Patents

Literature

2267 results about "Metal machining" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Metal Machining. Manufacturing companies require metal machining for a wide variety of metals. The machining process involves the use of various drill presses, lathes, and milling machines.

Emulsification type metal cutting liquor composition

InactiveCN101240218AImprove the lubrication effectImprove cooling effectAdditivesBase-materialsPhenolCutting fluid

Disclosed is an emulsifying metal-cutting-fluid composition comprising base oil or oily agent, mixed alcohol-amine, anionic surfactant, nonionic surfactant, antirust agent, copper alloy corrosion inhibitor, preservative and the like. The invention has a strong general usability, suitable for metal processing, particularly aluminum alloy metal processing with advantages of excellent lubricity, corrosion resistance, a low cost and being free of toxic or harmful substances such as nitrites and phenols, so as to keep the environment and operators away from harmfulness.

Owner:河北九熙新材料科技有限公司

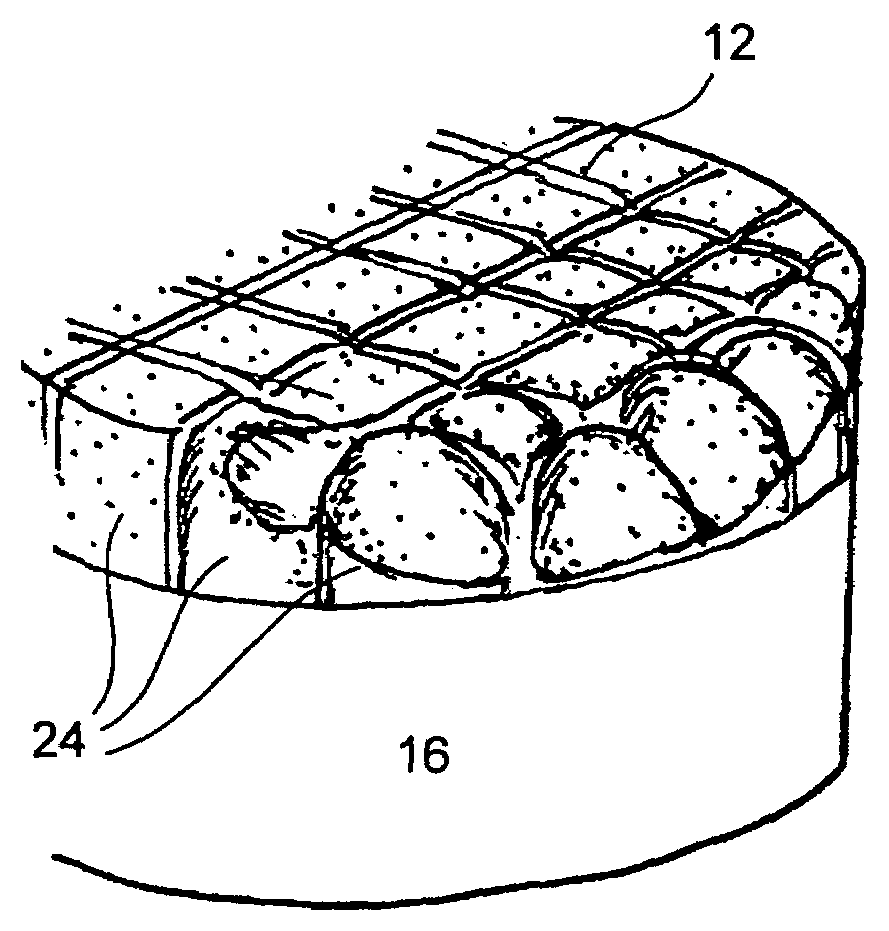

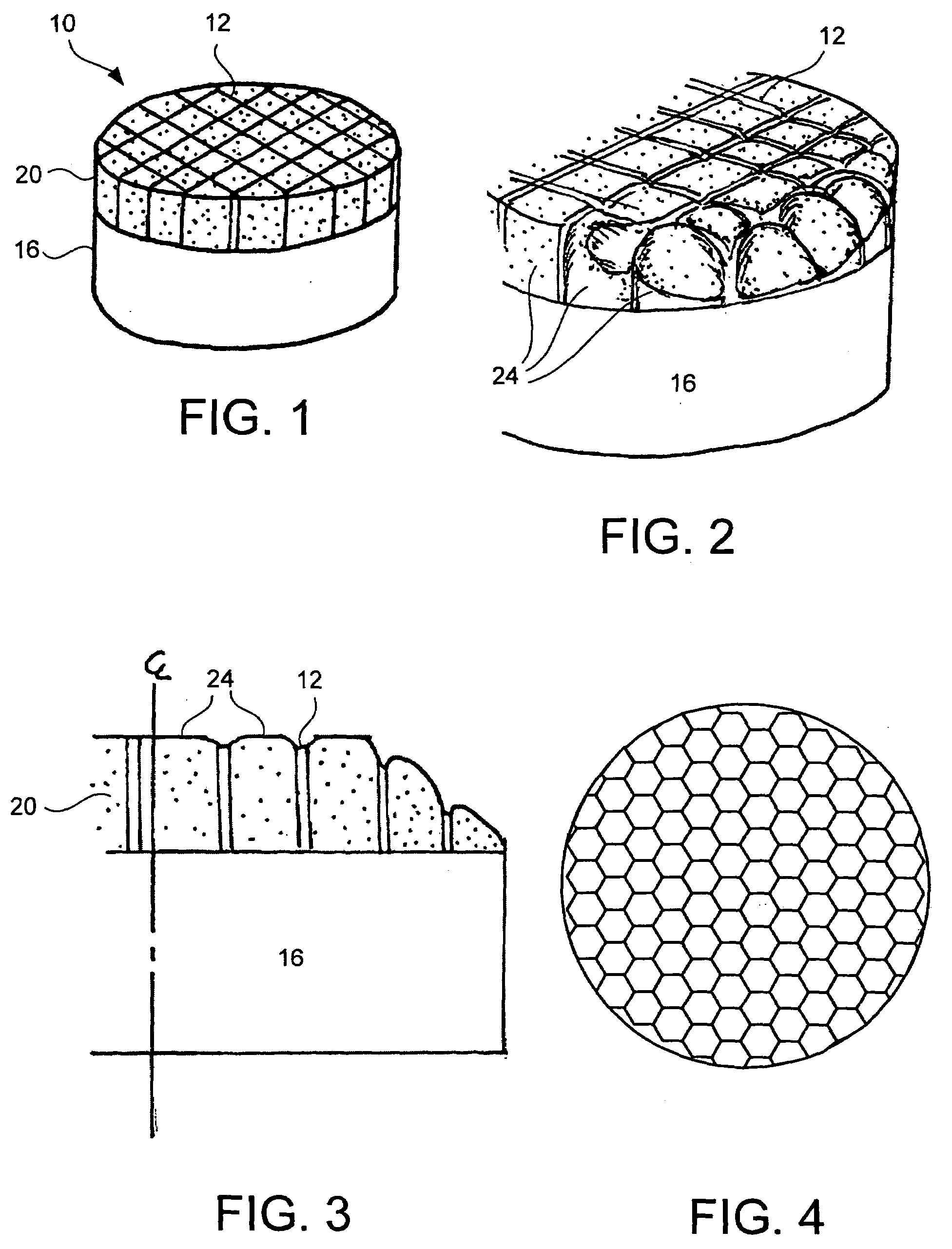

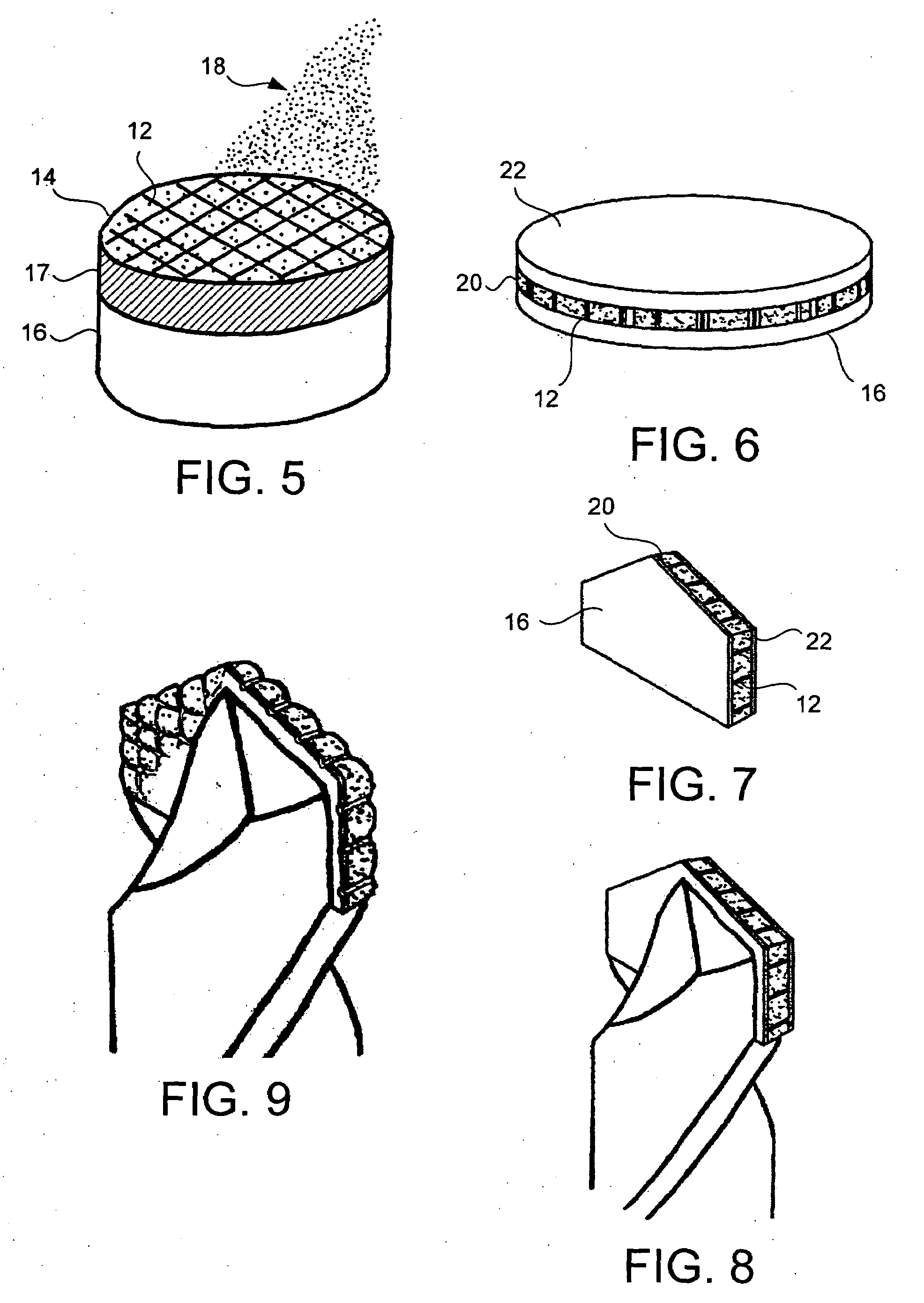

Polycrystalline superabrasive composite tools and methods of forming the same

ActiveUS20080023230A1Wide applicationProperty is limitedPigmenting treatmentDrill bitsCarbideHigh pressure

A polycrystalline superabrasive composite tool can be produced using high pressure high temperature processes allowing for increased thermal resistance, wear resistance and toughness of abrasive tools, and additionally allowing for increased effective thickness of abrasive tools. A polycrystalline superabrasive compact can include a support substrate and a superabrasive polycrystalline layer having a diffusion bridge embedded therein that includes a carbide former. Additionally, a working layer can be attached adjacent to the superabrasive polycrystalline layer and opposite the support substrate to form a drill bit sandwich segment. The diffusion bridge matrix of the present invention allows for a new welding phase at each interface between the superabrasive polycrystalline layer and support substrate and between the polycrystalline layer and the metal working layer, thus eliminating delamination failure at the interfaces. The superabrasive polycrystalline layer can include superabrasive particles of varying particle sizes such that the final composite tool is tailored for specific abrading characteristics. The polycrystalline superabrasive composite tools can be incorporated for use in machining, drilling, grinding, cutting, polishing and similar abrasive applications.

Owner:ADICO ASIA POLYDIAMOND

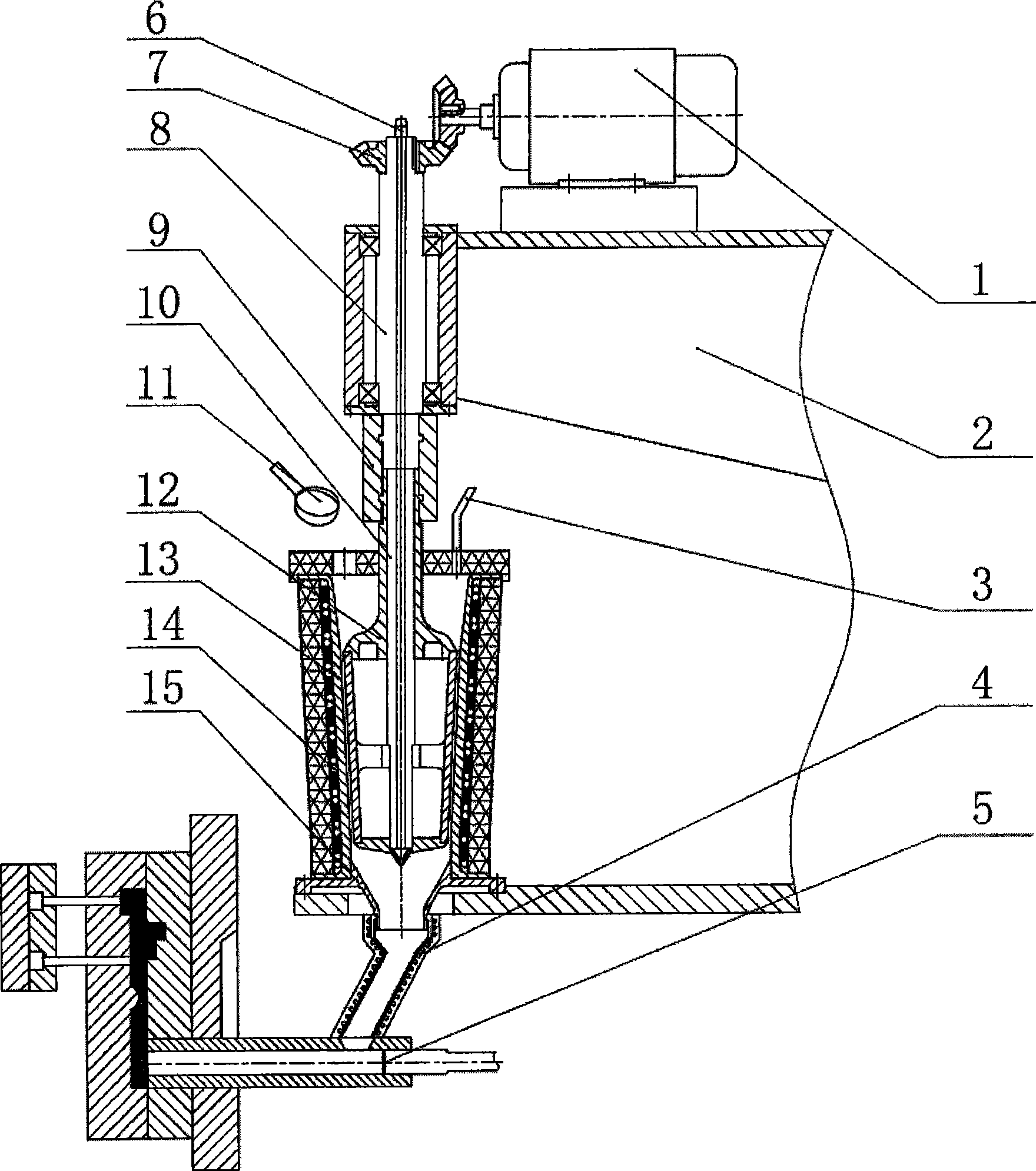

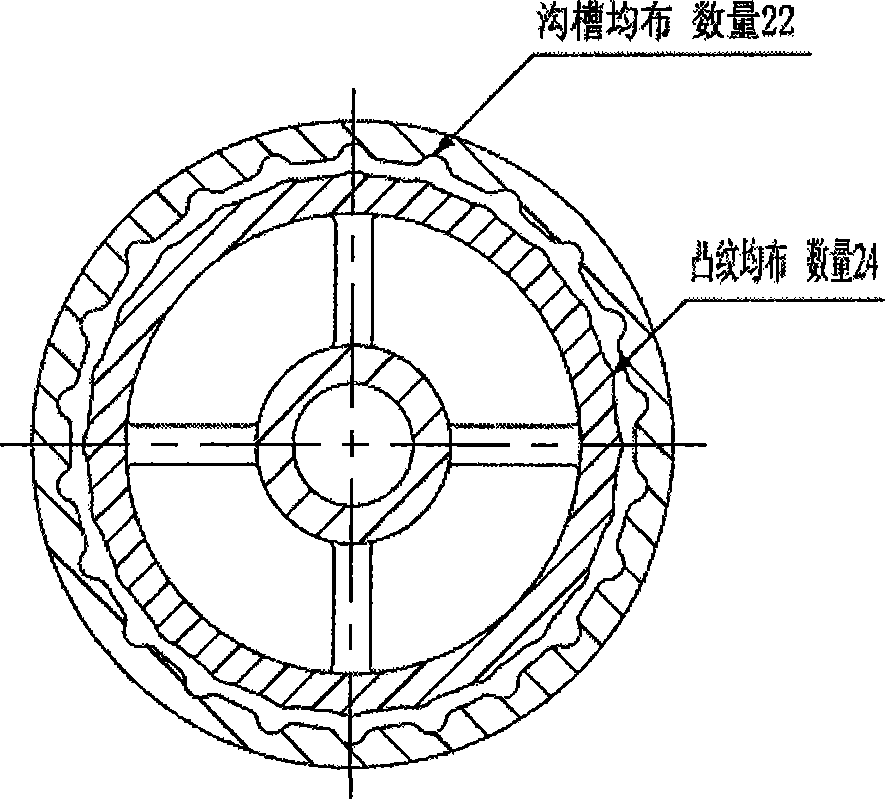

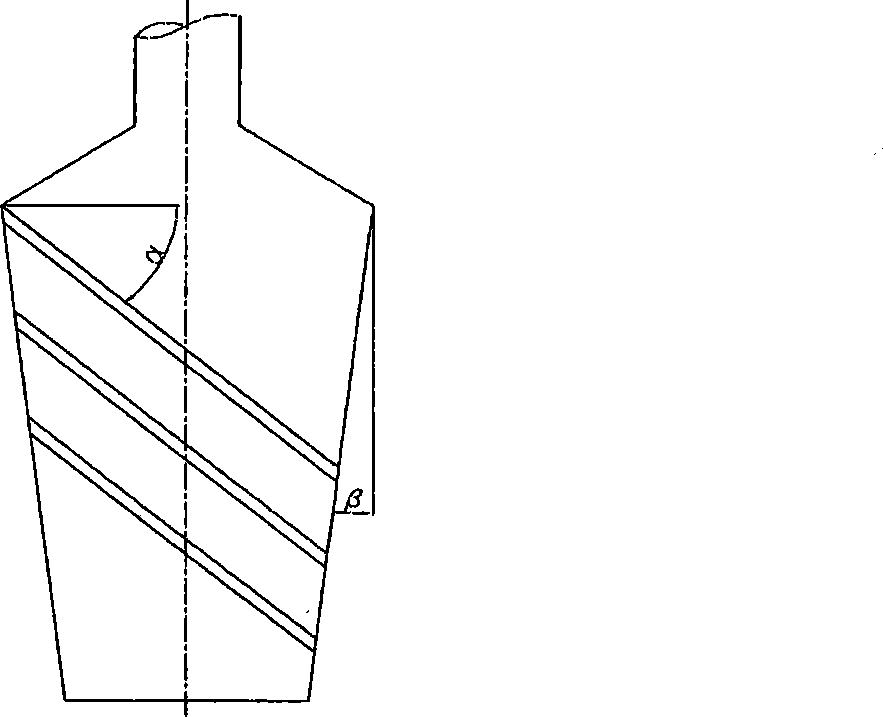

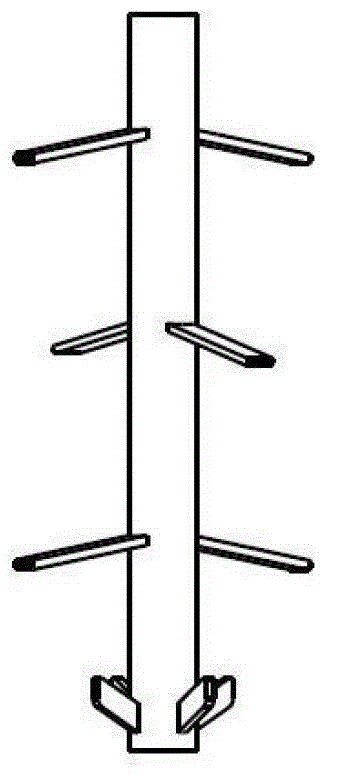

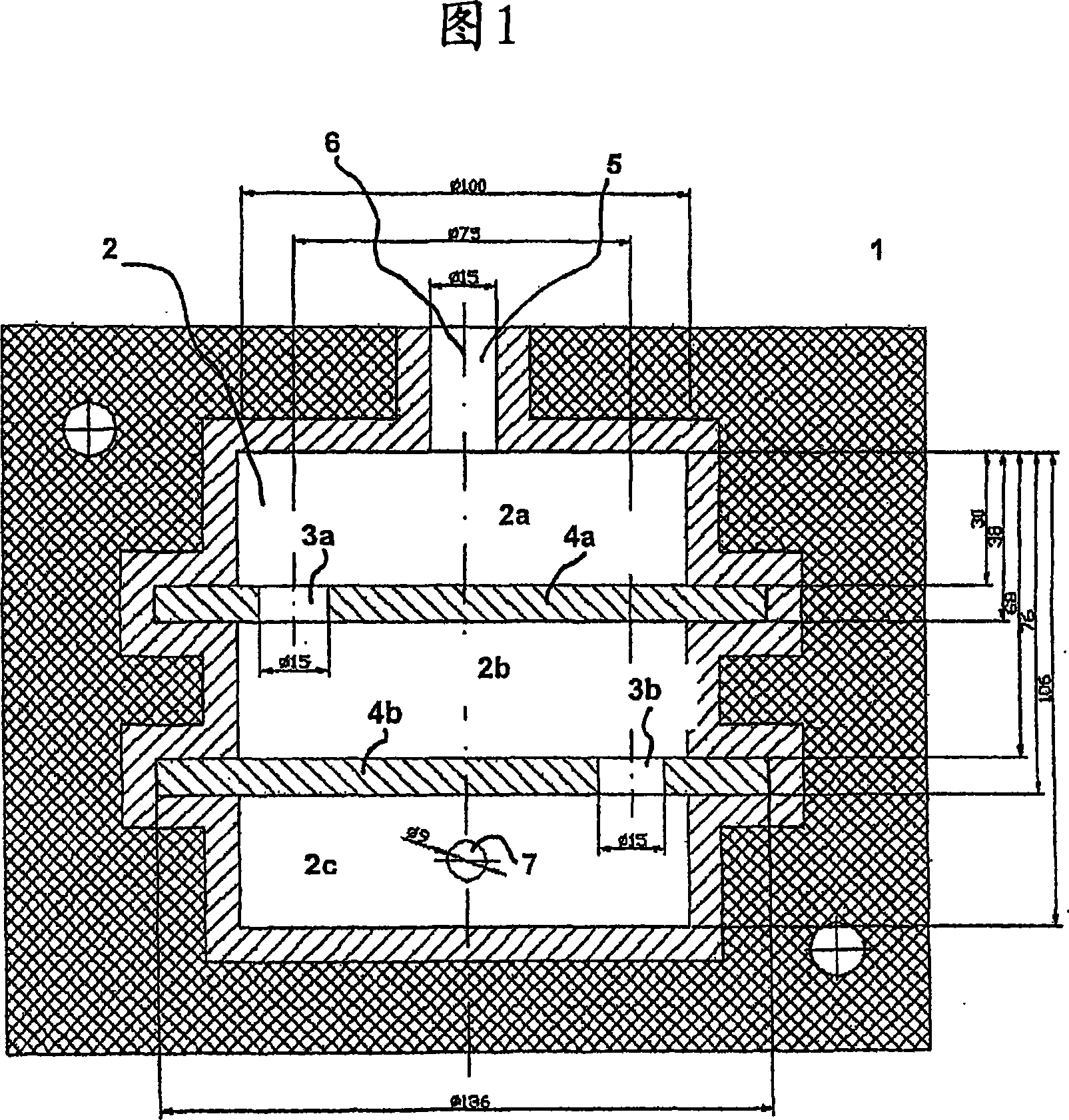

Suspension cone bucket type semi-solid metal slurry preparation and conveyor device

Disclosed is a suspending tapered bucket type semisolid metal slurry preparation and conveying apparatus, which belongs to the technique field semisolid metal machining. The apparatus comprises an adjustable speed motor 1, an elevating mechanism 2, an air pipe 3, a connecting device 4, a press-casting machine injection chamber 5, an air port 6, a transmission bevel gear 7, a mandrel 8, a coupling 9, an air pipe 10, a pony ladle 11, an inner tapered bucket 12, an outer tapered bucket 13, a heating and cooling element 14, a flanged disc 15 and the like. When in semisolid metal slurry preparation, according to the shearing deformation principle, the purpose of forming fine and even semisolid metal slurry can be achieved through the intense shearing function when the liquid state metal passes through gaps between the rotating inner tapered bucket and the outer tapered bucket which are inscribed with specific grooves, and the prepared semisolid metal slurry is conveyed to the press-casting machine injection chamber through the connecting device to realize the rheological die-casting molding. The invention has the advantages of: simple and compact equipment structure and light weight; high temperature control precision; convenient and reliable operation, and easy realization from semisolid metal slurry preparation, conveying to die-casting molding; and convenient maintenance and repair and industrialized continuous production.

Owner:UNIV OF SCI & TECH BEIJING

Production technology of aluminum alloy sectional bar for automobile bumper

ActiveCN102978488AUniform chemical compositionUniform temperatureStirring devicesFiltrationThermal deformation

The invention discloses a production technology of an aluminum alloy sectional bar for an automobile bumper and belongs to the technical field of metal machining. The aluminum alloy sectional baral bar for the bumper is processed through the steps of mixing, melting, permanent magnetic stirring, temperature measurement, sampling, ingredient and temperature adjustment, turning down, refining(first purification), standing still, online addition of Al-Ti-B wire, online removal of gas and sand (secondary purification), two-stage filtration, same-level hot top casting, cast ingot homogenization, machining of cast ingot, inspection of cast ingot, heating of cast ingot by an induction furnace, extrusion, precise on-line quenching, stretching and straightening, aging, structure and property inspection of sectional bars, and delivery. The aluminum alloy sectional bar processed by the technology is excellent in thermal deformation performance, and high in strength due to on-line quenching during extrusion. The product has excellent welding performance and corrosion resistance, certain resistance to stress corrosion, and especially has strong shock absorption and folding resistance.

Owner:丛林铝业科技(山东)有限责任公司

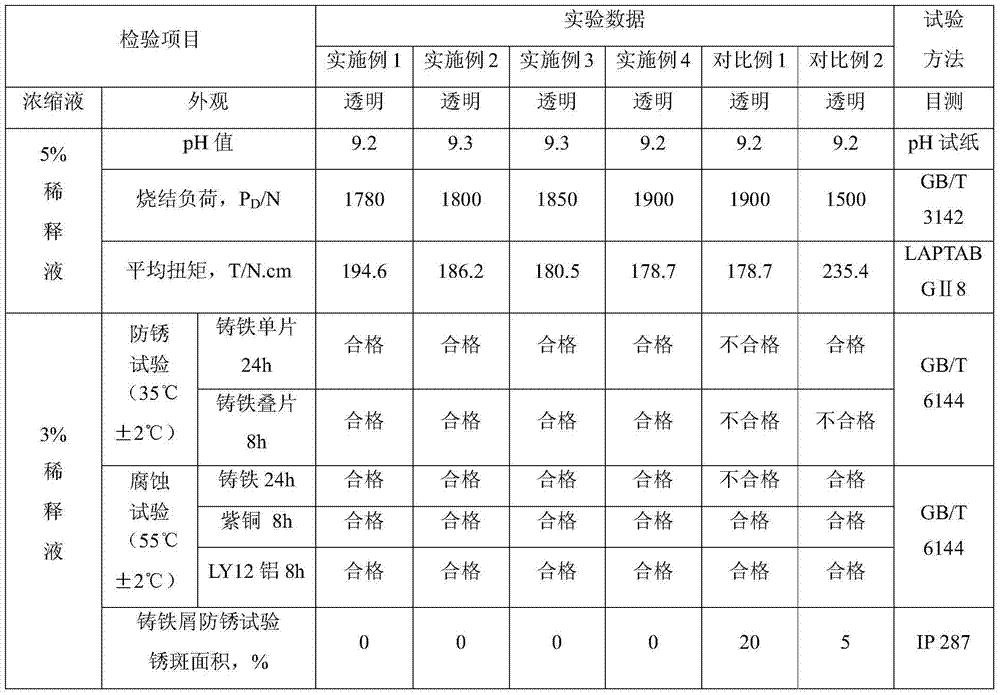

Heavy-load metal machining total synthesis cutting fluid as well as preparation method and application thereof

ActiveCN104277902AImprove the lubrication effectImprove extreme pressure performanceAdditivesMachine partsSuperalloy

The invention belongs to the field of metal machining fluids, and discloses a heavy-load metal machining total synthesis cutting fluid as well as a preparation method and an application thereof. The total synthesis cutting fluid comprises the following components in percentage by weight: 20%-30% of mixed alcohol amine, 6%-9% of anti-rust agents, 4%-6% of special amine, 6%-10% of lubricating agents, 15%-25% of extreme pressure agents, 6%-10% of cosolvents, 1%-2% of water-softening agents, 1%-3% of corrosion inhibitors and the balance of water. The total synthesis cutting fluid disclosed by the invention has excellent lubricating extreme pressure property, can meet the requirement for heavy-load machining, namely reaming, drilling, tapping, threading, broaching, thread machining and the like, of difficult-to-machine materials, namely high-temperature alloy steel, a titanium alloy and the like; a product is green and environment-friendly without containing boron, sodium nitrite, secondary amine, chlorine, phenol, formaldehyde, heavy metals and the like; in addition, the total synthesis cutting fluid disclosed by the invention has excellent anti-rust property, biological stability and machining property, and can enhance the surface quality of a machined part, prolong the service life of a cutter and reduce the rejection rate, thus improving the production efficiency.

Owner:广州国机润滑科技有限公司

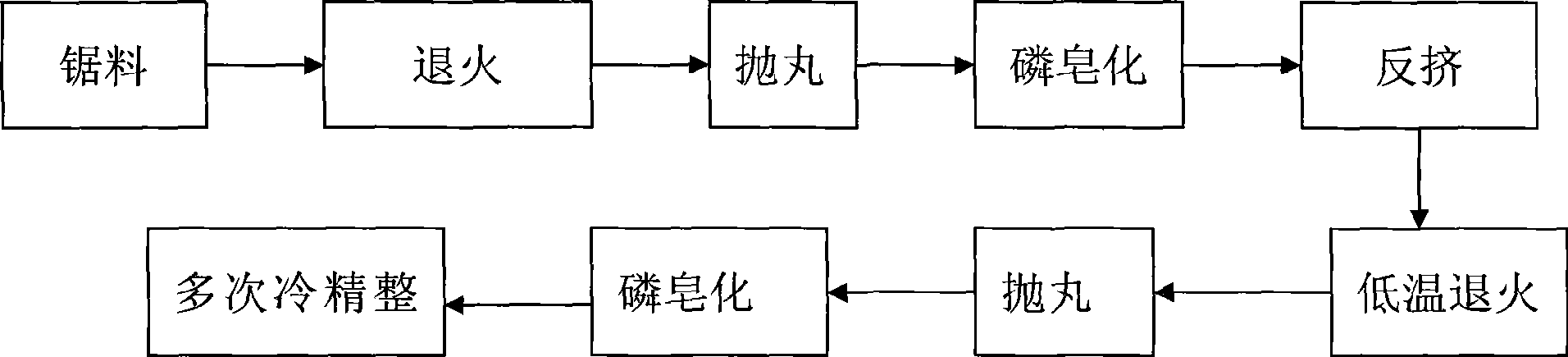

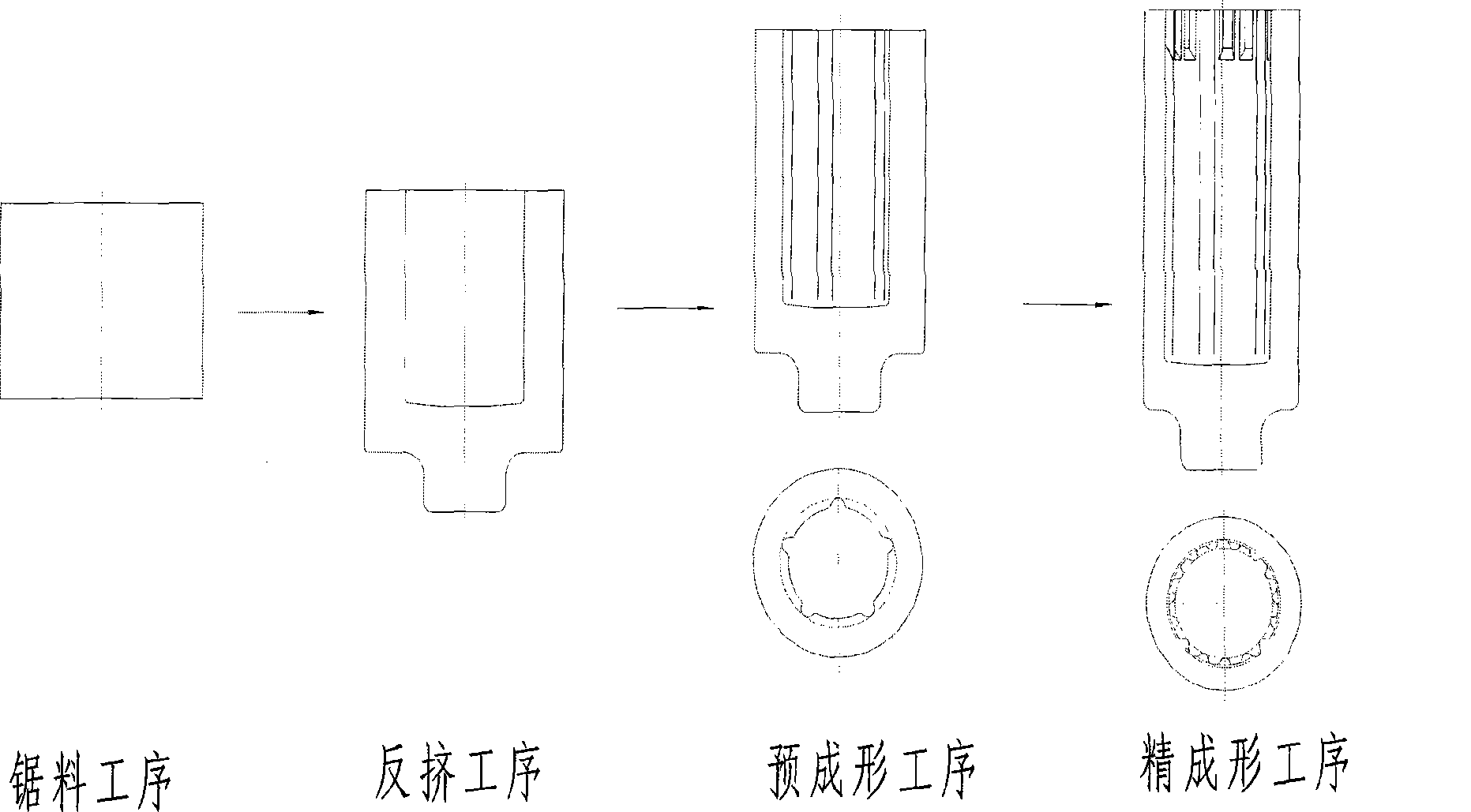

Accurate forming method of special-shape deep-hole type parts

ActiveCN101422861ADense internal organizationQuality improvementFurnace typesHeat treatment furnacesStructure propertyMetal machining

The invention provides a precision forming method of special-shaped parts with deep holes, which relates to the metal machining field with almost no cutting, especially a precision cold forging forming technology of special-shaped parts with deep holes. The invention comprises the process of saw-setting, annealing, shot blasting and phosphorus-saponification of part blank, and back extrusion with tremendous deformation of the part blank; thus, the preformed body with deep holes is completed; then the process of low temperature annealing, shot blasting, phosphorus-saponification is repeated; and subsequently by a plurality of cold finishing, the final product which meets the requirements of structure property and dimension precision is obtained. The method has the beneficial effect that by back extrusion, the preformed body is once completed. The metal streamlines inside the product are continuously distributed according to the shape, and the product has compact microstructure and stable quality, thereby prolonging the service life of the product.

Owner:JIANGSU SUNWAY PRECISION FORGING

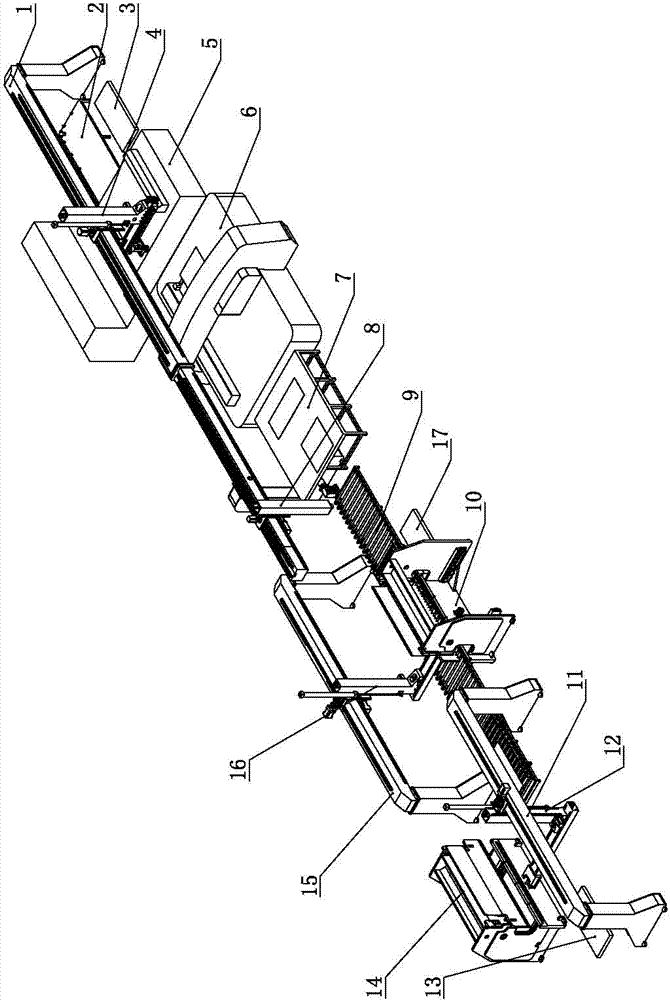

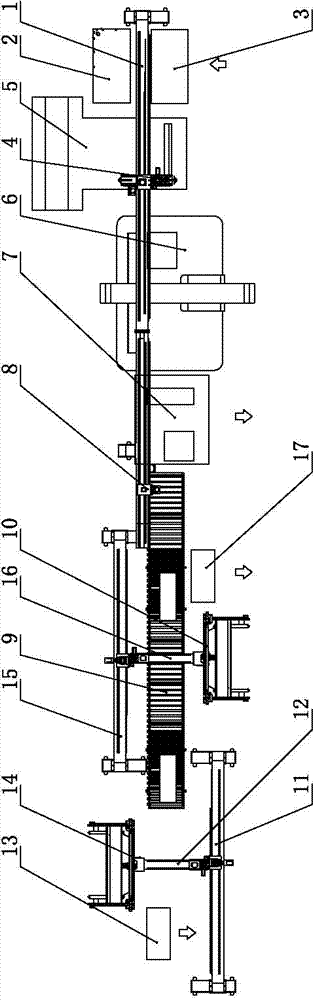

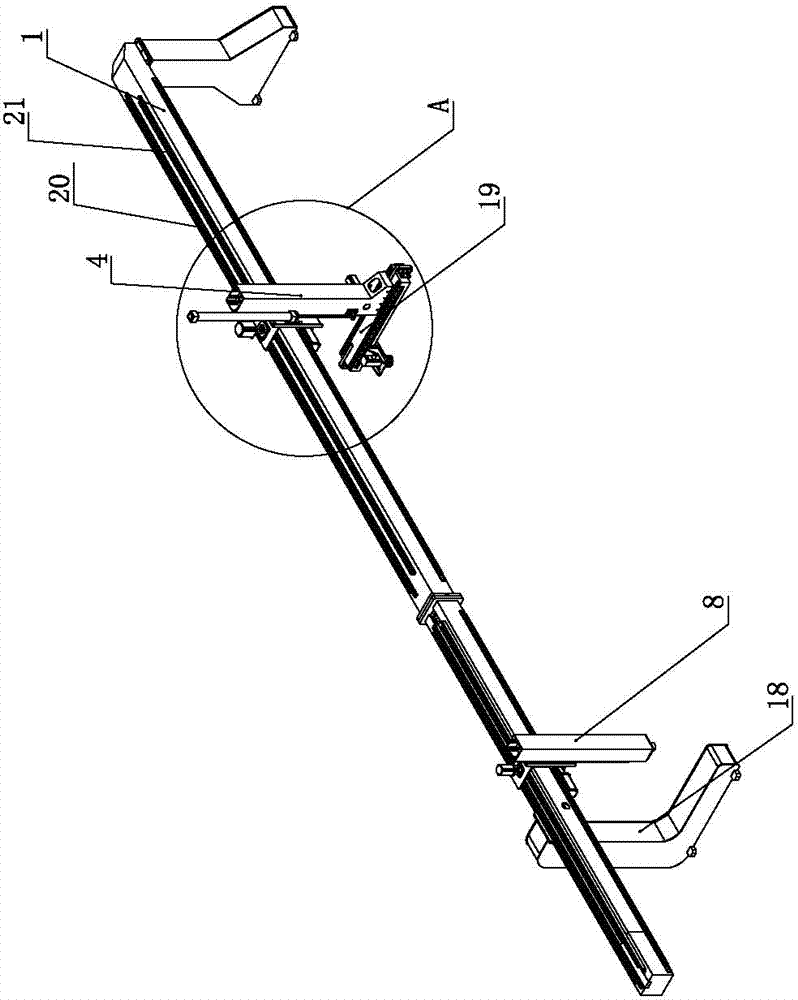

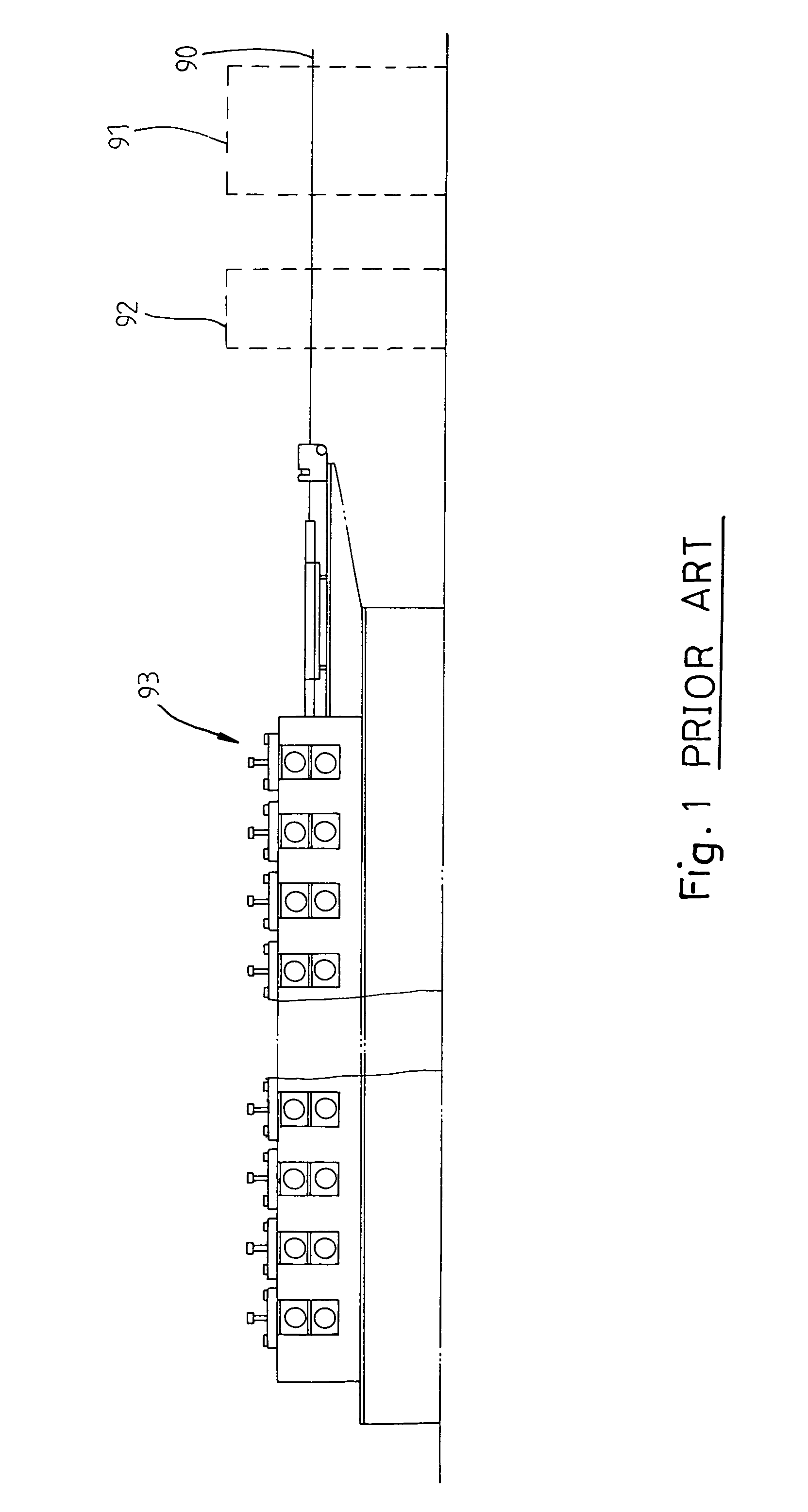

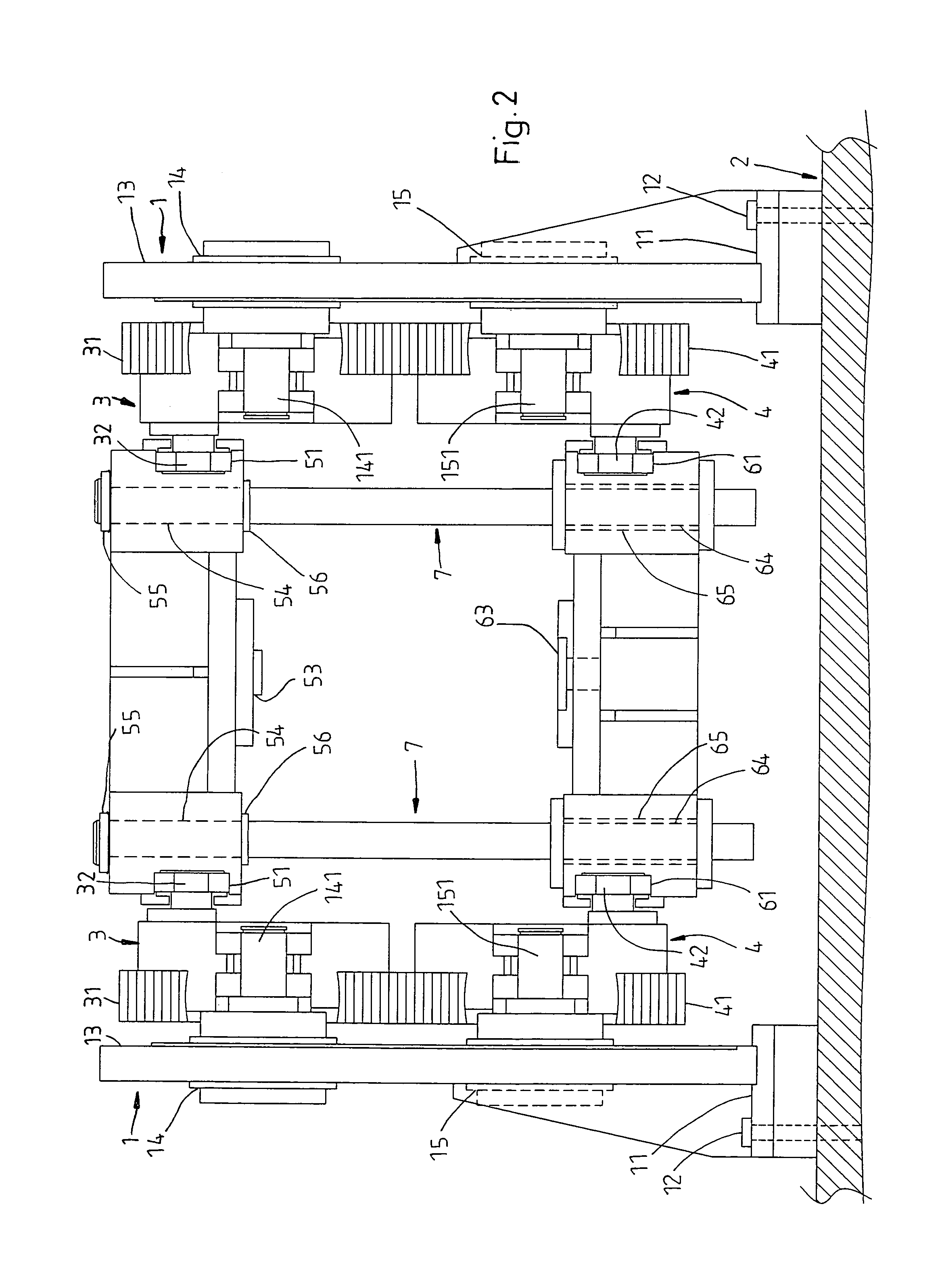

Machining production line for sheet metal

ActiveCN104759894ACompact structureImprove matchOther manufacturing equipments/toolsProduction lineNumerical control

The invention belongs to the field of sheet metal machining equipment and discloses a machining production line for sheet metal. The machining production line comprises a numerical control shearing machine, a numerical control punching machine and two or more numerical control bending machines which are arranged in sequence, the feeding side of the numerical control shearing machine is provided with a raw material rack and a locating platform, a first cross beam is arranged above the numerical control shearing machine and the numerical control punching machine, the two ends of the first cross beam are arranged across the numerical control shearing machine and the numerical control punching machine, the raw material rack and the locating platform are arranged below the two sides of the front end of the first cross beam respectively, the font end of the first cross beam is provided with a feeding mechanical arm, the rear end of the first cross beam is provided with a discharging mechanical arm, a temporary storage rack is arranged at the discharging side of the numerical control punching machine, the discharging mechanical arm corresponds to the temporary storage rack, and the numerical control bending machines are arranged at the two sides of a multistation conveying device respectively. According to the machining production line, the automation degree is high, cooperative work can be conducted without interference, and the consistency of the cooperative work is good.

Owner:YANGZHOU HENGJIA AUTOMATION EQUIP CO LTD

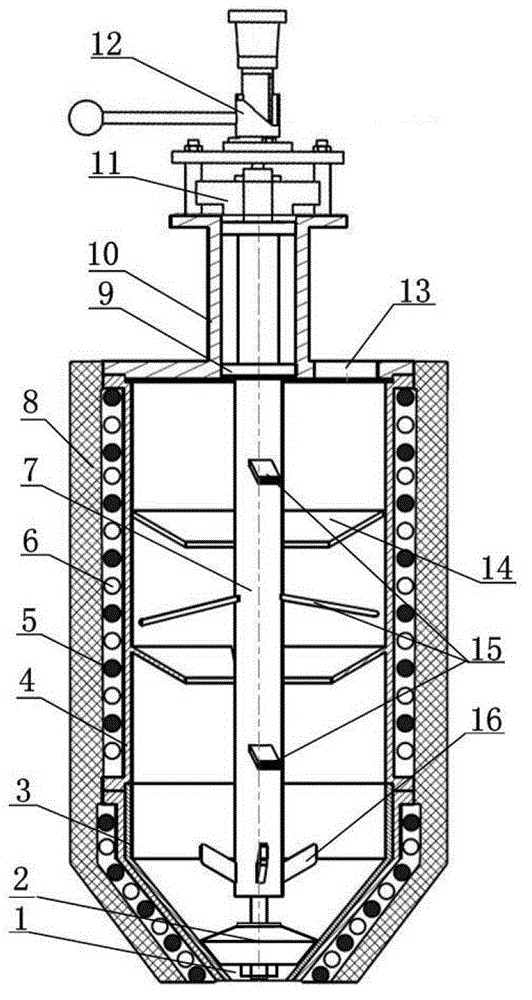

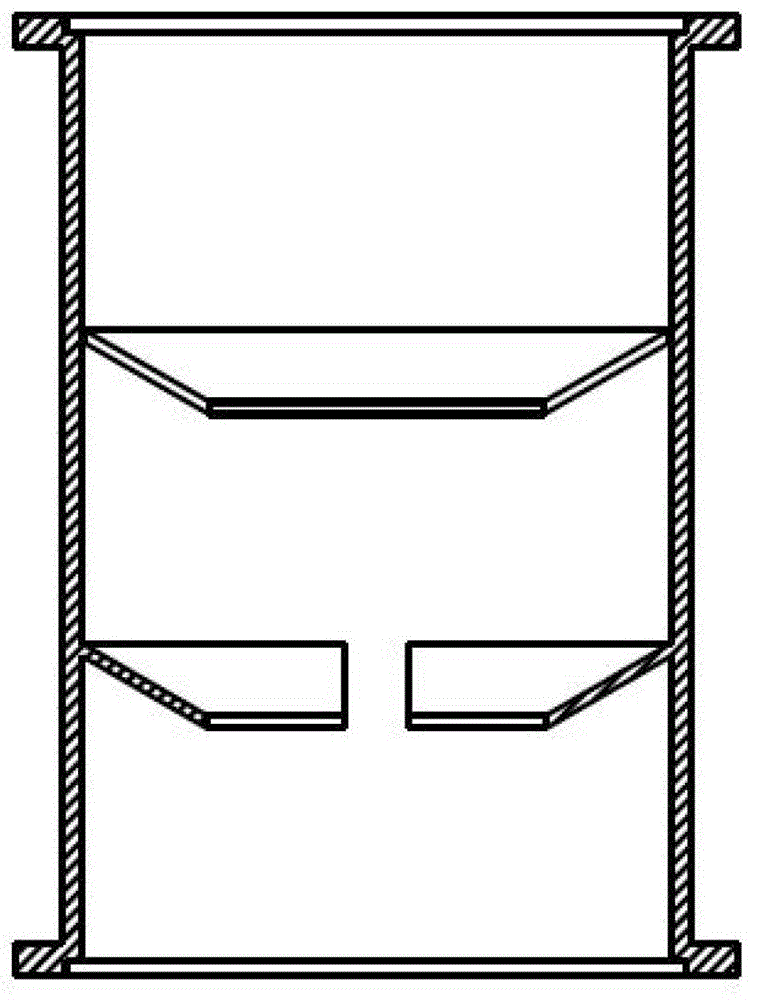

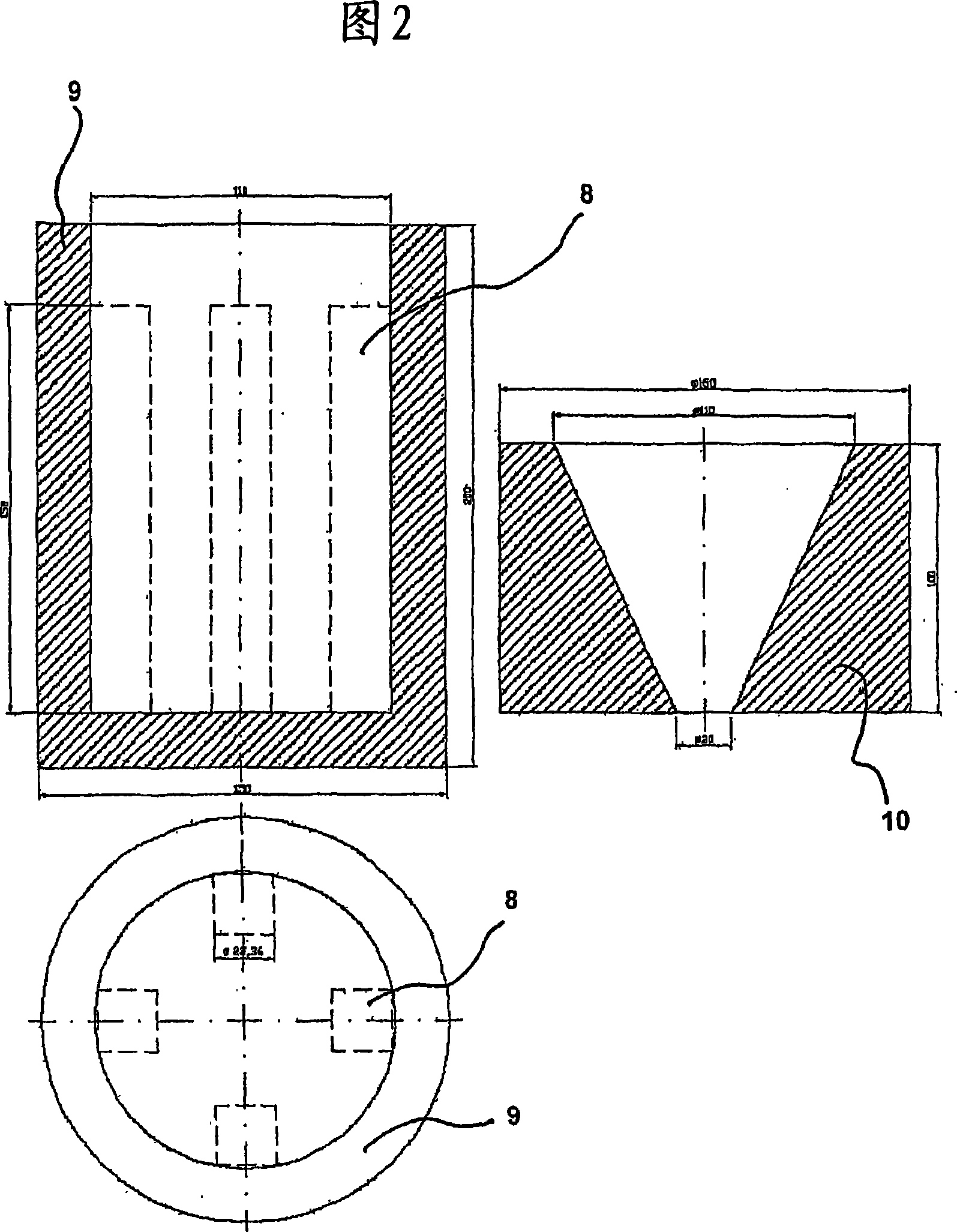

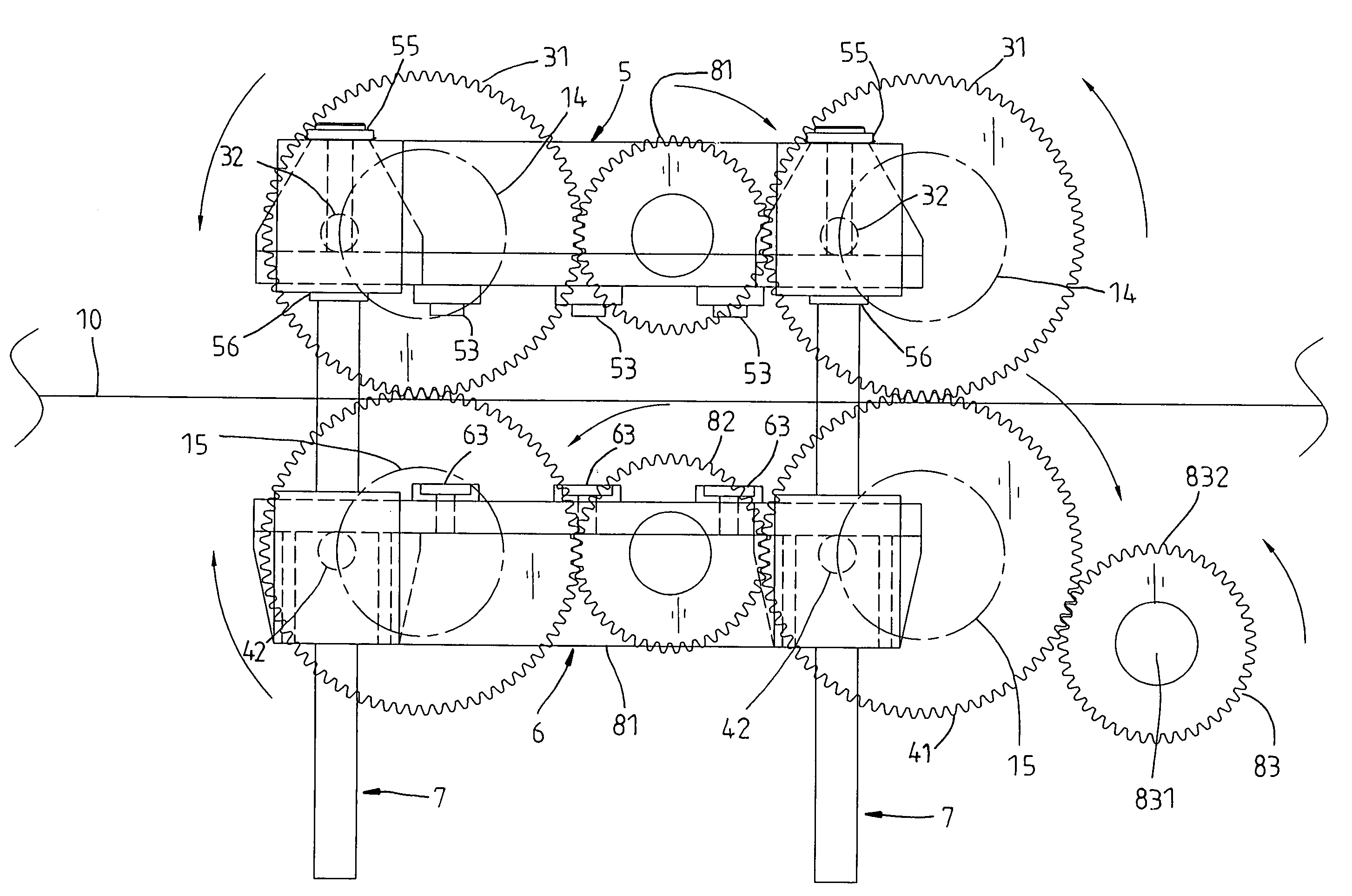

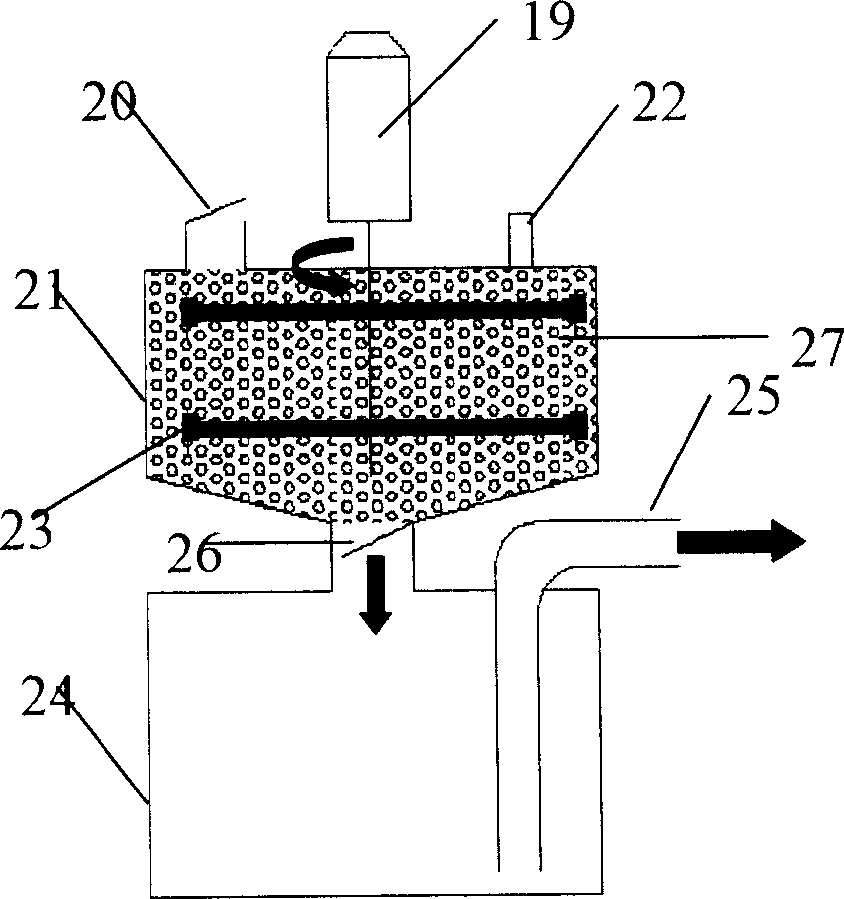

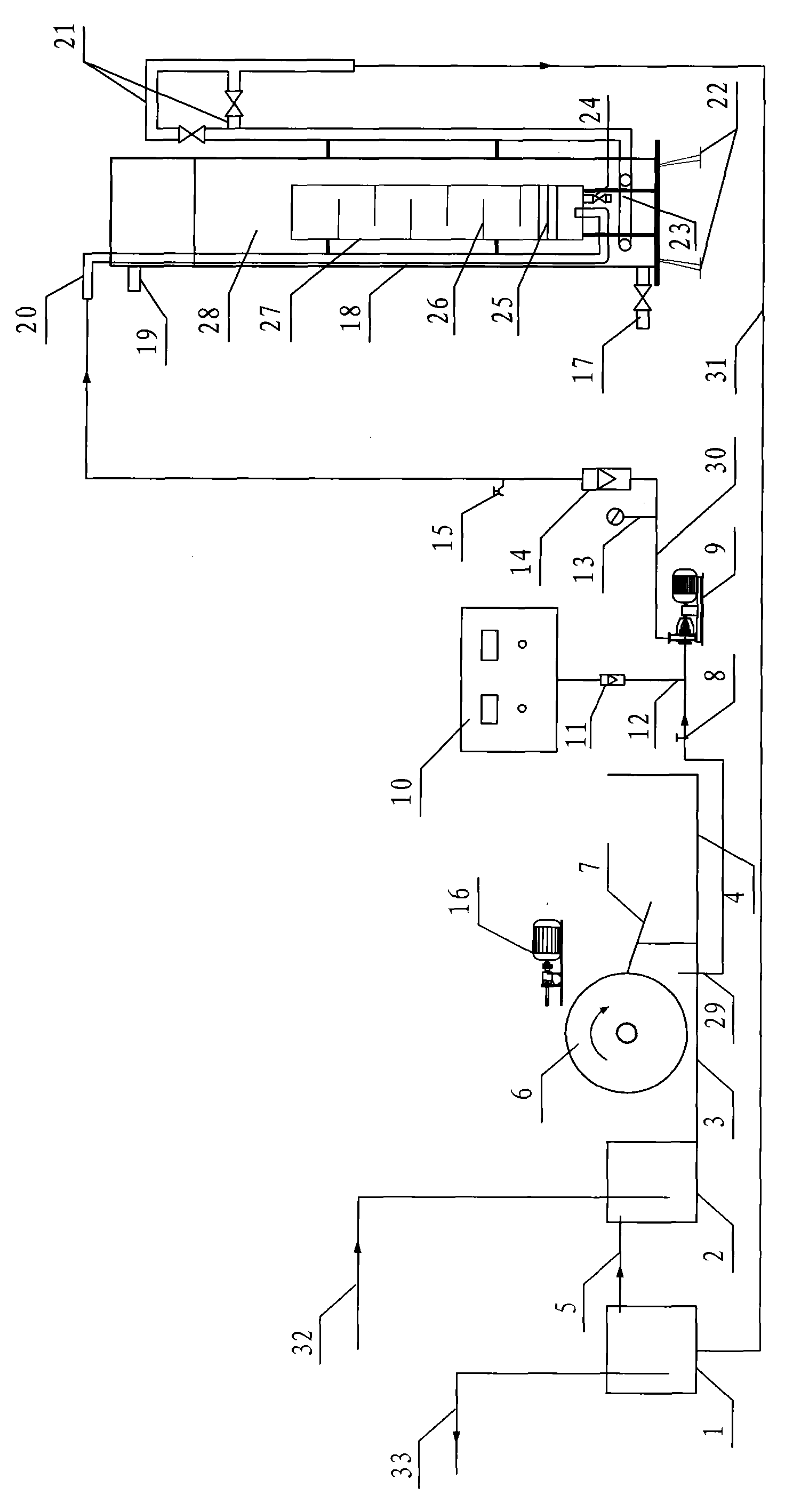

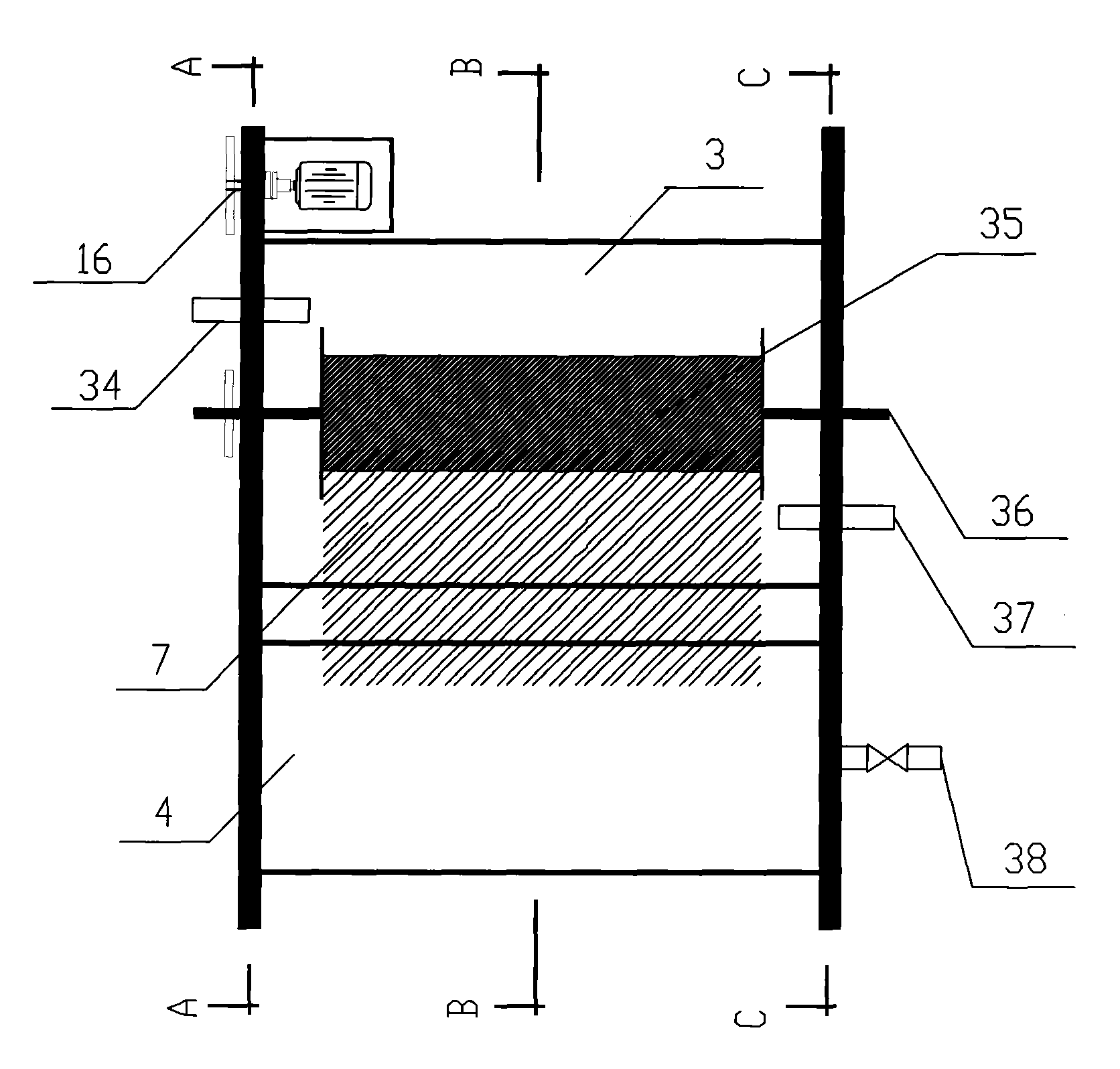

Continuous preparation device for composite stirred semi-solid slurry

The invention relates to a continuous preparation device for composite stirred semi-solid slurry, and belongs to the technical field of machining semi-solid metal machining. The device comprises a discharge outlet 1, a graphite plug 2, a graphite lining 3, a stainless steel tube 4, a heating element 5, a cooling element 6, a stirring shaft 7, a thermal insulating layer 8, a bearing 9, a bearing seat 10, a gear 11, a discharge handle 12, a feeding inlet 13, an oblique baffle 14, a rotary blade 15, a stirring blade 16 and the like. The semi-solid slurry is prepared through the following steps: after feeding an alloy fuse into the device, throwing onto the inner wall of a stirring chamber through the rotary blade rotating at high speed, enabling the fuse to flow downward along with the inner wall and flow downward along with the baffle when encountering the oblique baffle, then throwing the fuse on the inner wall of the stirring chamber by the rotary blade, after circulating the processes for two times, enabling the fuse to flow downward along the wall of the graphite lining at the lower part, carrying out convection at the bottom of a stirring bucket through driving of the stirring blade, generating a great deal of crystal nucleus in the fuse in the process, and directly growing into spheres. The flowing velocity of the slurry can be controlled through adjusting a gap between the graphite plug and the graphite lining, the semi-solid slurry can be subjected to rheoforming together with conventional equipment such as die casting, rolling and mold forging, and semi-solid ingot can also be continuously prepared.

Owner:UNIV OF SCI & TECH BEIJING

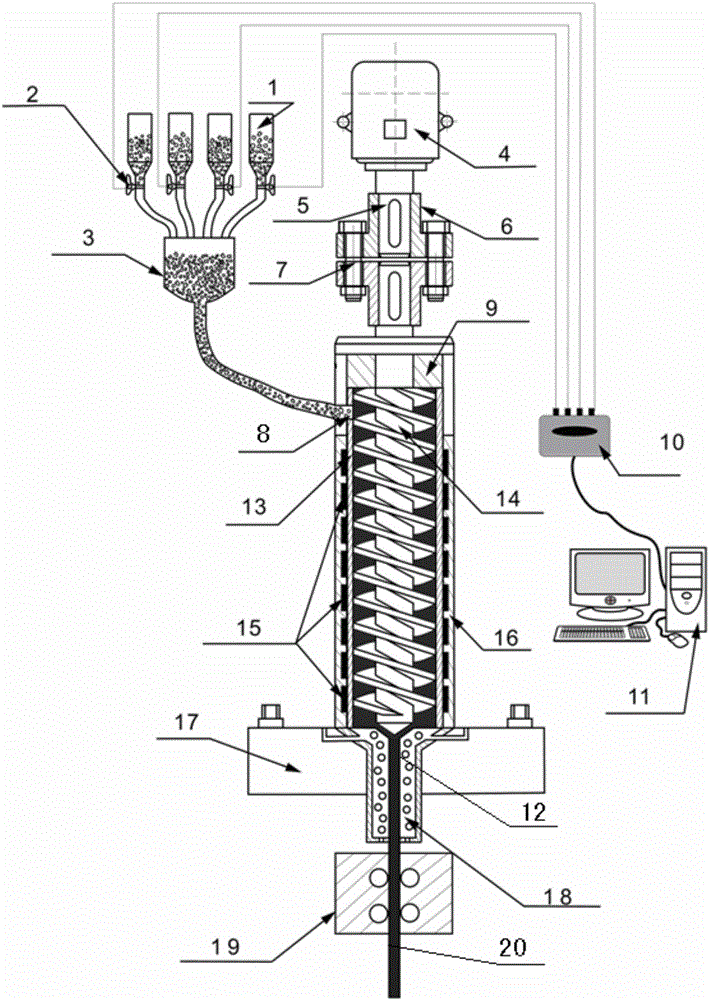

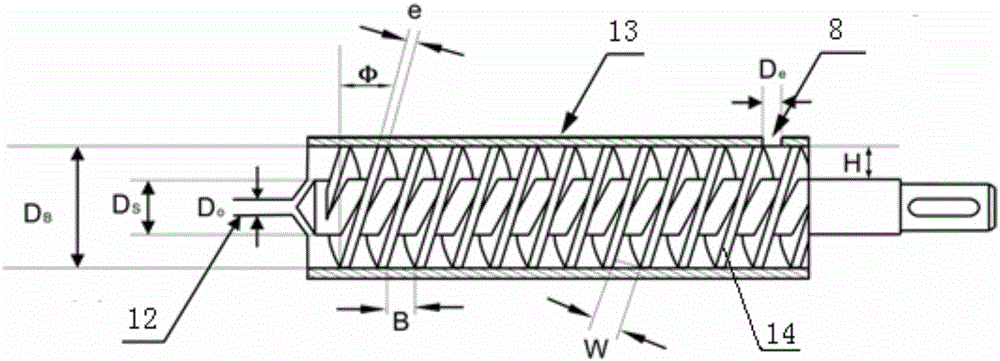

Device for high-throughput preparation of multi-component gradient metal materials

ActiveCN105954074ASimple structureEasy to useAdditive manufacturing apparatusPreparing sample for investigationGradient materialMetallic materials

The invention belongs to the field of metal processing preparation, and in particular, relates to a method for high-throughput preparation of multi-component gradient metal materials for multi-component alloy tubes, rods, sectional materials and other long materials with continuous gradient distribution of chemical components in the length direction. The device comprises a powder flow velocity on-line regulating system, a rotary feeding system, a heating system, a heat preservation system, a motor drive system, a blank forming system and a control system. By adopting the technical scheme, the device has the advantages of simple structure, convenient use and easy control; the device achieves preparation of high-throughput preparation of the multi-component gradient metal materials through controlling of molten metal components and a continuous casting process, shortens the time course of the materials in composition design, melting, performance preparation and application preparation, reduces the metallurgical energy consumption of multi-furnace smelting of the alloys, reduces development costs, and improves the preparation quality and efficiency of the new metal gradient materials.

Owner:UNIV OF SCI & TECH BEIJING

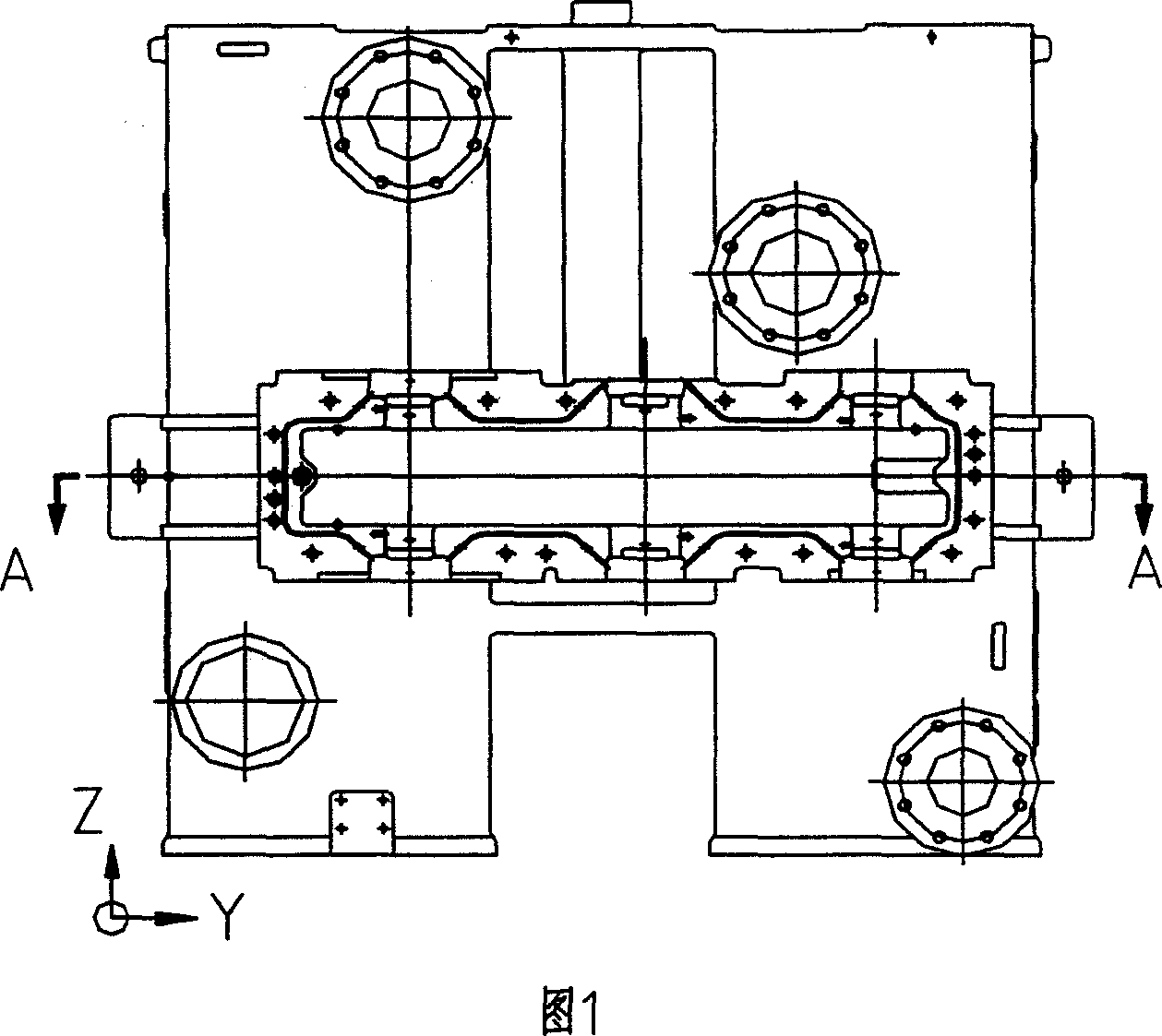

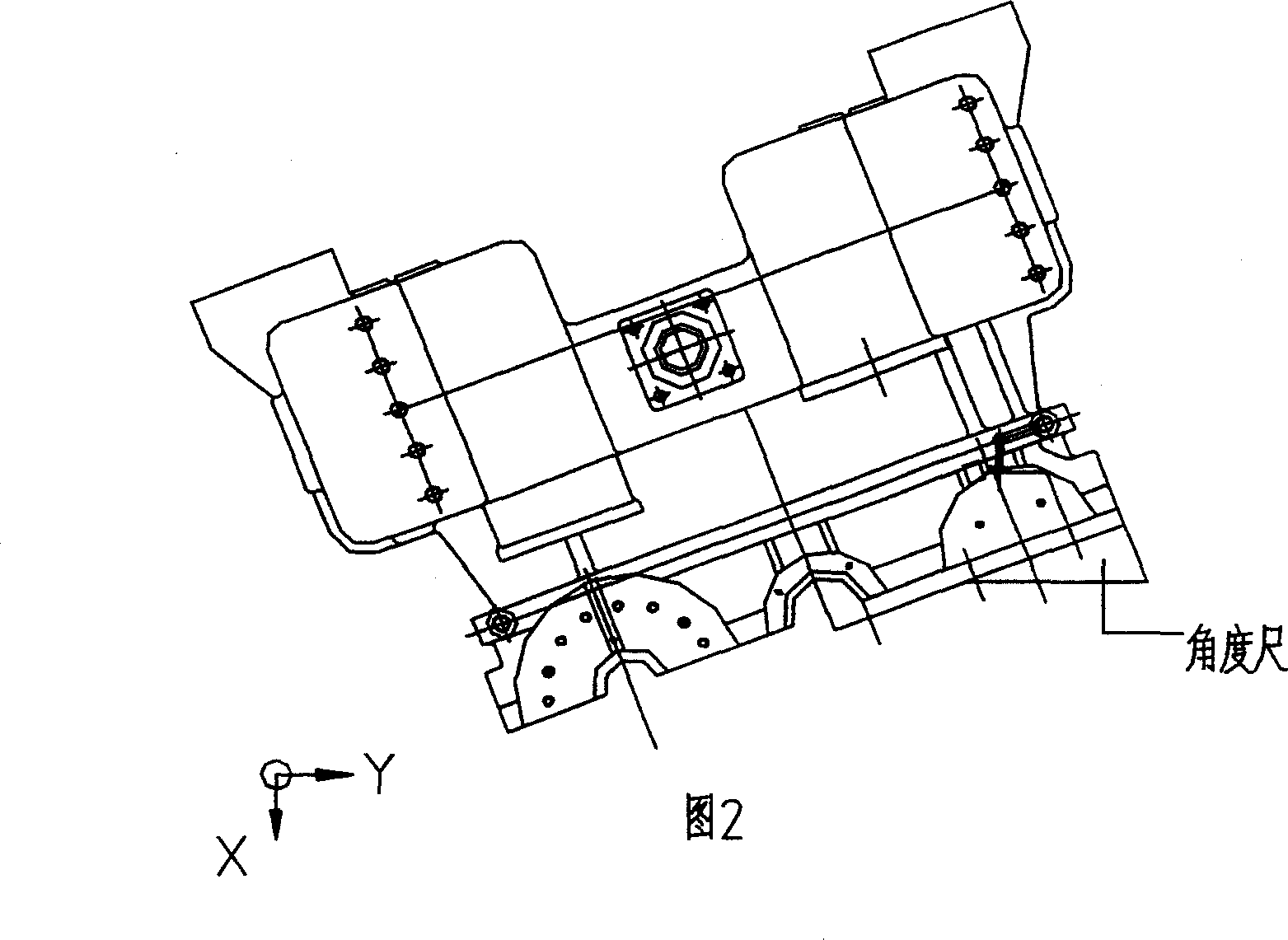

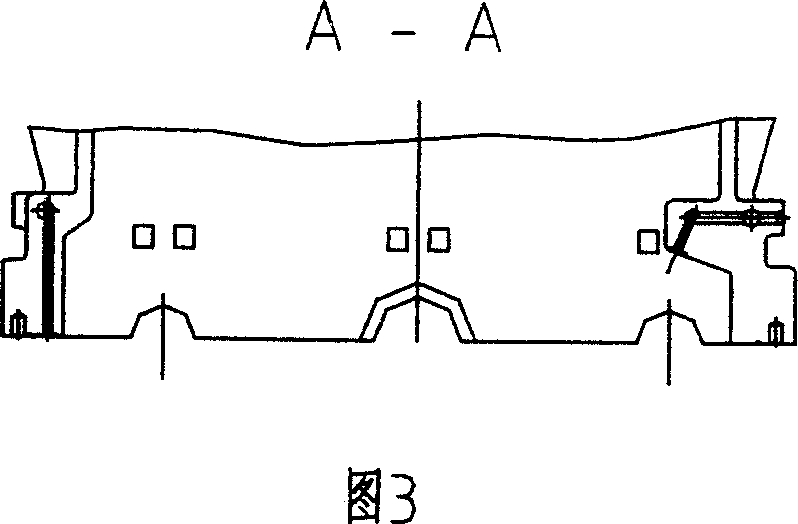

Making process of gear box casing for centrifugal compressor

InactiveCN1931512ASolve processing problemsImprove processing qualityAutomatic control devicesGearboxesNumerical controlAgricultural engineering

The present invention is machining process of gear box casing for TM type centrifugal compressor, and belongs to the field of metal machining technology. The gear box casing consists of one upper casing and one lower casing mainly. The lower casing is machined through fine milling the bottom, drilling hole, machining the combining surfaces, sides and holes, washing, oiling and other steps; the upper casing is machined through fine milling the combining surfaces, drilling holes, fine boring the bearing holes, cleaning, oiling and other steps. The present invention has simple machining process, low production cost, high machining precision and other advantages.

Owner:WUXI COMPRESSOR CO LTD

Green micro-emulsification metal machining liquid and preparation method thereof

The invention discloses green micro-emulsification metal machining liquid, which comprises materials by weight percentage: 20%-30% of base oil, 30%-50% of a nonionic surfactant, 5%-10% of an anion surfactant, 5%-8% of an antirusting agent, 3%-4% of a couplant, 0.5%-1% of a corrosion inhibition antisludging agent, 5%-6.9% of an extreme pressure agent, 0.3%-0.5% of an antifoaming agent, 0.2%-0.5% of bactericide and the balance water. The micro-emulsification metal machining liquid with plant oil and synthetizing ester as the base oil is excellent in antioxidation, obvious in abrasion resistance, capable of partial ecotoxicity of mineral oil, environmental-friendly, biodegradable, suitable for processing various materials and excellent in antirust performance on nonferrous metal.

Owner:SHANGHAI INST OF TECH

Material mixture for producing casting moulds for machining metal

The invention relates to a material mixture for producing casting moulds for machining metal, to a method for producing casting moulds, and to a method which produces said casting moulds and to the use thereof. A fire-resistant moulding base material and a binding agent based on water glass is used in the production of casting moulds. A proportion of the particle-shaped metal oxide is added to the binding agent, said metal oxide being selected from the group of silicon dioxide, aluminium oxide, titanium oxide and zinc oxide. Synthetic amorphous silicon dioxide is preferably used as a metal oxide.

Owner:ASK CHEM LP

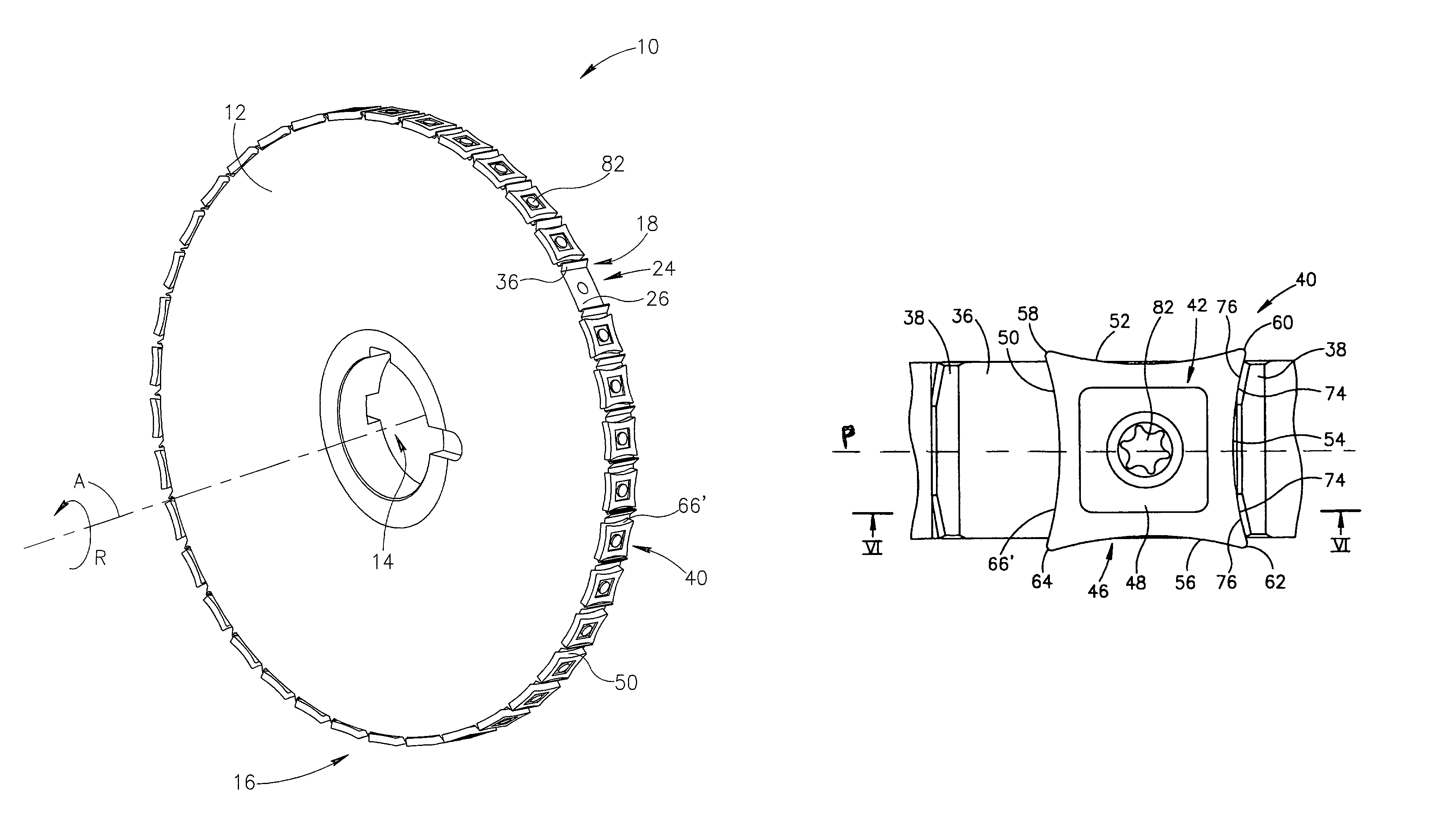

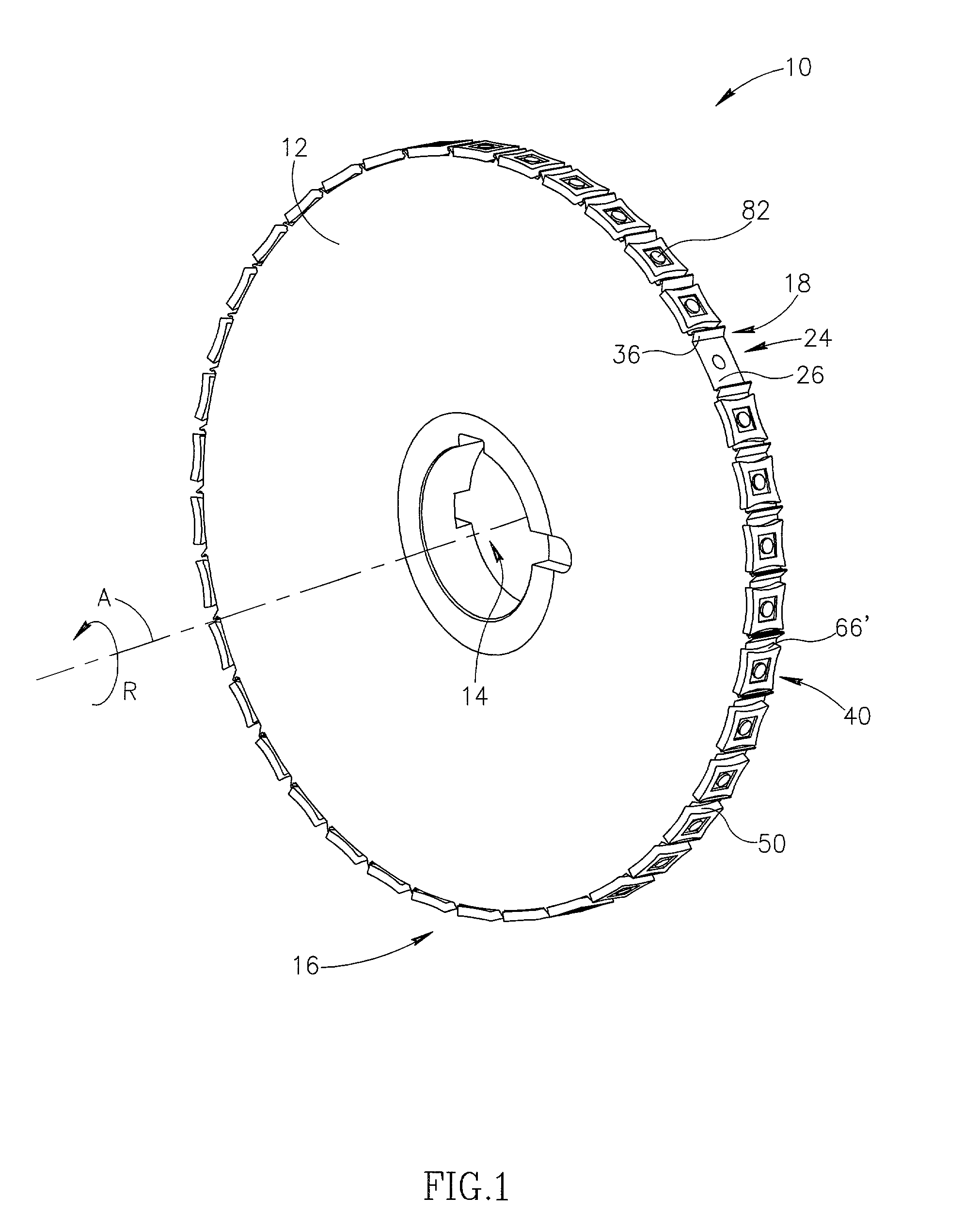

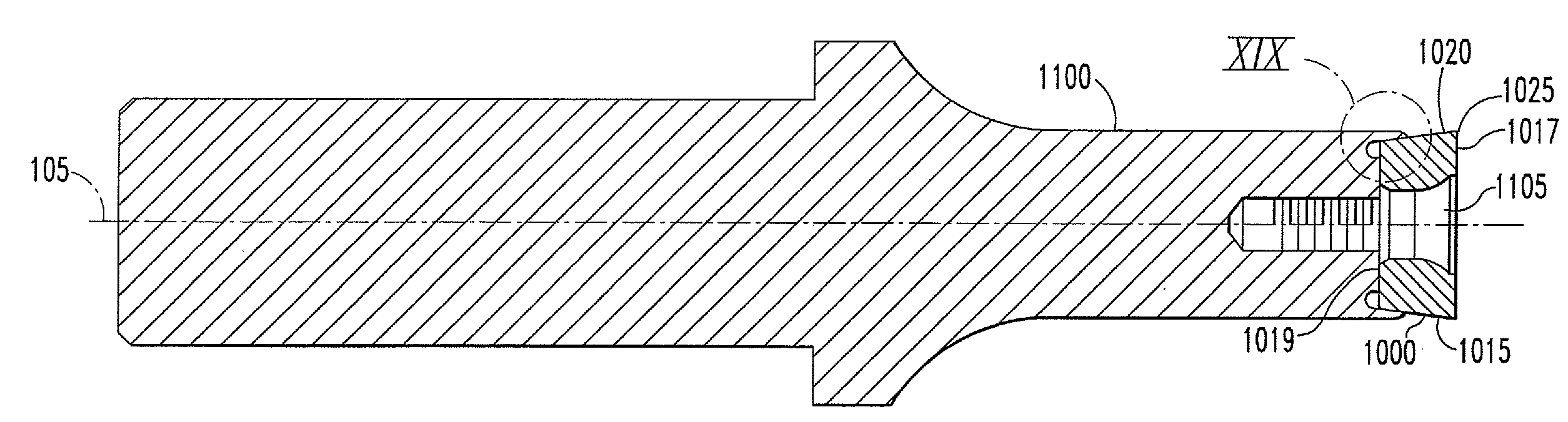

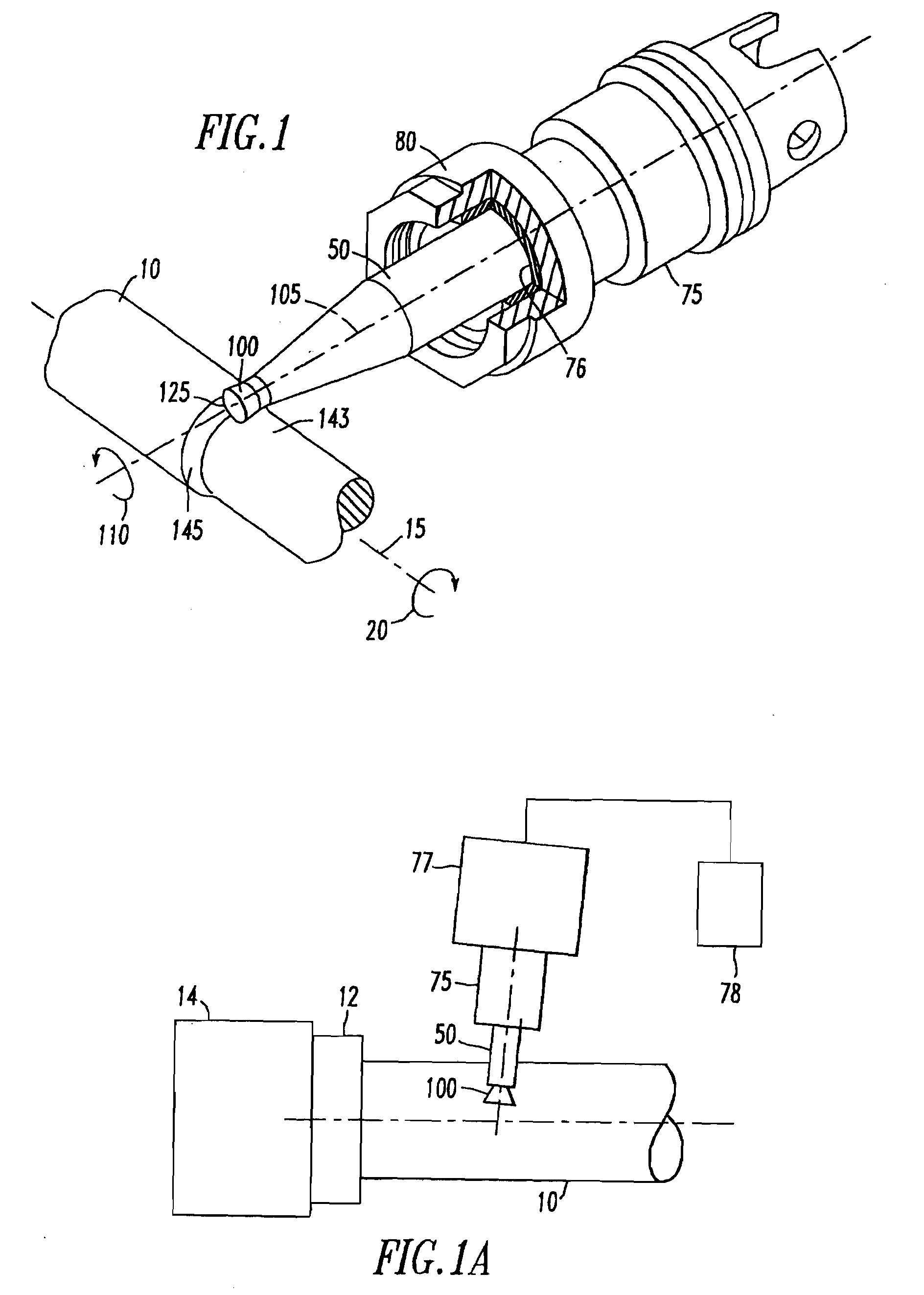

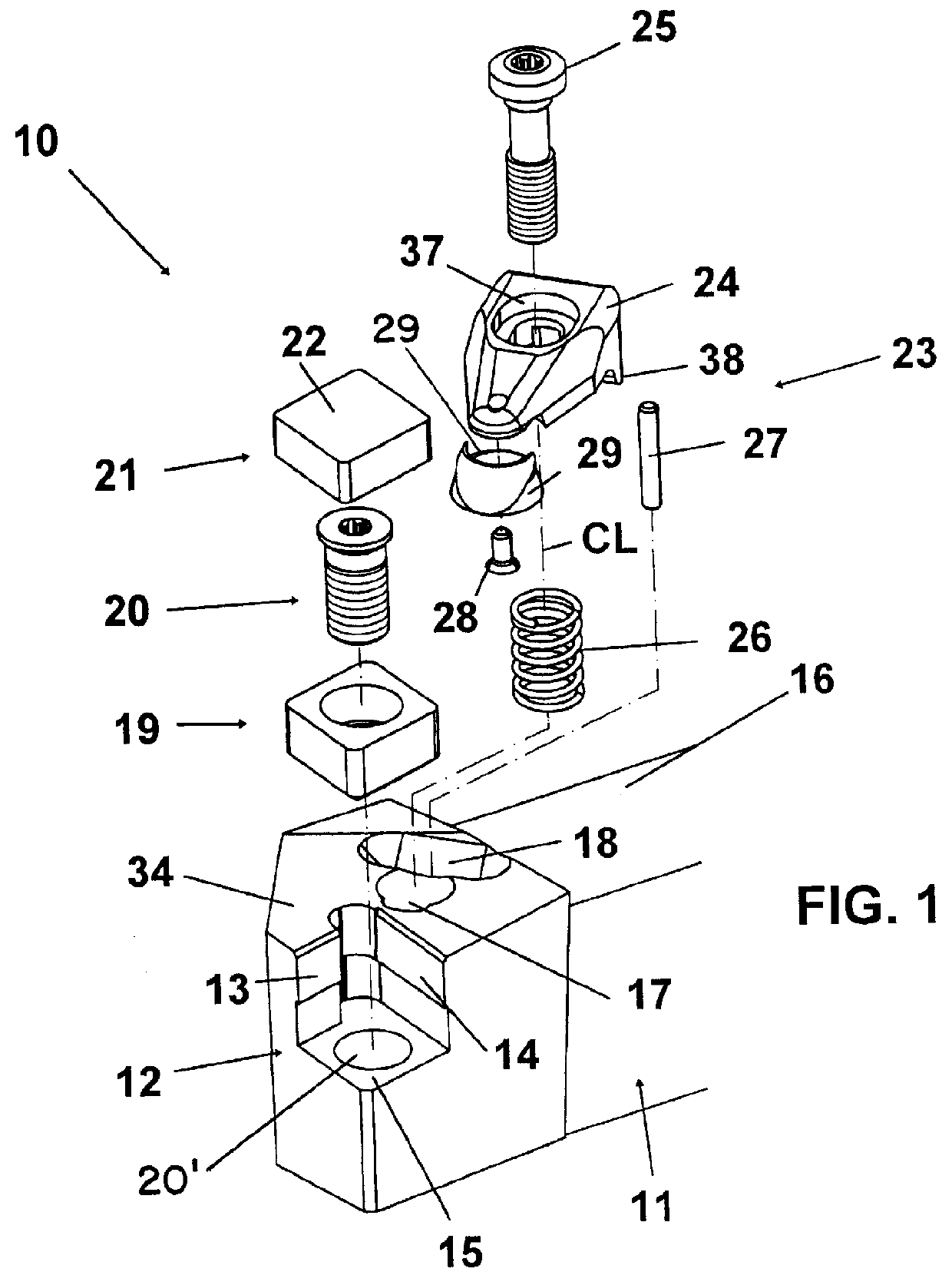

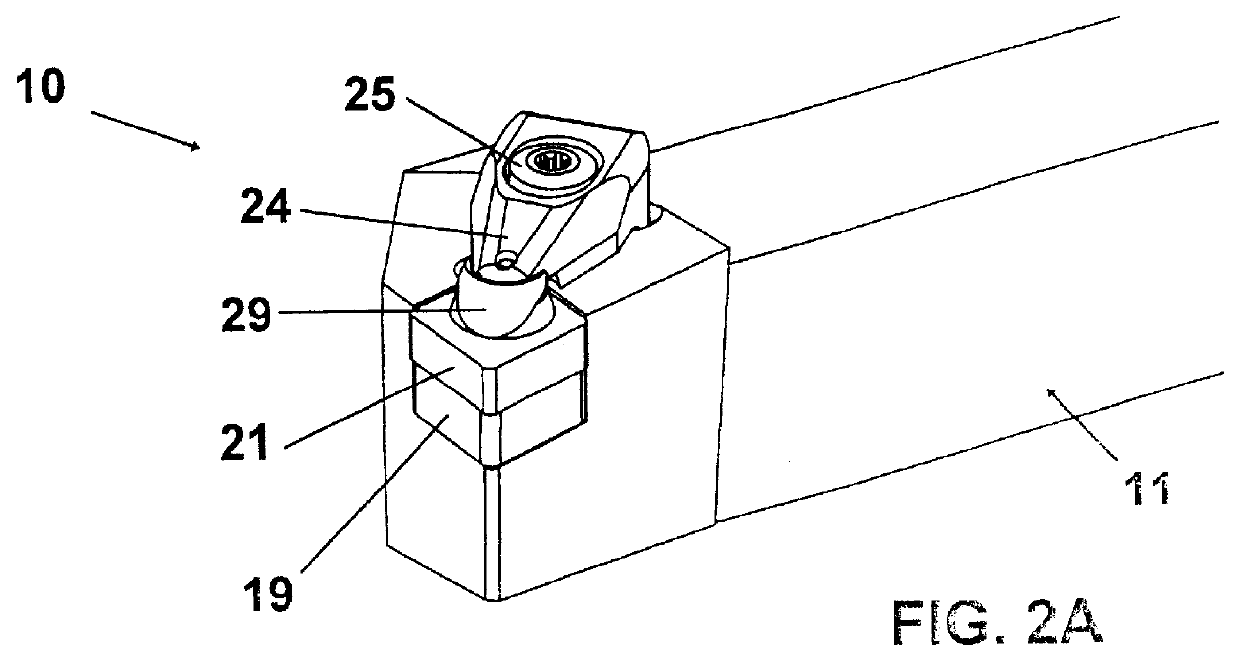

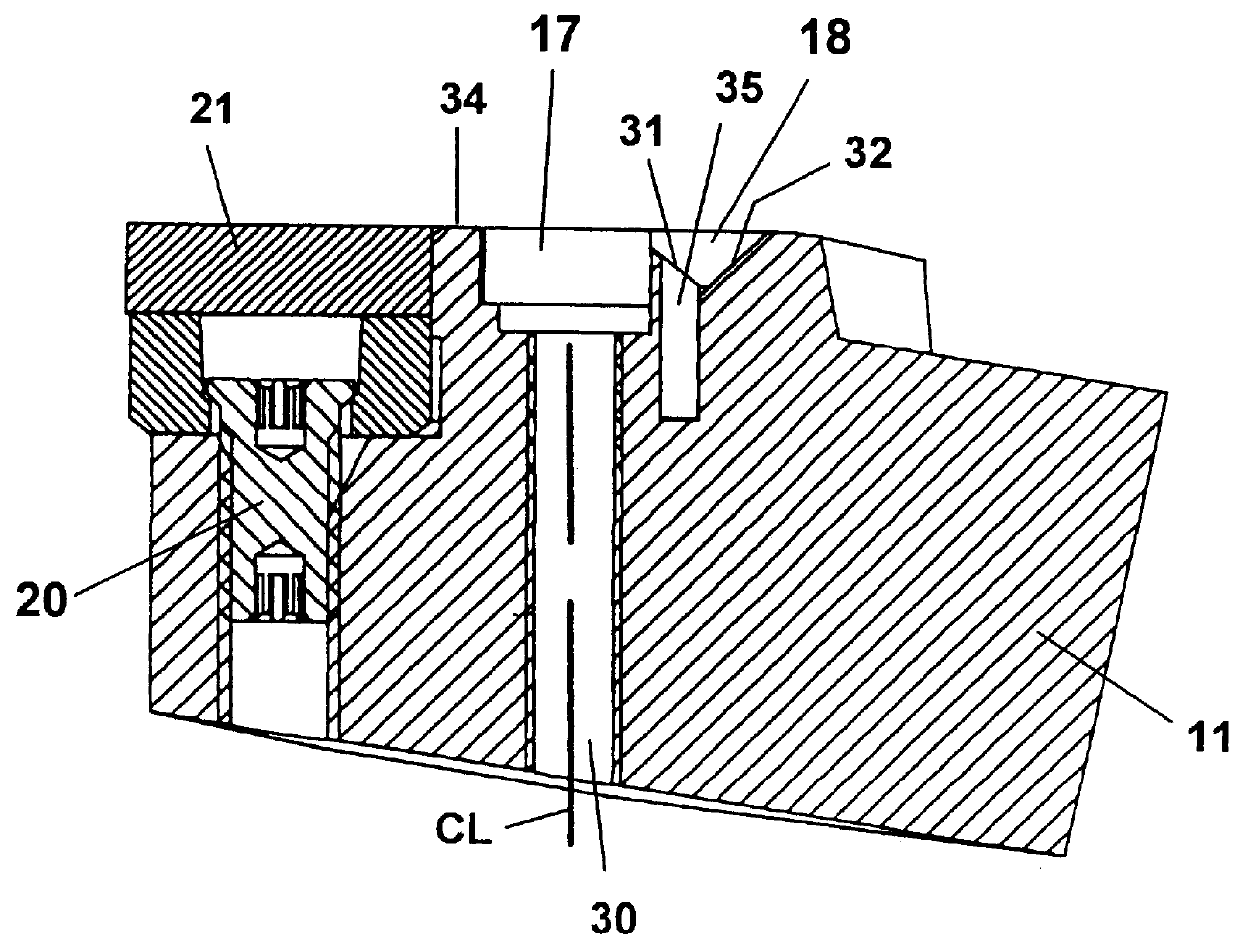

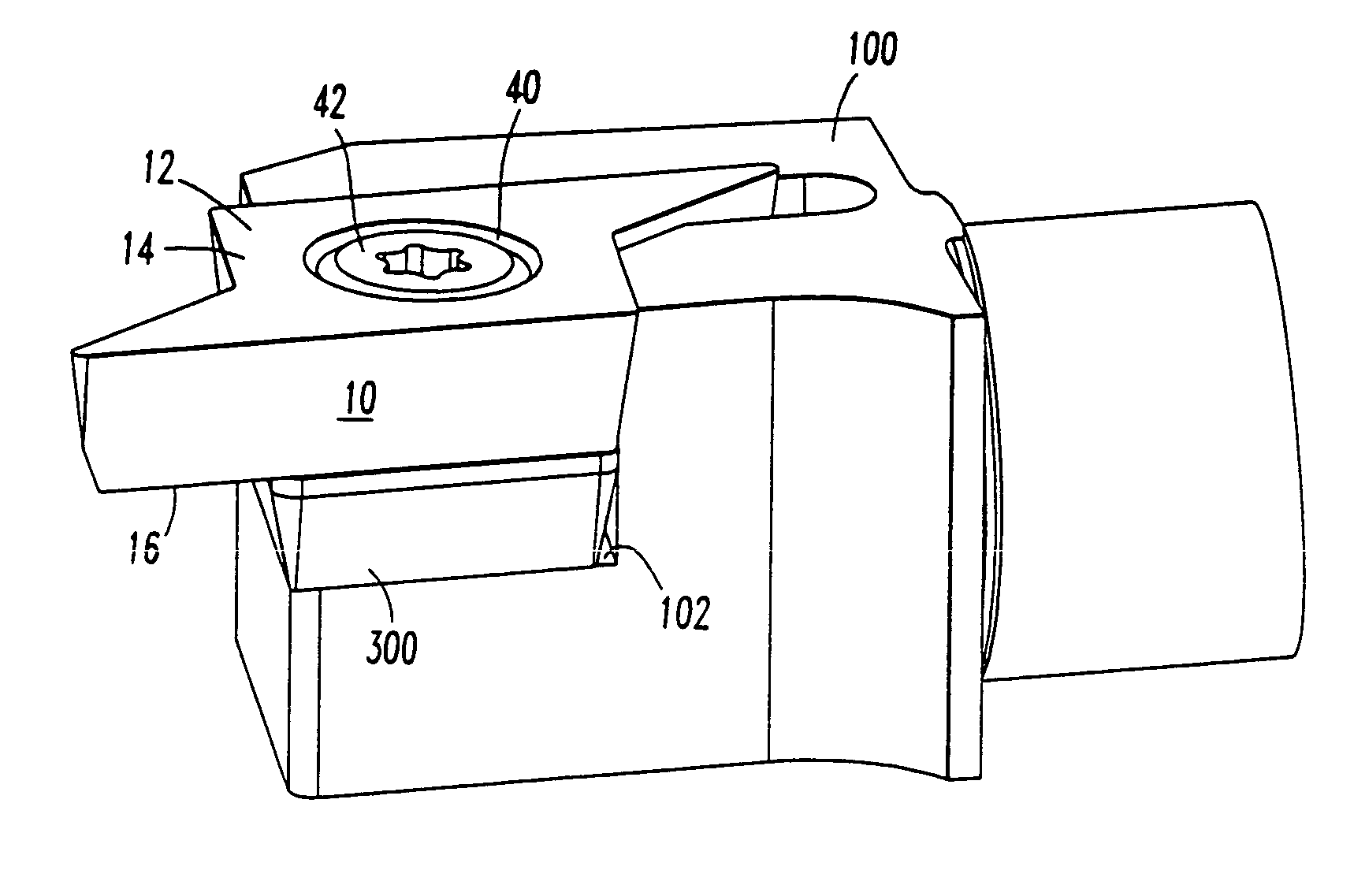

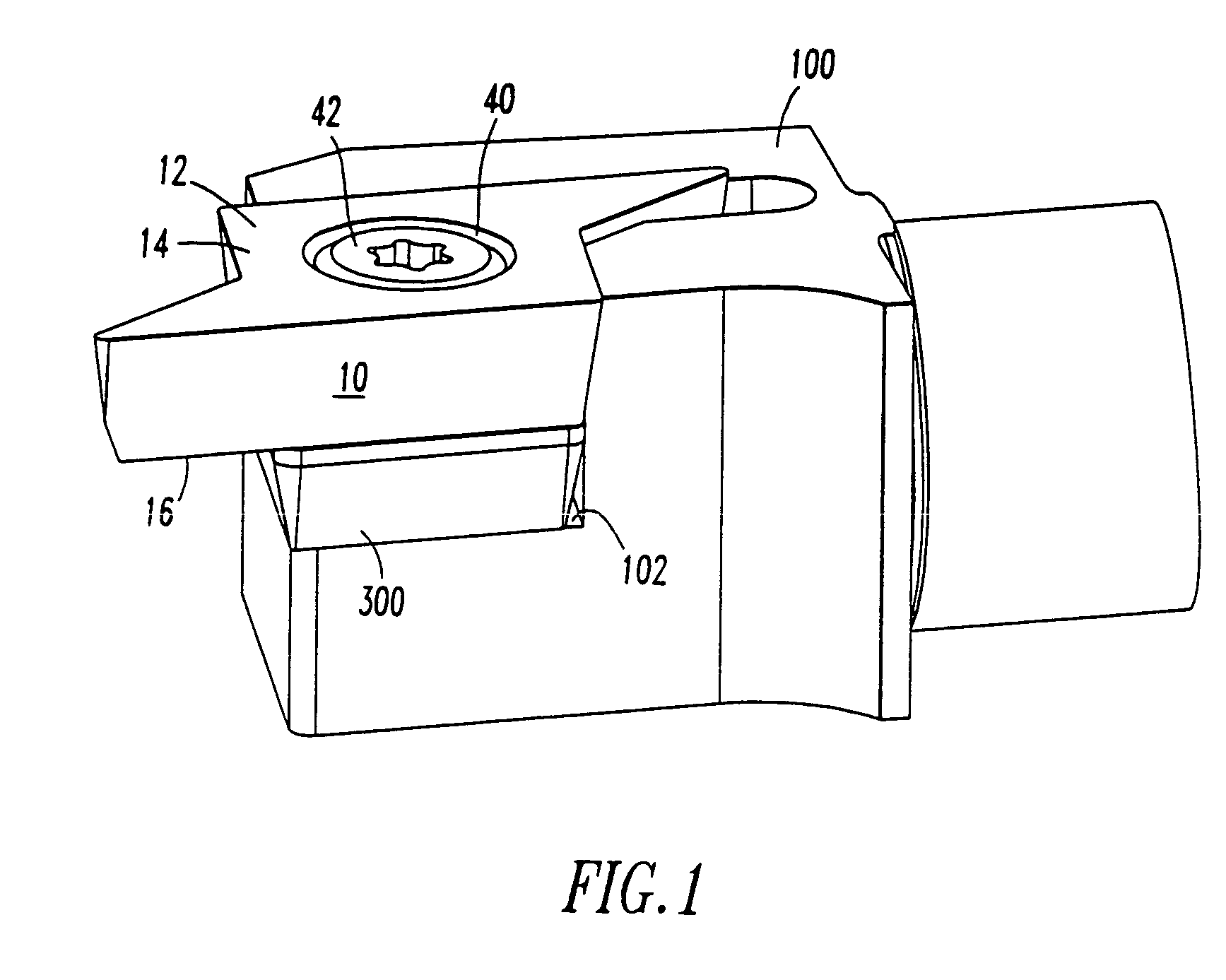

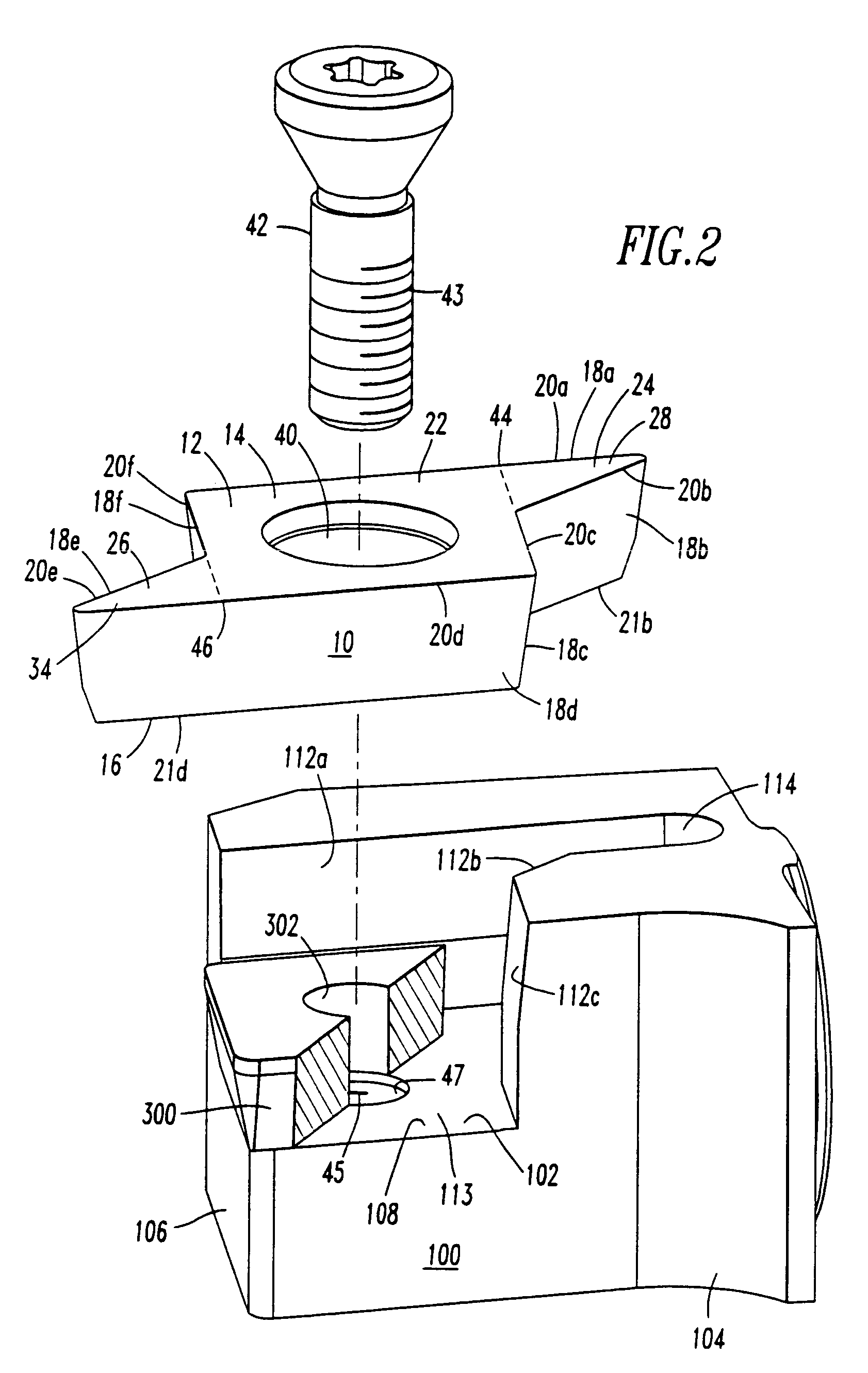

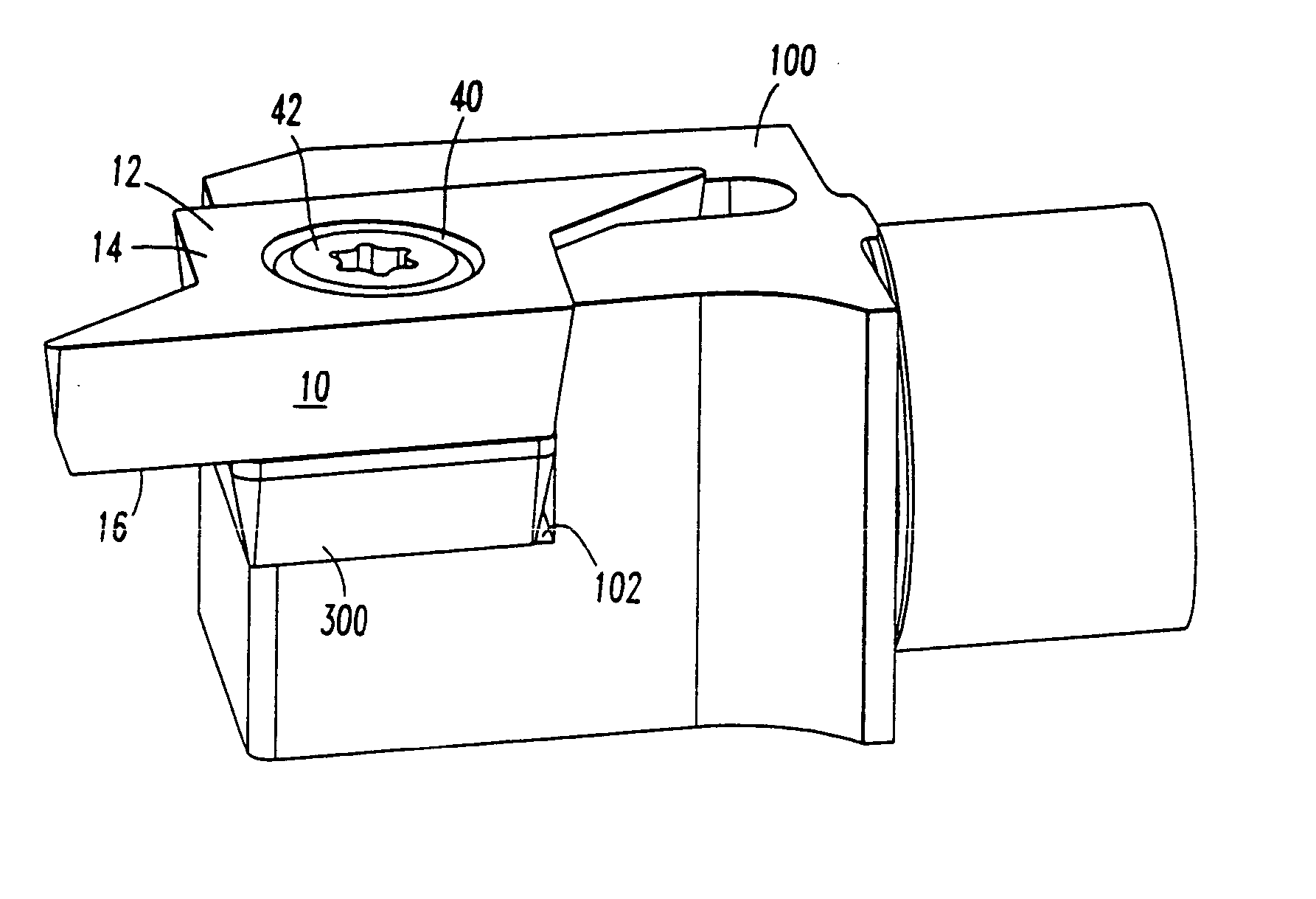

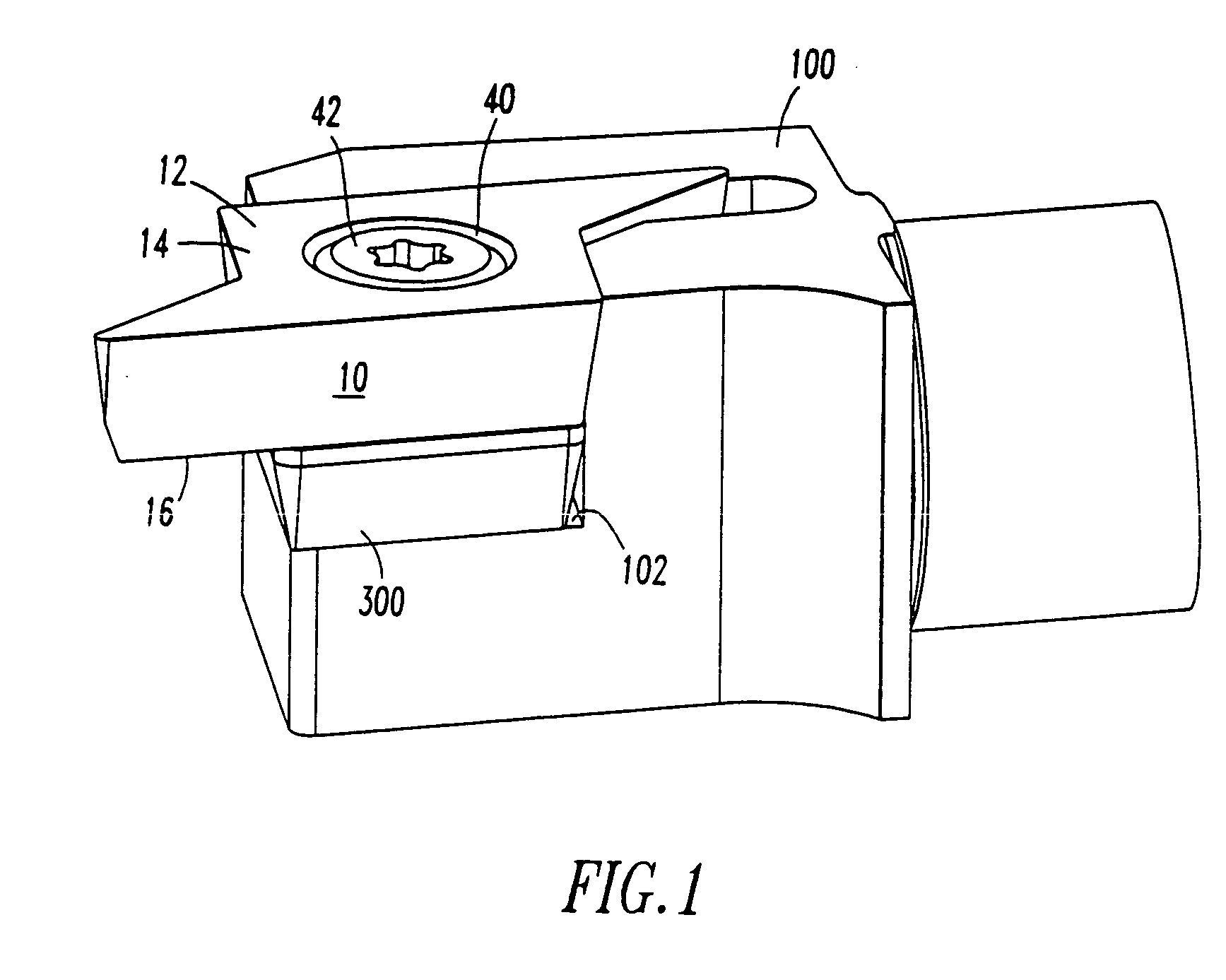

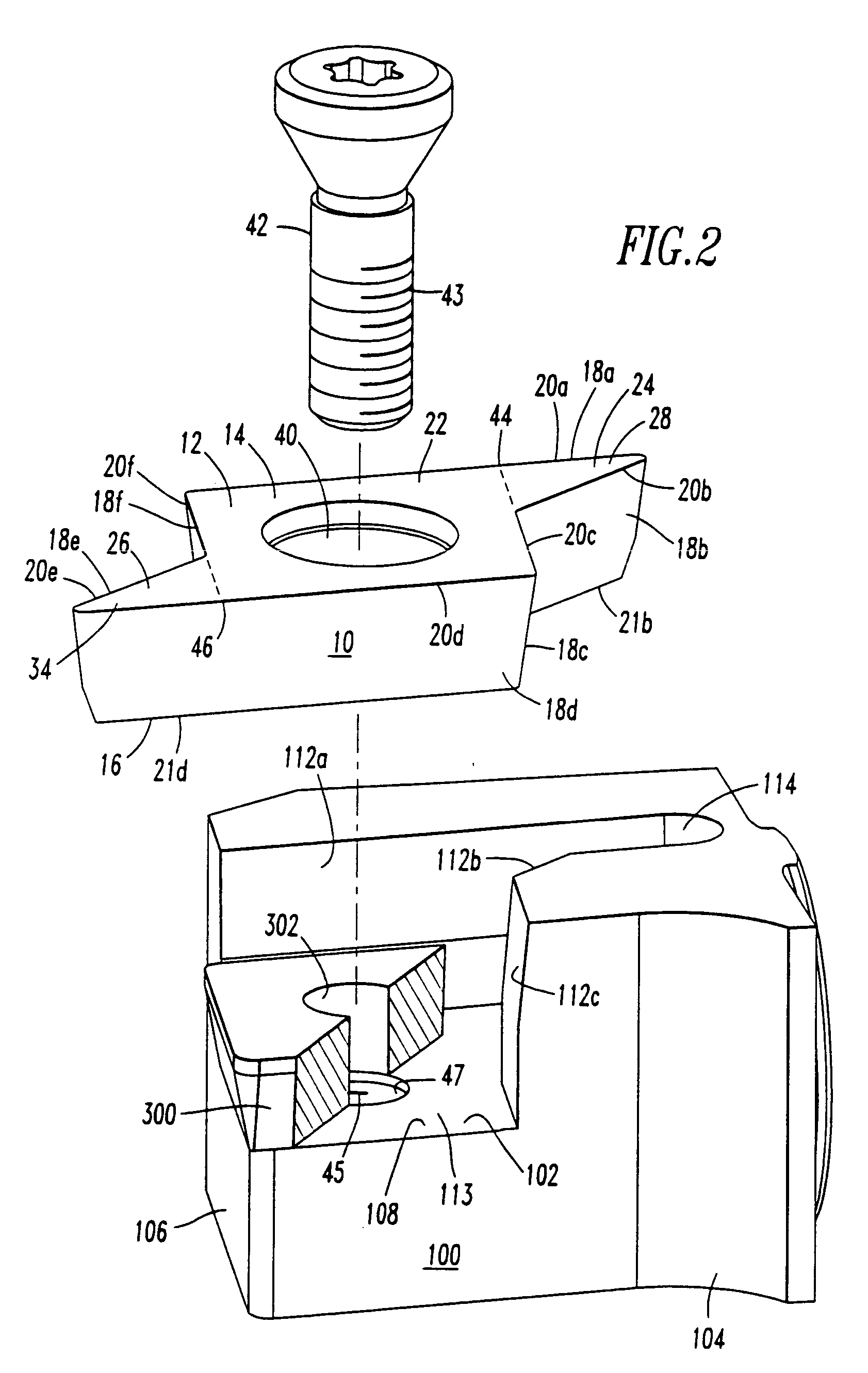

Assembly For Rotating A Cutting Insert During A Turning Operation And Inserts Used Therein

A cutting insert rotated about its axis may be utilized during a metalworking operation and applied against the rotating workpiece to enhance tool performance. The cutting insert is secured within a toolholder having features to secure the insert but at the same time make for efficient removal of the insert from the toolholder.

Owner:KENNAMETAL INC

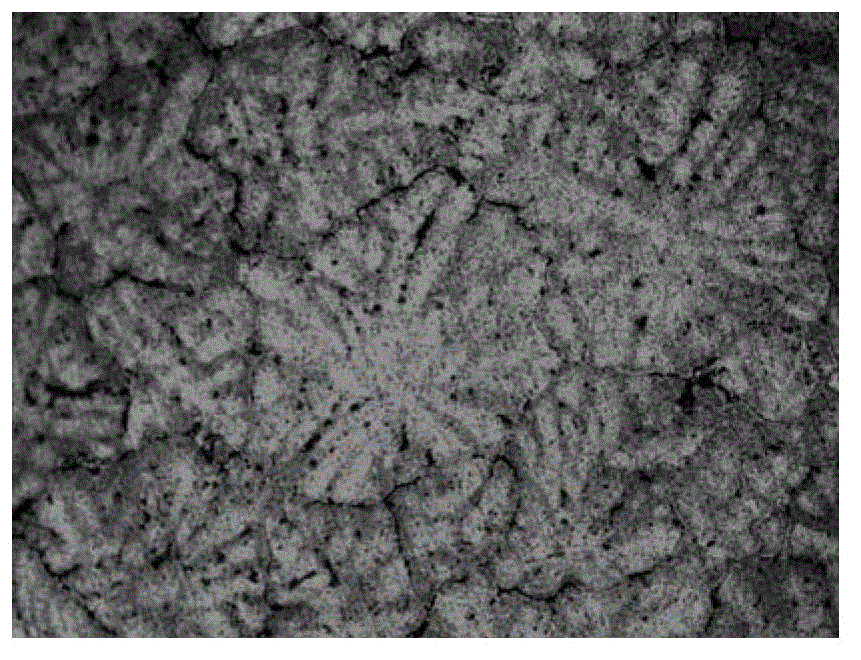

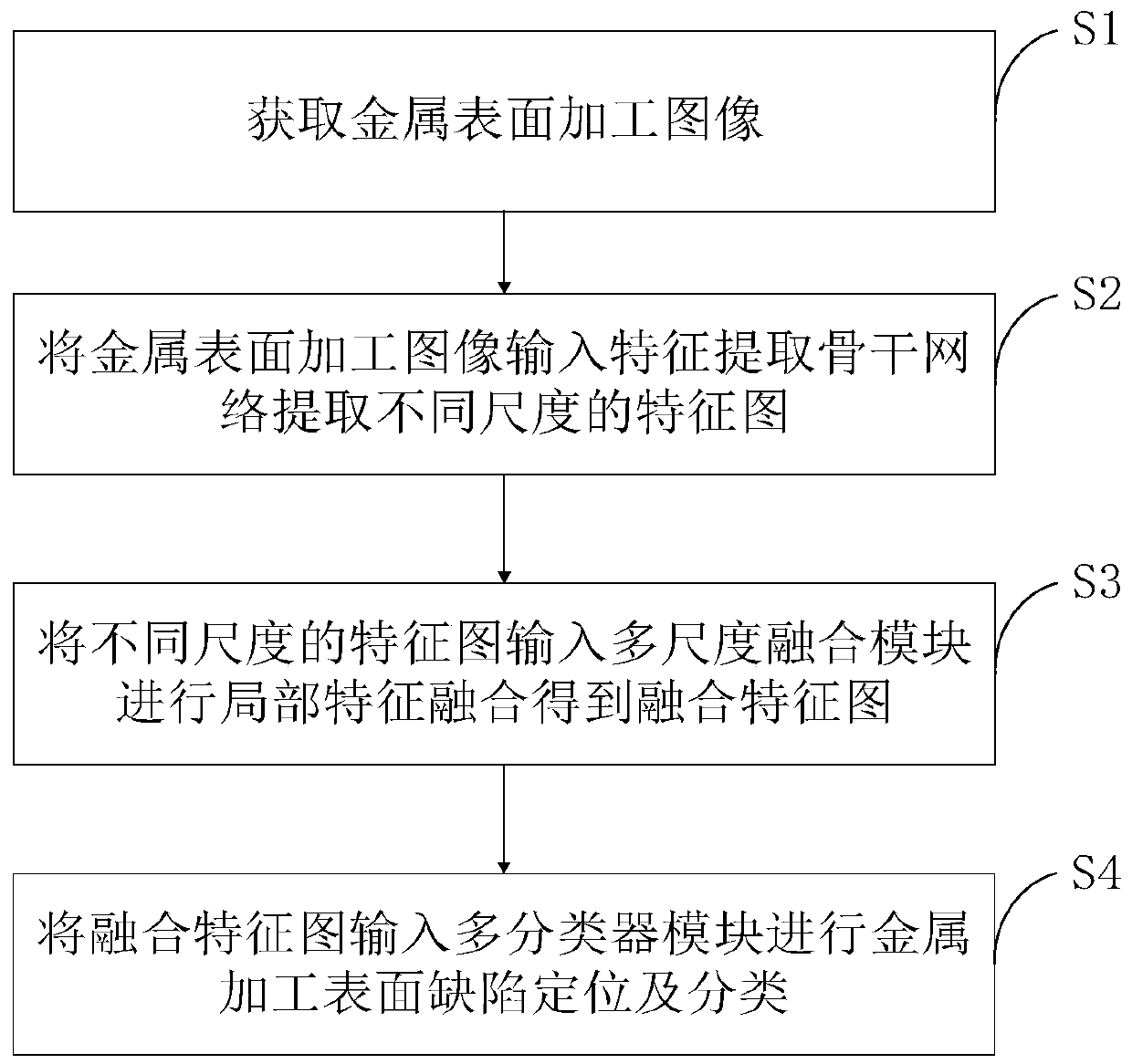

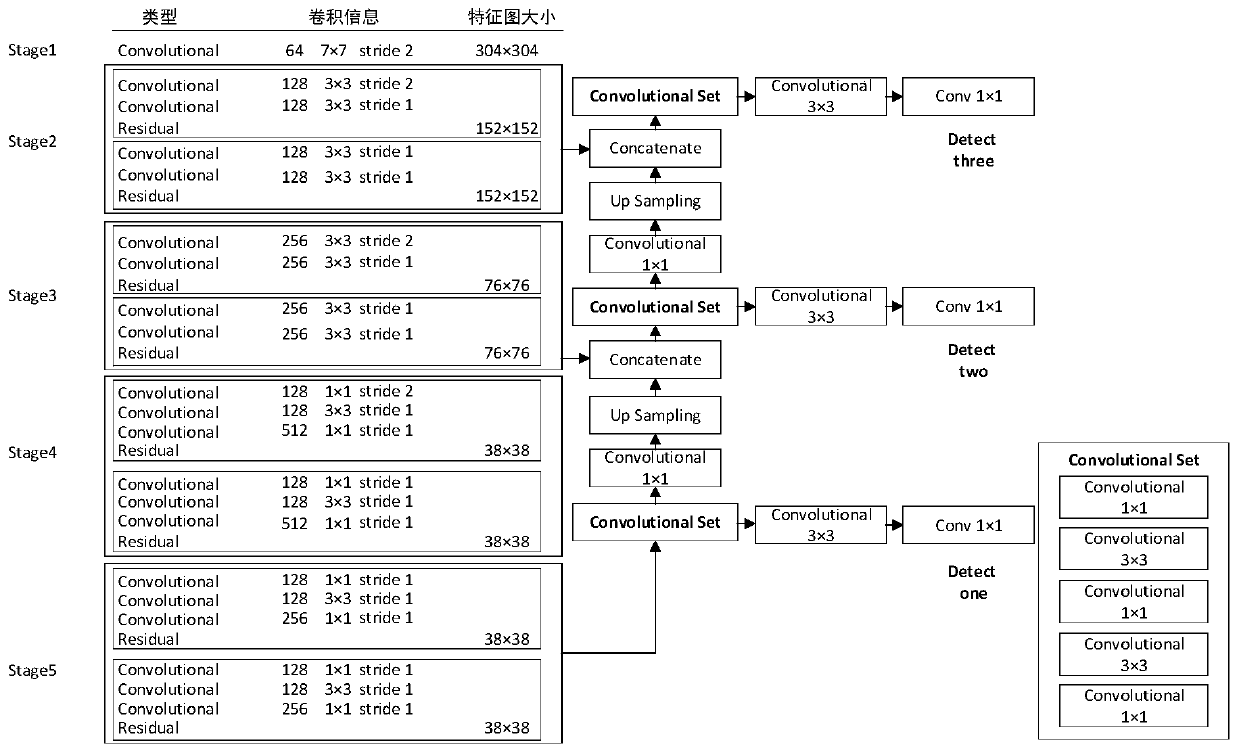

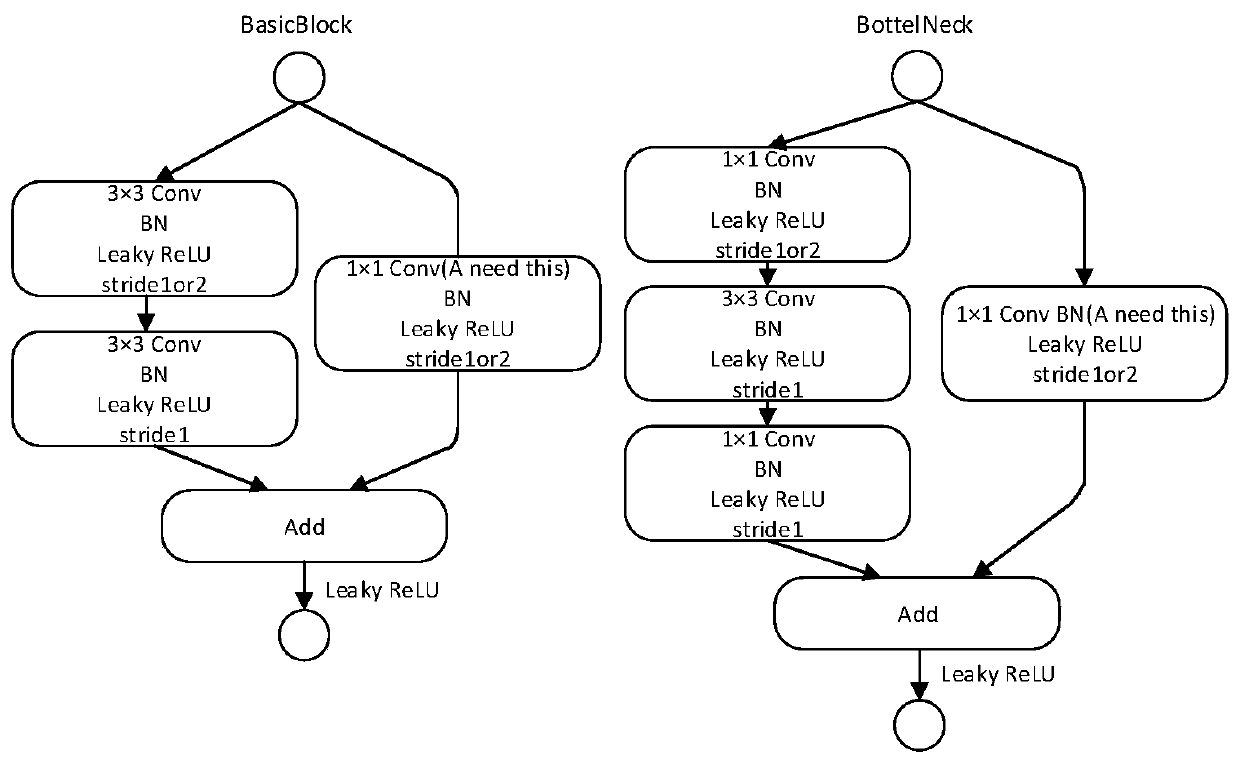

Improved YOLO-V3 metal processing surface defect detection method

ActiveCN111292305AHigh resolutionAvoid the problem of low-level feature lossImage enhancementImage analysisMetal machiningEngineering

The invention discloses an improved YOLO-V3 metal processing surface defect detection method. The method comprises the steps of acquiring a metal surface processing image; extracting feature maps of different scales from the feature extraction backbone network, wherein the feature extraction backbone network has no pooling layer, the downsampling factor is smaller than the downsampling factor of Darknet-53, and the convolution layer number is smaller than the convolution layer number of Darknet-53; inputting the feature map into a multi-scale fusion module for local feature fusion to obtain afused feature map; and inputting the fusion feature map into a multi-classifier module for metal processing surface defect positioning and classification. According to the invention, a pooling layer is omitted and a downsampling factor is reduced, and the problem of low-level feature loss generally caused in the down-sampling process of pooling operation is avoided. According to the method, the structural characteristic of high resolution of the deep features is guaranteed; the high resolution characteristic of the low-level features and the high semantic information characteristic of the deepfeatures are combined through local feature fusion; and finally accurate detection of small target defects on the metal machining surface is achieved.

Owner:CHONGQING UNIV

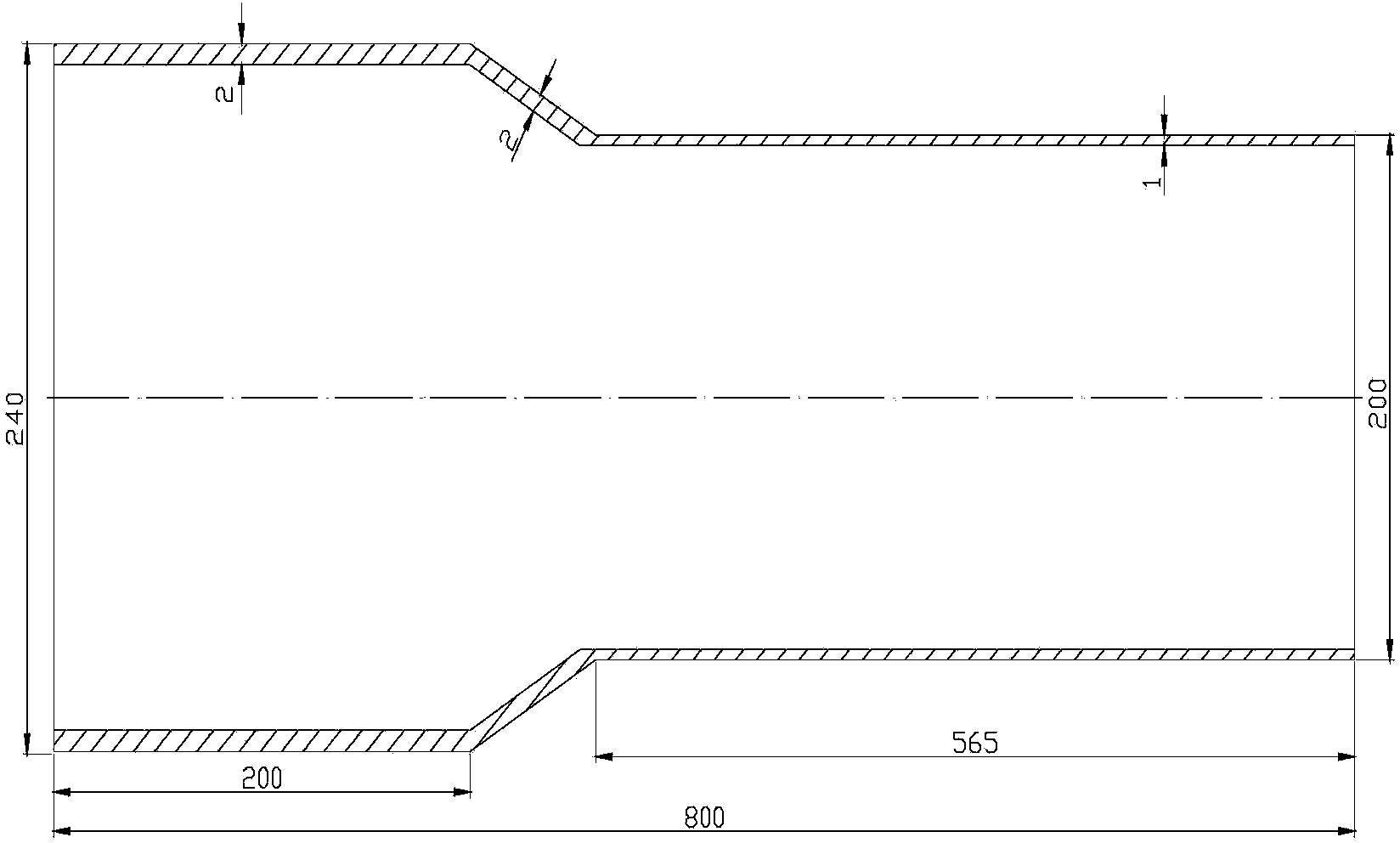

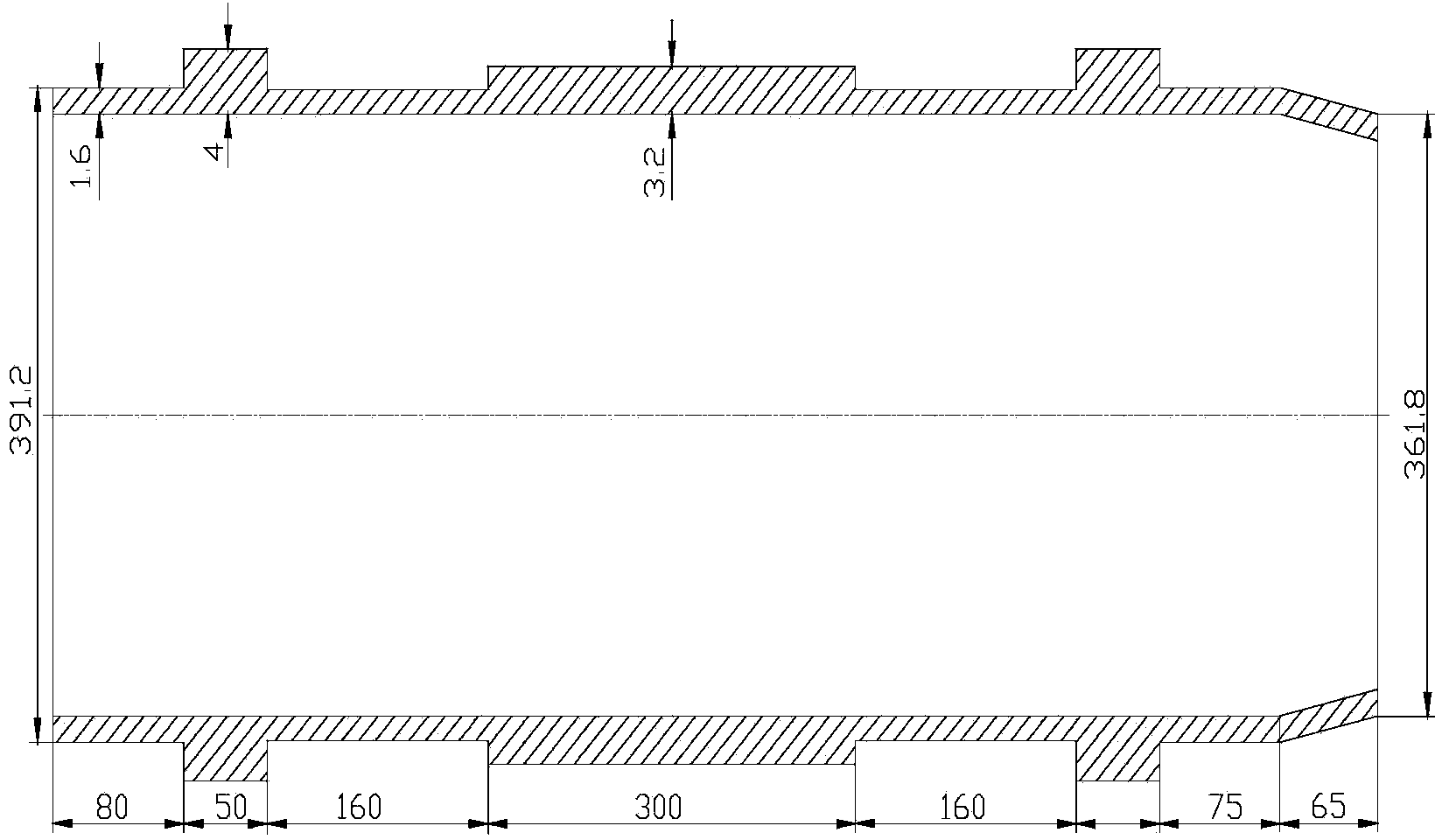

Roll forming and punching machine for metal sheet material

InactiveUS7340931B1Shorten speedMetal-working feeding devicesStock shearing machinesPunchingMetal machining

A punching machine installed in the machine base of a roller shape forming machine in a metal working system and controlled to punch holes on a metal sheet material being delivered through the roller shape forming machine during operation of the roller shape forming machine. The punching action, i.e., the cycling of the closing and opening actions of the punch mold of the punching machine is set to match with the delivering speed of the metal sheet material in the roller shape forming machine so that the punching operation of the punching machine is continued during processing operation of the roller shape forming machine.

Owner:CHUANG SEN JUNG

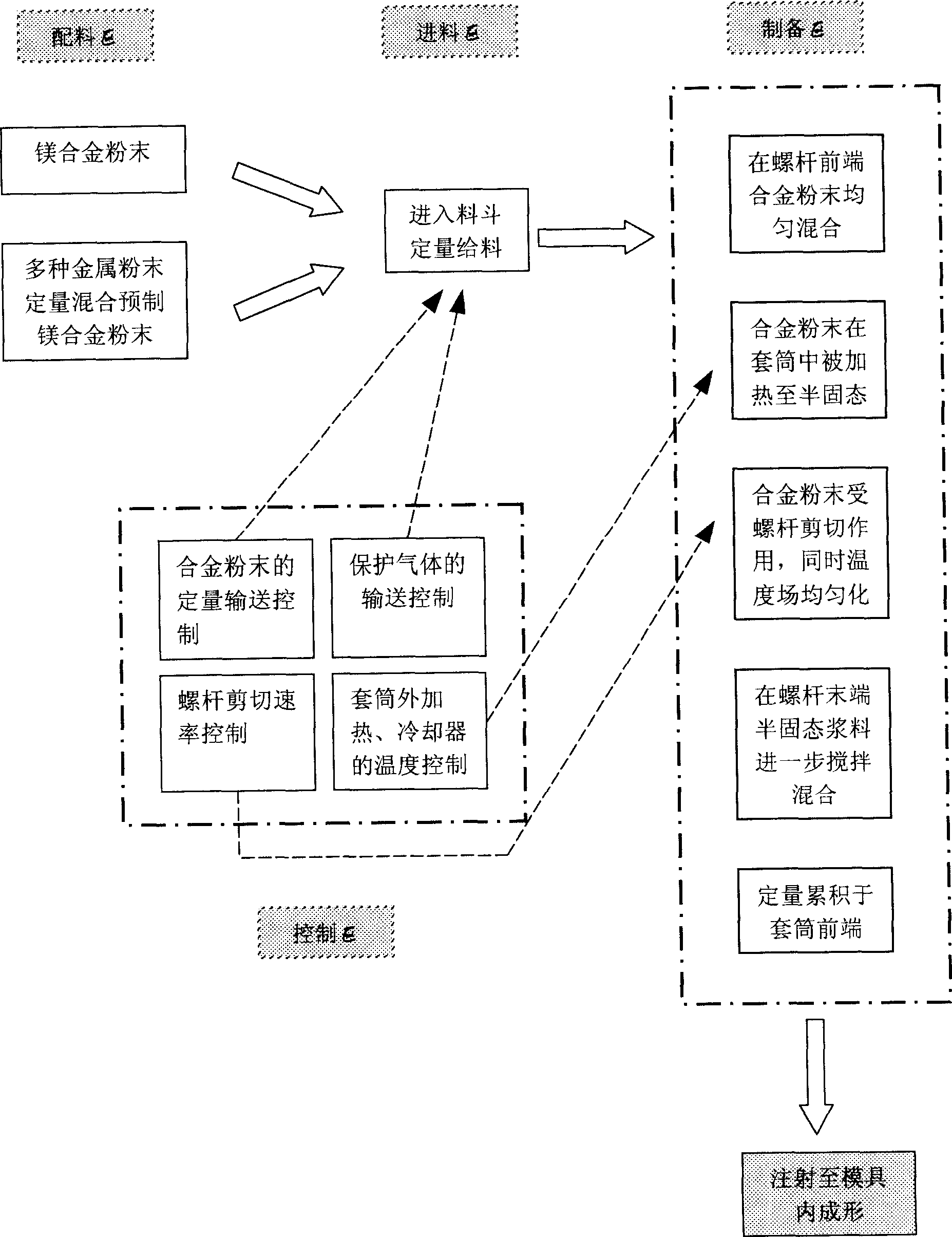

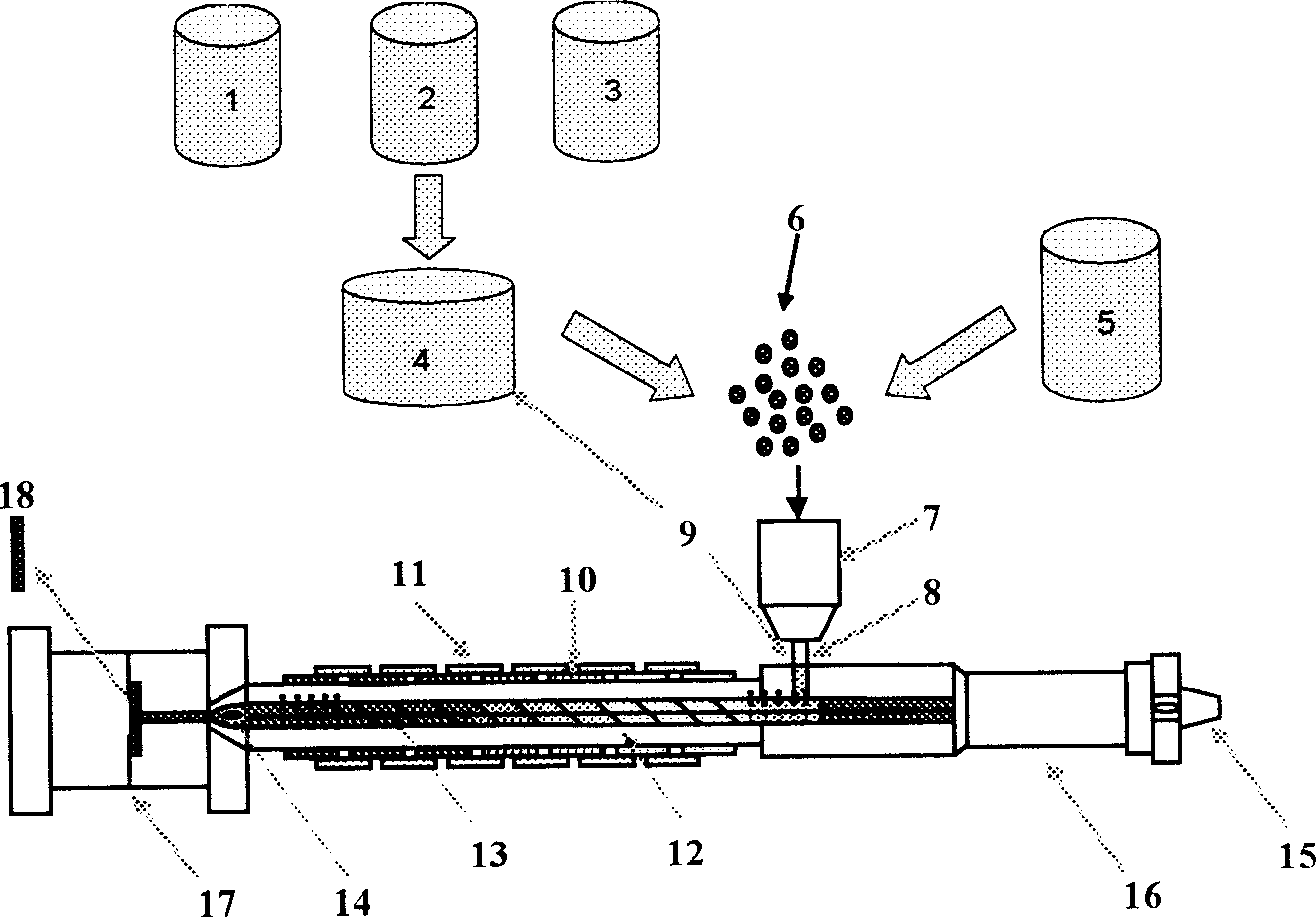

Semi-solid injection moulding method and device for magnesium alloy

A semi-solid injection moulding method for Mg alloy includes such steps as mixing metallic powder, gas protecting, quantitative supply, solid-liquid mixing, and semi-solid injection moulding. Its apparatus is composed of a metallic powder mixer consisting of stirring container and storage container, and an injection unit consisting of the metallic sleeve pipe unit comprising sleeve pipe and internal spiral delivering rod, and the cooler and heater for controlling the temp at different positions of sleeve pipe.

Owner:长春利镁科技发展有限公司

Rust-proof cutting fluid

The present invention relates to chemically synthesized assistant for metal cutting, and is especially one kind of water-base cutting fluid with cooling, rust-preventing, cleaning and lubricating functions. The present invention is obtained through mixing antirust agent, surfactant, lubricant and other metal machining assistants at certain condition. Specifically, the water-base cutting fluid contains p-tert-butyl benzoic acid 1-3 wt%, benzoic acid 2-5 wt%, boric acid 2-4 wt%, ethanolamine 2-8 wt%, polyethylene glycol of molecular weight 400-600 4-8 wt%, benzotriazole 0.1-0.5 wt%, non-ionic polyacrylamide 0.05-0.2 wt%, and water for the rest. The water-base cutting fluid has excellent abrasion dust settleability, no stickness to grinding wheel, excellent antirust performance, excellent cooling performance, good lubricating performance, environment friendship, etc.

Owner:JIANGSU UNIV OF SCI & TECH

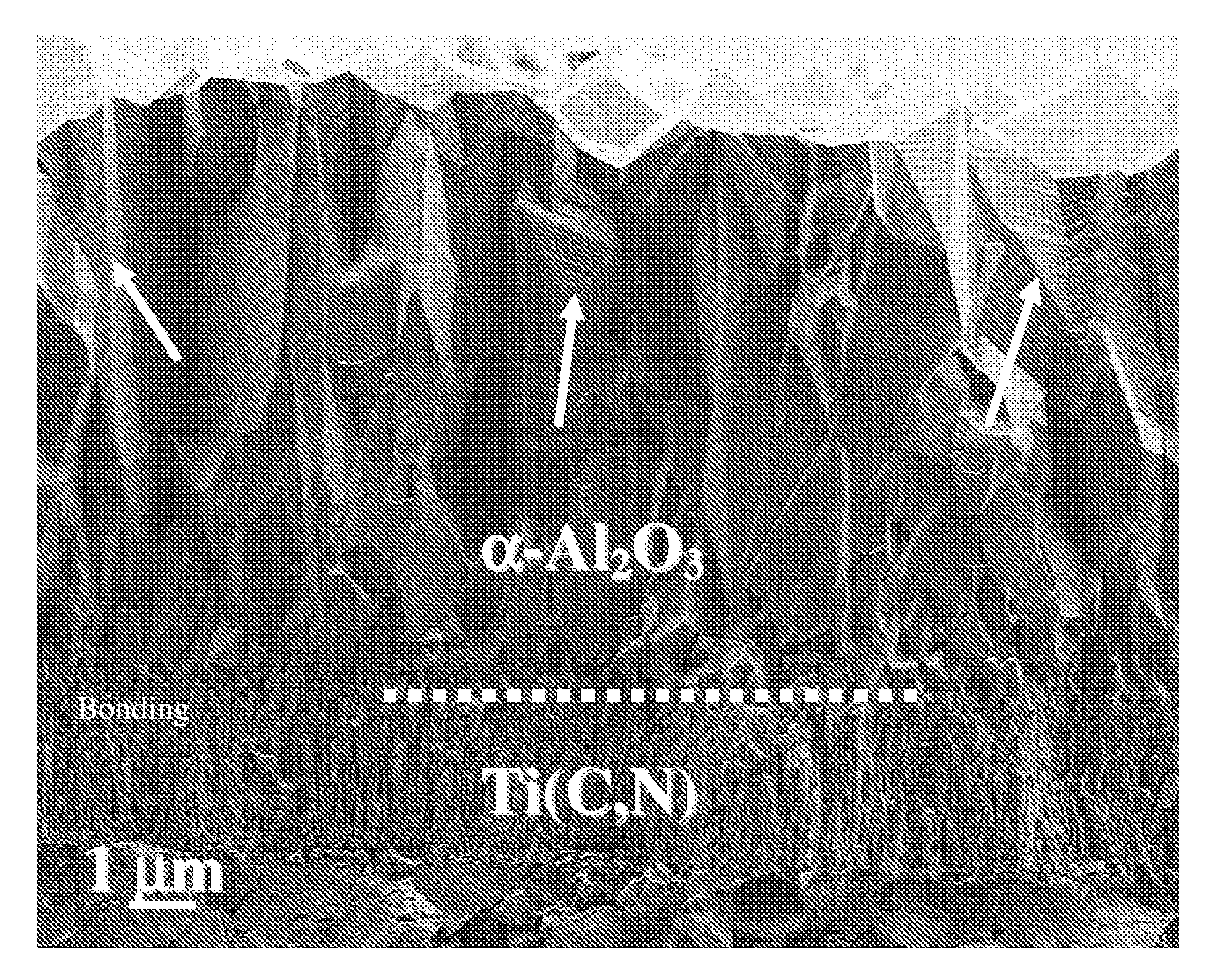

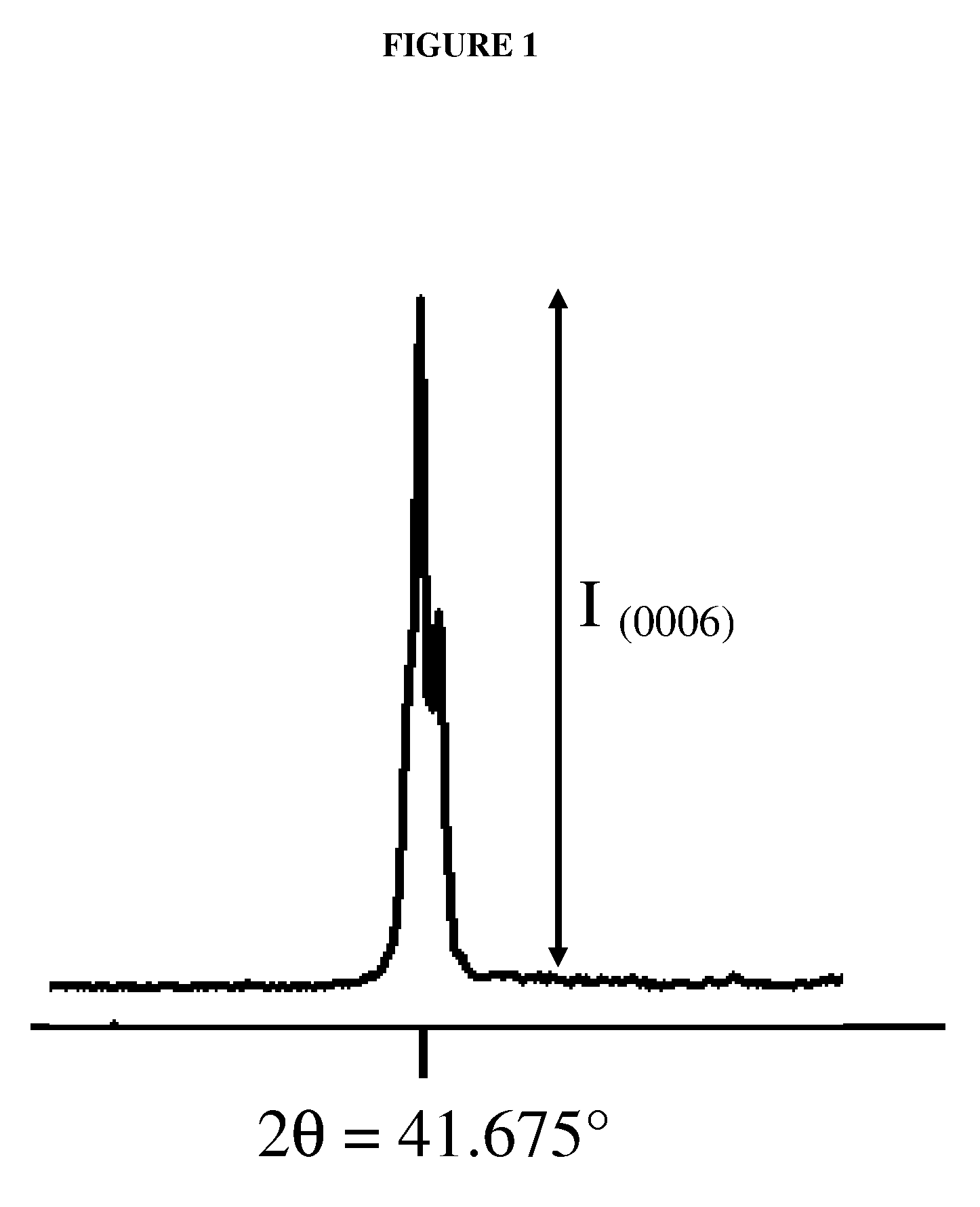

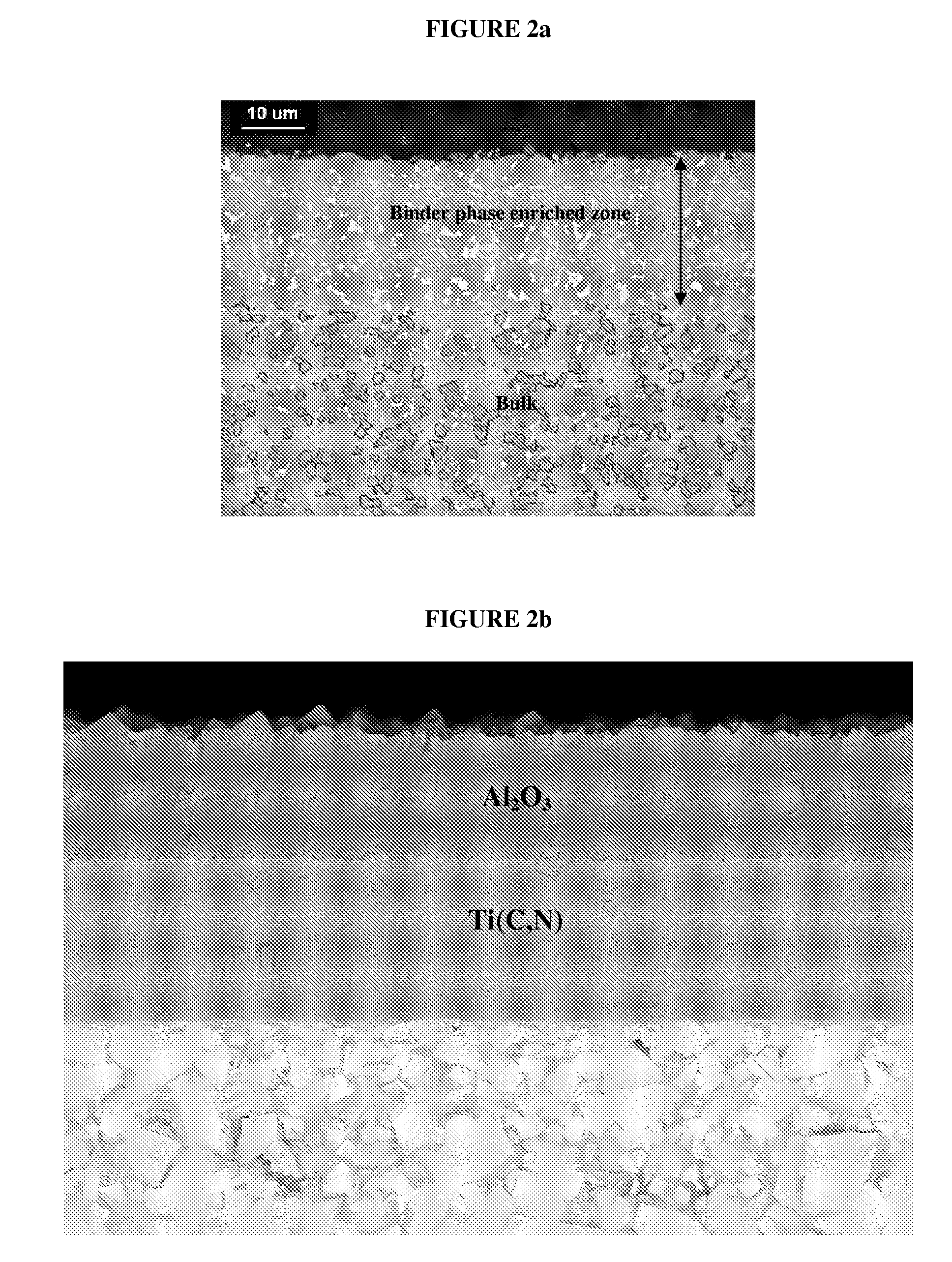

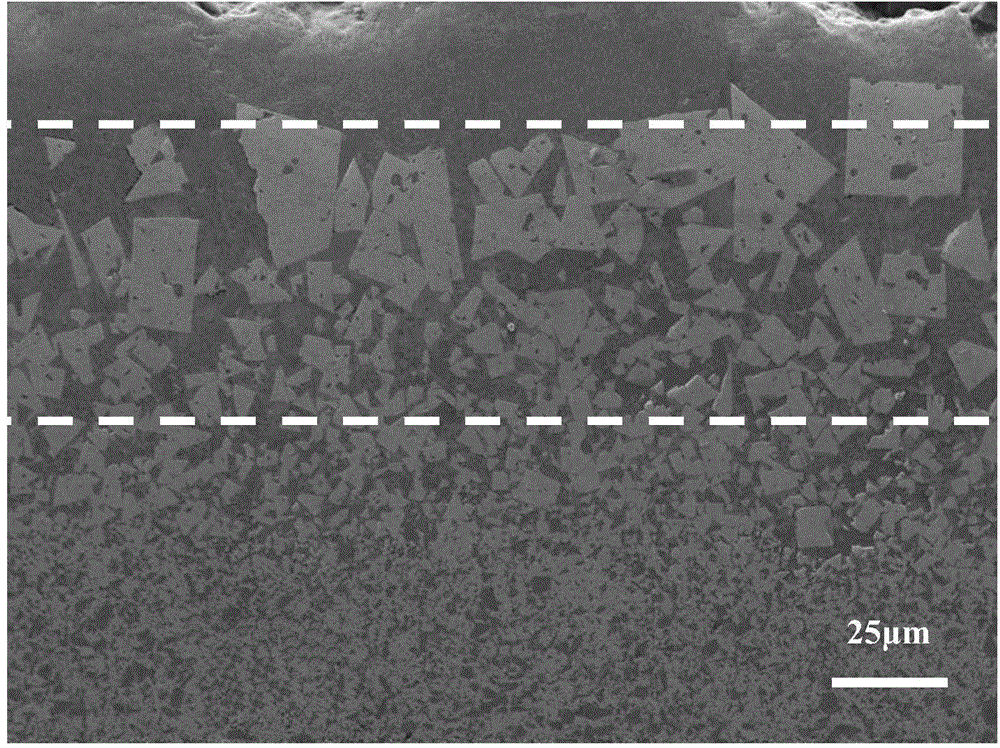

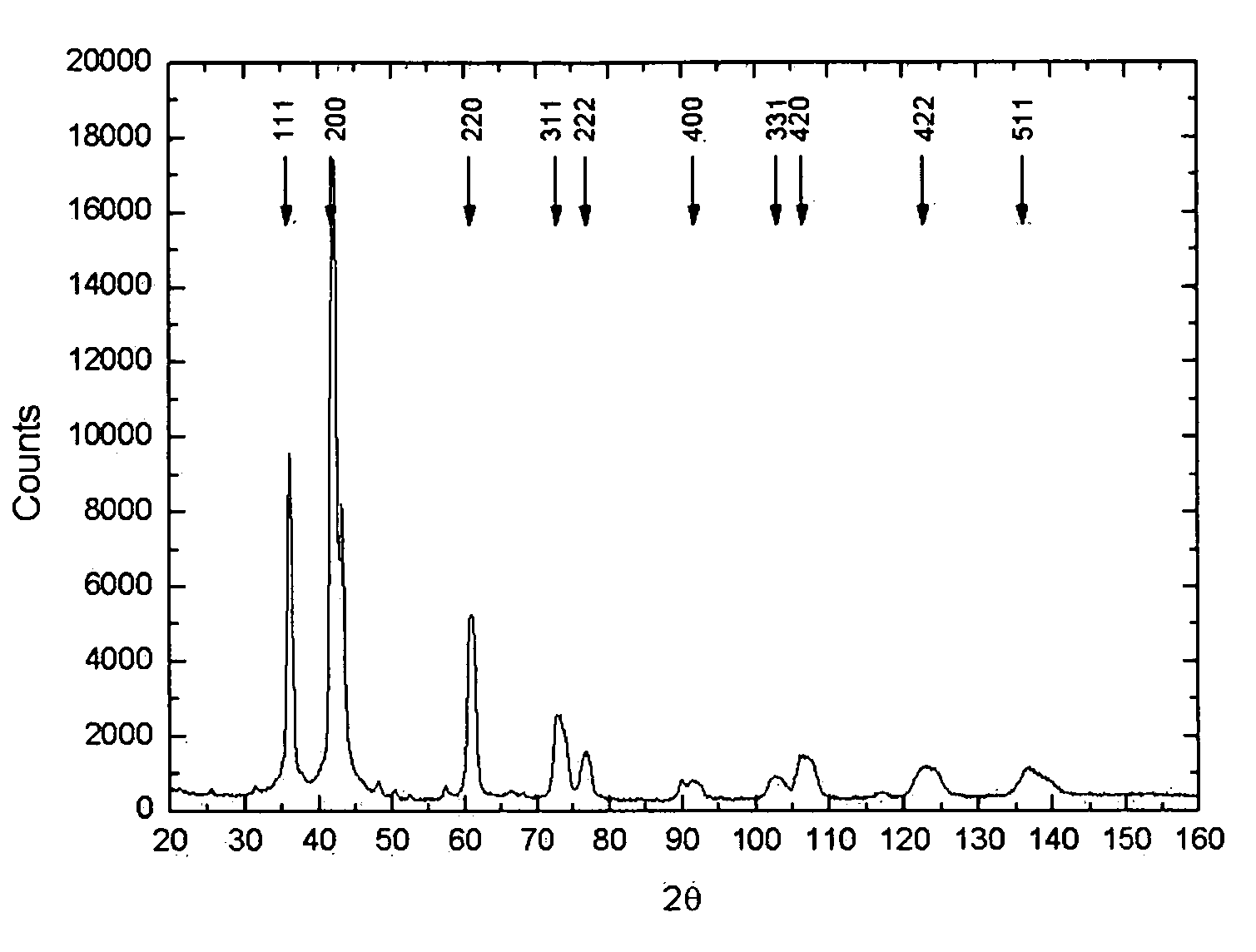

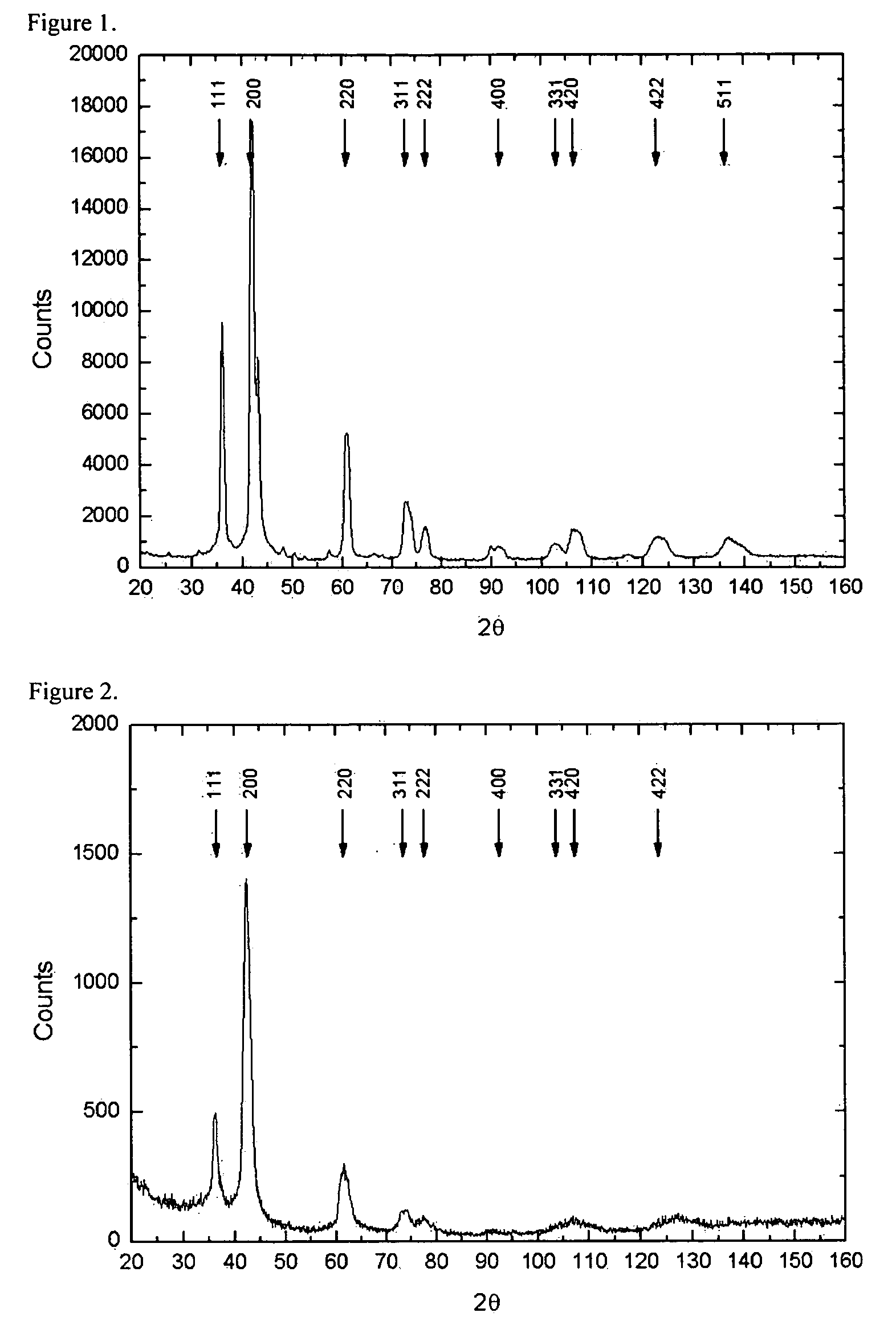

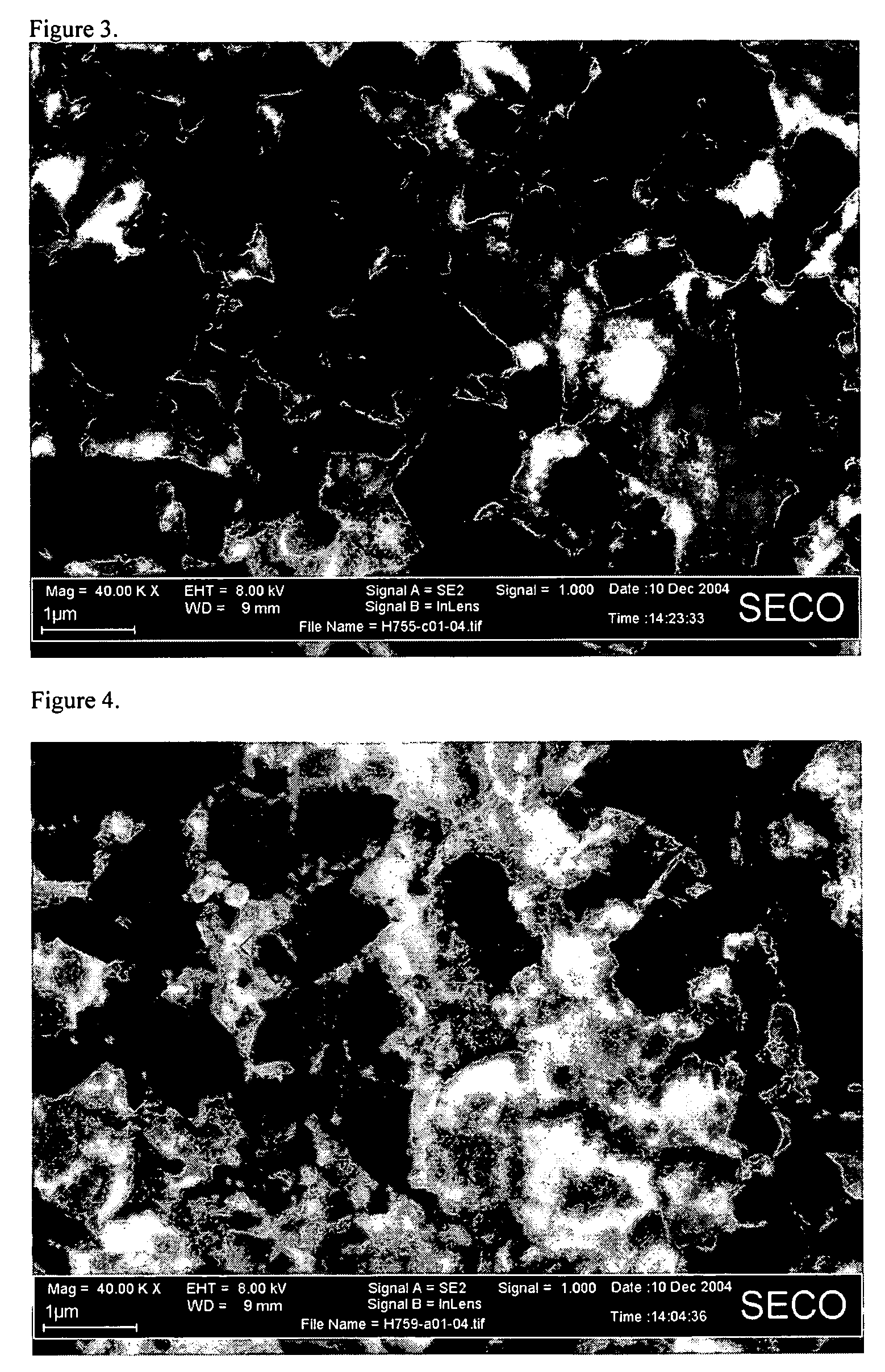

Texture-Hardened Alpha-Alumina Coated Tool

ActiveUS20080187774A1Improve wear resistanceSemiconductor/solid-state device manufacturingTurning toolsMetal machiningAlloy

The present invention relates to a coated cutting tool insert and a texture-hardened α-Al2O3 layer to be used in metal machining. The alumina layer is characterised by the improved toughness and it adheres to the substrate covering all functional parts thereof. The coating is composed of one or more refractory layers of which at least one layer is a texture-hardened α-Al2O3 having a thickness ranging from 2 to 20 μm being composed of columnar grains with a length / width ratio of 2 to 12. The α-Al2O3 exhibits a strong (0006) diffraction peak. The improved wear resistance and toughness can be obtained when the texture coefficient (TC) for the (0006) reflection is larger than 1.33 ln h+2, where h is the α-Al2O3 layer thickness and when the surface of the α-Al2O3 layer is wet-blasted to an Ra-value<1 μm. The alumina layer with a strong (0001) texture is applied on Binder phase enriched cemented carbide substrates. This combination contributes to enhanced wear resistance and toughness.

Owner:SECO TOOLS AB

Preparation of metal working fluid special for aluminum alloy

InactiveCN101696367AExcellent lubricity and protection against aluminumExcellent corrosion protectionLubricant compositionCorrosionSemi synthetic

The invention relates to a semi-synthetic metal working fluid special for aluminum and aluminum alloys, which has an excellent lubricating property and protective properties for aluminum and various aluminum alloys. The excellent lubricating property of the metal working fluid is manifested by simultaneously satisfying various processing modes of the aluminum alloys, such as turning, milling, drilling, tapping and the like. The excellent protective properties for the aluminum and the aluminum alloys are manifested by processing various aluminum alloys, generating no corrosion to the aluminum alloys and ensuring the requirements on the luminance brightness of the aluminum alloys. Besides, the metal working fluid also has excellent anti-rust properties and anti-foaming properties, and is added with a biological inhibitor which can effectively inhibit the growth and the reproduction of bacteria, prolong the service life of the metal working fluid and reduce the cost.

Owner:益田润石(北京)化工有限公司

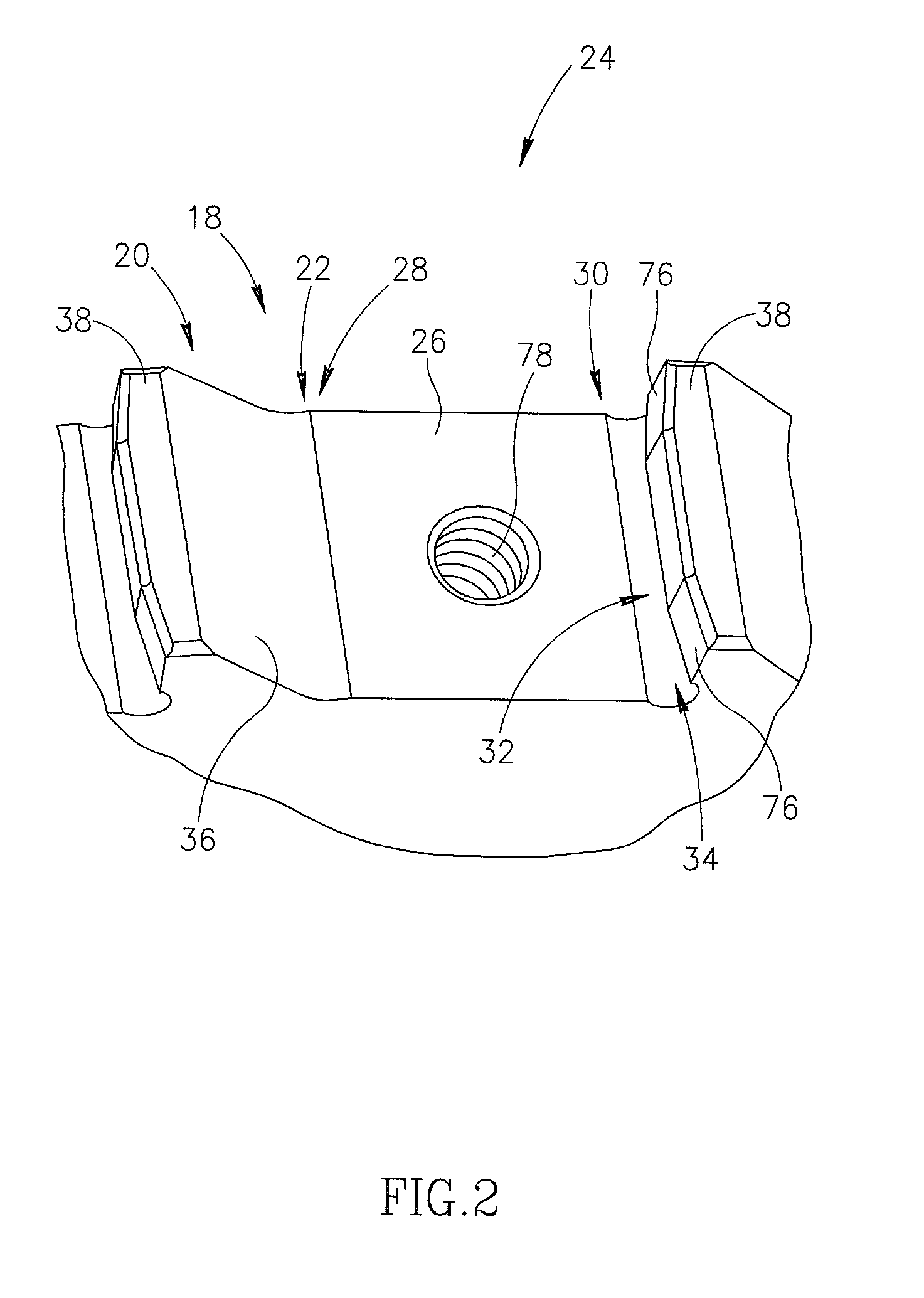

Tool and clamp for chip removing machining

A tool for chip removing metal machining includes a holder, a solid cutting insert mounted in a pocket of the holder, and a clamp for securing the insert. The clamp includes a clamping surface frictionally engaging a planar upper surface portion of the insert. The clamp is attached to the holder by a screw causing a downward projection of the clamp to slide along a sloping surface of the holder in order to displace the clamp and the insert rearwardly until the insert abuts an upstanding support surface of the holder. As the clamp is being tightened-down by the screw, an elastic lip of the clamp is elastically deformed by a surface of the holder to tilt the clamp in a direction causing the clamping surface to bear more firmly against the insert. A stop arrangement terminates the tightening down of the clamp before the clamp is plastically deformed.

Owner:SECO TOOLS AB

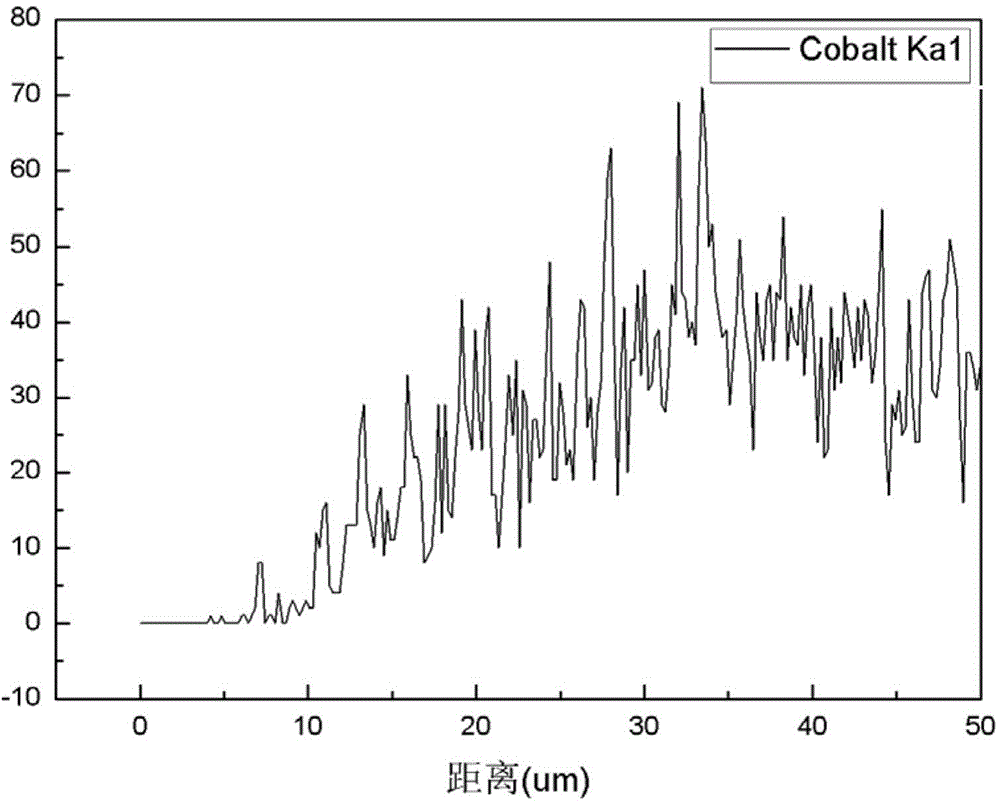

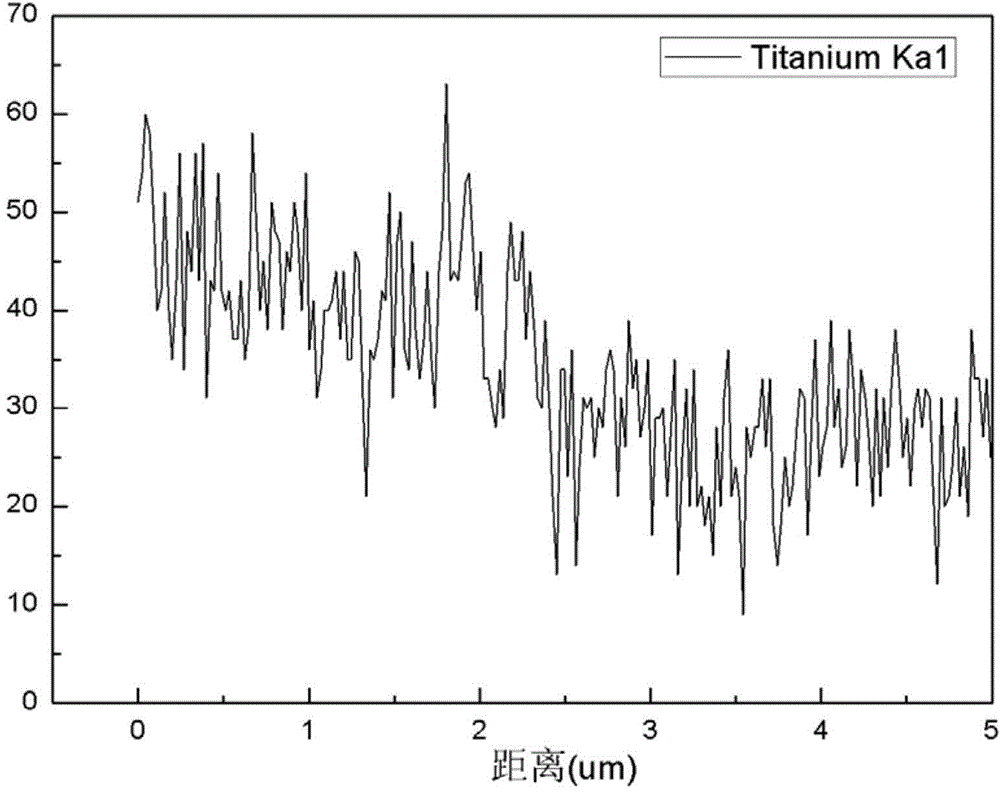

Surface-hardened gradient cemented carbide and preparation method thereof

The invention relates to the technical field of cemented carbide preparation, in particular to surface-hardened gradient cemented carbide and a preparation method thereof. By adjusting components of an alloy binding phase, the WC crystalline grains in the prepared cemented carbide are small, even in distribution, high in density and remarkable in gradient, the cemented carbide is made to have the more excellent mechanical property, and the red hardness of the cemented carbide is improved. The components and thickness of a gradient layer of the cemented carbide are controlled by adjusting blank formulas, sintering temperature, sintering time and other parameters, the surface layer of the cemented carbide is made to be rich in cubic phase and poor in binding phase, and due to the fact that a transition layer rich in alloying binding phase is arranged below the surface layer, the cemented carbide is excellent in hardness, wear resistance and roughness, and the cemented carbide can be used for metal machining. The cemented carbide prepared through the method has the excellent wear resistance, strength, hardness and toughness at the same time. According to the method, the functional gradient cemented carbide can be produced by slightly modifying existing equipment and processes, and is suitable for industrial production.

Owner:GUANGDONG UNIV OF TECH

Water-based synthetic metal machining liquid containing graphene dispersion liquid and preparation method thereof

The invention discloses water-based synthetic metal machining liquid containing graphene dispersion liquid and a preparation method thereof. The water-based synthetic metal machining liquid containing graphene dispersion liquid comprises an anti-attrition preservative, a pH stabilizer, a lubrication additive, namely graphene dispersion liquid, an antirust agent, a corrosion inhibitor, a hard water resistant agent, a pH conditioning agent and deionized water. The preparation method of the water-based synthetic metal machining liquid comprises the following steps of: firstly, uniformly stirring and mixing the deionized water, the anti-attrition preservative and the pH stabilizer at normal temperature and pressure to obtain a mixed solution; then stirring and mixing the corrosion inhibitor, the hard water resistant agent, the antirust agent and the pH conditioning agent at normal temperature and pressure, adding to the mixed solution, and continuing to uniformly mix to obtain a basic solution of the water-based synthetic metal machining liquid; and finally adding the lubrication additive, namely the graphene dispersion liquid to the obtained basic solution of the water-based synthetic metal machining liquid at normal temperature and pressure and uniformly mixing, thus obtaining the water-based synthetic metal machining liquid containing the graphene dispersion liquid, which has good stability, lubrication property, abrasion resistance and environmental protection property.

Owner:SHANGHAI INST OF TECH

On-line purification equipment for metal machining fluid and purification method thereof

InactiveCN101575153AAchieve purification effectRealize the use effectWater/sewage treatment by magnetic/electric fieldsWaste water treatment from metallurgical processLiquid wastePurification methods

The invention discloses on-line purification equipment for a metal machining fluid and a purification method thereof. The equipment comprises a purification fluid tank, a stock solution tank, a magnetic separation pool, a magnetic slag tank, a drum type multi-stage magnetic separation device, a gas-liquid mixing pump, an ozone generator, an ozone copolymerization air-float sterilization separation device and a Y-shaped water outlet pipe, wherein the drum type multi-stage magnetic separation device adopts a drum-shaped structure, the inner wall of the drum is embedded with a plurality of same permanent magnets at certain intervals along the same axial direction; and the inside of the ozone copolymerization air-float sterilization separation device is orderly provided with a grid, a baffle plate and an ozone contact generator from bottom to top, and the upper part of the ozone contact generator is a separation zone. The method comprises the main steps of magnetic separation, gas dissolution, sterilization and water and slag discharge. The method has the advantages of realizing the on-line circular purification and use of the machining fluid, prolonging the service life of the machining fluid, greatly reducing the amount of waste fluid generated and achieving the aims of water conservation, emission reduction and clean production.

Owner:DALIAN JIAOTONG UNIVERSITY

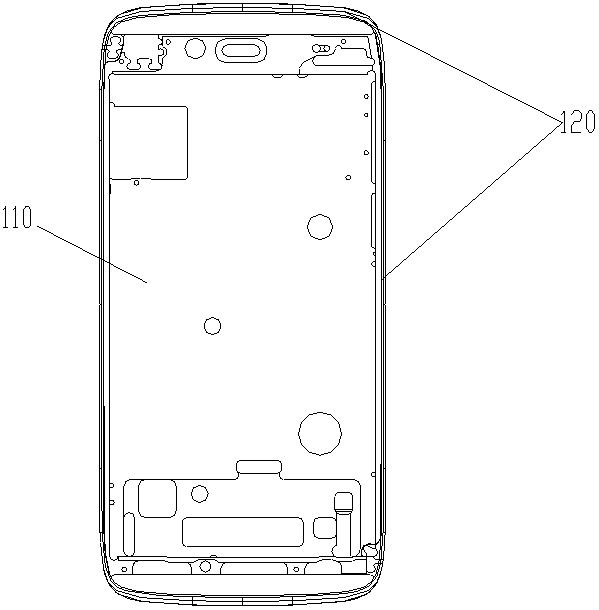

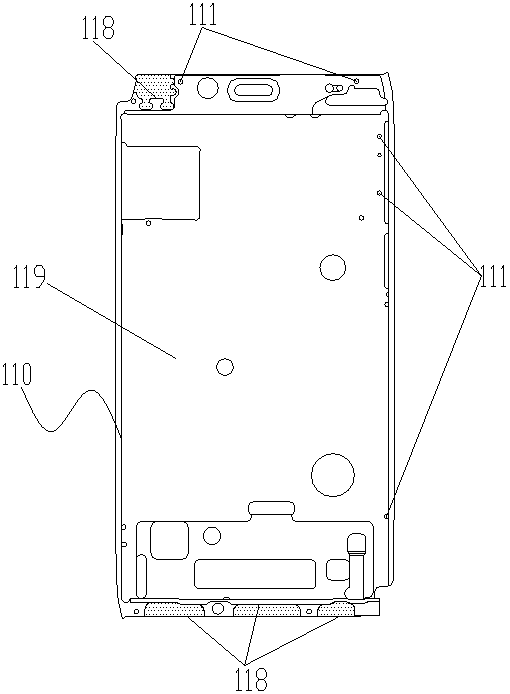

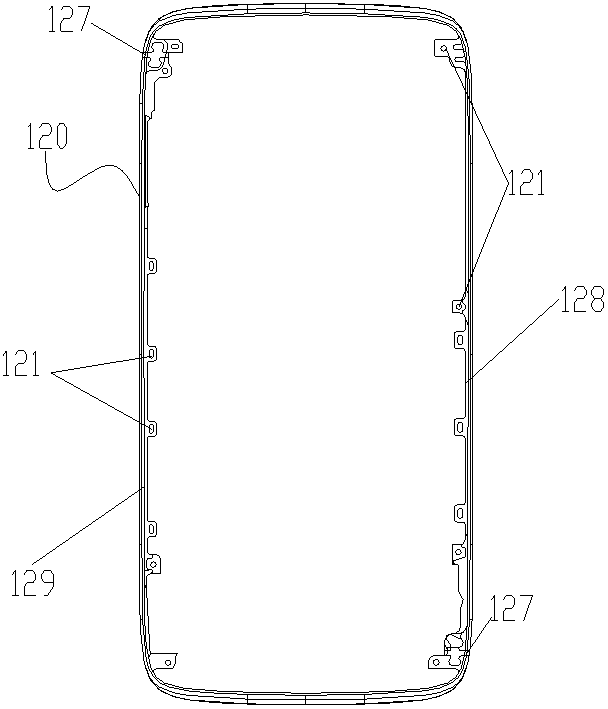

Mobile phone metal piece assembling structure and manufacturing method of mobile phone metal piece

ActiveCN103716429AGuaranteed mechanical reliabilityLow costTelephone set constructionsDie castingAgricultural engineering

The invention discloses a mobile phone metal piece assembling structure and a manufacturing method of the mobile phone metal piece. The mobile phone metal piece assembling structure comprises a middle plate and an outer frame, wherein an internal structural part of the middle plate is formed by die-casting of magnesium alloy, the outer frame is connected to the outer side of the periphery of the middle plate and has an antenna function, and the outer frame is machined and manufactured through CNC. According to the design of the mobile phone metal piece assembling structure, the mobile phone metal piece is low in cost, appearance of the metal piece is not affected, and the cost is lowered; the assembling structure is easy to design and manufacture and convenient to use and popularize; compared with a full-aluminum CNC metal machining method, the manufacturing method enables the cost to be lowered; the assembling process is easy and mass production performance is achieved.

Owner:HUIZHOU TCL MOBILE COMM CO LTD

Technological process of physical vapor deposition coating

InactiveCN102230154ALower requirementHigh bonding strengthVacuum evaporation coatingSputtering coatingGas phaseNitrogen gas

The invention discloses a technological process of a physical vapor deposition coating, relating to the technical field of metal machining and aiming at solving problems of large energy consumption and long treatment time in a traditional physical vapor deposition coating process. The technological process disclosed by the invention has the following steps of: (a) nitriding treatment: placing a matrix material on a deflection source in a reaction chamber and introducing nitrogen and inert gas into the vacuum reaction chamber, wherein the reaction time is 50-100 minutes; and (b) film deposition: closing the nitrogen , cooling the reaction chamber, introducing coating material plasma gas into the reaction chamber, and bombarding the matrix material nitrided in the step (a) by using the coating material plasma gas, wherein the reaction time is 50-100 minutes. The technological process of the physical vapor deposition coating, disclosed by the invention, is applicable to the coating treatment of the surfaces of most of tool molds and parts.

Owner:SHANGHAI BA ER & NEW MATERIAL SCI & TECH

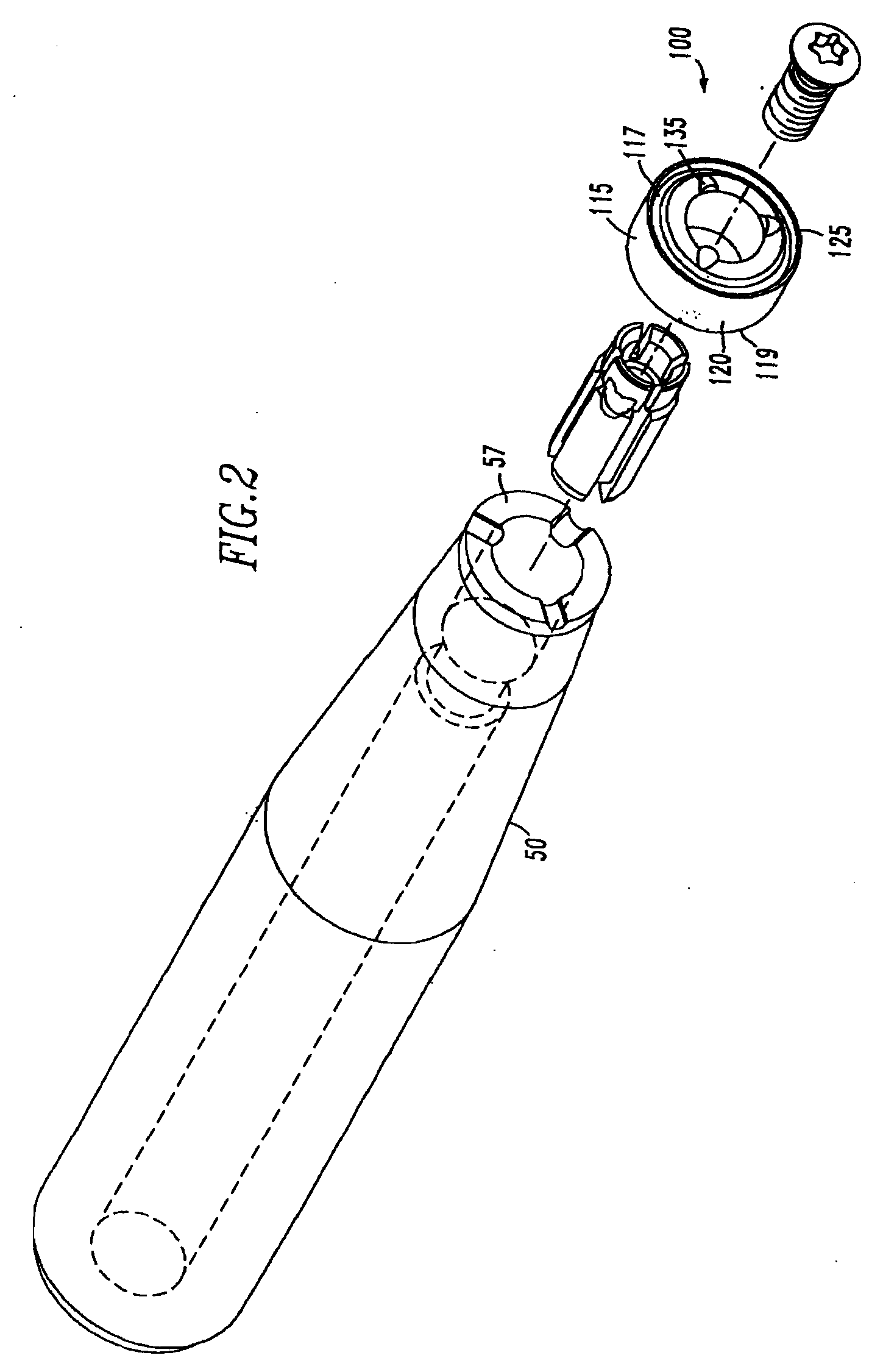

Cutting insert and toolholder for holding the same

A cutting insert for metalworking operations has an insert core with a pair of cutting portions having cutting tips extending therefrom such that a toolholder having a pocket to accept such a core is suitable to accept different cutting inserts having a common core plus different cutting portions. As a result, for example, an 80° diamond, a 55° diamond and a 35° diamond cutting insert may all be utilized within a common toolholder. The invention is also directed to a toolholder that will accept such a variety of cutting inserts.

Owner:KENNAMETAL INC

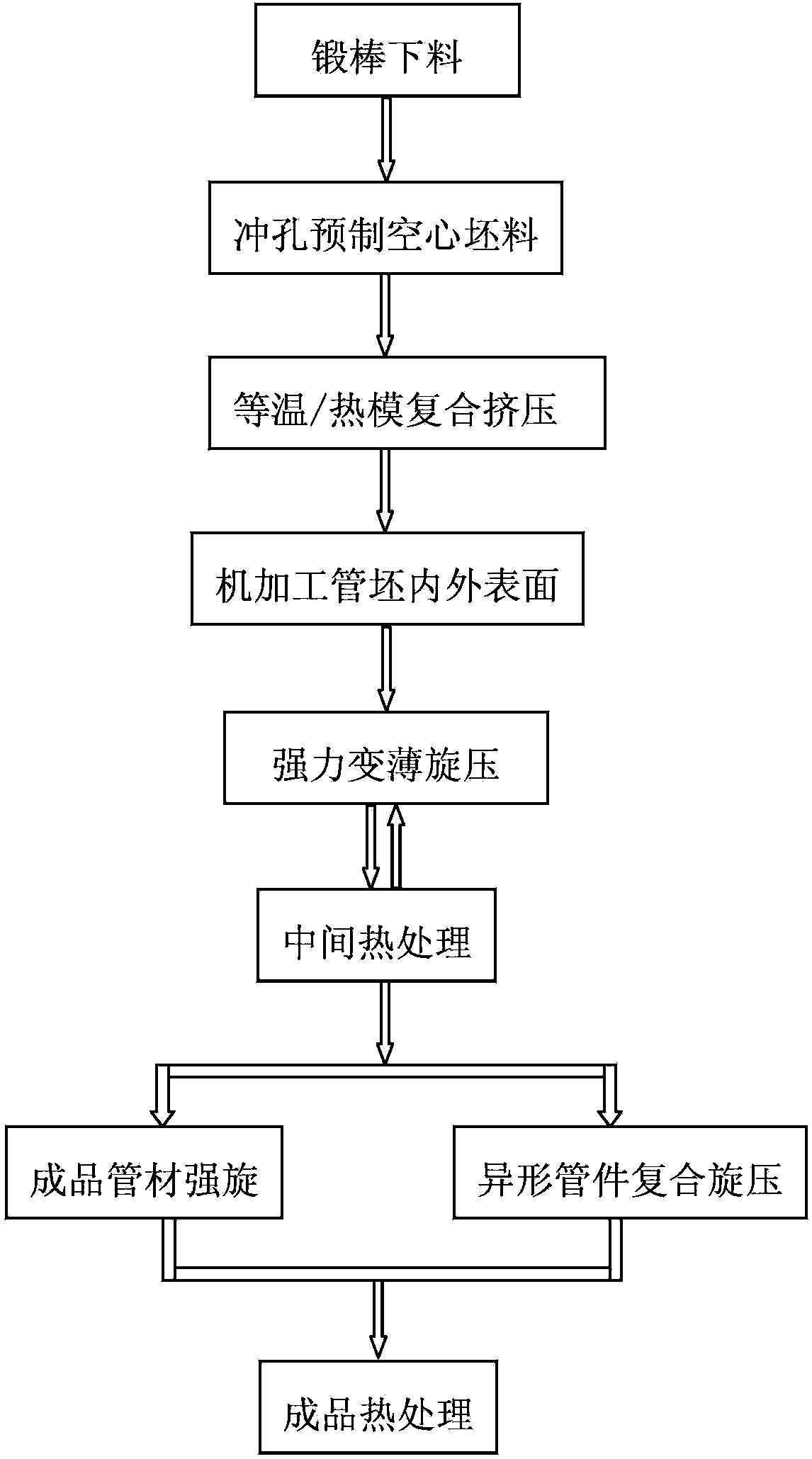

Preparation machining method of large-diameter pipe material and special-shaped pipe fitting

ActiveCN103846305AFormabilityForming labor-savingExtrusion control devicesSocial benefitsSolution treatment

The invention belongs to the technical field of metal machining, and particularly relates to a preparation machining method of a large-diameter pipe material and a special-shaped pipe fitting. The preparation machining method comprises the following steps of prefabricating a hollow blank by punching, carrying out isothermy or hot mould combined extrusion on the hollow blank, machining the inner and outer surfaces of an extruding tube blank, and carrying out multi-pass cold or hot power cone spinning on the machined tube blank; carrying out intermediate heat treatment (which can be annealing or solution treatment) on a semi-finished pipe material product; repeatedly and alternately carrying out multi-pass power cone spinning and the intermediate heat treatment, and carrying out power spinning on the finished pipe material product; carrying out multi-pass composite spinning forming on the semi-finished pipe material product after heat treatment so as to obtain the special-shaped pipe fitting; and carrying out acid pickling and cleaning on the obtained pipe fitting and special-shaped pipe fitting and then carrying out thermal treatment on the finished product. The preparation machining method of the large-diameter pipe material and the special-shaped pipe fitting provided by the invention has the advantages that the large-diameter pipe material and the special-shaped pipe fitting are prepared and machined, the product organization is uniform, the combination property is high, the forming is effort-saving, the additional value is high, and a product has good popularization and application prospect and definite economic benefits and social benefits.

Owner:GRIMAT ENG INST CO LTD

Cutting insert and toolholder for holding the same

InactiveUS20050019112A1Minimization requirementsCutting insertsTurning toolsDiamond cuttingMetalworking

A cutting insert for metalworking operations has an insert core with a pair of cutting portions having cutting tips extending therefrom such that a toolholder having a pocket to accept such a core is suitable to accept different cutting inserts having a common core plus different cutting portions. As a result, for example, an 80° diamond, a 55° diamond and a 35° diamond cutting insert may all be utilized within a common toolholder. The invention is also directed to a toolholder that will accept such a variety of cutting inserts.

Owner:KENNAMETAL INC

Composite coating for finishing of hardened steels

InactiveUS20060292399A1Improve adhesion strengthImprove performanceMilling cuttersVacuum evaporation coatingMilling cutterMetal machining

The present invention relates to a cutting tool insert, solid end mill, or drill, comprising a substrate and a coating. The coating is composed of one or more layers of refractory compounds of which at least one layer comprises a cubic (Me,Si)X phase, where Me is one or more of the elements Ti, V, Cr, Zr, Nb, Mo, Hf, Ta and Al, and X is one or more of the elements N, C, O or B. The ratio R=(at-% X) / (at-% Me) of the c-MeSiX phase is between 0.5 and 1.0 and X contains less than 30 at-% of O+B. This invention is particularly useful in metal machining applications where the chip thickness is small and the work material is hard e.g. copy milling using solid end mills, insert milling cutters or drilling of hardened steels.

Owner:SECO TOOLS AB

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com