Glass powder filling device for wafer manufacturing and using method thereof

A filling device and glass frit technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of poor painting stability, high production cost, and low painting speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

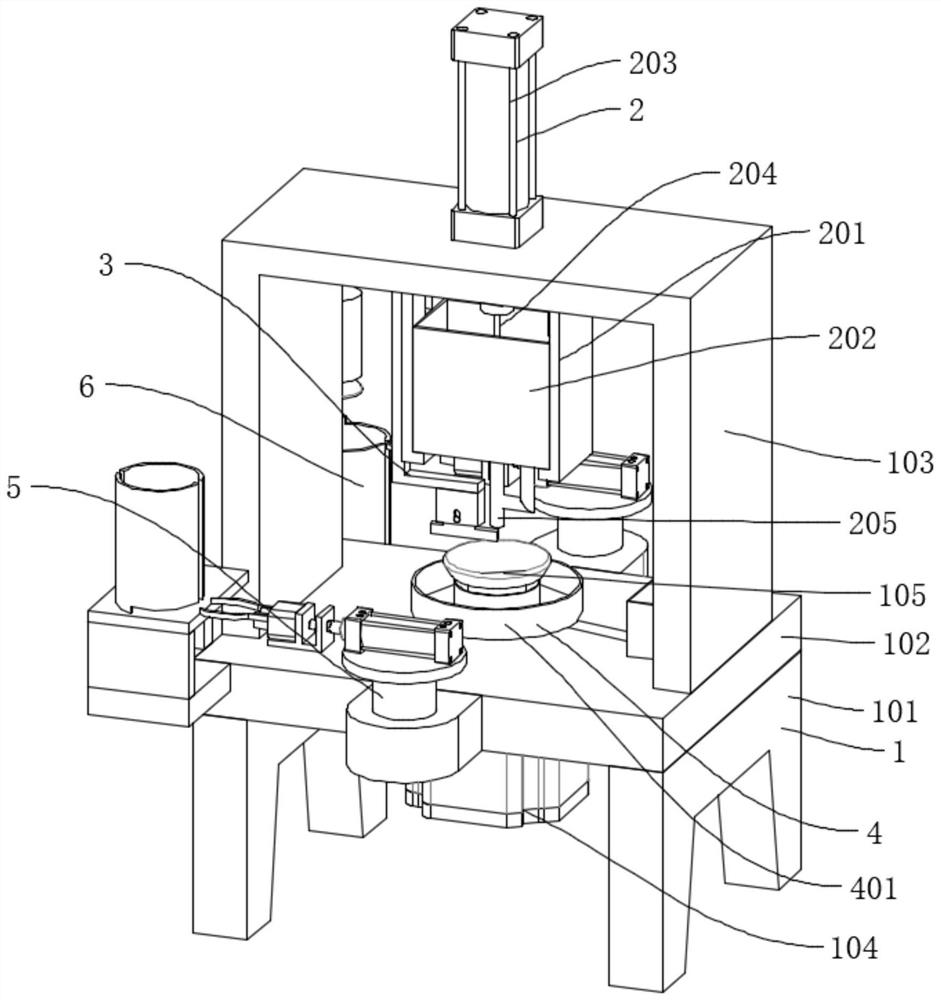

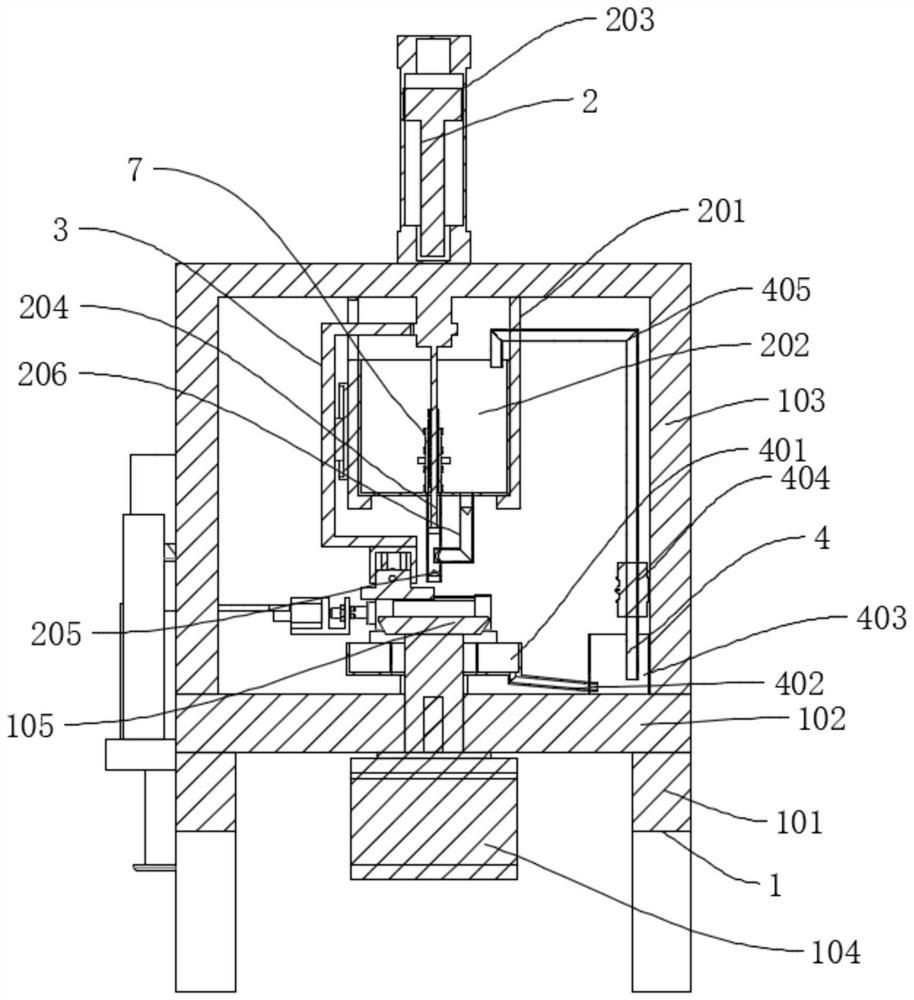

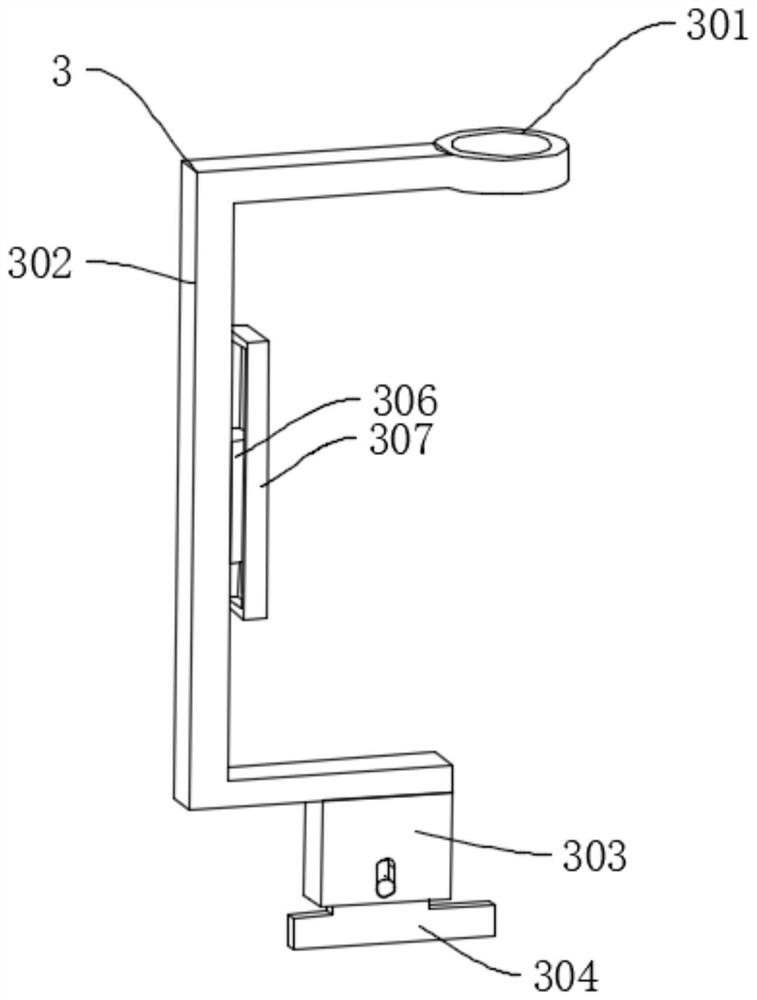

[0042] like Figure 1-7As shown, a glass powder filling device for wafer manufacturing includes a device body 1, a filling mechanism 2, an automatic feeding mechanism 5, and an automatic unloading mechanism 6. The device body 1 includes a support leg 101, a worktable 102, a machine A frame 103, a first motor 104, a wafer placement table 105, a worktable 102 is connected to the top of the support leg 101 by bolts, a frame 103 is connected to the top of the worktable 102 by bolts, a filling mechanism 2 is arranged inside the frame 103, and the worktable The center of the bottom of 102 is connected with a first motor 104 by bolts, the output end of the first motor 104 passes through the worktable 102, and is connected with a wafer placement table 105 by keys, and a recovery mechanism 4 is provided on the outer side of the bottom of the wafer placement table 105, so that The first motor 104 can drive the wafer placement stage 105 to rotate, and the wafer placement stage 105 drives...

Embodiment 2

[0050] like Figure 8-9 As shown, Embodiment 2 differs from Embodiment 1 in that: the blanking storage bucket 608 is connected above the blanking support plate 607 by bolts, and a drying assembly 609 is provided inside the blanking storage bucket 608, so that the drying assembly 609 The wafer is taken out from the inside of the blanking storage bucket 608. The drying assembly 609 includes a top plate 6091 and an ejector rod 6092. The upper end of the ejector rod 6092 passes through the blanking support plate 607 and is connected to the blanking support plate 607, and is welded with the top plate 6091 and the top plate. 6091 is located inside the unloading storage bucket 608. In this way, the ejector pin 6092 can be pushed, and the ejector pin 6092 drives the top plate 6091 to rise, and the top plate 6091 pushes the wafer, so that the wafer rises, so that the wafer is lifted from the inside of the unloading storage bucket 608. out.

[0051] A method for using a glass frit fill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com