Helical surface digital control enveloped milling method and integration control system thereof

A helical surface and milling technology, which is applied in the field of helical surface numerical control envelope milling method and its integrated control system, can solve the problems of high error rate, difficult realization, and heavy workload.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

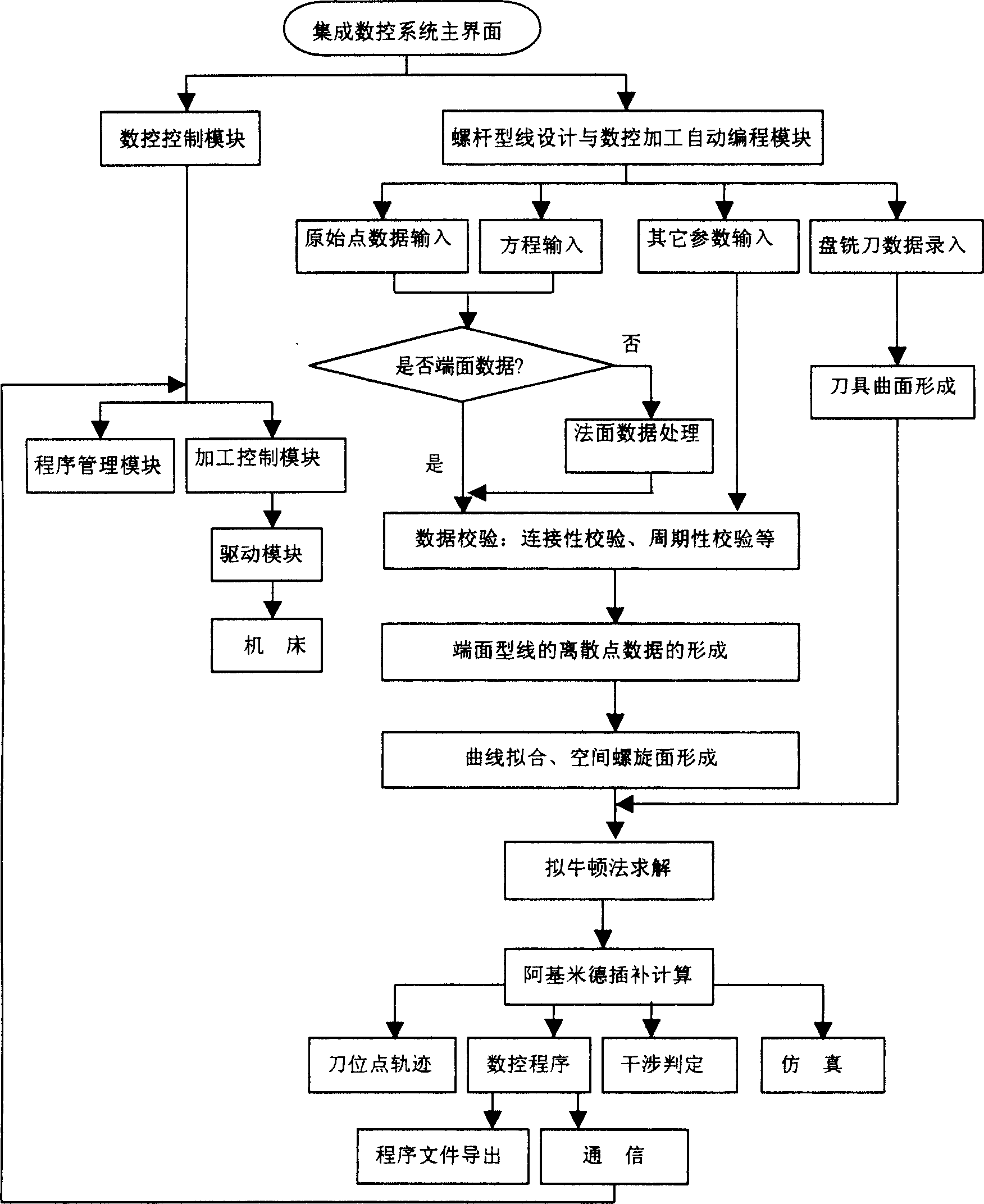

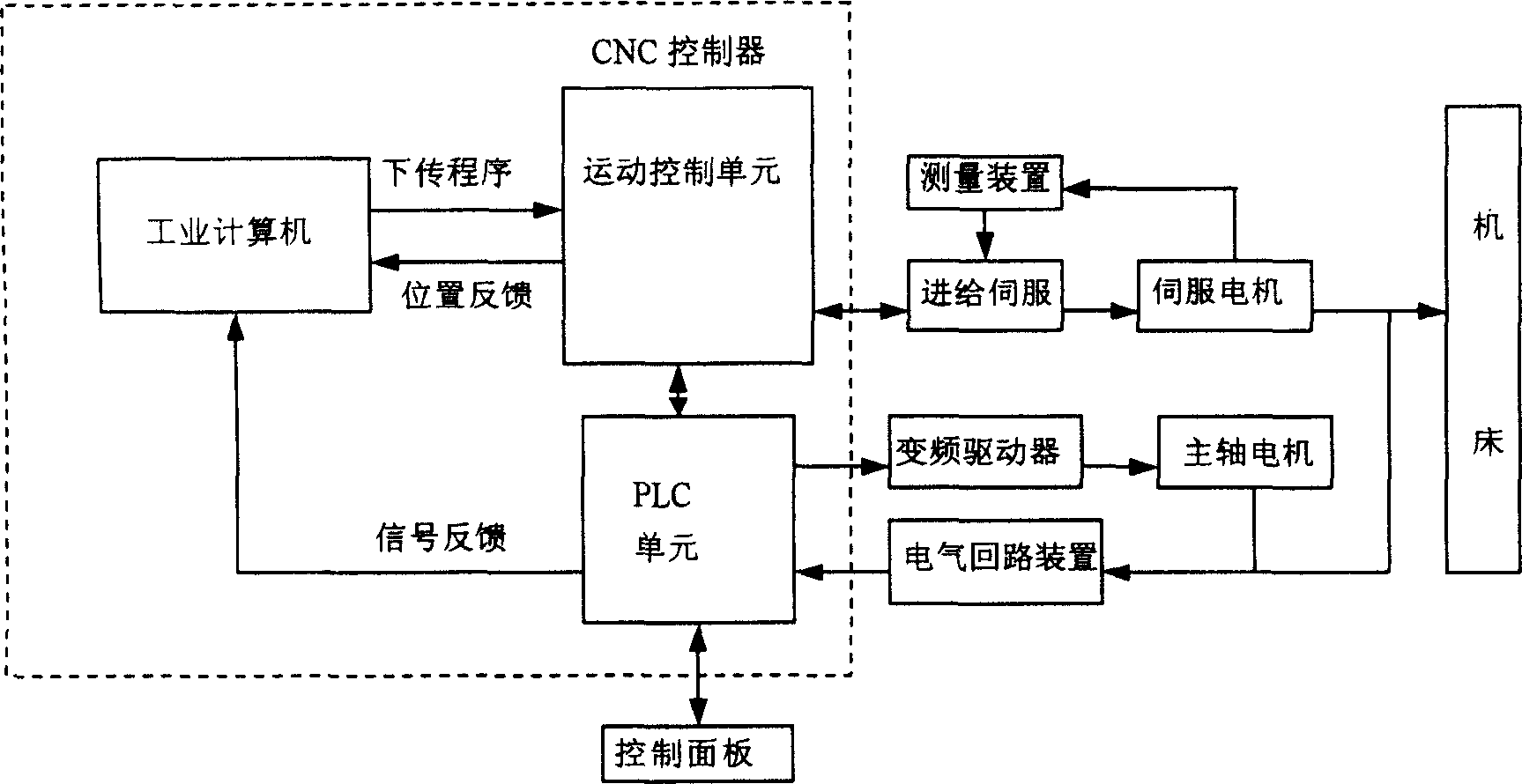

[0083] The data control flowchart of the inventive method is as figure 1 shown. If there is already a NC machining program for screw parts, you can enter the NC control module to directly perform NC machining operations on the parts, otherwise enter the screw profile design and NC machining automatic programming module to design the parts, and after the NC machining program is automatically generated, enter The CNC control module performs the CNC machining operations of the parts.

[0084] The input mode of data in the inventive method comprises original point data input mode and equation input mode, and following is specific embodiment:

[0085] ①Original point data input method:

[0086] Taking a certain type of screw as an example, the basic parameter data input is: screw with 5 heads, left-handed, lead 650mm, major diameter 102.0mm, minor diameter 74.0mm, disc milling cutter diameter Φ290mm, tool tip angle 35°, tool tip The arc radius is 1.2mm.

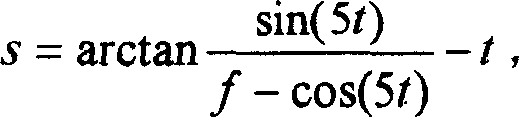

[0087] Use space meshi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com