Oil field fracturing pumping remote automatic control system

An automatic control system and oilfield fracturing technology, which is applied in the fields of engine, gearbox and signal control, can solve the problems of slow transmission speed, short transmission distance, and less transmission data, and achieve the effect of improving operation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

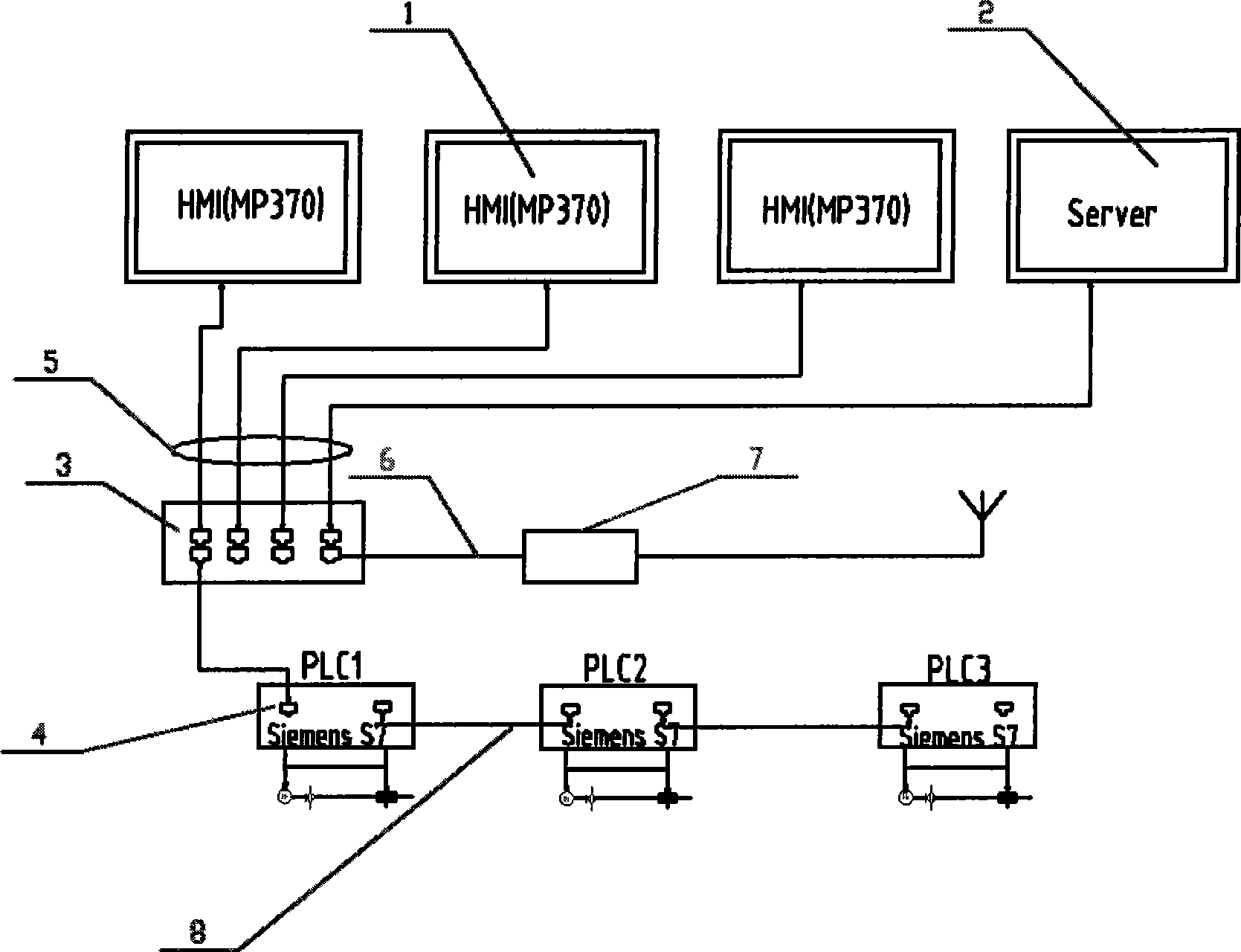

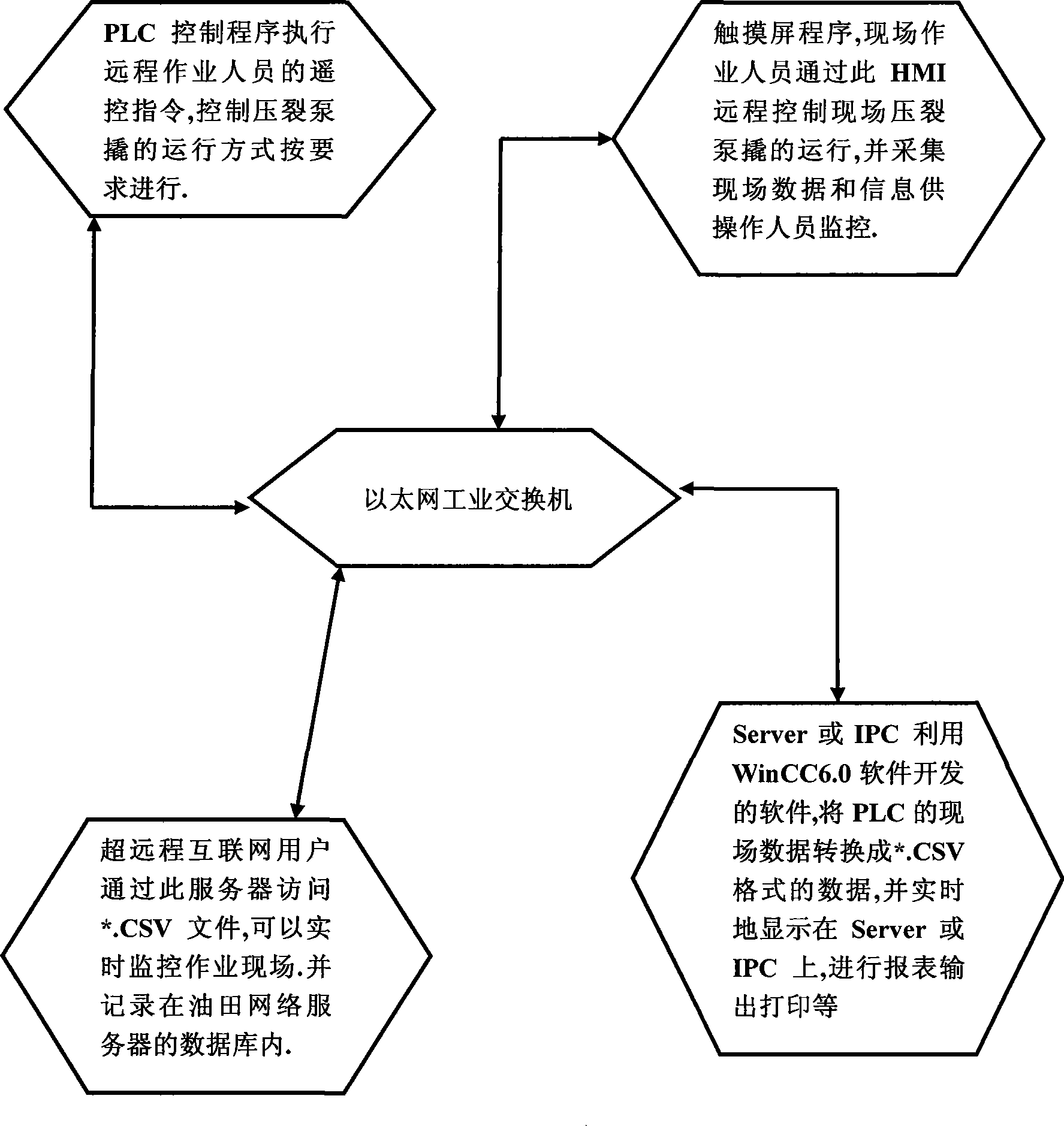

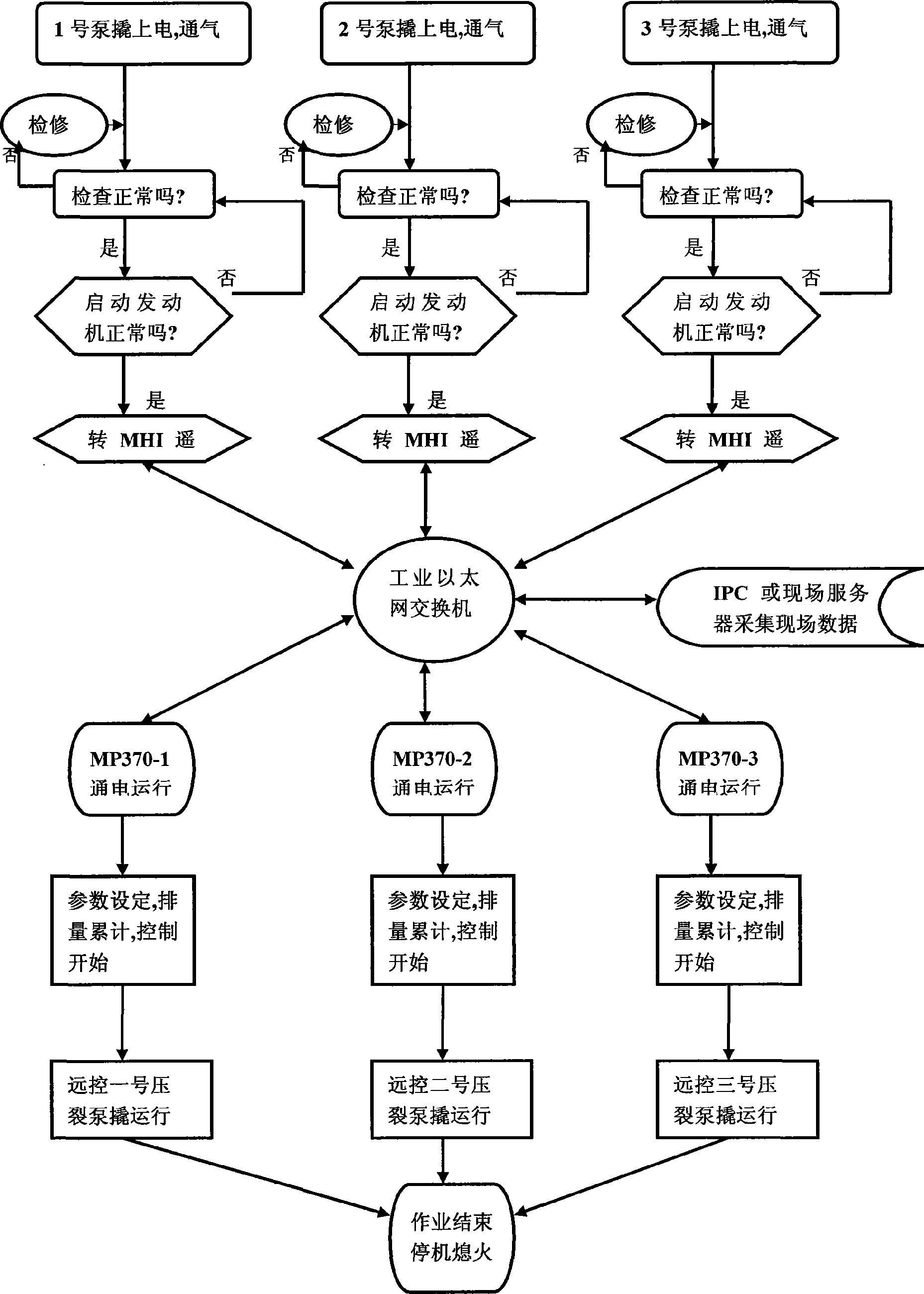

[0026] Example 1, see figure 1 , 2 , using Siemens S7-315 series programmable logic controller 4 from Germany, which can complete digital and analog input, output and data calculation processing and has an Ethernet interface, and works with the pump skid as a man-machine dialogue interface and display State, and the MP370 touch screen 1 of German Siemens company with Ethernet interface is connected with the switch 3 through the industrial super five Ethernet network cables 5, 8 to complete the bidirectional data transmission between the programmable controller 4 and the touch screen 1; the industrial PC Or the server 2 is connected to the switch 3, and the industrial PC or server 2 collects and organizes the field data and image information of the fracturing pump skid oilfield service equipment into * The text file in .CSV format is used by the VC++6.0 system data query system on the server 2, and the data is output and printed, and the server 2 is connected to the wireless t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com