Methods of applying a sorbent coating on a substrate, a support, and/or a substrate coated with a support

An adsorbent, substrate technology, applied in chemical instruments and methods, separation methods, gas treatment, etc., can solve problems such as difficulty in developing efficient and cost-effective carbon dioxide capture/separation technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

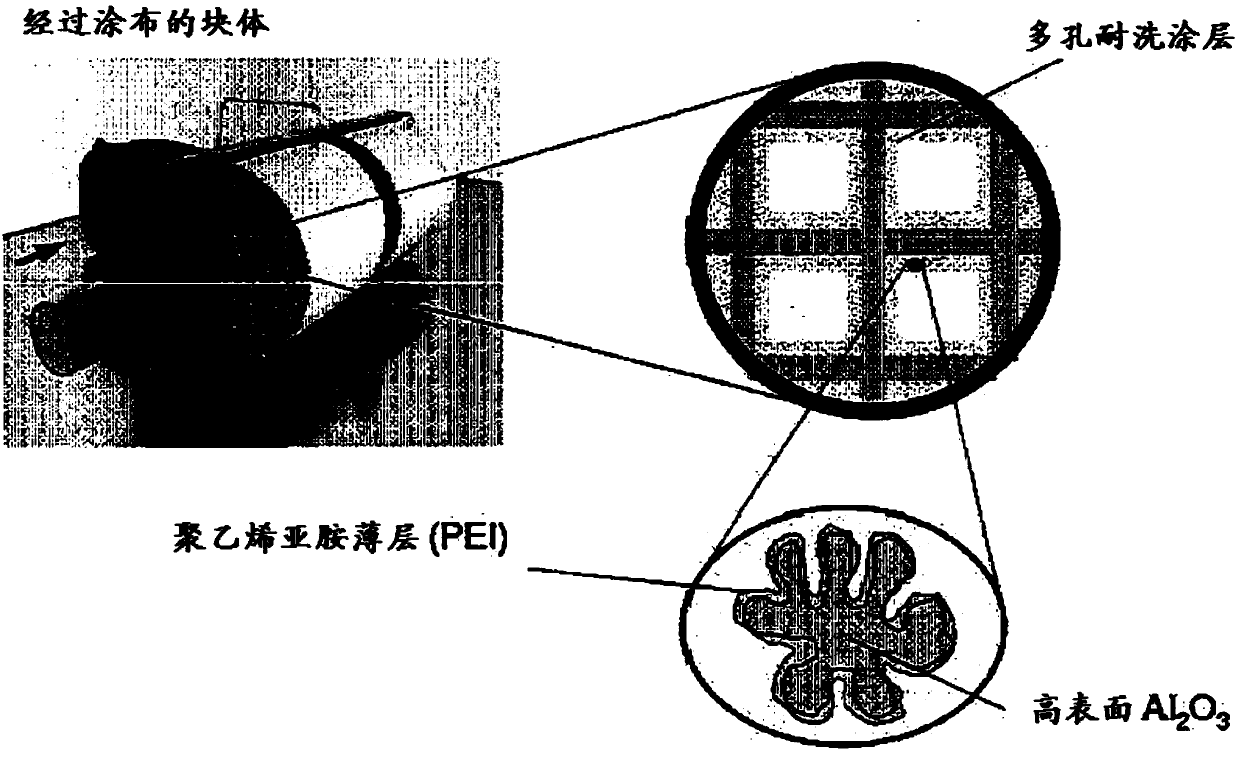

[0106] A slurry was made by mixing 45.22g alumina with 4.52g alumina hydroxide and 169.48g water. This slurry was coated onto a honeycomb structure made of cordierite, thereby applying a 1.15 g / in 3 alumina coating. This alumina-coated honeycomb structure was then infiltrated with polyethyleneimine (PEI) by immersing in an aqueous solution with 20% PEI. The cores thus prepared were tested for CO 2 Adsorption capacity (described below in Example 3 - Adsorption Test), and it was found that 4.20 mmol CO 2 / g PEI.

Embodiment 2

[0108] Adsorption test procedure

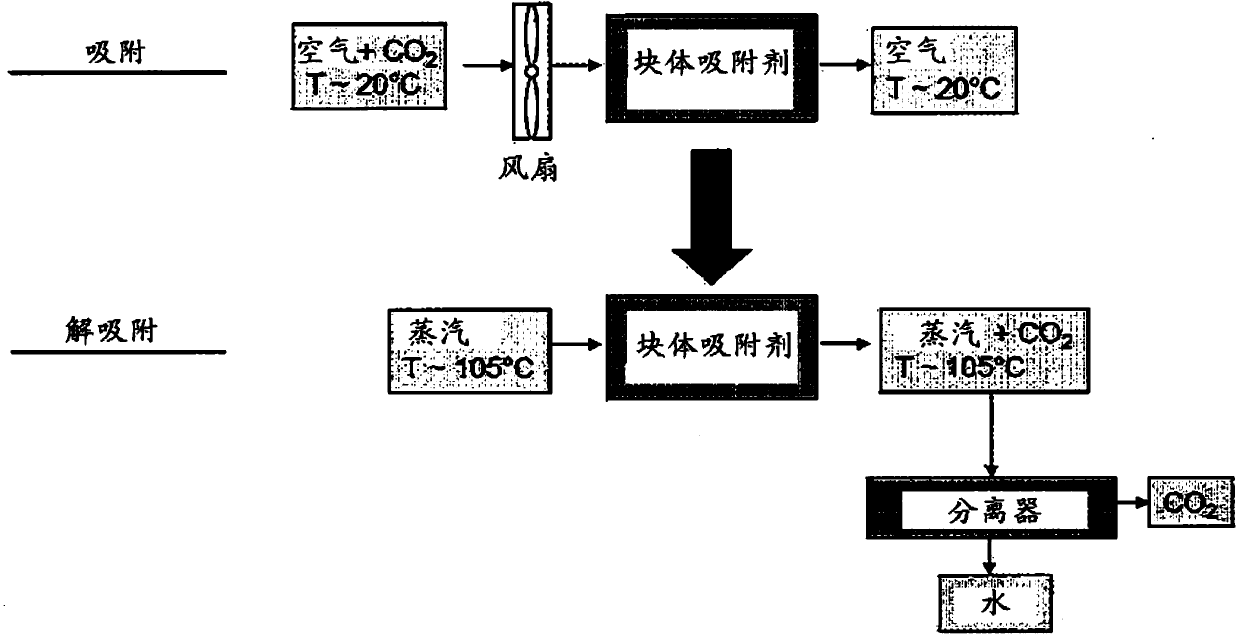

[0109] Make containing 400ppm CO 2 Air mixed with 1% water was flowed through the adsorbent-coated honeycomb structure at a velocity of 2.5 m / s at 35 °C until the sample was covered with CO 2 until saturated. CO was desorbed by flowing nitrogen with 1% water through the core at 110 °C 2 . CO was readsorbed under the same conditions as the previous adsorption 2 .

[0110] More detailed CO 2 Adsorption test procedure

[0111] Before performing the adsorption measurement, each sample was subjected to the following treatment: the sample was exposed to 400ppm CO 2 Air flow with 1% water until the sample is CO 2 until saturated. The sample is a sorbent impregnated onto a support coated on a substrate, such as PEI on alumina coated on a ceramic honeycomb structure. The sample was then cleaned of CO by flowing nitrogen gas containing 1% water over the sample at 2.5 m / s and a temperature of 110 °C 2 , until no longer released CO 2 until. ...

Embodiment 3

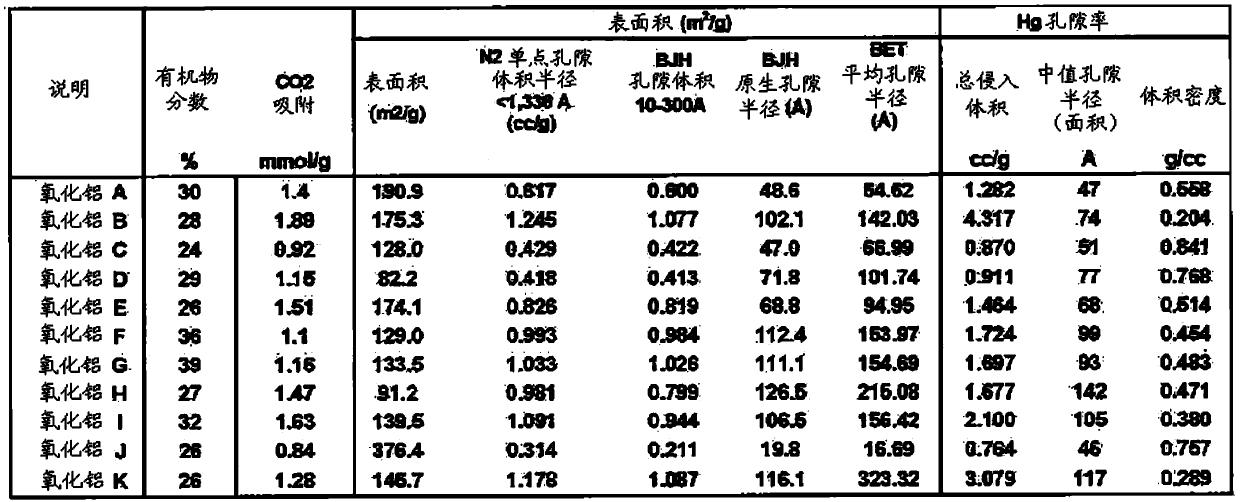

[0113] Samples were produced using a double dip coating method. The first coating was produced by coating a water-based slurry having the composition listed below onto the ceramic honeycomb structure. Each sample was fabricated using a different alumina (alumina A to K) with different surface area and pore structure properties.

[0114] First coat composition:

[0115] a. Alumina 92%

[0116] b. Binder (alumina sol) 6%

[0117] c. Dispersant 2%

[0118] This coating is calcined to make it adhere. The weight of this first coating was about 1.2 g / in3 honeycomb structure.

[0119] Polyethyleneimine was applied as a second dip from aqueous solution to give a total coating with an organic fraction of 26% to 39% (see table). (Organic fraction is PEI weight divided by (alumina plus binder weight), excluding dispersant since it was removed by the calcination step).

[0120] image 3 The table shown summarizes the properties of aluminas A to K used as supports for testing sorbe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com