Mask plate and encapsulating method for OLED device

A packaging method and mask technology, which are applied in the manufacturing of electric solid-state devices, semiconductor devices, semiconductor/solid-state devices, etc., can solve the problems of unfavorable narrow frame realization, intrusion, device failure, etc., and achieve narrow frame design and extended use. Longevity, the effect of improving the packaging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

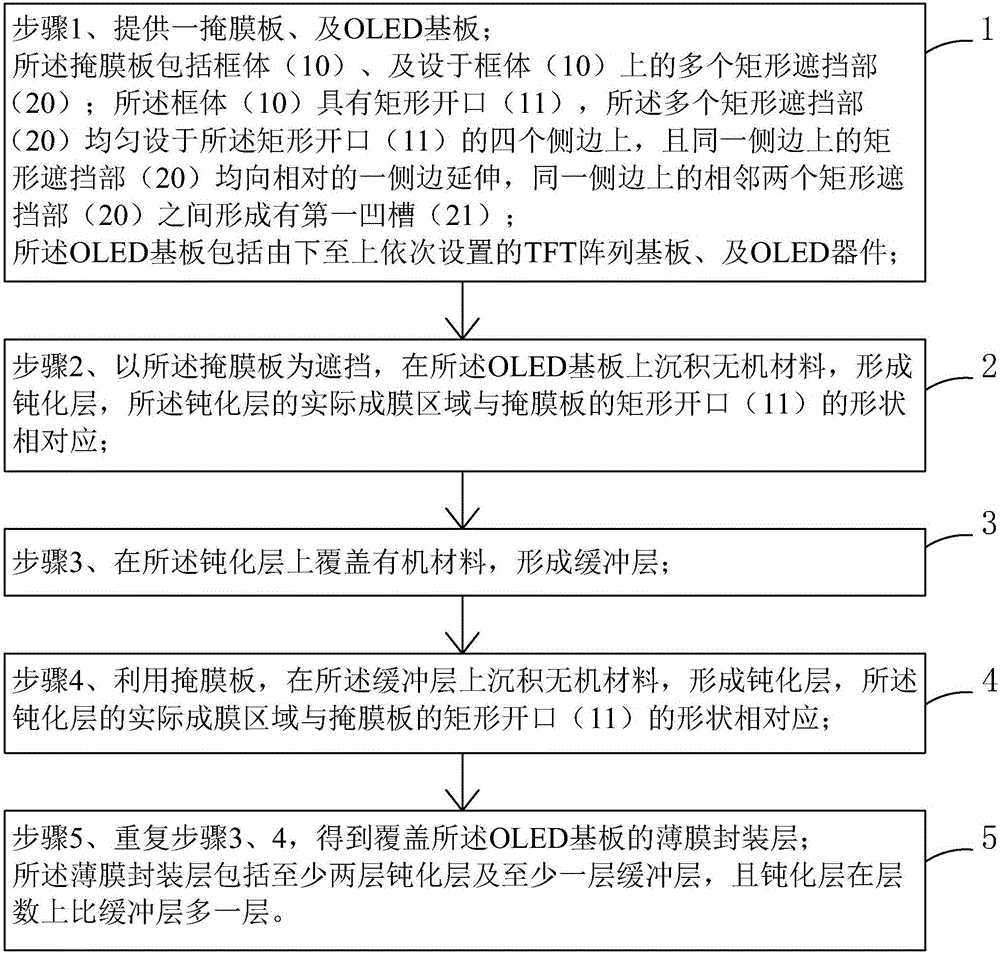

[0030] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

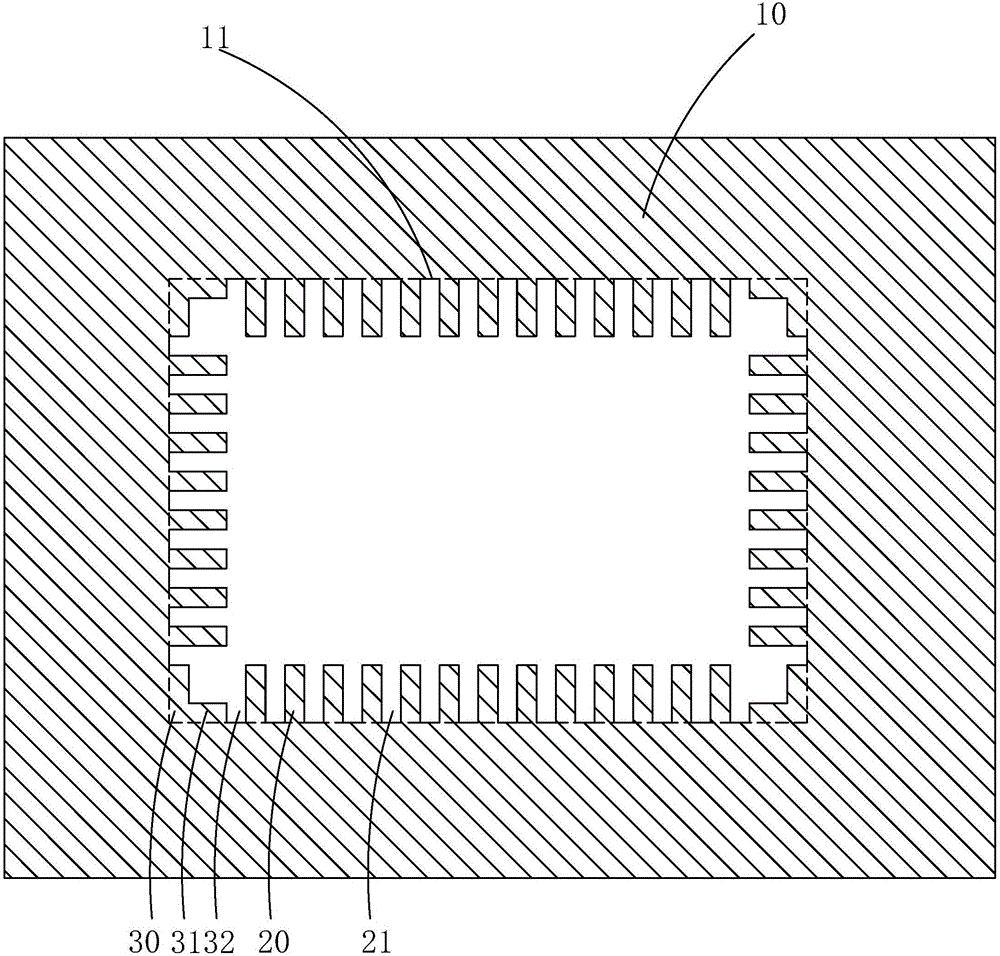

[0031] see figure 2 , the present invention provides a mask plate, comprising a frame body 10 and a plurality of rectangular shielding parts 20 arranged on the frame body 10; the frame body 10 has a rectangular opening 11, and the plurality of rectangular shielding parts 20 are uniformly arranged On the four sides of the rectangular opening 11, the rectangular shielding parts 20 on the same side all extend to the opposite side, and a second rectangular shielding part 20 is formed between two adjacent rectangular shielding parts 20 on the same side. A groove 21.

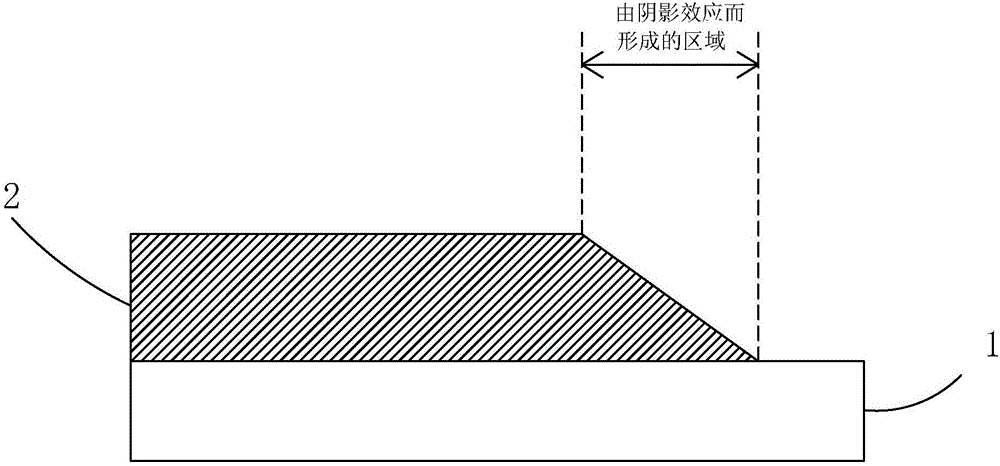

[0032]It should be noted that the mask plate of the present invention is used to deposit inorganic materials to form the passivation layer in the thin film encapsulation layer, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com