Method and device for auxiliary heating type ultrasound rapid forming

An auxiliary heating and forming method technology, applied in the direction of metal processing equipment, non-electric welding equipment, welding equipment, etc., can solve the problems of difficult ultrasonic welding of hard metals, low power, and restrictions on the width and thickness of weldable metal foil, and achieve a control platform Simplification, improved plasticity, and easy-to-achieve effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

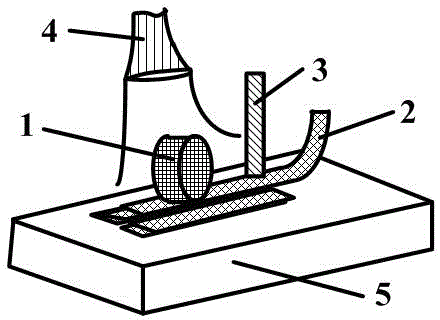

Embodiment 1

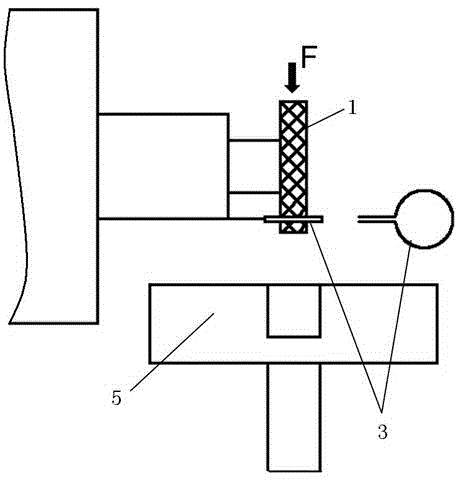

[0026] like figure 2 As shown, use 0.5mm thick aluminum foil for ultrasonic rapid prototyping under electromagnetic induction heating mode, first place the first layer of aluminum foil on the console 5 for clamping, then place a layer of aluminum foil on the first layer of aluminum foil, use ultrasonic Rolling welding is used to weld two layers of aluminum foil. During the welding process, the electromagnetic coil 6 (heating unit) is energized to heat the aluminum foil at the welding position. At the same time, pressure and ultrasonic vibration are applied to the ultrasonic rolling welding indenter 1 to make the two layers The aluminum foils are quickly connected together. After the welding of this layer is completed, the next layer of aluminum foil is placed, and the cyclic welding is carried out according to the above steps, and finally a rapid prototyping aluminum part is obtained.

Embodiment 2

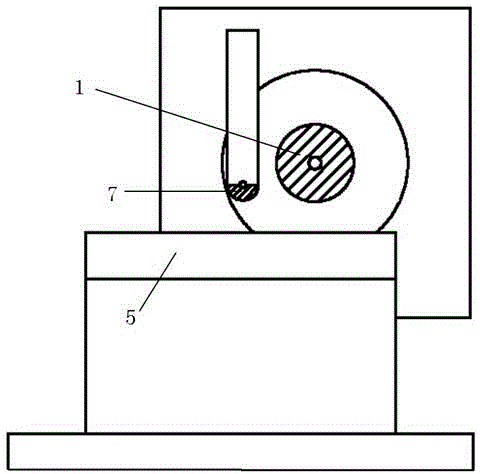

[0028] like image 3 As shown in the figure, 0.4mm thick nickel alloy foil was used for ultrasonic rapid prototyping on a 4mm thick titanium alloy plate. The titanium alloy was first clamped on the operating table 5, and then a layer of nickel alloy was placed on the titanium alloy plate for ultrasonic rolling. Pressure welding, a resistance seam welding roller 7 (heating unit) is installed in front of the ultrasonic rolling welding indenter 1, and the nickel alloy foil and the titanium alloy plate are rolled and preheated by low-power resistance seam welding, and then are rolled and heated by ultrasonic rolling. The final connection is completed by pressure welding. After the welding of this layer is completed, the next layer of nickel alloy foil is placed, and cyclic welding is carried out according to the above steps, and finally a rapid prototyping part with functional gradient is obtained.

[0029] Compared with the prior art, the present invention adopts the method of pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com