Patents

Literature

353results about "Plant waste comminuting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

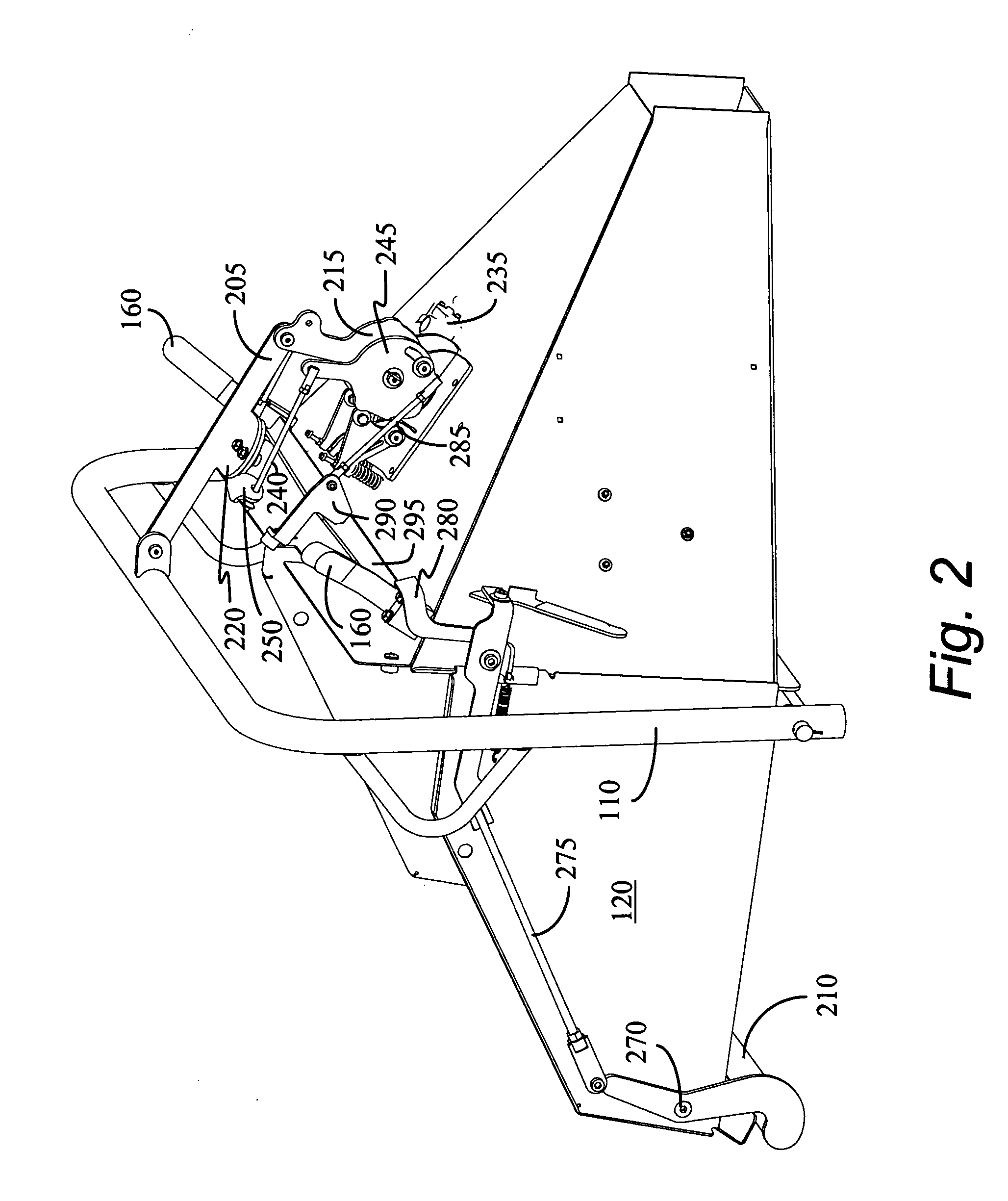

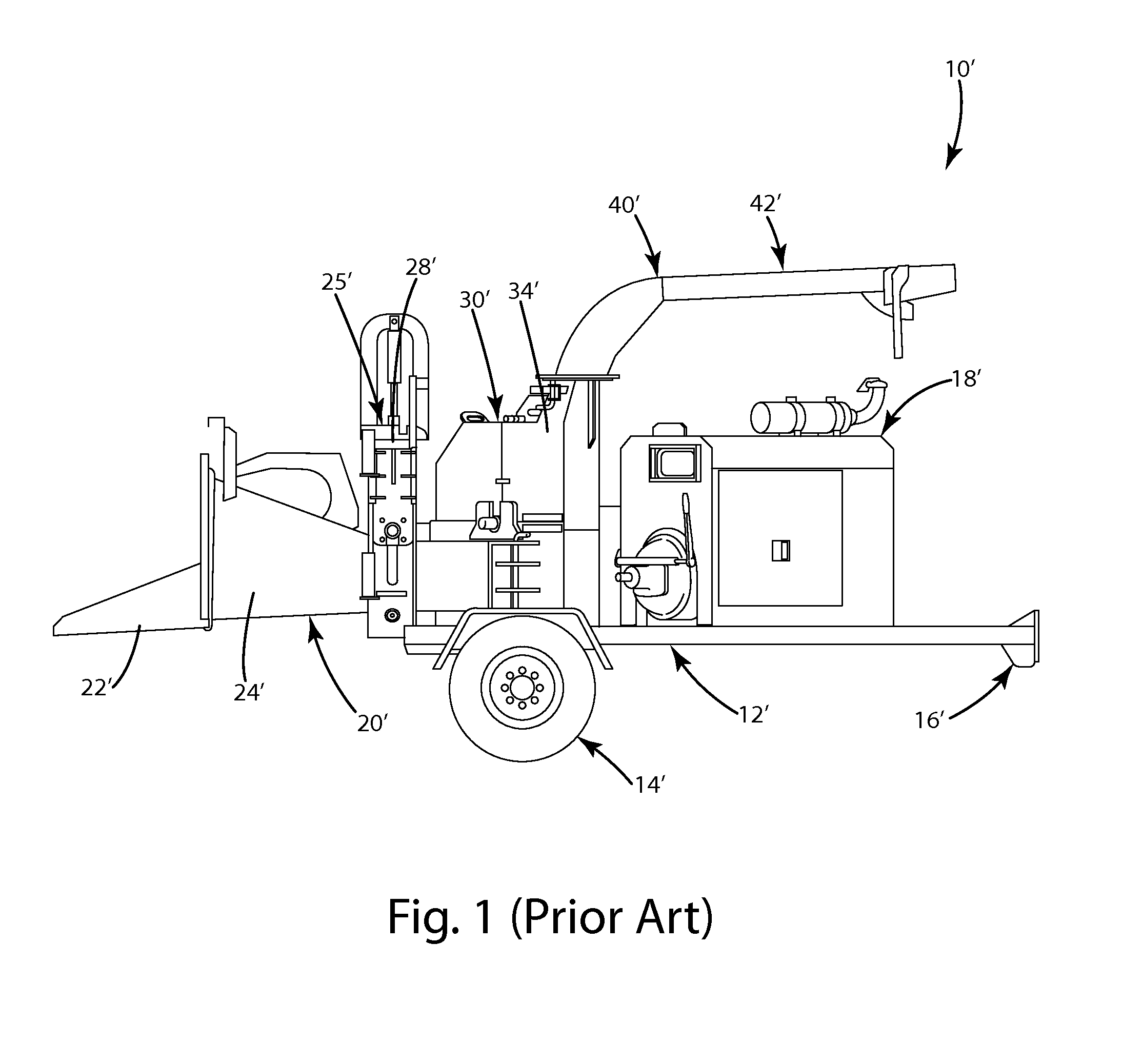

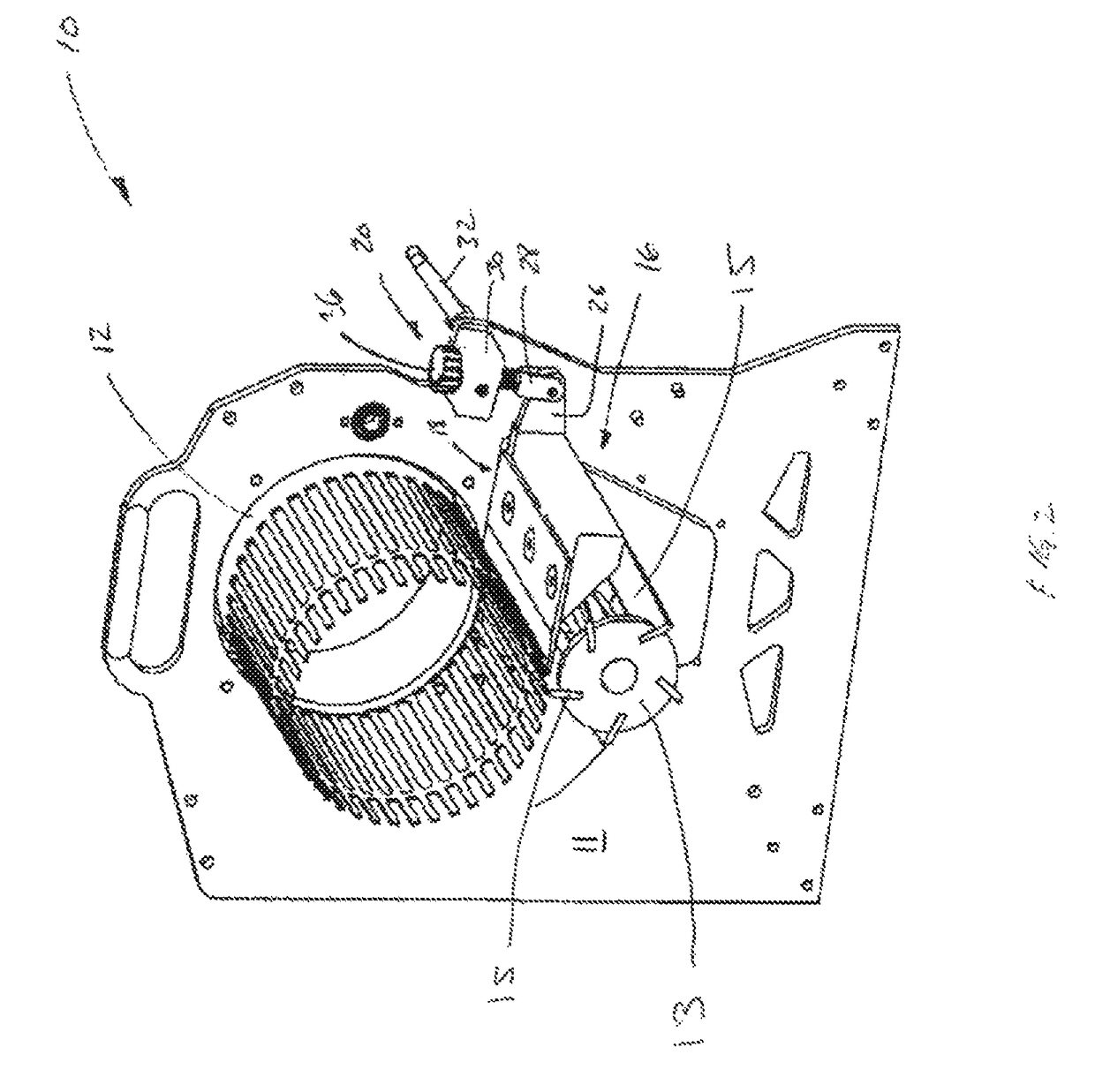

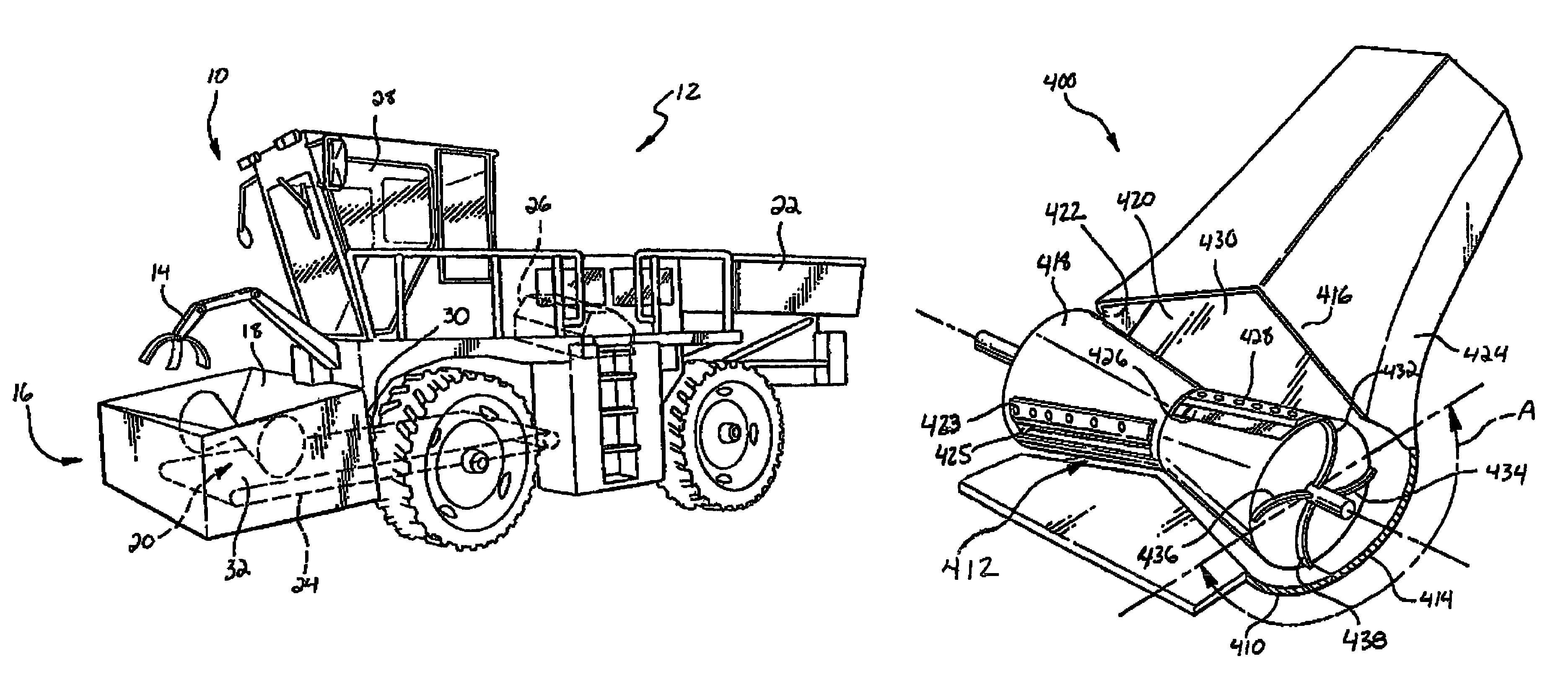

Reversing automatic feed wheel assembly for wood chipper

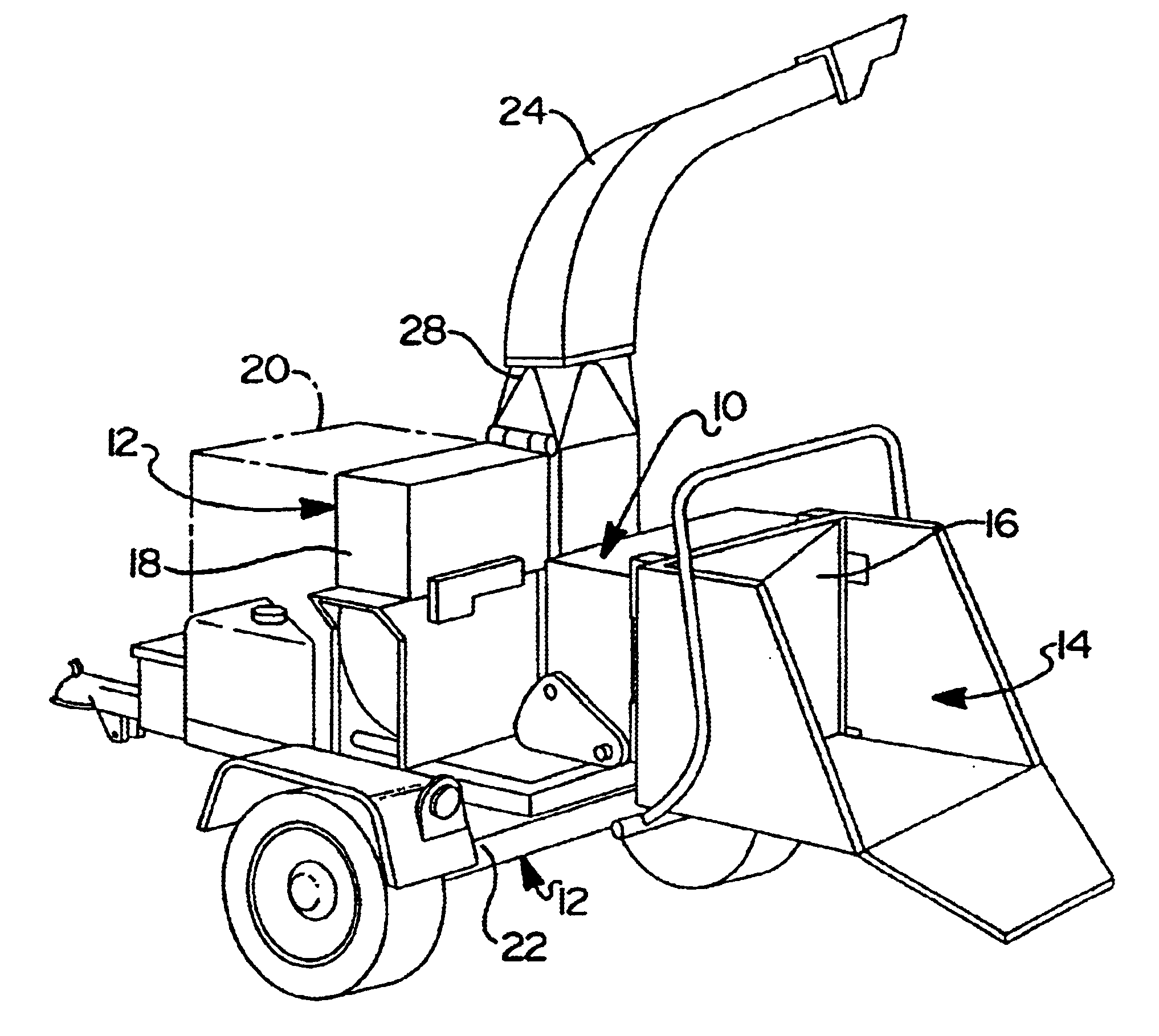

A reversing automatic feed wheel assembly for wood chipper includes an infeed assembly and a rotatable cutting assembly spaced from the infeed assembly. The reversing automatic feed wheel assembly also includes at least one feed wheel disposed between the infeed assembly and the cutting assembly to feed wood material to the cutting assembly. The reversing automatic feed wheel assembly further includes a control system operatively connected to the at least one feed wheel to automatically reverse / stop / restart the infeed of the wood material in response to a reduced speed or excessive load placed on the cutting assembly.

Owner:BANDIT IND

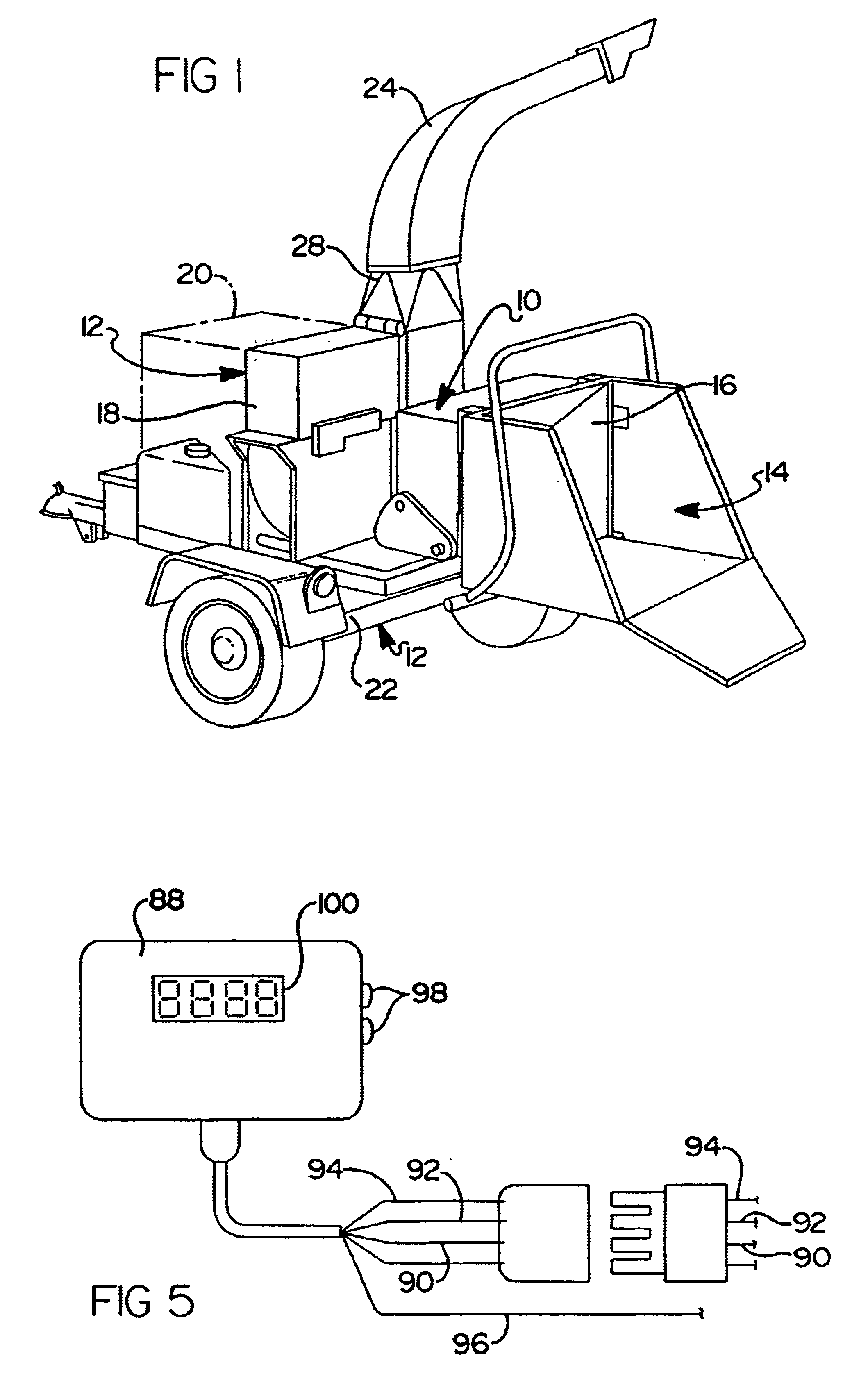

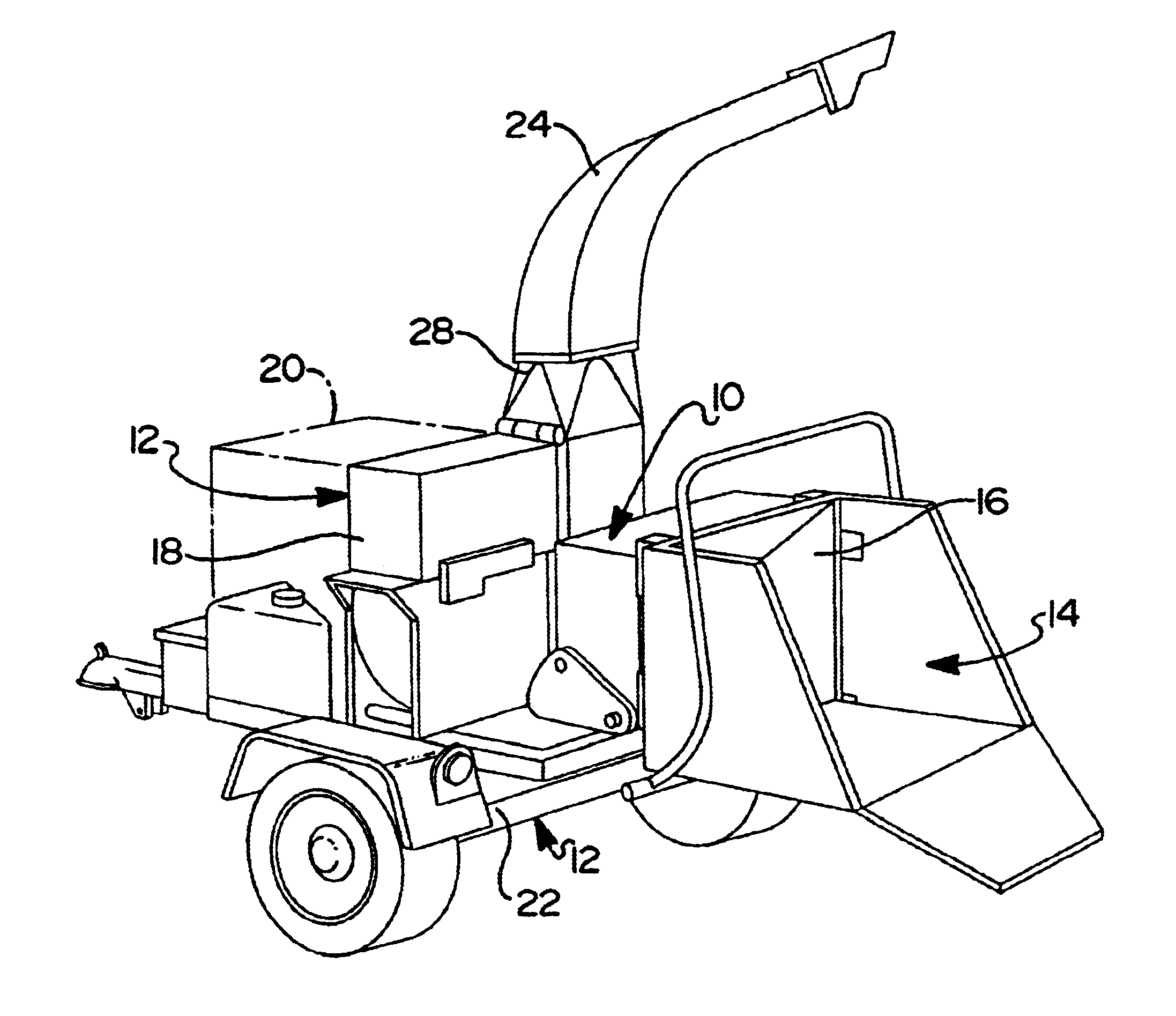

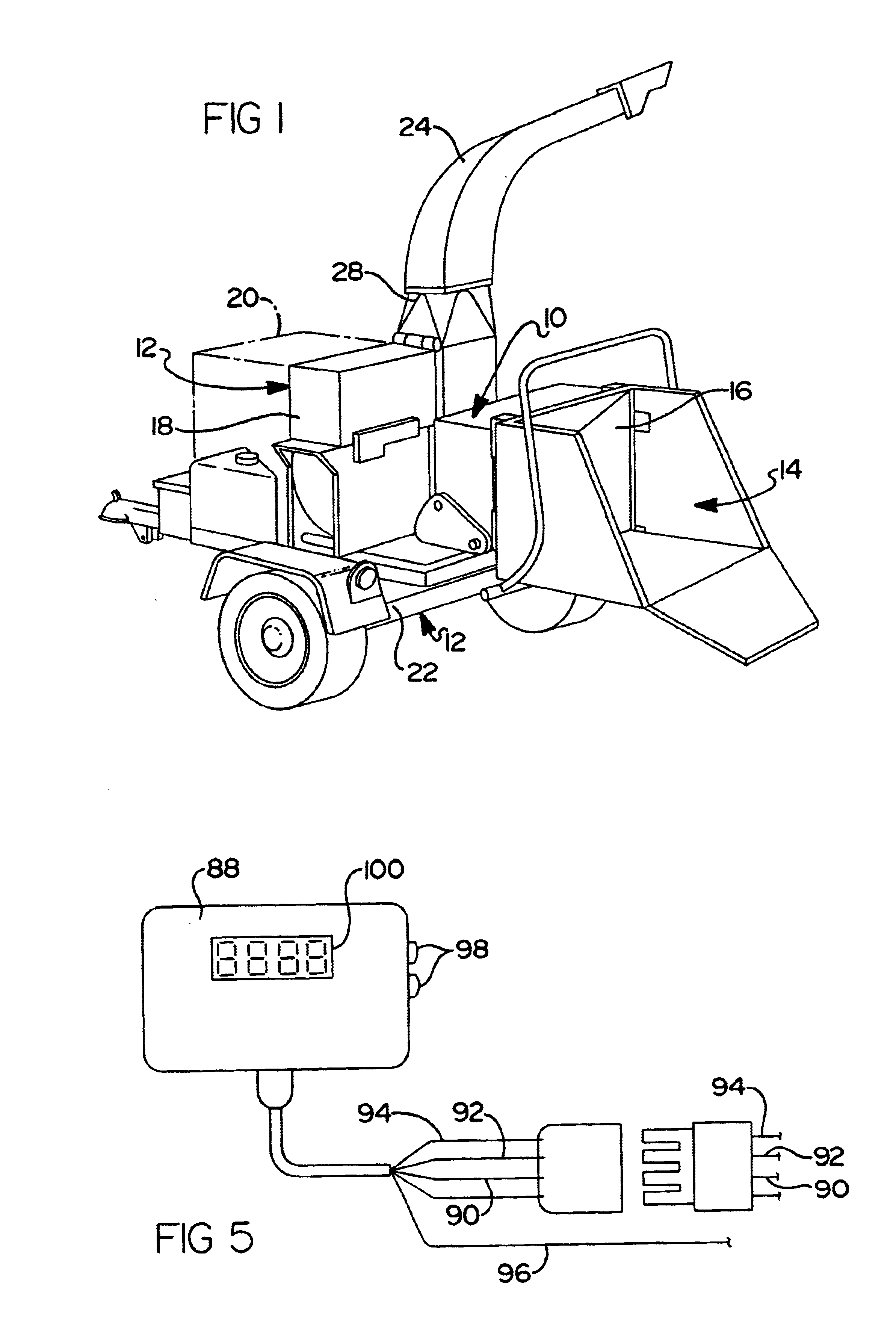

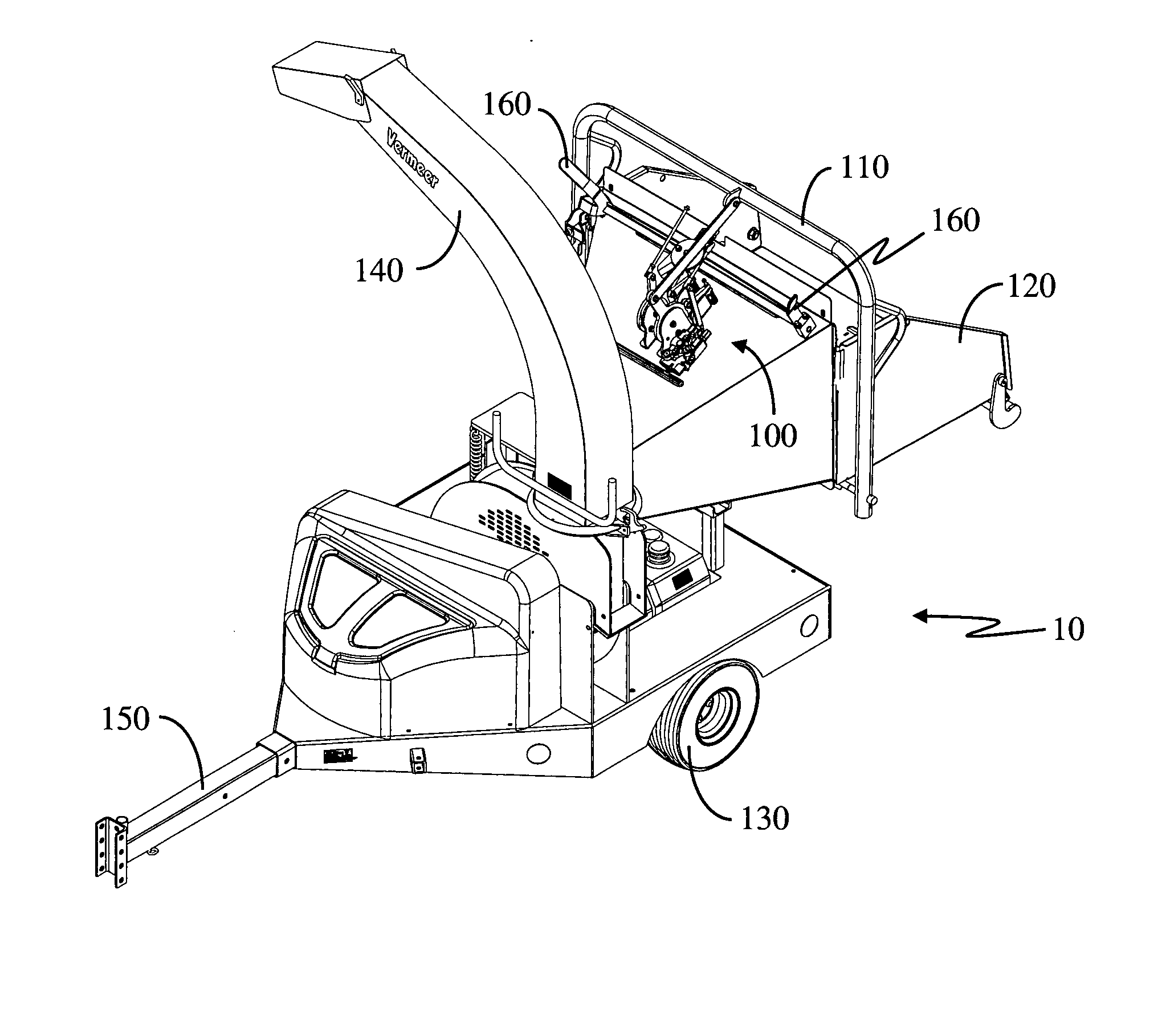

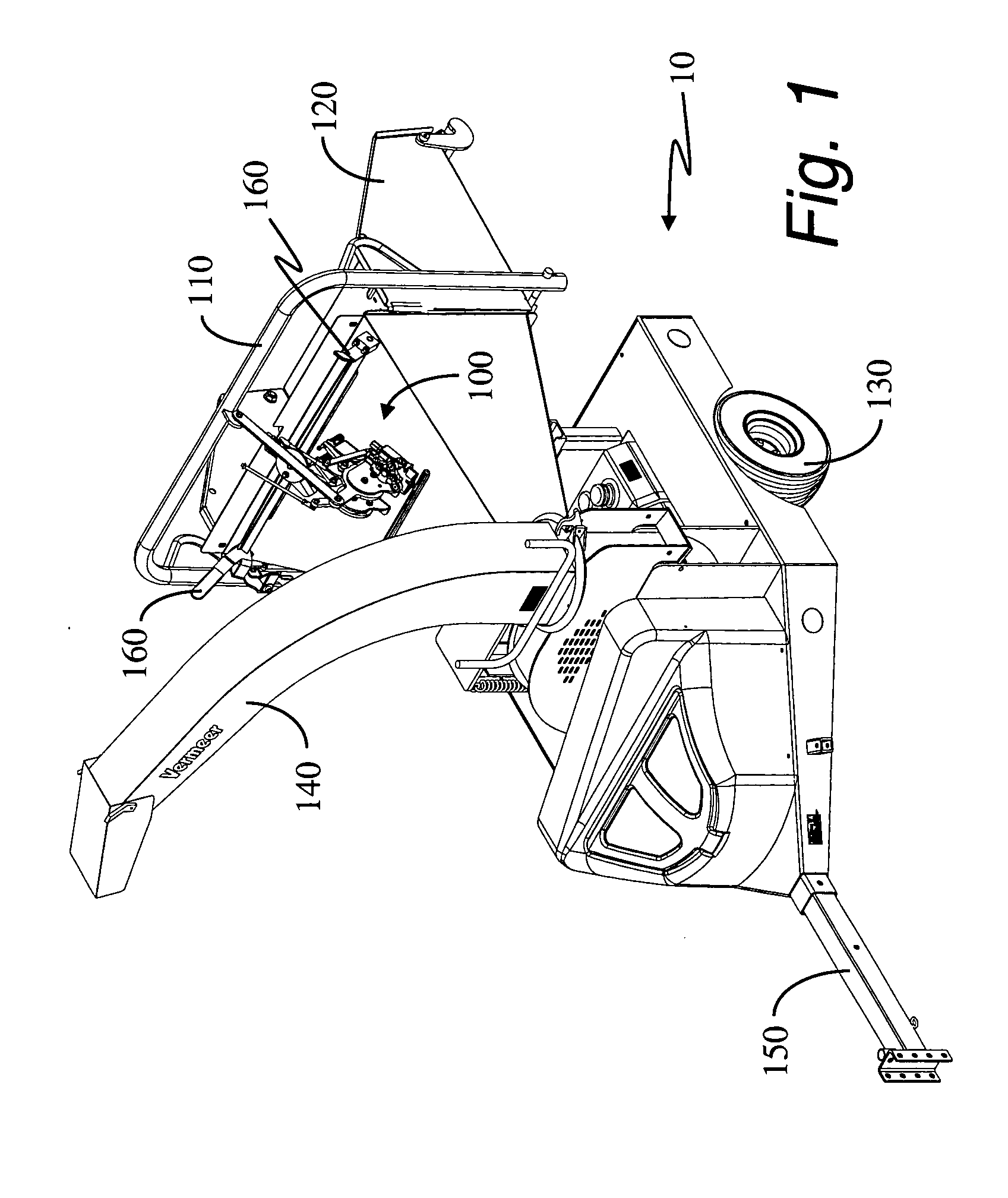

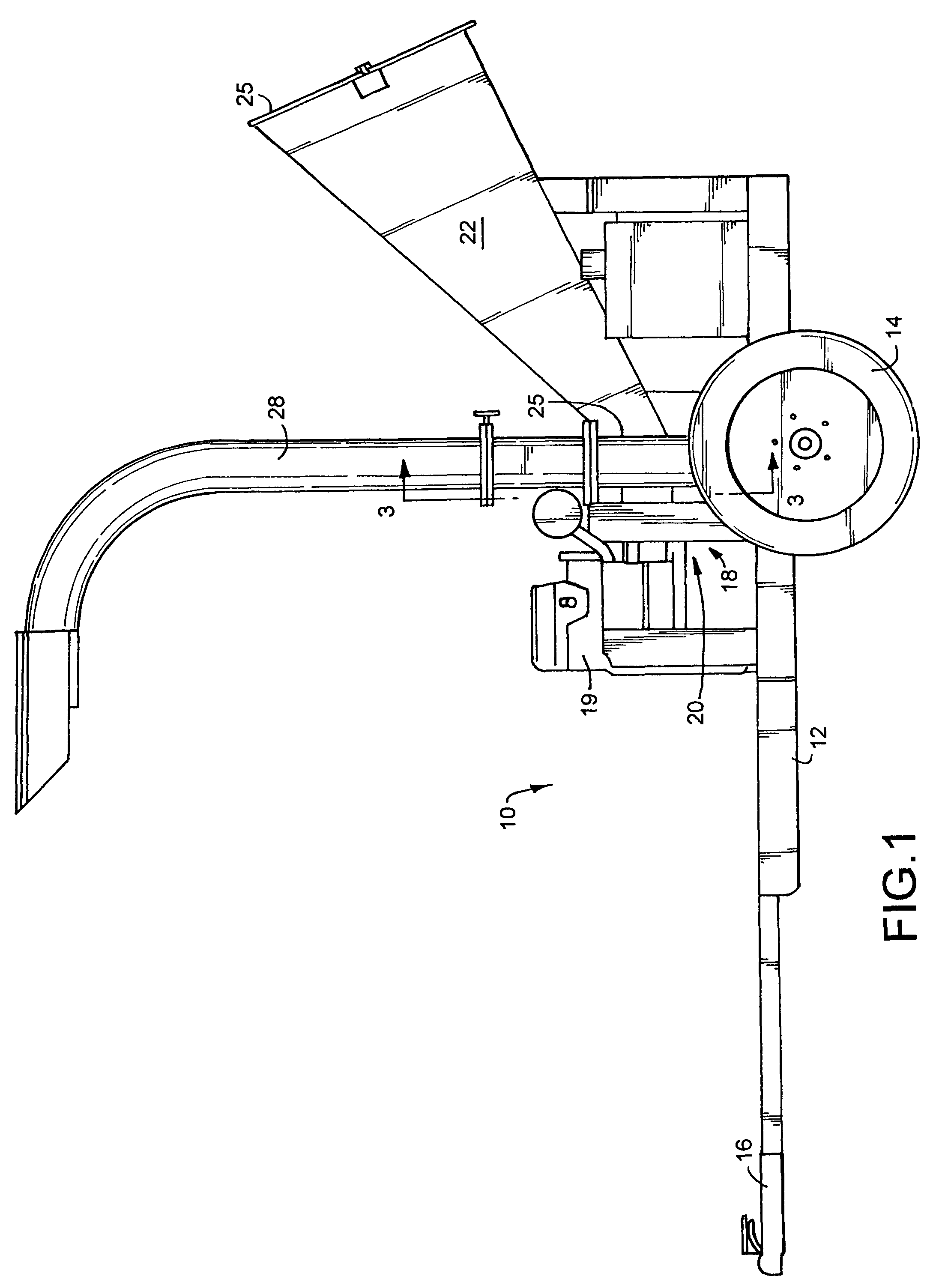

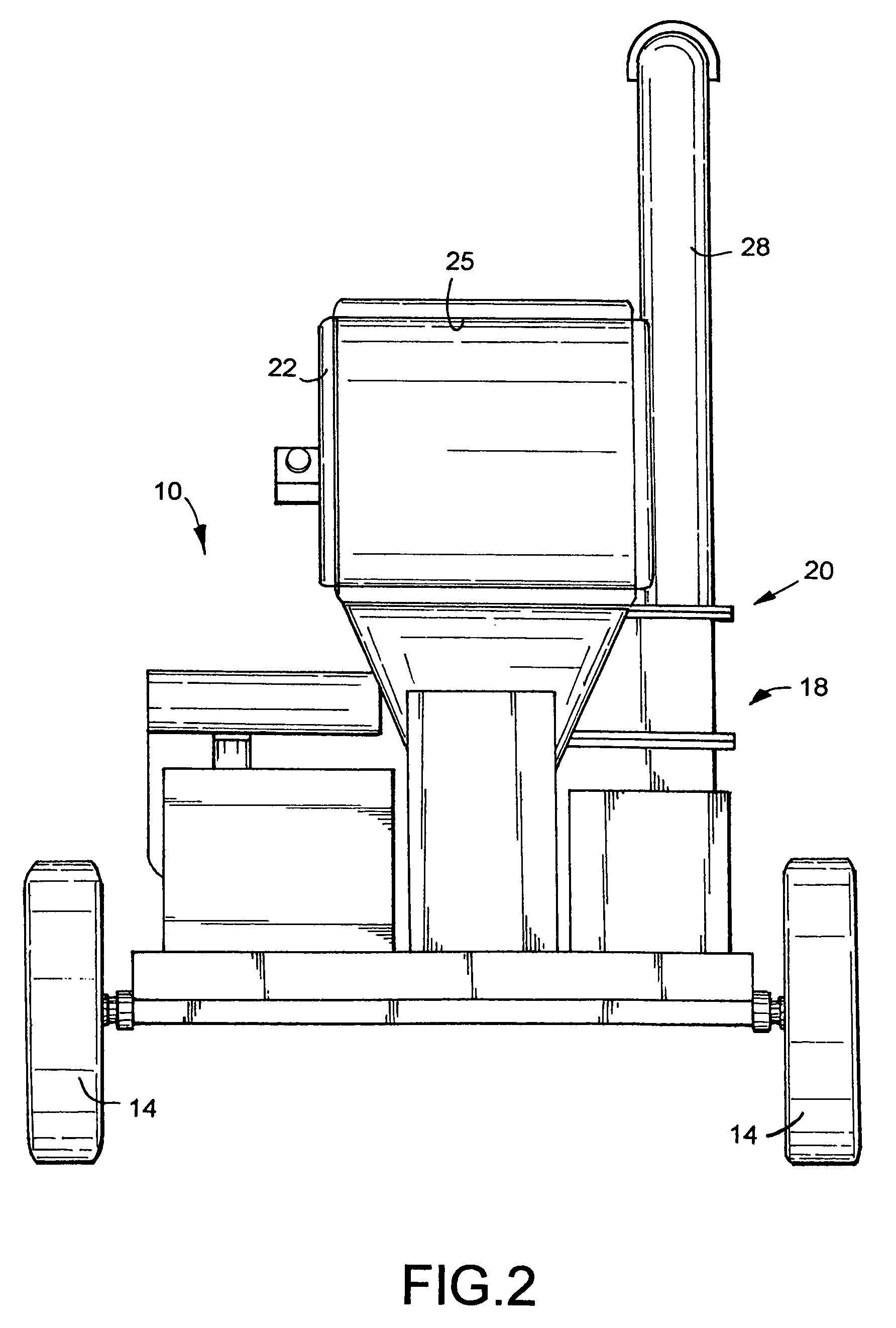

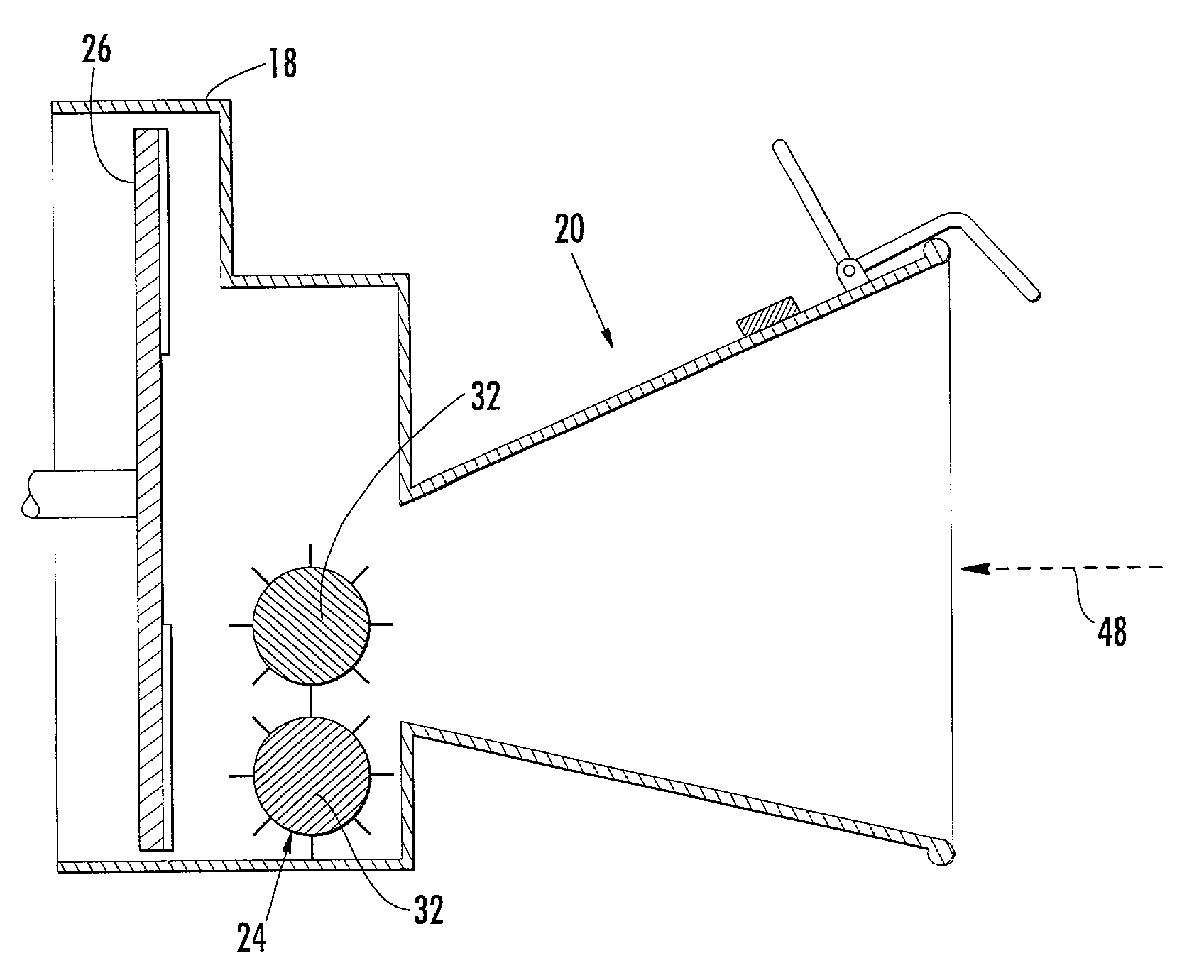

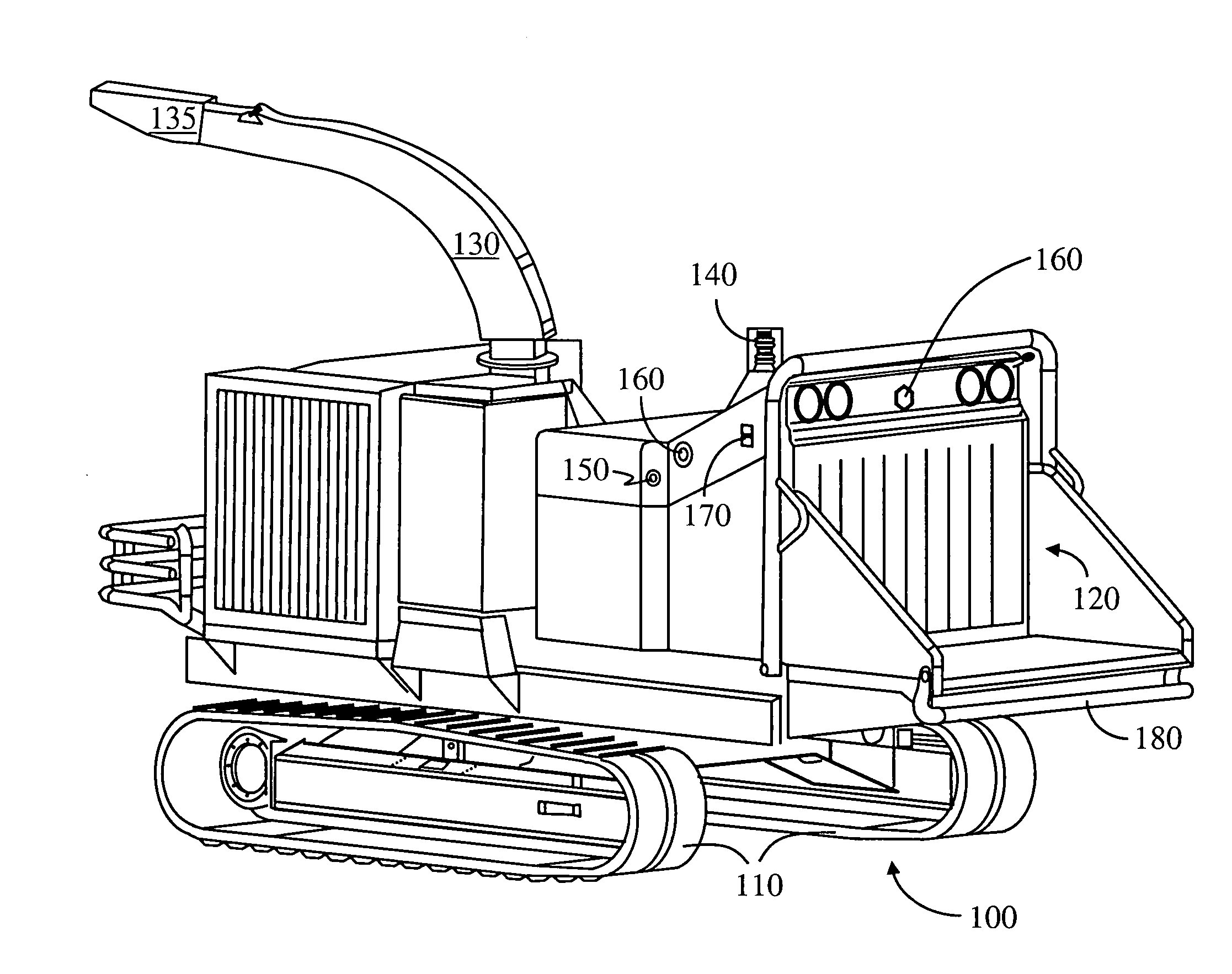

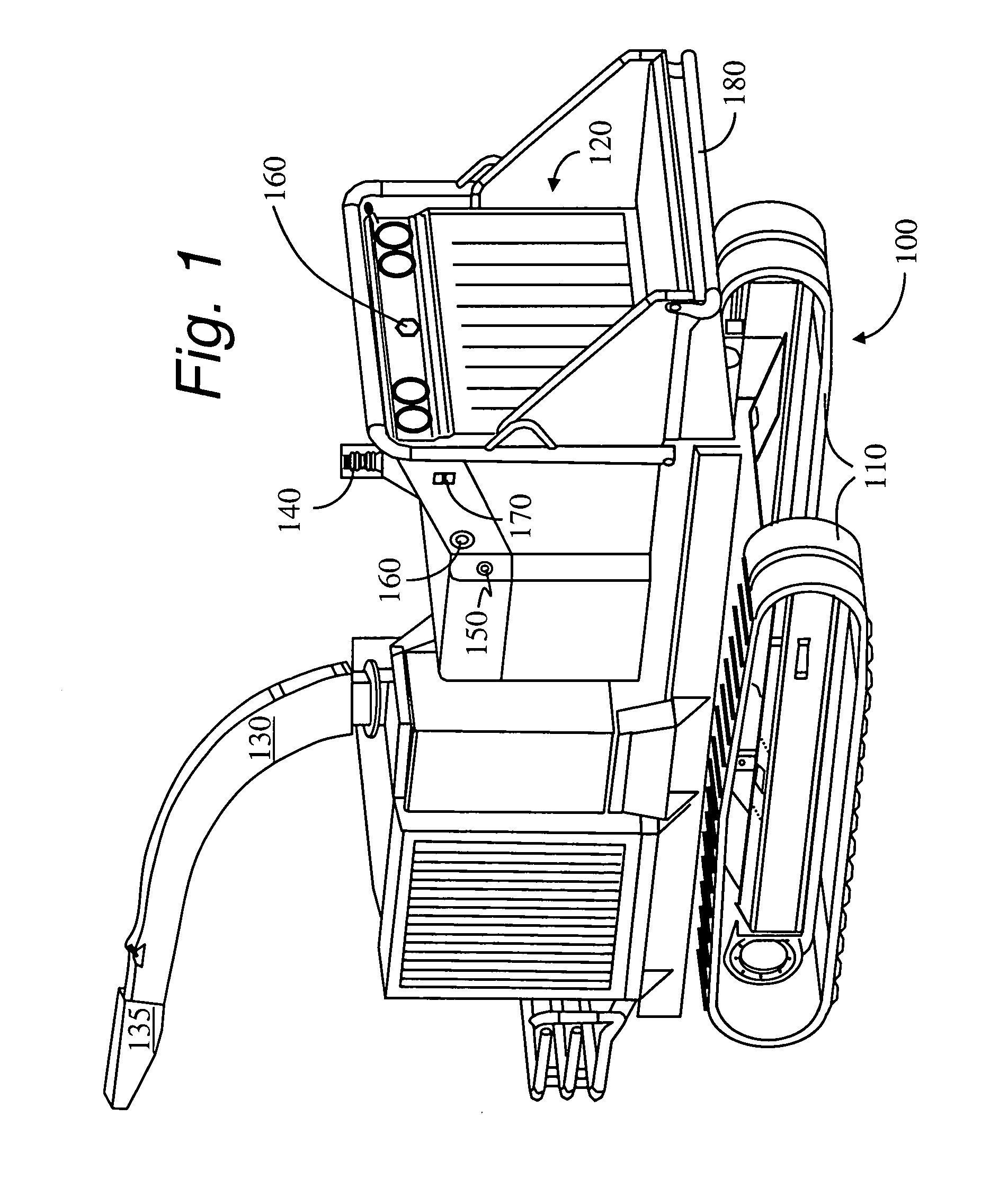

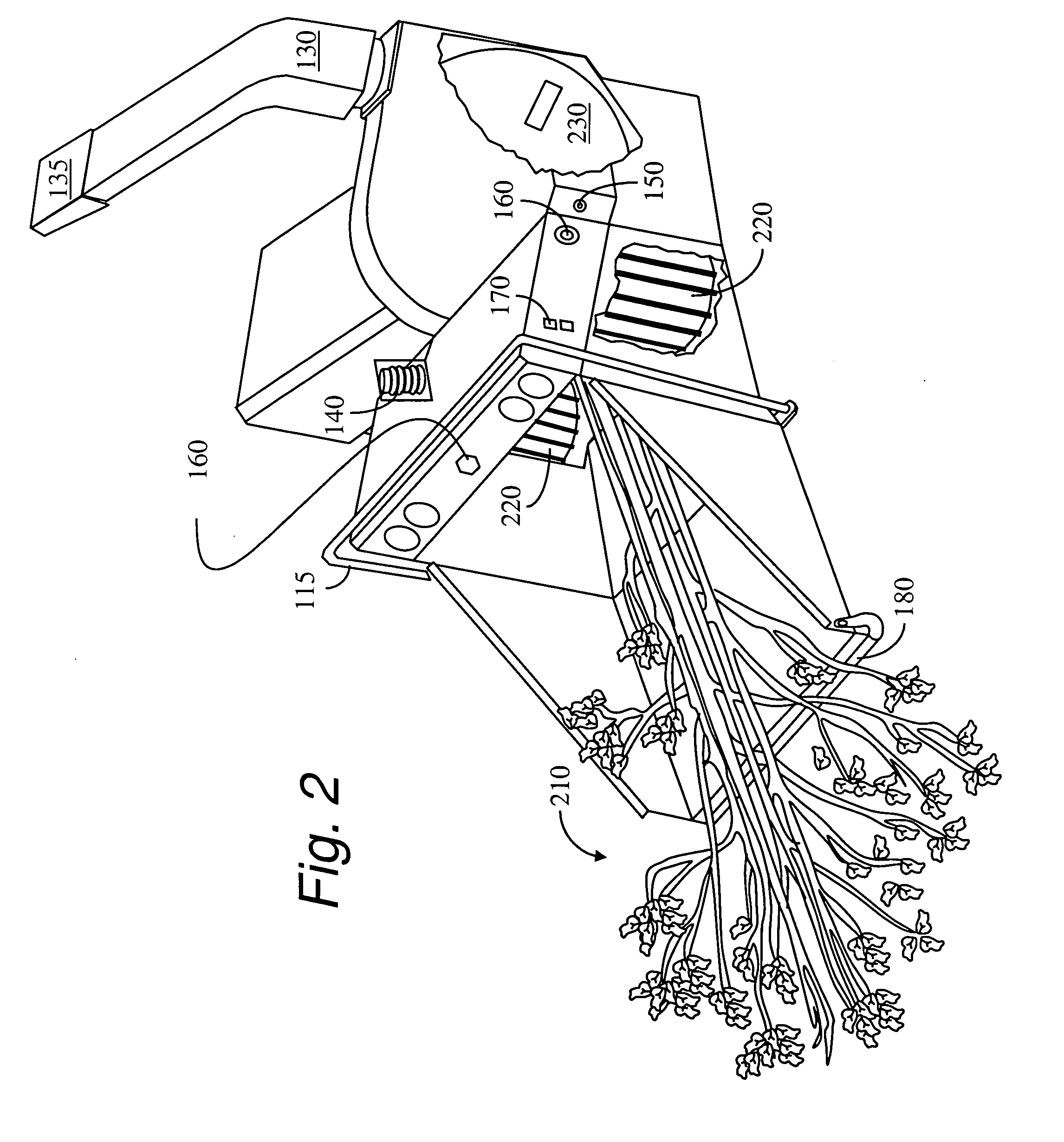

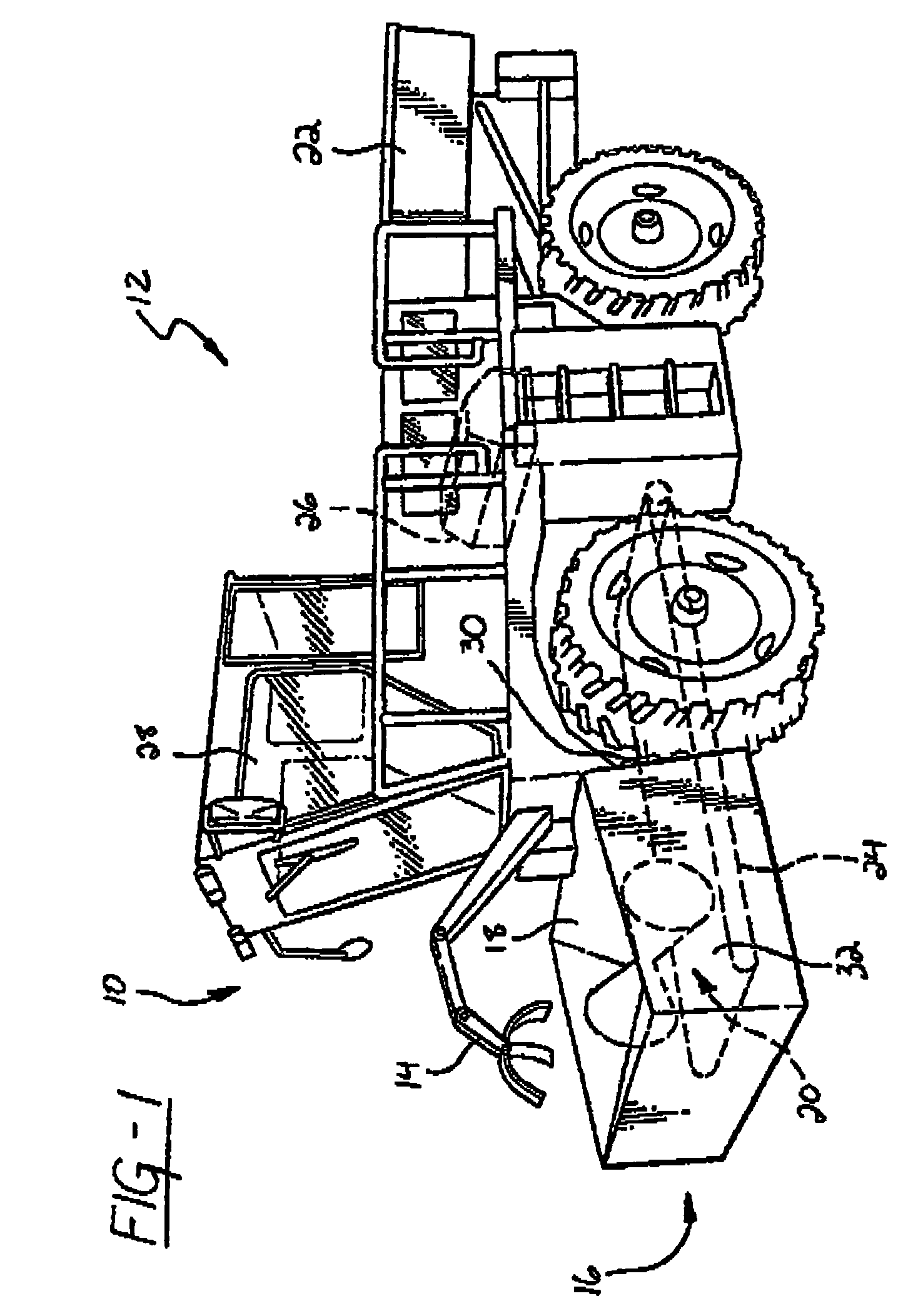

Brush chipper and methods of operating same

InactiveUS7011258B2Mechanism can be overcomeEliminate resistancePlant waste comminutingReed/straw treatmentHydraulic motorControl engineering

An improved brush cutter having an upper feed control member with stop, forward, neutral, and reverse positions also has a lower feed stop member with selectable sensitivity. Another aspect of the invention is to predict the feed roller shutoff point according to the rate of engine deceleration. According to another aspect, when the feed rollers stop feeding material into the cutters, to overcome drag on the cutters, a controller stops the feed rollers and then reverses them for a short time, and then reverses the rollers again if the problem is still present. To prevent jamming, a pressure switch senses when oil in a hydraulic motor system for rotating the feed rollers is too high and the controller momentarily reverses the feed rollers and then causes them to go forward, a cycle which can occur several times until the feed rollers are no longer stalled. By another aspect of the invention, the controller senses characteristics of the brush cutter and chooses an operating system based on the characteristics sensed. The controller can also sense if the brush chipper has not been used for a predetermined period of time and automatically reduce the idle speed of the engine until the brush chipper is used again, and then automatically return the engine to a normal idle speed before the feed rollers will pull brush into the brush chipper.

Owner:VERMEER MFG CO

Reversing automatic feed wheel assembly for wood chipper

A reversing automatic feed wheel assembly for wood chipper includes an infeed assembly and a rotatable cutting assembly spaced from the infeed assembly. The reversing automatic feed wheel assembly also includes at least one feed wheel disposed between the infeed assembly and the cutting assembly to feed wood material to the cutting assembly. The reversing automatic feed wheel assembly further includes a control system operatively connected to the at least one feed wheel to automatically reverse / stop / restart the infeed of the wood material including a sensor to sense pressure or reduced speed in the wood chipper as a result of an excessive load placed on either one of the cutting assembly and the at least one feed wheel.

Owner:BANDIT IND

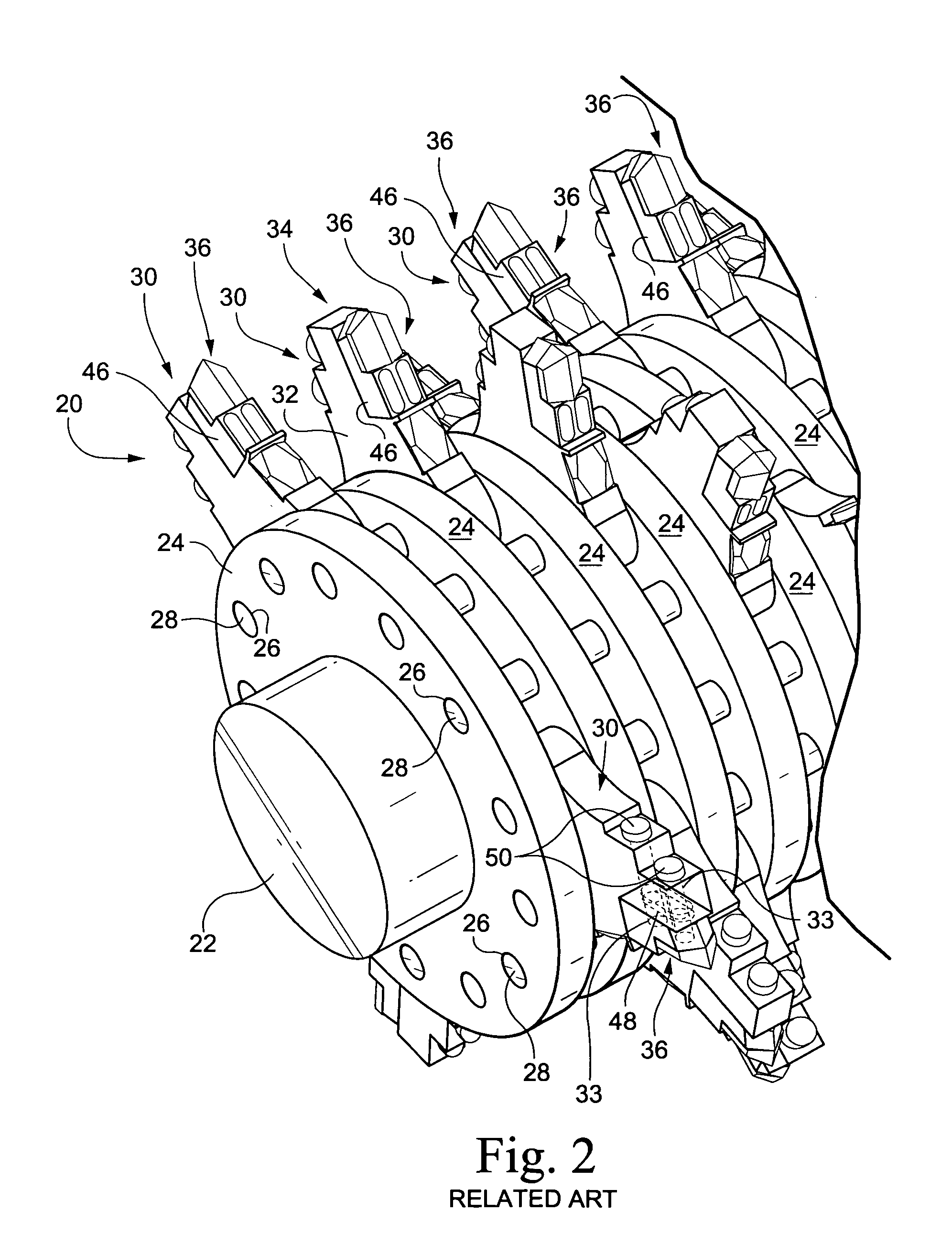

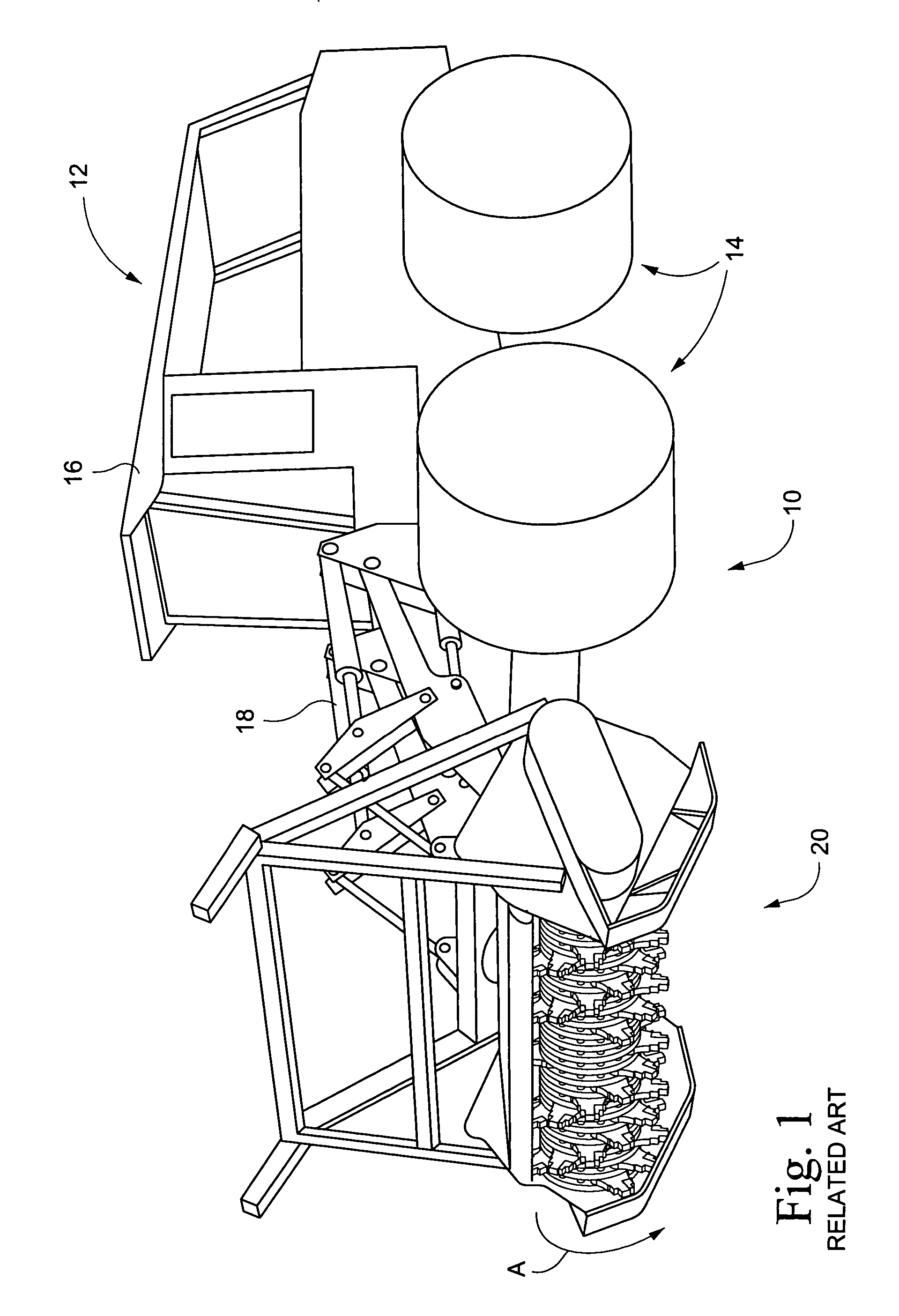

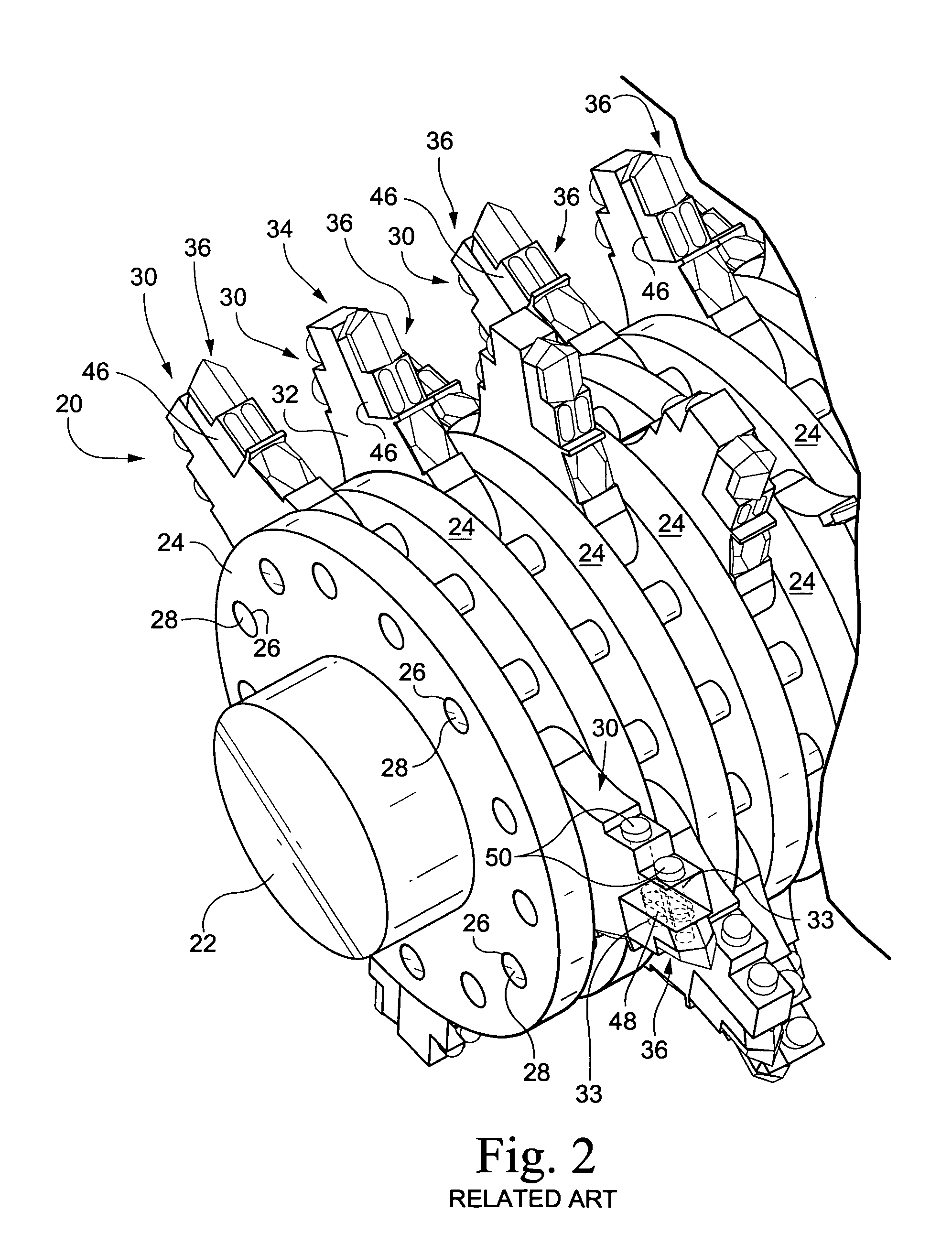

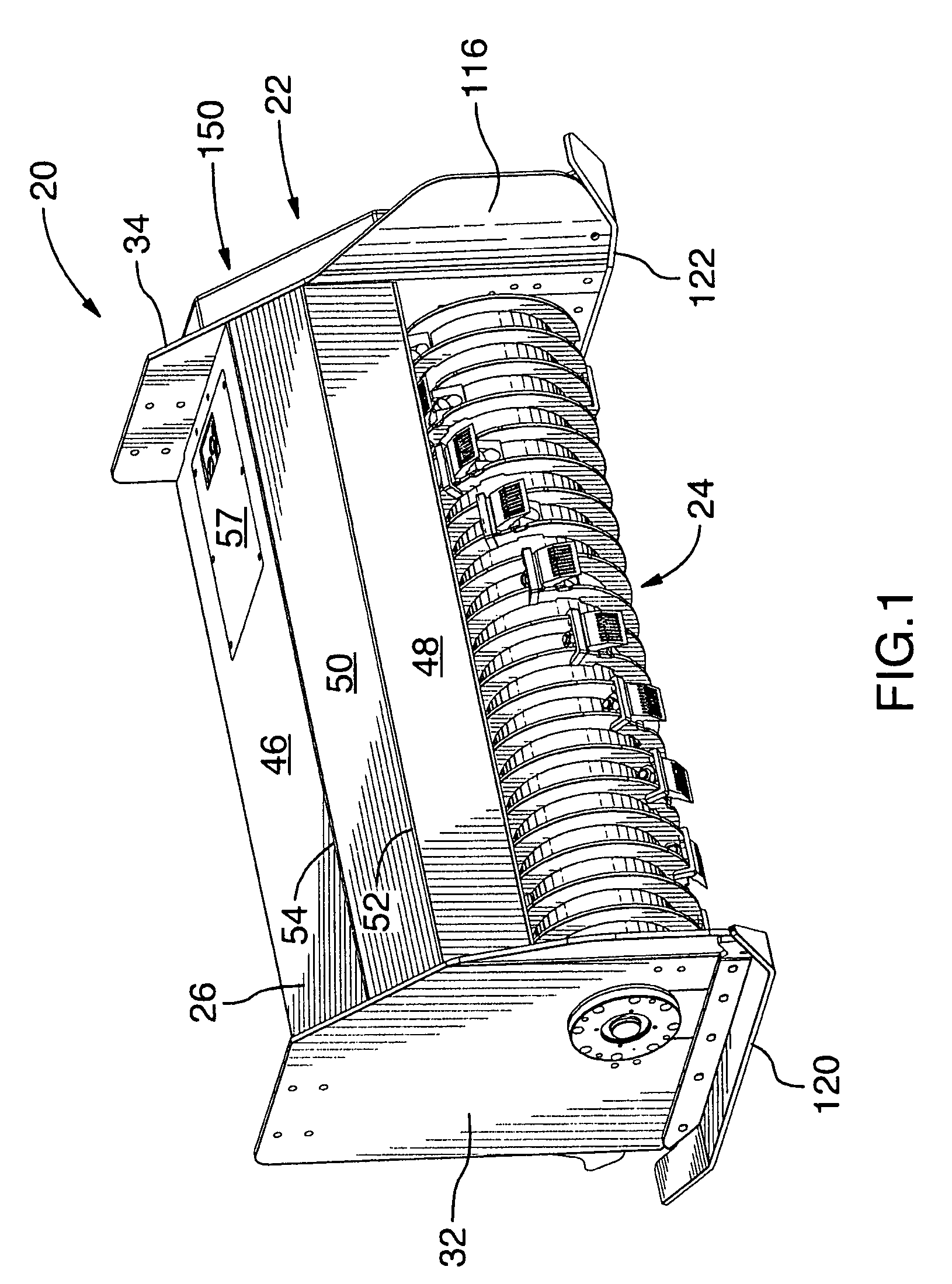

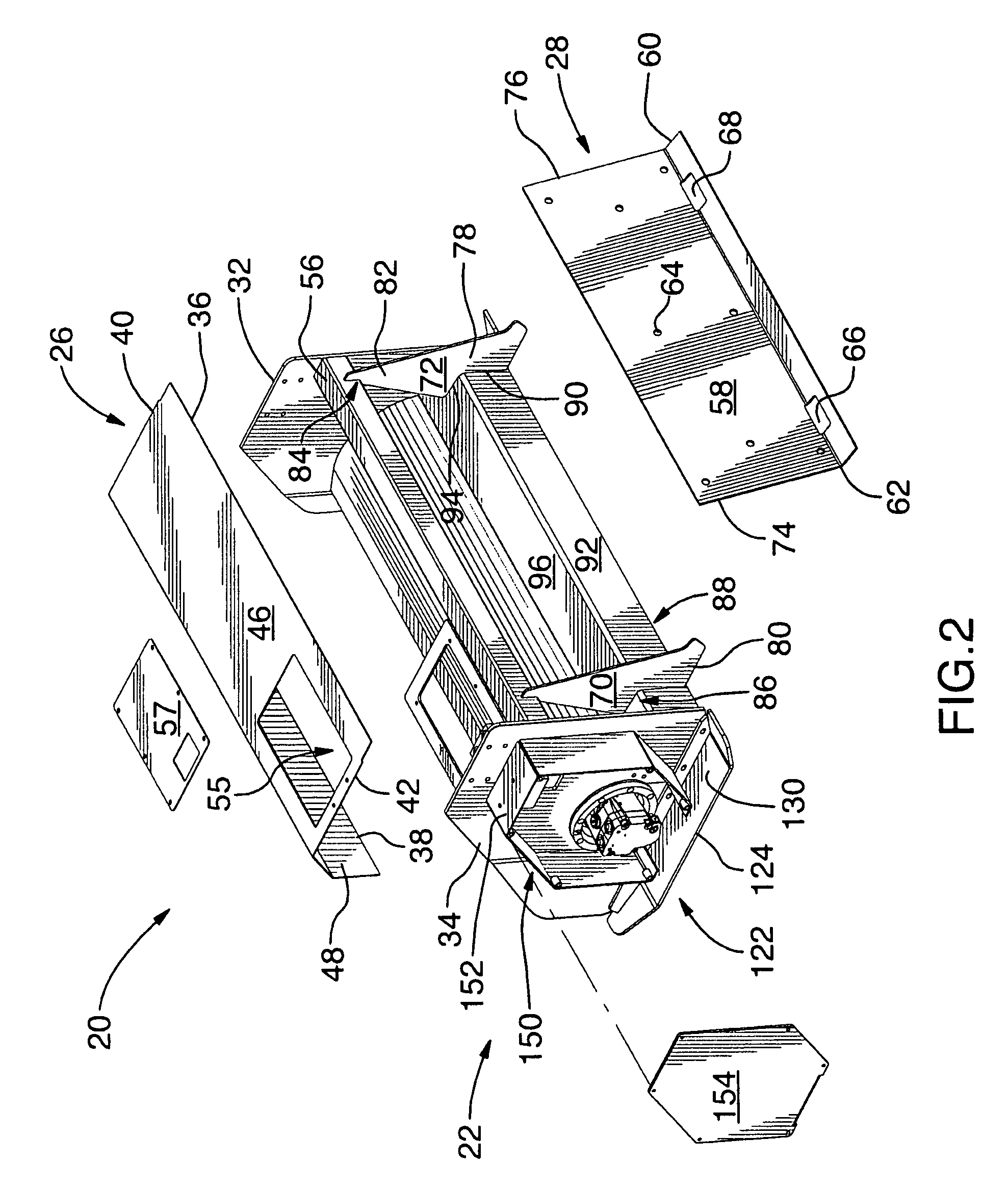

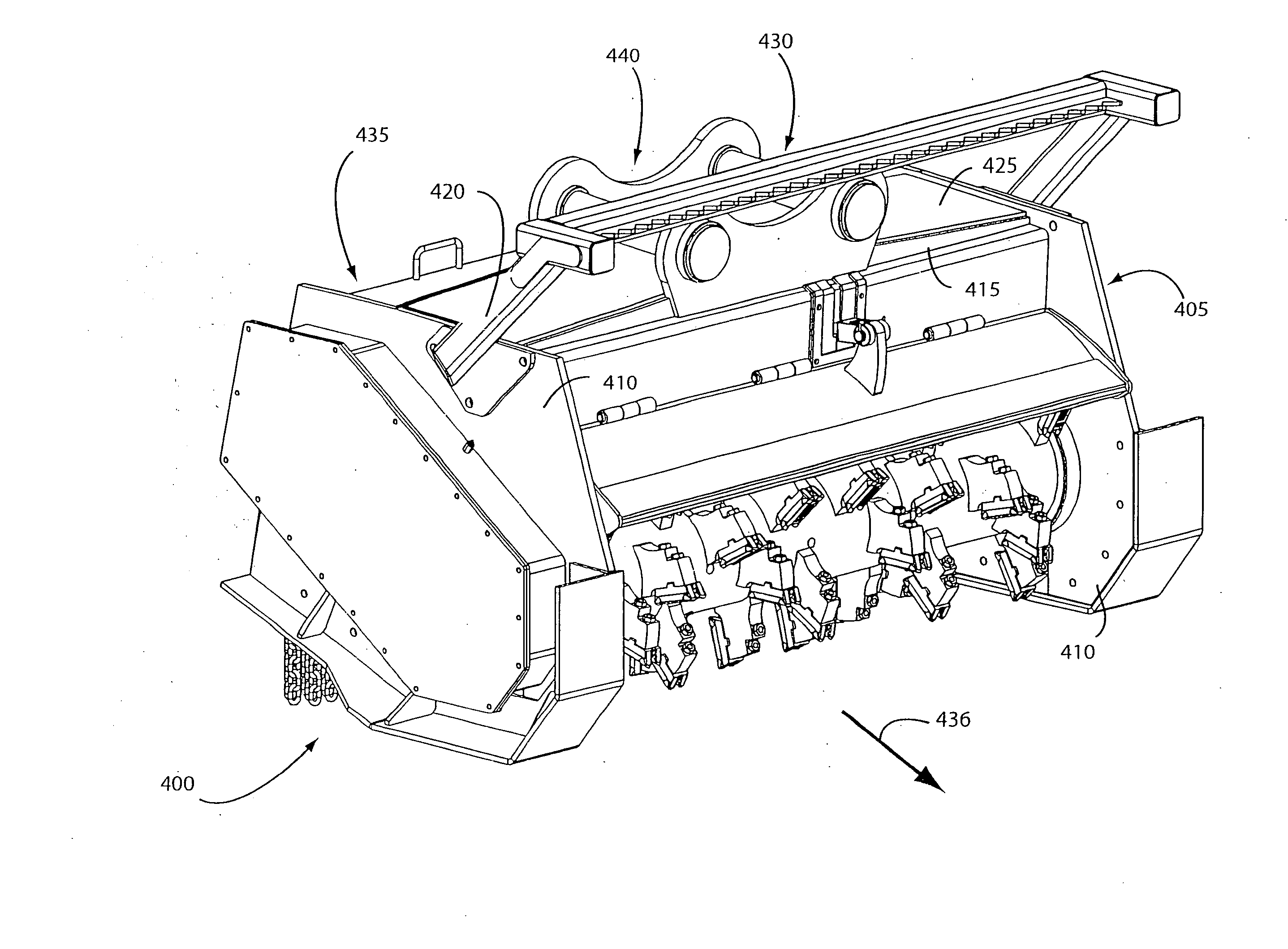

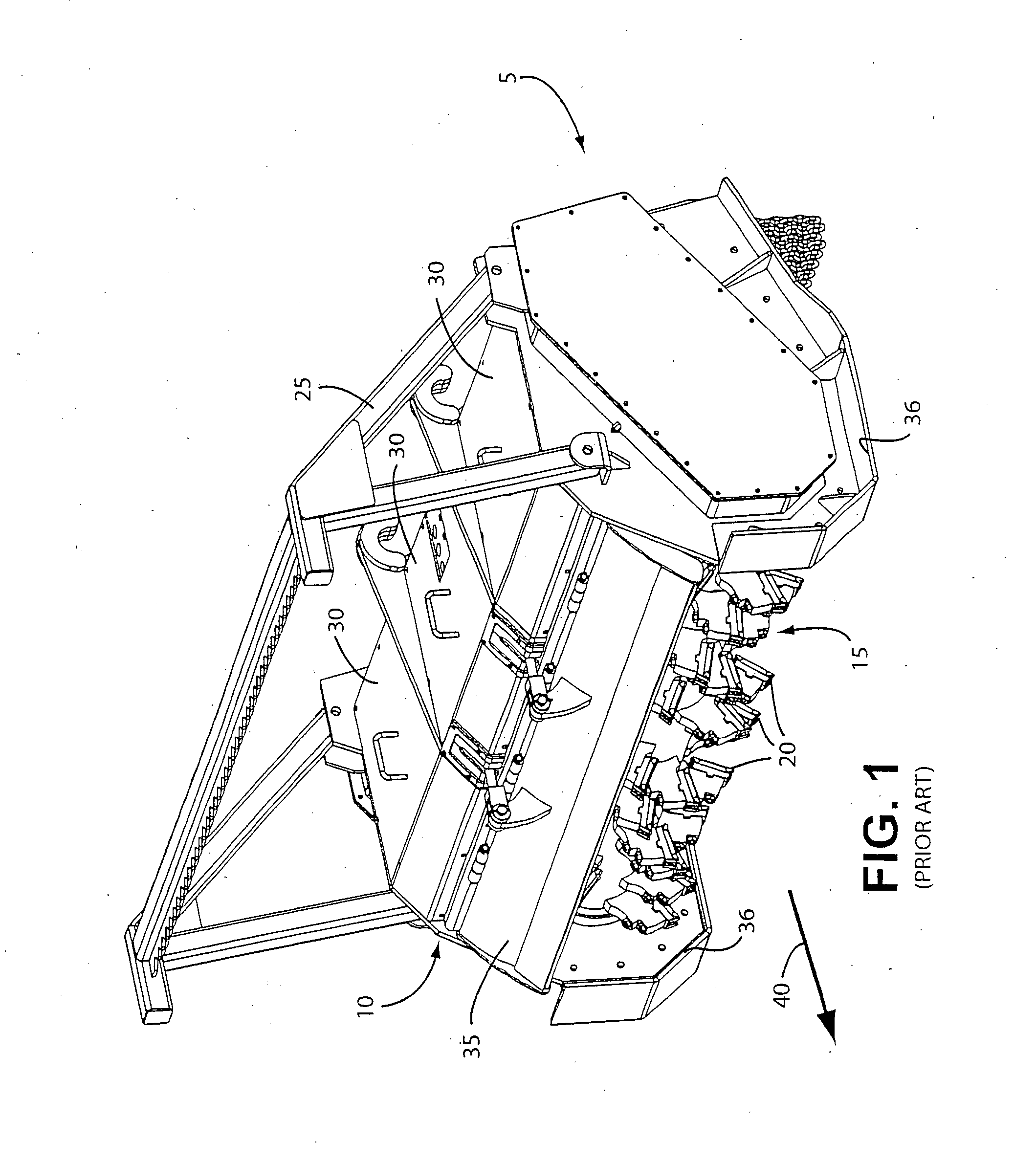

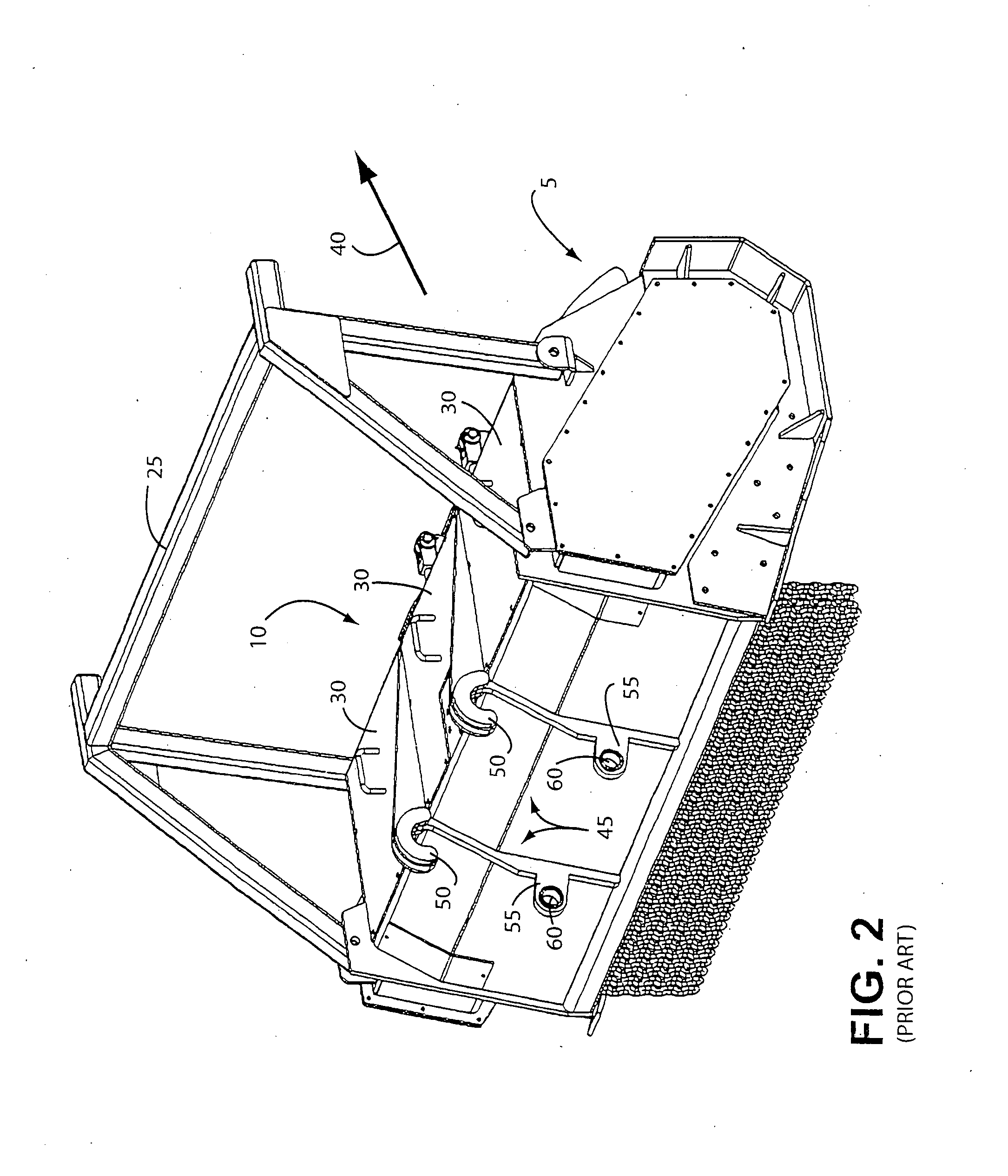

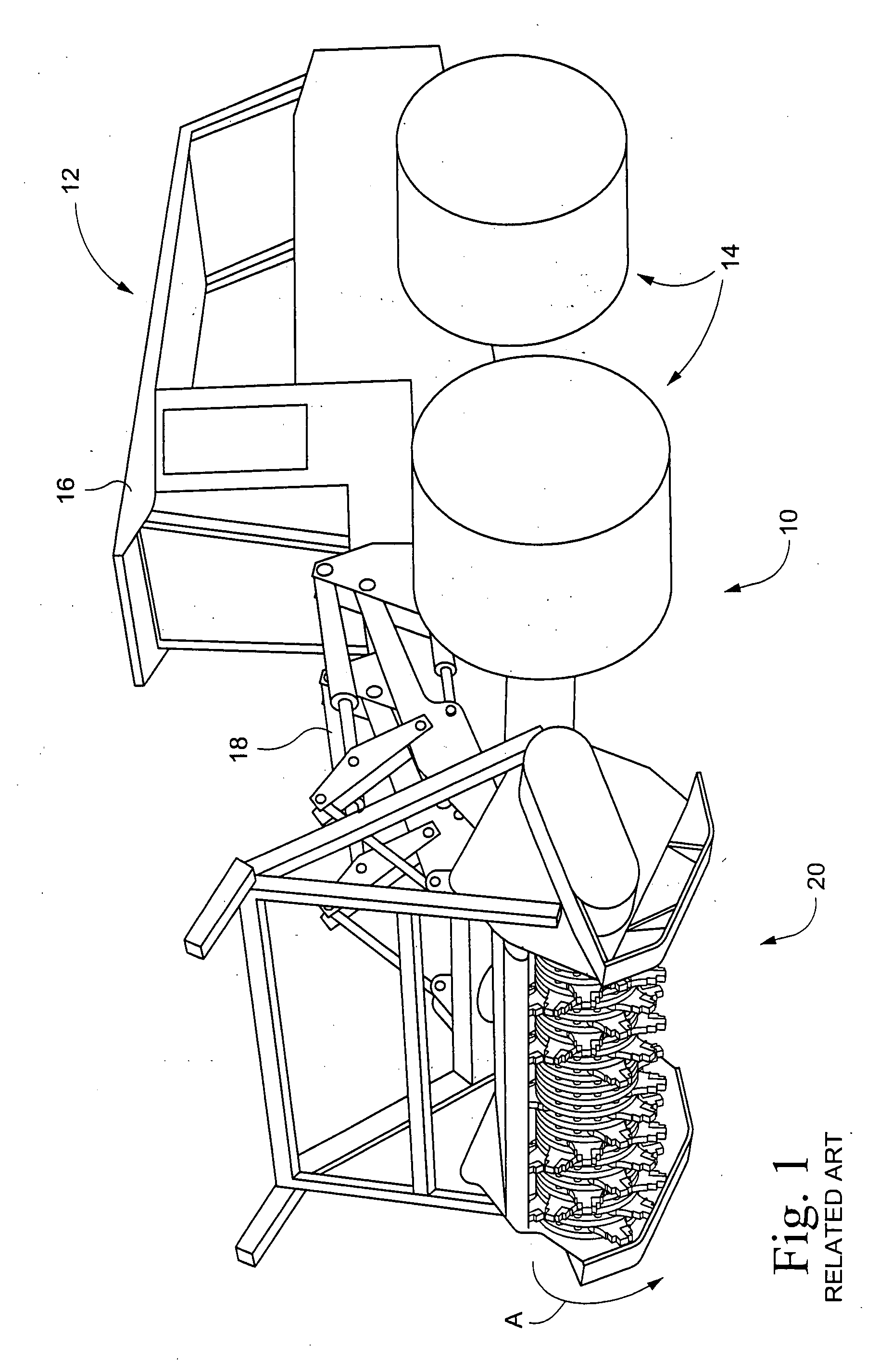

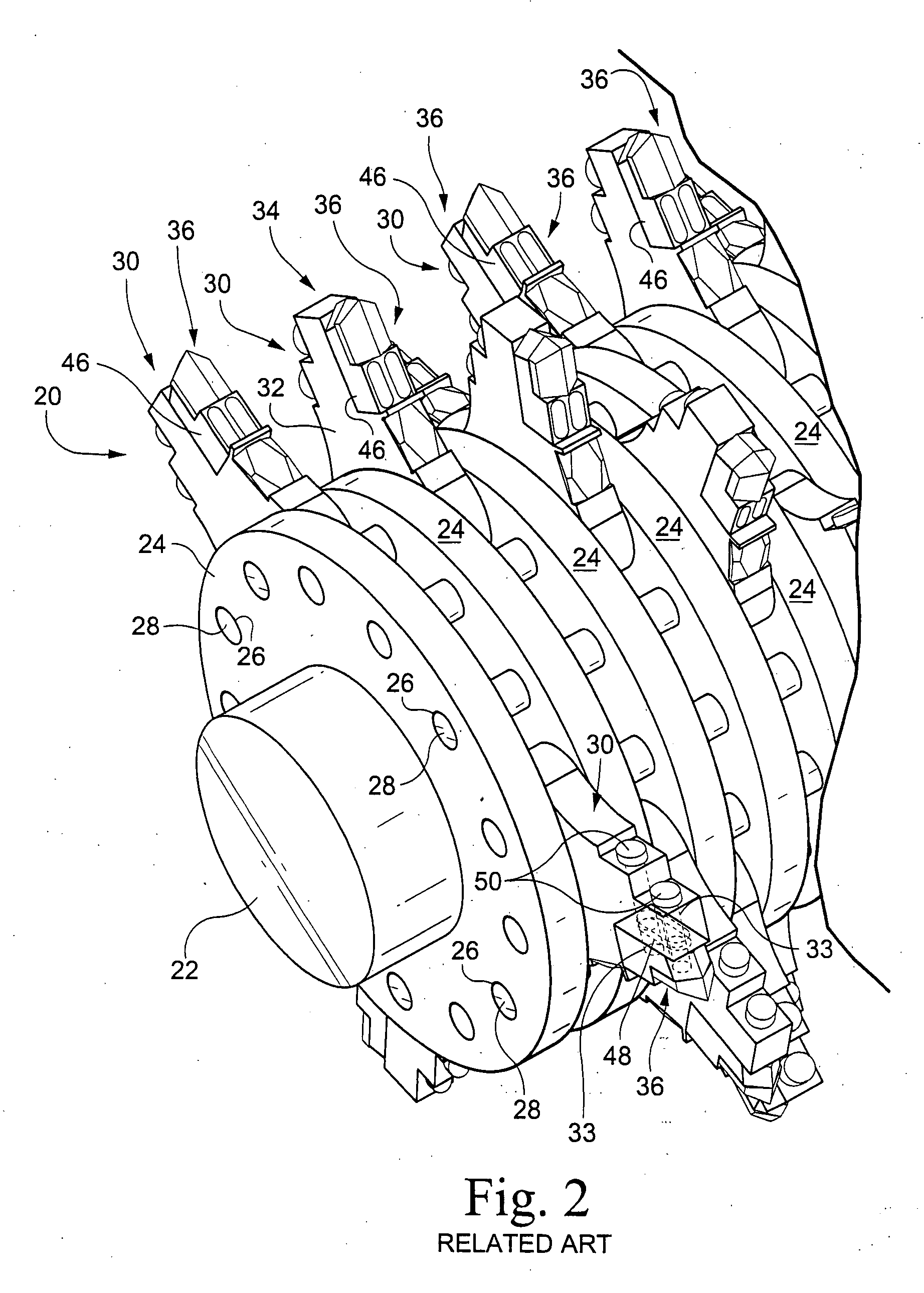

Mulcher with improved tooth design

ActiveUS20050098331A1Improve efficiencyIncrease laborMechanical machines/dredgersPlant waste comminutingCarbide coatingEngineering

A mulcher apparatus includes a tractor and a mulcher unit provided to the tractor. The mulcher unit includes a tooth assembly with a holder and a cutter element with a cooperating notch portion and cross bar arrangement. The notch portion can be retrofit to existing holder arrangements. The cutter element may include various features, to enhance cutting efficiency. For example, the cutter elements may include a double-ended structure, angle tab portions at each corner portion, carbide coatings, a pair of tip portions at each end with a space therebetween, and / or a generally H-shaped configuration.

Owner:PALADIN BRANDS GROUP

Mulcher with improved tooth design

ActiveUS7222808B2Improve efficiencyIncrease laborMechanical machines/dredgersPlant waste comminutingCarbide coatingEngineering

A mulcher apparatus includes a tractor and a mulcher unit provided to the tractor. The mulcher unit includes a tooth assembly with a holder and a cutter element with a cooperating notch portion and cross bar arrangement. The notch portion can be retrofit to existing holder arrangements. The cutter element may include various features, to enhance cutting efficiency. For example, the cutter elements may include a double-ended structure, angle tab portions at each corner portion, carbide coatings, a pair of tip portions at each end with a space therebetween, and / or a generally H-shaped configuration.

Owner:PALADIN BRANDS GROUP INC

Brush cutting head with internally housed drive and bearing assembly

A brush cutting head having internally housed drive and bearing assemblies which can be easily attached / detached from the brush cutter housing without having to dismantle the drive assembly for improved productivity. The brush cutting head includes a hollow support body, a drive and bearing assembly housed at least partially within the hollow of the support body, a drive block mounted to extend within the hollow of the support body, and a motor provided with a torque transmitting driveshaft.

Owner:ERNST & YOUNG INC +1

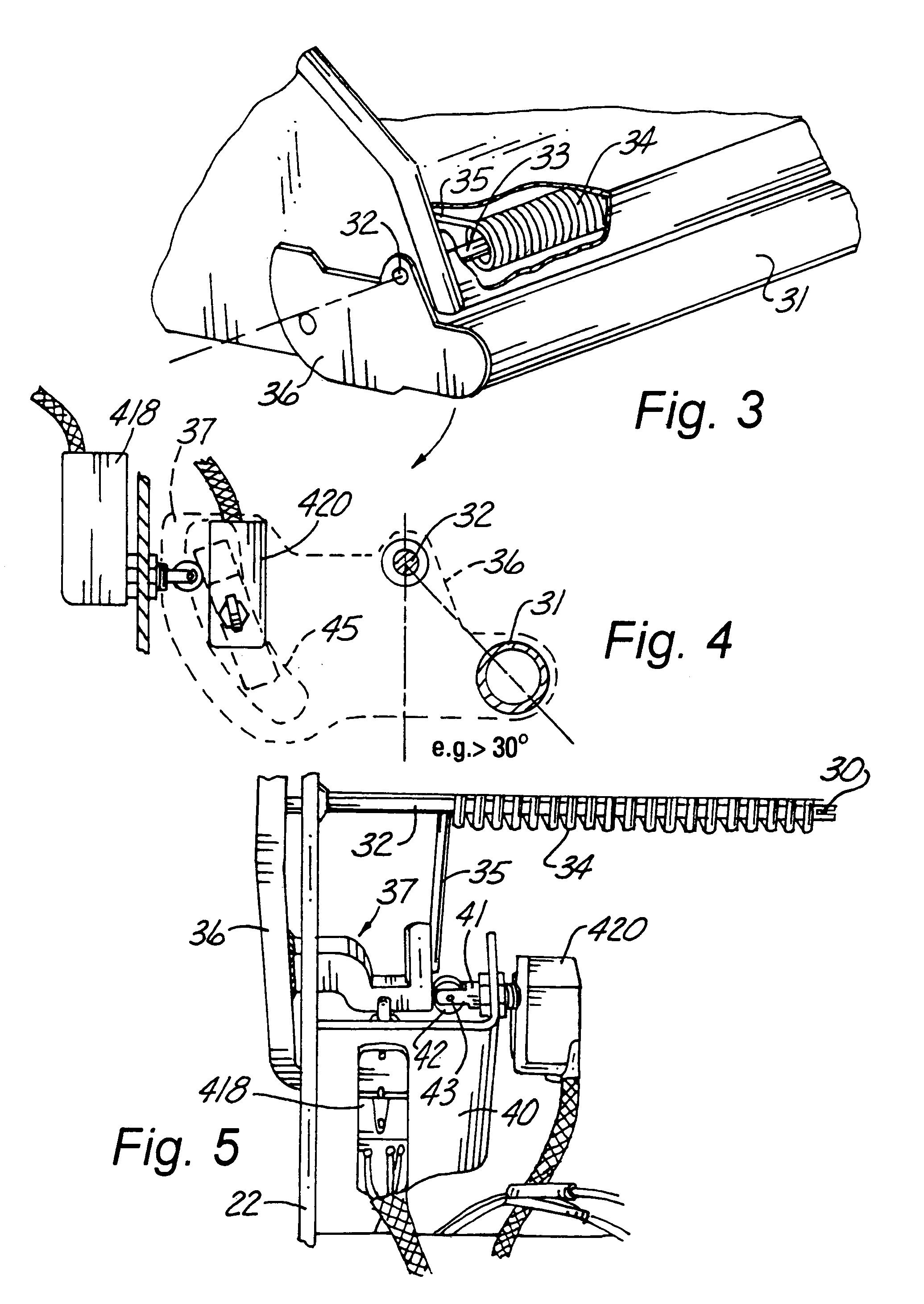

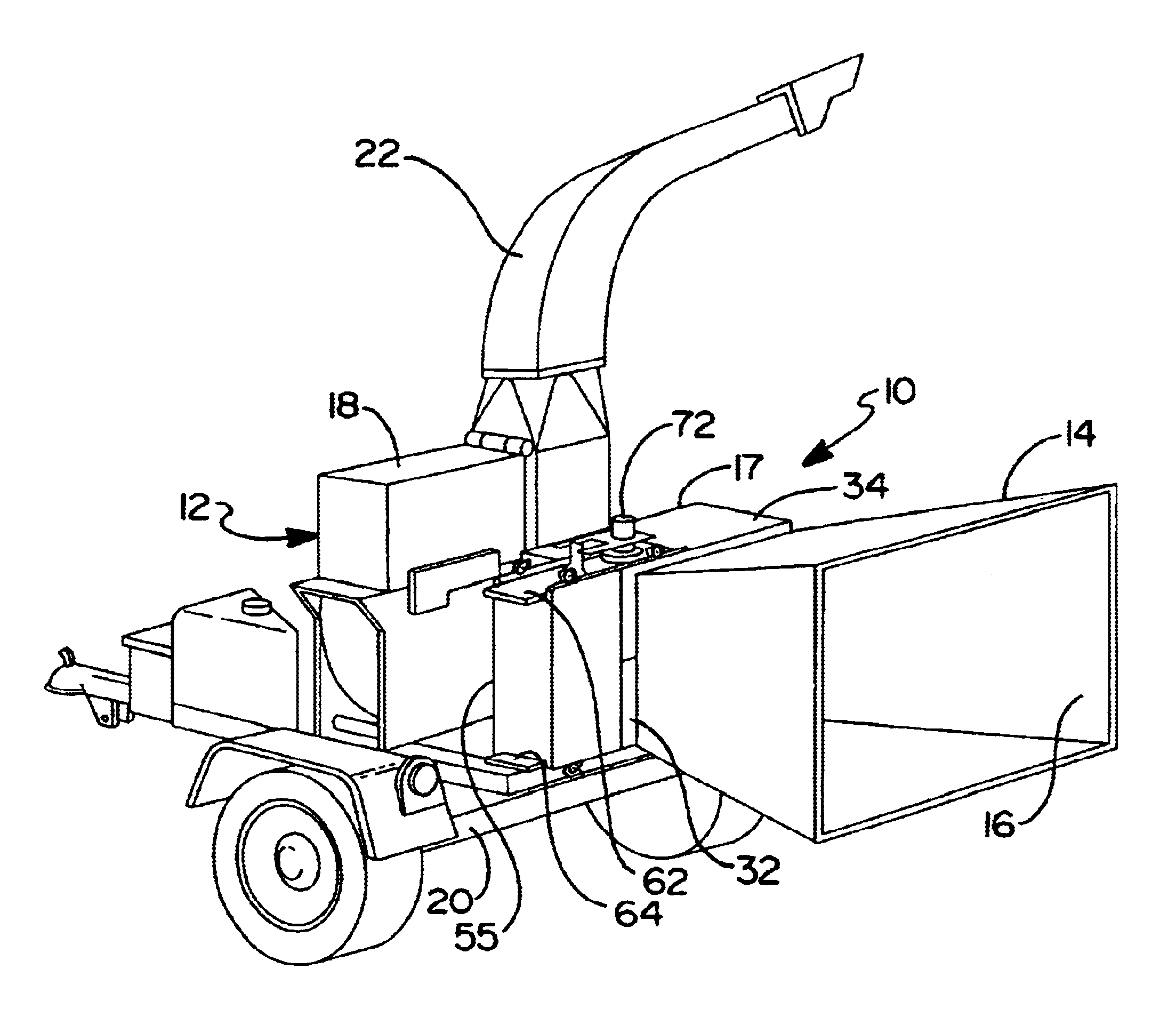

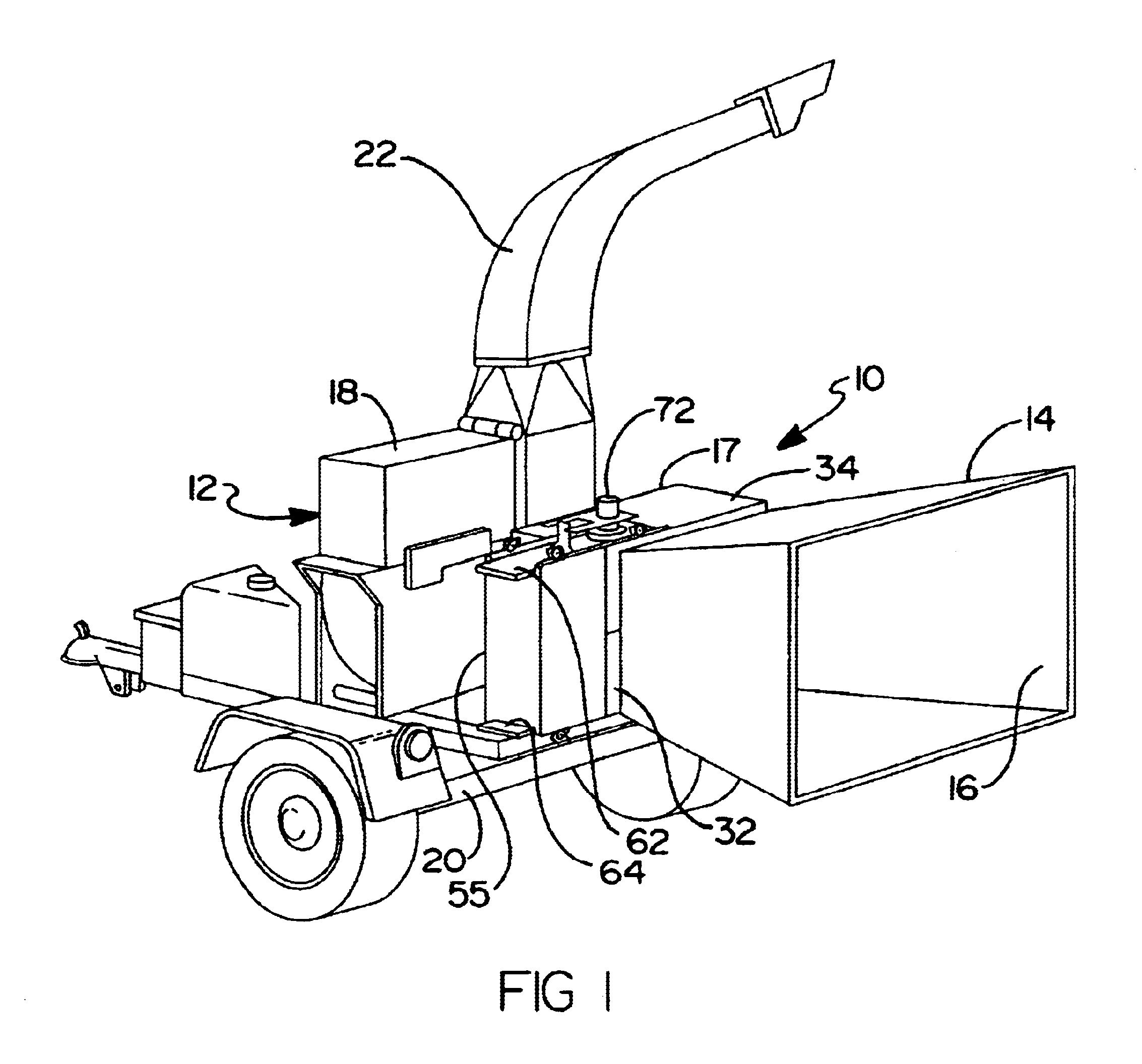

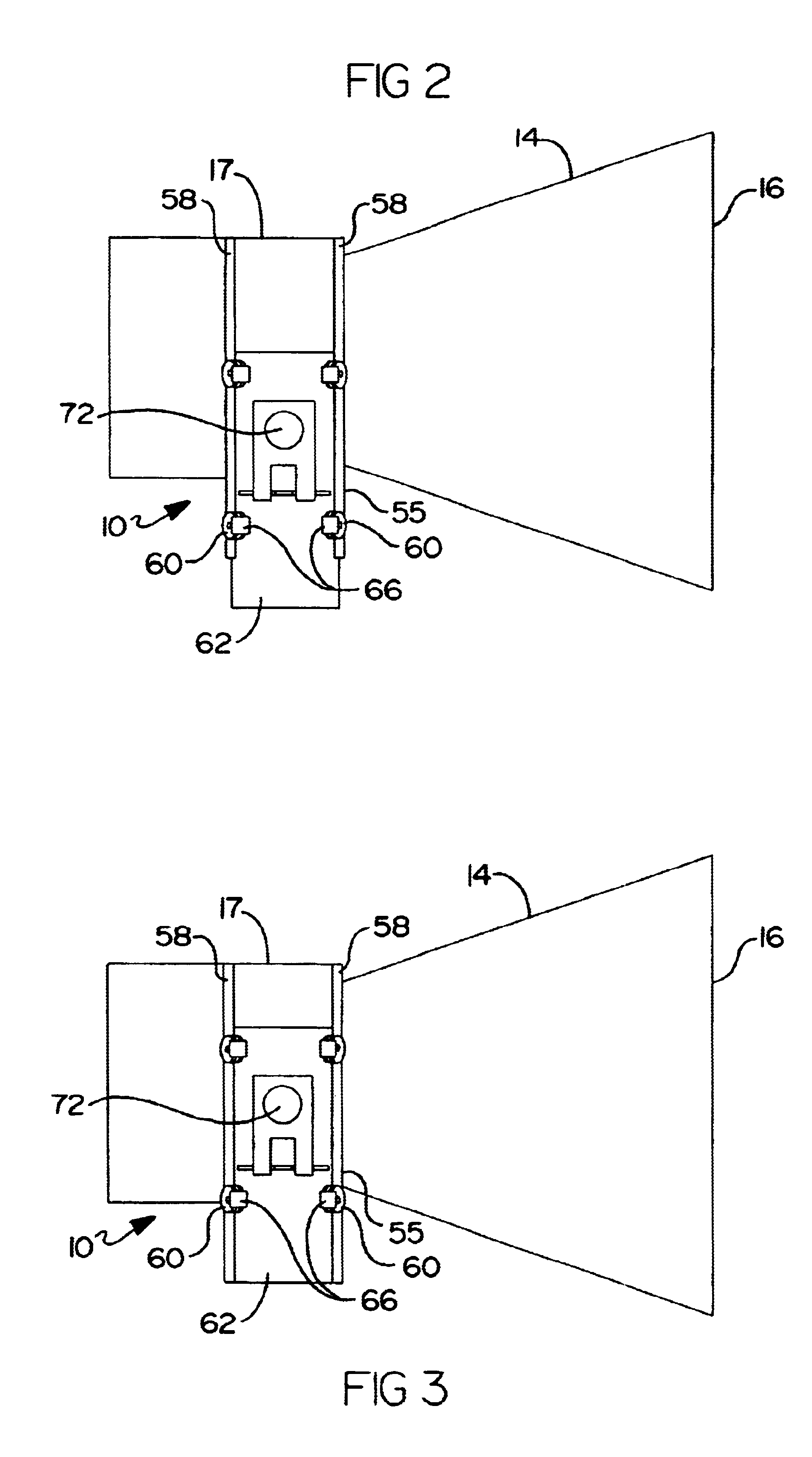

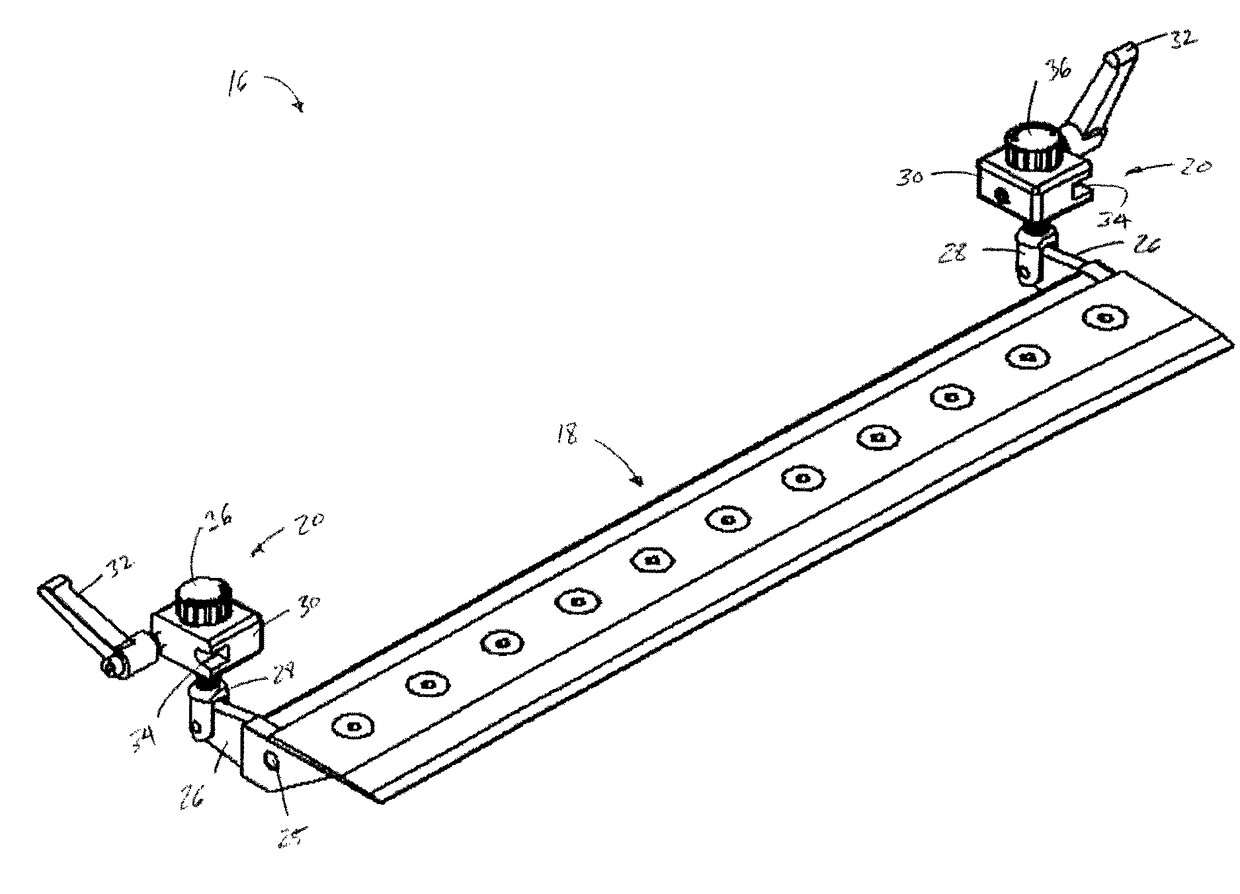

Mechanical four position brush chipper feed control bar

A mechanical control mechanism for the feed of a brush chipper is disclosed. The feed control bar has four positions: (1) forward or feed, (2) neutral, (3) reverse, and (4) stop. The hydraulic control valve has the three usual positions: (1) forward or feed, (2) neutral, (3) reverse. A function of the feed control bar is to provide the three function of the hydraulic control valve, plus the fourth in a fashion amenable to emergency situations. To these ends, the control bar has an extreme rearward position wherein the feed mechanism is stopped. The only permissible change to the stopped condition of the feed mechanism is to reverse the feed. Until a reset lever is manipulated, the hydraulic control valve cannot be put into a forward feed position.

Owner:VERMEER MFG CO

Side feed wheel assembly for wood chipper

A side feed wheel assembly for a wood chipper includes at least one side feed wheel adapted to be disposed adjacent at least one primary feed wheel of the wood chipper. The side feed wheel assembly also includes a mechanism for moving the at least one side feed wheel transversely relative to the at least one primary feed wheel to feed wood material to the at least one primary feed wheel of the wood chipper.

Owner:BANDIT IND

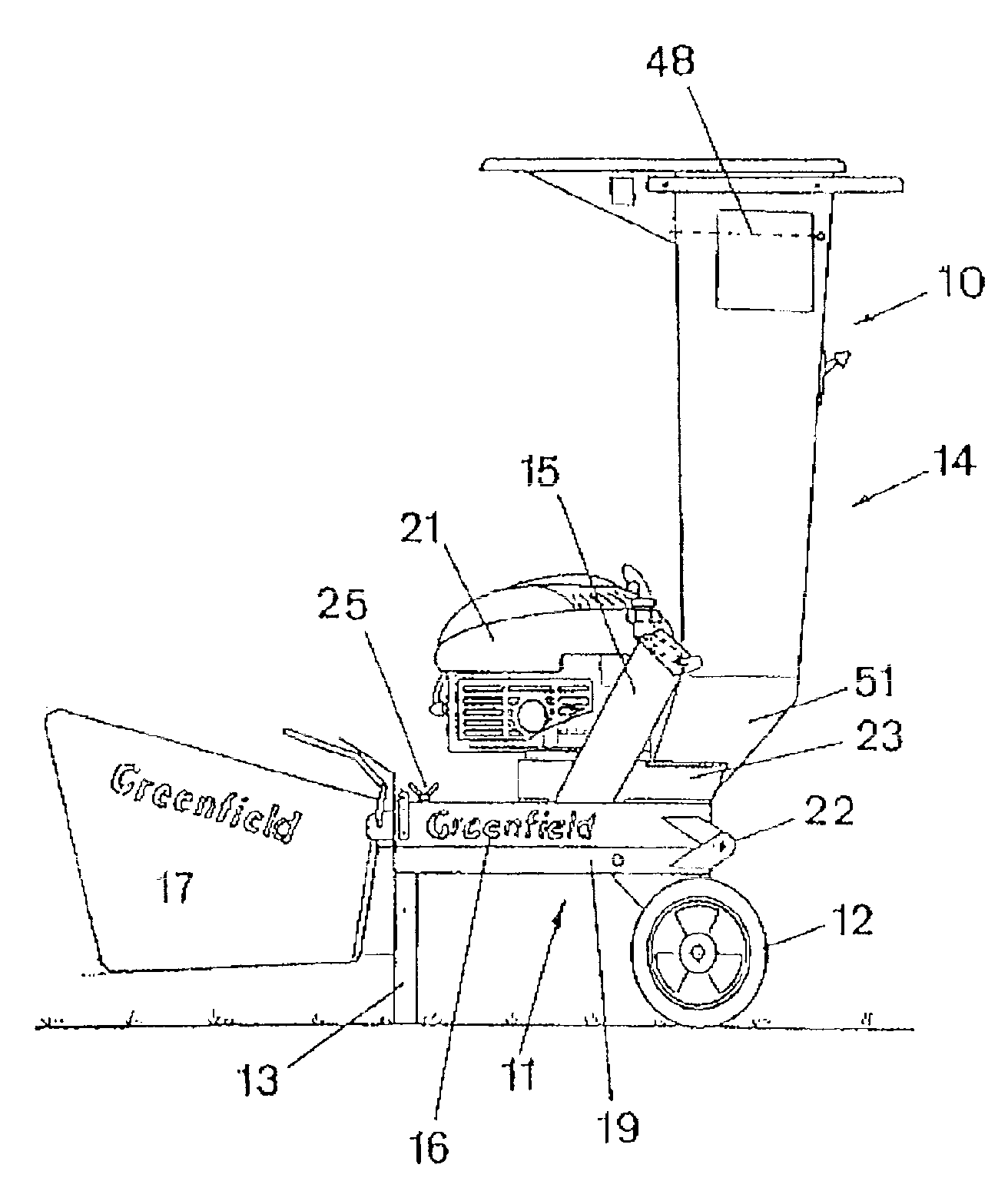

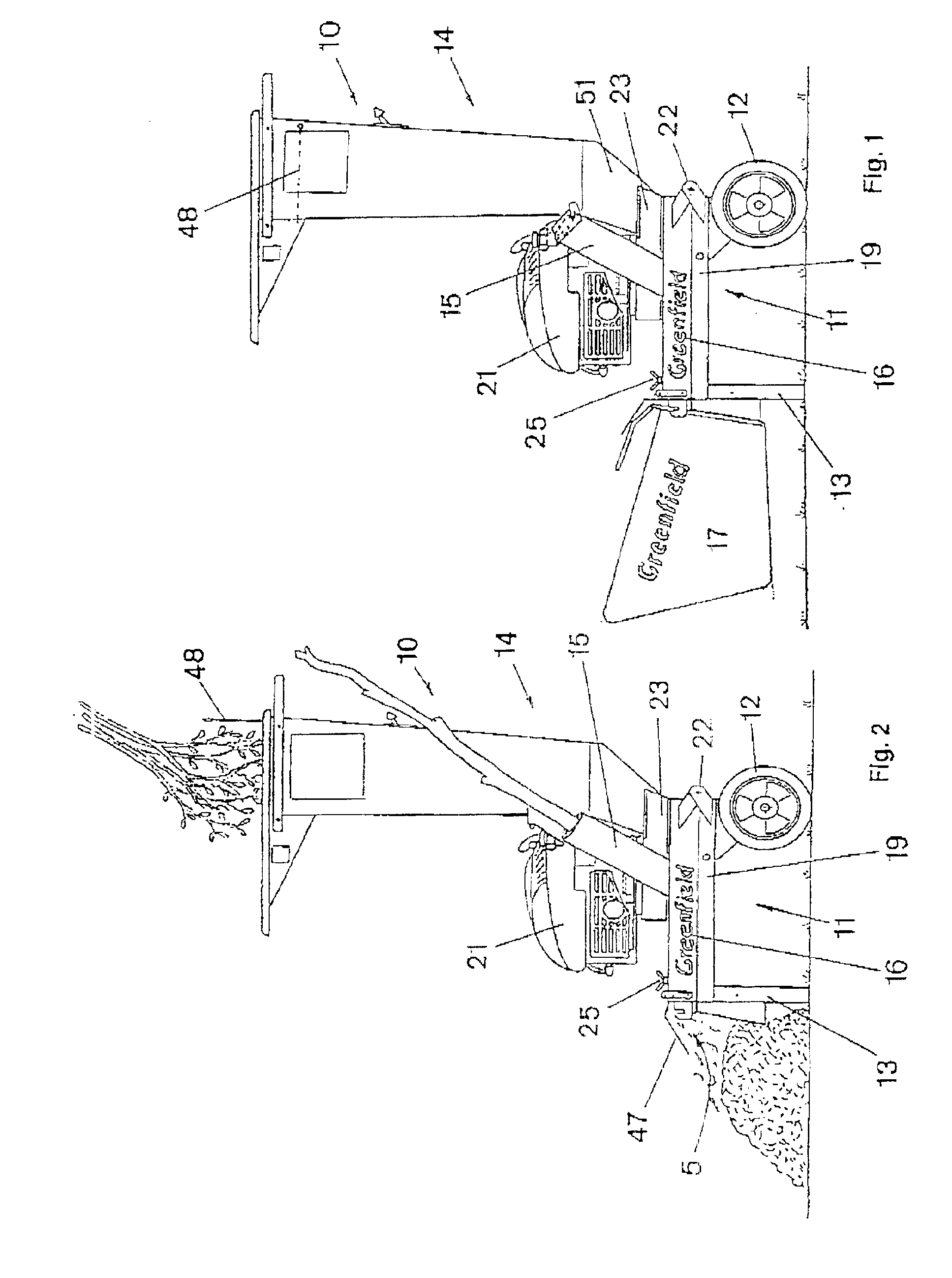

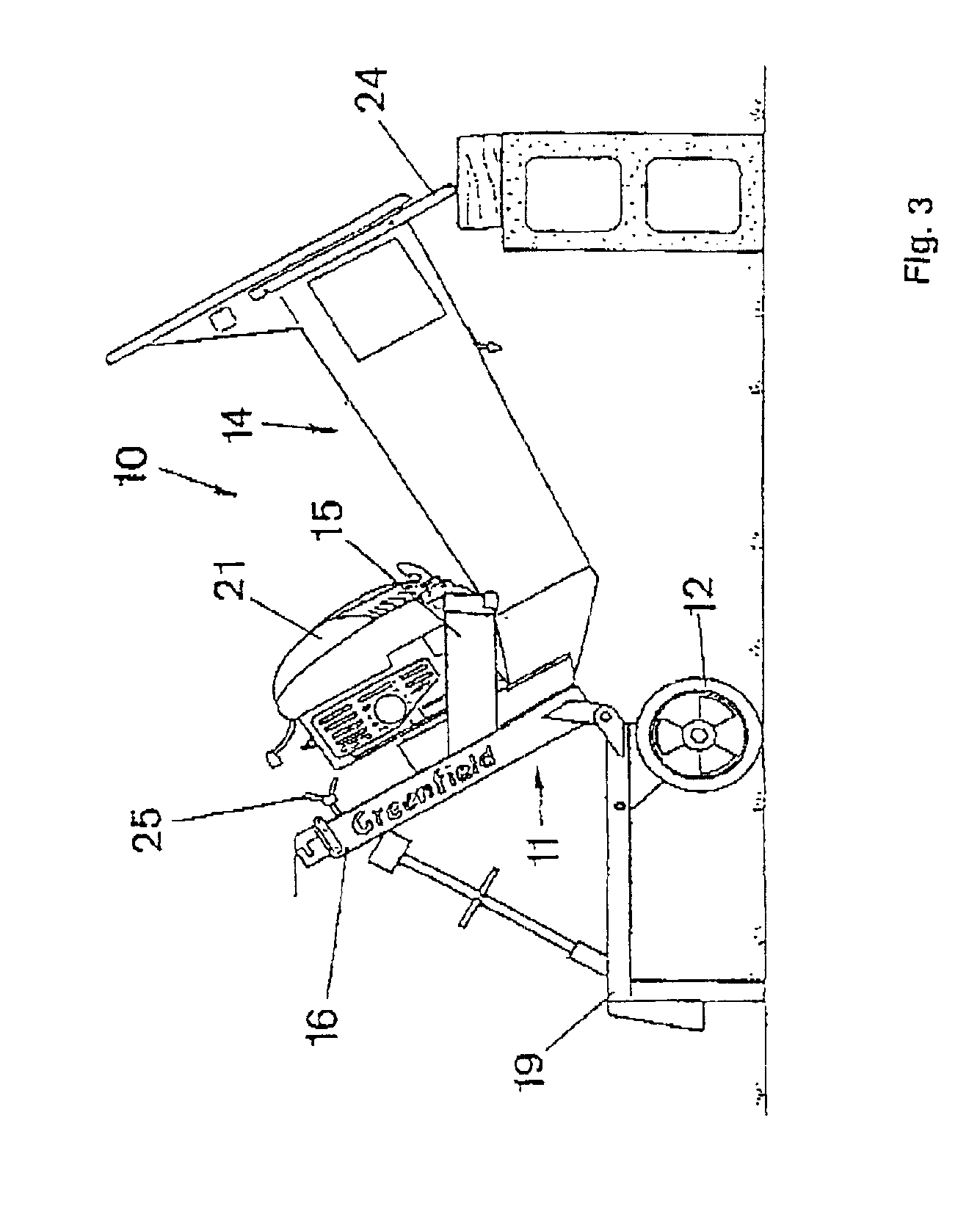

Garden refuse shredding apparatus

InactiveUS6910648B1Reduce loadSimple and cost-effectiveMowersPlant waste comminutingFan bladeAirflow

Owner:BARTLEM

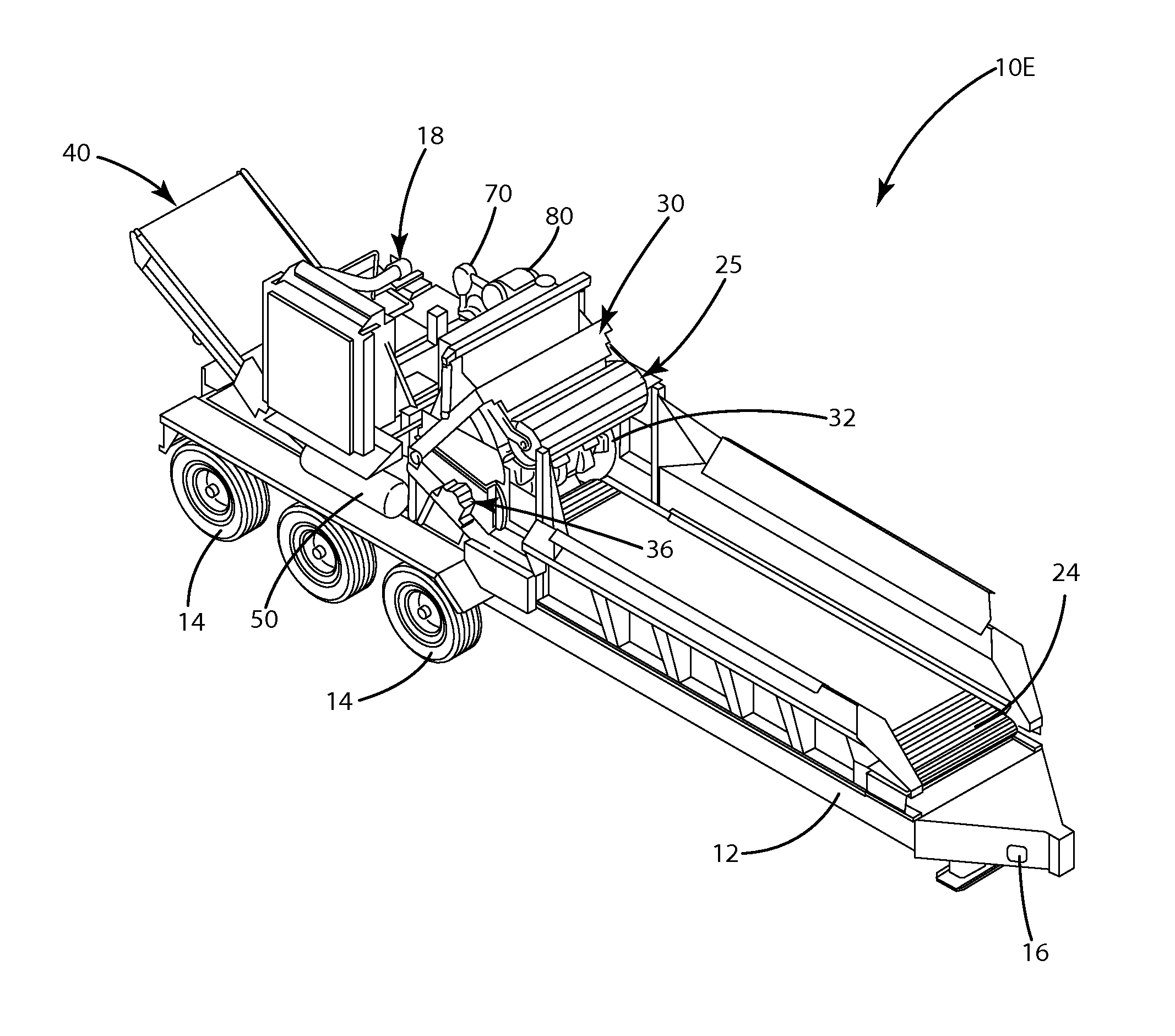

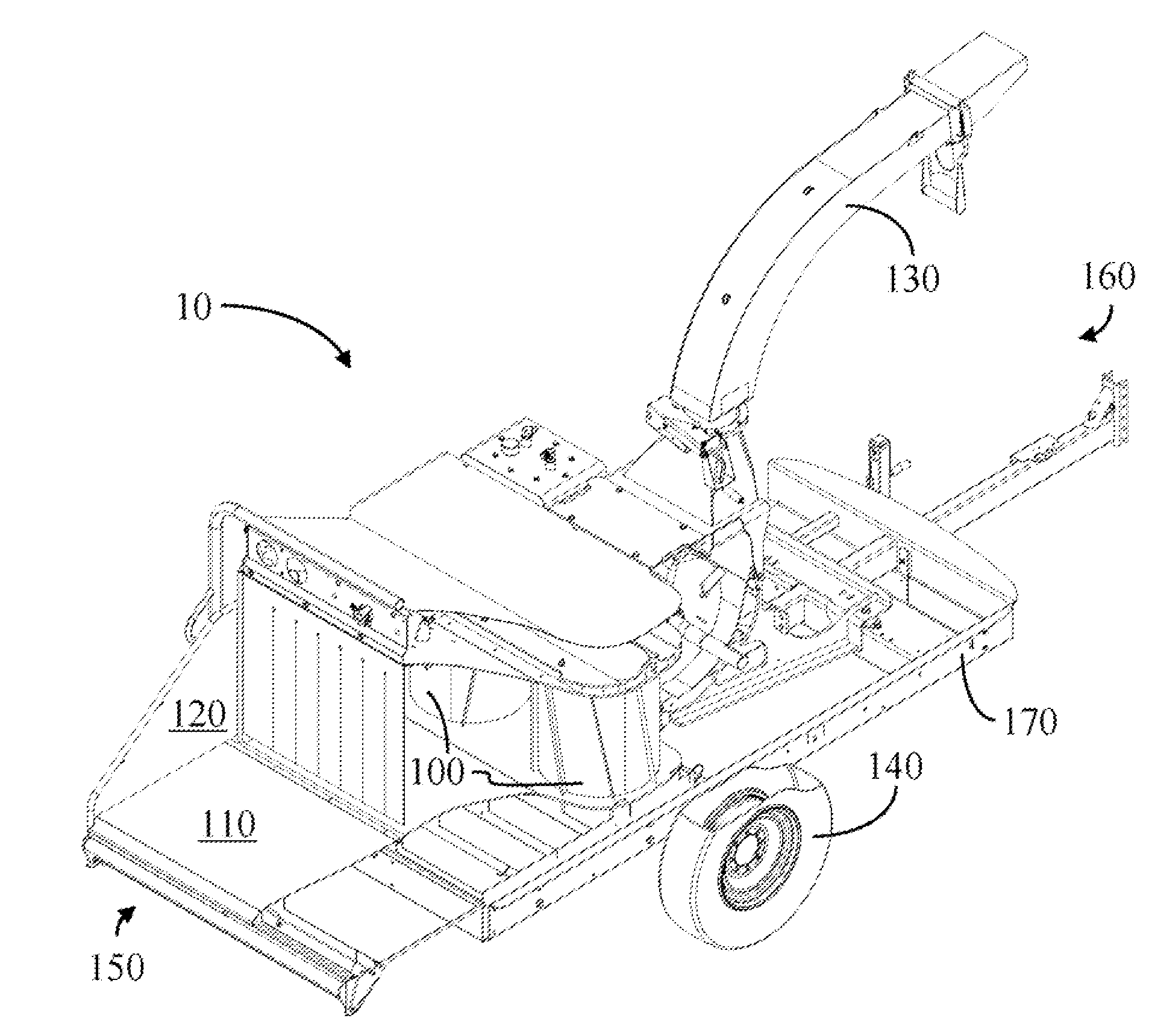

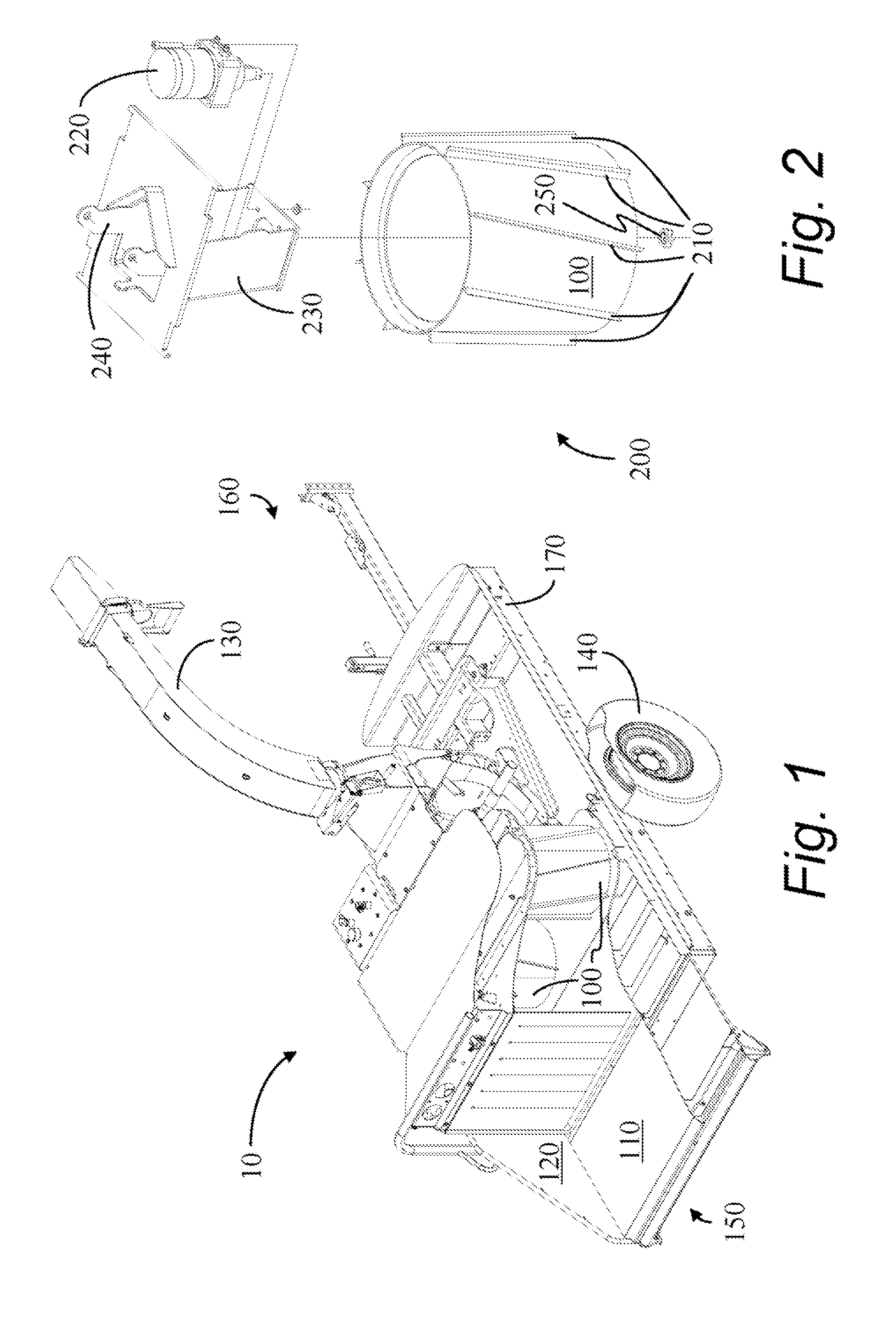

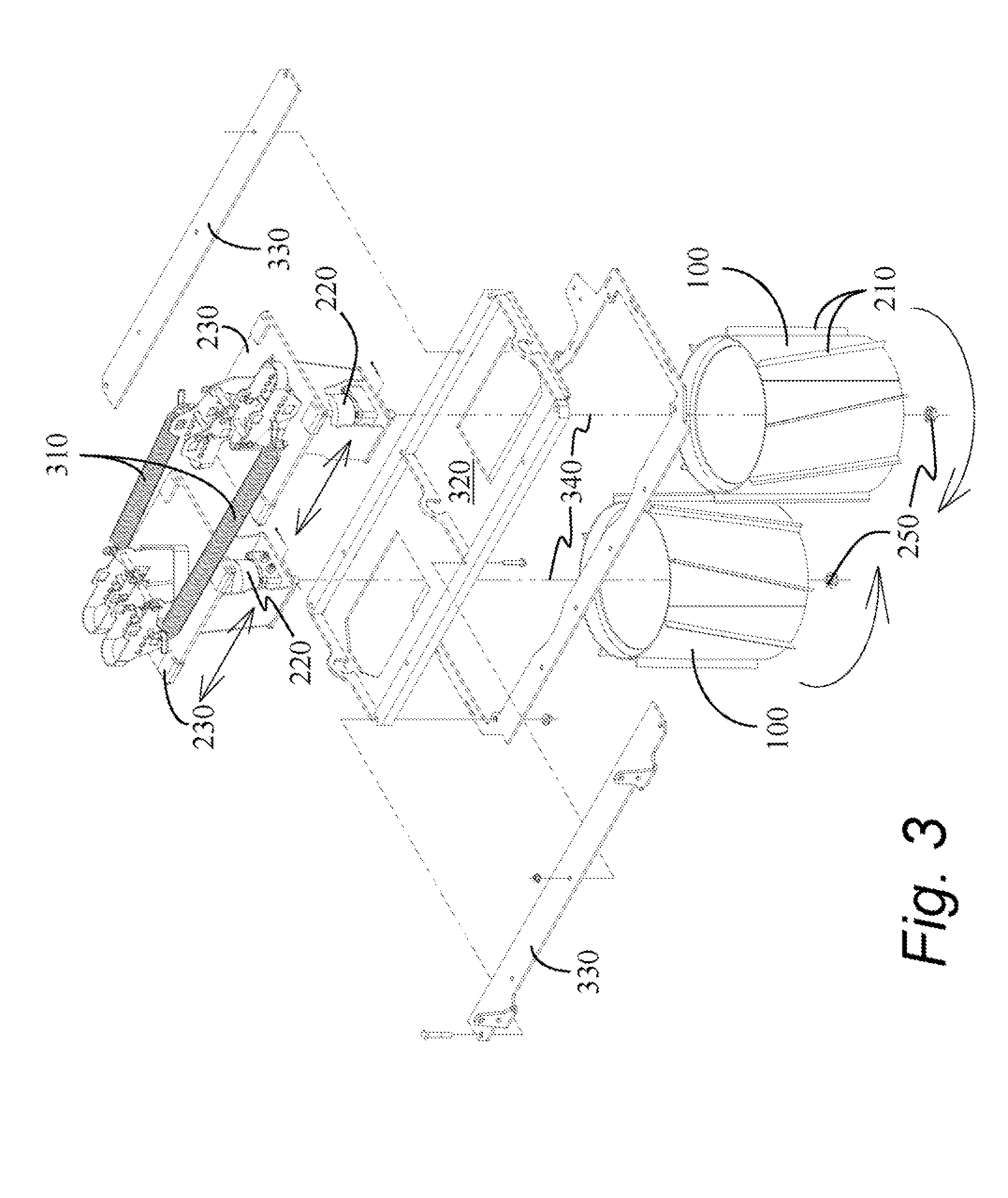

Waste processing system, machine and method thereof

ActiveUS20120234949A1Reduced material requiredMowersPlant waste comminutingWaste processingWood waste

a waste processing machine for reducing wood waste comprises an accumulator operatively connected to the cutting system so as to power the cutting system upon discharge thereof. The accumulator is adapted to receive, store, and release a charge developed from a charging device operatively connected to the accumulator and one or more systems of the waste processing machine.

Owner:BANDIT IND

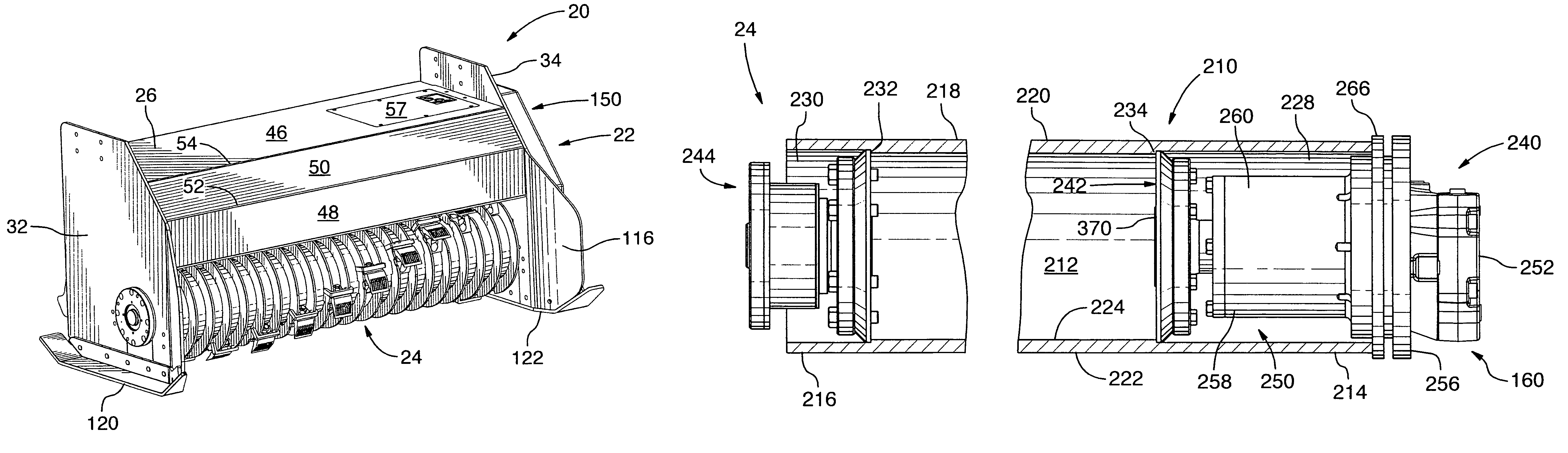

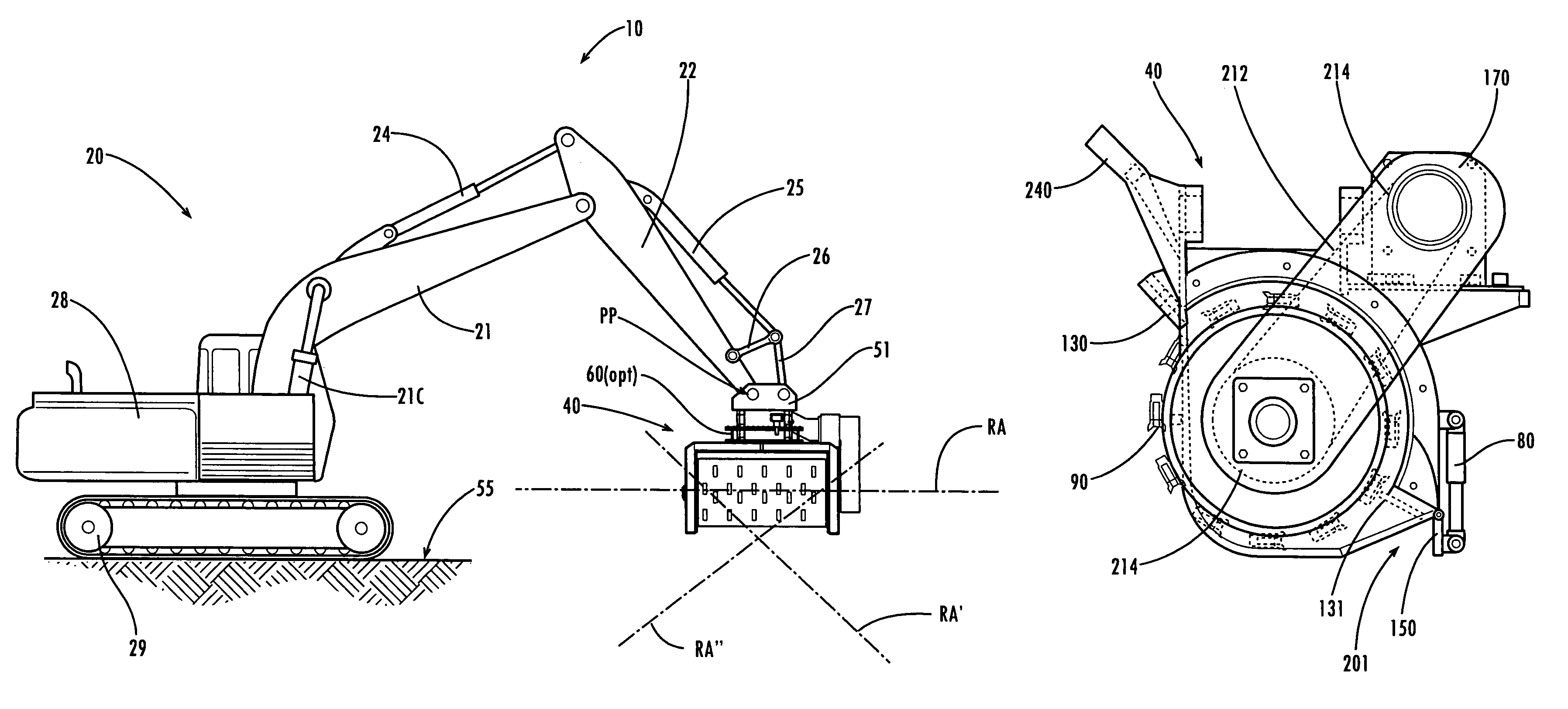

Cutter head with multiple mounts, bushing assembly and/or cooler assembly

A cutter head includes first and second mounts that are configured to allow coupling with various motive equipment, such as a tractor or an excavator. The first mount may be mounted on the rear of the cutter head chassis for coupling with the tractor, while the second mount may be mounted on the top of the cutter head chassis for coupling with the excavator. A pressure gauge includes an adjustment arrangement such that the position of the display of the pressure gauge can be adjusted for viewing of the operator of the tractor or excavator. The cutter head may include a cooler assembly that works off or in conjunction with a primary cooler assembly of the tractor or excavator. The cutter head may include an excavator linkage equipped with a bushing assembly.

Owner:PALADIN BRANDS GROUP

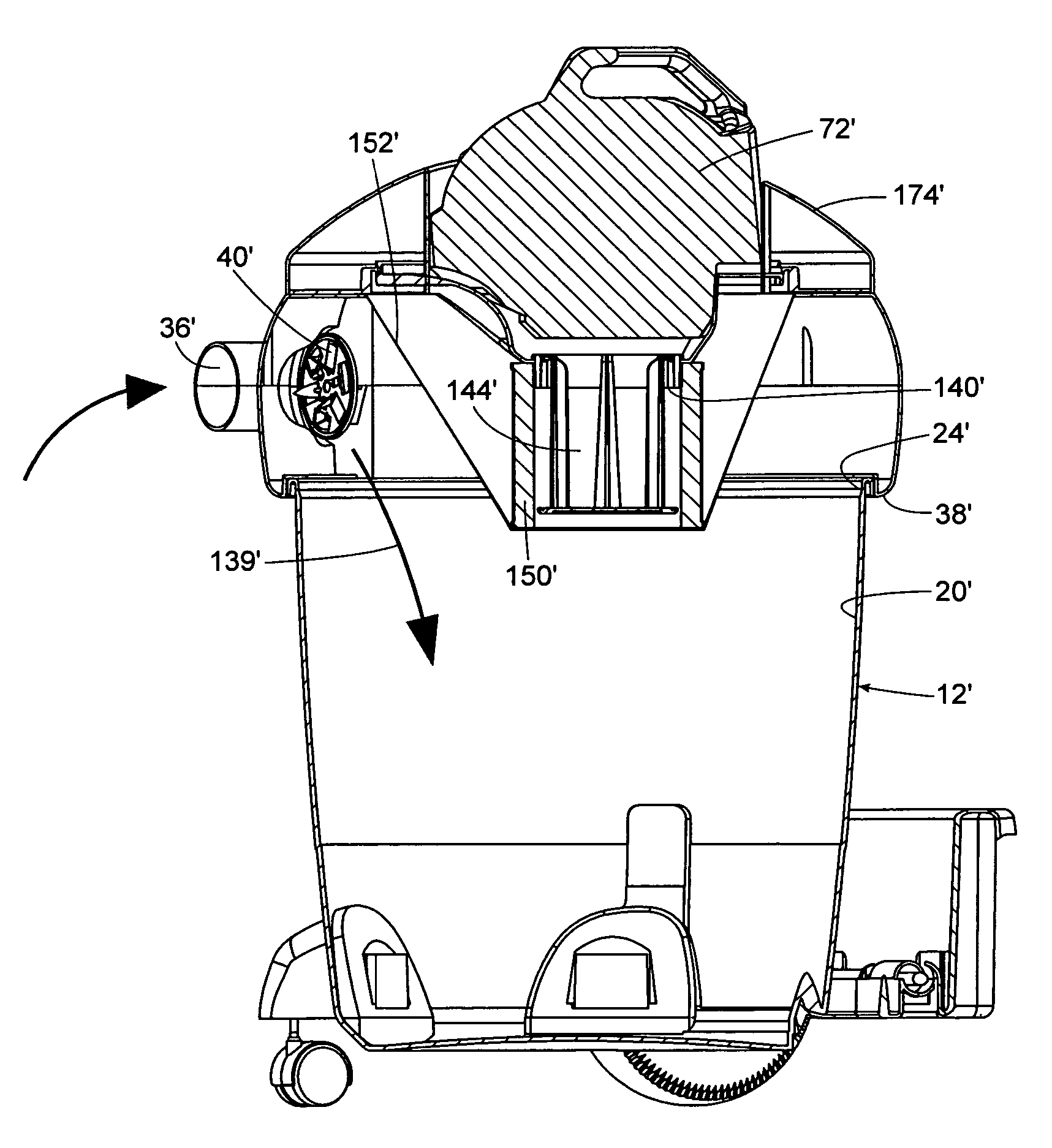

Mulcher

Owner:SHOP VAC

Portable rotary chipper apparatus

InactiveUS7798436B2Small sizeReduce chip sizeGas current separationPlant waste comminutingImpellerKnife blades

Owner:TORO CO THE

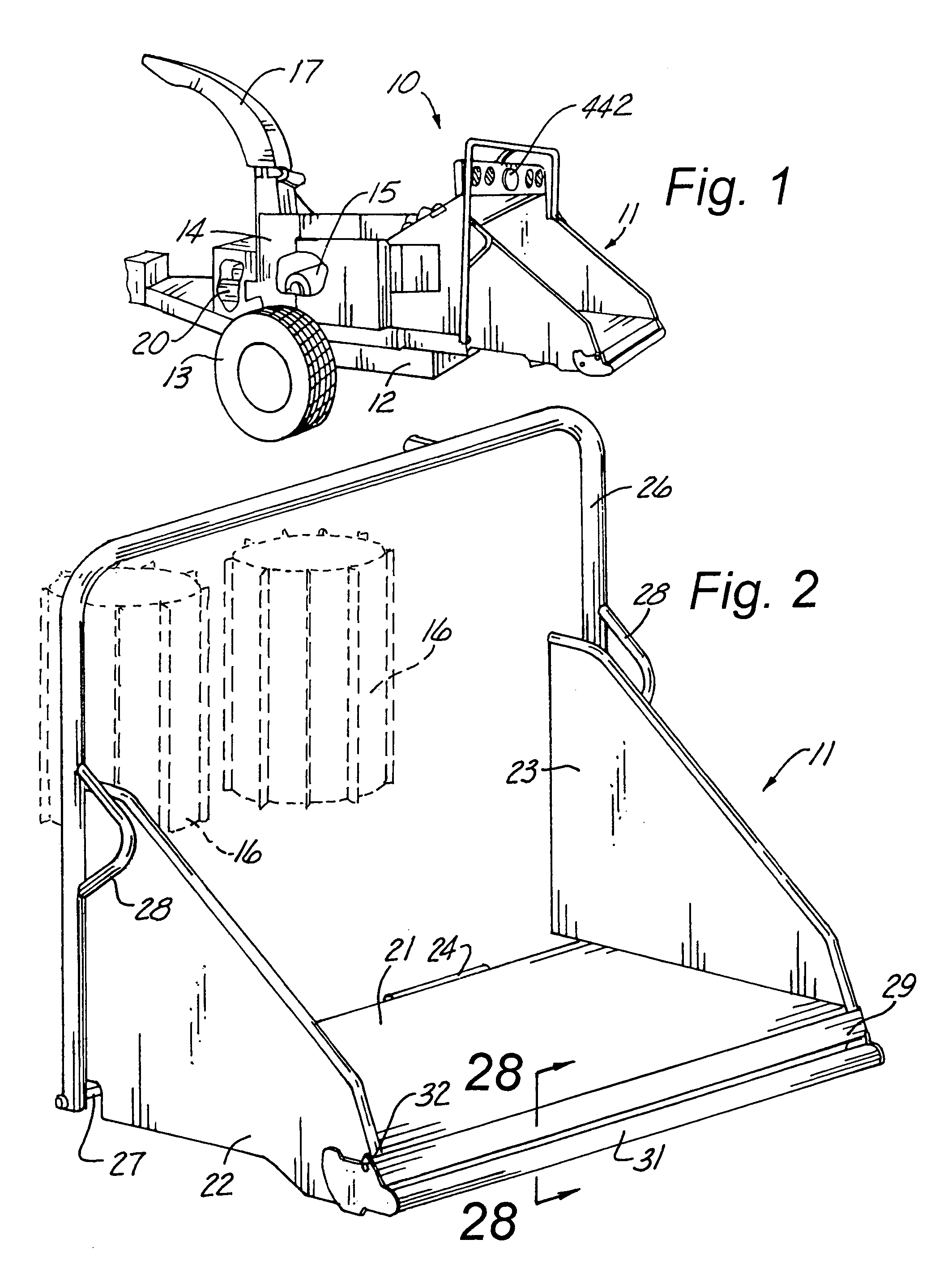

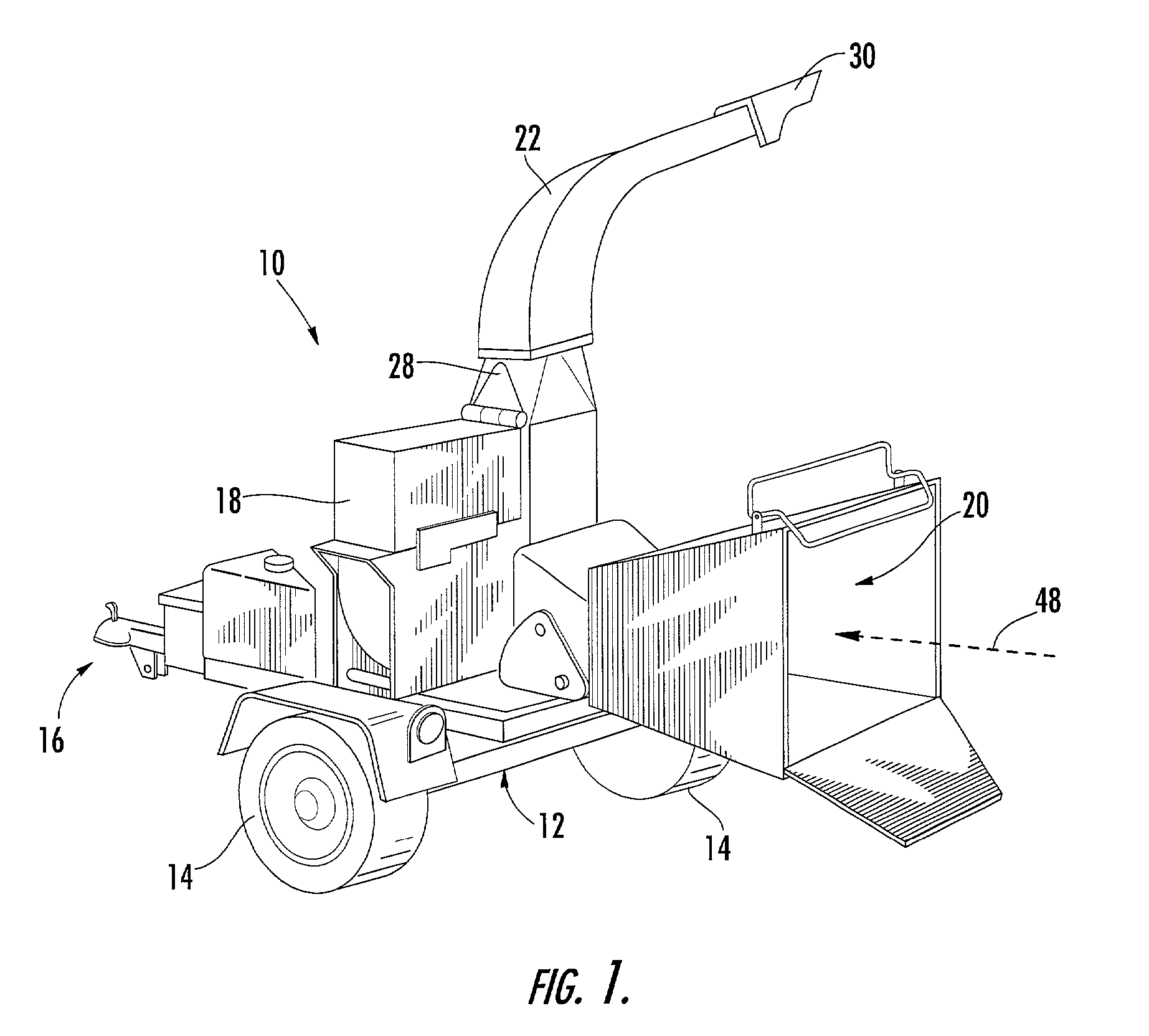

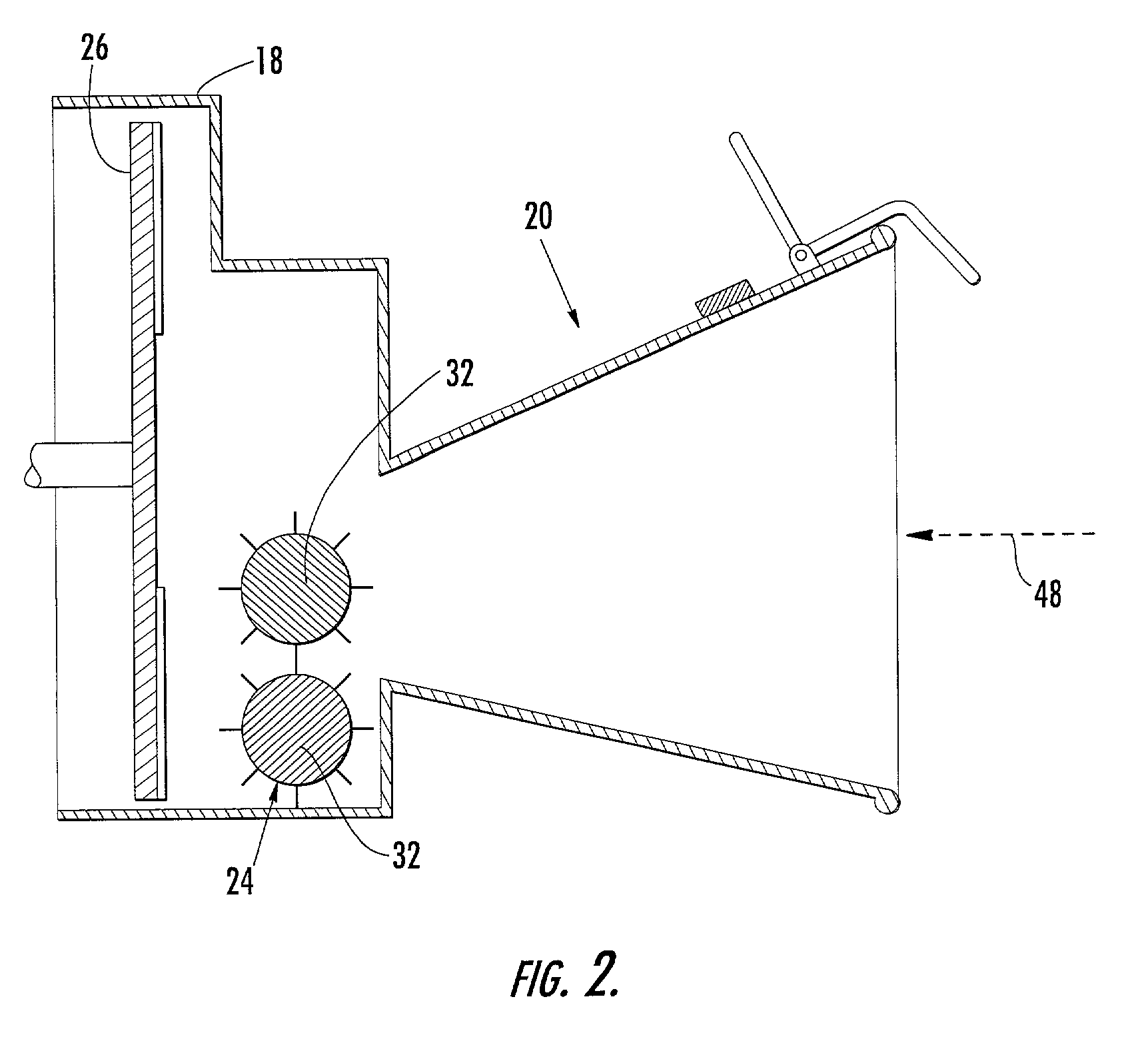

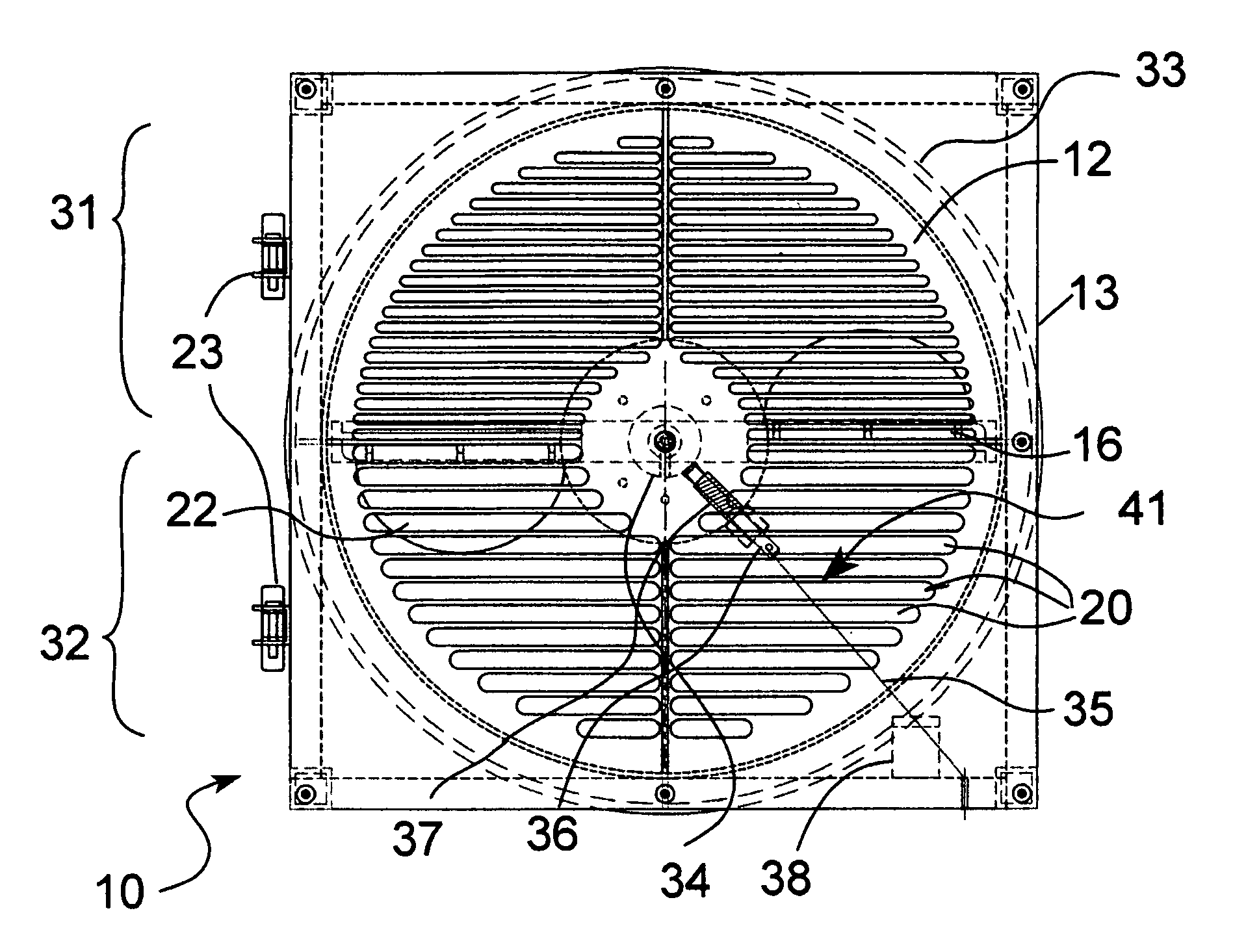

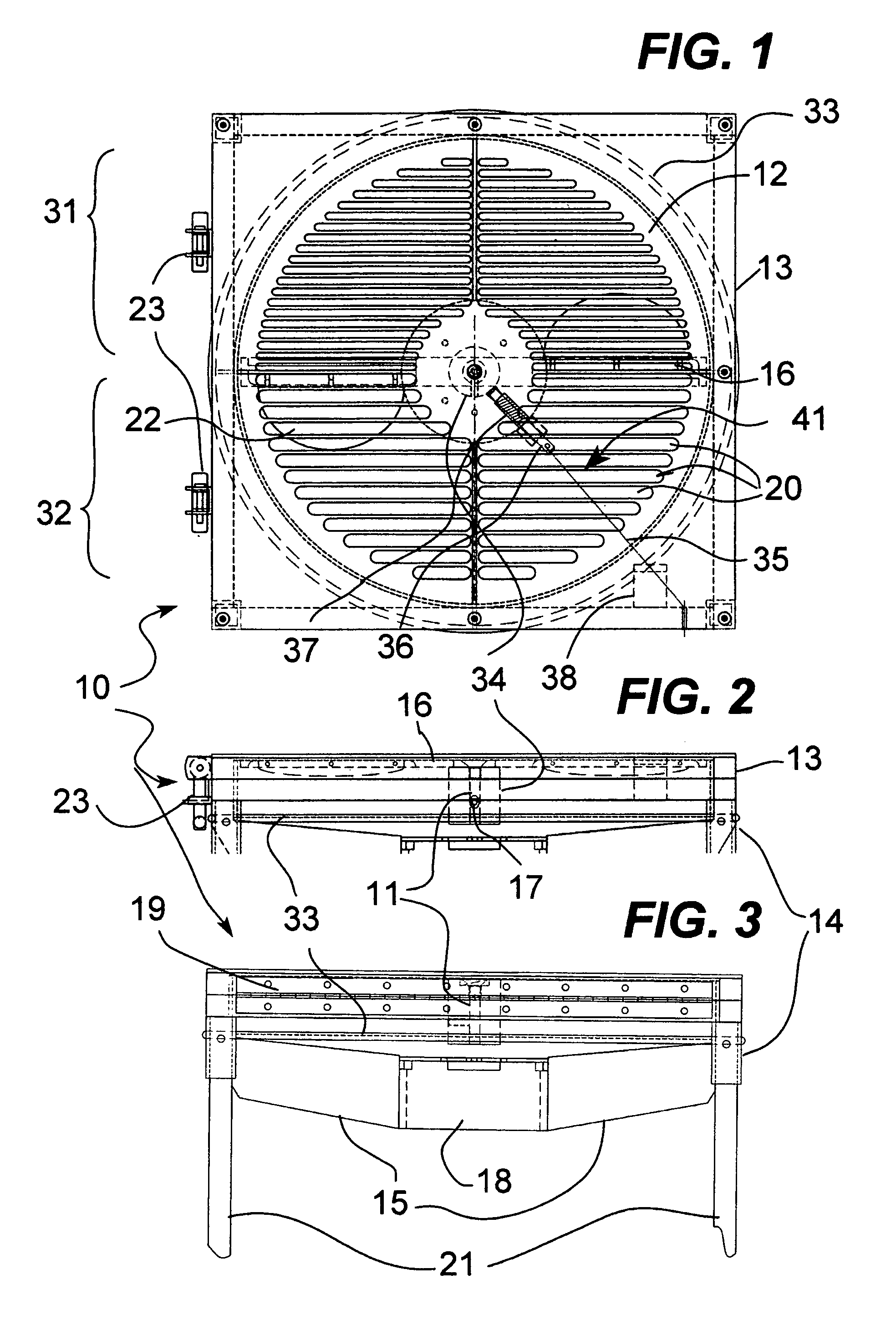

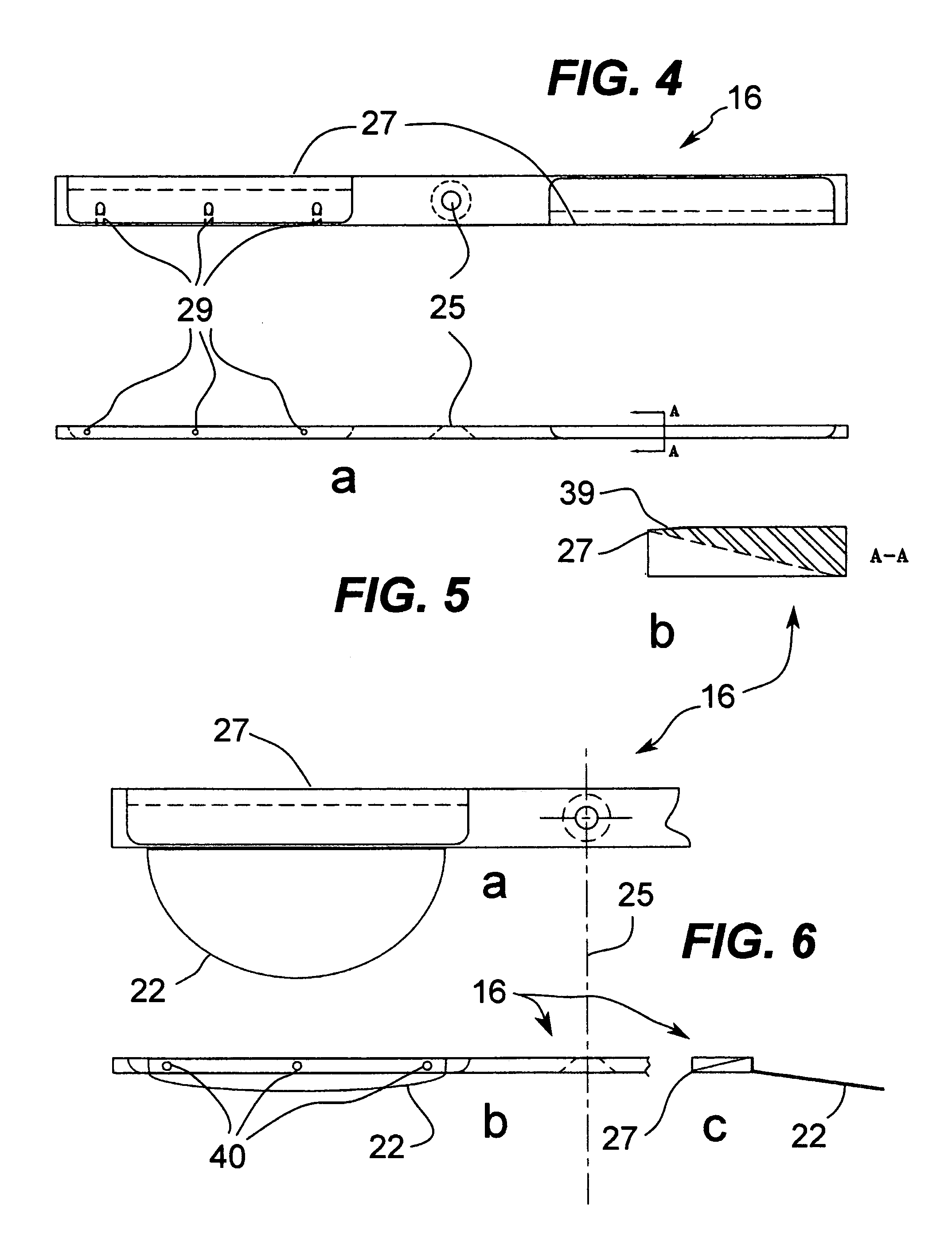

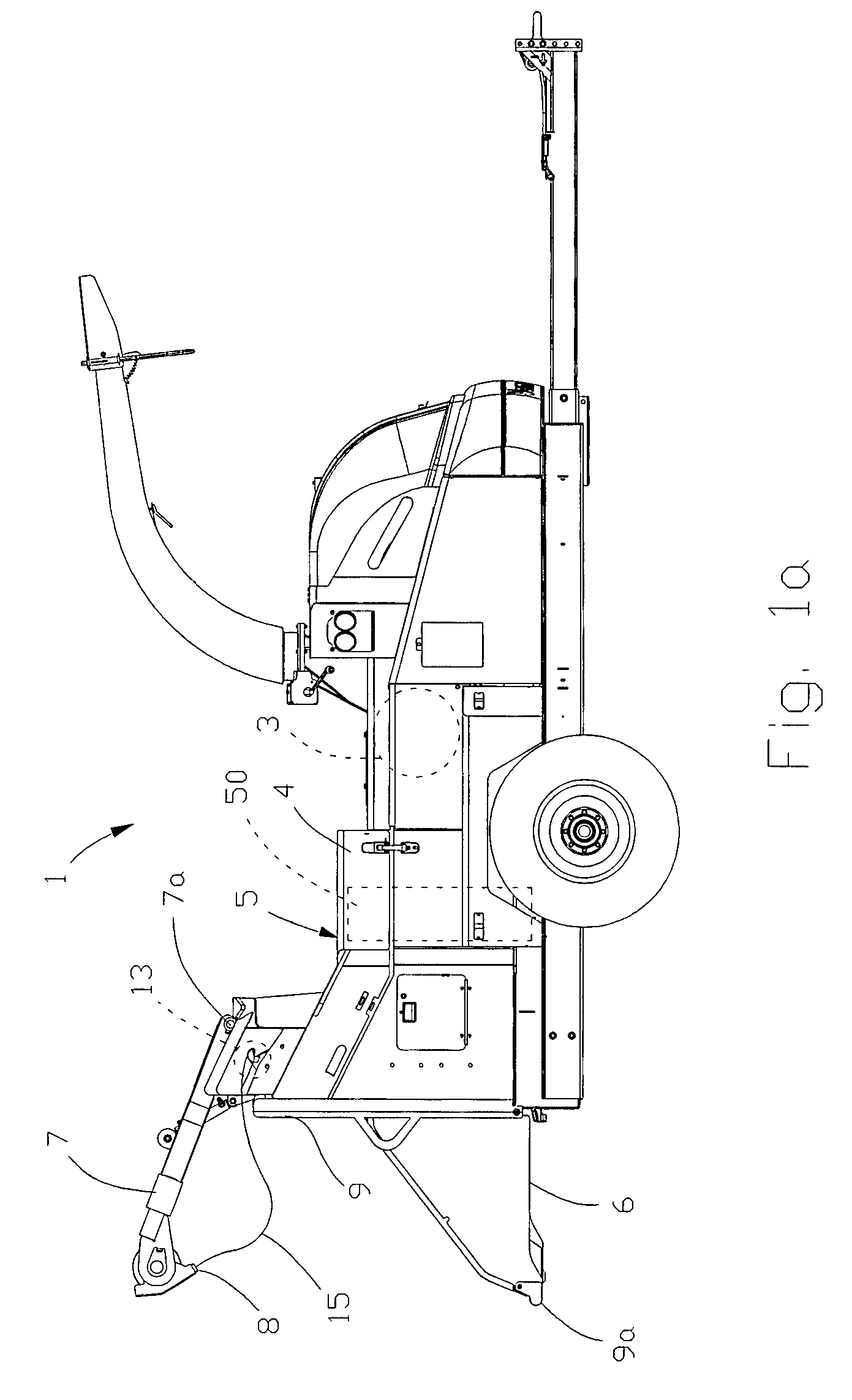

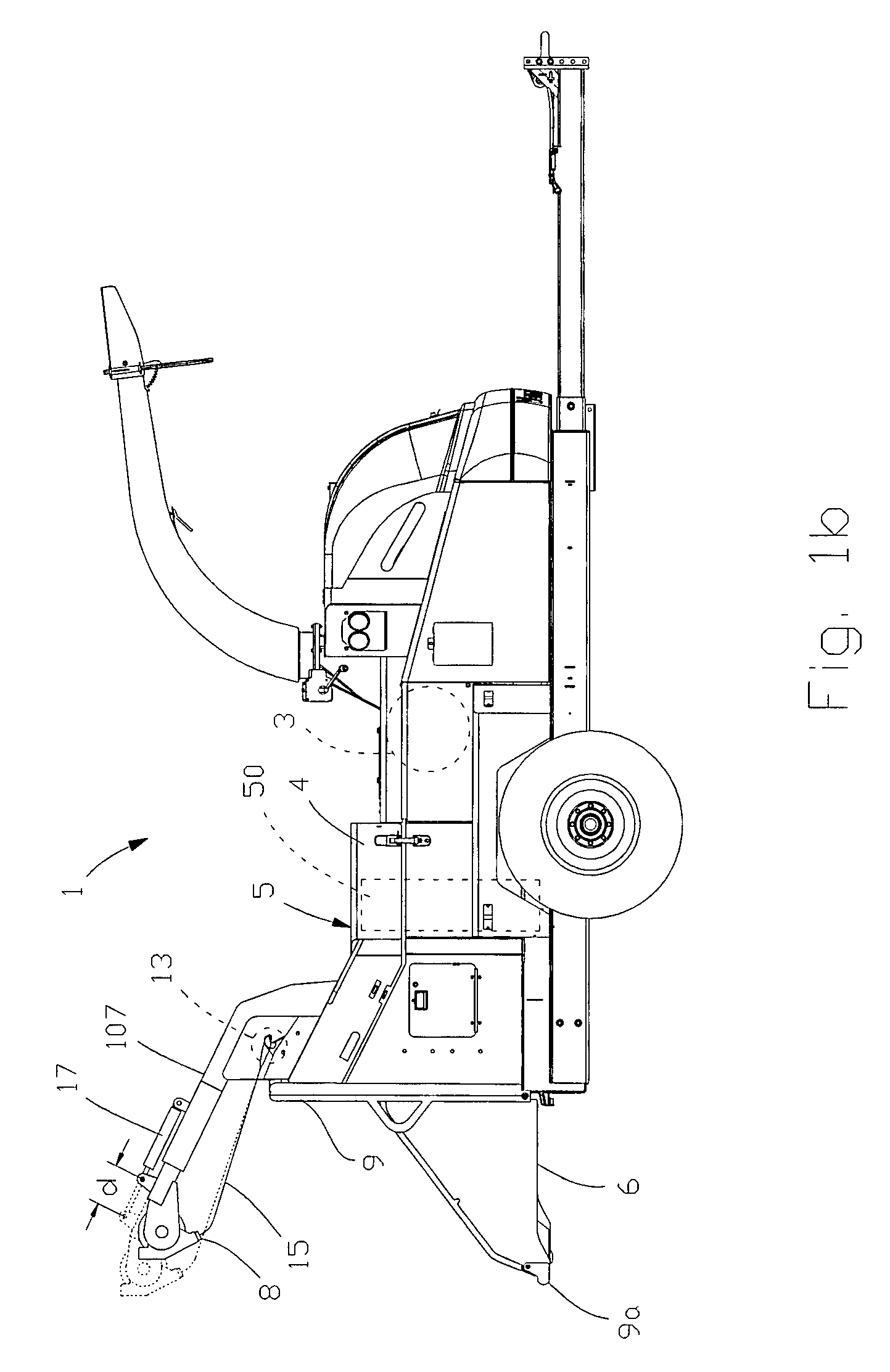

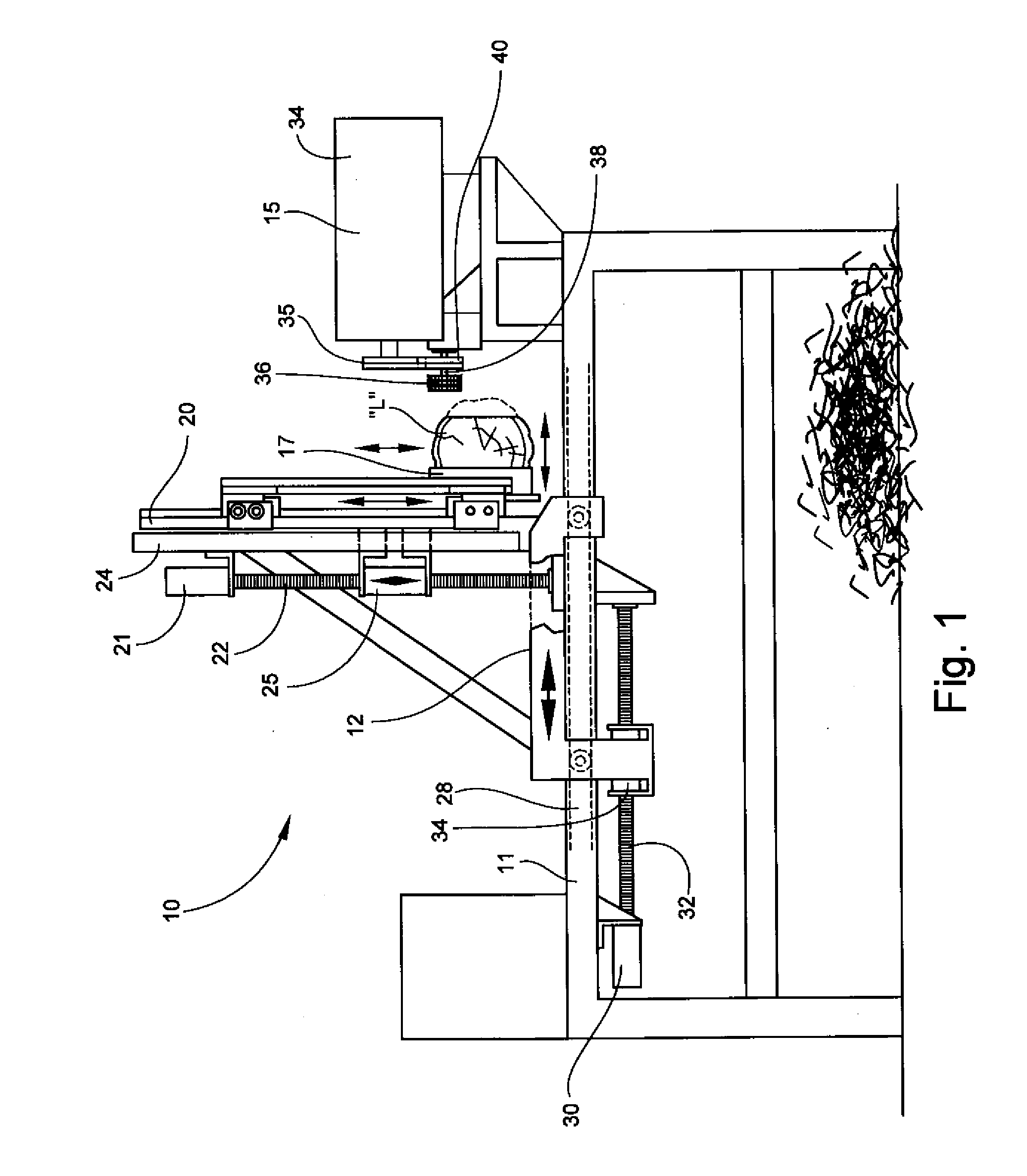

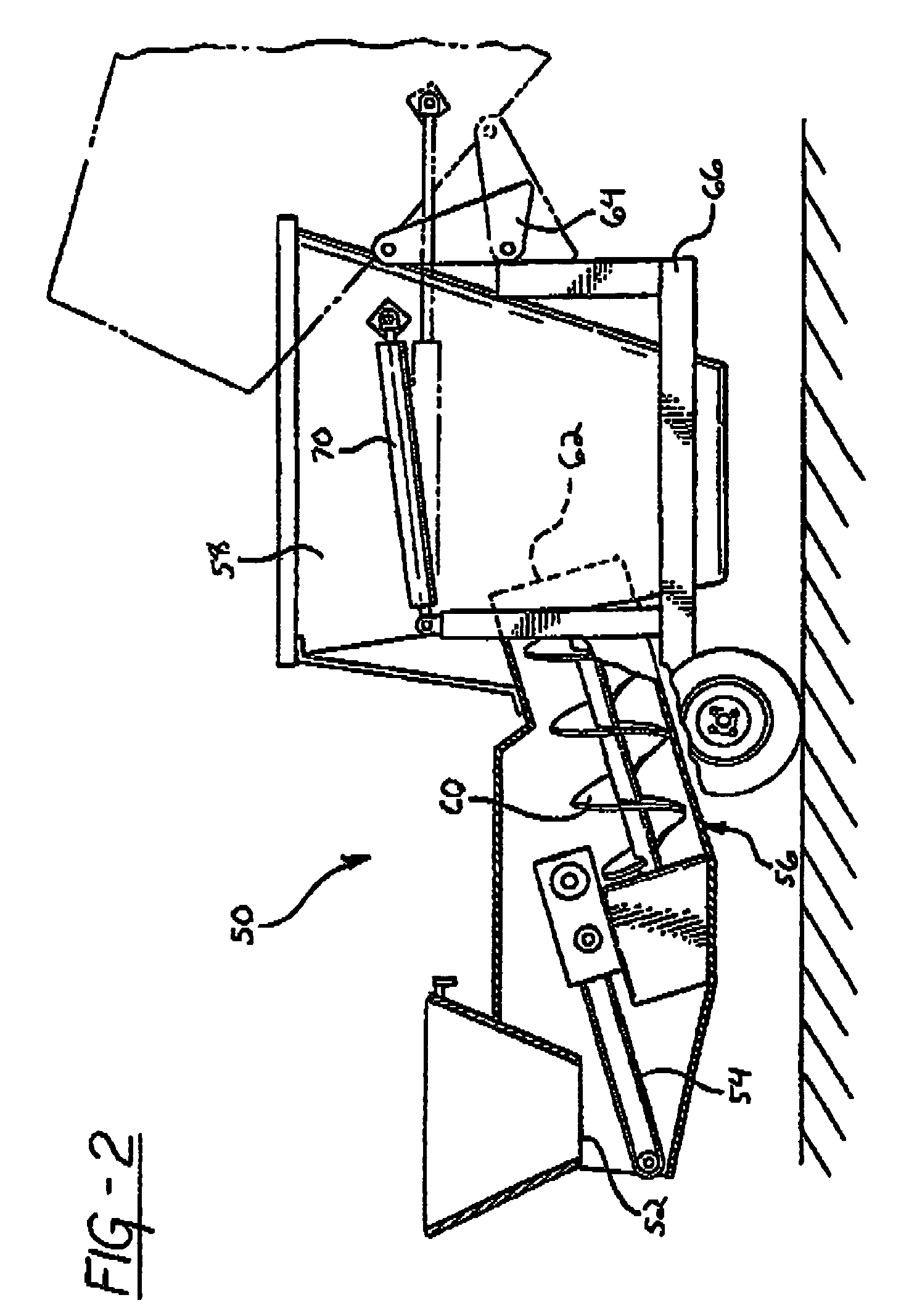

Wood chipper having an infeed chute safety device

InactiveUS7083129B2Effective and easy to operatePreventing and minimizing operator injuryPlant waste comminutingBalingMarine engineeringActuator

A waste reducing device, such as a wood chipper, having an infeed chute, a powered feed system, a powered cutting system, a discharge chute, and a safety device including an elongated structure positioned outside of and adjacent to the infeed chute of the wood chipper, the elongated structure movable vertically downward and radially inward towards the infeed chute between a plurality of positions, and an actuator operably connected to the elongated structure, the actuator having a plurality of operable positions corresponding to the plurality of positions of the elongated structure. The plurality of operable positions of the actuator permitting, interrupting, or reversing the motive operation of the powered feed and cutting systems of the wood chipper.

Owner:REASONABLE SOLUTIONS

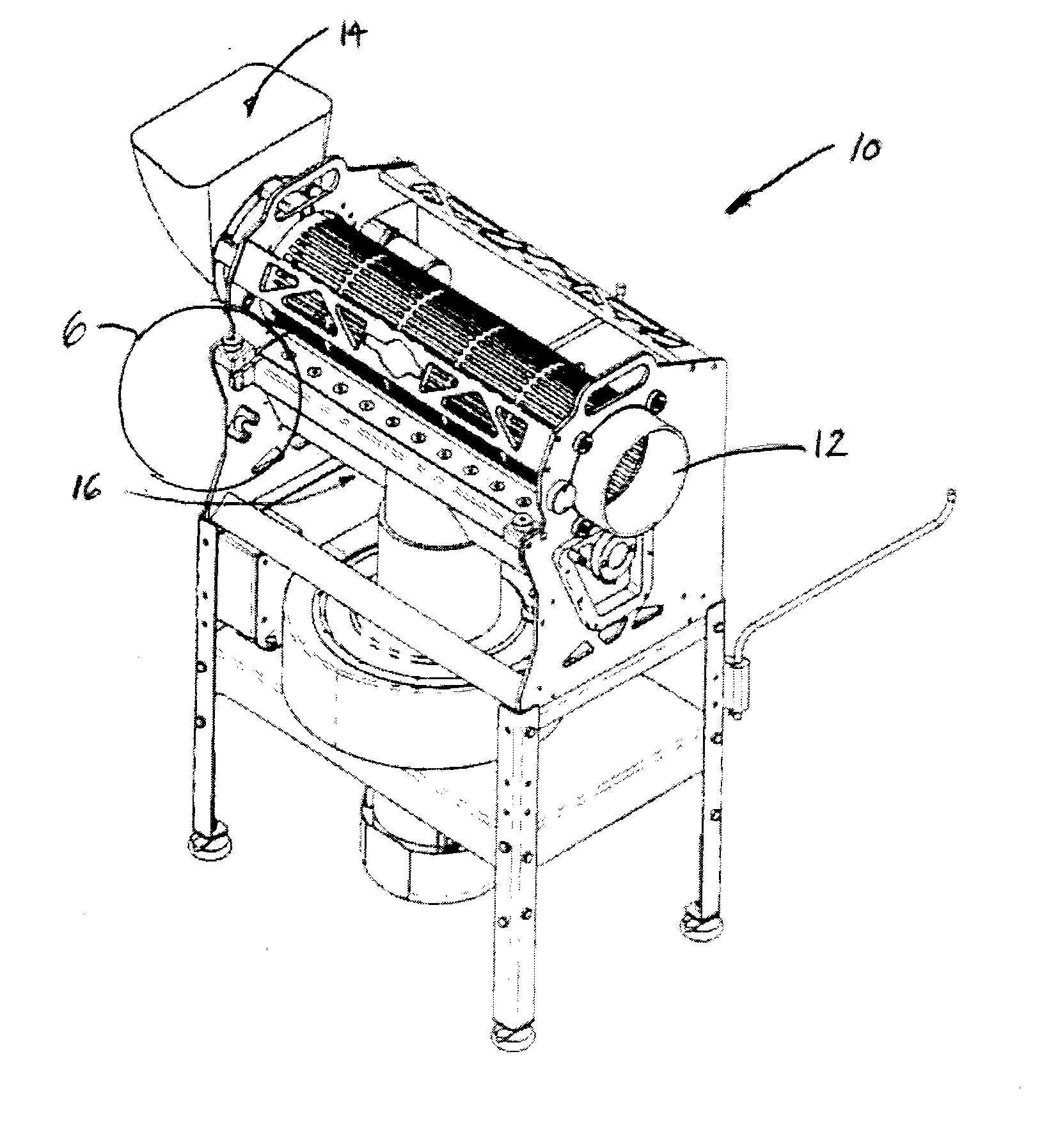

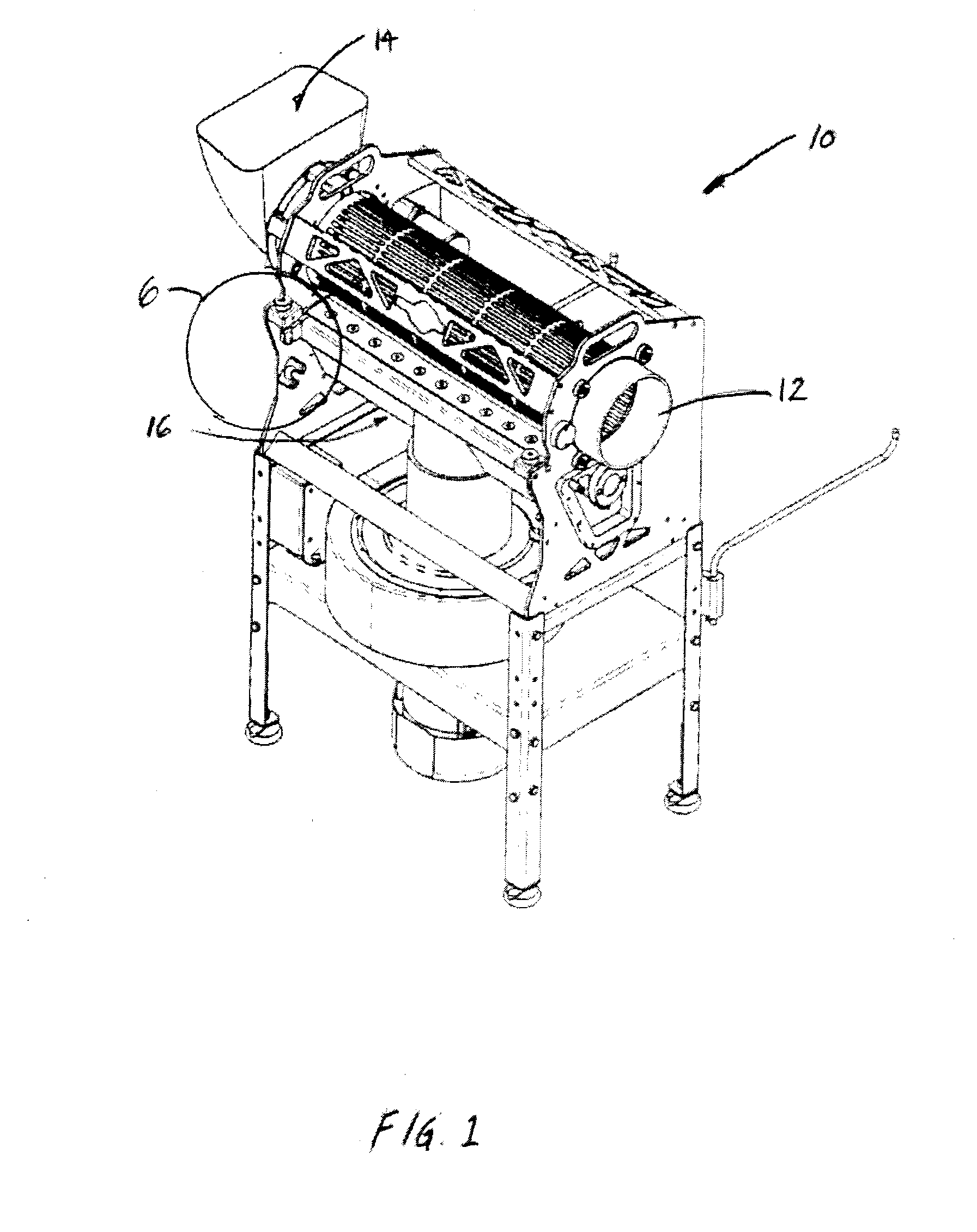

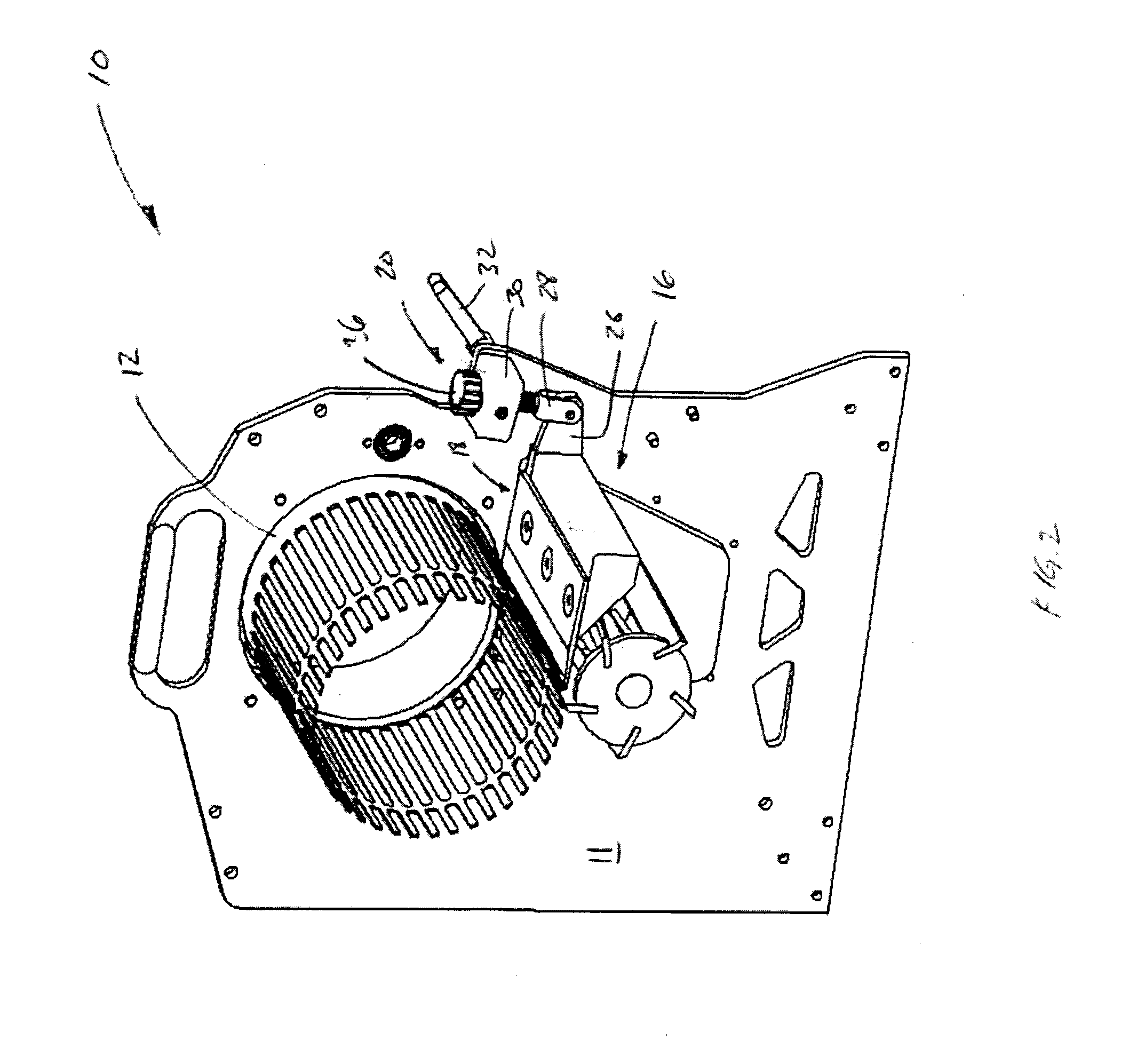

Blade mechanism for a plant material trimming device

A plant material trimming device includes two end walls supporting a rotatable perforated tumbler, a rotatable reel with helical blades, and a blade mechanism pivotably connected to the end walls of the device. The blade mechanism includes: (i) a blade bar configured to cut plant material in cooperation with the helical blades when the device is in operation; (ii) a first arm operatively associated with the blade bar; and (iii) a second arm pivotably connected to the first arm such that the second arm can pivot downward when the blade mechanism is unlocked. A tightening block may be threadedly connected to the second arm and connectable to one of the two end walls. The tightening block may be configured for adjusting the pitch of the blade bar relative to the helical blades when the blade mechanism is locked to the end walls.

Owner:KEIRTON

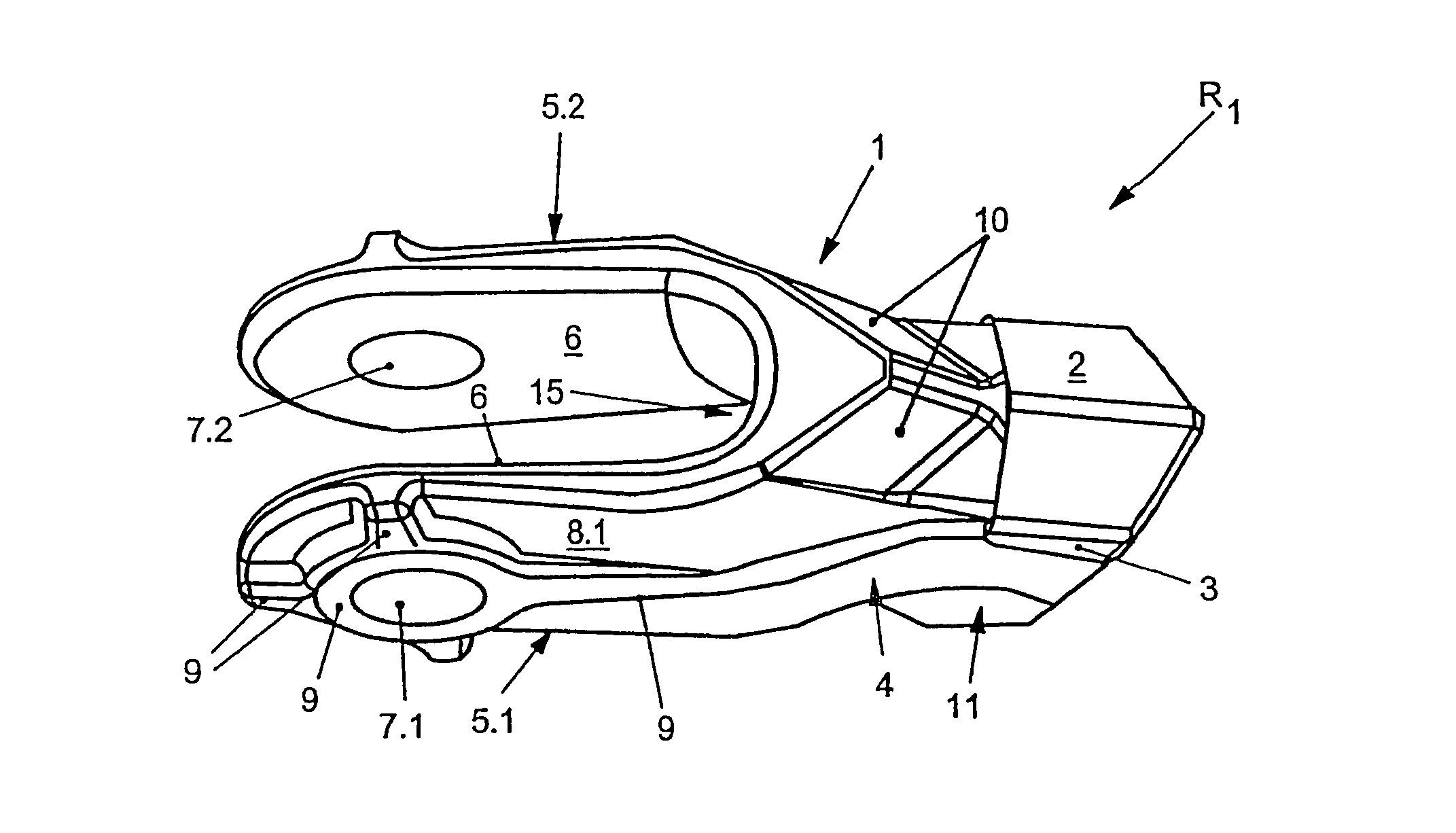

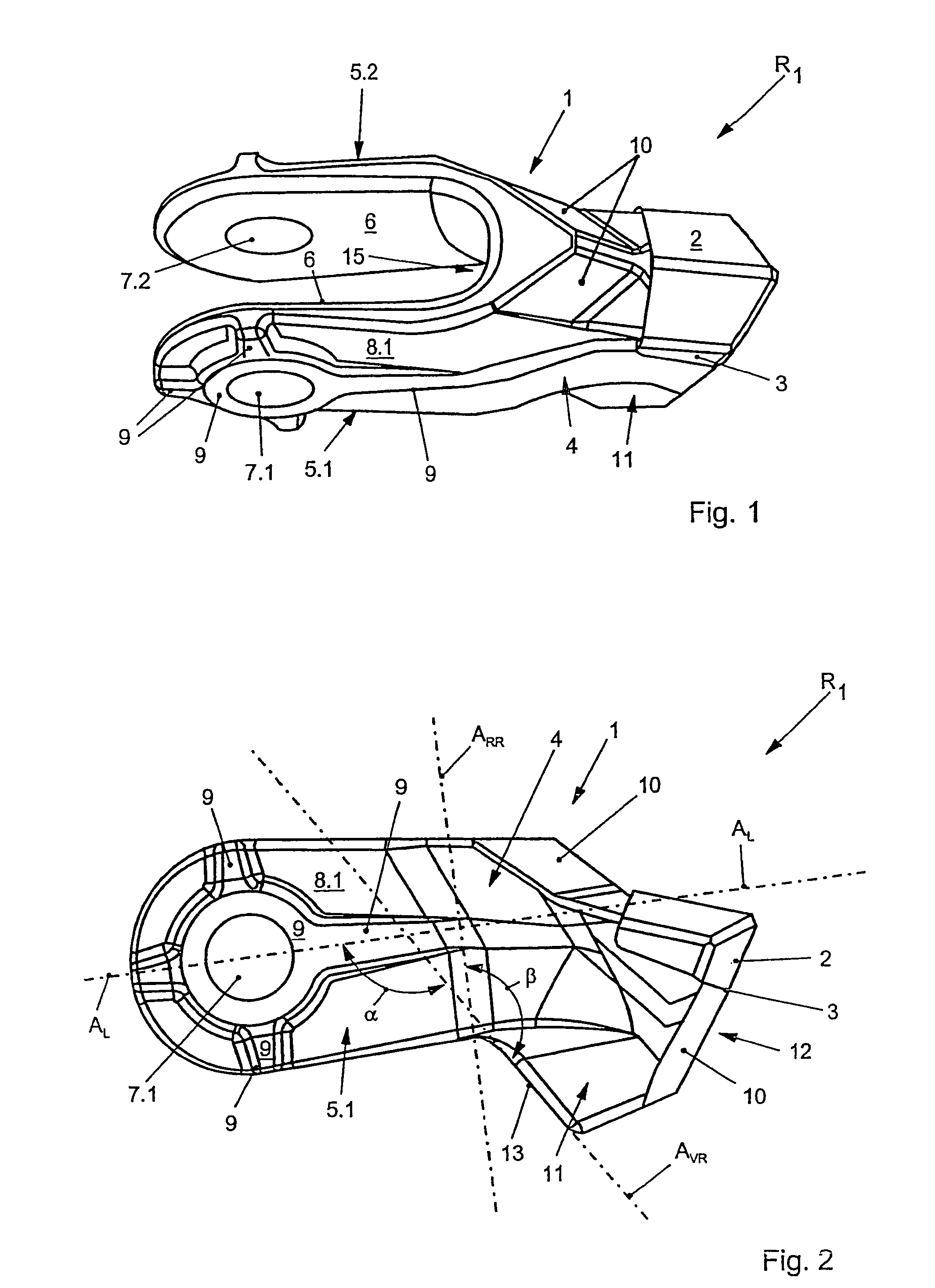

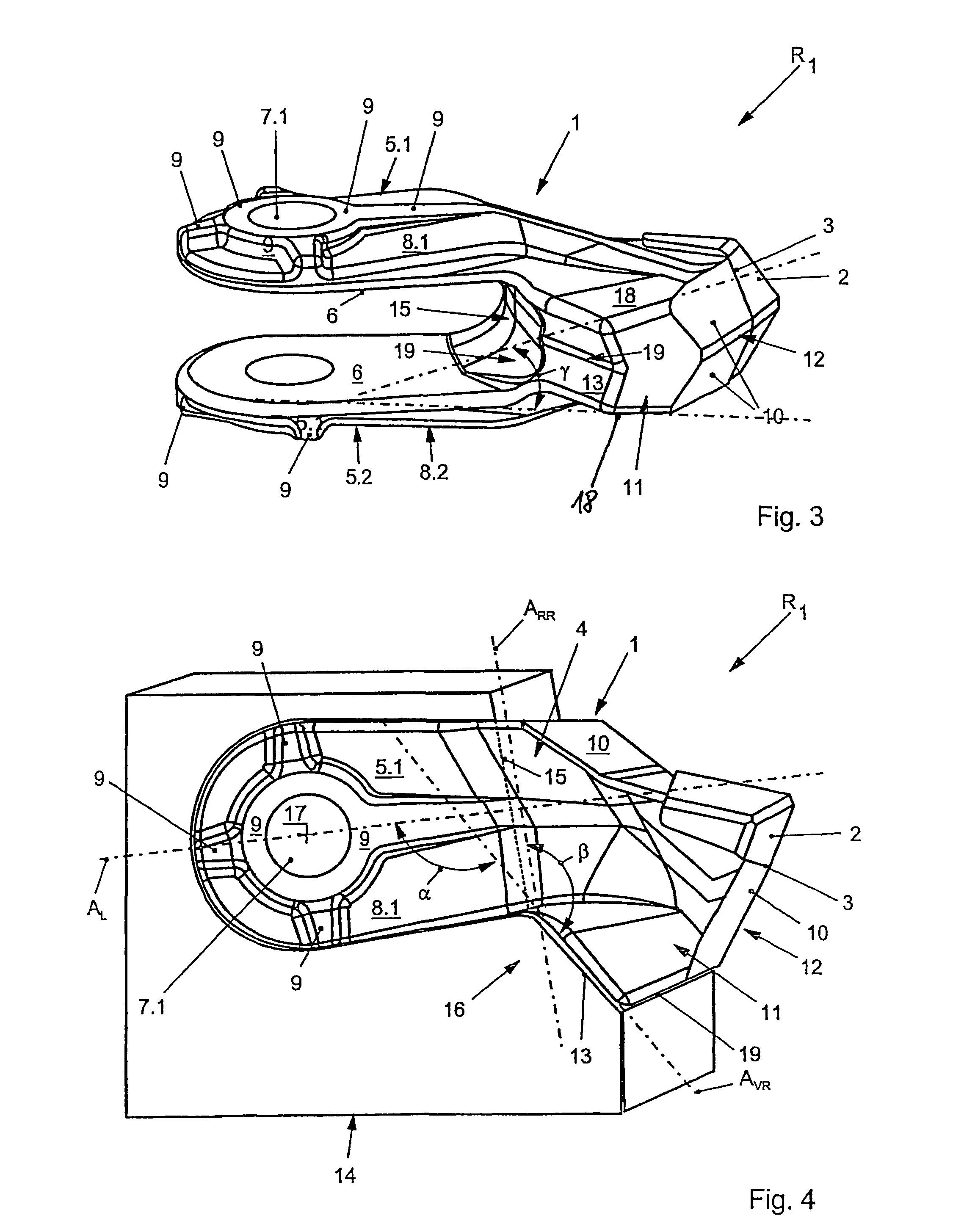

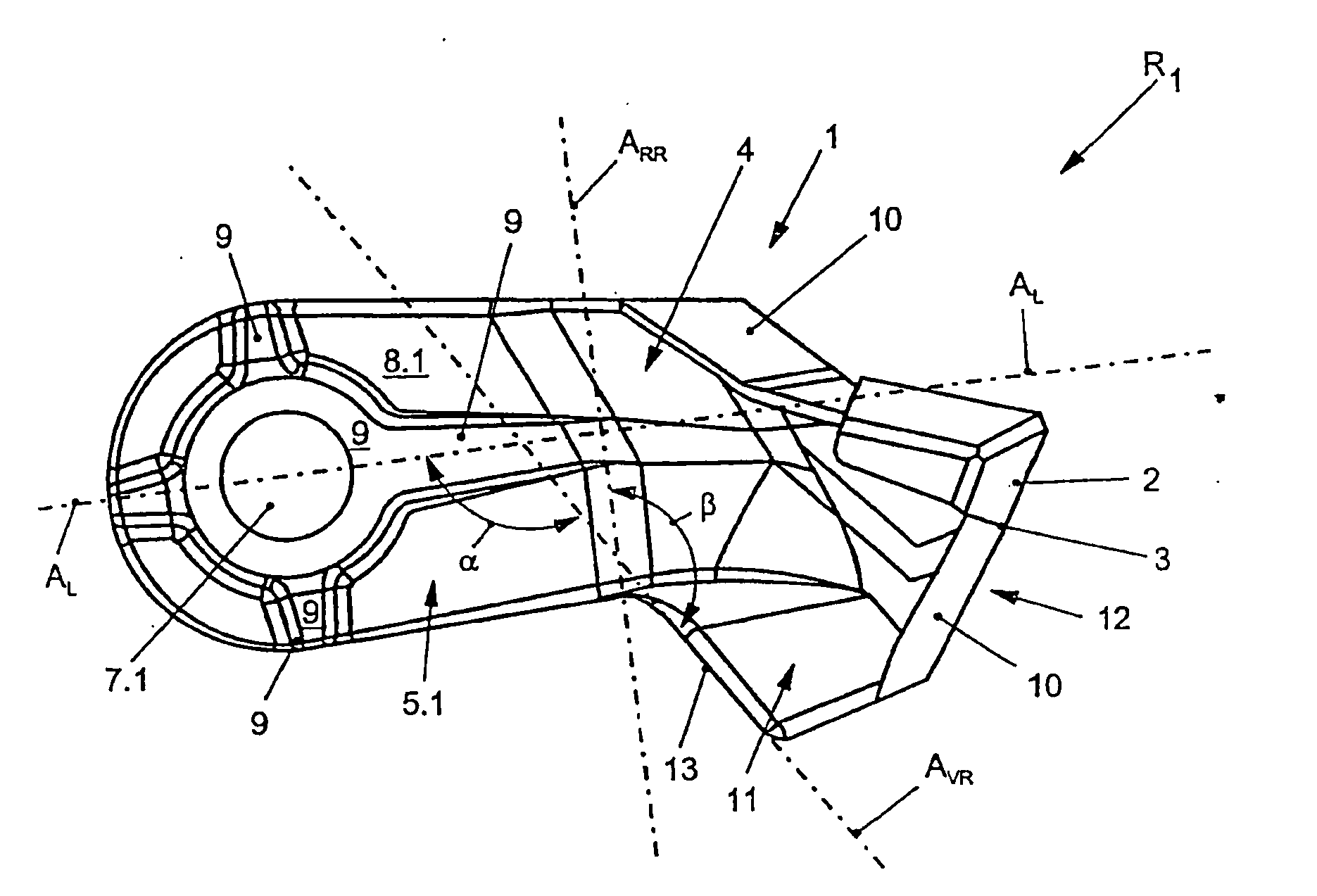

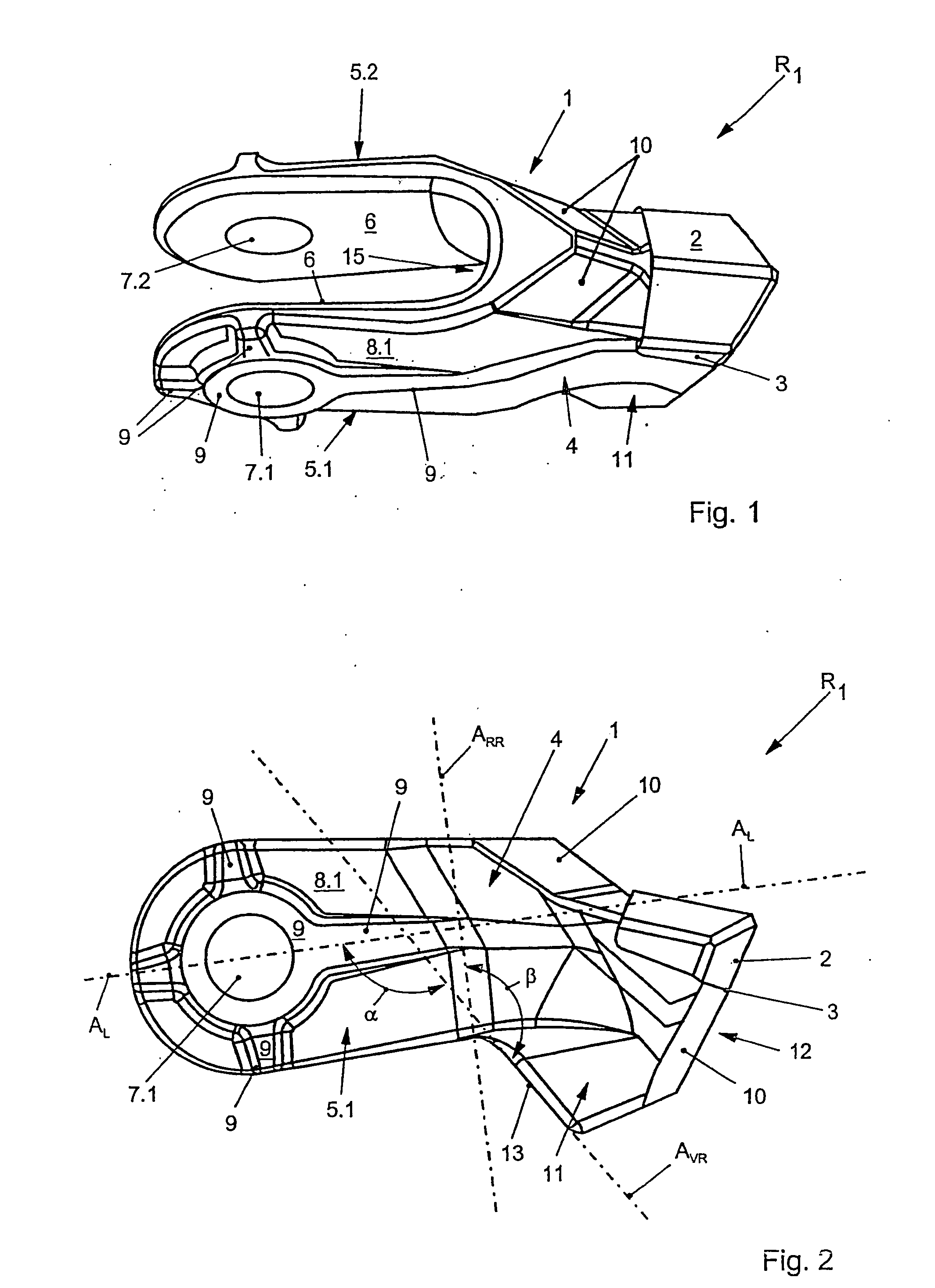

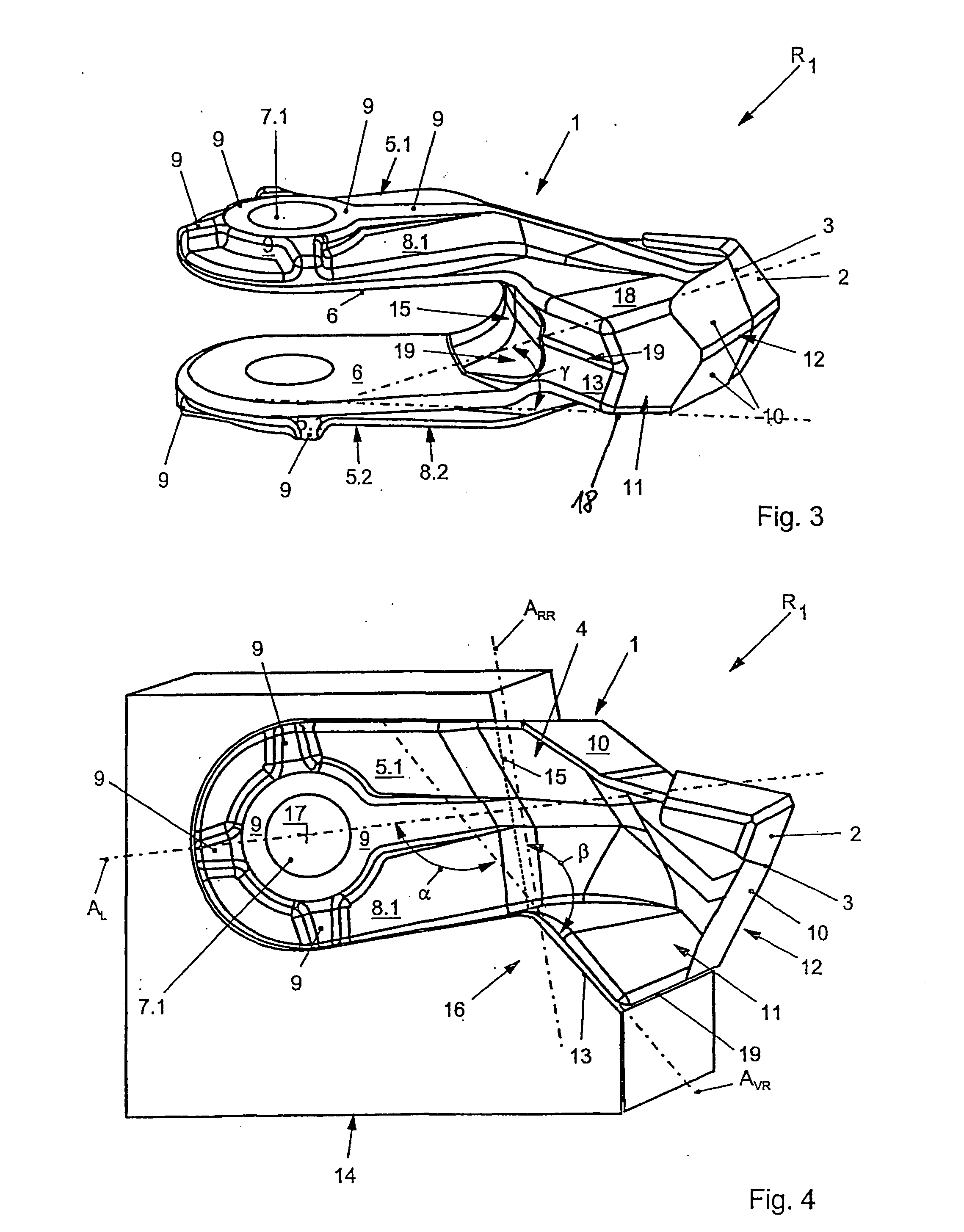

Cutting element

ActiveUS8231072B2Promote absorptionBetter mountingPlant waste comminutingTilling equipmentsEngineering

Owner:AHWI MASCHINENBAU

Leaf snatcher

Owner:9354 7453 QUEBEC INC

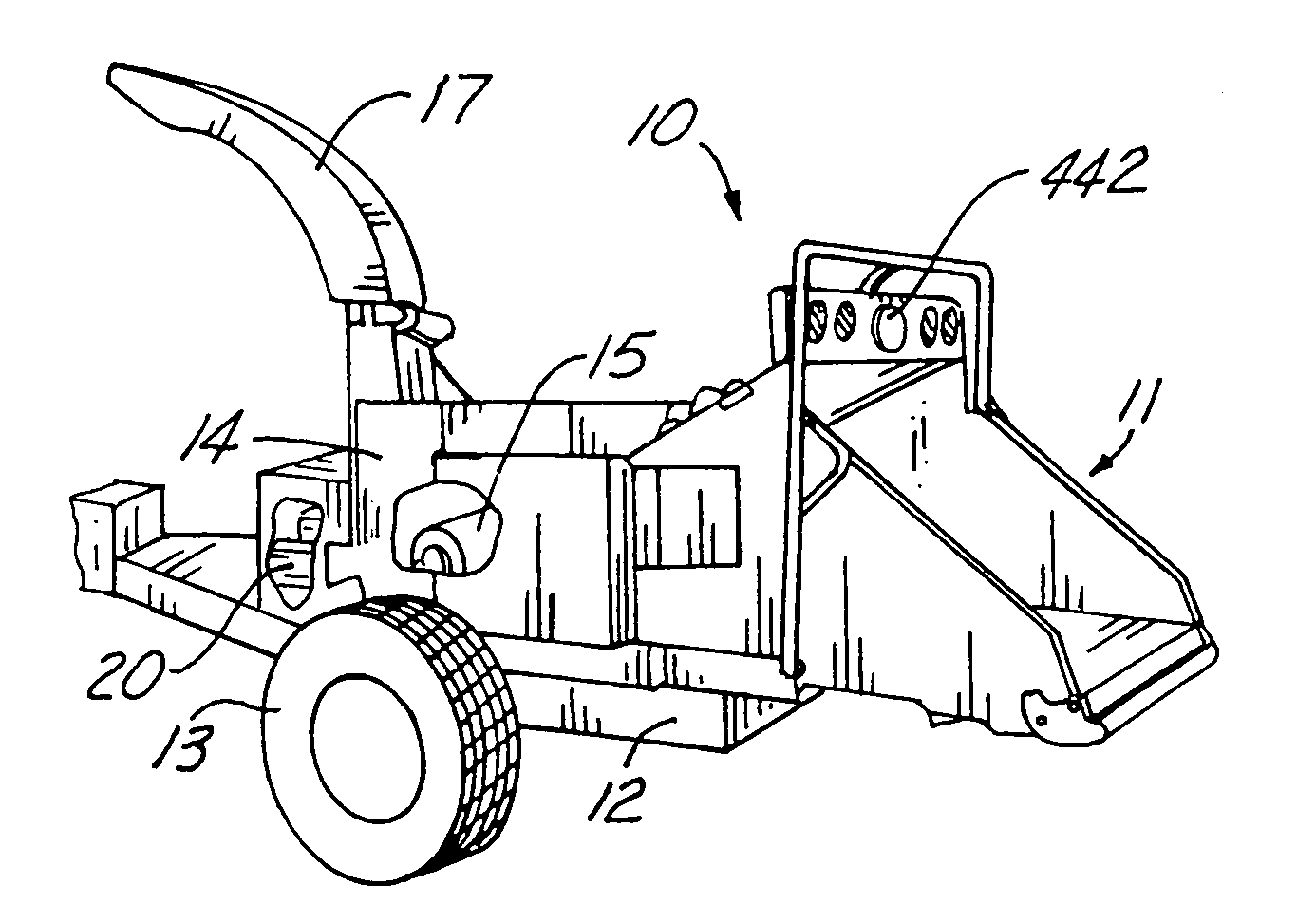

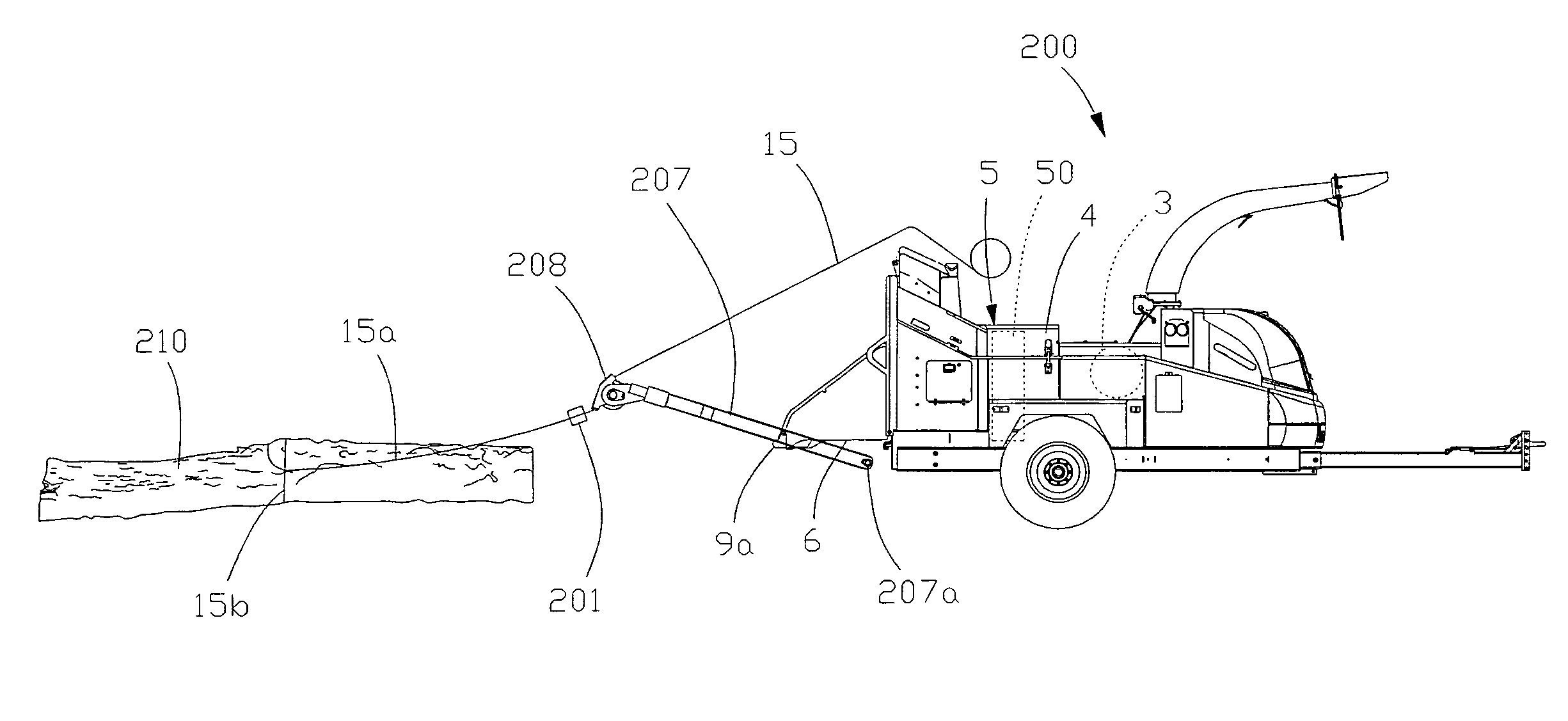

Pivoting/telescoping winch boom for a brush chipper and method of using same

ActiveUS7819348B2Prevents the rope from being snaggedLess restricted feedingMowersPlant waste comminutingEngineeringWinch

Owner:VERMEER MFG CO

Cutting element

ActiveUS20100090047A1Improve stabilityReduce weightPlant waste comminutingTilling equipmentsEngineering

Owner:AHWI MASCHINENBAU

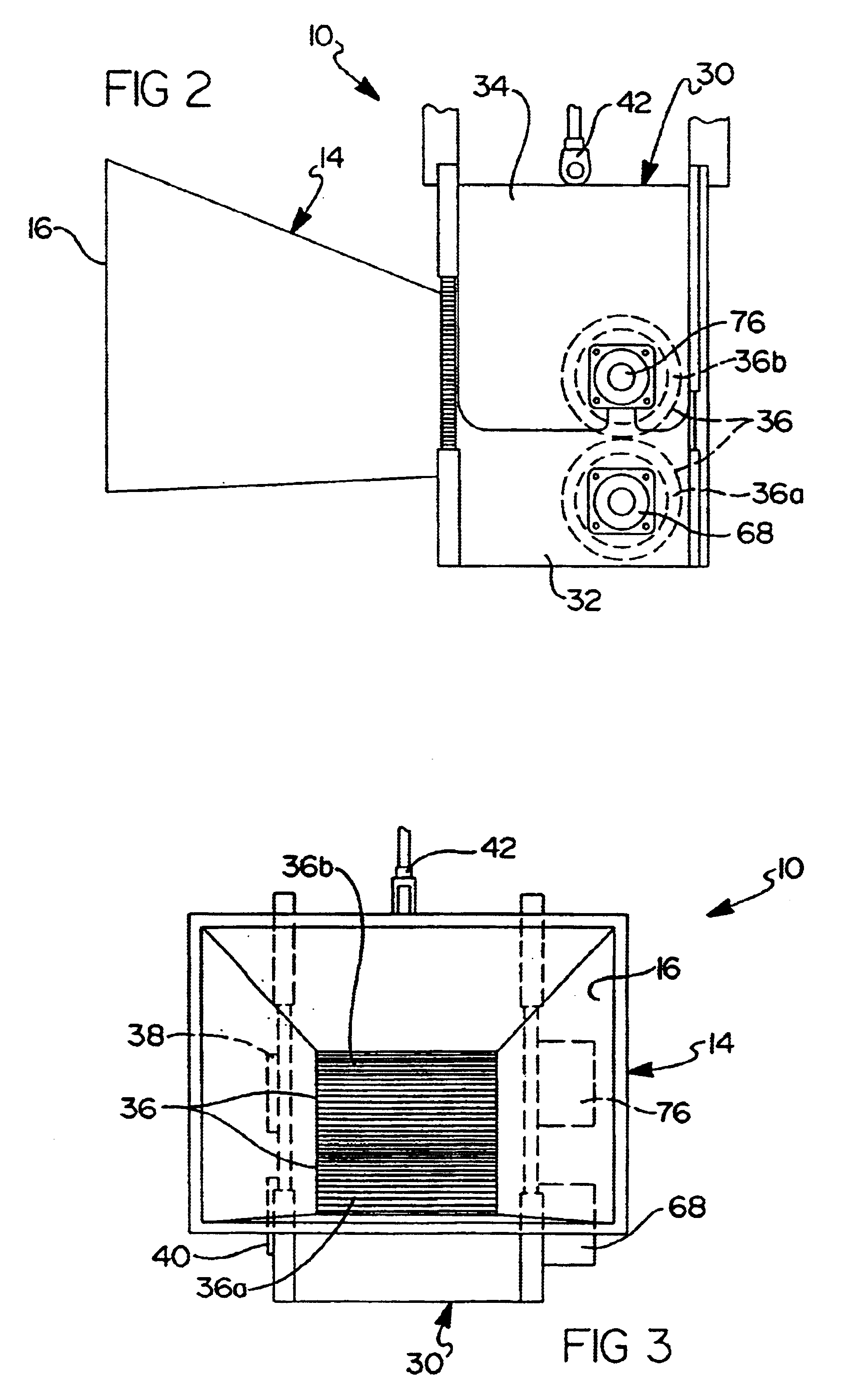

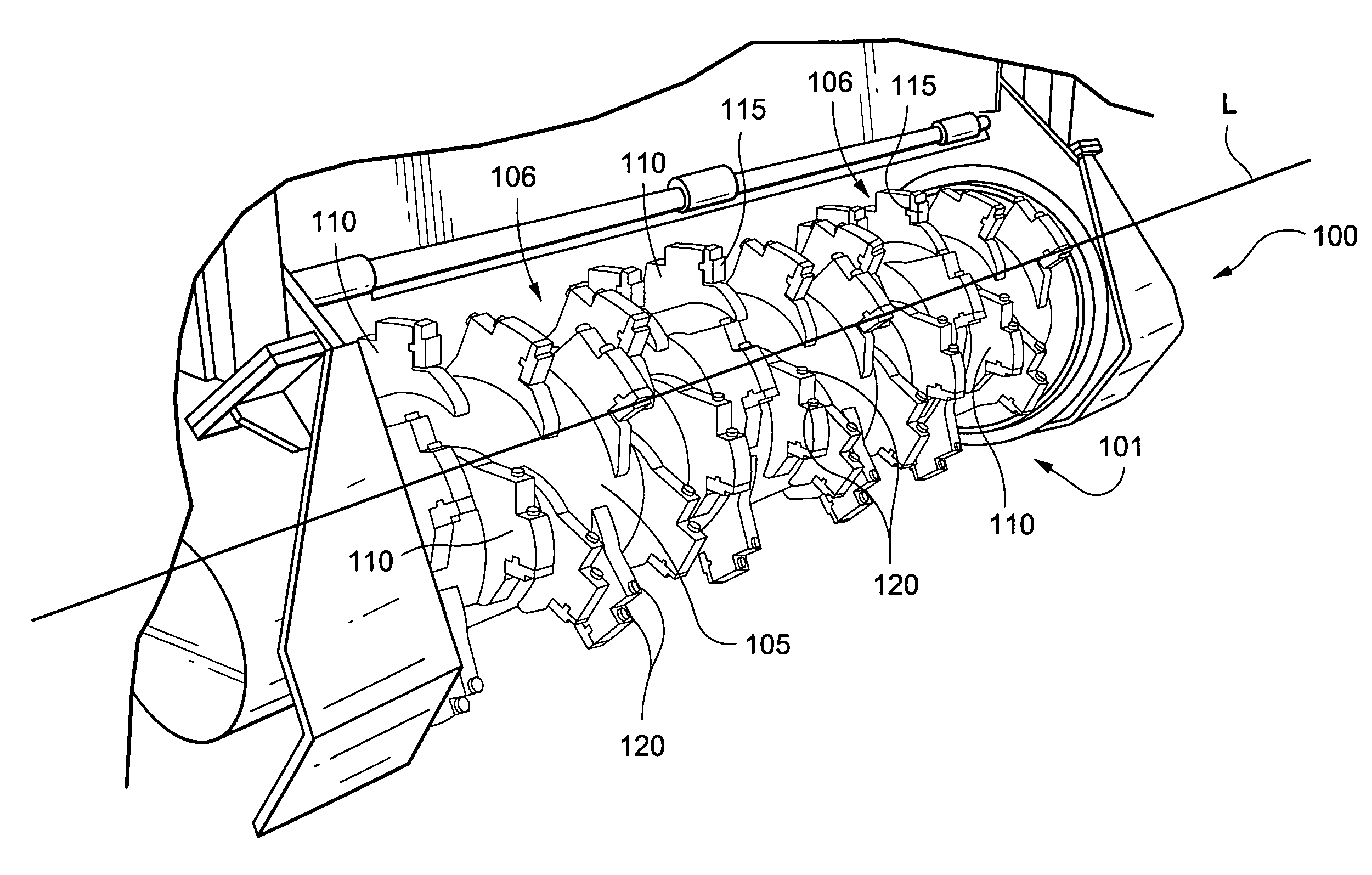

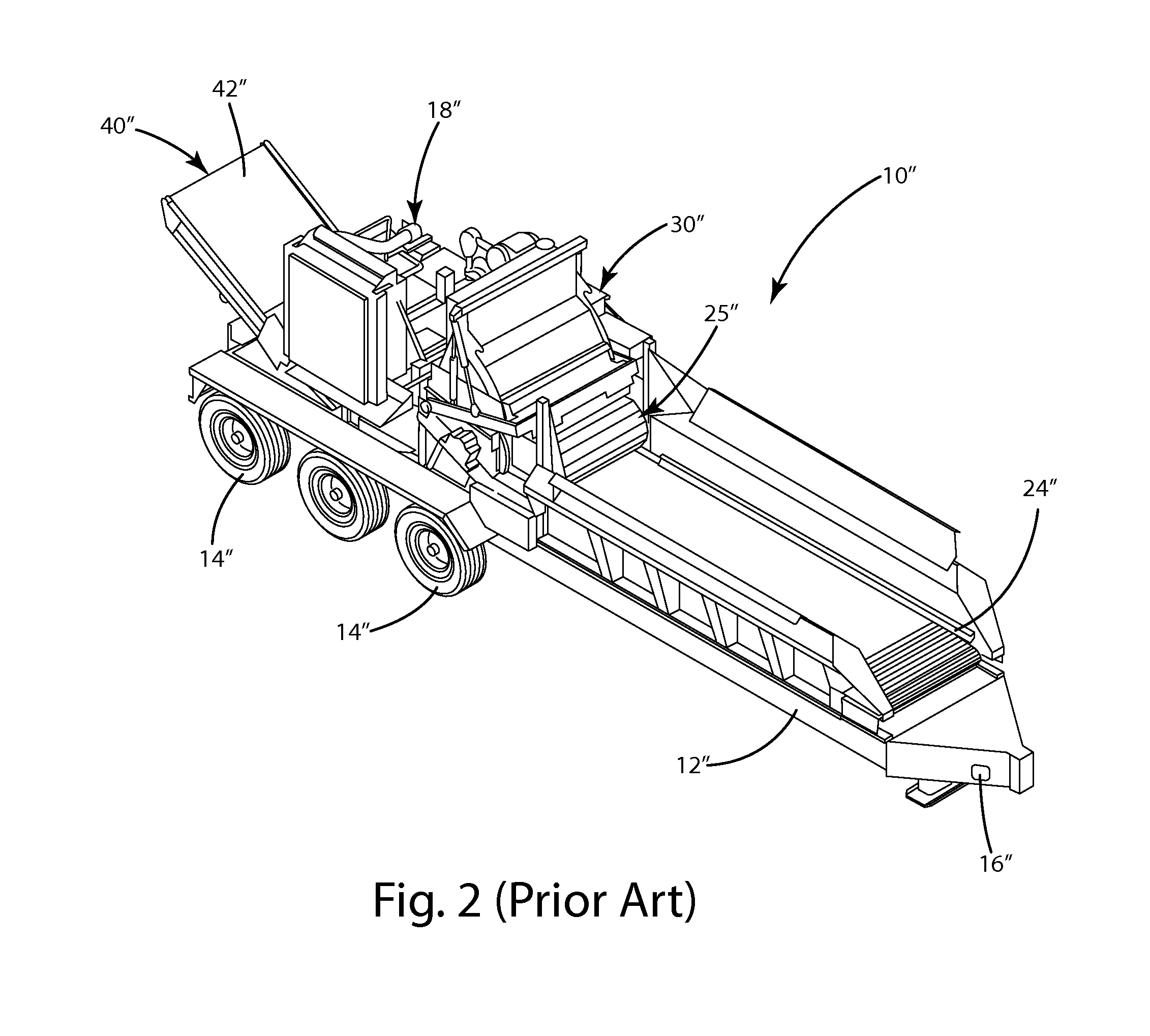

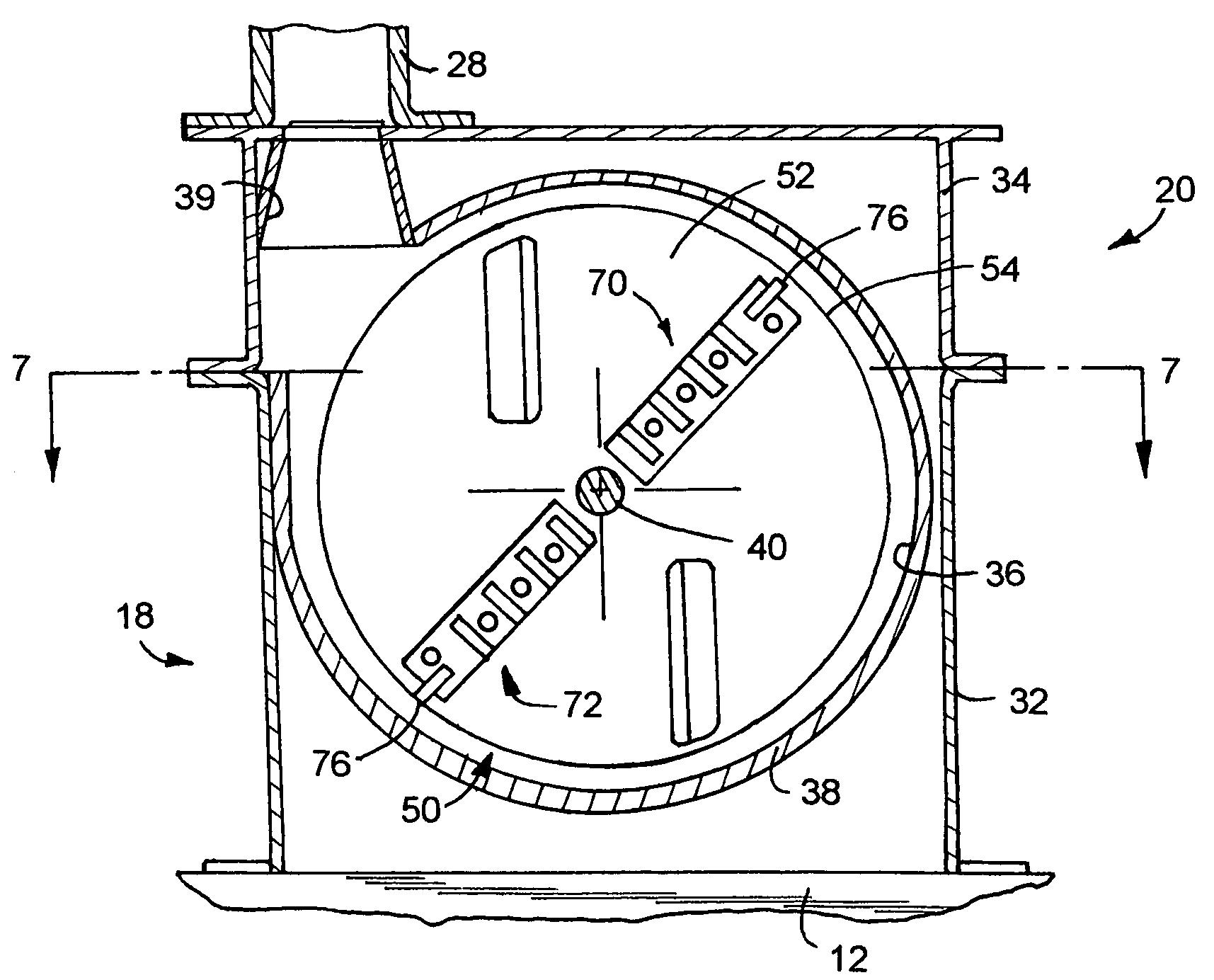

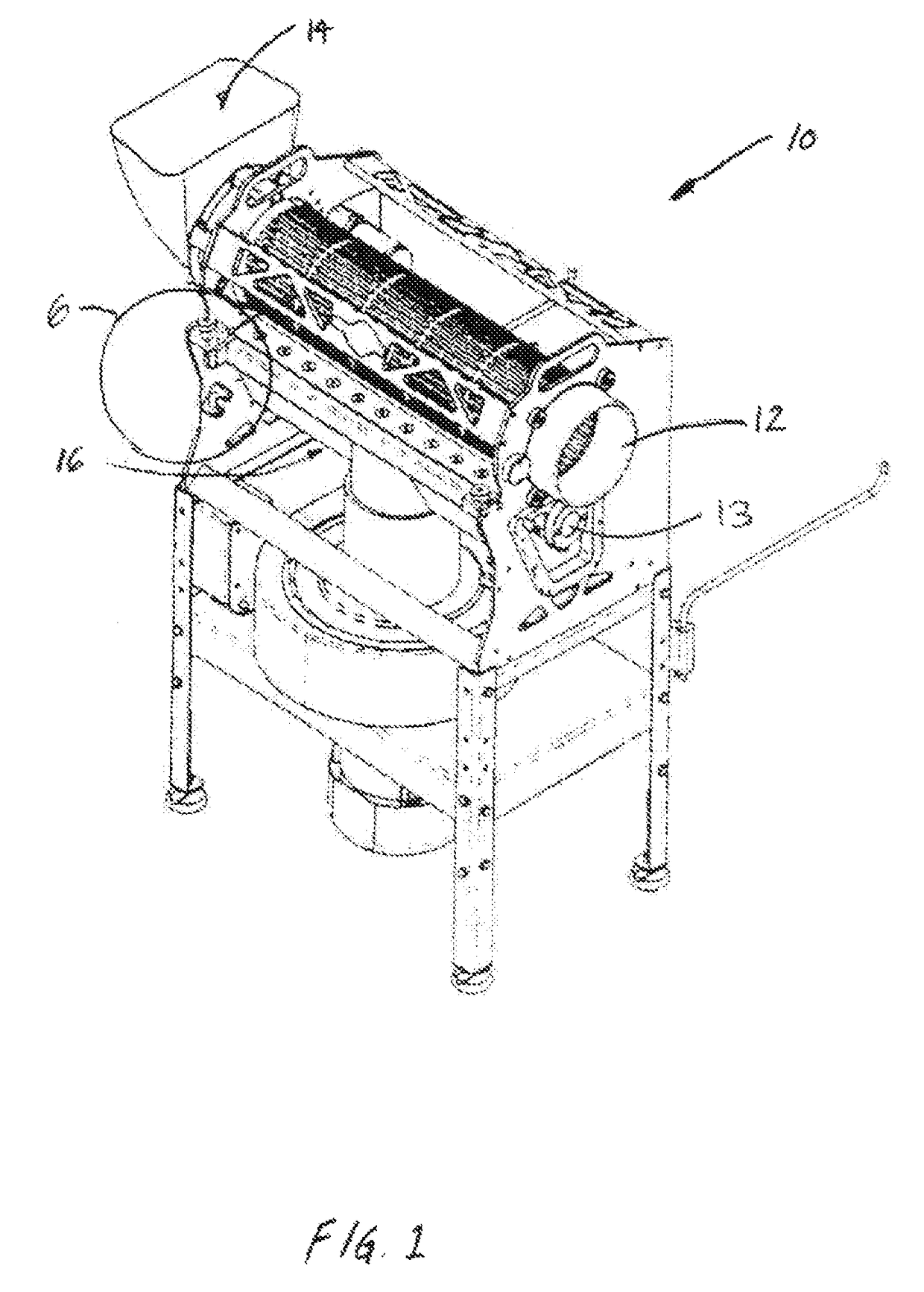

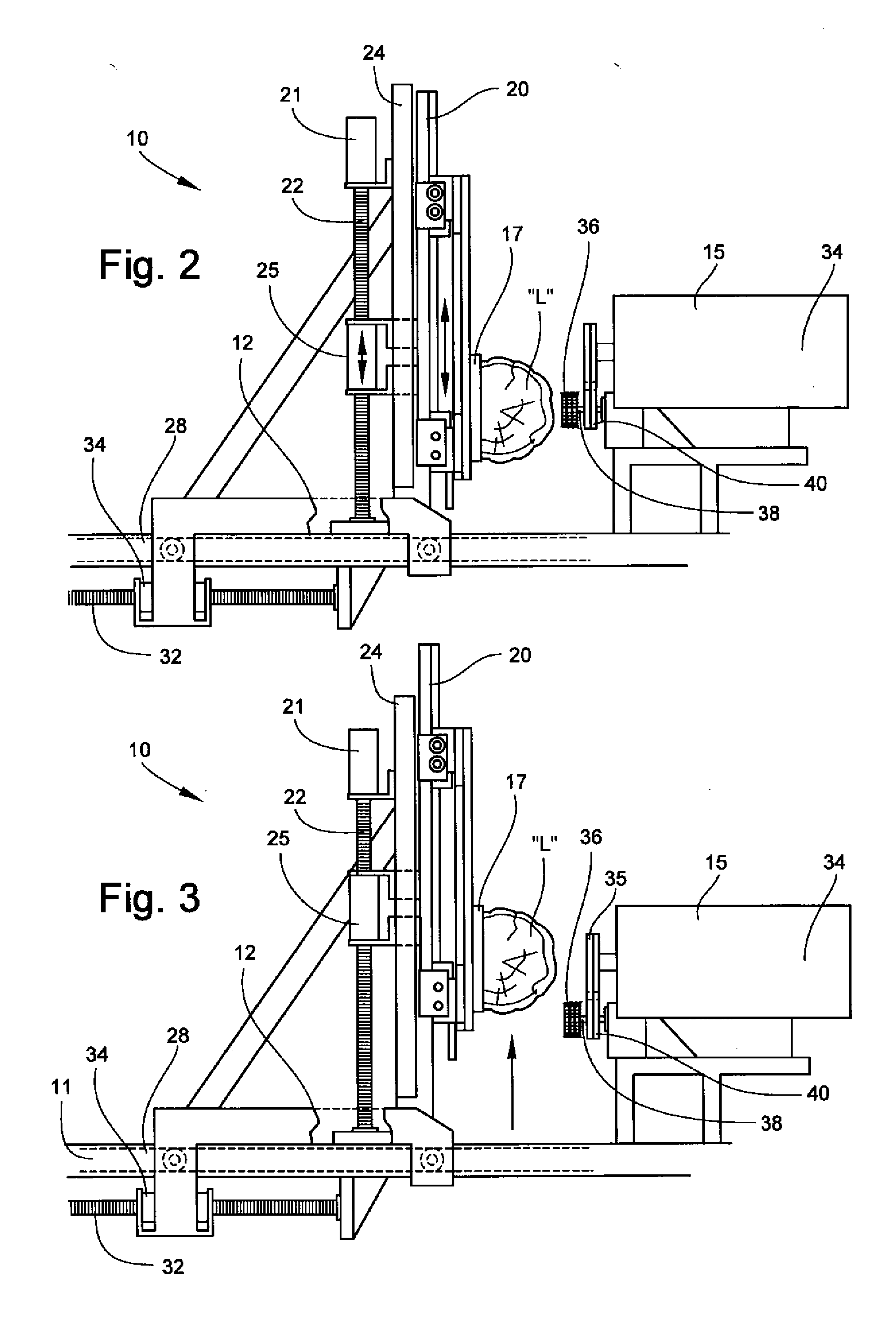

Brush chipper with improved feed rollers

ActiveUS7546964B2Reduce generationReduce chanceWood feeding arangementsFeeding devicesEngineeringMechanical engineering

An improved feed roller assembly wherein the feed roller provides a force perpendicular to the feed direction of the brush material. In a first embodiment, cleats that are not parallel to an axis of rotation of the feed roller are affixed to a periphery of the feed roller. When the feed roller is oriented with its axis of rotation in a substantially vertical position, each cleat is arranged with its upper end ahead of its lower end, in a direction of rotation. This configuration provides a downward force on the logs or brush being fed into the chipper, thereby reducing the occurrence of bucking. In an additional embodiment, the axes of rotation of the feed rollers lean toward the outfeed end of the brush chipper.

Owner:VERMEER MFG CO

Blade mechanism for a plant material trimming device

A removable blade mechanism for a plant material trimming device. The blade mechanism includes a blade bar connectable to the plant material trimming device and a tool-less adjustable locking device connectable to the blade bar and to the plant material trimming device to lock the blade bar to the plant material trimming device.

Owner:KEIRTON

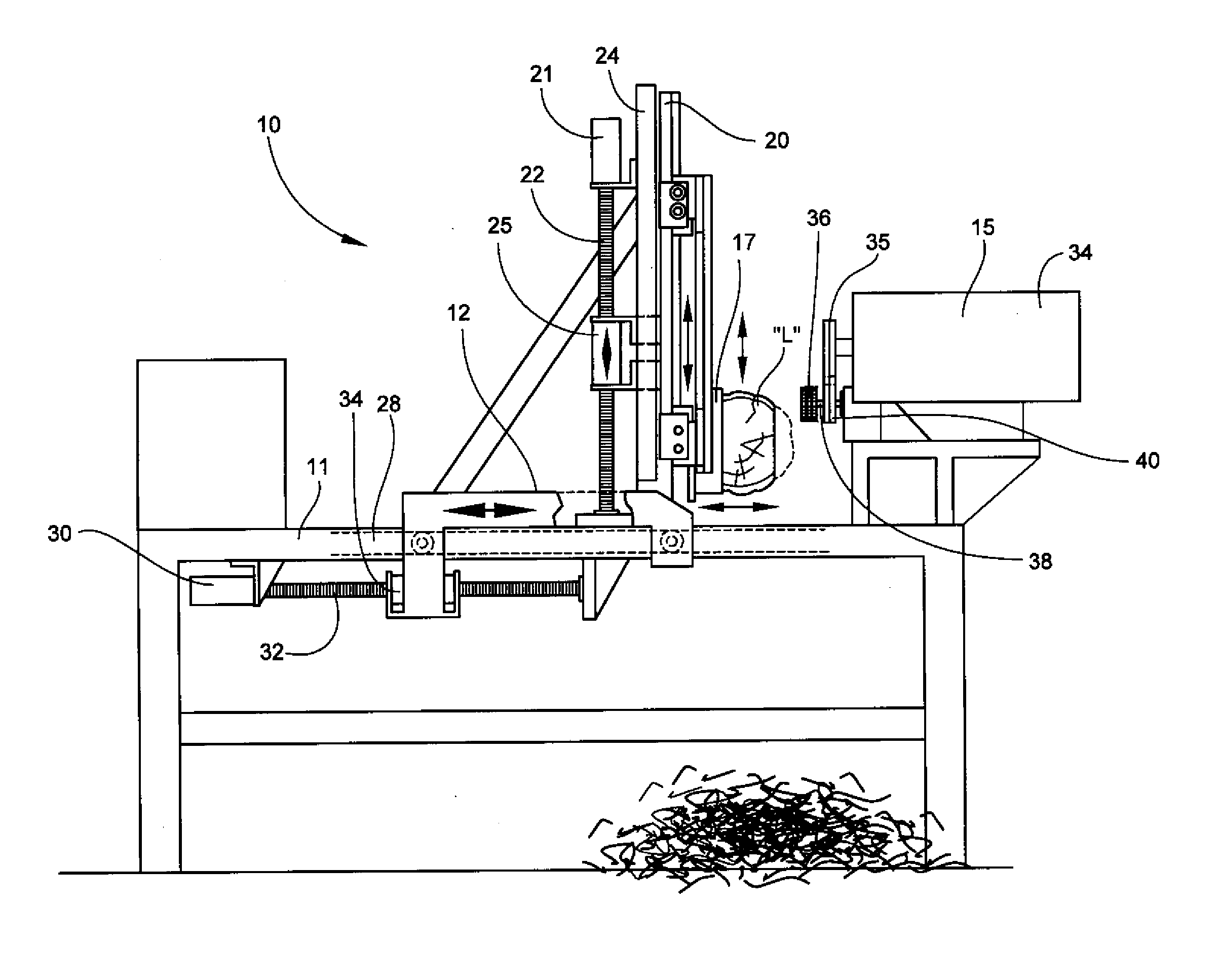

Method and apparatus for producing mulch

InactiveUS20060230893A1Avoid interferenceRetain moistureMetal sawing devicesPlant waste comminutingEngineeringMechanical engineering

A method and apparatus for producing mulch. The apparatus includes a saw blade assembly having a cutter defining a cutting plane, and a clamp assembly for holding a log. The clamp assembly holds the log with its grain substantially parallel to the cutting edge. The apparatus further includes a movement means for repetitively moving the clamp assembly and saw blade assembly relative to each other so as to feed the saw blade assembly into the log while the grain remains substantially parallel to the cutting plane, so that the saw blade assembly removes thin, narrow strips of wood mulch from the log.

Owner:BROOKS CHARLES ALLEN

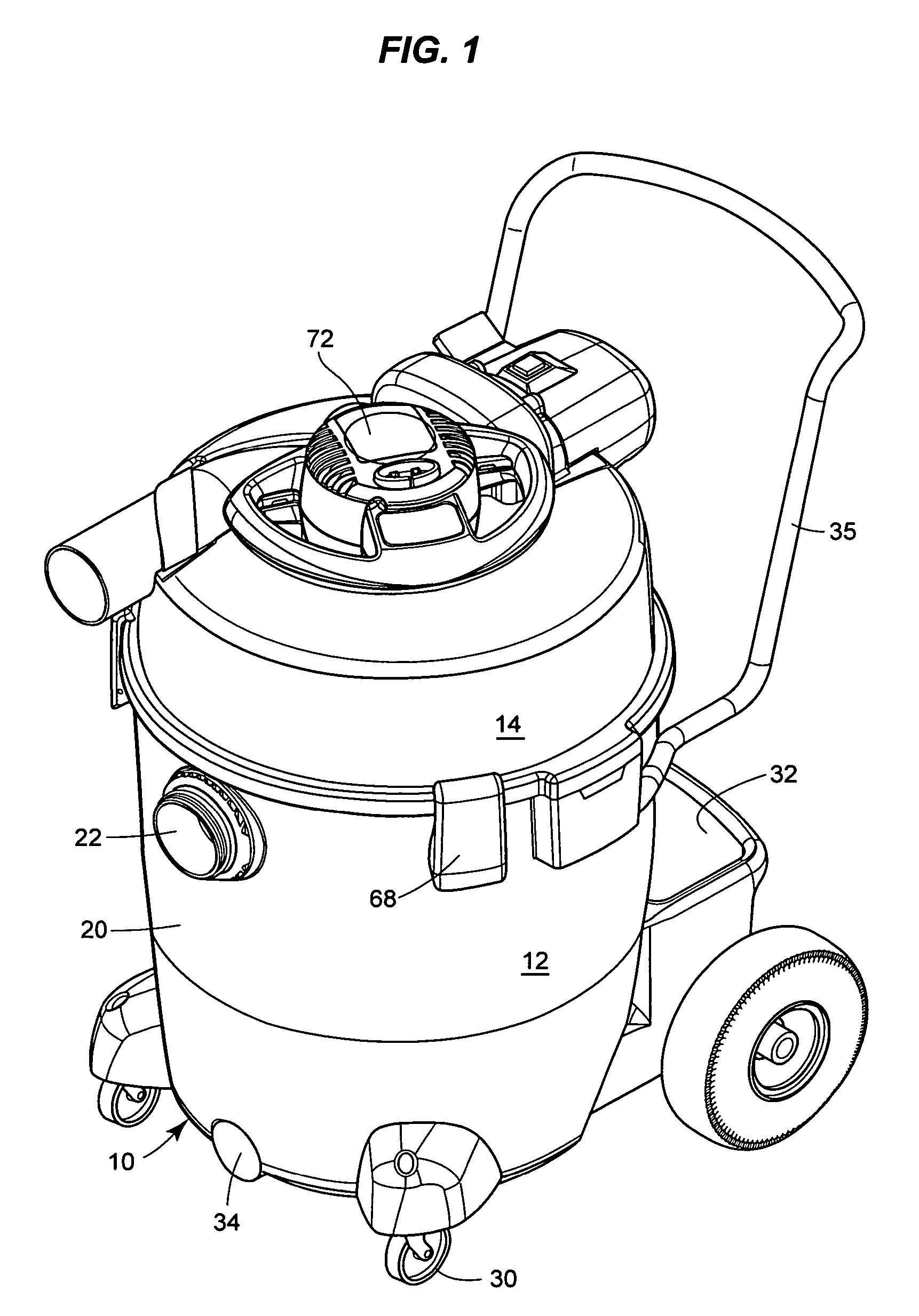

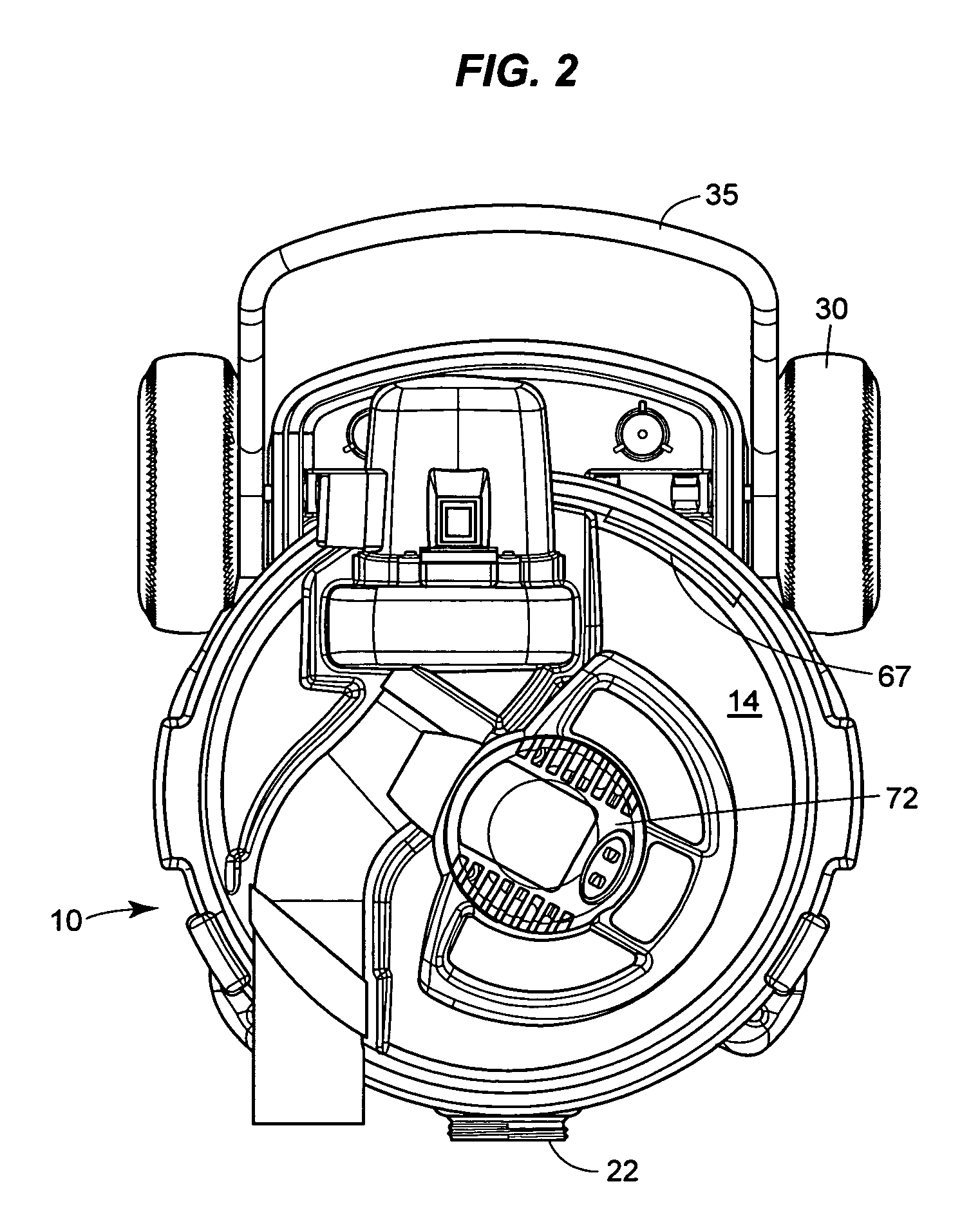

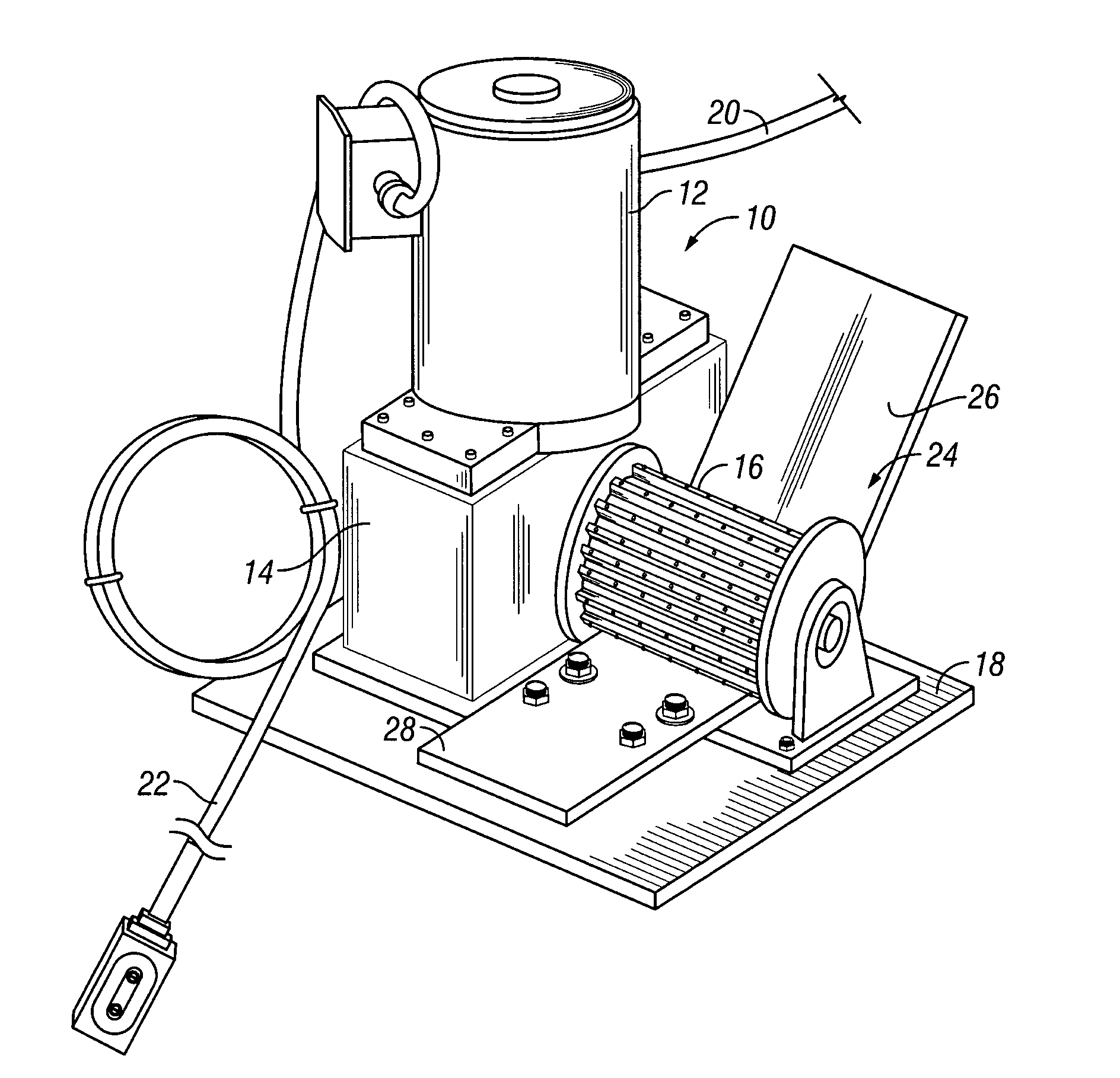

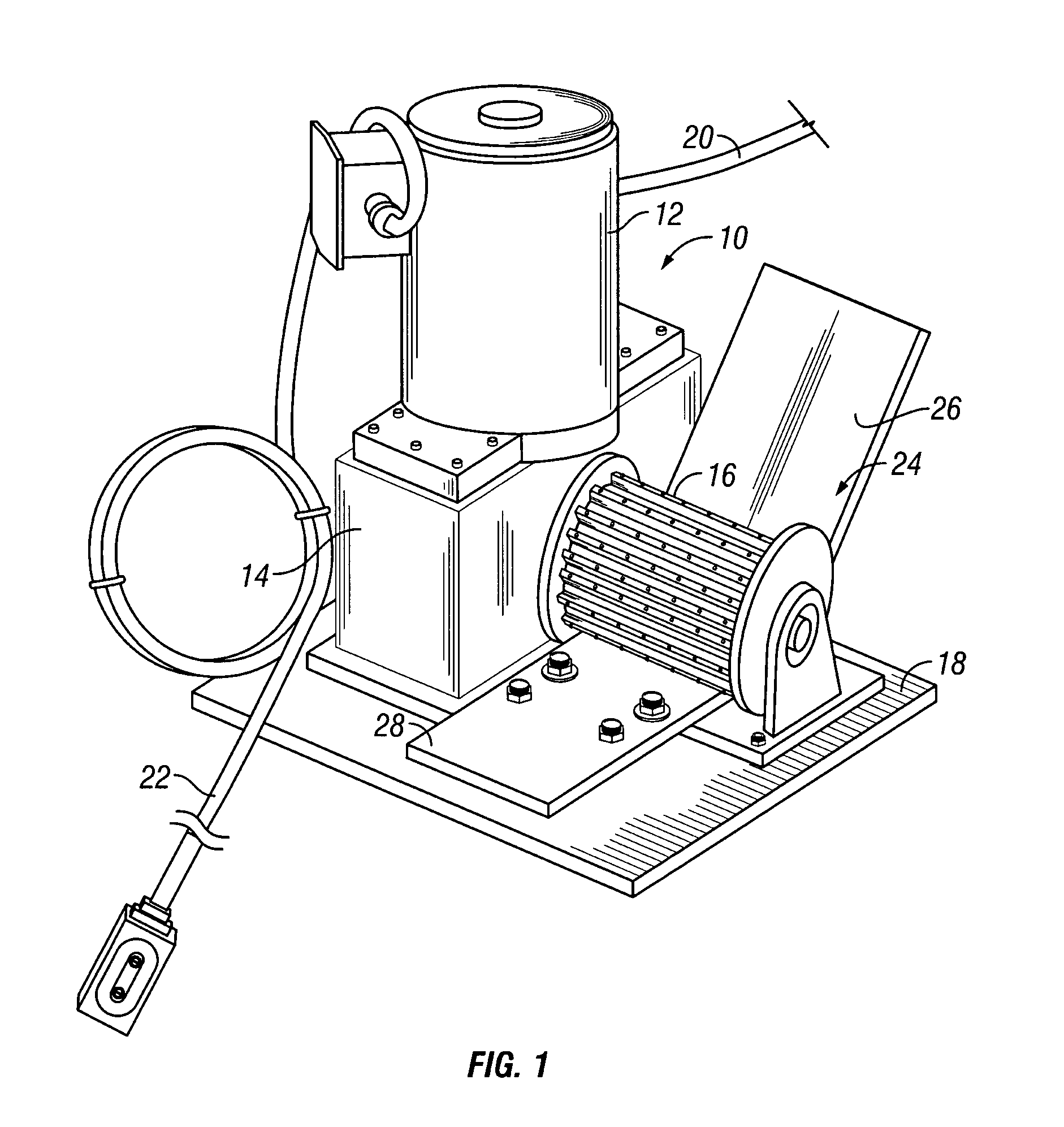

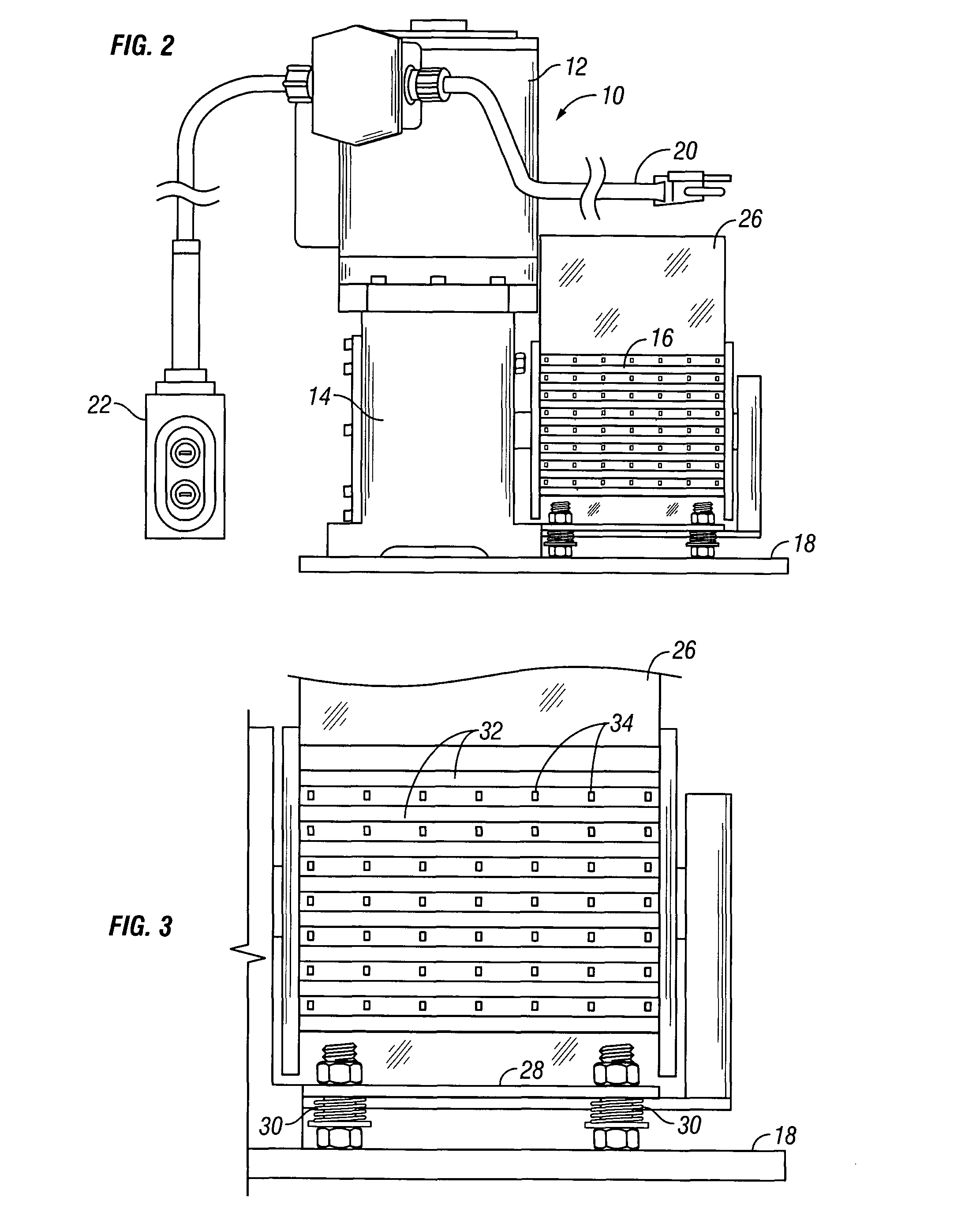

Low-speed high-torque chipper-shredder machine

ActiveUS7070132B1Easy to disassembleReduce speedPlant waste comminutingReed/straw treatmentLow speedElectric machinery

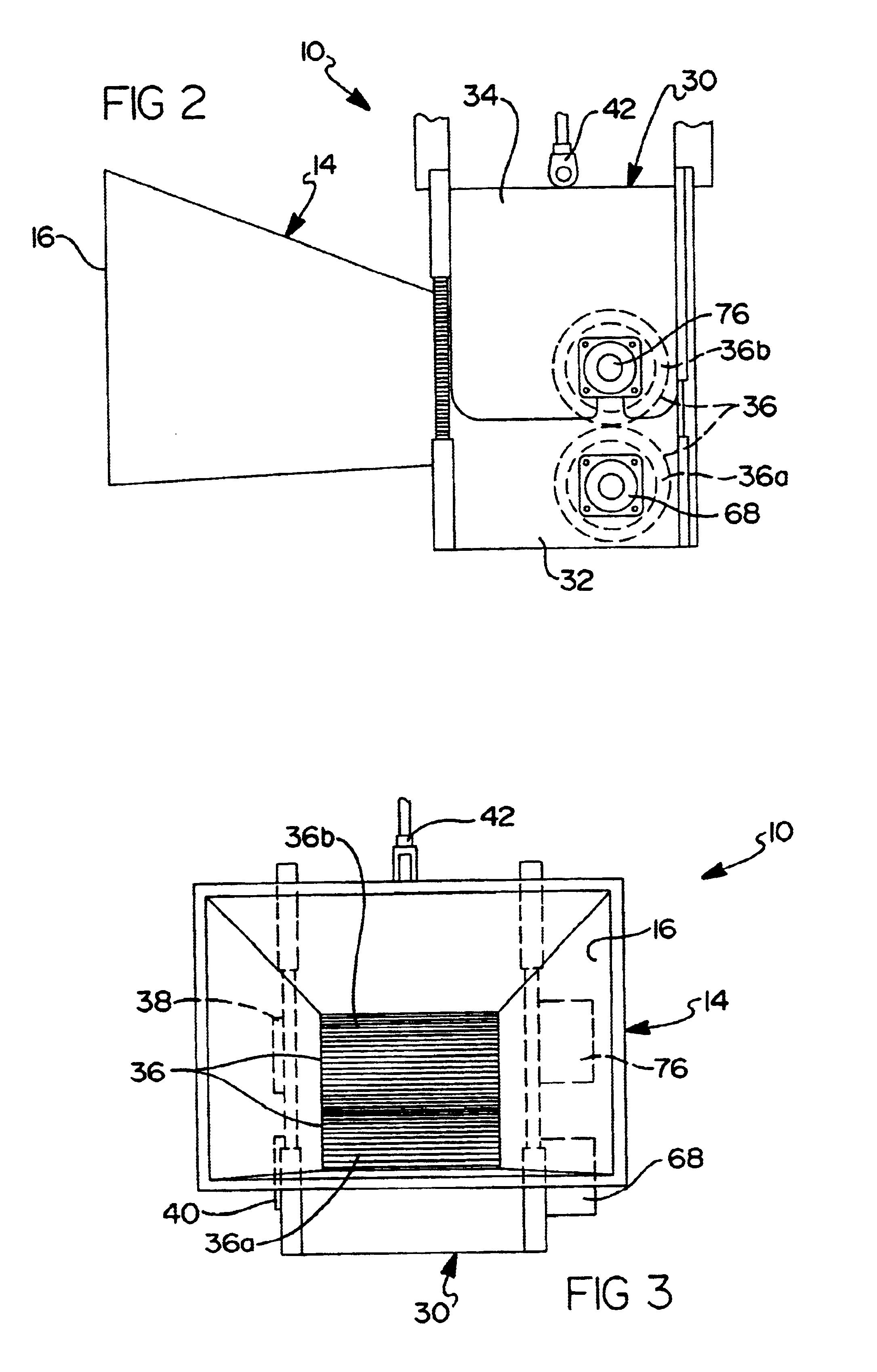

A yard waste chipper-shredder machine includes a reversible electric motor to drive a roller at low speed and high torque. The waste material is fed into an inlet chute and is crushed and ground into mulch between the roller and the chute for discharge through an outlet chute. The chute is spring biased to reduce jams. The machine operates quietly. Jams are quickly and easily removed by reversing the motor.

Owner:IOWA STATE UNIV RES FOUND

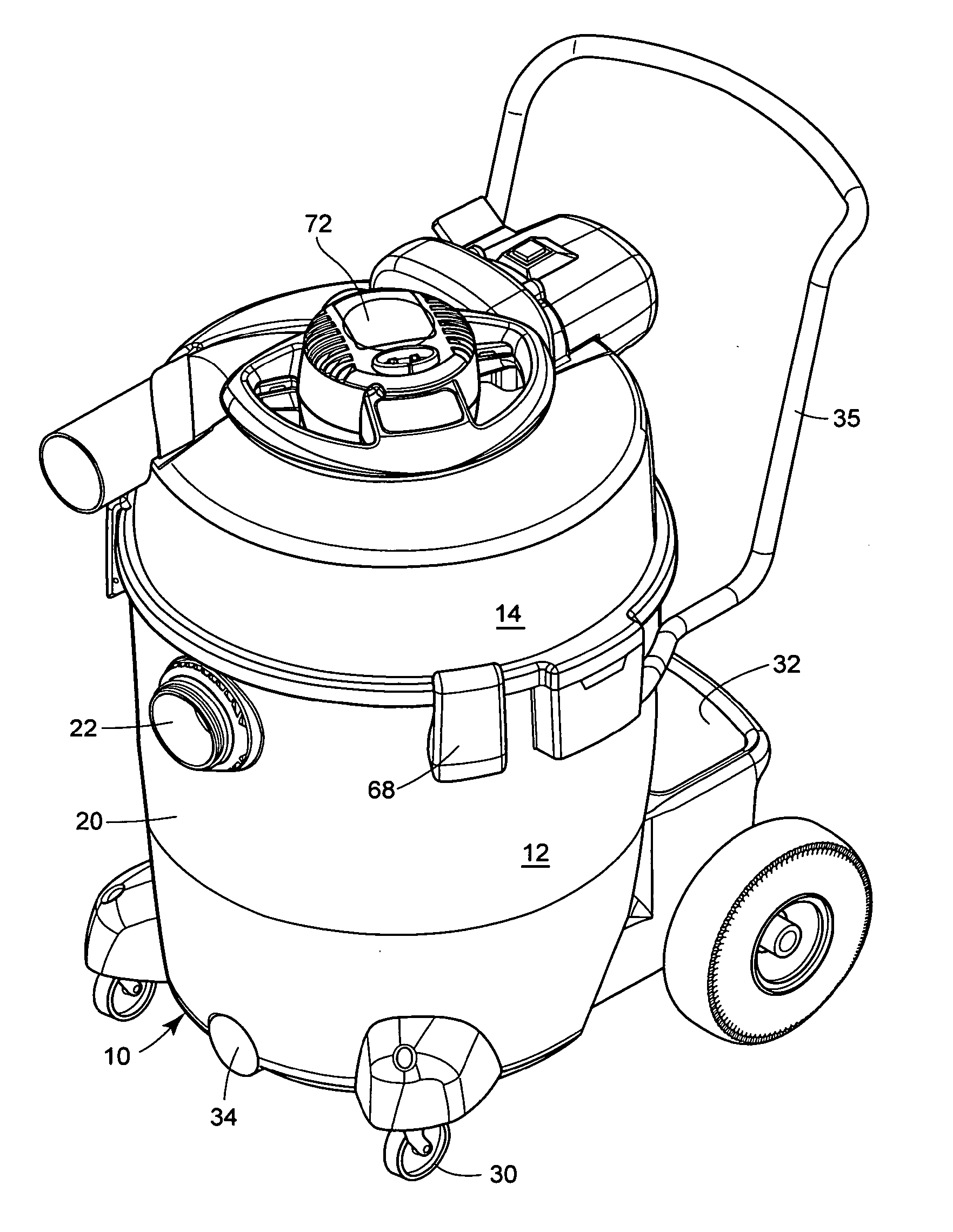

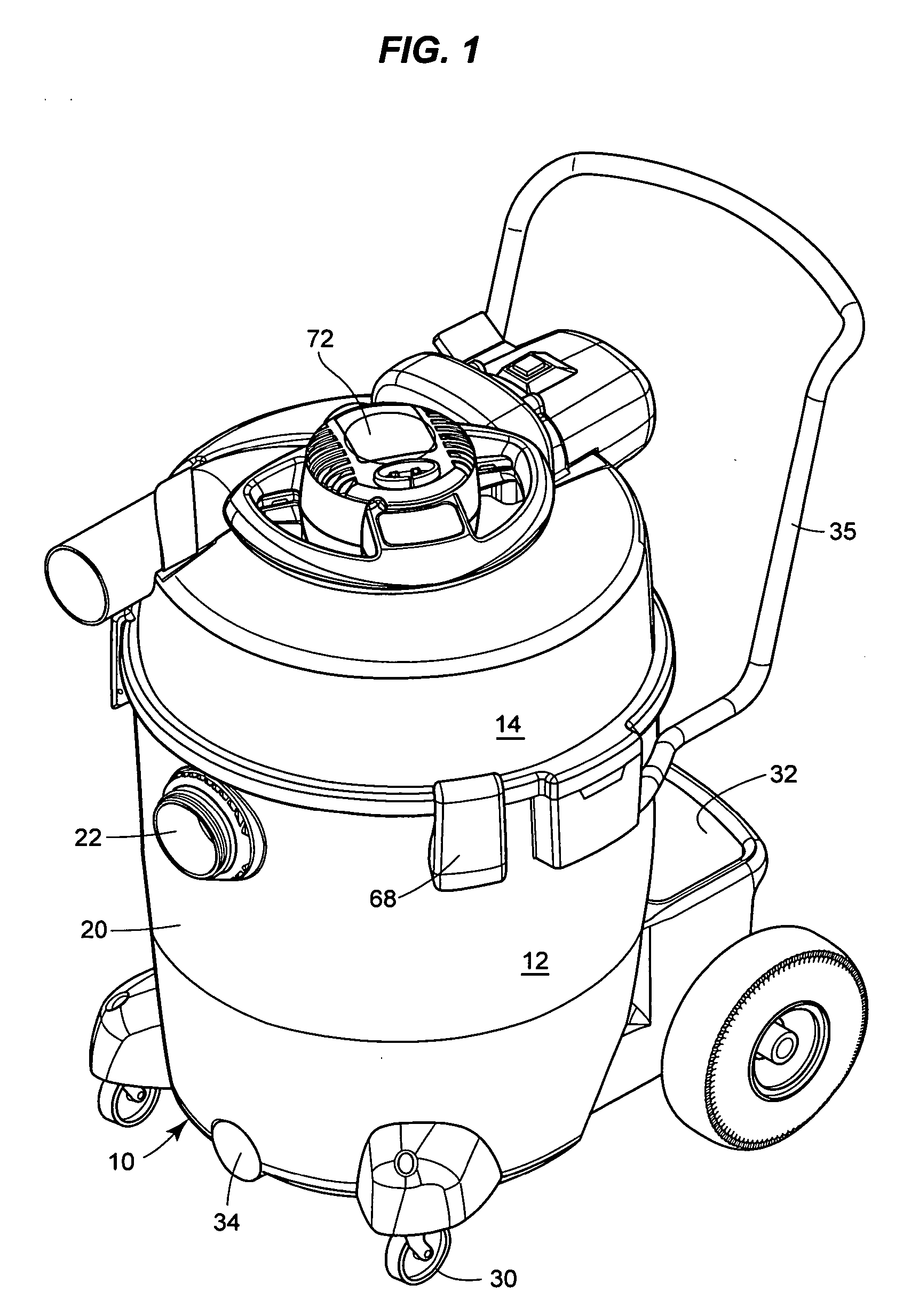

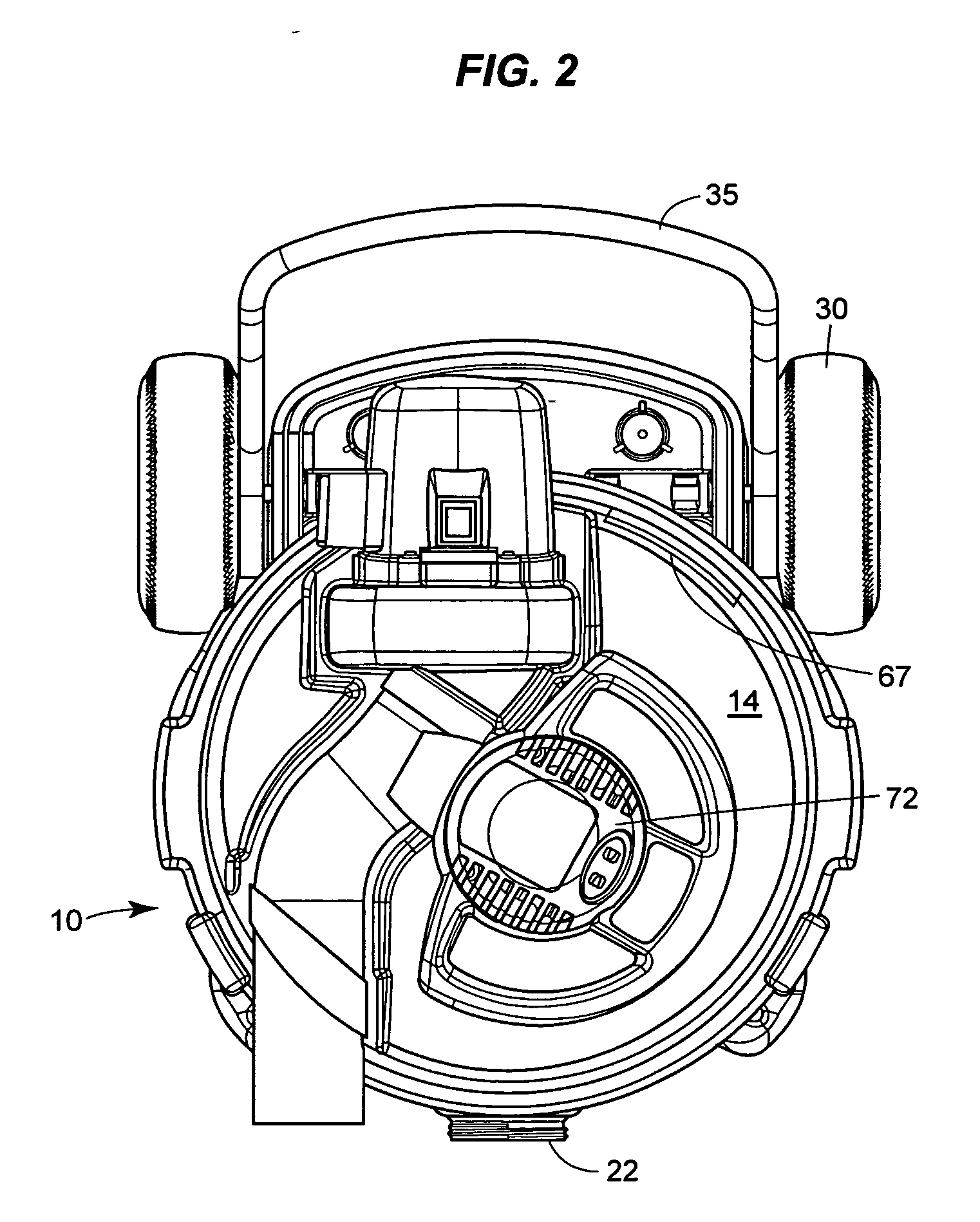

Mulcher

The disclosed mulcher has a base unit and a shredding blade in a removable assembly. Two different embodiments are disclosed. In both embodiments, shredded material is removed from air exiting the shredding blade before it reaches an exhaust port. In one embodiment, the material is removed by a filter. In the other embodiment, walls are arranged so that debris must double back against high-speed airflow leaving the shredding blade before exiting the unit. The shredding blade can be mounted in front of and on the same shaft as an air impeller, with the back surface of the shredding blade being supported by the impeller. In another embodiment, the air impeller and the shredding blade are carried in assemblies that are separable from each other and are each separately attachable to a base unit. A detachable power module and a detachable blower are also shown. The power module has a safety switch that disables the power module when it is removed. A power receptacle is shown with a switch that alternately switches power to either the shredder motor or to the power receptacle, but not to both simultaneously.

Owner:SHOP VAC

Mulcher with improved tooth design

ActiveUS20070181725A1Improve efficiencyIncrease laborMechanical machines/dredgersPlant waste comminutingCarbide coatingTractor

A mulcher apparatus includes a tractor and a mulcher unit provided to the tractor. The mulcher unit includes a tooth assembly with a holder and a cutter element with a cooperating notch portion and cross bar arrangement. The notch portion can be retrofit to existing holder arrangements. The cutter element may include various features, to enhance cutting efficiency. For example, the cutter elements may include a double-ended structure, angle tab portions at each corner portion, carbide coatings, a pair of tip portions at each end with a space therebetween, and / or a generally H-shaped configuration.

Owner:PALADIN BRANDS GROUP INC

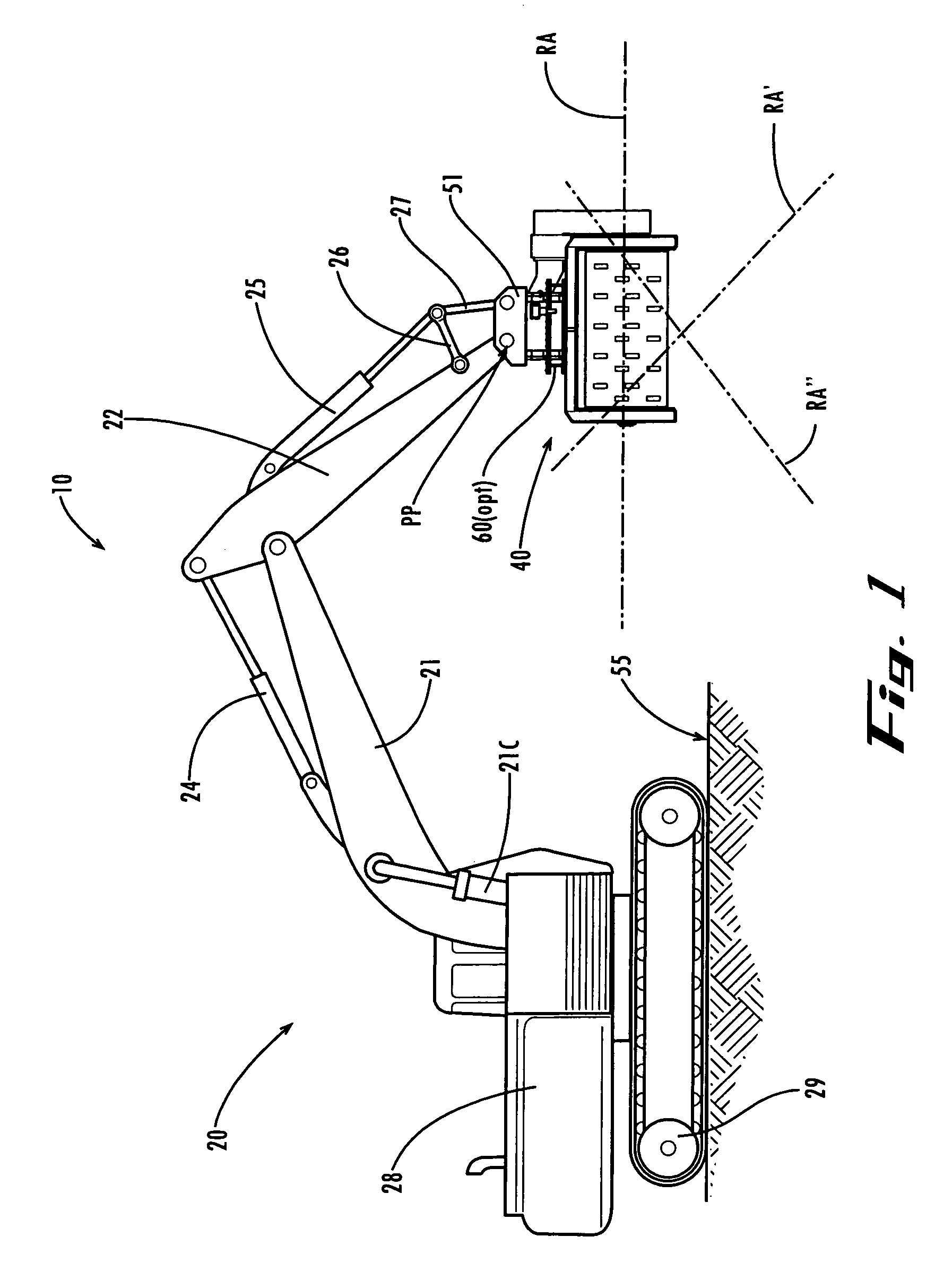

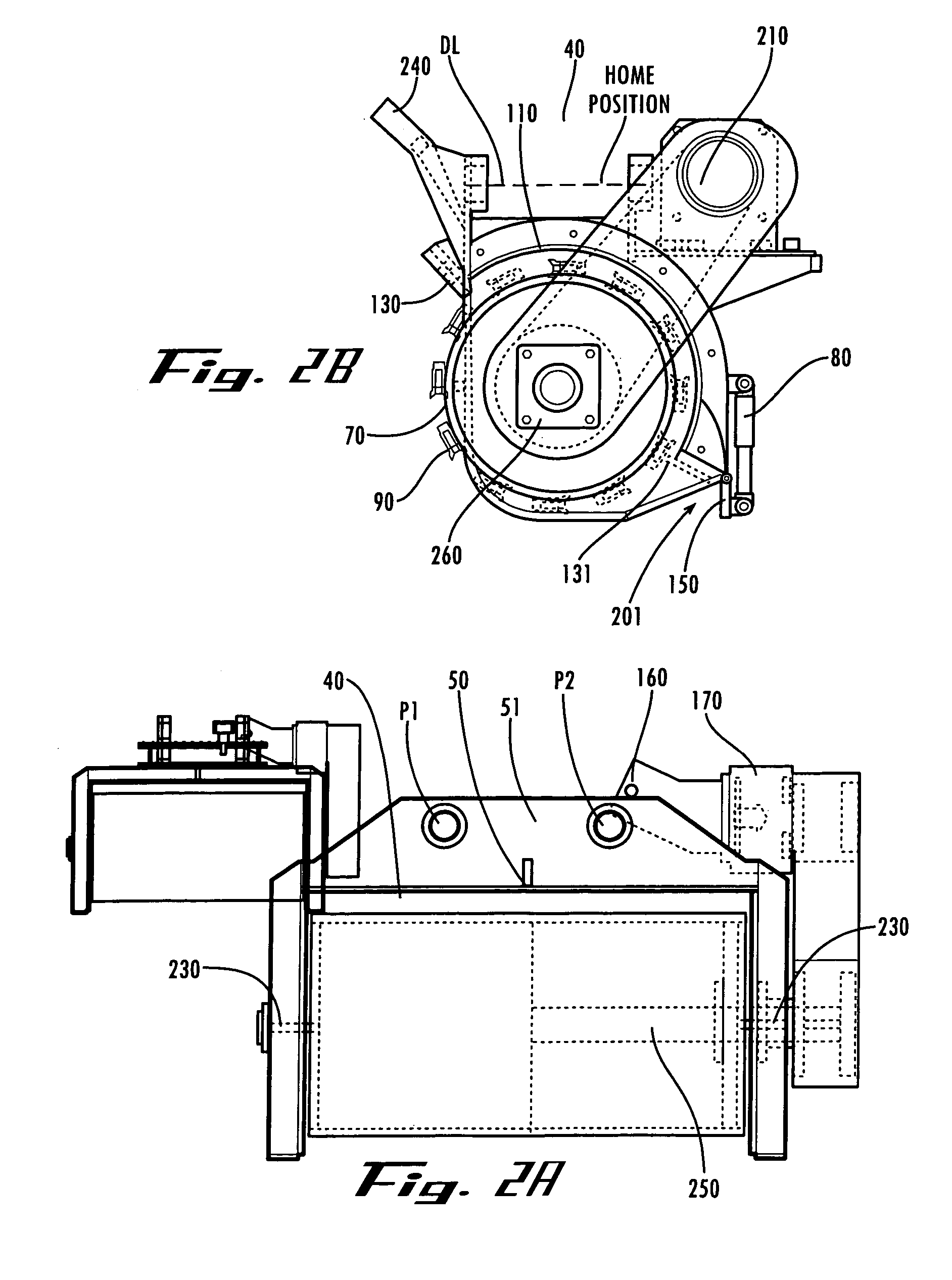

Portable apparatus for reducing vegetation and method for using same

ActiveUS7748421B2Safe and quick and economically meanReducing vehicle” inventionMowersPlant waste comminutingVegetationProximate

The concept of using a cutting element proximate the end of an excavator or similar device, along with the concept of using a cogged belt pulley configuration, an overhead load adaptor, a single- or multiple-pivoting drum configuration, and other concepts disclosed herein. The present invention also provides an improvement of the prior art by providing a chipping action, which is according to the present invention an improvement over prior art shredding configurations.

Owner:EVERETT DARRELL

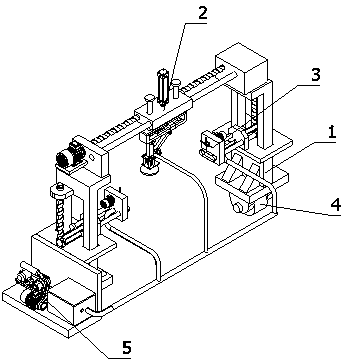

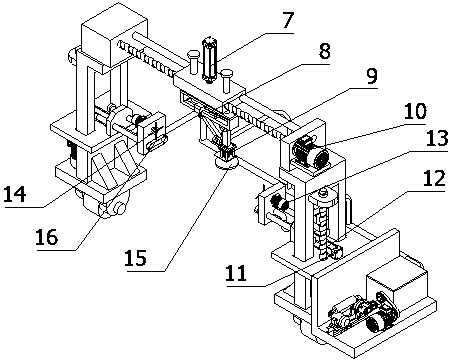

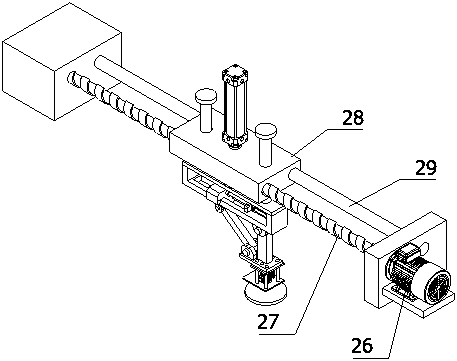

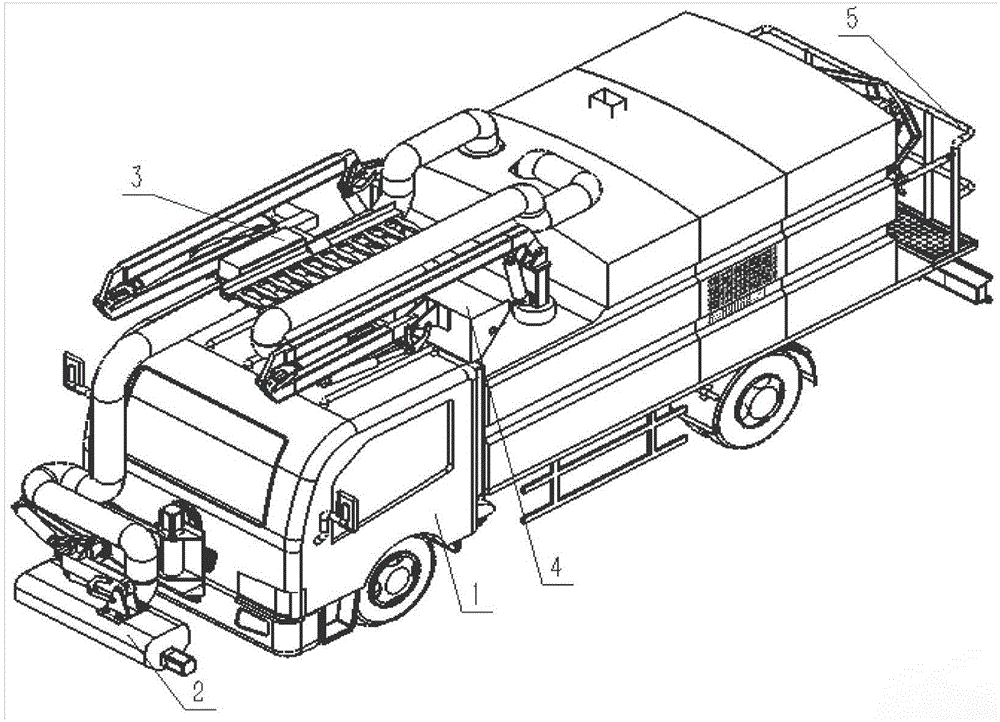

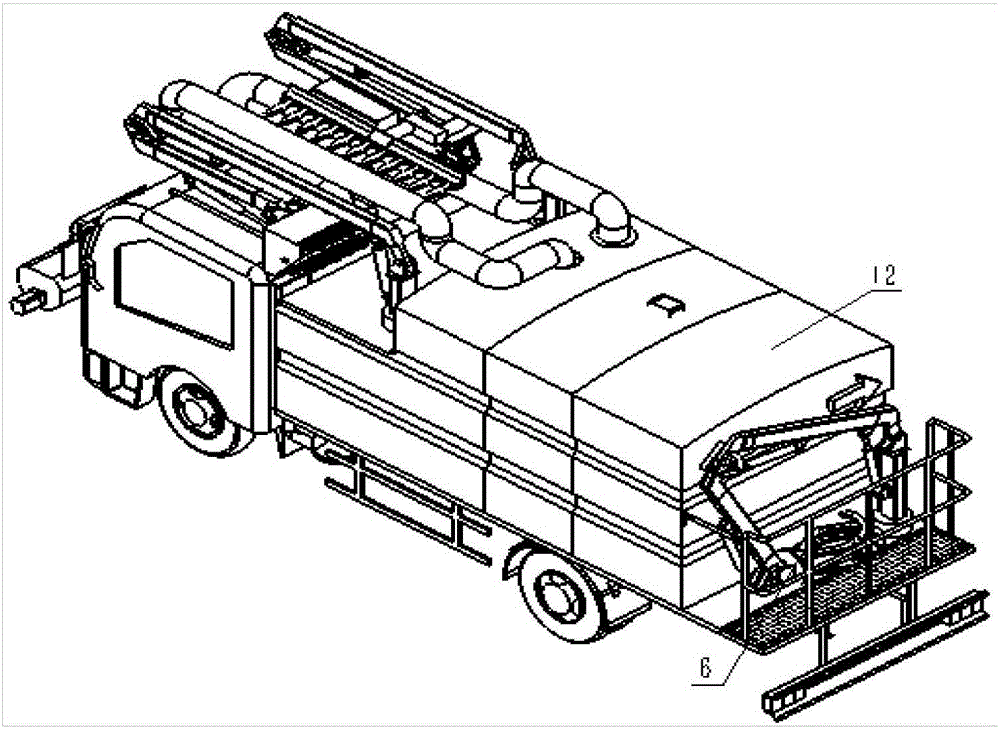

Secondary-sweeping-free green plant trimming equipment for municipal afforesting and implementation mode

InactiveCN111480470AEfficient pruning functionImprove cleaning efficiencyHedge trimming apparatusPlant waste comminutingAgricultural engineeringStructural engineering

The invention relates to the municipal afforesting field, and specifically relates to a secondary-sweeping-free green plant trimming equipment for municipal afforesting and an implementation mode. Theequipment comprises a vehicle body, a top end shearing assembly, a lateral shearing assembly, walking wheels and a sweeping assembly, wherein the top end shearing assembly comprises a first cutting knife, a first lifting mechanism, a first rotary driving mechanism, a first cutting driving mechanism and a first horizontal displacement mechanism, and the first cutting knife can be used for trimmingthe top end of a green belt; the lateral shearing assembly comprises a second horizontal displacement mechanism, a second lifting mechanism, a second cutting driving mechanism and a second cutting knife; and the sweeping assembly comprises an annular dust collecting head and two slot-shaped dust collecting heads. By automatically trimming the green belt through the secondary-sweeping-free green plant trimming equipment, trimmed parts and twigs on the ground can be collected, so that the cleaning efficiency is improved, and the manual labor intensity can be decreased; and the angle of the first cutting knife can be adjusted, so that the aesthetic degree is increased, and efficient trimming of the green belt is realized.

Owner:王燕

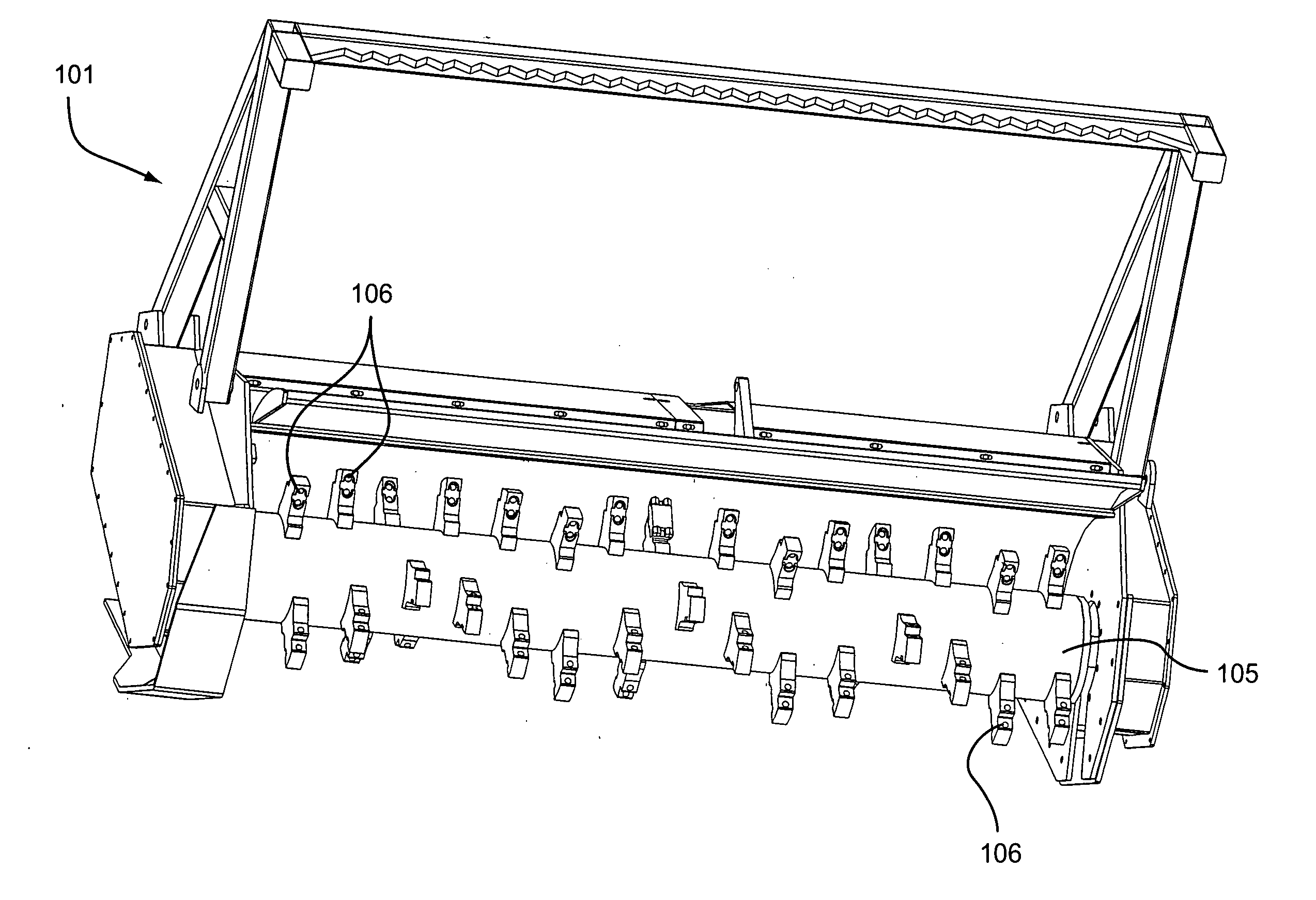

Remote operated brush chipper with conspicuity light

A method and apparatus for enhancing safety in operating a brush chipper. A remote-enabled warning light flashes any time the brush chipper may be operated via a wireless remote control module. Workers on the ground are thereby notified the functions of the brush chipper may be changed in a manner not evident from their vantage point. Additionally, for remote operation to be enabled, two switches must both be in a remote-enable position and a feed control bar must be in neutral. Any change in these aspects will remove control from the remote module and make the machine controllable only at the controls on the brush chipper.

Owner:VERMEER MFG CO

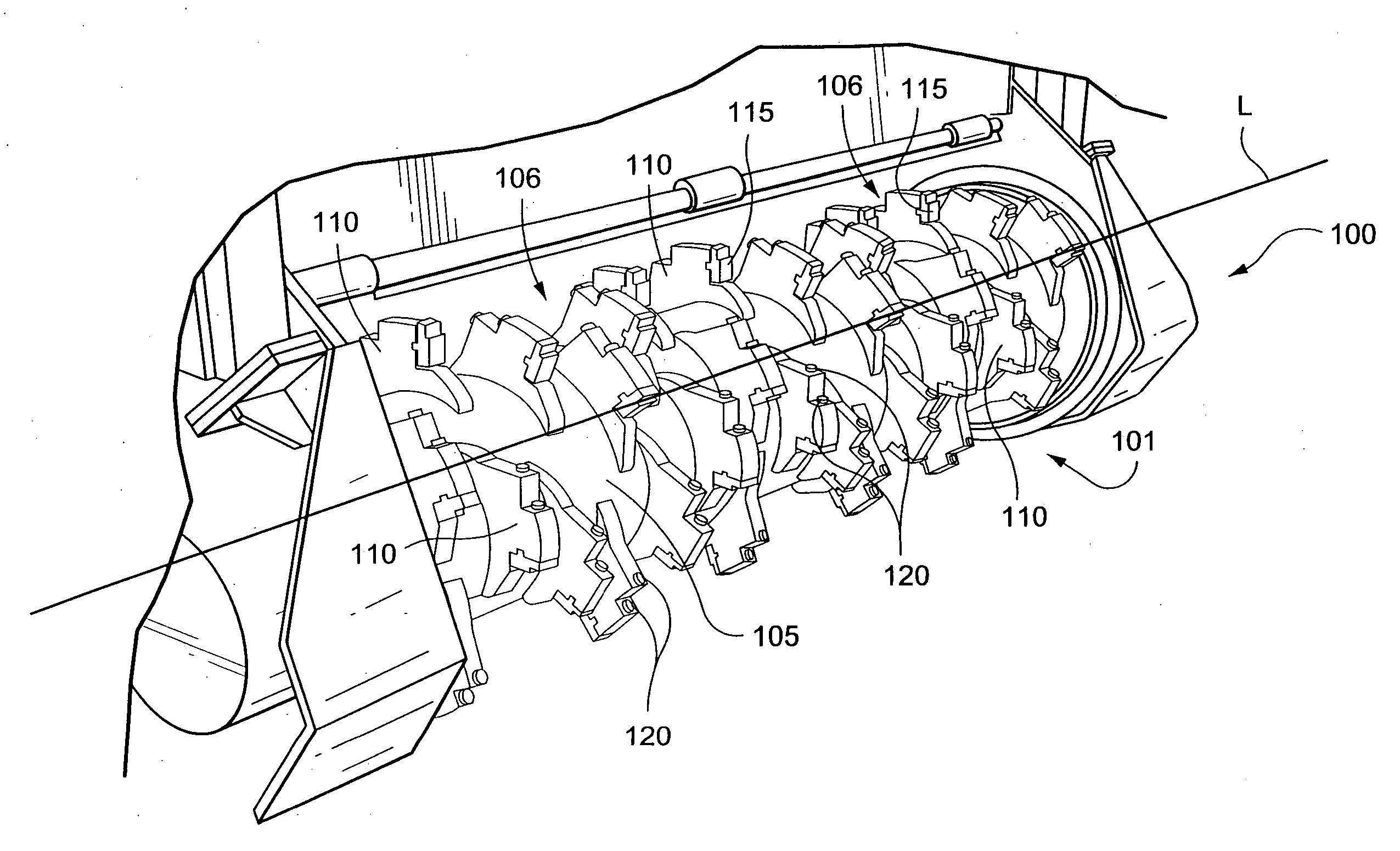

Wood collection and reducing machine

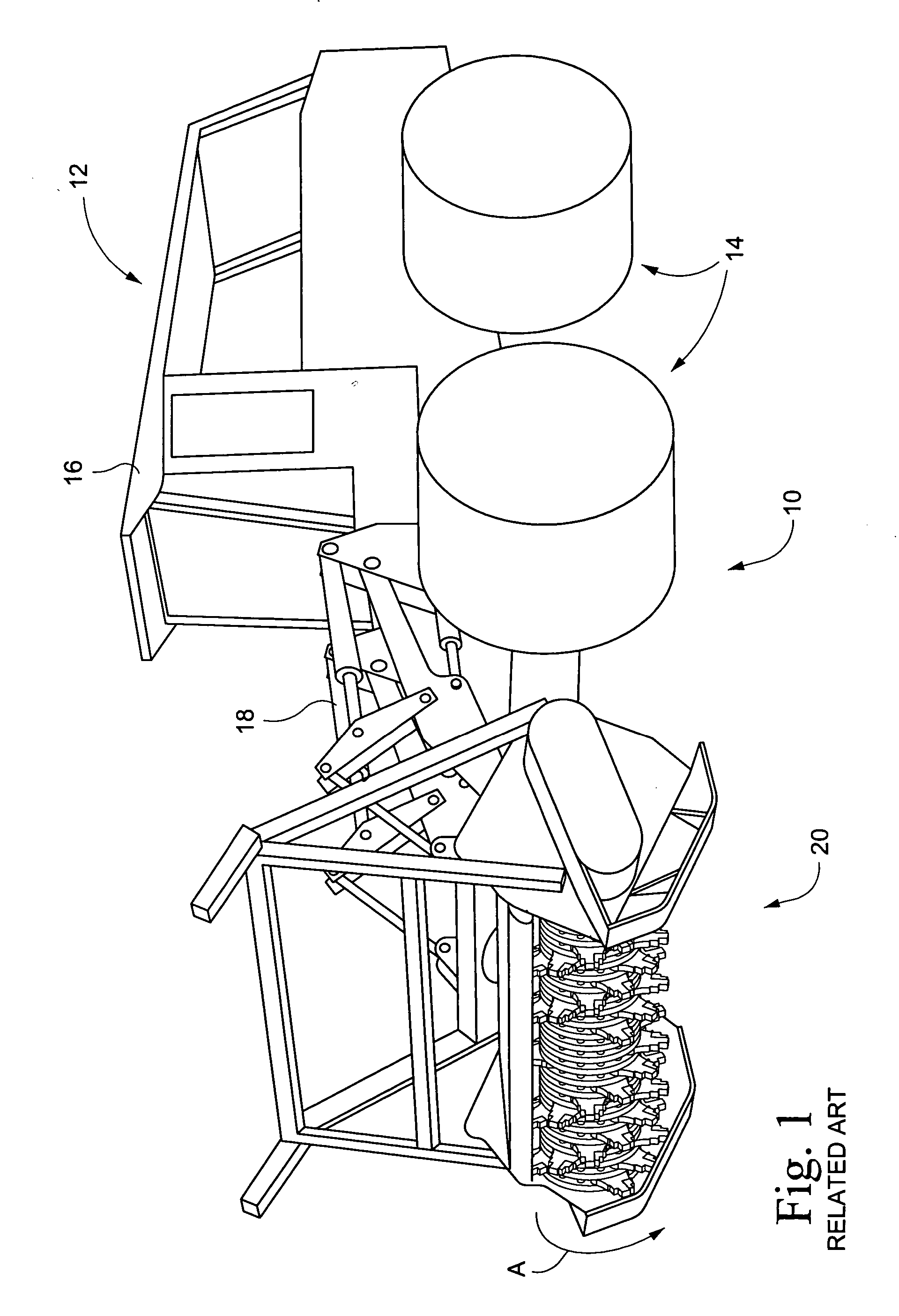

InactiveUS7513449B2Improve cutting efficiencyReduce materialMowersPlant waste comminutingBlood collectionEngineering

A shredder for reducing material which includes a conical cutting drum rotatably positioned within a housing and having an imperforate outer surface so as to carry shredded material radially with and externally of the drum; at least one cutting implement disposed about the outer surface of the cutting drum; an anvil disposed adjacent to the cutting drum; a bellyband wrapping around and conforming to the drum; and a transition interconnecting the bellyband with a discharge port and having a cross sectional configuration that inversely mirrors the cross sectional configuration of the bellyband.

Owner:BARKO SPECIALTY EQUIP

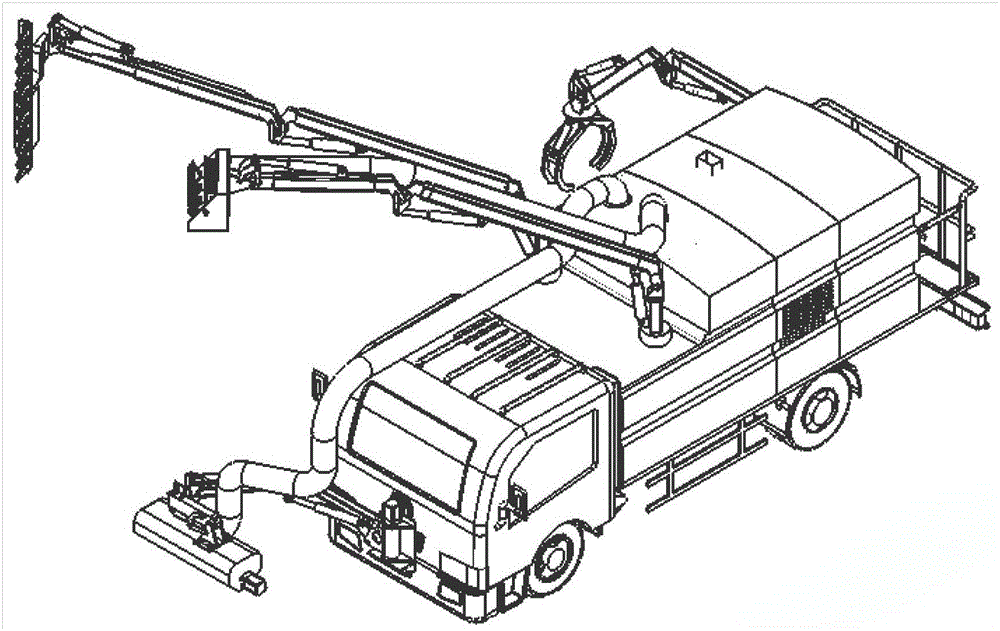

Comprehensive greening and maintaining vehicle

InactiveCN105875213ARealize shredding recyclingBeautifully trimmedHedge trimming apparatusPlant waste comminutingGreeningRoad surface

The invention relates to a comprehensive greening maintenance vehicle, which includes a car chassis and a pruning system for pruning branches and grass on the ground; a crushing system for crushing branches cut by the pruning system; a branch suction system for connecting the pruned branches respectively system and shredder system, which absorbs the cut branches to the shredder system. The greening comprehensive maintenance vehicle of the present invention can flexibly realize simultaneous pruning in three directions and crushing recovery of branches. During the operation, personnel do not need to get off the vehicle, and all operations are completed on the vehicle. After the operation, the road surface is clean, the pruning is beautiful, and the greening The efficiency of maintenance is greatly improved.

Owner:CHANGSHA WEINUO ELECTROMECHANICAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com