Patents

Literature

1058results about How to "Improve packaging effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

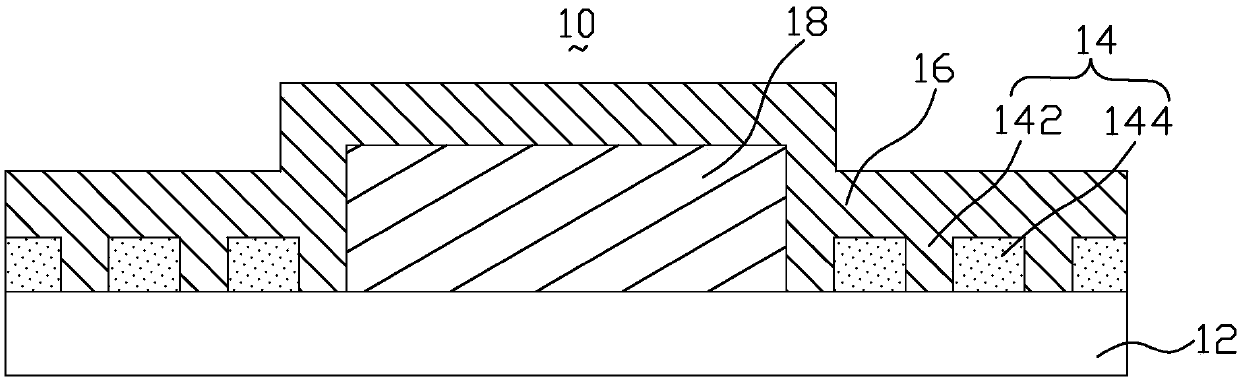

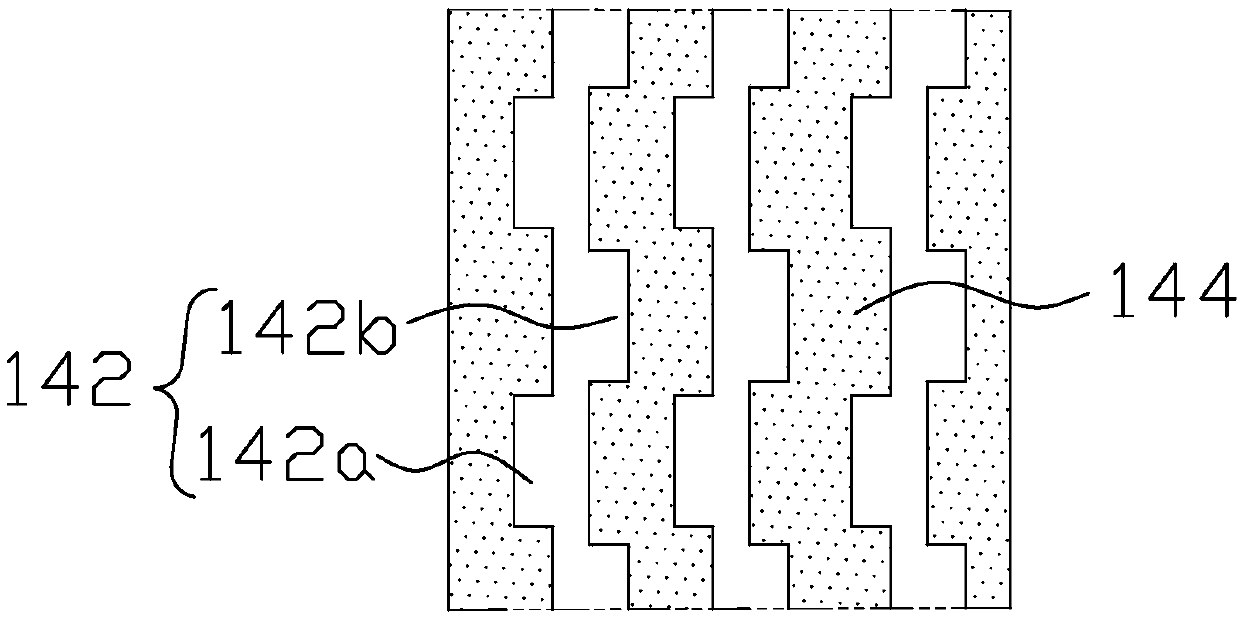

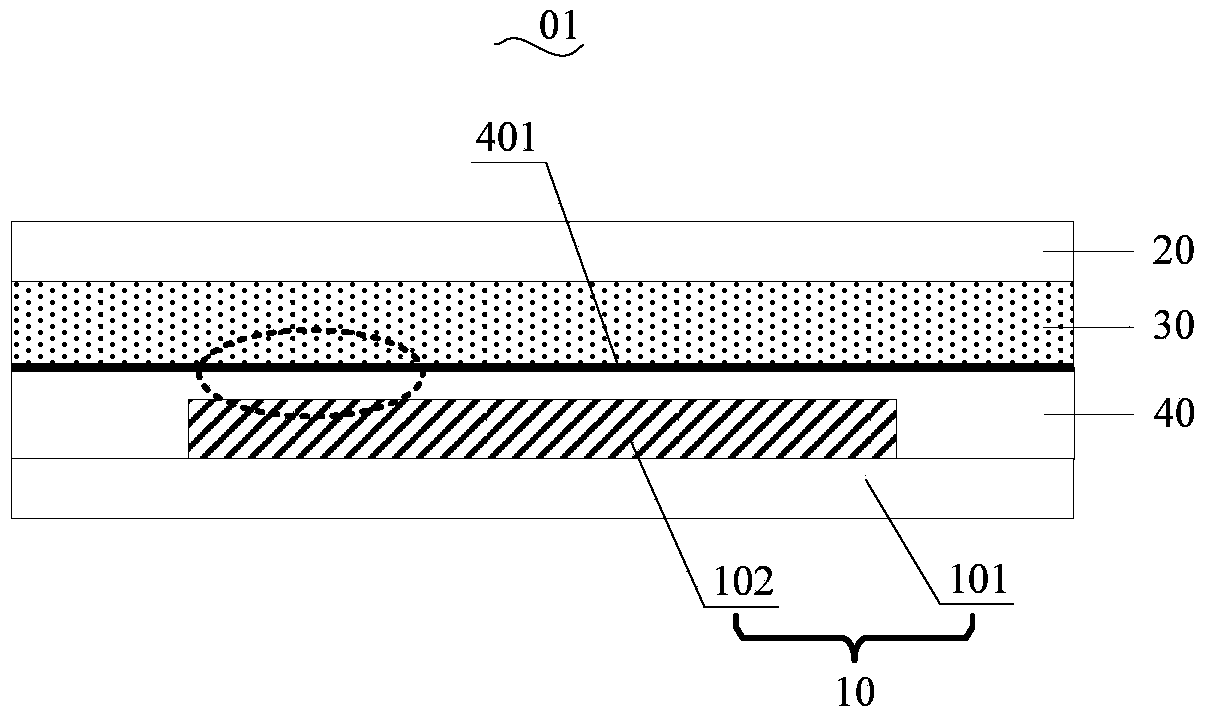

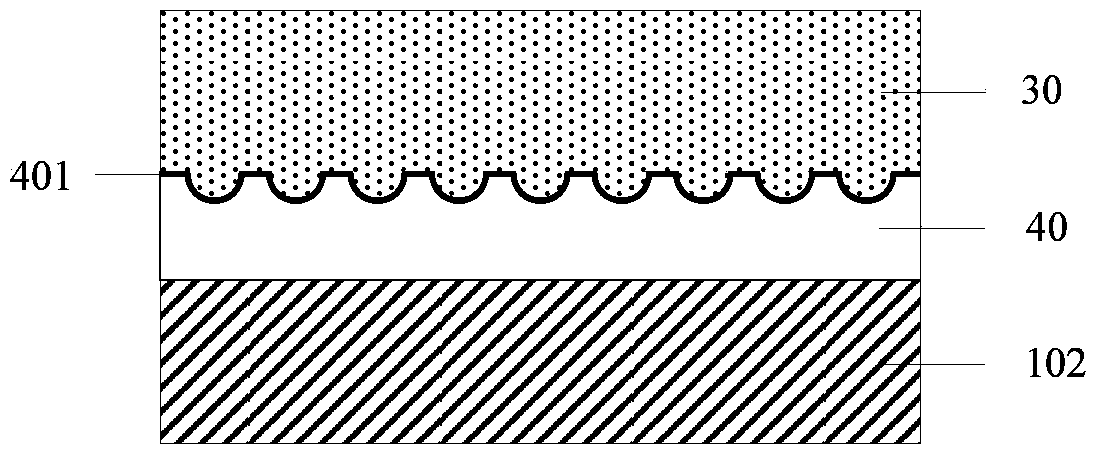

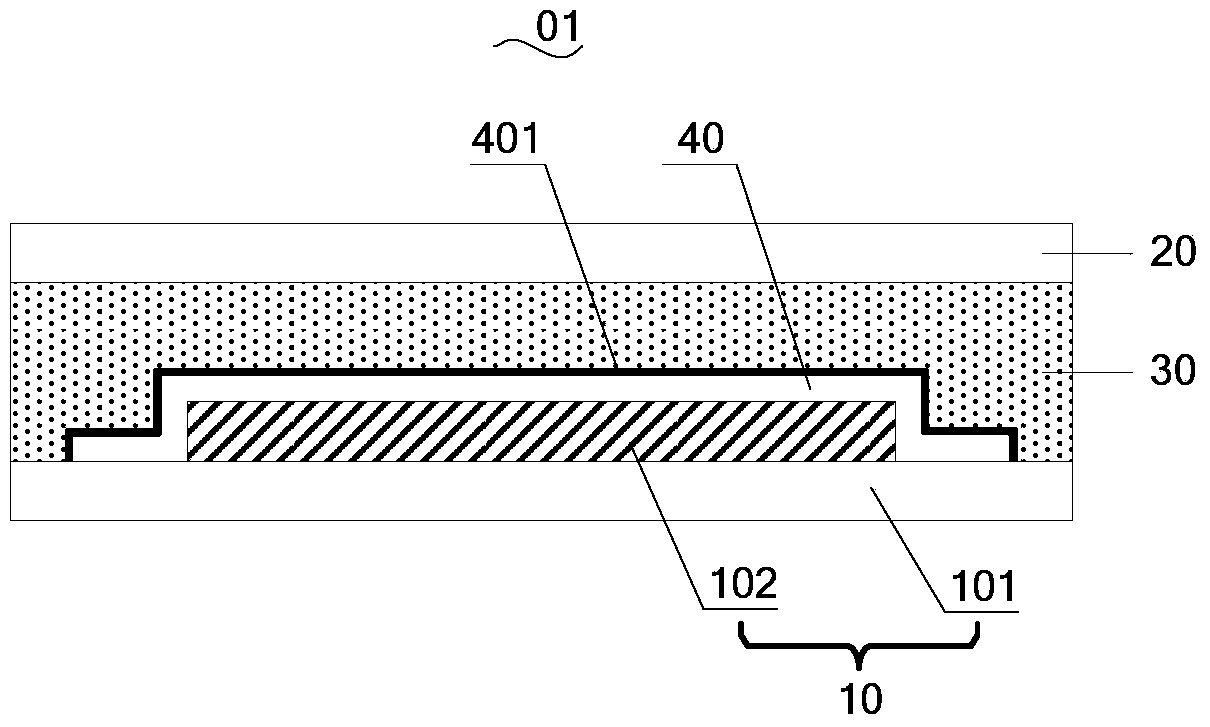

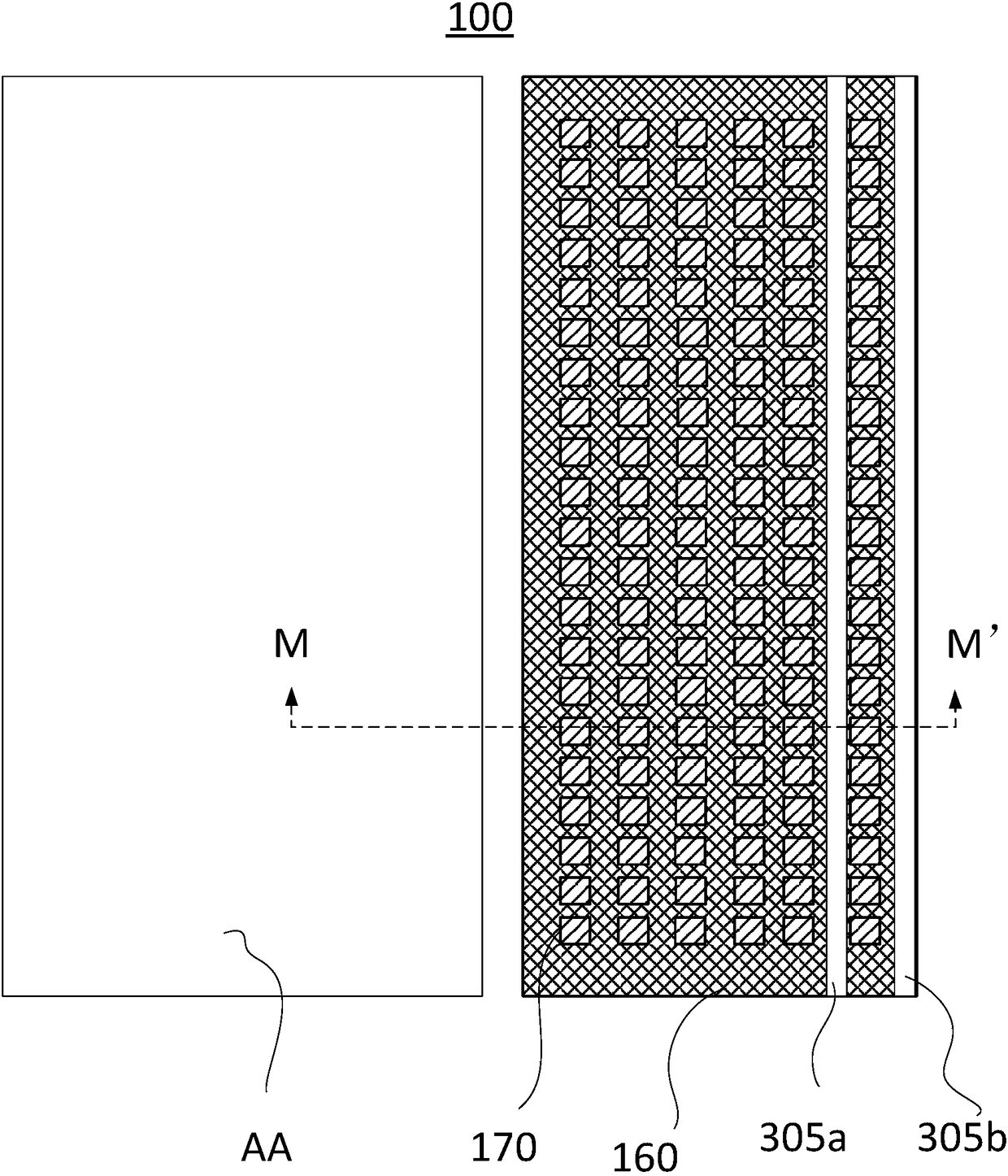

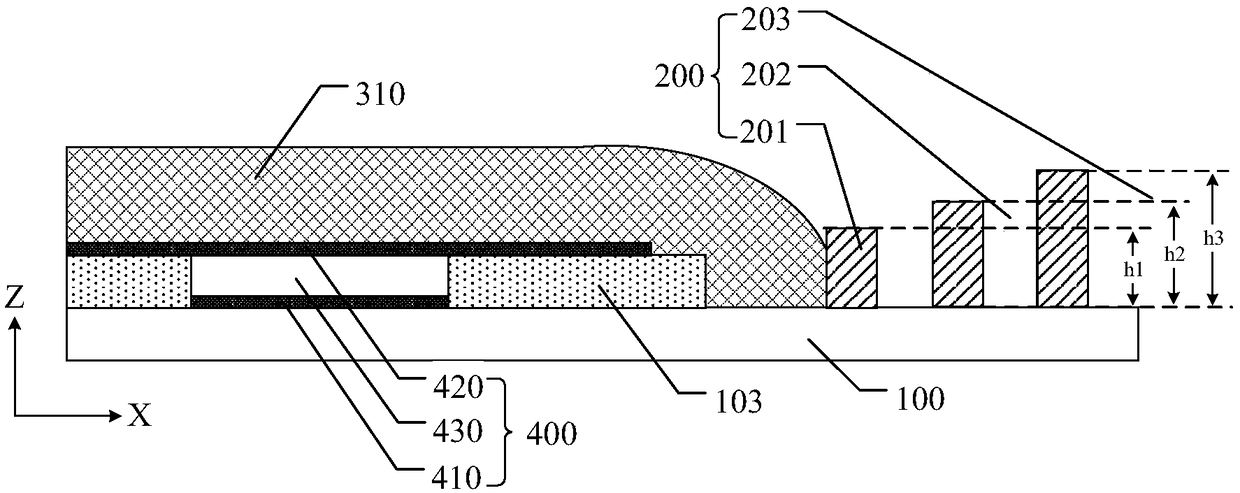

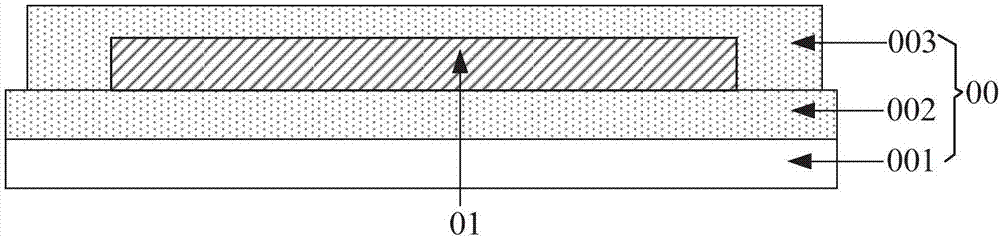

Display panel, display apparatus and preparation method for display panel

ActiveCN106653818AIncrease stressImprove packaging effectSemiconductor/solid-state device detailsSolid-state devicesOrganic light emitting deviceOptoelectronics

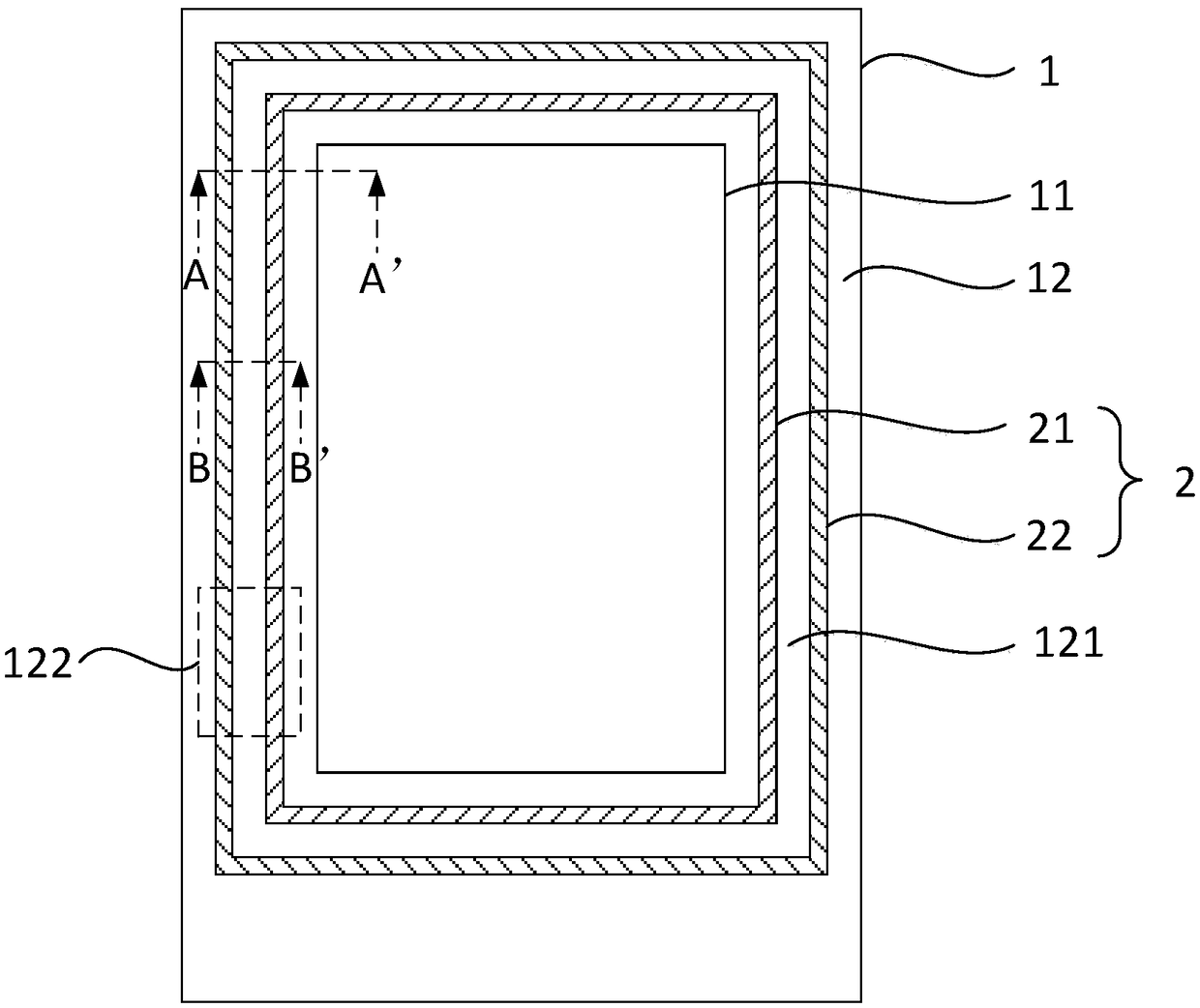

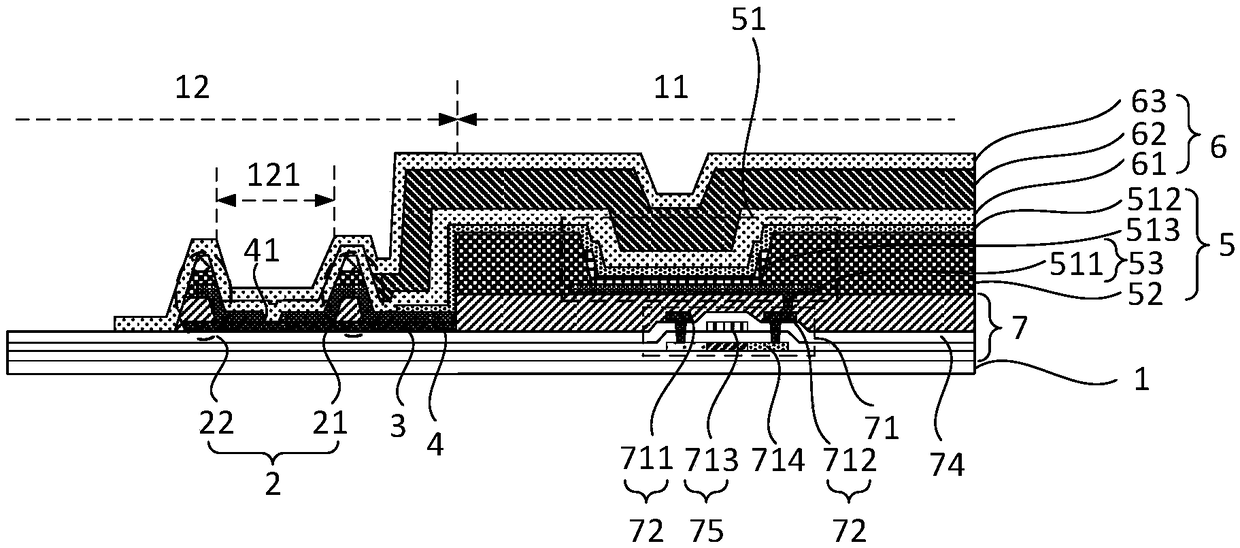

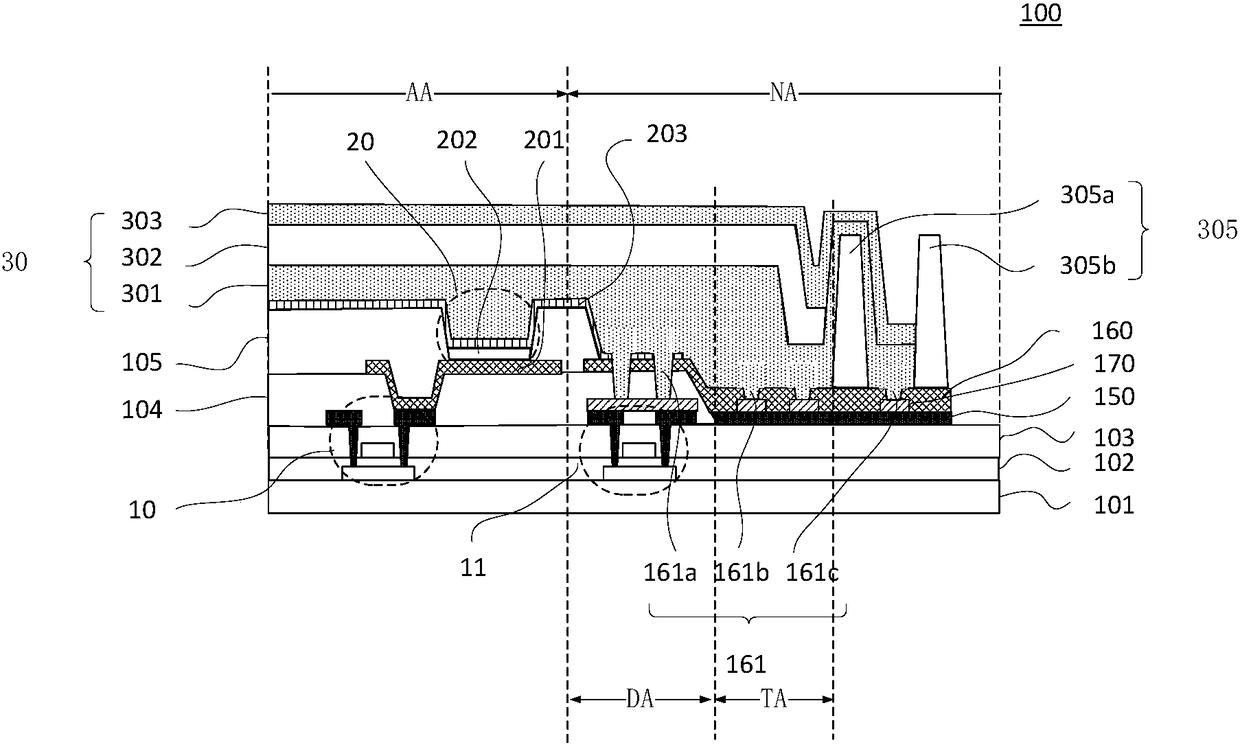

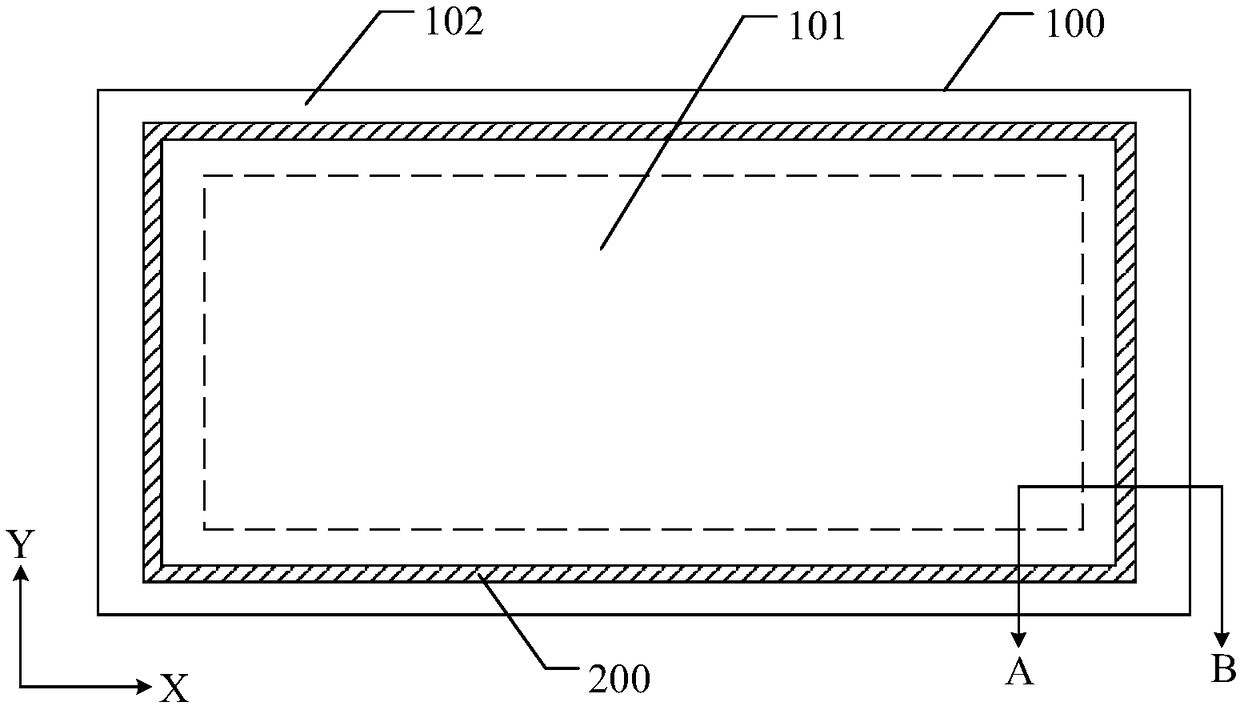

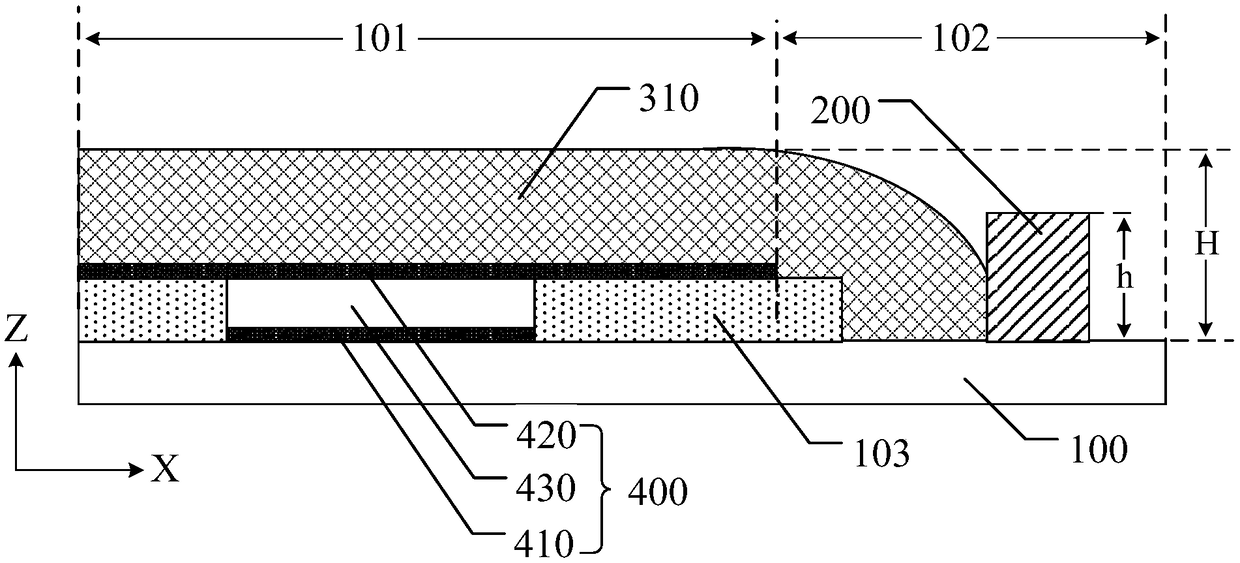

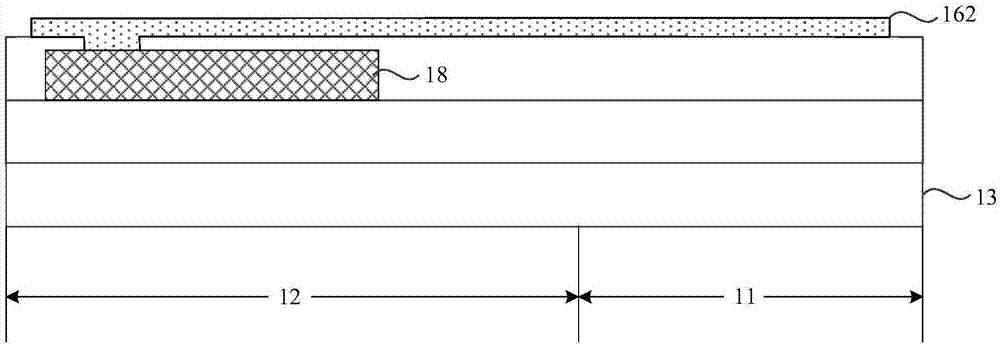

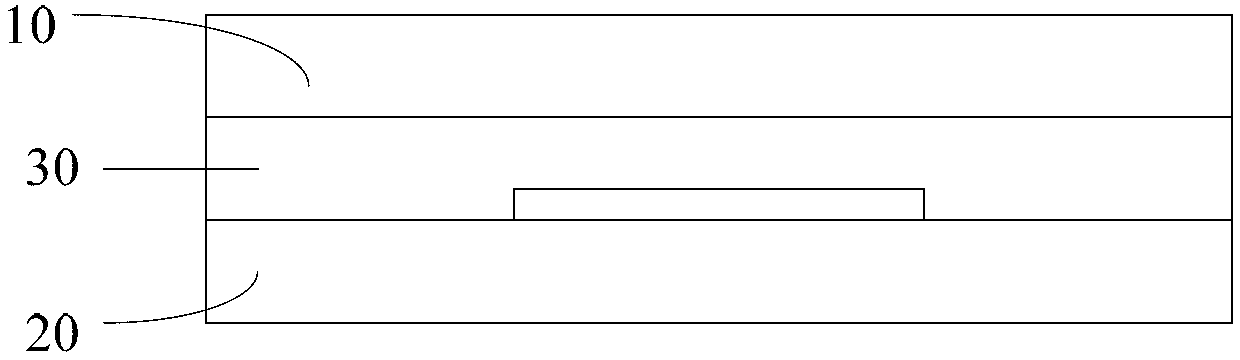

The invention discloses a display panel, a display apparatus and a preparation method for the display panel. The display panel comprises a substrate, an organic light emitting device, a thin film packaging layer, and a metal layer, wherein the substrate comprises a display region and a non-display region; the organic light emitting device is arranged in the display region of the substrate; the thin film packaging layer covers the organic light emitting device; the metal layer is positioned in the non-display region of the substrate; grooves are formed in the metal layer; and the grooves are filled with an organic layer. By virtue of setting the metal layer in the non-display region of the substrate, forming the grooves in the metal layer and filling the grooves with the organic layer, bending stress resistance and cutting stress resistance of an edge region are improved, so that risk of cracks on the edge is relieved, and crack expansion can be effectively prevented.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD

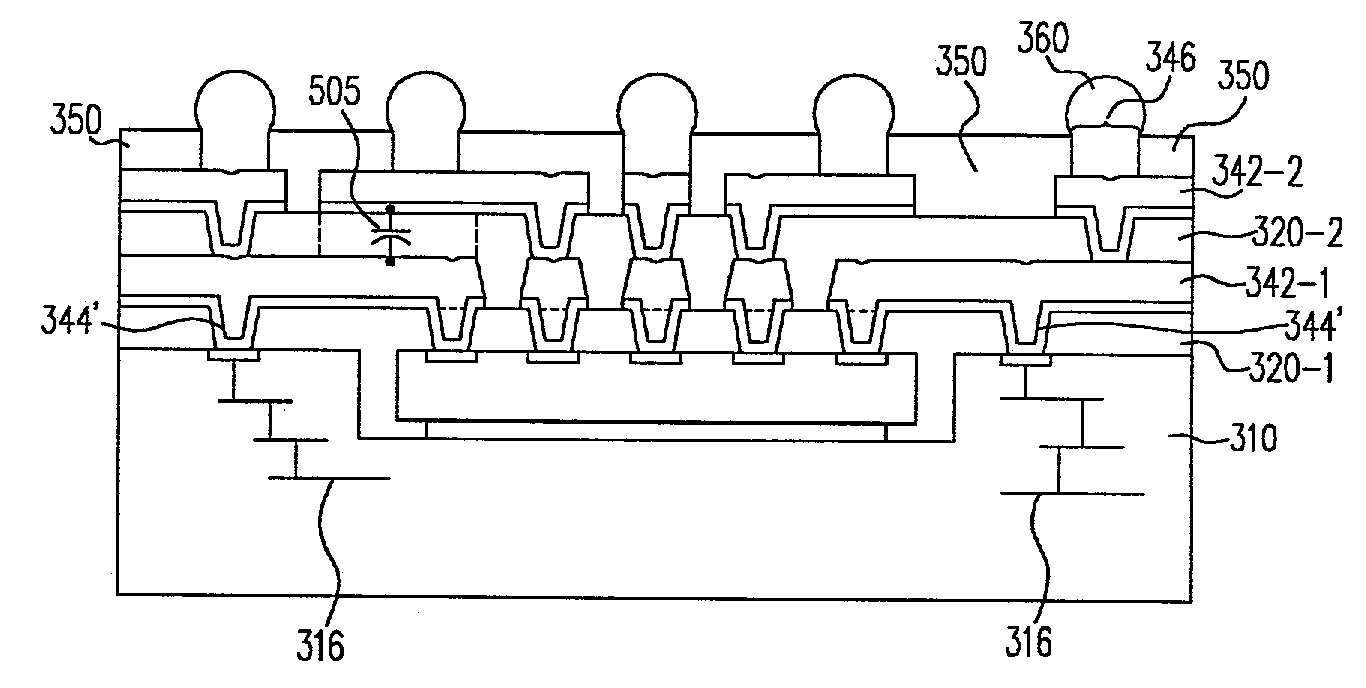

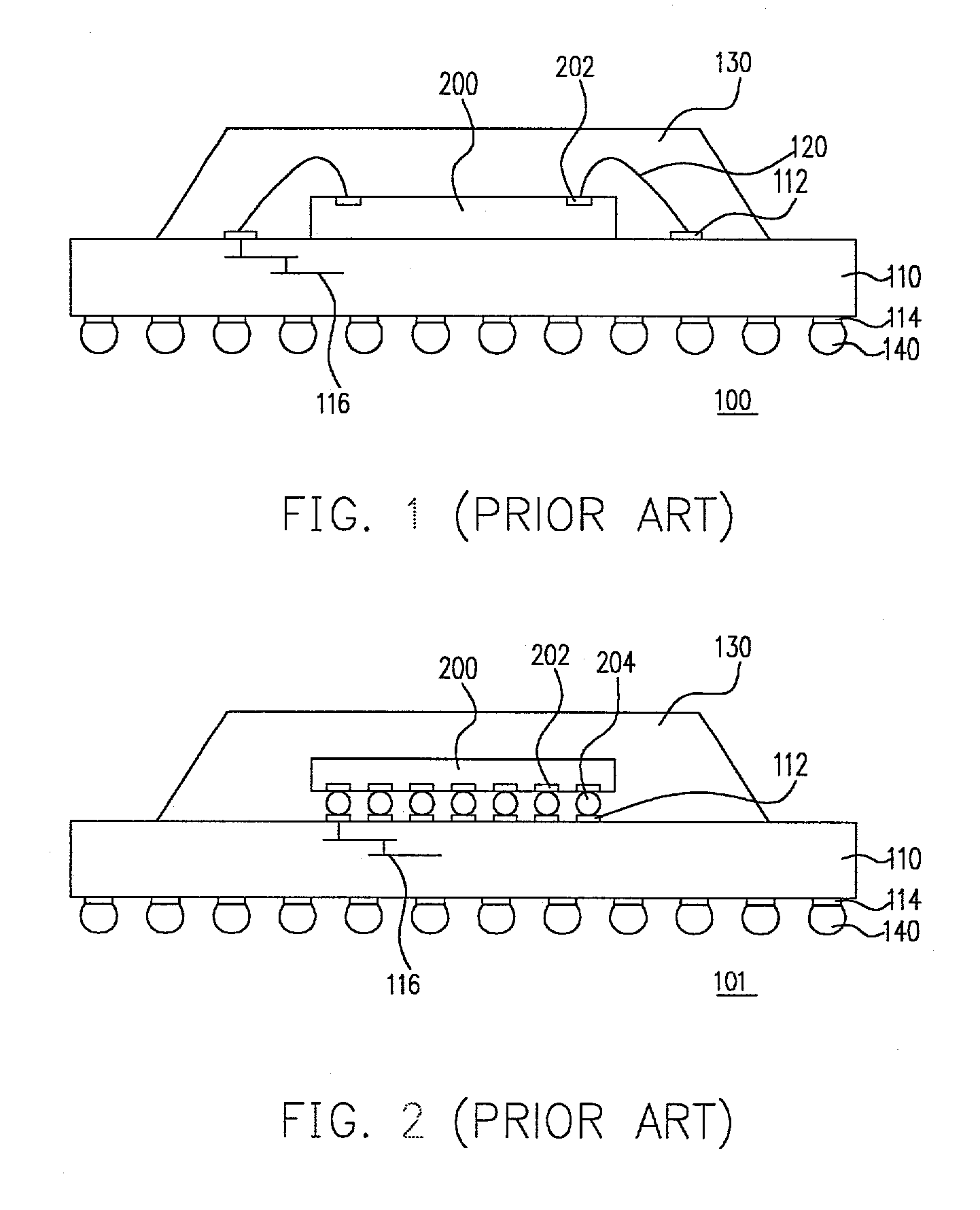

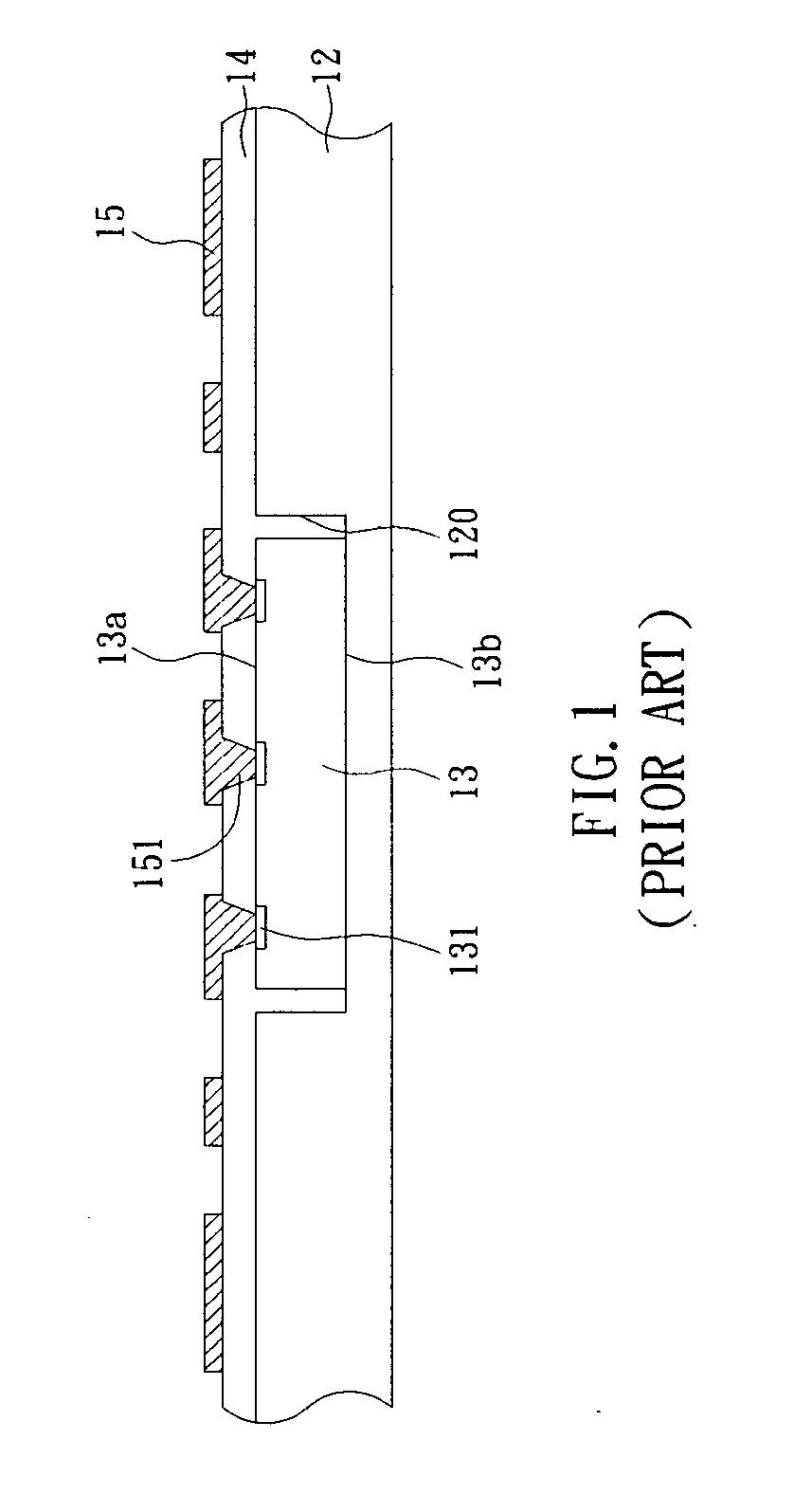

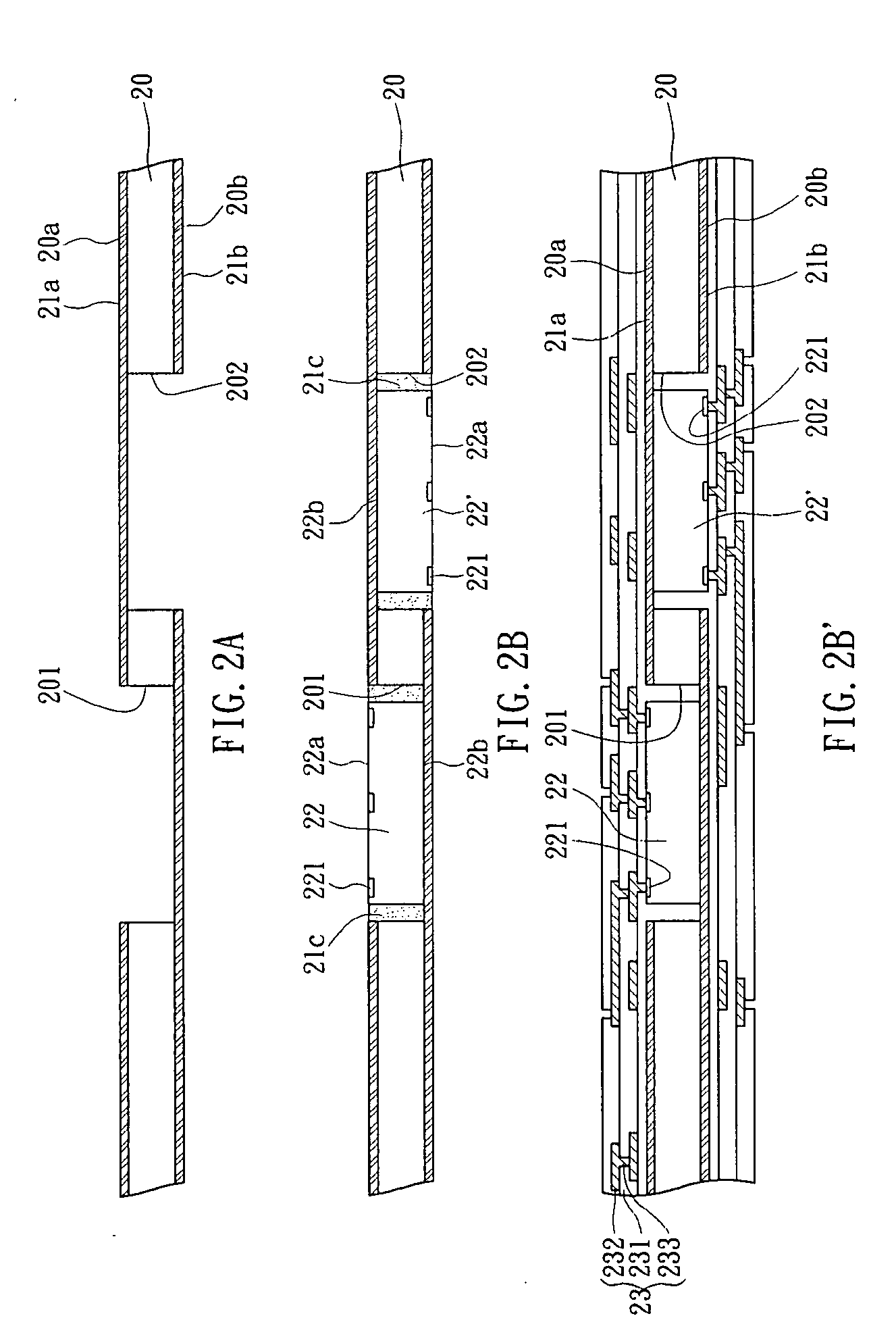

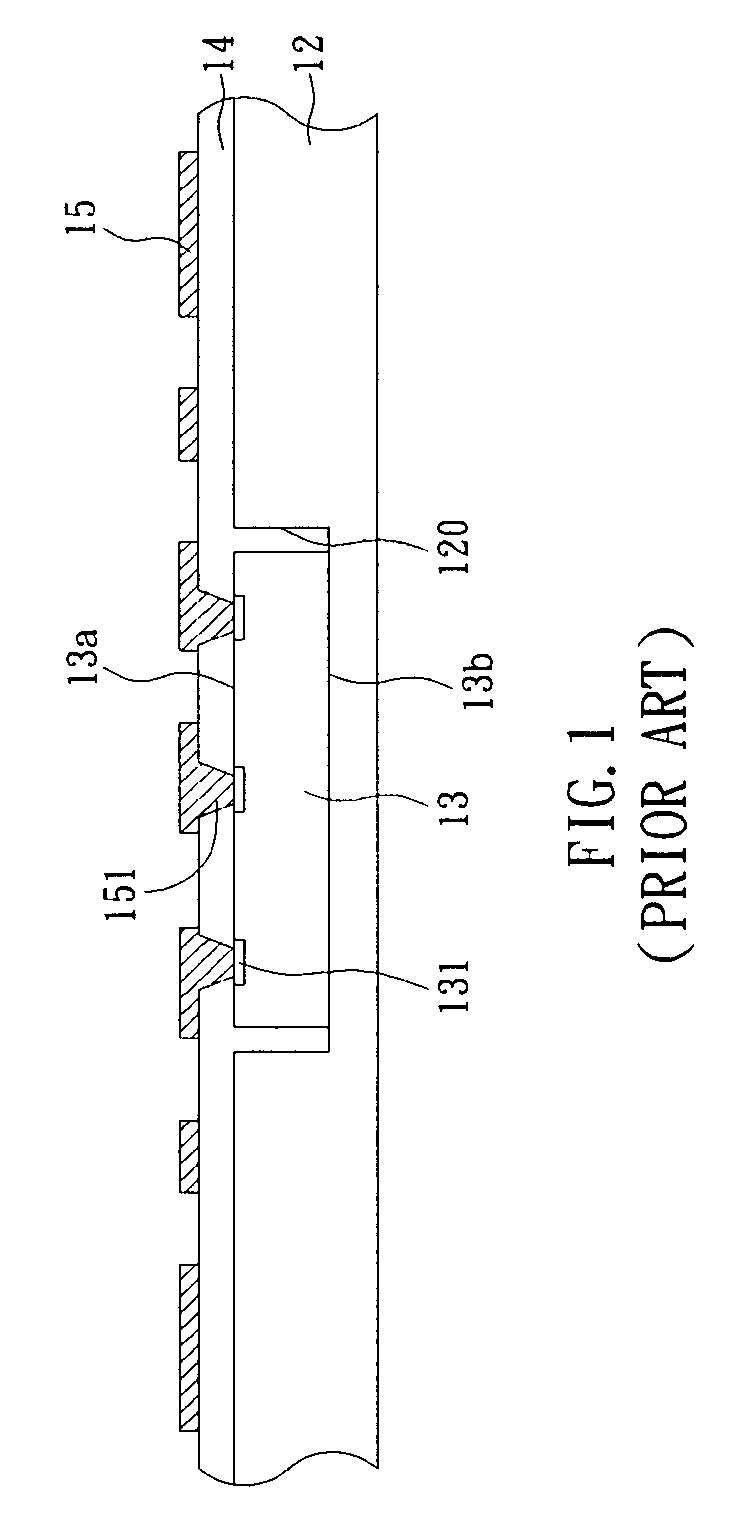

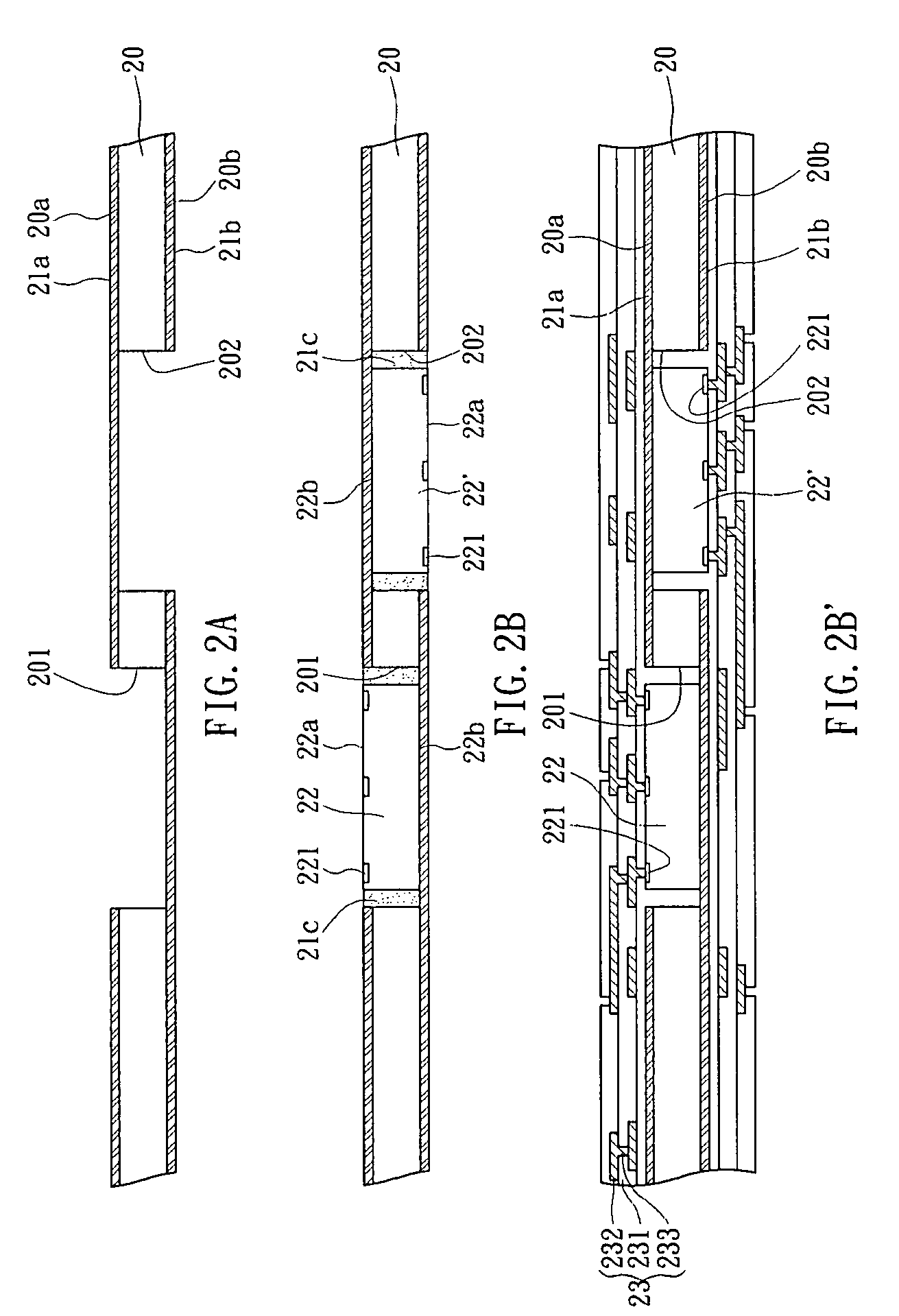

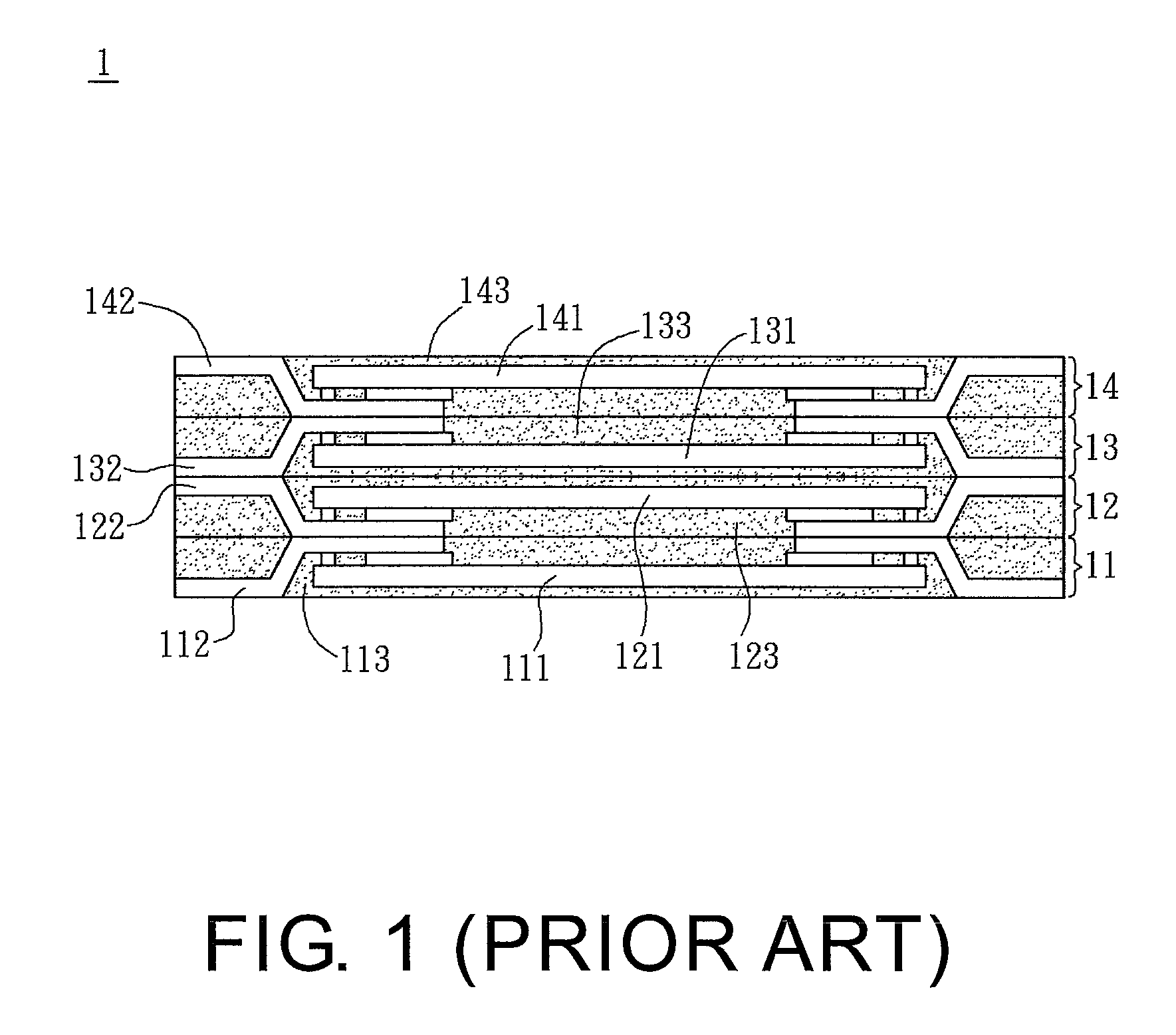

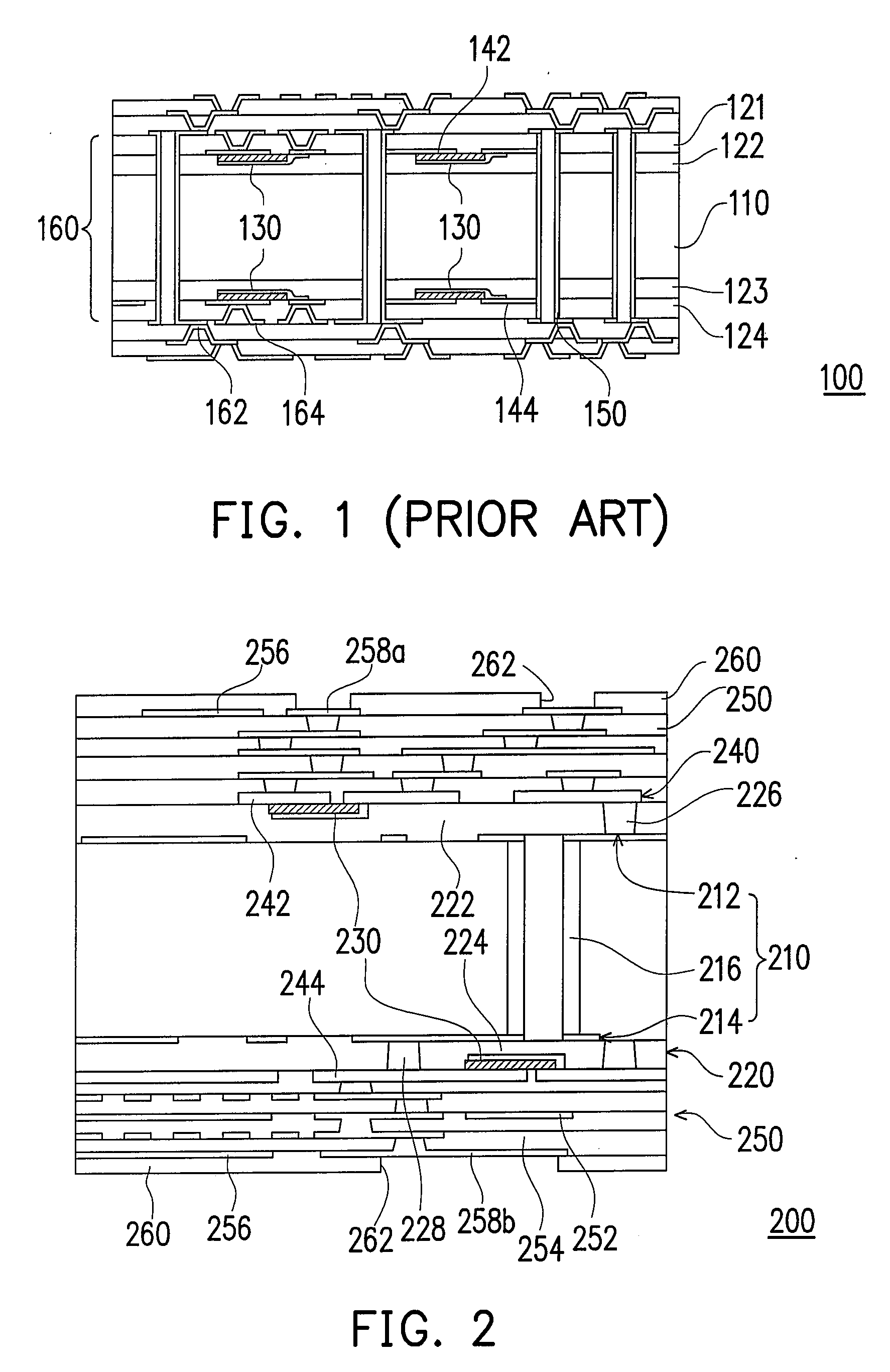

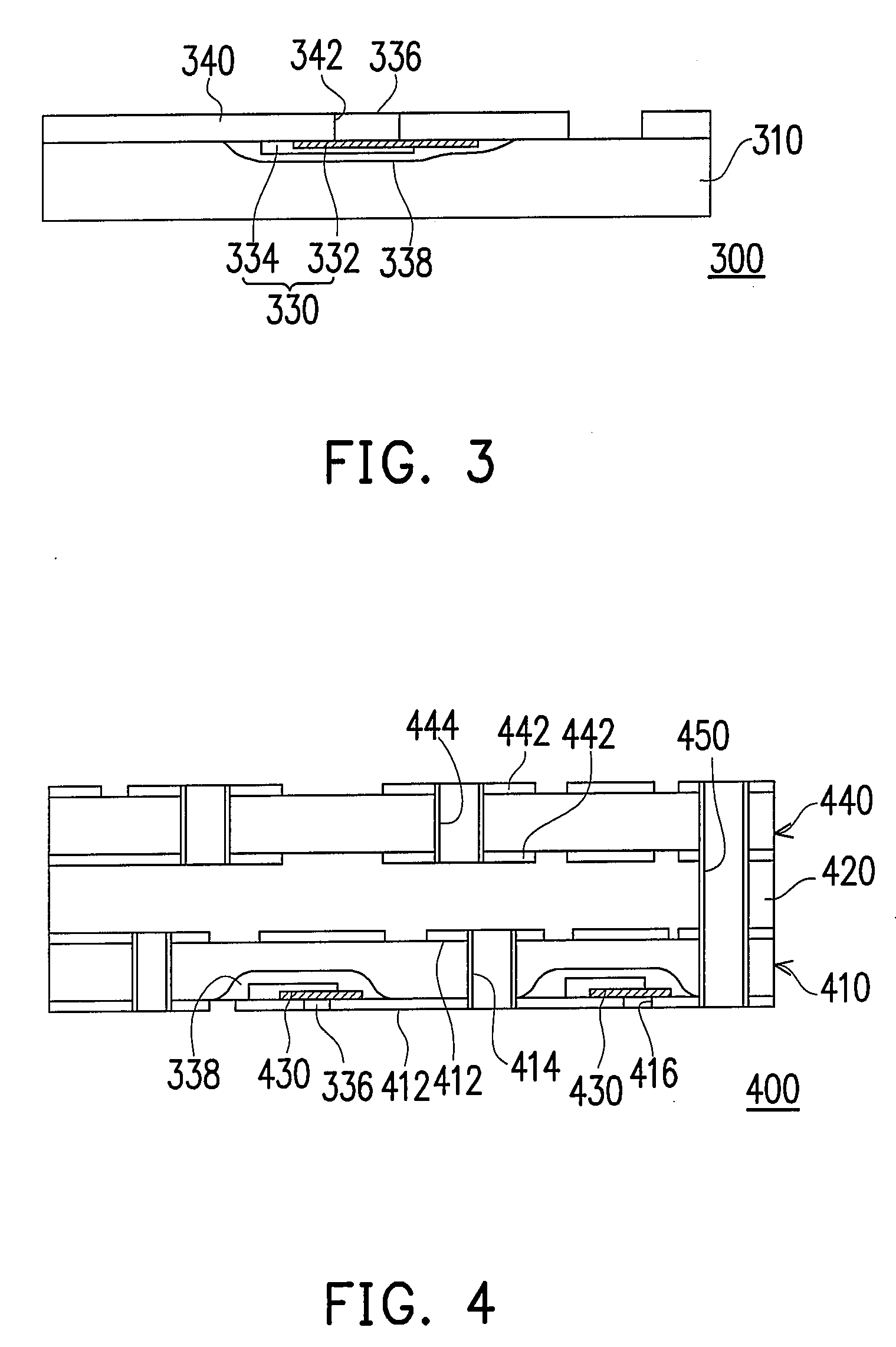

Integrated circuit package and method of manufacture

InactiveUS7087991B2Eliminates connective requirementImprove cooling effectPrinted circuit assemblingSemiconductor/solid-state device detailsInsulation layerSolder ball

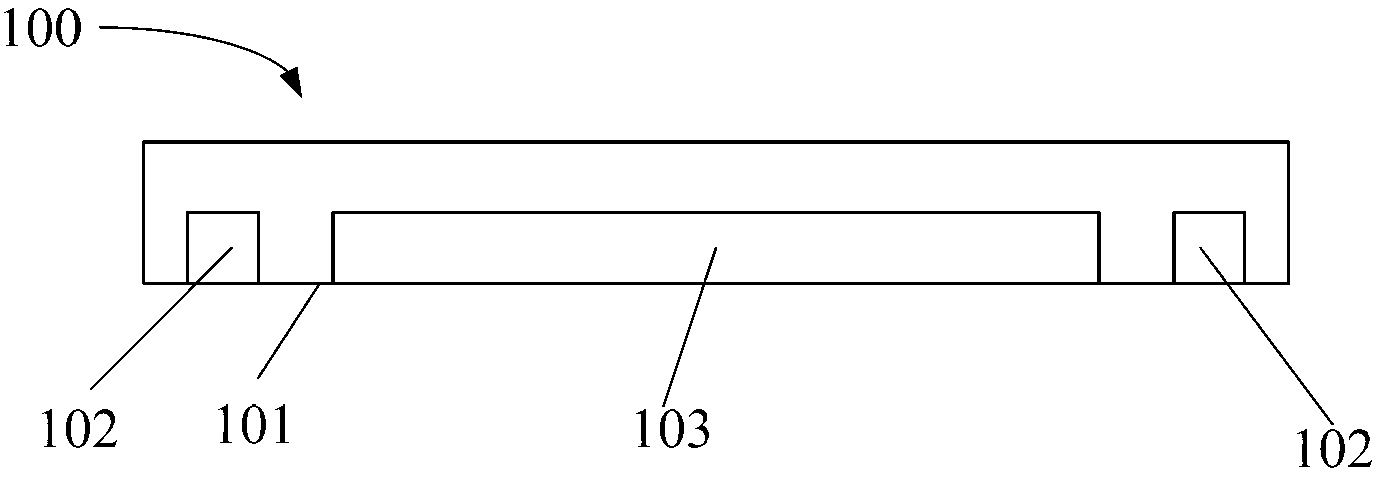

An integrated circuit package and a method of manufacturing the package. A silicon chip is attached to the surface of a substrate or attached to the bottom surface of a cavity in the substrate so that the active surface of the chip is exposed. One or more build-up circuit structures are formed over the substrate. Each build-up circuit structure has at least one insulation layer, at least one patterned circuit layer and a plurality of via openings with conductive material therein so that bonding pads on the active surface of the chip connect electrically with the patterned circuit layer through the vias. To form a ball grid array package, solder balls may also be attached to the solder ball pads on the patterned circuit layer so that the bonding pads on the chip are electrically connected to an external circuit through the build-up circuit structure and the solder balls.

Owner:VIA TECH INC

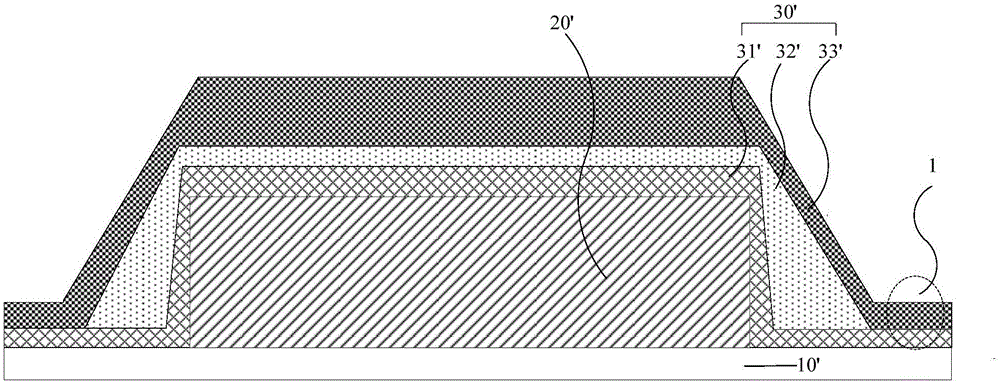

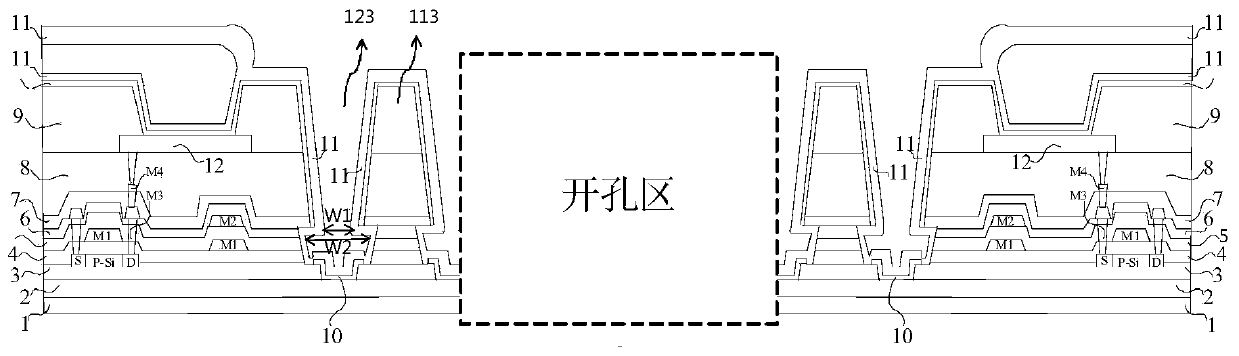

Display panel and preparation method thereof, and display device

InactiveCN110429118AImprove packaging effectExtended service lifeSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceOxygen

The invention provides a display panel and a preparation method thereof, and a display device. The display panel is configured to block an organic light-emitting material layer by arranging a partitioning groove, and the material of the bottom of the groove of the first partitioning groove is made of the same material as the material of a sealing layer covering the internal portion of the partitioning groove and being in contact with the bottom of the groove so as to improve the adhesion of the film layer, the inorganic film layer in the package layer and the inorganic film layer in the arraystructure layer are tightly connected to enhance the package effect, prevent the external water oxygen from entering the organic luminescent material layer in the display region from the opening region and improve the package effect of the display panel and the service life and the display effect.

Owner:YUNGU GUAN TECH CO LTD

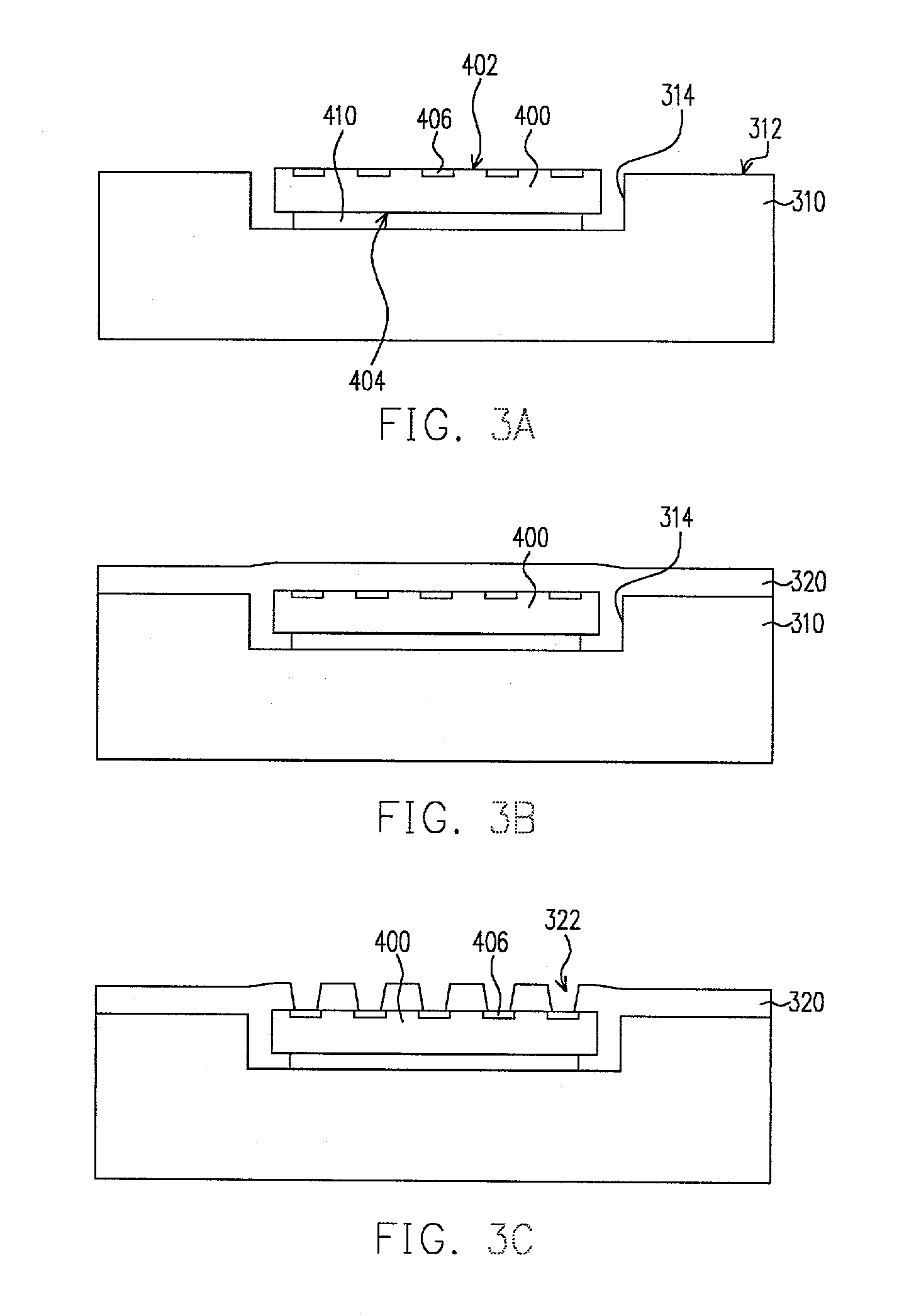

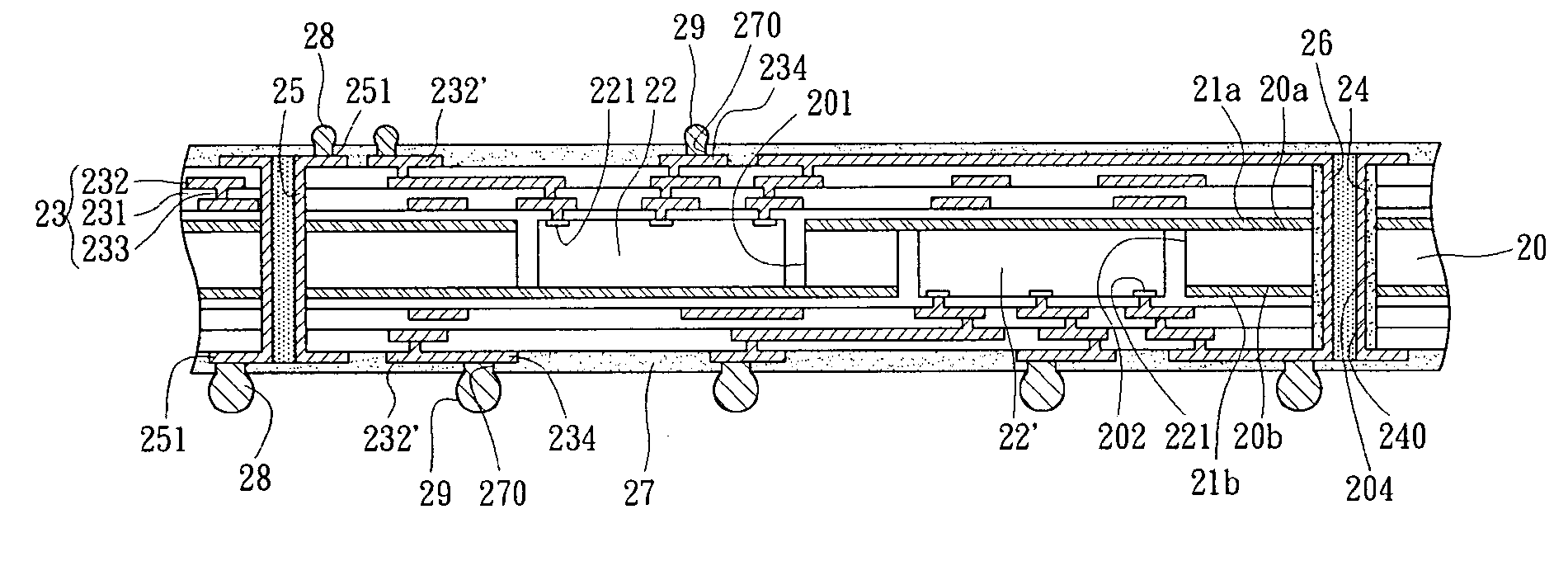

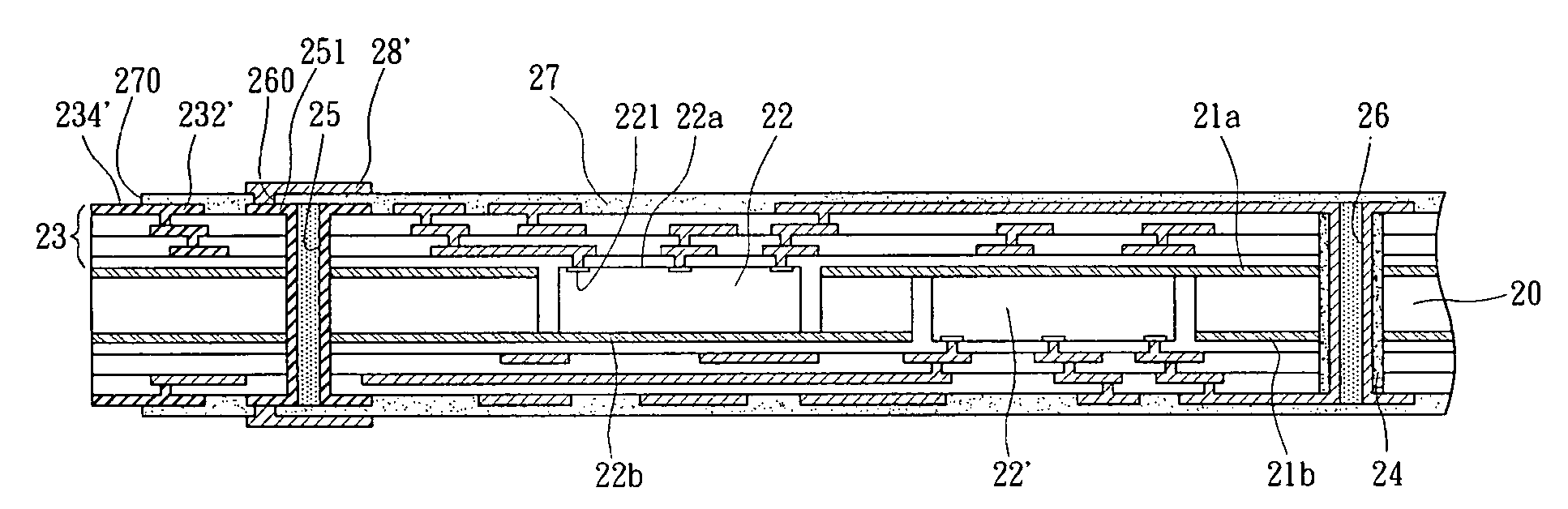

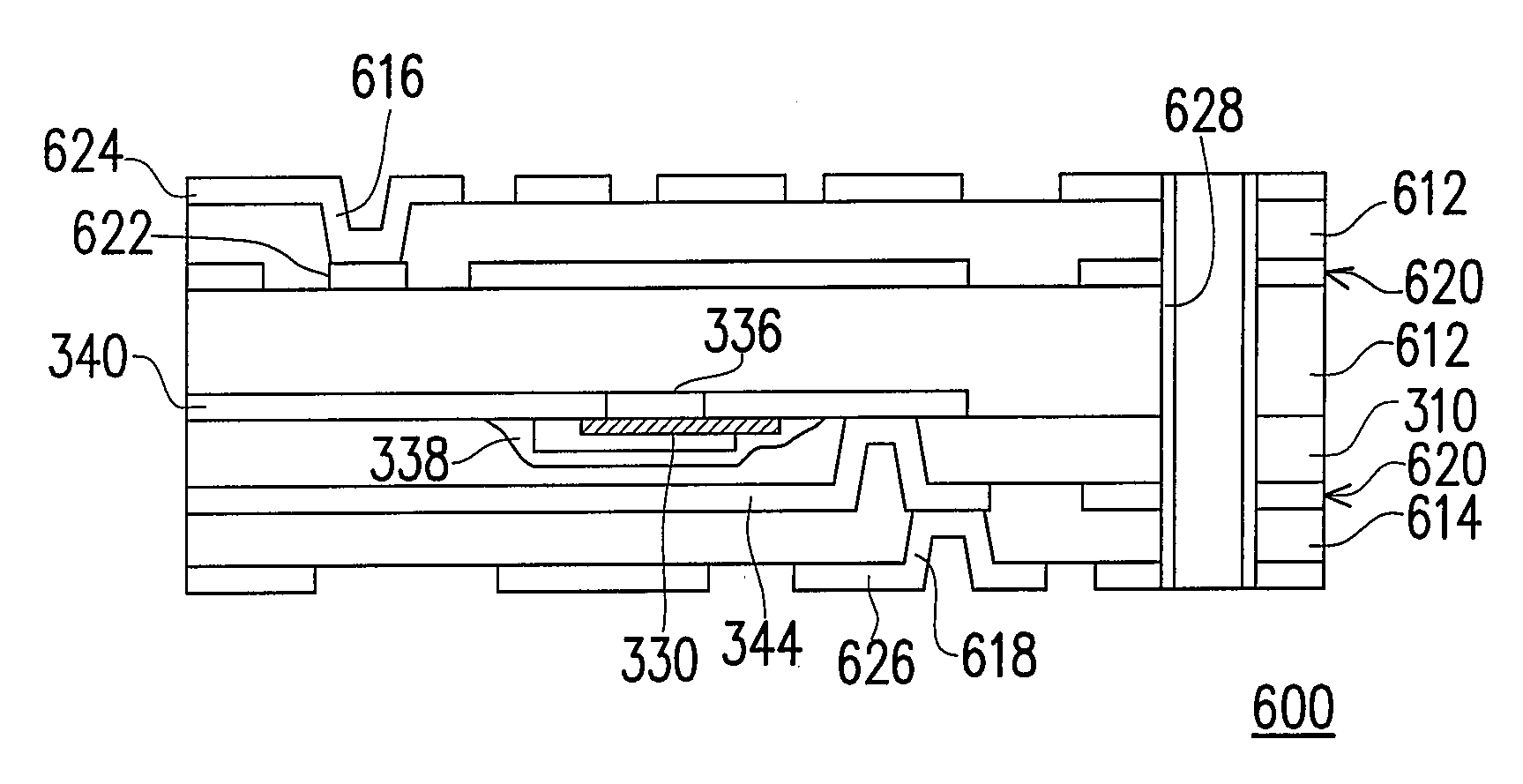

Packaging substrate having heat-dissipating structure

ActiveUS20090072384A1Improve cooling effectImprove electrical performanceSemiconductor/solid-state device detailsSolid-state devicesContact padSemiconductor chip

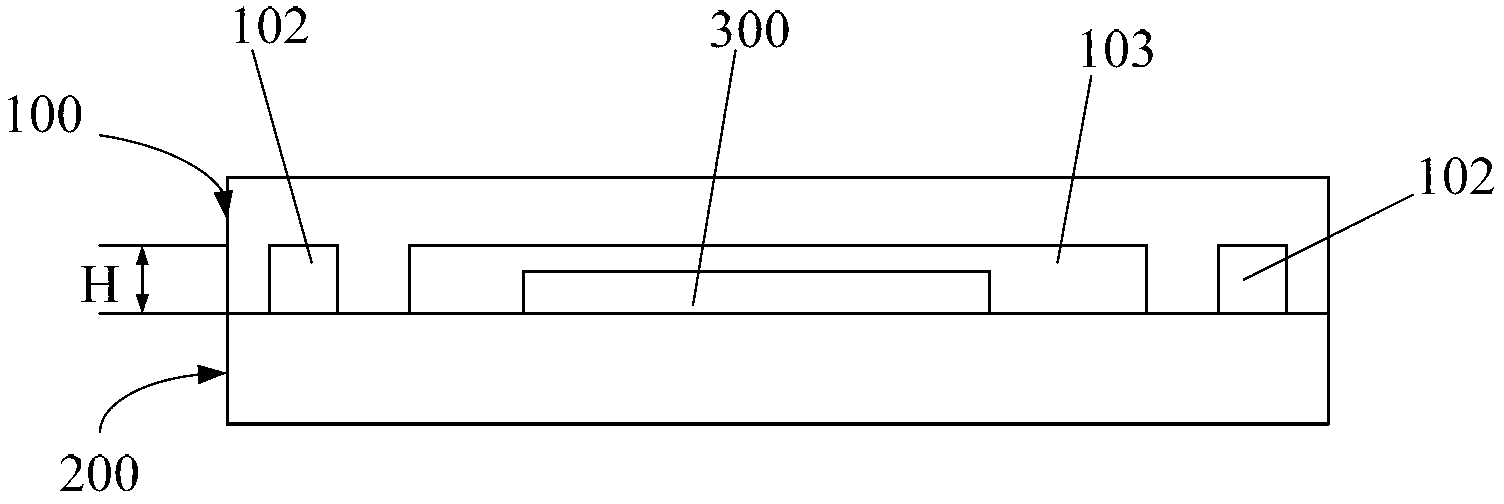

Provided is a packaging substrate with a heat-dissipating structure, including a core layer with a first surface and an opposite second surface having a first metal layer and a second metal layer respectively. Portions of the first metal layer are exposed from a second cavity penetrating the core layer and second metal layer. Portions of the second metal layer are exposed from a first cavity penetrating the core layer and first metal layer. Semiconductor chips each having an active surface with electrode pads thereon and an opposite inactive surface are received in the first and second cavities and attached to the second metal layer and the first metal layer respectively. Conductive vias disposed in build-up circuit structures electrically connect to the electrode pads of the semiconductor chips. A heat-dissipating through hole penetrating the core layer and build-up circuit structures connects the metal layers and contact pads.

Owner:PHOENIX PRECISION TECH CORP

Positive electrode active material powder for lithium secondary battery

ActiveUS20050271944A1Large volume capacity densityLow compression breaking strengthAlkali metal oxidesLi-accumulatorsBreaking strengthAlkaline earth metal

To provide a lithium-nickel-cobalt-manganese composite oxide powder for a positive electrode of a lithium secondary battery, which has a large volume capacity density and high safety and is excellent in the charge and discharge cyclic durability. A positive electrode active material powder for a lithium secondary battery characterized by comprising a first granular powder having a compression breaking strength of at least 50 MPa and a second granular powder having a compression breaking strength of less than 40 MPa, formed by agglomeration of many fine particles of a lithium composite oxide represented by the formula LipNixCoyMnzMqO2-aFa (wherein M is a transition metal element other than Ni, Co and Mn, Al or an alkaline earth metal element, 0.9≦p≦1.1, 0.2≦x≦0.8, 0≦x≦0.4, 0≦z≦0.5, y+z>0, 0≦q≦0.05, 1.9≦2−a≦2.1, x+y+z+q=1, and 0≦a≦0.02) to have an average particle size D50 of from 3 to 15 μm, in a weight ratio of the first granular powder / the second granular powder being from 50 / 50 to 90 / 10.

Owner:SUMITOMO CHEM CO LTD

Lithium-containing composite oxide and its production method

ActiveUS20090258296A1Low amountExcellent propertyElectrode manufacturing processesActive material electrodesComposite oxideHigh weight

To provide a lithium / nickel / cobalt / manganese-containing composite oxide powder which has a high weight capacity density, a high packing property, an excellent cycle property, an excellent discharge rate property and an excellent safety, and which has little content of free alkalis and is free from gelation at a time of producing a slurry.A lithium / nickel / cobalt / manganese-containing composite oxide powder represented by the formula LipNixCoyMnzMqO2-aFa (wherein M is at least one element selected from the group consisting of Al, Ge, Sn, alkaline earth metal elements and transition metal elements other than Co, Mn and Ni, 0.9≦p≦1.1, 0.2≦x≦0.5, 0.2≦y≦0.5, 0.1≦z≦0.4, 0≦q≦0.05, 1.9≦2-a≦2.1, p+x+y+z+q=2, and 0≦a≦0.02), characterized in that when the powder is classified into small particle size-classified particles with an average particle size of 2 μm≦D50≦8 μm and large particle size-classified particles with an average particle size of 10 μm≦D50≦25 μm, the ratio of (% by weight of the small particle size-classified particles) / (% by weight of the large particle size-classified particles) is from 15 / 85 to 40 / 60, the molar ratio (ps) of lithium to the total of nickel, cobalt, manganese and the M element contained in the small particle size-classified particles is smaller than the molar ratio (pl) of lithium to the total of nickel, cobalt, manganese and the M element contained in the large particle size-classified particles.

Owner:SUMITOMO CHEM CO LTD

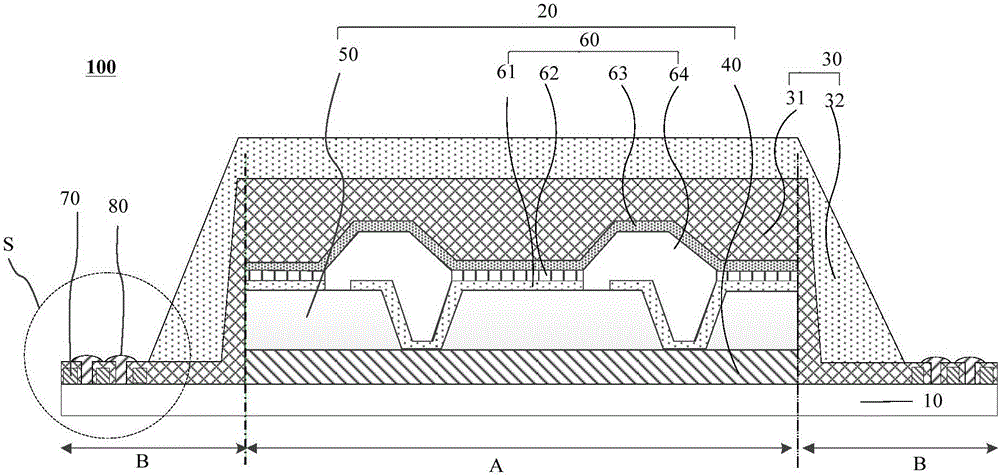

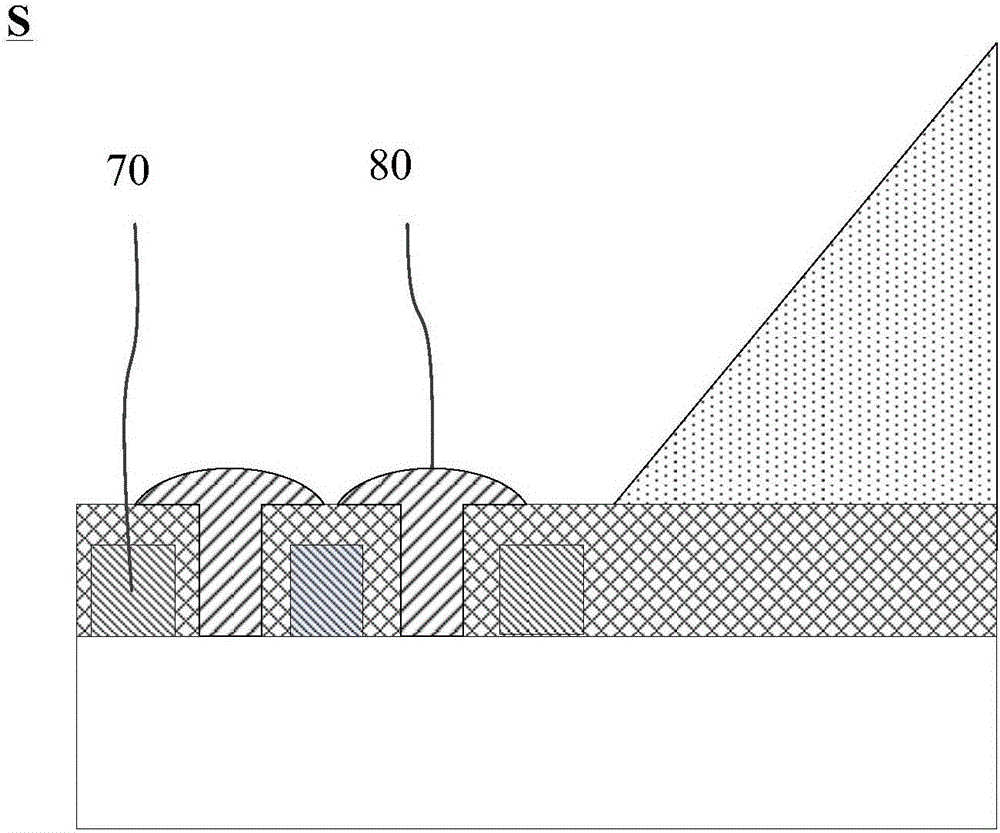

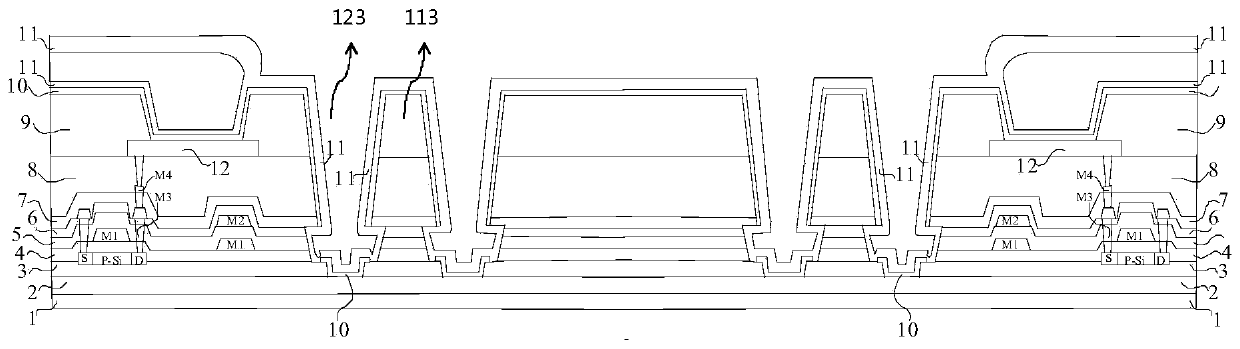

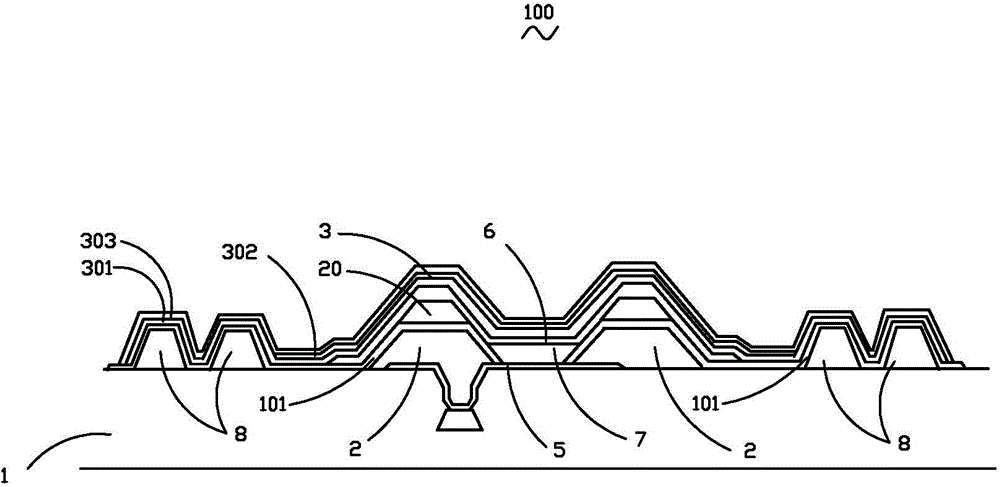

Flexible display panel and display device

ActiveCN108962947AGood adhesionImprove packaging effectSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

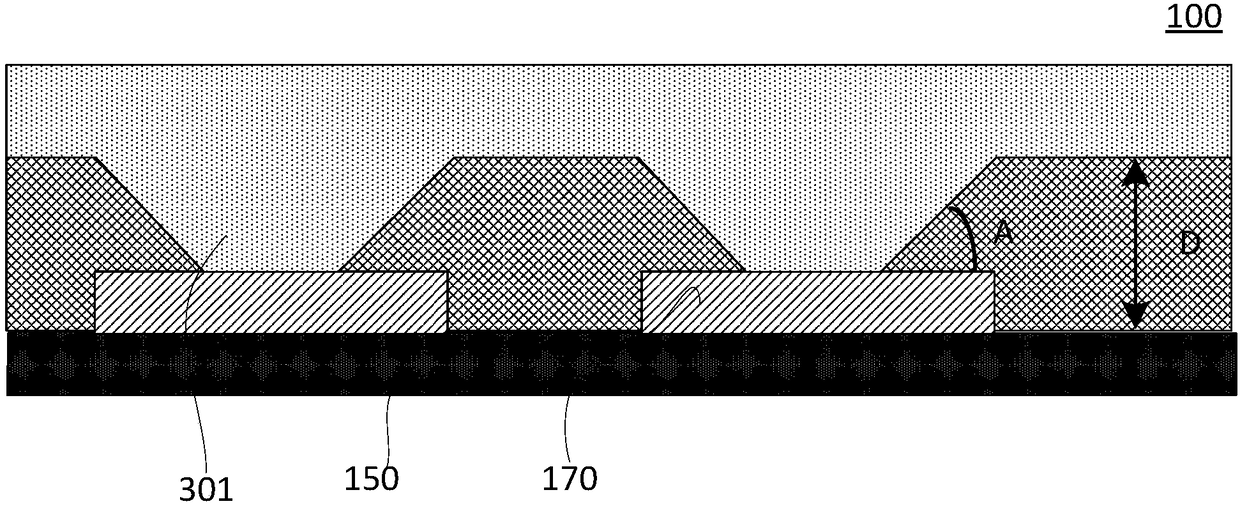

The invention provides a flexible display panel and a display device, which are used to solve the problem that the wiring in the border area affects the packaging structure of the display panel in theprior art. The flexible display panel includes a flexible substrate, a retaining wall structure, a first metal layer, an intermediate conductive layer, a light emitting element layer and a film packaging layer. The retaining wall structure at least includes a first retaining wall and a second retaining wall. The first retaining wall is located between a display area and the second retaining wall.The area between the first retaining wall and the second retaining wall is a first area. The intermediate conductive layer is located on the side of the first metal layer away from the flexible substrate, and the intermediate conductive layer is electrically connected with the first metal layer. In the first area, a first inorganic layer of the film packaging layer contacts with a metal film layer or an inorganic film layer located on the side of the intermediate conductive layer away from the first inorganic layer through a first through hole in the intermediate conductive layer.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

Thin-film packaging structure, thin-film packaging method and display panel

InactiveCN107689425ABy blockingImprove packaging effectSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringOxygen

The invention relates to a thin-film packaging structure, a thin-film packaging method and a display panel. The thin-film packaging structure comprises a substrate base plate, an organic adhesive layer and a packaging film layer, wherein the packaging film layer covers the organic adhesive layer; the organic adhesive layer is made into groove structures and dam structures formed by limitation of the groove structure in a non-display area; the groove structures and the dam structures are arranged around a display area; at least one of the groove structures and the dam structures is of a windingextending structure or a latticed structure. The thin-film packaging structure, the thin-film packaging method and the display panel disclosed by the embodiment of the invention have the beneficial effects that the organic adhesive layer is arranged on the non-display area of the substrate base plate, and a plurality of groups of groove structures with winding extending or latticed structures aredesigned on the organic adhesive layer, so that the path of water-oxygen invasion is prolonged and the bending resistance of the edge area of the display panel also can be improved; simultaneously, due to embedding combination of the groove structures and the dam structures, the water-oxygen blocking capability is improved, simultaneously the occupied space is smaller and the narrow-frame designis realized.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

Flexible OLED display panel

ActiveCN105261712AAvoid scratchesPrevent crushingSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringWater block

The invention discloses a flexible OLED display panel, which comprises a flexible substrate, an OELD device, a first encapsulation layer, a barrier layer and a second encapsulation layer, wherein the OLED device is arranged on the flexible substrate; the first encapsulation layer is arranged on the flexile substrate and covers the OLED device; the barrier layer is arranged on the flexible substrate, surrounds the periphery of the first encapsulation layer, and comprises a plurality of discontinuous barrier units; the plurality of barrier units are arranged in a chain form; and the second encapsulation layer is arranged on the flexible substrate and covers the first encapsulation material and the barrier layer. The flexible OLED display panel is capable of effectively blocking the diffusion effect of atomic deposition coating and enhancing the water blocking capacity of a thin-film encapsulation on the periphery of the flexible OLED display panel; meanwhile, the reelability of the barrier layer is increased; the development requirement of the flexible OLED display panel is relatively well met; and an important idea is also provided for development of the flexible OLED display panel.

Owner:EVERDISPLAY OPTRONICS (SHANGHAI) CO LTD

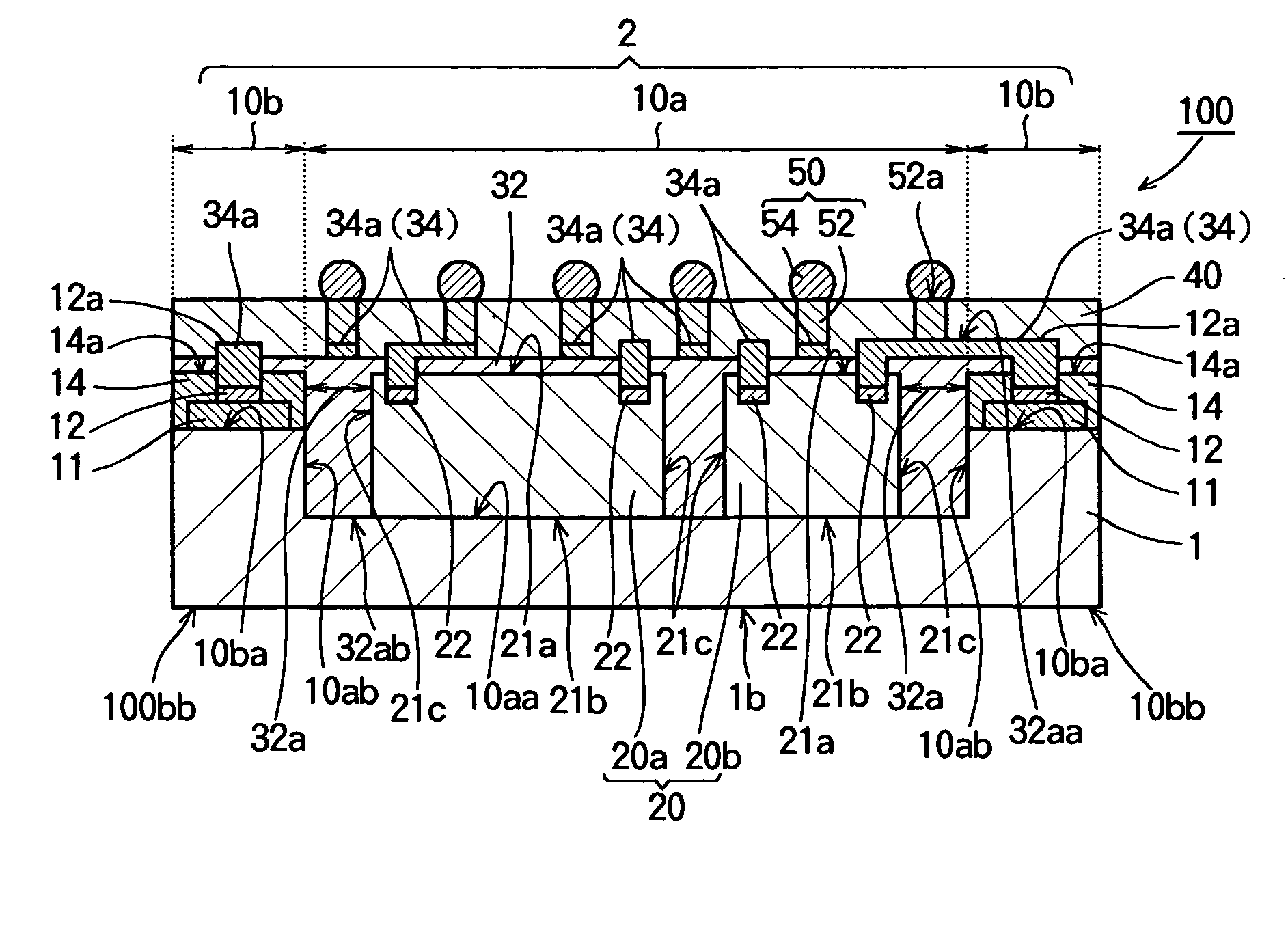

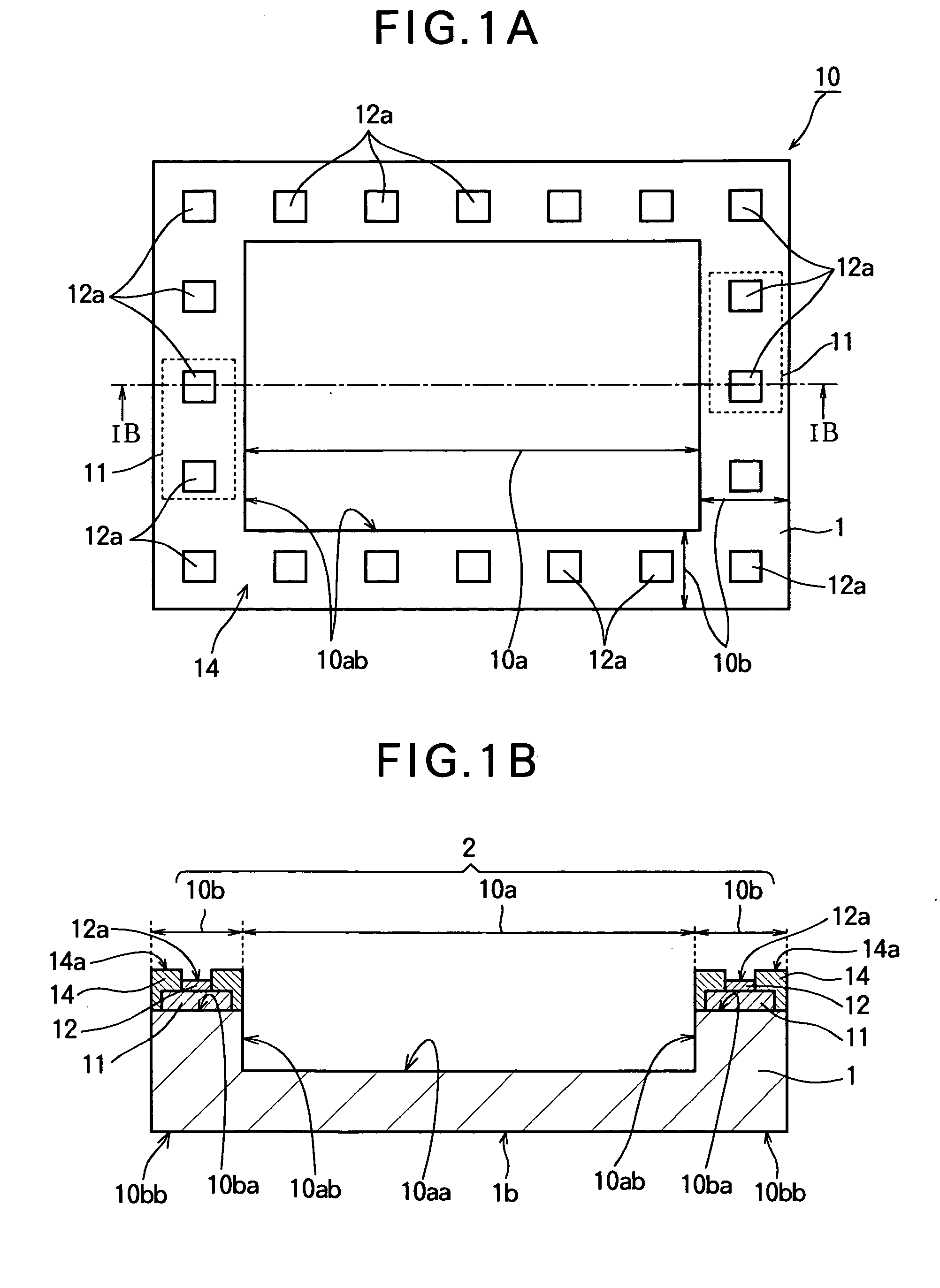

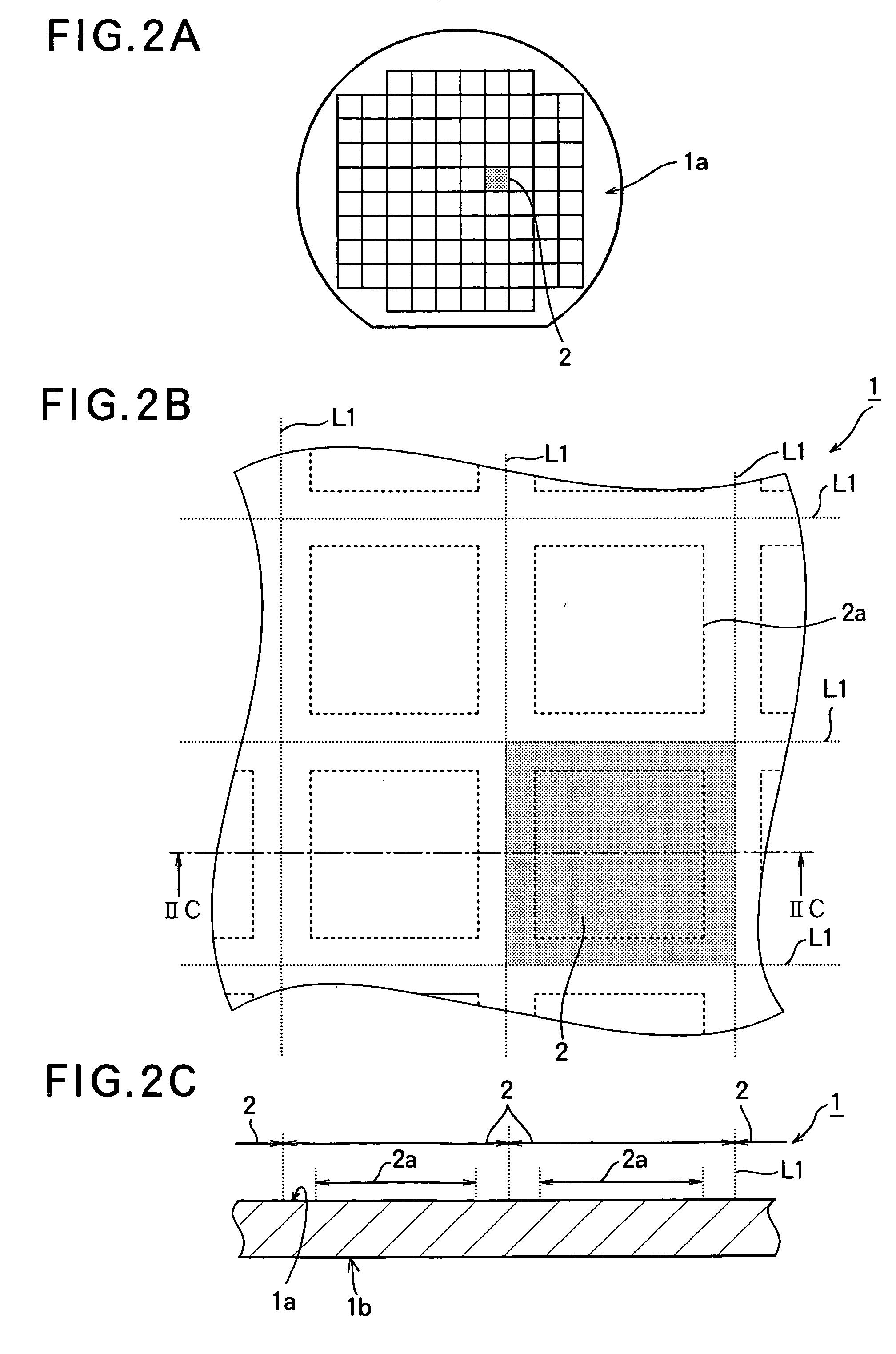

Semiconductor device

InactiveUS20060214288A1High package performanceEnhancing heat dissipation and high-frequency characteristicSemiconductor/solid-state device detailsSolid-state devicesEngineeringSemiconductor chip

A semiconductor chip includes a semiconductor substrate having an opening portion and a frame portion defining a periphery of the opening portion. At least one electric element is provided on the frame portion, and has at least one electrode terminal. A first insulation film is formed on the frame portion so that the electrode terminal is partially exposed at the first insulation film to form a plurality of electrode pads.

Owner:LAPIS SEMICON CO LTD

Positive electrode active material powder for lithium secondary battery

ActiveUS7381498B2Improve packaging effectSolve the small densityAlkali metal oxidesLi-accumulatorsBreaking strengthAlkaline earth metal

Owner:SUMITOMO CHEM CO LTD

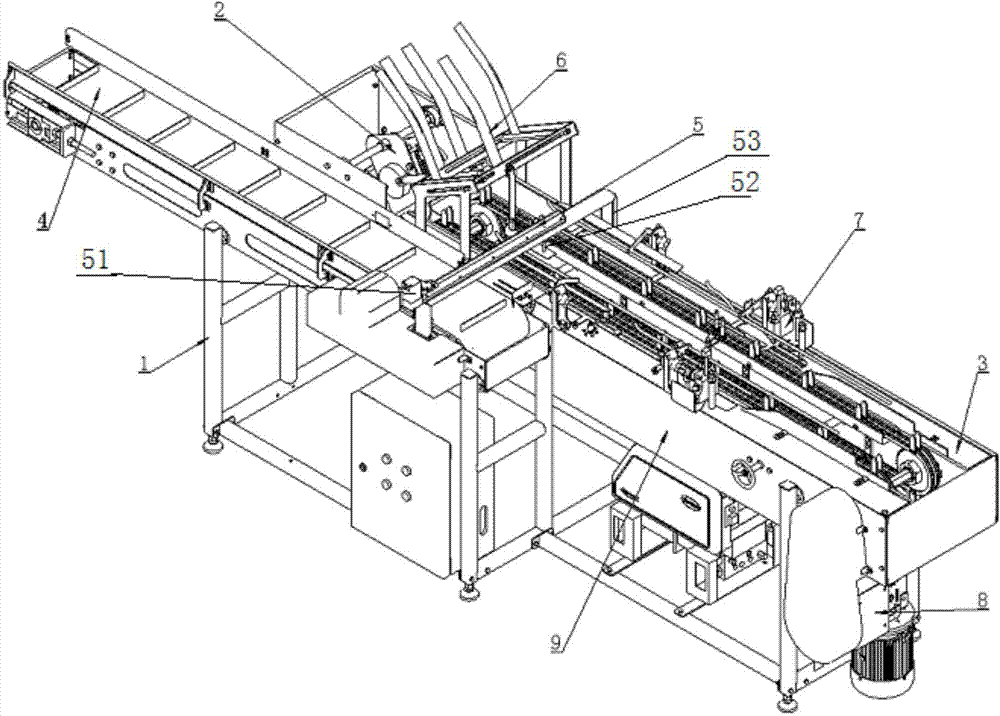

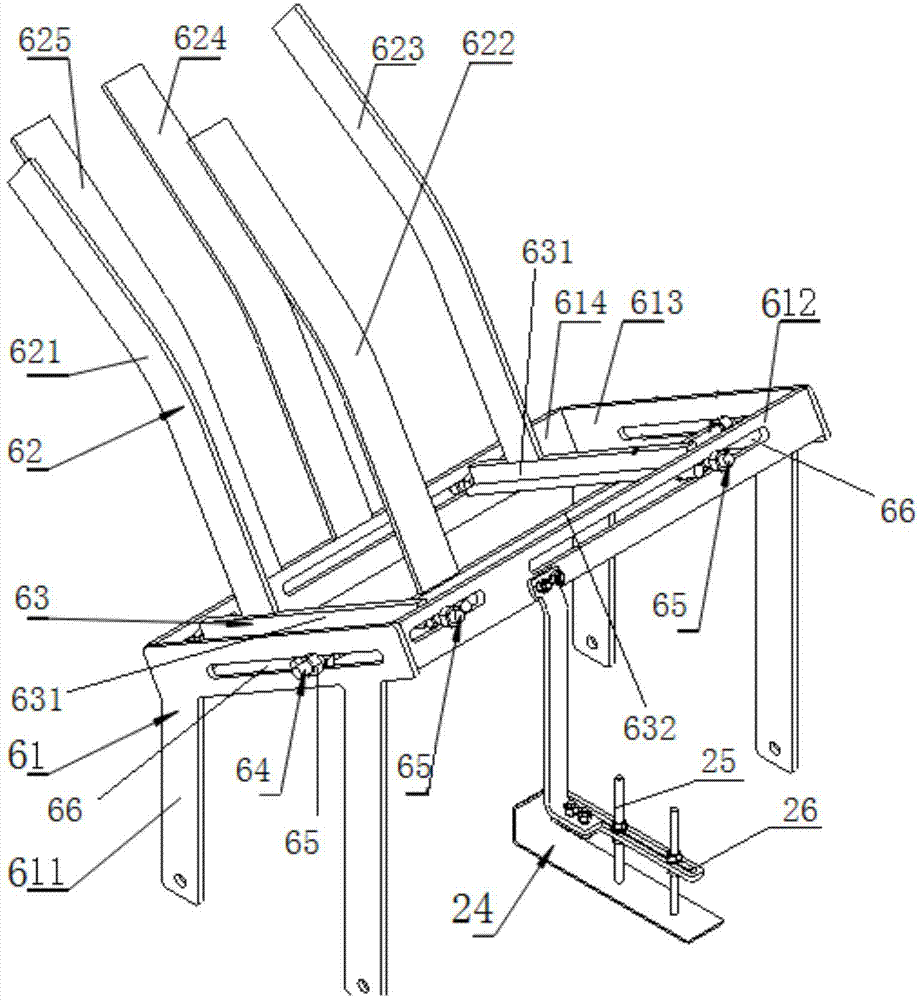

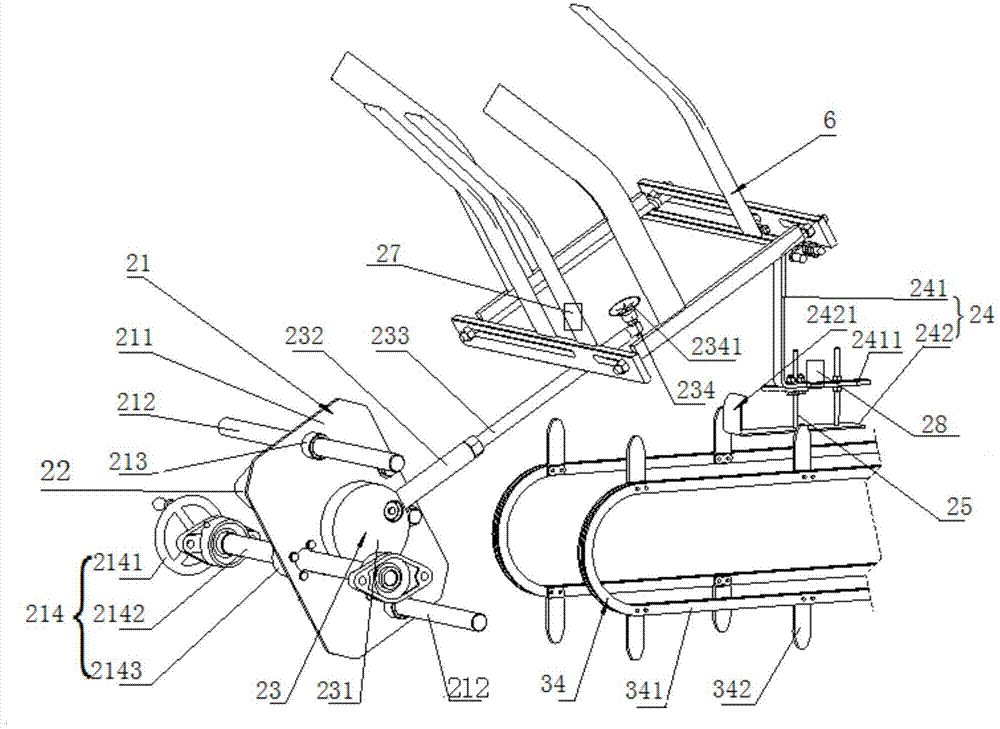

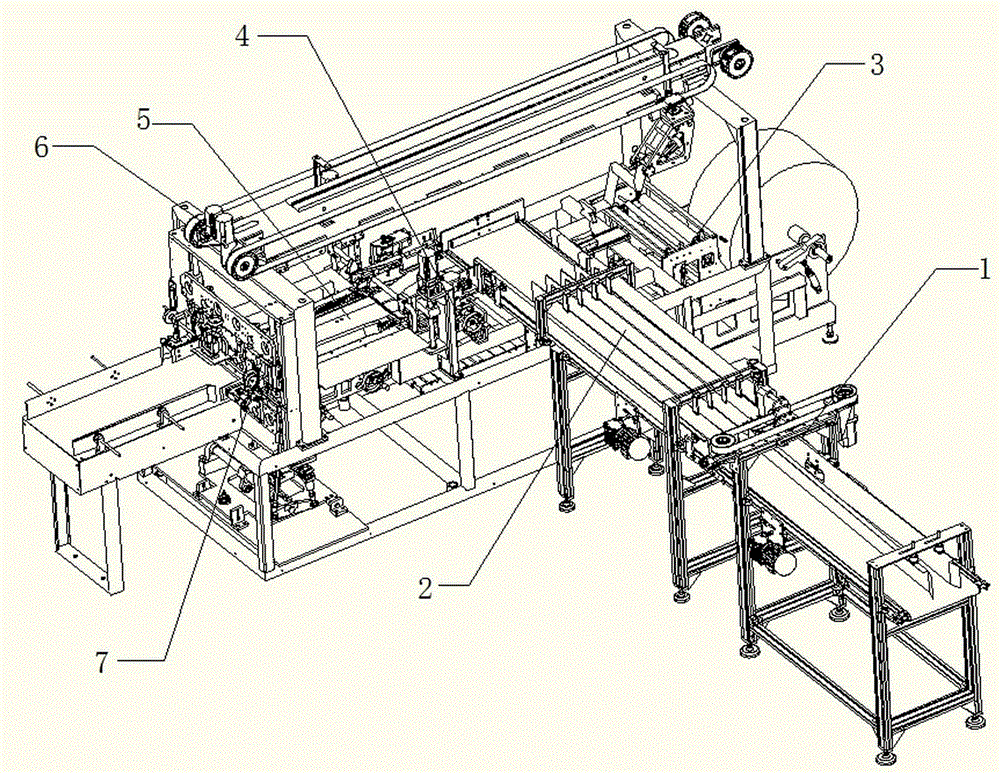

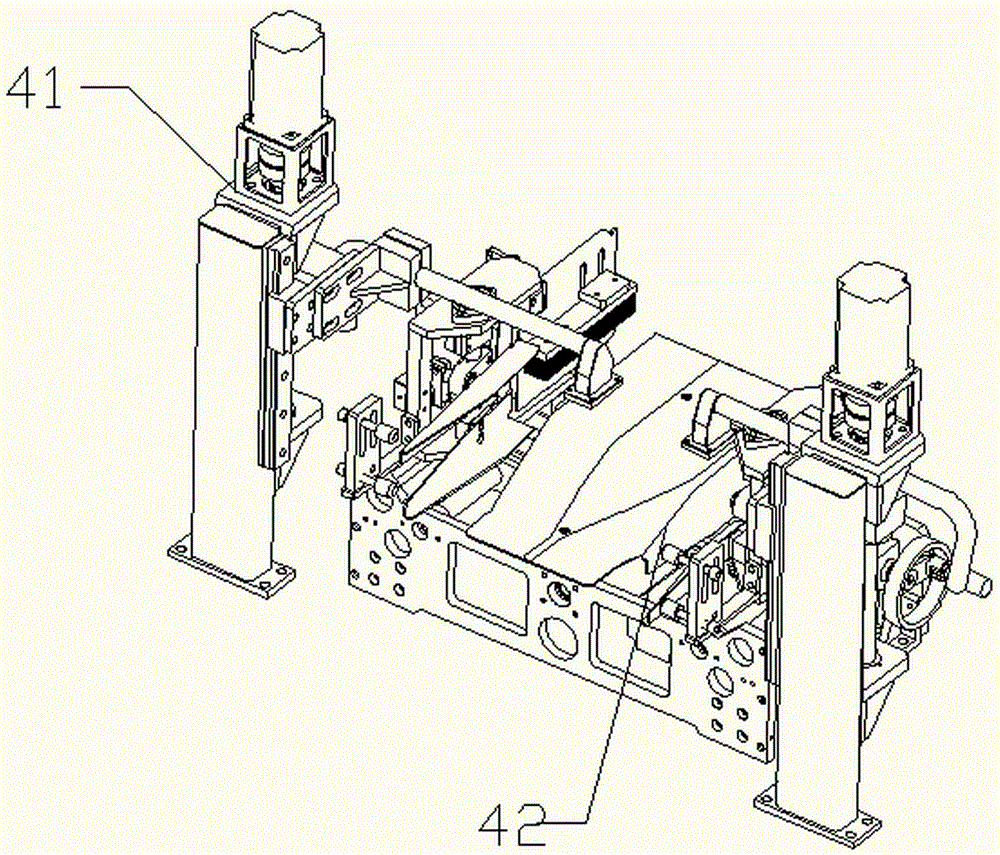

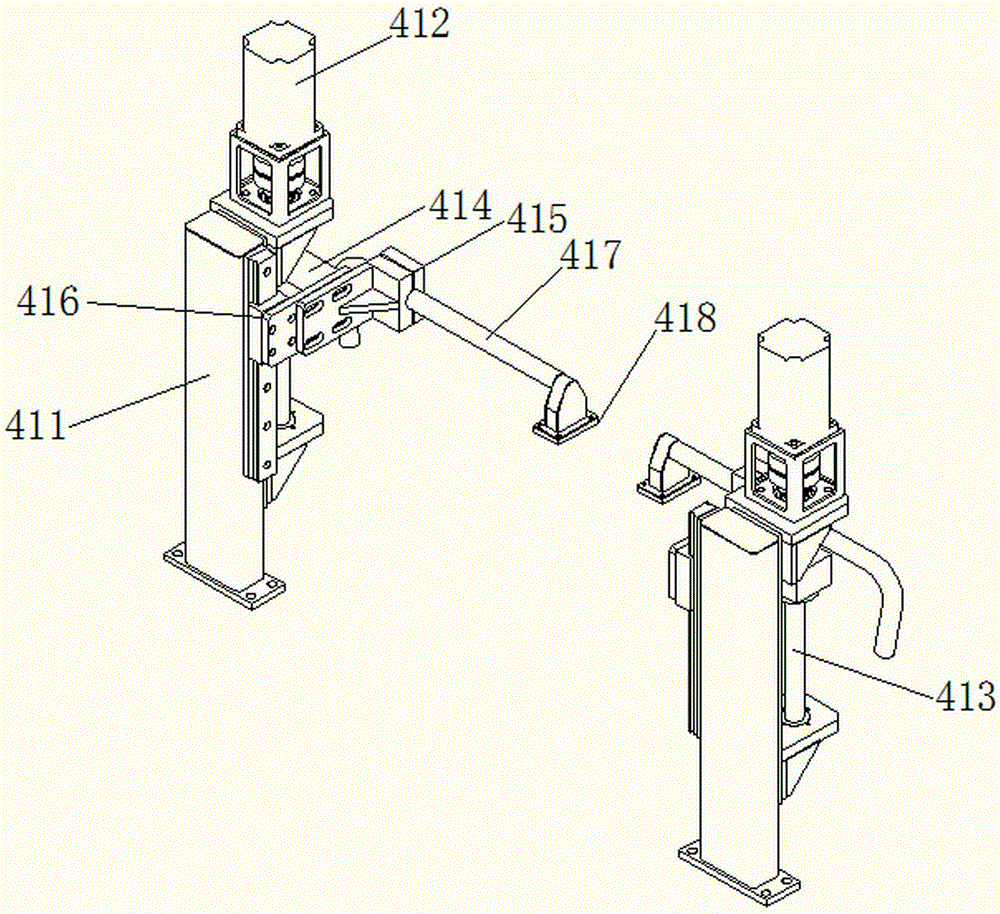

Full-automatic intermittent multi-specification carton boxing machine

InactiveCN104773333ARich packing specificationsRealize the purpose of one machine with multiple functionsPackaging automatic controlCartonEngineering

The invention relates to a full-automatic intermittent multi-specification carton boxing machine which comprises a machine frame, a carton opening system, a carton conveying system, a material conveying system, a material pushing device, a semi-finished carton cabin, a carton sealing device and a transmitting mechanism. The material conveying system the carton box conveying system synchronous drive and are partially overlapped, the carton opening device is distributed at the beginning end of a carton conveying chain, the carton conveying system and the carton opening device are arranged in a carton conveying cabin, the material pushing device is distributed above the overlapped portion between the material conveying system and the carton conveying system and is perpendicular to the carton conveying system, the semi-finished carton cabin is arranged on the carton conveying cabin and distributed above the carton opening system, and the carton sealing device is arranged on the carton conveying system. The full-automatic intermittent multi-specification carton boxing machine is simple in structure, low in manufacturing cost and good in generality and can meet the carton opening requirements of various-specification cartons by adjusting the carton opening device, the semi-finished carton cabin and the carton conveying system according to the sizes of different products.

Owner:CHINA NAT PACKAGING & FOOD MACHINERY

Encapsulation structure for OLED device and encapsulation method and lighting device of OLED device

InactiveCN103887446AImprove packaging effectExtended service lifeSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringOxygen

Owner:BOE TECH GRP CO LTD +1

Packaging substrate having heat-dissipating structure

ActiveUS7656015B2Effective coolingEvade increasing thickness and weightSemiconductor/solid-state device detailsSolid-state devicesContact padSemiconductor chip

Provided is a packaging substrate with a heat-dissipating structure, including a core layer with a first surface and an opposite second surface having a first metal layer and a second metal layer respectively. Portions of the first metal layer are exposed from a second cavity penetrating the core layer and second metal layer. Portions of the second metal layer are exposed from a first cavity penetrating the core layer and first metal layer. Semiconductor chips each having an active surface with electrode pads thereon and an opposite inactive surface are received in the first and second cavities and attached to the second metal layer and the first metal layer respectively. Conductive vias disposed in build-up circuit structures electrically connect to the electrode pads of the semiconductor chips. A heat-dissipating through hole penetrating the core layer and build-up circuit structures connects the metal layers and contact pads.

Owner:PHOENIX PRECISION TECH CORP

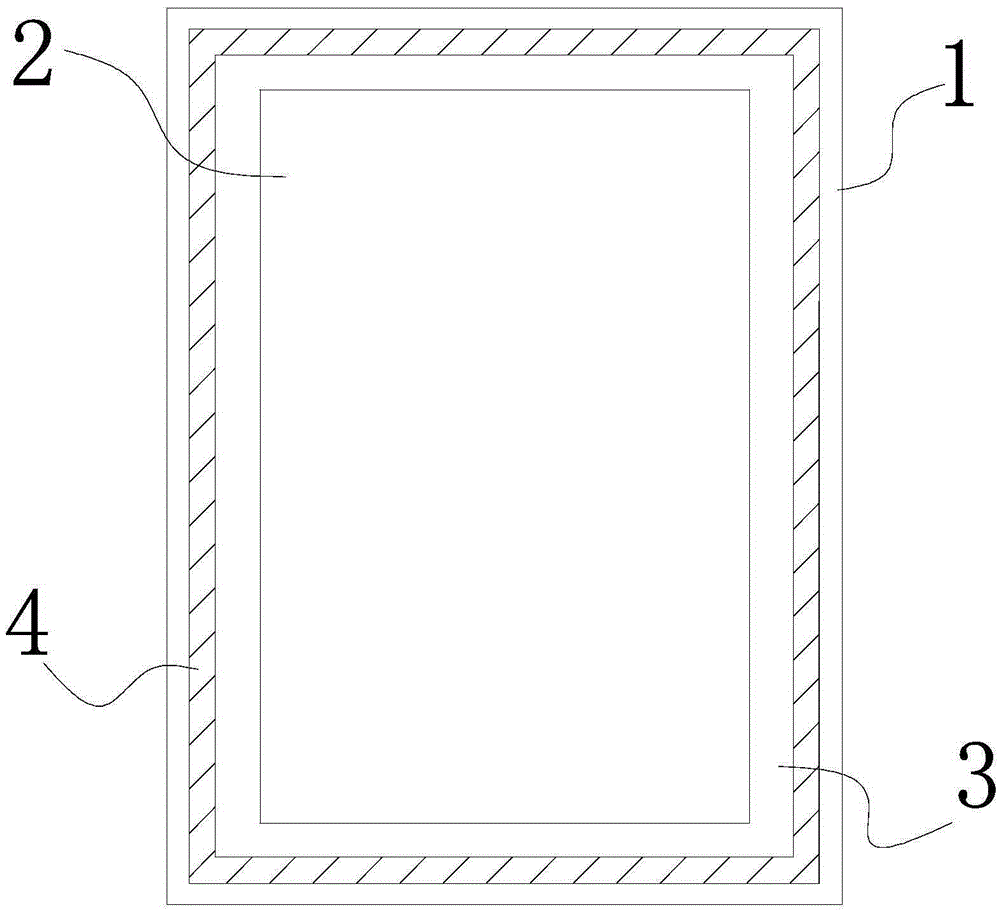

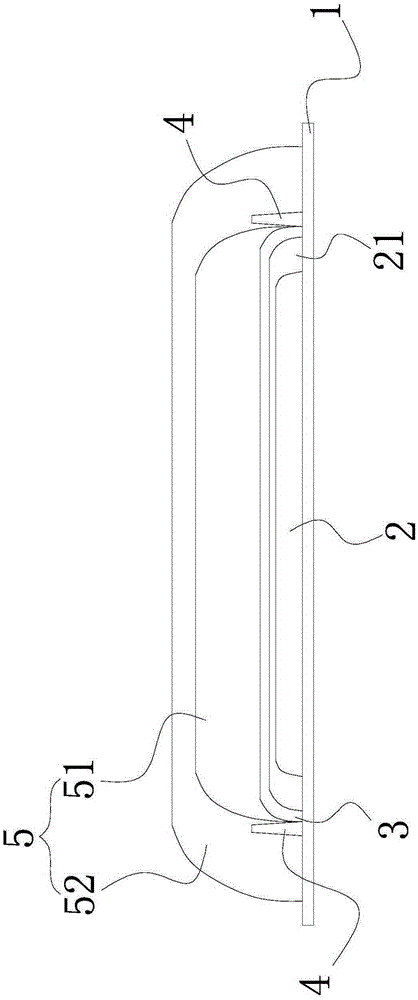

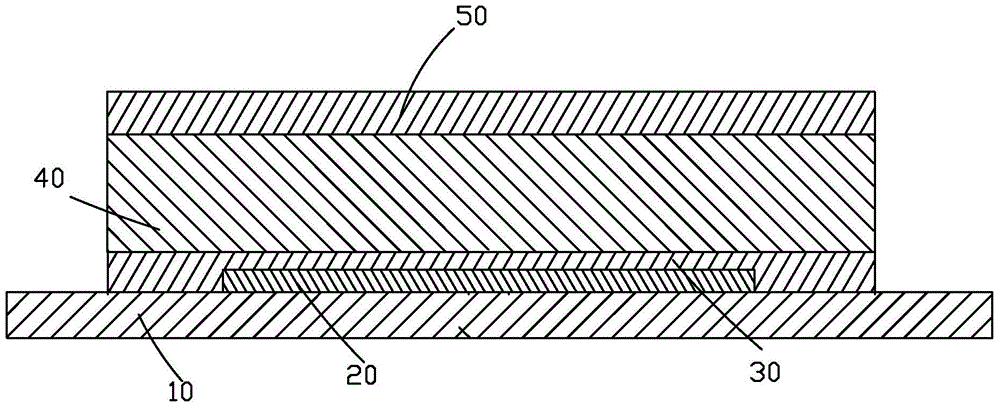

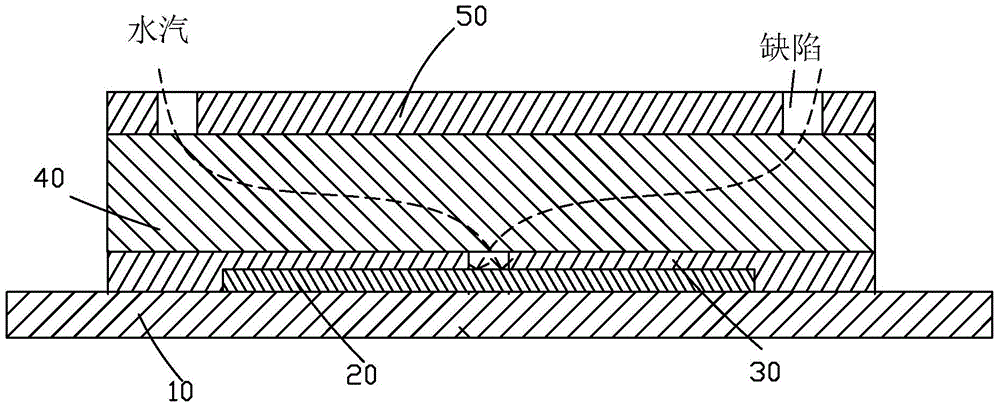

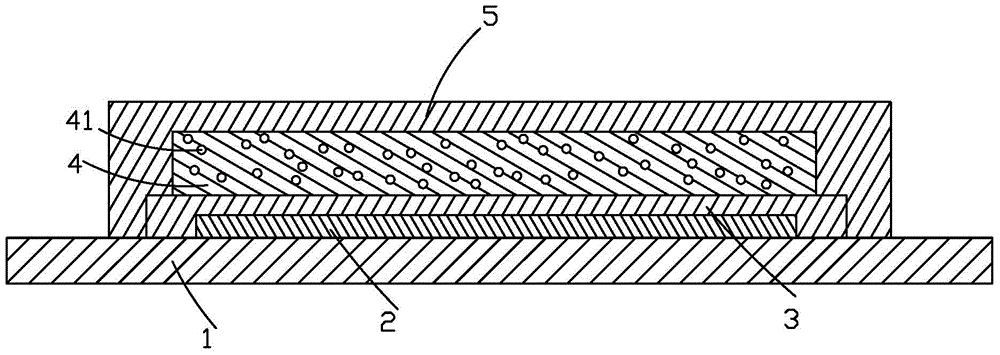

Package structure and package method of organic light-emitting diode (OLED) device

InactiveCN105098091AExtend your lifePrevent intrusionSolid-state devicesSemiconductor/solid-state device manufacturingMoistureLight-emitting diode

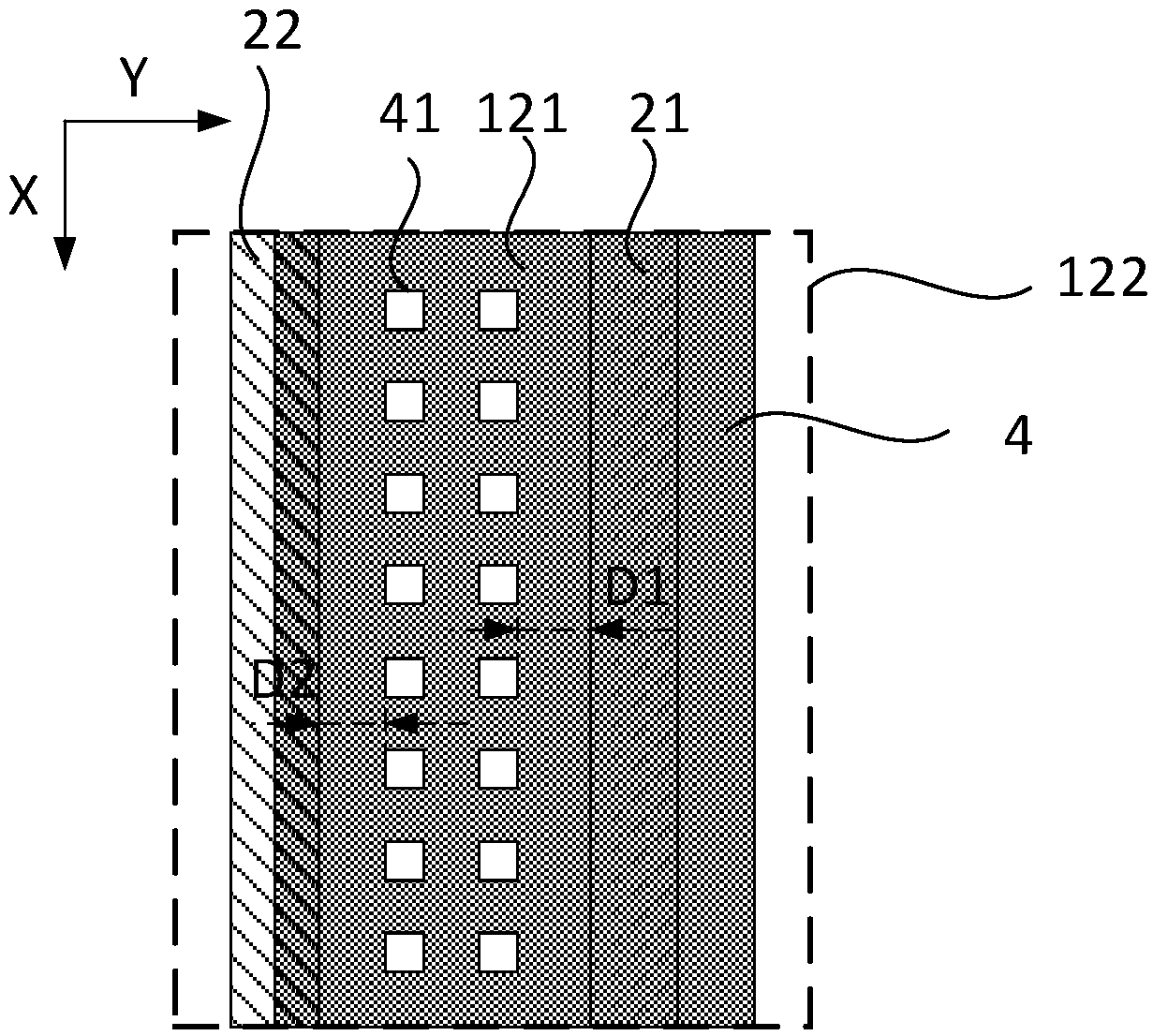

The invention provides a package structure and a package method of an organic light-emitting diode (OLED) device. The package structure of the OLED device comprises a substrate (1), an OLED device (2), a first blocking layer (3), a buffer layer (4) and a second blocking layer (5), wherein the OLED device (2) is arranged on the substrate (1), the first blocking layer (3) is formed on the OLED device (2), the buffer layer (4) is formed on the first blocking layer (3), the second blocking layer (5) is formed on the buffer layer (4), and the buffer layer (4) is doped with water absorption particles (41). By doping the water absorption particles into the buffer layer, the ability of preventing moisture of the package structure is enhanced, and thus, the service life of the OLED device can be effectively prolonged. According to the package method of the OLED device, moisture invasion can be effectively blocked, the package effect is improved, and the service life of the OLED is effectively prolonged. The method is simple and is high in operability.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

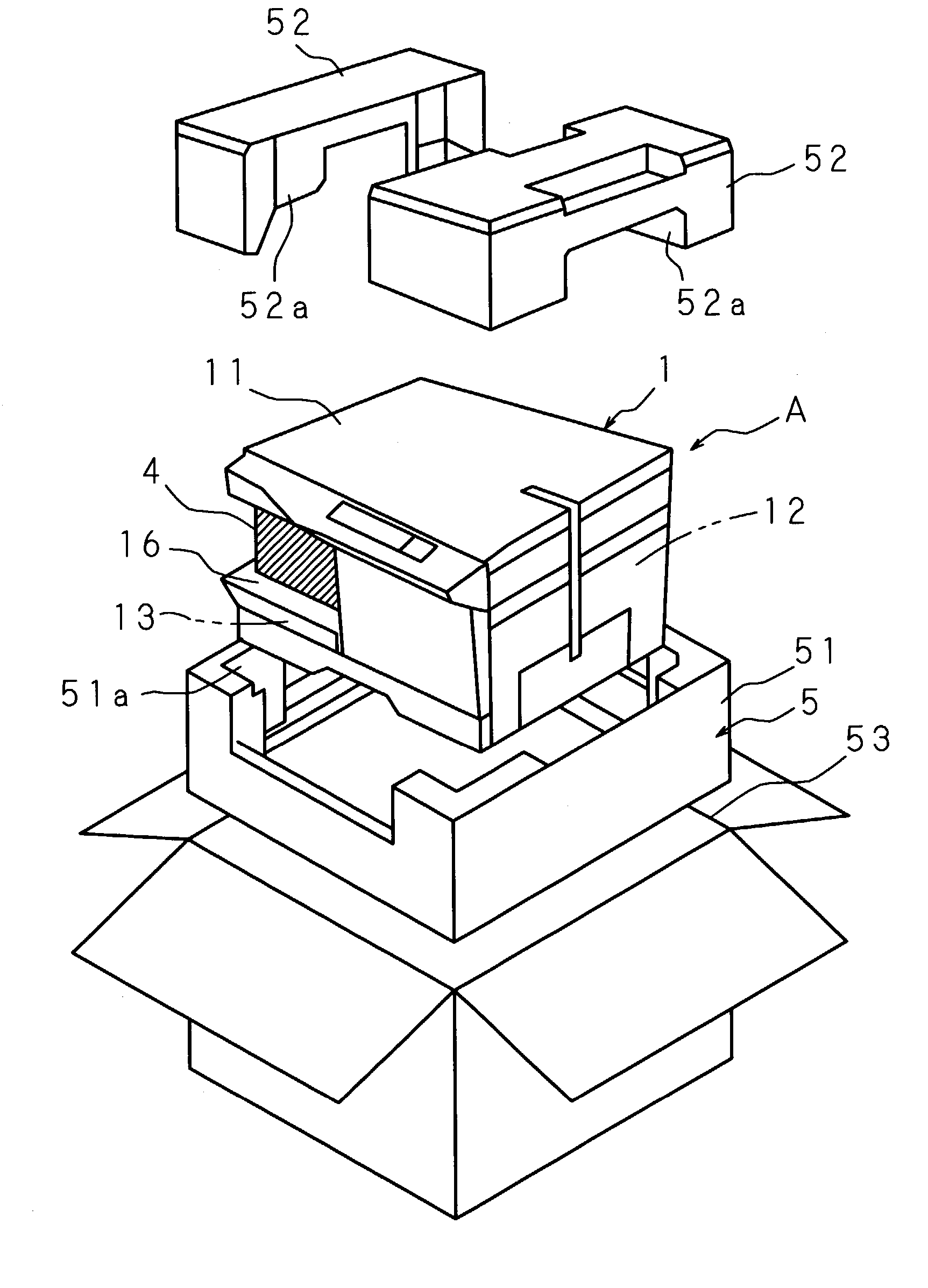

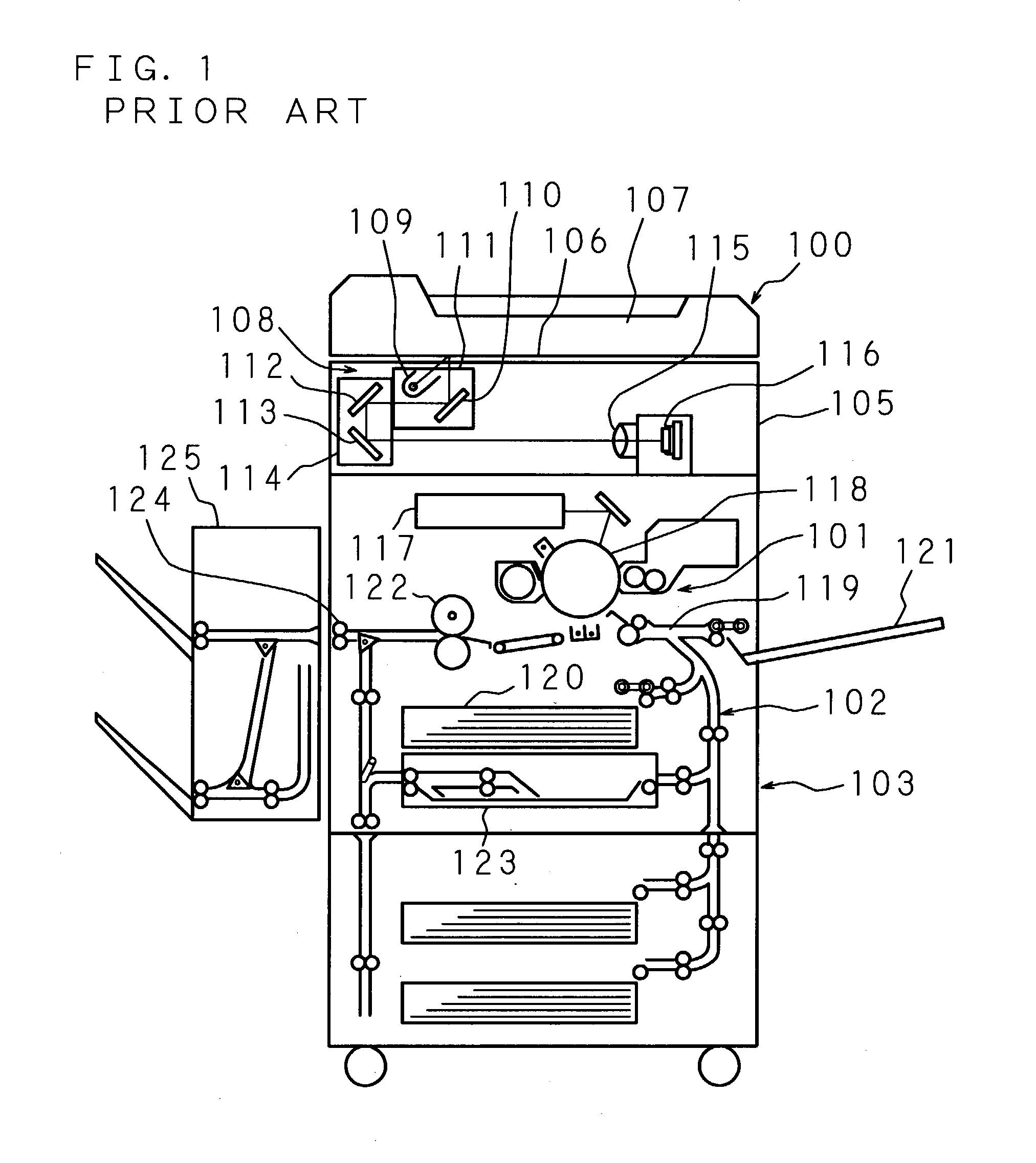

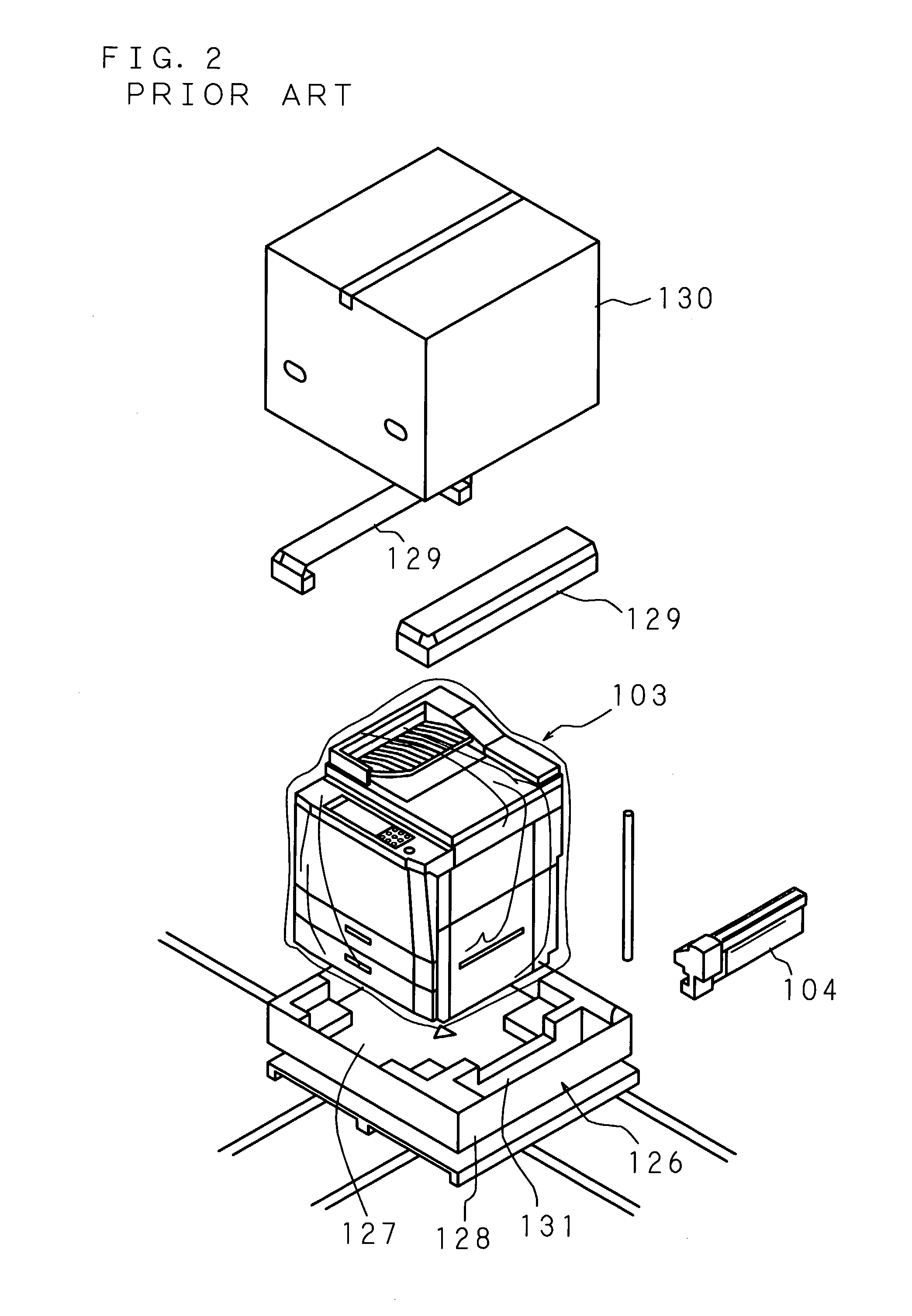

Packing case and packing method for packing image forming apparatus, and image forming apparatus

ActiveUS20030209464A1Easy to useSmall sizePackaging vehiclesContainers for machinesImage formationPaper document

A packing case for an image forming apparatus, comprising: a first packing member 5 for packing an image forming apparatus main body 1 including a reading section 11 having a scanner unit for reading a document image, an image forming section 14 having an image forming unit 12 for forming an image according to image data and a sheet feed unit 13 for feeding a sheet to the image forming unit 12, and a sheet storage space 16, formed to be open to outside between the reading section 11 and the image forming section 14, for storing a sheet transported from the image forming unit 12; and a second packing member 4 for packing a toner cartridge 2 containing toner to be supplied to the image forming unit 12 and capable of being inserted into and removed from the image forming apparatus main body 1, in which the second packing member 4 is inserted and fixed in the sheet storage space 16. This packing case enables a decrease in the overall size of the packing case and a reduction in the cost of the packing case.

Owner:SHARP KK

Display panel and display device

ActiveCN108550617AReduce the risk of strippingIncrease contact forceSolid-state devicesPhotovoltaic energy generationDisplay deviceContact layer

The embodiment of the invention provides a display panel and a display device. The display panel comprises a substrate base plate and a flexible packaging layer arranged on the substrate base plate, wherein the flexible packaging layer comprises a first inorganic layer; and a power signal line, a signal connection layer and a first electrode sequentially arranged on the substrate base plate, wherein the signal connection layer is connected with the power signal line and the first electrode. The display panel also comprises an inorganic contact layer arranged between the signal connection layerand the power signal line, wherein the signal connection layer comprises a plurality of via holes, and the first inorganic layer contacts the inorganic contact layer by the via holes. According to the display panel and the display device provided by the invention, through the arrangement of the inorganic contact layer and the via holes formed in the signal connection layer, the first inorganic layer used for packaging contacts the inorganic contact layer by the via holes, and thus the contact force between the first inorganic layer and the display panel is increased, the packaging effect is enhanced, and the risk that the first inorganic layer is peeled off during a flexible bending process is reduced.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD

Display substrate and preparation method thereof, and display panel

ActiveCN109037289AImprove packaging effectPrevent overflowSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringSurface plate

Owner:BOE TECH GRP CO LTD

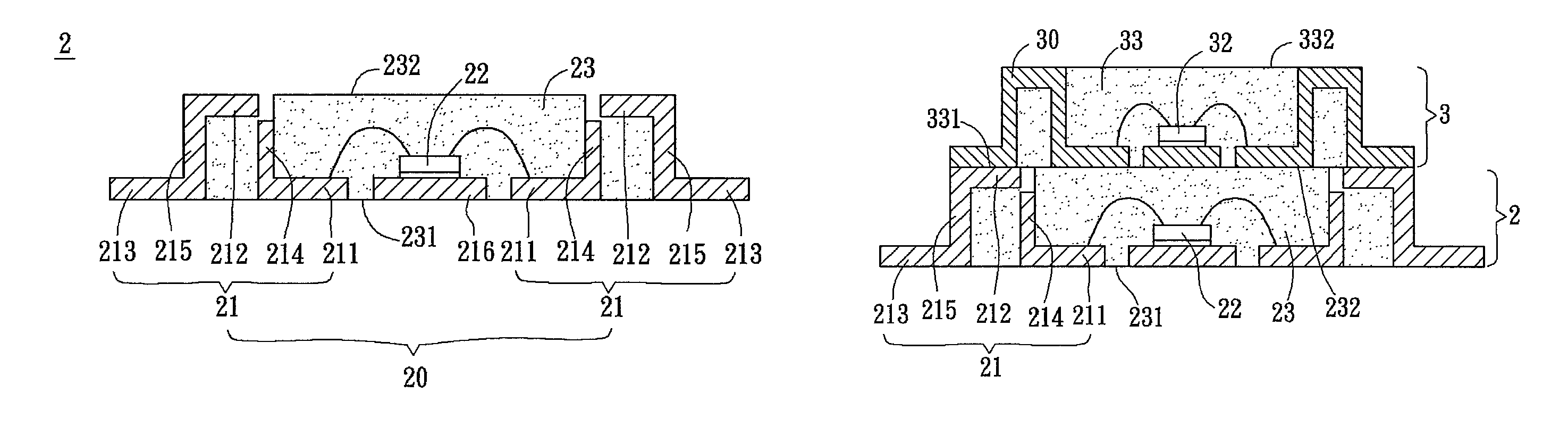

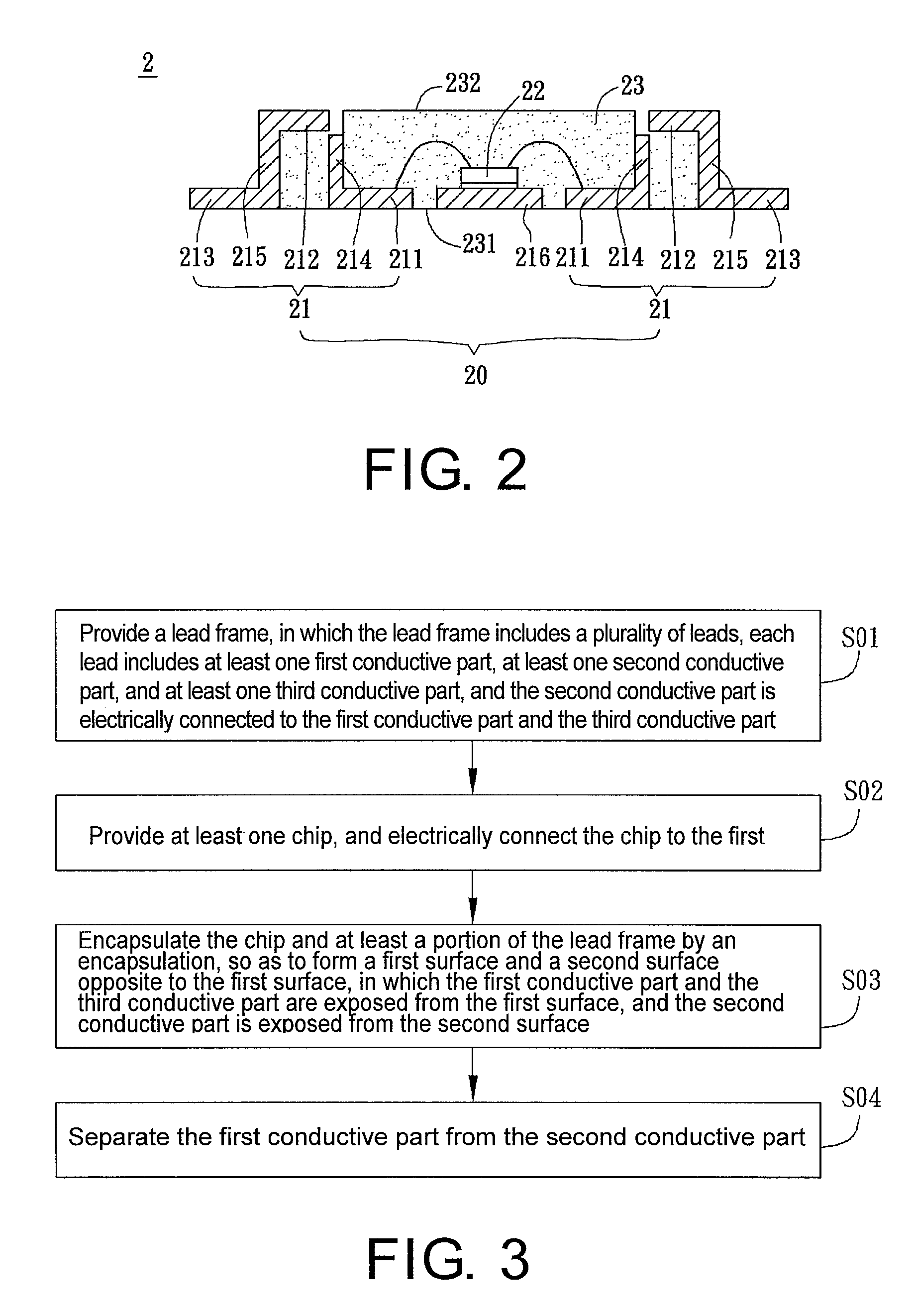

Semiconductor package and manufacturing method thereof

ActiveUS7719094B2Increase the number ofImprove packaging effectSemiconductor/solid-state device detailsSolid-state devicesSemiconductor packageEngineering

A semiconductor package includes a lead frame, at least one chip, and an encapsulation. The lead frame has a plurality of leads, and each of the leads includes at least one first conductive part, at least one second conductive part, and at least one third conductive part. The first conductive part is not electrically connected to the second conductive part, and the second conductive part is electrically connected to the third conductive part. The chip is electrically connected to the first conductive part. The encapsulation encapsulates the chip and at least a portion of the lead frame, and forms a first surface and a second surface opposite to the first surface. The first conductive part and the third conductive part are exposed from the first surface, and the second conductive part is exposed from the second surface.

Owner:ADVANCED SEMICON ENG INC

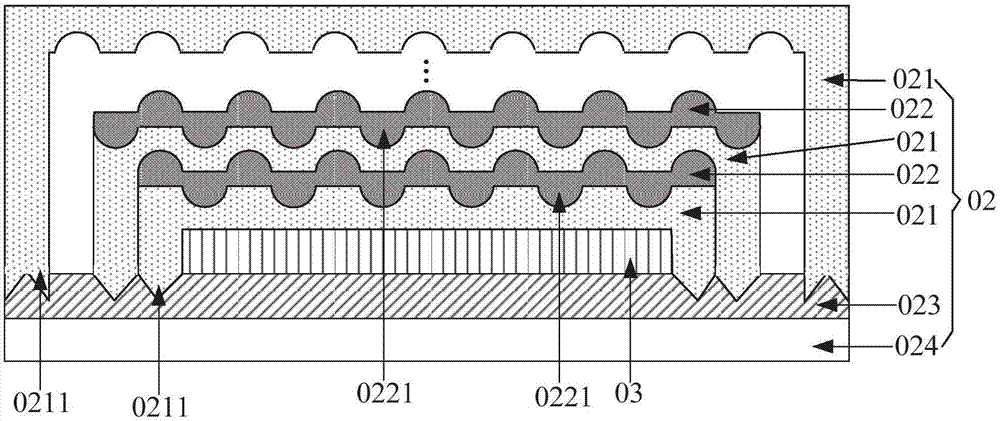

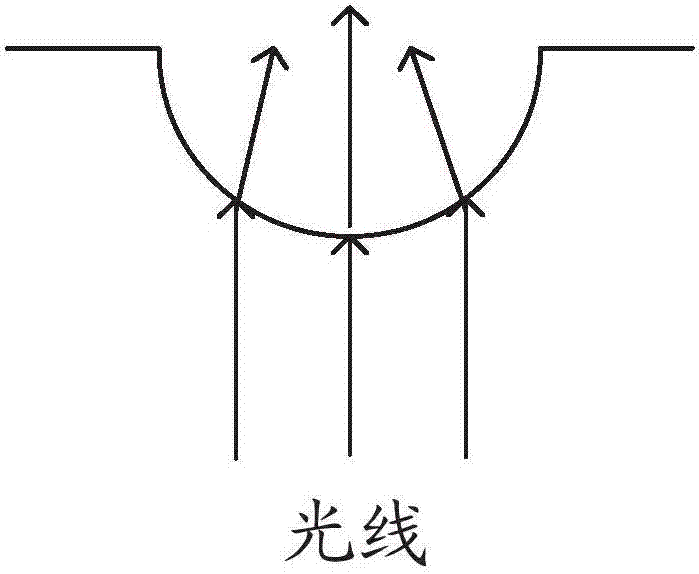

OLED package structure and manufacture method thereof and display device

InactiveCN107394059AGood encapsulation effectImprove packaging effectSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

The invention discloses an OLED package structure and a manufacture method thereof and a display device, and belongs to the field of display device package. The OLED package structure comprises a plurality of film layers covering an OLED device. The plurality of film layers comprise alternately-stacked inorganic layers and organic layers; and any two mutually-contacted film layers of the plurality of film layers are in clamp connection. The OLED package structure and the manufacture method thereof and the display device solve the problem of poor package effect of the OLED package structure; and the package effect of the OLED package structure is improved. The OLED package structure and the manufacture method thereof are used for package of the OLED device.

Owner:BOE TECH GRP CO LTD +1

Soft tissue packing machine

ActiveCN103950590AGuaranteed uniformityReduce labor costsPaper article packagingWrapping material feeding apparatusEngineeringSoft tissue

The invention discloses a soft tissue packing machine, and relates to the technical field of tissue packing machinery. The soft tissue packing machine comprises a path division conveying component, a material sorting conveying component, a membrane supporting and conveying component, a bag opening and strutting component, a negative pressure conveying component, a bag pushing component and a cutter seal component. The soft tissue packing machine disclosed by the invention has the advantages that the bag opening and strutting component, a membrane conveying mechanism and a membrane conveying mechanism are improved, according to the soft tissue packing machine, the bag opening size of packing bags can be regulated, the soft tissue packing machine is suitable for the package of products in any specifications, the soft tissue packing machine adopts integral operation, the efficiency is improved, the cost is reduced, and the packing quality can also be unified.

Owner:上海松川峰冠包装自动化有限公司

Array substrate, display panel and display device

ActiveCN107978622AImprove the display effectImprove packaging effectStatic indicating devicesSolid-state devicesSignal onDisplay device

The present invention discloses an array substrate, a display panel and a display device. The array substrate comprises: a substrate and a pixel unit; a first electrode wiring and a second electrode wiring formed at one side of the substrate, wherein the first electrode wiring is configured to provide first power voltage signals to the anode layer of the pixel unit, and the second electrode wiringis configured to provide second power voltage signals to the cathode layer of the pixel unit; and a first metal wiring and a second metal wiring formed at a non-display area and enclosing a display area, wherein the first metal wiring and the first electrode wiring are electrically connected, and the second metal wiring and the second electrode wiring are electrically connected. The first metal wiring and the first electrode wiring are electrically connected, and the second metal wiring and the second electrode wiring are electrically connected to reduce the transmission wiring resistance andreduce the voltage drops of power supply signals on the transmission wirings. The individually arranged metal wirings are divided into the first metal wiring and the second metal wiring which are arranged in an insulation mode so as to reduce the stress on the first metal wiring and the second metal wiring.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD

OLED encapsulation method and OLED encapsulation structure

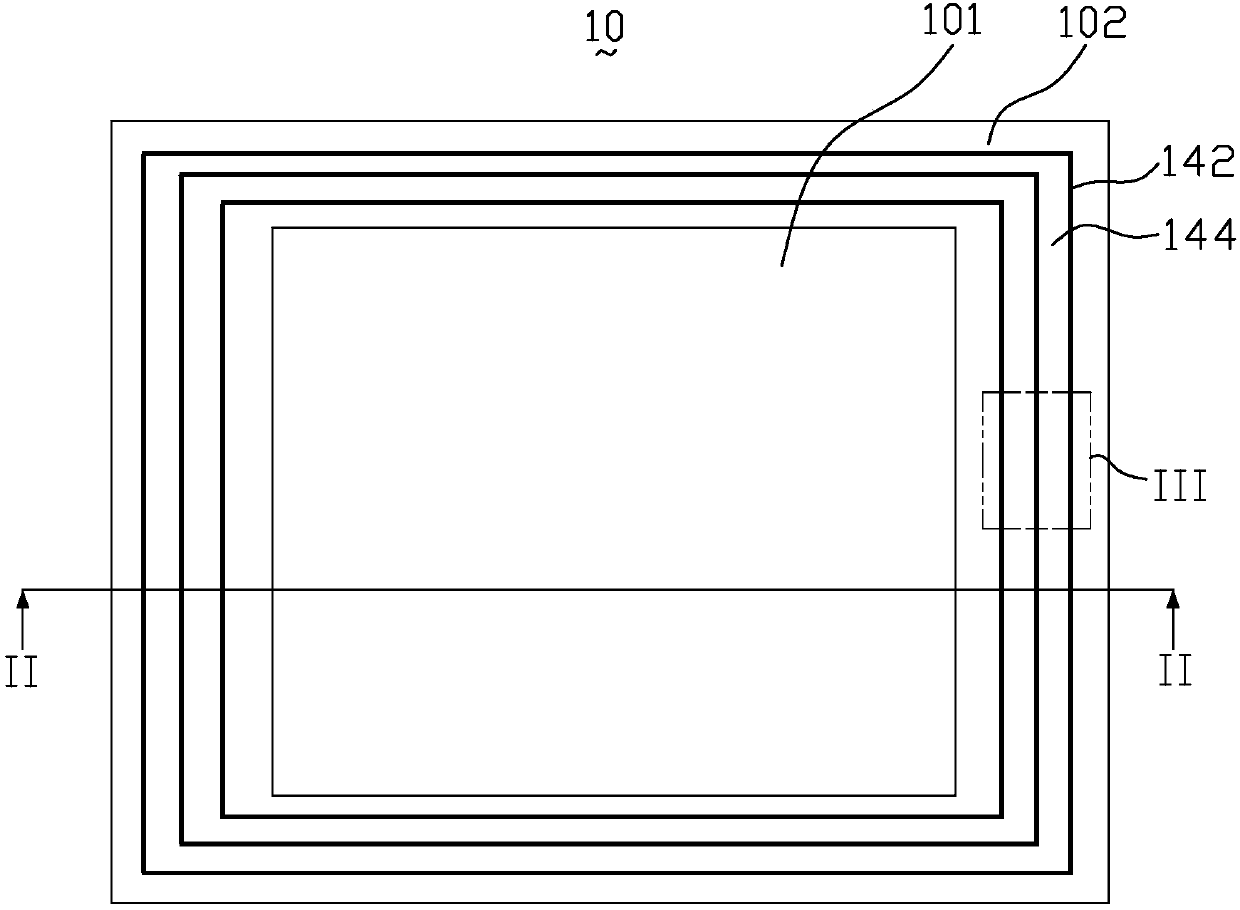

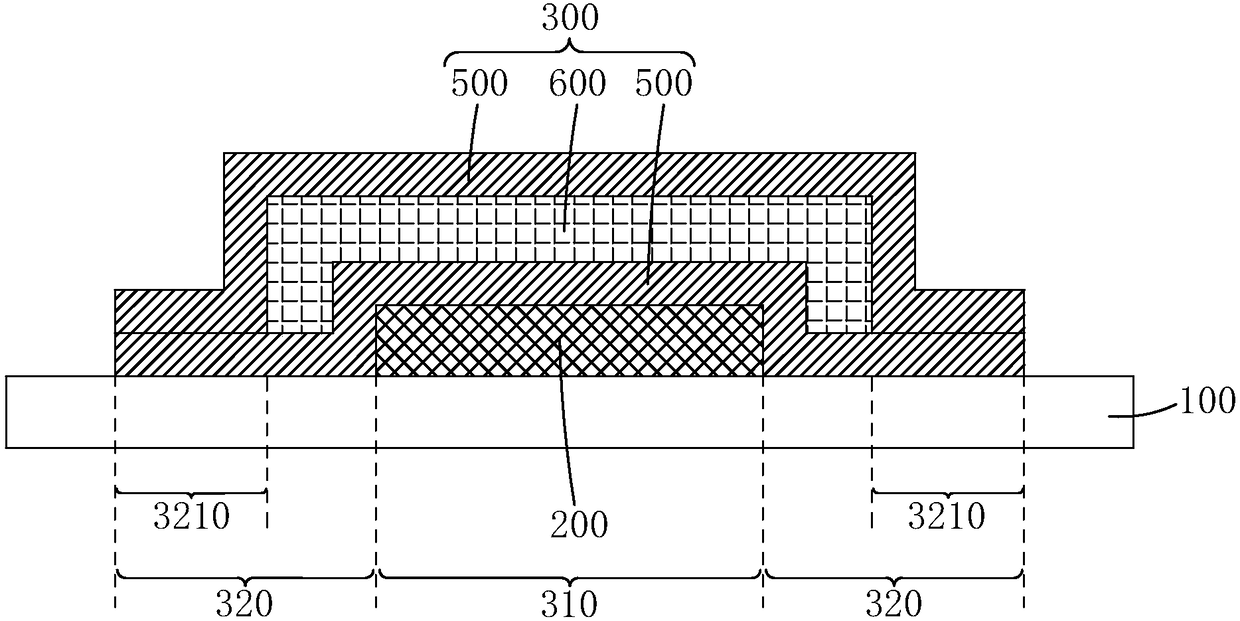

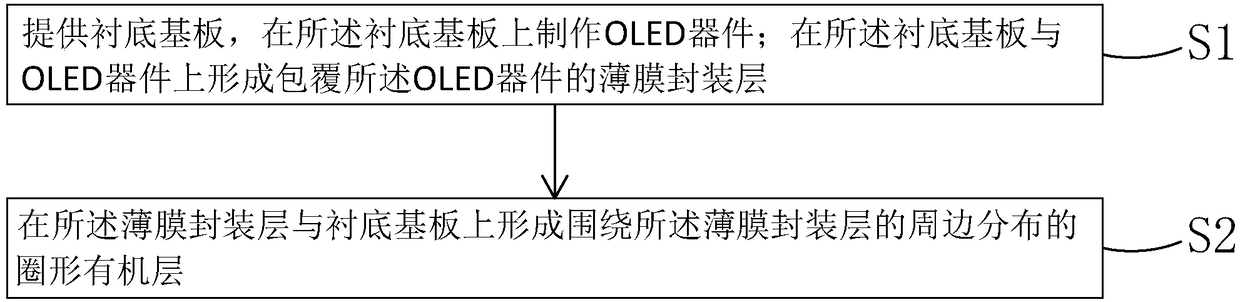

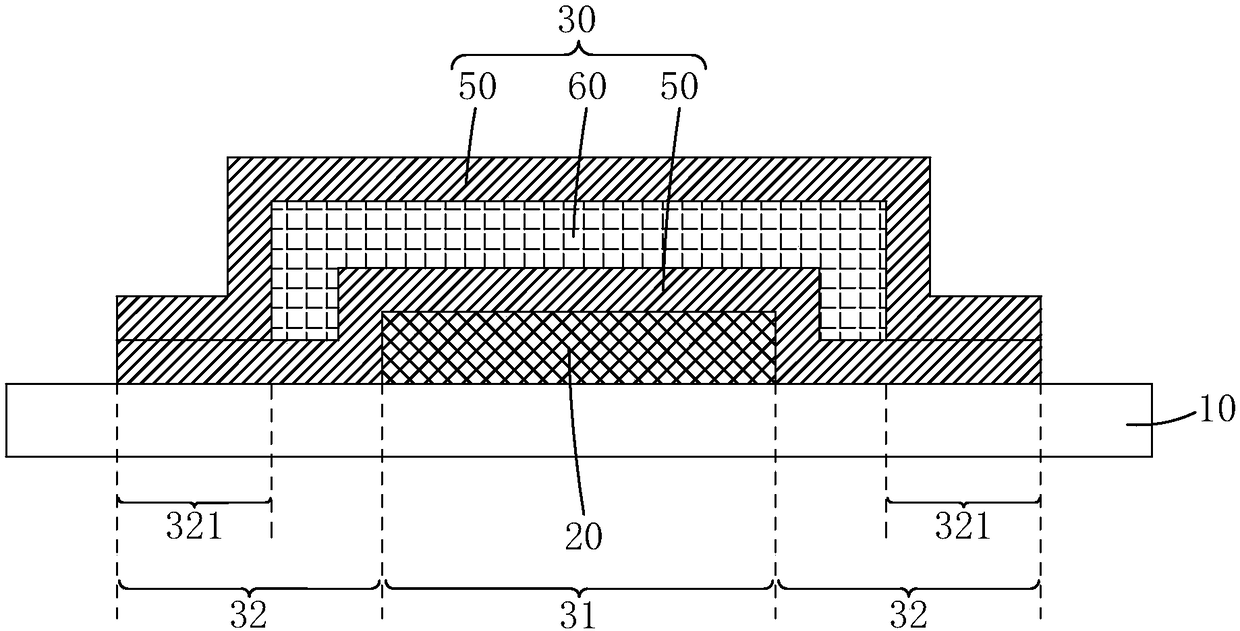

ActiveCN108198953AGood bending resistanceAchieve narrow bezel designSolid-state devicesSemiconductor/solid-state device manufacturingScreen designOrganic layer

The invention provides an OLED encapsulation method and OLED encapsulation structure. The OLED encapsulation method includes the following steps: a first step, providing a substrate, and manufacturingan OLED device on the substrate, and forming a thin film encapsulation layer covering the OLED device on the substrate and the OLED device; and a second step, forming a circular organic layer distributed around the periphery of the thin film encapsulation layer on the thin film encapsulation layer and the substrate. The circular organic layer is arranged on the periphery of the thin film encapsulation layer, and in this way, a hook surface screen design and a narrow frame design of an OLED display device can be achieved, and the ability to block water and oxygen of the OLED encapsulation structure is improved. The OLED encapsulation structure can achieve the hook surface screen design and the narrow frame design of an OLED display device, and has high ability to block water and oxygen.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

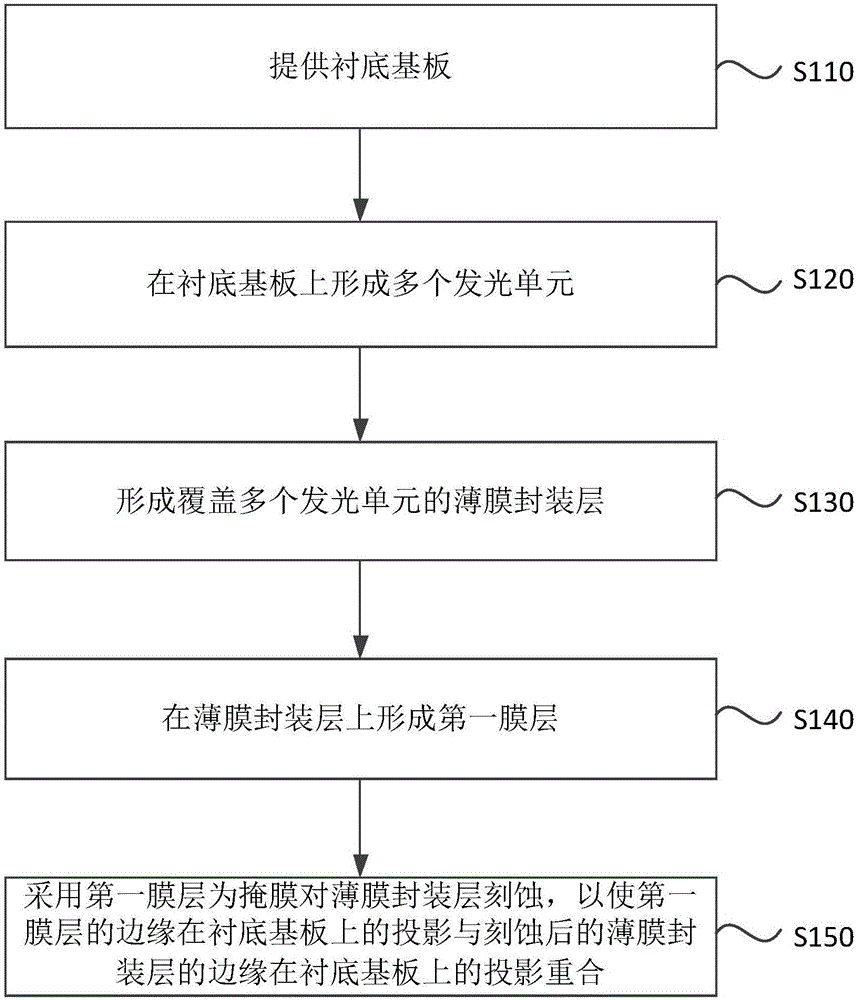

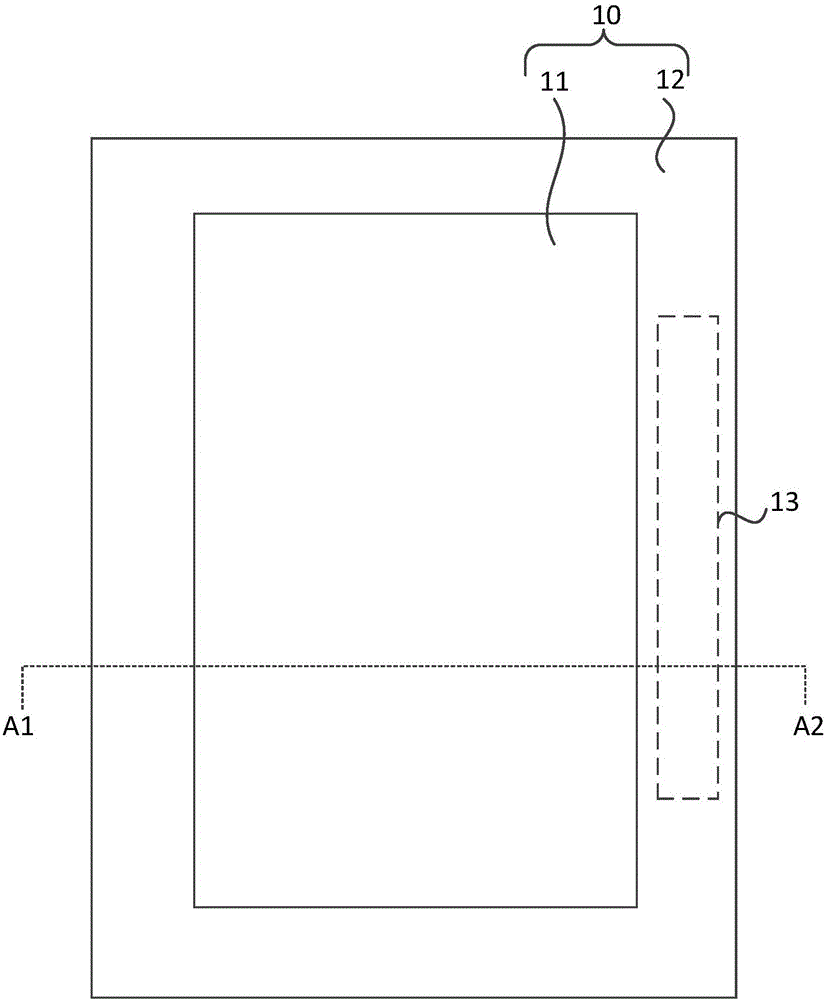

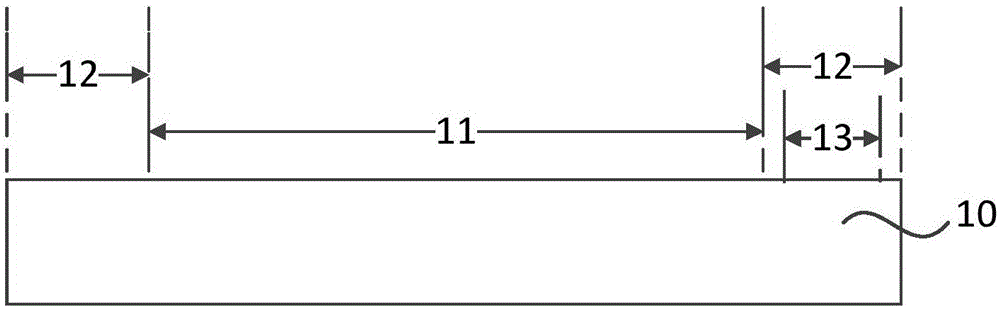

Display panel manufacturing method, display panel and display device

ActiveCN106711184AImprove packaging effectSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringSurface plate

The embodiment of the invention discloses a display panel manufacturing method, a display panel and a display device. The display panel manufacturing method comprises the steps of providing a substrate base plate; forming multiple light emitting units on the substrate base plate; forming a thin film packaging layer that covers the multiple light emitting units; forming a first film layer on the thin film packaging layer, wherein the distance between a projection, positioned on the substrate base plate, of a margin of a driver chip binding area on the display panel, which is adjacent to the light emitting units, and a projection, positioned on the substrate base plate, of a margin of the first film layer, which is adjacent to the driver chip binding area, is greater than or equal to 0 micron, or less than or equal to 100 microns; and positioning the projection, positioned on the substrate base plate, of the first film layer within a projection, positioned on the substrate base plate, of the thin film packaging layer; and to etching the thin film packaging layer by adopting the first film layer as a covering film so as to overlap the projection, positioned on the substrate base plate, of the margin of the first film layer generate and the projection, positioned on the substrate base plate, of the margin of the thin film packaging layer subjected to etching. According to the display panel manufacturing method, the display panel and the display device disclosed by the embodiment of the invention, the packaging effect of the thin film packaging layer in an organic light emitting display panel can be improved.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

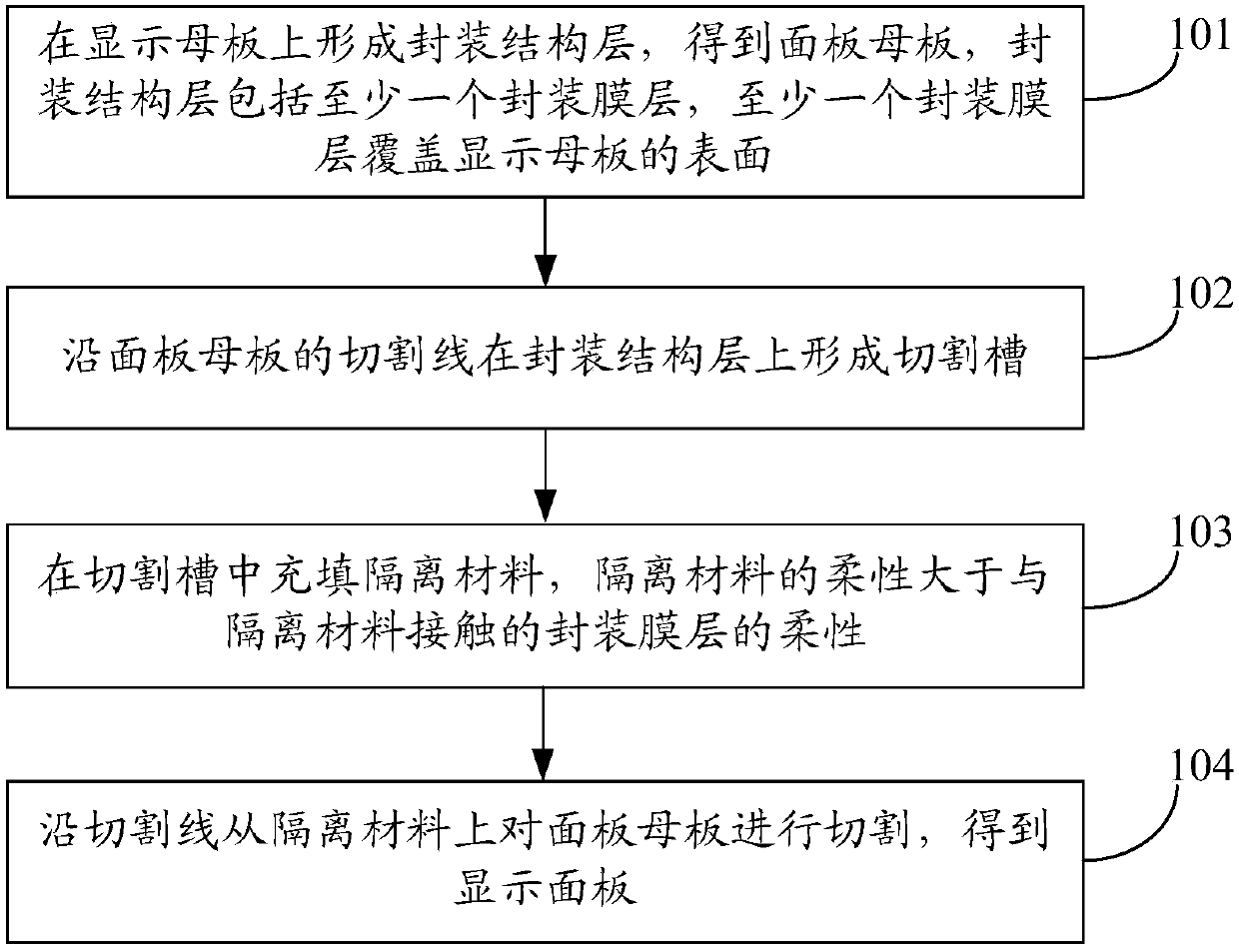

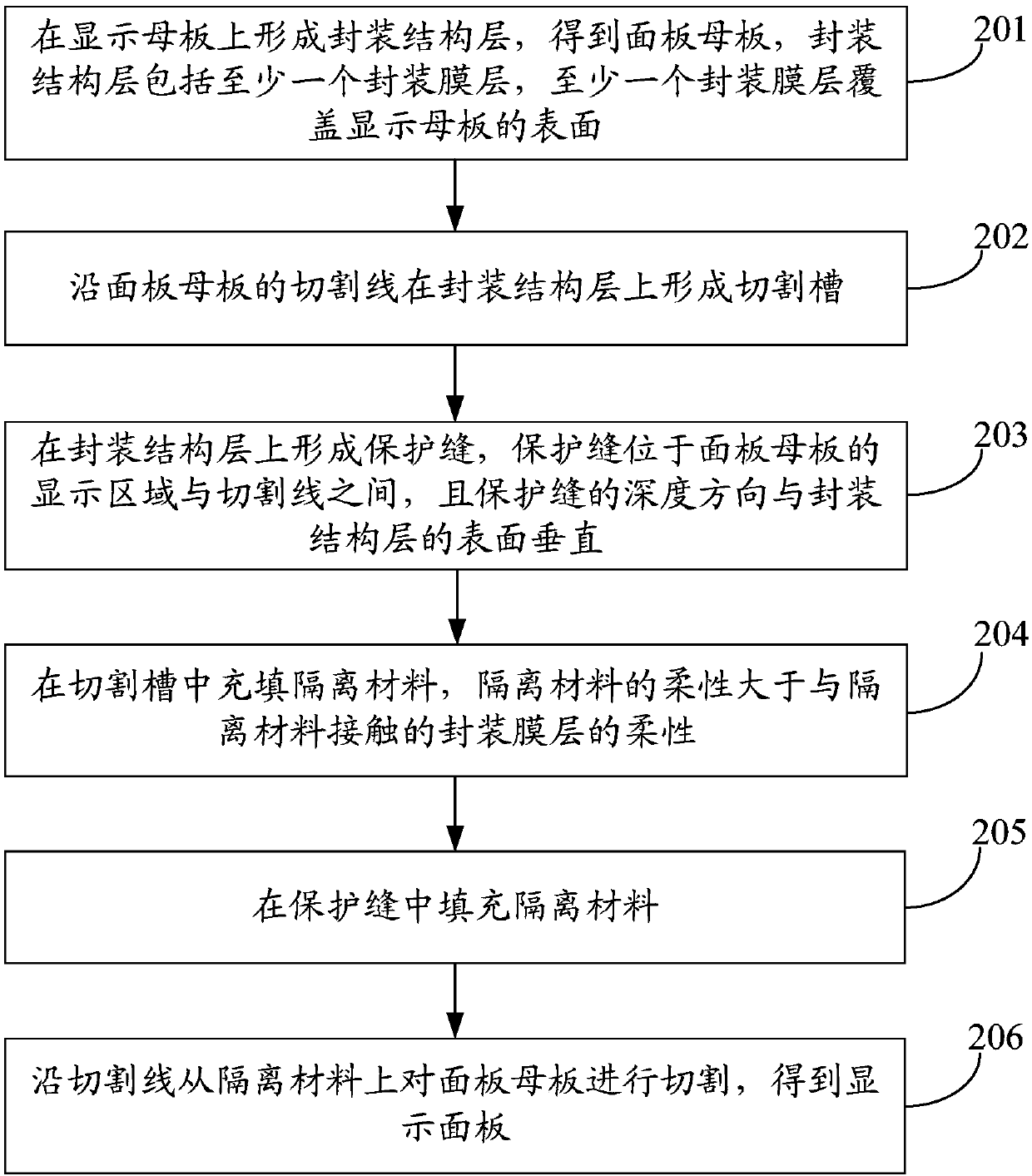

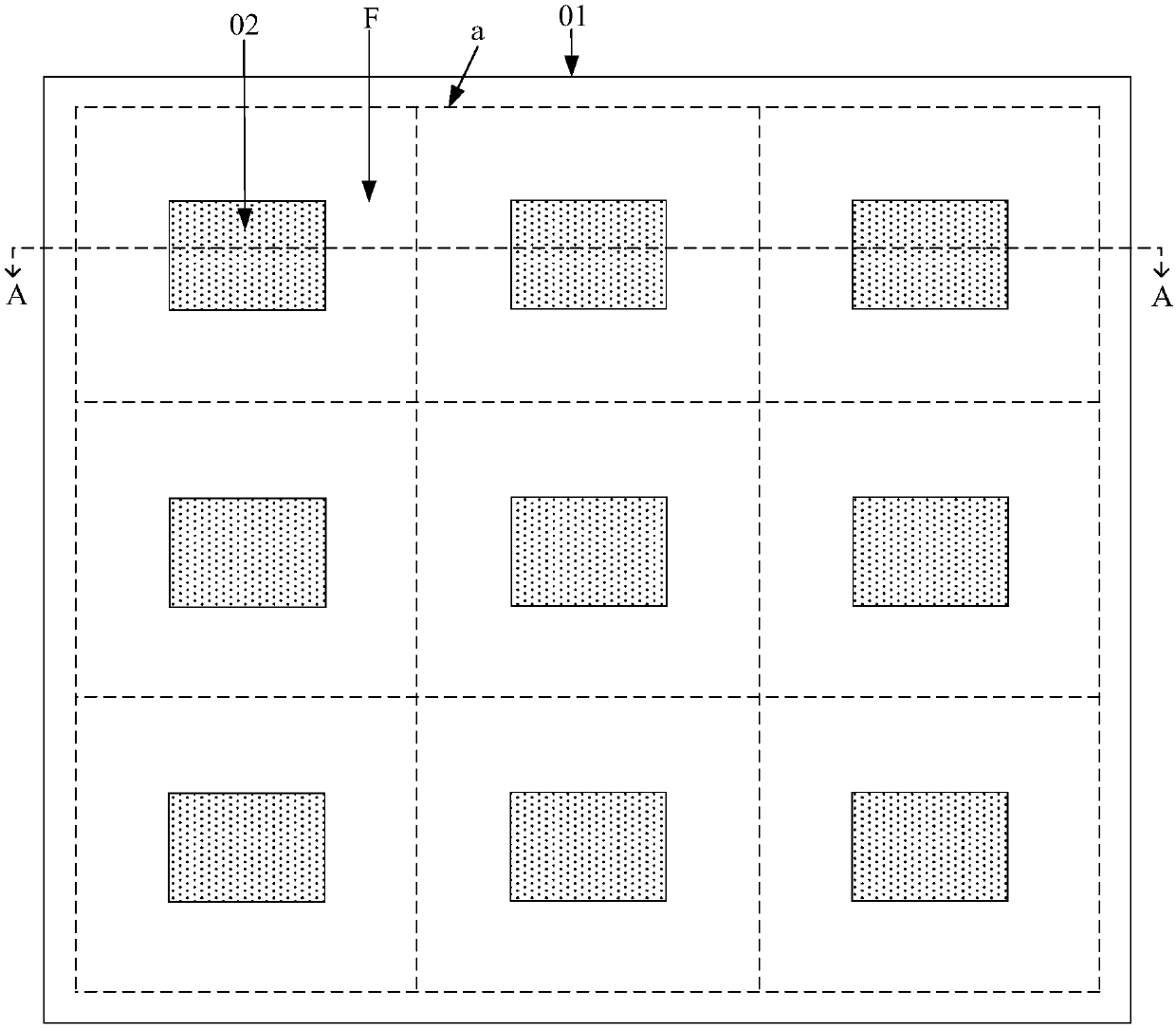

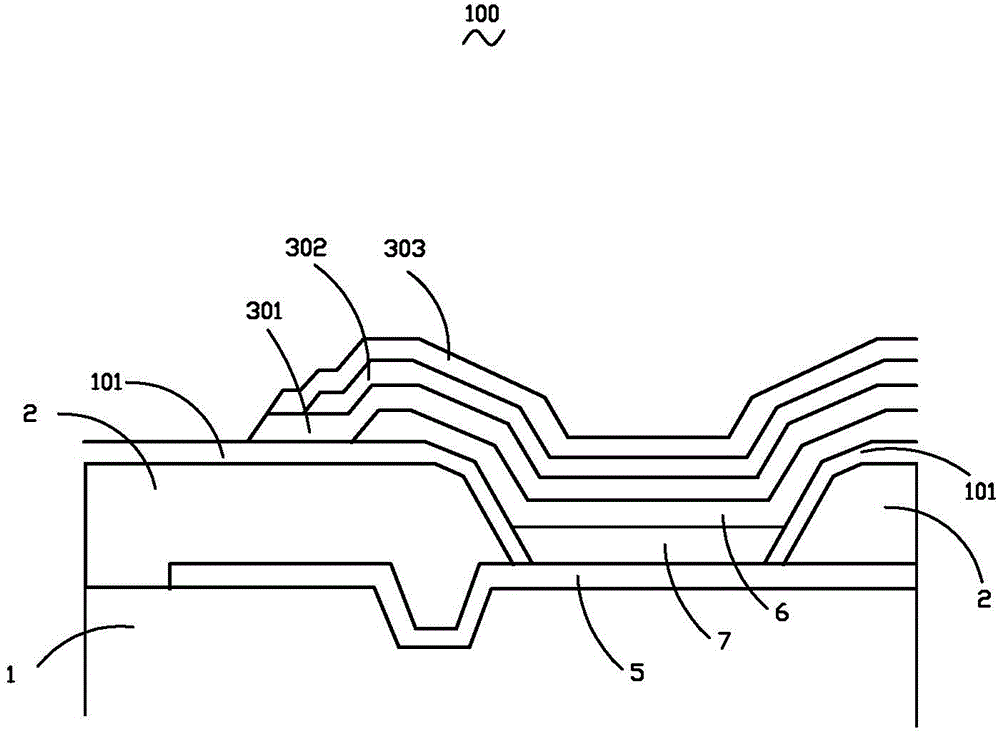

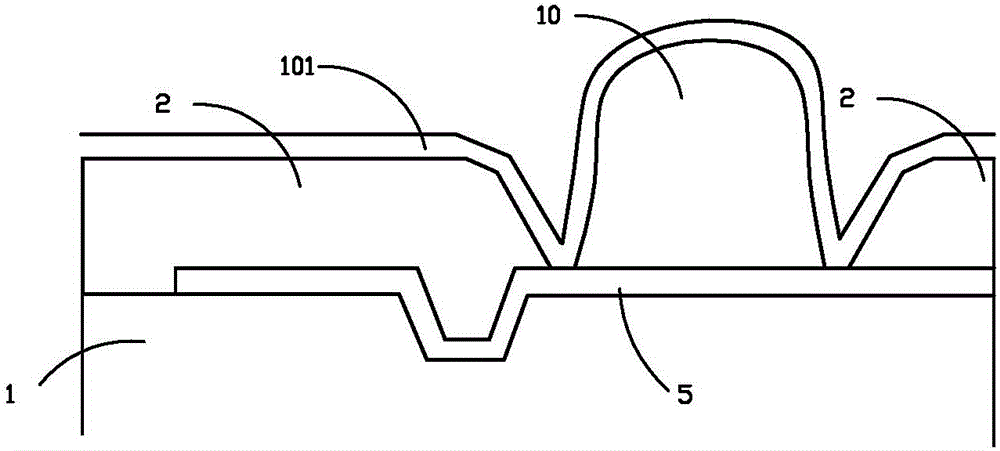

Display panel, manufacturing method of display panel and display device

ActiveCN107785505AGood encapsulation effectImprove packaging effectSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

The invention discloses a display panel, a manufacturing method of the display panel and a display device, and belongs to the technical field of display. The method comprises the steps that a packaging structure layer is formed on a display mother board to obtain a panel mother board, wherein the packaging structure layer comprises at least one packaging film layer, and the at least one packagingfilm layer covers the surface of the display mother board; a cutting groove is formed in the packaging structure layer along a cutting line of the panel mother board; the cutting groove is filled withan isolation material, wherein the flexibility of the isolation material is larger than that of the packaging film layer in contact with the isolation material; the panel mother board is cut from theisolation material along the cutting line to obtain the display panel. The problem that the packaging effect of a packaging structure is poor is solved, and the packaging effect of the packaging structure is improved. The method is used for manufacturing the display panel.

Owner:BOE TECH GRP CO LTD +1

OLED device and method thereof

ActiveCN104538558ASimple structureImprove moisture barrierSolid-state devicesSemiconductor/solid-state device manufacturingOptoelectronicsOxygen

The invention relates to an OLED device and a method of the OLED device. The OLED device comprises a substrate, a light emitting element on the substrate and a packaging cover, the light emitting element comprises a first electrode layer, a second electrode layer and a light emitting layer between the first electrode layer and the second electrode layer, and an inorganic pixel limiting layer used for sealing the light emitting element between the first electrode layer and the second electrode layer is arranged around the light emitting element. The inorganic pixel limiting layer is closely attached to the first electrode layer and the second electrode layer. Through the arrangement, the light emitting layer is surrounded in internal inorganic layer closed space, the capacity of blocking moisture and oxygen can be improved, and therefore the packaging effect is improved, and the structure is simple.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

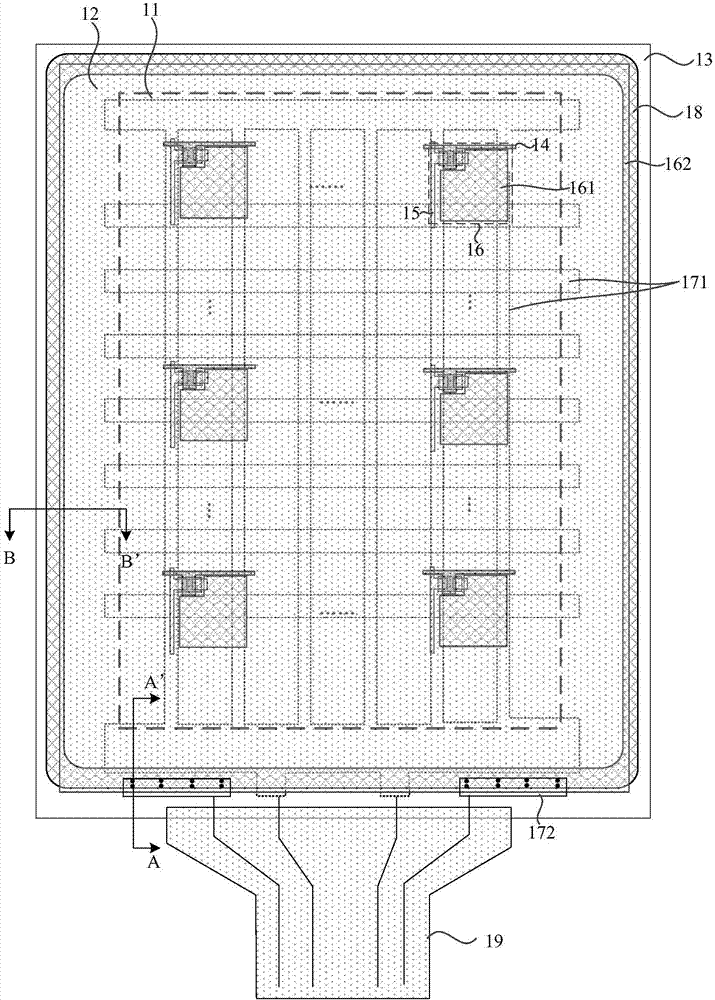

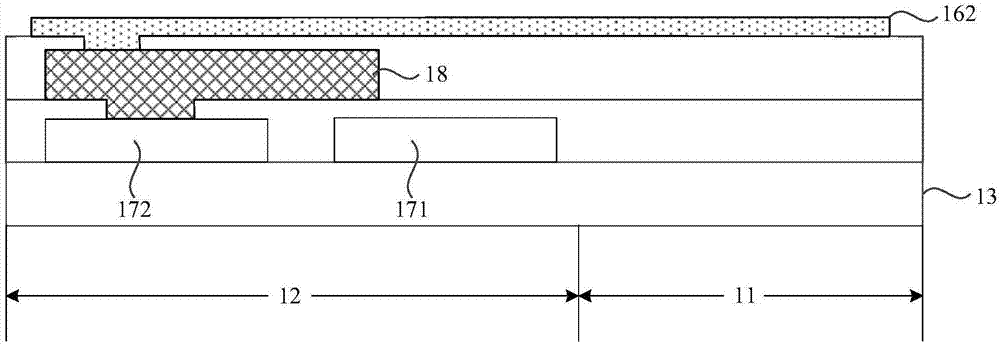

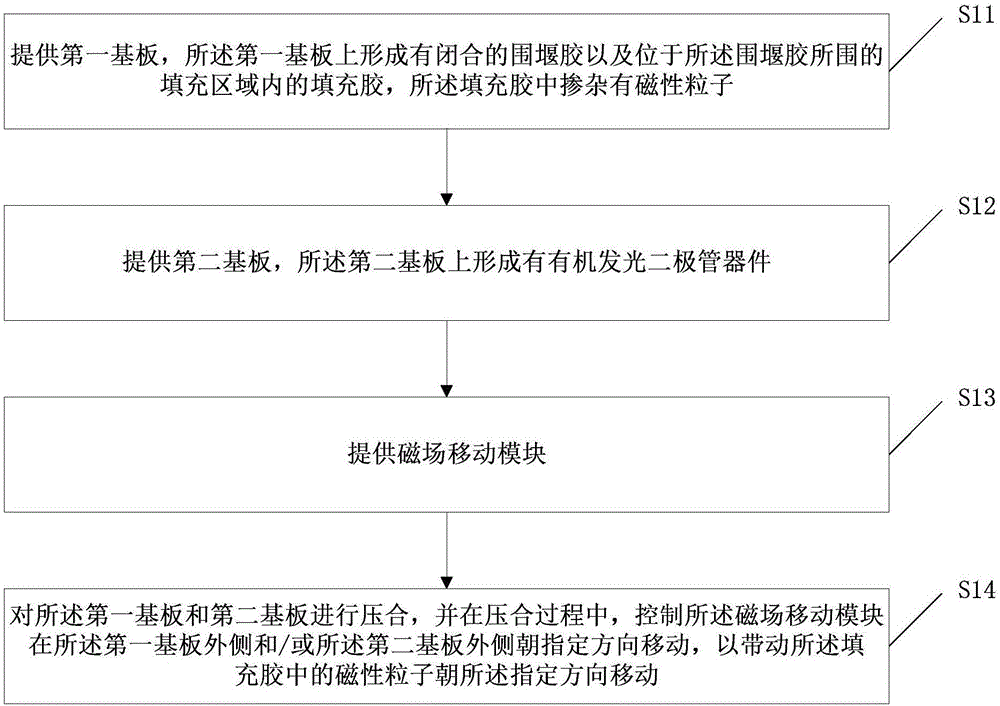

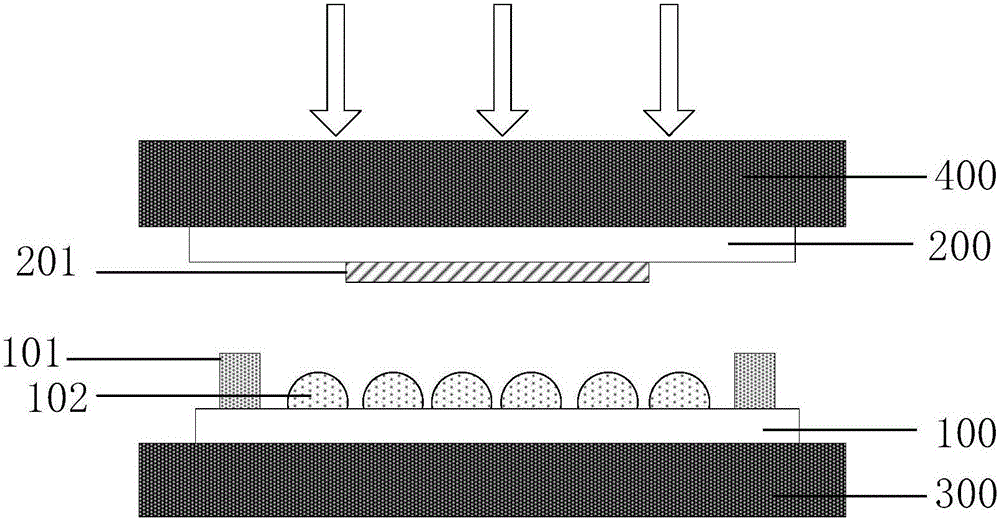

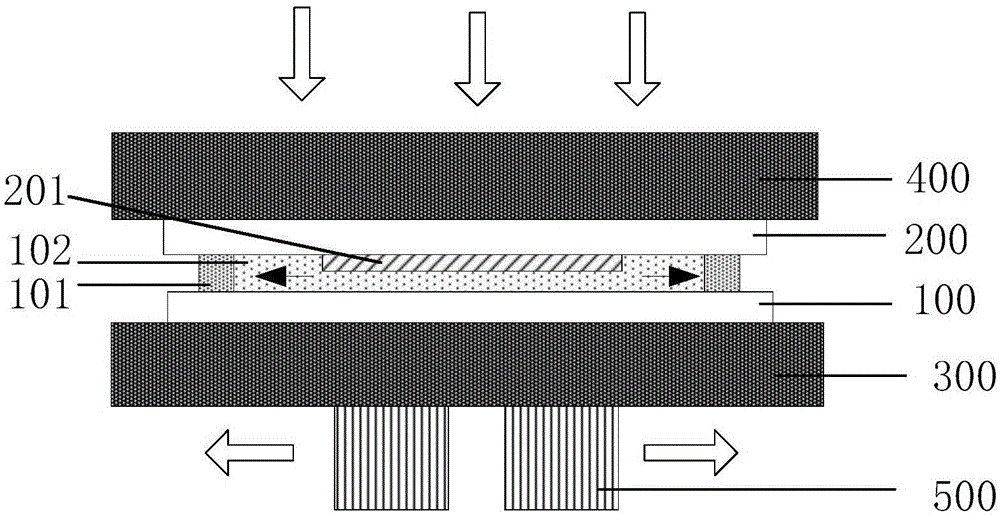

Organic light emitting diode device and packaging method and device thereof

ActiveCN106784360AImprove packaging effectSpread evenlySolid-state devicesSemiconductor/solid-state device manufacturingAdhesiveLight-emitting diode

The invention provides an organic light emitting diode device and a packaging method and device thereof. The packaging method comprises the steps that a first substrate is provided, wherein a closed cofferdam adhesive and a filling adhesive located in the filling area defined by the cofferdam adhesive are formed on the first substrate, and the filling adhesive is doped with magnetic particles; a substrate is provided, and the organic light emitting diode device is formed on the second substrate; a magnetic field moving module is provided; the first substrate and the second substrate are pressed, the magnetic field moving module is controlled to move in the designated direction on the outer side of the first substrate and / or the second substrate so as to drive the magnetic particles in the filling adhesive to move in the designated direction, the filling adhesive is forced to be dispersed all around in the filling area, air bubbles can be extruded from the inside of the filling adhesive, and the packaging effect of the organic light emitting diode device is improved.

Owner:BOE TECH GRP CO LTD

Organic light-emitting device packaging cover plate, organic light-emitting device and displayer

InactiveCN103325958AImprove packaging effectExtended service lifeSolid-state devicesSemiconductor/solid-state device manufacturingWater vaporOrganic light emitting device

The invention provides an organic light-emitting device packaging cover plate, an organic light-emitting device and a displayer. The packaging cover plate of the organic light-emitting device has a packaging surface bonded with a substrate through packaging glue, and the periphery of the packaging surface of the packaging cover plate forms a groove structure used for accommodating the packaging glue. Because the groove structure is formed in the packaging surface of the packaging cover plate, when an OLED device is packaged through the packaging cover plate, the packaging glue used for bonding the packaging cover plate and the substrate can be filled into the groove structure of the packaging cover plate, and therefore gaps between the packaging cover plate and the substrate can be substantially reduced, water vapor penetrating paths are reduced, packaging effect of the OLED device is improved, and service life of the OLED device is prolonged.

Owner:BOE TECH GRP CO LTD

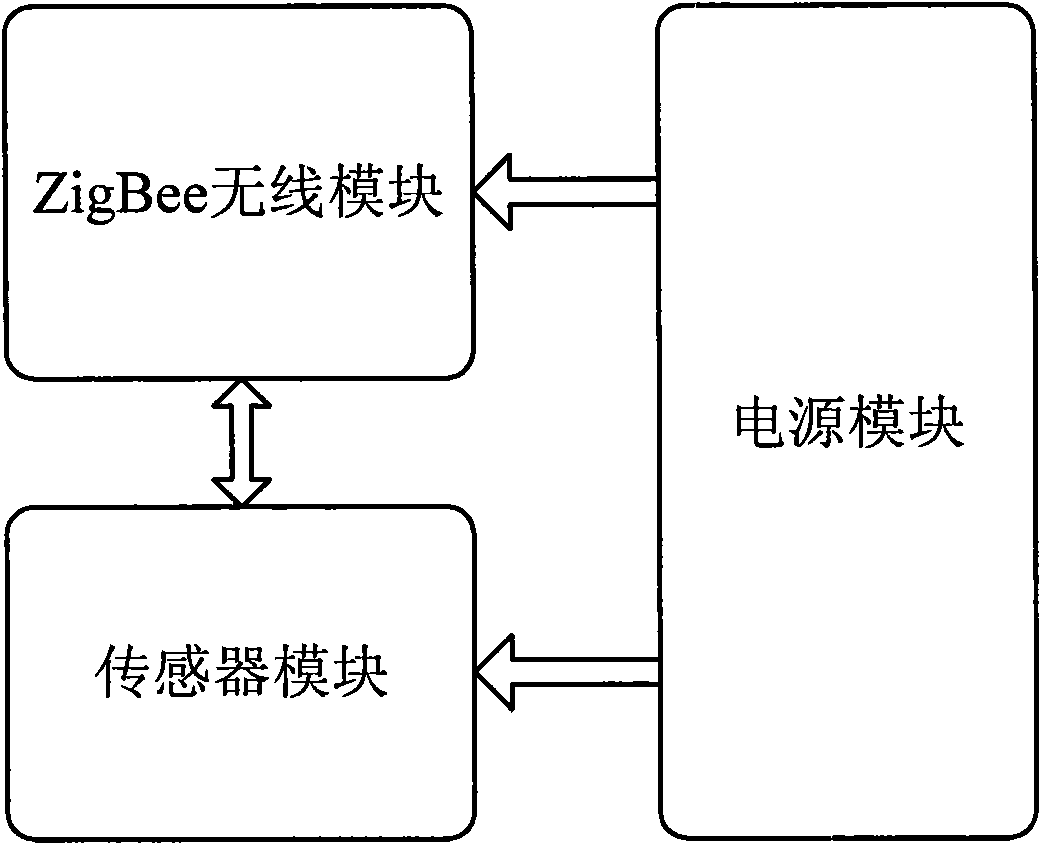

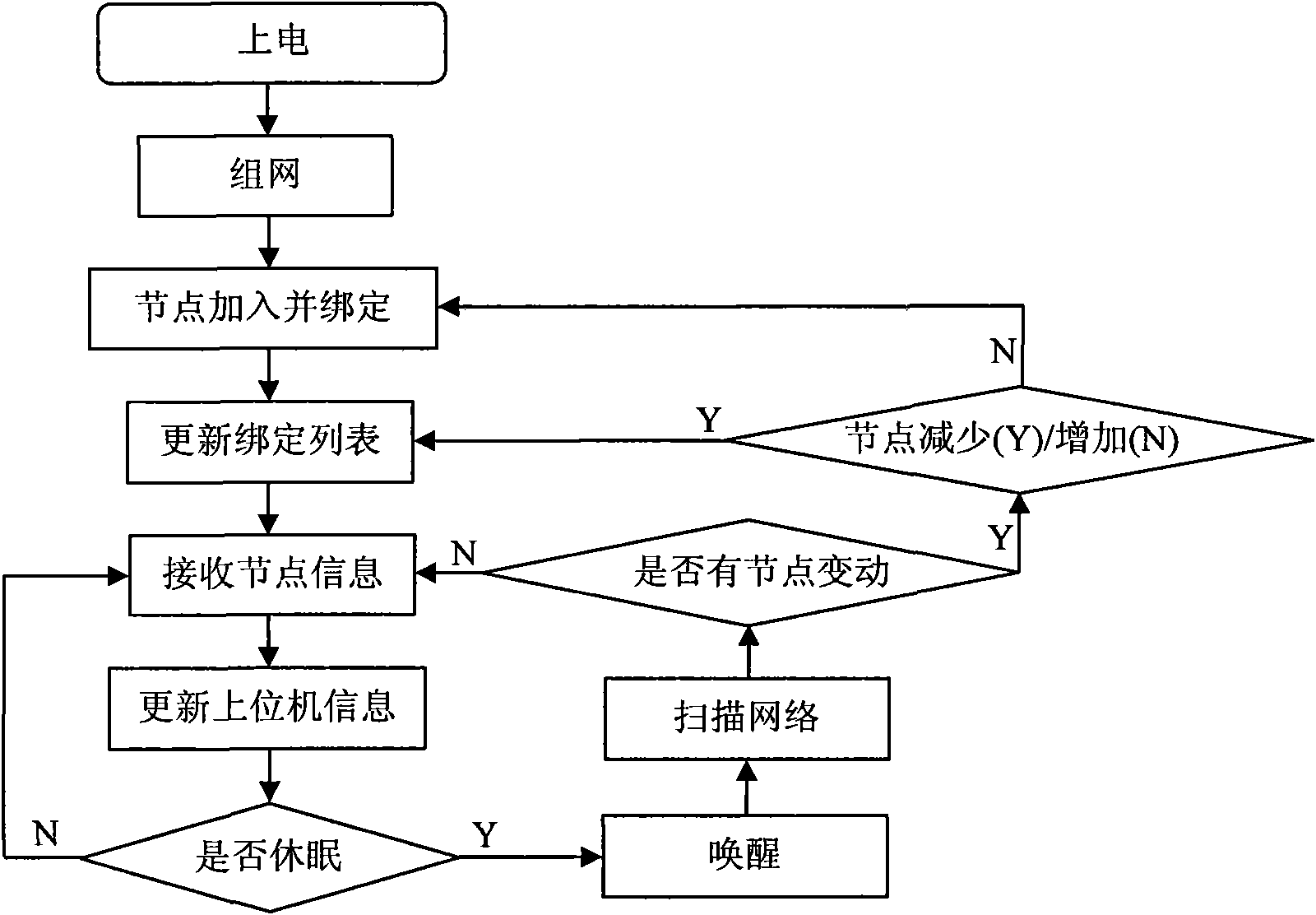

Leakage monitoring and positioning early-warning system in petrochemical industry and establishment method thereof

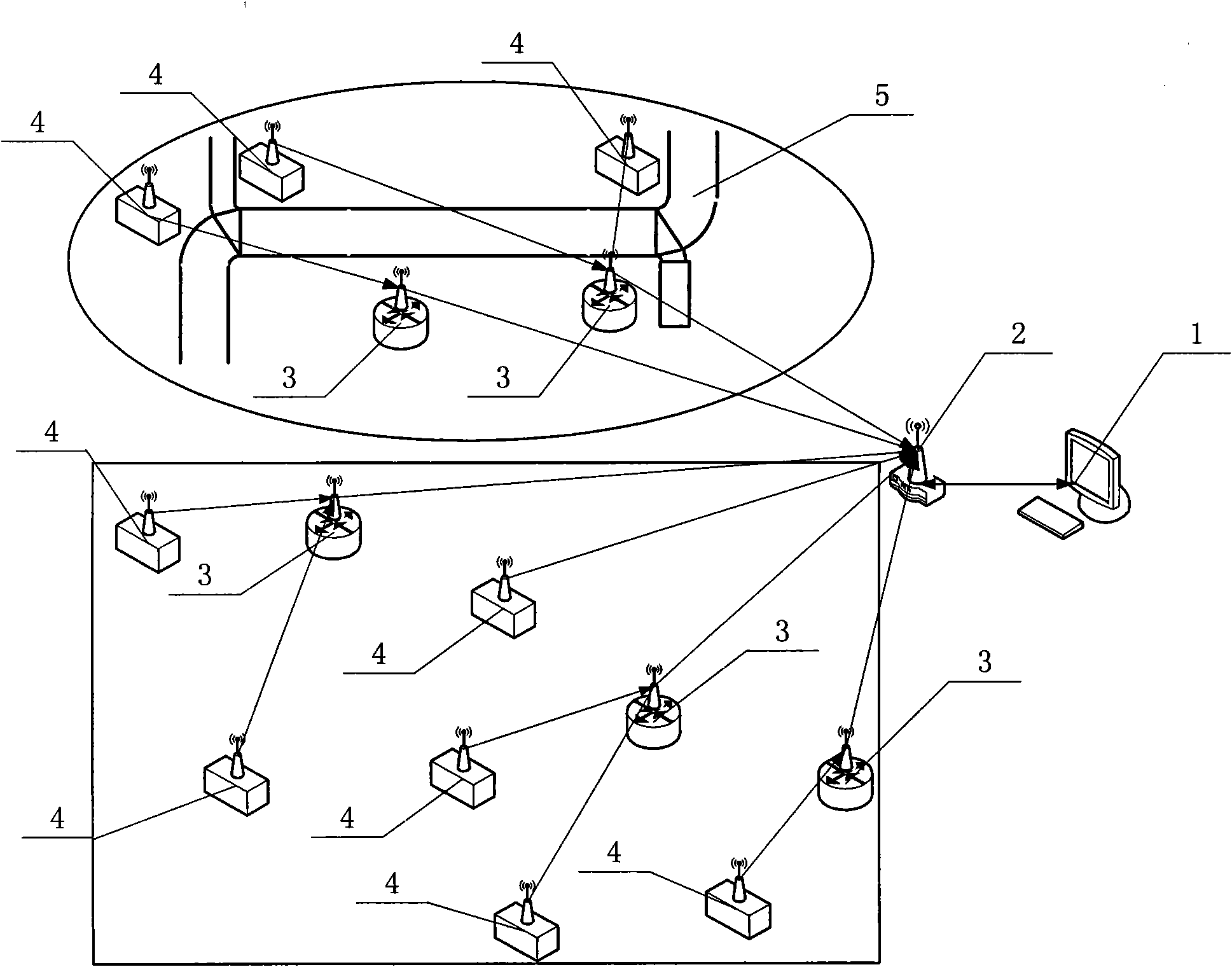

InactiveCN101888413AComprehensive monitoring functionsRealize real-time fixed-point accident monitoringNetwork topologiesTransmissionPotential accidentPetrochemical

The invention provides a leakage monitoring and positioning early-warning system in petrochemical industry and an establishment method thereof, relating to a device for prevention, inspection and position determination of gas leakage. The system comprises a host computer system, a central node, a routing node and a terminal node, wherein the software part in the host computer system comprises a geographic information system and a virtual reality control system; all the nodes are wireless network nodes comprising a ZigBee wireless module, a sensor module and a power supply module; and the ZigBee wireless module adopts a ZigBee wireless transport protocol, the sensor module carries a small leakage gas-sensitive transducer, and the power supply module is composed of a direct current cell of 3.6 V and a voltage conversion circuit. The invention achieves the synchronization of environment parameters of all monitoring points, early-warning information of potential accidents and correct positioning information of dangerous sources when an accident occurs in a monitoring center and the whole site, and the invention solves the problems that sudden leakage events can not be monitored and early-warned in time and the site information can not be acquired and transmitted in time in the prior art.

Owner:HEBEI UNIV OF TECH

Package substrate having embedded capacitor

InactiveUS20080121417A1Increased degrees of freedomIncrease spacingPrinted circuit aspectsPrinted circuit manufactureEngineeringDielectric layer

A package substrate having embedded capacitor is provided. The package substrate includes a first core circuit board, at least one embedded capacitor, a second core circuit board and a dielectric layer. At least one metal layer is disposed on a surface of the first core circuit board and at least one first conductive through hole of the first core circuit board is connected to the metal layer. The embedded capacitor is embedded in the first core circuit board and connected to the metal layer. A wiring layer is disposed on a surface of the second core circuit board and at least one second conductive through hole of the second core circuit board is connected to the wiring layer. The dielectric layer is laminated between the first and the second core circuit boards.

Owner:UNIMICRON TECH CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com