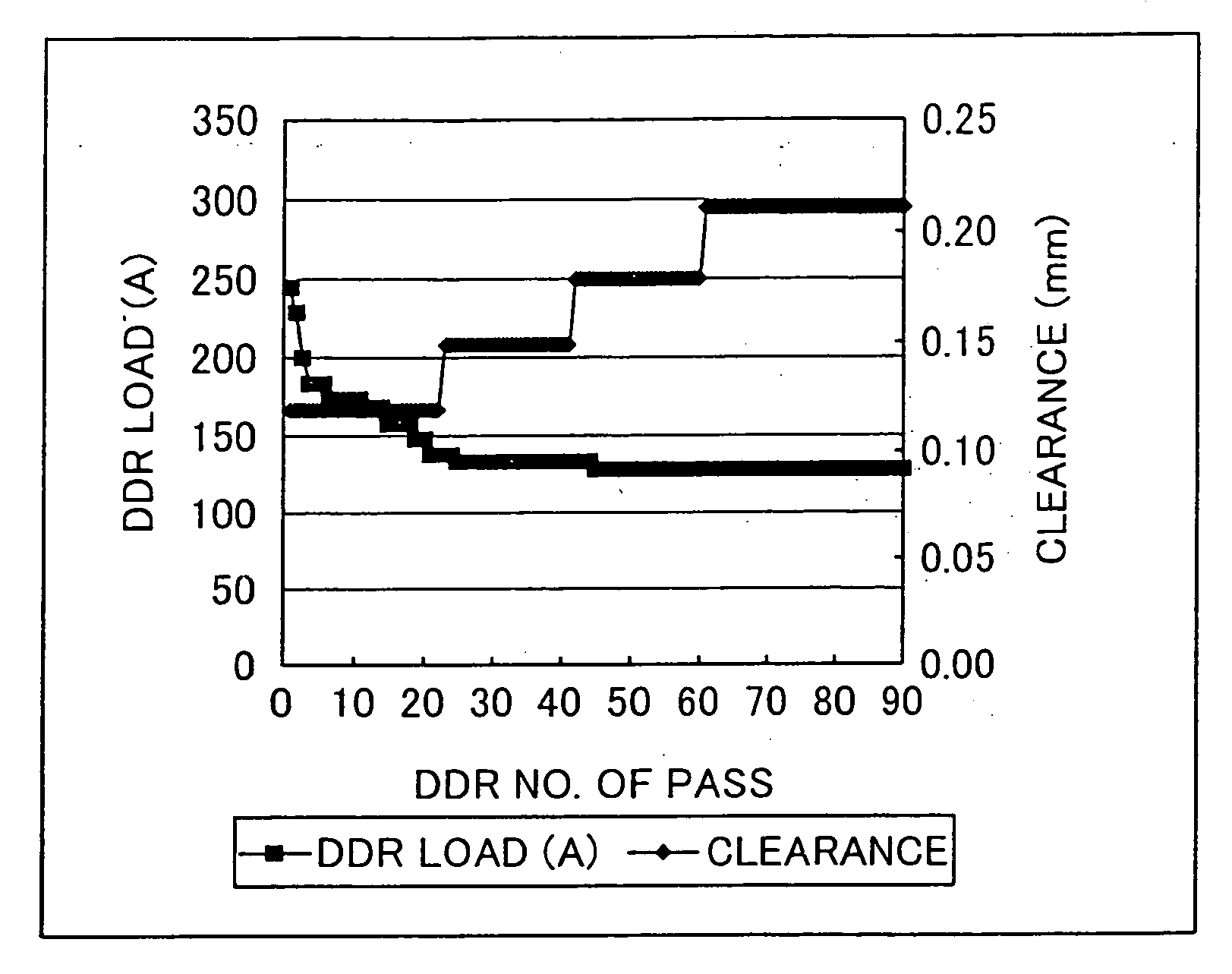

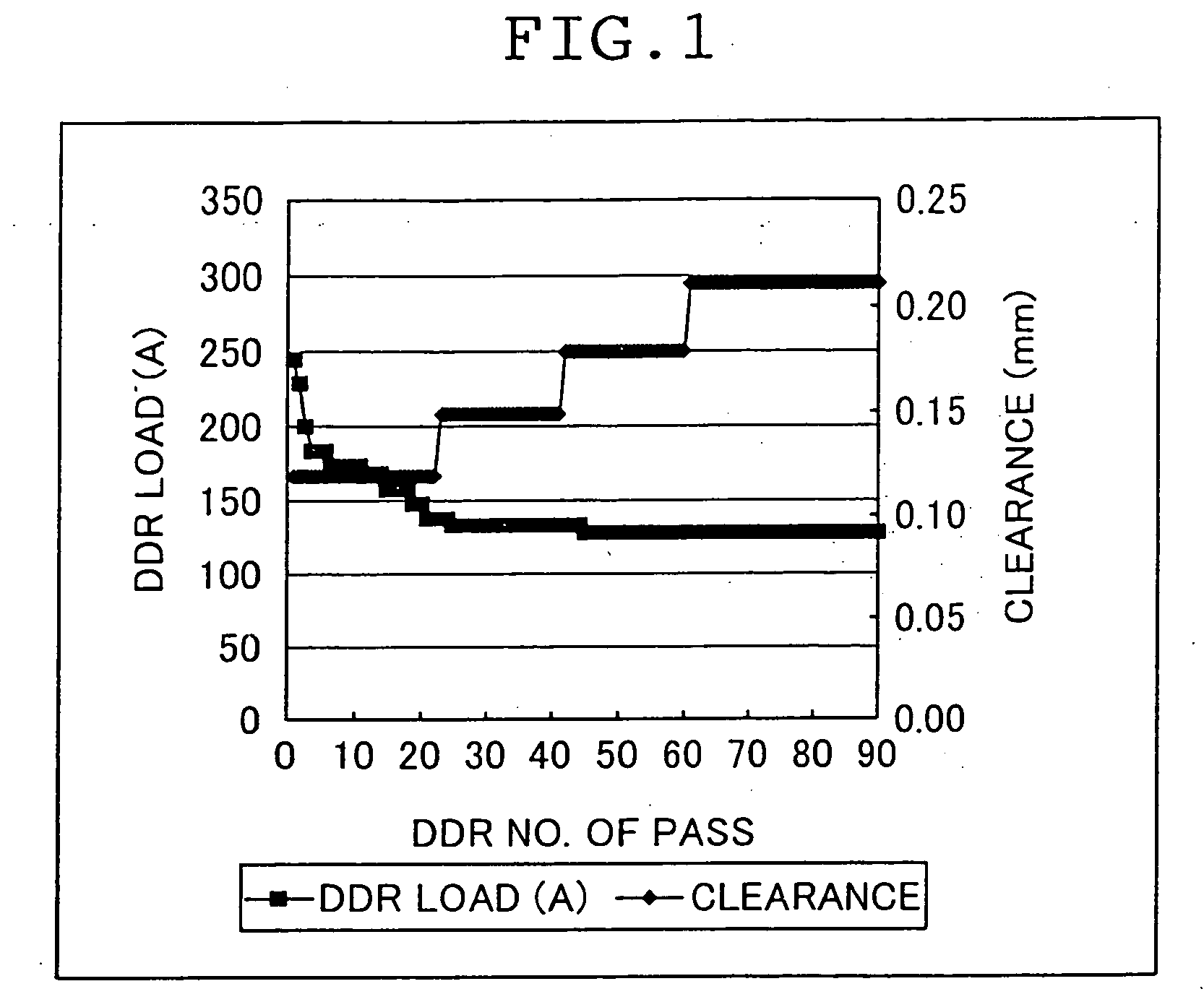

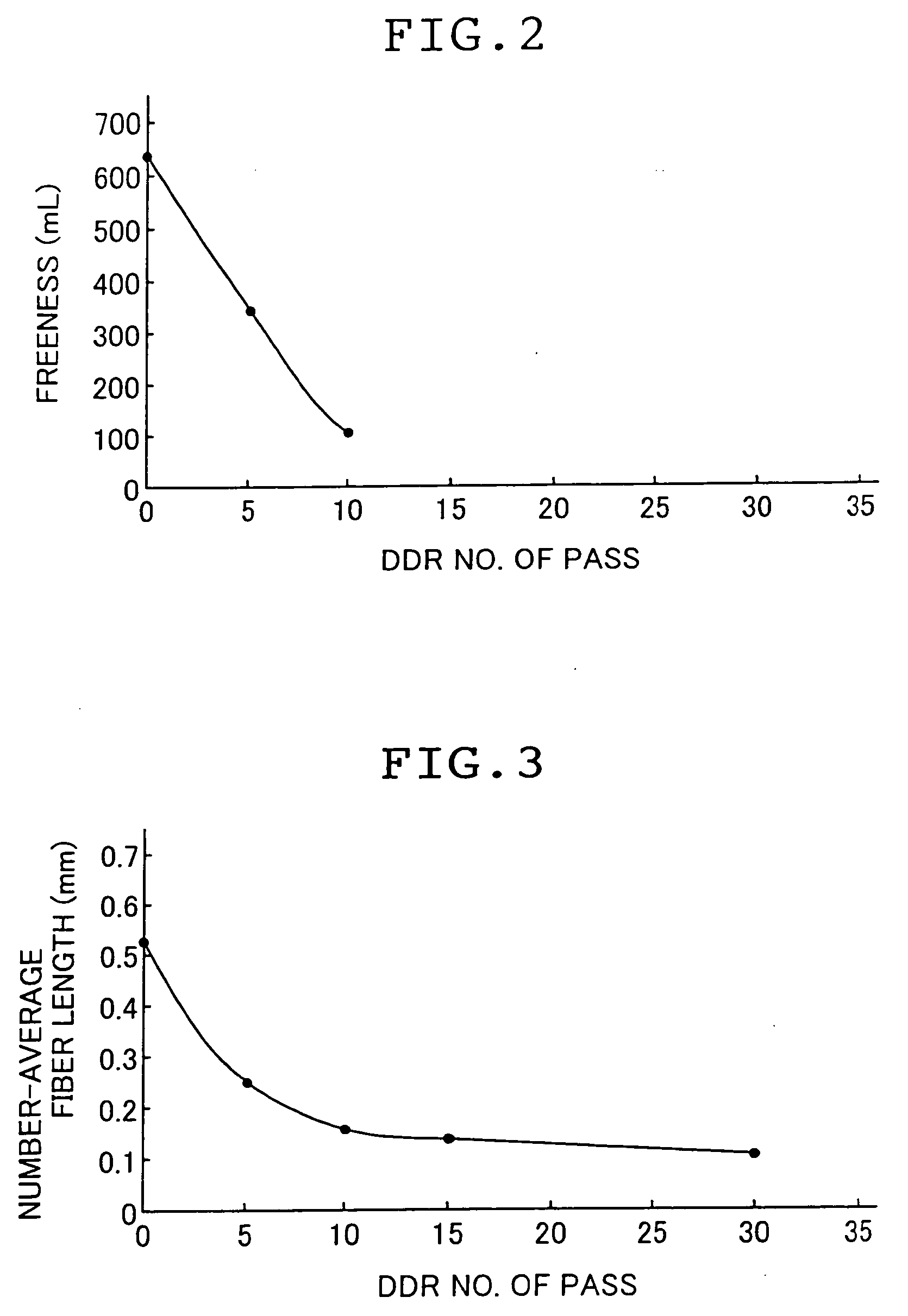

ActiveUS20050194477A1Efficient and stable productionQuality improvementNon-fibrous pulp additionNatural cellulose pulp/paperCellulose fiberSlurry

A method for producing a microfibrillated cellulose, which comprises subjecting a slurry containing a pulp having a solids concentration of 1 to 6 wt % to the treatment with a disc refiner repeatedly ten times or more, to thereby prepare a microfibrillated cellulose having a number average fiber length or 0.2 mm or less and an amount of water hold of 10 mL / g or more, the amount representing the volume of water capable of being held by a unit weight of the cellulose fiber. The method allows the production of a microfibrillated cellulose having high quality with stability and with good efficiency.

Owner:DSG INT LTD

Method for producing modified cellulose

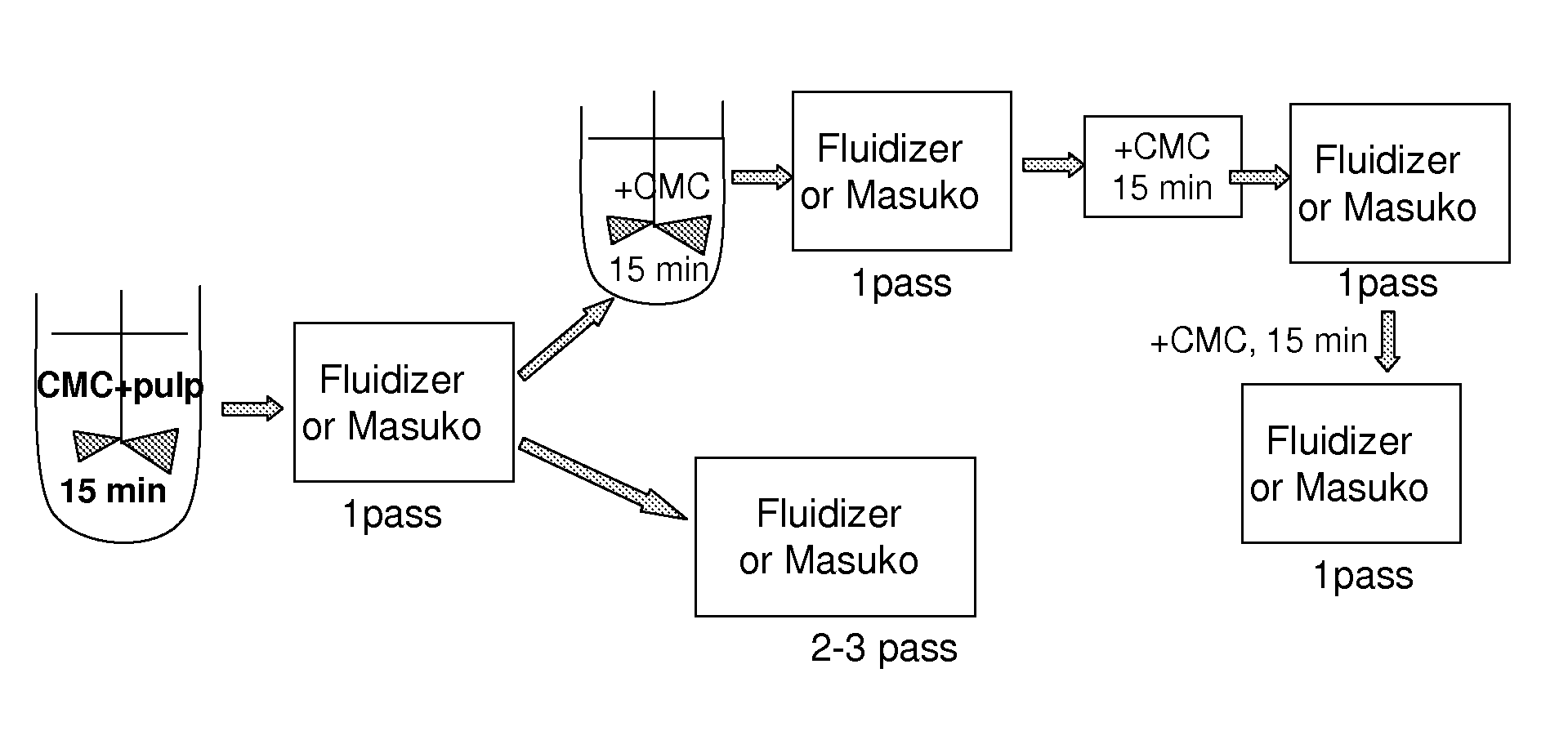

InactiveUS20120043039A1Improve propertiesEfficient productionSpecial paperPaper after-treatmentFiberFiber suspension

The present invention provides a method for producing modified nanofibrillated cellulose characterized by bringing cellulosic material into a fiber suspension, adsorbing a cellulose derivative or polysaccharide or polysaccharide derivative onto fibers in said fiber suspension under special conditions and subjecting the obtained fiber suspension derivative to mechanical disintegration. A modified nanofibrillated cellulose obtainable by a method of the present invention is provided. Furthermore, the invention relates to the use of said modified nanotibrillated cellulose.

Owner:UPM-KYMMENE OYJ

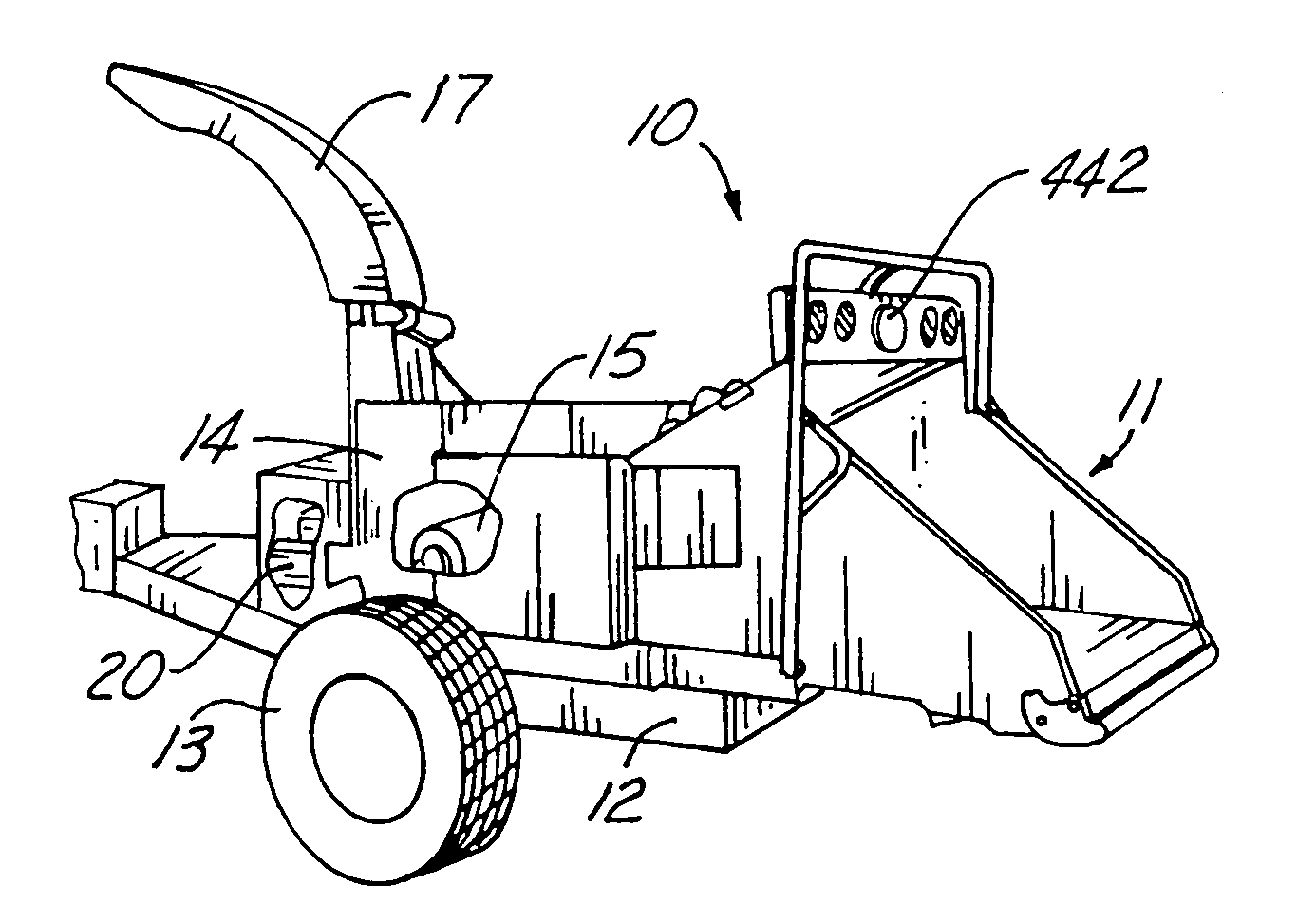

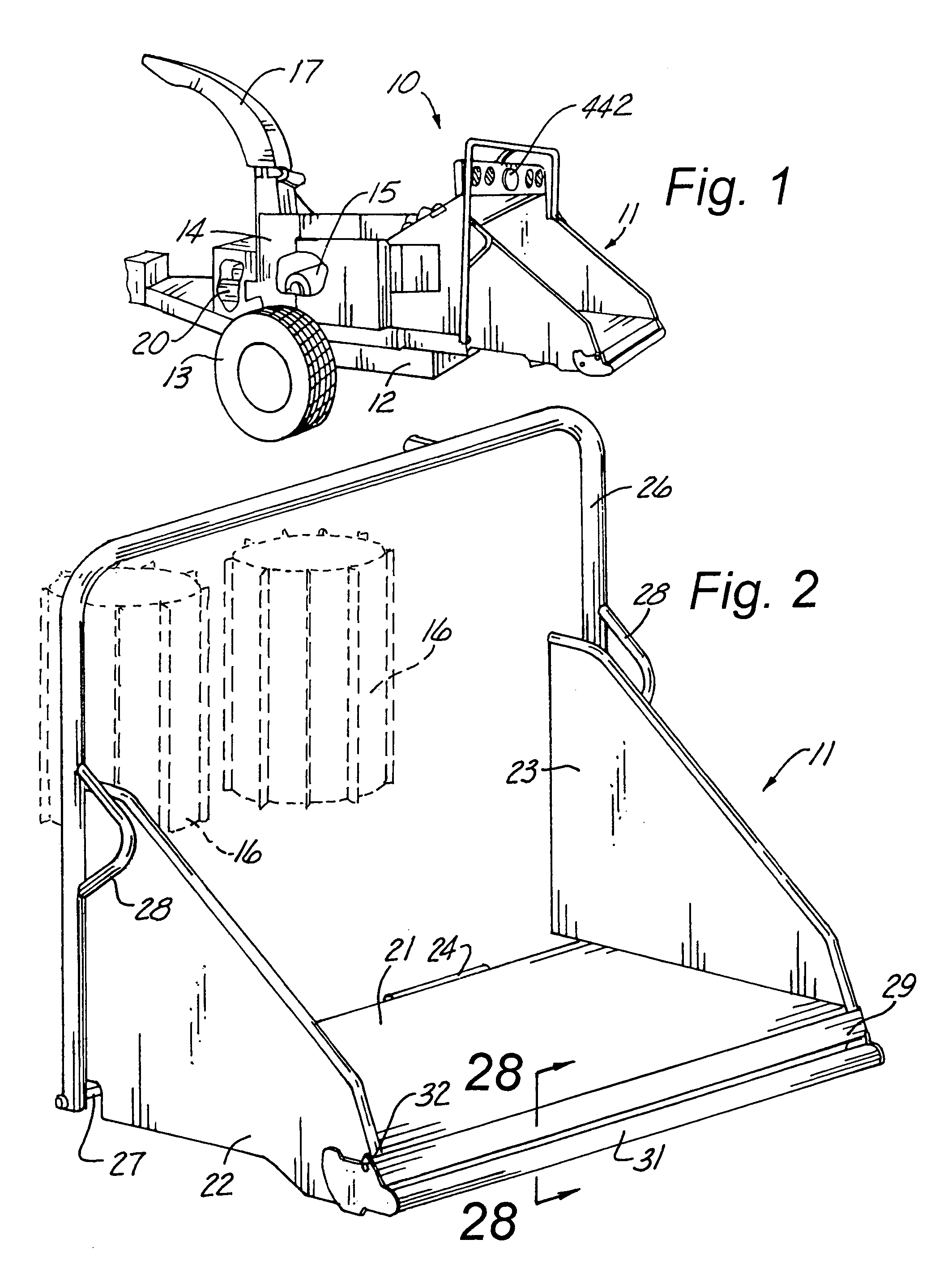

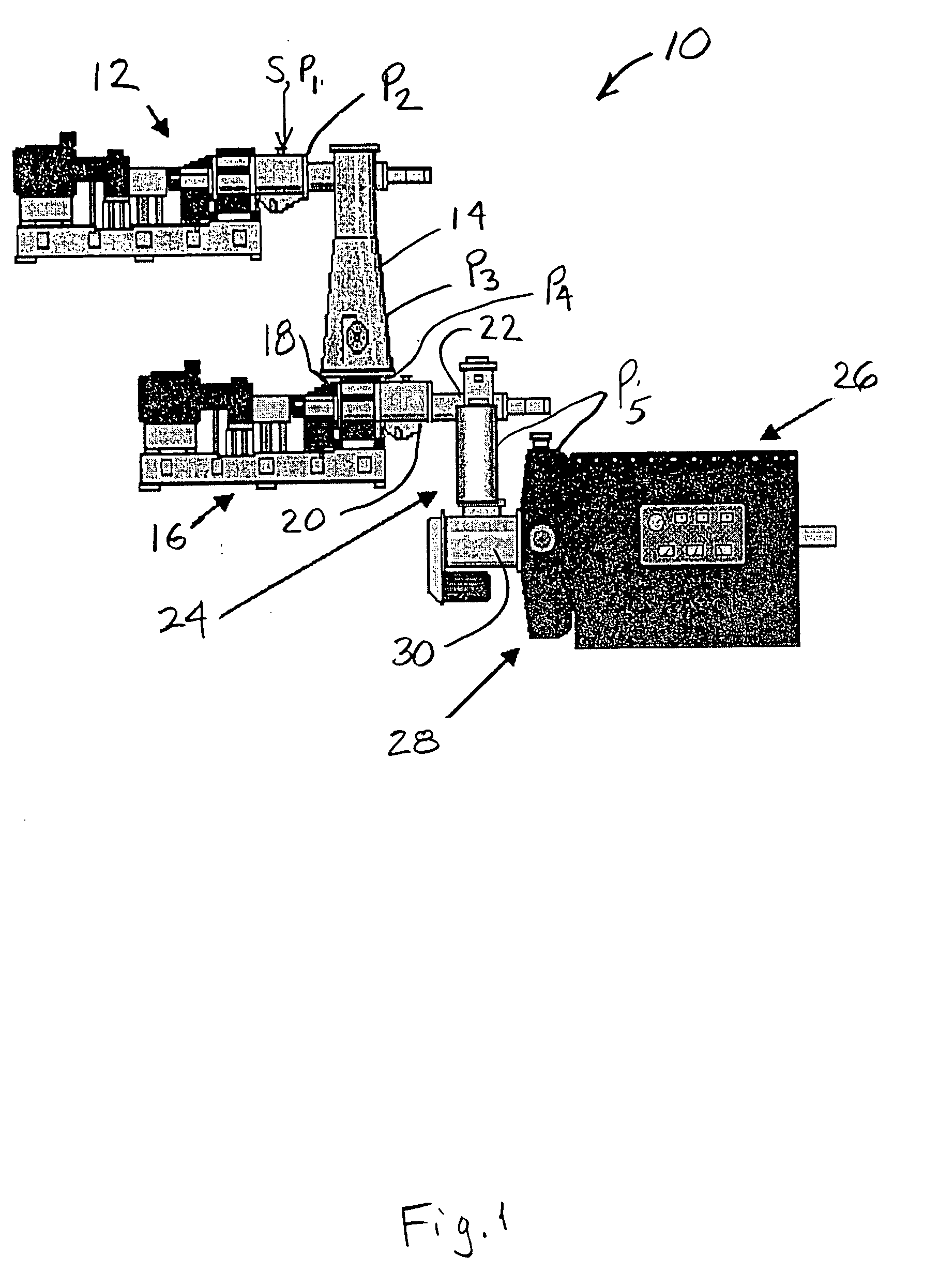

Brush chipper and methods of operating same

InactiveUS7011258B2Mechanism can be overcomeEliminate resistancePlant waste comminutingReed/straw treatmentHydraulic motorControl engineering

An improved brush cutter having an upper feed control member with stop, forward, neutral, and reverse positions also has a lower feed stop member with selectable sensitivity. Another aspect of the invention is to predict the feed roller shutoff point according to the rate of engine deceleration. According to another aspect, when the feed rollers stop feeding material into the cutters, to overcome drag on the cutters, a controller stops the feed rollers and then reverses them for a short time, and then reverses the rollers again if the problem is still present. To prevent jamming, a pressure switch senses when oil in a hydraulic motor system for rotating the feed rollers is too high and the controller momentarily reverses the feed rollers and then causes them to go forward, a cycle which can occur several times until the feed rollers are no longer stalled. By another aspect of the invention, the controller senses characteristics of the brush cutter and chooses an operating system based on the characteristics sensed. The controller can also sense if the brush chipper has not been used for a predetermined period of time and automatically reduce the idle speed of the engine until the brush chipper is used again, and then automatically return the engine to a normal idle speed before the feed rollers will pull brush into the brush chipper.

Owner:VERMEER MFG CO

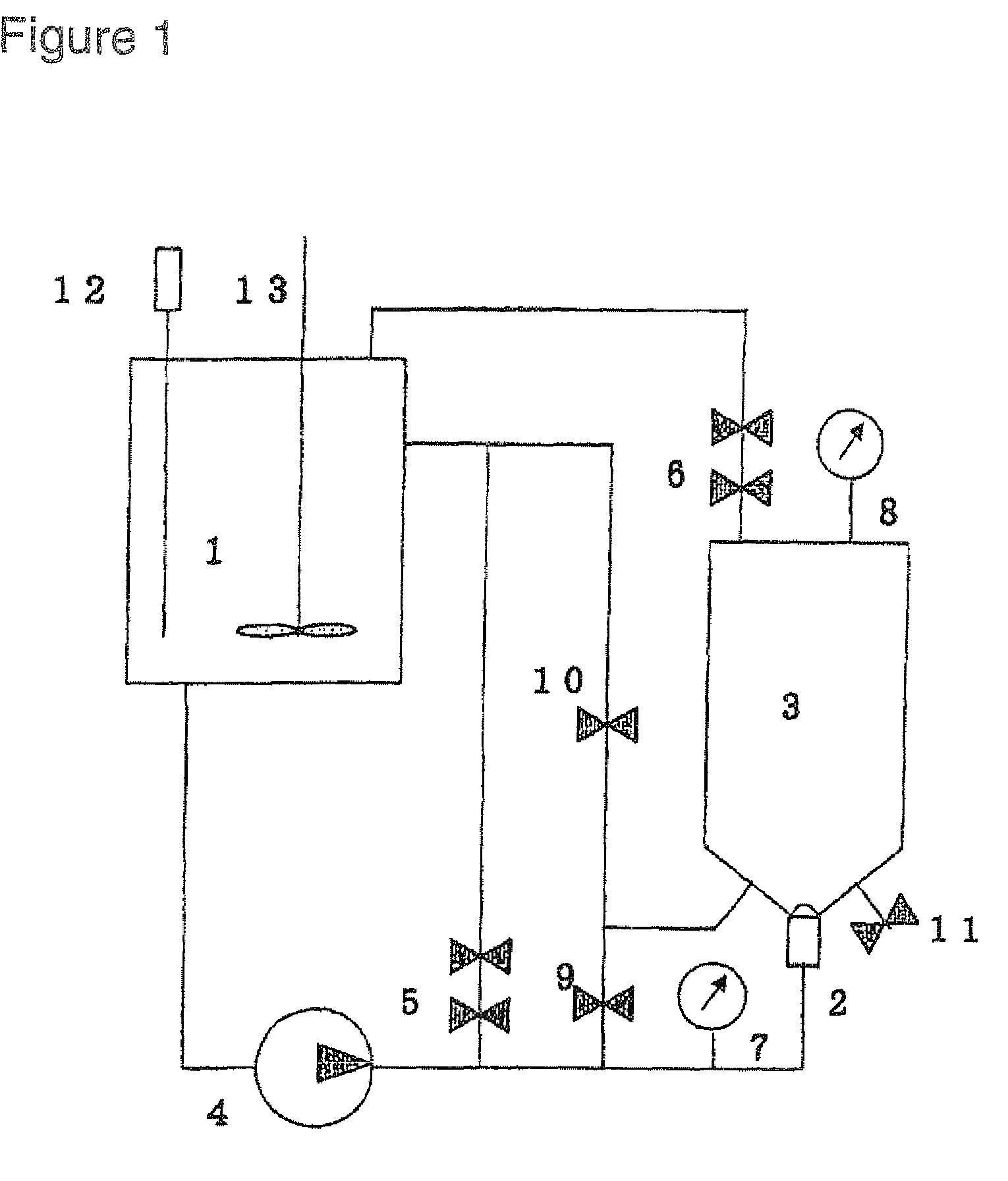

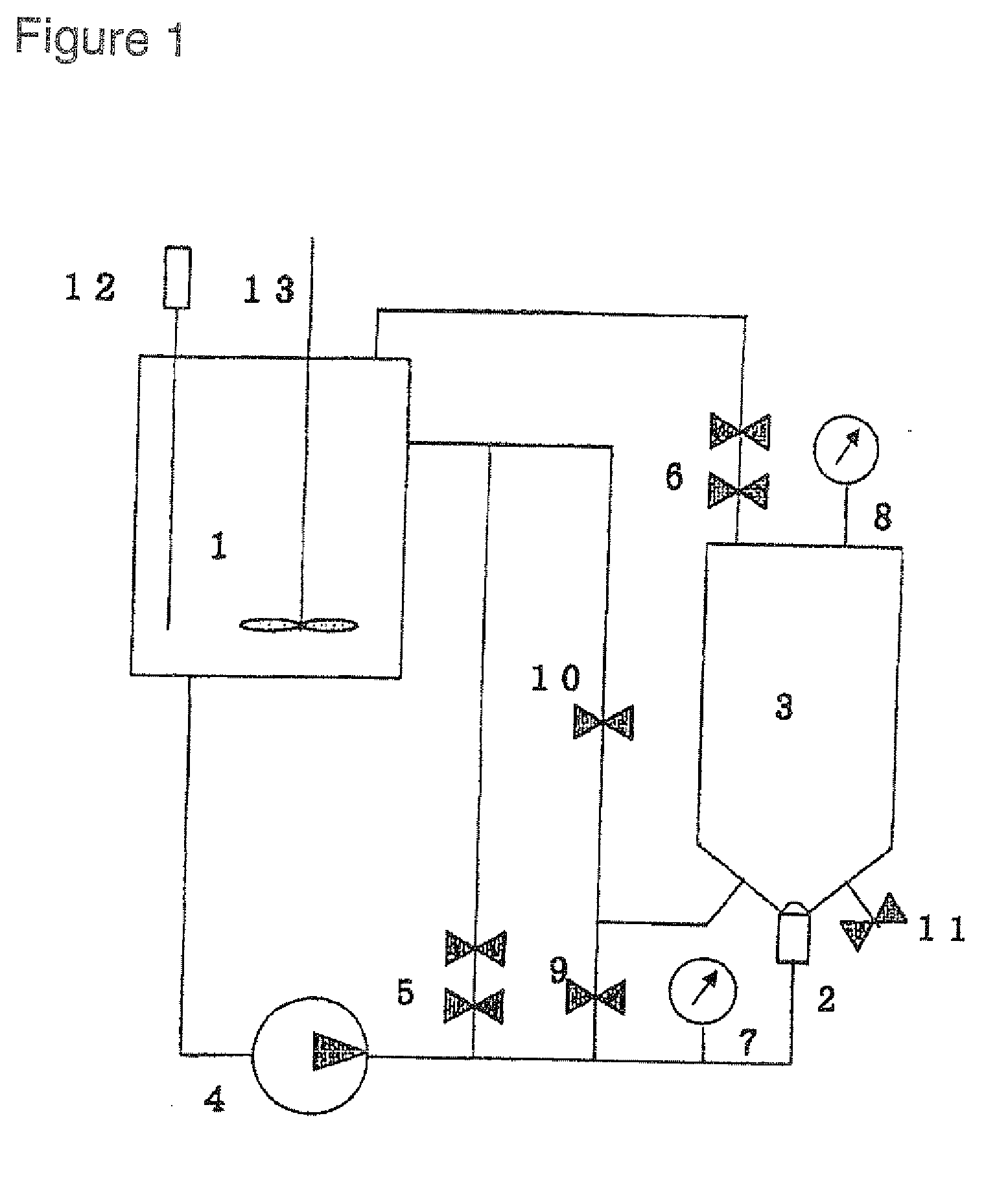

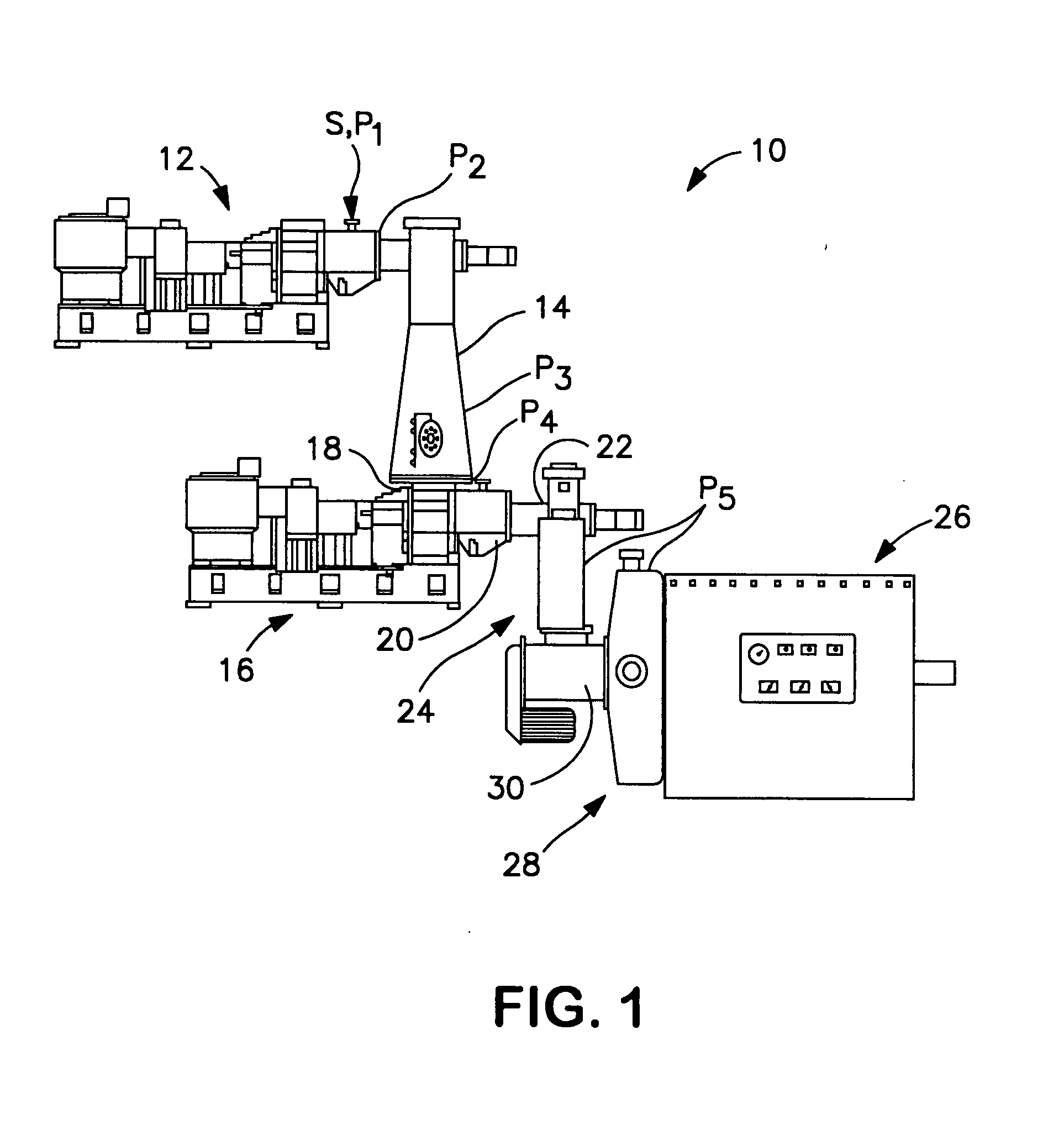

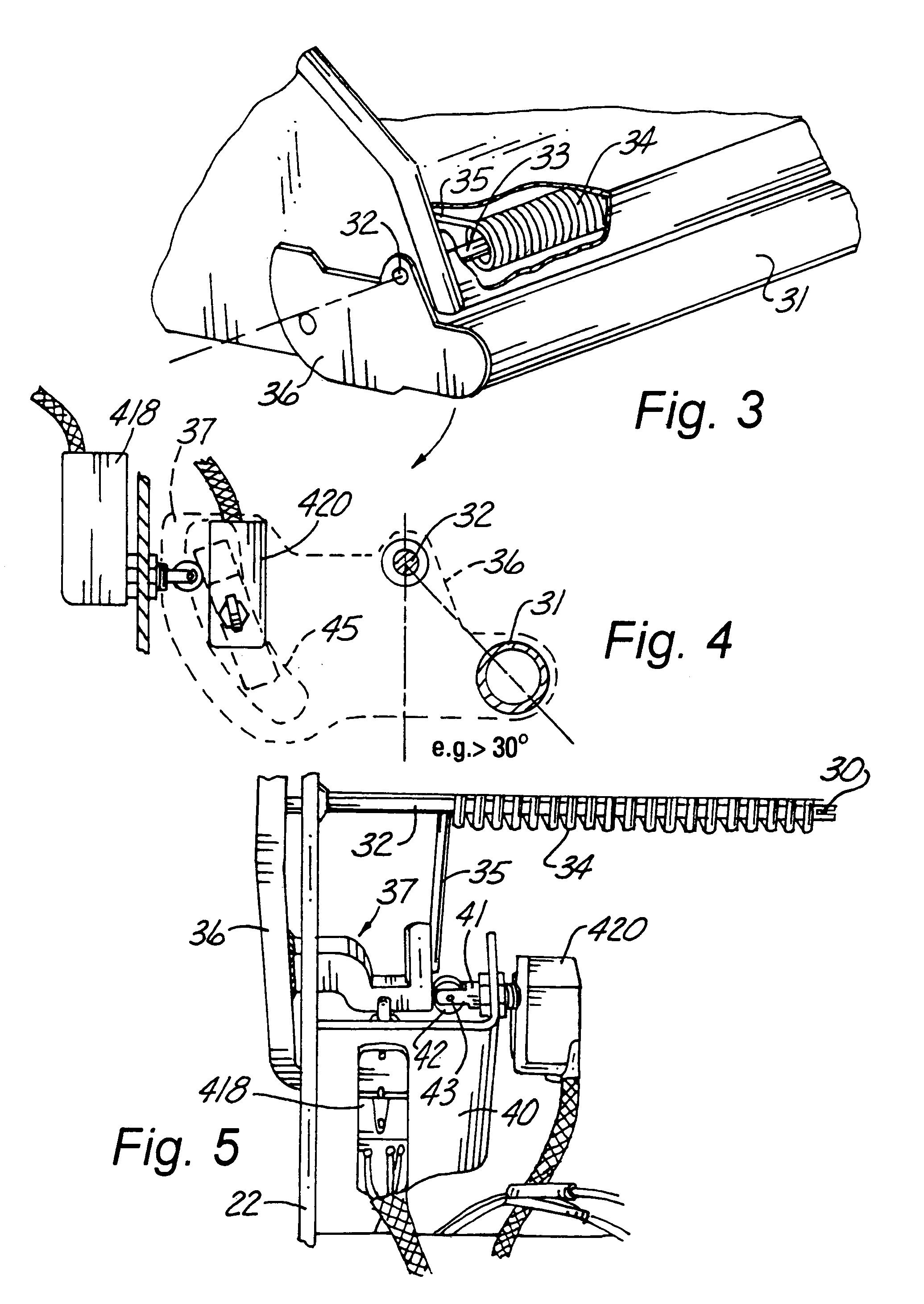

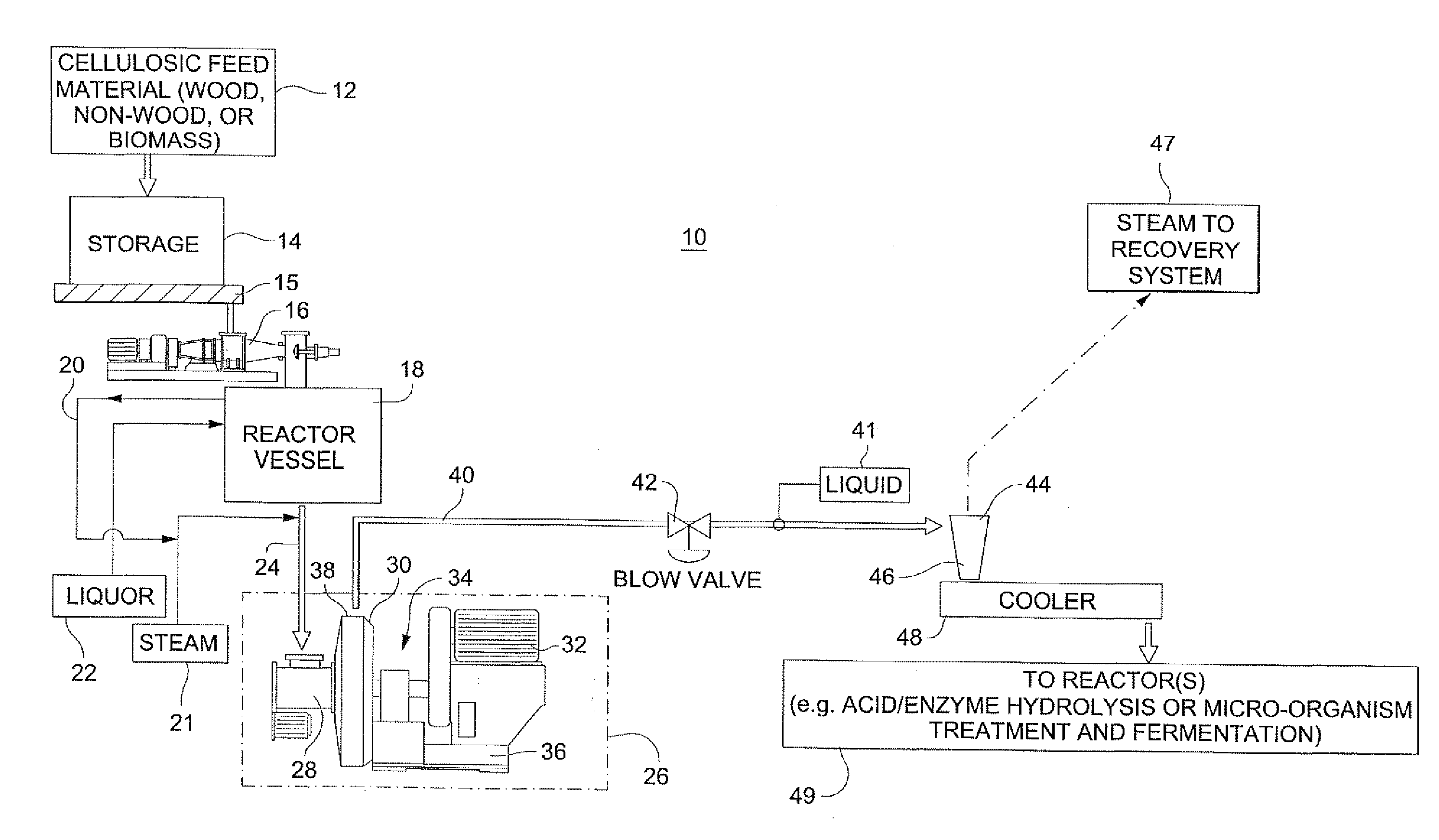

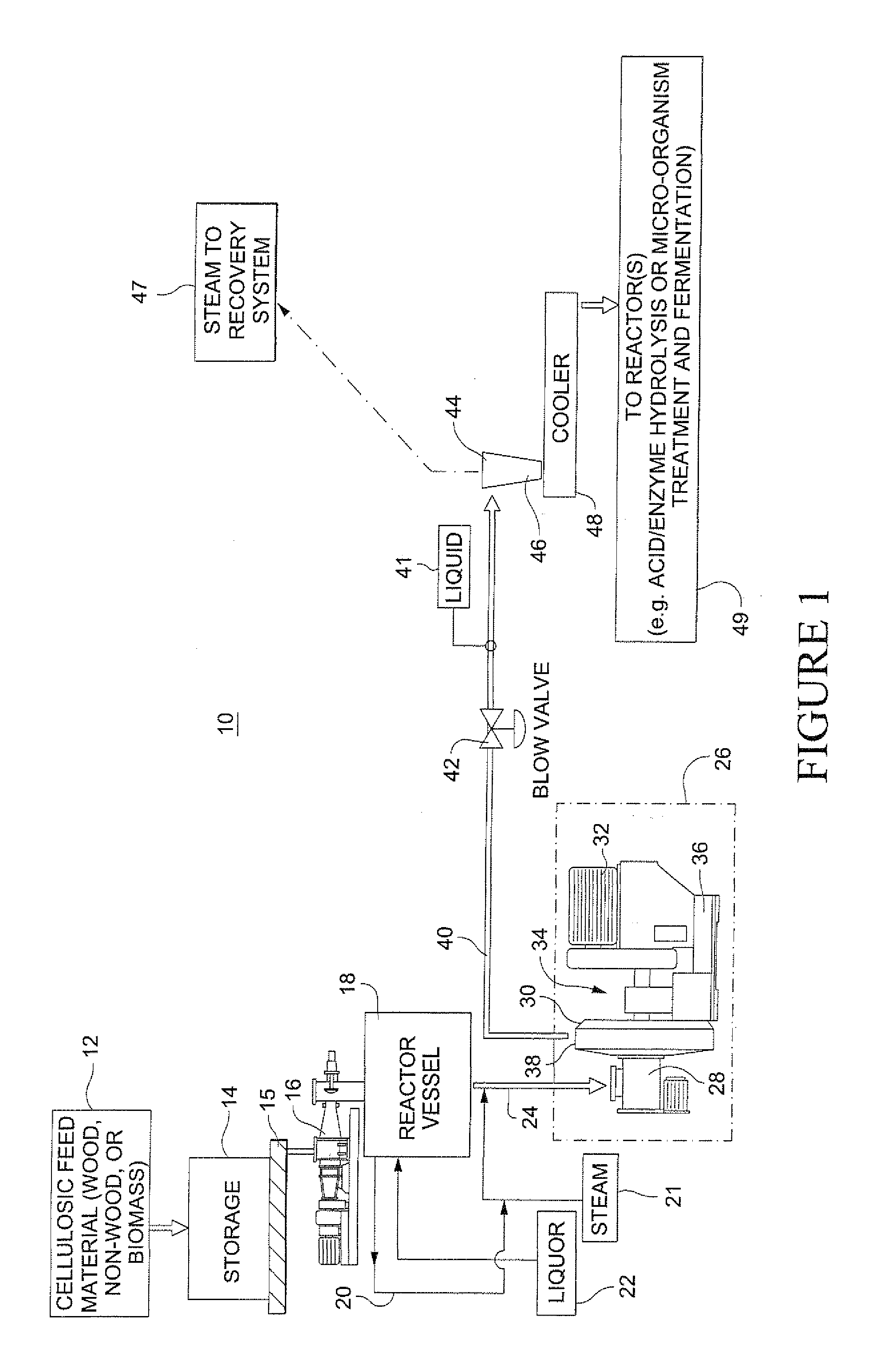

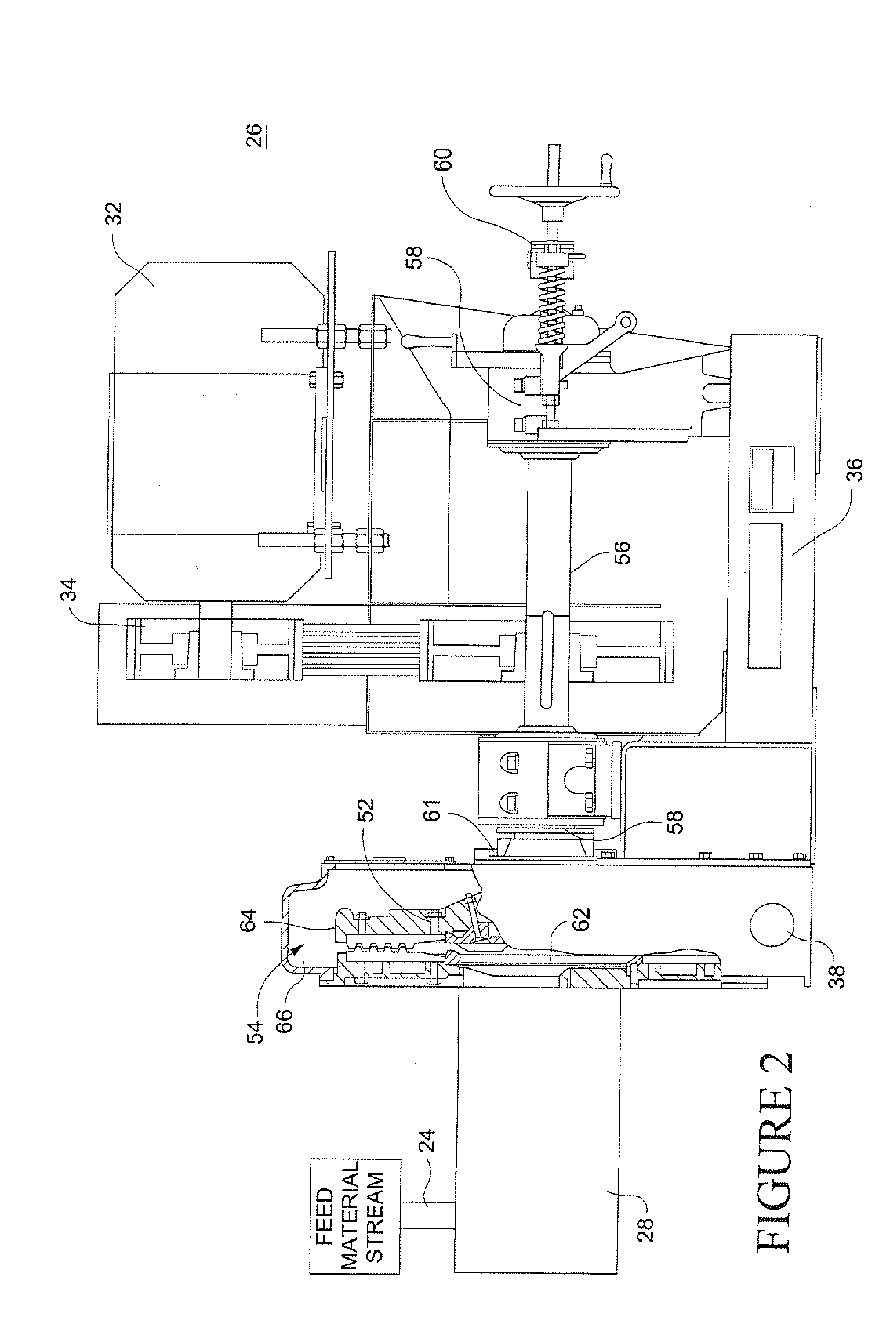

High pressure compressor and steam explosion pulping method

InactiveUS20080277082A1Reduce pressureRapid pressurePretreatment with water/steamPulp beating/refining methodsProcess engineeringHigh pressure

A steam explosion pulping method including: impregnating a cellulosic biomass feed material in a pressurized reactor vessel; discharging the impregnated feed material from the vessel to a high pressure compressor; elevating a pressure of the feed material in the compressor; discharging the pressurized feed material from the compressor to a conduit coupled to a blow valve; rapidly reducing pressure of the pressurized feed material as the feed material passes through the blow valve, and pulping the feed material by expansion of fluid in the feed material during the rapid pressure reduction.

Owner:ANDRITZ INC

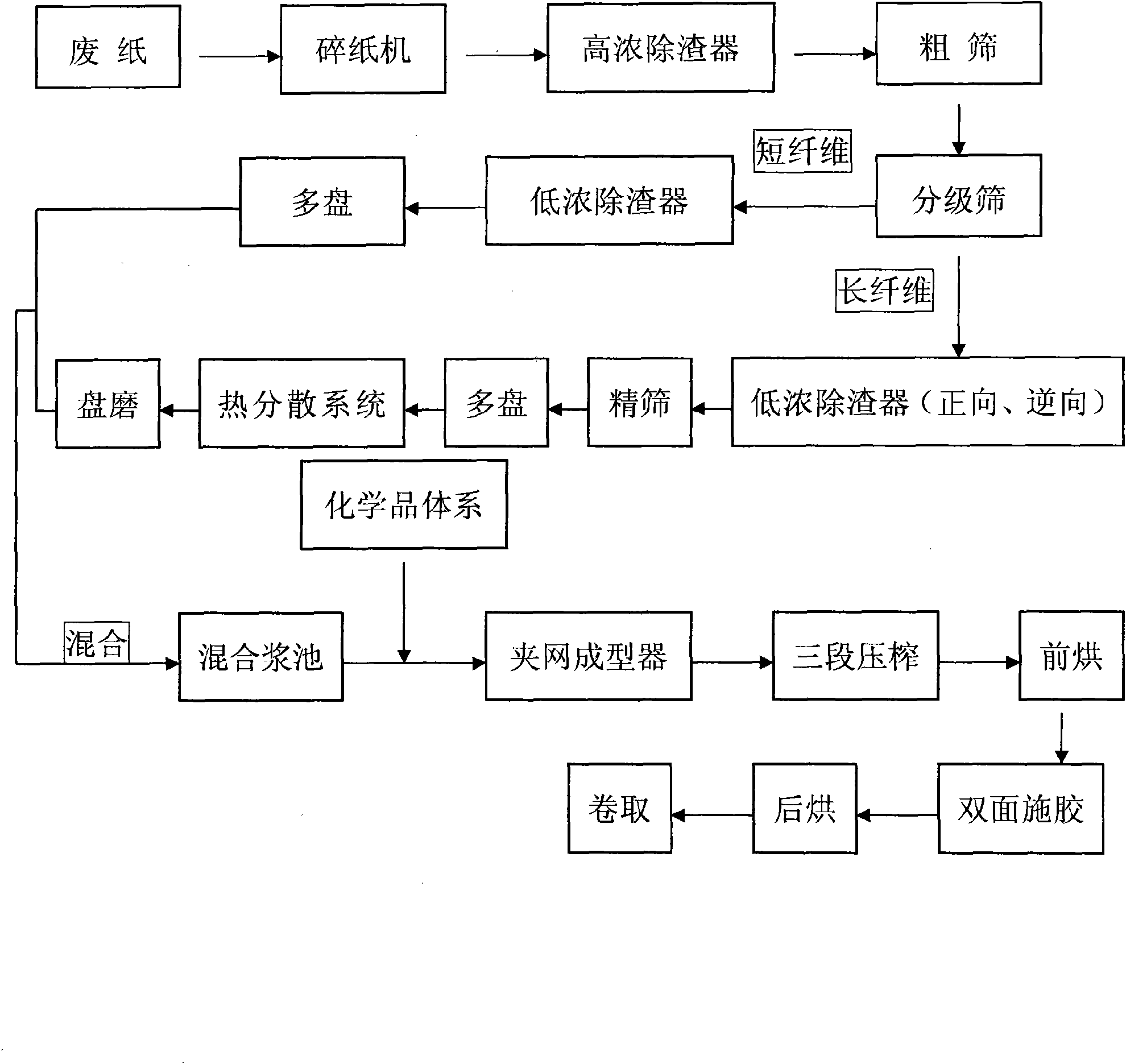

Method for producing corrugated paper with ultralow gram weight and high strength

The invention discloses a method for producing corrugated paper with ultralow gram weight and high strength. The method comprises the following technological steps: 1) mixing; 2) addition of water for size degradation to prepare pulp; 3) pulp combination and purification treatment; 4) medium-concentration pulping; 5) addition of a chemical medicine system into the pulp; 6) twin-wire forming, water filtration and paper-making with the pulp; 7) three-stage squeezing dehydration; 8) prebaking and drying; 9) double-faced sizing; 10) postbaking and drying; and 11) coiling. The method utilizes pulping and paper-making process combination and completely utilizes secondary fiber to make the corrugated paper with ultralow gram weight and high strength so as to reduce the gram weight of the corrugated paper, save the fiber amount, reduce the production cost, and simultaneously reduce the energy consumption and the discharge capacity and improve the economic benefit.

Owner:DONGGUAN NINE DRAGONS PAPER IND

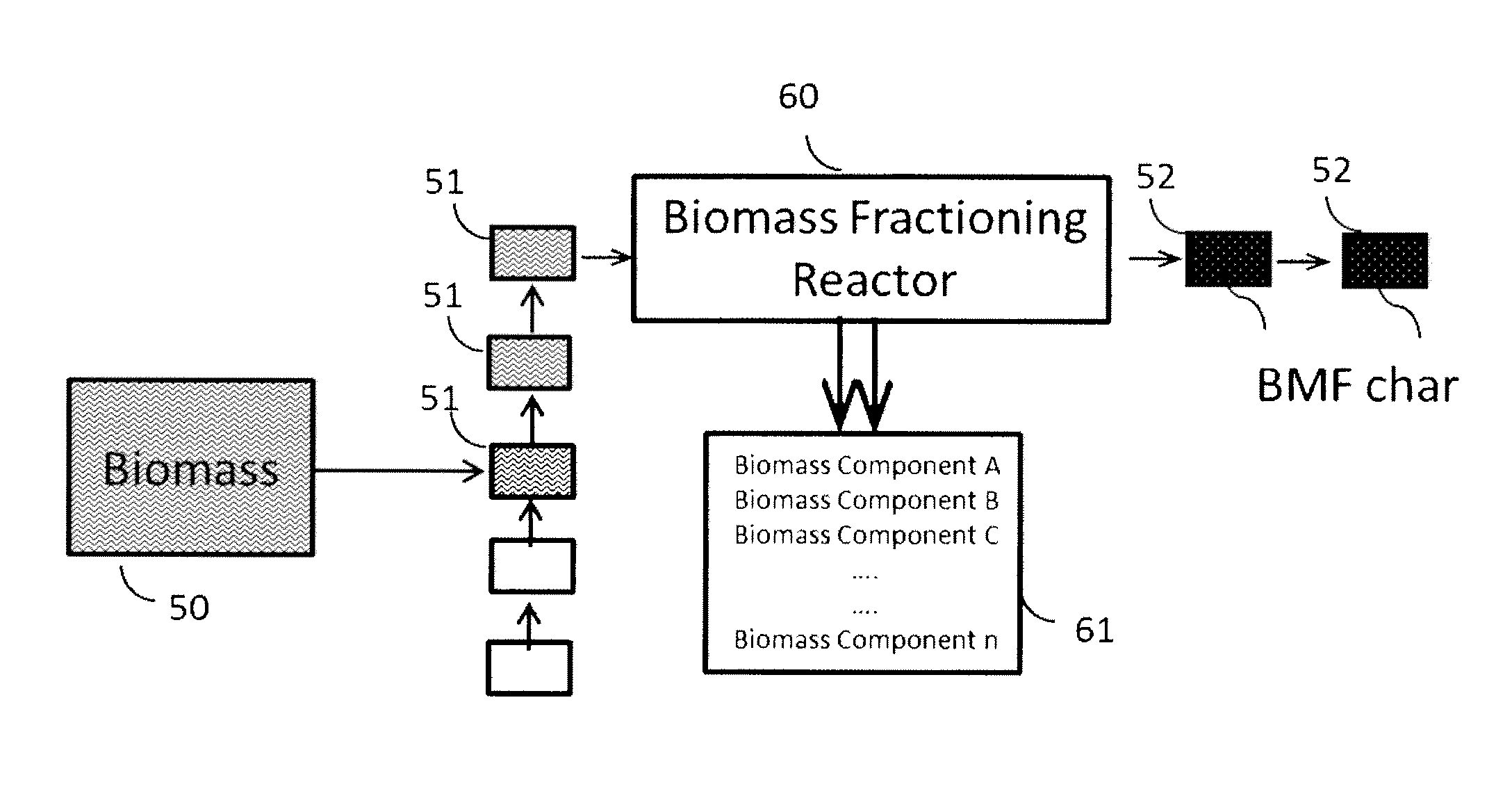

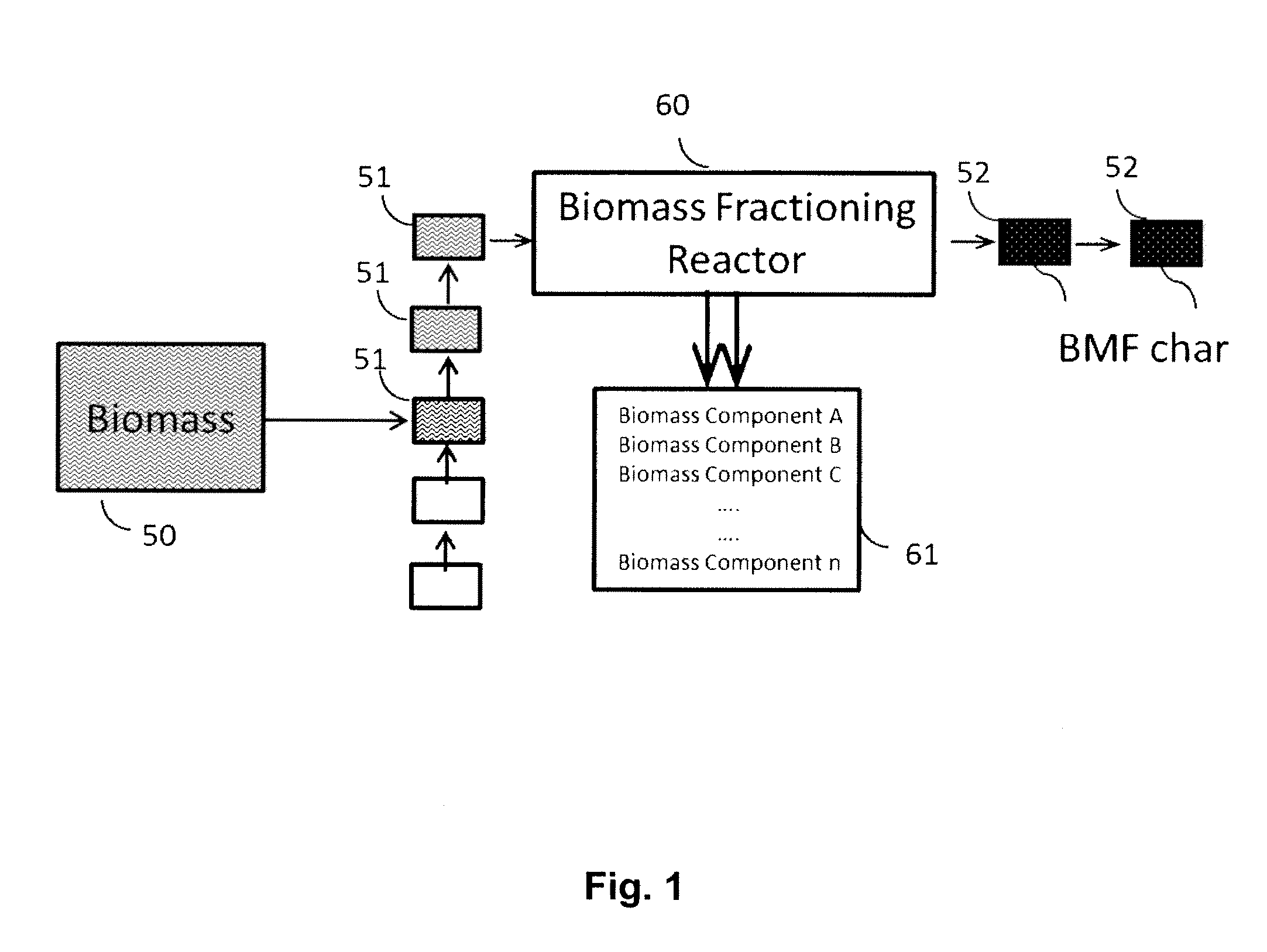

Method for biomass fractioning by enhancing biomass thermal conductivity

A method is disclosed for generating useful chemical intermediates from biomass using a novel pyrolysis reactor that utilizes the inherent thermal properties of carbon under compression as the biomass is subjected to sequential or concurrent temperature ramps. The ramps are sufficient to volatilize and selectively create different components, while the pressure application aids the selective decomposition of the biomass.

Owner:COOL PLANET ENERGY SYST

Method for manufacturing nanofibrillated cellulose pulp and use of the pulp in paper manufacturing or in nanofibrillated cellulose composites

InactiveUS20130000855A1Increase productivityPrevents hydrogen bondPulp properties modificationLuminescent/fluorescent substance additionPaper manufacturingPulp and paper industry

Owner:UPM-KYMMENE OYJ

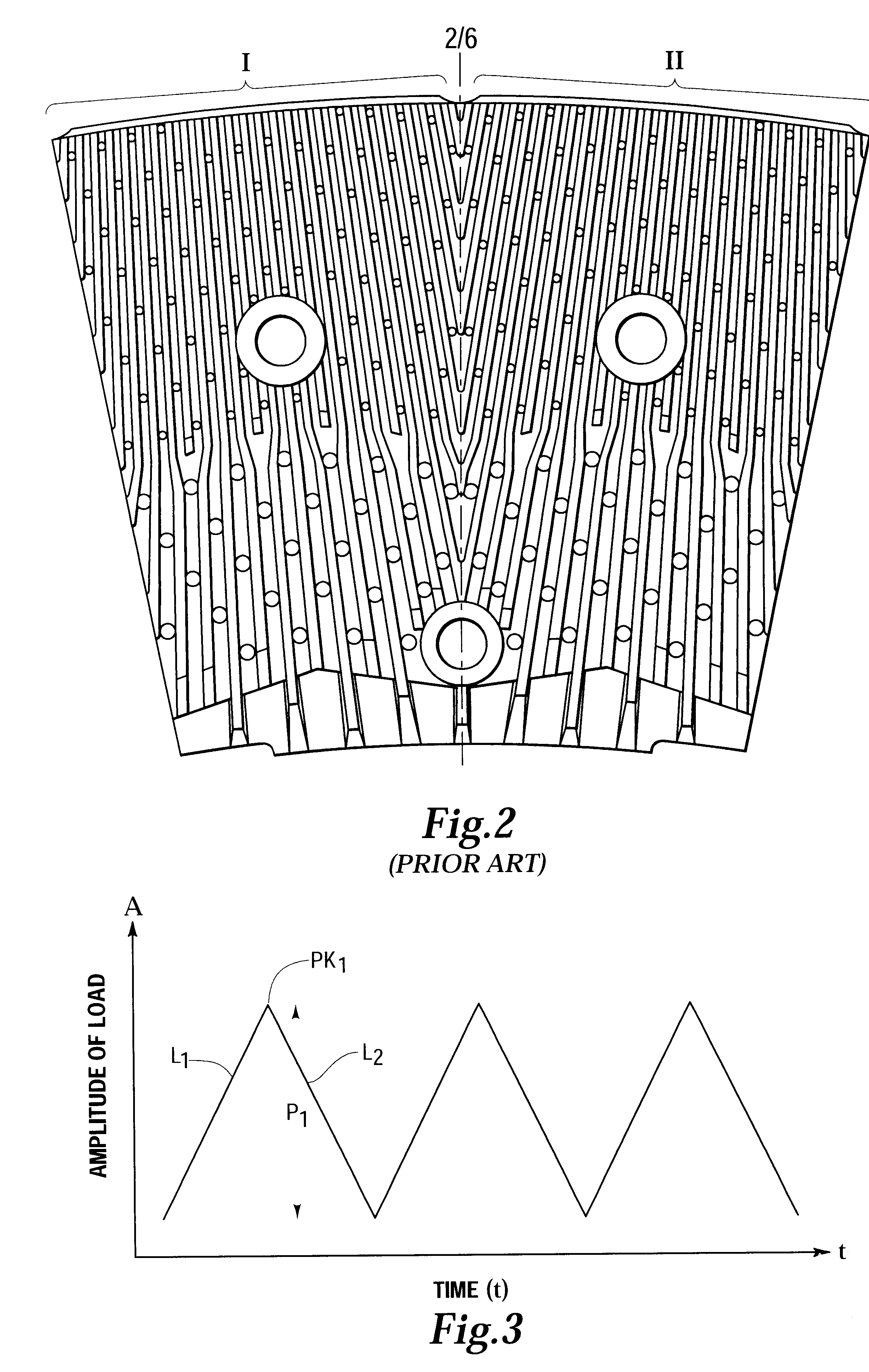

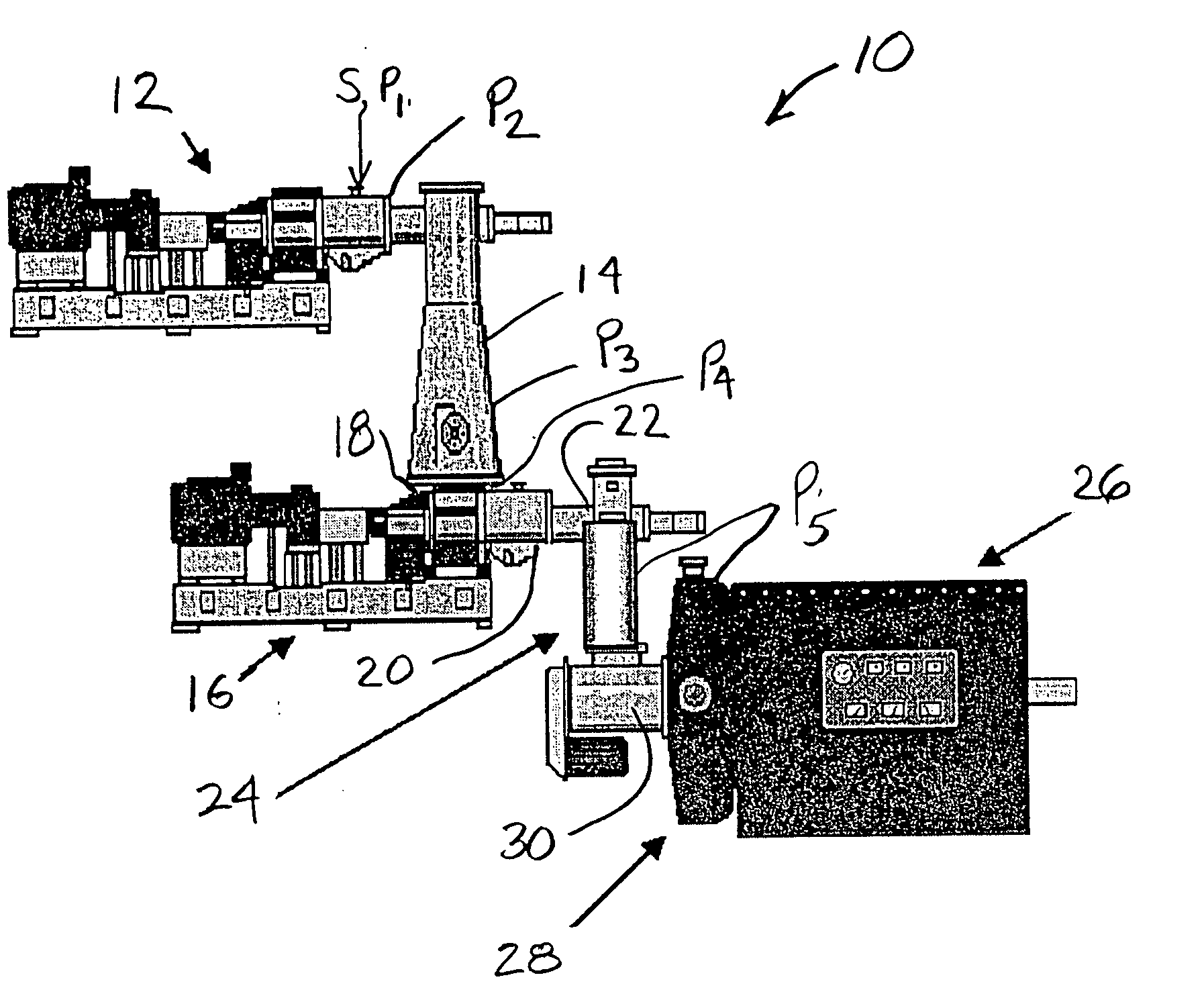

Refiner disc and method

A refiner disc and segment for a rotary disc fiber refiner which has a plurality of radial fields each having an angular extent no greater than 30° and preferably no greater than 22° for reducing the amplitude and duration of load swings that take place during pumping and holdback cycles. Each field has a refining zone with a refiner groove and a refiner bar and a second zone disposed radially outwardly of the refining zone that changes the direction of flow of stock to reduce stock flow momentum and magnitude of the load swings. Each field can have a third zone radially outward of the second zone that further changes the direction of flow of stock and an infeed zone radially inwardly of the refining zone. If desired, a zone that includes a breaker bar can be disposed radially inwardly of the infeed zone. Where the disc is segmented, the segment has at least three fields. In one preferred embodiment, the segment has at least four fields which reduces the duration and magnitude of load swings by at least 40% thereby reducing refiner vibration and wear while advantageously increasing consistency of pulp quality and throughput. The disc and segment are capable of bi-directional operation without loss of efficiency, quality, and throughput.

Owner:J & L FIBER SERVICES

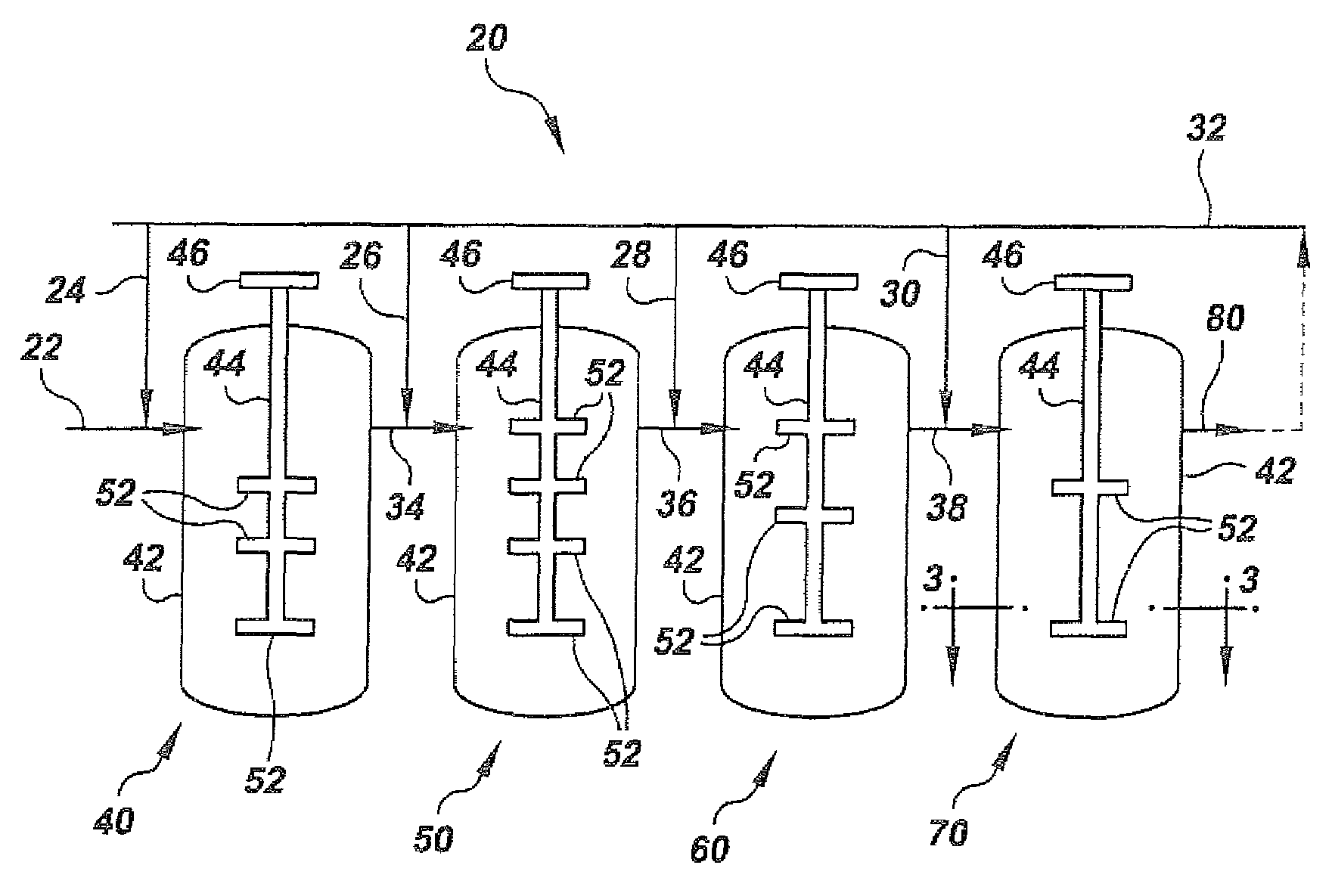

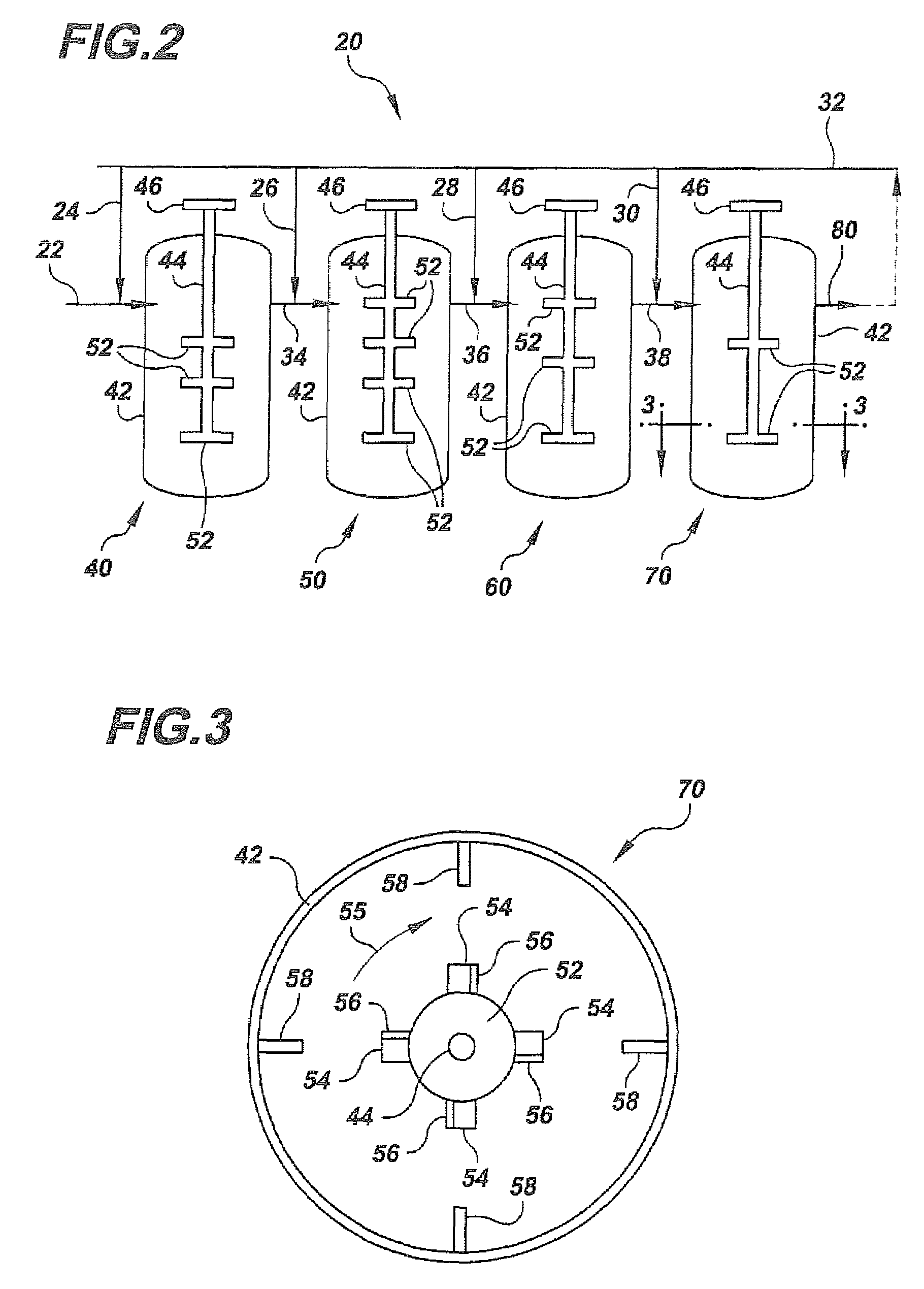

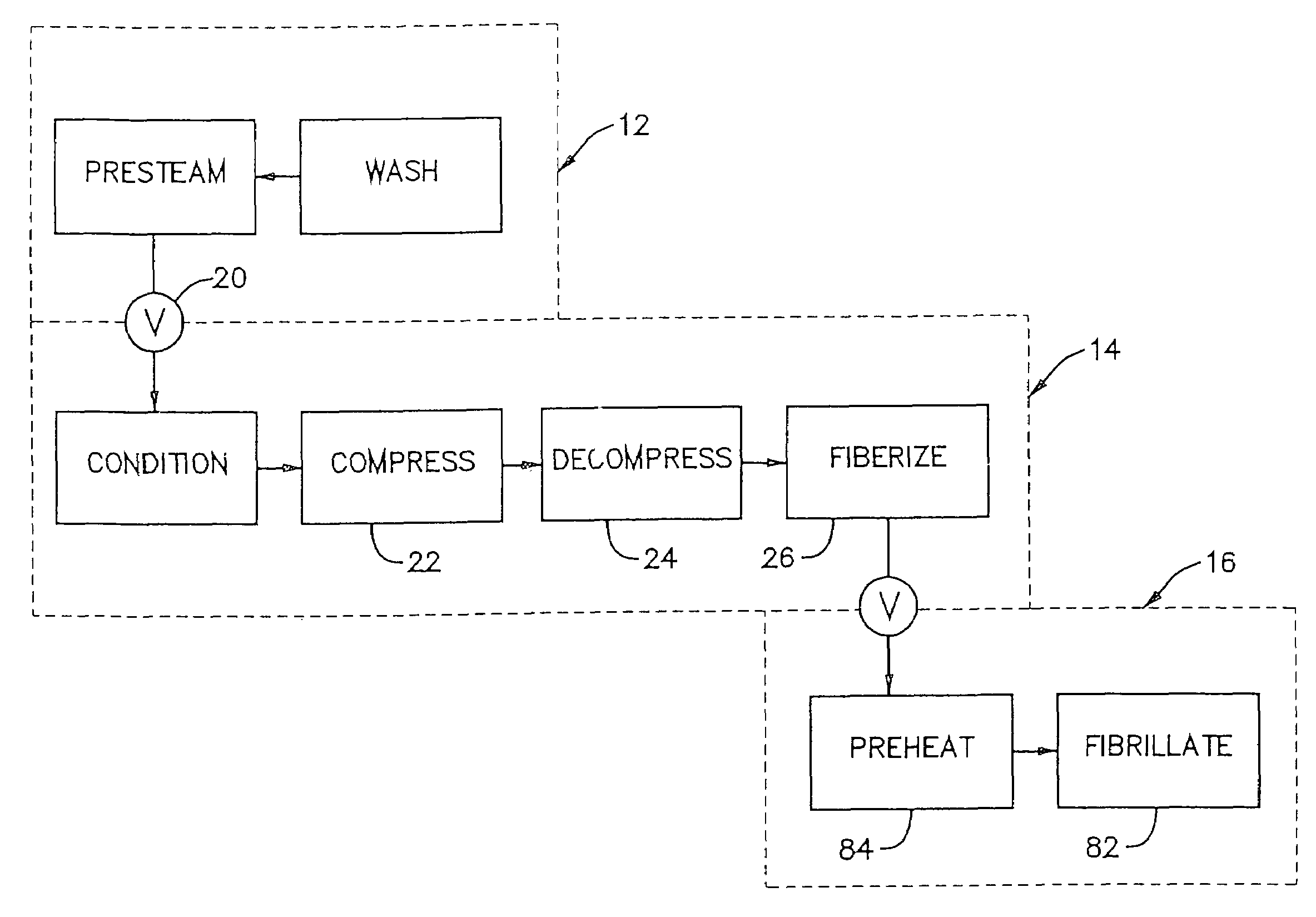

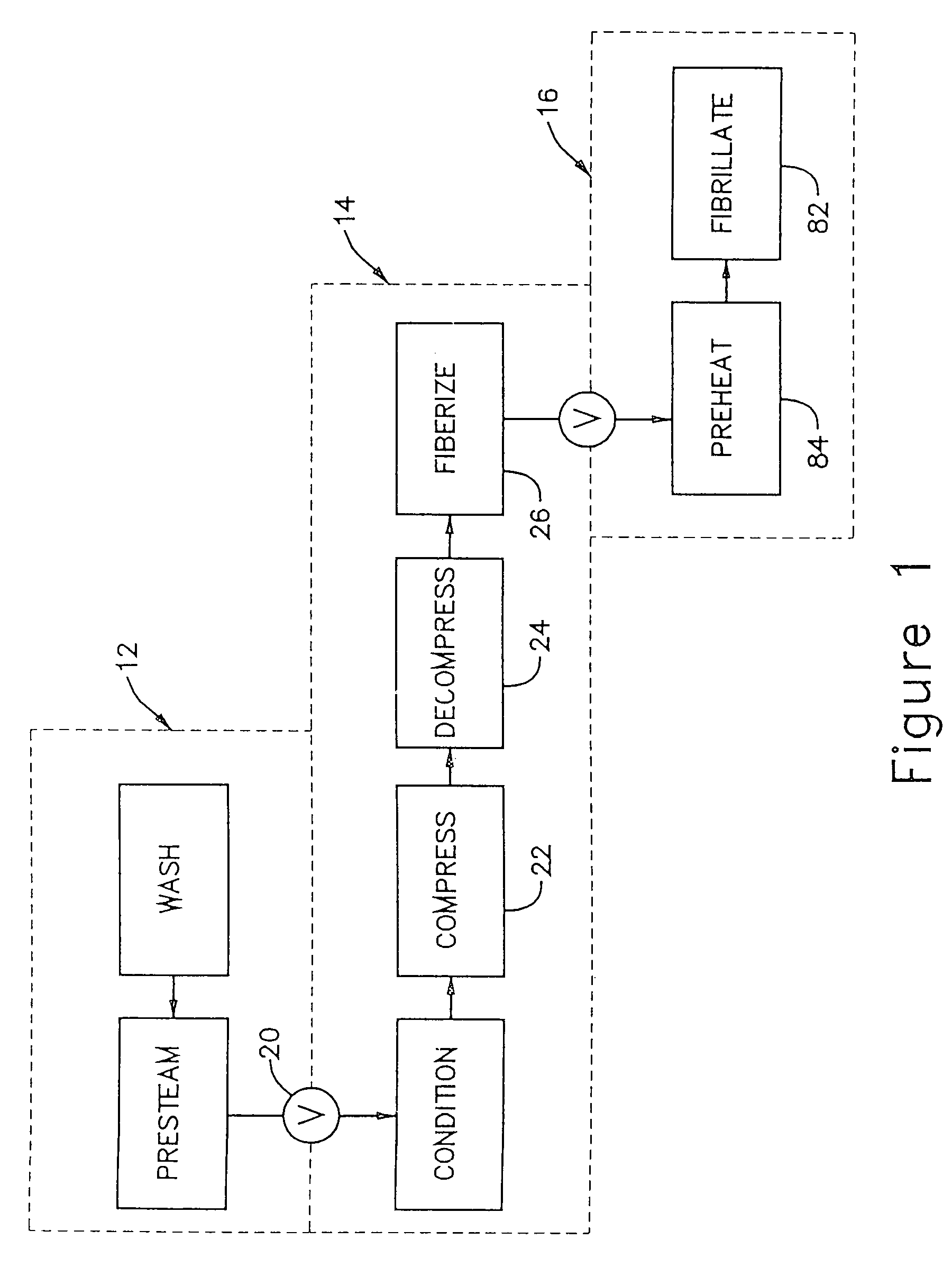

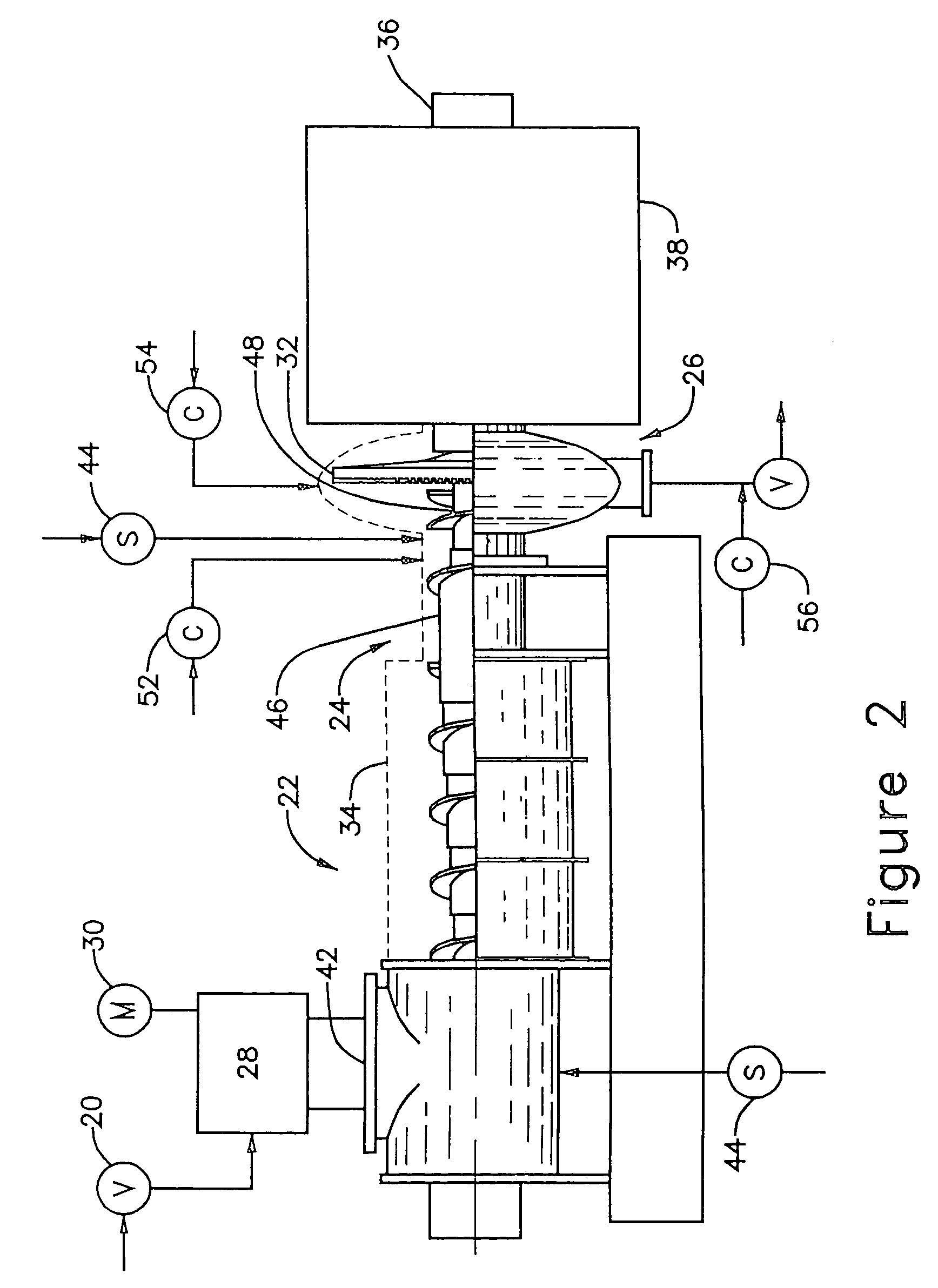

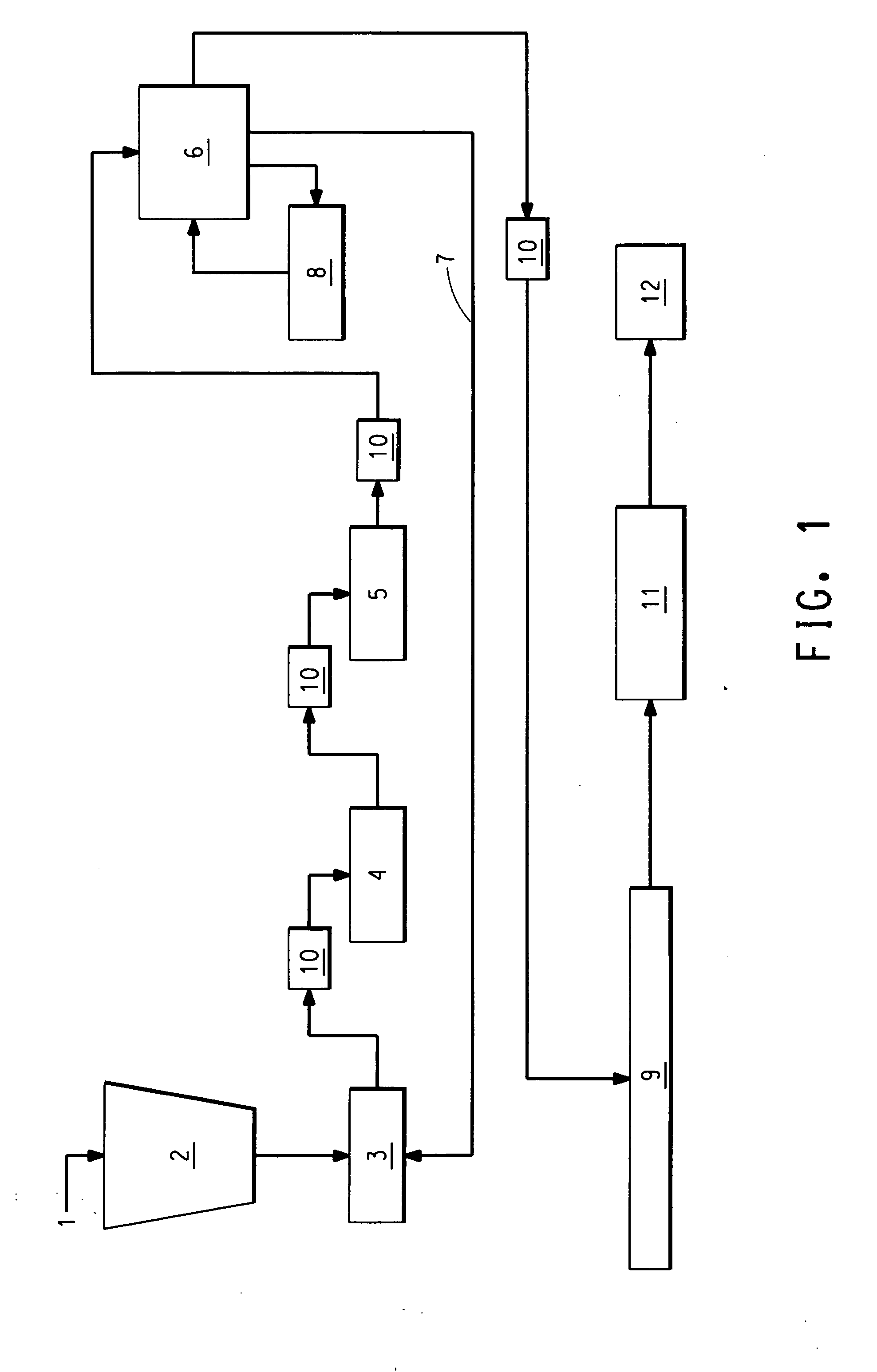

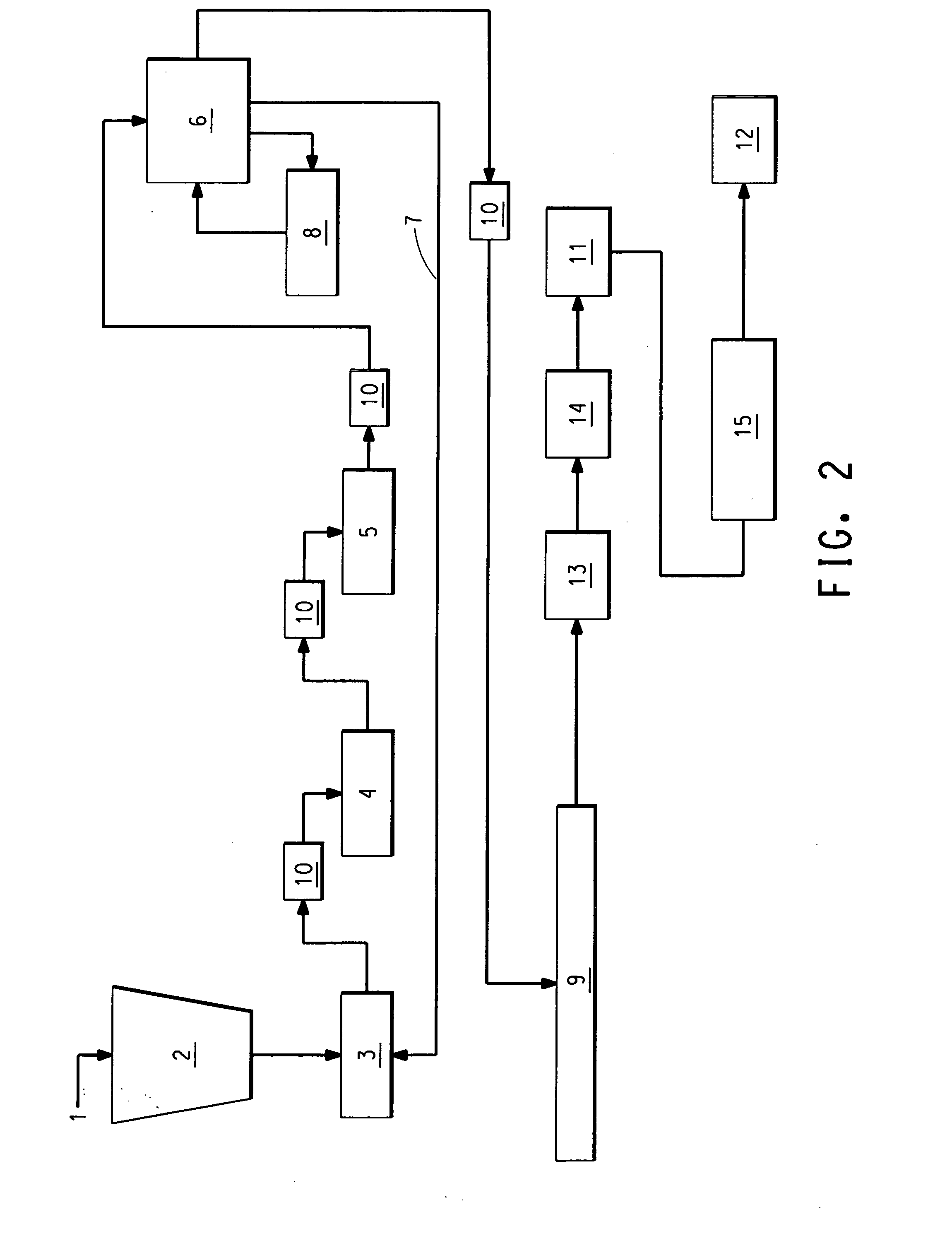

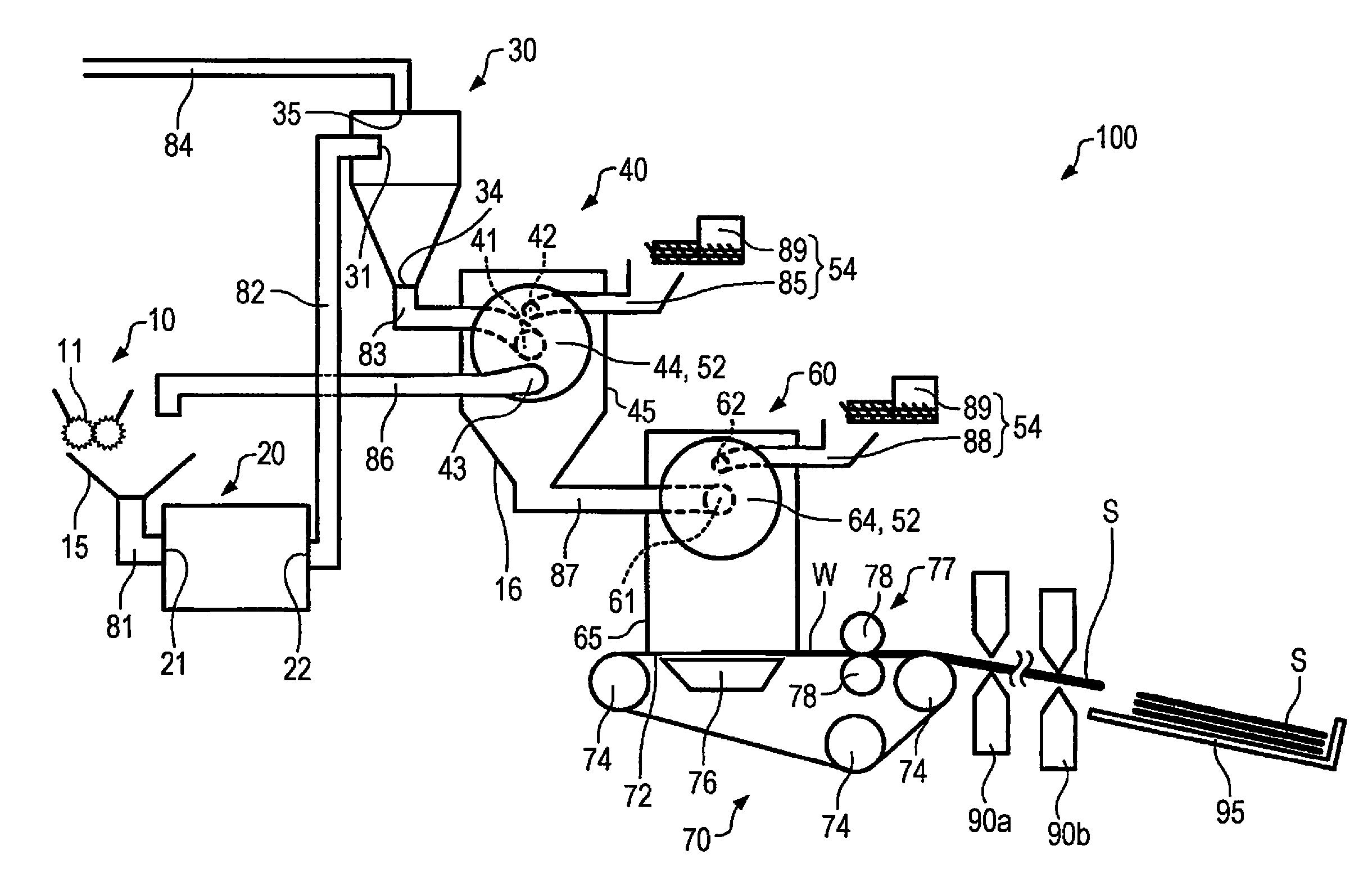

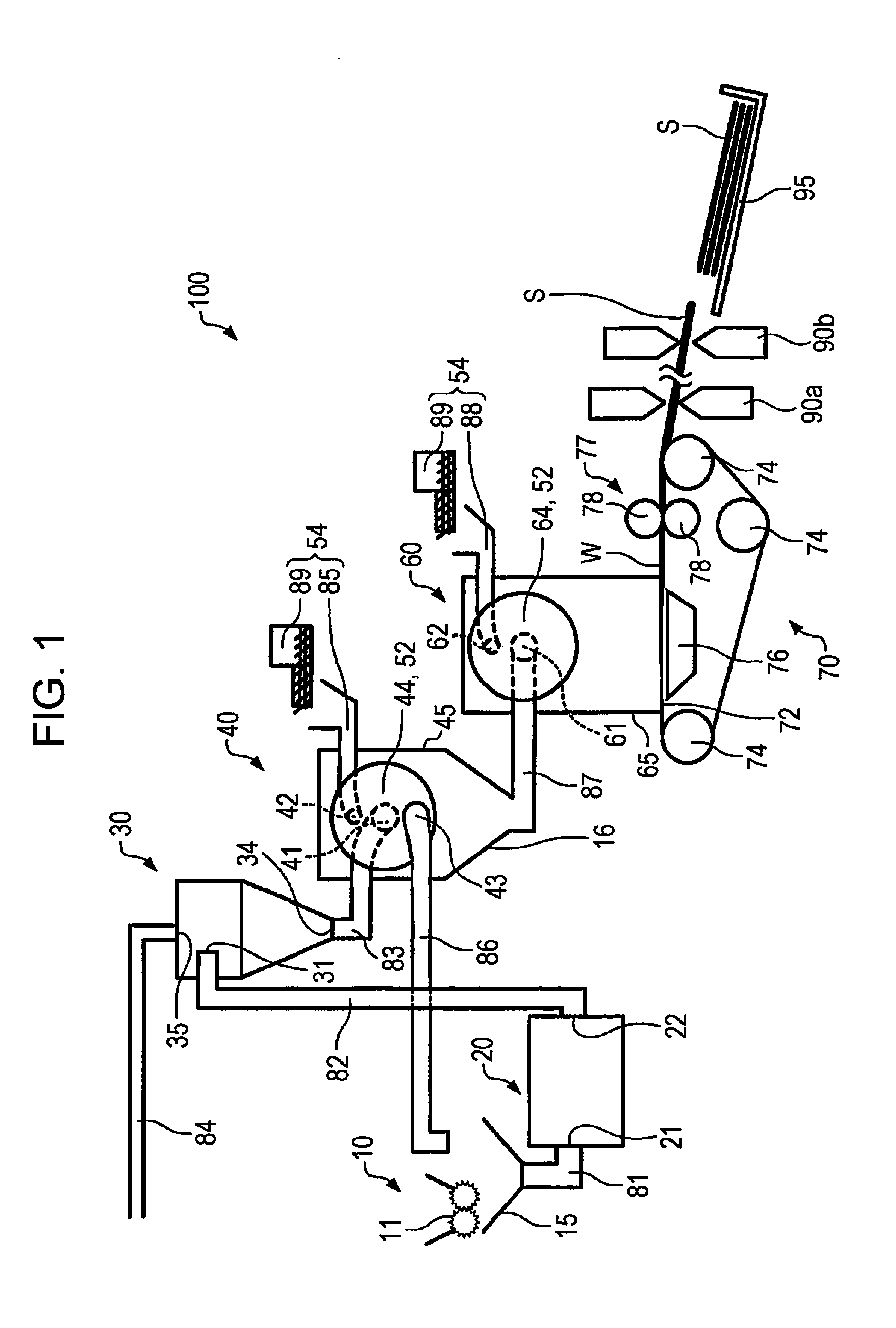

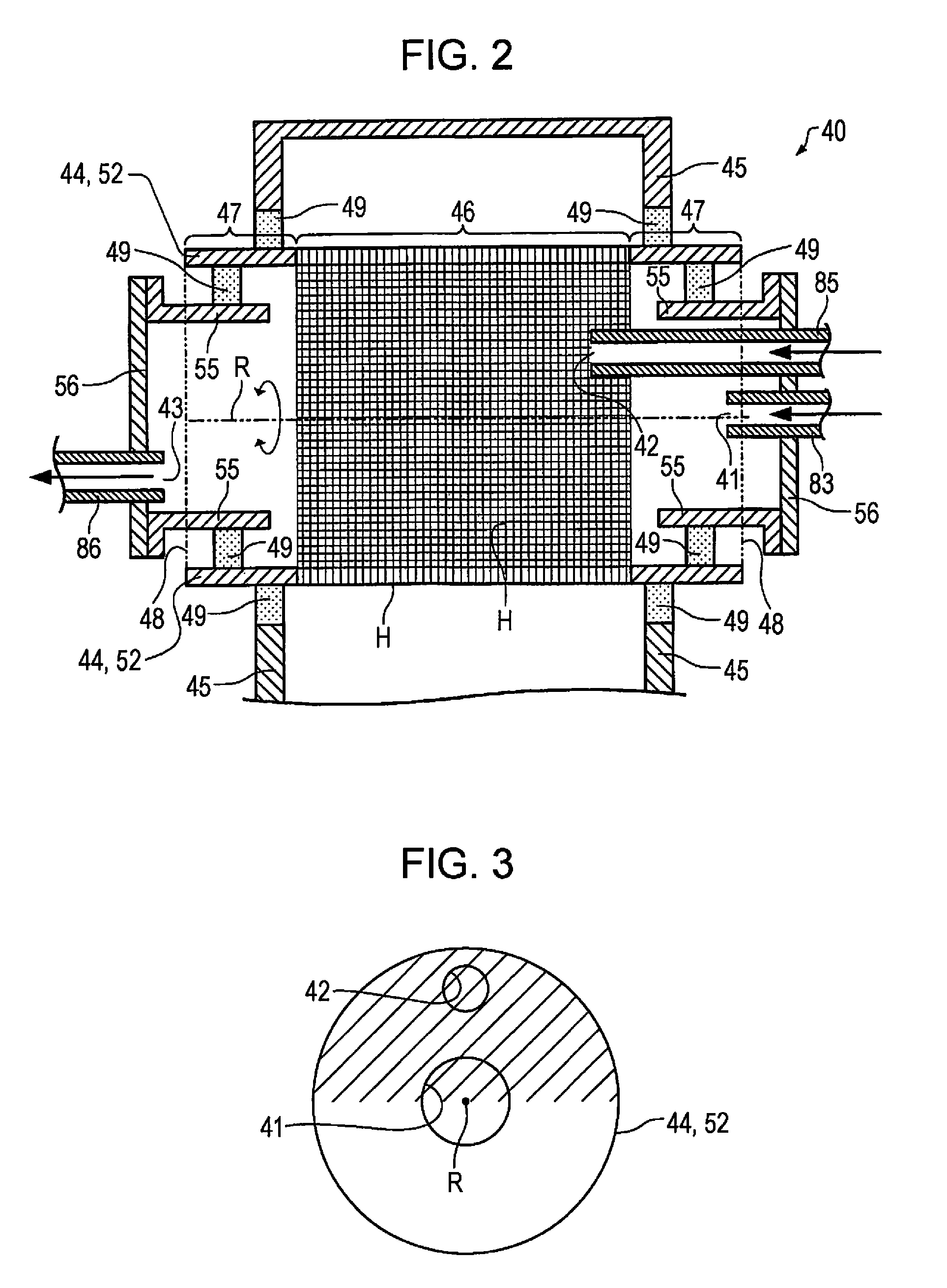

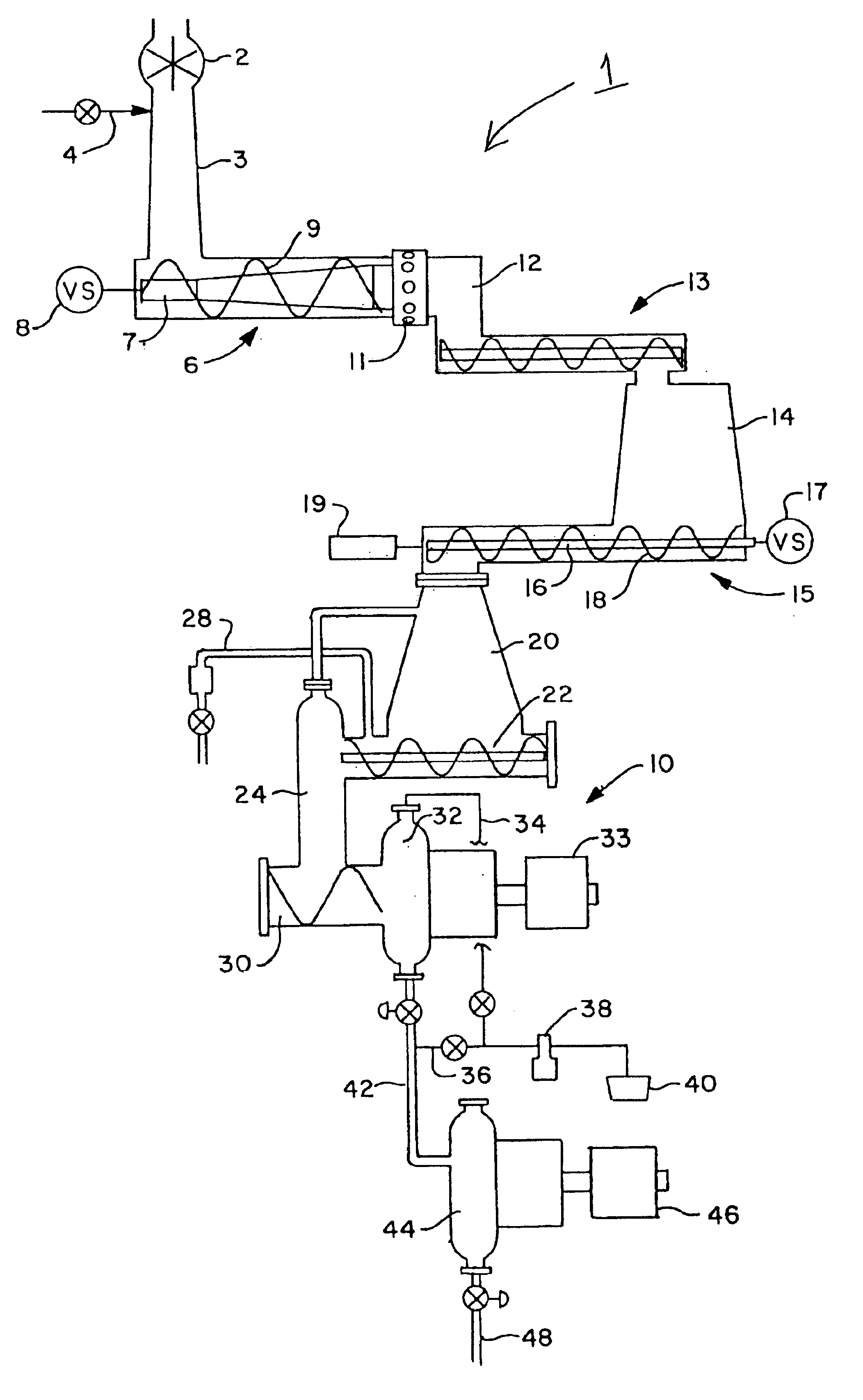

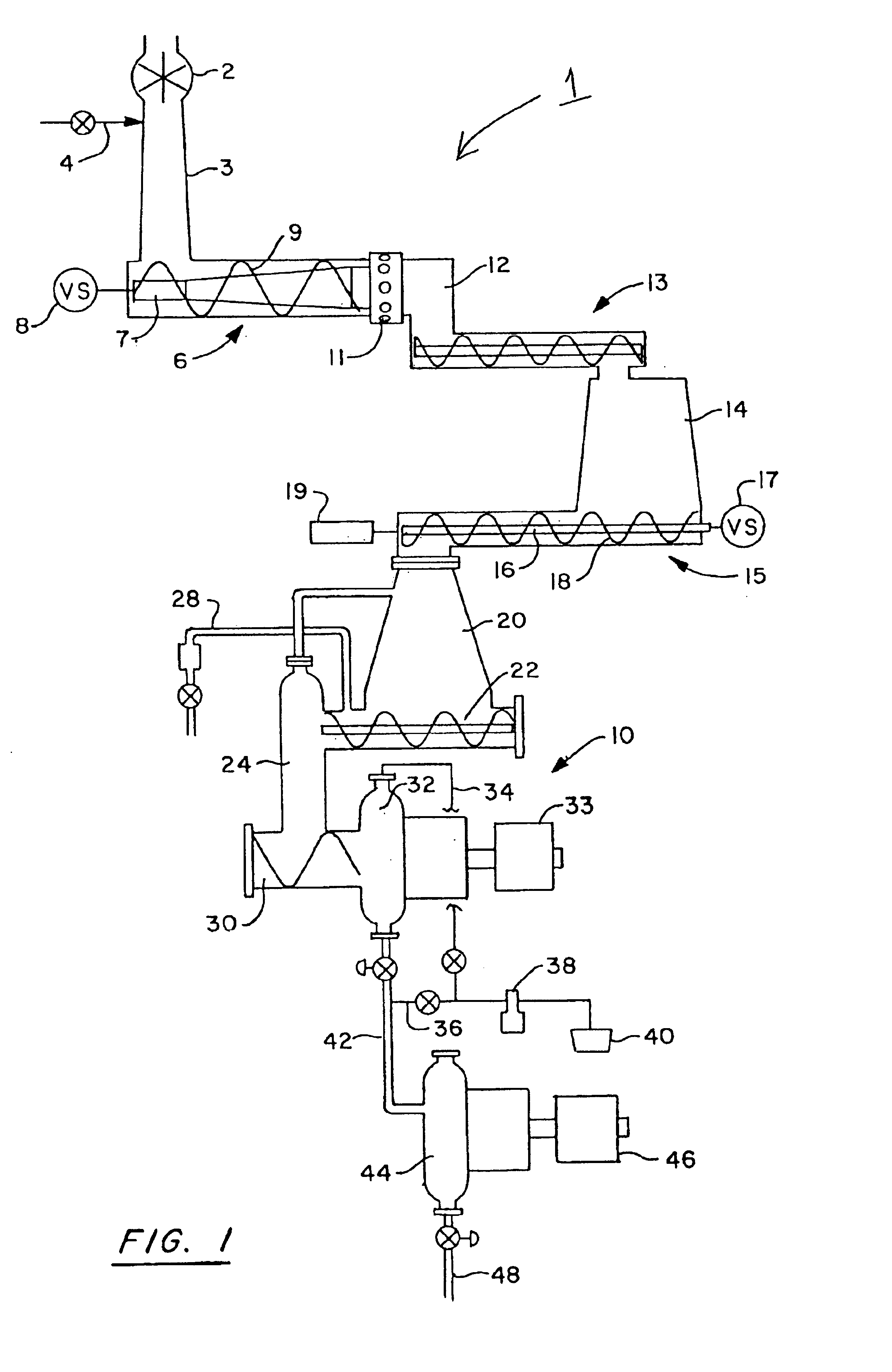

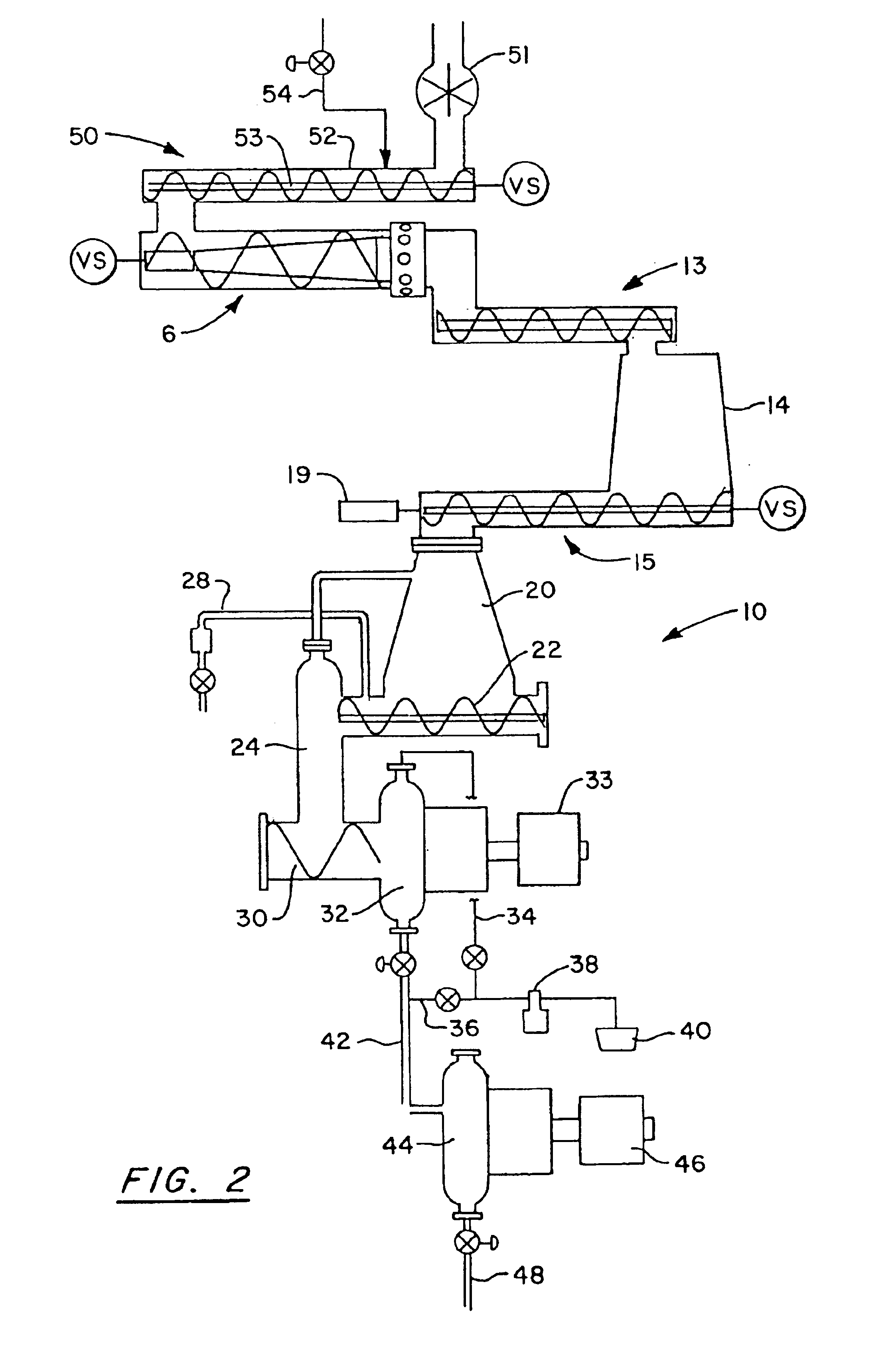

Energy efficient TMP refining of destructured chips

InactiveUS20060006264A1Quality improvementReduce energy consumptionCellulosic pulp after-treatmentPretreatment with water/steamFiberRing pattern

A system and method for thermomechanical refining of wood chips comprises preparing the chips for refining by exposing the chips to an environment of steam to soften the chips, compressively destructuring and dewatering the softened chips to a solids consistency above 55 percent, and diluting the destructured and dewatered chips to a consistency in the range of about 30 to 55 percent. The destructuring partially defibrates the material. This diluted material is fed to a rotating disc primary refiner wherein each of the opposed discs has an inner ring pattern of bars and grooves and an outer ring pattern of bars and grooves. The destructured and partially defibrated chips are substantially completely defibrated in the inner ring and the resulting fibers are fibrillated in the outer ring. The compressive destructuring, dewatering, and dilution can all be implemented in one integrated piece of equipment immediately upstream of the primary refiner, and the fiberizing and fibrillating are both achieved between only one set of relatively rotating discs in the primary refiner.

Owner:ANDRITZ INC

High aspect ratio cellulose nanofilaments and method for their production

ActiveUS9051684B2Improve consistencyImprove scalabilityFinely-divided cellulose conservationReed/straw treatmentMicrometerPaperboard

Owner:FPINNOVATIONS INC

High defiberization chip pretreatment

ActiveUS7300541B2Reduce energy consumptionGood removal effectCellulosic pulp after-treatmentPretreatment with water/steamChemical treatmentFiber bundle

A chip pretreatment process which comprises conveying the feed material through a compression screw device having an atmosphere of saturated steam at a pressure above about 5 psig, decompressing and discharging the compressed material from the screw device into a decompression region, feeding the decompressed material from the decompression region into a fiberizing device, such as a low intensity disc refiner, where at least about 30 percent of the fiber bundles and fibers are axially separated, without substantial fibrillation of the fibers. Preferably, the fibers are axially separated with less than about 5 percent fibrillation, and subsequently the fiberized material is refined in a high intensity disc refiner until at least about 90 percent of the fibers are fibrillated. In another form the invention combines chip fiberizing with chemical treatments, for improving the pulp property versus energy relationships.

Owner:ANDRITZ INC

Para-aramid pulp including meta-aramid fibrids and processes of making same

Owner:DUPONT SAFETY & CONSTR INC

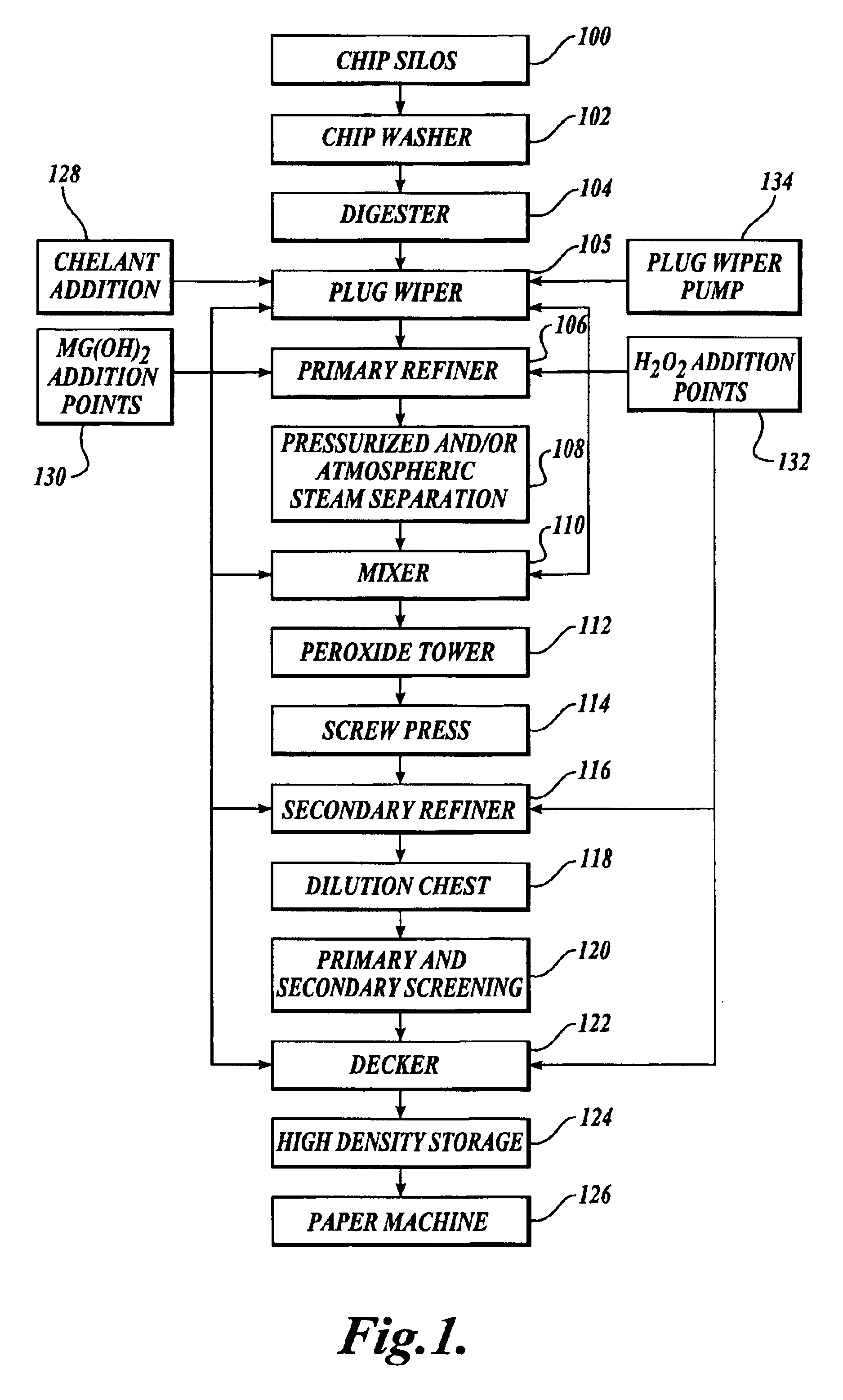

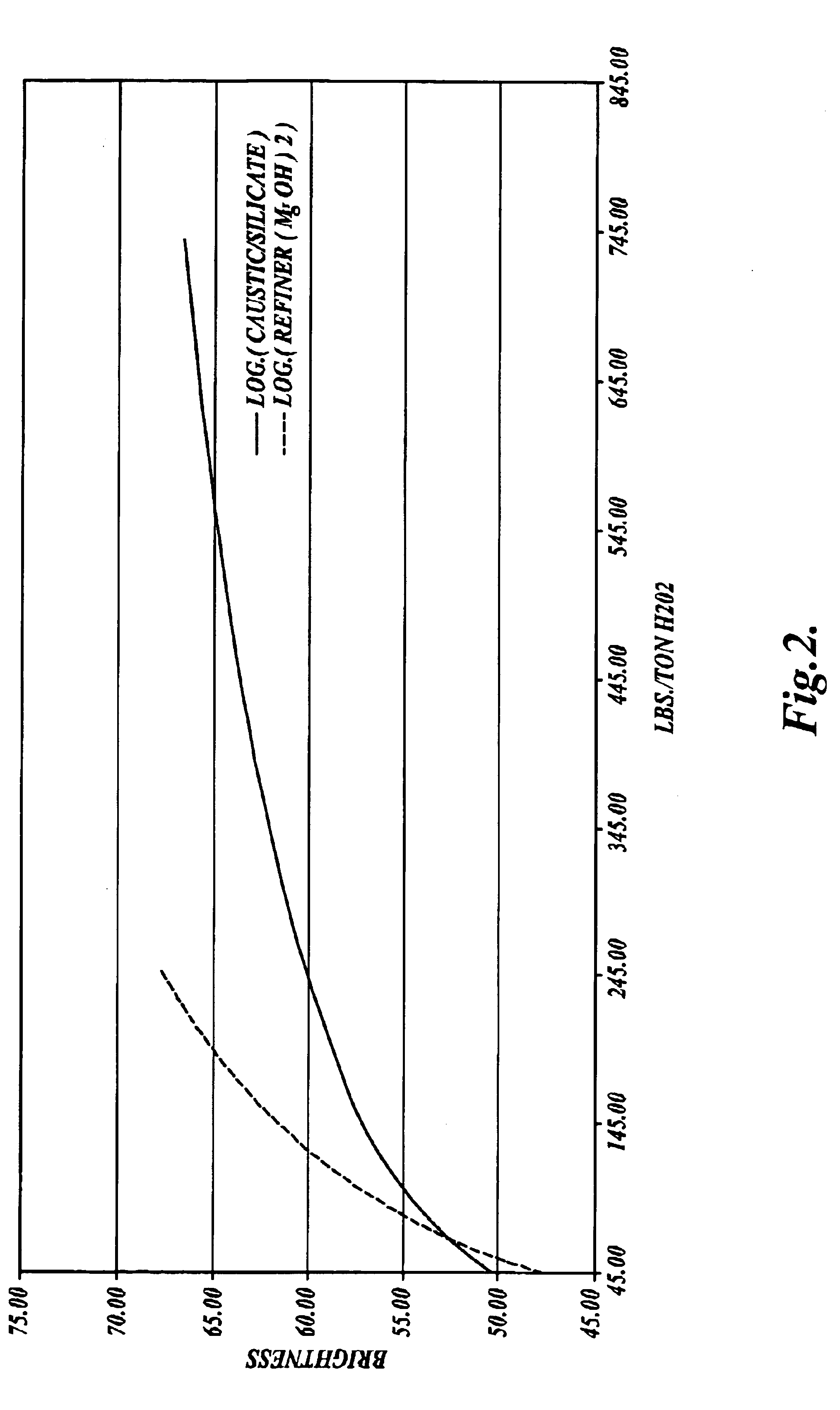

Refiner bleaching with magnesium oxide and hydrogen peroxide

InactiveUS6881299B2Eliminate useHigh retention rateFats/resins/pitch/waxes removal in pulpPulp de-wateringParticulatesMagnesium ion

Methods of bleaching mechanical pulp under alkaline conditions with hydrogen peroxide. The methods include introducing a source of magnesium ions and hydroxyl ions to a refiner. The wood particulates are refined into a pulp in the presence of the magnesium ions and hydroxyl ions, and optionally perhydroxyl ions to simultaneously refine and bleach the pulp in a refiner.

Owner:NORTH PACIFIC PAPER

Sheet manufacturing apparatus

ActiveUS20150275430A1Excellently mixImprove uniformityPaper/cardboardPulp beating/refining methodsFiberManufactured apparatus

Owner:SEIKO EPSON CORP

Cellulose nanofibers

ActiveUS20120277351A1Excellent water filtering propertyIncrease shear rateCellulosic pulp after-treatmentDigestersFiberCellulose

The present invention provides a novel production method of a cellulose nanofiber and a novel cellulose nanofiber.A method for producing a cellulose nanofiber comprising defibrating pulp by a single- or multi-screw kneader in the presence of water, the single or multi-screw kneader having a screw circumferential speed of 45 m / min. or more.

Owner:MITSUBISHI CHEM CORP +3

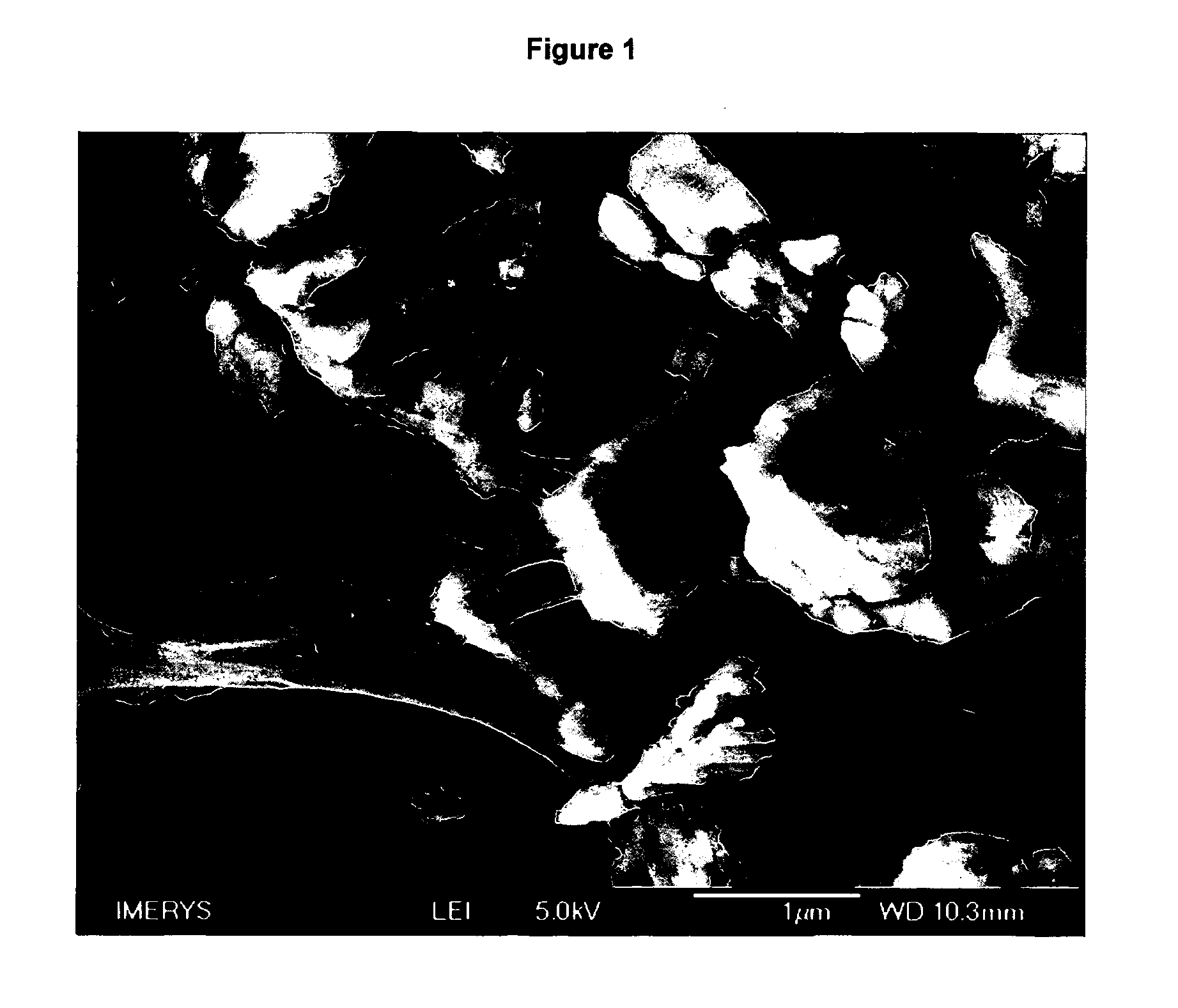

Paper filler composition

A method for preparing an aqueous suspension comprising microfibrillated cellulose and inorganic particulate material, the method comprising a step of microfibrillating a fibrous substrate comprising cellulose in an aqueous environment in the presence of an inorganic particulate material.

Owner:FIBERLEAN TECH LTD

Method of pretreating lignocellulose fiber-containing material in a pulp refining process

InactiveUS6899791B2Improvement in pulp strength property and shive content of pulpHigh strengthPretreatment with water/steamPulp beating/refining methodsCellulose fiberDigestion

A method and apparatus for pretreating or conditioning lignocellulose fiber containing feed material in preparation for conversion to pulp. Wood chips are pretreated under conditions of elevated temperature, pressure and humidity and subsequently compressed to cause destructuring of the fibers of the feed material. The pretreated wood chips are then converted to pulp using such methods as the ground wood pulping process or chemical digestion process.

Owner:ANDRITZ INC

Process for increasing the refiner production rate and/or decreasing the specific energy of pulping wood

InactiveUS20050133643A1Pose health riskIncrease ratingsPaper recyclingReed/straw treatmentProduction rateEngineering

The present invention relates to processes for enhancing a refiner's production rate and / or reducing the specific energy consumption for a freeness target through the use of lubricant(s) or carrier(s) / frictionizer(s), respectively.

Owner:SOLENIS TECH CAYMAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com