Patents

Literature

256 results about "Ceramic foam" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

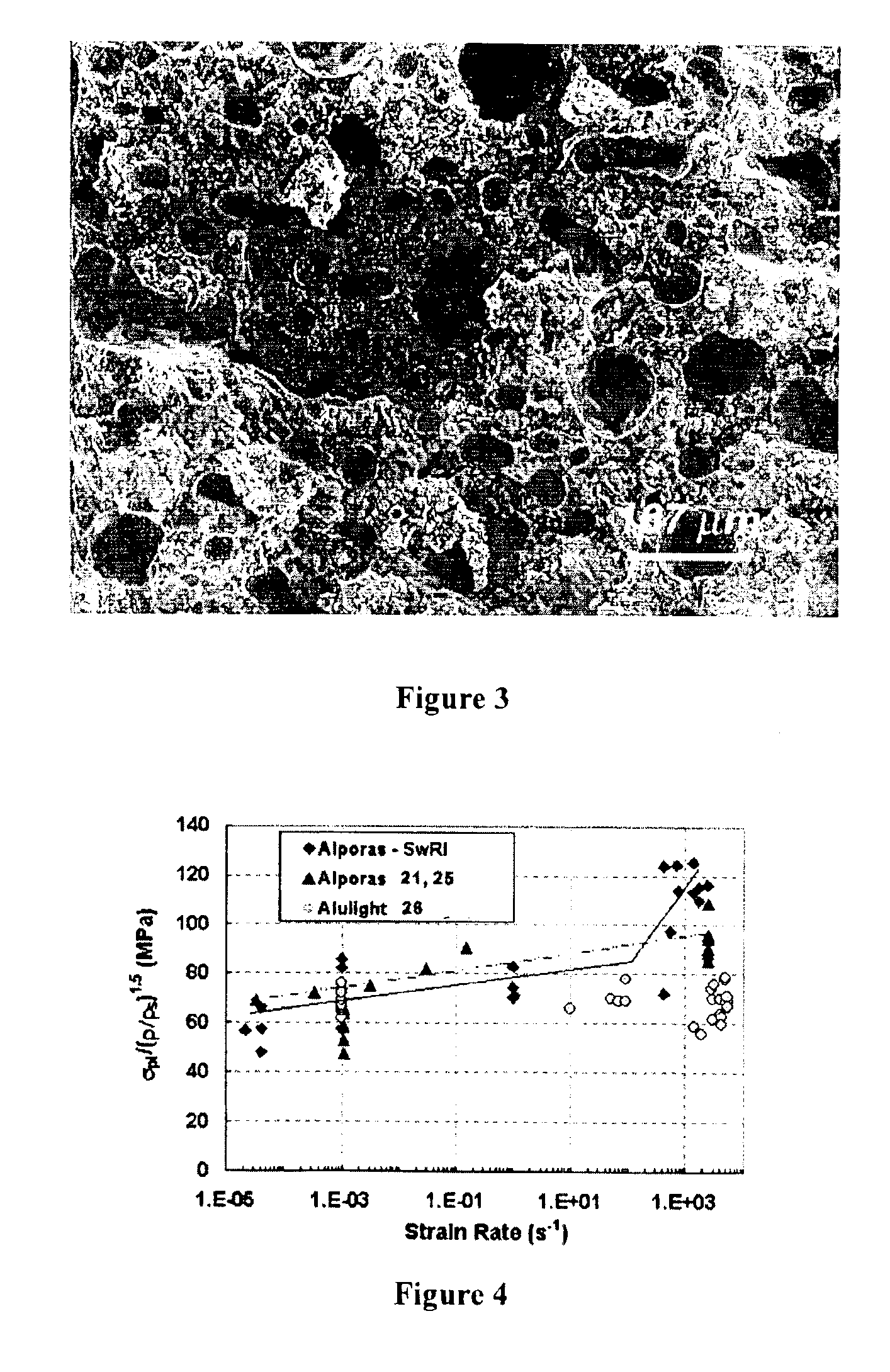

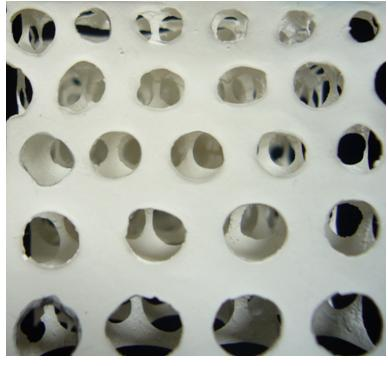

Ceramic foam is a tough foam made from ceramics. Manufacturing techniques include impregnating open-cell polymer foams internally with ceramic slurry and then firing in a kiln, leaving only ceramic material. The foams may consist of several ceramic materials such as aluminium oxide, a common high-temperature ceramic, and gets insulating properties from the many tiny air-filled voids within the material.

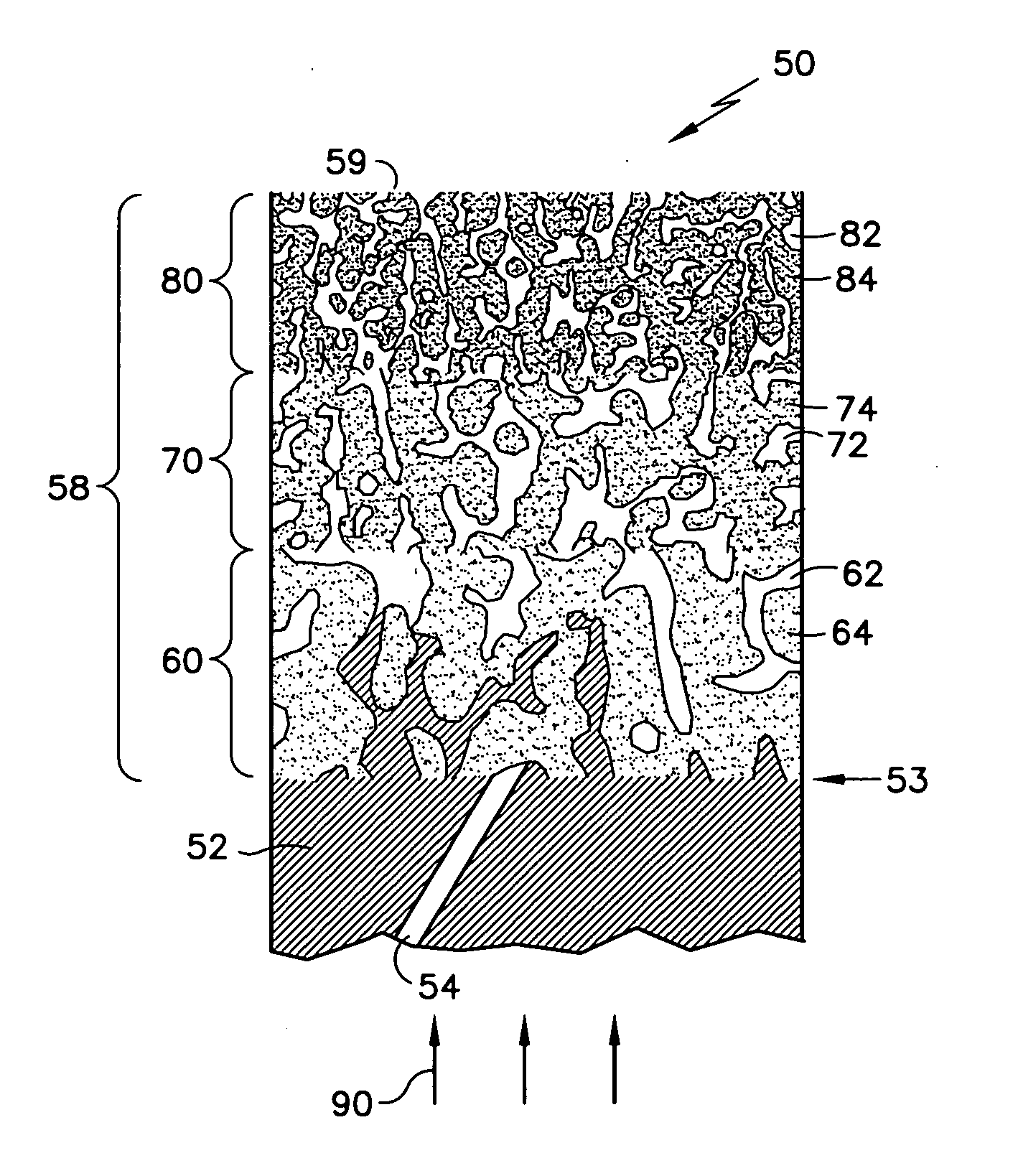

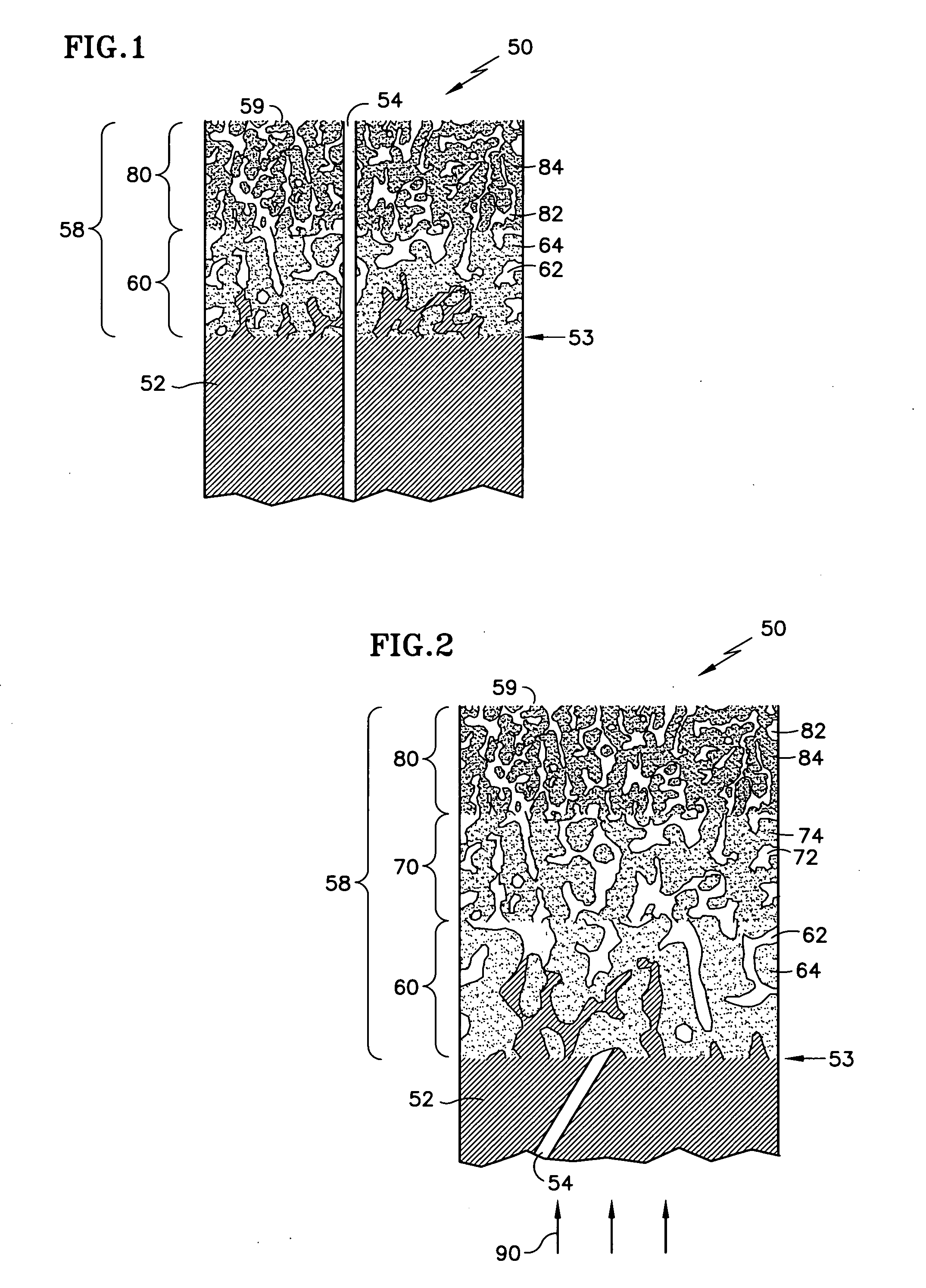

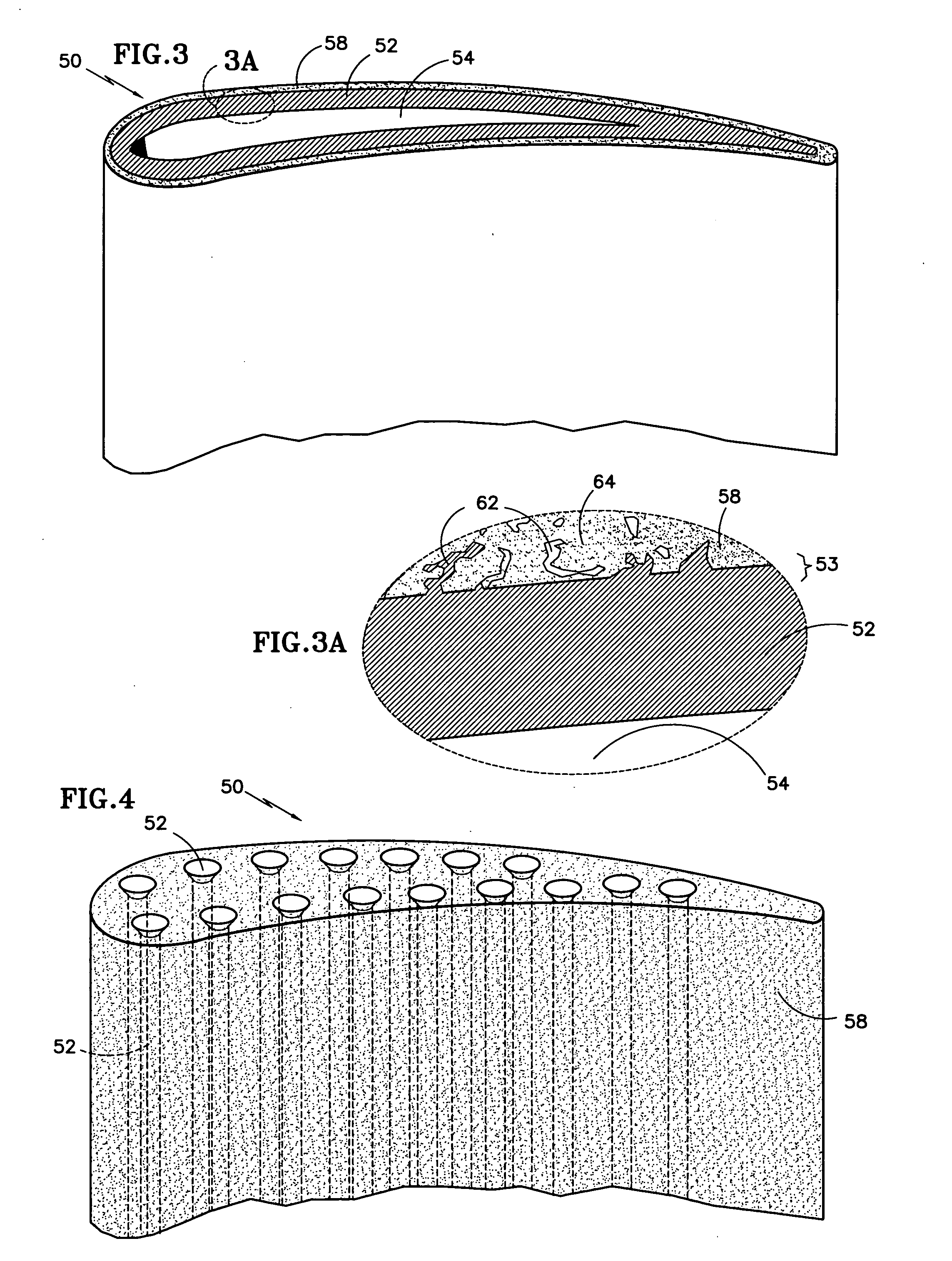

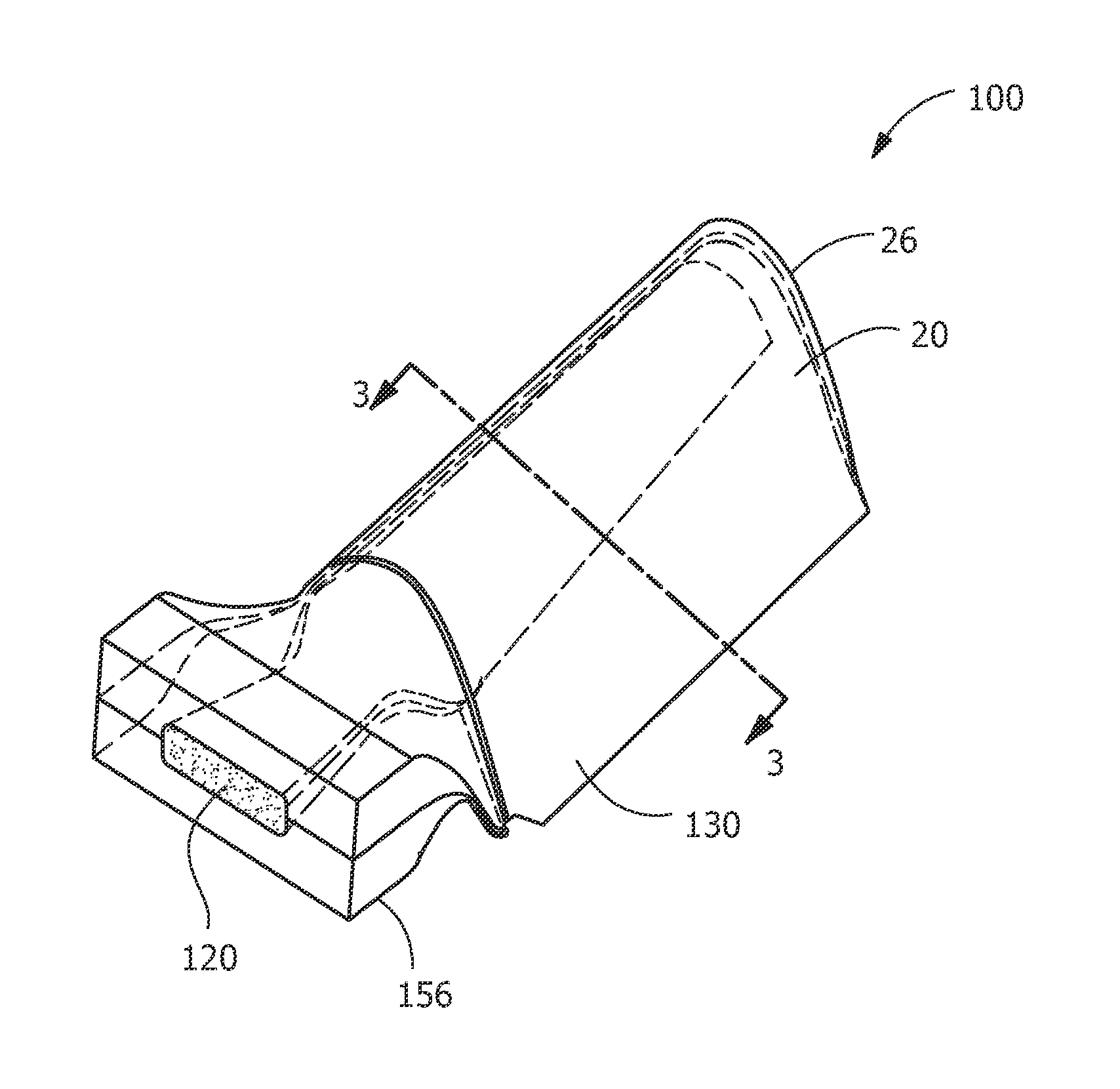

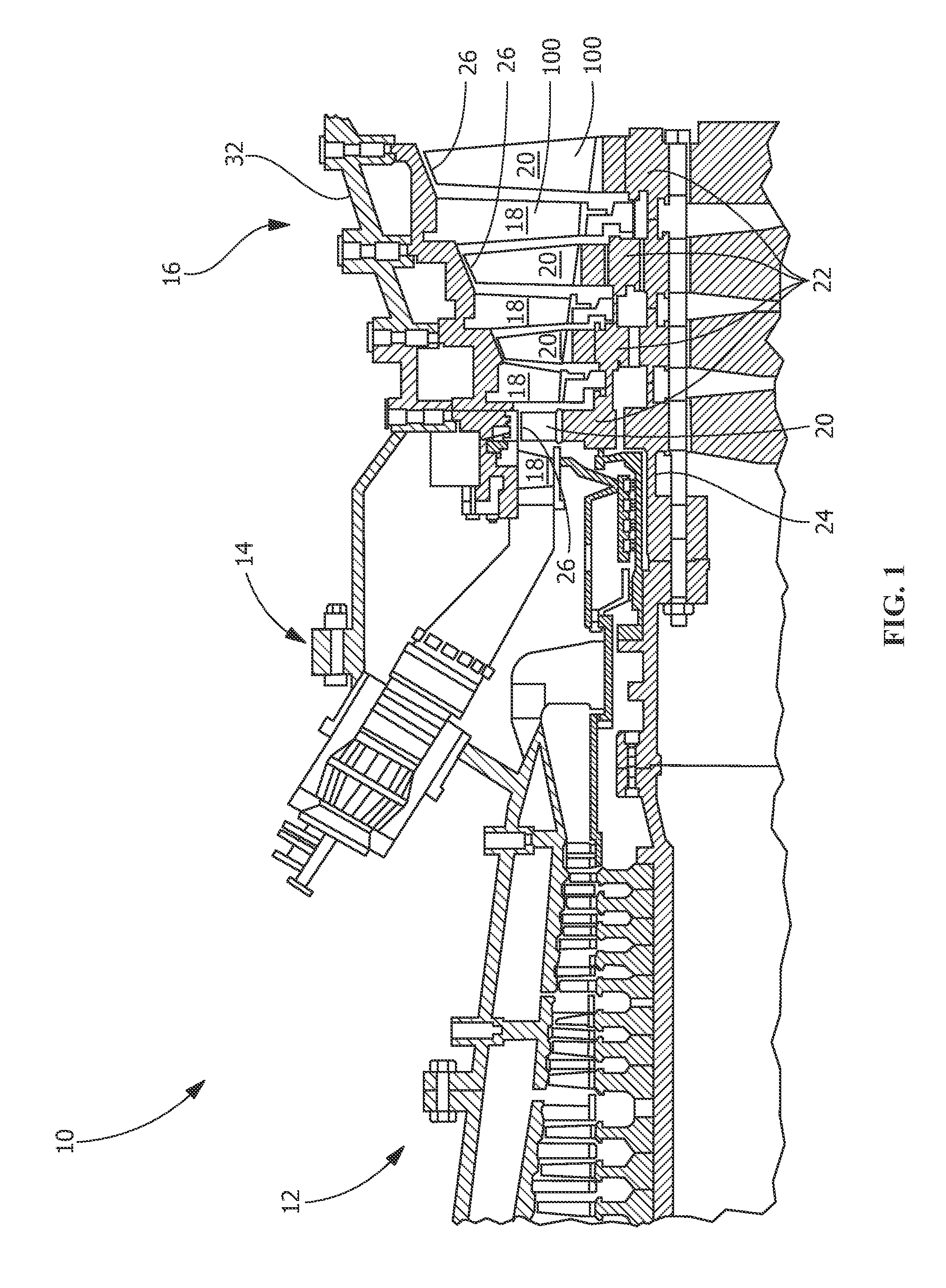

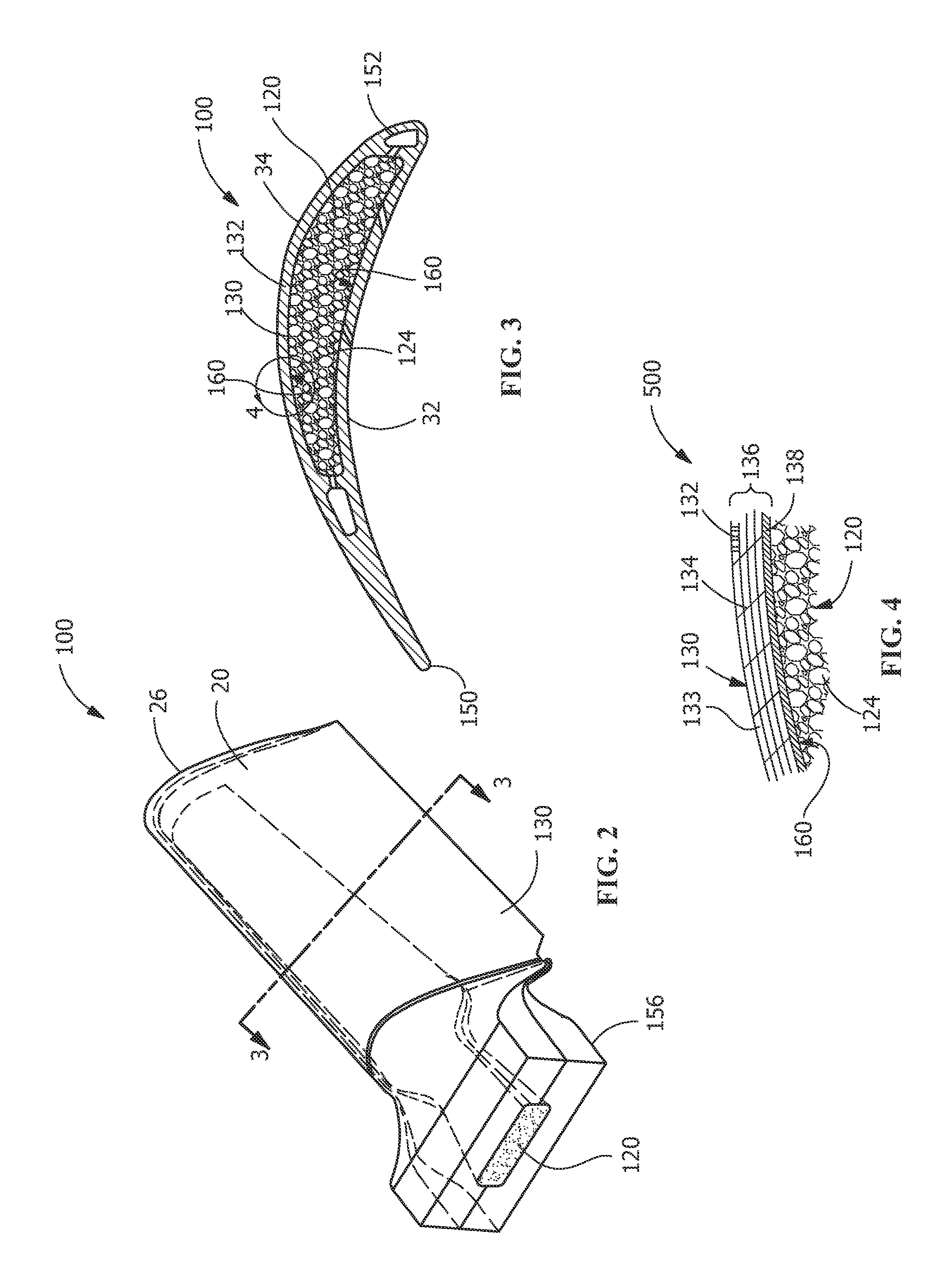

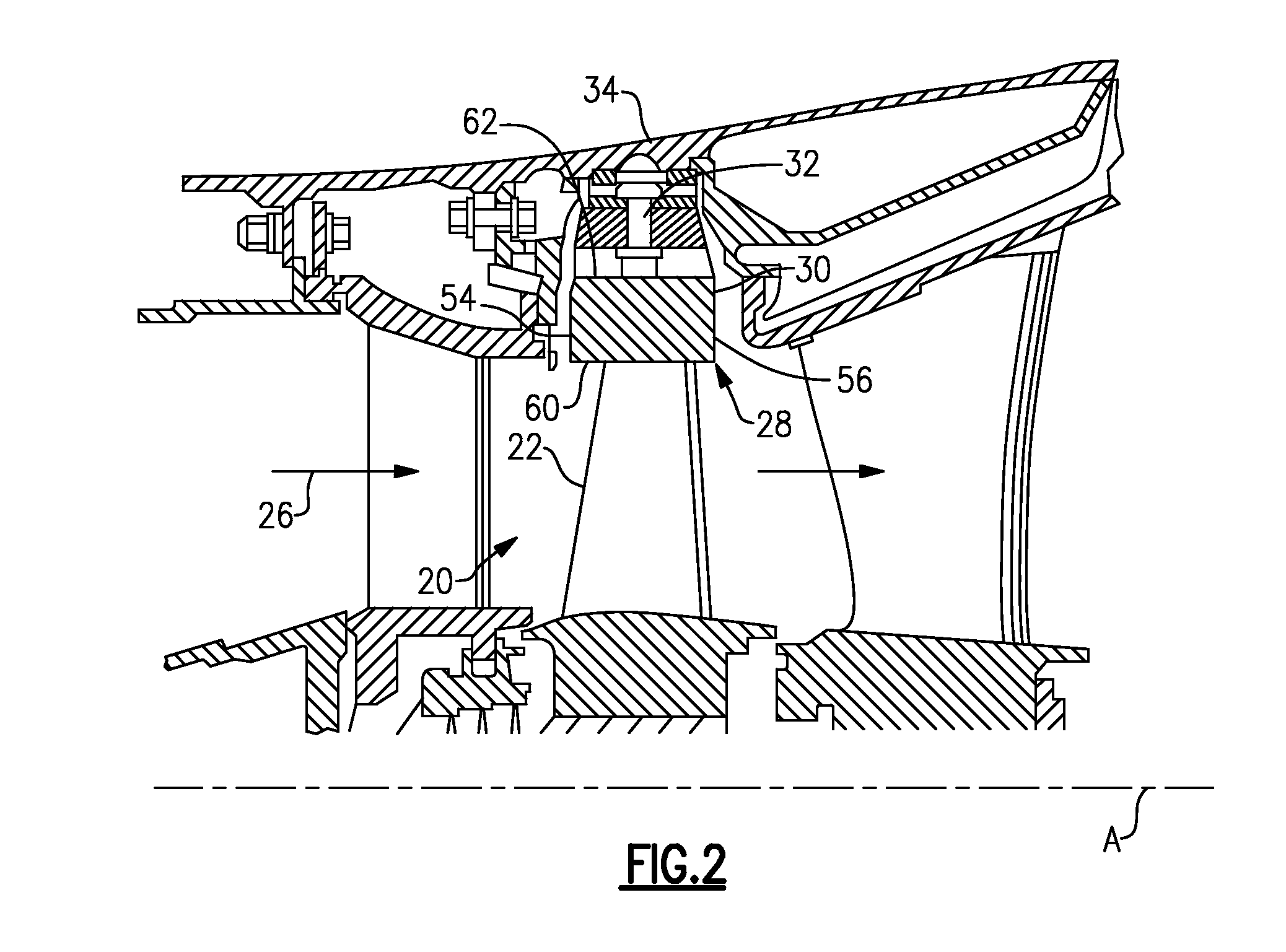

Integrated ceramic/metallic components and methods of making same

Integrated ceramic / metallic components and methods of making same are described herein. Embodiments of these integrated ceramic / metallic components comprise a metallic non-foam region; and a ceramic foam region comprising a gradient porosity therein, wherein the ceramic foam region and the metallic non-foam region are integrally formed together to create the integrated ceramic / metallic component. Embodiments of these integrated ceramic / metallic components comprise a metallic region; and a single piece ceramic foam construction comprising a plurality of ceramic foam regions therein, each ceramic foam region comprising a predetermined pore size and a predetermined volume percent porosity, wherein the single piece ceramic foam construction is integrally joined to the metallic region to form the integrated ceramic / metallic component. These components may be utilized in gas turbine engines.

Owner:UNITED TECH CORP

Method for preparation of metallic and ceramic foam products and products made

InactiveUS6852272B2Efficient and cost-effectiveImprove mechanical propertiesAdditive manufacturing apparatusTransportation and packagingEnergy absorptionMechanical property

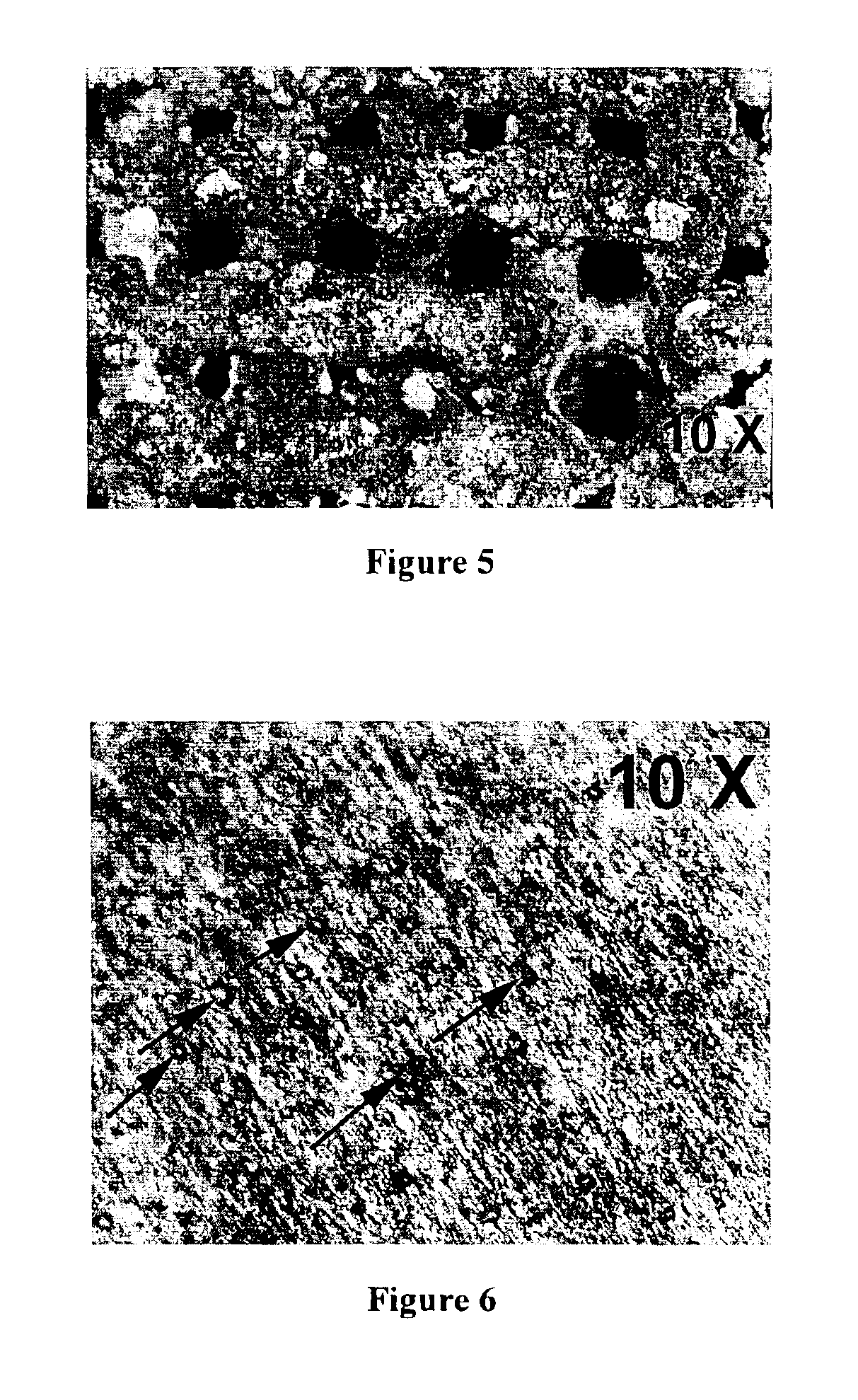

The present invention relates to the fabrication of low cost, in situ, porous metallic, ceramic and cermet foam structures having improved mechanical properties such as energy absorption and specific stiffness. Methods of fabricating the structures from compositions including ceramic and / or metallic powders are provided. The flowable compositions also include an immiscible phase that results in pores within the final structure. Furthermore, the structures may be shaped to have external porosity, such as with mesh-like structures.

Owner:ADVANCED CERAMICS

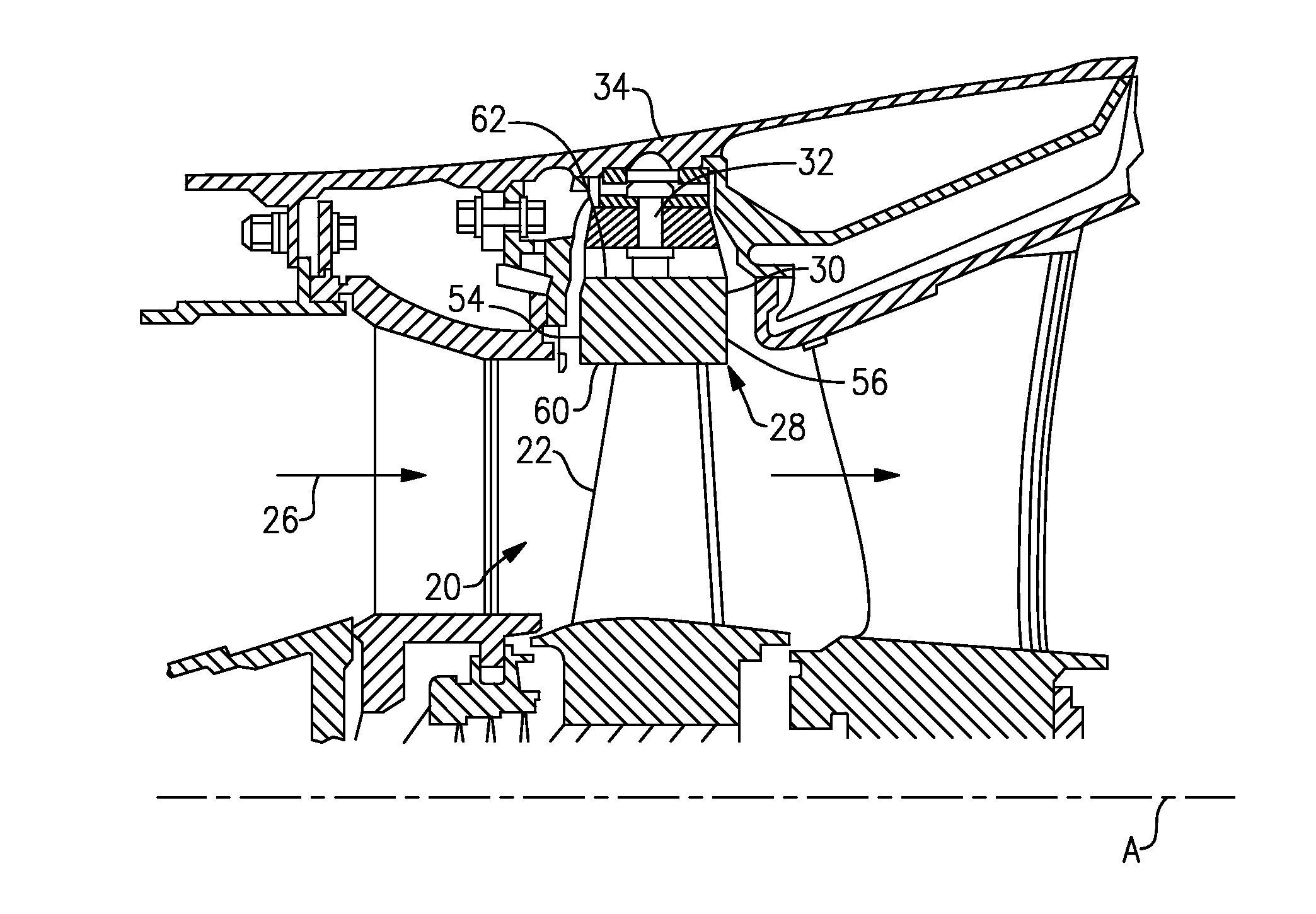

Reforming unvaporized, atomized hydrocarbon fuel

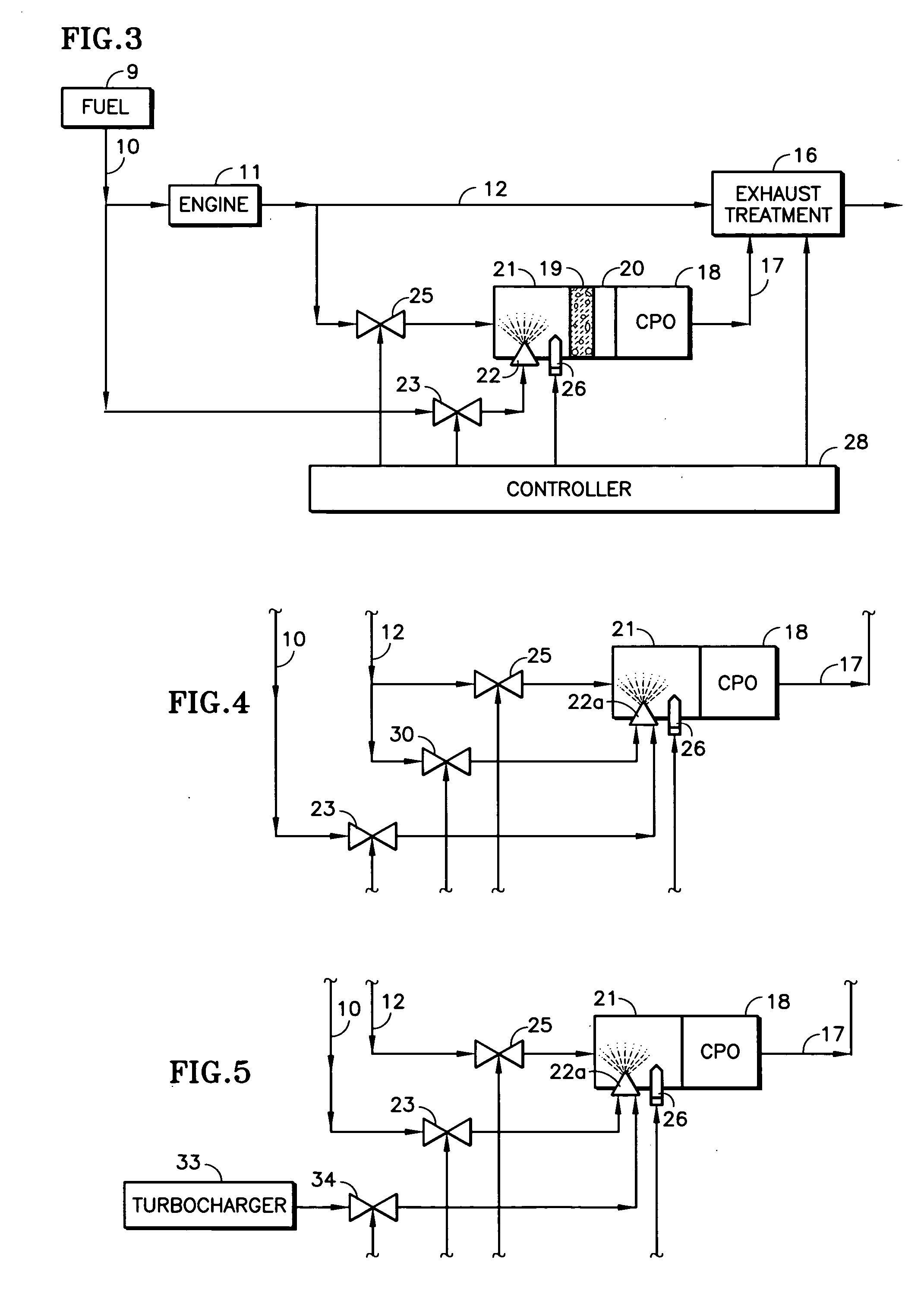

InactiveUS20050274107A1Improved hydrogen generationLow costHydrogenExhaust apparatusKeroseneTurbocharger

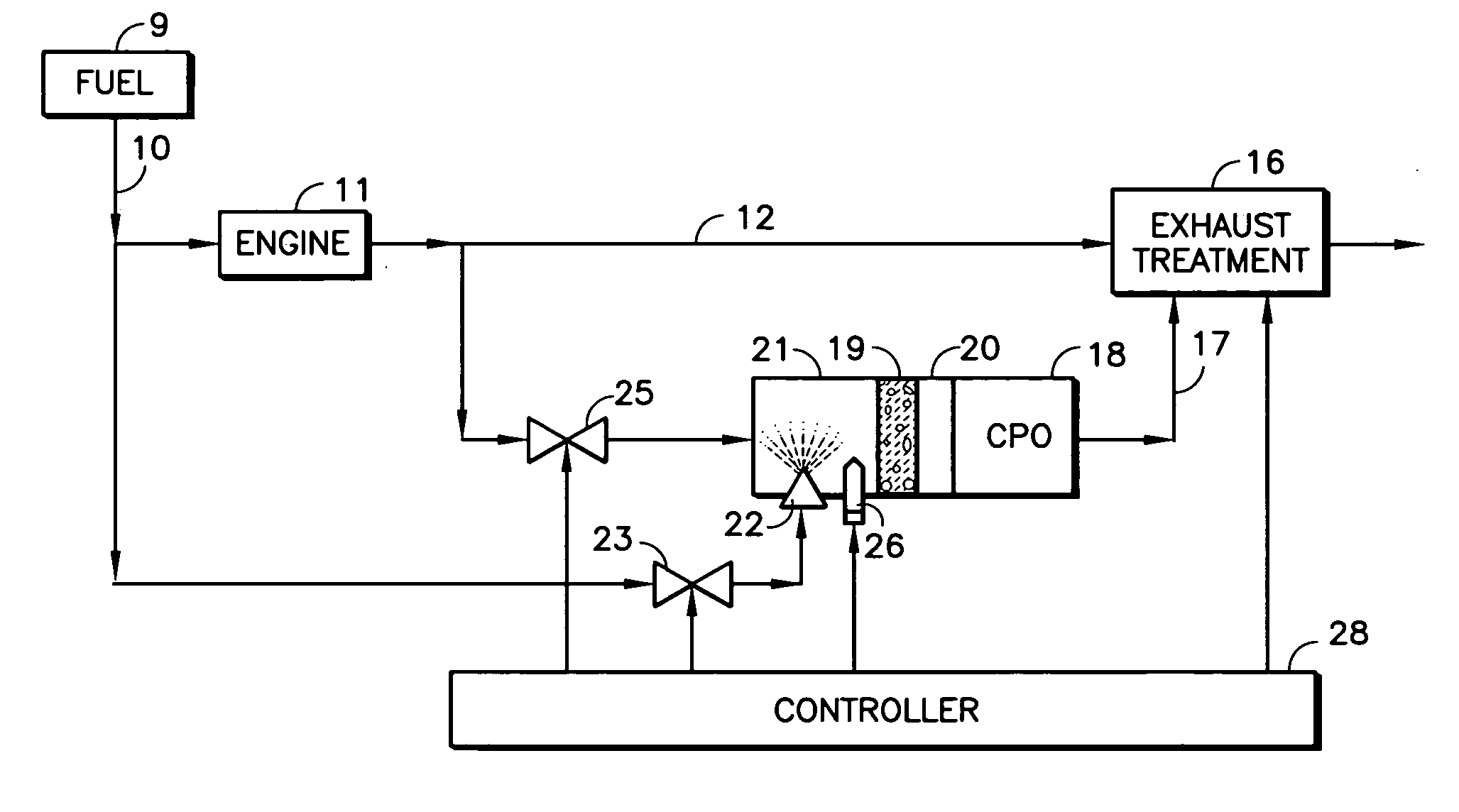

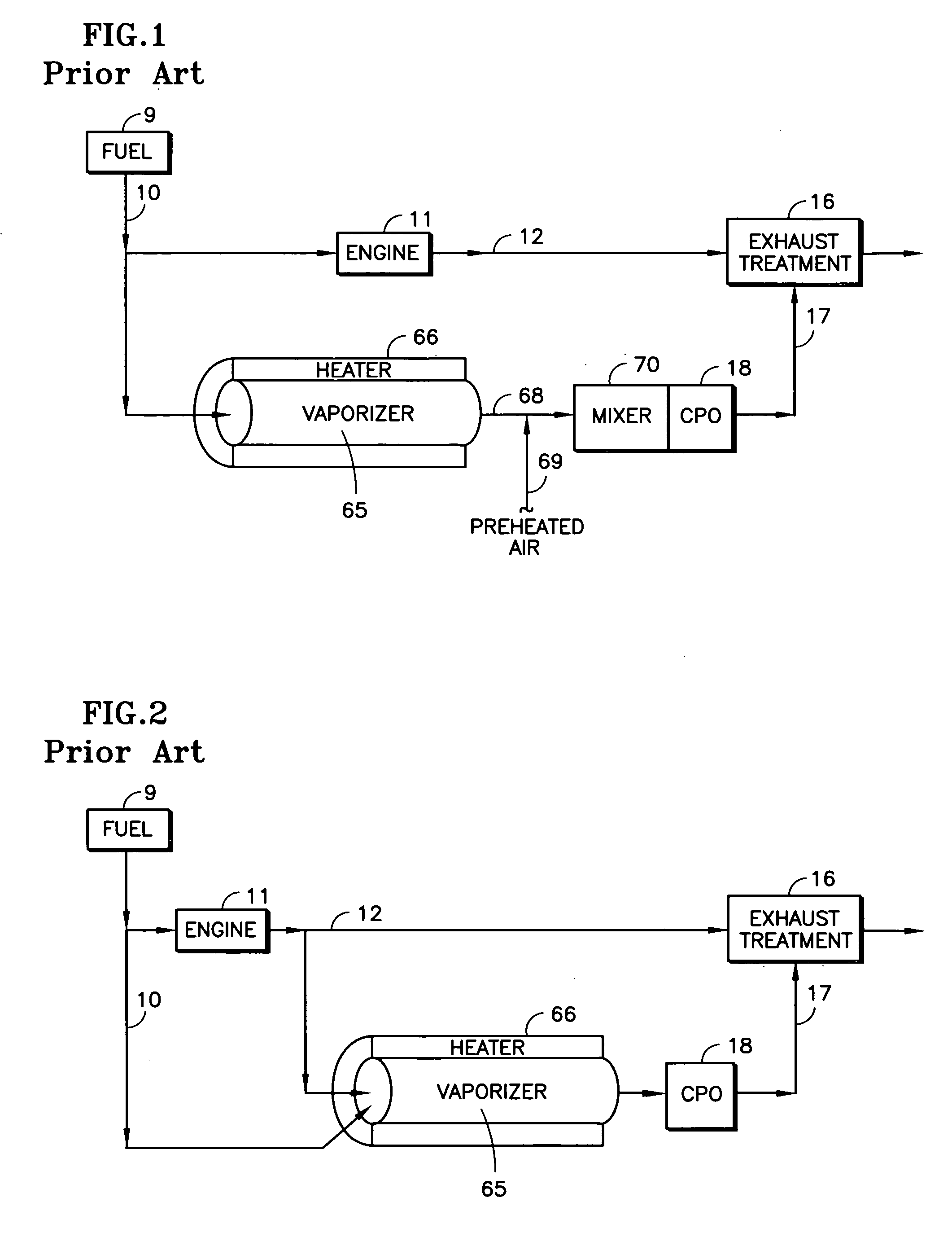

A reformer such as a CPO (18) receives a mix of fuel, moisture and oxygen from a mixing region (21) having an igniter (26, 66), which may include an inert ceramic foam (19), the fuel being provided by an atomizing nozzle (22), thereby avoiding the need for a vaporizer before use. The oxygen and moisture may comprise engine exhaust (11, 12). Fuel from a vehicle fuel tank (9), may be gasoline, diesel fuel, kerosene, jet fuel, or JP-8. The atomizing nozzle may be a gas-assist nozzle (22a), receiving the assisting gas from (a) engine exhaust (10), (b) a turbocharger (33), (c) an air pump (50) or (d) a steam generator (57). The oxygen and moisture may comprise moisturized air, which may be achieved by an ejector (41) which ingests water from a tank (43) in response to the flow of air from a pump (50) through a conduit (47). The air may be regeneratively heated (48) with the CPO exhaust. The igniter may be a glow plug (26) or a heater wire (66) coated with catalyst.

Owner:SHELL OIL CO

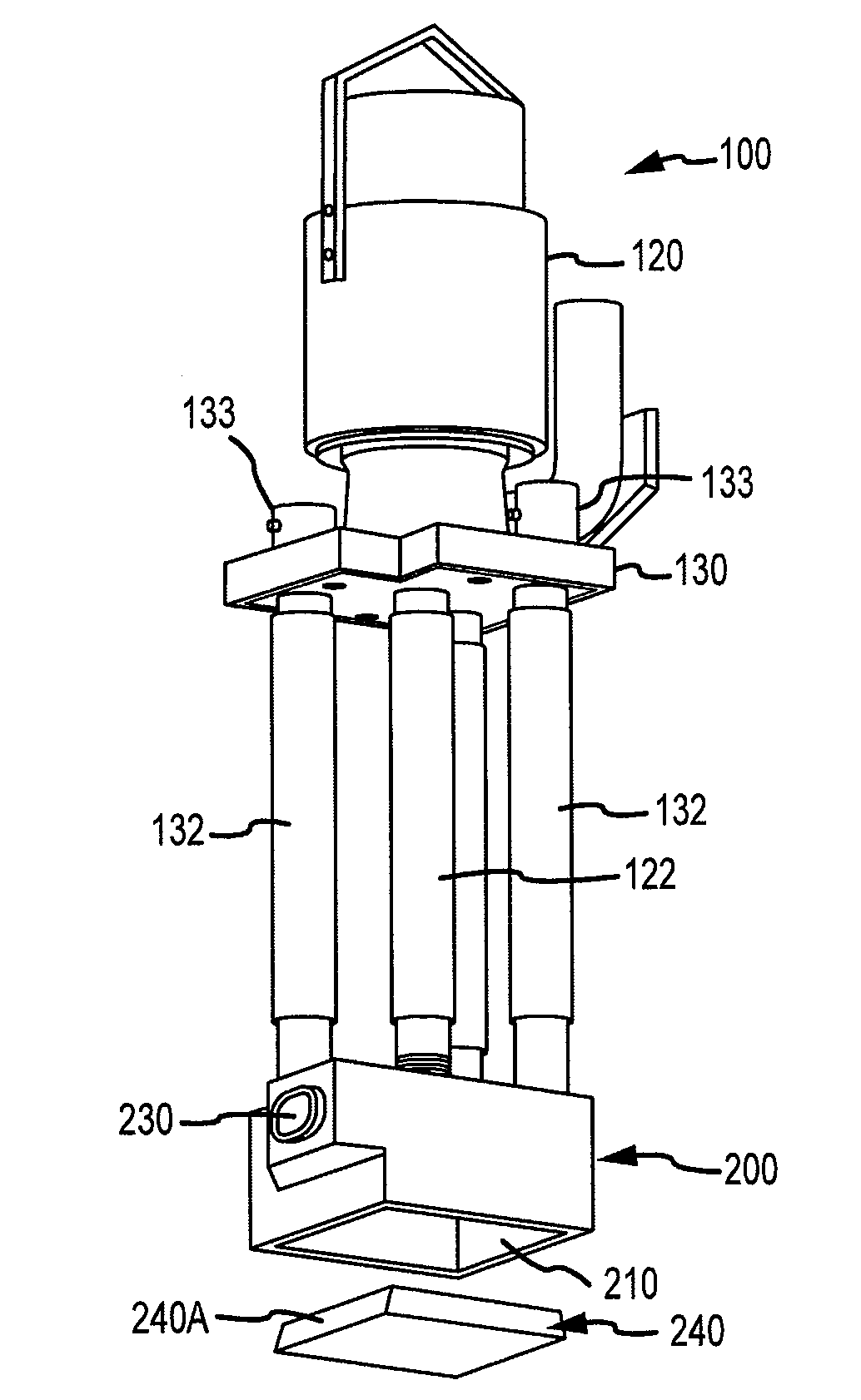

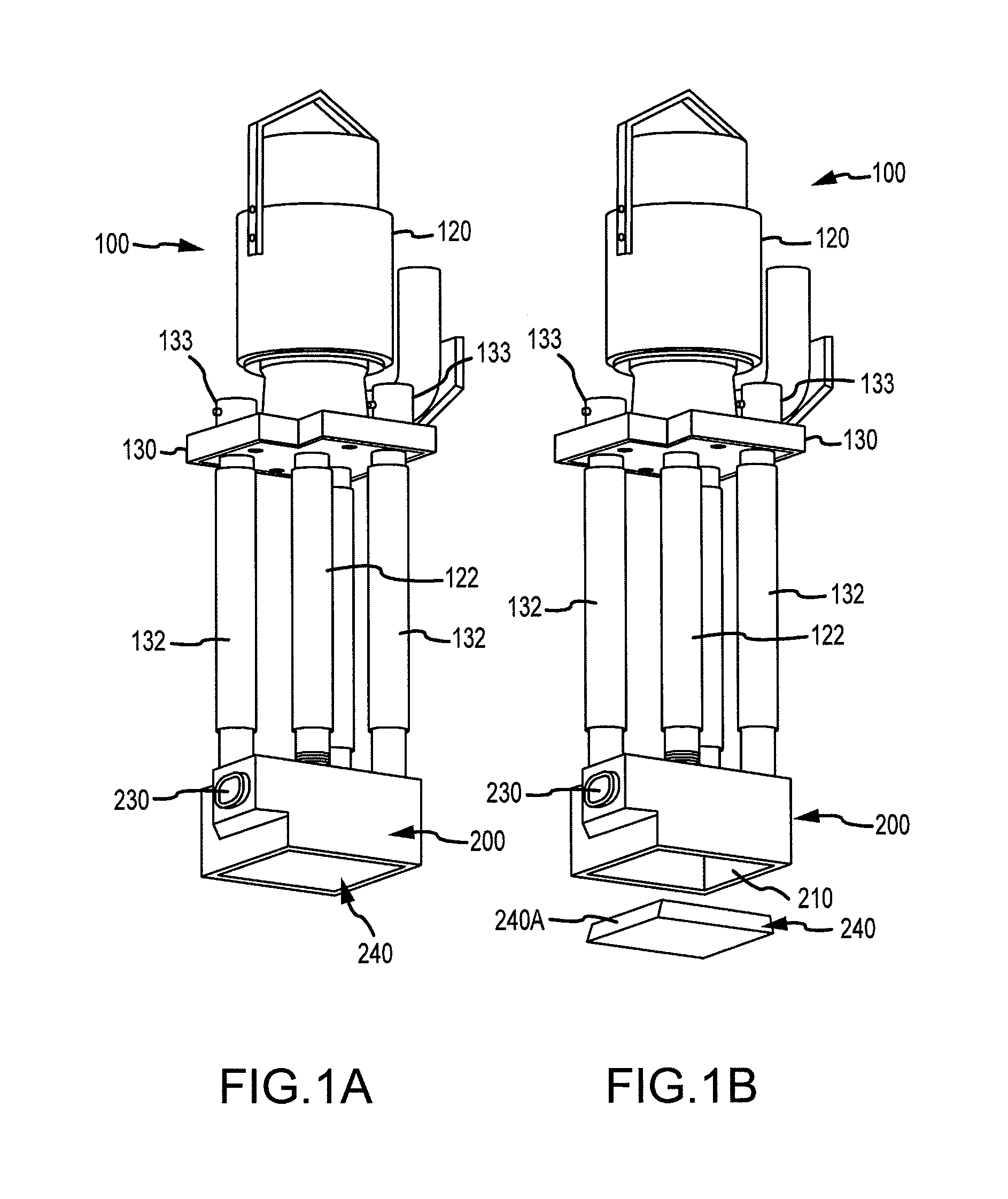

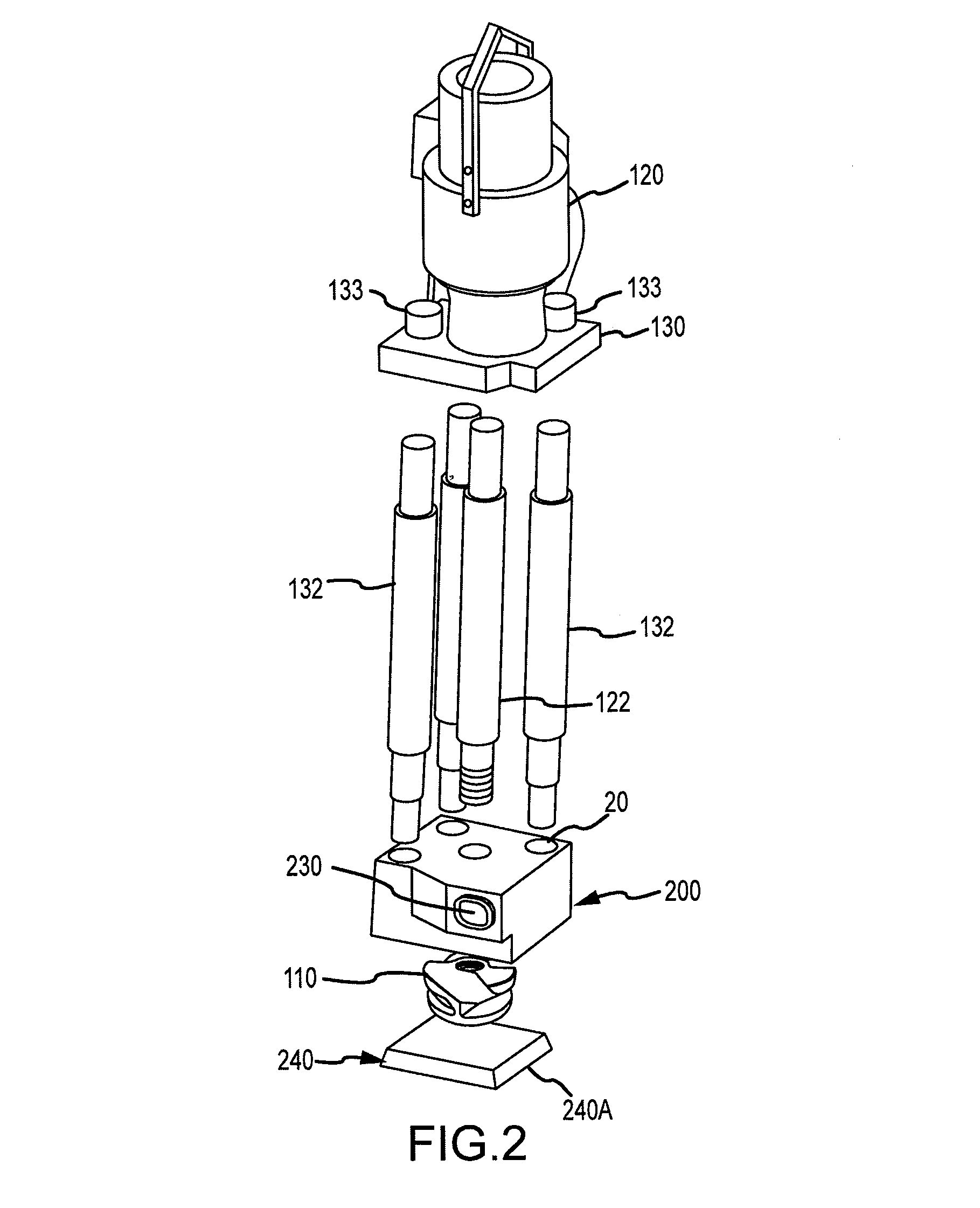

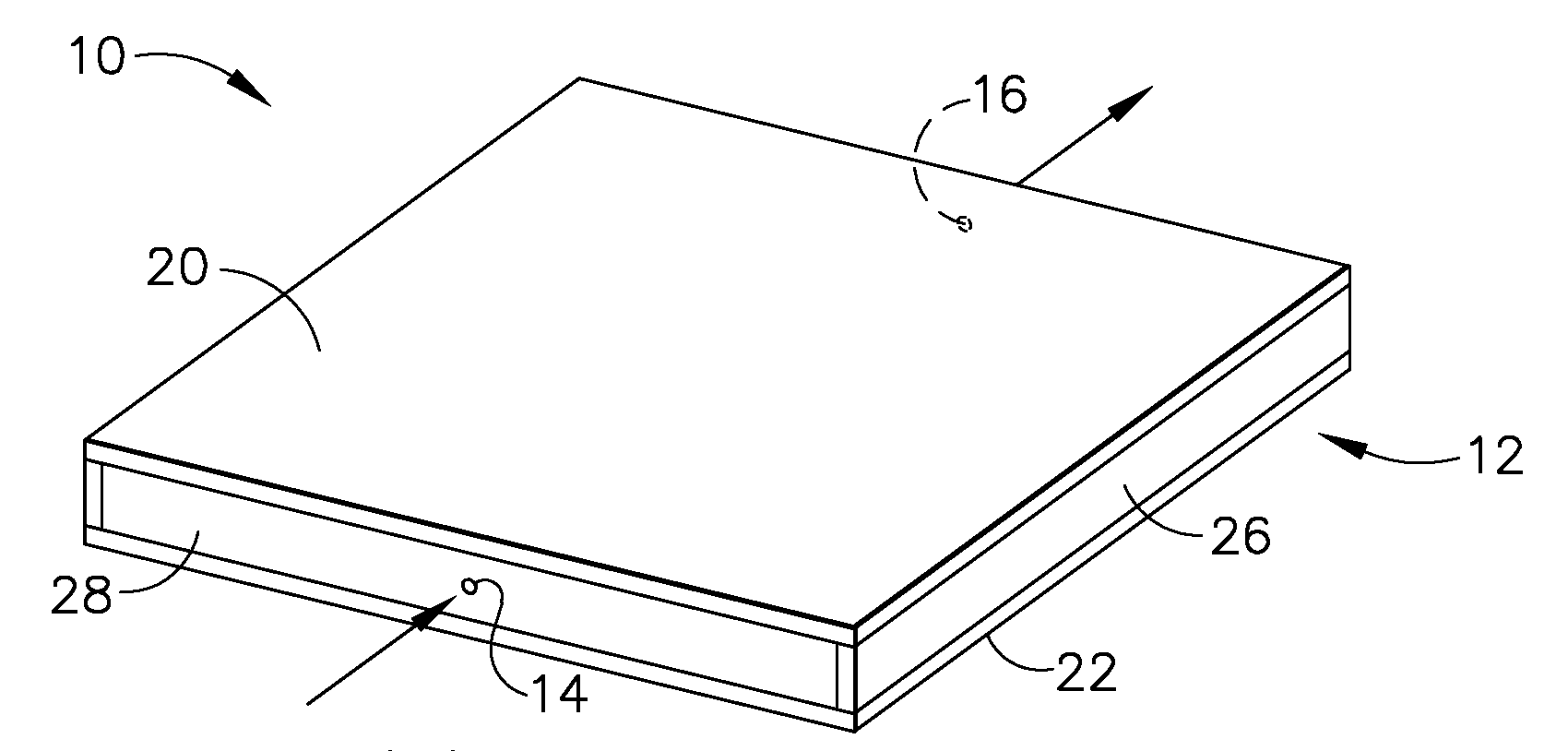

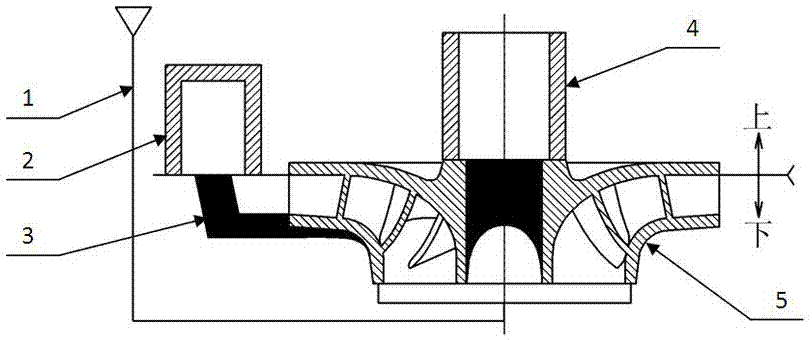

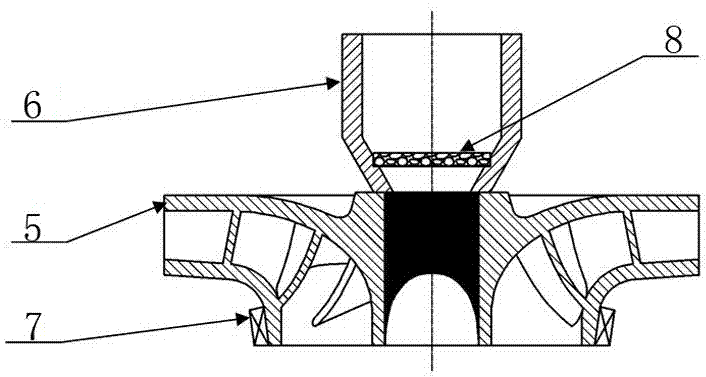

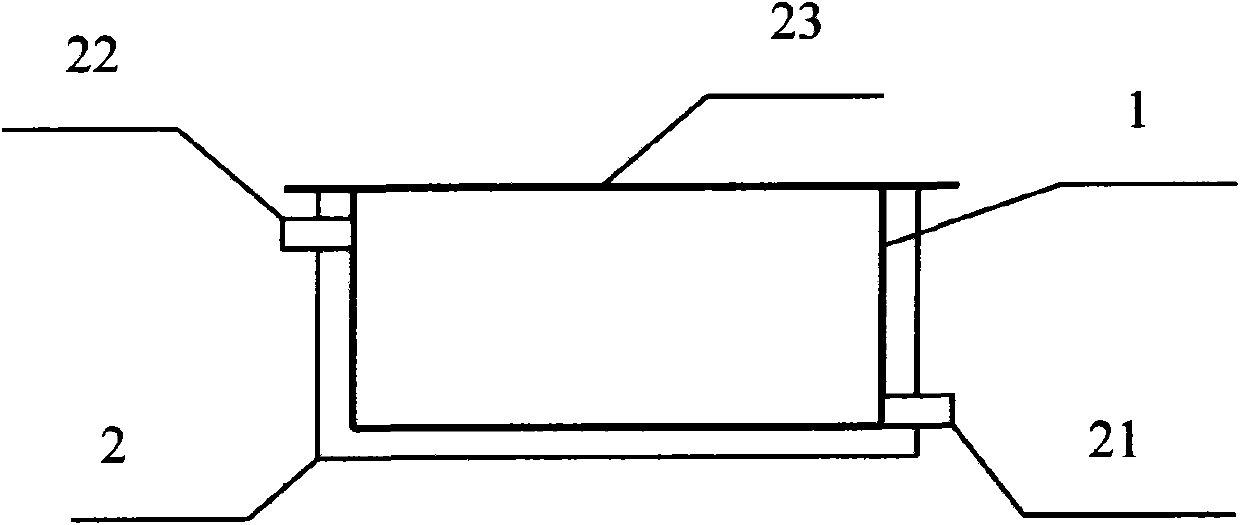

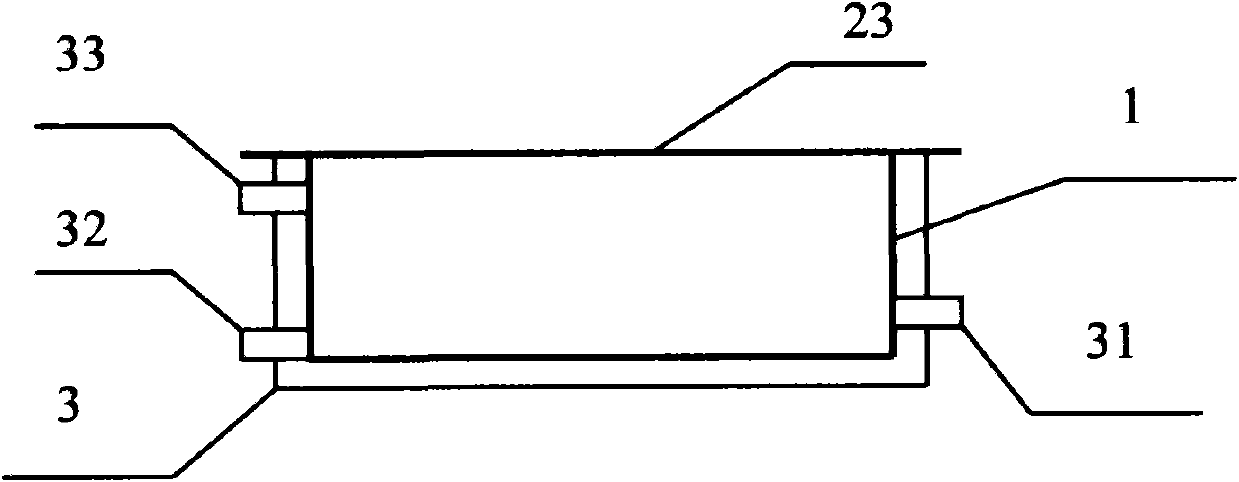

Molten metal pump filter

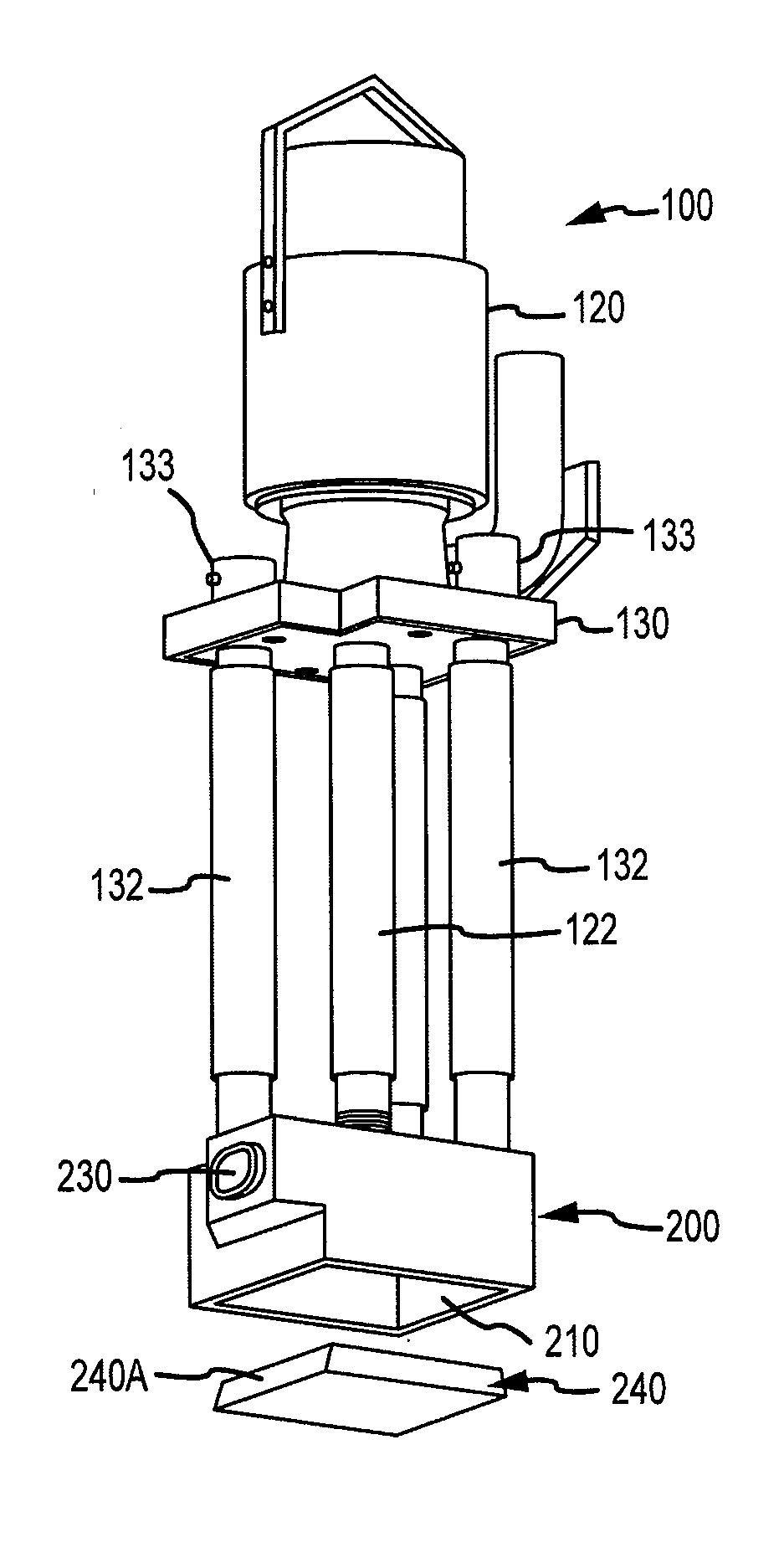

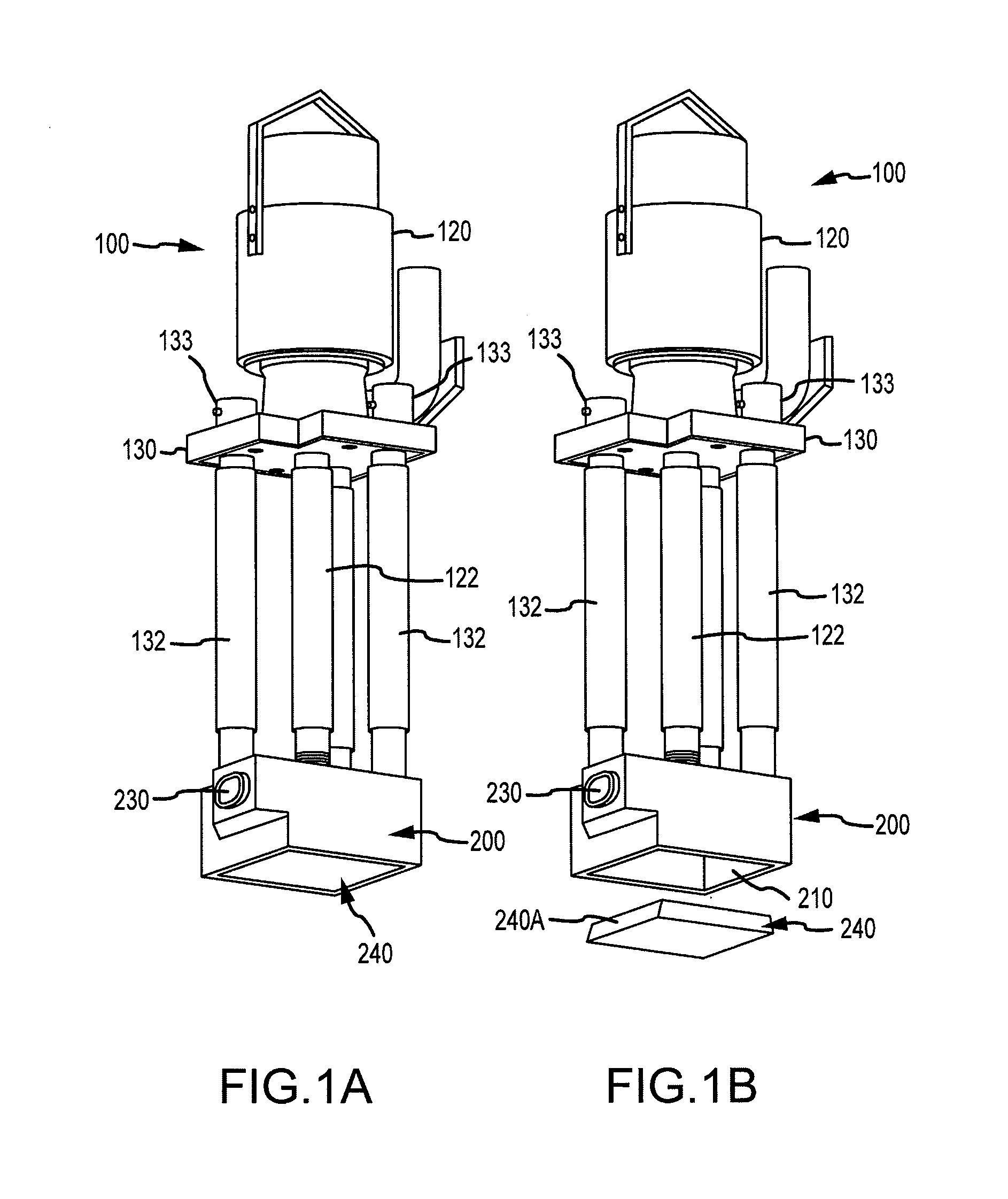

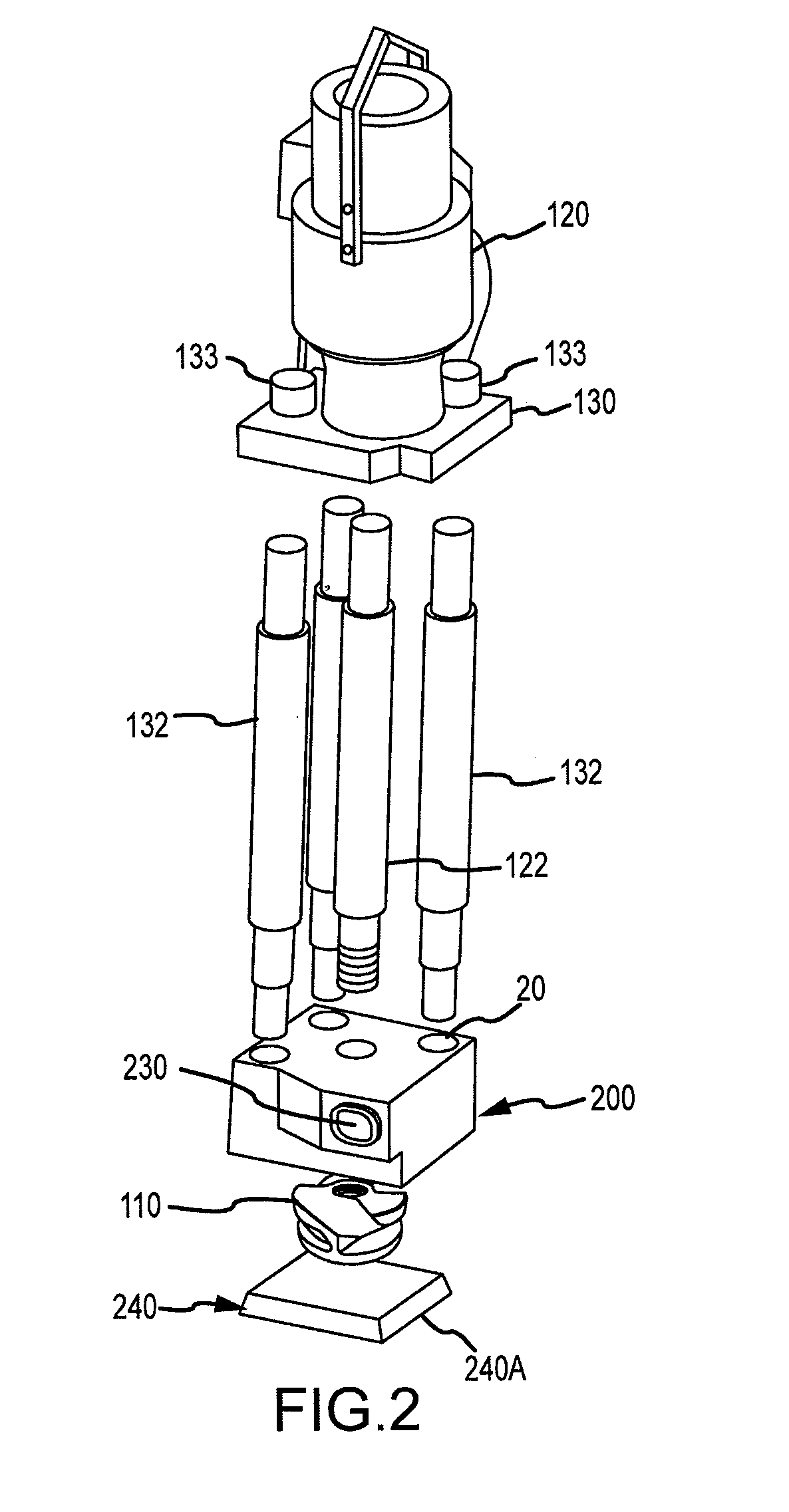

ActiveUS20110142603A1Avoid excessive densityShorten the timeSpecific fluid pumpsPump componentsCeramic foamMolten metal

The invention relates to filtering molten metal and more particularly, to a pump, pump base and filter for filtering molten metal, wherein the filter is preferably comprised of a ceramic foam material. The ceramic foam material may be buoyant in molten aluminum. In one embodiment, a molten metal pump includes a pump base configured to receive the molten metal pump filter without using cement.

Owner:MOLTEN METAL EQUIP INNOVIATIONS LLC

Molten metal pump filter

The invention relates to filtering molten metal and more particularly, to a pump, pump base and filter for filtering molten metal, wherein the filter is preferably comprised of a ceramic foam material. The ceramic foam material may be buoyant in molten aluminum. In one embodiment, a molten metal pump includes a pump base configured to receive the molten metal pump filter without using cement.

Owner:MOLTEN METAL EQUIP INNOVIATIONS LLC

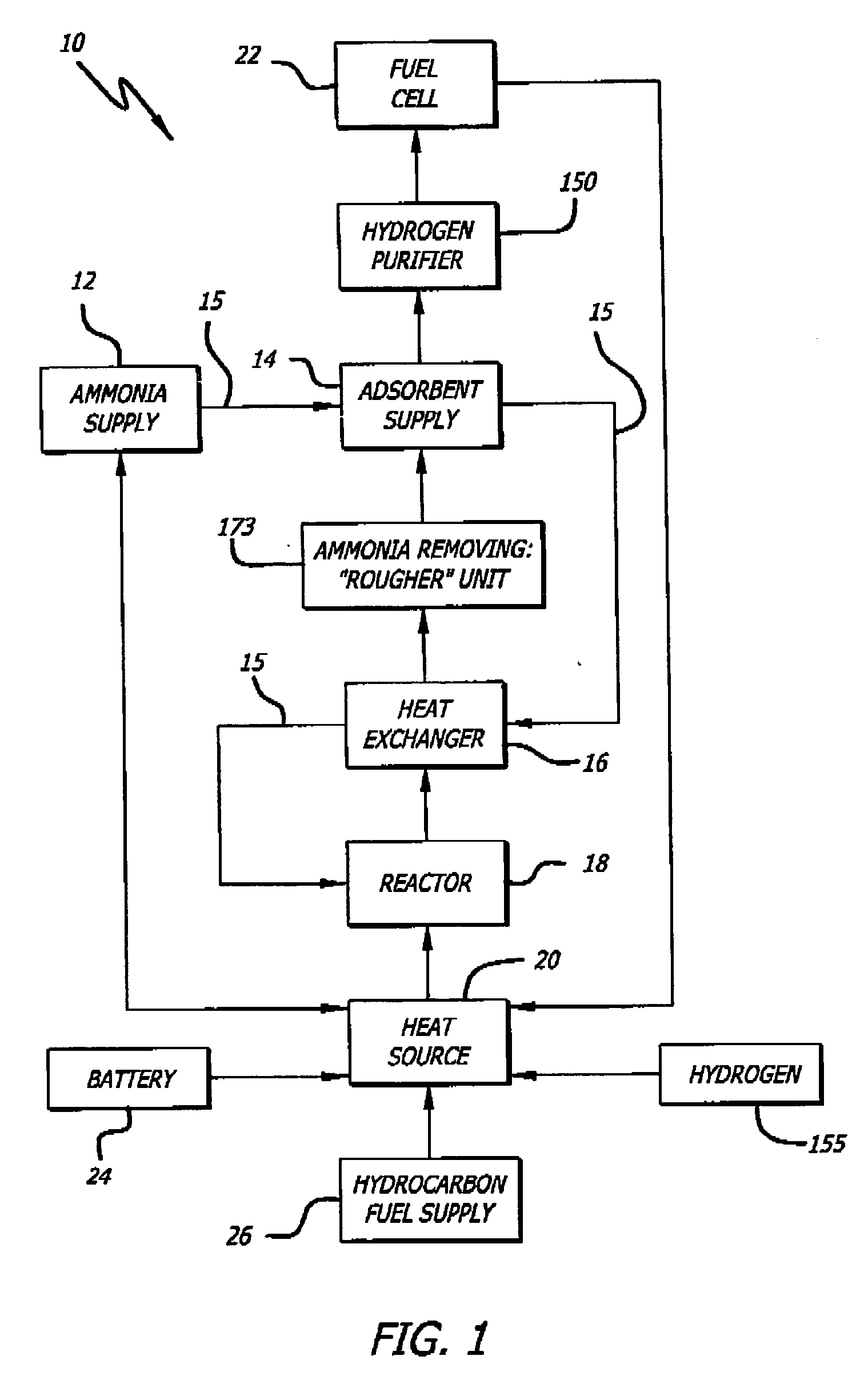

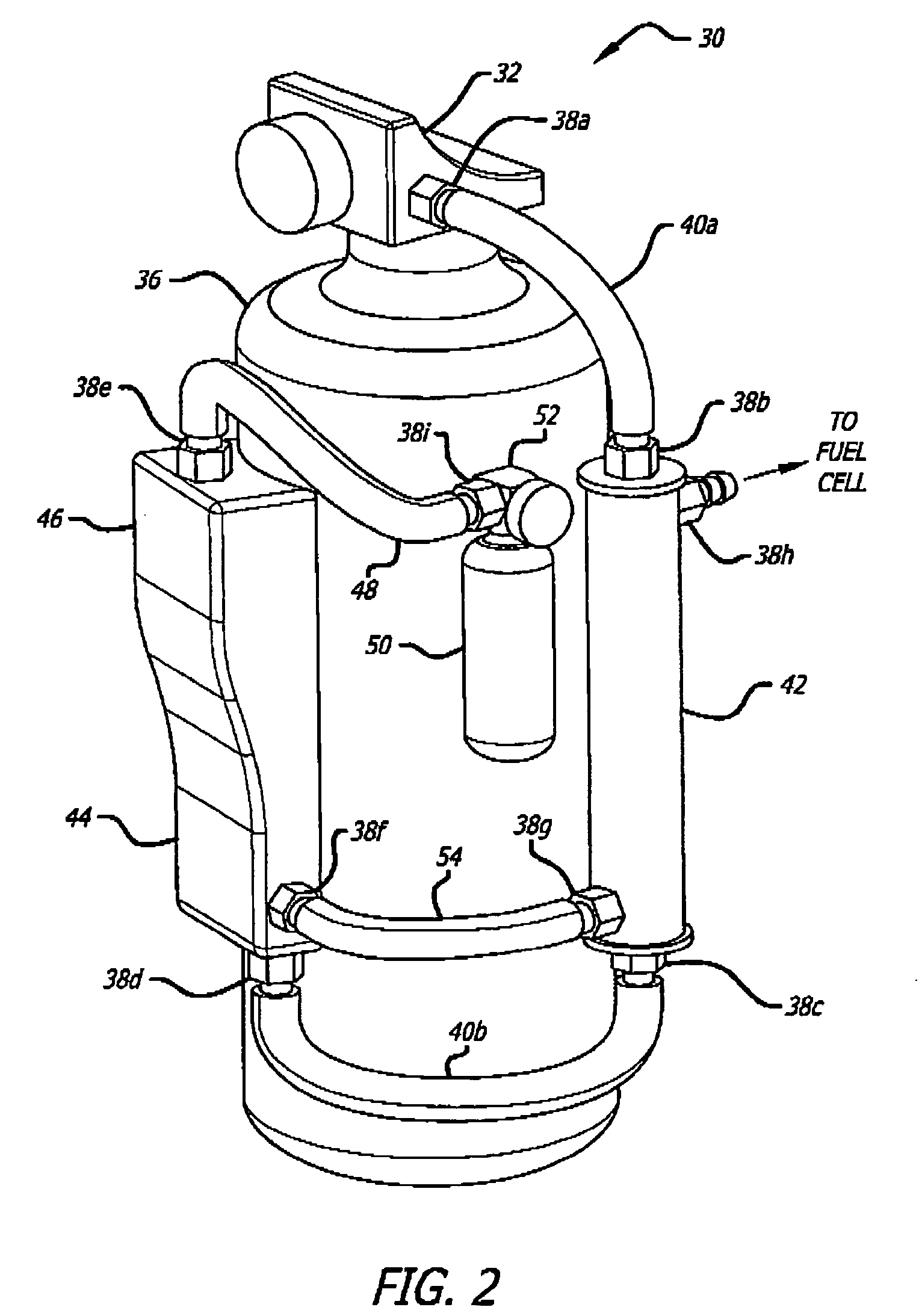

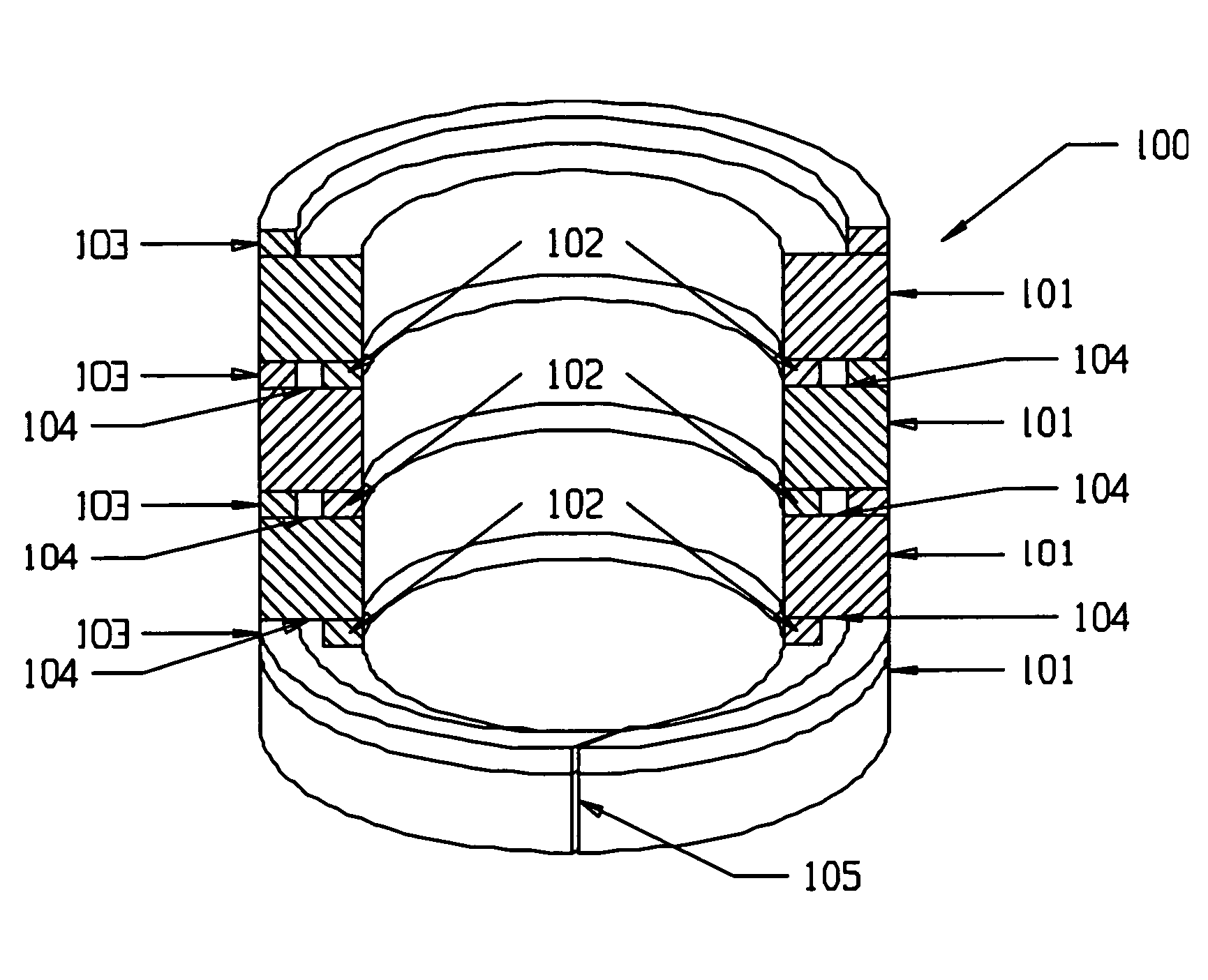

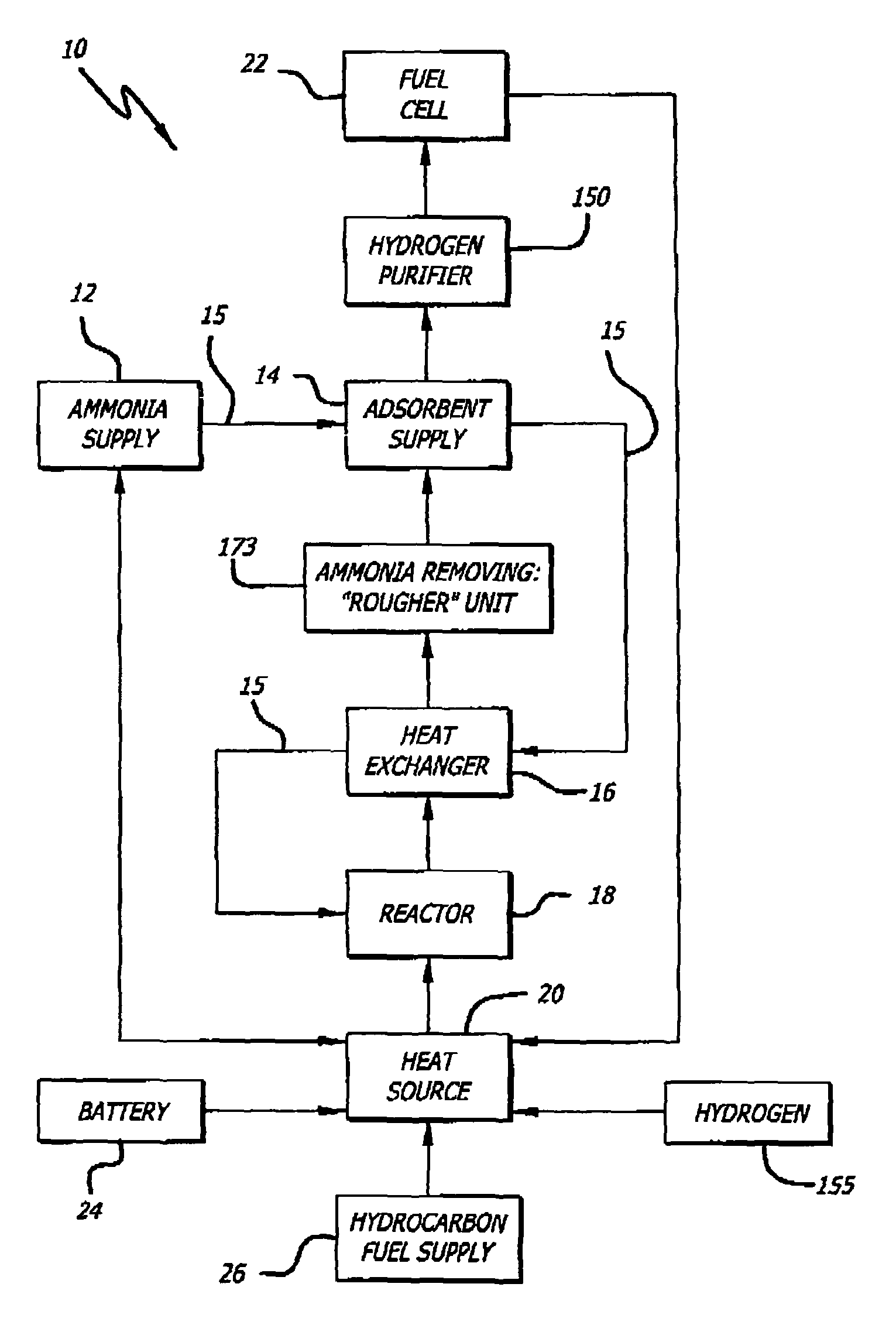

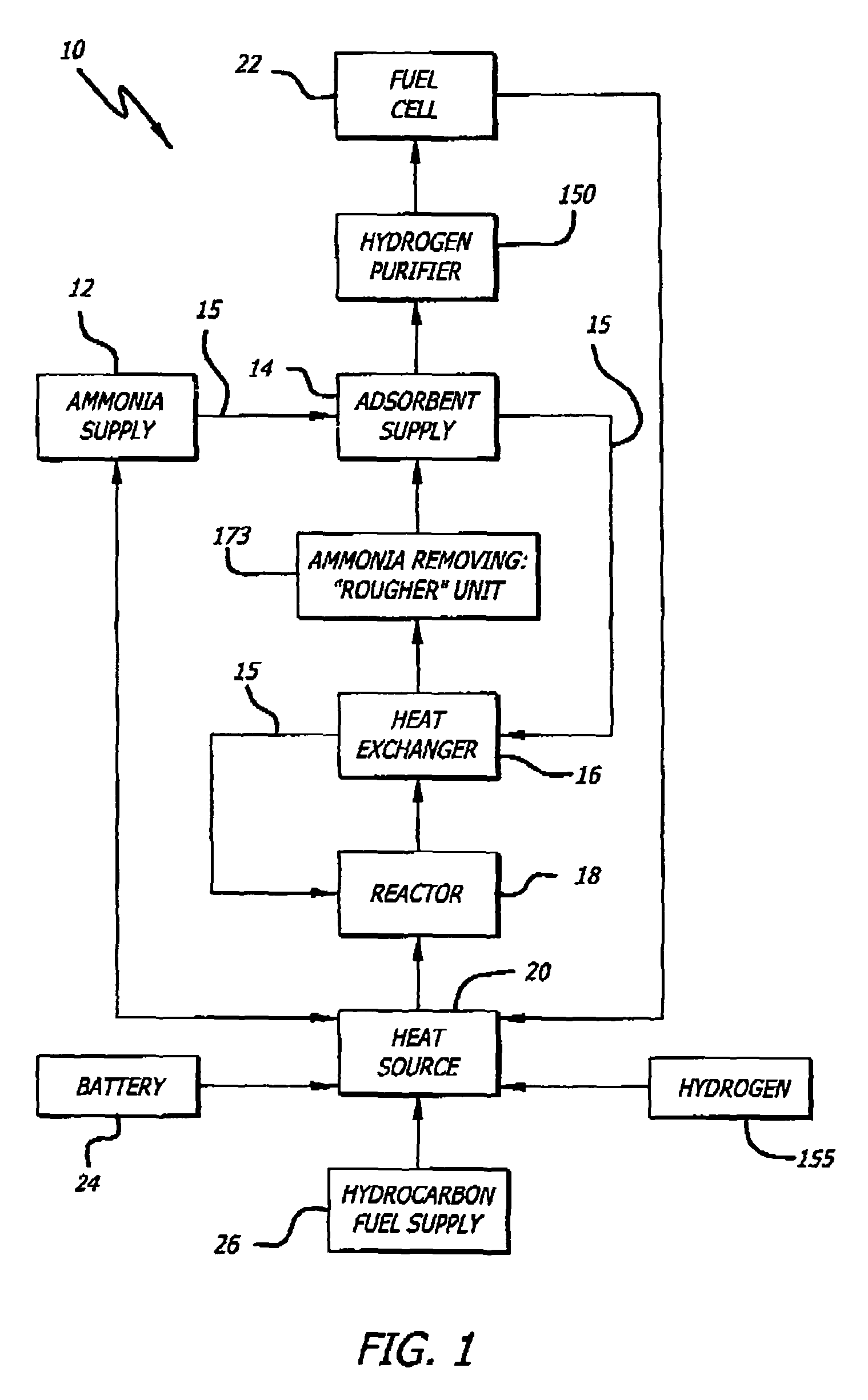

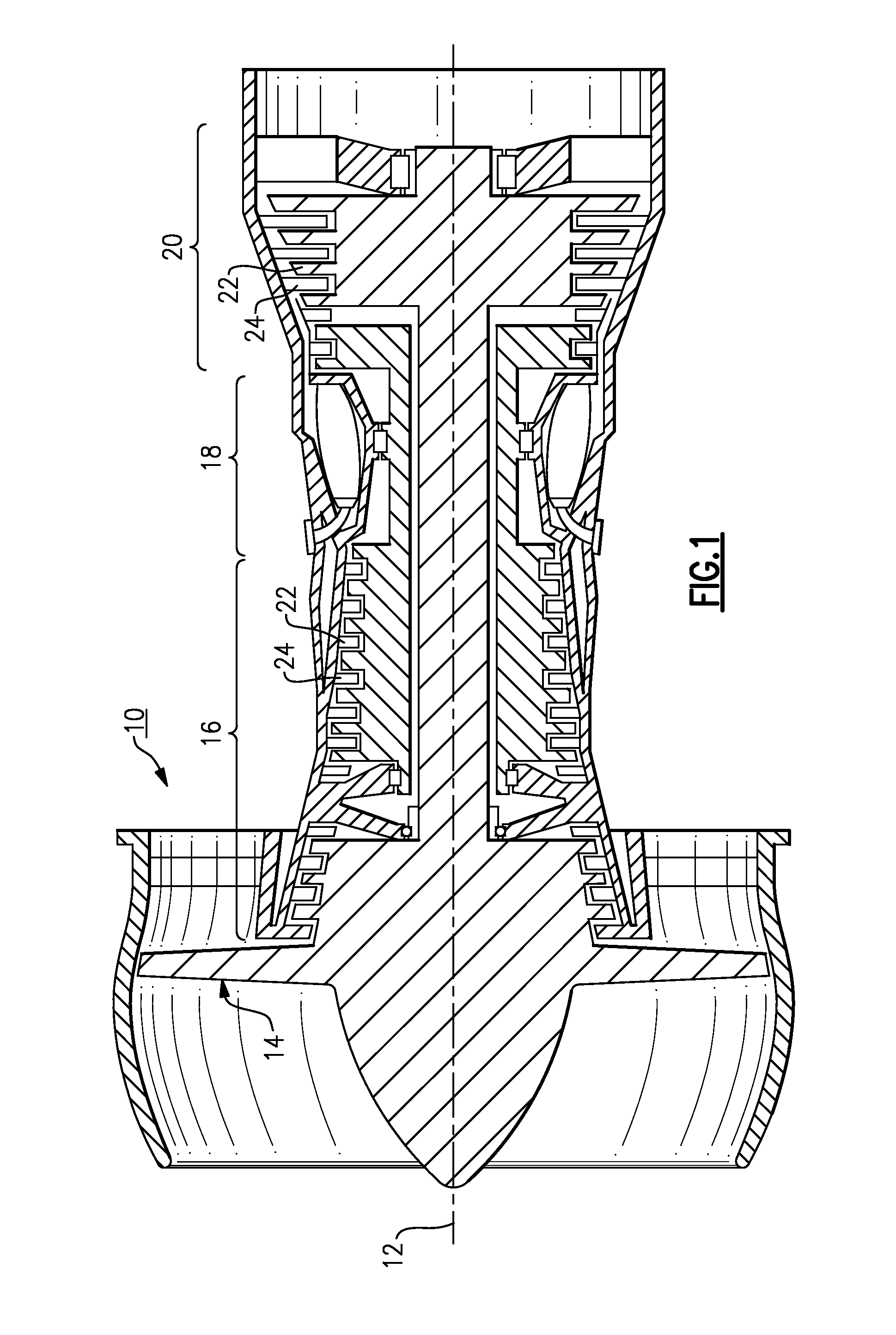

Ammonia-based hydrogen generation apparatus and method for using same

InactiveUS20060112636A1Reduce manufacturing costImprove heat transfer effectCyanogen compoundsNitrogen compoundsHydrogenCombustion chamber

The present disclosure provides teachings relating to ammonia-based hydrogen generation apparatus and associated methods of use. Exemplary methods and apparatus comprise a thermocatalytic hydrogen generation reactor which includes a reaction chamber containing a catalyst-coated substrate, and a combustion chamber containing a catalyst-coated substrate. Exemplary catalyst-coated substrates include, but are not limited to, metal foam, monolith, mesh, ceramic foam or ceramic monolith.

Owner:INTELLIGENT ENERGY INC

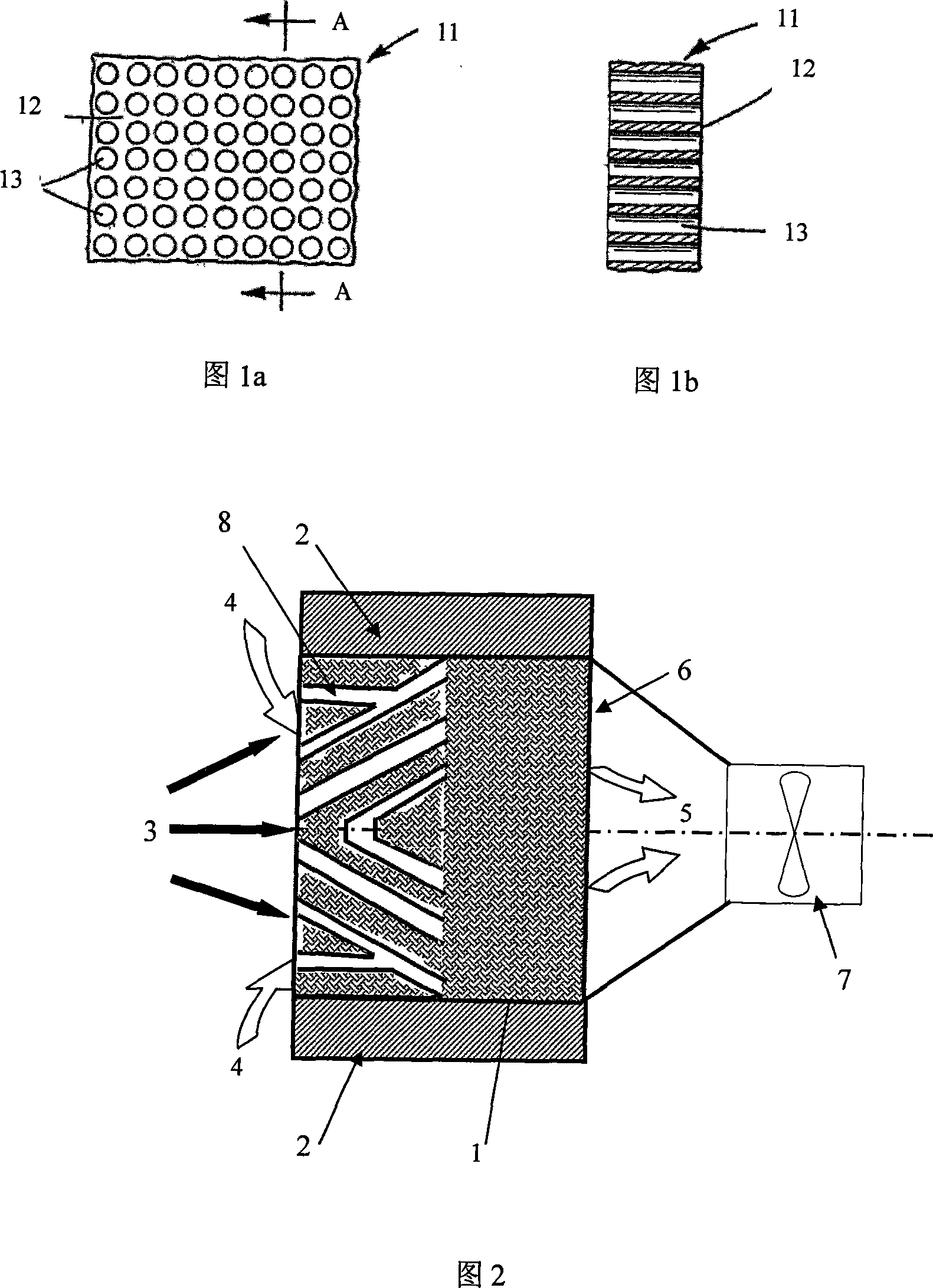

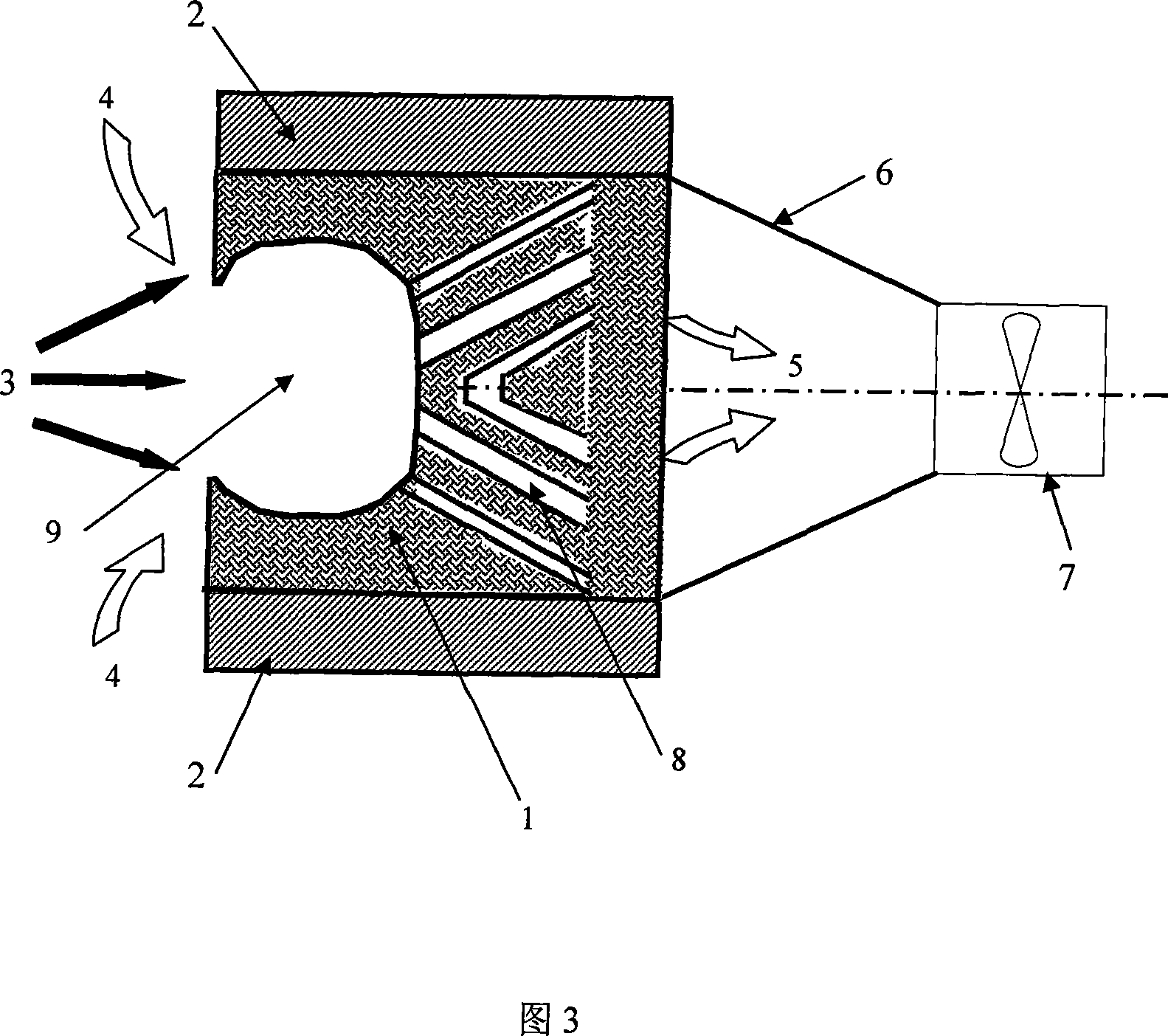

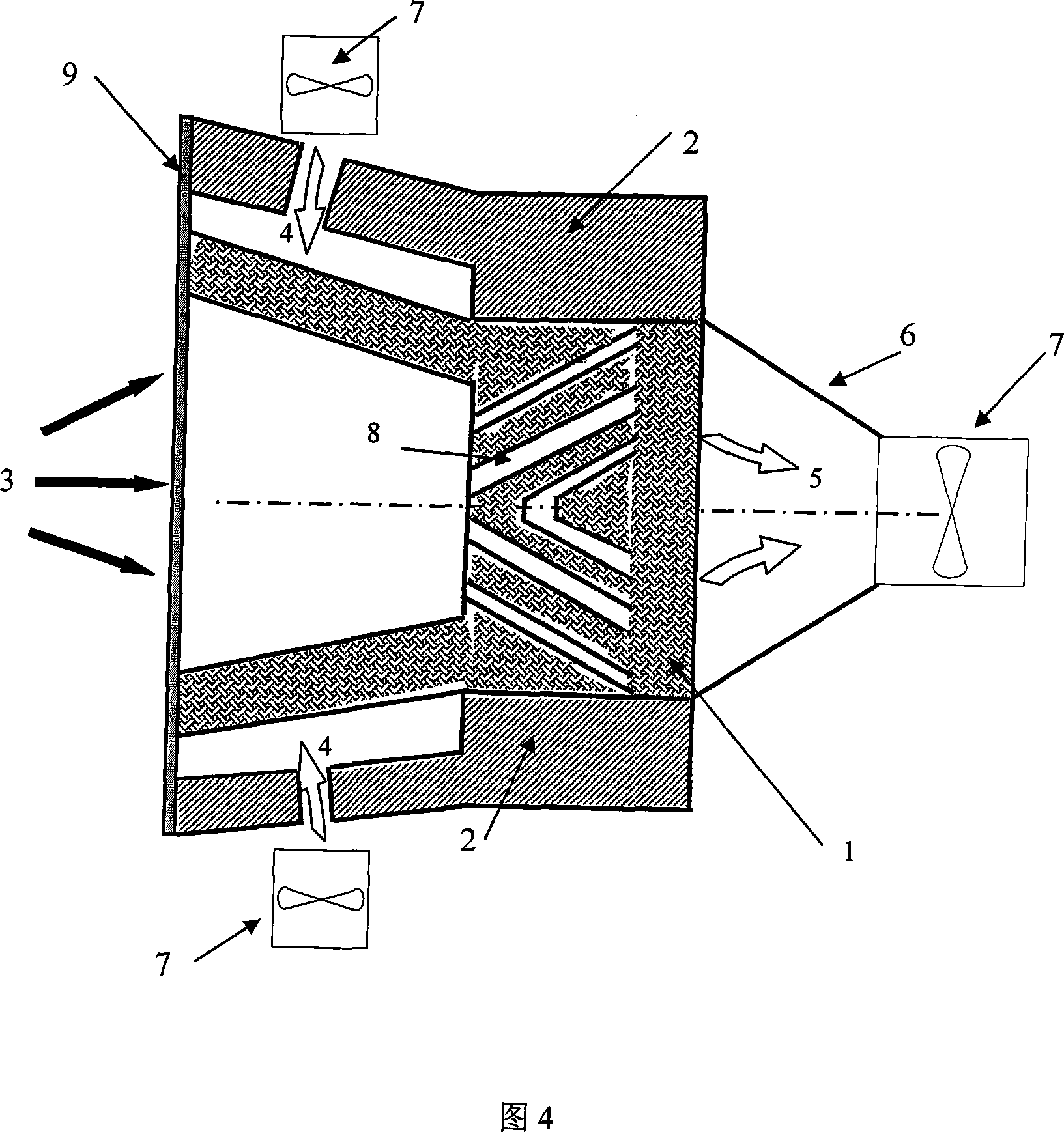

Silicon carbide foam ceramic solar energy air heat-absorbing device

InactiveCN101122425AImprove thermal conductivityFacilitate conductionSolar heating energySolar heat devicesCold airBlackbody cavity

A silicon carbide ceramic foam solar energy air heat absorber uses silicon carbide ceramic foam materials as solar energy absorber. The silicon carbide ceramic foam absorber is wrapped with an insulating layer (2). A radiant heat flux (3) projects onto the surface of the silicon carbide ceramic foam absorber (1) or into an artificial blackbody cavity (9) and is received by the silicon carbide ceramic foam absorber (1). Cold air (4) flows in from the side of the silicon carbide ceramic foam absorber (1) positive to the radiant heat flux (3). Hot air (5) is obtained through heat exchange of thecold air and the radiant heat flux. Or the cold air (4) flows in from the side of the silicon carbide ceramic foam absorber (1) positive to the radiant heat flux (3) or back to the radiant heat flux (3). The hot air (5) of 700 to 1300 DEG C is obtained through the heat exchange of the cold air and the radiant heat flux through a quartz window (10). The silicon carbide ceramic foam absorber (1) buries an air diversion channel (8) beforehand. The invention can effectively receive radiant heat and emit heat to the air and take advantage of self-sensible heat to store heat at the same time.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

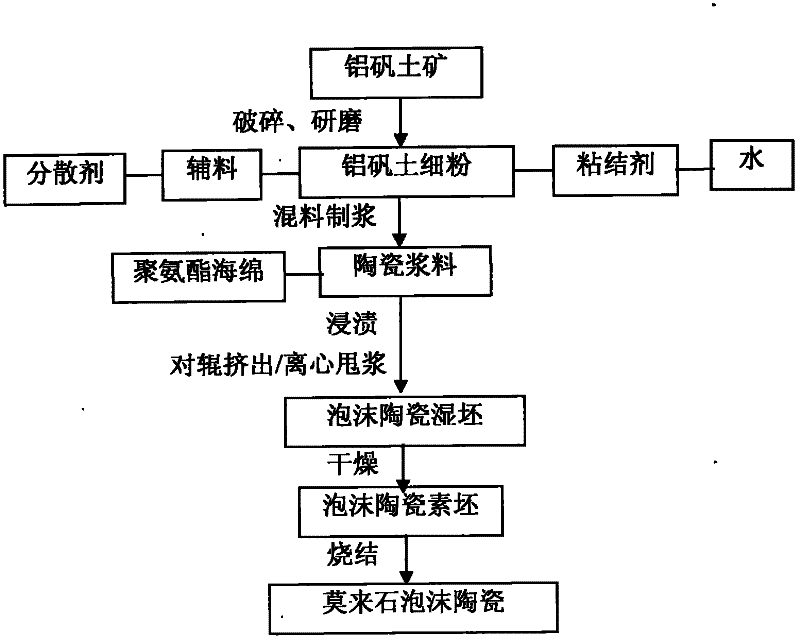

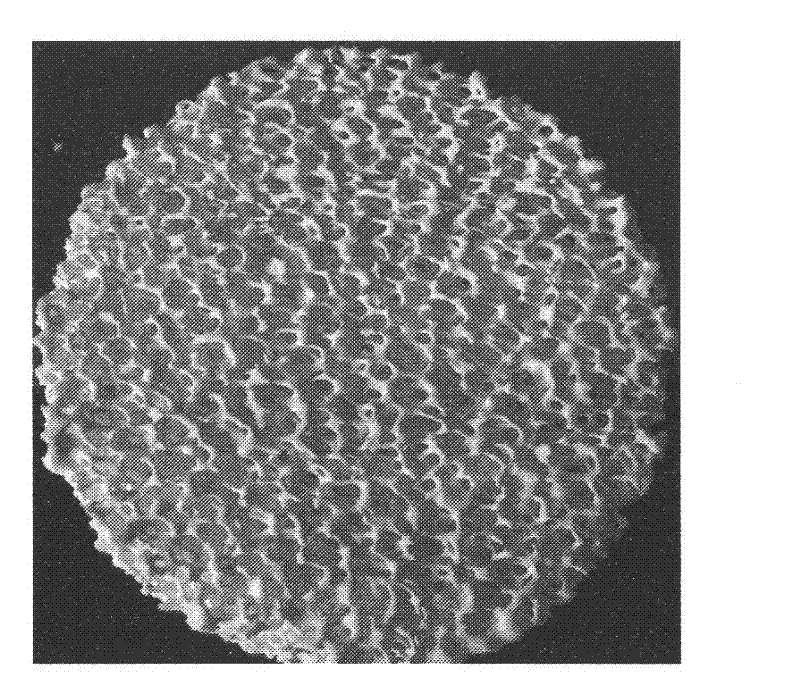

Mullite ceramic foam filter for casting and preparation method thereof

InactiveCN102173856AGood purification effectImprove filtering effectFiltration separationCeramicwareMulliteSlurry

The invention belongs to the field of porous ceramic, and provides a mullite ceramic foam filter for casting. The mullite ceramic foam filter for casting comprises the following chemical components: 40-80 wt% of Al2O3, 10-50 wt% of SiO2 and 1-10 wt% of alkali-earth oxide. The mullite ceramic foam filter for casting is in a mutually-communicated mesh porous structure. The preparation method comprises the following steps: using natural alumina containing 40-80 wt% of Al2O3 as the main raw material, adding one or more of silicon dioxide, aluminum oxide, kaolin, bentonite and talcum powder as the auxiliary material, and adding adhesive, dispersant and water to obtain a ceramic slurry; and immersing polyurethane sponge foam into the slurry, removing the excessive slurry, drying, and sintering at high temperature to obtain the mullite ceramic foam filter. The invention has excellent thermal impact resistance and molten metal attack resistance, and can be widely used for filtering, purifying and rectifying aluminum, aluminum alloy, copper, iron or any other molten metal liquid, thereby greatly enhancing the quality and yield of castings.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

Zirconium oxide foamed ceramic filter

InactiveCN101259347ALow costImprove product qualityFiltration separationCeramicwareHigh resistanceRare earth

The invention relates a ceramic filter used in the foundry industry, in particular to a zirconium oxide ceramic foam filter with high resistance to heat shock and elevated temperature strength. The raw material of the zirconium oxide ceramic foam filter of the invention has the following ingredients by weight portions: 80-97 percent of oblique crystal zirconium, 2-10 percent of stabilizer and 1-10 percent of binder; the stabilizers are two or more of calcium oxide, aluminium oxide, silicon oxide, magnesium oxide, yttrium oxide, cerium oxide and other rare earth oxides; the binder is inorganic or / and organic ones. The zirconium oxide ceramic foam filter of the invention can be used in the filtering of high-temperature alloys, and has advantages of low cost and superior quality compared with the filters made from pre-made stabilized zirconium.

Owner:JINAN SHENGQUAN GROUP SHARE HLDG

CMC component, power generation system and method of forming a CMC component

A ceramic matrix composite component for a power generation system includes a ceramic foam core and a ceramic matrix composite material surrounding at least a portion of the ceramic foam core. The ceramic foam core remains in place during operation of the component in the power generation system. Additionally, a method of forming the ceramic matrix composite component is provided.

Owner:GENERAL ELECTRIC CO

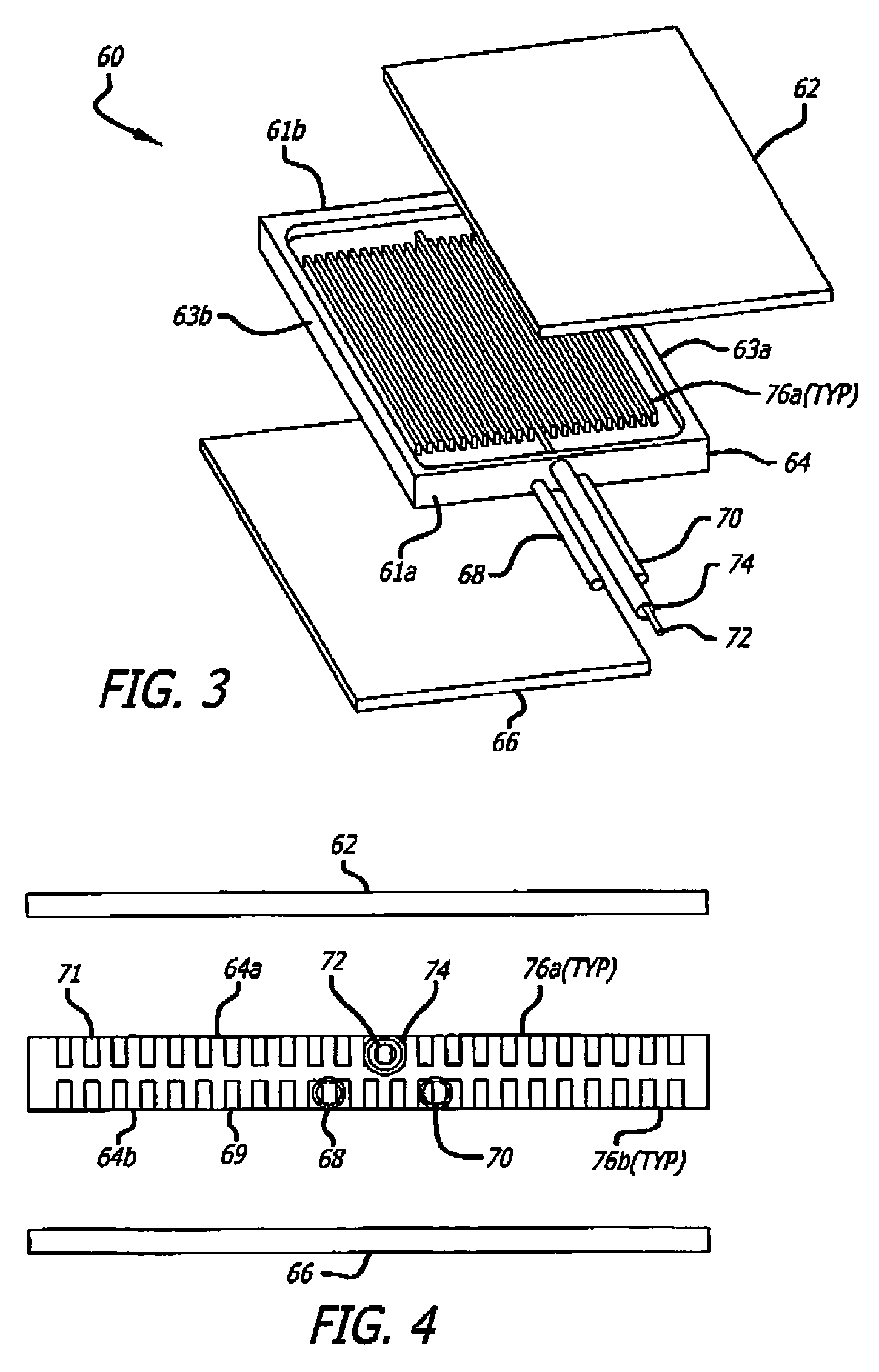

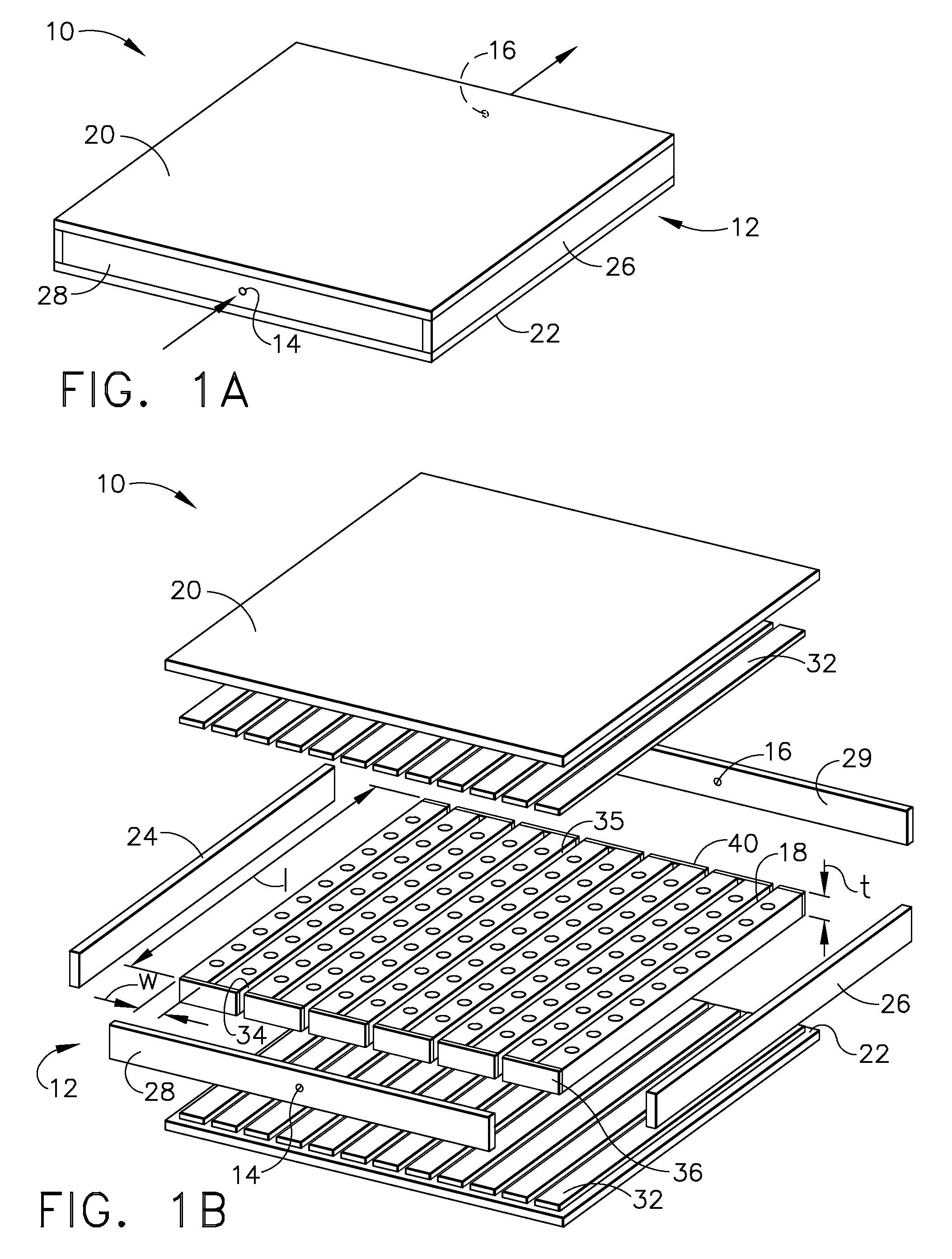

High conductivity ceramic foam cold plate

ActiveUS20080196869A1Improve cooling effectMaximizing performance of coldAir-treatment apparatus arrangementsIndirect heat exchangersMetallurgyCold plate

A cold plate and method for cooling using the cold plate are disclosed. The cold plate includes a housing having hyperporous, microchannel ceramic foam strips disposed therewithin. A plurality of plugs formed from a high thermal conductivity material are disposed into the ceramic foam strips. Heat is transferred in an extremely efficient manner by leveraging the high thermal conductivity of the plugs to transfer the energy deep into a high internal surface area ceramic foam, which in turn transfers the heat to a coolant via convection. Channels between the foam strips form coolant inlet and outlet plenums, which results in minimal coolant pressure drop through the cold plate. In one example, an exemplary cold plate may provide cooling to one or two printed circuit boards. In another example, a cold plate may be disposed within a heat exchanger housing to provide cooling to a fluid.

Owner:THE BOEING CO

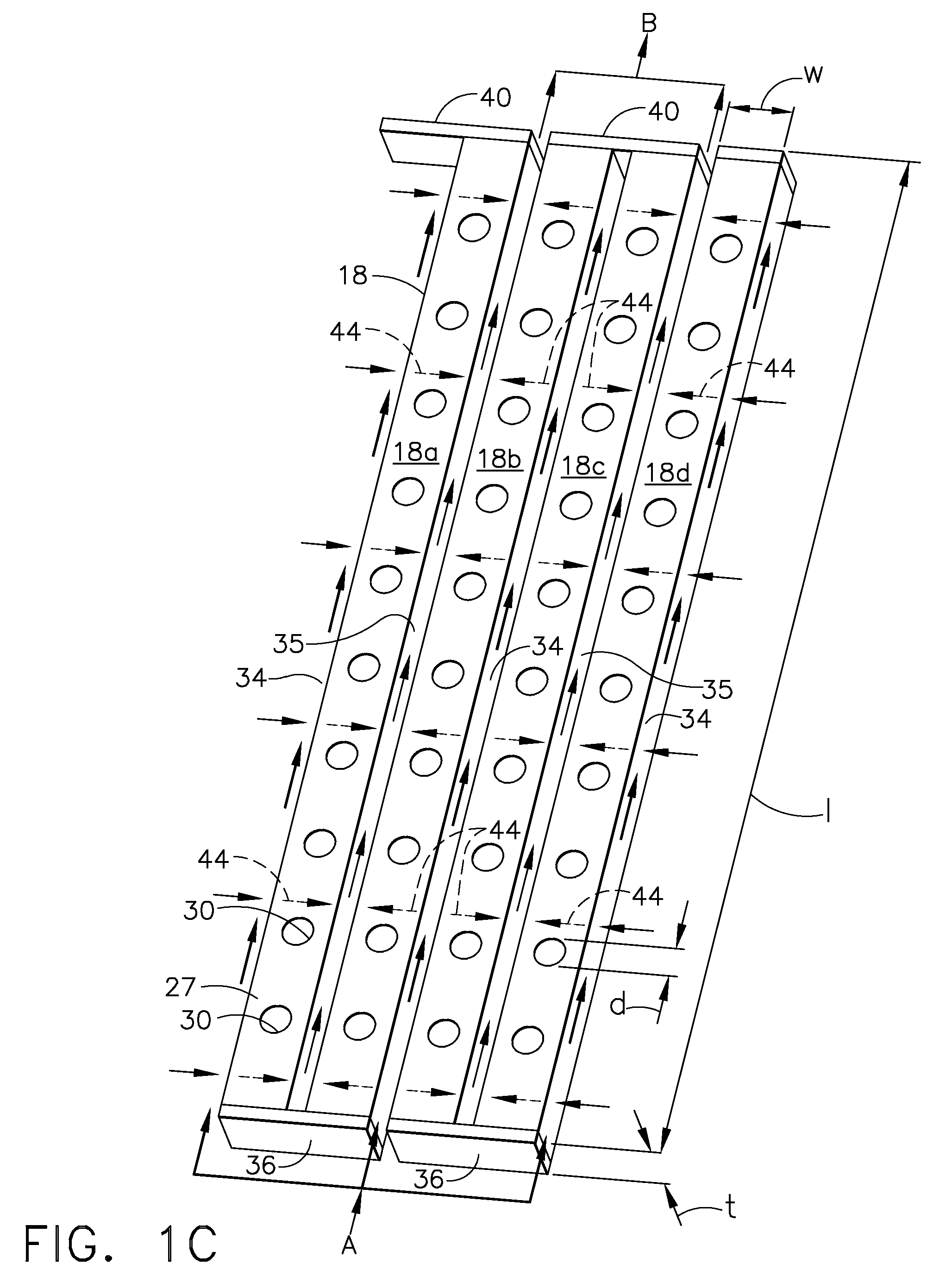

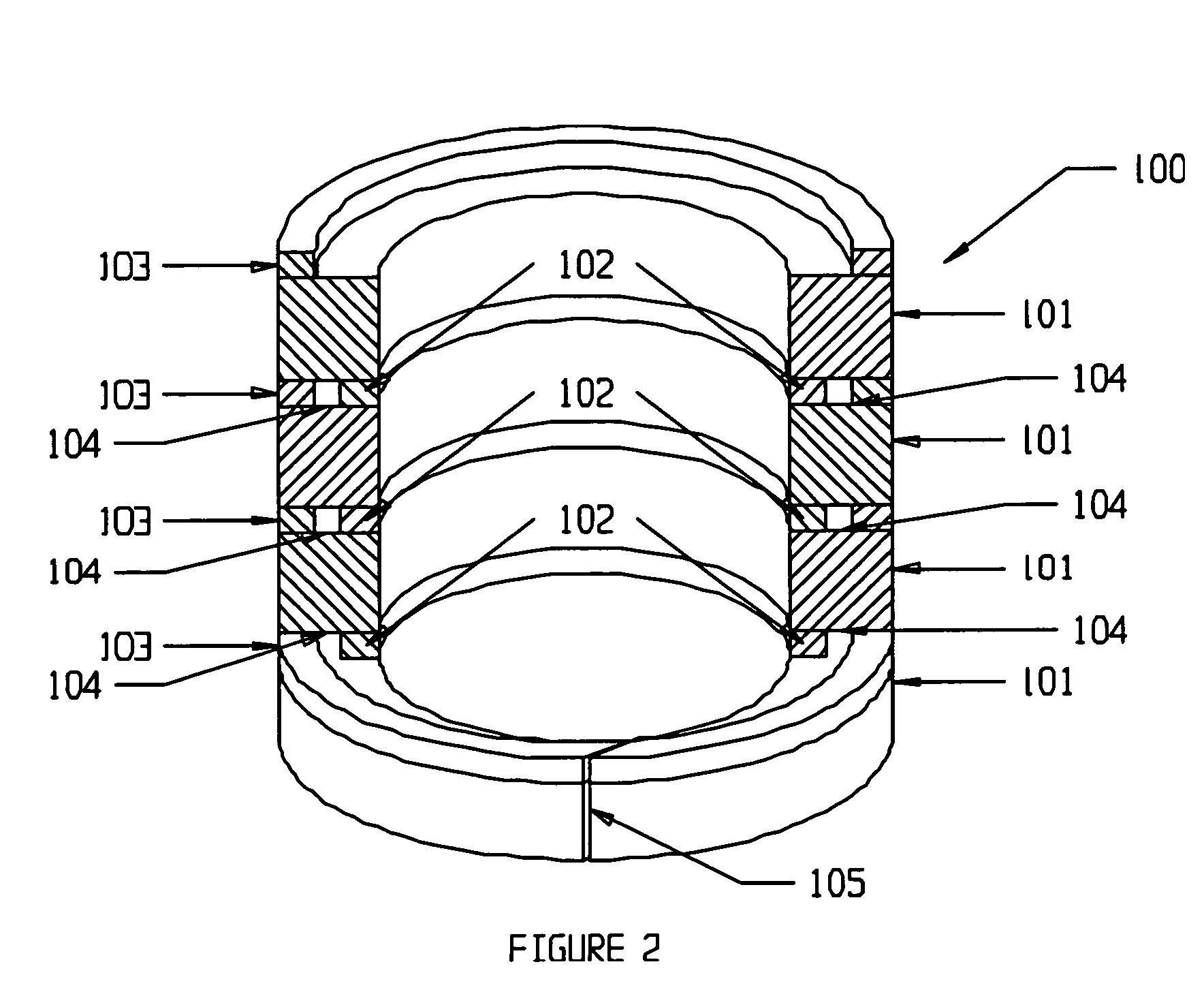

Ceramic foam insulator with thermal expansion joint

InactiveUS7316721B1Easy to useMore stressCombination devicesDispersed particle filtrationThermal expansionCeramic foam

A canister for maintaining entrained particles in a gas stream passing there through. The canister has an outer annular member and an inner porous annular member. The inner porous annular member has rings with at least one expansion zone in each ring. An annular interior volume is between the outer annular member and the inner porous annular member. A gas source is in flow communication with the annular interior volume for providing gas at a pressure sufficient to pass through the inner porous annular member to dislodge particles adhering thereto.

Owner:PORVAIR

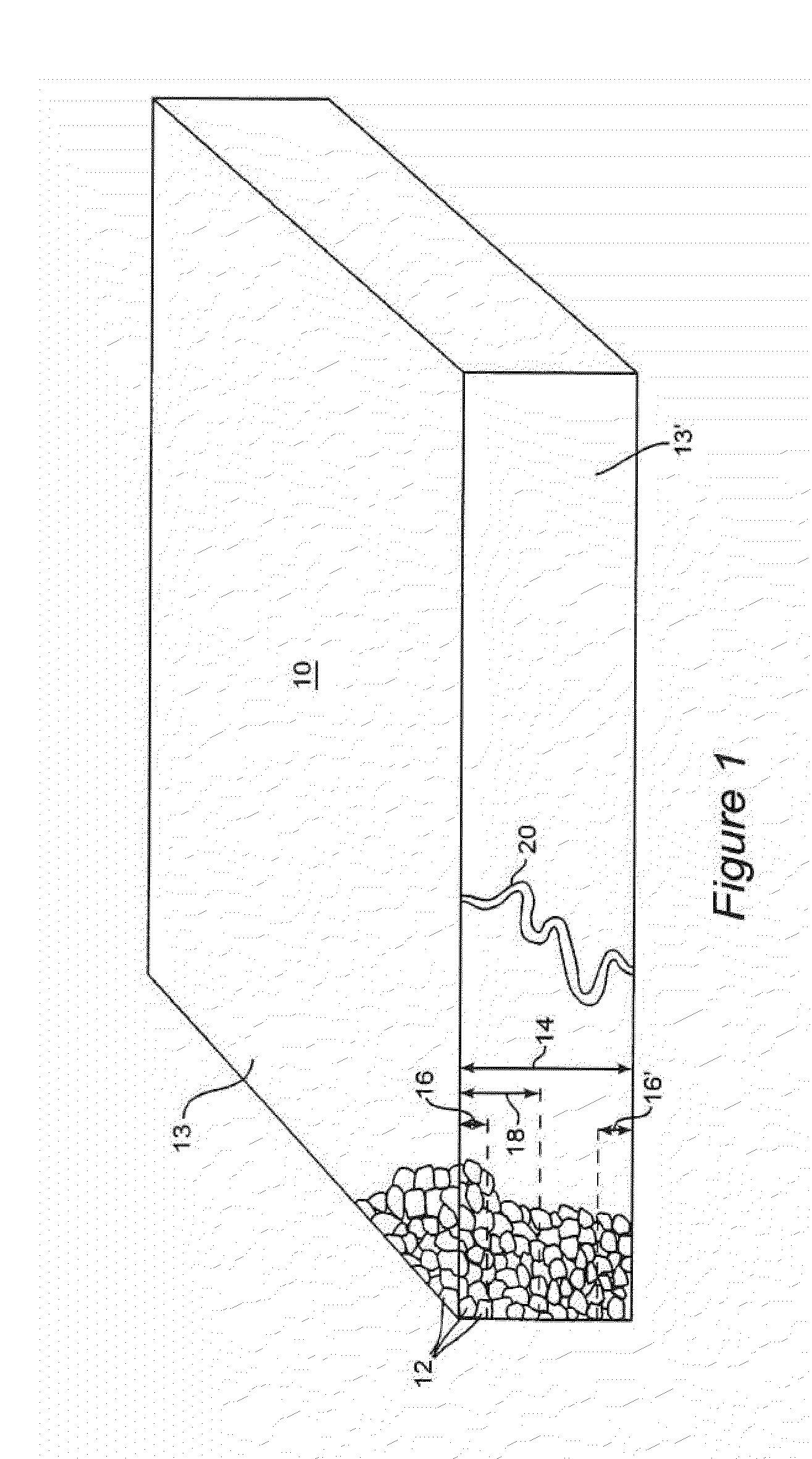

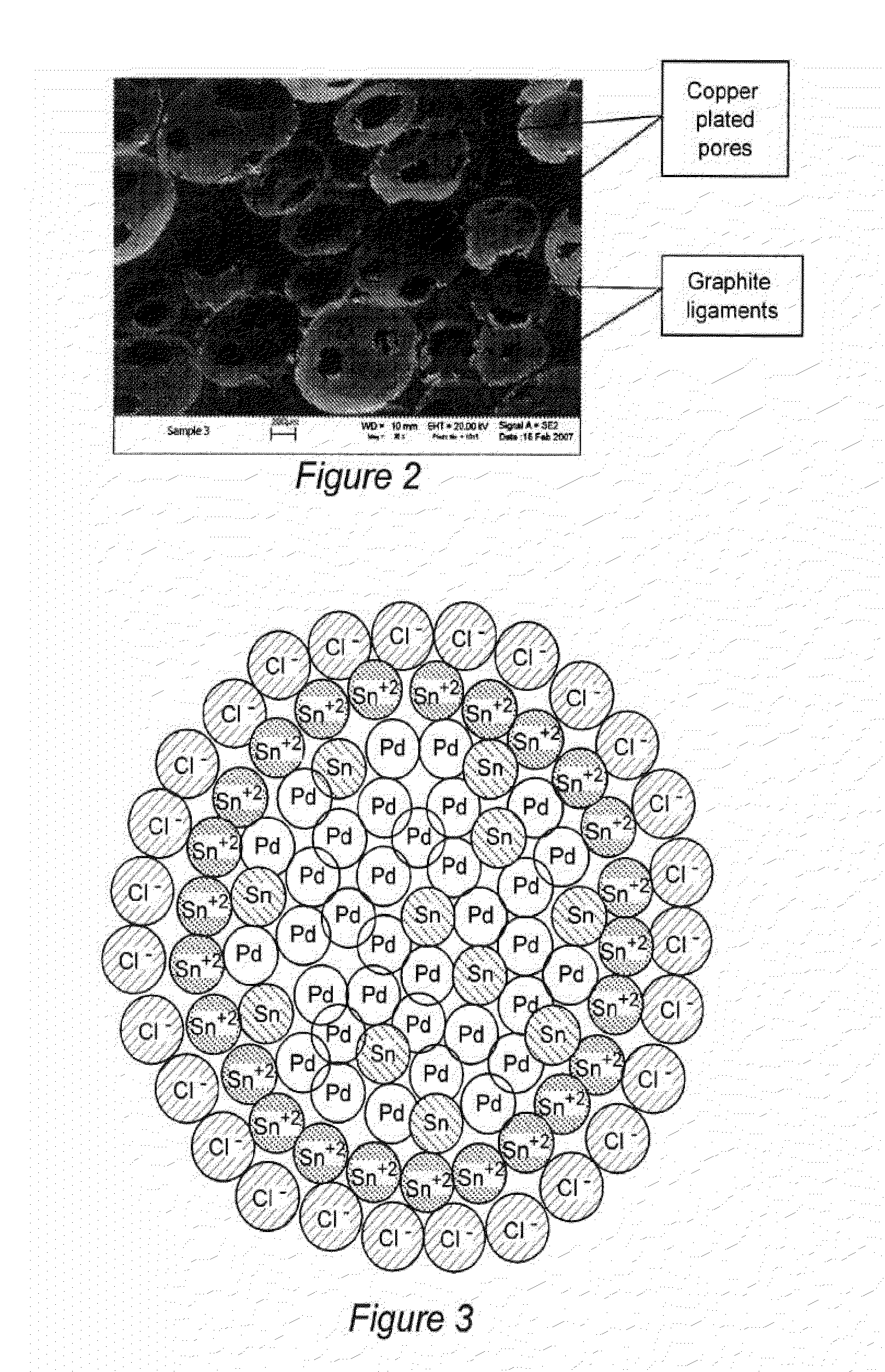

Open pore ceramic matrix coated with metal or metal alloys and methods of making same

InactiveUS20110117338A1Lower overall pressure dropMore laminar flowLayered productsEfficient propulsion technologiesElectrolysisMetal alloy

Open pore foams are coated with metal or metal alloys by electrolytic or electroless plating. The characteristics of the plating bath are adjusted to decrease the surface tension such that the plate bath composition can pass into the pores of the foam, preferably at least two and most preferably more than five pores in depth from the surface of the foam matrix. This can be accomplished by adding a surfactant, solvent or other constituent to reduce the surface tension of the plate bath. In addition, heat and pressure can be used to drive in the plate bath composition into the passage ways of connected open pores in the foam matrix. The net result is to plate the inside surfaces of the pores in the foam matrix, while maintaining the passageways through the foam. Pretreatment of the pore surfaces can be used to promote adhesion of the metal. Particularly advantageous results are achieved when the foam matrix is a ceramic foam.

Owner:VIRGINIA TECH INTPROP INC

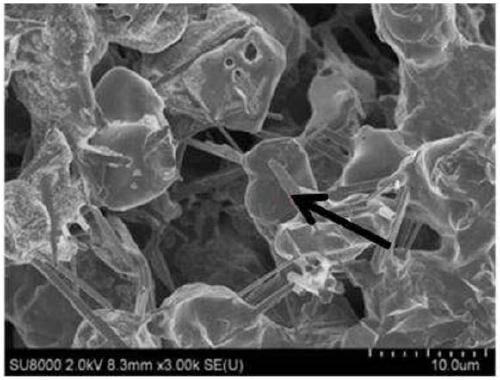

Multiphase nitride combined silicon carbide ceramic foam filter and preparation method thereof

The invention relates to a multiphase nitride combined silicon carbide ceramic foam filter and a preparation method thereof, and belongs to the technical field of refractory materials. The preparation method is realized in a way as follows: preparing slurry from silicon, silicon carbide, silicon dioxide, ball clay, admixtures and water; soaking the slurry by using soft polyurethane foam as the carrier to prepare a blank; and drying, and sintering at 1400-1500 DEG C in the nitrogen atmosphere to obtain the multiphase nitride combined silicon carbide ceramic foam filter. The ceramic foam filter of the invention has favorable high temperature stability in ferric and copper solutions, does not pollute alloys, has the open-cell rate of 80-90%, has favorable filtration and adsorption capacities on oxide inclusions and flux inclusions, and has the advantages of high filter capacity, favorable filtration and purifying effect, small hot melt and high thermal shock stability; the compression strength at normal temperature is not lower than 2.3 MPa; the ceramic foam filter can be cooled by water at 1100-20 DEG C for more than 23 times, and does not need preheating in use; and the highest service temperature is 1550 DEG C.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

Preparation method of magnesium oxide foam ceramic filter for filtering magnesium and magnesium alloy melt

InactiveCN101785944BHigh strengthImprove adhesionFiltration separationProcess efficiency improvementOxide ceramicWater based

The invention provides a magnesium oxide ceramic foam filter for filtering a magnesium and magnesium alloy melt and a preparation method thereof, relating to the field of metallurgy. The process is as follows: a polyurethane foam template is soaked in sodium hydroxide solution (10%) for 30 minutes under the temperature of 50 DEG C and is then washed by water and dried; electric-melting magnesium oxide, magnesium fluoride and water are mixed in a ball-milling manner according to the mass ratio so as to obtain water-based dispersion slurry; the polyurethane foam template is soaked in the slurry, and bisque is obtained through repeated slurry dipping and centrifugal slurry throwing; the bisque is put into an oven; finally, the dried bisque is put into a high-temperature furnace, is heated to 1,200 to 1,300 DEG C at the speed of 1 to 3 DEG C / min, is heat-preserved for 2 hours, and is then naturally cooled in a furnace body. An obtained product of the invention has good chemical stability in the magnesium and the magnesium alloy melt, does not pollute the magnesium and the magnesium alloy melt, has good functions of absorbing and filtering nonmetallic inclusions in the magnesium and the magnesium alloy melt, and is suitable for filtering as well as purifying the magnesium and the magnesium alloy melt.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

Magnesium oxide foam ceramic filter

InactiveCN100536986CImprove high temperature stabilityImprove filtration and purification effectFiltration separationCeramicwareBoron carbideSlurry

The invention relates to a magnesia foam ceramic filter with special high-temperature chemical stability, which is composed of magnesia, boron The high-quality polyurethane foam is used as the carrier, impregnated with the above slurry, extruded to form a billet, dried and sintered to obtain a magnesia foam ceramic filter. The ceramic foam filter of the present invention has good high-temperature stability in the magnesium alloy melt, does not pollute the alloy, has good filtration and adsorption capacity for oxidation inclusions and flux inclusions in the magnesium alloy melt, and has a good filtration and purification effect and is heat-resistant. Small capacity, no need to preheat when using, small fluid resistance, large filtration capacity, through the filtration and purification test of metal magnesium and magnesium alloy melt, all performances are good.

Owner:晋城市富基新材料股份有限公司

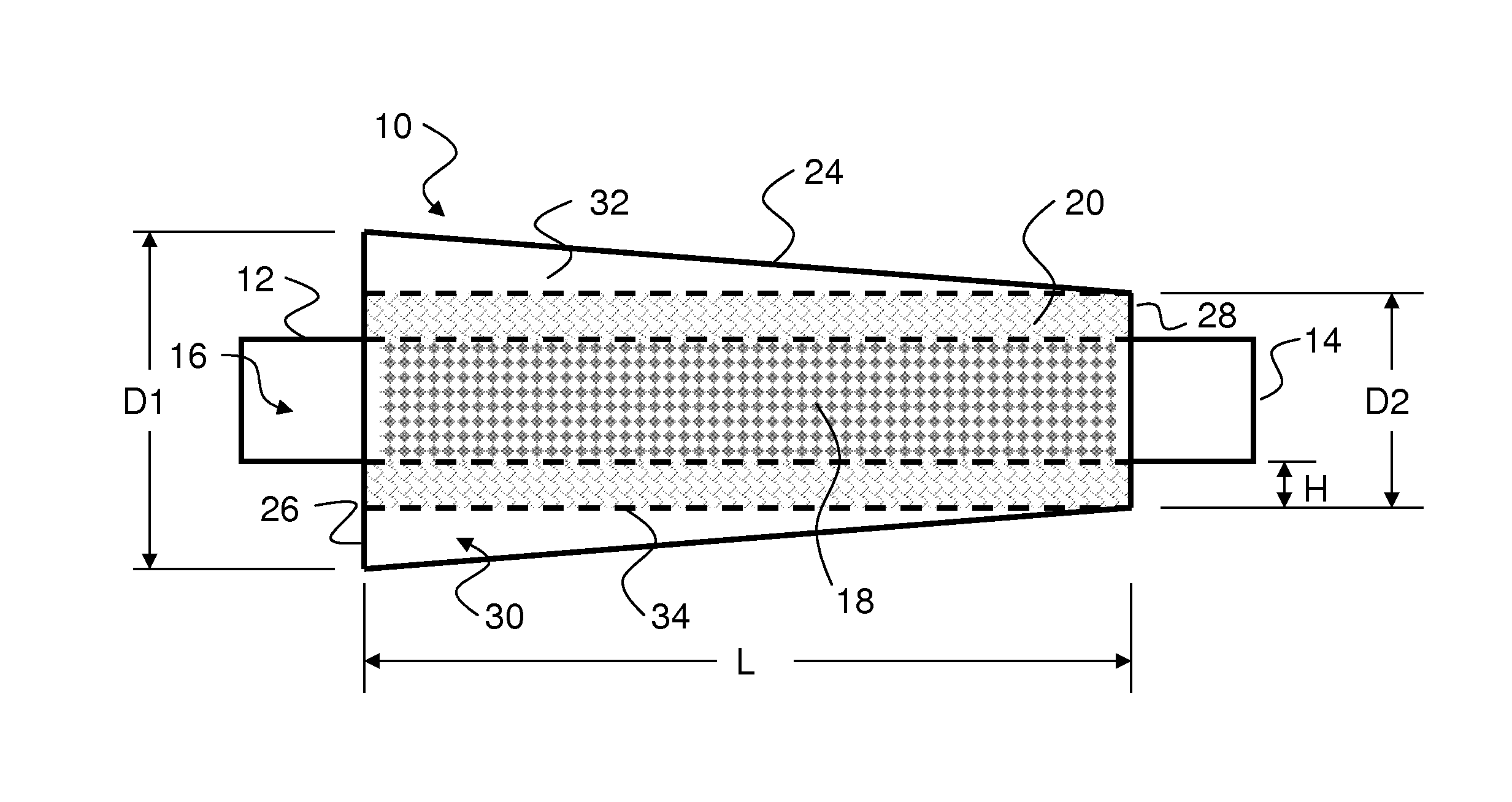

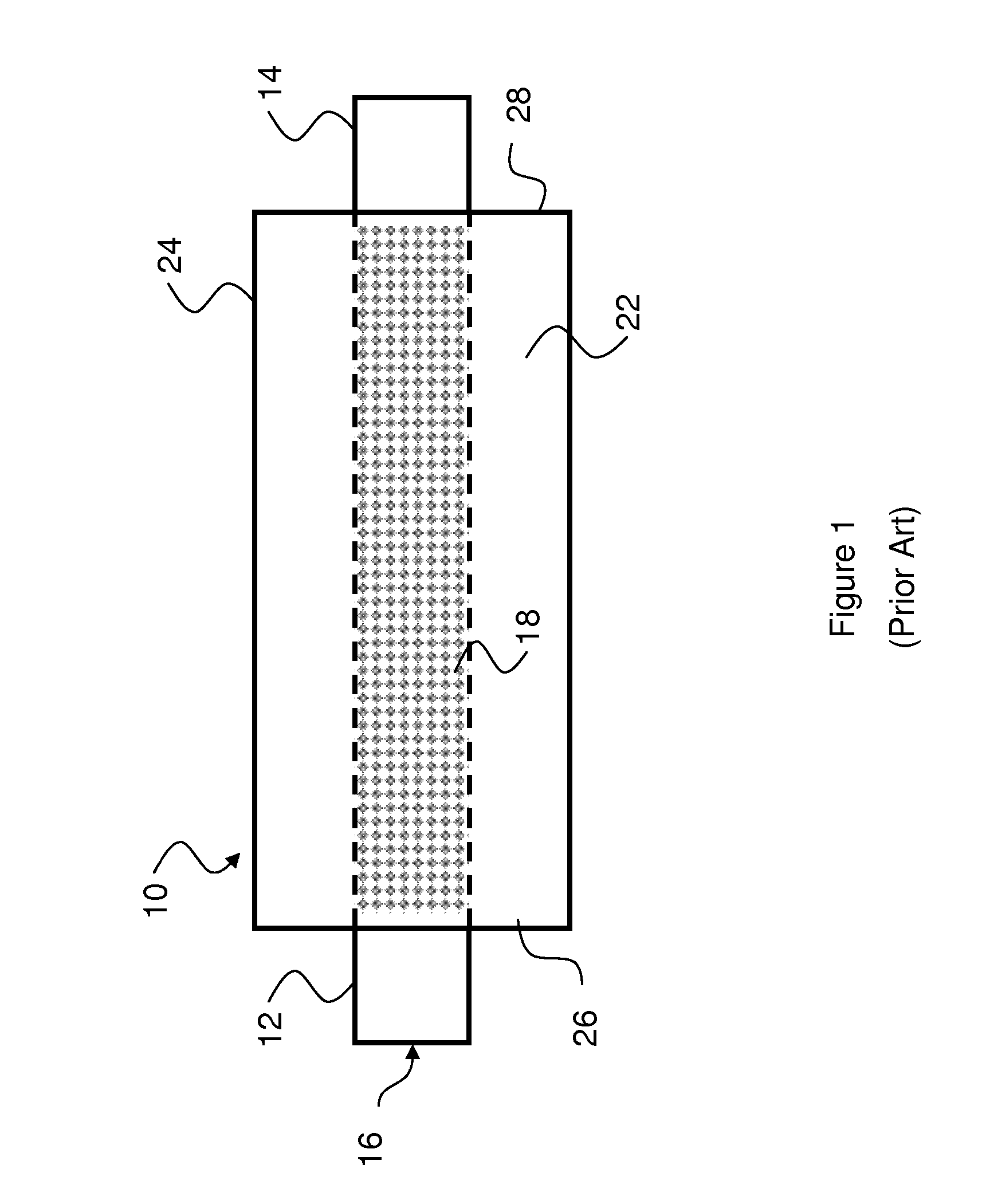

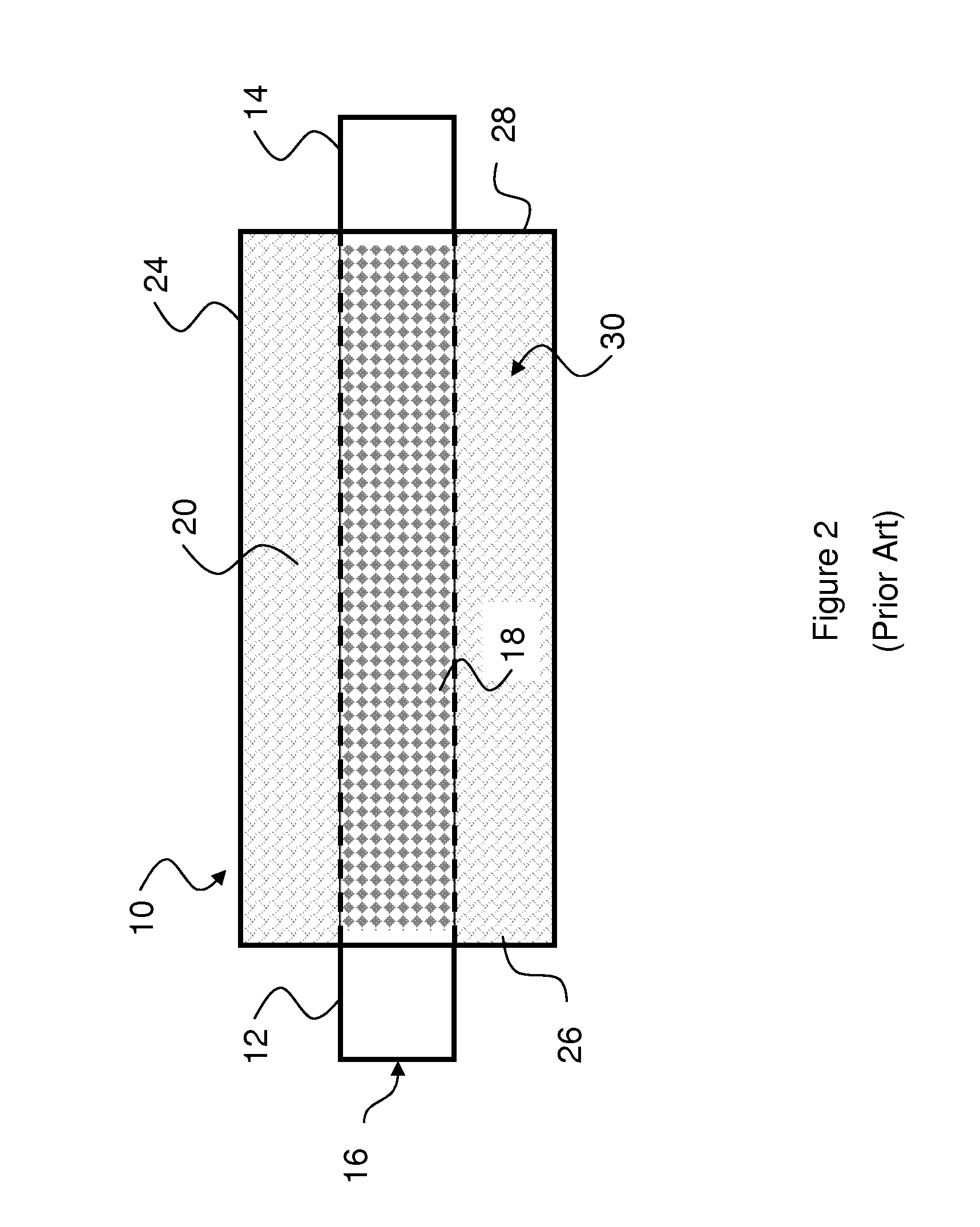

Exhaust sound attenuation device and method of use

A sound muffler combines a resonator chamber with a dissipative layer surrounding a through pipe. The muffler provides sound attenuation over a wide range of sound frequencies while maintaining unimpeded flow of gases through the pipe. This attenuation is achieved by combining dissipation with a frusto-conical resonant chamber. The dissipation is achieved by encircling the through passage with a layer of low density material such as metallic or ceramic foam or loosely packed fibers of a heat resistant material. The low density material attenuates the high frequency waves while permitting the passage of low frequency sound waves into the frusto-conical resonant chamber.

Owner:HUFF DENNIS L +1

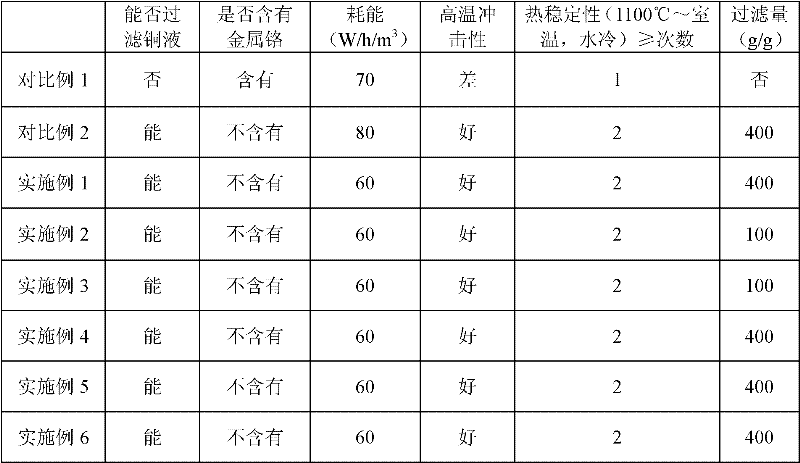

Ceramic foam filter, composition for preparing ceramic foam filter and preparation method for ceramic foam filter

The invention provides a ceramic foam filter, a composition for preparing the ceramic foam filter and a preparation method for the ceramic foam filter. The composition consists of the following components in percentage by weight: 25 to 85 percent of salic material, 10 to 60 percent of silicon carbide and 5 to 15 percent of inorganic binder or organic binder. The preparation method comprises the following steps of: preparing slurry by using the composition, preparing a green body, and drying and sintering to obtain the ceramic foam filter. The composition for preparing the ceramic foam filter does not contain metal chromium, cannot pollute the environment and jeopardize human health, and is safer and more environment-friendly.

Owner:JINAN SHENGQUAN DOUBLE SURPLUS CERAMIC FILTER

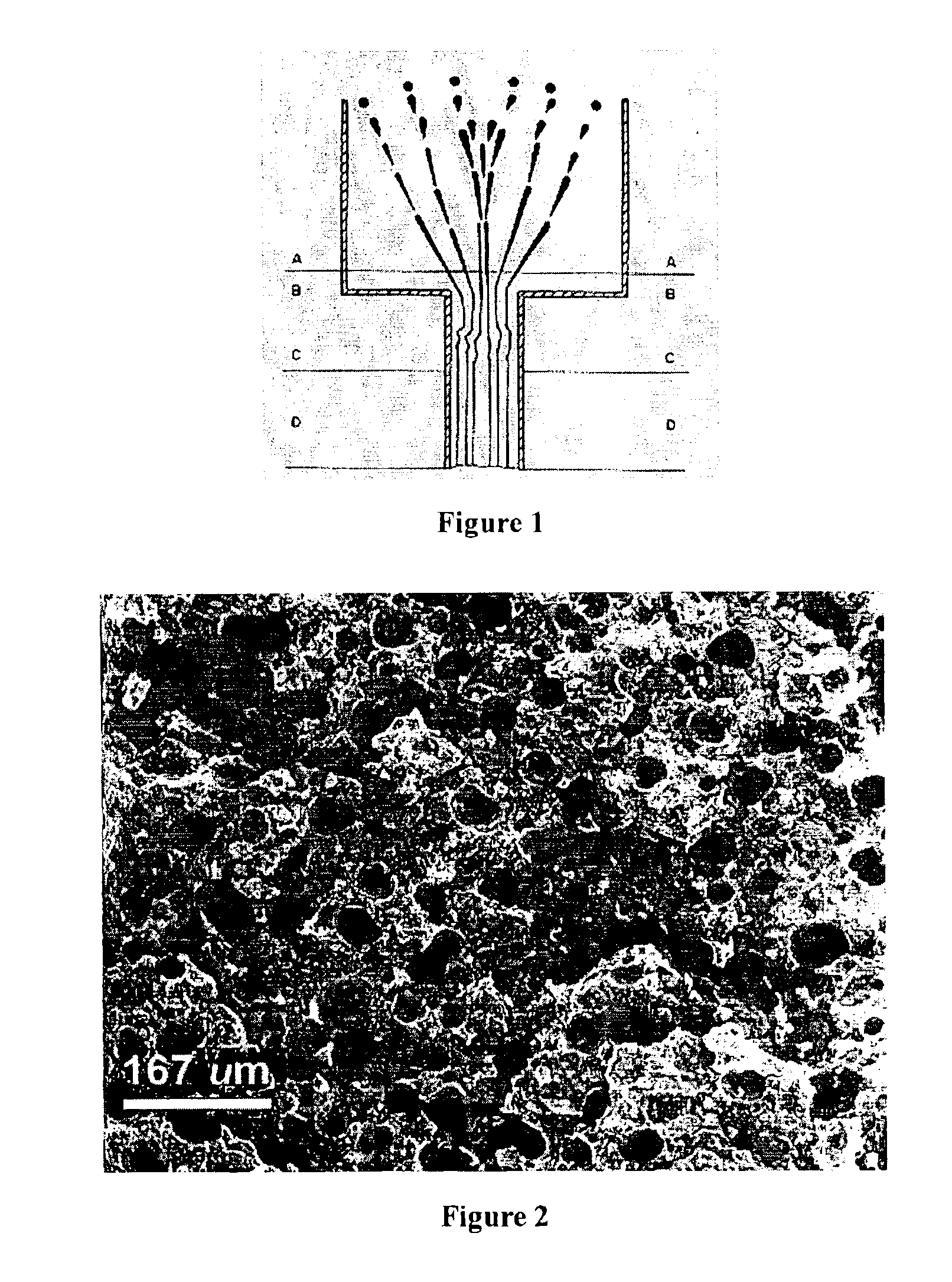

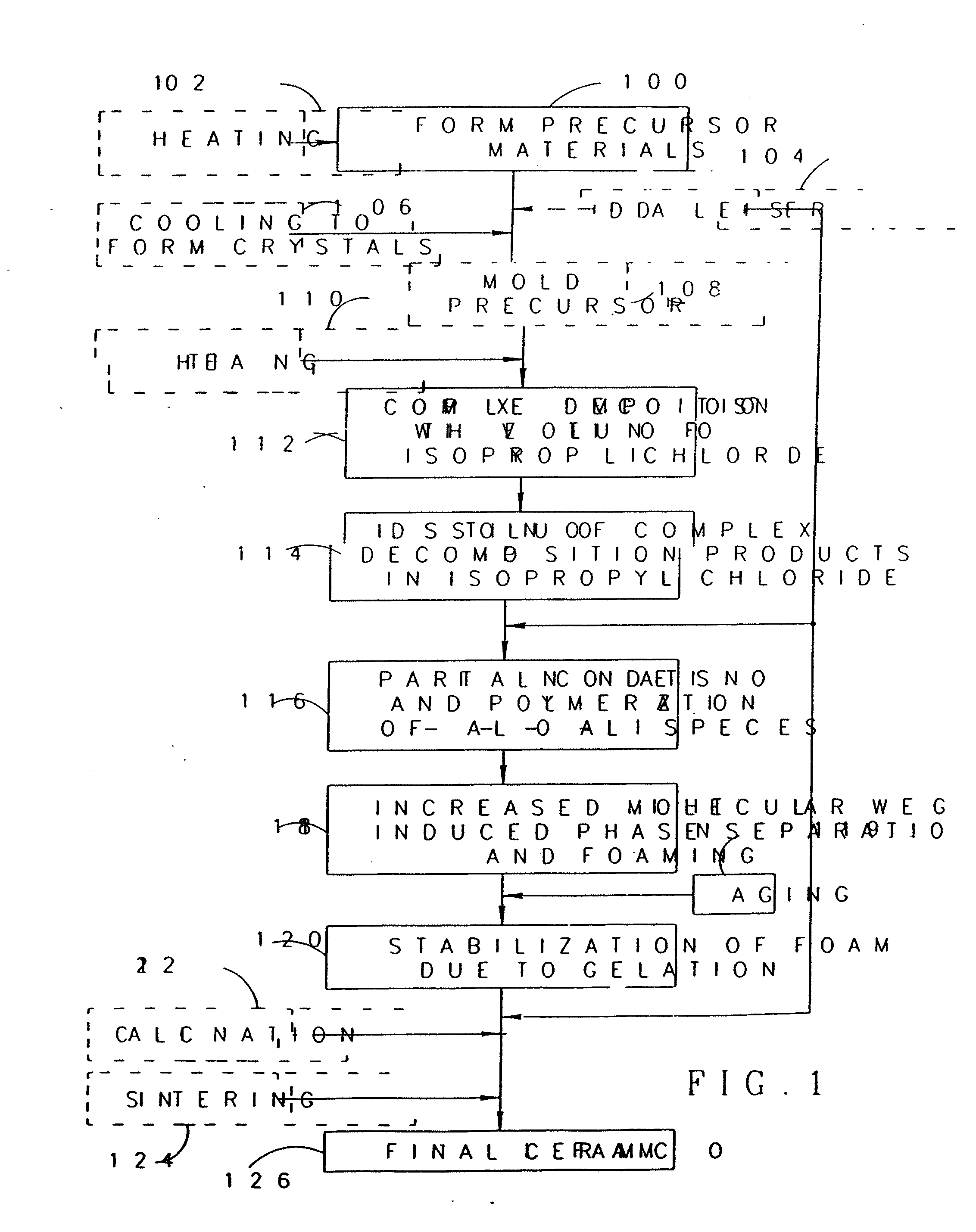

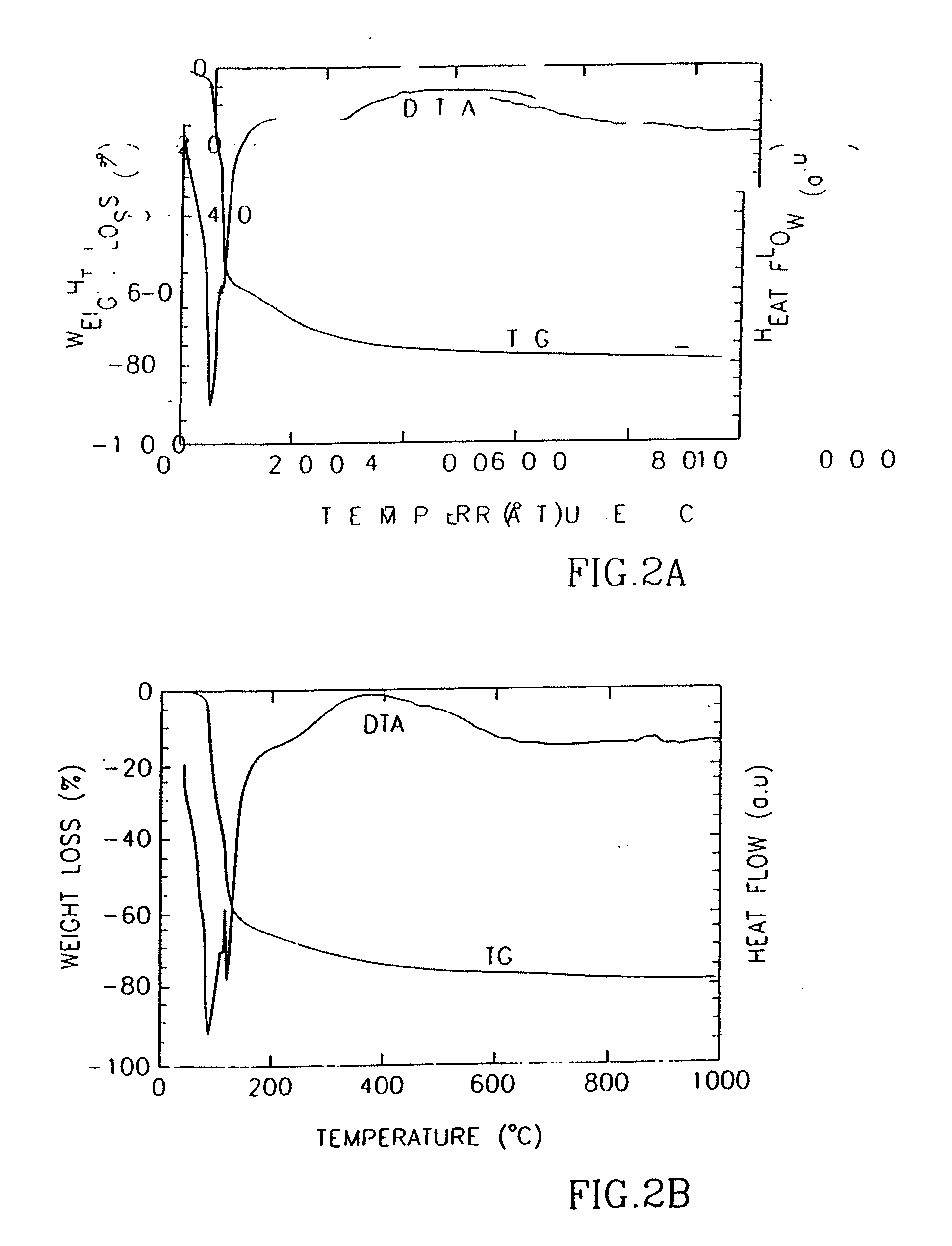

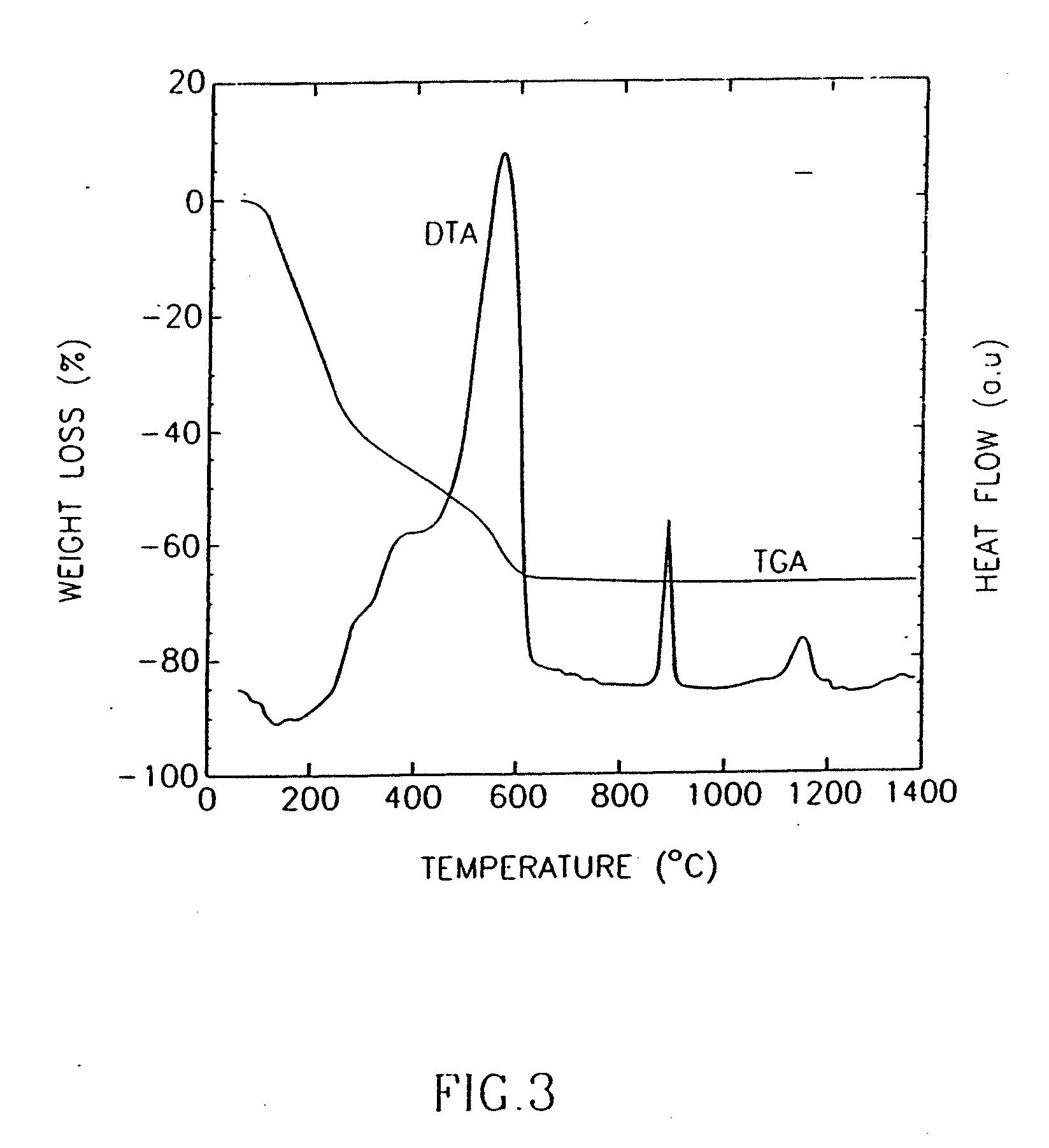

Method of producing ceramic foams

InactiveUS20080058194A1Easy to produceSimple in situ preparationPhysical/chemical process catalystsCeramic shaping apparatusPolymer scienceDecomposition

A process for foaming ceramic foams, in which the ceramic foams are produced from a precursor or a mixture of precursors which contain at least one ceramic-forming element and liberates at least one volatile reaction product during an inorganic gelation process. In one embodiment, foaming is based on a precursor containing crystals of the AICI3(Pri2O) complex. The decomposition of the initial precursor produces polymerizing species dissolved in liquid isopropyl chloride. The solvent and growing AIOxCIy(OPri)z species are mixed homogeneously so that the boiling point of the solution is raised above the boiling point of the pure isopropyl chloride. Polymerization takes place in the liquid until a critical polymer size is attained, whereupon a phase separation into polymer rich and solvent rich regions occurs. Since the expelled solvent is suddenly above its boiling point, bubbles start forming instantly. Foam stabilization takes place as a result of gelation in the polymer rich regions which comprise the cell walls in the foam. The net result of the process is a gelled ultra light foam.

Owner:CELLARIS LTD

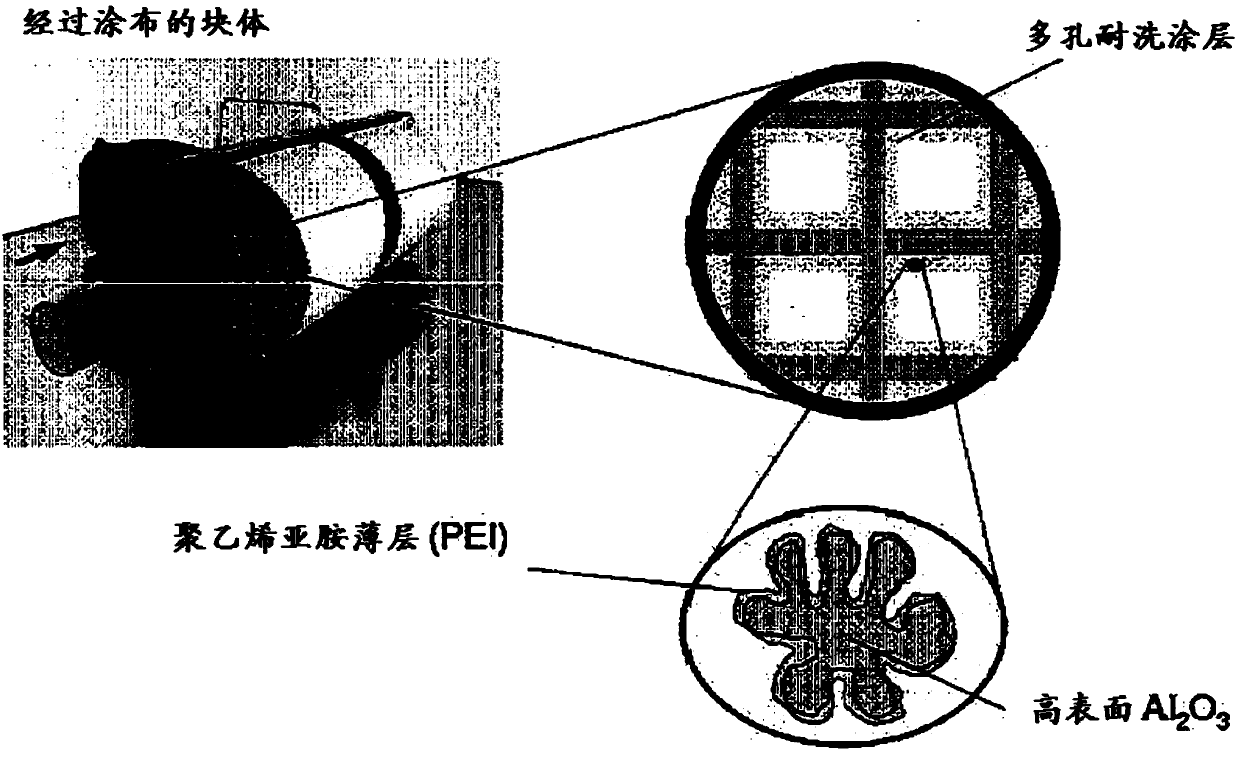

Methods of applying a sorbent coating on a substrate, a support, and/or a substrate coated with a support

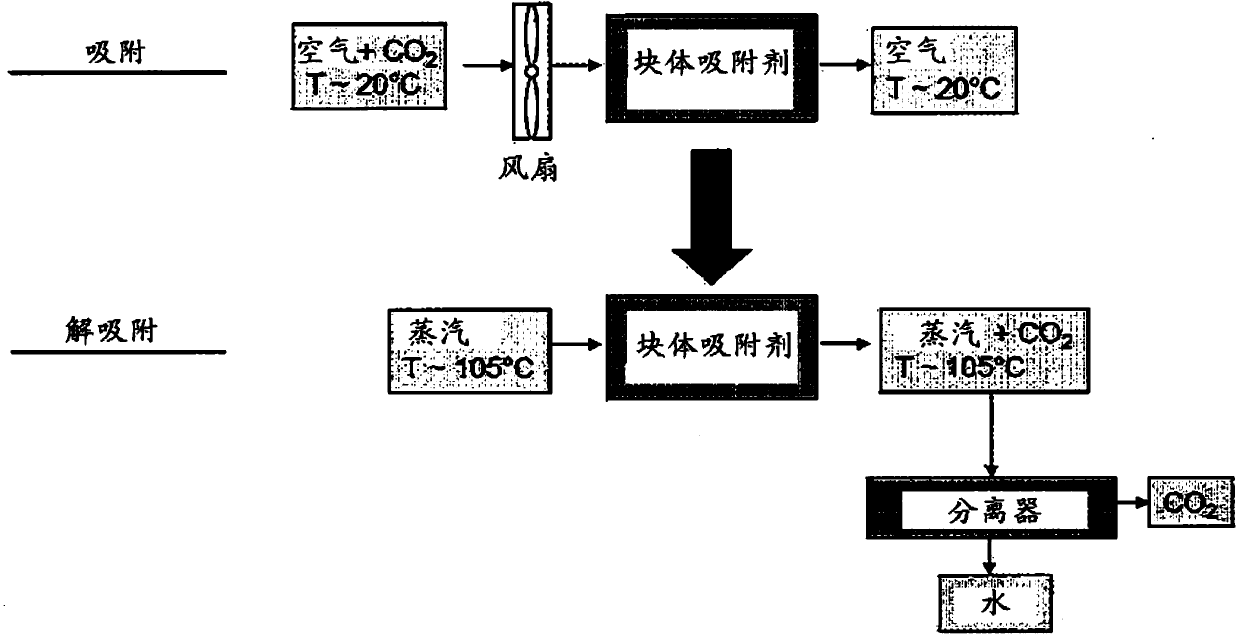

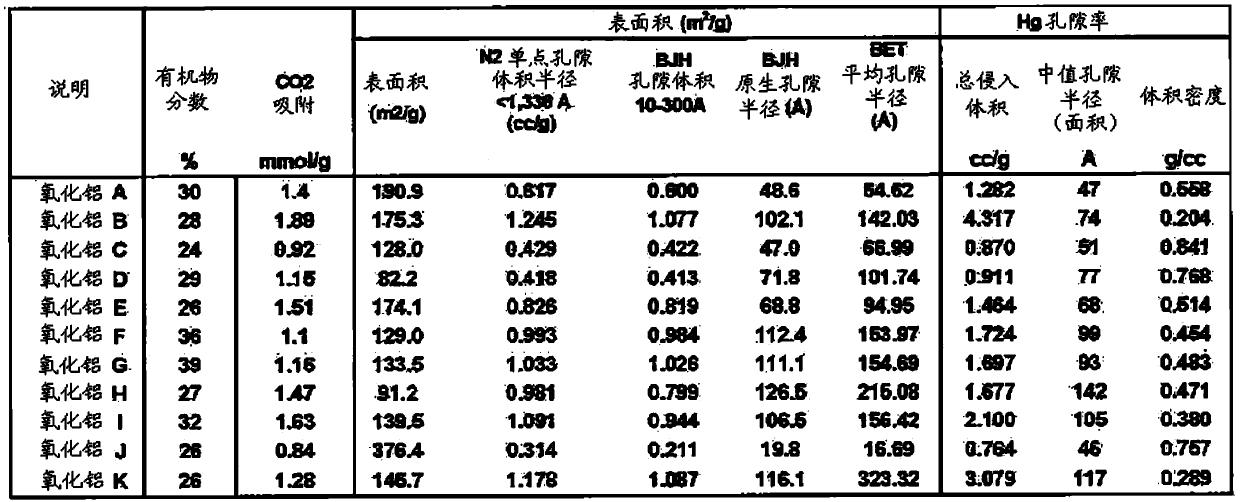

Methods of applying a sorbent coating on a substrate, a support, and / or a substrate coated with a support are described. One of the methods comprises: (i) optionally, preparing the substrate coated with the support by pre-treating the substrate with a slurry, wherein the slurry comprises: a. solvent, b. a binder, c. the support, and d. optional dispersant; and (ii) treating the substrate, the support, and / or the substrate coated with the support, with a sorbent; wherein the substrate is (a) a monolithic or honeycomb structure made of ceramic, metal, or plastic; (b) a polyurethane foam, a polypropylene foam, a polyester foam, a metal foam, or a ceramic foam; or (c) woven or non-woven plastic or cellulosic fibers, wherein the support is alumina, silica, silica-alumina, titania, zirconia, carbon, zeolite, metal-organic framework (MOF), or combinations thereof, and wherein the sorbent adsorbs carbon dioxide and the sorbent is selected from the group consisting of amines; monoethanolamine; diethanolamine; polyethylenimine (PEI); aminopropyltrimethoxysilane; polyethyleneimine-trimethoxysilane; amide or amine containing polymers including nylon, polyurethane, polyvinylamine, or melamine; and combinations thereof.

Owner:BASF CORP

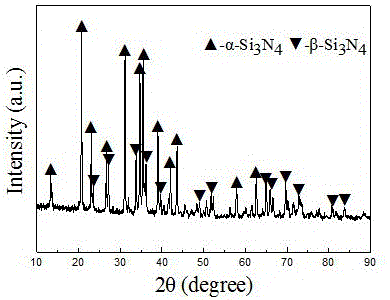

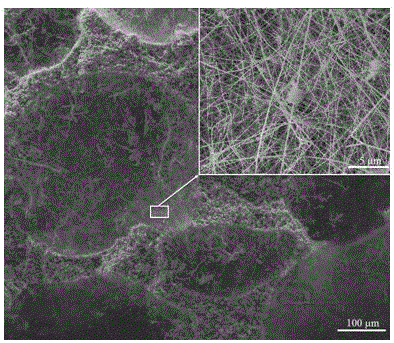

Nanowire self-reinforced porous silicon nitride ceramic and preparation method thereof

The invention relates to a nanowire self-reinforced porous silicon nitride ceramic and a preparation method thereof. The technical scheme is as follows: the preparation method comprises the following steps: using 70-80 wt% of silicon powder, 5-10 wt% of catalyst and 10-20 wt% of nitrogen source as raw materials, adding deionized water which accounts for 20-30 wt% of the raw materials, and stirring to obtain a ceramic slurry; adding foam prepared by adding a foaming agent (accounting for 10-20 wt% of the raw materials) into the ceramic slurry, and continuously stirring for 30-60 minutes to obtain a ceramic foam slurry; pouring the ceramic foam slurry into a mold, standing in a nitrogen environment, drying, and demolding to obtain a ceramic body; in a nitrogen atmosphere, heating the ceramic body to 1100-1150 DEG C, and keeping the temperature; heating to 1200-1600 DEG C, and keeping the temperature; and naturally cooling to obtain the nanowire self-reinforced porous silicon nitride ceramic. The method has the advantages of simple technique, low cost, high utilization ratio of raw materials and controllable process. The prepared product has the advantages of uniform pore size, uniform pore size distribution and high mechanical strength.

Owner:WUHAN UNIV OF SCI & TECH

Casting method for impeller made of super duplex stainless steel 5A material

ActiveCN107309405AAvoid crack defectsGuaranteed denseFoundry mouldsFurnace typesImpellerVolumetric Mass Density

The invention provides a casting method for an impeller made of a super duplex stainless steel 5A material. The method comprises the steps of preparation of a casting mould and a sand core, specifically, the casting mould and the sand core are prepared in the manner that alkaline phenolic resin is added to crude sand, the casting mould is provided with an impeller cavity for storing the sand core, and a dead head is internally provided with a ceramic foam filter; casting and pouring; and sand shakeout and heat treatment of a heat-filling furnace, and an impeller finished product is obtained. The temperature ranges of precipitation of brittle phases including Eta, Chi and Sigma can be avoided, precipitation of the brittle phases by an impeller casting structure is avoided, crack defects of an impeller casting are overcome fundamentally, density of the casting structure can also be guaranteed, and the yield rate of a casting finished product can be increased to 96% or above; and meanwhile, the casting production cost is greatly lowered as the technological yield is increased, and the heat-filling furnace process is implemented.

Owner:LUOYANG SUNRUI SPECIAL EQUIP

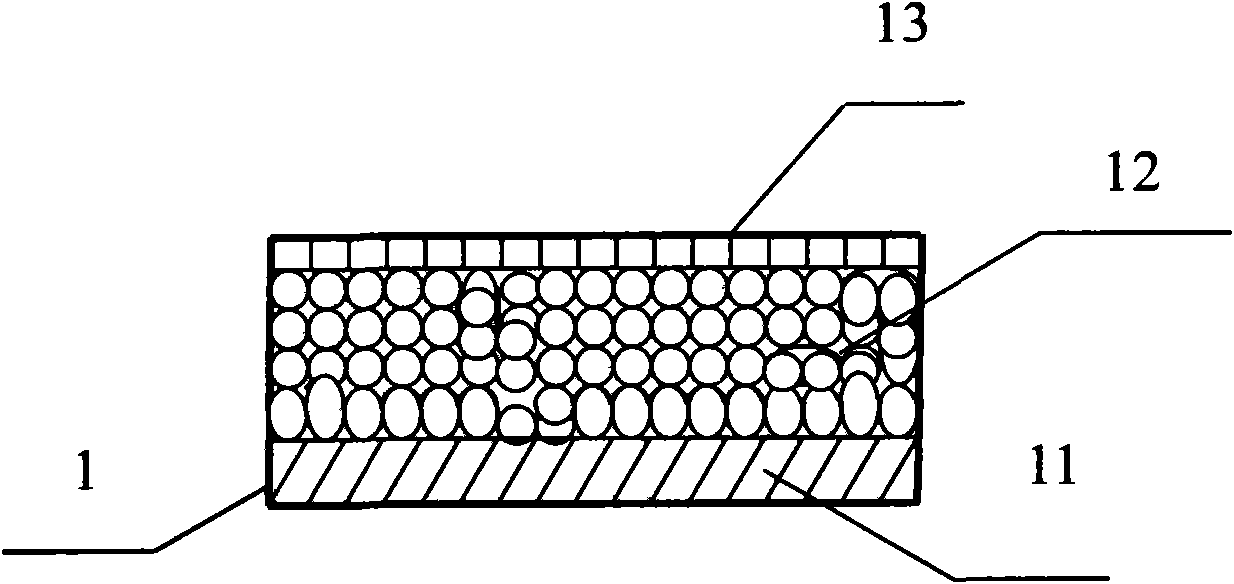

Composite foam black ceramic solar heat accumulating plate and producing method as well as production applications thereof

InactiveCN102200354AStable internal structureWith heat collection functionSolar heat devicesSolar thermal energy generationFoaming agentSurface layer

The invention relates to a composite foam black ceramic solar heat accumulating plate and a producing method as well as production applications thereof. The composite foam black ceramic solar heat accumulating plate 1 is composed of a basal layer common ceramic layer 11, a middle layer foam ceramic layer 12 and a surface layer black ceramic layer 13 which are burned into a whole. The producing method provided by the invention comprises the following steps: manufacturing common ceramic powder, foam ceramic powder and black ceramic powder respectively, and carrying out material arranging for three times, drying and sintering, wherein a traditional ceramic foaming agent is added for the common ceramic powder or the ceramic polishing solid waste is used as a foaming agent for the foam ceramic powder. According to the invention, the heat accumulation function and the temperature conservation function are integrated for the composite foam black ceramic solar heat accumulating plate 1, and the heat accumulating plate 1 can be merged with construction, the price is lower, heat, hot water and refrigeration are provided for the construction, and the heat accumulating plate also can be used for power generation; and compared with the prior art, the heat accumulating plate is more simple to manufacture, is easier to install, the heat preservation effect is better, the service life is longer, and creates more favorable conditions for developing and utilizing solar energy with low cost in large scale.

Owner:黄锦熙

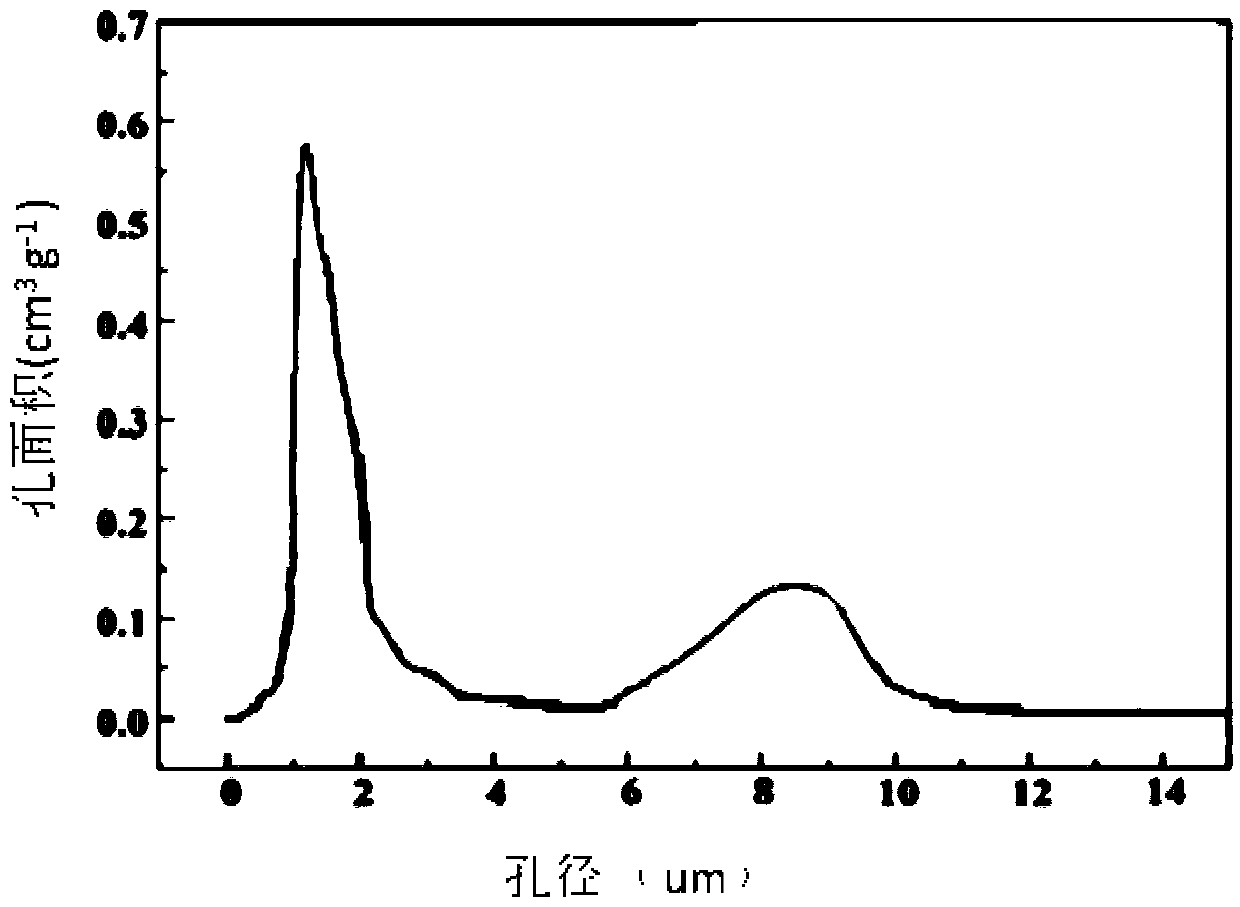

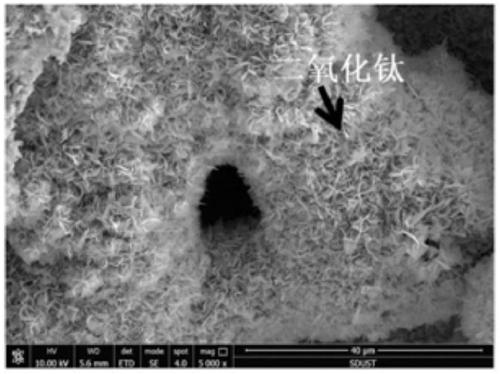

Porous ceramic membrane material for photo-thermal sea water desalination and preparation method and application

ActiveCN109530688AEnhanced light-to-heat conversionImprove catalytic purification effectGeneral water supply conservationWater treatment compoundsWater desalinationChemical synthesis

The invention discloses a porous ceramic membrane material for photo-thermal sea water desalination and a preparation method and application. The preparation method comprises the steps that a porous ceramic membrane foam board is used as a carrier, a nanometer heterostructure layer is synthesized on the carrier through a hydrothermal method, and a porous ceramic heterostructure membrane containingTiO2 on the surface is obtained through further calcination; and the pore diameter of the porous ceramic membrane foam board is 0.1-4.0 [mu]m, and the porosity is 30%-75%. According to the porous ceramic membrane material for the photo-thermal sea water desalination and the preparation method and the application, plasma beam heating control and chemical synthesis are combined, a porous ceramic membrane / nanometer oxide TiO2 heterostructure membrane with a controllable porous structure is prepared, the proportion of a pore forming agent and the technology parameters of plasma beam scanning heating are changed, ceramic foam boards with various porosities and pore diameters are obtained, a gradient structure can be assembled according to actual requirements, and photo-thermal conversion and sea water desalination multifunction application are realized.

Owner:SHANDONG UNIV OF SCI & TECH

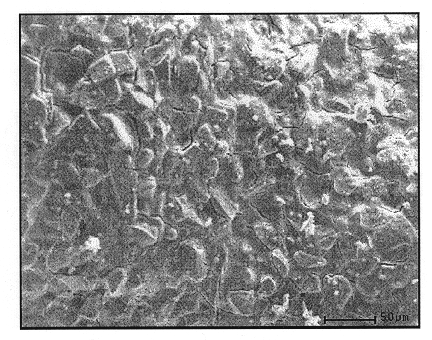

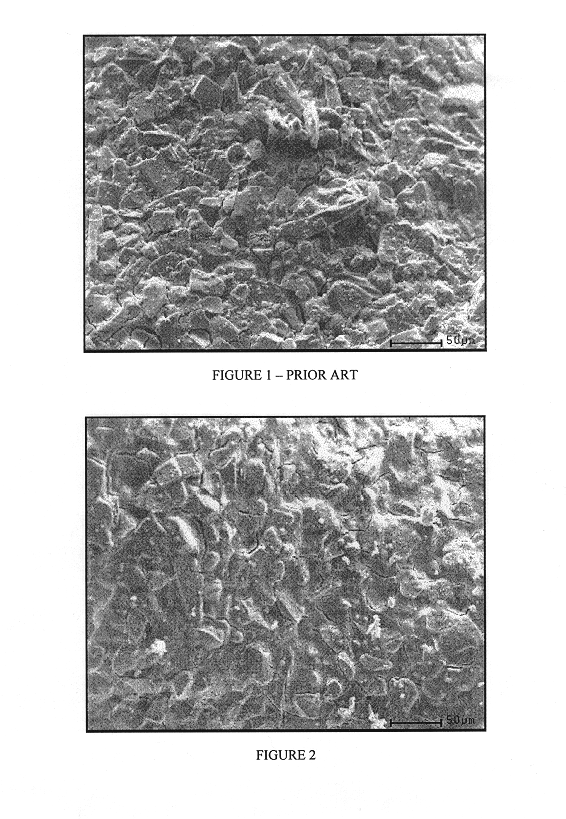

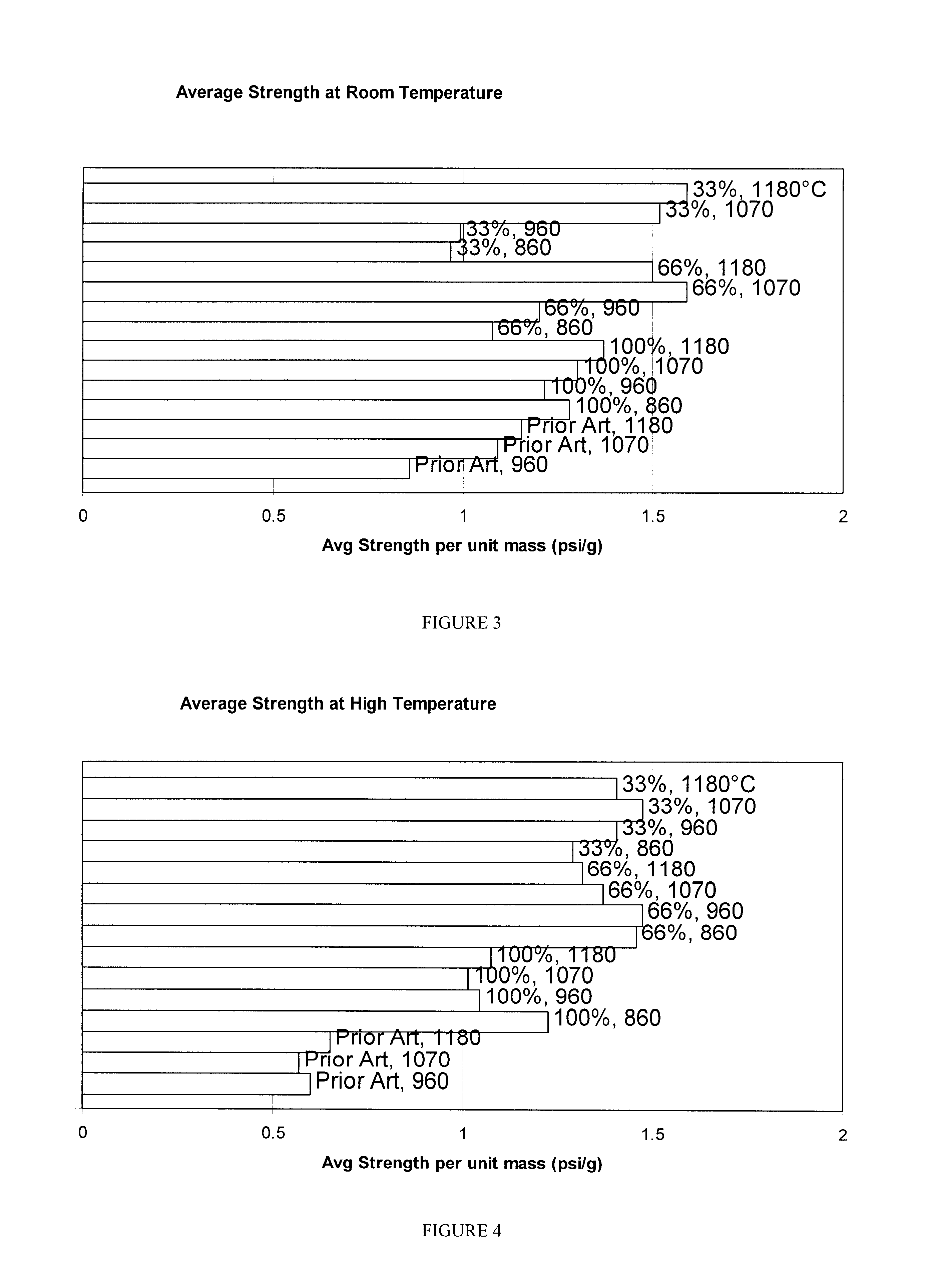

High strength SiC filter and method for the manufacture thereof

InactiveUS6663776B2Improve mechanical propertiesEasy to useLoose filtering material filtersGravity filtersColloidal silicaHigh intensity

There is provided an improved ceramic foam filter for use in filtering molten metals, metal prepared from a ceramic slurry containing silicon carbide, a colloidal silica binder and at least 10 percent of fumed silica. The filter has enhanced strength properties.

Owner:SELEE

Ammonia-based hydrogen generation apparatus and method for using same

InactiveUS7867300B2Reduce manufacturing costEnhance reactionCyanogen compoundsNitrogen compoundsHydrogenCombustion chamber

The present disclosure provides teachings relating to ammonia-based hydrogen generation apparatus and associated methods of use. Exemplary methods and apparatus comprise a thermocatalytic hydrogen generation reactor which includes a reaction chamber containing a catalyst-coated substrate, and a combustion chamber containing a catalyst-coated substrate. Exemplary catalyst-coated substrates include, but are not limited to, metal foam, monolith, mesh, ceramic foam or ceramic monolith.

Owner:INTELLIGENT ENERGY INC

Preparation method of mullite mesh ceramic foam filter

InactiveCN102173857AImprove filtering effectImprove adsorption capacityFiltration separationCeramicwarePolyvinyl alcoholPolyethylene glycol

The invention provides a preparation method of a mullite mesh ceramic foam filter, belonging to the field of porous ceramics. The preparation method of the mullite mesh ceramic foam filter comprises the following steps of: preparing a ceramic slurry by taking electric melted mullite powder as a main raw material, kaolin, bentonite and talcum powder as slurry rheology control agents, silica sol, polyvinyl alcohol and dextrin as binders, polyethylene glycol and polyacrylate as dispersing agents and water as a solvent; soaking a polyurethane sponge foam into the ceramic slurry; removing redundant slurries contained in a sponge soaking body; drying, and then sintering so as to prepare the mullite mesh ceramic foam filter. The mullite mesh ceramic foam filter has excellent high-temperature property and fluid filtering property and can be used for the purification of molten metals, i.e. aluminum, aluminum alloys, copper, irons, and the like, thereby enhancing the cast quality and reducing the rejection rate.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

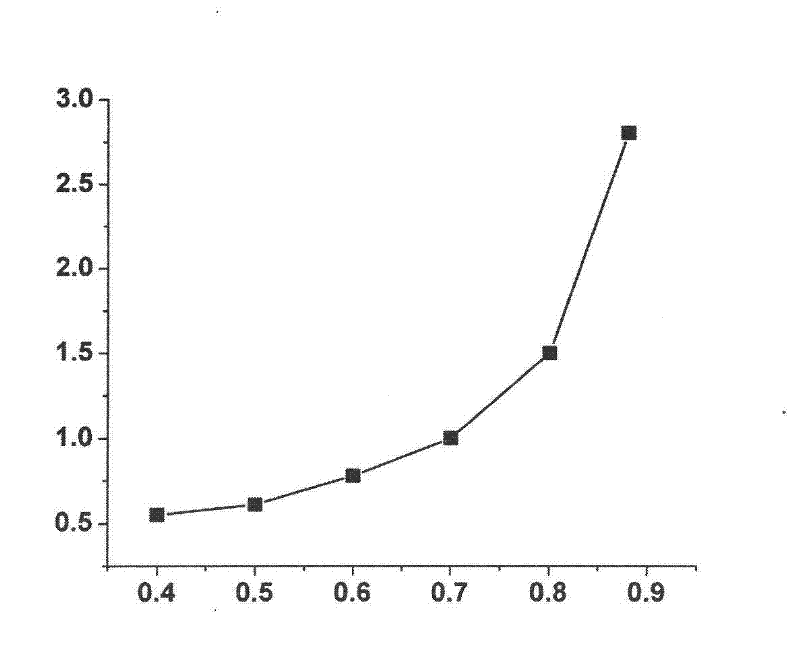

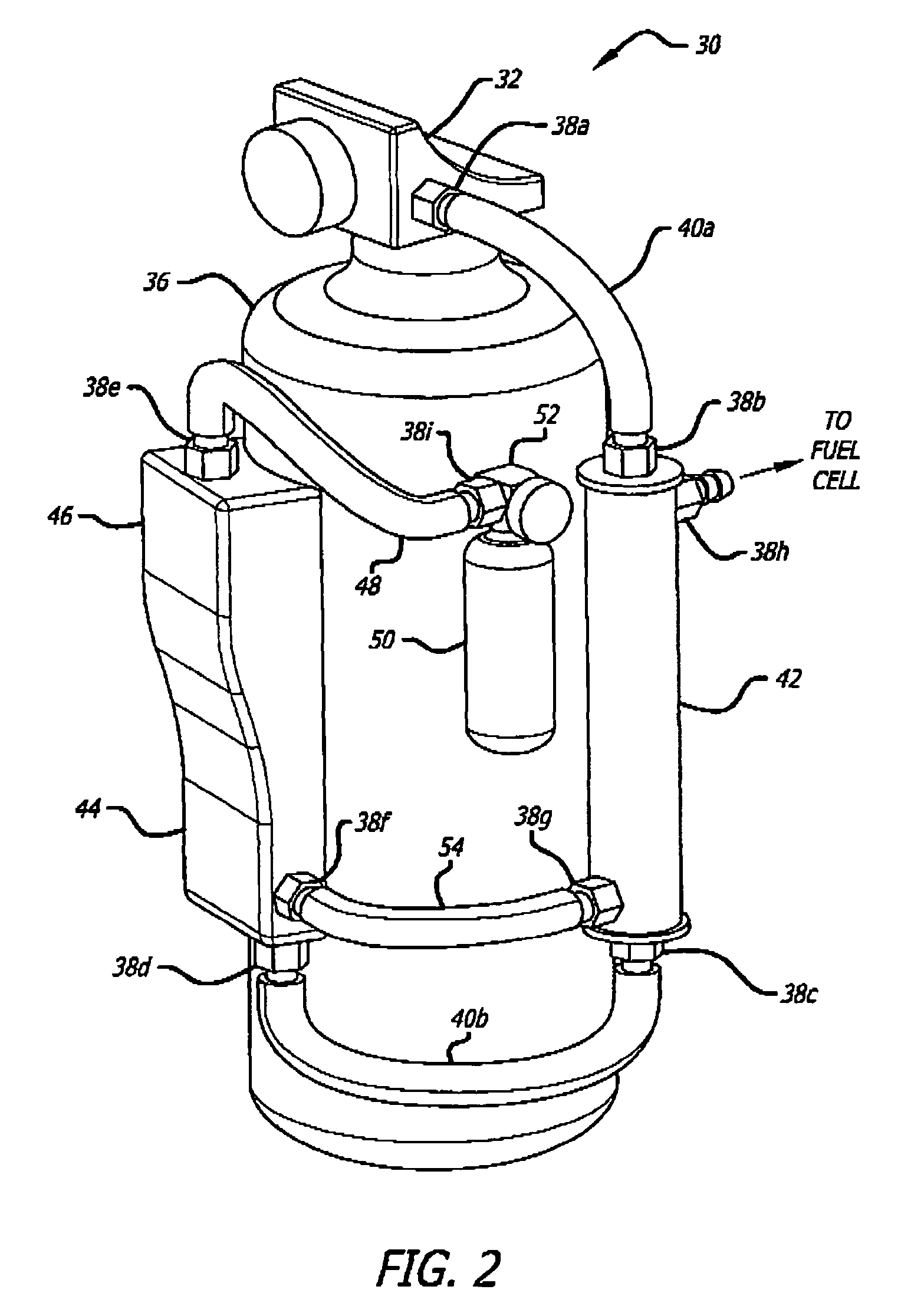

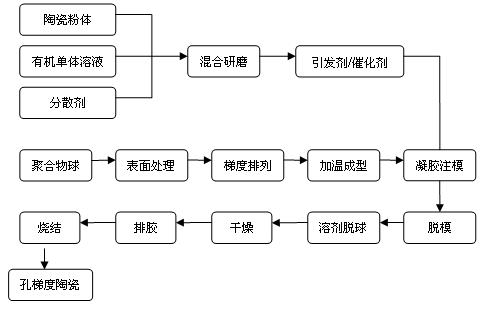

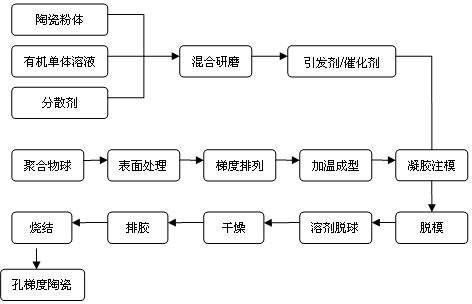

Method for preparing ceramic foams with pore gradient

The invention relates to a method for preparing ceramic foams with pore gradient. The method comprises the following steps: arranging polymers or organic matter spheres to form a template in gradient distribution according to the design requirement, carrying out heating and pressurizing to ensure the spheres to adhere to each other to form a whole, filling the whole into a moulding mould and then injecting slurry for gel casting and removing the mould after drying the spheres to obtain a moulded green body integrating the spheres and solidifying slurry, immersing the green body after removing the mould into a solvent or warming the green body, removing the spheres to obtain a network-shaped body only with the solidifying slurry and obtaining the ceramic foams with pore gradient after binder removal and high-temperature sintering. The ceramic foams prepared according to the technical scheme adopted by the invention have the following advantages: the pore diameters are in gradient distribution; the pore gradient can be designed and controlled; the moulded green body has high strength and can be processed and cut into needed shapes; the sizes and shapes of the products are controllable; the problem that the shapes and sizes of the products as well as the sizes of the pores are usually limited by organic carriers in the process of preparing the ceramic foams is solved; and the shortcomings of less slurry absorbed for moulding, more blind pores and low product strength in the impregnation method are overcome.

Owner:SUZHOU UNIV

Light floamed ceramic building board and preparation thereof

The invention belongs to the technical field of construction materials and discloses a light foamed ceramic construction board and a production method thereof. The light foamed ceramic construction board comprises the following components according to weight percentage: fly ash: 40 to 60 percent, porcelain clay: 30 to 50 percent, expanded material: 5 to 10 percent, rhombic quartz: 0 to 5 percent, and lepidolite stone: 0 to 1 percent; the board is prepared by carrying out the following procedures to the components: crashing, prilling, pressing and moulding and calcining. The ceramic construction board takes a great amount of the fly ash as raw materials which is low in cost; in the preparation process, the raw material is finely ground and all the components are mixed evenly; then the expanding foam matrix structure is reformed by the technique of prilling with power, thus causing the product to form foam and raise toughness degree; the finished board has ceramic foam structure which is formed by even, independent and closed small holes; the size of the small holes and the density of the product can be adjusted according to special application purpose; and the board can be used in walls and grounds for noise insulation, fire proof and flotation, and the like. The finished products can be cut and processed by a saw and can be taken as a substitute of wood plates.

Owner:RUIJING INVESTMENT HLDG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com