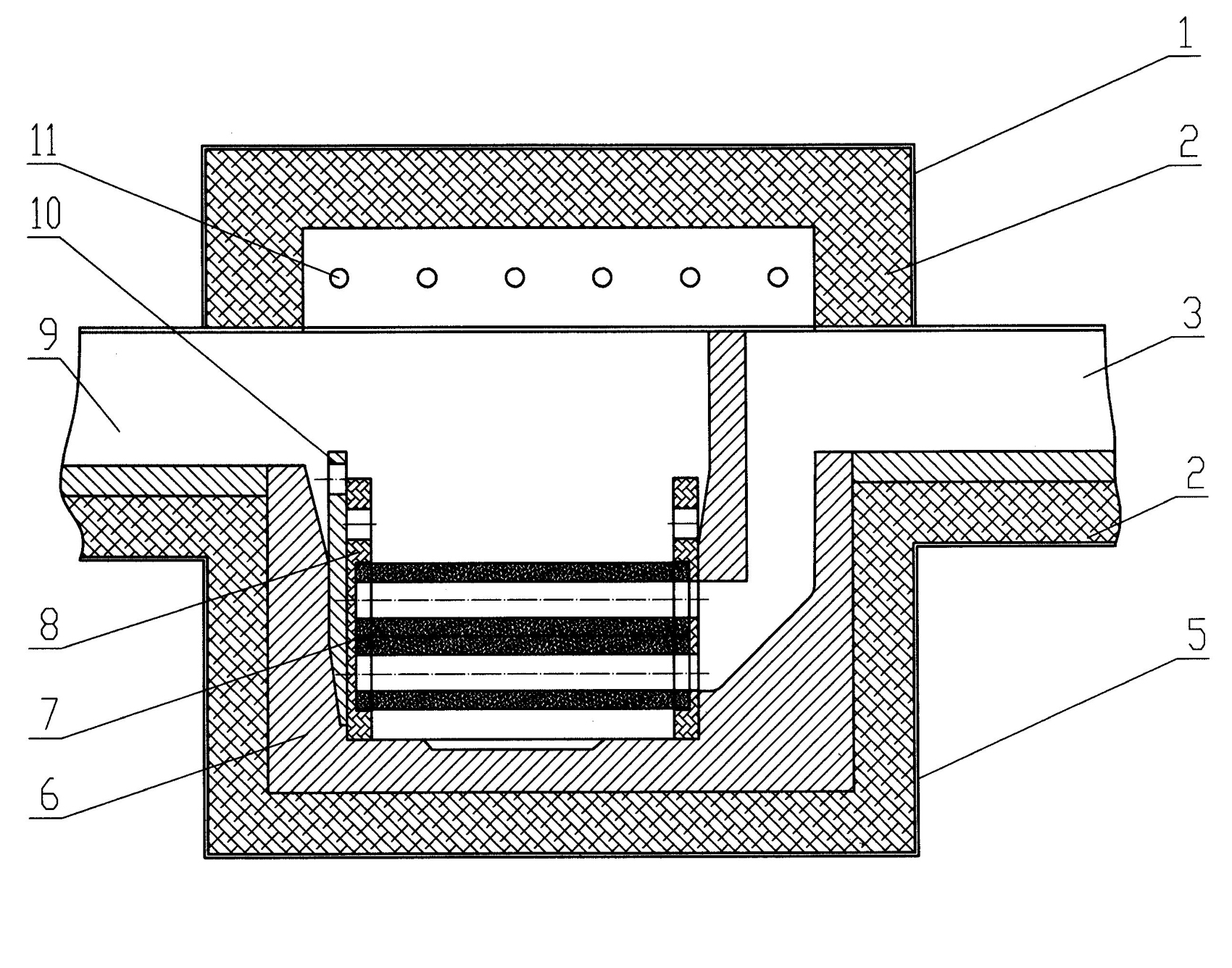

Foamed ceramic aluminum melt filter tube, manufacturing method and filtering device

A foam ceramic filter and filter device technology, which is applied in ceramic products, separation methods, filter separation, etc., can solve the problems of reduced filtration efficiency, impossibility of too large filter area of plate filter, insufficient flow rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

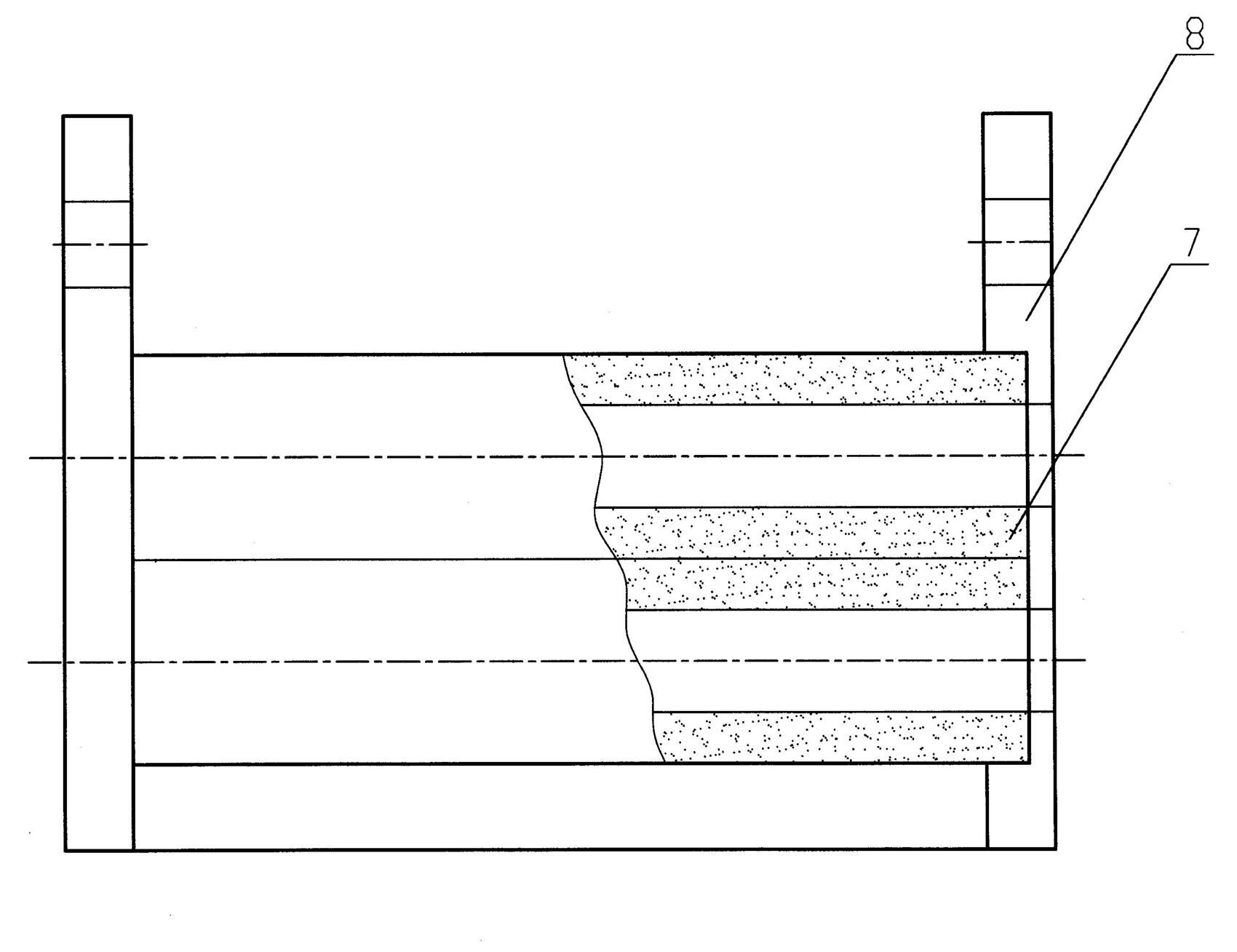

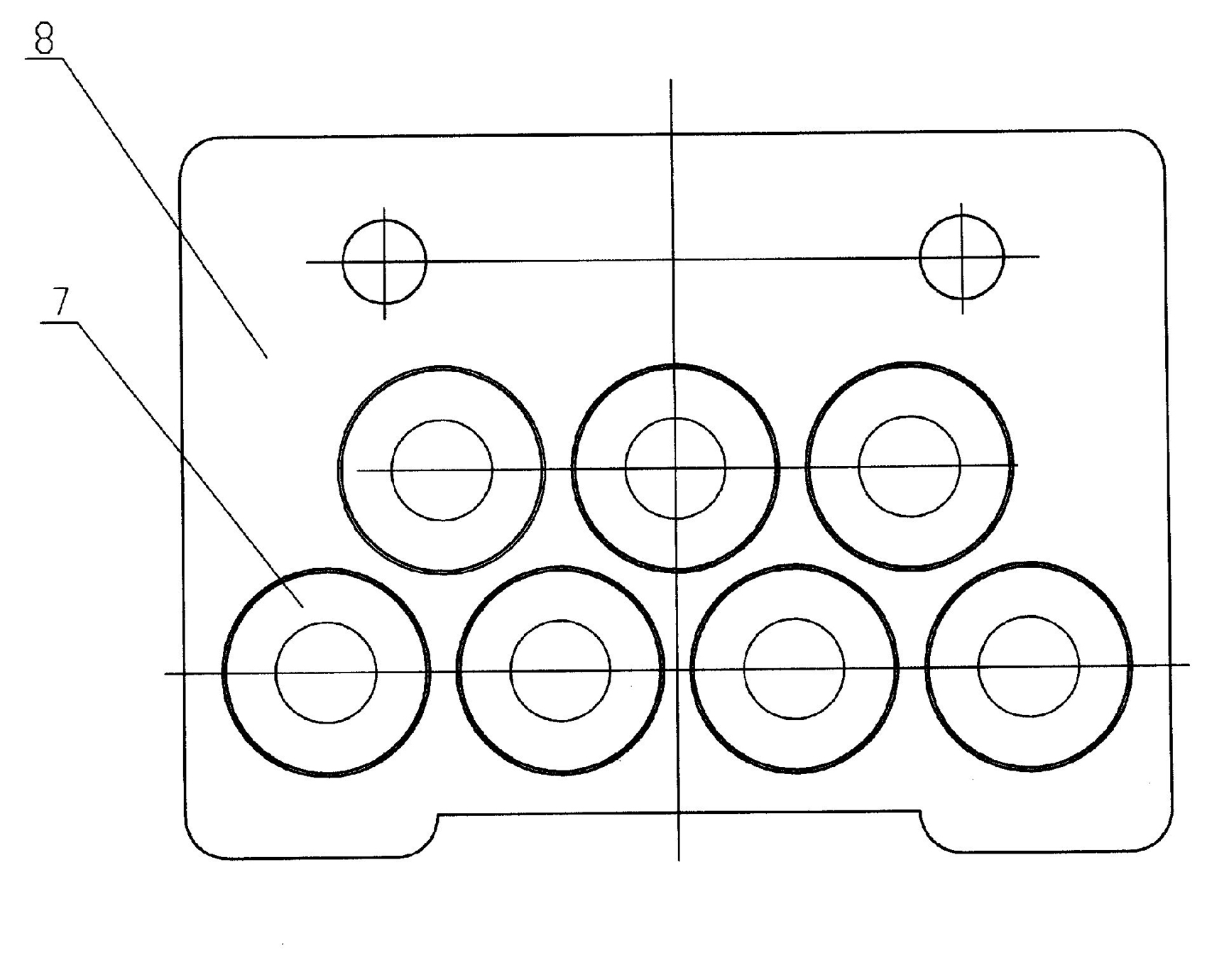

Embodiment 1

[0022] The length of the foam ceramic filter tube is 500mm, the outer diameter is 120mm, and the inner diameter is 60mm. 40ppi - Integrated filter with 7 filter tubes. Before filtering the aluminum melt, put the filter tube into the filter box as required. Heat the filter box first. For the filter box containing 7 filter tubes, it is generally preheated for 6-10 hours. For optimum filtration and subsequent performance, the preheating temperature should be a maximum of 800°C. When filtering, the average flow rate of the aluminum melt should be controlled to be about 50 tons / hour for the filter box of 7 40ppi pipes. A filter box containing seven 40ppi porous ceramic filter tubes can pass about 700-1000 tons of aluminum melt. According to statistics, the following table (1) can get the filtering effect of the filter box of 7 40ppi filter tubes.

[0023] Table I

[0024] Impurity particle size - micron

Embodiment 2

[0026] The length of the foam ceramic filter tube is 500mm, the outer diameter is 120mm, and the inner diameter is 60mm. 60ppi - Integrated filter with 7 filter tubes. According to embodiment 1, filter box is heated, and the maximum immersion temperature that makes preheating is 800 ℃. The filter box with 7 60ppi tubes should control the average flow rate of aluminum melt to about 40 tons / hour. According to statistics, a filter box containing 7 60ppi filter tubes can pass through about 600-800 tons of aluminum solution. According to the statistics, the filtering effect of the filter box of 7 60ppi filter tubes can be found in the following table (2).

[0027] Table II

[0028] Impurity particle size - micron

Embodiment 3

[0030] The length of the foam ceramic filter tube is 500mm, the outer diameter is 120mm, and the inner diameter is 60mm. 60ppi - Integrated filter with 14 filter tubes. According to embodiment 1, filter box is heated, and the maximum immersion temperature that makes preheating is 800 ℃. The filter box with 14 60ppi tubes should control the average flow rate of aluminum melt to about 80 tons / hour. According to statistics, a filter box containing 14 60ppi filter tubes can pass through about 1200-1600 tons of aluminum solution. According to statistics, the following table (3) can find out the filter effect of the filter box of 14 60ppi filter tubes.

[0031] Table three

[0032] Impurity particle size - micron

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com