Patents

Literature

346results about How to "Uniform pore structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing complexly shaped biomedical porous titanium molybdenum alloy implant body

InactiveCN102335742ADesign personalizationHigh dimensional accuracyIncreasing energy efficiencyProsthesisNatural boneMetallic materials

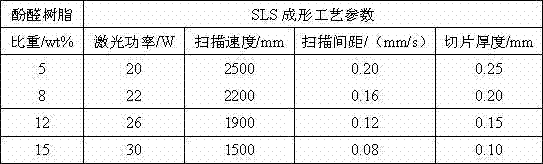

The invention provides a method for preparing a complexly shaped biomedical porous titanium molybdenum alloy implant body and belongs to the technical field of biomedical porous metallic material preparation. The method comprises the following steps of: taking a mixture of titanium and molybdenum metallic element powder and organic polymer powder as raw materials, and then preparing the biomedical porous titanium molybdenum alloy implant body by adopting the processes, such as three-dimensional modeling, selective laser-firing rapid forming, thermal de-greasing, vacuum sintering, and the like. The processing steps are simple, the period is short, the use ratio of materials is high, the cost is low, any complexly shaped porous titanium alloy implant body can be conveniently manufactured, and the method has efficiency and economic advantages in individual design and rapid manufacturing of the implant body. A titanium molybdenum alloy material prepared by using the method has the advantages that pore space is uniform, adjustment scopes of porosity, aperture ratio and aperture are wide, elasticity modulus and compression strength are in close proximity to natural bone, and the demand on biomechanical compatibility required by a biomedical material is met.

Owner:UNIV OF SCI & TECH BEIJING

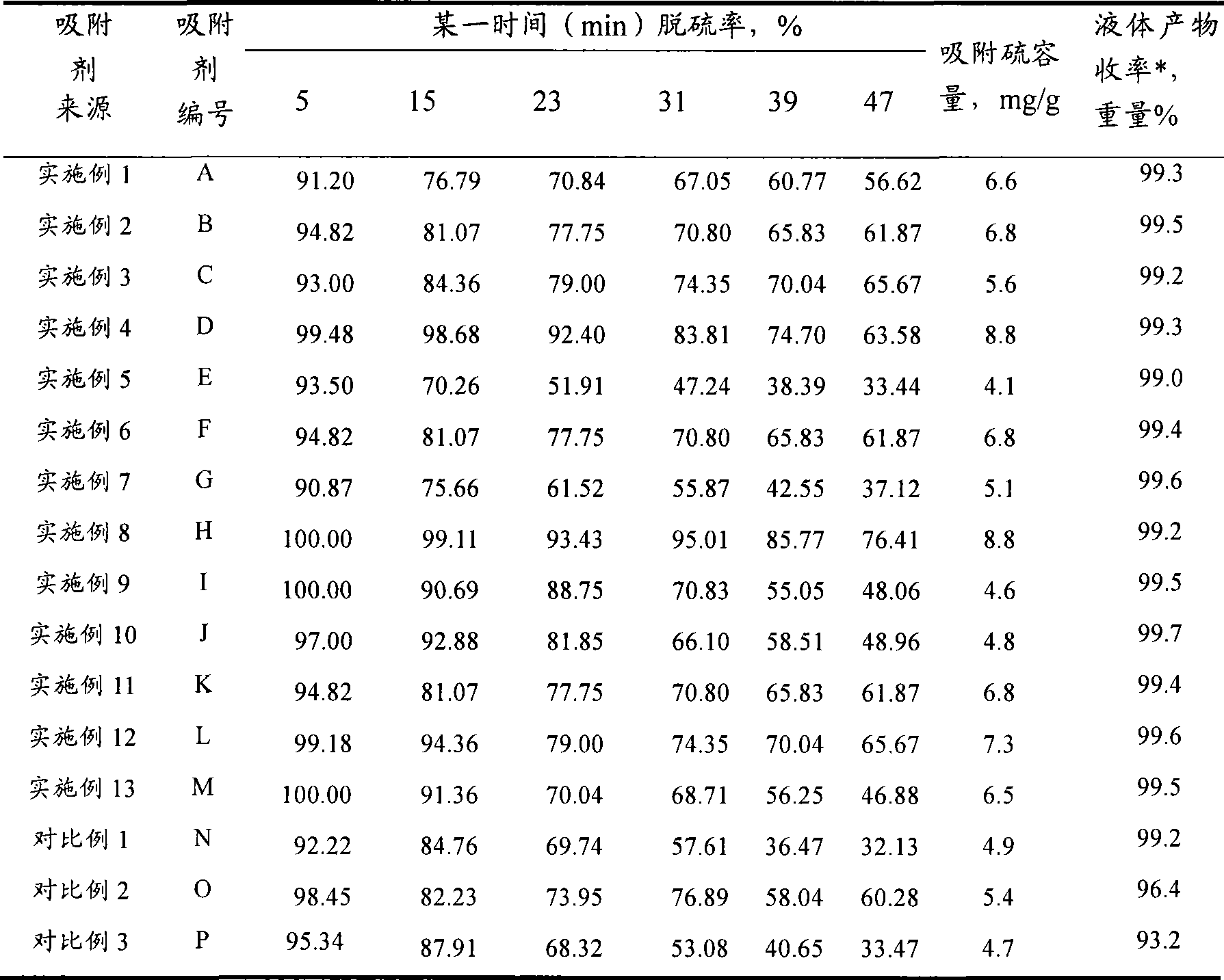

Hydrocarbon oil desulphurization adsorbing agent and use method thereof

ActiveCN101481627AUniform pore structureLarge adsorption and desulfurization capacityHydrocarbon oils refiningMolecular sieveSulfur

A spraytex desulfurization sorbent contains molecular sieve and metal oxide having the function of absorbing sulfur; wherein, the mol ratio between silicon atom and aluminium atom of the molecular sieve is 50-750, and the weight ratio between the molecular sieve and metal oxide having the function of absorbing sulfur is 45-98:2-55. The desulfurization sorbent has large capacity, and can be used for absorbing and decarbolizing spraytex, thus having high desulfurization efficiency and high yield of the spraytex.

Owner:CHINA PETROLEUM & CHEM CORP +1

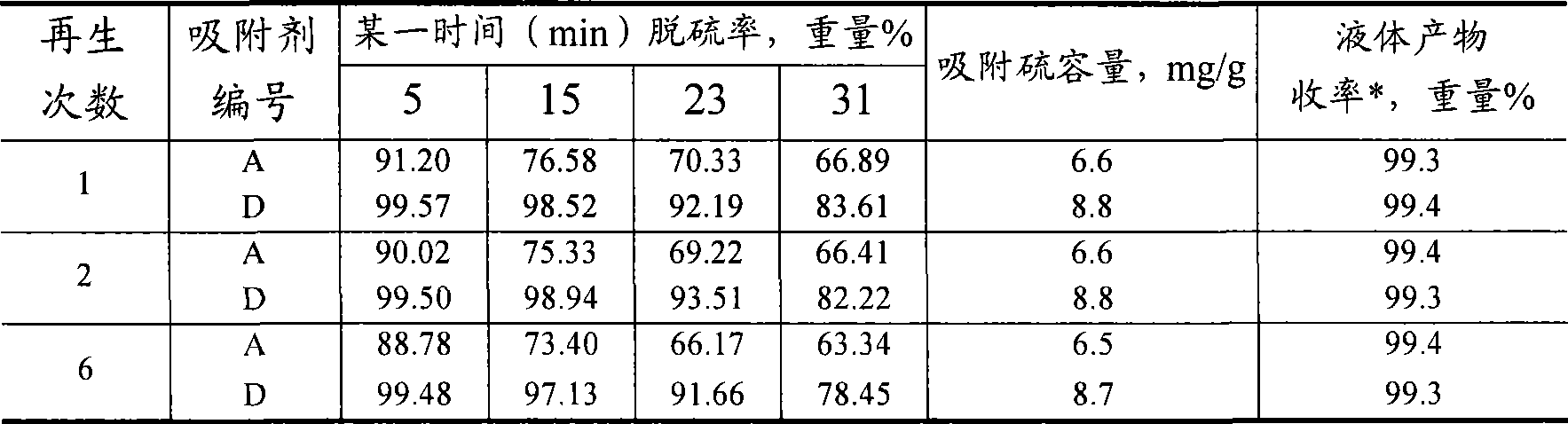

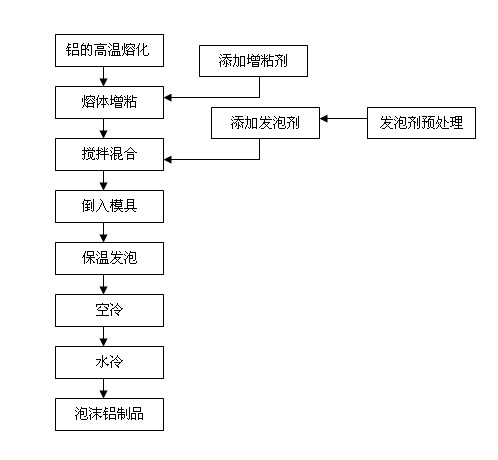

Method for preparing foamed aluminum by foaming melt

The invention relates to a preparation method of foamed aluminum, in particular to a method for preparing the foamed aluminum by primarily foaming a melt, which can prepare a foamed aluminum product by primarily foaming aluminum. The method comprises the following steps of: starting a thermoelectric furnace for heating to 800 DEG C until the aluminum is fully molten; lowering the temperature to 680 DEG C, adding metal calcium into aluminum liquid and stirring so as to increase the surface viscosity of the melt; pretreating titanium hydride, adding pretreated titanium hydride into the melt and stirring to uniformly distribute the titanium hydride in the melt for full decomposing; and heating a mold, putting the melt into the thermally-treated mold, preserving heat and foaming at the temperature of 650 DEG C, taking a prefabricated member out, performing air cooling to shape the high-temperature foam melt in the mold and taking the prefabricated member out for water cooling so as to obtain the foamed aluminum product. When applied to a filling piece of a regular cavity, the method simplifies a process, greatly lowers production cost, is suitable for diversified development of industrial production and brings convenience to the research of specific technology.

Owner:DONGGUAN UNIV OF TECH +4

Vehicle-used slowly-springback polyurethane foam composite material

ActiveCN104149455AHigh reactivityGood physical propertiesSynthetic resin layered productsEnvironmental resistanceSilicone oil

The invention discloses a vehicle-used slowly-springback polyurethane foam composite material which is compounded from slowly-springback polyurethane foam and an ethylene-vinyl acetate copolymer. The slowly-springback polyurethane foam is prepared from following components including, by weight, an A material: 40-80 parts of a polyether polyol 1421, 5-40 parts of a polyether polyol 2000D, 5-40 parts of a polyether polyol POP-36 / 28, 0.5-5 parts of diethanolamine, 1-6 parts of water, 0.1-1.5 parts of a catalyst EF-600, 0.1-0.5 parts of a catalyst ZF-10 and 1-6 parts of a silicone oil L-580; a B material: 40-80 parts of a modified MDI. During preparation of the slowly-springback polyurethane foam, a weight usage amount ratio of the A material to the B material is 100:40-80. The vehicle-used slowly-springback polyurethane foam is high in reaction activity, is low in toxicity, is environmental-protective, is high in damp loss factor, is high in sound-insulation performance and is free of addition of a foam-forming agent.

Owner:NINGBO TUOPU GROUP CO LTD

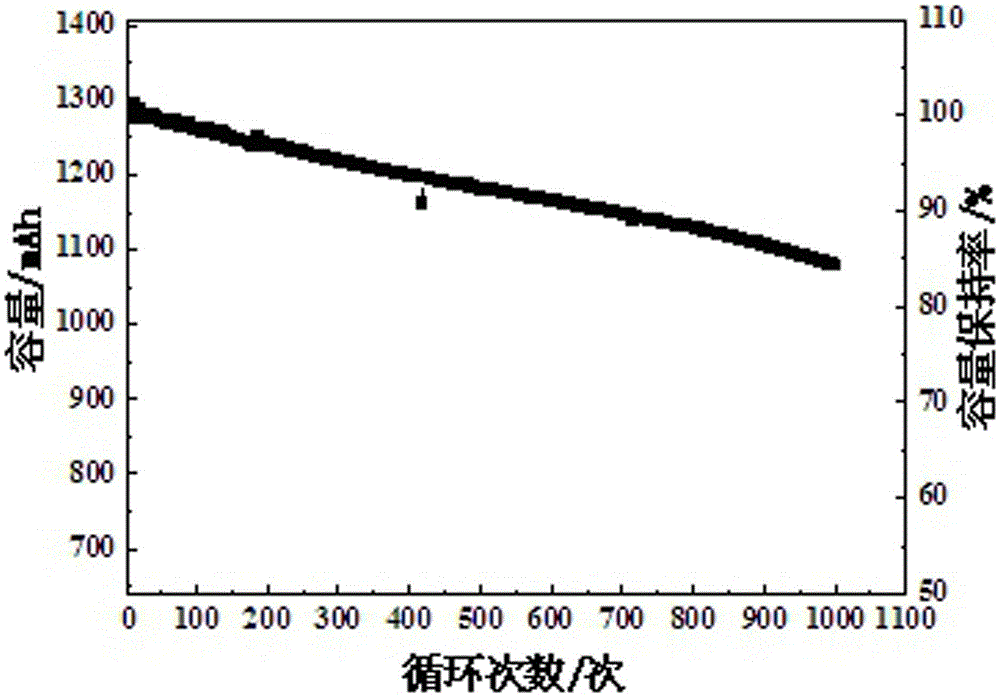

Lithium ion battery negative pole size and preparation method thereof

InactiveCN105406073AUniform pore structureExcellent electronic conductivity and chemical stabilityCell electrodesSecondary cellsIonChemistry

The invention discloses lithium ion battery negative pole size which consist of graphdiyne, Super-p, CMC, SBR, NMP and deionized water, wherein the mass ratio of the graphdiyne to the Super-p to the CMC to the SBR solution (the solid content is 50%) to the NMP to the deionized water is 95: (0.8-2): (1.0-2): (4-7): (5-8): (110-120). The preparation method of the lithium ion battery negative pole size comprises the following steps: mixing the CMC and the NMP at a low speed; adding the deionized water to evenly mix at a high speed; screening the CMC solution through a 200-mesh screen to stand for 8-12h; evenly mixing the Super-p and the CMC xolution at a high speed; adding the graphdiyne and the SBR in sequence to evenly mixing at a high speed; and finally adjusting the viscosity and screening through a 150-200-mesh screen to obtain the lithium ion battery negative pole size which is good in performance.

Owner:SHANDONG GOLDENCELL ELECTRONICS TECH

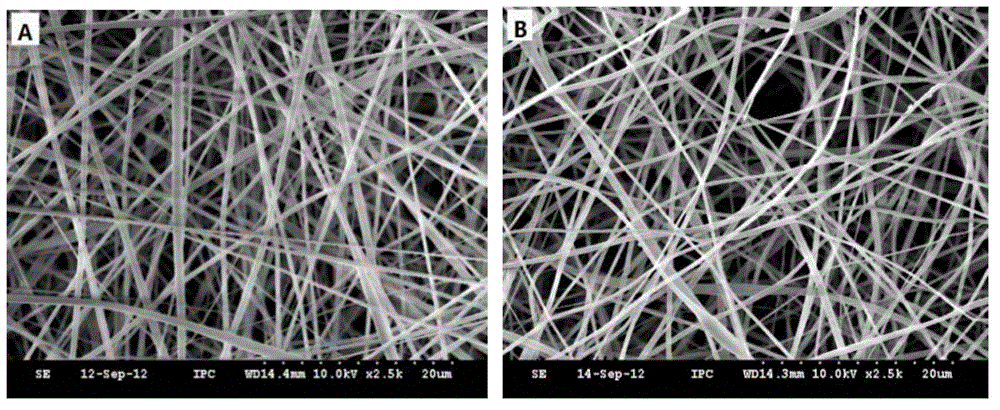

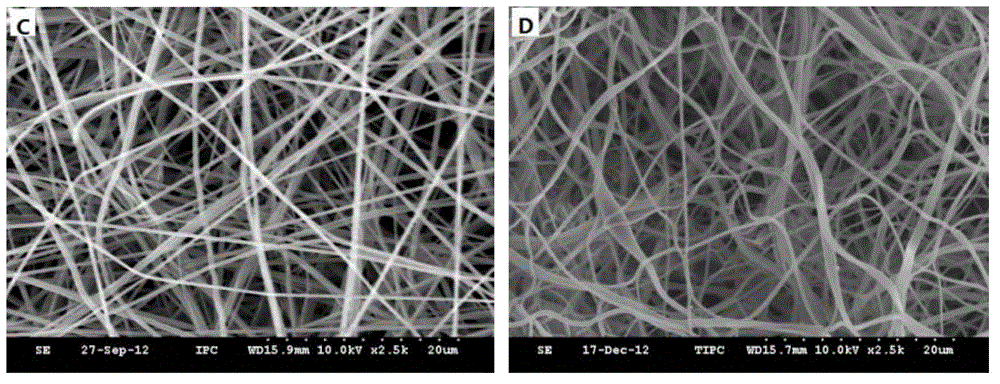

High-strength polyimide nano fiber porous membrane, and preparation method and application thereof

InactiveCN103147253AHigh porosityImprove mechanical propertiesHeating/cooling textile fabricsNon-woven fabricsFiberChemical composition

The invention discloses a high-strength polyimide nano fiber porous membrane. The porosity of the polyimide nano fiber porous membrane is 70-85%, the average pore diameter is 100-250 nm, the glass transition temperature is 260-400 DEG C, the tensile strength is 8-70 MPa, and the dimensional shrinkage after high-temperature 200 DEG C heat treatment for 1 hour is less than 0.3%. The chemical composition of the polyimide nano fiber porous membrane is copolymerized polyimide or blended polyimide. The invention also discloses a preparation method and application of the polyimide nano fiber porous membrane. The polyimide nano fibrous membrane disclosed by the invention is a membrane material having the advantages of high strength, low dimensional change rate, high porosity and favorable thermal properties.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI +1

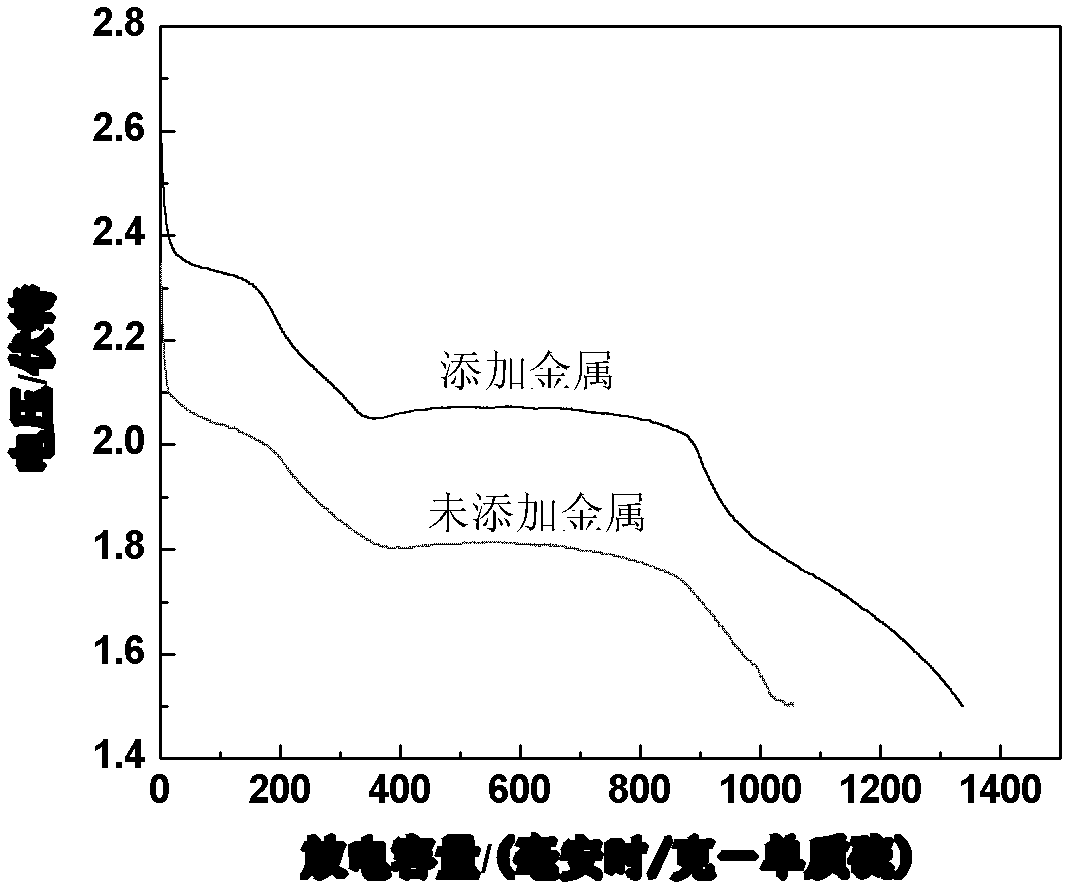

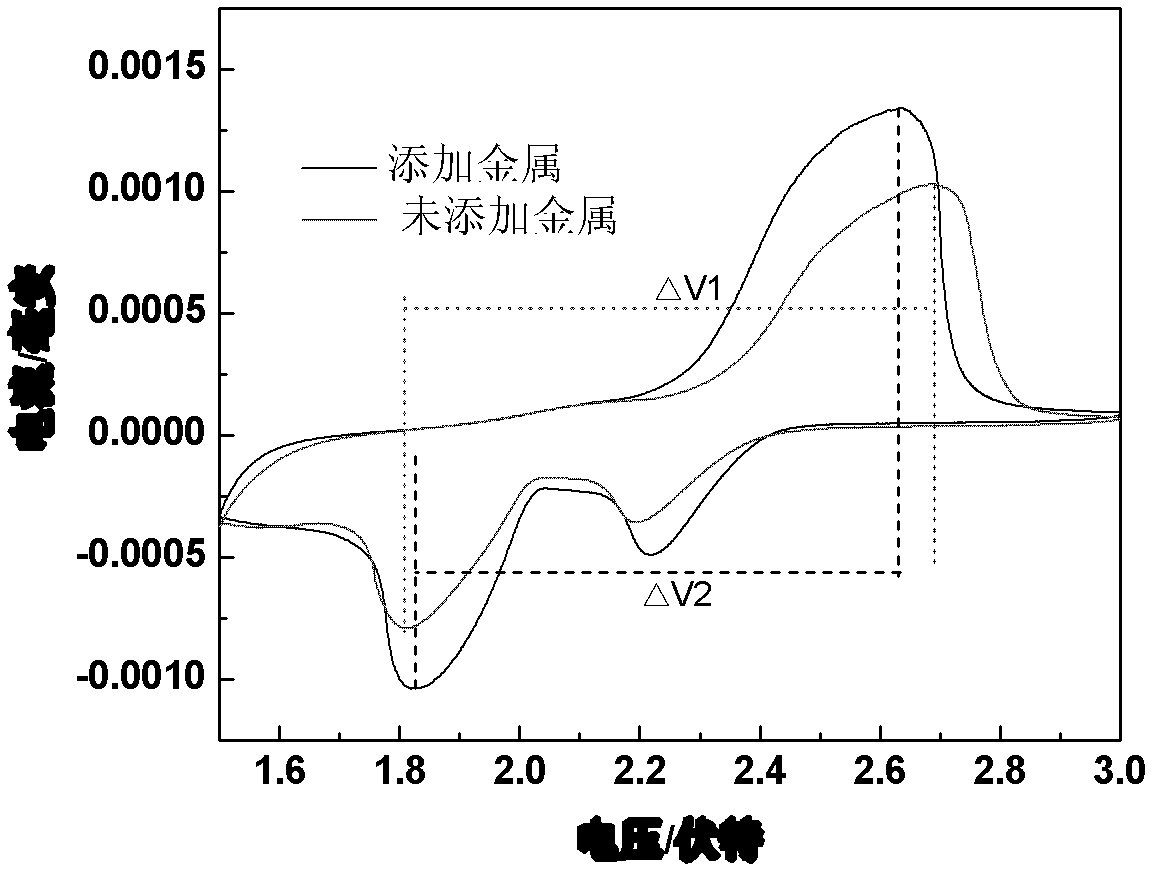

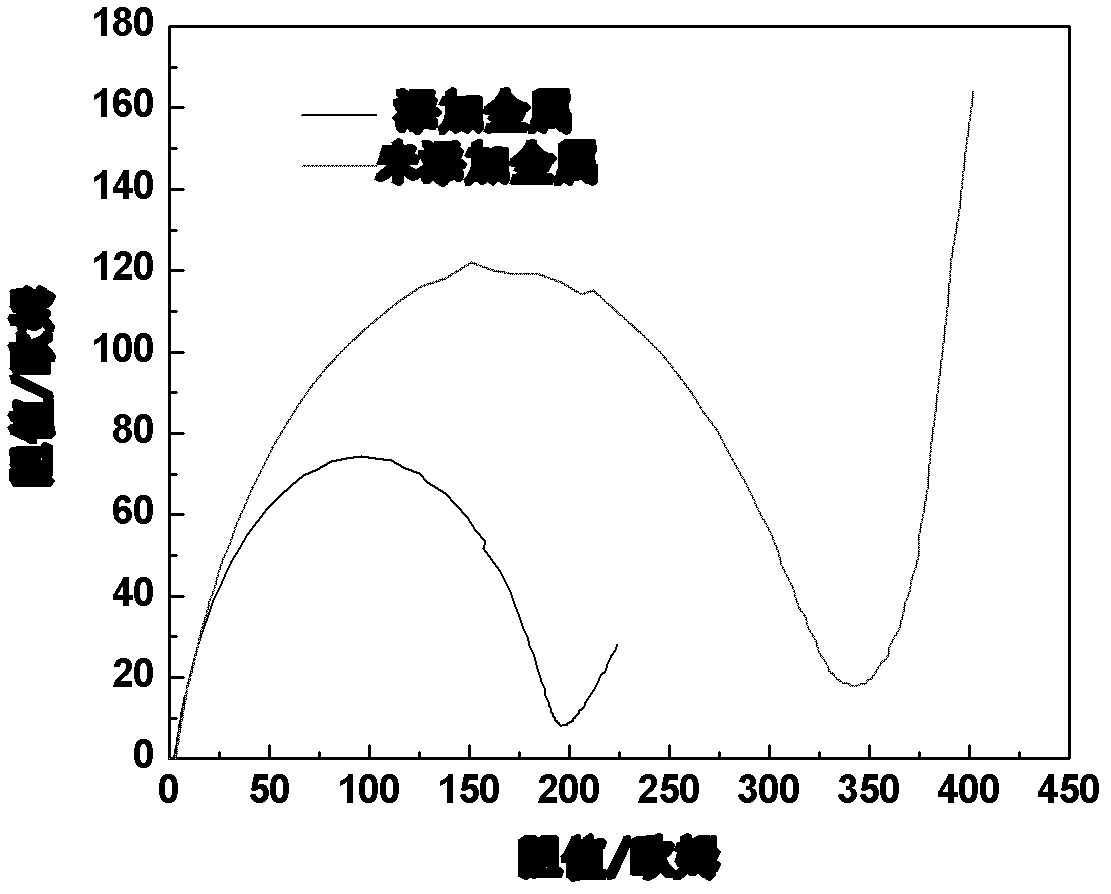

Metal-doped carbon/sulfur compound, and preparation and application thereof

The invention relates to a metal-doped carbon / sulfur compound, and preparation and application thereof. The metal-doped carbon / sulfur compound is prepared through the following steps: blending a carbon-containing organic substance and a metal salt solution, then adding a template agent, roasting at high temperature, and performing hot melt sulfur filling. In the preparation process, the metal element is simultaneously doped in the carbonization process, so that more abundant pore structures are formed in the carbon material, the pore volume and specific area of the carbon material are improved in the carbonization process, the reaction zone of the active substance sulfur is increased, the graphitization temperature of the carbon material is lowered, and the own stability of the carbon material is enhanced while the loading capacity of the active substance sulfur is improved.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

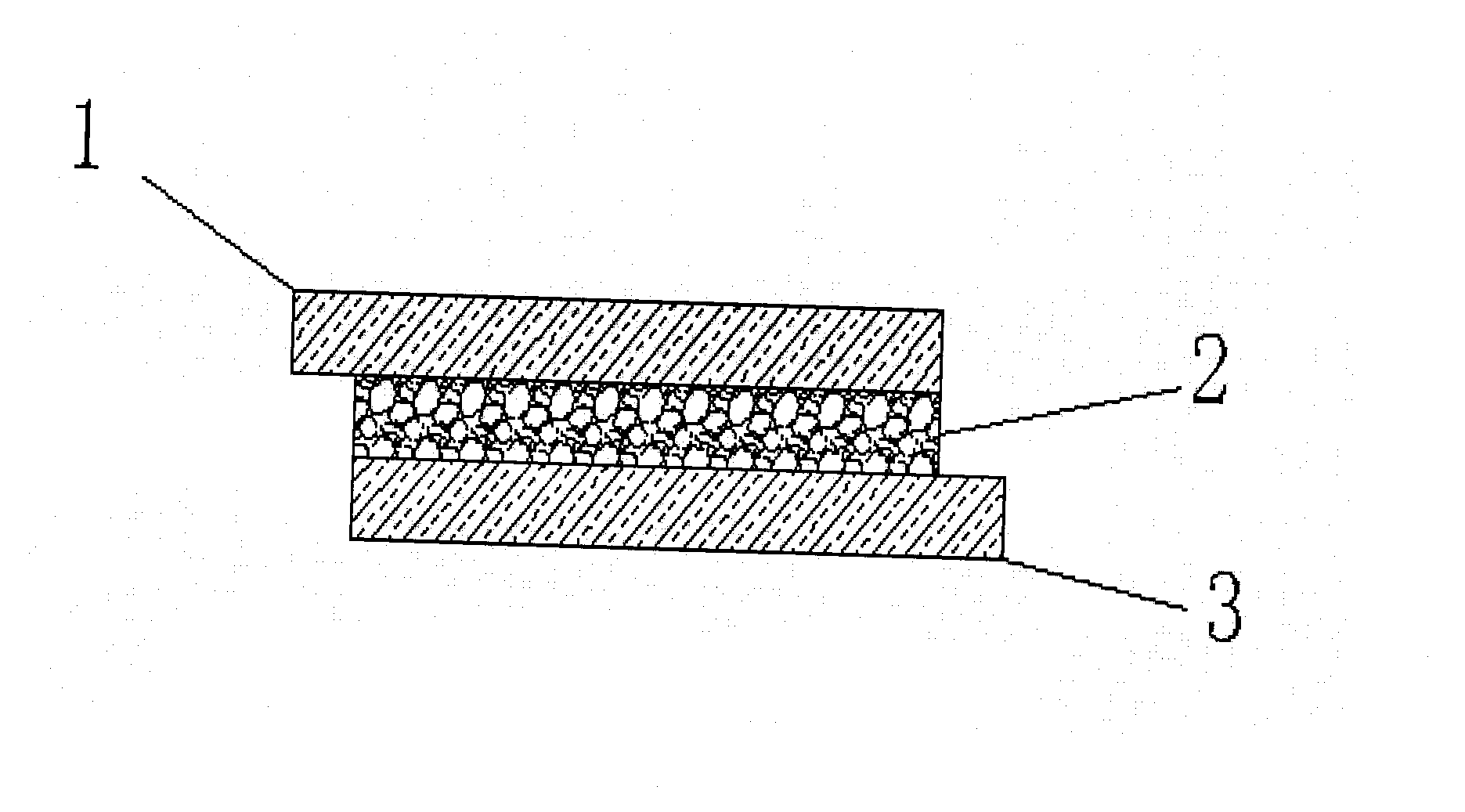

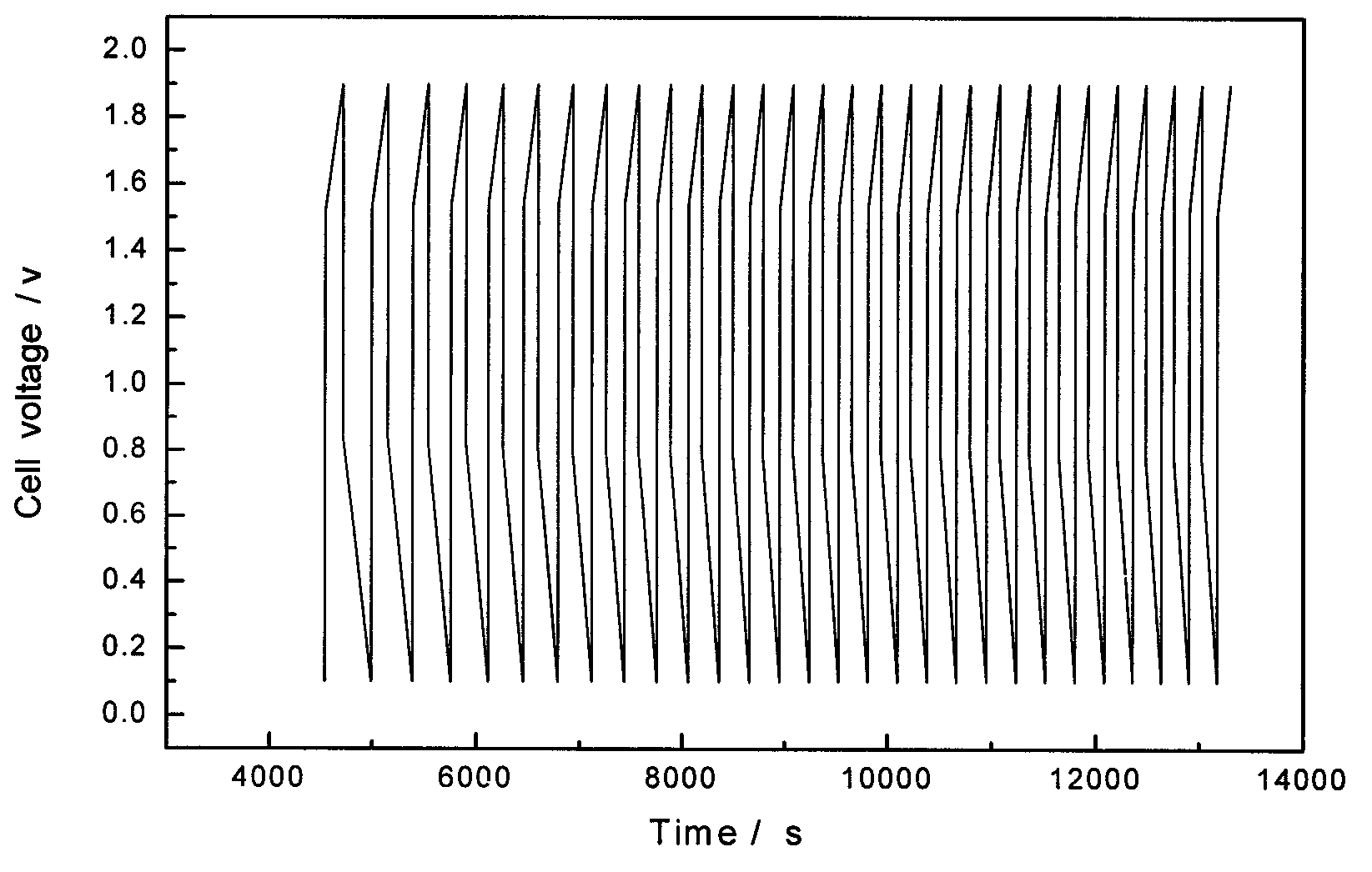

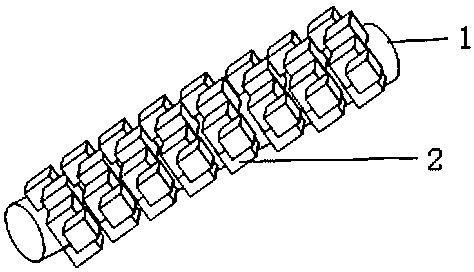

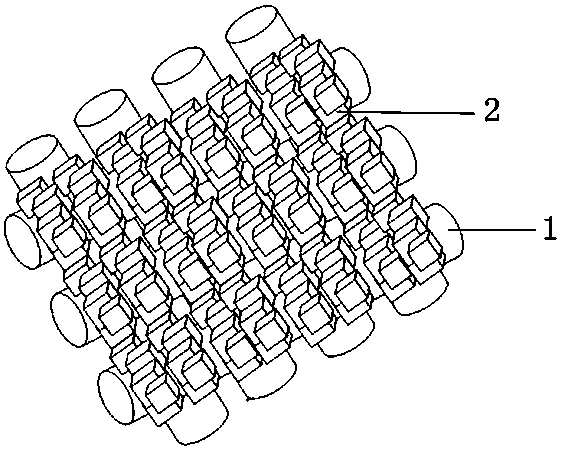

Fabric morphological polymer battery and preparation method thereof

InactiveCN103066314AUniform adhesionIncrease loadFinal product manufactureSecondary cells manufactureCapacitanceCharge rate

The invention relates to a fabric morphological polymer battery and a preparation method thereof, and belongs to the technical field of batteries. The fabric morphological polymer battery takes non-conductive fabric as flexibility base materials, conductive macromolecule is polymerized and deposited on the base materials, conductive fabric is obtained, and then the conductive fabric is used for machining two electrodes of a battery and is assembled to the battery with an electrolyte layer. Condition of the preparation method is easy to control, and the preparation method is simple in operation, low in raw material cost, small in energy consumption and suitable for large-scale industrialization production. The prepared fabric morphological polymer battery is light in weight, simple in structure, good in flexibility, pollution-free, high in safety, high in battery specific capacitance, good in circulation stability and rapid in charging rate. The fabric morphological polymer battery can be applied to certain flexibility electronic products and wearable electronic clothes.

Owner:WUHAN TEXTILE UNIV

Method for preparation of composite chromatographic stuffing of polymer carbon nanometer tube

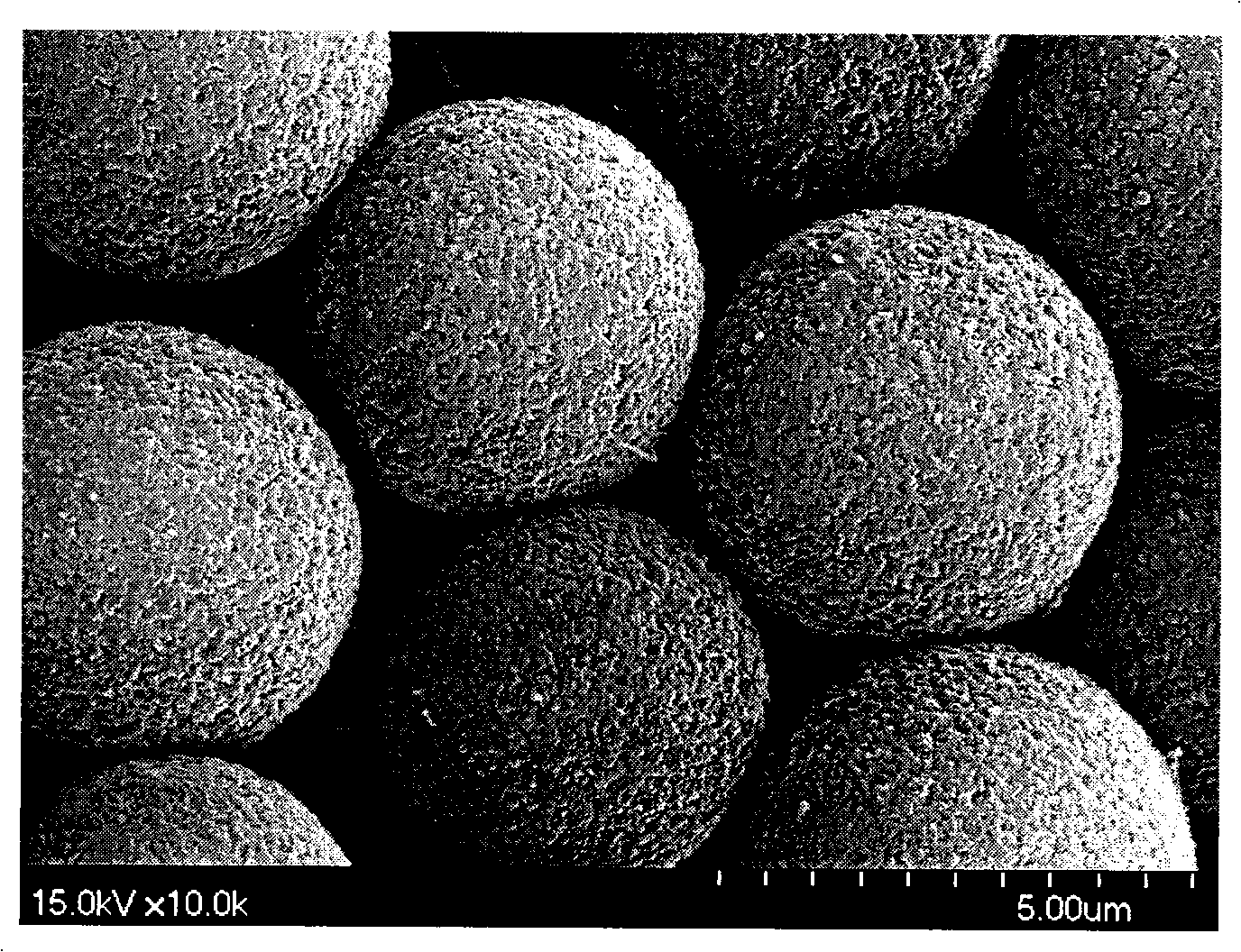

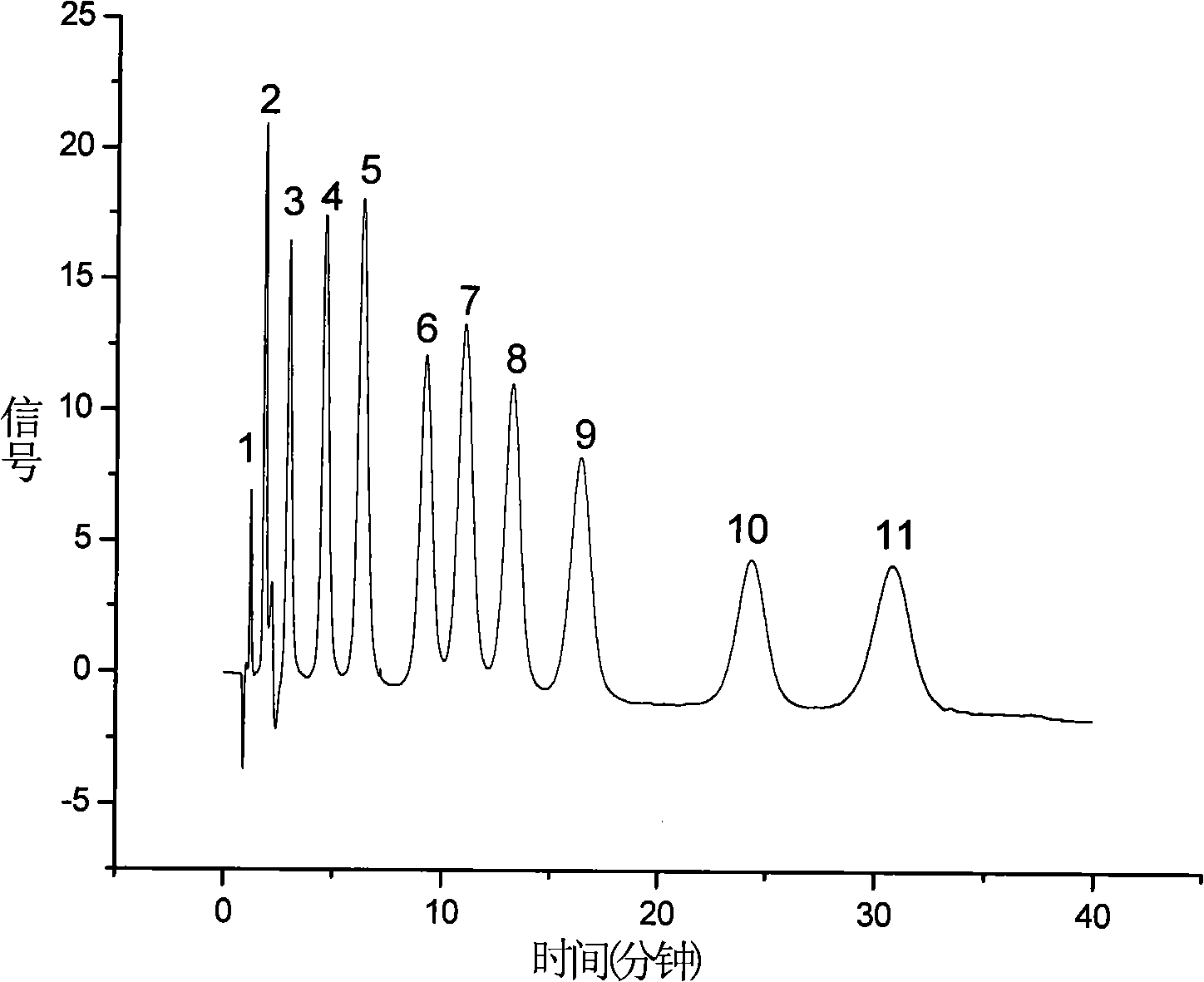

InactiveCN101513607AHomogeneous monodisperseAchieve simultaneous separationOther chemical processesMicroballoon preparationOrganic acidFoaming agent

The invention provides a method for the preparation of the composite chromatographic stuffing of the polymer carbon nanometer tube, comprising: taking polystyrene-divinylbenzene and carbon nanometer tube as the base material, adopting the dispersion polymerization method to prepare monodispersity linear polystyrene microsphere seed, activating the feed, taking uni-step seed swell method to prepare the polystyrene-divinylbenzene and carbon nanometer tube composite microsphere, extracting to remove the pore-foaming agent to obtain the chromatographic stuffing, packing column by the uniform method. The stuffing prepared by the method has uniform granularity without screening and enhanced hardness compared with the traditional polymer chromatographic stuffing, can bear bigger pressure and is suitable for the new UPLC. The obtained polystyrene-divinylbenzene and carbon nanometer tube liquid phase chromatographic column can be stably used for the ion-pair chromatograph for along time and better performs the simultaneous separation of over ten organic acids.

Owner:ZHEJIANG UNIV

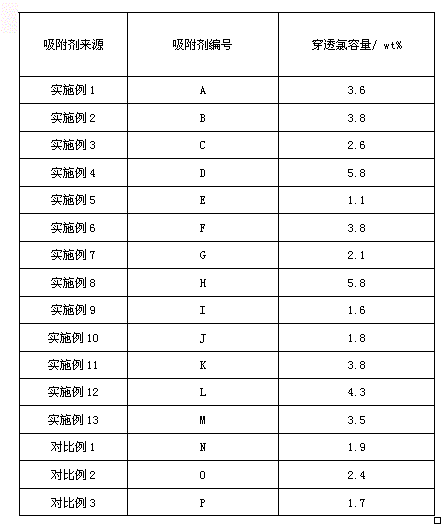

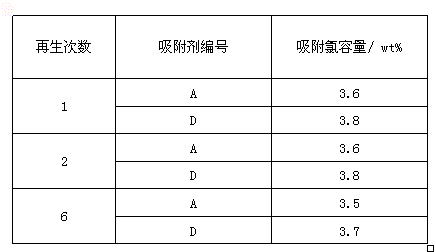

Liquefied petroleum gas dechlorination adsorbent and application method thereof

InactiveCN104689787AUniform pore structureLarge adsorption and dechlorination capacityOther chemical processesGaseous fuelsMolecular sieveBrown iron oxide

The invention provides a liquefied petroleum gas dechlorination adsorbent and an application method thereof. The technical scheme of the invention is as follows: the adsorbent comprises a molecular sieve and metallic oxides with a chlorine adsorption function, wherein the mol ratio of silicon atom to aluminum atom in the molecular sieve is 1 to 45; the specific surface area of the molecular sieve is 300 to 650 m2 / g; the weight ratio of the molecular sieve to the metallic oxides with the chlorine adsorption function is 45-98: 25-50; the molecular sieve is one or more selected from the group consisting of X type, Y type, A type and ZSM-5 type molecular sieves; and the metallic oxides with the chlorine absorption function comprise two metallic oxides, i.e., magnesium oxide, and one selected from the group consisting of zinc oxide, nickel oxide, copper oxide, platinum oxide, alumina, iron oxide or copper-based metal oxide. The adsorbent provided by the invention has the advantages of large specific surface, uniform pore structure, great dechlorination adsorption capacity, good stability, capability of maintaining high adsorption and dechlorination activities through multiple regeneration, and high adsorption and dechlorination efficiencies.

Owner:DONGYING K&T CHEM TECH

Light-weight concrete, multifunctional protective plate adopting concrete, and preparation method

ActiveCN103922668AGood flexibilityLarge specific surface areaSolid waste managementCeramicwareFiberFoam concrete

The invention belongs to the fields of building materials and construction technology. Light-weight concrete consists of a concrete base layer and waterproof surface layers, wherein the concrete base layer comprises the following components in parts by weight: 100 parts of cement, 0.1-10 parts of chrysotile fibers, 0.01-2 parts of water repellent, 10-30 parts of pulverized fuel ash, 0.1-6 parts of water reducer, 50-200 parts of water, and 1-20 parts of foaming agent or air entraining agent; the upper side and the lower side of the concrete base layer are coated with the waterproof surface layers which comprise the following components in parts by weight: 100 parts of penetrating type organosilicon waterproofing agent, 0.1-20 parts of nano TiO2, 0-2 parts of activity enhancer, 0.01-5 parts of dispersion stabilizer, and 50-200 parts of solvent. Correspondingly, the microporous structure of the foam concrete or air-entrained concrete is uniform, and the mechanical performance is improved.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

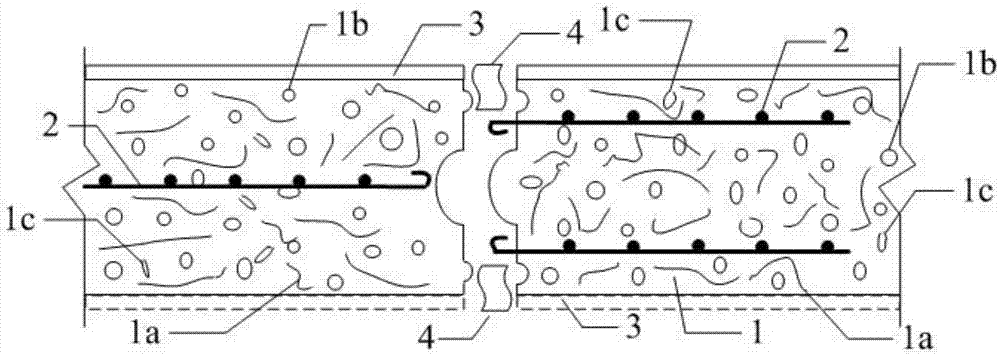

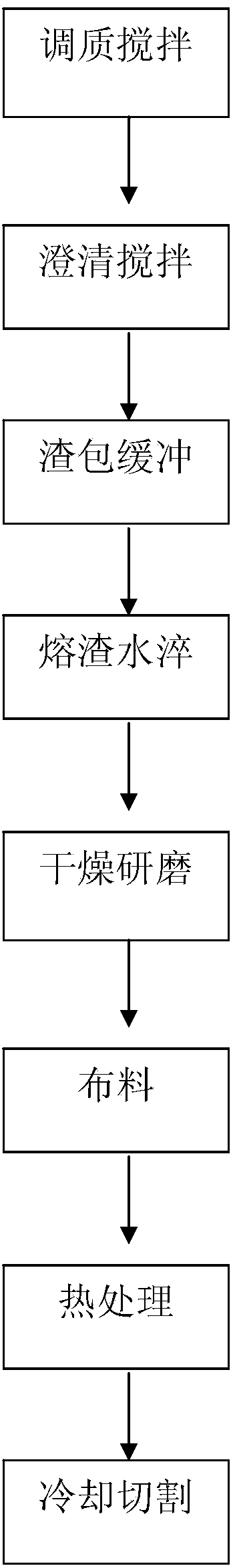

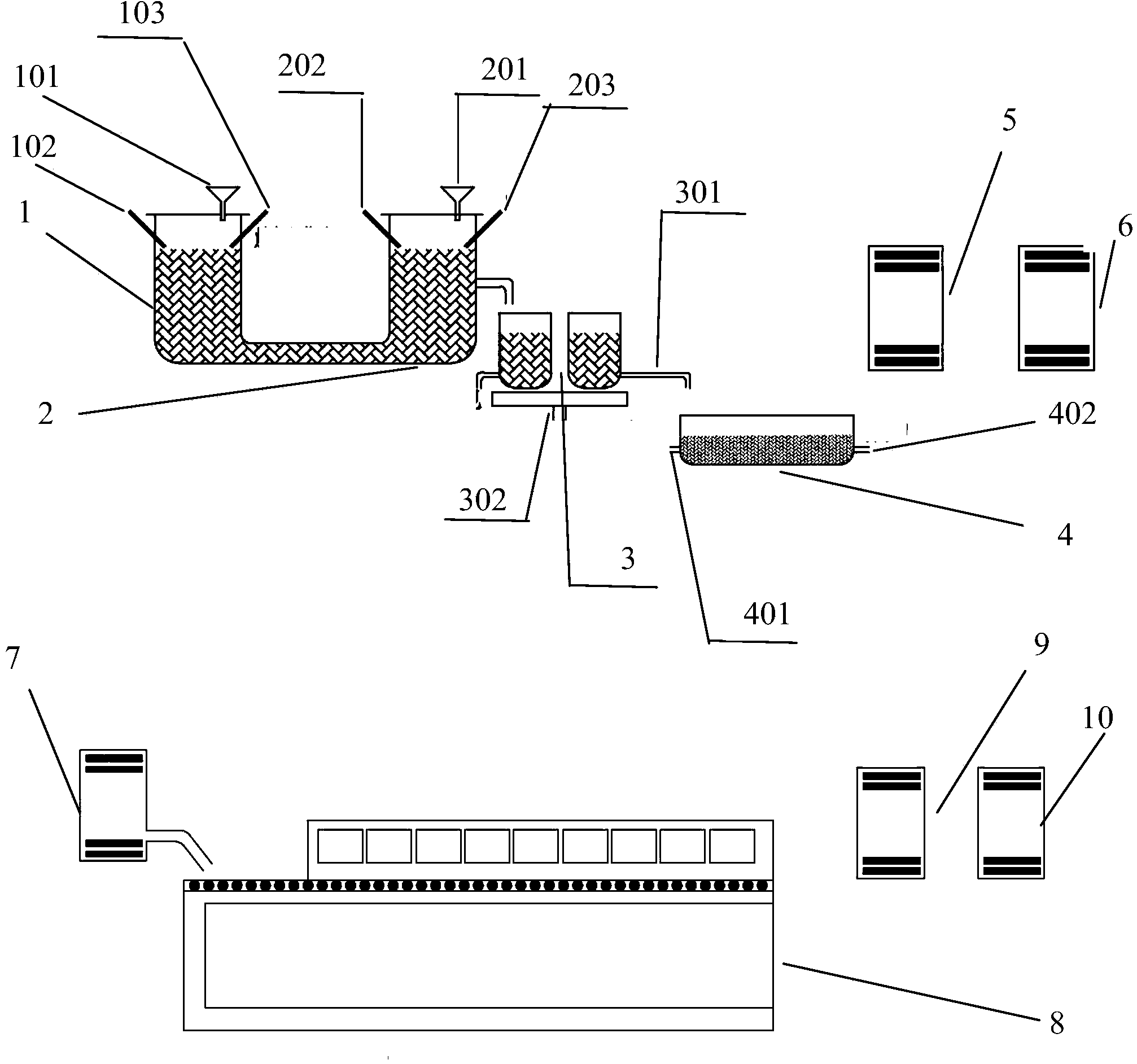

Method for using blast furnace slag to produce micro-crystalline light brick

The invention discloses a method for using blast furnace slag to produce a micro-crystalline light brick. The light brick uses the blast furnace slag as main raw material. The method for using the blast furnace slag to produce the micro-crystalline light brick includes that tempering and clearing the blast furnace slag to obtain slag with qualified ingredients, feeding to a water quenching pool to form micro-crystalline particles through water quenching, grinding and sieving the micro-crystalline particles to obtain micro-crystalline particles with proper granularity, uniformly mixing with foaming agent, putting the mixture in a casting mould, and sintering to form the micro-crystalline light brick with uniform air bubbles and stable ingredients. Compared with the traditional clay brick, the micro-crystalline light brick has lower density and higher intensity, so that the micro-crystalline light brick has better bearing ability, and moreover, the micro-crystalline light brick has good heat preservation effect and sound insulation effect due to the uniform air hole structure, so that the micro-crystalline light brick can replace the clay brick or ordinary light brick in a certain degree to serve as novel building material.

Owner:江西璞晶新材料股份有限公司

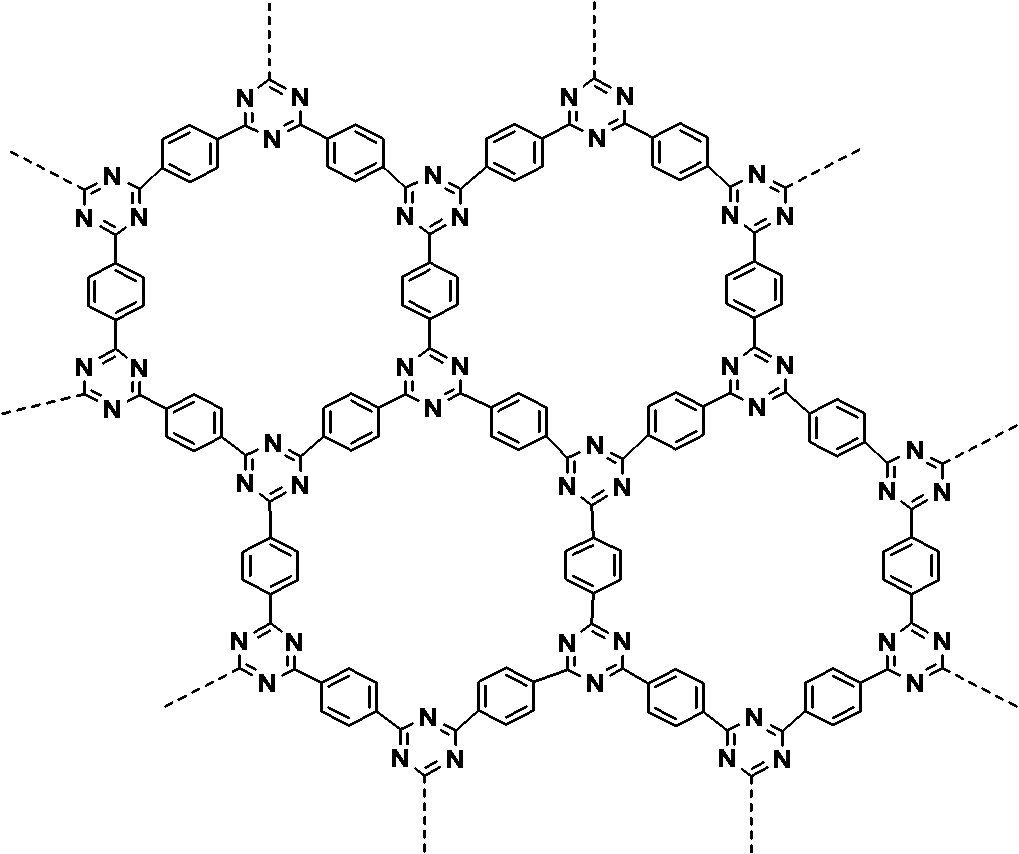

Application of porous covalent triazine polymer for removing aromatic compound from water

InactiveCN102153186AImprove adsorption capacityLarge specific surface areaWater/sewage treatment by sorptionTriazineAdsorption effect

The invention discloses an application of porous covalent triazine polymer for removing aromatic compound from water. A method for removing the aromatic compound from the water is as follows: at the temperature of 10-30DEG C, the porous covalent triazine polymer is put in aromatic pollutant-containing water body with pH value of 5.8-6.4 for adsorption for 20-30h, the concentration of aromatic compound pollutant in the water body is 0.5-90mg / L and the mass ratio of the porous covalent triazine polymer to the aromatic pollutant-containing water is 1:1700-2300. The porous covalent triazine polymer has excellent adsorption effect to the aromatic compound.

Owner:NANJING UNIV

ZIF-9-based porous carbon/carbon fiber composite material and preparation method thereof

ActiveCN109192985AHigh porosityLarge specific surface areaMaterial nanotechnologyElectrode carriers/collectorsFiberPorous carbon

A ZIF-9-based porou carbon / carbon fiber composite material and preparation method thereof belongs to the technical field of a preparation method of a metal nanoparticle doped porous carbon / carbon fiber conductive composite material, can solve the problems of poor conductivity and poor stability of the existing composite carbon material, wherein the carbon fiber of a carbon fiber fabric is taken asa growth substrate, and high-density arranged ZIF is grown on the growth substrate; 9, carbonize at high temperature in an inert gas atmosphere to generate porous carbon / carbon fib composite material, and that invention realizes a ZIF-9-based porous carbon and conductive substrate integrated conductive network structure, lithium sulfide batteries, sodium sulfide batteries, lithium-air batteries and fuel cells, electrocatalysis and other fields have a wide range of applications.

Owner:清创人和生态工程技术有限公司

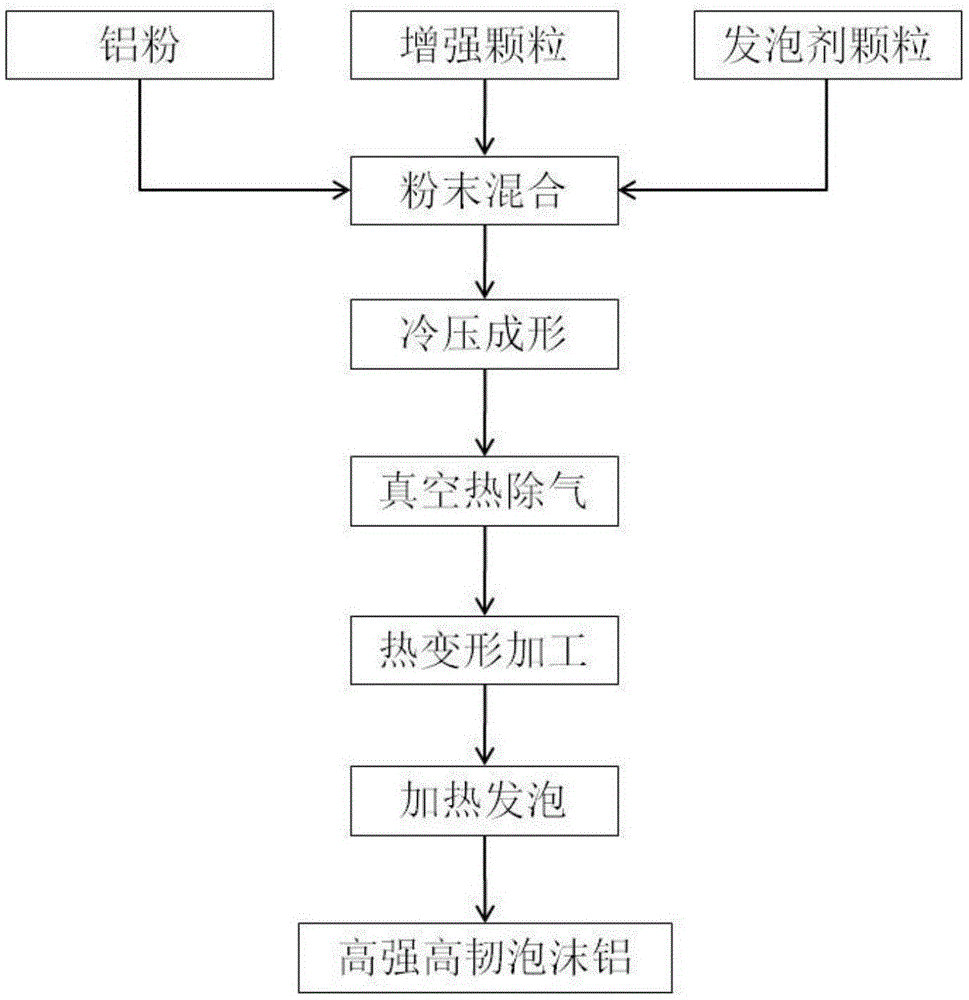

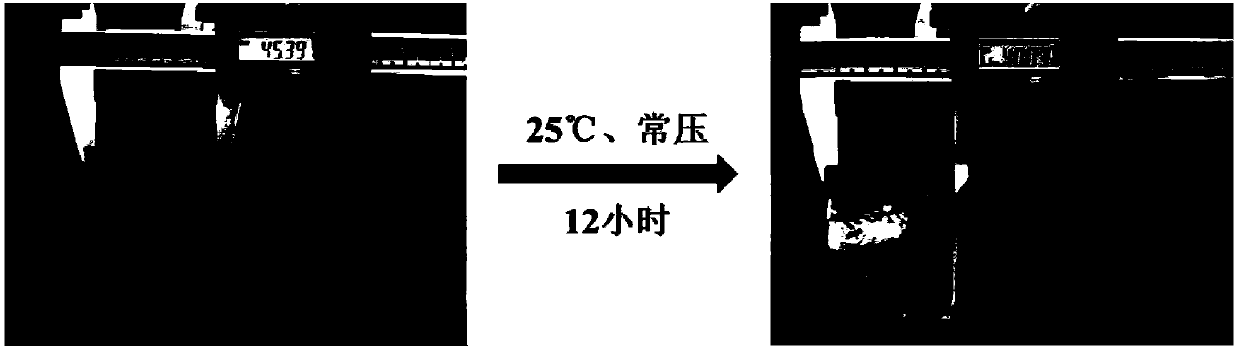

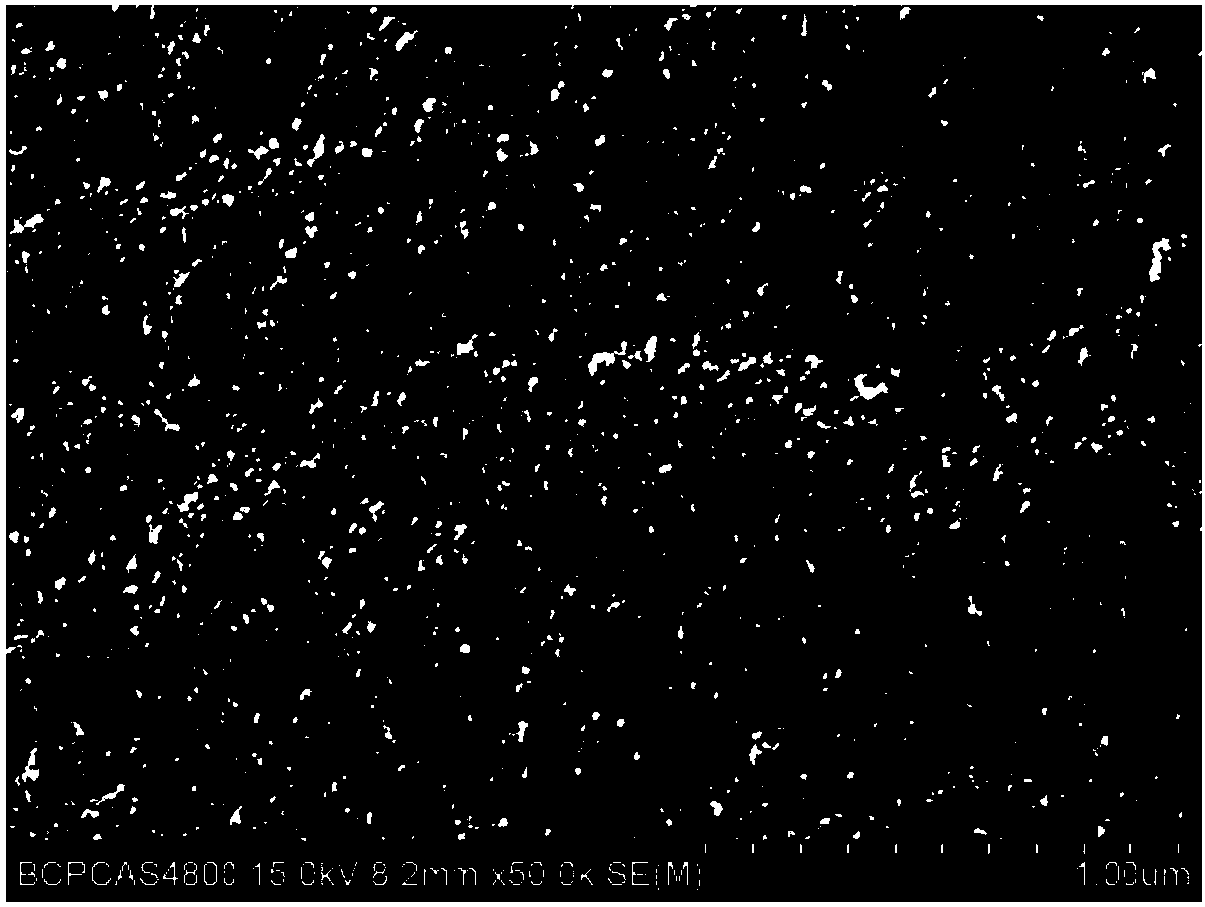

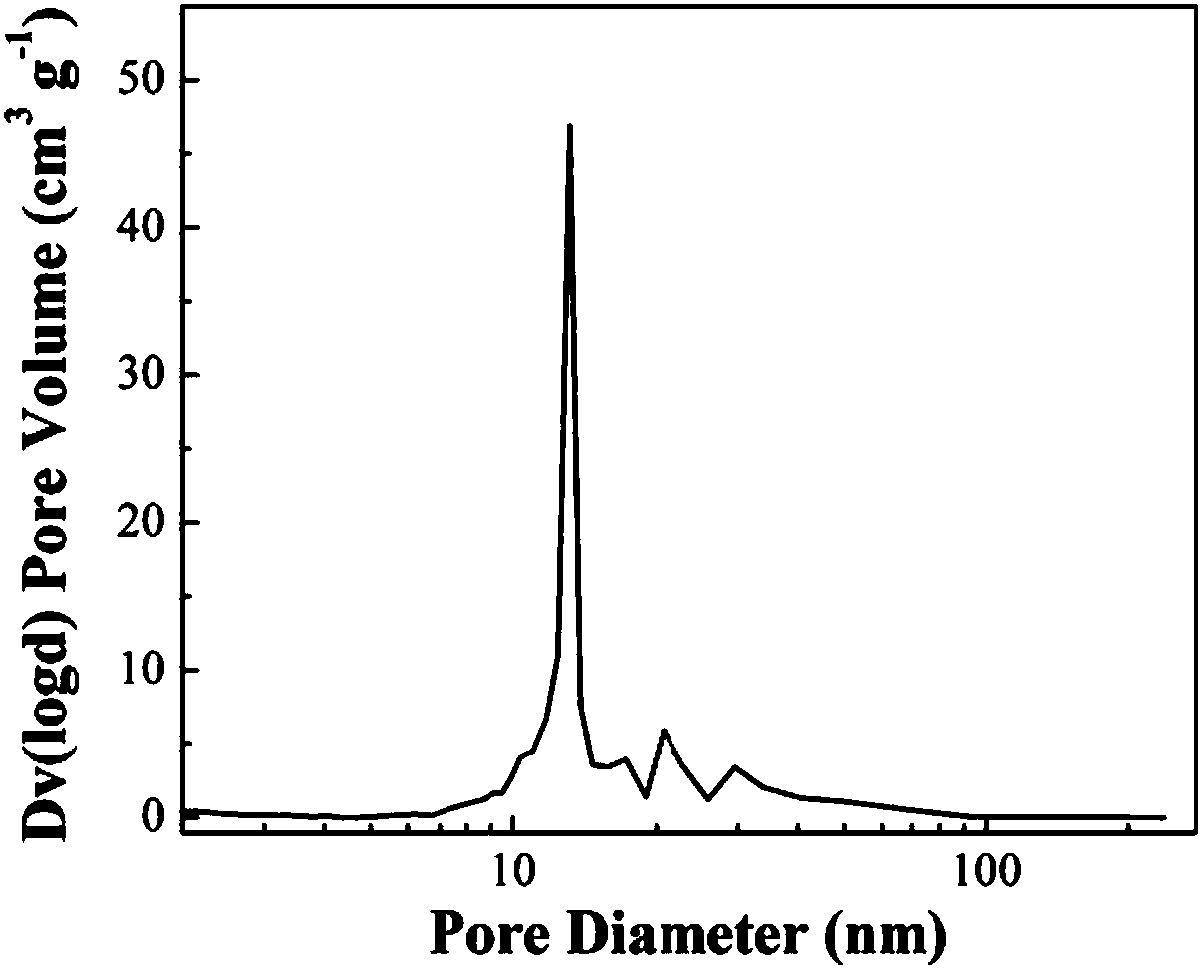

High-strength and high-toughness blind hole foam aluminum and preparation method thereof

The invention relates to high-strength and high-toughness foam aluminum and a preparation method thereof. The density of the foam aluminum is 0.4-1 g / cm3; the average size of foam holes is 2-5 mm; the hole walls consist of aluminum basal bodies and reinforcing particles dispersed therein; and the reinforcing particles and the aluminum basal bodies form high-strength-bonded metallurgy interfaces. Firstly, aluminum basal body powder, the reinforcing particles and foaming agent particles are uniformly mixed and coldly pressed to prepare a rough blank; and the rough blank is thermally deformed to prepare a foamable prefabricated body after vacuum heat degassing, and is heated and foamed to prepare the foam aluminum. The product has the characteristics of high strength, high toughness and high energy absorption, and can be applied to light support structural parts or high-damping vibration reduction and energy absorption parts in the fields of vehicles, rail traffic and spaceflight war industry; and the preparation method is flexible, strong in designability, nearly suitable for preparation of all alloy system foam aluminum, can randomly add matched reinforcing particles according to the alloy performance, and can be used for customizing the foam aluminum with different mechanical performances to satisfy the demands in all fields.

Owner:有研金属复材技术有限公司

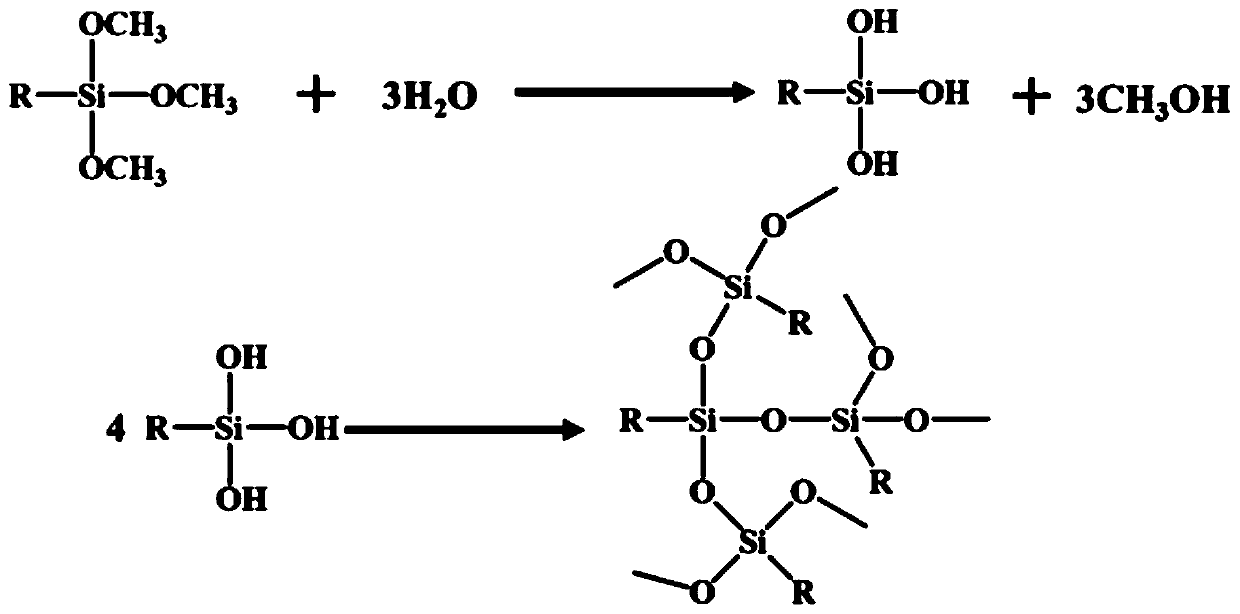

Preparation method of silicon dioxide aerogel

The invention discloses a preparation method of silicon dioxide aerogel, and belongs to the technical field of a nano-porous material. The preparation method includes steps of performing hydrolytic polymerization on methyl trimethoxy silane to obtain a wet gel; staying the wet gel under a certain temperature and acquiring a contracted wet gel; sealing and aging the contracted wet gel through solvent; drying the aged wet gel and acquiring the aerogel. Through applying the methyl trimethoxy silane and the surface active agent to prepare the wet gel, the wet gel can bear heavy contraction and deformation; through staying, fluid in the wet gel hole is volatilized, and the wet gel is contracted; under the condition of low addition of the methyl trimethoxy silane, the aerogel with high density can be acquired; meanwhile, the aerogel grain has small dimension, the hole structure is more uniform, and the contact area between grains is bigger; thus the optical transparency and the mechanical performance of the aerogel are promoted.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

Novel organic sulfur hydrogenation catalyst carrier and preparation method thereof

ActiveCN102489336AReduce catalysisImprove adsorption capacityCatalyst carriersDispersed particle separationPseudoboehmitePtru catalyst

The invention relates to a novel organic sulfur hydrogenation catalyst carrier. A preparation method of the carrier comprises steps that: a neutralization material, pseudoboehmite (gamma-alumina), an adhesive, a hole expansion agent and a metal additive are mixed; the mixture is subject to knead-molding, drying, and roasting, such that a finished product is obtained. The method is characterized in that the neutralization material is prepared through steps that: pseudoboehmite is soaked by using an alkaline solution, and is neutralized by using an acid solution; and the pseudoboehmite is subject to washing and press-filtrating, such that the neutralization material is obtained. Therefore, impurity content in the pores is greatly reduced, such that the loading of active components is promoted. A catalyst prepared by using the carrier is suitable to be used in hydrogenation catalyzing of organic sulfur in natural gas, coke oven gas, exhaust gas, and the like. Organic sulfur is converted into inorganic sulfides; and the sulfides are removed with the cooperation of an inorganic sulfur desulfurizing agent.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD +1

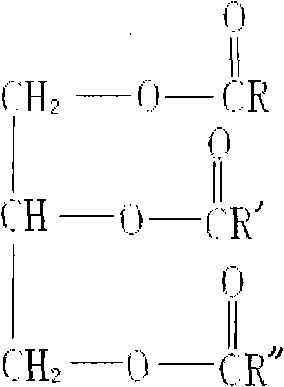

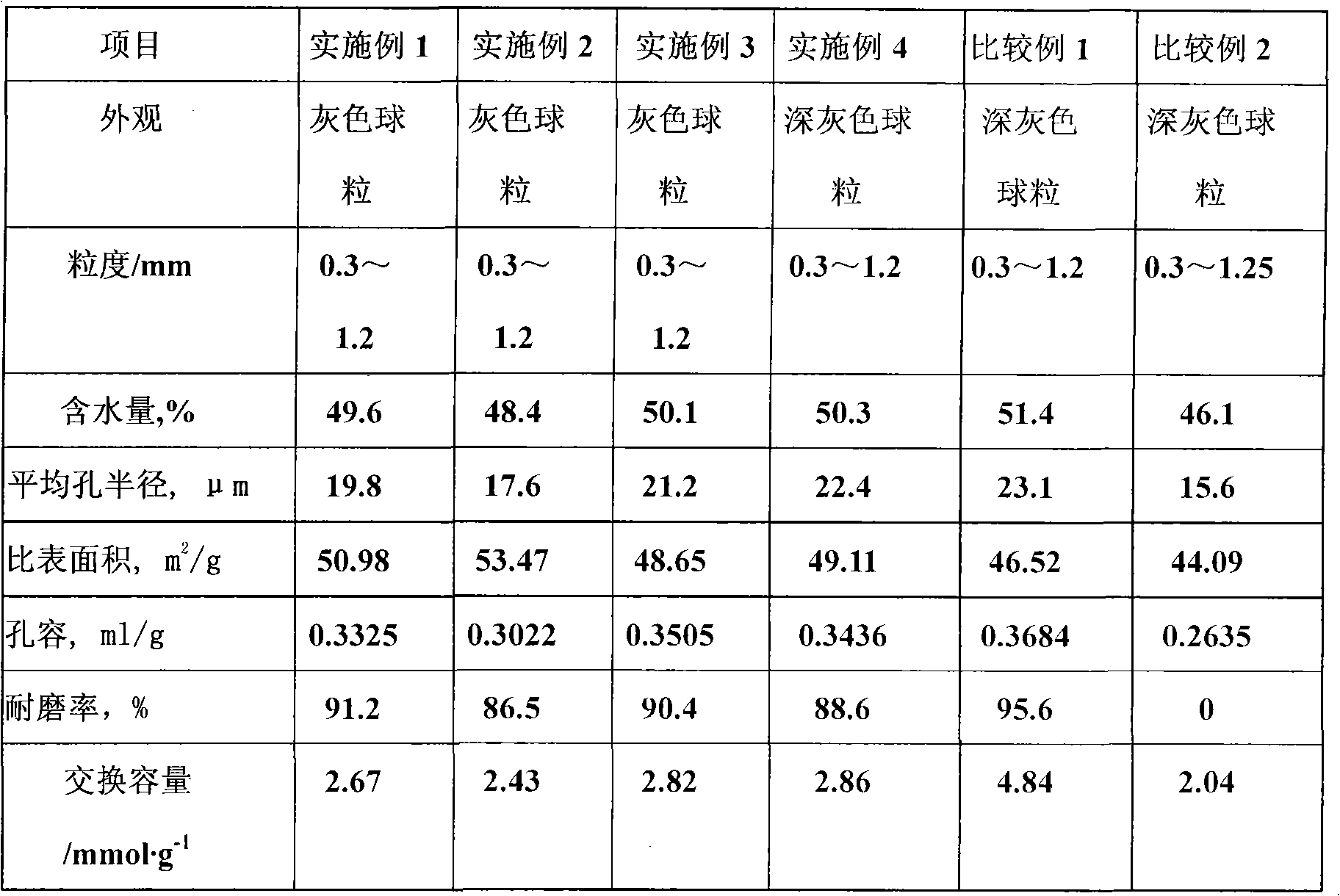

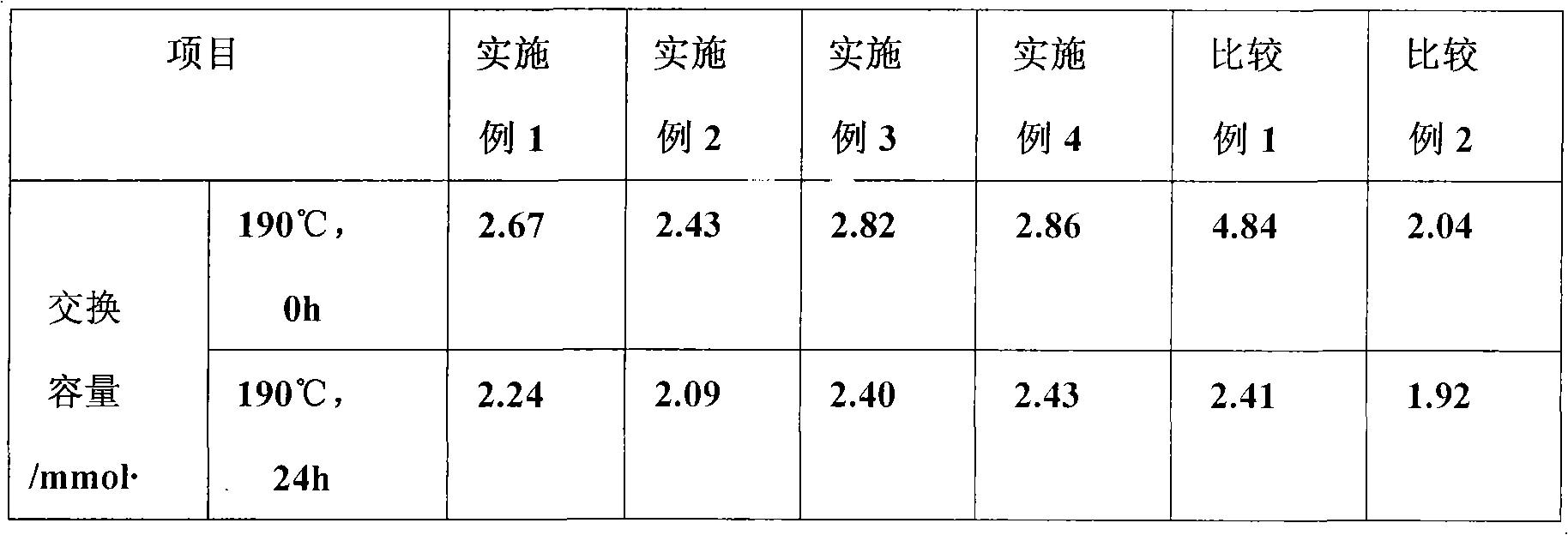

Preparation method for high temperature resistant macroporous cation exchange resin catalyst

ActiveCN102371181AHigh viscosityImprove dispersion stabilityOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationDivinylbenzenePorous channel

The present invention provides a preparation method for a high temperature resistant macroporous cation exchange resin catalyst. According to the preparation method, a linear chain saturated acid with carbon atoms of 4-25, any one component selected from a unsaturatcd fatty acid glyceride, or a mixture is adopted as a pore-foaming agent to prepare styrene-divinylbenzene copolymer containing the pore-foaming agent, wherein the mixture comprises two or more components selected from the unsaturatcd fatty acid glyceride; an organic solvent is adopted to extract the pore-foaming agent and low molecular weight impurities in the copolymer; the macroporous polymer is subjected to a halogenating reaction in the presence of a catalyst; the resulting halogenated product is subjected to a sulfonationreaction. According to the present invention, the polarity of the used pore-foaming agent by the preparation method of the present invention is similar to the polarity of the monomer, such that uniform porous channels can be formed during the polymerization process; the used materials by the preparation method of the present invention have characteristics of environmental protection, no toxicity,cheap price and easy availability; during the preparation process of the present invention, only a hydrocarbon solvent with low boiling point and low toxicity is adopted to clean the pore structure, such that the operation is simple and three wastes are not discharged; the pore structure-cleaned styrene-divinylbenzene copolymer is subjected to the halogenation and the sulfonation to obtain the resin catalyst with uniform pore structure, good high temperature resistance and high catalytic activity.

Owner:CHINA PETROLEUM & CHEM CORP

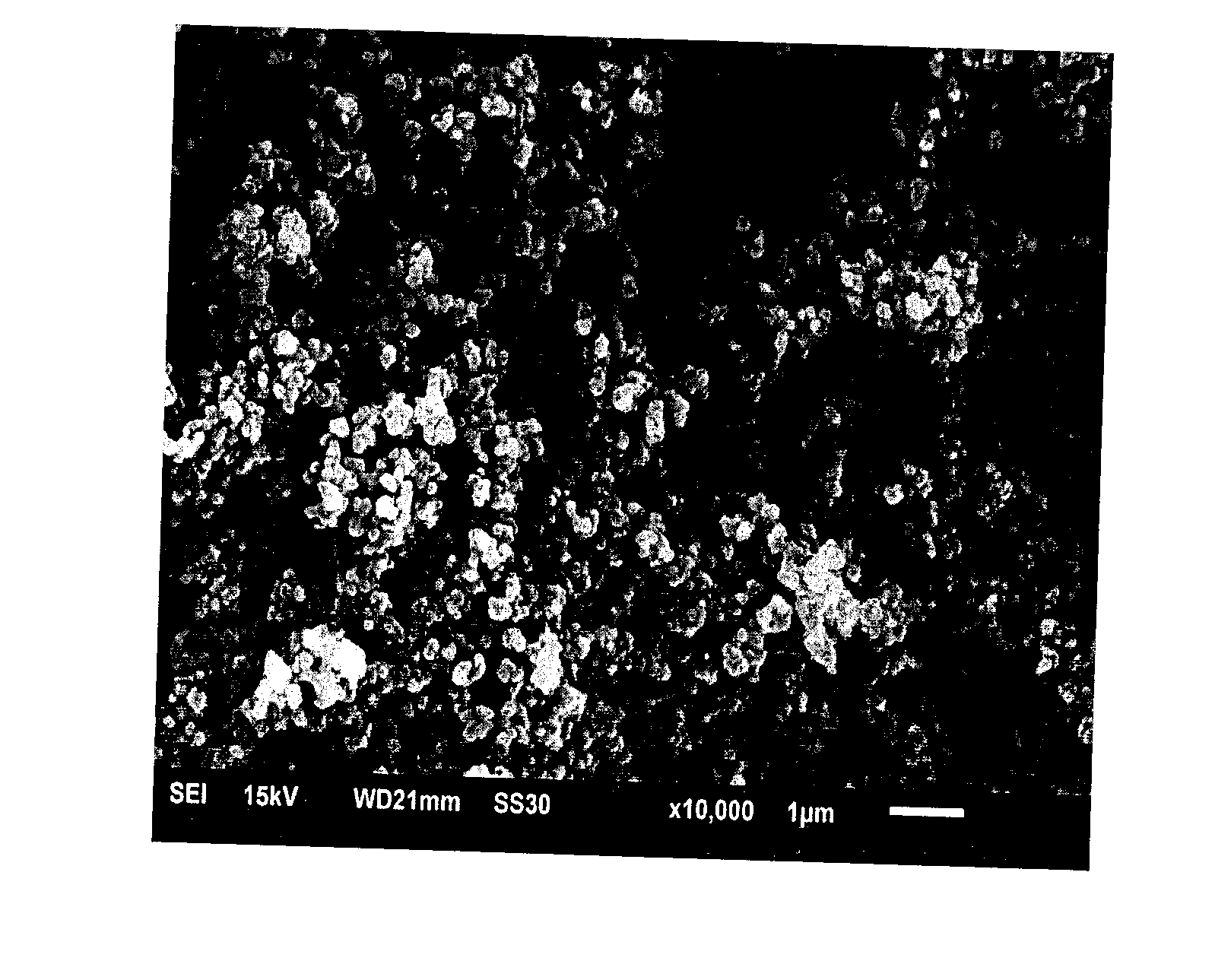

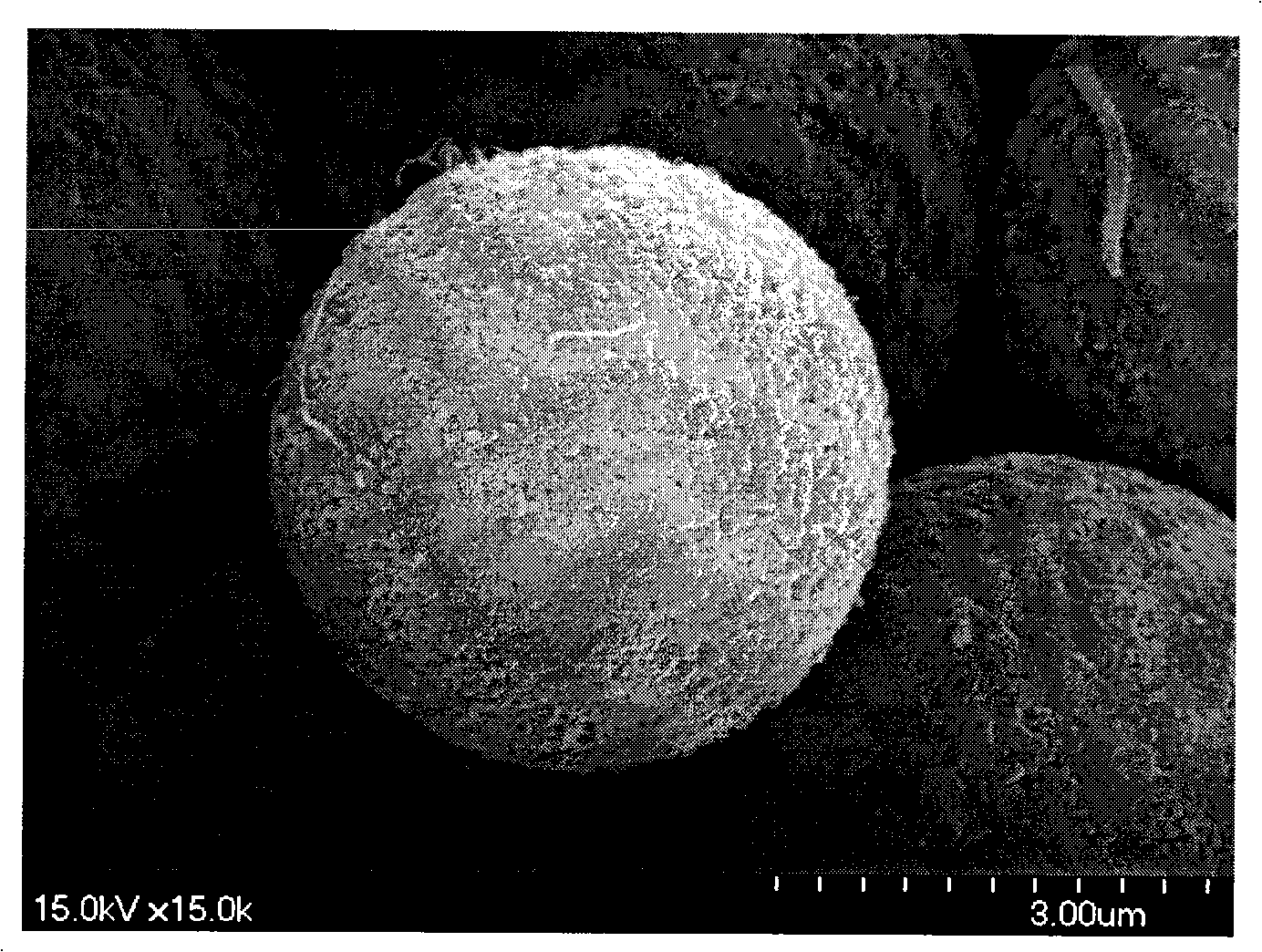

Process for producing spherical activated carbon

InactiveUS7781370B2High yieldMore solubilityPhysical/chemical process catalystsCarbon compoundsActivated carbonTar

A spherical activated carbon is produced from a starting pitch obtainable from a heavy hydrocarbon oil, such as petroleum tar, coal tar or ethylene, through a moderate process. The starting pitch has a softening point of at least 150° C., a toluene-insoluble content of at least 40% and a property of retaining optical isotropy even after being heated at 430° C. for 1 hour. The starting pitch is converted into a porous spherical pitch, which is then infusibilized, carbonized and activated to provide a spherical activated carbon.

Owner:KUREHA KAGAKU KOGYO KK

Low-porosity aluminum-magnesium-calcium rear earth based cellular Al alloy foam and preparation thereof

The invention discloses a low porosity rate Al-Mg-Ca-rare-earth-based closed-cell foamed aluminum alloy and a preparation method which are a foamed aluminum alloy with good corrosion-resistant performance, high strength, high finished product rate, simple method and low cost and a preparation method. The foamed aluminum alloy takes calcium carbonate as a foaming agent, the porosity rate is between 40 and 75 percent, wherein, the manganese accounts for 1 to 11 percent (mass percentage) of the alloy, the calcium accounts for 0.5 to 5 percent (mass percentage) of the alloy, the rare earth accounts for 0.10 to 1.2 percent (mass percentage) of the alloy. The preparation method is that: the pure aluminum is heated up for melting, the melting body is added with the manganese equivalent to 1 to 11 percent of the mass of the alloy, the calcium equivalent to 0.5 to 5 percent of the mass of the alloy and the rare earth equivalent to 0.10 to 1.2 percent of the mass of the alloy, and kept for 10 to 30 minutes; the temperature of the melting body is ensured between 650 and 690 DEG C, the melting body is stirred for 2 to 12minutes with the speed of between 300 and 600rpm; the calcium carbonate equivalent to 0.5 to 5 percent of the mass of the pure aluminum is added into the melting body to stir so as to make the aluminum alloy melting body to be foamed, the low porosity rate Al-Mg-Ca-rare-earth-based closed-cell foamed aluminum alloy is obtained after cooling.

Owner:SOUTHEAST UNIV

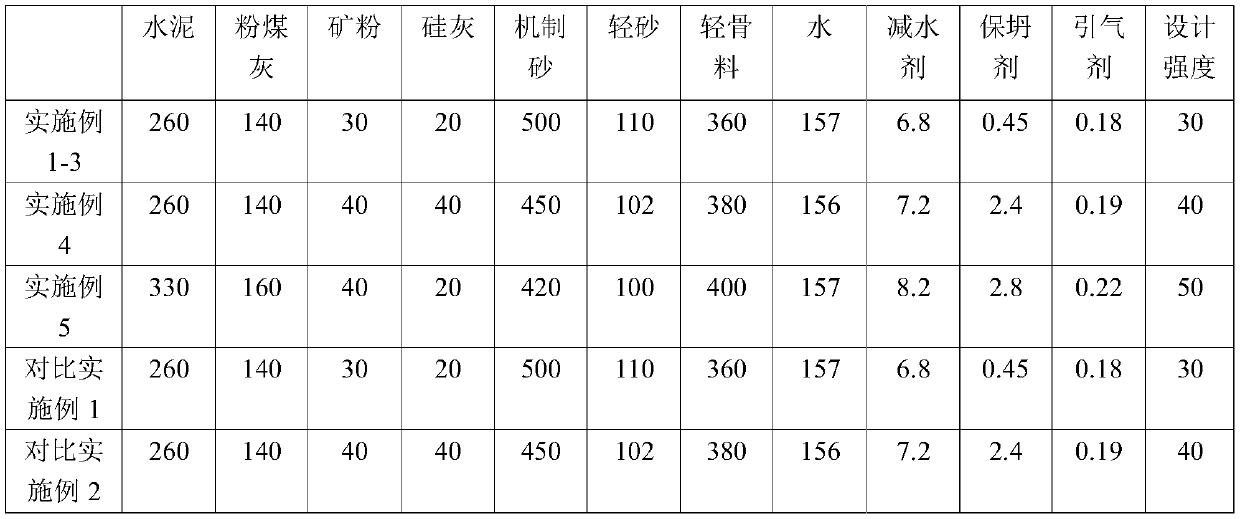

Self-compacting lightweight aggregate machine-made sand concrete and preparation method thereof

InactiveCN110240446ASolve the problem of insufficient resources and tight supplyImprove cohesionCeramicwareRosinWater reducer

The invention discloses self-compacting lightweight aggregate machine-made sand concrete. The sand concrete comprises the following raw materials in parts by weight: 260-330 parts of concrete, 140-160 parts of fly ash, 30-40 parts of mineral powder, 20-40 parts of silica fume, 420-500 parts of machine-made sand, 100-110 parts of light sand, 360-400 parts of lightweight aggregate, 150-160 parts of water, 6.8-8.3 parts of a water reducer, 0.45-2.8 parts of a slump preserving agent and 0.18-0.22 part of an air entraining agent, wherein the slump preserving agent is obtained by compounding isopentenol polyoxyethylene ether (TPEG), acrylic acid and a compound molecular weight regulator, the air entraining agent is a rosin soap type air entraining agent obtained by compounding rosin, caustic soda, triethanolamine and sodium lauryl sulfate. The machine-made sand is used to replace natural sand, and the concrete prepared by a secondary mixing method solves the problems of easy flotation of lightweight aggregate concrete aggregate, shortage of natural sand supply, and high water demand rate, easy separation and poor pumpability of lightweight aggregate machine-made sand concrete.

Owner:中建西部建设贵州有限公司

Preparation method of monolithic BEA molecular sieve catalyst for direct N2O catalysis decomposition

InactiveCN102921454AHigh catalytic decomposition activityStable catalytic decomposition activityMolecular sieve catalystsDispersed particle separationMolecular sieveDecomposition

The present invention relates to a preparation method of a monolithic BEA molecular sieve catalyst for direct N2O catalysis decomposition. According to the monolithic BEA molecular sieve catalyst, cordierite is adopted as a carrier, a Fe and Co metal ion modified BEA molecular sieve is adopted as an active component, and a silica sol and an alumina sol are adopted to load the modified BEA molecular sieve on the cordierite to prepare the monolithic catalyst, wherein a ratio of the silica sol to the alumina sol is adjusted and the silica sol, the alumina sol and the modified molecular sieve are subjected to the optimal activity matching during the preparation process so as to prepare the high activity monolithic catalyst. Research results show that under reaction conditions of an airspeed of 4000 hour<-1> and a ratio of He to N2O of 65:35, the monolithic catalyst formed by matching the Co-BEA and 5% silica sol has the optimal activity, and the monolithic catalyst formed by matching the Fe-BEA and 5% alumina sol has the inferior activity. The monolithic BEA molecular sieve catalyst prepared by the preparation method has good catalytic activity and thermal stability, wherein a N2O conversion rate is 100% at a temperature of 500 DEG C.

Owner:BEIJING UNIV OF CHEM TECH

Preparation method of nano porous high-efficiency heat insulation board

The invention provides a preparation method of a nano porous high-efficiency heat insulation board, belonging to the field of nano porous heat insulation materials. The preparation method comprises the following processes: uniformly mixing nano powder with fiber, a bonding agent, an opacifier, a plasticizer, a drying control agent, a dispersant and a right amount of dry-and-wet degree regulating reagent in a mechanical and chemical dispersion combined method; moulding in a manner of dry pressing moulding, curtain coating moulding or extrusion moulding and the like; and controlling drying conditions, drying a moulded sample, and then coating a reflecting layer with certain thickness and material quality, thus obtaining the nano porous high-efficiency heat insulation board. The invention has the advantages that the preparation method is simple and feasible, the prepared nano porous heat insulation board has high strength, uniform hole structure and good heat insulation performance.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

Lightweight wall special-purpose cell concrete, and production method thereof

InactiveCN105272352AReduce shrinkage cracksMaintain good performanceSolid waste managementCeramicwareFiberPolyvinyl alcohol

The invention discloses a lightweight wall special-purpose cell concrete, and a production method thereof. The production method comprises following steps: (1) rapid hardening sulphoaluminate cement, ordinary Portland cement, and dry discharge fly ash are delivered into a double helix conical mixer so as to obtain a composite cementing agent via premixing; (2) water, cold-water-soluble polyvinyl alcohol powder, polypropylene reinforcing fiber, calcium stearate water repellent, a silane coupling agent, expanded perlite, and polyphenyl foam particle are delivered into an agitator; (3) the composite cementing agent obtained via step (1) is delivered into the agitator, and micropore foam prepared from a micropore foaming agent via compressed air is sprayed into the agitator, an uniform slurry is obtained via mixing stirring, and slurry volume weight is controlled to be 1000 to 1200kg / m3; (4) the uniform slurry is pumped into lightweight wall products or cast-in-situ wall forming moulds; and (5) finished products are obtained via curing, hardening, moulding, and demoulding. The lightweight wall special-purpose cell concrete can be used for producing various lightweight wall products and cast-in-situ lightweight concrete walls, and is an ideal material used for producing energy-saving lightweight walls and products.

Owner:NORTHWEST UNIVERSITY FOR NATIONALITIES +2

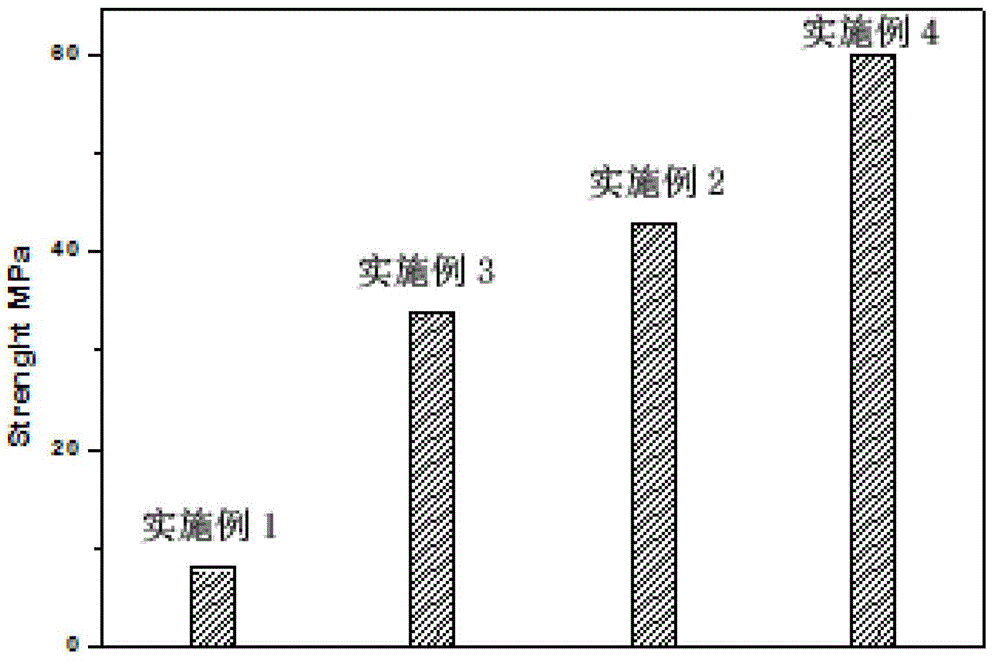

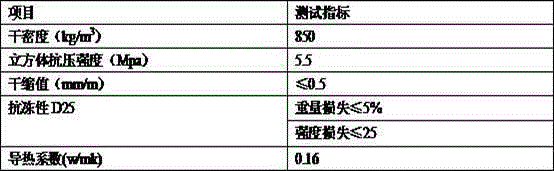

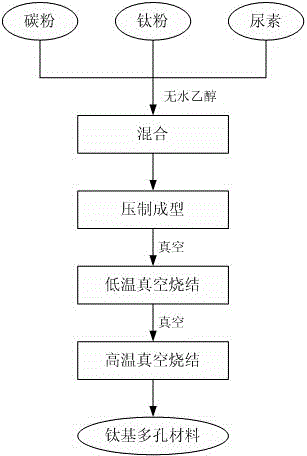

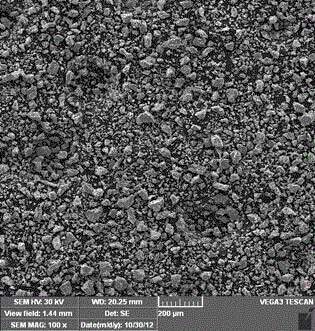

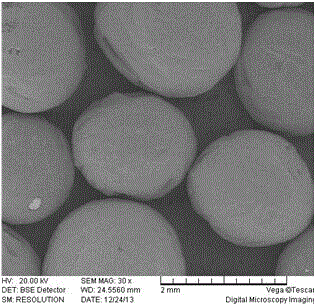

Preparing method of in-situ synthesis titanium carbide enhanced titanium-based multi-hole materials

The invention discloses a preparing method of in-situ synthesis titanium carbide enhanced titanium-based multi-hole materials. A powder metallurgy pore forming substance technology is used, and urea, carbon powder and titanium powder are used for being subjected to mixing, pressing forming and sintering to prepare the titanium-based multi-hole composite materials. The urea is used as a pore forming substance. Absolute ethyl alcohol is used as binding agents. Components of the titanium-based multi-hole materials are easy to control. Meanwhile, the advantage that raw material cost is low is achieved. A two-stage type sintering process is used for reducing energy consumption, equipment cost is lowered, and benefit is improved. In addition, the titanium-based multi-hole composite materials prepared with the preparing method of the in-situ synthesis titanium carbide enhanced titanium-based multi-hole materials are high in intensity, good in comprehensive mechanical property and high in anti-corrosion performance, the durability of the titanium-based multi-hole composite materials is improved, a new technology path is provided for sewage purification, biology implant materials and the like, and great application prospect is achieved.

Owner:CHONGQING UNIV

Production of foamed aluminium alloy deformed piece by secondary foam

The invention carried out a process to produce foamed aluminium alloy with the secondary foaming. The process is: first to melt the aluminium alloy and add the Ca into the molten, then adding into the titanium hydride to get the first foamed aluminium alloy, next to heat the first alloy and make it preformed unit, last to foam the preformed unit and cool to get the secondary foamed aluminium alloy.

Owner:SOUTHEAST UNIV

Mesoporous titanium dioxide and preparation method thereof and application thereof

InactiveCN102718254AOptimal Control StructureLow densityInorganic non-active ingredientsNanotechnologyActive agentSurface-active agents

The invention belongs to the field of medicine technology, and relates to a preparation method of mesoporous titanium dioxide with high biological compatibility and a controllable structure and application of the mesoporous titanium dioxide as a hard soluble drug carrier. The method adopts a soft template method, namely, adopts a surfactant as a structure guiding agent, isopropyl titanate as titanium source, and double distilled water as a reaction rate modifier to prepare the mesoporous titanium dioxide having different mesoporous passage structures. The prepared mesoporous titanium dioxide is of large specific surface area, chemical stability, non-toxic effect, no side effect and good biocompatibility, and is suitable for being used as the hard soluble drug carrier. The application of the titanium dioxide as the hard soluble drug carrier can lay a theoretical foundation for uses of multivariant functional carriers. The method adopts a solvent method and a fusion method to perform embedding and adsorption on a drug so as to uniformly disperse the drug inside the mesoporous or on surface of the carrier. The drug carrier system can assist in significantly enhancing water solubility of a hard soluble drug and improving dissolution rate in vitro and oral bioavailability.

Owner:SHENYANG PHARMA UNIVERSITY

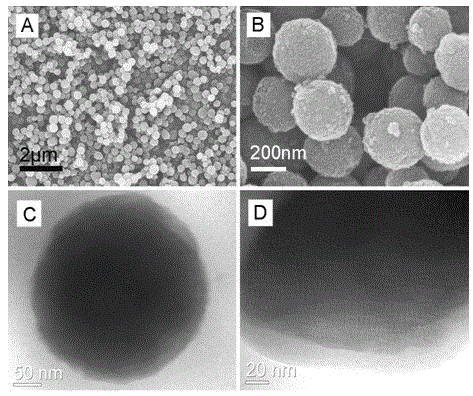

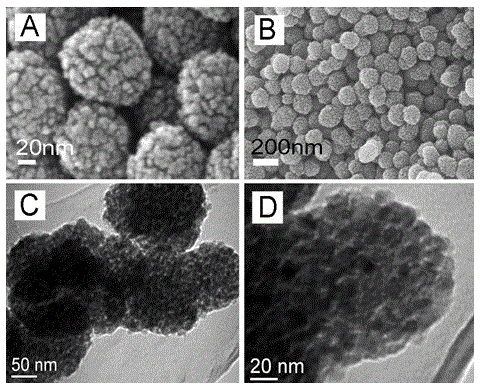

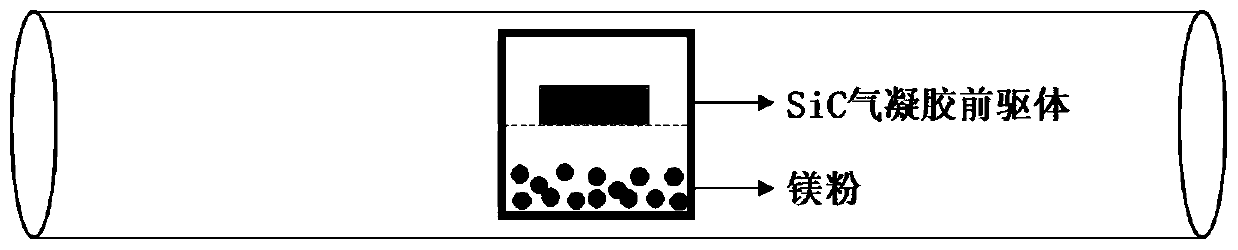

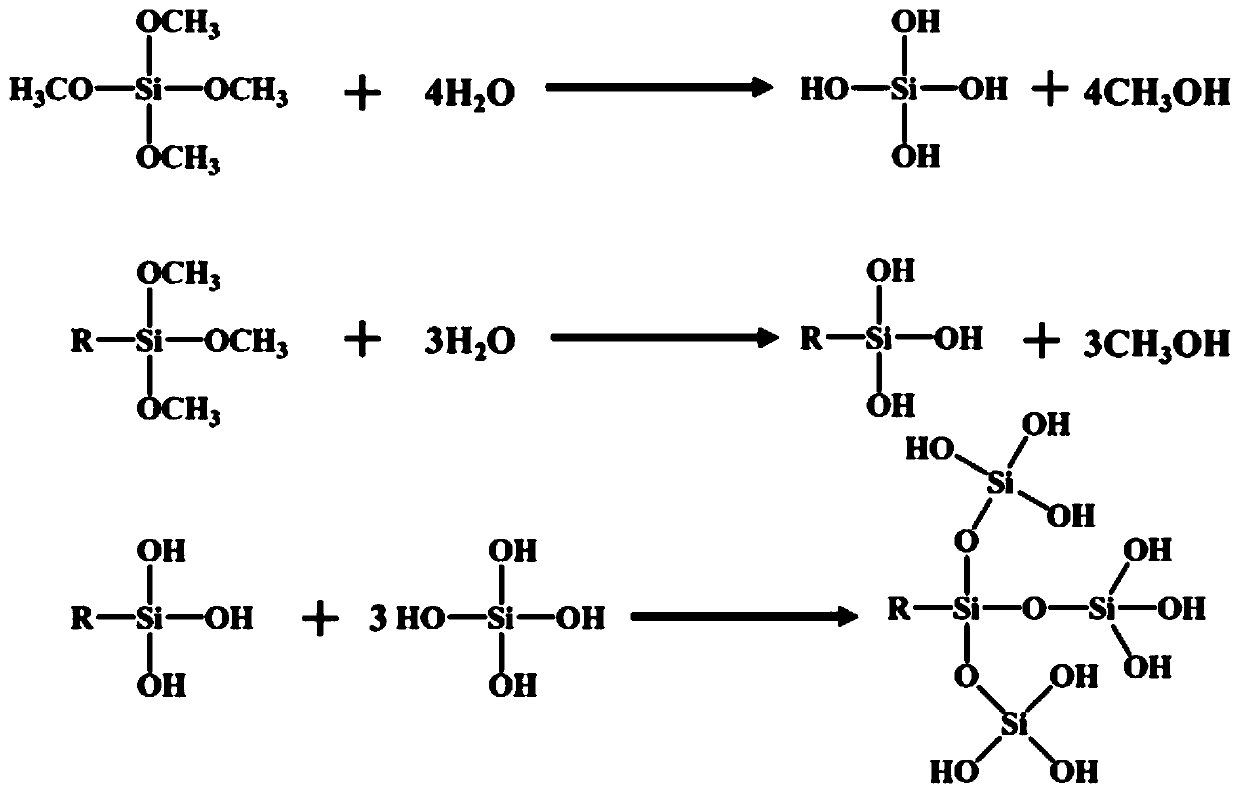

Preparation method of high temperature resistant SiC aerogel

ActiveCN110668446ASimple componentsUniform pore structureCarbon compoundsSupercritical dryingHydrolysate

The invention discloses a preparation method of high-temperature resistant SiC aerogel, relates to a preparation method of aerogel, and aims to solve the technical problems of low yield and easily damaged microstructure of the existing method for preparing the SiC aerogel. The method comprises the following steps: 1, preparing liquid A and liquid B and mixing the liquid A and the liquid B to obtain hydrolysate; (2) preparing wet gel; (3) preparing aerogel; (4) reacting the aerogel with magnesium powder, cleaning and drying to obtain the SiC aerogel. The method adopts magnesium thermal reduction to reduce an aerogel precursor into the SiC aerogel under the protection of an inert gas. The production of SiO gas during the reduction of R1SiO1.5 is successfully avoided, and the morphology of the product is kept intact to the greatest extent. The silicone aerogel with uniform pore structure and complete shape is prepared by supercritical drying, and belongs to the field of aerogel preparation.

Owner:HARBIN INST OF TECH

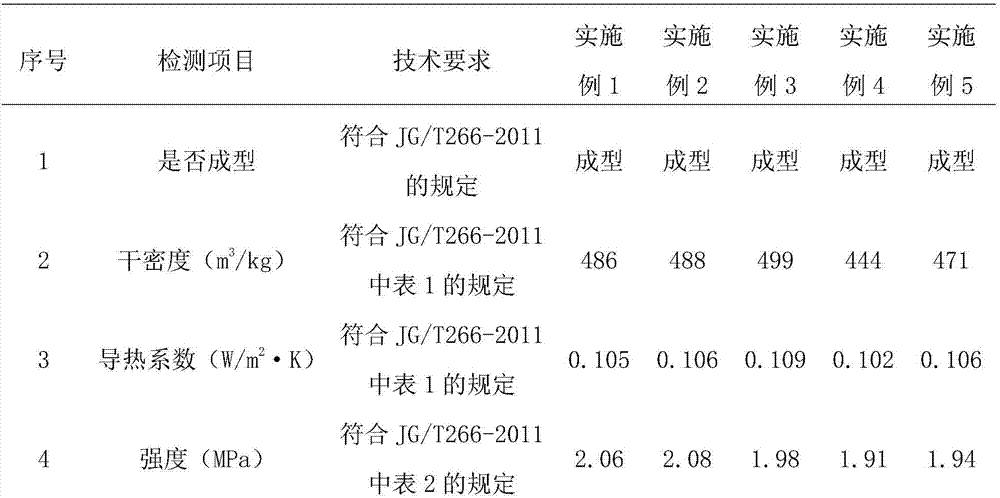

Non-autoclaved foam concrete material and preparation method thereof

The invention relates to a non-autoclaved foam concrete material and a preparation method of the material. The non-autoclaved foam concrete material is characterized by comprising the following raw material ingredients in parts by weight: 85-96 parts of cement, 2-8 parts of fine sand, 2-10 parts of slag powder, 1.4-2.2 parts of chemical foaming agent, 0.7-1.5 parts of additive, 0.5-1.0 part of fiber and 1-1.5 parts of assistant, wherein the additive is a foam stabilizer, a water reducer and an early strength agent, and a water-material mass ratio is 0.55-0.6. The prepared foam concrete material can reach various performance indexes (foam concrete JG / T 266-2011); various performance is excellent; and the method is simple and practicable, low in cost, obvious in energy conservation effect and appropriate for large-scale popularization and application.

Owner:NANJING UNIV OF TECH

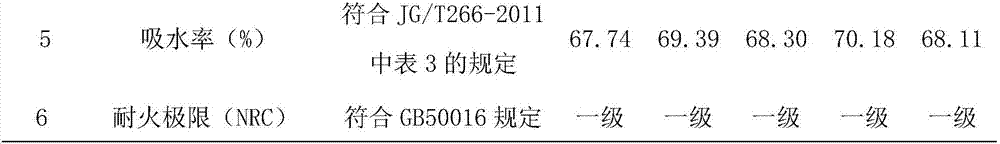

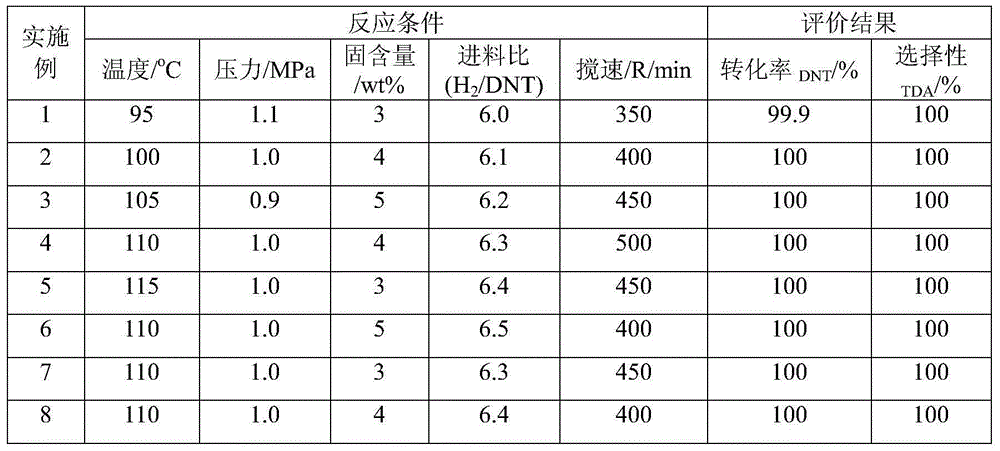

Raney nickel catalyst used for low-pressure hydrogenation of dinitrotoluenem, preparation method and application thereof

InactiveCN103977818AReduce energy consumptionTemperature rises fastOrganic compound preparationAmino compound preparationTolueneSolvent

A Raney nickel catalyst used for low-pressure hydrogenation of dinitrotoluenem. The catalyst is characterized by comprising, by mass, 80-90 wt% of nickel, 5-10 wt% of aluminium and 1.65-10 wt% of an auxiliary agent metal, wherein the nickel is in the form of a simple substance, the aluminium is in the form of the simple substance of an oxide and the auxiliary agent metal is in the form of the oxide. The catalyst is low in price and has an excellent performance of catalytic hydrogenation of the dinitrotoluenem (DNT) without an additional solvent and under a low-pressure condition of 1Mpa.

Owner:TAIYUAN UNIV OF TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com