Patents

Literature

51results about How to "Realize the purpose of one machine with multiple functions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

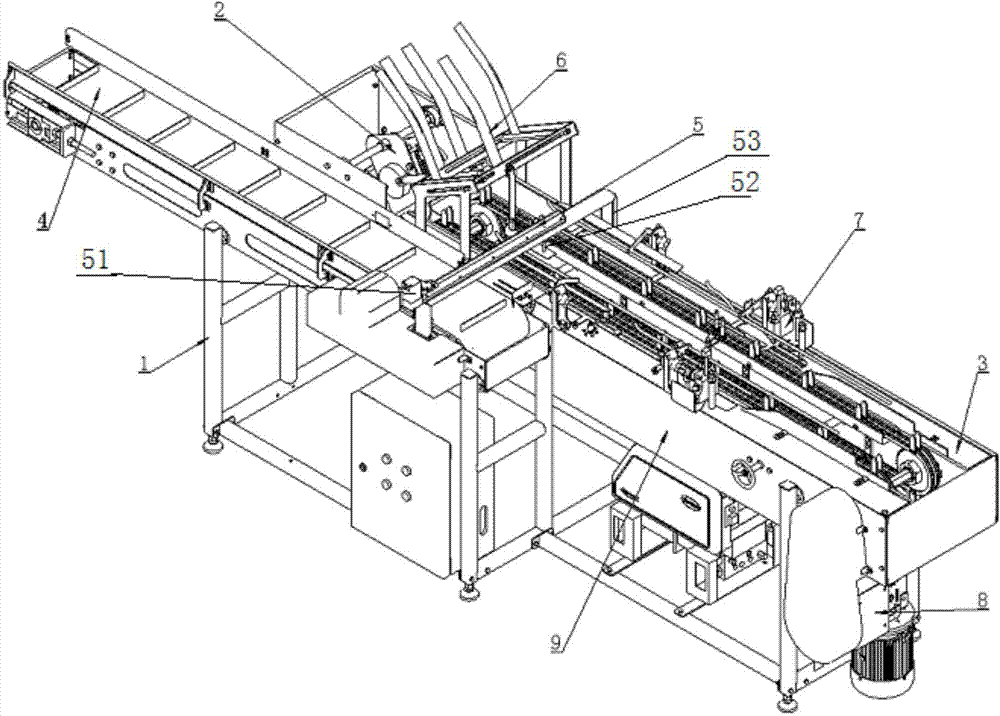

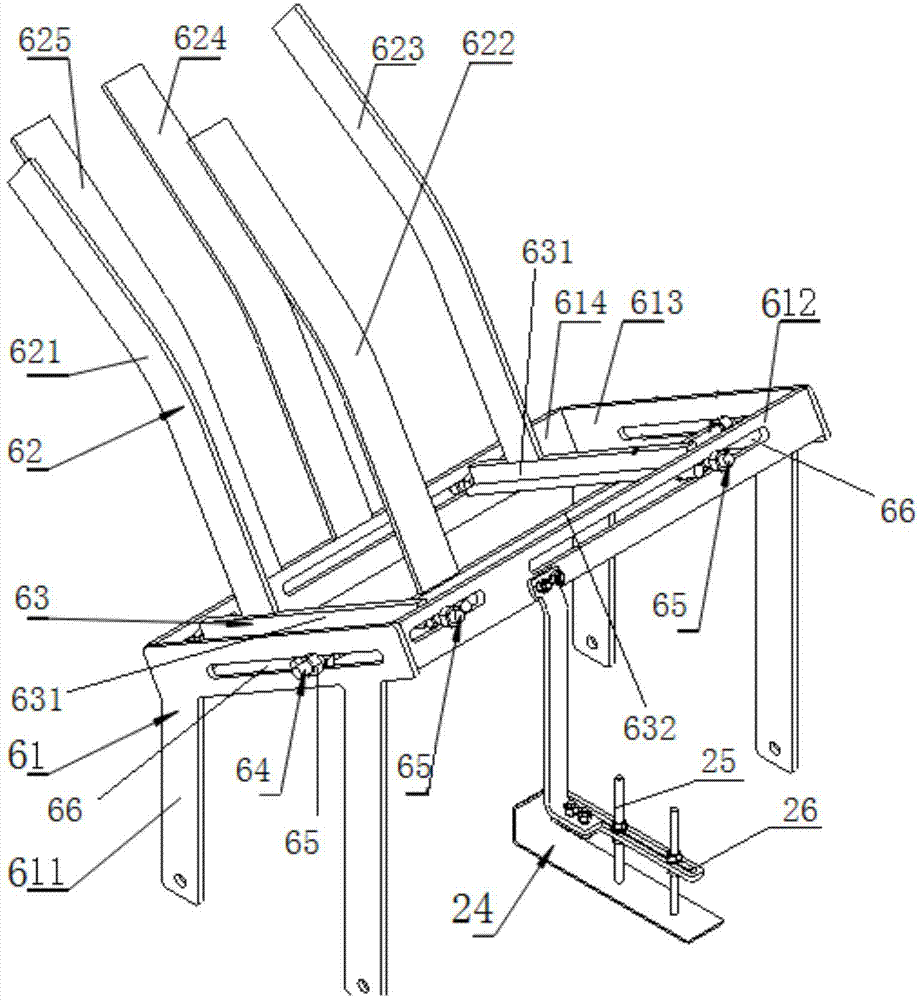

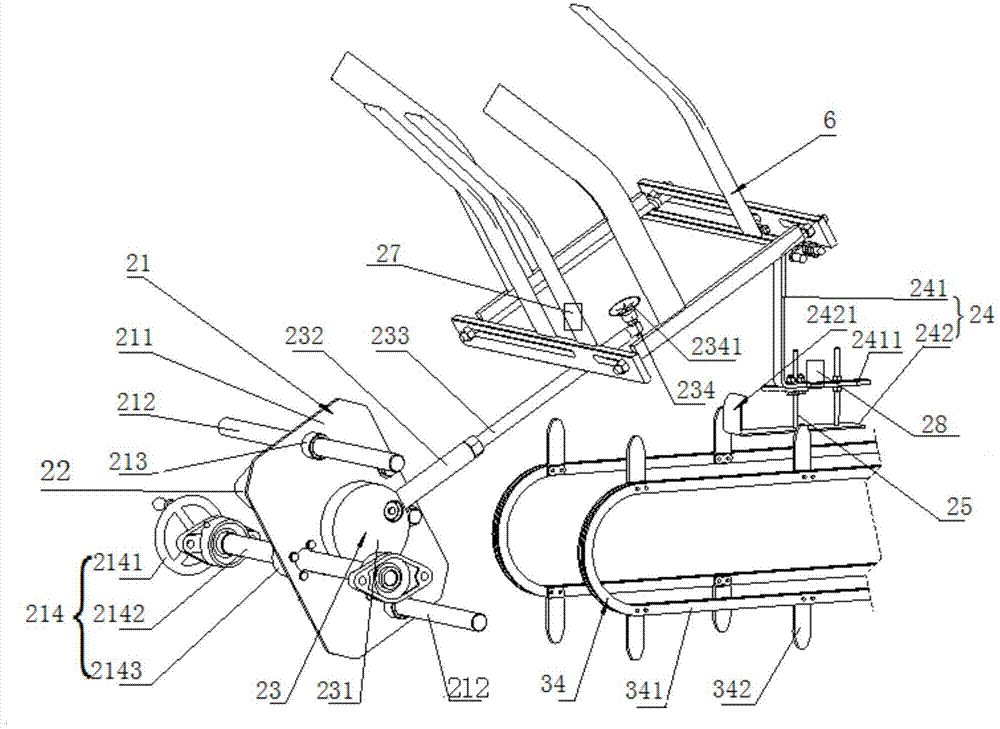

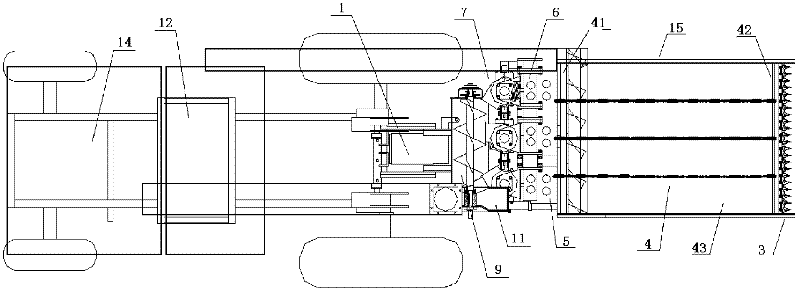

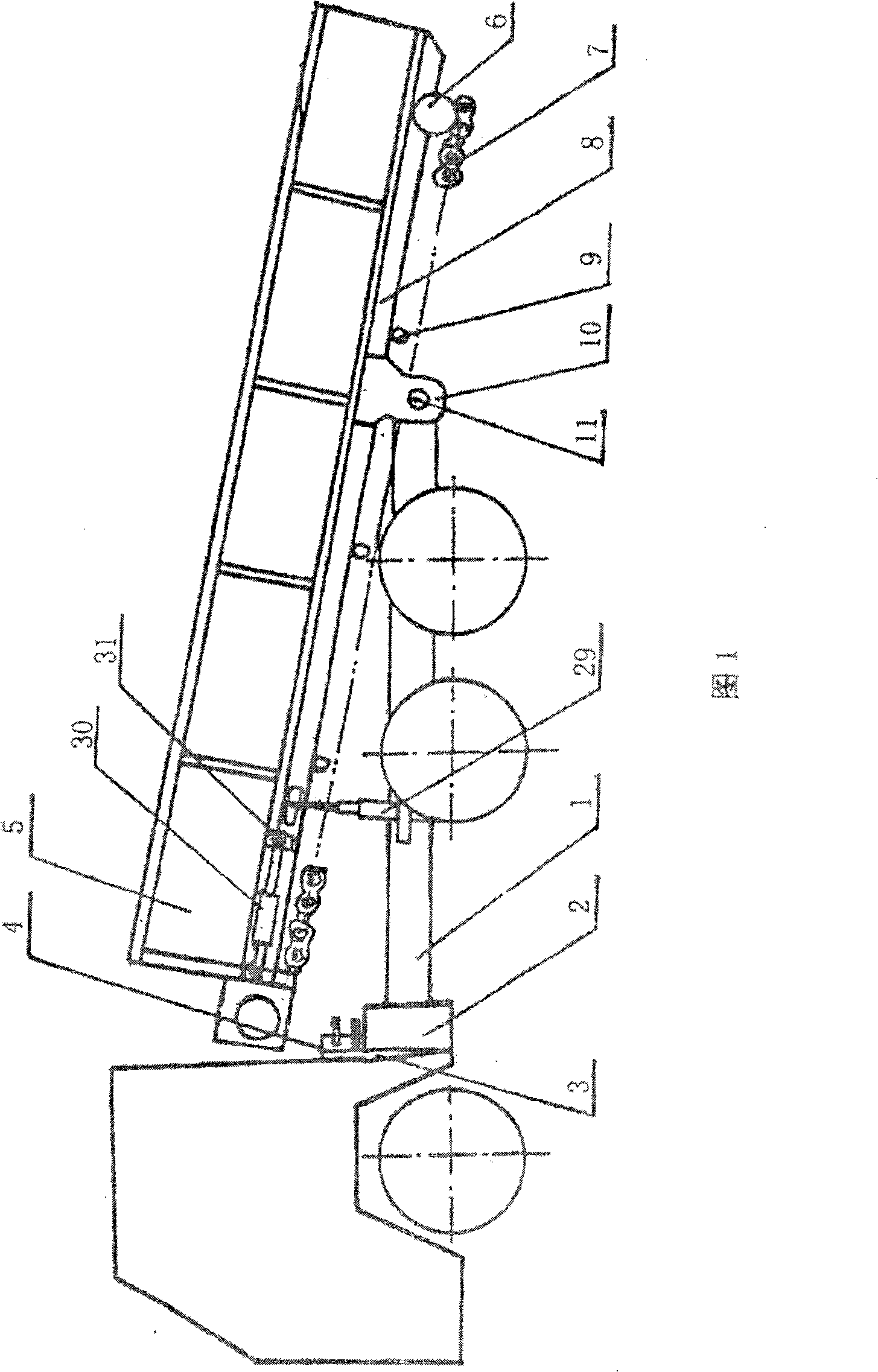

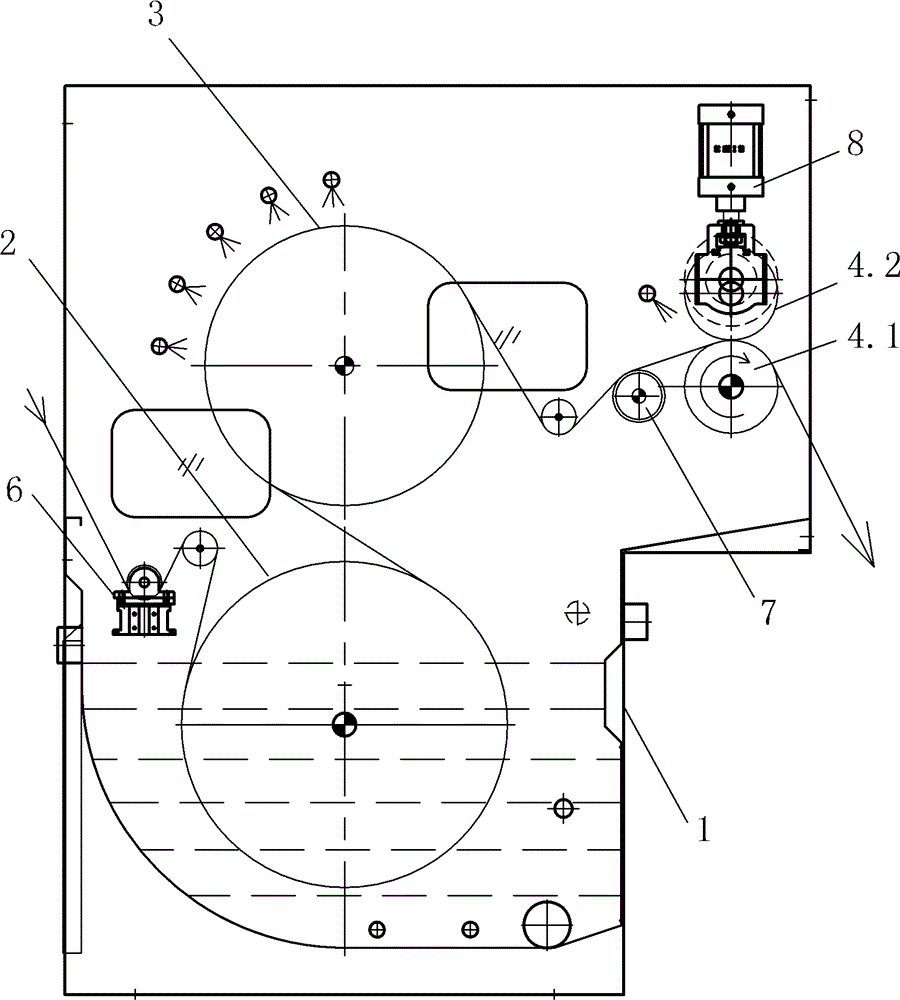

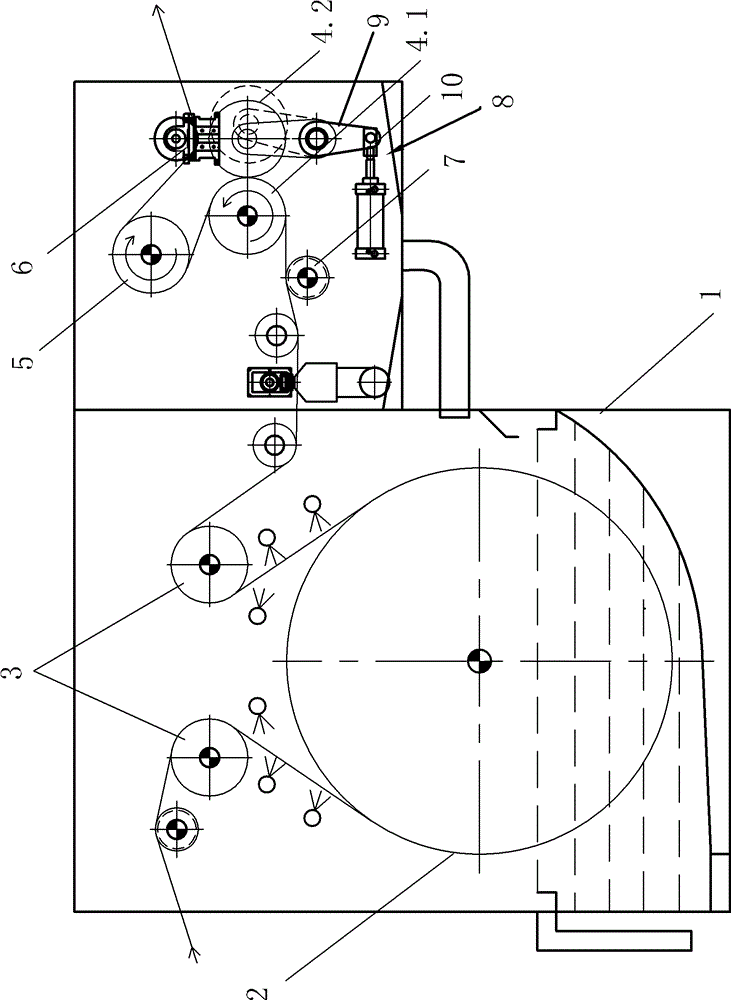

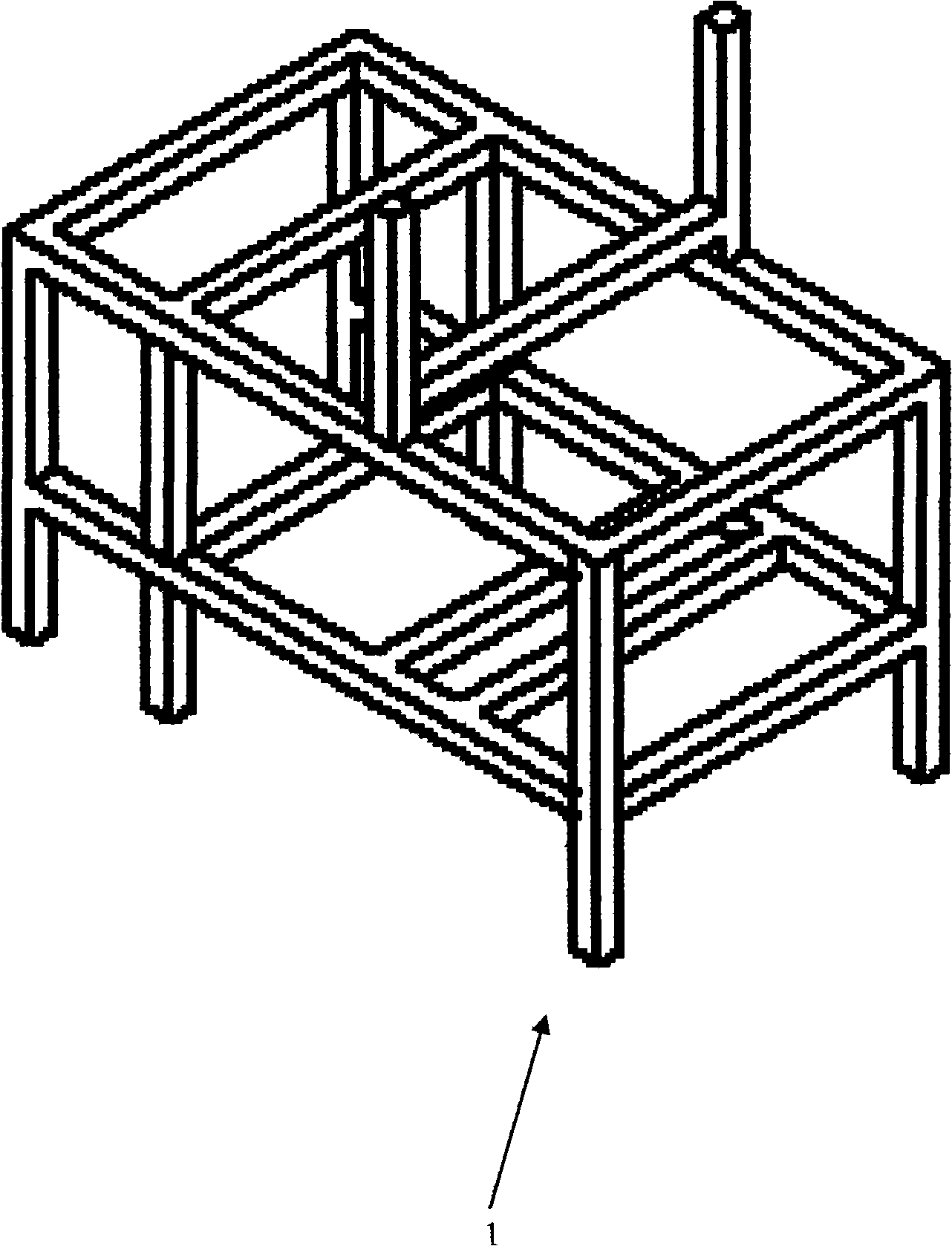

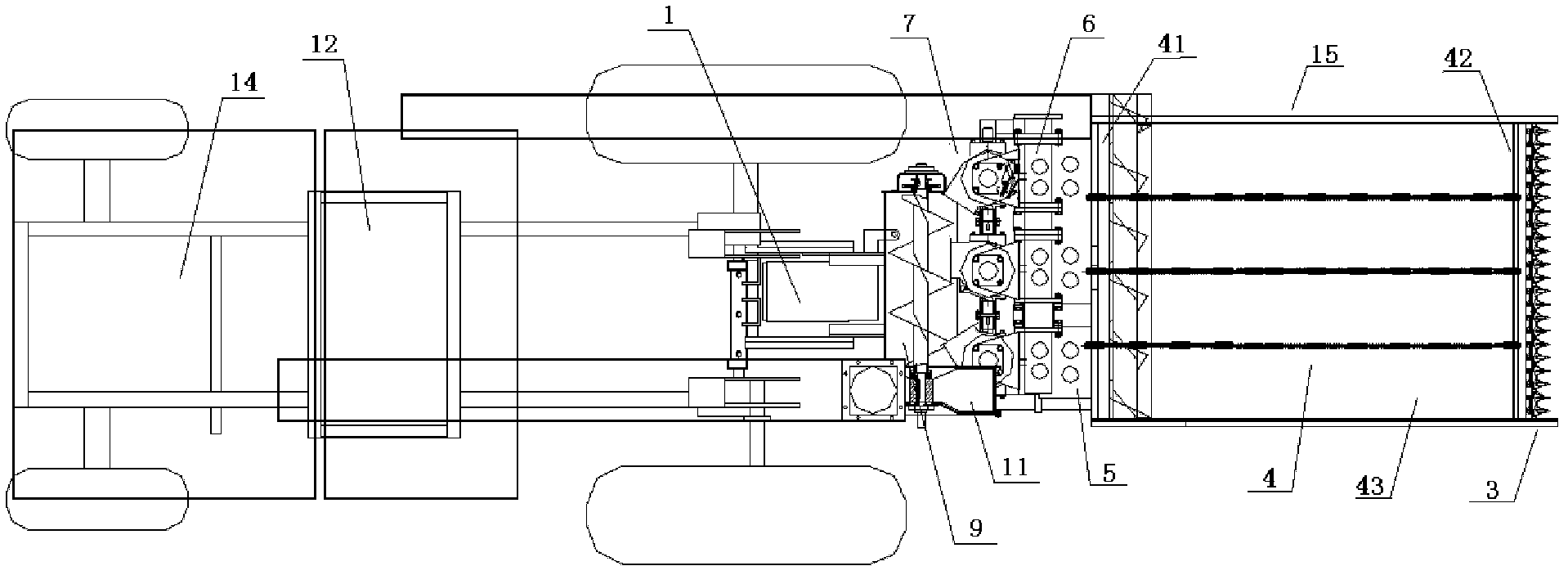

Full-automatic intermittent multi-specification carton boxing machine

InactiveCN104773333ARich packing specificationsRealize the purpose of one machine with multiple functionsPackaging automatic controlCartonEngineering

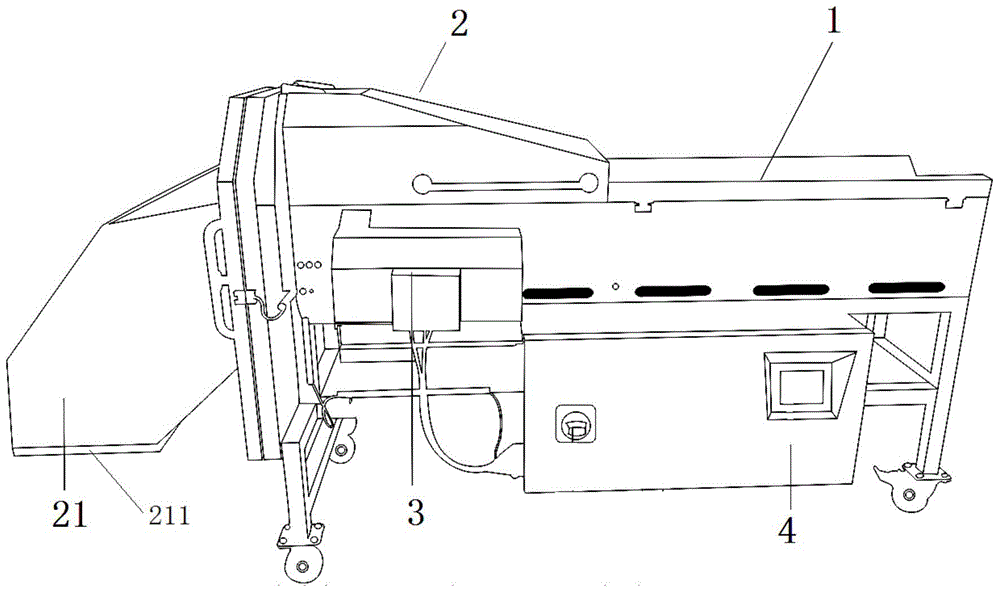

The invention relates to a full-automatic intermittent multi-specification carton boxing machine which comprises a machine frame, a carton opening system, a carton conveying system, a material conveying system, a material pushing device, a semi-finished carton cabin, a carton sealing device and a transmitting mechanism. The material conveying system the carton box conveying system synchronous drive and are partially overlapped, the carton opening device is distributed at the beginning end of a carton conveying chain, the carton conveying system and the carton opening device are arranged in a carton conveying cabin, the material pushing device is distributed above the overlapped portion between the material conveying system and the carton conveying system and is perpendicular to the carton conveying system, the semi-finished carton cabin is arranged on the carton conveying cabin and distributed above the carton opening system, and the carton sealing device is arranged on the carton conveying system. The full-automatic intermittent multi-specification carton boxing machine is simple in structure, low in manufacturing cost and good in generality and can meet the carton opening requirements of various-specification cartons by adjusting the carton opening device, the semi-finished carton cabin and the carton conveying system according to the sizes of different products.

Owner:CHINA NAT PACKAGING & FOOD MACHINERY

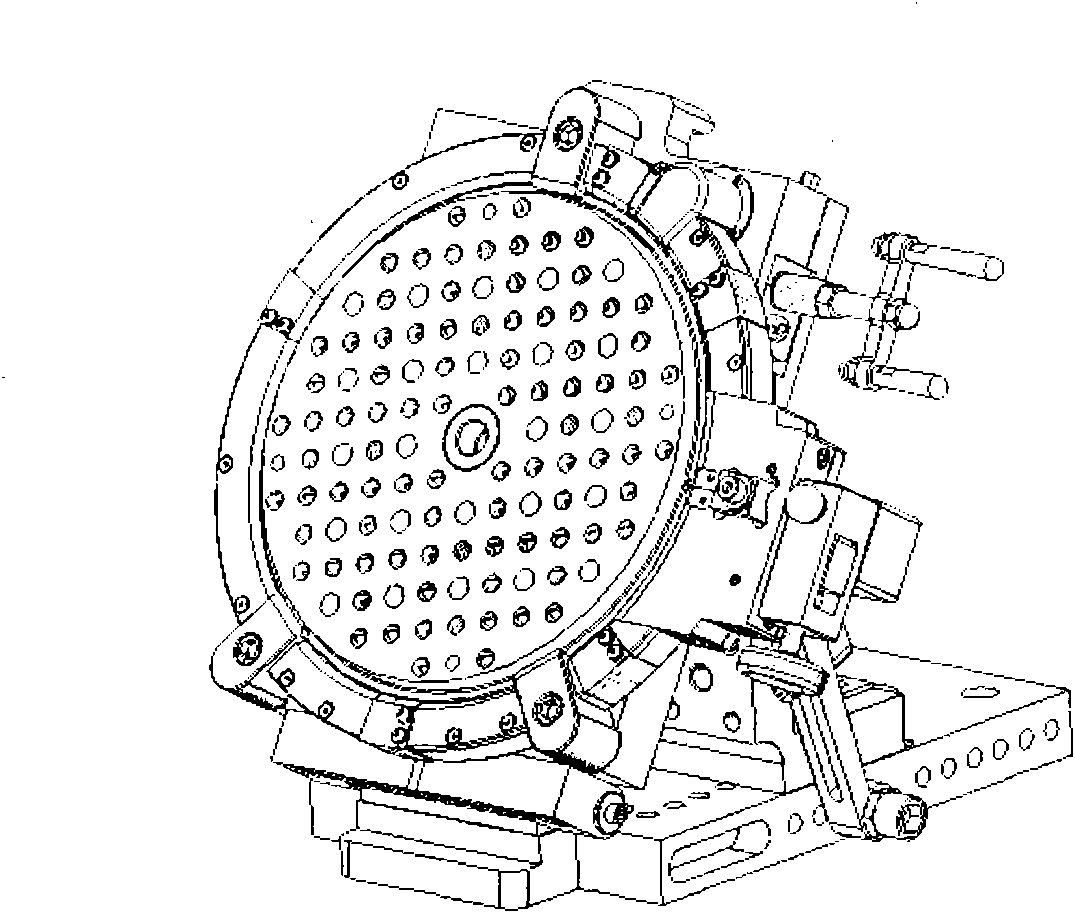

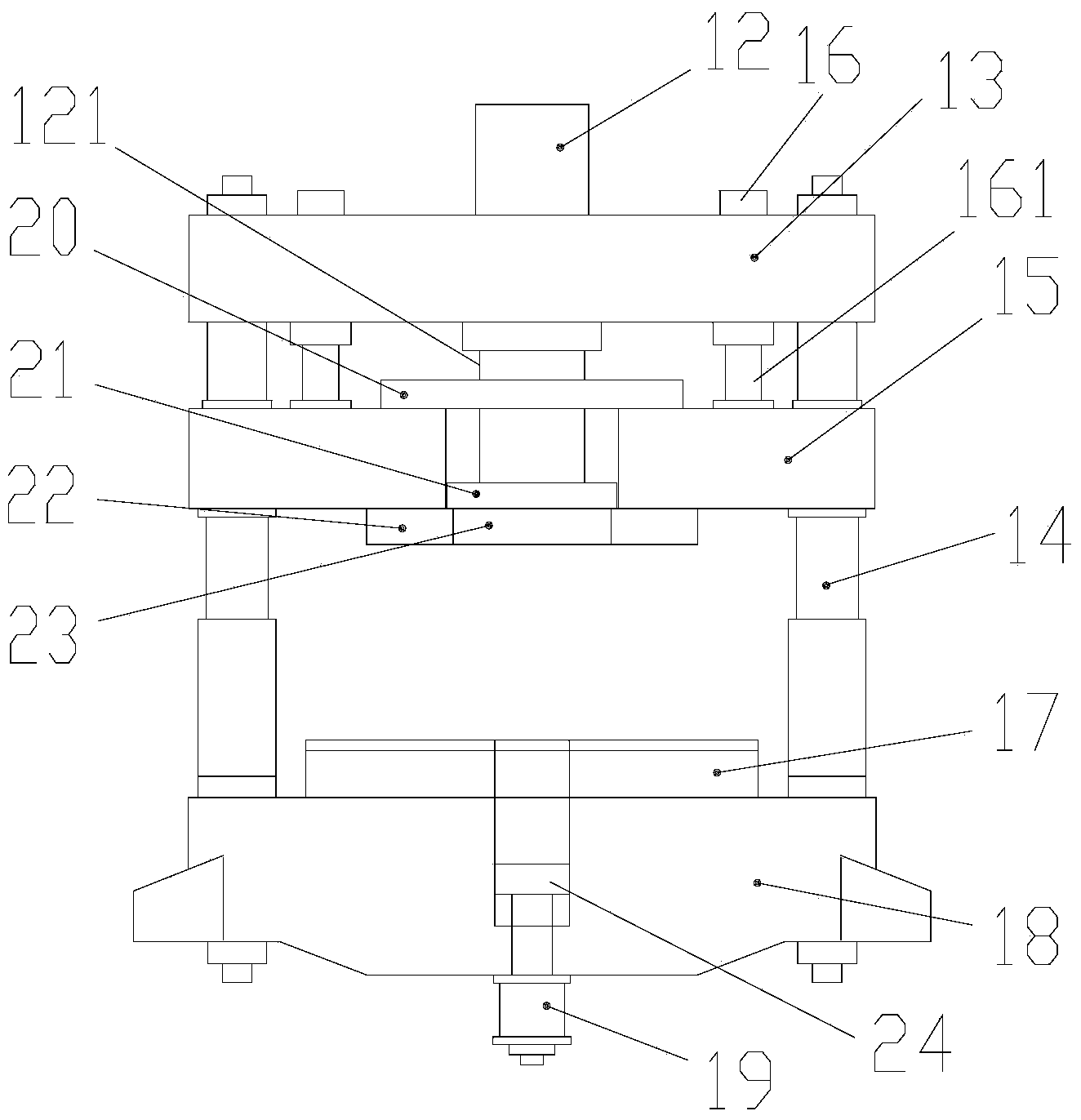

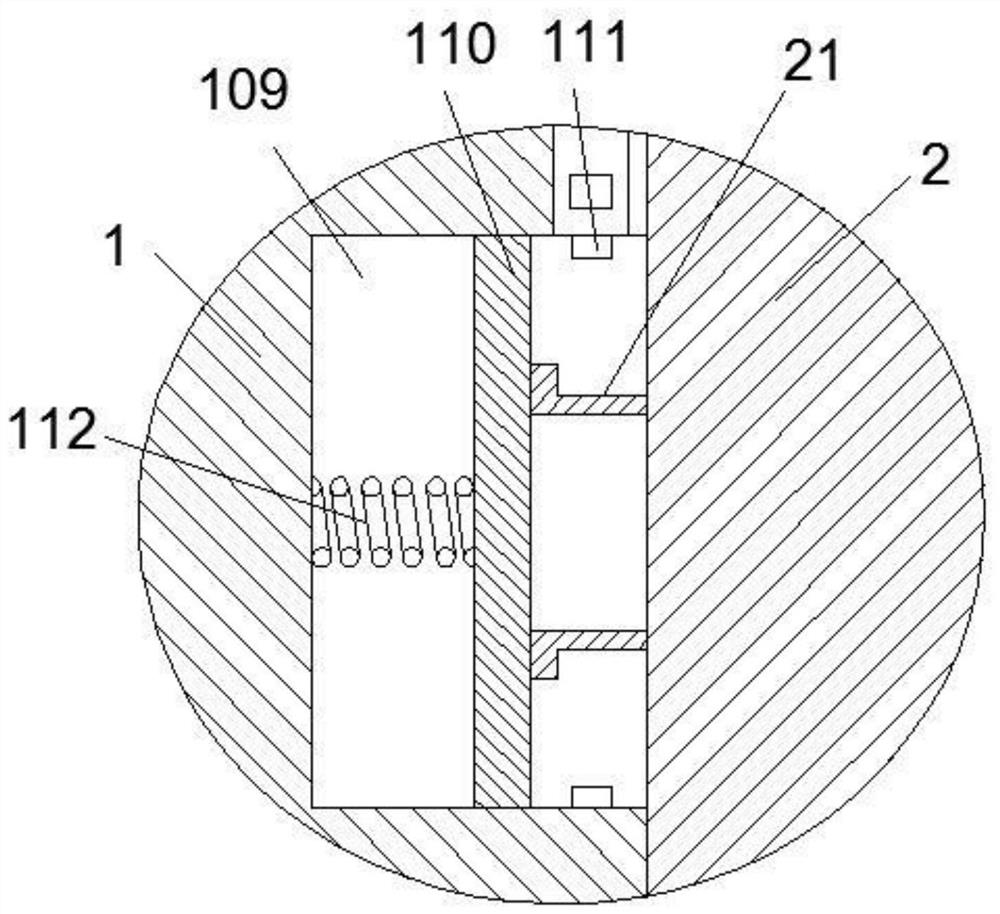

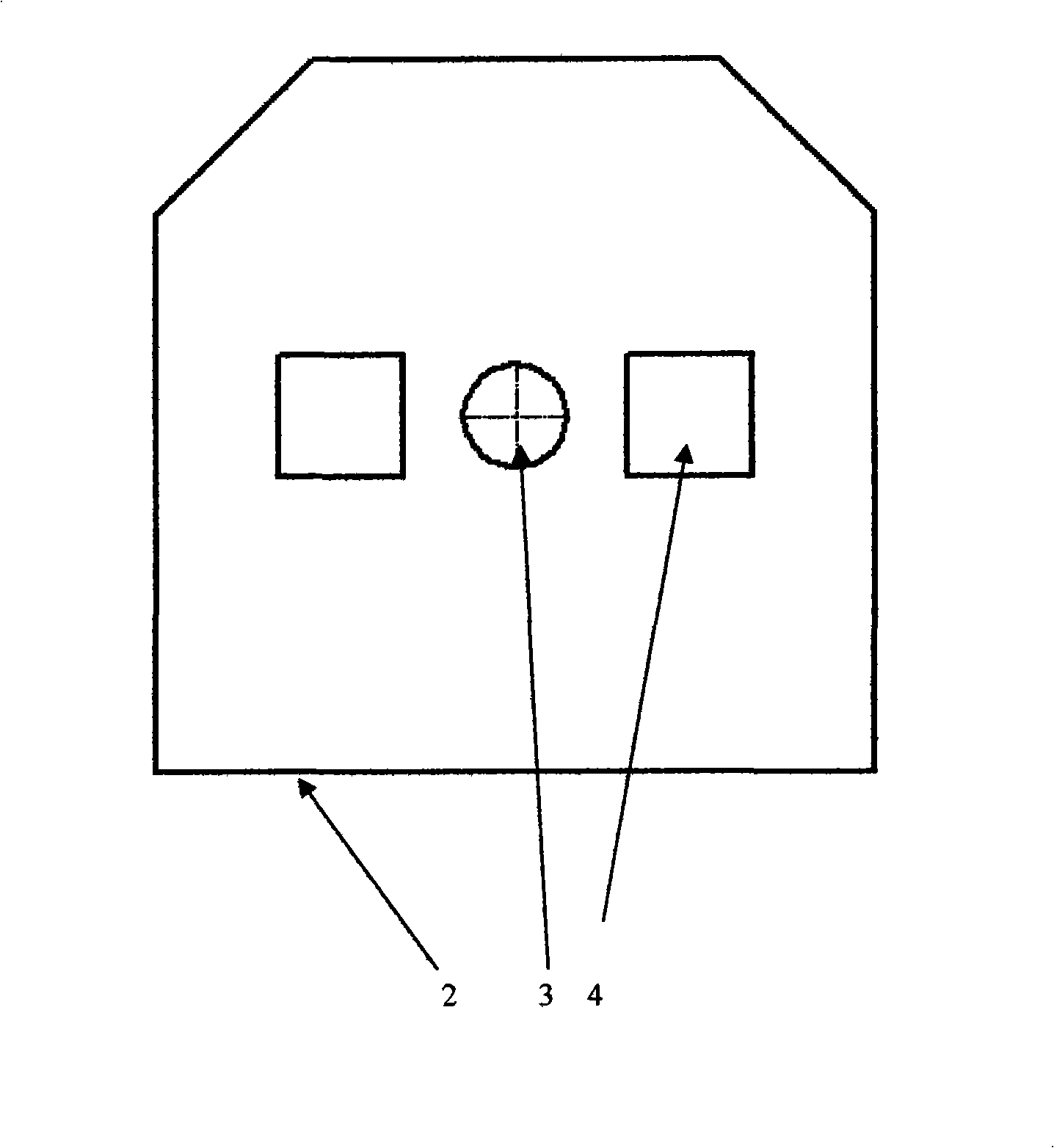

Combined fixture integrated platform

ActiveCN102554631ARealize the purpose of one machine with multiple functionsRealize functionPrecision positioning equipmentLarge fixed membersRight triangleAngular degrees

A combined fixture integrated platform comprises an indexing system, a fine adjustment system, a worm gear transmission system, a clamping system, a tensioning system, an upper bedplate, a lower bedplate, a support part, an adjusting gasket, a three-jaw chuck and flat tongs. The upper bedplate is connected with the lower bedplate by a hinge, the upper bedplate, the lower bedplate and the support part form three sides of a right-angled triangle, and a sinusoidal angle is changed correspondingly by means of changing the height of the support part by the aid of the sine law of the triangle. The indexing system can realize equal angular indexing, an indexing value of the minimum angle with 9.4-second difference can be achieved by the aid of the fine adjustment system, and a rotating system can realize a function of rotating a worktable. A sinusoidal table and an indexing disc are used together so as to obtain composite spatial angles. When the combined fixture integrated platform is placed at a limit angle of 0 degree or 90 degrees, functions of a planar worktable or a perpendicular worktable can be realized, workpieces in various shapes can be positioned and clamped by means of replacing the three-jaw chuck, the flat tongs and combined fixture elements, and multiple purposes of a combined fixture are realized.

Owner:BEIJING LANXINTE TECH CO LTD

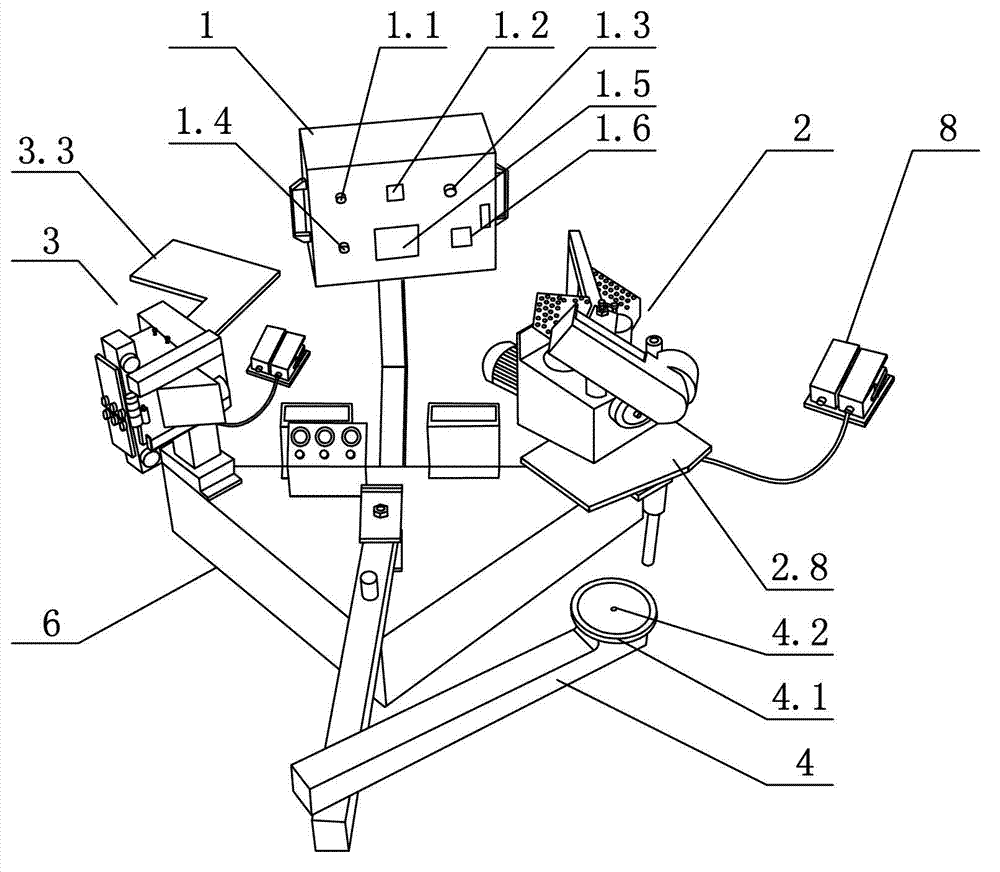

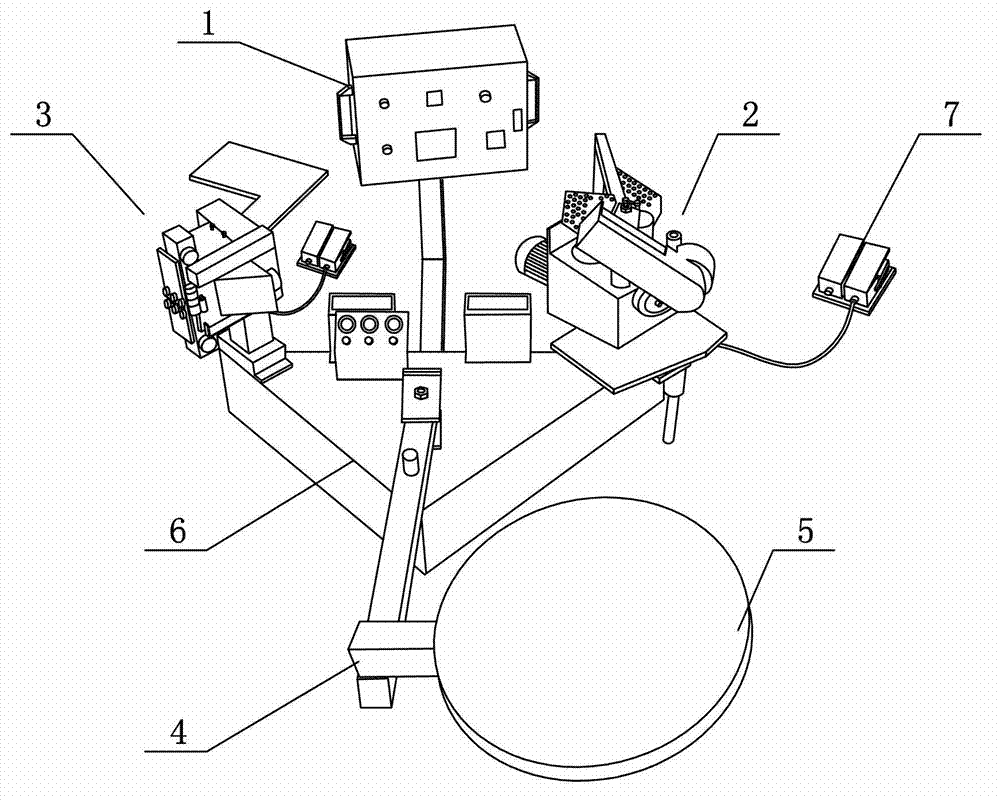

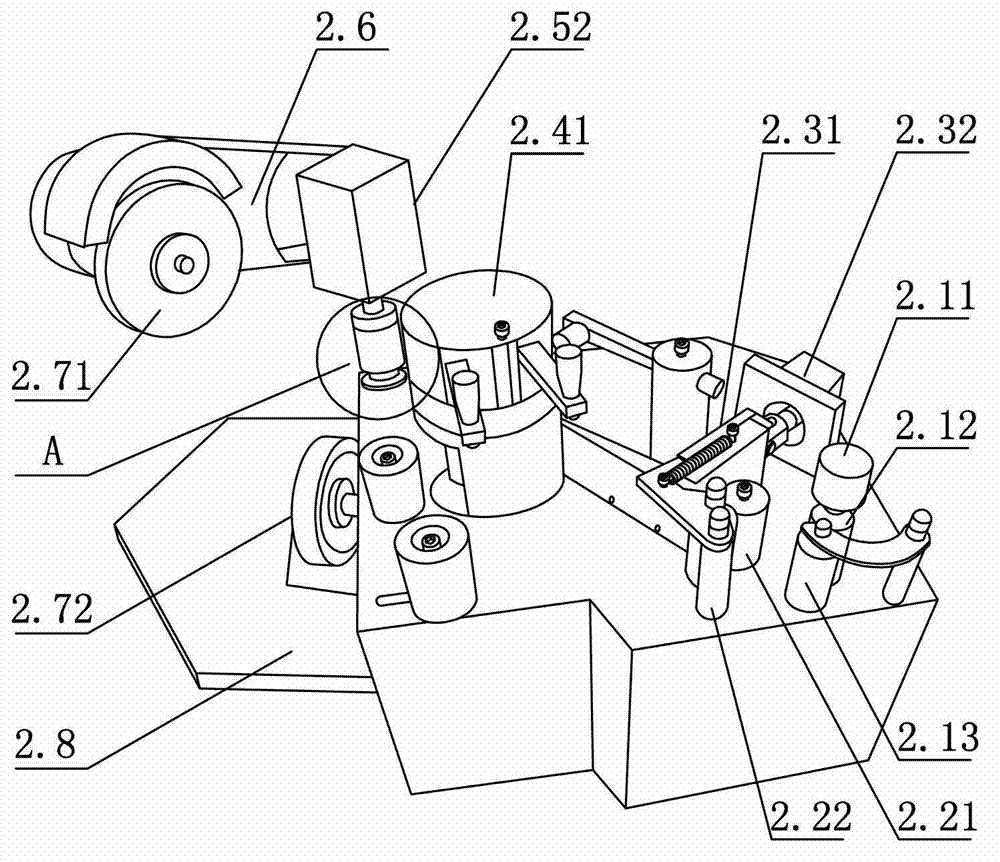

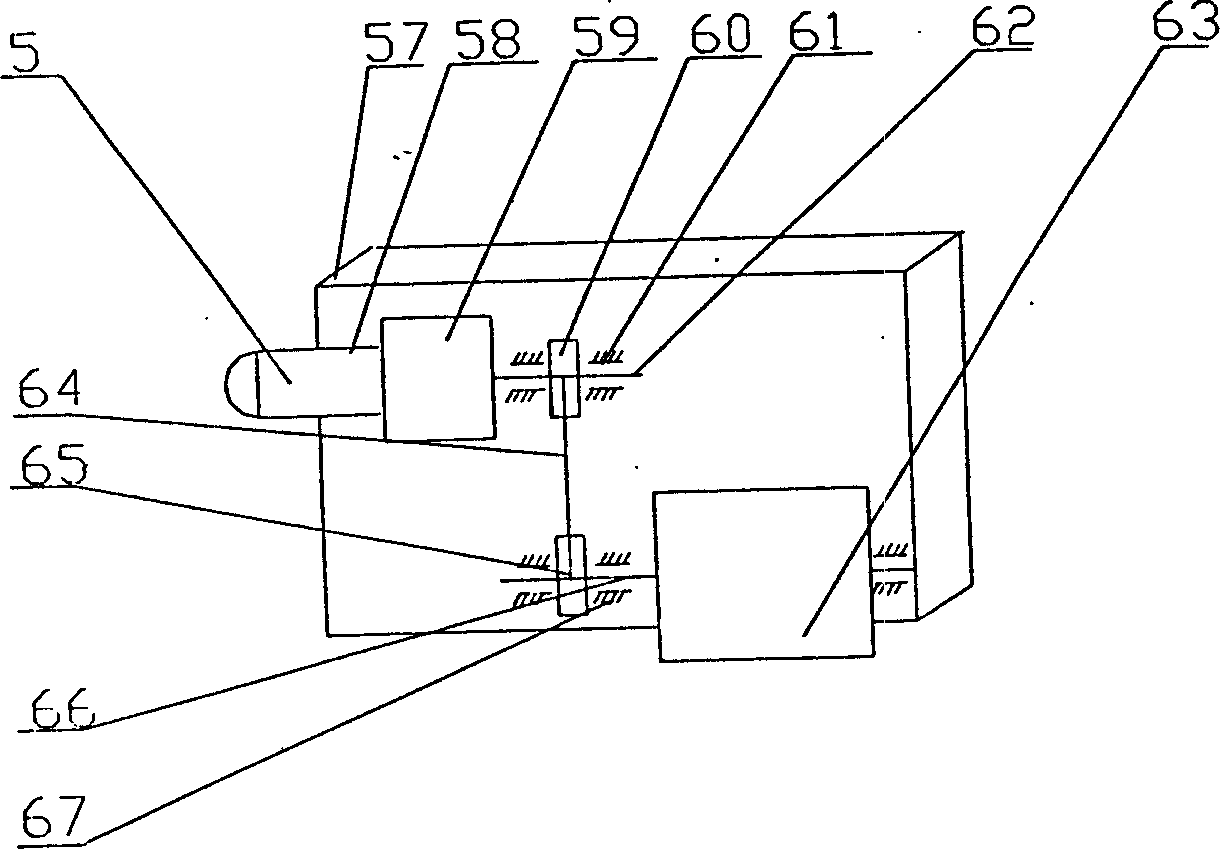

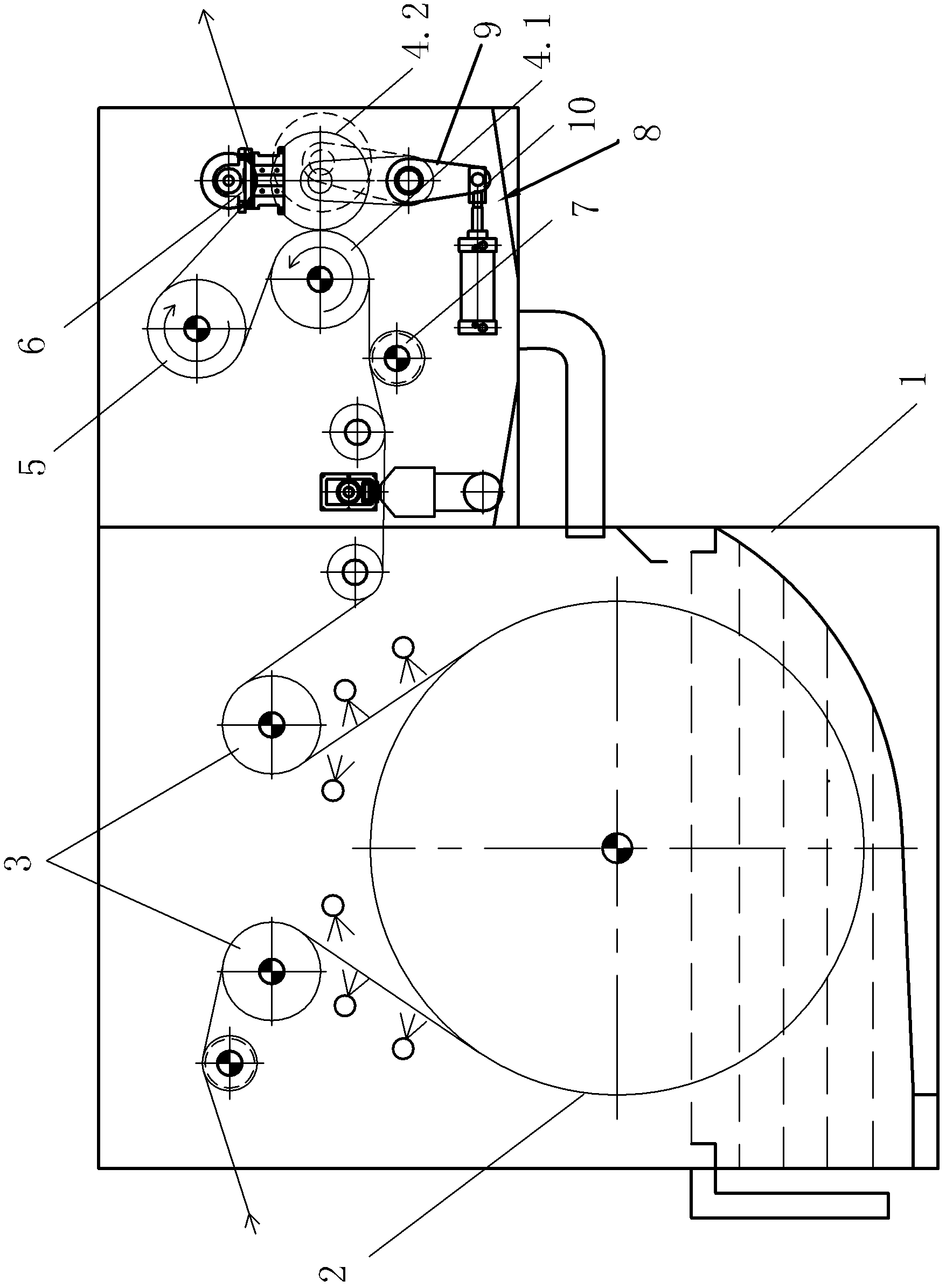

Numerical control irregular edge sealing and trimming system

ActiveCN103042583AControl the speed of edge bandingControl lengthWood working apparatusDomestic articlesNumerical controlEngineering

Disclosed is a numerical control irregular edge sealing and trimming system. A numerical control device is arranged above a rack, and a numerical control copying edge sealing assembly and a copying edge trimming assembly are arranged on two sides of the rack respectively. An irregular workpiece is fixed through a vacuum chuck of a swing arm arranged on the rack and machined at the position of the numerical control copying edge sealing assembly or the copying edge trimming assembly through the swing arm. The numerical control device and a treadle control the operation of the numerical control copying edge sealing assembly and the copying edge trimming assembly. According to the numerical control irregular edge sealing and trimming system, the numerical control copying edge sealing assembly, the copying edge trimming assembly and the numerical device are organically combined together, so that one independent numerical control copying edge sealer can complete edge sealing and trimming to irregular workpieces; and the numerical control device is added, so that the edge sealing band length, the workpiece edge sealing speed and the glue temperature can be accurately controlled in an irregular workpiece machining process. According to the system, applications are wide, the purpose of one machine with multiple purposes is effectively achieved, and the enterprise efficiency of edge sealing and trimming to irregular workpieces is improved.

Owner:FOSHAN HAOYANG WOODWORK MACHINERY MFR

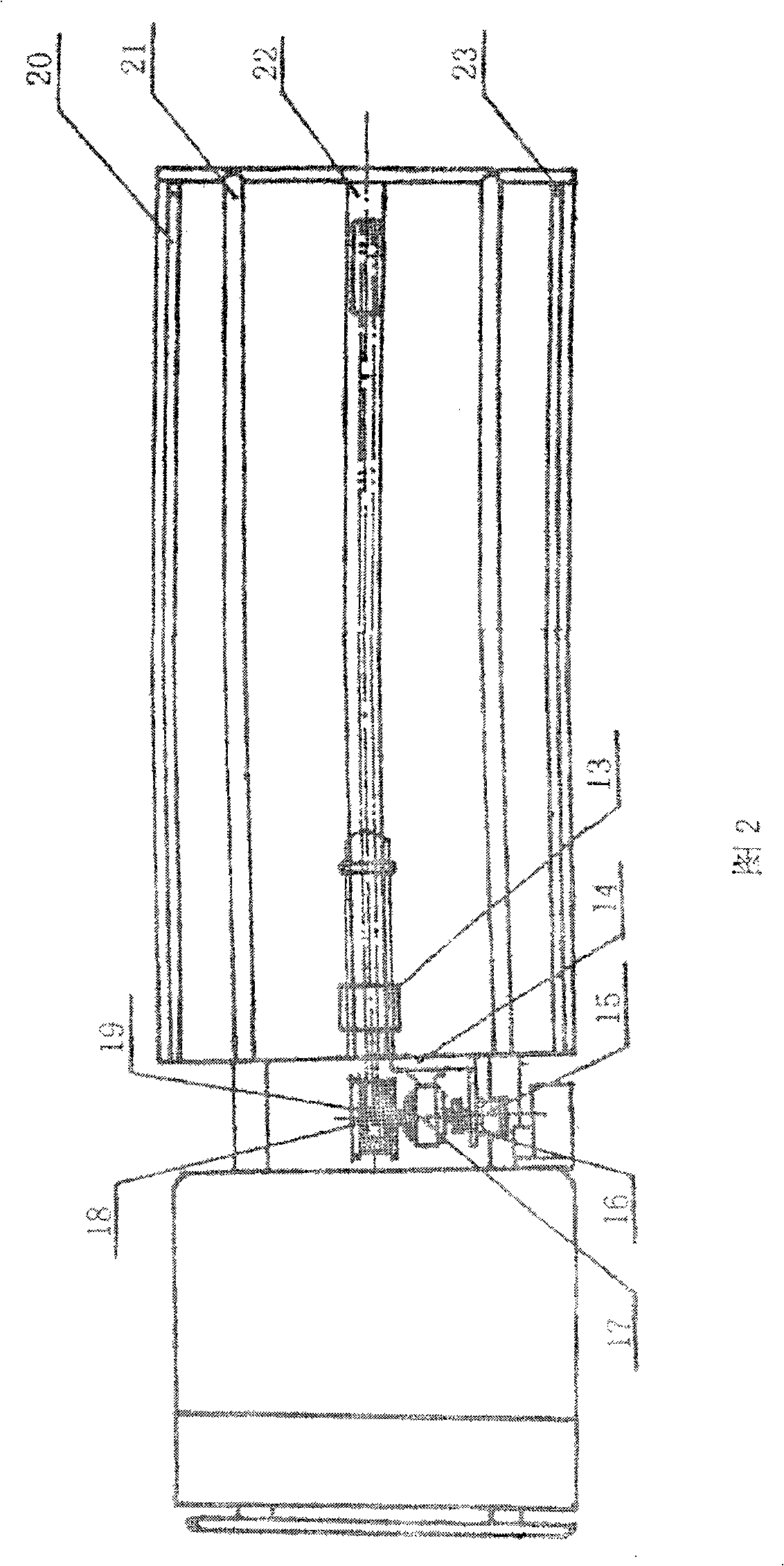

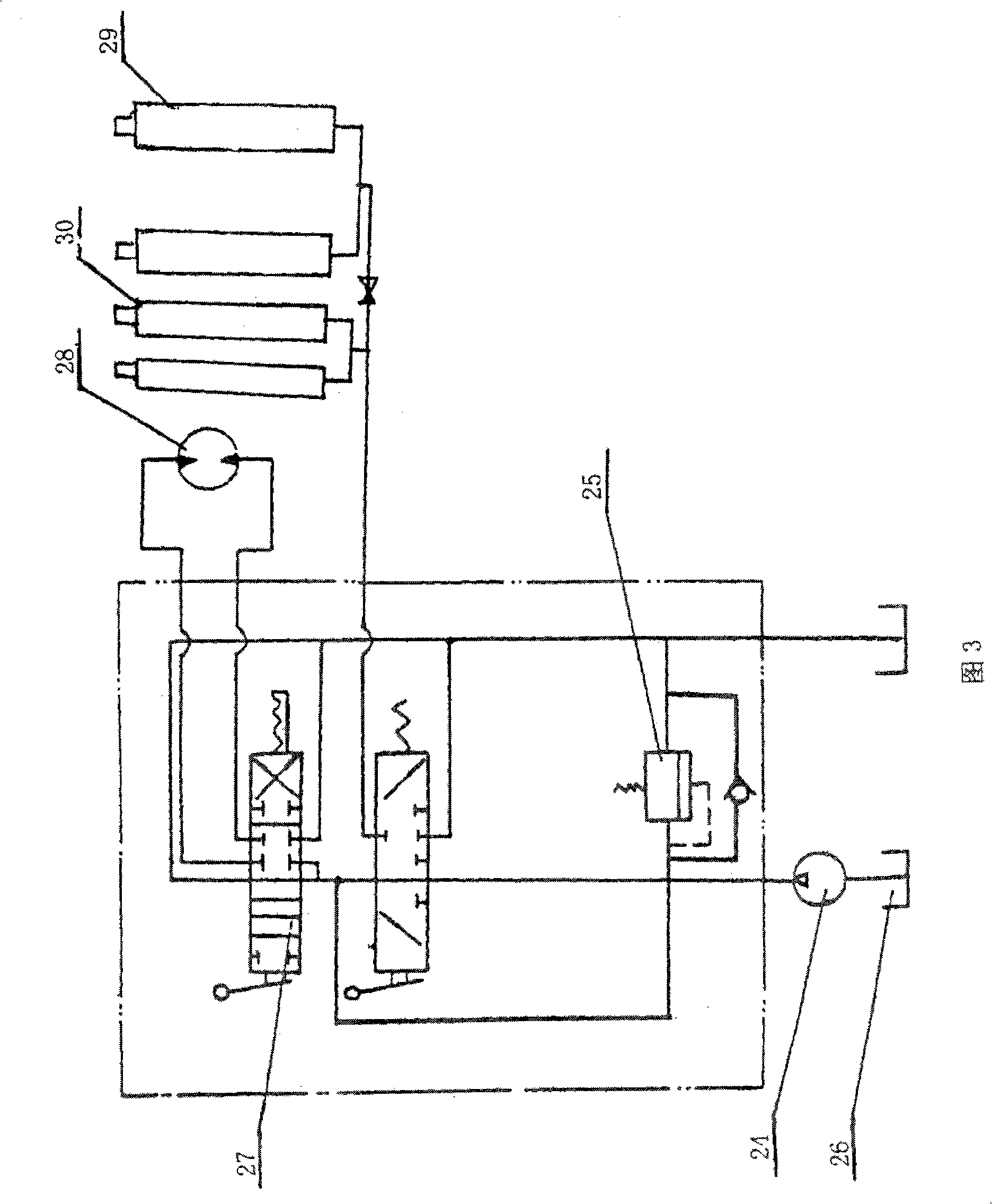

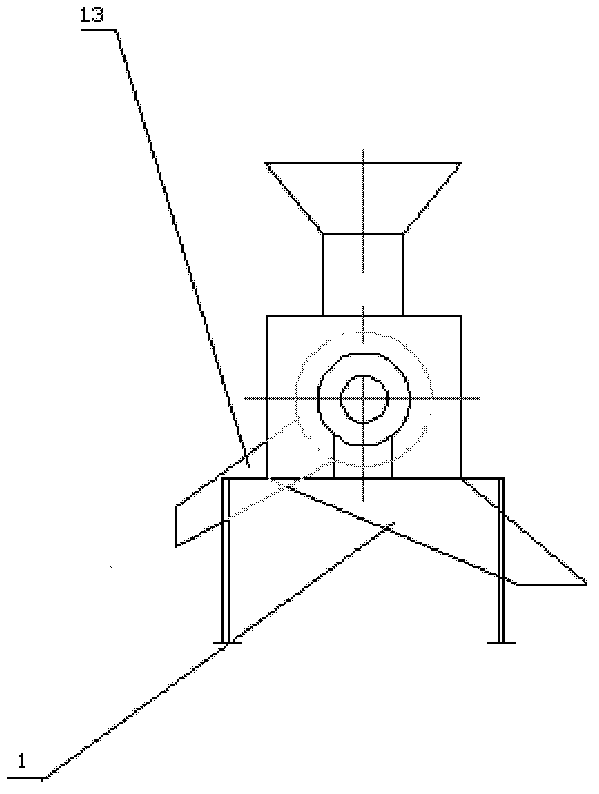

Multifunctional efficient rice husking machine

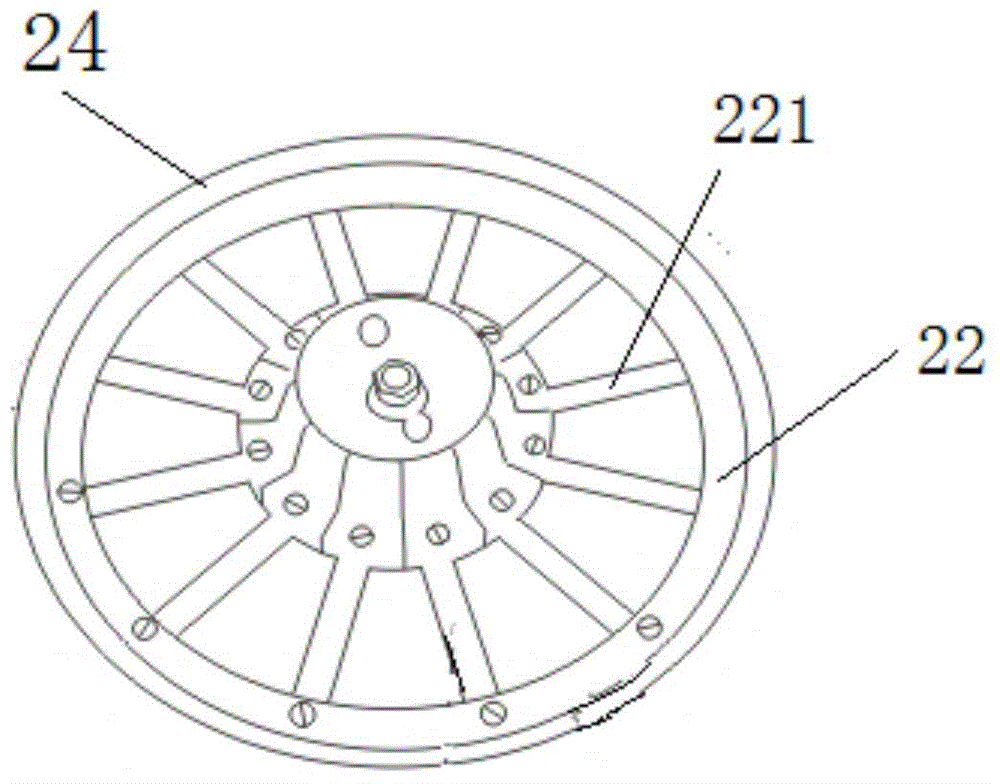

InactiveCN108160146ALow frictionLess corrosiveGrain huskingGrain polishingHydraulic cylinderPulp and paper industry

The invention discloses a multifunctional efficient rice husking machine and relates to the field of cereal processing equipment. The multifunctional efficient rice husking machine comprises a rice husking machine body, a feeding hopper, a control box and a hydraulic cylinder, wherein the hydraulic cylinder is arranged above the control box, the top of the hydraulic cylinder is connected to a telescopic rod, the upper end of the telescopic rod is connected to a platform plate, a first motor is arranged on the platform plate, a first rotating shaft is arranged below the first motor, the upper end of the first rotating shaft penetrates through the platform plate and is connected to the output end of the first motor, the lower end of the first rotating shaft extends into the rice husking machine, a grinding cone is arranged in the rice husking machine, a grinding disc matched with the grinding cone is arranged on the inner wall of the rice husking machine, and discharge ports are formed in the side walls of the left and right sides of the bottom of the rice husking machine. The rice husking machine disclosed by the invention is high in grinding efficiency and good in grinding effect,and the degree of purity of ground white rice meets the using demand. The multifunctional efficient rice husking machine has a function of adjusting the grinding strength, and is simple to operate andhigh in working reliability.

Owner:马斌祥

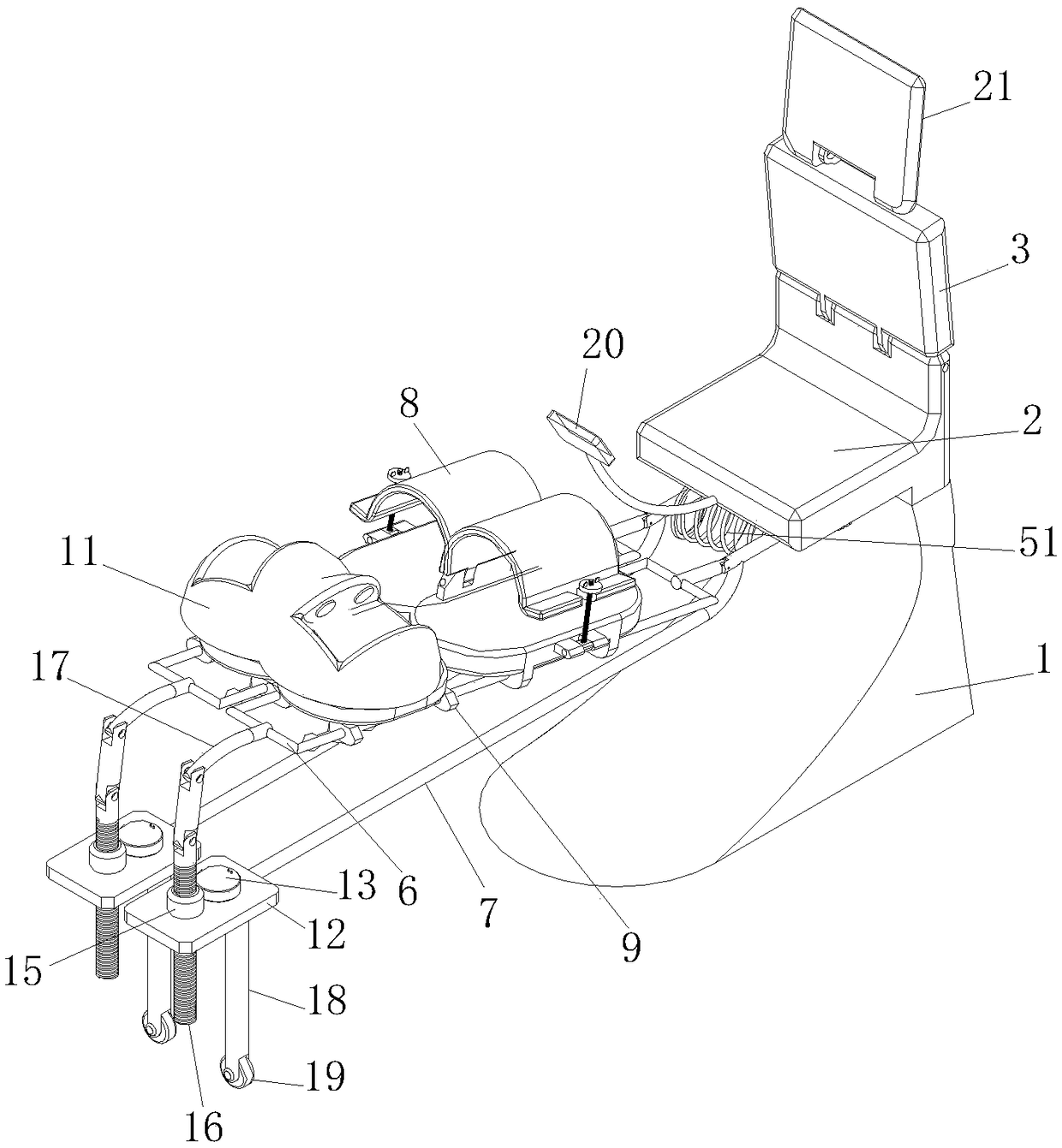

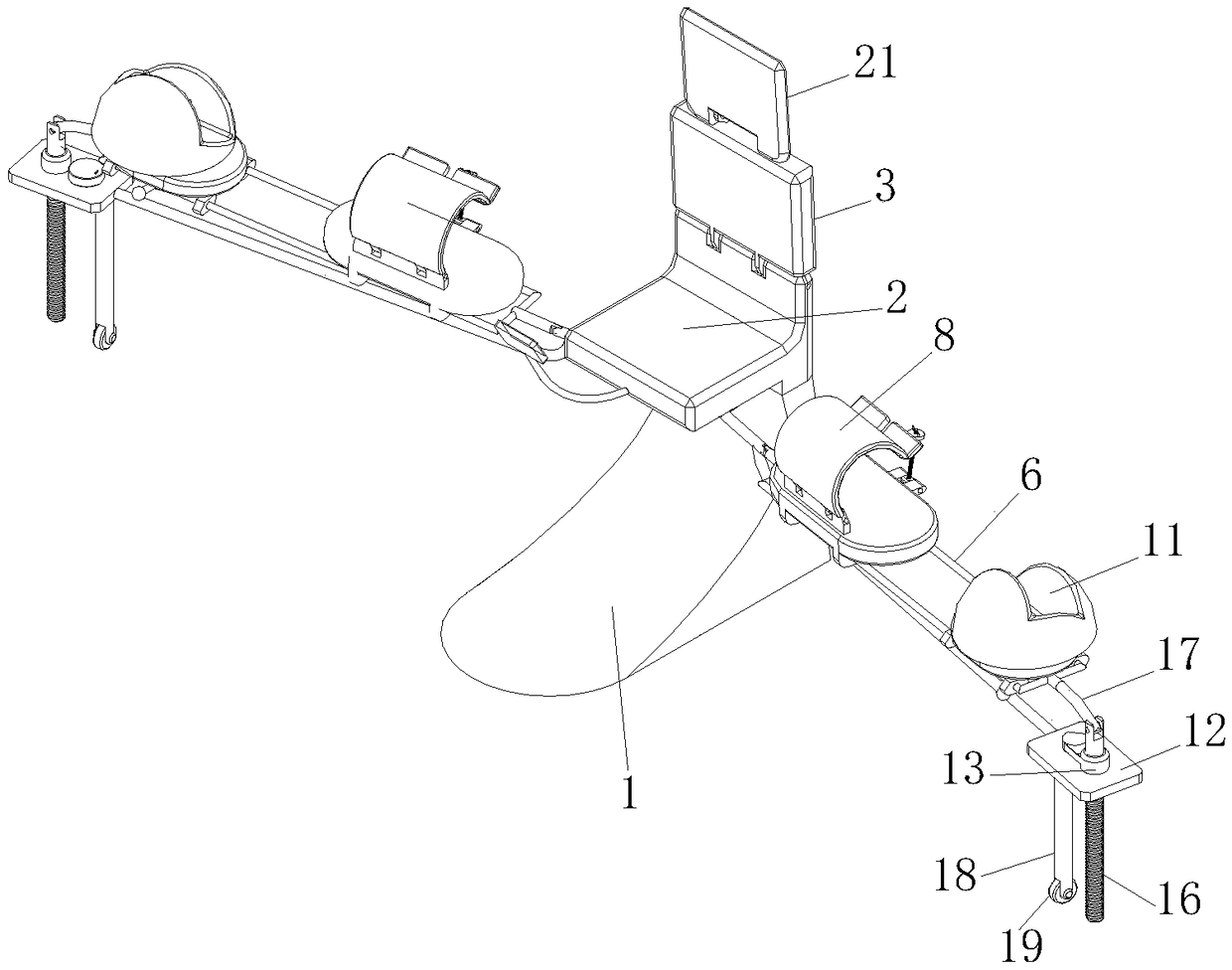

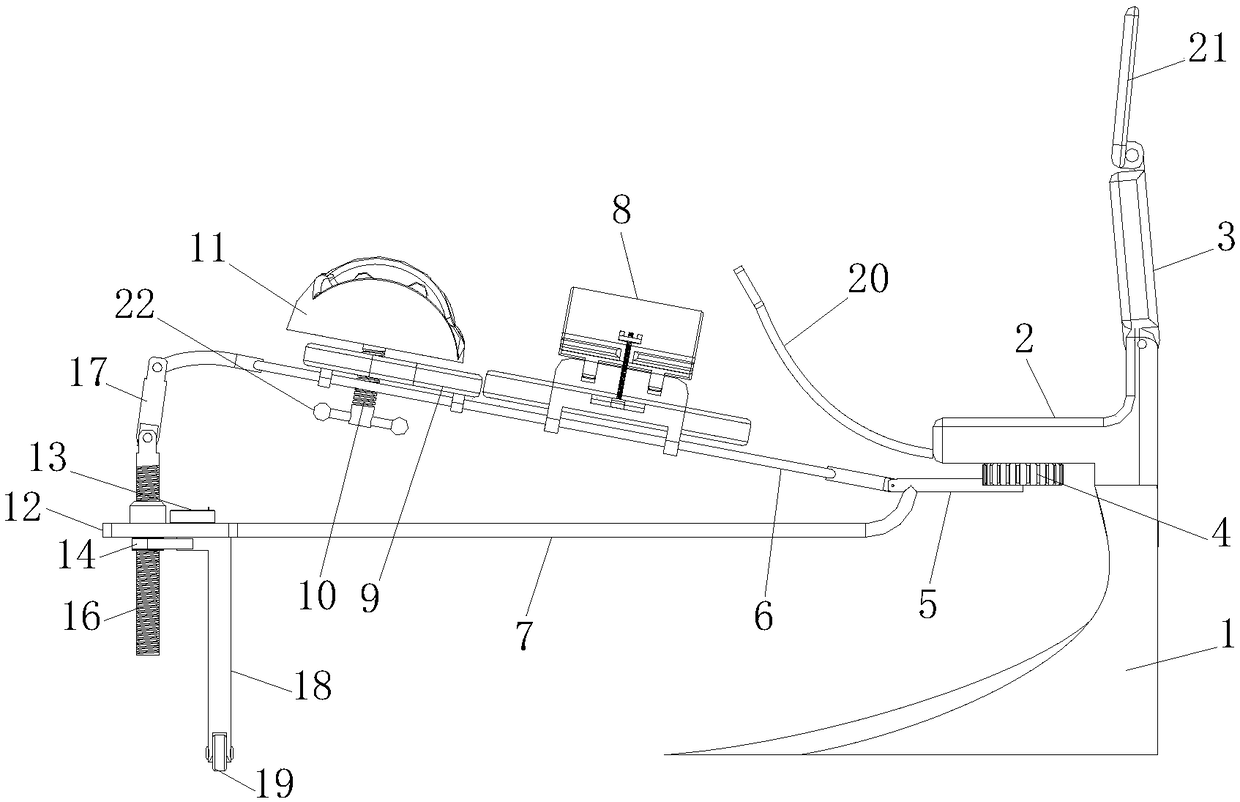

Novel physical fitness equipment

ActiveCN109331411AMeet Your Exercise NeedsRealize the purpose of one machine with multiple functionsResilient force resistorsExercise equipmentBody type

The invention discloses novel physical fitness equipment. The equipment comprises a base, a seat is fixedly installed at the top of the base, a backing plate is fixedly installed at the top of the seat, rotating gears are symmetrically and movably installed at the bottom of the seat, a rotating rod is fixedly installed at the bottom of each rotating gear, the rotating rods are connected through anextrusion spring, a guide rail is fixedly connected to the end, away from the corresponding rotating gear, of each rotating rod, a connecting rod is welded to the bottom of each rotating rod, and legfixing devices and sliding plates are slidingly installed on the guide rails. According to the novel physical fitness equipment, through the arrangement of a multifunctional exercise structure integrating center splits and sit and reach, the equipment achieves multiple purposes; the fitness equipment is provided with a tightness adjusting mechanism and a height adjusting mechanism, can meet the exercise needs of people of various body shapes and has a good exercise effect; meanwhile, through the height adjusting mechanism, the equipment can be applied to people different in performance status.

Owner:GUIZHOU INST OF TECH

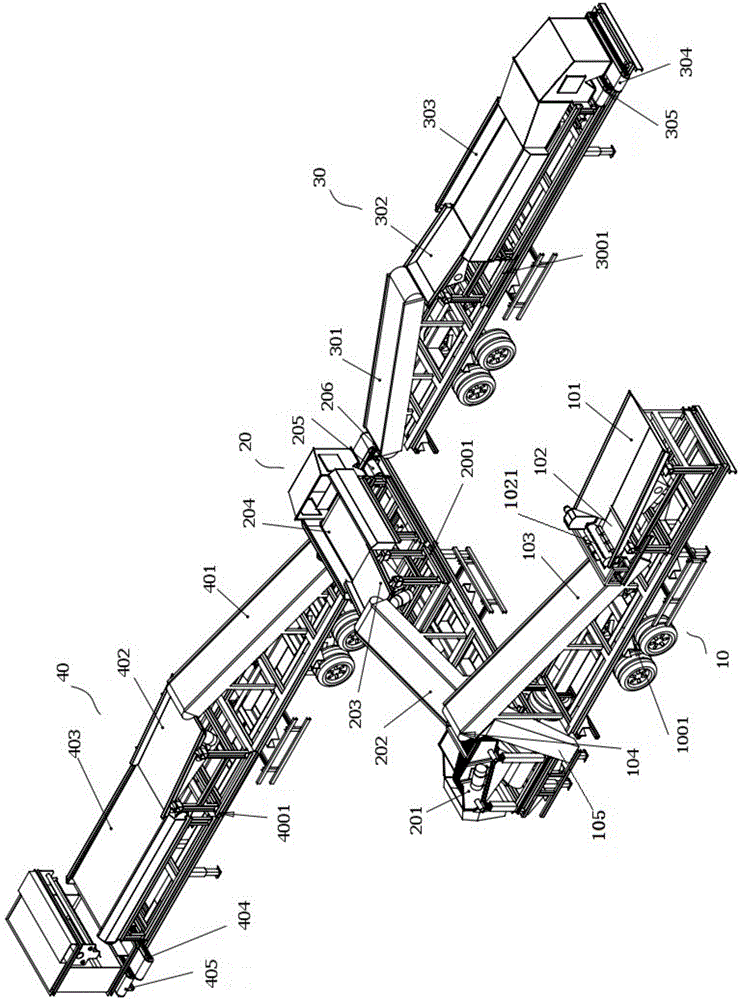

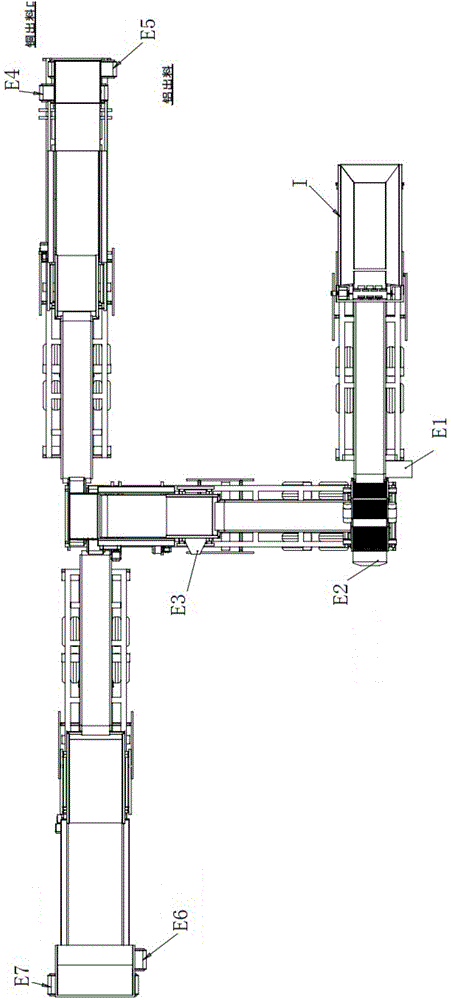

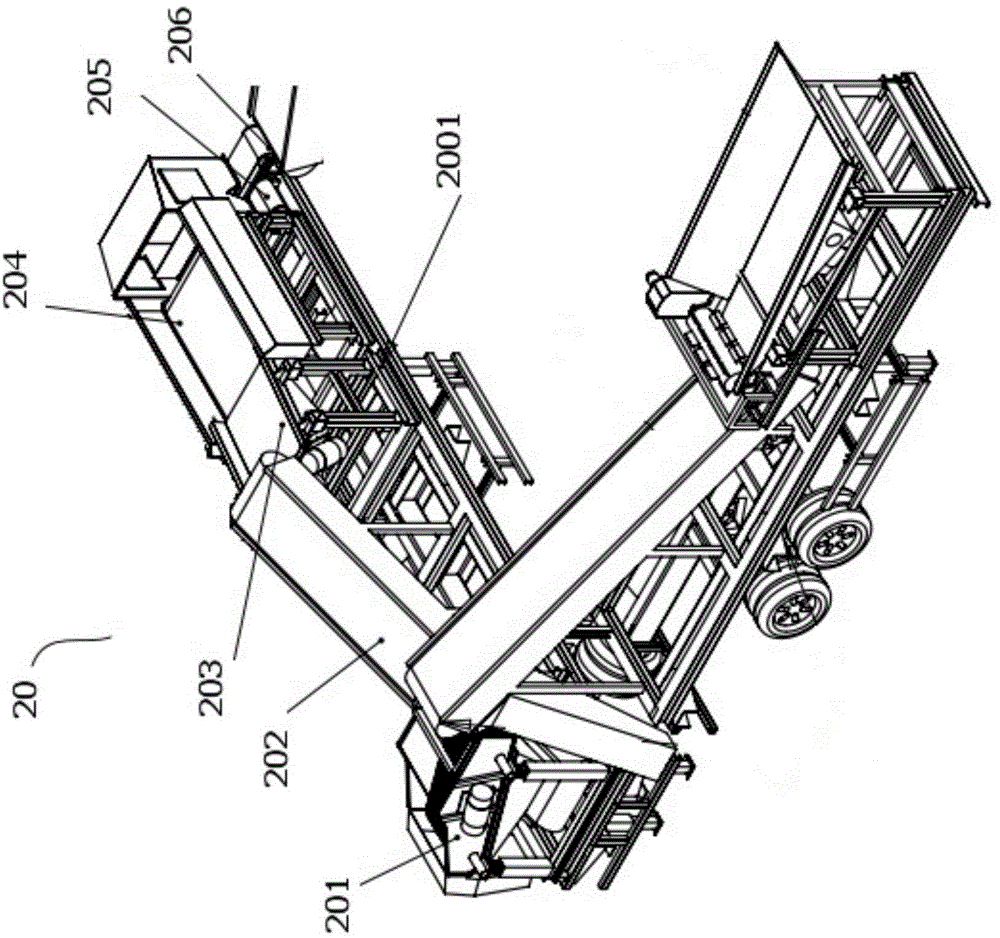

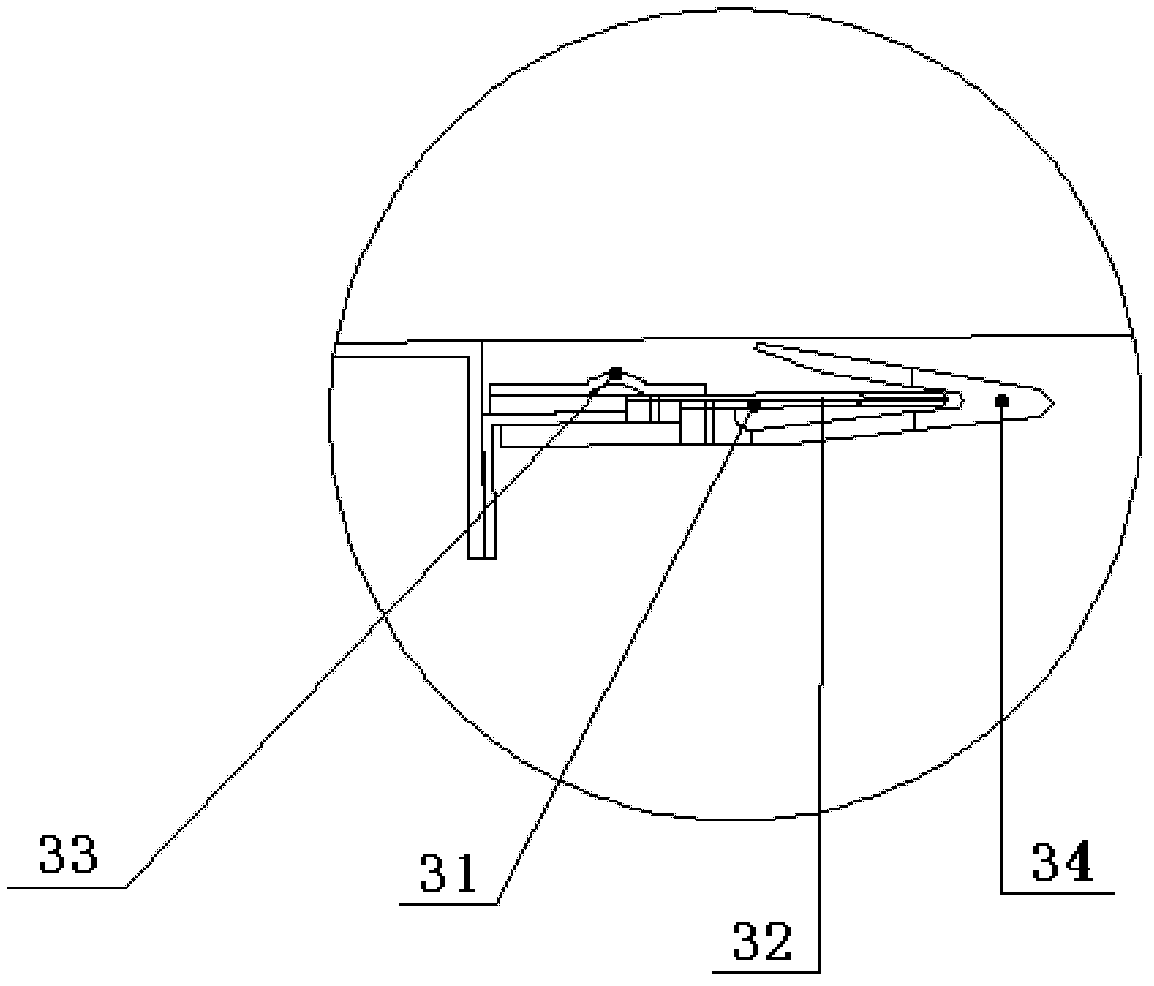

Detachable nonferrous metal sorting system

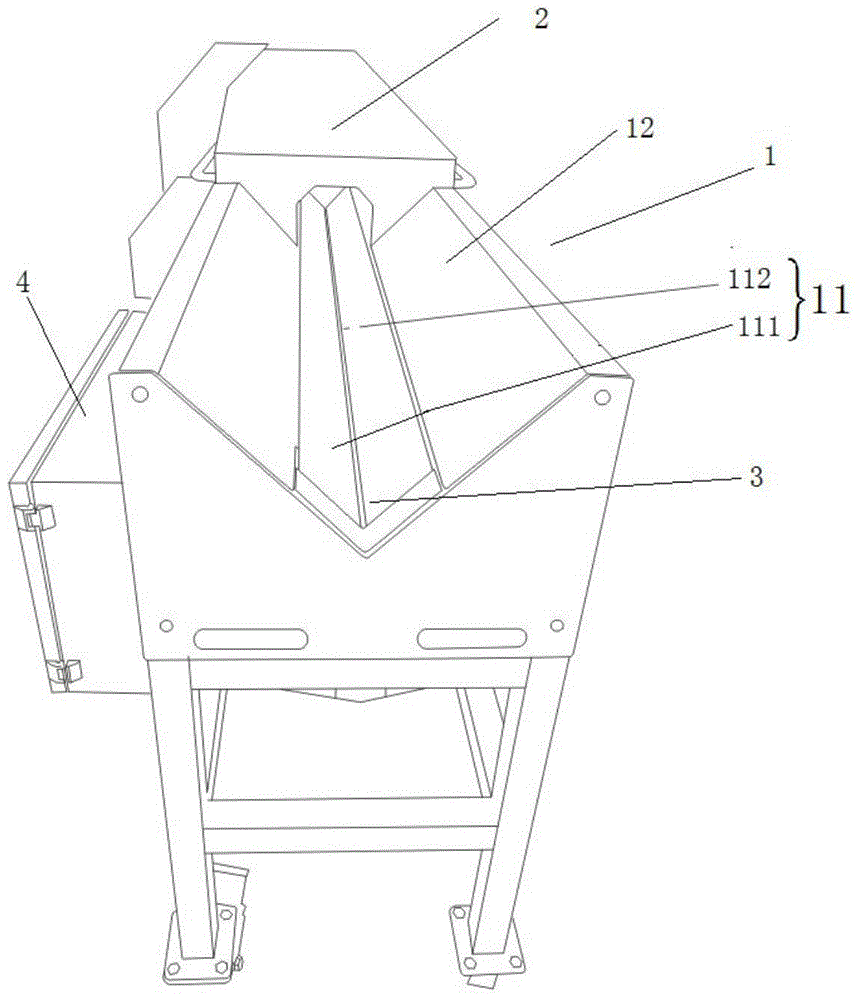

The invention discloses a detachable nonferrous metal sorting system comprising a modular feeding device, a modular vortex sorting device, a modular copper and aluminum sorting device and a modular stainless steel sorting device, wherein the modular vortex sorting device is respectively and detachably connected with the modular feeding device, the modular copper and aluminum sorting device and the modular stainless steel sorting device so as to receive materials from the modular feeding device and convey the materials sorted by the modular vortex sorting device to the modular copper and aluminum sorting device and the modular stainless steel sorting device. A feeding device, a vortex sorting device, a copper and aluminum sorting device and a stainless steel sorting device are subjected to modular design and are detachably connected, so that all the devices can be used through selective combination and are conveniently arranged, the floor area is reduced, the investment and using cost are reduced, and multiple purposes are realized by using one device.

Owner:中再生纽维尔资源回收设备(江苏)有限公司

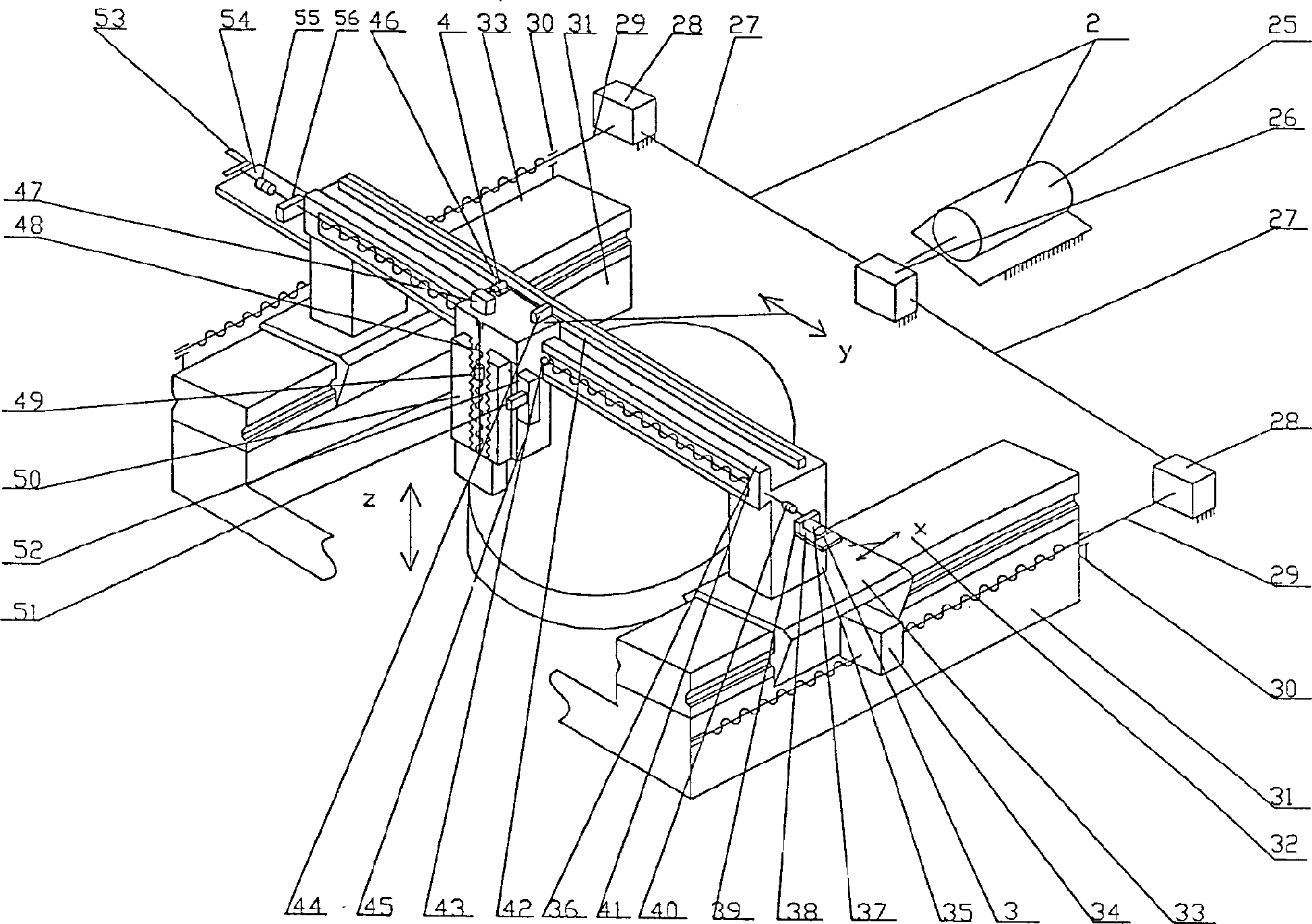

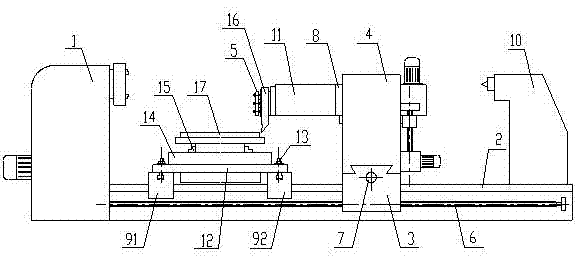

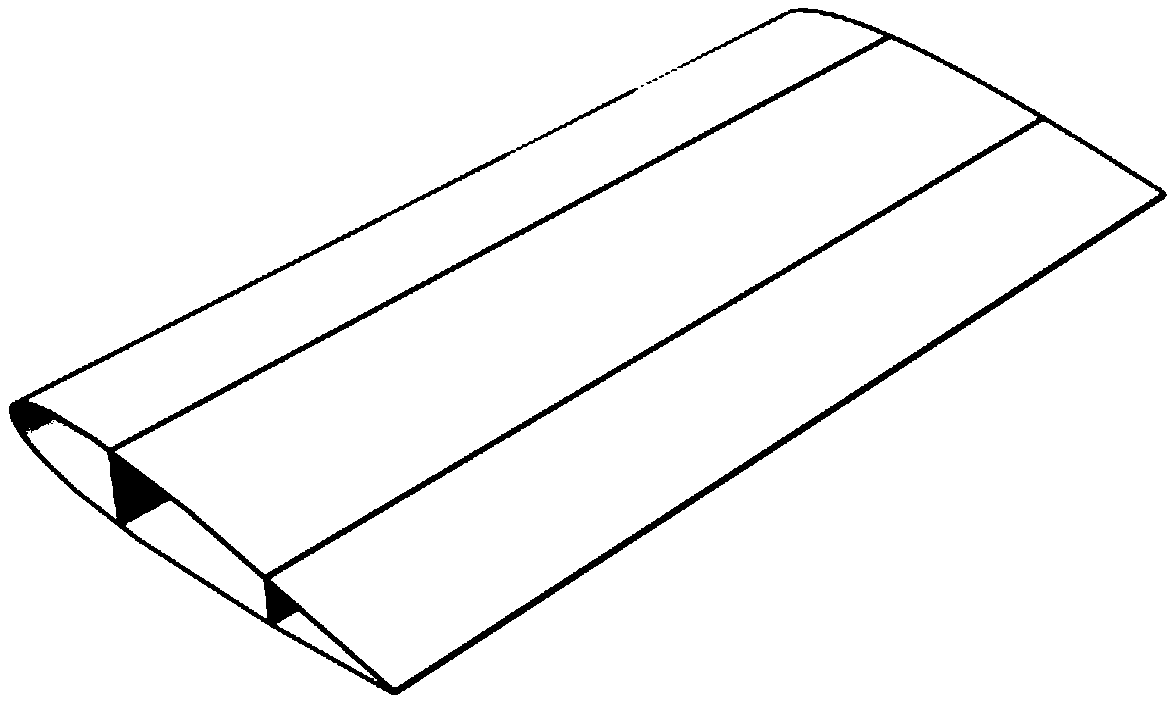

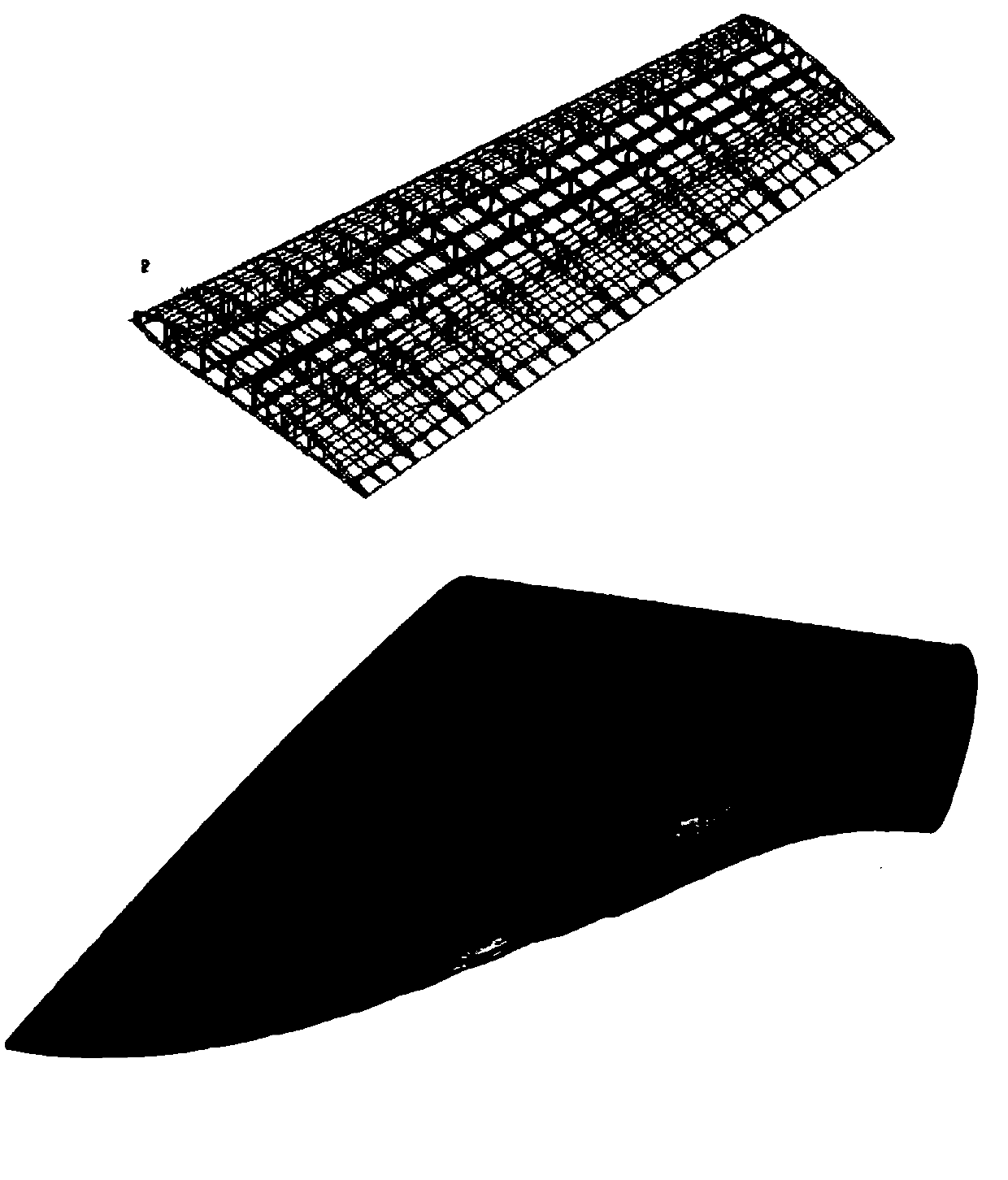

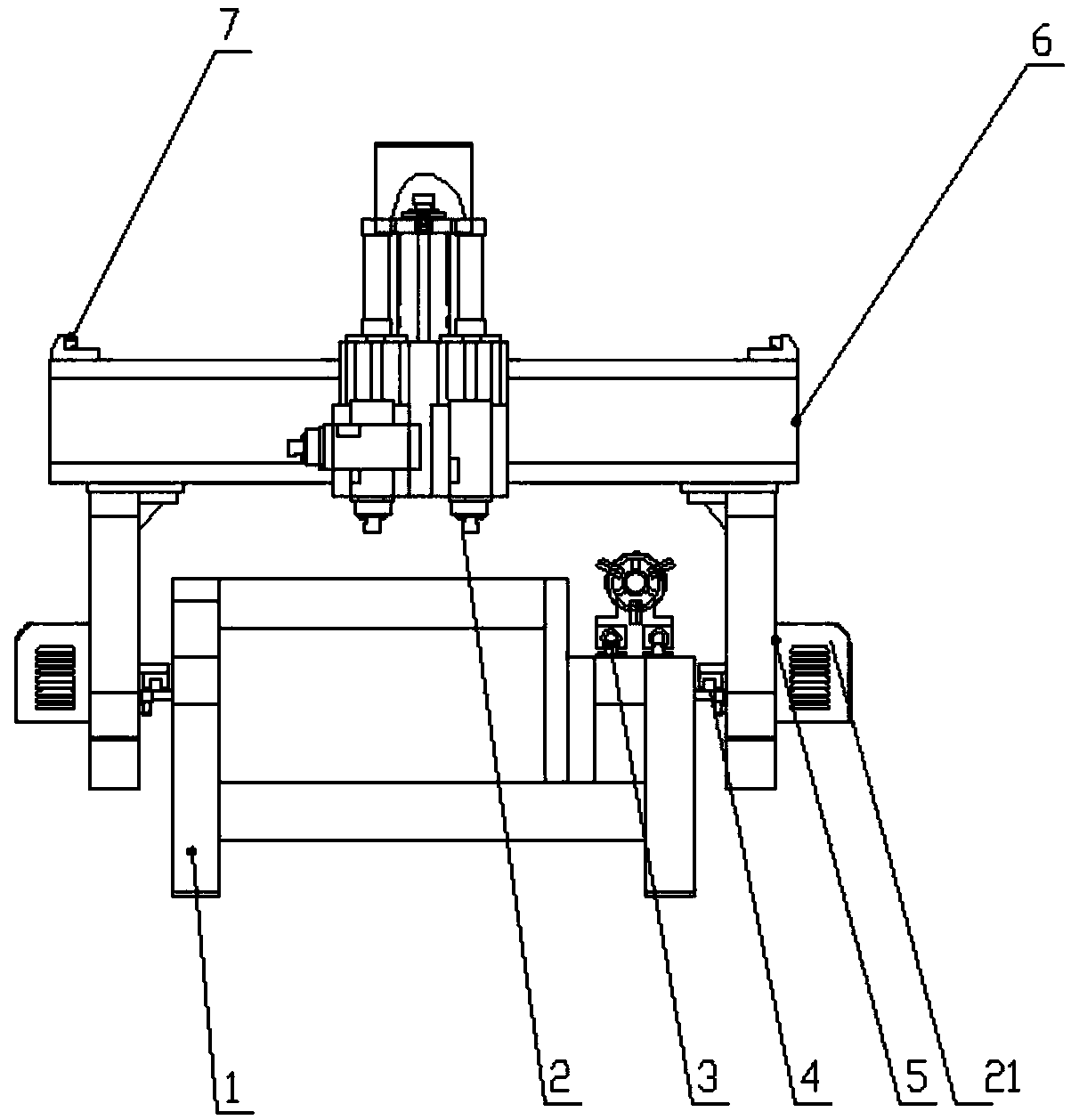

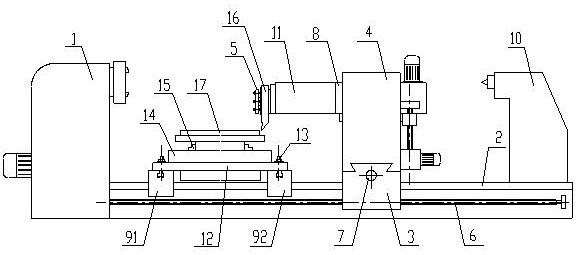

Multifunctional machine tool for making large screen template

InactiveCN1411948ARealize the purpose of one machine with multiple functionsLow costOther manufacturing equipments/toolsMilling cutterLarge screen

The multifunctional machine tool for machining large-screen template mainly includes rotary table driving mechanism, gantry x-direction driving mechanism, Y-direction driving mechanism, Z-direction driving mechanism of row of outters and driving mechanism of raw of milling cutters; the rotary table driving mechanism is fixedly connected with ground base, the gantry is supported on the machine tool body, said medicine tool is fixedly connected with ground base, Y-direction driving mechanism is set on the cross-beam of the gantry, and the Z-direction driving mechanism is row of cutters is set on the large carriage of Y-direction driving mechanism, and the driving mechanism of row of milling cutters is set on the small carriage of Z-direction driving mechanism of row of cutters.

Owner:SHANGHAI JIAO TONG UNIV

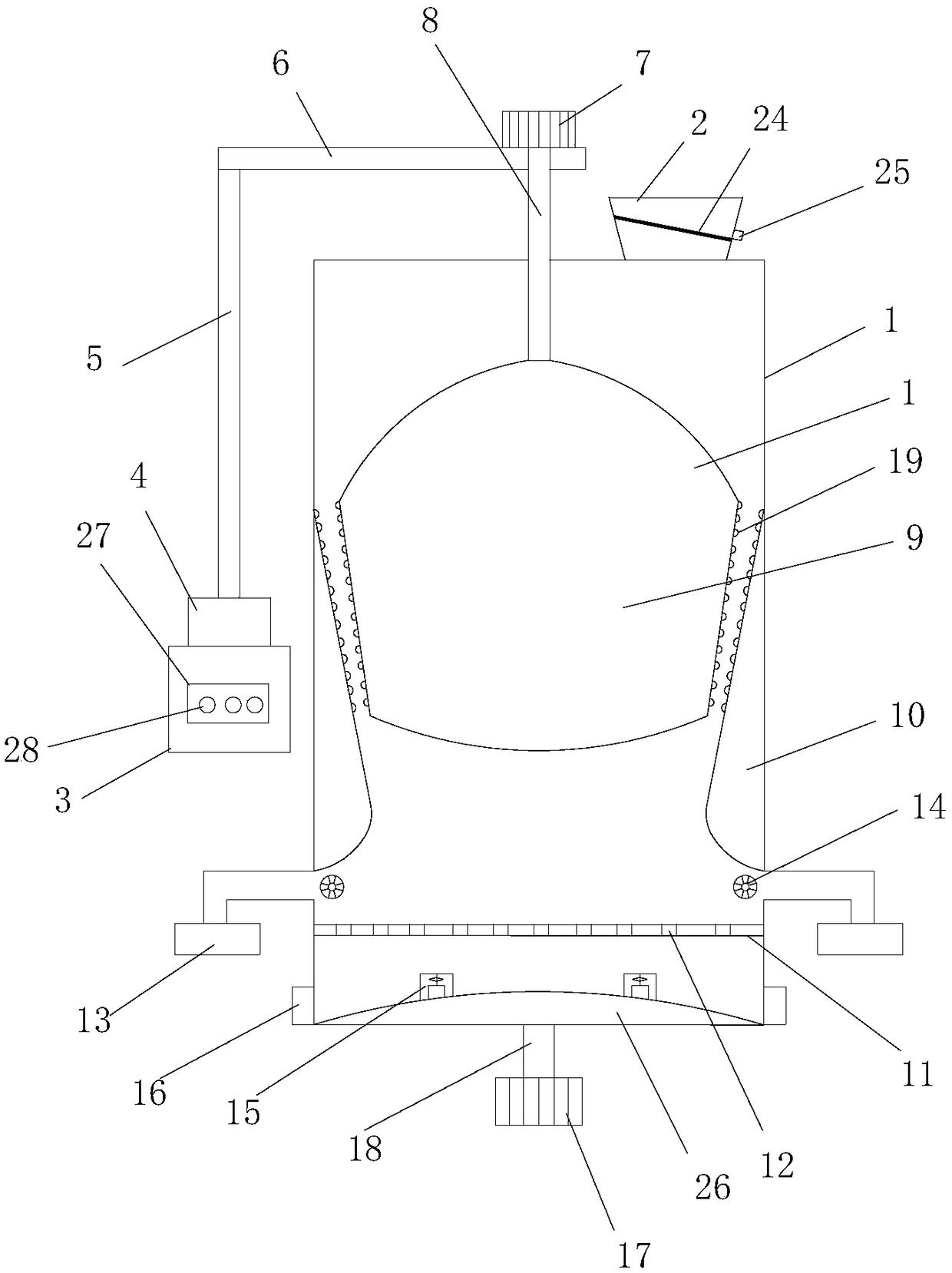

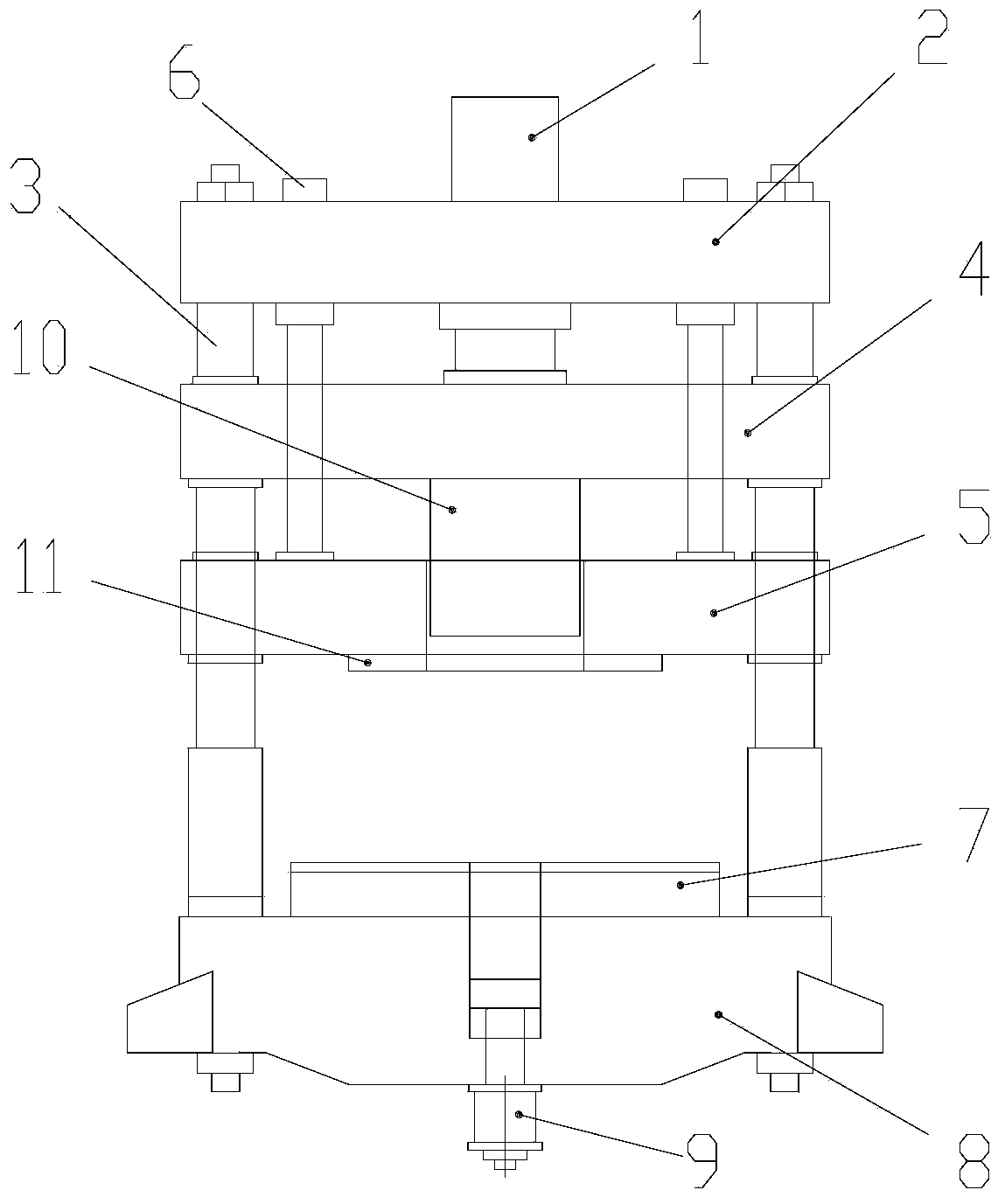

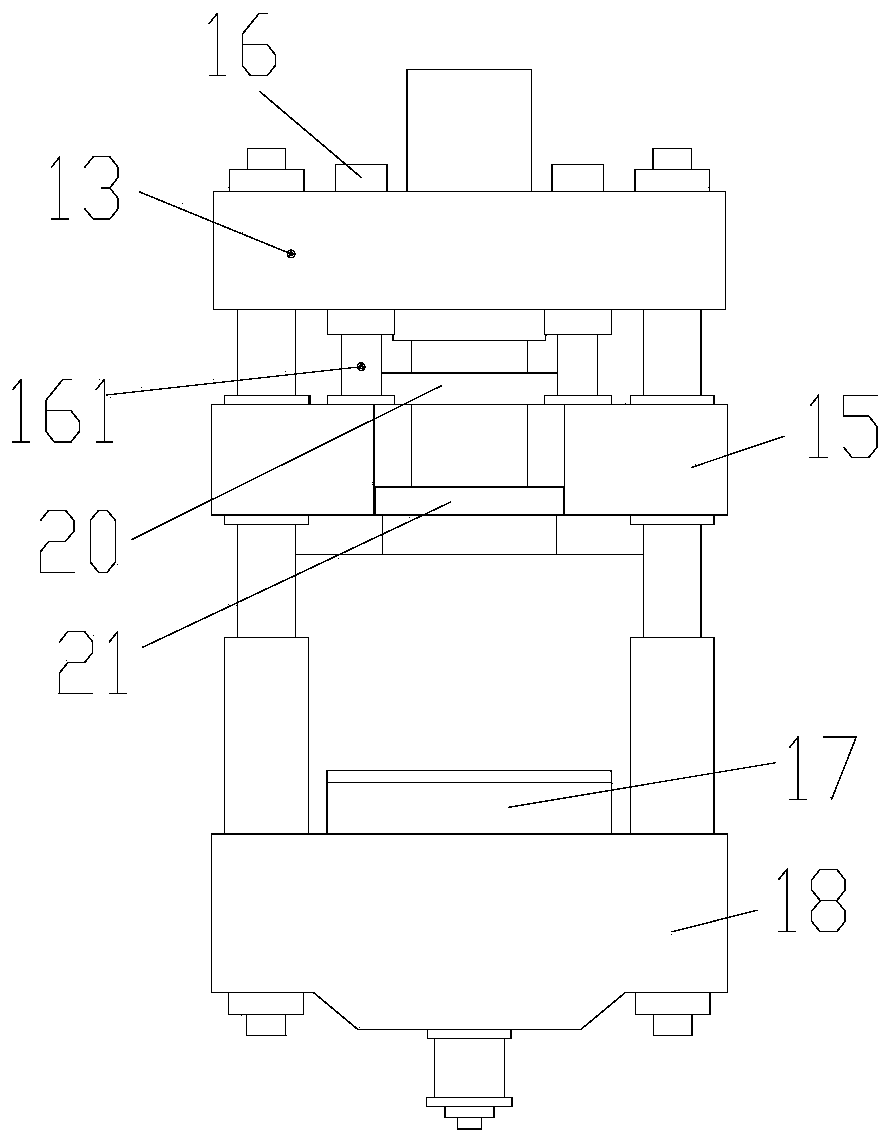

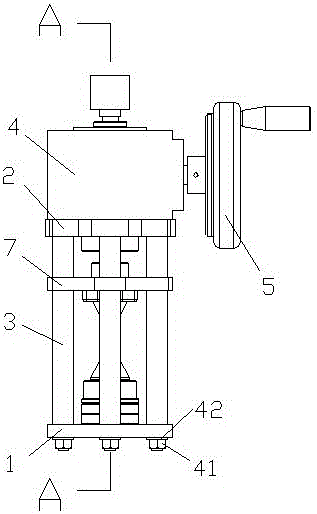

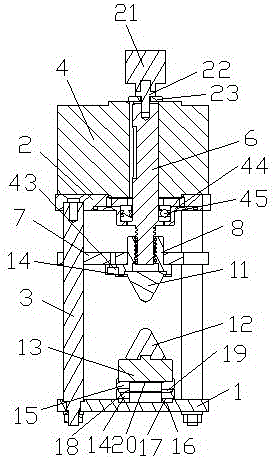

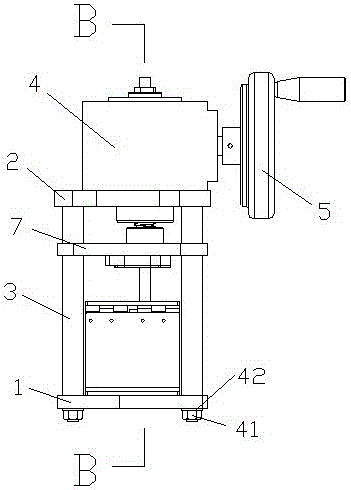

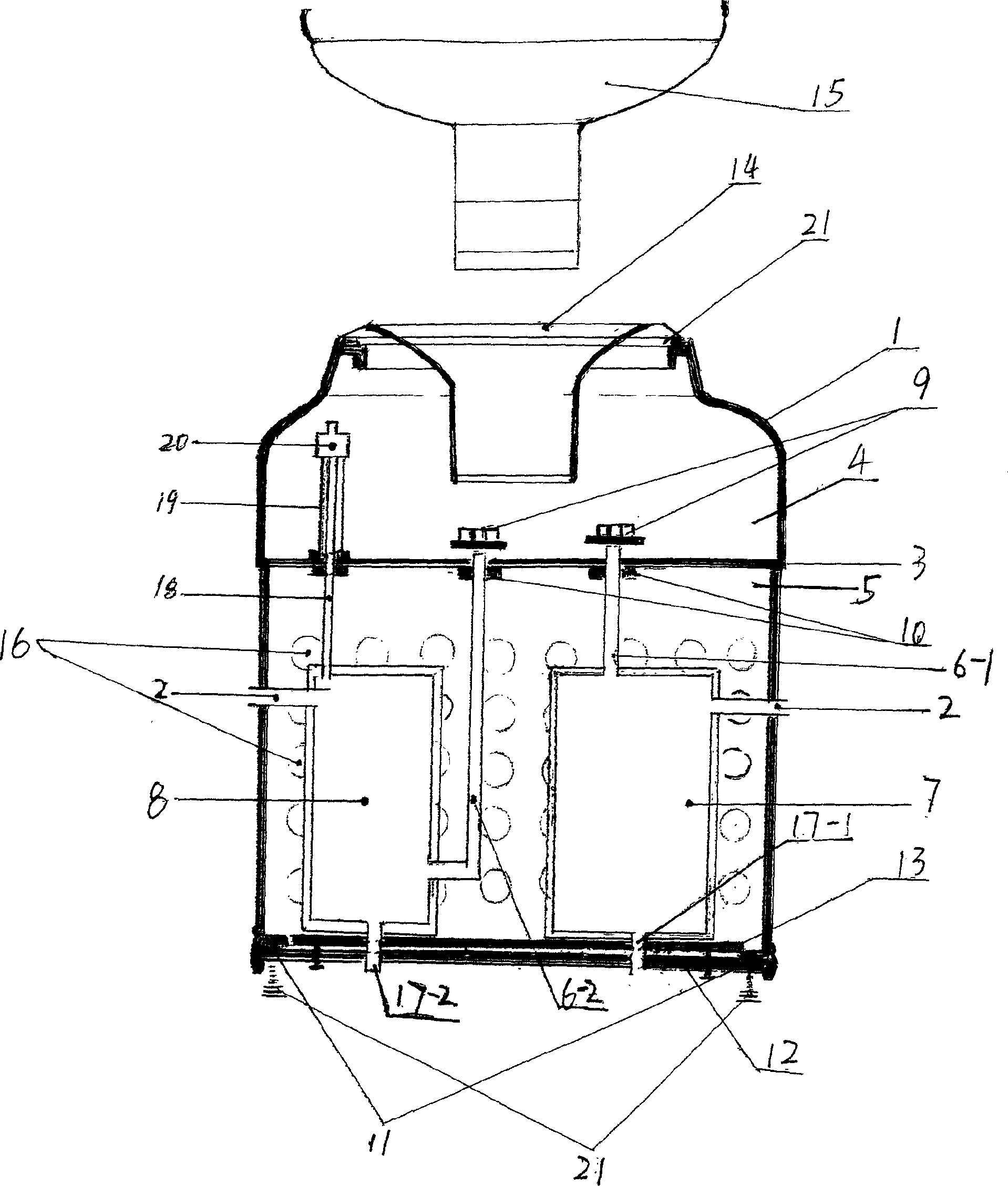

Forming hydraulic machine for hot-press seal head

ActiveCN103722069ASmall sizeSave materialPressesHollow articlesHydraulic cylinderMechanical engineering

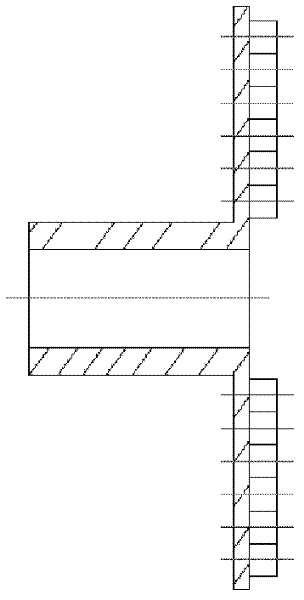

The invention discloses a forming hydraulic machine for a hot-press seal head. The forming hydraulic machine comprises a machine frame, four vertical columns arranged on the machine frame, an upper beam and a lower beam, wherein the upper beam and the lower beam are fixedly arranged on the four vertical columns. An edge pressing and sliding block capable of vertically moving along the vertical columns is arranged between the upper beam and the lower beam, a vertically through guide groove is formed in the middle of the edge pressing and sliding block, a tension hydraulic cylinder is arranged in the middle of the upper beam in a through mode, the lower end of a tension piston rod of the tension hydraulic cylinder is connected with a tension sliding block, the tension sliding block can vertically move in the guide groove of the edge pressing and sliding block, the lower end of the tension sliding block is fixedly provided with a bearing tube, and the lower end of the bearing tube is provided with an upper die. The upper beam is further provided with at least two edge pressing hydraulic cylinders, and the lower end of an edge pressing piston rod of each edge pressing hydraulic cylinder is connected with the edge pressing and sliding block. The forming hydraulic machine for the hot-press seal head has the following advantages of being good in guide performance, capable of achieving double movements into a single movement, simple in structure, safe, reliable and convenient to operate.

Owner:HEFEI METALFORMING MACHINE TOOL

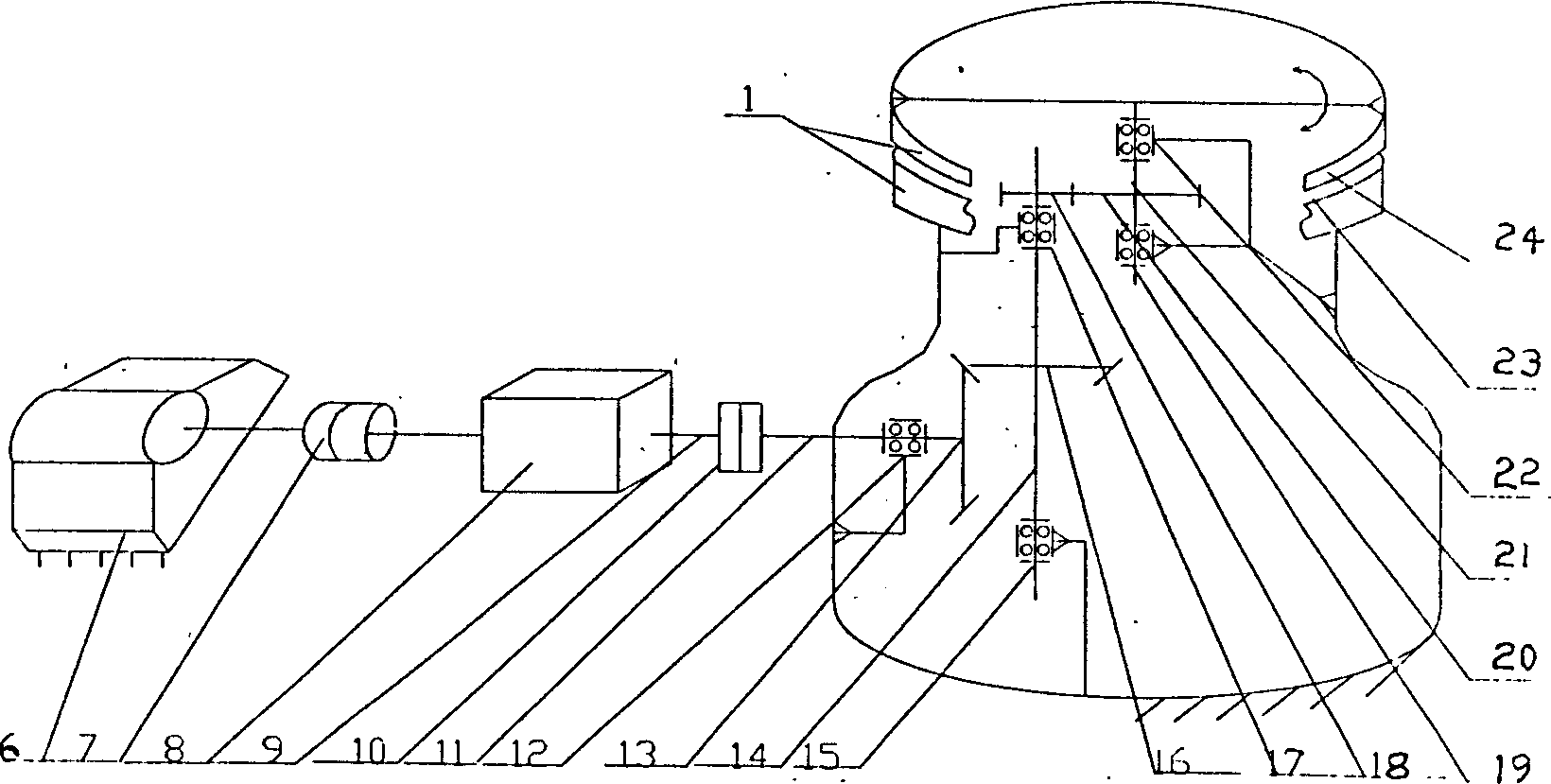

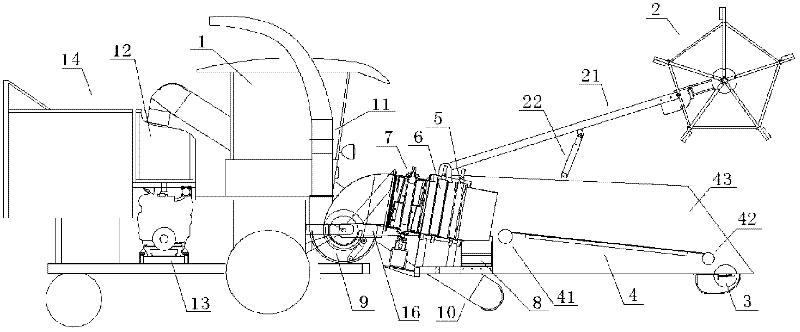

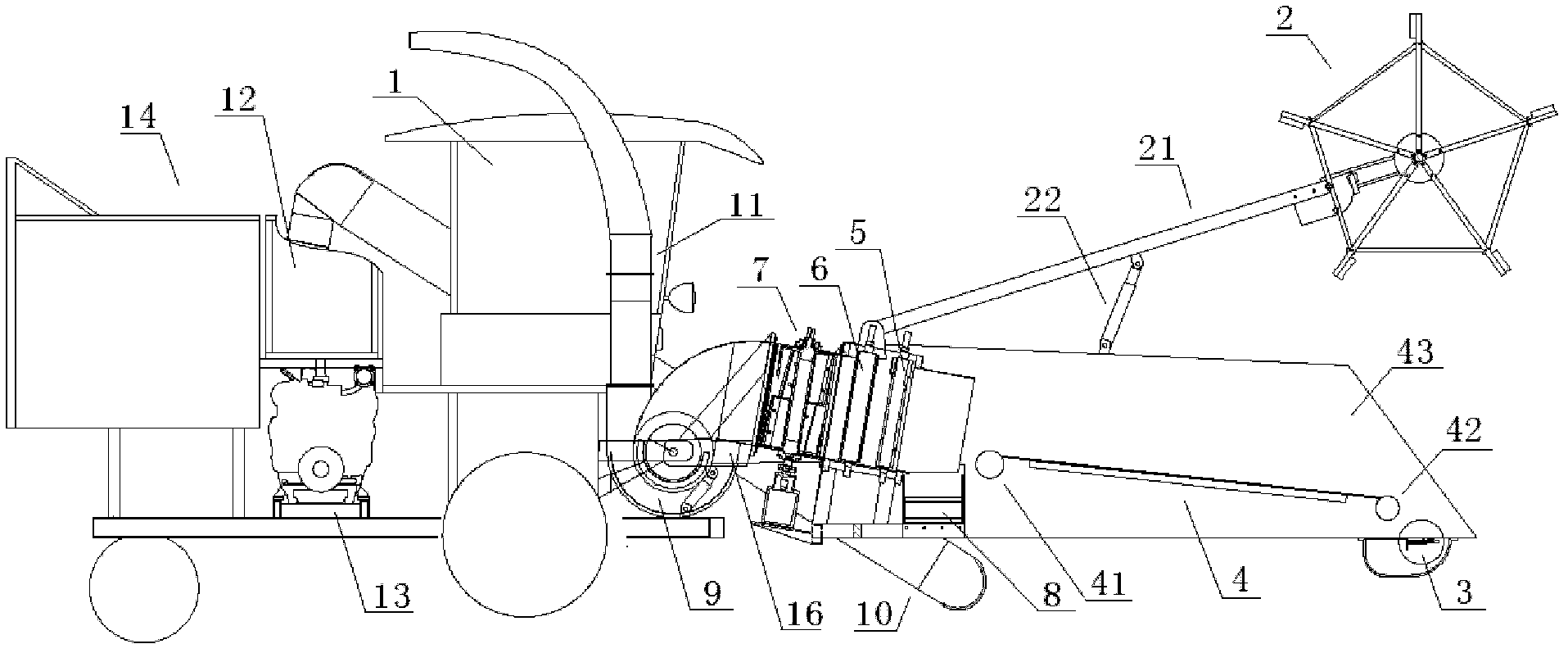

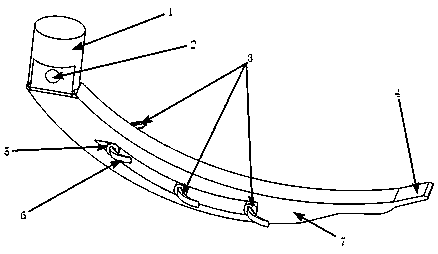

Vertical ear and stalk harvesting type corn harvester

ActiveCN102379191AReduce loss rateReduce impurityMowersAgricultural engineeringAgricultural machinery

The invention relates to the technical field of agricultural machinery, specifically a corn harvester. A vertical ear and stalk harvesting type corn harvester comprises a stand on which a cab and a harvesting platform are set. A reciprocating type cutter is set in front of the harvesting platform. A chain harrow type elevator, a vertical ear plucking device, a vertical stalk pulling device, a vertical cutting device are orderly set on the harvesting platform from the front to the rear. A crawler type ear collecting device is set in front of and below the vertical ear plucking device. A stalk collecting device is set below the cab. An ear elevator is set at left side of the cab. A throwing device is set at right side of the cab. An ear collecting box is set behind the cab. A grass collecting box is set behind the ear collecting box. By adoption of the mentioned technical proposal, the invention can harvest corn ear and stalk to be multi-purpose.

Owner:SHANDONG UNIV OF TECH

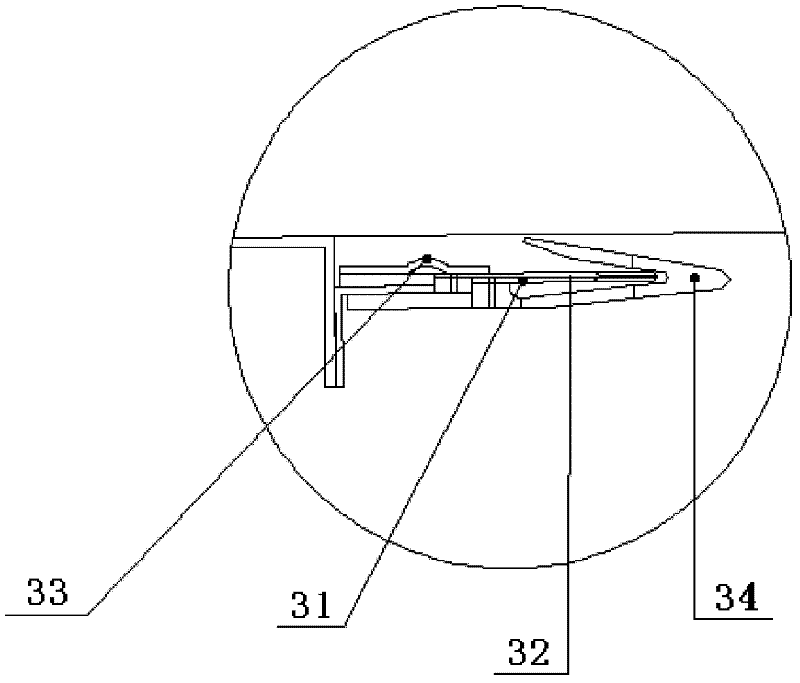

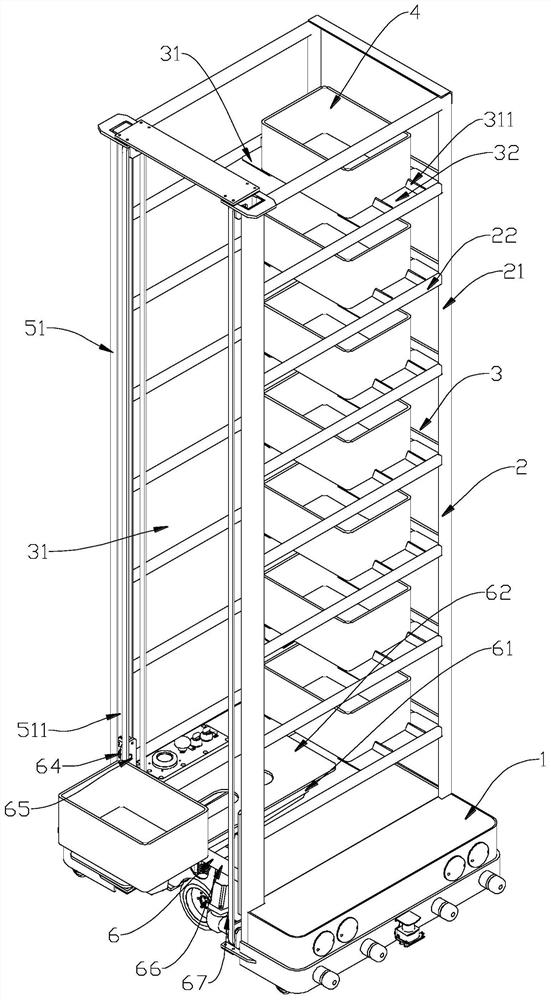

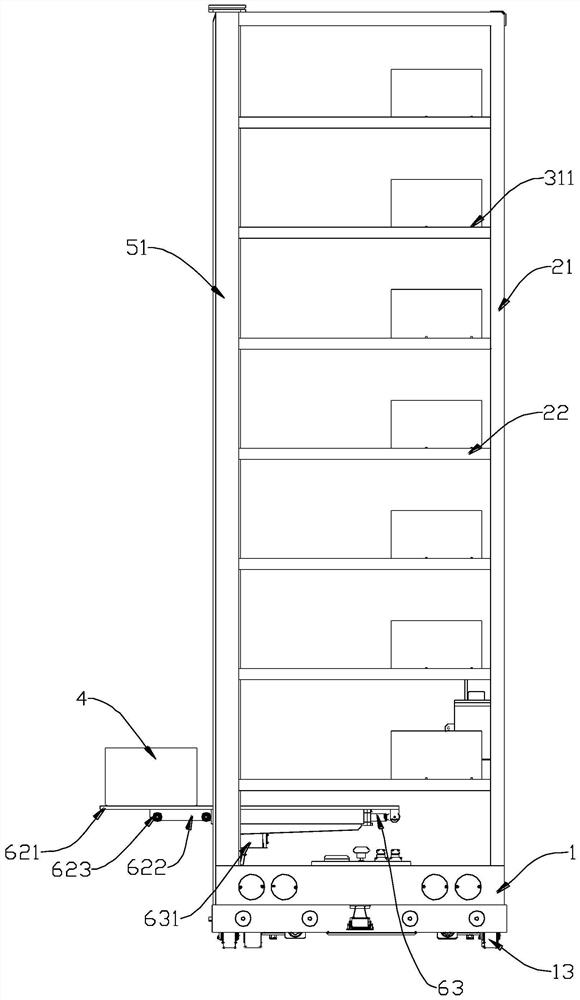

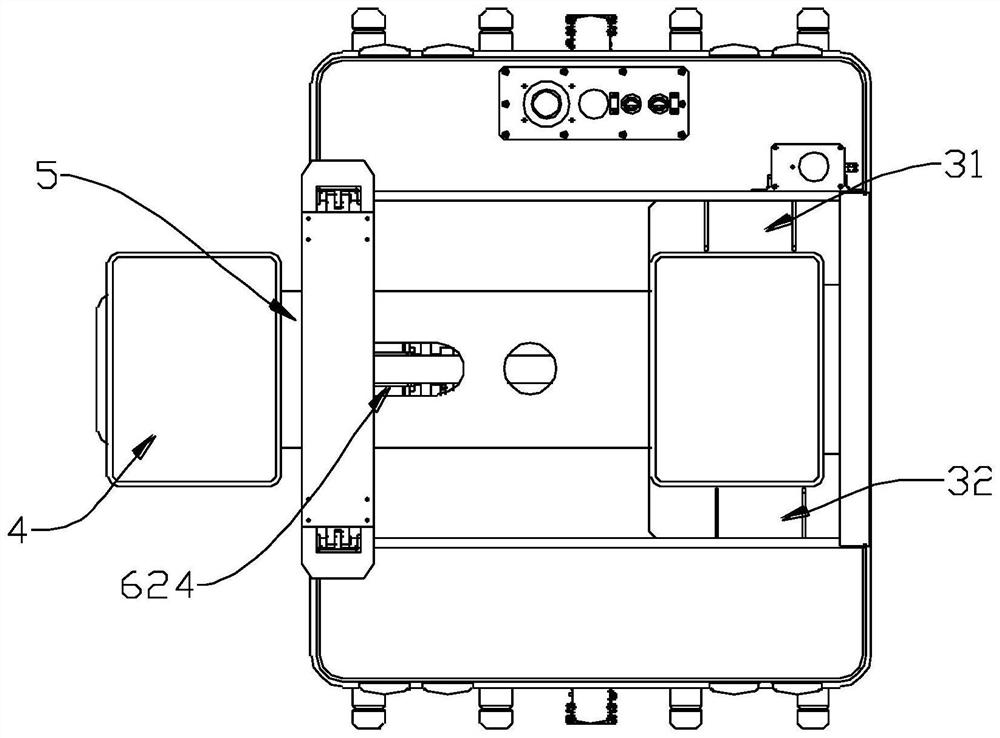

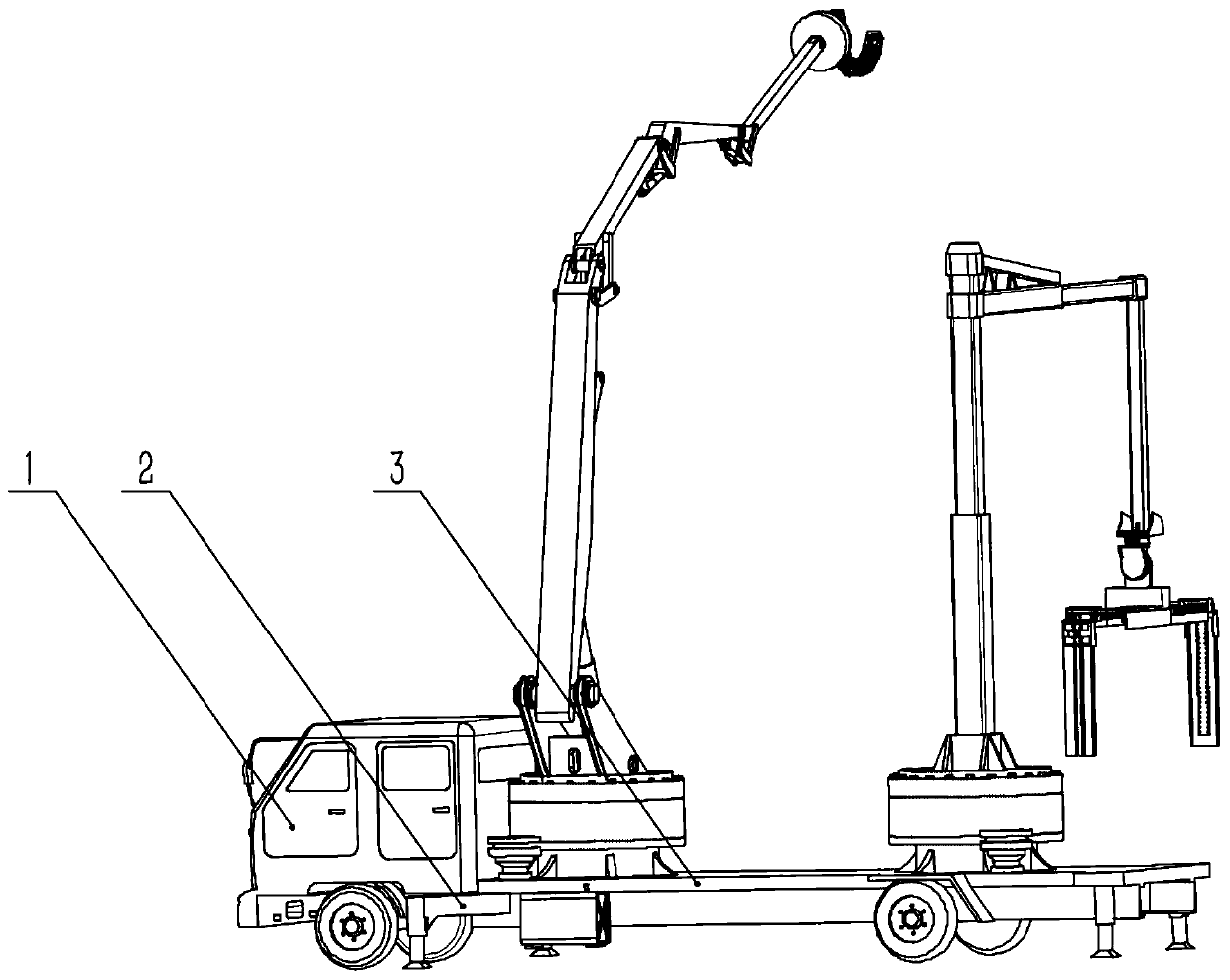

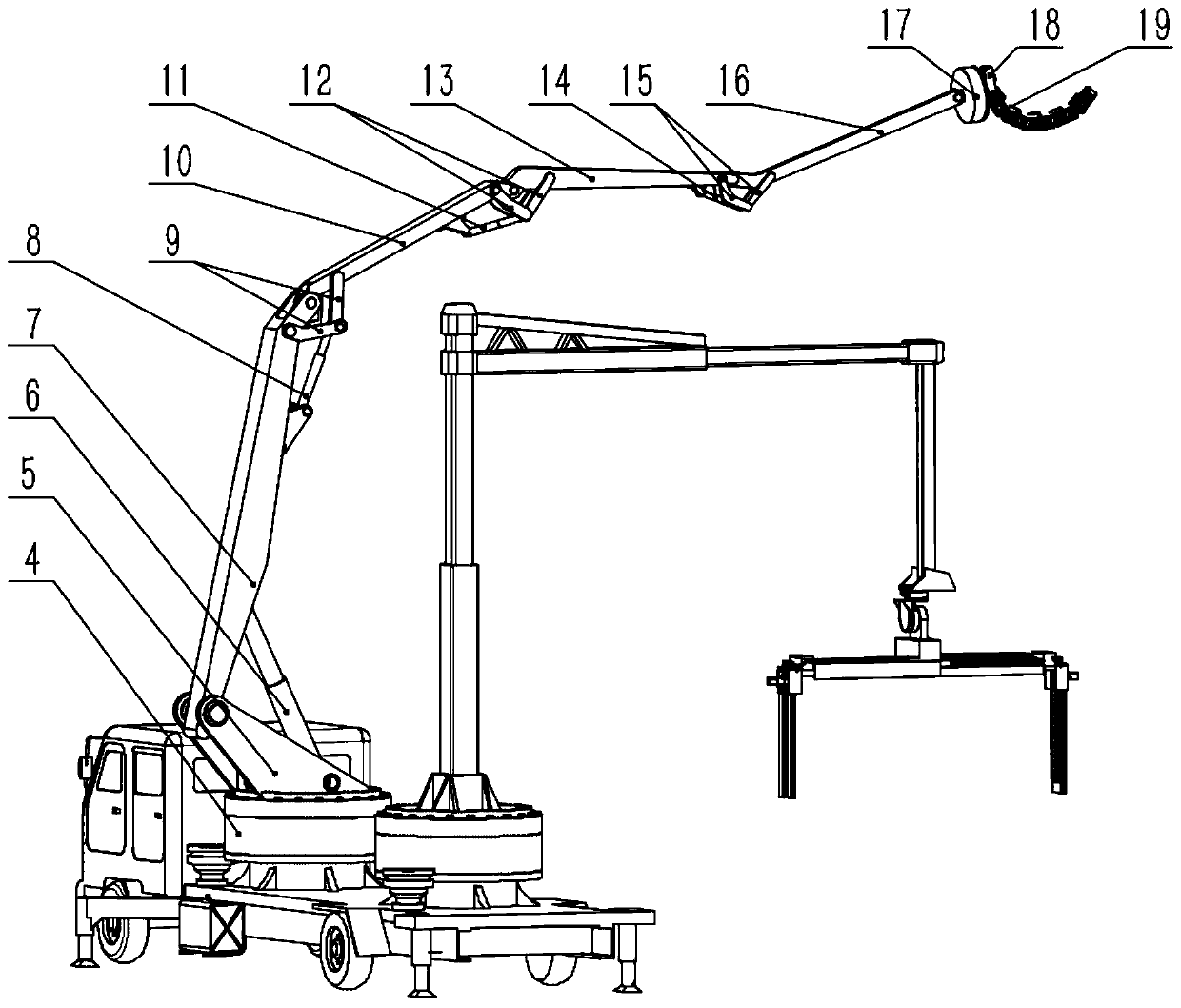

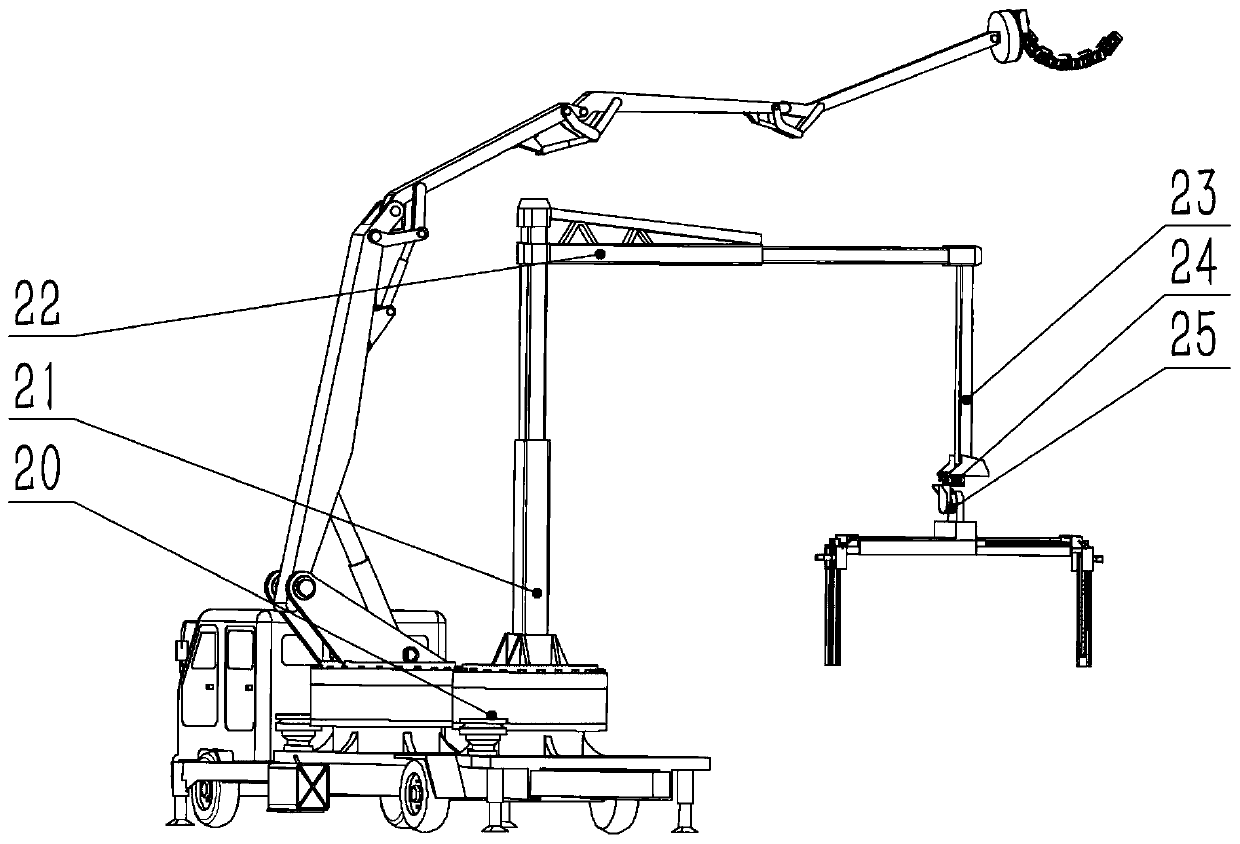

Multifunctional high-position order picker and operation method thereof

ActiveCN112079023AEfficient pickingProper selectionLifting devicesStorage devicesStructural engineeringMechanical engineering

Owner:杭州坤格智造科技有限公司

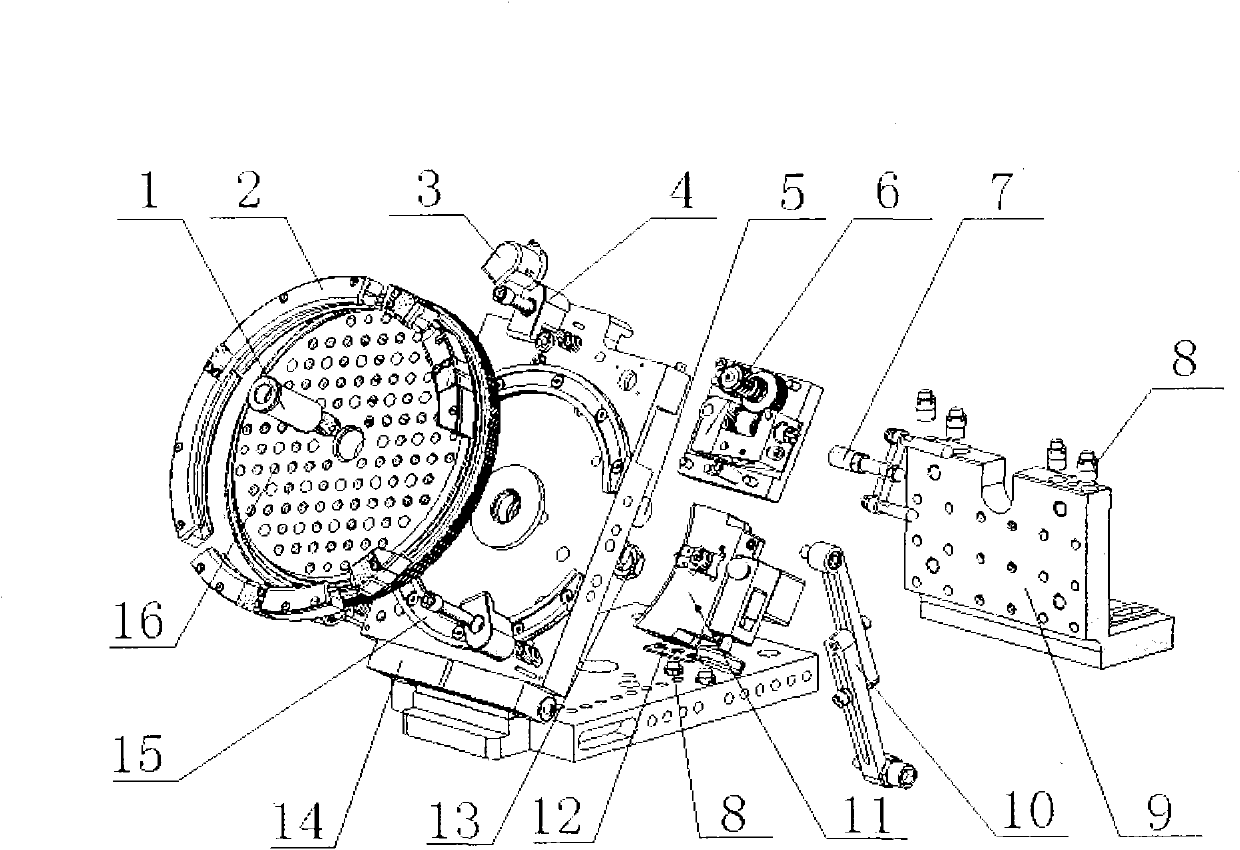

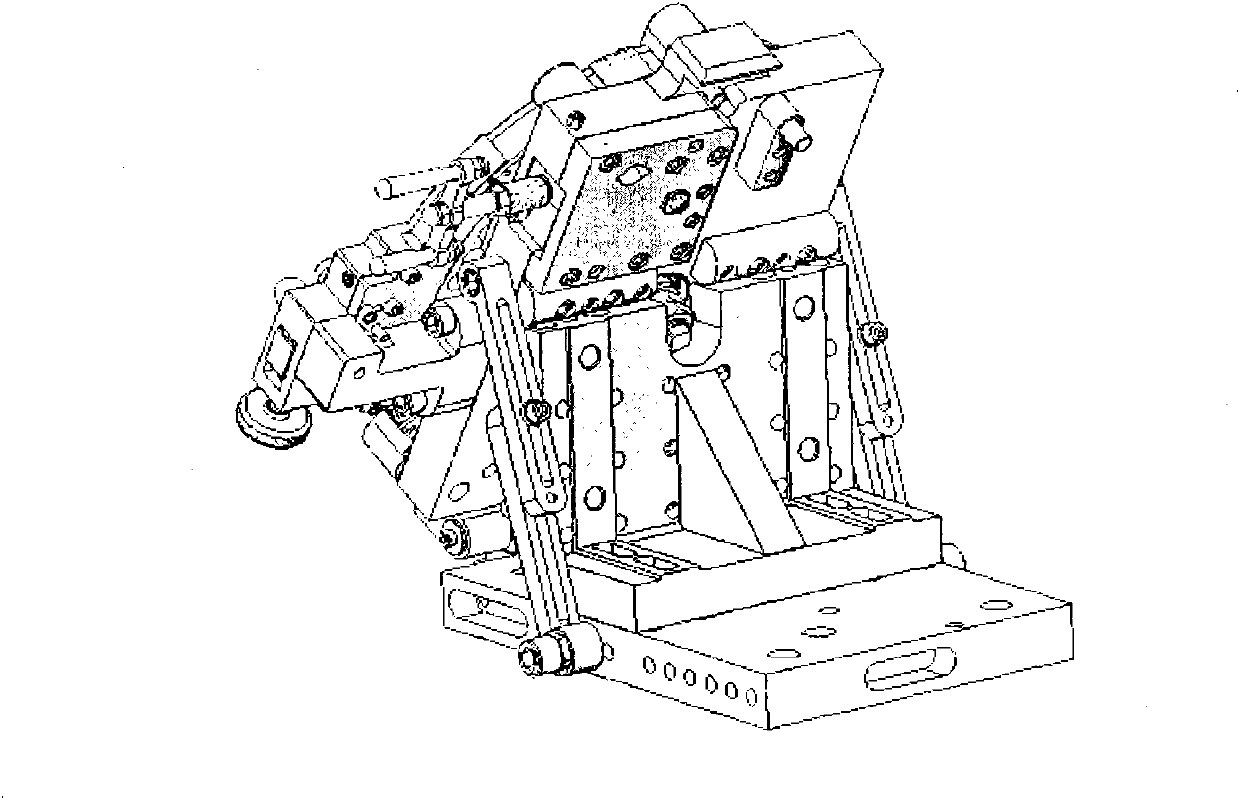

Instrument for measuring rock point load strength and structural surface frictional angle in field

InactiveCN106404540AReduce quality problemsIncrease friction angle measurement functionMaterial strength using tensile/compressive forcesUsing mechanical meansVisual inspectionEngineering

The invention discloses an instrument for measuring rock point load strength and a structural surface frictional angle in the field. The instrument comprises a lower bottom plate and an upper bottom plate, wherein support columns are mounted between the lower bottom plate and the upper bottom plate, and a turbine reducer is mounted on the upper bottom plate and connected with a storage hand wheel and a screw; a slider is mounted on the support columns, and the screw is connected with a connecting block which is connected with the slider; a rock point load strength measuring device or a rock structural surface frictional angle measuring device is mounted between the connecting block and the lower bottom plate. By means of the instrument for measuring rock point load strength and the structural surface frictional angle in the field, the weight of an existing rock point load instrument is reduced substantially, measurement parameters of the instrument are directly stored and transmitted without manual recording, requirements of rock point load strength measurement in the field for low weight and intelligence of the instrument are met, the way of measuring the rock structural surface frictional angle through visual inspection at the site is avoided, and the function of measurement of the structural surface frictional angle is increased.

Owner:SHAOXING UNIVERSITY

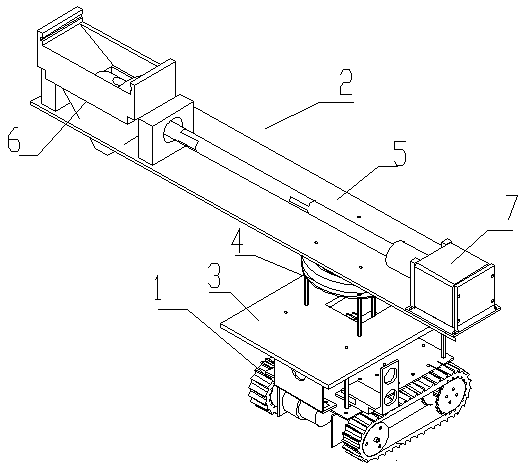

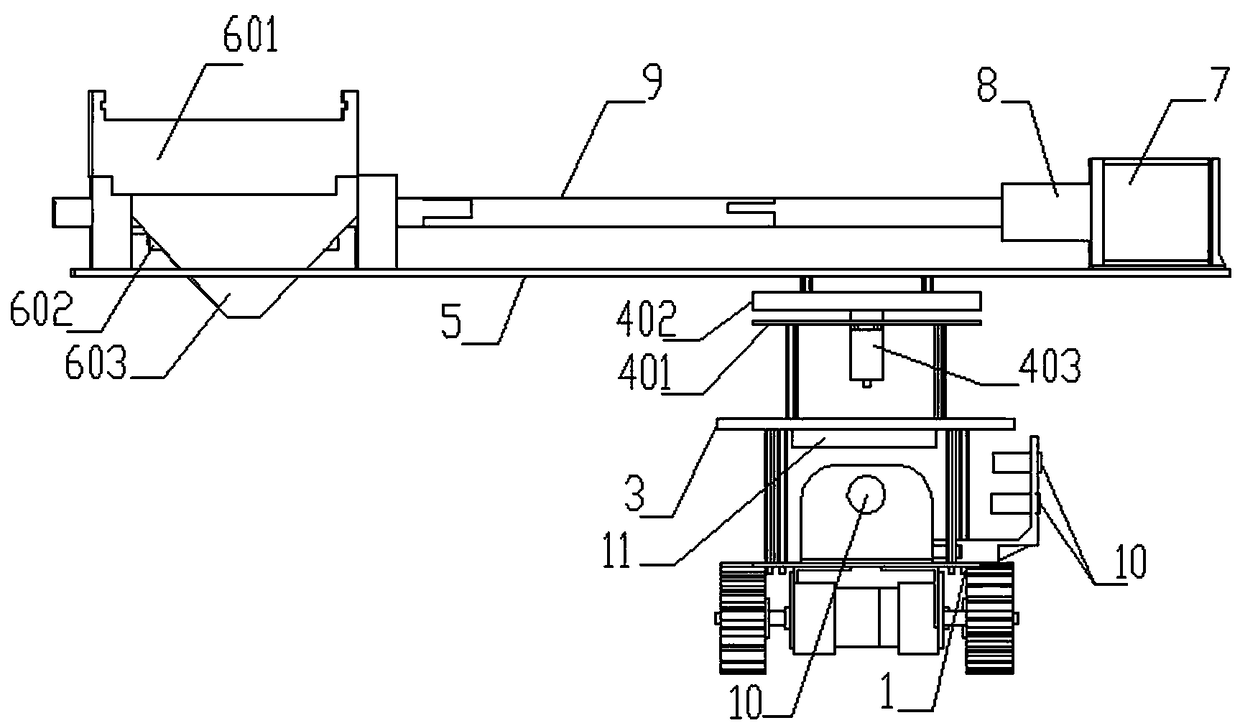

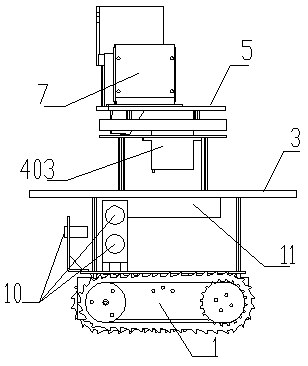

Self-propelling seeder for greenhouses

PendingCN108419487ALower the altitudeSimple structureSeed depositing seeder partsEngineeringSelf weight

A self-propelling seeder for greenhouses comprises a travelling mechanism, a seeding mechanism and a controller. The controller controls the traveling mechanism to drive the body of the seeder to move, and controls the seeding mechanism to seed. A crawler-type base plate is applied to the travelling mechanism, and is provided with a mounting platform for mounting the seeding mechanism and the controller. A horizontal rotating platform is arranged on the mounting platform. A cantilever for mounting the seeding mechanism is arranged on the horizontal rotating platform. One end of the cantileveris fixedly connected with the horizontal rotating platform, and the other end of the cantilever extends out towards one side perpendicular to the moving direction of the seeding mechanism. A seeding unit of the seeding mechanism is located at one end, away from the body of the seeder, of the cantilever. After the body of the seeder turns around, the controller controls the horizontal rotating platform to drive the seeding mechanism through the cantilever to rotate by 180 degrees within the horizontal plane, and accordingly, ridge jump of the seeding mechanism is avoided. The self-propelling seeder has the advantages of short body, compact structure, low weight and capability of well adapting to operation environments in the greenhouses.

Owner:HENAN UNIV OF SCI & TECH

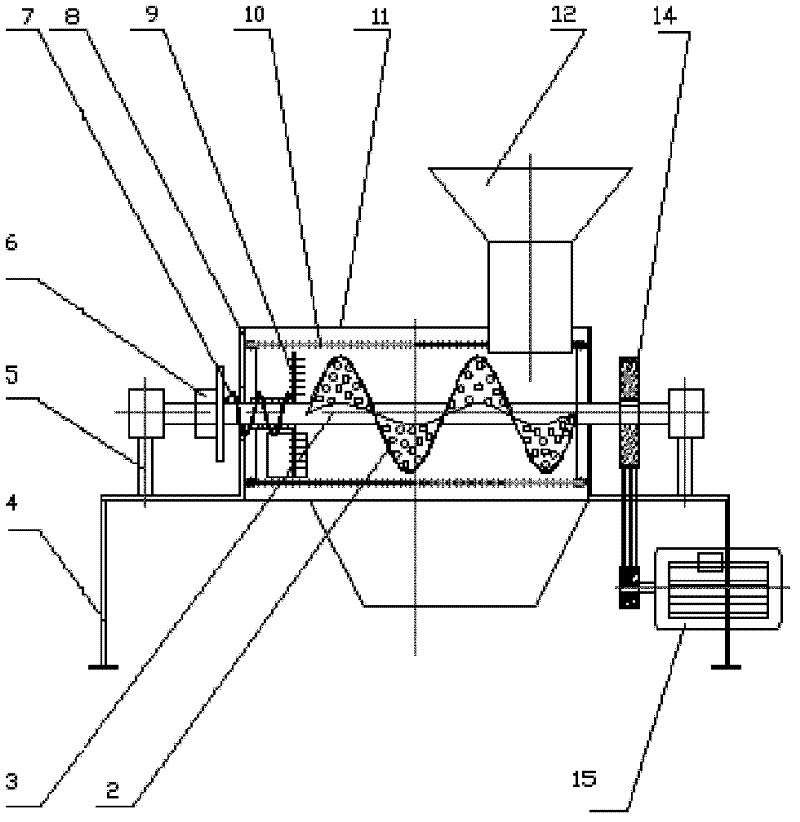

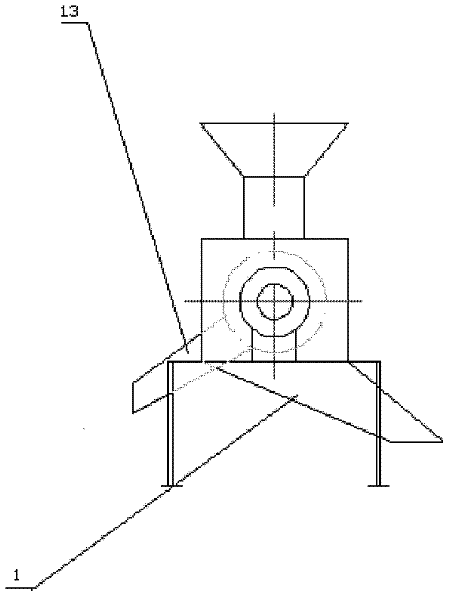

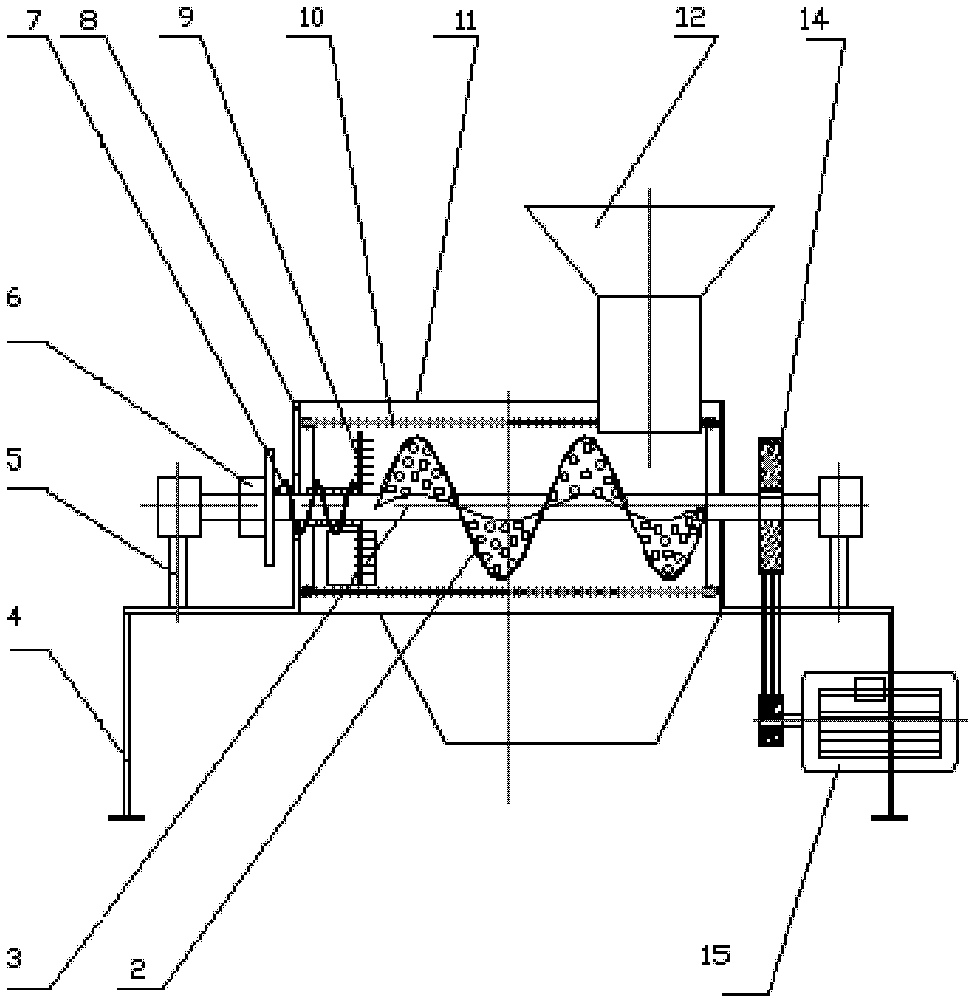

Extrusion soil breaker

InactiveCN102511208ASimple structureEasy to disassemble and repairClod-crushersAgricultural engineeringDual function

The invention discloses an extrusion soil breaker, which comprises a frame, a left wallboard, a right wallboard, a screw shaft, a casing and a pulley. The left wallboard and the right wallboard are disposed on the frame, the screw shaft supported via bearing blocks penetrates through the left wallboard and the right wallboard, the casing with a feeding port and a discharging port is fixedly connected to the left wallboard and the right wallboard, the pulley disposed on the screw shaft is driven by a motor, breaking claws are evenly distributed on a screw vane (2) on the screw shaft (3) inside the casing (11), a cylindrical screen (10) connected to the left and right wallboards (8) is radially arranged between the screw vane and the casing, a pressure disc (9) with evenly and peripherally distributed pressure claws (18) is sleeved on the screw shaft inside the cylindrical screen, and the pressure disc and the left wallboard adjacent to the same are provided with anti-rotating holes (19 and 20) respectively and correspondingly connected through anti-rotating pins (21). Impurities and bricks in soil can be effectively separated from the soil while soil breaking and screening functions are achieved by using the extrusion soil breaker, and the extrusion soil breaker is simple and compact in structure, convenient in disassembly and maintenance, low in cost, low in vibration, low in noise, low in power consumption and widely applicable.

Owner:ANHUI AGRICULTURAL UNIVERSITY

Vegetable cutter

InactiveCN104441004AImprove cutting stabilityRealize the purpose of one machine with multiple functionsMetal working apparatusElectric machineryCucumber family

The invention discloses a vegetable cutter. The vegetable cutter comprises a conveyor and a cutting unit, the cutting unit comprises a storage tank, a circular cutter disc and a first driving motor, the storage tank is provided with a discharge outlet, the circular cutter disc is vertically arranged in the storage tank and at the conveying tail end of the conveyor, the conveying direction of the conveyor is perpendicular to the circular cutter disc, and the middle of the circular cutter disc is fixedly connected with a driving end of the first driving motor; the circular cutter disc is provided with a plurality of blades uniformly distributed along the radius direction, a vegetable output end of the conveyor corresponds to the middle of the blades, and a gap formed between every two adjacent blades is larger than the size of a cutting section of the cut vegetables. The vegetable cutter can slice, cut or shred some materials (such as cucumbers, asparagus and leaf vegetables, and is multipurpose.

Owner:北京市裕农优质农产品种植有限公司

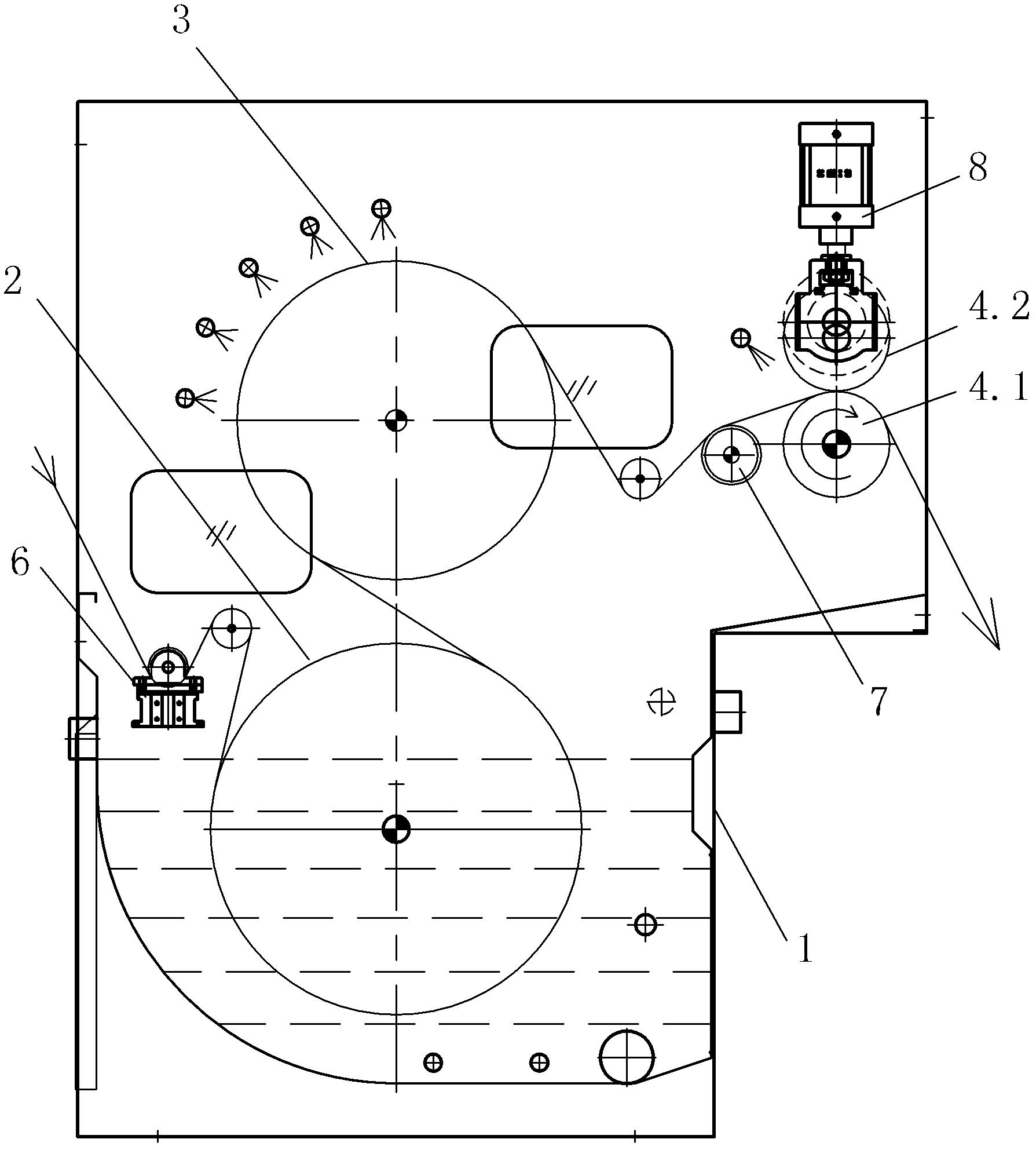

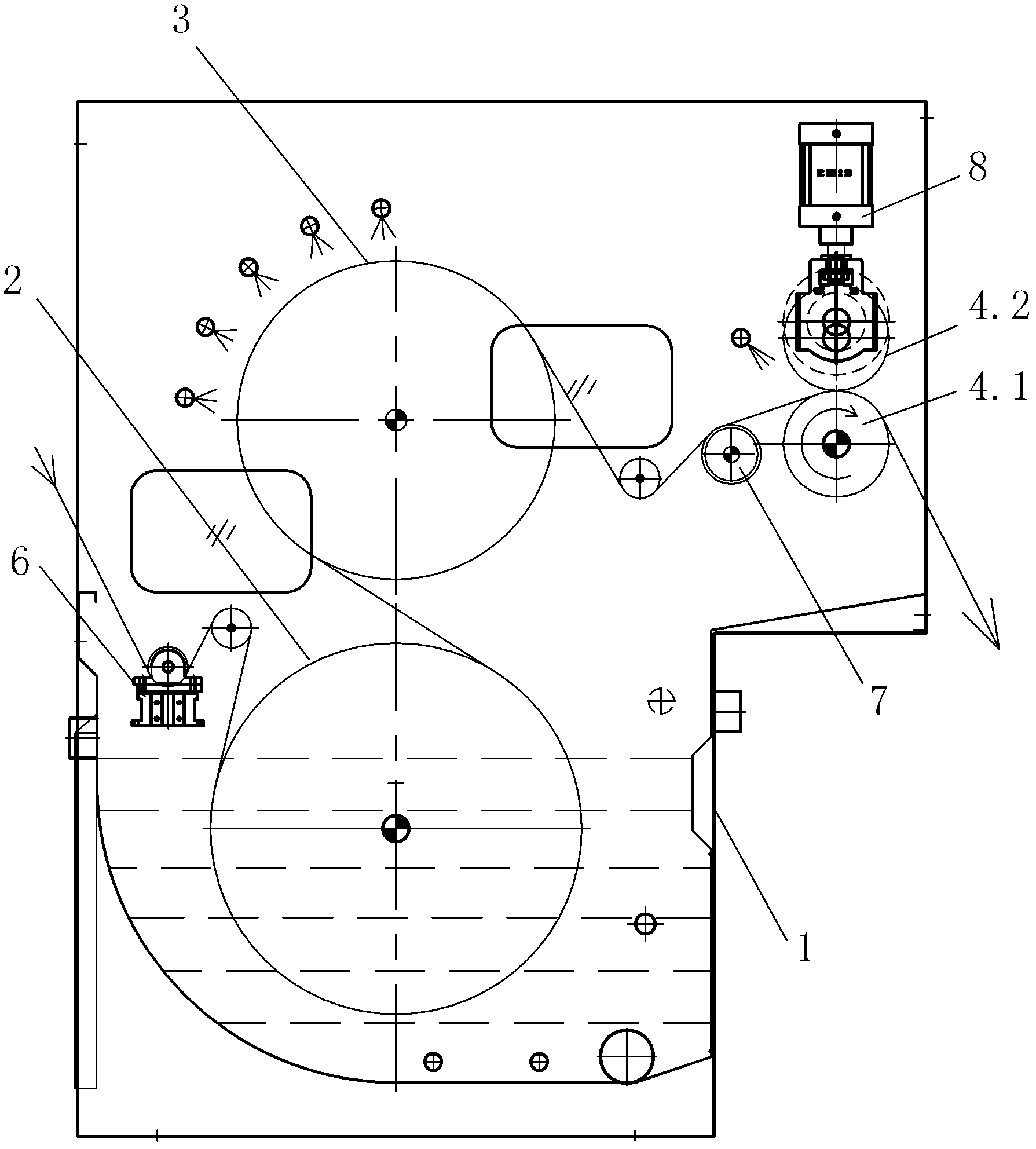

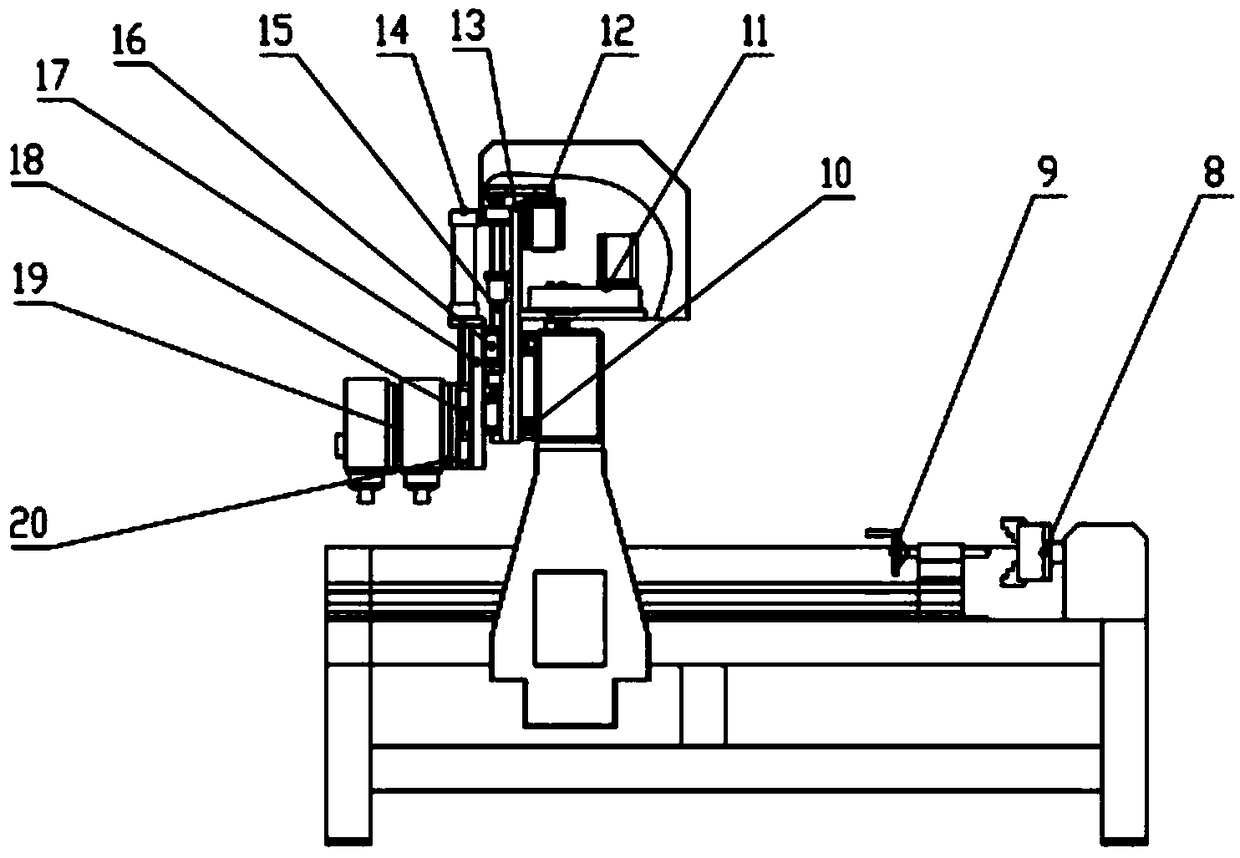

Vertical turning structure of turning milling boring multifunctional horizontal lathe

ActiveCN107225256AMulti-Metal Cutting CapabilitiesImprove processing efficiencyFeeding apparatusTurning machinesEngineeringWorkbench

The invention discloses a vertical turning structure of a turning milling boring multifunctional horizontal lathe. A turning power head and a tail support are arranged on two ends of a guide rail; a longitudinal driving lead screw passes through a longitudinal slide carriage mechanism and is parallel to the guide rail; the longitudinal slide carriage mechanism moves along the guide rail under drive of the longitudinal driving lead screw; a horizontal driving lead screw is arranged on the longitudinal slide carriage mechanism; a horizontal dragging plate mechanism is arranged on the top end of the longitudinal slide carriage mechanism and moves along the longitudinal slide carriage mechanism under drive of the horizontal driving lead screw; a turning cutter platform mechanism is arranged on a side surface of the horizontal dragging plate mechanism and can lift along the horizontal dragging plate mechanism; two slide platforms are arranged on the guide rail and move along the guide rail; a tail end of a connection long seat is detachably arranged on a front end surface of the turning cutter platform mechanism; a turning tool seat is arranged on a front end of the connection long seat; and the vertical lathe workbench support is arranged on two top surfaces of the two slide platforms. A vertical function is integrated in the turning milling boring horizontal lathe, the horizontal lathe can possess more metal machining functions and has multiple purposes, and the machining efficiency and precision of work pieces can be improved.

Owner:SHANGHAI BAOSTEEL IND TECHNOLOGICAL SERVICE

Automatic fabric tension control system suitable for knitting open-width wet processing unit

ActiveCN102517827AAvoid Stretch DeformationGuaranteed qualityTextile treatment carriersTextile treatment rollersControl systemStructural engineering

The invention relates to an automatic fabric tension control system suitable for a knitting open-width wet processing unit. The system comprises at least more than two groups of wet processing units, wherein adjacent wet processing units are in station connection to form the open-width wet processing unit; drum / roller group stations and roller groups which are matched with the drum / roller groups are arranged in box bodies of the wet processing units; and the system is characterized in that: the drum / roller groups are main driving components; and the roller groups comprise driving rollers and driven rollers which are matched with each other. The invention has outstanding characteristics that: the drums / rollers, rollers and traction rollers in each wet processing unit are main driving components; numerical values of various driving mechanisms can be directly set according to differences of fabric composition and technical requirements of fabrics machined by the unit, so that the fabrics do not have tension, the fabrics are prevented from being subjected to tensile deformation in each wet processing unit, and the quality of the fabrics is guaranteed.

Owner:绍兴东升数码科技有限公司

Multifunctional pruning vehicle suitable for city road green belts

InactiveCN110679318AExpand the trimming rangeRealize the purpose of "one machine with multiple functions"Hedge trimming apparatusCuttersAgricultural engineeringGreen belt

The invention discloses a multifunctional pruning vehicle suitable for city road green belts. The multifunctional pruning vehicle comprises a vehicle body, a traveling mechanism, a control mechanism,a spherical landscape plant pruning mechanism and a landscape plant trimming mechanism and is characterized in that the vehicle body serves as a moving platform and a bearing platform to carry the spherical landscape plant pruning mechanism and the landscape plant trimming mechanism, and the landscape plants of the green belts on two sides of a road can be pruned when the vehicle body moves on theroad; spherical landscape plant pruning can be achieved through the spherical landscape plant pruning mechanism, and the angles of pruning tools can be controlled to prune spherical landscape platesof different diameters; the trimming of landscape plants of different styles can be achieved by the landscape plant trimming mechanism which can transform. The multifunctional pruning vehicle has theadvantages that the pruning of most of landscape plants can be achieved by the two pruning mechanisms of the multifunctional pruning vehicle, automatic operation can be achieved, and the multifunctional pruning vehicle is simple to operate, capable of saving a large amount of manpower and material resources, capable of liberating labor force and capable of increasing green belt plant pruning efficiency and quality.

Owner:XUZHOU UNIV OF TECH

Manufacturing method of composite additional material

InactiveCN110341186AIncrease diversityImprove reliabilityAdditive manufacturing apparatusIncreasing energy efficiencyMulti materialElement analysis

The invention discloses a manufacturing method of a composite additional material. The manufacturing method of the composite additional material is invented aiming at the diversity of materials formedby multiple functionality of multi-functional multi-material structural model components. The manufacturing method of the composite additional material provided by the invention comprises the steps of firstly utilizing a structure design software for designing internal and external structures of a model, carrying out finite element analysis, defining the change situations of a component structureunder the physical actions such as stressing and heating, and designing material compositions and components of different stressing and heating structure parts; and secondly, by utilizing multiple additional material manufacturing methods and multiple materials, directly preparing some functional elements into a manufactured component in the manufactured structure components, so that high multifunctionality and a reliable structural performance of the manufactured component are realized.

Owner:SHEN ZHEN QIANHAI SCICORE 3D TECH CO LTD

Ceramic multifunctional drinking bowl apparatus and its manufacturing method

A multifunctional water drinking appliance is composed of a ceramic casing and a central functioning unit with cold water container, hot water container with heater and taps. Said ceramic casing has a partition to divide into upper cavity for storing water and lower cavity for installing said central functioning unit in it, and detachable bottom plate.

Owner:赵洪琪

Tank-carrying hydraulic automatic discharging vehicle

InactiveCN101323269ACompact and reasonable structureStable and safe drivingVehicle with tipping movementEngineeringTruck

A knapsack hydraulic automatic lift truck adopts a truck model with strong cross-country performance. A moveable vehicle body and a hydraulic loading and unloading transmission system are added on a second class chassis; a groove plate of the vehicle body is welded with a chain guide groove; the integration of the knapsack loading and knapsack unloading can be realized by the hydraulic transmission of the chain. Therefore, the working efficiency and safety factor are increased; the speed of the specialization of the logistic mechanical matching in oilfield developing operation is improved; the labor intensity of workers is decreased.

Owner:刘景田

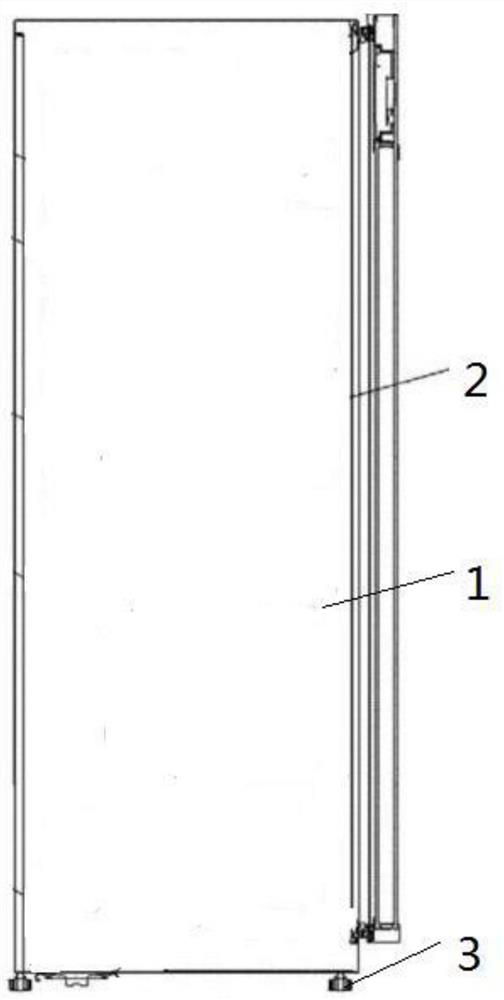

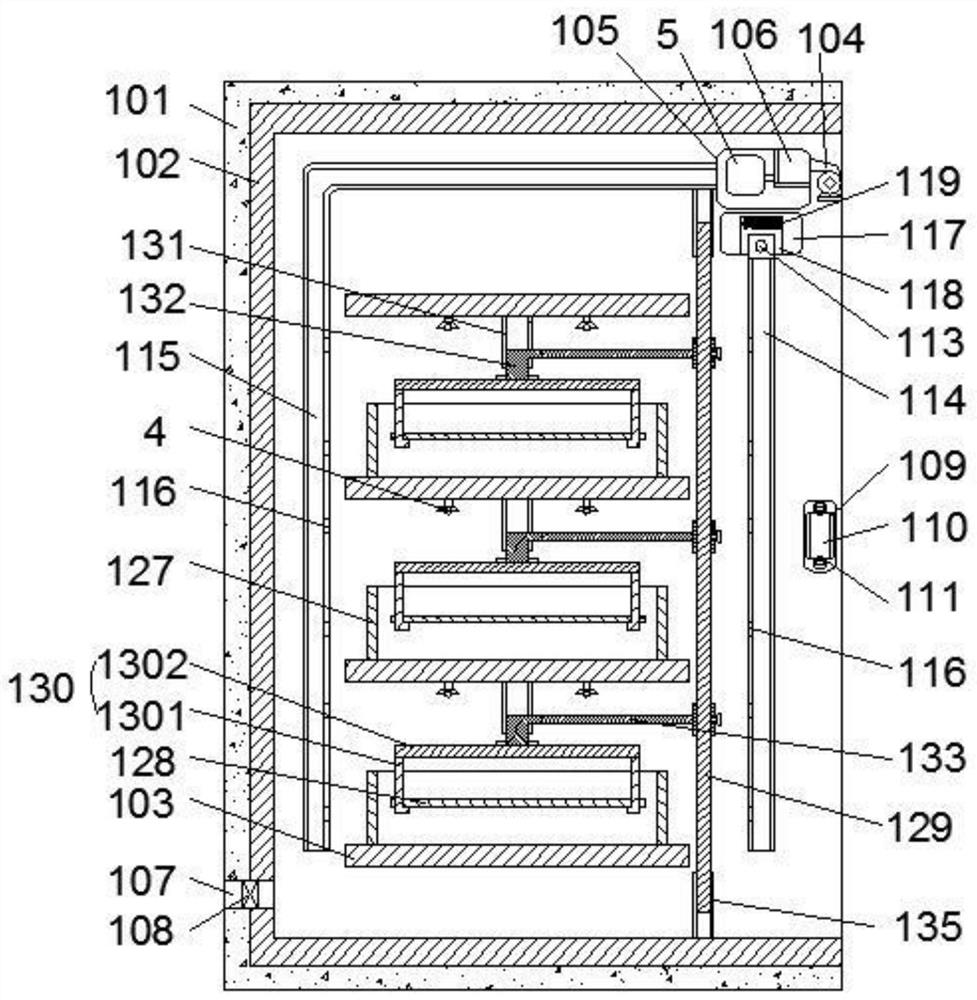

Constant-temperature device for cell tissue culture

PendingCN111670811AChanging uneven air distributionAvoid pollutionHorticulture methodsPlant tissue cultureCell tissue cultureCell organisation

The invention discloses a constant temperature device for cell tissue culture. When the constant temperature device for cell tissue culture is used, when a sealing door is opened, a sliding plate loses the acting force of an ejector rod, and the sliding plate slides under the action of a reset spring so as to touch a travel switch; the action of the travel switch triggers the electromagnetic reversing valve to reverse, so that the air flow is discharged from the other outlet of the electromagnetic reversing valve and enters the second air guide pipe, the air flow is discharged from the air outlet of the second air guide pipe, and the air flow is blown in the direction towards the sealing door; therefore, external air is prevented from entering the constant-temperature device when the sealing door is opened, external bacteria are prevented from entering the constant-temperature device and polluting plant cells, and normal cultivation of the plant cells is guaranteed.

Owner:GUANGXI ZHUANG AUTONOMOUS REGION ACAD OF AGRI SCI

Extrusion soil breaker

InactiveCN102511208BAchieve effective separationAchieve brokenClod-crushersBrickAgricultural engineering

The invention discloses an extrusion soil breaker, which comprises a frame, a left wallboard, a right wallboard, a screw shaft, a casing and a pulley. The left wallboard and the right wallboard are disposed on the frame, the screw shaft supported via bearing blocks penetrates through the left wallboard and the right wallboard, the casing with a feeding port and a discharging port is fixedly connected to the left wallboard and the right wallboard, the pulley disposed on the screw shaft is driven by a motor, breaking claws are evenly distributed on a screw vane (2) on the screw shaft (3) inside the casing (11), a cylindrical screen (10) connected to the left and right wallboards (8) is radially arranged between the screw vane and the casing, a pressure disc (9) with evenly and peripherally distributed pressure claws (18) is sleeved on the screw shaft inside the cylindrical screen, and the pressure disc and the left wallboard adjacent to the same are provided with anti-rotating holes (19 and 20) respectively and correspondingly connected through anti-rotating pins (21). Impurities and bricks in soil can be effectively separated from the soil while soil breaking and screening functions are achieved by using the extrusion soil breaker, and the extrusion soil breaker is simple and compact in structure, convenient in disassembly and maintenance, low in cost, low in vibration, low in noise, low in power consumption and widely applicable.

Owner:ANHUI AGRICULTURAL UNIVERSITY

Automatic fabric tension control system suitable for knitting open-width wet processing unit

ActiveCN102517827BAvoid Stretch DeformationGuaranteed qualityTextile treatment carriersTextile treatment rollersControl systemStructural engineering

The invention relates to an automatic fabric tension control system suitable for a knitting open-width wet processing unit. The system comprises at least more than two groups of wet processing units, wherein adjacent wet processing units are in station connection to form the open-width wet processing unit; drum / roller group stations and roller groups which are matched with the drum / roller groups are arranged in box bodies of the wet processing units; and the system is characterized in that: the drum / roller groups are main driving components; and the roller groups comprise driving rollers and driven rollers which are matched with each other. The invention has outstanding characteristics that: the drums / rollers, rollers and traction rollers in each wet processing unit are main driving components; numerical values of various driving mechanisms can be directly set according to differences of fabric composition and technical requirements of fabrics machined by the unit, so that the fabrics do not have tension, the fabrics are prevented from being subjected to tensile deformation in each wet processing unit, and the quality of the fabrics is guaranteed.

Owner:绍兴东升数码科技有限公司

Dicing and shredding machine

InactiveCN101574811ASimple structureIncrease production capacityMetal working apparatusEngineeringReducer

The invention relates to a dicing and shredding machine which is mainly used for dicing and shredding stem-type agricultural and sideline products such as radishes, potatoes, and the like. Materials go into a piston sleeve form a feeding hole, a crank link mechanism speed reducer drives a piston to push the materials into a shred device to cut into threads, and then a blade disc speed reducer drives a blade disc to rotate to cut the threads to blocks to complete cutting of the materials. The dicing and shredding machine has simple structure, high productivity of 2-4t / h and no consumption of materials, can realize the purpose that one machine has multiple uses by taking off a blade disc assembly.

Owner:EZHOU BAILONGMA FOOD MACHINERY

Sewing machine foot pressing and lifting device

ActiveCN107956048ALarge adjustment spaceIncrease heightNeedle severing devicesSewing-machine control devicesPRESSURE FEETSewing machine

The invention discloses a sewing machine foot pressing and lifting device and belongs to the technical field of sewing machines. The sewing machine foot lifting device comprises a drive as well as a foot pressing mechanism, wherein the drive is fixedly arranged on one side of a sewing machine shell; the foot pressing mechanism comprises a pull rod base which is fixedly arranged on one side of thesewing machine shell and is used for adjusting a foot pressing height; an adjusting groove is formed in the pull rod base; a lifting connecting rod is arranged at the lower end part of the drive; a propping part and an adjusting part are respectively formed at two ends of the lifting connecting rod; the drive is propped against the propping part; an adjusting component is arranged between the adjusting part and the pull rod base; the adjusting component is hinged with the adjusting part; the adjusting component is matched with the adjusting groove and is clamped inside the adjusting groove; apressure regulator is arranged on one side of the adjusting part in a lifting manner; the pressure regulator is propped against the upper end part of the adjusting part. As the lifting height of a sewing machine foot pressing part is adjusted in a stepless manner, a common sewing machine can be transformed into an automatic thread cutting sewing machine conveniently.

Owner:台州市速普机电有限公司

Vertical ear and stalk harvesting type corn harvester

ActiveCN102379191BReduce loss rateReduce impurityMowersAgricultural engineeringAgricultural machinery

The invention relates to the technical field of agricultural machinery, specifically a corn harvester. A vertical ear and stalk harvesting type corn harvester comprises a stand on which a cab and a harvesting platform are set. A reciprocating type cutter is set in front of the harvesting platform. A chain harrow type elevator, a vertical ear plucking device, a vertical stalk pulling device, a vertical cutting device are orderly set on the harvesting platform from the front to the rear. A crawler type ear collecting device is set in front of and below the vertical ear plucking device. A stalk collecting device is set below the cab. An ear elevator is set at left side of the cab. A throwing device is set at right side of the cab. An ear collecting box is set behind the cab. A grass collecting box is set behind the ear collecting box. By adoption of the mentioned technical proposal, the invention can harvest corn ear and stalk to be multi-purpose.

Owner:SHANDONG UNIV OF TECH

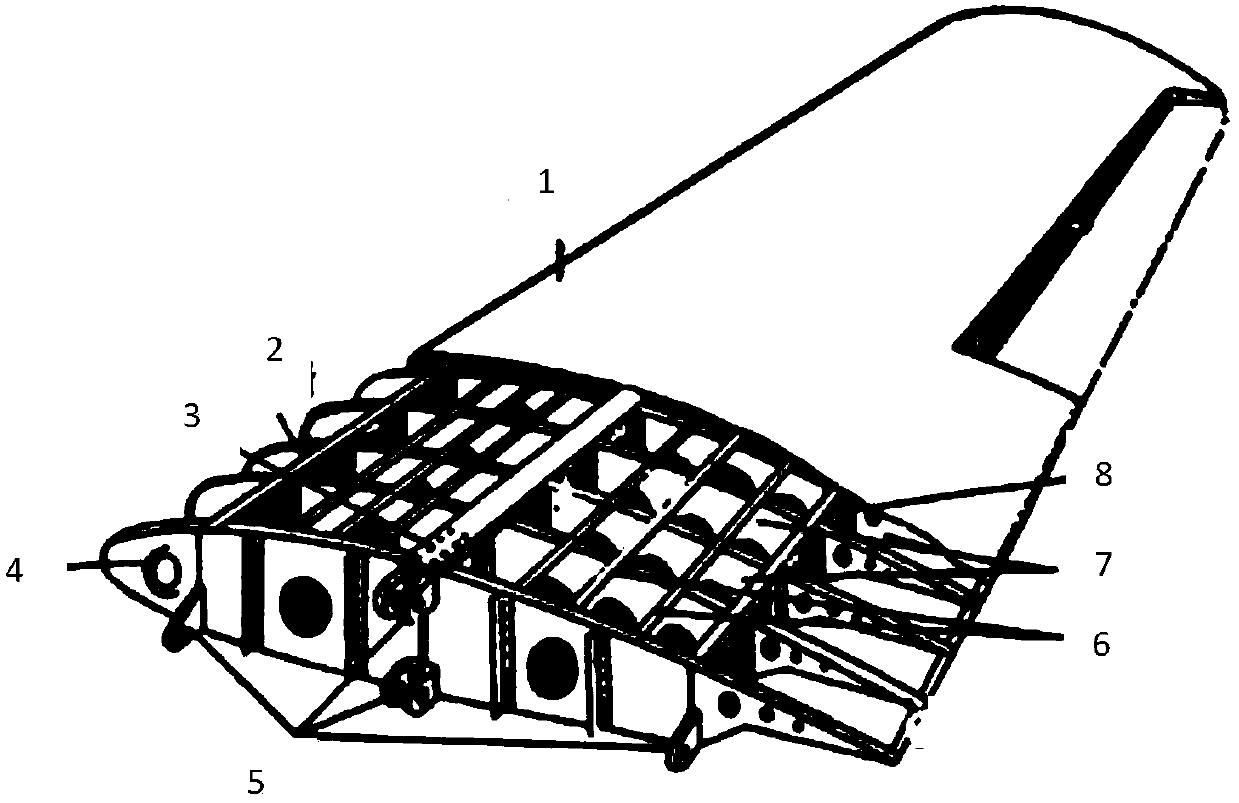

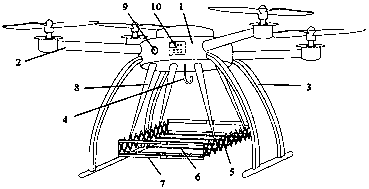

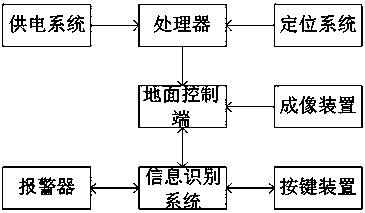

Unmanned aerial vehicle for conveying goods

InactiveCN108557078APracticalAvoid shakingRemote controlled aircraftFreight handlingElectricityUncrewed vehicle

The invention discloses an unmanned aerial vehicle for conveying goods. The unmanned aerial vehicle for conveying the goods comprises a machine body and a processing system used for controlling the action of the machine body, and the machine body is electrically connected with the processing system. The machine body comprises a fuselage, wings used for providing lift force and connected with the fuselage, a cargo hold used for containing the goods, supporting frames used for supporting the unmanned aerial vehicle and a hanging hook used for hanging the goods. The cargo hold comprises telescopic side walls, a plurality of telescopic pipes, a plurality of telescopic plates and connecting rods, one ends of the connecting rods are connected with the telescopic side walls, and the other ends ofthe connecting rods are connected with the fuselage. The processing system comprises a processor, a power supply system, a positioning system, a keypad device, an alarm, an information identificationsystem and an imaging device. The unmanned aerial vehicle for conveying the goods can realize stretching and fixation of the goods, expands the transportation range of the goods, and improves the conveying efficiency.

Owner:FOSHAN SHENFENG AVIATION SCI & TECH

Rotary type overall carving equipment for door and window lock holes

InactiveCN108859548ASolve the defects of simultaneous processingRealize the purpose of one machine with multiple functionsEngravingBall screwEngineering

The invention provides rotary type overall carving equipment for door and window lock holes. The rotary type overall carving equipment for the door and window lock holes comprises a longitudinal sliderail fixed onto a lathe bed, a side stand column arranged on the longitudinal slide rail, a cross beam fixed onto the side stand column, a horizontal stepping motor fixed onto a machine head drive plate, a drive screw rod stepping motor fixed to the upper end of a horizontal sliding plate, an up-and-down ball screw rod connected with the drive screw rod stepping motor and arranged on the horizontal sliding plate, a sliding plate arranged on the up-and-down ball screw rod, two independent switching air cylinders, two independent carving heads, an A-axis speed reducer, a three-jaw chuck and anejector pin, wherein the two independent switching air cylinders, the two independent carving heads, the A-axis speed reducer, the three-jaw chuck and the ejector pin are arranged on the sliding plate; a longitudinal stepping motor for driving the side stand column to move longitudinally is arranged on the side stand column; and one independent carving head is provided with a 90-degree oscillatingangle under the drive of the corresponding air cylinder. The rotary type overall carving equipment for the door and window lock holes provided by the invention is used for processing the lock holes in the planes and the side surfaces of doors and windows, the operation mode is different from the single material carving mode, and the rotary type overall carving equipment is convenient to operate,so that the aim of multiple functions is achieved.

Owner:江阴市军协机械有限公司

A new type of cultivated land shovel

The invention discloses a novel cultivated land shovel, belongs to the field of farmland machinery, including the main shovel and the flank shovel, The tillage angle of the flank shovel is adjustable,The quantity and height of the flank shovel can also be adjusted according to the different specifications of the ridge when loosening the soil, which ensures that the best tillage requirements can be achieved when the soft and hard soil is cultivated, thereby realizing the purpose of one machine for multiple purposes, and has the advantages of simple structure, convenient use, high operation quality, low use cost, easy popularization and the like.

Owner:李彦利

Vertical Turning Structure of Turning, Milling and Boring Multifunction Horizontal Lathe

ActiveCN107225256BMulti-Metal Cutting CapabilitiesImprove processing efficiencyFeeding apparatusTurning machinesMilling cutterMetal machining

The invention discloses a vertical turning structure of a turning milling boring multifunctional horizontal lathe. A turning power head and a tail support are arranged on two ends of a guide rail; a longitudinal driving lead screw passes through a longitudinal slide carriage mechanism and is parallel to the guide rail; the longitudinal slide carriage mechanism moves along the guide rail under drive of the longitudinal driving lead screw; a horizontal driving lead screw is arranged on the longitudinal slide carriage mechanism; a horizontal dragging plate mechanism is arranged on the top end of the longitudinal slide carriage mechanism and moves along the longitudinal slide carriage mechanism under drive of the horizontal driving lead screw; a turning cutter platform mechanism is arranged on a side surface of the horizontal dragging plate mechanism and can lift along the horizontal dragging plate mechanism; two slide platforms are arranged on the guide rail and move along the guide rail; a tail end of a connection long seat is detachably arranged on a front end surface of the turning cutter platform mechanism; a turning tool seat is arranged on a front end of the connection long seat; and the vertical lathe workbench support is arranged on two top surfaces of the two slide platforms. A vertical function is integrated in the turning milling boring horizontal lathe, the horizontal lathe can possess more metal machining functions and has multiple purposes, and the machining efficiency and precision of work pieces can be improved.

Owner:SHANGHAI BAOSTEEL IND TECHNOLOGICAL SERVICE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com