Patents

Literature

2223 results about "Idle speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Idle speed (or idle) is the rotational speed an engine runs at when the engine is idling, that is when the engine is uncoupled from the drivetrain and the throttle pedal is not depressed. In combustion engines, idle speed is generally measured in revolutions per minute (rpm) of the crankshaft. At idle speed, the engine generates enough power to run reasonably smoothly and operate its ancillaries (water pump, alternator, and, if equipped, other accessories such as power steering), but usually not enough to perform useful work, such as moving an automobile.

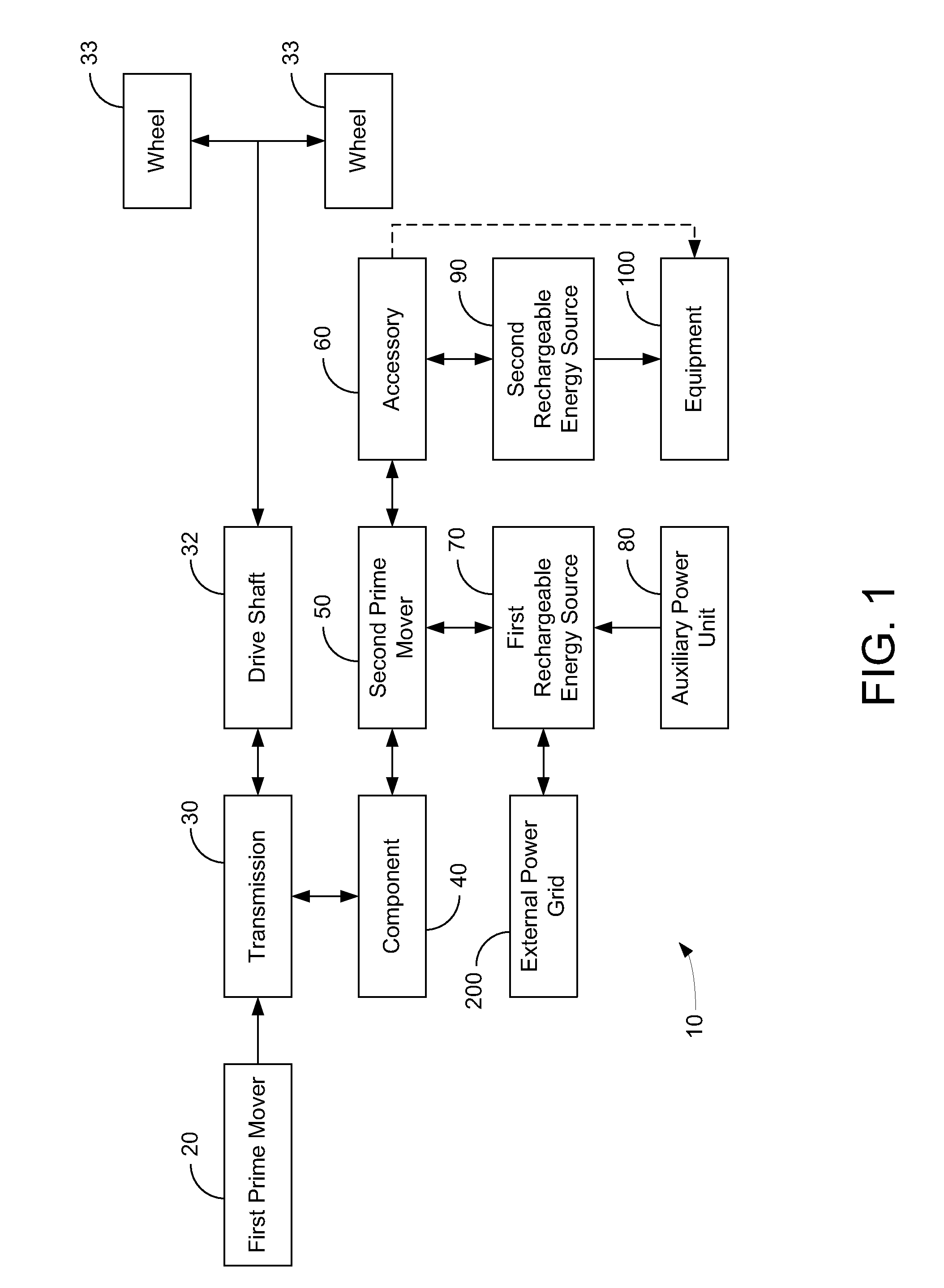

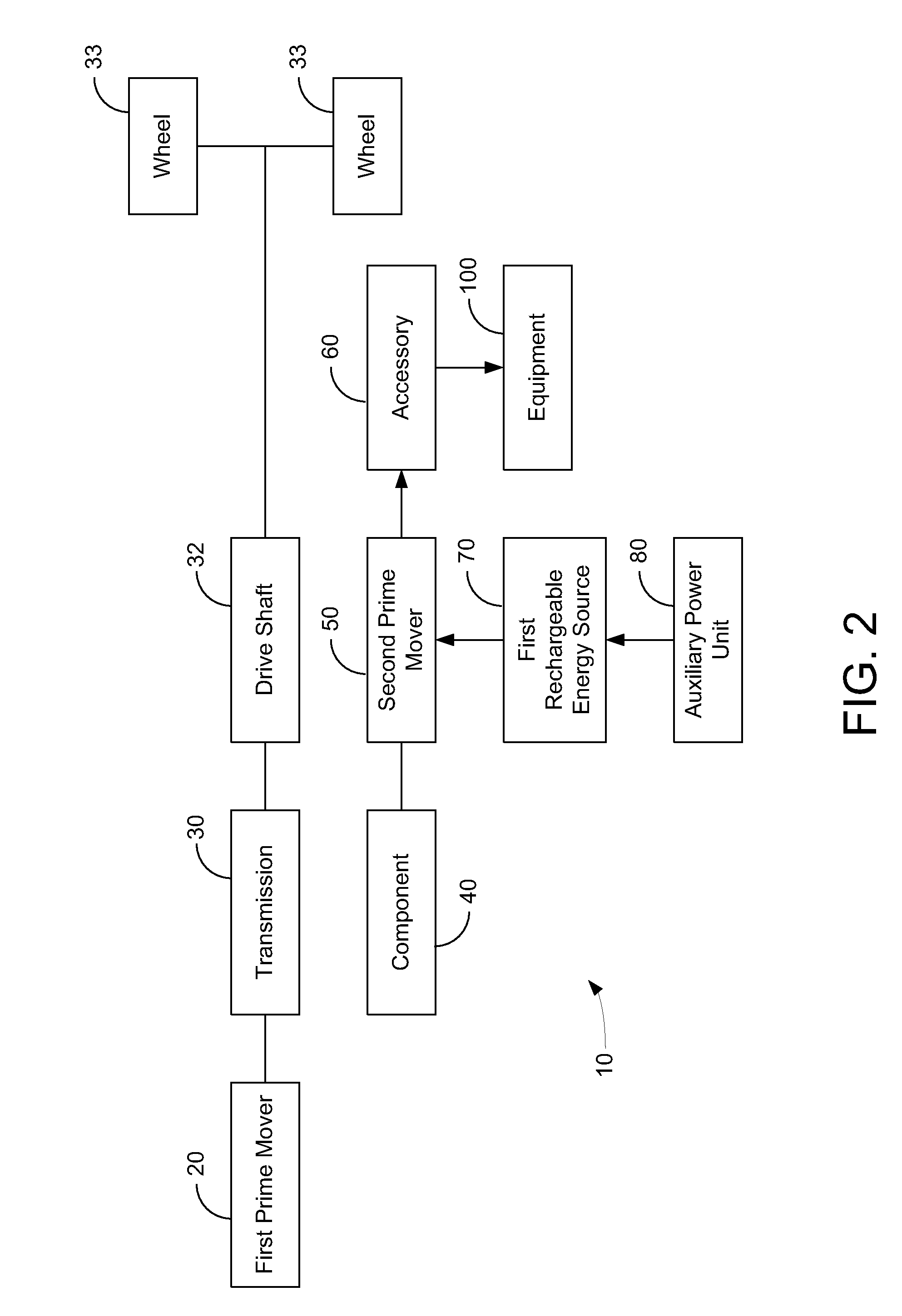

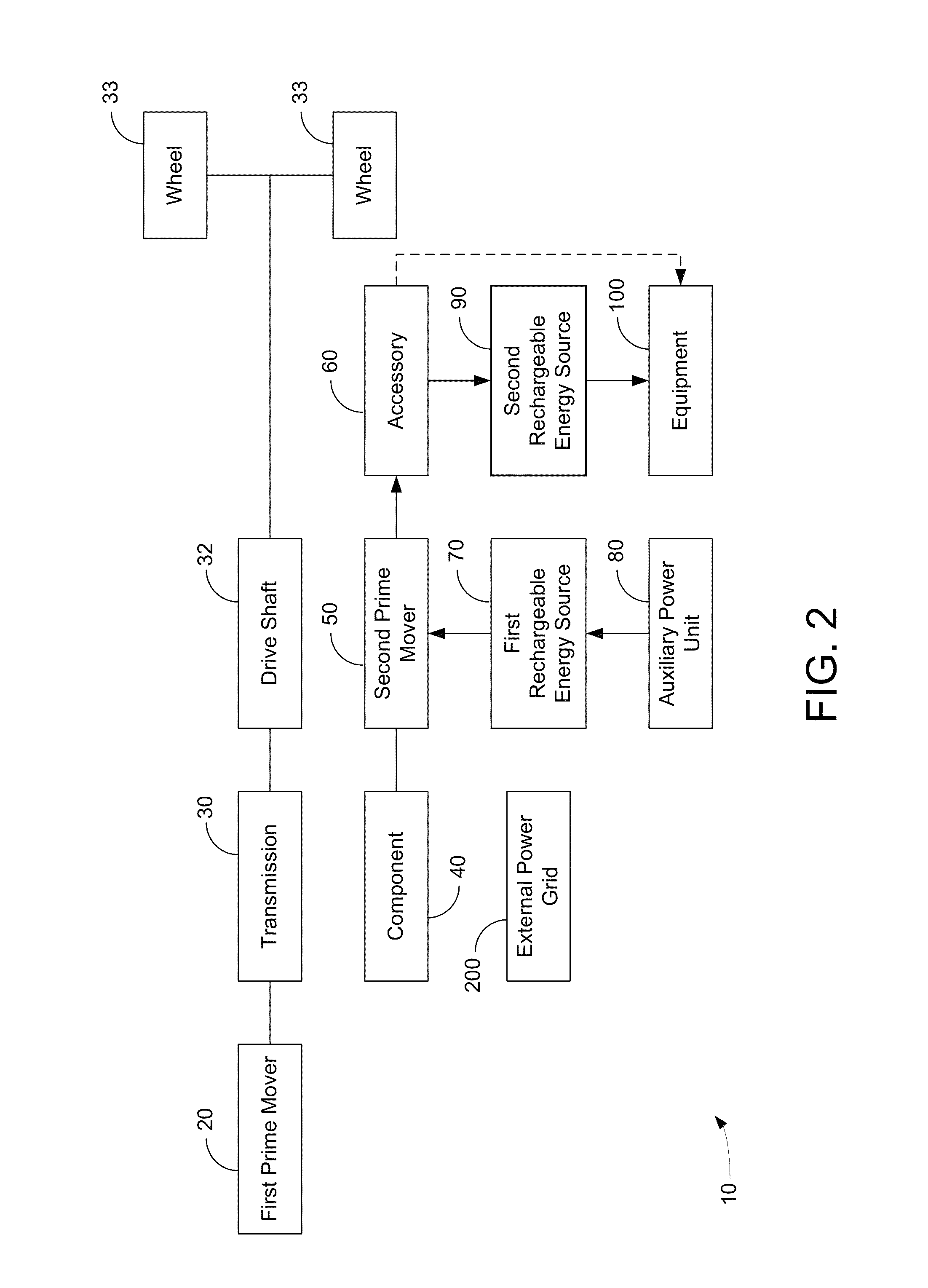

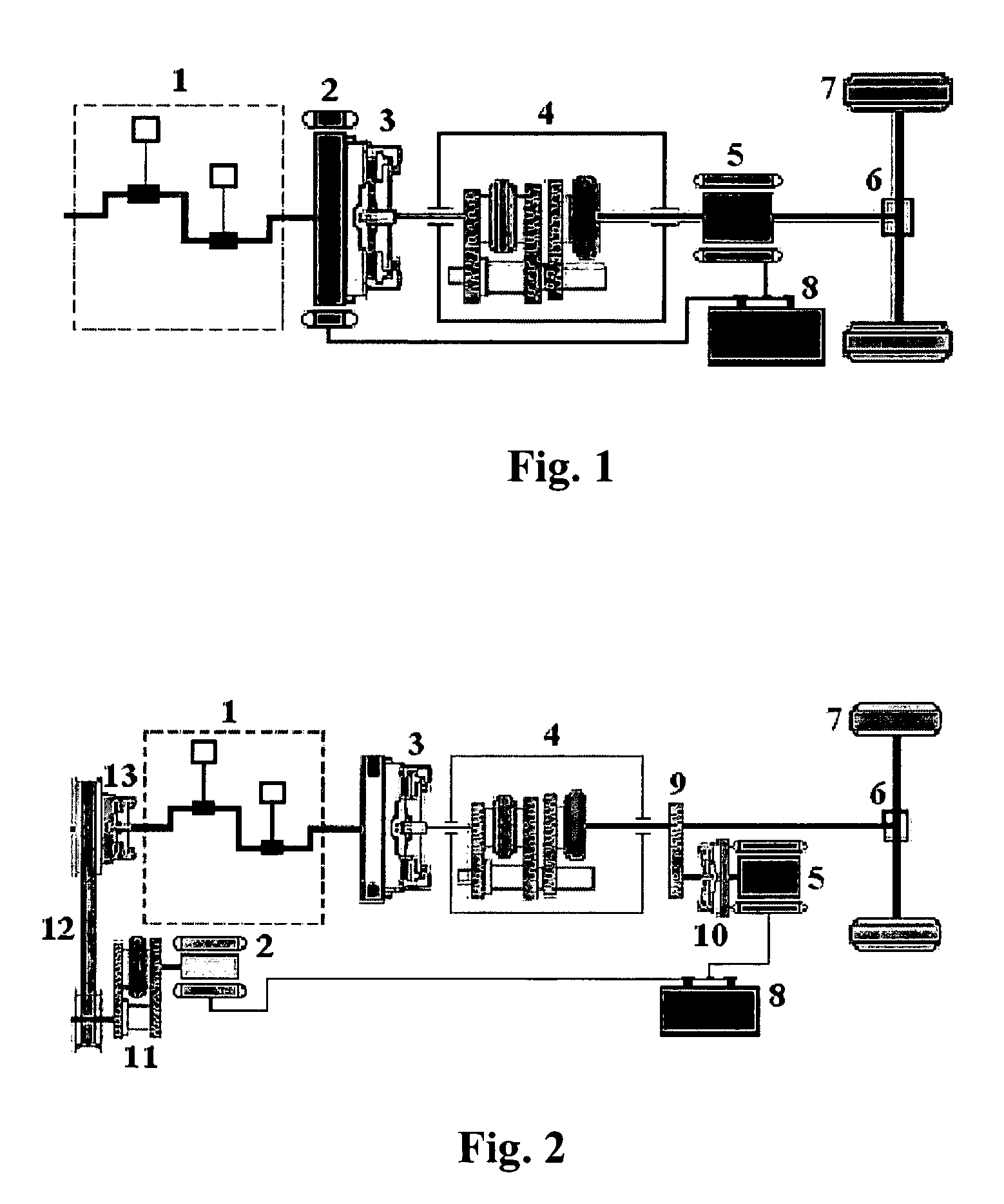

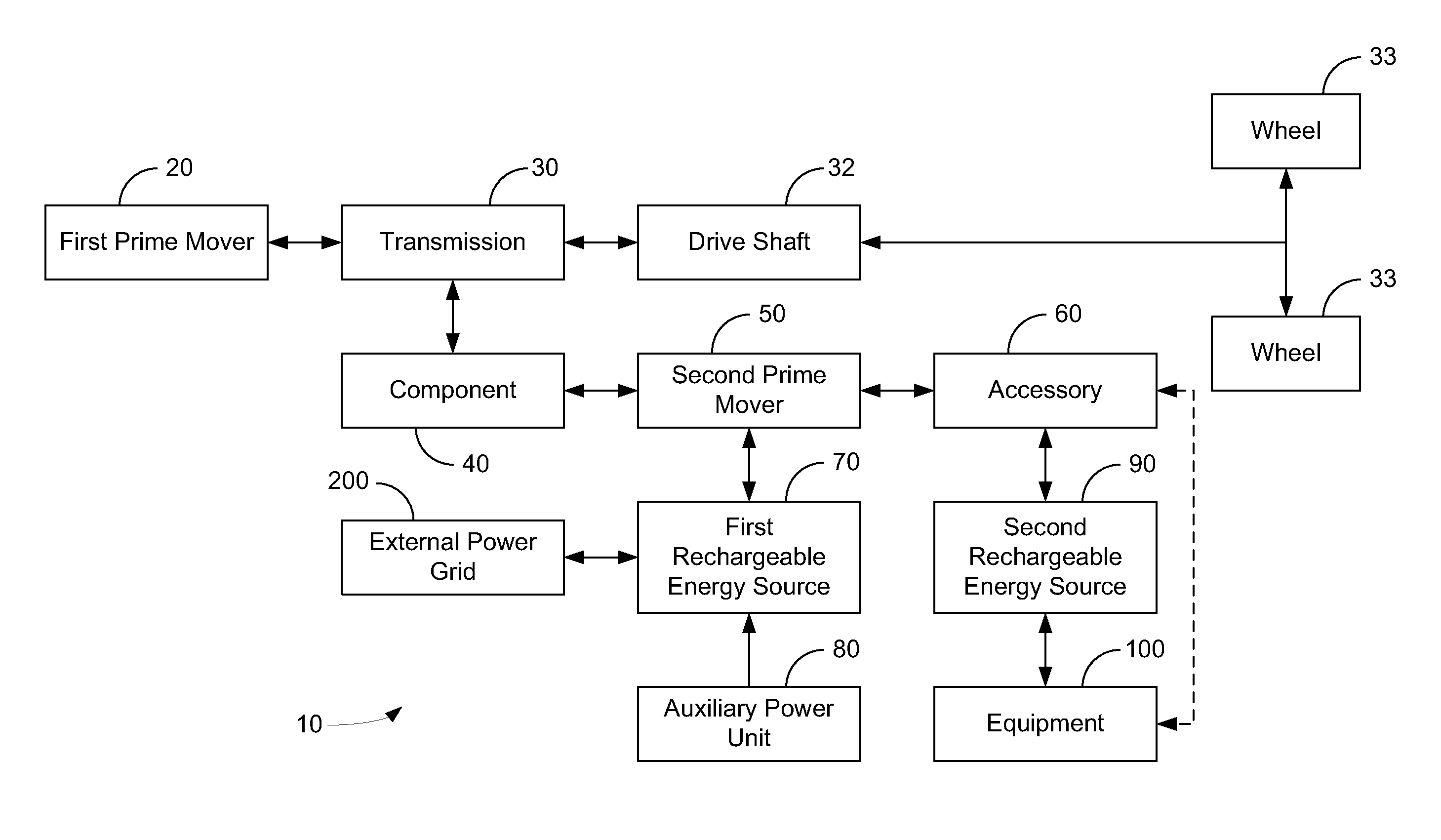

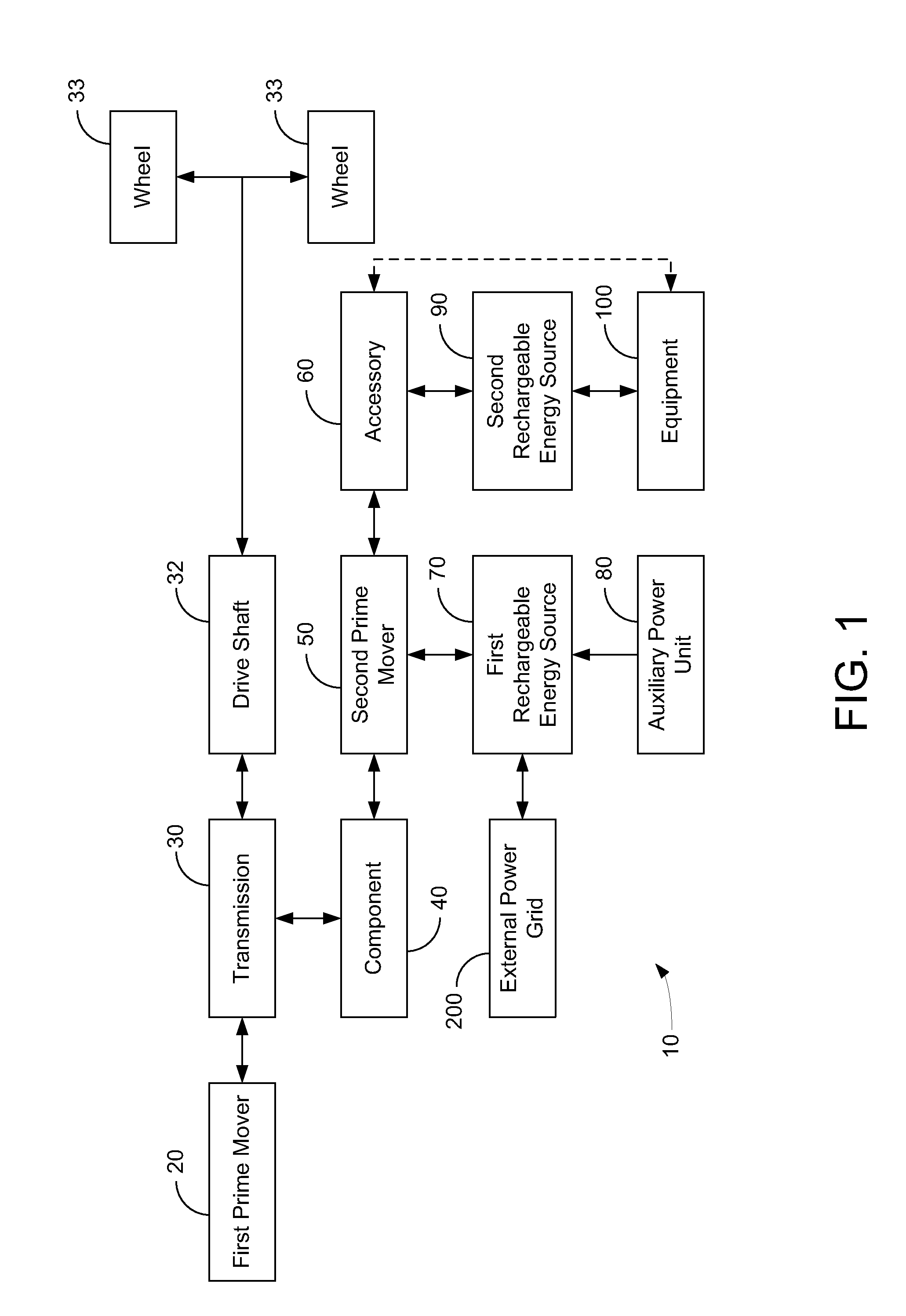

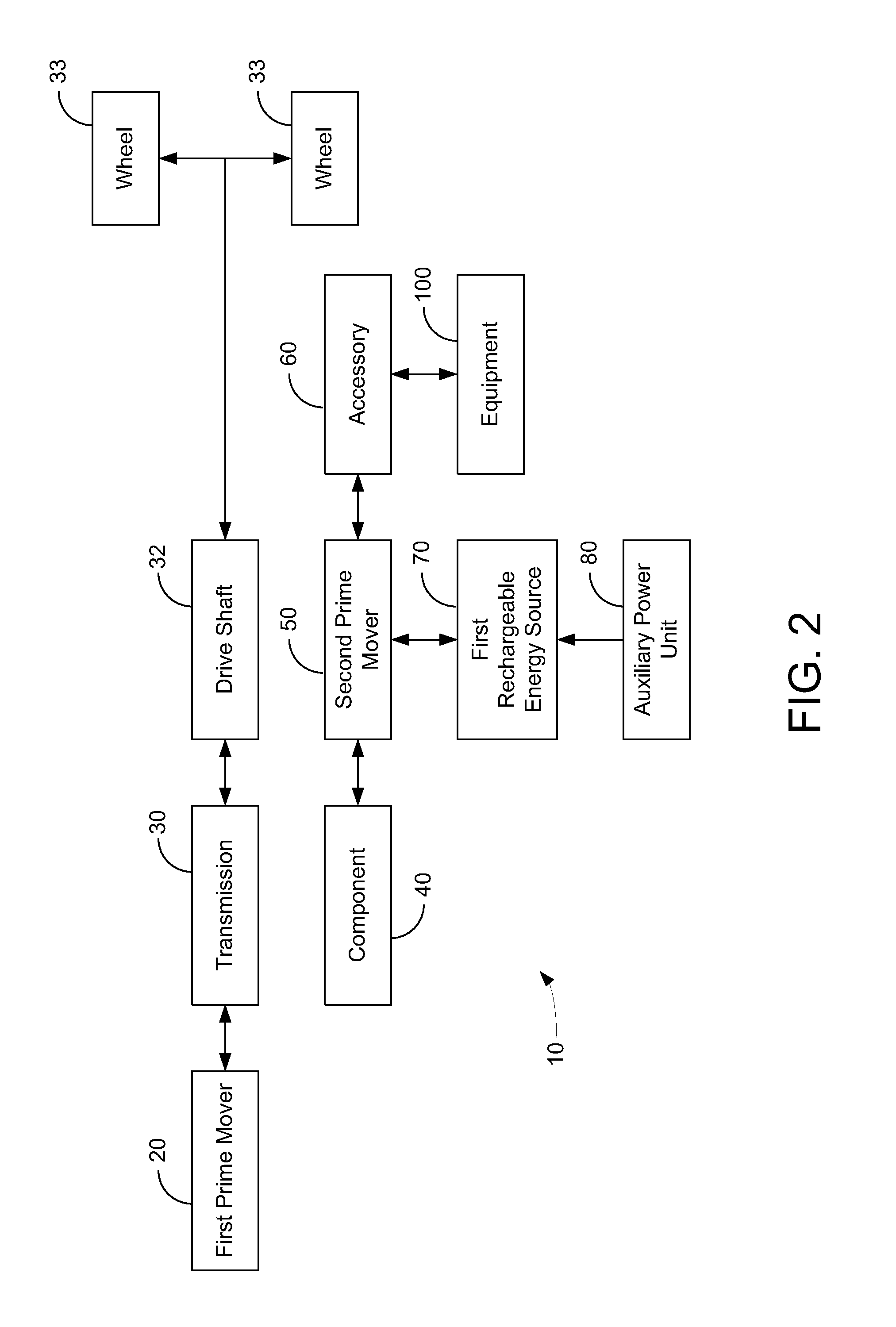

Hybrid vehicle drive system and method and idle reduction system and method

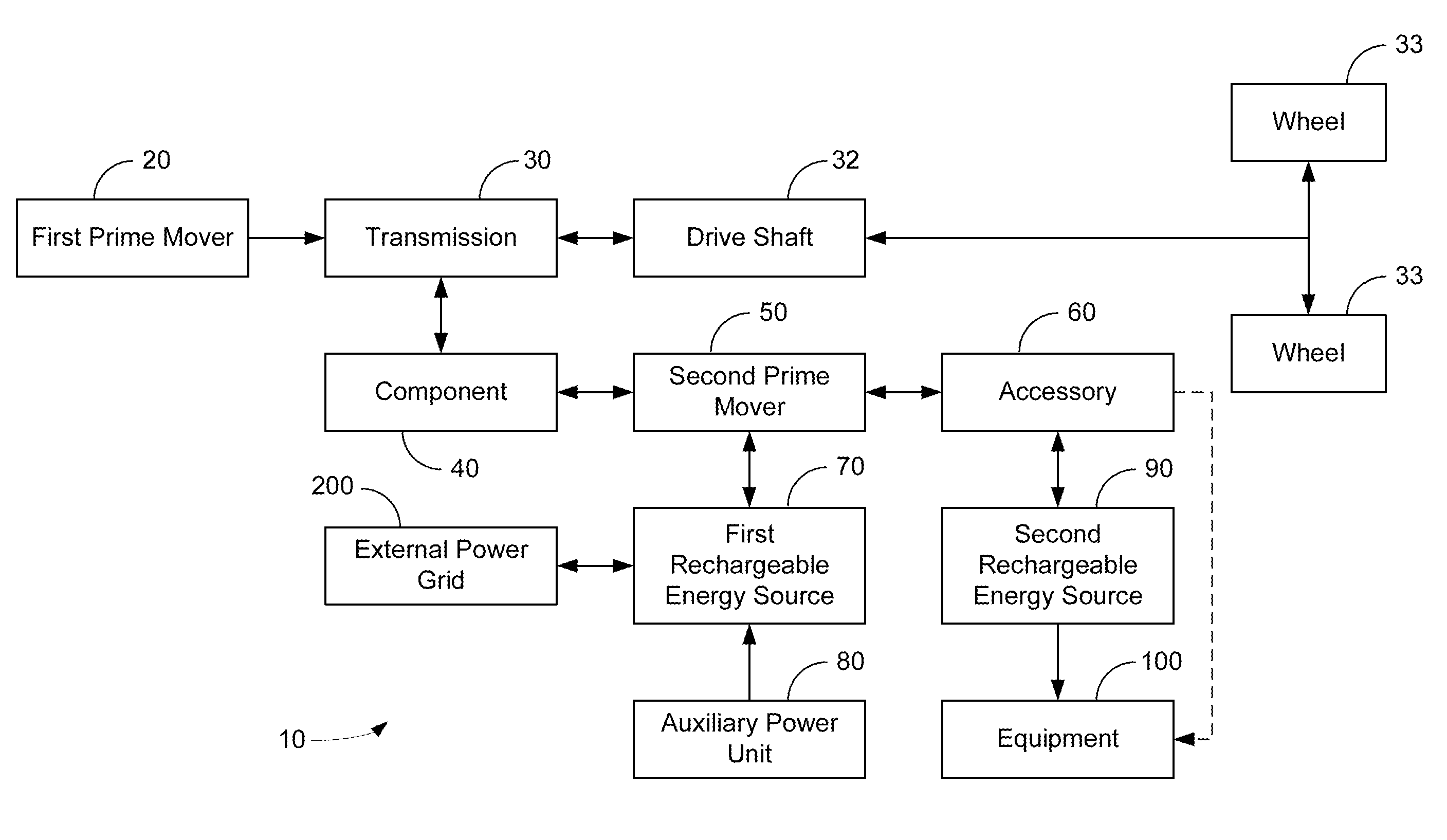

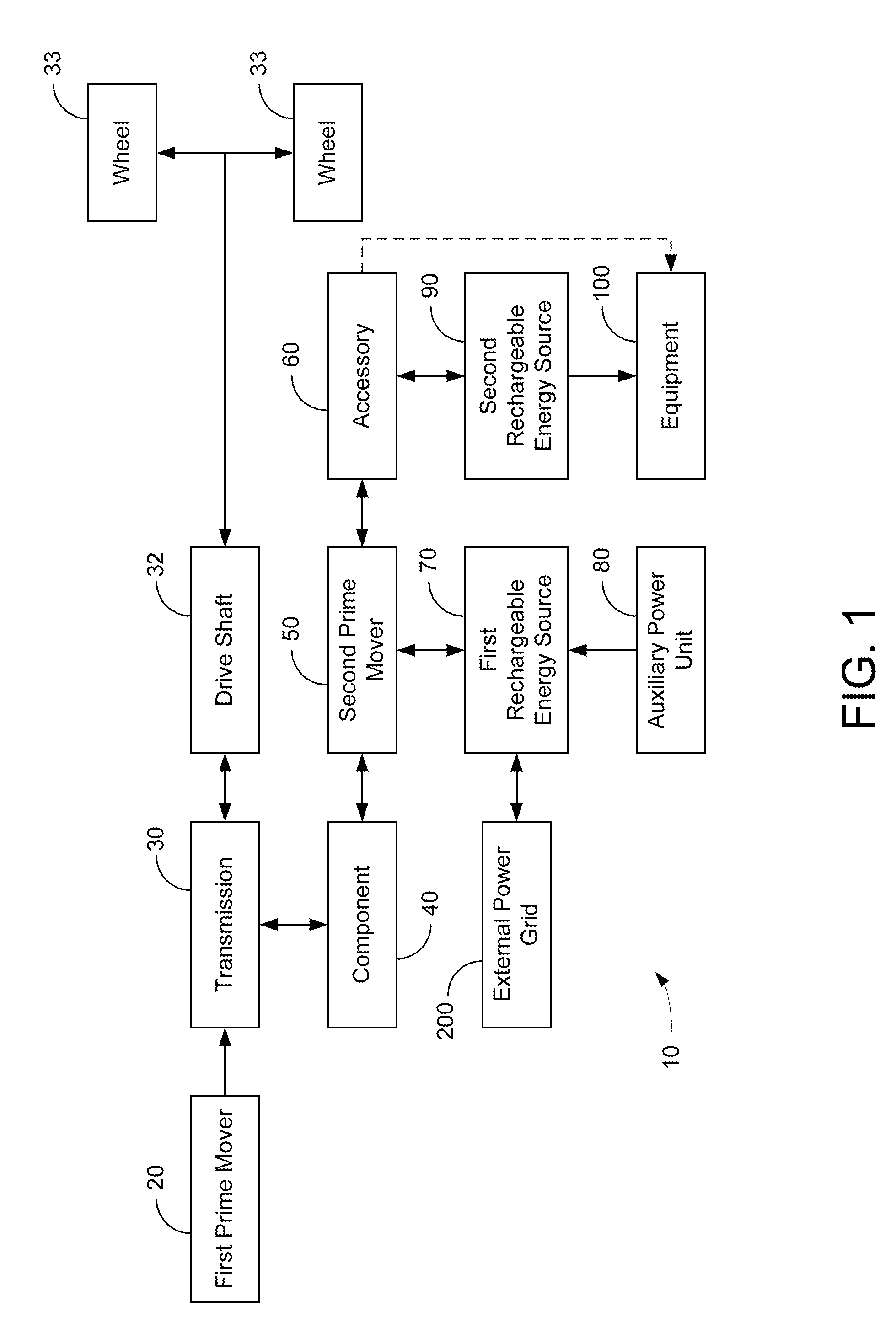

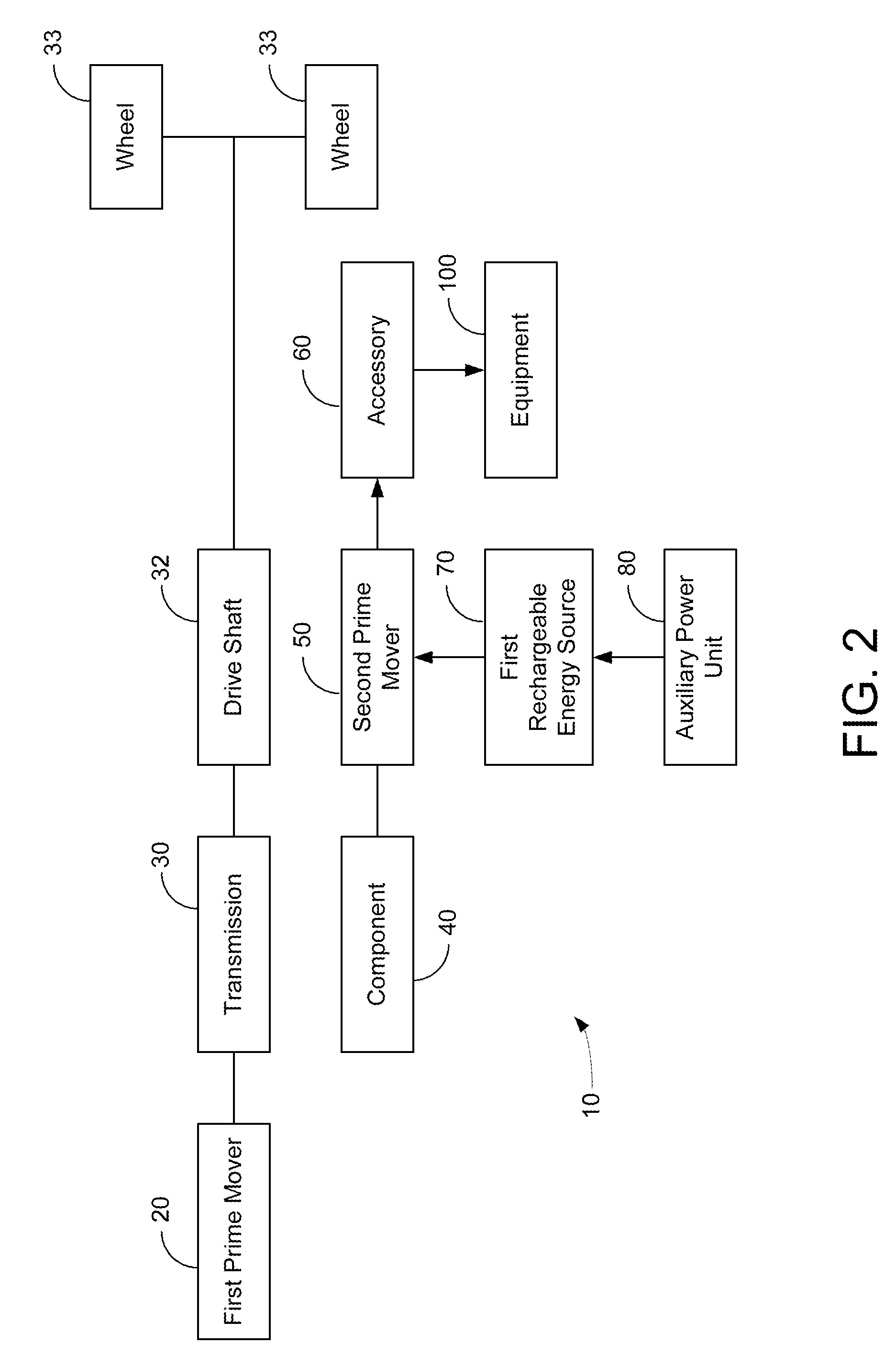

One embodiment relates to a hybrid vehicle drive system for a vehicle including a first prime mover, a first prime mover driven transmission, a rechargeable power source, and a PTO. The hybrid vehicle drive system further includes a hydraulic motor in direct or indirect mechanical communication with the PTO and an electric motor in direct or indirect mechanical communication with the hydraulic motor. The electric motor can provide power to the prime mover driven transmission and receive power from the prime mover driven transmission through the PTO. The hydraulic motor can provide power to the prime mover driven transmission and receive power from the prime mover driven transmission through the PTO.

Owner:POWER TECH HLDG LLC

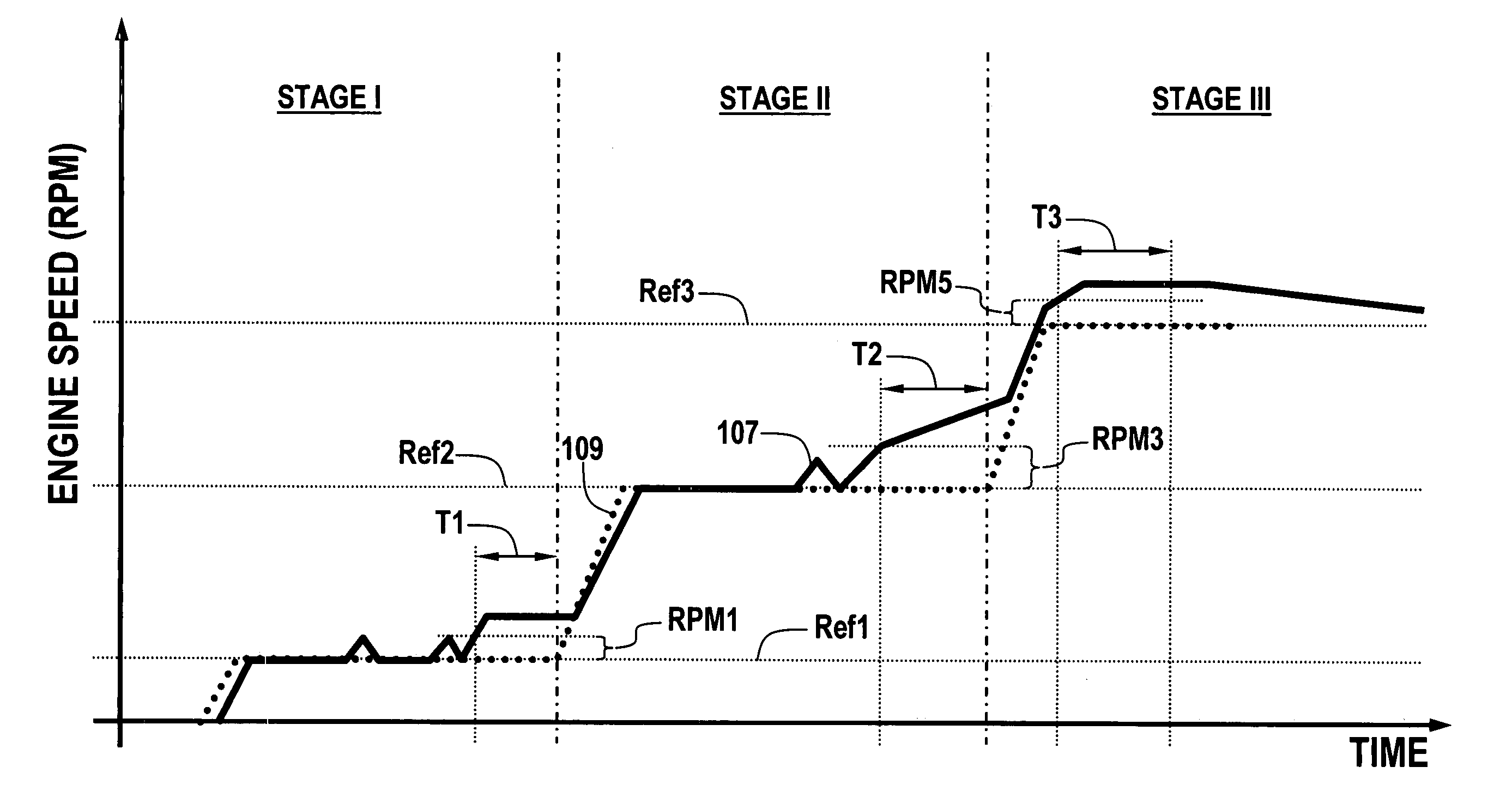

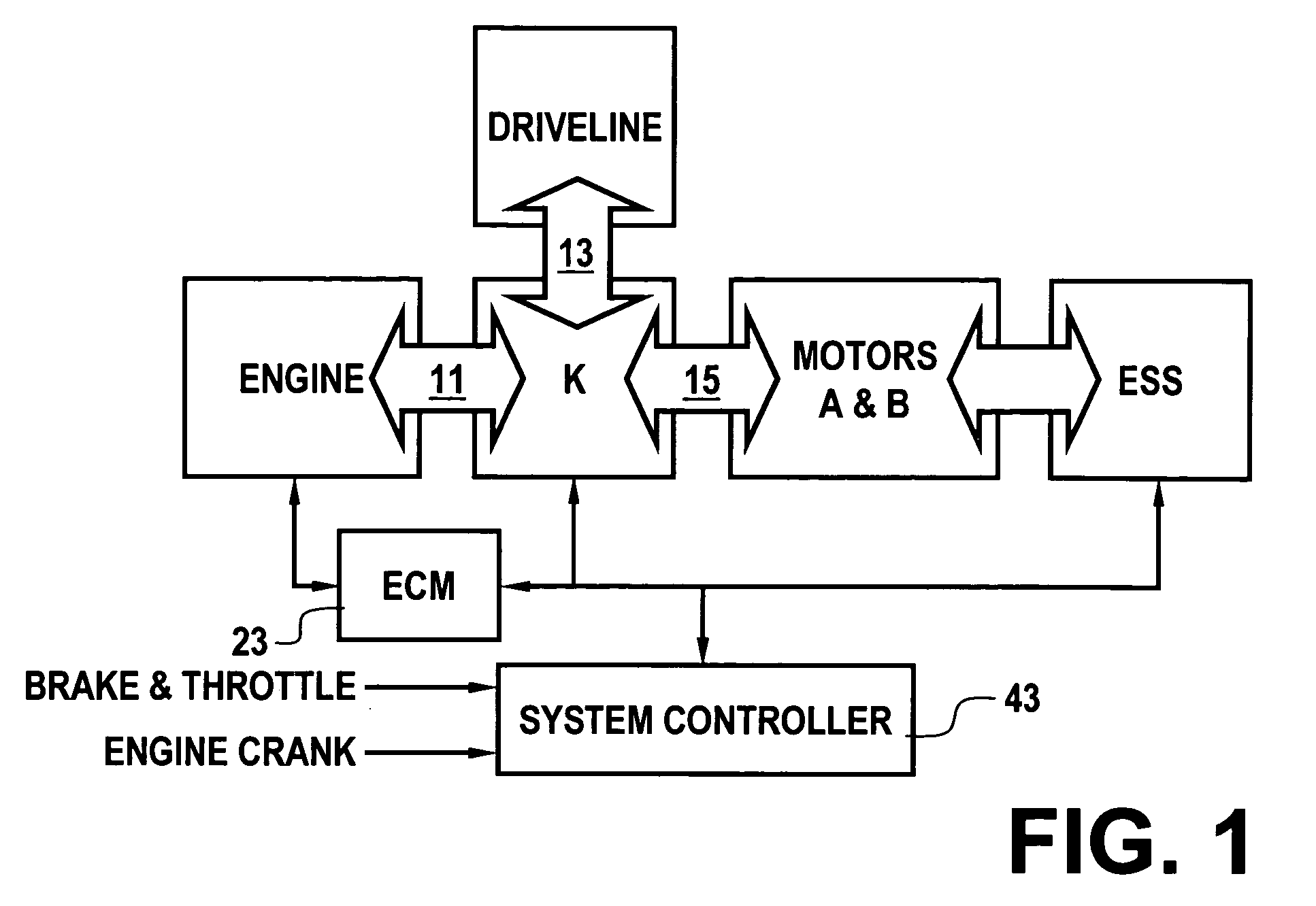

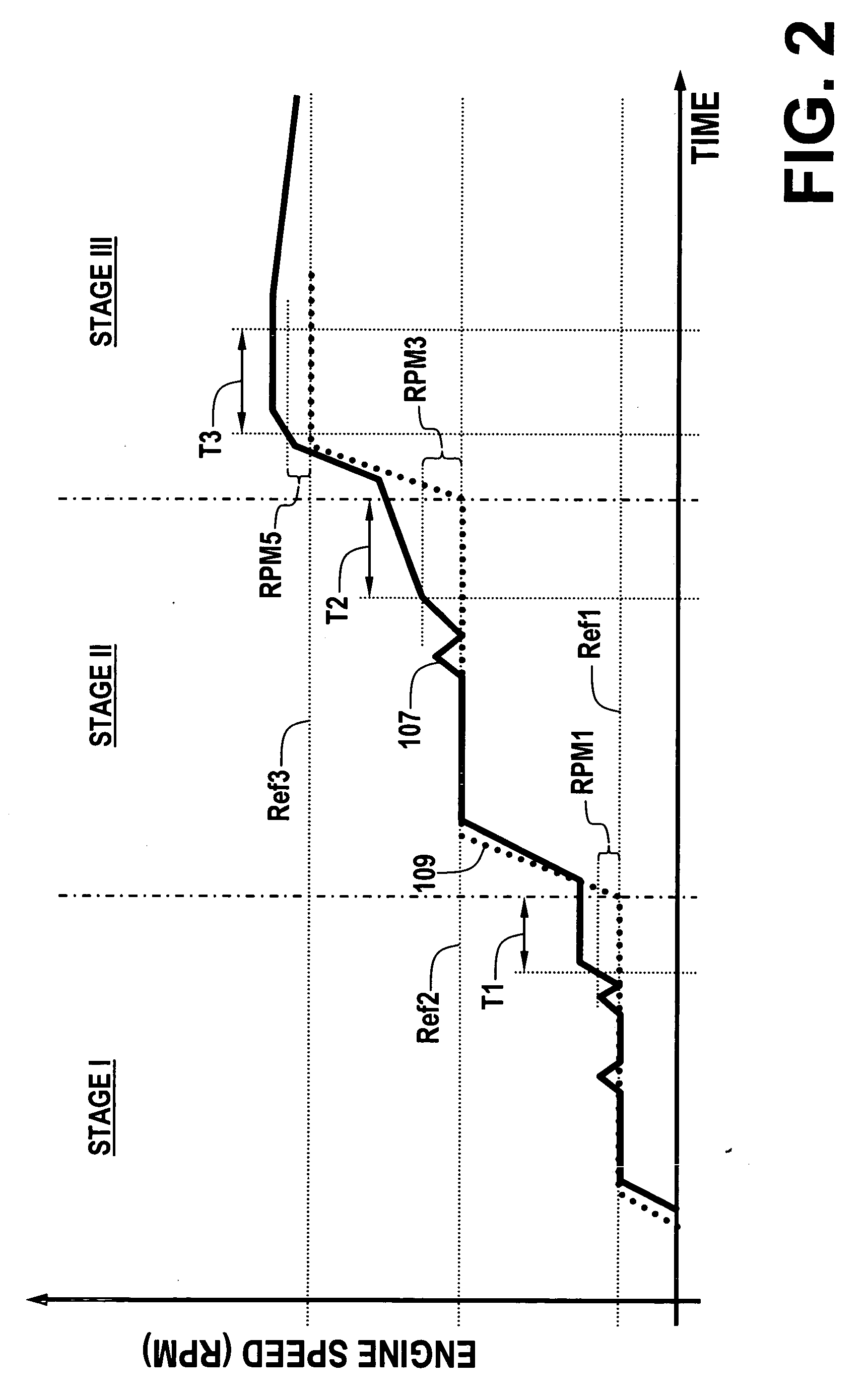

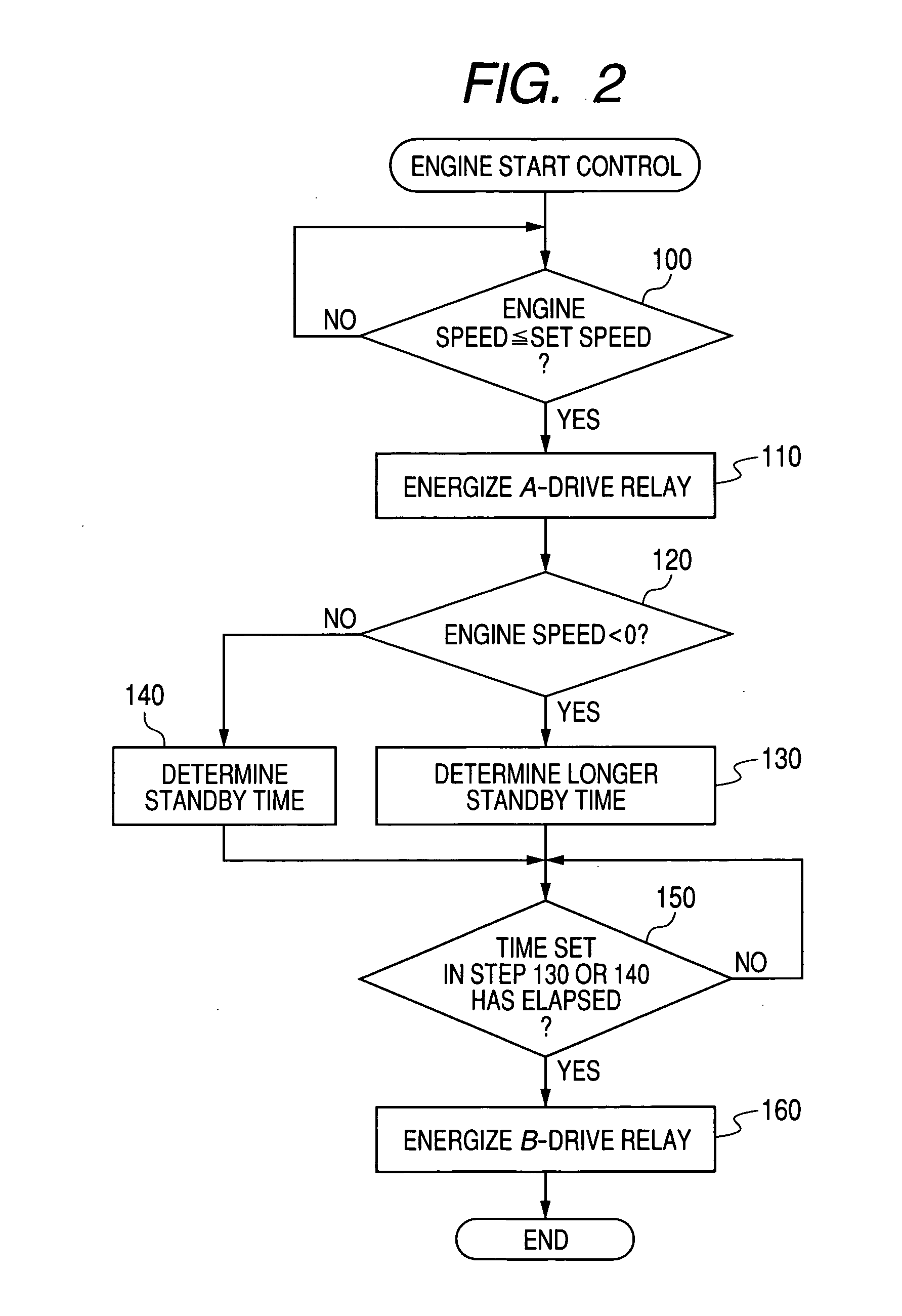

Multi-stage compression ignition engine start

A powertrain includes a diesel compression engine and an electric machine operatively coupled thereto and effective to rotate the engine during engine cranking. Cold engine cranking is accomplished in a staged manner including a first stage wherein the engine is cranked to a first speed below the resonant speed of the coupled engine and electric machine combination for a first duration and thereafter cranked to a second speed above the resonant speed for a second duration. Transition out of cranking at the first and second speeds is accomplished when relative combustion stability is demonstrated. Cranking at the first or second speed is aborted when excessive crank times or if low battery voltages are observed. A third stage is included wherein the engine is cranked to a third speed below the engine idle speed. Transition out of cranking at the third speed is accomplished when relative combustion stability is demonstrated, whereafter normal engine control takes over.

Owner:ALLISON TRANSMISSION INC

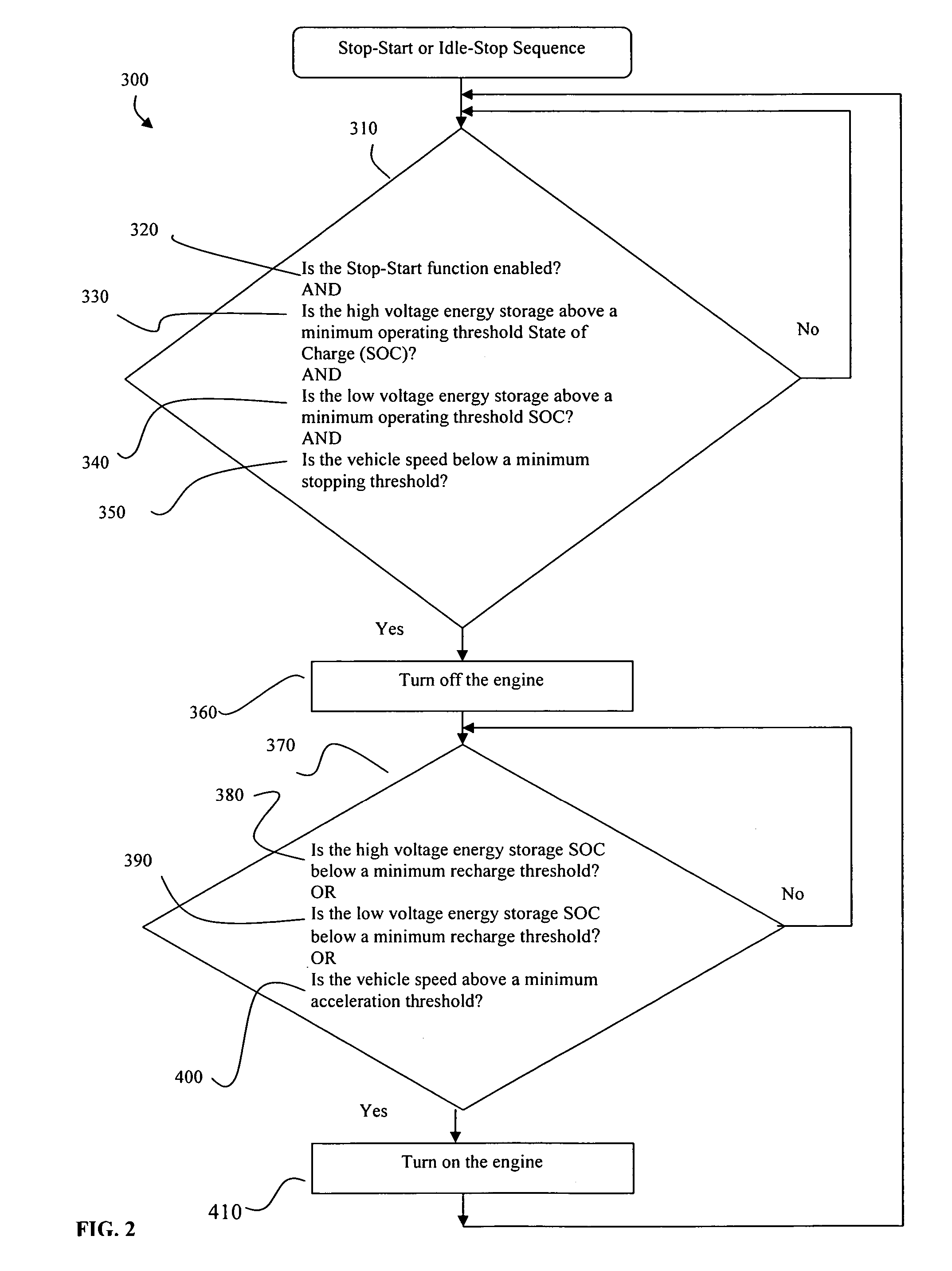

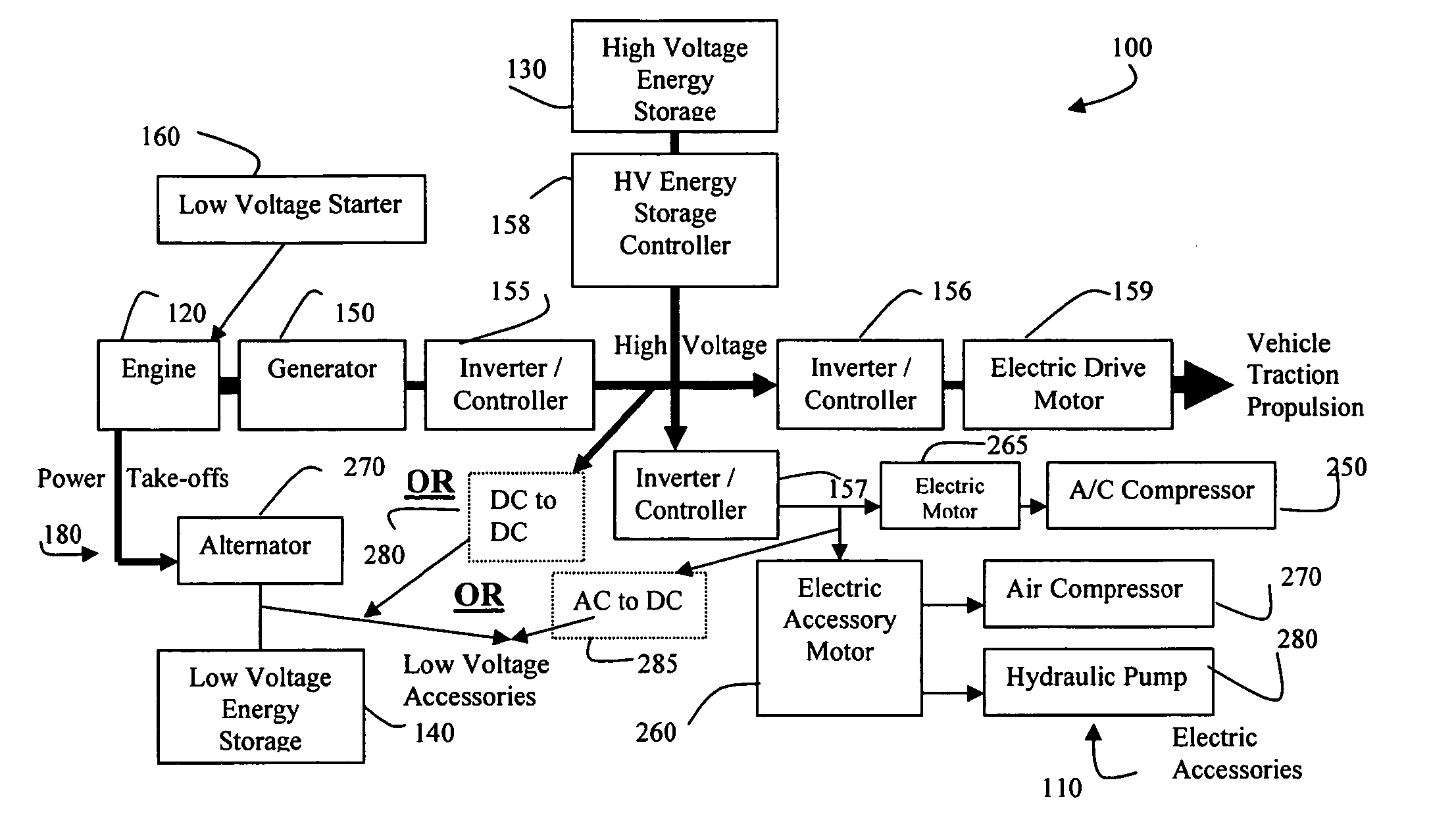

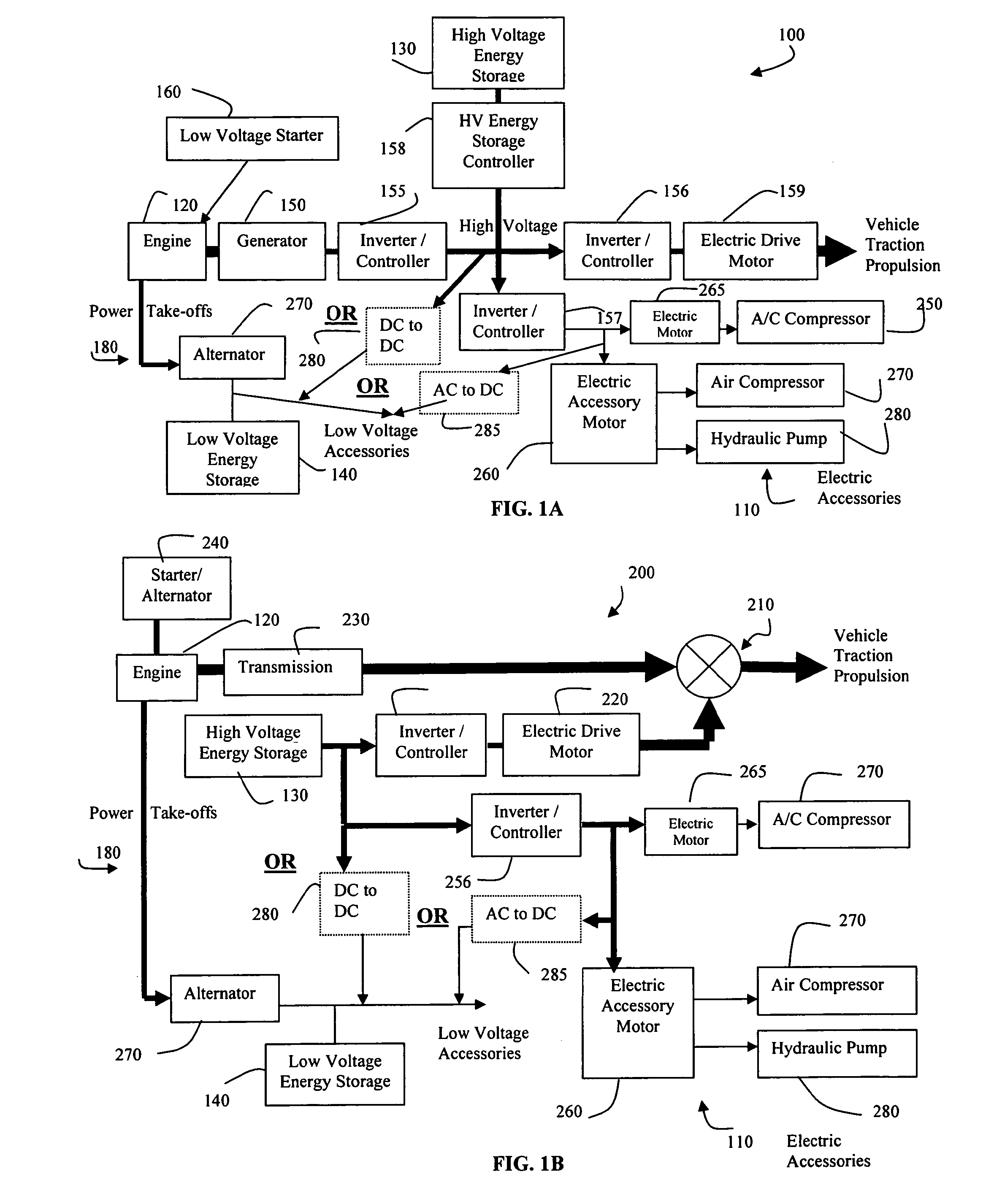

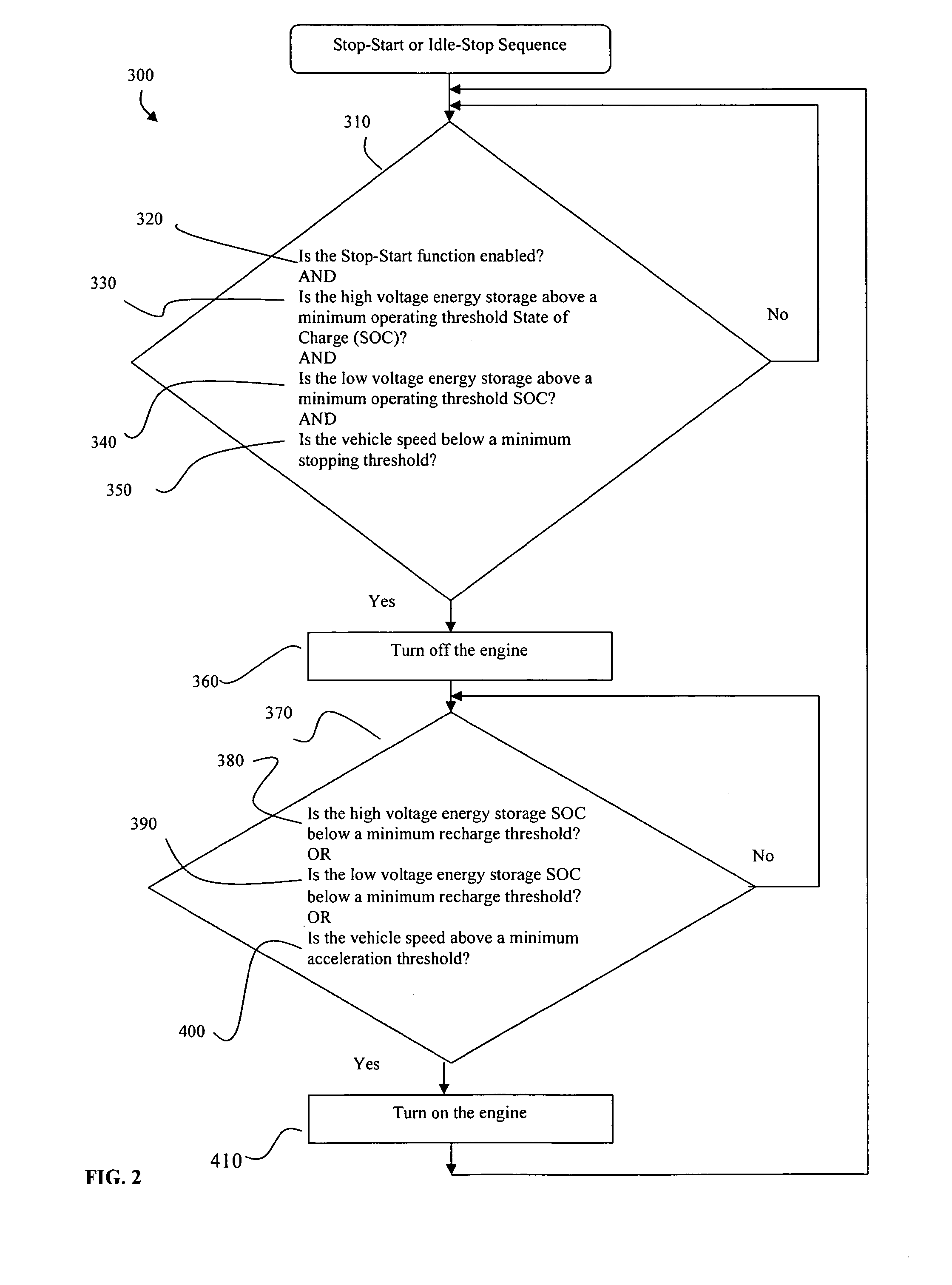

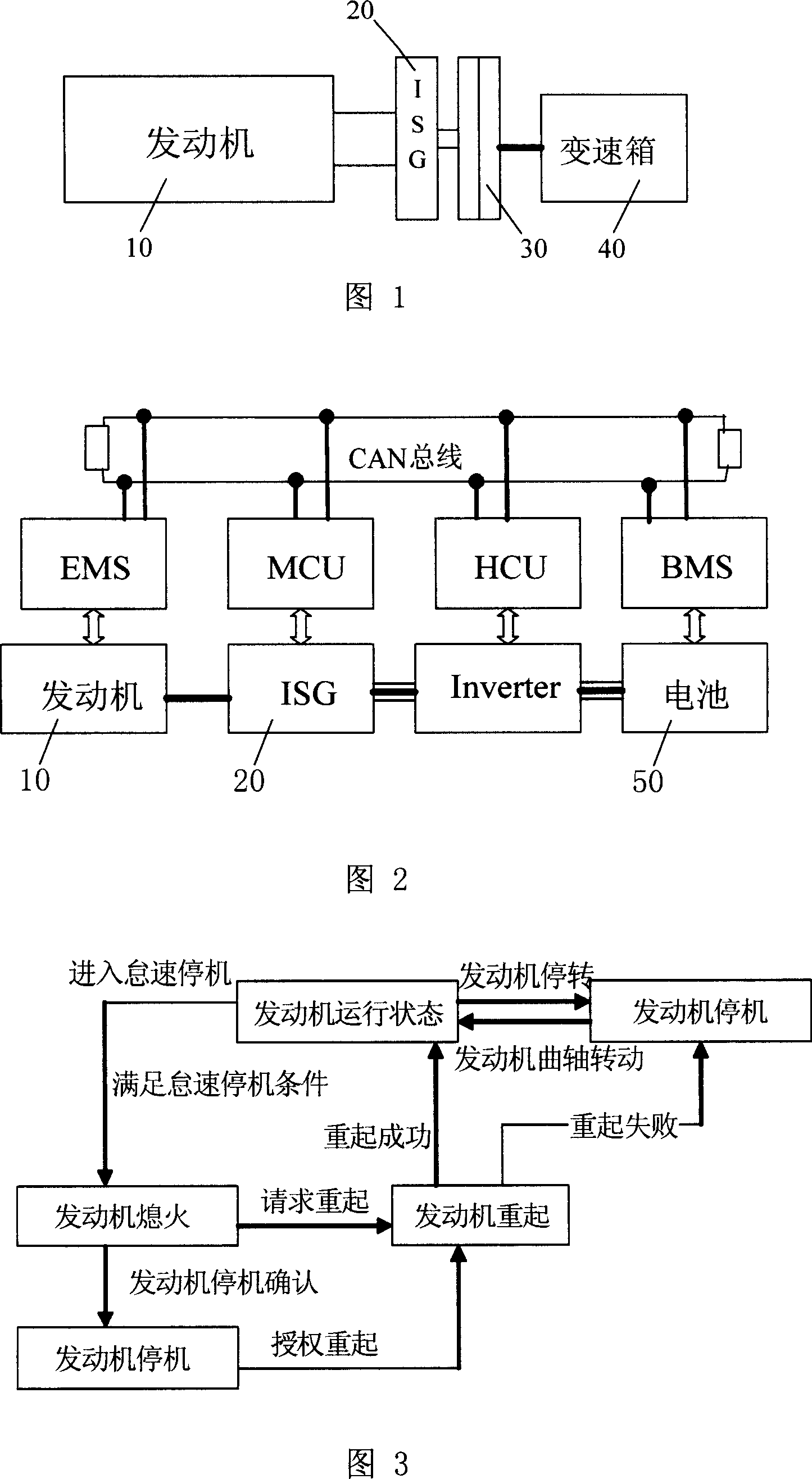

Method of controlling engine stop-start operation for heavy-duty hybrid-electric and hybrid-hydraulic vehicles

InactiveUS20070124037A1Minimizes engine noiseNoise minimizationInternal combustion piston enginesDigital data processing detailsEngineeringInternal combustion engine

A start-stop or idle-stop method for a heavy-duty hybrid vehicle that turns off the fuel supply while maintaining the crankshaft rotation of the internal combustion engine when the vehicle stops or, optionally, when the vehicle travels downhill, travels in a noise sensitive location, travels in an exhaust emissions sensitive location, or operates in an emergency situation. The stop-start or idle-stop method automatically turns on the engine fuel supply to restart combustion when the vehicle starts accelerating, is no longer traveling downhill, is no longer traveling in a noise sensitive or exhaust sensitive location, is no longer in an emergency situation, or has dropped below the minimum energy storage restart level.

Owner:SHEPPARD MULLIN RICHTER & HAMPTON

Method of Controlling Engine Stop-Start Operation for Heavy-Duty Hybrid-Electric Vehicles

InactiveUS20100145562A1Noise minimizationHybrid vehiclesInternal combustion piston enginesElectric vehicleInternal combustion engine

A start-stop or idle-stop method for a heavy-duty hybrid vehicle that turns off the fuel supply while maintaining the crankshaft rotation of the internal combustion engine when the vehicle stops or, optionally, when the vehicle travels downhill, travels in a noise sensitive location, travels in an exhaust emissions sensitive location, or operates in an emergency situation. The stop-start or idle-stop method automatically turns on the engine fuel supply to restart combustion when the vehicle starts accelerating, is no longer traveling downhill, is no longer traveling in a noise sensitive or exhaust sensitive location, is no longer in an emergency situation, or has dropped below the minimum energy storage restart level. The stop-start or idle-stop may be inhibited upon certain override conditions.

Owner:SHEPPARD MULLIN RICHTER & HAMPTON

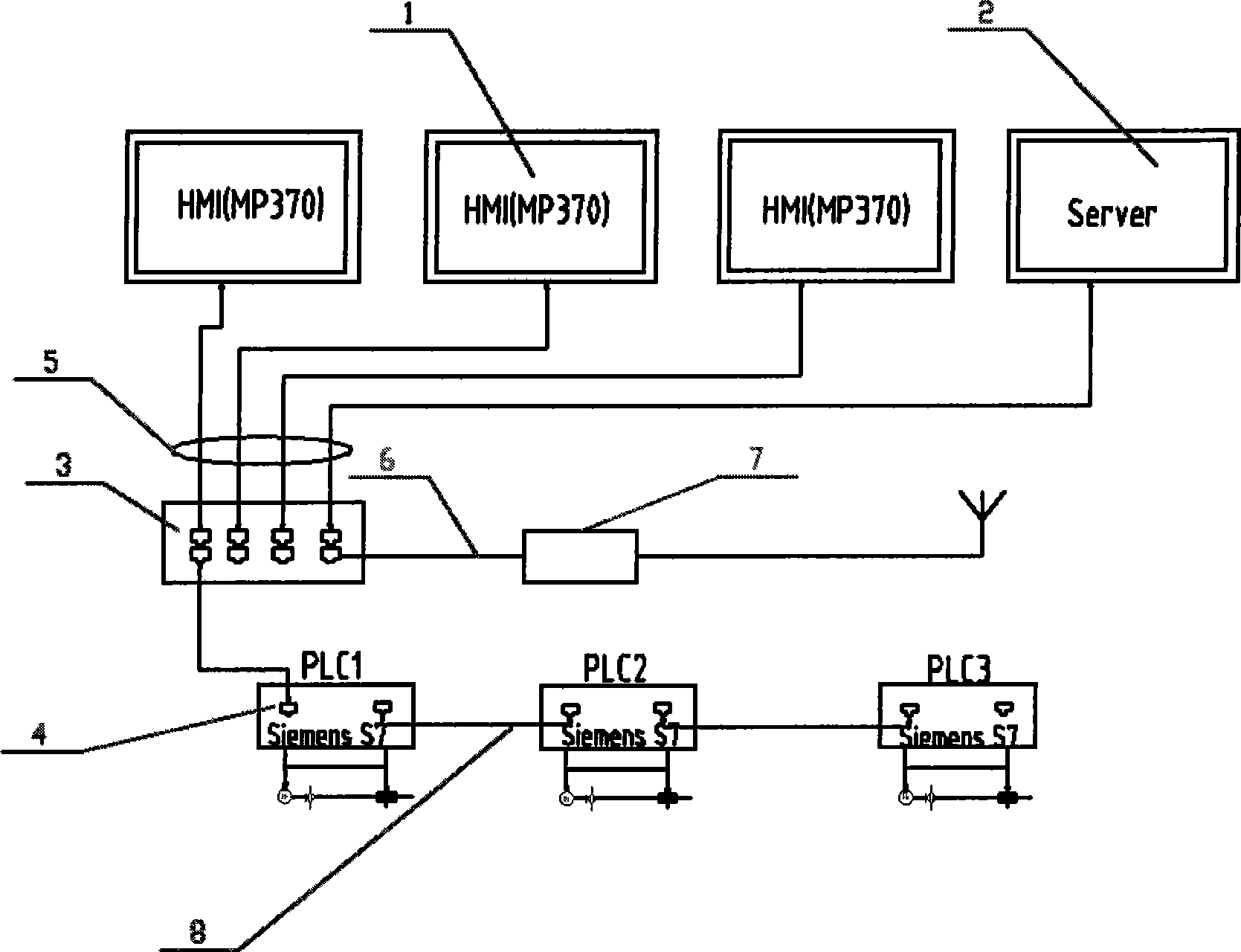

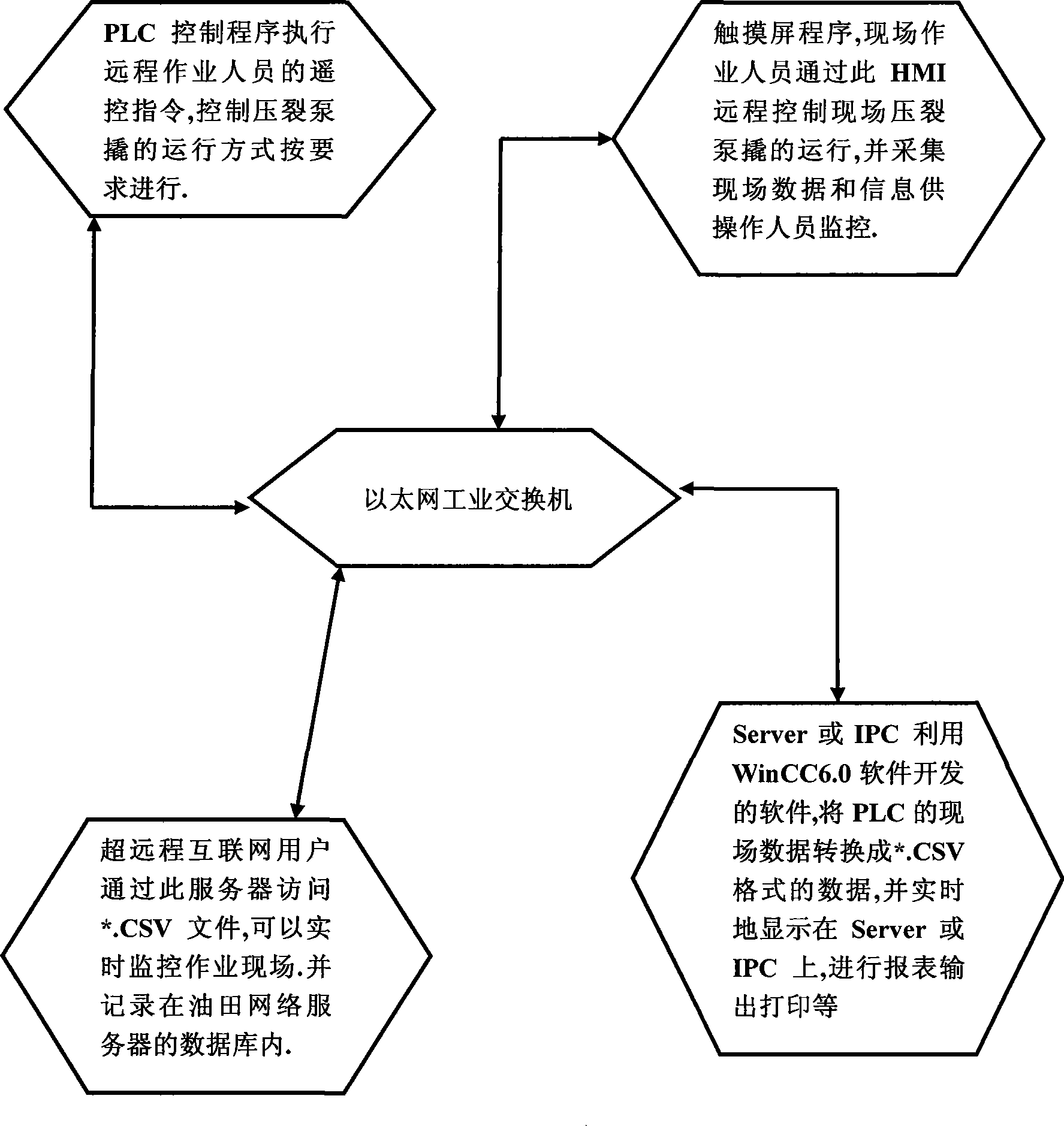

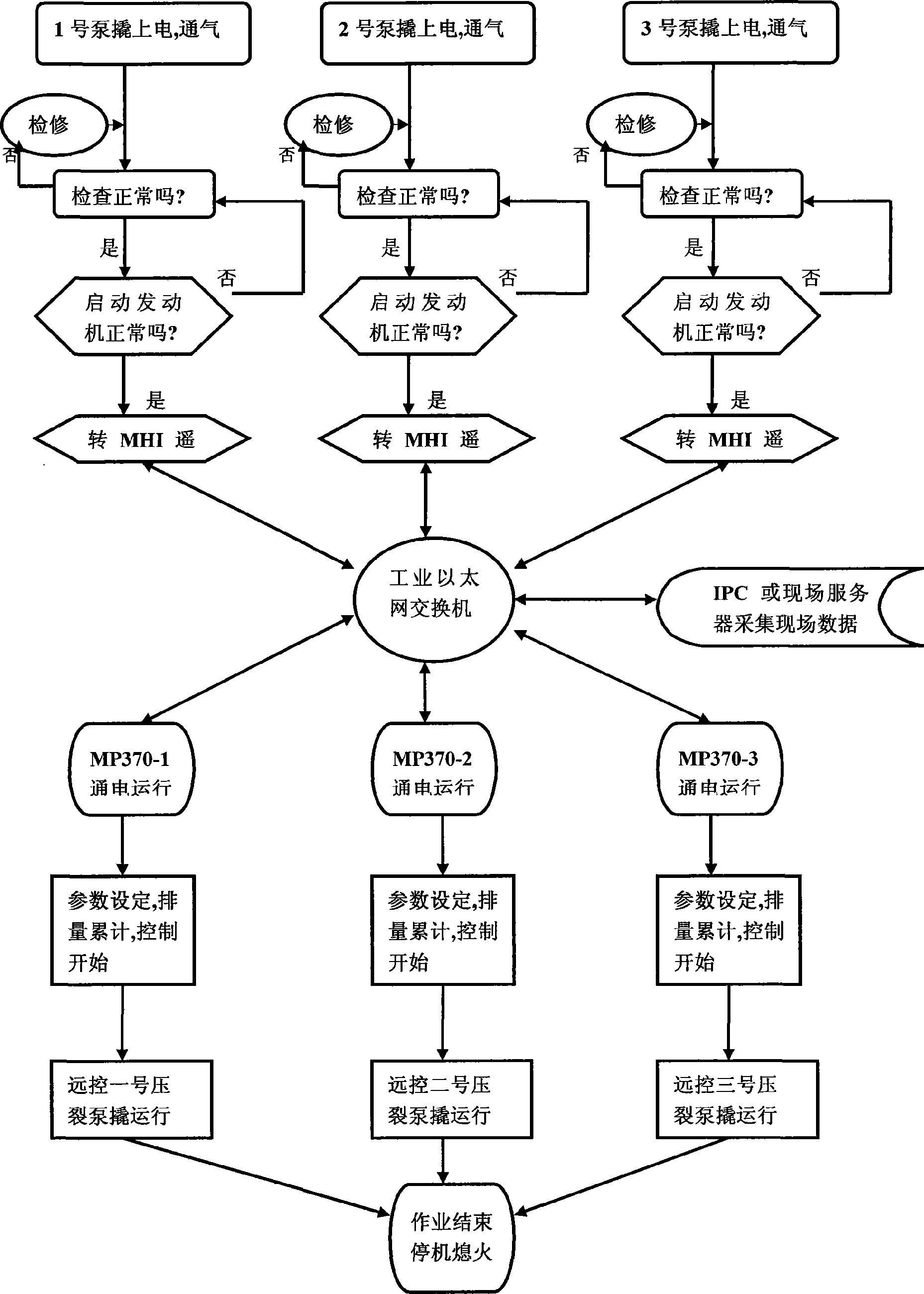

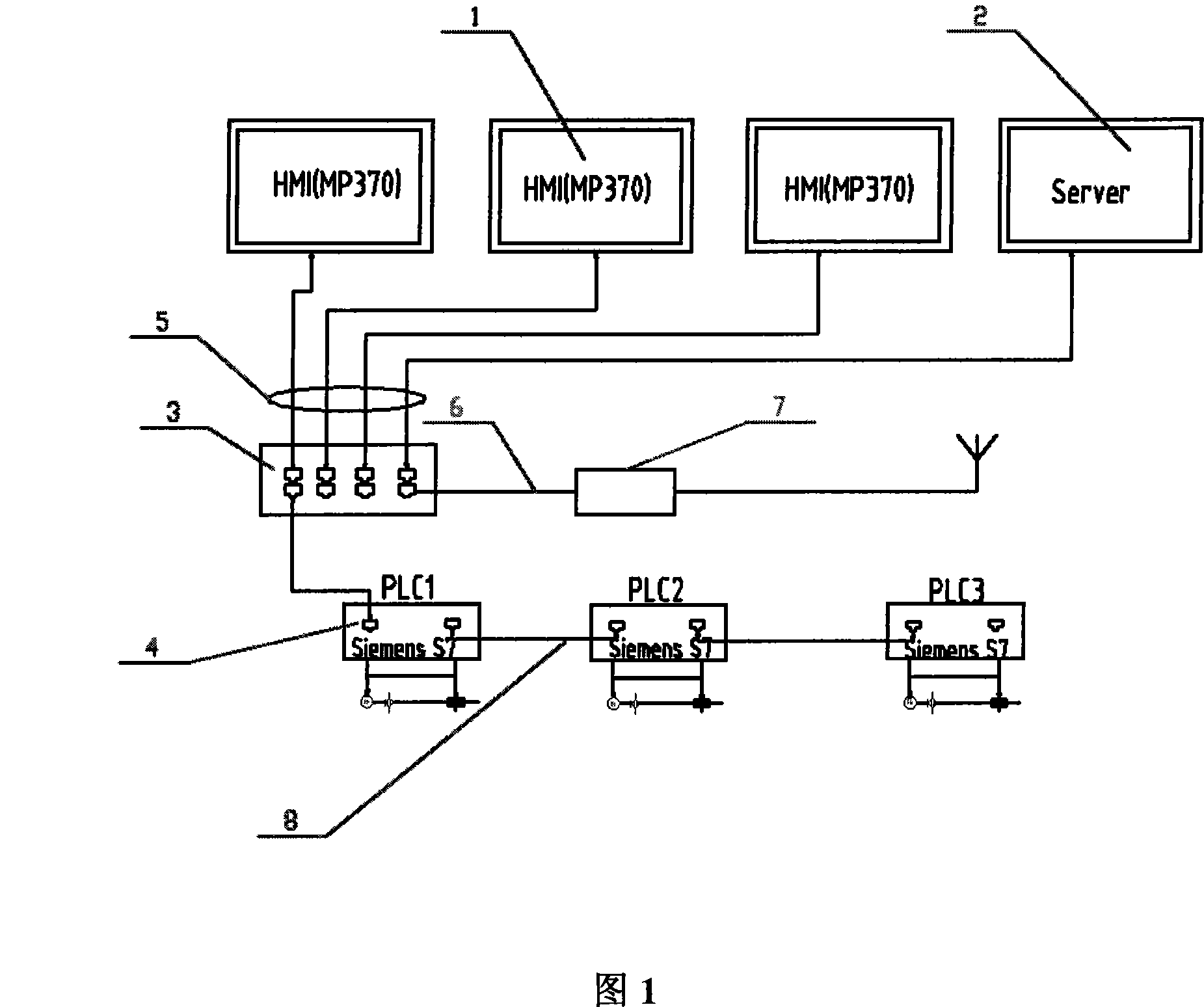

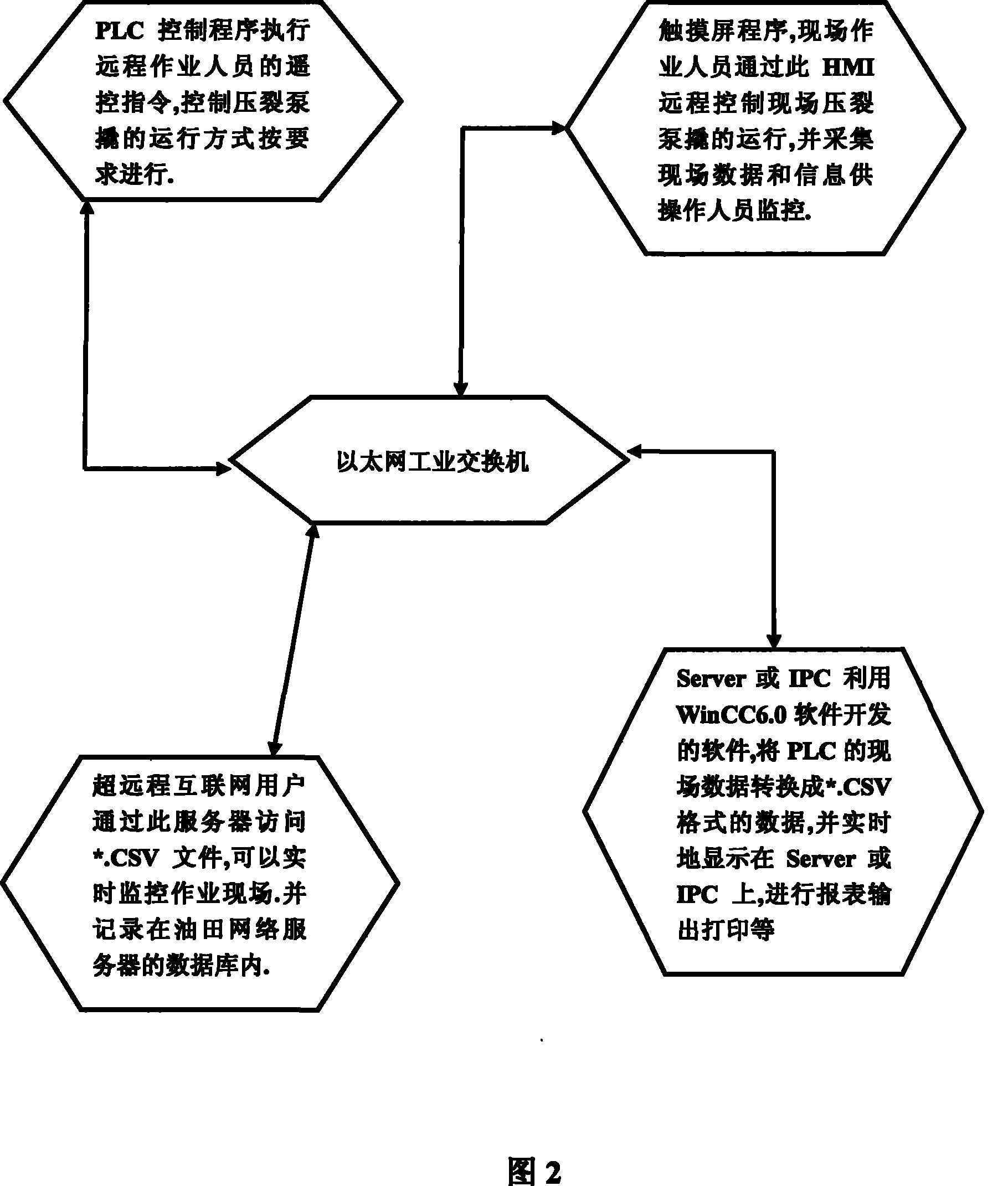

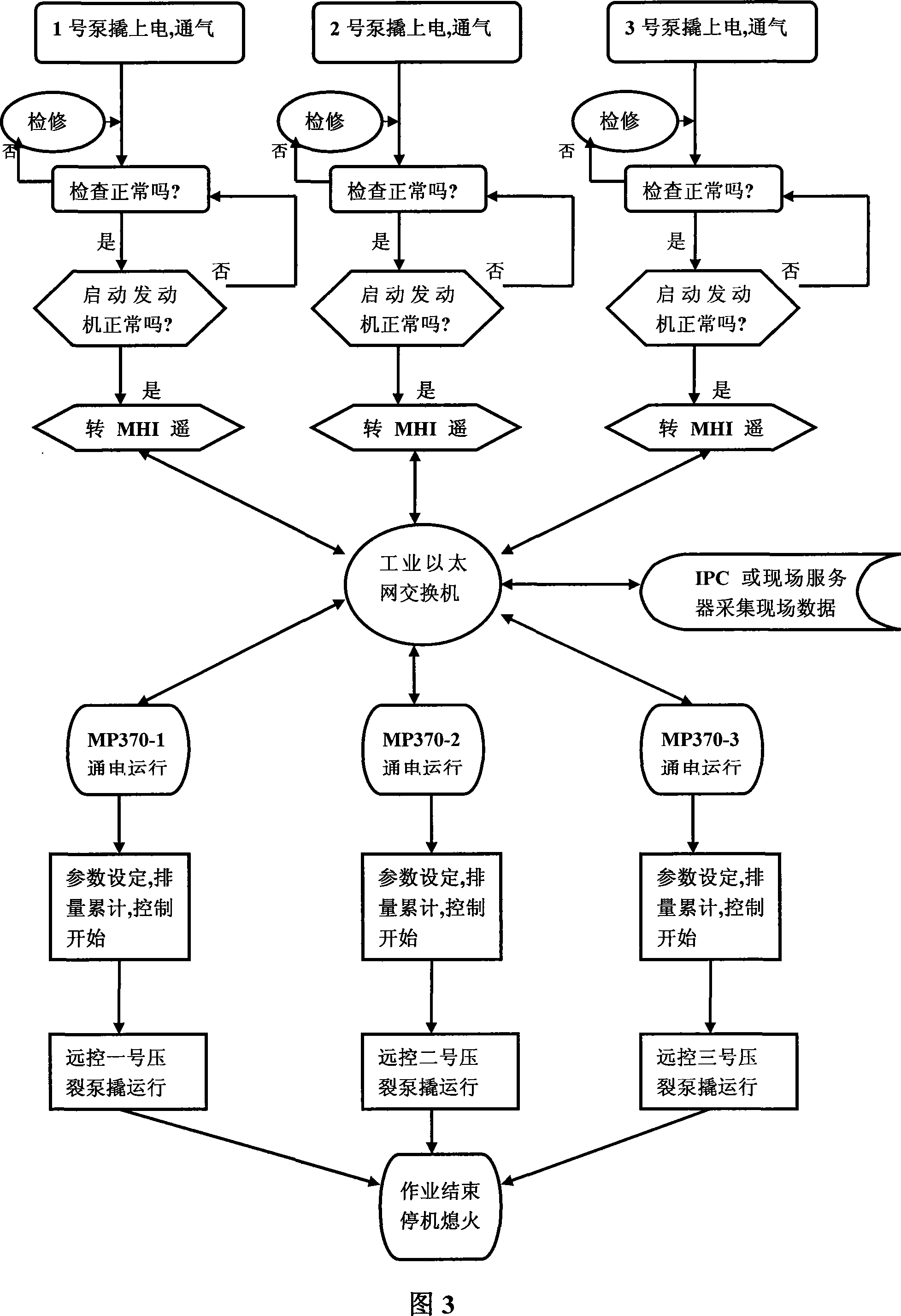

Oil field fracturing pumping remote automatic control system

ActiveCN101414171AMonitor and control operationsOrderly and stable operationTotal factory controlProgramme total factory controlAutomatic controlHuman–machine interface

The invention discloses a remote automatic control system of a fracturing pump skid used in an oil field. The system is used for remote automatic control of a well service pump skid and a truck-mounted skid used in the oil field; the remote automatic control system consists of a field control system which consists of Siemens S7-315 series PLCs which are taken as a core, a Siemens MP370 which is taken as a remote control human-machine interface, and Ethernet which is taken as a transmission media; the system can achieve remote control functions such as start, stop and emergency stop of an engine, gear shifting, braking, turning back to a neutral position and idle speed of a gearbox and the like, and the system can modify field running parameters in a remote manner, thus realizing bidirectional transmission between the pump skid and the human-machine interface (HMI); the Ethernet is taken for communication so that the pump skid can transmit the field data to a remote controller or a server at the speed of 100MB / S; an industrial exchanger is taken to connect the devices such as the PLC, the HMI and the like to achieve more group controls; the exchanger can convert the field data into the data formats such as a standard *.CSV format and the like, and directly transmit the data to the server for data processing.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

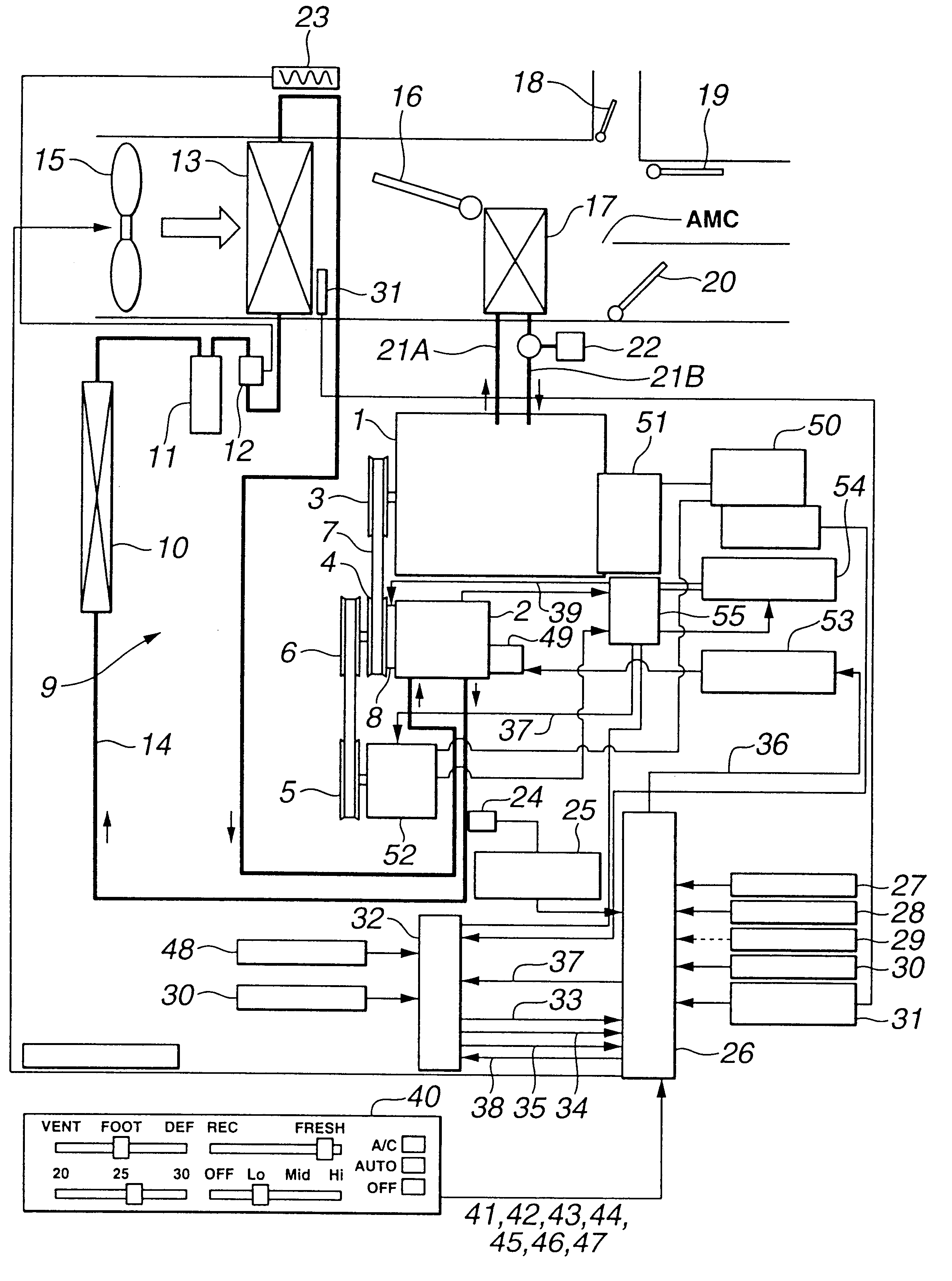

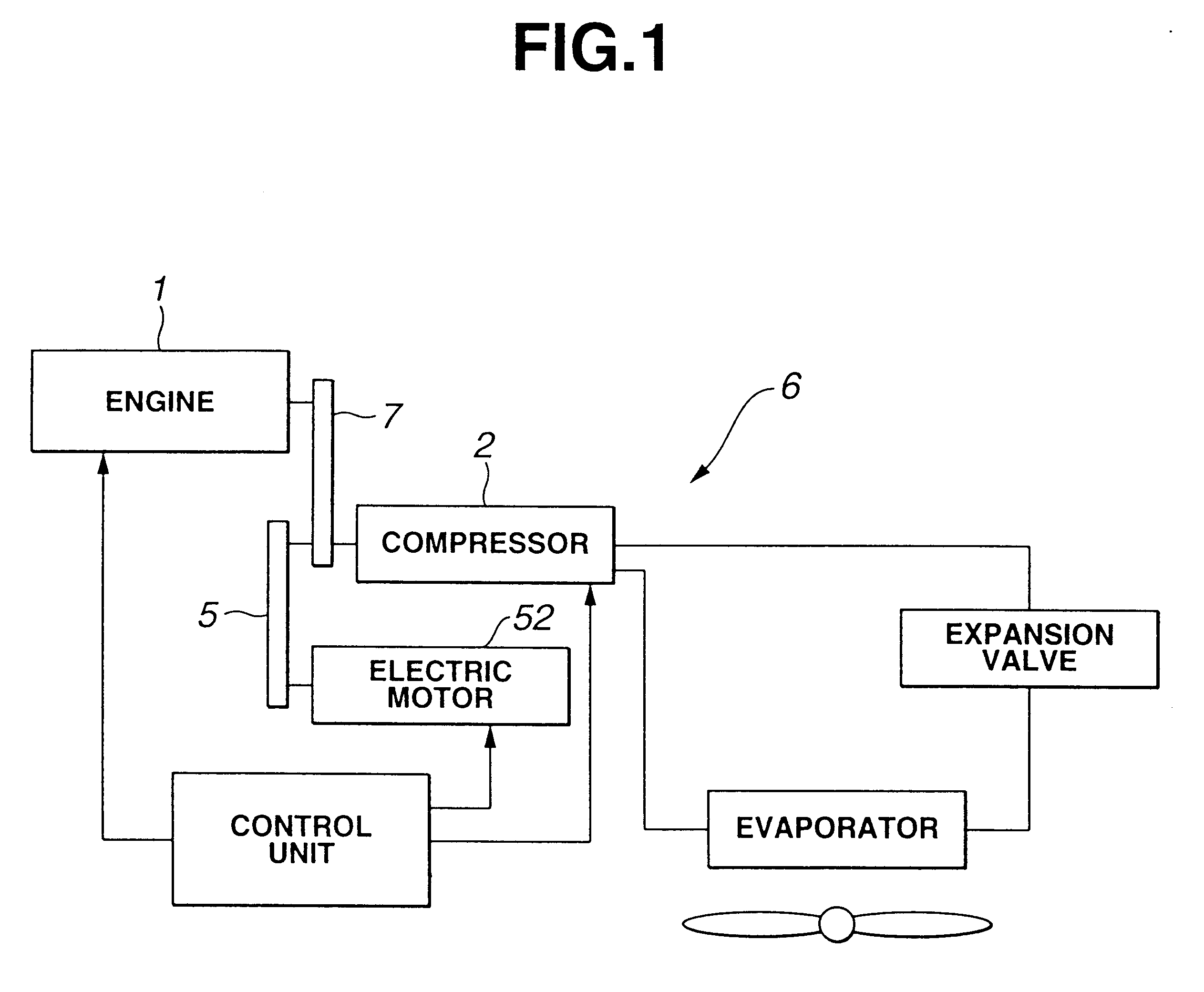

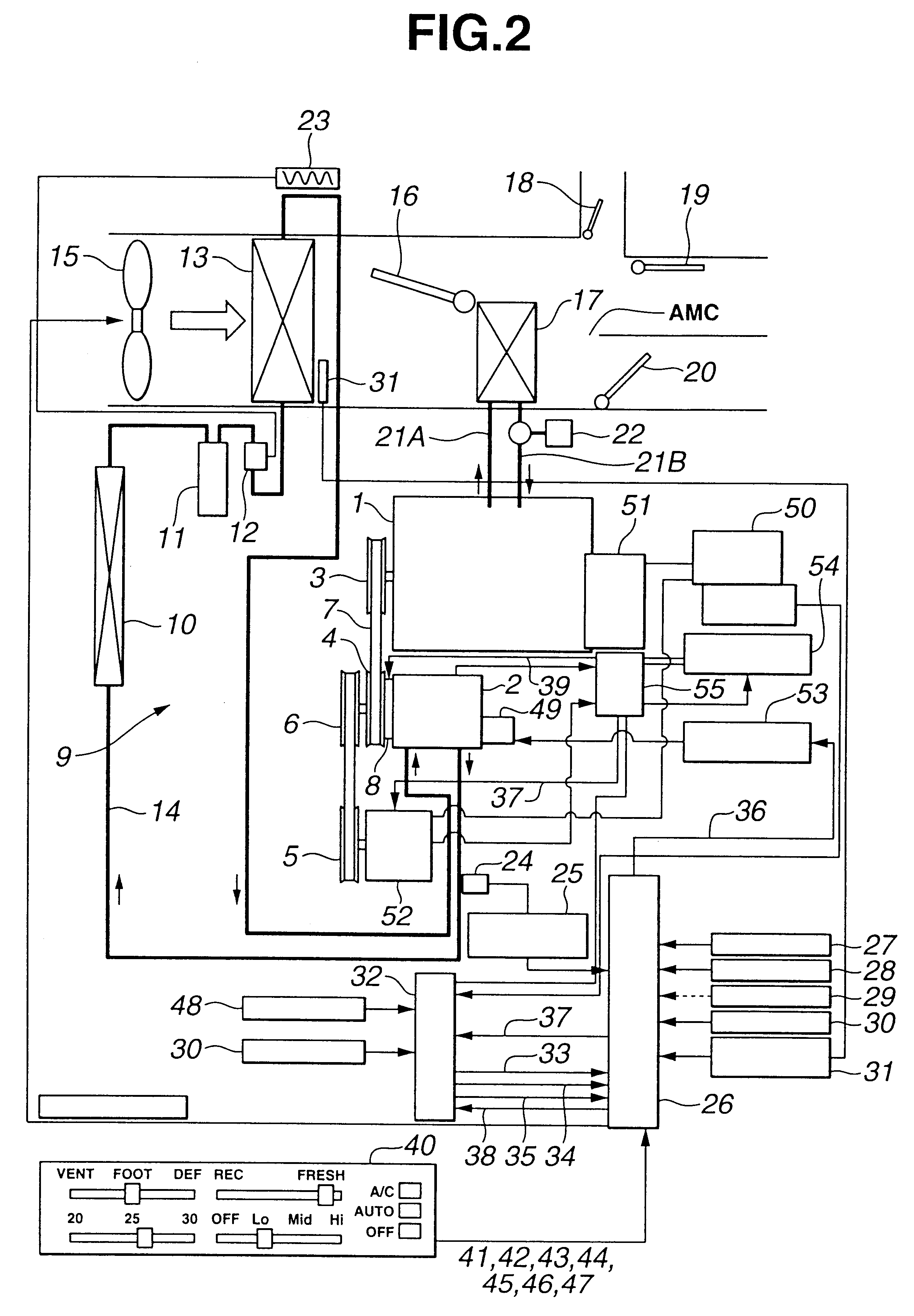

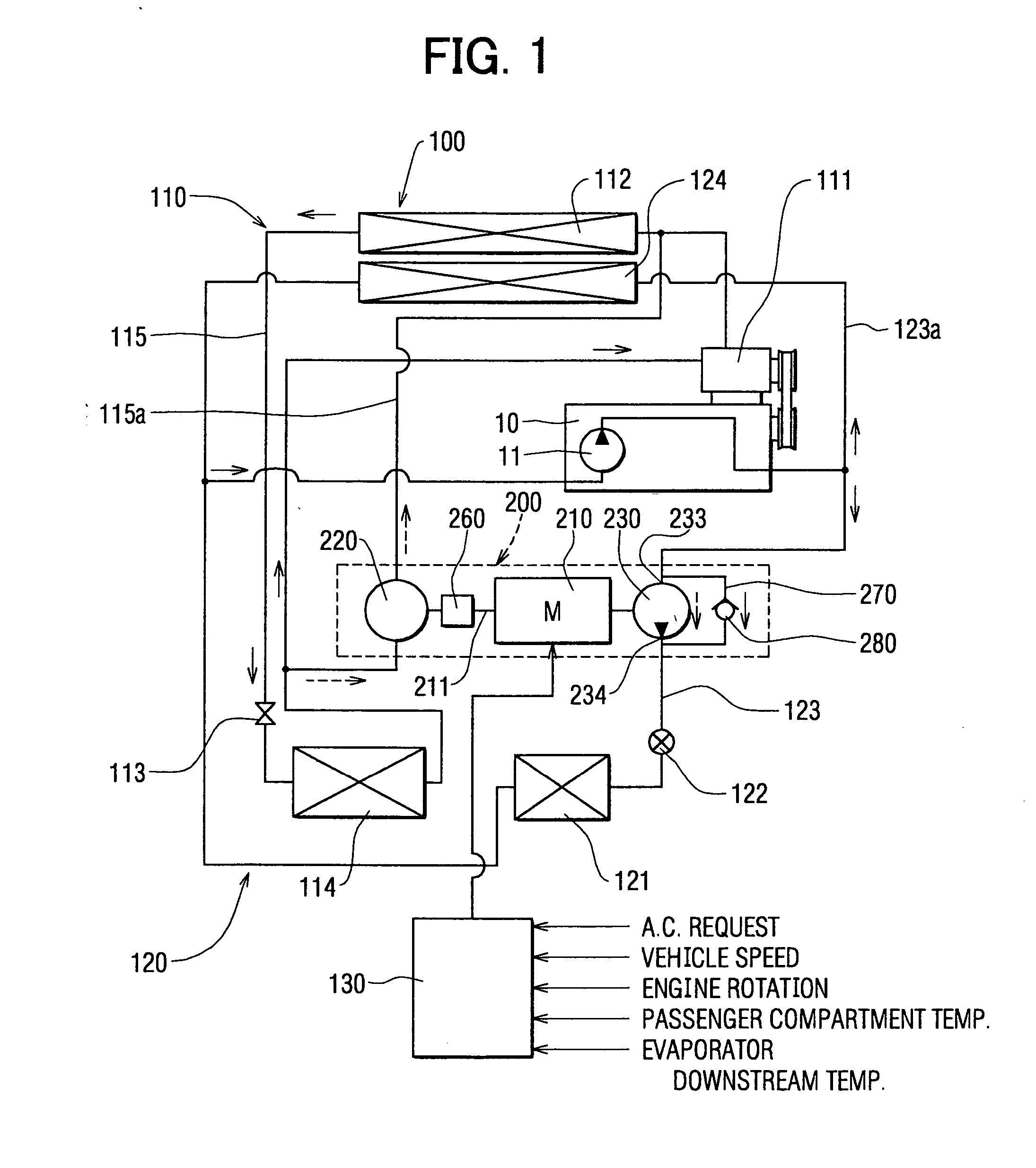

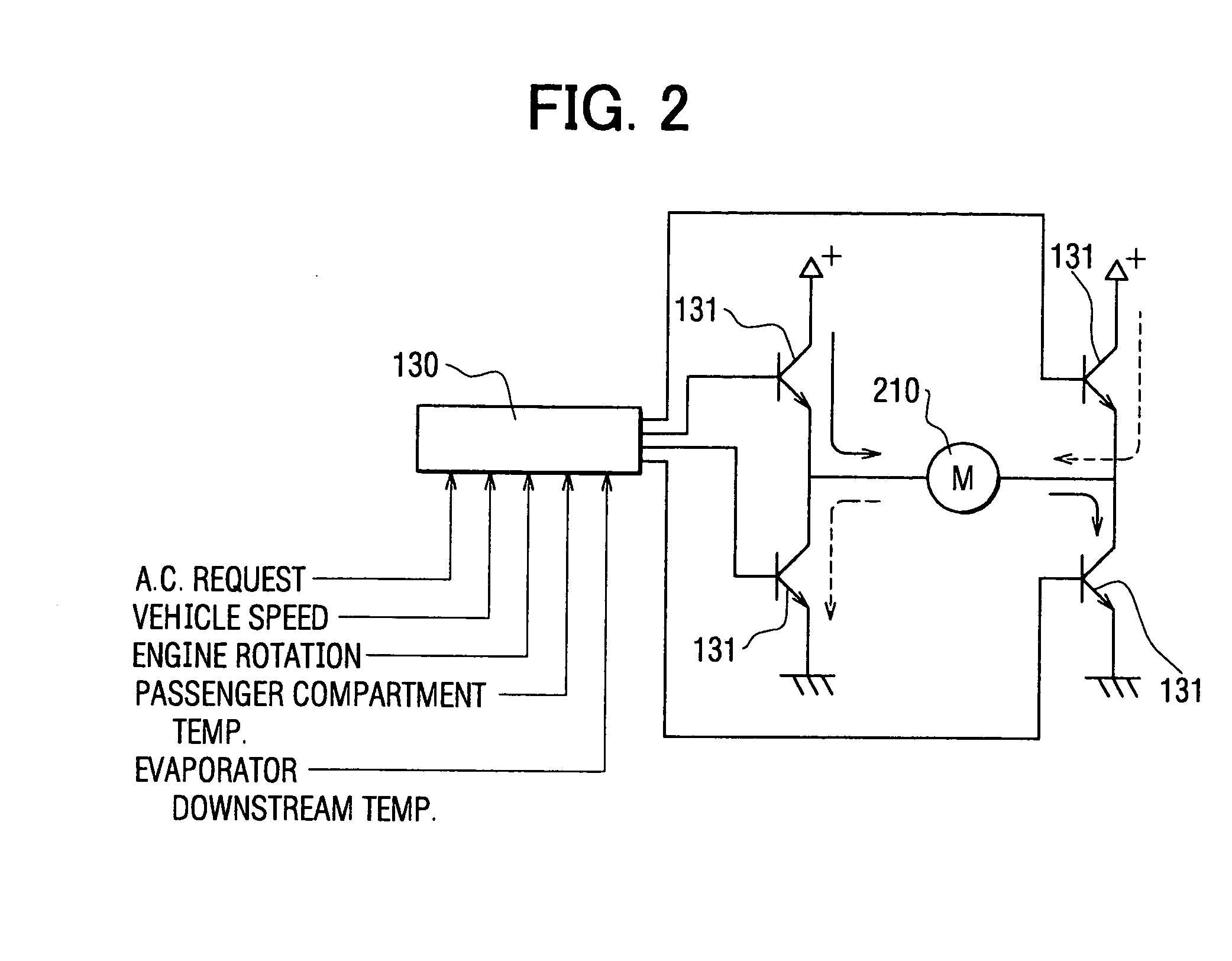

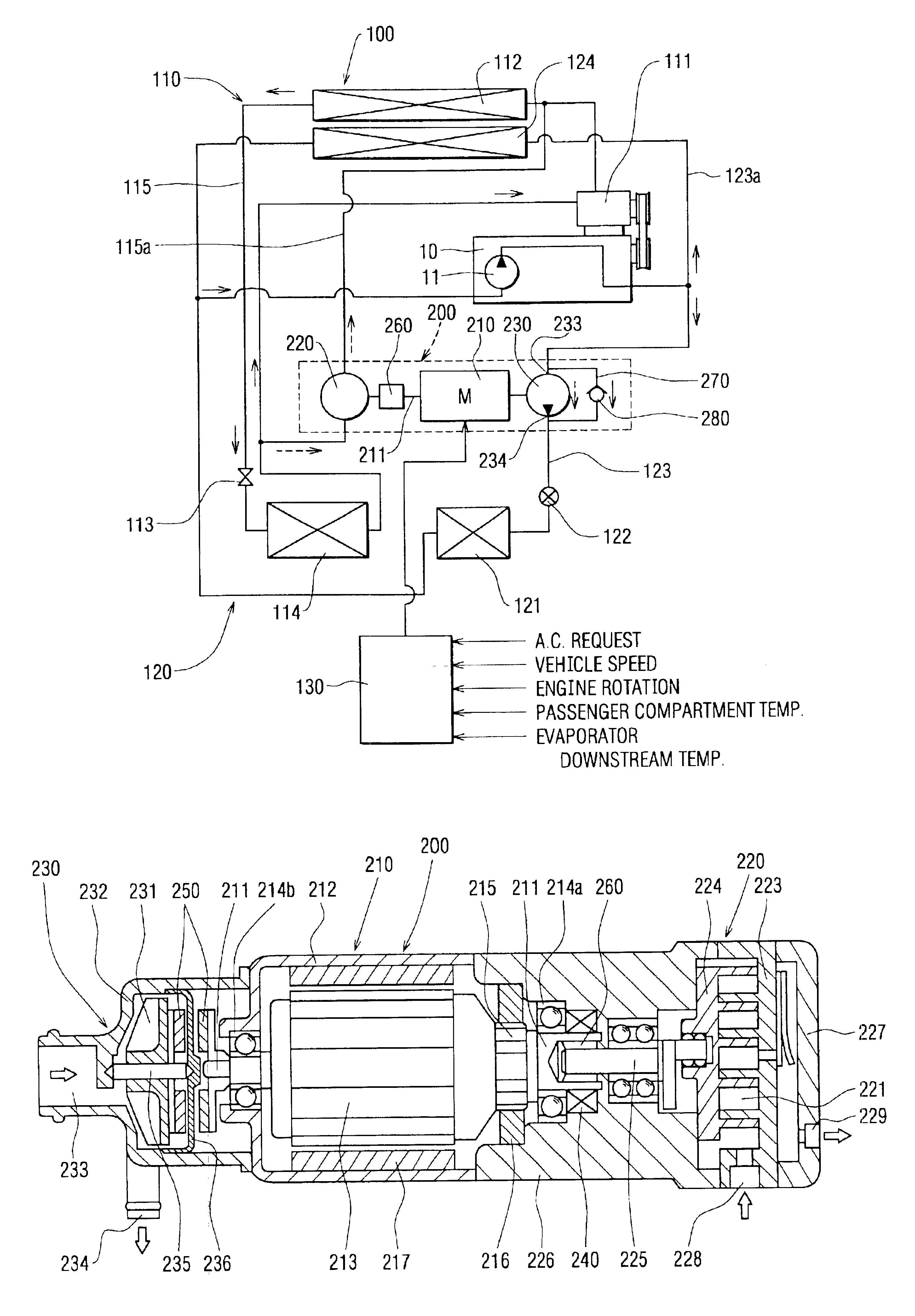

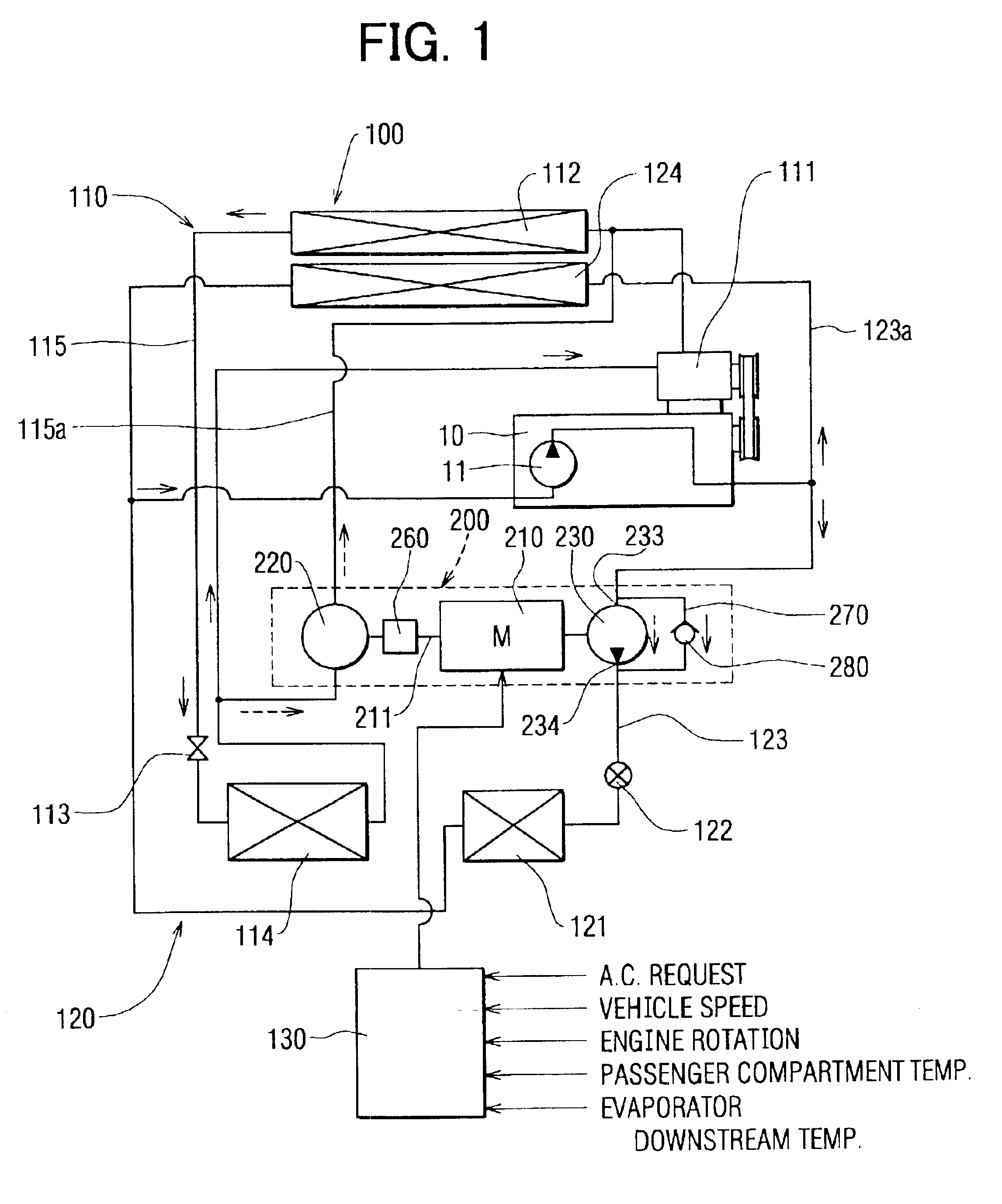

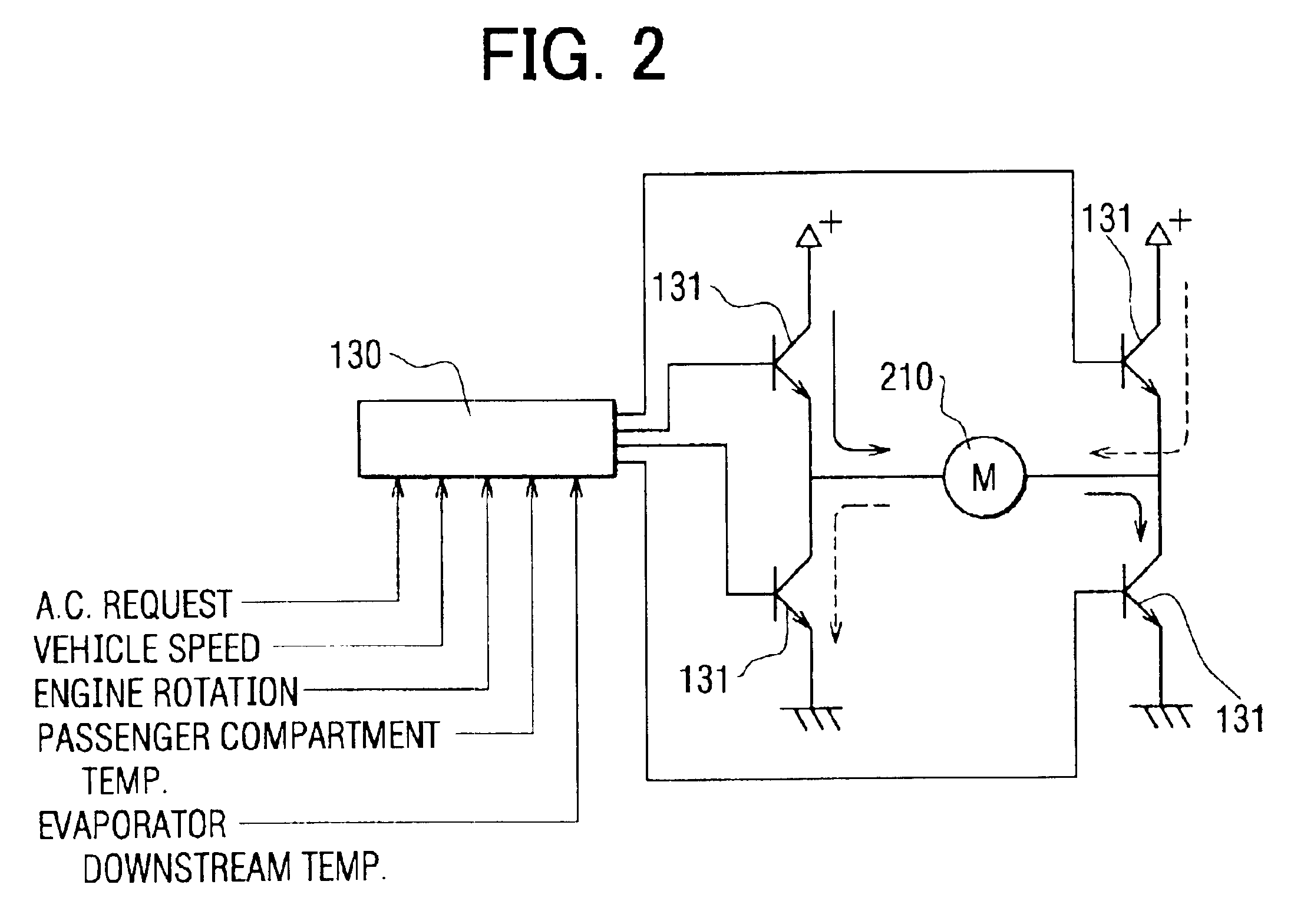

Automotive air conditioning system

An air conditioning system for use in a motor vehicle powered by an internal combustion engine is described. The system comprises an electric motor powered by a battery; a compressor arranged to be powered by at least one of the internal combustion engine and the electric motor; and a control unit that controls the driving of the compressor. The control unit is configured to execute driving the compressor by only the electric motor when the combustion engine is under an idling stop; restarting the combustion engine upon expiration of a first given time from the time when the idling stop has occurred, so that thereafter the compressor is driven by both the combustion engine and the electric motor; and stopping the driving of the compressor by the electric motor upon expiration of a second given time from the restarting of the combustion engine, so that thereafter the compressor is driven by only the combustion engine.

Owner:CALSONIC KANSEI CORP

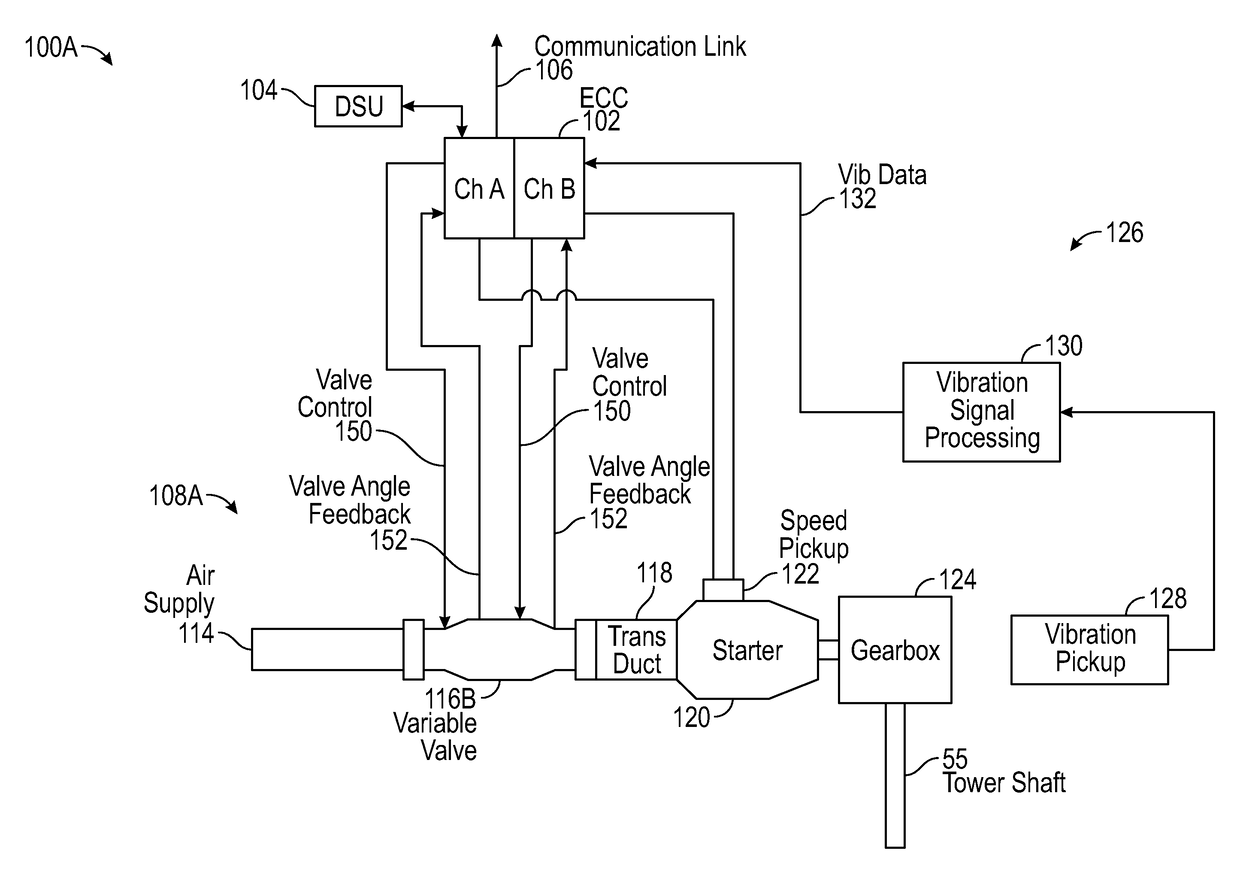

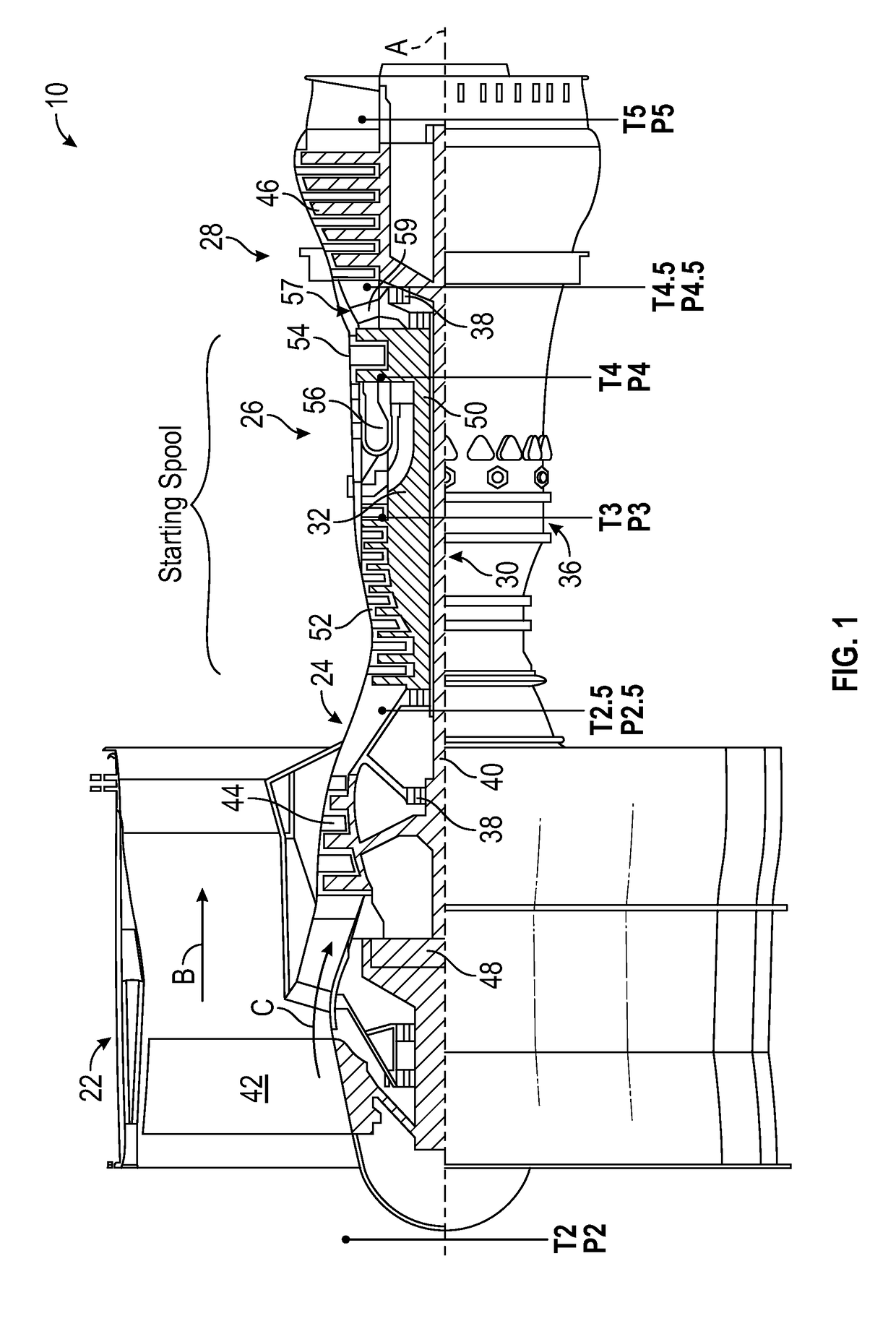

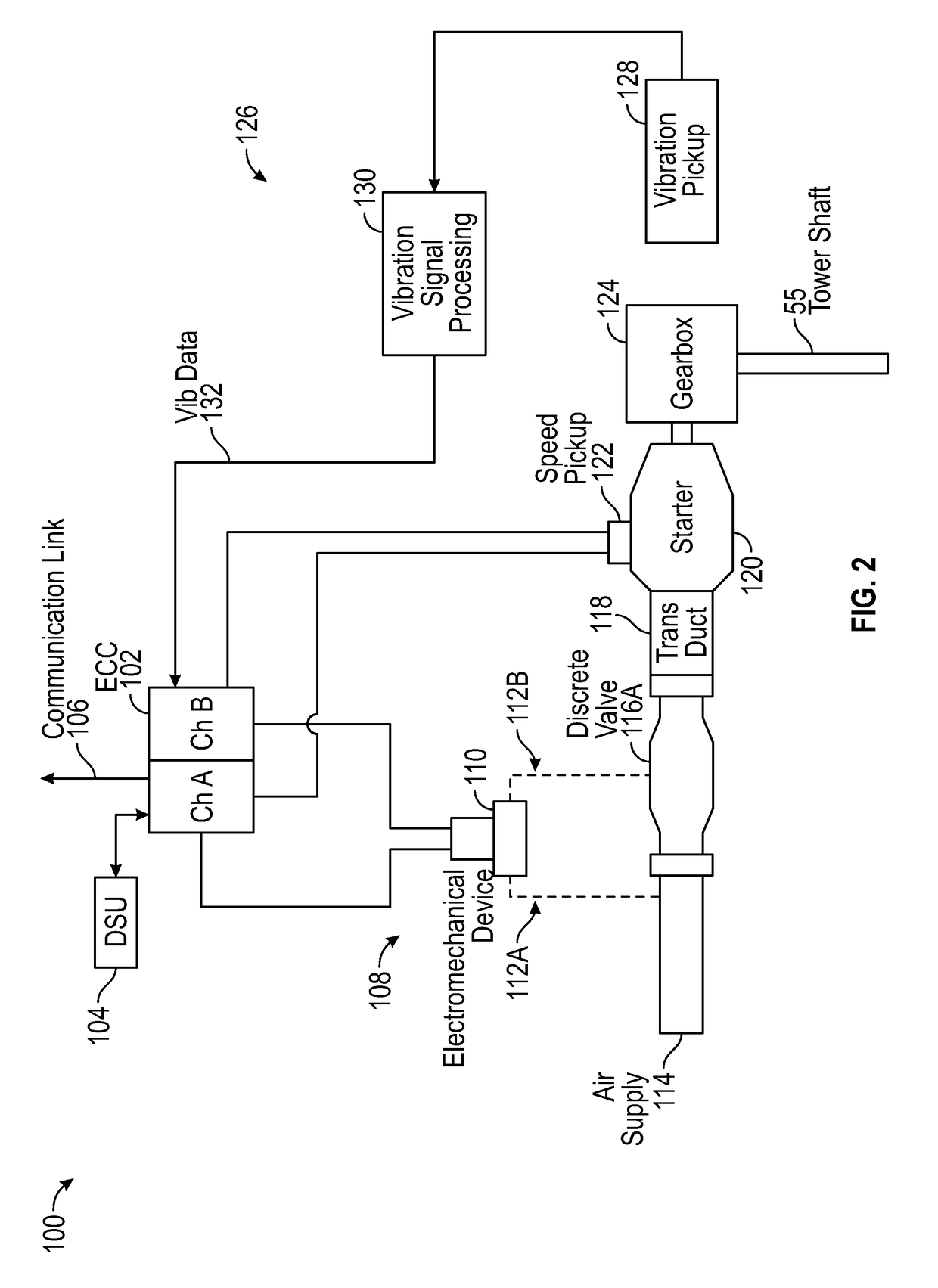

Modified start sequence of a gas turbine engine

ActiveUS20170233103A1Increase rotation speedEngine fuctionsJet type power plantsIdle speedEngineering

A system for starting a gas turbine engine of an aircraft is provided. The system includes a pneumatic starter motor, a discrete starter valve switchable between an on-state and an off-state, and a controller operable to perform a starting sequence for the gas turbine engine. The starting sequence includes alternating on and off commands to an electromechanical device coupled to the discrete starter valve to achieve a partially open position of the discrete starter valve to control a flow from a starter air supply to the pneumatic starter motor to drive rotation of a starting spool of the gas turbine engine below an engine idle speed.

Owner:RAYTHEON TECH CORP

Remote, automatic control system for oil field fracturing pumping

ActiveCN101414171BMonitor and control operationsOrderly and stable operationTotal factory controlProgramme total factory controlAutomatic controlHuman–machine interface

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

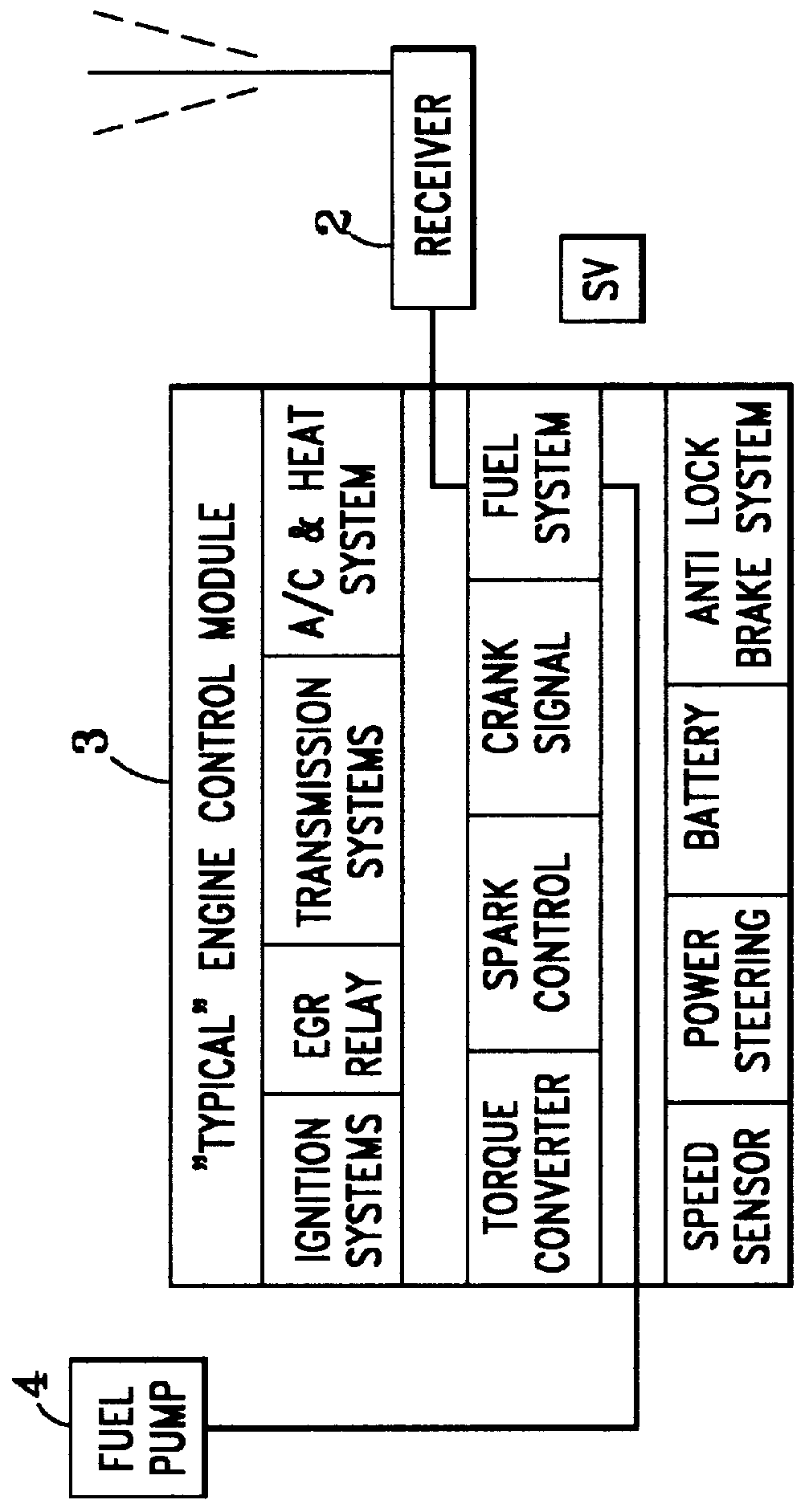

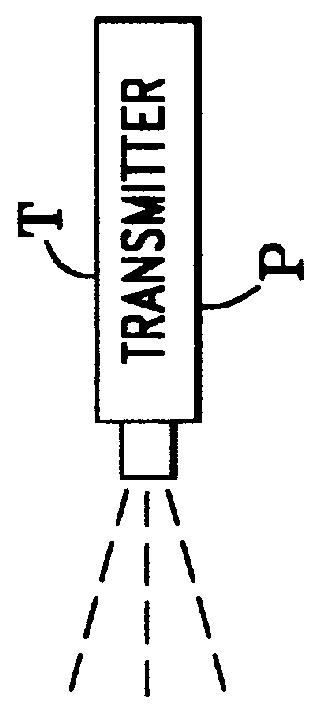

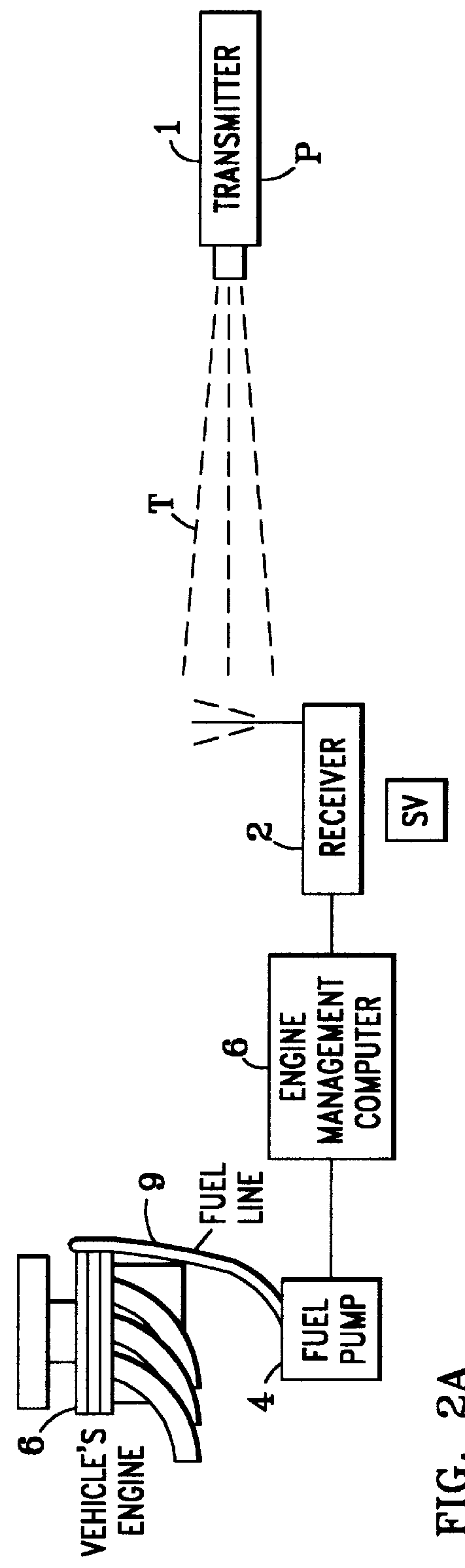

Method of and system for externally and remotely disabling stolen or unauthorized operated vehicles by pursuing police and the like

InactiveUS6072248ASafe and effectiveEase and safetyAnti-theft cycle devicesAnti-theft devicesControl signalIdle speed

A method of and system for enabling pursuing police cruisers or the like to remotely and safely stop the engine of an appropriately equipped stolen or improperly operated vehicle, wherein the cruiser transmits a control signal to a receiver pre-provided in the vehicle, to initiate, preferably through modified engine control modules, a forced and over-riding multiple-stage reduction in fuel supplied to the engine, first to slow down the vehicle below idling speed, and then to stall the engine by total fuel shut off.

Owner:MUISE CHRISTOPHER RUSSEL +1

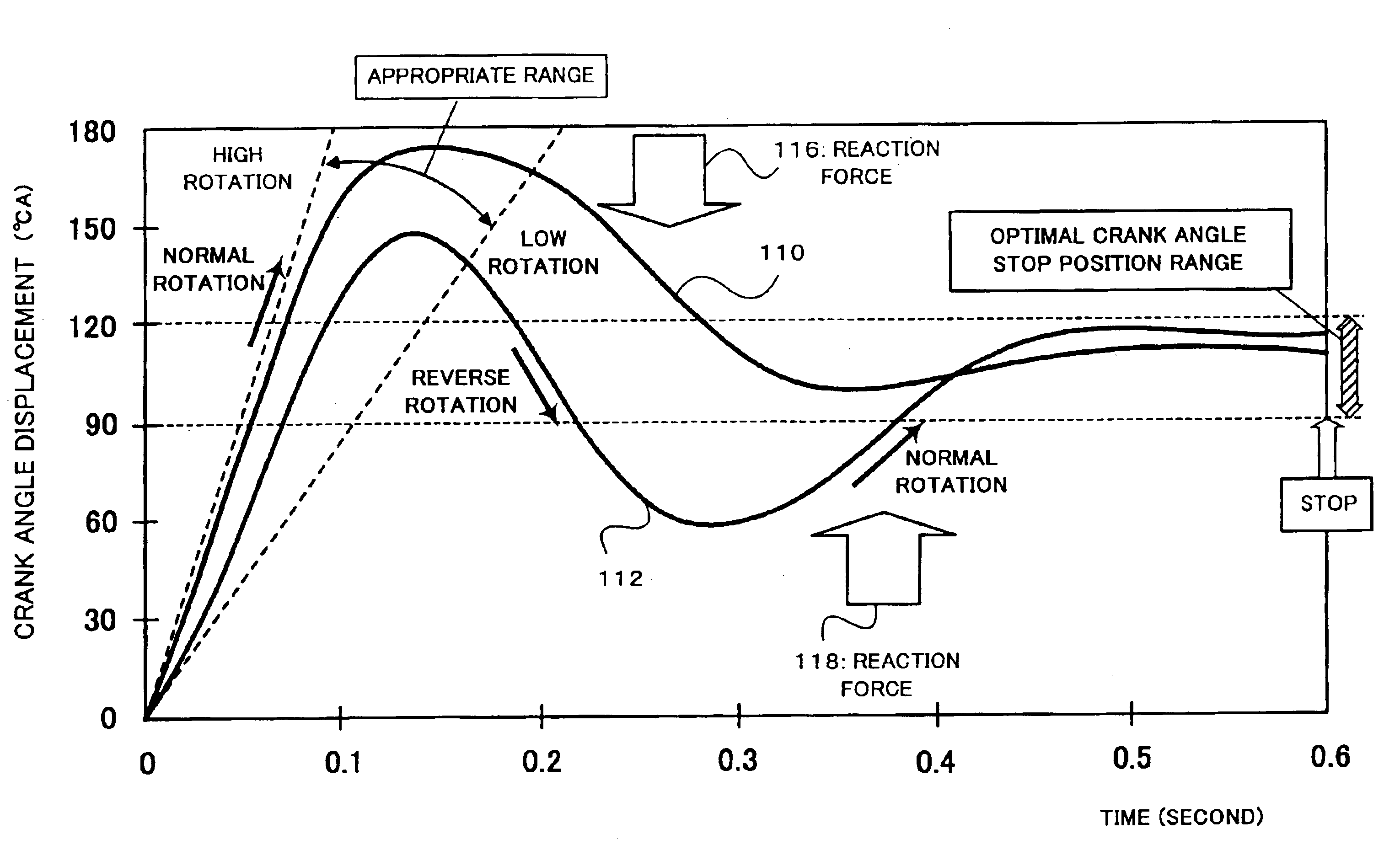

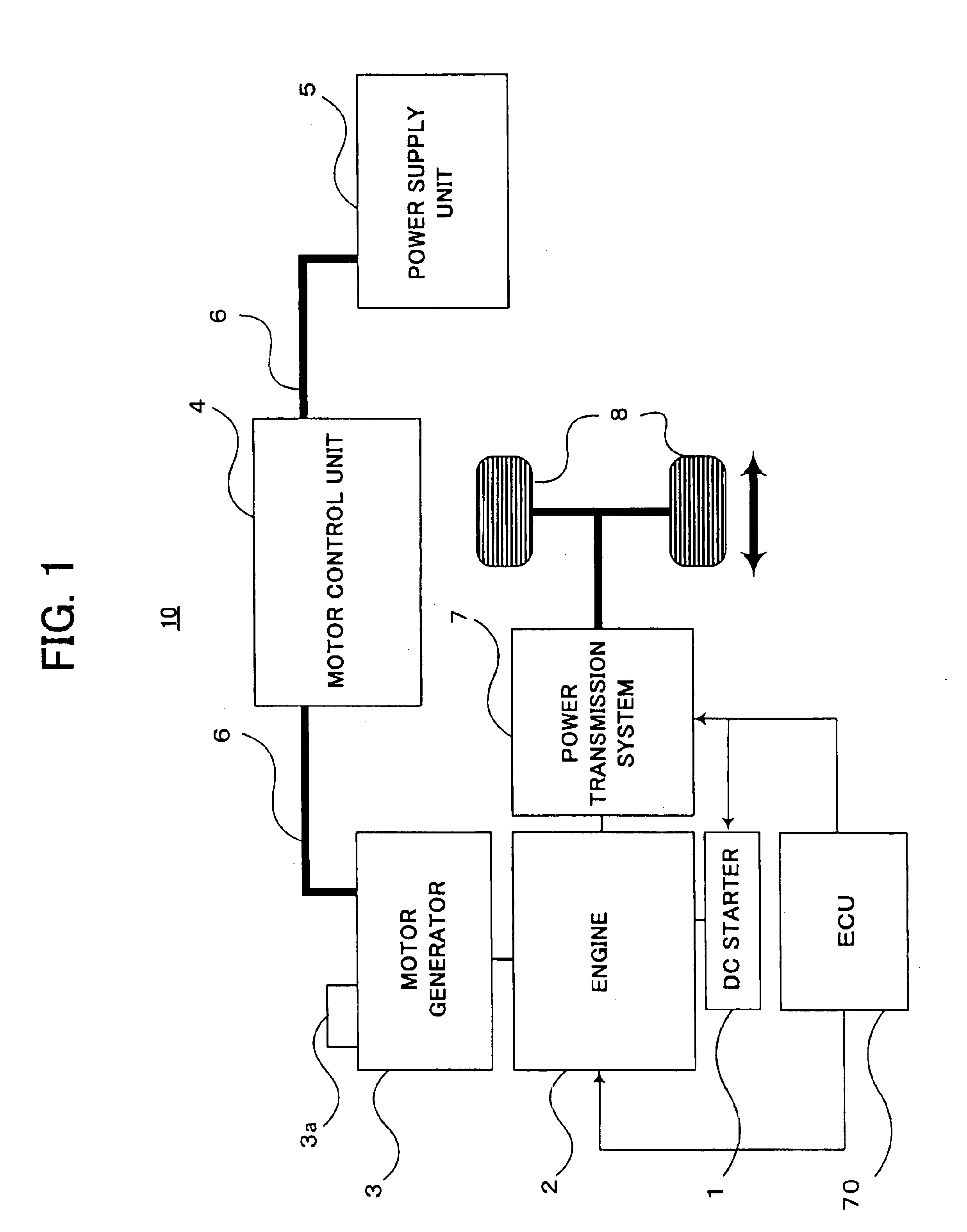

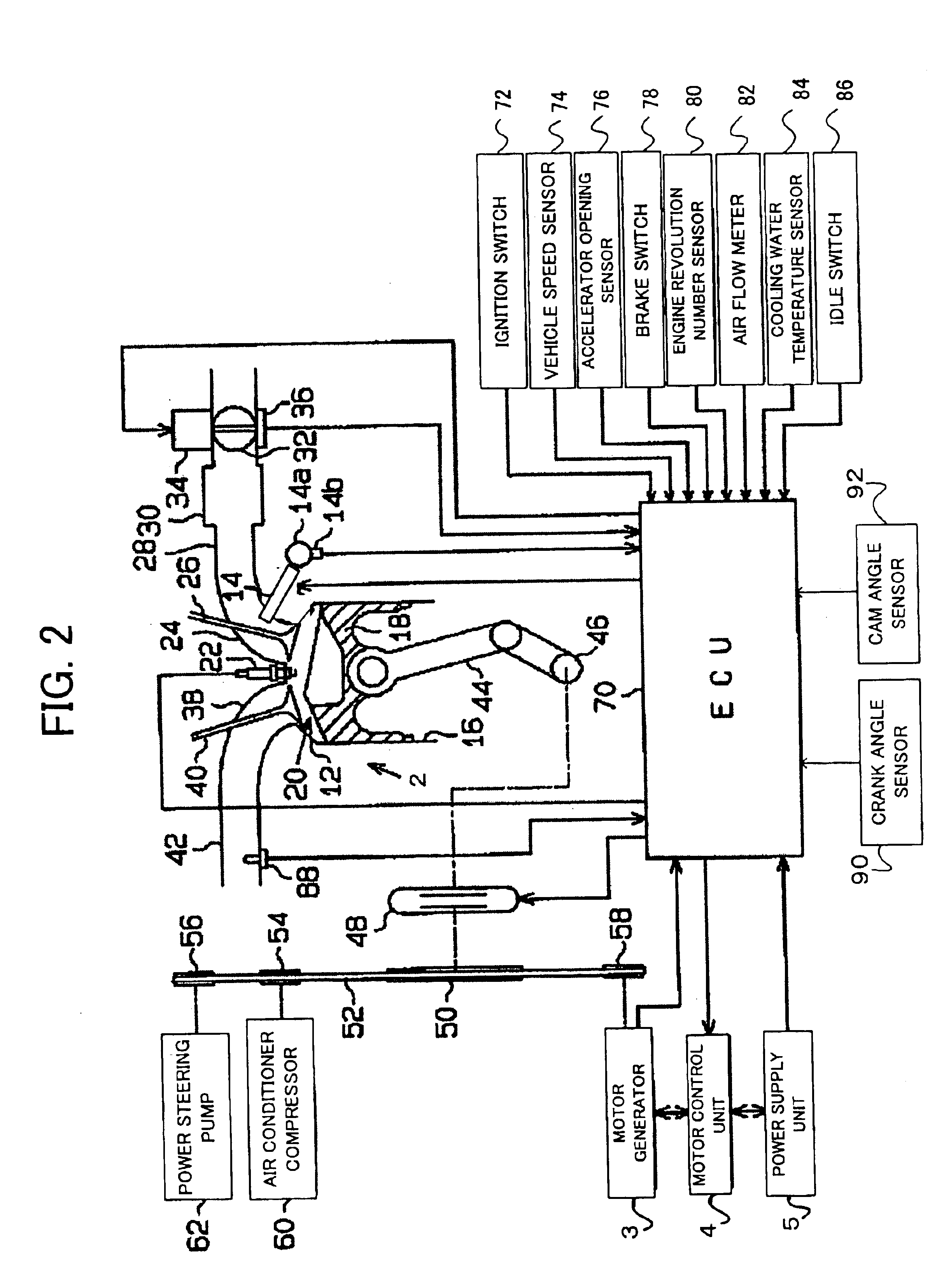

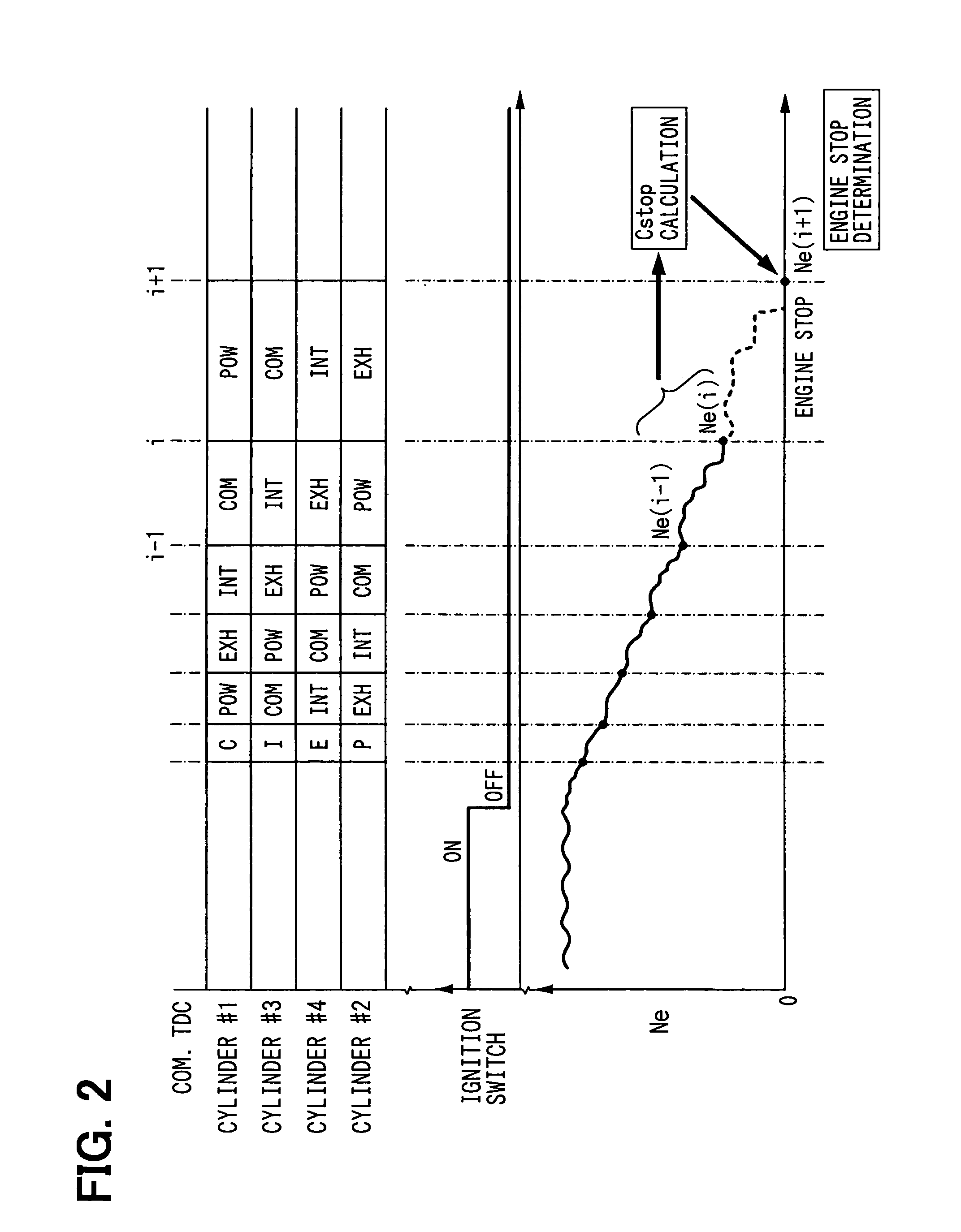

Stop and start control apparatus of internal combustion engine

A stop and start control apparatus of an internal combustion engine prevents fuel supplied in a specific cylinder at the time of stopping the engine from being discharged in an unburned state. When an ignition switch is turned off in a state that the unburned fuel is sealed in the combustion chamber of a specific cylinder during idling stop, the unburned fuel is combusted to prevent the unburned fuel from being discharged. The vibration occurring at that time can be suppressed by rotating the motor generator in the counter direction to the rotation direction of the crankshaft. After the unburned fuel is sealed in the combustion chamber of the specific cylinder, if it is estimated that the unburned fuel is discharged, the exhaust valve corresponding to the specific cylinder is closed at the predetermined timing, or the unburned fuel is combusted, whereby the unburned fuel is prevented from being discharged. Thus, deterioration of emission can be avoided.

Owner:TOYOTA JIDOSHA KK

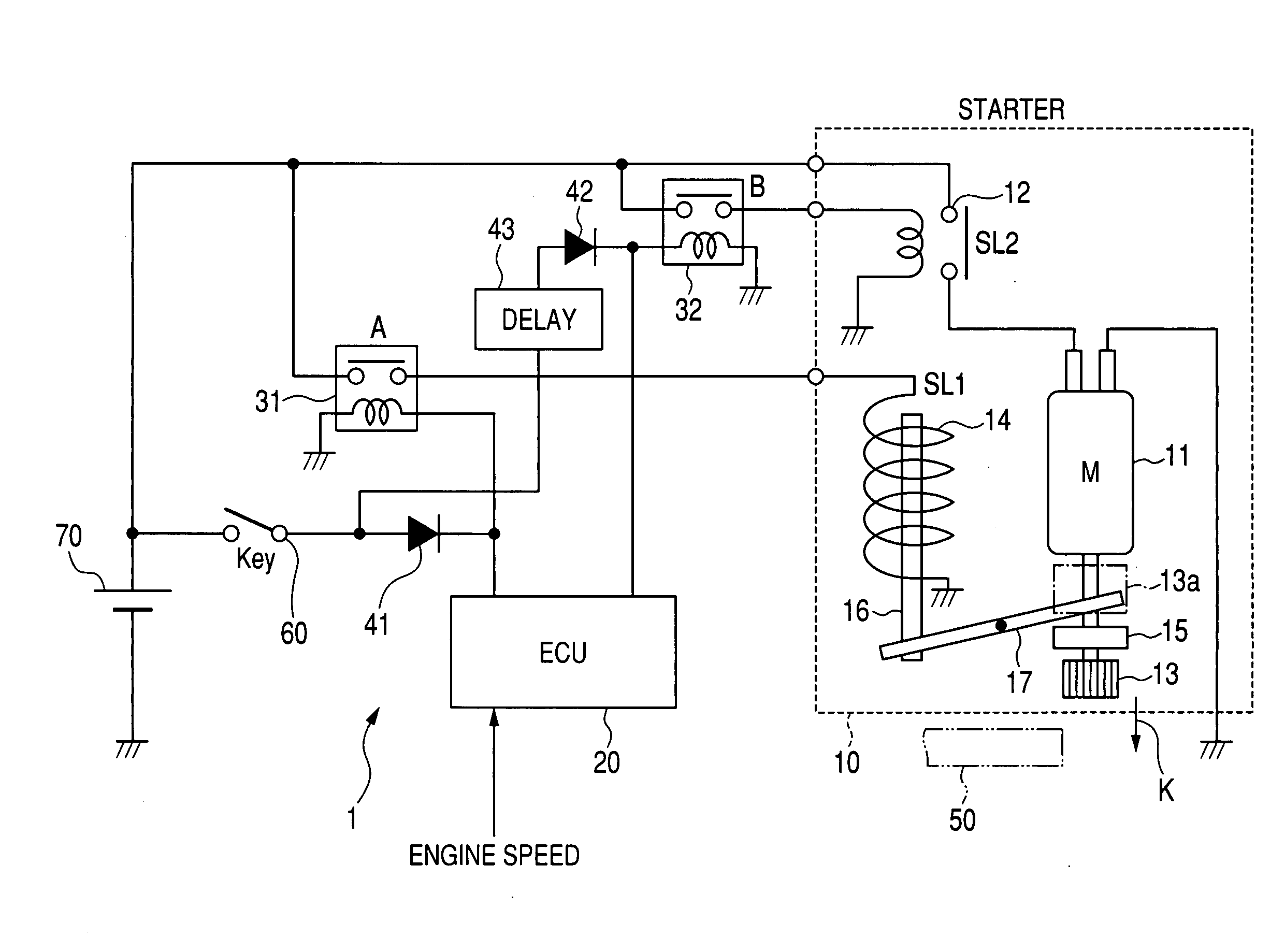

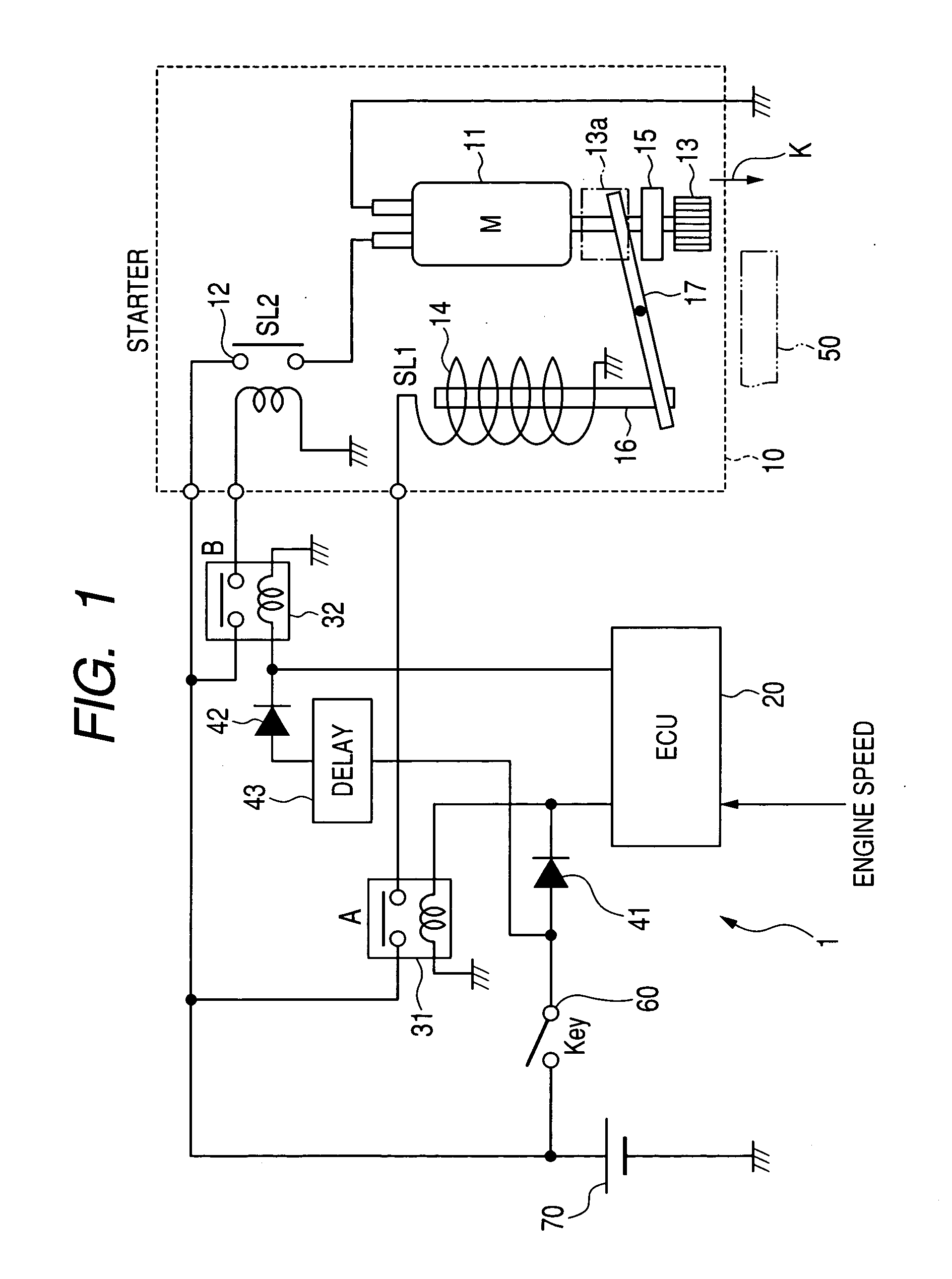

Engine start system for use in idle stop system for automotive vehicle

ActiveUS20100059007A1Fuel consumption is minimizedSimple structurePower operated startersInternal combustion piston enginesMaximum levelGear wheel

An engine start system which may be employed in automotive idle stop systems. The engine start system includes a pinion gear to be pushed to a ring gear coupled to an engine for achieving meshing engagement with the ring gear. After the pinion gear engages the ring gear, the engine start system starts to rotate the pinion gear using a starter motor to crank the engine. Specifically, when an engine restart request is made following an engine stop request, the engine start system waits until after the speed of the engine drops below a preselected gear engageble speed and then moves the pinion gear toward the ring gear without rotating the pinion gear. This minimizes the consumption of fuel in the vehicle in supplying electric power to the starter motor and a maximum level of mechanical noise arising from the engagement of the pinion gear with the ring gear.

Owner:DENSO CORP

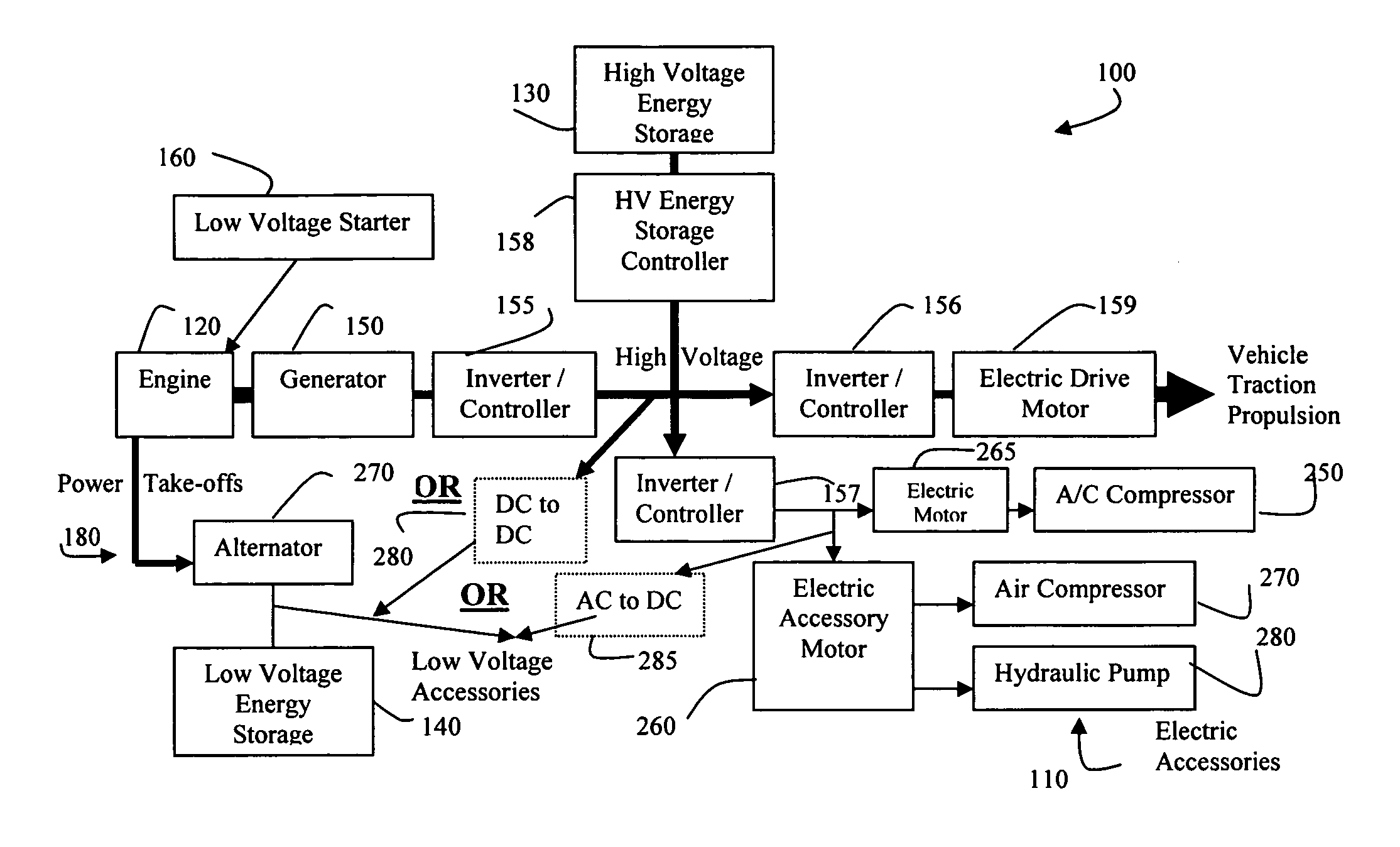

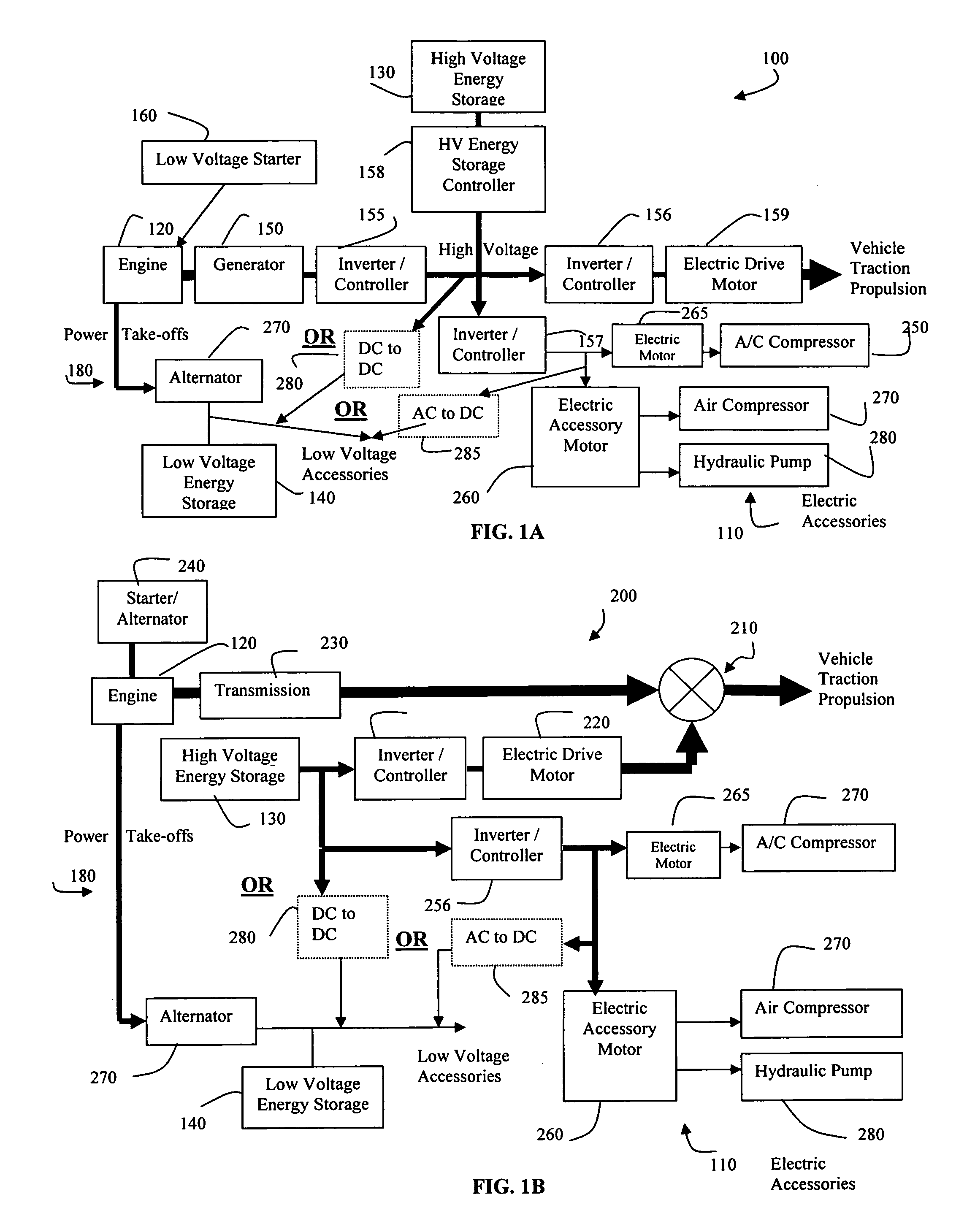

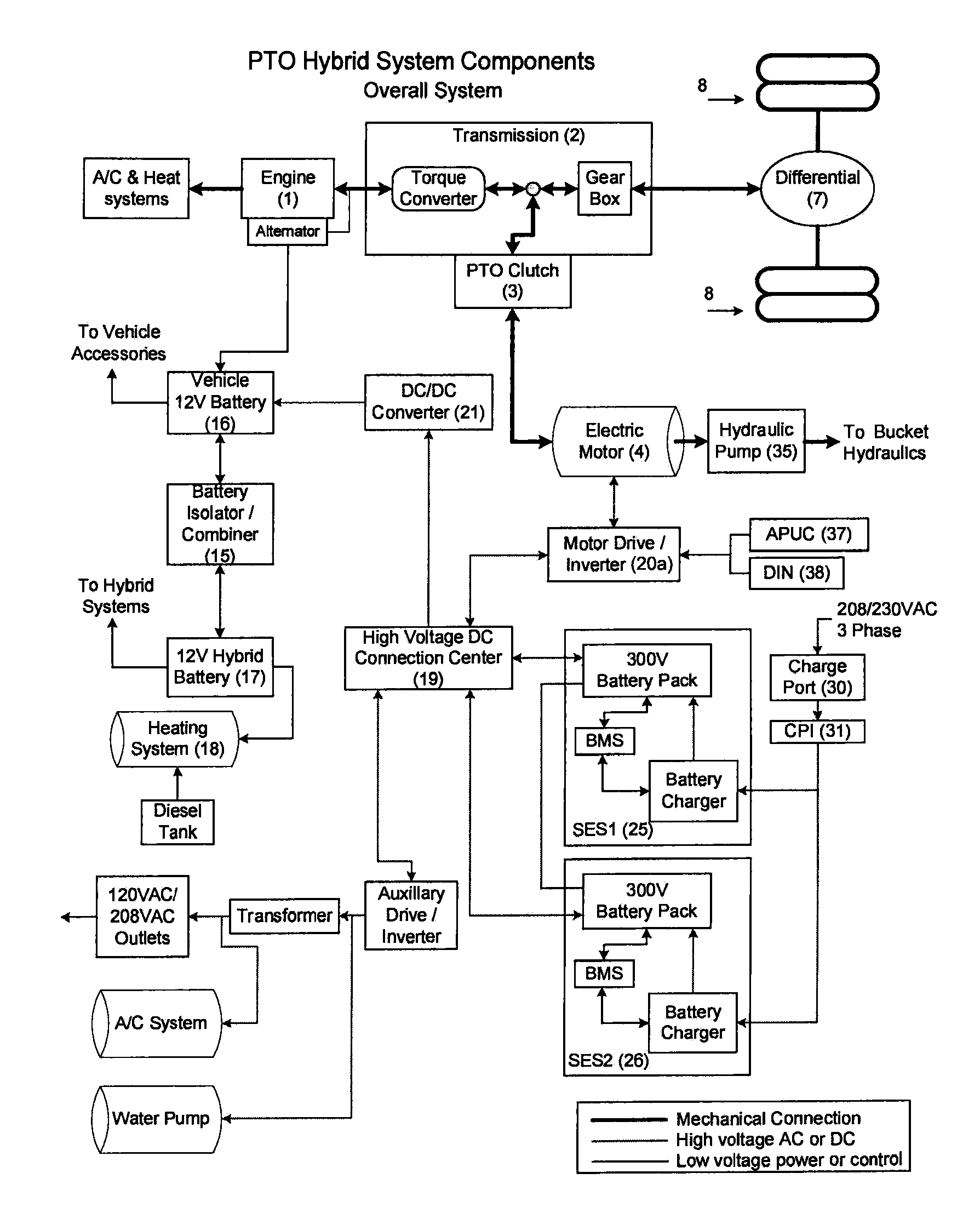

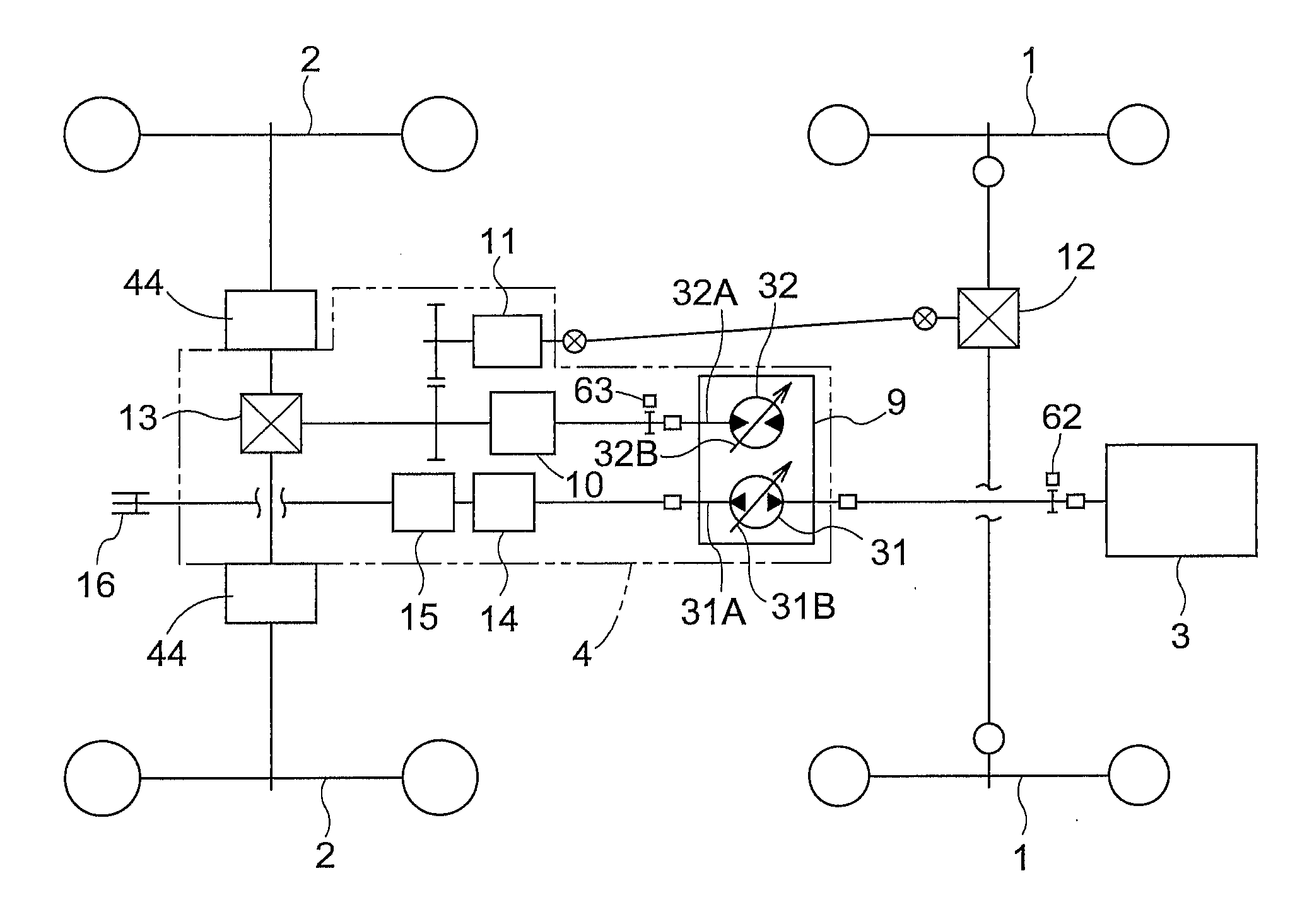

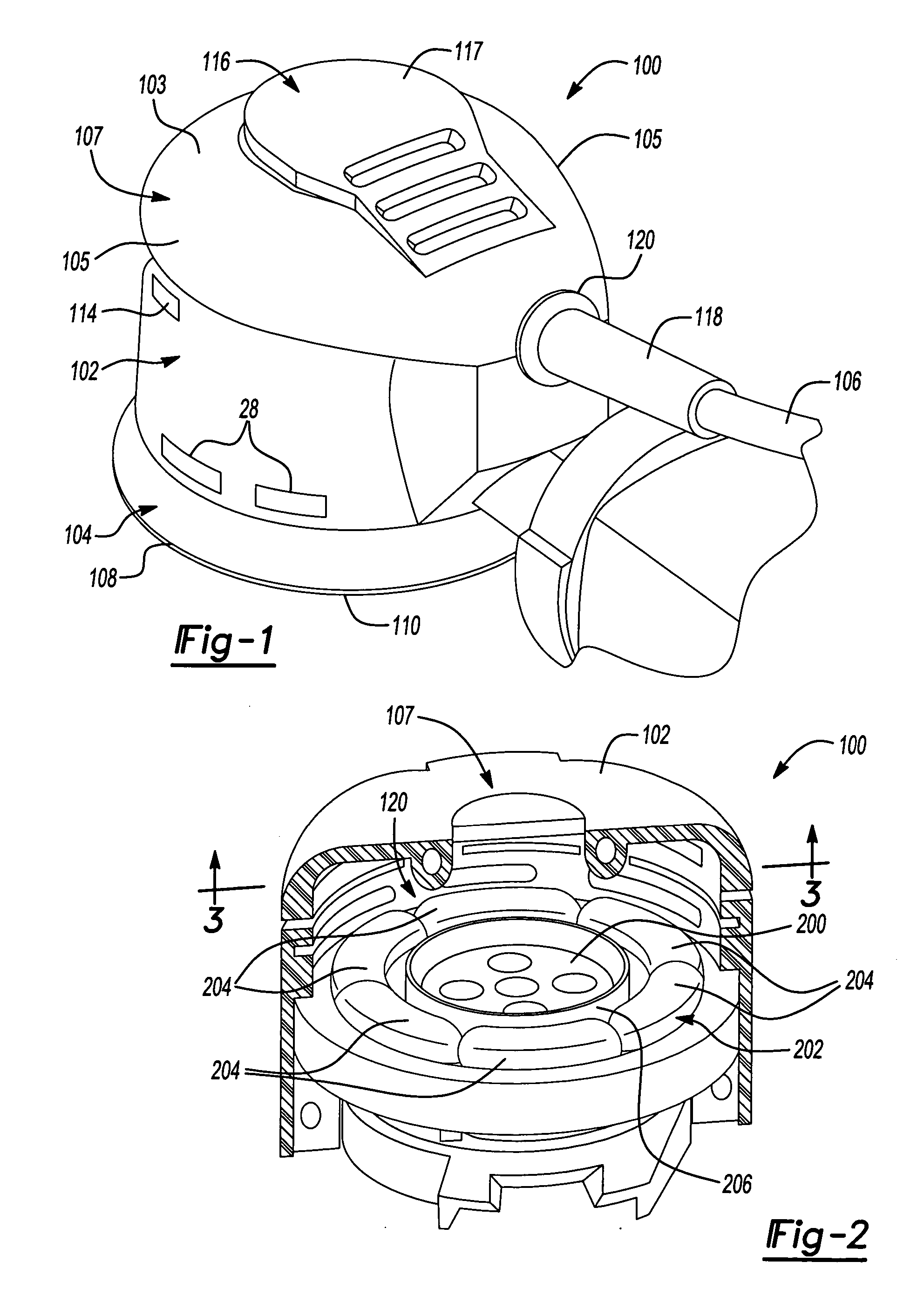

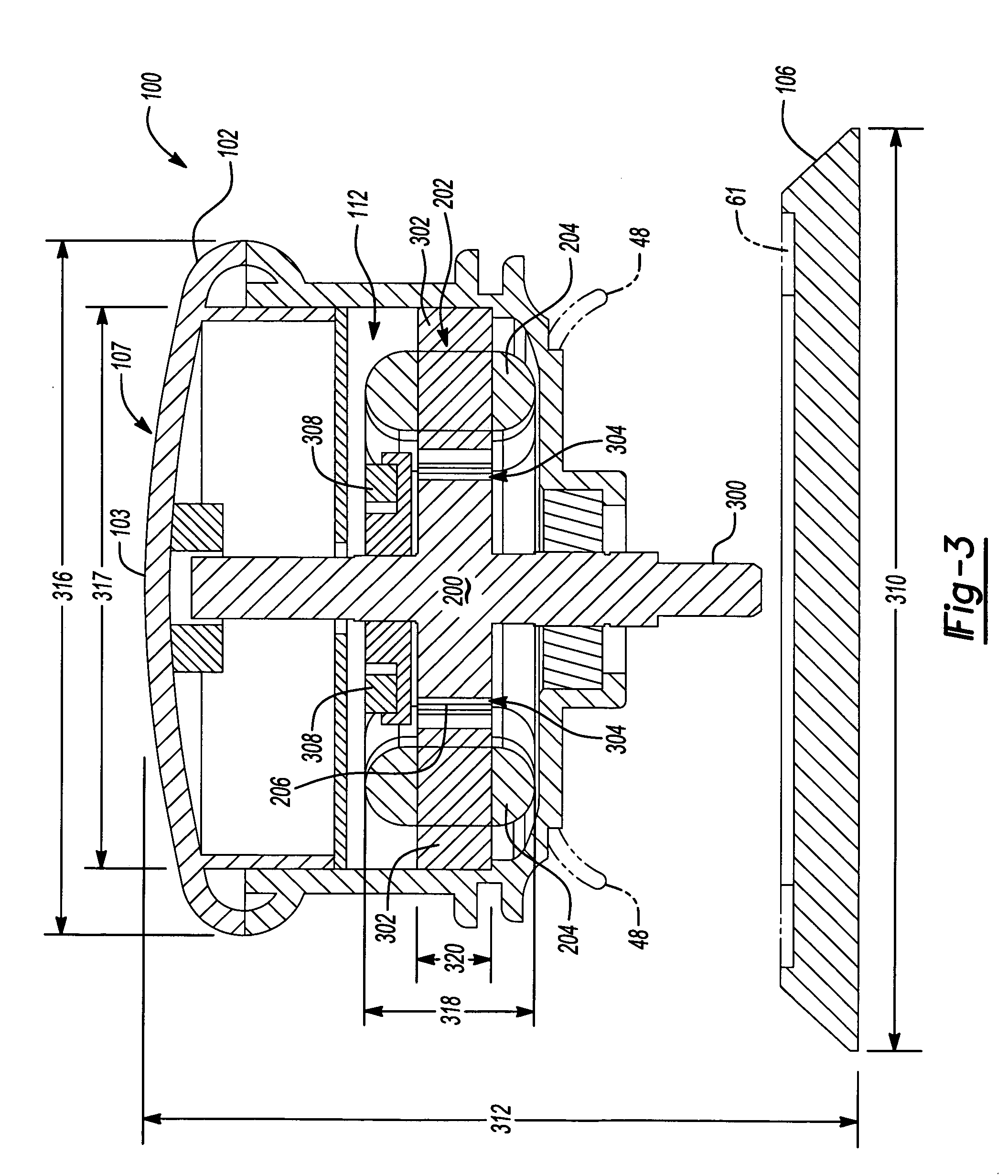

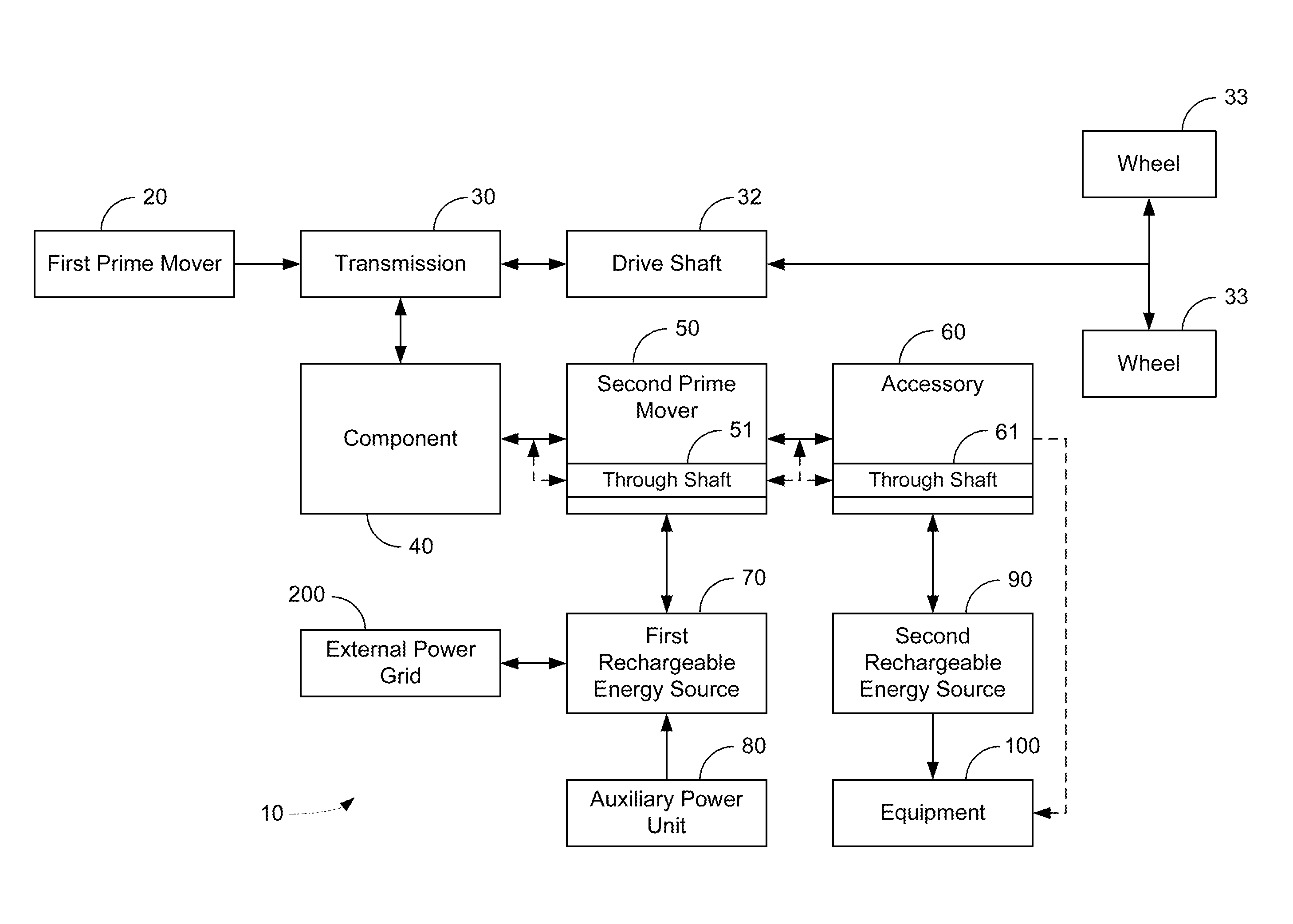

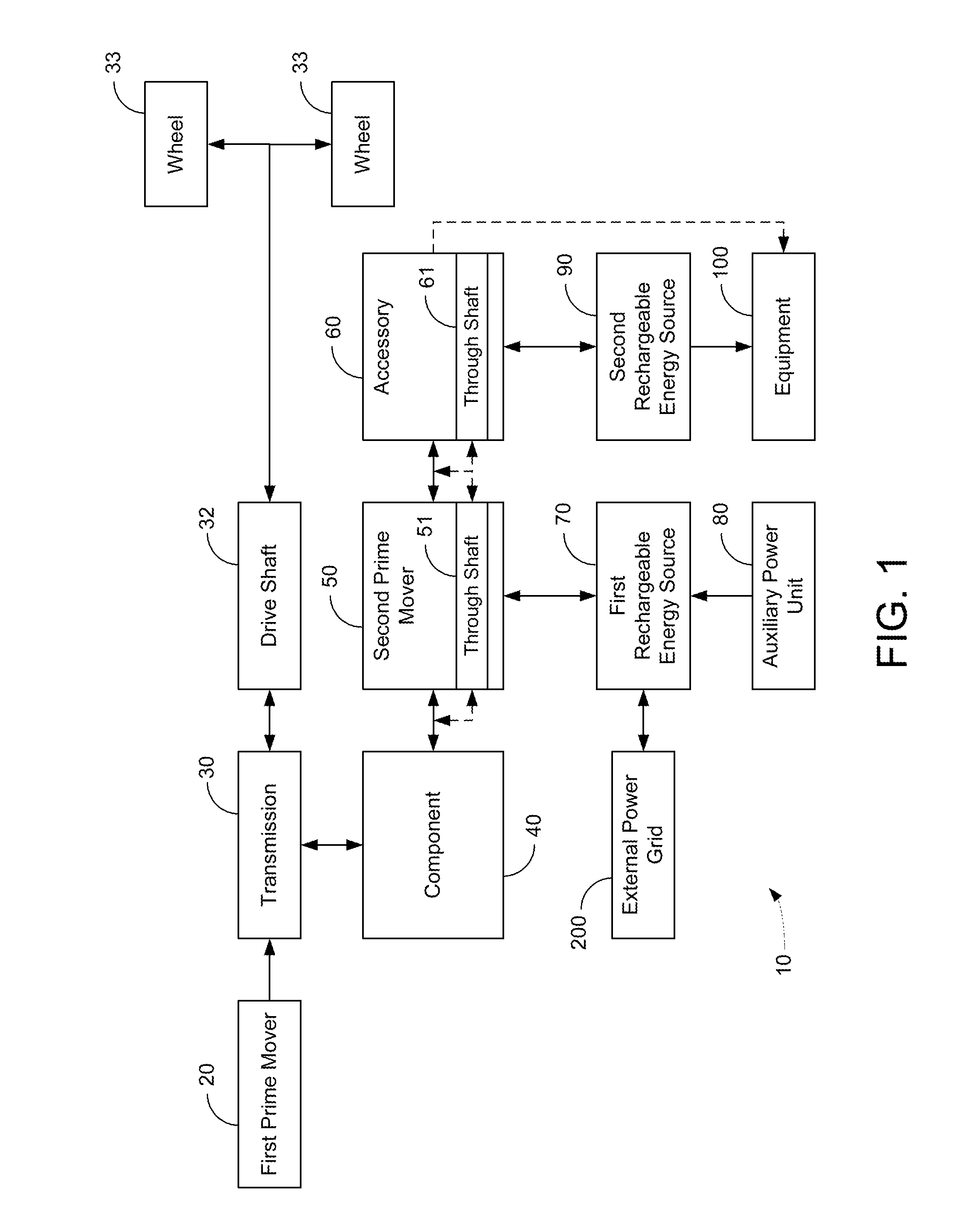

Hybrid vehicle drive system and method and idle reduction system and method

InactiveUS20120207620A1Auxillary drivesPlural diverse prime-mover propulsion mountingHydraulic motorIdle reduction

One embodiment relates to a hybrid vehicle drive system for a vehicle including a first prime mover, a first prime mover driven transmission, a rechargeable power source, and a PTO. The hybrid vehicle drive system further includes a hydraulic motor in direct or indirect mechanical communication with the PTO and an electric motor in direct or indirect mechanical communication with the hydraulic motor. The electric motor can provide power to the prime mover driven transmission and receive power from the prime mover driven transmission through the PTO. The hydraulic motor can provide power to the prime mover driven transmission and receive power from the prime mover driven transmission through the PTO.

Owner:ODYNE SYST

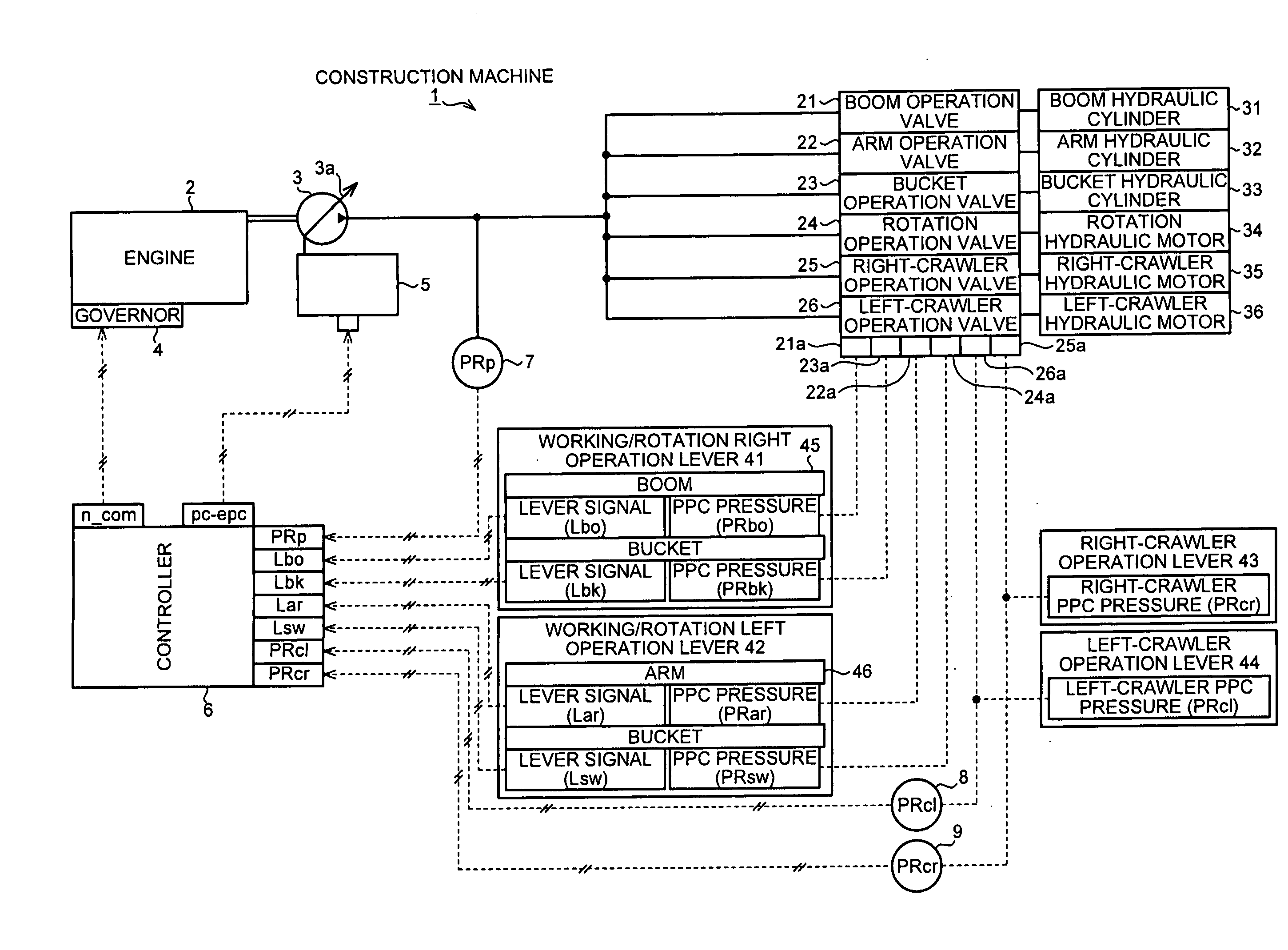

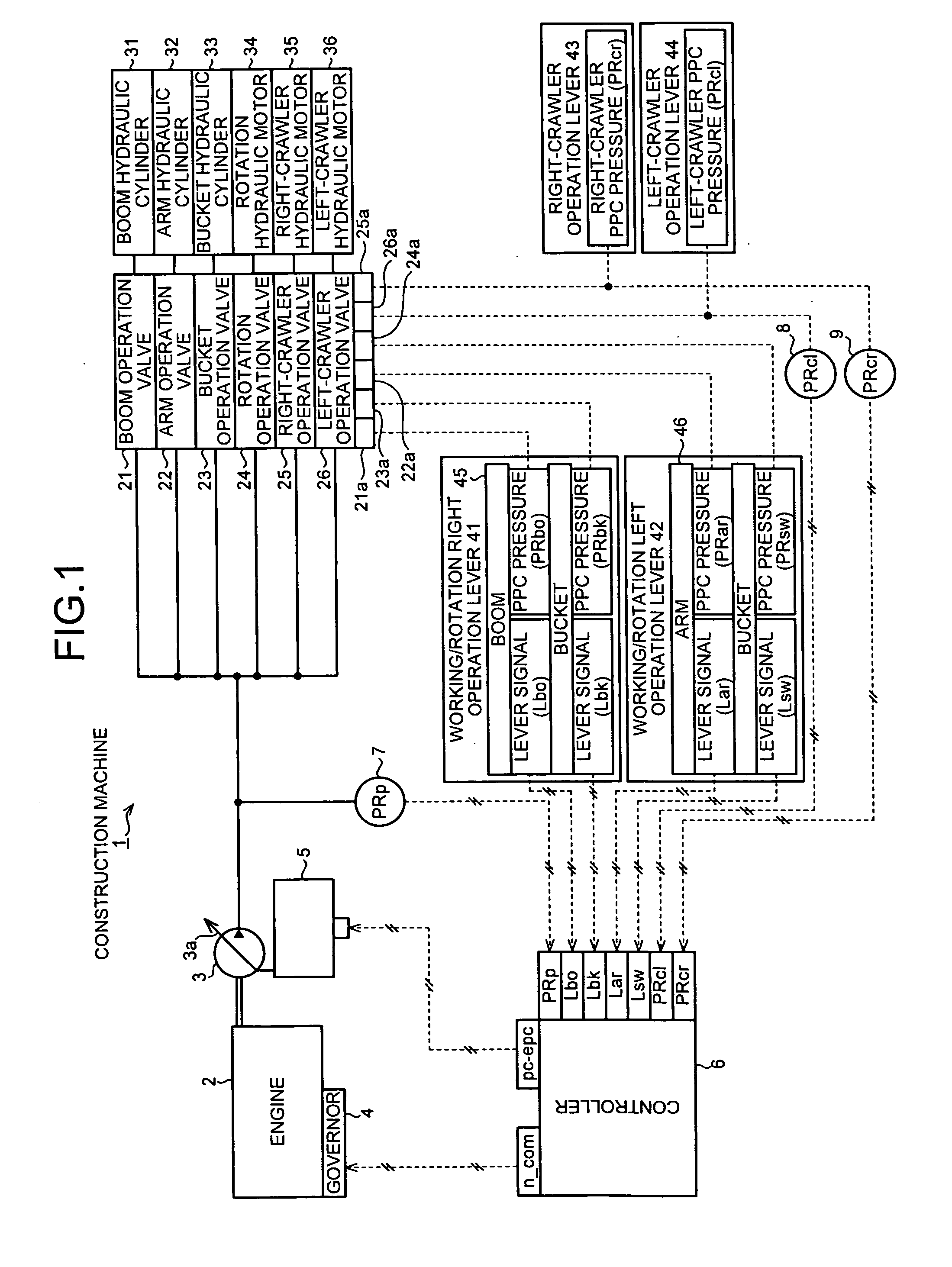

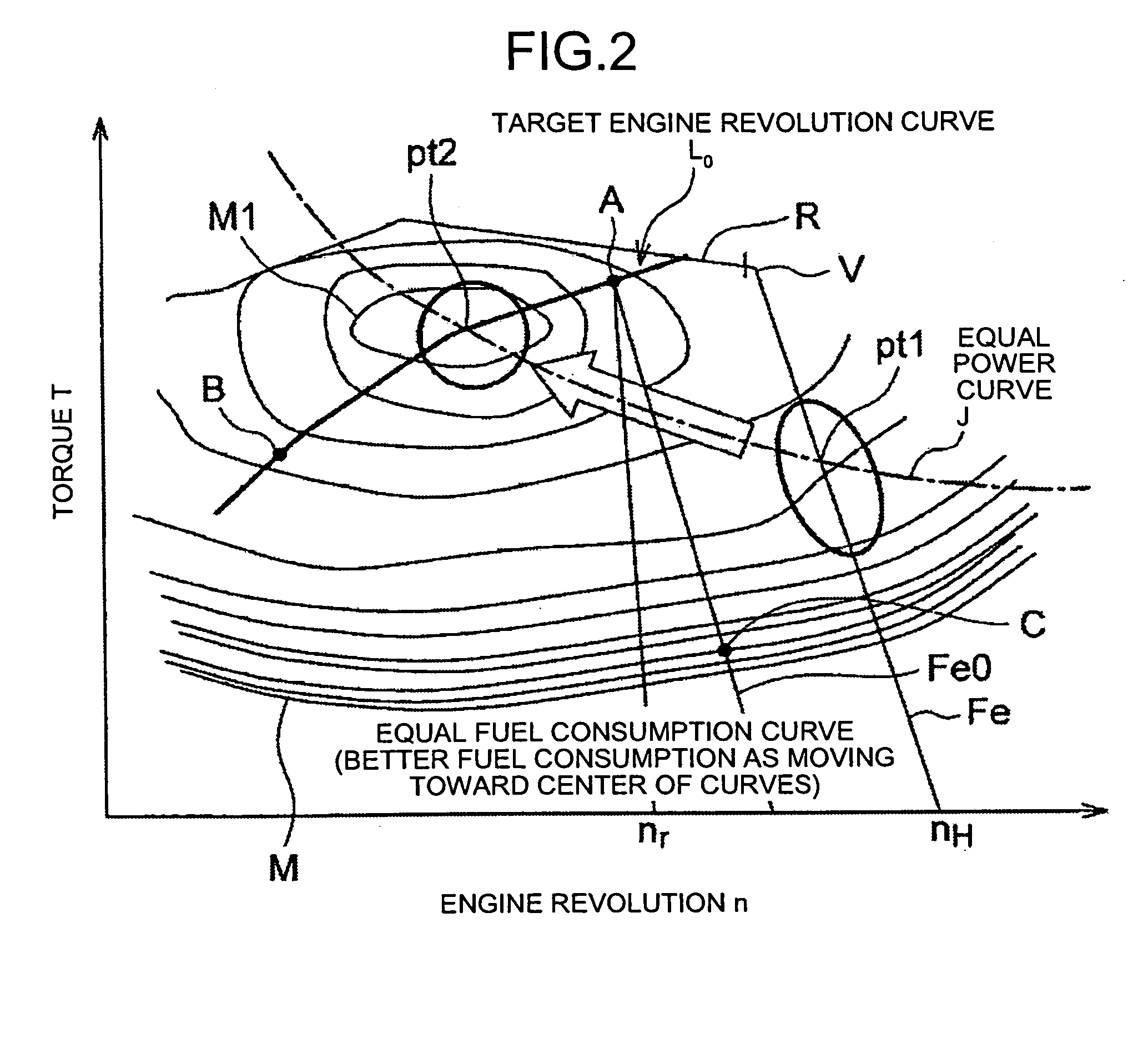

Control device of engine, control device of engine and hydraulic pump, and control device of engine, hydraulic pump, and generator motor

InactiveUS20090320461A1Shorten the switching timeReduction in assisting forceElectrical controlFluid couplingsEngine efficiencyHydraulic pump

An object of the present invention is to operate the working machine etc. with satisfactory responsiveness as intended by the operator while enhancing engine efficiency, pump efficiency, and the like, where a first engine target revolution ncom1 adapted to a current pump target discharge flow rate Qsum is set, and when determined that the current pump target discharge flow rate Qsum is greater than a predetermined flow rate (10 (L / min)), a revolution nM (e.g., 1400 rpm) greater than an engine low idle revolution nL is set as a second engine target revolution ncom2 determining that operation levers 41 to 44 switched from a non-operation state to an operation state. The engine revolution is controlled so that the second engine target revolution ncom2 is obtained if the second engine target revolution ncom2 is equal to or greater than the first engine target revolution ncom1.

Owner:KOMATSU LTD

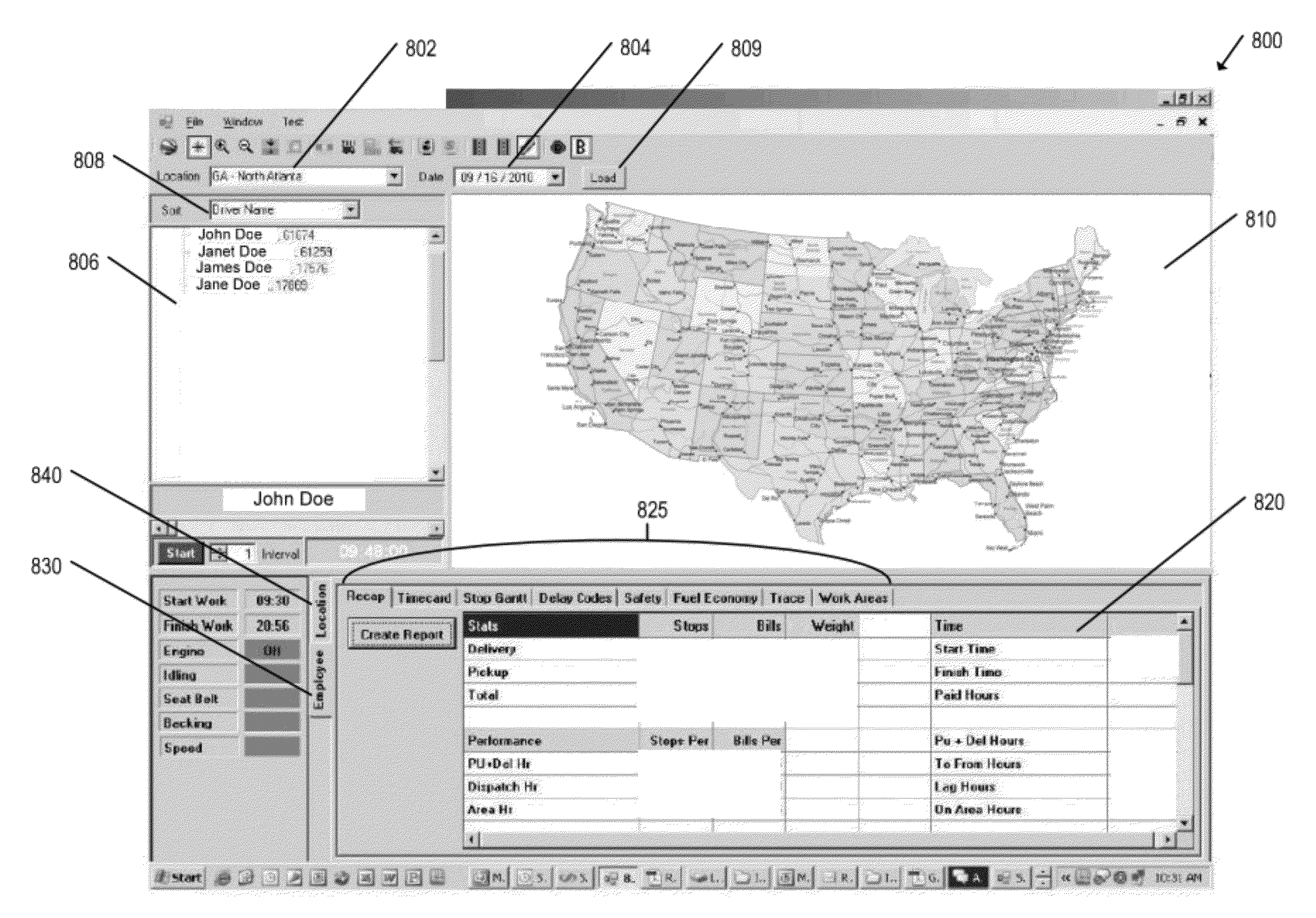

Systems and methods for assessing vehicle and vehicle operator efficiency

ActiveUS20120253888A1Analogue computers for vehiclesRegistering/indicating working of vehiclesGraphicsFleet management

Various embodiments of the present invention are directed to a fleet management computer system for assessing vehicle efficiency. According to various embodiments, the fleet management computer system is configured for receiving and assessing vehicle telematics data in order to determine an idle percentage of engine run time value representing the percentage of the vehicle's engine run time during which the vehicle's engine was idling during the one or more time periods. In addition, the fleet management computer system may be configured for assessing vehicle telematics data in order to identify segment of engine idle time and generate a graphical display indicating various attributes of the identified idle time segments. The idle time percentage and idle time segments generated by the system can be used to assess the efficiency of vehicles and / or vehicle operators in an associated fleet.

Owner:UNITED PARCEL SERVICE OF AMERICAN INC

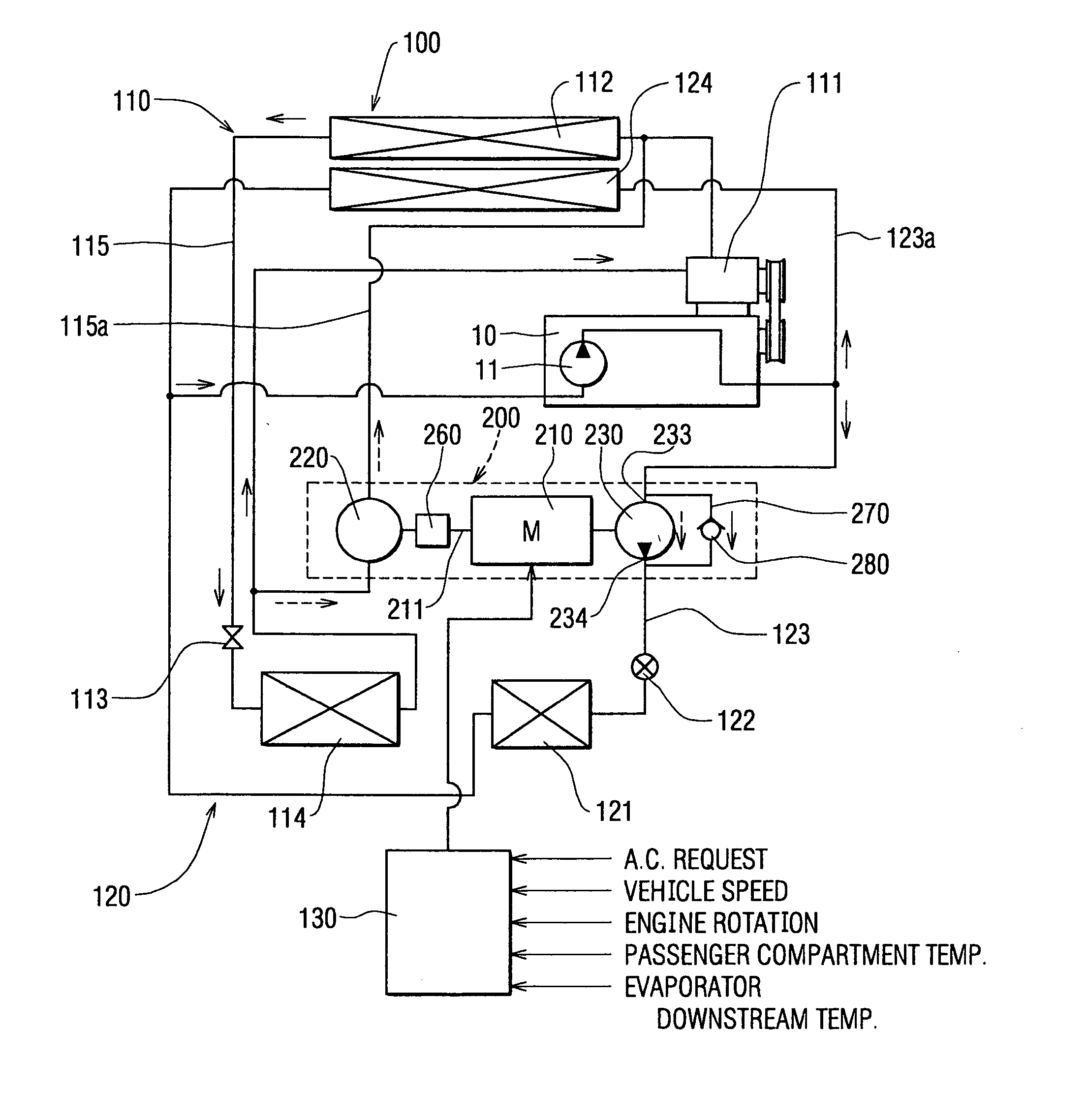

Air-conditioning apparatus including motor-driven compressor for idle stopping vehicles

InactiveUS20050109499A1Low costSatisfactory air-conditioning performanceAir-treating devicesSpace heating and ventilation safety systemsMotor driveElectrical battery

A low-cost vehicle air-conditioning apparatus for idle stopping vehicles is capable of performing both cooling and heating operations throughout the year. The air-conditioning apparatus includes an engine-driven compressor and engine-driven pump for a heating unit. The air-conditioning apparatus includes a motor-driven compressor and pump. A control unit drives the motor such that the motor-driven compressor is operated when there is a need for cooling and the motor-driven pump is operated when there is a need for heating when the engine is stopped. Battery power is conserved through various methods.

Owner:DENSO CORP

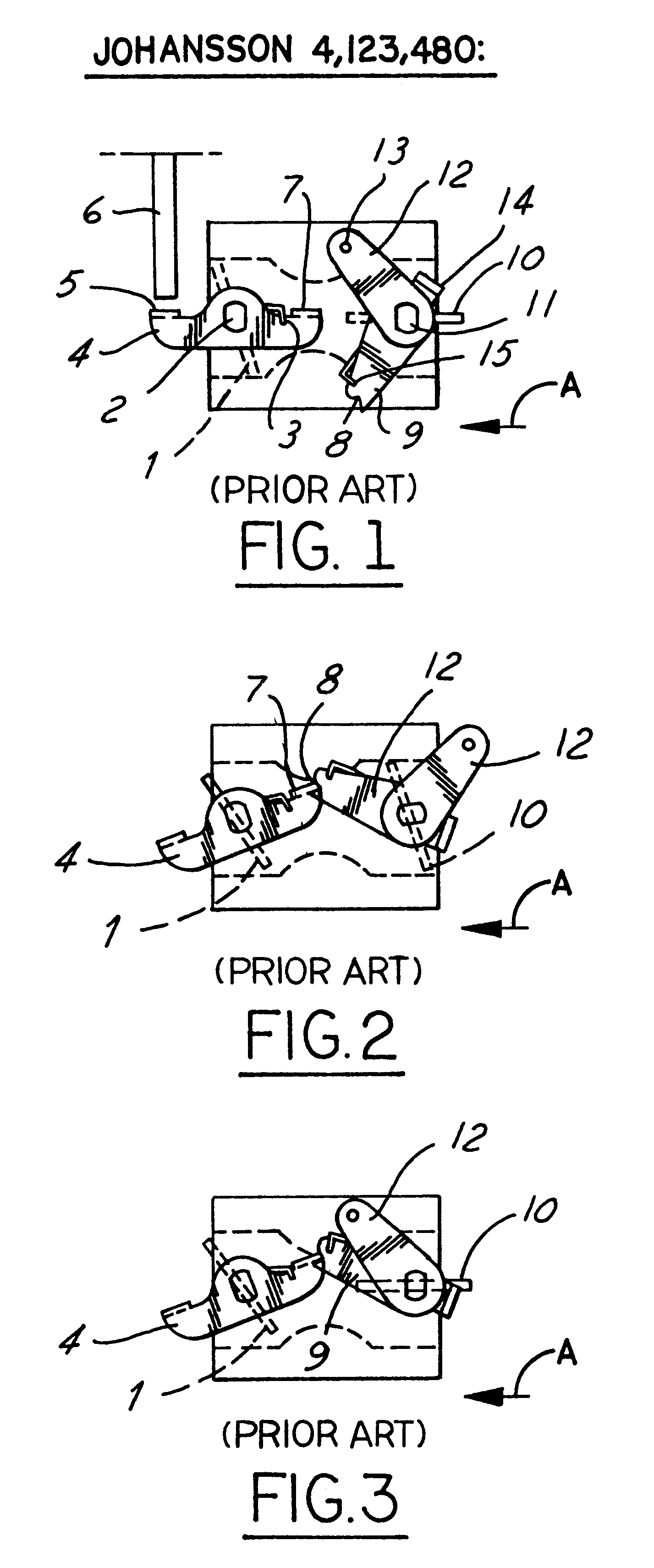

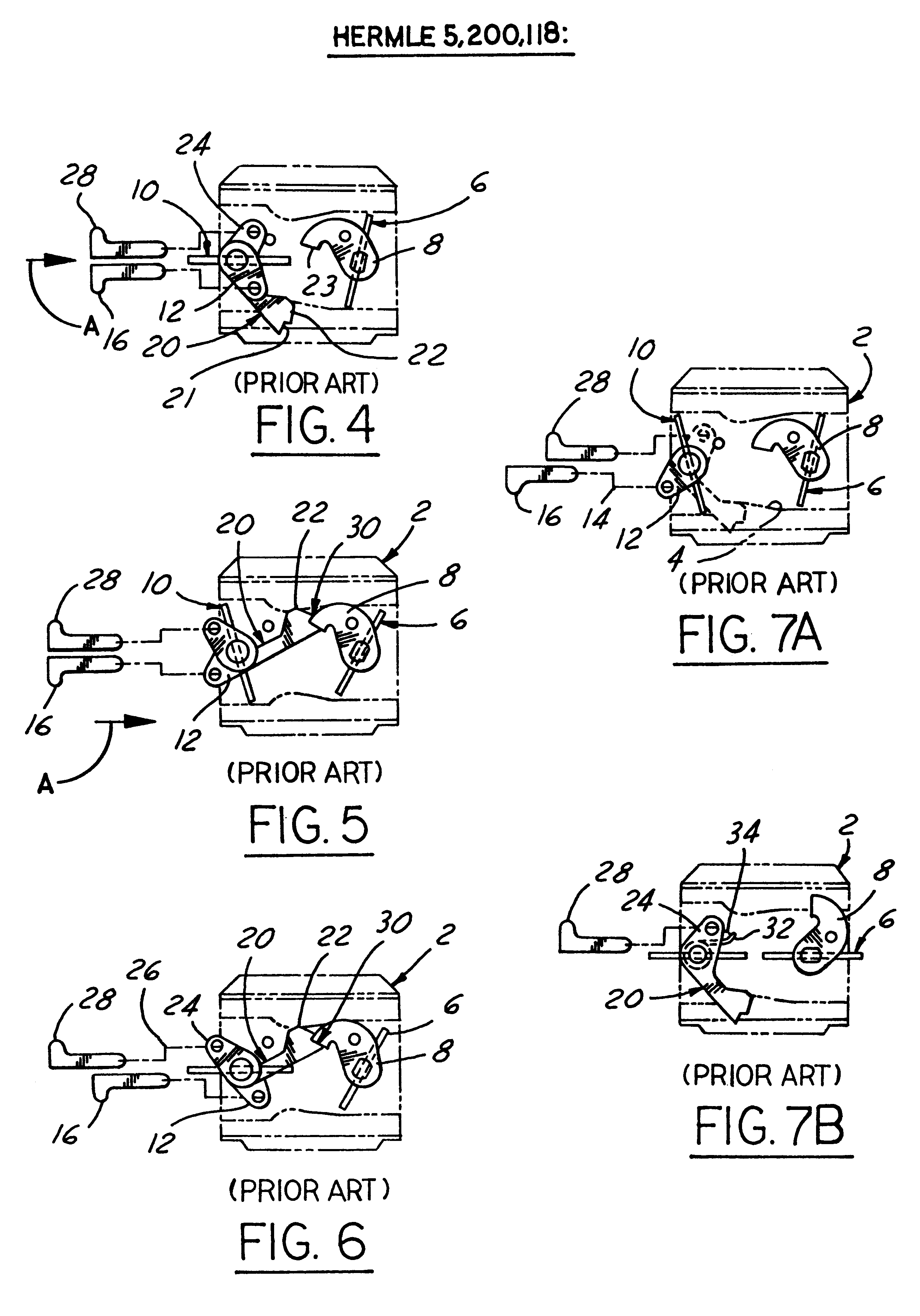

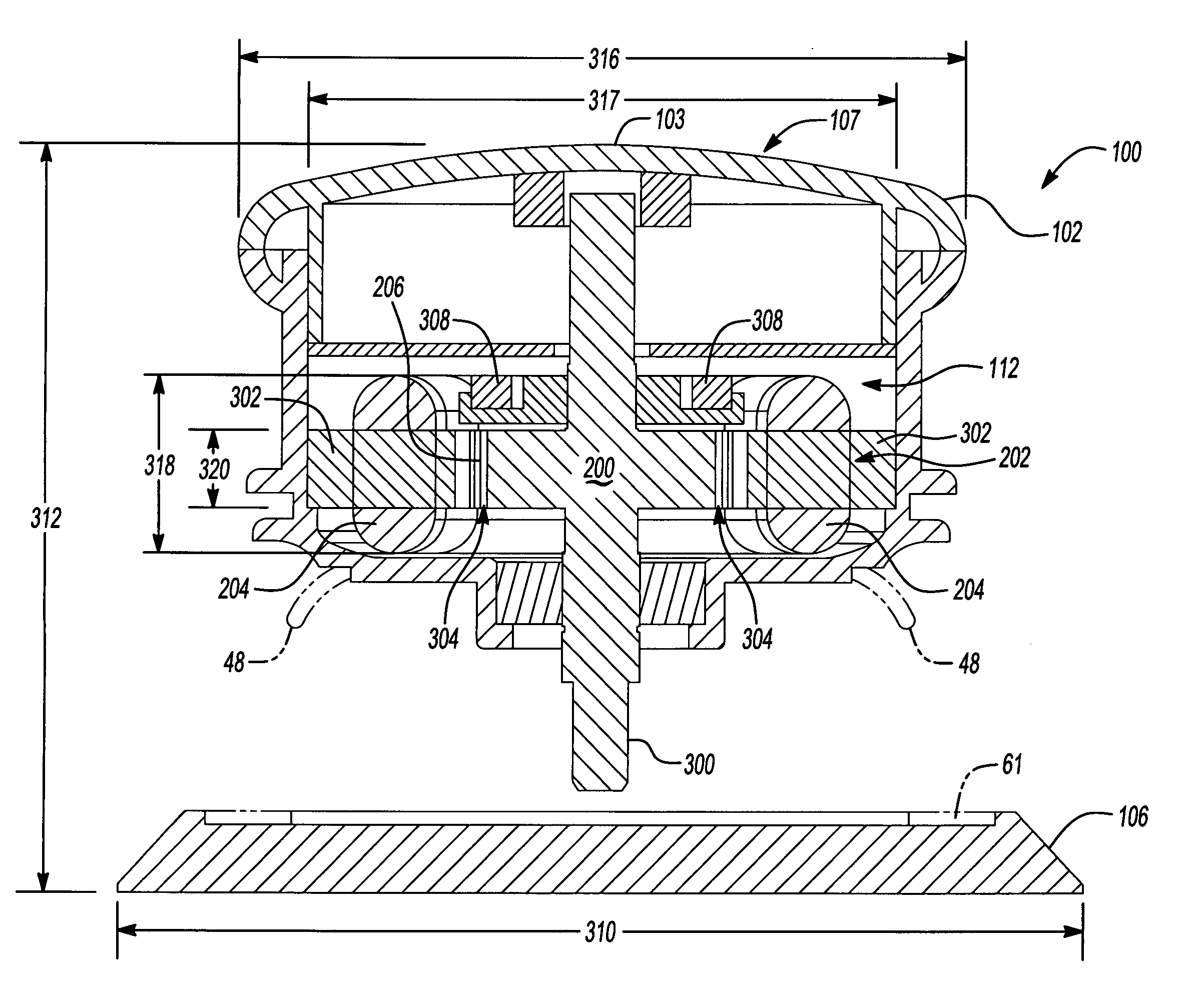

Carburetor throttle and choke control mechanism

InactiveUS6202989B1Low costEasy to modifyElectrical controlLighting and heating apparatusIdle speedCarburetor

A control mechanism for a carburetor having a throttle valve and a choke valve each having at least a cold-starting position and a full-speed position. The throttle valve is spring biased toward its third, low idle position, and the choke valve is mounted on a choke shaft and is spring biased toward its full-speed open position. When the choke valve is moved by a choke shaft lever from its open position toward its cold start closed position a fast idle lever associated with the choke valve shaft engages, via releasable latch parts, a throttle lever associated with the throttle valve. The interengaging latch parts of these fast idle and throttle levers hold both valves in their respective cold-starting positions in opposition to their respective biasing springs. These latch levers can be released by operator actuation of the throttle valve control, thereby causing the choke valve to be automatically returned to its open position by its biasing spring, or, alternatively, the choke valve can be moved independently to its full-speed position. One of these fast idle and throttle latch levers has a notch, and the other has a pawl selectively engaging the notch when it becomes aligned therewith when the latch levers are operator-actuated to their respective cold start positions. The choke shaft is torsionally resilient so that when the choke shaft lever is forced to override initial-choke-closed position, it thereby twists the choke shaft after the choke valve has been bore-stopped at closed position. Upon release of operator actuating force, this feature prevents most, if not all of the previous retrograde movement of the choke and throttle valves out of their design cold start positions, despite operating slack in the latch system due to manufacturing tolerance stack-up in the various parts of the latch system parts and / or control mechanism in their assembly and operation.

Owner:WALBRO ENGINE MANAGEMENT

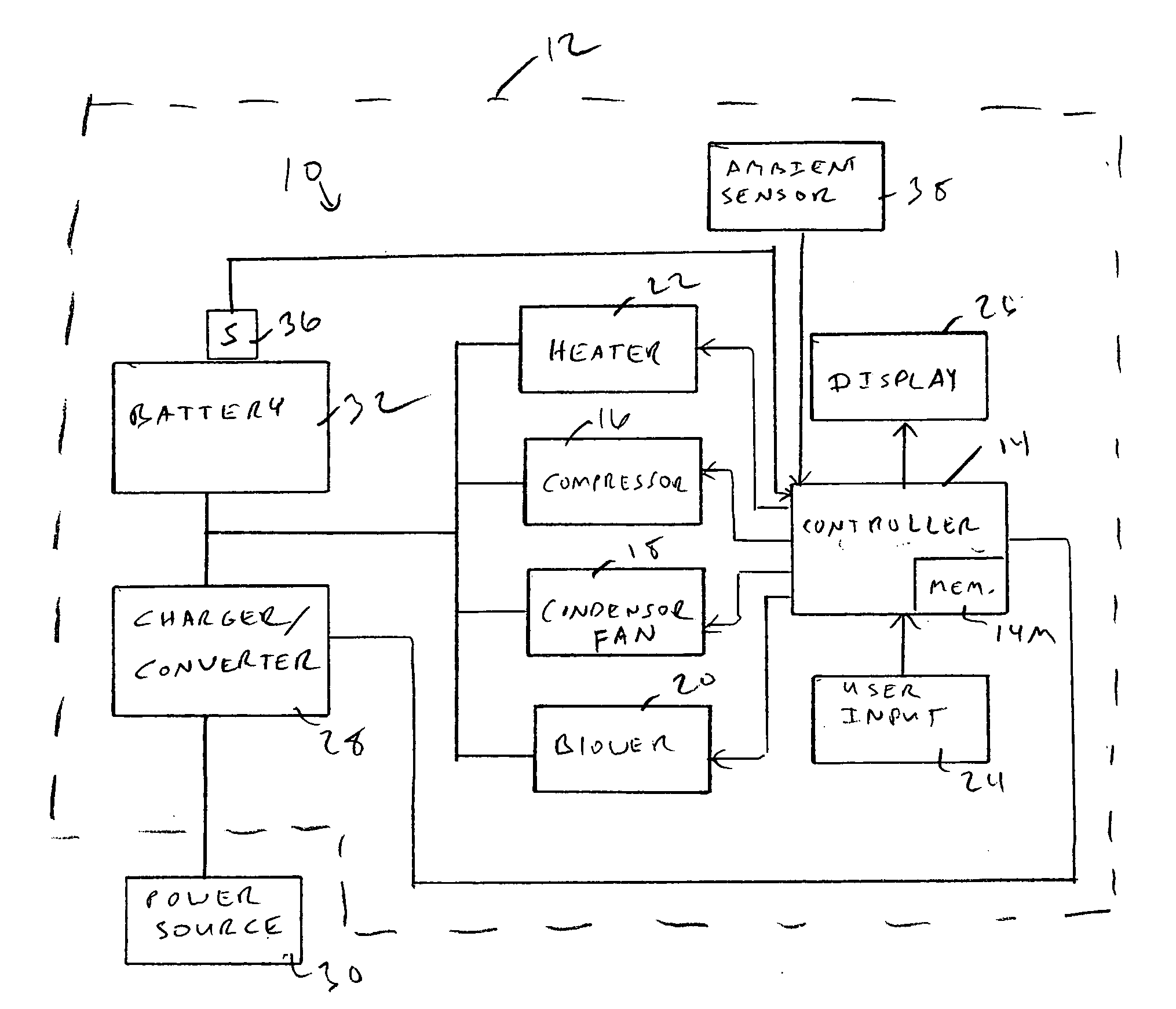

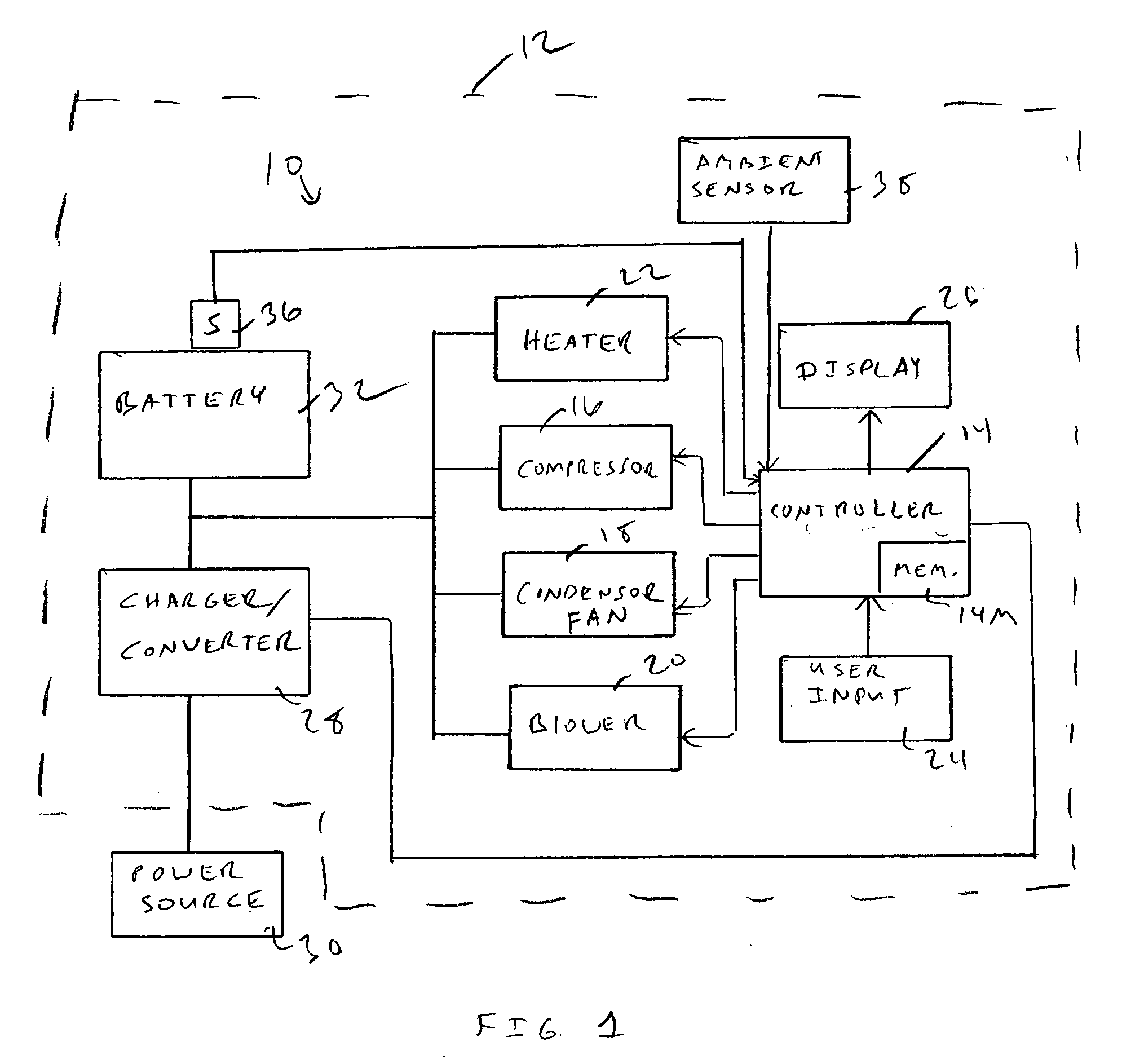

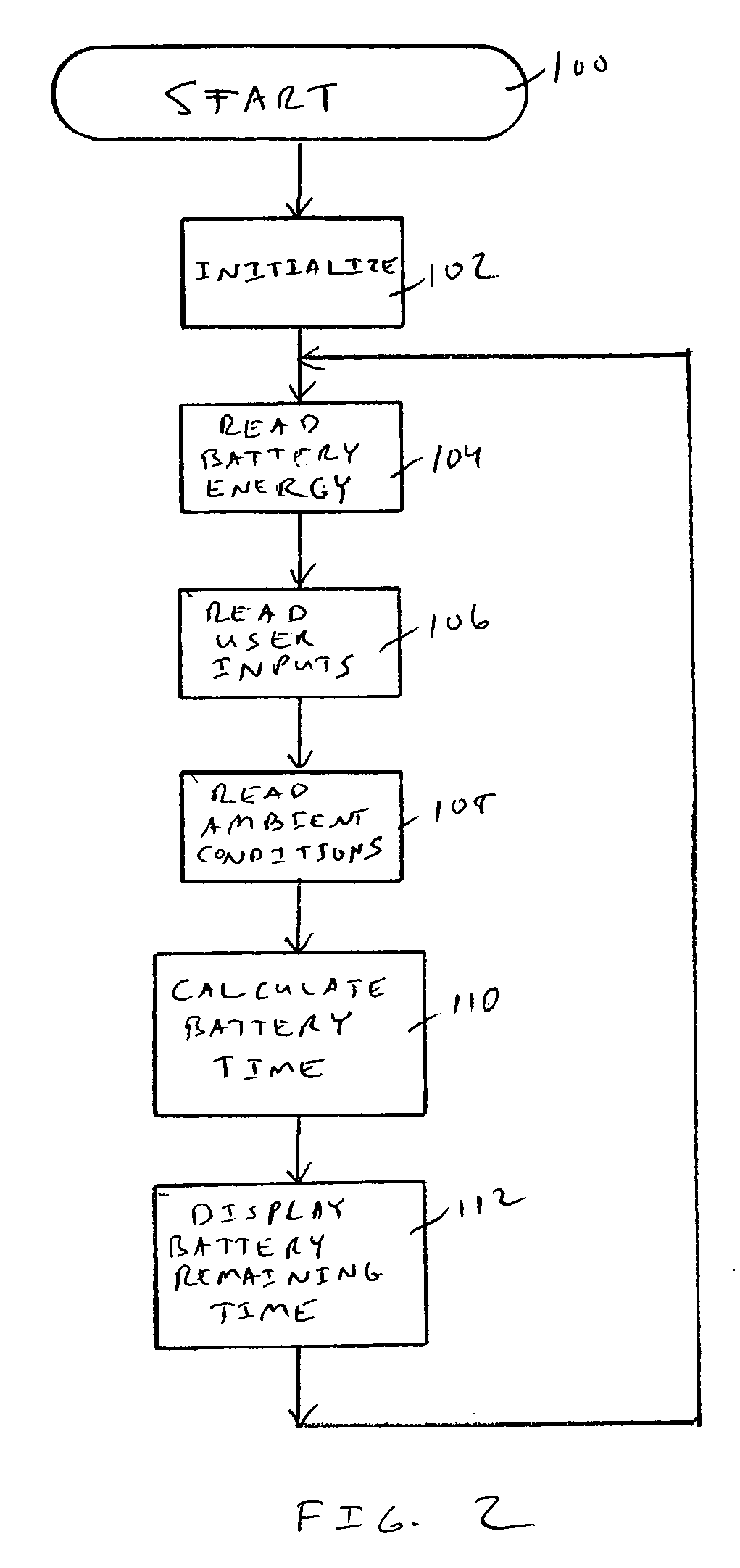

Air conditioner control for vehicular no-idle system using batteries

An HVAC control system for a passenger compartment of an over the road vehicle comprises a controllable air conditioner for directing cooled air flow through the passenger compartment and a controllable heater for directing heated air flow through the passenger compartment. A battery selectively powers the air conditioner and the heater. A sensor senses battery energy. A control panel includes user input devices for manually selecting operating parameters of the HVAC system and a battery remaining time display. A controller is operatively connected to the air conditioner, the sensor and the user control panel, the controller determining estimated battery remaining time based on battery energy and the manually selected operating parameters, and displaying the estimated battery remaining time on the battery remaining time display.

Owner:MODINE MFG CO

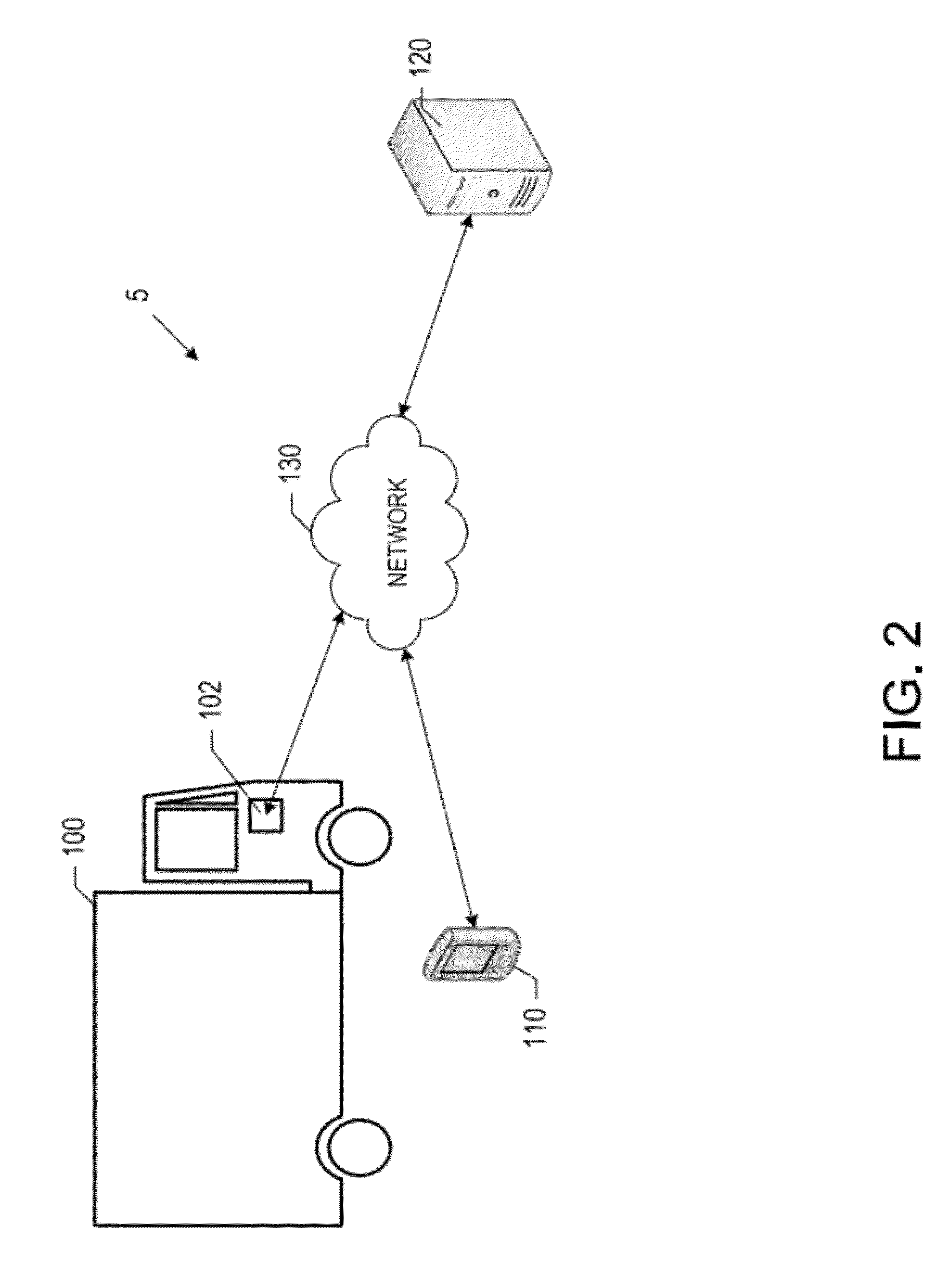

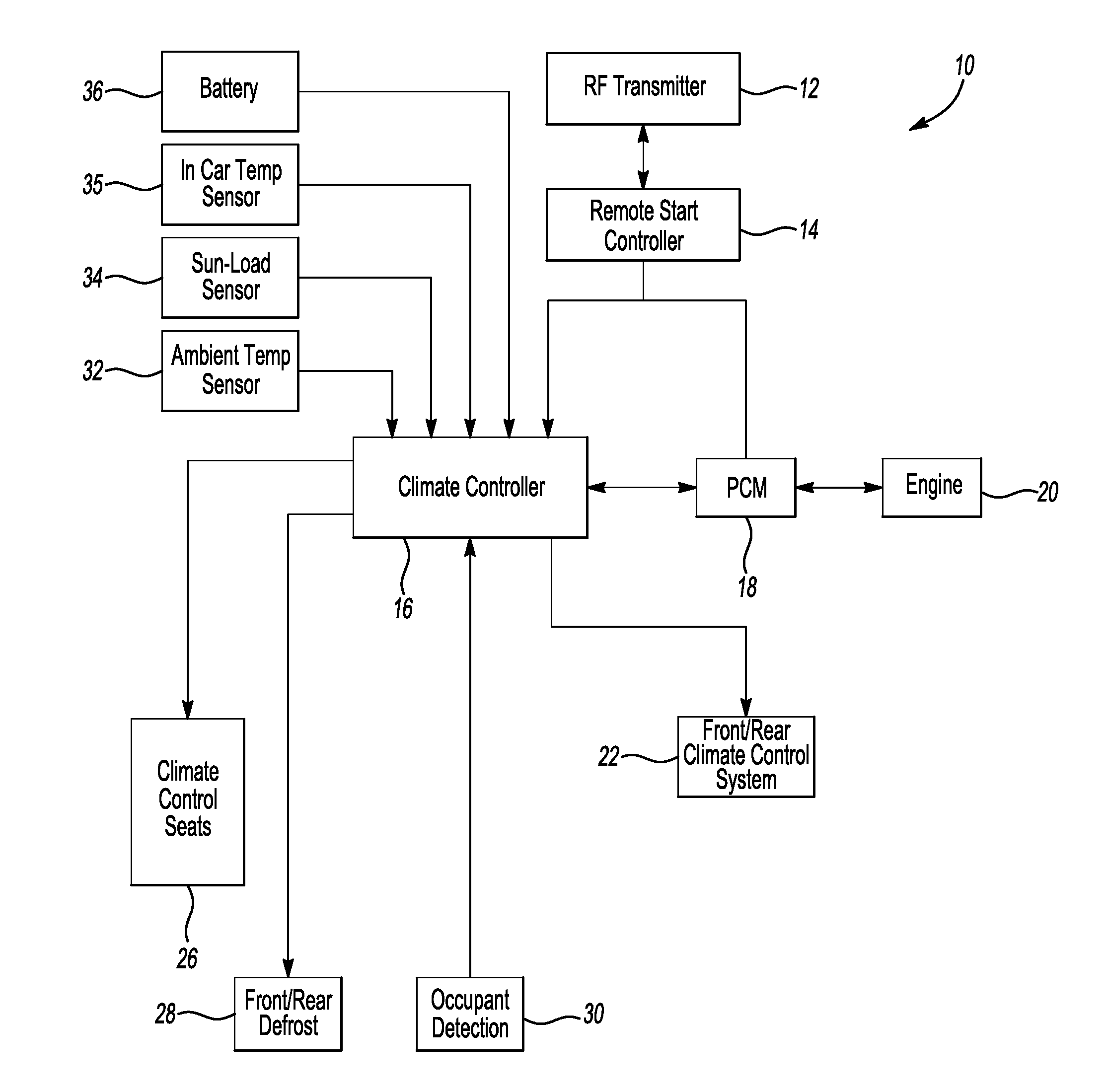

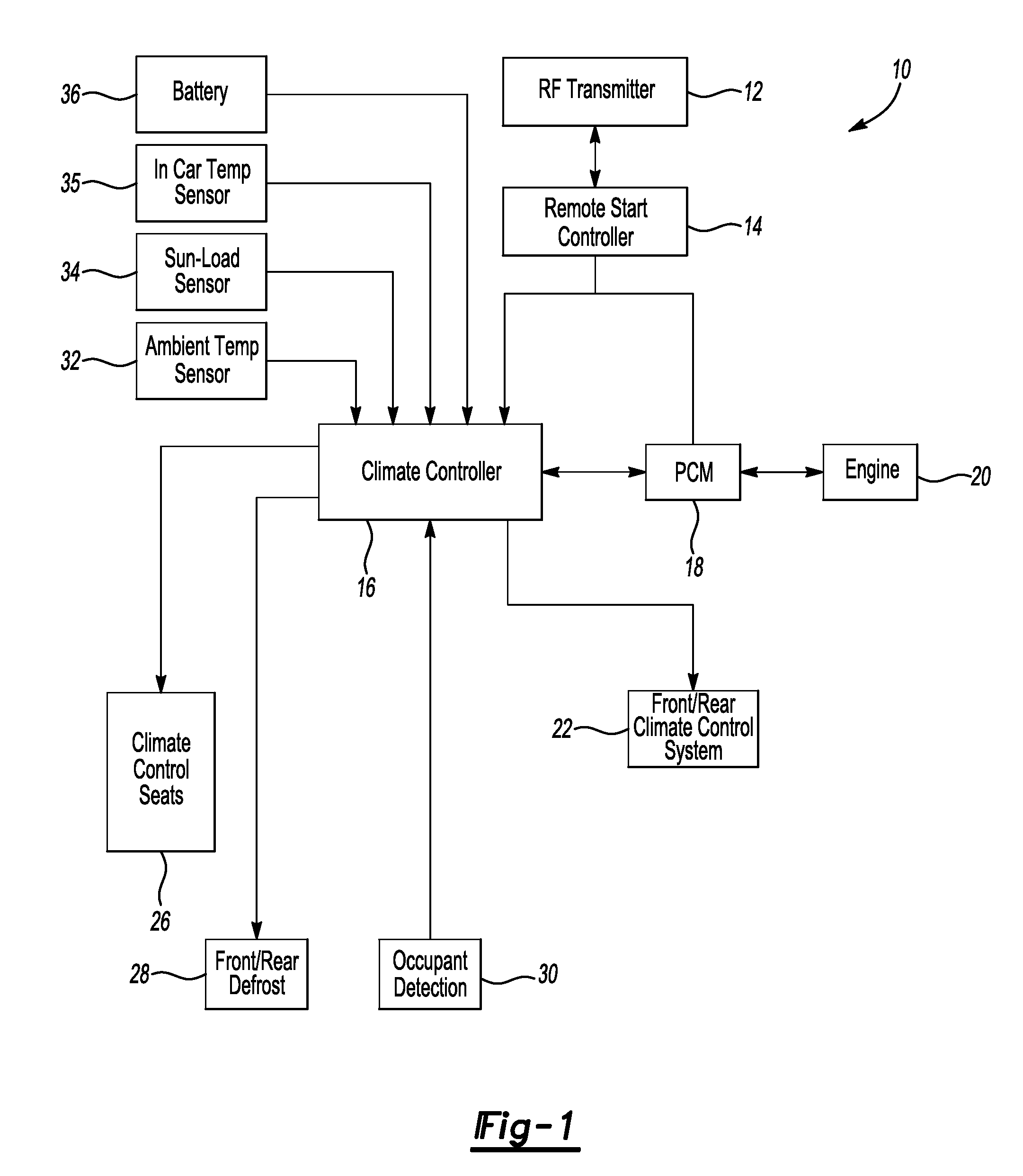

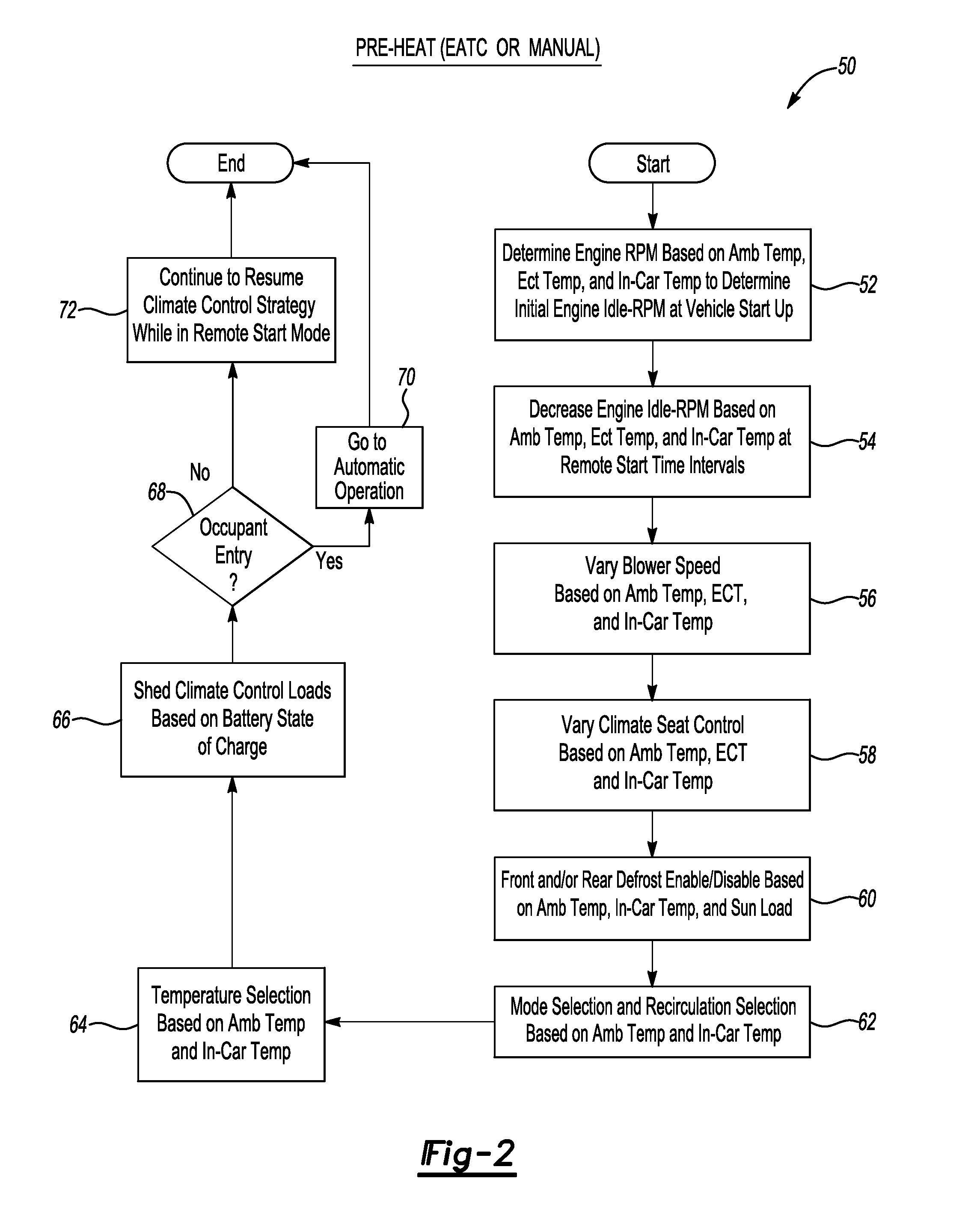

System and method for controlling a climate control system with remote start operation

In at least one embodiment, a system for controlling a vehicle climate control system in response to starting an engine with a remote start operation is provided. The system includes a first sensor for generating a cabin temperature signal indicative of a temperature within the vehicle. The system further includes a controller for controlling idle speed of the engine in response to the cabin temperature signal such that the controlled idle speed enables the climate control system to achieve a desired temperature.

Owner:FORD GLOBAL TECH LLC

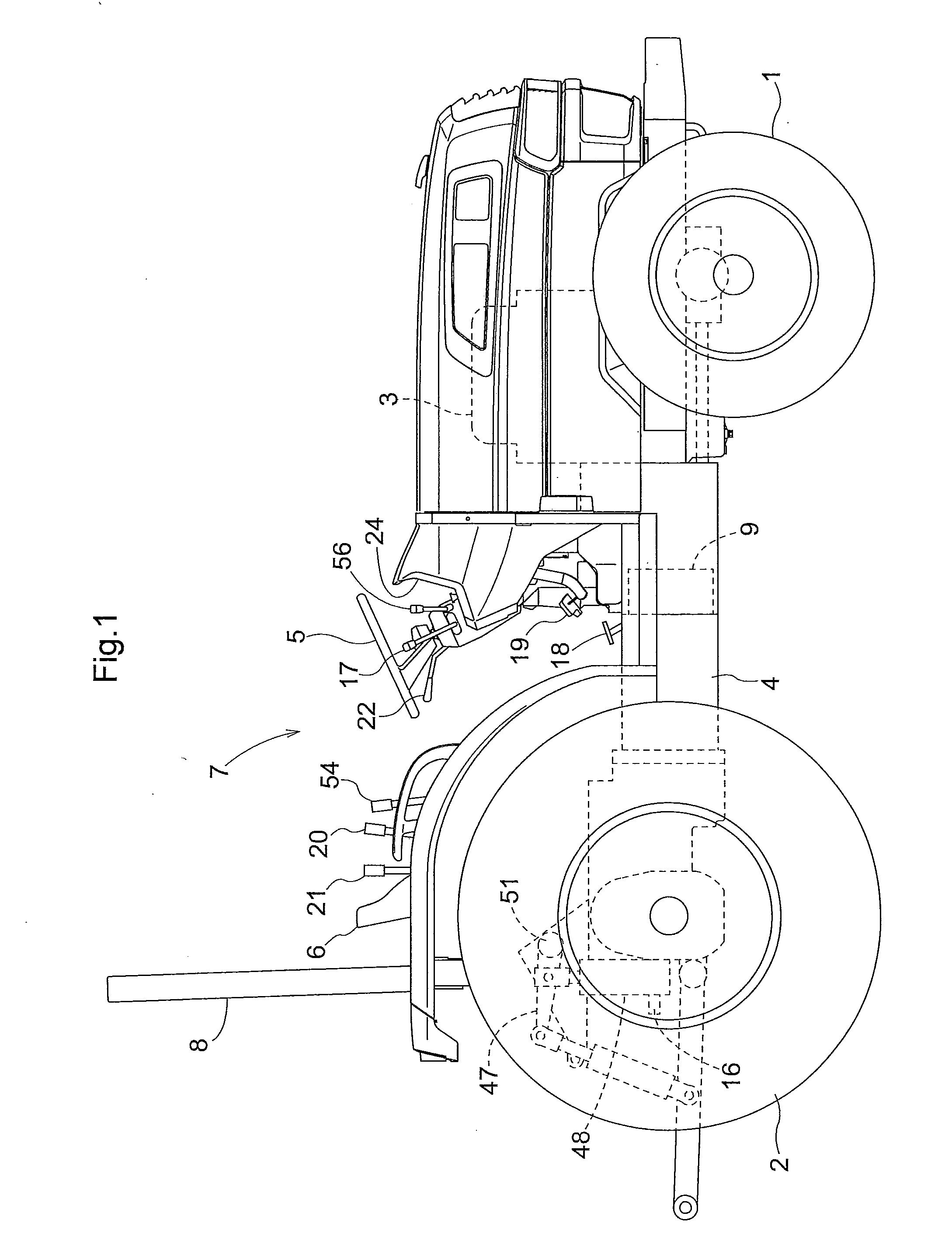

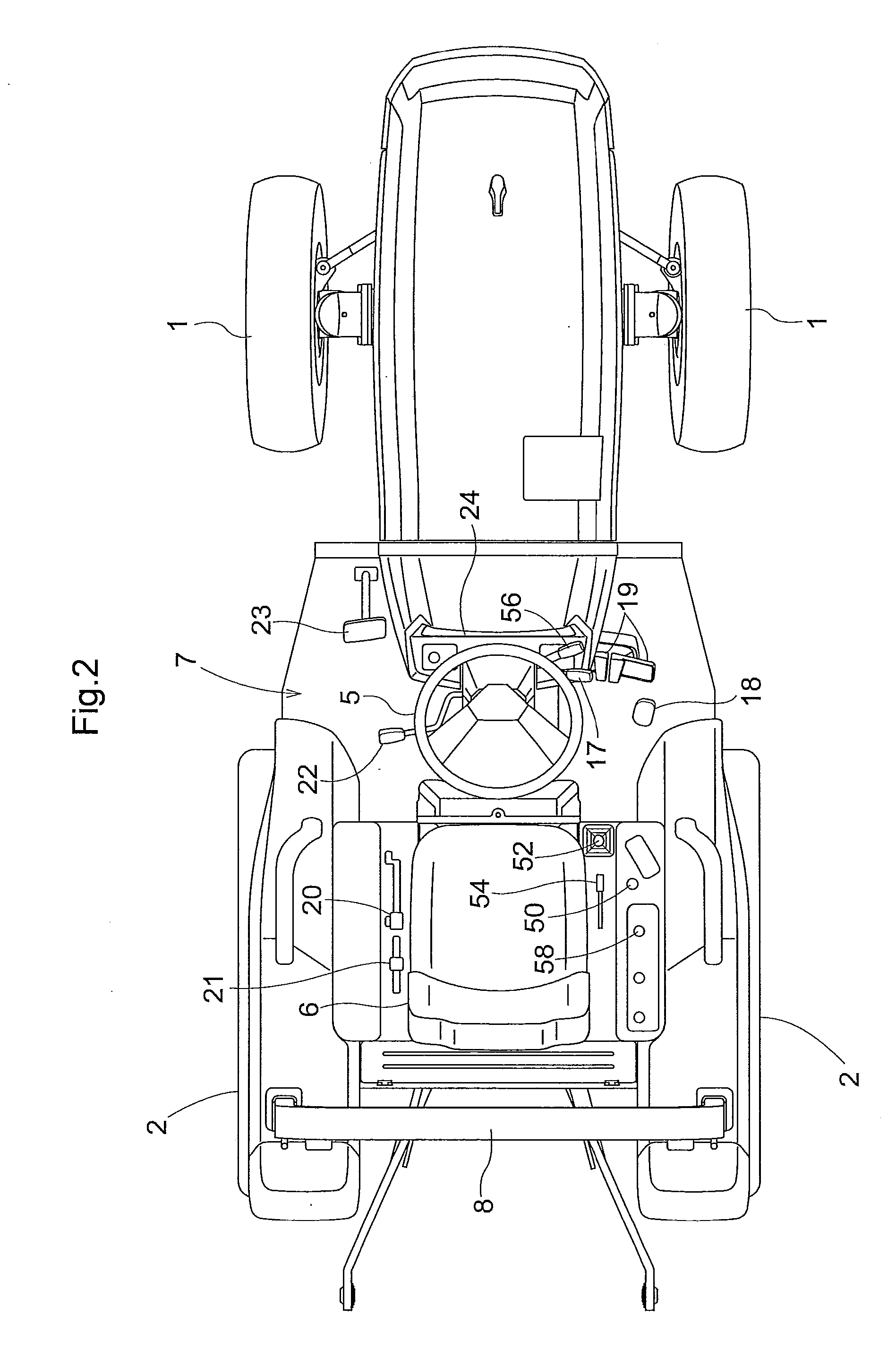

Speed Change System for Work Vehicle

ActiveUS20110178684A1Improve performanceLow maneuverabilityFluid couplingsDigital data processing detailsIdle speedControl theory

A speed change system for work vehicle having a continuously variable transmission device selects a first change gear ratio which is set larger than a smallest change gear ratio, when an engine rotational speed is a first set rotational speed which is set equal or close to an idling rotational speed of an engine; retains the change gear ratio of the continuously variable transmission device at the smallest change gear ratio, when the engine rotational speed is equal to or above a second set rotational speed set on a high-speed side relative to the first set rotational speed; and makes the change gear ratio of the continuously variable transmission device larger between the first change gear ratio and the smallest change gear ratio, as the engine rotational speed at that moment becomes lower, when the engine rotational speed is between the first and second set rotational speeds.

Owner:KUBOTA LTD

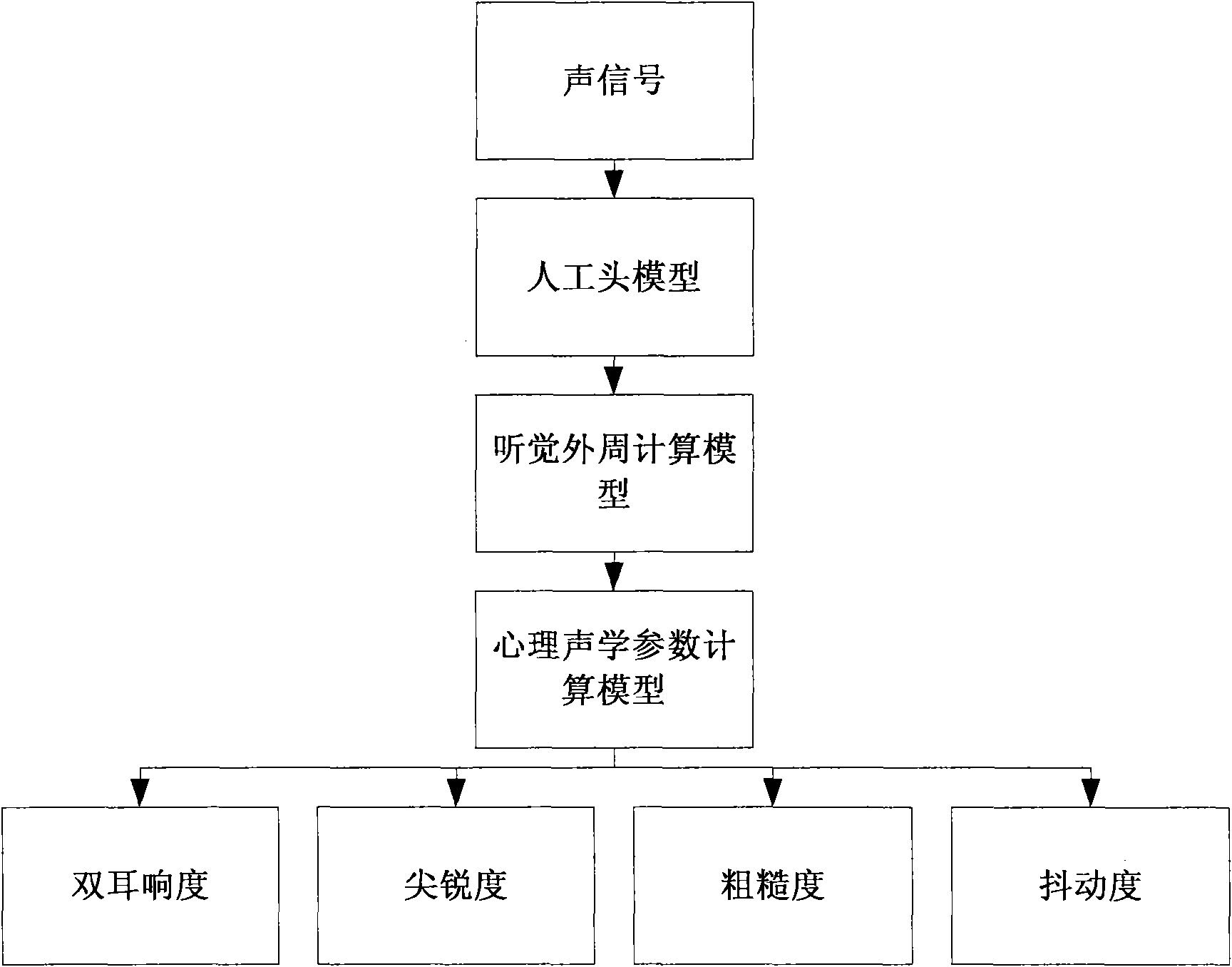

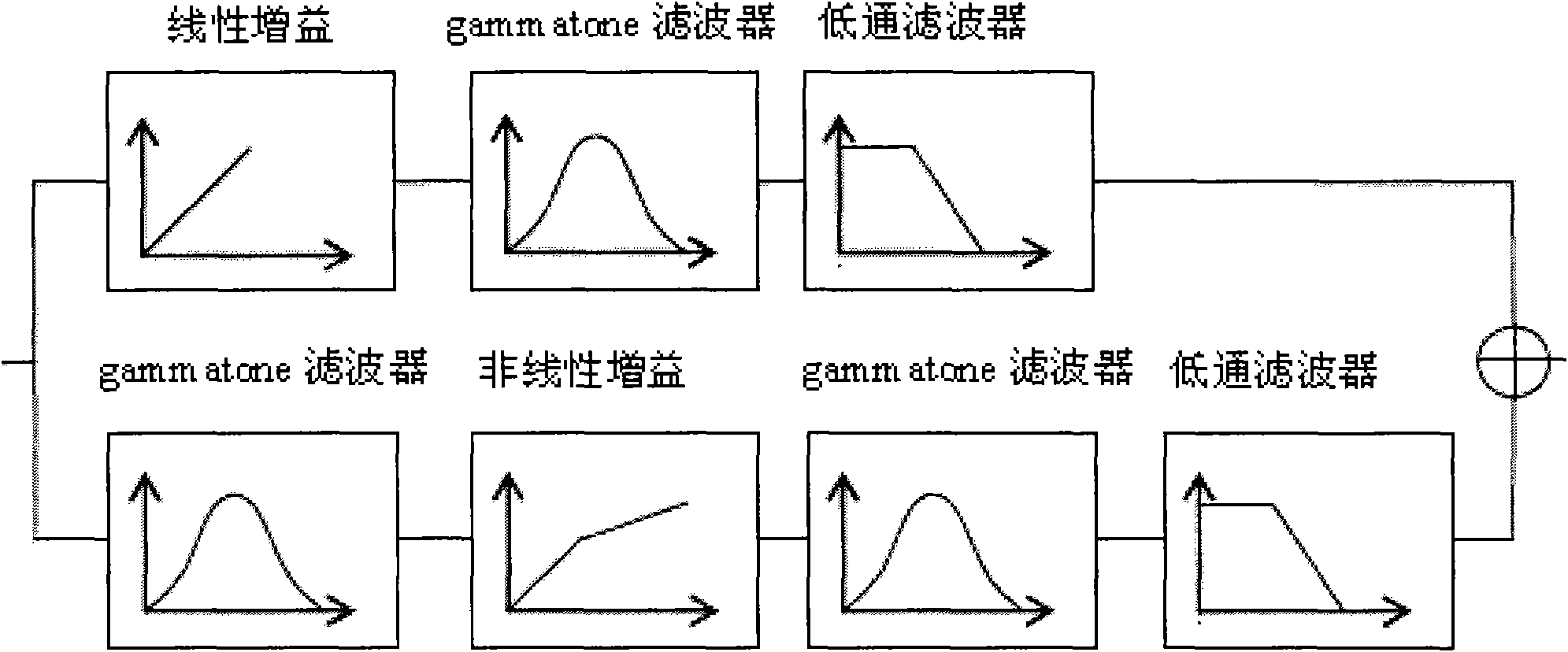

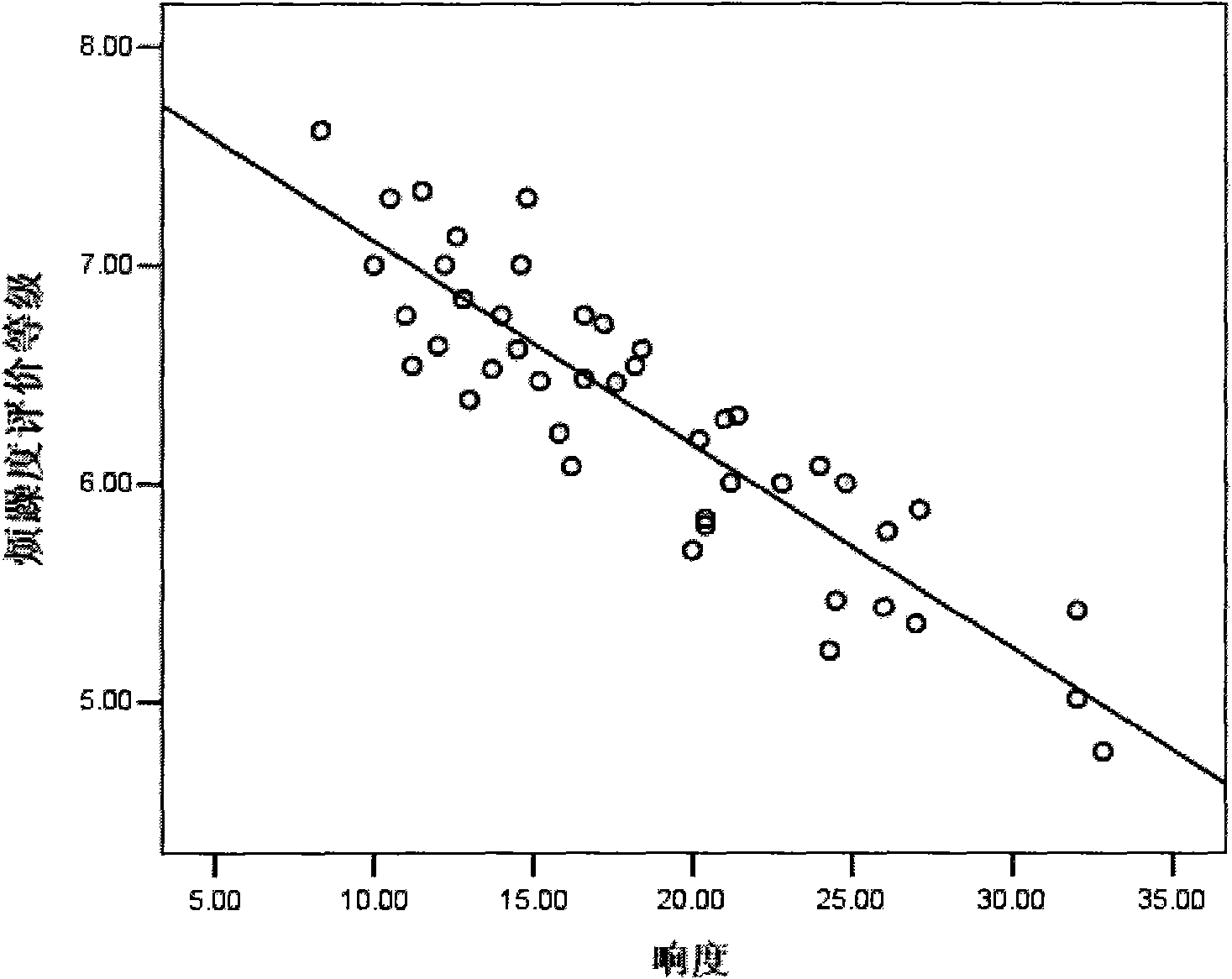

Method for objectively and quantifiably evaluating noise fret degree in vehicle based on auditory model

InactiveCN101672690AImprove performanceOvercoming complexityVibration measurement in fluidPsychotechnic devicesHuman bodyProcess mechanism

The invention relates to a method for objectively and quantifiably evaluating noise fret degree in a vehicle based on an auditory model, in particular to an evaluation method of psychoacoustics and vehicle sound quality. The method comprises the following steps: designing a dummy head model; imitating a processing mechanism of the middle ear and the inner ear of a human body to the sound by usingan auditory peripheral calculation model; collecting vehicle noise signals under the working conditions of uniform, accelerated and idle speed; pre-treating the noise sample and processing the loudness in specification; obtaining a psychoacoustics parameter by using a sound quality calculation model; obtaining subjective evaluation result test data by using a grouped and paired comparison method;calculating and painting a correlated scatter plot chart between each parameter and the ranking value of the subjective evaluation result; and analyzing and calculating to obtain the objectively quantifiable model of the subjective fret degree under each working condition. The invention can realize the psychoacoustic parameter calculation of objectively evaluating the sound quality with differentvehicle types, gears and speeds, wherein the calculated value has good pertinence and consistency with the evaluated result of the subjective evaluation method. The invention has stable evaluated result and high reliability, and can improve the sound quality and competitiveness of vehicles combined with the design of new CAE cars.

Owner:JILIN UNIV

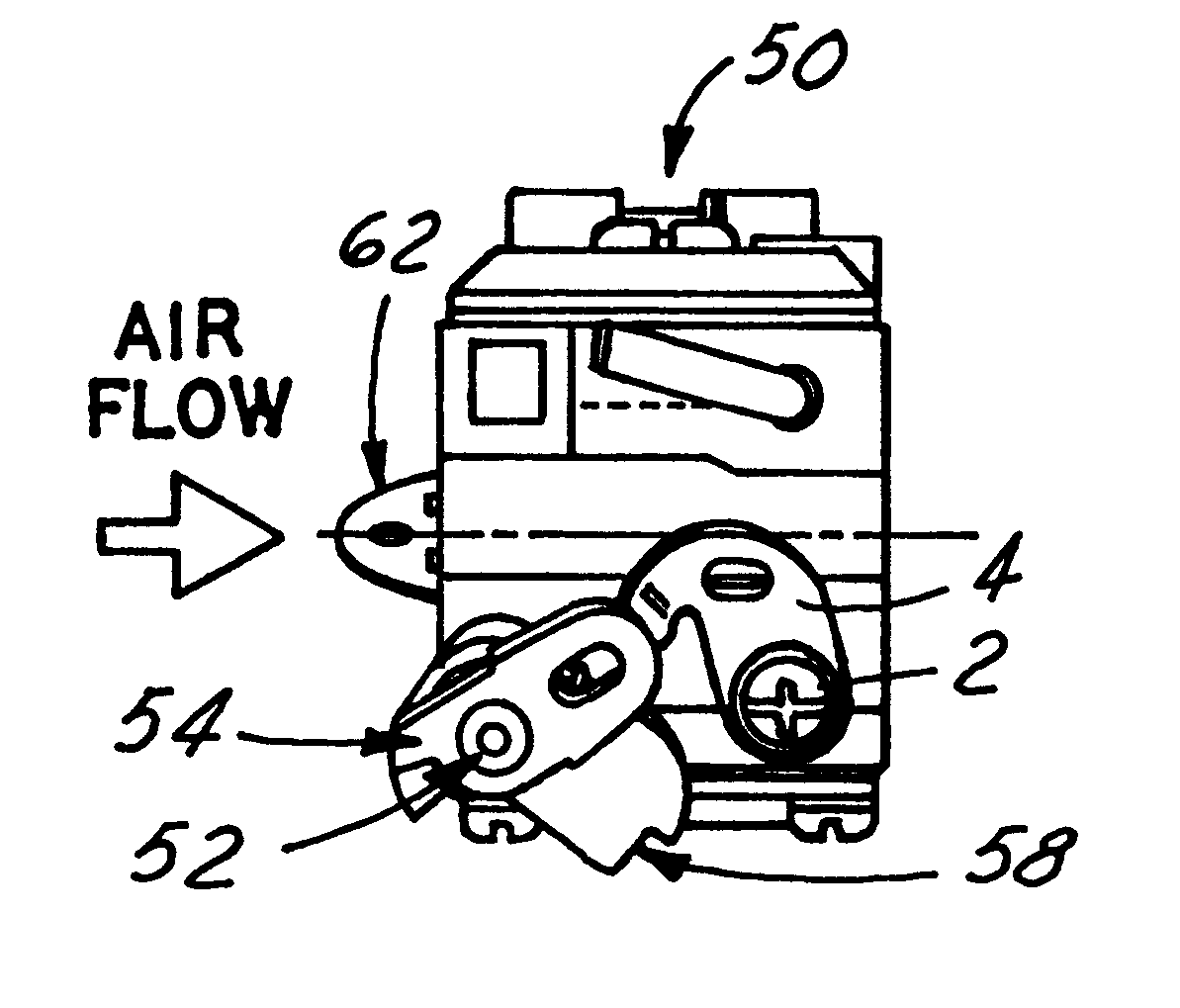

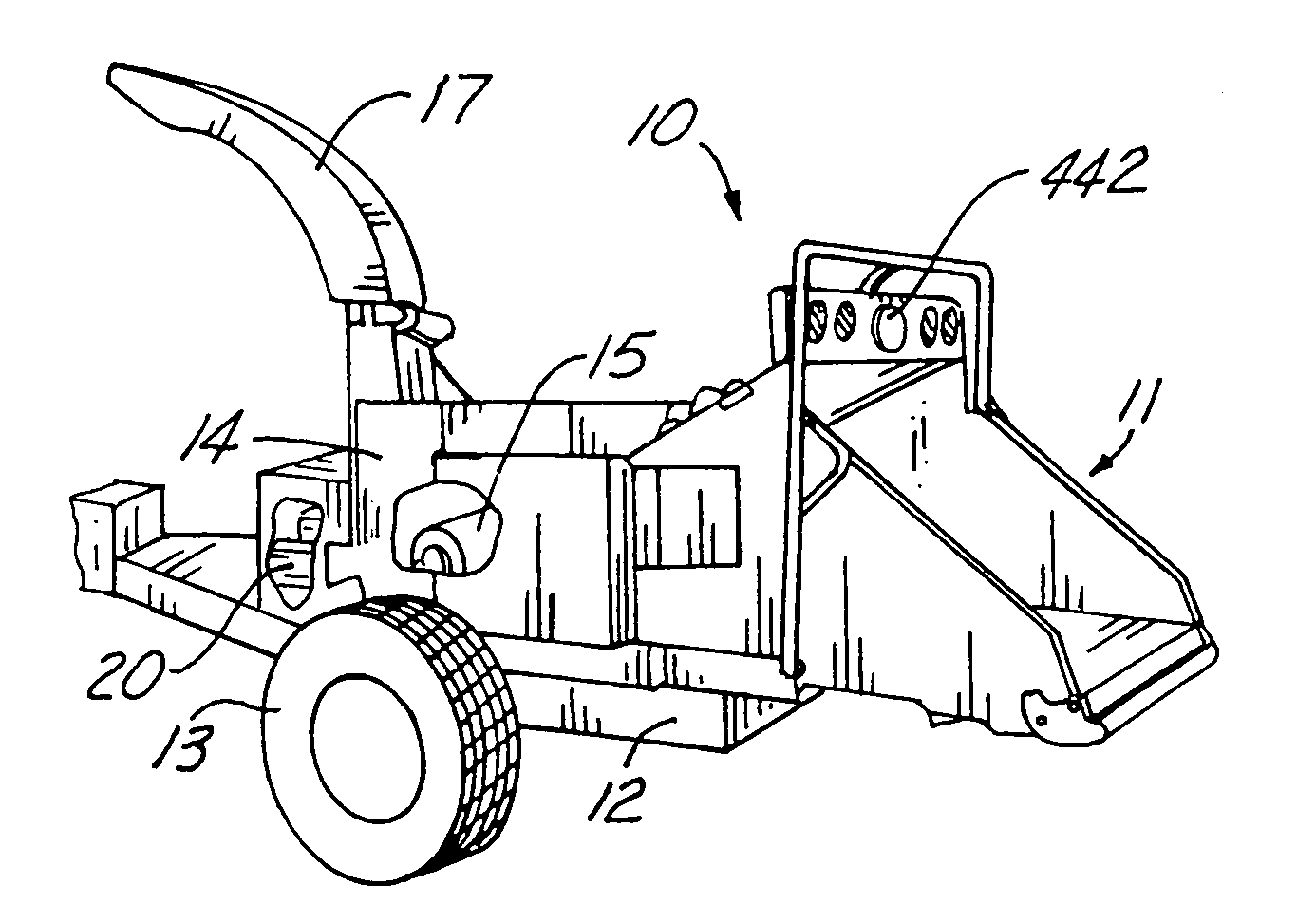

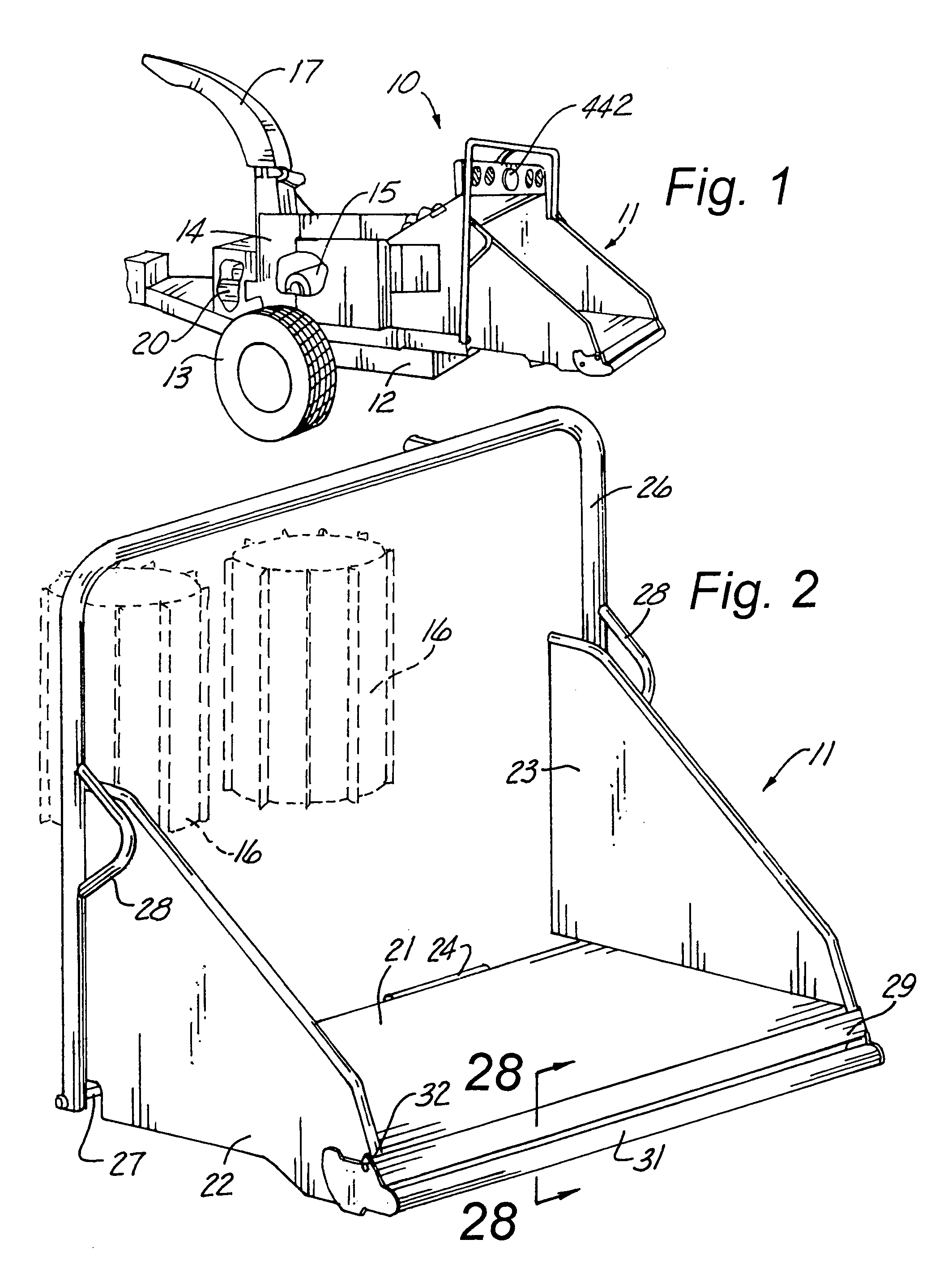

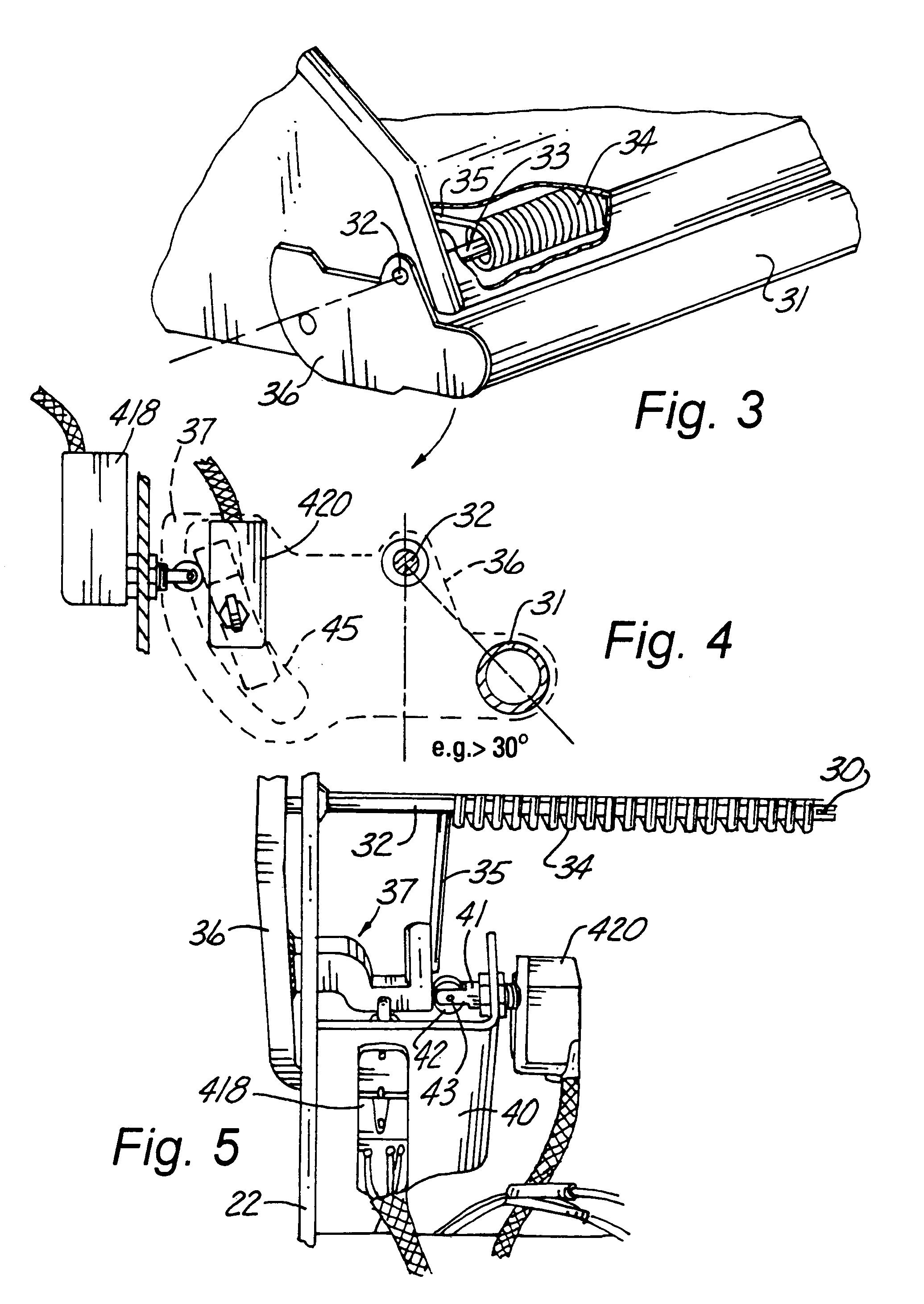

Brush chipper and methods of operating same

InactiveUS7011258B2Mechanism can be overcomeEliminate resistancePlant waste comminutingReed/straw treatmentHydraulic motorControl engineering

An improved brush cutter having an upper feed control member with stop, forward, neutral, and reverse positions also has a lower feed stop member with selectable sensitivity. Another aspect of the invention is to predict the feed roller shutoff point according to the rate of engine deceleration. According to another aspect, when the feed rollers stop feeding material into the cutters, to overcome drag on the cutters, a controller stops the feed rollers and then reverses them for a short time, and then reverses the rollers again if the problem is still present. To prevent jamming, a pressure switch senses when oil in a hydraulic motor system for rotating the feed rollers is too high and the controller momentarily reverses the feed rollers and then causes them to go forward, a cycle which can occur several times until the feed rollers are no longer stalled. By another aspect of the invention, the controller senses characteristics of the brush cutter and chooses an operating system based on the characteristics sensed. The controller can also sense if the brush chipper has not been used for a predetermined period of time and automatically reduce the idle speed of the engine until the brush chipper is used again, and then automatically return the engine to a normal idle speed before the feed rollers will pull brush into the brush chipper.

Owner:VERMEER MFG CO

Electric sander and motor control therefor

ActiveUS20050245183A1More fatigueConvenient heightGrinding feed controlPortable grinding machinesSanderMotor speed

A hand held orbital sander has a housing having an electronically commutated motor disposed therein and an orbit mechanism disposed beneath the housing. A motor controller is coupled to the motor. The motor controller changes the speed of at which it runs the motor from an idle speed to a sanding speed upon the motor speed dropping from idle speed to an idle speed threshold value and changes the speed at which it runs the motor from sanding speed to idle speed upon the motor speed increasing from sanding speed to a sanding speed threshold value. The sander may have a mechanical brake that brakes the orbit mechanism and the motor controller also dynamically brakes the motor.

Owner:BLACK & DECKER INC

Hybrid vehicle drive system and method and idle reduction system and method

One embodiment relates to a hybrid vehicle drive system for a vehicle including a first prime mover, a first prime mover driven transmission, a rechargeable power source, and a PTO. The hybrid vehicle drive system further includes a hydraulic motor in direct or indirect mechanical communication with the PTO and an electric motor in direct or indirect mechanical communication with the hydraulic motor. The electric motor can provide power to the prime mover driven transmission and receive power from the prime mover driven transmission through the PTO. The hydraulic motor can provide power to the prime mover driven transmission and receive power from the prime mover driven transmission through the PTO.

Owner:POWER TECH HLDG LLC

Air-conditioning apparatus including motor-driven compressor for idle stopping vehicles

InactiveUS6981544B2Satisfactory air-conditioning performanceSolve insufficient capacityAir-treating devicesRailway heating/coolingMotor driveEngineering

A vehicle air-conditioning apparatus for idle-stop vehicles is capable of performing both cooling and heating operations throughout the year. The air-conditioning apparatus includes an engine-driven compressor and engine-driven pump for a heating unit. The air-conditioning apparatus includes a motor-driven compressor and pump. A control unit drives the motor such that the motor-driven compressor is operated when there is a need for cooling and the motor-driven pump is operated when there is a need for heating when the engine is stopped.

Owner:DENSO CORP

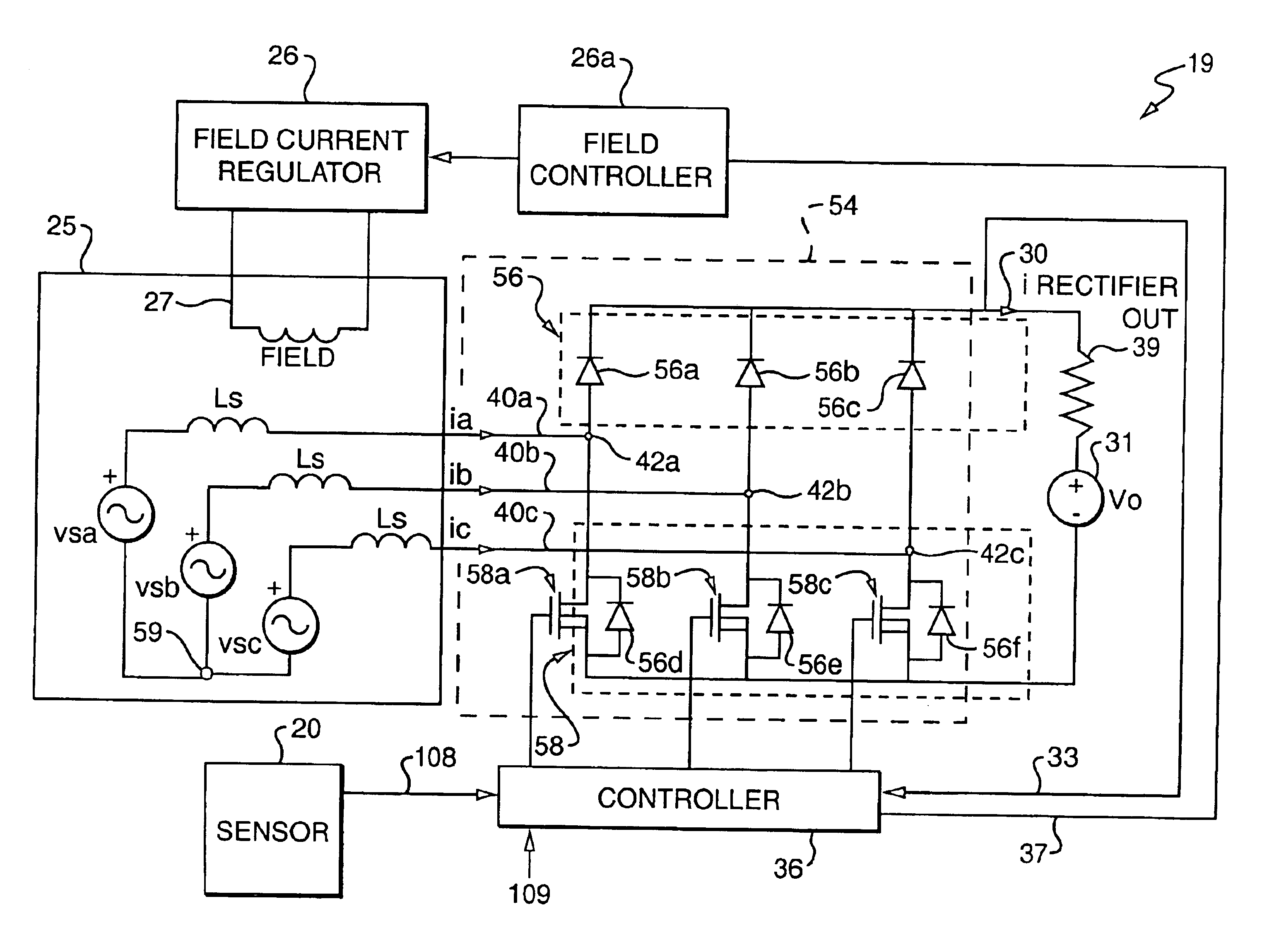

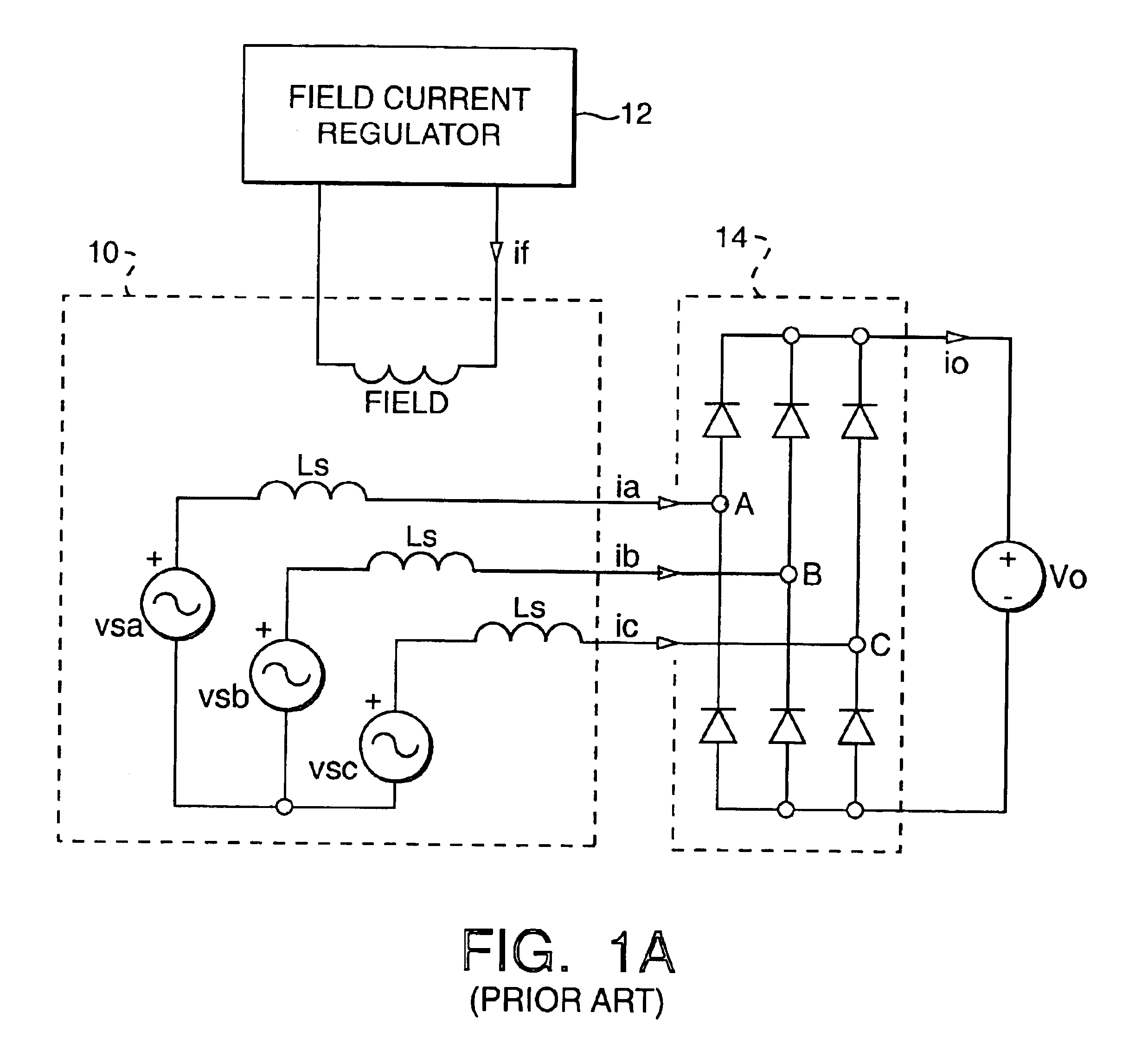

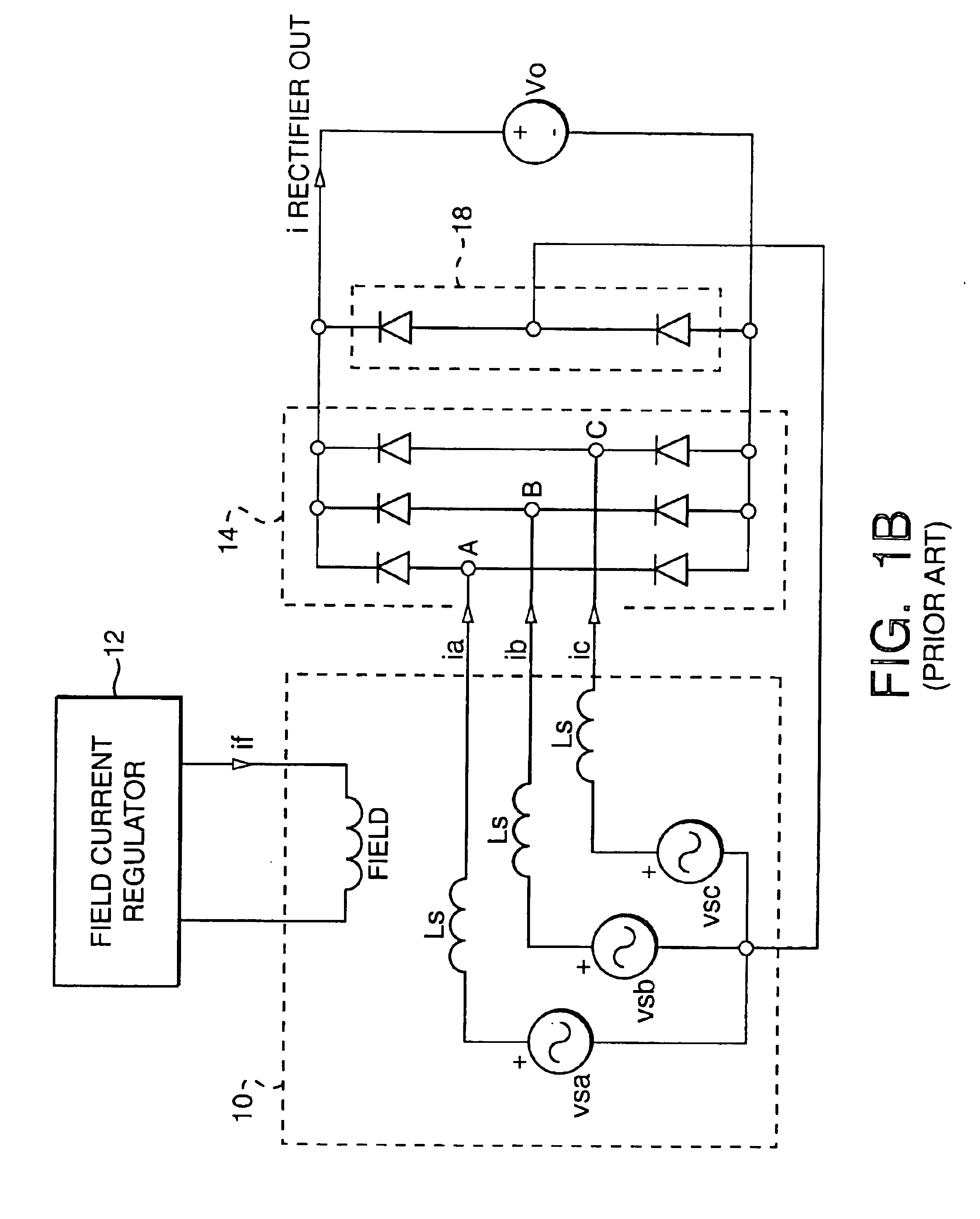

Alternator control circuit and related techniques

InactiveUS6912142B2Increase power levelLow costBatteries circuit arrangementsAc-dc conversion without reversalAlternatorIdle speed

An alternator system having an alternating current (ac) voltage source includes a switched-mode rectifier (SMR) coupled to the ac voltage source and having an output port coupled to an output of the alternator system, and a controller coupled to said switched-mode rectifier so as to provide a controlled pulse sequence synchronized with an angular rotor position of the (ac) voltage source to activate and deactivate the switched-mode rectifier. The controller further includes a PWM generator having a first input to receive a total duty ratio signal synchronized with an angular rotor position of the (ac) voltage source. The switched mode rectifiers are controlled to increase power output levels at lower speeds near idle. The controller combines improved idle speed power output levels with load matching improvements from PWM control for more efficient operation when compared to circuits using conventional control or PWM load matching control alone.

Owner:MASSACHUSETTS INST OF TECH

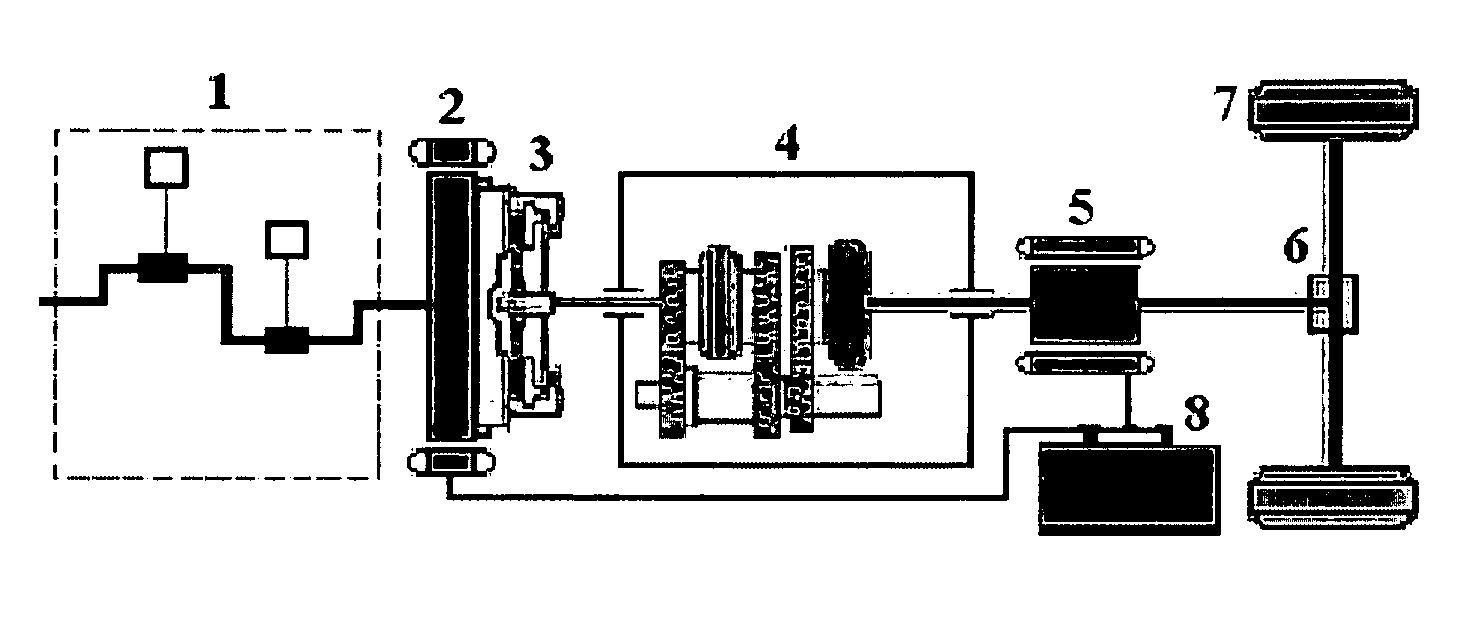

Power system for dual-motor hybrid vehicle

InactiveUS20060113127A1Simple and compact structureLight weightDigital data processing detailsElectric propulsion mountingExhaust gas emissionsEnergy recovery

A power system for dual-motor hybrid vehicle is a combined driving unit fed with fuel and electric power, comprising: an internal combustion engine, a motor, a clutch, a transmission, a power battery, a braking system and an entire vehicle controller, wherein the system further comprises: a main motor, an auxiliary motor, and a mechanical stepped transmission, a rotor shaft of the main motor being connected with the output shaft of the transmission, a rotor shaft of the auxiliary motor being connected with the crankshaft of the internal combustion engine; the main motor and the auxiliary motor being electrically connected with the power battery. With the control of the entire vehicle controller, the vehicle can be driven automatically by the hybrid power system in the follow modes: pure motor driving mode, series driving mode, parallel driving mode, hybrid driving mode, idling stop mode of the internal combustion engine, braking energy recovery mode, independently driving mode of the internal combustion engine, and motor auxiliarily driving mode during shifting. The present invention provides a new power system for hybrid vehicle, with simple structure, lower cost, less energy consumption and less exhaust gas emissions.

Owner:CHINA FIRST AUTOMOBILE GRP

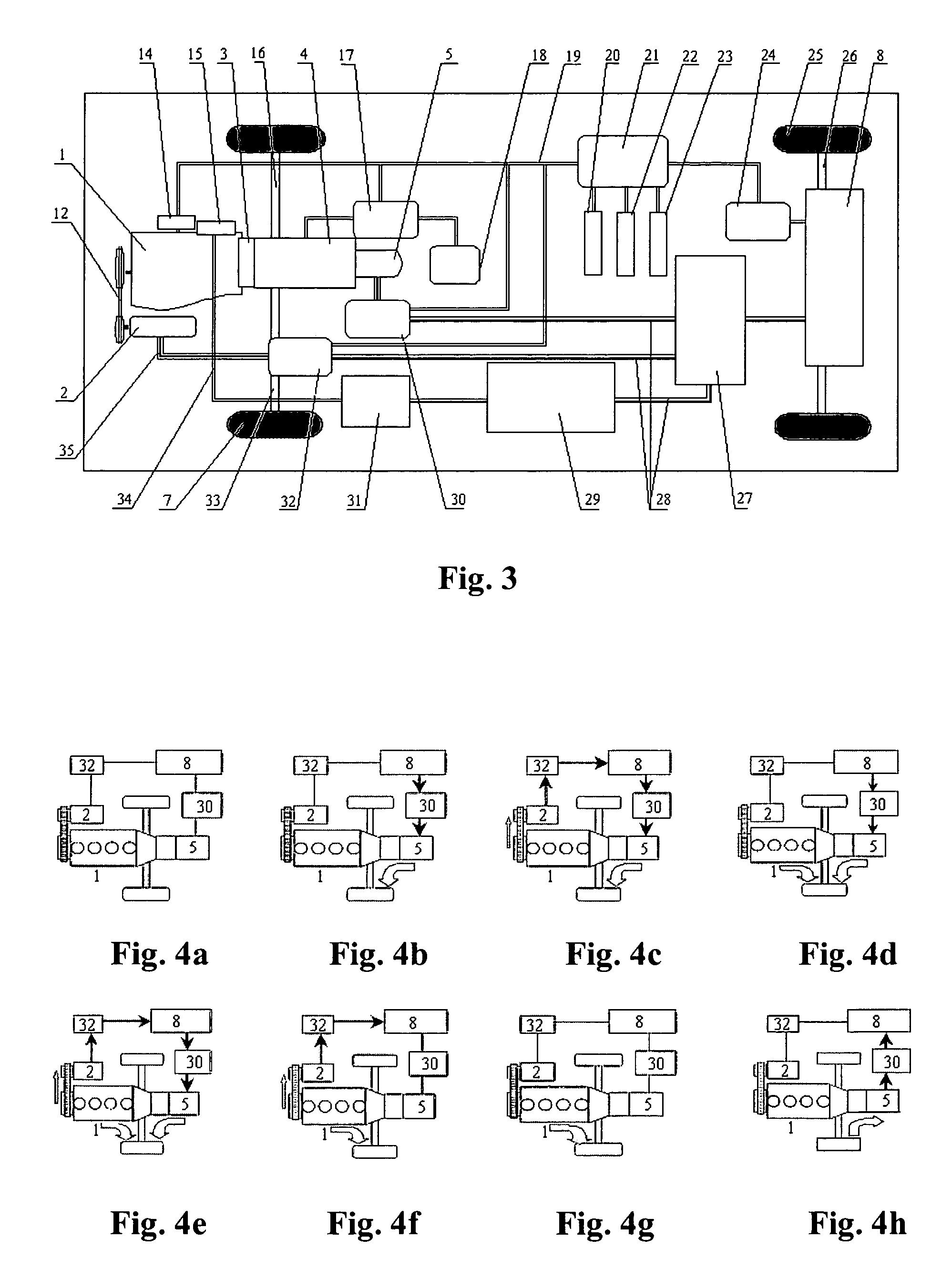

Engine on-off control method for mixed power automobile

InactiveCN1986307AWith vacuumStart fastHybrid vehiclesGas pressure propulsion mountingMotor driveIdle speed

The present invention relates to engine on-off control method for mixed power automobile. In condition of engine coolant temperature higher than preset value, automobile speed lower than the preset idle speed, air conditioner in off state, no treading on the accelerator pedal, auxiliary braking vacuum pump with certain vacuum degree, etc., the engine will be in idle stop state and may be re-started only after the EMS receiving starting signal. The present invention realizes the idle stop of the engine by means of the EMS, controls the fast starting of the engine with the EMS to control the motor, and makes the engine to jet oil and ignite after the motor drives the engine to certain rotation speed. The said control method can start the engine fast and raise the starting exhaust performance of the engine.

Owner:CHERY AUTOMOBILE CO LTD

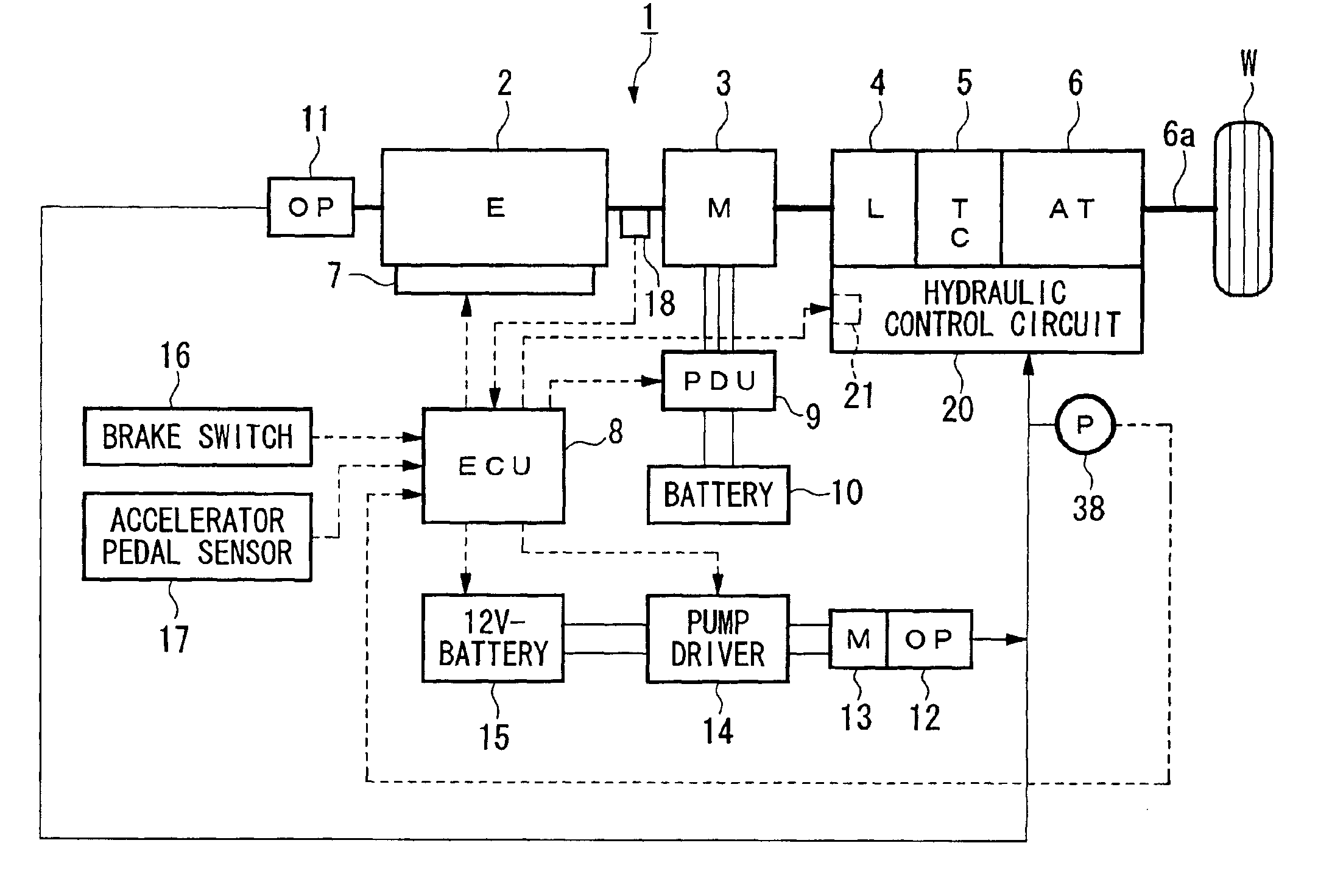

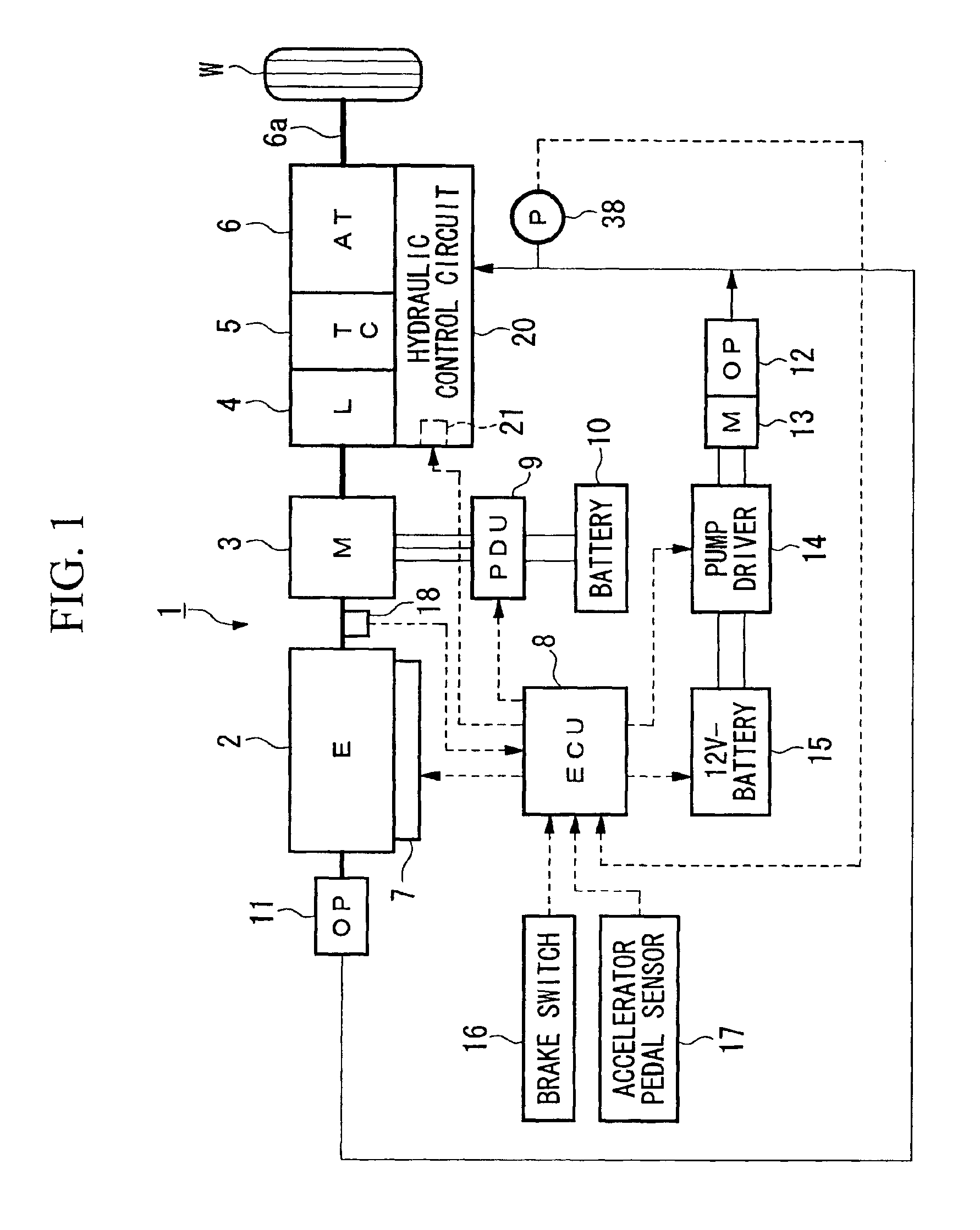

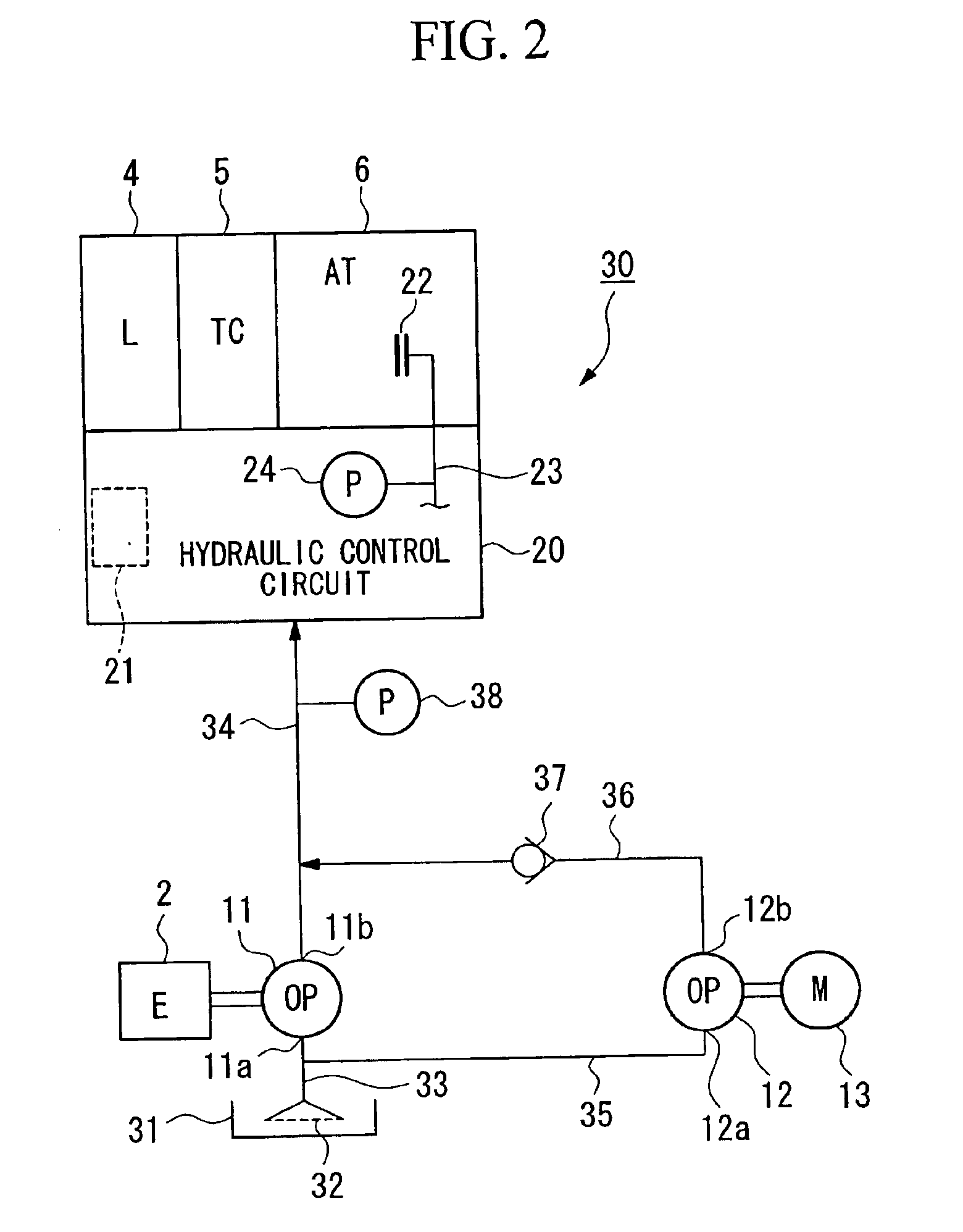

Hydraulic control apparatus for hybrid vehicle

InactiveUS7041030B2Smooth transmissionClutchesInternal combustion piston enginesMotor driveTorque transmission

A hydraulic control apparatus for a hybrid vehicle, which enables a smooth torque transmission when an engine of the vehicle is started from an idling stop state. The hydraulic control apparatus includes an engine and a motor as power sources, a transmission having a torque converter, a clutch for a starting gear, an engine automatic stop and start device which is associated with the engine, a motor-driven oil pump for supplying oil pressure to the transmission, a brake pedal sensor, an accelerator pedal sensor, an engine revolution rate sensor. The oil pressure applied to the clutch is controlled to a level corresponding to a creeping torque when the engine is automatically stopped. When the brake pedal is released, the engine is automatically started, the accelerator pedal is not depressed, and the engine revolution rate is less than an idling revolution rate, the oil pressure applied to the clutch is maintained to the level corresponding to the creeping torque.

Owner:HONDA MOTOR CO LTD +1

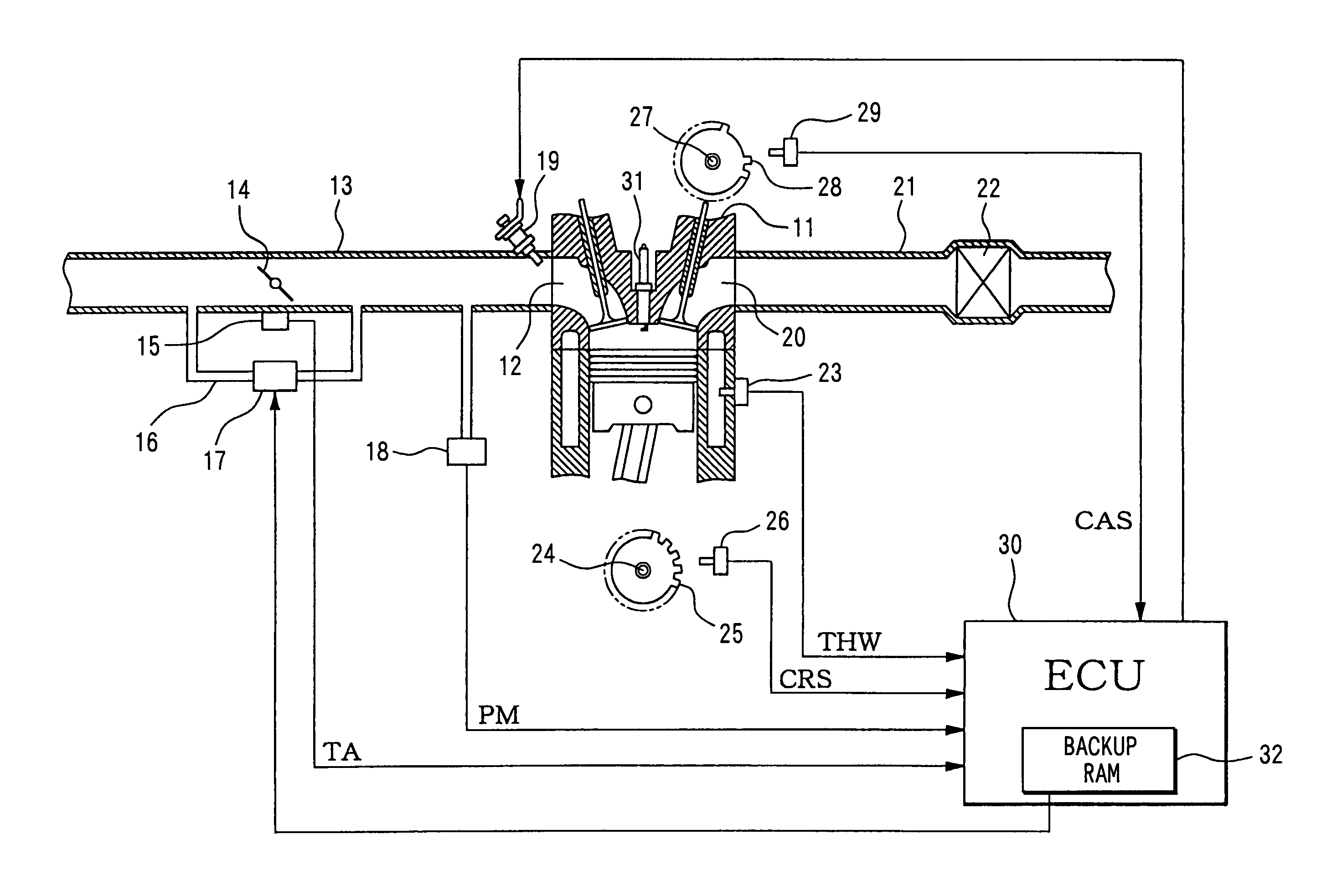

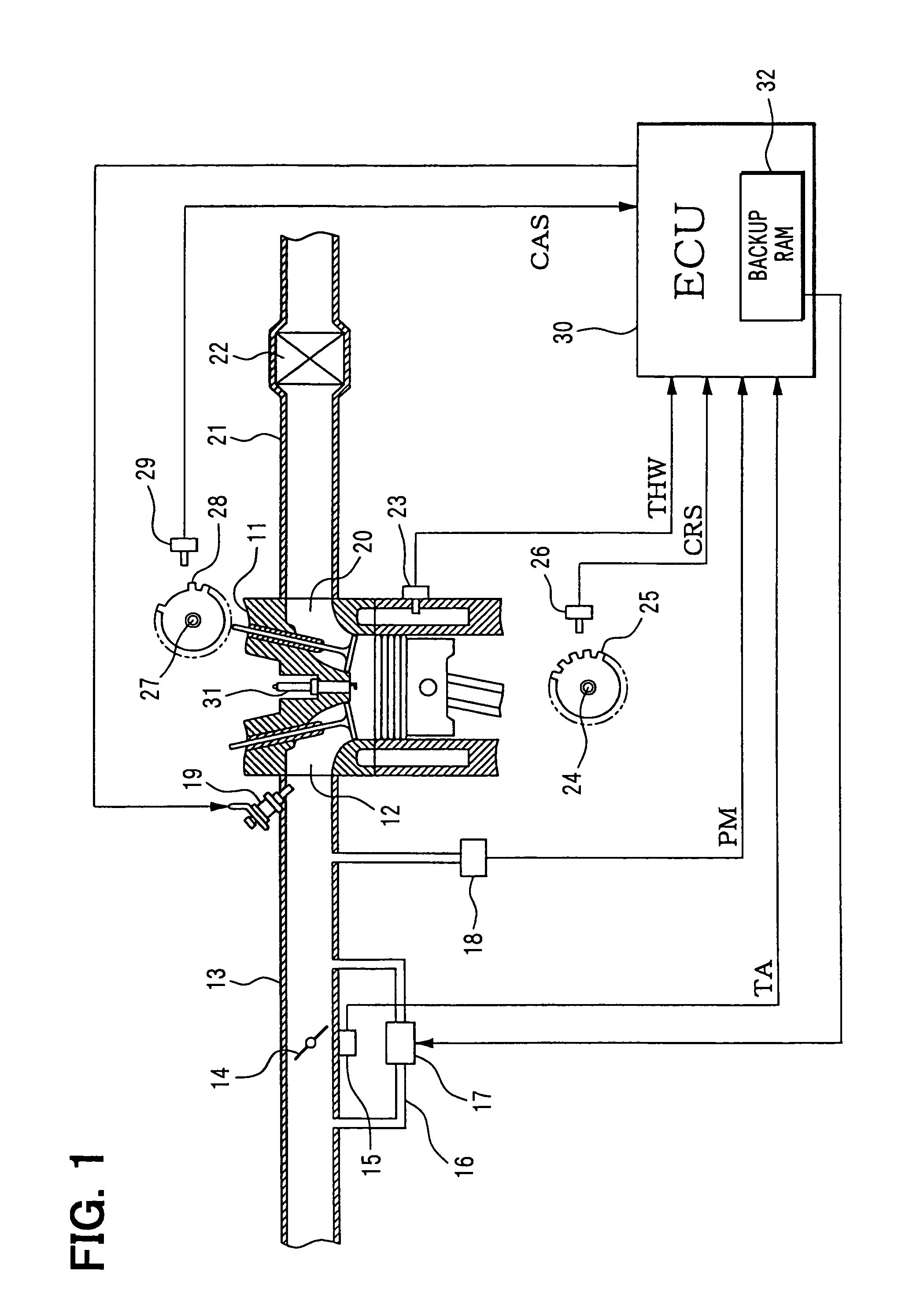

Engine controller for starting and stopping engine

InactiveUS7066128B2Low costQuick stopAnalogue computers for vehiclesElectrical controlIdle speedIgnition timing

During a shut-down period of an engine based on an idle stop control, a computer estimates a power stroke cylinder and a compression stroke cylinder when the engine is stopped. A fuel is injected into the power stroke cylinder and the compression stroke cylinder in an intake stroke just before the engine is stopped. An air-fuel mixture is hold in each cylinder with the engine stopped. When an auto start is required while the engine is stopped, a spark ignition is performed in the power stroke cylinder to start cranking of the engine by combustion energy. At nest ignition timing, a spark ignition is performed in the compression stroke cylinder to start the engine without an aid of a starter.

Owner:DENSO CORP

Hybrid vehicle drive system and method and idle reduction system and method

One embodiment relates to a hybrid vehicle drive system for a vehicle including a first prime mover, a first prime mover driven transmission, a rechargeable power source, and a PTO. The hybrid vehicle drive system further includes a hydraulic pump in direct or indirect mechanical communication with the PTO. The hybrid vehicle drive system further includes an electric motor in direct or indirect mechanical communication with the hydraulic pump. The electric motor can receive power from the prime mover driven transmission through the PTO. The hydraulic pump can receive power from the electric motor when the electric motor rotates, the electric motor using power from the rechargeable energy source, or from the prime mover driven transmission through the PTO.

Owner:POWER TECH HLDG LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com