Patents

Literature

1204 results about "Pore distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pore Size Distribution. There is not a unique definition of “pore diameter” or “pore size”. Every method of pore size determination defines a pore size in terms of a pore model which is best suited to the quantity measured in the particular experiment. There is the same situation for the definition of void space.

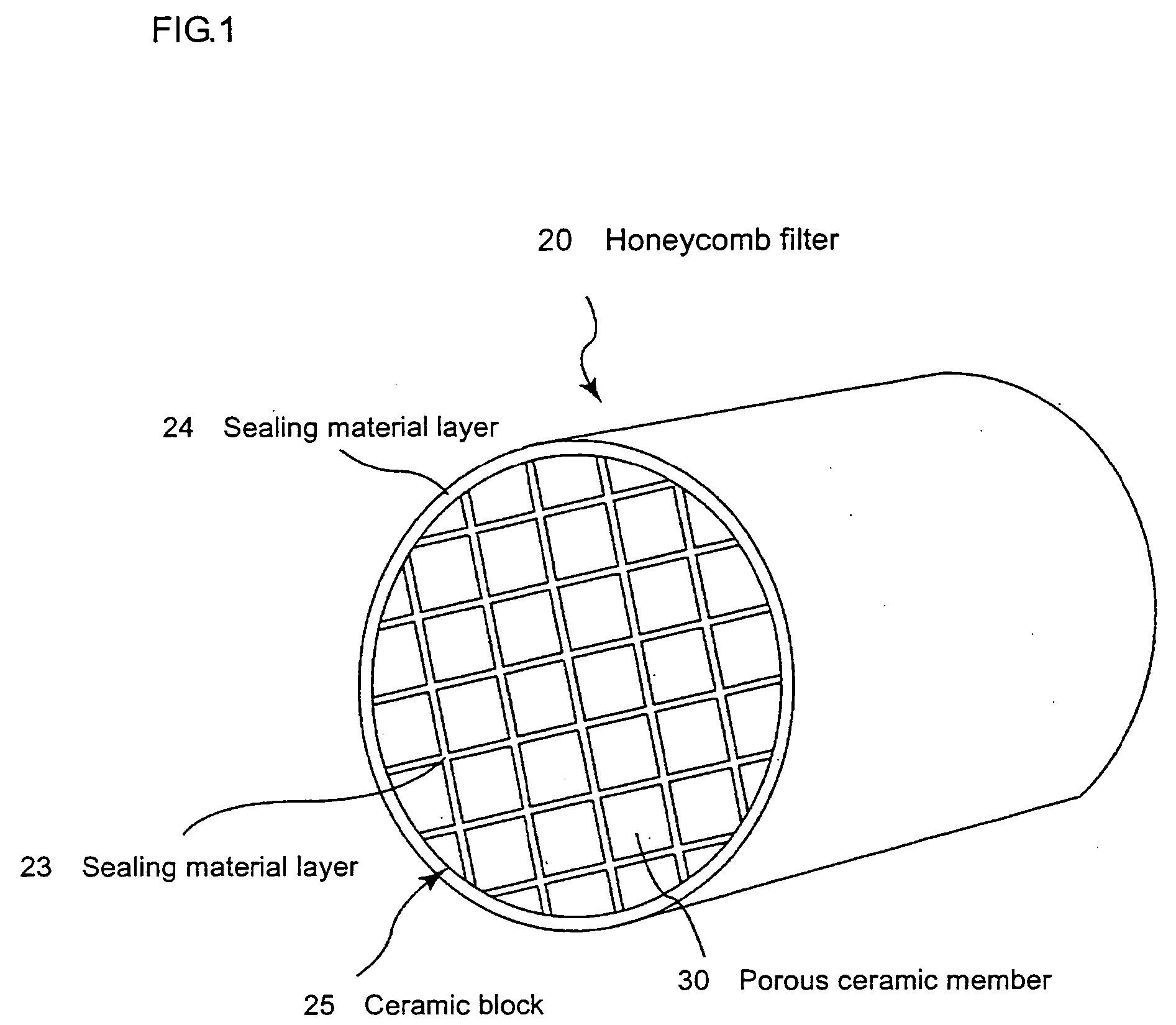

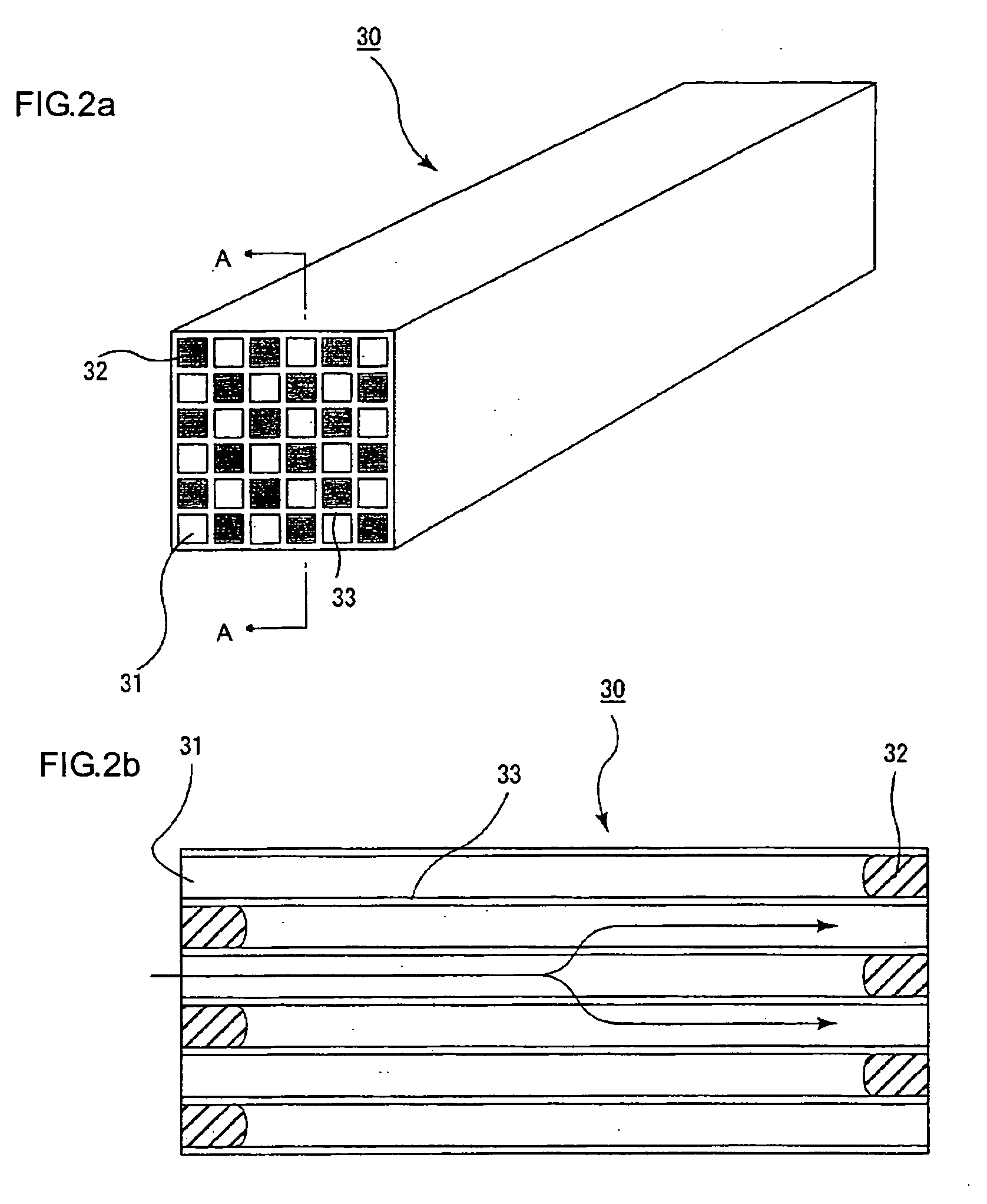

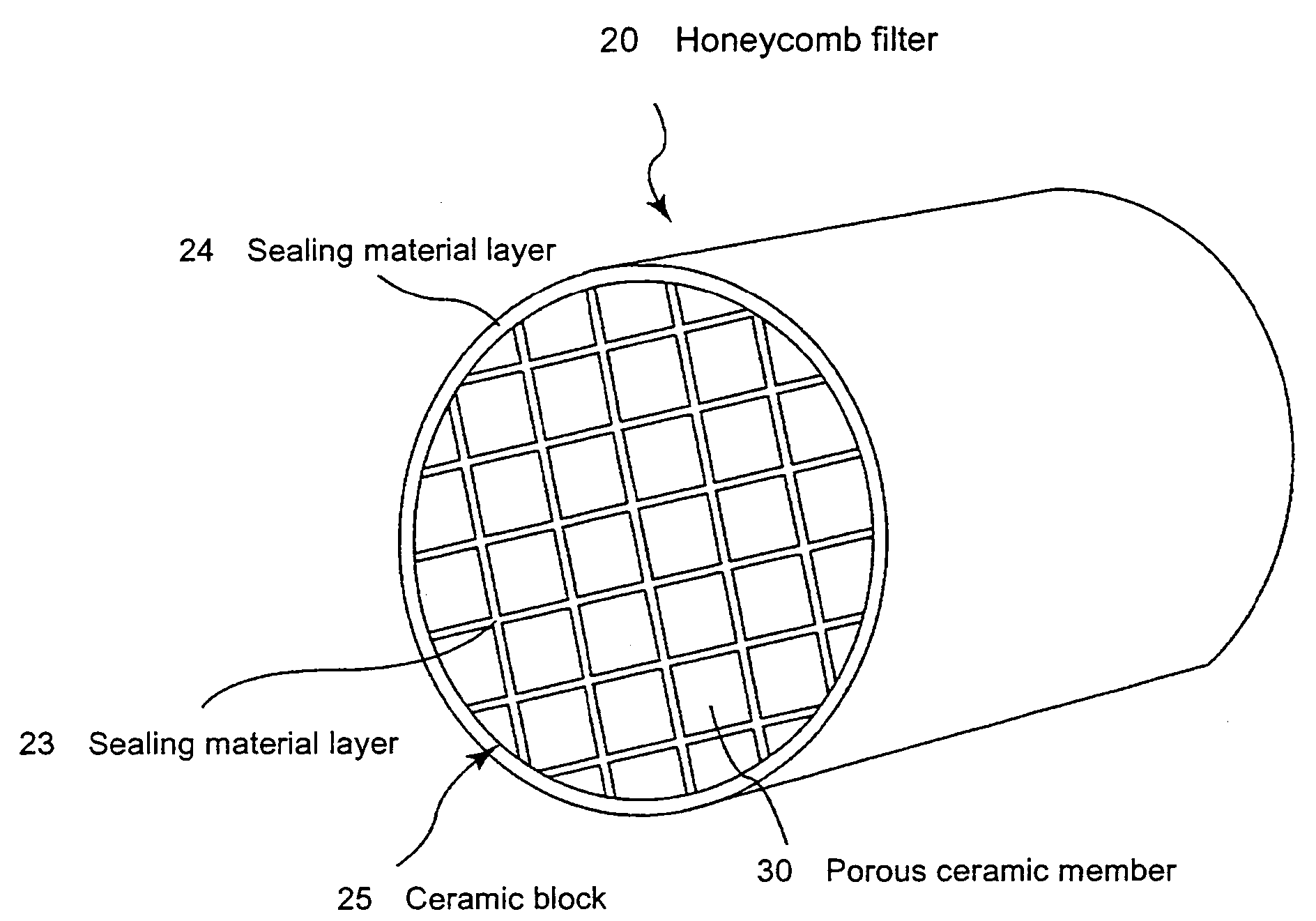

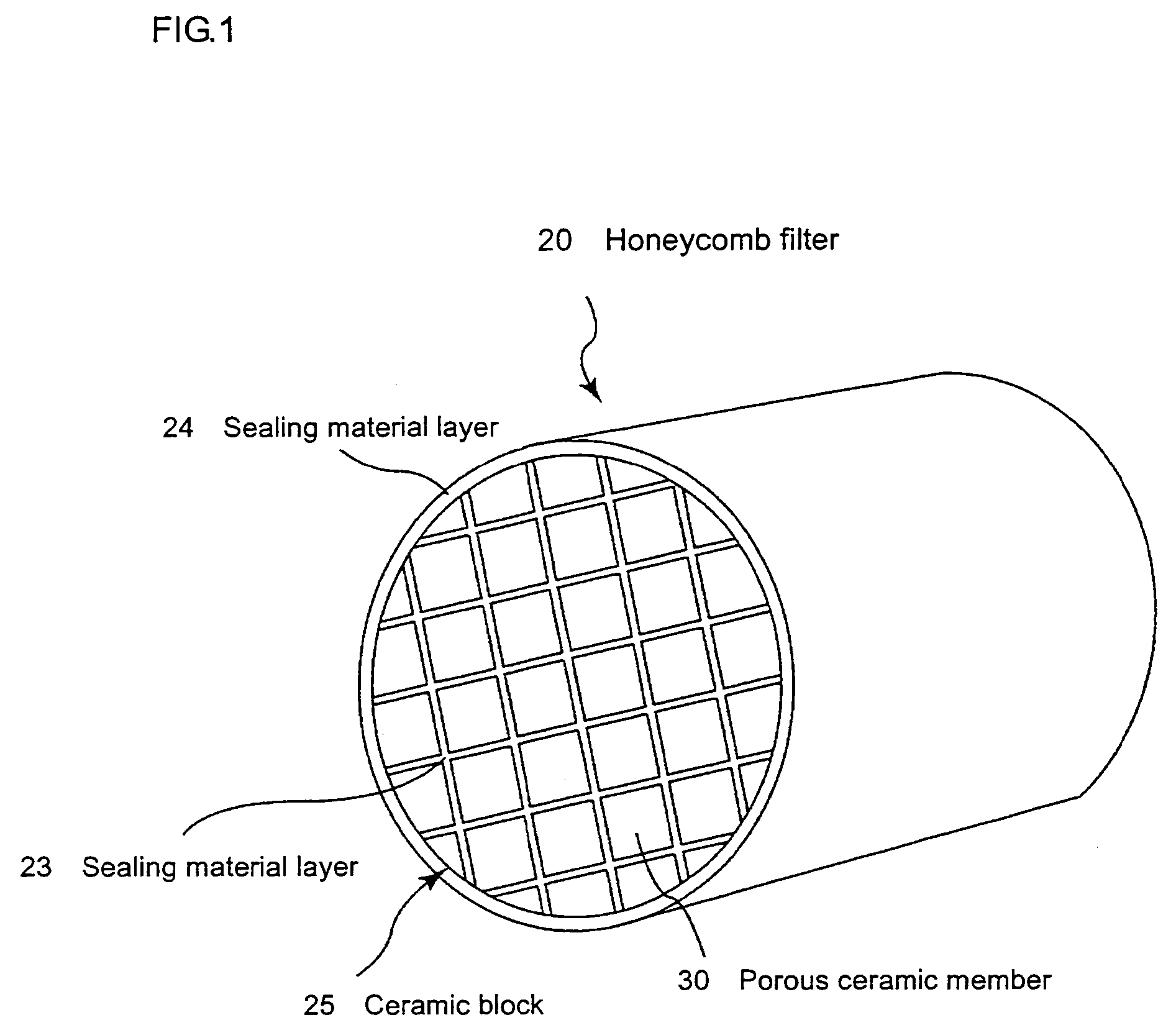

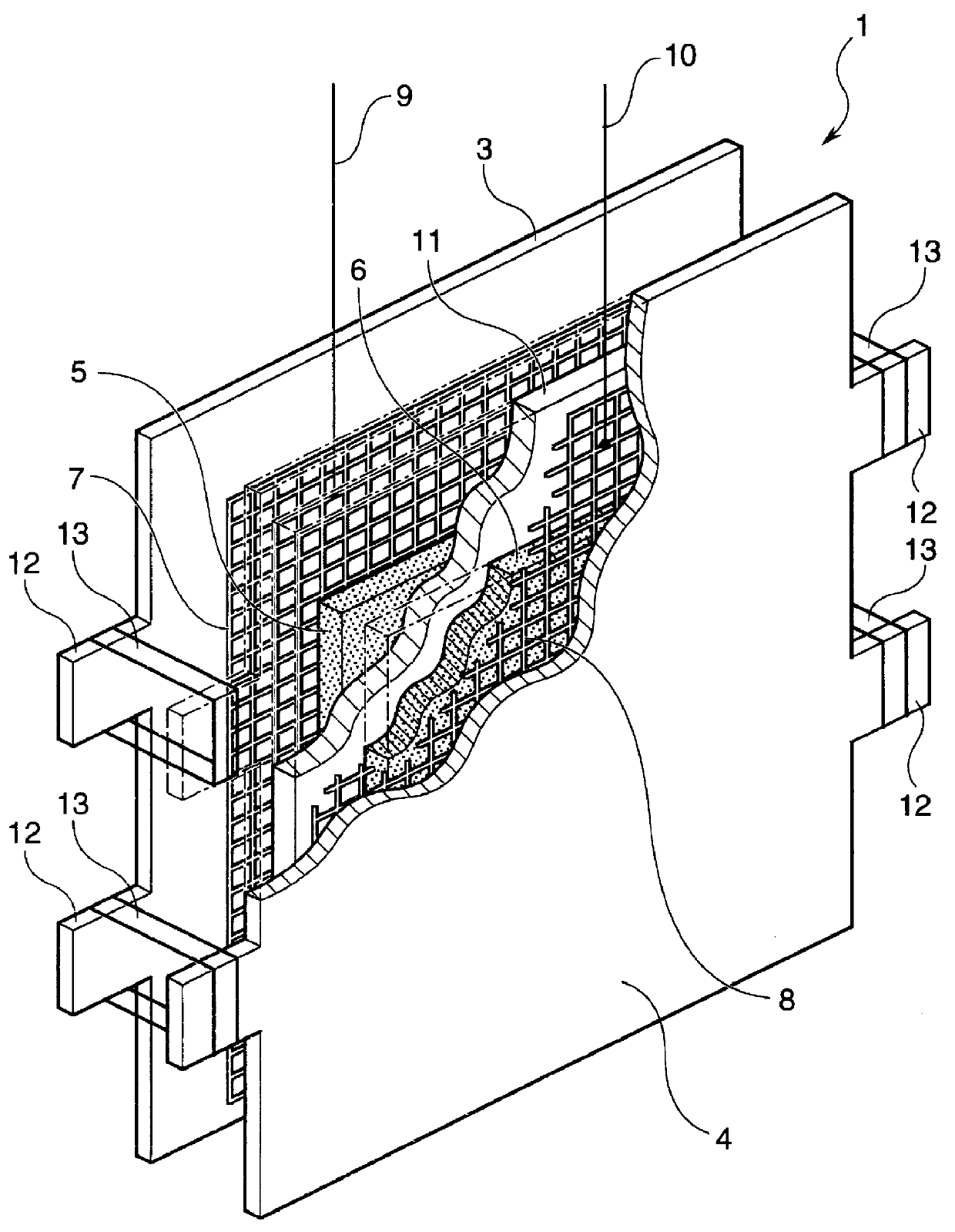

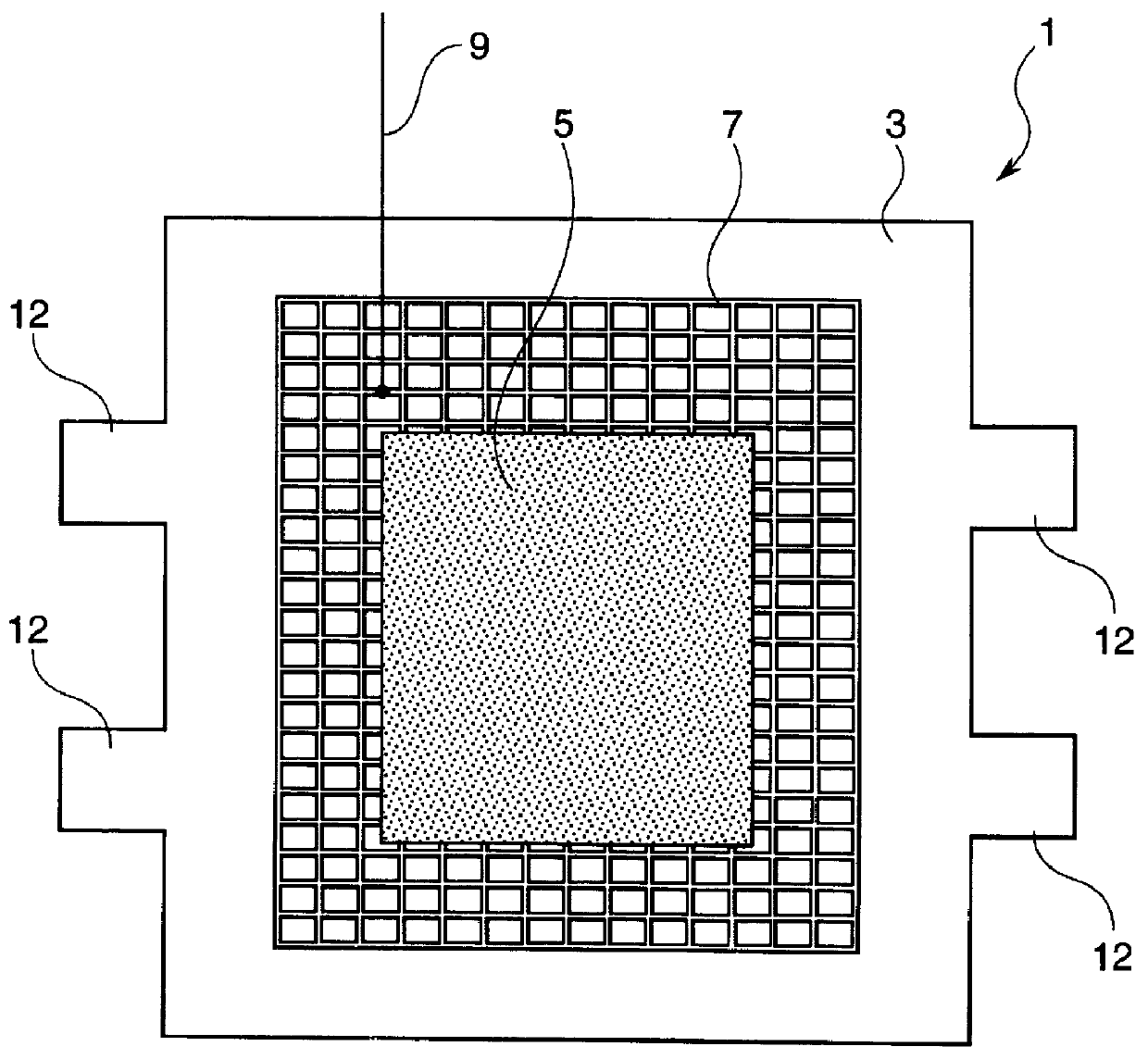

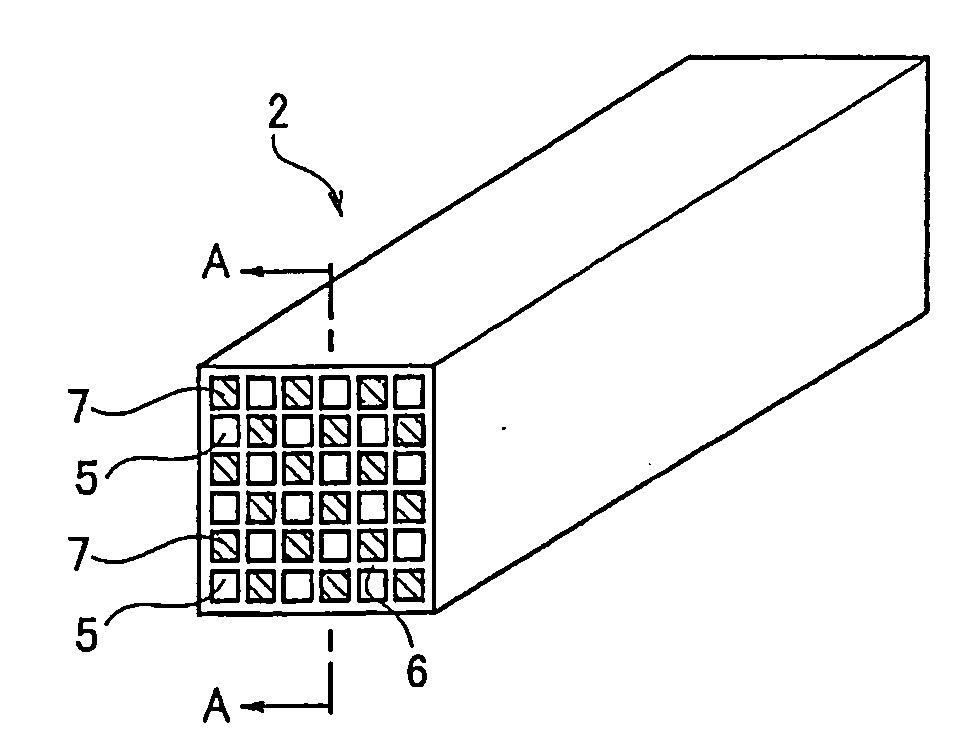

Ceramic honeycomb structure

ActiveUS20060166820A1Excellent in pressure loss and catching efficiencyHigh catalytic activityDispersed particle filtrationExhaust apparatusPore distributionSurface roughness

A honeycomb structural body comprises one or plural pillar-shaped porous ceramic members in which many through-holes are arranged side by side in a longitudinal direction through partition walls and either one end portions of these through-holes are sealed. The partition wall forming the structural body has a surface roughness of not less than 10 μm as a maximum roughness Rz defined in JIS B0601-2001 and an average pore size of 5-100 μm in a pore distribution measured by a mercury pressure method, and satisfies the following relationship: A≧90−B / 20 or A≦100−B / 20 when a ratio pores having a pore size of 0.9-1.1 times the average pore size to total pore volume is A (%) and a thickness of the partition wall is B (μm), and there is proposed an effective honeycomb structural body having excellent pressure loss and catching efficiency and a high catalyst reactivity.

Owner:IBIDEN CO LTD

Hydrotreating guard catalyst and application thereof

ActiveCN101890381AMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsPore distributionFixed bed

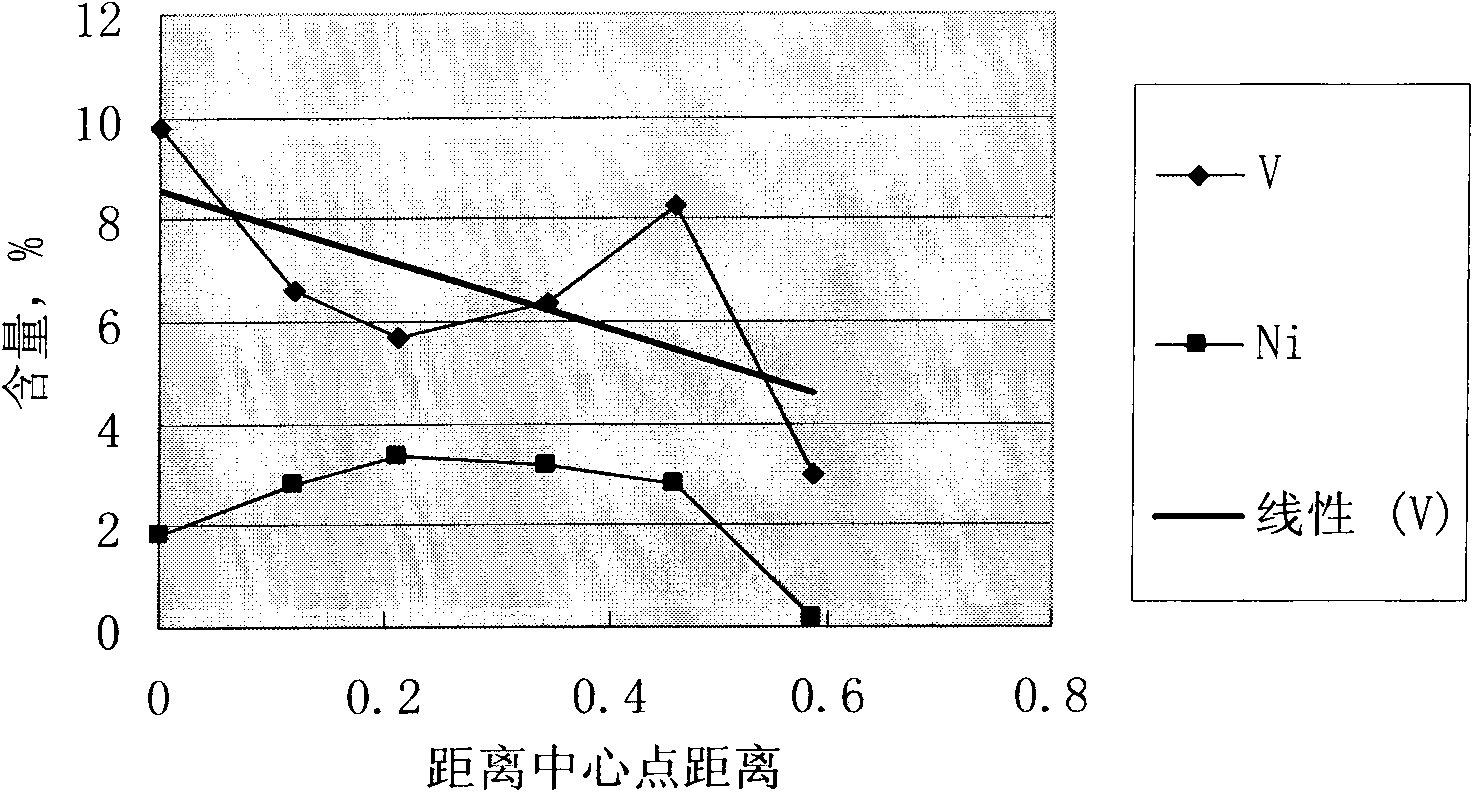

The invention discloses a hydrotreating guard catalyst for residual oil and application thereof. The catalyst has the advantages of large pore volume, large aperture, high porosity, rational pore distribution, larger external orifice, high pore canal penetrability and over 36 percent of 1,000nm pore canals, and is particularly applied to a hydrotreating method of a residual oil fixed bed to ensure that precipitated metals are uniformly deposited on the whole catalyst bed and impurities, namely vanadium and calcium, can be deposited inside the pore canals so as to improve the utilization ratio of pores and maintain long-period running.

Owner:CHINA PETROLEUM & CHEM CORP +1

Filtration and flow distribution method for chemical reactors using reticulated ceramics with uniform pore distributions

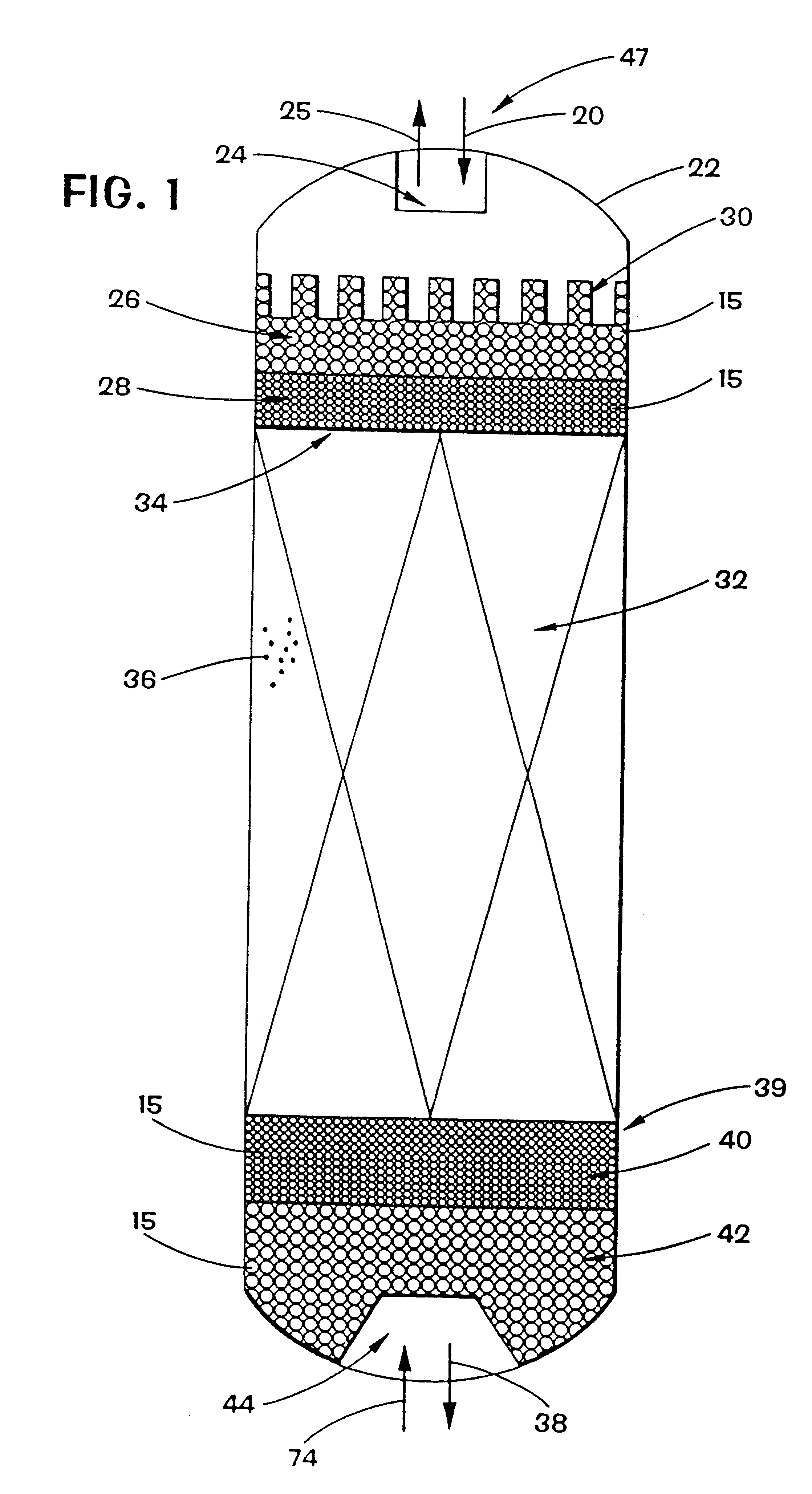

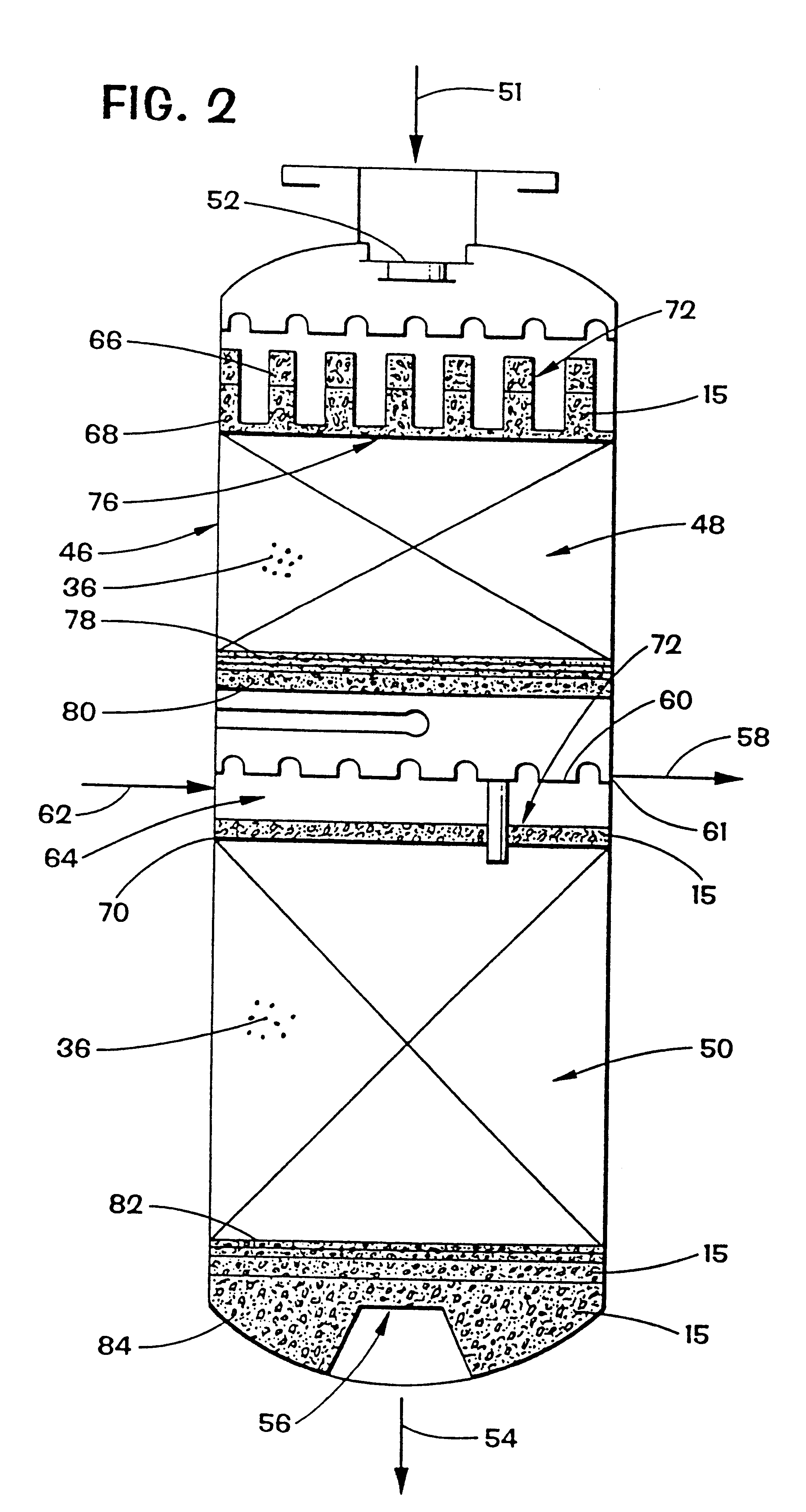

InactiveUS6291603B1Reduce turbulenceEntrance losses may be reducedCatalytic naphtha reformingMembrane filtersPore distributionFiltration

Owner:CRYSTAPHASE PRODS

Catalyzer for oxalic ester hydrogenation synthesizing of glycolate and method of preparing the same

ActiveCN101138730AHigh reactivitySolving problems with Cr/Cu catalystsOrganic compound preparationCarboxylic acid esters preparationOxalatePore distribution

A catalyst for hydrogenated synthesis of glycollate with oxalate and a preparation method for the catalyst belong to the glycollate preparation technical field. The catalyst of the present invention uses the copper metal as the main active component, and silver as the promoter, and is manufactured with the method of immersion. A carrier of the catalyst is the modified silica sol. The select content of the copper metal is 5 to 45 percent of the carrier weight, and the optimal content of the copper metal is 10 to 40 percent. The content of silver metal is 0.1 to 15 percent of the carrier weight, and the optimal content of silver metal is 1 to 8.0 percent. The select carrier is the silica sol with a double peak pore distribution structure and the specific surface area of the carrier is 100-300m2 / g; and the optimal specific surface area of the carrier is 120-240m2 / g. The present invention settles the problem of applying a Cr / Cu catalyst in the oxalate gas-phase catalytic hydrogenation. Proven by experiments, the catalyst is provided with the very high reaction activity and glycollate selectivity in the reaction to synthesize glycollate with oxalate and hydrogen Moreover, the catalyst is provided with the long usable life and the stable reaction performance, and can be easily controlled.

Owner:TIANJIN UNIV

Porous 4 group metal oxide and method for preparation thereof

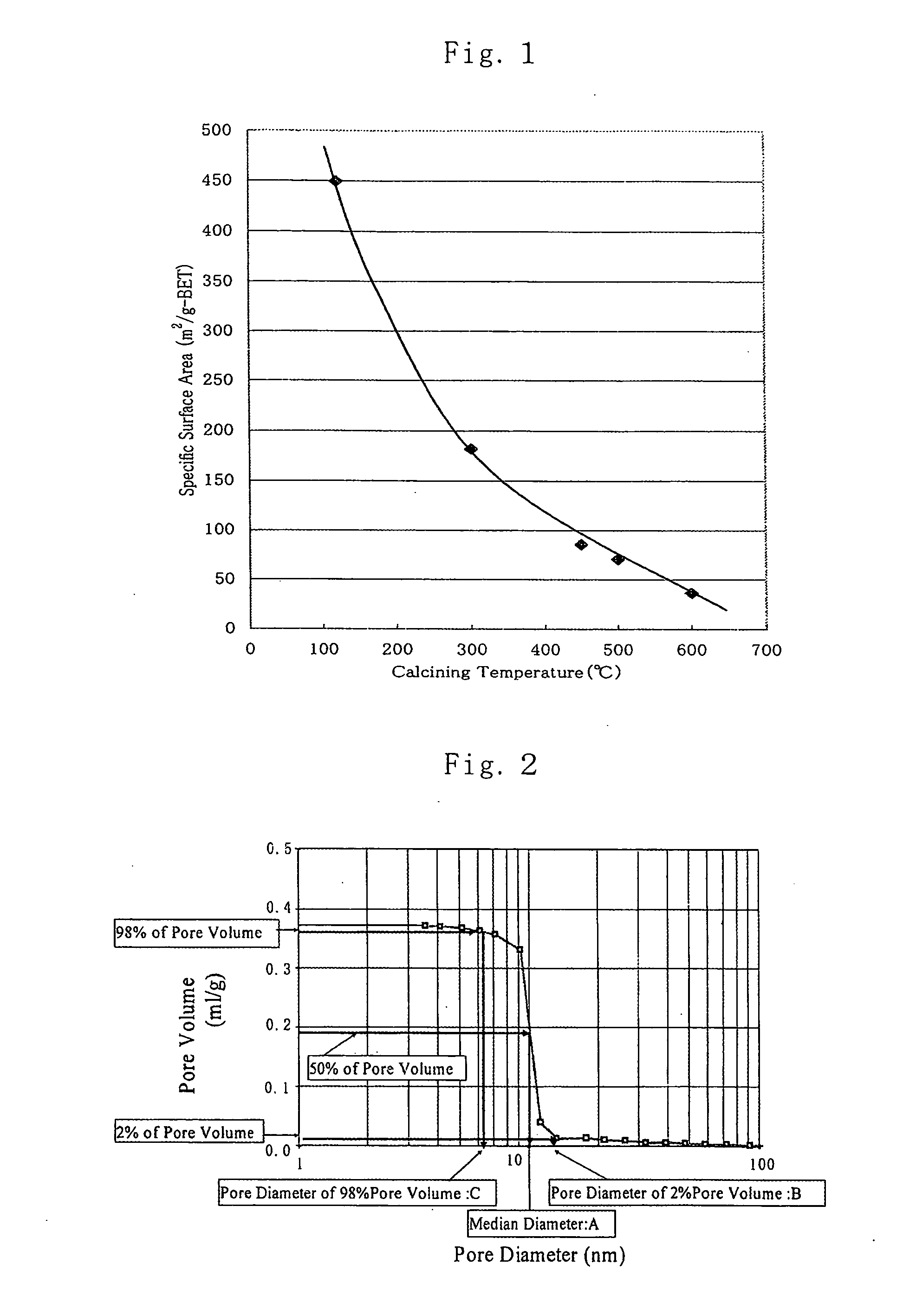

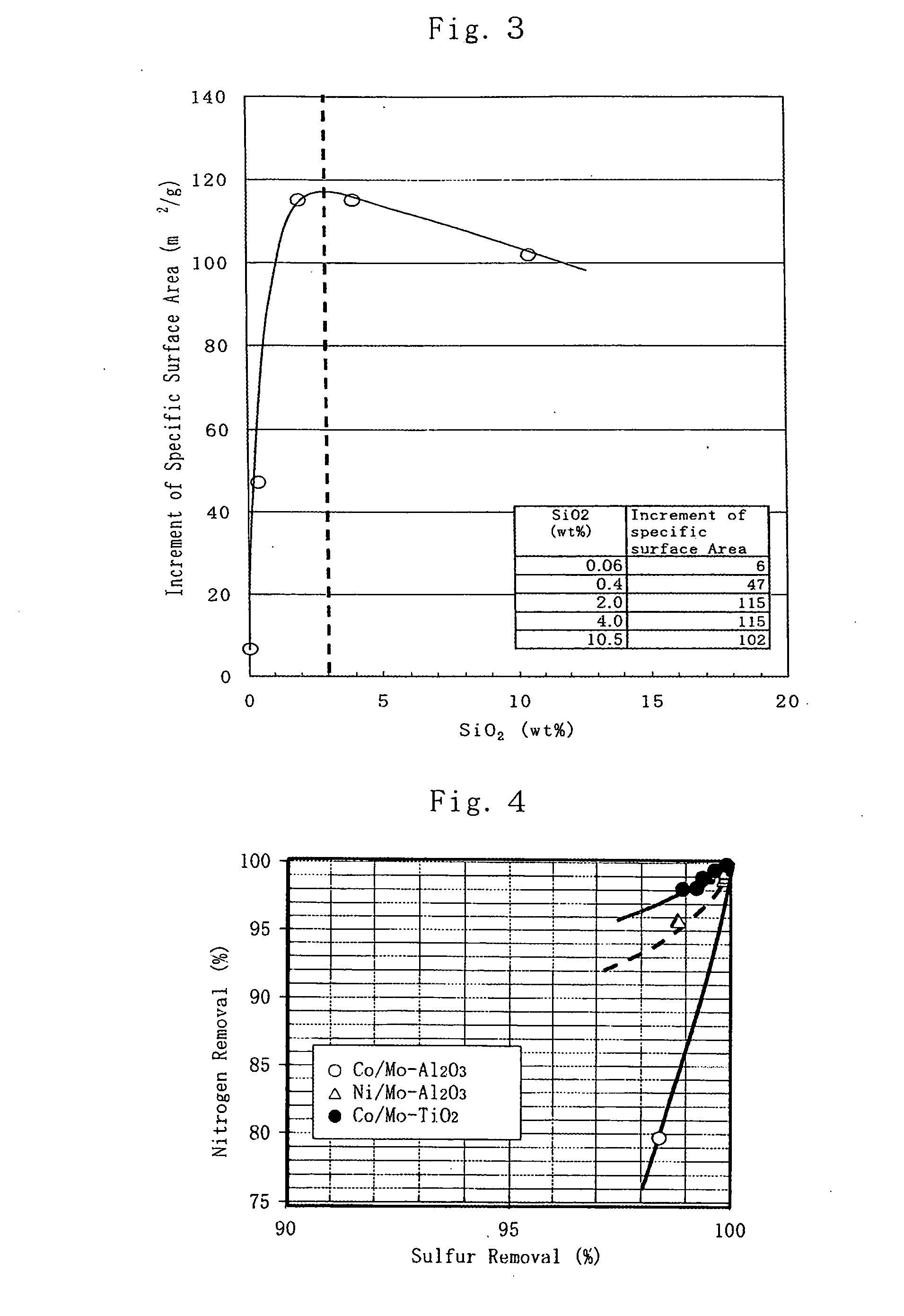

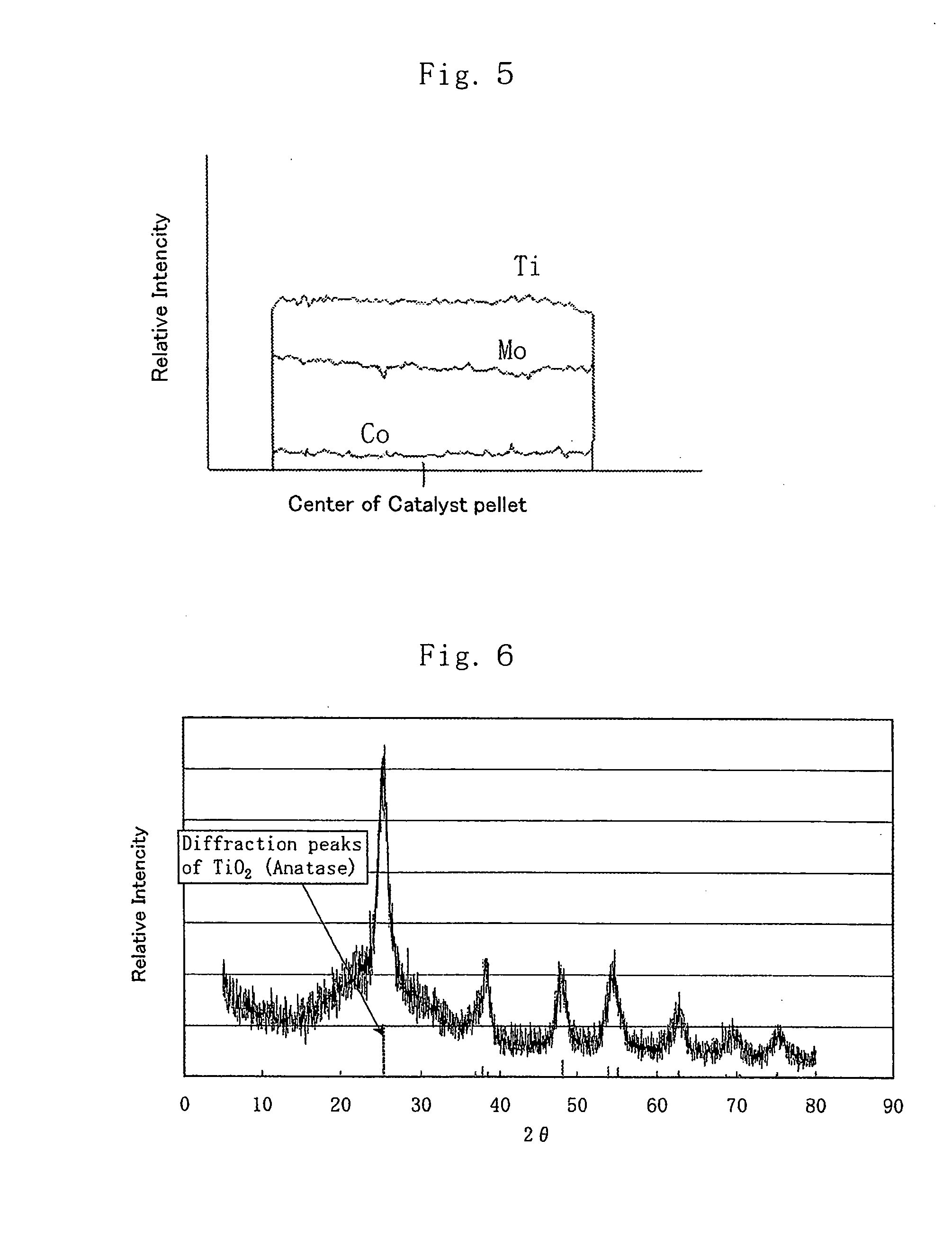

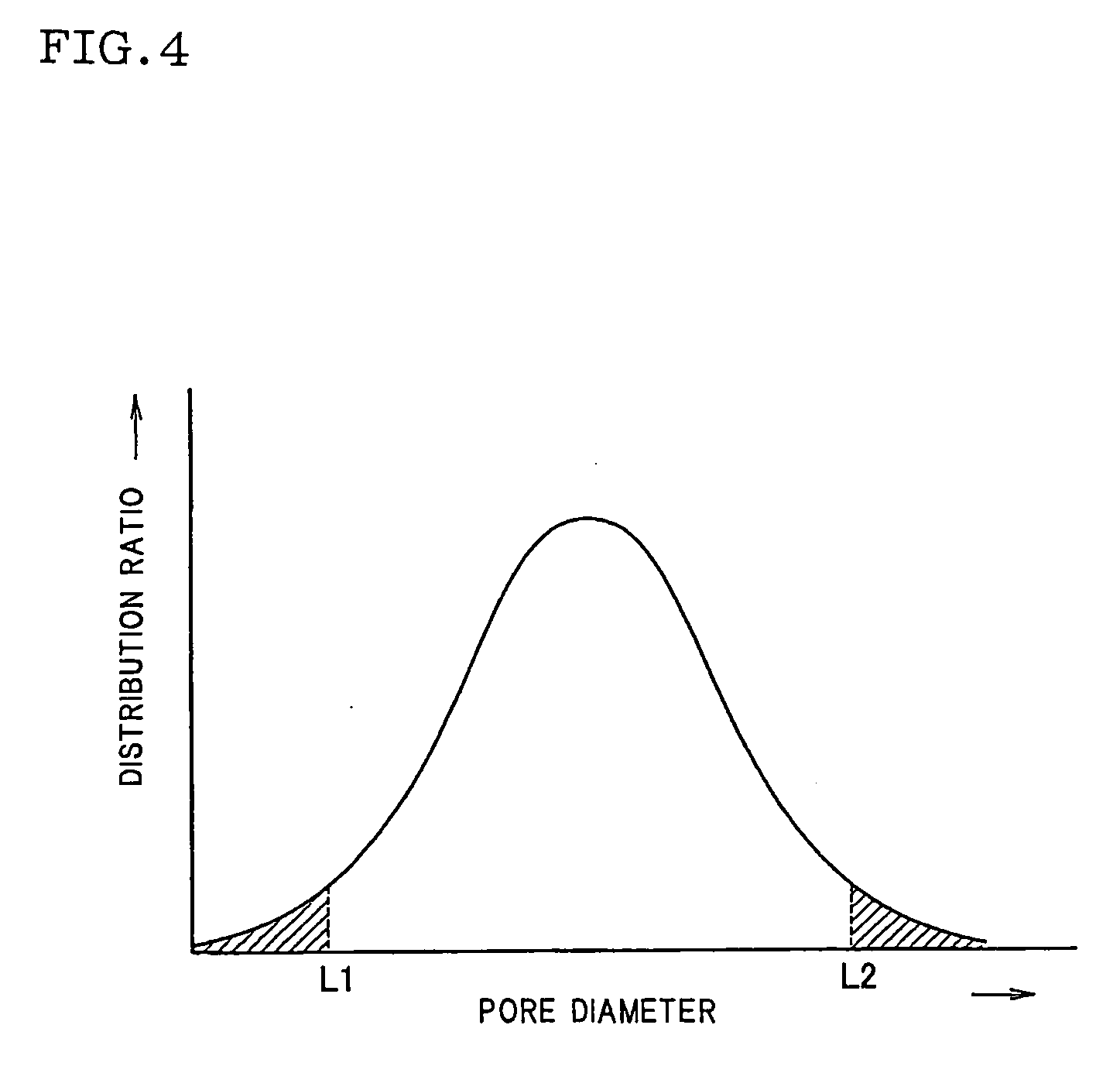

This invention relates to a 4 group metal oxide and to a method for preparation thereof and the 4 group metal oxide prepared by adding a particle growth inhibiter to a hydrosol a hydrogel or a dried product of a hydrous 4 group metal oxide represented by MO(2-x)(OH)2x (wherein M denotes a 4 group metal and x is a number greater than 0.1 or x>0.1) followed by drying and calcining has a specific surface area of 80 m<2> / g or more, a pore volume of 0.2 ml / g or more and a pore sharpness degree of 50% or more and excellent heat stability and is useful for a catalyst or a catalyst carrier in which a catalyst metal is dispersed to a high degree. This invention further relates to a porous 4 group metal oxide and to a method for preparation thereof and the 4 group metal oxide prepared by application of a pH swing operation is characterized by a large specific surface area, excellent heat stability, high dispersion of a catalyst metal and a controlled and sharp pore distribution and is useful for a catalyst or a catalyst carrier of excellent reaction selectivity.

Owner:CHIYODA CORP

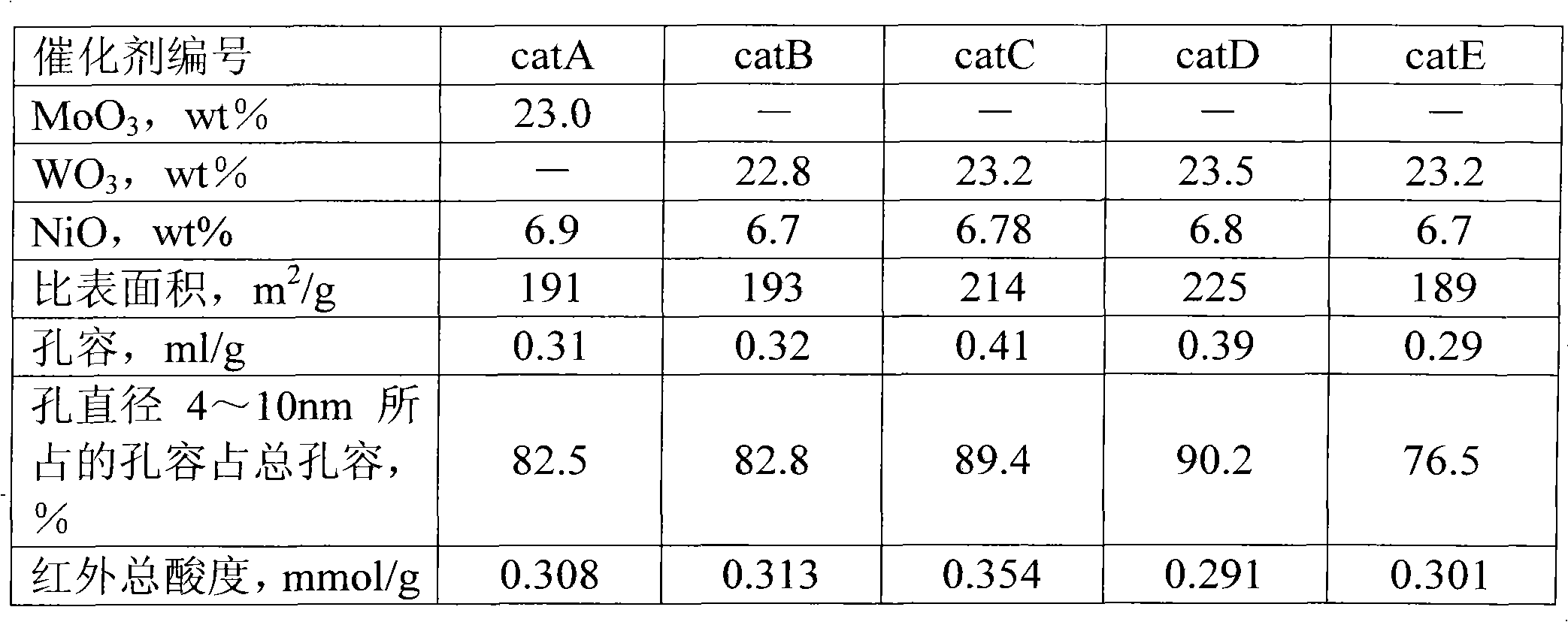

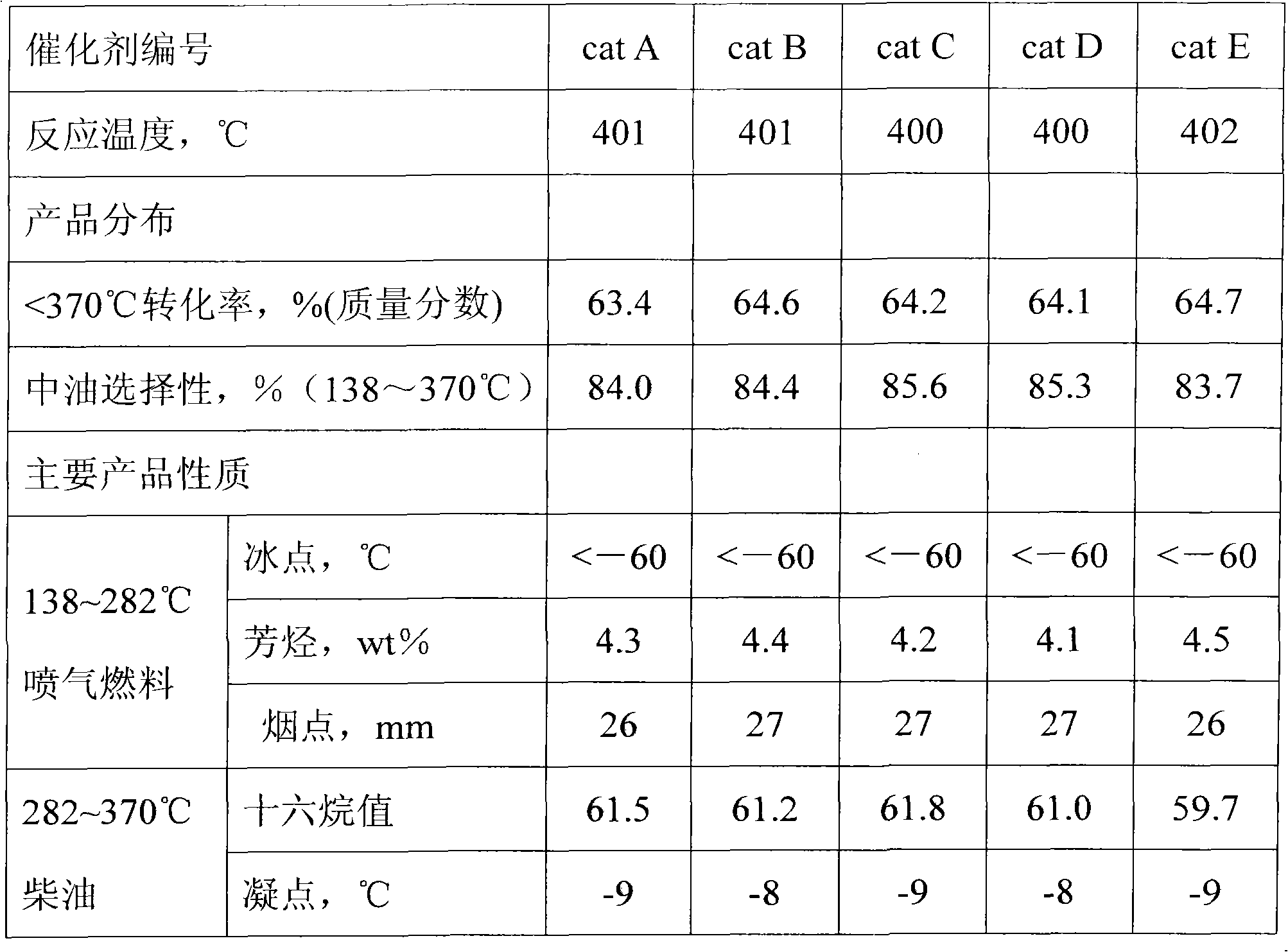

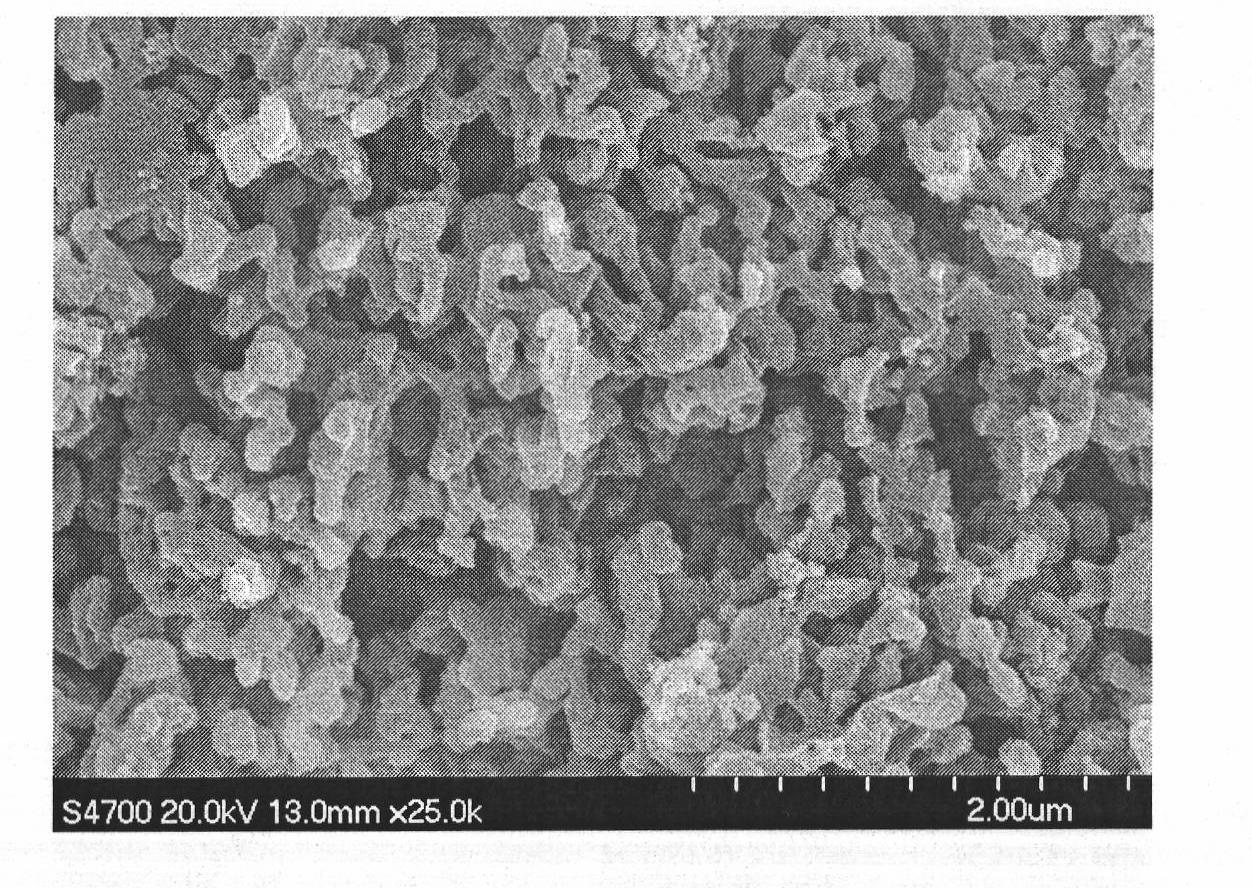

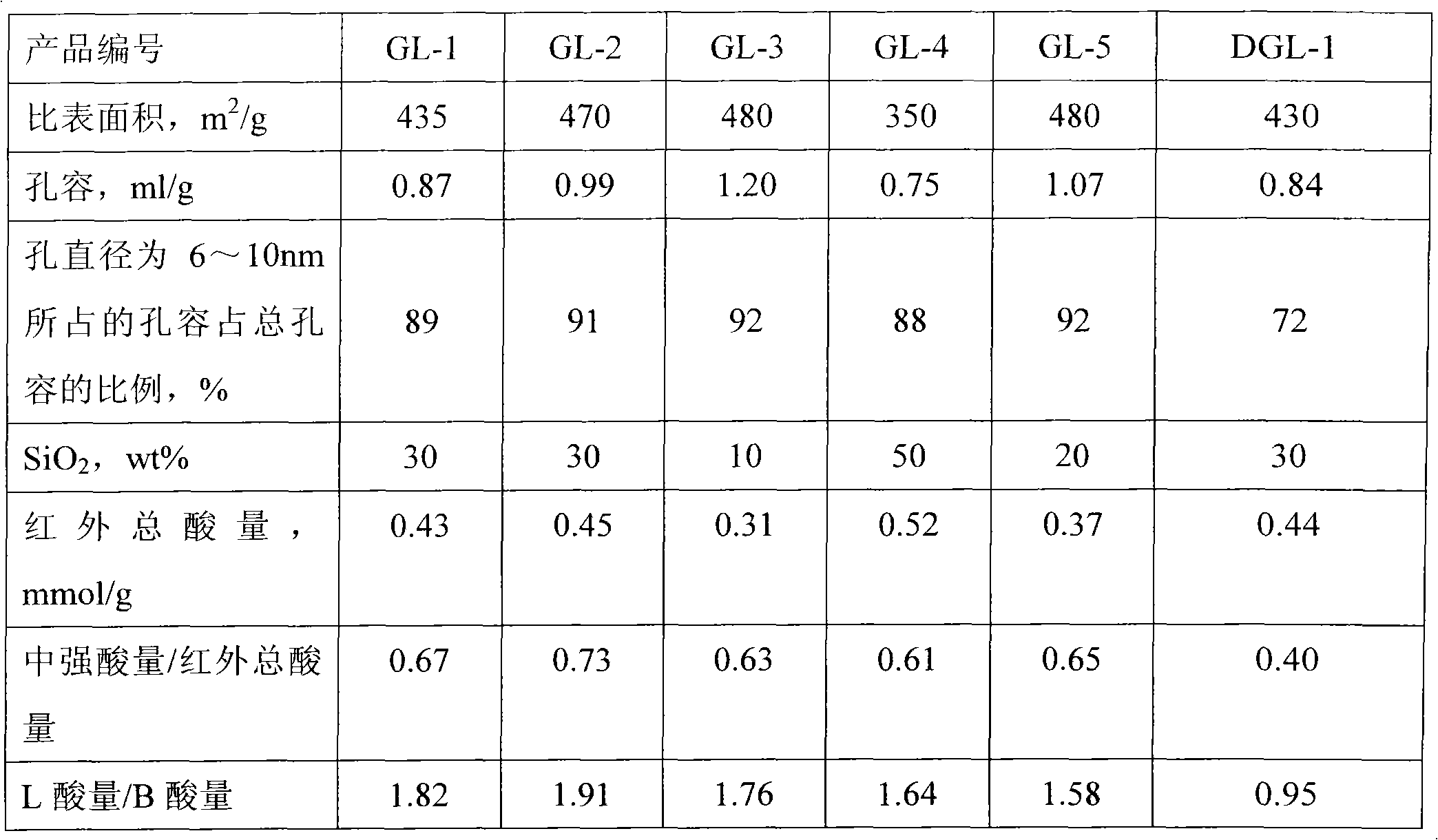

Hydrocracking catalyst and preparation method thereof

ActiveCN102039151AImprove hydrogenation activityHigh selectivityMolecular sieve catalystsCatalyst activation/preparationPore distributionSingle stage

The invention discloses a hydrocracking catalyst and a preparation method thereof. The catalyst is prepared by a carbonization method and is amorphous silica aluminum subject to hydro-thermal treatment. The amorphous silica aluminum prepared by the method has the characteristics of large specific surface, large pore volume, centralized pore distribution and appropriate acidity; an enough channel is provided for reactants, the reactants and products are convenient to enter / exit, the active ingredients of the carrier are greatly increased, and the distribution uniformity of the acid centre in the pore channel is improved; and moreover, as a larger space and a specific surface are provided for loading metal, the hydrogenated metal has higher dispersibility, the metal utilization rate is improved, and the catalyst provided by the invention has appropriate cracking activity as well as high hydrogenation activity and medium oil selectivity. The catalyst provided by the invention is particularly suitable for finishing the single-stage hydrocracking process once.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst for preparing alkane of diesel oil fraction from synthetic gas and its prepn

InactiveCN1417292AHydrocarbon from carbon oxidesLiquid hydrocarbon mixture recoveryAlkanePore distribution

The catalyst consists of three parts including active component, assistant and carrier. The main active component is metal Co. The first assistant element is group IVB metal element, such as Ti and Zr or group IIIB metal element, such as La and Ce; and the second ssistant element is group VIII metal element, such as Rh, Ru and Pt. The carrier is active carbon of apricot kernel, coconut shell, oilpalm or coal; has specific surface area of 200-2000 sq mg, pore volume of 0.5-2.0 cu cm / g and pore distribution of 4-1000 angstrom. Of the catalyst weight, metal Co accounts for 4-50 %, the first assistant element 0.01-20.0% and the second assistant element 0.01-50 %. The catalyst may be used in the Fischer-Tropsch reaction of synthetic gas to prepare high-quality diesel oil as clean liquid fuel.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Porous carbon material and preparation method thereof

InactiveCN102107863ALow costSimple processOther chemical processesCapacitor electrodesPore distributionMass ratio

The invention relates to a porous carbon material and a preparation method thereof. The porous carbon material with fish scale as a raw material is prepared by using the organic and inorganic matters in fish scales as a carbon source and a natural template, and the particular method comprises the following steps: allowing dry fish scale to perform precarbonization at 300-350 DEG C; well mixing the precarbonized fish scale and an alkaline activator with a mass ratio of 1:0.5-1:3, performing activation and carbonization, performing post-treatment to remove inorganic salts, washing with deionized water to obtain a neutral solution, drying to obtain a carbon material with multilevel pore distribution. The preparation method of the invention is simple and low in cost, is applicable to industrial production; and the prepared porous carbon material is applicable to adsorption materials and super capacitors, and has a high adsorption quantity and a good specific energy rate property. The invention opens up a new way for the effective utilization of fish scale which is a waste in fishery.

Owner:BEIJING UNIV OF CHEM TECH

Ceramic honeycomb structure

ActiveUS7504359B2Excellent in pressure loss and catching efficiencyHigh catalytic activityDispersed particle filtrationExhaust apparatusPore distributionSurface roughness

A honeycomb structural body comprises one or plural pillar-shaped porous ceramic members in which many through-holes are arranged side by side in a longitudinal direction through partition walls and either one end portions of these through-holes are sealed.The partition wall forming the structural body has a surface roughness of not less than 10 μm as a maximum roughness Rz defined in JIS B0601-2001 and an average pore size of 5-100 μm in a pore distribution measured by a mercury pressure method, and satisfies the following relationship:A≧90−B / 20 or A≦100−B / 20when a ratio pores having a pore size of 0.9-1.1 times the average pore size to total pore volume is A (%) and a thickness of the partition wall is B (μm), and there is proposed an effective honeycomb structural body having excellent pressure loss and catching efficiency and a high catalyst reactivity.

Owner:IBIDEN CO LTD

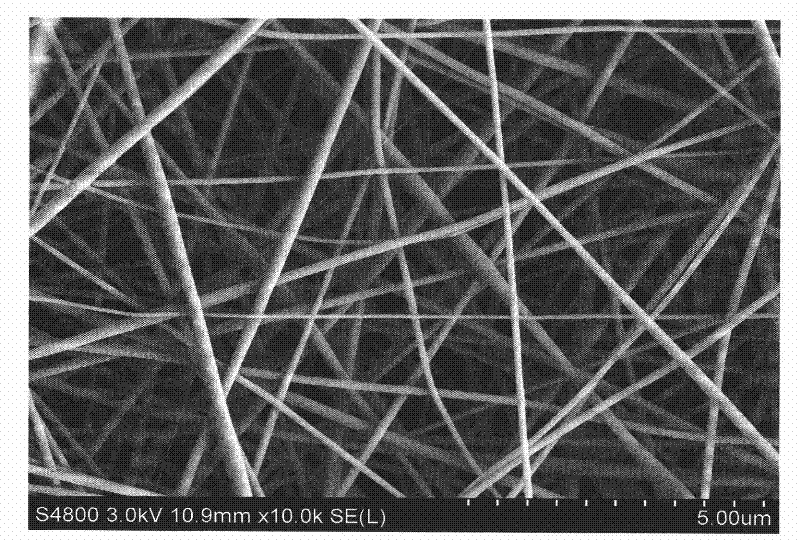

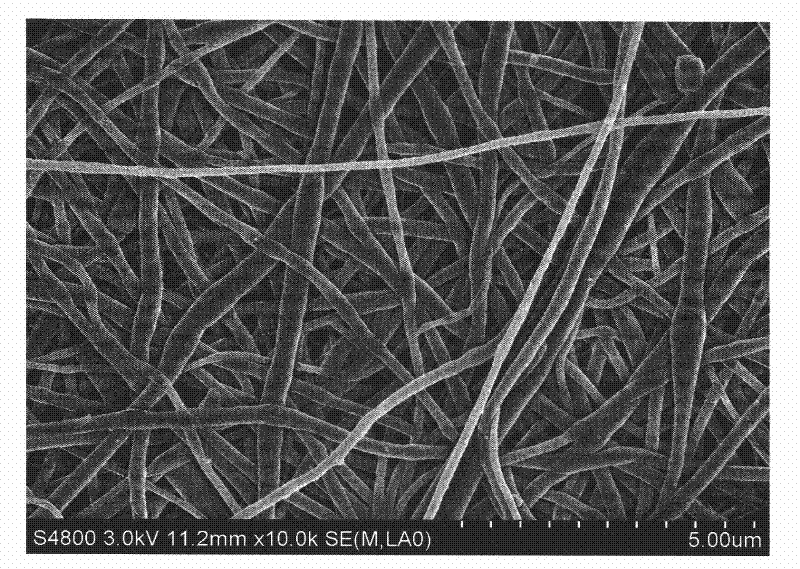

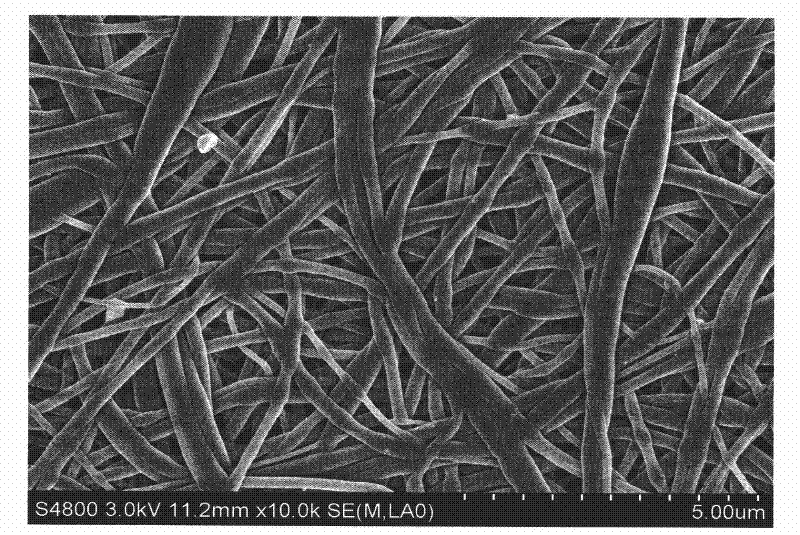

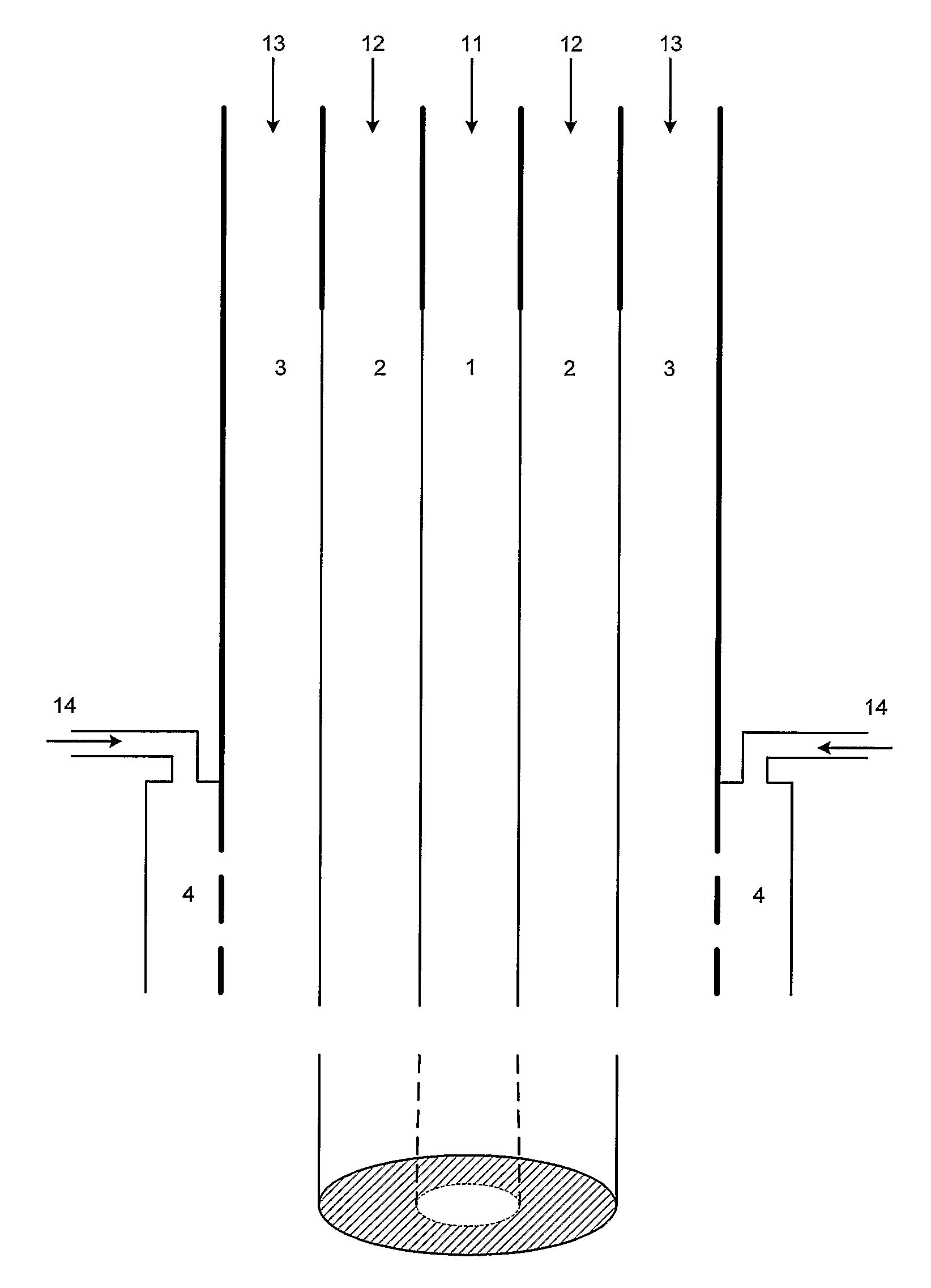

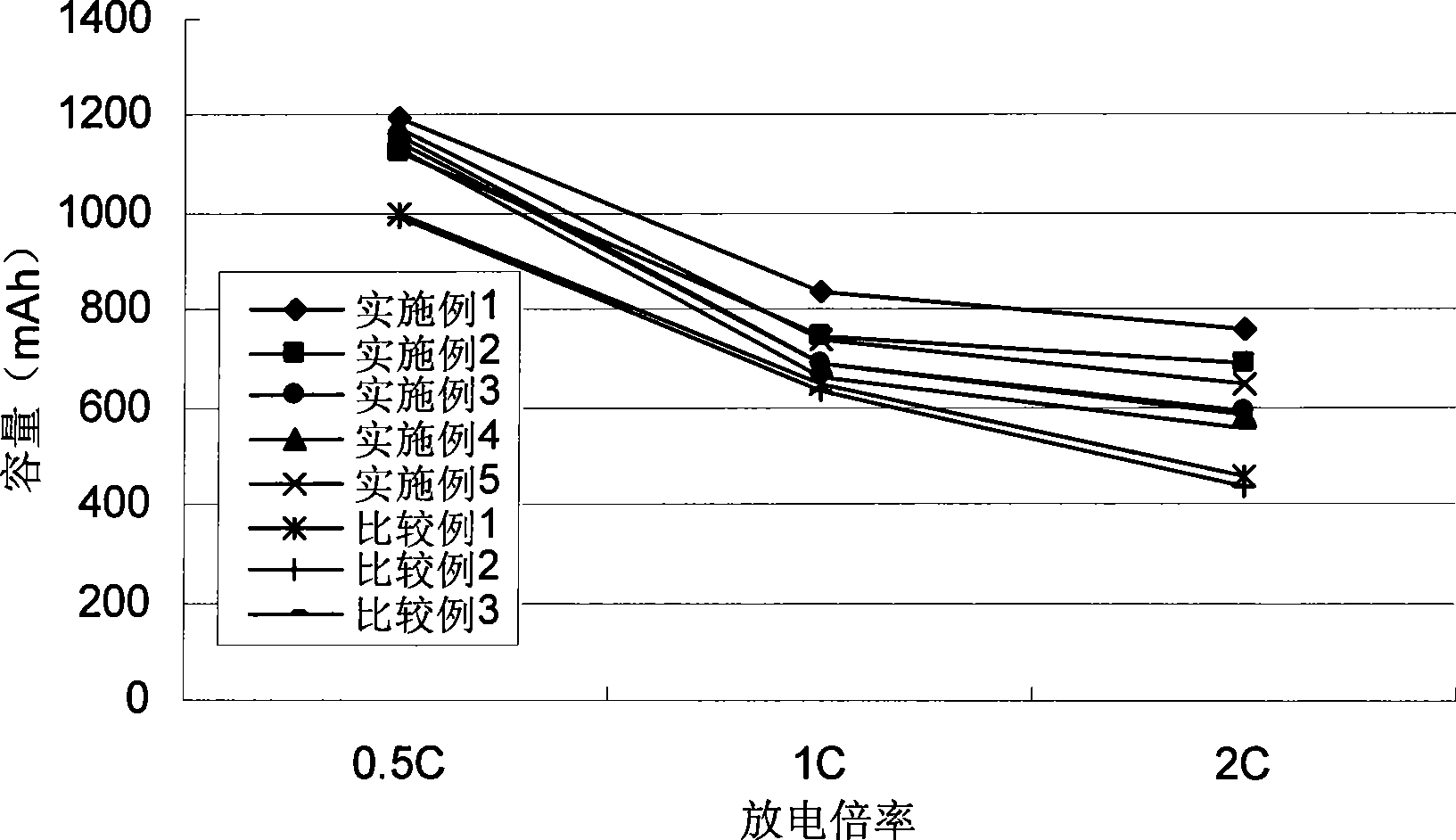

Polyimide-base nano fibrous membrane, and preparation method and application thereof

ActiveCN102251307AEasy to manufactureUniform pore structureFilament/thread formingMonocomponent synthetic polymer artificial filamentFiberPore distribution

The invention discloses a polyimide-base nano fibrous membrane which can be used as a lithium ion secondary battery membrane. The polyimide-base nano fibrous membrane is composed of polyimide nano fibers of which the diameters are 20-500 nanometers, the membrane thickness is 15-100 micrometers, and the air penetrability of the membrane is 10-500 seconds; and the pore distribution of the upper andlower surfaces and the inside is symmetrical and uniform, the average pore size is 100 nanometers, and the tensile strength is 100-250mpa. The invention also discloses a preparation method of the polyimide-base nano fibrous membrane. When being used as the lithium ion battery membrane, the polyimide-base nano fibrous membrane has favorable heat resistance, and can not produce the phenomenon of short circuit even at 150 DEG C; and therefore, the battery membrane disclosed by the invention is especially suitable for high-capacity and high-power lithium ion batteries.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

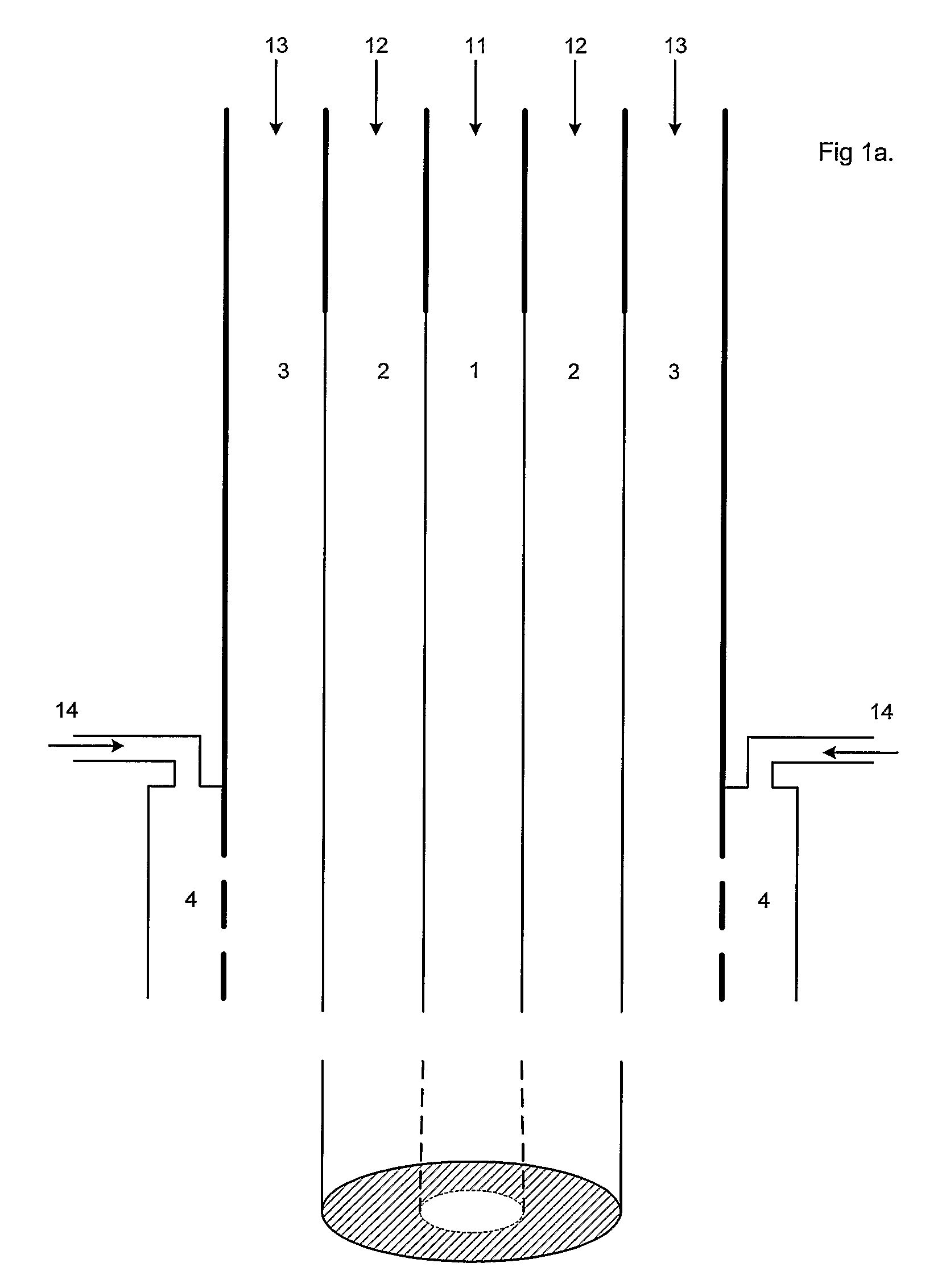

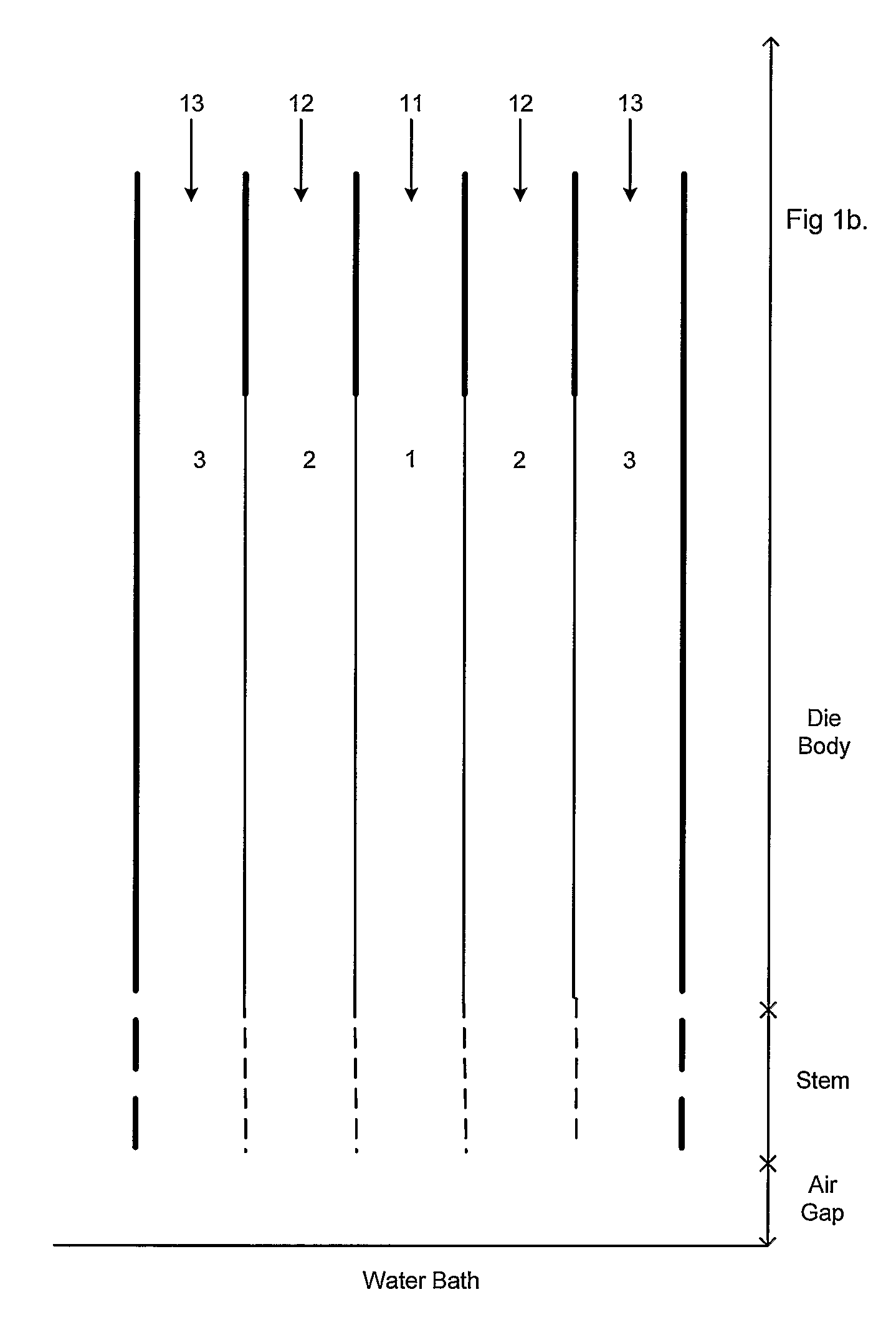

Gas transfer membrane

Porous polymeric membranes formed from a hydrophobic polymer, such as halar having membrane pores of a size sufficient to permit gas and / or vapor permeation 0.05 μm to 5 μm without permitting the flow of a hydrophilic fluid across the membrane. Pore distribution is uniform and porosity is high, in some cases up to 80%. Membranes may be in the form of a flay sheet or hollow fibre for example and can be used in a variety of applications such as stripping HF gas, degassing of caustic solution, chlorine gas / alkaline filtration, degassing tap water to remove dissolved chlorine. Processes used to make such membranes can be carried out using relatively non toxic solvents such as citric acid ethyl ester or glycerol triacetate.

Owner:EVOQUA WATER TECH LLC

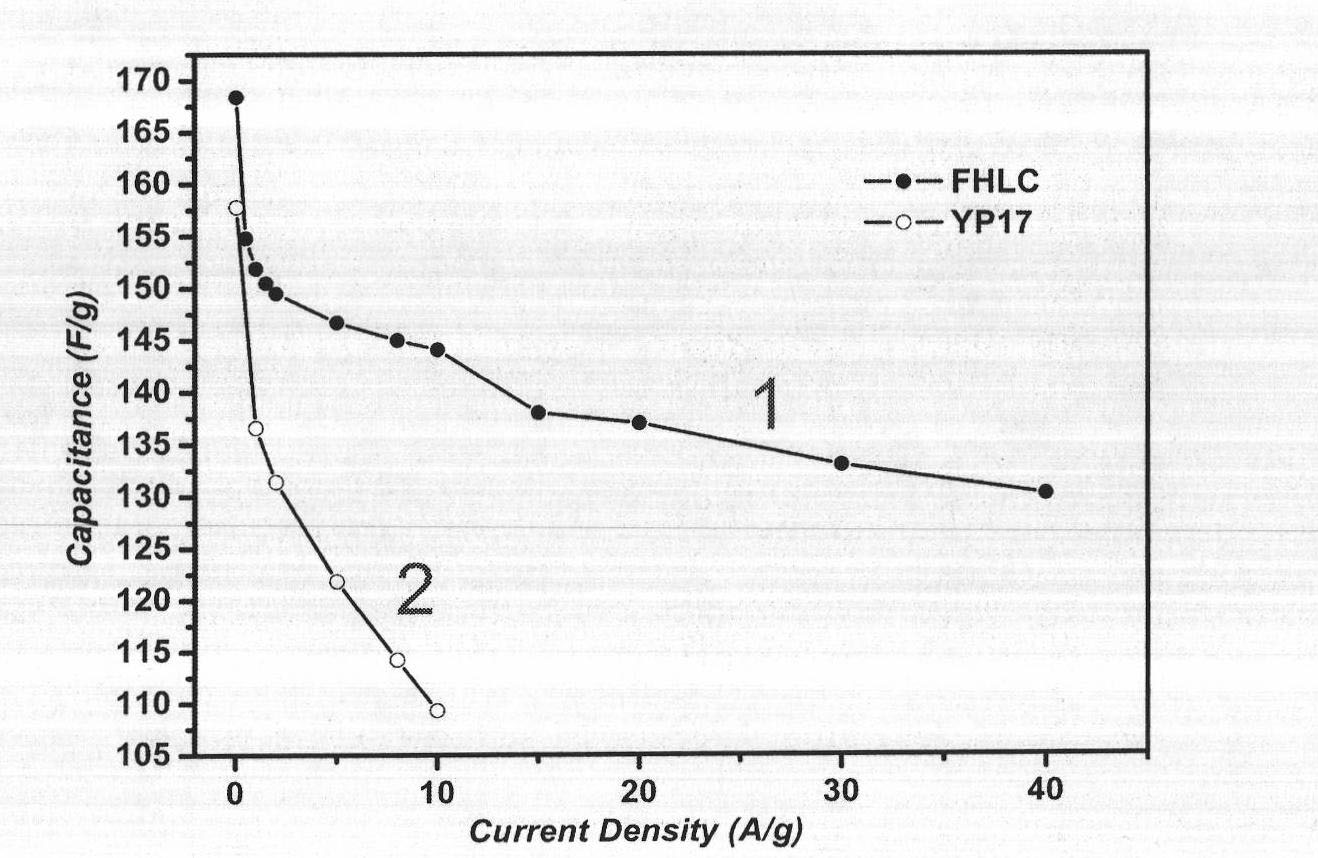

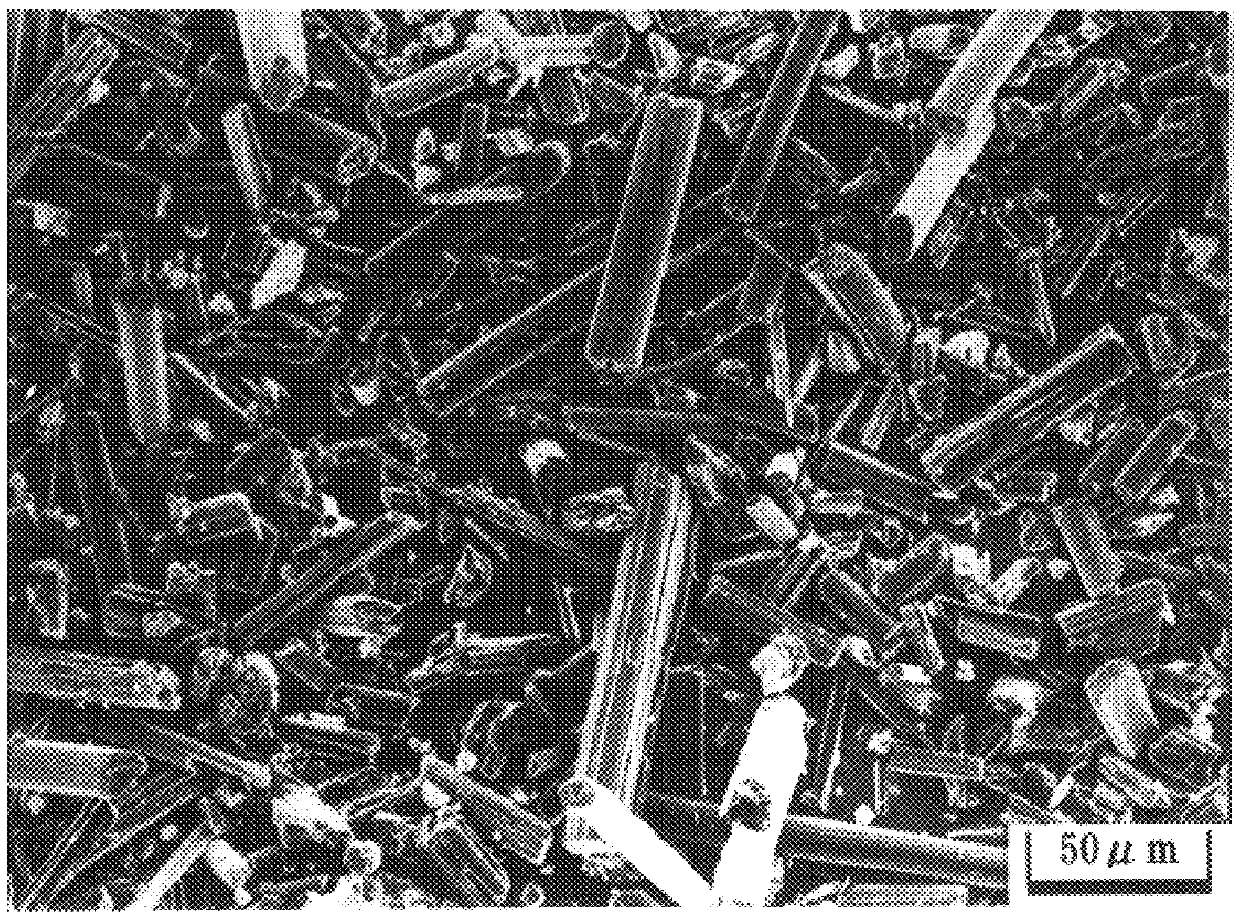

Mesophase pitch-based activated carbon fibers and electric double layer capacitor using the same

InactiveUS6118650ALower internal resistanceImprove conductivityHybrid capacitor electrodesLiquid electrolytic capacitorsActivated carbonFiber

Mesophase pitch-based activated carbon fibers which are obtained by milling infusibilized mesophase pitch fibers, as they are or after carbonizing at a temperature of 350 to 1,000 DEG C., to an average particle diameter of 5 to 50 mu m and then activating in the presence of an alkali metal compound. The activated carbon fibers have a pore distribution suitable for forming a electric double layer and is excellent as the material for an electrode of an electric double layer capacitor. The electric double layer capacitor having the electrode using the activated carbon fiber exhibits high discharge capacity.

Owner:HONDA MOTOR CO LTD

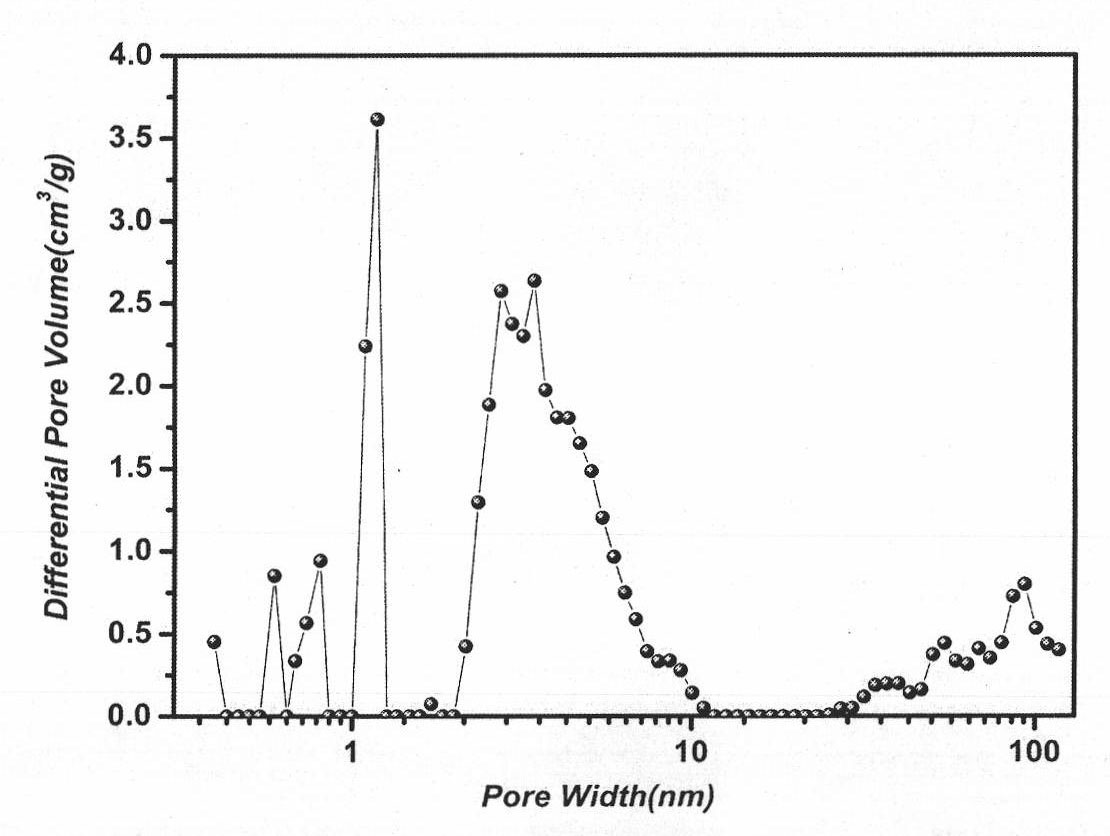

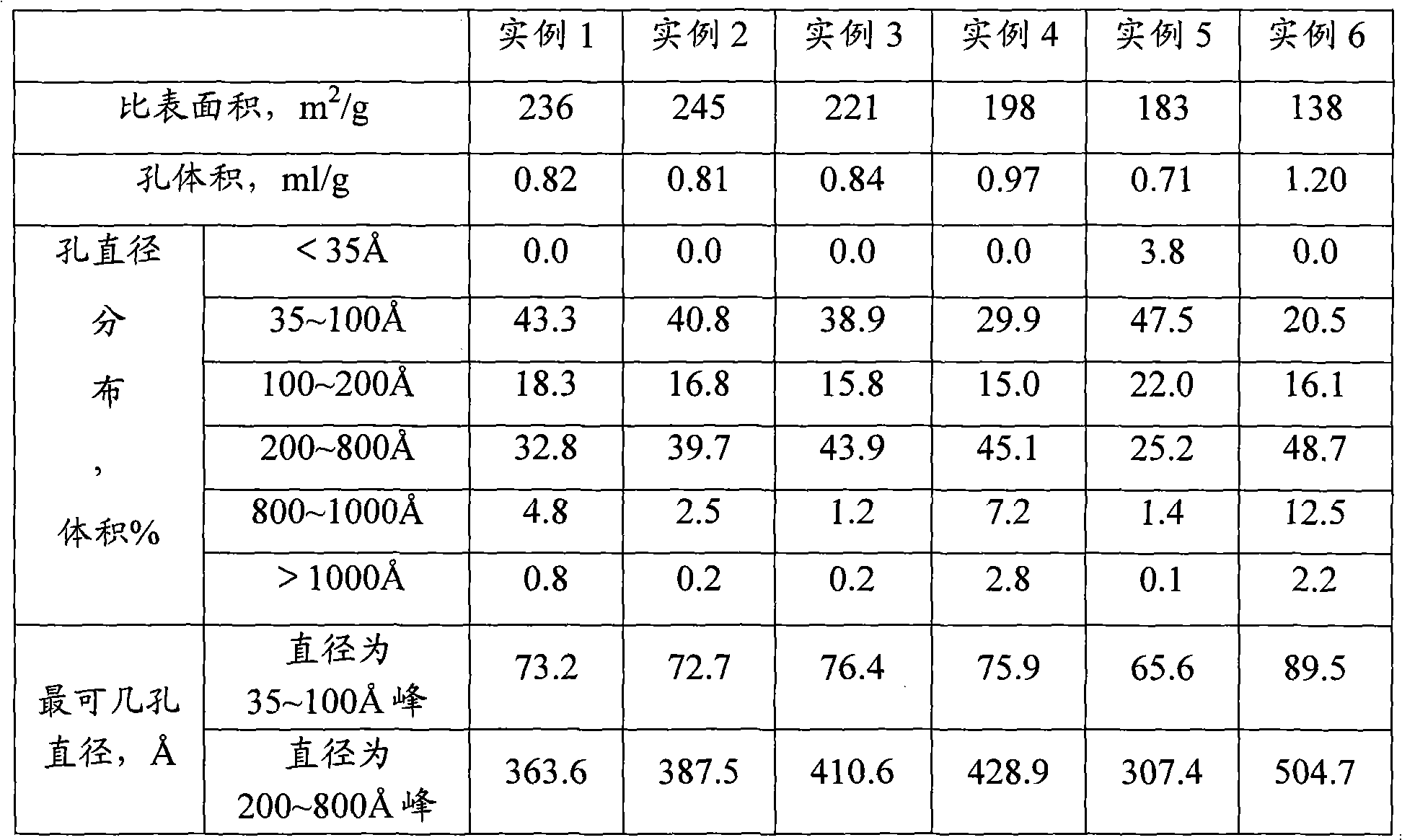

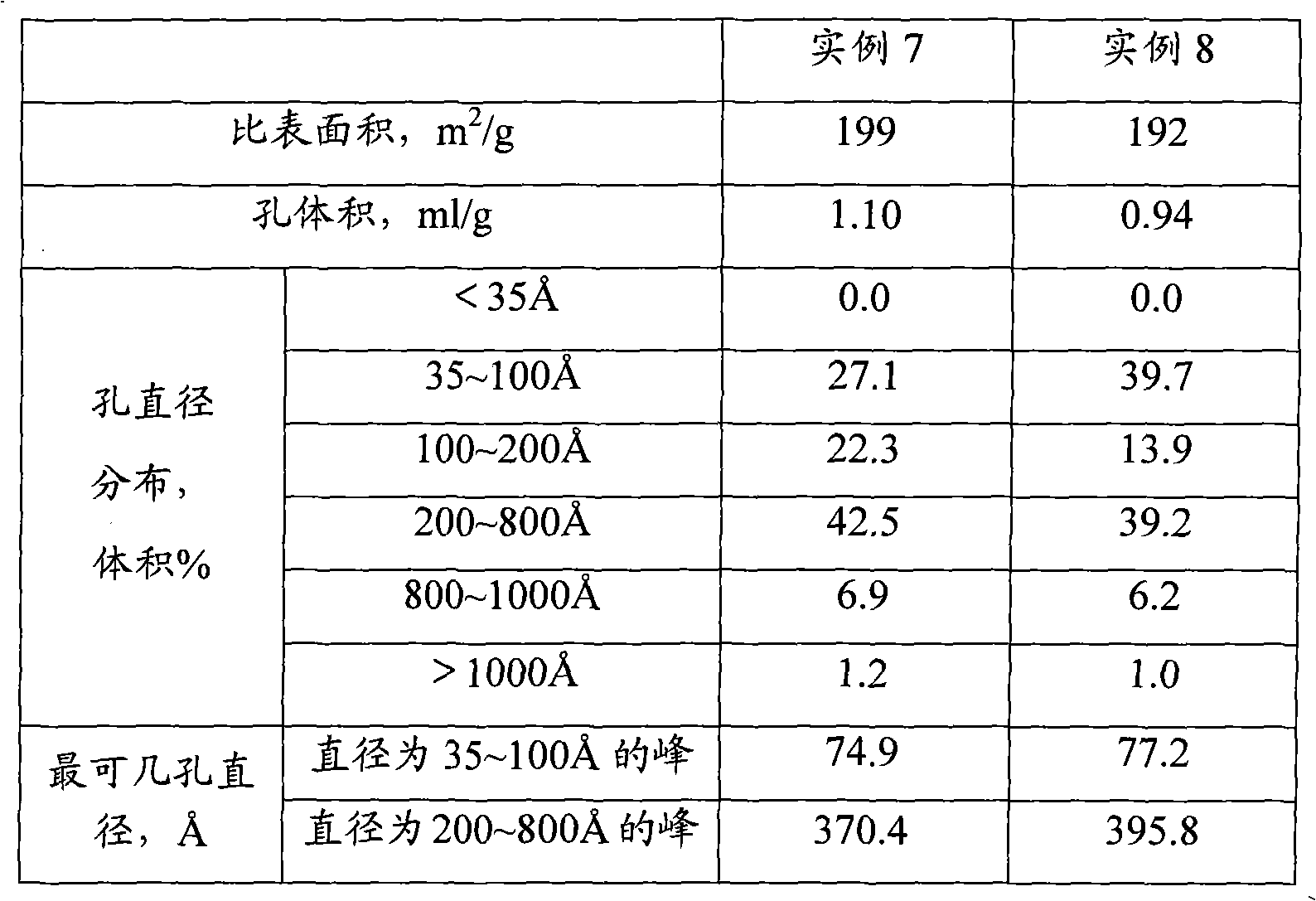

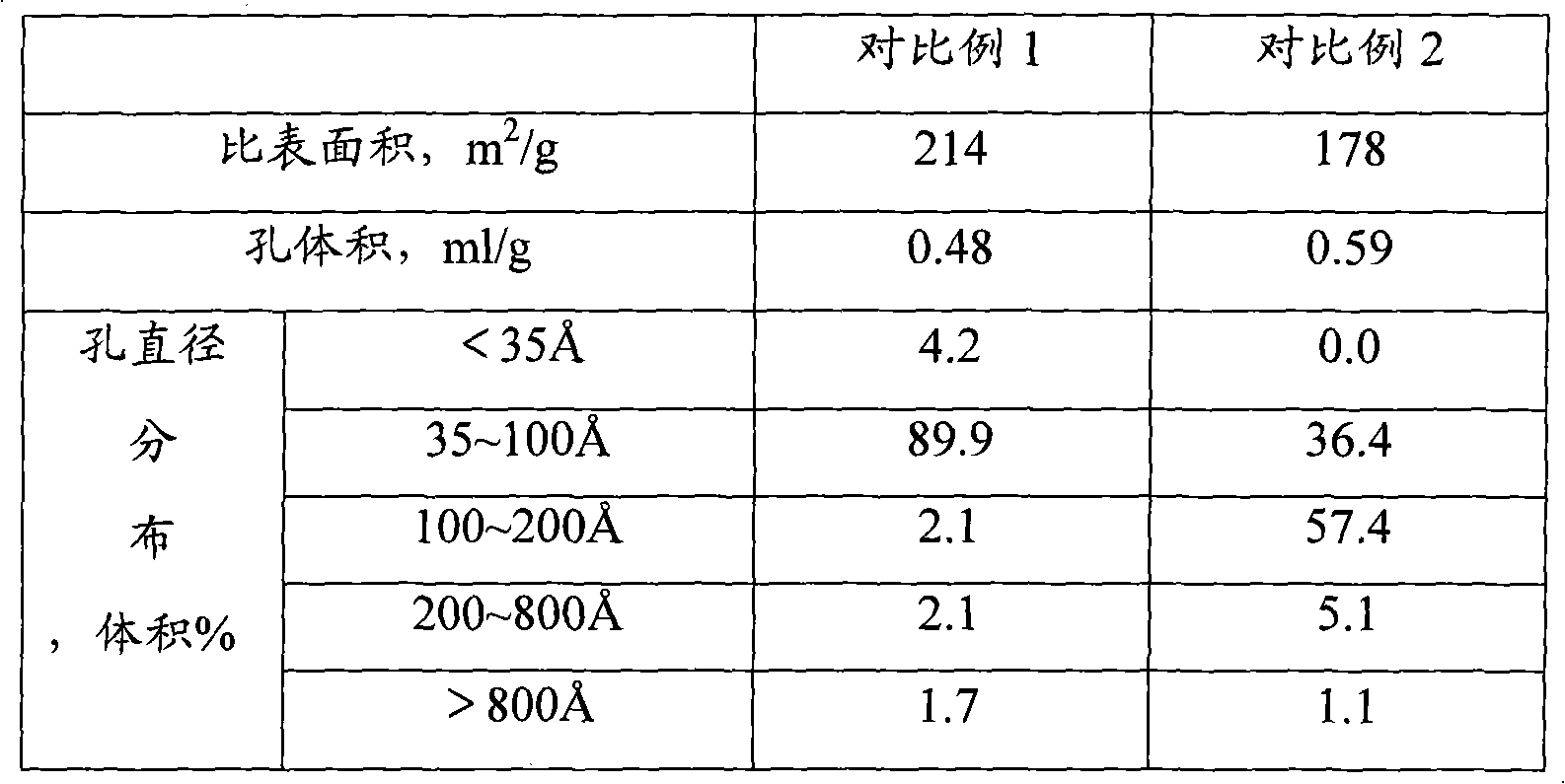

Macroporous aluminum oxide with bimodal pore distribution and preparation method thereof

ActiveCN102030351AAvoid flying temperatureReduce manufacturing costAluminium oxides/hydroxidesPore distributionOrganic solvent

The invention discloses macroporous aluminum oxide with bimodal pore distribution. The pore volume of the macroporous aluminum oxide is 0.6 to 3.0ml / g, the specific surface area is 90 to 300sq.m / g, wherein the pores with aperture of between 35 and 100 angstroms account for 20 to 55 percent of the total pore volume, and the most probable aperture is between 50 and 90; and the pores with aperture of between 200 and 800 angstroms account for 20 to 55 percent of the total pore volume, and the most probable aperture is between 300 and 600. The aluminum oxide is prepared by a two-section aging method without a hole expansion agent or an organic solvent, so the raw materials are saved, the flow is simplified, and the production cost is greatly reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Amorphous silicon aluminium and preparation method thereof

ActiveCN102039197ASimple processEasy to controlCatalyst carriersCatalytic crackingPore distributionStrong acids

The invention discloses an amorphous silicon aluminium and a preparation method thereof. In the invention, hydro-thermal treatment is carried out on amorphous silicon aluminium obtained by a carbonization method, so that the amorphous silicon aluminium has higher specific surface area and bigger pore volume, the pore distribution is more intensive, and the pore volume the pore diameter of which is 6-10nm accounts for 80-95% of the total pore volume; meanwhile, the acid distribution of the amorphous silicon aluminium is improved; the amount of moderately strong acid and L acid is improved to effectively prevent raw material modules from excessively cracking, which is favourable for improving the selectivity of a target product.

Owner:CHINA PETROLEUM & CHEM CORP +1

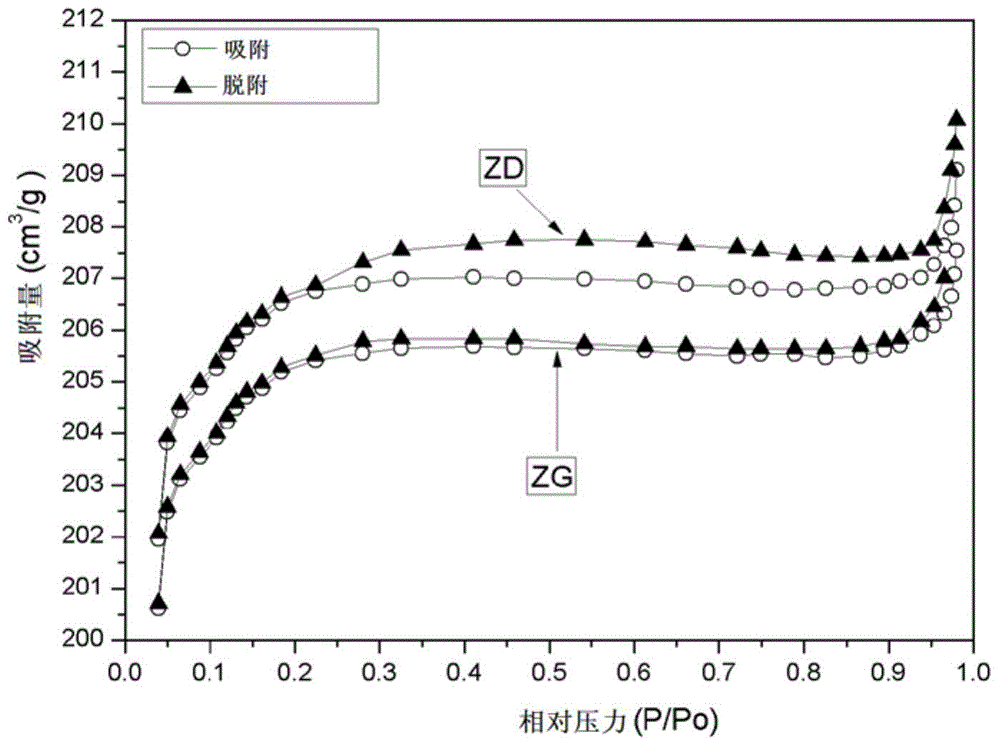

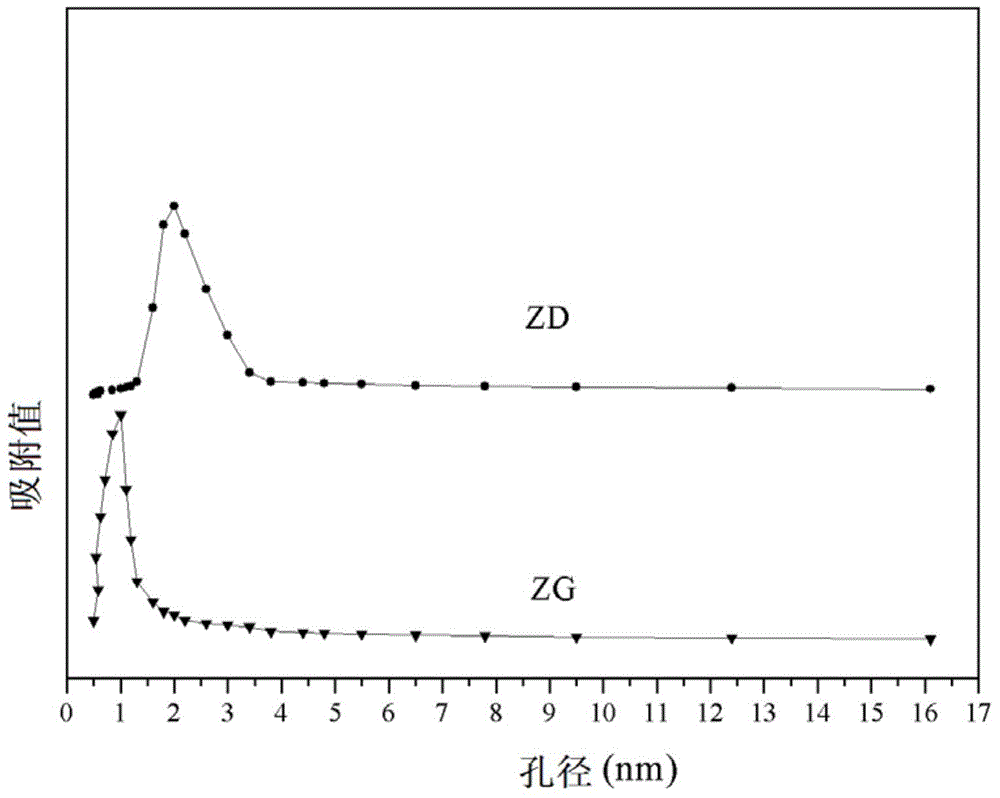

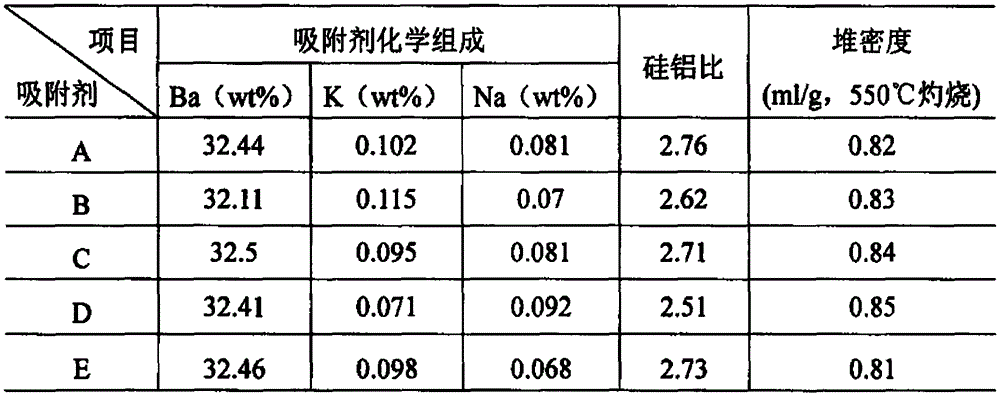

Mesoporous X-type molecular sieve, adsorbent based on molecular sieve, and preparation and application thereof

InactiveCN104477937AHigh adsorption selectivityImprove adsorption capacityOther chemical processesFaujasite aluminosilicate zeolitePore distributionSorbent

The invention relates to a preparation method of a mesoporous X-type molecular sieve and a method for preparing an adsorbent by using the molecular sieve as an active component. The prepared adsorbent based on the mesoporous X-type molecular sieve is used as a paraxylene adsorptive separation adsorbent. The method for preparing the mesoporous X-type molecular sieve comprises the following steps: by using water glass as a silicon source and aluminum hydroxide as an aluminum source, adding a template, and carrying out hydrothermal synthesis to obtain the mesoporous X-type molecular sieve. The mesoporous molecular sieve and kaolin are proportionally molded to obtain 0.3-0.8mm granules, and the granules are subjected to barium ion or (and) potassium ion exchange until the exchange degree is greater than 99%, thereby obtaining the adsorbent which has excellent adsorptive separation capacity for paraxylene in C8 aromatic hydrocarbons. Compared with the prior art, the active component mesoporous X-type molecular sieve of the adsorbent, which is prepared by using the template, has the crystal form structure of the X-type molecular sieve and the pore distribution of the mesoporous and microporous dual models; the mesoporous pore size distribution is 2nm or so; and thus, the problem of overlow mass transfer rate in the adsorbent can be solved.

Owner:SHANGHAI LVQIANG NEW MATERIALS CO LTD +1

Selectivity hydrogenation method for whole fraction crack petroleum

ActiveCN101121899AGood activity at low temperatureGood choiceRefining by selective hydrogenationRefining by aromatic hydrocarbon hydrogenationPore distributionReaction temperature

The invention relates to a method for selective hydrogenation of full-run pyrolysis gasoline, which mainly solves the technical problem in the prior art that it is difficult to selectively hydrogenate full-run pyrolysis gasoline with high colloid and free water content. The present invention adopts the pyrolysis gasoline and hydrogen of the hydrocarbon compound fraction with C5 hydrocarbon to dry point of 204 DEG C as raw materials, the reaction temperature is 30 to 80 DEG C, the reaction pressure is 2.0 to 3.0 MPa, and the fresh oil space velocity is 2.5 to 5.0 hour-1, under the condition that the hydrogen / oil volume ratio is 60-120:1, the raw material is contacted with the catalyst and reacts to convert the diolefin and alkenyl aromatic components in the raw material into monoolefin and alkylaromatic. Including alumina support, active component metal palladium or its oxide, at least one element selected from IA or IIA in the periodic table or its oxide, at least one element selected from IVA or VA in the periodic table or its oxide Oxide, the specific surface area of the carrier is 40-160 m2 / g, the total pore volume is 0.3-1.2 ml / g, and the carrier has a technical solution of composite pore distribution, which solves this problem well and can be used for full-run pyrolysis gasoline In the industrial production of selective hydrogenation.

Owner:CHINA PETROLEUM & CHEM CORP +1

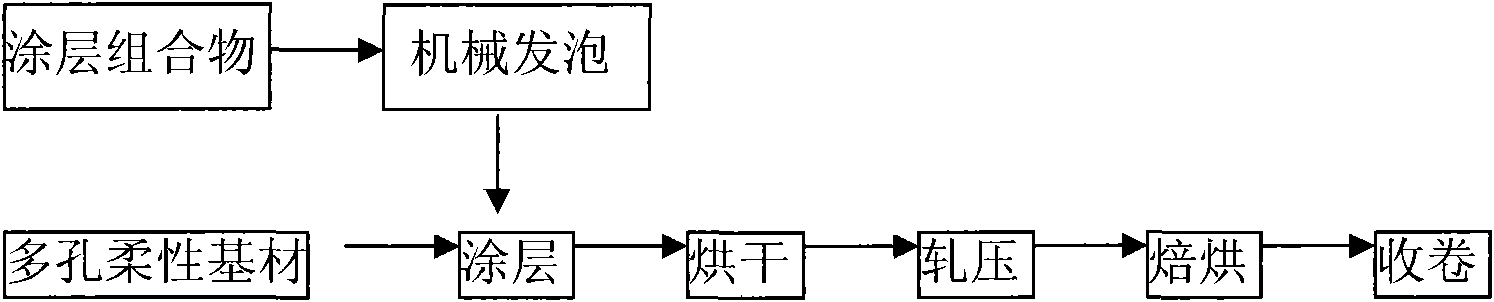

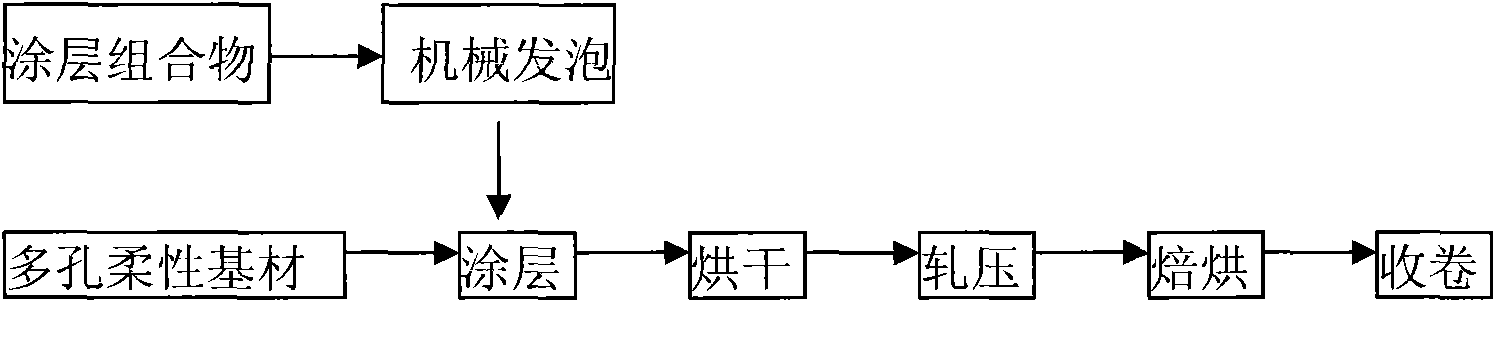

Coating composite for lithium ion battery separator and foam gluing method

ActiveCN101789499AGood adhesionNot easy to fall offCell component detailsCoatingsPore distributionFoaming agent

The invention relates to a coating composite for a lithium ion battery separator, wherein the coating composite contains porous electro-insulated oxide particles, binding agent, foaming agent or foam stabilizing agent. The invention further relates to a foam gluing method for the lithium ion battery separator, comprising the steps: mechanically foaming and the coating suspension on the surface of a porous flexible substrate, drying, curing and roll compacting to form a film with micro pores, wherein the suspension contains the coating composite according to the invention. Adopting the coating composition according to the invention and the lithium ion battery separator prepared therefrom can achieve the purpose of small pore diameter, even pore distribution and ensuring the charging and discharging uniformity of lithium ion.

Owner:CHINA HAISUM ENG

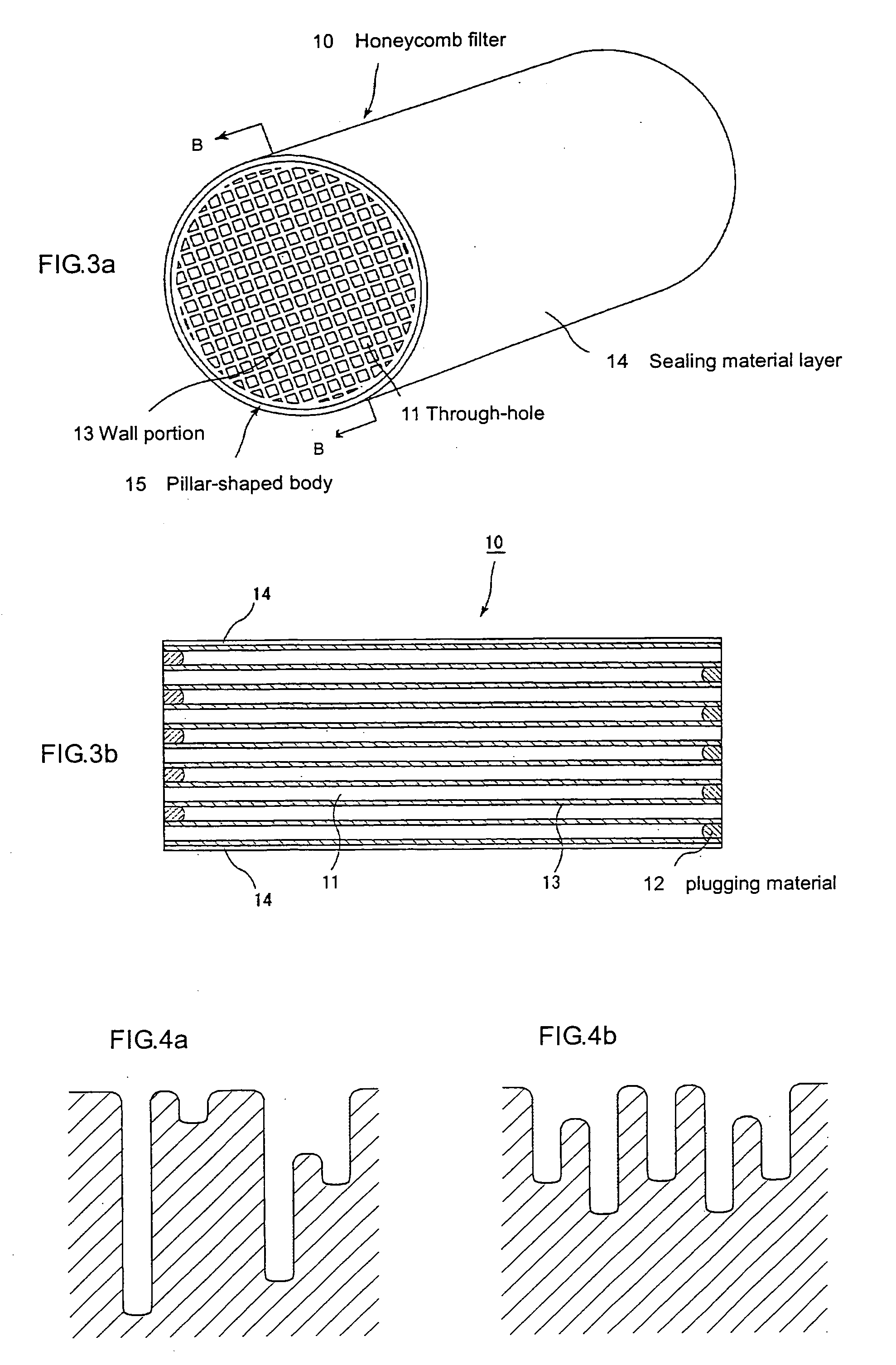

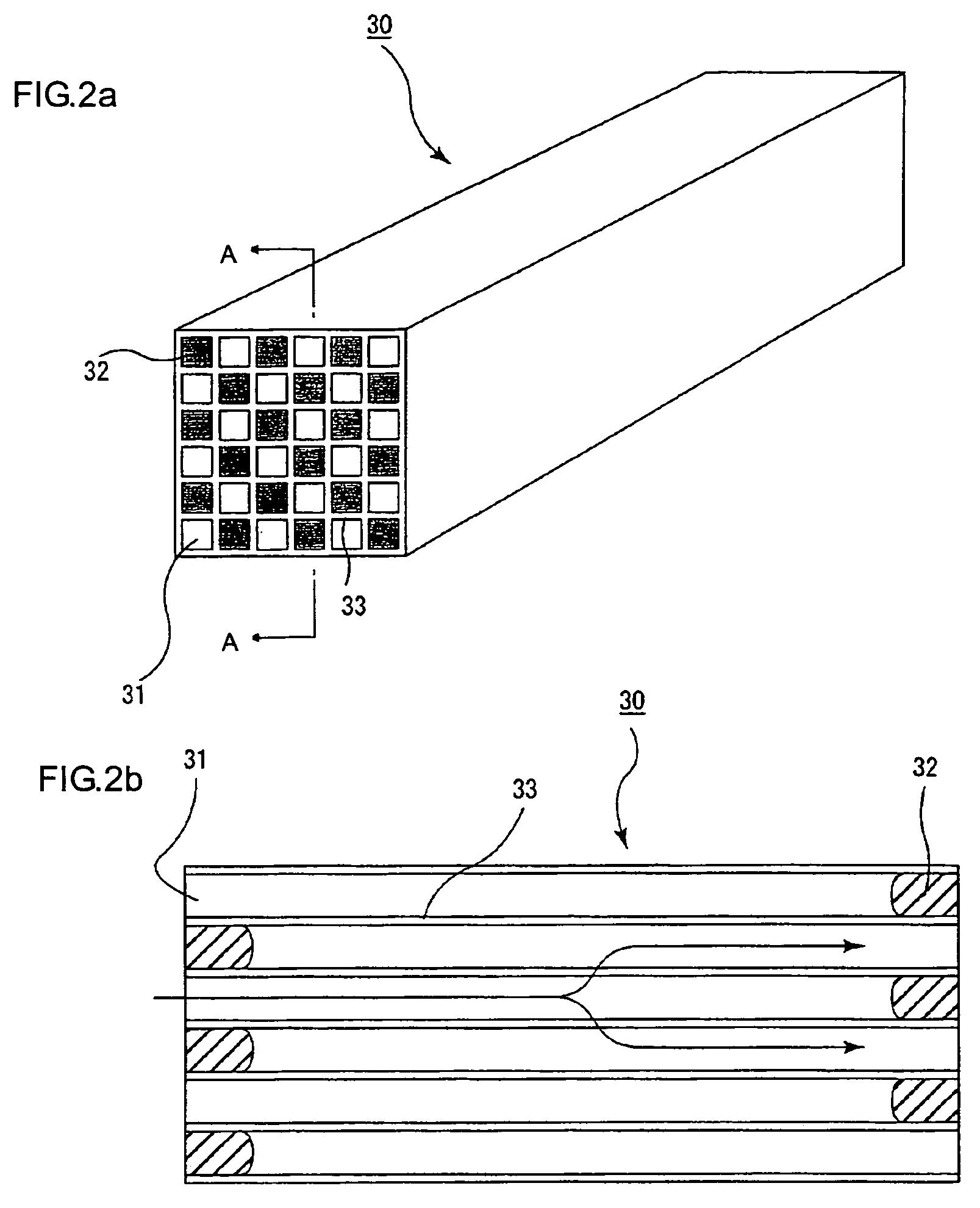

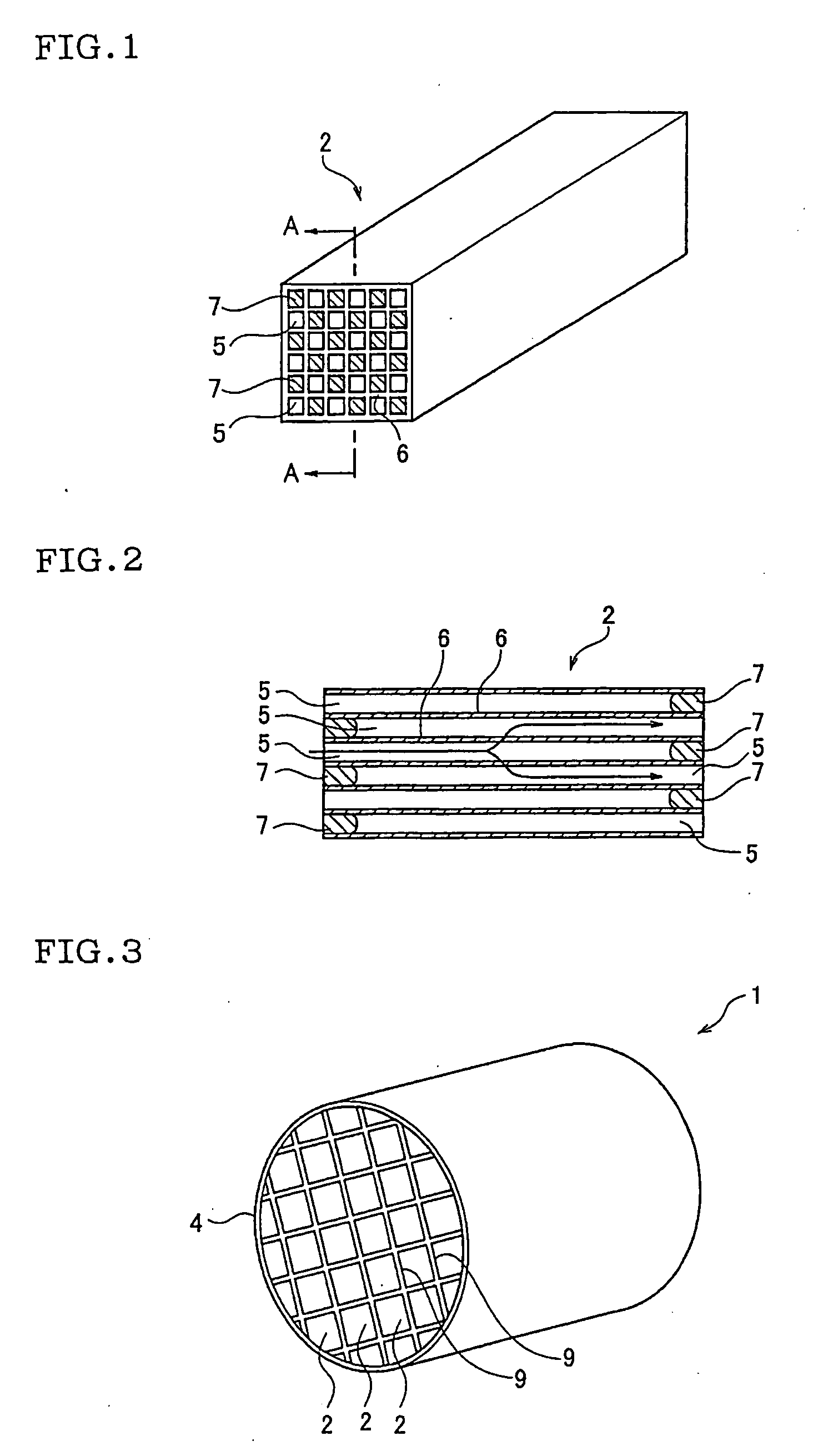

Porous Honeycomb Filter

InactiveUS20080092499A1Drop in trapping efficiencyIncreased pressure lossPhysical/chemical process catalystsDispersed particle filtrationPore distributionHoneycomb

There is disclosed a porous honeycomb filter whose trapping efficiency does not drop even when a porosity fluctuates and which is capable of balancing the trapping efficiency and a pressure loss. The porous honeycomb filter is a filter whose pore distribution has been controlled. A volume of pores having a pore diameter of 15 μm or less is 0.07 cc / cc or less, and a volume of pores having a pore diameter of 40 μm or more is 0.07 cc / cc or less.

Owner:NGK INSULATORS LTD

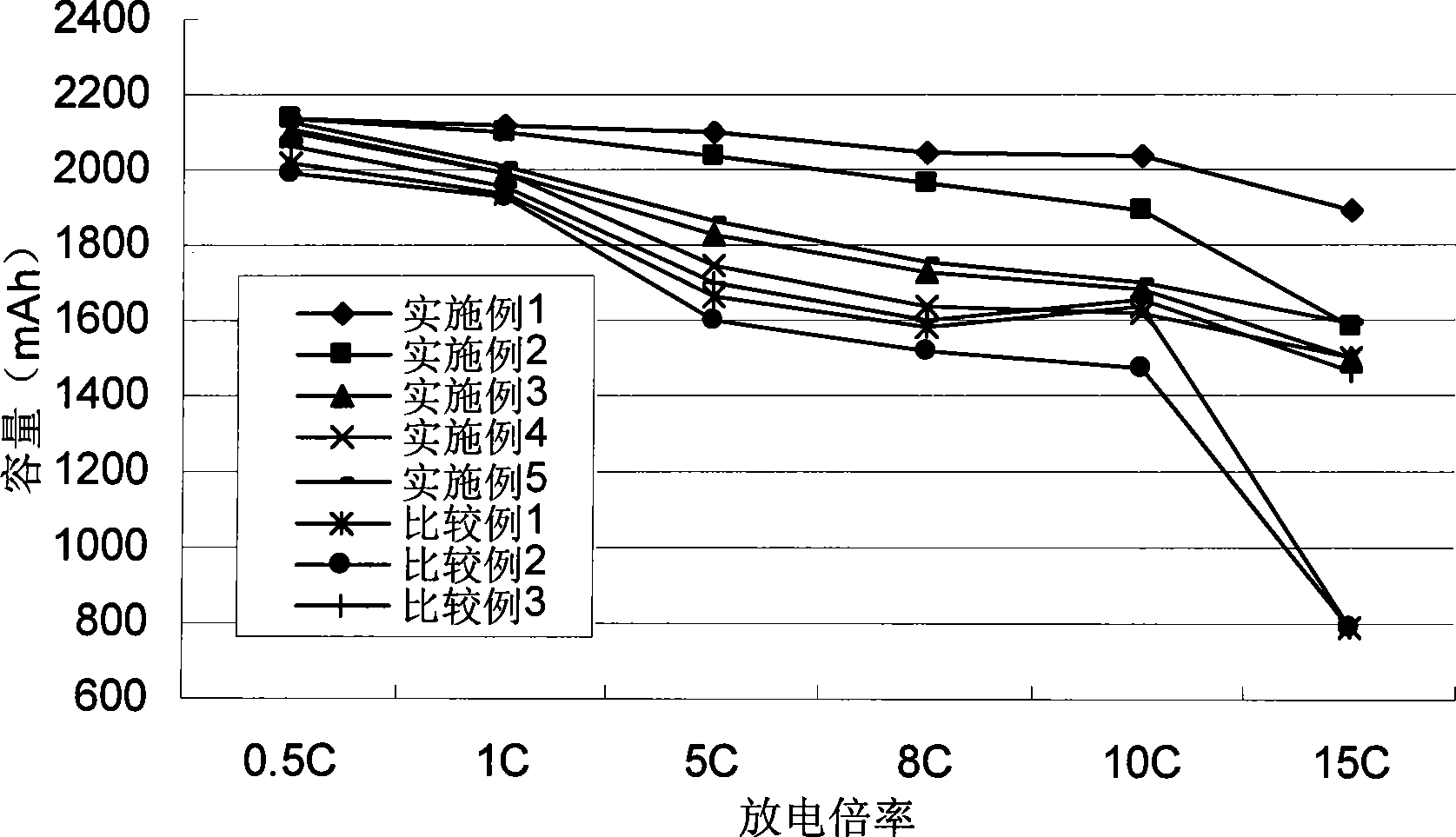

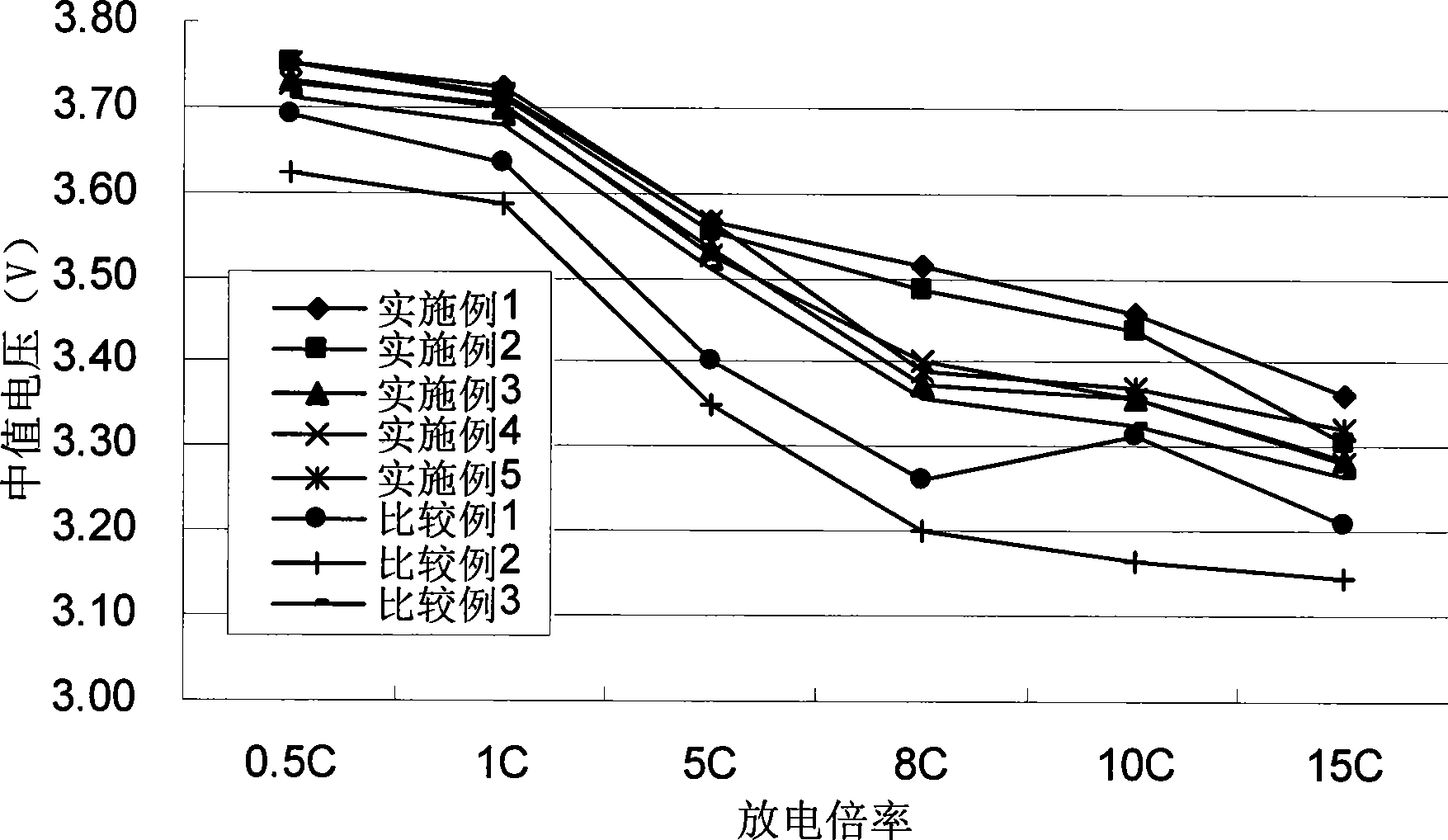

Diaphragm and preparation method thereof as well as lithium ion battery

InactiveCN101471432AMeet the requirements of high rate batteryGood discharge performance at low temperatureSecondary cellsCell component detailsPore distributionHigh rate

A diaphragm is selected from a composite membrane containing polyethylene terephthalate membrane as the base material. The composite membrane contains at least one organic polymer membrane consisting of polymer film-forming materials with a thermal resistant temperature of 170 DEG C to 500 DEG C and heat shrinkage of 0% to 5%. Preferably, a plasticizer is added during solution preparation to achieve more uniform pore distribution so as to obtain the composite membrane with excellent performance. The diaphragm has high temperature resistance and high safety when used for battery diaphragm. In addition, the diaphragm has good solution adsorption performance, so that the diaphragm can adsorb the electrolyte to improve the circle performance of the battery. The invention also provides the diaphragm preparation method, which is simple and convenient. Compared with the conventional battery and the battery using PET composite diaphragm with inorganic coating, the battery using the diaphragm has higher capacity, better high-rate discharge characteristics and low-temperature discharger performance, no flame and liquid leakage during high-temperature test, and excellent high-temperature safety performance.

Owner:BYD CO LTD

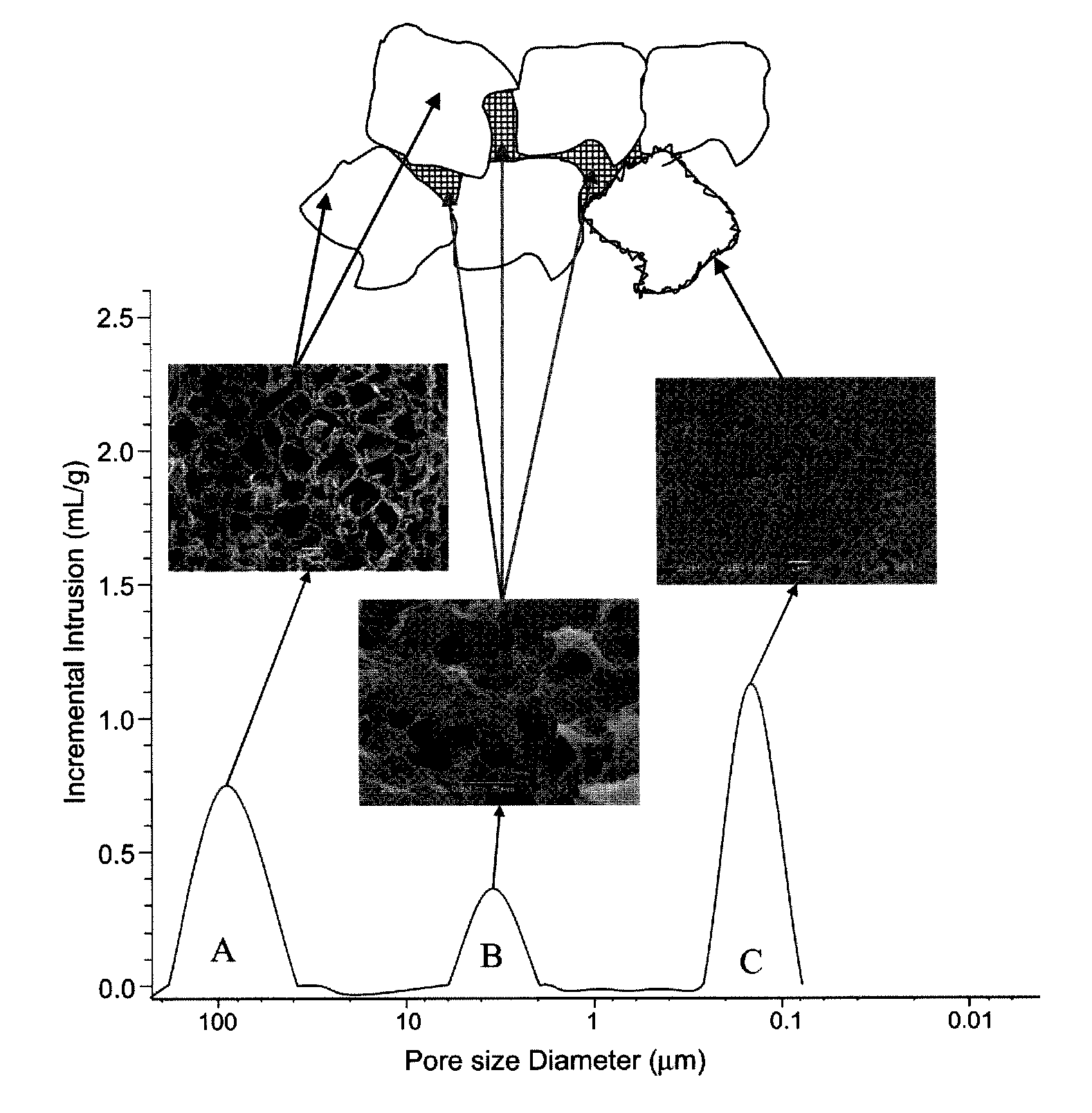

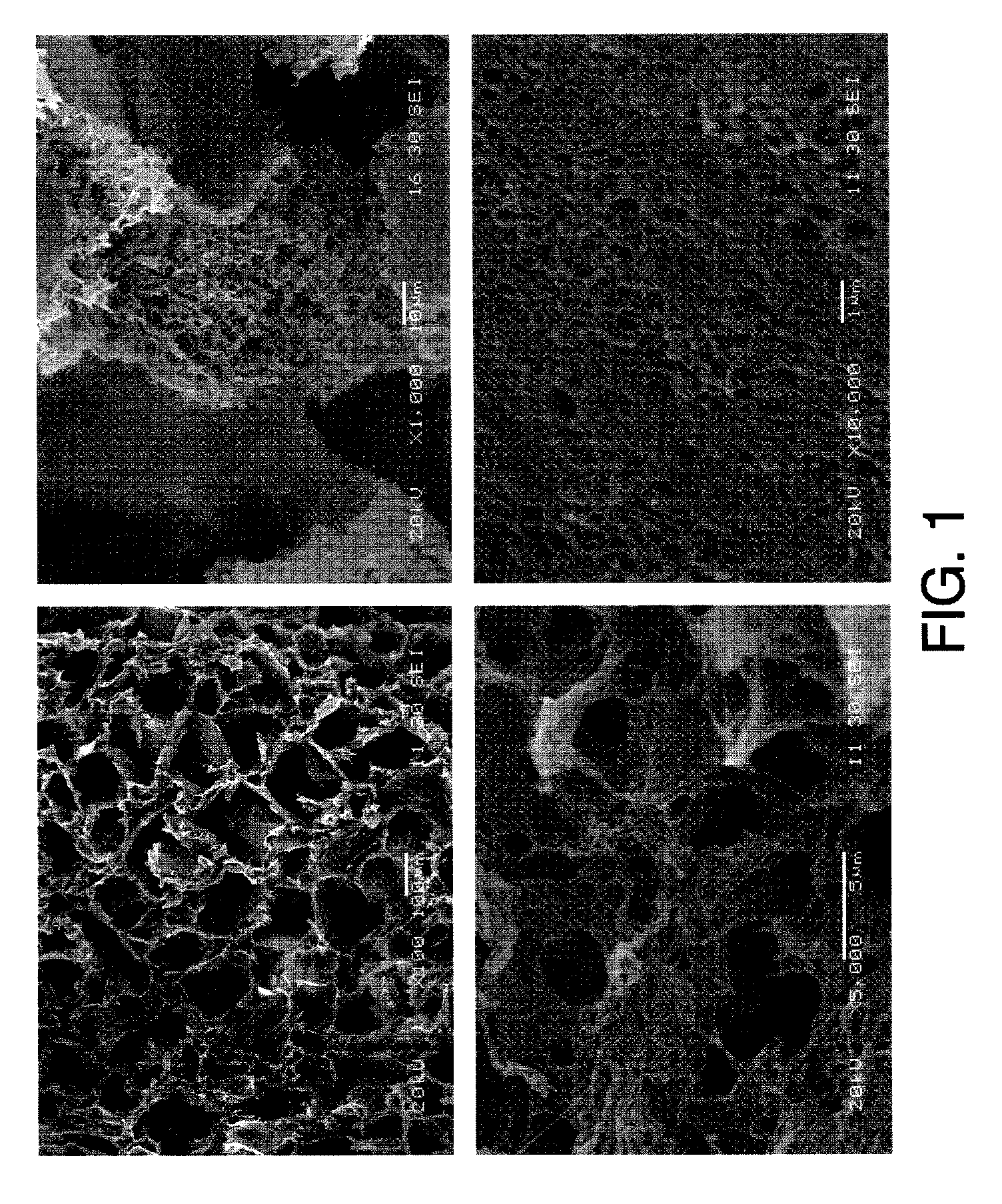

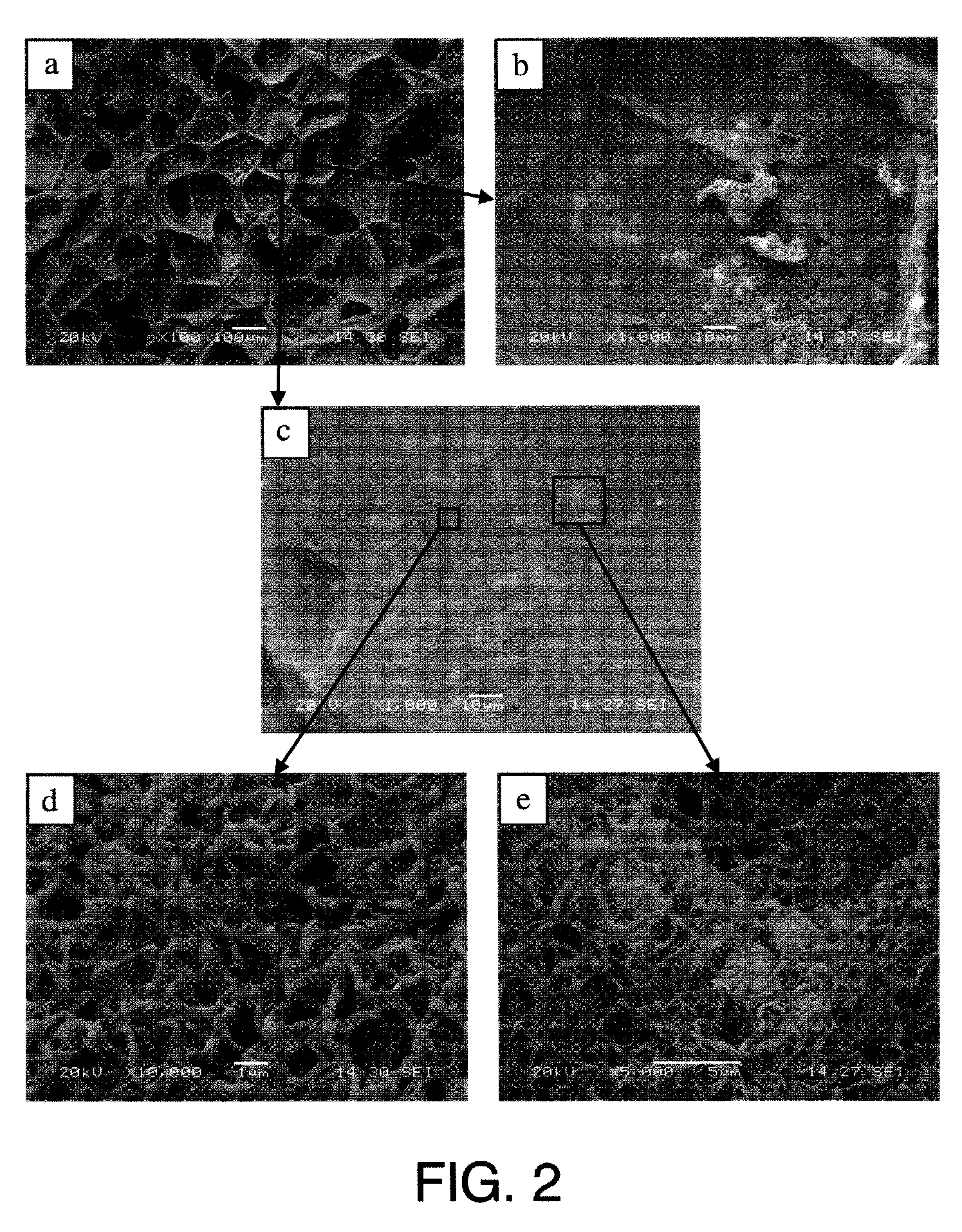

Porous peek article as an implant

The present invention refers to a porous PEEK-type polymer article comprising a porous PEEK-type polymer structure and presenting at least a trimodal pore distribution. The invention describes a process for the production of said porous PEEK-type polymer article comprising: a) contacting a PEEK-type polymer with a composition comprising at least a organic solvent, b) heating at a temperature at which the PEEK-type polymer is dissolved, c) adding at least a porogen agent, d) cooling the mixture obtained in c) at a temperature at least equal or lower than the temperature at which the PEEK-type polymer precipitates, e) forming said cooled mixture into a shaped article, f) removing the organic solvent and the porogen agent, and g) recovering the PEEK-type polymer article.

Owner:FUNDACION TECNALIA RES & INNOVATION

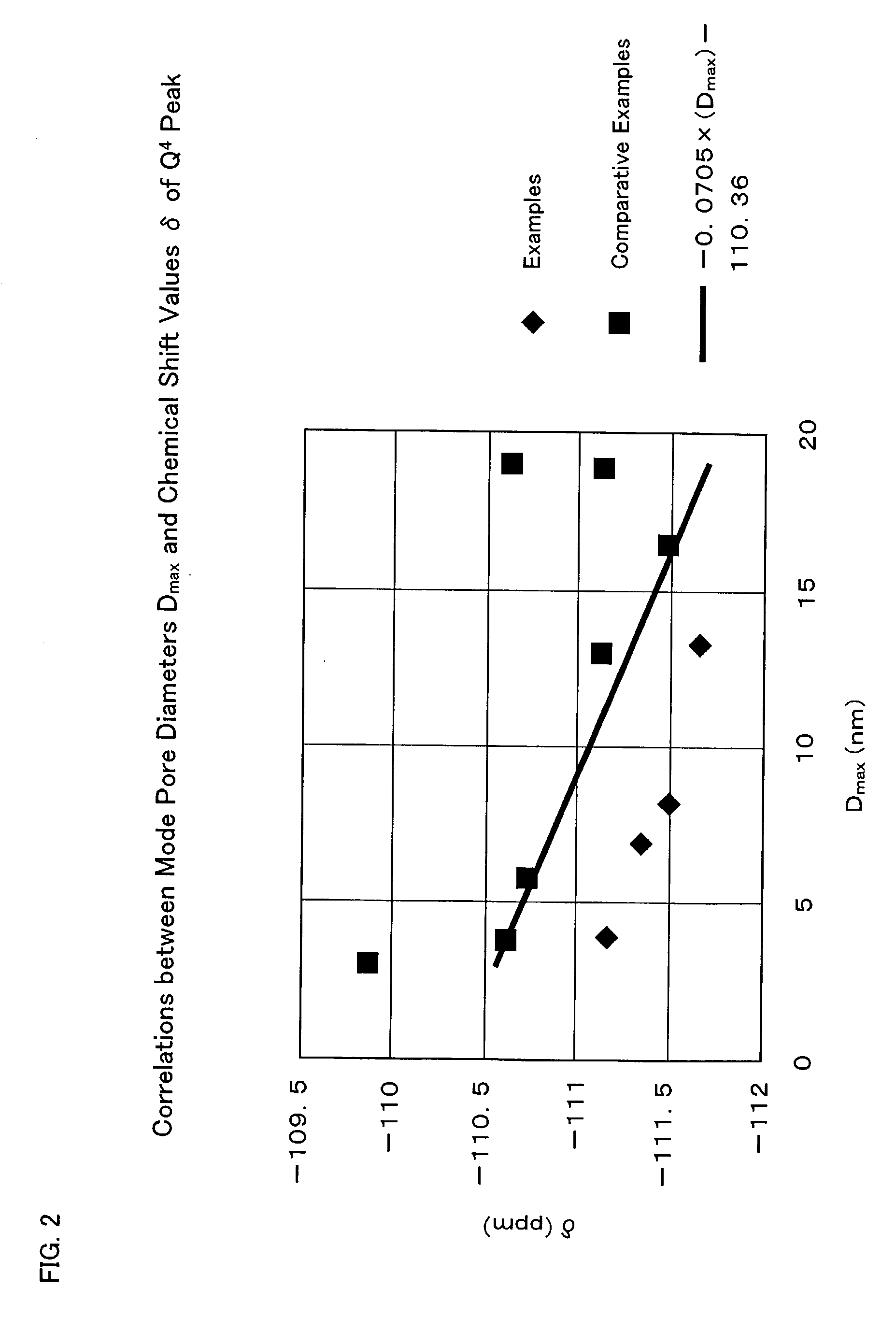

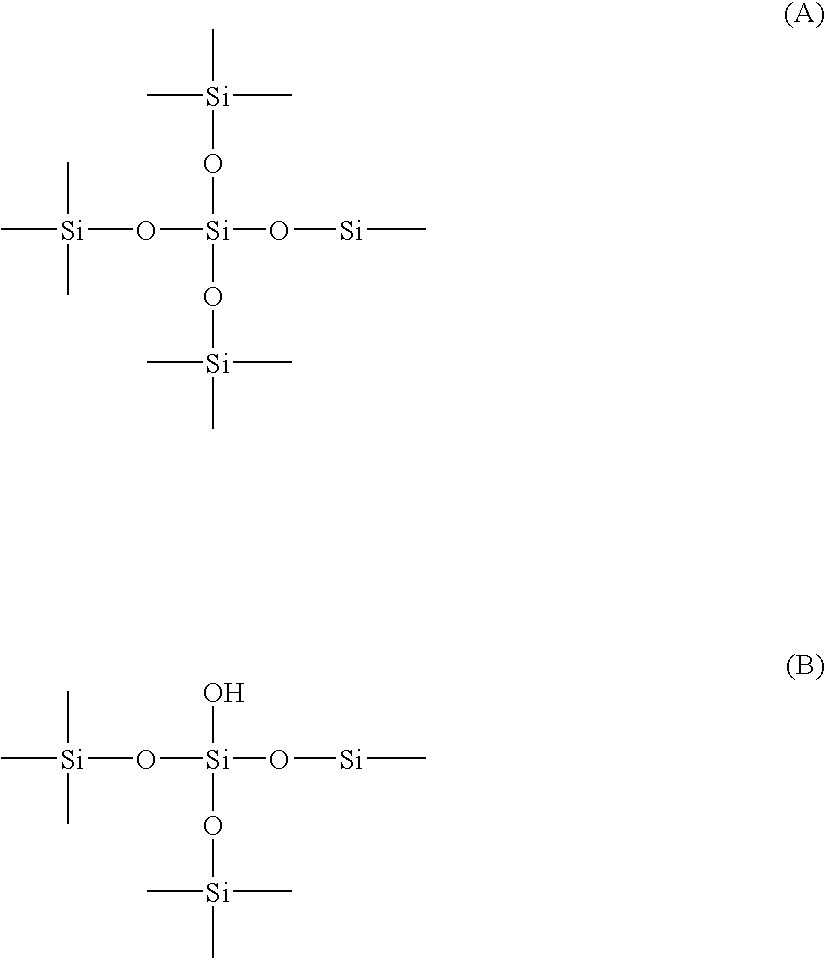

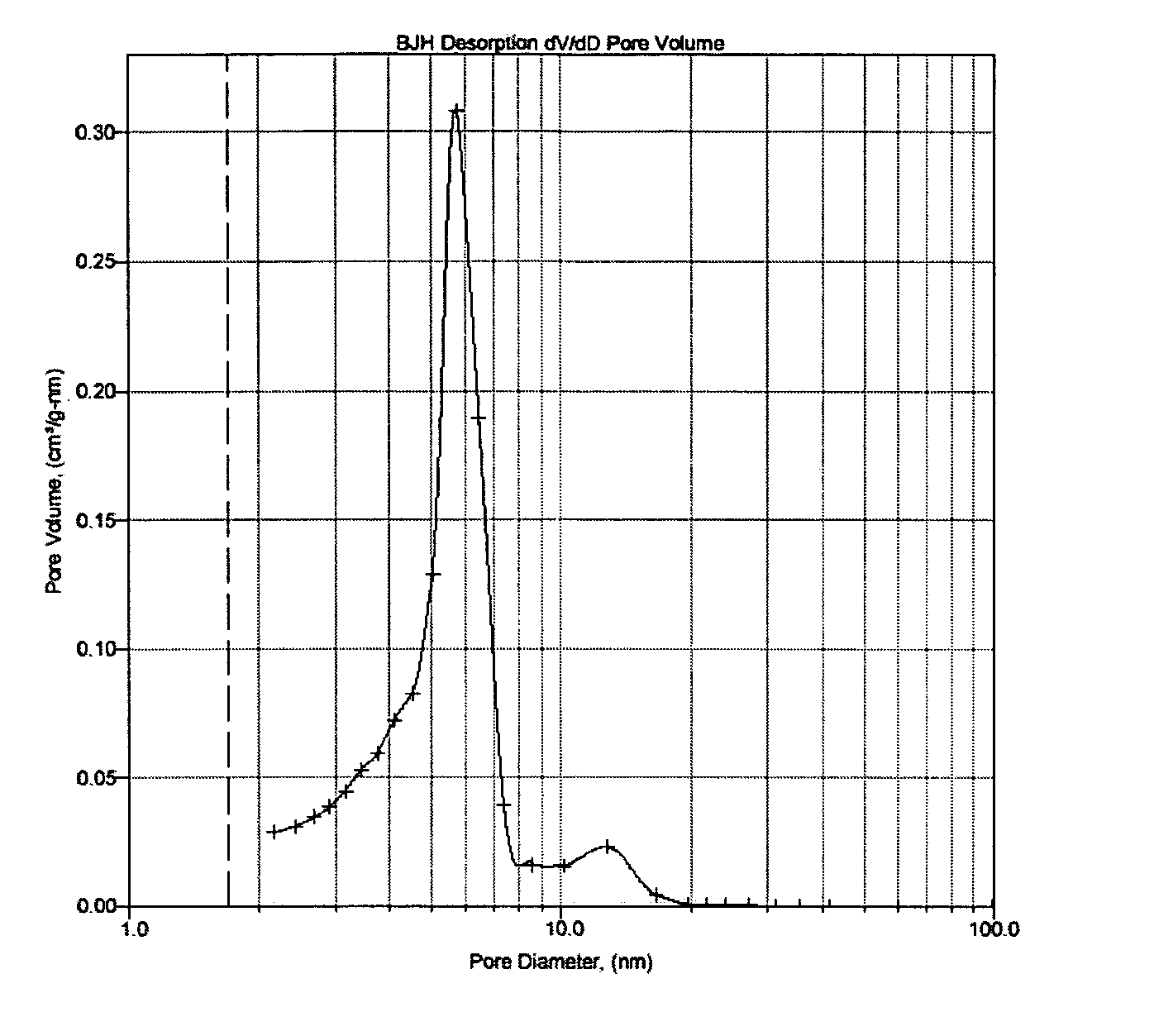

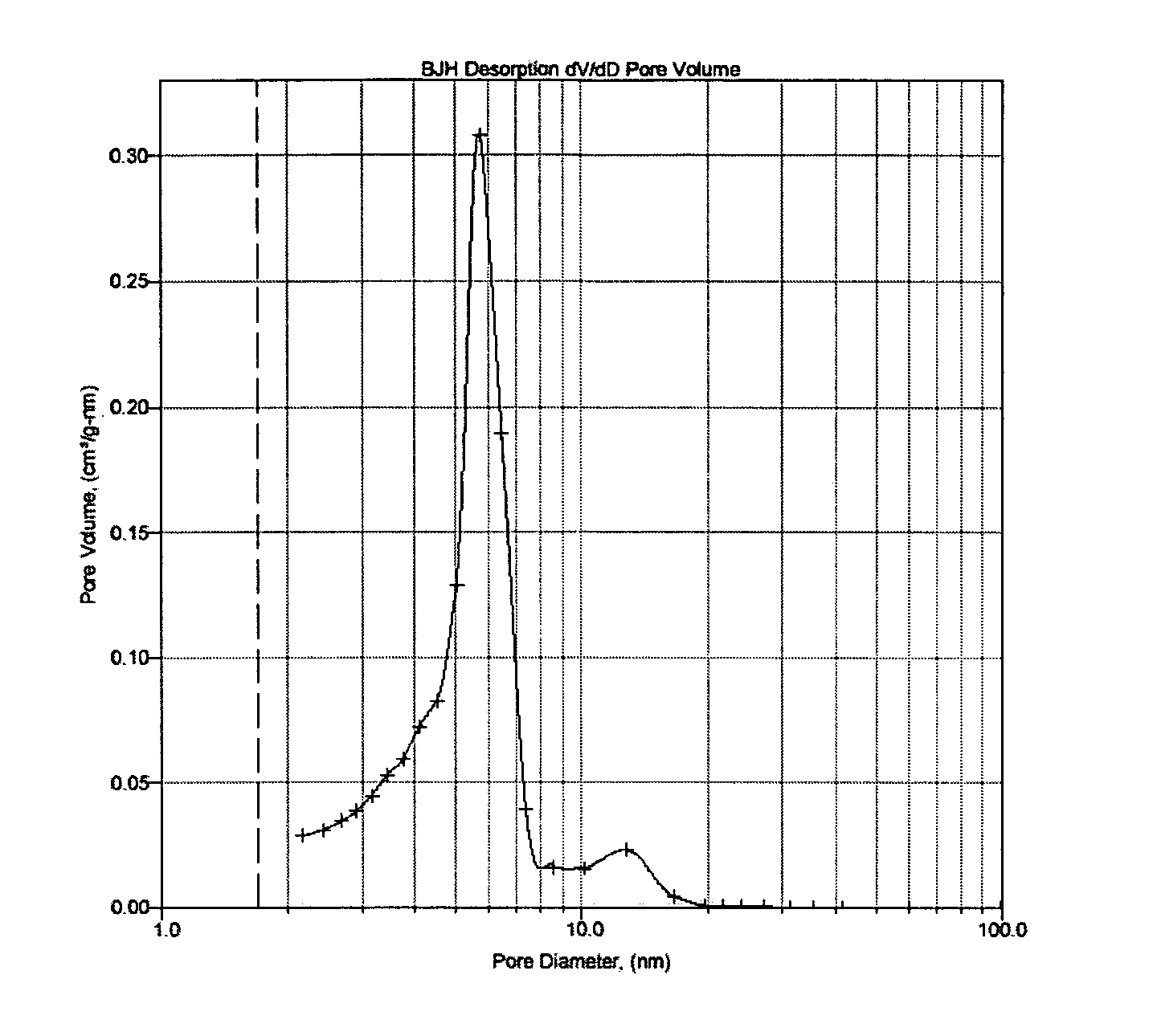

Silica

Silica with a large pore volume, a large specific surface area, a narrow pore distribution, low contents of unwanted metal impurities, and excellent physical properties such as high heat-resistance and water-resistance is provided. The silica has a mode pore diameter (Dmax) of 20 nm or less, and a solid-state Si nuclear magnetic resonance (hereinafter called solid-state Si NMR) spectrum of the silica includes a chemical shift (δ ppm) of Q4 peak meeting the following inequality (I). −0.0705×(Dmax)−110.36>δ (I) The silica with such properties can be suitably used in fields of which particularly excellent heat resistance and water resistance are required, and moreover controlled pore properties, and the fact that physical properties scarcely change over a long period of time are required among the above-mentioned applications.

Owner:MITSUBISHI CHEM CORP

Silica-alumina catalyst support with bimodal pore distribution, catalysts, methods of making and using same

ActiveUS20050107479A1Dispersion of catalytic metal and product diffusion can be optimizedMolecular sieve catalystsOrganic compound preparationPore distributionSilicon dioxide

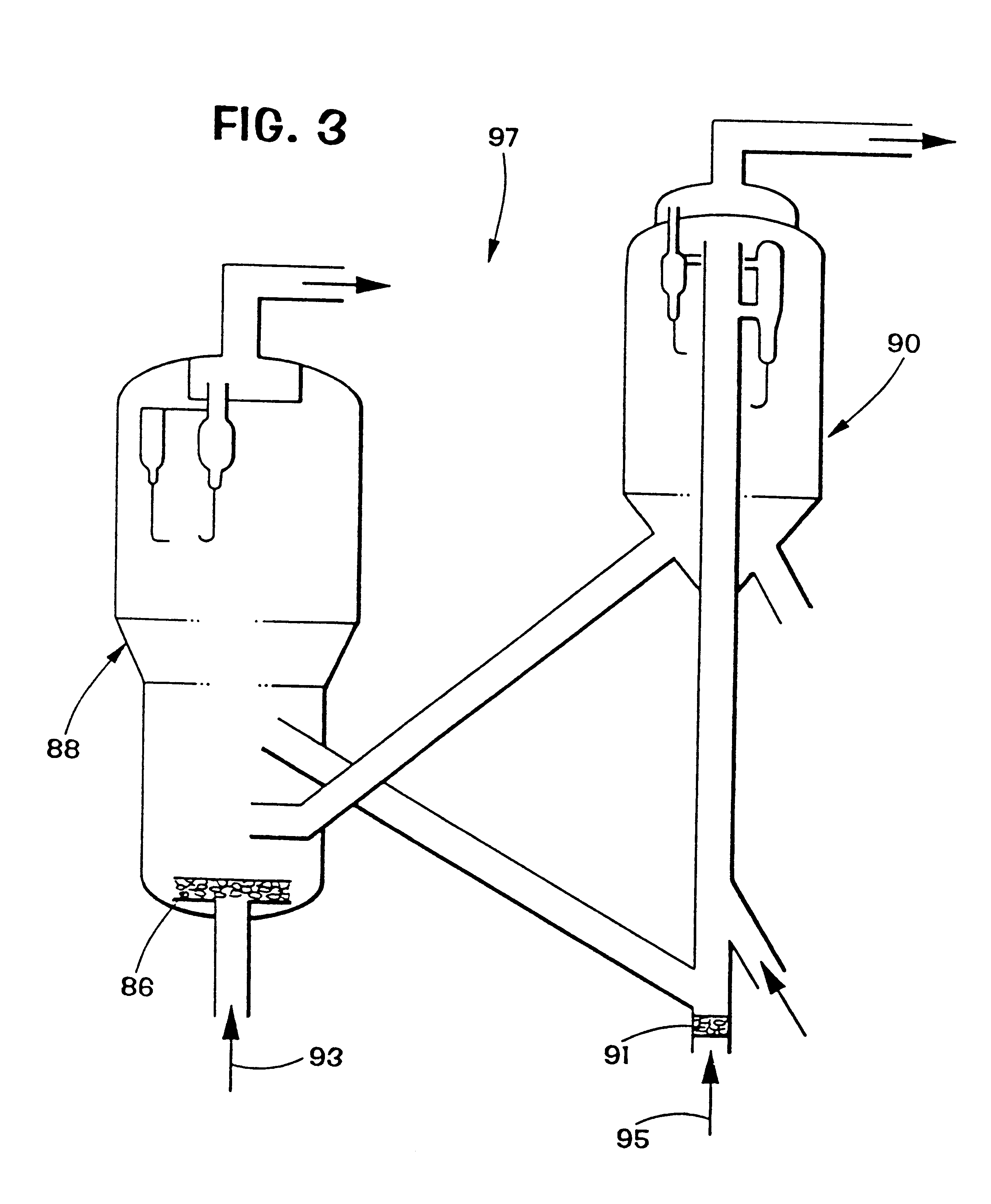

An effective catalyst includes an amorphous silica-alumina support having a bimodal pore size-distribution. The support may be prepared by a method that includes the physical mixing of two silica-alumina gels prepared so as to have two different average pore sizes. The catalyst has the advantage that both metal dispersion on the support and product diffusion in the pores are optimized. Further, the catalyst has improved performance in the production of hydrocarbons from synthesis gas.

Owner:CLARIANT INT LTD

Alumina support containing silicon and titanium and preparation method thereof

ActiveCN1768945AImprove pore structureLarge specific surface areaCatalyst carriersPore distributionAluminium hydroxide

The invention discloses property-transformation alumina carrier which contains titanium and silica agent and its relative preparing method. Said silica agent is added in the sol process of aluminum hydroxide to improve the specific surface, pore diameter and pore capacity of alumina; after the sol process, individually using acid agent and alkali agent to adjust the pH value of mixed paste solution for several times to make the attained alumina with more centralized pore distribution; the titanium agent is added after the sol process and before the aging process, to improve the surface acid property, surface acid amount and B acid amount of carrier. In addition, the surface of alumina is modified by titanium to decrease the interactive condition between active metal and carrier, which can apply the diffusion of active metal components in the catalyst. The property transformation of said invention can be used as catalysis material when processing oil, especially as the catalyst carrier of hydrogenation treatment and hydrogenation transformation.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing alumina supporter

ActiveCN1768946AWide variety of sourcesExpand sourceCatalyst carriersCatalyst activation/preparationChemical industryPore distribution

The invention discloses a method for preparing AL2O3 carrier. Said invention uses the farina as pore-expansion agent, which is added as powder after mixing other raw materials uniformly, and its added amount is 10-20wt% of alumina. Compared to present technique, said inventive alumina carrier has high strength, larger pore diameter, and centralized pore distribution, while said inventive method has simple process without special raw material and the cost of material and production are lower. The invention can be used as catalyst in the areas of oil refining, chemical industry and environmental protection, especially as the hydrogenation catalyst of heavy and residual oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

Dual-pore distribution silica synthesis method

ActiveCN101767790ALarge specific surface areaLarge hole volumeSilicaPore distributionSynthesis methods

A dual-pore distribution silica synthesis method includes that water, silicon source and template agent are mixed, and the pH value of the mixture is regulated to 4-12, the mixture is aged for 0.5-4 days at the temperature of 40-120 DEG C, and then the mixture is filtered, rinsed, dried and roasted; the template agent is the mixture of sugar and surfactant, the weight ratio of sugar and surfactant of the template agent is 0.5-2, the molar ratio of silicon and water is 1:30-1:200, the molar ratio of silicon and template agent is 1:0.005-2. The portable pore diameter of the pore with smaller pore diameter of the dual-pore distribution silicon-aluminum material is 2-10 nm, the portable pore diameter of the pore with larger pore diameter is 10-25nm, the specific area is 400-750 m2 / g, and the pore volume is 0.8-1.5cm3 / g. The dual-pore distribution silicon-aluminum material can be used as absorbent and catalyst, or used as the carriers of absorbent and catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of gradient silicon carbide ceramic membrane for water purification

ActiveCN104174298AHigh connected porosityHigh strengthSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisBreaking strengthPore distribution

The invention belongs to the fields of material science and engineering, and particularly relates to a preparation method of a gradient silicon carbide ceramic membrane for water purification. The method comprises the following steps: (1) preparing a silicon carbide ceramic support body; (2) preparing a silicon carbide intermediate layer; and (3) preparing a silicon carbide film, and finally preparing the gradient silicon carbide ceramic membrane for the water purification. The method has the beneficial effects that the prepared silicon carbide ceramic membrane material is high in communicating porosity, high in strength, high in pure water flux, and high in strong acid and alkali resistance; the pore distribution is in a gradient shape, different levels of connection surface are high in bonding strength, the method is simple and convenient to operate, and the gradient silicon carbide ceramic membrane is high in yield. According to the prepared gradient silicon carbide ceramic membrane material for water purification, the breaking strength is greater than 30MPa, the pure water flux is greater than 5m<3> / (m<2>h), and the range tolerance of the pH value is 0-14.

Owner:湖北迪洁膜科技有限责任公司

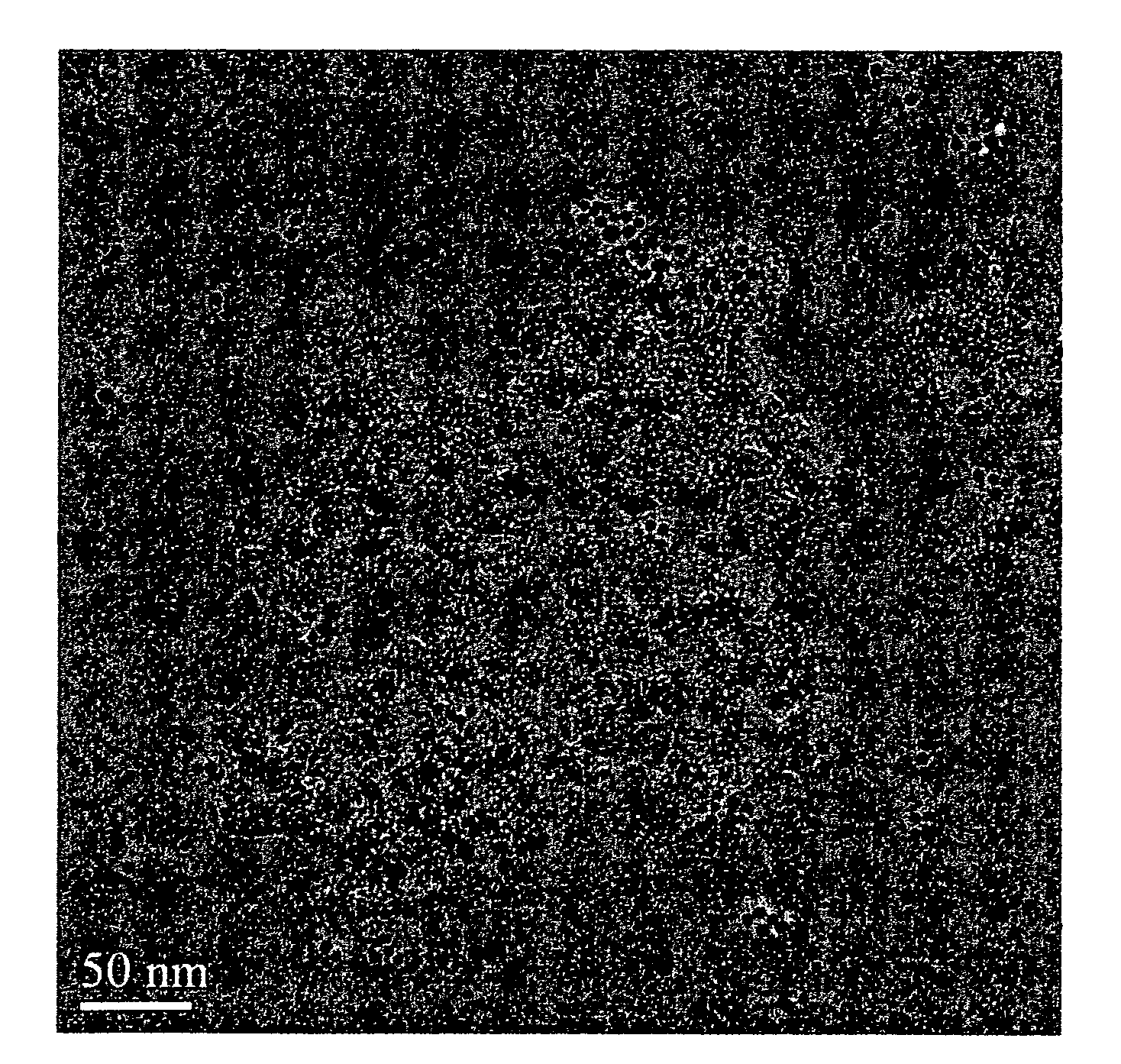

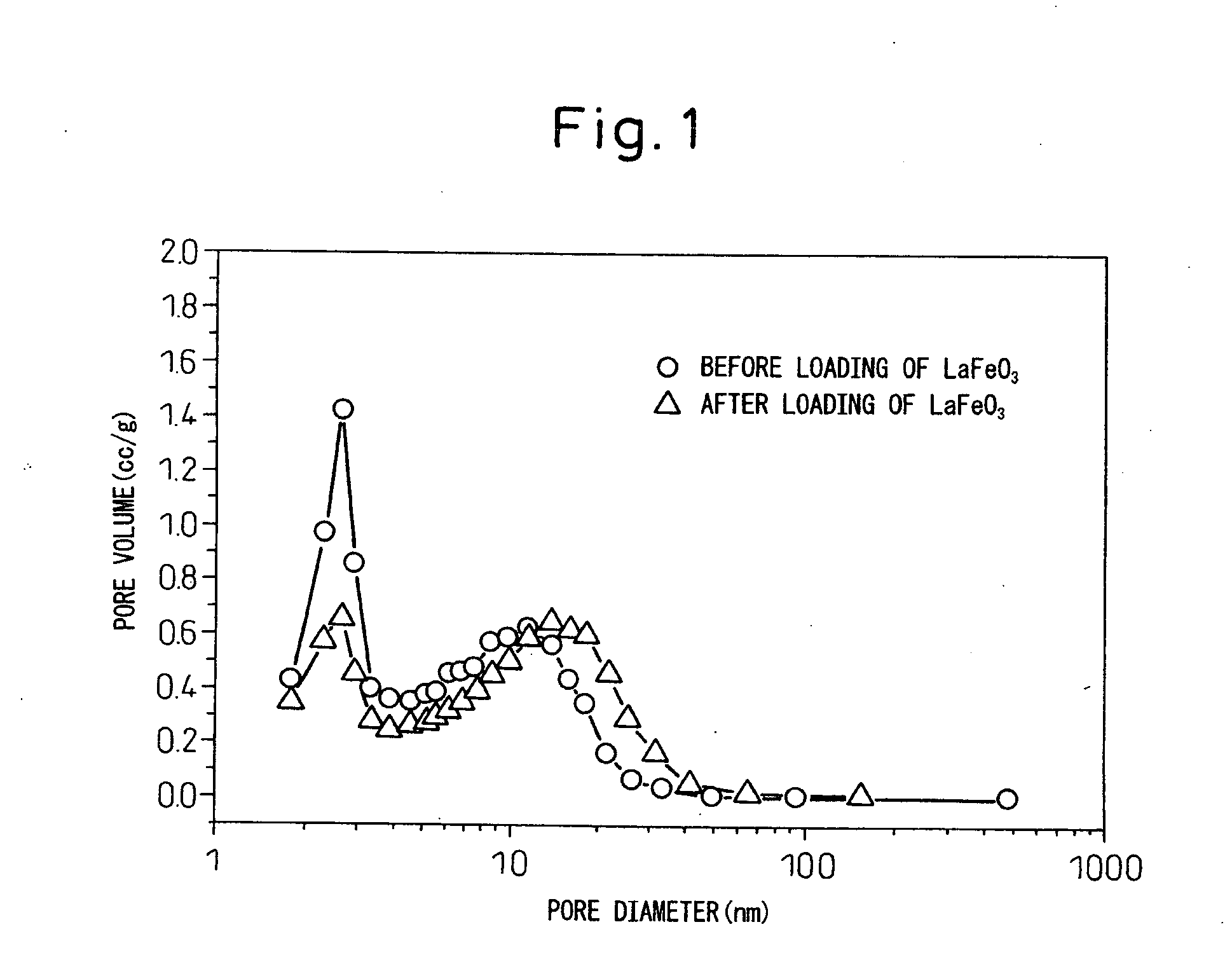

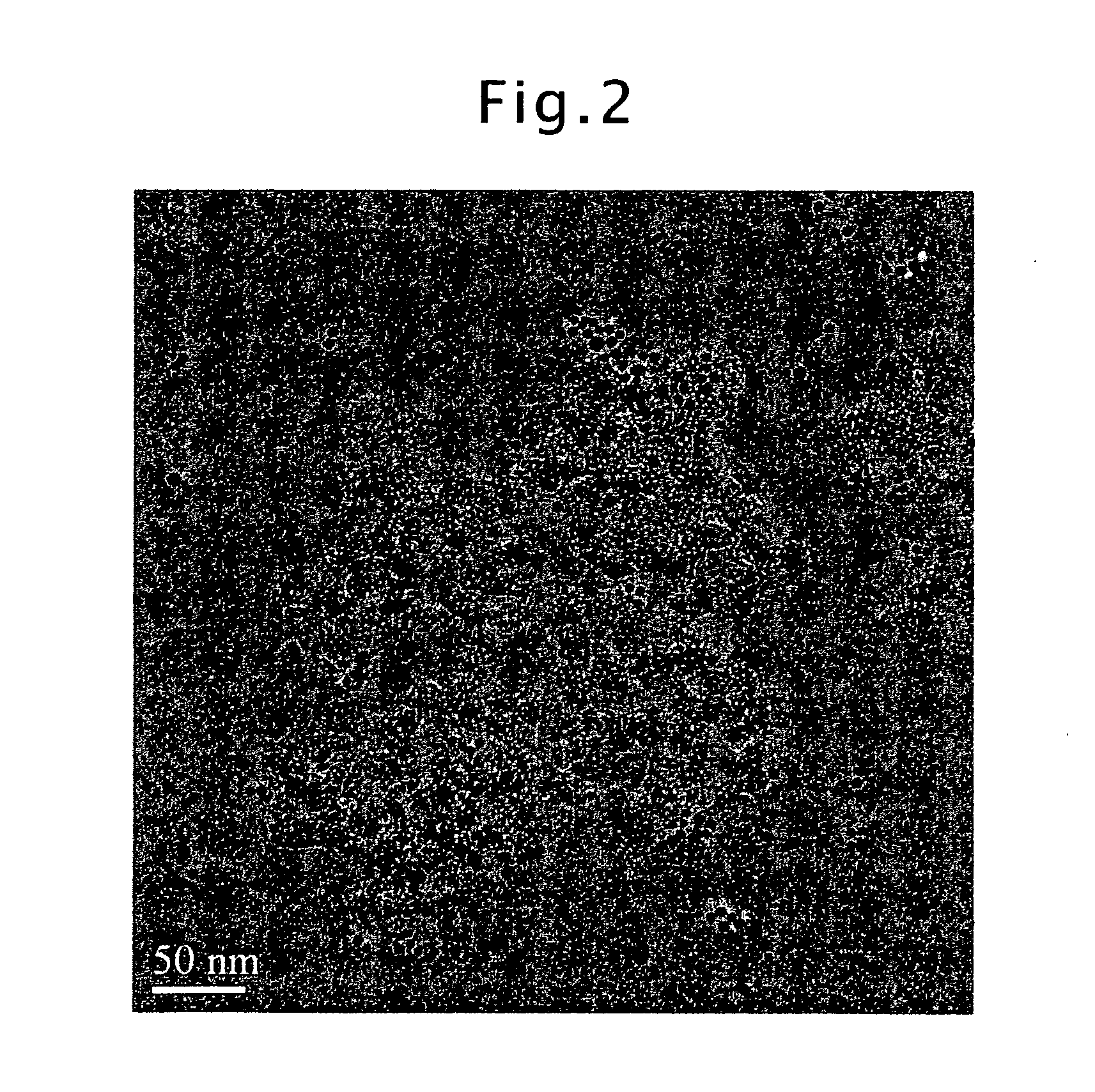

Exhaust gas purifying catalyst

InactiveUS20090286677A1Molecular sieve catalystsInternal combustion piston enginesPore distributionSilicon dioxide

According to the present invention, an exhaust gas purifying catalyst is provided. The catalyst comprises a porous silica support comprising silica having a pore structure, and a perovskite-type composite metal oxide particle supported in the pore structure of the porous silica support. Further, the peak attributable to the space between silica primary particles is in the range of 3 to 100 nm in the pore distribution of the porous silica support.

Owner:TOYOTA JIDOSHA KK

Ternary positive material of core-shell structure lithium ion battery and preparation method thereof

InactiveCN108172799AAvoid corrosionFacilitated DiffusionMaterial nanotechnologyCell electrodesNickel saltPore distribution

The invention discloses a preparation method of a ternary positive material of a core-shell structure lithium ion battery. The preparation method comprises the following steps: (1) preparing a multi-element mixed solution of nickel salt, cobalt salt, manganese salt and aluminum salt; (2) under a protective atmosphere, adding the multi-element mixed solution, ammonia water and sodium hydroxide intoa reaction device containing a base solution, and carrying out a co-precipitation reaction to obtain an NCM hydroxide precursor; (3) introducing carbon dioxide gas so that an aluminum hydroxide coating layer is formed on the surface of the NCM precursor; and (4) filtering, washing and drying the precursor, and then adding a lithium source to carry out heat treatment so as to obtain an NCM material, wherein the surface of the NCM material is coated with aluminum oxide. The obtained precursor of a core-shell structure is uniform in pore distribution, moderate in interval and large in specific surface area. The positive material of the core-shell structure lithium ion battery is obtained through further treatment of the obtained precursor and the lithium salt, and the positive material has high charge-discharge specific capacity, long cyclic stability performance and good rate capability.

Owner:QINGYUAN JIAZHI NEW MATERIAL RES INST CO LTD +1

Hydrotreating catalyst for bad heavy distillate, and preparation method

ActiveCN1916120AGood dispersionHigh catalytic activityHydrocarbon oils refiningMolecular sievePore distribution

This invention relates to a method for preparing hydrogenation catalyst for hydrogenating low-grade heavy fraction gasoline. The hydrogenation catalyst uses microporous molecular sieve / mesoporous composite oxide as the carrier. The carrier is prepared by in-situ growing Ti-Si or Ti-Al mesoporous composite oxide on the surface of the microporous molecular sieve. The pores can be expanded by acid treatment or by adding acidic component P in the composite carrier to obtain hydrogenation catalyst with large specific surface area, high pore volume, gradient pore distribution and controllable acidity, which can satisfy the requirements of desulfurization, denitrification and aromatic hydrocarbon saturation with different degrees. The catalyst has good performance on hydrogenation, desulfurization and denitrification.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

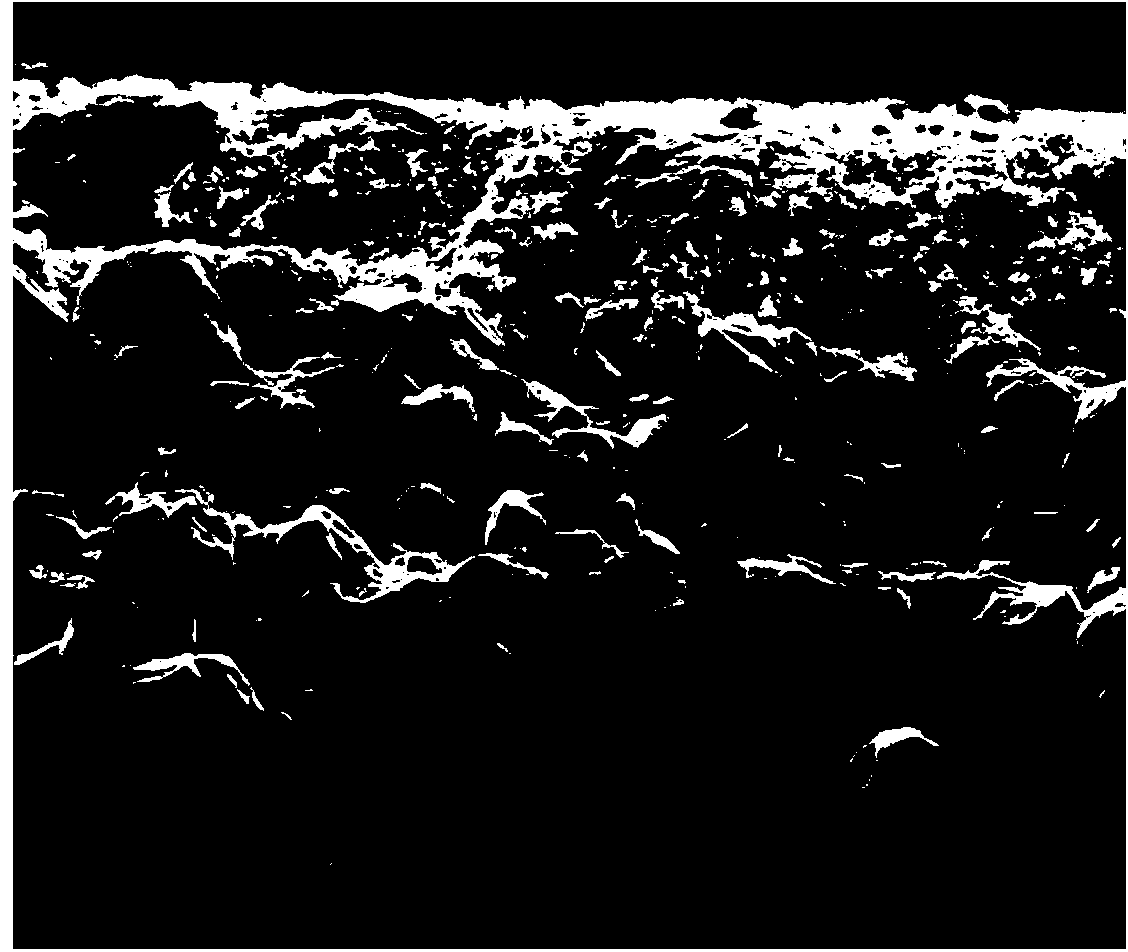

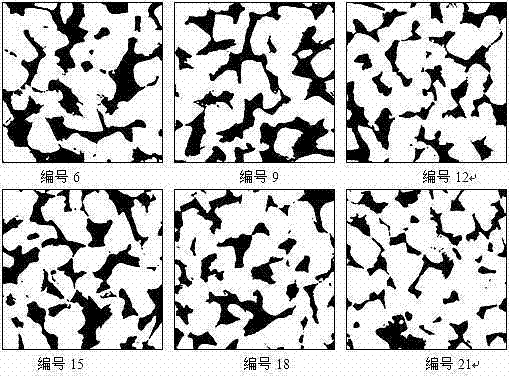

Characterization method of pore structure of porous concrete based on CT (Computerized Tomography) technology

InactiveCN103575751ASimple test methodShort detection timePermeability/surface area analysisMaterial analysis by transmitting radiationPore distributionImaging processing

The invention discloses a characterization method of a pore structure of porous concrete based on a CT (Computerized Tomography) technology. Pore structure parameters such as the plane porosity, the effective aperture and the aperture distribution of the porous concrete are obtained by analyzing a CT-scanned two-dimensional cross-sectional image through an image processing method. The characterization method specifically comprises the following steps: firstly, acquiring the two-dimensional cross-sectional image of the porous concrete by a CT scanner, and acquiring a clear pore distribution map by white and black binarization of the image by a computer; then, calculating the area representing a pore region by image processing software and converting the region into a circle with equal area; and finally, carrying out statistic analysis on data with pore grater than 1mm to obtain the pore structure parameters such as the plane porosity, the effective aperture and the aperture distribution of the porous concrete. By adopting the characterization method of the pore structure of the porous concrete, not only is the test method simple, but also the precision is high and the error is small.

Owner:UNIV OF JINAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com