Multifunctional machine tool for making large screen template

A multi-functional machine tool and large-screen technology, applied in the field of multi-functional machine tools, can solve problems such as machining accuracy, cutting ability, and limited automation, and achieve cost-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

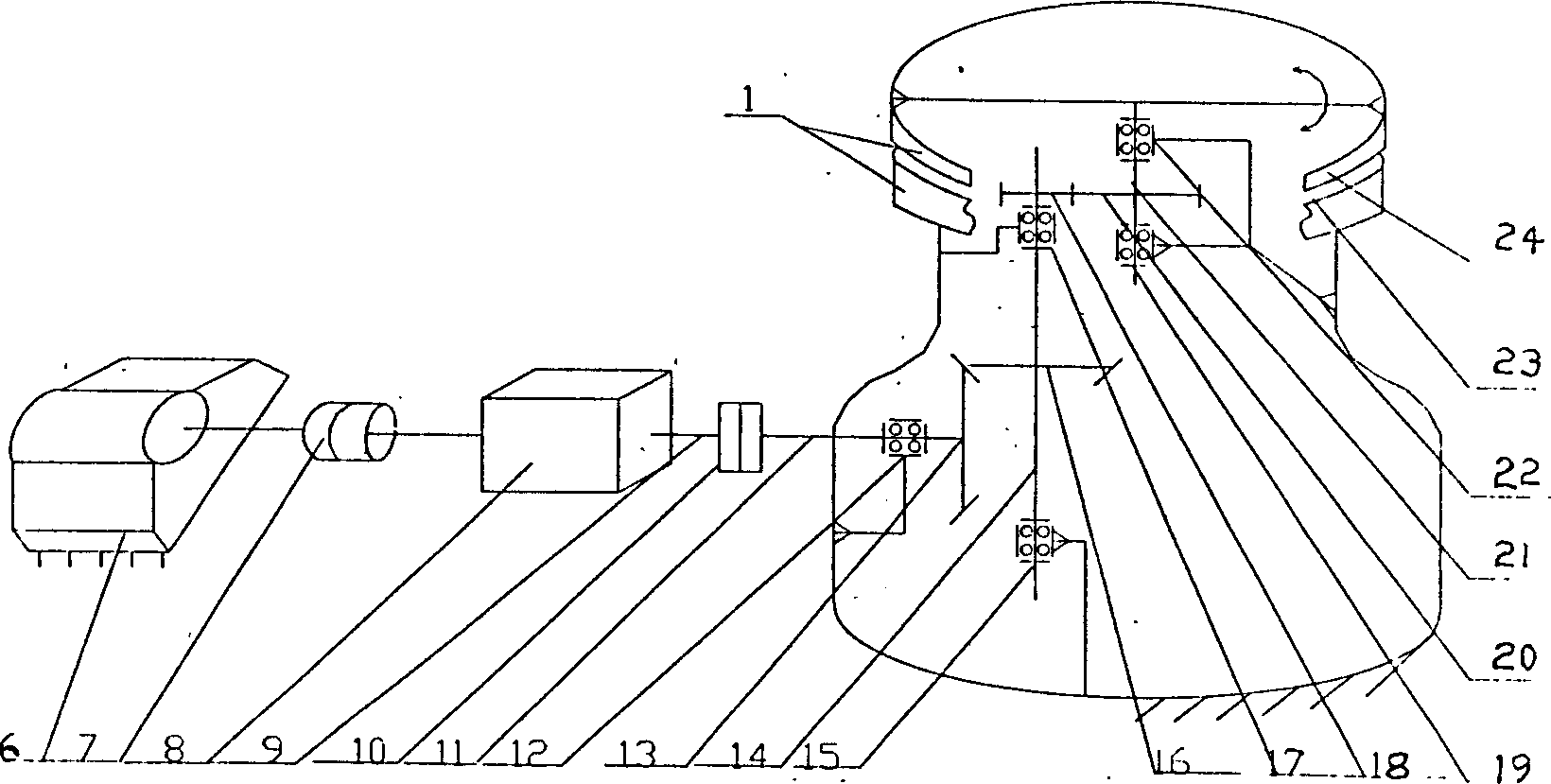

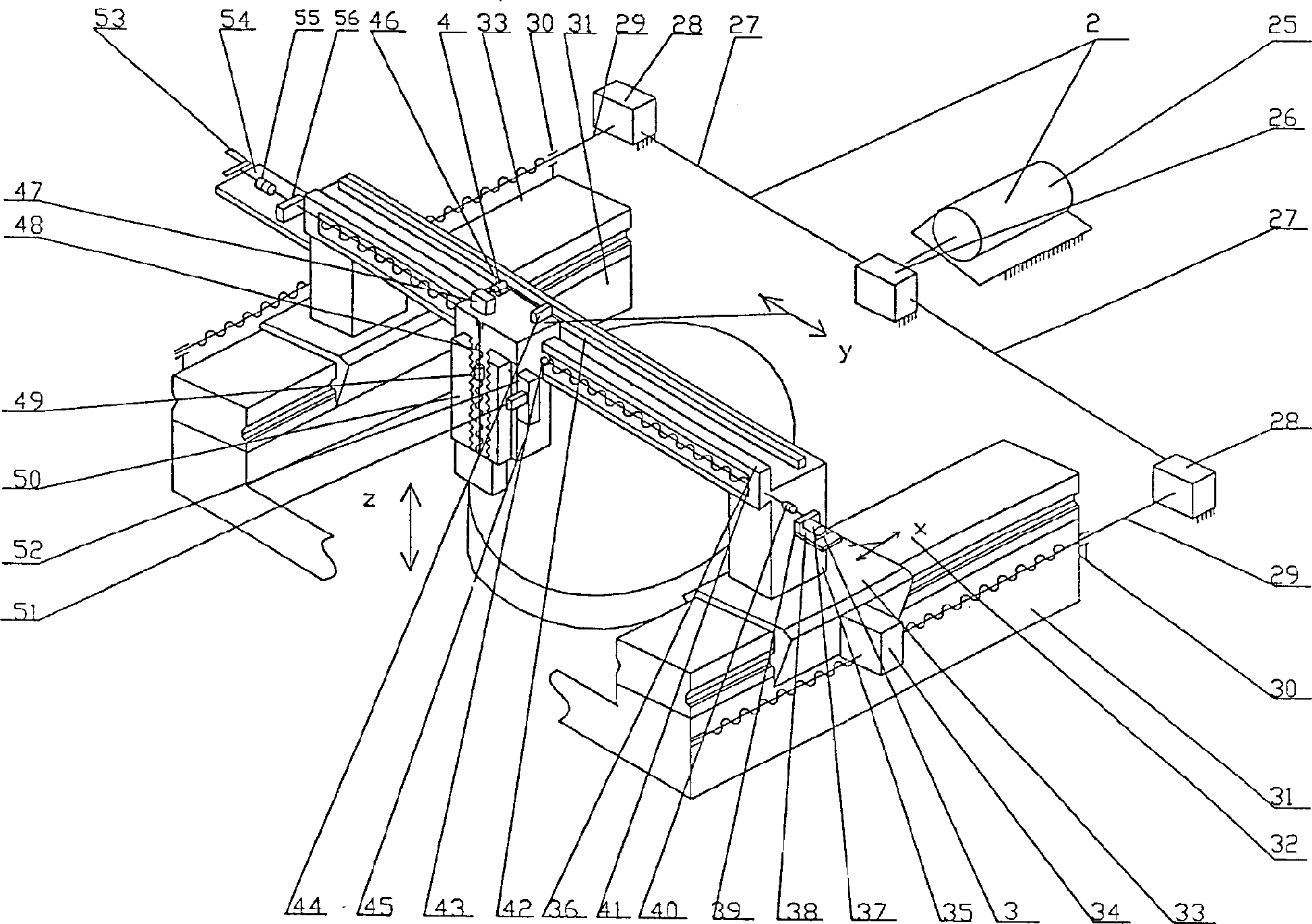

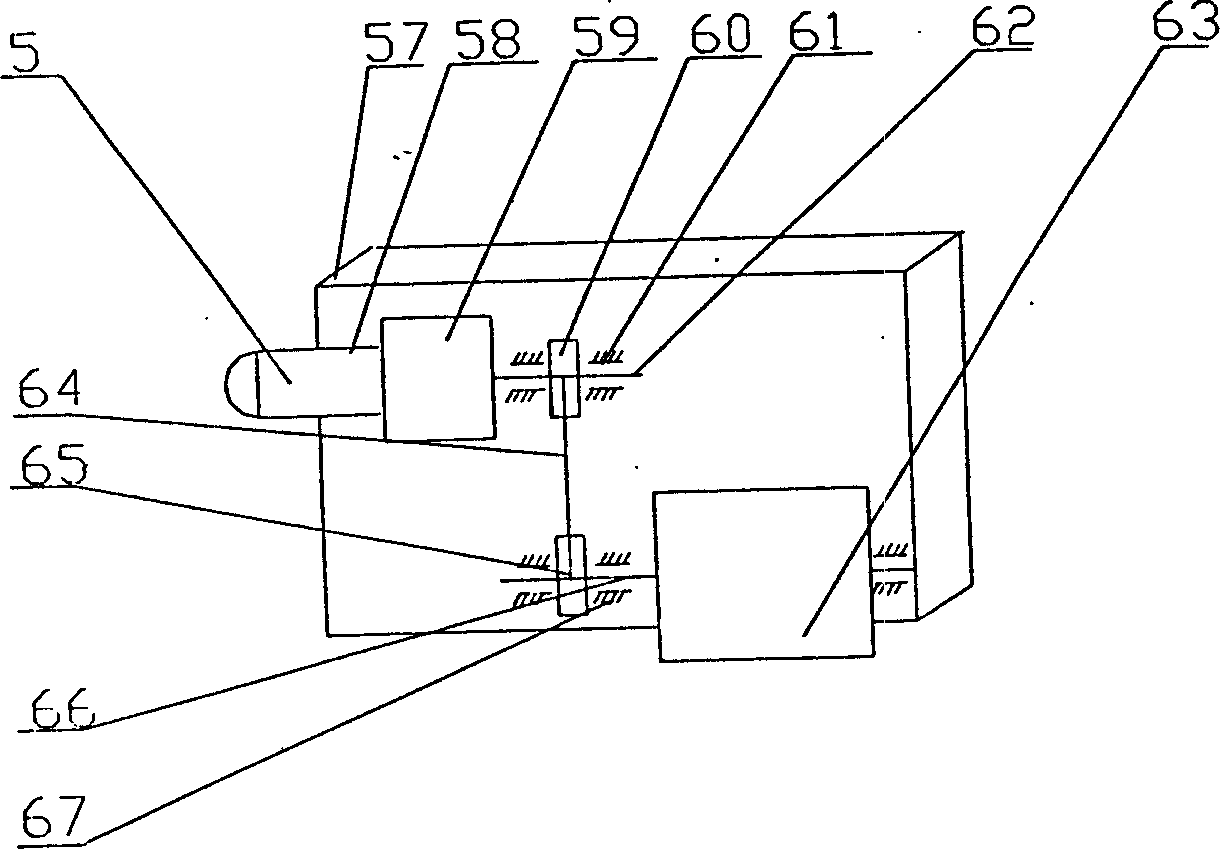

[0011] Such as figure 1 , figure 2 , image 3 As shown, the present invention mainly includes: a turntable transmission mechanism 1, a gantry X-direction transmission mechanism 2, a Y-direction transmission mechanism 3, a cutter row Z-direction transmission mechanism 4, a milling cutter row transmission mechanism 5, a turntable 24, a ball linear guide 32, The large carriage 45, the small carriage 50, the grating scale 52, the turntable transmission mechanism 1 is consolidated with the foundation, the gantry is supported on the bed, the bed is consolidated with the foundation, and the Y-direction transmission mechanism 3 is set on the beam of the gantry. The cutter row Z-direction transmission mechanism 4 is arranged on the large carriage 45 of the Y-direction transmission mechanism 3 , and the milling cutter row transmission mechanism 5 is arranged on the small carriage 4 of the cutter row Z-direction transmission mechanism 4 .

[0012] Turntable transmission mechanism 1 su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com