Pipeline photobioreactor for scale culture of microalgae

A technology of photobioreactor and pipeline, which is applied in the direction of photobioreactor, specific-purpose bioreactor/fermenter, combination of bioreactor/fermenter, etc. Hinder the normal flow of algae, oxidative damage of algae cells, etc., to achieve the effect of reducing photodamage, increasing culture thickness, and enhancing mutual shielding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] 30-ton scale pipeline photobioreactor.

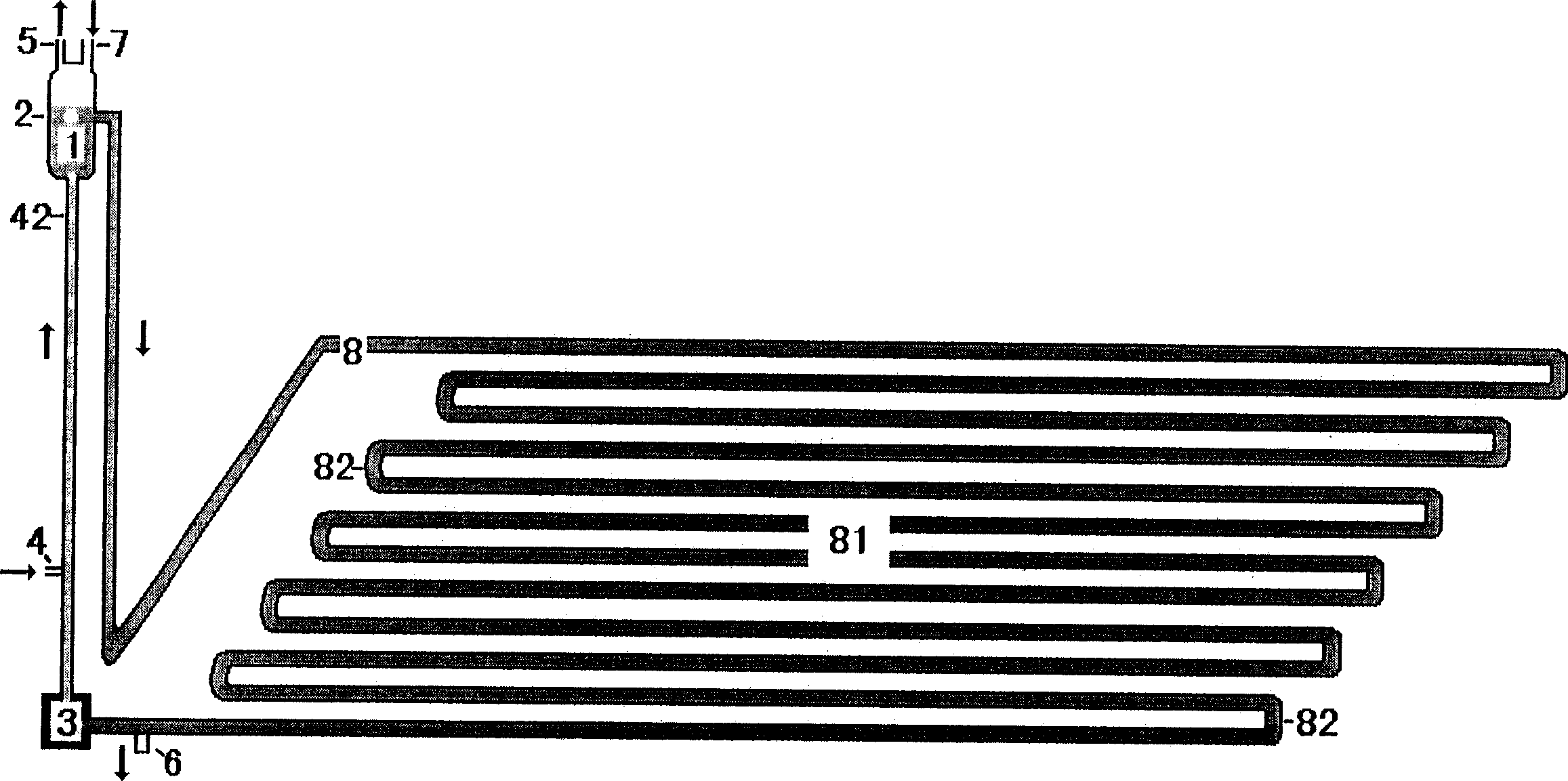

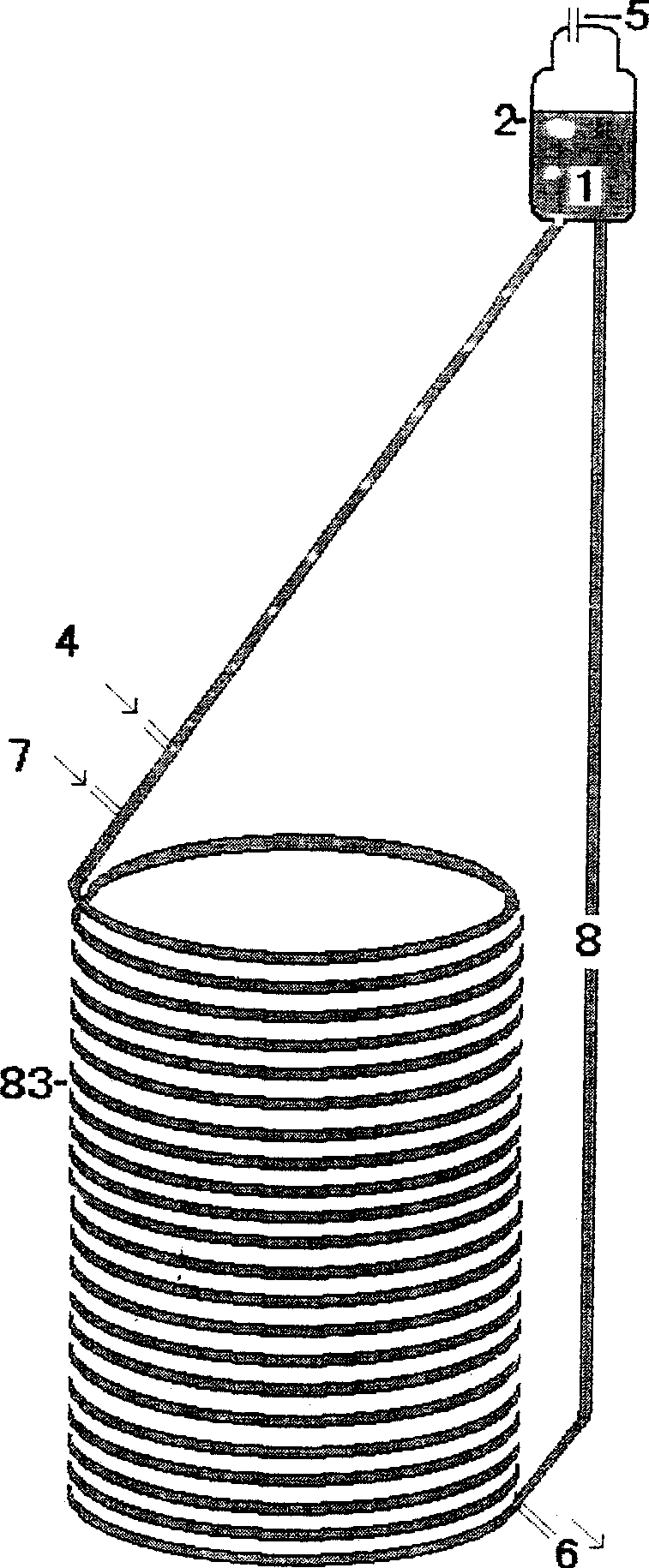

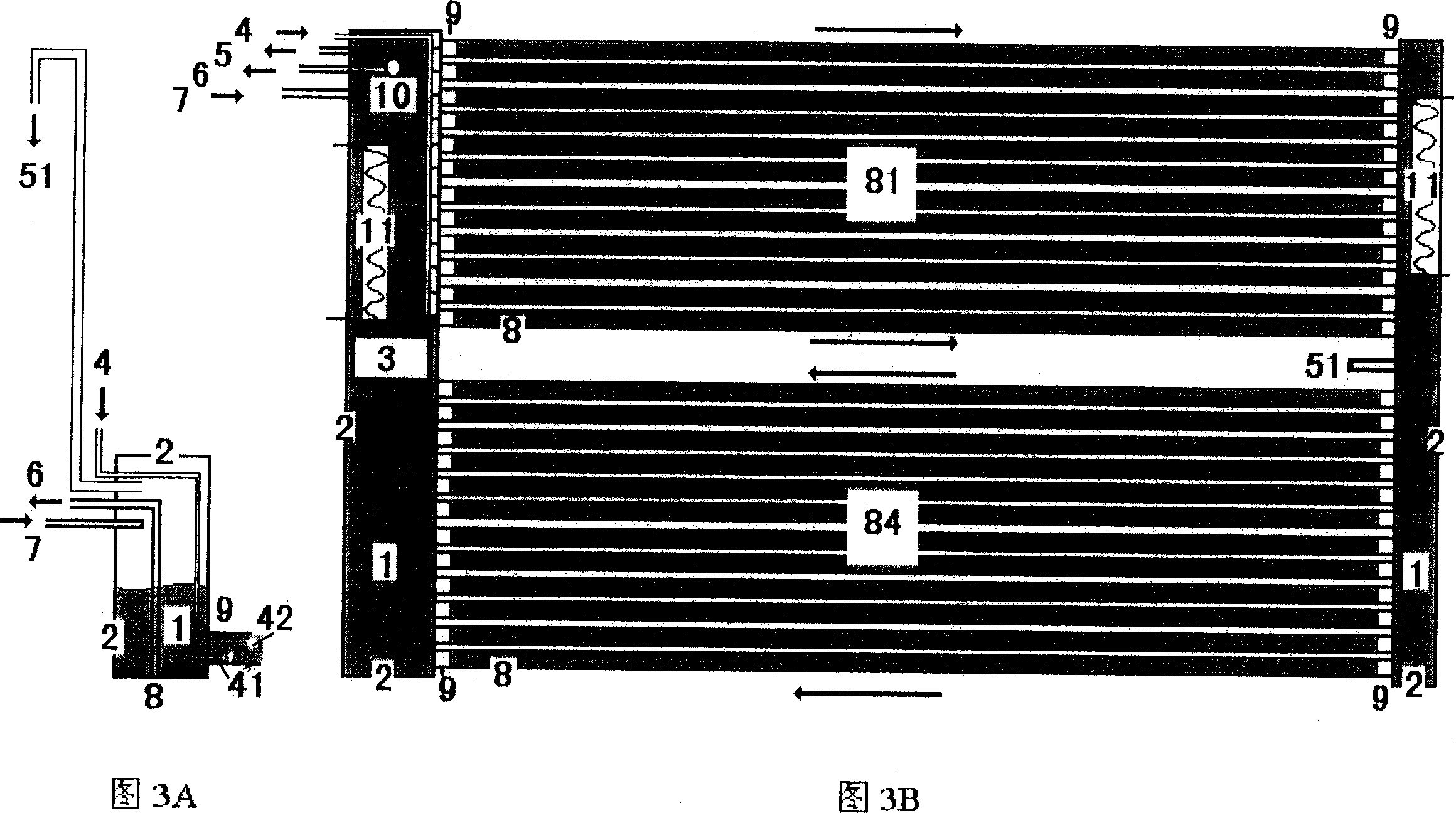

[0039] In a standardized plastic greenhouse (length 66m, width 10m, net area 1 mu of land), according to Figure 3A and Figure 3B, design a new microalgae scale cultivation photobioreactor.

[0040] First, build a large-scale gas analysis device 2 at both ends of the greenhouse. 50 circular parallel pipe connections 9 are respectively arranged on one side of the inner surface of each gas analysis device 2, the circumference of the connections is 36 cm, and the connections are evenly arranged. The pipe interface of the large-scale gas analysis device at the two ends requires remote correspondence, and the upper end of the large-scale gas analysis device is provided with a filtered compressed gas pipeline 4, a gas analysis pipeline 5, a discharge pipeline 6 and a material feeding pipeline 7. Filtered compressed gas (air or carbon dioxide enriched air) release pipeline port 41 is placed in the pipeline interface 9 of the gas analysi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com