Patents

Literature

4940 results about "Honeycomb structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Honeycomb structures are natural or man-made structures that have the geometry of a honeycomb to allow the minimization of the amount of used material to reach minimal weight and minimal material cost. The geometry of honeycomb structures can vary widely but the common feature of all such structures is an array of hollow cells formed between thin vertical walls. The cells are often columnar and hexagonal in shape. A honeycomb shaped structure provides a material with minimal density and relative high out-of-plane compression properties and out-of-plane shear properties.

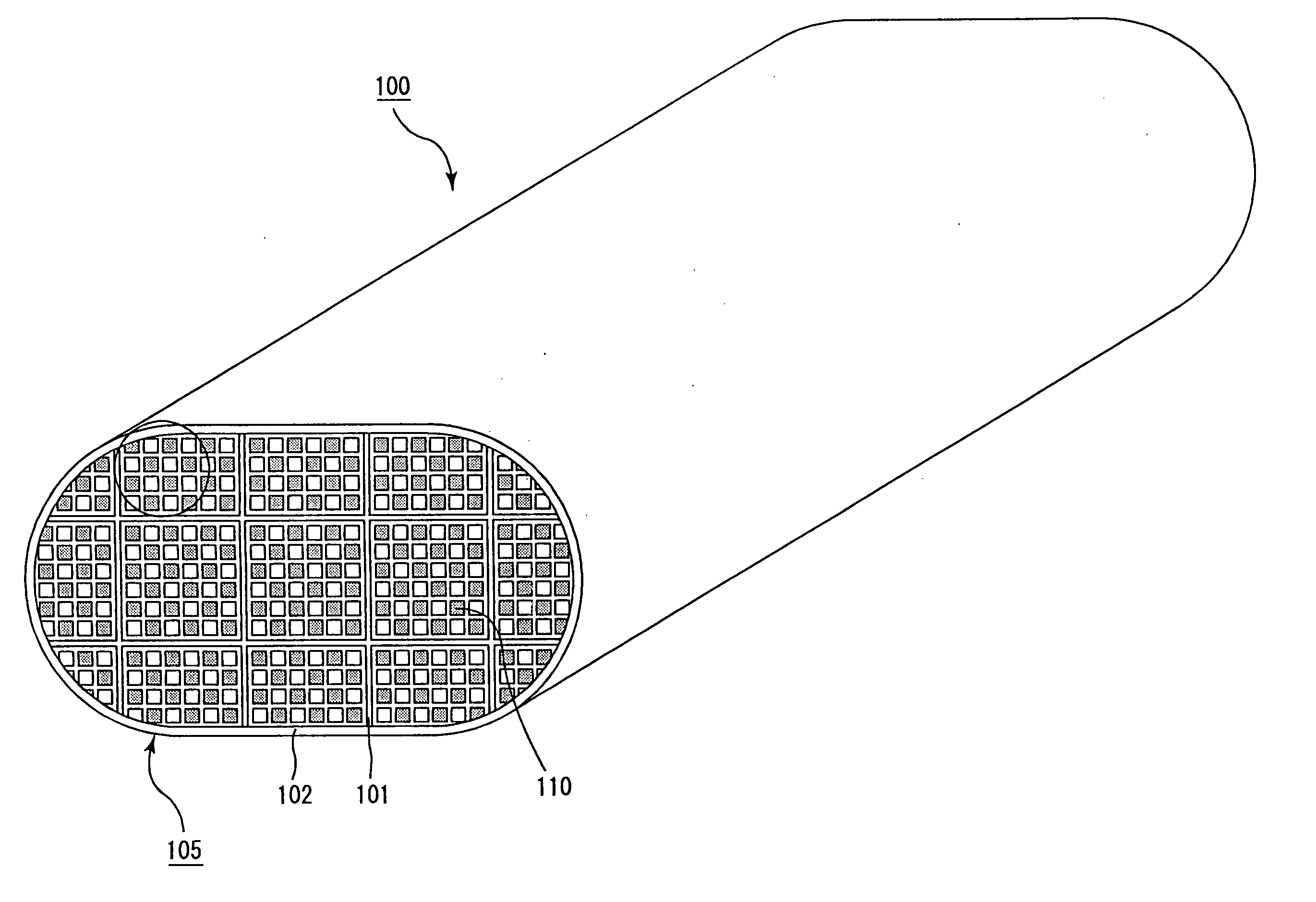

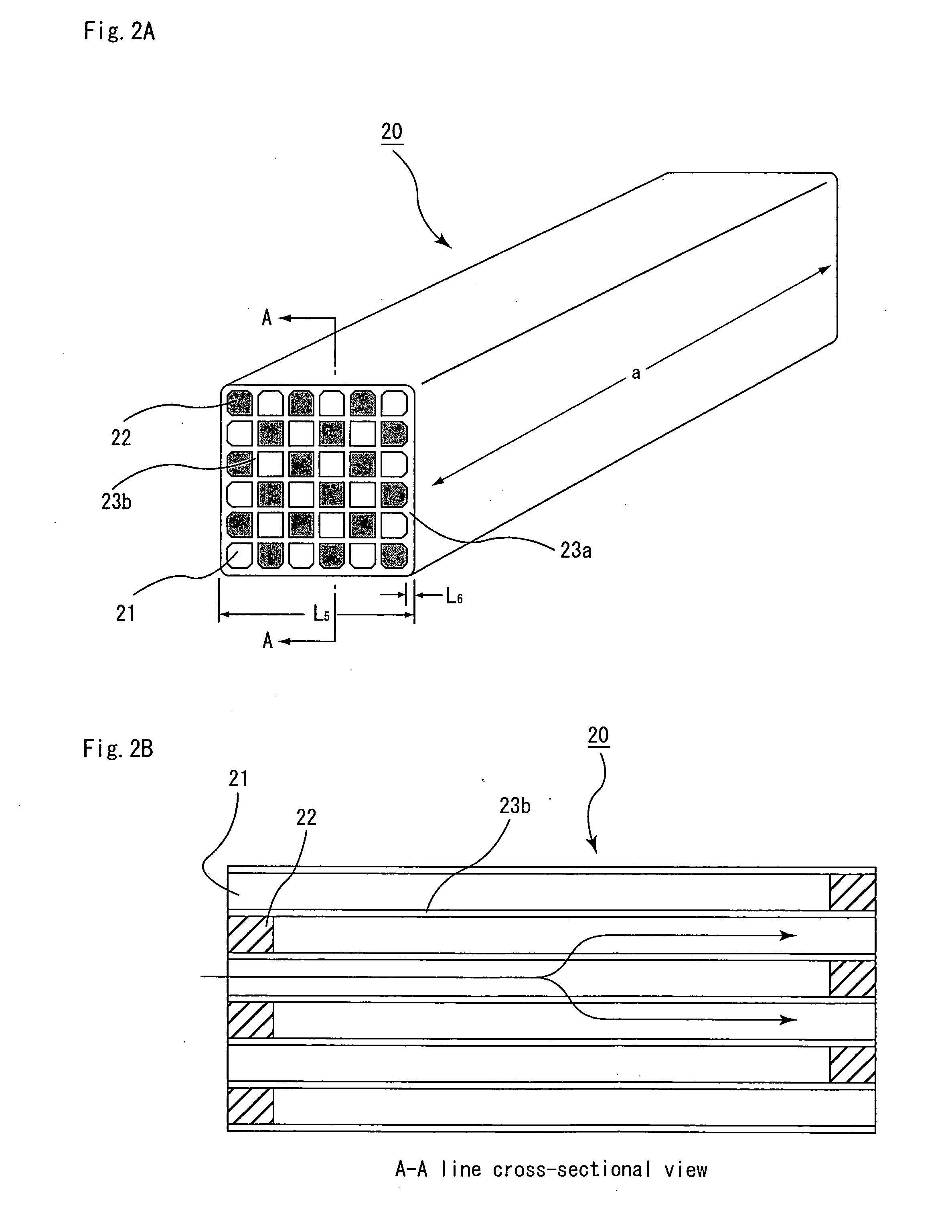

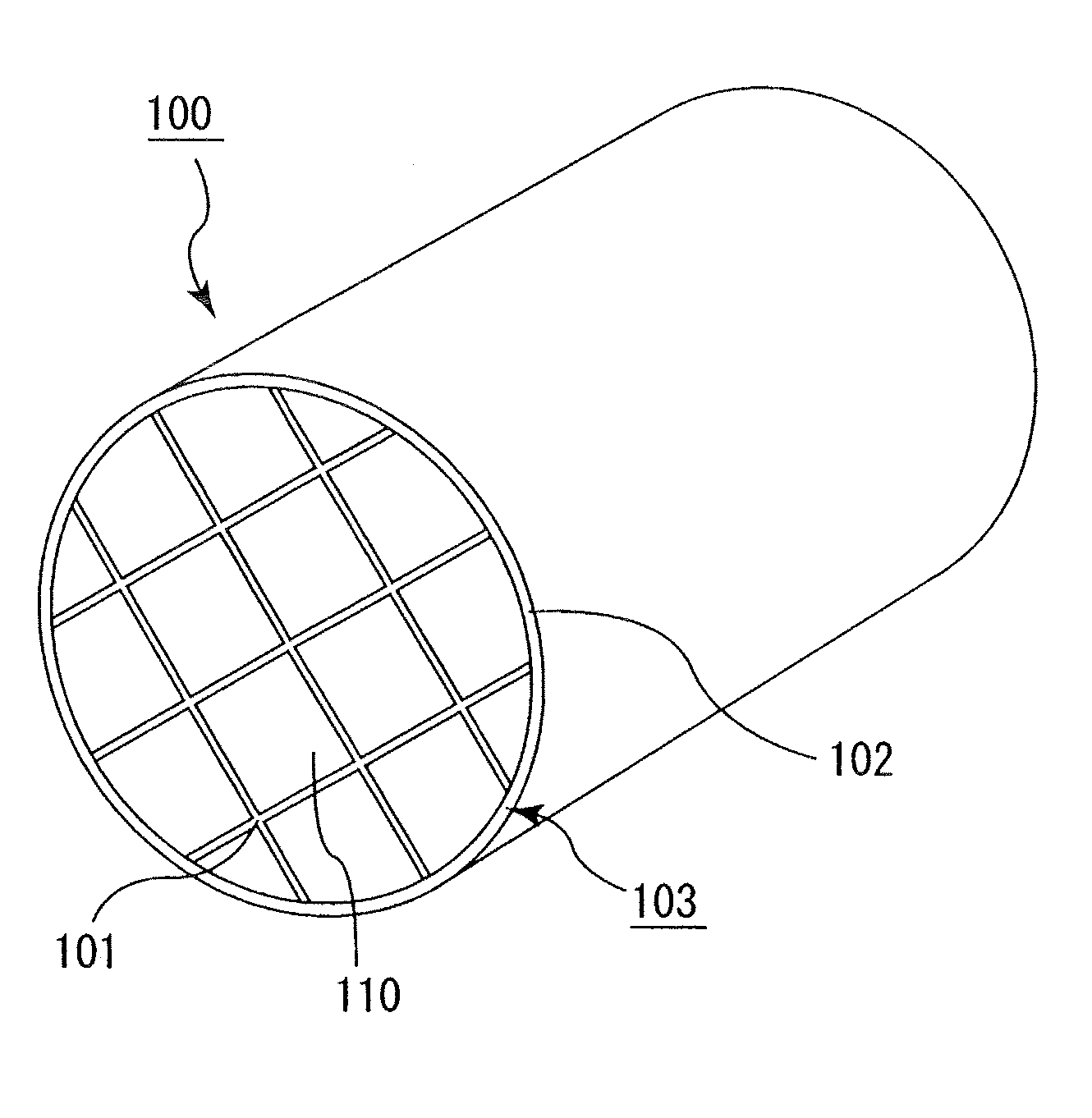

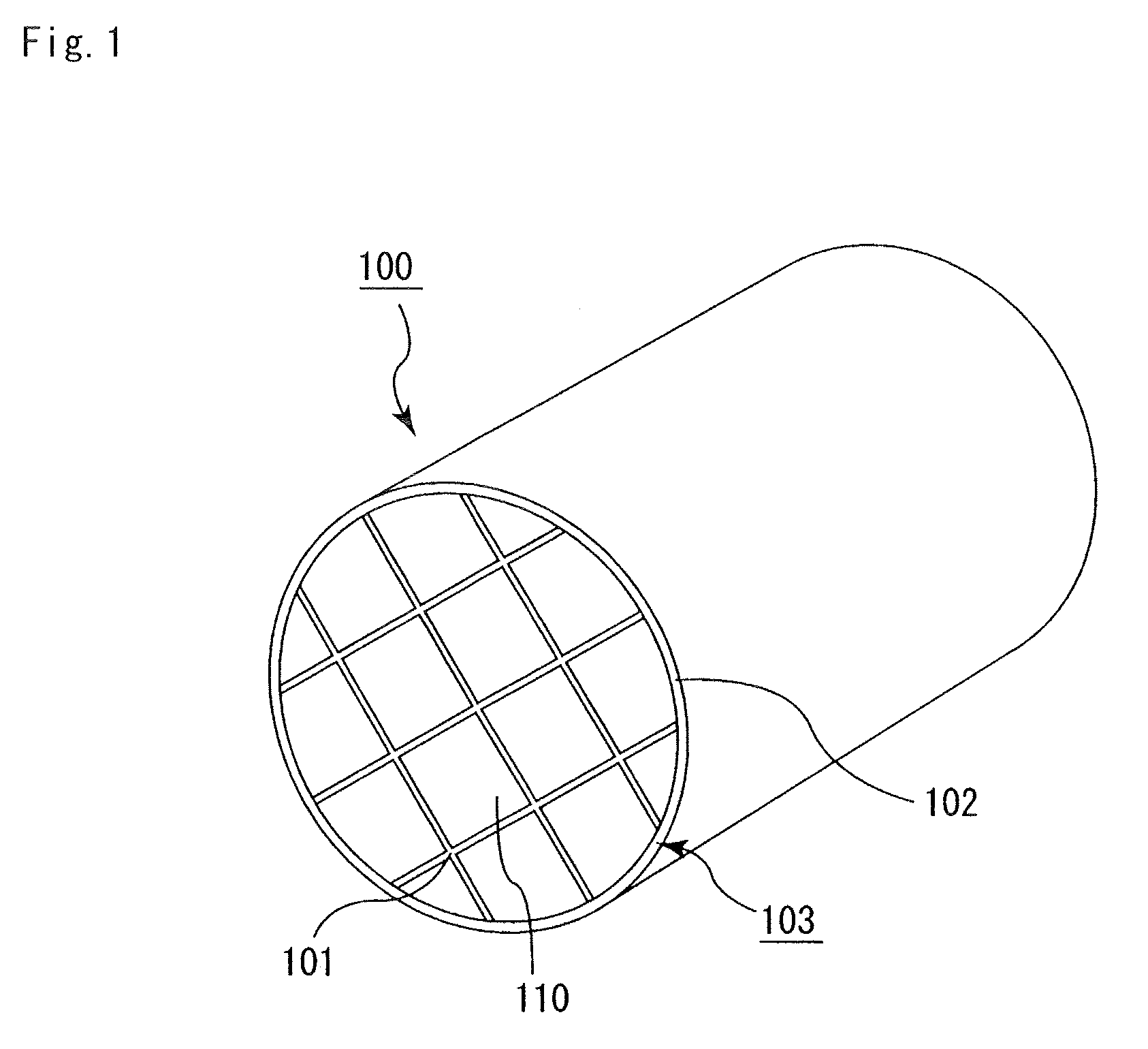

Honeycomb structural body and manufacturing method thereof

ActiveUS20050247038A1Great resistance to physical impactIncreased durabilityCatalyst carriersGas treatmentDiagonalHoneycomb structure

A honeycomb structural body comprising: a ceramic block having a flat shape in which a plurality of honeycomb units are bonded to each other through a sealing material layer, said honeycomb unit mainly comprises porous ceramic and includes a large number of through holes placed in parallel with one another in a longitudinal direction with a partition wall interposed therebetween; and a sealing material layer formed on a peripheral portion thereof, wherein the sealing material layer among the honeycomb units on a cross section perpendicular to the longitudinal direction has a pattern that is formed in a diagonal direction with respect to a major axis of a shape forming a contour of the cross section.

Owner:IBIDEN CO LTD

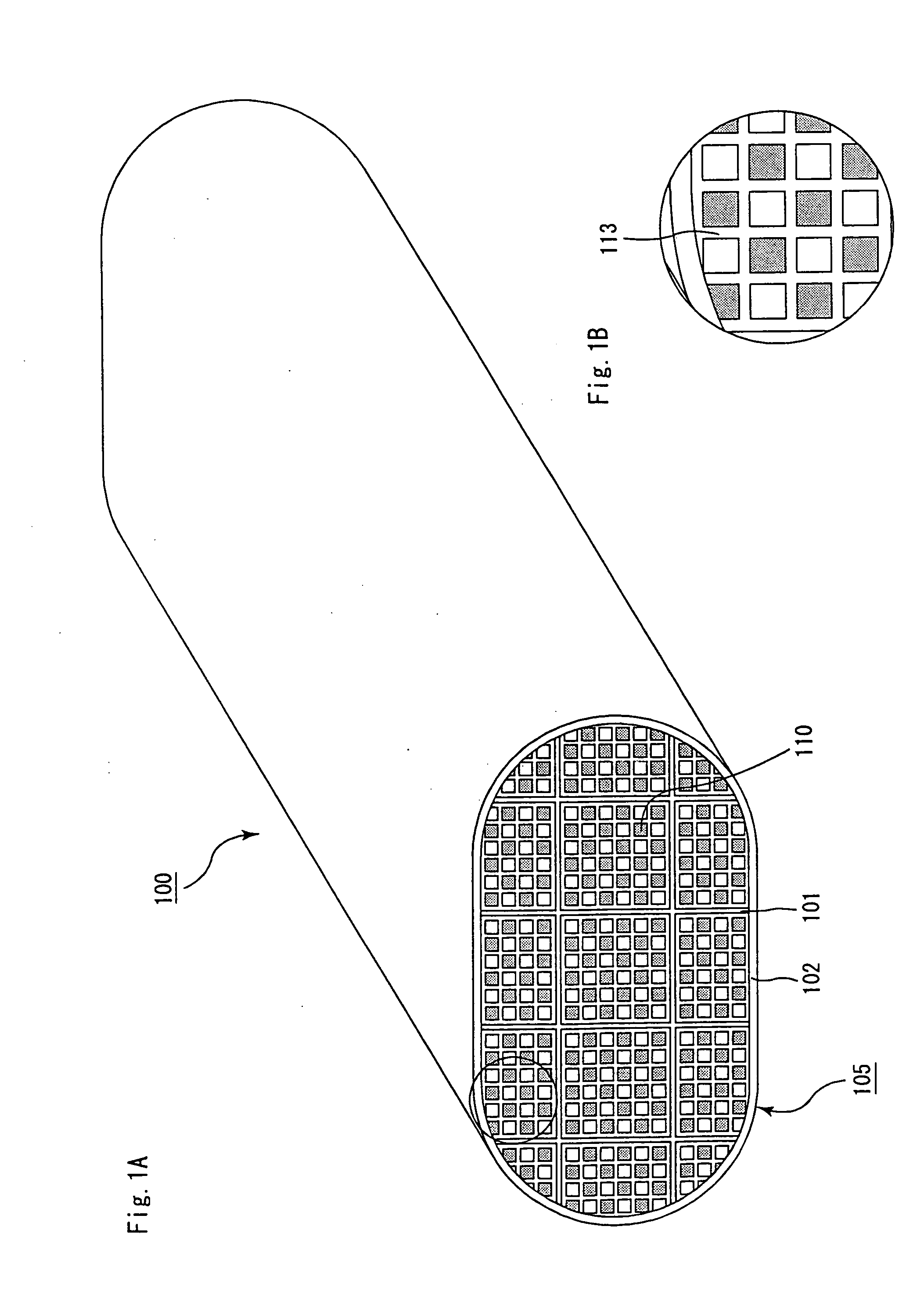

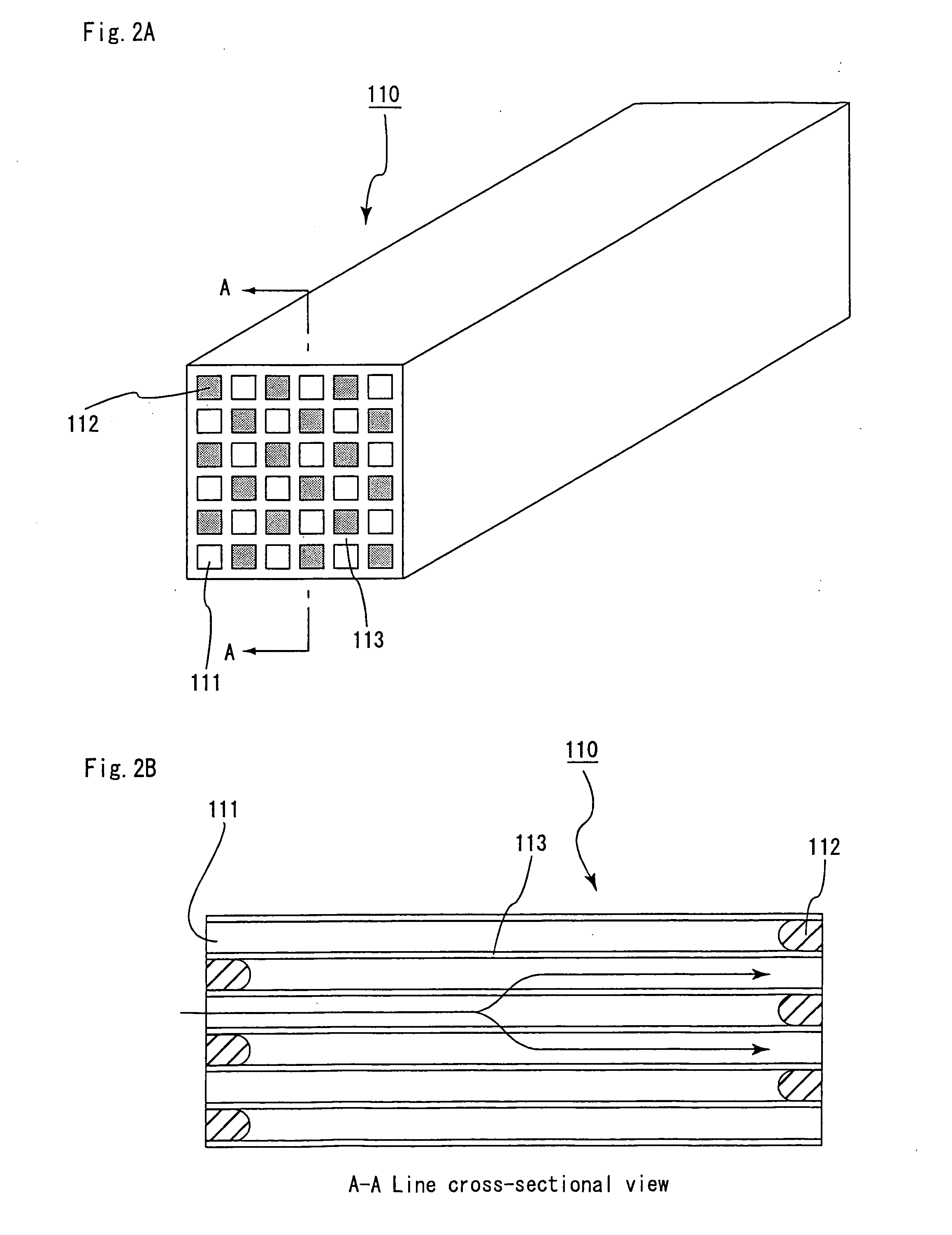

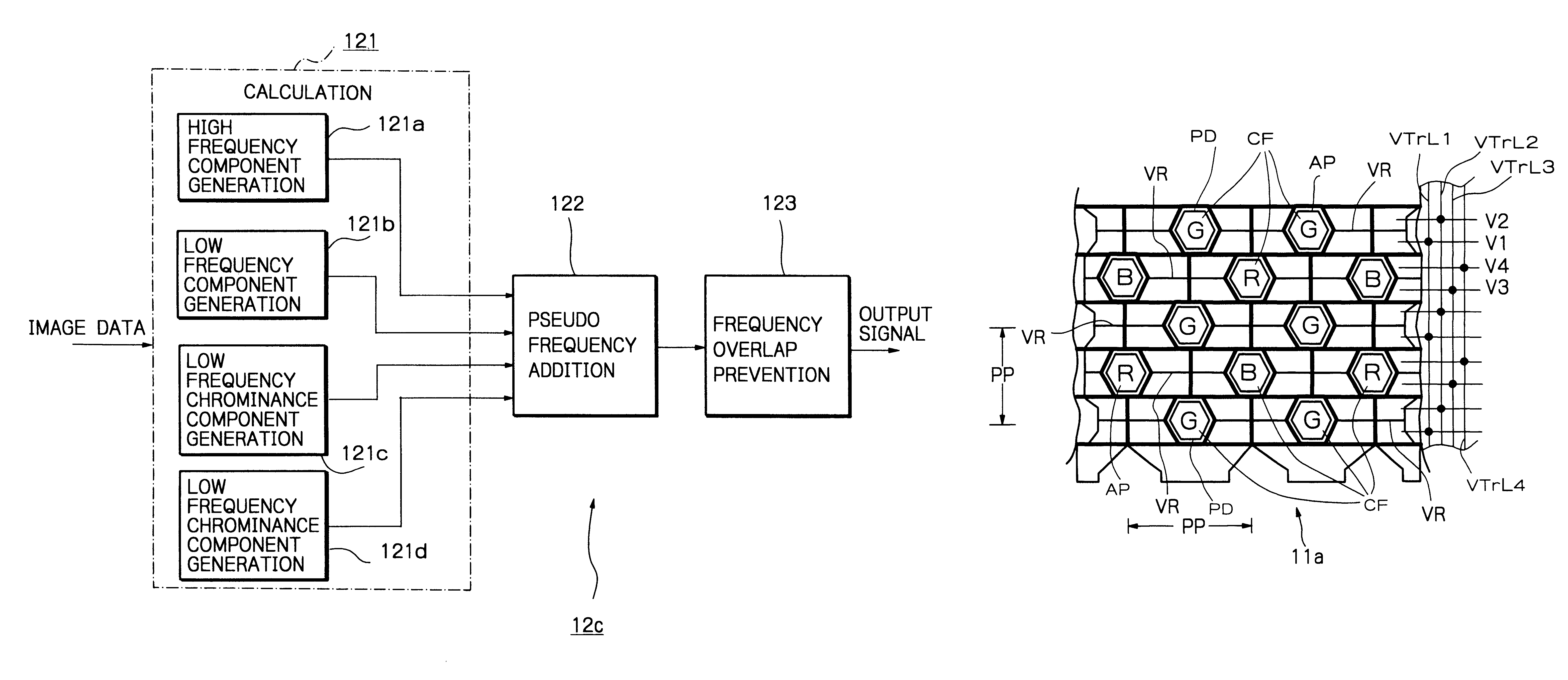

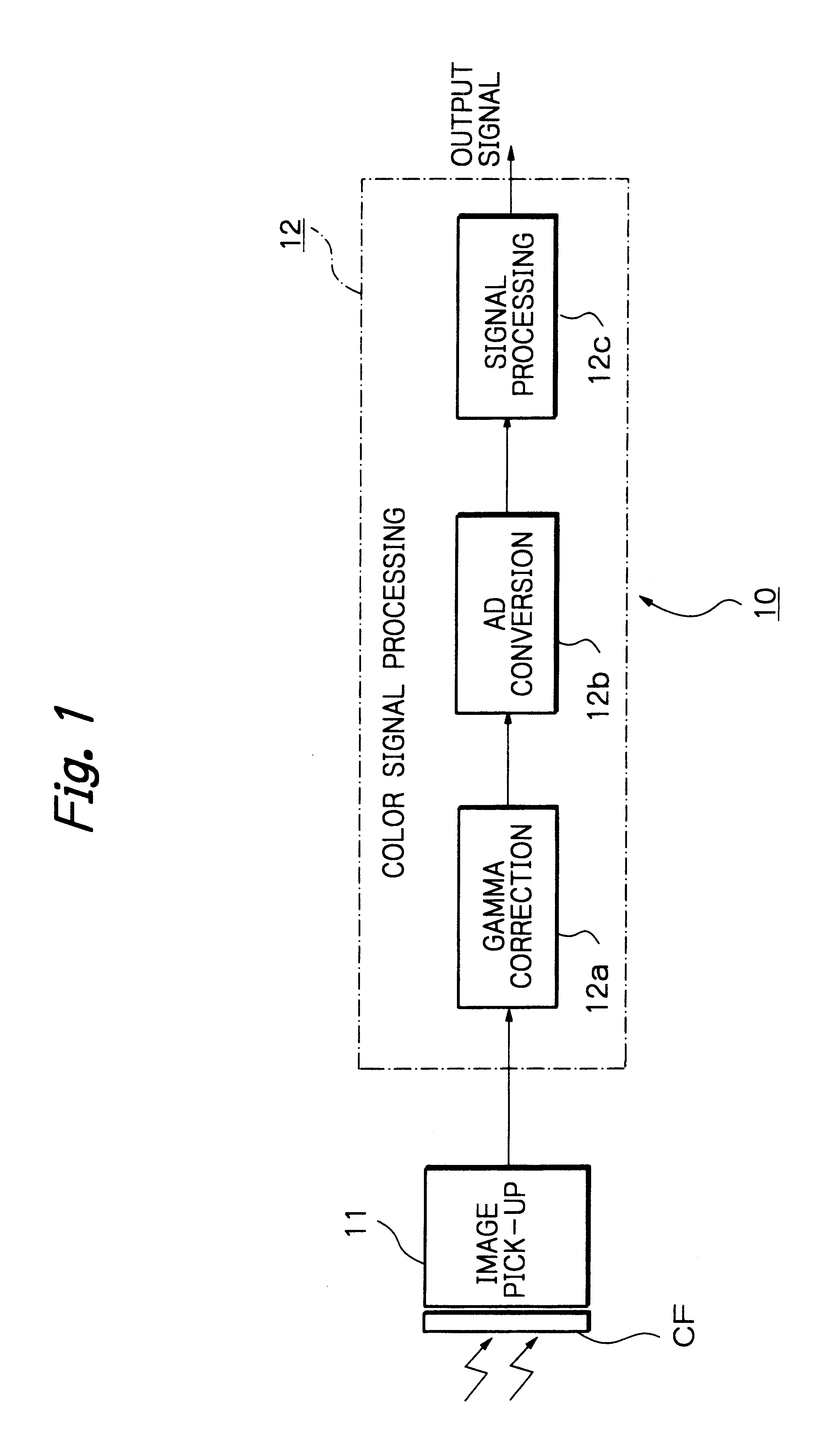

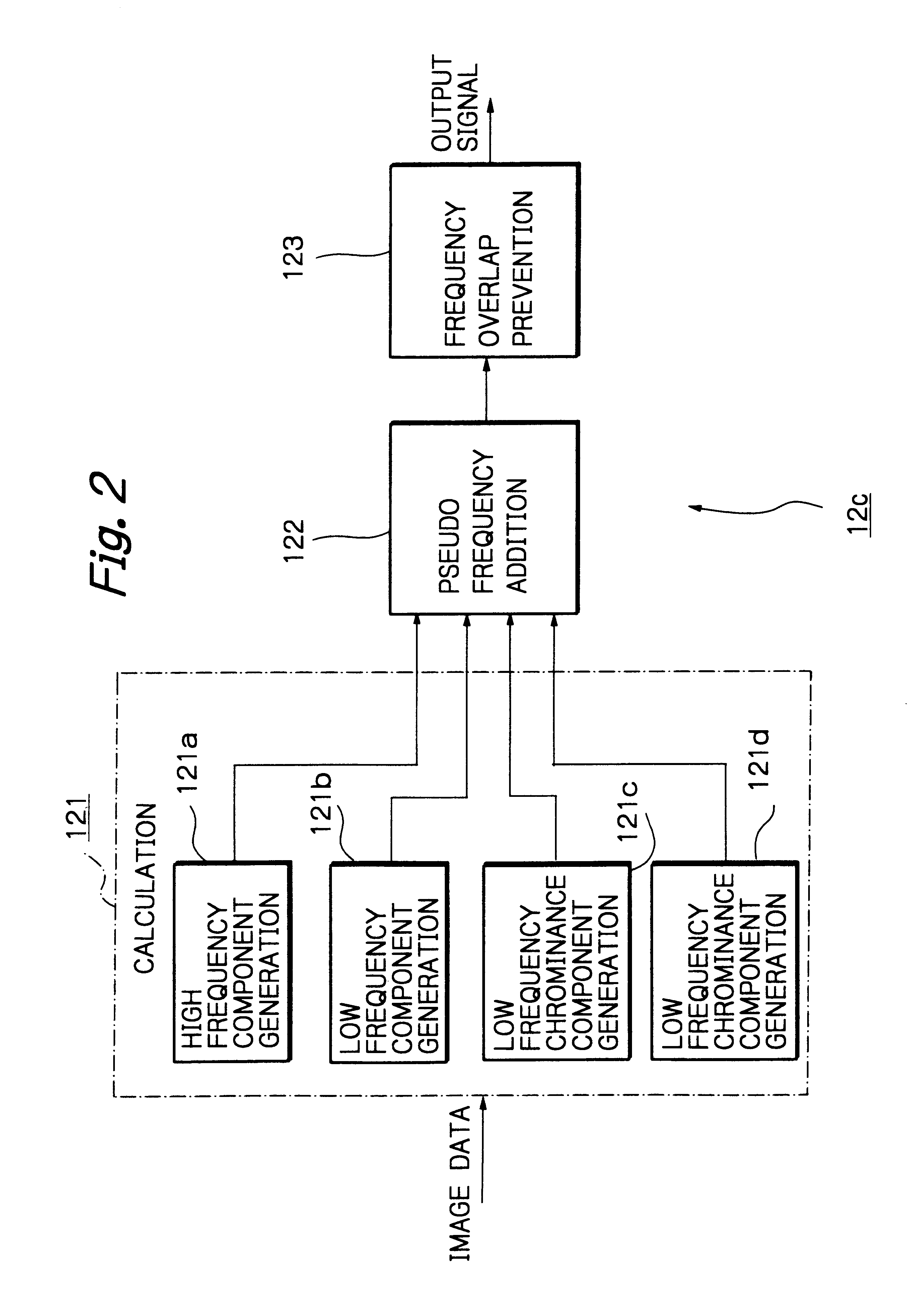

Solid-state imaging apparatus and signal processing method for transforming image signals output from a honeycomb arrangement to high quality video signals

InactiveUS6882364B1High outputWithout delayTelevision system detailsColor signal processing circuitsLow-pass filterFalse color

A solid-state imaging apparatus includes an image pick-up section in which photosensitive devices are arranged in, e.g., a honeycomb G square lattice, RB full-checker pattern due to shifted pixels. Regions void of the photosensitive devices are assumed to be virtual photosensitive devices. A signal processing section generates data for the virtual photosensitive devices by using the data of surrounding photosensitive devices while attaching importance to accurate color reproduction and horizontal and / or vertical resolution. As a result, the number of pixel data are increased in a square lattice arrangement. Therefore, high quality image signals are readily achievable with a smaller number of photosensitive devices than conventional with a conventional apparatus. Interpolation can be executed with the high quality signals to the limit of resolution with an adequate circuit scale. The honeycomb arrangement guarantees the required size of the individual pixel and thereby the sensitivity of the entire apparatus while increasing yield on a production line. False colors particular to a single photosensitive portion can be reduced by, e.g., uniform interpolation. Particularly, when a digital camera is constructed by using an imaging apparatus including optics operable with a silver halide sensitive type of film, false colors can be reduced without resorting to an optical low pass filter.

Owner:FUJIFILM CORP

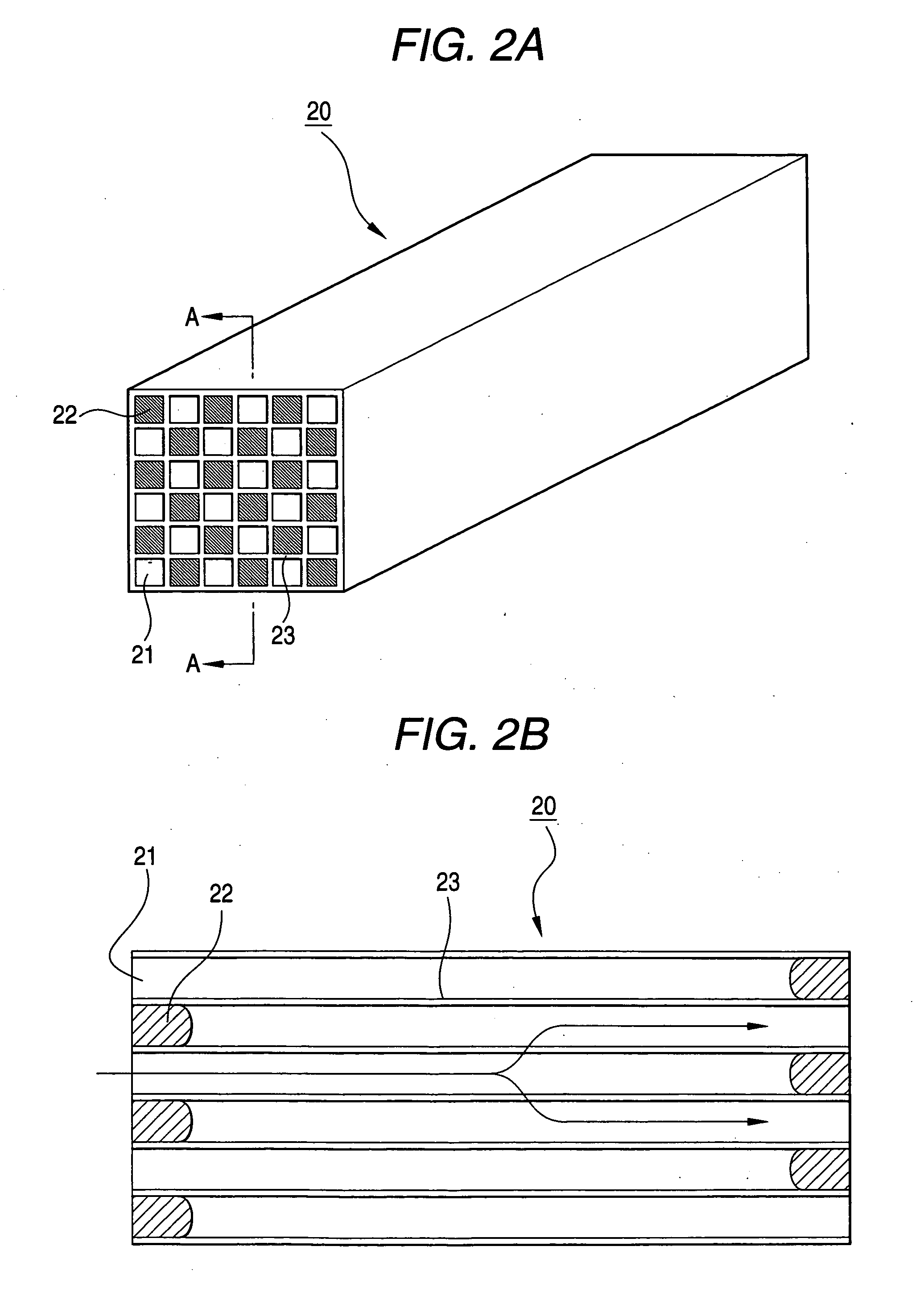

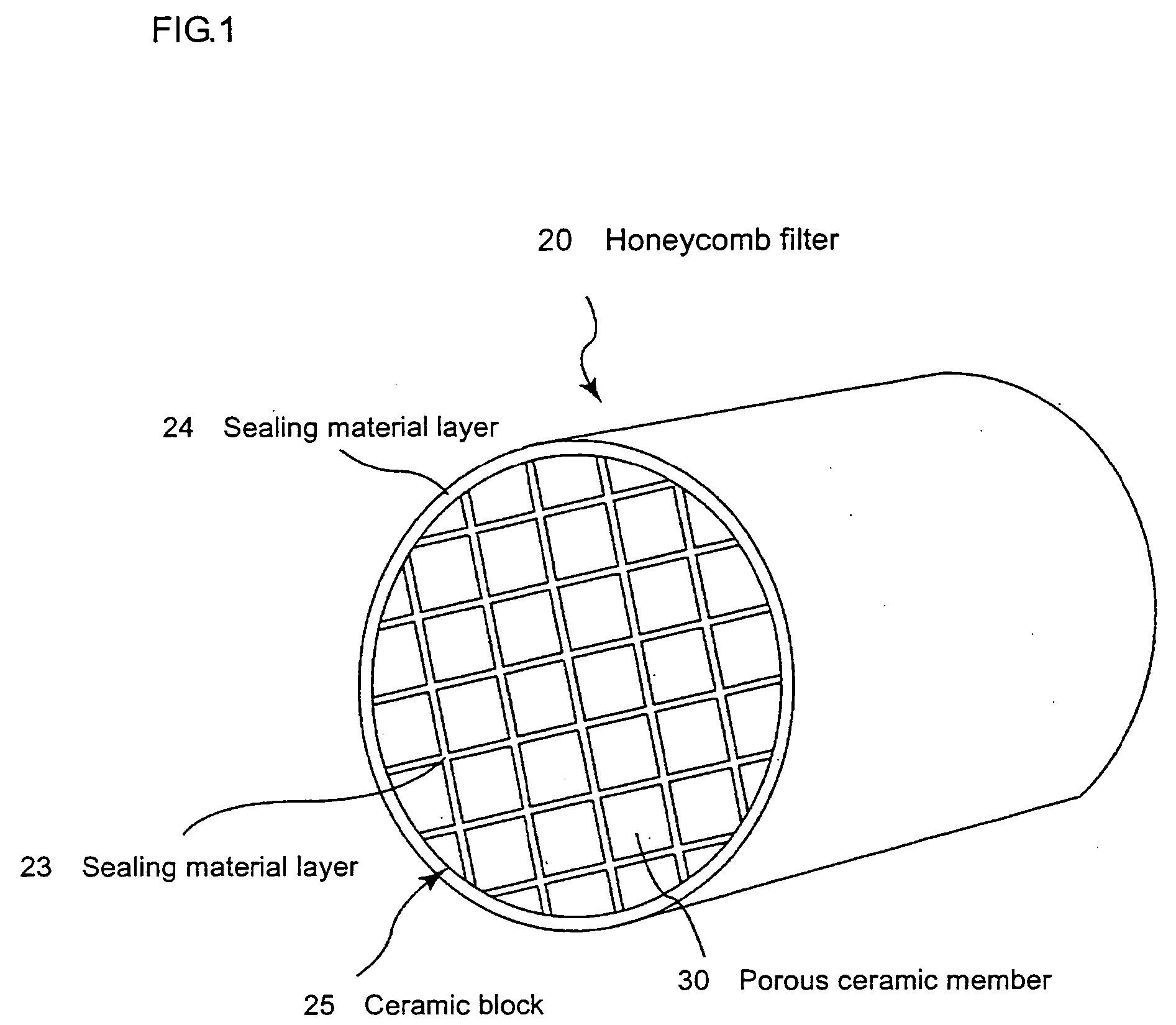

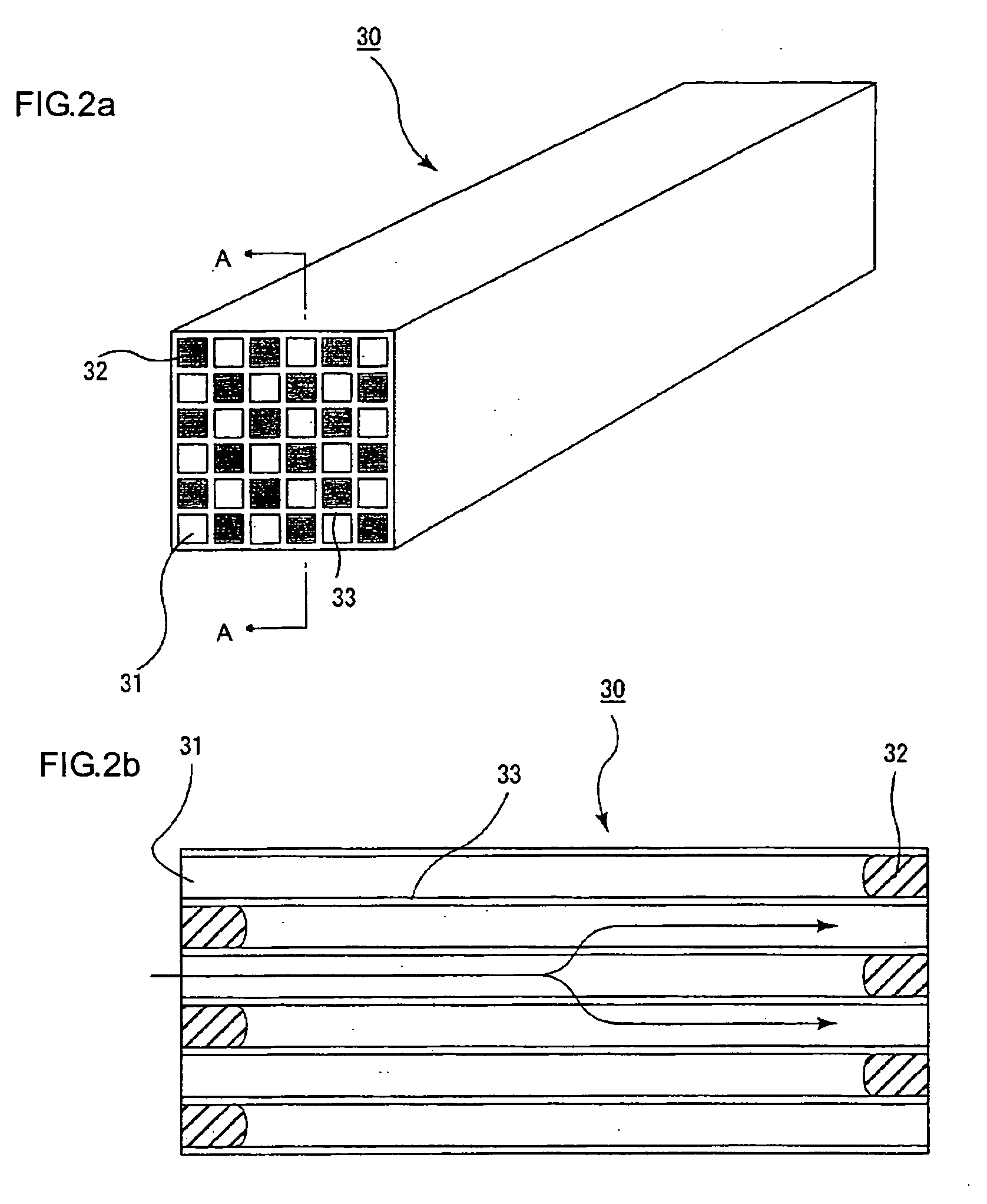

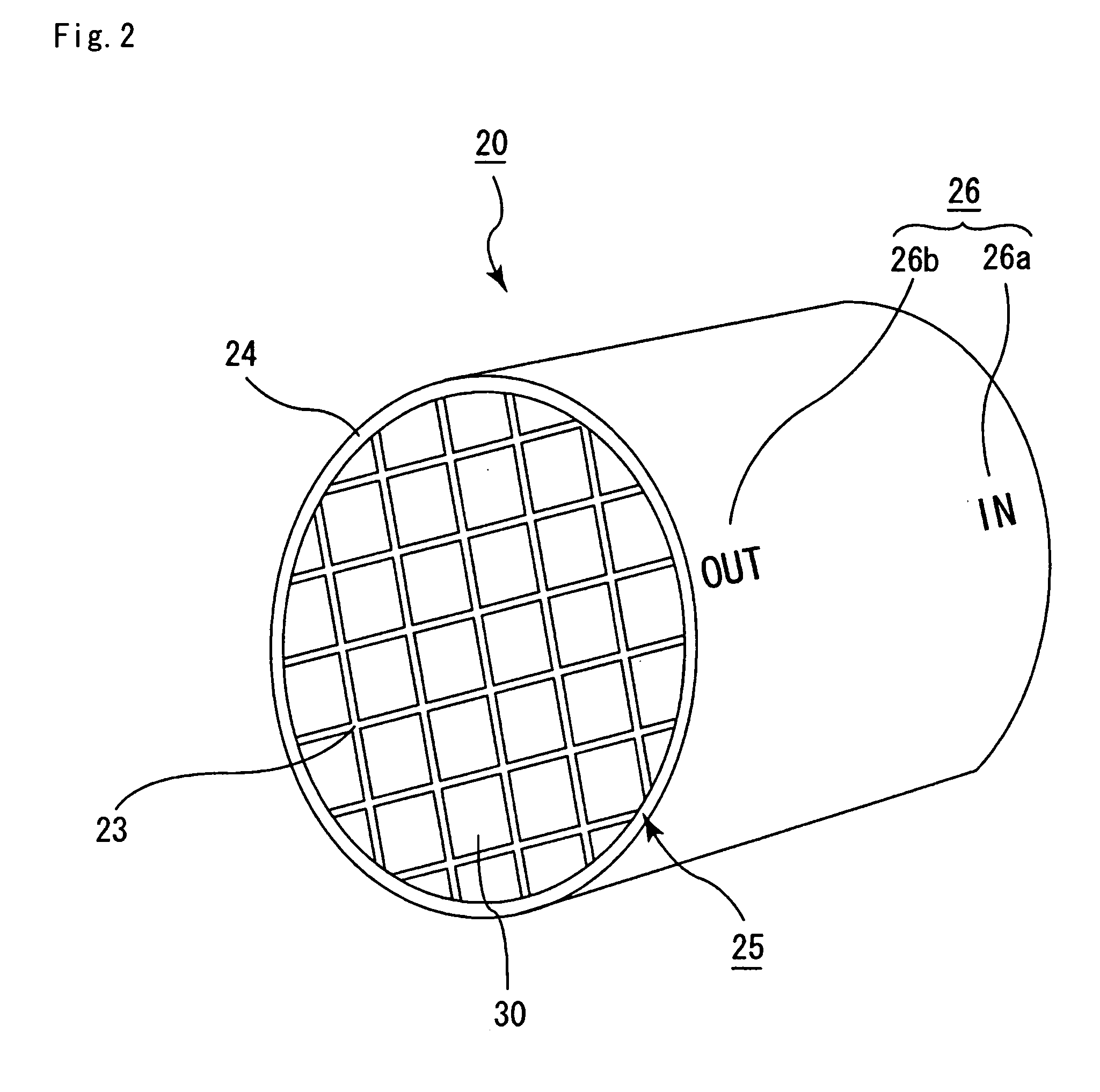

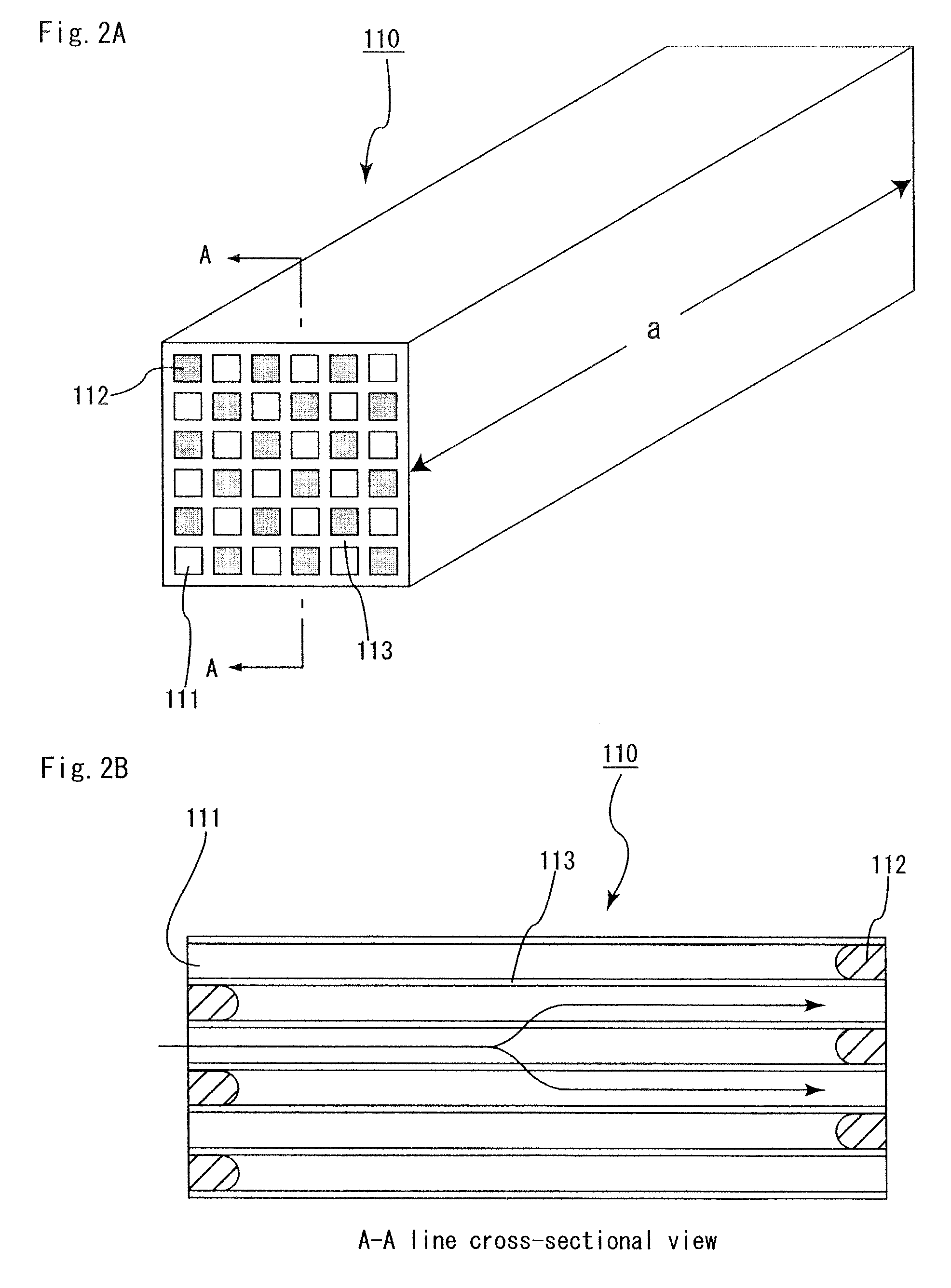

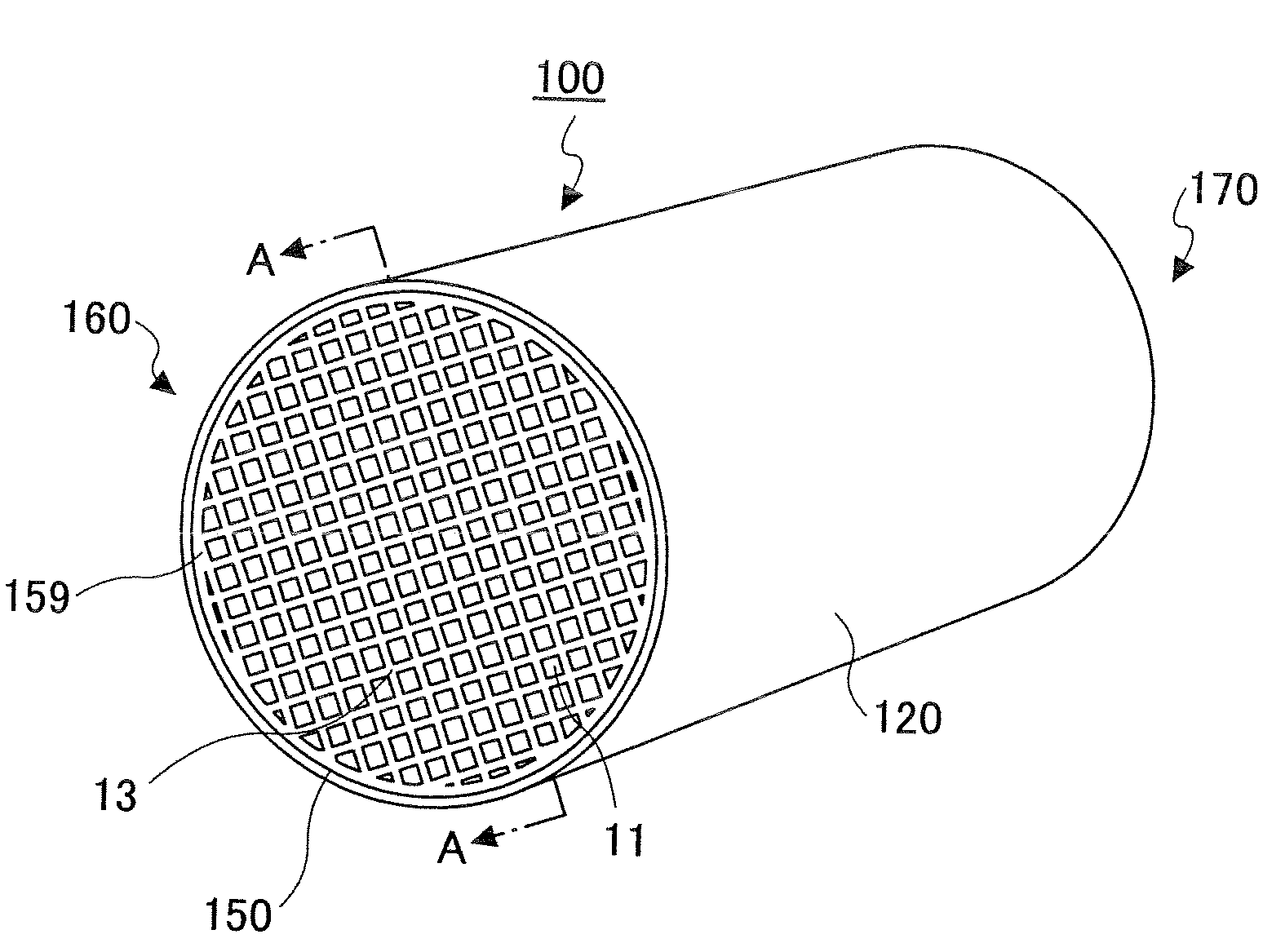

Honeycomb structured body, method for manufacturing honeycomb structured body and exhaust gas purifying device

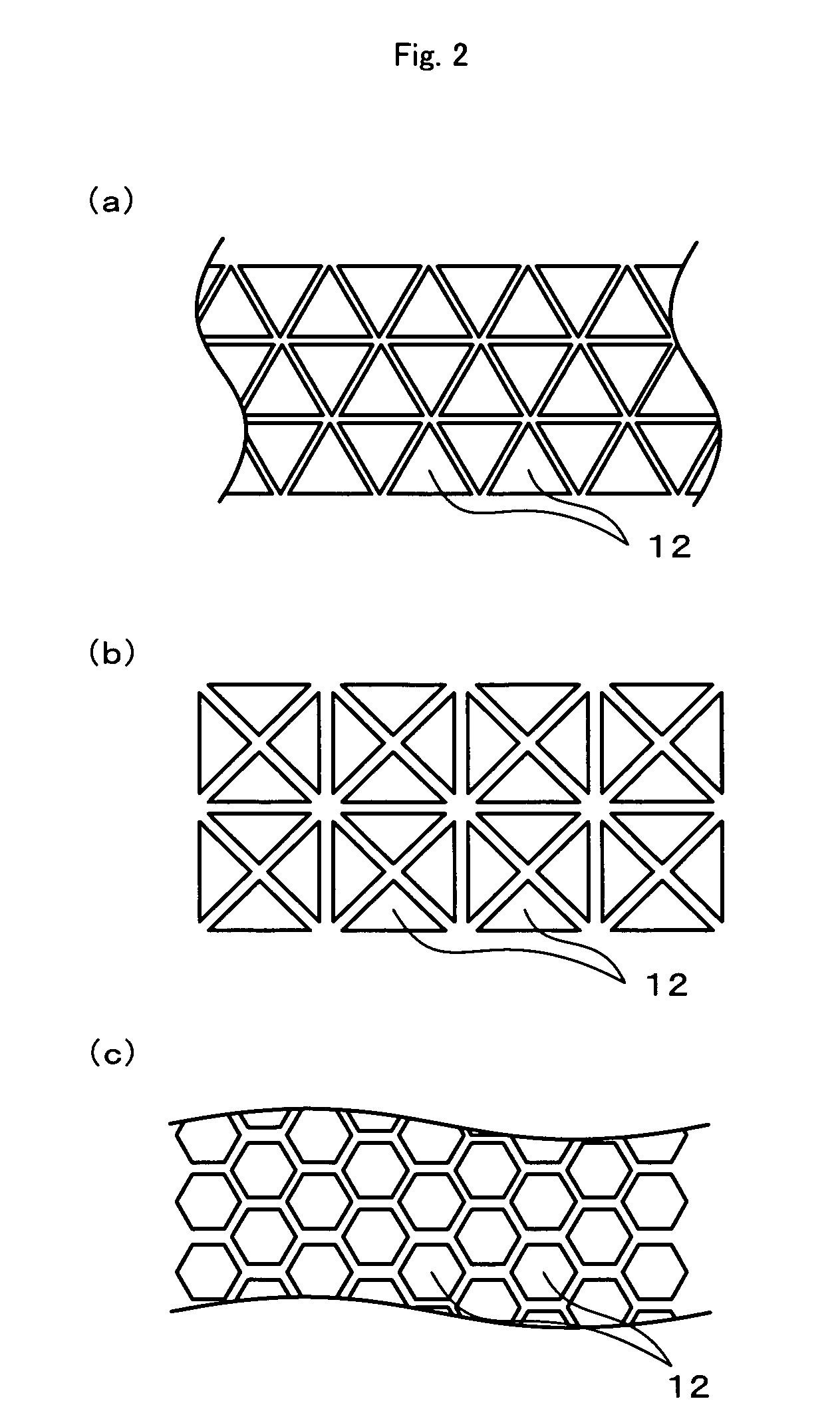

ActiveUS20070128405A1Secure strengthLoss levelingPhysical/chemical process catalystsInternal combustion piston enginesRight triangleEdge surface

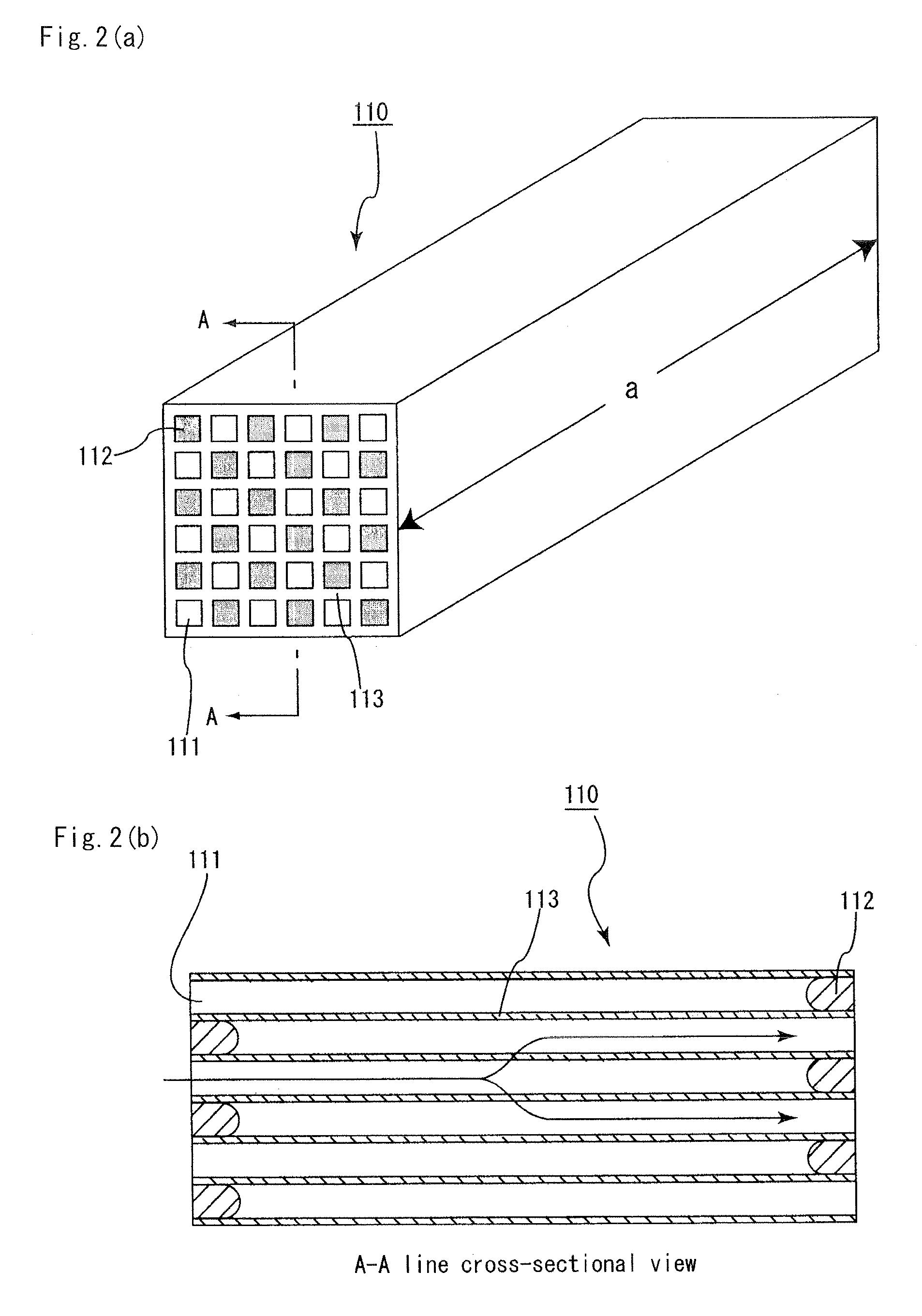

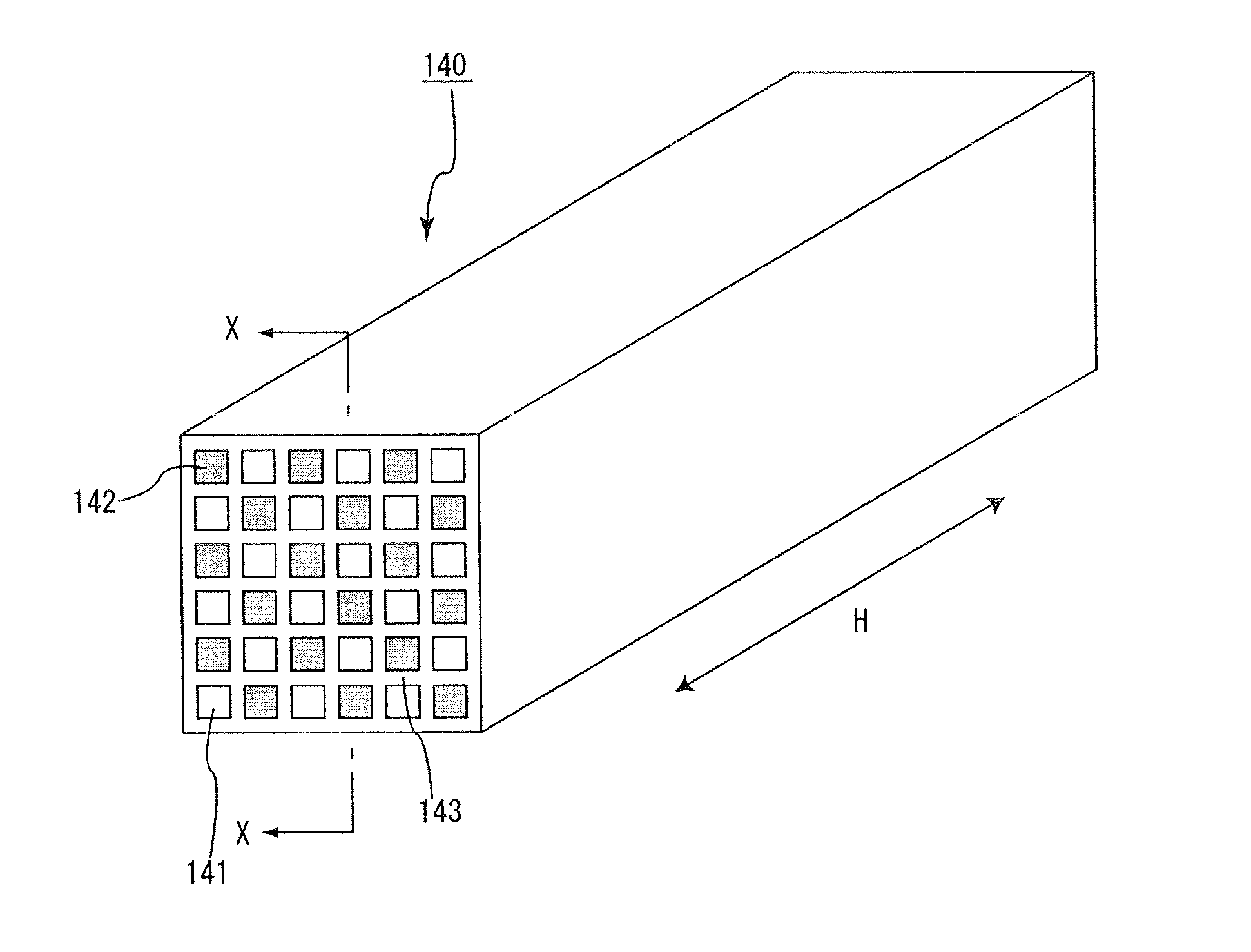

A honeycomb structured body in which a plurality of porous ceramic members are combined with one another by interposing an adhesive layer, each of the porous ceramic members having a plurality of cells placed in parallel with one another in a longitudinal direction with a cell wall therebetween and having an outer edge wall on the outer edge surface thereof, wherein each of the porous ceramic members has a filling body which is provided so as to fill in at least one corner portion of at least one outermost cell of the porous ceramic members, a cross-sectional shape of the outermost cell at the face orthogonal to the longitudinal direction of the cells is an almost tetragon, and a cross-sectional shape of the filling body at the face orthogonal to the longitudinal direction of the cells is an almost right triangle.

Owner:IBIDEN CO LTD

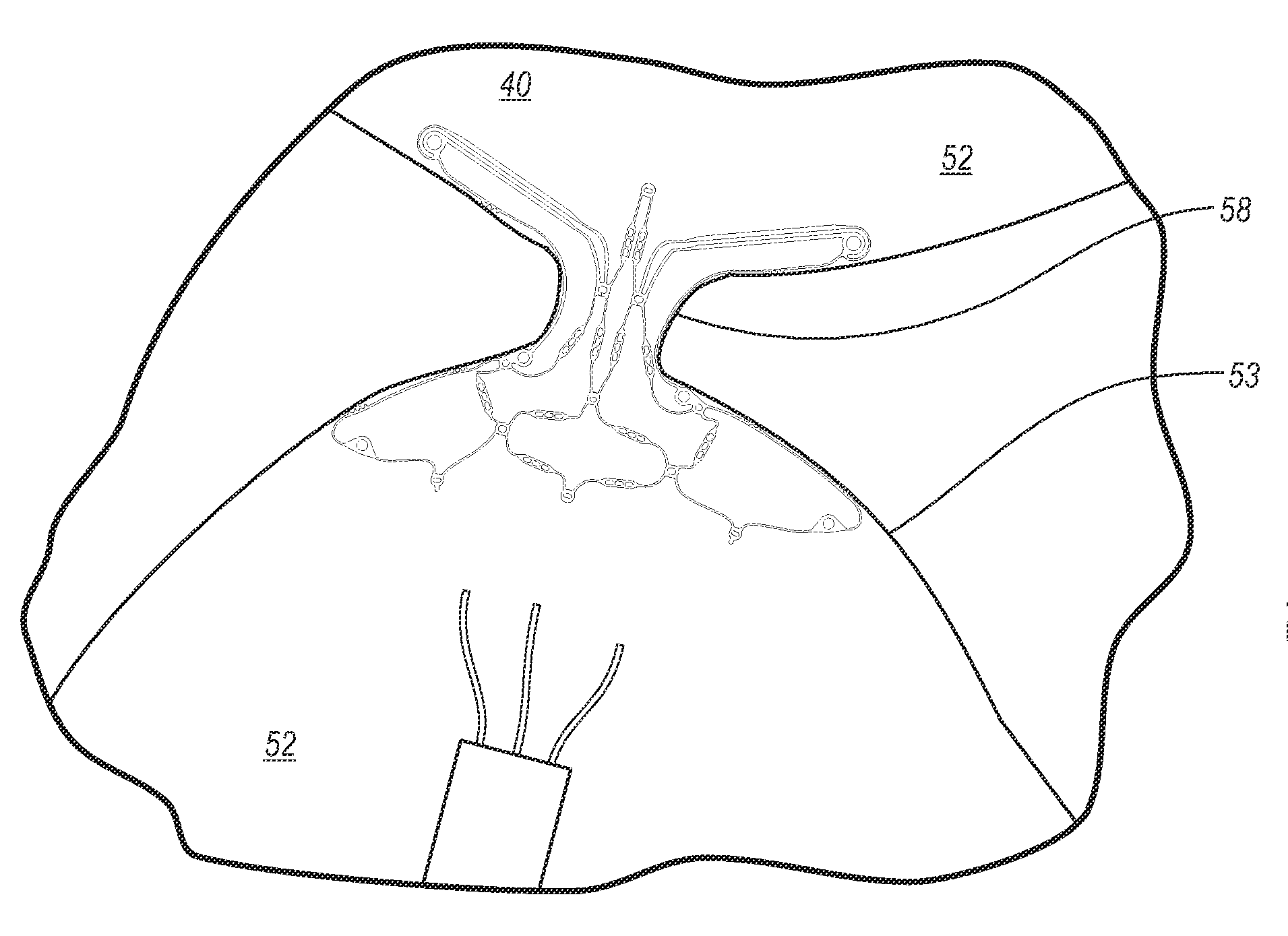

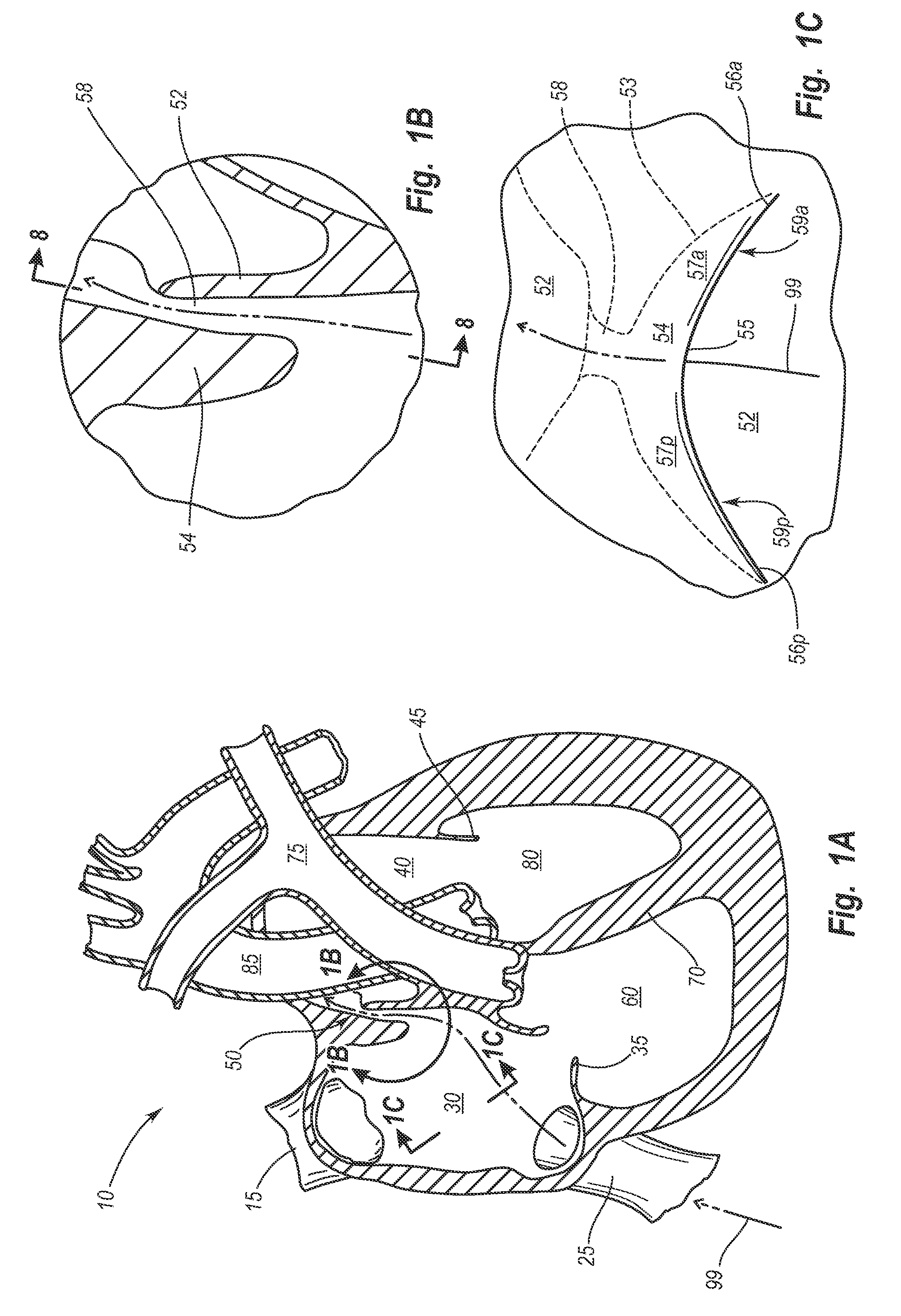

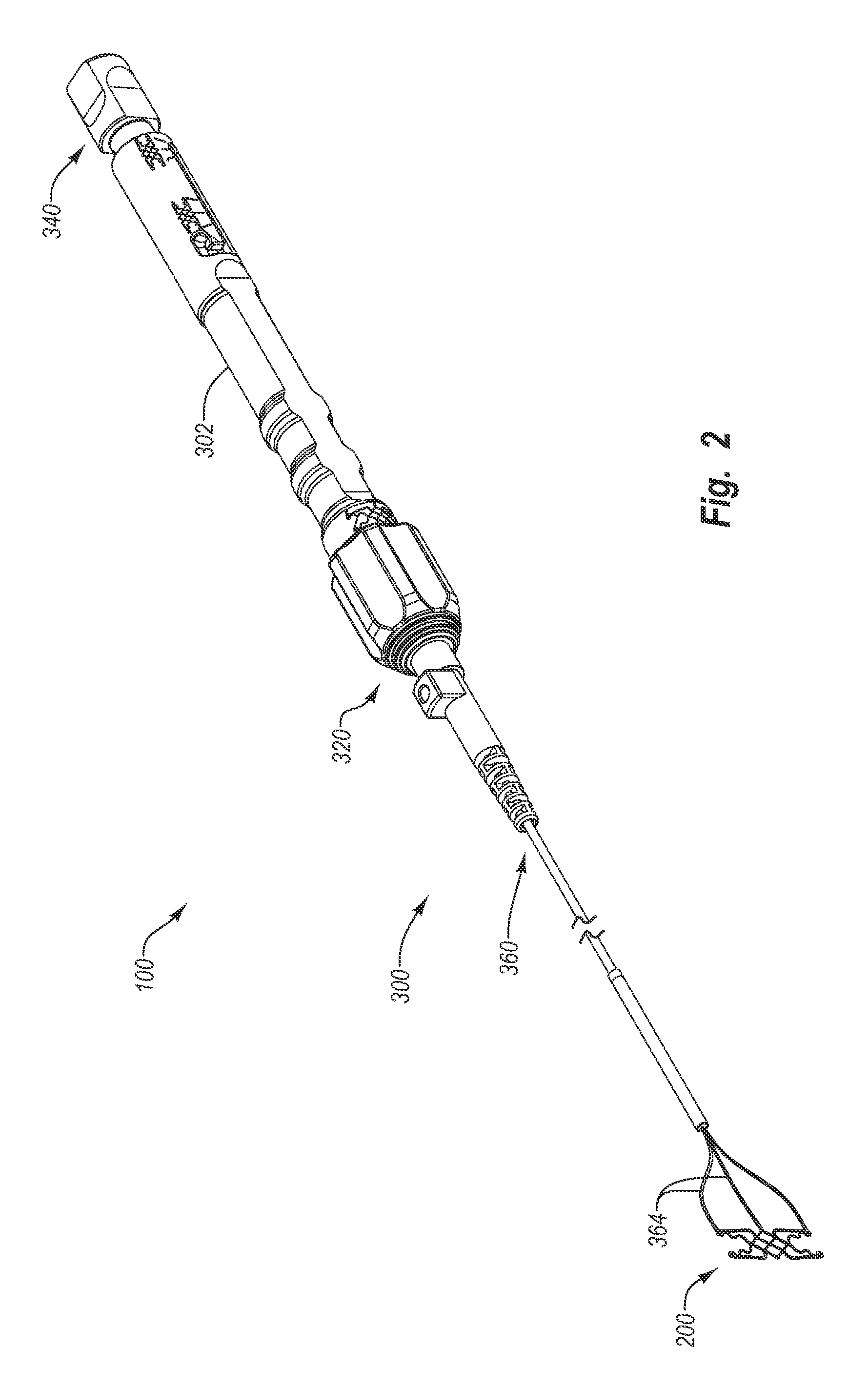

Devices for reducing the size of an internal tissue opening

A medical system for treating an internal tissue opening can include a closure device and associated delivery device. The closure device can include a body portion operatively associated with a first anchor and a second anchor. The body portion can include a plurality of segments defining a multi-cellular structure. The closure device can be configured to apply lateral force to tissue of the internal tissue opening to bring tissue together. The closure device can have a substantially flat aspect, and have a depth thickness that is substantially greater than the thickness or width of a majority of the members forming the closure device to reduce out of plane bending. The closure device can also include a member adapted to induce tissue growth.

Owner:COHEREX MEDICAL

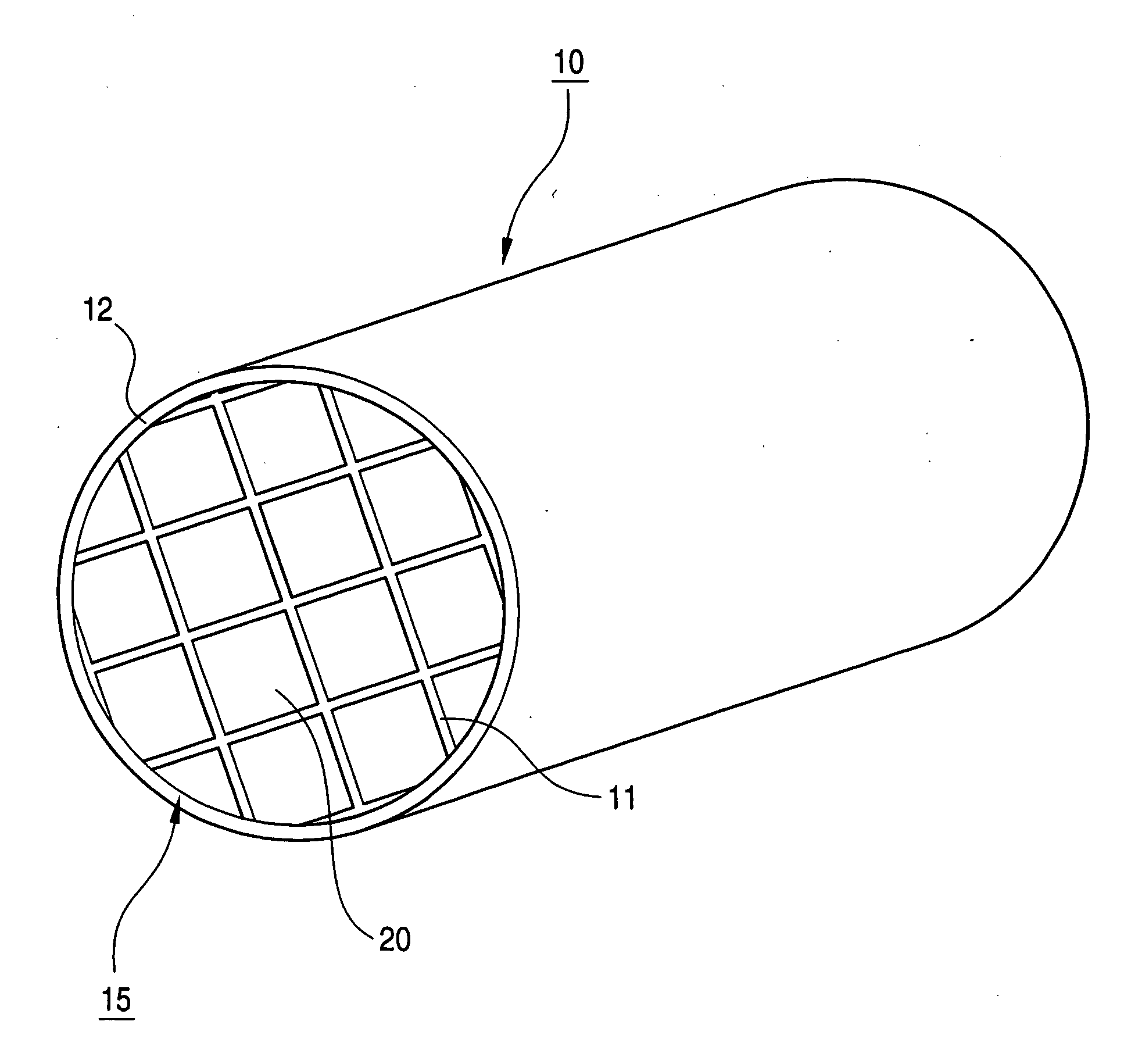

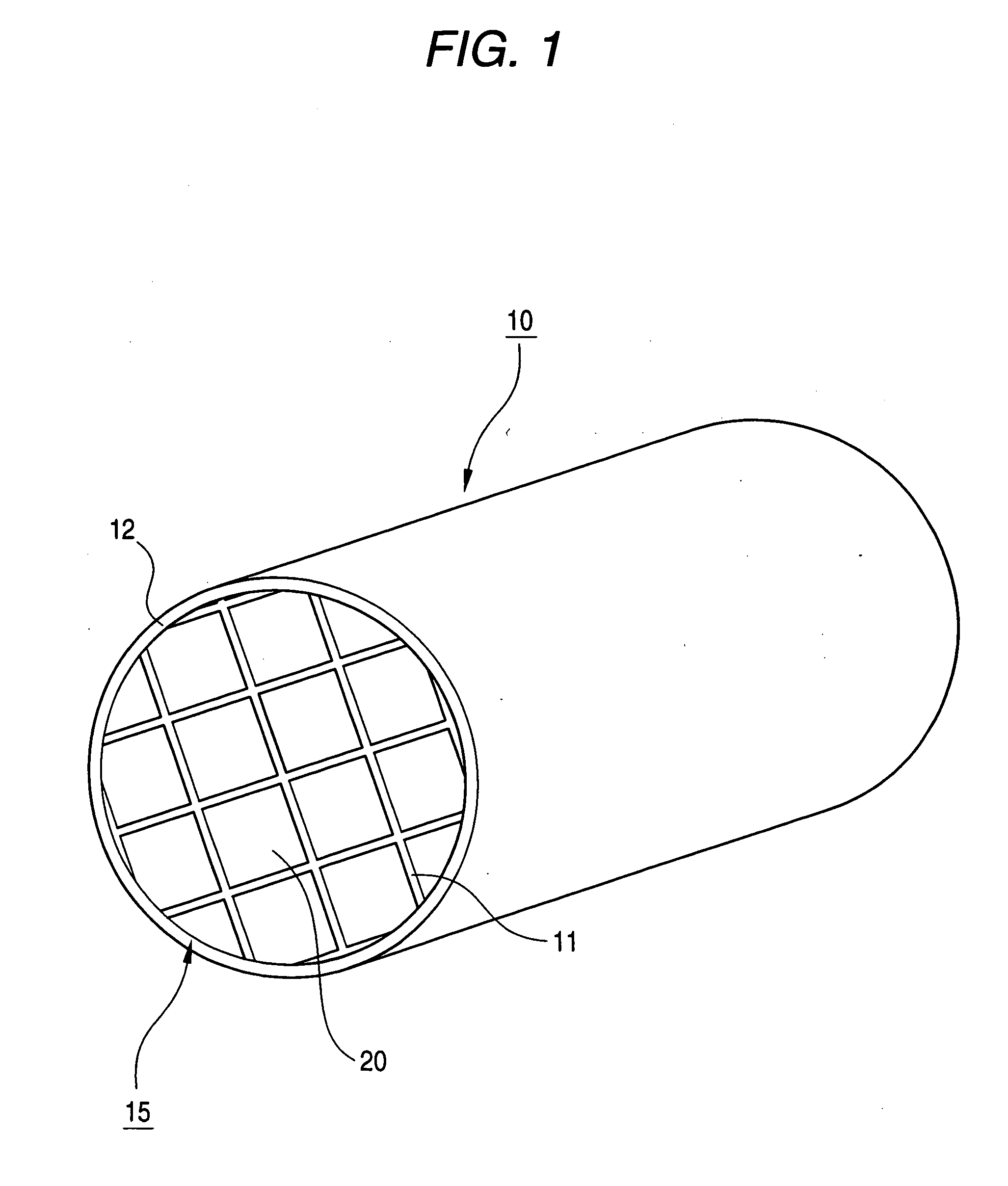

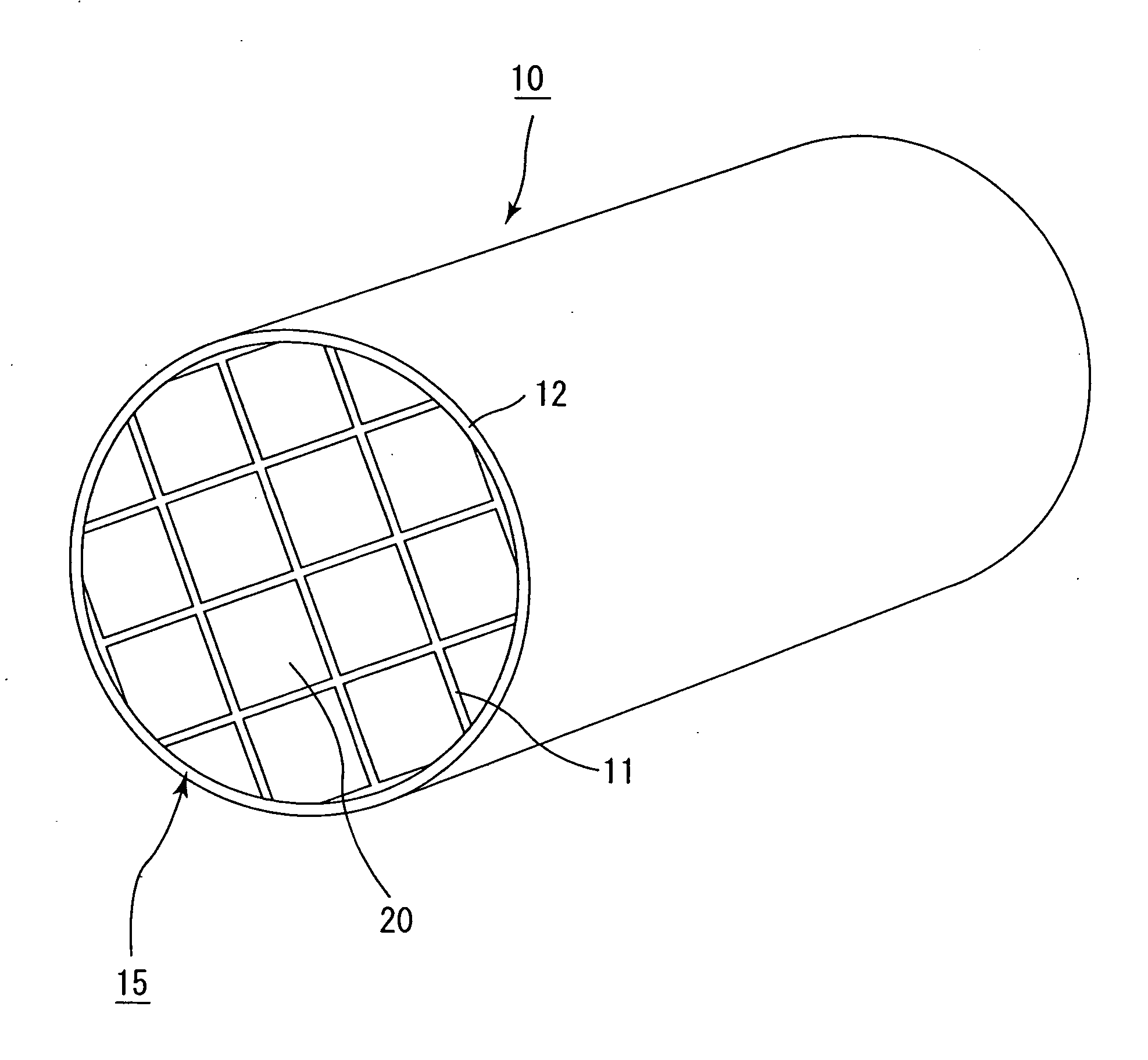

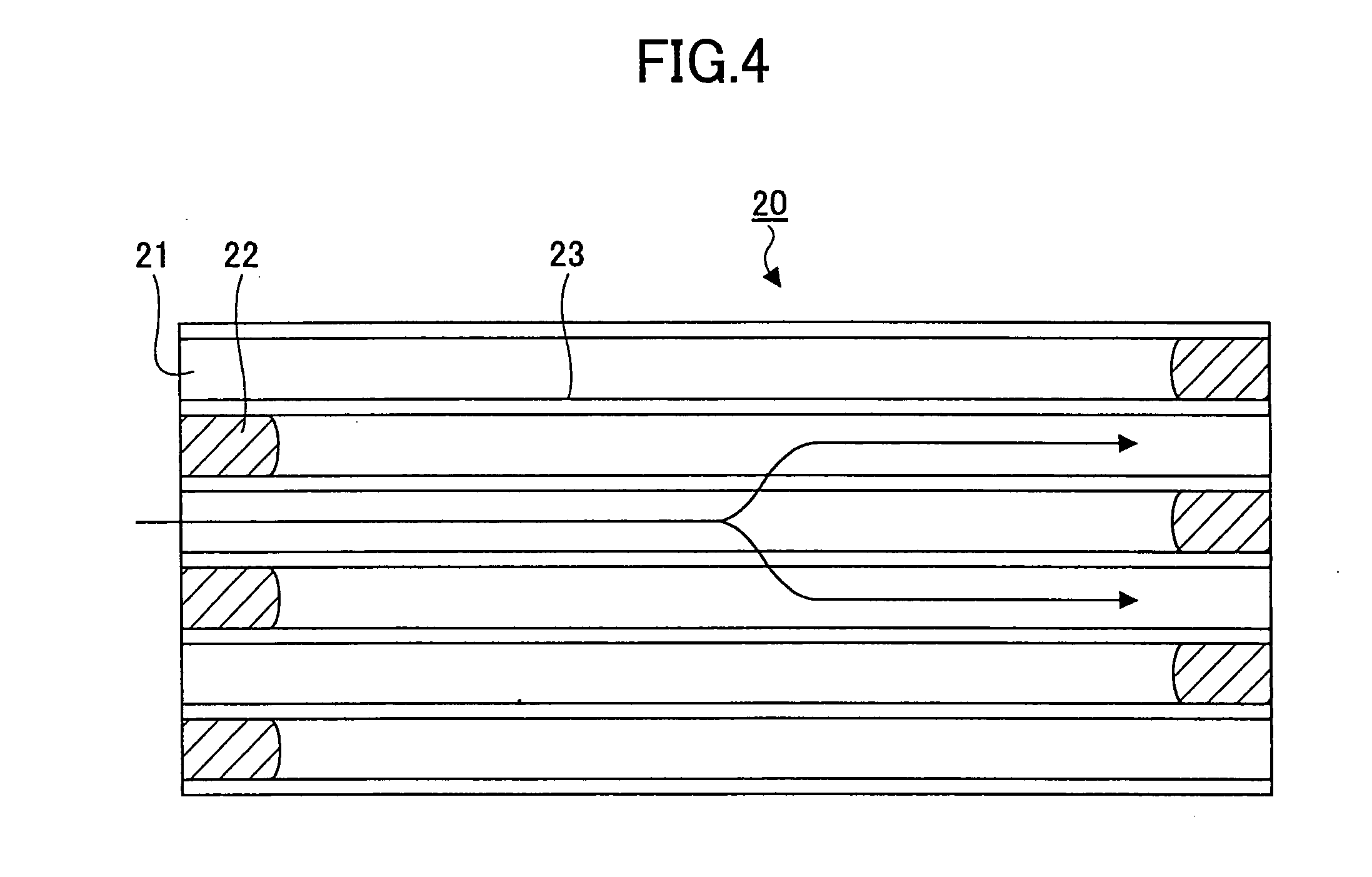

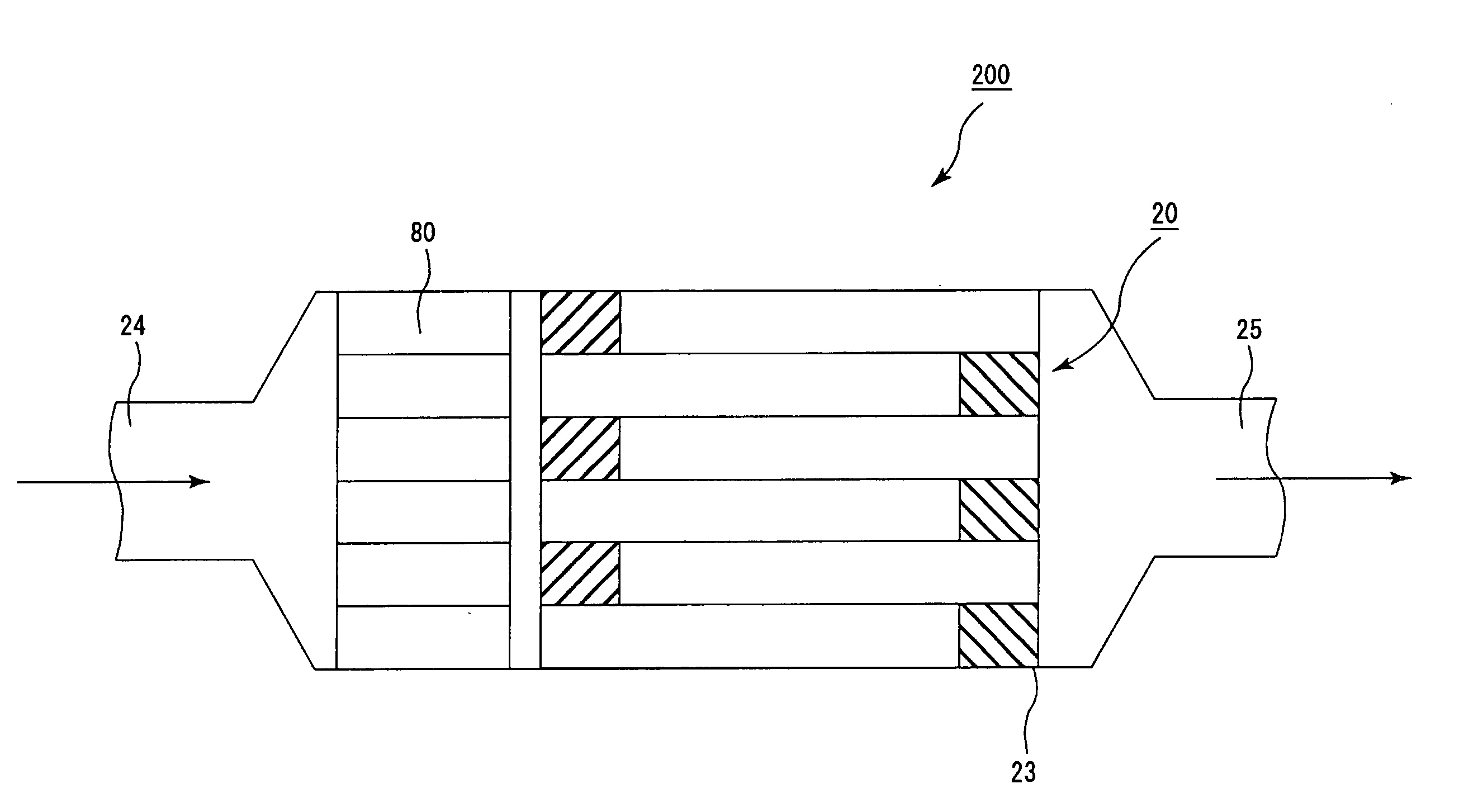

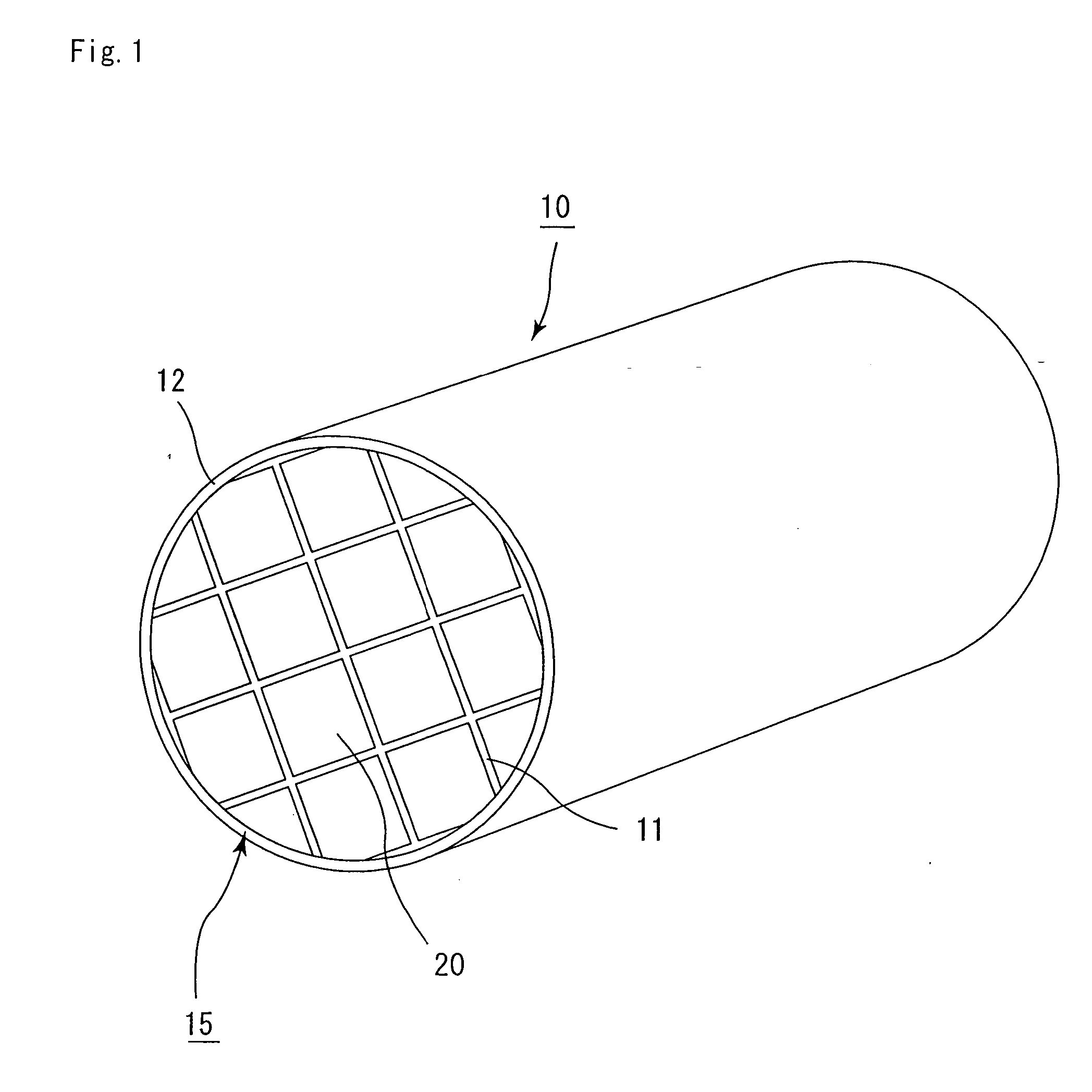

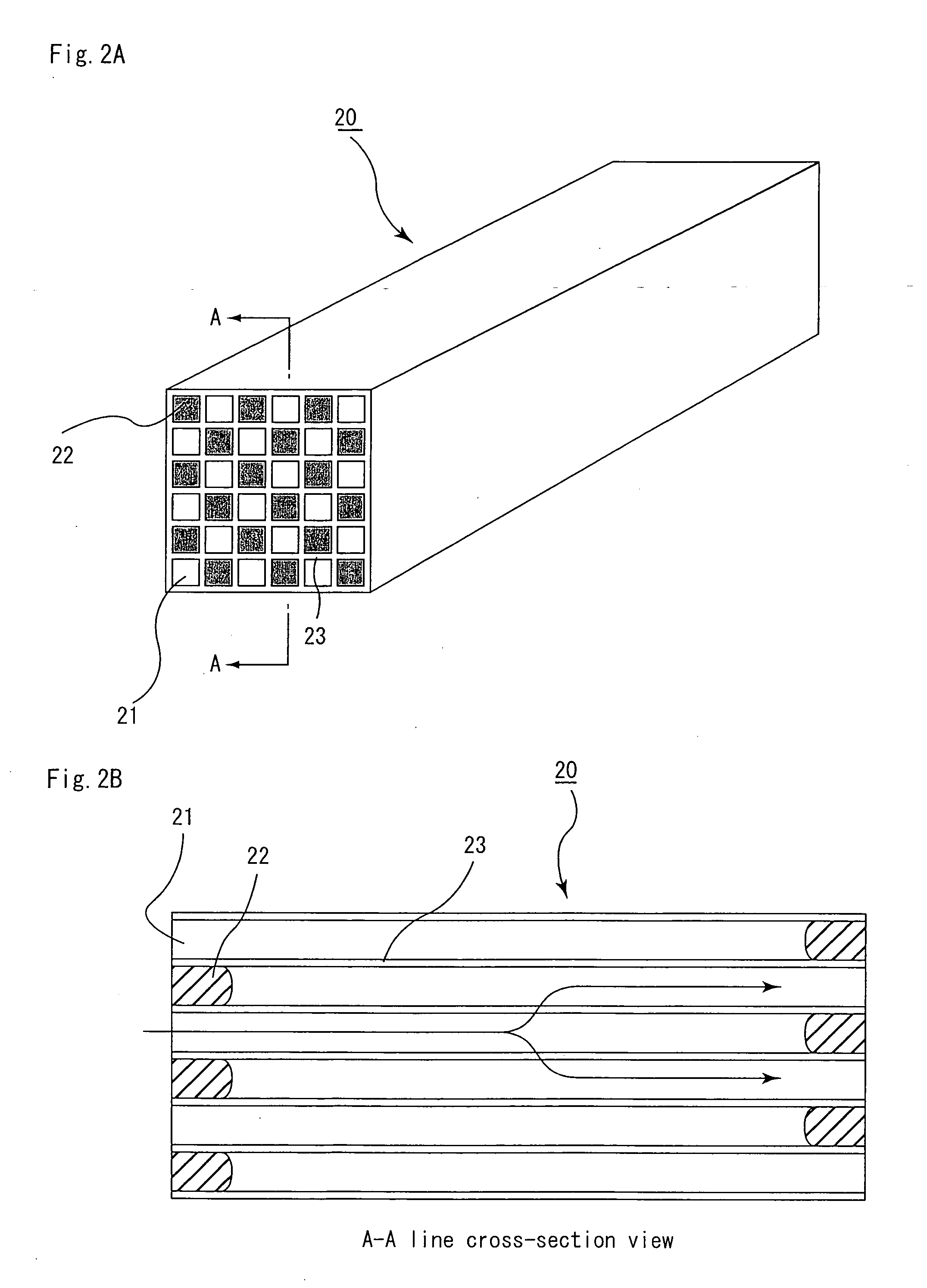

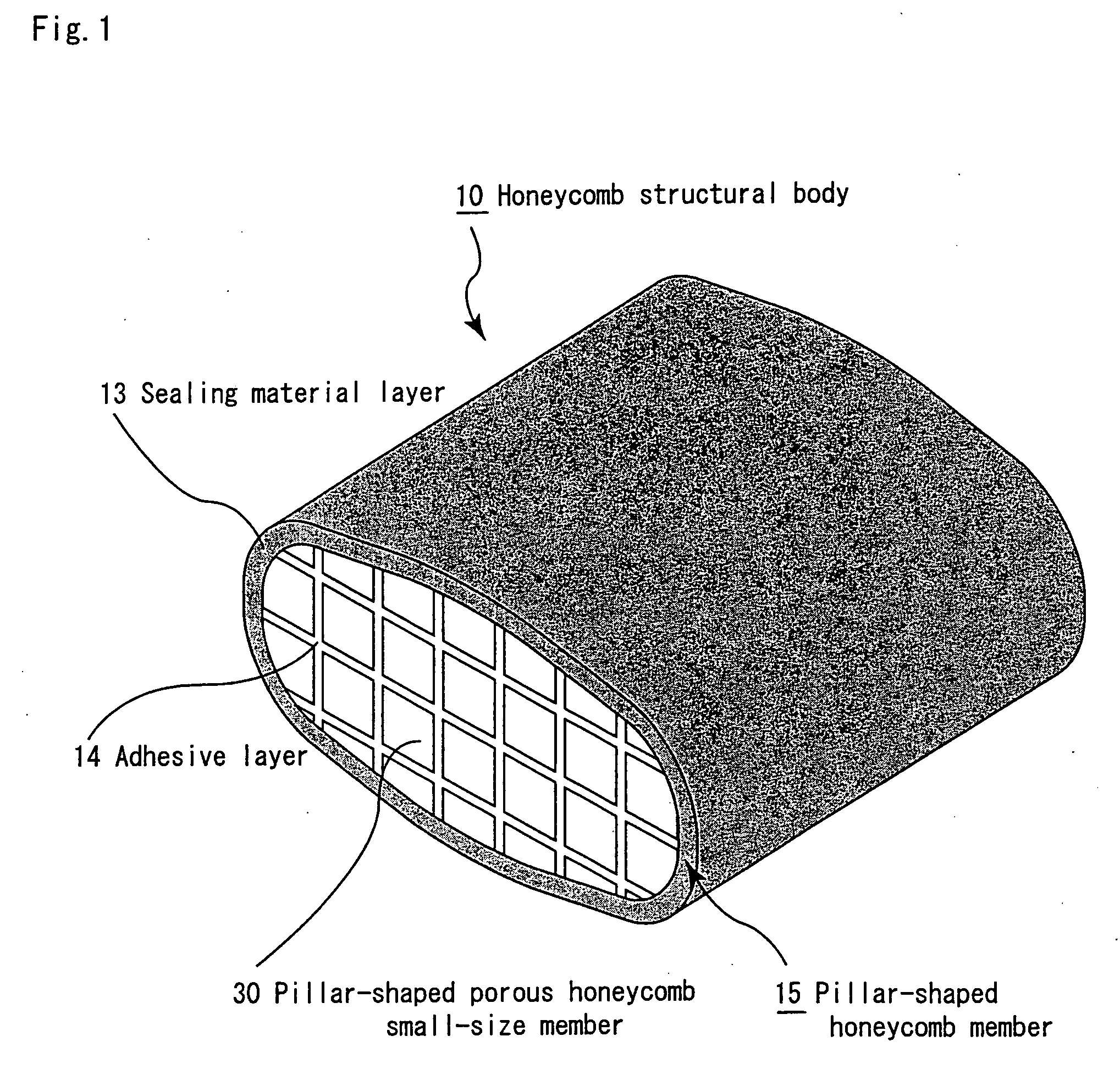

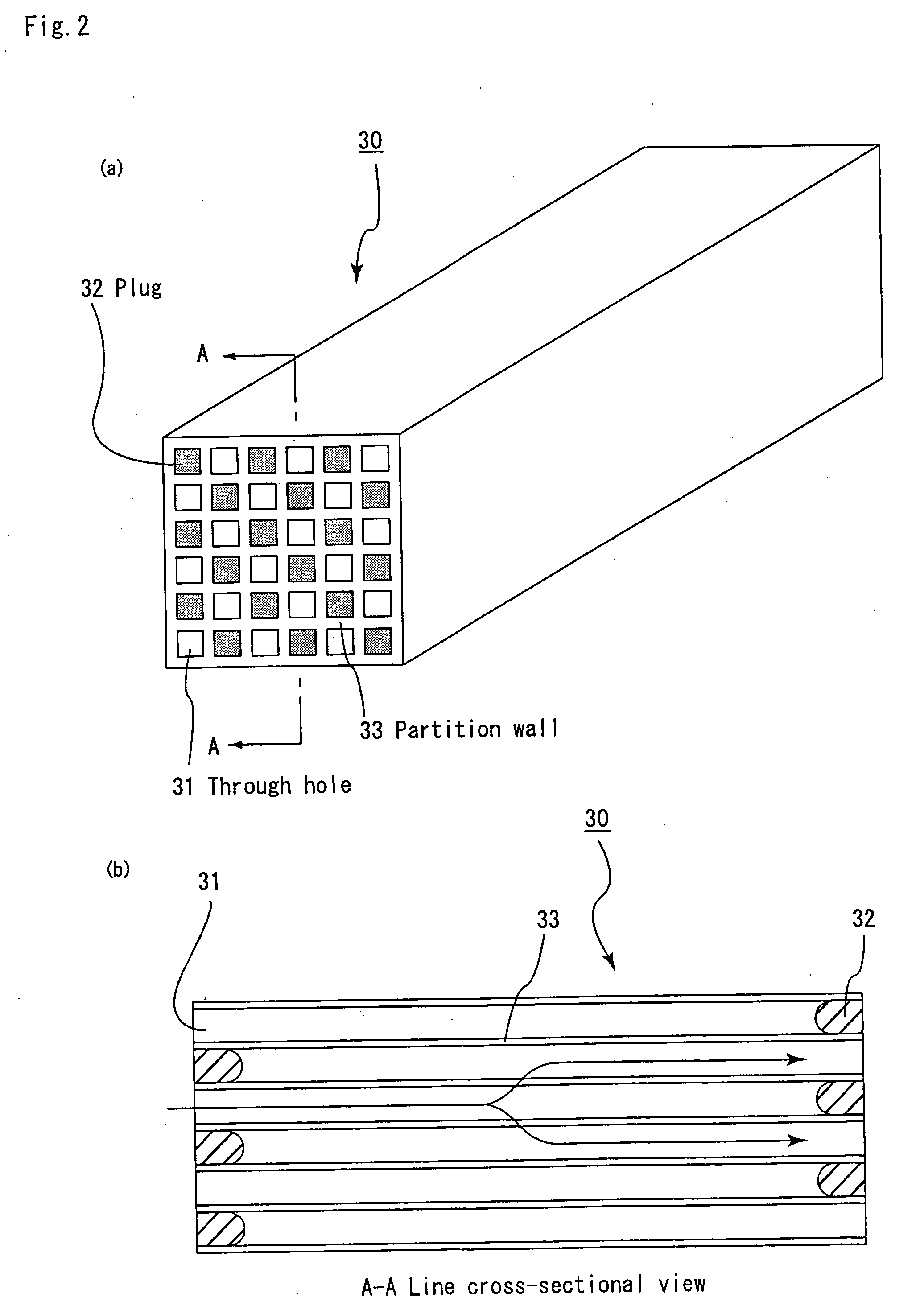

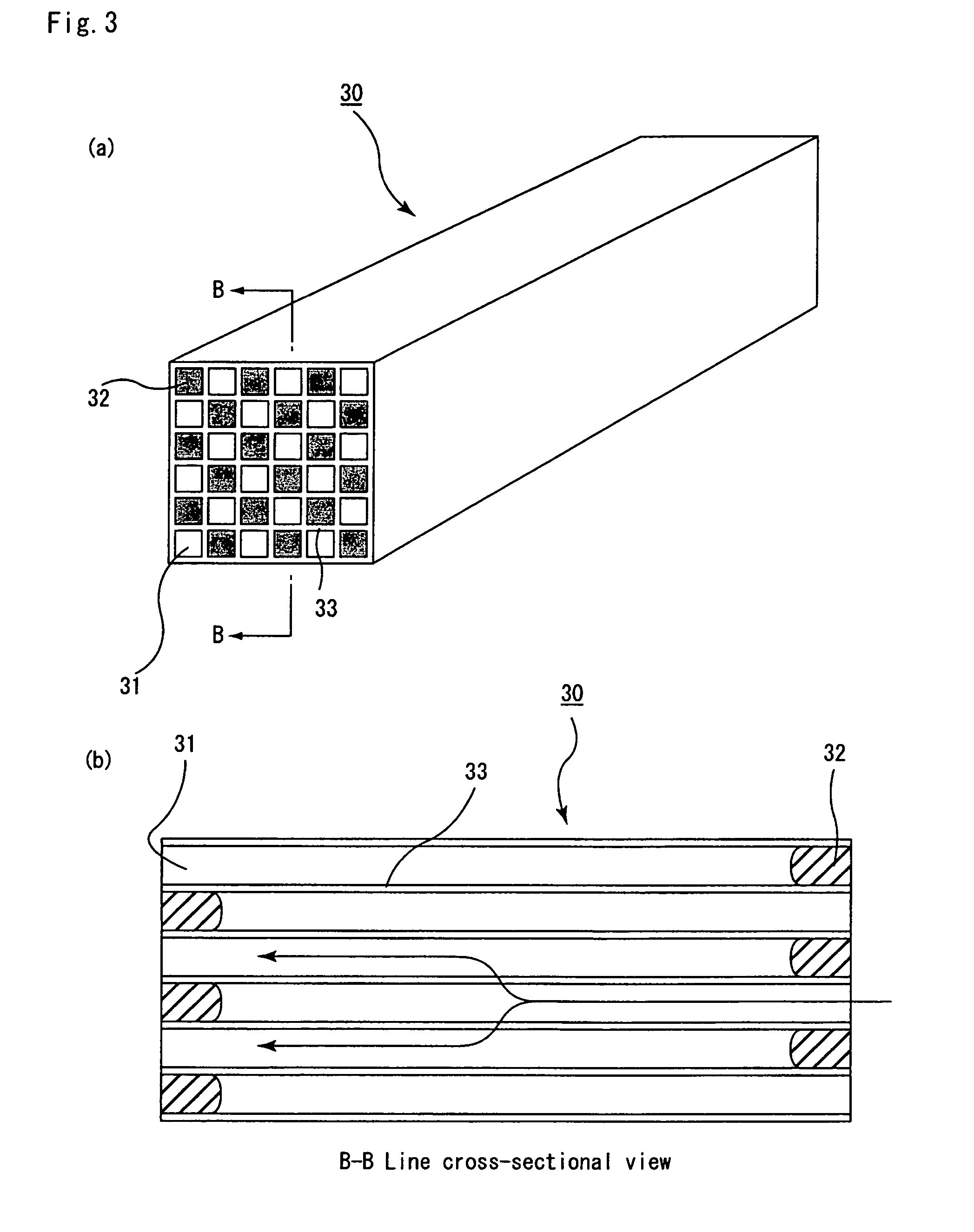

Honeycomb structure

ActiveUS20060230732A1Light weightSmall heat capacityDispersed particle filtrationOther chemical processesApparent densityYoung's modulus

A honeycomb structure including a plurality of porous ceramic members which are bonded through an adhesive layer, each of the porous ceramic members has a plurality of cells, which are arranged in parallel while being separated by cell walls. The cells extend in a longitudinal direction of the honeycomb structure. In the honeycomb structure, the following relationship is satisfied: 2≦B≦100 / 3×A−10 / 3 (1) where A (g / cm3) designates apparent density of the porous ceramic members, and B (GPa) designates Young's modulus of the adhesive layer.

Owner:IBIDEN CO LTD

Honeycomb structured body, method for manufacturing honeycomb structured body, and exhaust gas purifying device

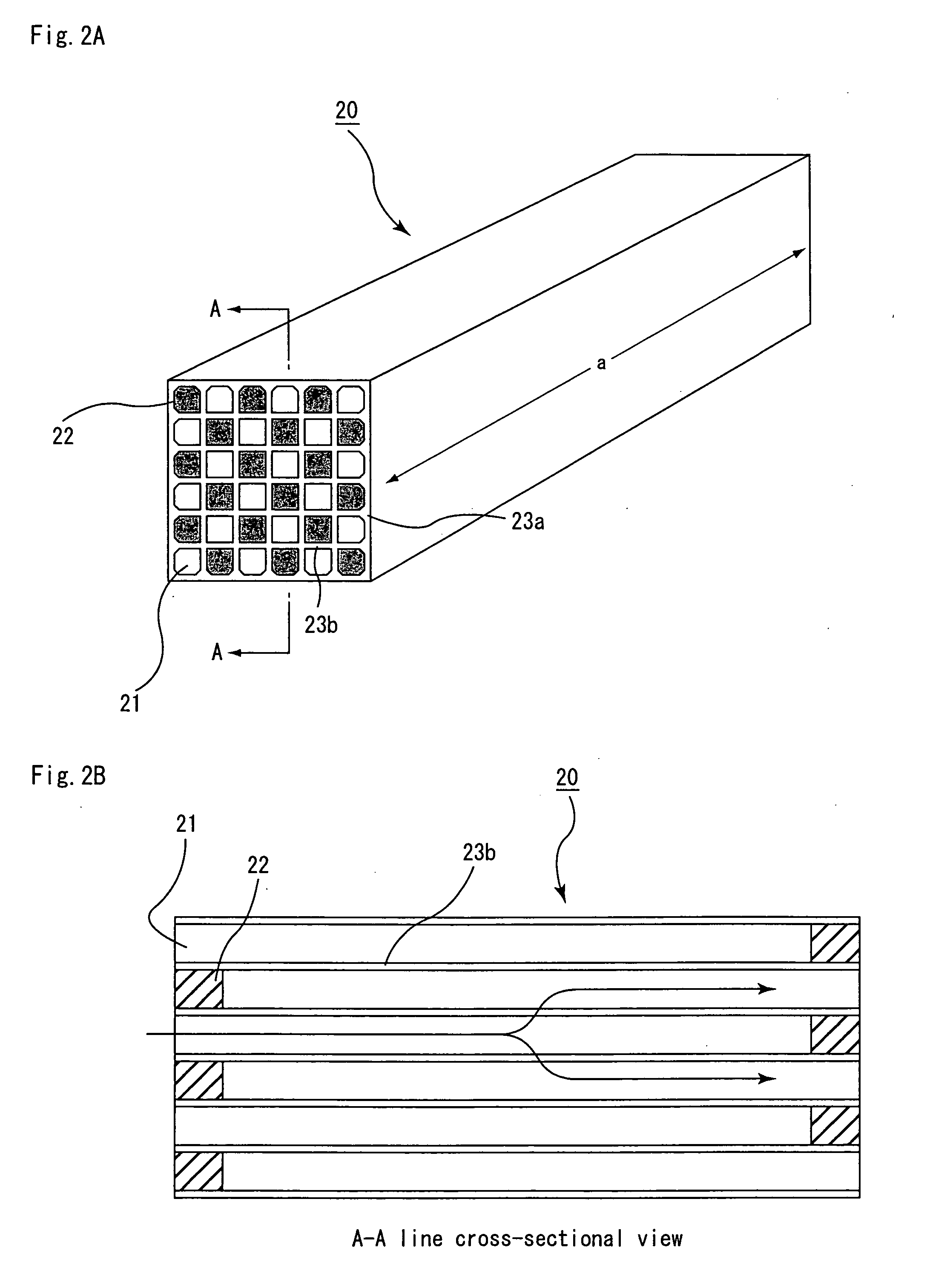

InactiveUS20070130897A1Avoid deformationReduce generationPhysical/chemical process catalystsInternal combustion piston enginesEdge surfaceCell wall

A honeycomb structured body in which a plurality of porous ceramic members are combined with one another by interposing an adhesive layer, each of the porous ceramic members having a plurality of cells placed in parallel with one another in a longitudinal direction with a cell wall therebetween and an outer edgewall on the outer edge surface thereof, wherein the thickness of the outer edge wall of the porous ceramic member is greater than the thickness of the cell wall, and each of the porous ceramic members has a filling body which is provided so as to fill in at least one corner portion of at least one outermost cell of the porous ceramic members.

Owner:IBIDEN CO LTD

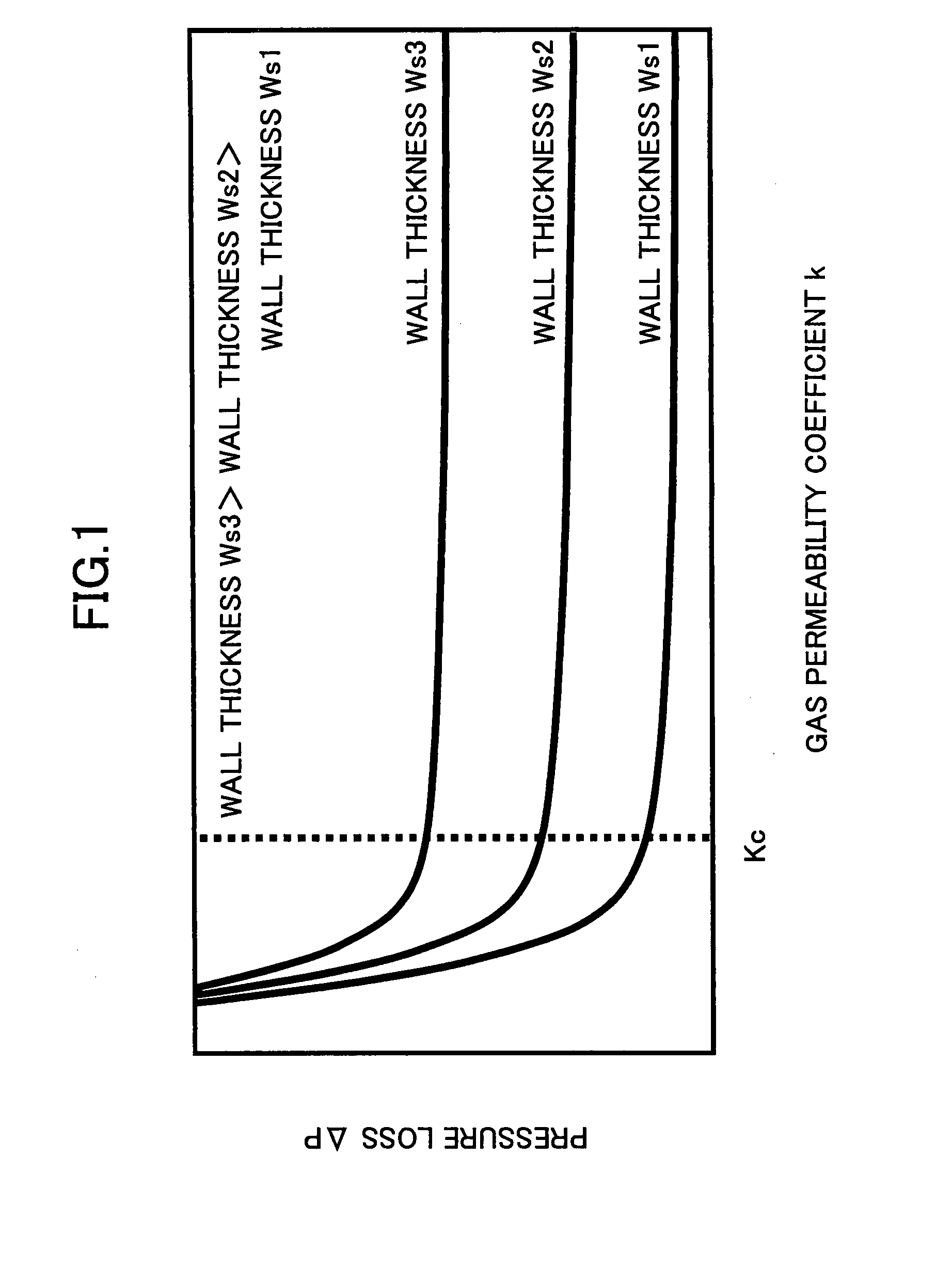

Honeycomb structure and exhaust gas purifying device

ActiveUS20070196620A1Combination devicesInternal combustion piston enginesCell wallPermeability coefficient

Owner:IBIDEN CO LTD

Honeycomb structured body and exhaust gas purifying device

InactiveUS20070020155A1Simple processReduce the temperatureCombination devicesGas treatmentApparent densityEngineering

A honeycomb structured body of the present invention comprises a plurality of cells placed in parallel with one another in a longitudinal direction with a cell wall therebetween, wherein an oxide catalyst is supported on at least one portion of the cell wall, and the honeycomb structured body has an apparent density of about 0.7 g / cm3 or less.

Owner:IBIDEN CO LTD

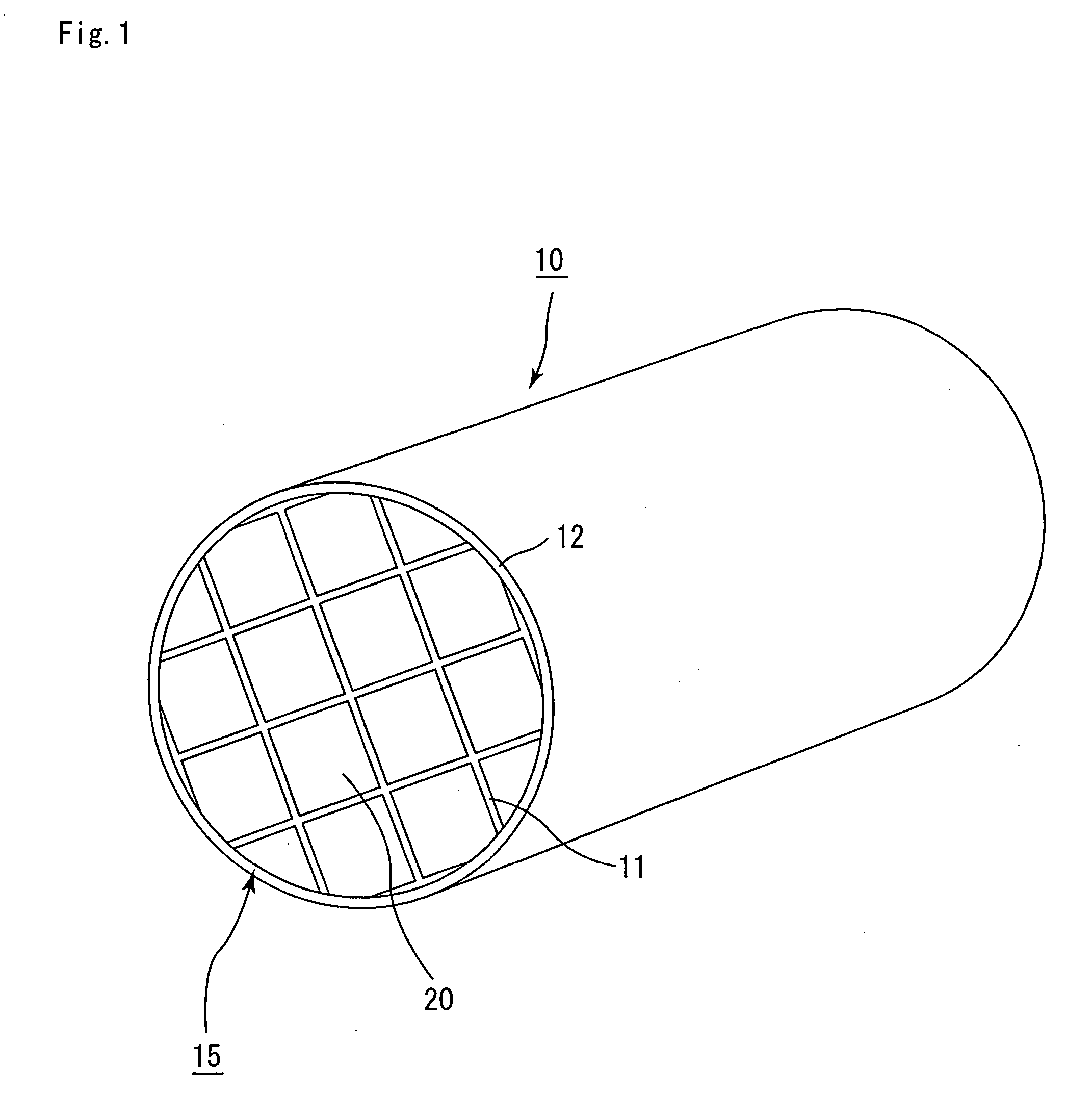

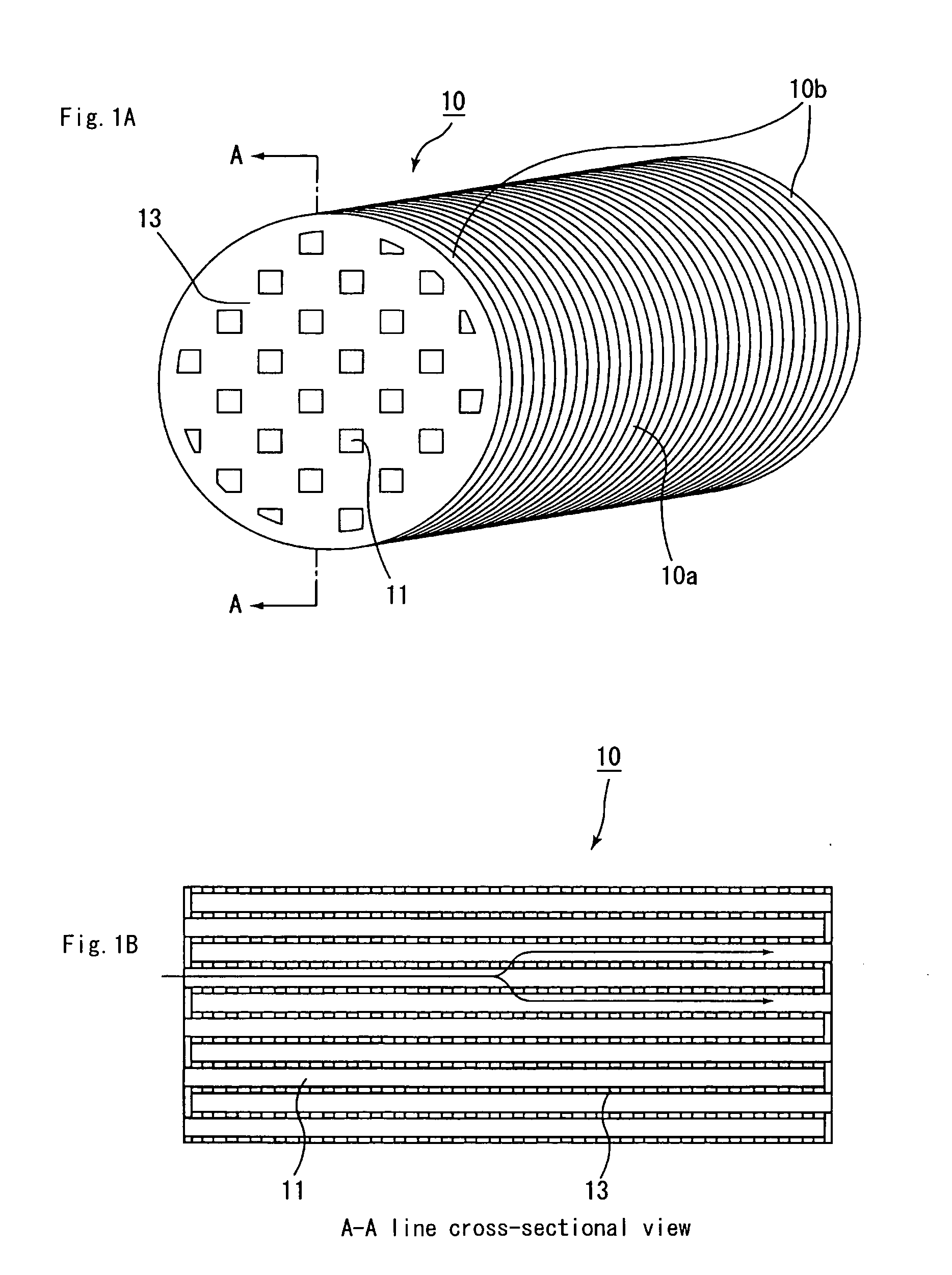

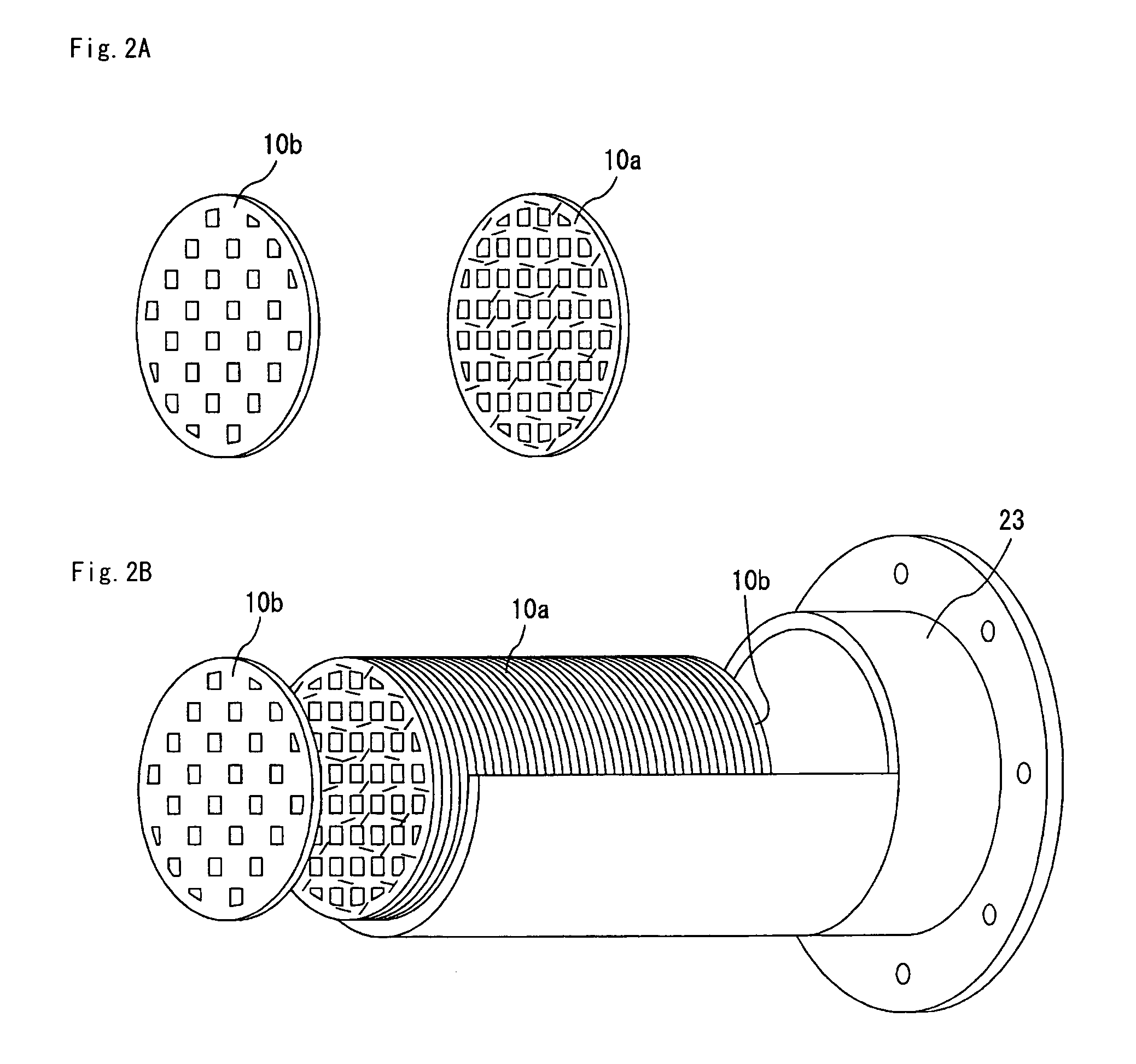

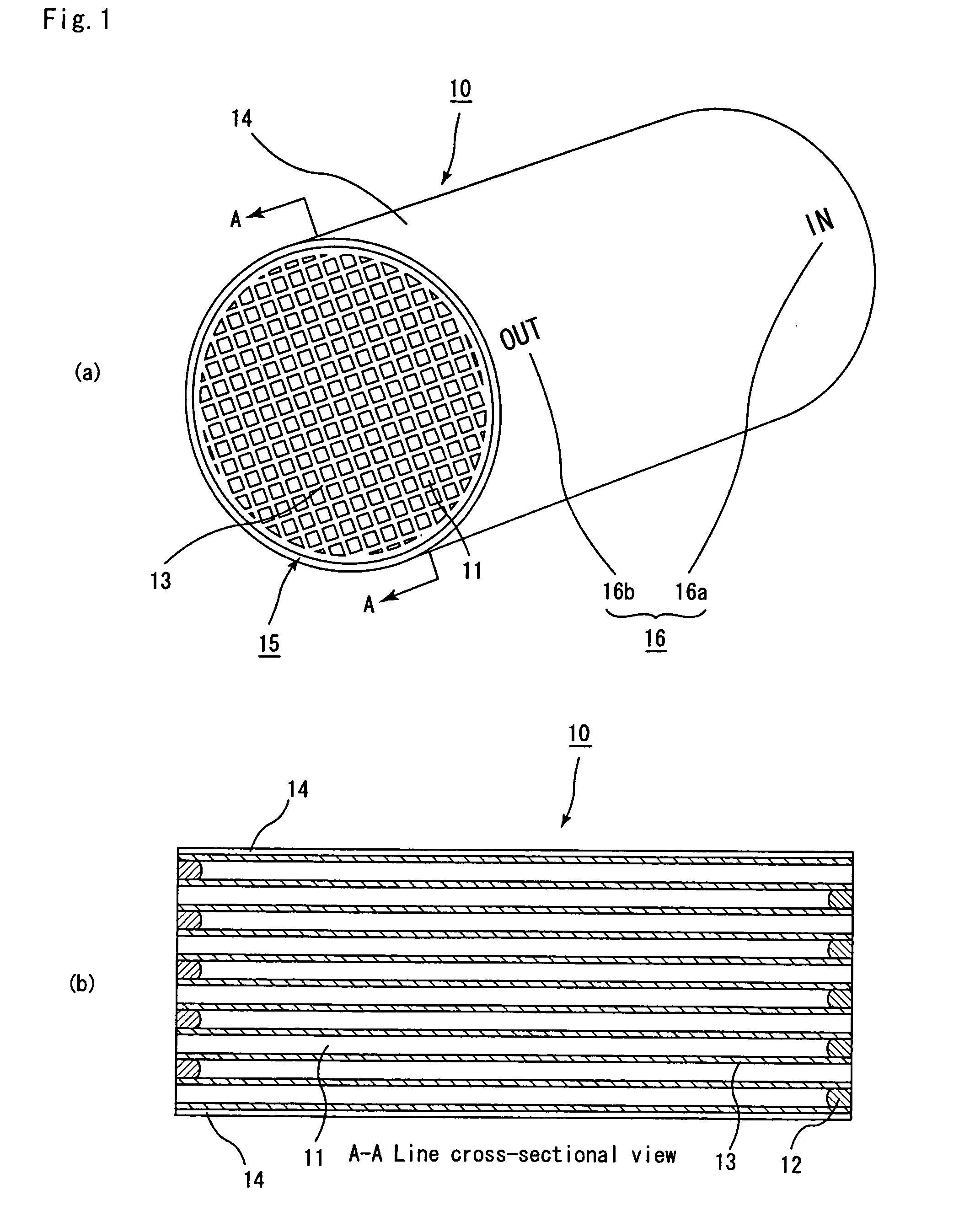

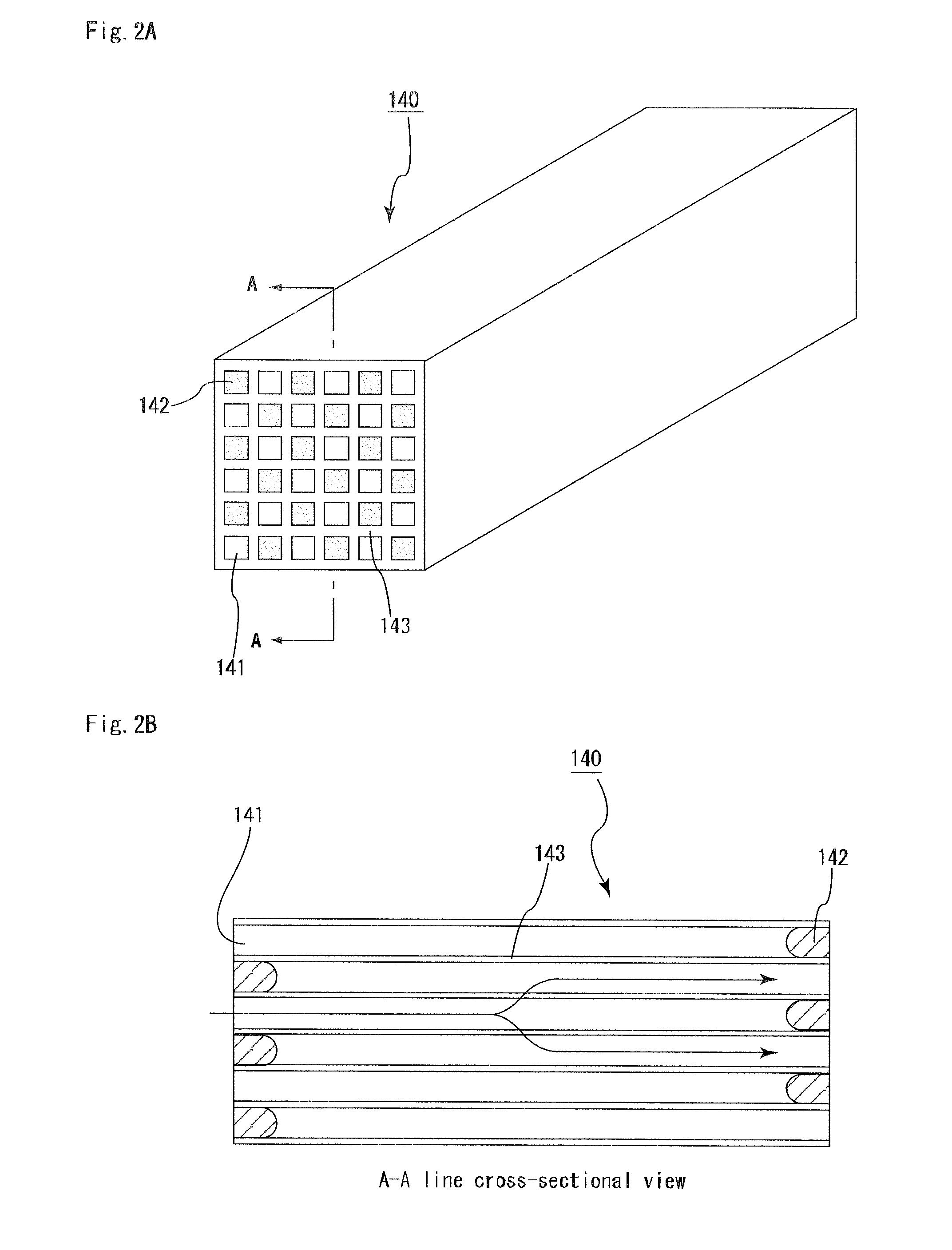

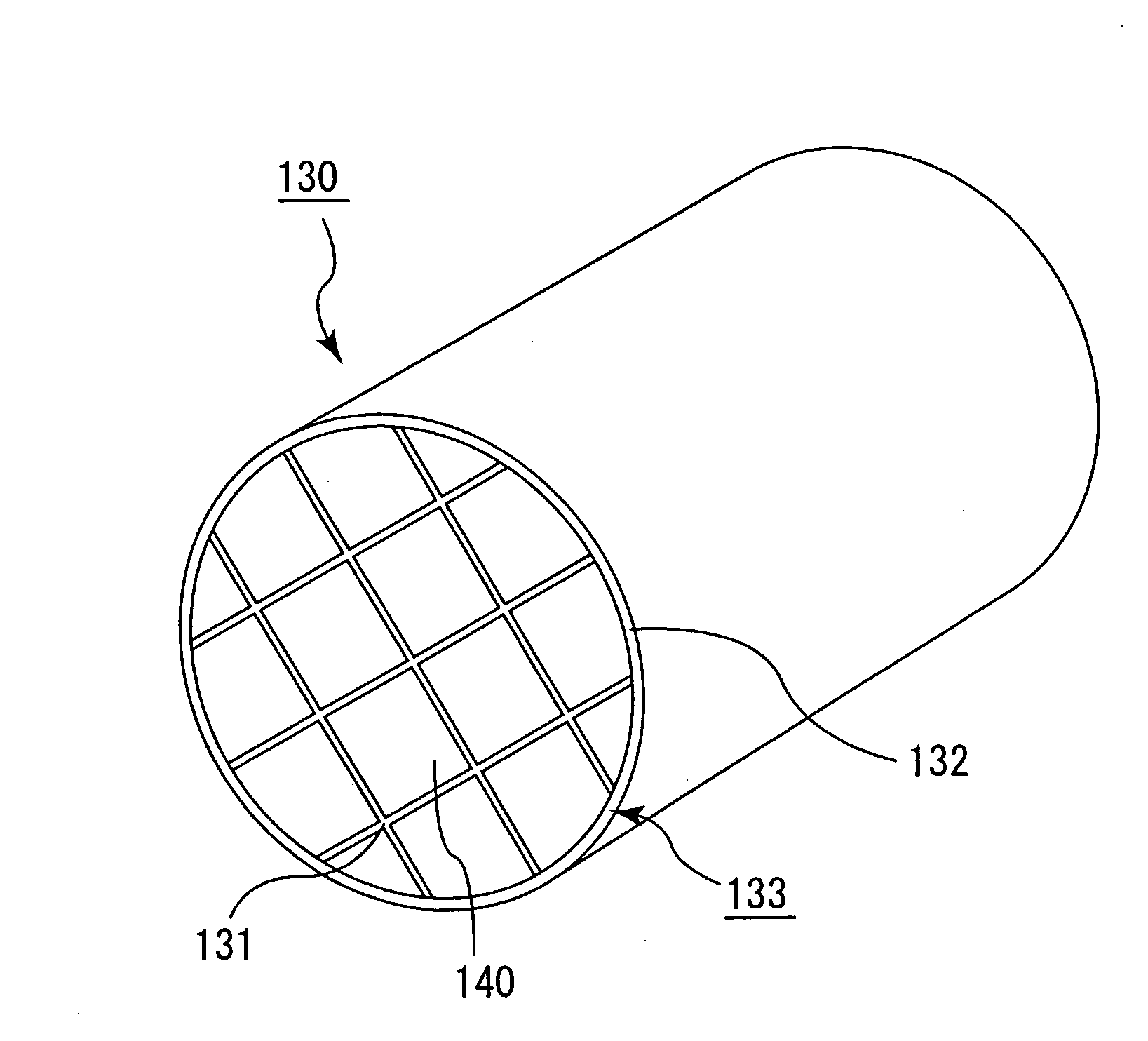

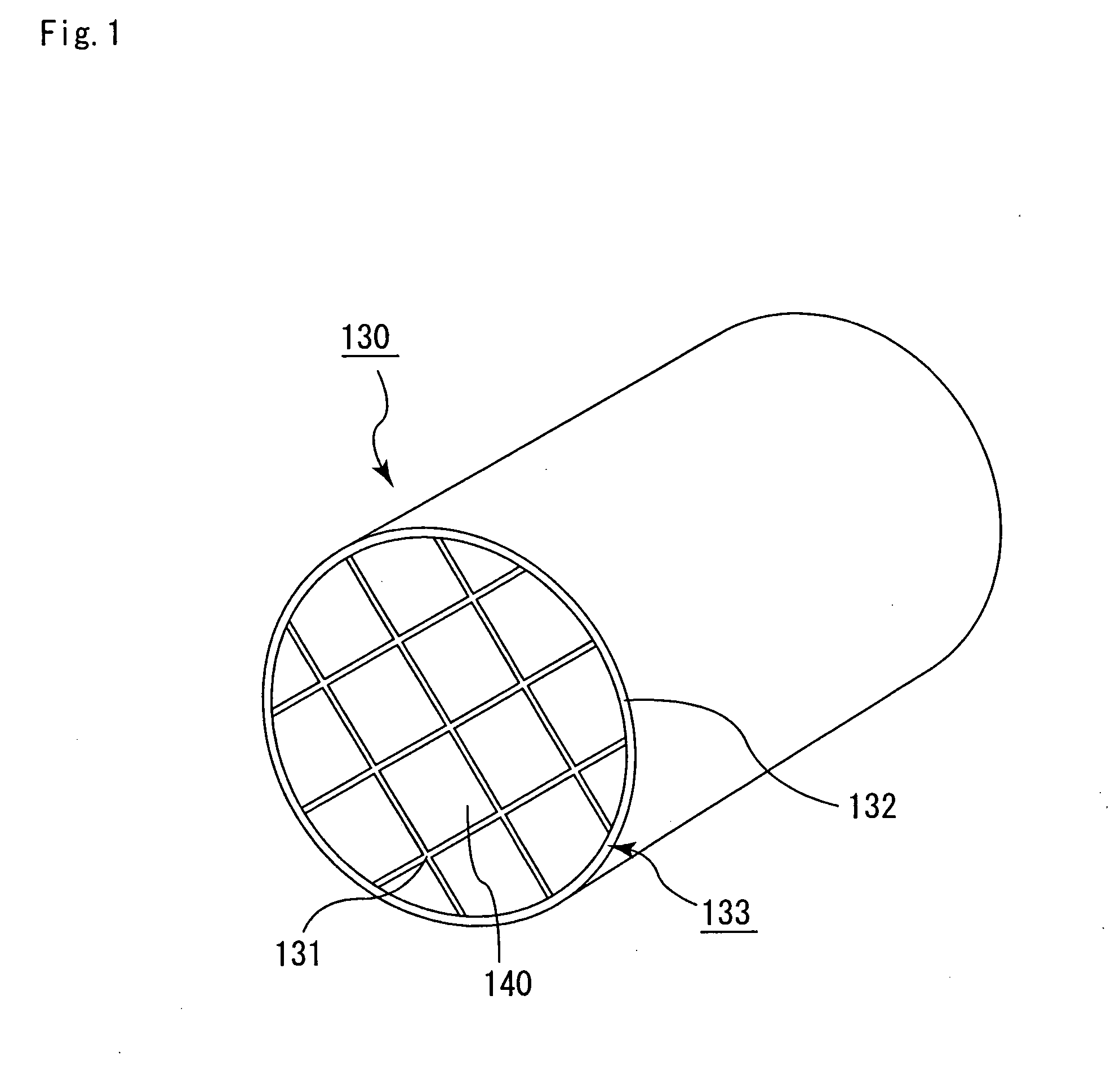

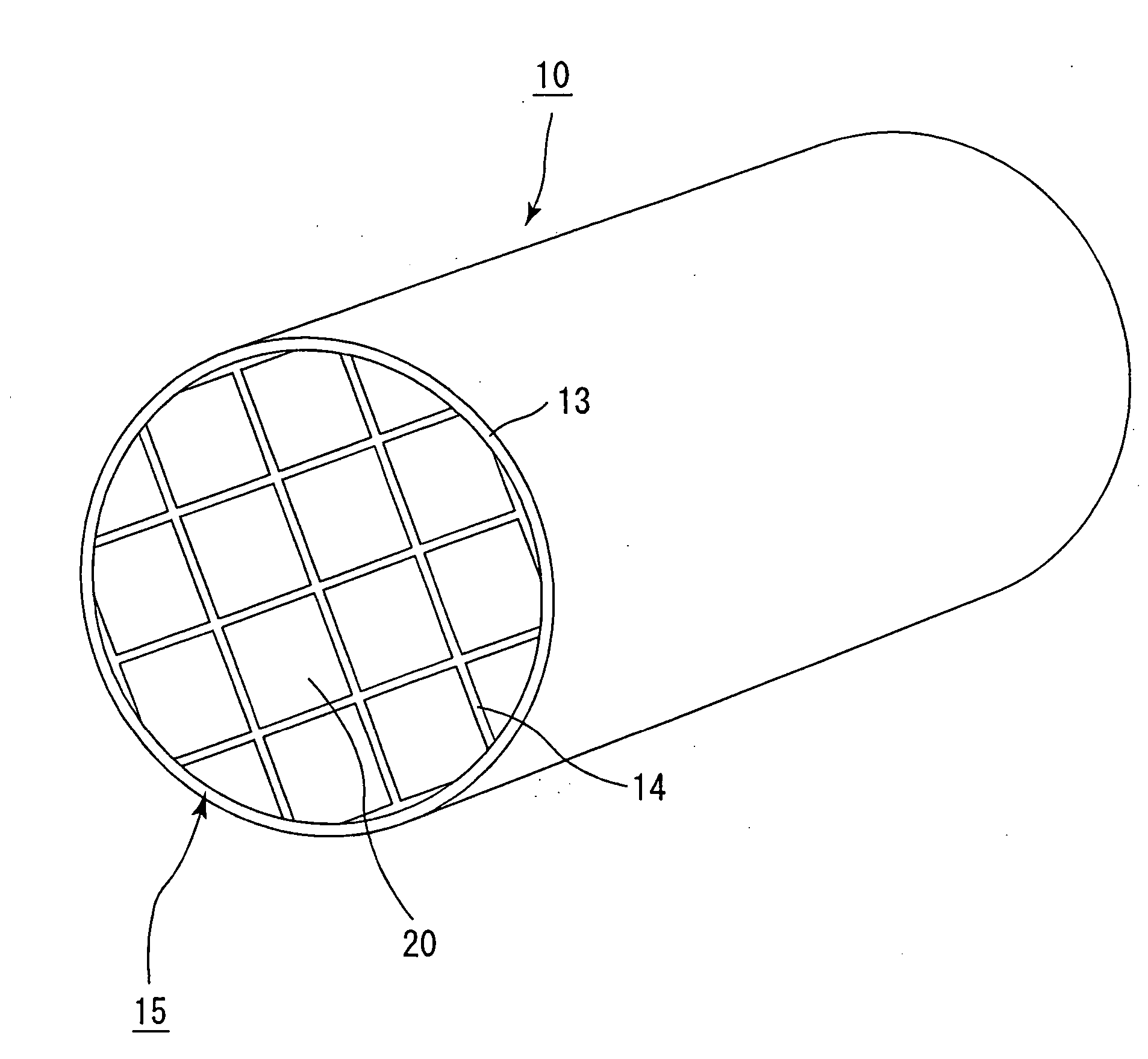

Honeycomb structure

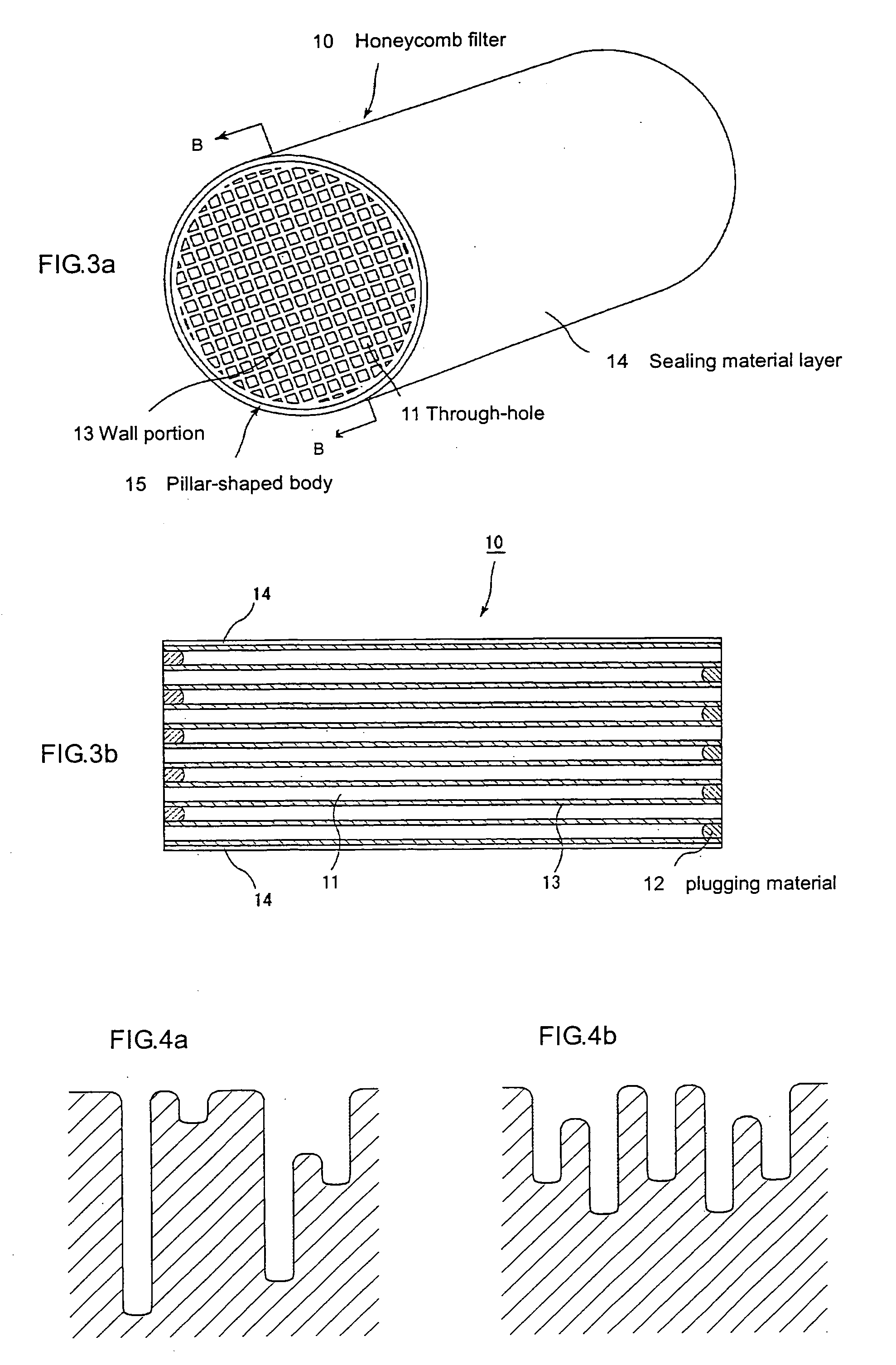

InactiveUS20050266992A1High strengthGood dispersionDispersed particle filtrationExhaust apparatusFiberHoneycomb structure

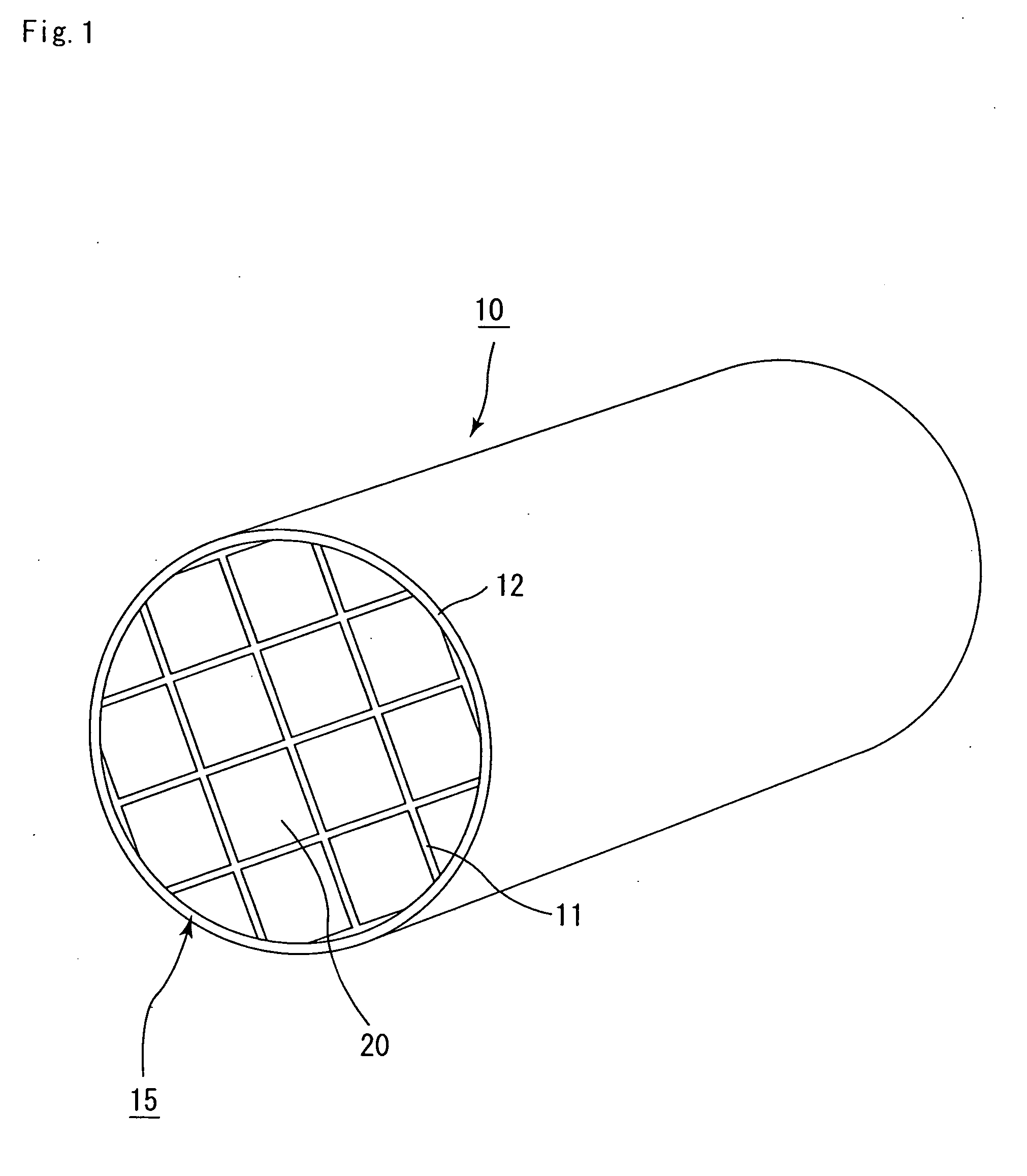

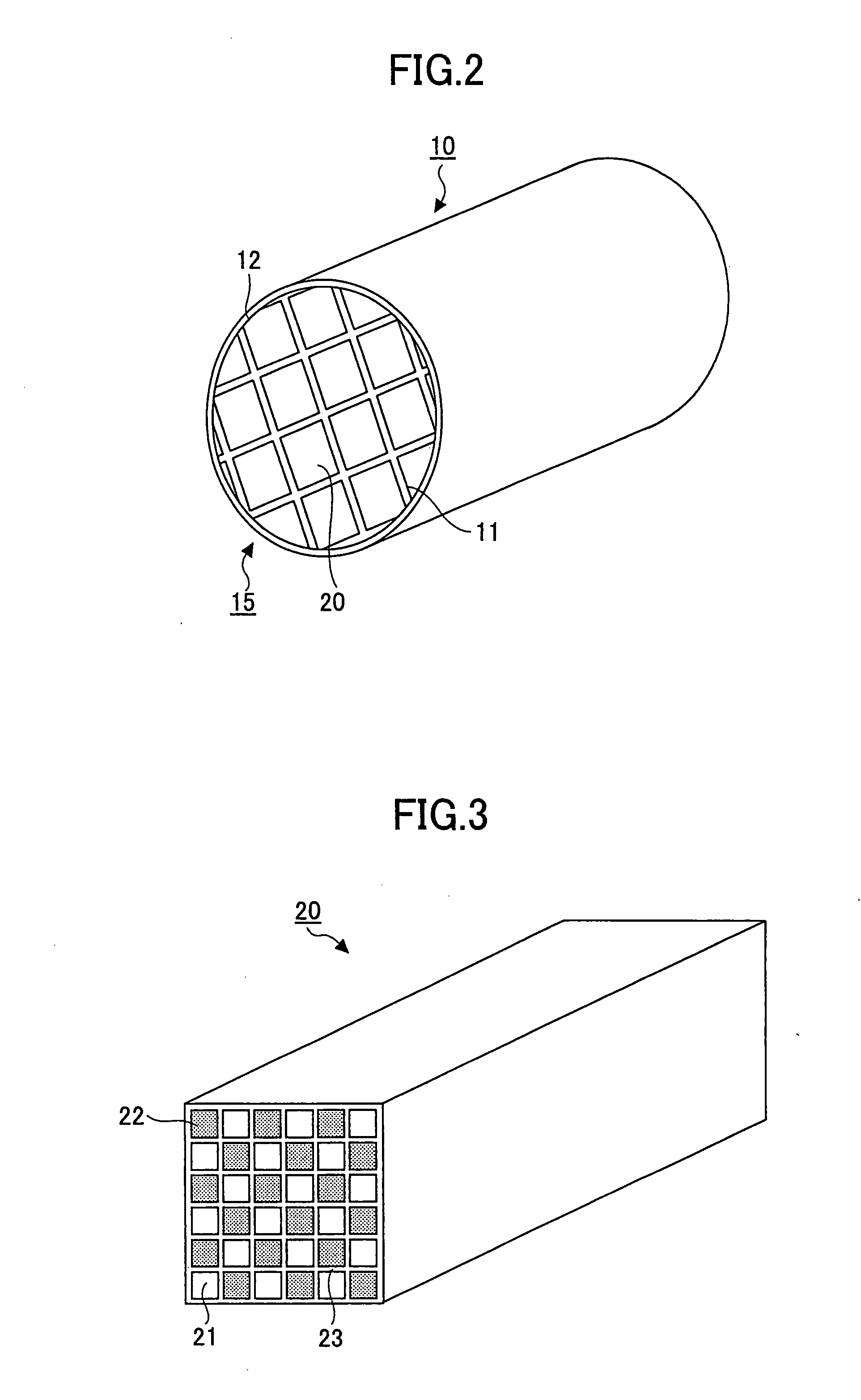

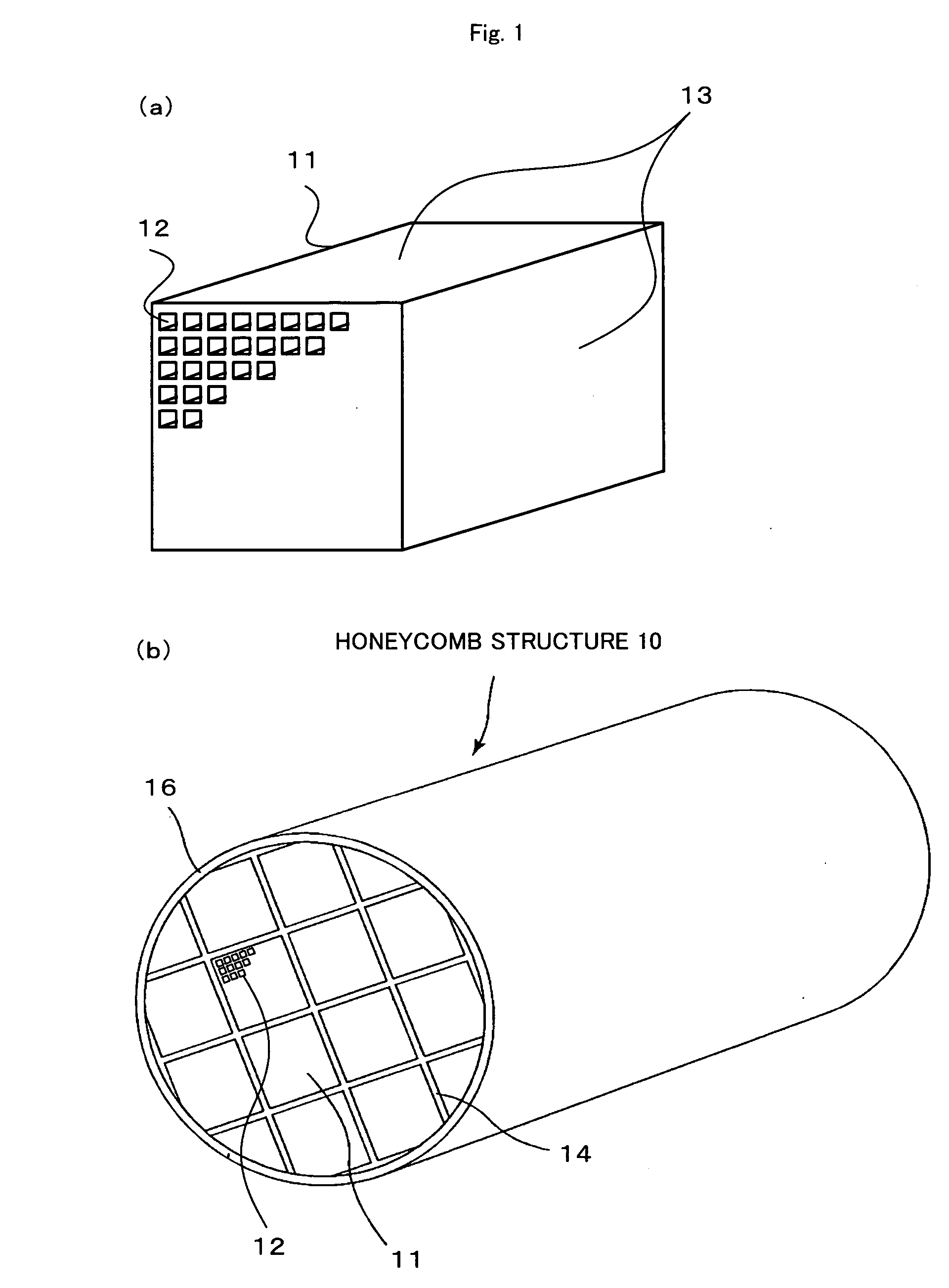

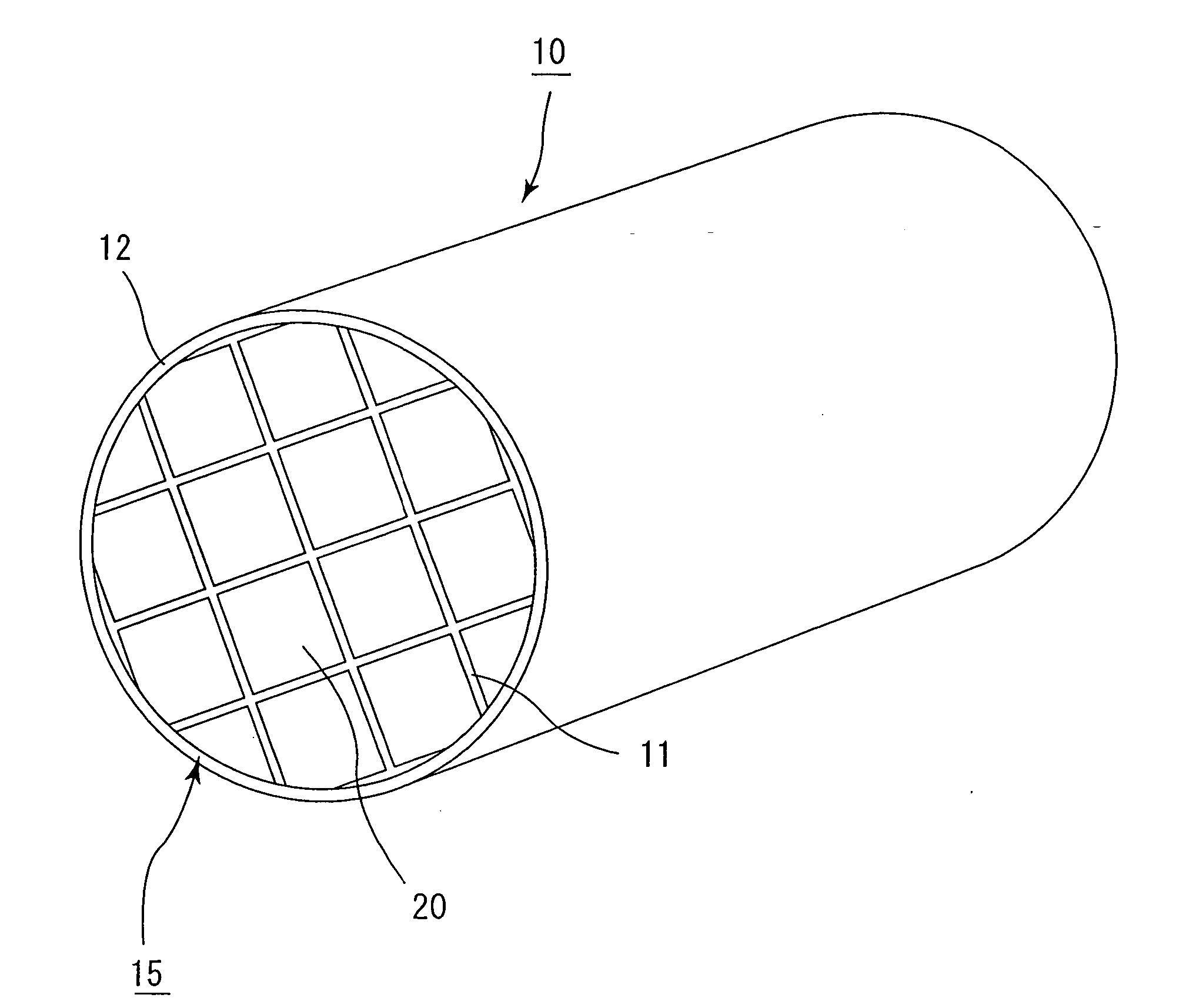

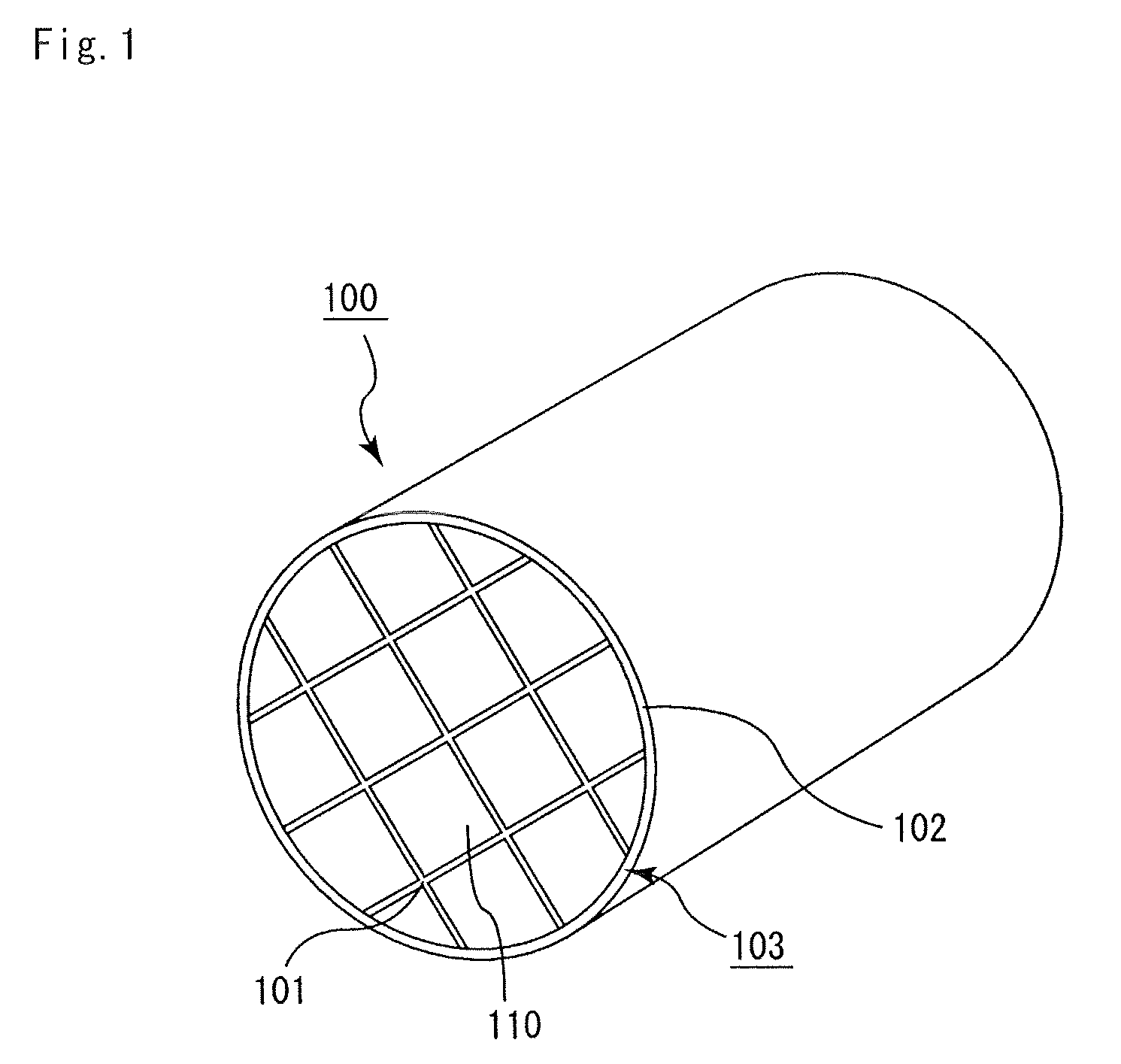

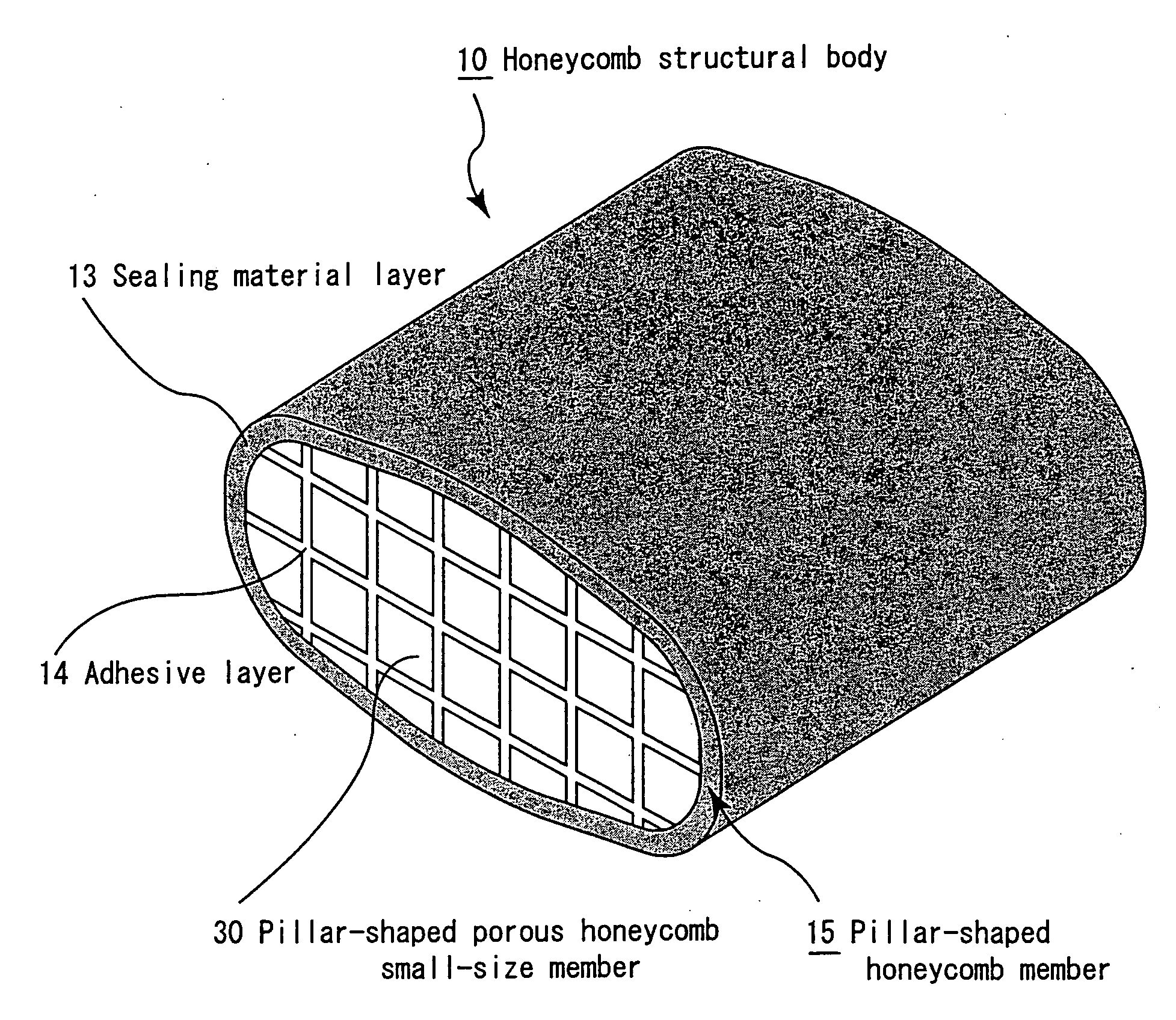

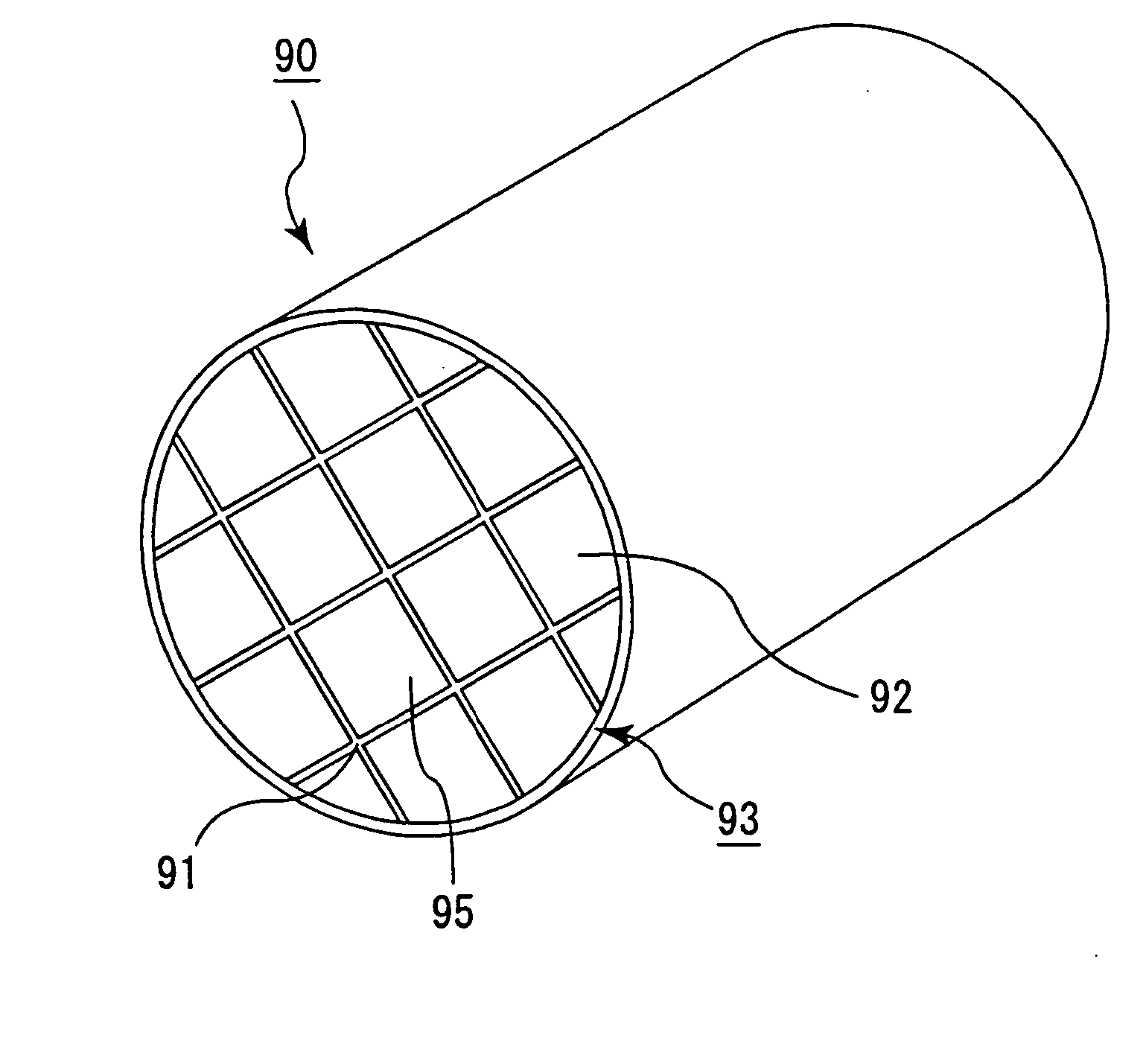

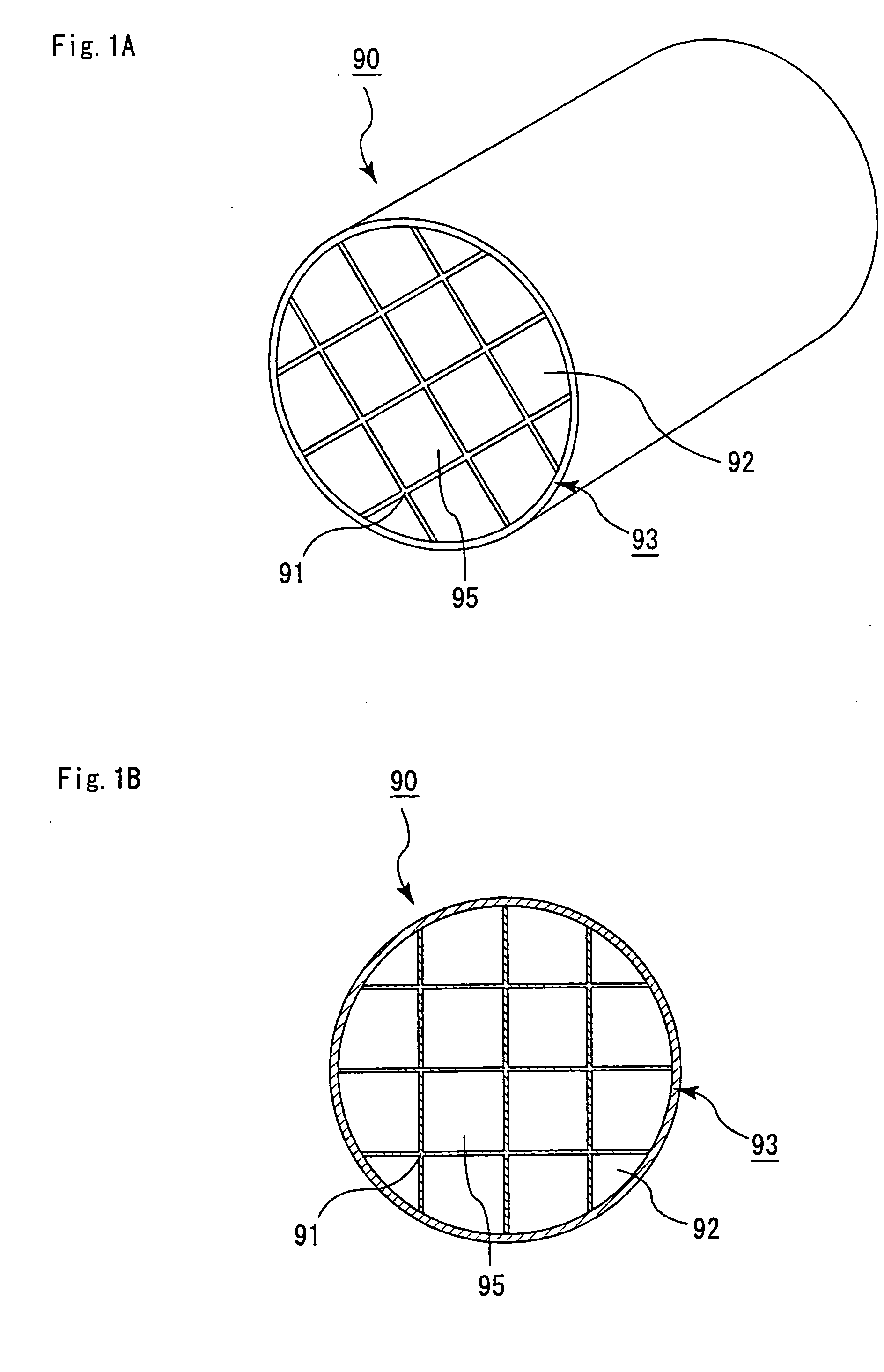

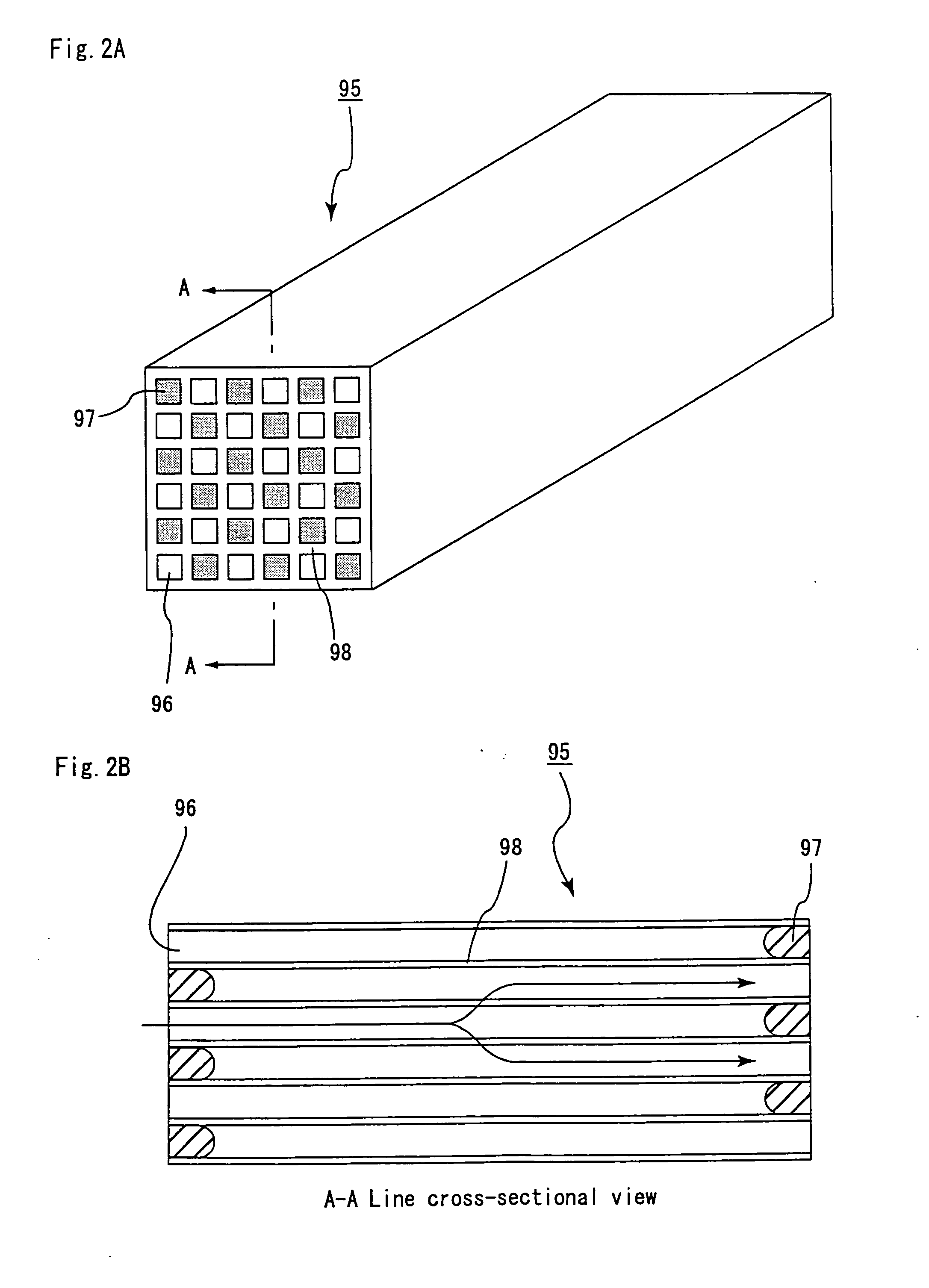

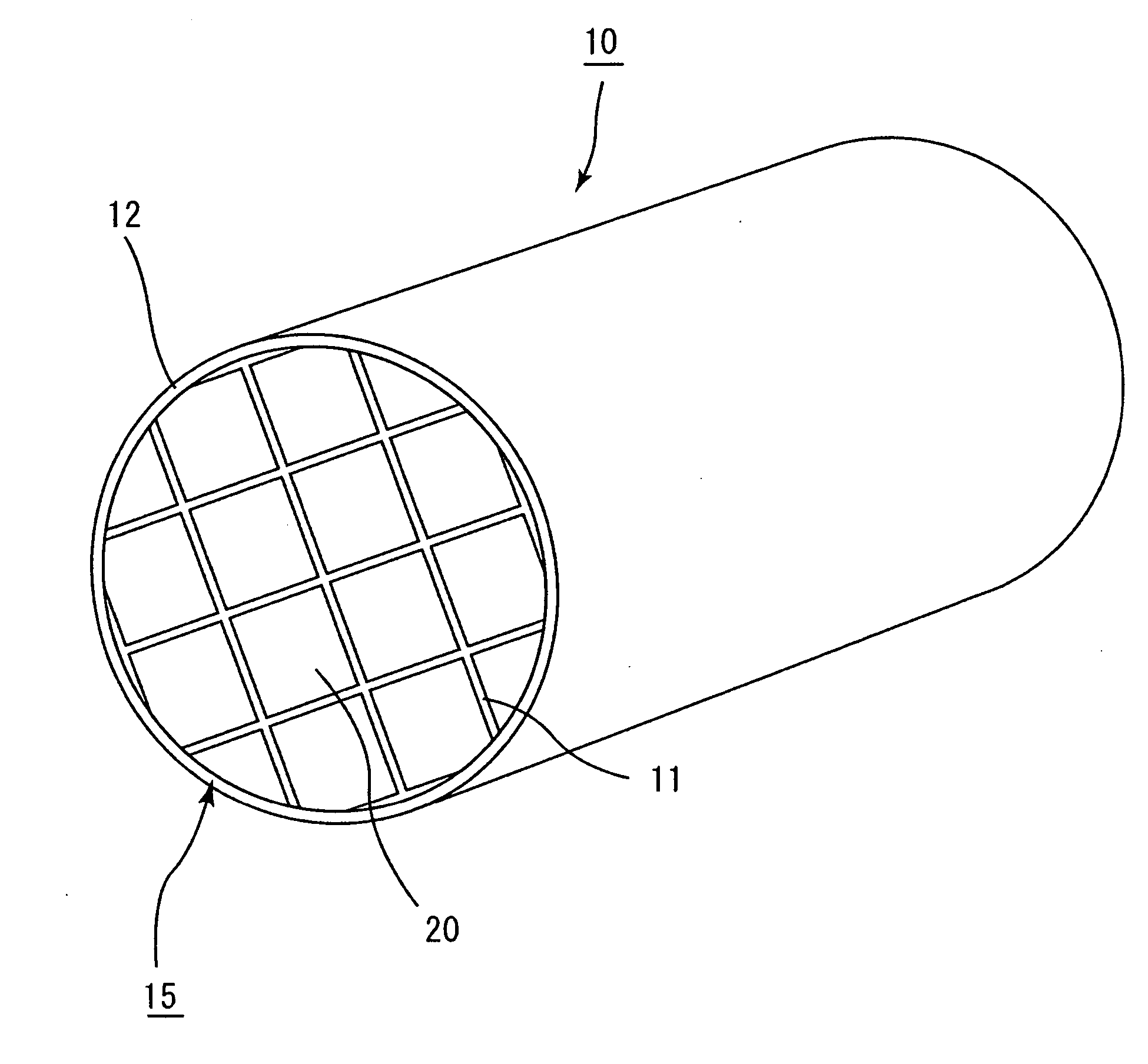

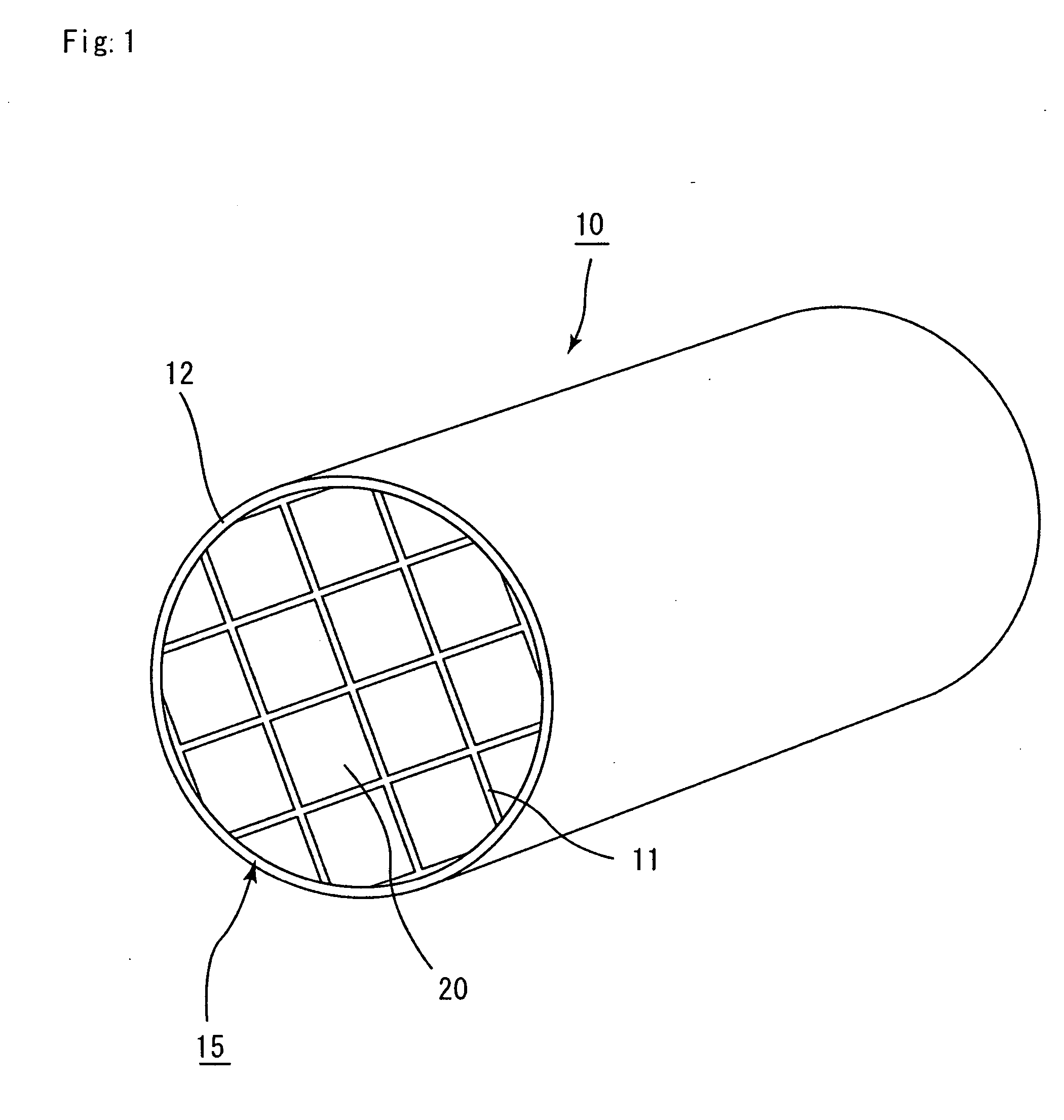

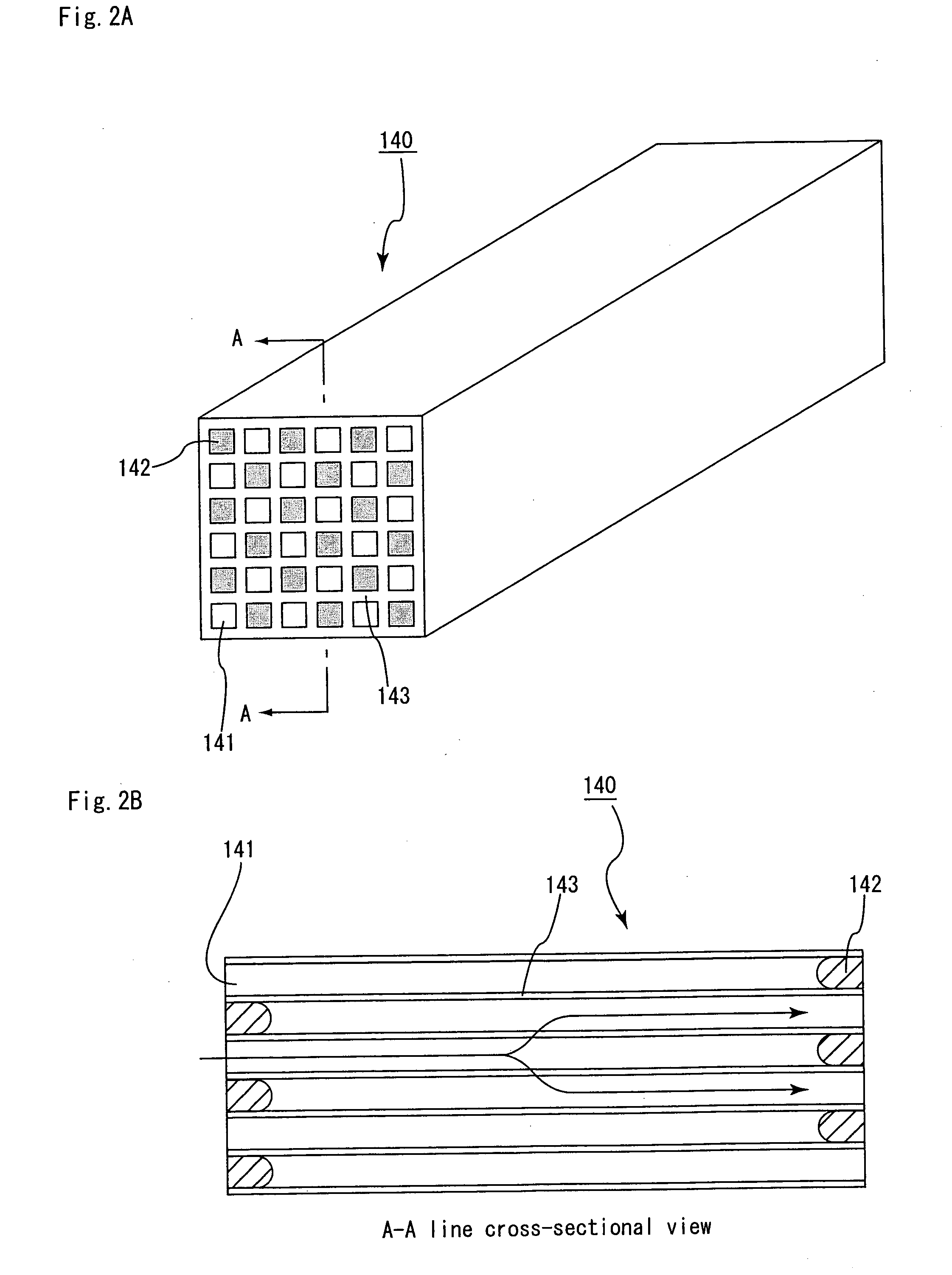

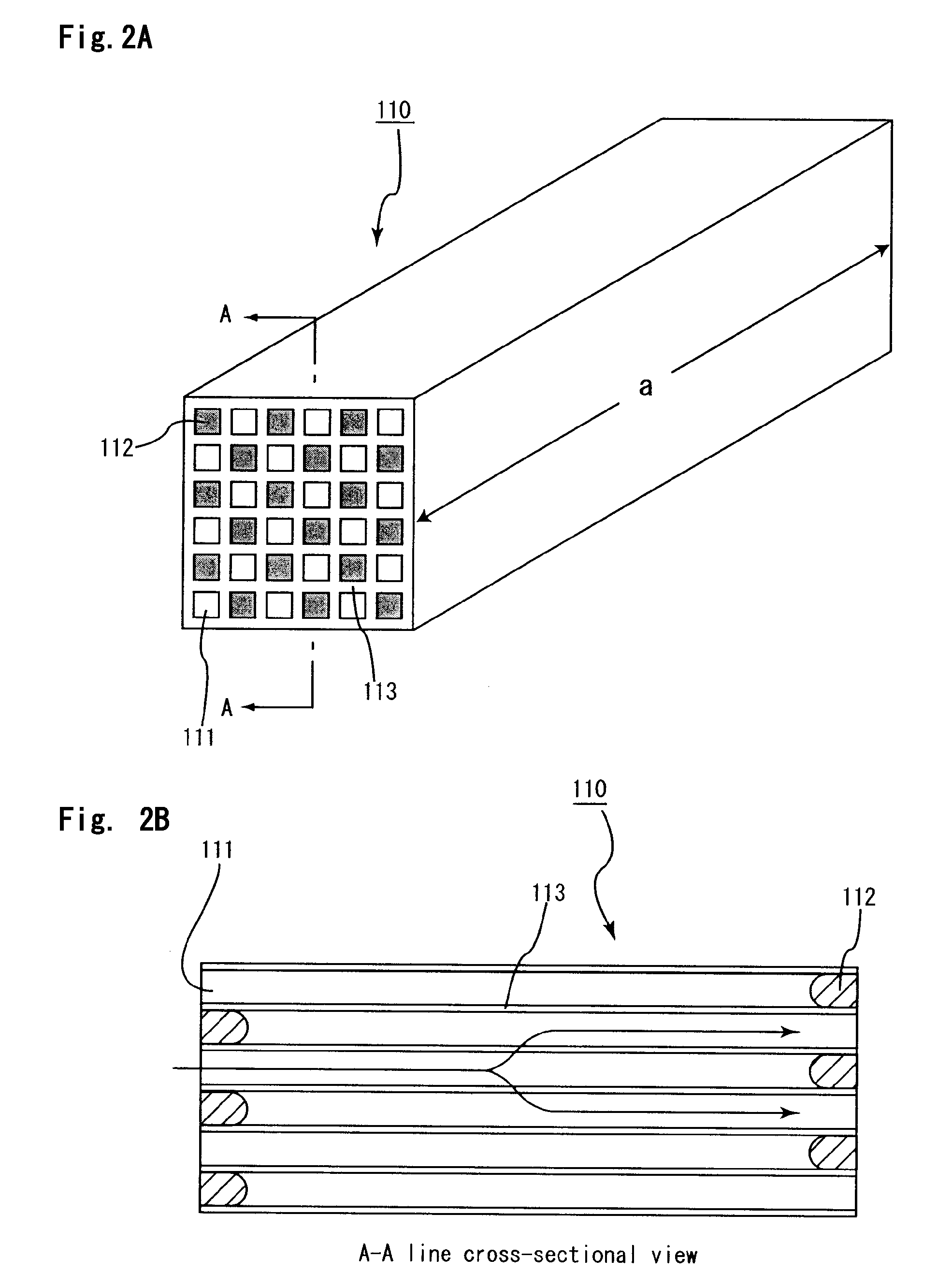

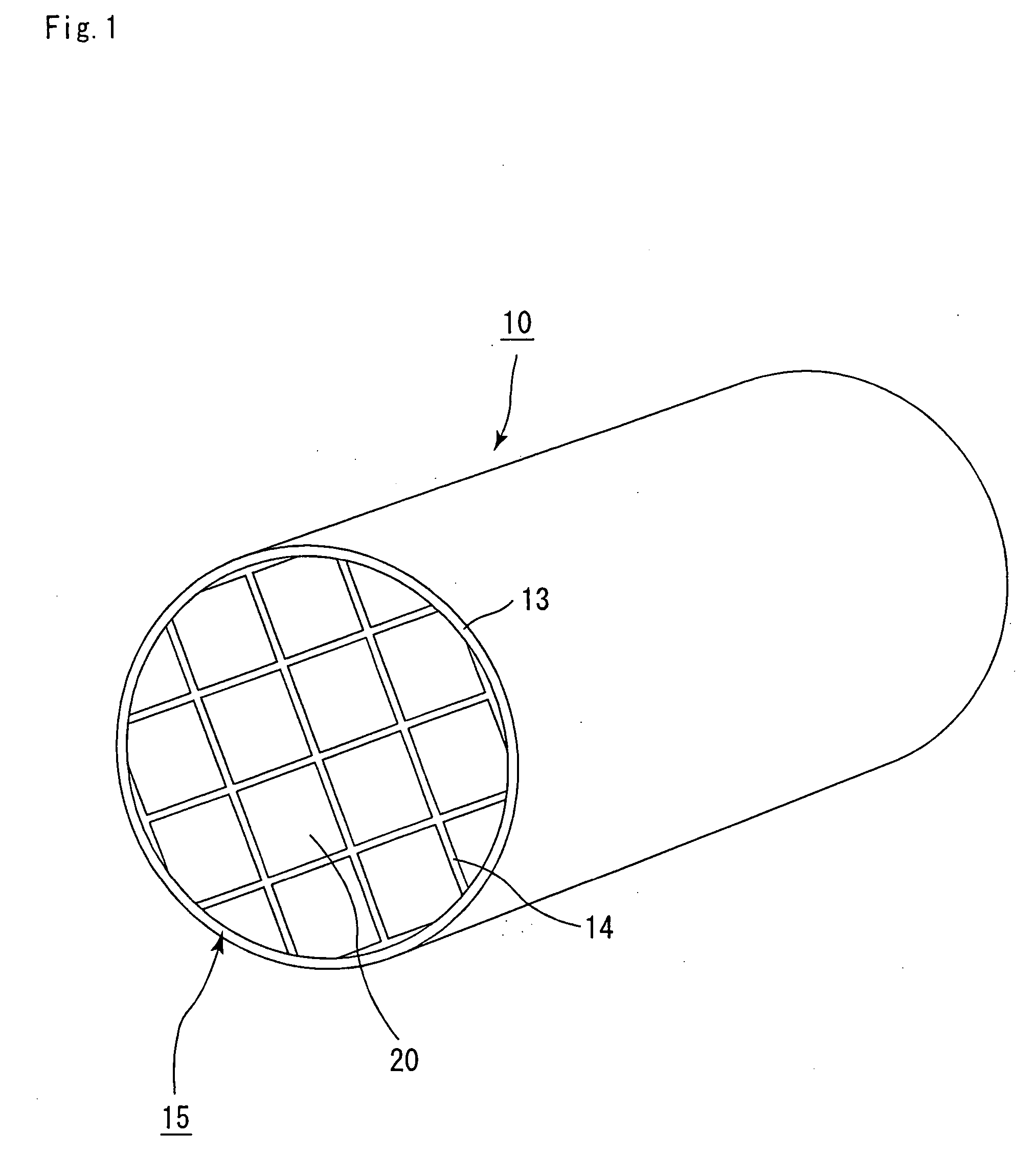

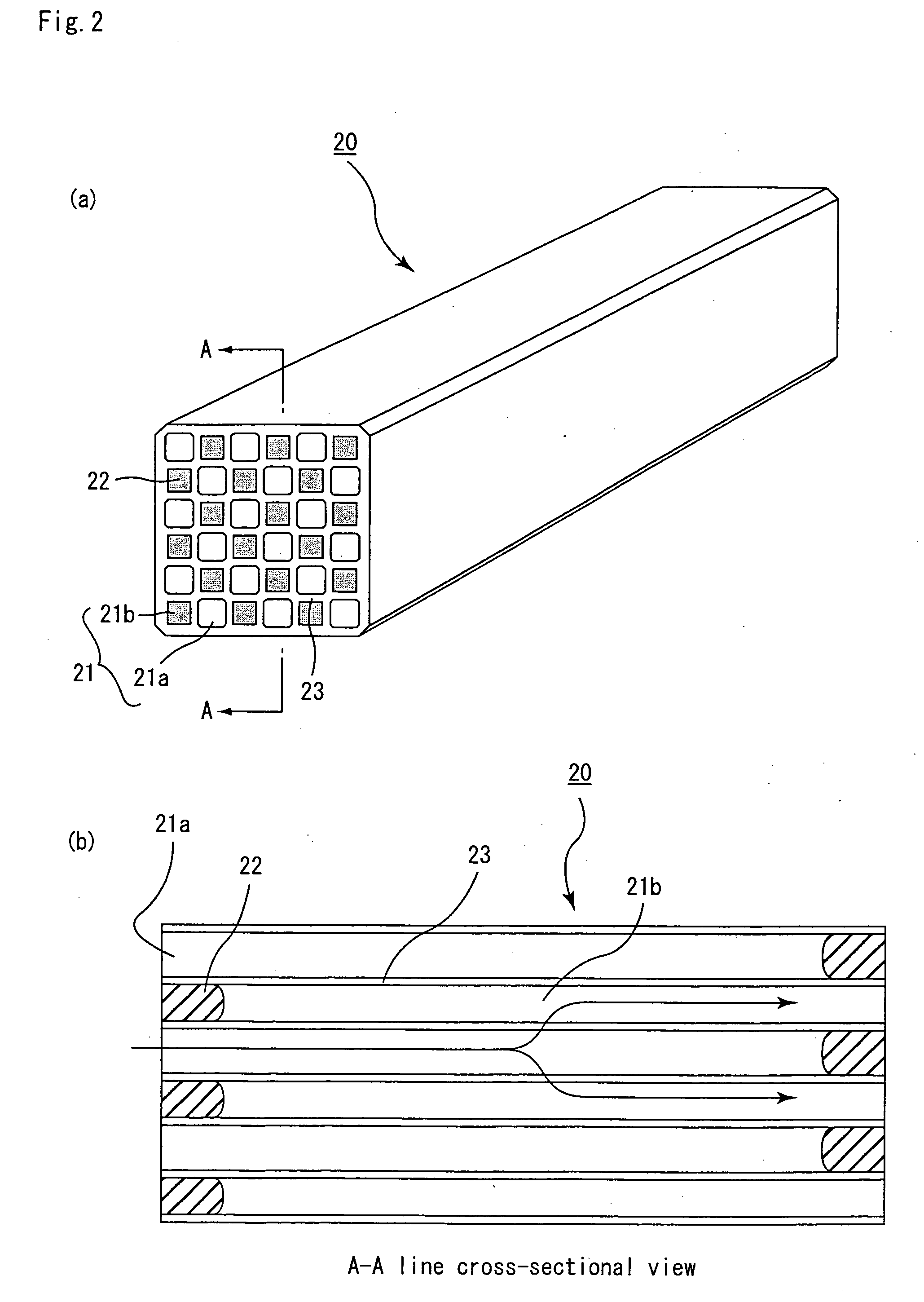

A honeycomb structure 10 of the present invention comprises: porous honeycomb units 11 having multiple through-holes, including the first form of an inorganic material (for example, ceramic particles), the second form of an inorganic material (for example, inorganic fibers or ceramic particles having large particle sizes), and an inorganic binder; and sealing material layers 14 jointing the porous honeycomb units 11 at outer surfaces 13 where the through-holes are not open. The cross-sectional area perpendicular to the through-holes is about 5 to about 50 cm2. The ratio of the total cross-sectional area of the porous honeycomb units 11 to the cross-sectional area of the honeycomb structure 10 is not less than about 85%. The honeycomb structure 10 reduces thermal stress or vibration applied to each porous honeycomb unit 11, by the sealing material layers 14, and allows for amore effective use of surface on which catalyst components are dispersed.

Owner:IBIDEN CO LTD

Honeycomb structured body

A honeycomb structured body of the present invention is a honeycomb structured body in which a plurality of porous ceramic members are combined with one another through an adhesive layer, each of the porous ceramic members having a plurality of cells which are allowed to penetrate in a longitudinal direction with a wall portion therebetween and either one end of which is sealed, with a catalyst supporting layer being adhered to the wall portion, wherein, supposing that the rate of the pore volume of pores having a pore diameter of 10 μm or less to the entire pore volume of the porous ceramic member is X1 (%), the porosity is Y1 (%) and the weight of the catalyst supporting layer is Z1 (g / l), these X1, Y1 and Z1 are allowed to satisfy the following expressions (1) and (2): X1≦20−Z1 / 10 (1), and Y1≧35+7Z1 / 40 (2) (where about 20≦Z1≦about 150).

Owner:IBIDEN CO LTD

Ceramic honeycomb structure

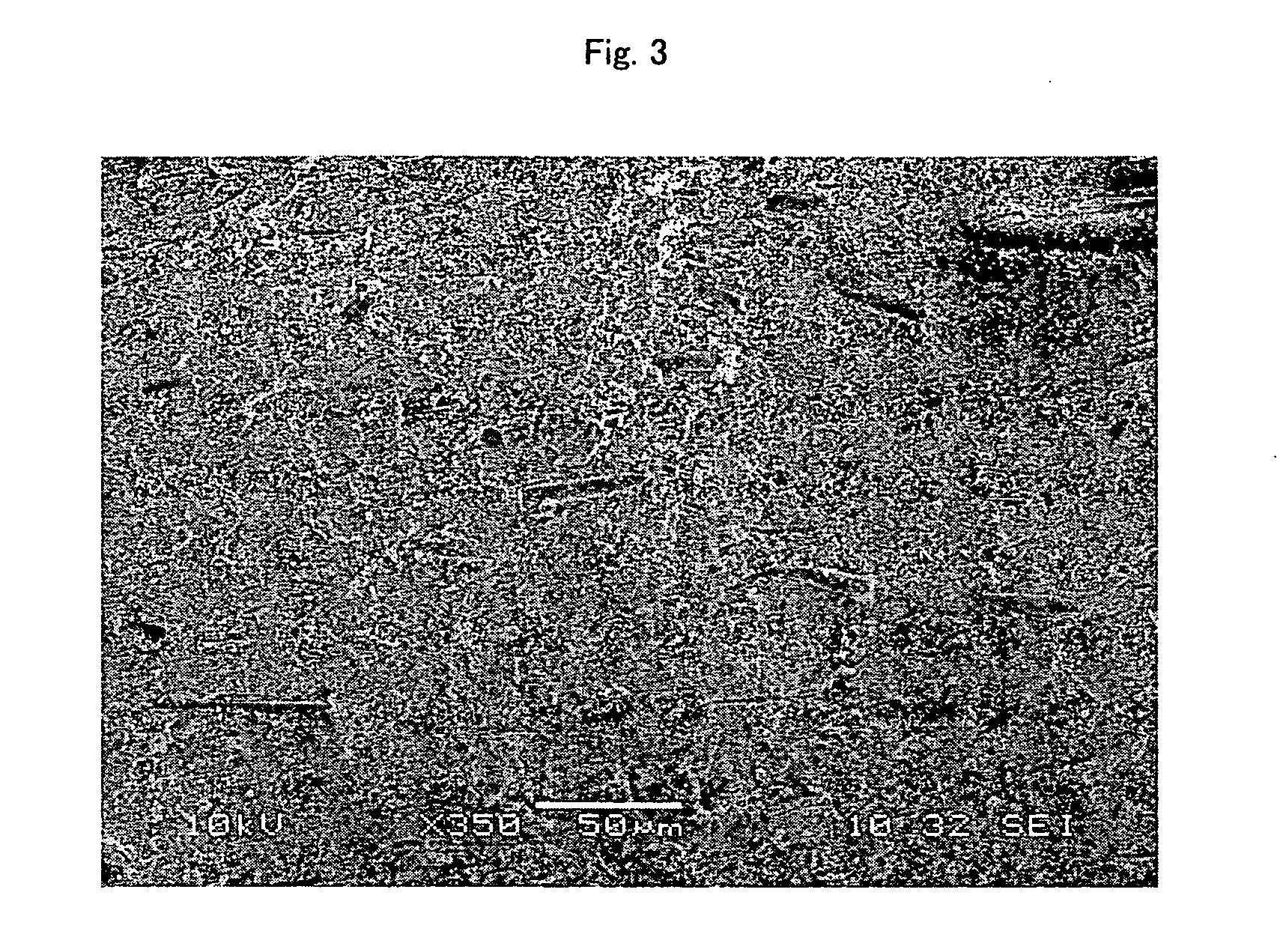

ActiveUS20060166820A1Excellent in pressure loss and catching efficiencyHigh catalytic activityDispersed particle filtrationExhaust apparatusPore distributionSurface roughness

A honeycomb structural body comprises one or plural pillar-shaped porous ceramic members in which many through-holes are arranged side by side in a longitudinal direction through partition walls and either one end portions of these through-holes are sealed. The partition wall forming the structural body has a surface roughness of not less than 10 μm as a maximum roughness Rz defined in JIS B0601-2001 and an average pore size of 5-100 μm in a pore distribution measured by a mercury pressure method, and satisfies the following relationship: A≧90−B / 20 or A≦100−B / 20 when a ratio pores having a pore size of 0.9-1.1 times the average pore size to total pore volume is A (%) and a thickness of the partition wall is B (μm), and there is proposed an effective honeycomb structural body having excellent pressure loss and catching efficiency and a high catalyst reactivity.

Owner:IBIDEN CO LTD

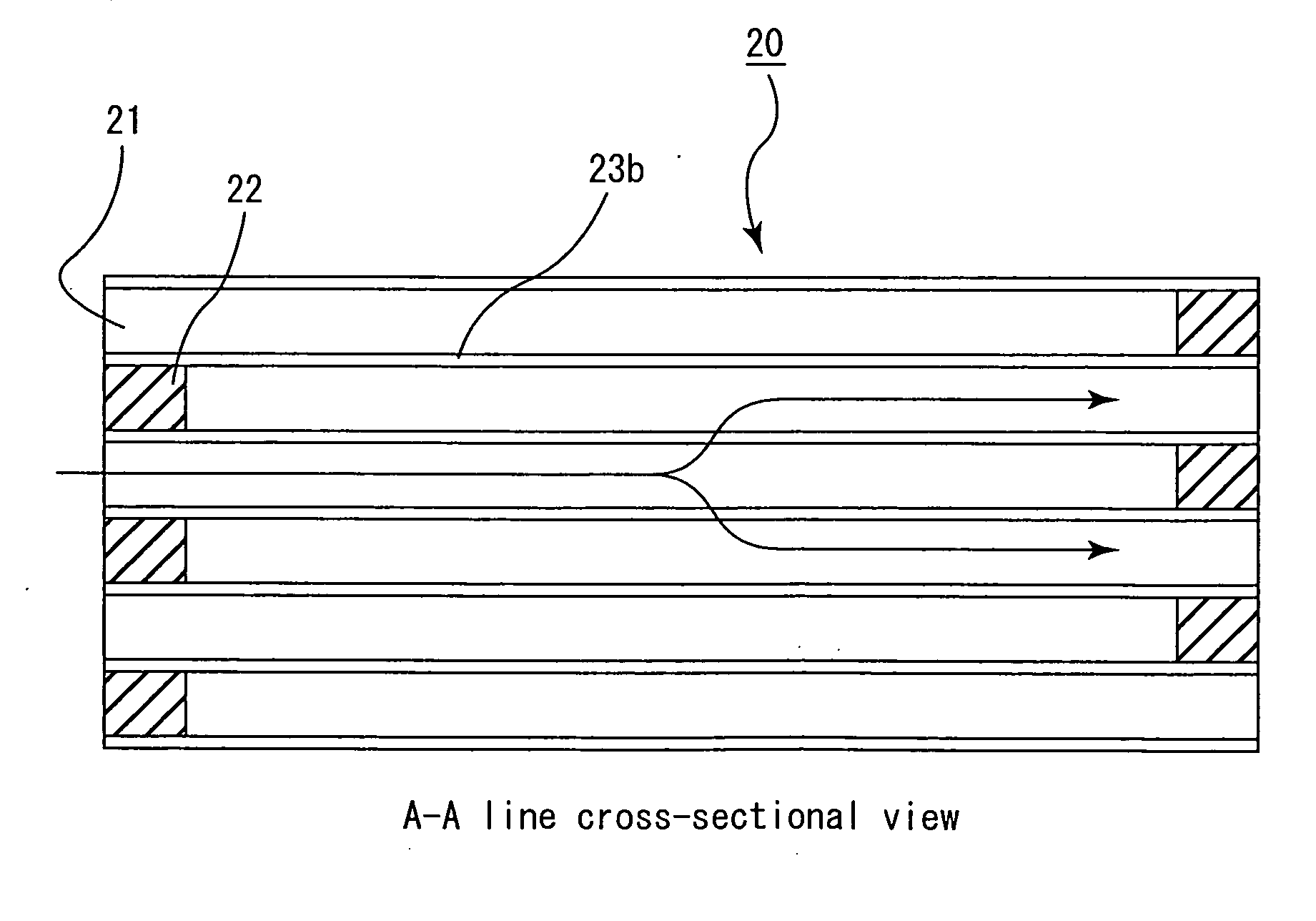

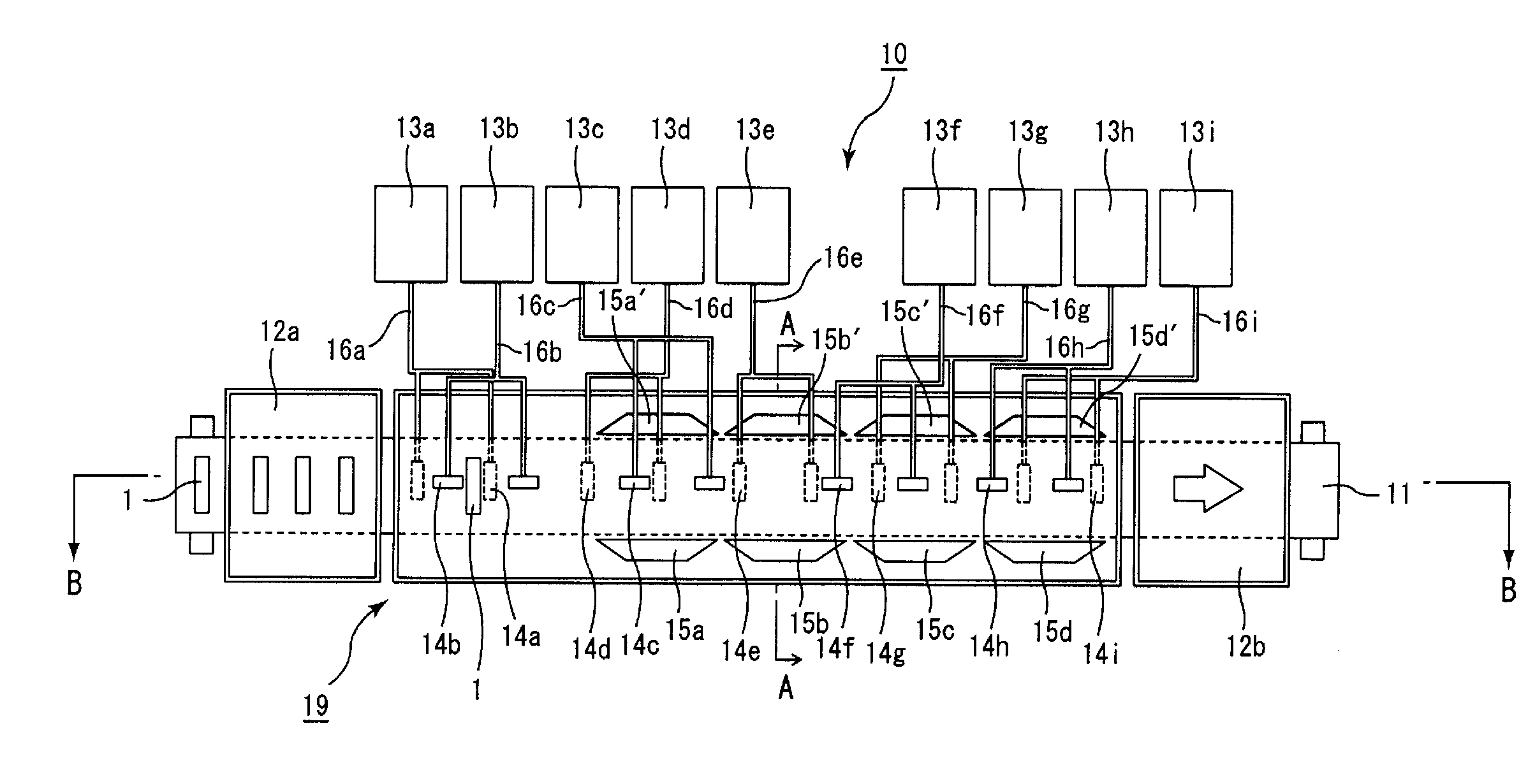

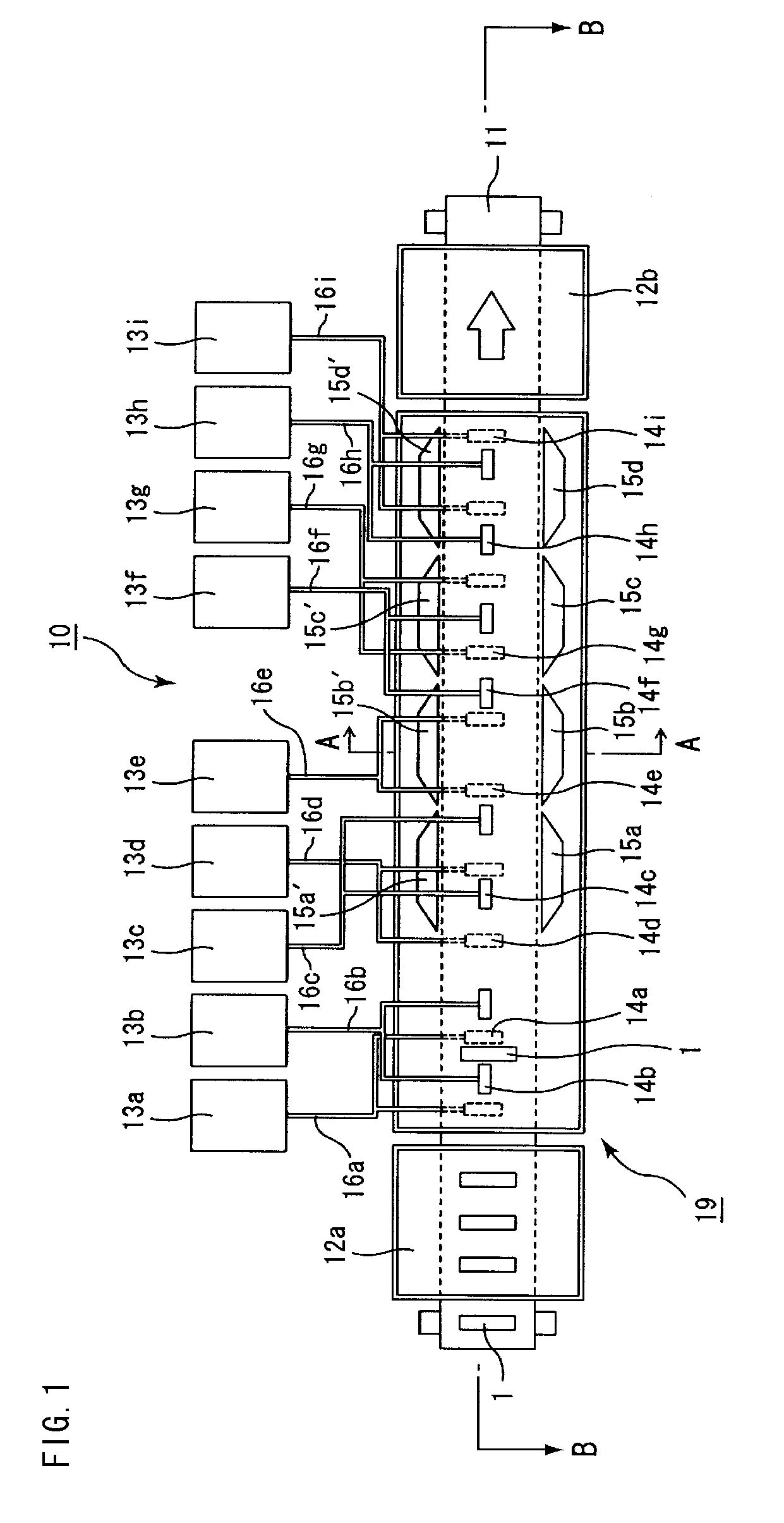

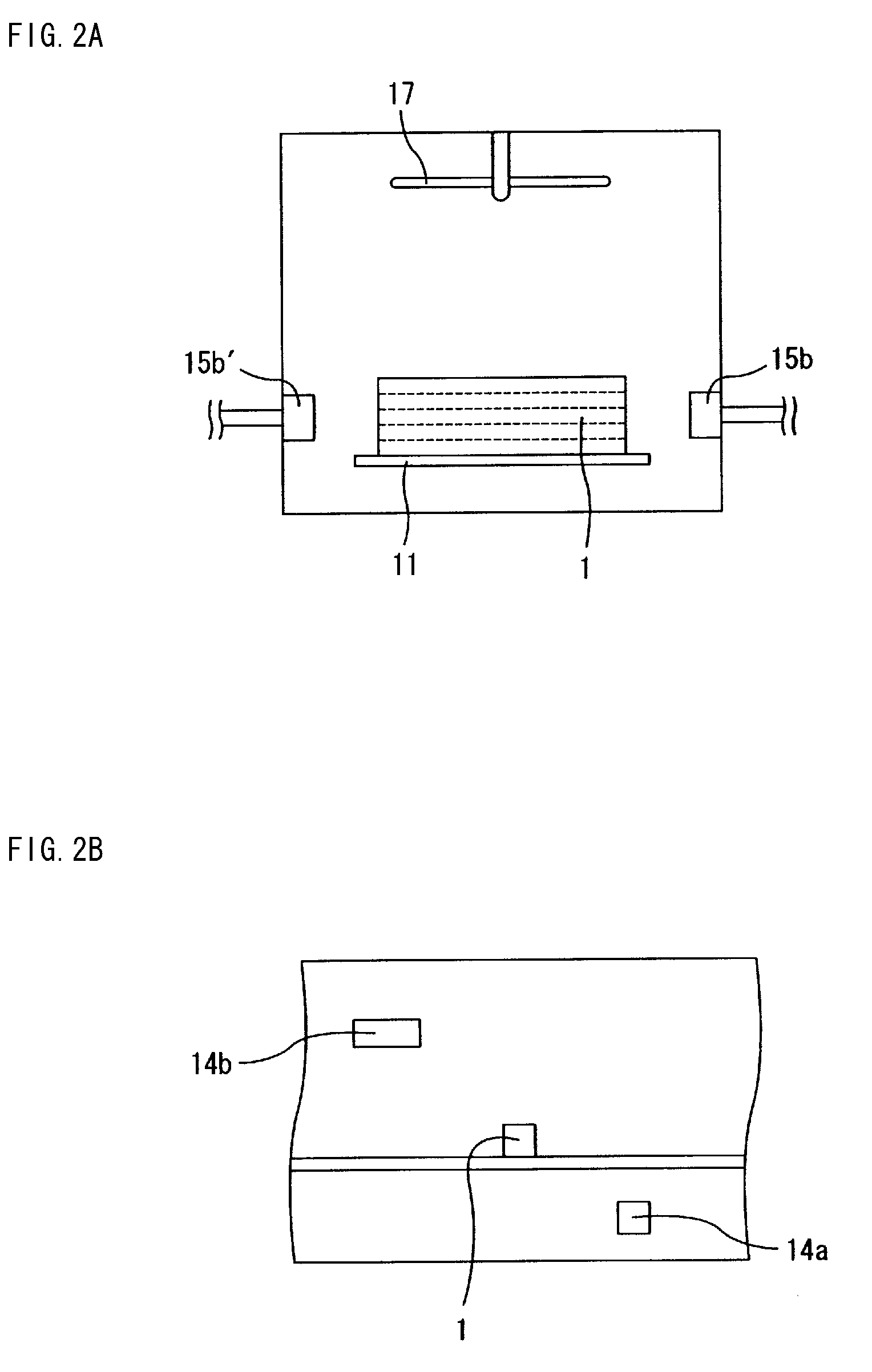

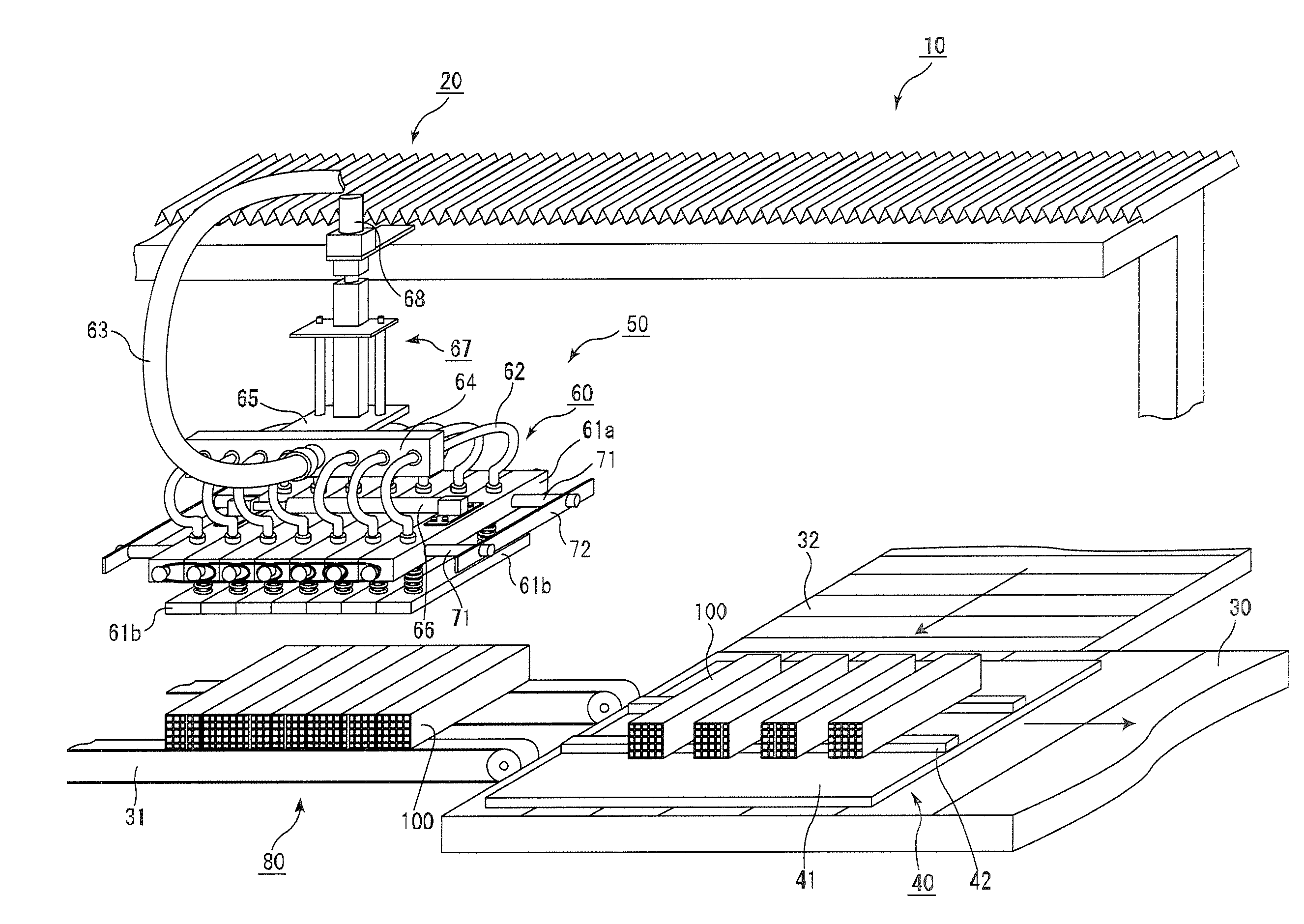

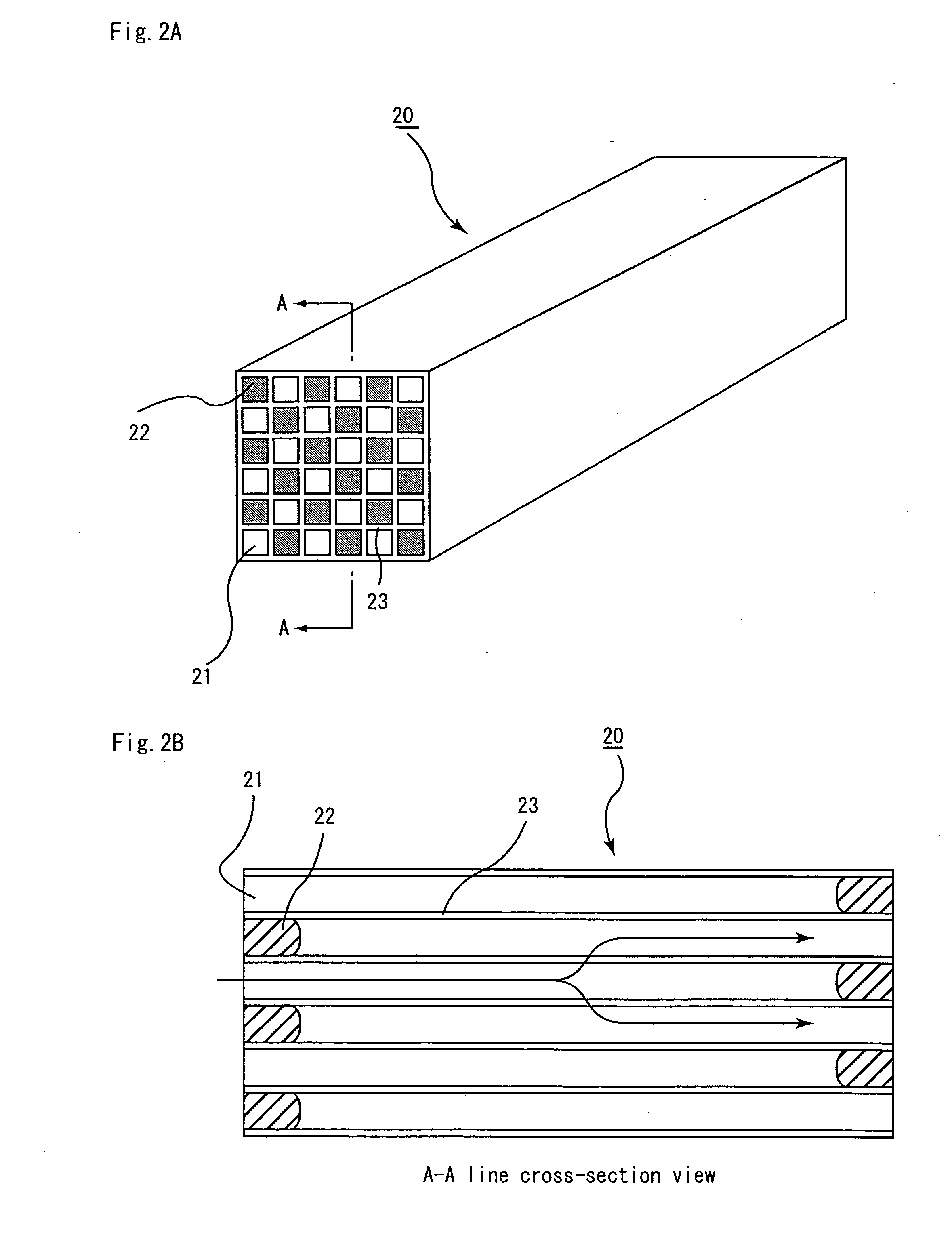

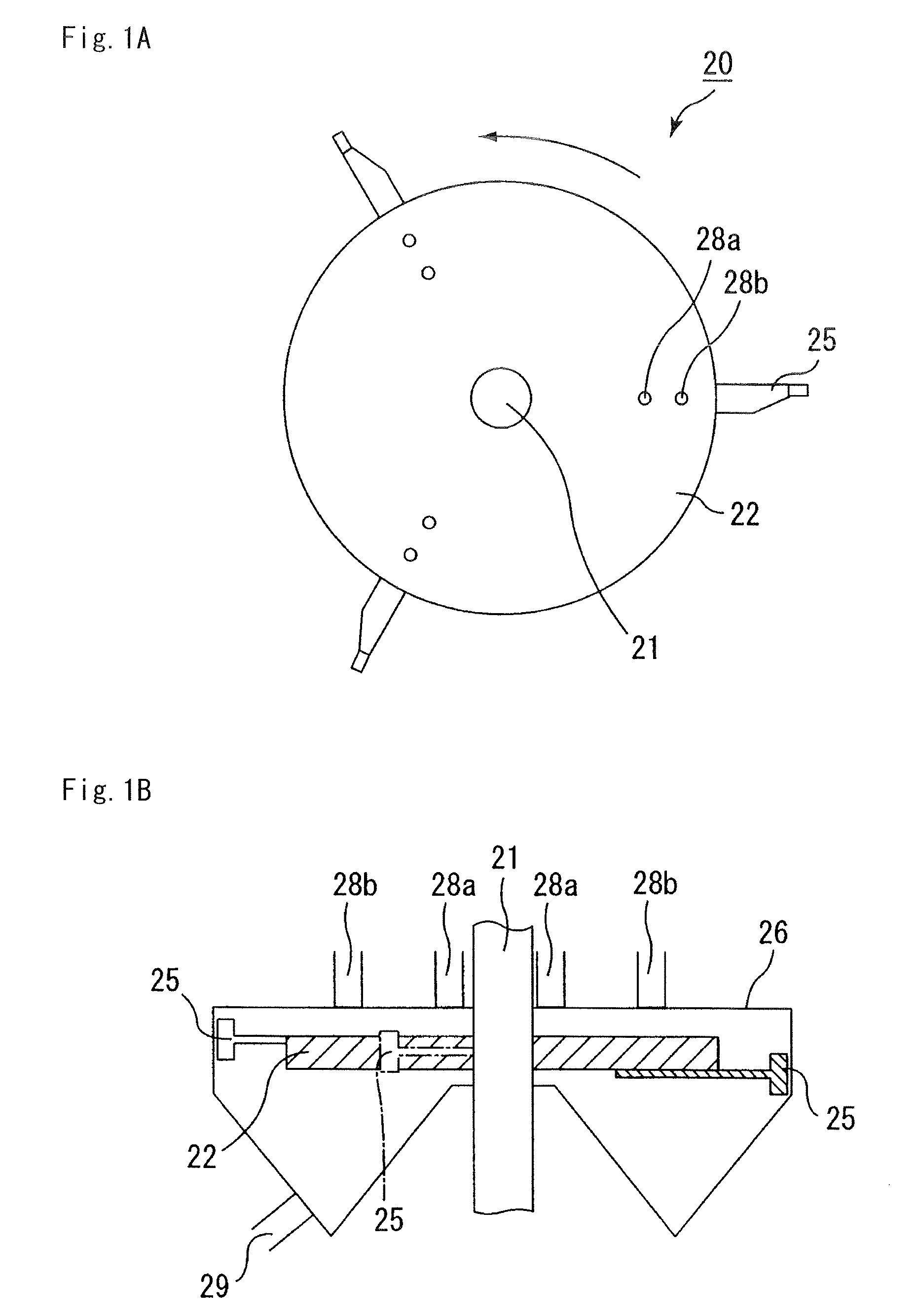

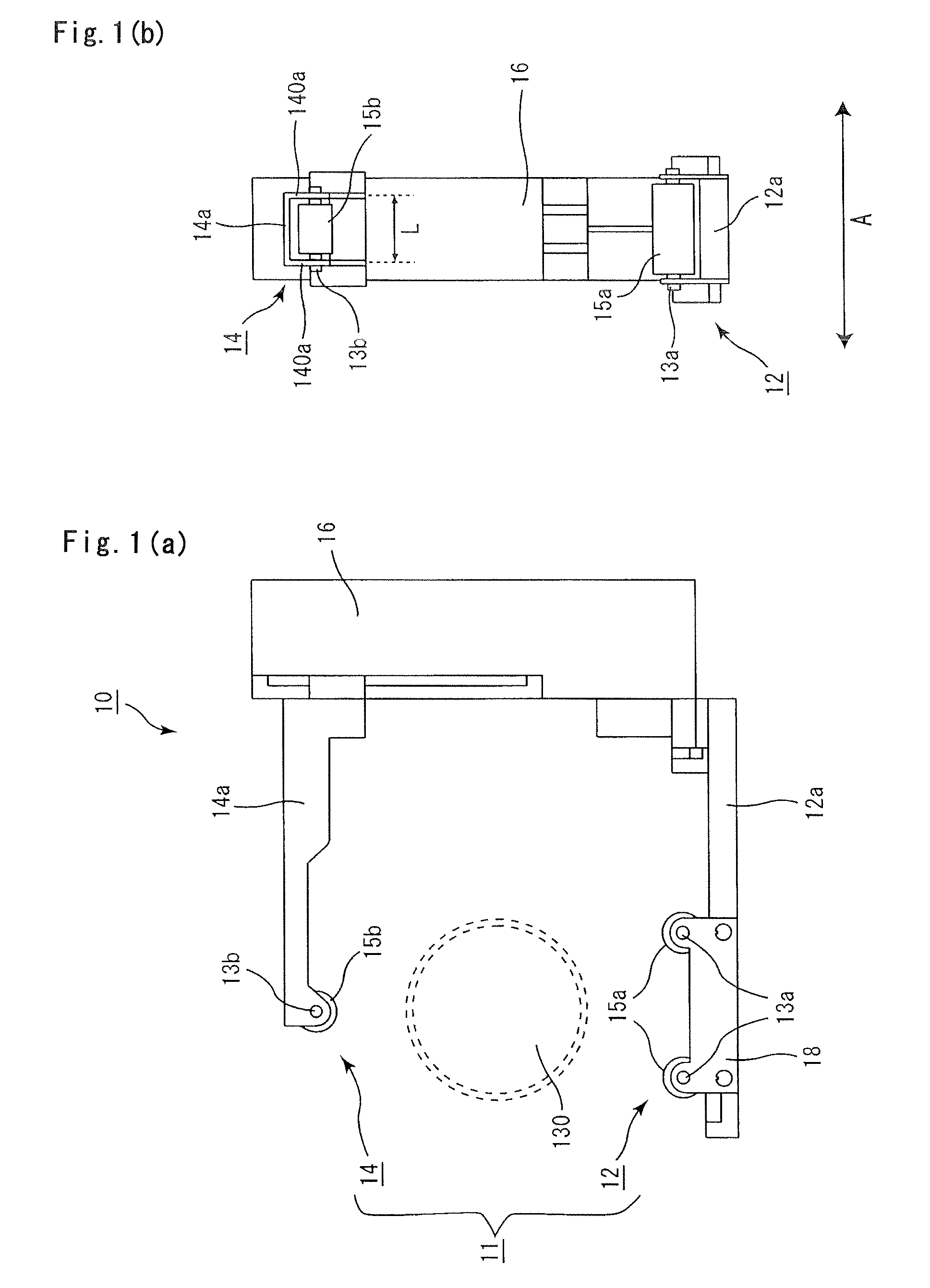

Drying apparatus, method for drying ceramic molded body, and method for manufacturing honeycomb structure

InactiveUS20080136062A1Remove moistureDrying solid materials with heatDrying gas arrangementsCeramic moldingIrradiation

A drying apparatus including a conveying member configured to convey an item to be dried, a plurality of microwave irradiation portions disposed alternately at an upper side and a lower side of the conveying member, and a plurality of hot air blowing portions. The microwave irradiation portions are configured to irradiate the item to be dried with microwaves in an alternating manner from the upper side and the lower side. The hot air blowing portions are configured to apply hot air to the item to be dried in parallel with irradiation of the microwaves by the microwave irradiation portions.

Owner:IBIDEN CO LTD

Method for manufacturing honeycomb structure and material composition for honeycomb fired body

InactiveUS20080067725A1Other chemical processesCeramic shaping apparatusChemical compositionHigh intensity

A method for manufacturing a honeycomb structure having a low pressure loss and a high strength includes preparing a material composition containing a silicon carbide powder, a binder and an additive; molding the material composition to manufacture a pillar-shaped honeycomb body molded having cells disposed in parallel with one another and in a longitudinal direction; carrying out a degreasing treatment on the honeycomb molded; and carrying out a firing treatment on the honeycomb degreased body to manufacture a honeycomb fired body. The silicon carbide powder of the material composition contains a silicon carbide coarse powder and a silicon carbide fine powder having an average particle diameter (D50) smaller than that of the silicon carbide coarse powder, and the additive contains a metal oxide power. An amount of the metal oxide powder in the material composition is in the range of about 0.8 to about 4.0% by weight.

Owner:IBIDEN CO LTD

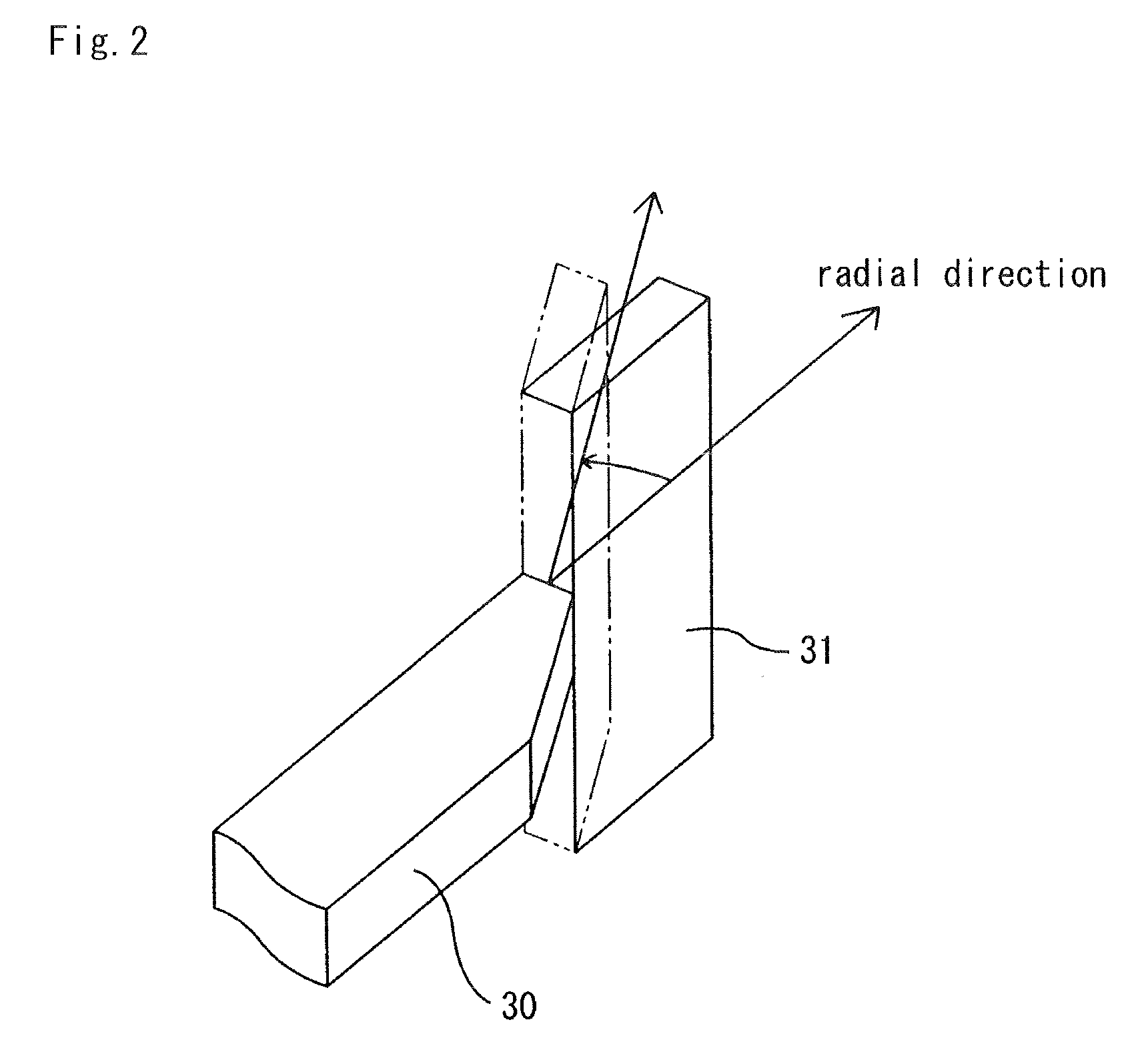

Manufacturing method of honeycomb structural body, and sealing material

ActiveUS20070126160A1Improve assembly effectAvoid separationExhaust apparatusConfectioneryHoneycomb structureRaw material

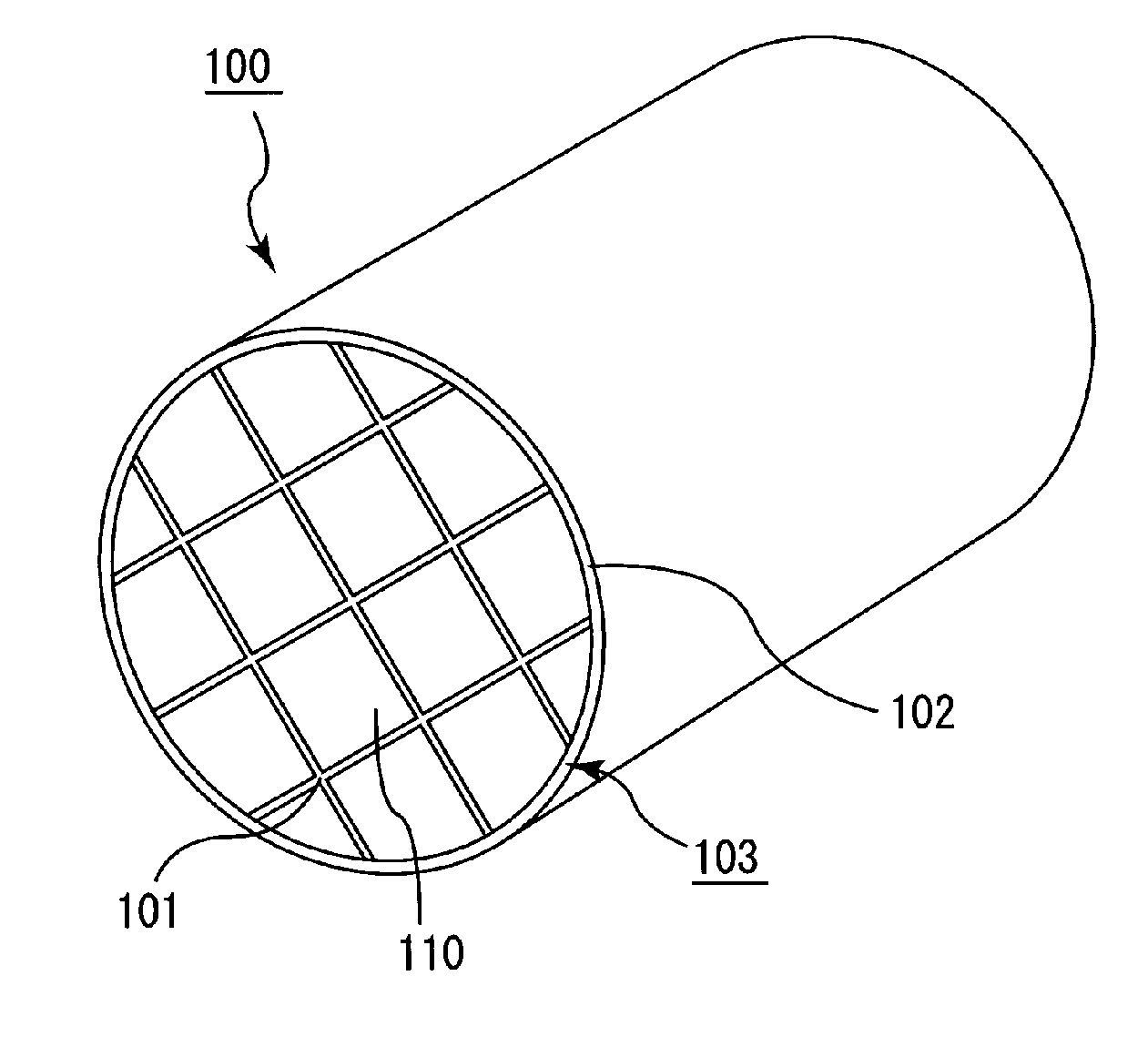

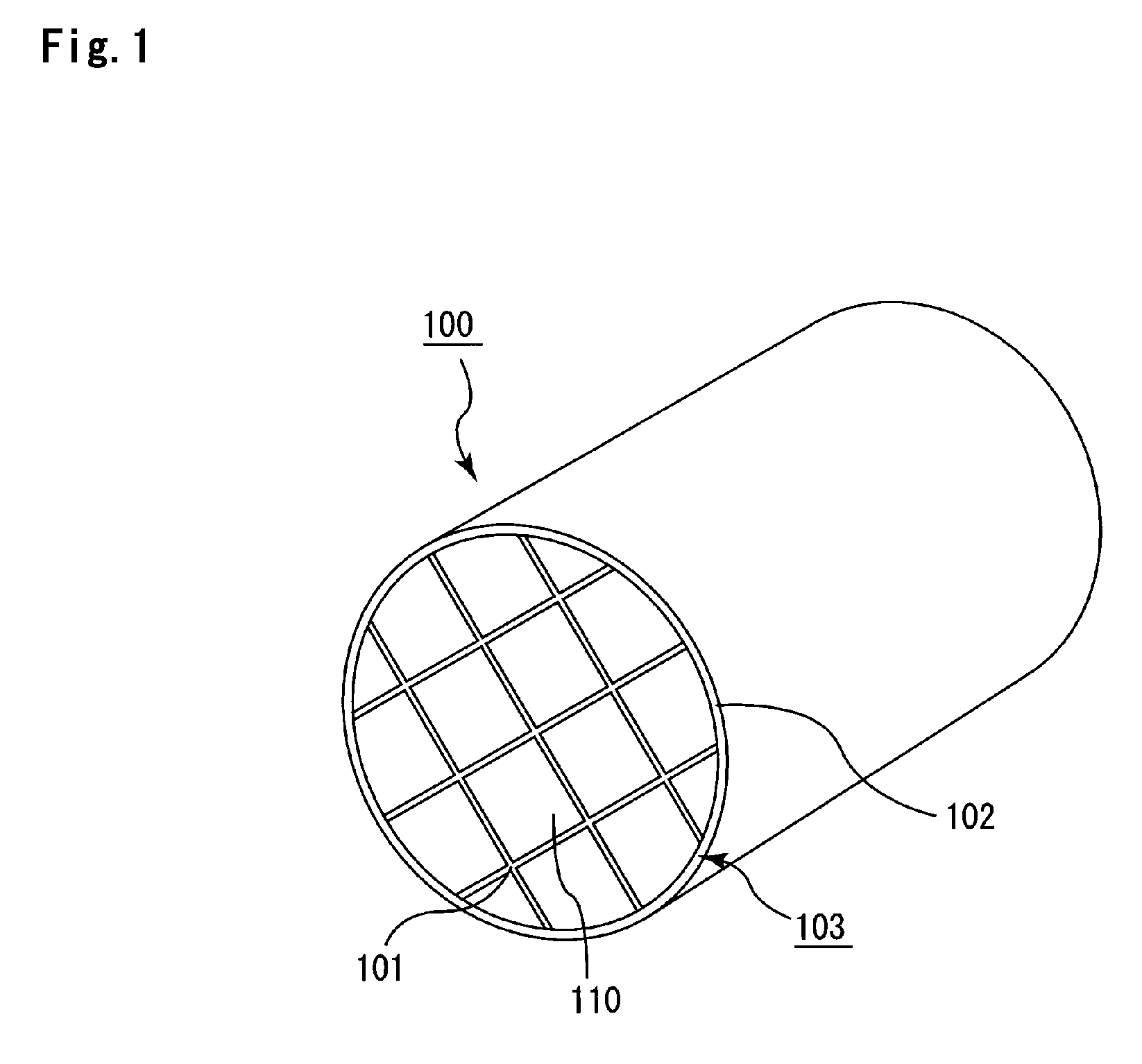

An object of the present invention is to provide a manufacturing method of a honeycomb structural body which makes the profile of a cross section perpendicular to the length direction thereof less likely to generate dispersion, and also makes the thickness of its sealing material layer thinner, and a sealing material that is suitably used in the manufacturing method of the honeycomb structural body. According to the present invention, the manufacturing method of a honeycomb structural body with a sealing material layer formed on the peripheral portion of a pillar-shaped porous honeycomb member includes a sealing material applying step of applying a paste-like sealing material, which is a raw material of the sealing material layer, onto a circumferential face of the pillar-shaped porous honeycomb member, and a scraping step of fitting a ring-shaped scraper, which can be brought into contact with the circumferential face of the pillar-shaped porous honeycomb member so as to slide thereon, to the pillar-shaped porous honeycomb member and moving said ring-shaped scraper in the length direction, thereby expanding the paste-like sealing material applied onto the circumferential face of the pillar-shaped porous honeycomb member so as to spread over the entire circumferential face of the pillar-shaped porous honeycomb member.

Owner:IBIDEN CO LTD

Honeycomb structure body

InactiveUS20060073970A1Distinguish clearlyInternal combustion piston enginesDispersed particle filtrationExternal combustion engineEngineering

An object of the present invention is to provide a honeycomb structural body which is inserted, for use, into a pipe forming an exhaust passage of an internal combustion engine, and makes it possible to clearly distinguish an exhaust gas flow-in side and an exhaust gas flow-out side. The present invention is directed to a columnar honeycomb structural body comprising porous ceramics each including a number of through holes that are placed in parallel with one another in the length direction with a wall portion interposed therebetween, wherein information regarding the honeycomb structural body is displayed on a circumferential surface and / or an end face thereof.

Owner:IBIDEN CO LTD

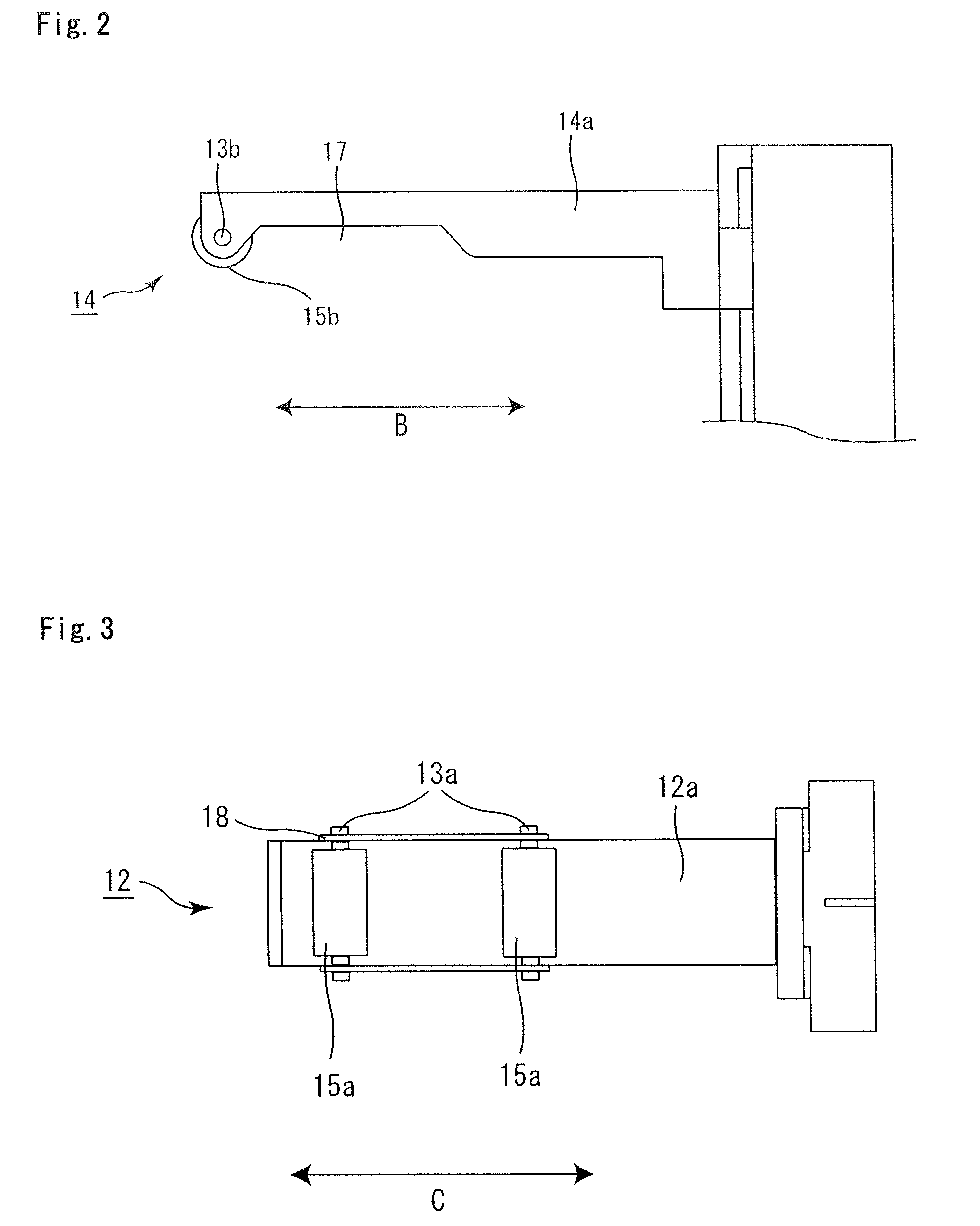

Degreasing furnace loading apparatus, and method for manufacturing honeycomb structure

A degreasing furnace loading apparatus including a molded body moving mechanism configured to move a plurality of ceramic molded bodies simultaneously, and a transporting table configured to transport a degreasing jig for mounting the ceramic molded bodies thereon to a degreasing furnace. The molded body moving mechanism is configured to simultaneously place the plurality of ceramic molded bodies on the degreasing jig, such that each of the ceramic molded bodies is placed to have predetermined intervals therebetween.

Owner:IBIDEN CO LTD

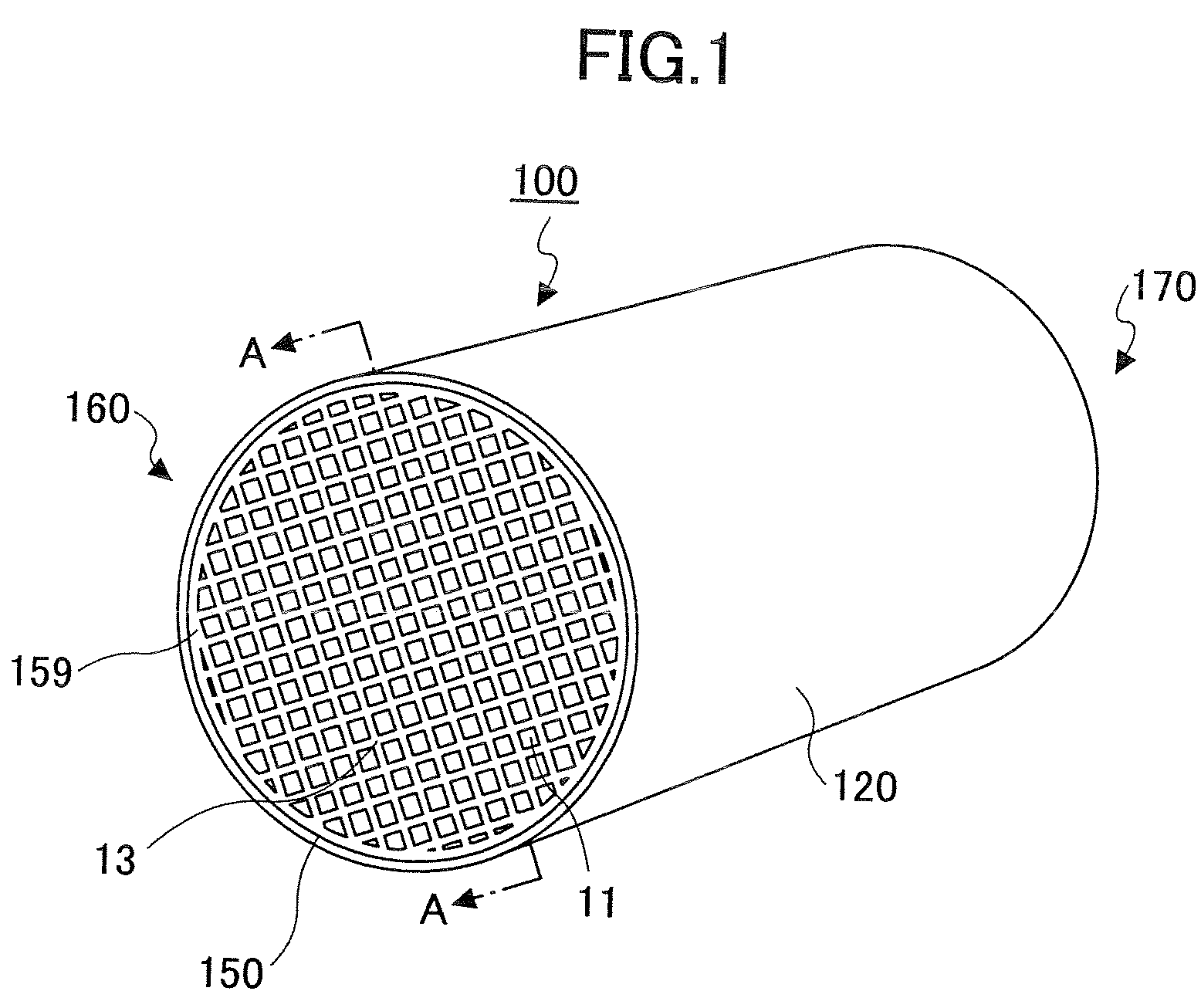

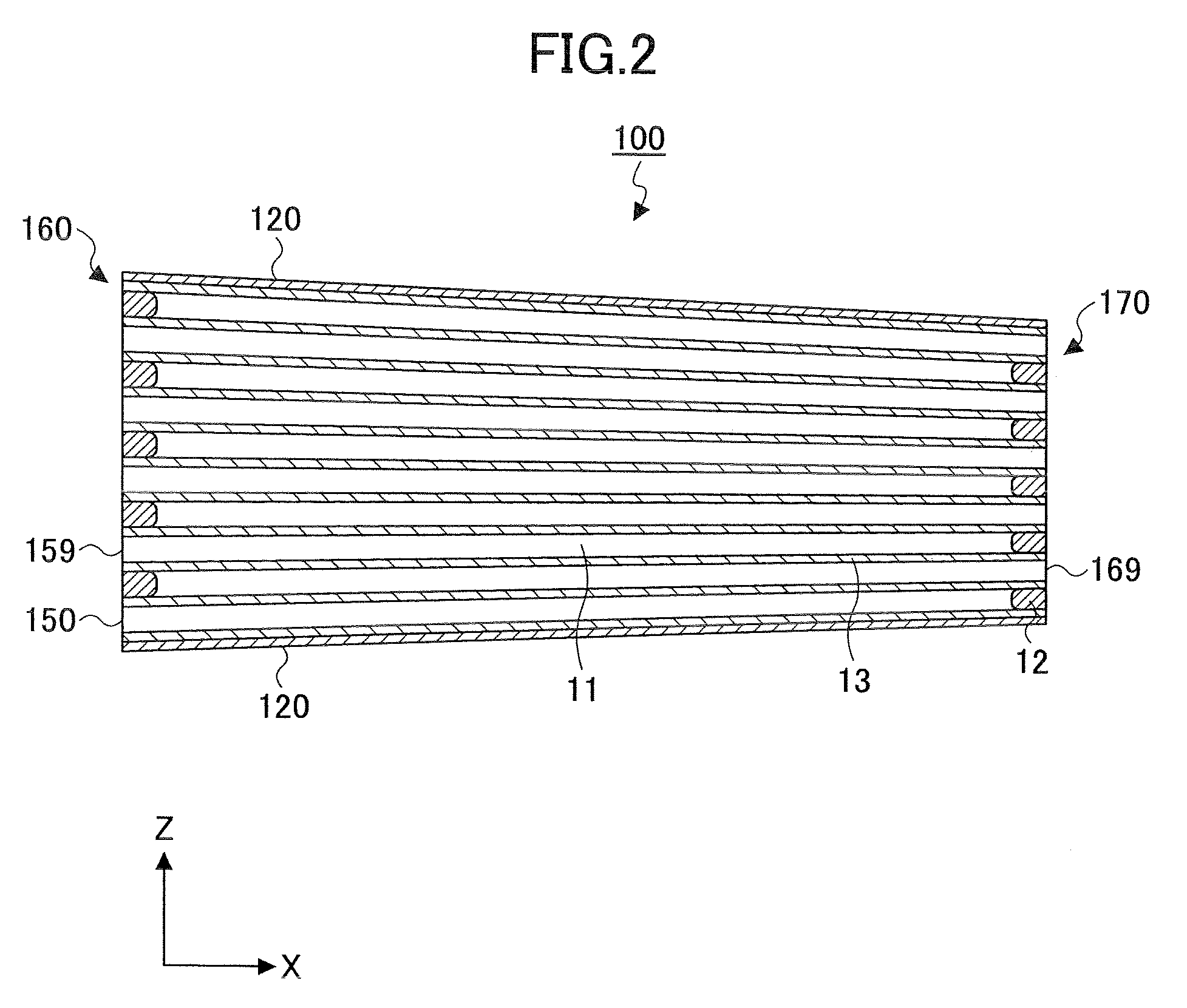

Honeycomb structural body, manufacturing method of the honeycomb structural body, and exhaust gas purifying device

ActiveUS20050229565A1High strengthIncreased durabilityCombination devicesCatalyst protectionLeast squaresHoneycomb structure

A honeycomb structural body comprising: a pillar-shaped ceramic block and a sealing material provided on an outer peripheral portion of said ceramic block, each of them having irregularities formed on an outer peripheral face wherein: when a least square curve is determined by a least square method on the basis of points constituting the contour of a cross-section, a center-of-gravity is defined as c1, a distance between a minimum concentric circumscribed curve having c1 and the center-of-gravity c1 is defined as D1, a distance between a maximum concentric inscribed curve having c1 and the center-of-gravity c1 is defined as D2, and the following inequality is satisfied: about 0.3 mm≦(D1−D2); same definition is applied to said ceramic block, a center-of-gravity thereof is defined as c2, a distance between a minimum concentric circumscribed curve having c2 and the center-of-gravity c2 is defined as D3, a distance between a maximum concentric inscribed curve having c2 and the center-of-gravity c2 is defined as D4, and the following inequality is satisfied: about 0.5 mm≦(D3−D4)≦about 7.0 mm.

Owner:IBIDEN CO LTD

Honeycomb structured body

Owner:IBIDEN CO LTD

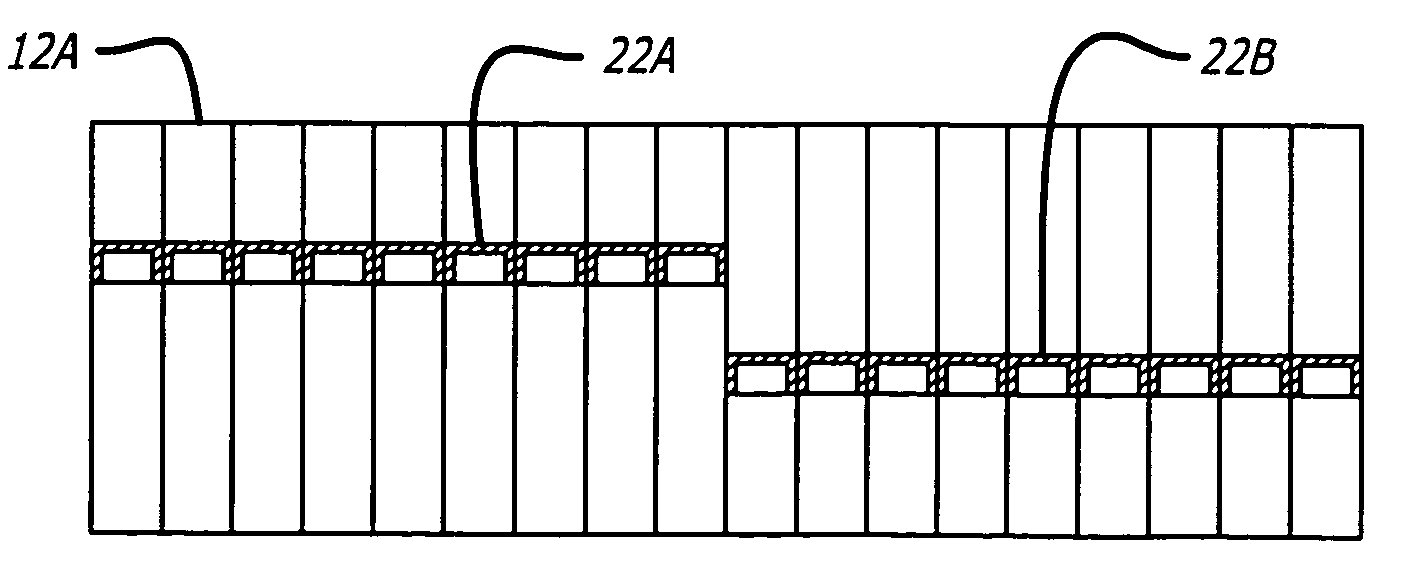

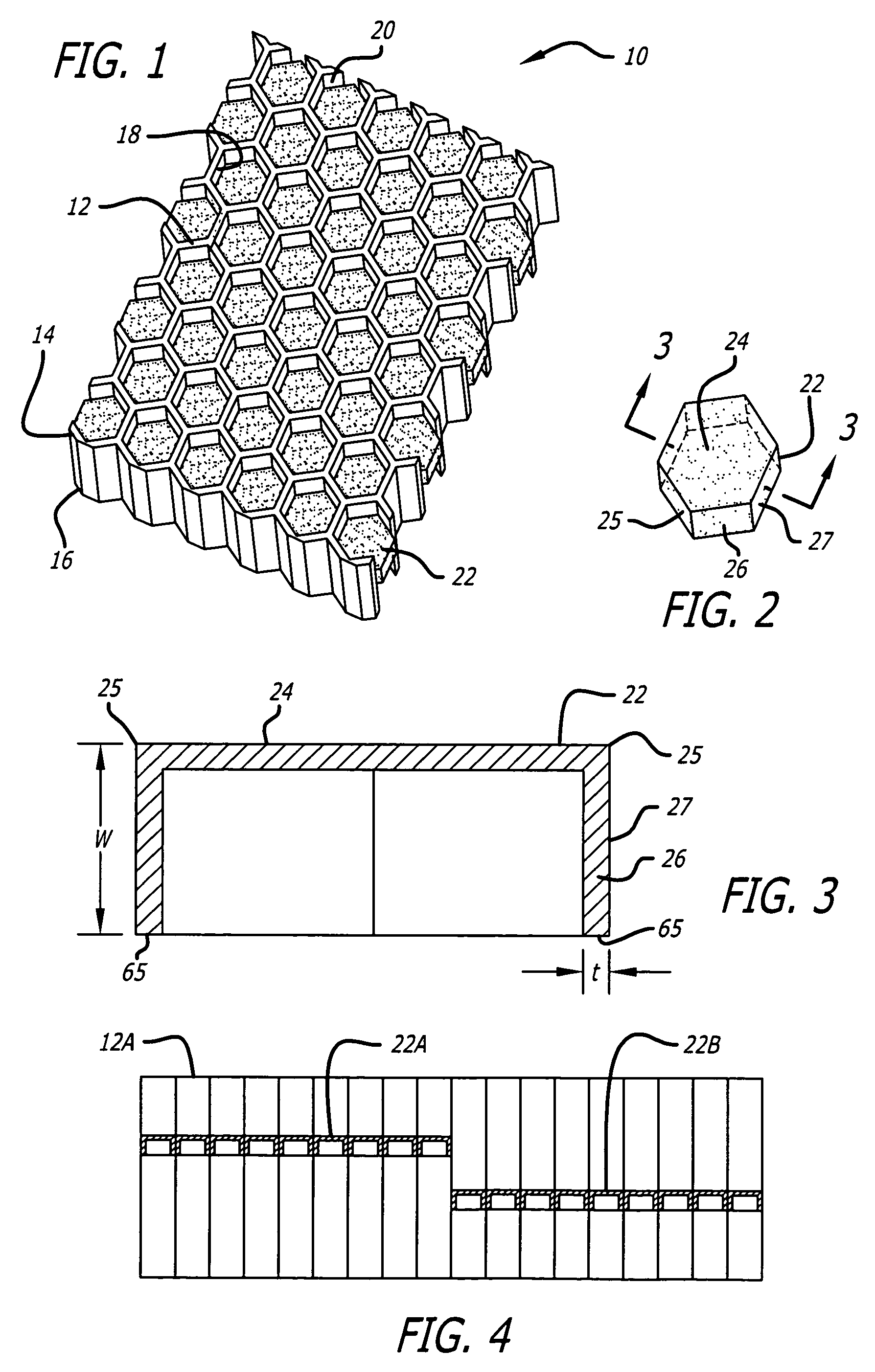

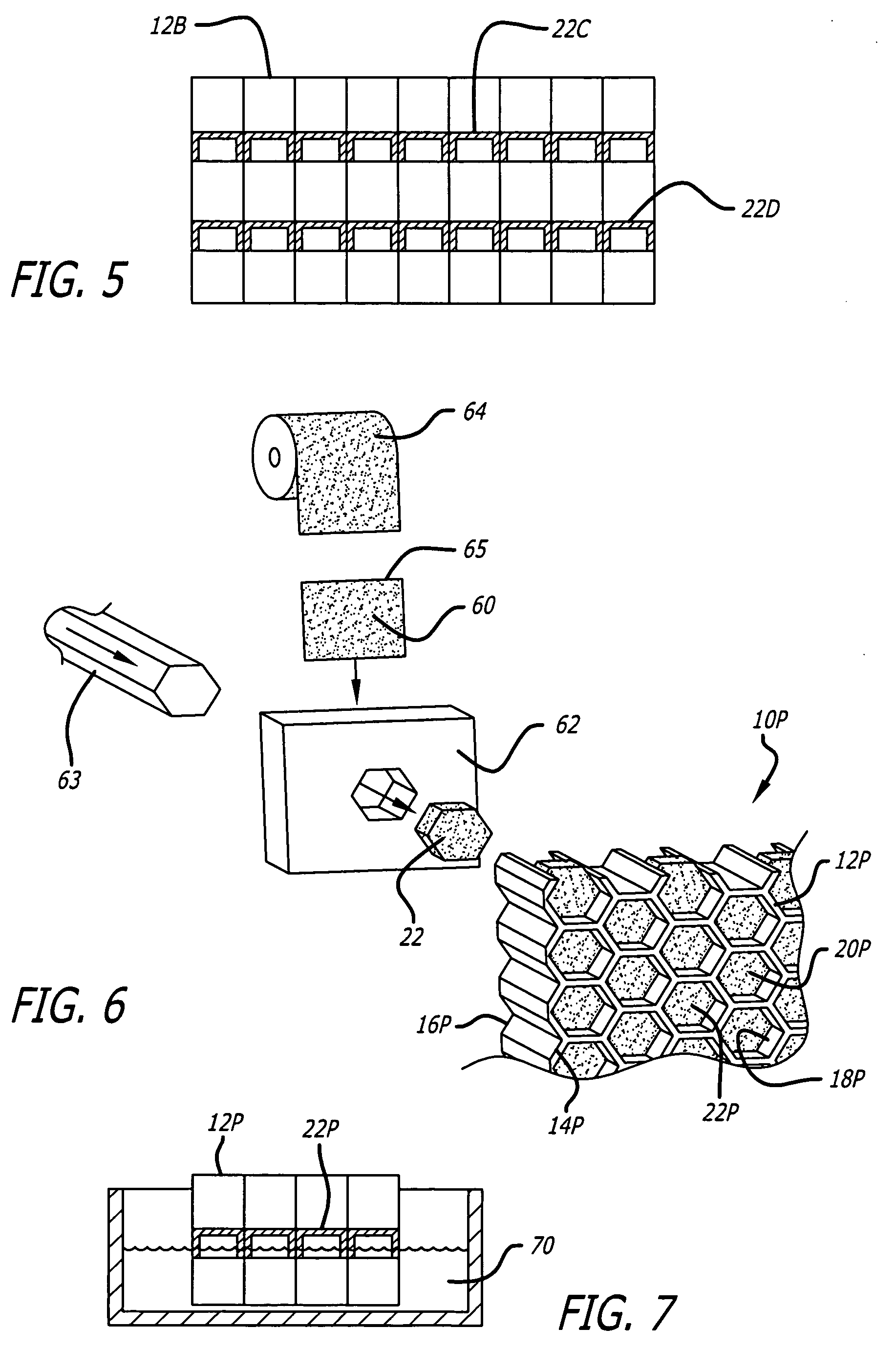

Acoustic septum cap honeycomb

Owner:HEXCEL

Vacuum insulation panel

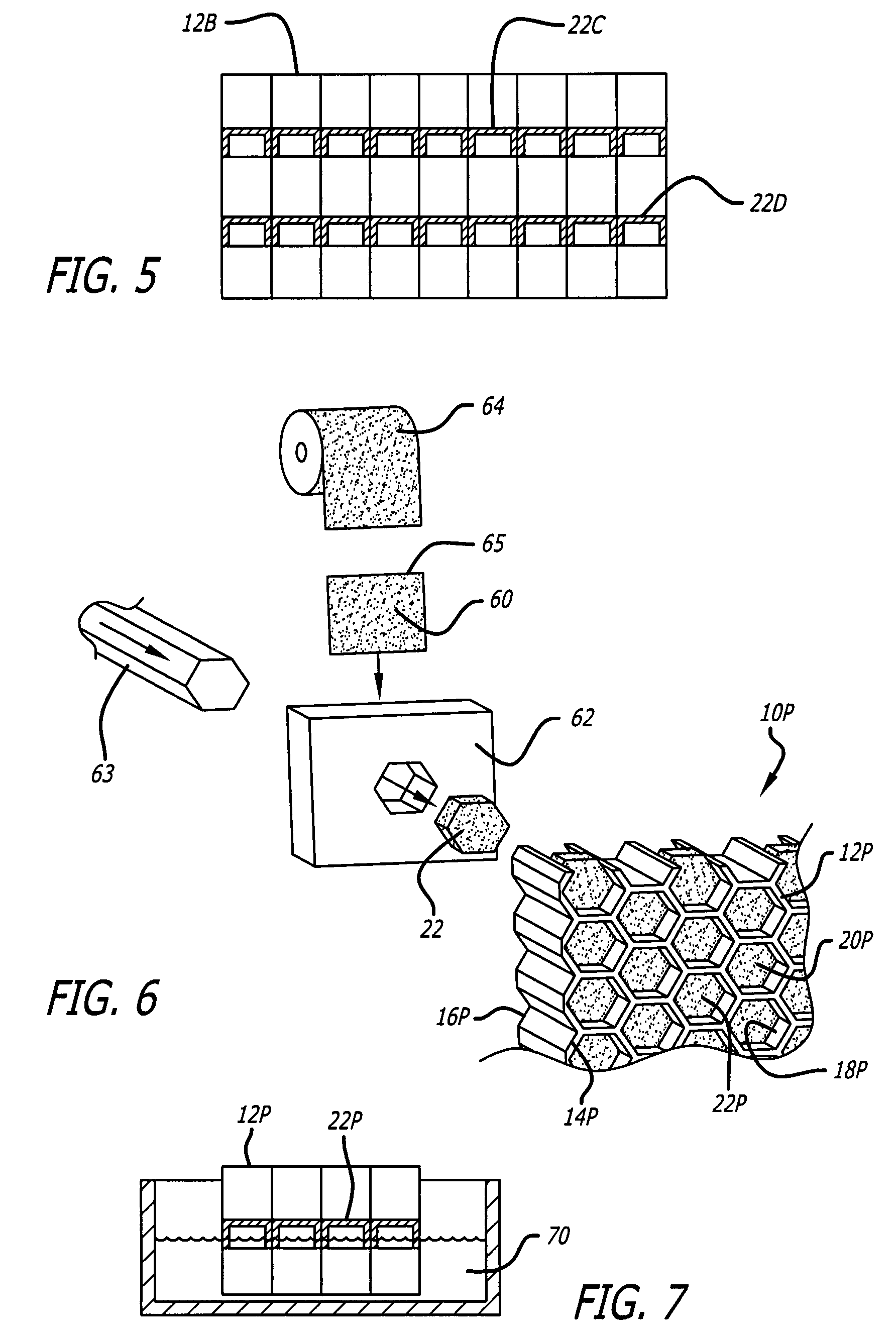

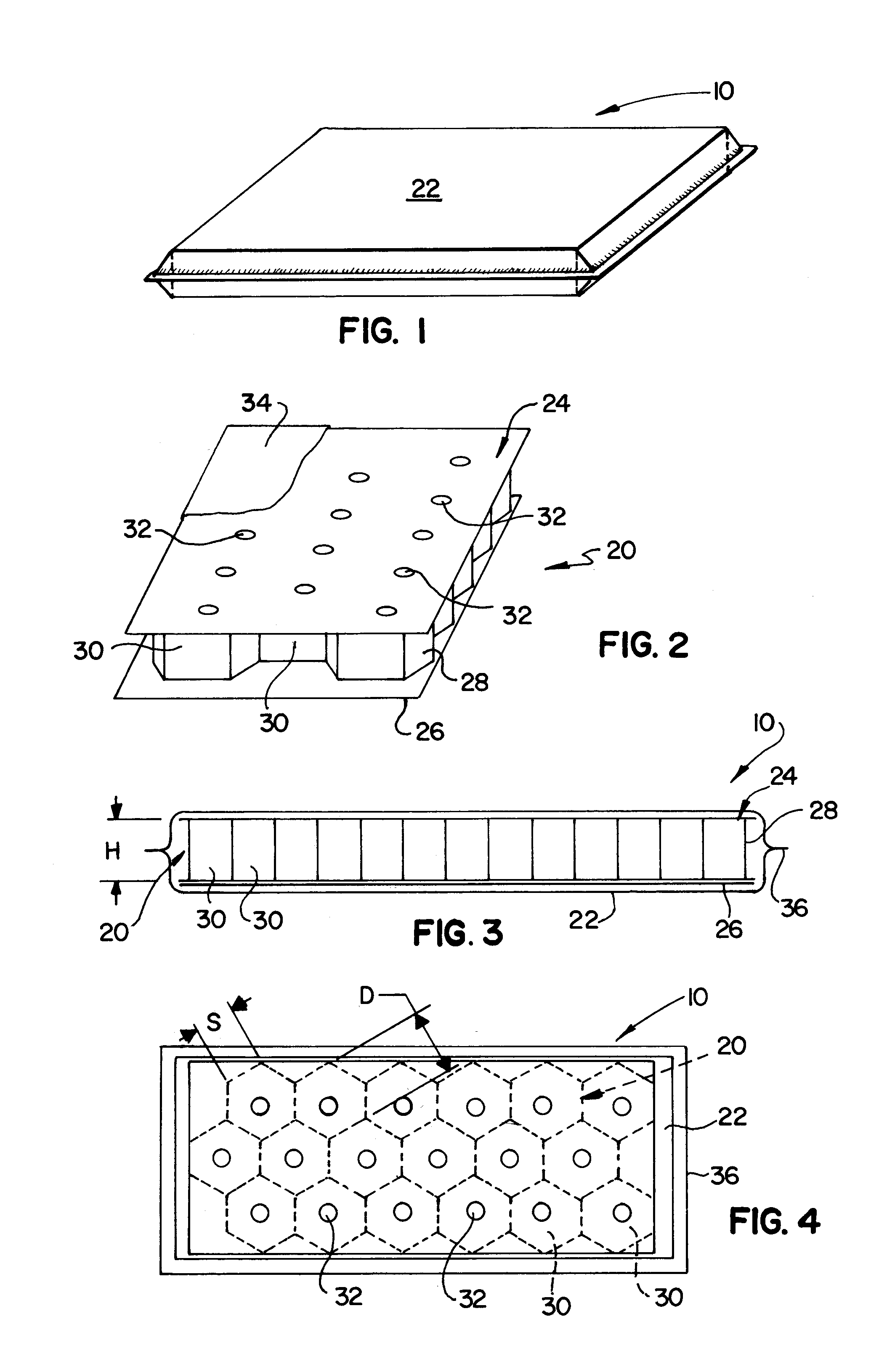

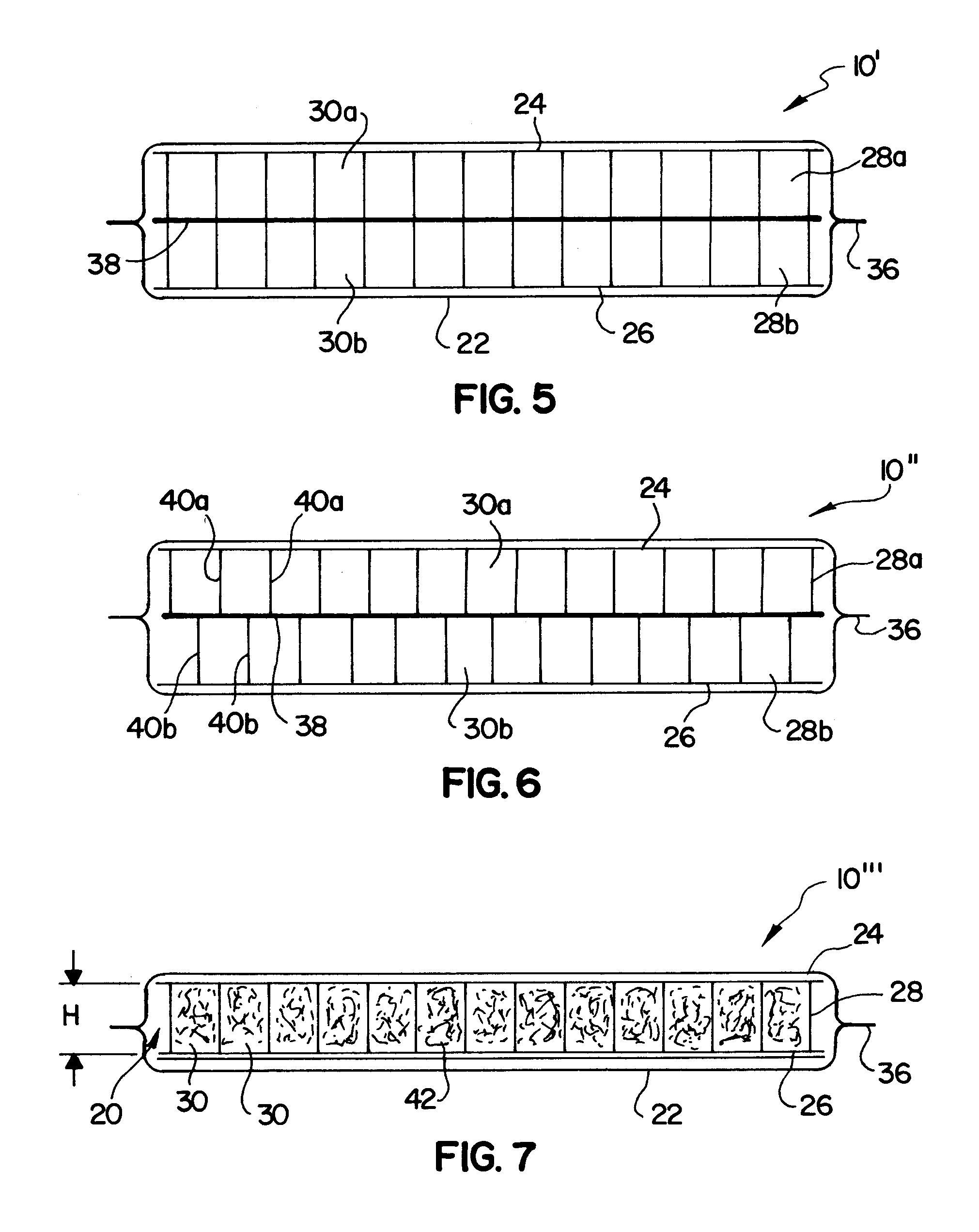

InactiveUS20120031957A1Low costDomestic cooling apparatusLighting and heating apparatusEngineeringFace sheet

A vacuum insulation panel that includes a paper core made of at least one panel consisting of first and second facing sheets, made of paper, that sandwich a paper honeycomb structure. The honeycomb structure preferably includes a plurality of cells that extend from the first facing sheet to the second facing sheet. The panel also includes an outer shell that surrounds the core, wherein the outer shell is made of a material of low gas permeability and is sealed to form a substantially airtight container around the core. In preferred embodiments, an interior of said outer shell has been evacuated to a pressure of between approximately 1-10 Torr, resulting in an insulating panel that has an R-value of approximately 3.

Owner:PACKAGINGPRICE COM

Method for manufacturing honeycomb structure and material composition for honeycomb fired body

The method for manufacturing a honeycomb structure includes preparing a material composition containing at least a silicon carbide powder, a binder and an additive; molding the material composition to form a pillar-shaped honeycomb molded body in which a number of cells are placed in parallel with one another in a longitudinal direction with a cell wall therebetween; carrying out a degreasing treatment on the honeycomb molded body; and carrying out a firing treatment on the honeycomb degreased body to manufacture a honeycomb fired body. The additive contains at least one kind selected from the group consisting of alumina, silica, titania, zirconia, magnesia, and a chemical composite containing any of alumina, silica, titania, zirconia and magnesia.

Owner:IBIDEN CO LTD

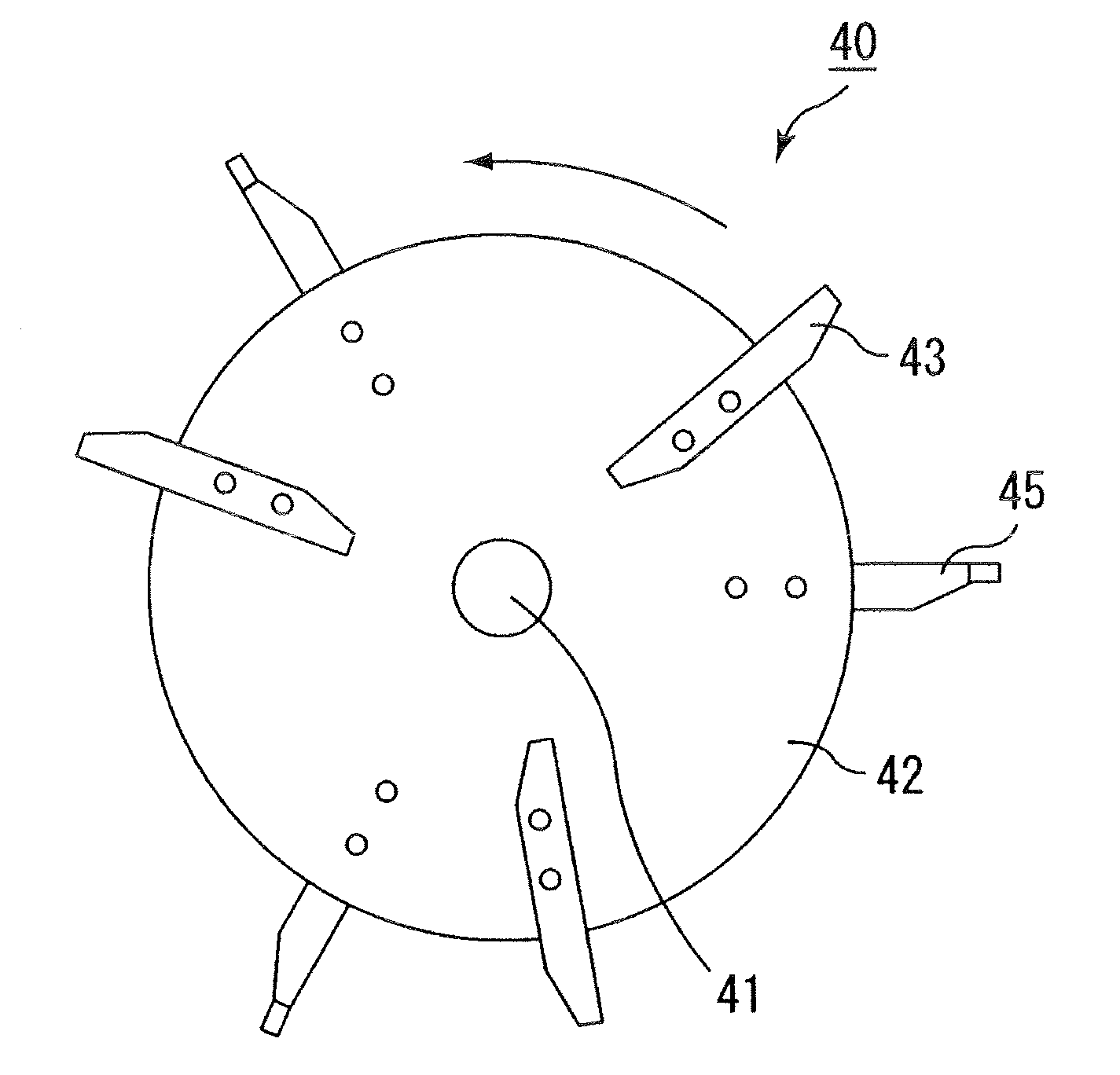

Wet mixing apparatus, wet mixing method and method for manufacturing honeycomb structure

A wet mixing apparatus includes a disc and a casing. The disc has a circular plate-shaped structure, is equipped with a vertically placed rotary shaft member as a central axis and has a plurality of agitation blades provided on a side face of the disc. The casing is provided with a raw material feeding port and a mixture discharging port. The raw material feeding port is disposed above the disc and the mixture discharging port is disposed below the disc.

Owner:IBIDEN CO LTD

End-face heating apparatus, end-face drying method for honeycomb aggregated body, and method for manufacturing honeycomb structured body

InactiveUS20070199205A1Drying using combination processesDrying solid materials with heatHoneycomb structureMaterials science

An end-face heating apparatus of the present invention comprises: a heating tool that is placed almost in parallel with an end face of a honeycomb aggregated body in which a plurality of pillar-shaped honeycomb fired bodies are integrated with one another by interposing a sealing material paste layer formed on the side face of the honeycomb fired body; a heating tool translation device for translating said heating tool toward said honeycomb aggregated body; and a holding jig that holds said honeycomb aggregated body.

Owner:IBIDEN CO LTD

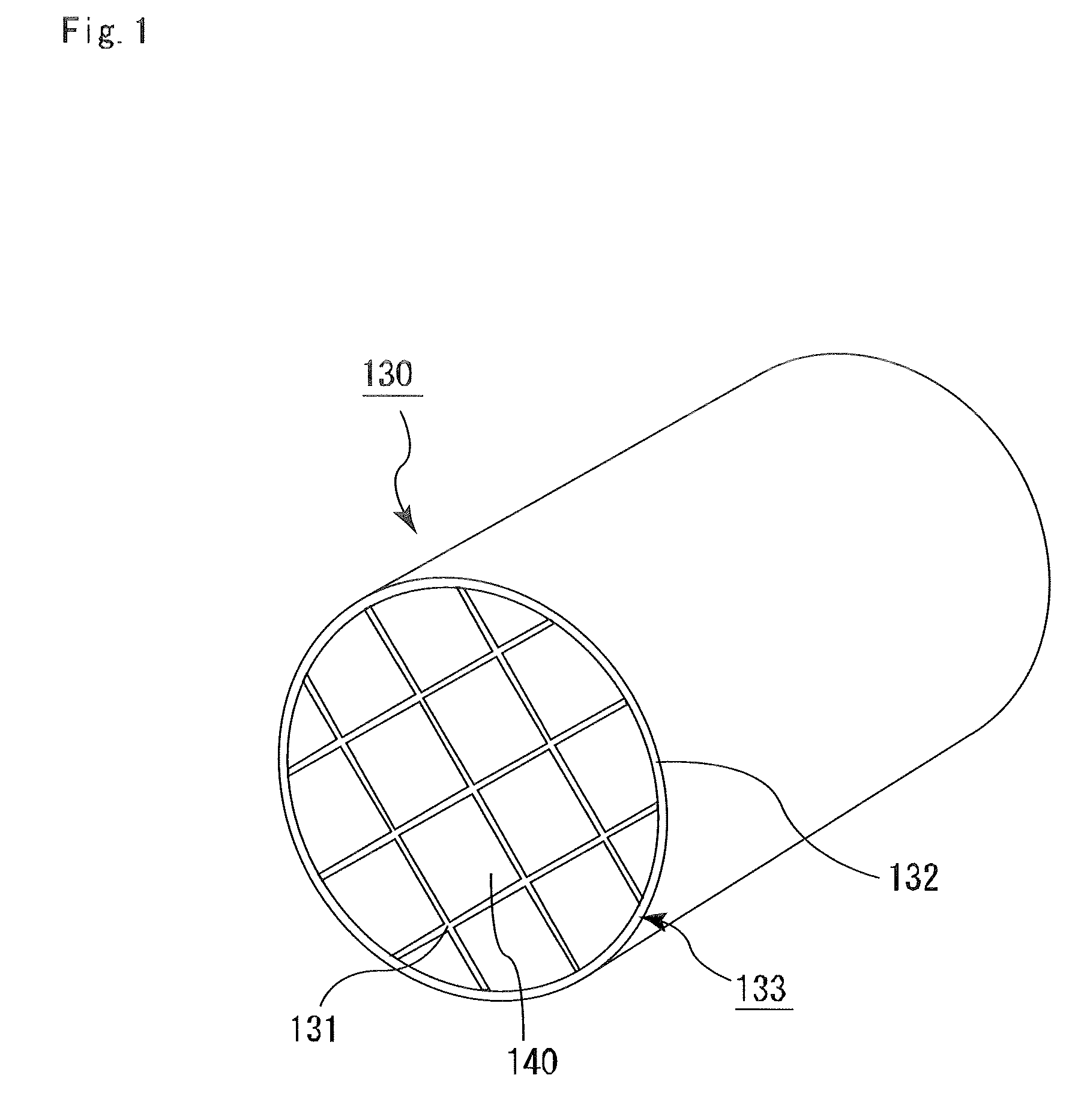

Honeycomb structural body and exhaust gas treating apparatus

ActiveUS20080190083A1Combination devicesEnvelopes/bags making machineryEngineeringHoneycomb structure

A pillar-shaped honeycomb structural body includes a first end face and a second end face substantially parallel to each other; and a peripheral surface connecting the first end face and the second end face. The first end face and the second end face have similar peripheral shapes. A taper rate P satisfies 0<P≦ approximately 4%, the taper rate P being expressed by the formula (1), taper rate P(%)=(D1−D2) / (2L)×100, wherein the maximum width of the first end face is D1, the maximum width of the second end face is D2, and the distance between the first end face and the second end face is L.

Owner:IBIDEN CO LTD

Method for manufacturing material for silicon carbide fired body and method for manufacturing honeycomb structure

InactiveUS20080284067A1Mixing operation control apparatusCeramic shaping apparatusManufactured materialHoneycomb structure

A material for a silicon carbide fired body is manufactured by wet mixing at least a silicon carbide powder and an iron compound powder. A honeycomb structure is manufactured by molding a raw material composition containing the material for a silicon carbide fired body and an additive to manufacture a honeycomb molded body which has cell walls extending along a longitudinal direction of the honeycomb molded body to define a plurality of cells extending along the longitudinal direction. The honeycomb molded body is degreased to manufacture a honeycomb degreased body. The honeycomb degreased body is fired to manufacture a honeycomb structure including a honeycomb fired body.

Owner:IBIDEN CO LTD

Holding apparatus and method for manufacturing honeycomb structure

ActiveUS20080088072A1Discharging arrangementAuxillary shaping apparatusEngineeringMechanical engineering

Owner:IBIDEN CO LTD

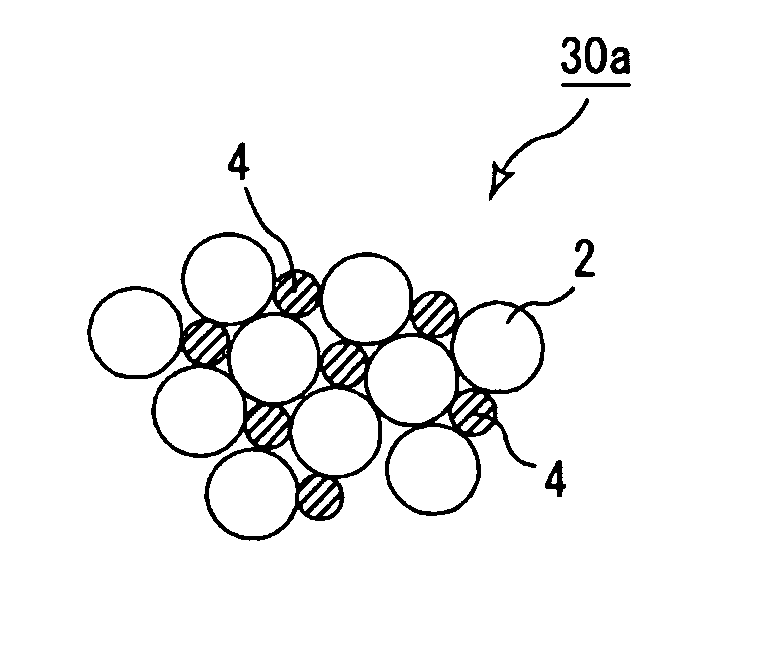

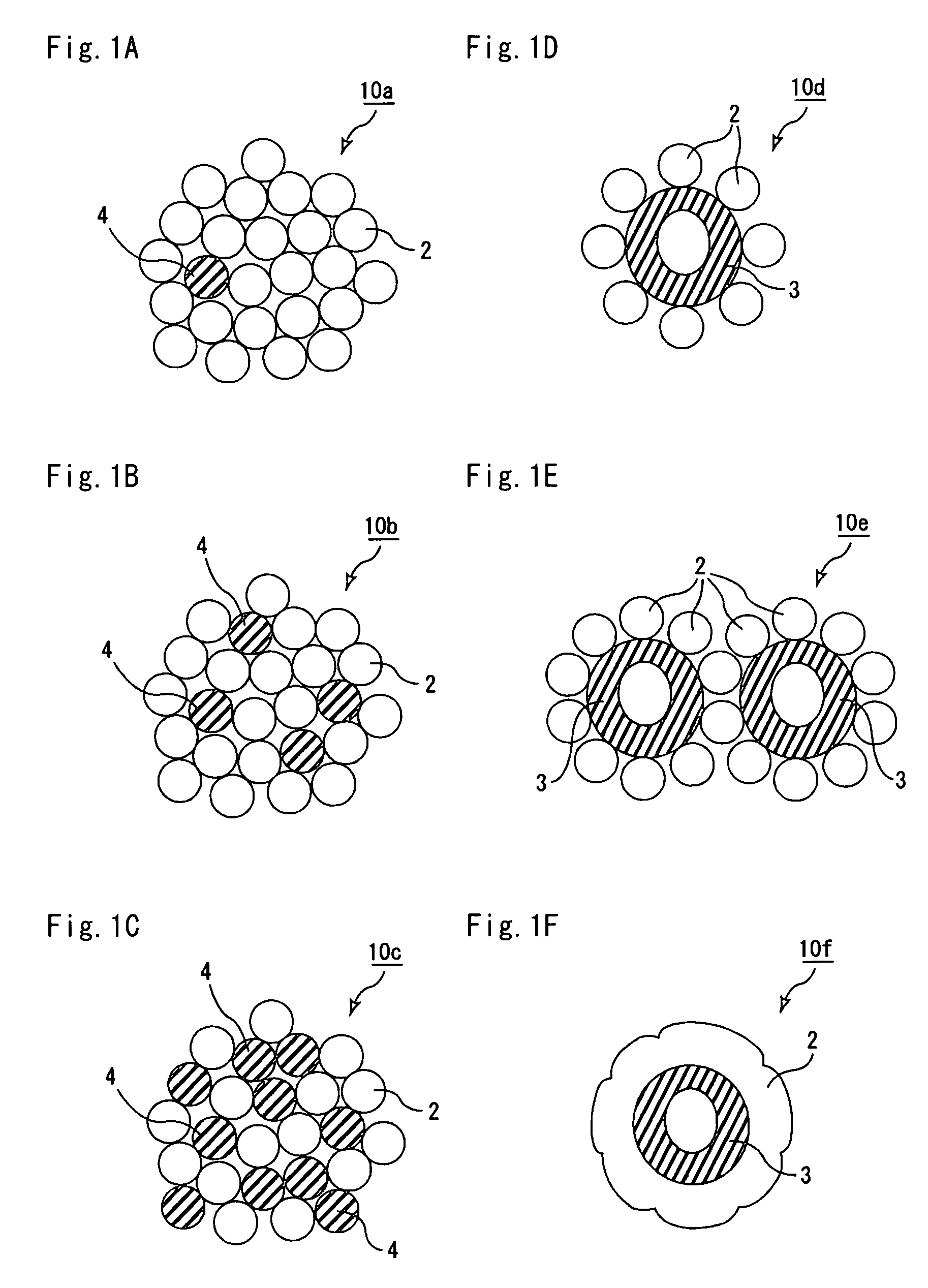

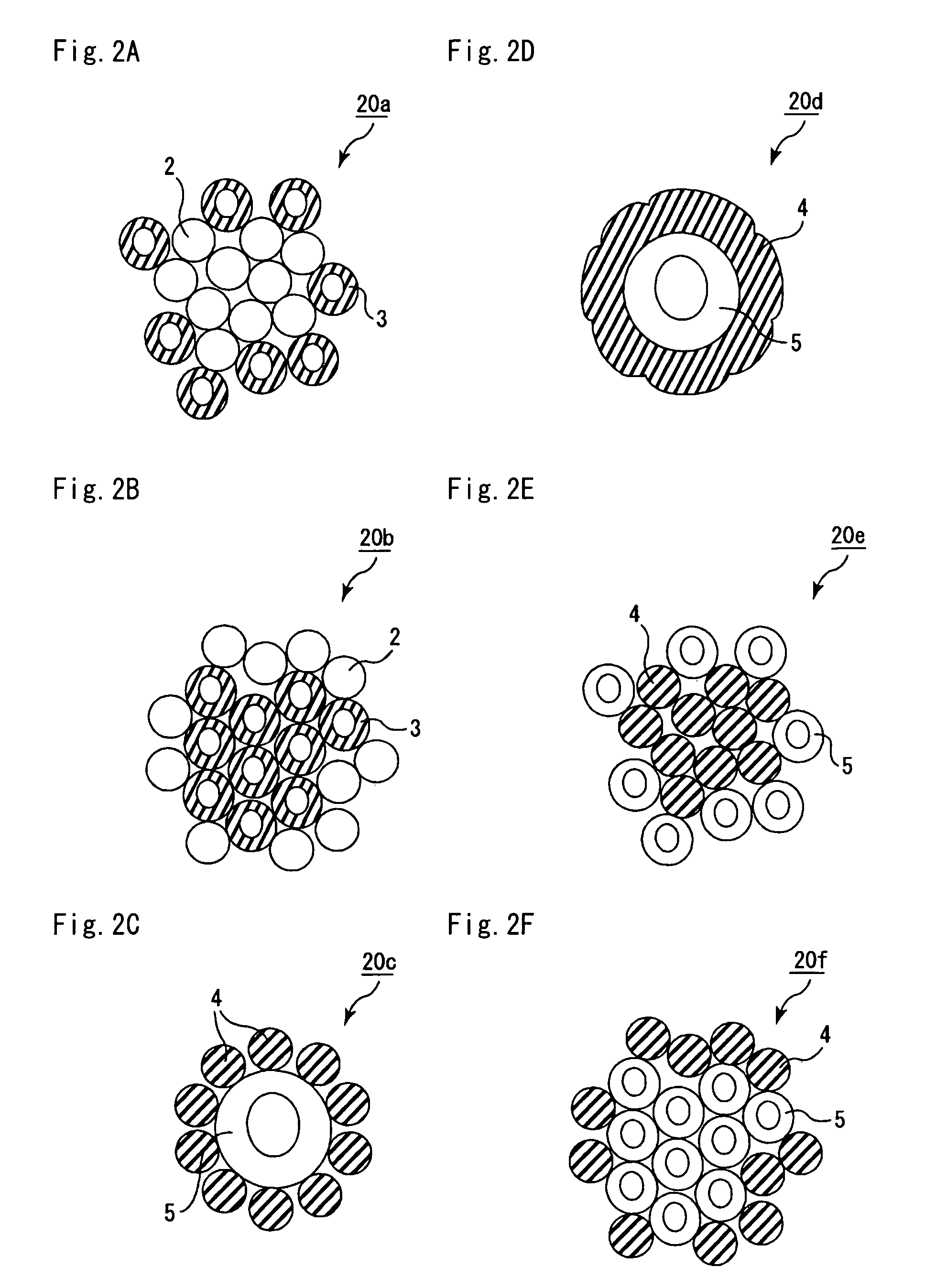

Pore forming material for porous body, manufacturing method of pore forming material for porous body, manufacturing method of porous body, porous body, and honeycomb structural body

InactiveUS7396586B2High porosityAvoid crackingSolid waste managementExhaust apparatusInorganic particleMicrosphere

The pore forming material for a porous body of the present invention comprises organic polymer particles and inorganic particles. As the embodiment thereof, there may be mentioned one having a structure in which the inorganic particles are contained in the organic polymer particles, and an aggregate body of the organic polymer particles and the inorganic particles. The inorganic particles may be inorganic micro-balloons, and the organic polymer particles may be organic micro-balloons.

Owner:IBIDEN CO LTD

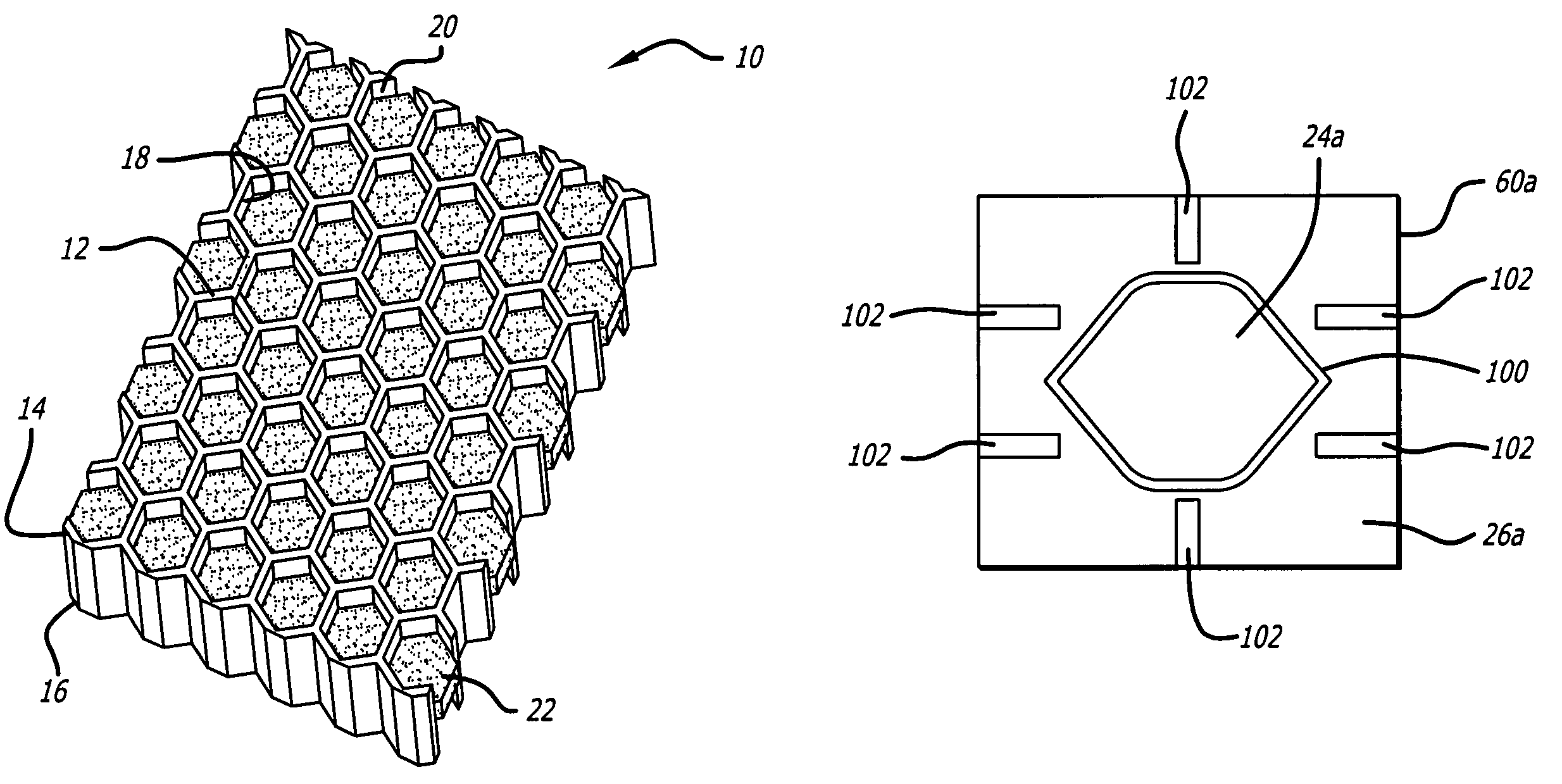

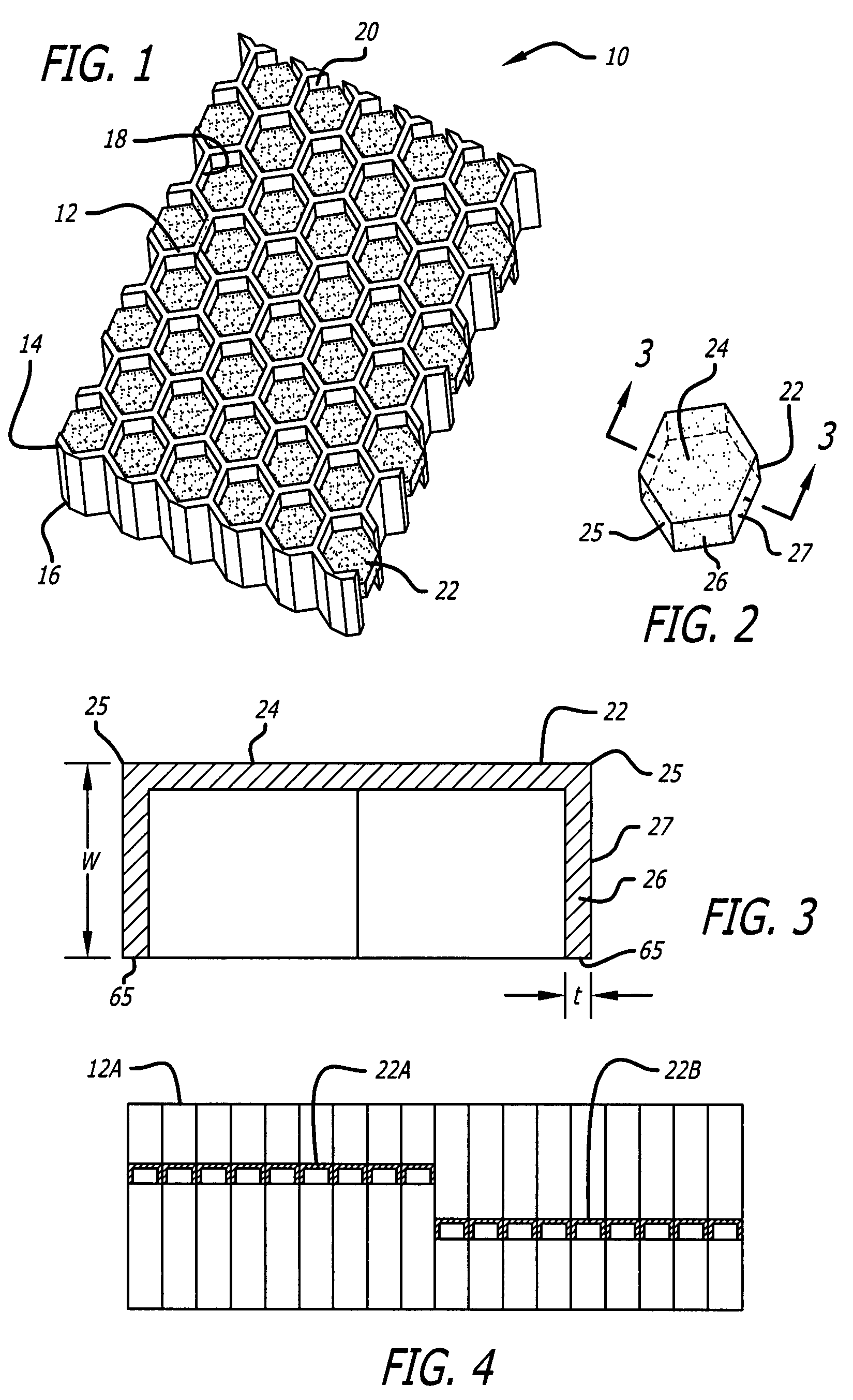

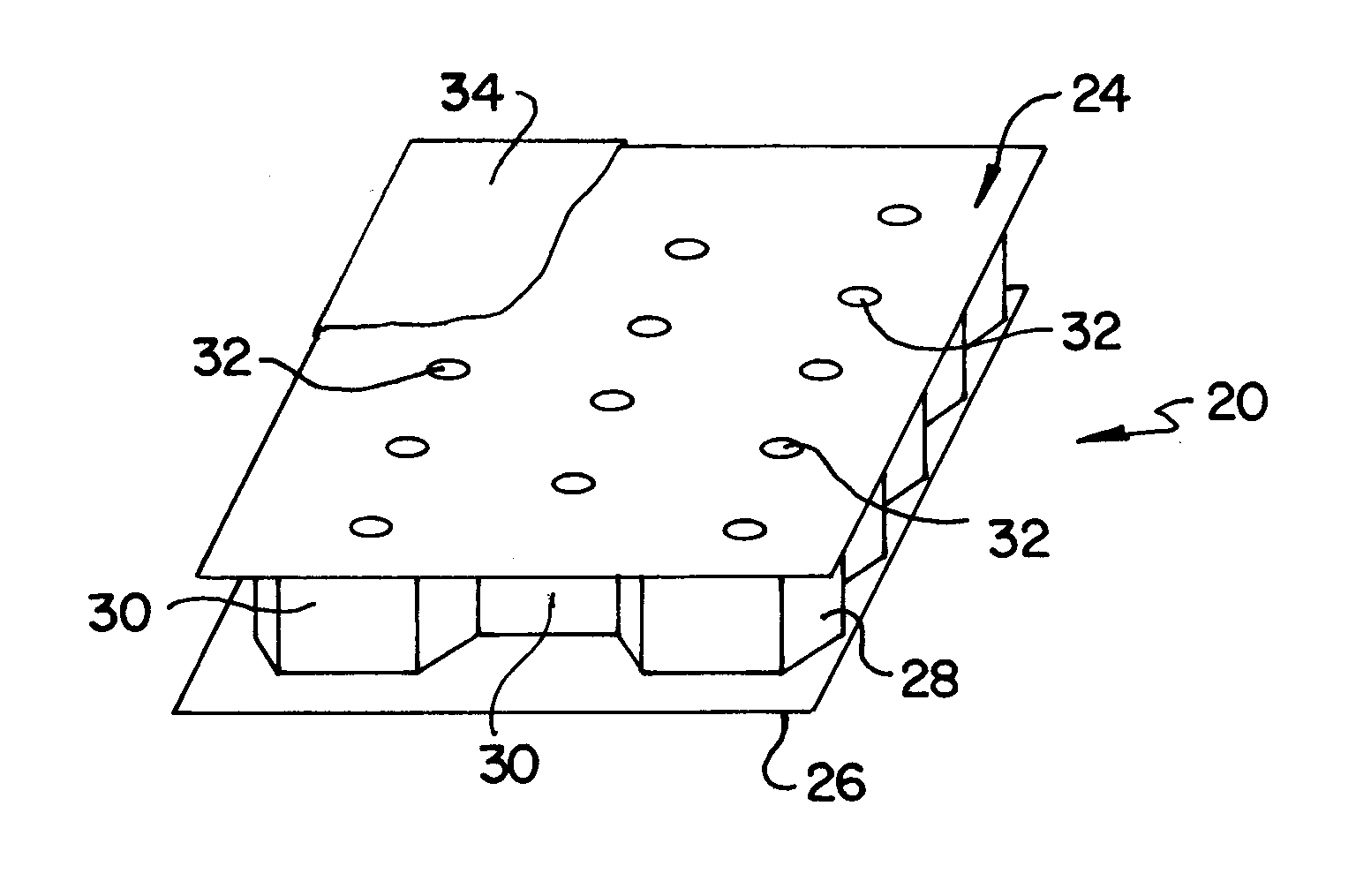

Acoustic septum cap honeycomb

An acoustic structure that includes a honeycomb having cells in which septum caps are located. The septum caps are formed from sheets of acoustic material and include a resonator portion and a flange portion. The flange portion has an anchoring surface that provides frictional engagement of the septum caps to the honeycomb cells when the caps are inserted into the honeycomb during fabrication of the acoustic structure. An adhesive is applied to the anchoring surface of the septum caps after the caps have been inserted into the honeycomb cells to provide a permanent bond.

Owner:HEXEL CORP

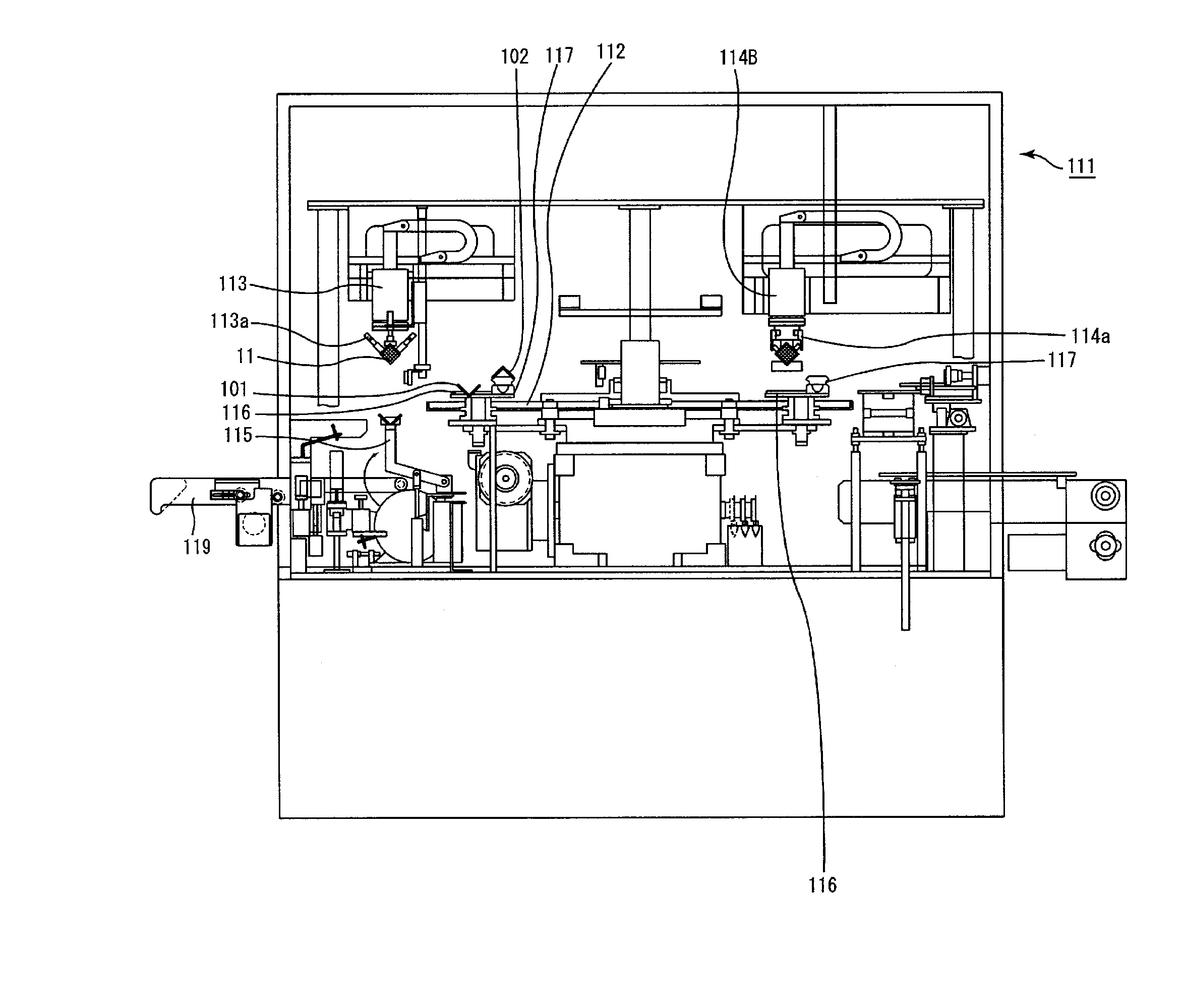

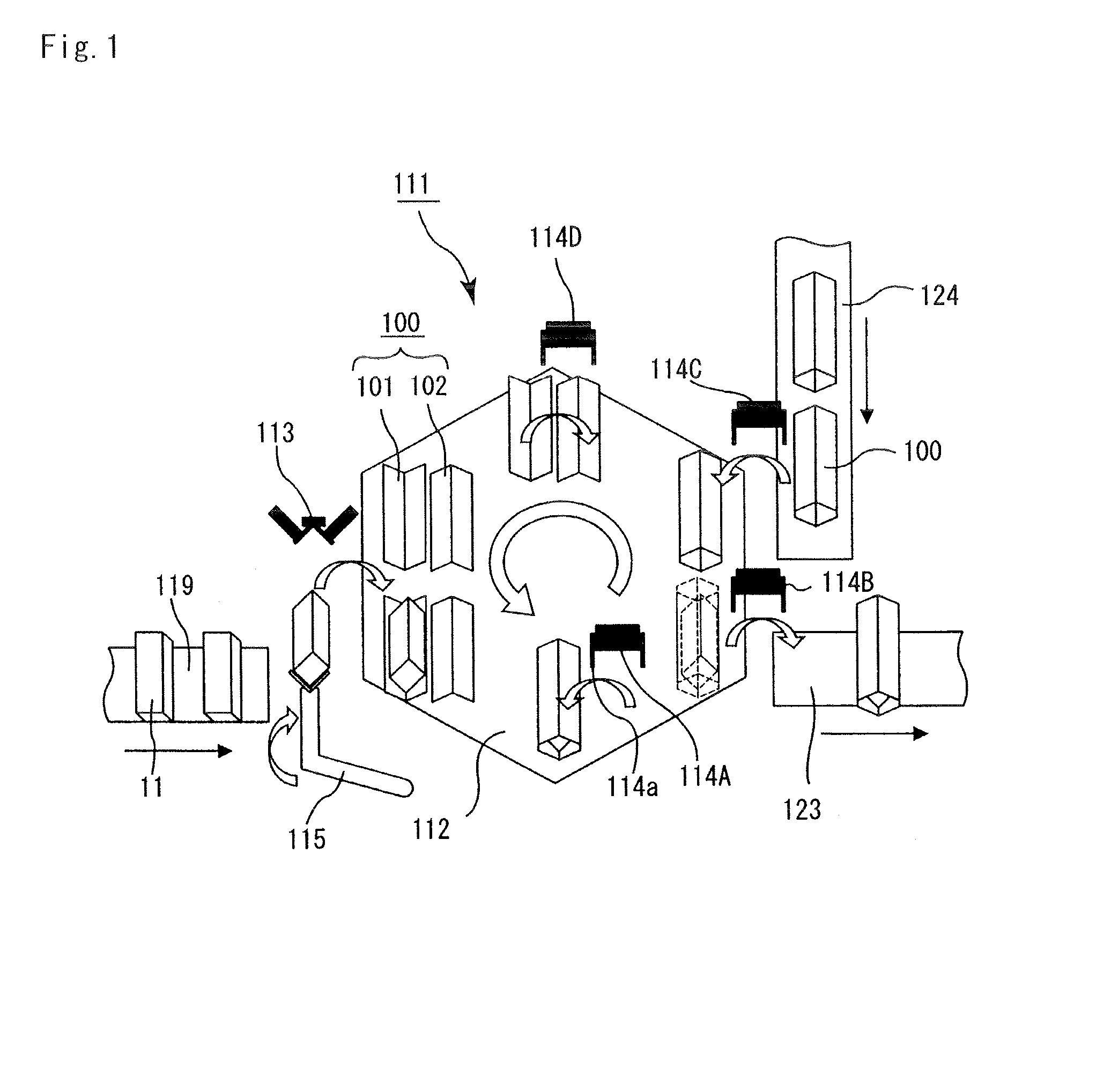

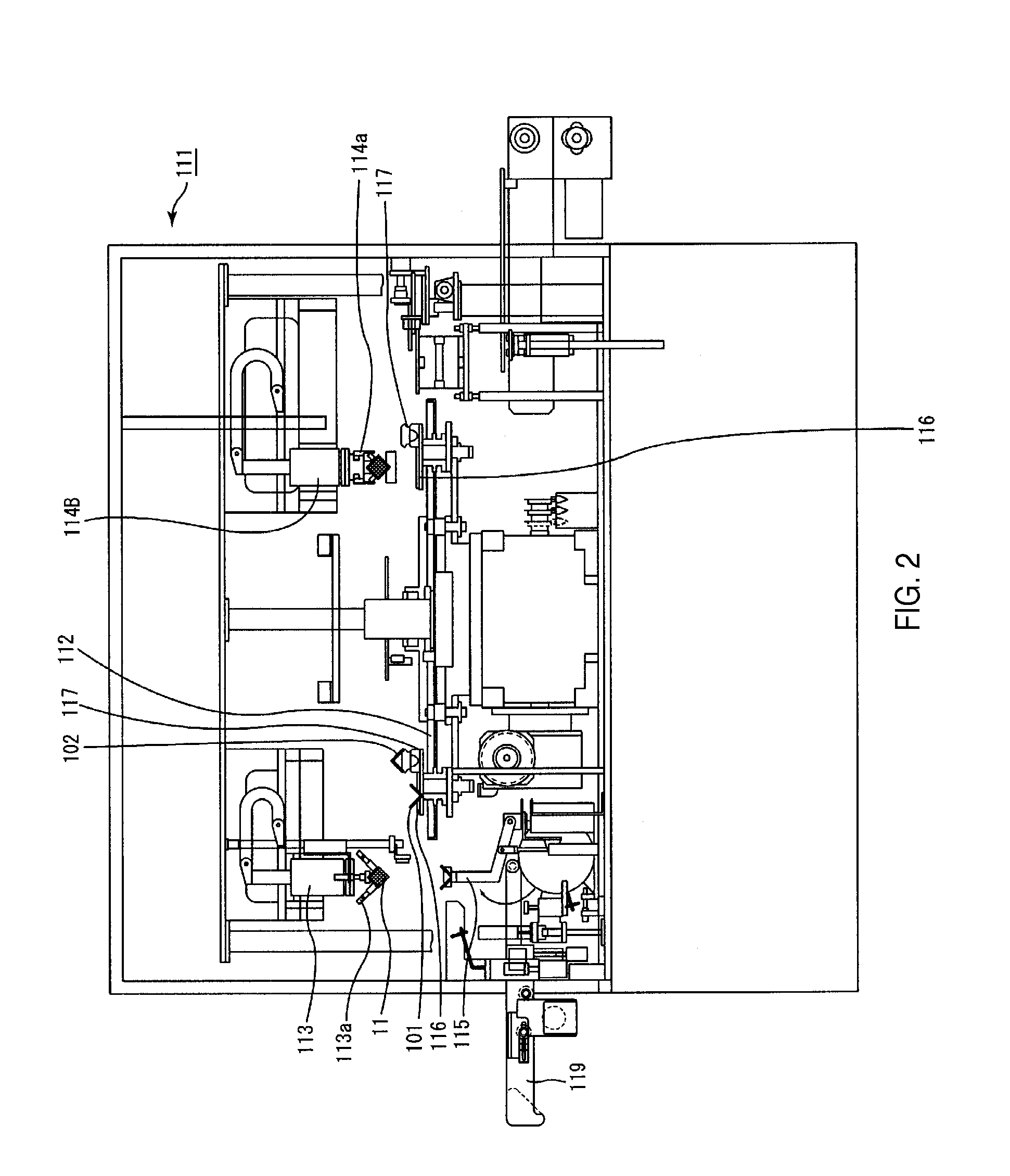

Drying jig assembling apparatus, drying jig disassembling apparatus, drying jig circulating apparatus, drying method of ceramic molded body, and method for manufacturing honeycomb structure

InactiveUS20080106008A1Drying using combination processesAuxillary shaping apparatusHoneycomb structureClosed state

A drying jig circulating apparatus includes a drying jig assembling apparatus for assembling a drying jig on a movable table, a drying apparatus for drying a ceramic molded body held by the drying jig, and a drying jig disassembling apparatus for disassembling the drying jig on a movable table, and a drying jig circulating conveyor for transporting the drying jig from the disassembling apparatus to the assembling apparatus. The drying jig is configured by two or more separate jigs with a fixing member that integrates the separate jigs, or formed by one openable jig with a fixing member for maintaining a closed state. The drying jig assembling apparatus further includes a molded body mounting mechanism, a ceramic molded body holding mechanism, and a jig delivering mechanism. The drying jig disassembling apparatus further includes a jig receiving mechanism, a jig releasing mechanism, and a molded body taking-out mechanism.

Owner:IBIDEN CO LTD

Honeycomb structure

ActiveUS20050011174A1Increasing limiting collection amountReduce total pressure lossCombination devicesAuxillary pretreatmentParticulatesEngineering

A honeycomb structural body which is capable of increasing the limiting collection amount of particulate, reducing the pressure loss in use, and reducing fluctuations in the pressure loss even if the flow rate from an internal combustion engine of exhaust gases fluctuates. The honeycomb structural body is a columnar honeycomb structural body in which a large number of through holes are arranged side by side in the length direction with a partition wall interposed therebetween. The large number of through holes are constituted by a group of large-capacity through holes, with one end thereof sealed to make the total cross-sectional areas perpendicular to the length direction relatively greater, and a group of small-capacity through holes, with the other end thereof sealed to make the total cross-sectional areas relatively smaller. The honeycomb structural body includes a plurality of columnar porous ceramic members.

Owner:IBIDEN CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com