Patents

Literature

1683 results about "Type metal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In printing, type metal (sometimes called hot metal) refers to the metal alloys used in traditional typefounding and hot metal typesetting. Historically, type metal was an alloy of lead, tin and antimony in different proportions depending on the application, be it individual character mechanical casting for hand setting, mechanical line casting or individual character mechanical typesetting and stereo plate casting. The proportions used are in the range: lead 50‒86%, antimony 11‒30% and tin 3‒20%. Antimony and tin are added to lead for durability while reducing the difference between the coefficients of expansion of the matrix and the alloy. Apart from durability, the general requirements for type-metal are that it should produce a true and sharp cast, and retain correct dimensions and form after cooling down. It should also be easy to cast, at reasonable low melting temperature, iron should not dissolve in the molten metal, and mould and nozzles should stay clean and easy to maintain. Today, Monotype machines can utilize a wide range of different alloys. Mechanical linecasting equipment use alloys that are close to eutectic.

Micro-emulsion type metal cutting liquor composition

InactiveCN101240217AEasy to handleImprove the lubrication effectAdditivesBase-materialsMaterials scienceCutting fluid

Disclosed is a microemulsifying metal-cutting-fluid composition, comprising base oil or oily agent, mixed alcohol-amine, boric acid, anionic surfactant, nonionic surfactant, antirust agent, copper alloy corrosion inhibitor, preservative, deionized water and the like. The invention has the advantages of excellent lubricity, cooling ability, cleaning ability and a long lifetime of metal cutting fluid, being suited to various metal processing technologies such as cutting, reaming, boring, grinding. Also, the wastewater is easy to treat.

Owner:益田润石(北京)化工有限公司

Perovskite-type metal oxide compounds

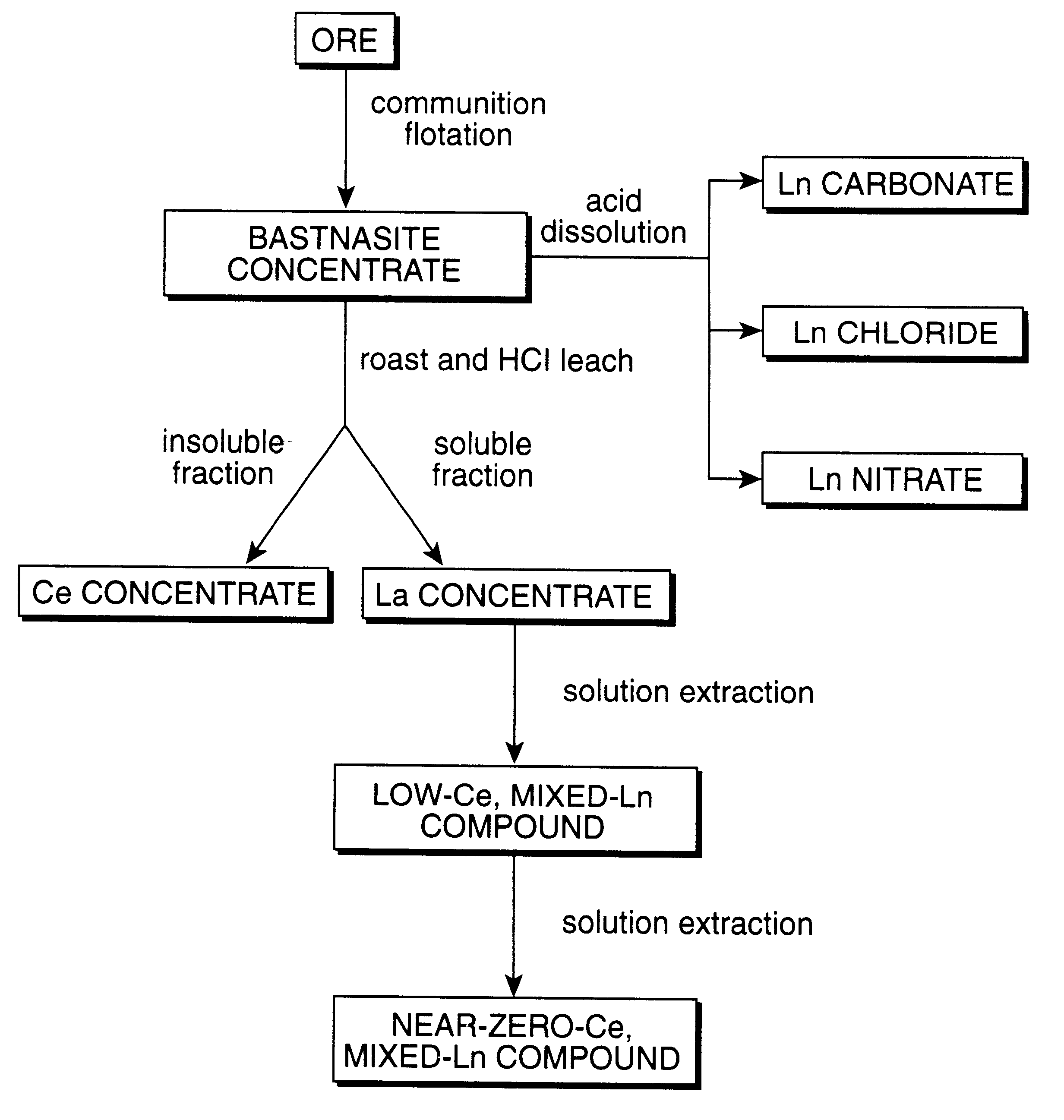

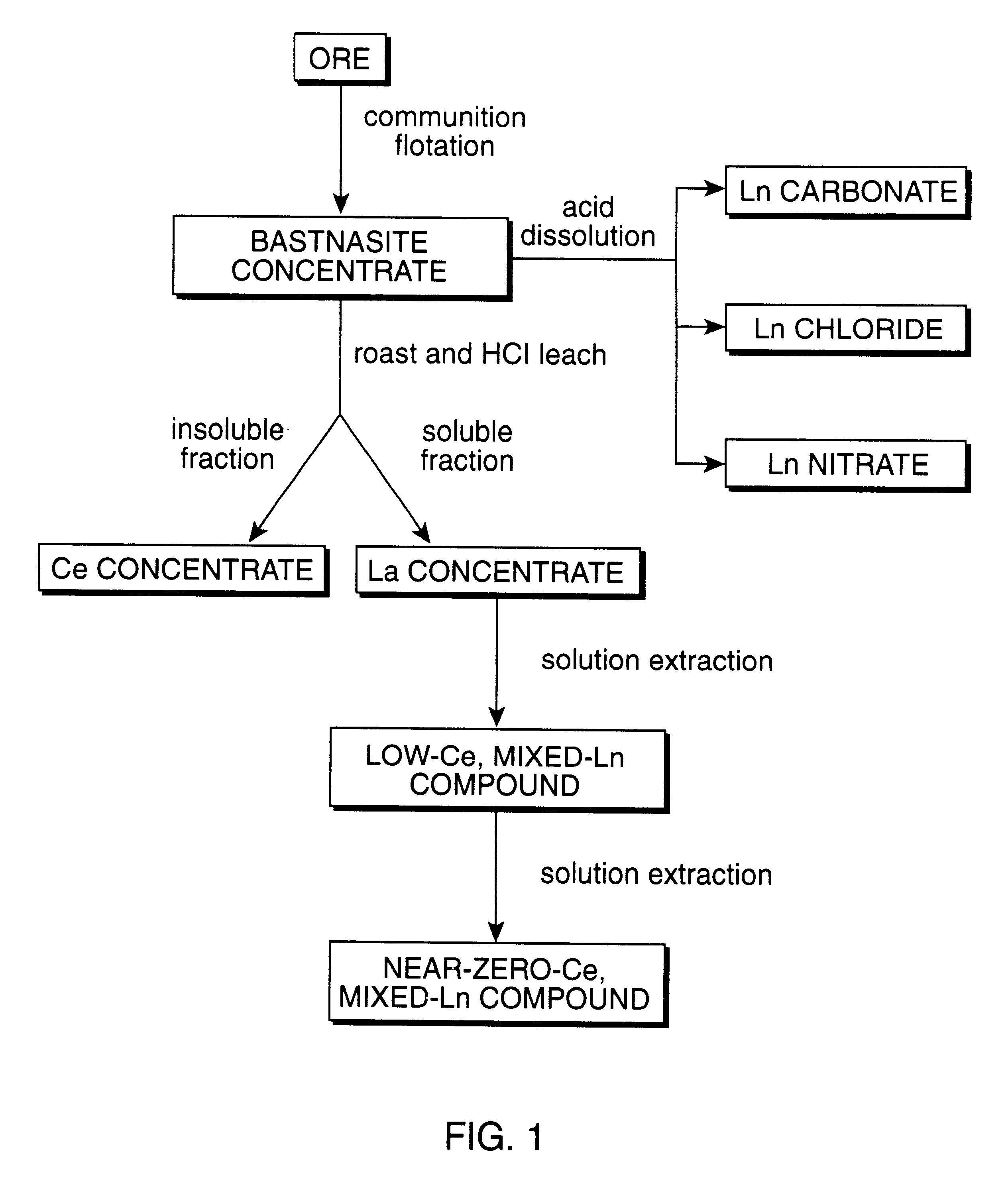

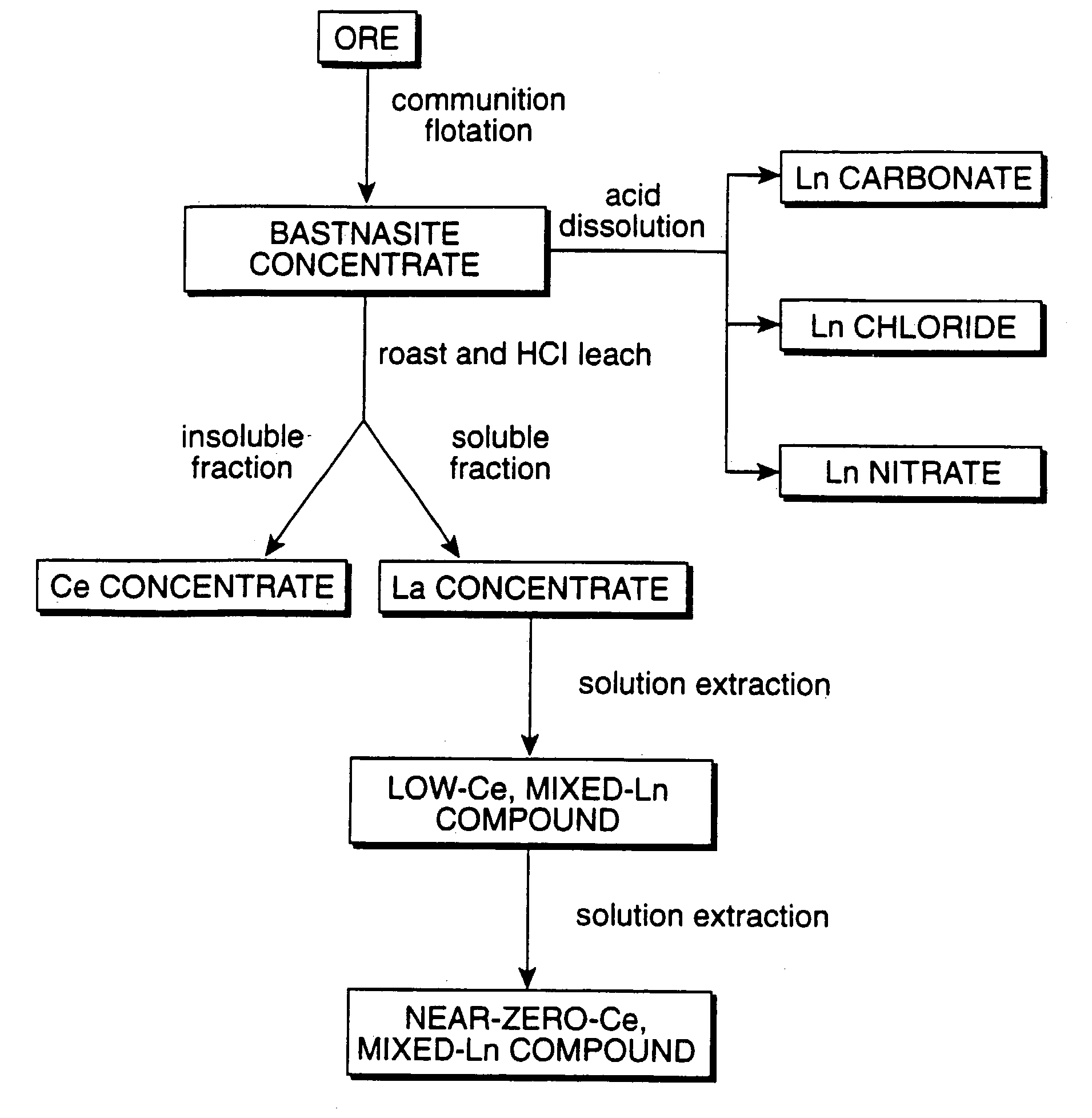

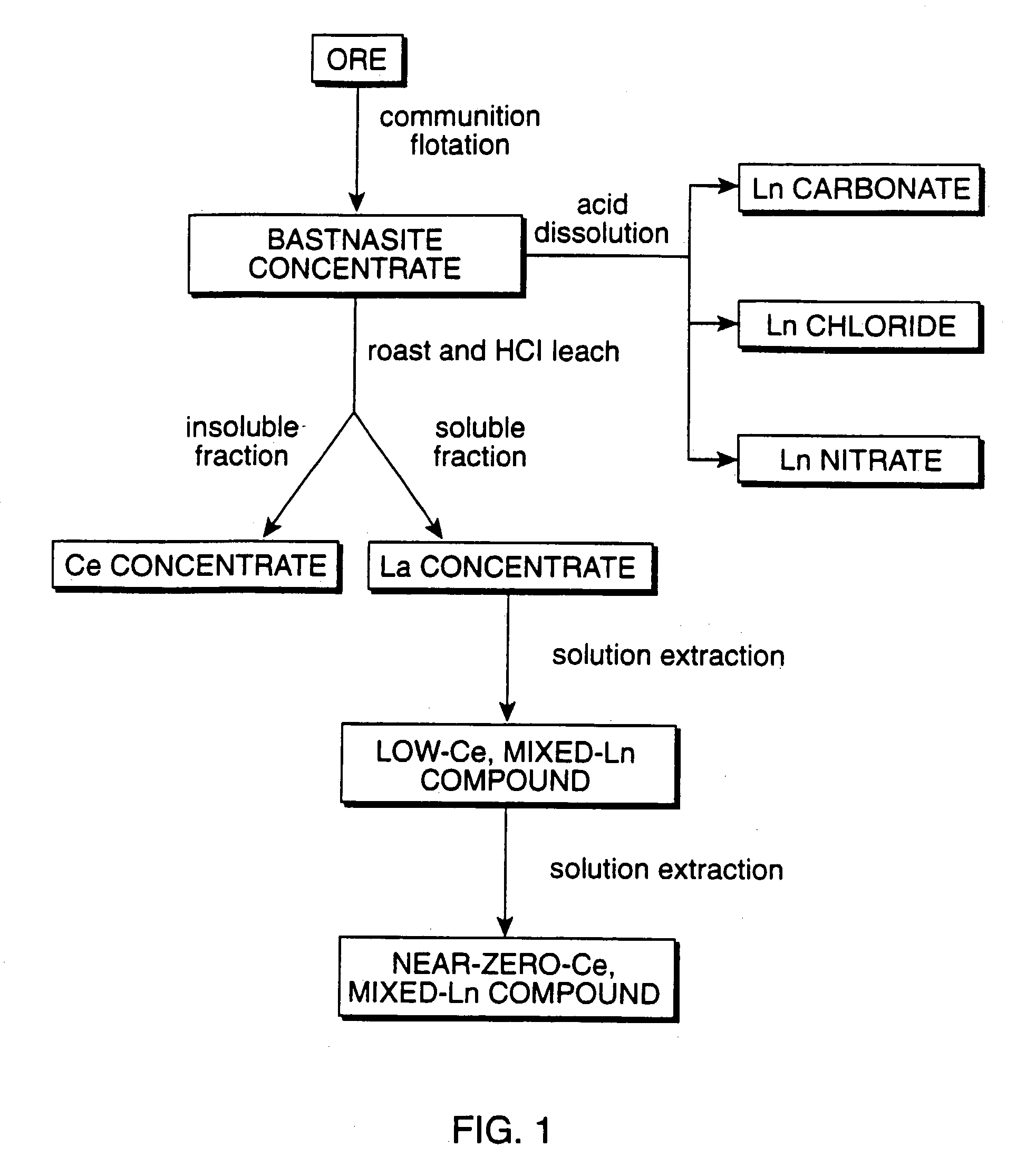

Perovskite-type catalyst consists essentially of a metal oxide composition is provided. The metal oxide composition is represented by the general formula A.sub.1-x B.sub.x MO.sub.3, in which A is a mixture of elements originally in the form of single phase mixed lanthanides collected from bastnasite; B is a divalent or monovalent cation; M is at least one element selected from the group consisting of elements of an atomic number of from 22 to 30, 40 to 51, and 73 to 80; and x is a number defined by 0.ltoreq.x<0.5.

Owner:CATALYTIC SOLUTIONS INC

Emulsification type metal cutting liquor composition

InactiveCN101240218AImprove the lubrication effectImprove cooling effectAdditivesBase-materialsPhenolCutting fluid

Disclosed is an emulsifying metal-cutting-fluid composition comprising base oil or oily agent, mixed alcohol-amine, anionic surfactant, nonionic surfactant, antirust agent, copper alloy corrosion inhibitor, preservative and the like. The invention has a strong general usability, suitable for metal processing, particularly aluminum alloy metal processing with advantages of excellent lubricity, corrosion resistance, a low cost and being free of toxic or harmful substances such as nitrites and phenols, so as to keep the environment and operators away from harmfulness.

Owner:河北九熙新材料科技有限公司

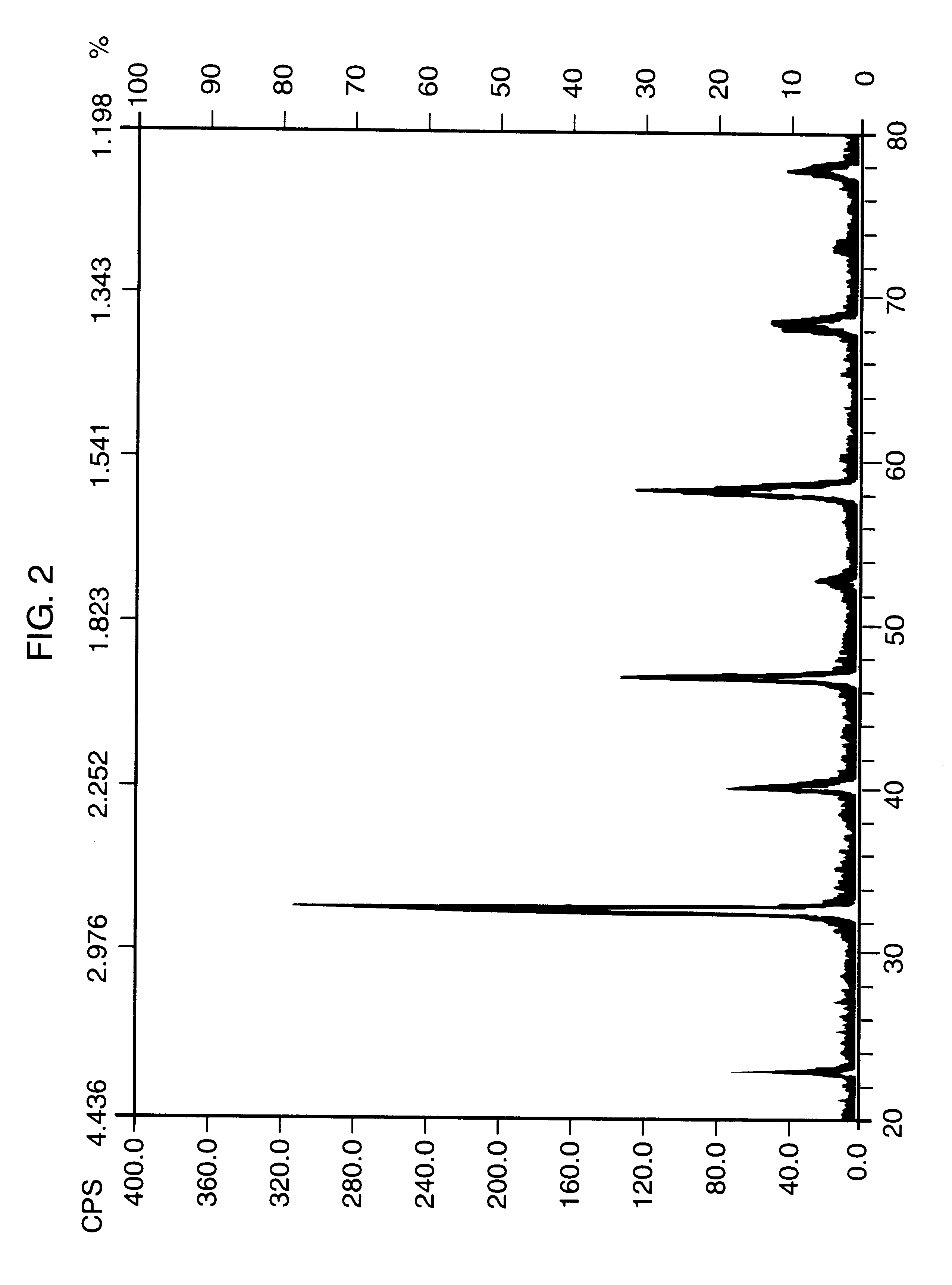

Raspberry-type metal oxide nanostructures coated with ceo2 nanoparticles for chemical mechanical planarization (CMP)

InactiveUS20120077419A1Efficient processCost-effective and convenient processMaterial nanotechnologySilicaCeo2 nanoparticlesWater soluble

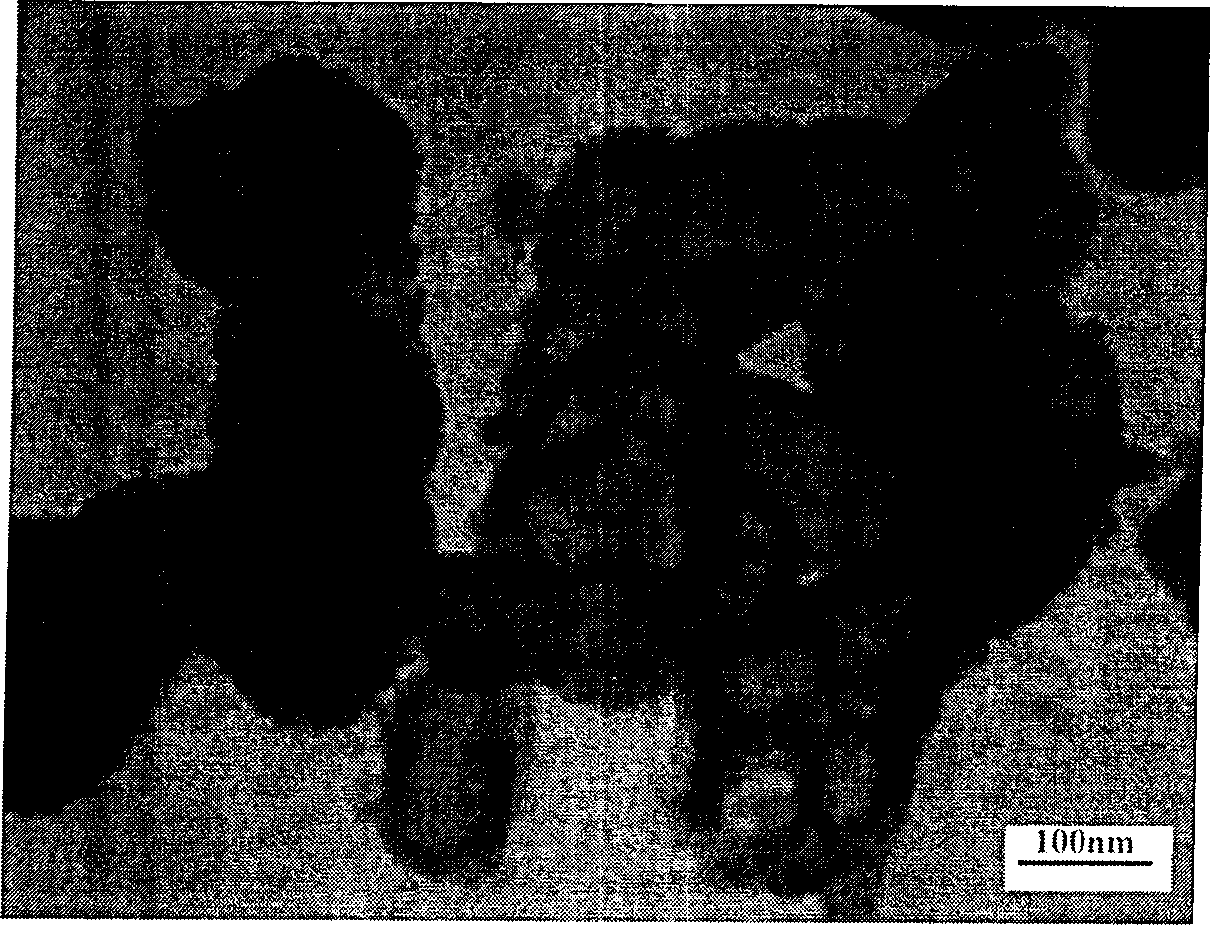

Raspberry-type coated particles comprising a core selected from the group consisting of metal oxides of Si, Ti, Zr, Al, Zn and mixtures thereof with a core size of from 20 to 100 nm wherein the core is coated with CeCO2 particles having a particle size below 10 nm; process for preparing raspberry type coated particles comprising the steps of i) providing a mixture containing: a) core particles selected from the group of metal oxides of Si, Ti, Zr, Al, Zn and mixtures thereof, with a particle size of from 20 to 100 nm; b) a water soluble Ce-salt and c) water; ii) adding an organic or inorganic base to the mixture of step i) at temperatures of from 10 to 90° C. and iii) aging the mixture at temperatures of from 10 to 90° C.; and polishing agents containing the particles and their use for polishing surfaces.

Owner:BASF AG

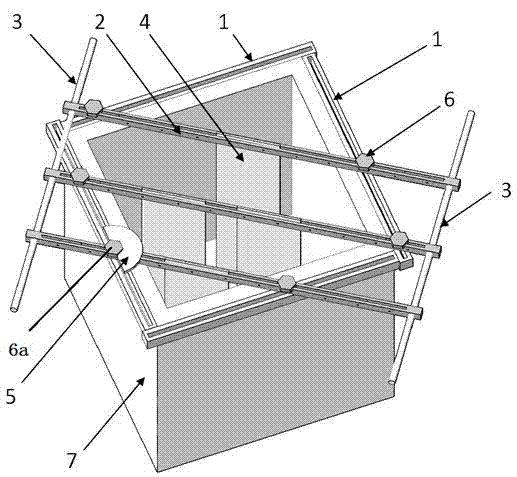

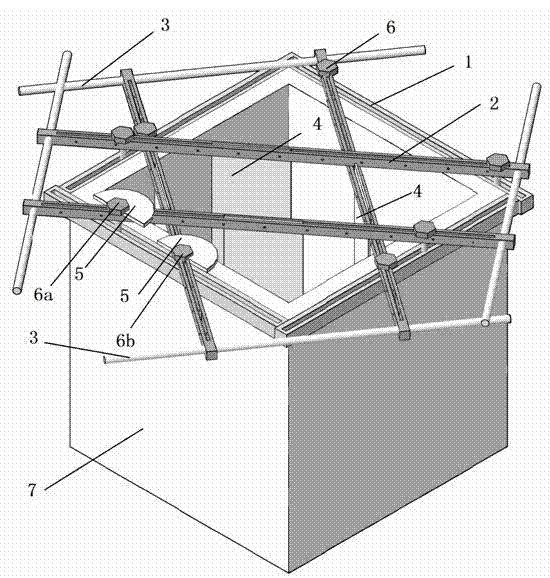

Mould for manufacturing fissure surface of rock like test block

InactiveCN102519767APrevent movementEasy to transformPreparing sample for investigationCeramic shaping apparatusProtractorSheet steel

The invention discloses a mould for manufacturing a fissure surface of a rock like test block. The mould comprises a sliding groove, a sheet steel locating rod, a protractor, a sliding rod and a sheet steel, wherein the sliding groove is a long strip type metal component provided with a straight groove hole; the sheet steel locating rod is a metal rod; the sliding rod is a metal rod marked with ascale; a sheet steel fixing sheet is a hard sheet provided with a notch and stuck on the bottom surface of the test block mould; the sliding groove is fixed on the top of the side wall of the test block mould; the sheet steel locating rod is fixed above the sliding groove; the circle centre of the protractor passes through any bolt and is fixed above the sheet steel locating rod; the sliding rod passes through holes at two ends of the sheet steel locating rod and is vertical to the sheet steel locating rod; one end of the sheet steel is fixed in a through groove of the sheet steel locating rod; and the other end of the sheet steel is clamped in the notch of the sheet steel fixing sheet. The mould disclosed by the invention is capable of conveniently and rapidly adjusting parameters of thefissure surface of the test block, such as an inclination angle, an interval, a communication rate and the like. The mould is easy to process and can be repetitively utilized, thus, the manufacture efficiency and the precision of the test block are increased.

Owner:WUHAN UNIV

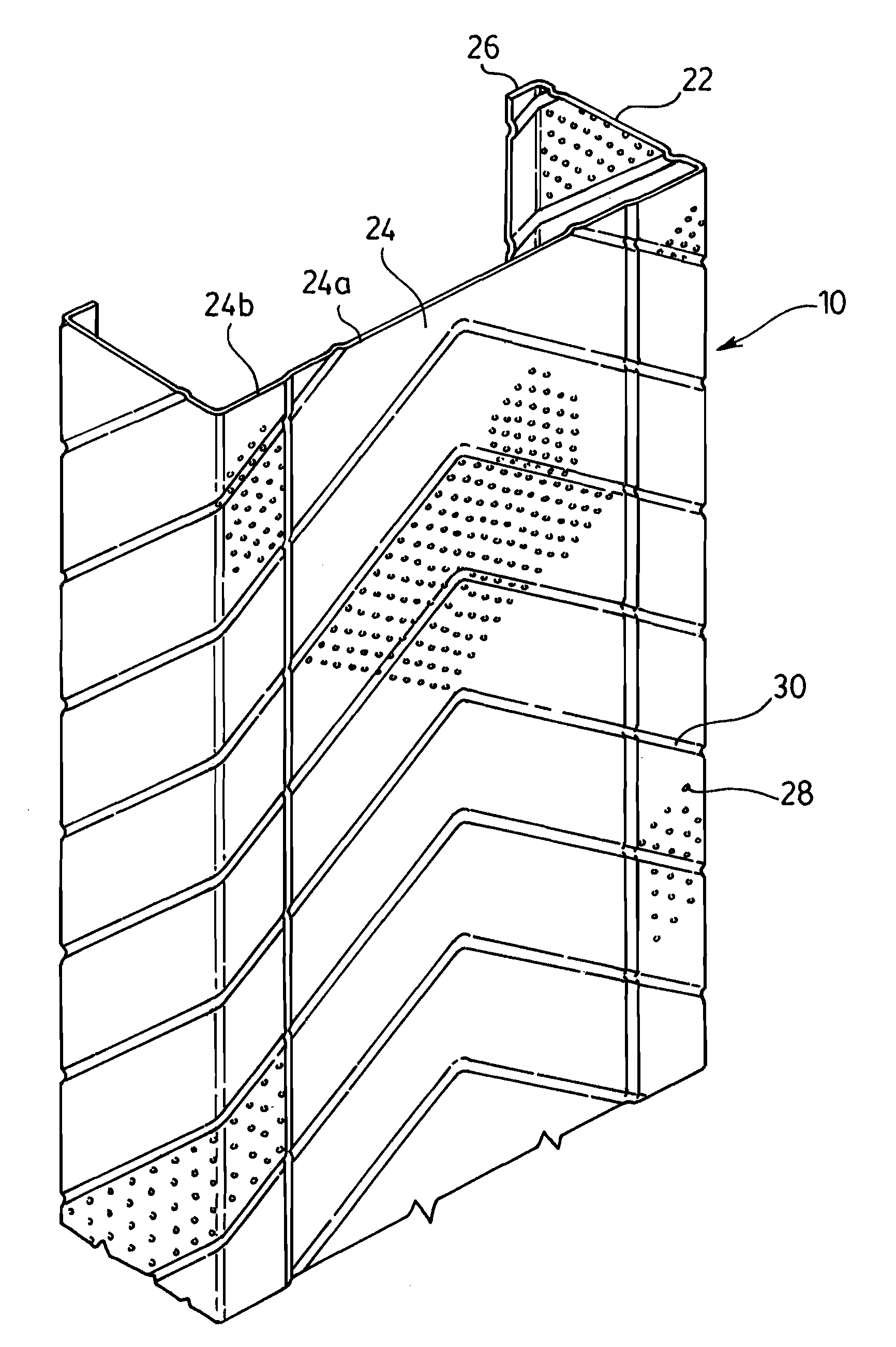

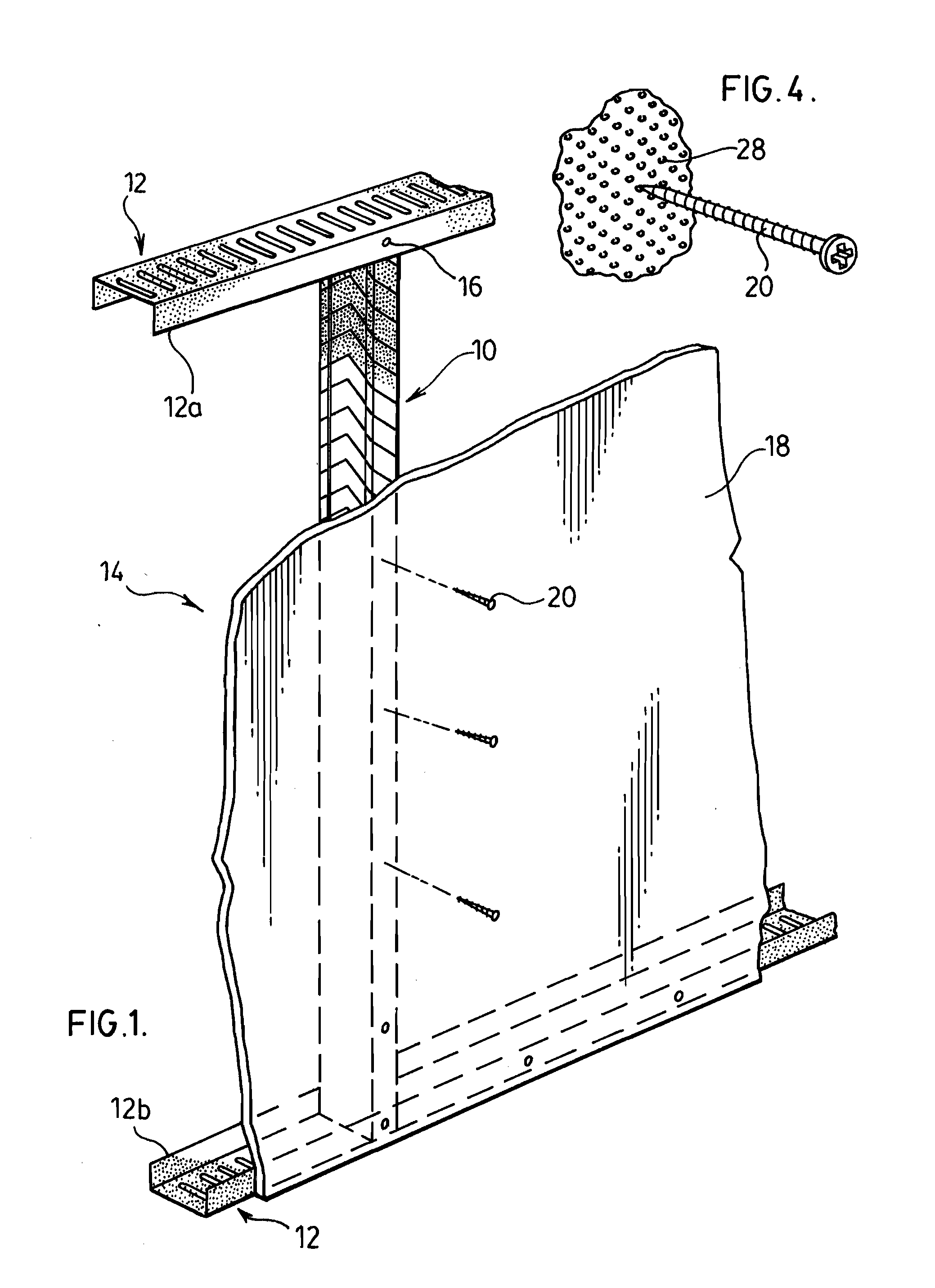

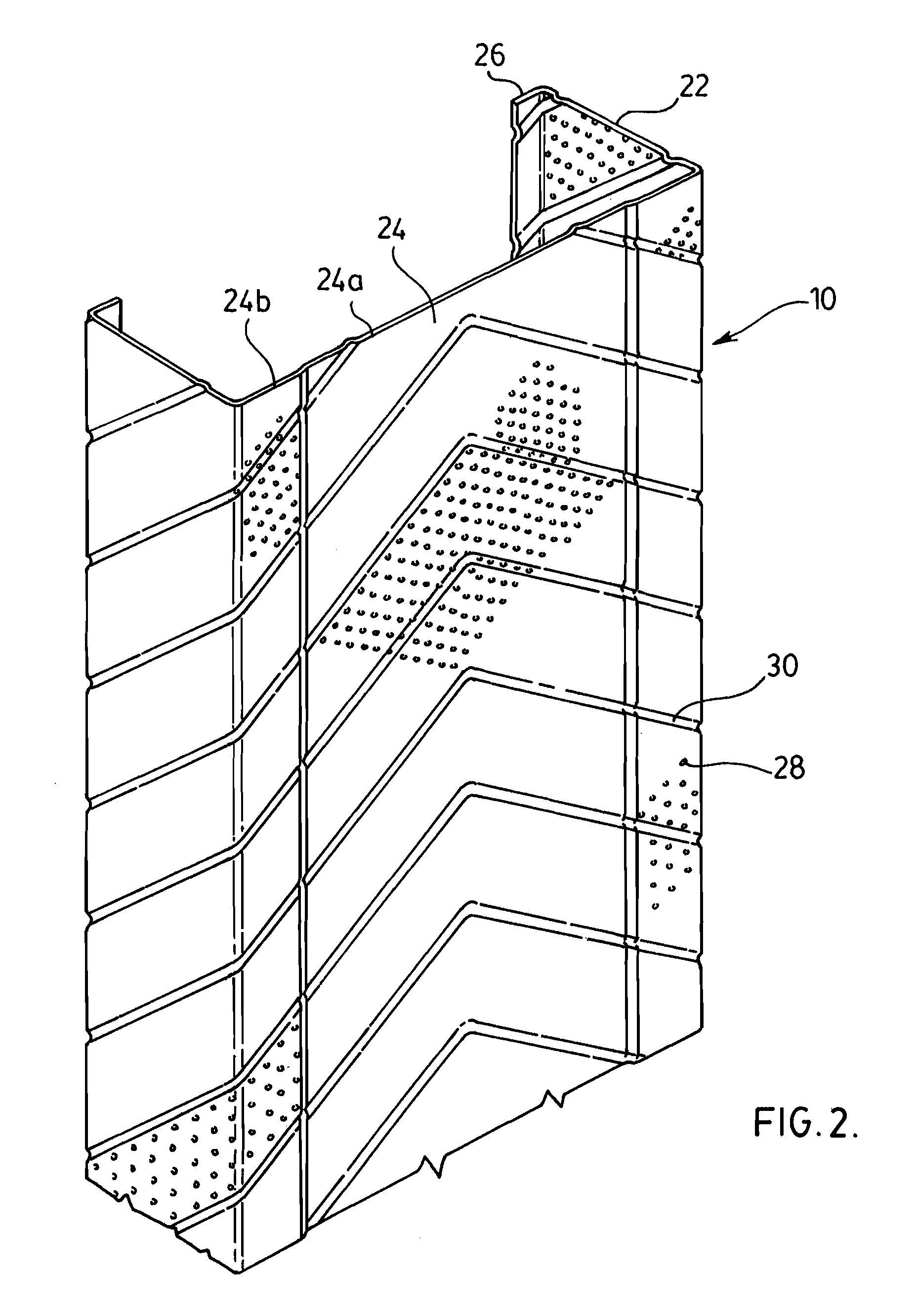

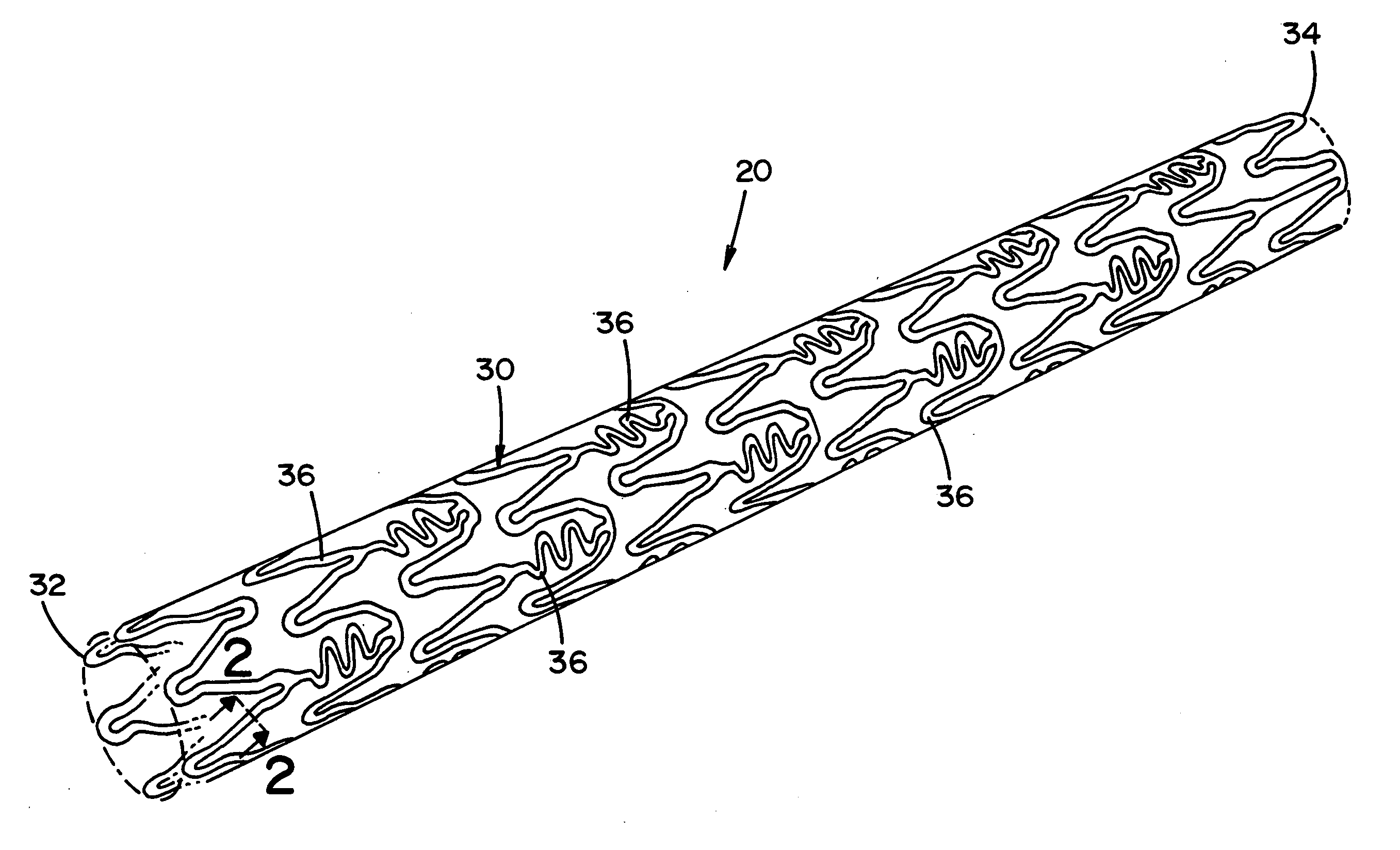

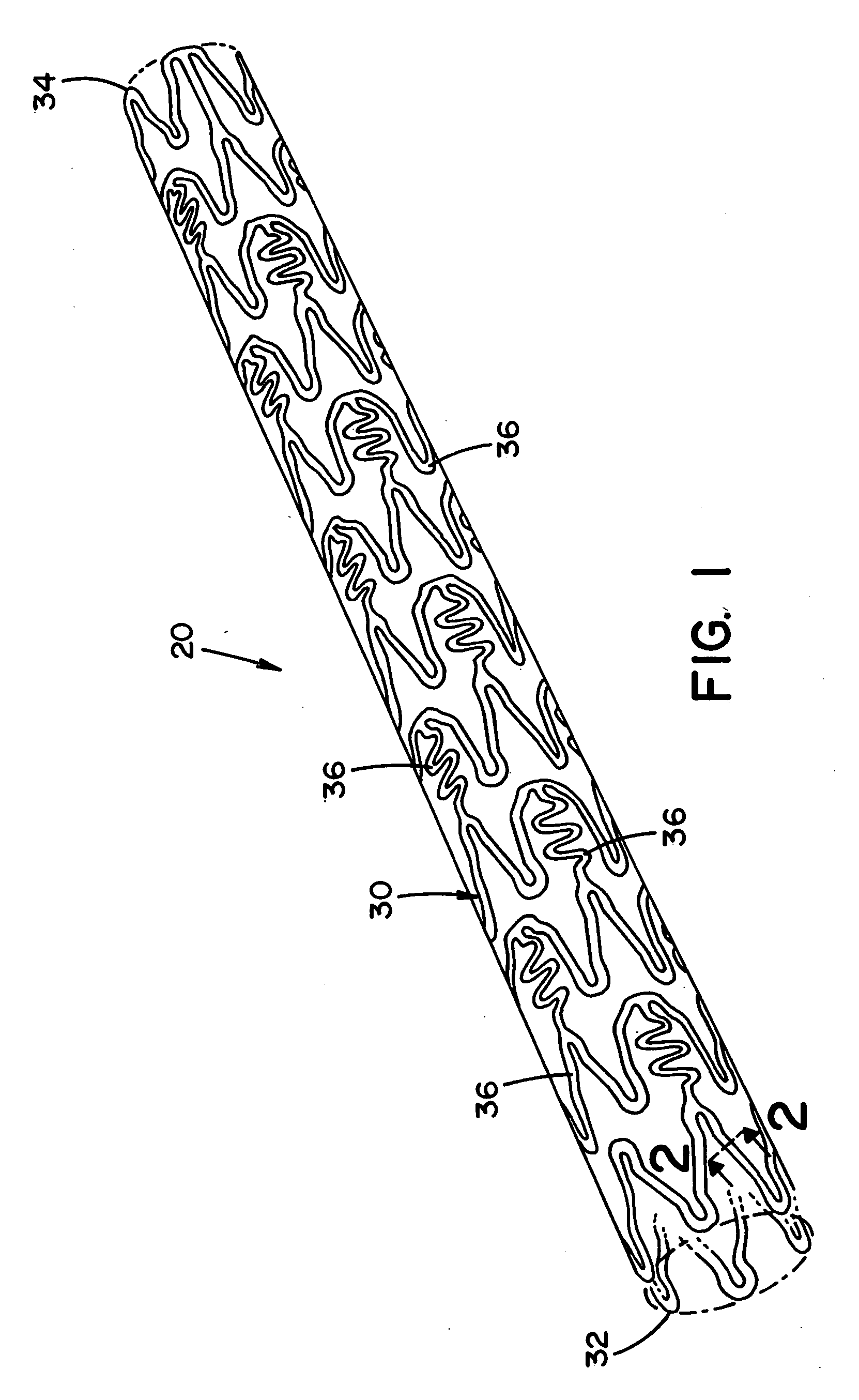

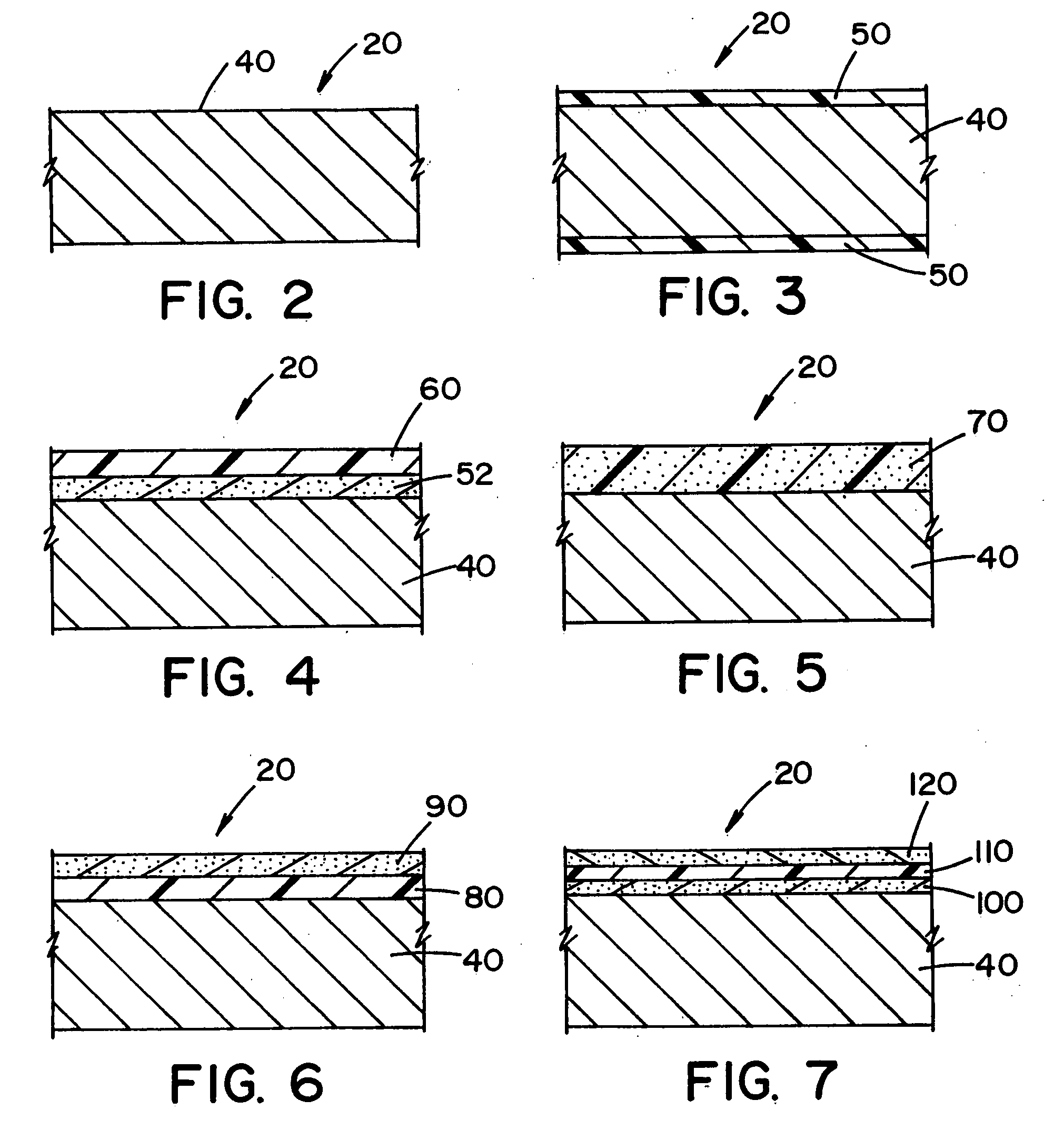

Light Weight Metal Framing Member

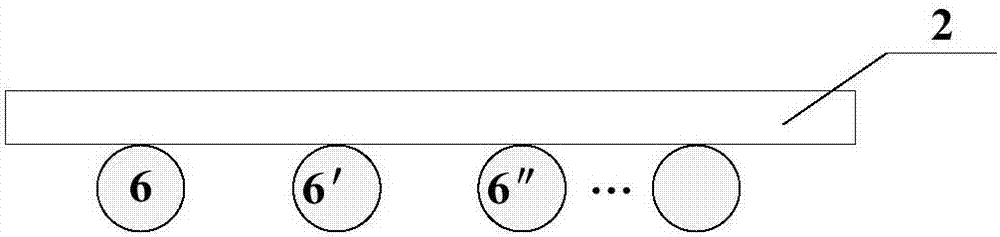

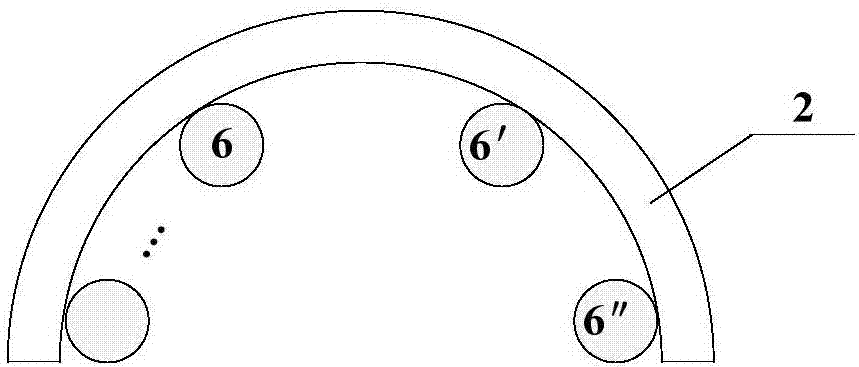

The present invention provides for a lightweight metal framing member having a plurality of depressions and a plurality of reinforcing ribs on the surface thereof, the depressions and ribs both being inwardly oriented and cooperating to aid in stiffening of the metal stud. The present invention also provides a method of manufacturing a metal framing member having a plurality of depressions and a plurality of reinforcing ribs on the surface thereof, the depressions and ribs both being inwardly oriented and cooperating to aid in stiffening of the metal stud. The method utilizes a cold roll forming apparatus having a first roller with a plurality of projections on its surface and a second roller having a surface provided with holes aligned with the projections on the surface of the first roller to form the depressions in the surface of the material having clearly defined edges generally aligned with the plane of the metal sheet. A second roll forming apparatus is used having a first roller with projections on its surface to form the reinforcing ribs in the surface of the sheet material and a second roller to allow for a softer transition between the surface of the sheet material and the edges of the reinforcing ribs and so as not to unduly deform the depressions formed in the first roll forming step. A third roll forming apparatus is used having rollers to form the metal stud or track.

Owner:BAILEY METAL PROD

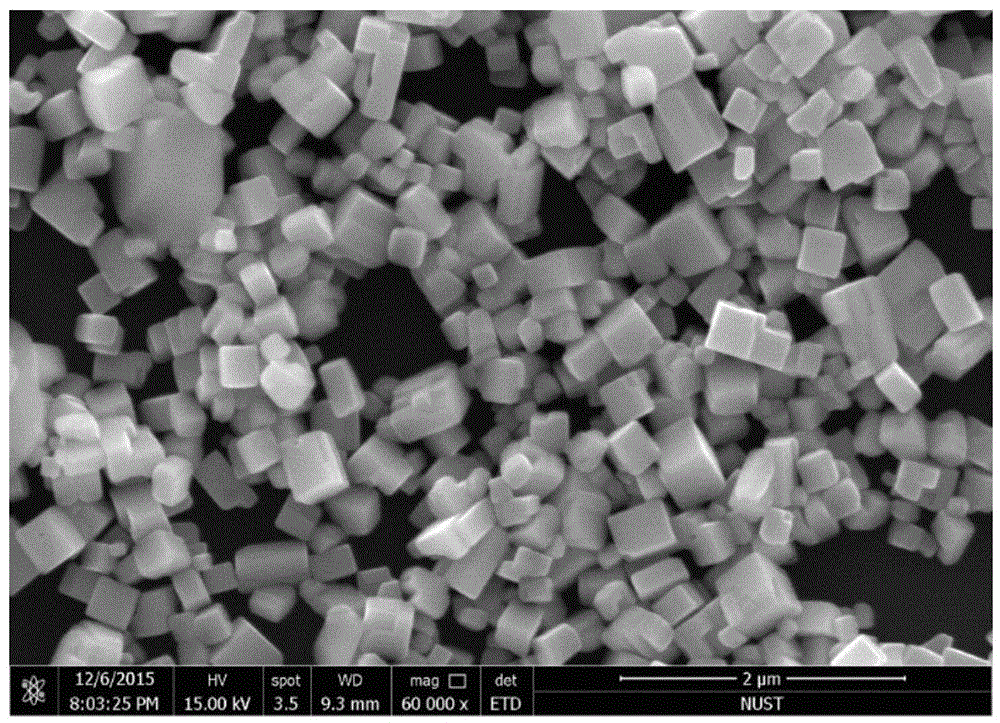

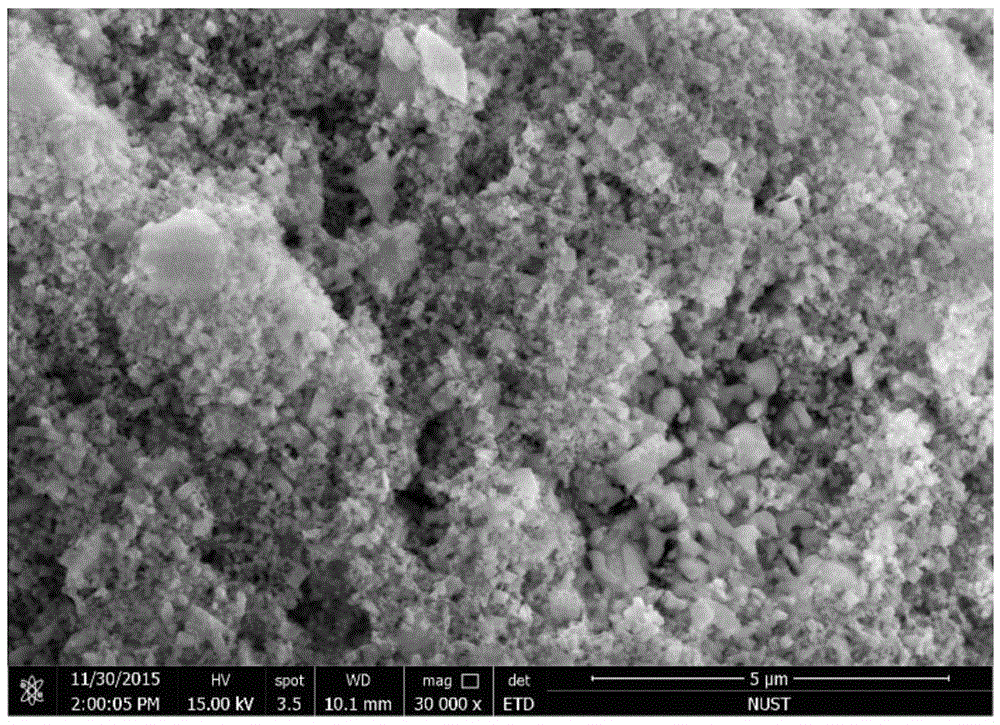

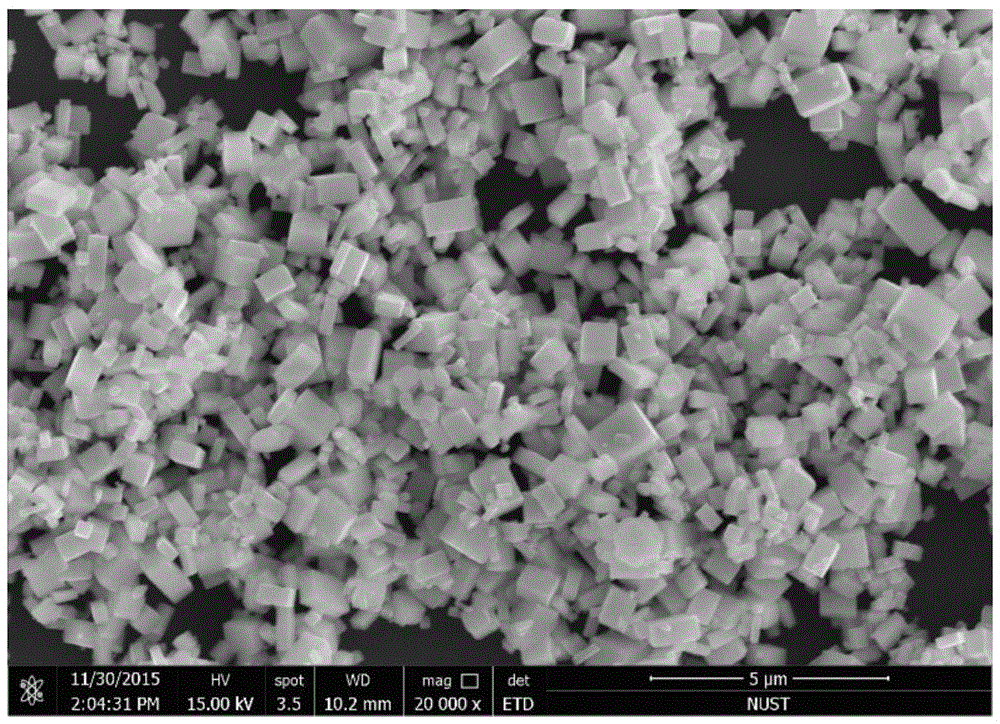

Preparation method of metal halide inorganic perovskite quantum dots

The invention discloses a preparation method of metal halide inorganic perovskite quantum dots. The method includes the steps of firstly, dissolving metal halide salt BX2 and AX in DMSO, and adding surface active agents; secondly, rapidly injecting the mixed liquid in reaction solvent; thirdly, making BX2 and AX rapidly react under the effect of the surface active agent to generate the ABX3 type metal halide inorganic perovskite quantum dots of different morphologies. According to the method, in the low-temperature solution method system, by using different surface active agents and reaction solvent for changing the morphologies of the metal halide inorganic perovskite quantum dots, the performance of the metal halide inorganic perovskite quantum dots is regulated and controlled, and the method has profound significance in constructing high-performance full-solution photoelectric devices.

Owner:NANJING UNIV OF SCI & TECH

Egg shell type metal catalyst, its preparing process and application method

InactiveCN1736604AImprove conversion rateHigh selectivityCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsCarbon numberAlcohol

The invention discloses an egg- shell metallic catalyst and the method for preparation and the application. The catalyst is an egg- shell supported metallic catalyst with a carrier of hollow silica dioxide, which is a hollow material of certain wall and bore diameter, and comprises a noble metal of 0.1%- 5.0% and / or a transient metal of 5.0%- 40.0%, a non- noble metallic catalyst promoter of 0- 0.5% and a hollow silica dioxide carrier of 60.0%- 99.0%, with the weight ratio of catalyst as a datum level. The egg- shell metallic catalyst can prepare with immersion method or in- situ supporting method. The catalyst has good metal dispersibility, and the metal particle diameter is minor, dispersing on the external surface, inner surface and in the pore passage. And the egg- shell metallic catalyst can catalyze CO and CO2 to prepare lower carbon number hydrocarbons and alcohol, and it also can catalyze olefin and alkyne selectively.

Owner:BEIJING UNIV OF CHEM TECH

Preparation method of load type metal compound catalyst used for water treatment

ActiveCN101579623ALow costWide variety of sourcesWater contaminantsMetal/metal-oxides/metal-hydroxide catalystsAir atmosphereLayer thickness

The invention relates to a preparation method of a load type metal compound catalyst used for water treatment, in particular to a catalyst comprising a metal oxide and metal salt. The method comprises the following steps: a porous inorganic material carrier, metal salt, a dispersant, a stabilizing agent and a accelerant which are treated are added into an organic solvent and stirred to form a load type catalyst before-preparation body mixture, the load type catalyst before-preparation body mixture stands for 1 to 9 days under a sealed condition until the load of the catalyst is completed, a steady load type catalyst before-preparation body is prepared, put in a baking oven for baking, moved into a muffle furnace and heated to 300 DEG C to 600 DEG C under air atmosphere at the speed of 2 DEG C / min to 6 DEG C / min, the temperature is kept for 1 to 8 hours, and finally, the load type metal compound catalyst used for water treatment, which forms a fixed catalyst layer with the layer thickness of 15nm to 28mum on the surface of the carrier, is prepared. The method has lower cost, little loss of raw materials in the preparation technology process and simple preparation technology, and is suitable for industrial mass production.

Owner:内蒙古海驰创新中心有限公司

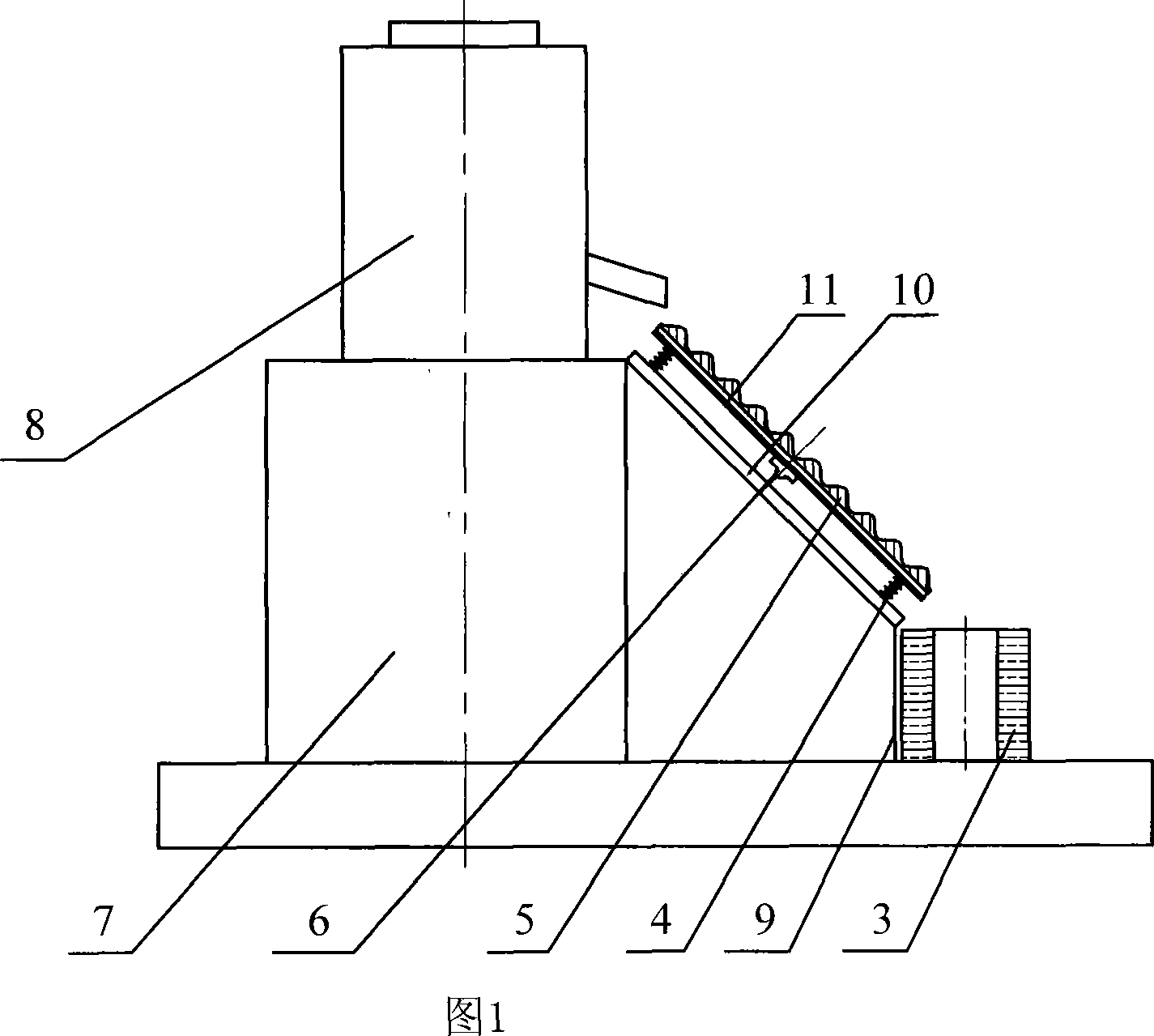

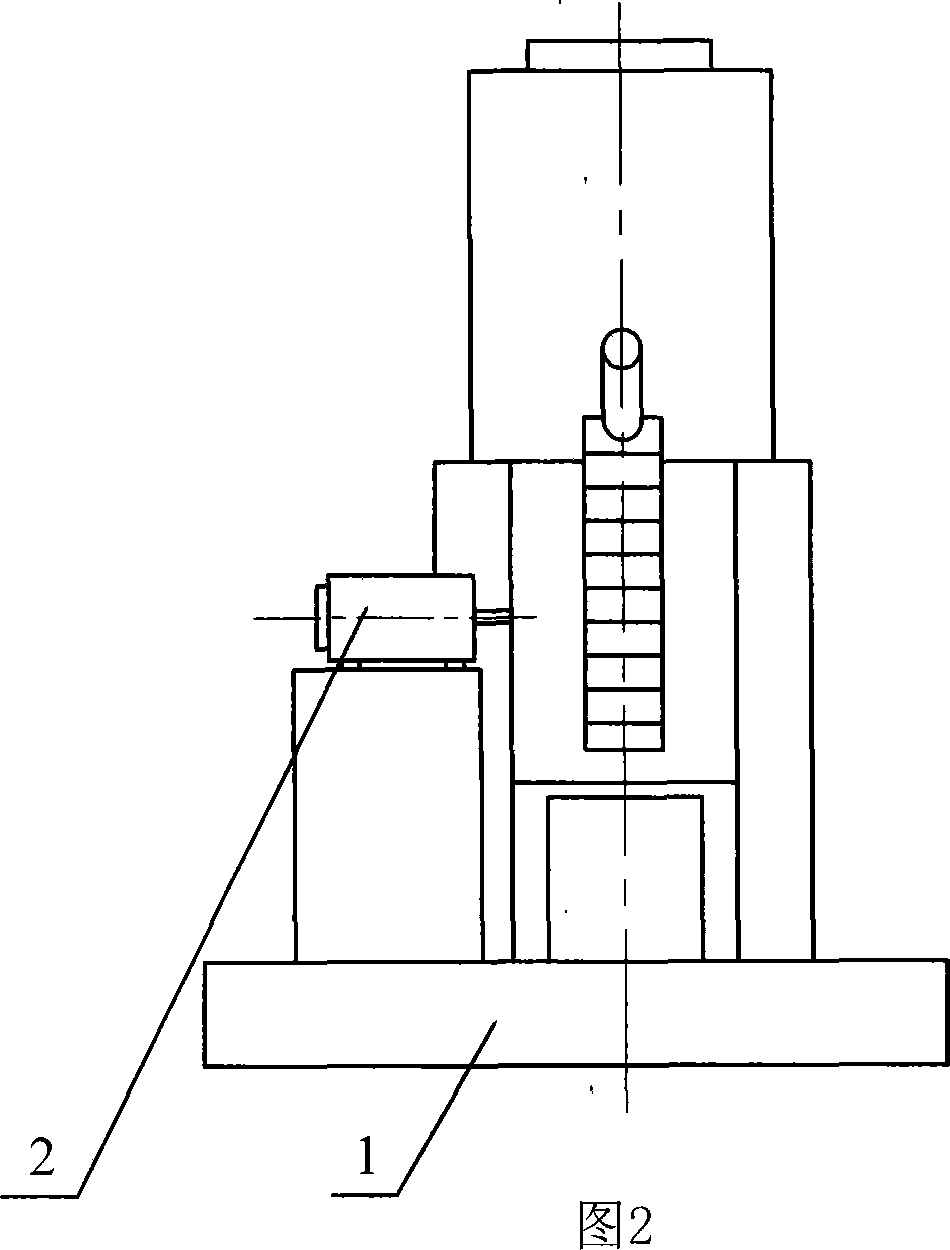

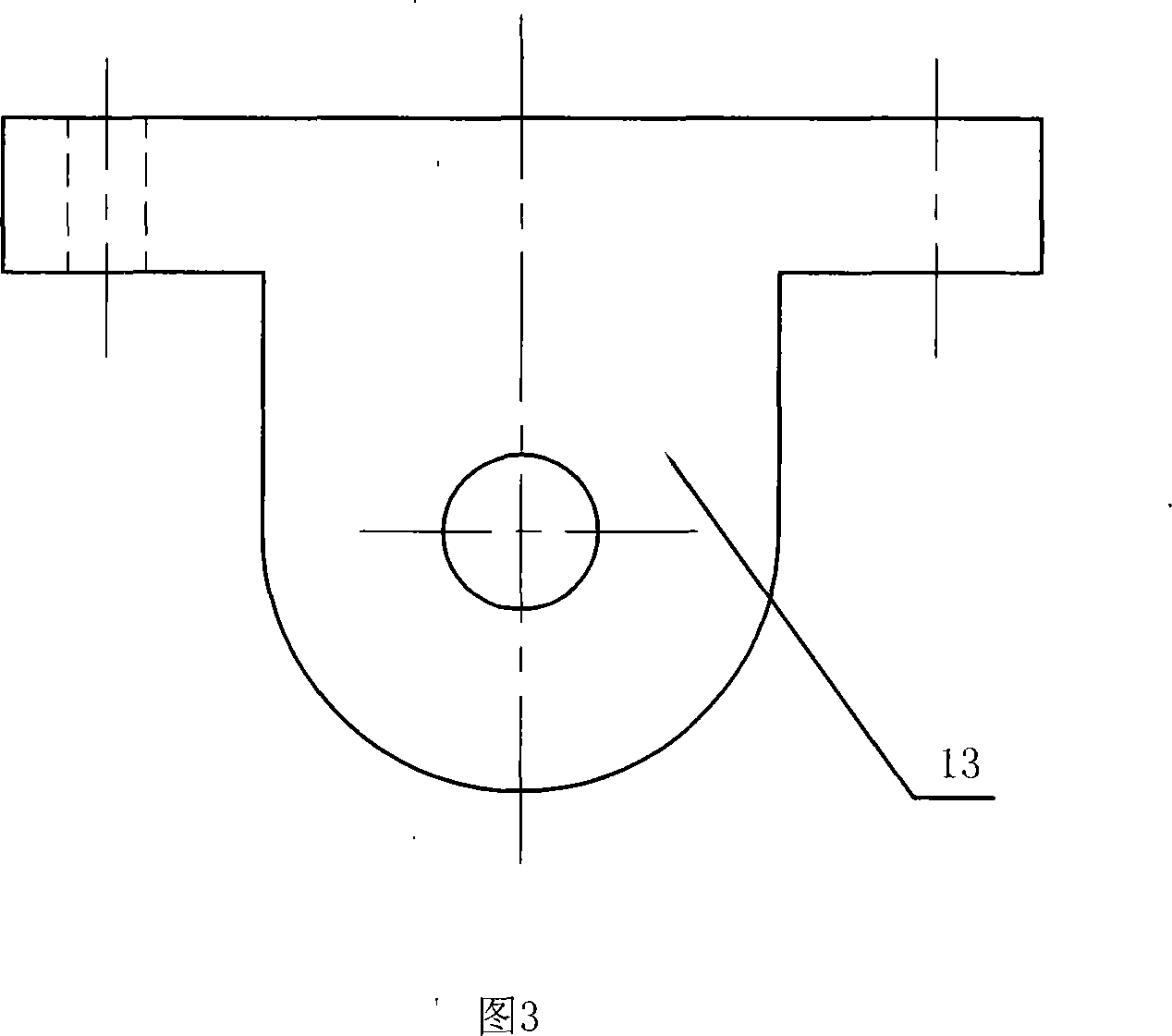

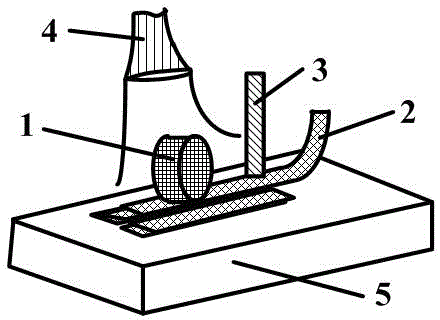

Wave type inclined plate vibration device for preparing semisolid state alloy and preparation method thereof

A wave-type inclined plate vibration device for preparing semi-solid alloy belongs to the field of preparation of semi-solid alloy technology. Said device includes a bracket , a wave-type metallic plate, a cam wheel vibration mechanism, a water-cooling typpe matrix, an electric motor and a frequency modulation mechanism, wherein a pouring box is fixed on the bracket, a supporting plate is fixed parallel to the bracket, the water-cooling typpe matrix is set at one side of the supporting plate, a fixed plate is mounted between the supporting plate and the bracket and is connected to the lug support of the wave-type metallic plate through a spring, the cam roller assembly is fixed at the lug support of the wave-type metallic plate, and the electric motor is connected respectively to the cam roller assembly and the voltage-regulating transformator.Said invention possesses the advantages of low cost of manufacture, short process flow, enhanced stirring action effects, excellent semi-solid alloy organization prepared, fine and round organizing, high spheroidizing degree, with a minimum of 10 mu m reached.Said invention is capable of preparing semi-solid-state materials of high melting point and realizing semi-solid condition shaping of steel material with high melting point.

Owner:NORTHEASTERN UNIV

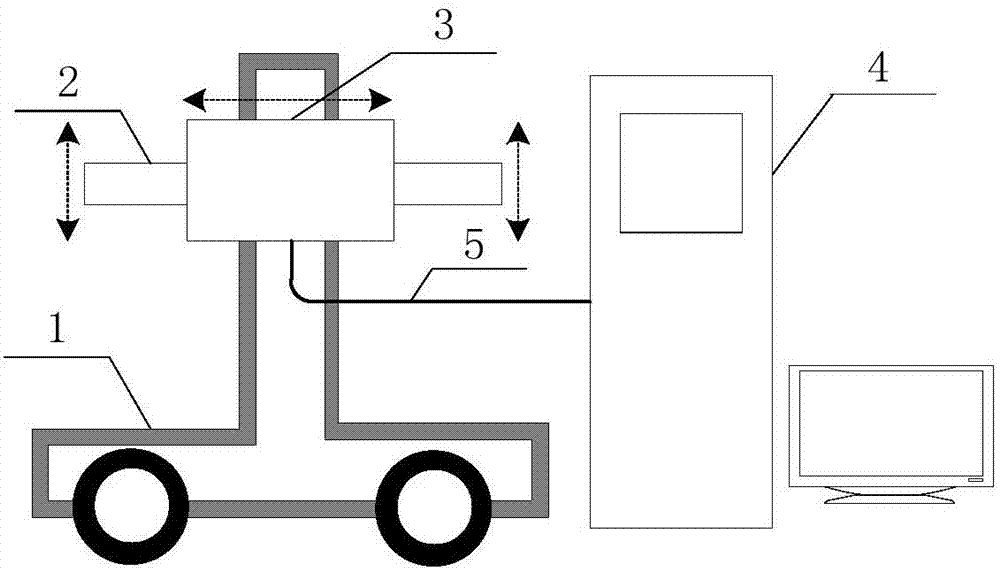

Online nondestructive detection system and method of quality of manufacturing members of metal additional materials

ActiveCN107402044ARealize online non-destructive testingReduce in quantityMeasurement devicesMarine engineeringControl system

The invention discloses an online nondestructive detection system and method of quality of manufacturing members of metal additional materials and belongs to the field of online nondestructive detection. The system comprises a moving detection vehicle, a guidance rail, an online signal detection module and a control system. A column is arranged on the vehicle body of the moving detection vehicle. The guidance rail is movably connected to the column. The online signal detection module is movably connected to the guidance rail. Multiple probes are integrated into the online signal detection module and comprise probes used for detecting compositions, defects, deformation, stress, size precision and surface coarseness. During detection, the probes can be embedded into a 3D printing head of a feeding type additional material manufacturing device or be fixed on the moving detection vehicle. The probes are in signal connection with the control system. The invention also provides a method for carrying out online nondestructive detection of the system. According to the invention, the system and the method are widely applicable, highly expandable and capable of achieving onsite or remote online detection of manufacturing processes of feeding type metal additional materials.

Owner:HUAZHONG UNIV OF SCI & TECH

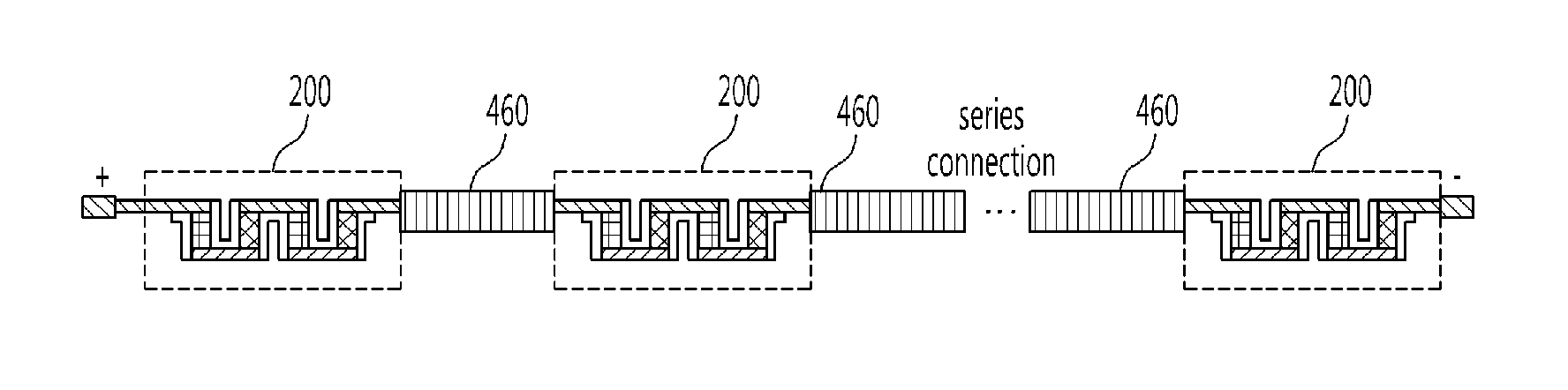

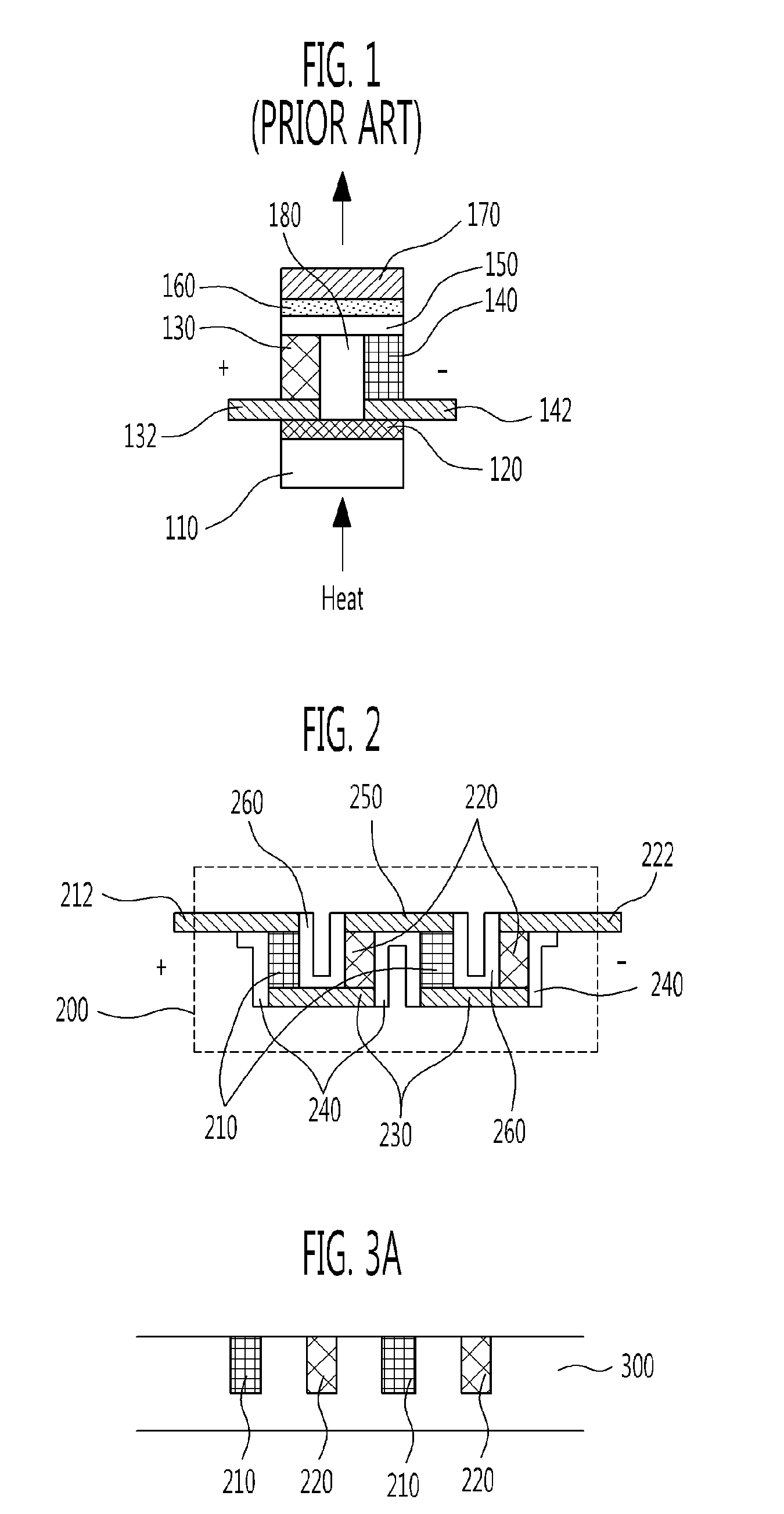

Flexible thermoelectric generator, wireless sensor node including the same and method of manufacturing the same

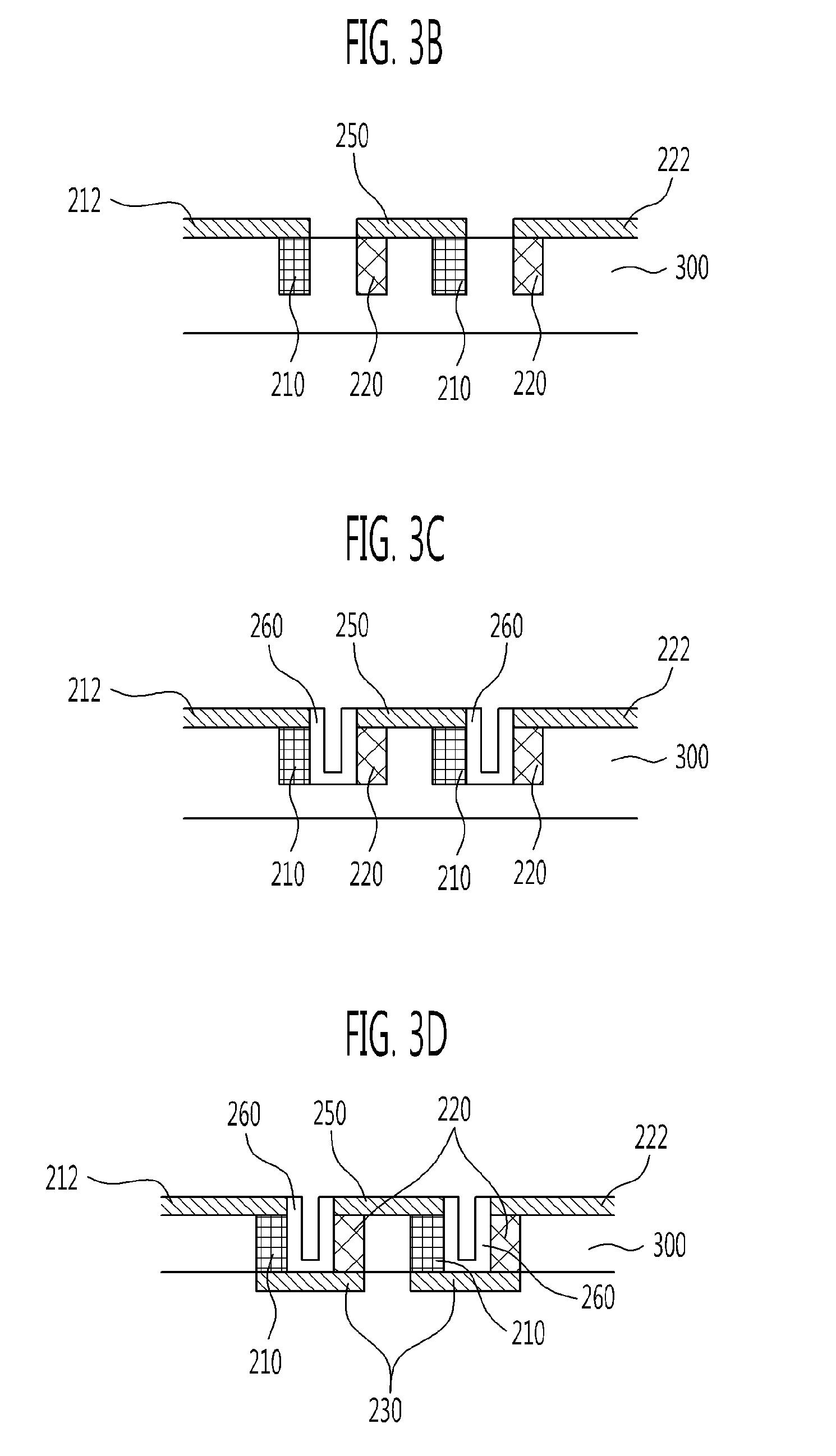

InactiveUS20110150036A1Thermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentEngineeringSemiconductor

Provided are a flexible thermoelectric generator, a wireless sensor node including the same and a method of manufacturing the same. The flexible thermoelectric generator includes a plurality of P-type semiconductors and a plurality of N-type semiconductors, which are alternately arranged, an upper metal for connecting upper surfaces of the adjacent P-type semiconductor and N-type semiconductor, a lower metal for connecting lower surfaces of the adjacent P-type semiconductor and N-type semiconductor, and alternately disposed with respect to the upper metal, a P-type metal connected to at least one P-type semiconductor among the plurality of P-type semiconductors, and an N-type metal connected to at least one N-type semiconductor among the plurality of N-type semiconductors.

Owner:ELECTRONICS & TELECOMM RES INST

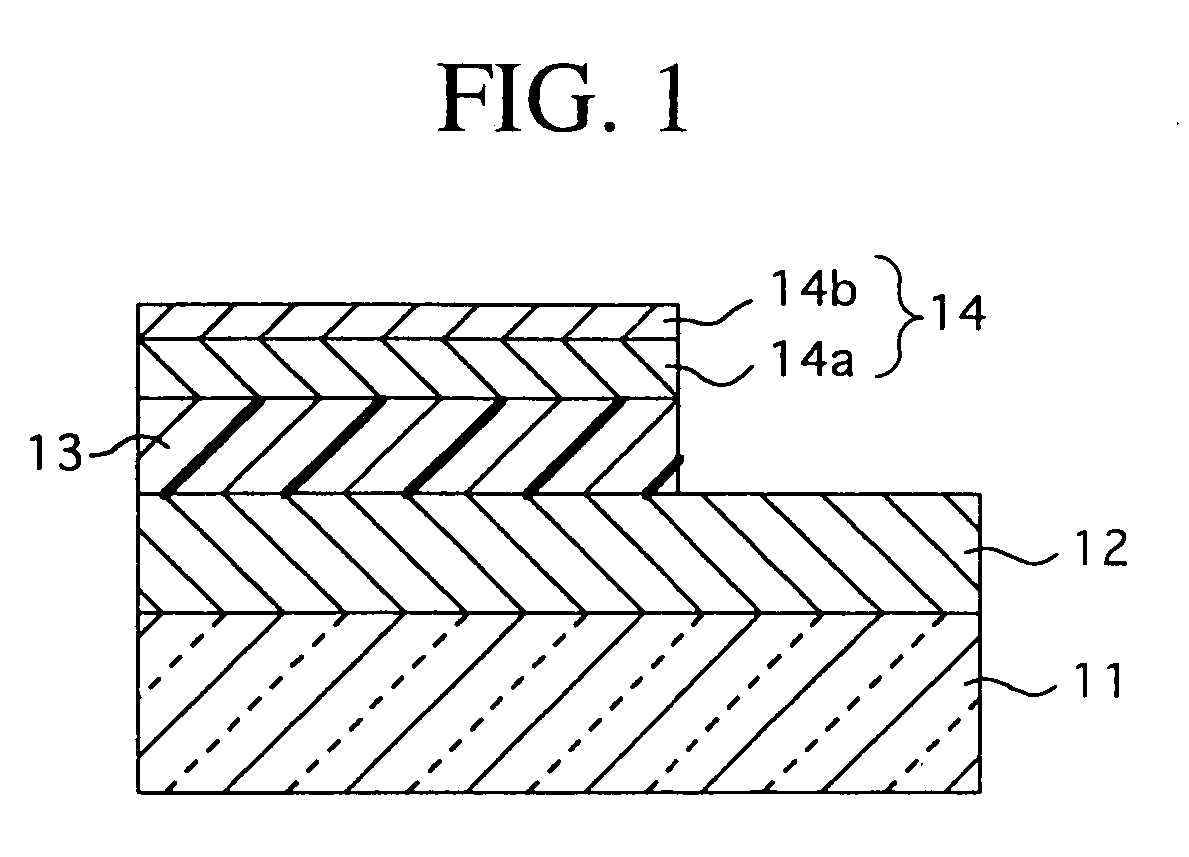

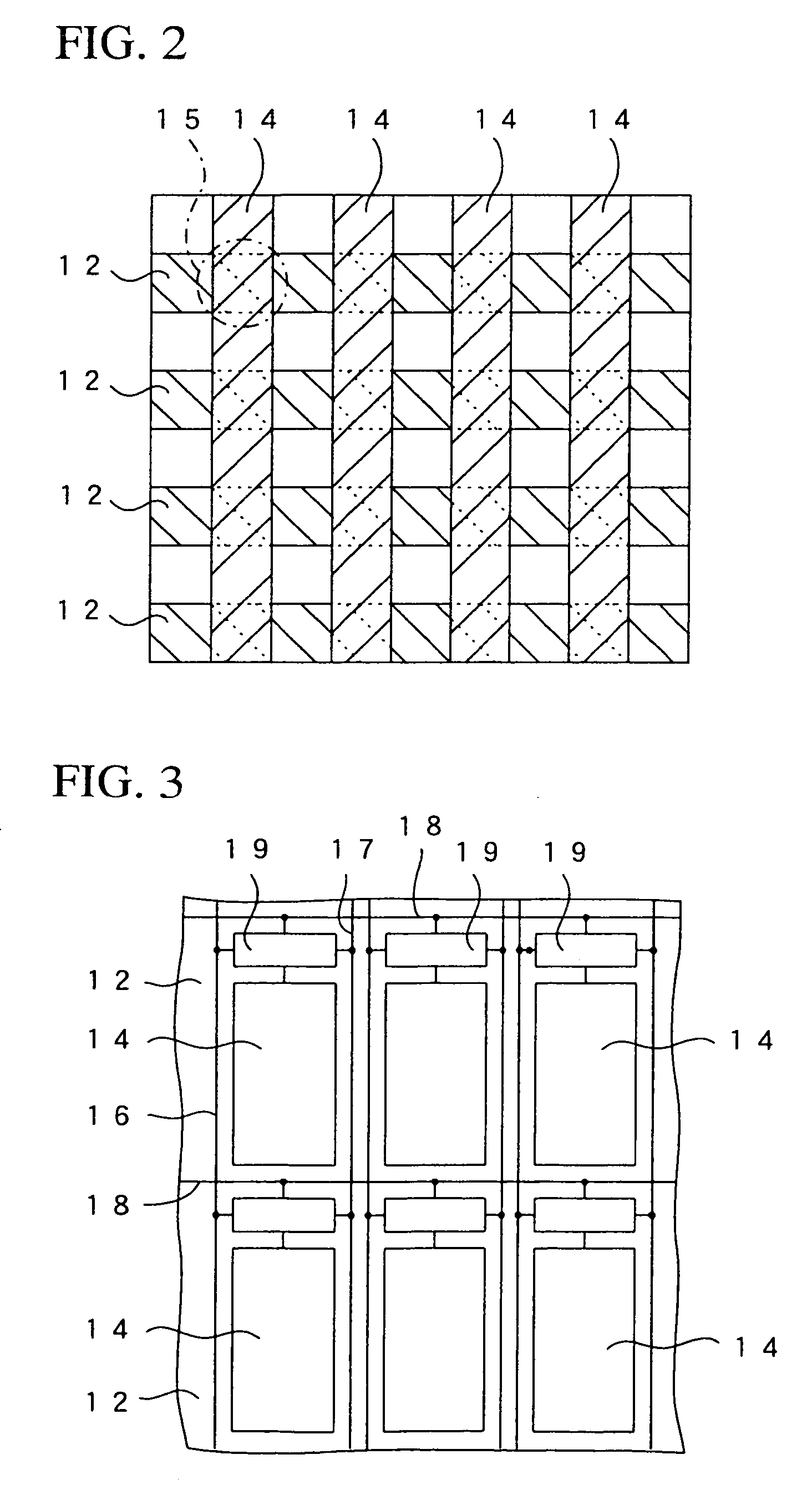

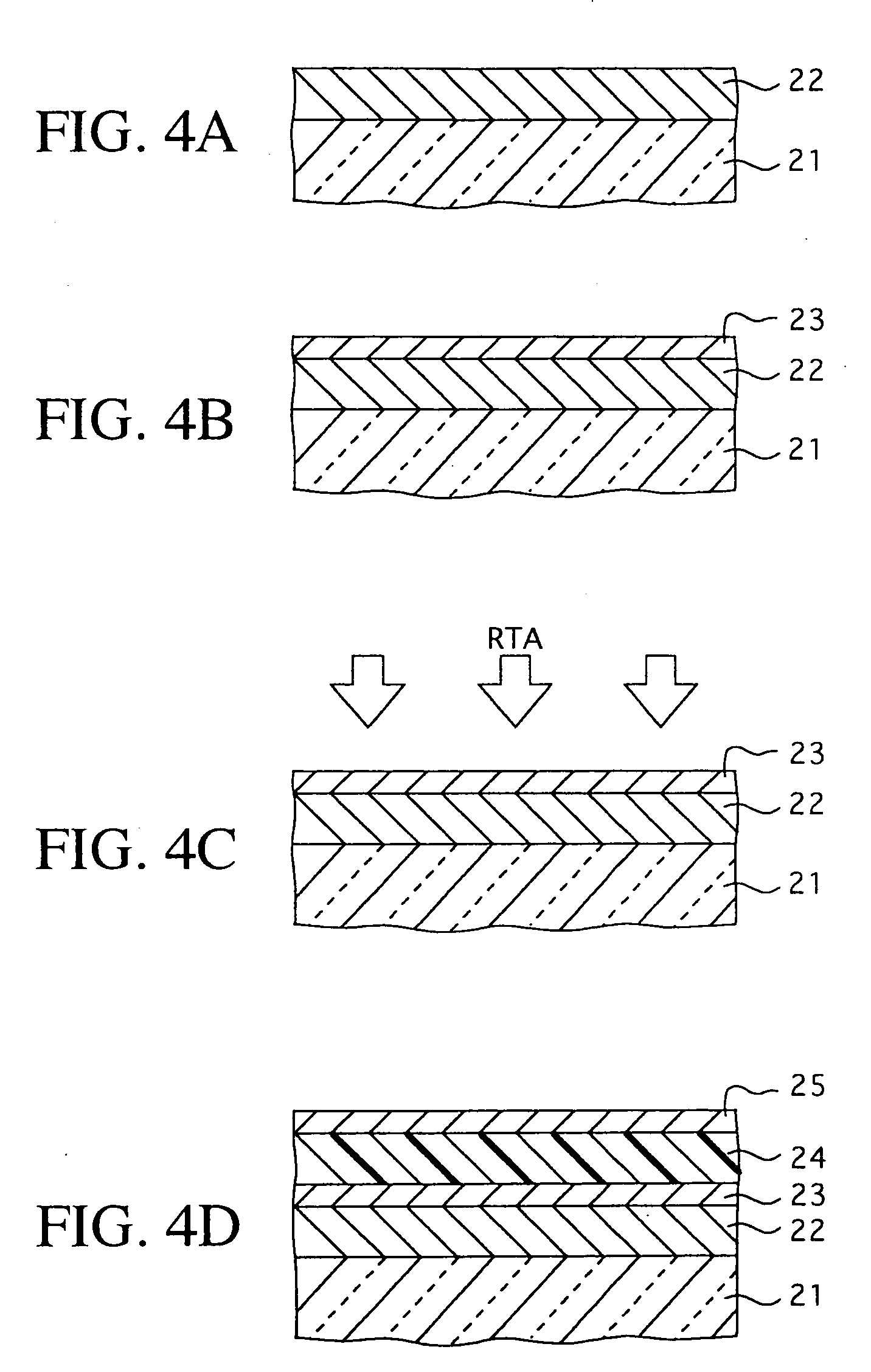

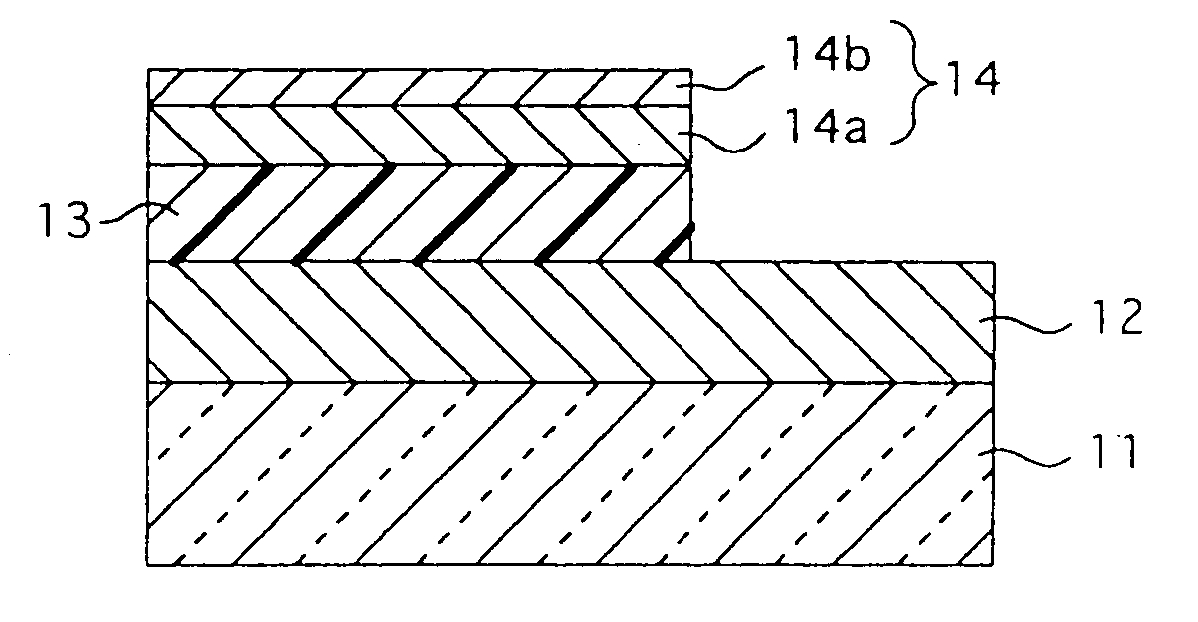

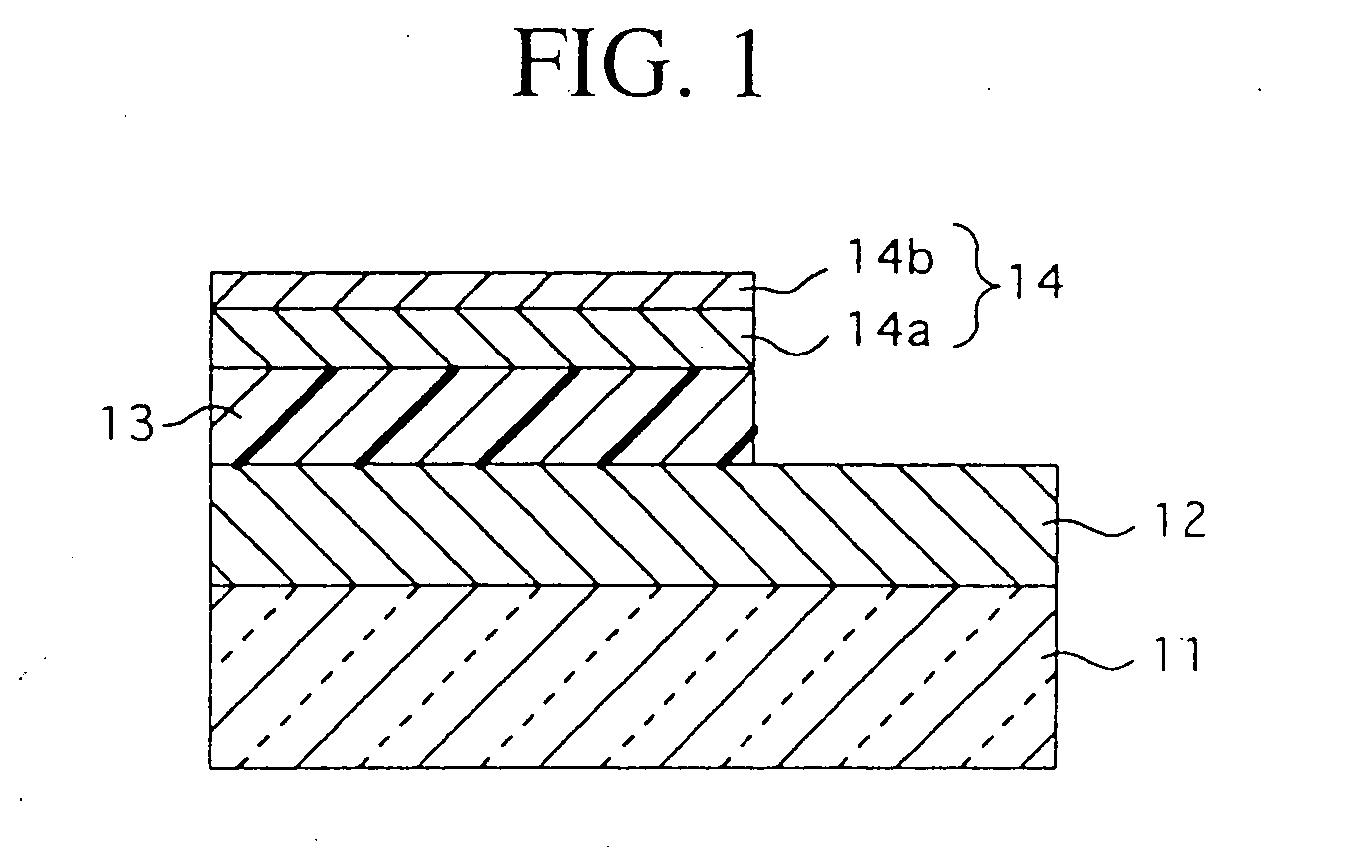

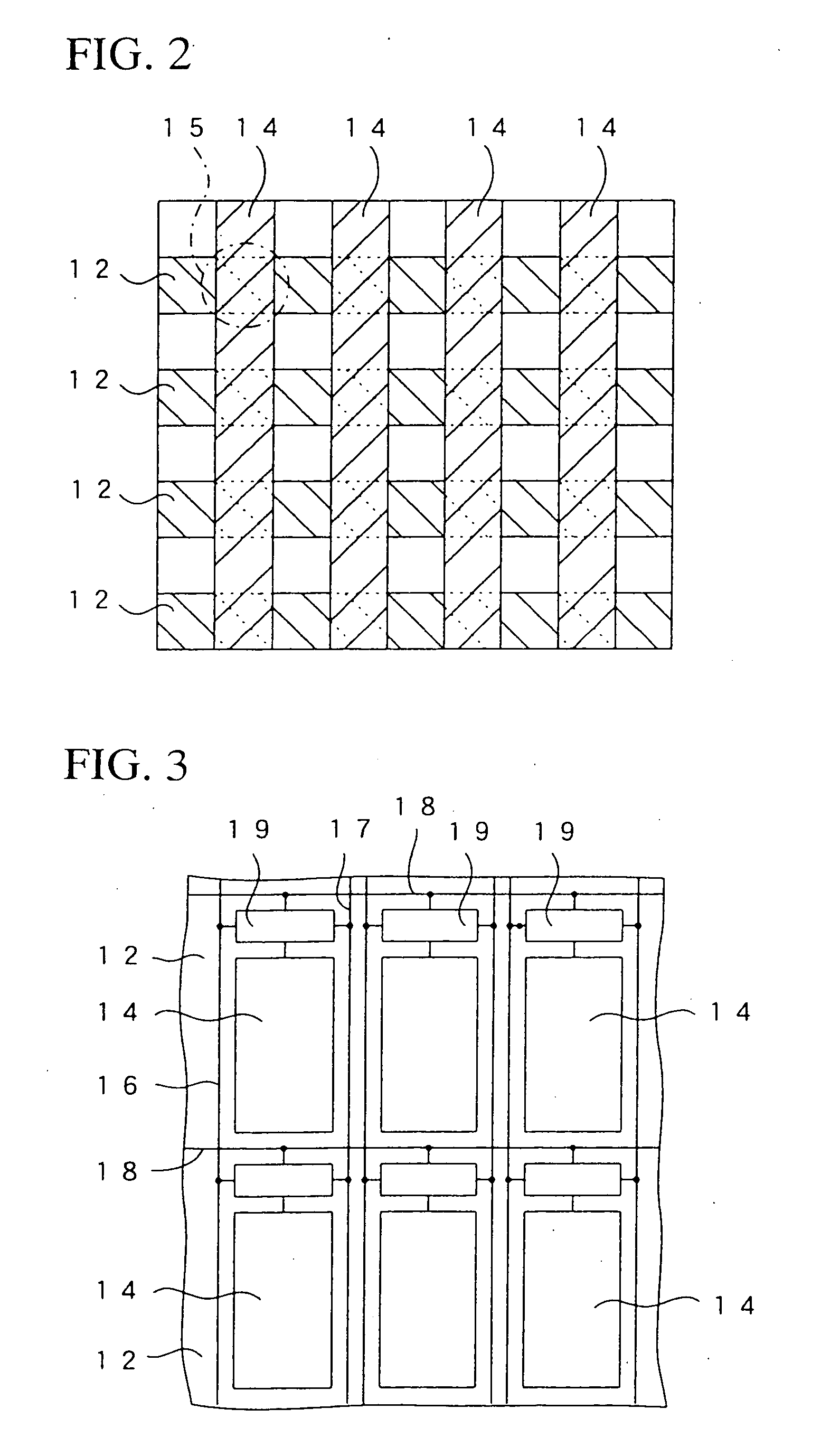

Organic EL element and method of manufacturing the same, organic EL display device using the element, organic EL material, and surface emission device and liquid crystal display device using the material

InactiveUS20060204788A1Avoiding degradation in luminescence characteristicSimplify manufacturing stepsOrganic chemistrySolid-state devicesRheniumIridium

In an organic EL element, an organic EL layer is interposed between anodes and cathodes formed on a substrate. Each of the cathodes is made of a first conductive film that comes into contact with the organic EL layer and a second conductive film that constitutes a laminated structure together with the first conductive film. The first conductive film contains any one of an alkaline metal and an alkaline earth metal. The second conductive film contains any one of at least one type metal selected from a group consisting of Ru (ruthenium), Rh (rhodium), Ir (iridium), Os (osmium) and Re (rhenium) and its oxide.

Owner:FUJITSU LTD

Metal alloys for medical devices

InactiveUS20060264914A1Good physical propertiesIncrease success rateStentsSurgeryMetal alloyMedical device

A medical device that is at least partially formed of a novel metal alloy which improves the physical properties of the medical device.

Owner:ICON MEDICAL CORP

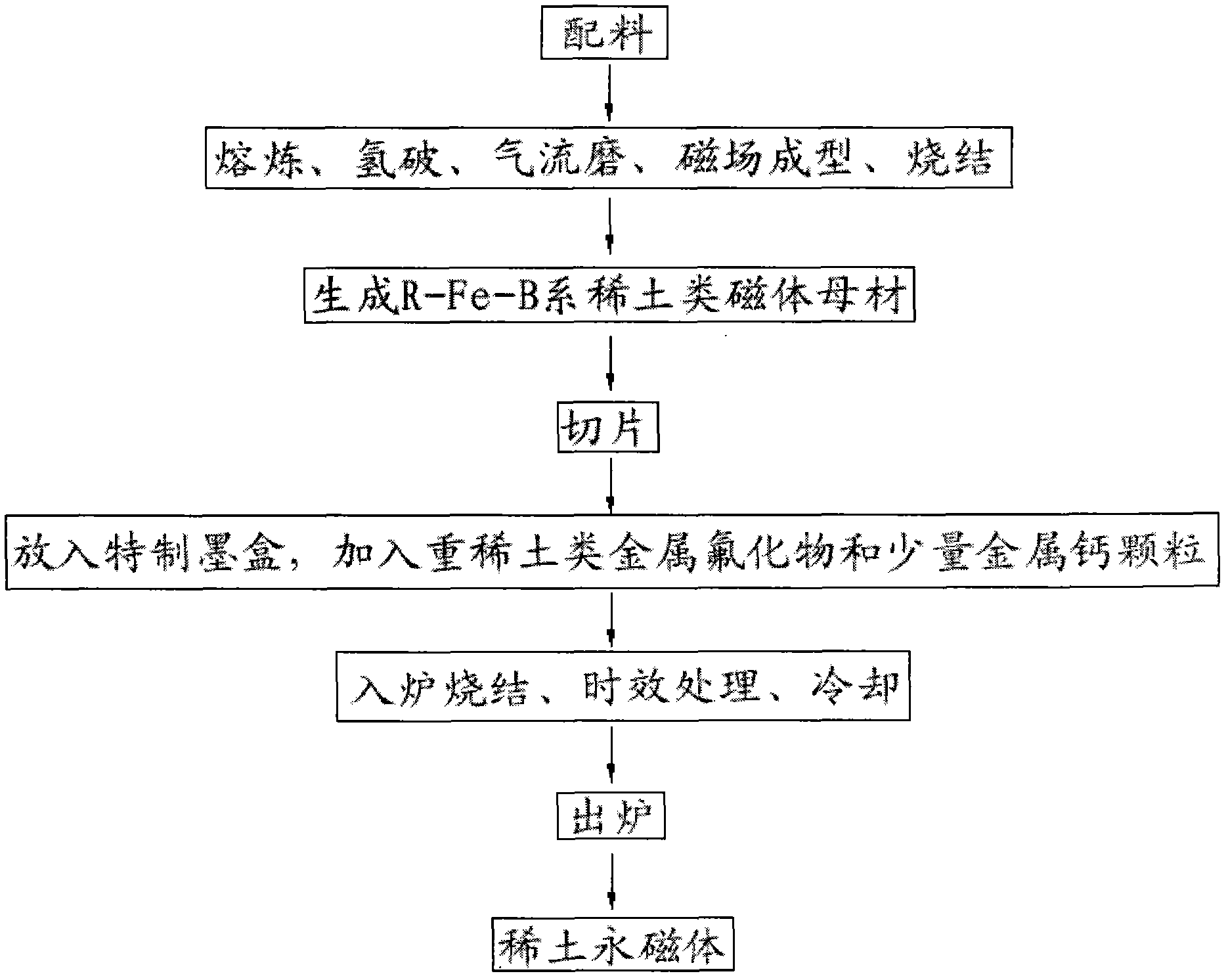

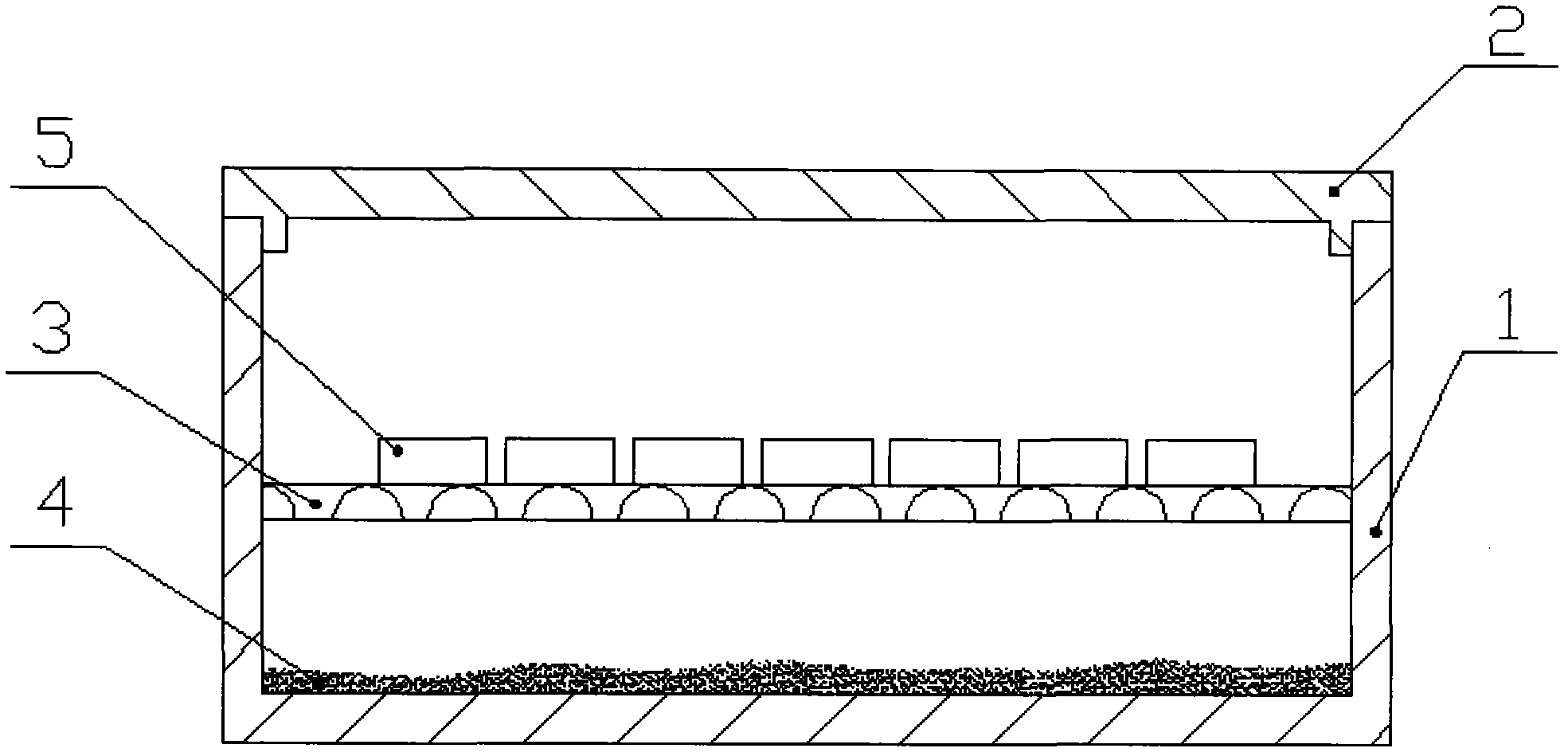

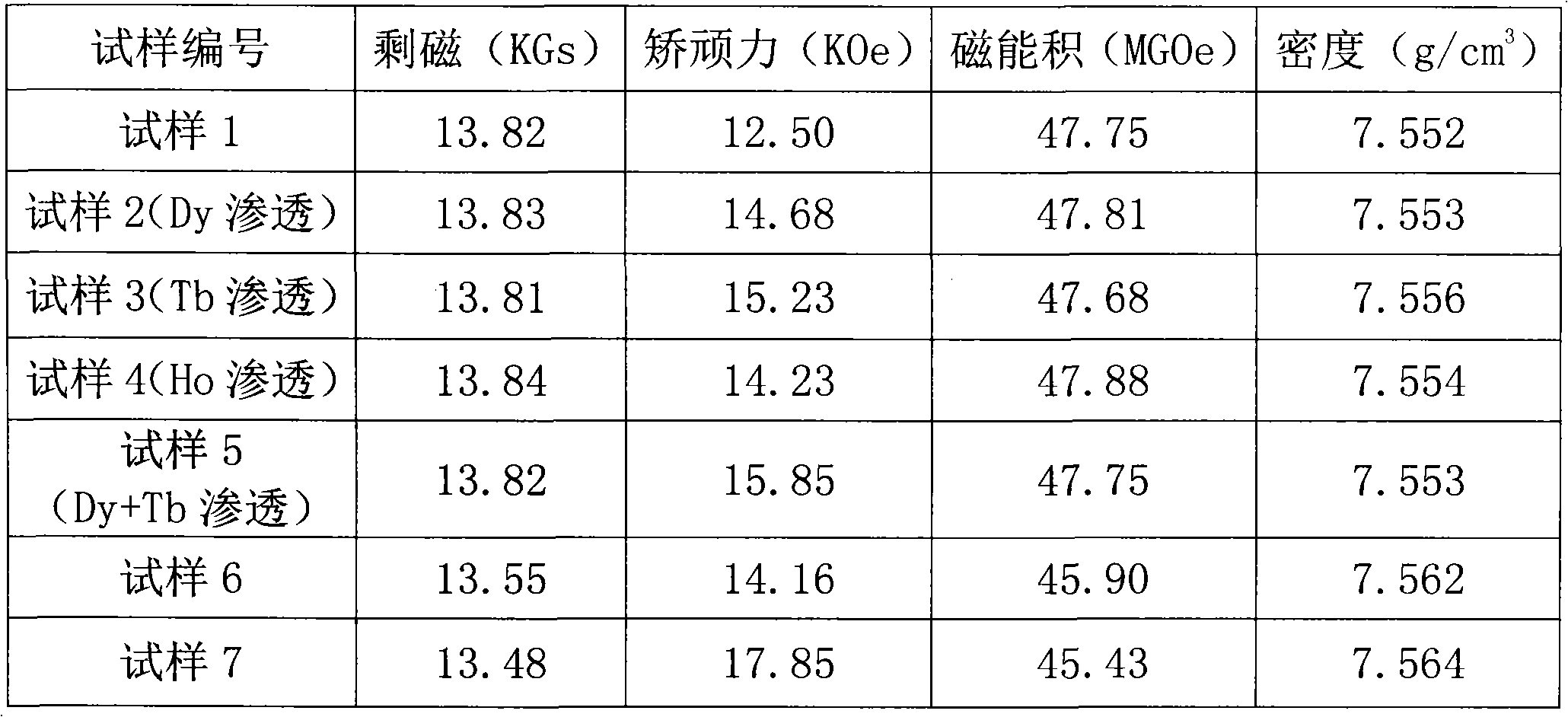

Method for preparing rare-earth permanent magnets by infiltration process and graphite box utilized in method

InactiveCN102568806AReduce manufacturing costReduce usagePermanent magnetsSolid state diffusion coatingRare earthMaterials science

Disclosed are a method for preparing rare-earth permanent magnets by the infiltration process and a graphite box utilized in the method. The method includes: preparing base materials of R (rare earth)-Fe (ferrum)-B (boron) rear earth magnets by prepared raw materials which are subjected to smelting, hydrogen decrepitation, magnetic field forming, sintering and the like; cutting the base material into slices with the thickness ranging from 2mm to 10mm; placing the slices into a specially-made graphite box and placing heavy rare earth type metal fluoride and a few of metal calcium particles into the bottom of the graphite box; sintering the graphite box in a sintering furnace, inflating air into the sintering furnace to cool the temperature to be lower than 60 DEG C, finally ageing magnets, then inflating Ar gas into the sintering furnace to cool the temperature to be lower than 60 DEG C after ageing, and finally obtaining the rare-earth permanent magnets. Elements including Dy (dysprosium), Tb (terbium), Ho (holmium) and the like are infiltrated into the crystal boundary of the R-Fe-B to prepare high-coercivity rare-earth permanent magnets by means of infiltration process, usage of heavy rare earth metal can be greatly reduced, and production cost of magnets can be effectively reduced. Additionally, the method for preparing rare-earth permanent magnets by the infiltration process is simple in operation and suitable for batch production.

Owner:BAOTOU TIANHE MAGNETICS TECH CO LTD

Organic EL element and method of manufacturing the same, organic EL display device using the element, organic EL material, and surface emission device and liquid crystal display device using the material

InactiveUS20050208206A1Simplify manufacturing stepsLow production costOrganic chemistryDischarge tube luminescnet screensRheniumIridium

In an organic EL element, an organic EL layer is interposed between anodes and cathodes formed on a substrate. Each of the cathodes is made of a first conductive film that comes into contact with the organic EL layer and a second conductive film that constitutes a laminated structure together with the first conductive film. The first conductive film contains any one of an alkaline metal and an alkaline earth metal. The second conductive film contains any one of at least one type metal selected from a group consisting of Ru (ruthenium), Rh (rhodium), Ir (iridium), Os (osmium) and Re (rhenium) and its oxide.

Owner:FUJITSU LTD

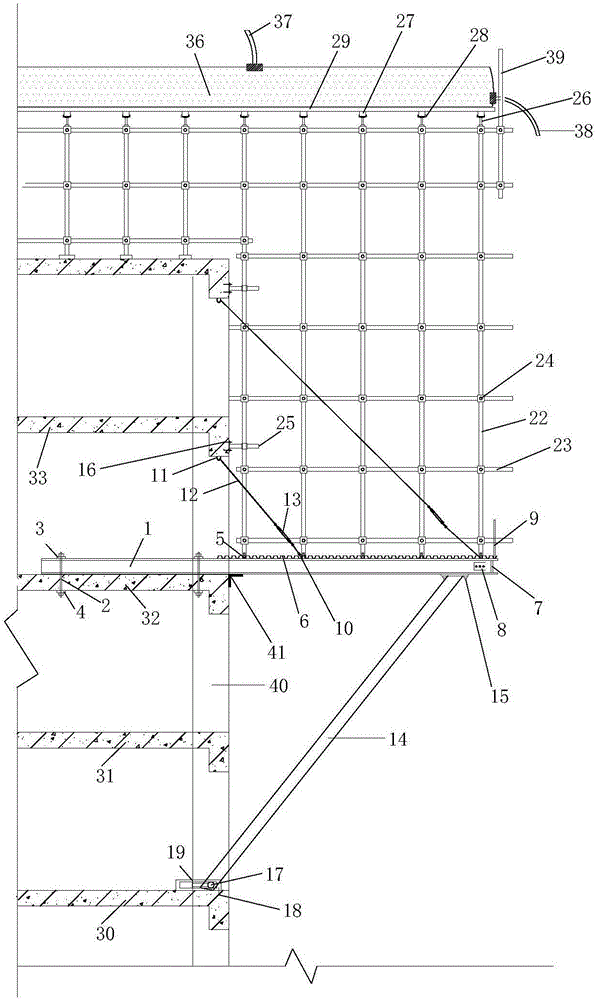

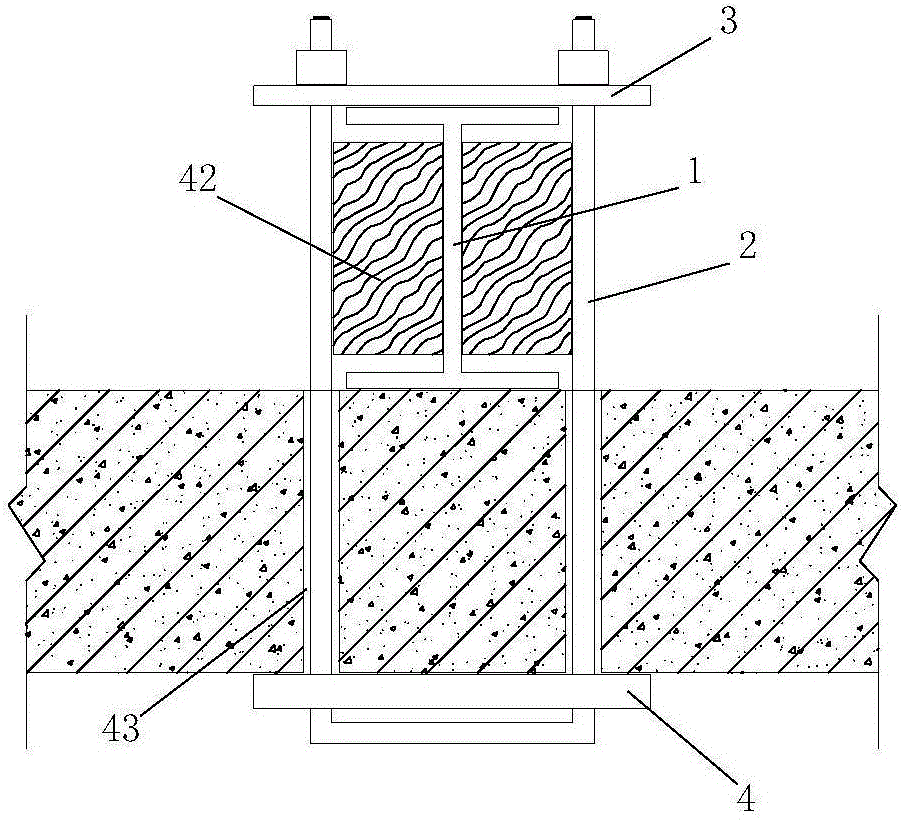

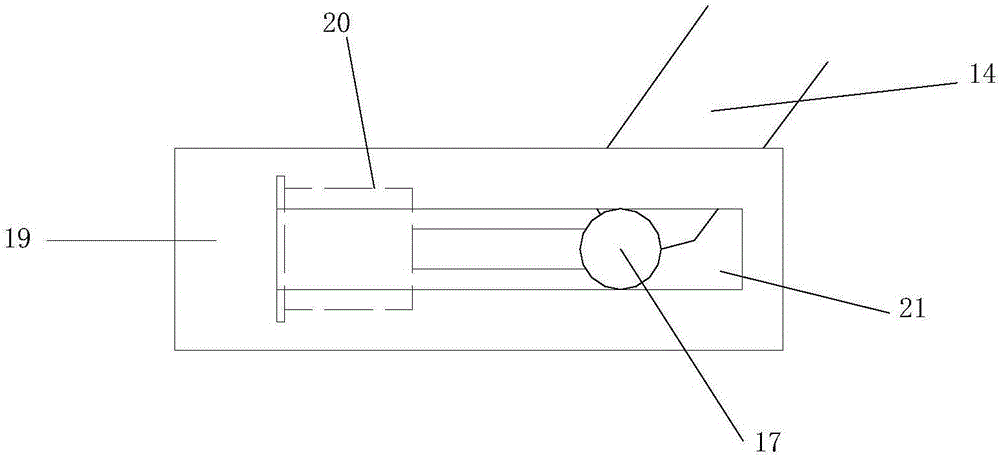

Large cantilever beam board combined type formwork supporting system and construction method

ActiveCN106150088AAchieve measurable and controllable effectsSafe setupForms/shuttering/falseworksScaffold accessoriesSupporting systemEngineering

The invention relates to a large cantilever beam board combined type formwork supporting system. The large cantilever beam board combined type formwork supporting system mainly comprises: a cantilever beam, a connecting beam, a steel wire rope, an inclined strut, a pre-pressing water bag, a bottom adjusting part, a jack, a U-shaped bolt, a turnbuckle, a bottom-layer protection board, an anti-sliding angle steel board and an angle steel clamp. The invention further relates to a construction method of the large cantilever beam board combined type formwork supporting system; the construction method mainly comprises the following steps: (1) setting the bottom adjusting part; (2) manufacturing and mounting the cantilever beam; (3) mounting the bottom inclined strut; (4) mounting the steel wire rope; (5) erecting a formwork support; (6) pre-pressing the supporting system; (7) carrying out concrete pouring construction. The structure provided by the invention is convenient to detach and convenient to pre-press; the cantilever beam supporting system has a multi-safety effect through the combined action of flexible unloading of the steel wire rope, a lower supporting structure and the bottom adjusting part, and the safety of cantilever beam supporting is sufficiently guaranteed; a tool type metal pressing protection board is arranged on a bottom layer of a frame body, so that the frame body is safe to erect and the economic and technical benefits are relatively good.

Owner:SHANGHAI JIASHI (GROUP) CO LTD

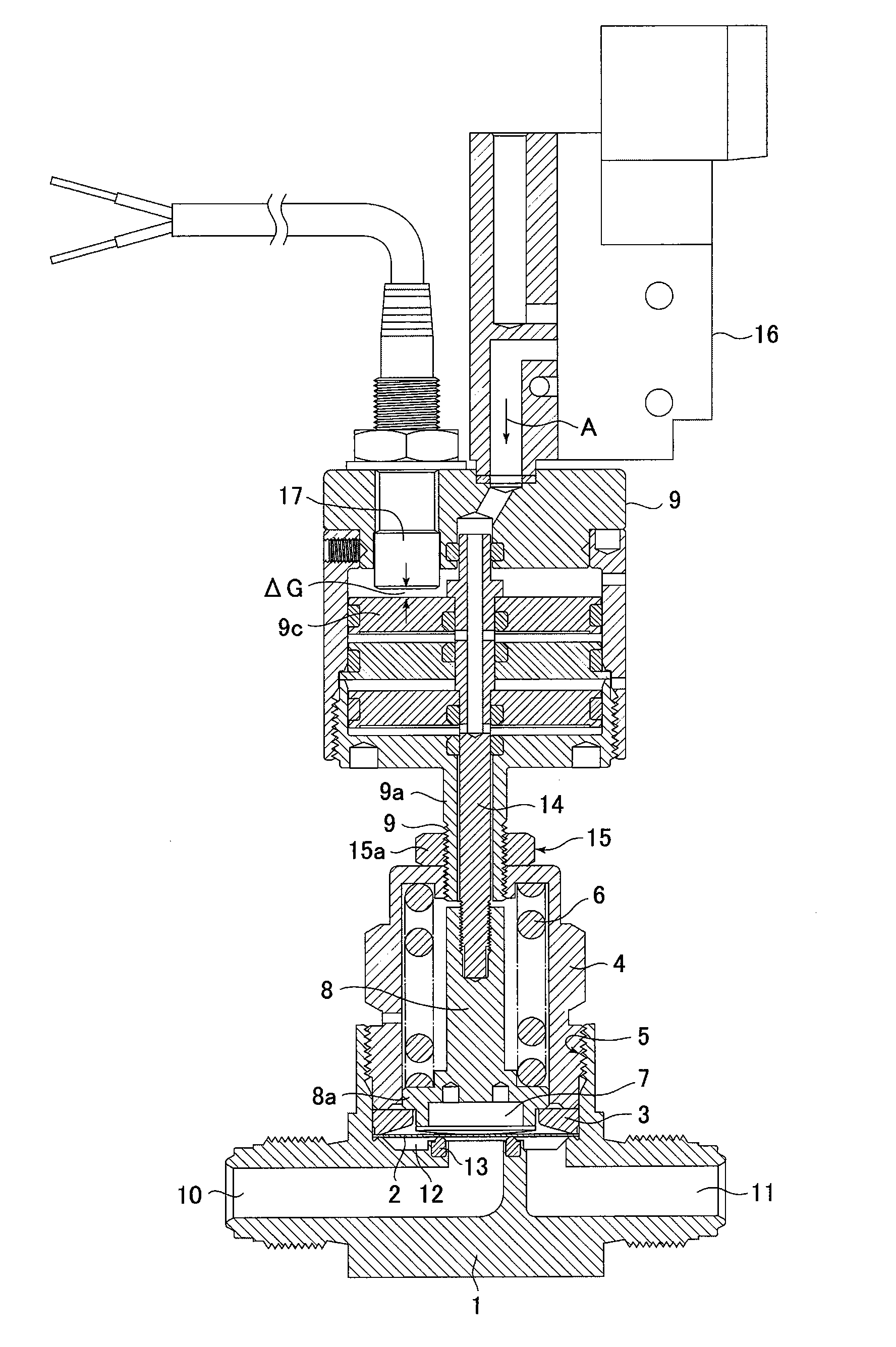

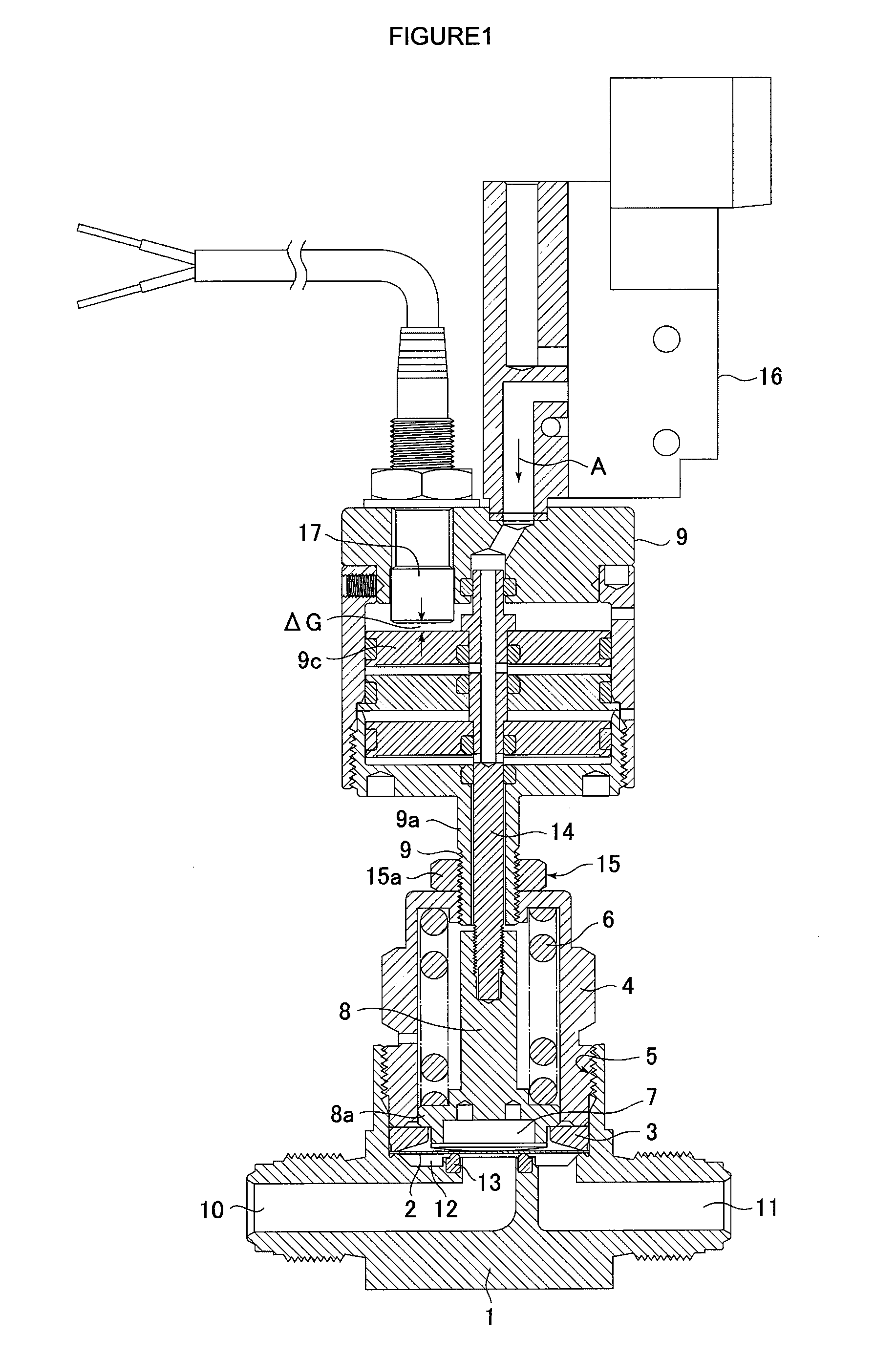

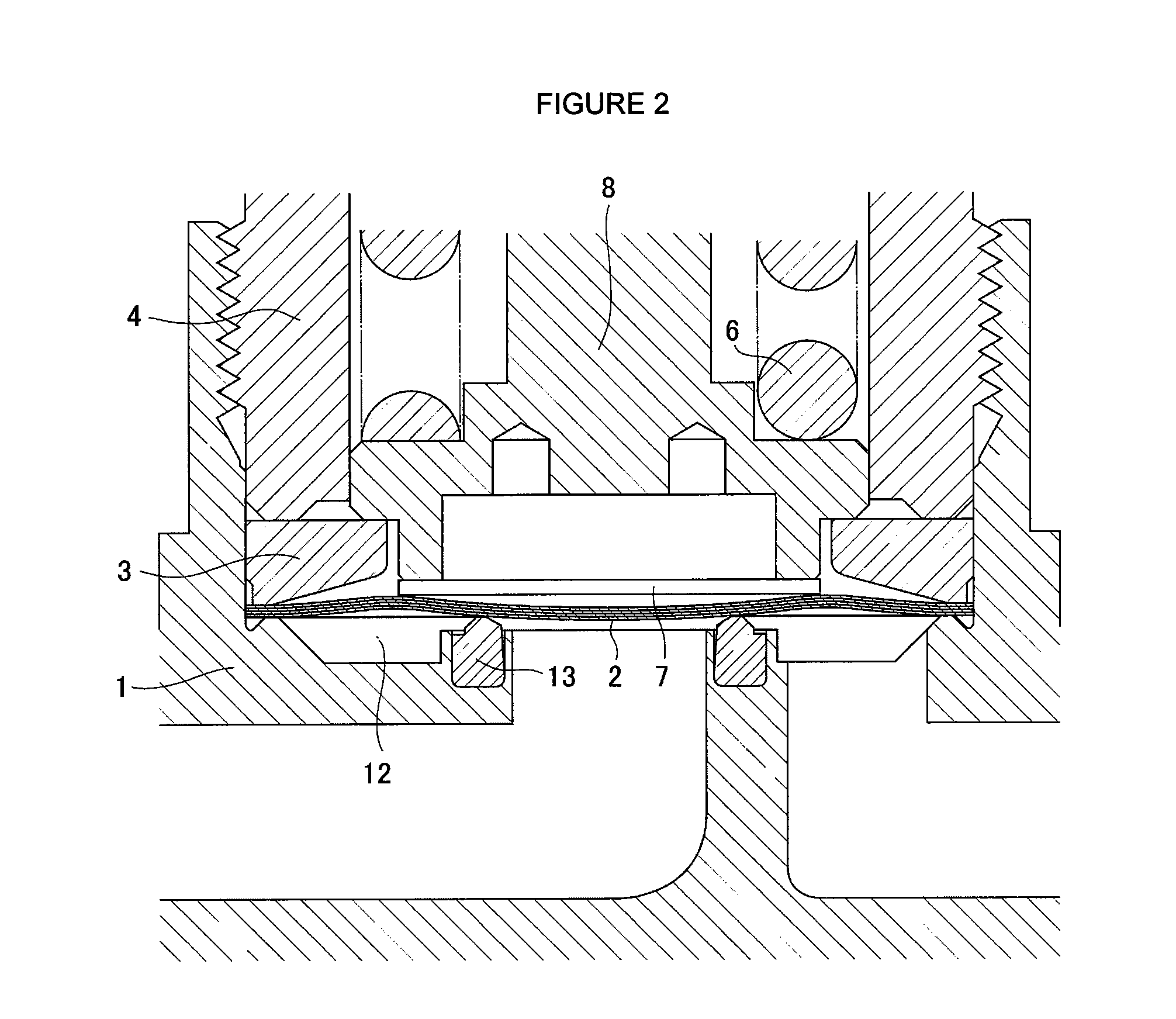

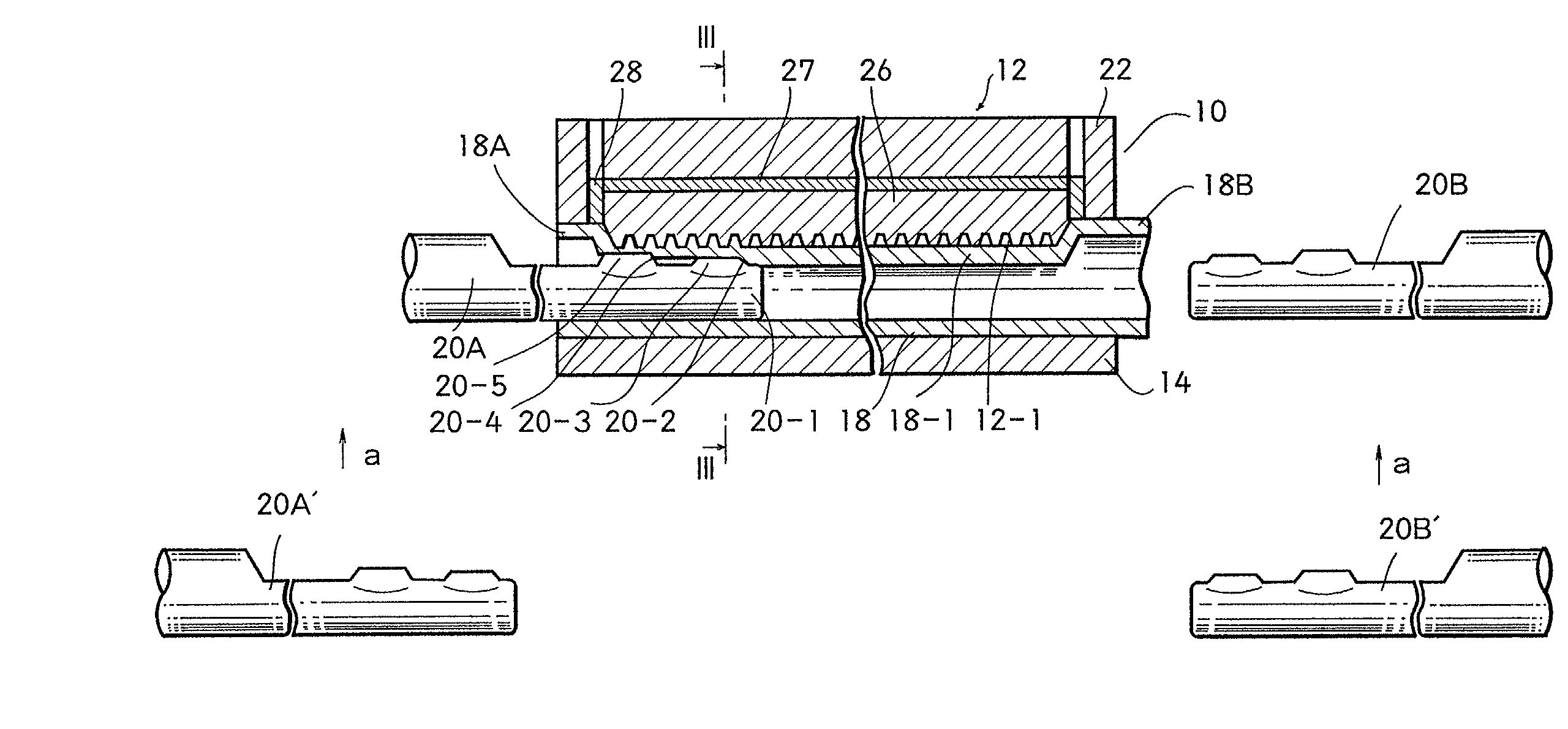

Direct touch type metal diaphragm valve

ActiveUS20100090151A1Reduce replacement timeAchieve stabilityDiaphragm valvesOperating means/releasing devices for valvesDirect touchEngineering

A direct touch type metal diaphragm valve, wherein durability of the valve, that is to say, the ensured number of continuous open / close operations of the valve, is substantially increased under conditions that an appropriate flow rate coefficient Cv is maintained, and changes of the afore-mentioned Cv value over time are mitigated by means of restricting the deformation of the valve seat over time. The afore-mentioned metal diaphragm is formed in a round, reverse-dish shape by laminating a plural number of thin stainless steel plates and a thin Nickel.Cobalt alloy plate, and its center part is bulged upward, and the maximum valve stroke of the valve is regulated to be 55% to 70% of the distance of the maximum bulge height Δh of the afore-mentioned metal diaphragm.

Owner:FUJIKIN INC

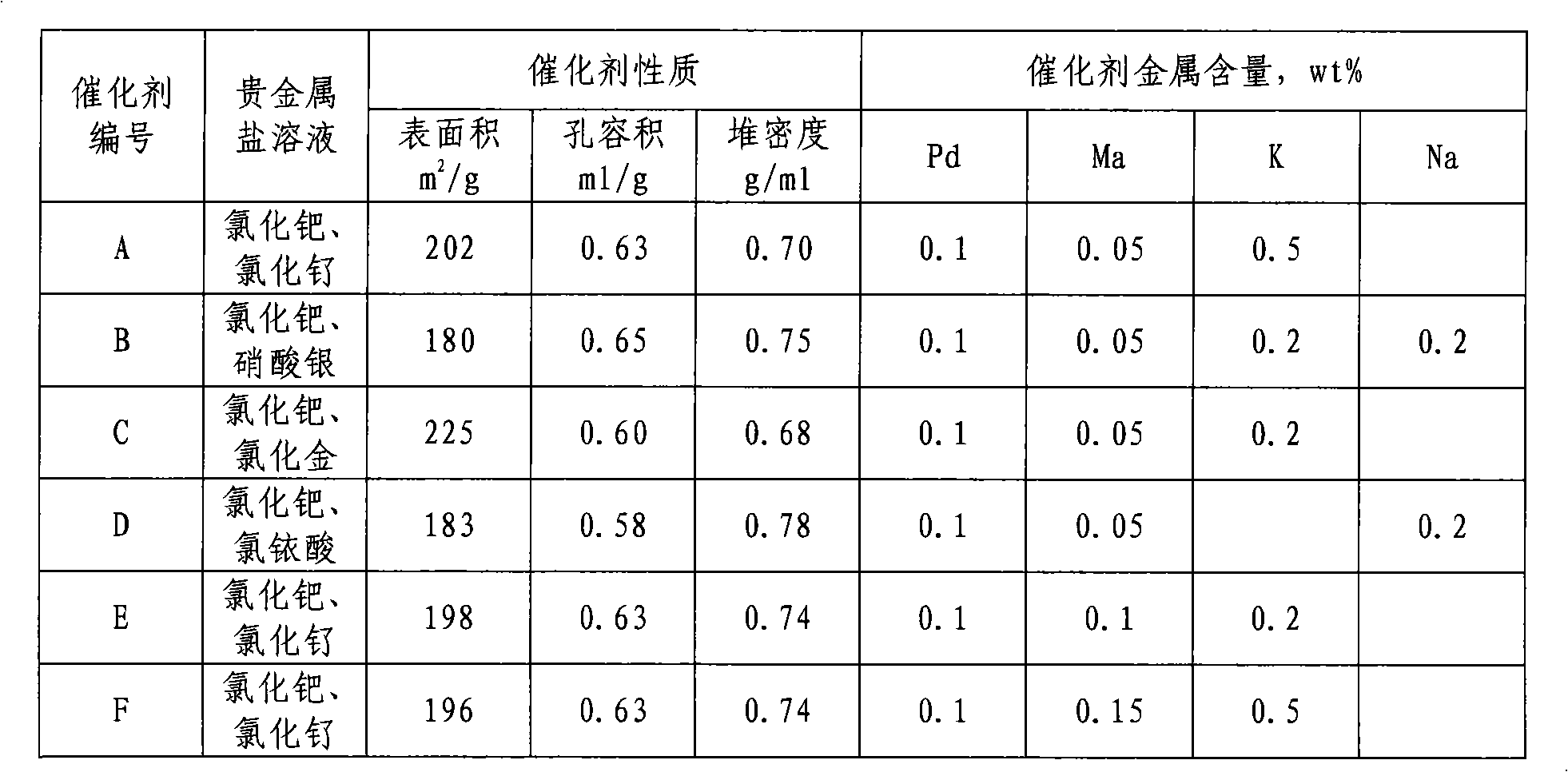

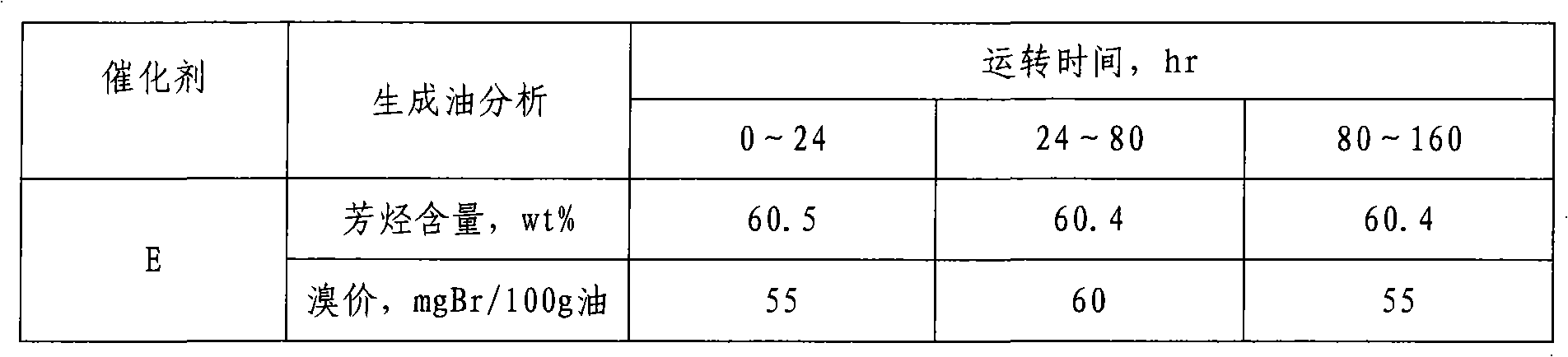

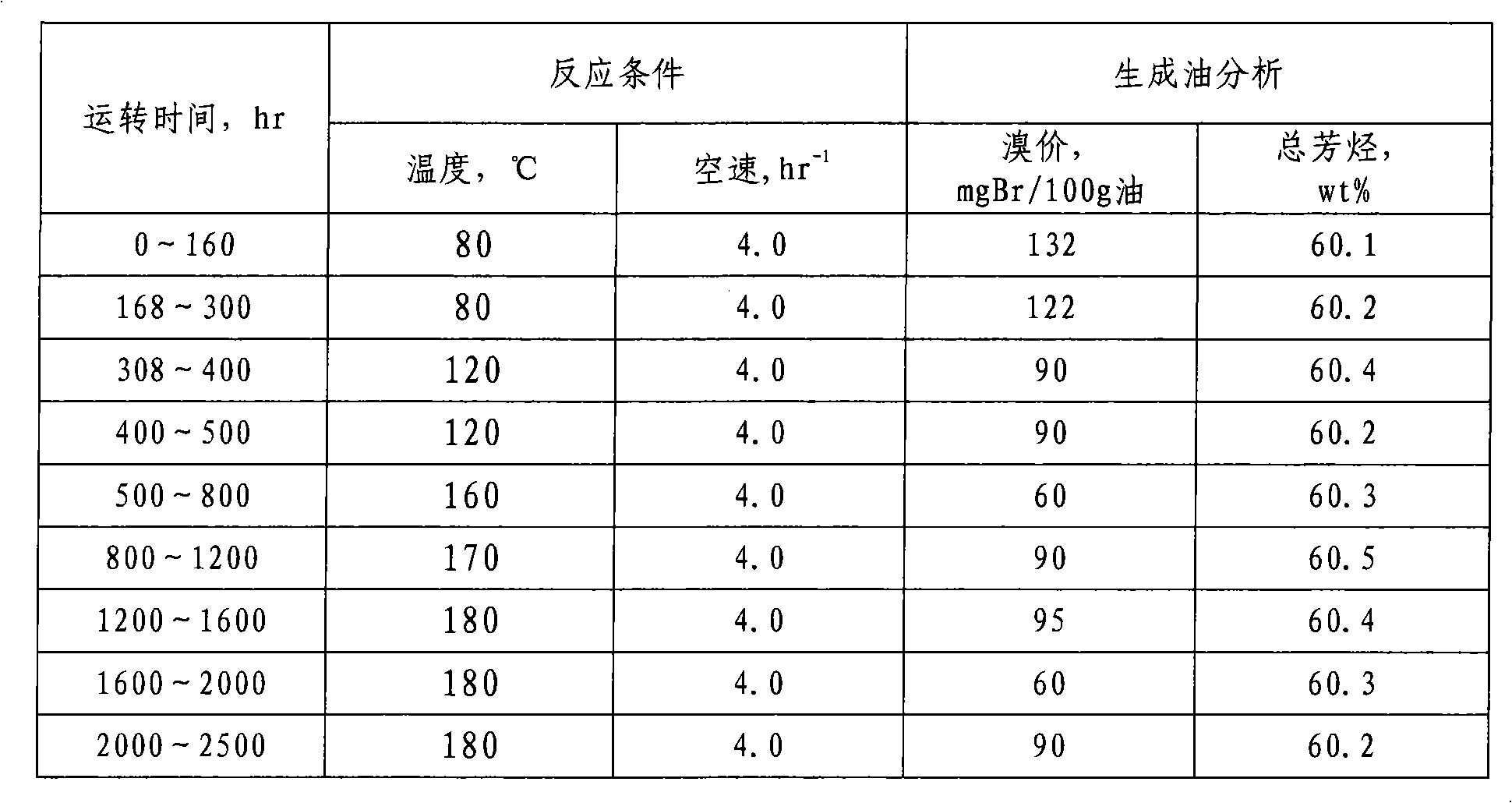

Selectivity hydrodeolefin catalyst used for continuously reforming gasoline and preparation method thereof

InactiveCN101260320ANo need to regenerateReduce lossesRefining to eliminate hetero atomsActive componentGasoline

The invention relates to a catalyst for selective hydrogenation of olefin in reformate, belonging to the improvement of a hydrofinishing catalyst of petroleum hydrocarbon products, in particular, a hydrofinishing catalyst for selective hydrogenation of olefin in reformate. The invention has the characteristics that precious metal active components on a carrier is distributed in a form of egg shell, and has the advantages that the utilization ratio of the precious metal active component is improved and the content of the precious metal active component (1 time lower than the prior technology) and the cost of the catalyst (the precious metal occupies more than 90 percent in the manufacture cost of the load-type metal catalyst) are obviously reduced on one hand, and the activity of aromatic hydrogenation is obviously reduced, the selectivity of olefin hydrogenation is improved and the loss of the aromatic hydrogenation is reduced on the other hand.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

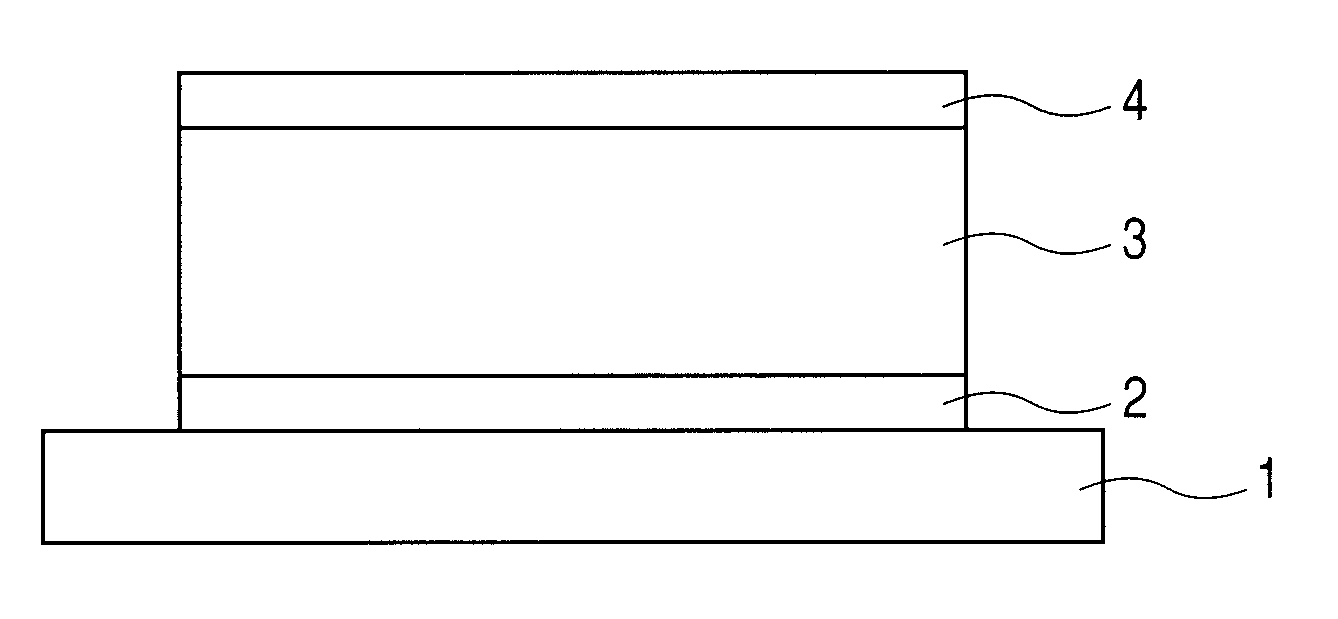

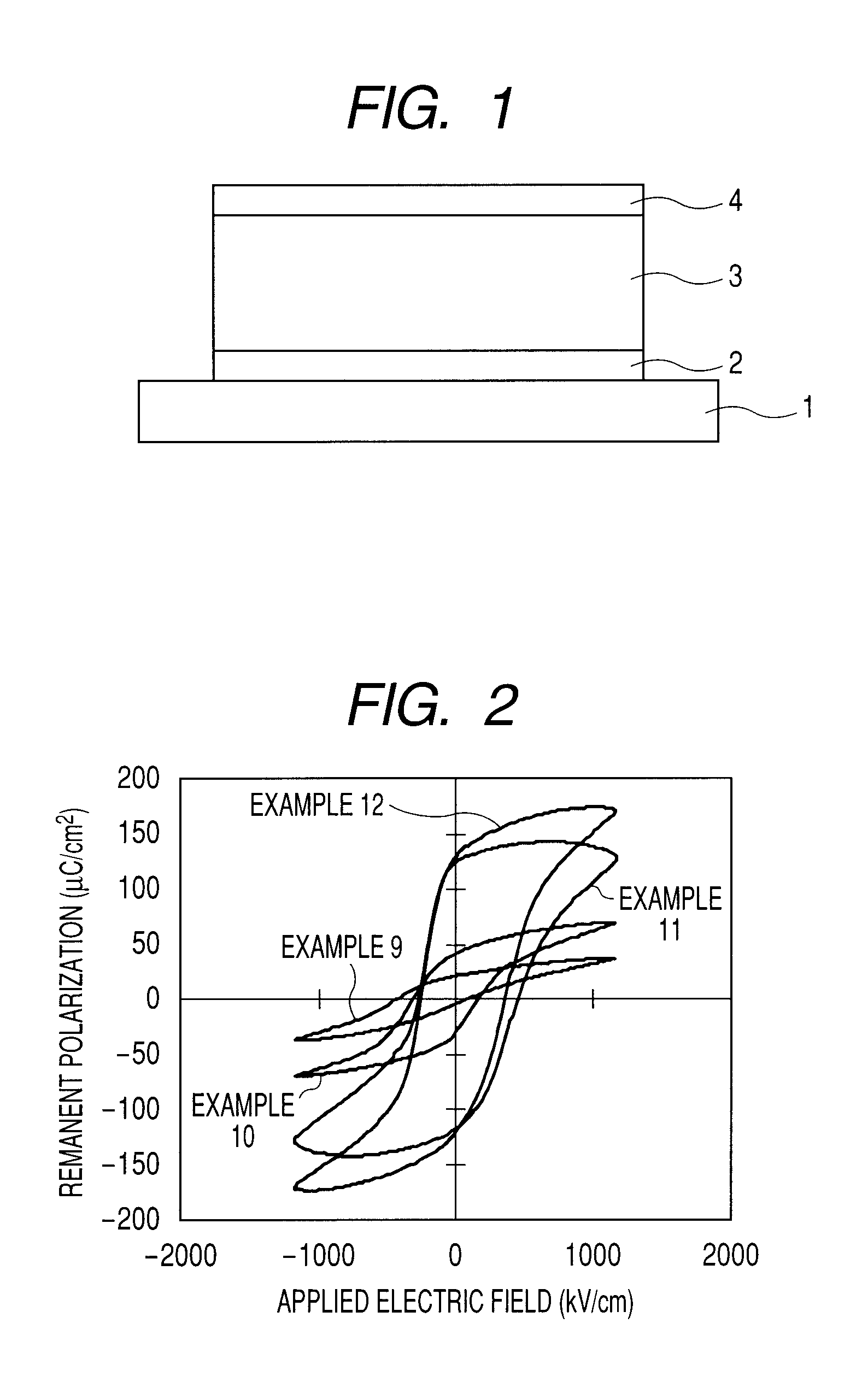

Piezoelectric material, piezoelectric device, and method of producing the piezoelectric device

ActiveUS20100231095A1Increased durabilityImprove insulation performancePiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesType metalBismuth

Provided are a bismuth-based piezoelectric material whose insulation property is improved while its performance as a piezoelectric body is not impaired and a piezoelectric device using the piezoelectric material. The piezoelectric material includes a perovskite-type metal oxide represented by the following general formula (1):Bix(Fe1-yCoy)O3 (1)where 0.95≦x≦1.25 and 0≦y≦0.30, and a root mean square roughness Rq (nm) of a surface of the piezoelectric material satisfies a relationship of 0<Rq≦25y+2 (0≦y≦0.30).

Owner:CANON KK +2

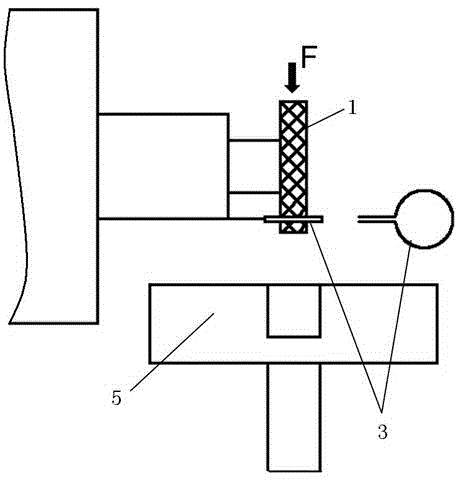

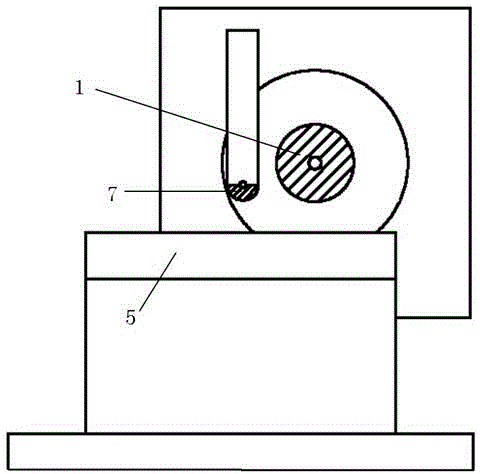

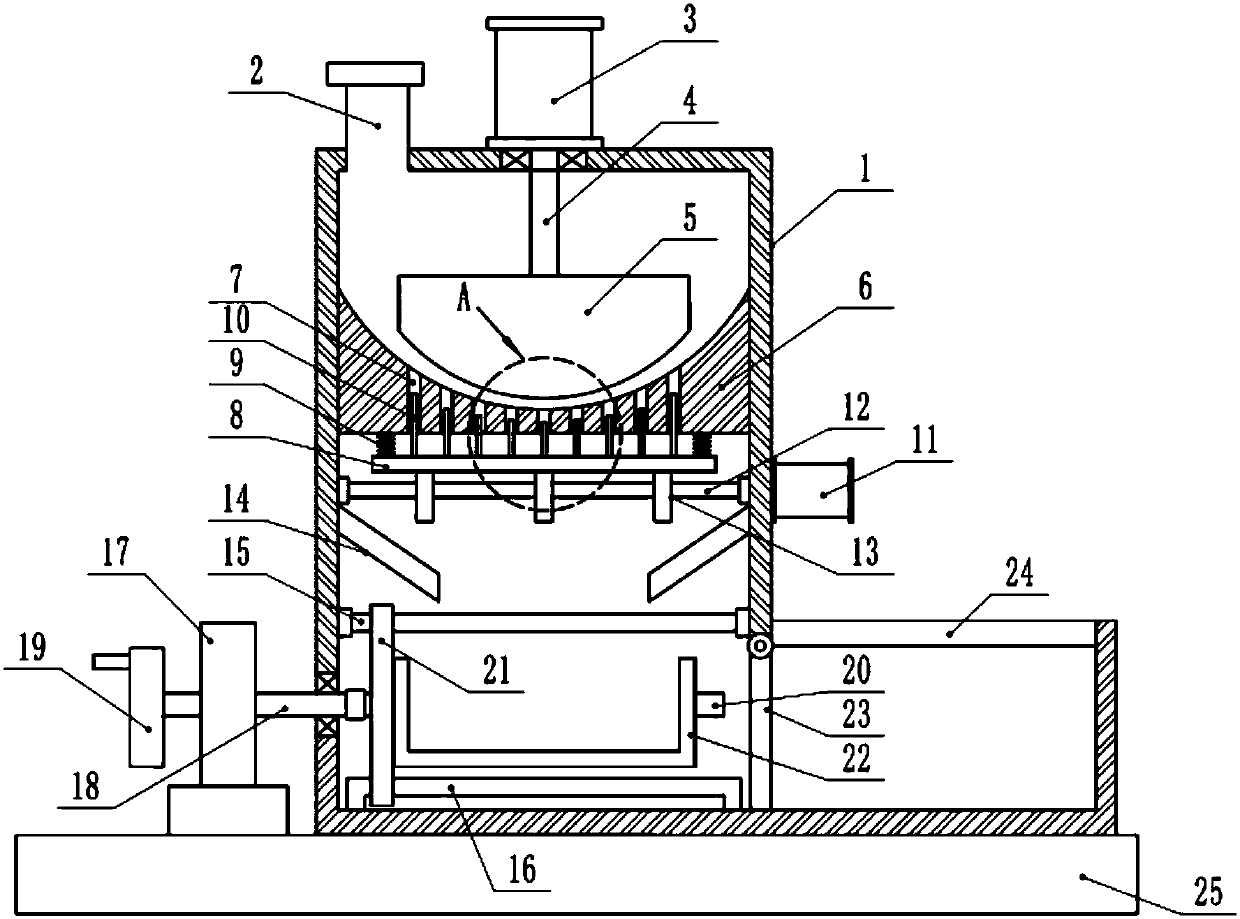

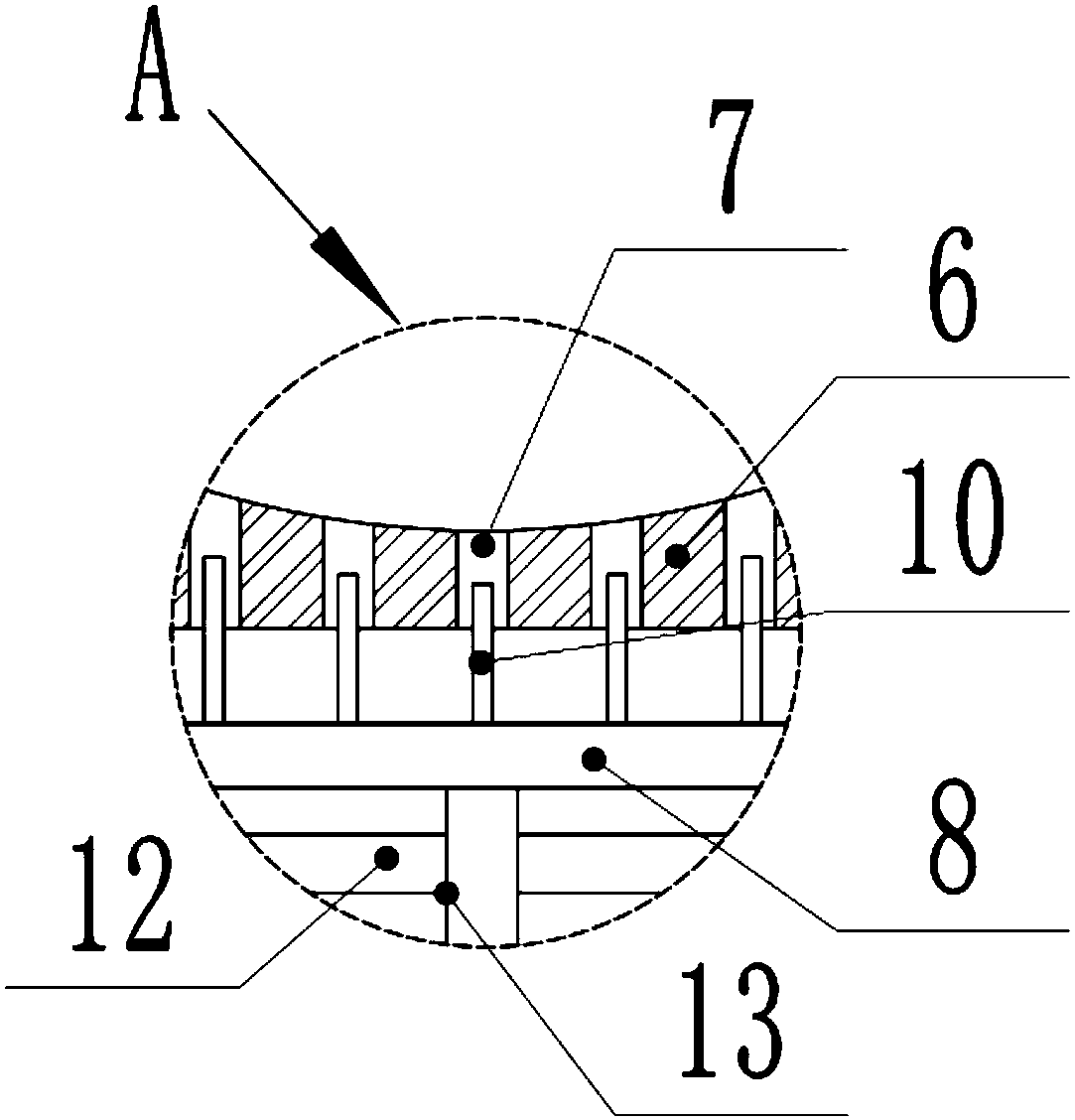

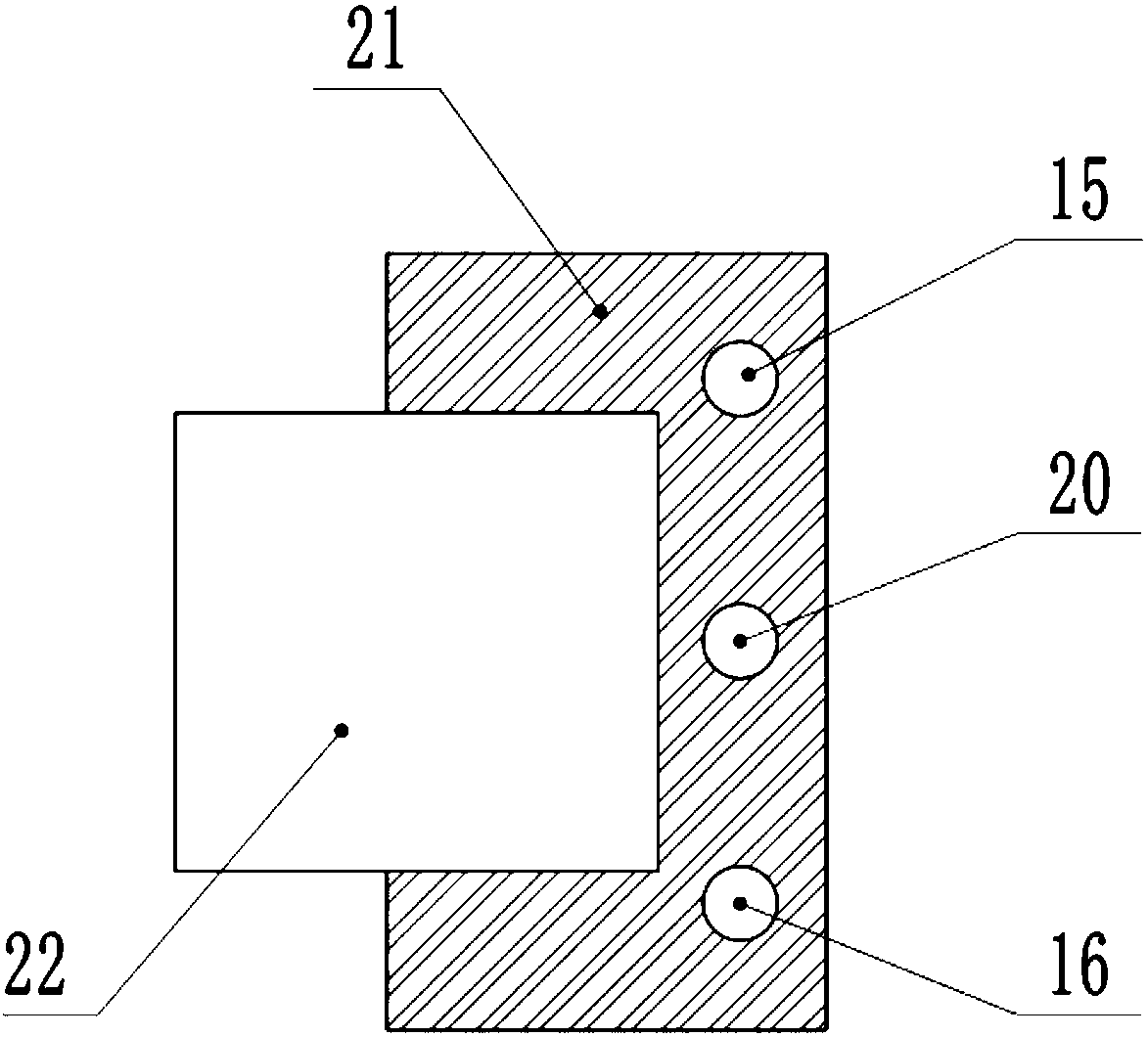

Method and device for auxiliary heating type ultrasound rapid forming

ActiveCN103600166AAvoid formingGuaranteed solid phase junction propertiesNon-electric welding apparatusNumerical controlMetal foil

The invention belongs to the technical field of rapid forming, and particularly relates to a method for achieving multilayer bead welding of metal foil strips through combination of extra auxiliary heating and ultrasonic welding. According to the method, preheating is conducted on metal foil or a base body material in rapid forming, the metal foil or the base body material is softened through preheating conducted by an external heating field, good gas protection is provided, and the welding thickness and width of a metal foil sheet are increased under the condition that the ultrasonic welding power is limited, so that multilayer one-time ultrasonic bead welding or multilayer multi-time ultrasonic bead welding of the metal foil is achieved and a three-dimensional solid block is formed in the solid-phase connection mode. Finally, a machining platform controlled by a numerical control program is applied, so that geometrical characteristic machining of a needed part is achieved. A metal piece obtained according to the method has the advantages of being low in cost, high in efficiency, compact in organization, free of casting-state structure, capable of achieving rapid forming of a functionally gradient material and the like.

Owner:WEIHAI WANFENG MAGNESIUM IND DEV

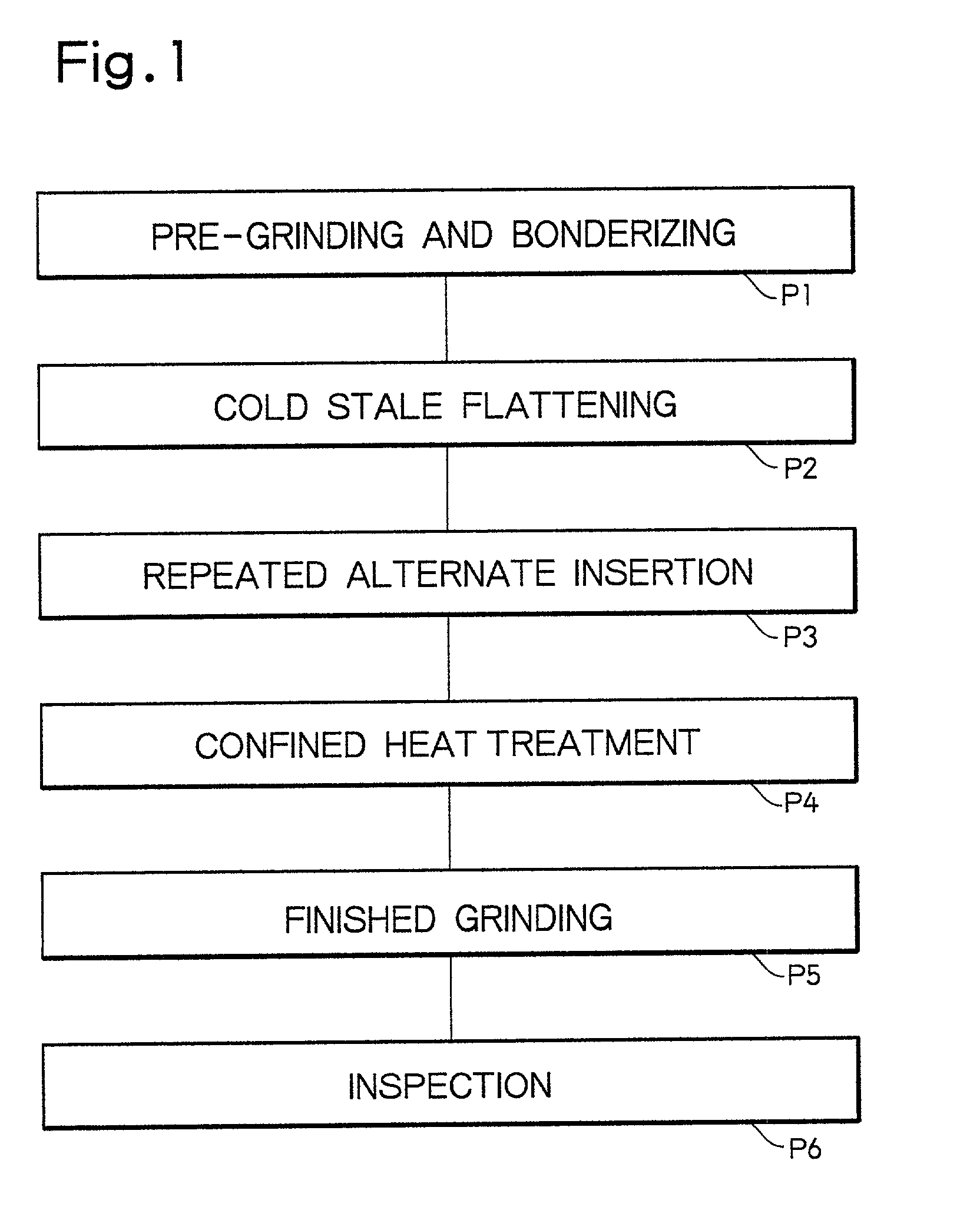

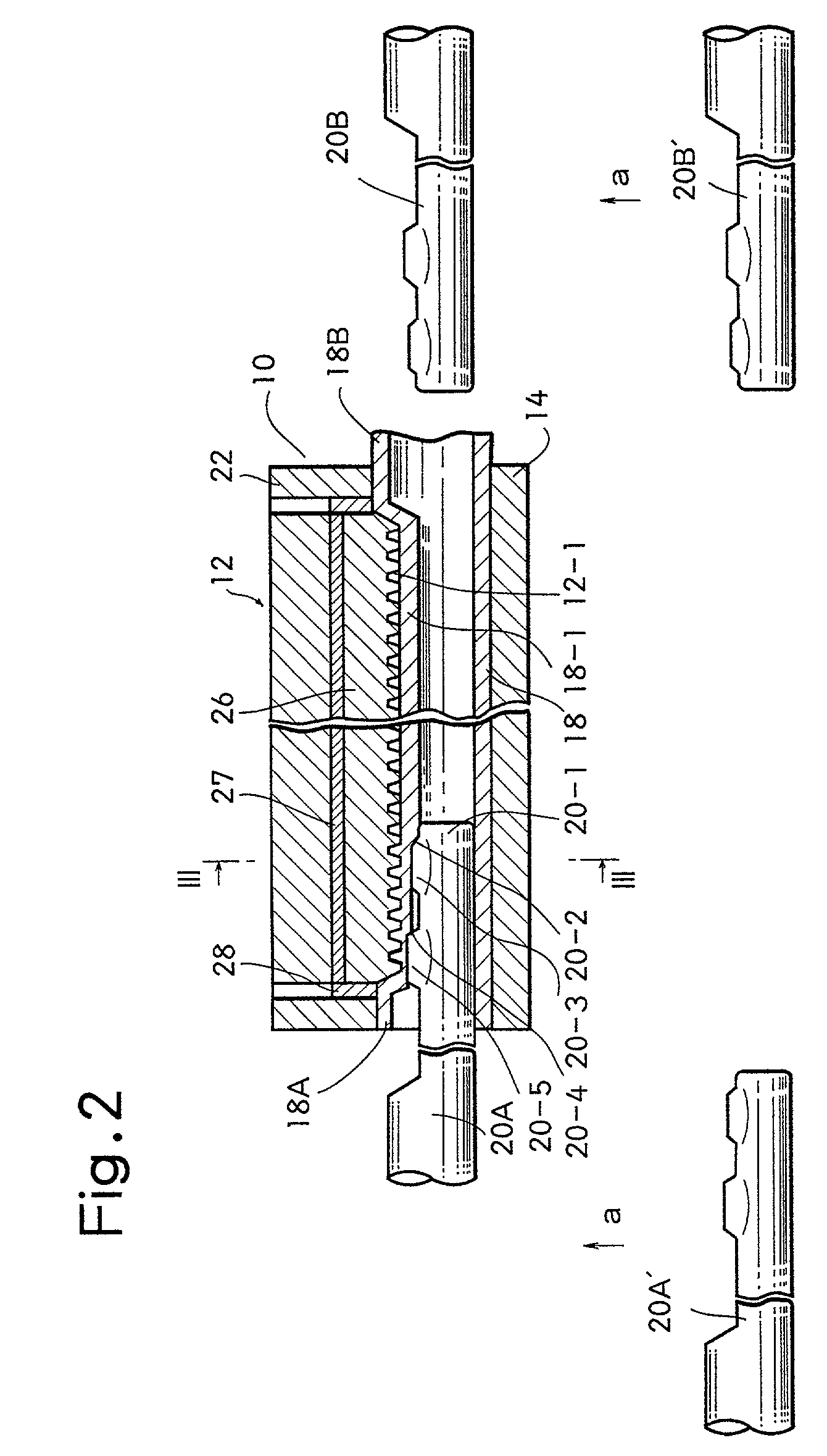

Mandrel insertion type metal forming of rack bar

InactiveUS20020044439A1High precisionReduce processing stepsFoundry mouldsMechanical steering gearsMetal formingEngineering

A method for producing a rack bar for a steering mechanism in an automobile. A blank pipe is held in a die, which has, at its inner surface, linear tooted portions. Mandrels are inserted repeatedly to the blank pipe while the direction of the insertion is alternately changed, while the insertion of the mandrel on one side of the blank pipe and the withdrawal of the mandrel on the other side are overlapped. Furthermore, lubrication is controlled so that an increased temperature of the work around 200° C. as generated under the plastic deformation of the metal is kept. An increased efficiency as well as reduced cost are obtained.

Owner:KOSHINGIKEN

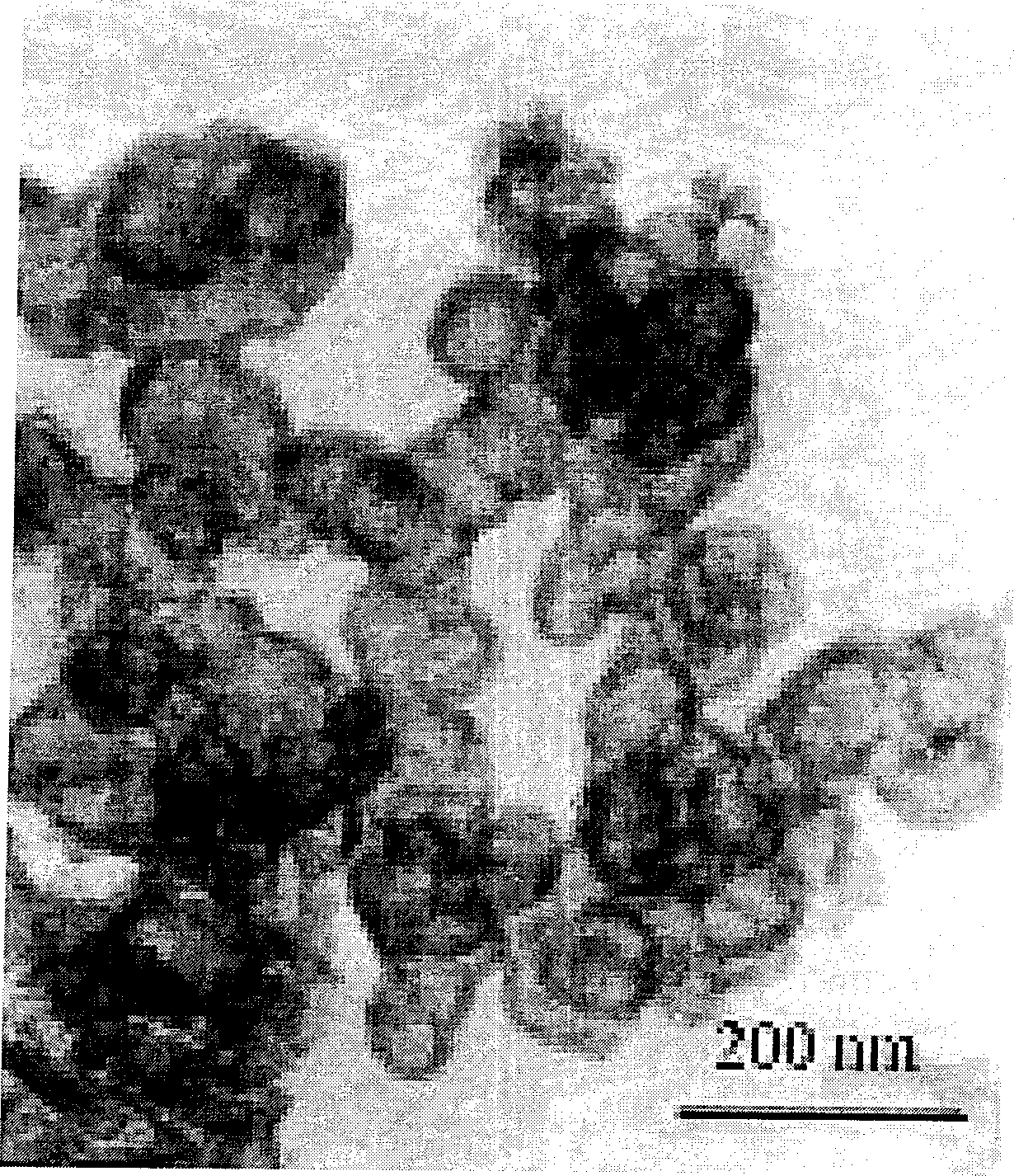

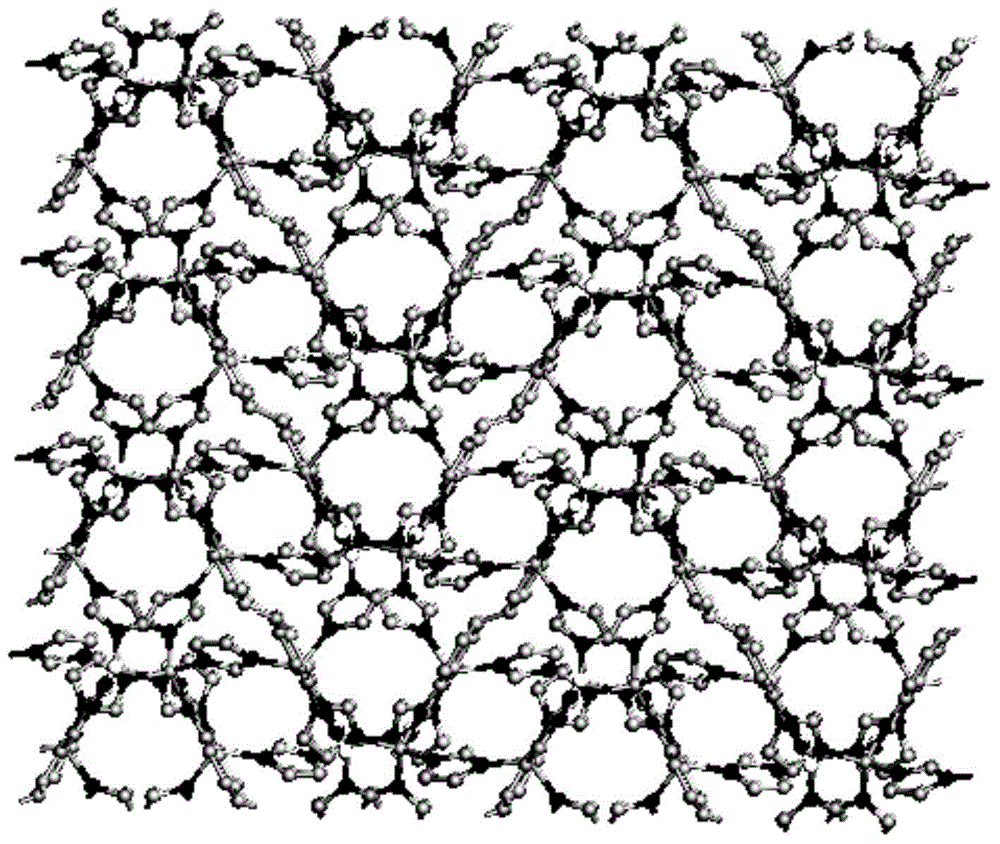

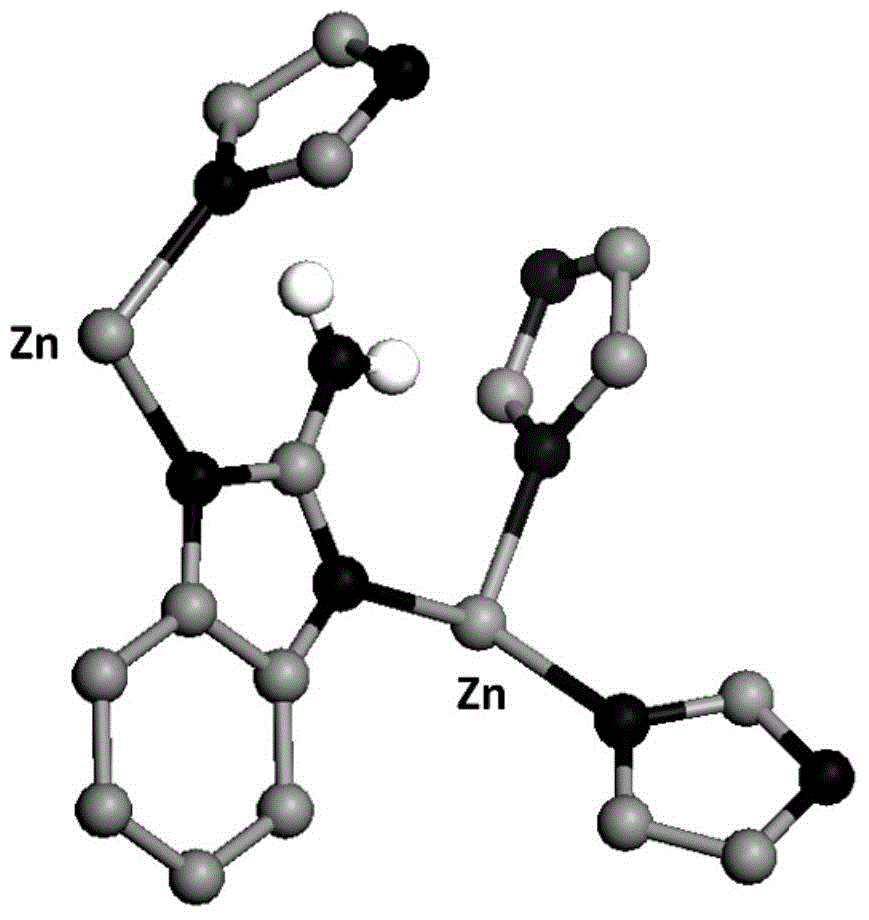

Functionalized ZIF type metal organic framework (MOF) porous material as well as preparation method and application of material

ActiveCN104307482AExcellent discharge specific capacityThe first discharge specific capacity is highOther chemical processesCell electrodesMetal-organic frameworkLithium-ion battery

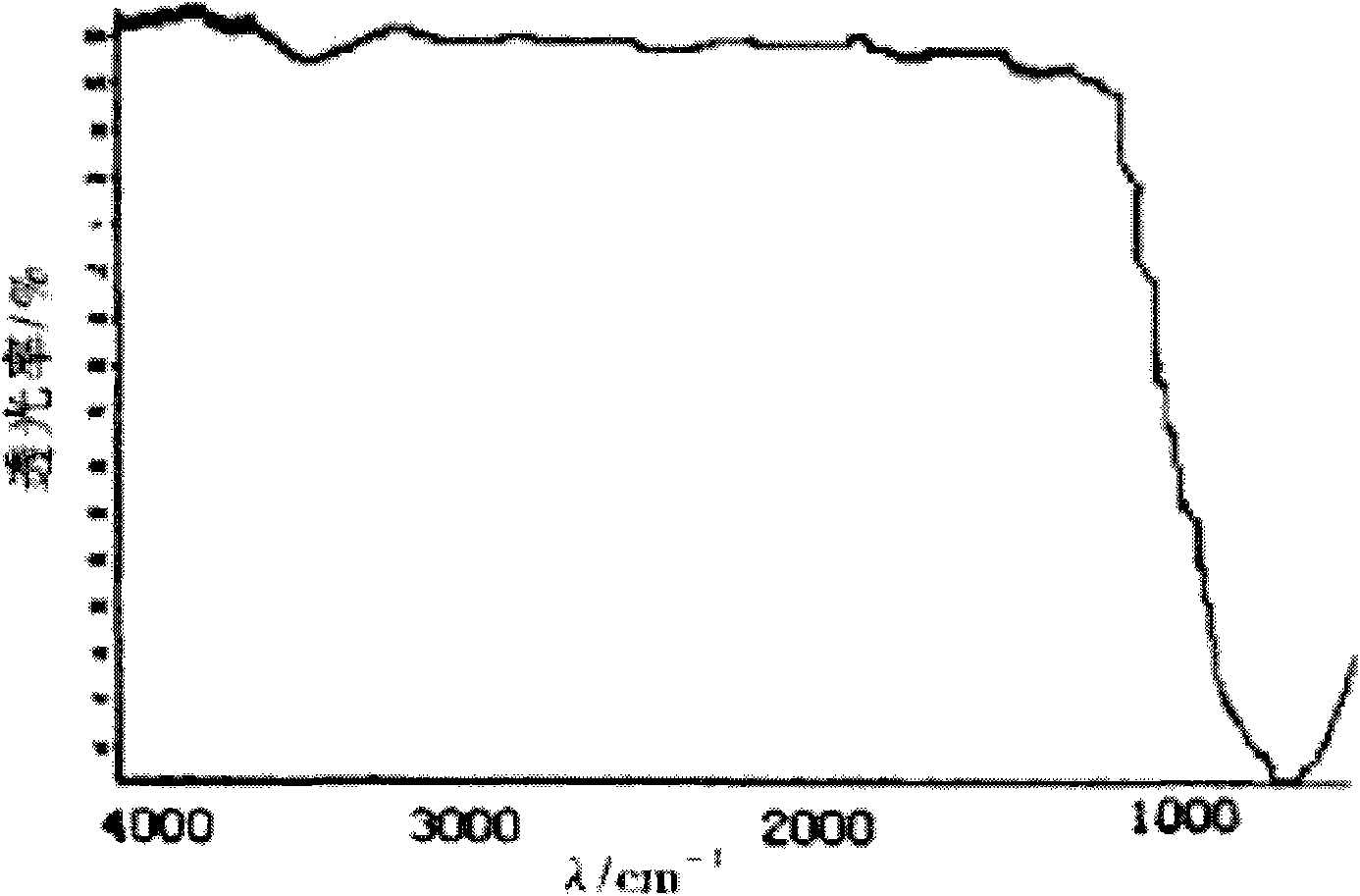

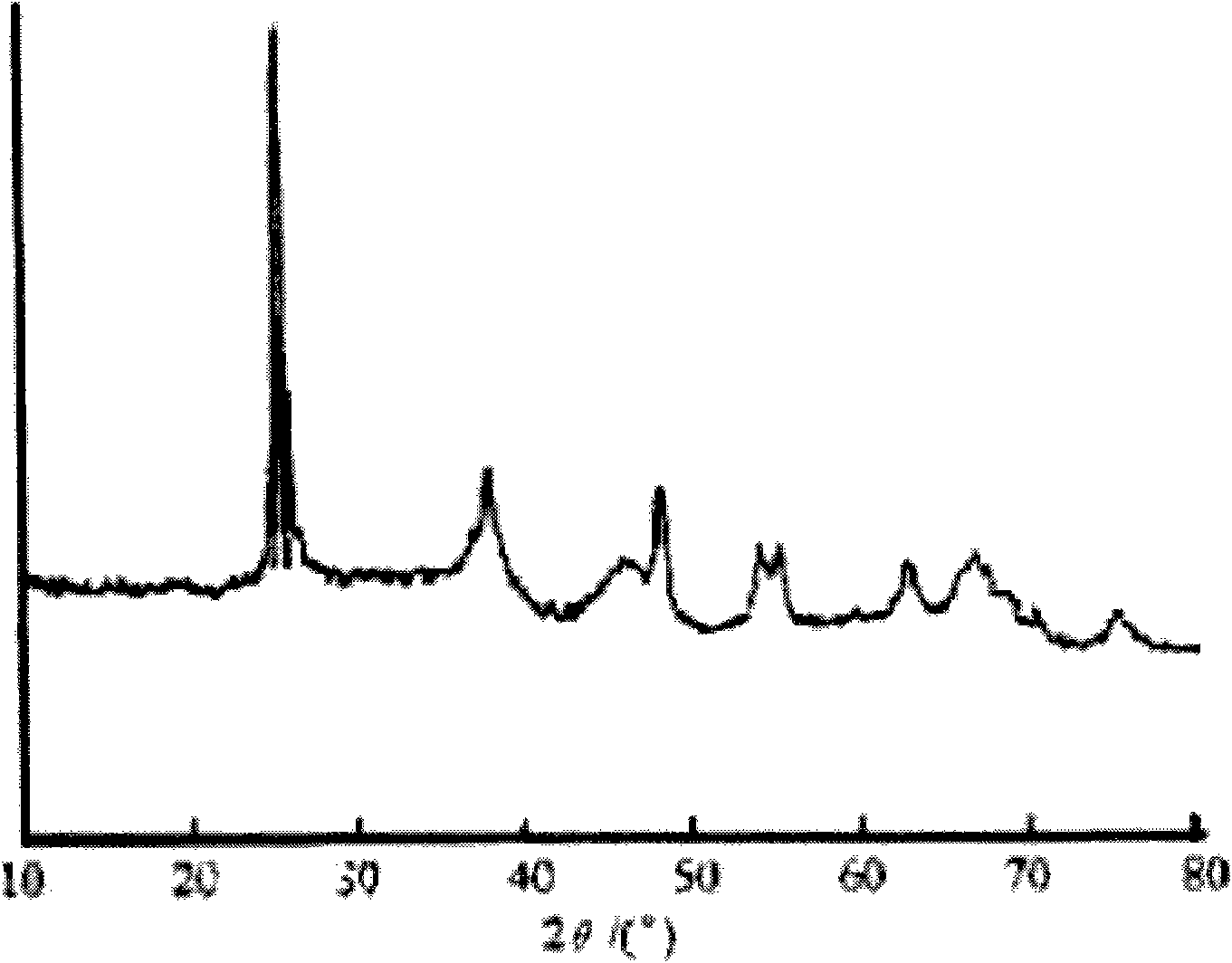

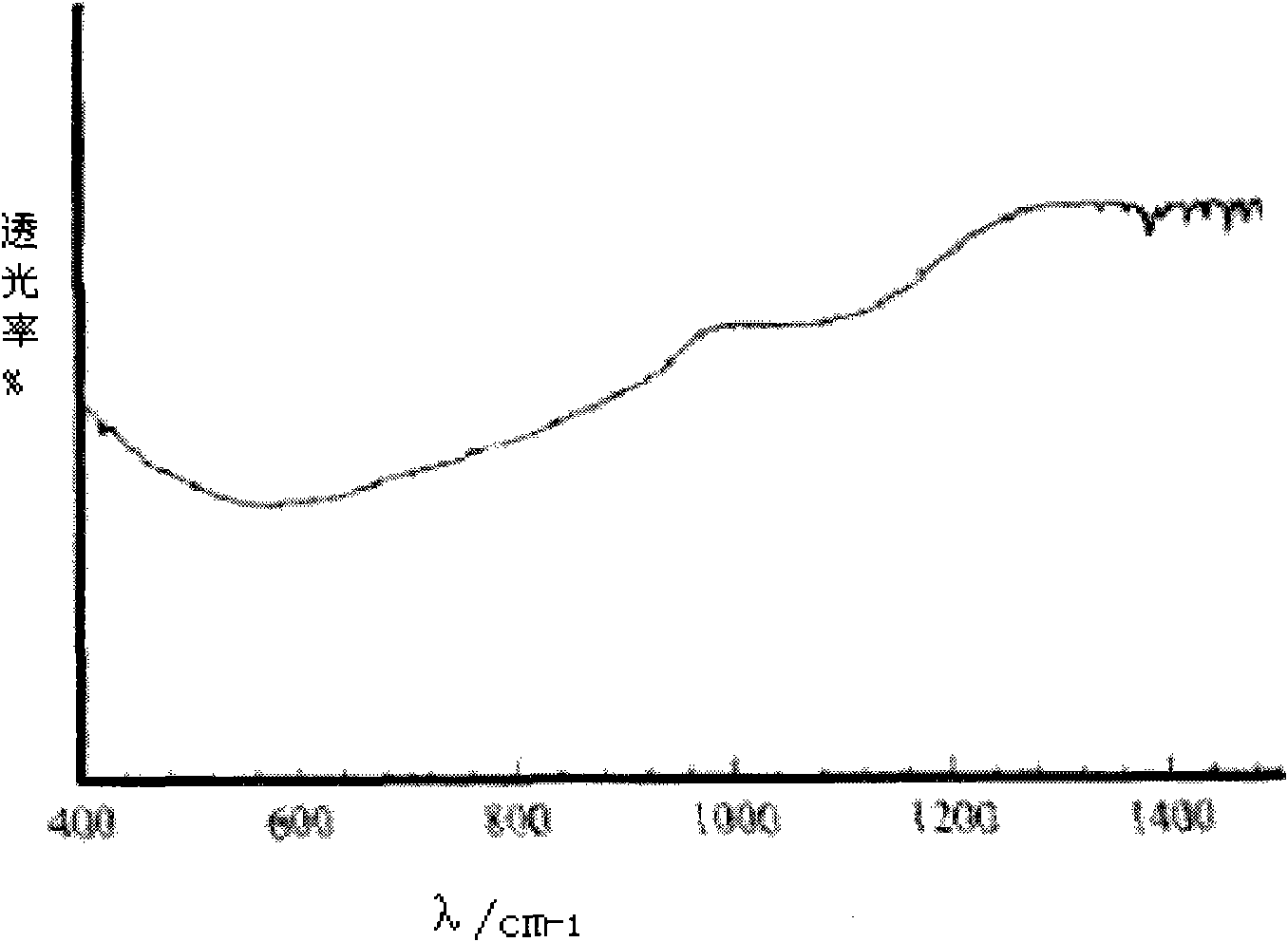

The invention provides a functionalized ZIF type metal organic framework (MOF) porous material. A framework of the material comprises metal ions Zn<2+> or Co<2+> as well as imidazole and aminobenzimidazole. The material is excellent in physical and chemical stability and overcomes the defect that a traditional MOF porous material is sensitive to water; the material has a good CO2 adsorption property; besides, a lithium ion battery manufactured with the material as an electrode material has good electrochemical properties, and furthermore, after N cycles, the specific discharge capacity of the lithium ion battery tends to be stable, wherein N is greater than or equal to 10; as a result, the functionalized ZIF type MOF porous material has bright application prospect in the field of lithium ion batteries.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

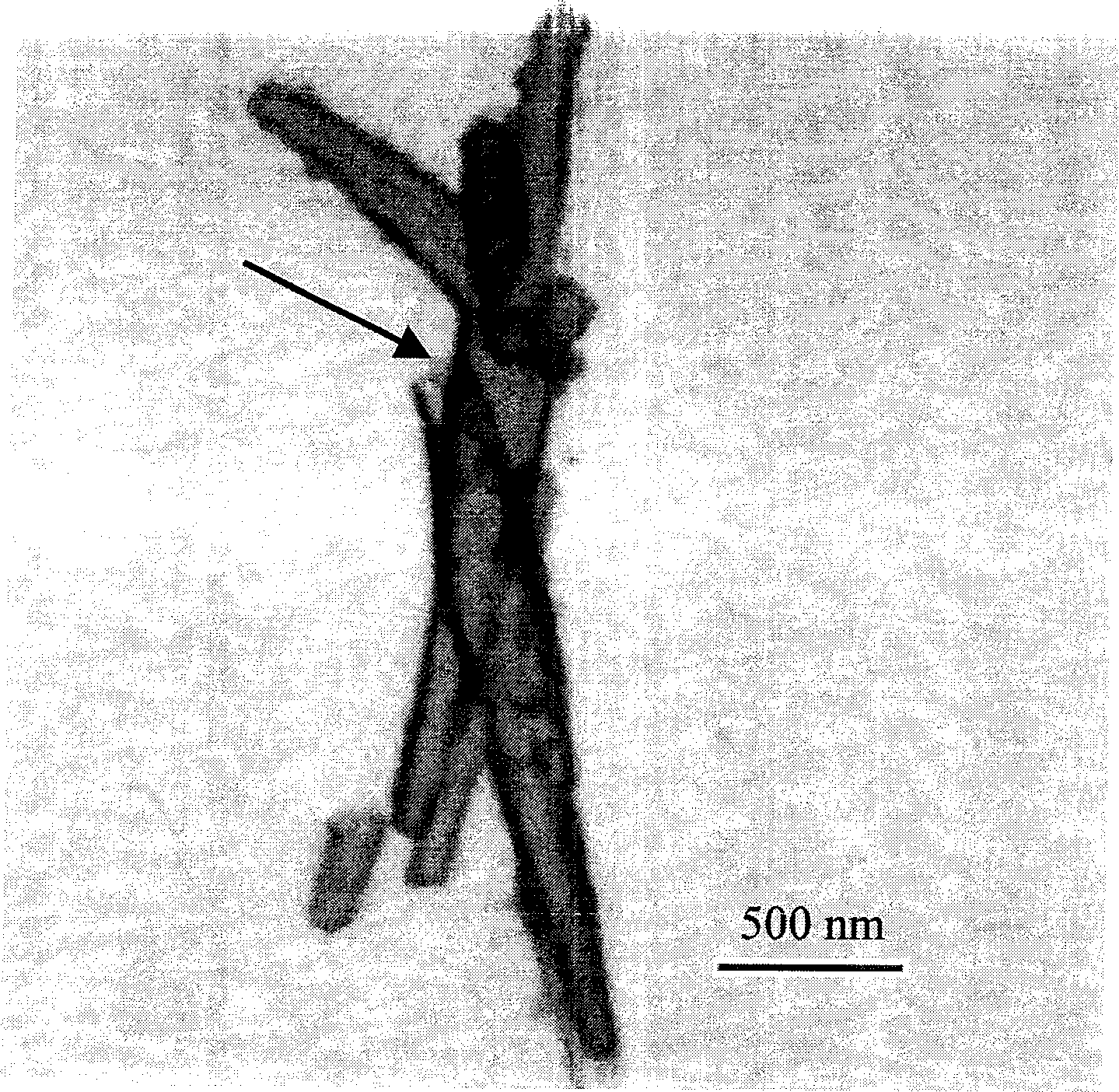

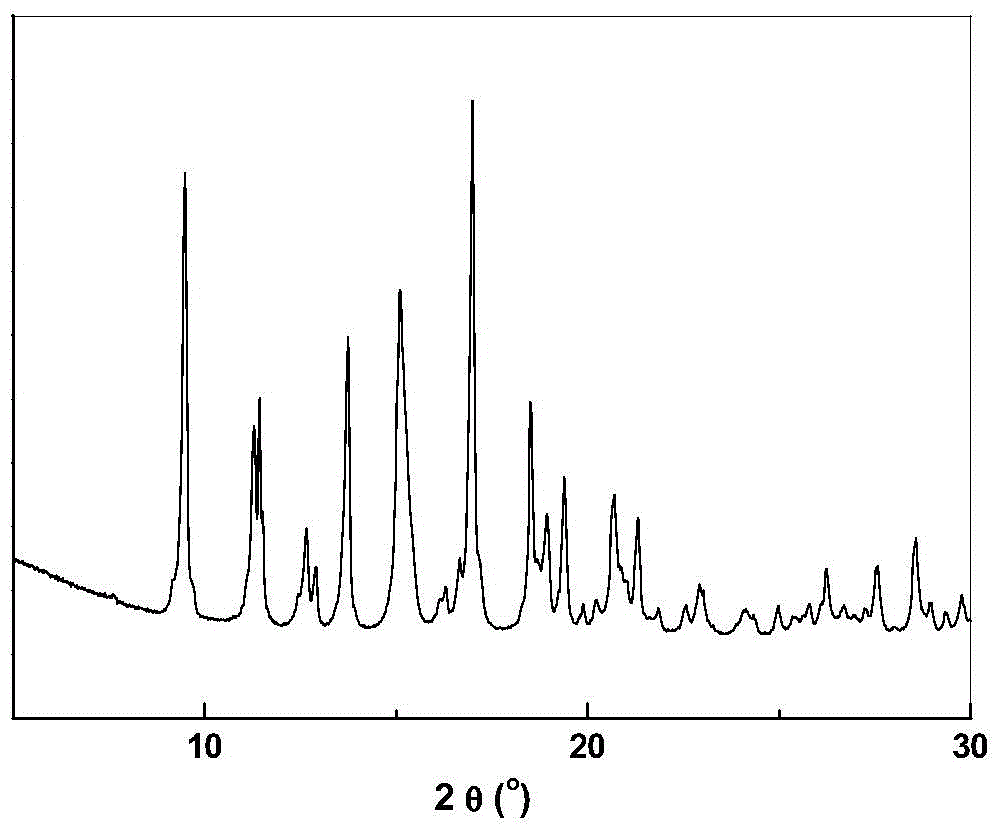

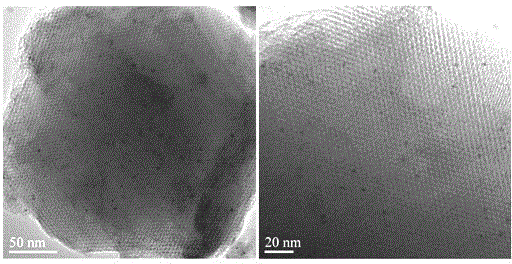

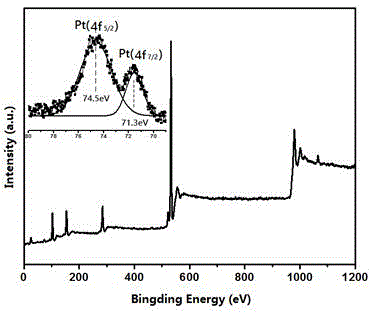

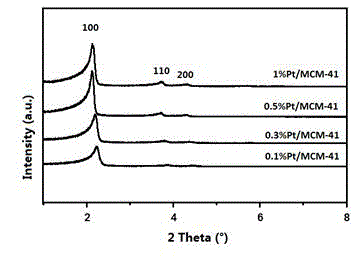

Load type metal mesoporous molecular sieve noble metal catalyst and preparation method thereof

InactiveCN104857983AImprove stabilityAvoid gatheringMolecular sieve catalystsCarbon compoundsIsomerizationCatalytic oxidation

The invention relates to a load type metal mesoporous molecular sieve noble metal catalyst and a preparation method thereof. The preparation method comprises serving a complex which is formed by long-chain surfactant molecules and a metal complex as a template agent, producing a metal platinum doped molecular sieve Pt-MCM-41 by a hydrothermal crystallization method after a silicon source is added and uniformly fixing metal platinum in molecular sieve frame lattices in the process; washing and drying a sample after crystallization and directly reducing the sample in the hydrogen; removing the residual surfactant through low temperature after-treatment to obtain a required sample. According to the load type metal mesoporous molecular sieve noble metal catalyst and the preparation method thereof, the prepared catalyst comprises a regular mesoporous structure, active site centers are distributed in a highly ordered mode, the specific surface area and the pore volume are large, the thermal and hydrothermal stability is good, and the catalyst can serve as a catalytic oxidation, catalytic cracking and catalytic isomerization catalyst.

Owner:BEIJING UNIV OF CHEM TECH

Perovskite-type metal oxide compounds and methods of making and using thereof

Perovskite-type catalyst consists essentially of a metal oxide composition and methods of using them are provided. The metal oxide composition is represented by the general formula Aa−xBxMOb, in which A is a mixture of elements originally in the form of single phase mixed lanthanides collected from bastnasite; B is a divalent or monovalent cation; M is at least one element selected from the group consisting of elements of an atomic number of from 23 to 30, 40 to 51, and 73 to 80; a is 1 or 2; b is 3 when a is 1 or b is 4 when a is 2; and x is a number defined by 0≦x<0.5. Methods of making and using the perovskite-type catalysts are also provided. The perovskite-type catalyst may be used to reduce nitrogen oxides, oxidize carbon monoxide, and oxidize hydrocarbons in an exhaust stream from a motor vehicle. Methods of such a use are provided.

Owner:CATALYTIC SOLUTIONS INC

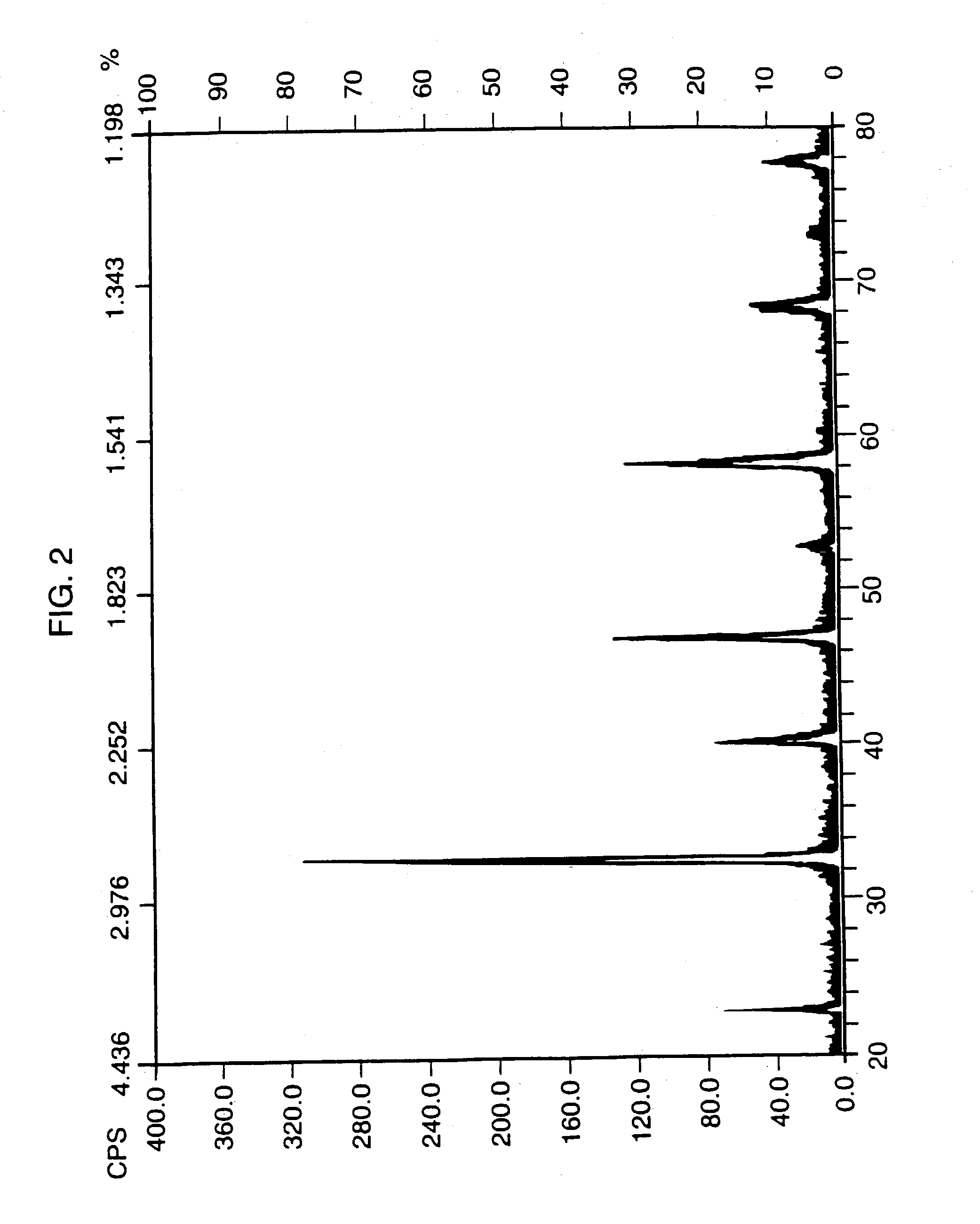

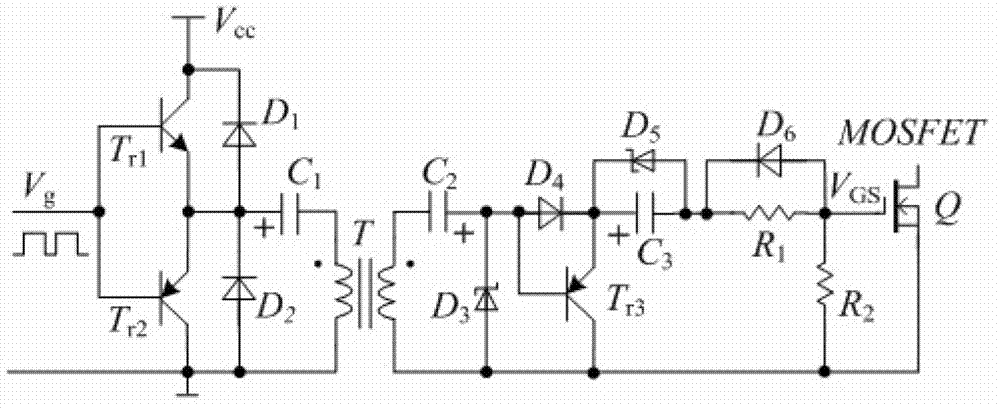

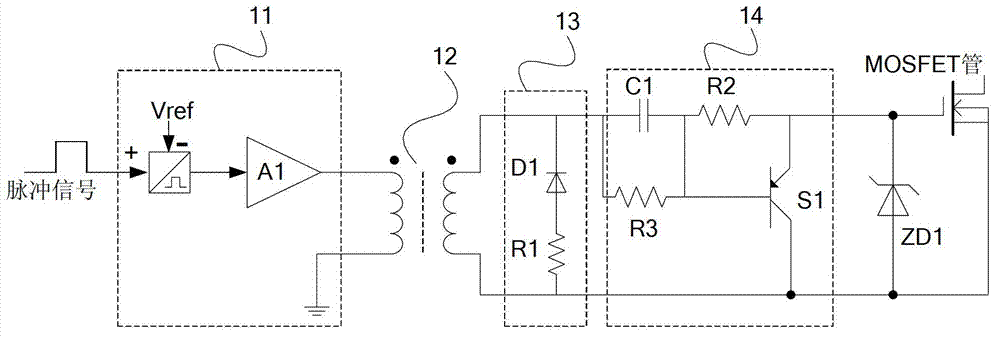

One-way isolated type metal-oxide-semiconductor filed-effect transistor (MOSFET) drive circuit

The invention discloses a one-way isolated type metal-oxide-semiconductor filed-effect transistor (MOSFET) drive circuit. The one-way isolated type MOSFET drive circuit comprises a level transformation and pulse drive circuit, a pulse transformer, a magnetic reset circuit and an acceleration turn-off circuit. The level transformation and pulse drive circuit is used for level transformation and power amplification on input pulse signals so as to drive the pulse transformer to work. The magnetic reset circuit is used for enabling the pulse transformer to carry out reliable magnetic reset. The acceleration turn-off circuit is used for accelerating turn-on and turn-off of a MOSFET tube, and comprises a capacitor, a second resistor, a third resistor and a PNP type triode. One end of the capacitor is connected with an auxiliary edge synonym end of the pulse transformer, the other end of the capacitor is connected with the second resistor, and the other end of the second resistor is connected with a grid electrode of the MOSFET tube. The third resistor is connected with the capacitor in parallel, a collector electrode of the PNP type triode is connected with an auxiliary edge non-synonym end of the pulse transformer, a base electrode of the PNP type triode and the capacitor are connected with one end of the second resistor, and an emitting electrode of the PNP type triode is connected with the grid electrode of the MOSFET tube.

Owner:LG ELECTRONICS CHINA RANDD CENT SHANGHAI CO LTD

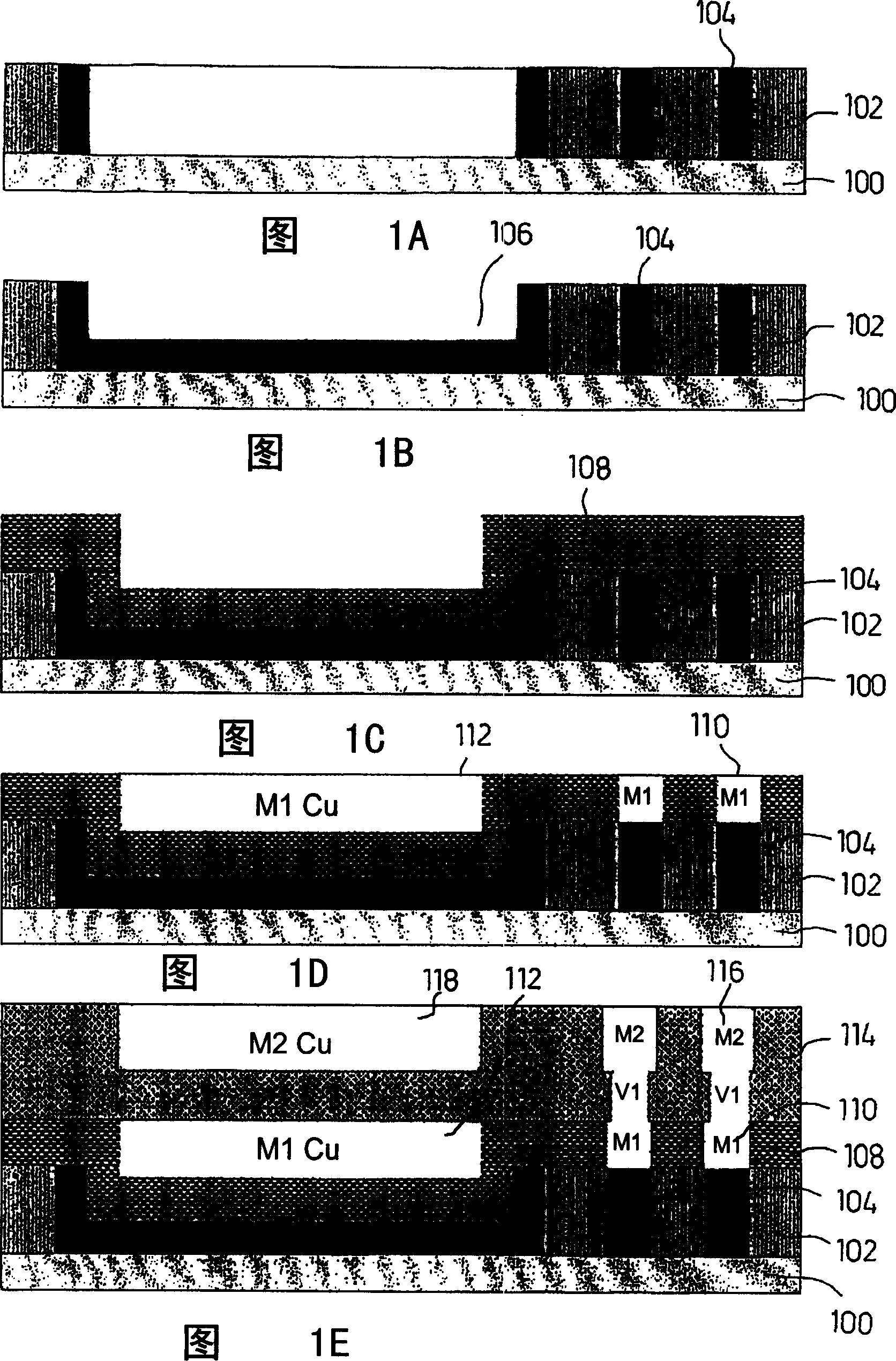

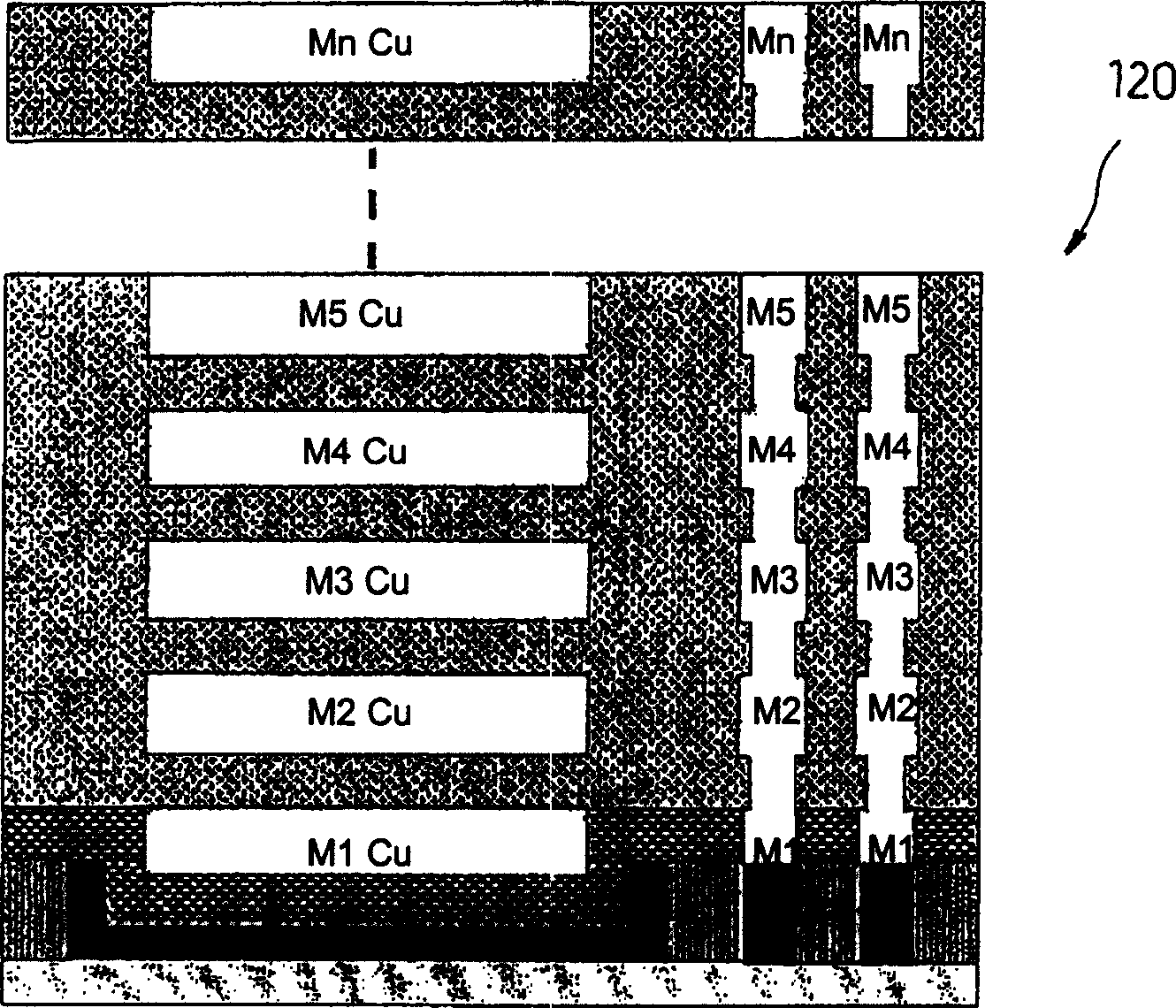

Laminated method insulator metal capacitor and manufacturing method thereof

ActiveCN1624894AEfficient manufacturingReduce leakageSolid-state devicesSemiconductor/solid-state device manufacturingDielectricCapacitance

The invention discloses a manufacturing method of laying-type metal-insulation-metal capacitor, in the process of integrated circuit and in the conducting layer of the multi-layer metal form the embedding metal-insulation-metal capacitor. The manufacturing of the metal-insulation-metal capacitor and the metal conduction wire adopt the common methods such as patternization and smoothing and so on and does not need extra luminous cover and procedure, so as to reduce the manufacturing approaches and therefore improve the producing efficiency and lower the cost, can greatly reduce the electric leakage between the flat plates but increase the unit area of the capacitance value.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

Method for preparing coating with metal surface corrosion inhibition and self-repair functions

InactiveCN101613543AShape is not limitedUnlimited sizeAnti-corrosive paintsTectorial membraneLayer by layer self assembly

The invention belongs to the field of anticorrosion materials, and relates to a green and environment-friendly method for protecting metal from corroding, which can particularly control metal corrosion for long time effectively, and play a role in self-repairing the metal surface to a certain extent. The method is characterized in that an inhibitor molecule and polyelectrolyte are alternately deposited on the surface of a silicon dioxide nano-particle through green environment-friendly type metal inhibitor micromolecules and polyelectrolyte by adopting layer-by-layer self-assembly technology and utilizing the penetrating controllability of a polyelectrolyte self-assembly membrane so as to prepare a functional nano-particle with the inhibitor and the polyelectrolyte self-assembly composite membrane which are coated on the surface; and the prepared functional nano-particle is mixed with sol-gel to prepare the functional sol-gel membrane coated on the metal surface to be protected. The coating has the function of metal surface self-repairing, and ensures that the inhibitor molecules released by the functional membrane are adsorbed on the metal surface to reform a protecting membrane in a coating damaged microsection to play a certain role in self repairing. The method is applicable to corrosion protection of various metals.

Owner:UNIV OF SCI & TECH BEIJING

Anti-blocking type metal powder grinding device for cemented carbide processing

The invention discloses an anti-blocking type metal powder grinding device for cemented carbide processing. The anti-blocking type metal powder grinding device comprises a grinding machine box, a grinding motor, a grinding head, a grinding sieve plate, multiple sets of sparse hole needles, cams and a receiving box. The grinding machine box is arranged on a base. The grinding sieve plate is fixedlymounted in the grinding machine box. A connecting frame is arranged below the grinding sieve plate. The sparse hole needles are fixedly mounted on the upper surface of the connecting frame and vertically and upwardly arranged and correspond to sieve holes in the grinding sieve plate. An output shaft of the drive motor is fixedly connected with a rotary shaft through a coupling in the grinding machine box. The cams are mounted on the rotary shaft at equal intervals. The sparse hole needles are driven to continuously move up and down in the grinding process, the sieve holes are dredged, blocking caused by excessive powder in the sieve holes is avoided effectively, and meanwhile the situation of frequently replacing the grinding sieve plate due to blocking of the sieve holes is avoided, so that the situation of frequently replacing the grinding sieve plate can be avoided while the cost is saved, and the production efficiency is improved greatly.

Owner:喻为科技服务(上海)有限公司

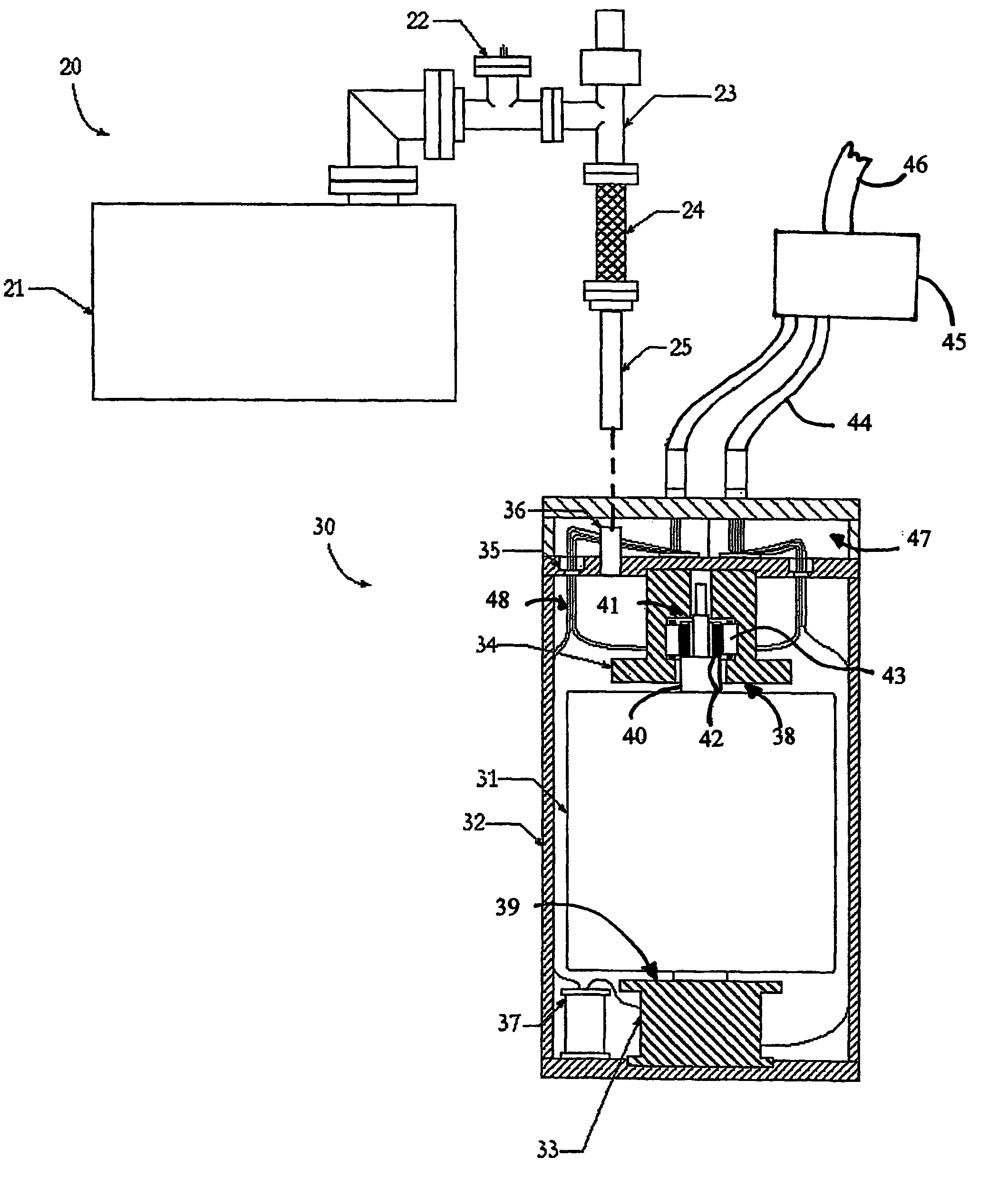

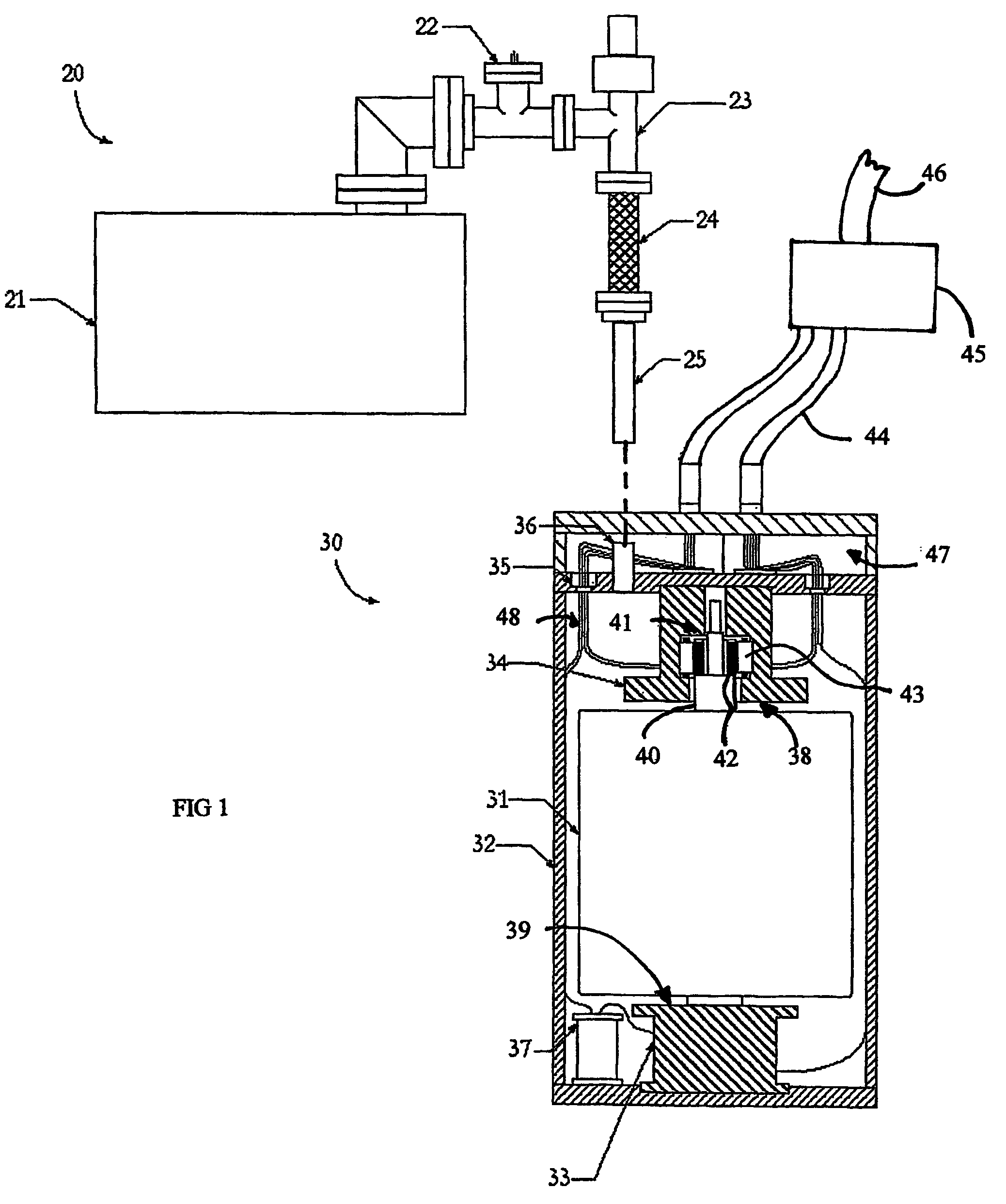

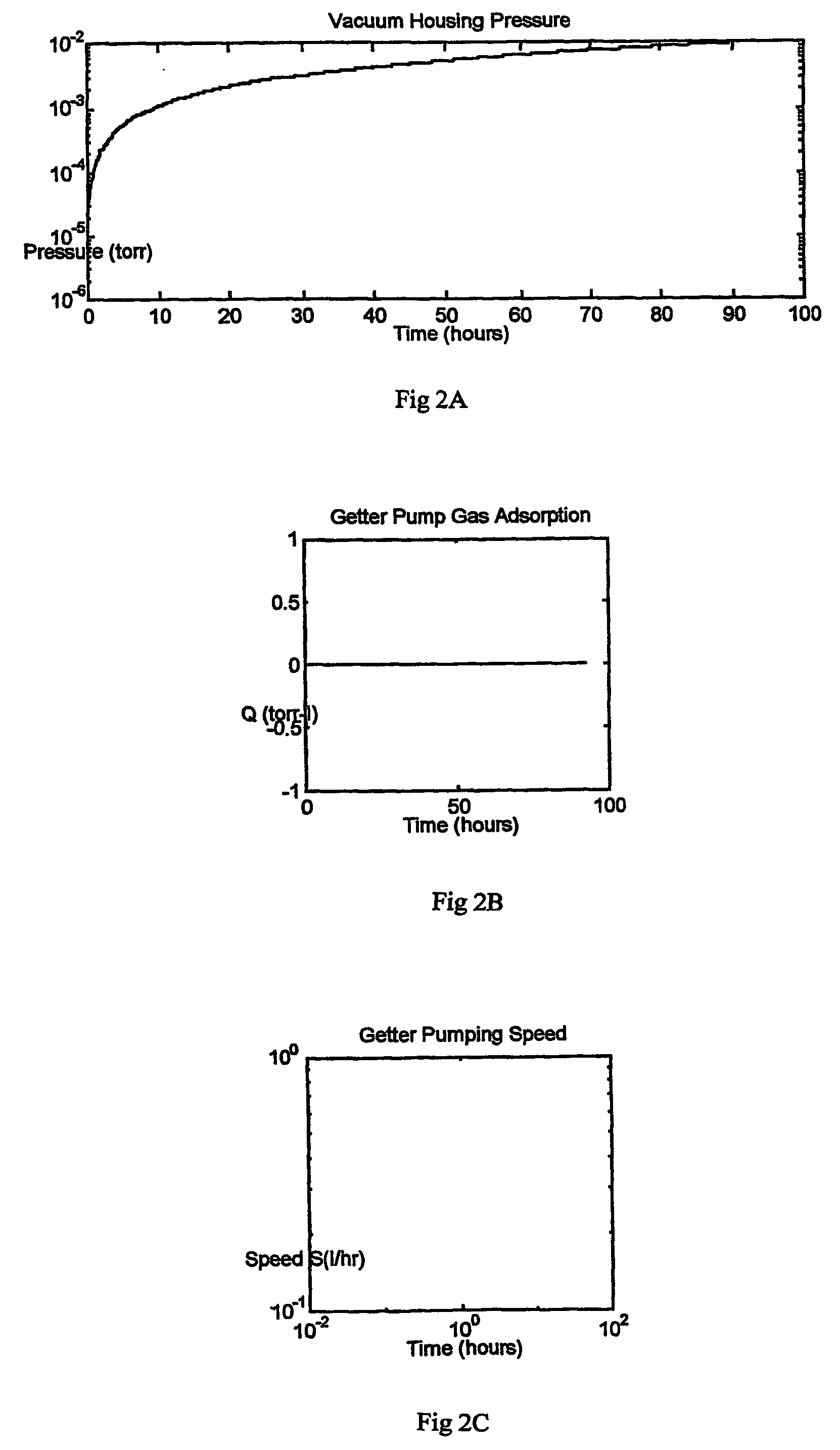

Long-life vacuum system for energy storage flywheels

InactiveUS7053589B2Improve adsorption capacityIncrease chanceAC/DC convertorsFlywheelsAlloyEngineering

The invention, intended primarily for use in a steel flywheel power source (30), provides a vacuum system and a method of maintaining a vacuum inside a flywheel chamber (32) for the life of the power source (30). The vacuum system combines the use of cleaning and de-gassing treatments in the chamber (32) and vacuum tempering of the steel flywheel (31) with the use of a chemical type metal alloy nonevaporable getter, such as zirconium-vanadium-iron, that cooperatively matches the outgassing of the flywheel (31) and chamber (32) by sorbing those gases that are released. The getter may be reactivated throughout the life of the flywheel system by reheating it with an integral heater that is triggered by a timer instead of a vacuum gauge to increase the system reliability, using power taken directly from the energy stored in the flywheel. The electronics (45) of the flywheel power source are used to signal an alarm or prevent achieving or maintaining full speed of the flywheel when the vacuum in the chamber degrades.

Owner:INDIGO ENERGY INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com