Patents

Literature

541results about How to "Small filter resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

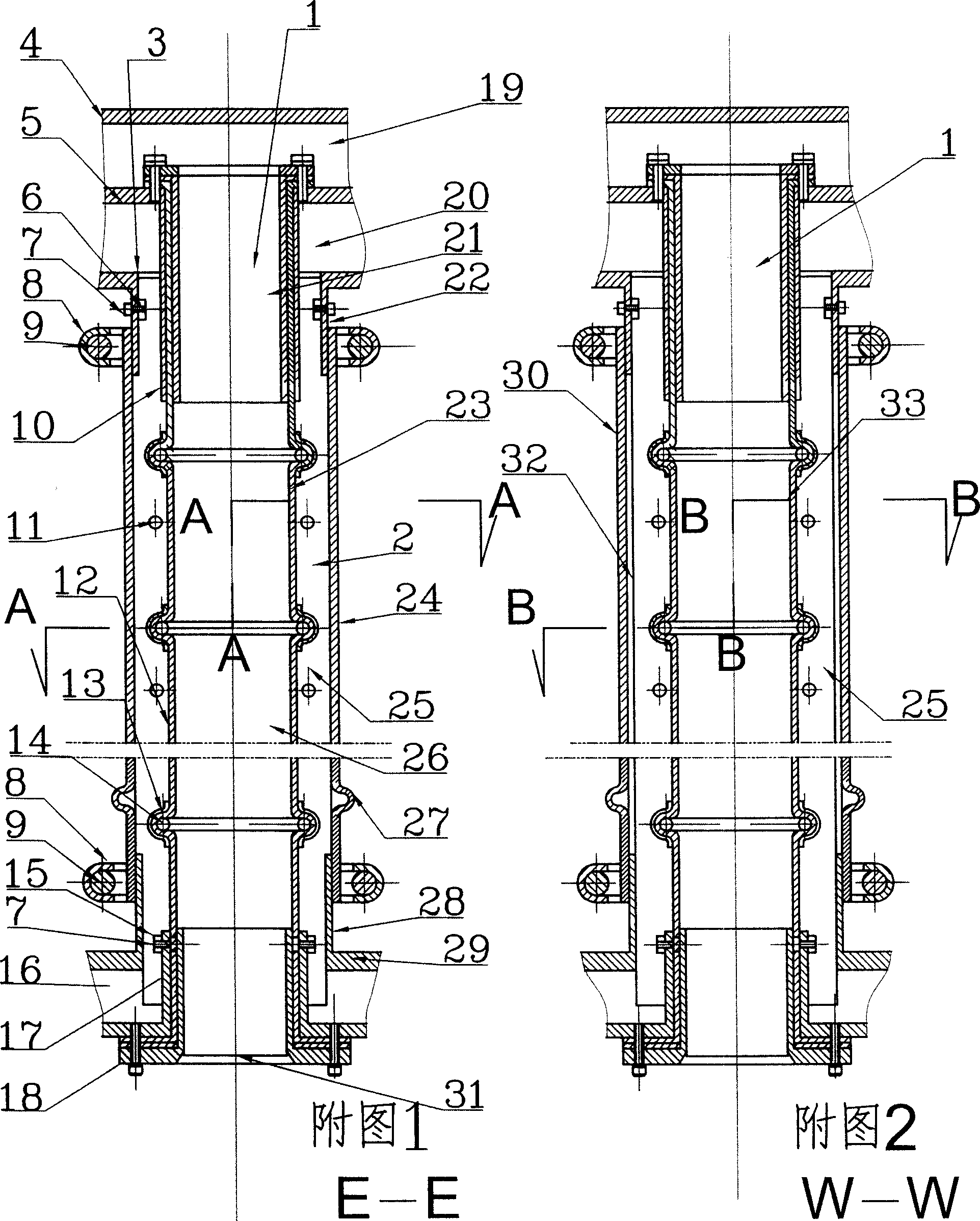

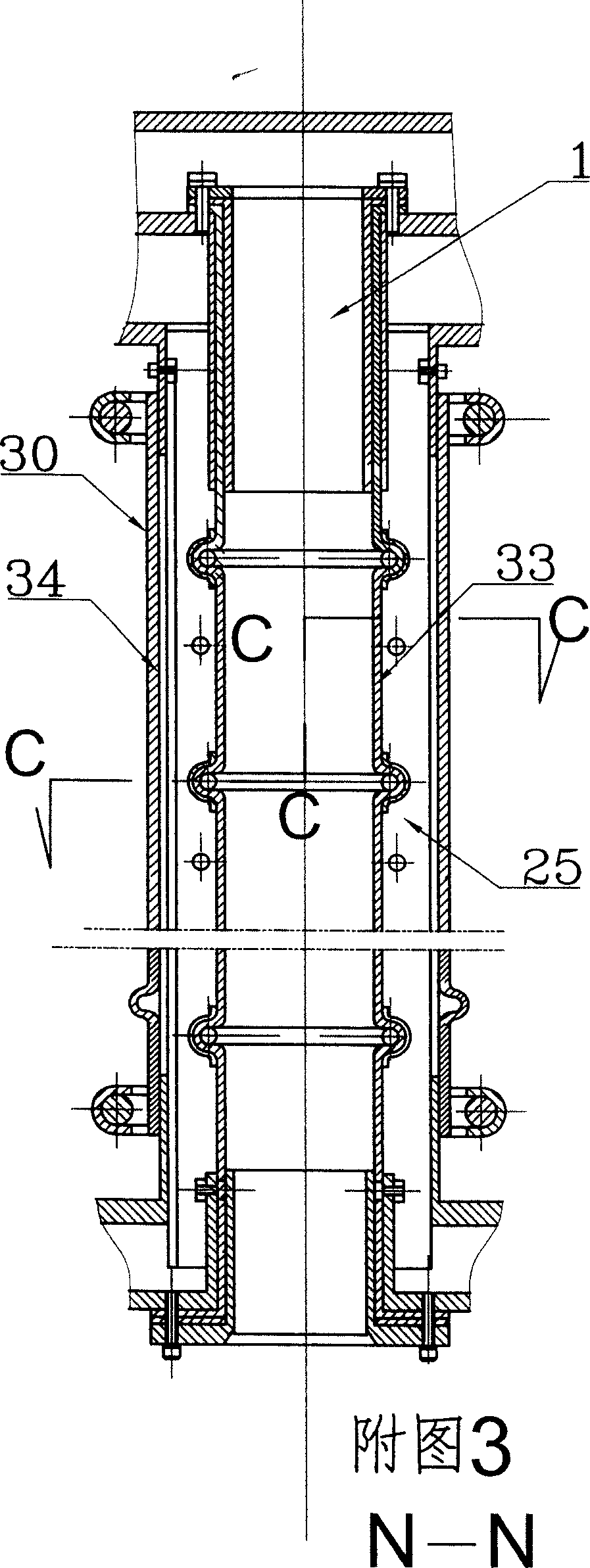

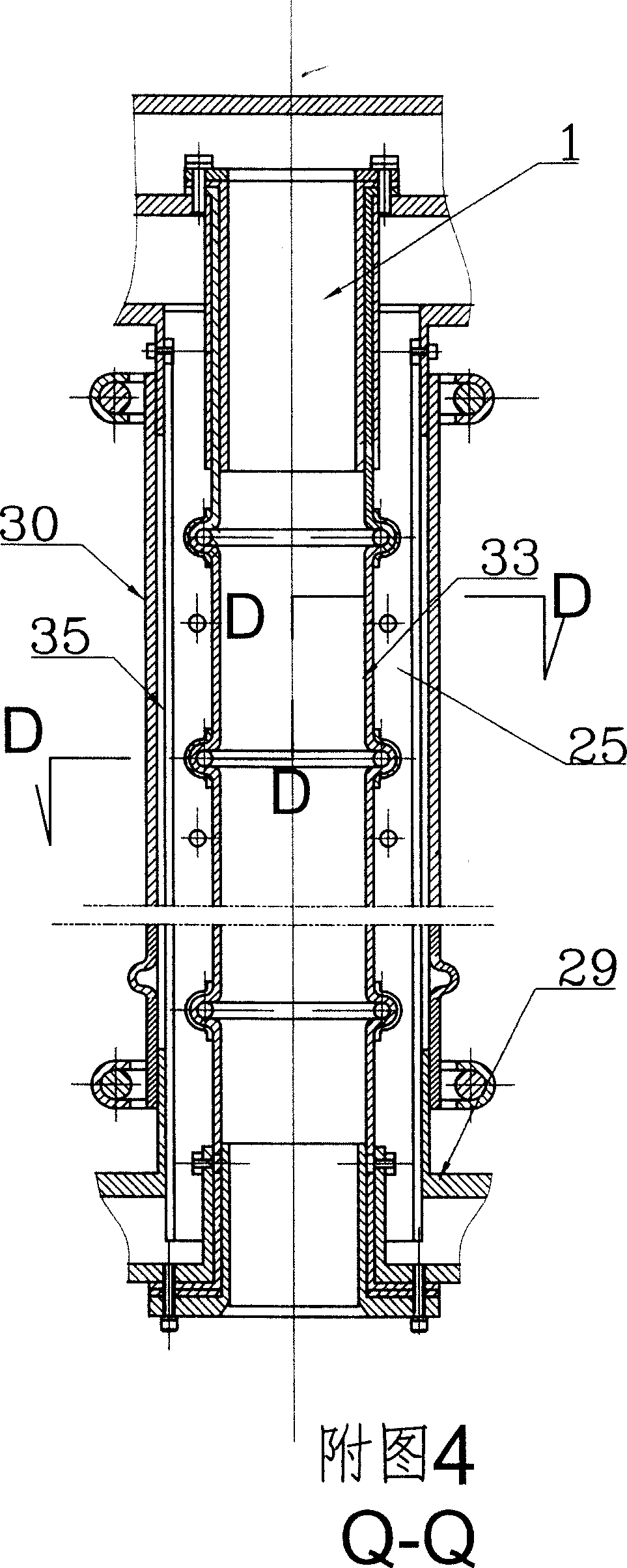

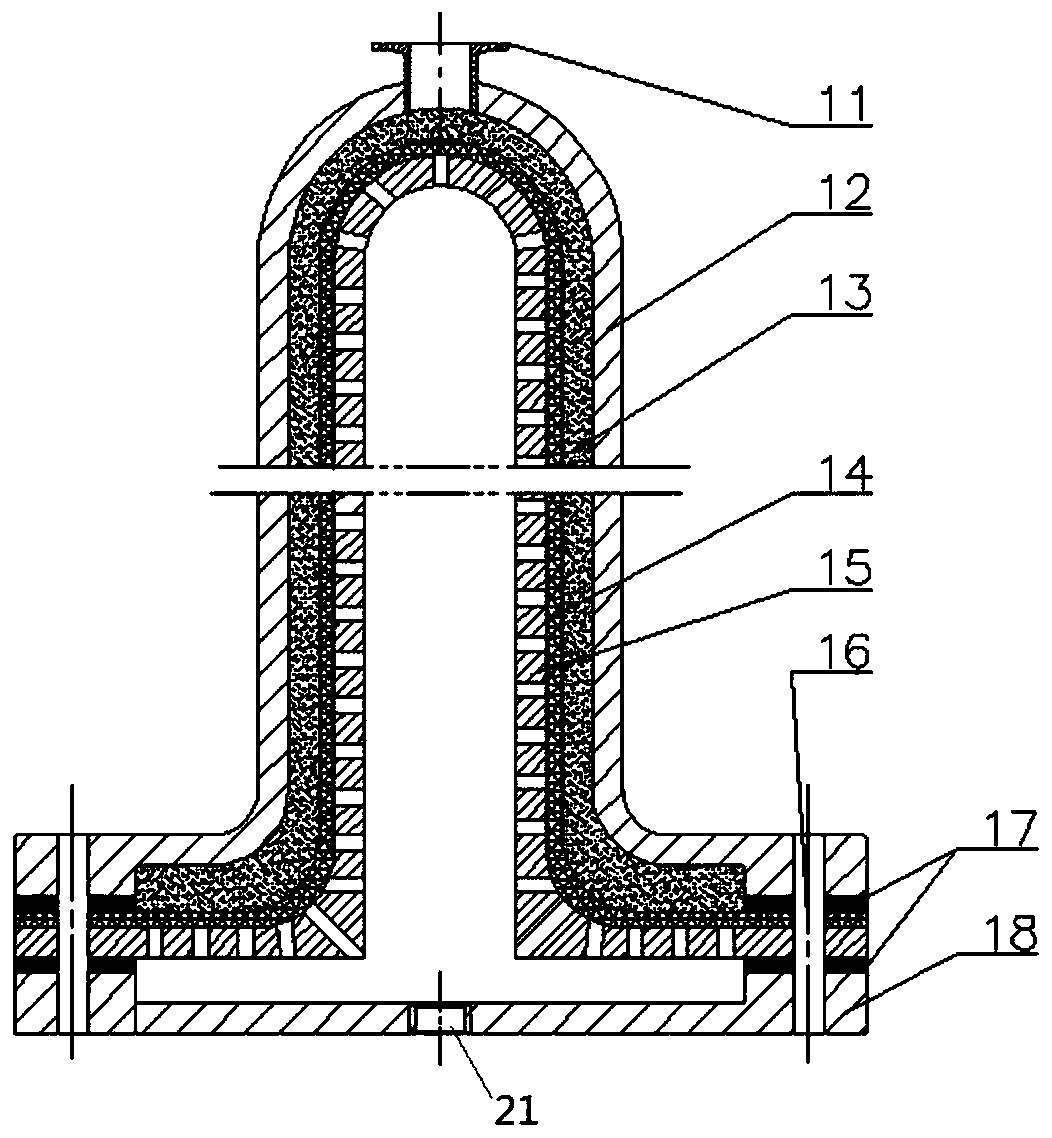

Flexible tube type solid-liquid processing machine with filtering, heat-exchange and hot compression function

InactiveCN1966129ALow costSimplify equipment componentsSemi-permeable membranesStationary filtering element filtersSlagEngineering

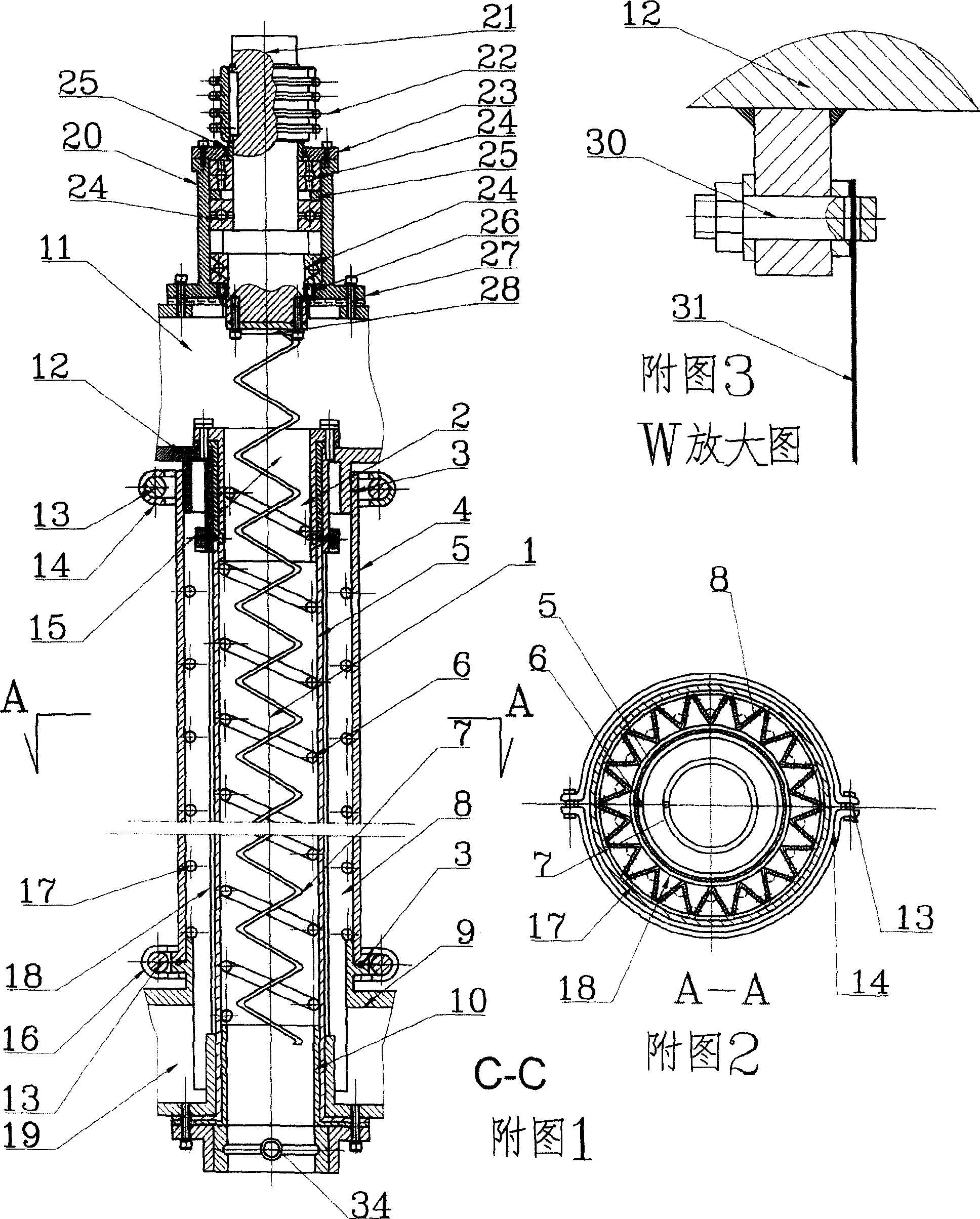

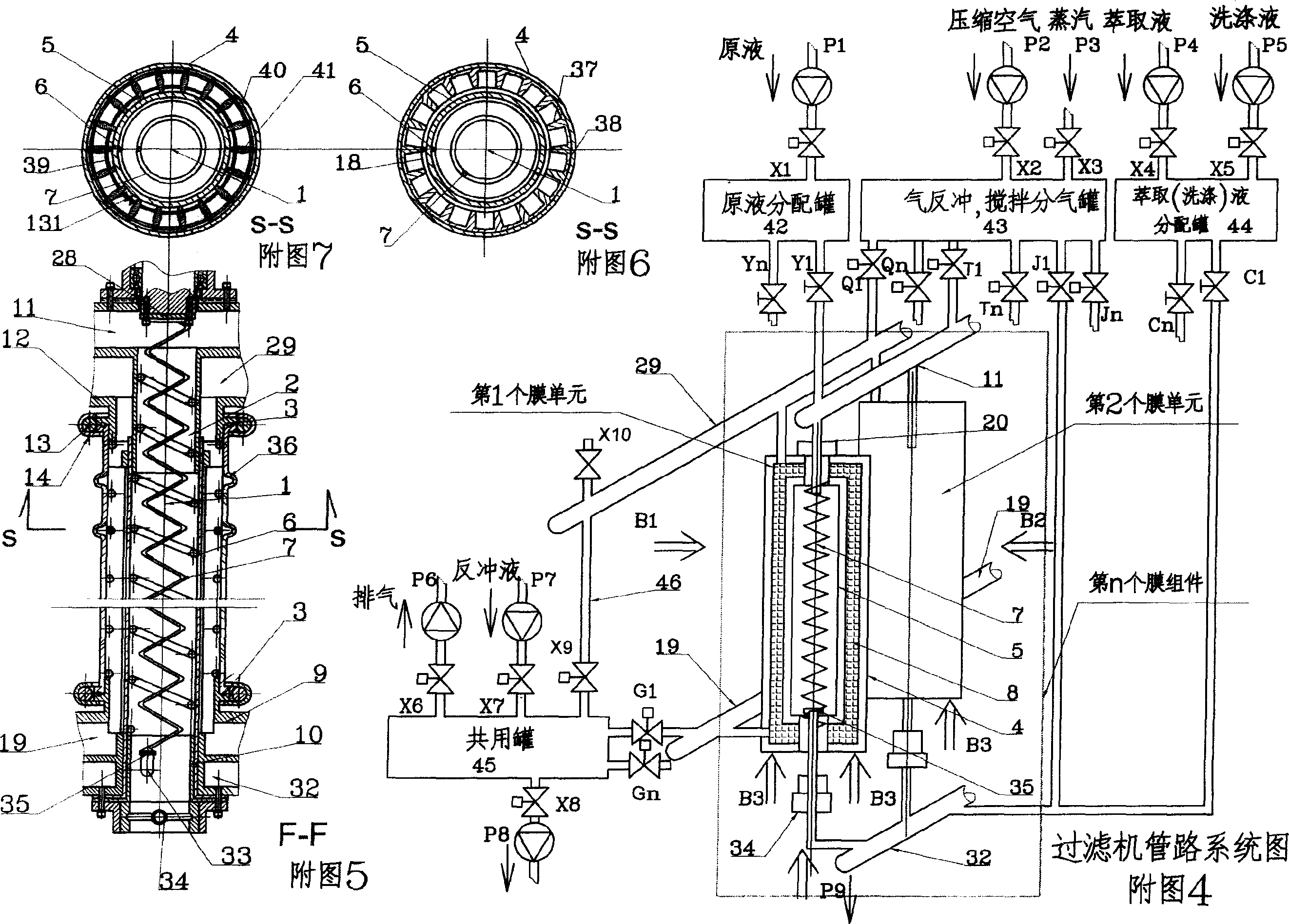

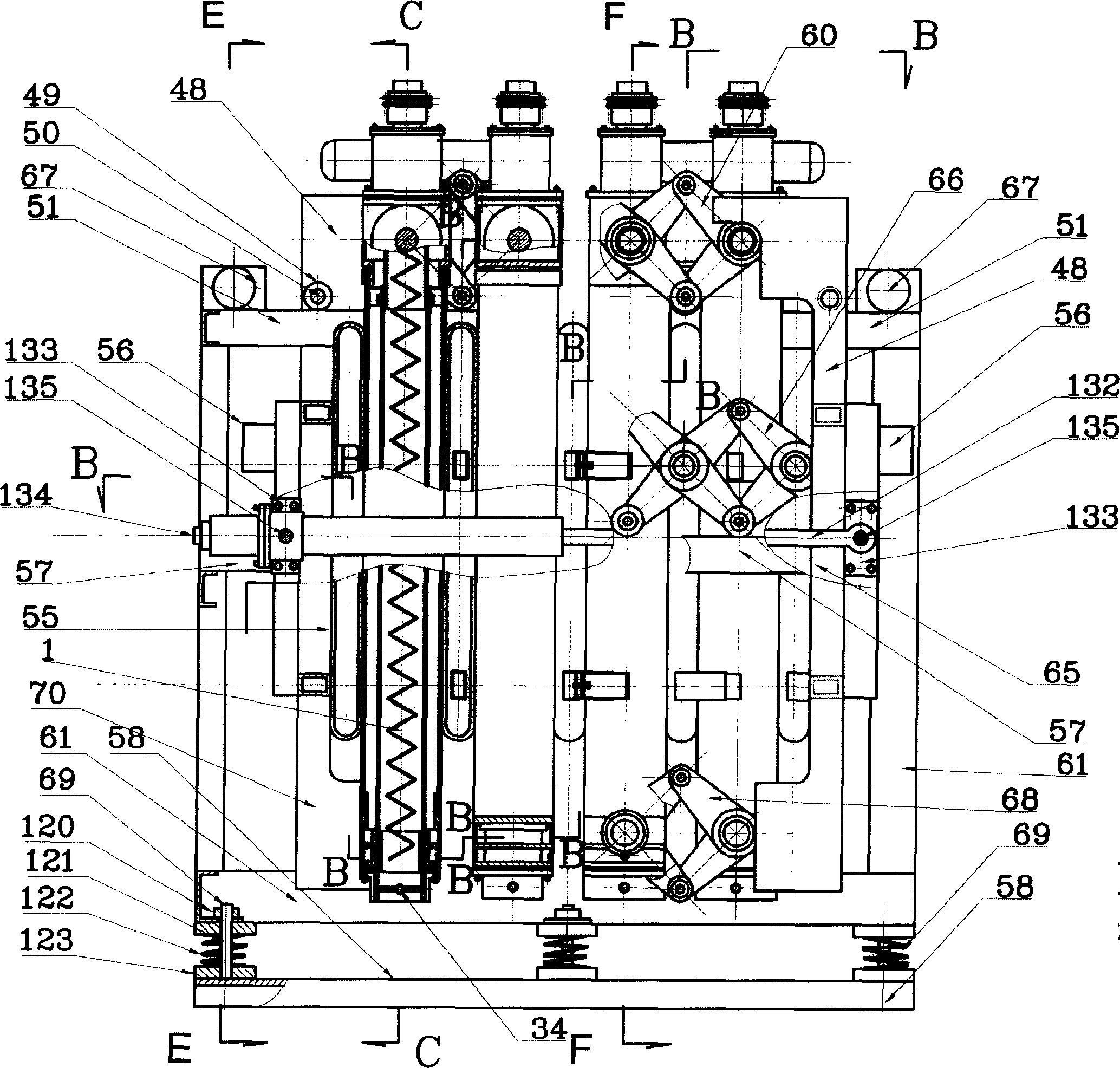

The invention relates to a flexible tubular solid liquid processor, with filter, heat exchange and thermal extraction functions, wherein the filter element at least comprises one flexible tubular membrane unit, upper flange room and lower flange room; the hydraulic extracting system comprises pressure container, extract pump and tubes; the material liquid of container can be filtered by the tubular filter membrane of membrane unit, and said material liquid can be used as work medium to extract the concentrated material liquid in the filter room of membrane unit and discharge filter slag; the pressure container or the filter room of membrane unit can be filled with medium to exchange heat, to realize thermal filter or extraction; the filter element is arranged on the bearing base inside the pressure container; the filter rotator can rotate the filter element to realize cross-flow filter; and the invention can be arranged with gas or water reverse tube and vacuum filter tube; the slag discharge system comprises slag discharger or tubular inner / outer membrane scraper, or vibration slag discharger, or compression slag discharger.

Owner:张民良

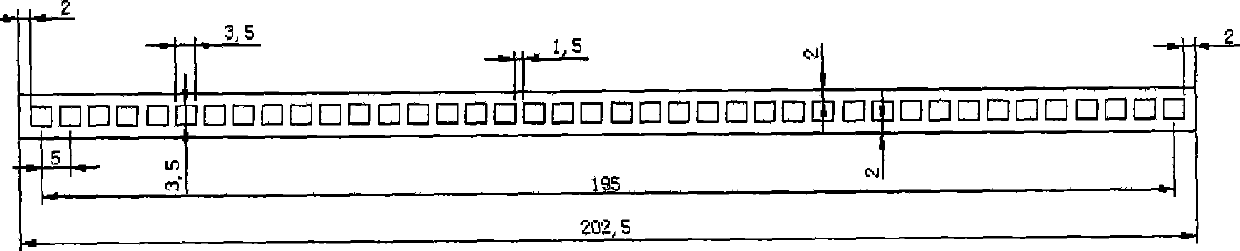

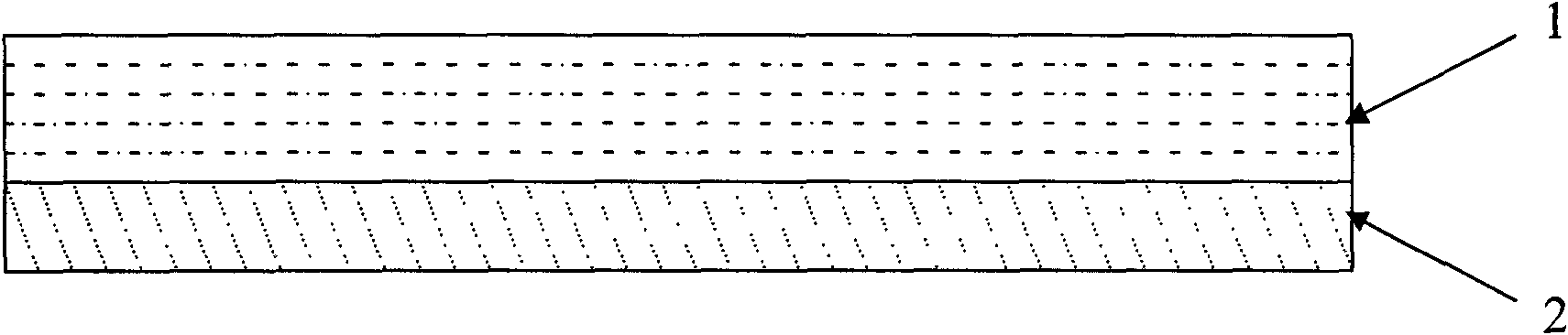

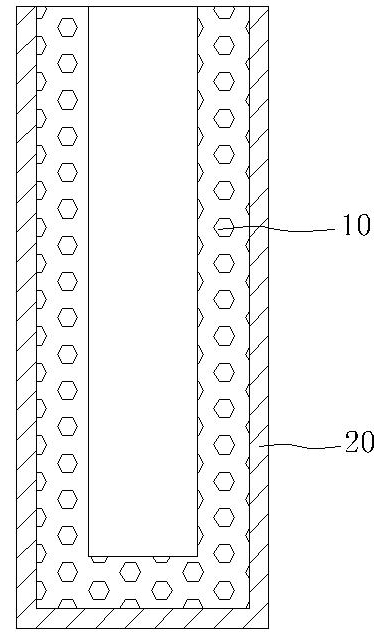

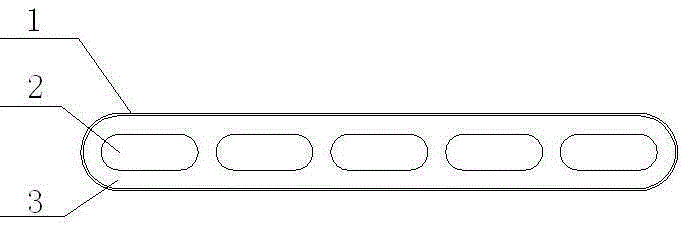

Preparation method of hollow flat plate structure type ceramic filter membrane element

ActiveCN103623711ALower sintering temperatureSmall filter resistanceSemi-permeable membranesAluminium hydroxideChemical separation

The invention provides a preparation method of a hollow flat plate structure type ceramic filter membrane element. The method comprises the following steps: (1) preparing a hollow structure type ceramic membrane supporting body by using an extrusion molding method, namely sintering aluminum hydroxide obtained by calcination at 600 DEG C as a main raw material to prepare the ceramic membrane supporting body; (2) preparing the ceramic filter membrane by using a plasma spray method. When the ceramic membrane supporting body is prepared, the selected and used raw material is calcined aluminum hydroxide, so that the sintering temperature of the ceramic membrane supporting body can be greatly reduced, and the sufficient strength of the supporting body can be guaranteed; when the ceramic filter membrane layer is prepared, the thickness of the filter membrane can be excellently controlled by using the plasma spray process, and the filter resistance is reduced; the membrane layer has the uniform pore size distribution and the high separation accuracy; the membrane layer is closely combined with the supporting body. The ceramic filter membrane is prepared by using plasma spraying without sintering, so that the process is simple, the production cost of the ceramic filter membrane can be effectively reduced, the production efficiency is improved, and the process can be widely applied to the fields of sewage treatment and filtration, solid-liquid chemical separation, and the like.

Owner:雅安沃克林环保科技有限公司

Method for manufacturing dendrobium officinale fresh juice stock solution

InactiveCN102008654ANot easy to clarifyNot easy to filterMetabolism disorderAlcoholic beverage preparationFlavorAdditive ingredient

The invention discloses a manufacturing method for extracting and processing fresh juice stock solution by using dendrobium officinale as a raw material. The method furthest protect the color, flavor, nutrition and effective ingredients of dendrobium officinale fresh juice by surface sterilization of the collected fresh dendrobium officinale and technology of juicing, enzymolysis, vacuum degasification, micro-filtration, ultra-filtration, sterile filling, high-temperature instantaneous sterilization and the like, and meanwhile, the product is favorable for storing and realizing industrialized production. The dendrobium officinale is processed into the dendrobium officinale fresh juice stock solution which is easy to store, convenient to carry, simple to administrate, good in mouthfeel and easy to absorb and has health-care nutritional components and medicinal functions; the fresh juice stock solution does not contain any additive; and the content of the fresh juice stock solution reaches over 99 percent. The dendrobium officinale fresh juice stock solution can be administrated separately, also can be added into mineral water to form health-care beverage, also can be dissolved into wine to form nourishing health-care wine, and can be added into high-grade dishes to form nourishing dishes for eating.

Owner:杨军

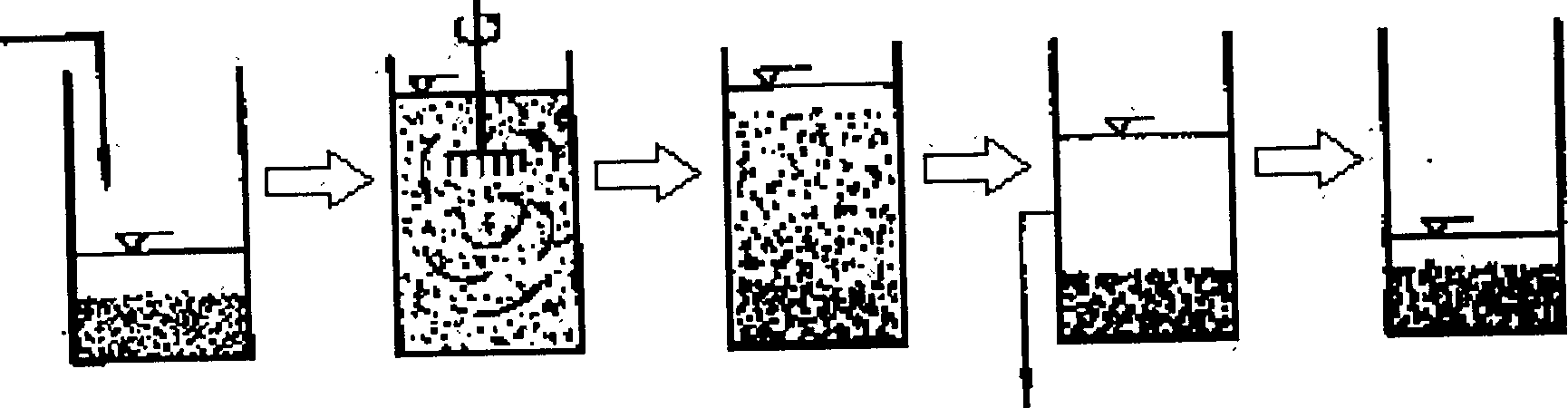

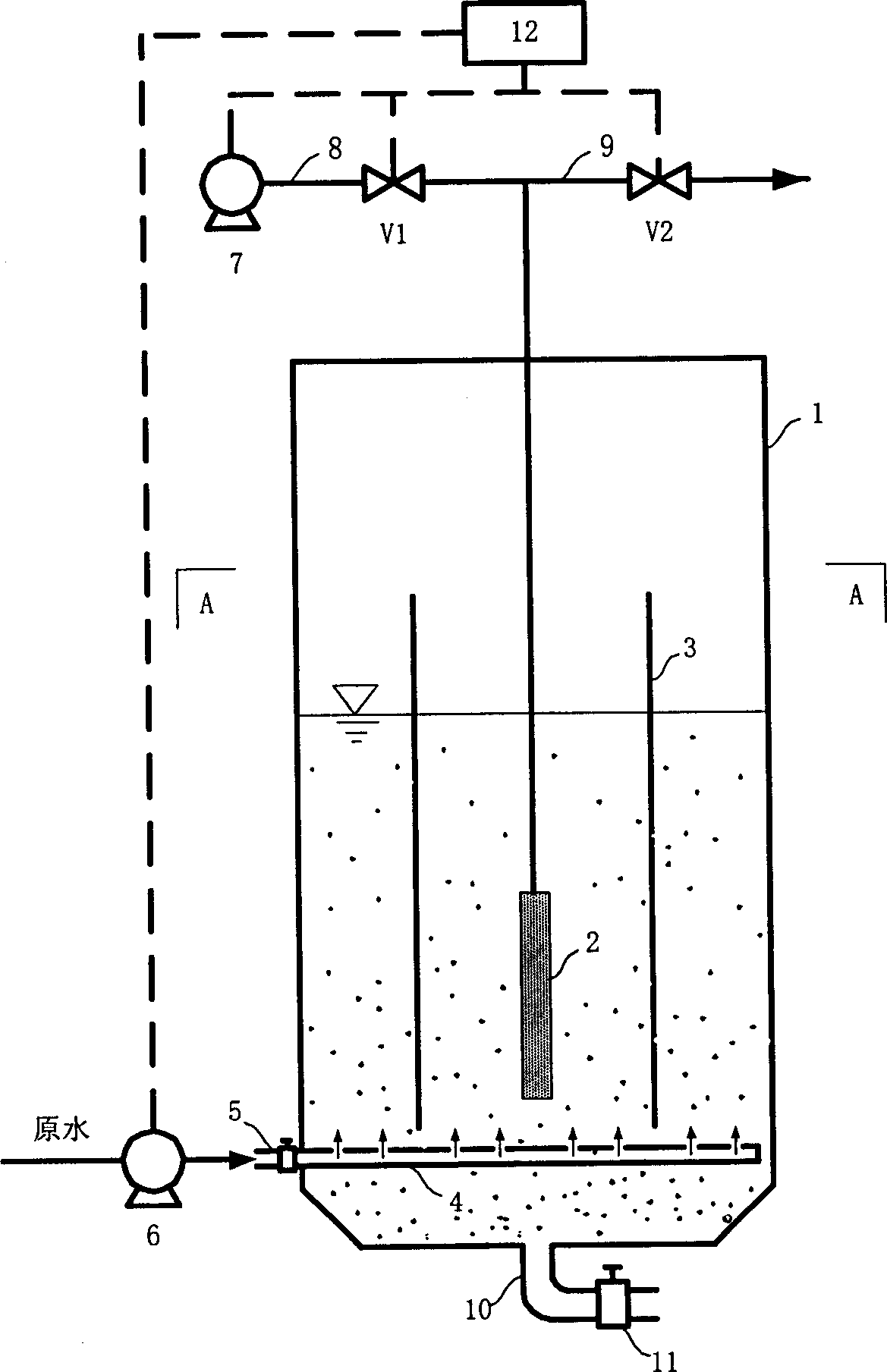

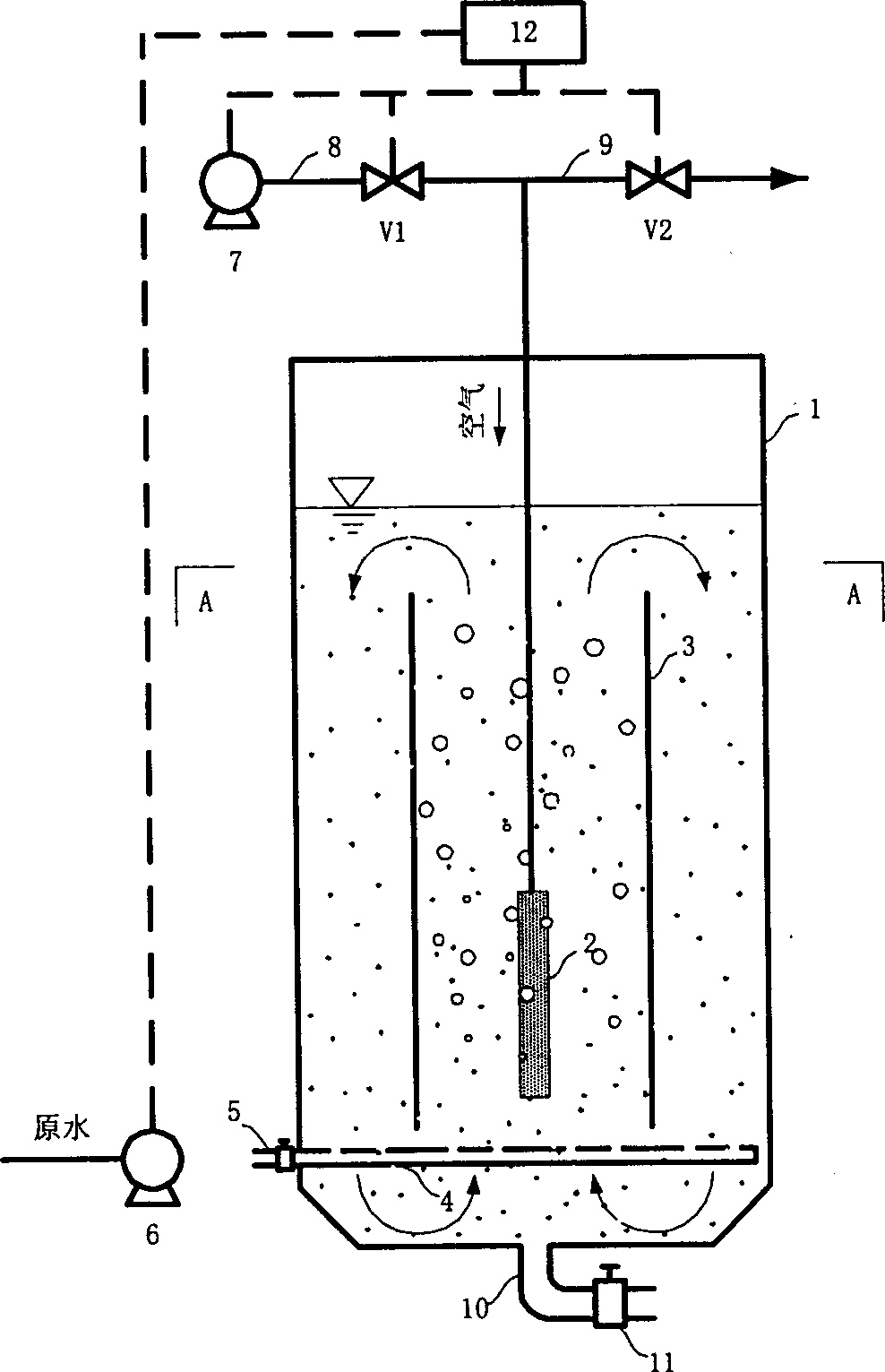

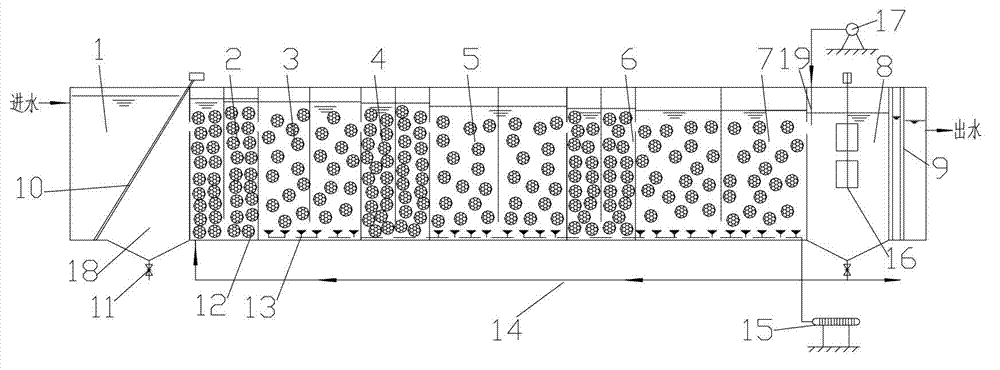

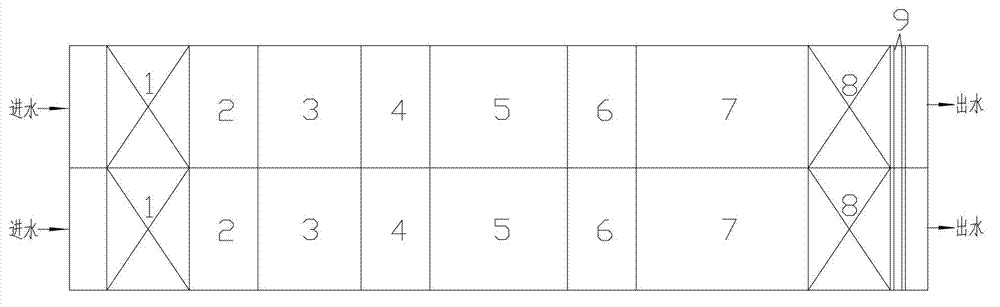

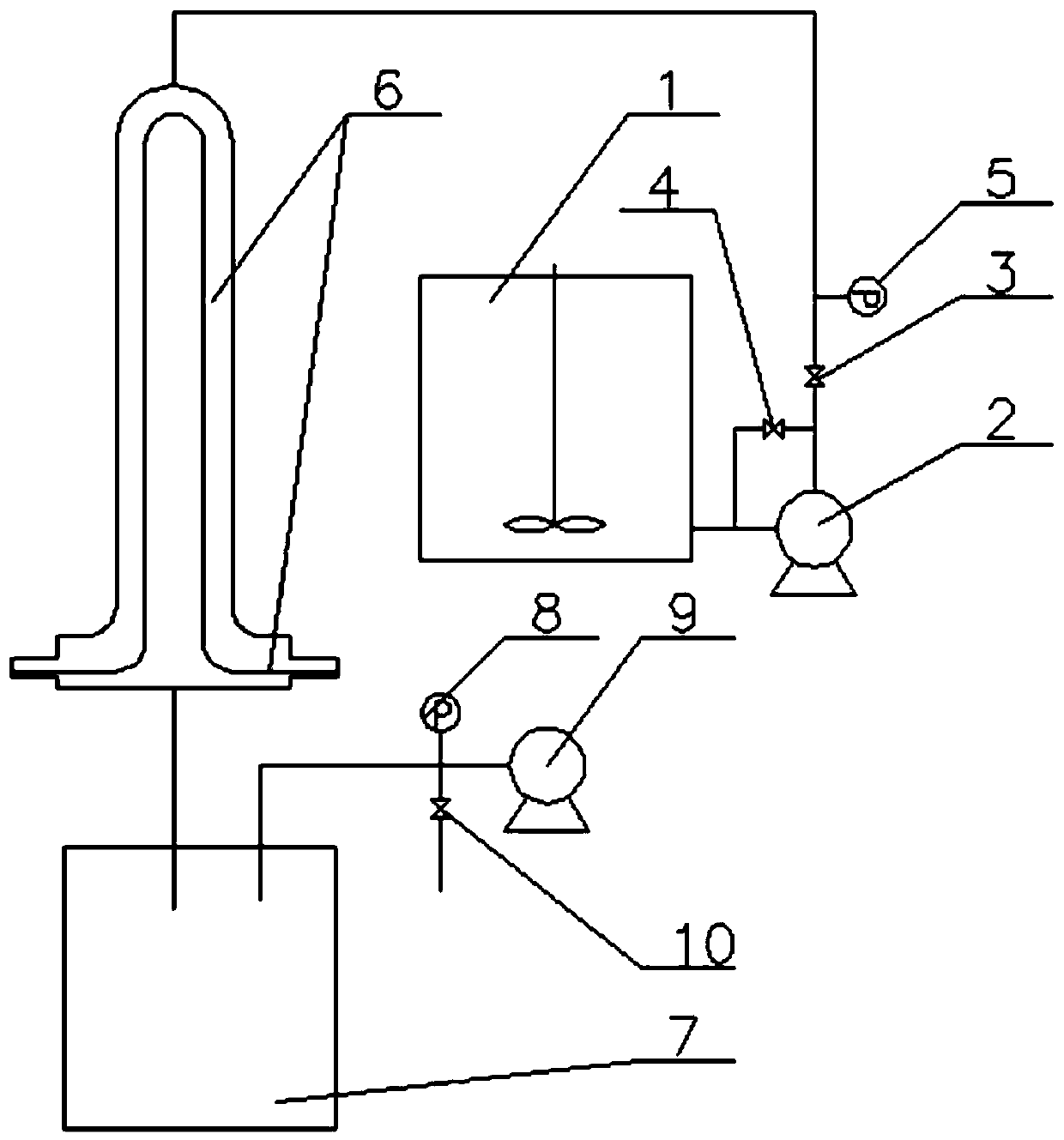

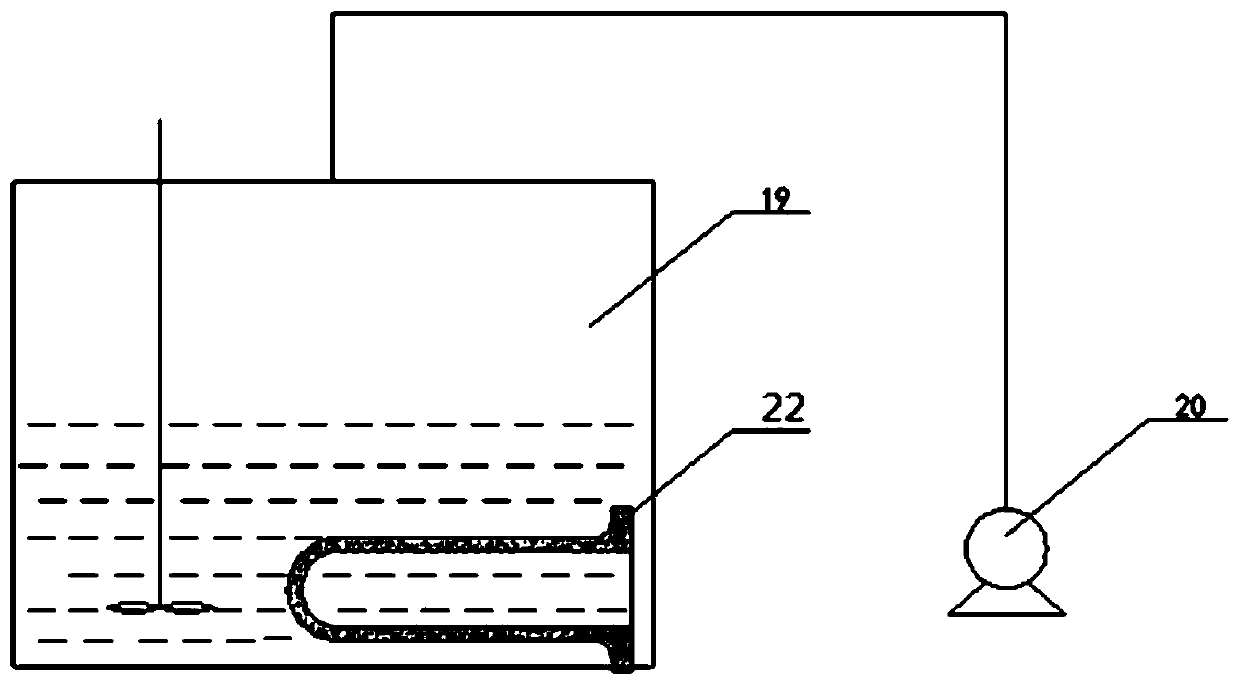

Process and apparatus for wastewater by batched membrane-bioreactor

InactiveCN1424265AGood water qualitySimple device structureWater/sewage treatment bu osmosis/dialysisTreatment with aerobic and anaerobic processesAutomatic controlPollutant

A process for treating sewage by integrating sequential active sludge method with membrane-bioreactor features that the membrane assembly is put in bioreacting pool, its outlet is respectively connected to air inlet pipe and water outlet pipe via two control valves, the whole system sequentially passes through flow-in, reaction, discharge and idle steps, that is, anaerobic, aerobic and anoxic states, and said membrane assembly plays the roles of aerating unit in reaction step or separator in discharge step. Its advantages are simple structure and high effect.

Owner:TSINGHUA UNIV

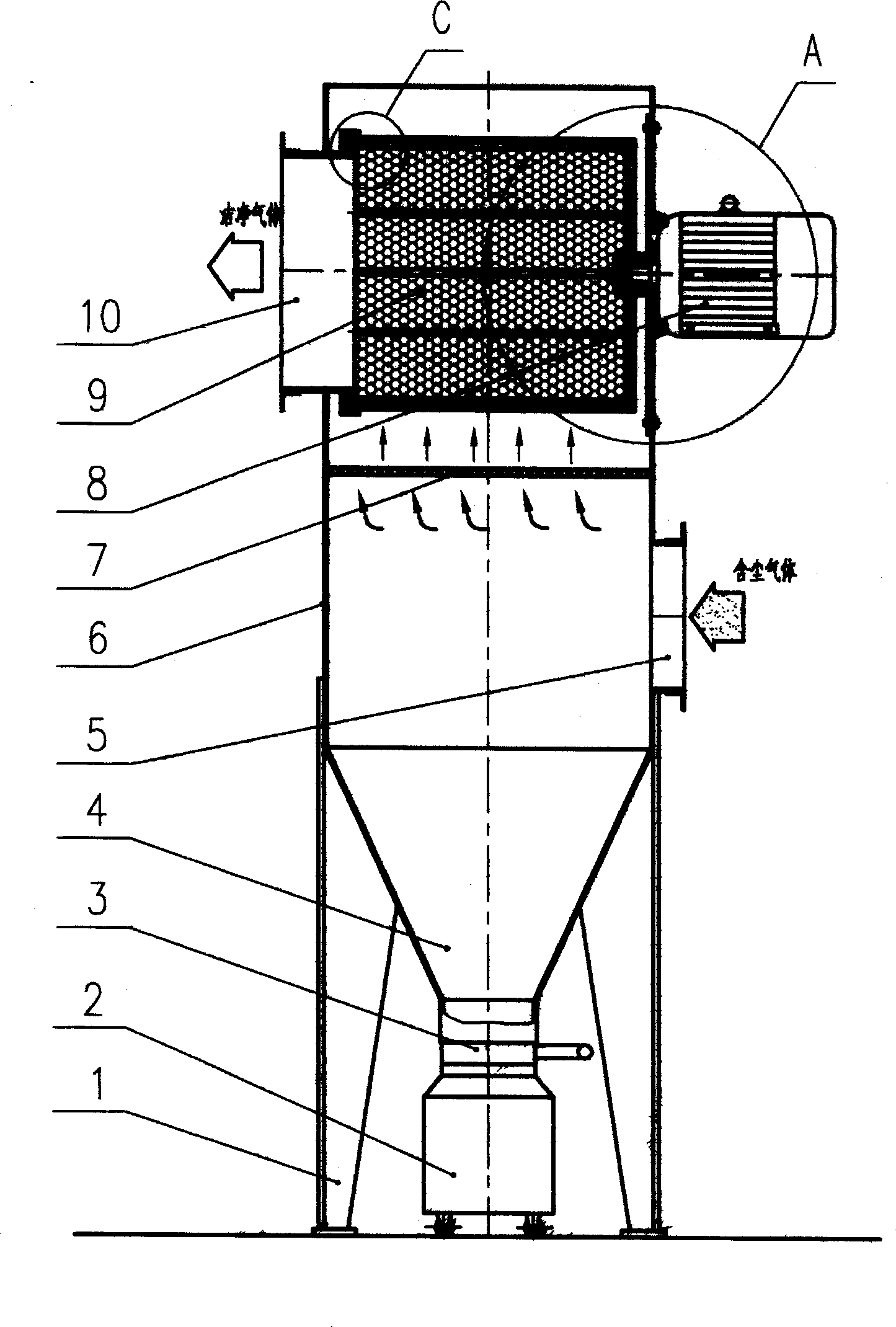

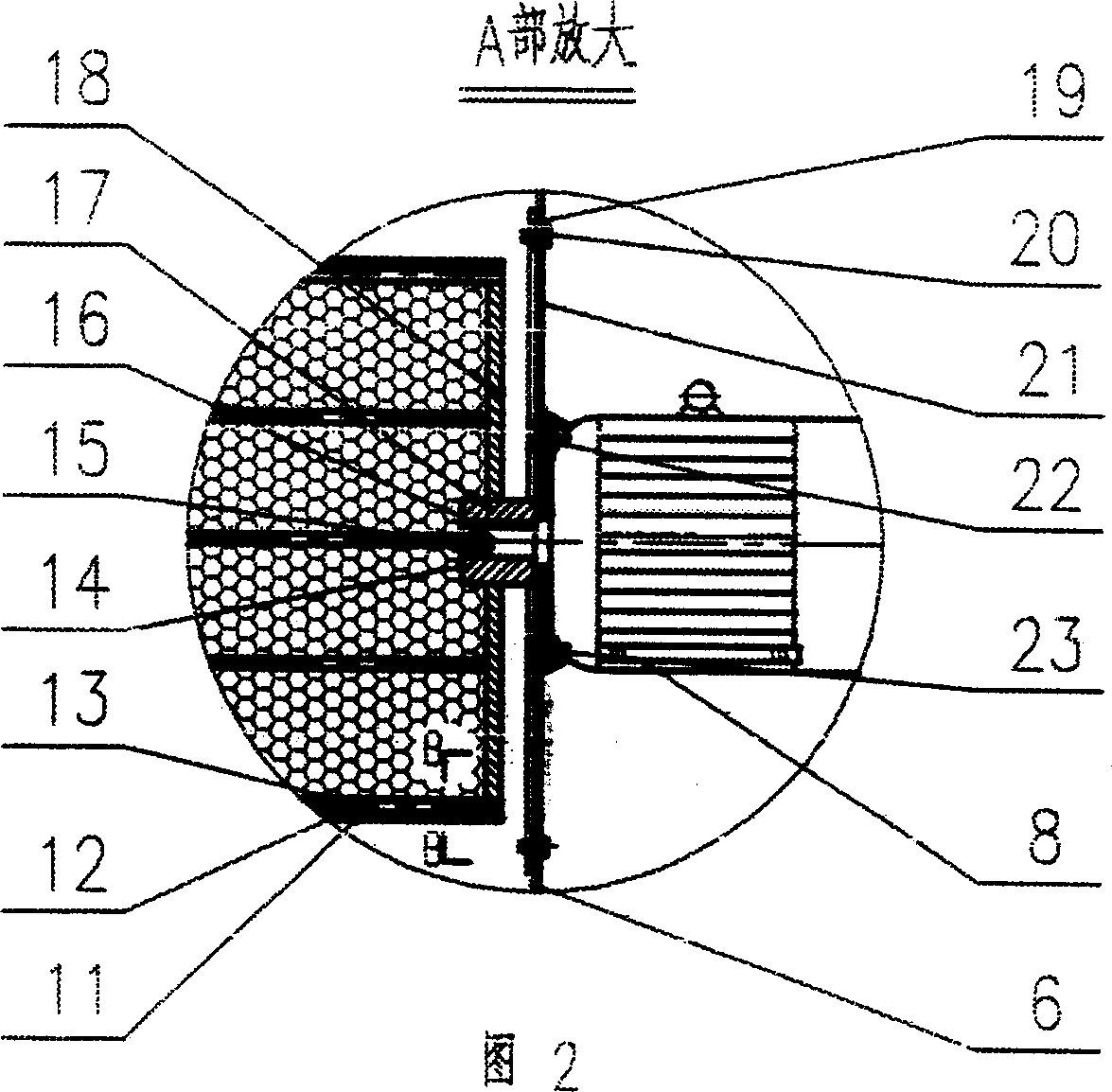

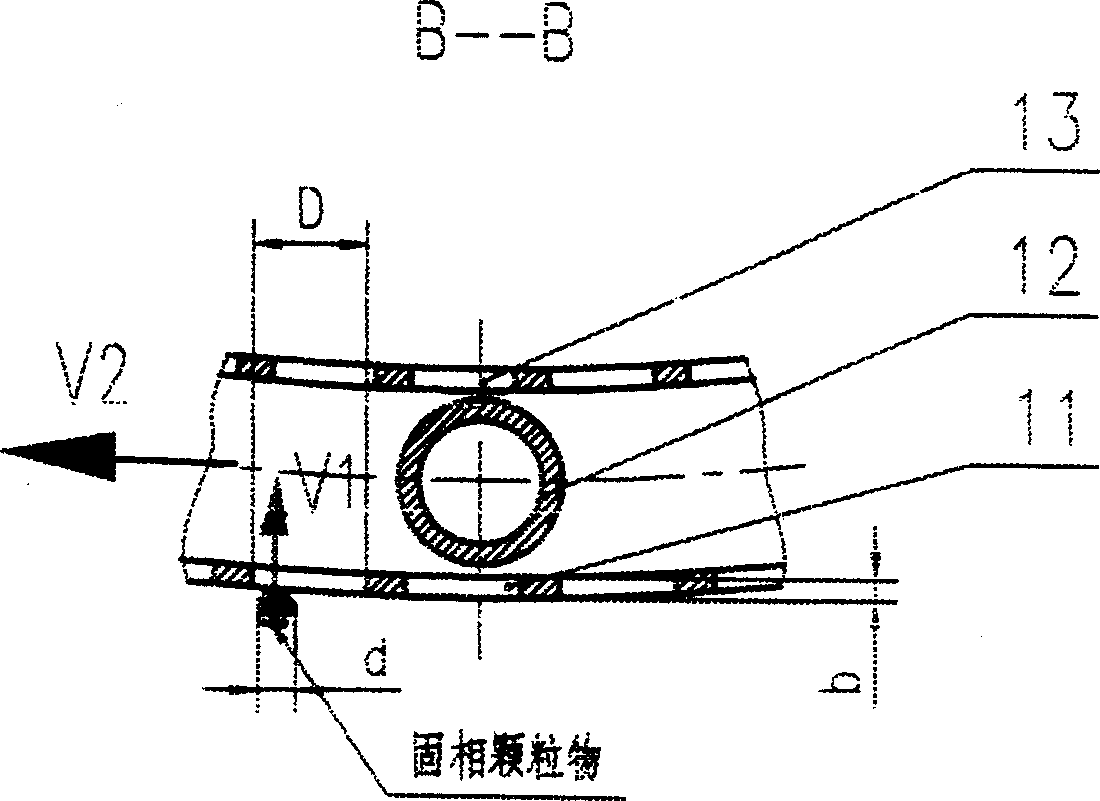

Filtration type gas separation and purification equipment with rapid moving filtering layer

InactiveCN1480239AEfficient separationEffective separation and purificationDispersed particle filtrationFiltrationProduct gas

A filter-type gas separating-cleaning apparatus with quickly moving filter layer features that its filter cylinder rotating at high speed is composed of external filter net, supporting posts, internal filter net, shaft sleeve, shaft disk and supporting rings, and the gas containing solid particles and / or liquid drops is filtered by said filter cylinder. Its advantage is use of big-mesh filter material to remove fine solid particles and / or liquid drops, resulting in high filter speed, and easy cleaning.

Owner:暴辰生 +1

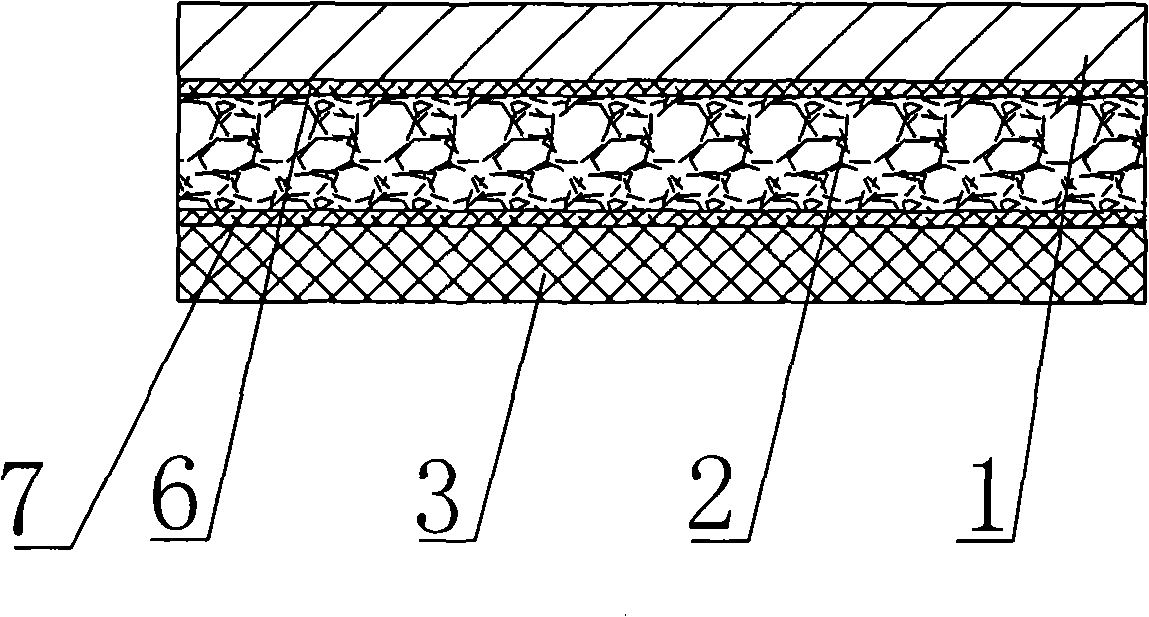

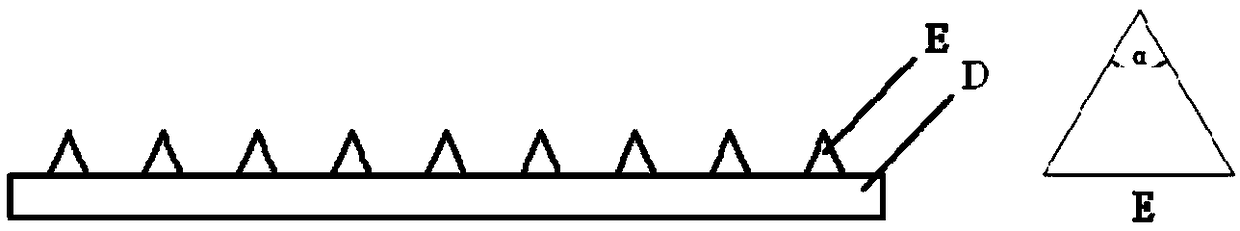

Composite air filtering material for filtering bag and preparation method thereof

InactiveCN101491742AHigh strengthImprove breathabilityDispersed particle filtrationFiltration separationSodium bicarbonateAir filter

The invention relates to a compound air filter material and a method for preparing the same. The composite air filter material used for filter bags comprises a protective layer, a deodorizing layer and a filter layer, wherein the protective layer and the filter layer are compounded on two side faces of the deodorizing layer respectively; the protective layer is made of wood pulp fiber filter paper, spun-bond non-woven fabric or spun-lace non-woven fabric, and the gram weight of the material of the protective layer is 10 to 200g / m; the deodorizing layer is made of one of active carbon, zeolite , sodium bicarbonate, magnesium aluminum silicates and silica gel or a mixture of any two of the wood pulp fiber filter paper, the spun-bond non-woven fabric and the spun-lace non-woven fabric, and the gram weight of the material of the deodorizing layer is 10 to 300g / m; and the filter layer is made of melt-blown non-woven fabric, wood pulp fiber filter paper or SMS non-woven fabric, and the gram weight of the material of the filter layer is 10 to 100g / m. The compound air filter material has high filtration efficiency and deodorization efficiency, low filtration resistance and high dust capacity.

Owner:上海曾韩进出口有限公司

High temperature resistance basalt fiber composite filter material and preparation method thereof

InactiveCN101612496AStable structureHigh filtration precisionLayered productsFiltration separationFiltrationPore diameter

The invention relates to a high temperature resistance basalt fiber composite filter material and a preparation method thereof; the composite filter material comprises basalt fiber base fabric and high-performance fiber mesh in a weight ratio of 7:1-2:1; the preparation method comprises the following steps: forming high-performance fiber mesh on the basalt fiber base fabric, combining and strengthening the material more by spunlaced process, hot rolling the material, then soaking the material in water repellent oil-proofing agent, sizing and obtaining the finished product. The filter material of the invention has the advantages of stable structure, high filtration accuracy, small bore diameter, concentrated pore diameter distribution and high temperature resistance, can bear 450 DEG C of instantaneous high temperature and can be used stablely for long time below 280 DEG C.

Owner:DONGHUA UNIV

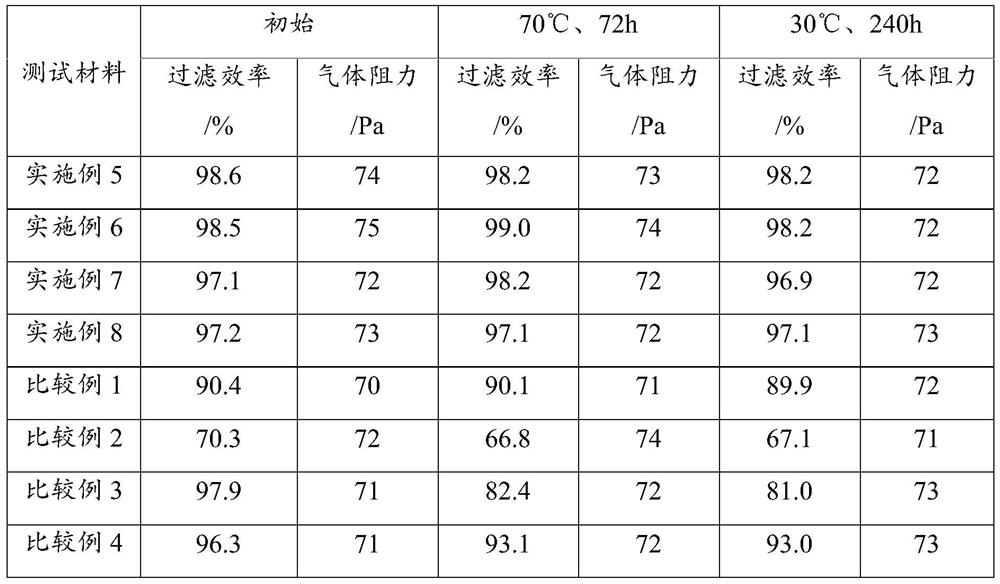

Preparation method for efficient low-impedance antibacterial air purification filter membrane

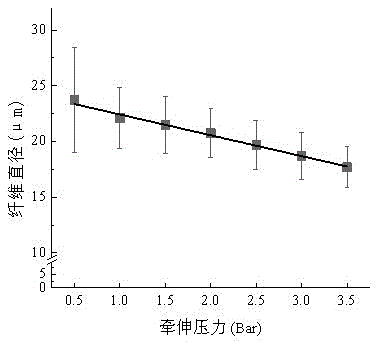

ActiveCN103774345ANo reduction in filtration efficiencySmall filter resistanceDispersed particle filtrationFiltration separationEscherichia coliCrude fibre

The invention discloses a preparation method for an efficient low-impedance antibacterial air purification filter membrane. Two polymers A and B which can be used for preparing nanofibers with great diameter differences by an electrostatic spinning technology are selected, and are mixed with graphene oxide and a solvent to prepare two spinning solutions respectively, and a composite nanofiber filter membrane with a multilayer composite structure is prepared in a parallel electrospinning way. According to the preparation method, the graphene oxide is doped, so that the prepared nanofiber filter membrane is antibacterial; rough fiber layers are inserted into fine fiber layers to enable the fine fiber layers to be looser, so that the filter resistance of the membrane is reduced without reduction in the filter efficiency of the membrane; the filter membrane is detected to have sodium chloride aerosol particle rejection rate of over 96 percent, pressure drop of a less-than-28mm water column and Escherichia coli inhibition rate of over 90 percent.

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI

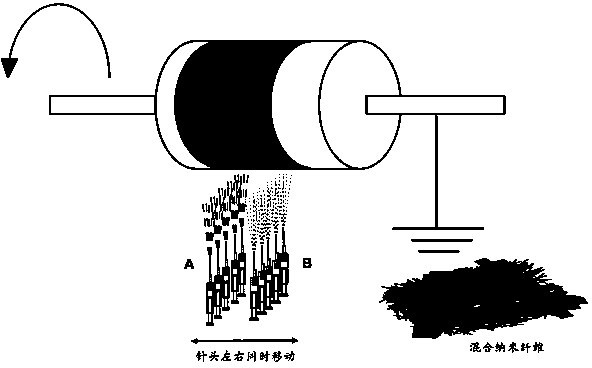

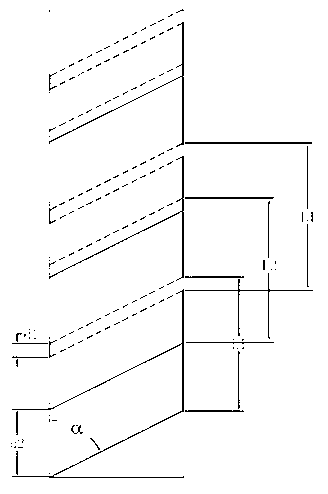

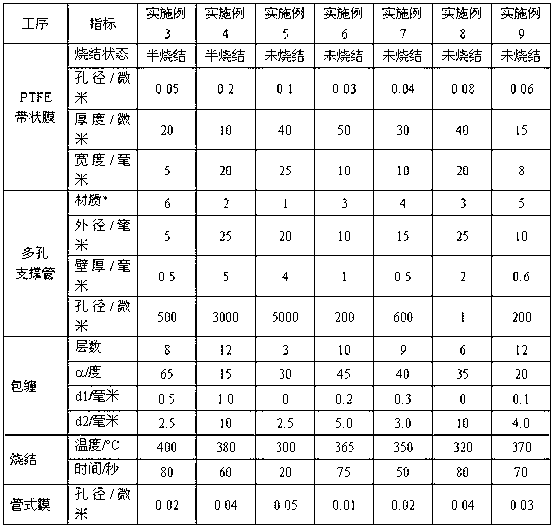

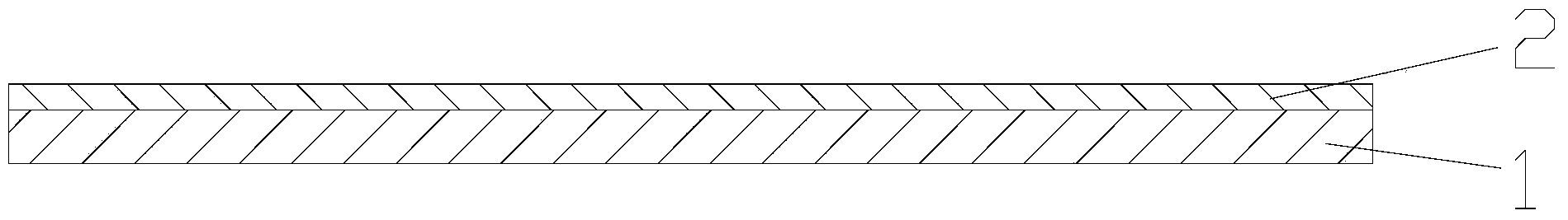

Preparation method of wrapped polytetrafluoroethylene ultra-micro filter tube membrane

ActiveCN103007788AAvoid layeringUniform filtering effectSemi-permeable membranesPorosityOrganic solvent

The invention discloses a preparation method of a wrapped polytetrafluoroethylene ultra-micro filter tube membrane. A sintered or unsintered drown polytetrafluoroethylene membrane of which the aperture is 0.03-0.3micon and the thickness is 10-50micon is cut into polytetrafluoroethylene strip-shaped membranes which are 5-25mm in width; the membranes are wrapped on a porous support tube which resists a temperature of 300-500 DEG C and is corrosion resistant and organic solvent resistant; and the support tube wrapped with the prepared polytetrafluoroethylene membranes is sintered for 20-80s at the temperature of 300-400 DEG C so as to prepare the wrapped polytetrafluoroethylene ultra-micro filter tube membrane of which the aperture of a filtering layer is 0.01-0.05micon. The wrapped polytetrafluoroethylene ultra-micro filter tube membrane has the advantages of high porosity, small aperture, uniformity in filtering layer, blocking resistance, internal and external pressure resistance, capability of back washing and the like, and can be used in solid-liquid and gas-liquid separation with high viscosity, high solid content and high pollution in food concentration, waste penetration liquid treatment, oil-water separation, membrane biologic reactor and the like.

Owner:ZHEJIANG SCI-TECH UNIV

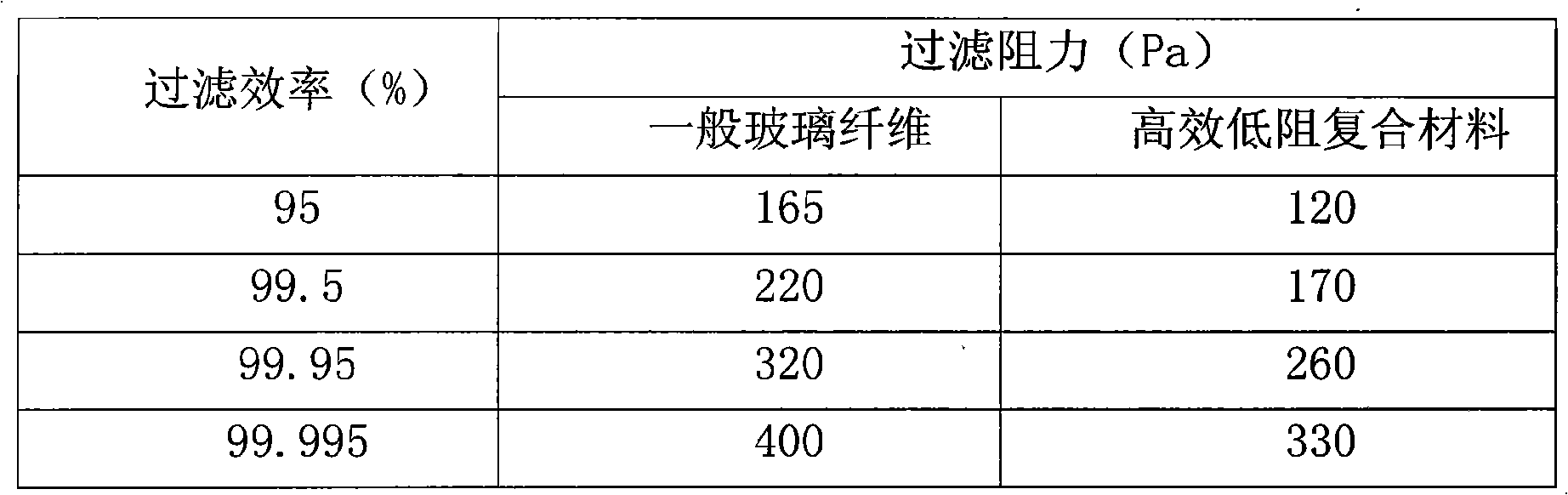

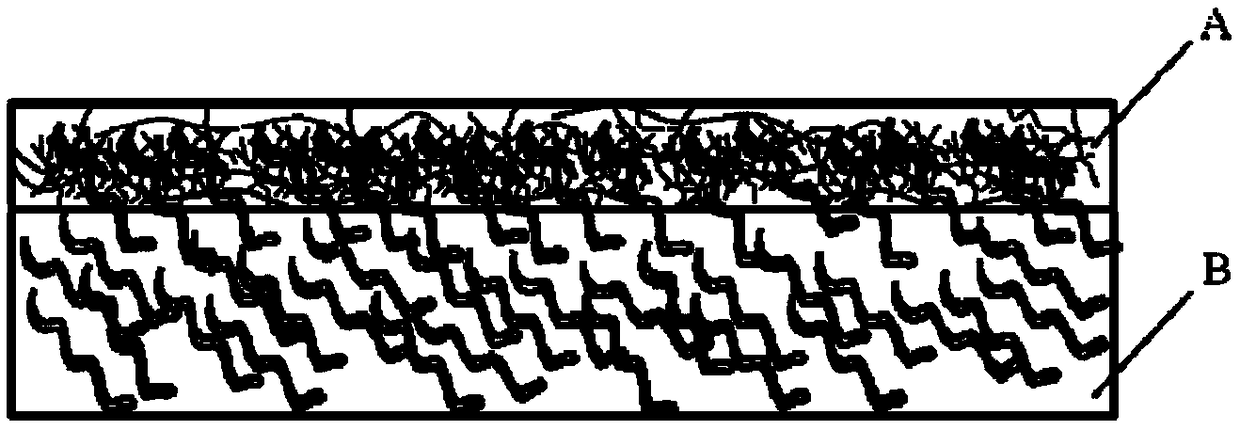

High-efficient low-resistance compound filter material and preparation method thereof

ActiveCN101352631AImprove filtration efficiencyFiltration efficiency reachesLaminationLamination apparatusFiberComposite filter

The invention provides a high-efficiency and low-resistance composite filter material and a preparation method thereof. The high-efficiency and low-resistance composite filter material is formed by the composing of at least a layer of fusing spray filter material and a layer of fibreglass filter material; the preparation method of the high-efficiency and low-resistance composite filter material comprises the following steps that: the fusing spray filter material and the fibreglass material are arranged on a material receiving frame and pass through a guiding roller; a hot fusing glue fibre gun is used for coating the fibre glue on the surface of the fibreglass; subsequently, the fusing spray filter material is attached to the fibreglass; finally, the finished product is gained by coiling. The high-efficiency and low-resistance composite filter material of the invention has high filter efficiency, extremely low filter resistance and high dust receiving capacity.

Owner:TONGXIANG JIANMIN FILTER MATERIALS

Integrated sewage treatment device with high efficiency and low consumption and treatment method

The invention relates to an integrated sewage treatment device with high efficiency and low consumption and a treatment method, and belongs to the field of sewage treatment. The integrated sewage treatment device comprises a pretreatment unit, a multi-oxidation-deoxidation environment coupling biological reaction pond unit and a deep treatment unit sequentially connected. The multi-oxidation-deoxidation environment coupling biological reaction pond unit adopts a three-stage anoxia-aerobiotic alternating reaction pond filled with a circular composite glass ball porous microbial carrier. The deep treatment unit comprises a filter cloth dynamic film biological reaction pond and first and second dynamic films. Sewage is treated through the devices sequentially. The device provided by the invention cannot only remove carbon containing organic matters, but also has good nitrogen and phosphorus removal capacity.

Owner:BEIJING UNIV OF TECH

High-performance high-temperature ceramic film material and preparation method thereof

InactiveCN106007722AImprove permeabilityHigh porositySemi-permeable membranesCeramicwarePorosityFiber

The invention belongs to the field of ceramic materials in the field of inorganic non-metallic materials, and in particular relates to a high-performance high-temperature ceramic membrane material and a preparation method thereof. It is made of an inner support layer and an outer film layer, both of which are composite structures of refractory ceramic aggregate and polycrystalline mullite short fiber. The present invention has better mechanical strength and toughness while ensuring the high permeability, low resistance, high porosity and high thermal stability of the high-density ceramic membrane material, and solves the problems of poor toughness and poor toughness that currently hinder the promotion and application of high-density ceramic membrane materials The technical problem of being easy to break; the invention also provides its preparation method.

Owner:SHANDONG RES & DESIGN ACADEMY OF IND CERAMICS

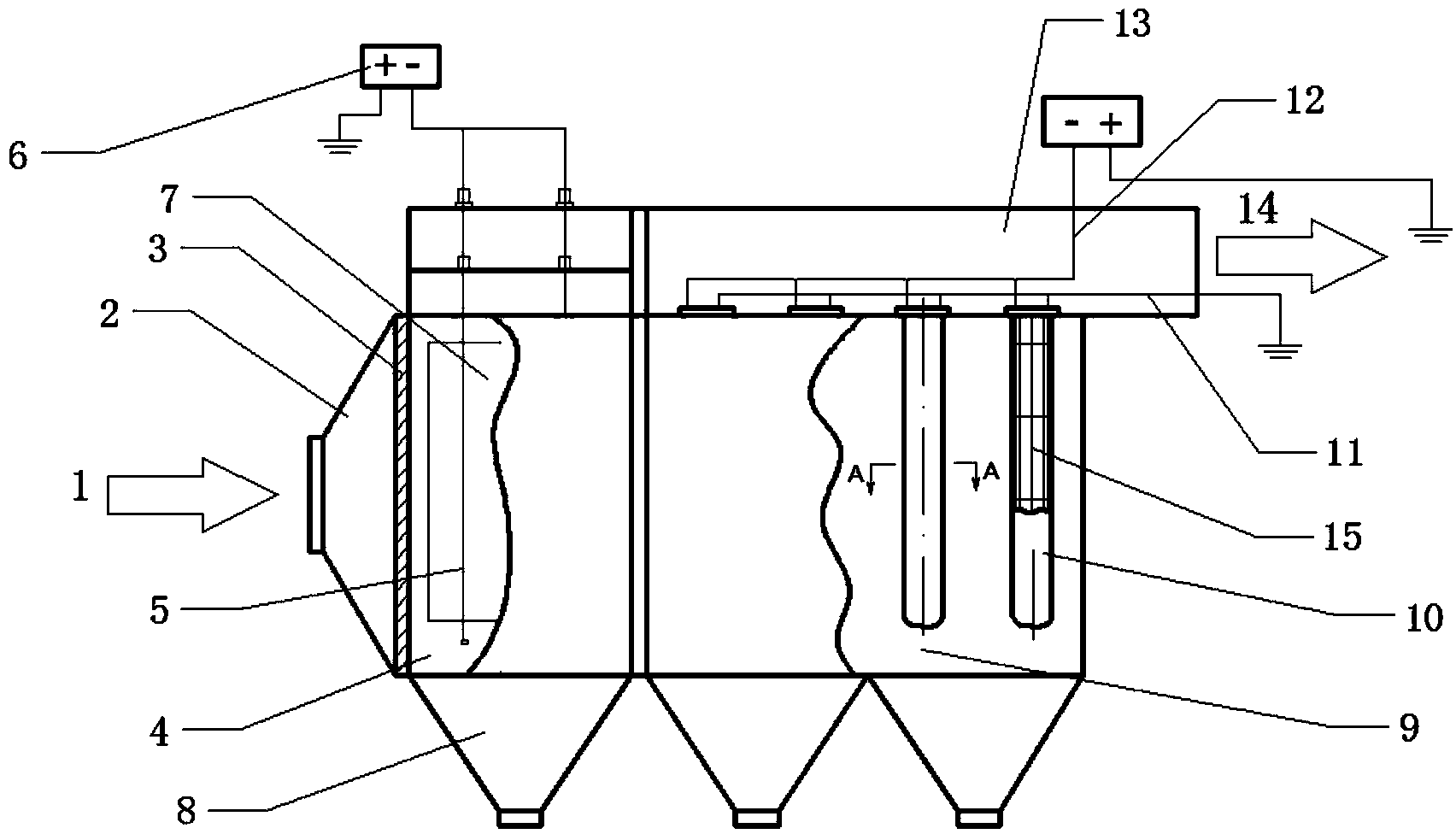

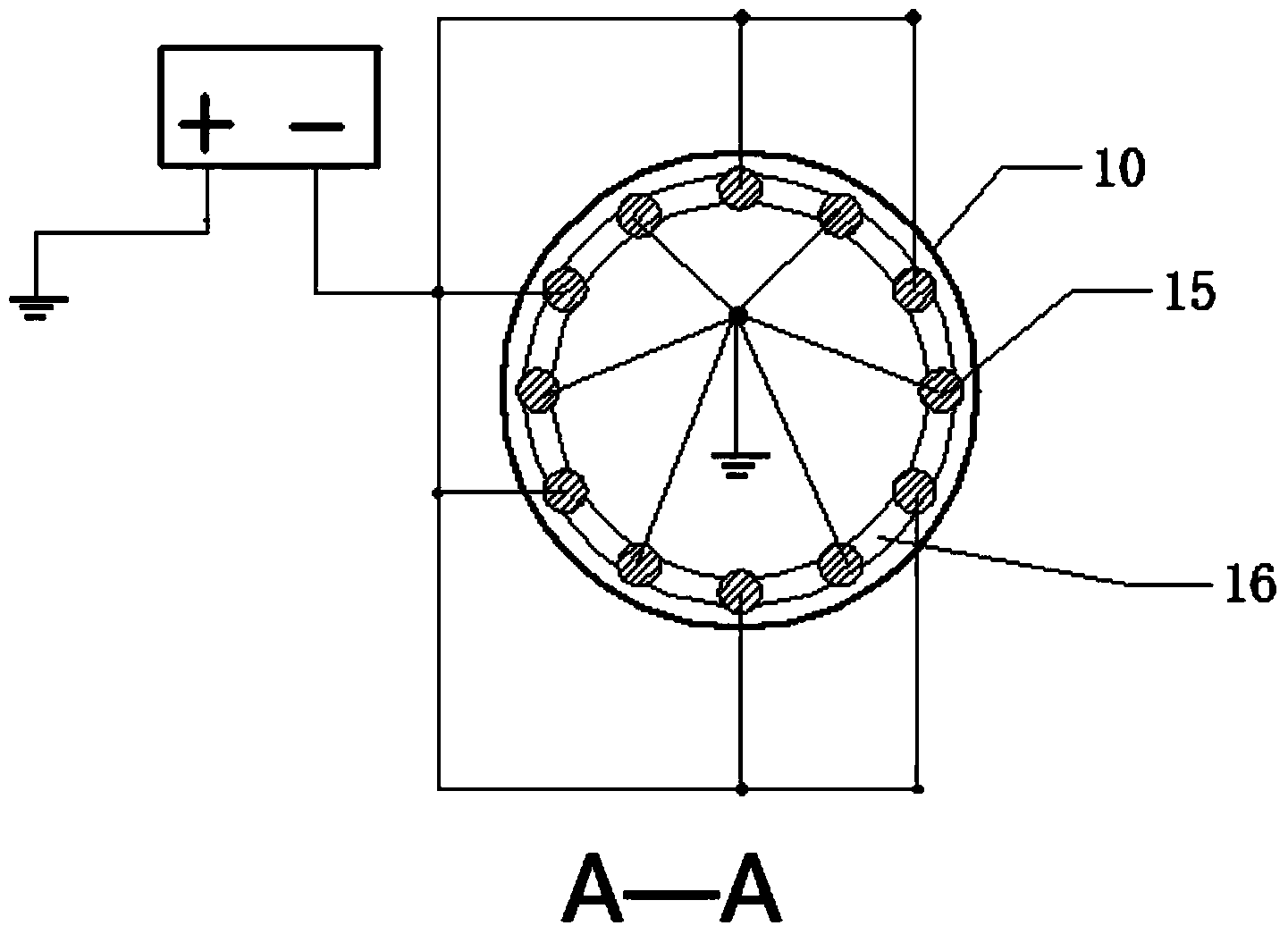

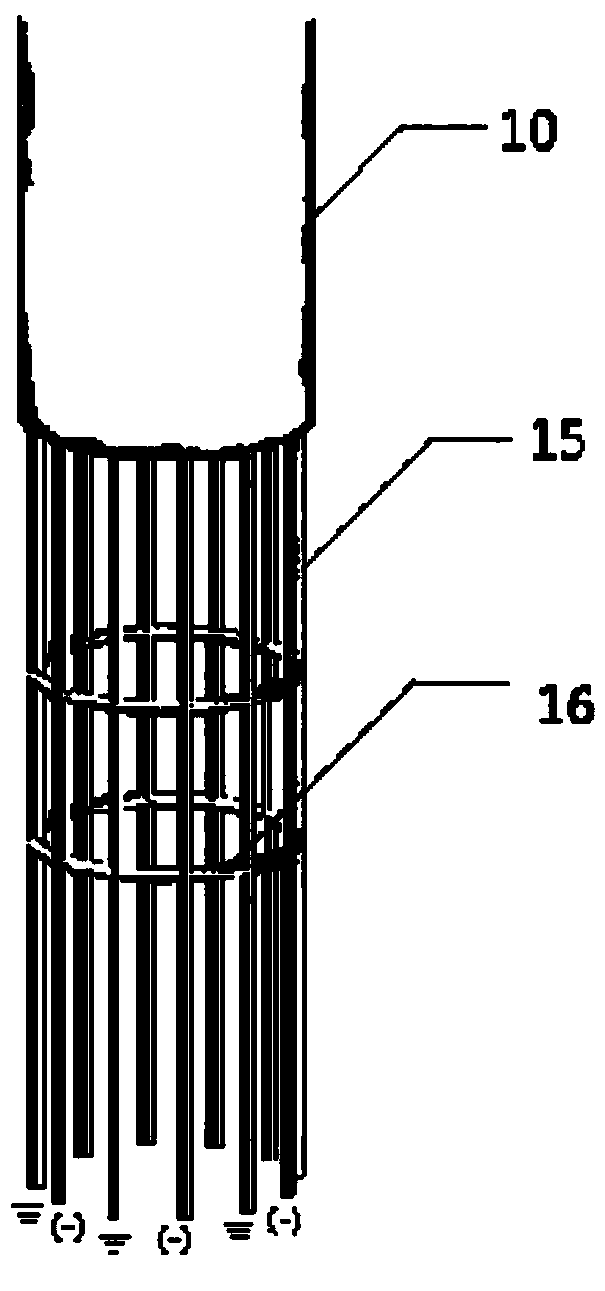

Electrostatically-enhanced electric-bag compound dust remover

ActiveCN103657316ADifficult to enterExtend your lifeCombination devicesFiltrationHigh-voltage direct current

An electrostatically-enhanced electric-bag compound dust remover comprises a high-voltage power supply arranged outside a casing and a compound dust removing area arranged in the casing; the compound dust removing area comprises a forestage electrostatic dust removing area and a rear-stage bag type dust removing area, wherein the forestage electrostatic dust removing area comprises a high-voltage discharge polar line and a dust collecting pole plate; filtering bags uniformly distributed are arranged in the bag type dust removing area; conductive cage bones are arranged in the filtering bags; vertical reinforcement bars in the conductive cage bones are connected with the ground and the negative pole of a high-voltage direct-current power supply, and each two adjacent vertical reinforcement bars are opposite in polarity; a plurality of insulating rings are arranged in the vertical direction; the vertical reinforcement bars are fixed on the insulating rings. The electrostatically-enhanced electric-bag compound dust remover has the characteristics that a non-uniform electric field is added in the bag type dust removing area, so that charged dust particles are distributed non-uniformly on the surfaces of the filtering bags; meanwhile, the particles are polarized into chains through the electric field, and then the probability of collecting the particles can be increased, so that the air-to-cloth ratio can be improved, the filtration resistance can be lowered at the same time, the soot cleaning frequency can be reduced, and the dust remover has the advantages of low energy consumption and long service life.

Owner:TSINGHUA UNIV

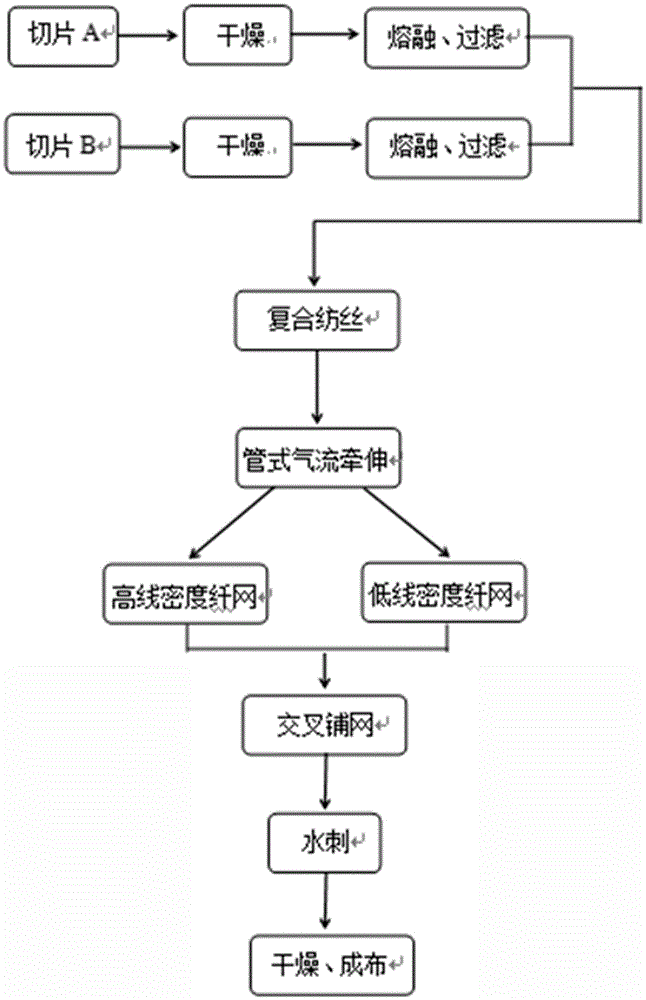

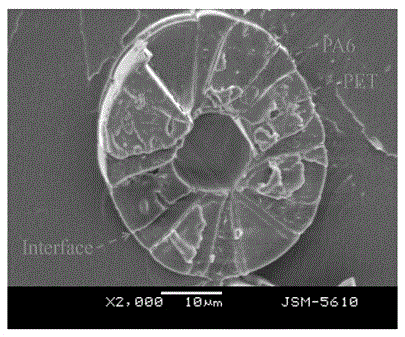

Manufacturing method of two-component superfine non-woven filtering material

InactiveCN105671791AImprove filtration efficiencyExpand application spaceNon-woven fabricsPolyesterSpinning

The invention discloses a manufacturing method of a two-component superfine non-woven filtering material. Any two of polyester (PET), polyamide (PA6) and polyethylene (PE) serve as raw materials for composite spinning, the pressure in the airflow drafting process is controlled, and two types of spun viscose webs which are greatly different in fiber line density are obtained; lapping is conducted on the two types of spun viscose webs, multiple cycles of spunlace splitting and solidification formation are conducted, and the superfine non-woven filtering material is finally formed. According to the two-component superfine non-woven filtering material manufactured through the method, due to the fact that two-component hollow orange-slice fibers are cracked and separated into superfine fibers under the spunlace pressure, a special three-dimensional stereo structure is formed after solidification, different fiber density gradients exist, and the manufacturing method has the advantages of being high in filtering efficiency, small in resistance, large in dust containing capacity and the like.

Owner:ZHEJIANG SCI-TECH UNIV

Toughness tube (pipe) type filtration machine

InactiveCN1751769APrevent excessive displacementSimple structureStationary filtering element filtersControl systemFiltration

A flexible pipe type filter is composed of at least one filter element consisting of at least one membrane module comprising at least one membrane unit, raw liquid delivering system, pressure generator for pressing the flexible membrane units to remove clean liquid from raw liquid, filtrate draining system filtered dregs discharging system and control system. Its advantages are high filtering speed and dry dregs.

Owner:张民良

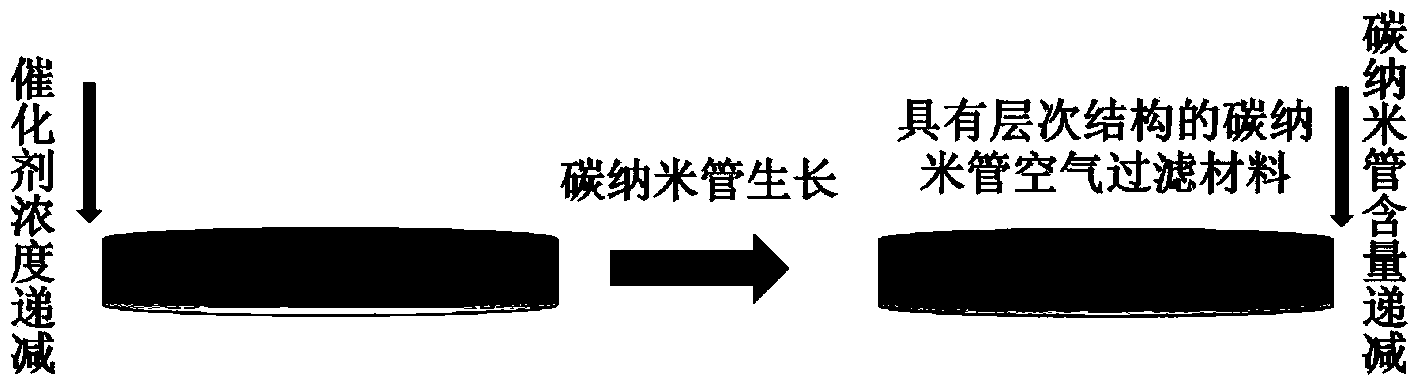

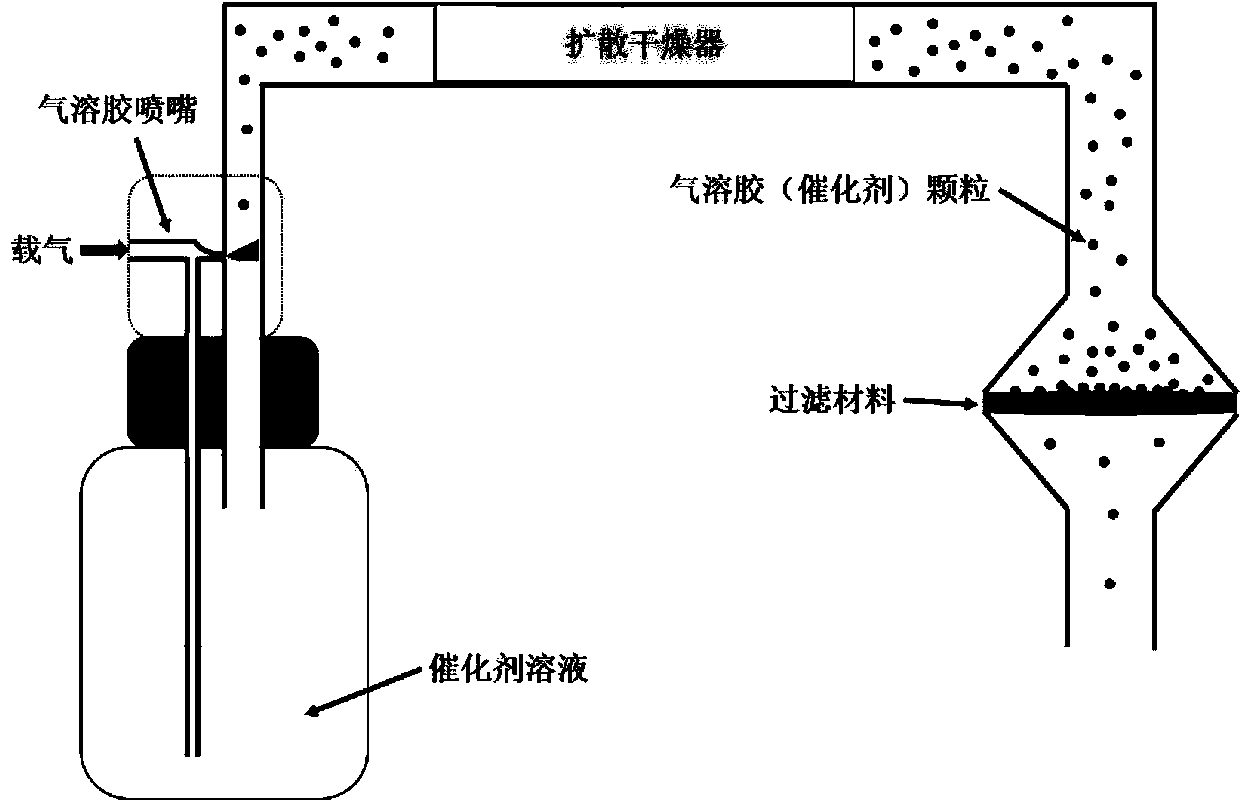

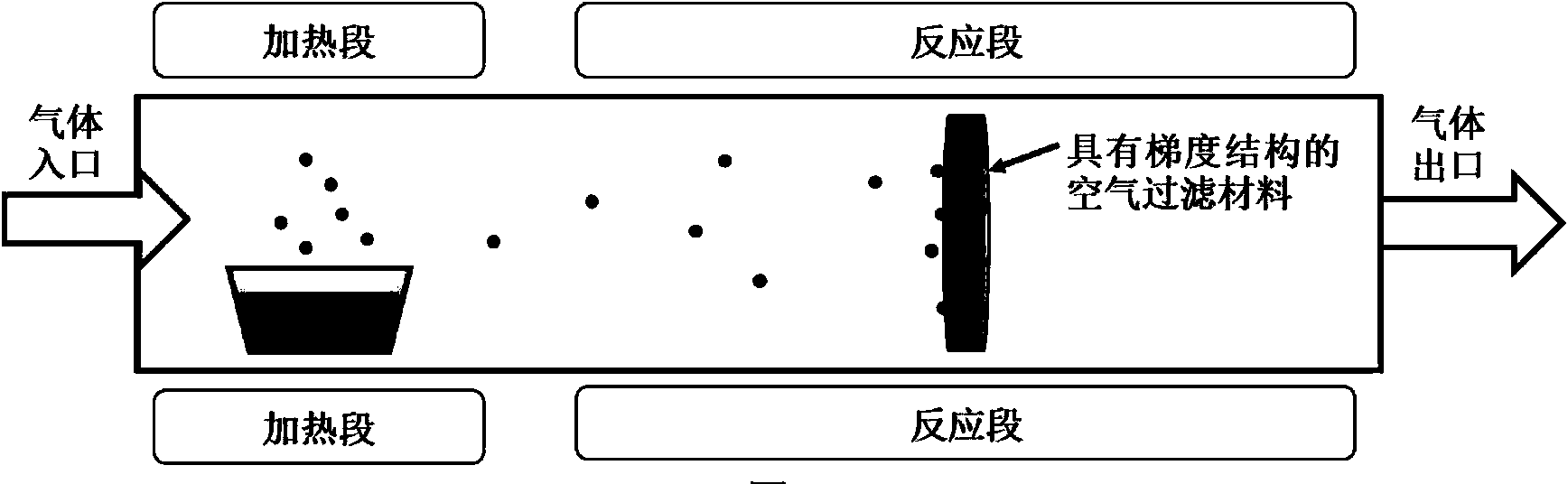

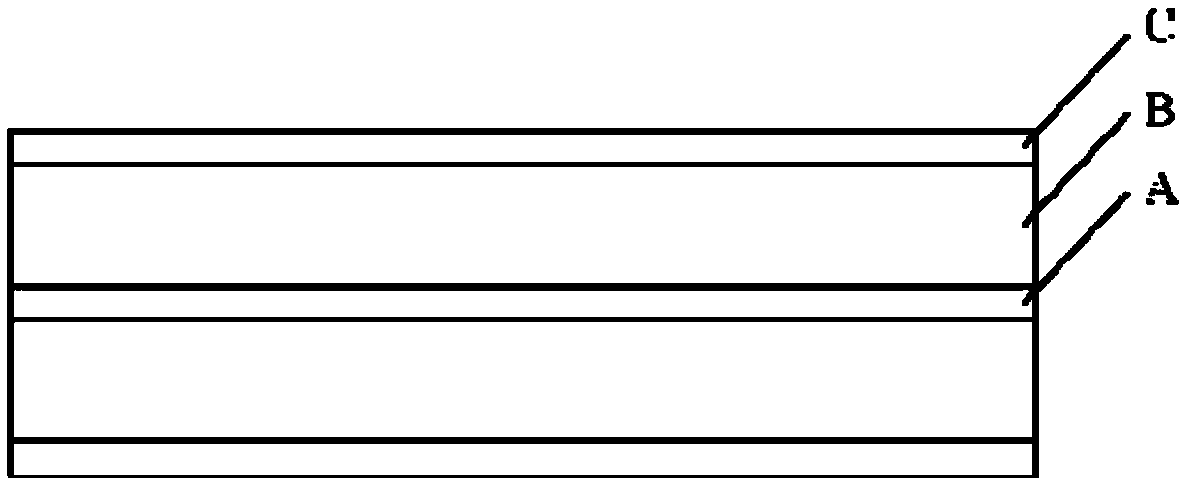

Carbon nanotube air filtering material with gradient structure and preparation method thereof

ActiveCN103446804AIncrease dust holding capacitySolve the strength problemFiltration separationChemical vapor deposition coatingAir filtrationFiber

The invention discloses a carbon nanotube air filtering material with a gradient structure and a preparation method thereof. The method comprises the following steps: with a fiber filtering medium as a substrate, preparing a metal catalyst; distributing the metal catalyst along the thickness direction of the substrate in a gradient manner; and growing a carbon nanotube on the surface of the fiber filtering medium through a chemical vapor deposition method to obtain the carbon nanotube air filtering material with a gradient structure. The carbon nanotube air filtering material with a gradient structure, provided by the invention, has a multilevel structure, and the carbon nanotube grows on the fiber surface to both solve the strength problem of the nano material in macro scale and fully utilize the excellent performance of the nano material in nano scale; meanwhile, the gradient structure exists in the thickness direction of the filtering material, the design can greatly improve the dust holding capacity of the filtering material, and the prepared filtering material has long service life.

Owner:TSINGHUA UNIV

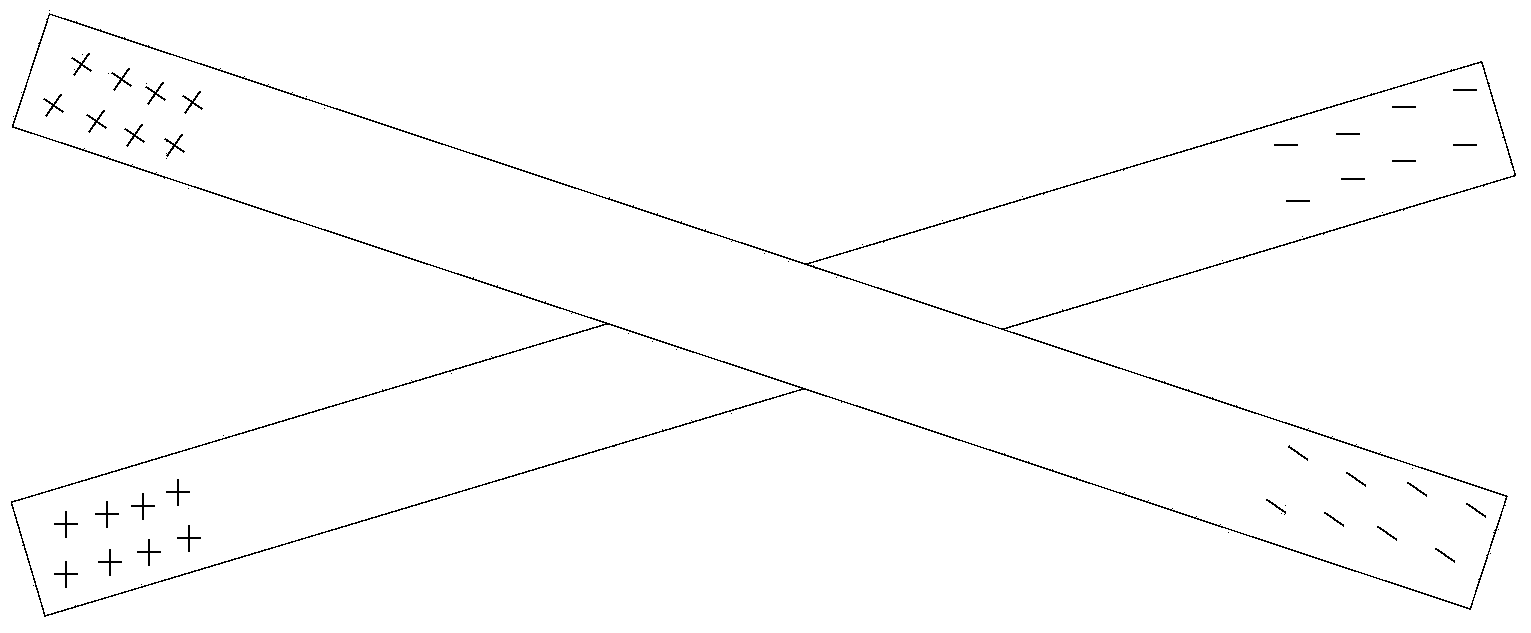

Efficient low-resistance nano-fiber microscopic gradient structure filtering material and preparation method thereof

ActiveCN108796823ASimple preparation processUniform tapered tapered stacked structureMembrane filtersFiltration separationElectricitySurface layer

The invention discloses an efficient low-resistance nano-fiber microscopic gradient structure filtering material and a preparation method thereof. The filtering material comprises a nanometer fine filtering layer, a micrometer support primary filtering layer and protective surface layers, wherein the micrometer support primary filtering layer and the nanometer fine filtering layer are interactively overlaid, and arranged between the two protective surface layers. The nanometer fine filtering layer has a grid structure, and the nanometer fine filtering layer is composed of a plane matrix fiberlayer and cone structures, wherein fibers between the tips of the cone structures and a grid matrix fiber layer have an oriented structure along the tips and the plane matrix fiber layer. By means ofthe filtering material without electricity, the efficiency of filtering NaCl aerosol with the mass median aerodynamic diameter of 0.26 micrometer is 99.9-99.999%, and the pressure is reduced to 130-300 Pa; by means of the filtering material which is treated by electricity, the efficiency of filtering the NaCl aerosol with the mass median aerodynamic diameter of 0.26 micrometer is 99.9-99.999%, andthe pressure is reduced to 30-250 Pa.

Owner:SOUTH CHINA UNIV OF TECH +1

Preparation method of high temperature resistant ceramic fiber gas filter material

ActiveCN101966410ASmall filter resistanceImprove separation efficiencyFiltration separationCalcium silicateFiber

The invention belongs to the field of fine ceramic filtering, particularly relates to a preparation method of a high temperature resistant ceramic fiber gas filter material. The preparation method comprises the following steps of: firstly, mixing ceramic fibers with a bonding solution according to the mass ratio of 0.5-1.5:100, uniformly stirring, forming, drying and sintering to obtain a ceramic fiber support body; mixing calcium silicate with the bonding solution according to the mass ratio of 0.5-1.5:100, and uniformly stirring; and applying a solution obtained by mixing the calcium silicate with the bonding solution to the surface of the ceramic fiber support body, drying and sintering to obtain a finished product; or forming and drying the solution obtained by mixing the calcium silicate with the bonding solution, and sintering to obtain a calcium silicate film, drying and sintering the ceramic fiber support body and the calcium silicate film to obtain a finished product. The high temperature resistant ceramic fiber gas filter material prepared by the method can resist the high temperature of 1,200 DEG C, has low filtration resistance and is easily regenerated.

Owner:HEFEI FOUND TECH

Needling static filter cotton and preparation method thereof

ActiveCN103537142ASmall filter resistanceLarge dust holding capacitySynthetic resin layered productsUltrasonic/sonic fibre treatmentBrute forcePressure resistance

The invention discloses needling static filter cotton. The needling static filter cotton comprises a needling non-woven layer, wherein any surface or two surfaces of the upper surface and the lower surface of the needling non-woven layer is or are provided with a spunbonded nonwoven fabric layer. A preparation method of the needling static filter cotton comprises the following steps of producing a needling cotton, drying, compositing the needling cotton, applying static electricity and packaging a finished product. The needling static filter cotton provided by the invention has the advantages that the needling cotton is composited, the wind pressure resistance of the needling cotton is enhanced, so that the needling cotton plays the supporting role, the high-density electrostatic charge is applied on the needling cotton, so that not only is the filter efficiency greatly improved to enable the filtration efficiency to be more than 98%, and also the filtration resistance is greatly reduced to be reduced to be below 7Pa. The needling static filter cotton after processing has the outstanding characteristics that the filtration efficiency is high, the filtration resistance is ultralow and the service life is long, the physical properties such as longitude and latitude brute force property and a wear-resisting property are excellent, and the needling static filter cotton is greatly superior to the common melt-blow static filter cotton at present.

Owner:常州百朋纺织有限公司

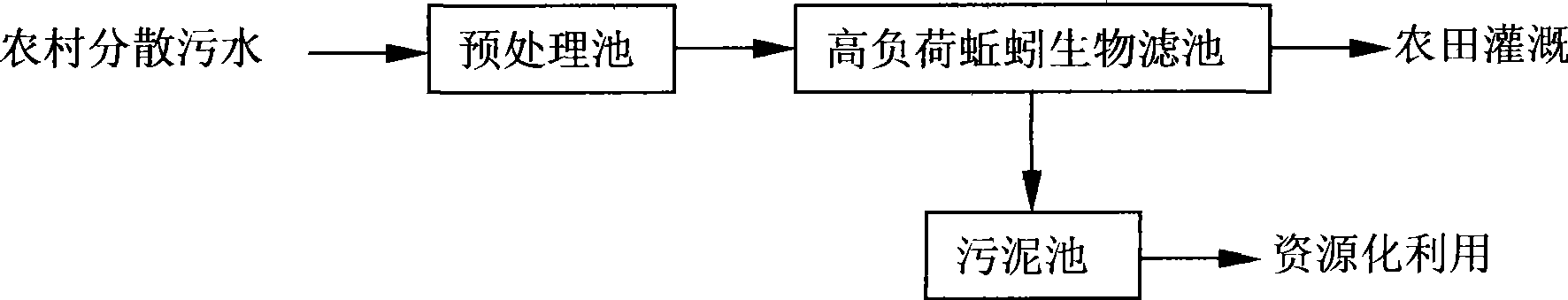

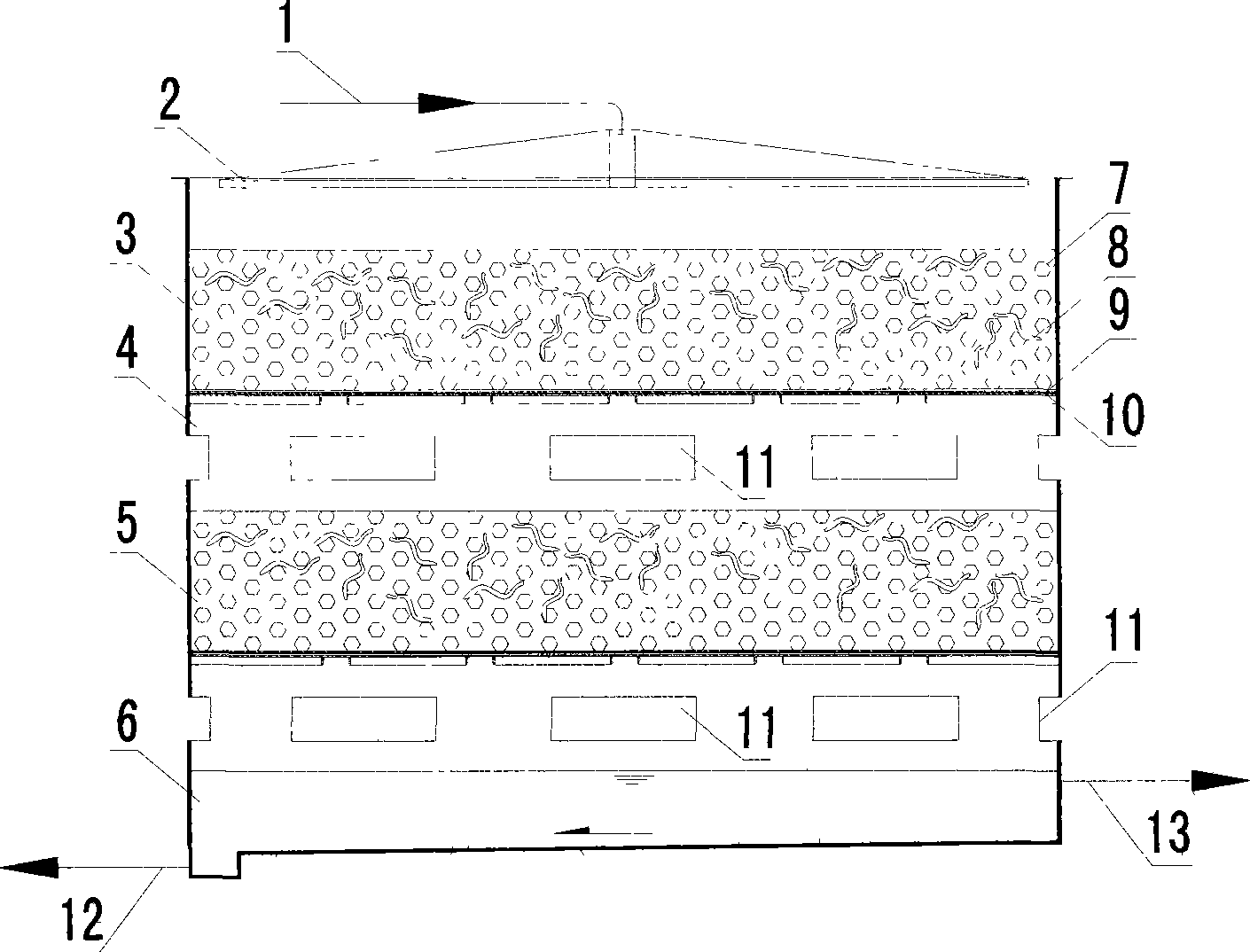

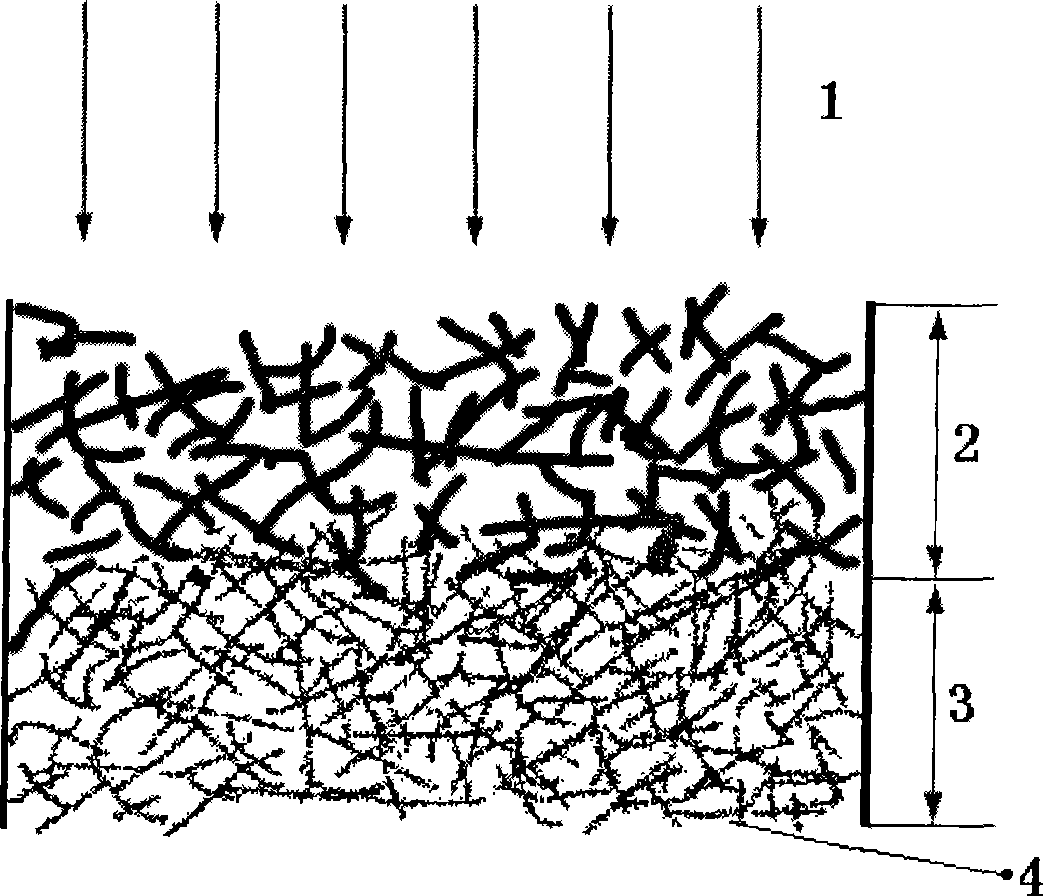

Method for treating rural disperse sewage by using high load vermibiofilter

InactiveCN101391855AChemically stableLow priceBio-organic fraction processingMultistage water/sewage treatmentFertilizerSewage

The invention discloses a method for utilizing high-load earthworm biological filter to treat decentralized sewage in countries, and relates to a sewage treatment method. The treatment method comprises the following steps: the decentralized sewage in the countries is firstly collected; suspended matter and floating matter are removed by a pretreatment tank; BOD5 is led to be 110 to 160mg / L, COD is 120 to 150mg / L and SS is 90 to 130mg / L; then the obtained mixture is pumped into the high-load earthworm biological filter according to hydraulic loading of 4 to 6m<3>(m<2> question mark d); after passing through a first earthworm biological filtering layer and a second earthworm biological filtering layer which are filled with light shale spherical porcelain granules (7) filtering media with the diameter of 3 to 7mm and 15000 to 28000 eisenia foetidas (8) are added on the surface of the filtering media per square meter, the water which is discharged from a settling tank (6) and has BOD5 of less than 15mg / L, COD of less than 60mg / L and SS of less than 15mg / L reaches the national water quality standard for field irrigation; little amount of residue sludge which is collected by the settling tank (6) and contains wormcast is used for improving the soil or is used as fertilizers. The method has large hydraulic loading, small occupy area, is hard to be blocked, has simple process and operation, good water outlet quality and low construction cost and operating cost and can be widely used for treatment of the waste water in rural areas.

Owner:TONGJI UNIV

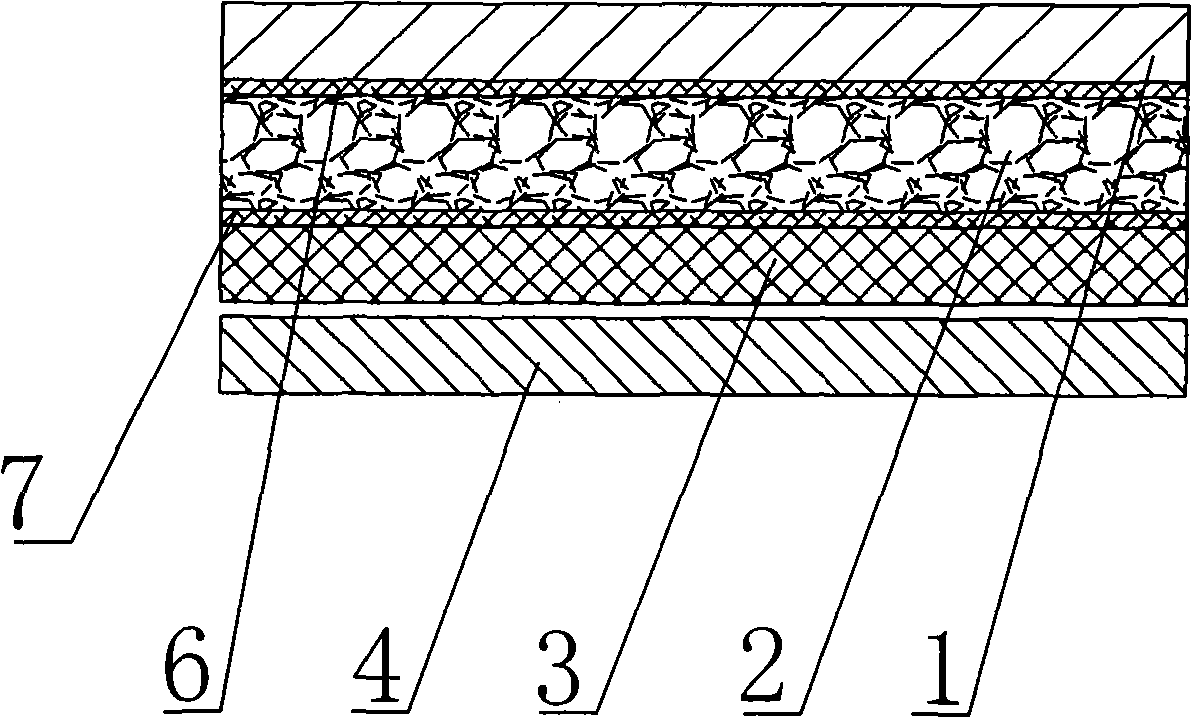

Double-layer filter material for internal combustion engine

InactiveCN101367020ASmall filter resistanceIncrease dust holding capacityLayered productsCombustion-air/fuel-air treatmentMetallurgyFiltration

The invention provides a double-layer filtering material for an internal combustion engine. The double-layer filtering material is provided with a coarse filtering layer and a fine filtering layer according to the direction of flow; the fine filtering layer consists of fibrillating fiber with the quality fraction between 2 to 100 percent and natural fiber with the quality fraction between 0 to 98 percent, wherein the diameter of the trunk of the fibrillating fiber is 1 to 20 microns, the length of the fibrillating fiber is 0.1 to 10 millimeters, the beating degree of the fibrillating fiber is 12 to 65 degrees SR, the diameter of the natural fine filtering layer fiber is 5 to 30 microns, and the length of the natural fine filtering layer fiber is 0.5 to 3.5 millimeters. The double-layer filtering material realizes to improve the filtering efficiency of the filtering material while keeping low filtration resistance and high capacity of holding dust.

Owner:SOUTH CHINA UNIV OF TECH

Micrometer/nanometer fiber composite filtering material and preparation method thereof

PendingCN109157915AImprove uniformityGuaranteed stabilityMembrane filtersFiltration separationFiberElectrospinning

The invention discloses a micrometer / nanometer fiber composite filtering material and a preparation method thereof. The material comprises nanometer fiber and a single-layer micrometer fiber net; andthe structure is as follows: single or bunchy nanometer fiber is distributed on the surface of the single-layer micrometer fiber net uniformly or is embedded in a fiber assembly gap of the single-layer micrometer fiber net uniformly. The method comprises the following steps: preparing electrostatic spinning liquid; preparing the single-layer micrometer fiber net from micron-sized fiber and conveying the single-layer micrometer fiber net to a net conveying curtain with meshes; starting to perform electrostatic spinning by using the electrostatic spinning liquid, jetting single or bunchy nanometer fiber on the single-layer micrometer fiber net uniformly from an electrostatic spinning nozzle to form a single-layer micrometer / nanometer fiber composite net; and forming a continuous multi-layerstructure composite fiber net by using the single-layer micrometer / nanometer fiber composite net by a cross lapping mode, and performing mechanical consolidation to obtain the micrometer / nanometer fiber composite filtering material. The method is simple in production process, high in controllability and easy in industrialization.

Owner:TIANJIN POLYTECHNIC UNIV

Polypropylene electret master batch, preparation method thereof and polypropylene melt-blown non-woven fabric

ActiveCN111875886AImprove liquidityStable melt indexTextile/flexible product manufactureNon-woven fabricsLong chain fatty acidPolymer science

The invention relates to the technical field of high polymer materials, in particular to a polypropylene electret master batch, a preparation method thereof, and a polypropylene melt-blown non-woven fabric. The polypropylene electret master batch comprises the following components in parts by weight: 70-90 parts of polypropylene resin, 10-30 parts of an electret agent, 2-5 parts of a nucleating agent, 1-3 parts of a compatilizer, 3-5 parts of a lubricant and 0.5-2 parts of an antioxidant; wherein the electret comprises any one or more of zinc salt, magnesium salt and aluminum salt of long-chain fatty acid with the carbon atom number of 14-22. The preparation method comprises the following steps: uniformly mixing the components in proportion to obtain a premix, and granulating the premix. The polypropylene electret master batch obtained through cooperation of the components has high fluidity, the volatile components and the melt index of the polypropylene electret master batch are morestable, the electret effect of the polypropylene melt-blown non-woven fabric produced by the electret master batch can be effectively improved, the electret effect is stable, the filtering efficiencyis improved, and the filtering resistance is reduced.

Owner:GUANGZHOU LUSHAN NEW MATERIALS +2

Foamed ceramic aluminum melt filter tube, manufacturing method and filtering device

ActiveCN101927105AImprove efficiencyRealize large-area high-precision filtrationProcess efficiency improvementCeramicwareAluminiumPhosphate

The invention relates to a foamed ceramic aluminum melt filter tube, a manufacturing method and a filtering device. The filter tube is prepared from the following raw materials in part by weight: 30 to 40 parts of aluminum dihydrogen phosphate, 1 to 2 parts of fumed silica, 2 to 3 parts of kaolin clay, 1 to 2 parts of aerogel, 60 to 62 parts of alpha alumina, 1 to 2 parts of anti-foaming agent, and 0.5 to 1 part of dispersant. The filter tube consists of a filter and a filter box which are integrated by a foamed ceramic tube, has the combined advantages of high efficiency of aluminum melt filtration by a plate-like foamed ceramic filter and large-area and high-precision filtration of a tube-like porous ceramic filter in a small box, and replaces the plate-like ceramic filters and the porous ceramic filter tubes in the conventional process boxes. When aluminum melt is passed through filter box provided with an integrated foamed ceramic filter tube, because the foamed ceramic filter tube has the characteristics of high open ratio, small filtration resistance, small static difference, high surface energy, strong impurity adsorption, low cost and the like, the aluminum molten liquid can be filtered in large area and high efficiency in the small filter box.

Owner:HUNAN HUAKE MACHINERY

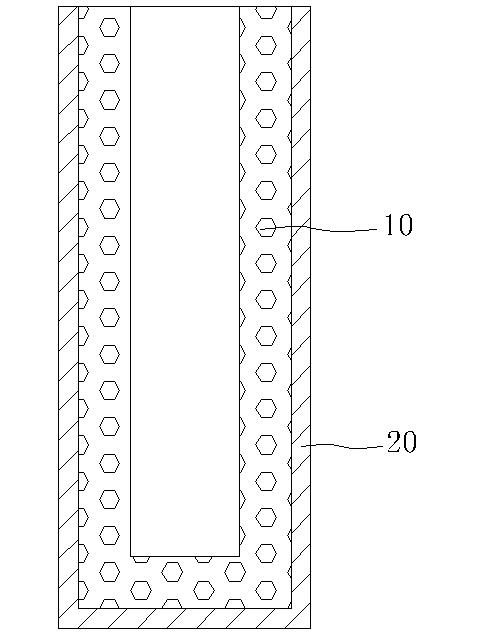

High-flux ceramic flat sheet membrane and preparation method thereof

The invention relates to a high-flux ceramic flat sheet membrane and a preparation method thereof. The high-flux ceramic flat sheet membrane comprises a ceramic flat sheet membrane supporting body and a separation membrane layer wrapping the outer surface of the ceramic flat sheet membrane supporting body. The ceramic flat sheet membrane support body is prepared from the following raw materials in parts by mass: 40-57 parts of diatomite, 30-40 parts of alpha-alumina powder, 4-12 parts of a pore forming agent, 20-40 parts of a support body binding agent, 8-12 parts of a lubricant, 9-13 parts of a plasticizer and 12-18 parts of chopped fibers. The separation membrane layer is prepared from the following raw materials in parts by mass: 40-43 parts of ceramic powder particles, 4-6 parts of ethanol, 19-40 parts of a separation membrane layer binding agent and 9-12 parts of polyethylene glycol. The high-flux ceramic flat sheet membrane product is low in sintering temperature, low in production cost, high in product porosity, small in filtering resistance and high in water flux.

Owner:SHANDONG RES & DESIGN ACADEMY OF IND CERAMICS

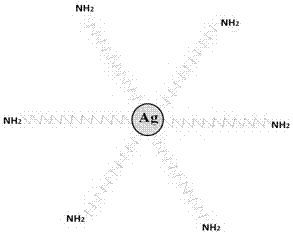

Making method of antibacterial high-efficiency filtering nonwoven fabric

ActiveCN106917267AImprove antibacterial propertiesImprove adsorption capacityFibre typesNon-woven fabricsEthylenediamineFiltration

The invention relates to a making method of an antibacterial high-efficiency filtering nonwoven fabric. The method comprises the following steps: adding a silver nitrate solution to an amino-containing hyper branched polymer solution prepared through reacting methyl acrylate with ethylenediamine in order to obtain an amino-containing Ag / HBP, and mixing the silver nitrate solution with a coupling agent to carry out surface treatment; and impregnating a nonwoven fabric in an Ag / HBP mixed solution, and carrying out heat treatment to obtain the filtering nonwoven fabric. The nonwoven fabric made in the invention can be used in personal protective articles, also can be used in air purifiers of household and office environments, greatly improves the filtration of miniature particles, and can kill bacteria carried by dust particles in air.

Owner:上海盈兹无纺布有限公司

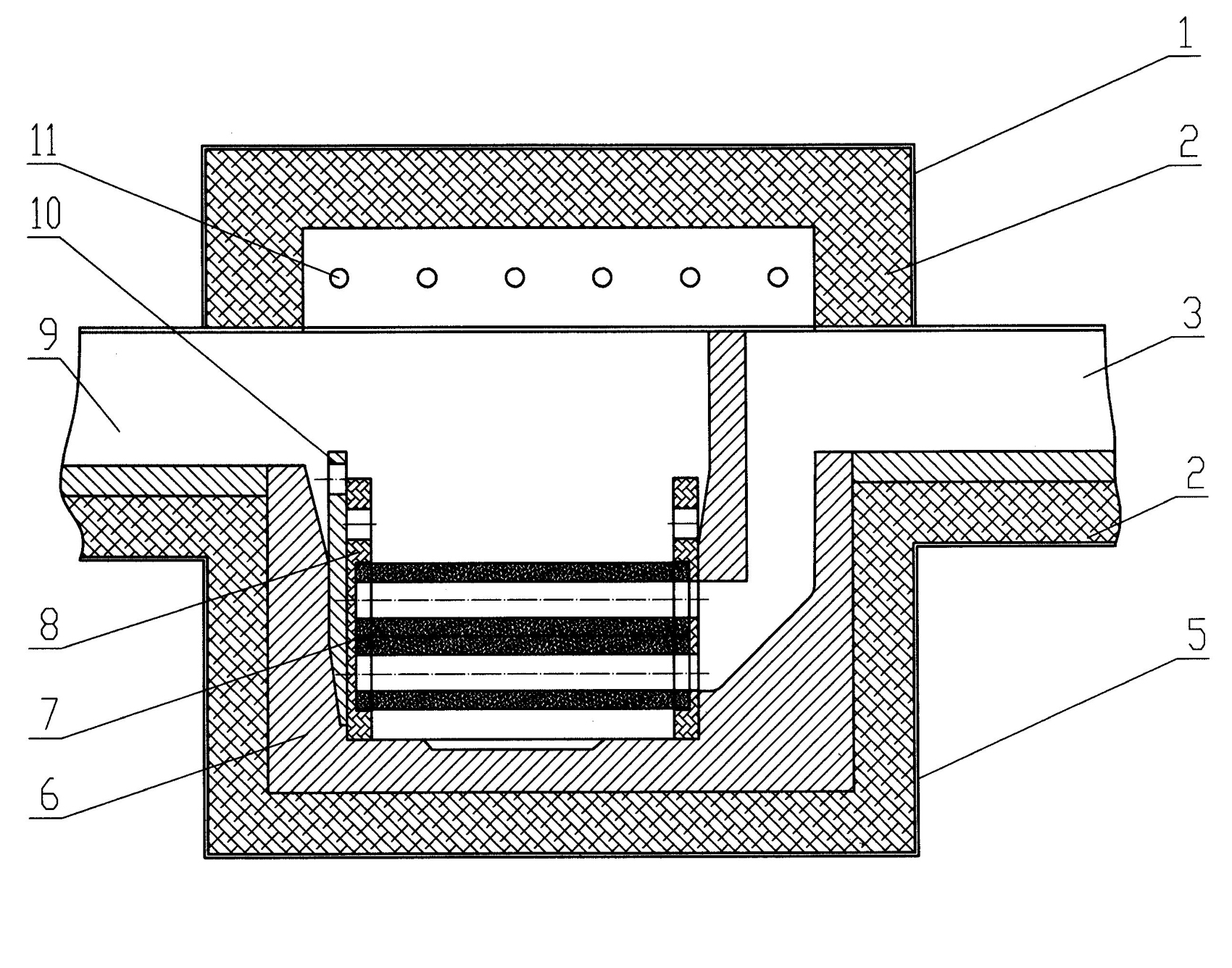

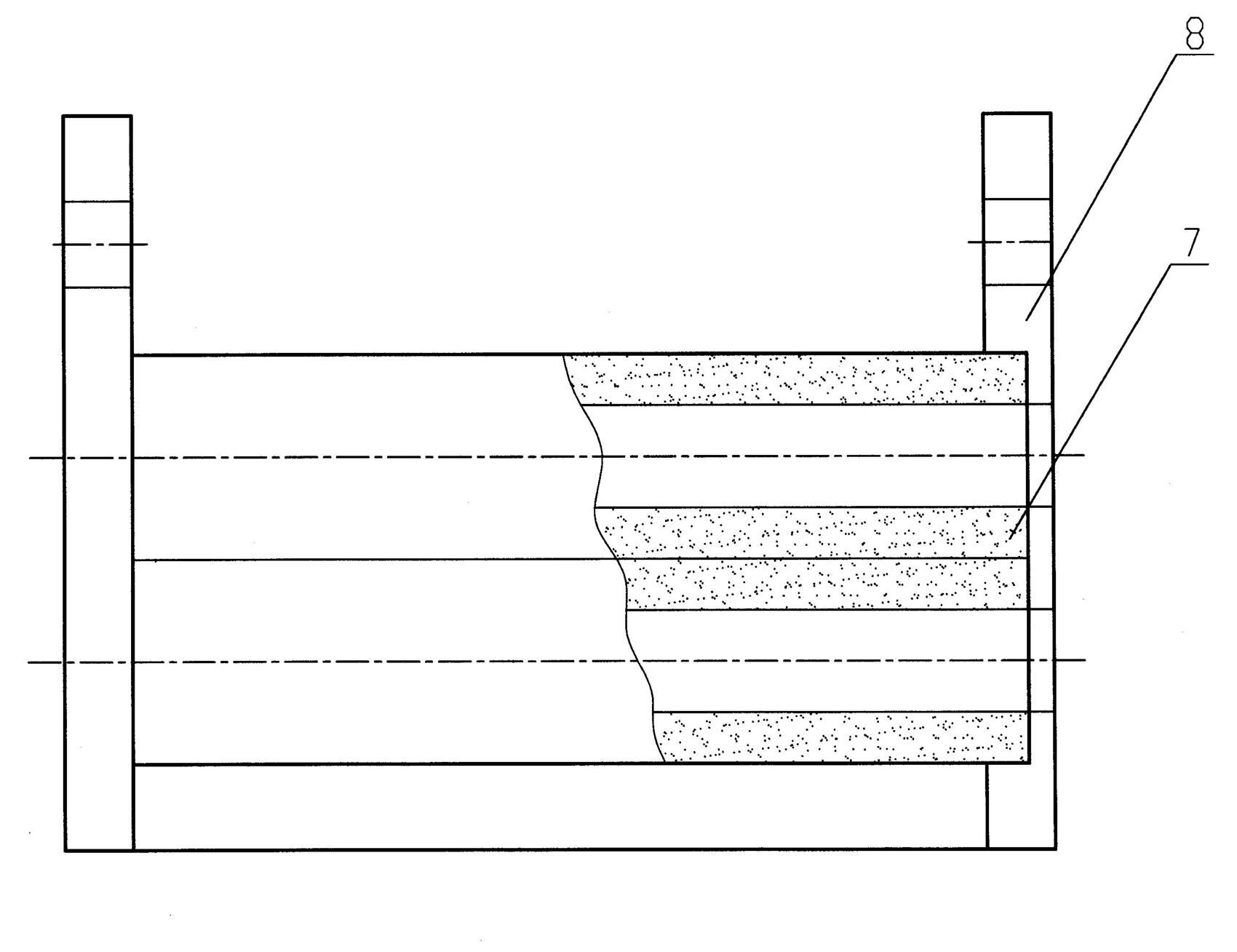

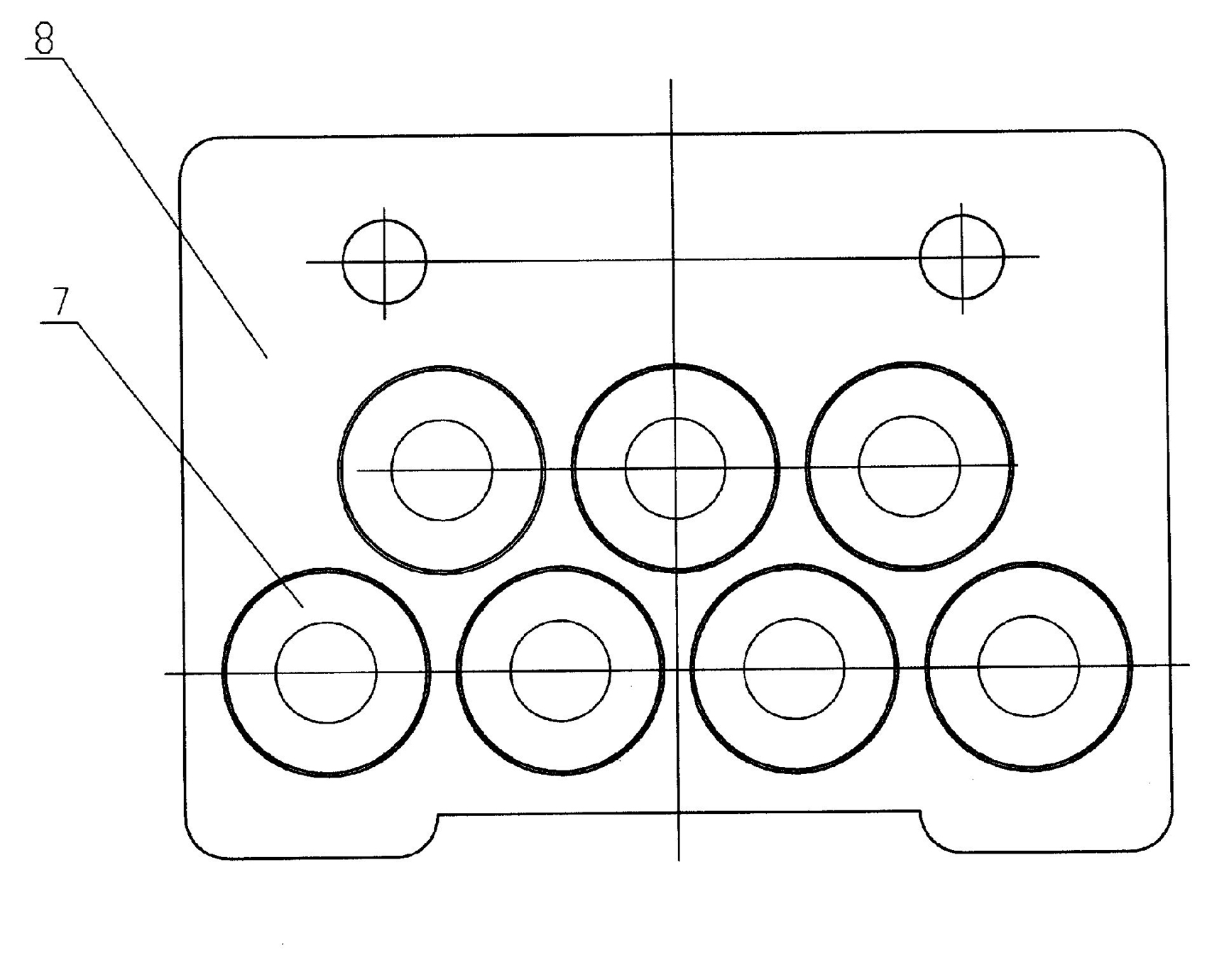

Ceramic fiber filtering tube, preparation method and pressurization and suction forming device

ActiveCN110038368AHigh strengthUniform densityDispersed particle filtrationMembrane filtersFiberVacuum pressure

The invention discloses a ceramic fiber filtering tube, a preparation method and a pressurization and suction forming device. The pressurization and suction forming device comprises a forming mold, apressurization pump, a dosage bunker, a vacuum pump and a vacuum filtrate tank, wherein the forming mold comprises an inner template, an upper template, a lower template, filter cloth and a blank tubecavity; the filter cloth and the blank tube cavity are arranged between the inner template and the upper template respectively; the filter cloth is arranged on the inner template; the lower templateis connected with the upper template; the upper and lower flange faces of the inner template are provided with sealing gaskets respectively; the top of the upper template is provided with a quick coupler for charging water or slurry; the quick coupler is connected with the pressurization pump; the pressurization pump is connected with the dosage bunker; the middle part of the lower template is provided with a water outlet for discharging water or slurry; the water outlet is connected with the vacuum filtrate tank; the vacuum filtrate tank is connected with the vacuum pump; a vacuum pressure gauge and a blow-off valve are arranged between the vacuum filtrate tank and the vacuum pump. The pressurization and suction forming device adopts a pressurization forming and suction sizing demolding form, is simple in structure, is convenient for forming, and is convenient to operate.

Owner:HEFEI HEYI ENVIRONMENTAL PROTECTION TECH ENG

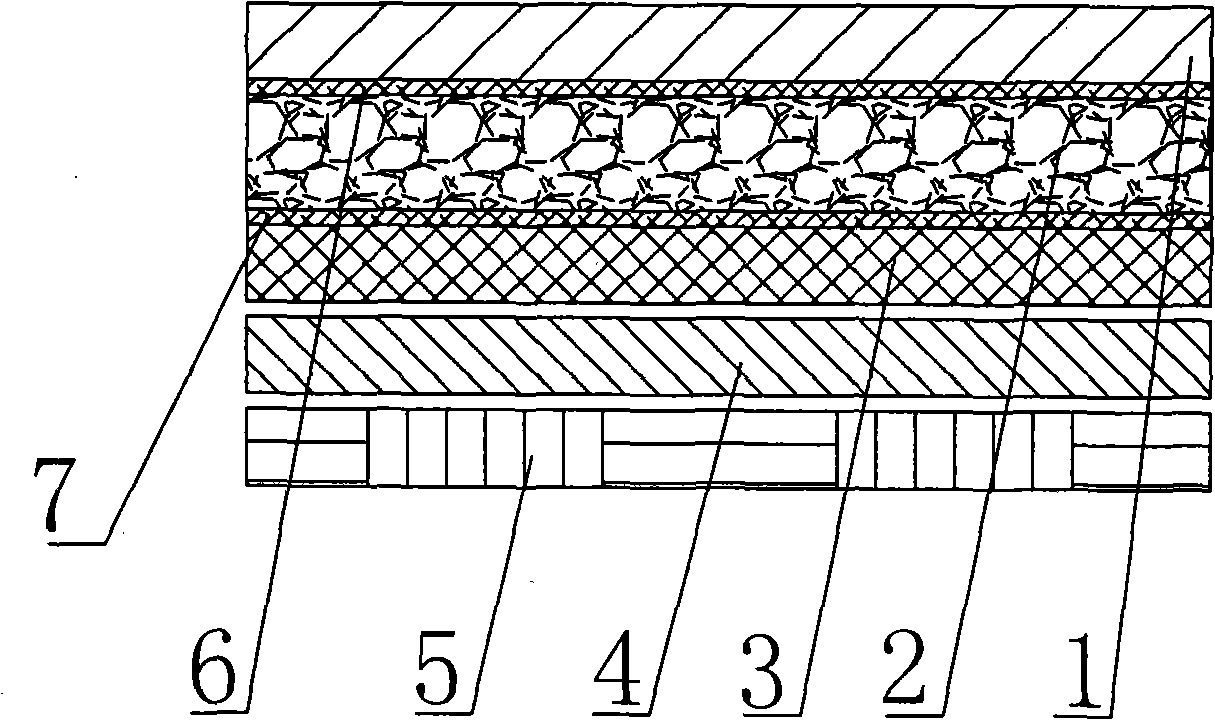

Quantitative filter paper and preparing method and application thereof

InactiveCN104878642AGuaranteed Filtration SpeedFast filtrationPaper/cardboardChemical/chemomechanical pulpFilter paperFiber

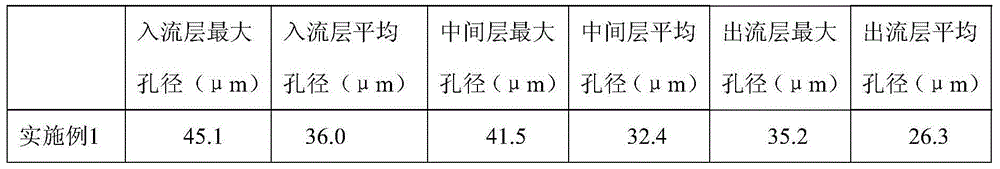

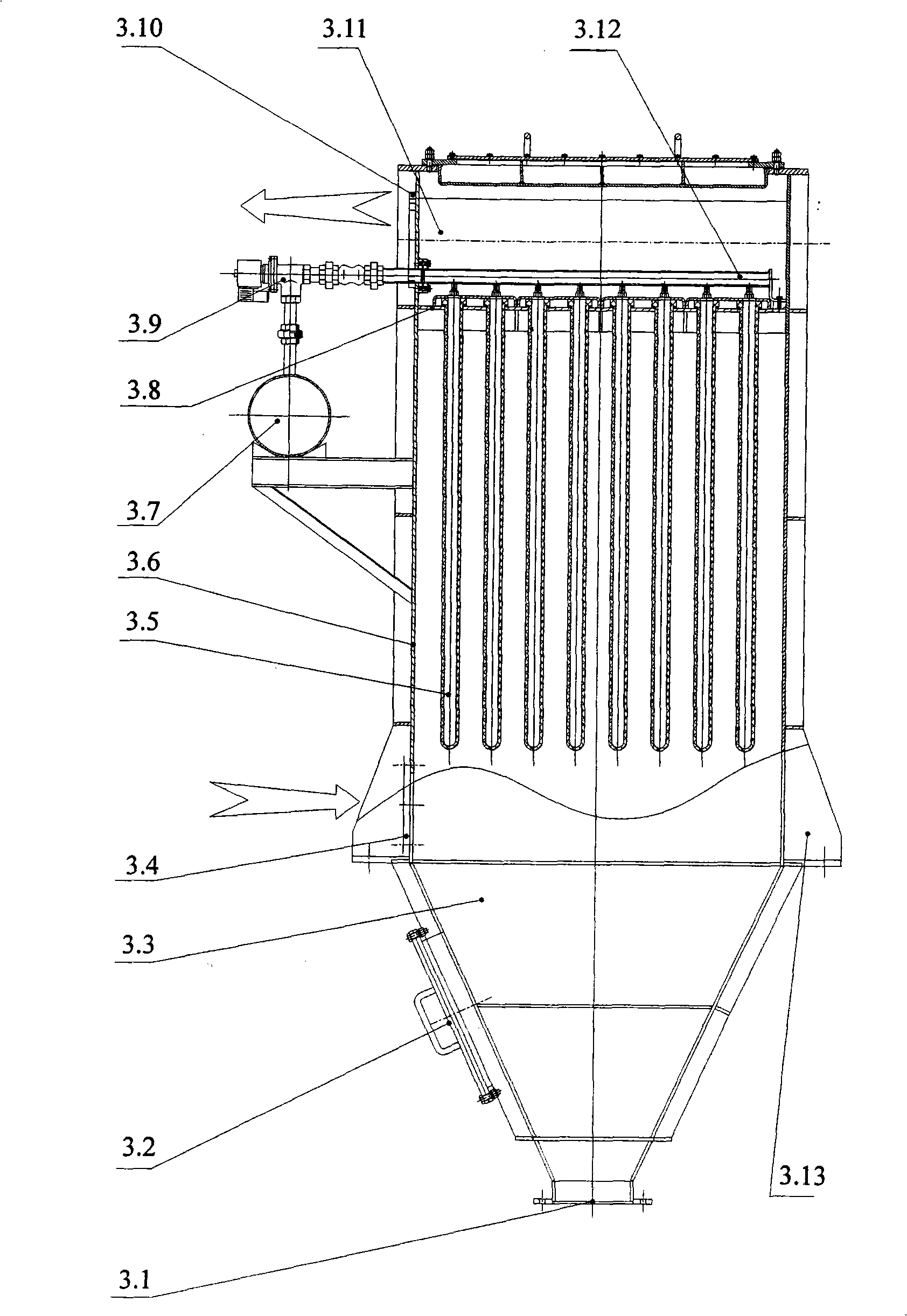

The invention discloses quantitative filter paper, comprising an inflow layer, a middle layer and an outflow layer. The inflow layer is made by forming, pressing and drying slurry 14 DEG SR to 17 DEG SR in beating degree; the middle layer is made by forming, pressing and drying pulp 19 DEG SR to 21 DEG SR in beating degree; the outflow layer is made by forming, pressing and drying pulp 23 DEG SR to 25 DEG SR; the inflow layer, the middle layer and the outflow layer are made of the pulp of same material. The invention further discloses a preparing method of and application of the quantitative filter paper. The layers have different beating degrees of the pulp, the different void distributions of the insides are ensured, and high filtering speed, high precision and high stability are integrated; the preparing method ensures that the fibers in the layers are tightly tangled together, no evident interface occurs, the three-layer composite filter payer manufactured with the pulp is in a complete structure, and smoothness of the separating process is ensured.

Owner:杭州特种纸业有限公司

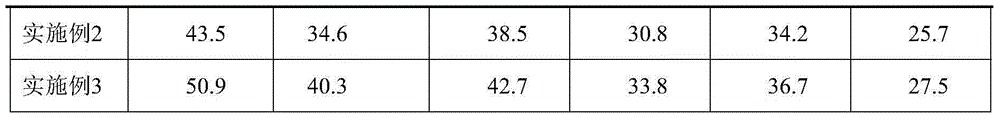

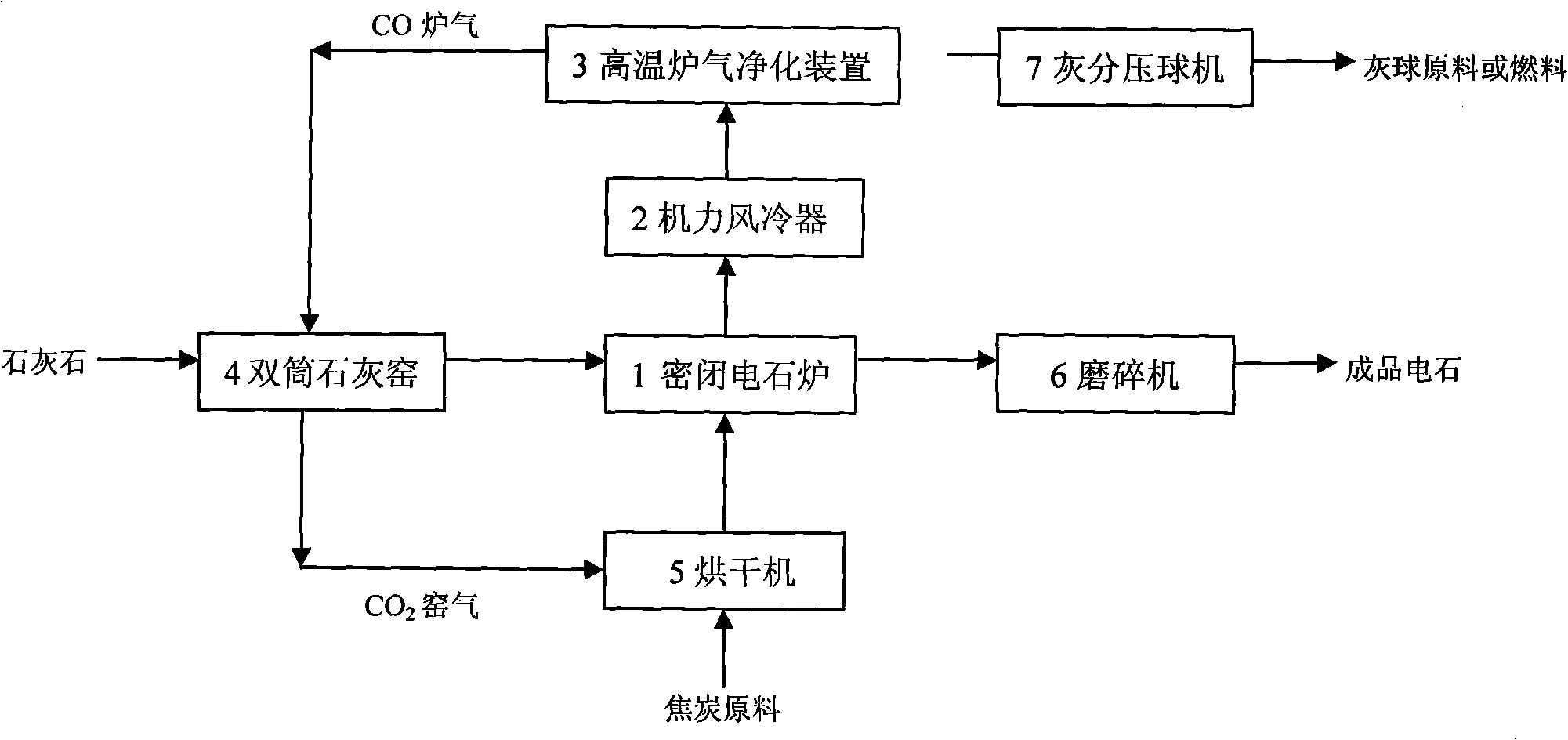

Comprehensive utilization system for high temperature furnace gas of sealed calcium carbide furnace

InactiveCN101284666AImprove separation efficiencyImprove dust removal effectChemical industryCalcium carbideFiberFiltration

The invention discloses a system for comprehensive utilization of the high-temperature furnace gas in a hermetic calcium carbide furnace. Two inlets of the hermetic calcium carbide furnace are respectively connected with a dual-drum limekiln for supplying calcium oxide and a dryer for supplying coke. One outlet of the calcium carbide furnace is connected with a grinding machine used for grinding the calcium carbide; the inlet and the outlet of a mechanical air cooling device are respectively connected with another outlet of the calcium carbide furnace and an inlet of a high-temperature furnace gas purifying device; two outlets of the high-temperature furnace gas purifying device are respectively connected with an inlet of the dual-drum limekiln and an ash content ball press; and the dual-drum limekiln is connected with an inlet of the dryer. The high-temperature furnace gas purifying device in the system takes a foaming aluminum silicate fiber material as a filtration medium which resists high temperature and corrosion and has small resistance and high separative efficiency. The whole system has good energy-saving and environment-friendly characteristics. On the one hand, the recycle of the high-temperature CO furnace gas in the hermetic calcium carbide furnace and the kiln gas of CO2 in the limekiln can satisfy the energy need of the system; on the other hand, the coke consumption and the CO2 emission are reduced.

Owner:SHENWU ENVIRONMENTAL TECH CO LTD

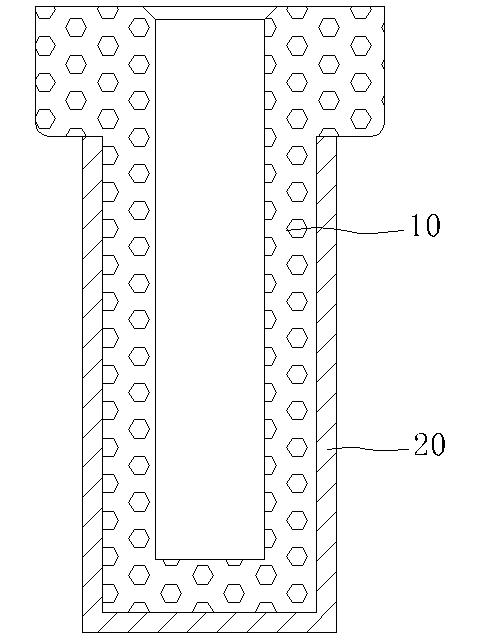

Diatomite-based low-cost ecological environment-friendly type flat ceramic membrane and preparation method thereof

ActiveCN105413484ALow priceLow costMembranesSemi-permeable membranesWater processingCeramic membrane

The invention discloses a diatomite-based low-cost ecological environment-friendly type flat ceramic membrane. The diatomite-based low-cost ecological environment-friendly type flat ceramic membrane comprises a ceramic flat support body and a separating layer membrane coated an outer surface of the ceramic flat support body, the water outlet holes are arranged in the ceramic flat support body; an integral body of the ceramic flat support body is a flat plate, and each corner angle of the flat plate is designed as round corner. The invention also provides a preparation method of the diatomite-based low-cost ecological environment-friendly type flat ceramic membrane, which comprises the steps of preparation of a ceramic flat membrane support body and preparation of a separating flat ceramic membrane. The raw materials have the advantages of low cost and no toxicity, the ceramic membrane is the ecological environment-friendly type filter membrane, is easily decomposed after being discard, and secondary pollution on environment cannot be generated. The ceramic membrane has wide utilization scope, can be used for water processing and gas processing, and especially used for processing and purifying harmful gas due to indoor decoration and processing outdoor environment gas PM2.5.

Owner:安徽名创新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com