Patents

Literature

214results about How to "Realize the stirring function" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Multifunctional combined appliance

InactiveCN102058327AEnough room to exerciseAffect normal workVessels with intergral heatingEngineeringMotion space

The invention discloses a multifunctional combined appliance comprising a power supply control device, a driving part and a heating part, wherein the driving part and the heating part are arranged in a body on which a detachable vessel is arranged, and the vessel is a sealing body provided with an opening; a stirring and foaming assembly is arranged at a driver position of the driving part corresponding to the vessel; and the stirring and foaming assembly comprises a mesh bracket and a stirring head with a magnetic element which is arranged at the lower part of the stirring head. The invention has the characteristics of simple and reasonable structure, easiness for cleaning, convenience and safety for operation and low manufacture cost. By additionally arranging the mesh bracket and the stirring head which are freely detached on the vessel, one machine with multiple functions is realized; the driving part drives the stirring head in a magnetic force way to rotate at high speed so as to drive liquid in the vessel to flow and dissolve massive beverage additives in the mesh bracket. A convex column on the mesh bracket ensures that the stirring head has enough motion space and also prevents added massive beverage additives from influencing the normal work of the stirring head, thereby achieving the functions of heating, foaming and stirring a beverage.

Owner:GUANGDONG XINBAO ELECTRICAL APPLIANCES HLDG CO LTD

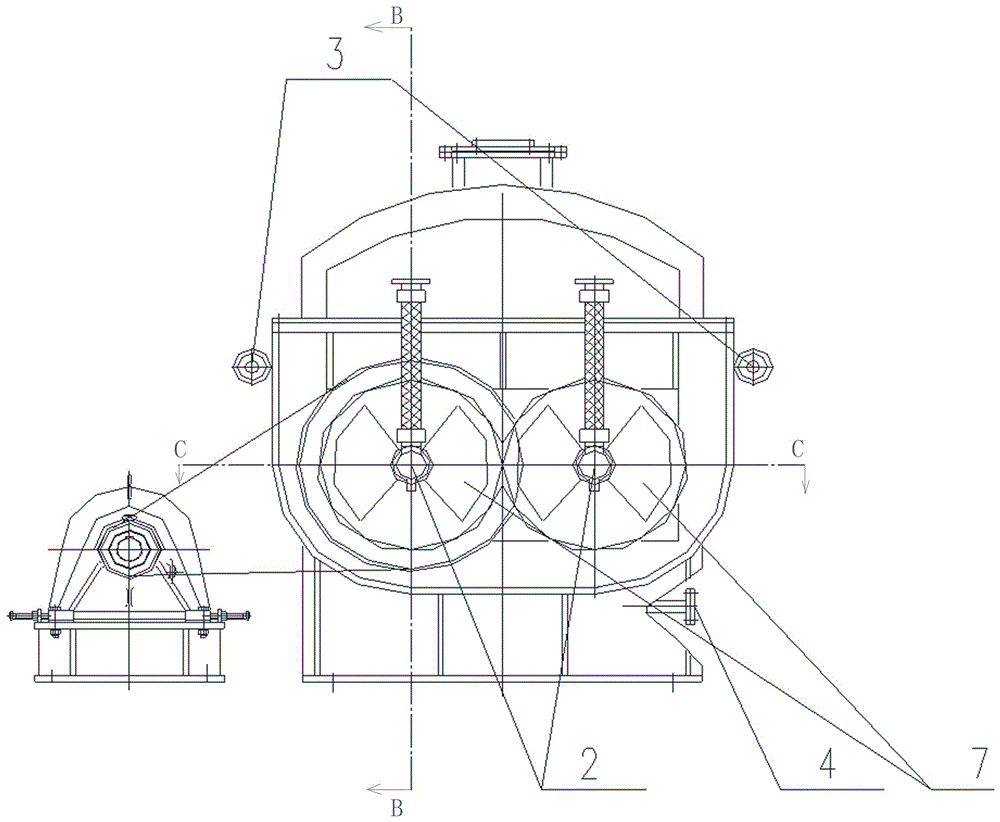

Drying machine

ActiveCN105737571AAchieve recyclingReduce energy consumptionDrying machines with non-progressive movementsDrying solid materialsEngineeringMechanical engineering

The invention relates to a drying machine. The drying machine comprises a shell, hollow shafts, rotating joints and driving devices, wherein the interior of the shell is a cavity for storing materials to be dried; a charging hole, a discharging hole and a hot carrier gas outlet are formed in the shell; and hollow blades are arranged on the hollow shafts. The drying machine is characterized in that three sections of jackets for preheating or heating the materials are arranged on the periphery of the shell; gas discharged by the hot carrier gas outlet is led into a hot carrier gas preheating section jacket; heat exchange fluid is led into a steam heating section jacket; and steam flashing discharged by the hollow shafts through the rotating joints and steam flashing discharged by the steam heating section jacket are led into a steam condensate preheating section jacket. The drying machine has the beneficial effects that the recycling of energy carried by waste heat and waste gas in a material drying process is realized by arranging the three sections of jackets; and the drying machine has the advantages of high heat efficiency, low energy consumption, small material loss and the like, reduces energy consumption and belongs to environmental friendly equipment.

Owner:NINGXIA G R FINE CHEM CO LTD

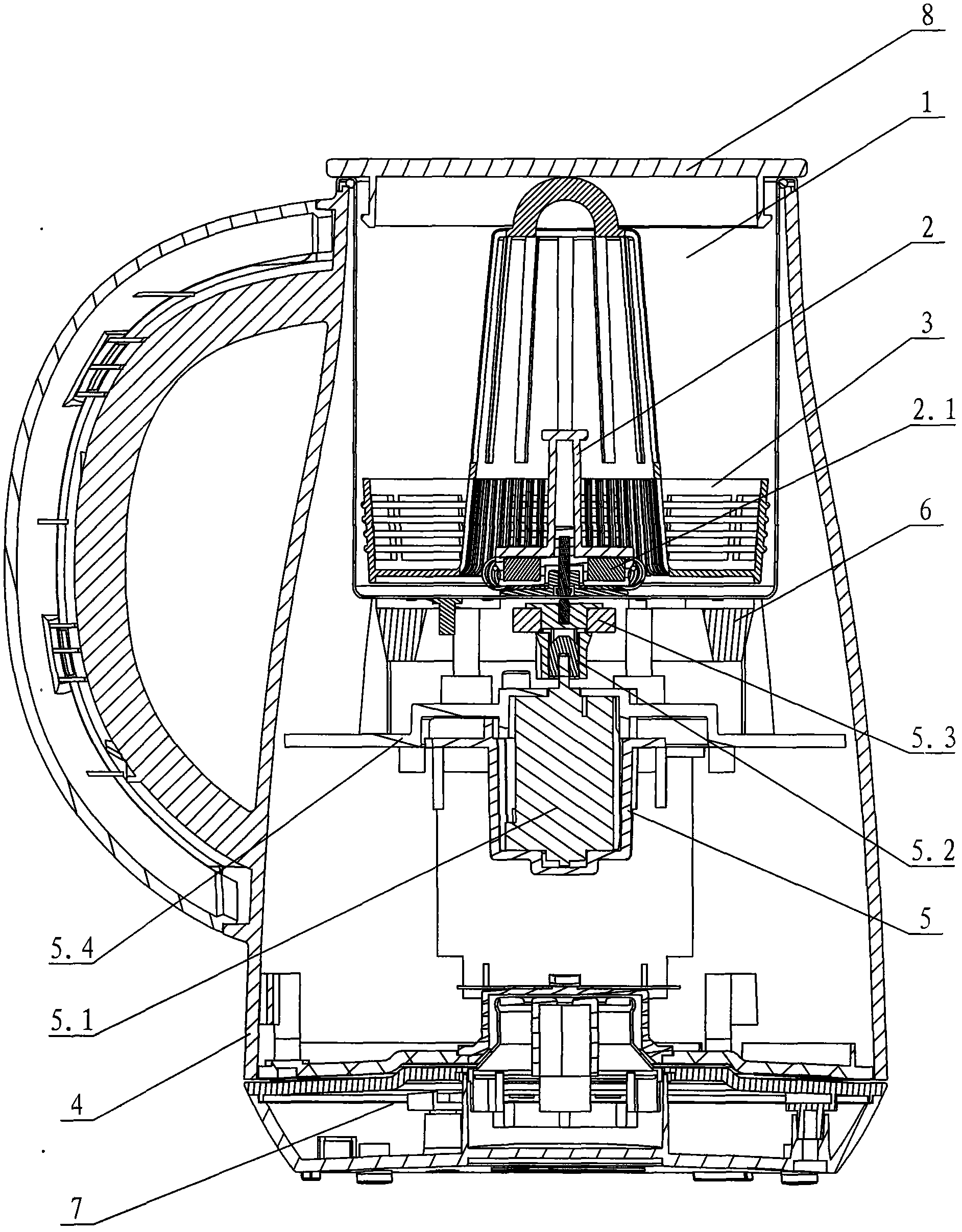

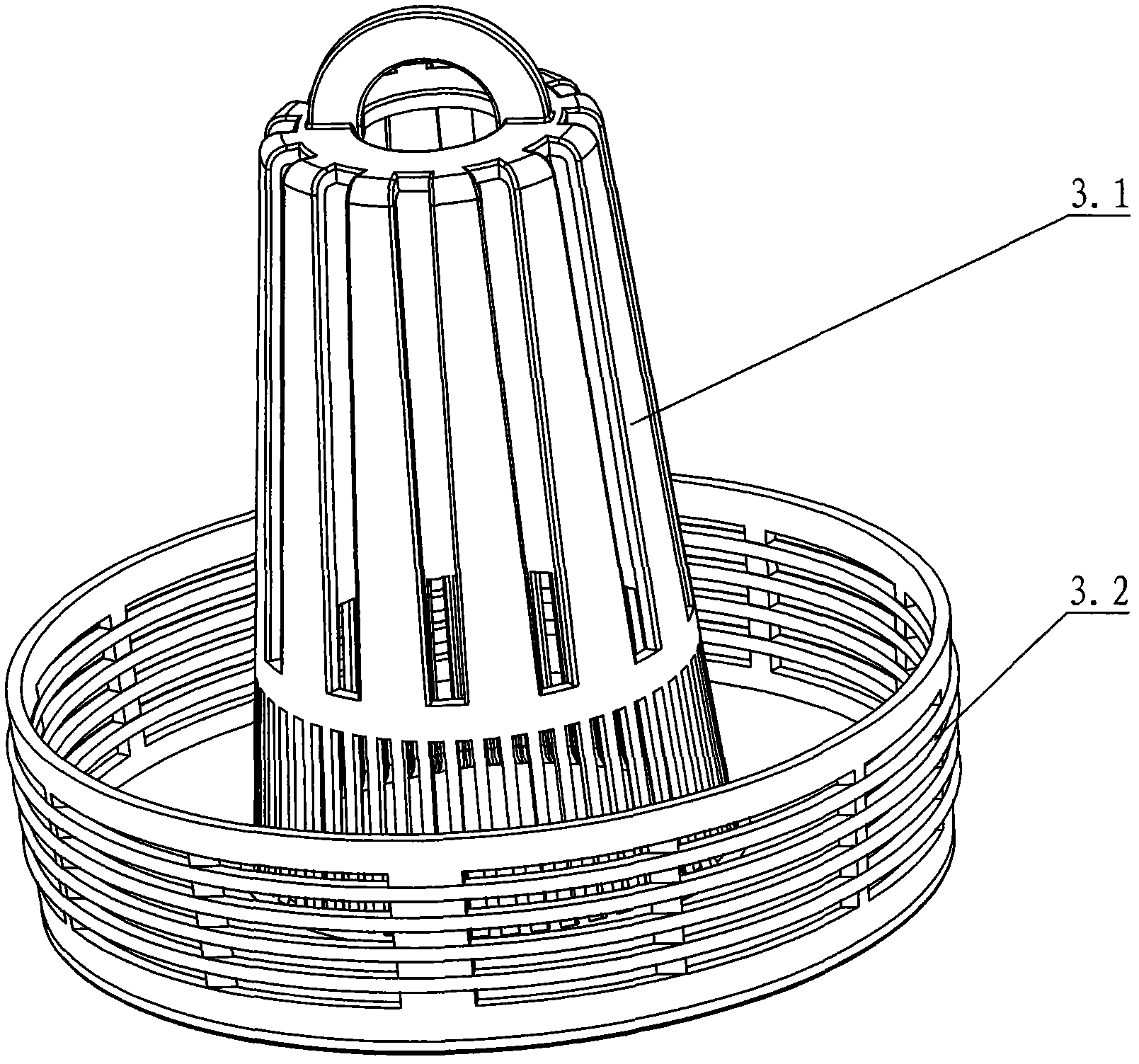

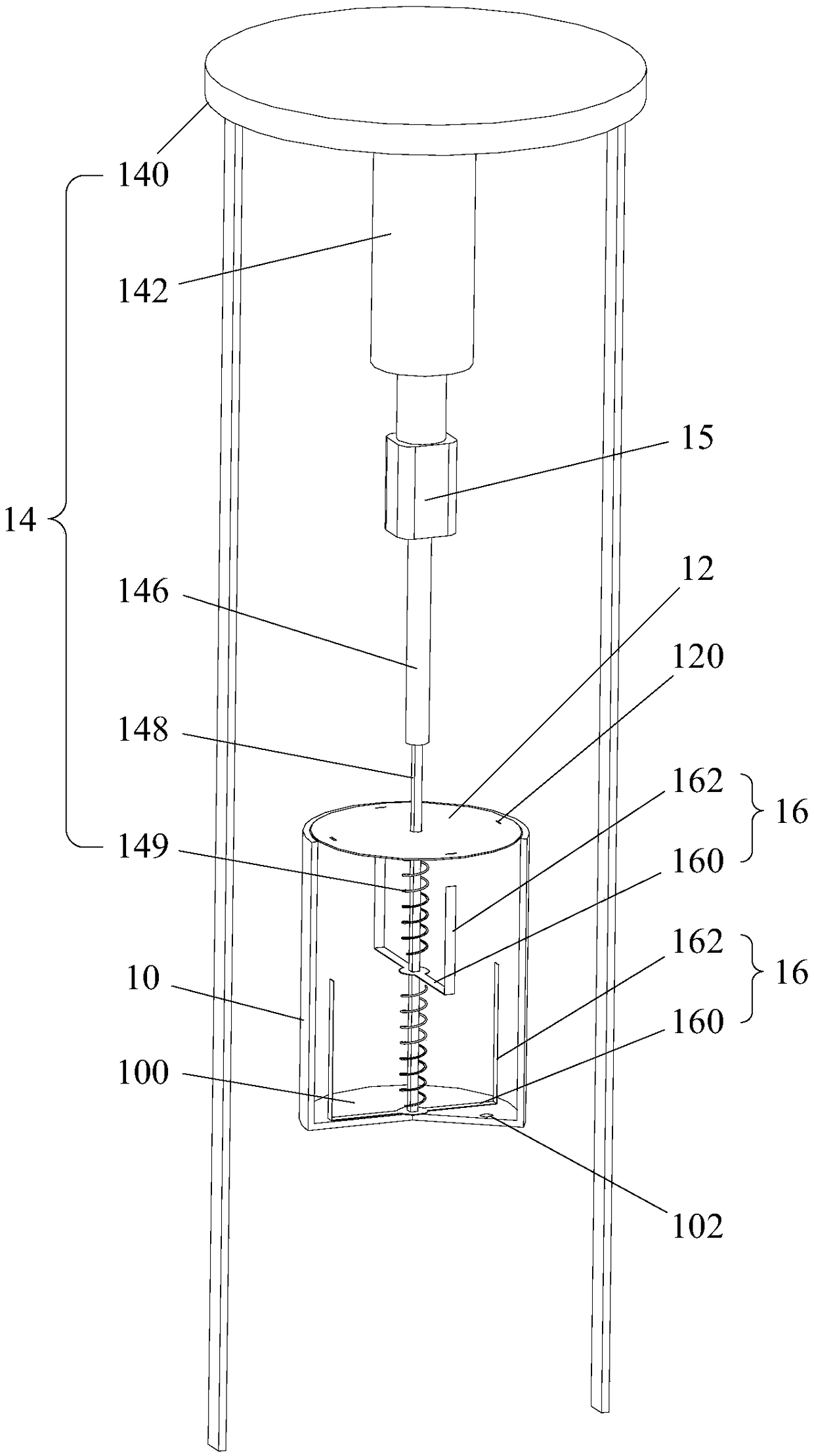

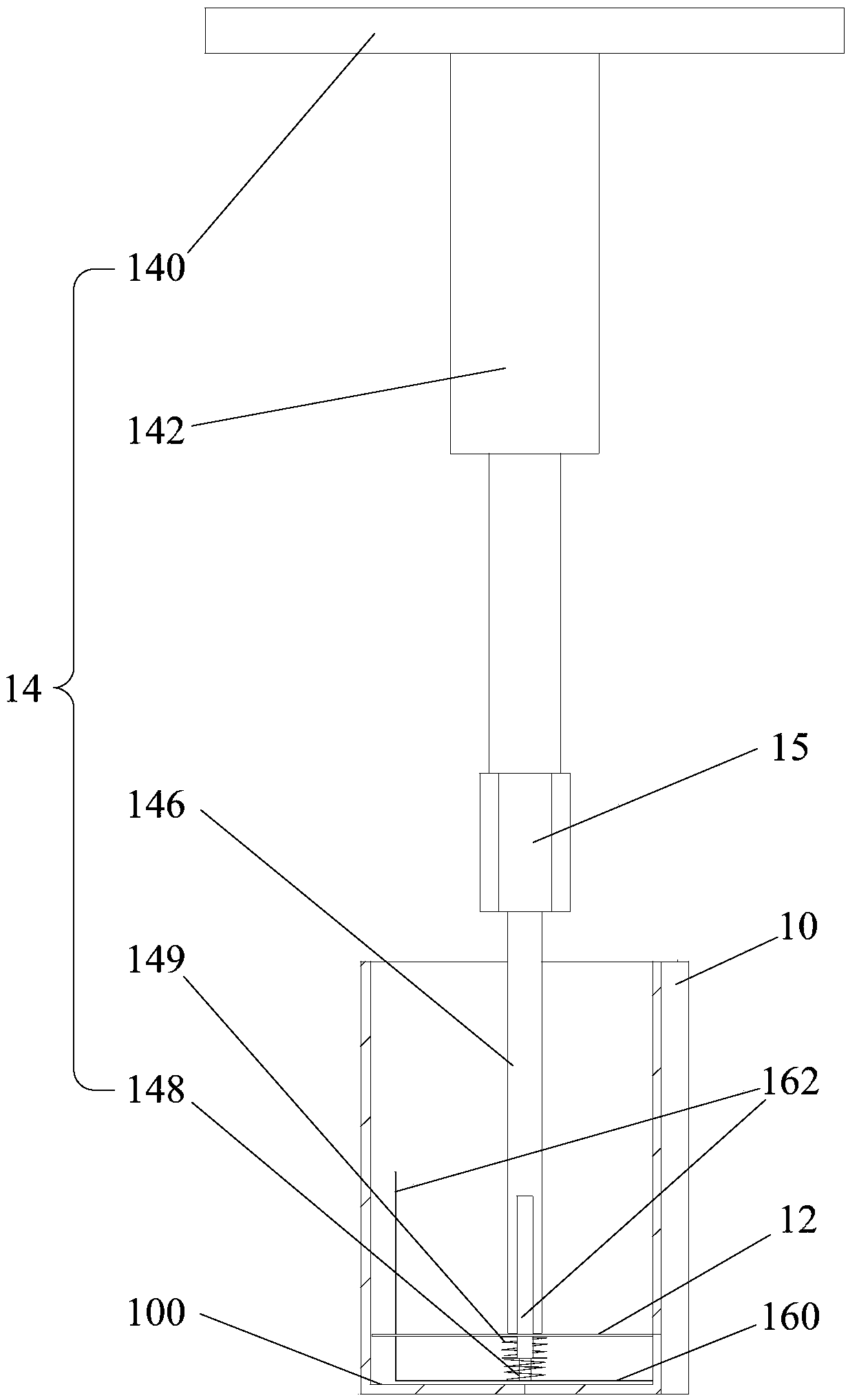

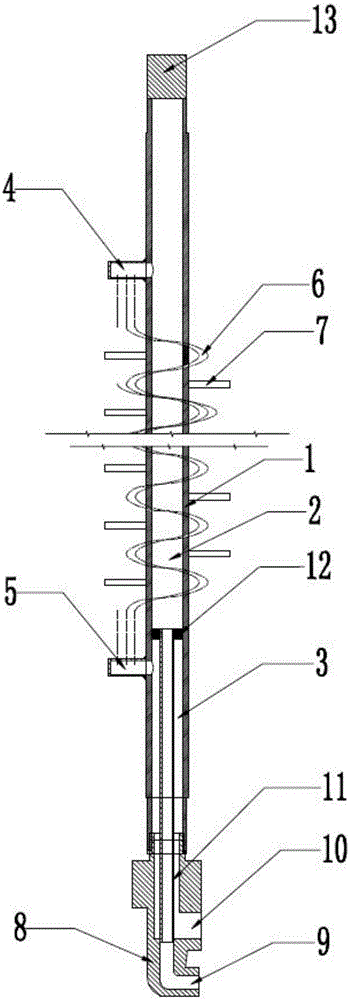

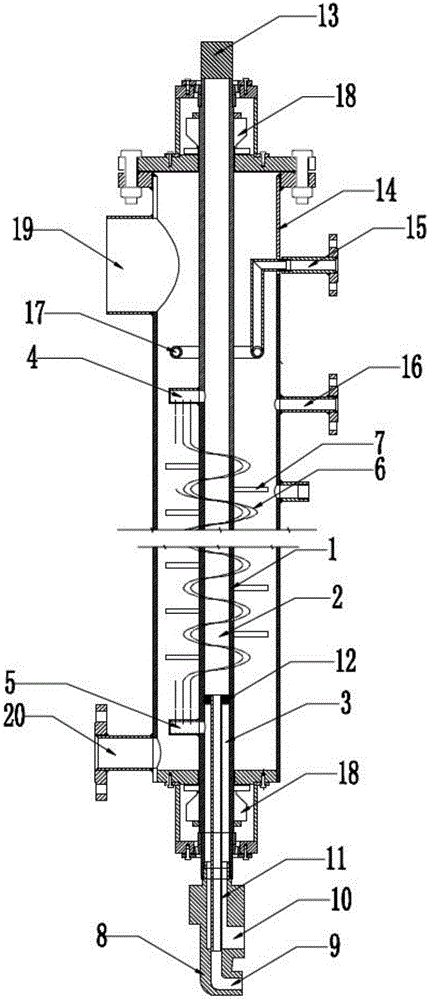

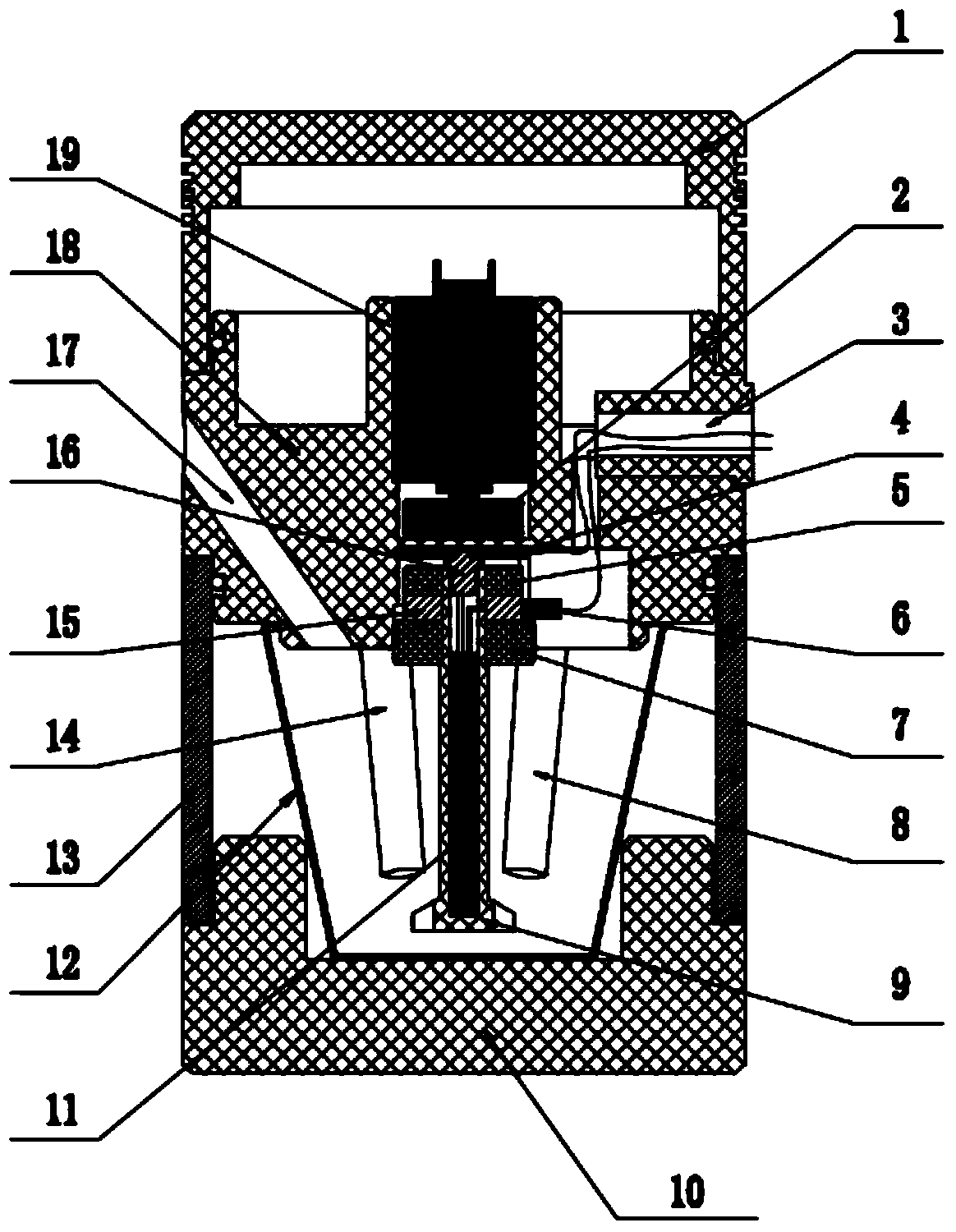

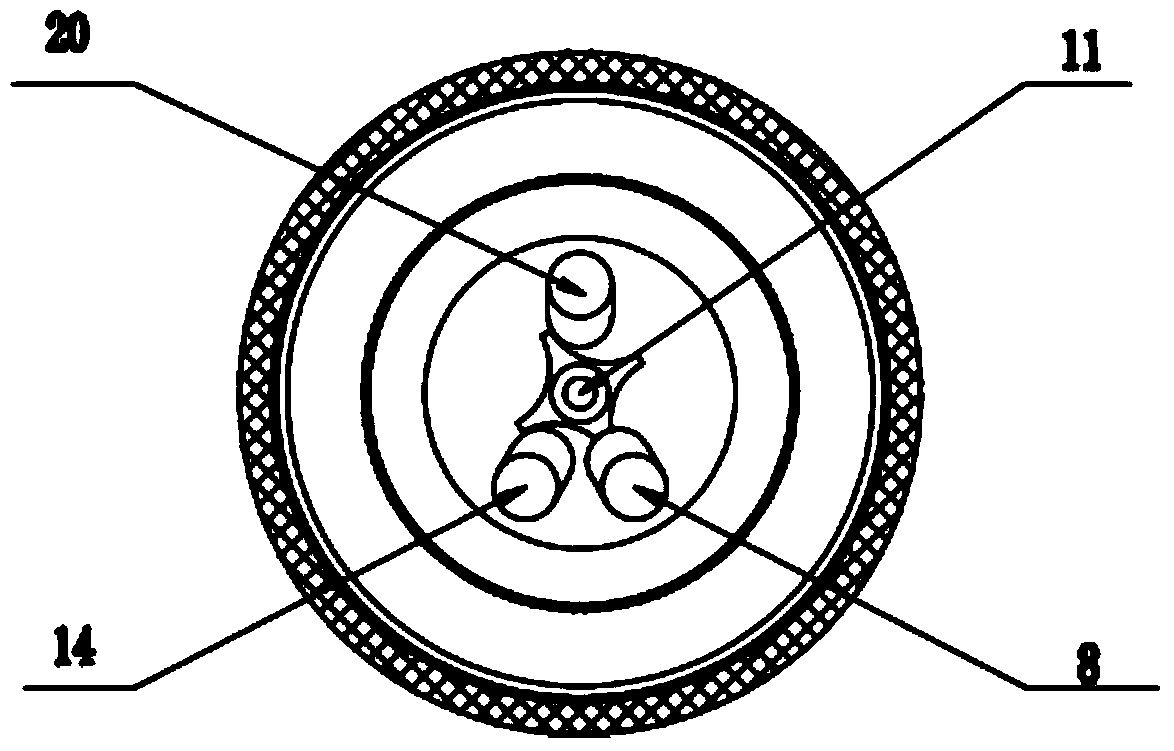

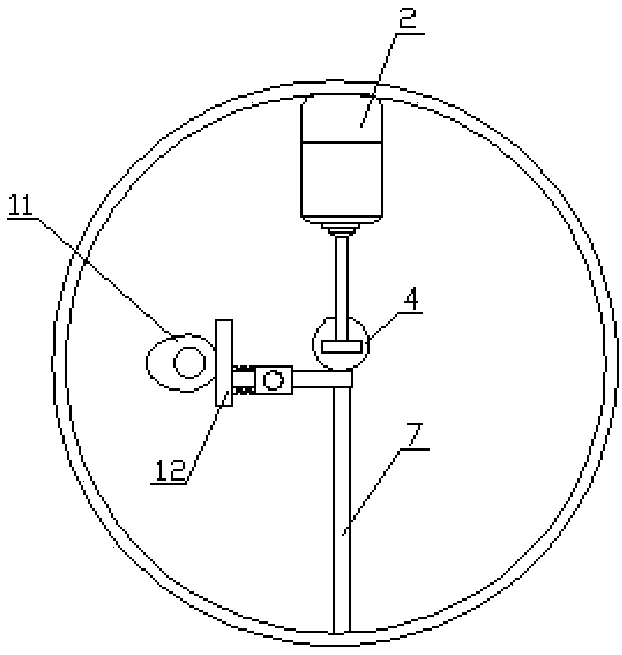

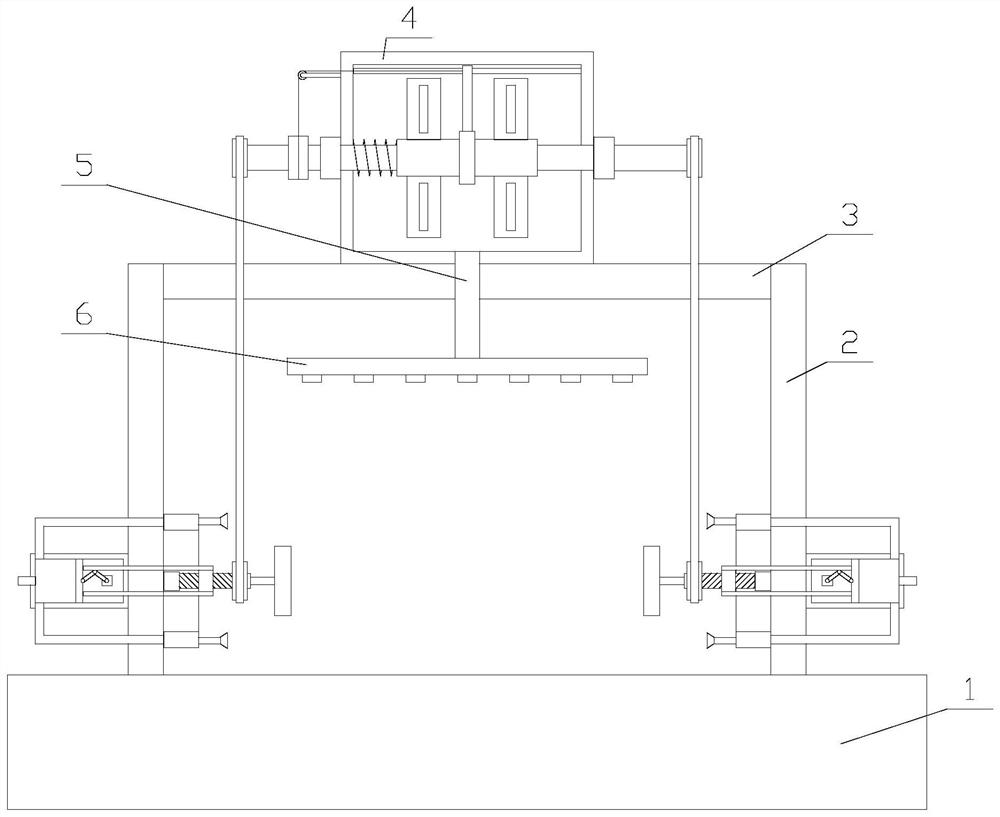

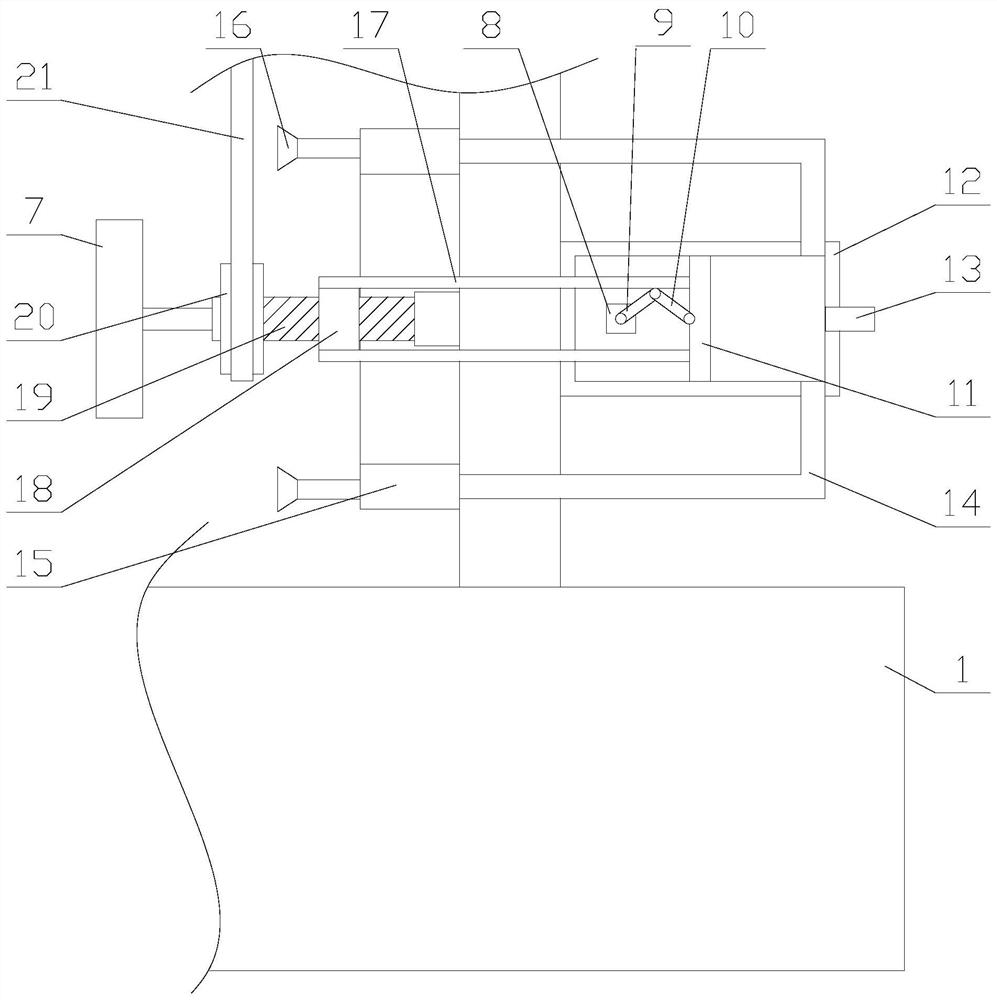

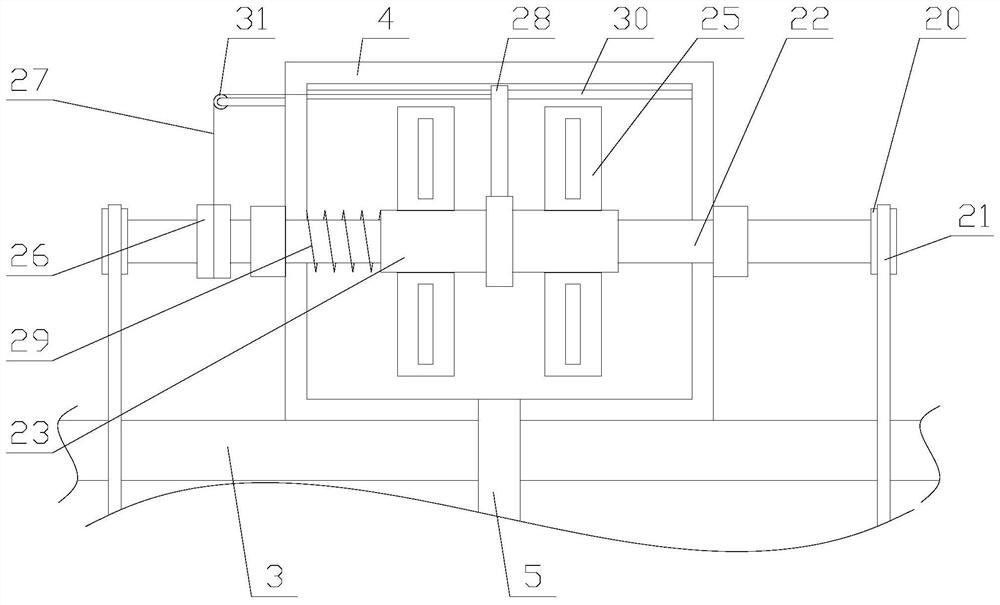

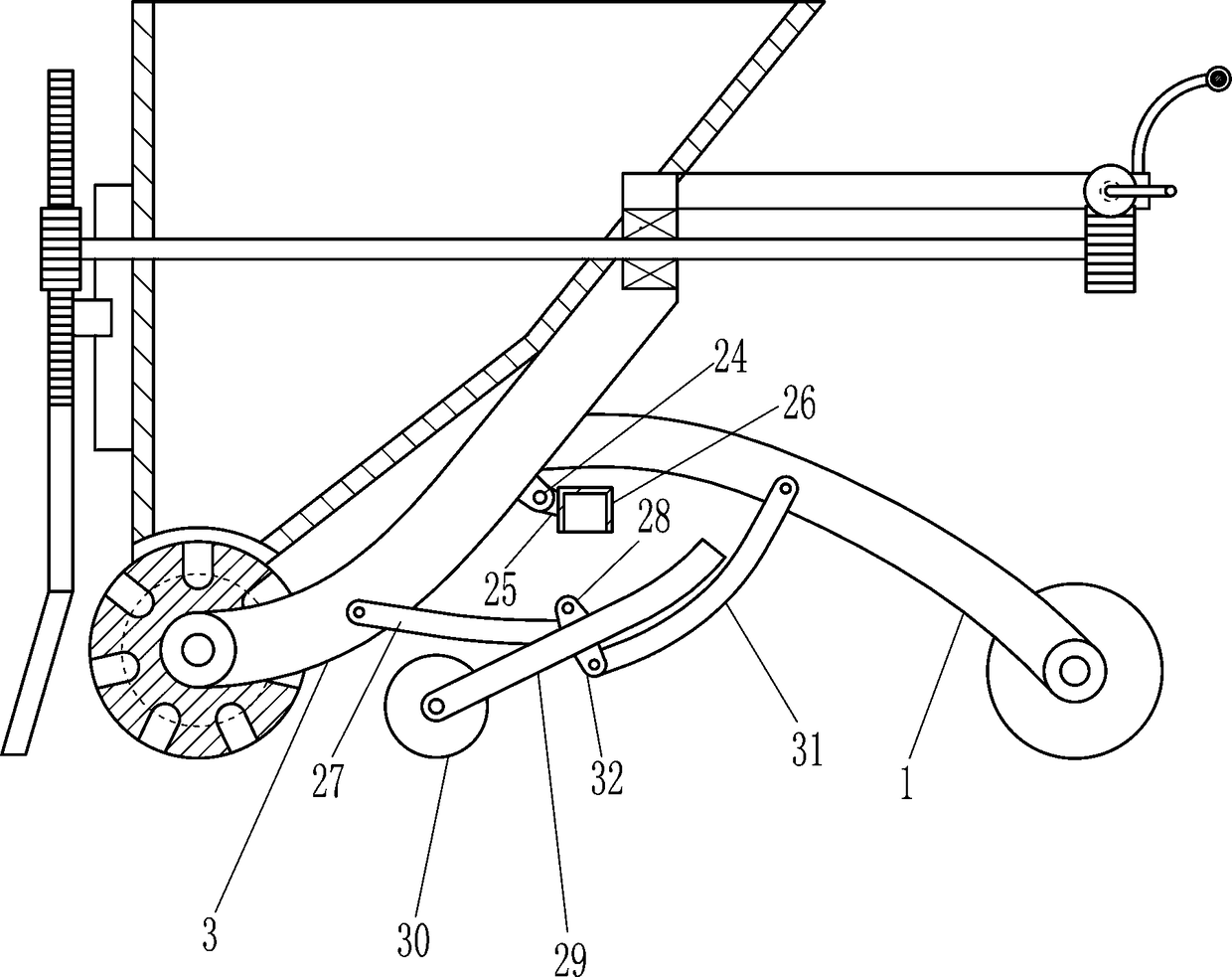

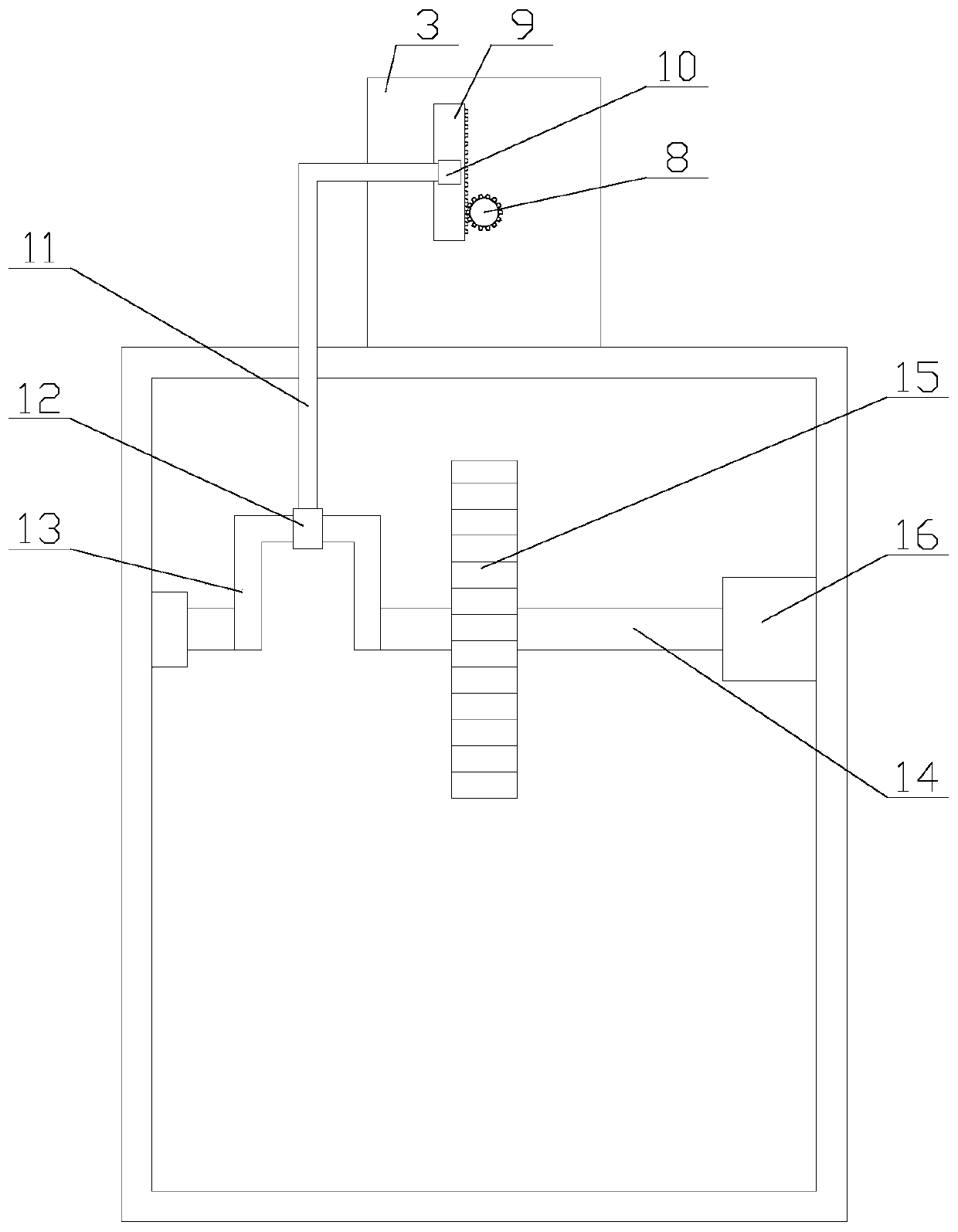

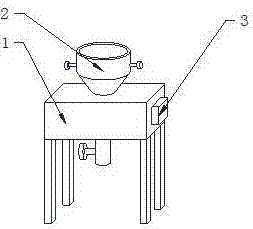

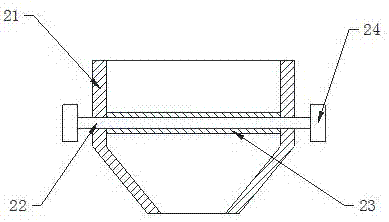

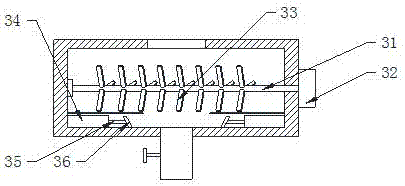

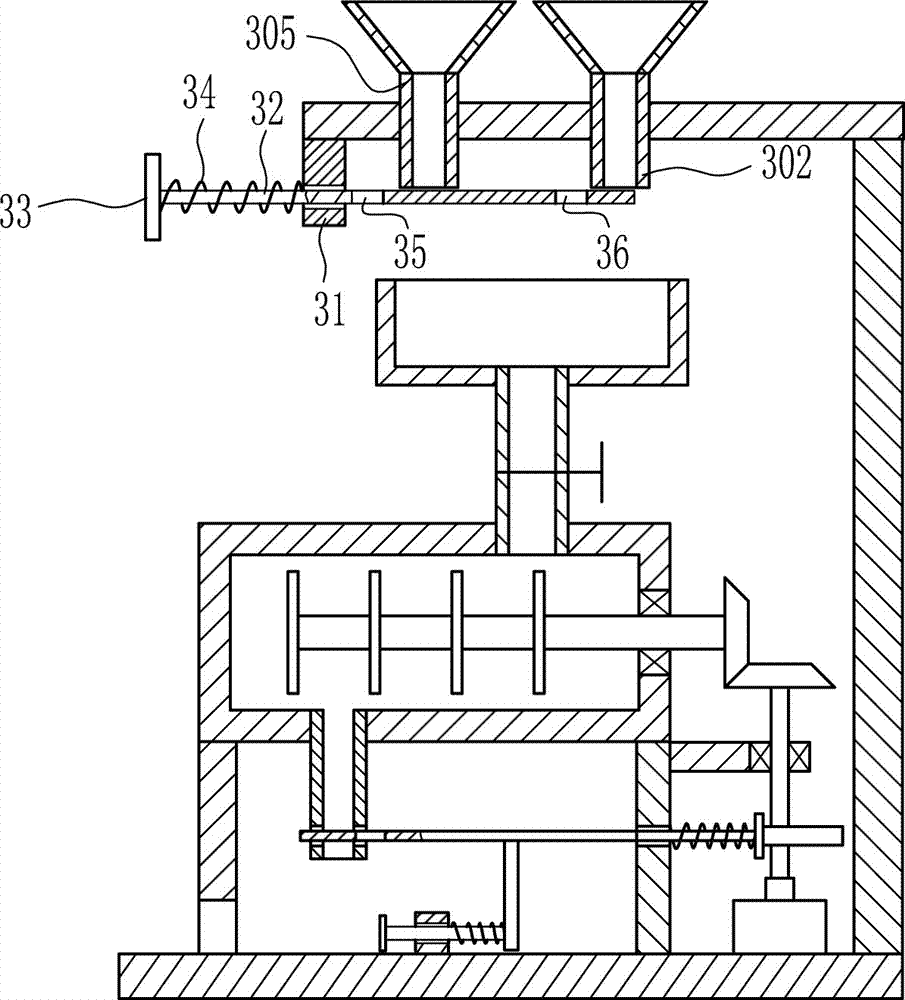

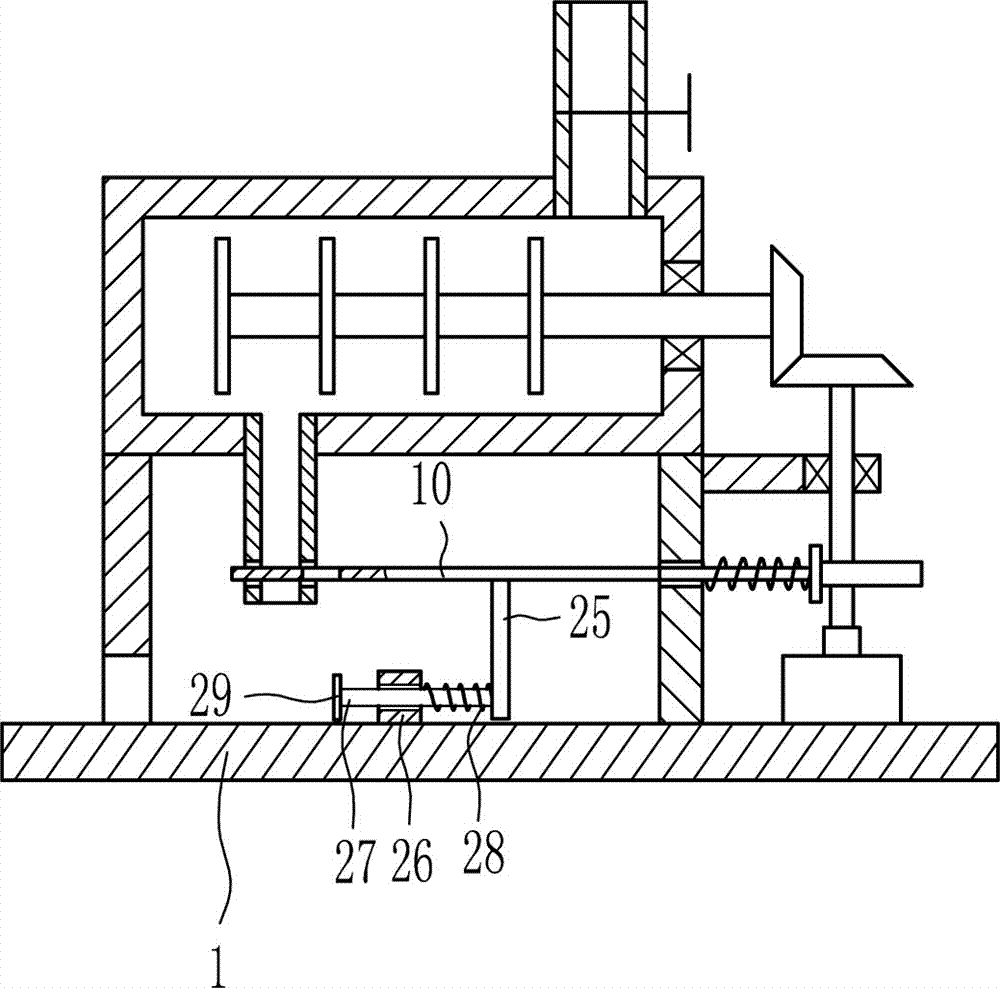

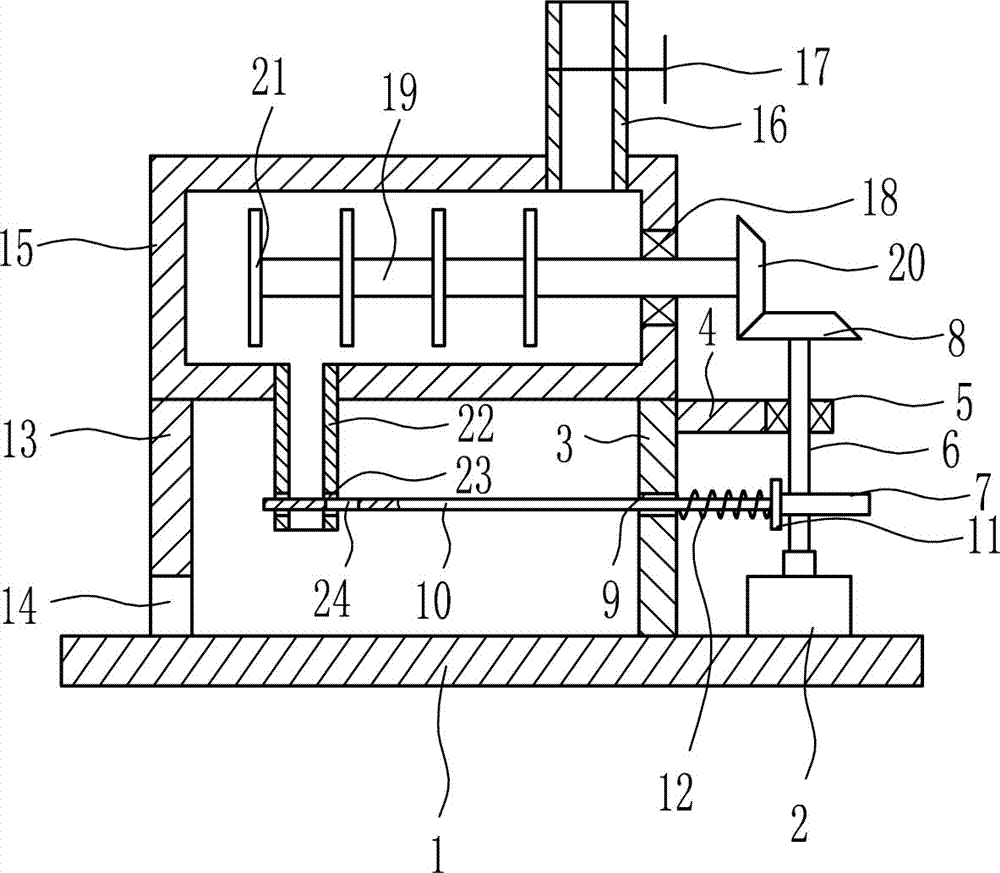

Milk maker

InactiveCN101589913ARealize the stirring functionAchieve self-heatingBeverage vesselsDrive motorEngineering

The invention discloses a milk maker, which comprises a support cylinder, a base for placing a milk making bottle, and a water barrel, wherein the inside of the support cylinder is provided with a driving motor, the support cylinder is provided with a powdered milk barrel, a rotating shaft is inserted into the bottom surface of the powdered milk barrel, and the rotating shaft is linked with an output shaft of the driving motor; the inside of the powdered milk barrel is provided with a link mechanism, the link mechanism is connected with a powder pushing block, and the powder pushing block can travel to the outer wall, which is provided with a powder falling cavity, of the powdered milk barrel; the milk making bottle is arranged below the powder falling cavity, a stirring shaft is inserted into the bottom surface of the milk making bottle and is provided with stirring blades, and the stirring blades are positioned in the milk making bottle; the inside of the base is provided with a mechanism for driving the rotation of the stirring shaft; and the inside of the water barrel is provided with a water pump, the water pump is connected with a water outlet pipe, and a tail-end water outlet of the water outlet pipe aligns with a bottle mouth of the milk making bottle. The milk maker realizes the integrated automation of automatic and quantificational powdered milk taking, water feeding and automatic stirring.

Owner:王光力

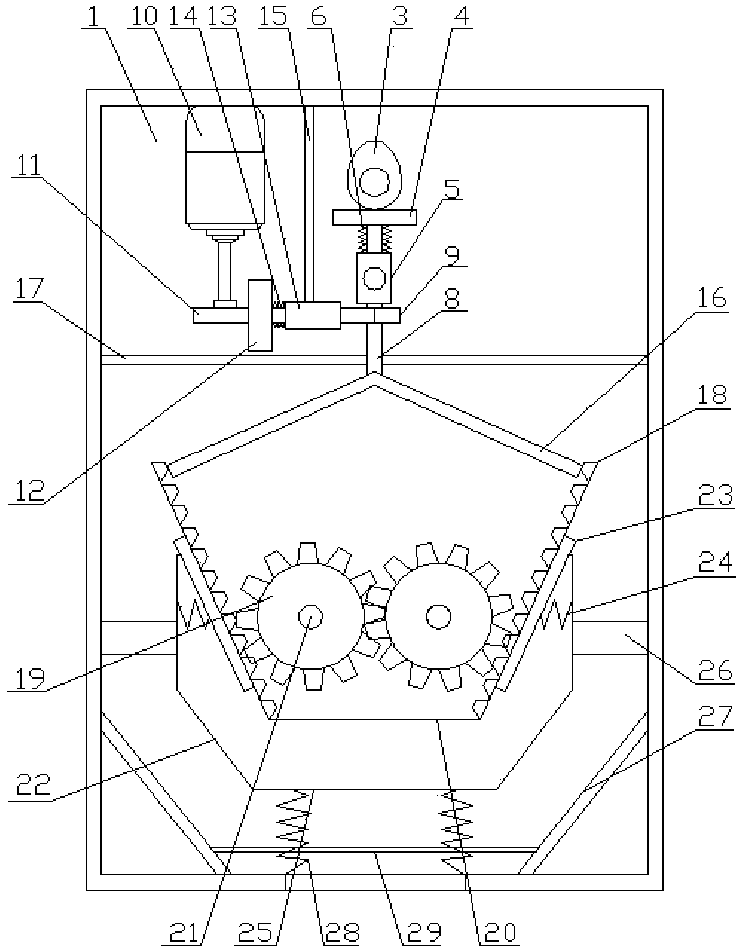

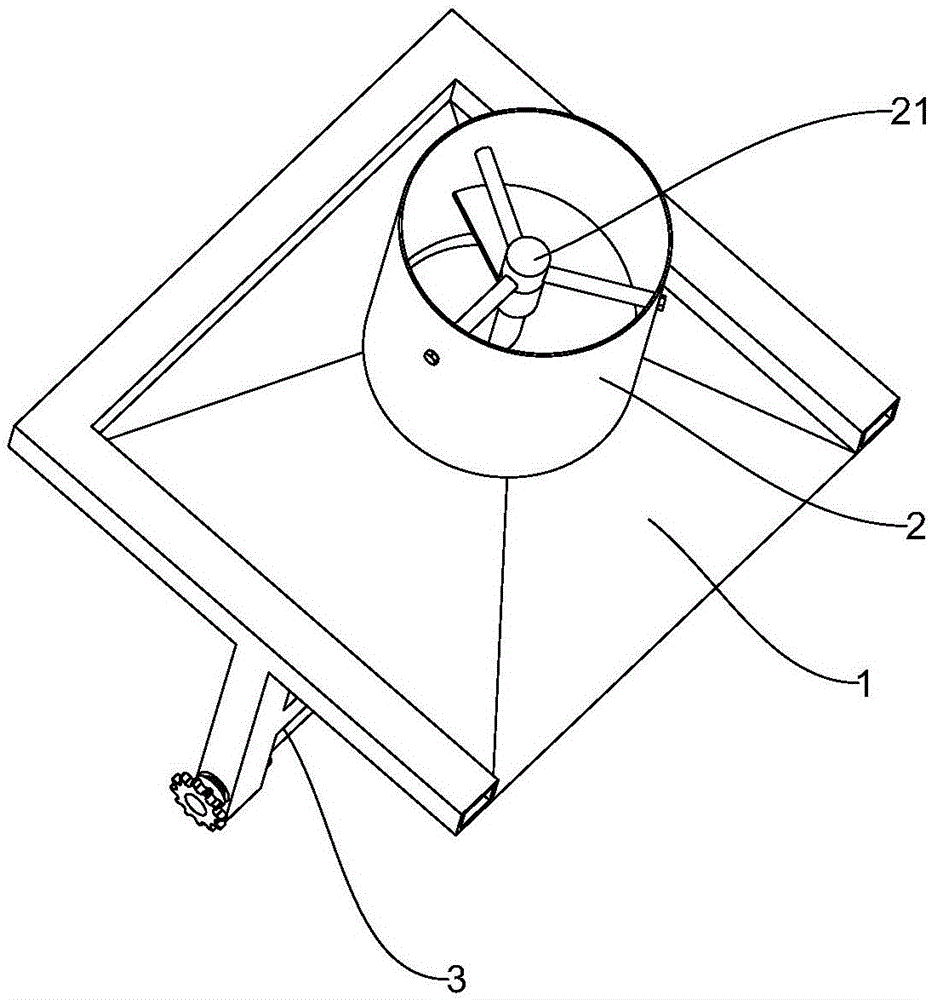

Coating stirring machine

PendingCN108854726AImprove automationRealize the stirring functionTransportation and packagingRotary stirring mixersRelative motionEngineering

The invention provides a coating stirring machine. The coating stirring machine comprises a barrel body, a barrel cover and a telescopic device, wherein a feeding opening is formed in one end of the barrel body; the barrel body is used for accommodating a coating; the diameter of the barrel cover is smaller than or equal to the inner diameter of the barrel body; the barrel cover is arranged at thefeeding opening so as to block the feeding opening; the telescopic device is connected with the barrel cover or the barrel body; under the driving of the telescopic device, the edge of the barrel cover can scrape off residual coating on the inner wall of the barrel body in the axial direction of the barrel body by relative motion between the barrel cover and the barrel body. According to the technical scheme provided by the invention, the residual coatings on the inner wall of the barrel body and stirring blades can be effectively, automatically and quickly cleaned. In addition, the coating stirring machine has the advantages of simple structure, convenience in mounting and easiness in operation; use convenience of the coating stirring machine is improved.

Owner:JINHUA WANLIYANG MACHINERY MANUFACTURING CO LTD

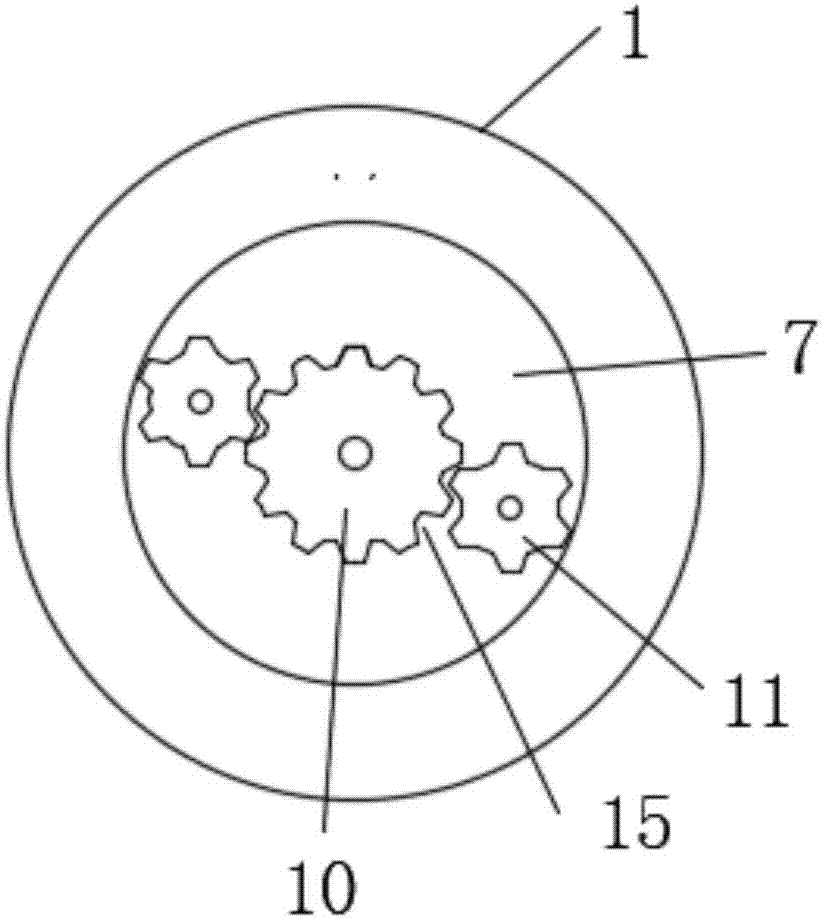

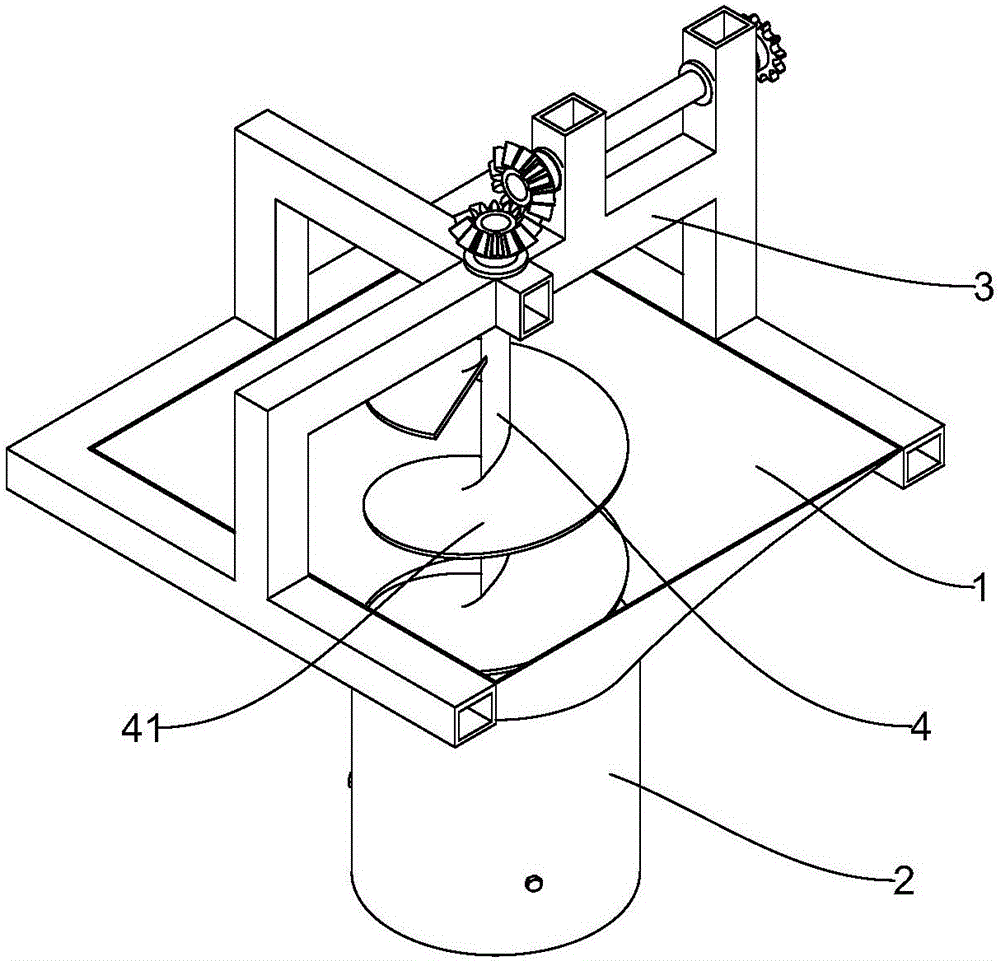

Material stirring equipment which is used for baijiu production and is capable of uniformly stirring

PendingCN107541372ARealize the stirring functionReduce labor intensityAlcoholic beverage preparationGear wheel

Owner:重庆市红槽坊酒业有限公司

Novel heat exchange stirring shaft and tubular reactor

ActiveCN106179038ARealize the delivery functionStir wellRotary stirring mixersTransportation and packagingChemical reactionEngineering

The invention discloses a novel heat exchange stirring shaft, and belongs to the field of chemical reaction devices. The novel heat exchange stirring shaft comprises a main shaft, wherein a first chamber and a second chamber which are isolated from each other are formed in the main shaft; an opening is formed in each of the first and second chambers at one end of the main shaft; a first connecting pipe communicated with the first chamber is arranged on the main shaft; a second connecting pipe communicated with the second chamber is arranged on the main shaft; at least one spiral pipe for communication is arranged between the first and second connecting pipes. According to the novel heat exchange stirring shaft, a heat exchange medium is introduced into an inner communicated pipeline area to implement heat exchange in a reactor; by a structure formed by spirally winding the main shaft with the spiral pipe, a function of stirring a reaction raw material is realized, and meanwhile, the reaction raw material is driven to be delivered to one end of the axial direction of the main shaft; a heat exchange pipeline can be in contact with the reaction raw material more fully by the rotary movement of stirring columns, so that the heat exchange efficiency is greatly improved.

Owner:HIMILE MECHANICAL MFG

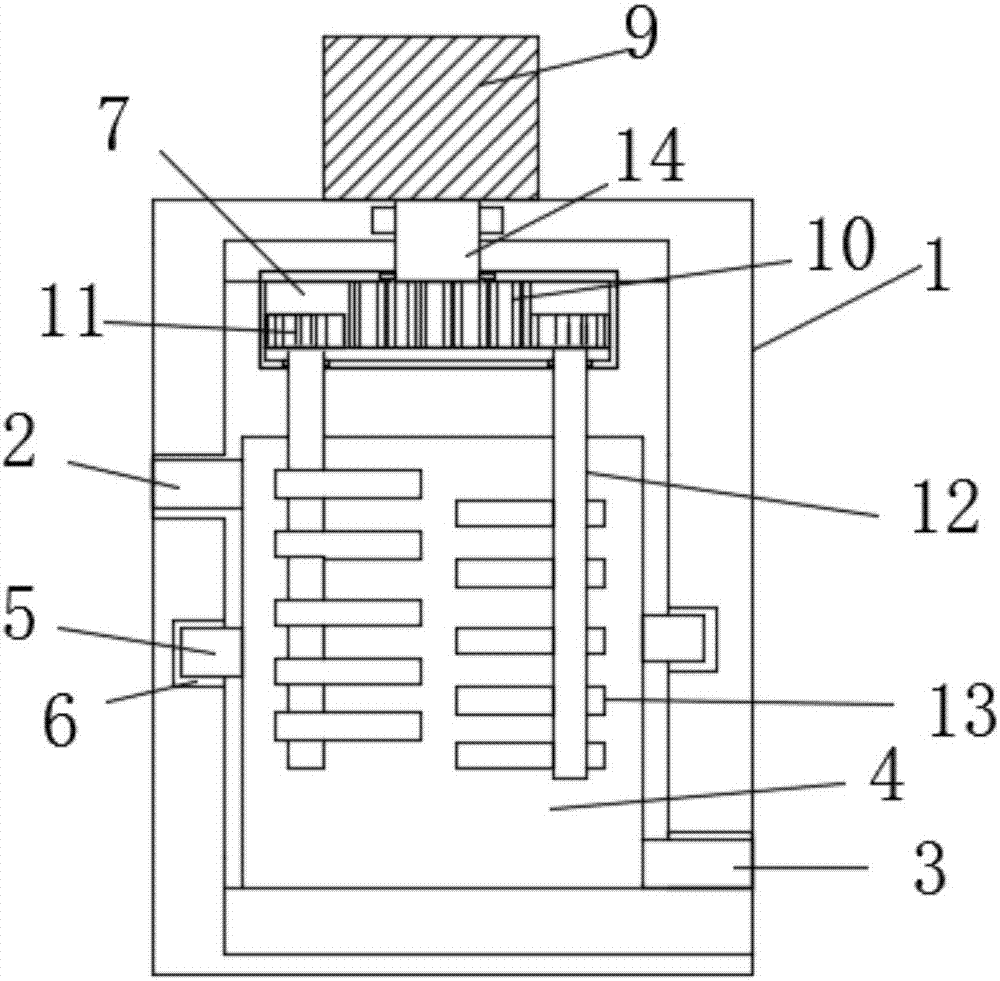

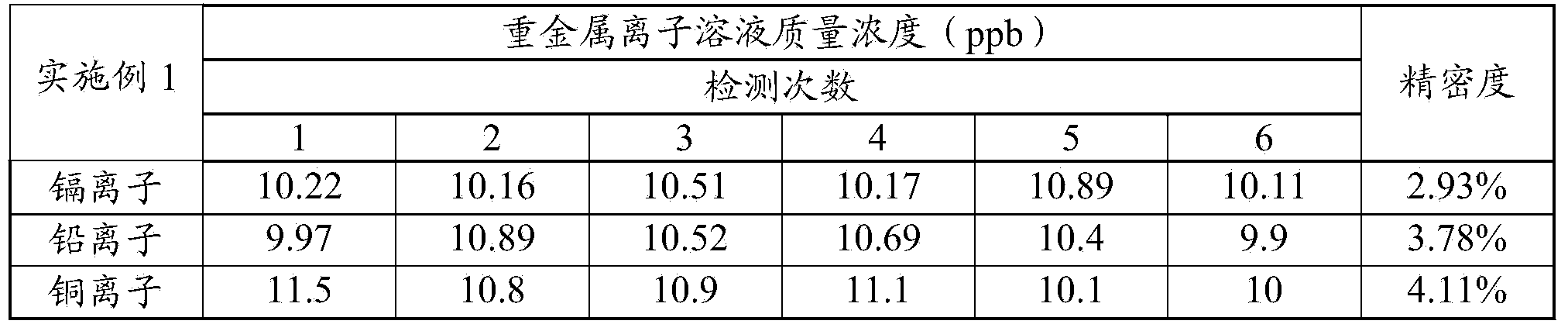

Electrochemical electrolytic cell

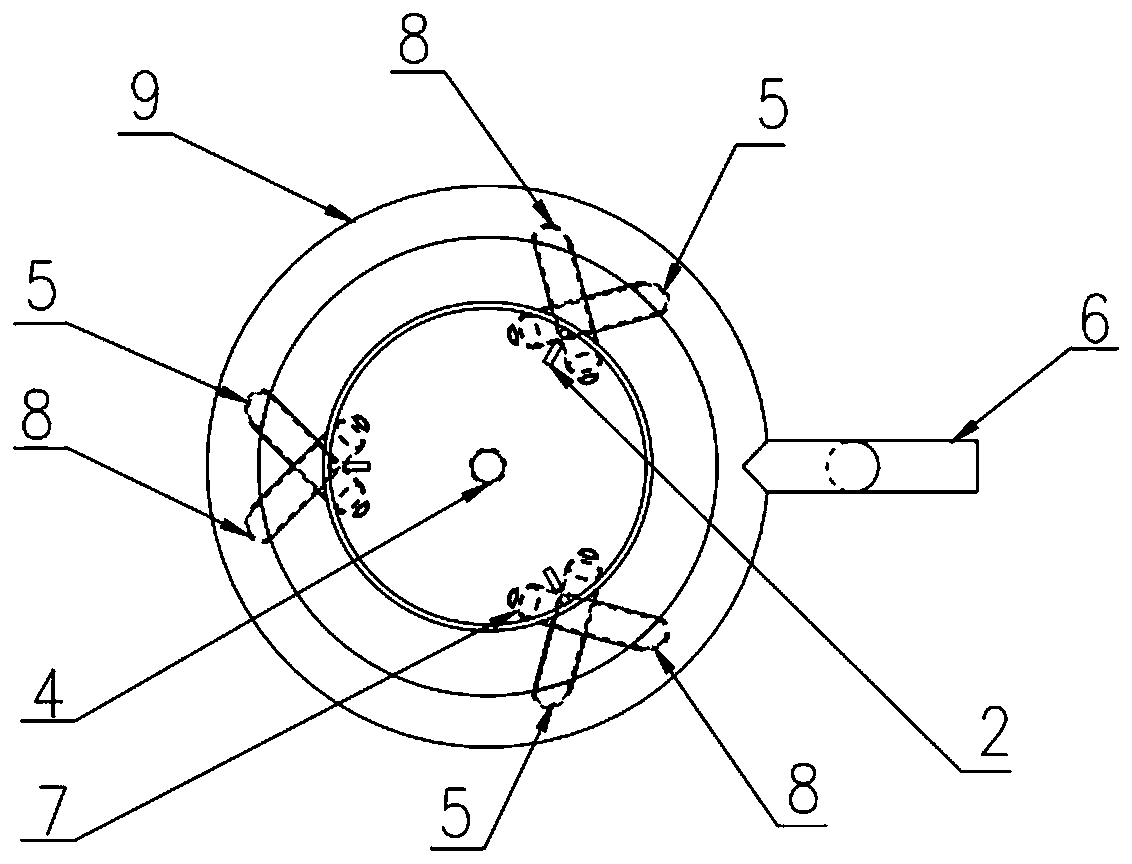

ActiveCN104034771ACompact structurePortableMaterial electrochemical variablesElectrochemical responseEngineering

The invention provides an electrochemical electrolytic cell which comprises a solution containing device, a working electrode and a reference electrode which are arranged in the solution containing device, a stirring device in the solution containing device, and a heating device in the stirring device, wherein the working electrode and the reference electrode are distributed on two sides of the stirring device. According to the electrochemical electrolytic cell provided by the invention, the heating device is arranged in the stirring device, so that the electrochemical electrolytic cell can simultaneously achieve stirring and heating functions, and has stable electrochemical reaction conditions in the working process. Therefore, the electrochemical electrolytic cell provided by the invention is high in accuracy in the process of detecting heavy metal ions.

Owner:HANGZHOU GREAN WATER SCI & TECH INC

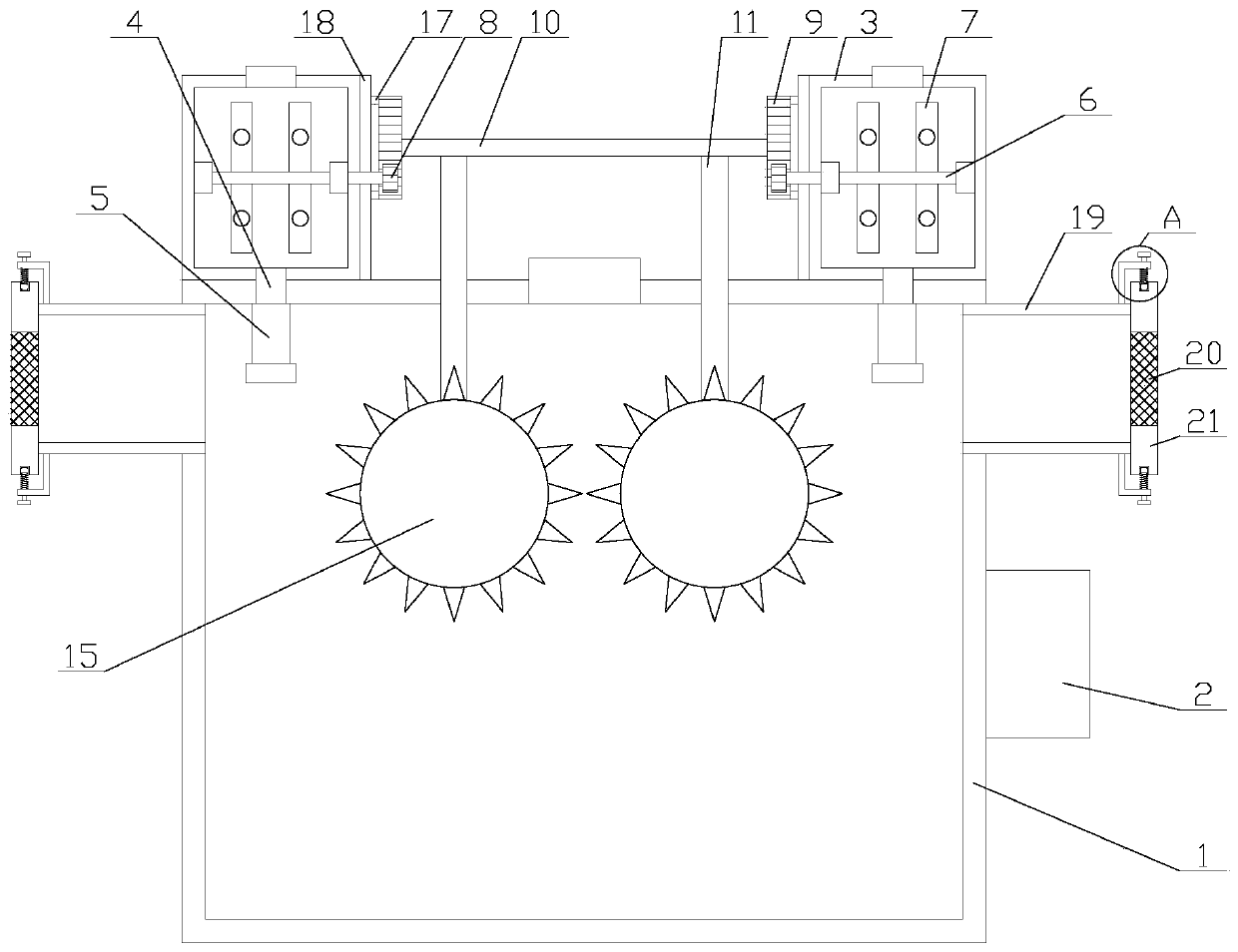

Feed stirring device

ActiveCN107744851AImprove crushing effectImprove work efficiencyFlow mixersTransportation and packagingAgricultural engineeringSlide plate

The invention discloses a feed stirring device, and relates to the technical field of agricultural machinery. The feed stirring device comprises a box body, wherein a vertical reciprocating mechanismis arranged on the box body; the lower end of the vertical reciprocating mechanism is equipped with a lifting rod; a rotary wheel is arranged on the lifting rod; a horizontal reciprocating mechanism is arranged on the box body; the lifting rod is connected with a processing device; the processing device comprises a filter plate, a crushing room and a raw material room; the crushing room comprisesa crushing gear and a crushing cavity; the crushing cavity consists of partition plates, wherein racks are arranged the partition plates, and the partition plates are rotatably connected with a stirring plate; the raw material room comprises a sleeve; a slide plate is arranged at the upper end of the sleeve; a resisting spring is arranged between the slide plate and the sleeve; two containing plates are rotatably connected under the sleeve; a fixed column is arranged outside the sleeve; the fixed column is fixedly arranged on the inner wall of the box body; the bottom of the box body is equipped with a fan; and a raw material inlet and outlet is formed in the outer side of the box body. With the adoption of the technical scheme, the feed stirring device overcomes the problems that existingstirring machinery cannot crush and stir simultaneously, and is uneven in stirring, and can be used for stirring feed in a farm.

Owner:梁晓容

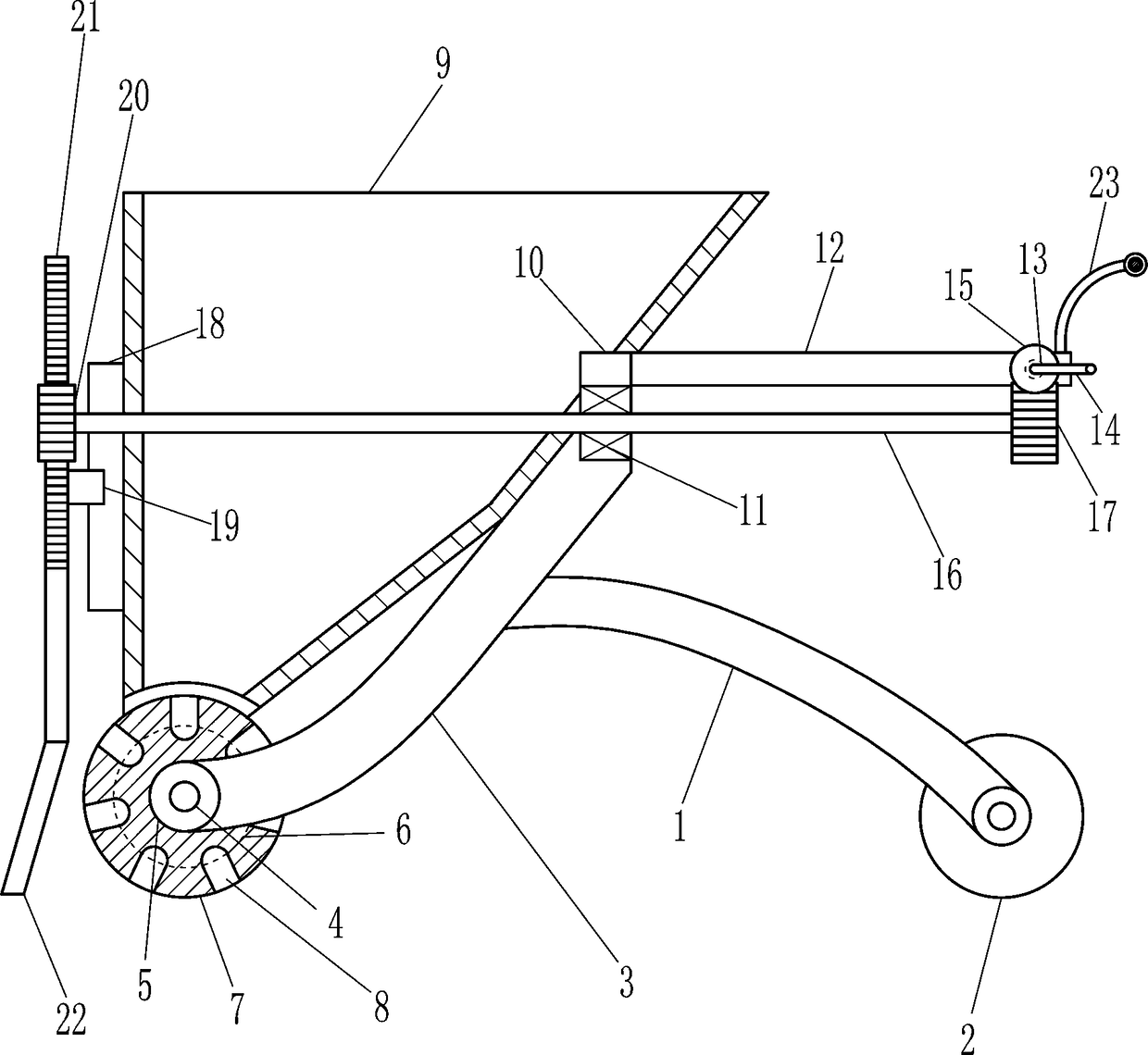

Paint spraying device for steel pipe processing

InactiveCN111841985AImprove work efficiencyQuality improvementPretreated surfacesCoatingsBall screwExhaust pipe

The invention relates to a paint spraying device for steel pipe processing, comprising a base, a top plate, a fixed box, a communication pipe, a paint spraying pipe, two support columns and two fixingapparatuses, and further comprising a stirring mechanism and two air blowing mechanisms. The air blowing mechanisms comprise connection boxes, air cylinders, pistons, intake pipes, drive assemblies,rotation assemblies, transmission assemblies, two exhaust pipes and multiple nozzles; the rotation assemblies comprise first bearings, lead screws, ball screw bearings and two support rods; and the stirring mechanism comprises a rotation shaft, a connection pipe, a moving assembly, a second bearing, two third bearings, multiple connection blocks and multiple stirring plates. The paint spraying device for steel pipe processing achieves an air blowing function by means of the air blowing mechanisms to accelerate the circulation speed of air around a steel pipe so as to accelerate solidificationof paint, and achieves a stirring function by means of the stirring mechanism to accelerate the flowing speed of the paint in the fixed box so as to reduce the probability of generating the paint agglomeration phenomenon.

Owner:南京江宁区上峰国银标准件厂

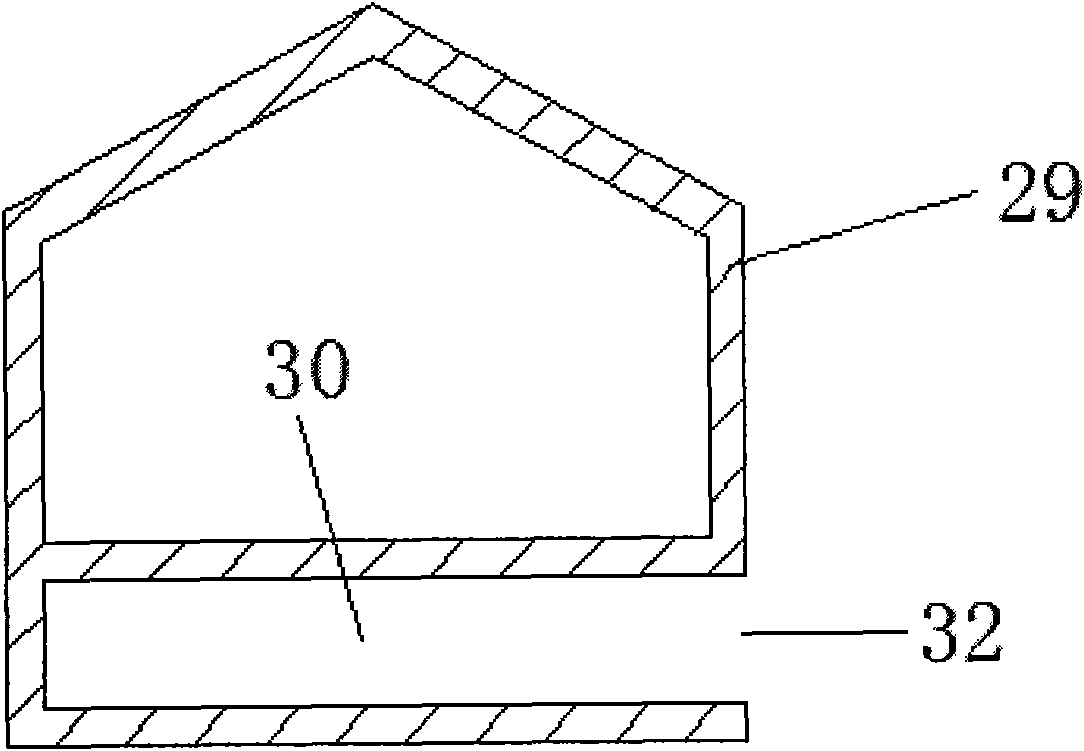

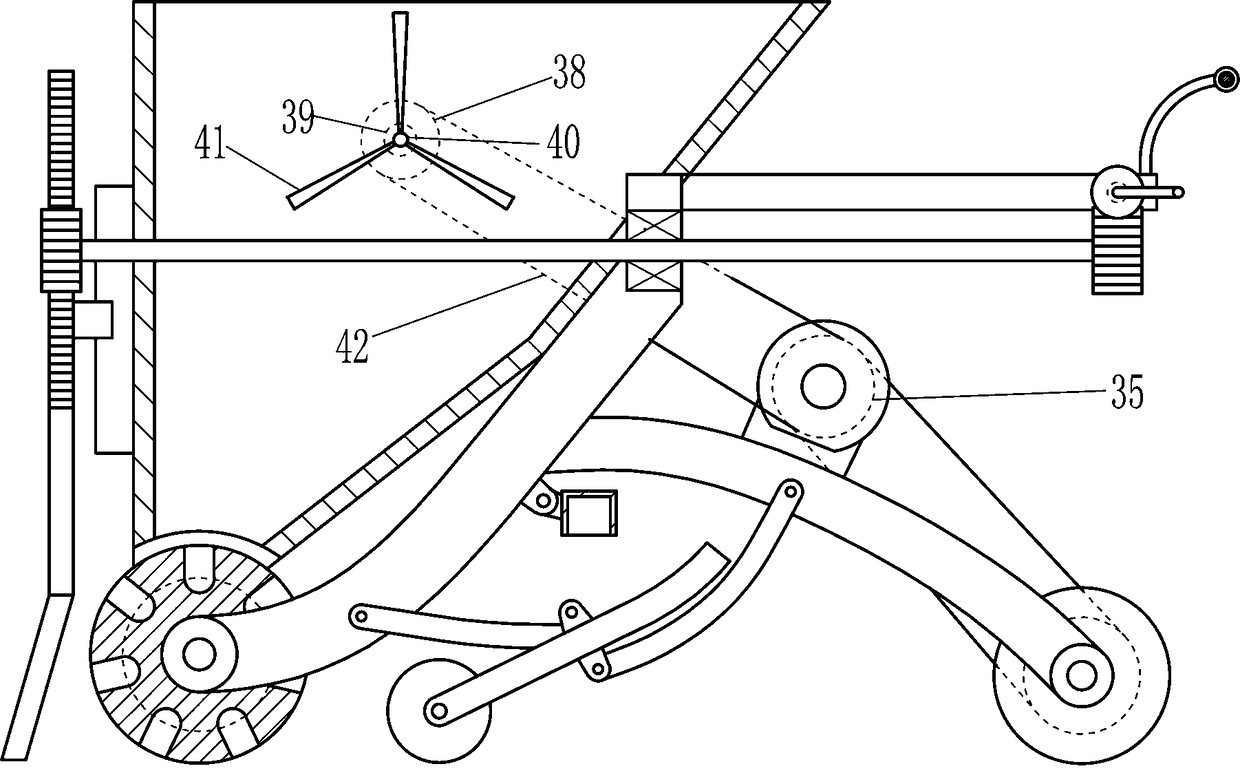

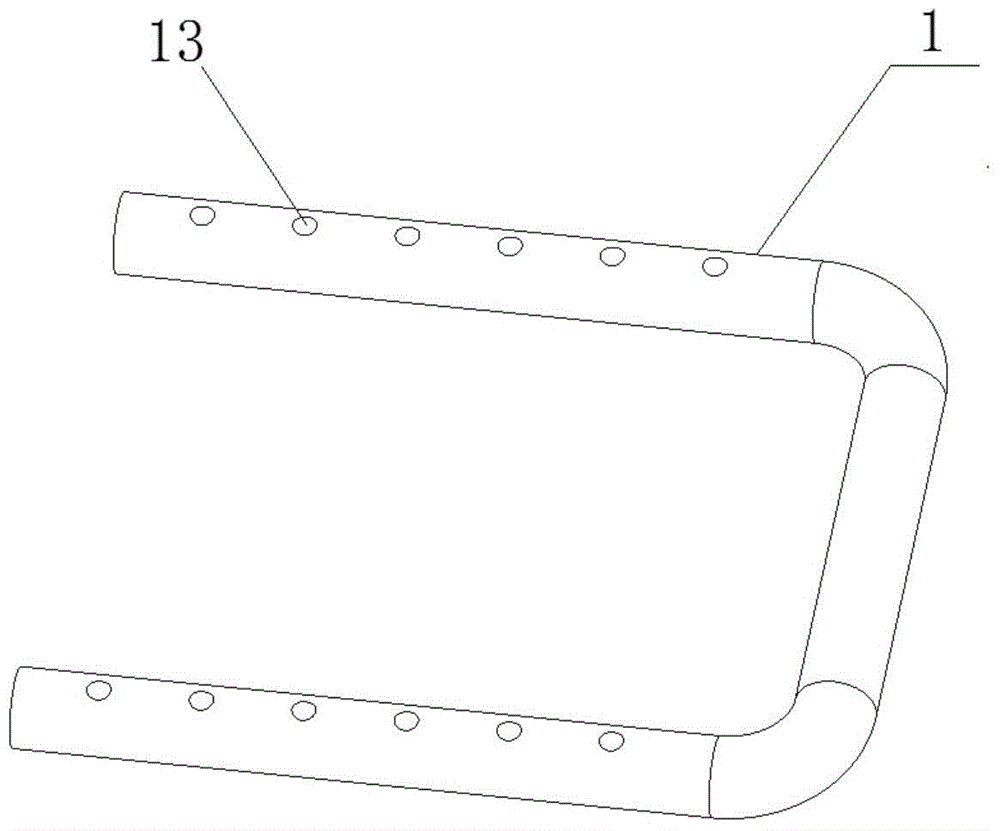

Indoor cement laying device for construction

InactiveCN109138389ALay evenlyAdjustable thicknessBuilding constructionsInterference fitArchitectural engineering

The invention relates to a laying device, in particular to an indoor cement laying device for construction and with cement laying thickness adjusting and uniform laying. According to the technical scheme, the indoor cement laying device for construction comprises a first supporting plate, wheels, a second supporting plate, a first bearing seat, a first rotating shaft, a servo motor, a feeding rotating disc and the like. The wheels are arranged at the bottom of the first supporting plate. The second supporting plate is fixedly connected to the left end of the first supporting plate. The first bearing seat is embedded in the bottom of the second supporting plate. The first rotating shaft is connected into the first bearing seat in an interference fit mode. The function of indoor cement laying is achieved. Cement laying is more uniform. The function of cement stirring is achieved as well as cement laying thickness adjusting, and therefore the cement does not solidify. The indoor cement laying device has the characteristics of cement laying thickness adjusting, uniform laying and cement stirring to enable the cement not to solidify.

Owner:浙江年代建设工程有限公司

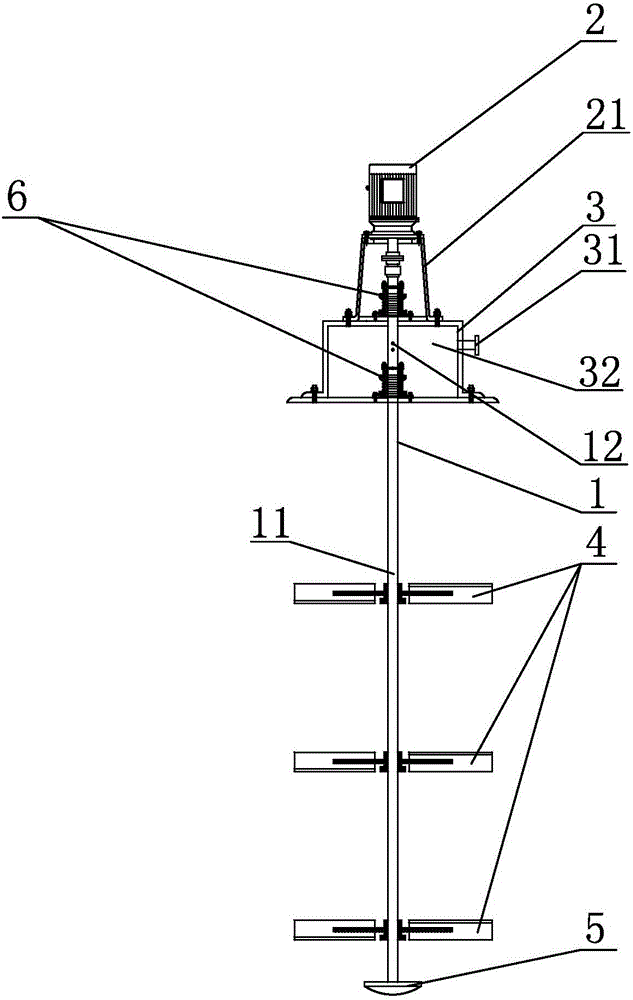

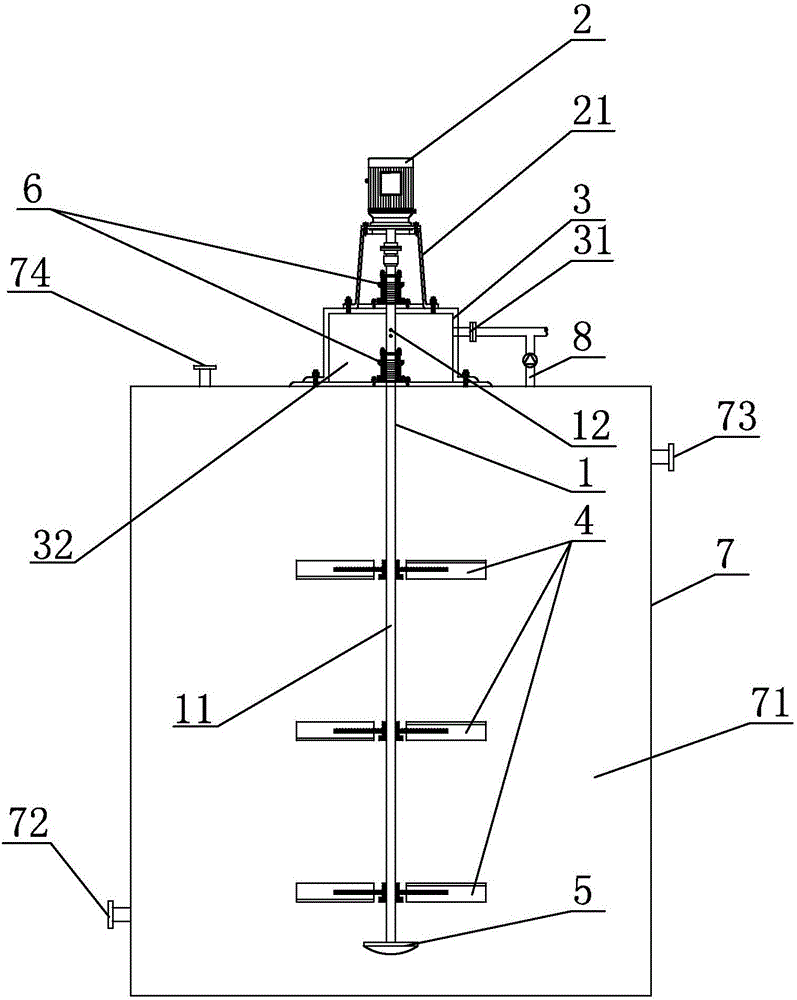

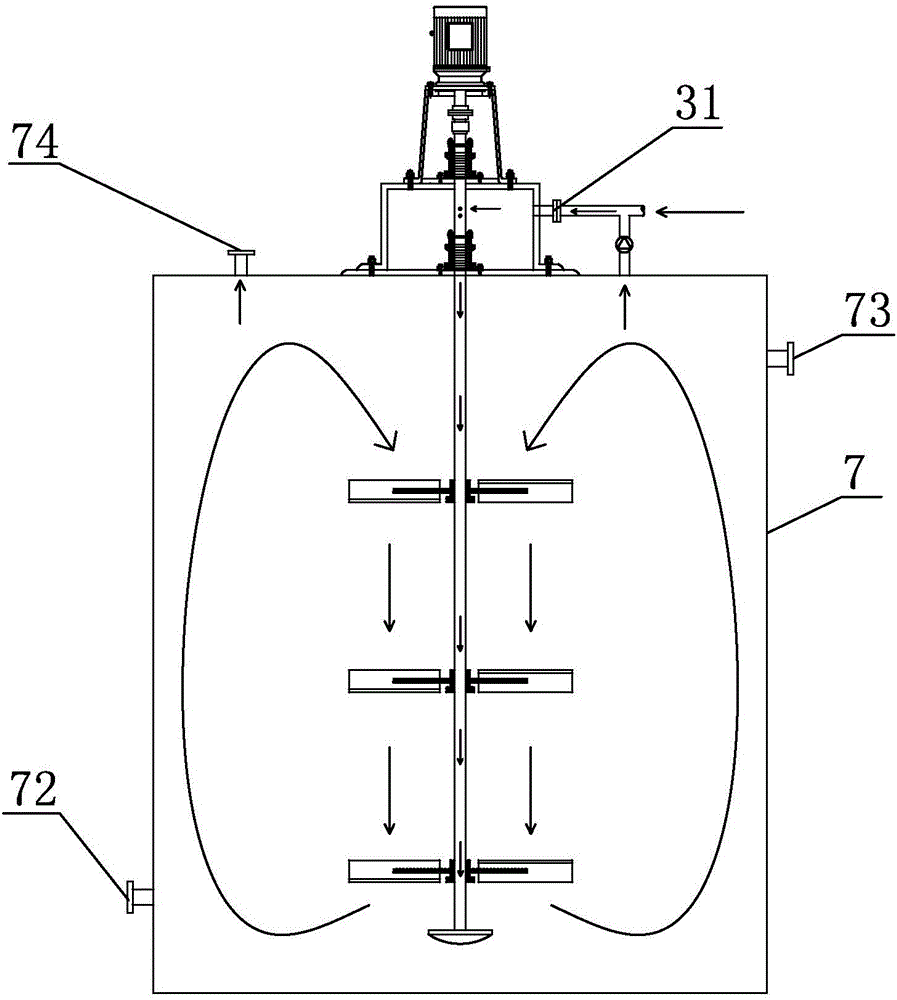

Fermentation equipment with good stirring effect for producing yogurt

InactiveCN110100888AImprove mixing uniformityIngenious structureMilk preparationBiochemical engineeringDrive shaft

The invention relates to fermentation equipment with a good stirring effect for producing yogurt. The fermentation equipment comprises a main equipment body, a driving motor and a transmission shaft;the main equipment body is in a cylindrical shape, the transmission shaft is coaxial with the main equipment body, a through hole is formed in the top of the main equipment body, and the transmissionshaft penetrates through the through hole, then slides and is hermetically connected with the through hole; the driving motor is arranged at the top of the main equipment body and is in transmission connection with the transmission shaft, the main equipment body is internally provided with a stirring mechanism and an auxiliary mechanism, the stirring mechanism is connected with the transmission shaft and comprises a driving gear and two stirring assemblies, and the driving gear is installed on the transmission shaft and located between the two stirring assemblies. The fermentation equipment with the good stirring effect for producing the yogurt has the advantages that the stirring function is achieved through the stirring mechanism, and moreover, the discharging effect is improved throughthe auxiliary mechanism.

Owner:武桂英

Integrated device for conveying gas and stirring materials, and bioreactor comprising same

InactiveCN105695309AReduce shockEfficient and thorough conversionBioreactor/fermenter combinationsBiological substance pretreatmentsCircular discEngineering

The invention discloses an integrated device for gas conveying and material stirring, which comprises a rotating stirring shaft and a motor; The connection between them is sealed; the stirring part of the rotating stirring shaft is equipped with a slanted blade disc turbine agitator, and the bottom end is equipped with a microporous aeration device; the shaft wall of the rotating stirring shaft in the buffer air inlet chamber is provided with ventilation The ventilation channel is arranged in communication with the microporous aeration device through the air inlet chamber provided in the rotating stirring shaft. The invention increases the buffer air intake chamber to reduce the impact on the microorganisms when the air intake velocity fluctuates, and uses a microporous aeration device to increase the contact area between fine air bubbles and microorganisms, and at the same time cooperates with a multi-layer oblique blade disc turbine agitator The material in the bioreactor can be circulated downward from the center and then upward along the inner wall around the main body of the bioreactor to strengthen the biotransformation process of the gas.

Owner:BEIJING UNIV OF CHEM TECH +1

Novel medical mechanical cleaning structure with sterilization and disinfection functions and use method thereof

InactiveCN110813855AAchieve stirring and mixingRealize the stirring functionLavatory sanitoryCleaning using liquidsWater storageWater storage tank

The invention discloses a novel medical mechanical cleaning structure with sterilization and disinfection functions and a use method of the novel medical mechanical cleaning structure. Stirring bladesare arranged on the periphery of the lower end of a first rotating shaft. The structure realizes the stirring function of articles in a water storage tank. A plurality of through holes are formed inthe two ends of each cleaning frame so that small medical machines in the cleaning frames can be cleaned, and cleaning is convenient, uniform and quick. The length of an electric telescopic rod is adjusted through an intelligent controller, and ultraviolet sterilization lamps are located at the inner side positions of the cleaning frames, so that disinfection and sterilization of the cleaned smallmedical machines are facilitated, and cross infection is avoided; and in addition, the ultraviolet sterilization lamps also have the functions of heating and drying. Through the work of a second rotating motor, the rotation of a second rotating shaft is achieved, and then a rotating disc is driven to rotate, so that the cleaning frames are more beneficial to cleaning in the rotating process. Through the flow guide effect of flow guide plates and flow guide pipes, the used water is guided to the lower end of a structure main body, and finally the water is collected through a water outlet.

Owner:孙阎强

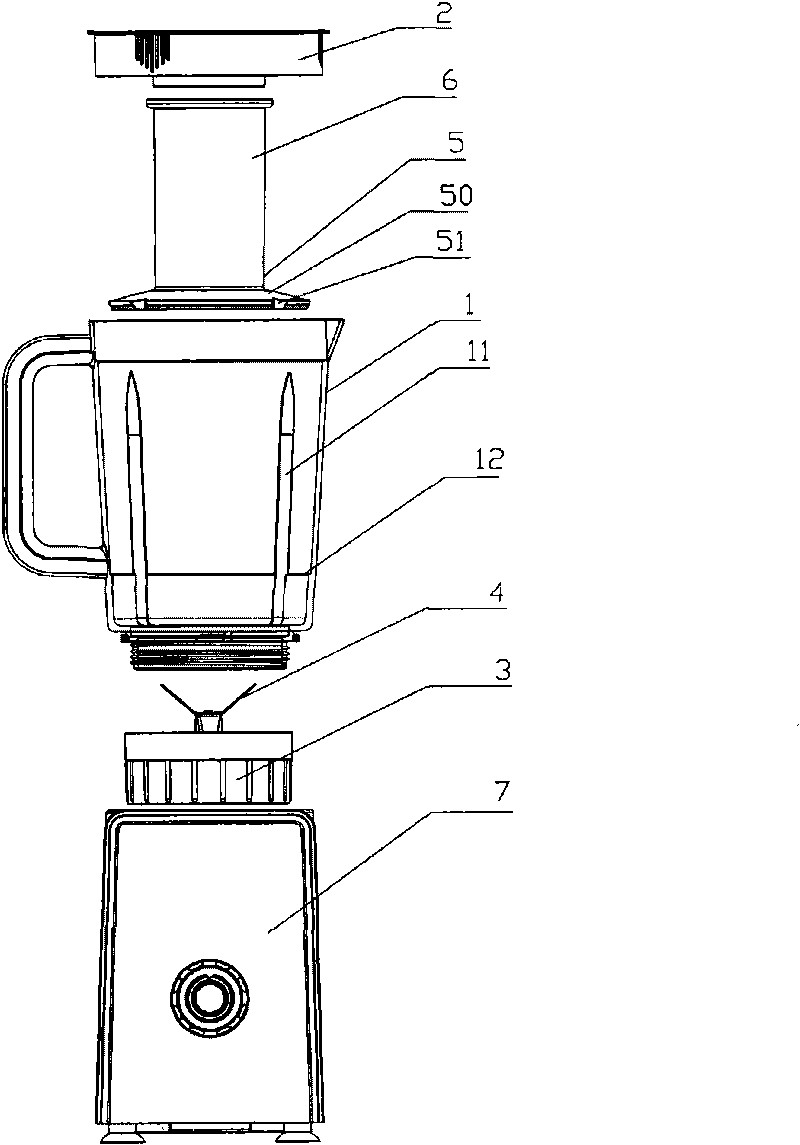

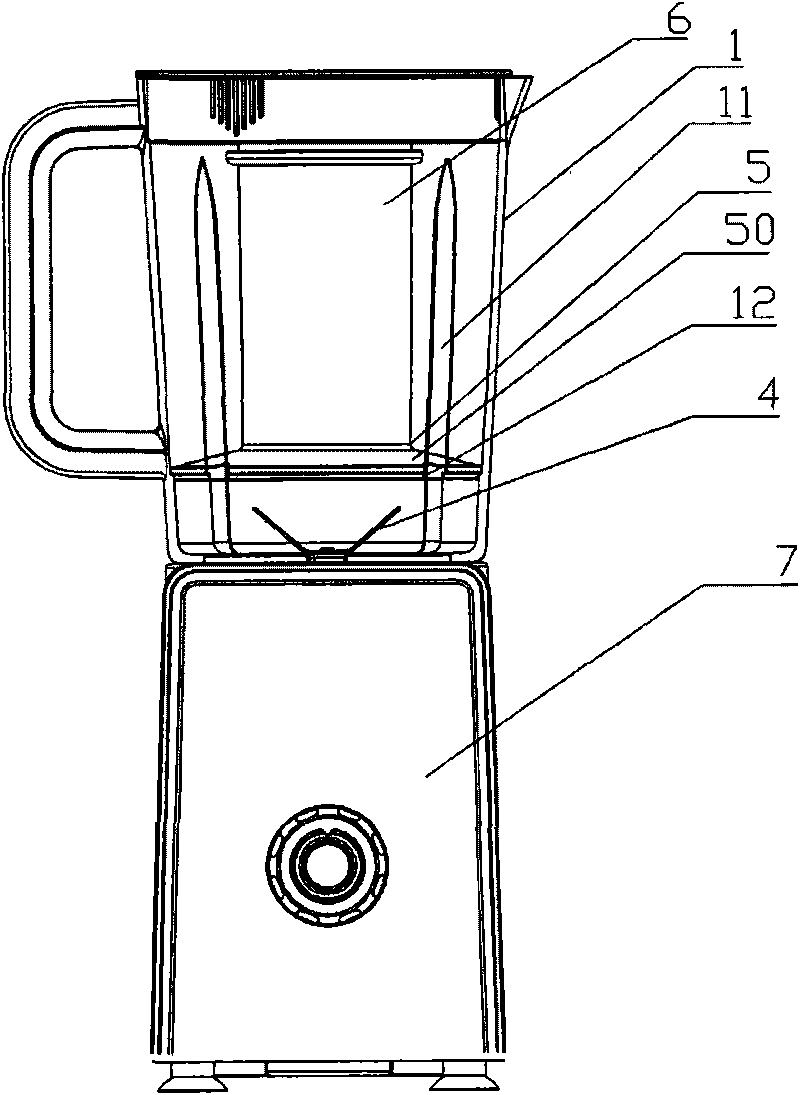

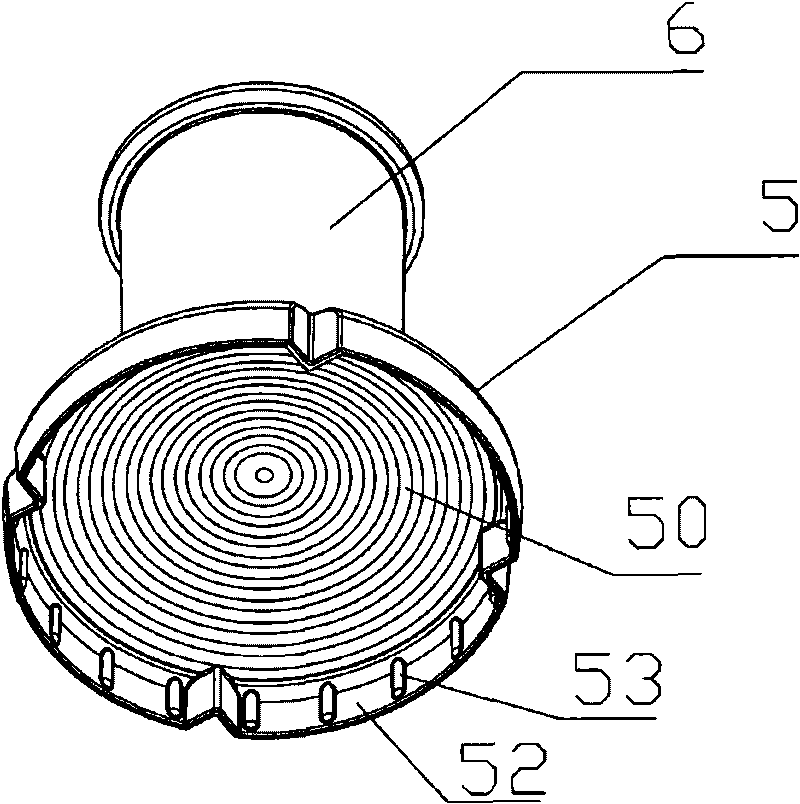

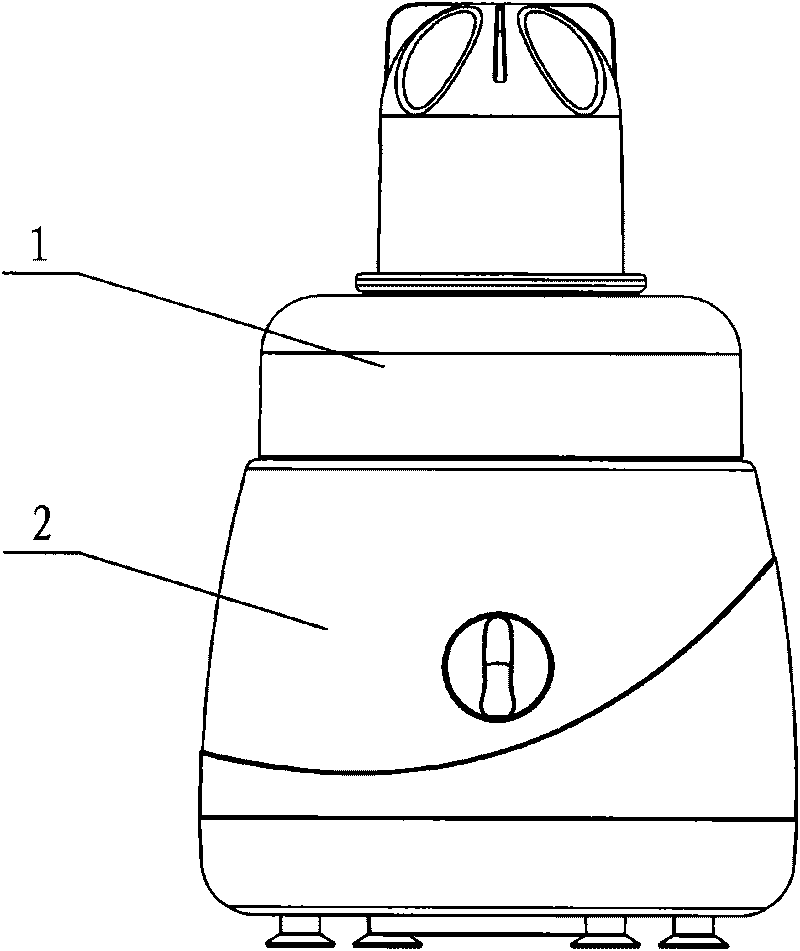

Single-cup multipurpose cooking machine

ActiveCN101731965ARealize the stirring functionImprove ease of useKitchen equipmentProcess engineeringDry grinding

The invention discloses a single-cup multipurpose cooking machine which comprises a cooking cup, a cup cover, a cutter block and an engine base, wherein the cooking cup is arranged on the engine base; the cup cover covers on an upper opening of the cooking cup; the cutter block is arranged at the bottom of the cooking cup; a cutter is arranged on the cutter block; and the engine base is internally provided with a motor. The cooking machine also comprises an auxiliary pulverization part which can be detachably arranged in the cooking cup. The auxiliary pulverization part is arranged in the cooking cup and matched with the cutter block and the cooking cup to form a smaller pulverization space so as to realize the functions of conditioning, meat mincing, dry grinding, and the like. When the auxiliary pulverization part is not installed in the cooling cup, the cooking cup can realize the function of stirring. Through arranging the auxiliary pulverization part, a single cooking cup can achieve the purposes of stirring, conditioning, meat mincing, dry grinding, and the like, thereby increasing the use convenience of users and reducing troubles of daily collections. In addition, the cooking machine also saves the material cost and the packaging cost of cooking machine manufacturers and has better industrial values.

Owner:JOYOUNG CO LTD

Kitchen and bath daily necessity production and processing equipment with foam removing function

InactiveCN111013447ARealize the stirring functionImprove mixing uniformityLiquid degasificationRotary stirring mixersDrive shaftGear wheel

The invention relates to kitchen and bath daily necessity production and processing equipment with foam removing function. The equipment comprises a main body, a discharge pipe and a sealing cover, wherein the main body is cylindrical and is vertically arranged, the sealing cover covers the top end of the main body and is hermetically connected with the main body, the discharge pipe is arranged atthe bottom end of the main body and is communicated with the main body, a sealing device is arranged on the discharge pipe, a stirring mechanism and an auxiliary mechanism are arranged in the main body, the stirring mechanism comprises a first motor, a transmission shaft, a screw rod, a fixed pipe, a transmission assembly and two stirring assemblies, the transmission assembly comprises a connecting shaft, a driving gear and a first stirring rod, and the stirring assembly comprises a driven gear, a bearing, a rotating shaft and a second stirring rod. According to the invention, the equipment achieves the stirring function through the stirring mechanism, and achieves the defoaming function through the auxiliary mechanism.

Owner:深圳华音时代文化科技有限公司

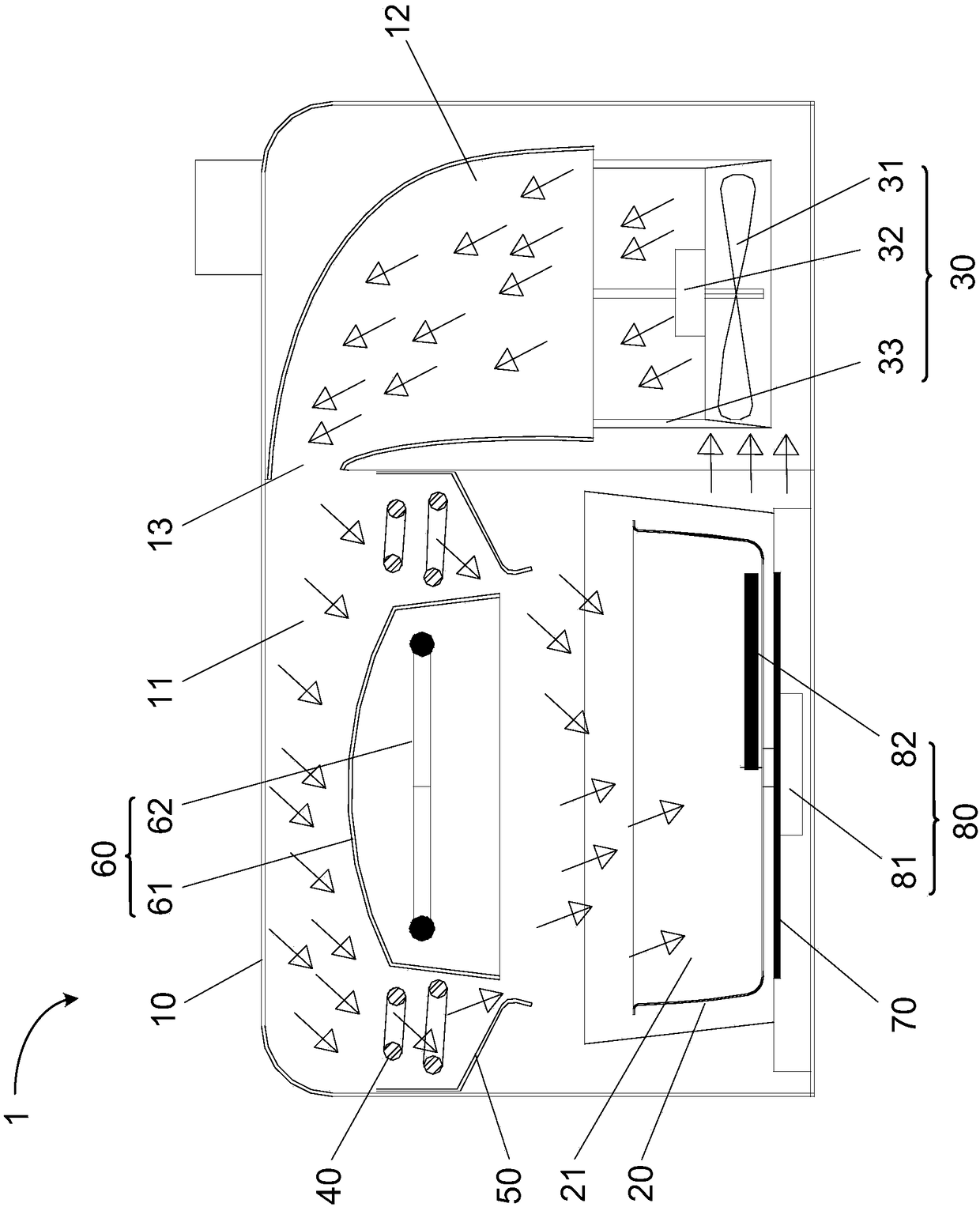

Air fryer

ActiveCN108209614AImprove the heating effectImprove heat transfer effectDeep fat fryersHeat flowCompression device

The invention provides an air fryer. The air fryer comprises a fryer body, an inner pot and an air supply device, wherein the fryer body is provided with a first space and a second space, the first space and the second space are communicated with each other through an air duct, the inner pot is arranged in the first space, and the air supply device is arranged in the second space; a convective heating device is arranged above the inner pot to heat flowing air, and a compression device is arranged between the inner pot and the convection heating device so as to increase the flow speed of the flowing air. According to the air fryer, the flowing air flowing to the inner pot is compressed by the compression device so as to increase the flowing speed, heat exchange between the flowing air and food in the inner pot is enhanced, and the heating is more uniform; besides, the distance between the air supply device and the inner pot is long, and the distance between the flowing air and the innerpot is long so that the air can be sufficiently pre-heated before flowing into the inner pot.

Owner:ZHEJIANG SHAOXING SUPOR DOMESTIC ELECTRICAL APPLIANCE CO LTD

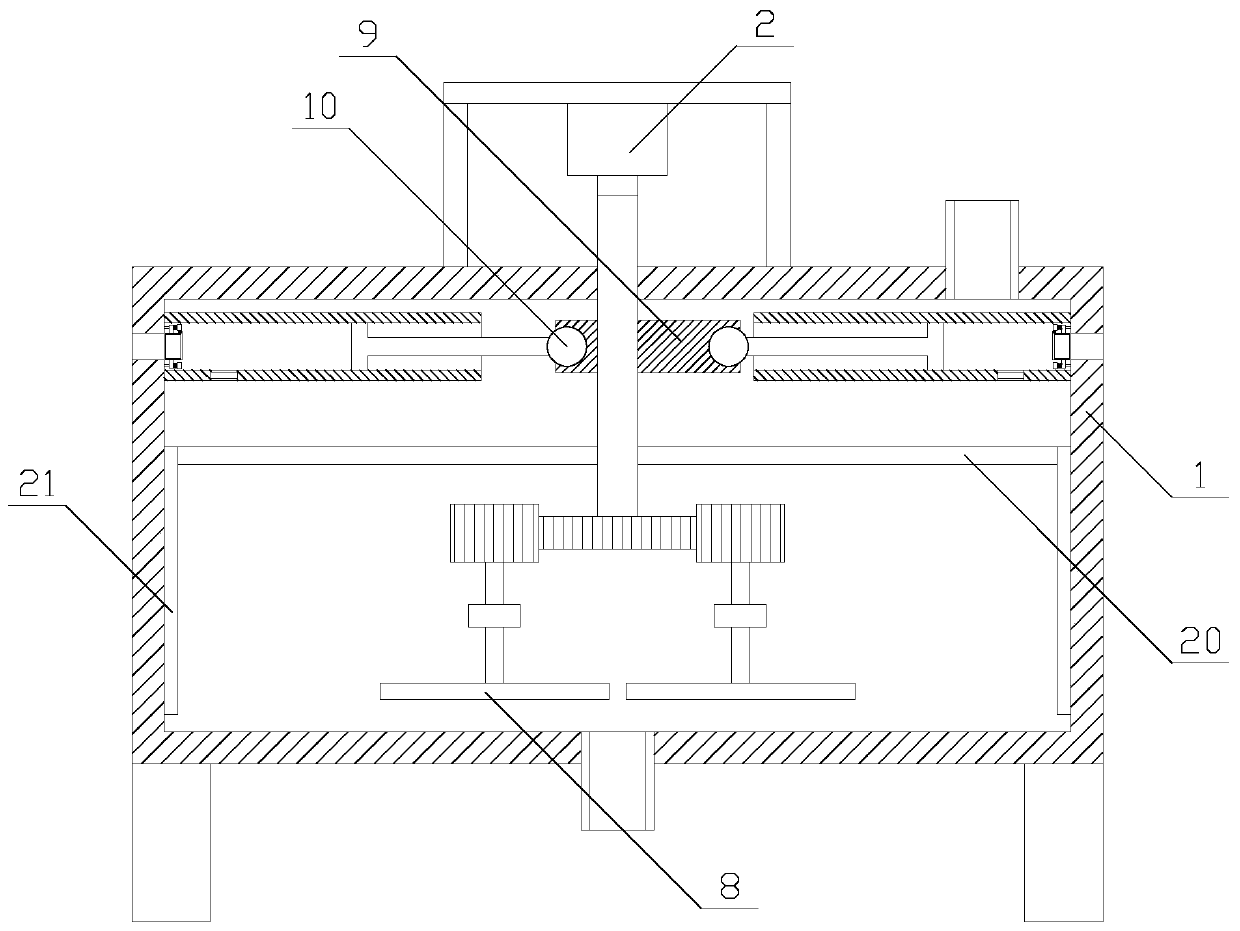

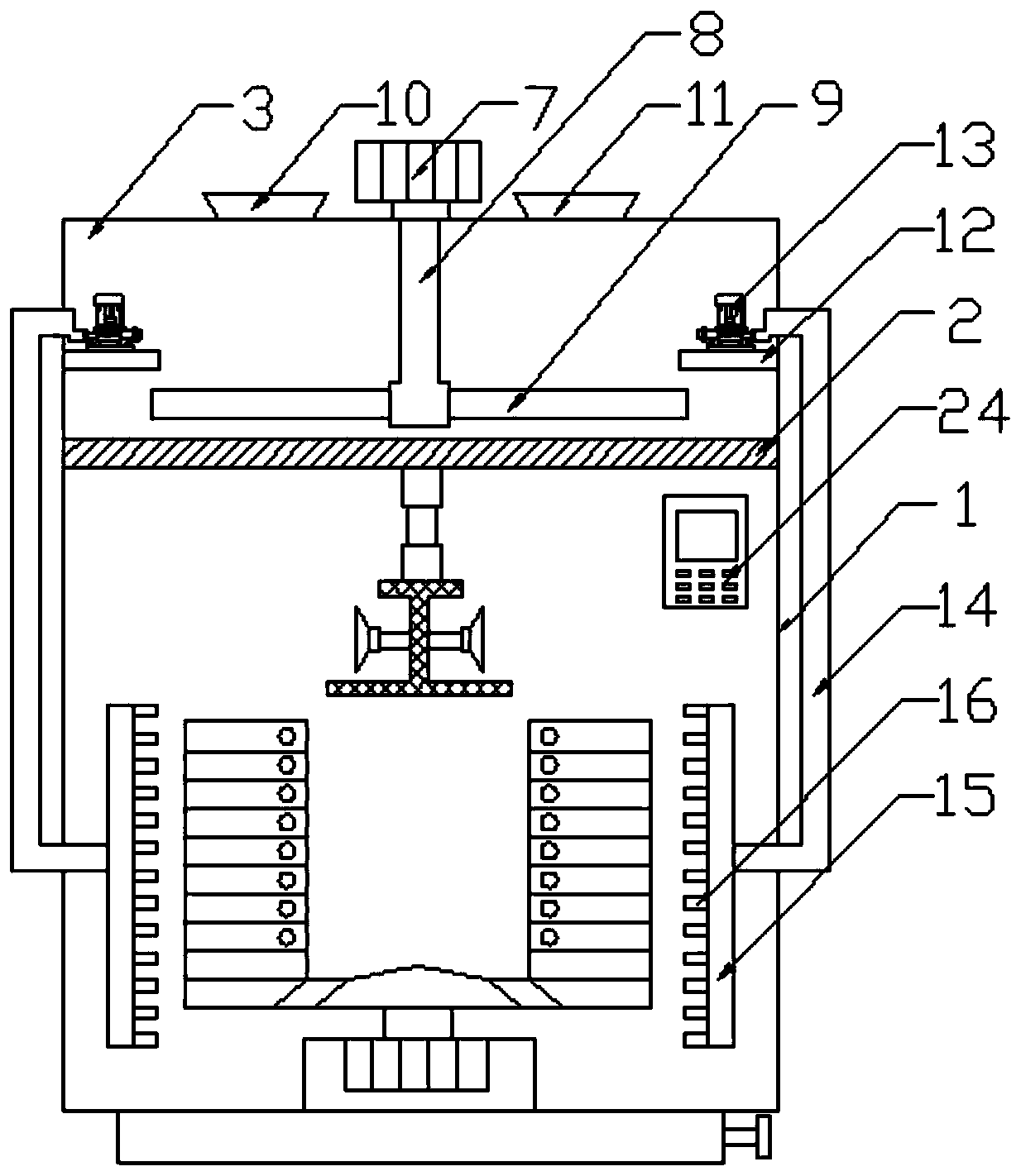

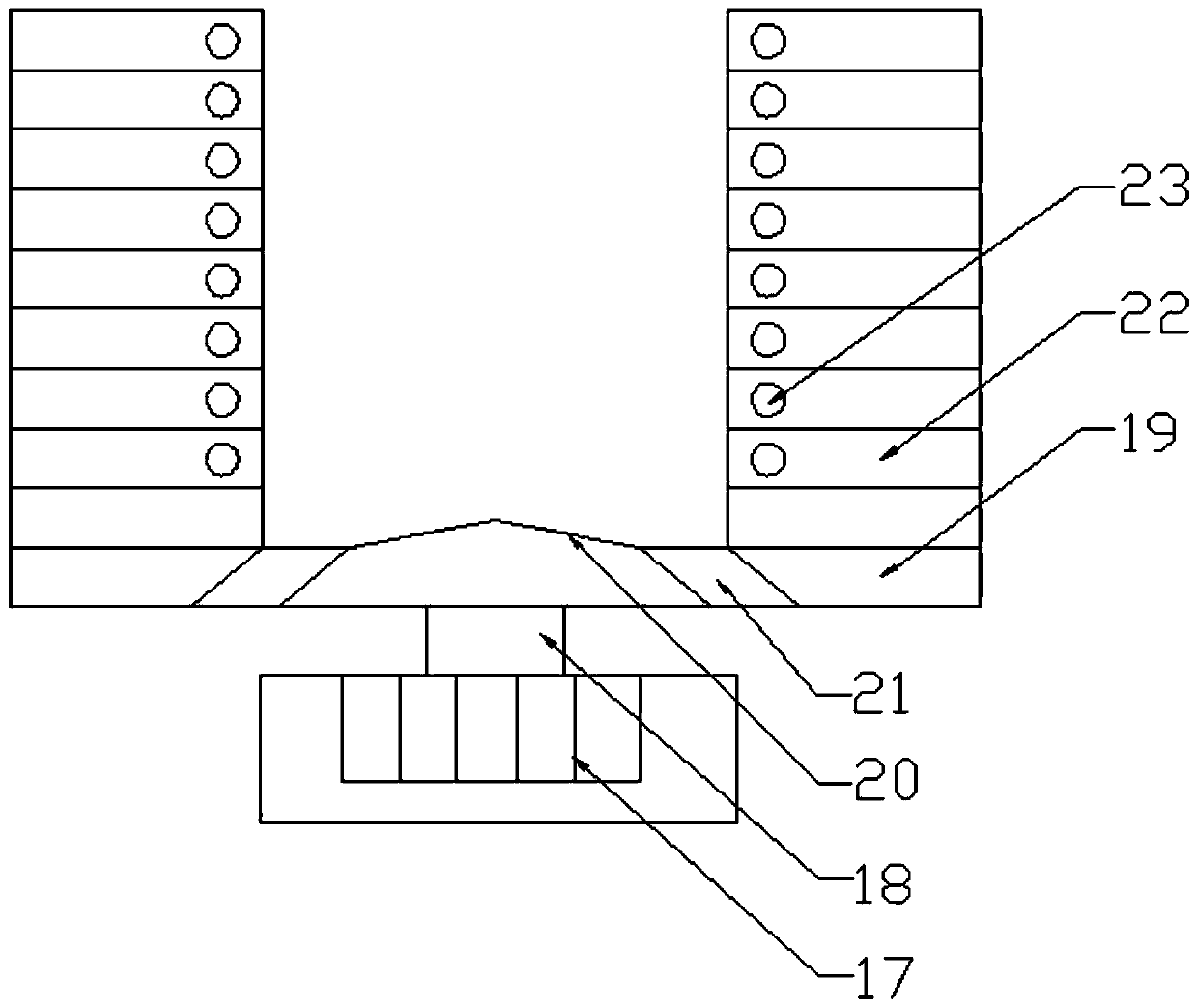

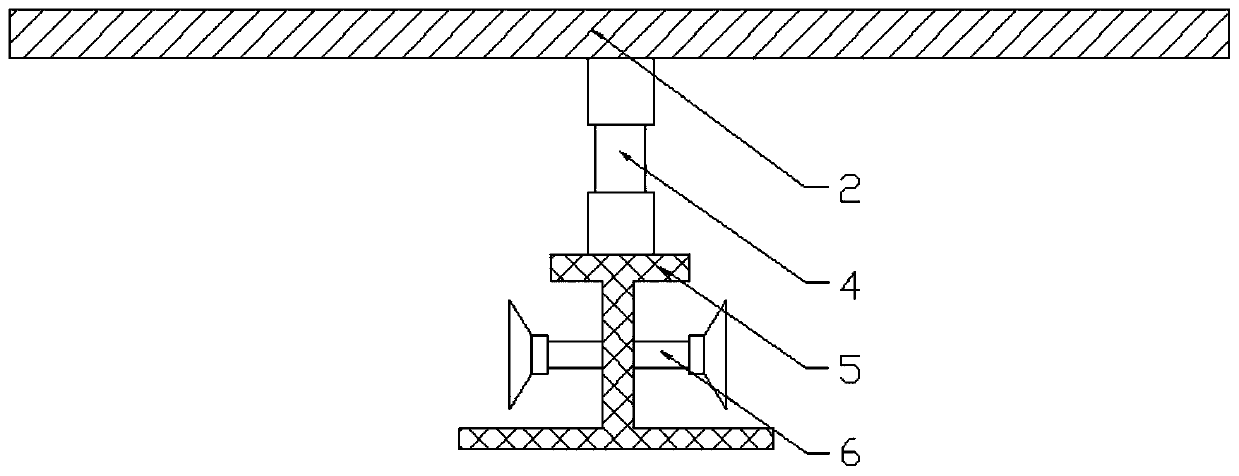

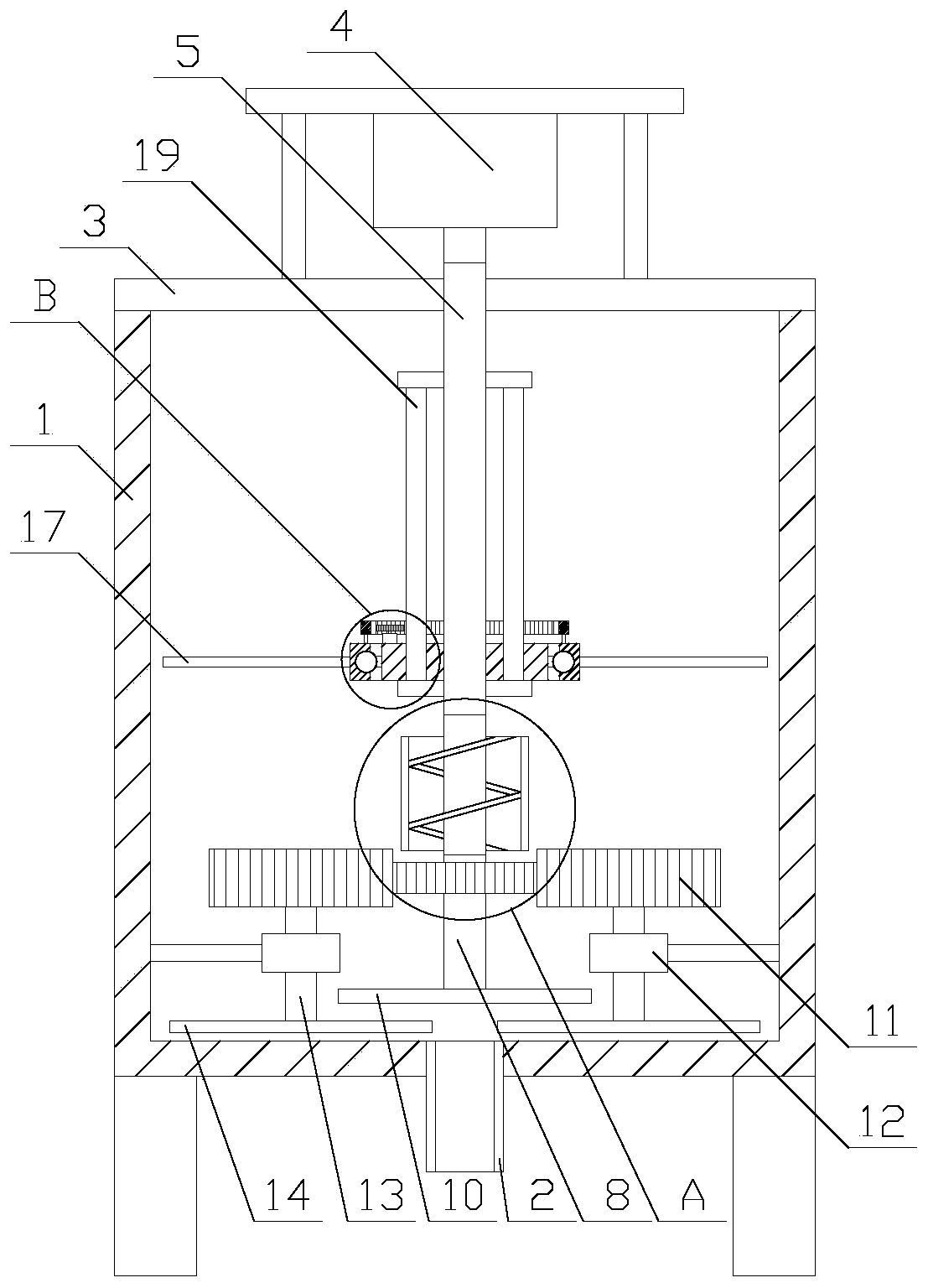

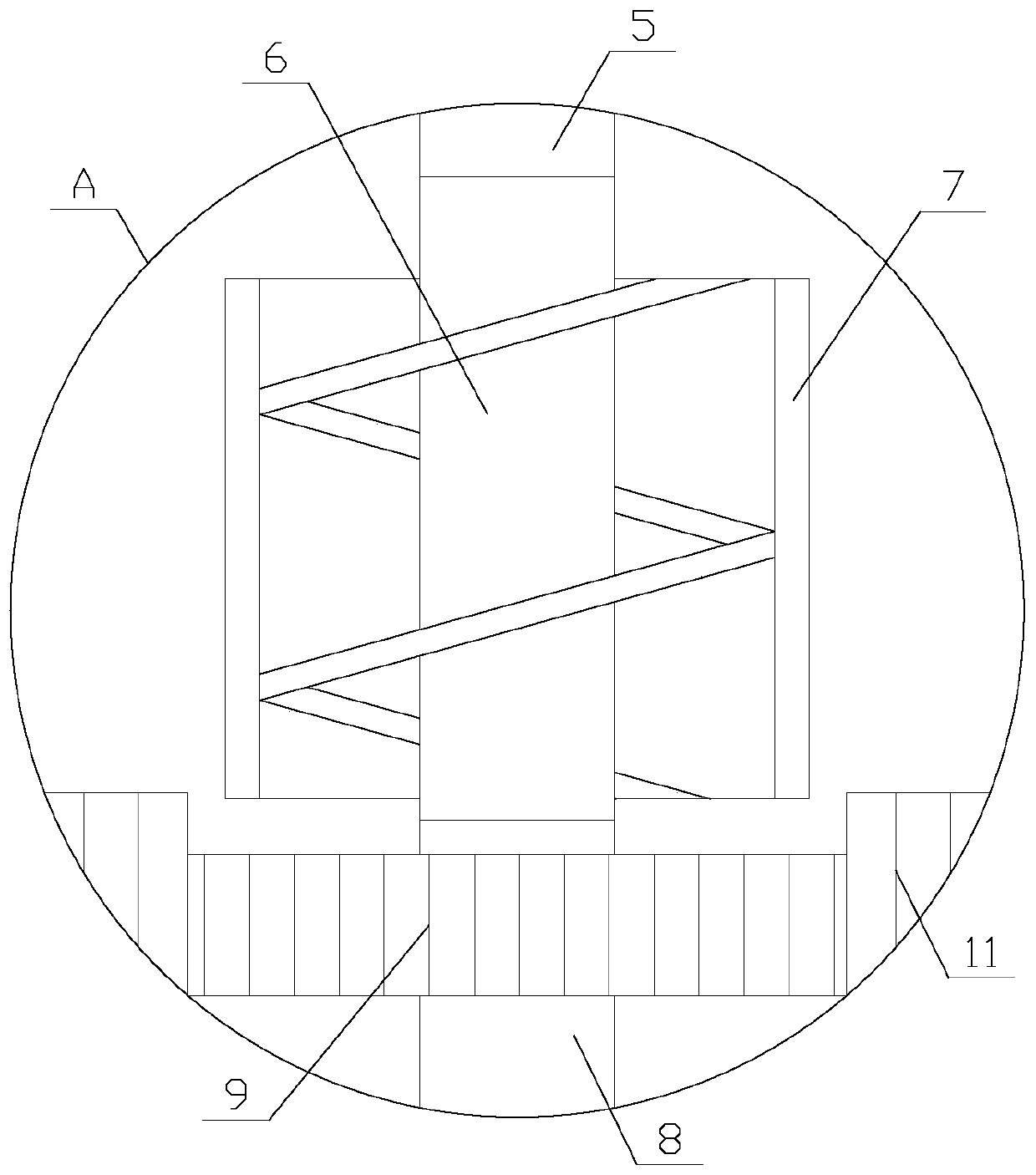

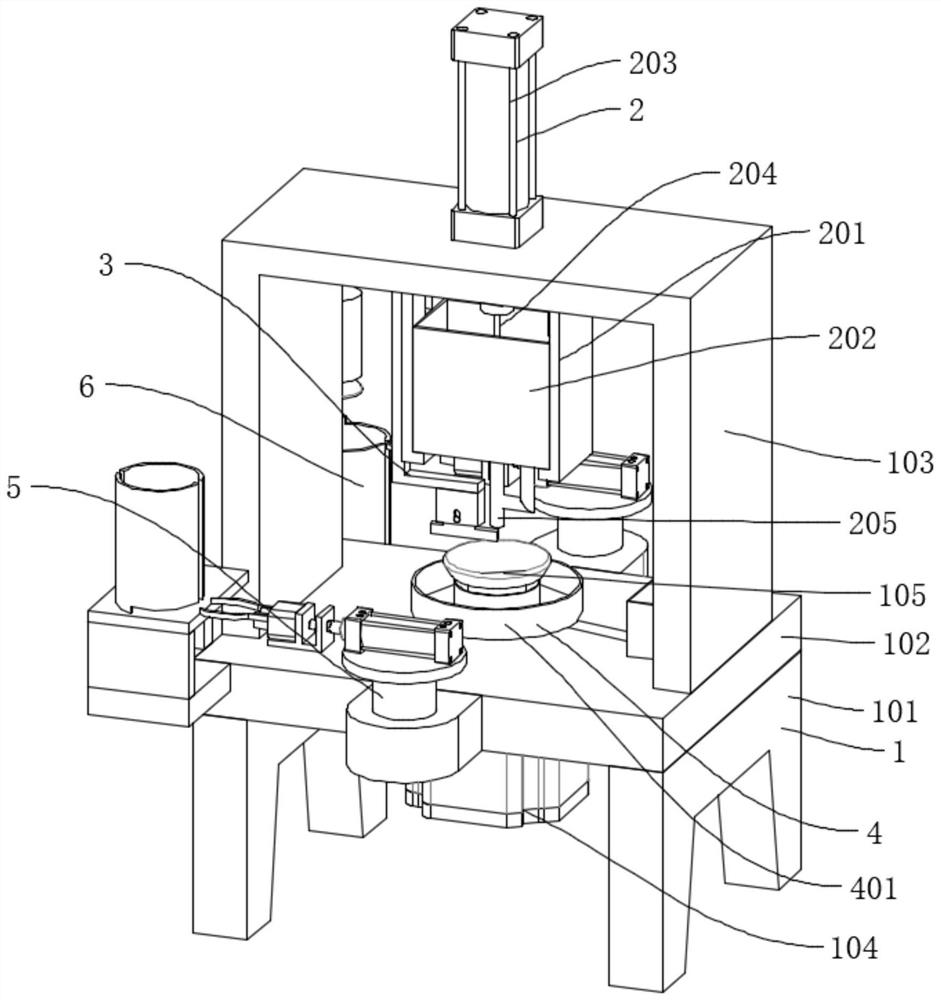

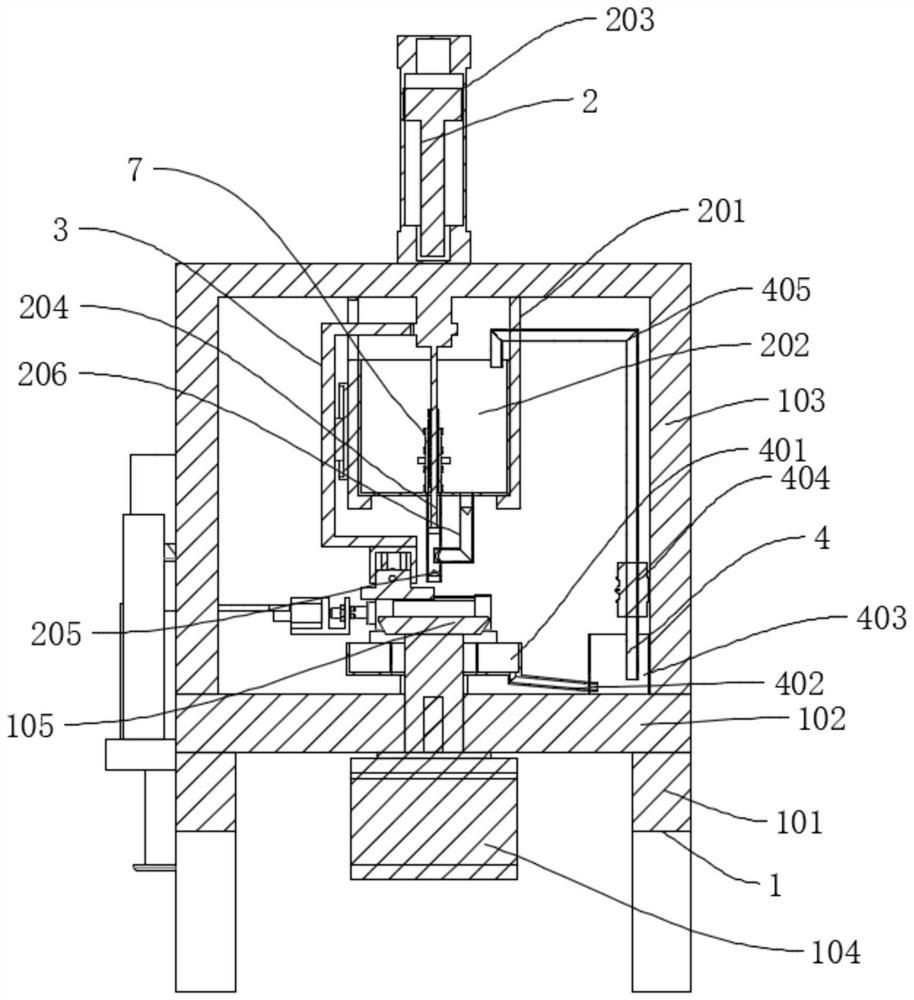

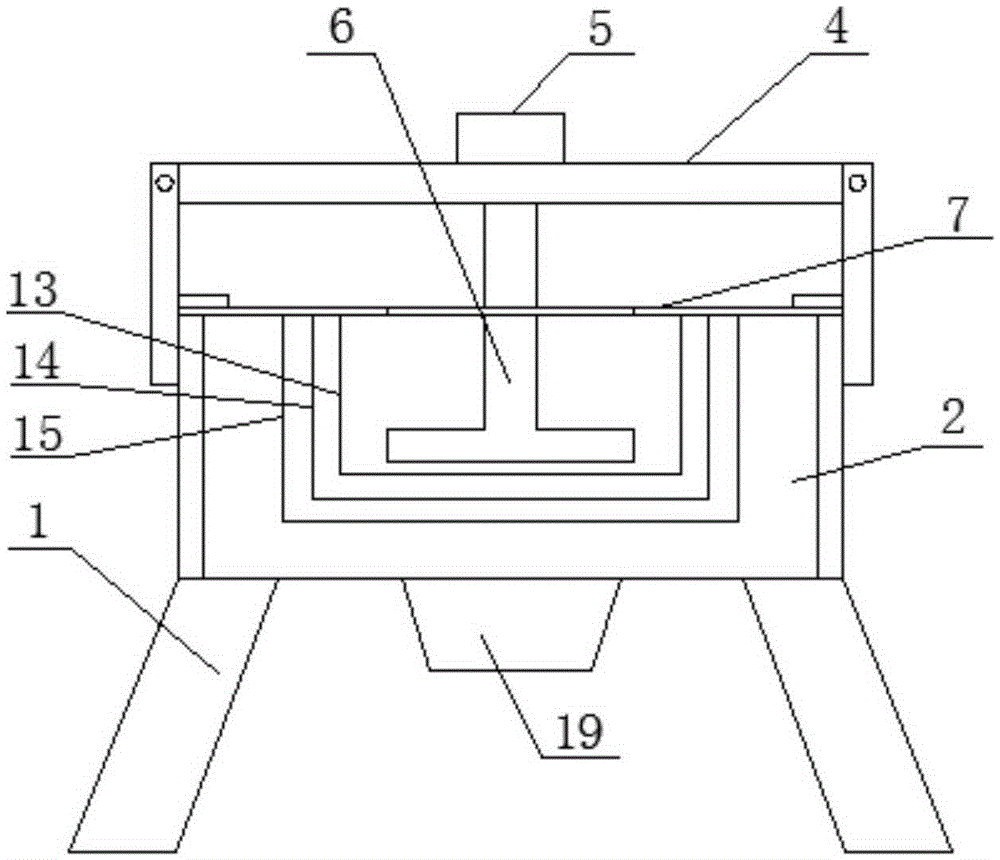

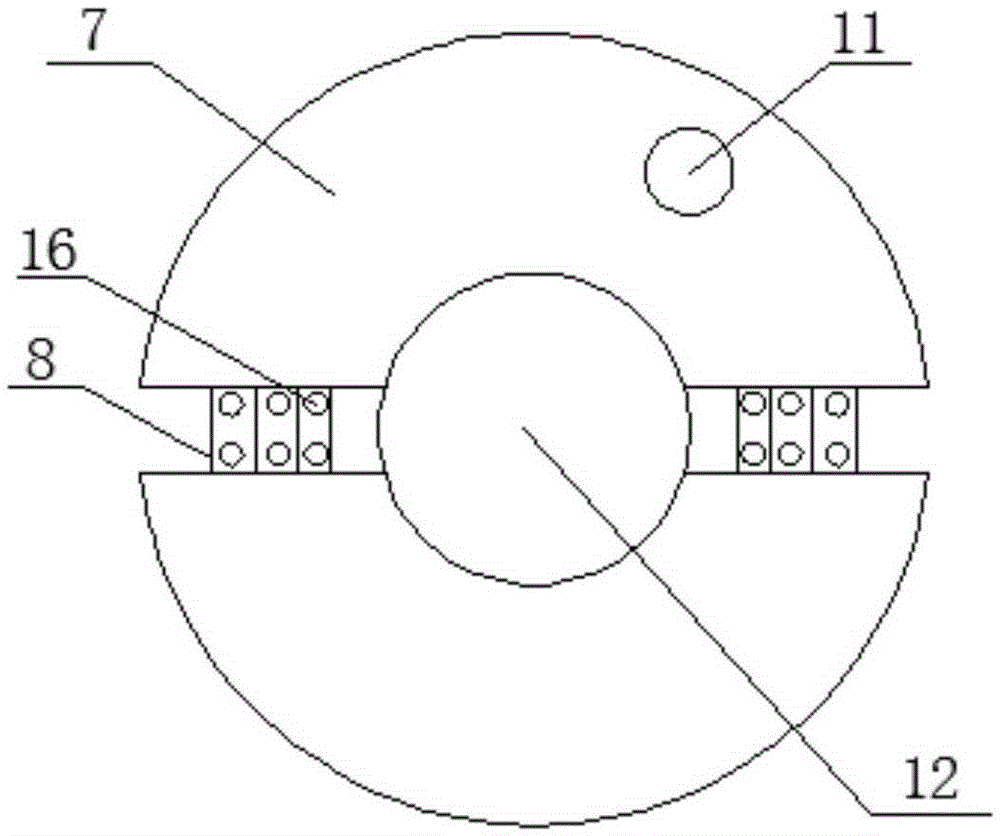

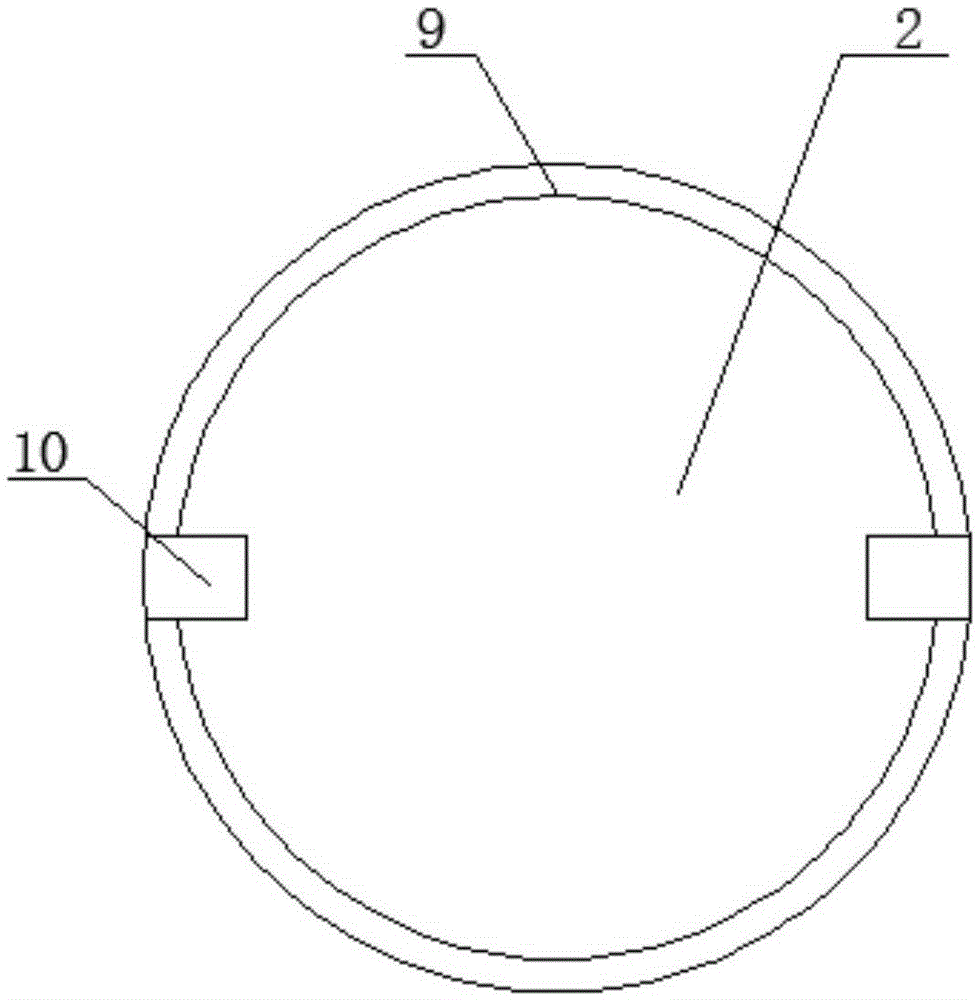

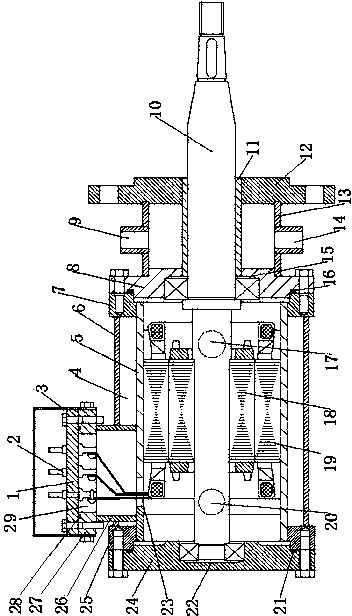

Aluminum oxide ceramic integrated hot-pressing molding machine and working method

InactiveCN111002437AImprove air tightnessReduce frictionFeeding arrangmentsAuxillary shaping apparatusOxide ceramicTemperature control

The invention discloses an aluminum oxide ceramic integrated hot-pressing molding machine and a working method. The aluminum oxide ceramic integrated hot-pressing molding machine comprises a pressingdevice and a hot-pressing device which are fixed to a rack, wherein the hot-pressing device is located below the pressing device, a stirring device is arranged in the hot-pressing device, and a hot-pressing mold is arranged above the hot-pressing device; the pressing device enables one path of high-pressure gas to act on the hot-pressing mold, and enables the other path of high-pressure gas to enter the hot-pressing device to enable slurry to flow into a cavity of the hot-pressing mold; the stirring device is used for stirring the slurry in the hot pressing device so as to enable an aluminum oxide blank to be more uniformly distributed in the slurry; and temperature measuring elements for detecting the temperature of internal oil and the temperature of slurry at the slurry outlet are arranged in the hot-pressing device, the power of an electric heating device is regulated and controlled in real time according to the temperature detected by the temperature measuring elements, and the purpose of accurate temperature control is achieved. Through the mold and the heating device, the temperature field distribution tends to be reasonable, the slurry temperature can be accurately controlled, the heating efficiency is obviously improved, and the distribution of the aluminum oxide powder in liquid paraffin can significantly improve the molding quality of the casting.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY +1

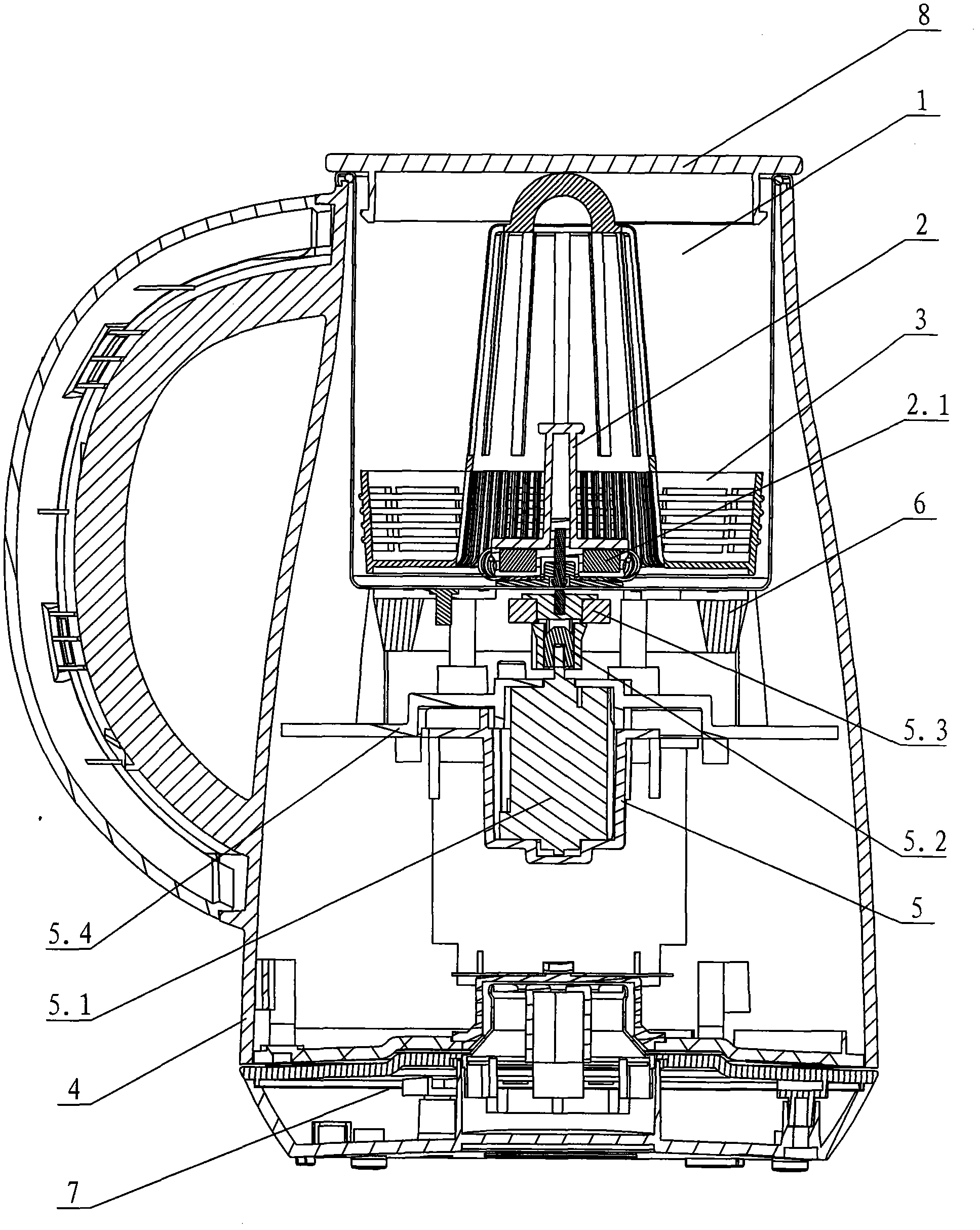

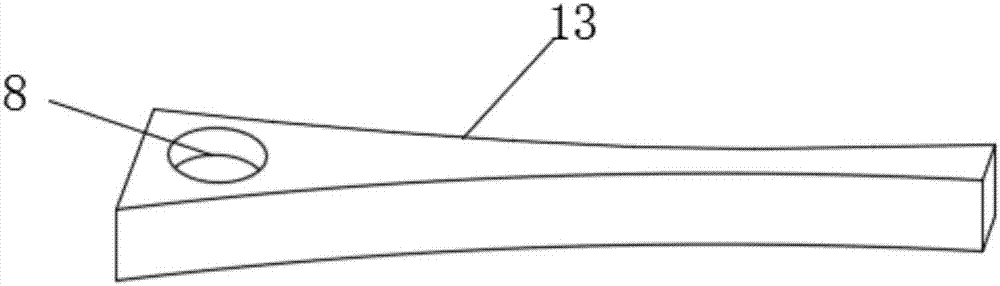

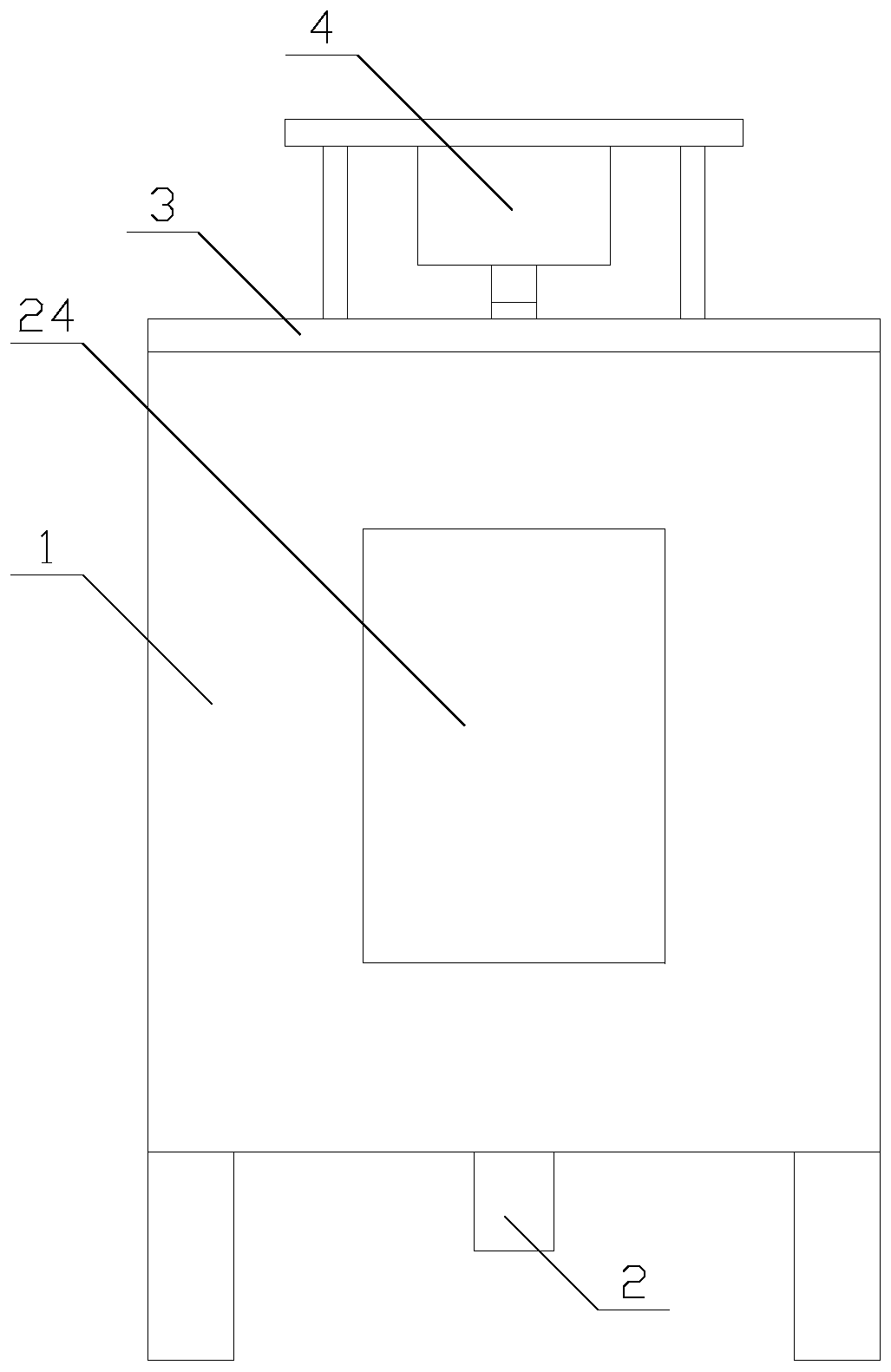

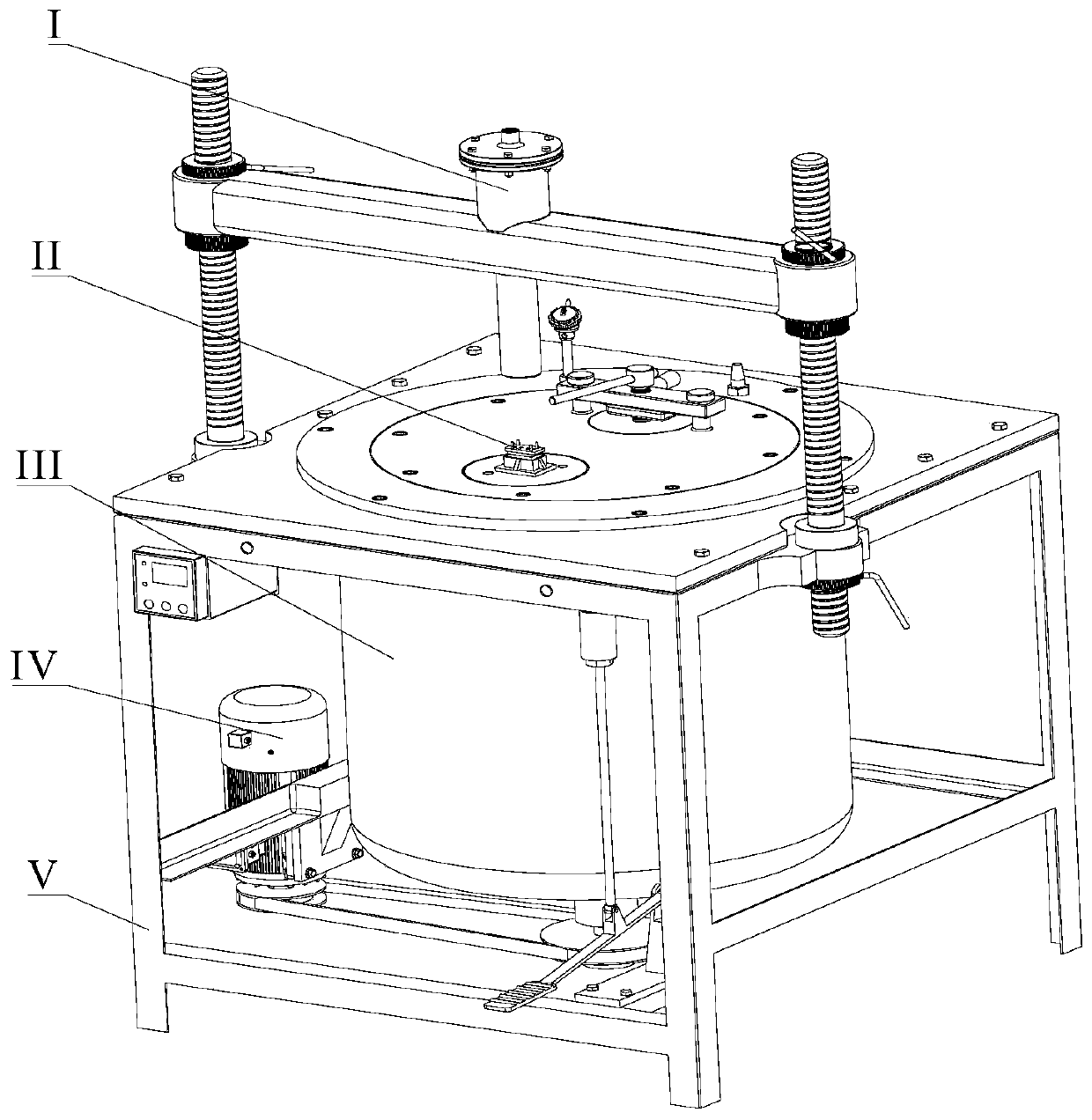

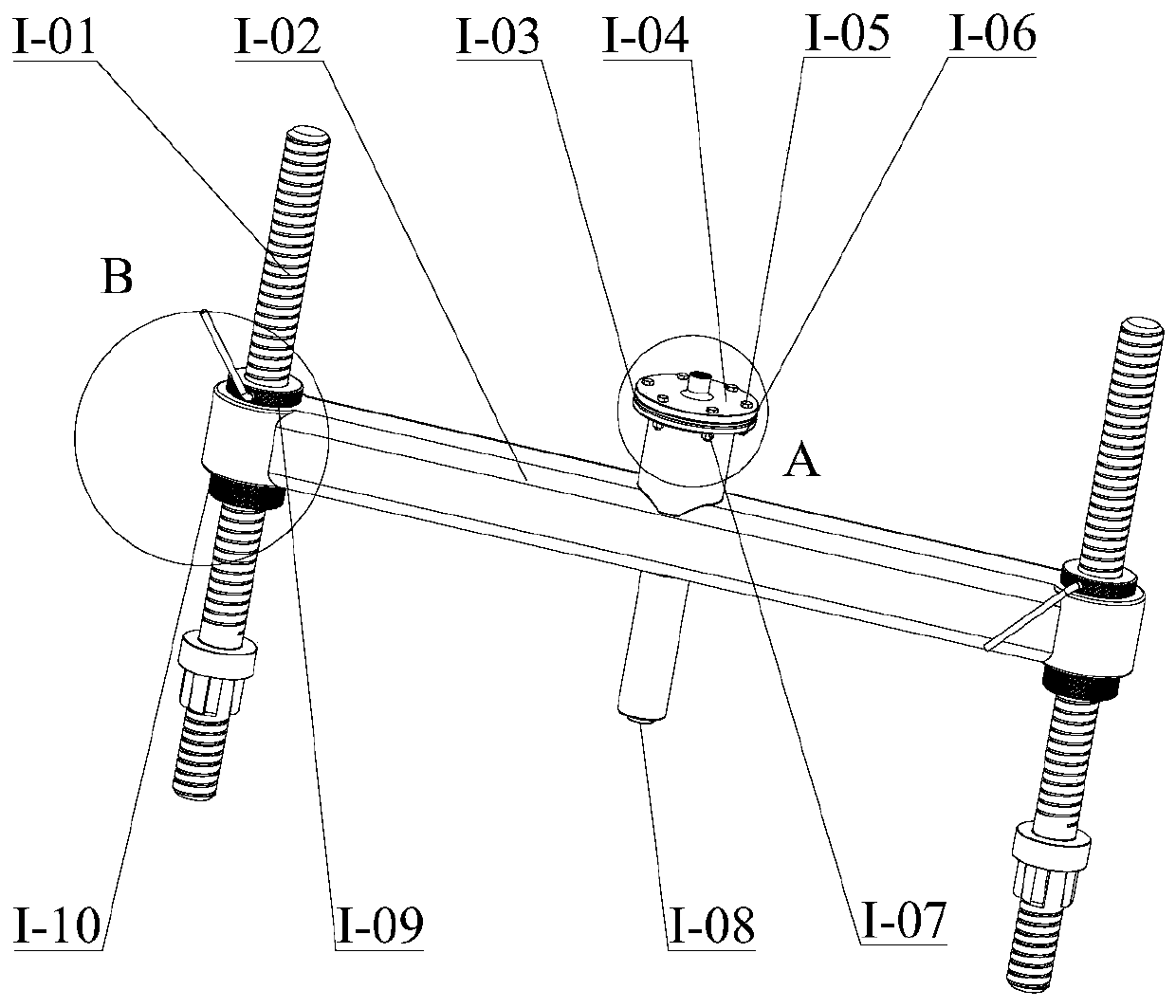

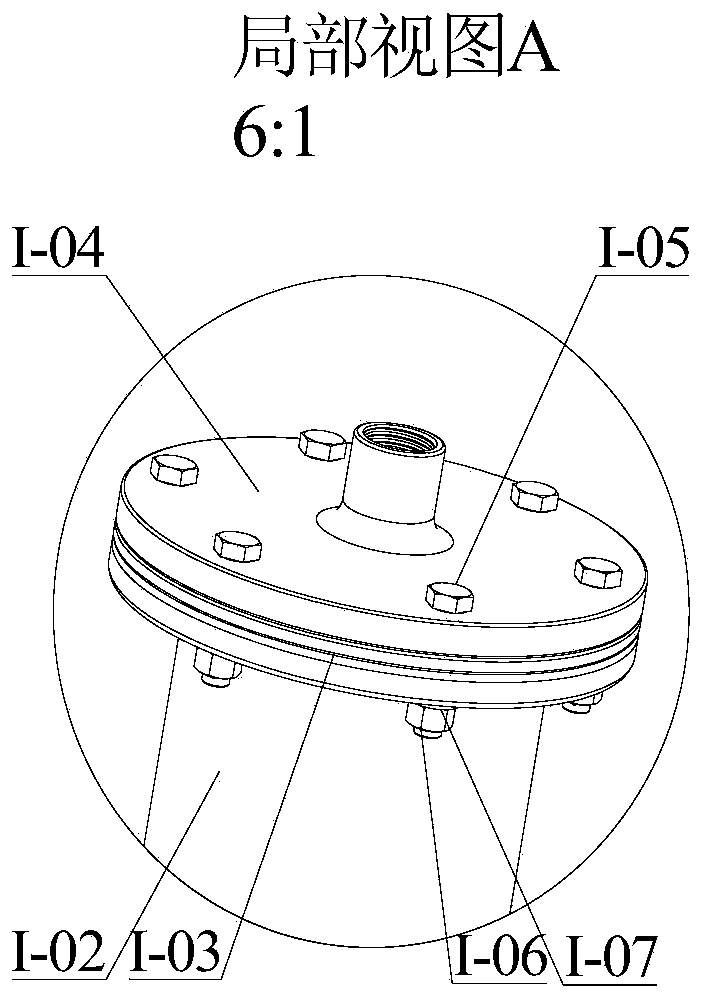

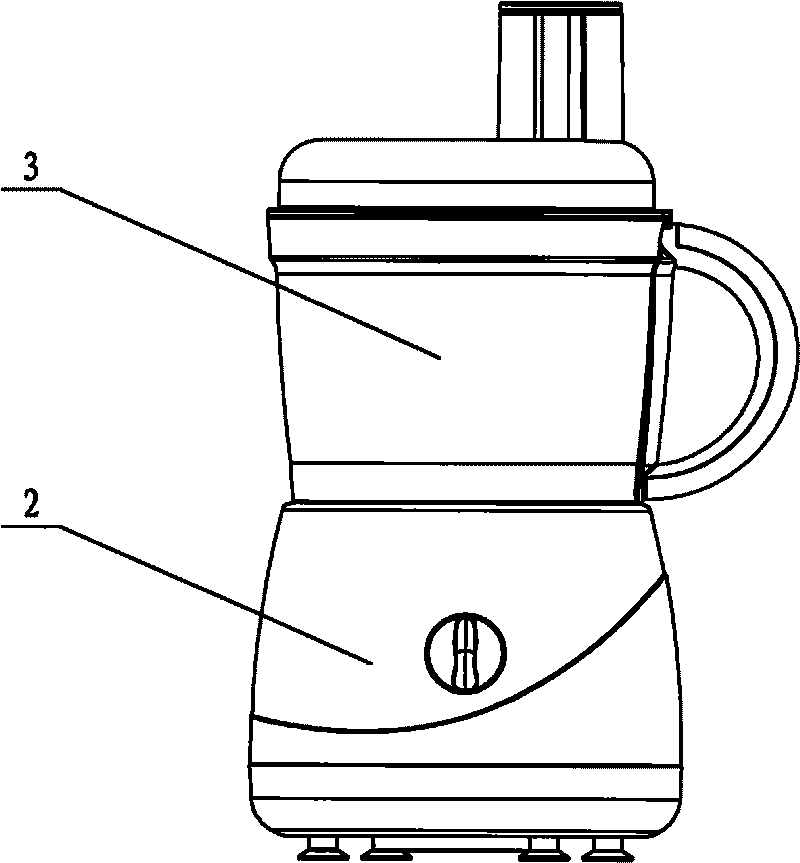

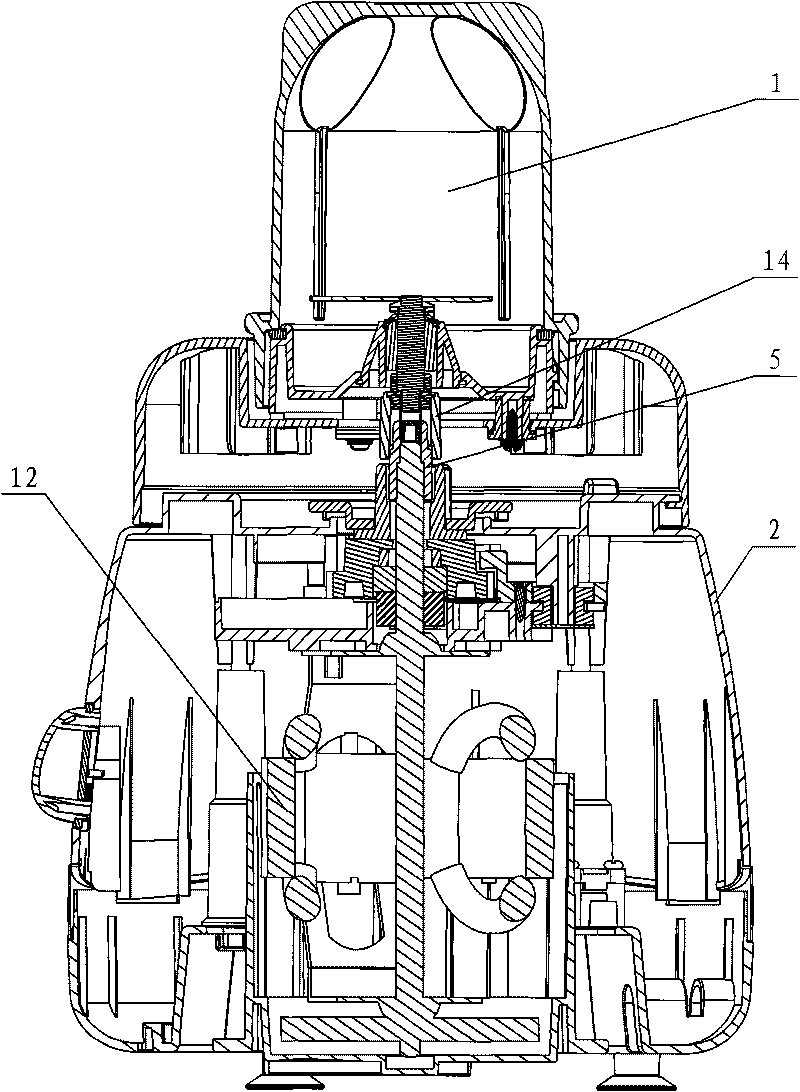

Coaxial two-speed food processor

The invention relates to a coaxial two-speed food processor, which comprises a host machine, and a bean grinding cup component, a fruit juice cup component or a processing cup component. The coaxial two-speed food processor is characterized in that: a gearbox component is arranged in the host machine, and the upper end of a motor shaft is provided with an inner connector and an outer connector respectively. The rotating speed of the inner connector is synchronous with that of a motor; because gear speed changes, the speed of the outer connector changes so that the outer connector is not synchronous with the motor; the motor shaft outputs different rotating speeds in the same direction to realize different functions. When the bean grinding cup component or the fruit juice cup component is used, a bean grinding cut connector of a bean grinding cup or a fruit juice cup can cooperate with a lower connecting head device; and when the processing cup component is used, a processing cup connector in the processing cup component can cooperate with the outer connector. The coaxial two-speed food processor has a simple and reasonable structure and a low manufacturing cost, the inner connector and the outer connecter rotate stably, the machine body has a light and handy volume, the appearance and the function are various, and the coaxial two-speed food processor is convenient to use.

Owner:GUANGDONG XINBAO ELECTRICAL APPLIANCES HLDG CO LTD

Environmentally-friendly soil remediation equipment with anti-precipitation function

InactiveCN111085534APrevent soil cakingPromote environmental protectionDispersed particle filtrationRotary stirring mixersChemical additionSoil remediation

The invention relates to environmentally-friendly soil remediation equipment with an anti-precipitation function. The environmentally-friendly soil remediation equipment comprises a main body, a control panel, two chemical addition mechanisms, an anti-precipitation mechanism and two purification mechanisms, wherein the anti-precipitation mechanism comprises a connecting plate, two stirring assemblies and two crushing assemblies; each stirring assembly comprises a rotating shaft, a gear, a rack, a limiting unit, two first bearings and a plurality of stirring blades; and each purification mechanism comprises a communicating pipe, a cover plate, a filter screen and two fixed assemblies. The environmentally-friendly soil remediation equipment with the anti-precipitation function has the following advantages: through the anti-precipitation mechanism, the function of stirring a remediation liquid in a chemical box is achieved, so the situation that the remediation liquid is precipitated andaffects the remediation effect is avoided; and through the purification mechanisms, the function of purifying waste gas is achieved, and the situation that the waste gas is directly exhausted out of the main body and affects the surrounding air environment is avoided, so the environmental protection property of the equipment is improved.

Owner:深圳市伊乐农产品有限公司

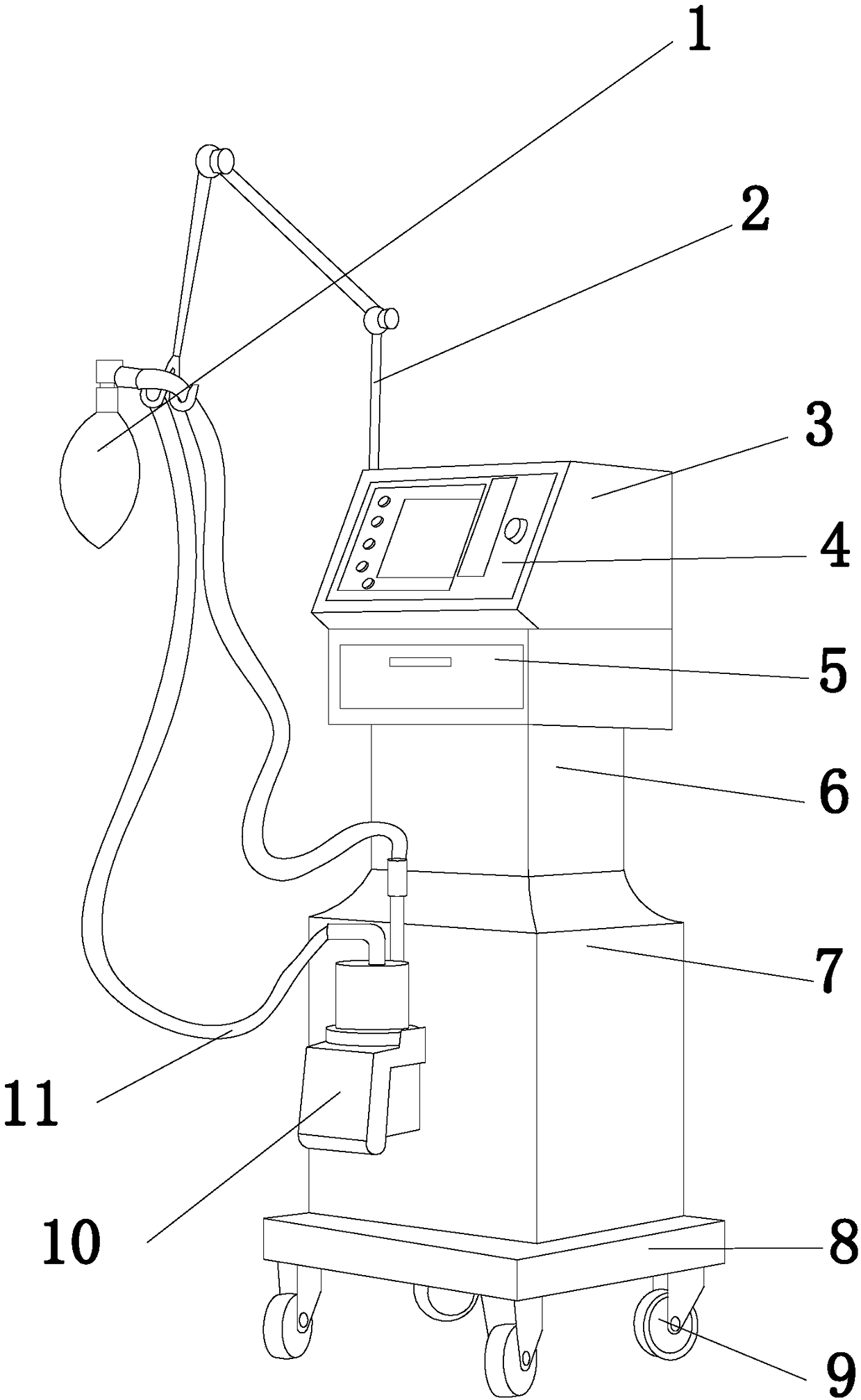

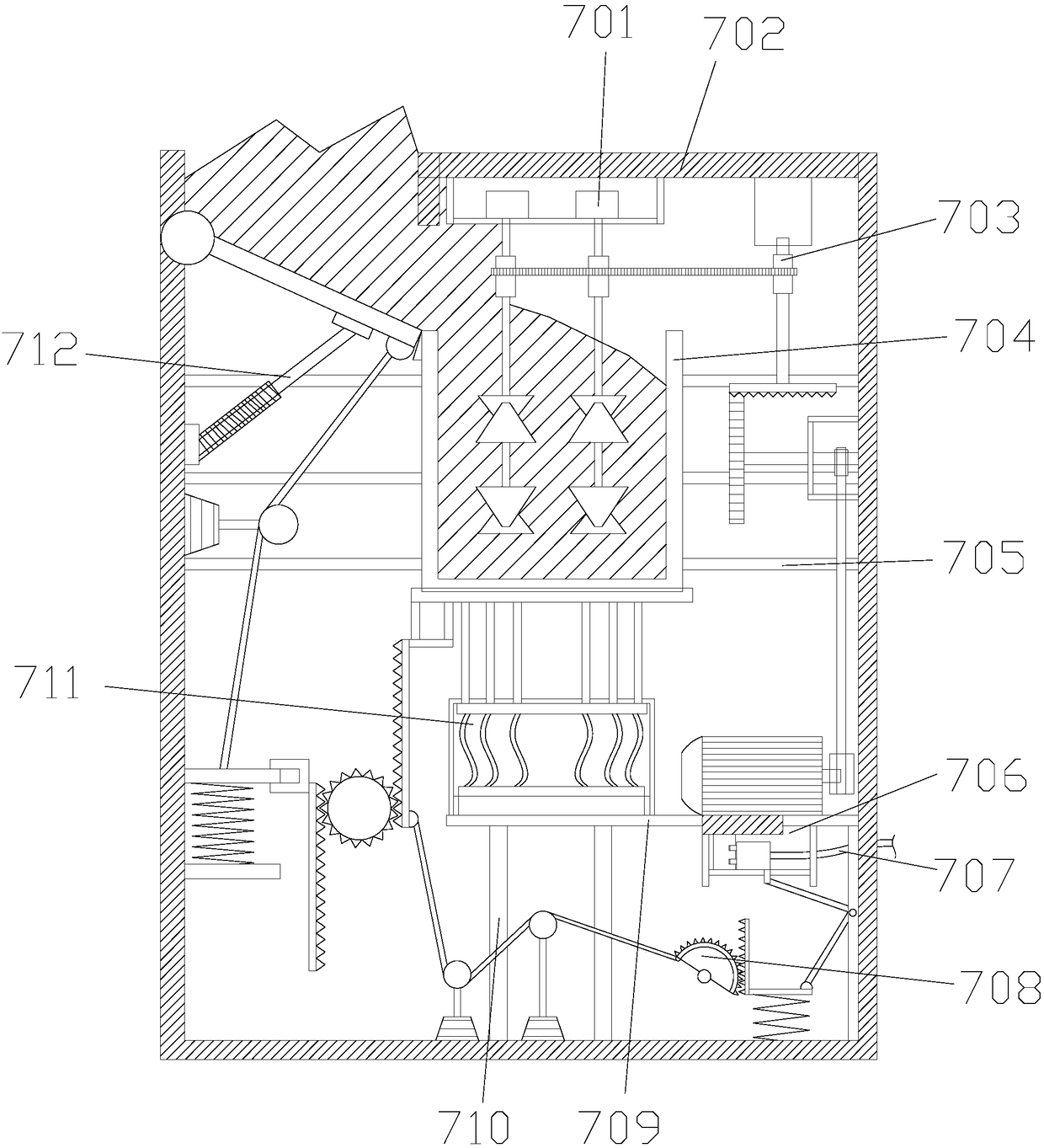

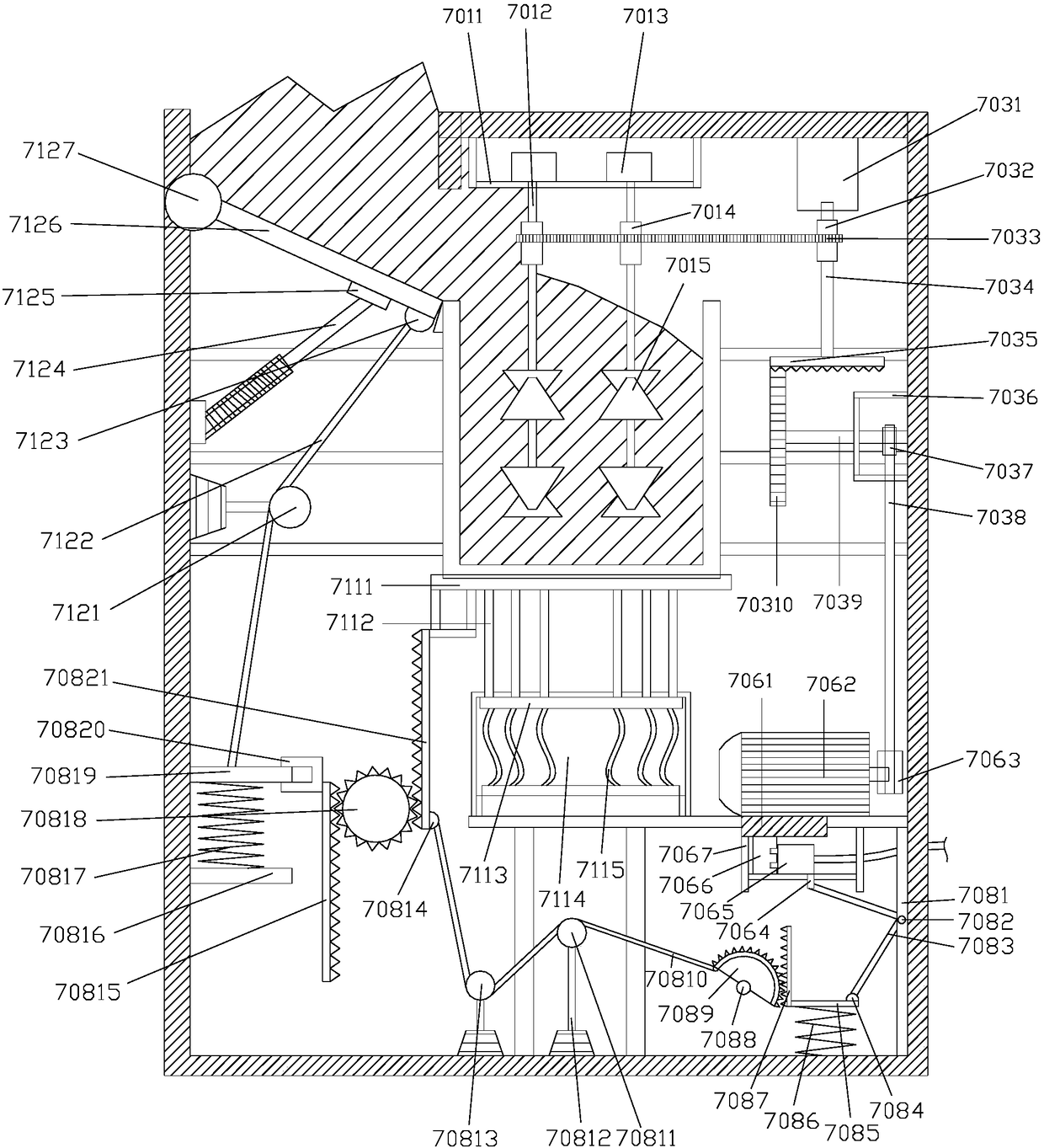

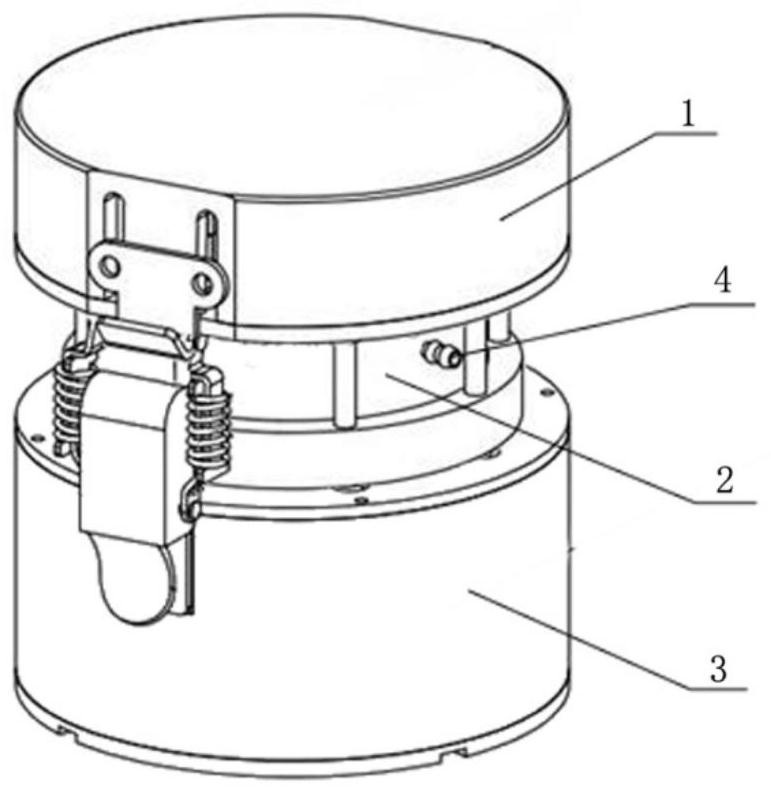

Medicament applicator special for respiratory medicine

InactiveCN108325055ARealize the heating functionRealize the stirring functionMedical devicesEngineeringOxygen mask

The invention discloses a medicament applicator special for respiratory medicine, structurally comprising an oxygen mask, a positioning support, a main unit, an operating panel, a storage drawer, a medicament box, an application box, a fixing base, four universal wheels, an atomizer, and a breather tube. The four universal wheels are mounted at the four bottom corners of the fixing base in fastened manner; the fixing base is of rectangular structure, and the upper end of the fixing base is connected with the bottom of the application box in fastened manner. The medicament applicator has the advantages that a baffle in the application box is controlled to open according to weight of medicament powder so that a second transmission rope is released and lowered, a second spring plate controlsa third gear to drive both the heating plate and a first transmission rope for control purpose, heating and stirring in a liquid medicament jar are achieved, the medicament applicator can provide heating and warmth retention during use, cold and temperature discomfort are avoided for a patient, influence on the condition of the patient is prevented, and the medicament applicator is further optimized.

Owner:吴凤炎

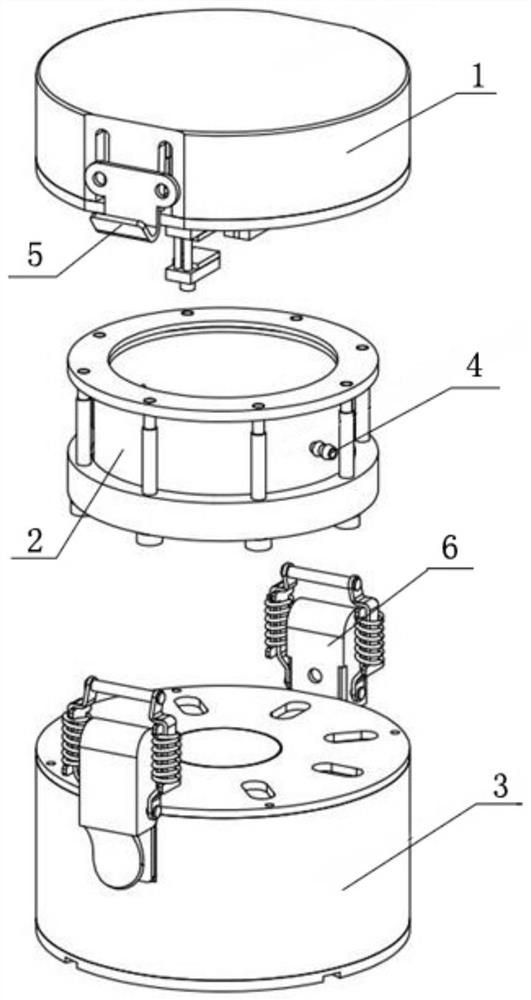

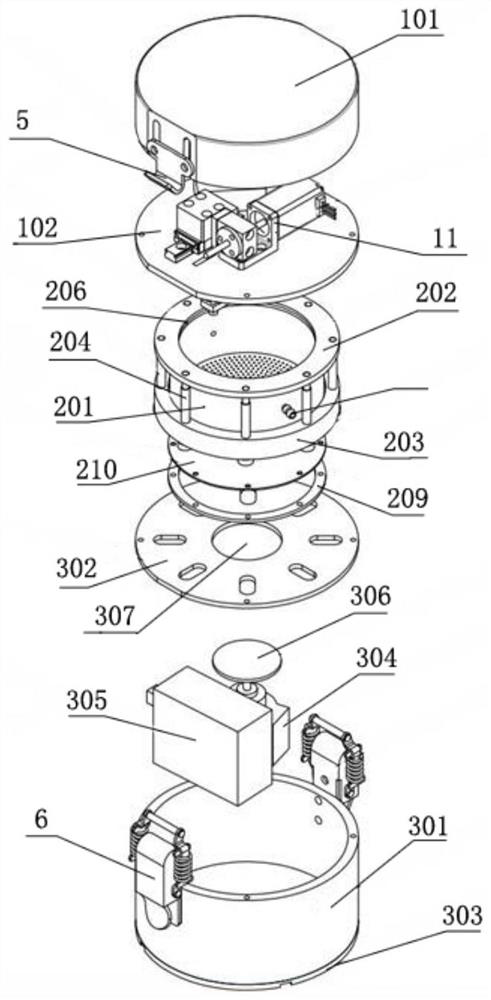

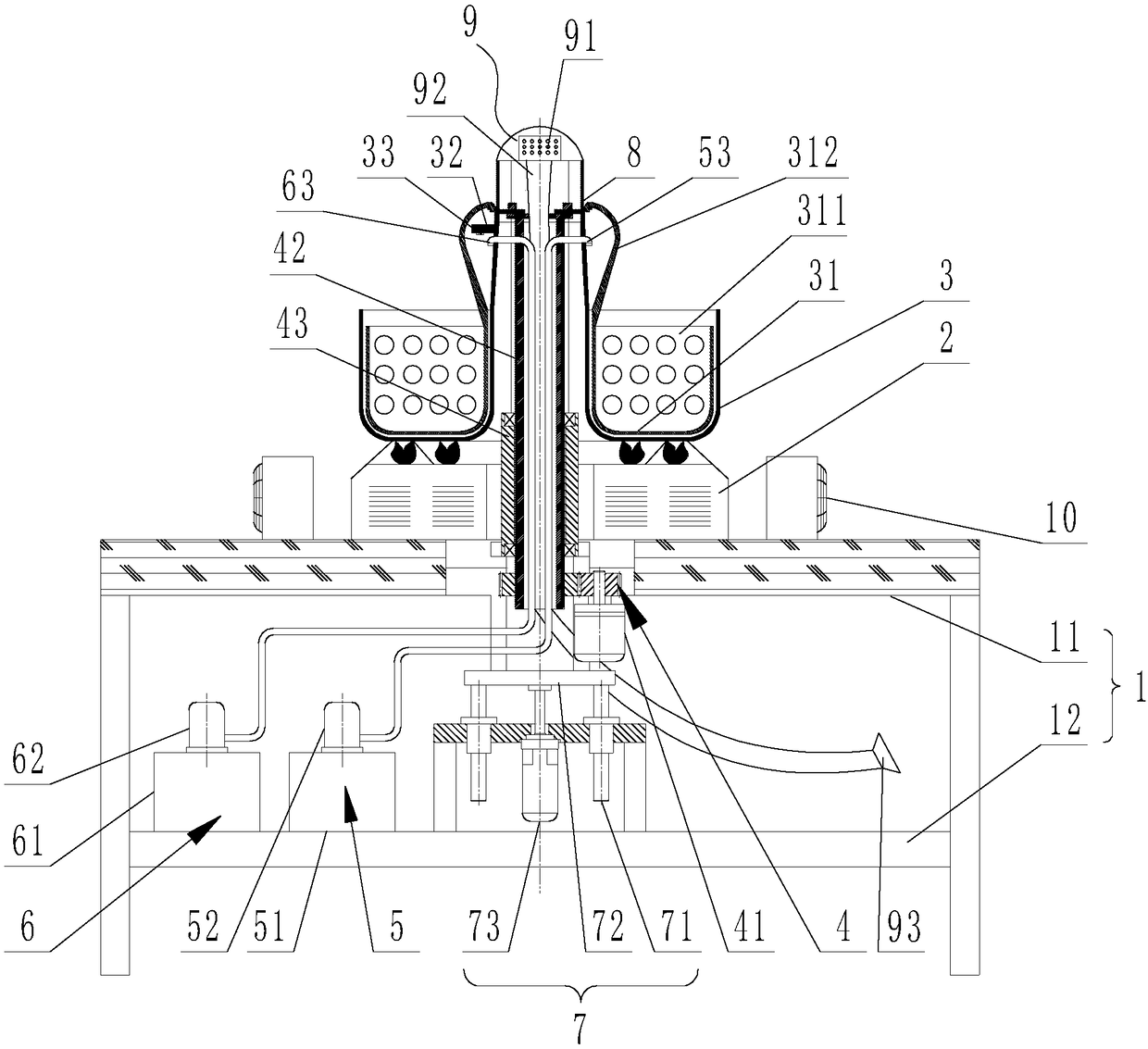

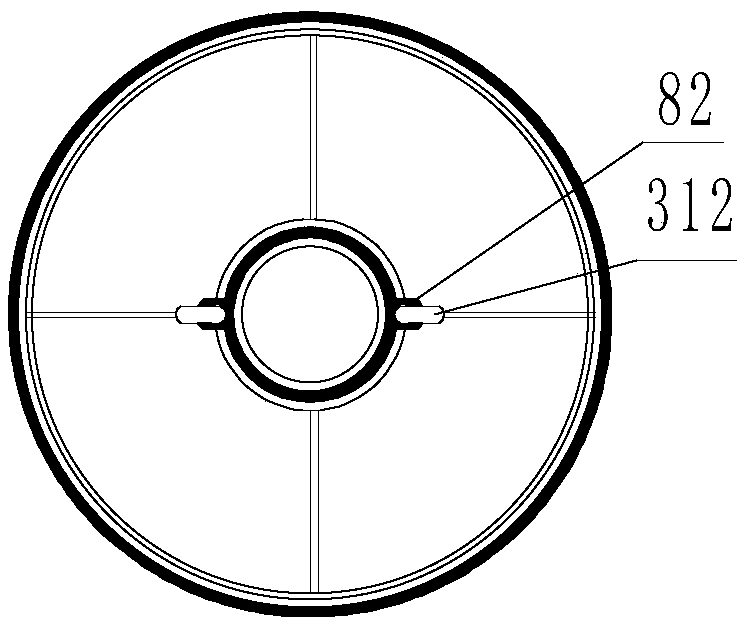

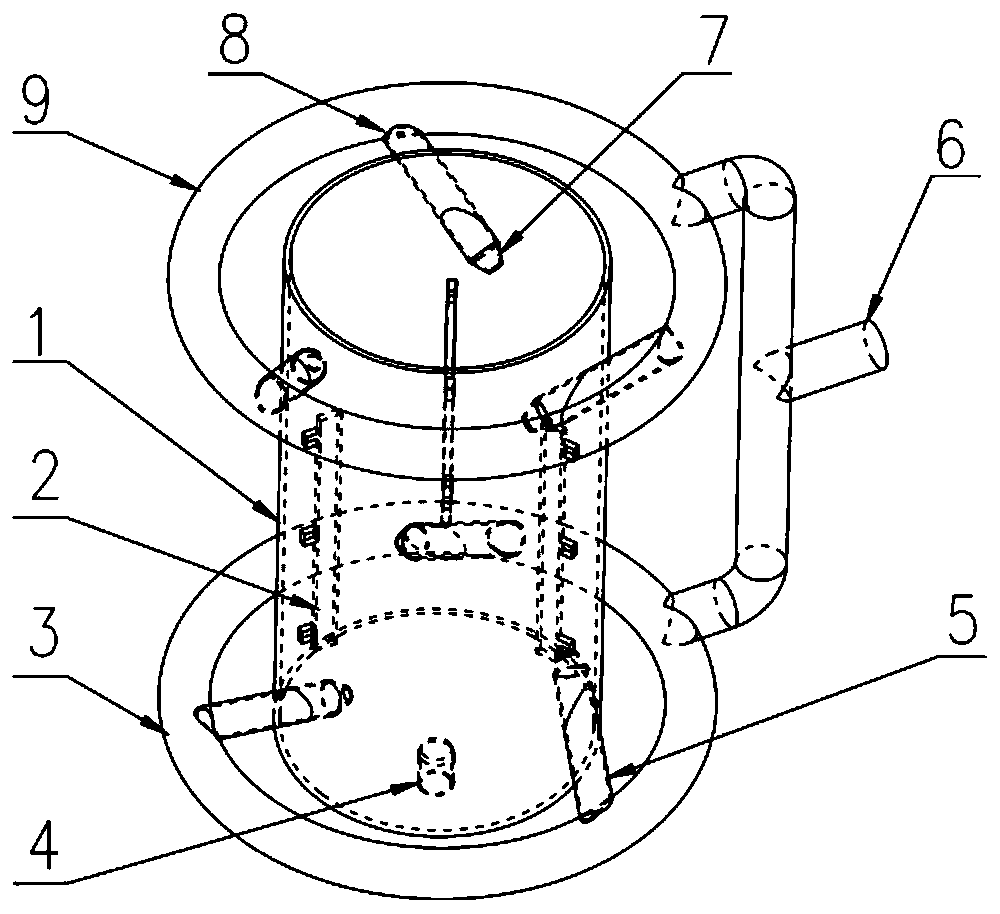

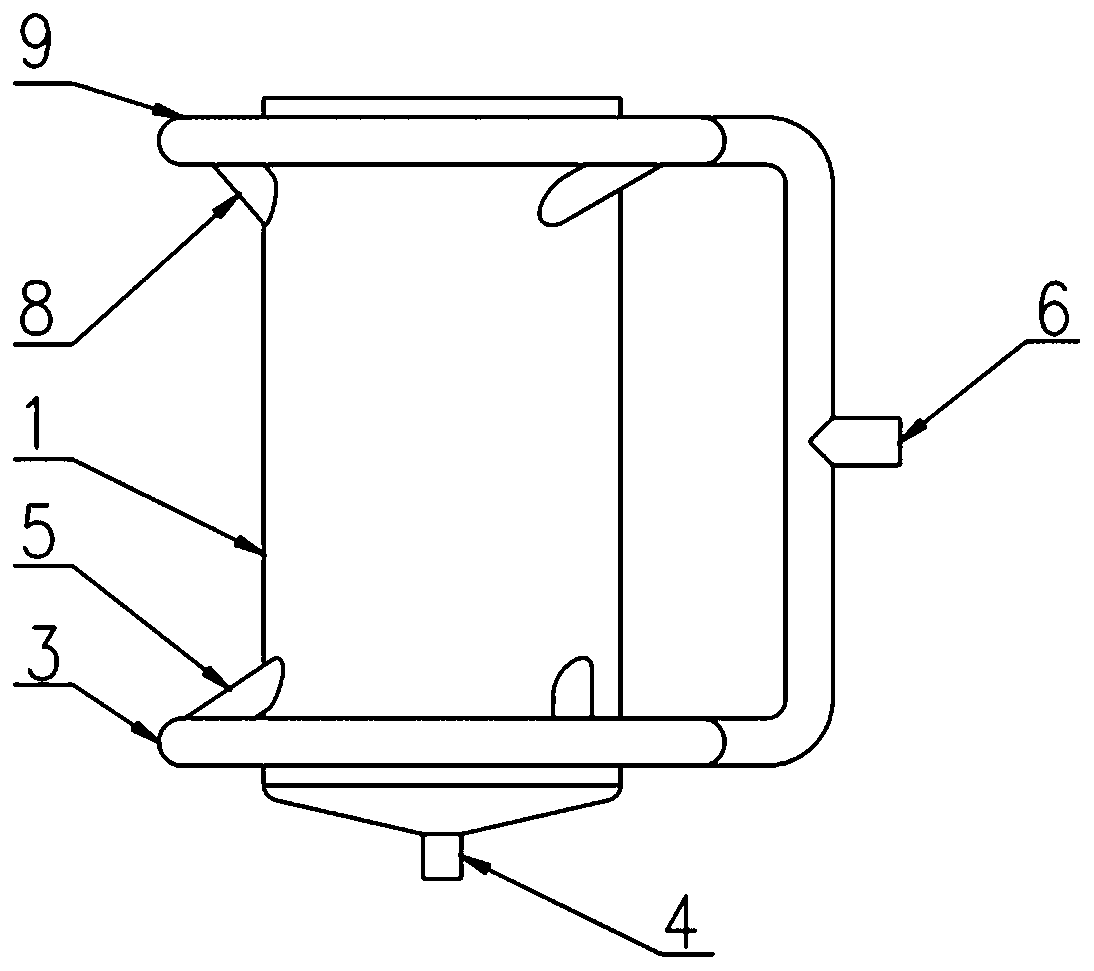

Bioreactor and bioreaction system with the bioreactor

PendingCN112625902AThe connection structure is ingeniousHighly integratedBioreactor/fermenter combinationsBiological substance pretreatmentsBiomechanicsCulture fluid

The invention provides a bioreactor. The bioreactor comprises a mechanics generation chamber, a circulating culture chamber and a pulsating flow generation chamber which are detachably connected in sequence from top to bottom, a pulsating flow generation device is arranged at the bottom of the circulating culture chamber and in the pulsating flow generation chamber, and a culture solution inlet and a culture solution outlet for a culture solution to enter and exit are formed in the side wall of the circulating culture chamber; and the mechanics generation chamber is provided with a mechanics module used for providing a biomechanics simulation environment for to-be-cultured tissues. The invention also provides a bioreaction system with the bioreactor. The invention is high in integration degree, capable of achieving functions of pulsating perfusion and mechanics stimulus at the same time, ingenious in connecting structures between the chambers and convenient to disassemble to take out culture.

Owner:MEDPRIN REGENERATIVE MEDICAL TECH

Barrier-free soup-adding hot pot

InactiveCN108903588AConvenient diningLarge dining areaCooking insertsCooking vessel constructionsFuel tankFood material

The invention provides a barrier-free soup-adding hot pot, and relates to an intelligent hot pot. The intelligent hot pot comprises a table body, a heating device, a pot body, a rotating mechanism, anautomatic oil tank system, an automatic soup system, a lifting mechanism, an upper cover body and the like, wherein the table body comprises a table panel and a bottom plate; the center of the tablepanel is hollowed-out; the heating device is mounted at the hollowed-out position; the pot body is placed on the heating device; the heating device and the pot body are annular; the automatic oil tanksystem and the automatic soup system are mounted on the bottom plate; and the output end of the automatic oil tank system successively penetrates through the hollowed-out position of the table panel,the central hole of the heating device and the pot wall of the inner side of the pot body and extends to the position above a cavity of the pot body. Soup and edible oil can be added automatically, the space of the table body does not need to be occupied, the hot pot does not hinders diners, splashing can further be prevented when soup and water are added, the barrier-free soup-adding hot pot hasthe characteristics of convenience in cleaning, simplicity and attractiveness, convenience in isolation of a seasoning from food materials, stirring and clamping are facilitated, food is convenient to find, lampblack is small, degree of automation is high, the hot pot is convenient to use, and the like, and the barrier-free soup-adding hot pot is easy to popularize and use.

Owner:LUSHAN COLLEGE OF GUANGXI UNIV OF SCI & TECH

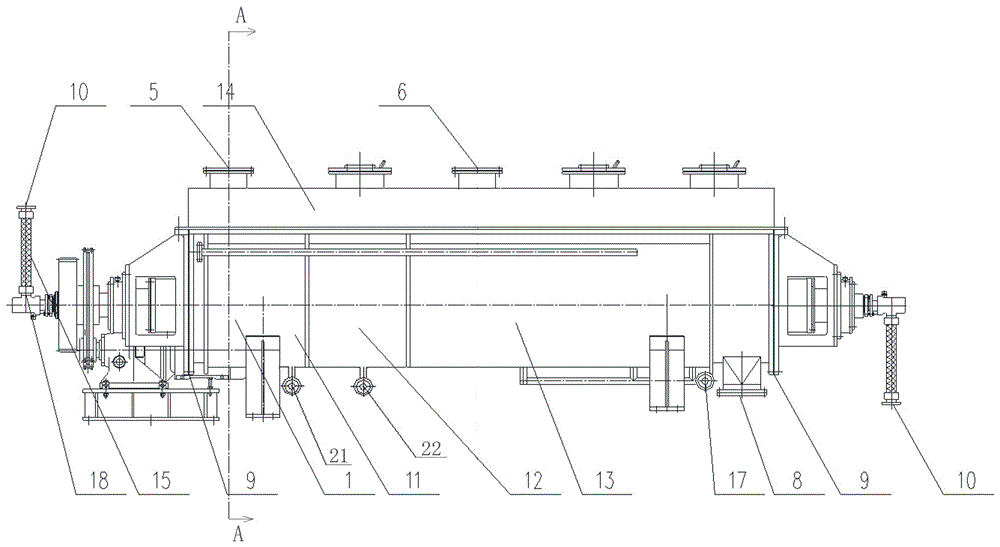

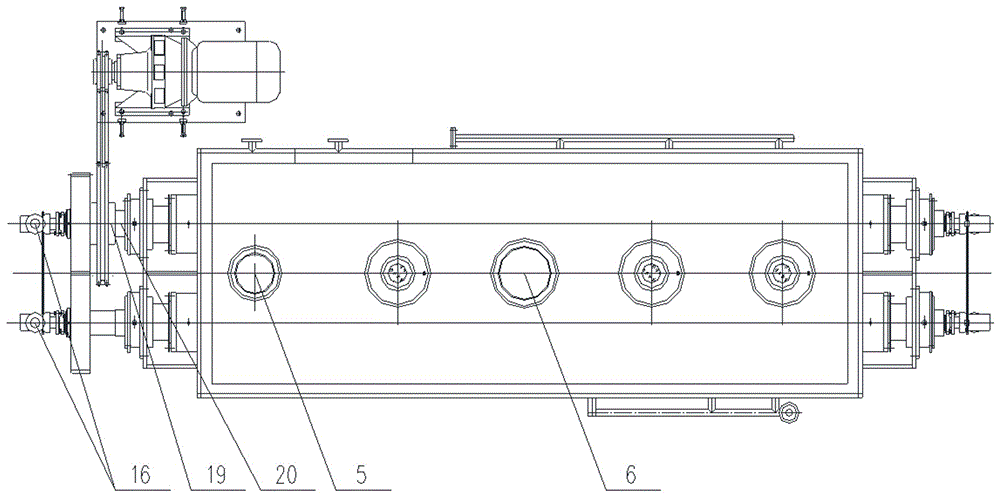

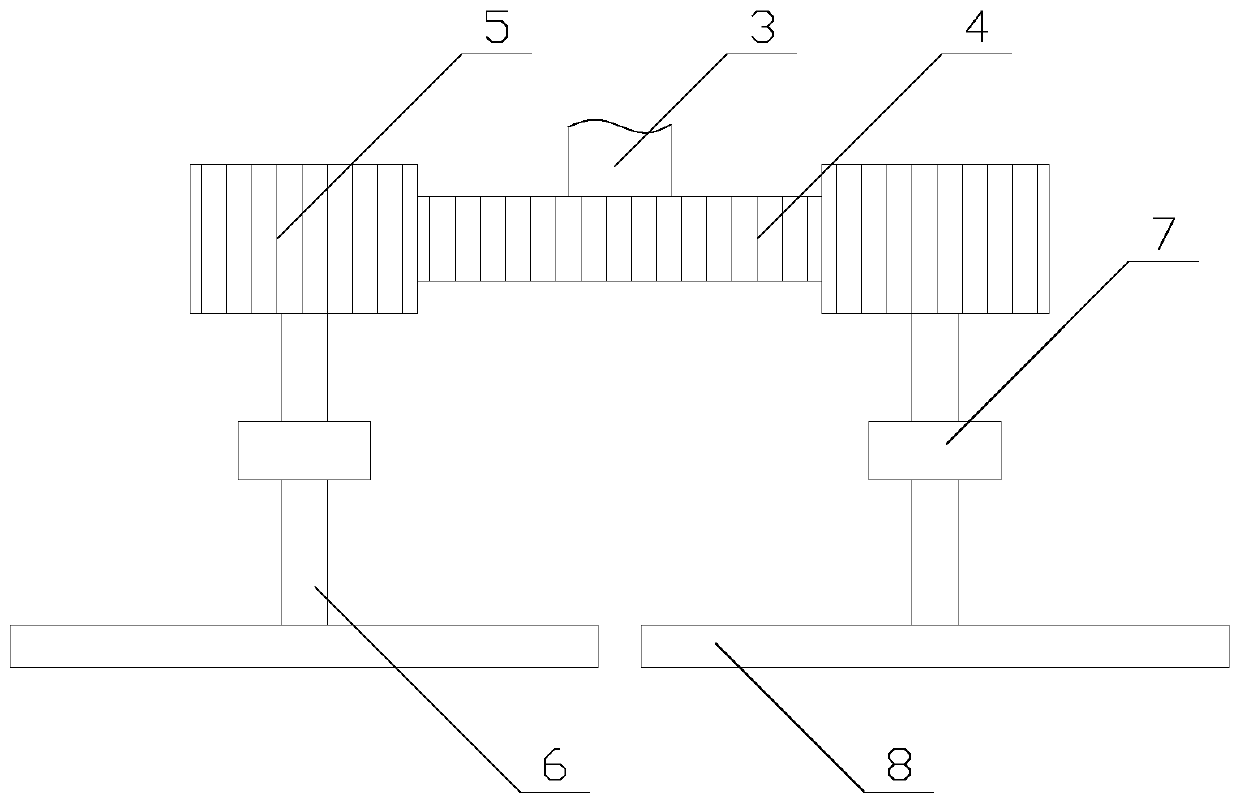

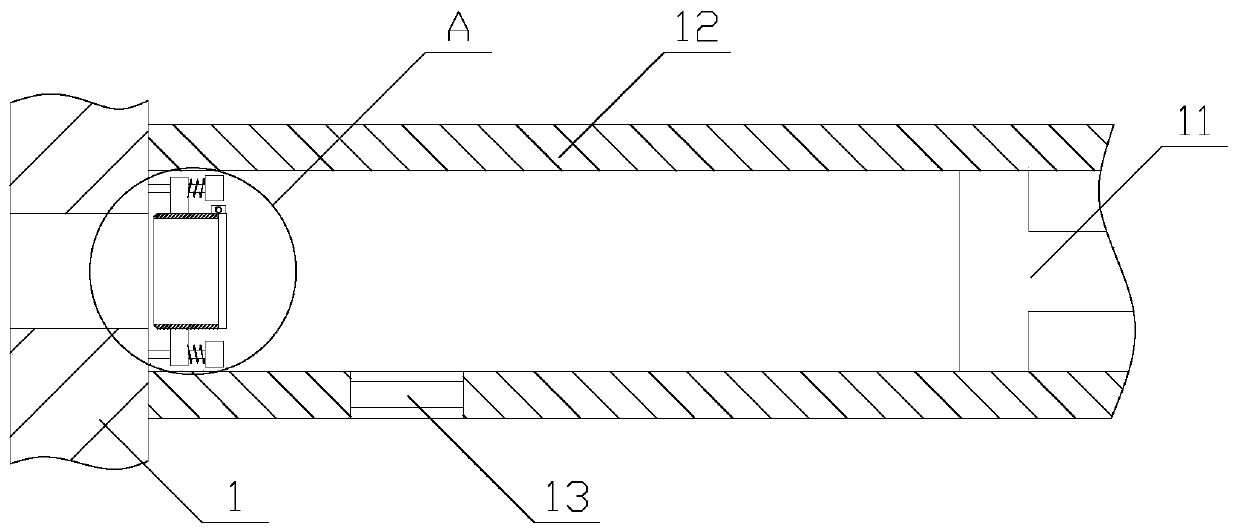

Horizontal type new material color master batch drying device

The invention provides a horizontal type new material color master batch drying device. The device comprises a drying machine body, a material feeding barrel, a rotary shaft, a baffle, hand wheels, a servo motor, a transmission shaft, stirring paddles, an electric cylinder, push rods and oblique material feeding plates. The material feeding barrel is fixed on the upper end face of the drying machine body, the rotary shaft is installed in the material feeding barrel, the baffle is assembled to the outer ends of the rotary shaft and arranged at the inner end of the material feeding barrel, the hand wheels are fixed to the outer ends of the rotary shaft respectively, and the flow control function is achieved due to the design; the servo motor is fixed to the right end face of the drying machine body, the transmission shaft is arranged on the left wall in the material feeding barrel, the stirring paddles are installed at the outer end of the transmission shaft, the electric cylinder is installed at the bottom in the drying machine body, the push rods are arranged at the inner end of the electric cylinder, the oblique material feeding plates are fixed to the inner ends of the push rods respectively, and the stirring function is achieved due to the design. By means of the horizontal type new material color master batch drying device, the flow control function and the stirring function are achieved; besides, the horizontal type new material color master batch drying device is high in practicality, convenient to use, good in stability and high in reliability.

Owner:曹学虎

Glass powder filling device for wafer manufacturing and using method thereof

InactiveCN112053979ARealize the stirring functionPrevent precipitationSemiconductor/solid-state device manufacturingWafer fabricationElectric machinery

The invention discloses a glass powder filling device for wafer manufacturing and a using method thereof. The glass powder filling device comprises a device body, a filling mechanism, an automatic feeding mechanism and an automatic discharging mechanism, the device body comprises supporting legs, a workbench, a rack, a first motor and a wafer placing table, and the workbench is connected to the upper portions of the supporting legs through bolts; the top of the workbench is connected with the rack through bolts, the filling mechanism is arranged on the inner side of the rack, the center of thebottom of the workbench is connected with the first motor through bolts, and the output end of the first motor penetrates through the workbench and is connected with the wafer placing table through akey. And a recovery mechanism is arranged on the outer side of the bottom of the wafer placing table. The operation of a scraping mechanism, a passive stirring mechanism and a lifting rod is driven by a filling cylinder, so that unnecessary driving equipment is reduced, the overall structure is more compact, and the size of the overall equipment is reduced.

Owner:王丽丽

Counter-rotating bladeless stirring device and method

ActiveCN110180424AIncreased turbulenceAchieving the purpose of stirring and mixingFlow mixersTransportation and packagingEngineeringSlurry

The invention relates to a counter-rotating bladeless stirring device and a method, which are suitable for use in the field of coal chemical industry. The counter-rotating bladeless stirring device includes a cylinder body of a columnar structure and a stirring and mixing device, wherein a discharge port of a funnel structure is arranged below the cylinder body, three vertical baffles are evenly distributed on the inner wall surface of the cylinder body, and the top of the cylinder body is provided with a feeding port and a dosing port; the mixing and stirring device includes a lower distribution ring and an upper distribution ring arranged outside the cylinder body in a surrounding mode, wherein the lower distribution ring and the upper distribution ring are connected through a tee jointwhere a feed port is provided, the feed port and the discharge port are connected to each other by a pipe, and the pipe is provided with a pump for pressurization; the discharge port is further provided with a taking port, a plurality of lower feed pipes are arranged between the lower distribution ring and the cylinder body, and a plurality of upper feed pipes are arranged between the upper distribution ring and the cylinder body. The counter-rotating bladeless stirring device has the advantages of simple structure, convenient use, convenient installation and maintenance, low cost and good stirring effect, and has no need of a stirring device, since stirring and mixing can be realized by just using pressurized slurry per self to agitate and disturb the flow field.

Owner:CHINA UNIV OF MINING & TECH

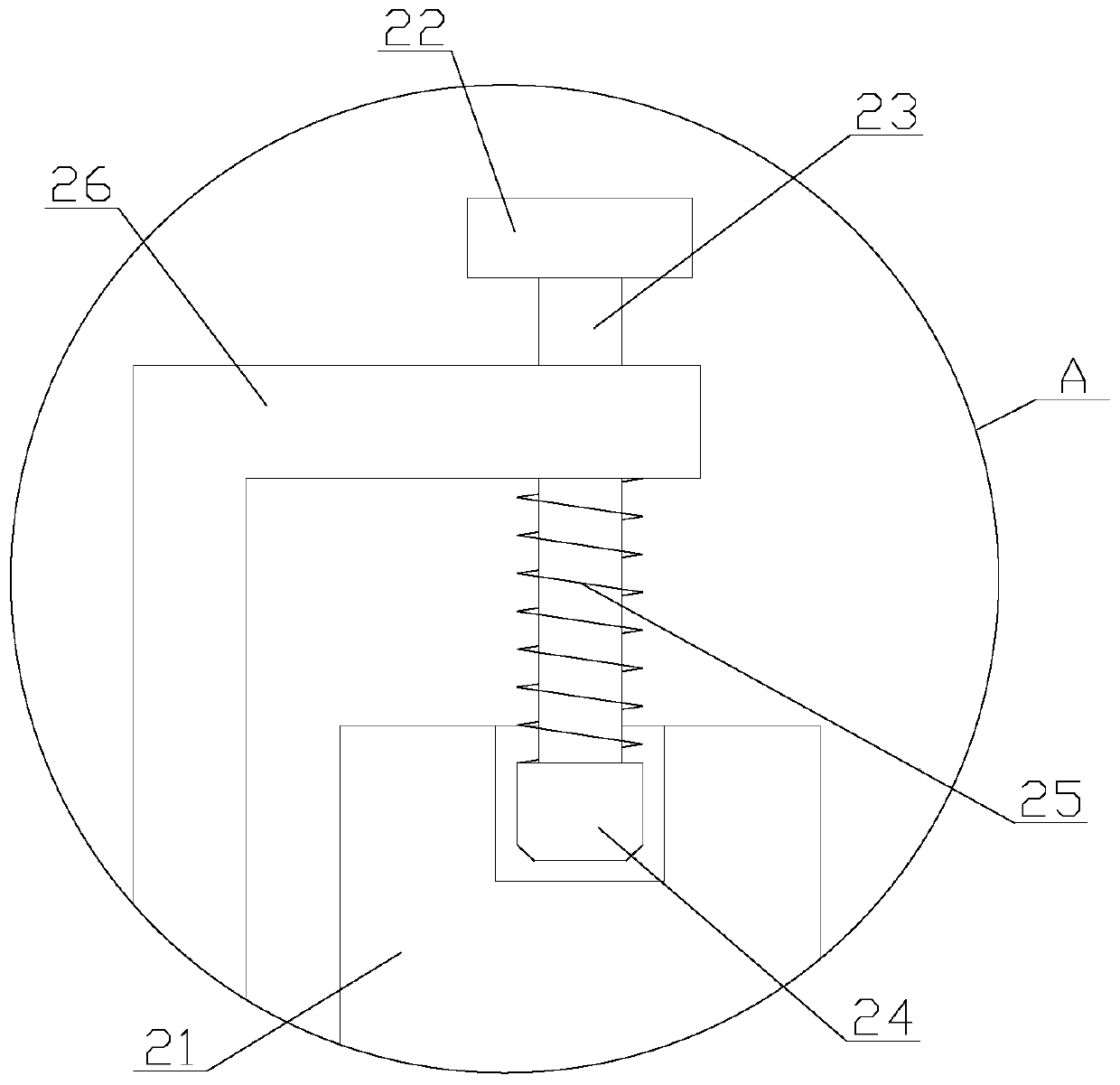

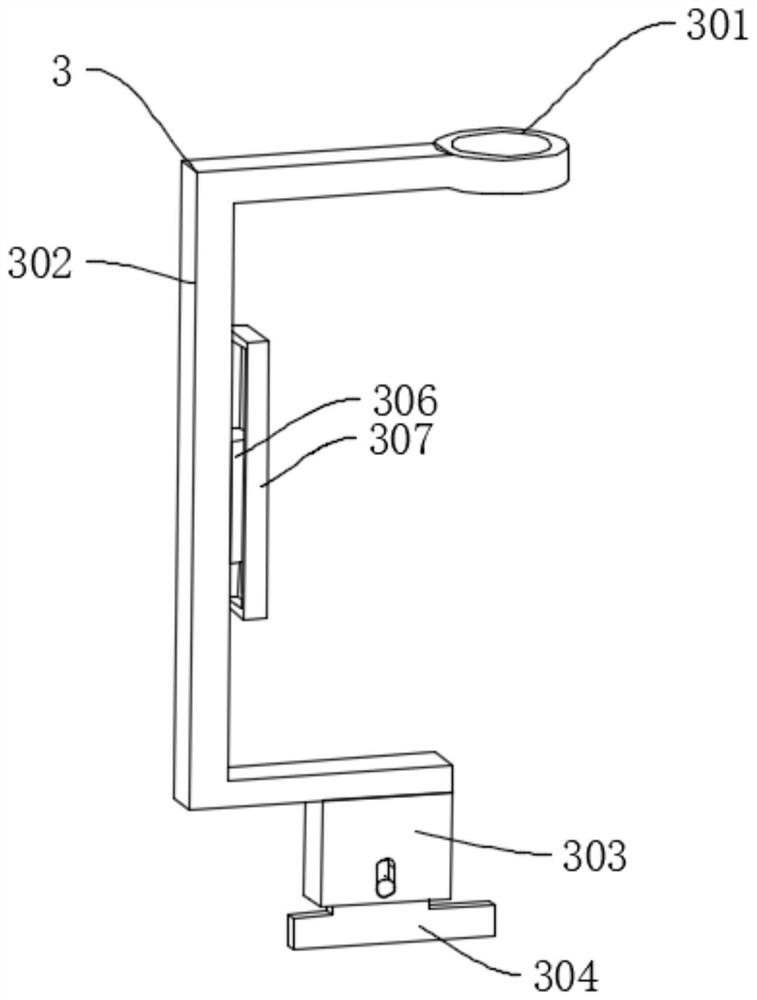

Ball stirring equipment for probability teaching

InactiveCN107993529ARealize the stirring functionRealize the function of indirect ballEducational modelsEngineeringCam

The invention relates to stirring equipment, in particular to ball stirring equipment for probability teaching and provides the ball stirring equipment which is used for probability teaching and is convenient to use and simple to operate. The ball stirring equipment for probability teaching comprises a base, a motor, a first support, a second support, a first bearing, a first rotating shaft, a cam, a first bevel gear, a first guide rod, a first baffle and the like, wherein the motor is fixedly connected with the upper right side of the base, the first support is fixedly connected with the upper right side of the base and located on the left side of the motor, and the second support is fixedly connected with the upper right side of the first support. The ball stirring equipment realizes thefunction of stirring balls for probability teaching, quickly stirring the balls and indirectly discharging the balls and has the characteristics of being convenient and safe to use, simple to operate, low in production cost and the like.

Owner:赣州市亿研机械设计研究院有限公司

Filtration mechanism

InactiveCN105233549ASmall filter resistanceQuality improvementStationary filtering element filtersBiochemical engineeringFiltration mechanism

The present invention provides a filtration mechanism, and belongs to the technical field of coating material processing. The filtration mechanism comprises a bracket, wherein the bracket is provided with a material collection container, a stirrer bracket is arranged above the material collection container, the stirrer bracket is provided with a motor, the output terminal of the motor is connected to a stirrer, a filtration device is arranged inside the material collection container and comprises a filtration bracket, the filtration bracket is detachably fixed inside the material collection container, the lower surface of the filtration bracket is provided with a first filtration barrel, a second filtration barrel and a third filtration barrel, the second filtration barrel is positioned inside the third filtration barrel, the first filtration barrel is positioned inside the second filtration barrel, the stirrer extends into the first filtration barrel, the filtration hole of the first filtration barrel is larger than the filtration hole of the second filtration barrel, and the filtration hole of the second filtration barrel is larger than the filtration hole of the third filtration barrel. According to the present invention, the filtration mechanism has characteristics of simple structure, convenient operation, reasonable structure design, high automation degree, stirring and filtration function achieving, convenient disassembly during maintenance and cleaning, high filtration efficiency, and good quality of the filtered coating material.

Owner:天津市欣跃涂料有限公司

Fertilizer mixer

InactiveCN106334484AUniform dischargeRealize the stirring functionRotary stirring mixersMixer accessoriesAgricultural engineeringCounter rotation

The invention discloses a fertilizer mixer. The fertilizer mixer comprises a funnel stirring chamber, a discharging drum, a connection crossbeam and a stirring shaft, wherein the discharging drum is connected with the lower end of the funnel stirring chamber, the upper end of the stirring shaft is rotatably connected with the connection crossbeam, the stirring shaft is provided with a spiral stirring blade, the lower end of the spiral stirring blade is arranged in the discharging drum, and the diameter of the spiral stirring blade is equal to the internal diameter of the discharging drum. The fertilizer mixer has the advantages that since the fertilizer mixer is provided with the spiral stirring blade, the fertilizer mixer can continuously turn fertilizer located at the bottom of the funnel stirring chamber over to the top to realizing a stirring function during co-rotation; and the fertilizer mixer can discharge fertilizer at a uniform speed during counter-rotation, so the fertilizer mixer is convenient to use.

Owner:季德贵

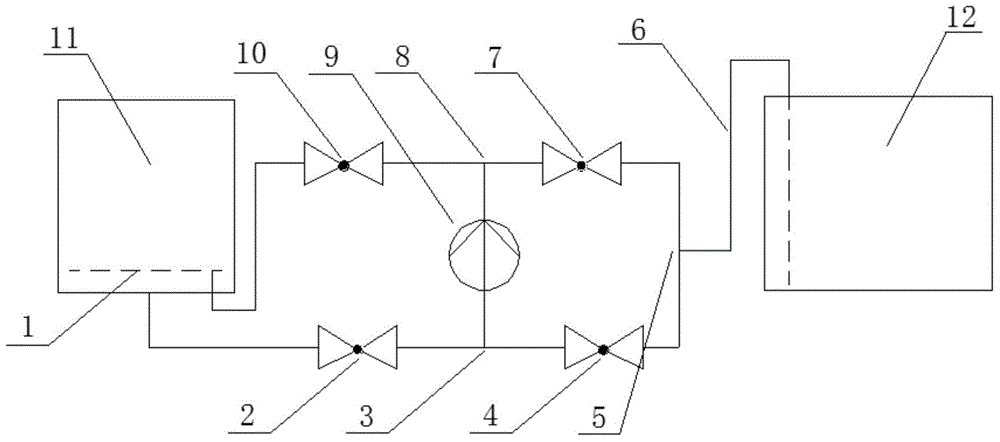

Drainage stirring device and polishing equipment

ActiveCN105862118AReduce equipment costsReduce equipment footprintElectrolysis componentsLiquid storage tankEngineering

The present invention discloses a drainage stirring device and polishing equipment. The drainage stirring device includes a process tank, a liquid storage tank, a stirring tube and a transport pump. The stirring tube is located in the process tank and the stirring tube is provided with injection holes. An inlet of the transport pump and the process tank are connected in a way of controllable on-off; an outlet of the transport pump and the stirring tube are connected in a way of controllable on-off; and the inlet and / or outlet of the transport pump tank and the liquid storage tank are connected in a way of controllable on-off. According to the drainage stirring device, proper control of the continuity between transport pump and stirring tube, process tank and the liquid storage tank not only can achieve stirring function, but also can achieve one of the drainage function and liquid function; compared with the three pumps for realizing the agitation, draining and liquid inlet functions in the prior art, the invention eliminates one or two pumps in the three pumps, thereby saving equipment costs, and reducing equipment land occupation.

Owner:XCMG CONSTR MACHINERY

Electromotor combined with pressure vessel

InactiveCN104300731AEasy to useImprove heat resistanceMechanical energy handlingSupports/enclosures/casingsEngineeringHigh pressure

The invention relates to an electromotor combined with a pressure vessel. The electromotor comprises an electromotor shell, a rotating shaft, a stator, a rotor, a shaft extension end cover, a non-shaft extension end cover, a terminal box, a terminal box cover, a terminal board and electric connection components, wherein the terminal board and the electric connection components are arranged in the terminal box, and connection components are arranged at the two ends of the electromotor shell. The electromotor is characterized in that a bearing hole in the non-extension shaft end cover does not penetrate through the outer end face, a shaft sleeve is fixed to the outer end face of the shaft extension end cover in a sealed mode, a flange is fixed to the other end of the shaft sleeve in a sealed mode, the shaft extension end of the rotating shaft penetrates through the shaft extension end cover and the shaft sleeve and extends out of the flange, sealing elements are arranged between the connection components of the shaft extension end cover, the non-shaft extension end cover and the electromotor shell, and a sealing element is arranged between the terminal board and the terminal box. The rotating shaft of the electromotor is used as the rotating shaft of a stirrer of the pressure vessel, the pressure in the pressure vessel shifts into the electromotor through the shaft sleeve, and the problem that the pressure vessel is difficult to seal is well solved through the good sealing performance of the electromotor shell and all the components. The electromotor is suitable for high-pressure operation environments.

Owner:荣成市先锋电机厂

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com