Patents

Literature

1053 results about "Industrial PC" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An industrial PC is a computer intended for industrial purposes (production of goods and services), with a form factor between a nettop and a server rack. Industrial PCs have higher dependability and precision standards, and are generally more expensive than consumer electronics. They often use complex instruction sets, such as x86, where reduced instruction sets such as ARM would otherwise be used.

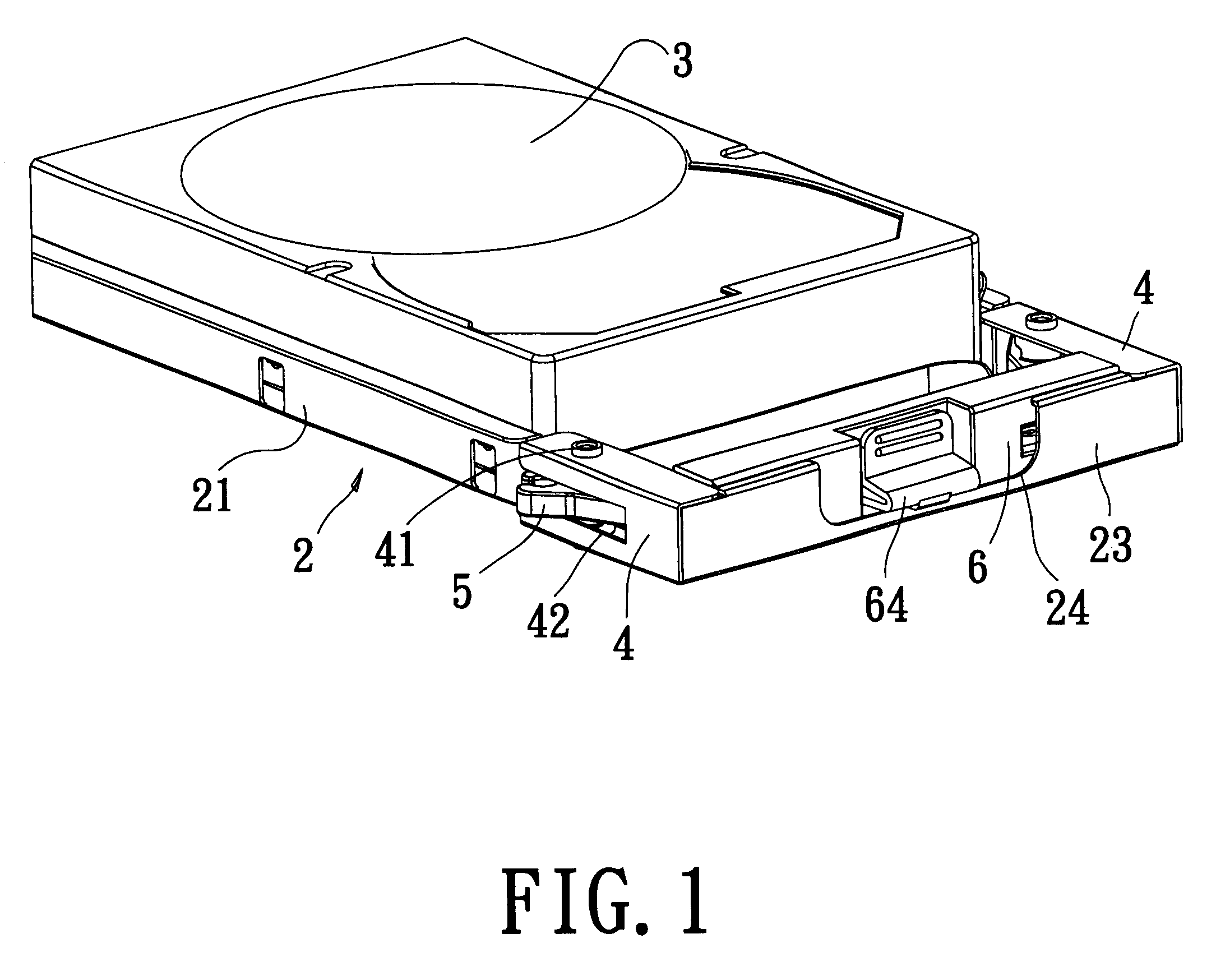

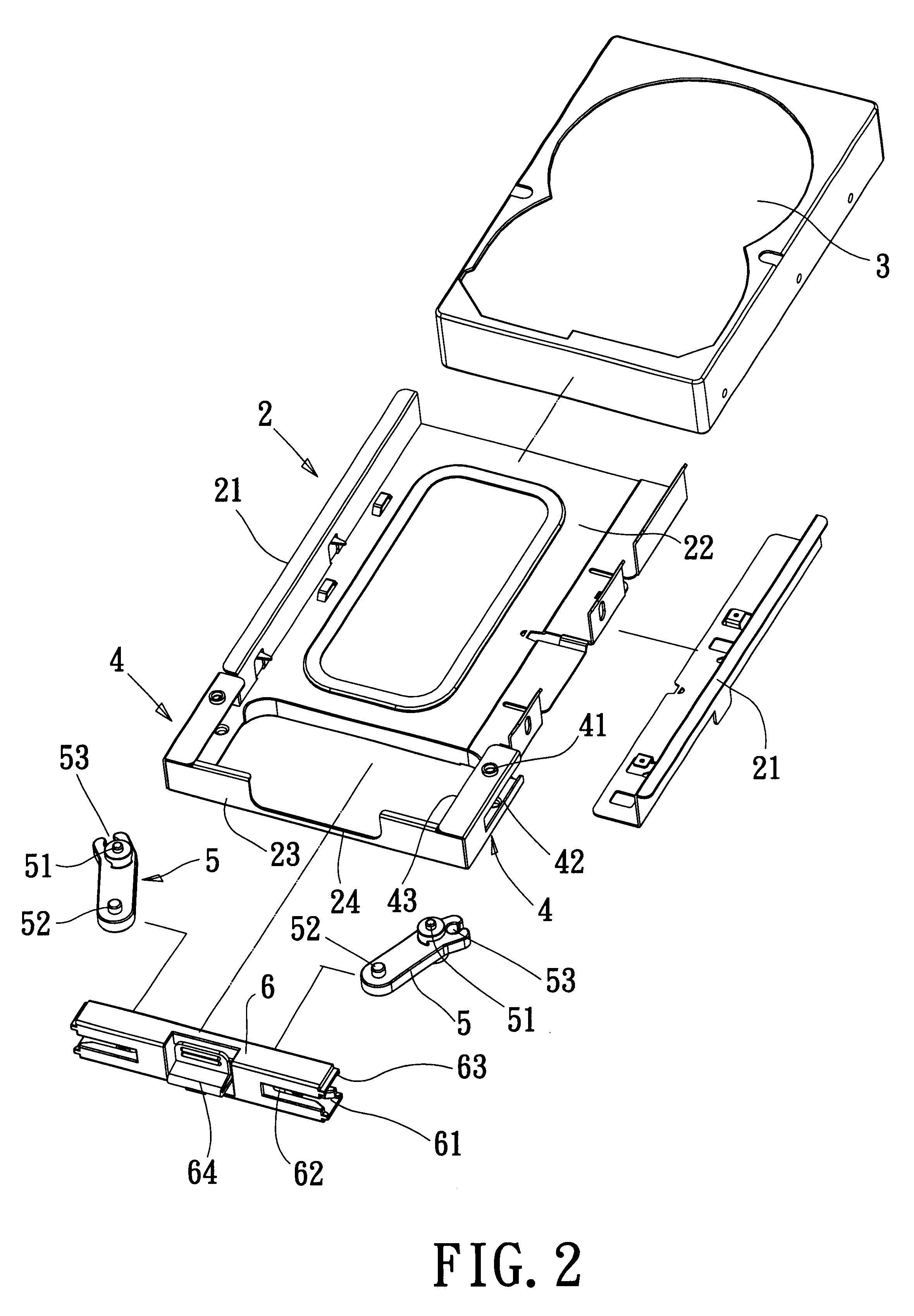

Extracting and positioning structure for hard disk drive

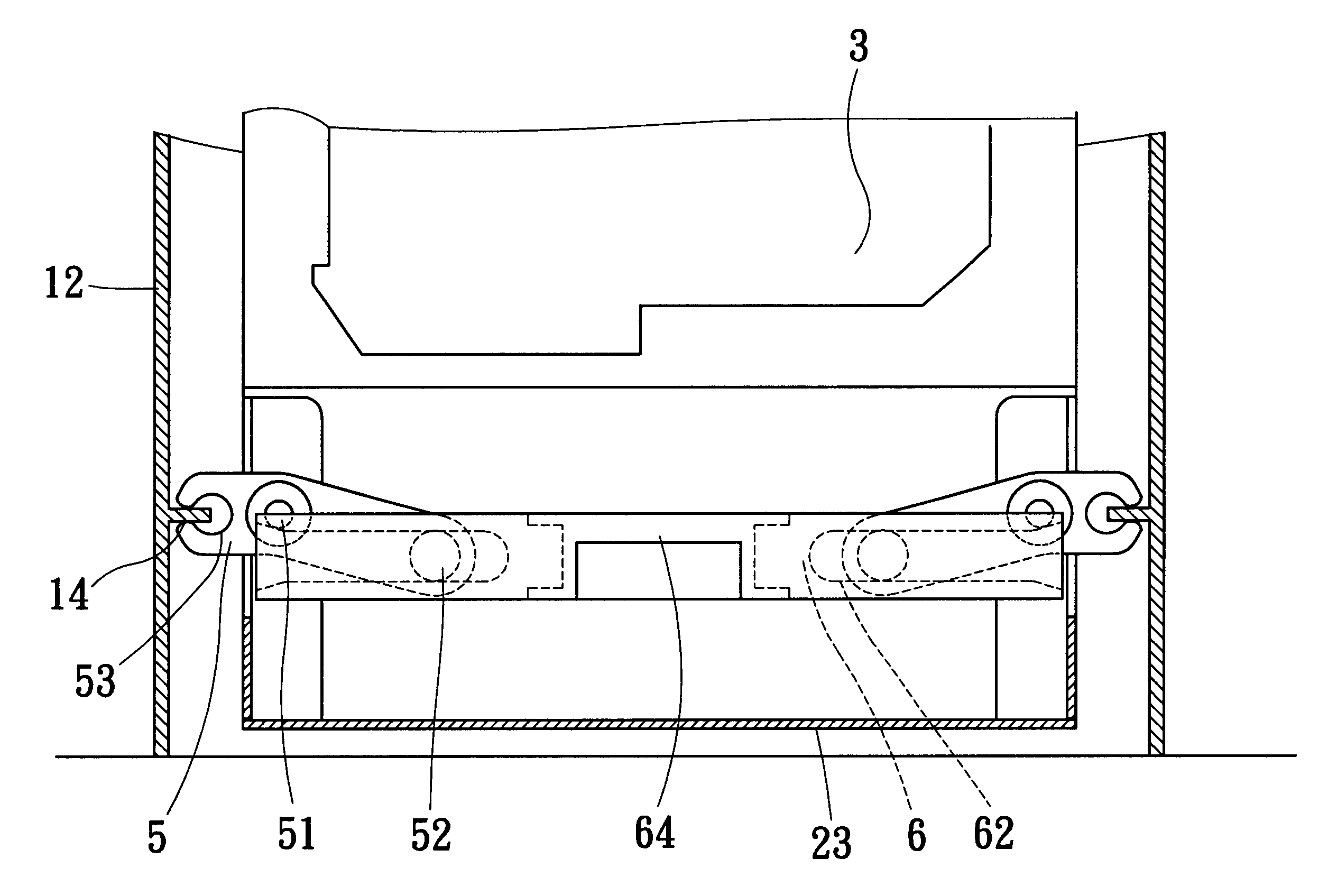

InactiveUS6351379B1Simple structureCarrier constructional parts dispositionDigital data processing detailsHard disc driveTransverse groove

Owner:LITE ON ENCLOSURE

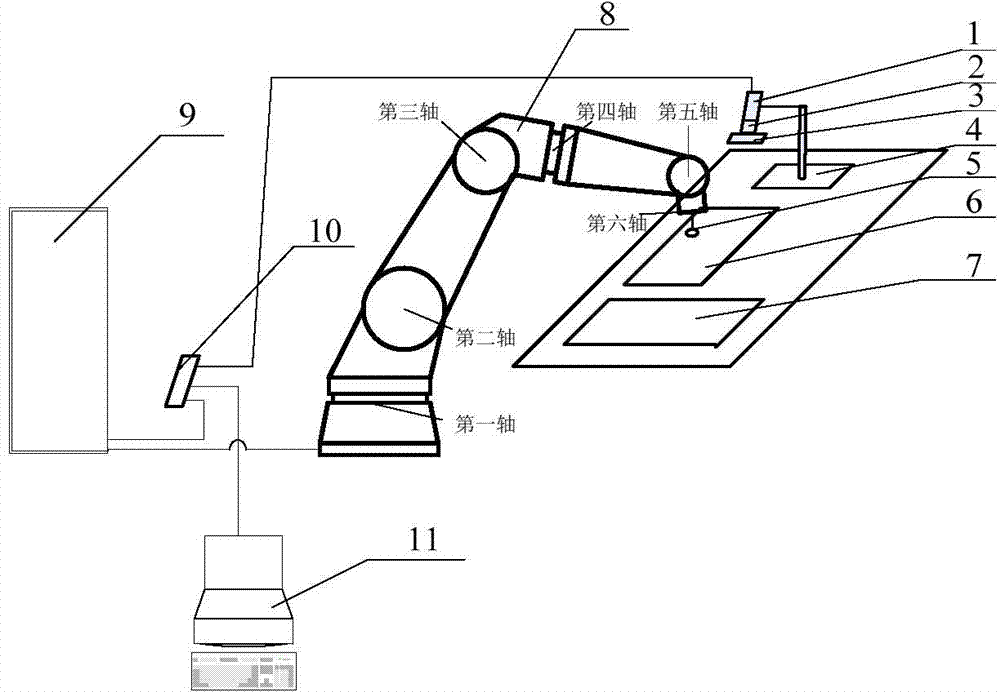

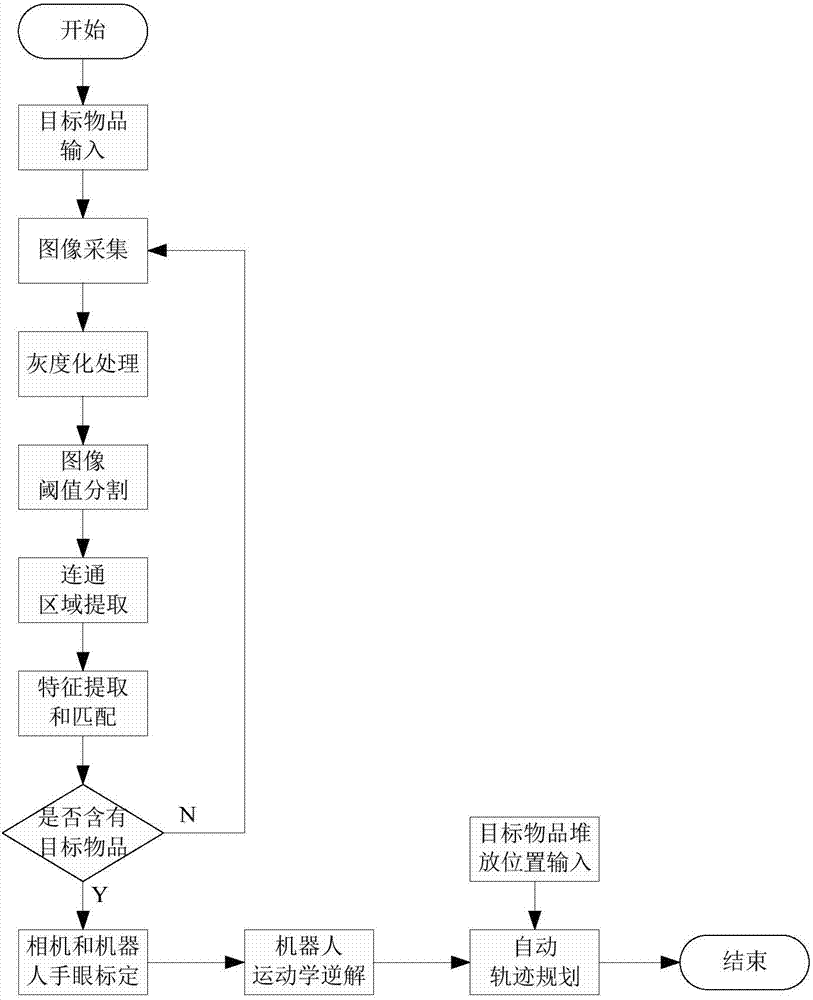

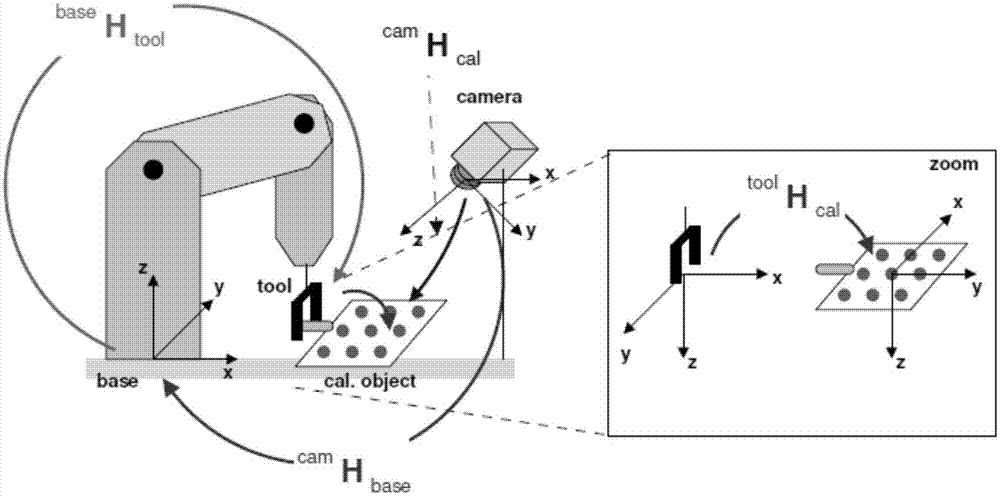

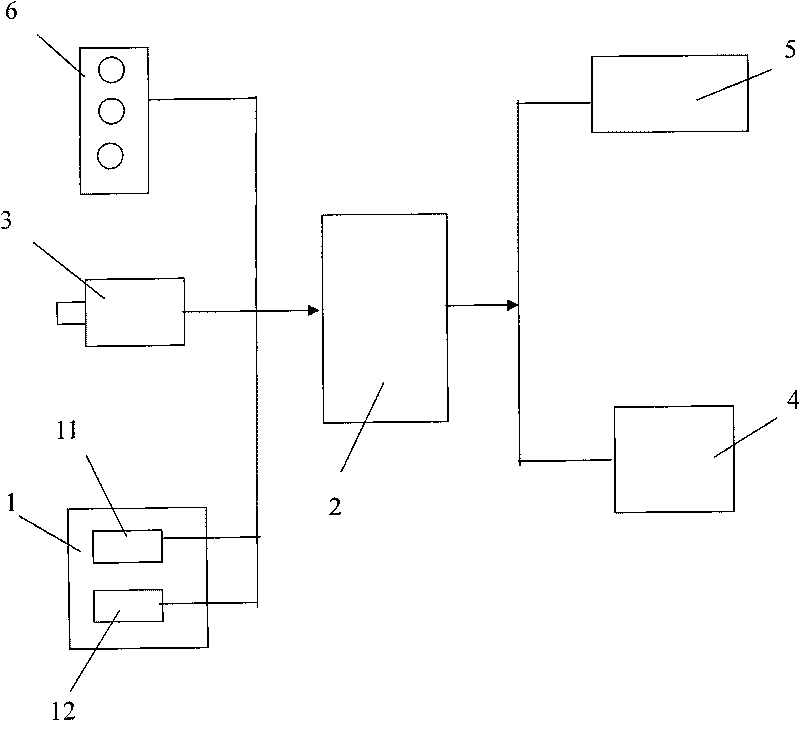

System and method for machine vision-based robot sorting

The invention discloses a system and a method for machine vision-based robot sorting. The system comprises a CCD digital camera, a camera lens, a light source, a six-axle joint robot main body, an electrical control cabinet and a vacuum sucker. The CCD digital camera is connected to an industrial computer by a switch. The six-axle joint robot main body is connected to the electrical control cabinet. The electrical control cabinet accesses the switch. The vacuum sucker is rigidly fixed to the tail end of the six-axle joint robot main body. The camera unit is used for making a photo of an object to be sorted, collecting data and transmitting the data to the industrial computer by the switch. The industrial computer is used for treating the acquired photo of the object to be sorted, carrying out accurate positioning and then transmitting a control signal to the electrical control cabinet by the switch. The electrical control cabinet is used for controlling the six-axle joint robot main body to carry out corresponding sorting processes according to the received control signal. The system and the method improve work efficiency, reduce operation workers and reduce a production cost in sorting.

Owner:716TH RES INST OF CHINA SHIPBUILDING INDAL CORP

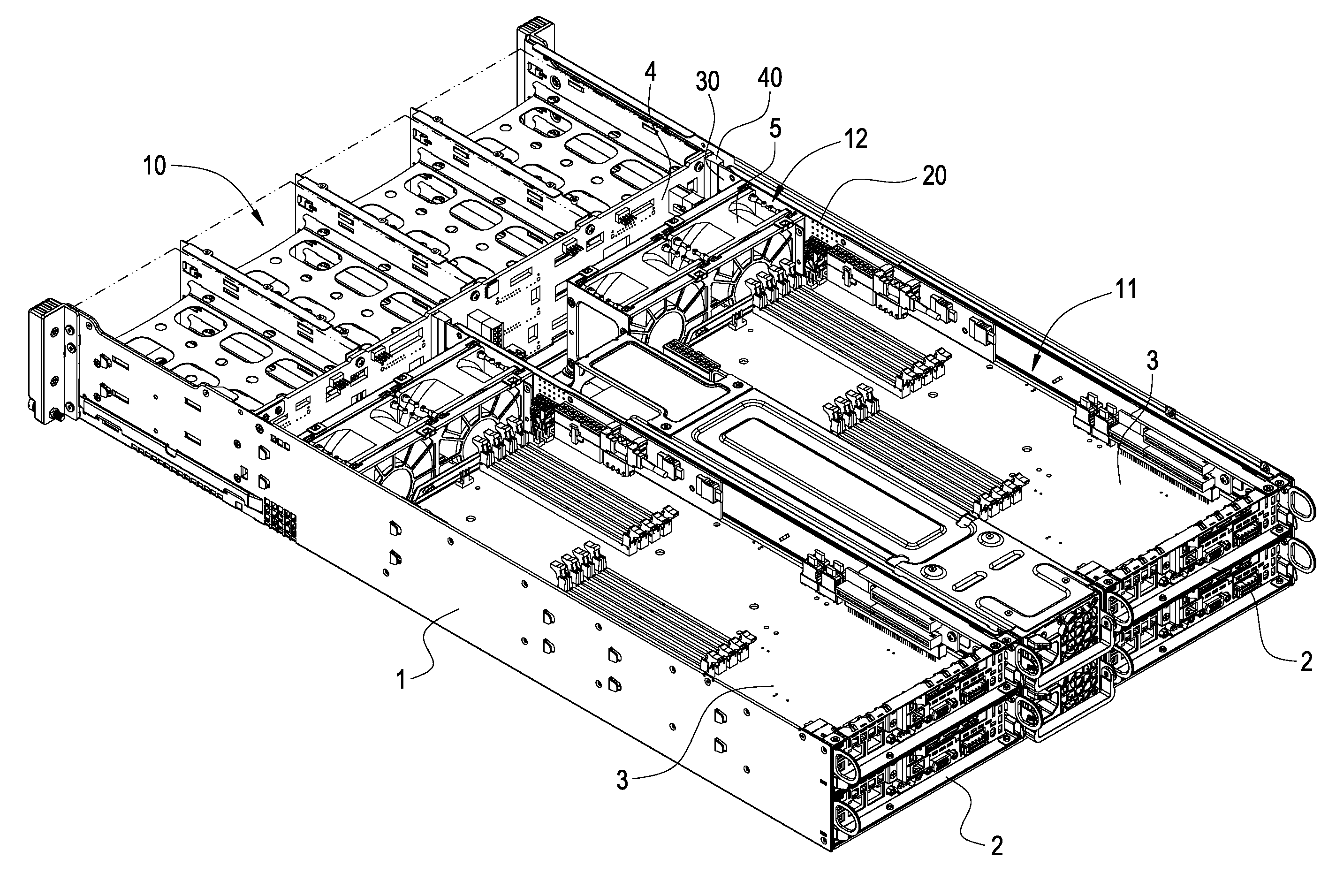

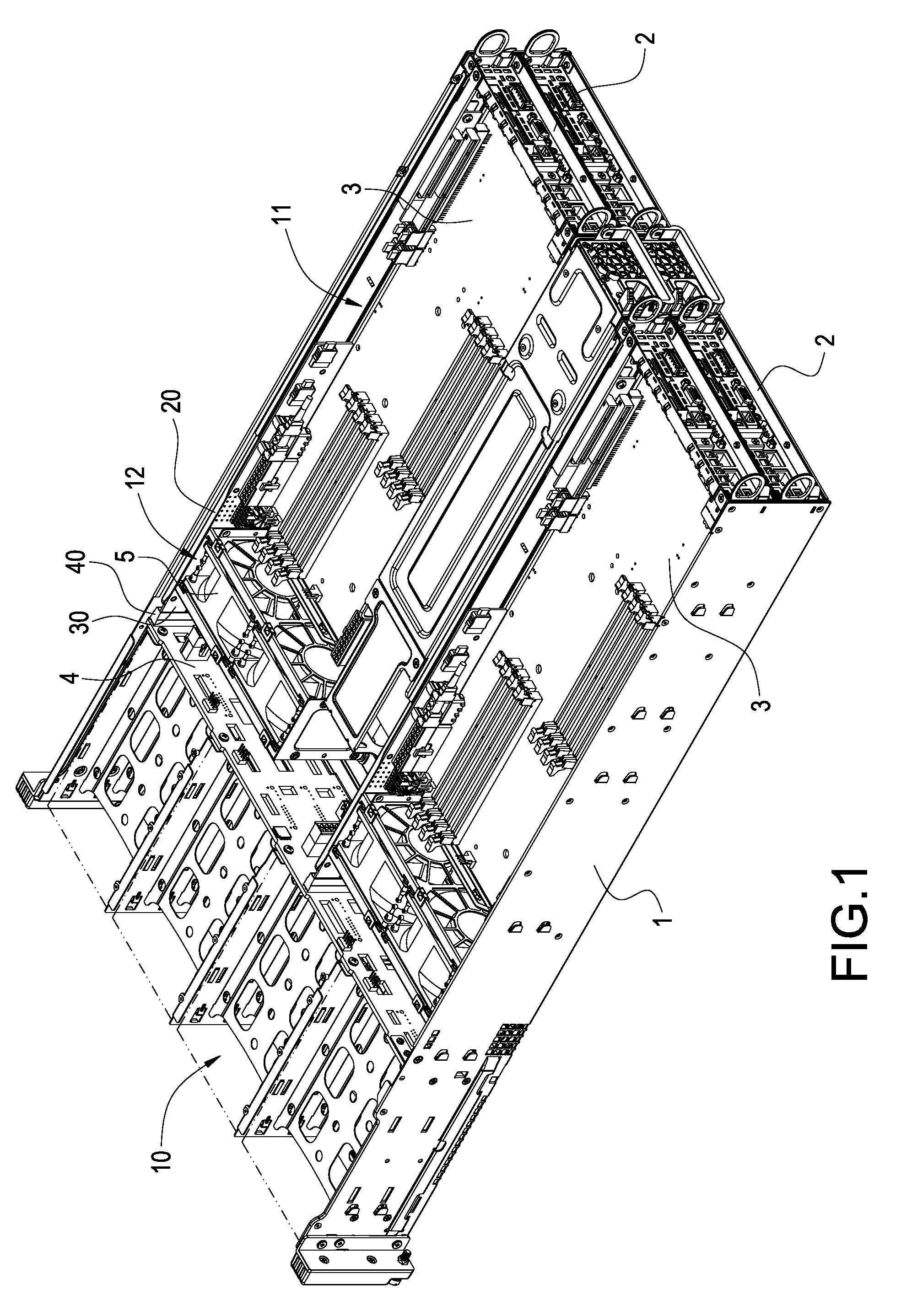

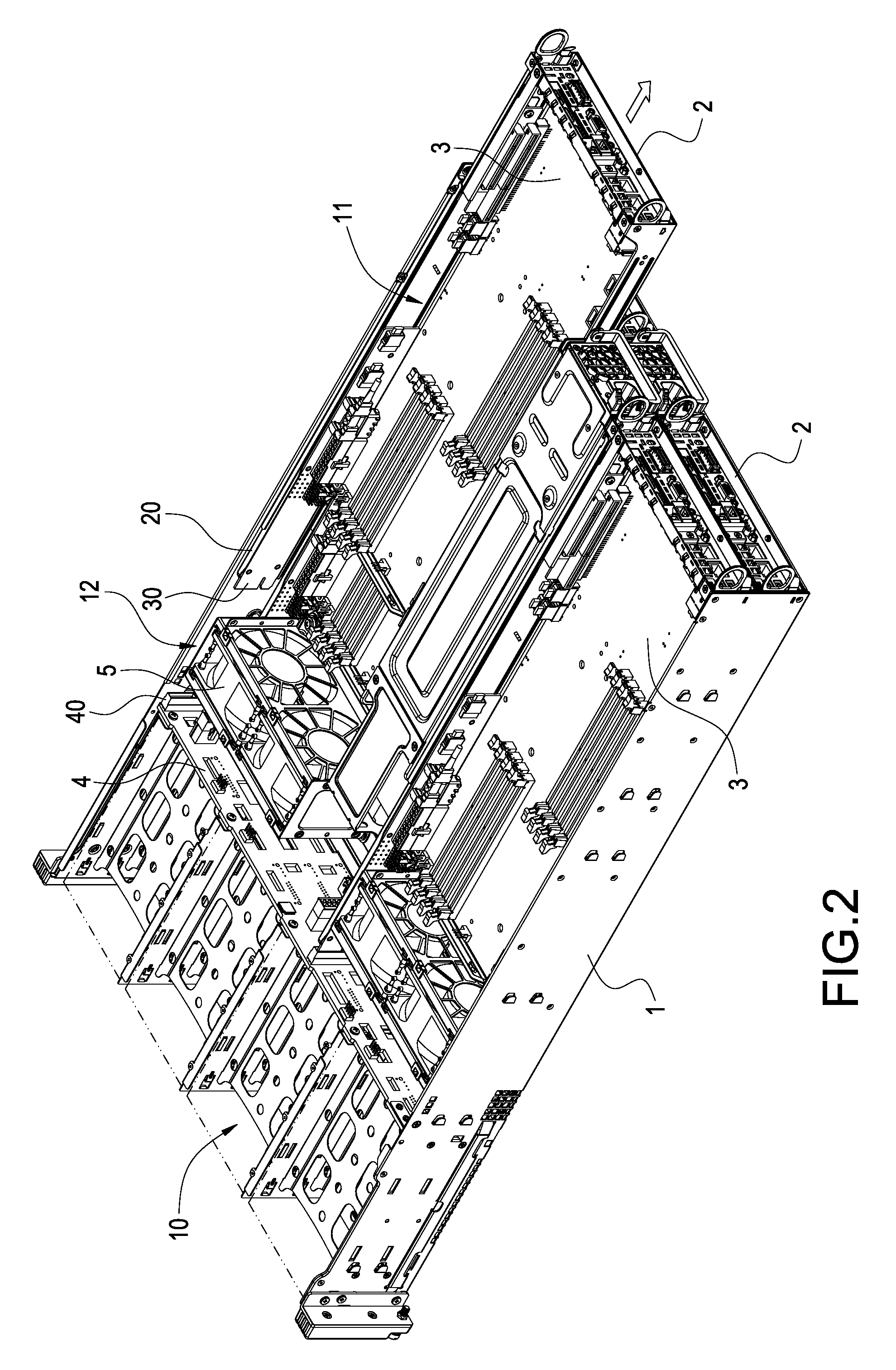

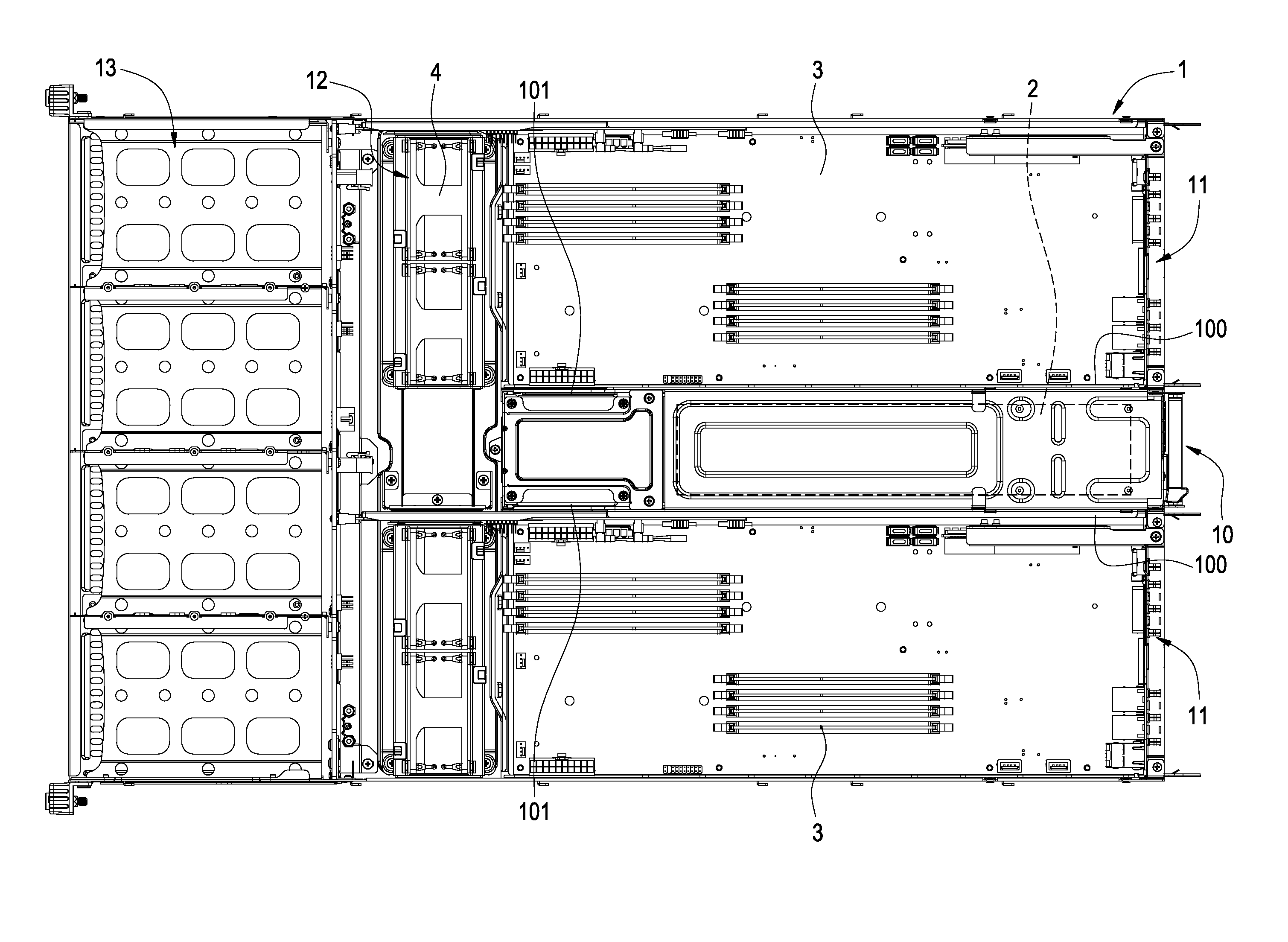

Disposing structure for hot swappable motherboard in industrial computer chassis

ActiveUS20100271766A1Low costAdd application functionsServersDigital data processing detailsHot swappingMotherboard

A disposing structure of industrial computer chassis includes a chassis shell, two motherboard trays and a back plate. The interior of the chassis shell is divided into a storage unit section and a motherboard section. The interior of the storage unit section is arranged at least one storage unit, while two motherboard trays are disposed in the motherboard section. The interior of each motherboard tray is arranged a motherboard. In the motherboard trays, at least one motherboard tray is extended a wedge frame toward the storage unit section. A transfer card having a hot swapping function is arranged on the wedge frame and is arranged by inserting into the corresponding motherboard. In addition, a back plate is arranged between the storage unit section and the motherboard section. Corresponding to the wedge frame, a slot capable of a hot swapping function is arranged on the back plate. In so doing, the transfer card may be inserted into the slot, thereby, providing a hot swapping function.

Owner:SUPER MICRO COMP

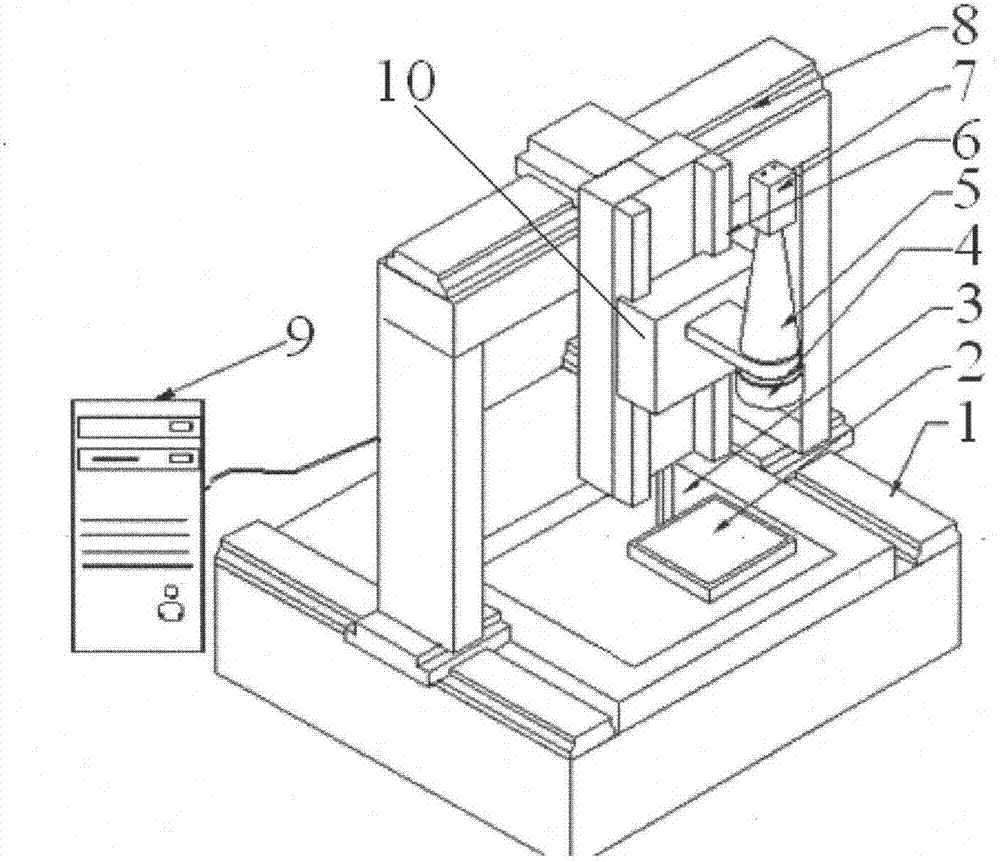

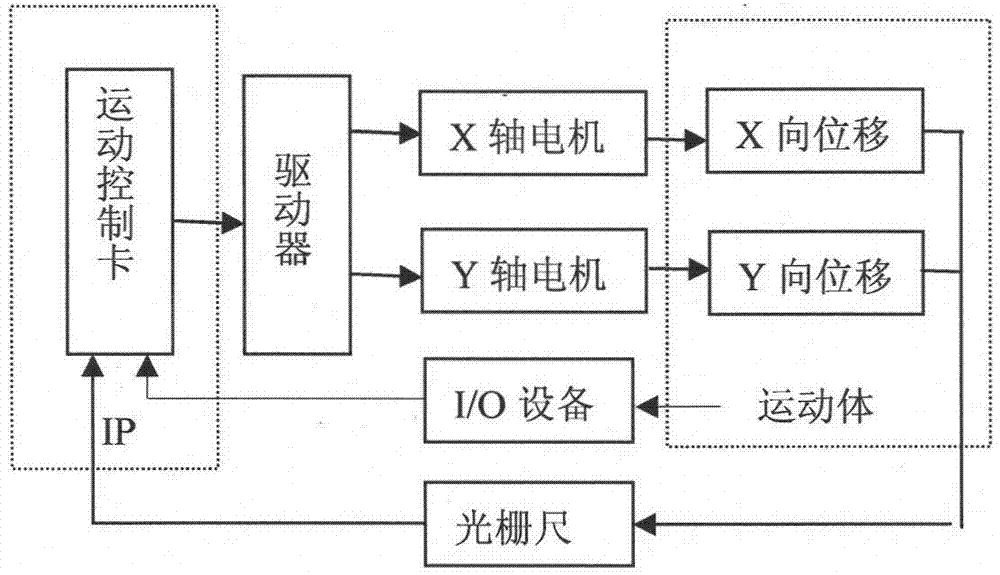

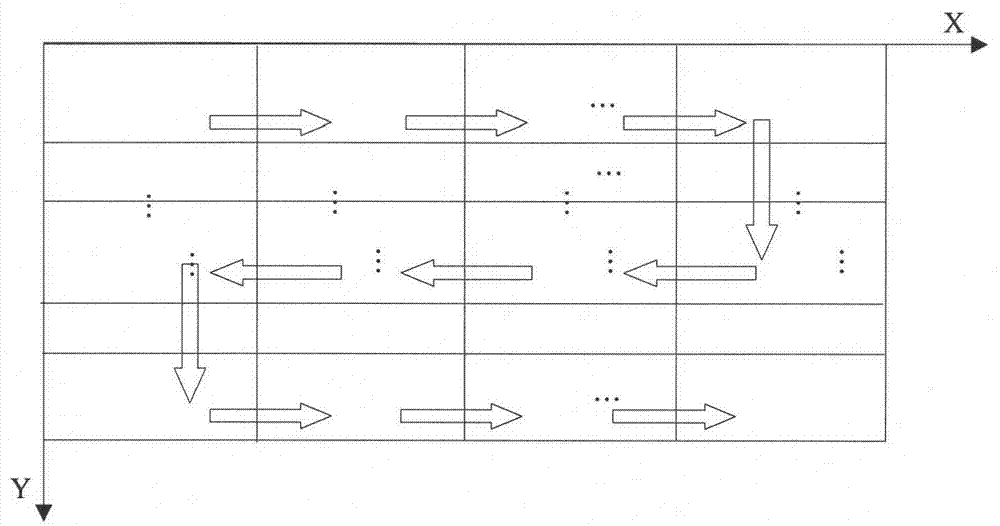

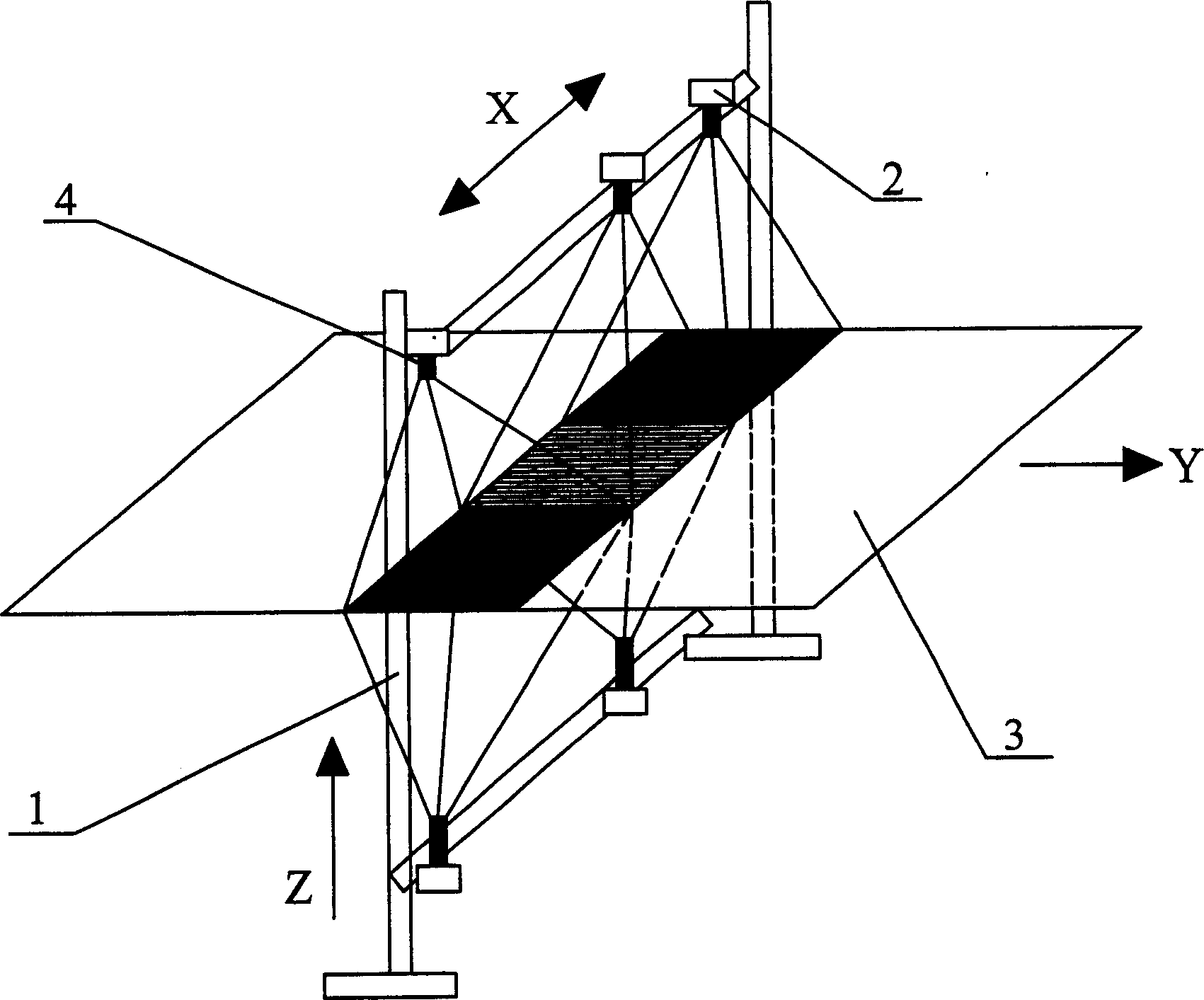

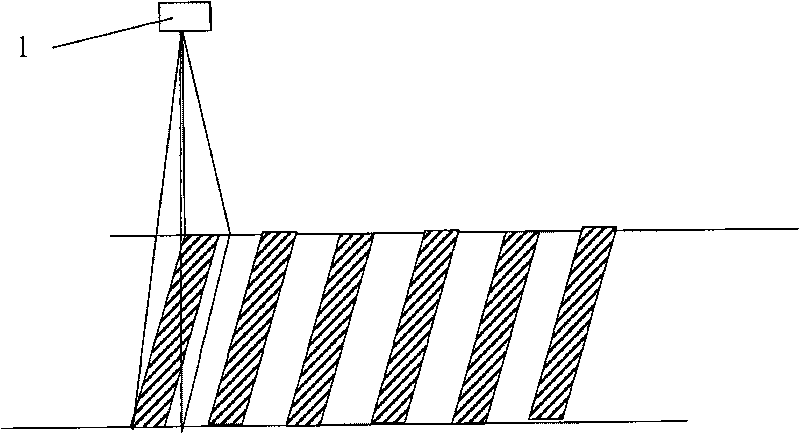

System and method for numerical control (NC) workbench error self correction based on machine vision

InactiveCN103197599AHigh positioning accuracyImprove efficiencyNumerical controlNumerical controlAlgorithm

The invention provides a system for numerical control (NC) workbench error self correction based on machine vision. The system comprises an X-Y-Z-coordinate motion workbench, an image collecting system is arranged on a motion body of the X-Y-Z-coordinate motion workbench, a calibration plate is arranged on an objective table of the X-Y-Z-coordinate motion workbench, and an industrial computer is connected with the image collecting system. The invention further provides a method for NC workbench error self correction based on the machine vision. The method comprises the following steps: controlling the motion body and a high-resolution industrial camera to move, and collecting sequential images; obtaining a current absolute coordinate according to the imaging data of the motion body at different positions, comparing with a movement directive the encoder feedback value of a servo motor, and obtaining positioning error compensation values; and continuously conducting positioning detecting at different positions, and enabling the positioning error compensation values of all positions to be stored into a databank. According to the system and the method for NC workbench error self correction based on the machine vision, the defects of the prior art are overcome, self calibration and compensation can be conducted to the X-Y positioning error of the whole workbench, and positioning accuracy is markedly improved.

Owner:DONGHUA UNIV

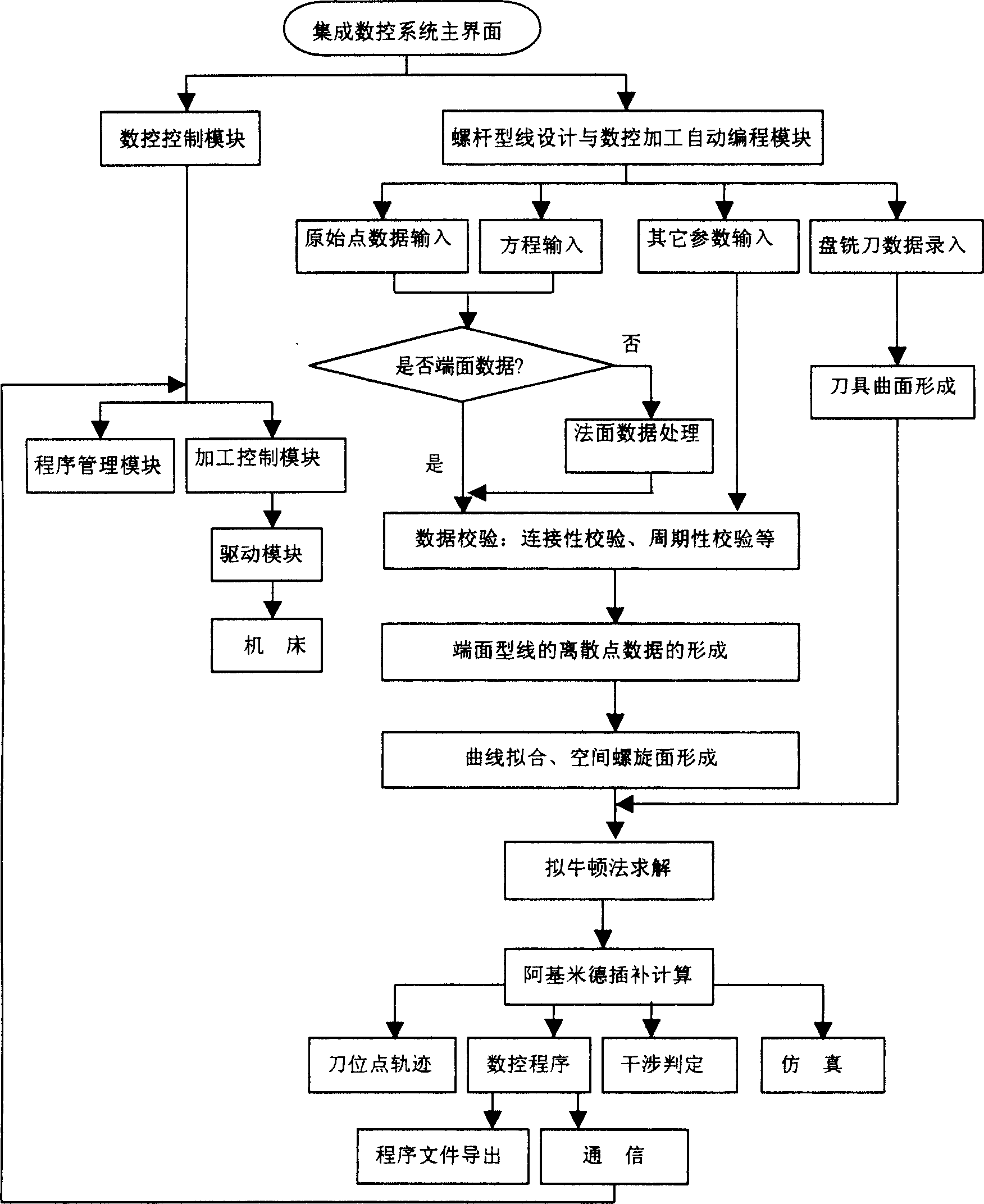

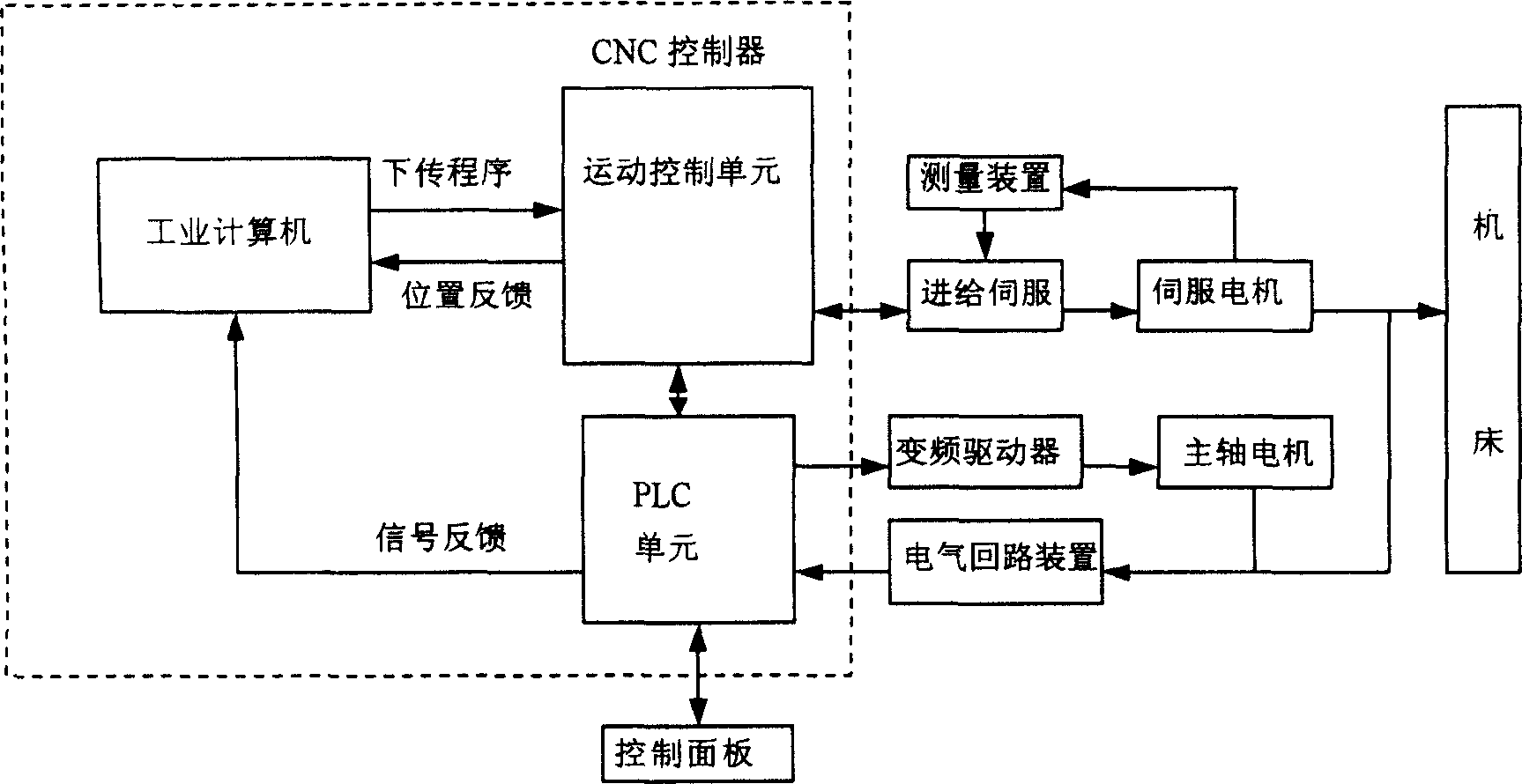

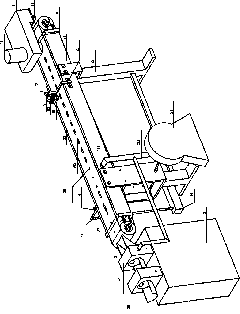

Helical surface digital control enveloped milling method and integration control system thereof

InactiveCN1621984ARealize the designTake advantage ofProgramme controlComputer controlNumerical controlMeasurement device

The present invention provides one control technology for numerically controlled machine tool. The numerically controlled spiral camber envelope milling method includes: inputting basic parameter from the industrial computer to the data base; contour design and calculation comprising extracting or inputting basic parameter data, establishing screw bolt profile mold and fairing treatment in curve interpolation course and storing the datan into data base; automatically programming the numerically controlled machining course; and performing numerically controlled machining via transmitting the machining program to the motion controlling unit and machining with the driving module. The integrated control system includes control panel, CNC controller, measuring unit, feeding servo unit, servo motor, frequency varying driver, mainshaft motor and electric loop unit.

Owner:SHENYANG POLYTECHNIC UNIV

Machine visual on-line detection method and equipment for tank cover quality in high-speed production line

InactiveCN101799431ARealize communicationReduce dependenceOptically investigating flaws/contaminationUsing optical meansProduction lineMachine vision

The invention discloses machine visual on-line detection method and equipment for the tank cover quality in a high-speed production line. The method comprises the following steps of: in an automatic production line, separating tank covers to be detected into single tank covers moving on a delivering device; imaging the tank covers by using an imaging system at a high speed when the tank covers move to a detection station of the delivering device; transmitting an acquired tank cover image to an industrial computer for processing; carrying out quality detection on a plurality of detection areas to generate quality detection signals; eliminating unqualified products by using an eliminating device positioned at the eliminating station of the delivering device; making the qualified products continuously move on the delivering device and pass through a shaping device and outputting the qualified products in sequence. The equipment comprises a cover feeding device, the delivering device, the shaping device, the eliminating device, the imaging system, the industrial computer and an electric control system. The invention has the advantages of simple and compact structure, low cost, simple and convenient operation, high precision, high detection speed and the like.

Owner:HUNAN UNIV

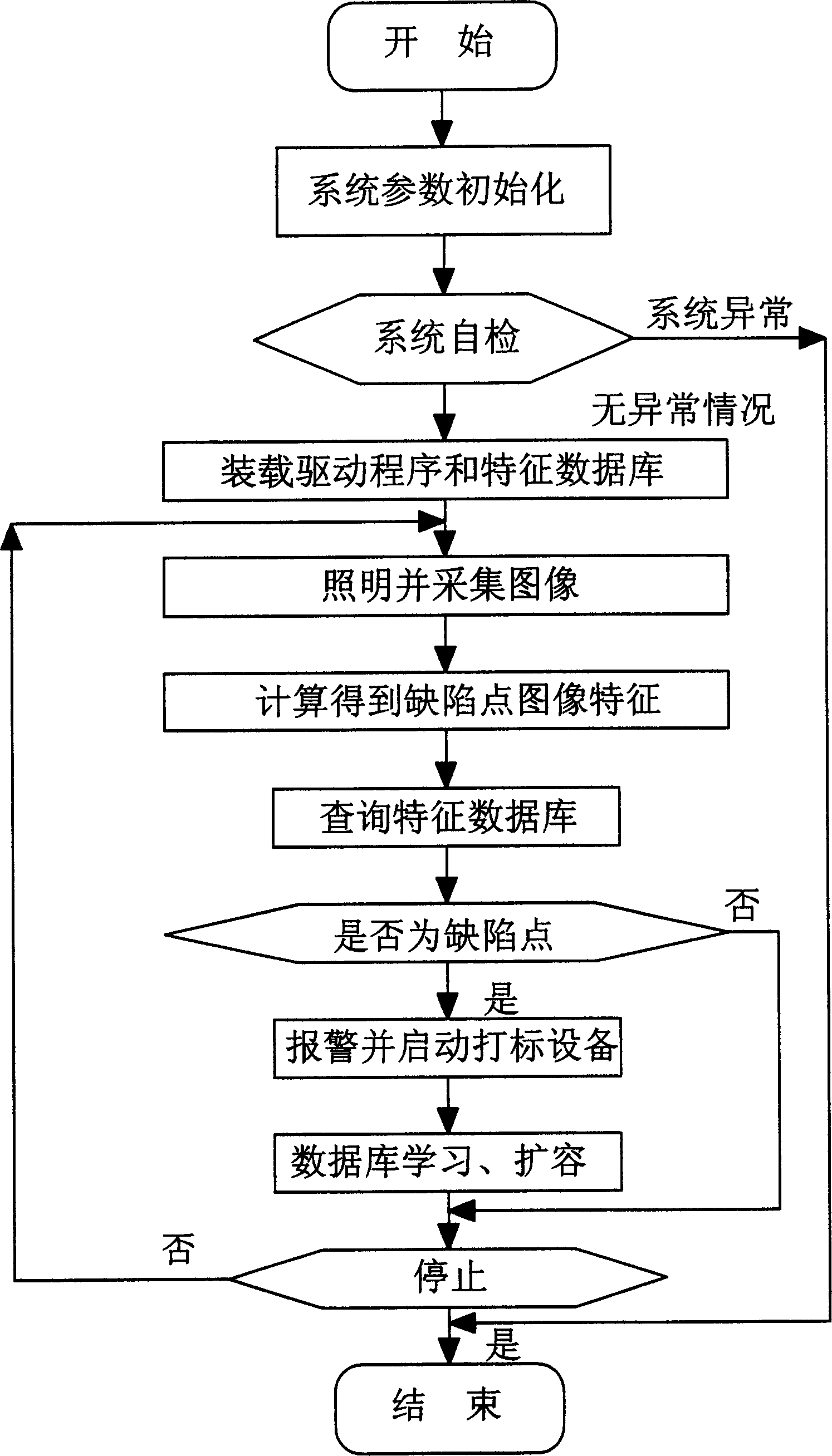

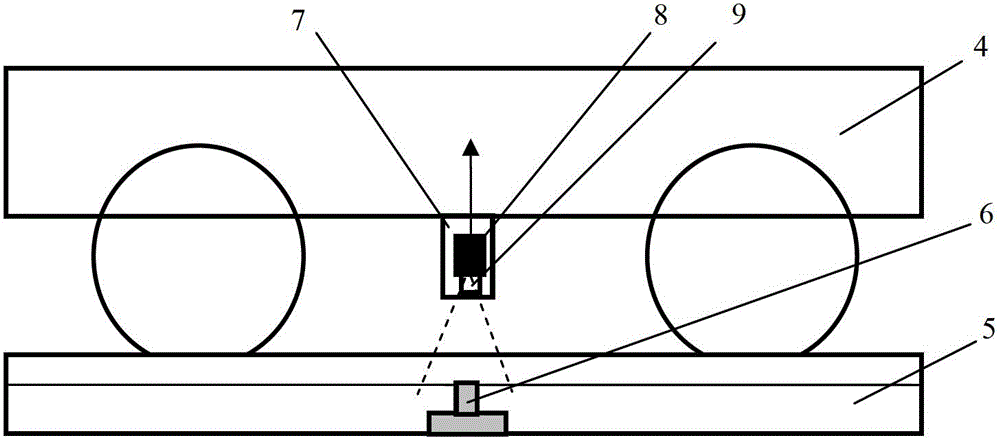

Automatic online detection method for defects on upper and lower surfaces during steel plate pretreatment process

InactiveCN1789990ASafe and reliable workIncrease productivityImage enhancementImage analysisMeasurement deviceEngineering

The invention discloses an on-line self-detecting method of surface defect in the ship formation steel predisposing course, which comprises the following steps: allocating the steel surface luminous equipment to form light field on two faces of on-line steel; setting several cases of independent imaging measuring device corresponding to each light field; proceeding real-time image of two faces of steel simultaneously when the steel moves along horizontal direction; disposing the image and marking the defect point; gathering the image grey scale and colority information separately through grey scale image information collector and colority image signal collector; analyzing and disposing the gathered grey scale and colority information through industrial computer software; adapting image grey scale character to identify and classify the defect point; starting the marking device to mark the defect point when the defect point is detected. The invention shortens the ship formation period greatly, which improves the ship body structure quality and detecting precision.

Owner:BOHAI SHIP HEAVY IND CO LTD

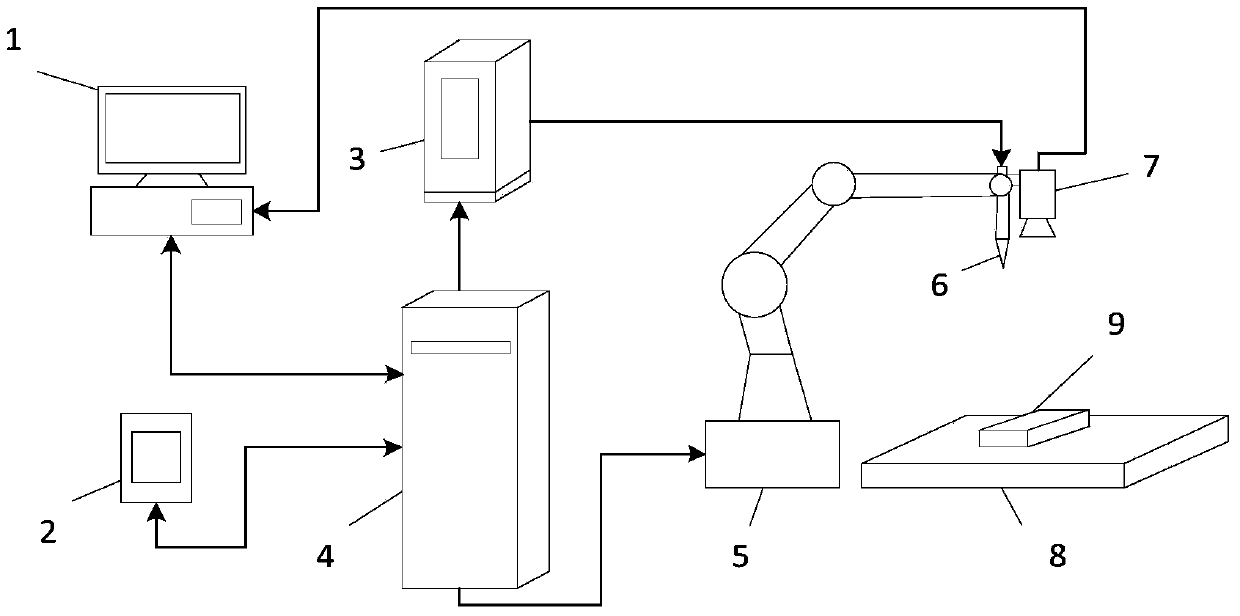

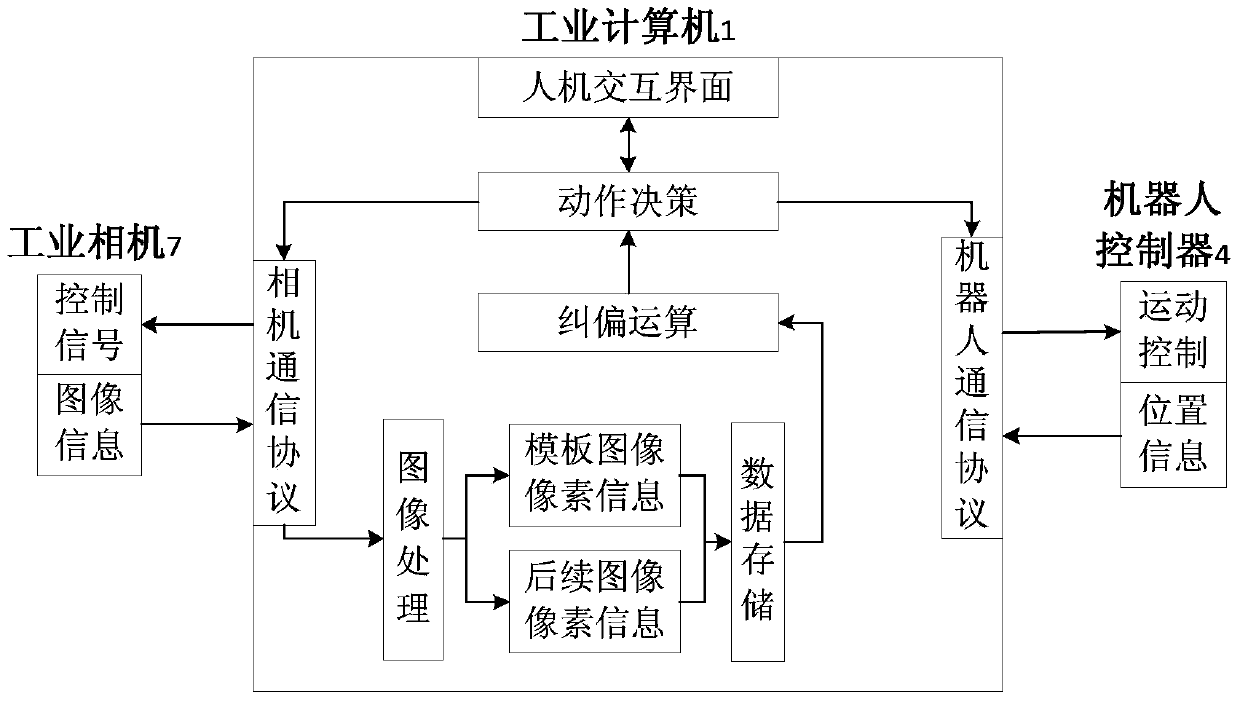

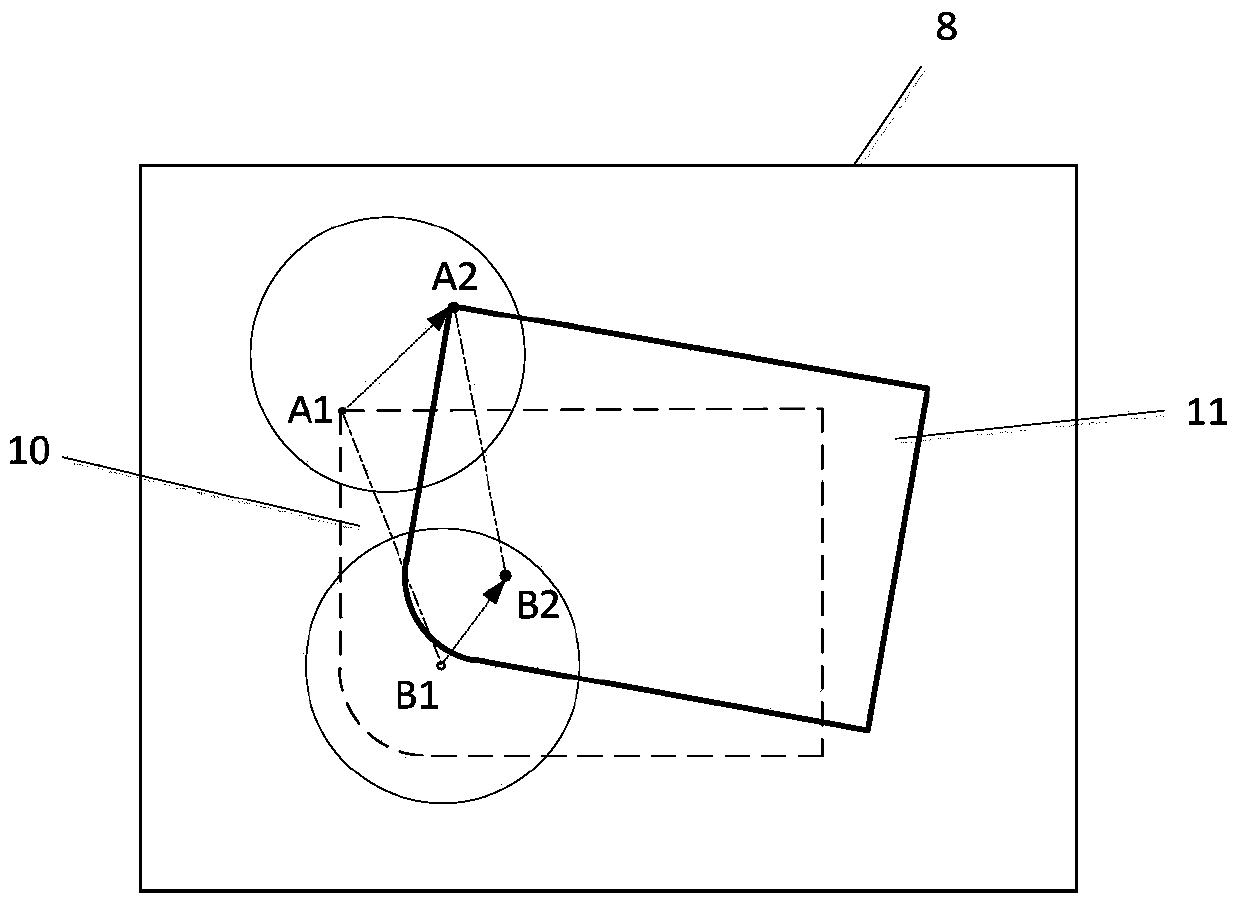

Welding robot with automatic correction function and welding method employing same

InactiveCN104175031AReduce labor intensityMaster quicklyWelding/cutting auxillary devicesAuxillary welding devicesImaging processingWelding power supply

The invention belongs to the field of welding and relates to a welding robot with an automatic correction function and a welding method employing the same. An industrial computer is connected with both a robot controller and an industrial camera; the robot controller is connected with a robot and a welding power supply; the welding power supply is connected with a welding torch; the industrial camera and the welding torch are fixed at the tail end of an arm of the robot; a shooting plane of the industrial camera is perpendicular to the welding torch; a work platform is arranged correspondingly. The method includes the steps: the robot is started to demonstrate a template workpiece, shooting is performed in two characteristic regions to determine a spatial position of the workpiece, the industrial camera transmits images of the characteristic regions to the industrial computer, the robot automatically corrects a deviation of an original demonstration path through an image processing technique and software algorithms. The welding robot is simple to operate and widely applicable; by the application of the welding robot in batch welding operations, repeated demonstrations can be effectively avoided, and work efficiency is improved.

Owner:BEIJING UNIV OF TECH

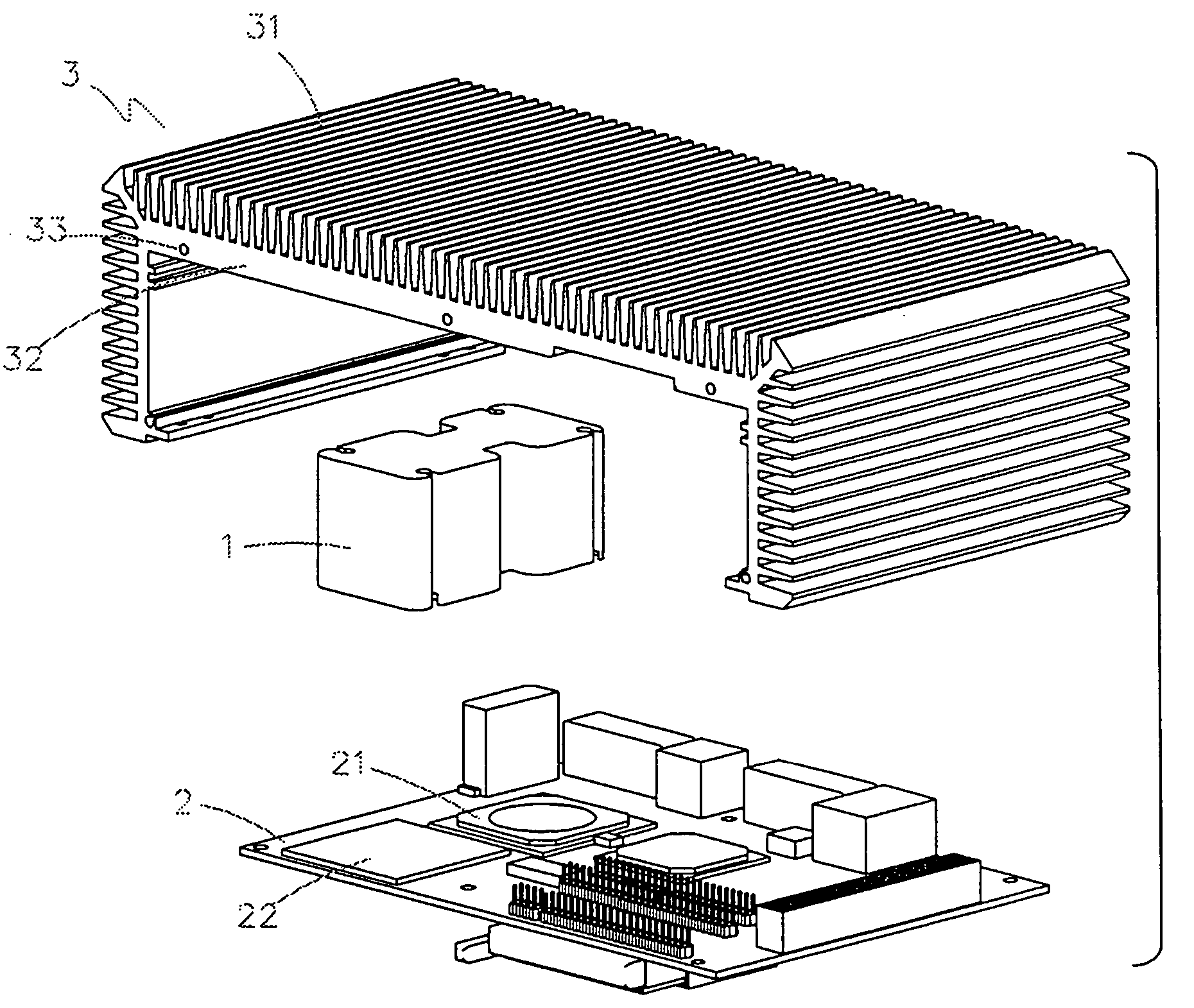

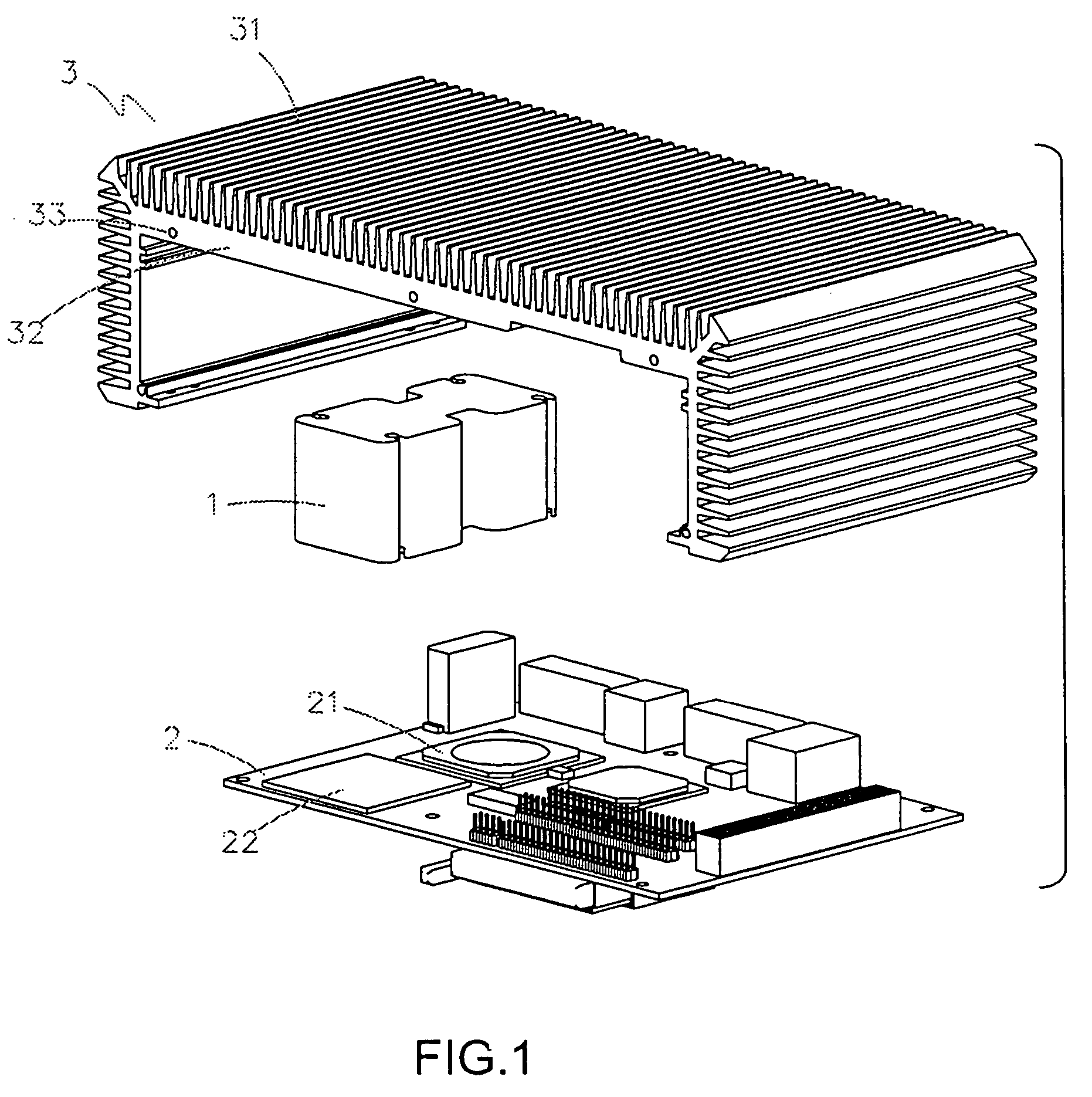

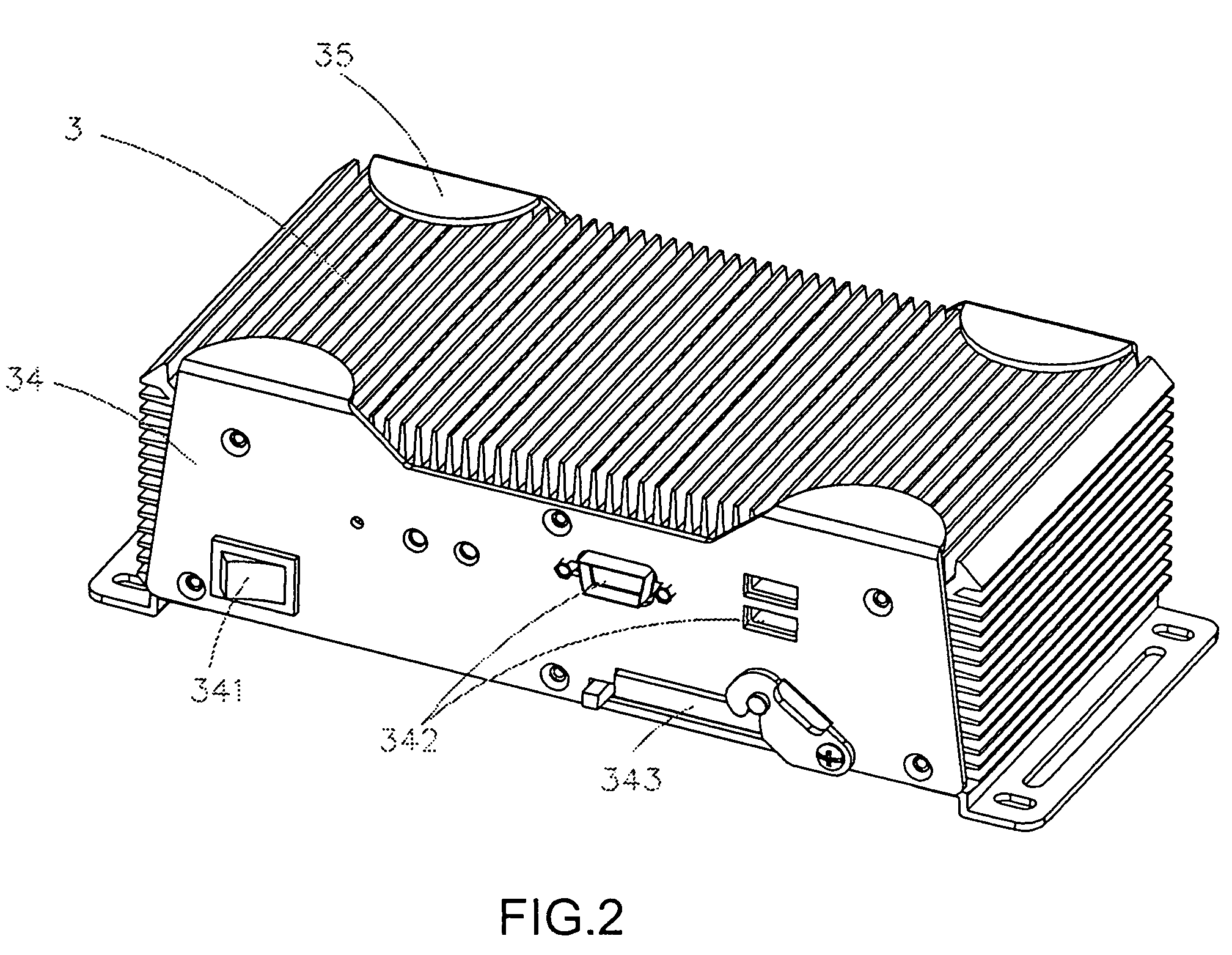

Industrial computer with aluminum case having fins as radiating device

InactiveUS7136286B2The process is simple and effectiveDigital data processing detailsCooling/ventilation/heating modificationsChipsetHeat sink

An industrial computer without a fan is provided. The industrial computer comprises an aluminum case including a plurality of top fins projected toward a vertical direction and a plurality of side fins projected toward a horizontal direction; a motherboard including a plurality of heat-generating members such as CPU and north-bridge chipset formed thereon; and a radiating member having a top in contact with an inner surface of the case and a bottom rested upon the heat-generating members.

Owner:AAEON TECHNOLOGY INC

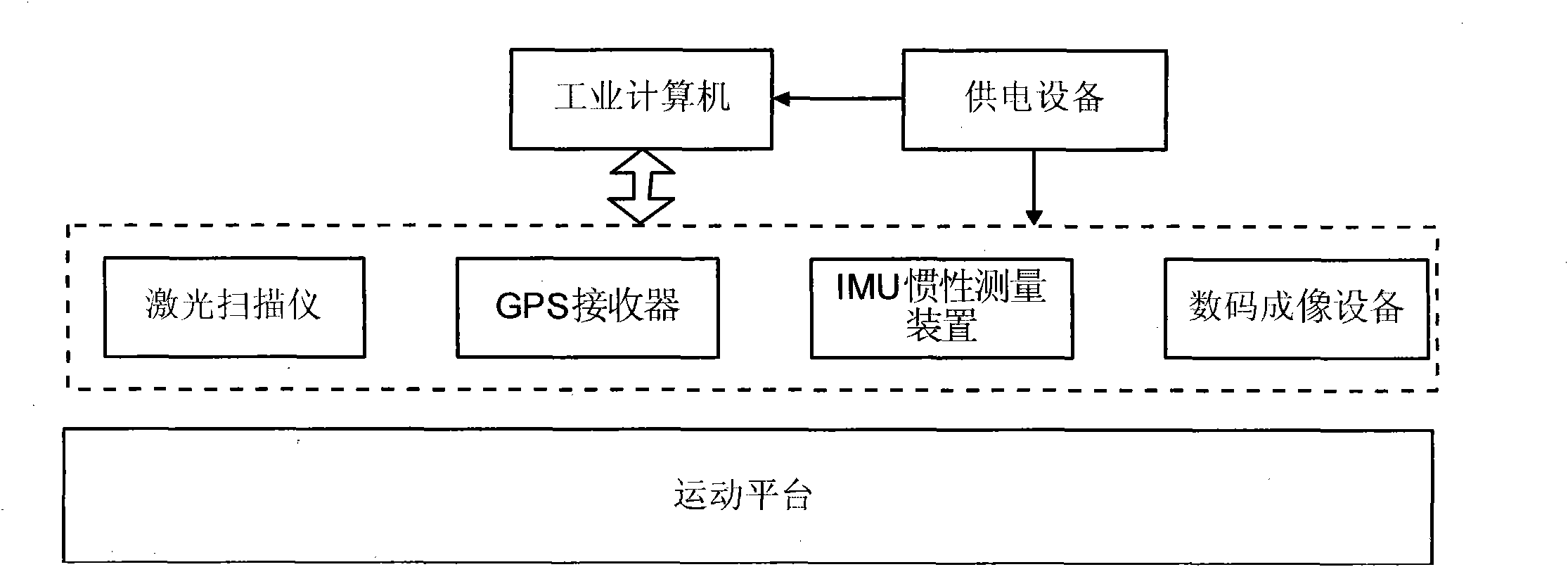

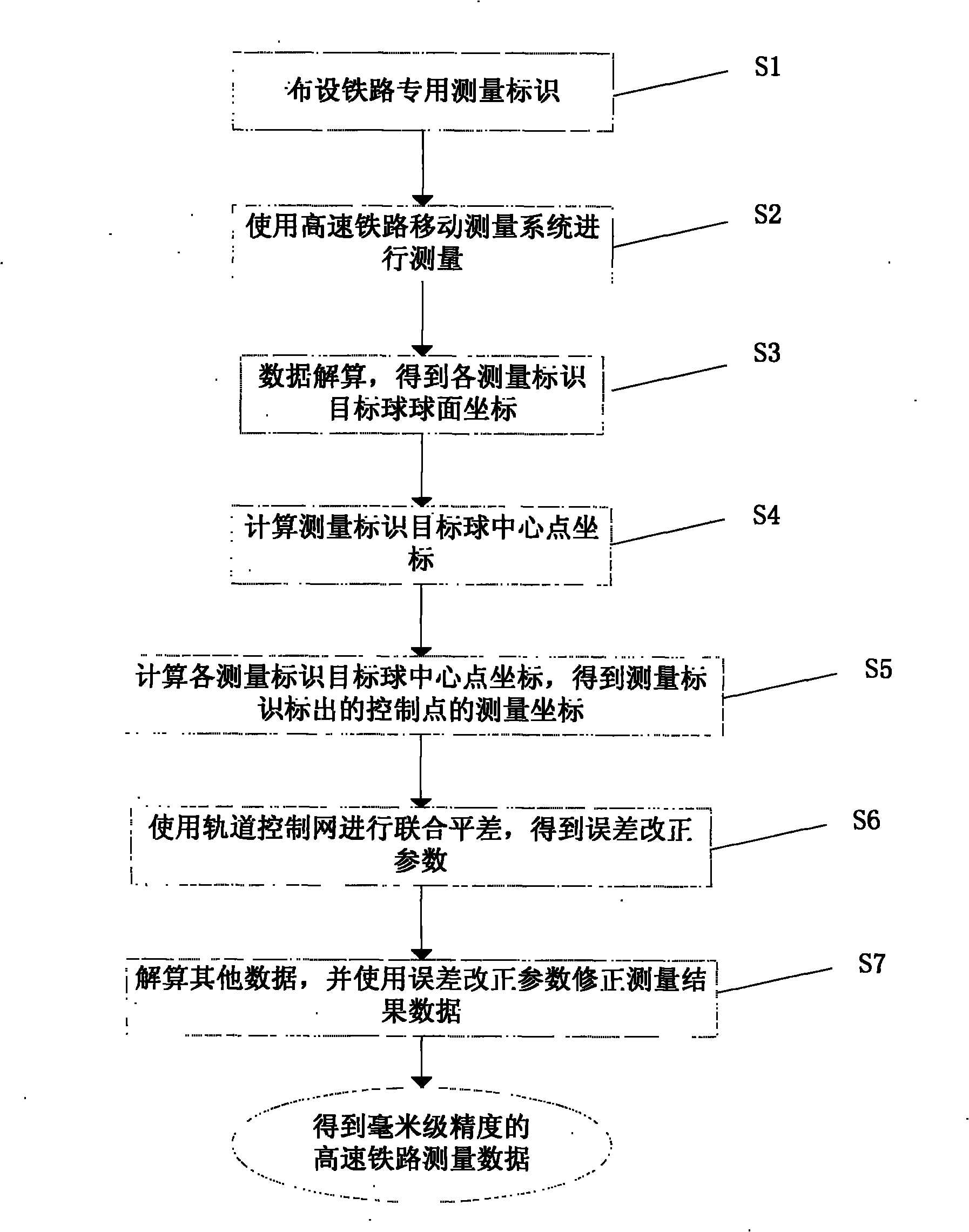

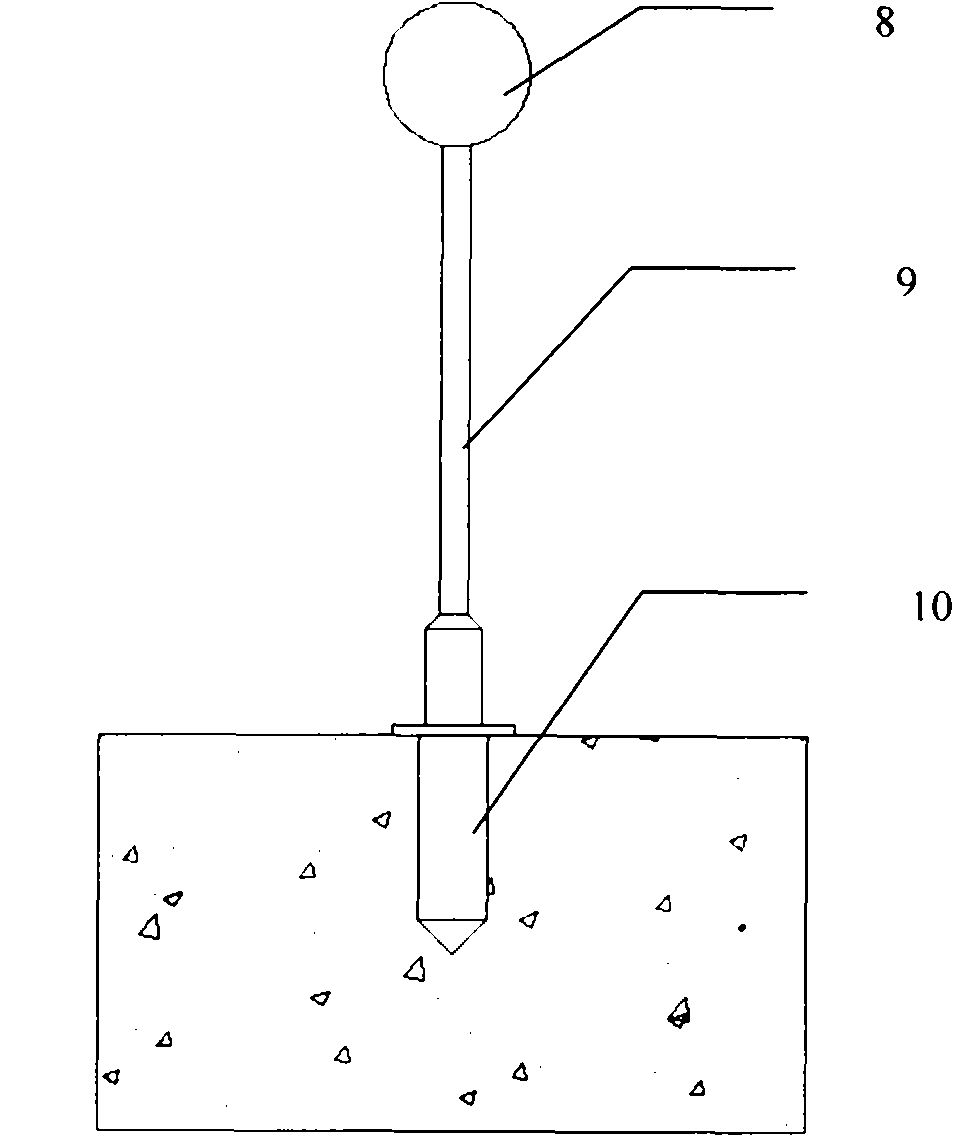

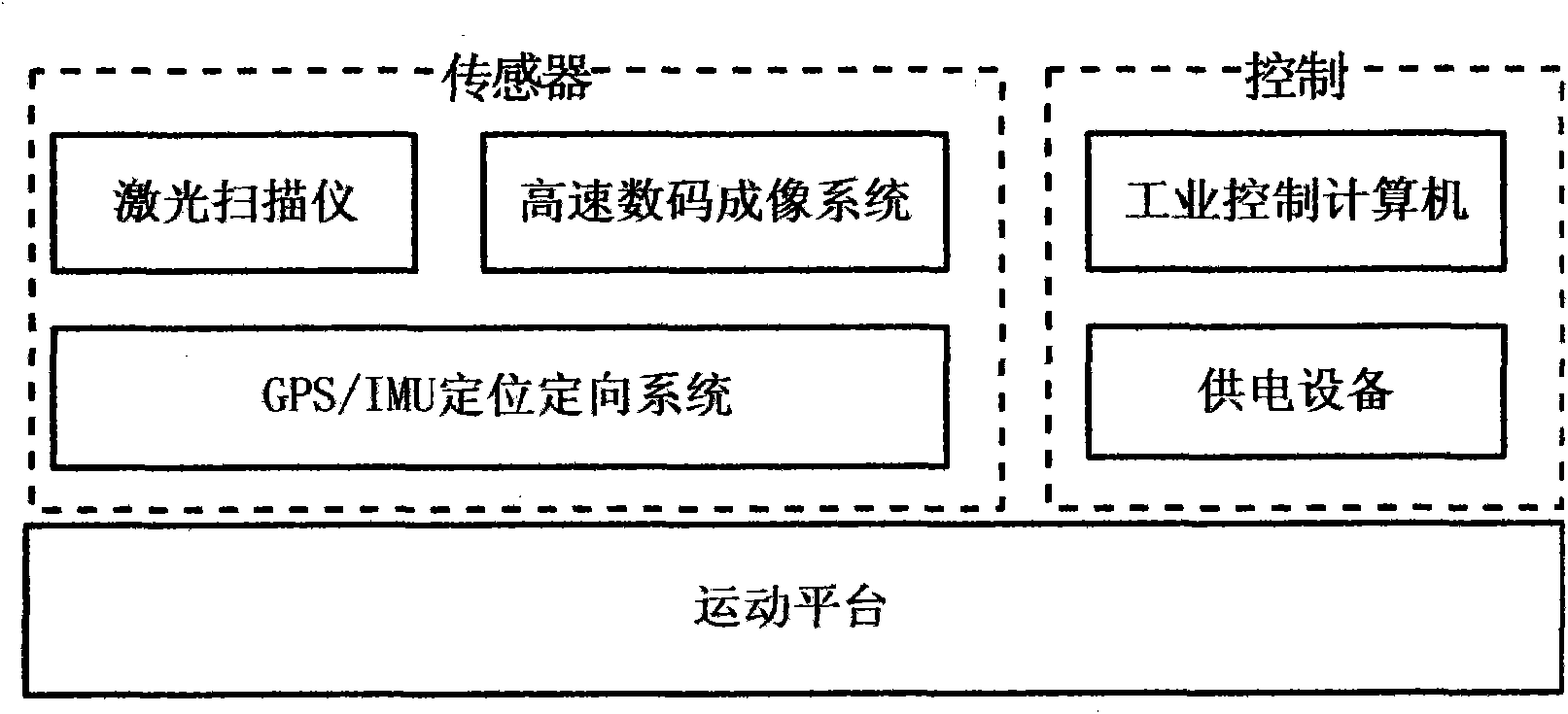

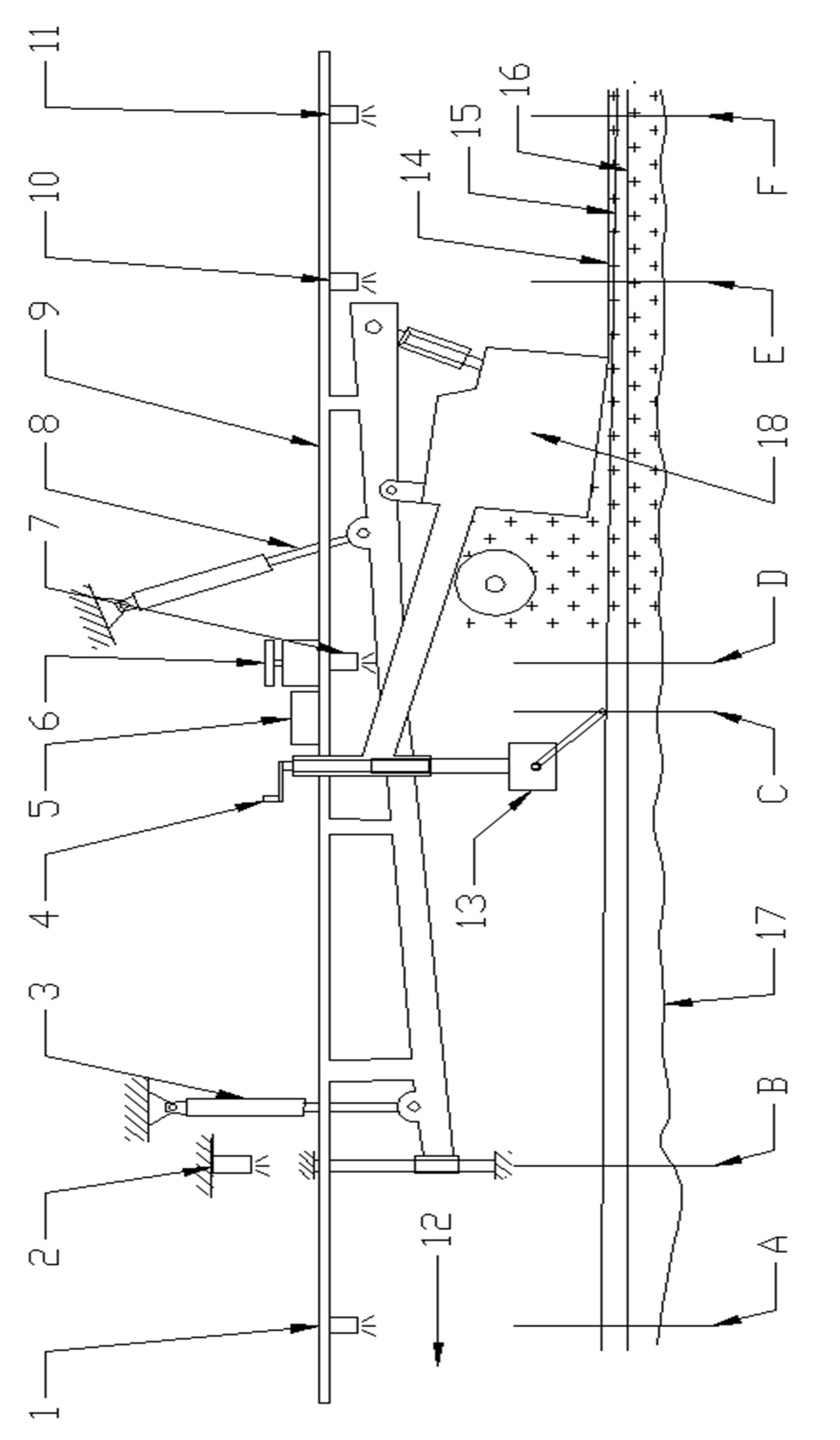

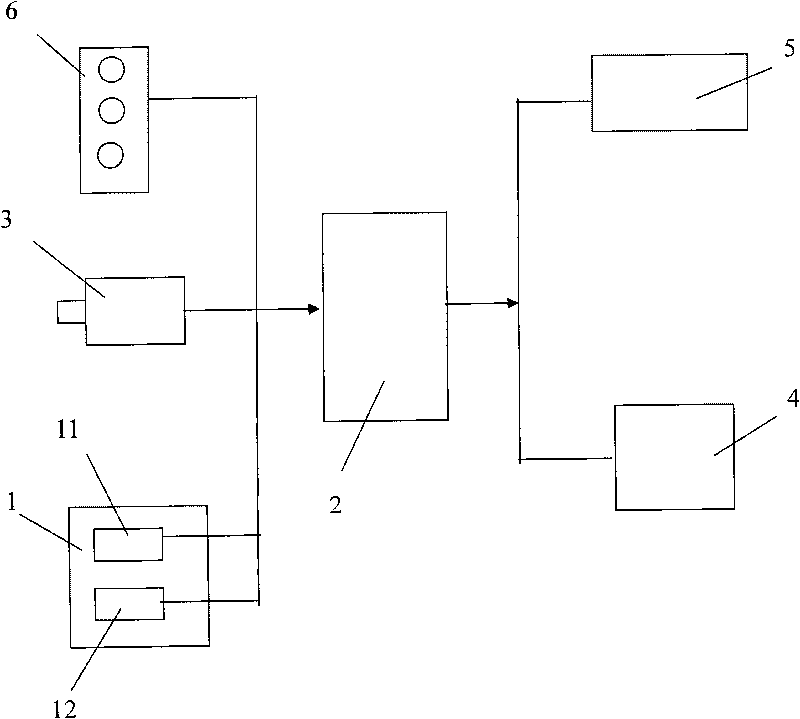

System and method for fast precise measurement and total factor data acquisition of high speed railway

InactiveCN101913368AGuaranteed safe operationMeasuring points markingRailway auxillary equipmentMeasurement deviceData acquisition

The invention relates to the field of precise railway measurement, high speed railway rail detection and security and digital railway, in particular to a system and a method for carrying out movable precise measurement of the high speed railway and synchronously obtaining total factor data along the line of the railway on the basis of GPS (Global Positioning System) / IMU (Inertia Measurement Unit) positioning and orientation, laser scan and digital imaging technologies. The invention further relates to a special railway measurement mark. The system consists of a laser scanner (1), a digital imaging device (2), a GPS receiver (3), an IMU (4), an industrial computer (5) and a power supply unit (6), and the system can obtain three-dimensional point clouds of rail, roadbed and peripheral environment of the high speed railway and digital images oriented by the earth. The method comprises a method for carrying out movable precise measurement movable precise measurement of the high speed railway and a method for improving the measurement precision by carrying out the simultaneous adjustment with a control point of a rail control network (such as a CPIII foundation pile control network). The system has high integration degree and has the characteristics of high efficiency and high precision, and the precision of the data can reach millimeter level.

Owner:扬州德可达科技有限公司

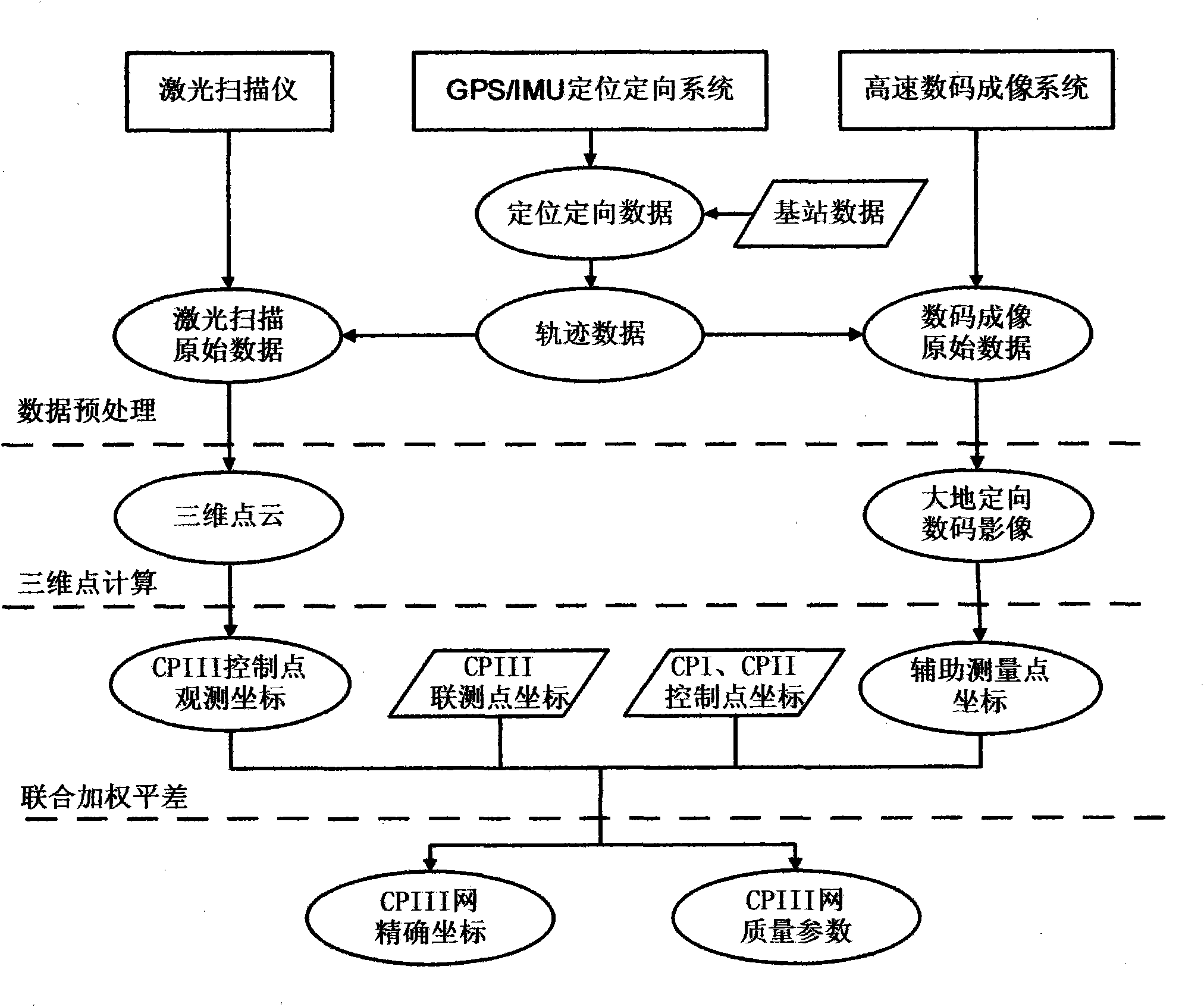

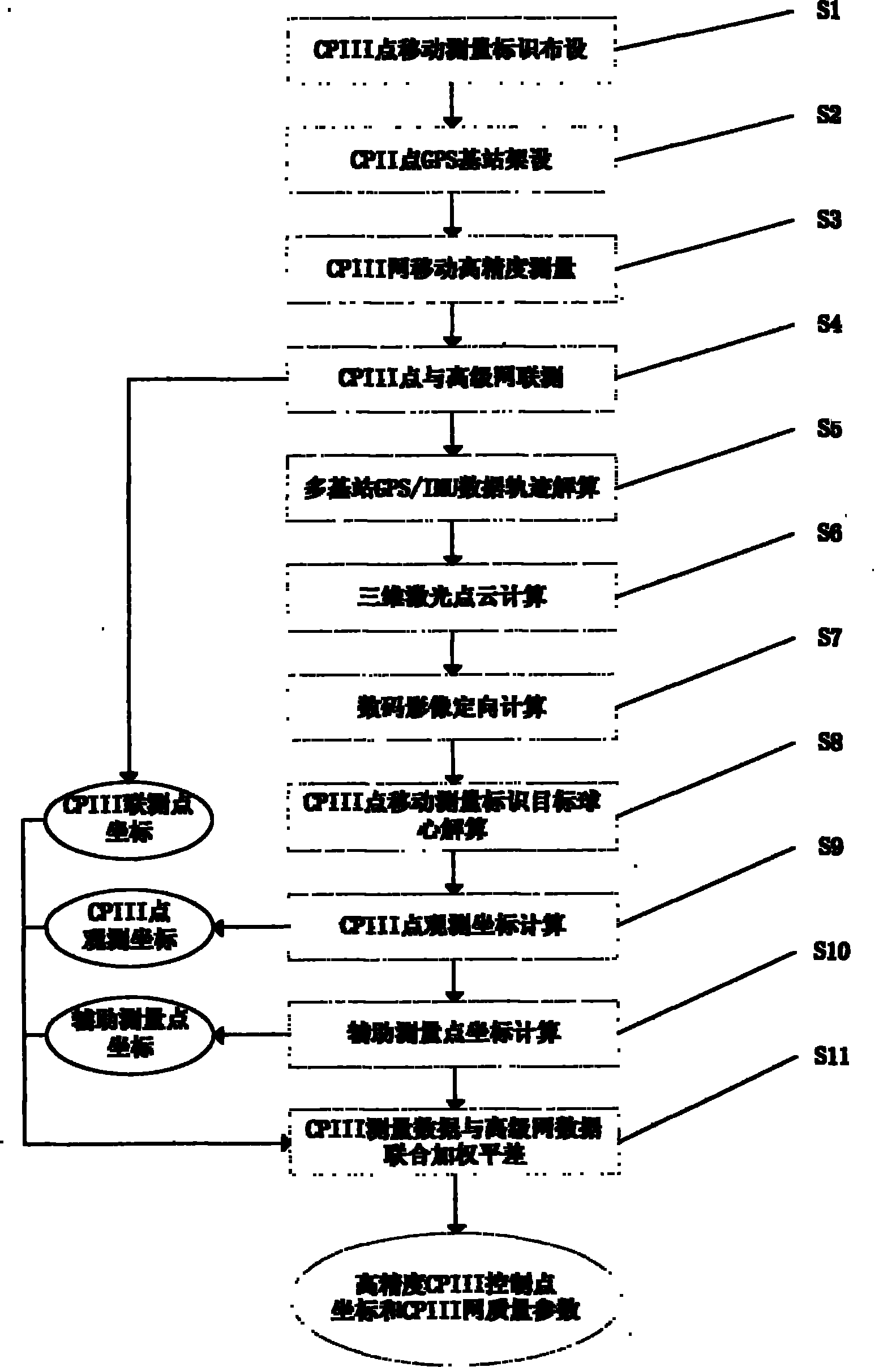

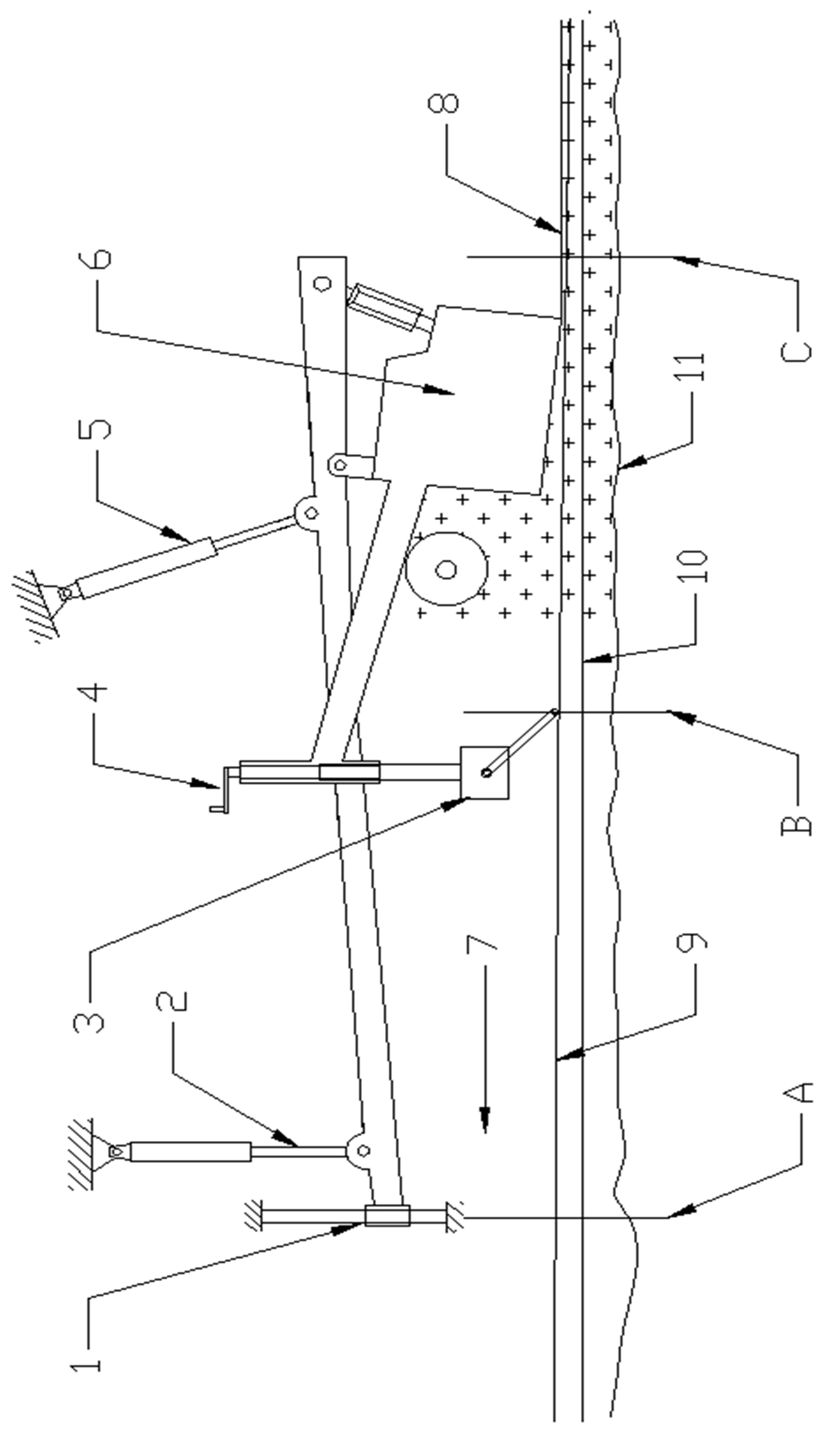

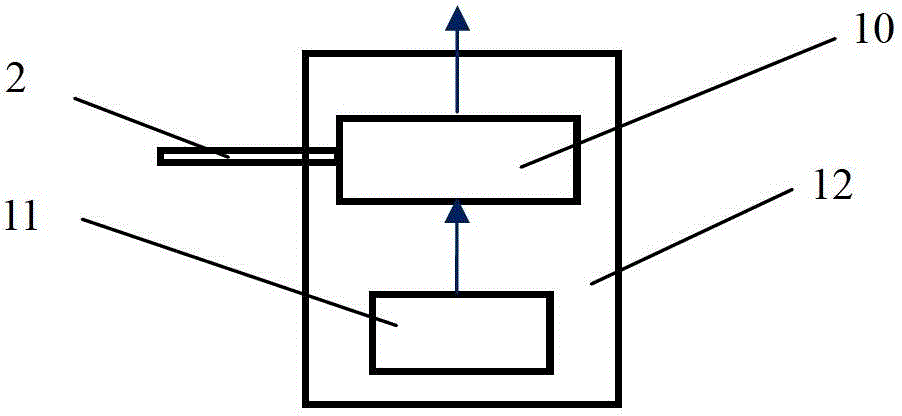

Method for rapidly measuring foundation pile control net (CPIII) of rapid transit railway

InactiveCN101914881AReduced measurement timeSimplify your measurement workSurveying instrumentsMeasuring apparatusFast measurementRelative precision

The invention relates to the field of precise engineering survey, in particular to a method for rapidly measuring a foundation pile control net (CPIII) of a rapid transit railway on the basis of movable laser radar measuring technology and high-speed digital imaging technology. control net (CPIII) measurement data is obtained by using a movable high-precision measurement system comprising a laser scanner (1), a GPS / IMU positioning and orientating system (2), a high-speed digital imaging system (3), an industrial computer (4) and a power supply device (5); and united weighted adjustment is carried out on advanced net data, united measured data and auxiliary measurement points extracted from images to obtain high-precision control net (CPIII) control point coordinates. The invention can greatly shorten the measurement time of the control net (CPIII), overcomes the defect of little total correlation of discrete single-point measurement, carries out integral adjustment on all control points, has good closing property and high relative precision, obtains plane and elevation coordinates of all control points, and greatly simplifies the measurement work of the control net (CPIII).

Owner:扬州德可达科技有限公司

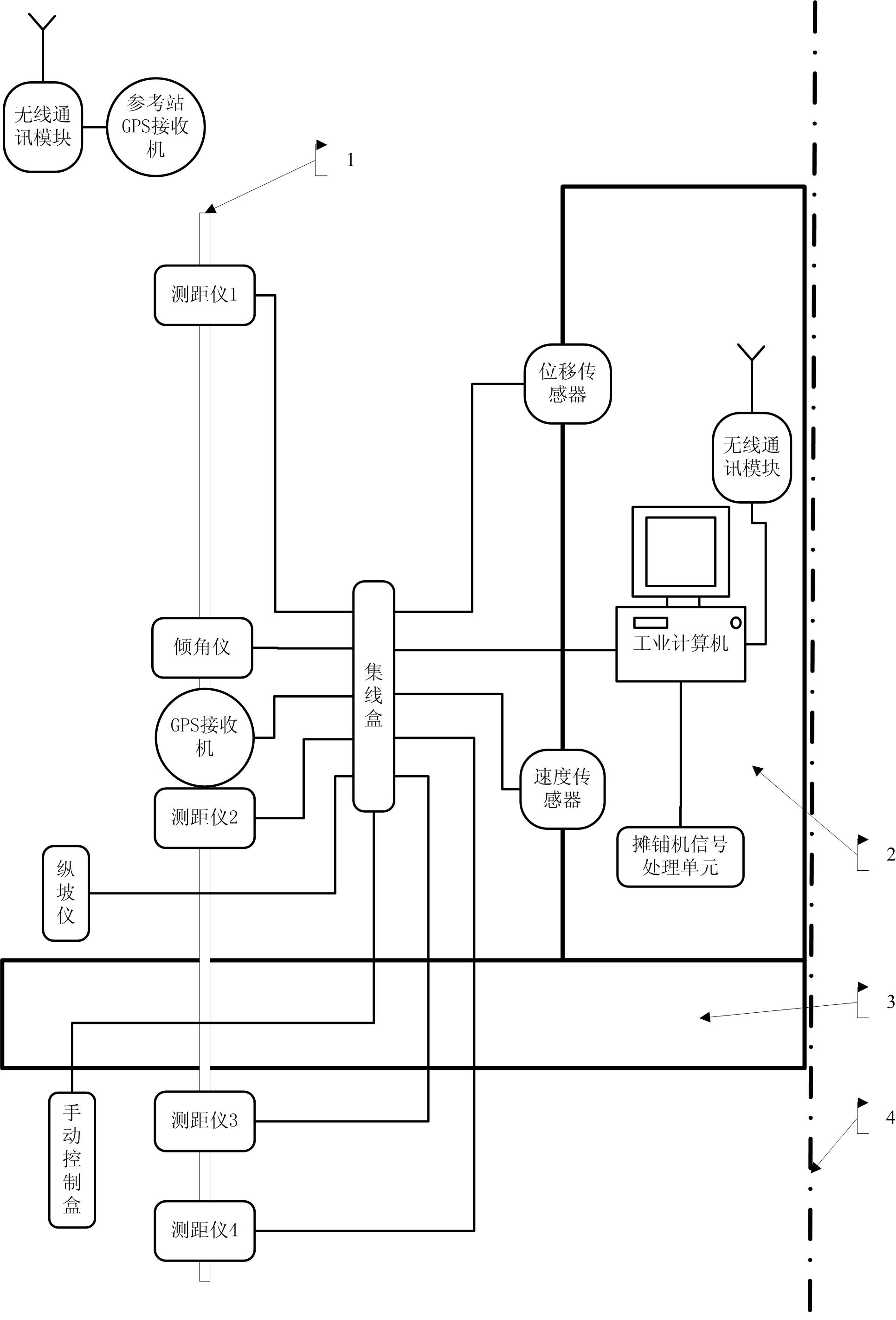

Intelligent GPS (global positioning system) elevation and average thickness control system of floated screed plate paver

InactiveCN102174792AEliminate manual measurement errorsEliminate erection errors of elevation pointsRoads maintainenceScreedGps receiver

The invention provides an intelligent elevation and average thickness control system of a floated screed plate paver, and the system provided by the invention comprises an industrial computer, a measuring type GPS receiver, a distance meter, an inclinometer, a displacement transducer, a velocity transducer, a longitudinal slope instrument and other devices. In a GPS mode, design data is input in advance only, a levelling instrument is not required for measuring the elevation of the original ground, an elevation datum line is not erected, and leveling operation hands are not used at two sides of the paver, so that the elevations of the original ground and a newly paved road surface can be accurately recorded; in a compensating beam mode, measured data are participated in calculation of the average thickness for mileage per millimeter, thus the paved thickness can be recorded accurately; and in a longitudinal slope mode, the actual paved thickness can be recorded accurately on the basis of the traditional control method. In addition, the three operating modes can be converted quickly, thus overcoming the defects at the starting stage of the original compensating beam mode, ensuring continuous paving under the condition of abnormal GPS signals, and realizing flexible conversion under the condition of complicated road condition design.

Owner:合肥年代智能科技有限公司

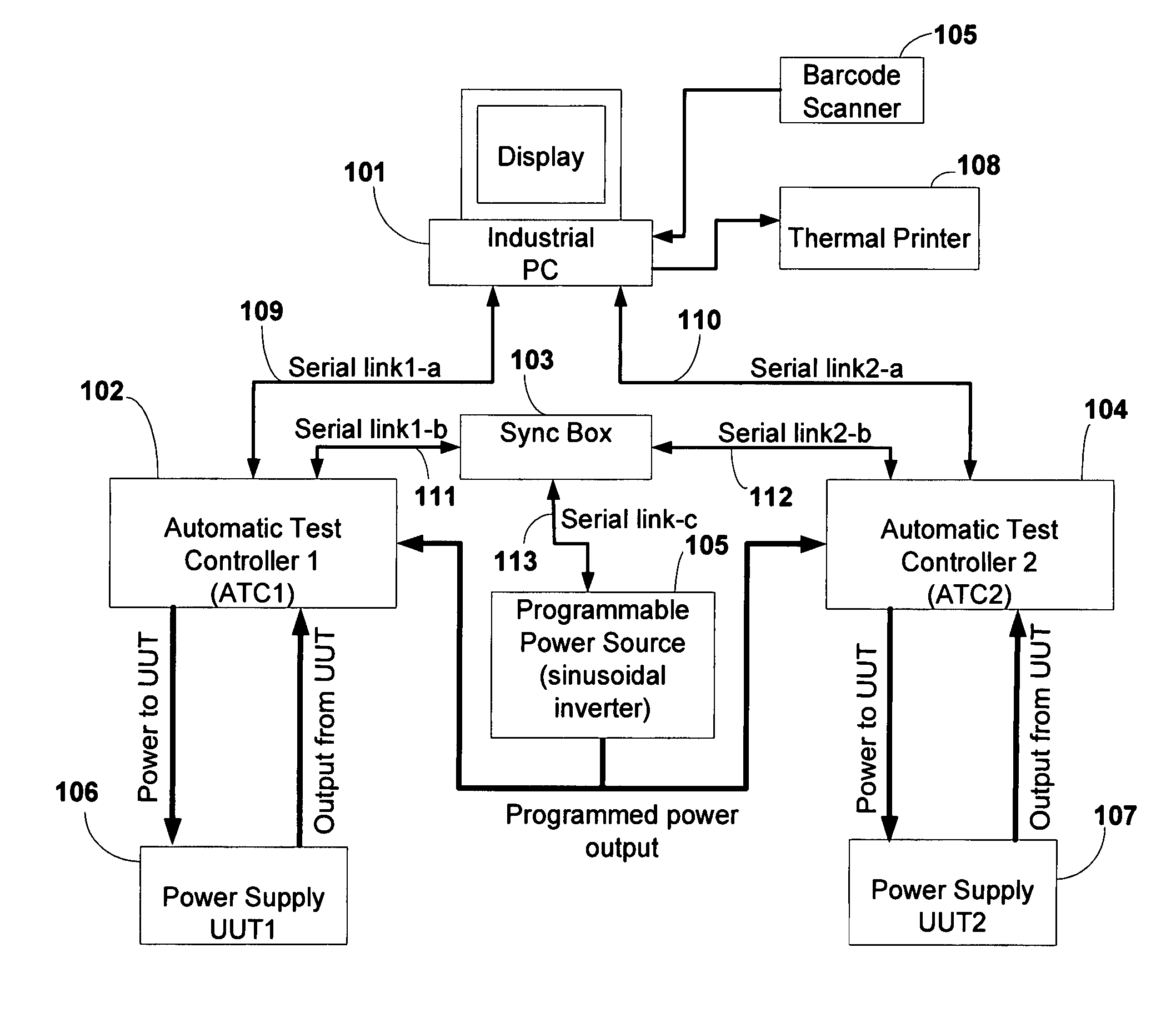

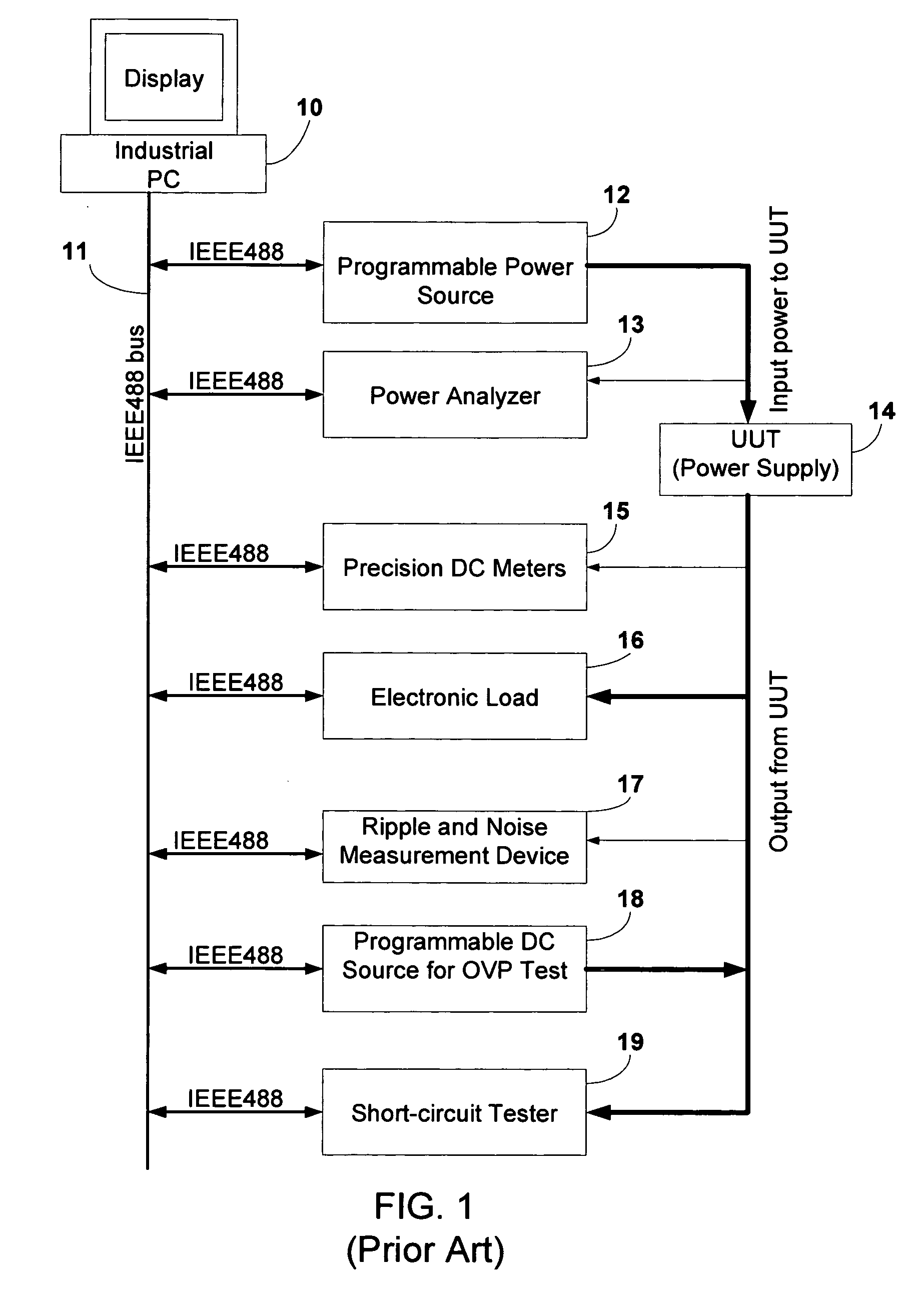

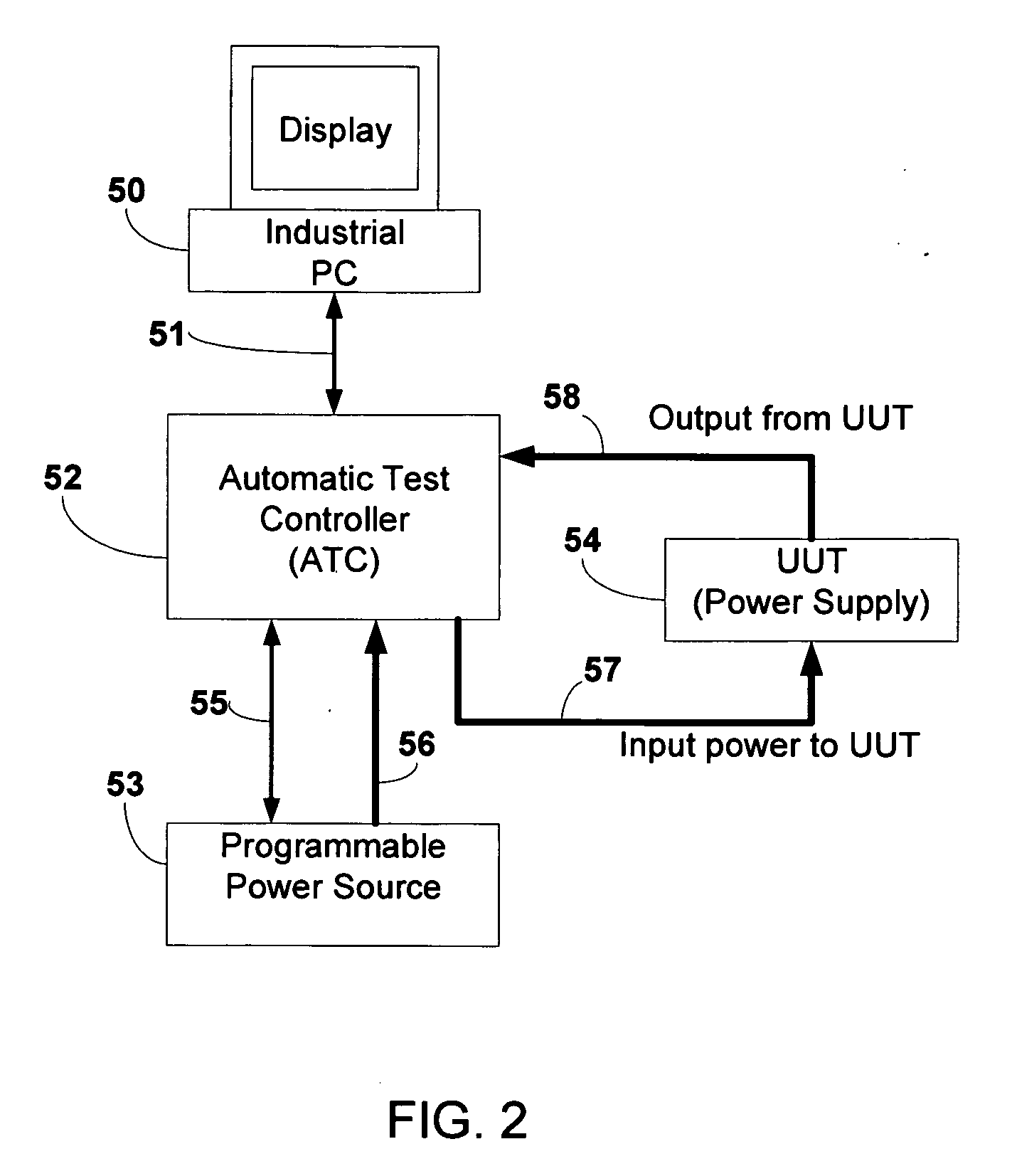

System architecture and apparatus for programmable automatic power supply testing

InactiveUS20100225466A1Low costReduce equipment costsElectric devicesResistance/reactance/impedenceAutomatic test equipmentSystem testing

A cost-effective system architecture and apparatus for programmable automatic power supply testing. The system utilizes board level interface between various system testing modules and an Automatic Test Controller (ATC). The ATC receives coded test requests from the software on an industrial PC and control the various testing modules inside ATC to execute the tests. Test results were sent back to the PC and saved in a result file. A single industrial PC can control two or more ATC's and test two or more power supply units simultaneously. The ATC based test system is lower cost than the conventional Automatic Test Equipment which uses device level interface and standardized test devices.

Owner:SYNERGISTIC TECH SOLUTIONS

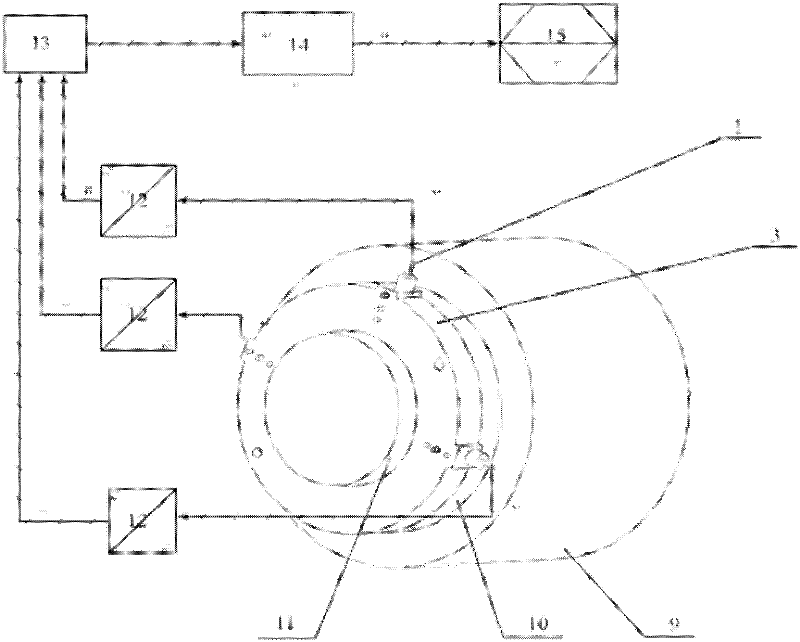

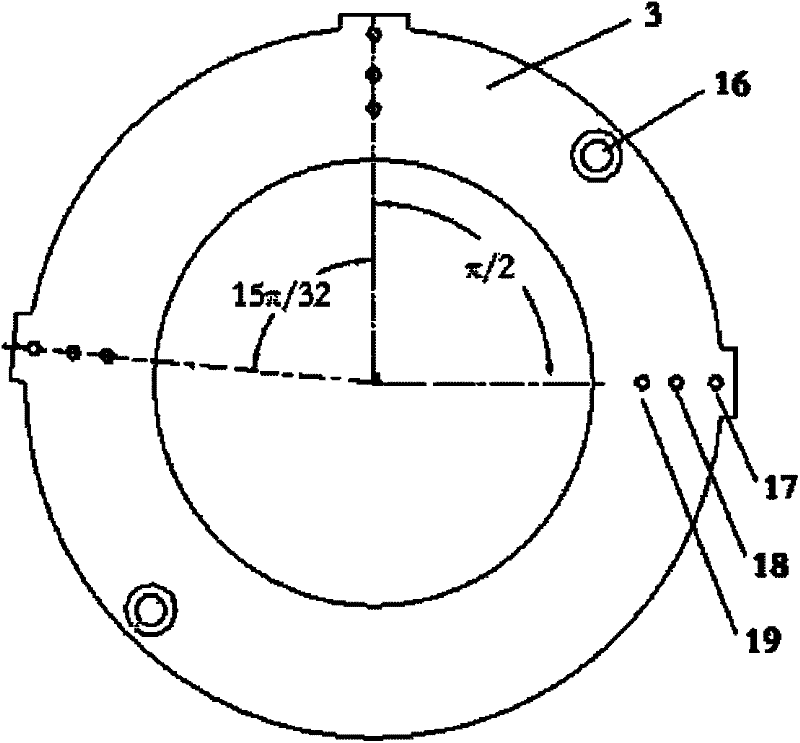

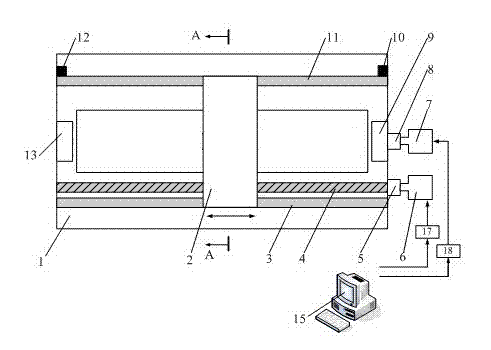

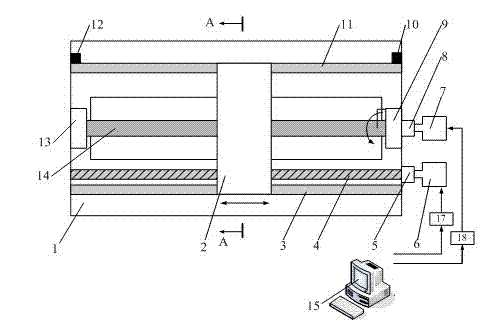

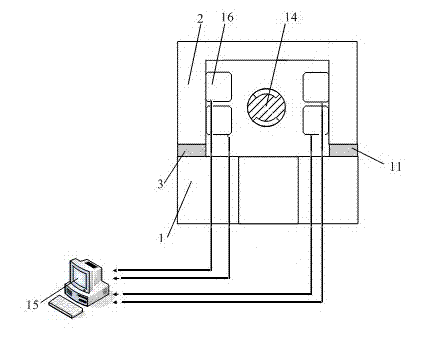

Online monitoring device for radial rotation accuracy of main shaft

ActiveCN102501137AReal-time online monitoringAccurate rotation accuracyMeasurement/indication equipmentsSeparation technologyData acquisition

An online monitoring device for the radial rotation accuracy of a main shaft is disclosed, wherein a monitoring ring is installed at the radial measuring position of the main shaft; three eddy-current displacement sensors are installed on the monitoring ring; the proximitors of the eddy-current displacement sensors are connected with the terminal board of a data acquisition board card; the data acquisition board card is connected to an industrial computer via a PCI (peripheral component interconnection) slot; when the main shaft is in a rotating state, the eddy-current displacement sensors convert the measured voltage signal to a standard voltage signal via the proximitors; the analog signal is converted to a digital signal via a signal conditioning circuit module and an A / D (analog / digital) conversion module on the data acquisition board card, and then the digital signal enters into the industrial computer; the radial displacement signal of the main shaft is obtained by signal acquisition and analysis software; the roundness error of the main shaft is separated out by applying a three-point error separation technology, thereby obtaining the rotation error of the main shaft; and finally the analysis result of the rotation accuracy of the main shaft is displayed. The online monitoring device for the radial rotation accuracy of a main shaft has the advantages of being high in accuracy and convenient in adjustment.

Owner:XI AN JIAOTONG UNIV +1

Automatic alarm and monitoring system for pedestrian running red light

InactiveCN101739809AReduce red light runningThe effect is positive and obviousRoad vehicles traffic controlMonitoring systemComputer science

The invention relates to an automatic alarm and monitoring system for a pedestrian running a red light, comprising an infrared curtain detector, an industrial computer and a camera, wherein the infrared curtain detector is connected with the industrial computer, the camera is connected with the industrial computer in which an image identifying program and a violation distinguishing program are arranged, and the industrial computer judges whether the event that the pedestrian runs the red light happens or not by utilizing the violation distinguishing program according to signals returned by the infrared curtain detector, then identifies the image of the pedestrian by utilizing the image identifying program, and saves the image. The infrared curtain detector consists of a first infrared detector and a second infrared detector, wherein the detecting infrared ray of the first infrared detector is projected in one zone in pedestrian street crossing, and the detecting infrared ray of the second infrared detector is projected in one adjacent zone in the pedestrian street crossing. The invention automatically distinguishes the phenomenon that the pedestrian runs the red light, gives out an alarm and records the picture information of a violator by utilizing an infrared detecting technique and an image identifying technique.

Owner:上海经达信息科技股份有限公司

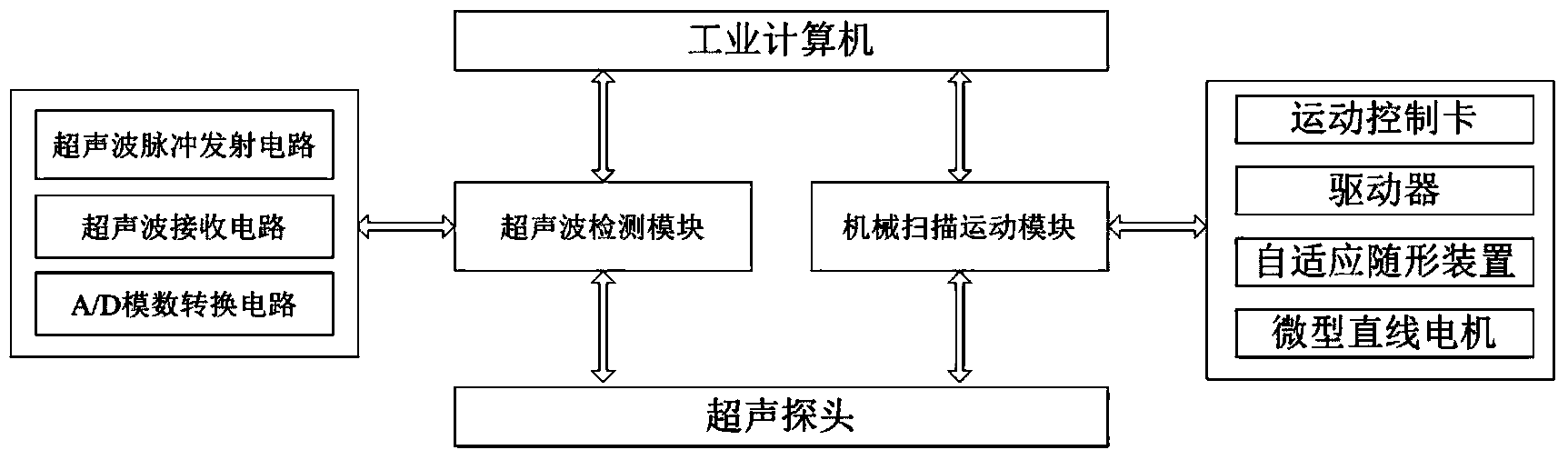

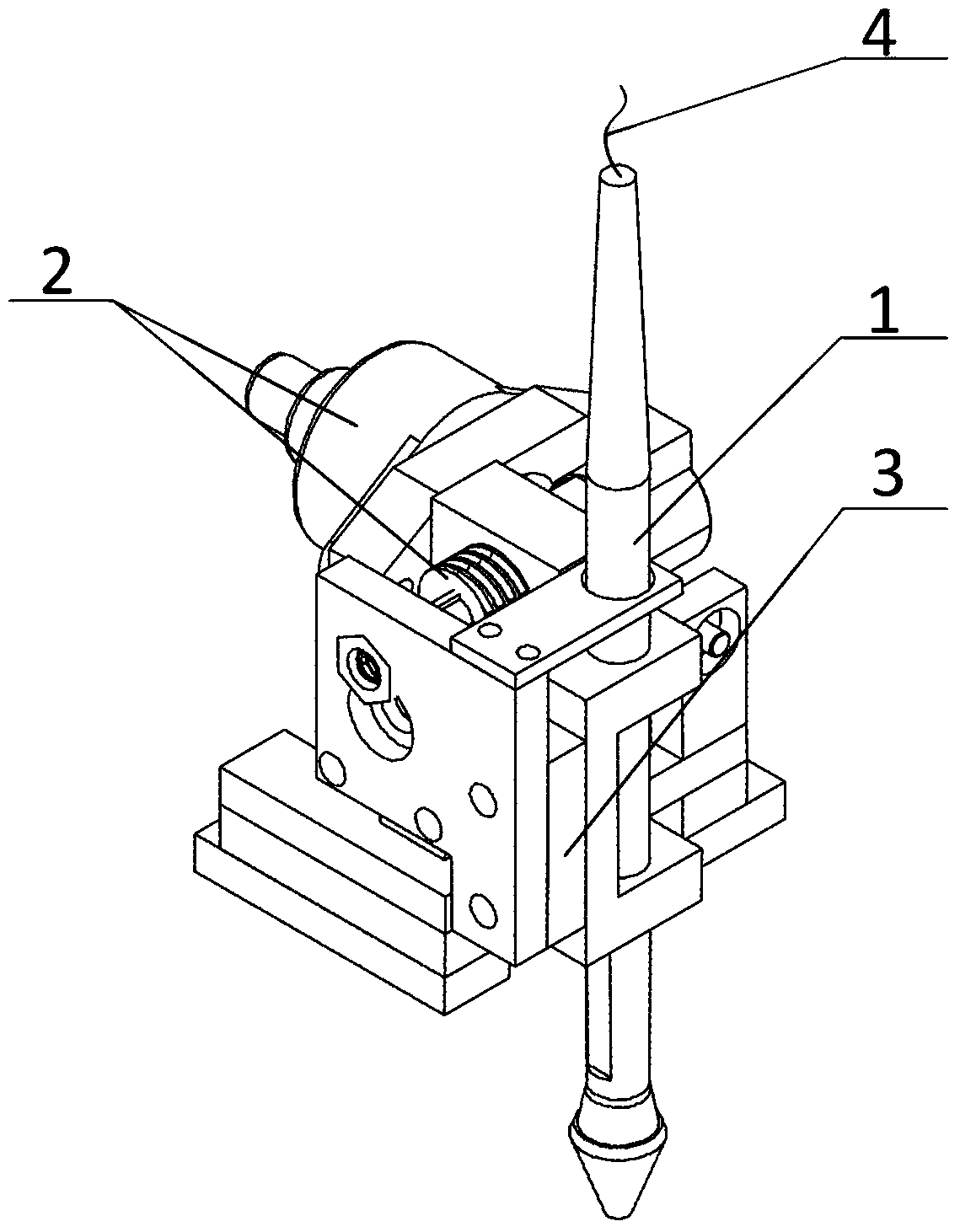

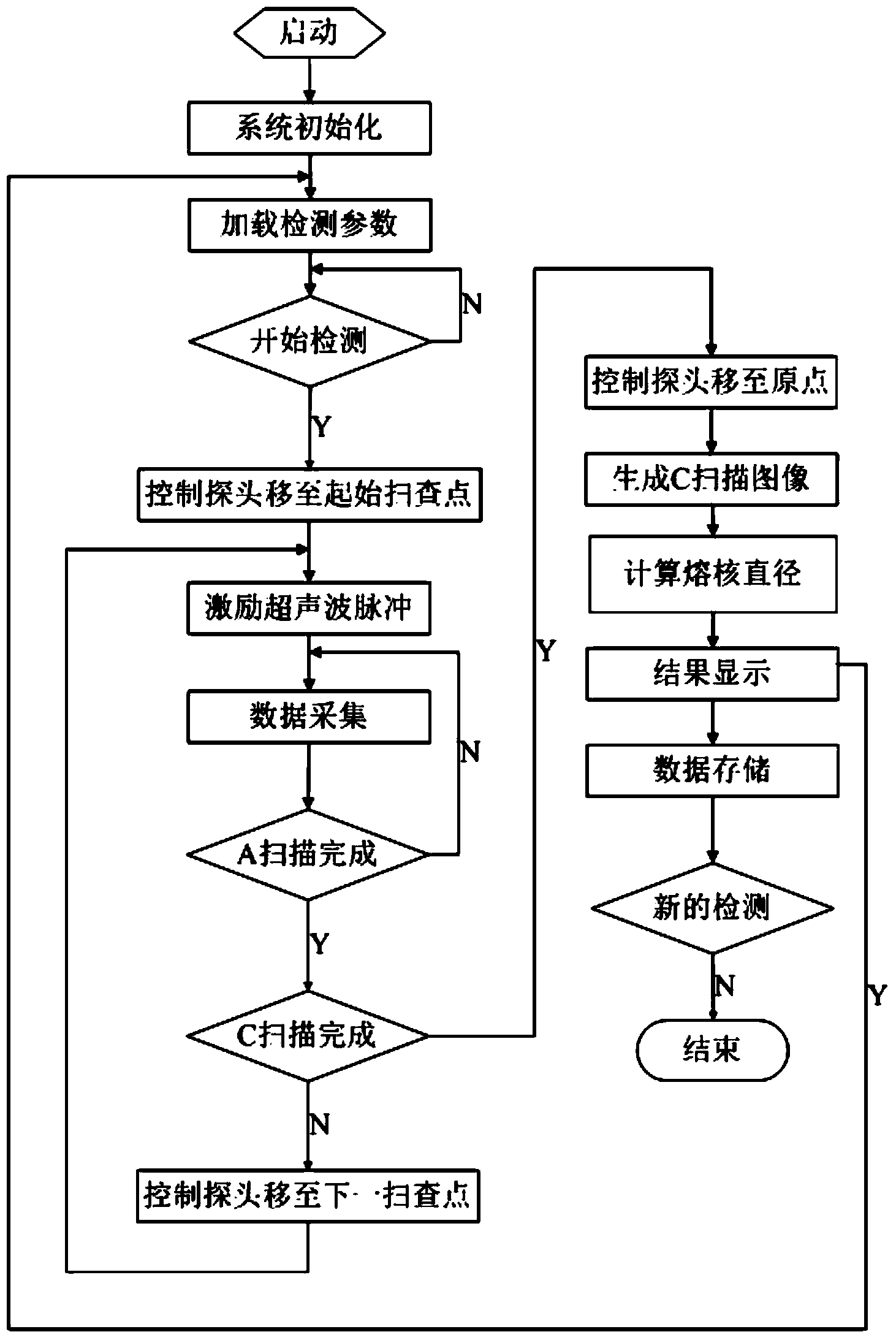

Portable full automatic resistance spot welding ultrasonic detecting instrument and detecting method

InactiveCN103822970ACompact structureReduce volumeAnalysing solids using sonic/ultrasonic/infrasonic wavesAnti jammingWater immersion

The invention relates to a portable full automatic resistance spot welding ultrasonic detecting instrument and a detecting method. The portable full automatic resistance spot welding ultrasonic detecting instrument comprises an industrial computer, an ultrasonic probe, an ultrasonic detecting module integrated in an IPC (Industrial Personal Computer), a compact-type two-dimension mechanical scanning motion module, and an ultrasonic analyzing module, wherein the ultrasonic detecting module comprises an ultrasonic pulse radiating circuit, an ultrasonic receiving circuit and an A / D conversion circuit; the compact-type two-dimension mechanical scanning motion module comprises a micro-scale linear motor, a driver, a motion control card, and a self-adaption profile-followed device; the ultrasonic analyzing module comprises a data and image processing module, a database storage module, and a manual playback and analysis module. Functions such as self-adaption scanning and detecting to the resistance spot welding joint surface, automatic generation of a C scanning image, and quantitive calculation of nugget diameter of the ultrasonic probe in the situation of non-water immersion are realized; compared with the prior art, the portable full automatic resistance spot welding ultrasonic detecting instrument and the detecting method have the advantages of simplicity in operation, portability, reliability, strong anti-jamming capability, high detection and analyzing speed and the like.

Owner:JILIN UNIV

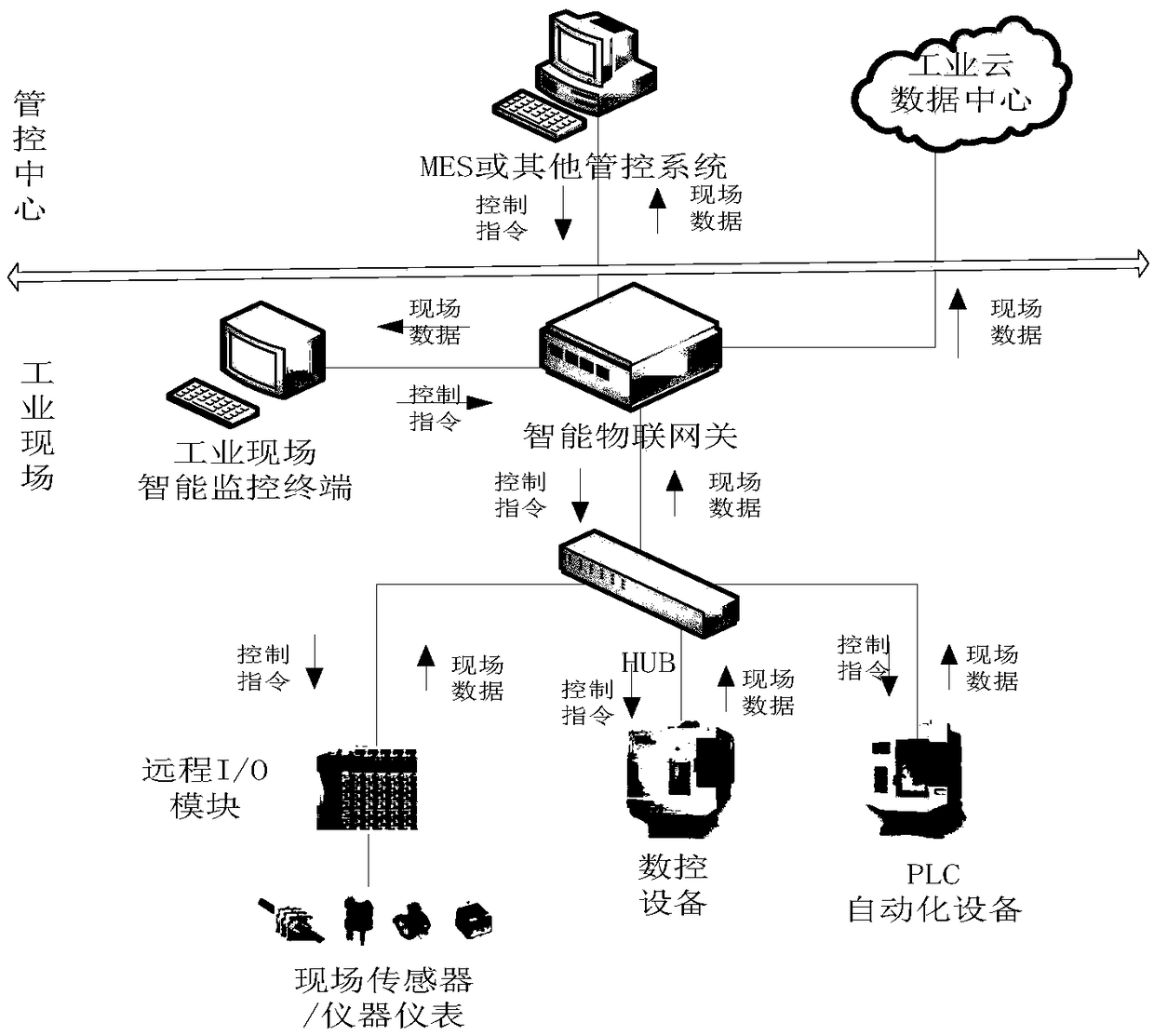

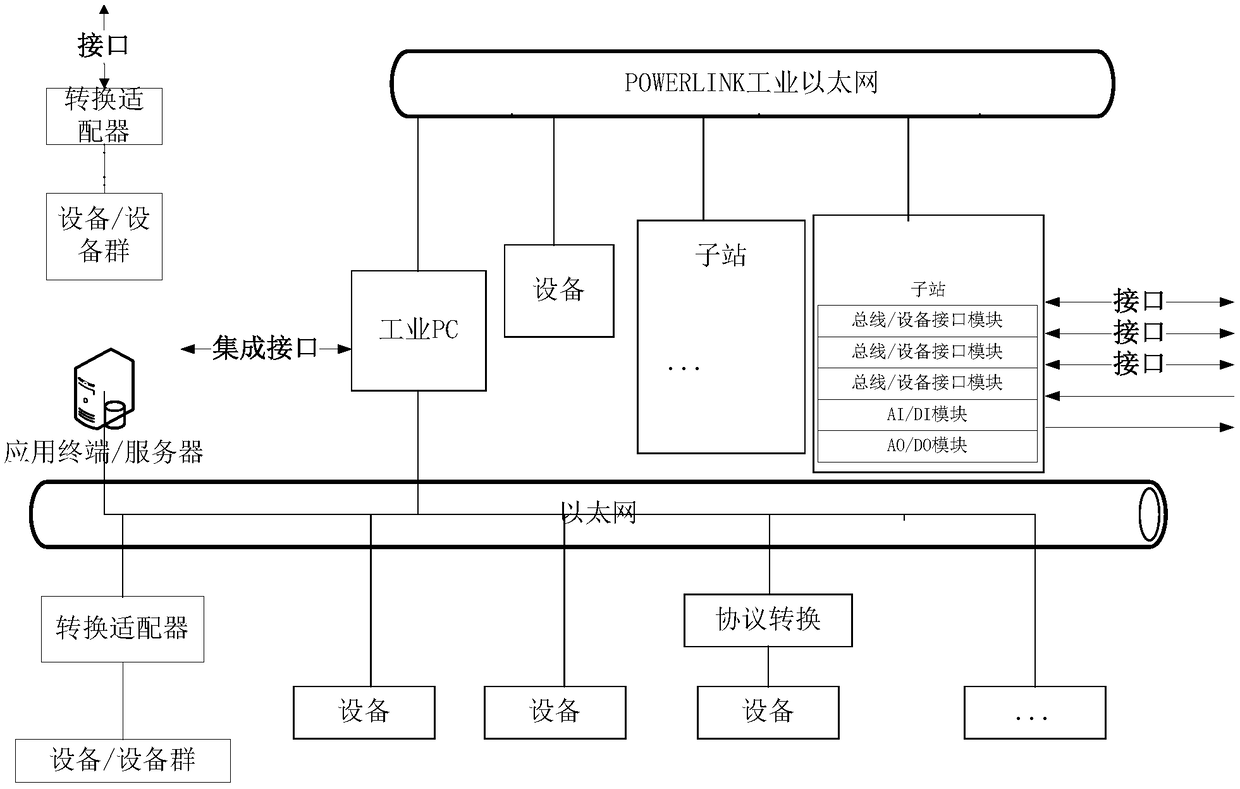

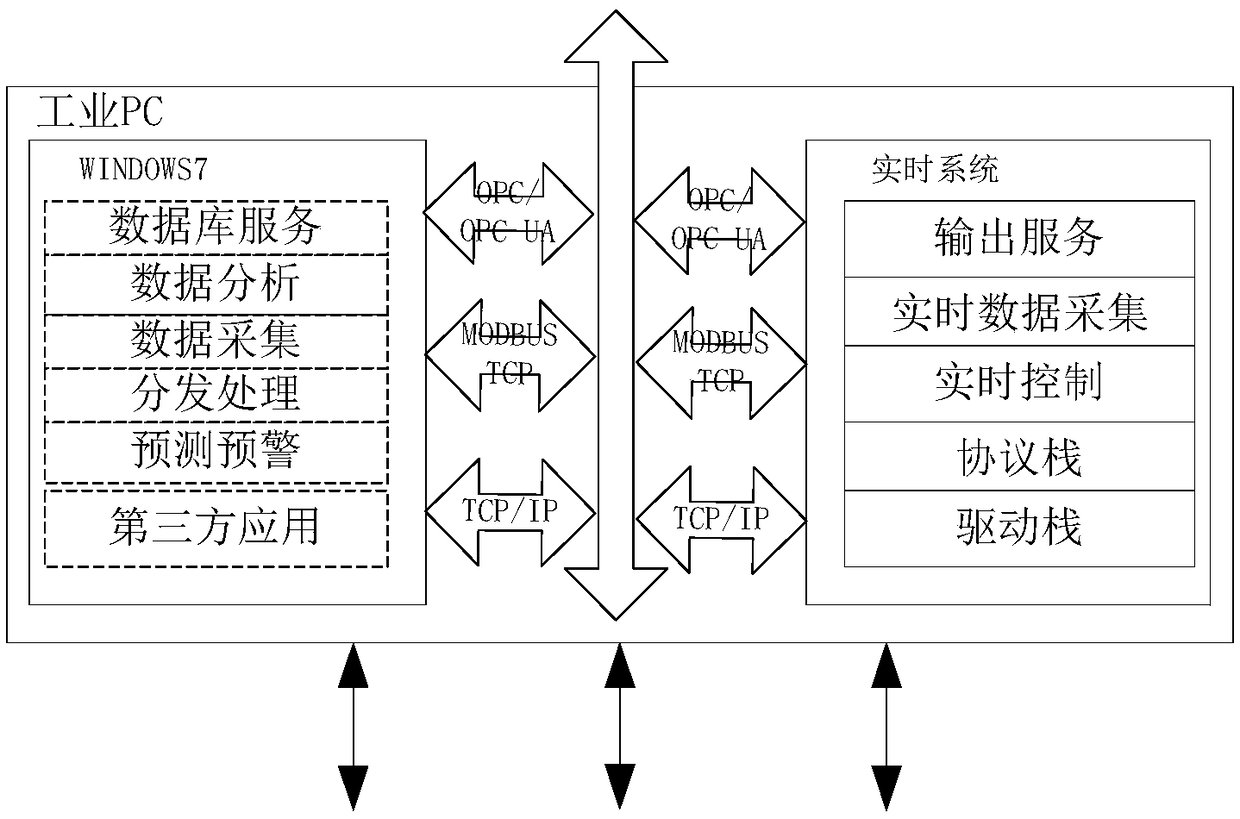

Industrial field oriented intelligent Internet-of-things gateway

ActiveCN108833269ARealize transparent management and controlHighly integratedNetwork connectionsUSBIntelligent equipment

The invention discloses an industrial field oriented intelligent Internet-of-things gateway which comprises an industrial PC. The industrial PC is provided with an Ethernet interface, a POWERLINK interface, a USB interface and a serial port. The industrial PC performs communication with external equipment through an OPC / OPC UA protocol. Along with economy development and manpower cost increase, amanufacturing enterprise tends to utilize automatic and intelligent equipment or system for replacing or reducing working of the man. But for truly realizing few man working and no-man working in a production process, cooperated control of producing steps of production field processing, conveying, ensuring, detecting and the like is required in a production process control system. Furthermore functions such as real-time monitoring of a field state and in-time response elimination of a field abnormity are required. The industrial field oriented intelligent Internet-of-things gateway can realizereal-time acquisition of field data, intelligent perception and real-time optimization control of the process. Furthermore the industrial field oriented intelligent Internet-of-things gateway can supply basic supporting for realizing a production process intelligent control function.

Owner:中国兵器装备集团自动化研究所有限公司

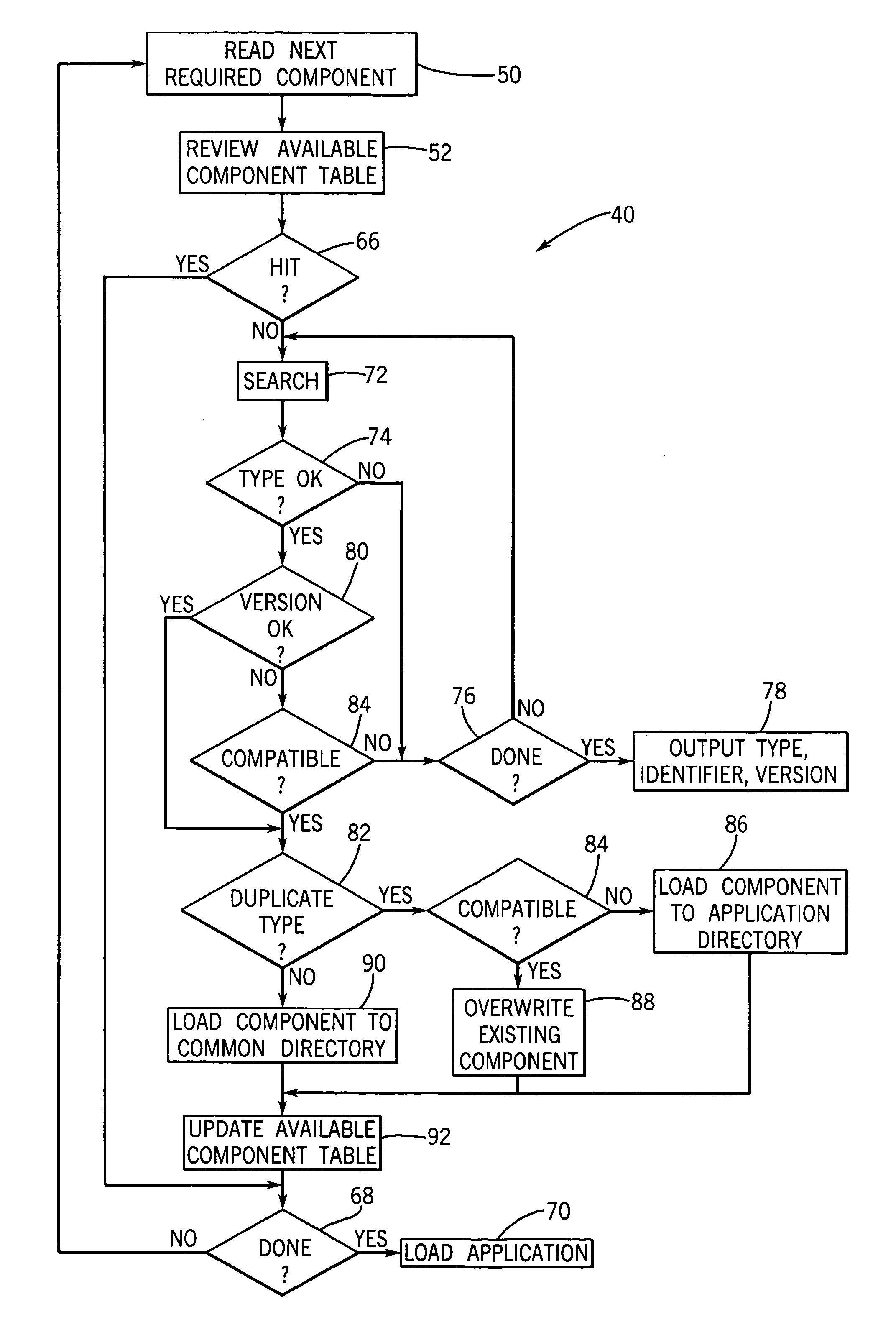

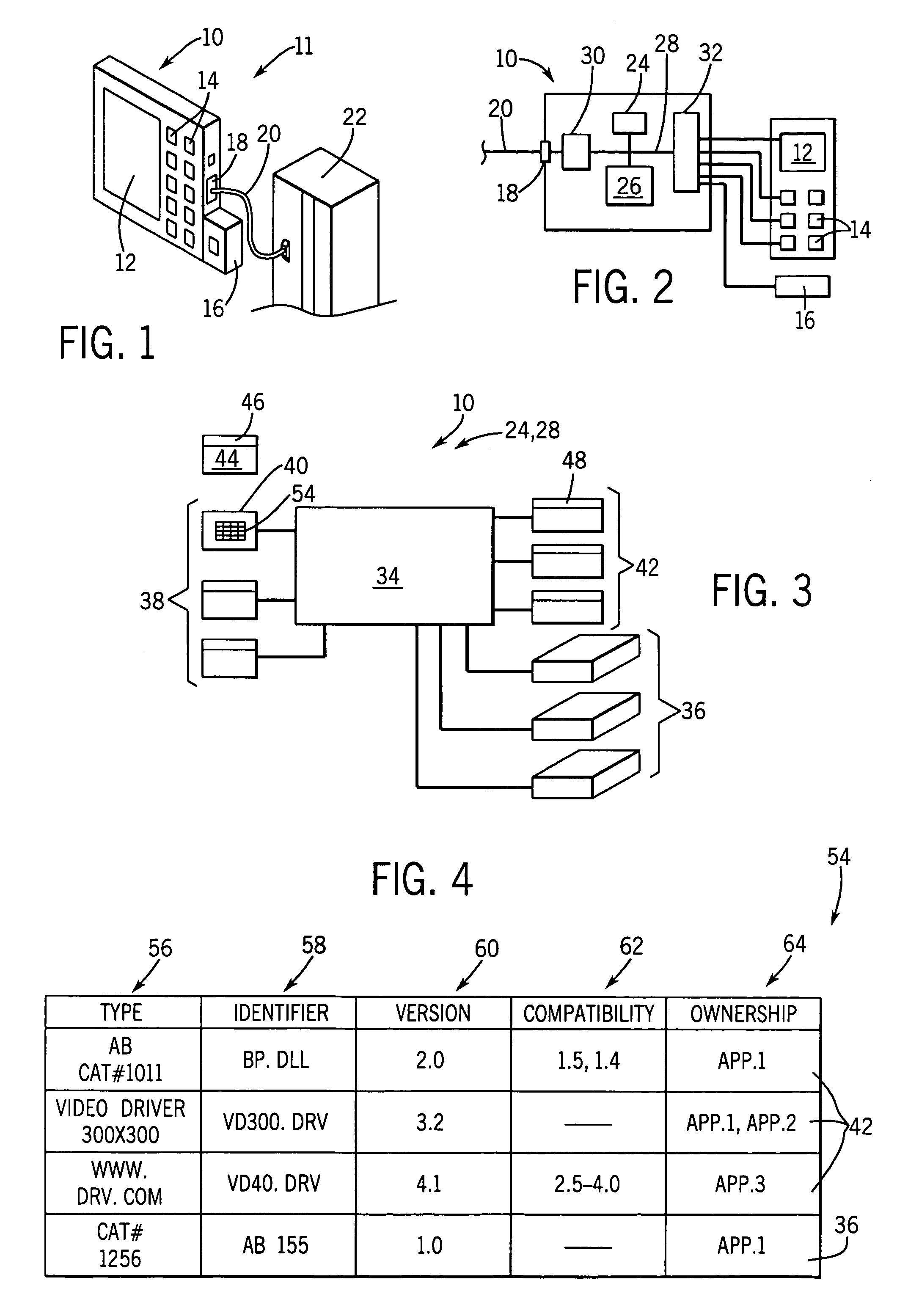

Component loader for industrial control device providing resource search capabilities

The installing of components into an industrial computer observes a pulling paradigm in which a required resource list associated with each component is reviewed against resources in the target-industrial control device. Missing resources are obtained through a searching process that may include but is not limited to the media holding or associated with the installed component. This approach allows compatibility between different versions of the resources to be evaluated with the possibility of coexisting different version numbers being, or one version replacing the other for automatic upgrade. Collecting the resources in a available resource table allows more complete information to be provided to the user in the event the resource cannot be found and allows more complete removal of components by making an explicit attribution of ownership of each resource to one or more installed components.

Owner:ROCKWELL AUTOMATION TECH

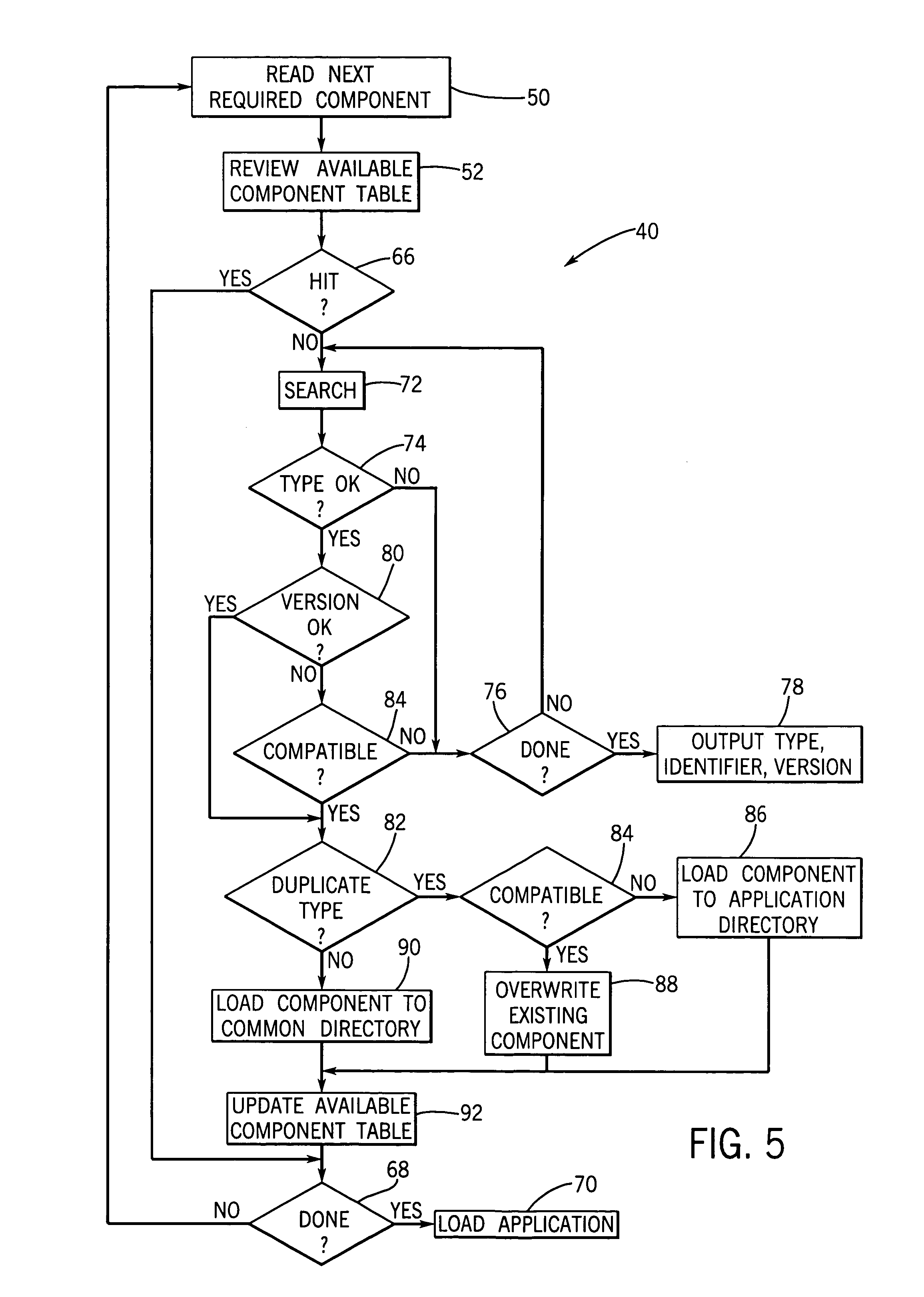

Megawatt level wind power generation oar-changing bearing friction torque numeric control testing machine and test approach

InactiveCN101256103ASmall sizeSimple structureMachine bearings testingEngine testingFriction torqueClosed loop

The invention provides a megawatt wind power generation adjustable blade bearing friction moment numerical control testing machine and a testing method. The tested bearing outer ring is fixed on the machine rack; a main axis is equipped, one end of the bearing inner ring is fixed on the bearing inner ring, the other end is equipped with a radial and axial loading mechanism, in which the radial and axial load cylinder are separately pressured, and is equipped with variable-frequency motor of torque sensor, the driving pinion is meshed with the tested bearing inner ring, which form the loading and transmission system. The testing machine is determined by force analysis and analog loading principle, which is reasonable and reliable, and has simple structure and small size. The closed-loop numerical control system, which is composed of an industrial computer, a hydraulic pressure control member, a hydro cylinder, a feedback element and other components, can realize overall monitor, data collection, analysis, process, and number and graph double output; the size, direction, variation period of the load are accurate, the curves of the load output and friction torque are intuitive, the testing process is highly automatic. And the invention can be matched with manual adjustment. The machine is shutdown automatically if any failure happens. The test provides data support for the bearing wind turbines, which assures that the machine can meet the test need after loading.

Owner:文鉴恒

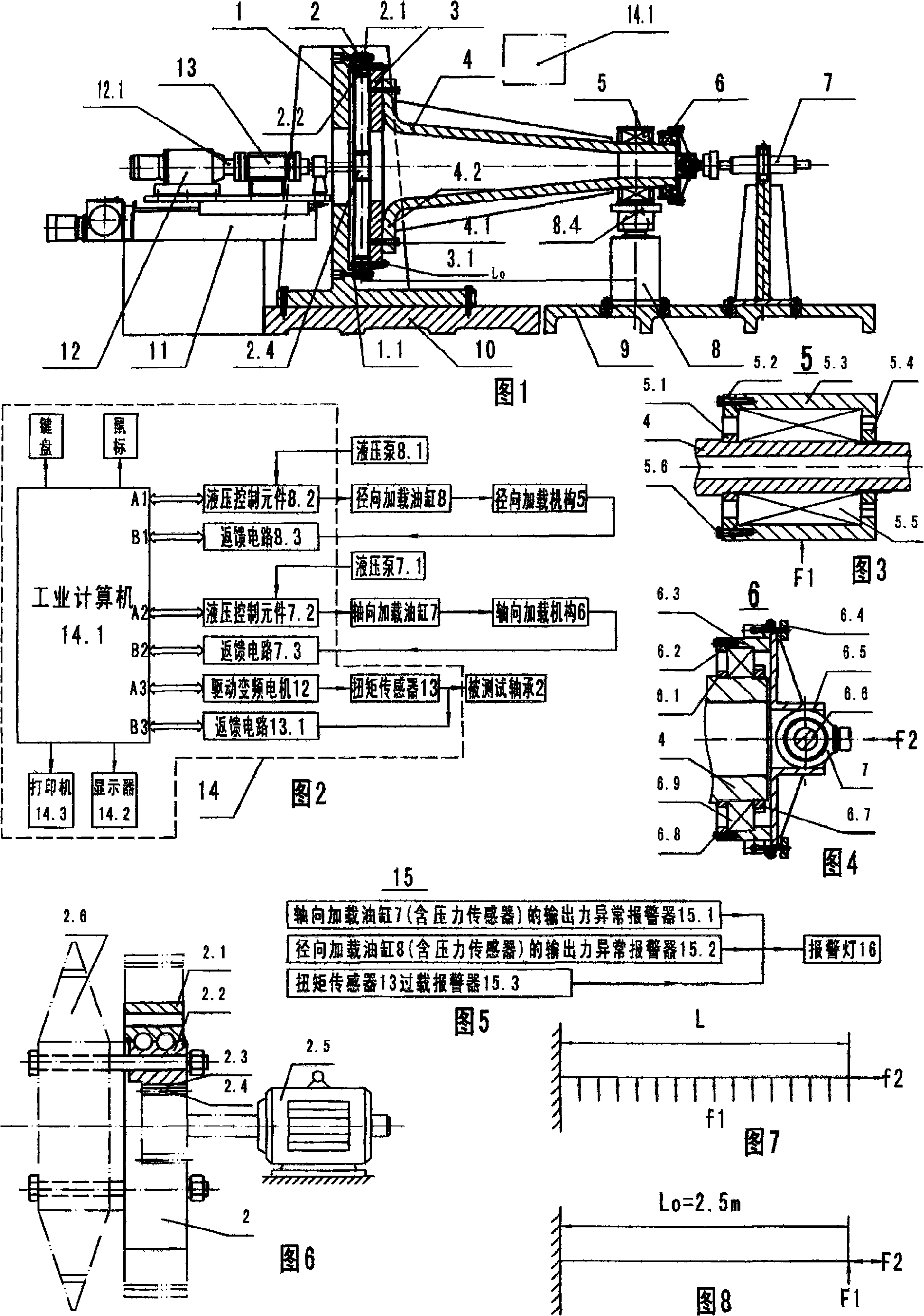

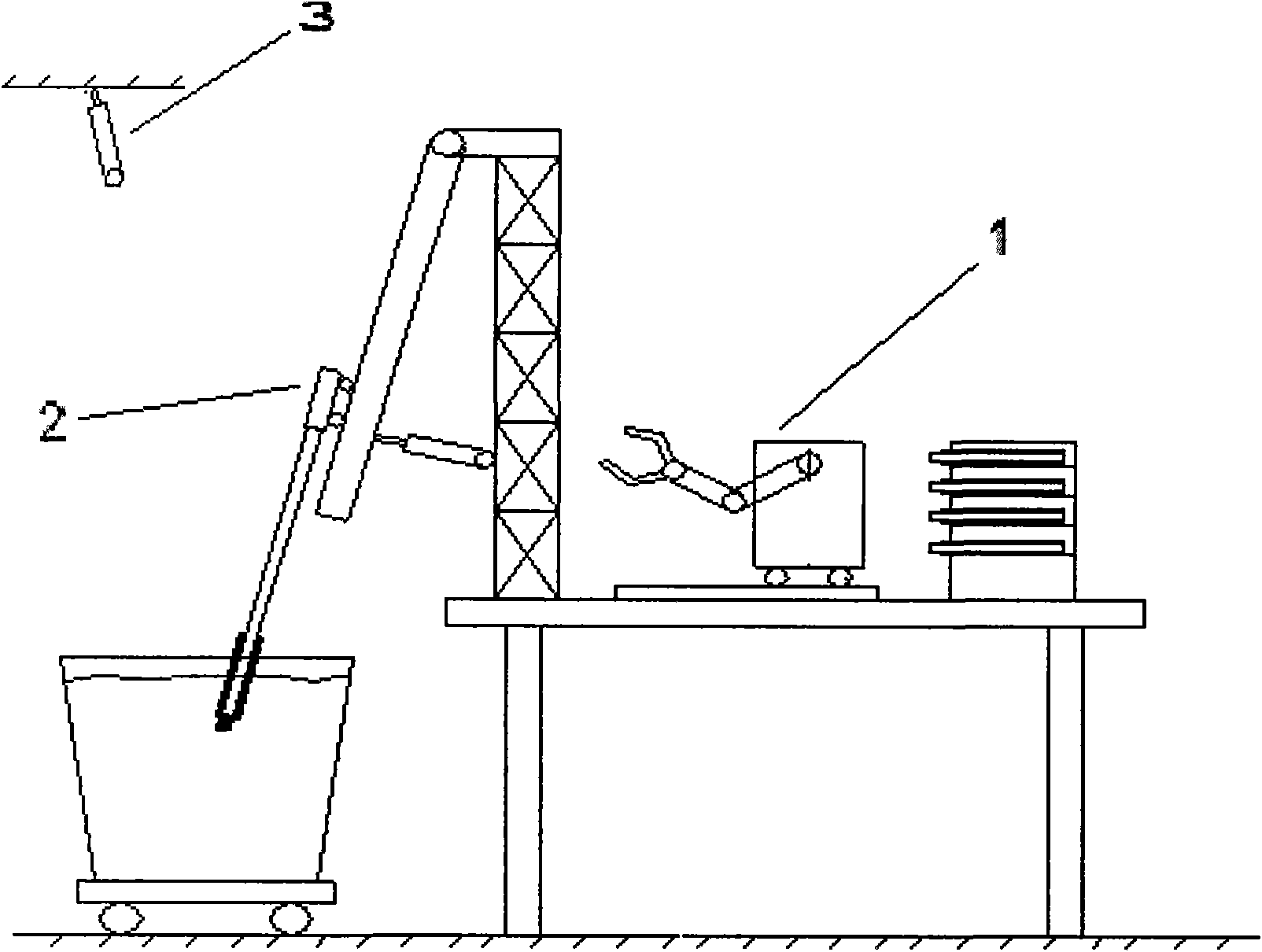

Exactly temperature-measuring and sampling system of molten steel and method thereof

ActiveCN101975679AEasy to controlHigh precisionWithdrawing sample devicesMachines/enginesLiquid statePosition control

The invention discloses an exactly temperature-measuring and sampling system of molten steel and a method thereof, belonging to the technical field of liquid metal treatment process in the metallurgy field, and comprising an intelligent robot system, an automatic temperature measuring and sampling gun system, a liquid level height detector and an industrial control computer. The whole system is integrally controlled by the industrial control computer. The liquid level height detector is used for measuring the depth of the liquid level of the molten steel firstly, and then the intelligent robot is responsible for of installing probes, finally the automatic temperature measuring and sampling gun system is used for realizing the automatic temperature measurement and sampling. The invention has the advantages of realizing the exact position of temperature measurement and sampling of each gun on the basis of the infrared molten steel liquid level measurement and the servo position control, completely eliminating the system accidental error of measuring results caused by a manual measuring manner and providing reliable guarantee for improvements on the quality control and the precision of the molten steel.

Owner:BEIJING SHOUGANG CO LTD

Automatic detecting device of screw rod straightness and applications thereof

ActiveCN102889863AGuaranteed parallelGuaranteed accuracyUsing optical meansBall screwControl engineering

The invention discloses an automatic detecting device of screw rod straightness and applications thereof, and belongs to the field of automatic straightness detecting devices. The automatic detecting device of screw rod straightness comprises a base platform, a laser displacement sensor, a moving measuring platform, a measuring platform control system and a to-be-measured screw rod rotary system, wherein the laser displacement sensor is installed on the moving measuring platform and is connected with an industrial computer through a data transmission line; the measuring platform moving control system comprises a first moving guide rail, a second moving guide rail, a rolling ball screw rod, a first coupling, a first servo motor and a first servo controller. According to the invention, straightness of a screw rod with spiral groove characteristics can be detected automatically, and the automatic detecting device has the advantages of rapid detection process, accurate results and low product detection cost.

Owner:NANJING KANGNI MECHANICAL & ELECTRICAL +1

Brake disc dimension measurement equipment

ActiveCN103837112AReasonable structural designCompact structureMeasurement devicesPackagingDimension measurementMechanical engineering

The invention relates to brake disc dimension measurement equipment and belongs to the technical field of brake disc dimension measurement equipment structures. The brake disc dimension measurement equipment comprises an industrial PC. The industrial PC is in control connection with a brake disc dimension measurement device, a feeding and conveying device and a discharging and packaging device, wherein the feeding and conveying device is used for conveying brake discs to be measured to the brake disc dimension measurement device, and the discharging and packaging device is used for placing the measured brake discs to designate positions. The brake disc dimension measurement equipment has the advantages of being compact in structure, high in speed and accuracy and capable of saving time and labor.

Owner:龙口市埃迪克自动化设备有限公司

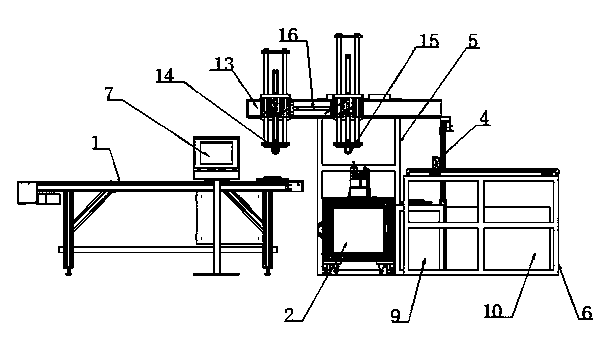

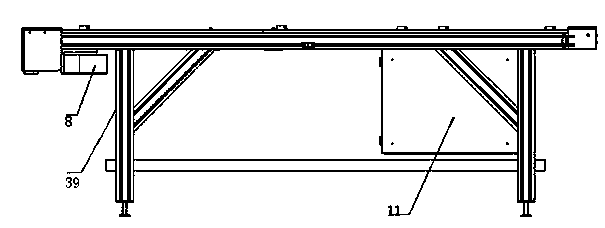

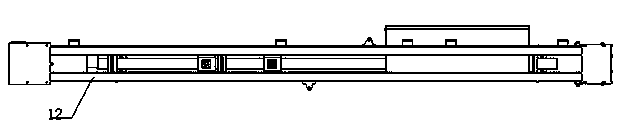

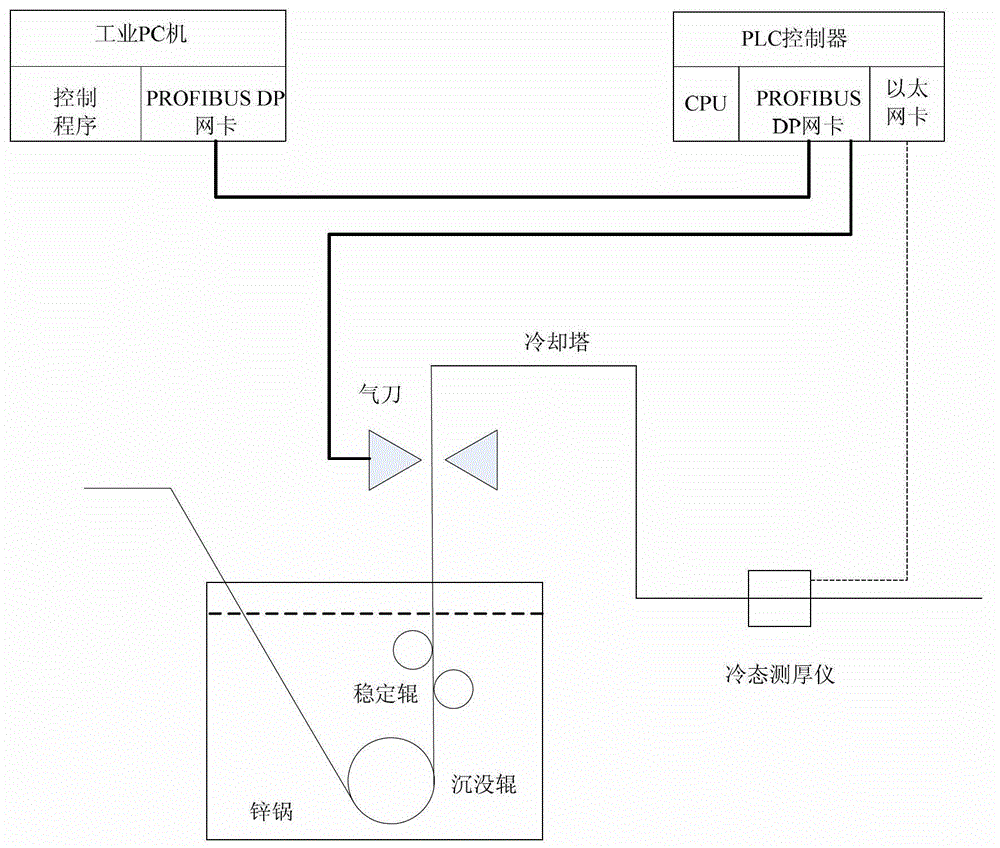

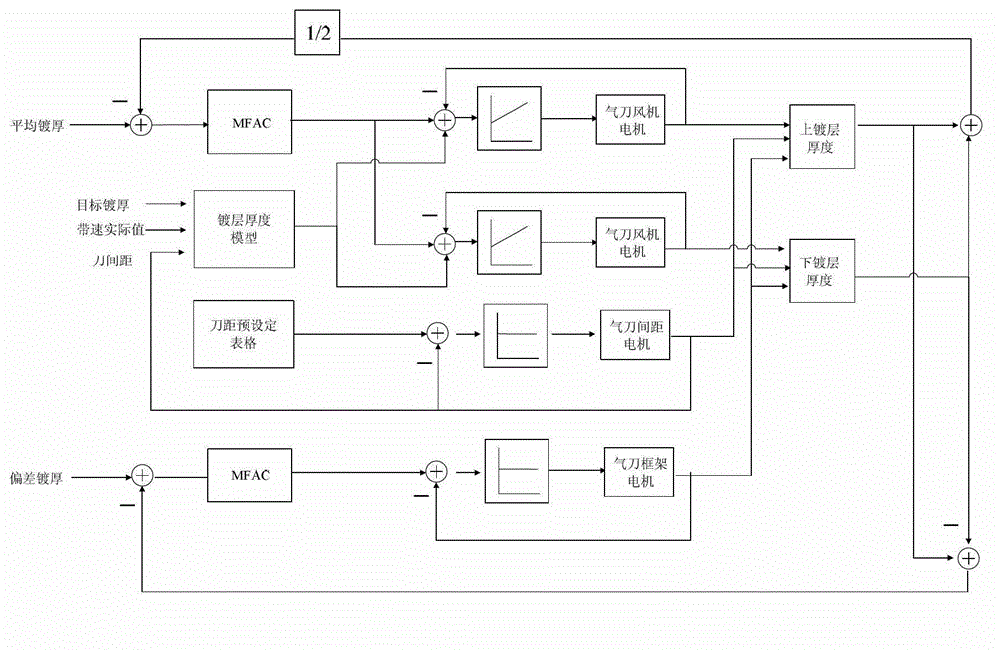

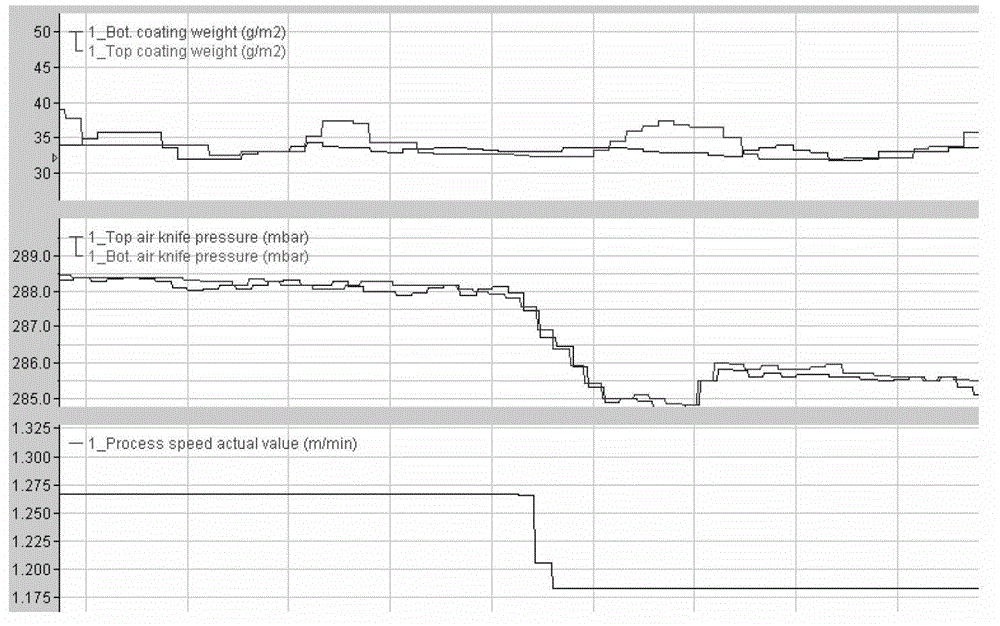

Automatic control system for plating thickness of hot galvanizing line

ActiveCN102912275AEliminate thickness errorsEliminate thickness deviationHot-dipping/immersion processesAutomatic controlAutomatic train control

The invention provides an automatic control system for plating thickness of cold rolling hot galvanizing line, which comprises an air knife, a thickness gauge, an industrial PC (Personal Computer), a PLC (Programmable logic Controller) and a plating thickness control program, wherein the control program is run in the industrial PC; the industrial PC and the PLC controller are connected by using a PROFIBUS (Process Field Bus) DP field bus; the PLC controller acquires the actual value of plating thickness and data in production process and sends into the industrial PC; the control program adopts cascade control method; a minor loop is designed into a servo system by utilizing the advantages of conventional PID (Proportion Integration Differentiation) dense sampling; the sampling period of a major loop is 50-100 times of that of the minor loop; the control program calculates the setting values of air knife pressure, distance and frame position in real time according to the actual value of plating thickness and the data in production process and sends into the PLC controller so as to realize the adjustments of the air knife pressure, distance and frame position; and simultaneously, the controls for undisturbed switching and plating variable specification switching in manual / automatic mode are further designed. According to the automatic control system, the deviation of plating thickness can be quickly eliminated, and the system has good control effect on variable specification in the processes of accelerating and decelerating.

Owner:ANGANG STEEL CO LTD

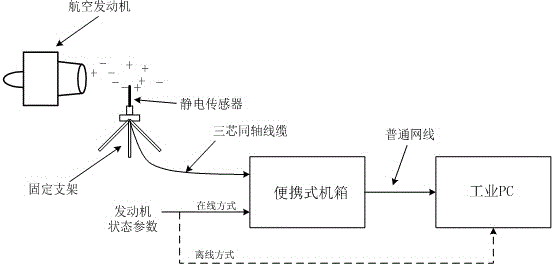

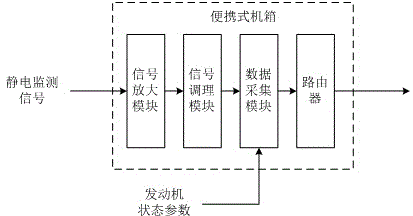

Portable failure detection system and method for aero-engine gas path component

InactiveCN102980771AImprove securityLow costInternal-combustion engine testingAviationSignal conditioning

The invention relates to a portable failure detection system and method for an aero-engine gas path component. According to a principle that the tail gas electrostatic-charge level keeps in a certain level range under the condition that an aero-engine is failure-free, and the tail gas electrostatic-charge level can change once the gas path component has a failure, the system and the method detect the health status of the aero-engine gas path component. The system comprises a tail gas static-electricity monitoring sensor subsystem, a signal conditioning, collecting and transmitting subsystem and an industrial PC (Personal Computer). First, a baseline model of engine tail gas electrostatic signals is established, and the health status of an engine is judged through deviation of the analyzed and actually-measured characteristic parameters of the tail gas electrostatic signals and a baseline value. Aiming at the problems of false dismissal and early warning lag in the traditional engine status monitoring method, the invention designs the portable failure detection system for the gas path components. The system is used for engine ground run, can increase the safety of the engine, is low in cost, and is easily realized in engineering.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

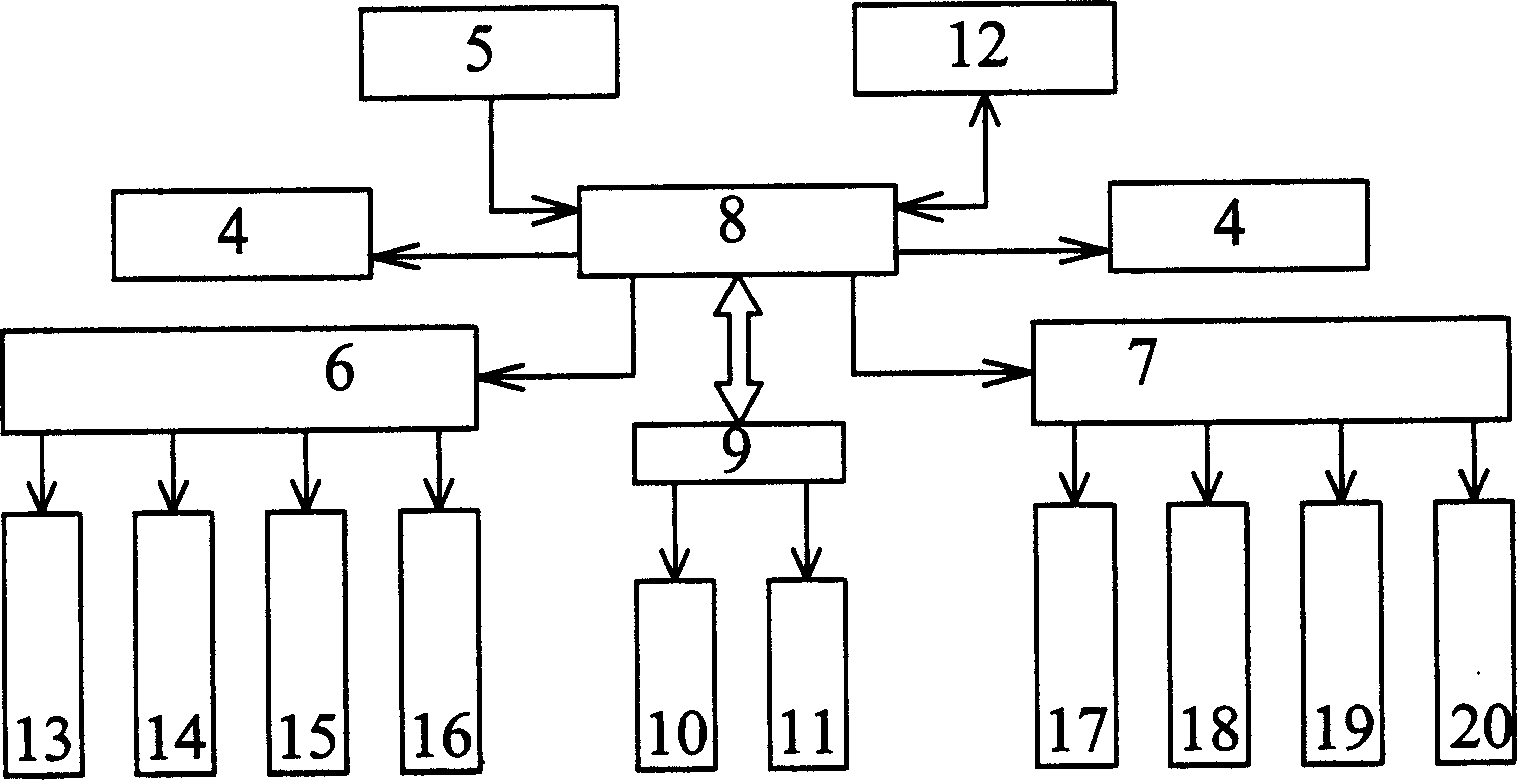

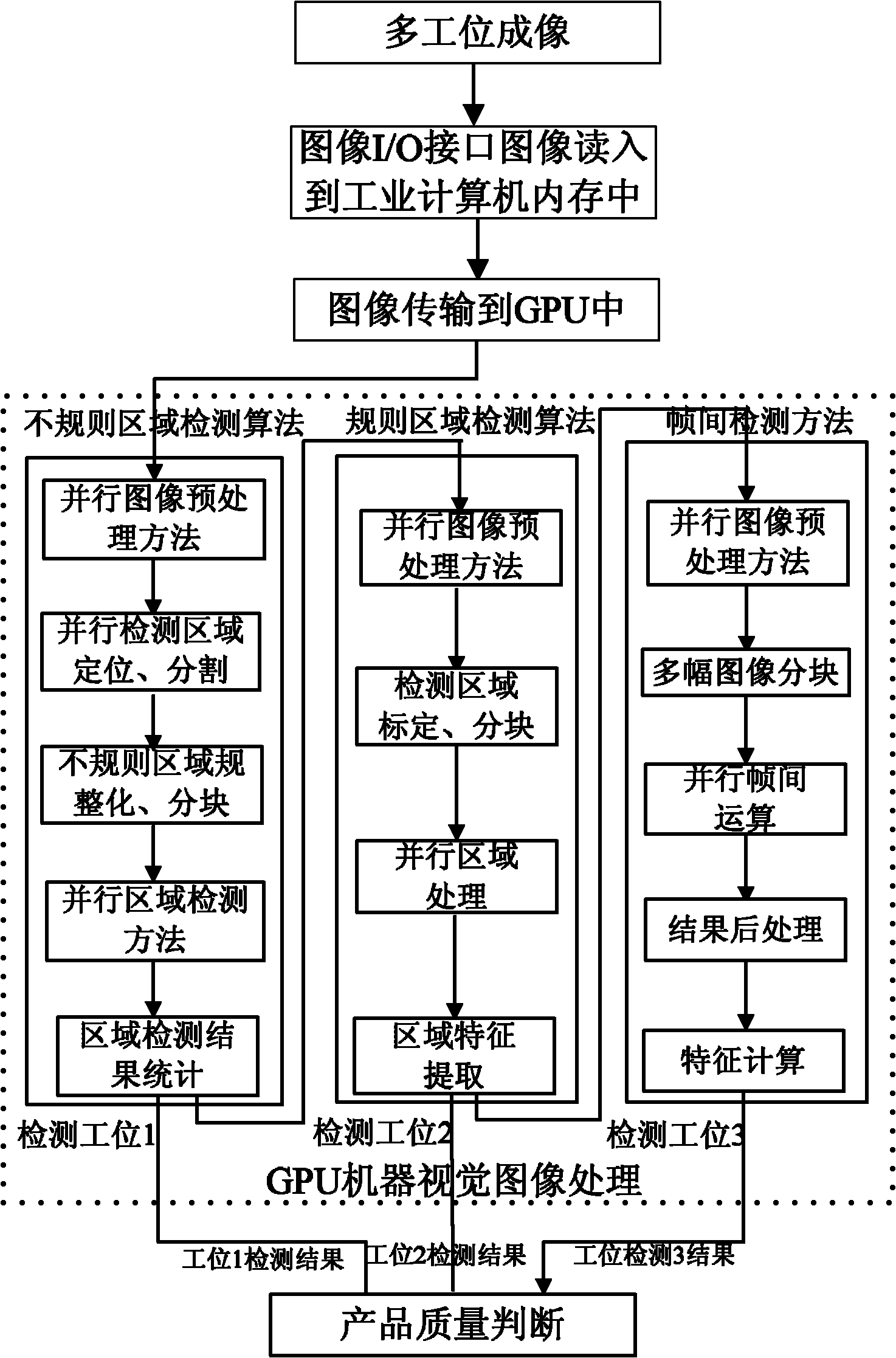

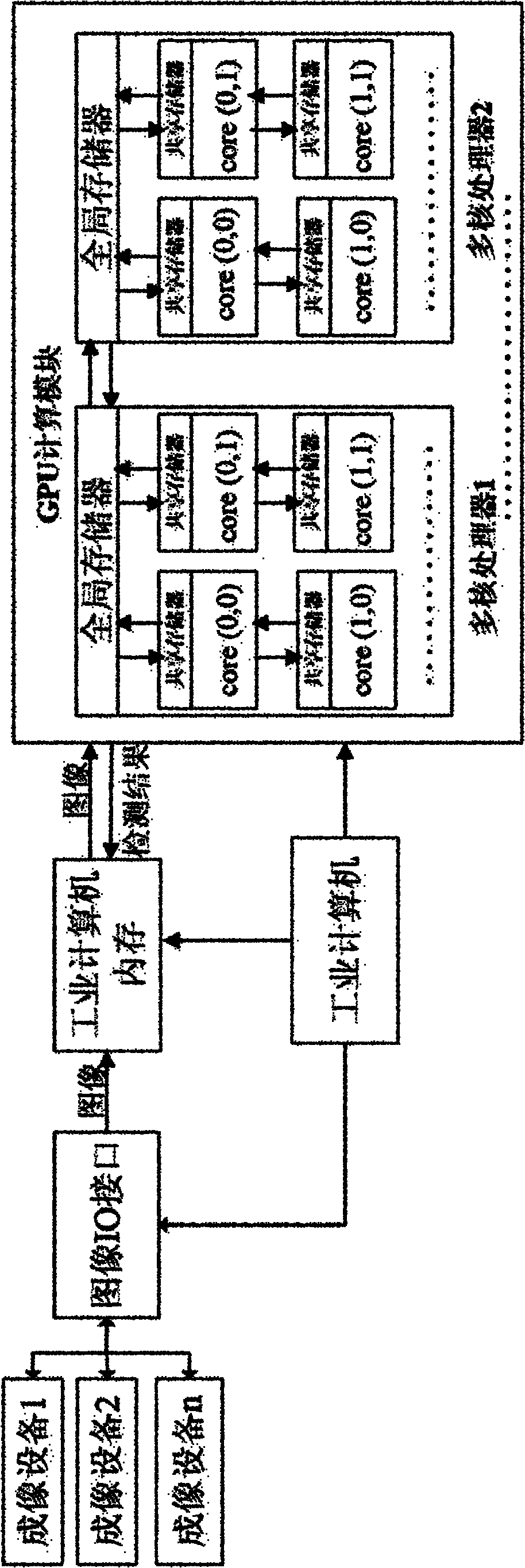

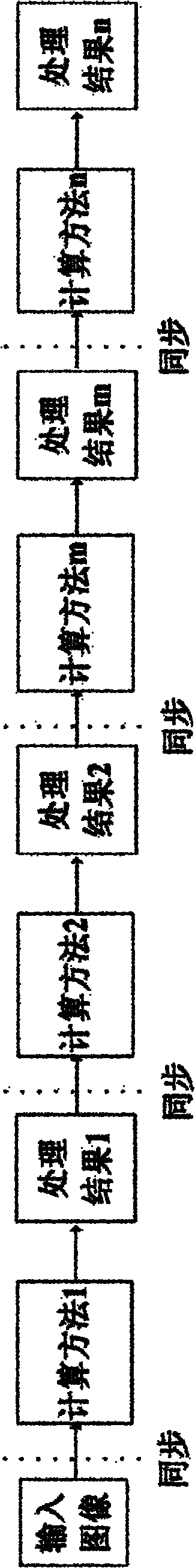

Multi-station machine vision imaging detection method and system based on graphics processor

InactiveCN102169093AReduce volumeHighly integratedOptically investigating flaws/contaminationClosed circuit television systemsGraphicsMachine vision

The invention relates to a multi-station machine vision imaging detection method and a system based on the graphics processor. The method comprises following steps: arranging an imaging device on each detection station, controlling more than one image I / O interfaces through the industrial computer, and transmitting the image obtained from imaging device connected with each I / O interface of the image to the industrial computer memory; transmitting the image to GPU calculating modules by the industrial computer which can do real-time processing to image obtained from each detection station and transmit the result to the industrial computer. The system comprises an industrial computer, more than one GPU calculating modules, more than one image I / O interfaces, more than one imaging system, a multi-station position detecting device, a whole machine time schedule controller, a winkling controller and a winkling device. The invention has advantages of simple and compact structure, low cost, high integrated level, good stability, reliability and versatility, etc.

Owner:HUNAN UNIV

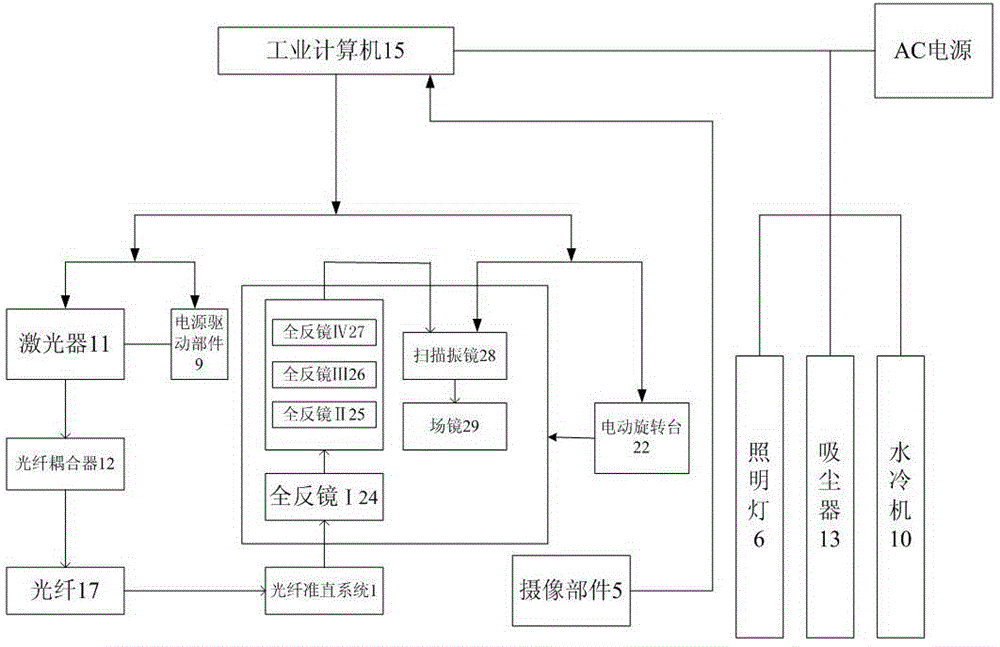

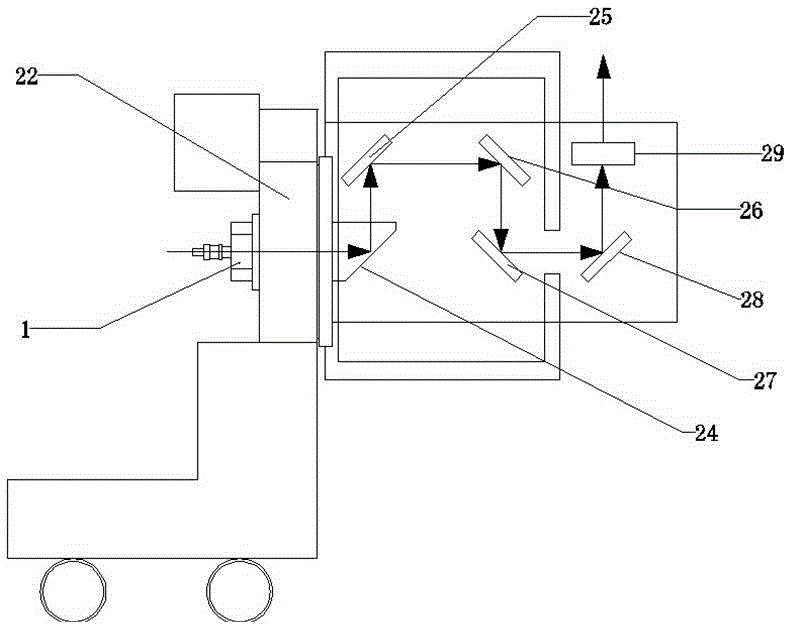

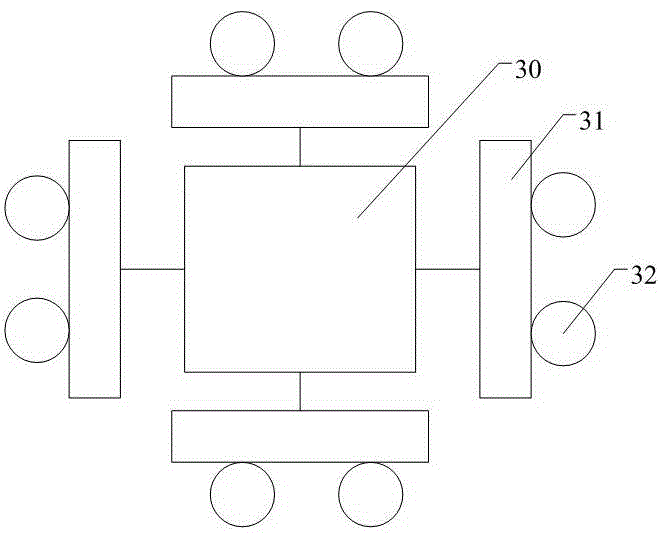

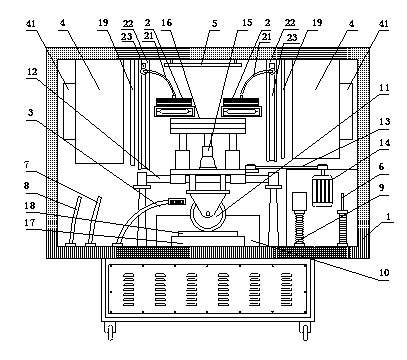

Robot for cleaning metal pipeline by laser light

The invention provides a robot for cleaning a metal pipeline by laser light. The robot comprises a wheel type trolley, a connecting component and an equipment cabinet. The wheel type trolley comprises a laser light output component, a camera shooting component and a dust collection mechanism. The connecting component comprises an optical fiber, a cable, a data line and a dust collection pipe. The equipment cabinet comprises a laser device, an optical fiber coupler, a power driving component, a water cooling machine, a dust collector and an industrial computer. Laser light is output by the laser device, coupled into the optical fiber through the optical fiber coupler and transmitted to an optical fiber collimation system in the laser light output component loaded on the wheel type trolley through the optical fiber, and then passes through a scanning galvanometer and a rotary accessory component in the laser light output component, so that a linear light spot capable of rotating by 360 degrees is output. The linear light spot rotates by 360 degrees to scan the inner wall of the metal pipeline, and therefore the purpose of cleaning the pipeline is achieved. The robot is used for cleaning the metal pipeline on line, and therefore the cleanness of the metal pipeline is kept on line.

Owner:LASER FUSION RES CENT CHINA ACAD OF ENG PHYSICS

Multifunctional rut testing instrument

The invention discloses a multifunctional rut testing instrument, and relates to a rut testing instrument. The provided multifunctional rut testing instrument solves the problem that the conventional rut stimulation testing devices cannot obtain the data that is most approximate to the actual data under comprehensive conditions. The rut testing instrument is composed of a testing box, an industrial computer, and a control table; a rut testing assembly, an ultraviolet lamp, a spraying nozzle, a refrigerator, a heater, a temperature sensor, an oxygen gas jet pipe, a nitrogen gas jet pipe, and an oxygen gas concentration sensor are arranged in the testing box, the industrial computer controls the rut testing assembly through program software, and the control table is used to control the switch of the ultraviolet lamp, the spraying of the spraying nozzle, the temperature, and the oxygen gas concentration. The provided multifunctional rut testing instrument can carry out stimulation tests under comprehensive environment with different sunlight strengths, rain water amounts, temperature ranges, and oxygen gas concentrations so as to obtain the asphalt road surface aging situation data, which is closest to the actual data, under the comprehensive conditions. The test results have a good adaptability, and thus the testing instrument is very helpful for the researches on the aging rules of asphalt road surface.

Owner:FUZHOU MEIDE TESTING INSTR +2

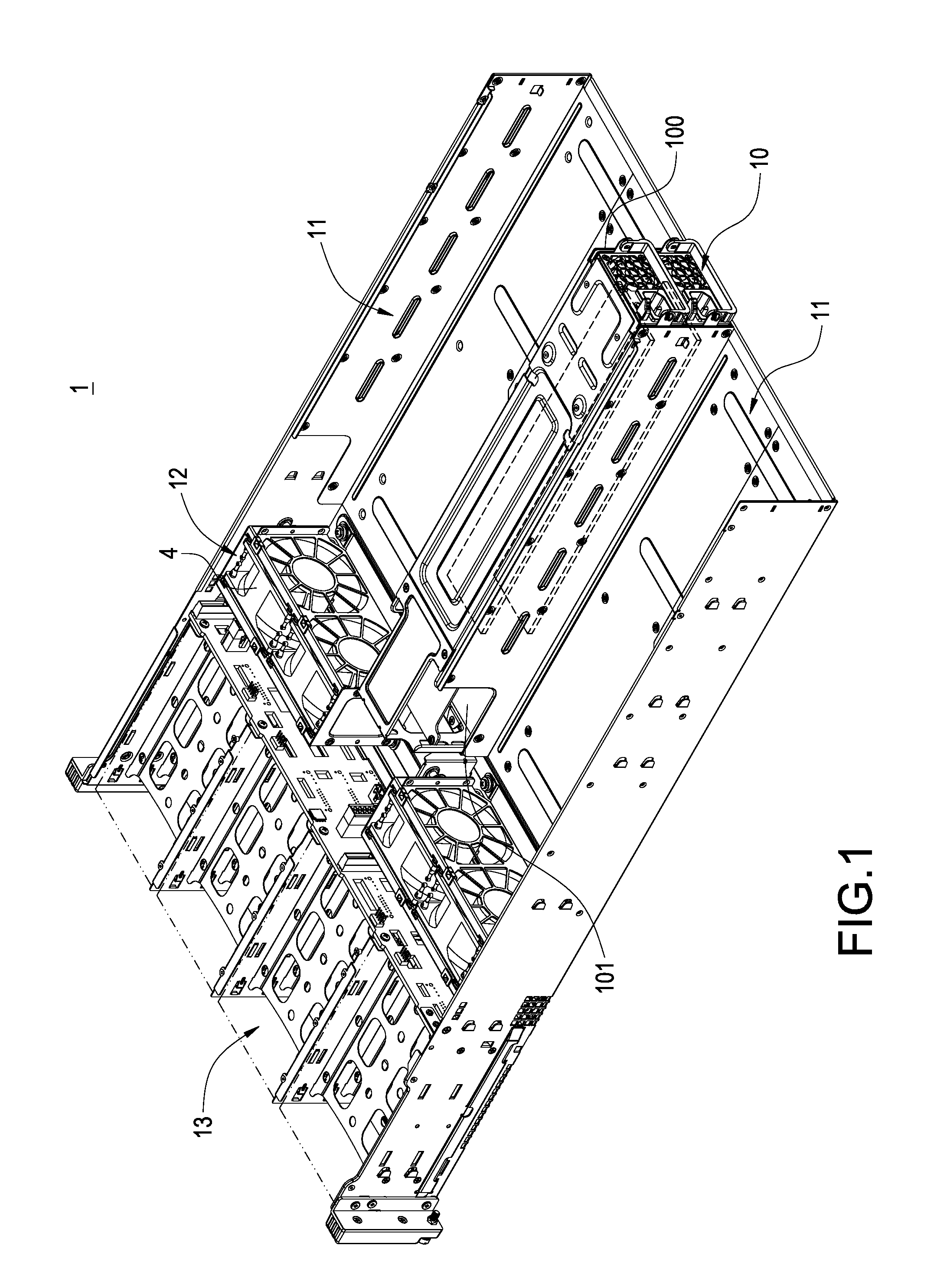

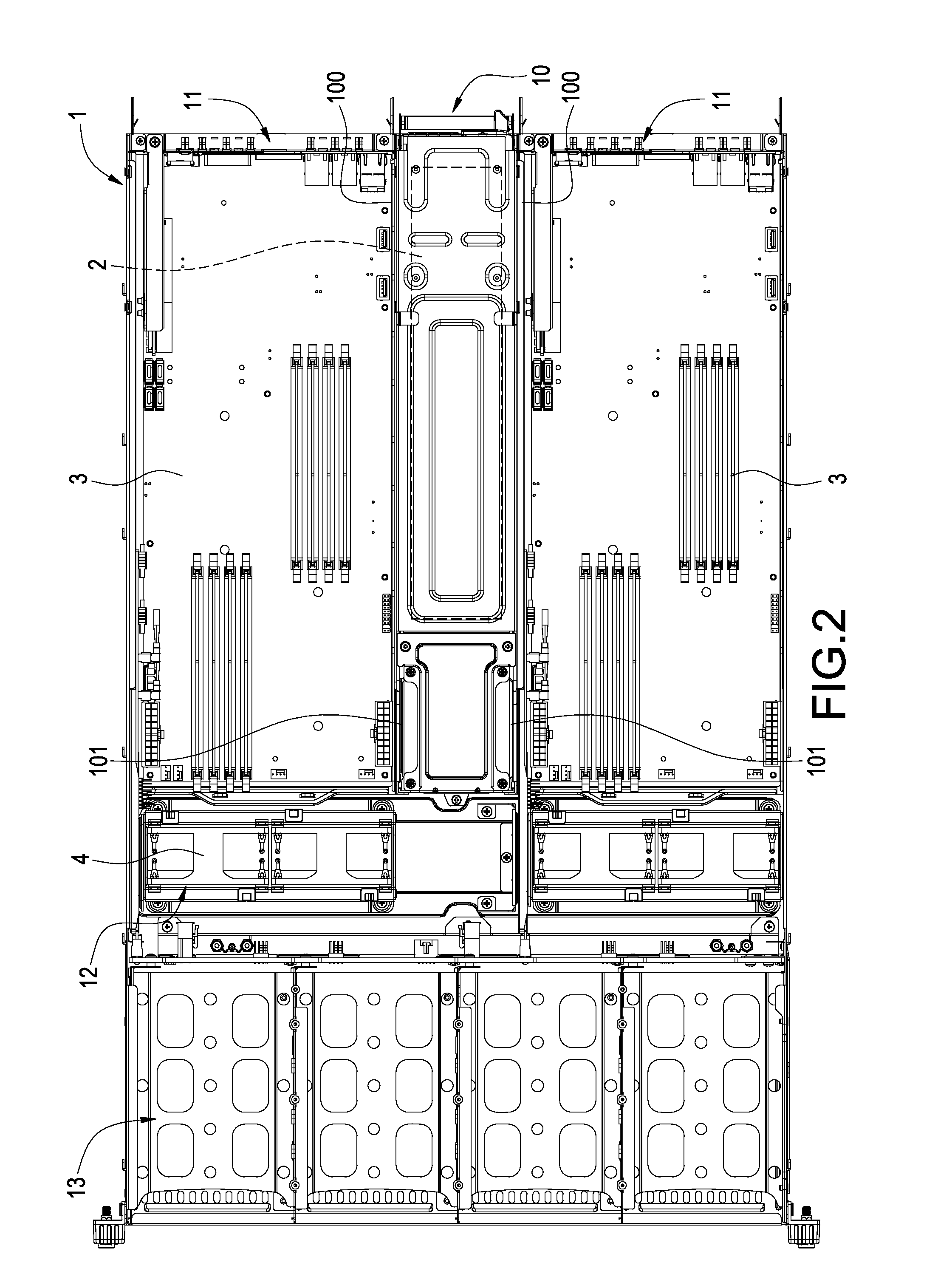

Industrial computer chassis structure with power source disposed centrally

ActiveUS7839624B2Digital data processing detailsElectrical apparatus contructional detailsSoftware systemEngineering

An industrial computer chassis structure is mainly to partition at least two motherboard sections in the shell of the computer chassis, in each of which a motherboard tray capable of being pulled and drawn is arranged and is provided for placing a motherboard therein. Meanwhile, the two motherboard sections are horizontally disposed by being parallel with each other, in the space between which a power source arrangement section is formed. The power source arrangement section is provided for arranging power supplies of the computer therein. Through this kind of disposition structure, all motherboards in the motherboard sections can be close to the power source arrangement section as near as possible, such that a function of common usage can be achieved for both the hardware connection and the software system control.

Owner:SUPER MICRO COMP

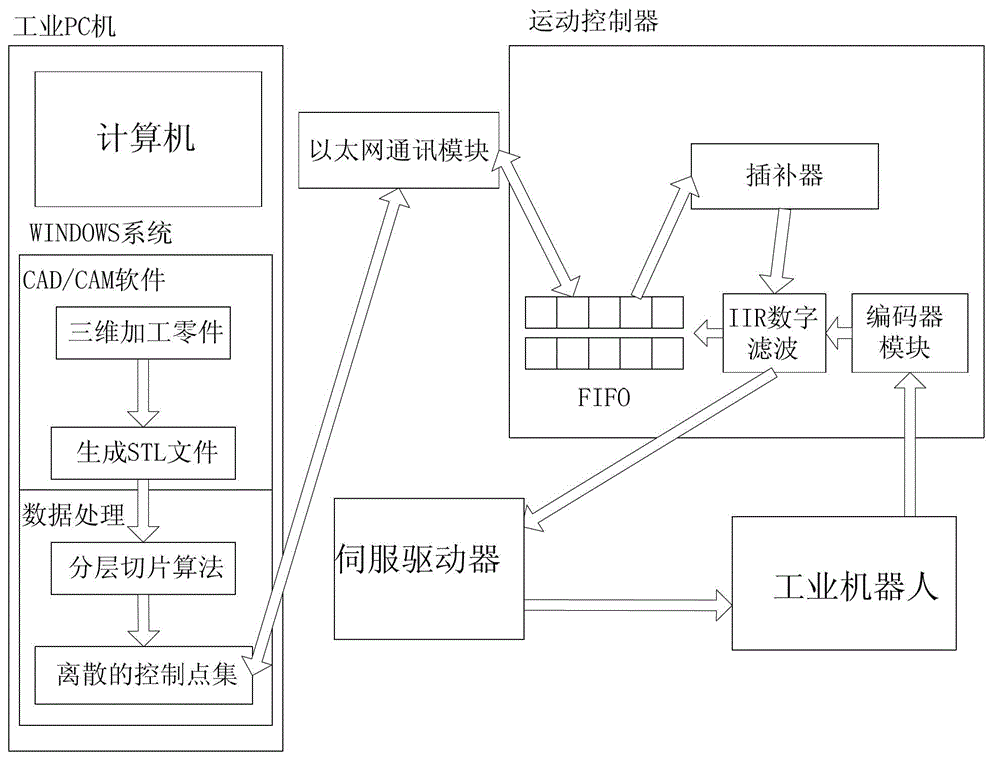

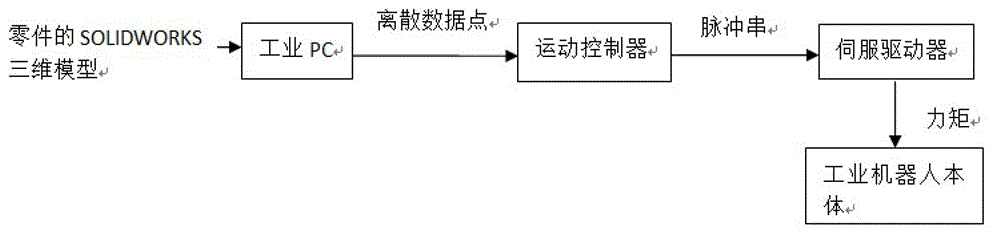

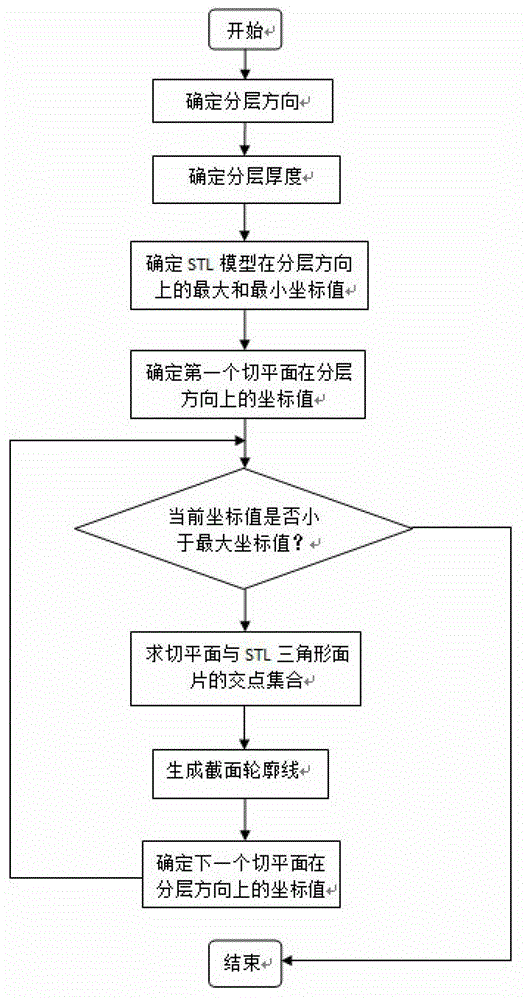

Track generating method facing toward complex curved surface processing and track generating system thereof

InactiveCN103064343AOvercoming the inability to resolve model voidsReduce the number of timesProgramme controlComputer controlIntersection of a polyhedron with a lineMotion controller

The invention discloses a track generating method facing toward complex curved surface processing and a track generating system thereof. The track generating method includes that a to-be-processed complex curved surface is chosen and a standard template library (STL) file is generated; layer dividing direction and layer dividing thickness are determined; group dividing is conducted on a triangular patch; the point of intersection is obtained by an incremental method; a coordinate minimum value point of each section point of intersection gather in the direction of being vertical to the layer dividing direction is found out, another point of intersection of the same triangular patch is searched and connected with the minimum value point, and the process continues until the outline of each tangent plane is obtained and eventually the generating route track is obtained. The track generating system comprises an industrial personal computer (PC), a motion controller, a servo driver and an industrial robot body. The industrial PC generates three-dimensional to-be-processed components into a scattered control point set and transmits the control point set to the motion controller. The motion controller conducts an interpolation calculation on the control point set and outputs pulse trains to the servo driver, and drives the industrial robot body to conduct coordinated movement in a torque control mode. The track generating method facing toward complex curved surface processing and the track generating system thereof have the advantages of small calculation quantity, short calculation time, and high calculation efficiency.

Owner:SOUTH CHINA UNIV OF TECH

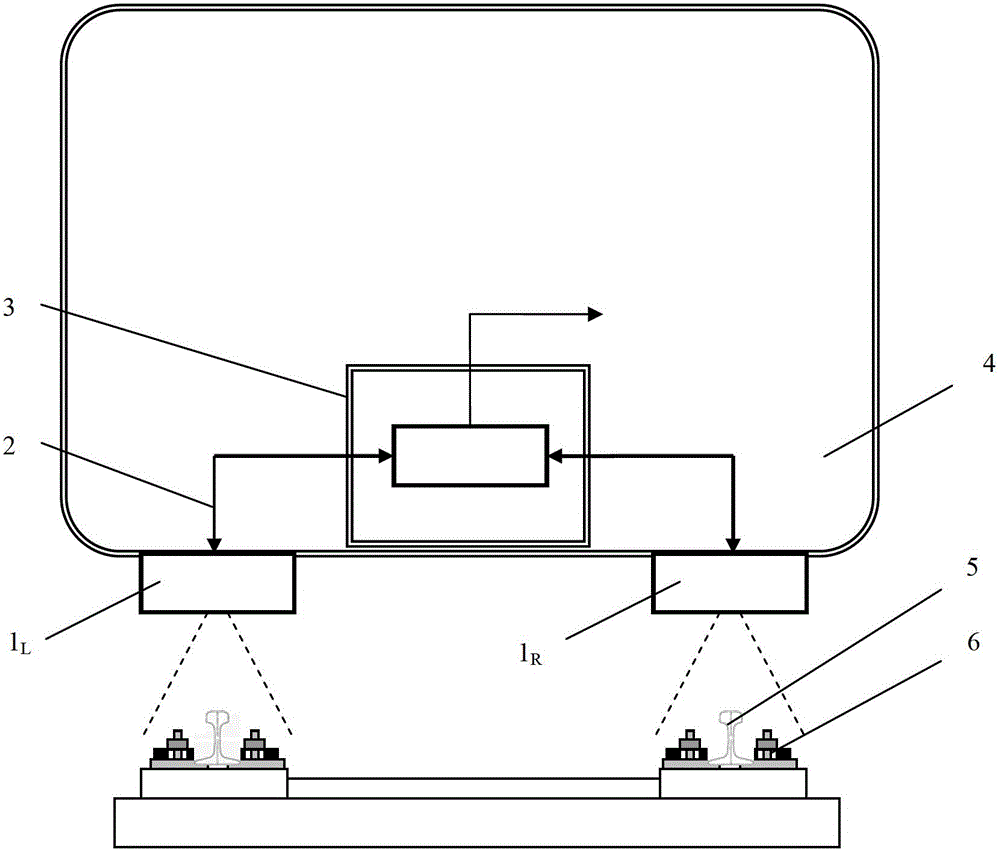

System and method for high-speed detection of loosening of railway fasteners on basis of infrared thermal imaging

InactiveCN102721700AHigh precisionImplement automatic detectionForce measurement by measuring optical property variationOptically investigating flaws/contaminationImaging processingStress point

The invention discloses a system and a method for high-speed detection of loosening of railway fasteners on the basis of infrared thermal imaging. The system comprises two detectors, a controller and cables, the two detectors are positioned on the lower side of a body of a train and respectively opposite to the upper side of a left steel rail and the upper side of a right steel rail, the controller is mounted in a carriage and connected with the two detectors by the cables, digital infrared cameras are arranged inside the detectors, and whether the fasteners are loosened or lost or not is automatically judged by direct acquisition of infrared thermal images generated by contact stress of the fasteners and the steel rails, image processing and mode identification. The viewing field of each camera is centered at the position of the corresponding fastener, and image sampling and processing are carried out in selective small ranges of the fields of the view. During running of the train, sampling interval is adjusted if the positions of the fasteners are improper. Whether the maximum stress points in the infrared images are lower than a critical threshold or not is judged by an industrial computer so as to judge whether the fasteners are loosened or not, warning signals are transmitted if the fasteners are loosened, and early warning is realized before the fasteners are lost.

Owner:上海砺晟光电技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com